Kubota D1803-CR-TIE4B-KEA-2, D1803-CR-TIE4B-KEA-1, D1803-CR-TIE4BG-KEA-1, V2403-CR-TIE4B-KEA-1, V2403-CR-TIE4B-KEA-2 Installation Instructions Manual

...Page 1

K

ubota

Installation Instructions

CAR

B/EPA certified Tier

4f engines:

D1803-CR-TIE4B-KEA-1 (1J497-10000)

D

1803-CR-T

D

1803-CR-T

V2403-CR-T

V2403-CR-T

V2403-CR-T

IE4B-KEA-2 (1J497-20000

IE4BG-KEA-1 (1J478-10000

IE4B-KEA-1 (1J498-10000

IE4B-KEA-2 (1J498-20000

IE4BG-KEA-1 (1J488-10000

Append

ix 5

)

)

)

)

)

T

he instructions in this document supersede any other previous instructions provided by Kubota.

Kubota Emissi

Document Number : KEA-S

on-R

elated Installation Instructions

TD-03-CRS-DOC-

001

-

④

Page No

.

1

Page 2

Contents

Append

ix 5

Important Notice

Objectiv

1. Ex

e Items

haust System ------------------------------------------------------------

----------------------------------------------------------------

-----------------------------------------------------------------

2. Intake System ---------------------------------------------------------------

3.Fuel System -----------------------------------------------------------------

4.Engine Control Unit (E

5. Engine Control System (Wire Harness

6.Certification Labels

7.App

licati

on Review Requirement

8. Installation Instructions Re

CU) ----------------------------------------------

/

Display P

ane

l)----------

-------------------------------------------------------

s--------------------------------------

visi

on Log

----------------------------------

page 3

page 4-5

page 6-15

page 16-36

page 37-43

page 44-57

page 48-50

page 51

page 52

page 53

Kubota Emissi

Document Number : KEA-S

on-R

elated Installation Instructions

TD-03-CRS-DOC-

001

-

④

Page No

.

2

Page 3

Append

ix 5

Important Not

ice

EMISSION-RELATED INSTALLATION INSTRUCTIONS

These instructions ar

the engine, exhaust

sensor), engine control system etc, are installed correctly in the engine’s certifi

c

onfiguration. The e

tail pipe or

wir

e harness and contro

useful life of the component without any failure.

Faili

ng to follow these instructions when insta

piece of nonroad equipment violates federal law (40

and is subject to fines or other penalties as de

e provided for the final engine assemblers (FEA) who must ensure

system (After Treatment De

missi

on related parts which FEA pr

ls) mus

t be designed to function throughout the

vic

e: ATD), i

lli

scri

ntake

system (Air flow

epare (for example the exhaust

ng a certified engine in a

CFR

1068.105(b)),

bed in the Clean Air Act.

ed

Kubota Emissi

Document Number : KEA-S

on-R

elated Installation Instructions

TD-03-CRS-DOC-

001

-

④

Page No

.

3

Page 4

1. Exhaust Syste

K

ubota supplies a certified diesel oxidation cata

m

treatment and assemble the exhaust

for use with these

KEA s

tandard engine models. Therefore, no other exhaust after treatment can be used.

Objective Items

lyst (DOC) assembly. FEA must use the Kubota supplied certified exhaust after

system

parts according to the instructions. No other exhaust after treatment is certified

Append

ix 5

2. Intake Syste

These Tier

m

4 common rail engines ut

iliz

e a mass air flow (MAF) sensor to control the EGR flow rate. The air cleaner location

and piping layout must be installed according to these installation instructions to maintain proper performance of the MAF

sensor

output. Als

resis

tance and charge air cooler performance must be kept within certain

3. Fuel Syste

m

In order to maintain the common rail fuel injection pump performance and durab

mus

t be checked during the app

o, to prevent decreases of engine output performance and to maintain e

criteri

a.

ility

the pressure and temperature of the fuel

licati

on review.

missi

on compliance, intake

4. Engine Control System (Engine Control Unit (ECU)

T

he Engine Control Unit (E

correctly

within K

and that the requirements and specifications are checked during the app

ubota specification. Othe

5. Engine Control System (Engine Control Unit (ECU), Wire Harness, Operator Display Panel

T

he

wir

e harness is also considered an e

correctly

and that the requirements and specifications are checked during the app

be within Kubota specification. Othe

CU) is consider

rwis

e, engine and e

rwis

e, engine and e

ed an e

missi

on control de

missi

missi

on control de

missi

Kubota Emissi

Document Number : KEA-S

vic

e. It is

critical

to ensure that the ECU is install

licati

on review. The elect

on performance cannot be guaranteed.

)

vic

e. It is

critical

to ensure that the

wir

licati

on review. The elect

on performance cannot be guaranteed.

on-R

elated Installation Instructions

TD-03-CRS-DOC-

001

-

④

rical si

e harness is installed

rical si

ed

gnal must be

gnals must

Page No

.

4

Page 5

Objective Items

Append

ix 5

6. Certif

7.

ication Labels

K

ubota insta

lls

the certification label on the

cyli

nder head cover. If the final engine assembler insta

makes the engine’s emission control information label hard to read during normal

assembler must place a dup

App

lication Review Requirements

Distri

butor is responsible for completing full app

lic

ate label on the equipment, as de

licati

on review for standard engine to ensure quality engine installation. The

scri

bed in 40

lls

the engine in a way that

engine maintenance, the final engine

CFR

1068.105.

application review should be completed according to Kubota’s application review standards and application manual

r

equirements.

Kubota Emissi

Document Number : KEA-S

on-R

elated Installation Instructions

TD-03-CRS-DOC-

001

-

④

Page No

.

5

Page 6

Append

ix 5

1-1. Ex

1-1-1. Ex

haust System S

haust System S

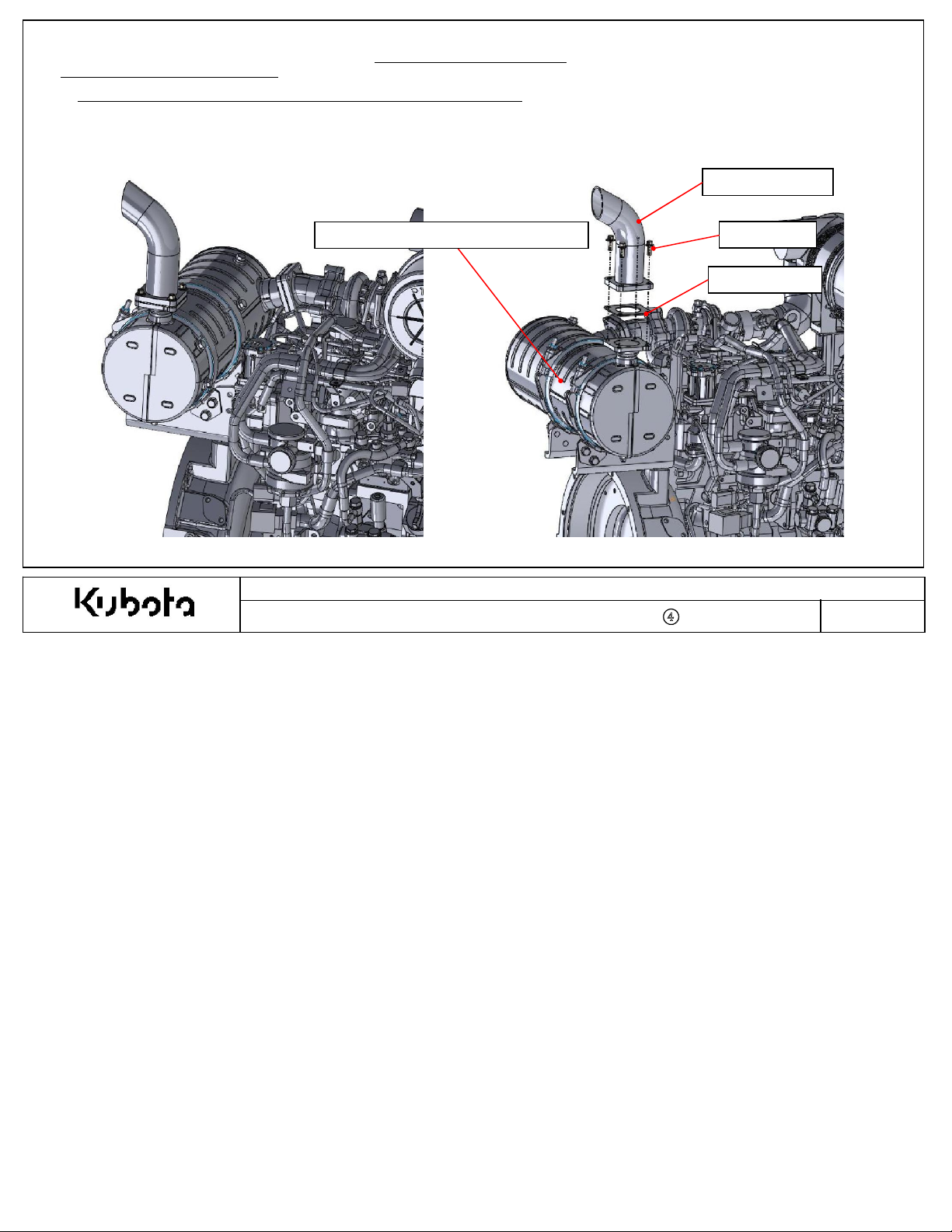

Exhaust

A

system m

n example of exhaust

upp

1. Exhaust System

ly

upply for

eans the layout of all parts from the exhaust manifold to the exhaust exit.

KEA S

tandard CRS-DOC Engines

system is show

N

o.1 : Diesel Oxi

n below.

dation Cata

lyst (DOC)

N

o.4 : Tail Pi

N

o.3 : Bolt

N

o.2 : Gasket

pe

Kubota Emissi

Document Number : KEA-S

on-R

elated Installation Instructions

TD-03-CRS-DOC-

001

-

④

Page No

.

6

Page 7

supplied

1J497- 1810△ 1 D1803- CR- TIE4 Engine Code: 1J497- 10000 , 1J478- 10000

1J807- 1810△ 1 D1803- CR- TIE4 Engine Code: 1J497- 20000

1J808- 1810△ 1 V2403- CR- TIE4 All V2403- CR- TIE4 Models

M8 x 1.25mm ISO 8.8

Meet t he back pressure and flange requirements.

1. Exhaust System

K

ubota supplies the following parts as shown below, these parts must be used in the exhaust

FEA supplied parts must meet the installation instruction requirements.

system

Append

ix 5

.

No. Part Name FEA

Diesel Oxidation Catalyst1

2 Gasket

3 Bolt

4 Tail Pipe

N

ote: Part numbers / assemblies for item #1, Diesel Oxi

○

○

Kubota

○

○

KBT Part No. Q'ty Engine Model Remarks

Qty: 1 Gasket supplied with engine.

17326- 1223△ 1 All 03 Series

Qty: 3 Gaskets are required for remote DOC installation.

(See page 12- 13 f or remote DOC installation details)

- 4

- -

dation Cata

Kubota Emissi

Document Number : KEA-S

lys

t, vary based on the base engine.

on-R

elated Installation Instructions

TD-03-CRS-DOC-

001

-

④

Page No

.

7

Page 8

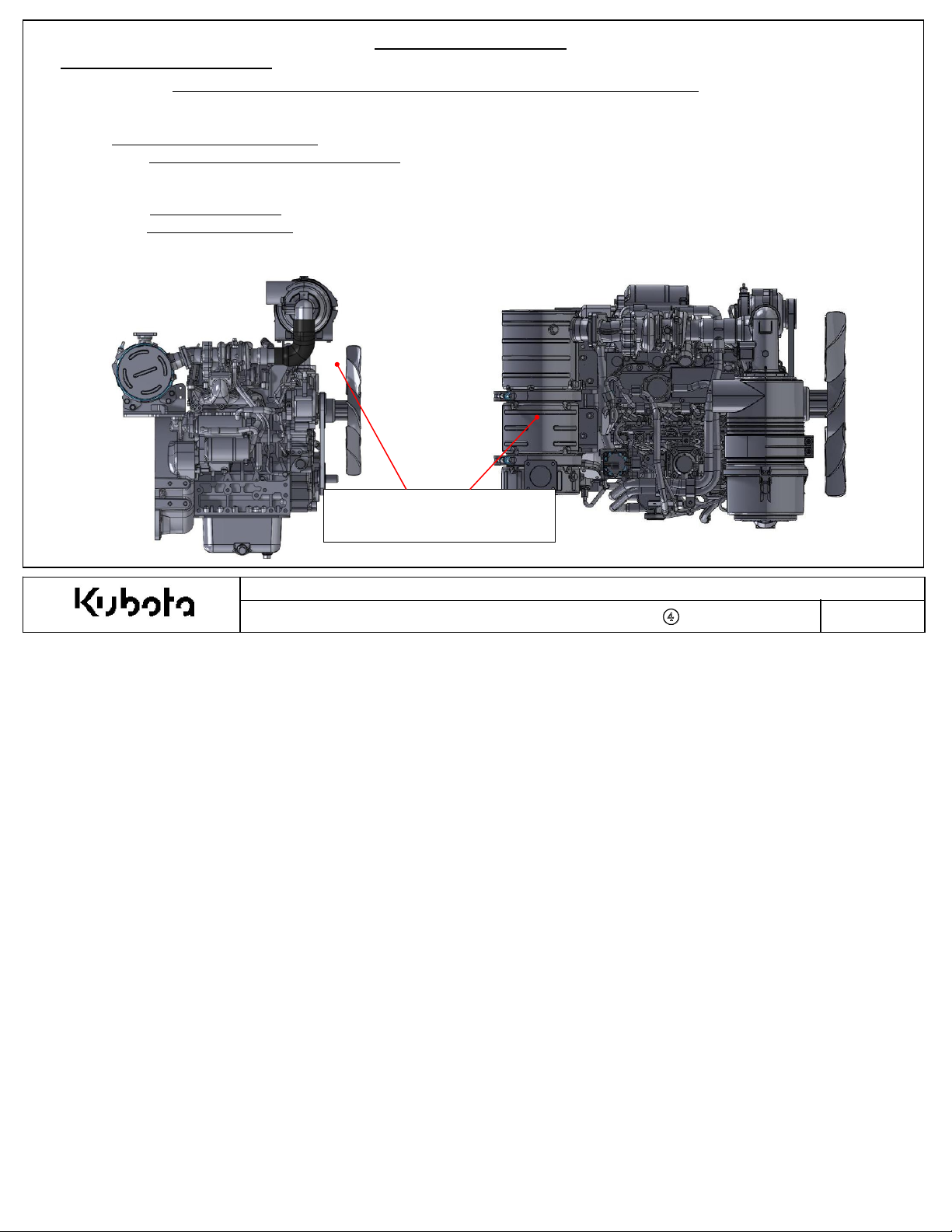

1-2. Ex

haust System

Layout

DOC (Diesel Oxidation Cata

Incorrect DOC inst

allation will cause emission

1-2-1. DOC Installation Options:

A

. Standard DOC Installation Position: T

K

ubota production fa

cility as

the standard configuration. Kubota recommends to keep the DOC in this

factory location.

B. DOC Outlet

C. Remote

It is

critical

Angle: C

Mount DOC: Certai

hanging the DOC outlet angle is acceptable. See following pages.

n app

to follow the instructions outlined in this installation manual to guarantee e

1. Exhaust System

lyst)

Installation for

he DOC is installed onto the top side of the f

lications will r

KEA CRS-DOC S

non-comp

equire for the DOC to be relocated.See following pages.

tandard Engines

liance and/or damage to the DOC

lyw

heel housing at the

missi

on compliance.

Append

ix 5

.

DOC (Diesel Oxidation Cata

Factory

Document Number : KEA-S

Location

Kubota Emissi

lyst)

on-R

elated Installation Instructions

TD-03-CRS-DOC-

001

-

④

Page No

.

8

Page 9

Industrial

Industrial

BG

Industrial

Industrial

BG

1. Exhaust System

Append

ix 5

1-2-1.A Factory Mounted Installation Position (DOC): Ex

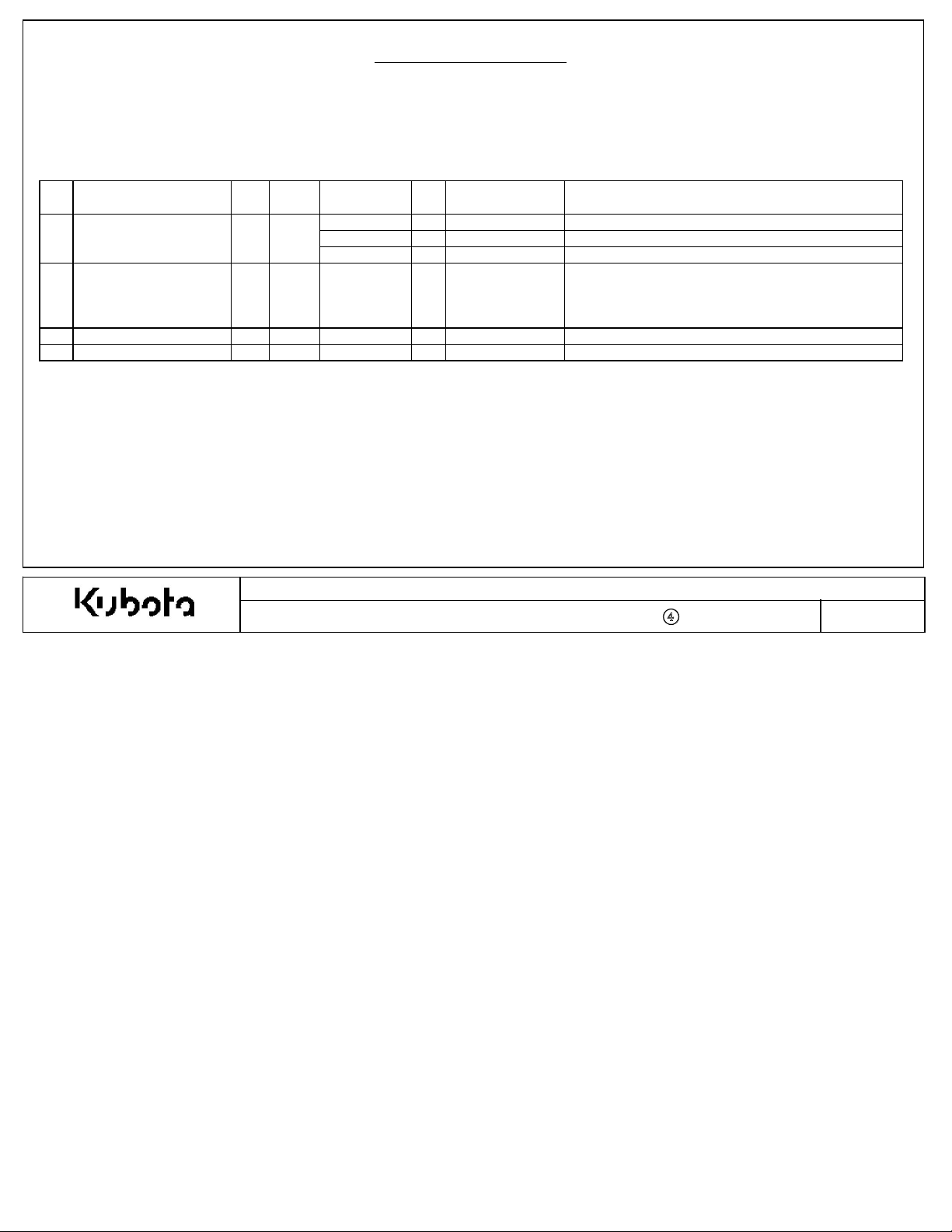

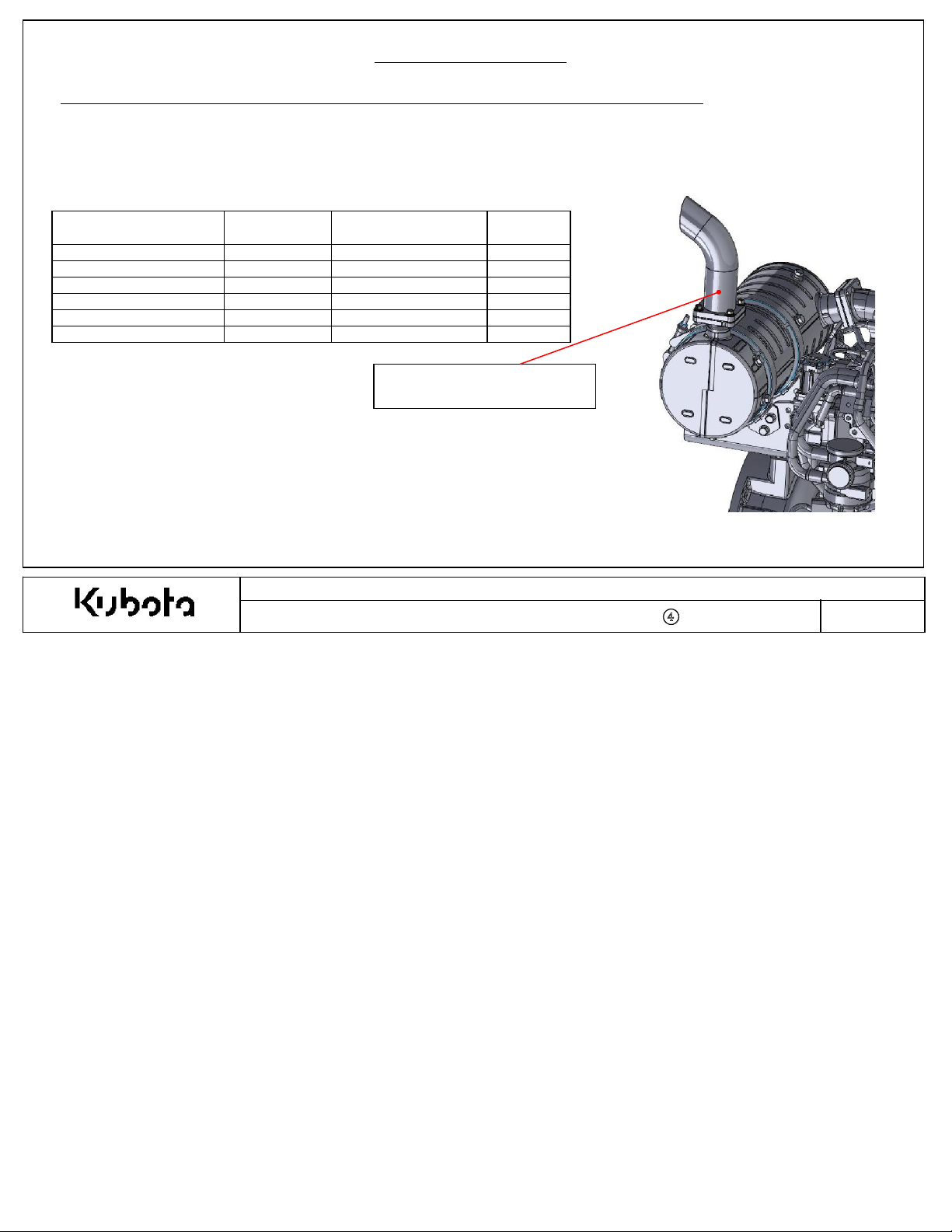

Back pressur

Measurem

Engine Model 10 Digit Code Maximum Back Pressure Remarks

D1803- CR- TIE4B- KEA- 1 1J497- 10000 50 mm Hg

D1803- CR- TIE4B- KEA- 2 1J497- 20000 50 mm Hg

D1803- CR- TIE4BG- KEA- 1 1J478- 10000 40 mm Hg

V2403- CR- TIE4B- KEA- 1 1J498- 10000 50 mm Hg

V2403- CR- TIE4B- KEA- 2 1J498- 20000 50 mm Hg

V2403- CR- TIE4BG- KEA- 1 1J488- 10000 40 mm Hg

e of exhaust tail pipe at full load, rated speed condition must be according to table below.

ent point of back pressure of exhaust

system is within 1” (25.4 mm) of the DOC outlet.

Back Pressure Measurement

Location

haust Back Pressure Check

Kubota Emissi

Document Number : KEA-S

on-R

elated Installation Instructions

TD-03-CRS-DOC-

001

-

④

Page No

.

9

Page 10

1. Exhaust System

1-2-1.B DOC Outlet Angle Adjustment Proc

1.Kubota recommends to keep the DOC outlet angle in the standard position, but certain app

2.Adjusting the DOC outlet angle is acceptable to meet the installation requirements of the machine.

•Installati

•Angle adjustment must be completed only 1 time (to min

•Angle adjustment must be completed before customers run the engine(to min

on instructions must be carefu

lly

followed to ensure e

edure (Option)

missi

imize risk

of clamp breakage).

on compliance.

imize risk

lications will r

of clamp deterioration due to heat).

equire adjustment.

Append

ix 5

Procedure

STEP

STEP

STEP

STEP

STEP

N

ote 1: It is NOT allowed to adjust the DOC inlet portion of the DOC.

Only

N

ote 2: Any exhaust gas leakage or failures due to incorrect modification is not

cover

:

1: Loosen DOC band clamp at DOC outlet position and remove DOC outlet portion.

2: Replace gasket with new parts. Refer to

3: Ori

ent the DOC outlet to the de

4: Tighten Band clamp nut to 16-20 Nm.

5: Start engine and conf

the DOC outlet position can be adjusted.

ed under standard/e

irm

missions warr

sir

that there are no exhaust leaks.

anty.

STANDARD DOC CONFIGURATIO

ed angle

illustr

ated parts

(similar

lis

to image to the right).

Loosen This DOC

B

and Clamp

N

Kubota Emissi

Document Number : KEA-S

t for gasket P/N.

A

DJUSTED DOC OUTLET ANGLE

on-R

elated Installation Instructions

TD-03-CRS-DOC-

001

-

④

Do NOT

DOC B

Loosen This

and Clamp

Page No

.

10

Page 11

1. Exhaust System

1-2-1.C Remote Mounting the DOC (Option)

Rem

ote DOC Installation Option

Certai

n app

lications will r

equire for the DOC to be relocated.See below installation

criteri

Append

ix 5

a.

1.Exhaust Backpr

A.T

outlet must be less than 113

essure Requirement:

he ma

ximum allowabl

e exhaust back pressure for the complete exhaust

mmH

2.Exhaust Temperature Drop Requireme

A. T

he ma

ximum allowabl

r

ated speed full load condition. Ex

e temperature drop across the intermediate exhaust pipe must be less than 25 deg. C at the

EXAMPLE REMOTE MO

system measur

ed at the muffler flange

g. The back pressure must be measured at the rated speed full load condition.

nt:

haust pipe insulation may be required and is recommended to meet this requirement.

M

uffler Flange

Measurem

Exhaust Back Pressur

Measurem

ent Location for

e

ent Location for

Exhaust Temperature (∆T)

UNT DOC

Kubota Emissi

on-R

elated Installation Instructions

Document Number : KEA-S

TD-03-CRS-DOC-

001

-

④

Page No

.

11

Page 12

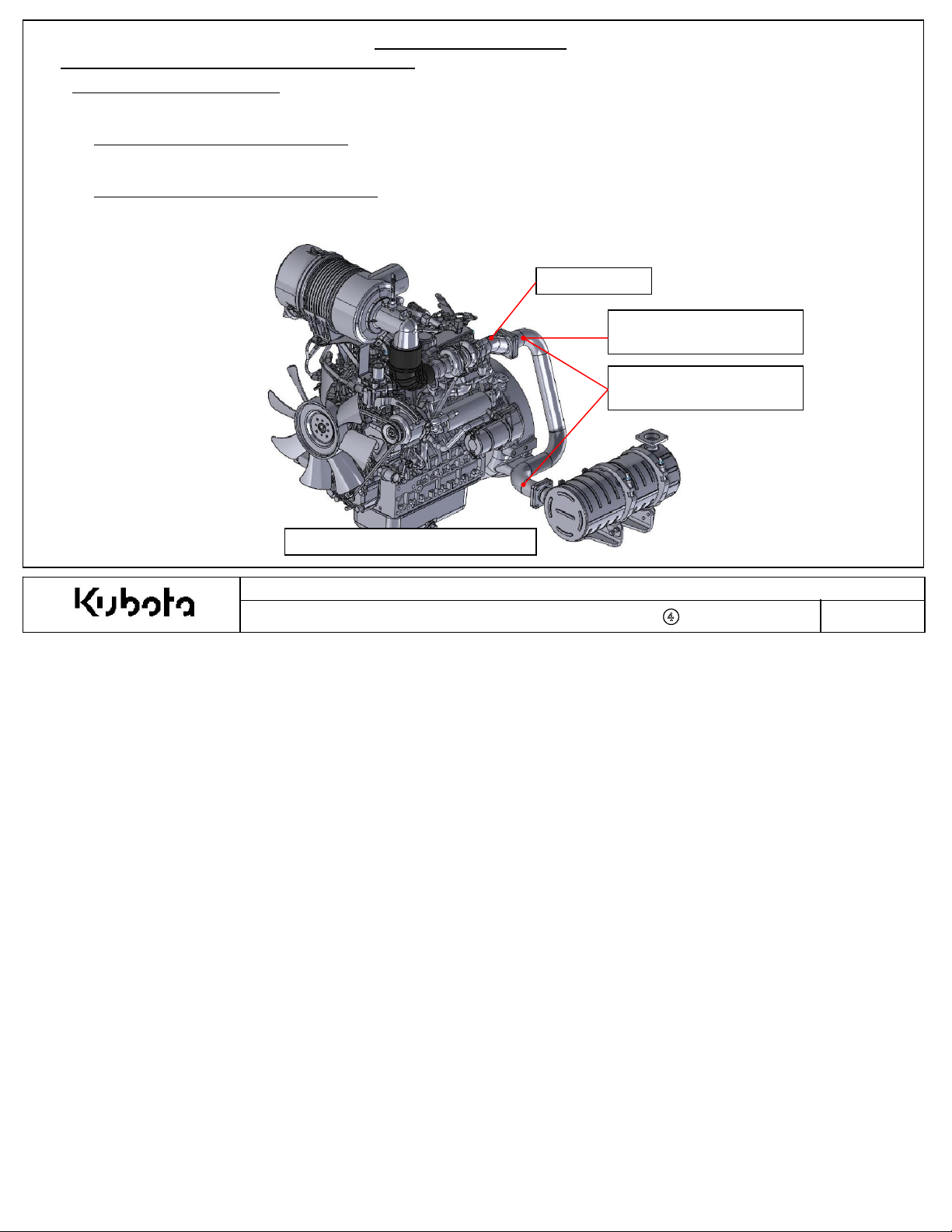

1. Exhaust System

1-2-1.C Remote Mounting the DOC (Option)

Remote DOC Installation Option Continued…

Append

ix 5

3. Other Inst

A

. Intermediate pipe for remote DOC (from turbo-out to DO

B.T

he muffler flange must not be removed from the engine. The intermediate exhaust pipe must connect to the outlet of the

m

uffler flange.

C.T

he intermediate exhaust pipe and flexible coupling must not leak exhaust gases during operation.

D.New m

remov

E.Ti

ghtening torque for the muffler flange outlet and DOC inlet M8 fasteners is 24-27

F.Reloc

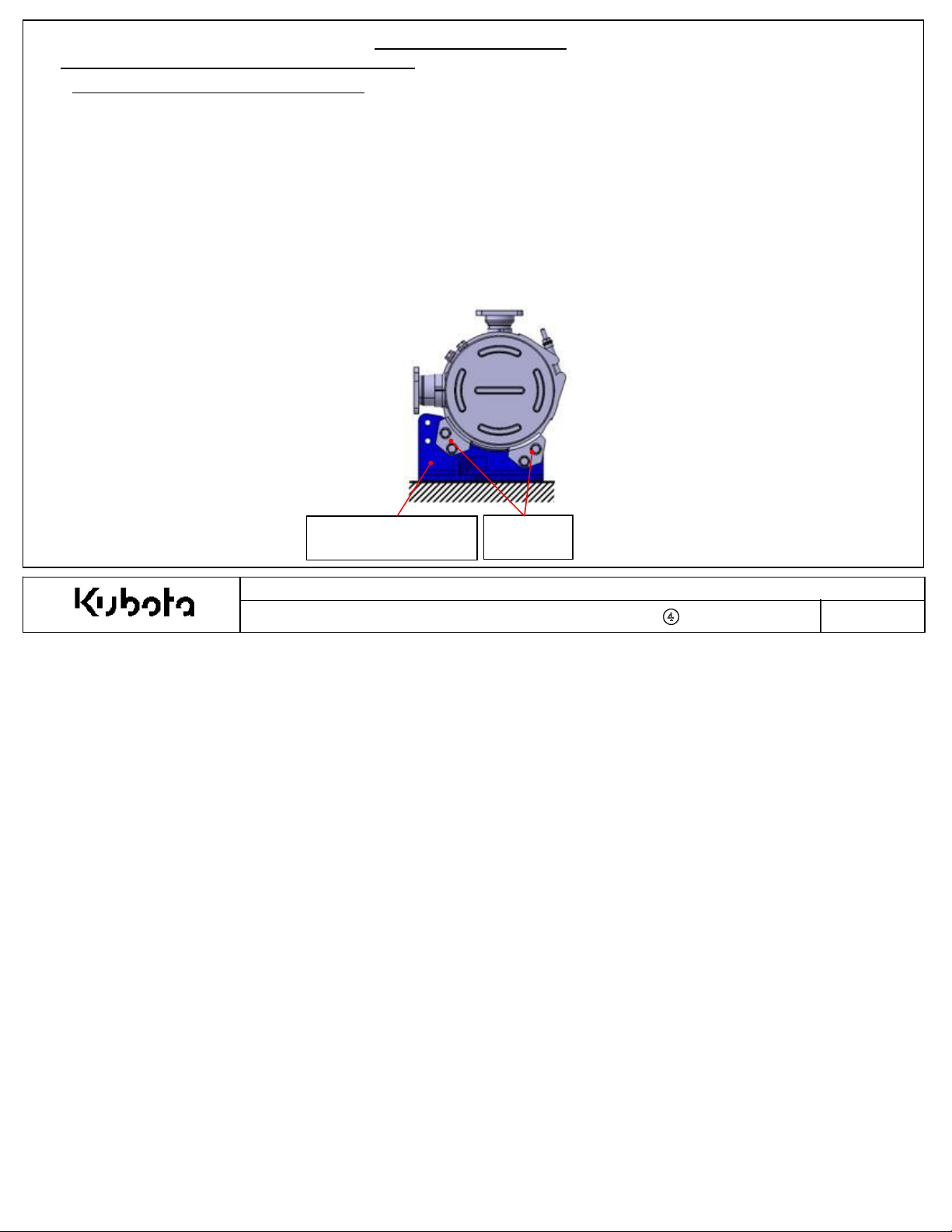

G

. It is strongly recommended to use the Kubota supplied DOC mounting brackets (shown below in blue).

H.DOC incli

allation Requirements for Remotely Installed DOC

C-inlet) must incl

ude a flexible portion.

uffler flange outlet gasket, DOC inlet gasket, studs, and nuts on muffler flange outlet are required when DOC is

ed from engine for remote installation. Refer to the

ated DOC needs to be mounted without exce

illustr

ssive strain/l

ated parts

oad on V-

lis

t for the correct replacement part numbers.

N·m

.

band clamps.

nation angle must follow the required installation angles defined in the next page.

K

ubota Supplied DOC

M

ounting Brackets

V-band

Clamps

Kubota Emissi

Document Number : KEA-S

on-R

elated Installation Instructions

TD-03-CRS-DOC-

001

-

④

Page No

.

12

Page 13

Append

ix 5

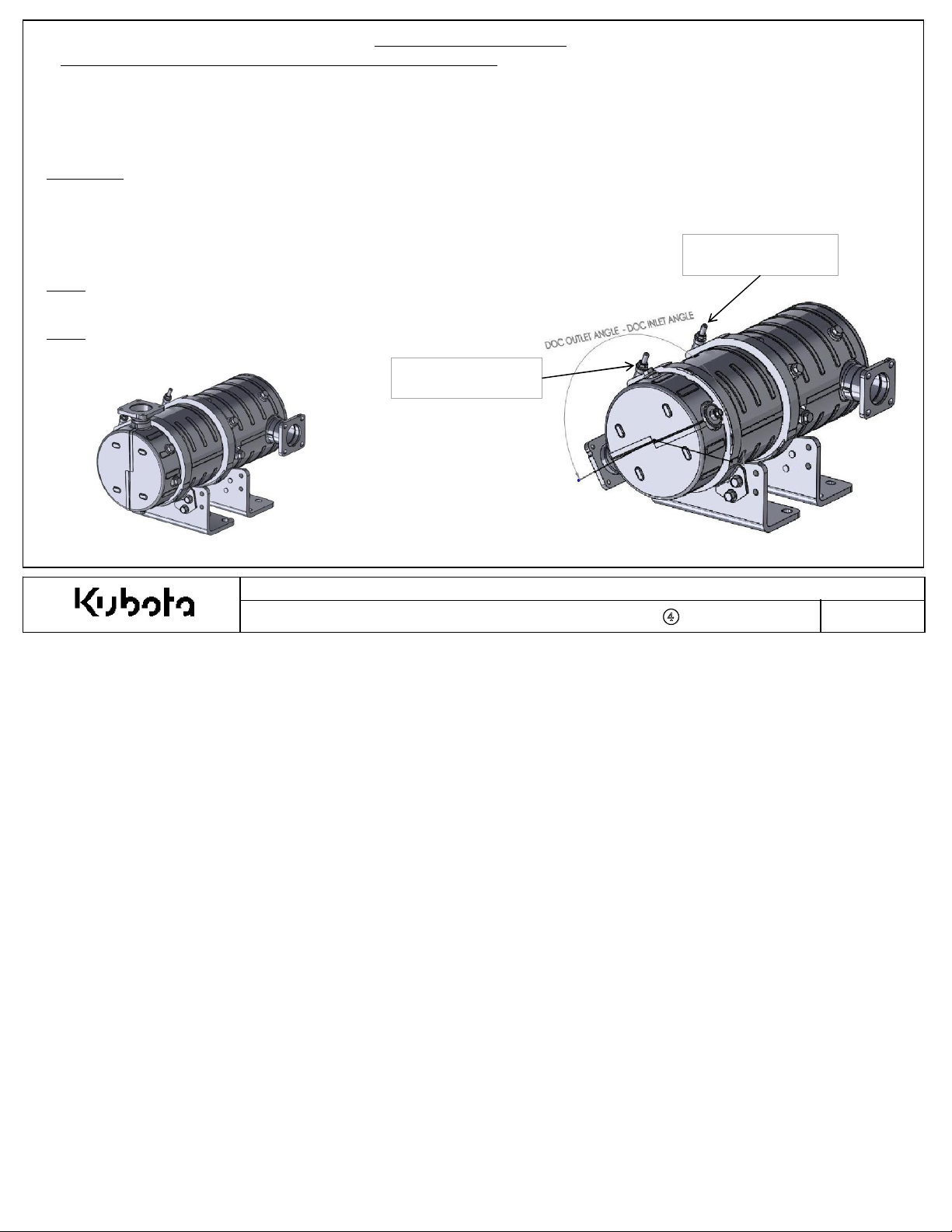

1-2-1.C Remote Mounting the DOC (Option)

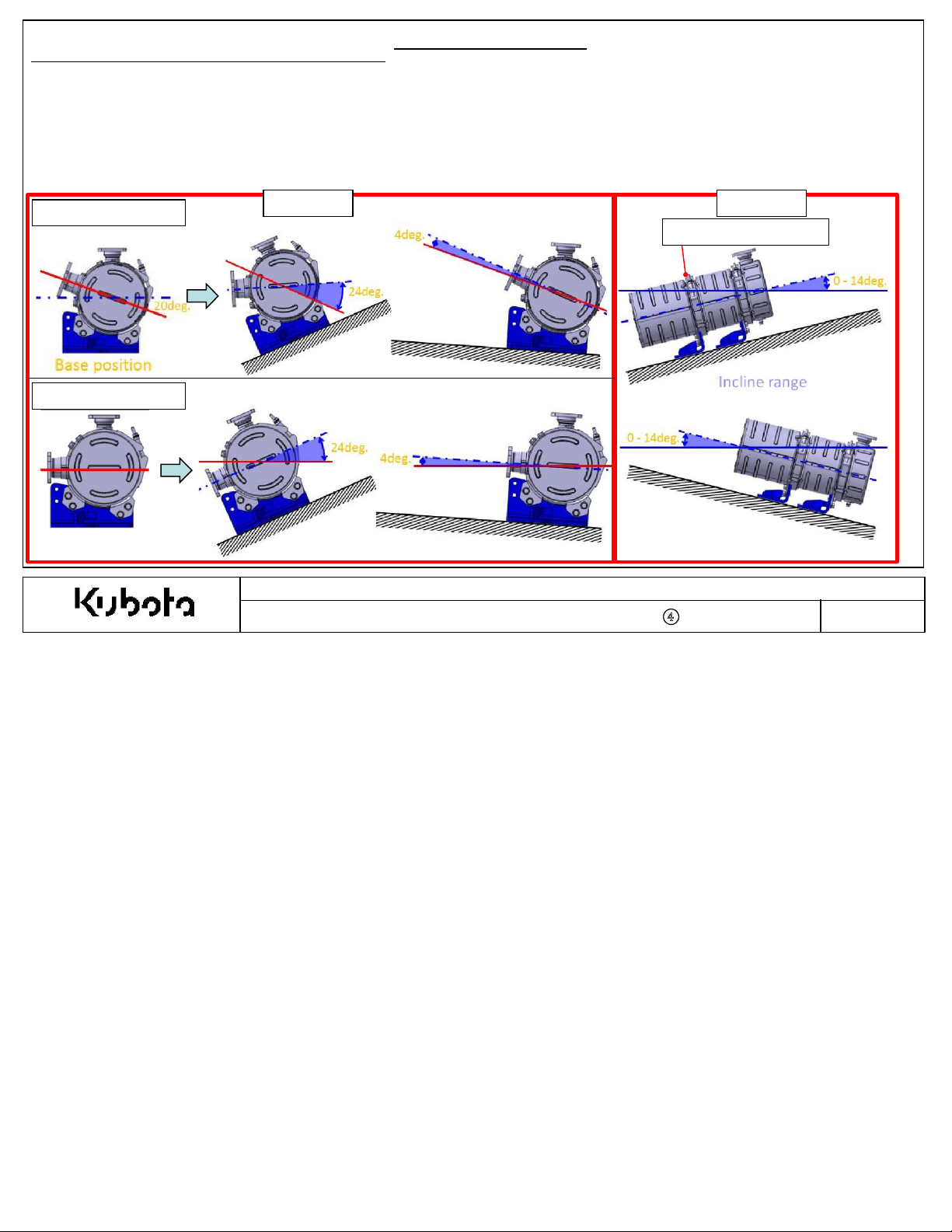

4. Other Inst

A.DOC incli

B.T

C.T

D

1803

V

2403

he DOC inlet band clamp cannot be loosened or modified in any way.

he DOC can only be in

-CR-TIE4B-***

-CR-TIE4B-***

allation Requirements for Remotely Installed DOC

nation angle must be installed according to the angles defined below.

cli

ned according to option #1 or option #2, not the combination.

I.Option #1: Rotate the DOC about the DOC cente

i.Please note the required installation angle

II.Option #2: In

cli

ne the DOC up to +/-14 deg.

Option #1

1. Exhaust System

rli

ne a

xis

.

limits

below

(view

ed from DOC inlet side

Option #2

DOC

Inlet Band Clamp

)

Base position

Kubota Emissi

Document Number : KEA-S

on-R

elated Installation Instructions

TD-03-CRS-DOC-

001

-

④

Page No

.

13

Page 14

1. Exhaust System

Append

ix 5

1-3 DOC

(Diesel Oxidation Cata

lyst)

Installation

Criteria {Applies for engine mounted or remote mounted DOC}

1.DOC vibration:

-Accelerati

-Vibrati

on/

Displacem

ent must not exceed the

on must be checked during the app

licati

limits prescri

on review.

bed in the app

licati

on review form.

2. The DOC shall not support mounting loads from adjacent or mated components (tail pipe/intermediate pipe):

- Check DOC

tail pipe vibration during app

licati

on review to ensure it

will

not damage the DOC during long term operation.

-

Intermediate exhaust pipe for remote mount DOC may require support brackets.

3. Pleas

4. OEM Tail Pi

e note that the DOC

- Check surr

ounding component temperatures during the app

pe Requirements:

ski

n temperature can reach about 250

° C

licati

:

on review.

- FEA supplied bolts:

- Fl

ange bolts: M8 x 1.25, strength cla

- Ti

ghtening torque; 24-27

N·m

ssificati

on is ISO

8.8

- Tail Pipe Flange:

- Fl

ange th

- Fl

atness of the flange face is ma

ickness is 8mm or mor

e.

ximum

0.1mm.

-Surface finish of the flange face is 3.2Ra.

5. Intermediate Ex

-Accelerati

app

-Vibrati

haust Pi

licati

on review form.

on/

Displacem

pe Vibrati

on: for remote mounted DO

ent must not exceed the

on must be checked during the app

licati

C

limits prescri

on review.

bed in the

Kubota Emissi

Document Number : KEA-S

on-R

elated Installation Instructions

TD-03-CRS-DOC-

001

-

④

Page No

.

14

Page 15

1-4. Other Notice

1. Exhaust System

Append

ix 5

1. The exhaust

etc. around the exhaust

system will

be very hot, so to protect elect

system

and for the safety of operators, FEA s

rical

parts such as the starter, the alternator, fuel

hould install heat shields or insulating blankets as

system

necessary. It is acceptable to wrap the DOC if necessary. However, heat shield must not be welded to the DOC.The

temperature of these surrounding components must be conf

pre

scri

bed

2. Conf

limits shown i

irm

that water does not enter the exhaust

po

ssibl

e, install a rain cover or

n the app

similar

licati

on review form.

system from

de

vic

e.

irm

ed during the app

licati

on review and must be within the

the tail pipe outlet in all operating conditions. If water entry is

Kubota Emissi

on-R

elated Installation Instructions

parts,

wiri

ng,

Document Number : KEA-S

TD-03-CRS-DOC-

001

-

④

Page No

.

15

Page 16

Append

ix 5

2-1. Intake System Scope of Supply for

Intake

system m

A

n example of an intake

N

o.1 : Air Cl

N

o.2 : Mass Air Flow Sensor

eans the layout of all parts from the air inlet / pre

system wi

th the

eaner Assembly

2. Int

KEA S

KEA S

tandard CRS-DOC engine is shown below.

N

o.7 : Rain Cap / Pre-cl

ake System

tandard CRS-DOC Engines

-cl

eaner hose to the intake manifold or turbo charger.

eane

N

o.6 : Pre-Cl

N

o.4 : Air

Inlet Hose

r

eaner Hose

N

o.3 : Air Cl

eaner Band Clamp

N

o.5 : Air Cl

eaner Brack

Document Number : KEA-S

et

Kubota Emissi

on-R

elated Installation Instructions

TD-03-CRS-DOC-

001

-

④

Page No

.

16

Page 17

supplied

1J497- 1101△ 1 7" Non- Rotatable A/ C (S/ N: <7HU* * ** )

1E690- 1101△ 1 7" Rotatable A/ C (S/ N: >7HU* ** * )

1J497- 1101△ 1 7" Non- Rotatable A/ C (S/ N: <7HU* * ** )

1E690- 1101△ 1 7" Rotatable A/ C (S/ N: >7HU* ** * )

7" Non- Rotatable A/ C (All S/ N's)

1J498- 1101△ 1 8" Non- Rotatable A/ C (S/ N: <7HU* * ** )

1E691- 1101△ 1 8" Rotatable A/ C (S/ N: >7HU* ** * )

1J498- 1101△ 1 8" Non- Rotatable A/ C (S/ N: <7HU* * ** )

1E691- 1101△ 1 8" Rotatable A/ C (S/ N: >7HU* ** * )

1J456- 1100△ 1 V2403- CR- TIE4BG- KEA- 1 7" Non- Rotatable A/ C (All S/ N's)

comes pre- assembled into air cleaner body

for 7" A/ C

for 7" A/ C

for 7" A/ C

for 8" Non- Rotatable A/ C (S/ N: <7HU* * * * )

for 8" Rotatable A/ C (S/ N: >7HU* ** * )

for 7" A/ C

KEA- 1, KEA- 2, and KEA- 1 (BG)

Extension Pipe ○ - 1 All 03 Series (example of parts on pg. 27- 28)

1E691- 1162△ V2403- CR- TIE4B- KEA

2. Intake System

K

ubota supplies the following parts as shown below, these parts MUSTbe used in the intake

No. Part Name FEA

Air Cleaner Assembly

1

Kubota

○

KBT Part No. Q'ty Engine Model Remarks

D1803- CR- TIE4B- KEA- 1

D1803- CR- TIE4B- KEA- 2

1J497- 1100△ 1 D1803- CR- TIE4BG- KEA- 1

V2403- CR- TIE4B- KEA- 1

V2403- CR- TIE4B- KEA- 2

system

Append

ix 5

.

2 Mass Air Flow Sensor

Air Cleaner Band Clamp

3

4 Air Inlet Hose

5 Air Cleaner Bracket

6 Pre- Cleaner Hose

7 Rain Cap

○

○

8

9 Rubber Coupling Supplied with engine S/ N: >7HU** **○

○

1J520- 1070△ 1 All 03 Series

1E441- 1125△ 1 D1803- CR- TIE4B- KEA- 1

1E441- 1125△ 1 D1803- CR- TIE4B- KEA- 2

1E441- 1125△ 1 D1803- CR- TIE4BG- KEA- 1

○

(Integrated Type) 1 V2403- CR- TIE4B- KEA- 1,2

1J498- 1125△ 1 V2403- CR- TIE4B- KEA- 1,2

1E441- 1125△ 1 V2403- CR- TIE4BG- KEA- 1

1J497- 1164△ 1 D1803- CR- TIE4B

1J498- 1164△ 1 V2403- CR- TIE4B- KEA- 1

○

1J498- 1164△ 1 V2403- CR- TIE4B- KEA- 2

1J456- 1164△ 1 V2403- CR- TIE4BG- KEA- 1

○

1J456- 1157△ 1 All 03 Series

- -

- -

1J419- 1162△ 1 D1803- CR- TIE4B- KEA

Kubota Emissi

Document Number : KEA-S

on-R

TD-03-CRS-DOC-

Meet t he intake resistance requirements.

elated Installation Instructions

001

-

④

Page No

.

17

Page 18

Append

ix 5

2-2. Standard Intake System

2-2-1. Air

Intake System

Incorrect air intake

Air Intake System lay

1. To maintain e

These Tier

Layout for

system lay

out must comply with the following.

missions complianc

4 common rail engines ut

air cleaner location and piping layout must be installed according to these installation instructions to

mai

ntain proper performance of the MAF sensor output. The next pages in this section

correct installati

on location for each air intake

Mass Air Flow Senso

Layout

KEA CRS-DOC S

out

will caus

r

2. Int

ake System

tandard Engines

e e

missi

on non-compliance.

e

iliz

e a mass air flow (MAF) sensor to control the EGR flow rate. The

illustr

system

.

ate the

Kubota Emissi

Document Number : KEA-S

on-R

elated Installation Instructions

TD-03-CRS-DOC-

001

-

④

Page No

.

18

Page 19

Append

ix 5

2-2. Standard Intake System

2-2-2. Standard Air

Incorrect air intake

T

he standard air intake

Intake System

system lay

system lay

Layout

Layout for D1803

out

will caus

out is

illustr

2. Int

e e

missi

ated below.

ake System

-CR-TIE4B-KEA-1 and D1803

on non-compliance.

-CR-TIE4B-KEA-2 Models

Kubota Emissi

Document Number : KEA-S

on-R

elated Installation Instructions

TD-03-CRS-DOC-

001

-

④

Page No

.

19

Page 20

Append

ix 5

2-2. Standard Intake System

2-2-3. Standard Air

Incorrect air intake

T

he standard air intake

Intake System

system lay

system lay

Layout

Layout for D1803

out

will caus

out is

illustr

2. Int

e e

missi

ated below.

ake System

-CR-TIE4BG-

on non-compliance.

KEA-1

Kubota Emissi

Document Number : KEA-S

on-R

elated Installation Instructions

TD-03-CRS-DOC-

001

-

④

Page No

.

20

Page 21

Append

ix 5

2-2. Standard Intake System

2-2-4. Standard Air

Incorrect air intake

T

he standard air intake

Intake System

system lay

system lay

Layout

Layout for V2403

out

will caus

out is

illustr

2. Int

ake System

-CR-TIE4B-KEA-1 and V2403

e e

missi

on non-compliance.

ated below.

-CR-TIE4B-KEA-2 Models

Kubota Emissi

Document Number : KEA-S

on-R

elated Installation Instructions

TD-03-CRS-DOC-

001

-

④

Page No

.

21

Page 22

Append

ix 5

2-2. Standard Intake System

2-2-5. Standard Air

Incorrect air intake

T

he standard air intake

Intake System

system lay

system lay

Layout

Layout for V2403

out

will caus

out is

illustr

2. Int

-CR-TIE4BG-

e e

missi

ated below.

ake System

KEA-1

on non-compliance.

Kubota Emissi

Document Number : KEA-S

on-R

elated Installation Instructions

TD-03-CRS-DOC-

001

-

④

Page No

.

22

Page 23

Append

ix 5

2-3 Intake System Flexibility Eligib

2. Int

ility

ake System

In some cases the standard intake system layout may not fit within the OEM’s engine compartment due to interference or servic

concerns

Th

tab

Intake

. Kubota has added the intake

system flexibility

e intake system flexibility is only allowed on

le to see if the intake system

ENGINE MODE

D

1803

-CR-TIE4BG-

V

2403

-CR-TIE4BG-

D

1803

-CR-TIE4B-KEA-1 1J497-10000

D

1803

-CR-TIE4B-KEA-2 1J497-20000

V

2403

-CR-TIE4B-KEA-1 1J498-10000

V

2403

-CR-TIE4B-KEA-2 1J498-20000

systems

on engines MUST NOT be modified from the standard layout defined in the previous pages if the flexib

L

KEA-1 1J478-10000

KEA-1 1J488-10000

option

s are eligible for th

10 DIGI

T COD

options to certain engine models to overcome these installation challenges.

certain engine models and serial numbers. Please refer to the list in the below

e engine being installed i

I

NTAK

E

FLEXIBILITY OPTIONS

E SYSTEM

NOT AVAILABLE

NOT AVAILABLE

AVAILABLE

AVAILABLE

AVAILABLE

AVAILABLE

nto the OEM equipment.

FLEXIB

FLEXIB

>7HU

>7HU

>7HU

>7HU

SERIAL

**** (Pr

**** (Pr

**** (Pr

**** (Pr

NUMBER BREAK:

ILITY NOT AVAILABLE

ILITY NOT AVAILABLE

oduced from Oc

oduced from Oc

oduced from Oc

oduced from Oc

ility is

t. 2017

t. 2017

t. 2017

t. 2017

not

available in the above table.

eab

ility

)

)

)

)

*See the next

slides

for flexib

ility

option definitions and

limi

tations.

Kubota Emissi

Document Number : KEA-S

on-R

elated Installation Instructions

TD-03-CRS-DOC-

001

-

④

Page No

.

23

Page 24

Append

ix 5

2. Int

2-4 Intake System Flexibility Options

2-4-1. Air

For

engines eligible for intake

Opti

on #1: Rotate the air cleaner inlet relative to the air cleaner body a

Opti

on #2: Ex

Opti

on #3: Rotate the air cleaner relative to the air cleaner outlet a

Opti

on #4: Rotate the air cleaner relative to the turbo charger inlet a

Multiple combi

Intake System Flexibility Opti

system flexibility

tend the air cleaner position by insta

on Introduction

the following options are available.

lli

ng an extension pipe (OEM procured)

nations of option #1, 2, 3, and 4 are acceptable. See examples of a few variations on the next page.

U

p to 500

ake System

xis

.

xis

.

xis

.

mm

.

Kubota Emissi

Document Number : KEA-S

on-R

elated Installation Instructions

TD-03-CRS-DOC-

001

-

④

Page No

.

24

Page 25

2. Intake System

2-4 Intake System Flexibility Options

2-4-2. Examples

Multiple combi

combi

nation of option #1, 2, 3, and 4is available except for

Opti

on #1: Rotate the air cleaner inlet relative to the air cleaner body a

Opti

on #2: Ex

Opti

on #3: Rotate the air cleaner relative to the air cleaner outlet a

Opti

on #4: Rotate the air cleaner relative to the turbo charger inlet a

nations of option #1, 2, 3, and 4 are acceptable. Some examples of intake

tend the air cleaner position by insta

Opti

of Air

Intake System Flexibility Combi

Opti

on #1: 180 deg.

on #2: 200 mm extension

Opti

on #3: 40 deg.

O

#

limi

lli

ng an extension pipe (OEM procured)

Opti

nation

s

system installations are show

tations shown on the following pages.

xis

.

.

xis

.

xis

.

Opti

on #1: 0 deg.

on #2: No extension

Opti

on #3: 50 deg.

n below. Any

Opti

on #1: 90 deg.

Opti

on #2: 100 mm extension

Opti

on #3: 285 deg.

Append

ix 5

Kubota Emissi

Document Number : KEA-S

on-R

elated Installation Instructions

TD-03-CRS-DOC-

001

-

④

Page No

.

25

Page 26

Append

ix 5

2-4 Intake System Flexibility Options

2-4-3. Air

S

ee below for installation

Opti

on #1: Rotate the air cleaner inlet relative to the air cleaner body a

T

he air cleaner that is provided for the standard

adjust the air cleaner inlet to any angle (0-360 deg.) as

Intake System Flexibility Opti

not

es and limitations for option

on #1

KEA

engines with intake

illustr

2. Int

ake System

#1.

xis

.

system flexibility

ated below except for the

has a rotatable inlet. It is acceptable to

limi

tations outlined in the following pages.

Kubota Emissi

Document Number : KEA-S

on-R

elated Installation Instructions

TD-03-CRS-DOC-

001

-

④

Page No

.

26

Page 27

2-4 Intake System Flexibility Options

2-4-4. Air

S

ee below for installation

Opti

on #2: Ex

Th

e extension pipe must be OEM procuredand it must comp

A.T

he OEM must use the rubber coupling which is supplied by Kubota.

B.T

he rubber coupling must fit tightly on the air cleaner and extension pipe in order to avoid dust in the intake

C.T

he OEM must install a hose clamp on each end of the rubber coupling to avoid dust in the intake

D.N

o gap is allowed between the extension pipe and air cleaner outlet. (S

E.“Flexibility” engines include an air cleaner with a rotatable outlet. There is possibility that the air cleaner outlet could r

pipe weight, vibration, etc. It is the responsib

able to guarantee that the extension pipe installation angle follows the design intent angle throughout the life of the machine.

F.S

ee the next page for detailed extension pipe requirements and dimensions.

Intake System Flexibility Opti

not

es and limitations for option

tend the air cleaner position as

on #2

illustr

ated below except for the

ility

of the OEM to evaluate if the air cleaner extension pipe requires support. The OEM must be

2. Intake System

#2.

limi

tations outlined in the following pages.

ly with the below requirements:

ee image below)

EXTENSION PI

PE

system

system

.

.

RU

NO GAP

RU

BBER COUPLIN

G

Append

otate due to the extension

BBER COULPING

< 500

mm

ix 5

Kubota Emissi

Document Number : KEA-S

on-R

elated Installation Instructions

TD-03-CRS-DOC-

001

-

④

Page No

.

27

Page 28

Append

ix 5

2-4 Intake System Flexibility Options

2-4-4. Air

Installation

Opti

on #2: Ex

Extension Pipe Requirement

G

. The pipe must be clean and de-burred prior to installation.

H

. The pipe must be seamless stainless steel or aluminum (re

I. The pipe must fall within the dimensions outlined in the below drawing.

J

. Pi

pe spec must follow ASTM A

Intake System Flexibility Opti

not

es and limitations for option

tend the air cleaner position as

s and Dimensions

511, ASTM A

on #2

#2

illustr

ated below except for the

:

519, or

2. Int

conti nued…

sis

similar s

ake System

tant to corrosion).

tandards.

limi

tations outlined in the following pages.

FOR 7” Air Cleaner

(2 3/8” OD)

FOR 8” Air Cleaner

(3 ½” OD)

Kubota Emissi

Document Number : KEA-S

on-R

elated Installation Instructions

TD-03-CRS-DOC-

001

-

④

Page No

.

28

Page 29

Append

ix 5

2. Int

ake System

2-4 Intake System Flexibility Options

2-4-5. Air

S

ee below for installation

Opti

on #3: Rotate the air cleaner relative to the air cleaner outlet a

It is acceptable to adjust the air cleaner installation to any angle (0-360 degree)

the following pages.

Intake System Flexibility Opti

not

es and limitations for option

on #3

#3.

xis

.

illustr

ated below except for the

limi

tations outlined in

Kubota Emissi

Document Number : KEA-S

on-R

elated Installation Instructions

TD-03-CRS-DOC-

001

-

④

Page No

.

29

Page 30

Append

ix 5

2. Int

ake System

2-4 Intake System Flexibility Options

2-4-6. Air

S

ee below for installation

Opti

on #4: Rotate the air cleaner relative to the turbo charger inlet a

It is acceptable to adjust the air cleaner installation to exactly90 degrees as

pe

rmi

tted. Als

Intake System Flexibility Opti

not

es and limitations for option

o, see other

limi

tations outlined in the following pages for option #4.

on #4

#4.

xis

.

illustr

ated below. Other angles besides 90 degree are not

Kubota Emissi

Document Number : KEA-S

on-R

elated Installation Instructions

TD-03-CRS-DOC-

001

-

④

Page No

.

30

Page 31

Append

ix 5

2. Int

2-5 Intake System Flexibility Limi

2-5-1. Air

S

ee below for installation limitations for the following engines

D

1803

-CR-TIE4B-KEA-1 (1J497-10000

D

1803

-CR-TIE4B-KEA-2 (1J497-20000

S

ee below for air cleaner installation locations that are NOT acceptable. These installations cause the mass air flow sensor to fall

outside of the acceptable sensor performance range.

Intake System Flexibility Limi

tation

)

)

s

tation

s

ake System

:

Configuration NOTacceptable for D1803-CR-TIE4B-KEA-1, D1803-CR-TIE4B-KEA-2

AIR CLEANER INSTALLATION ANGLE

EXTENSION PIPE NOT

INSTALLED (OPTION #2).

AIR INLET HOSE (1J497-1164

STANDARD POSITION

(OPTION

#4

0 DEG.

)

△ )

(OPTION

THIS CONFIGURATION

IS NOT ALLOWED

#3): Perpendicular to Crankshaft 0 +/-45

AIR CLEANER INLET ANGLE

(OPTION

#1): Downward Facing 180 +/-90

°

°

Kubota Emissi

Document Number : KEA-S

on-R

elated Installation Instructions

TD-03-CRS-DOC-

001

-

④

Page No

.

31

Page 32

Append

ix 5

2. Int

2-5 Intake System Flexibility Limi

2-5-2. Air

S

ee below for installation limitations for the following engines

D

1803

-CR-TIE4B-KEA-1 (1J497-10000

D

1803

-CR-TIE4B-KEA-2 (1J497-20000

If the air inlet hose is rotated 90 deg. about the turbo charger a

acceptable:

A.T

he exactcombination of AC

B.Any

other combination not

Intake System Flexibility Limi

Inlet, AC Angl

lis

ted in this table is not pe

tation

s

tation

s

)

)

e, and Heights in this table can be used as specified.

ake System

:

xis (

option #4), the following air cleaner installation combinations ARE

rmi

tted.

Inlet Hose Angle

(Option #4)

Acceptable Combinations for D1803-CR-TIE4B-KEA-1, D1803-CR-TIE4B-KEA-2

ACInlet ACAngle Height

90 90 Standard ( 0mm Extension )

0 180 Standard ( 0mm Extension )

90 180 St andard ( 0mm Extension )

0 270 Standard ( 0mm Extension )

90 270 St andard ( 0mm Extension )

0 90 Extension =250mm Fixed Length

90 90 Extension = 500 mm Fixed Length

0 180 Extension =500mm Fixed Length

270 270 Extension = 500mm Fixed Length

ACInlet

(Option #1)

Height

(Option #2)

ACAngle

(Option #3)

Kubota Emissi

Document Number : KEA-S

on-R

elated Installation Instructions

TD-03-CRS-DOC-

001

-

④

Page No

.

32

Page 33

Append

ix 5

2. Int

2-5 Intake System Flexibility Limi

2-5-3. Air

S

ee below for installation limitations for the following engines

V

2403

-CR-TIE4B-KEA-1 (1J498-10000

V

2403

-CR-TIE4B-KEA-2 (1J498-20000

If the air inlet hose is rotated 90 deg. about the turbo charger a

acceptable:

A.T

he exactcombination of AC

B.Any

other combination not

Intake System Flexibility Limi

Inlet, AC Angl

lis

ted in this table is not pe

tation

s

tation

s

)

)

e, and Heights in this table can be used as specified.

ake System

:

xis (

option #4), the following air cleaner installation combinations ARE

rmi

tted.

Inlet Hose Angle

(Option #4)

Acceptable Combinations for V2403-CR-TIE4B-KEA-1, V2403-CR-TIE4B-KEA-2

ACInlet ACAngle

0 90 90 St andard ( 0 mm Extension )

180 90 90 Standard ( 0mm Extension )

180 180 90 Standard ( 0mm Extension )

0 270 90 Standard (0 mm Ext ension )

180 90 90 Extension = 250 mm Fixed Length

0 180 90 Extension = 250 mm Fixed Length

180 90 90 Extension = 500 mm Fixed Length

Inlet Hose

Angle

Height

ACInlet

(Option #1)

Height

(Option #2)

ACAngle

(Option #3)

Kubota Emissi

Document Number : KEA-S

on-R

elated Installation Instructions

TD-03-CRS-DOC-

001

-

④

Page No

.

33

Page 34

Append

ix 5

2-6 Intake System

1.Air cl

2. Air i

eaner vibration:

-Accelerati

-Vibrati

ntake temperature should be checked during the app

- T

he air inlet temperature should not be more than 5 deg. C higher than ambient temperature, othe

performance

-

If the temperature is high a pre

Installation

on/

Displacem

on must be checked during the app

will

be reduced.

ent must not exceed the

-cl

eaner hose can be added to the air cleaner to

help reduce inlet temperature.

3. En

vironm

ent:

-

It is

critical

that water does not enter the intake

-Add a pre

-T

he dust evacuation valve must point downward to prevent water from entering

-cl

eaner hose and/or rain cap as necessary.

the air cleaner.

4. Pre-Cl

eaner Hose Requirements:

- FEA supplied pre

-cl

eaner hose:

- Thickness ≥ 6 mm (for rubber molded hoses)

- T

he inner surface of the pipe should be smooth.

5. Air Cl

eaner Brack

- T

he OEM is responsible to prepare the air cleaner mounting bracket if the

et:

air cleaner is moved from the standard position (intake

2. Int

licati

on review.

system

ake System

limits prescri

licati

.

system flexibility)

bed in the app

on review:

licati

on review form.

rwis

e engine

.

Kubota Emissi

Document Number : KEA-S

on-R

elated Installation Instructions

TD-03-CRS-DOC-

001

-

④

Page No

.

34

Page 35

Append

V2403- CR- TIE4BG- KEA- 1 250 500

Intake Resistance

ix 5

2. Int

2-7. Intake Re

T

o prevent decreases of engine output performance and to maintain e

less

than the following

is c

hanged the intake rest

- Measurem

-Measur

- Measure i

sis

tance

limits

. If a pre

ricti

on MUSTbe checked during the app

ent point of intake re

e as close as po

ntake rest

ssibl

ricti

on at rated speed, full load.

-cl

eaner hose, rain cap, or any other modification from the standard intake

sis

tance is between the air cleaner and the inlet of the turbo charger.

e to the compressor inlet.

ake System

Measurem

Poi

nt

ent

missi

on compliance, the total intake

licati

on review with the final intake

Engine Model

D1803- CR- TIE4B- KEA- 1 400 630

D1803- CR- TIE4B- KEA- 2 400 630

D1803- CR- TIE4BG- KEA- 1 250 500

V2403- CR- TIE4B- KEA- 1 400 630

V2403- CR- TIE4B- KEA- 2 400 630

system restricti

system c

Initial limit

w/ clean

filter

(mmH2O)

system c

onfiguration.

Limit

w/ dirty

filter

(mmH2O)

on must be

onfiguration

Kubota Emissi

Document Number : KEA-S

on-R

elated Installation Instructions

TD-03-CRS-DOC-

001

-

④

Page No

.

35

Page 36

Append

ix 5

2-8. Charge Air Cooler

T

he Kubota 03

mai

ntain e

-CRS DOC engines require a charge air cooler. To prevent decreases of engine output performance and to

missi

on compliance, the charge air cooler must meet the following

Installation Requirement

temperature drop MUSTbe checked during the app

1.Ma

ximum allowabl

2.Ma

ximum allowabl

N

ote: Measure charge air cooler pressure drop and intake manifold temperature at rated speed, full load.

e pressure drop from turbo charger outlet to intake manifold inlet = <10 kP

e temperature at intake manifold inlet = < Ambi

2. Int

s

licati

ake System

on review.

criteri

ent + 25

a. The charge air cooler pressure drop and

a

° C

Kubota Emissi

Document Number : KEA-S

on-R

elated Installation Instructions

TD-03-CRS-DOC-

001

-

④

Page No

.

36

Page 37

Append

ix 5

3-1. Fuel System S

upp

3-1-1. Fuel System S

Fuel system m

A

n example of the standard fuel

show

n below. An alternative fuel

m

anual.

⑨Fuel C

eans the layout of all parts from the fuel tank to the fuel rail and back.

= Fuel S

= Fuel R

upply

eturn

ap

⑩

Clam

p

ly

upply for

system lay

system lay

⑬Fuel

Cooler

⑤⑥⑦

Eye-bolt

A

ssy

3. Fuel System

KEA S

tandard CRS-DOC Engines

out for the 03

out can be found in the app

⑧C

oupler

A

ssy

-CRS-DOC

⑫Fuel Hos

⑪T

fitt

e

①Li

engine is

licati

ft Pump

on

Comm

Rail

on

Engi

ne: V2403

(some com

-CR-TIE

4

ponents not shown

Pre

-

S

upply

Pum

p

)

S

upply

Pum

p

④W

S

eparato

ater

r

Document Number : KEA-S

②Check

Valv

Kubota Emissi

e

on-R

elated Installation Instructions

TD-03-CRS-DOC-

001

③Filter

-

④

Page No

.

37

Page 38

3. Fuel System

Supplied

Comes with Water In Fuel sensor installed

K

ubota has the parts shown in the previous drawing and recommends that these parts be used in the fuel

FEA supplied parts must meet the installation instruction requirements.

system

Append

ix 5

.

No. Part Name FEA

1 Pump, Electric Lift

2 Valve, Check

3 Fuel Filter Assembly

4 Wat er Separat or Assembly

5 Joint, Bolt

6 Joint, Eye

7 Washer, Packing

8 Coupler Assy, Electrical

9 Fuel Cap

10 Clamp, hose

11 Tee fitt ing, 8mm ID

12 Hose, Fuel

13 Cooler, Fuel

○

○

○

○

○

Kubota

○

○

○

○

○

○

○

○

KBT Part No. Q'ty Engine Model Remarks

1G639- 5203△ 1 All 03 Series

1G911- 4246△ 1 All 03 Series

1J456- 4301△ 1 All 03 Series

2

1J430- 4335△ 1 All 03 Series

16541- 9579△ 4 All 03 Series M14x1.5 thread, used for inlet/ outlet of Separator and Filter

15401- 9569△ 4 All 03 Series Used for inlet/ outlet of Separator and Filter

17105- 3368△ 8 All 03 Series Used for inlet/ outlet of Separator and Filter

19838- 6583△ 1 All 03 Series Electrical connector for electric lift pump

- 1 All 03 Series

- 18 All 03 Series for 8mm ID fuel hose

- 2 All 03 Series for 8mm ID fuel hose, one after Separat or, one before Filter

- - All 03 Series 8mm ID fuel hose, rat ed for f uel per SAE 30R9

- - All 03 Series Fuel cooler may be added to keep temperature < 75° C

Kubota Emissi

on-R

elated Installation Instructions

Document Number : KEA-S

TD-03-CRS-DOC-

001

-

④

Page No

.

38

Page 39

3. Fuel System

Append

ix 5

3-2. Fuel System

3-2-1. Fuel System

Incorrect fuel

Fuel System layout must comply with the following:

1. To maintain e

These Tier

pump are mounted to the engine and must remain in this configuration. The fuel supply lines, return

hoses, and other loose components must be installed according to the guidelines shown on the following

pages.

Layout

Layout for

system lay

missions complianc

4 common rail engines ut

KEA CRS-DOC S

out may cause decreased engine performance and/or fuel

tandard Engines

e

ilize com

system

durab

pute

r-c

ontrolled fuel injection. The Pre-Supply and Supply

ility issues

.

Kubota Emissi

Document Number : KEA-S

on-R

elated Installation Instructions

TD-03-CRS-DOC-

001

-

④

Page No

.

39

Page 40

3-3. Fuel Line

3-3-1. Fuel Hose Measurement for

Fuel pressur

Review. Please note the expected values and measurement locations

e and temperature measurements are taken during the Ap

3. Fuel System

KEA CRS-DOC S

tandard Engines

to Fu

el Rail

Append

ix 5

= Fuel S

= Fuel R

upply

eturn

D

esign Target

Fuel Pressure < 20 kP

Kubota Emissi

Document Number : KEA-S

on-R

a

D

Fuel > -

elated Installation Instructions

TD-03-CRS-DOC-

001

-

④

esign Target

30 kP

Fuel <

75

° C

a

Page No

.

40

Page 41

3-4. Fuel Pump and Check Valve

from Water

Separato

r

Installation Requirements

Elect

150mm pigtail with Yaz

c

onnector 7122-2820-

te

rminals

:

rical c

onnection in

7114-2630-02

3. Fuel System

Pair

of slots for M6

m

ounting bolt.

Bar

b fittings for

8mm ID hose

to Fu

Append

el Filte

ix 5

r

1. Ma

ximum vibrati

2. Pump can be mounted in ho

on levels not to exceed 3G.

riz

ontal or vertical orientation.

4. Do not mount Pump in high temperature en

vironm

ents which can create cavitation or vapor lock conditions.

Kubota Emissi

Document Number : KEA-S

on-R

elated Installation Instructions

TD-03-CRS-DOC-

001

-

④

Page No

.

41

Page 42

3. Fuel System

Append

ix 5

3-5. Fuel

Filter

and Water Separato

K

ubota supplies fuel filter (1J456-4301

Fuel filter shall

be installed between feed pump and injection pump.

W

W

ater-In-Fuel Sensor:

1J430-4388

C

onnector: AMP

JuniorPowe

△

rTimer

o

282911

r

△ )

.

S

upply

Pum

p

= Fuel S

upply

= Fuel R

eturn

M14x

1.5 x 15mm

ports for banjo

fitting

s

Fuel

Inlet

r

PWR

SENGND

Fuel Filter

uel Outlet

12V –Switched Powe

Kubota Emissi

Document Number : KEA-S

on-R

r

elated Installation Instructions

TD-03-CRS-DOC-

001

-

④

Page No

.

42

Page 43

3. Fuel System

Append

ix 5

3-6 Fuel System

1. Vibrati

on must be checked during the app

- Fuel Pum

- Fuel Pum

- Fuel Filter accelerati

- Fuel Filter displacem

Installation

licati

on review:

p acceleration must not exceed 2

p displacement must not exceed 0.5mm continuous at any condition.

on must not exceed 5

ent must not exceed 0.7mm continuous at any condition.

G’s continuous

2. Fuel temperature should be checked during the app

- T

he temperature should not be more than 75

3. Installation/orientation of Components:

- W

ater separator and fuel filter should be mounted with the filter oriented vertica

- F

eed pump and check valve can be mounted vertica

4. En

vironm

ent:

-

It is

critical

that water content in fuel does not exceed 0.14%.

-

It is

critical

that Bio c

-

It is strongly recommended to not use zinc coated fuel tank or components.

ontent does not exceed 5% ASTM D

5. Fuel component Requirements:

- FEA-sourc

- Fuel Filter

ed Supply/Return hose:

- Hos

e I.D. = 8mm nomina

-Supply pressure > -30 kPa @

- Temper

- R

ature < 75

eturn pressure < 20 kPa @

l

° C @

the supply pump

the supply pump

the tan

:

- Filtration ≥ 98.7% at 3-5µm (per ISO

k

19438

G’s c

ontinuous at any condition.

at any condition.

licati

on review:

° C

.

lly or

ho

riz

onta

6751, EN

)

lly

.

lly

.

14214 (7%; EU EN 590: 2009

)

Kubota Emissi

Document Number : KEA-S

on-R

elated Installation Instructions

TD-03-CRS-DOC-

001

-

④

Page No

.

43

Page 44

Append

ix 5

4. Engine Control Unit (ECU

1. Operational Specification

1-1. Operating voltage : 8 to 16 VDC

1-2. Max. Vibrati

on : 5G

1-3. Normal operating temperature : -30 to 105

1-4. Water Pr

2. Installation Note

oof : IP69

s

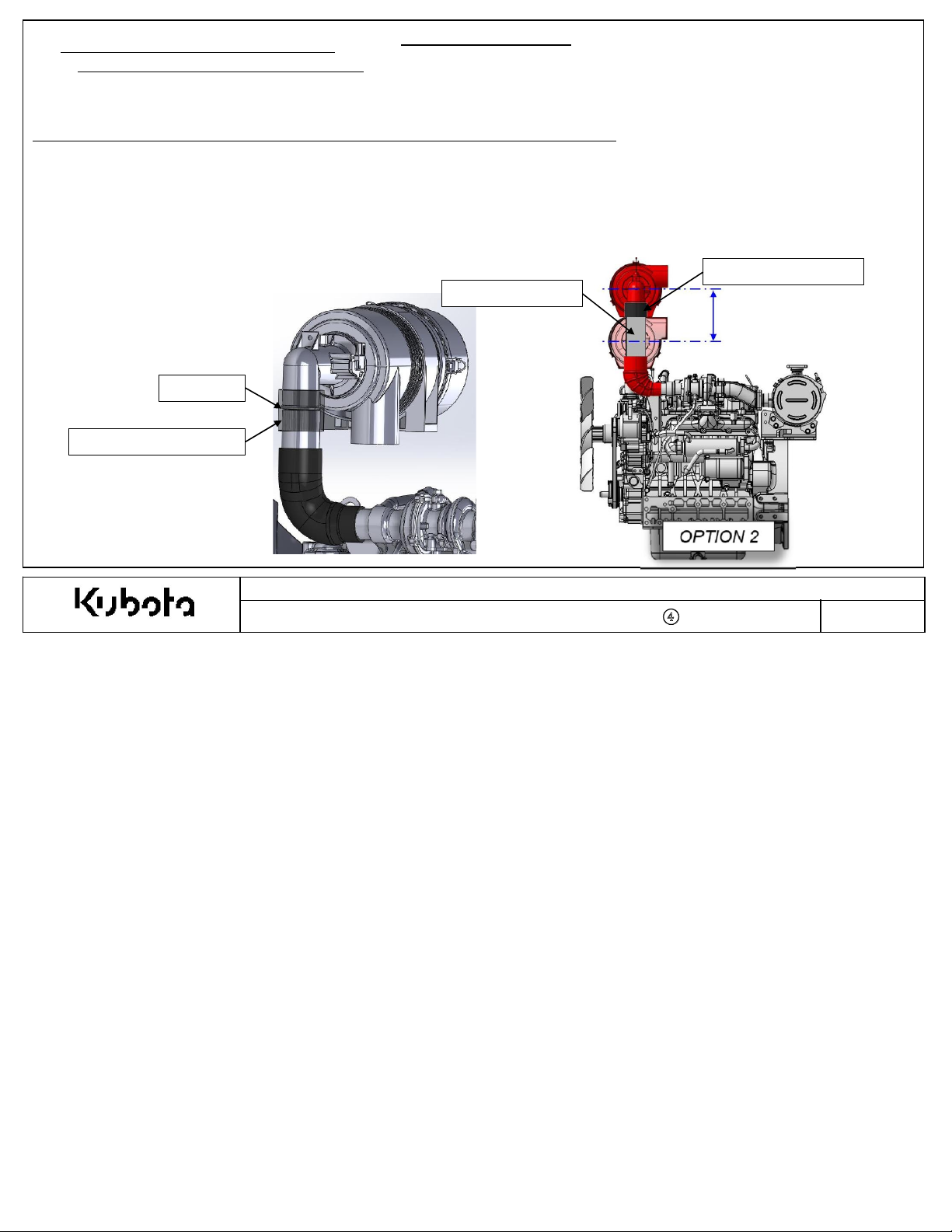

2-1. The ECU mus

2-2. The ECU

temperature must be checked during the app

2-3. The ECU vibrati

2-4. The ECU mus

s

.

K

t be mounted on the equipment cha

on levels must be checked during the app

t be mounted within the installation angles shown below:

° C

ssis

. Engine mounted ECU's ar

licati

on review.

licati

on review.

)

e not approved for warranty.

Kubota Emissi

Document Number : KEA-S

on-R

elated Installation Instructions

TD-03-CRS-DOC-

001

-

④

Page No

.

44

Loading...

Loading...