Kubota D1803-CR-TIE4B-KEA-2, D1803-CR-TIE4B-KEA-1, D1803-CR-TIE4BG-KEA-1, V2403-CR-TIE4B-KEA-1, V2403-CR-TIE4B-KEA-2 Installation Instructions Manual

...

K

ubota

Installation Instructions

CAR

B/EPA certified Tier

4f engines:

D1803-CR-TIE4B-KEA-1 (1J497-10000)

D

1803-CR-T

D

1803-CR-T

V2403-CR-T

V2403-CR-T

V2403-CR-T

IE4B-KEA-2 (1J497-20000

IE4BG-KEA-1 (1J478-10000

IE4B-KEA-1 (1J498-10000

IE4B-KEA-2 (1J498-20000

IE4BG-KEA-1 (1J488-10000

Append

ix 5

)

)

)

)

)

T

he instructions in this document supersede any other previous instructions provided by Kubota.

Kubota Emissi

Document Number : KEA-S

on-R

elated Installation Instructions

TD-03-CRS-DOC-

001

-

④

Page No

.

1

Contents

Append

ix 5

Important Notice

Objectiv

1. Ex

e Items

haust System ------------------------------------------------------------

----------------------------------------------------------------

-----------------------------------------------------------------

2. Intake System ---------------------------------------------------------------

3.Fuel System -----------------------------------------------------------------

4.Engine Control Unit (E

5. Engine Control System (Wire Harness

6.Certification Labels

7.App

licati

on Review Requirement

8. Installation Instructions Re

CU) ----------------------------------------------

/

Display P

ane

l)----------

-------------------------------------------------------

s--------------------------------------

visi

on Log

----------------------------------

page 3

page 4-5

page 6-15

page 16-36

page 37-43

page 44-57

page 48-50

page 51

page 52

page 53

Kubota Emissi

Document Number : KEA-S

on-R

elated Installation Instructions

TD-03-CRS-DOC-

001

-

④

Page No

.

2

Append

ix 5

Important Not

ice

EMISSION-RELATED INSTALLATION INSTRUCTIONS

These instructions ar

the engine, exhaust

sensor), engine control system etc, are installed correctly in the engine’s certifi

c

onfiguration. The e

tail pipe or

wir

e harness and contro

useful life of the component without any failure.

Faili

ng to follow these instructions when insta

piece of nonroad equipment violates federal law (40

and is subject to fines or other penalties as de

e provided for the final engine assemblers (FEA) who must ensure

system (After Treatment De

missi

on related parts which FEA pr

ls) mus

t be designed to function throughout the

vic

e: ATD), i

lli

scri

ntake

system (Air flow

epare (for example the exhaust

ng a certified engine in a

CFR

1068.105(b)),

bed in the Clean Air Act.

ed

Kubota Emissi

Document Number : KEA-S

on-R

elated Installation Instructions

TD-03-CRS-DOC-

001

-

④

Page No

.

3

1. Exhaust Syste

K

ubota supplies a certified diesel oxidation cata

m

treatment and assemble the exhaust

for use with these

KEA s

tandard engine models. Therefore, no other exhaust after treatment can be used.

Objective Items

lyst (DOC) assembly. FEA must use the Kubota supplied certified exhaust after

system

parts according to the instructions. No other exhaust after treatment is certified

Append

ix 5

2. Intake Syste

These Tier

m

4 common rail engines ut

iliz

e a mass air flow (MAF) sensor to control the EGR flow rate. The air cleaner location

and piping layout must be installed according to these installation instructions to maintain proper performance of the MAF

sensor

output. Als

resis

tance and charge air cooler performance must be kept within certain

3. Fuel Syste

m

In order to maintain the common rail fuel injection pump performance and durab

mus

t be checked during the app

o, to prevent decreases of engine output performance and to maintain e

criteri

a.

ility

the pressure and temperature of the fuel

licati

on review.

missi

on compliance, intake

4. Engine Control System (Engine Control Unit (ECU)

T

he Engine Control Unit (E

correctly

within K

and that the requirements and specifications are checked during the app

ubota specification. Othe

5. Engine Control System (Engine Control Unit (ECU), Wire Harness, Operator Display Panel

T

he

wir

e harness is also considered an e

correctly

and that the requirements and specifications are checked during the app

be within Kubota specification. Othe

CU) is consider

rwis

e, engine and e

rwis

e, engine and e

ed an e

missi

on control de

missi

missi

on control de

missi

Kubota Emissi

Document Number : KEA-S

vic

e. It is

critical

to ensure that the ECU is install

licati

on review. The elect

on performance cannot be guaranteed.

)

vic

e. It is

critical

to ensure that the

wir

licati

on review. The elect

on performance cannot be guaranteed.

on-R

elated Installation Instructions

TD-03-CRS-DOC-

001

-

④

rical si

e harness is installed

rical si

ed

gnal must be

gnals must

Page No

.

4

Objective Items

Append

ix 5

6. Certif

7.

ication Labels

K

ubota insta

lls

the certification label on the

cyli

nder head cover. If the final engine assembler insta

makes the engine’s emission control information label hard to read during normal

assembler must place a dup

App

lication Review Requirements

Distri

butor is responsible for completing full app

lic

ate label on the equipment, as de

licati

on review for standard engine to ensure quality engine installation. The

scri

bed in 40

lls

the engine in a way that

engine maintenance, the final engine

CFR

1068.105.

application review should be completed according to Kubota’s application review standards and application manual

r

equirements.

Kubota Emissi

Document Number : KEA-S

on-R

elated Installation Instructions

TD-03-CRS-DOC-

001

-

④

Page No

.

5

Append

ix 5

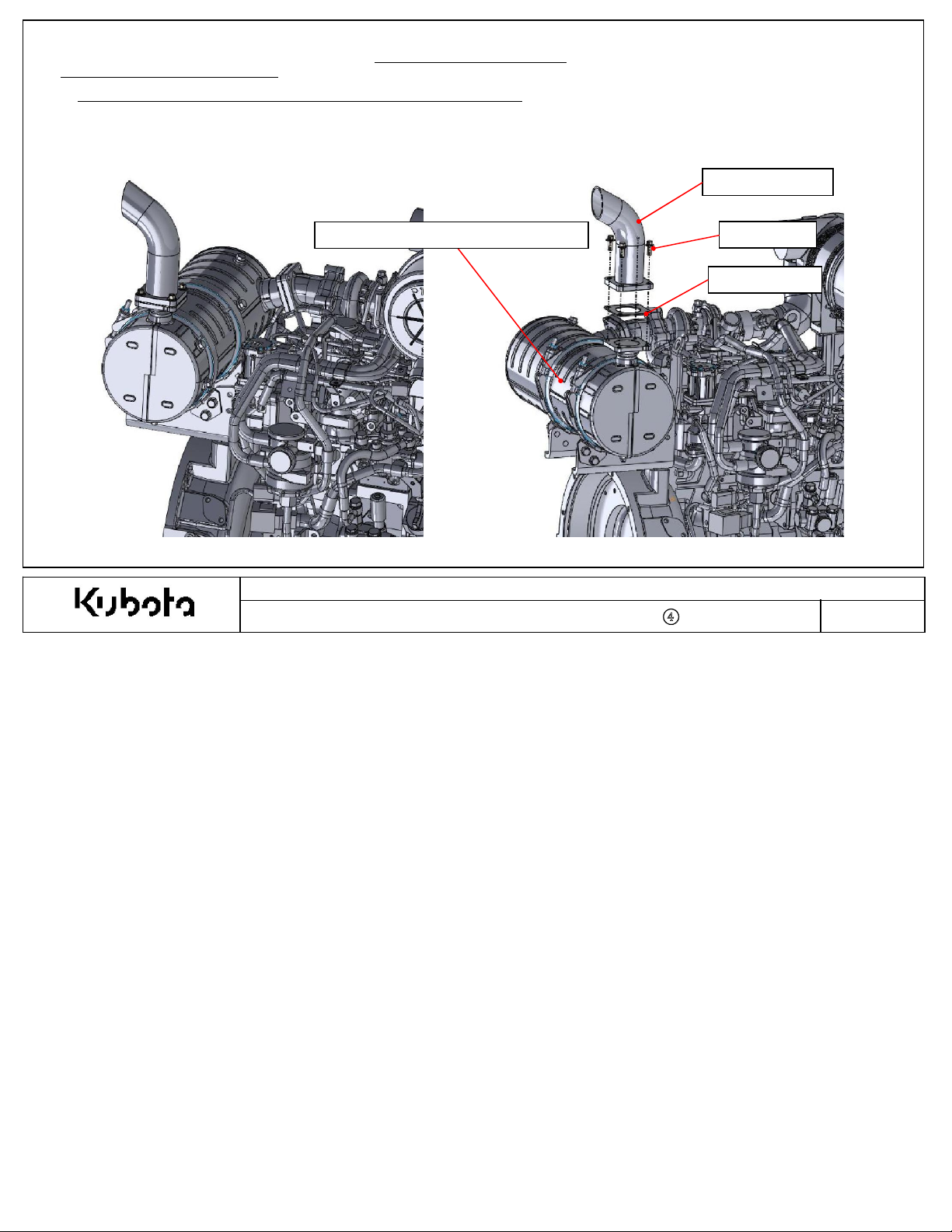

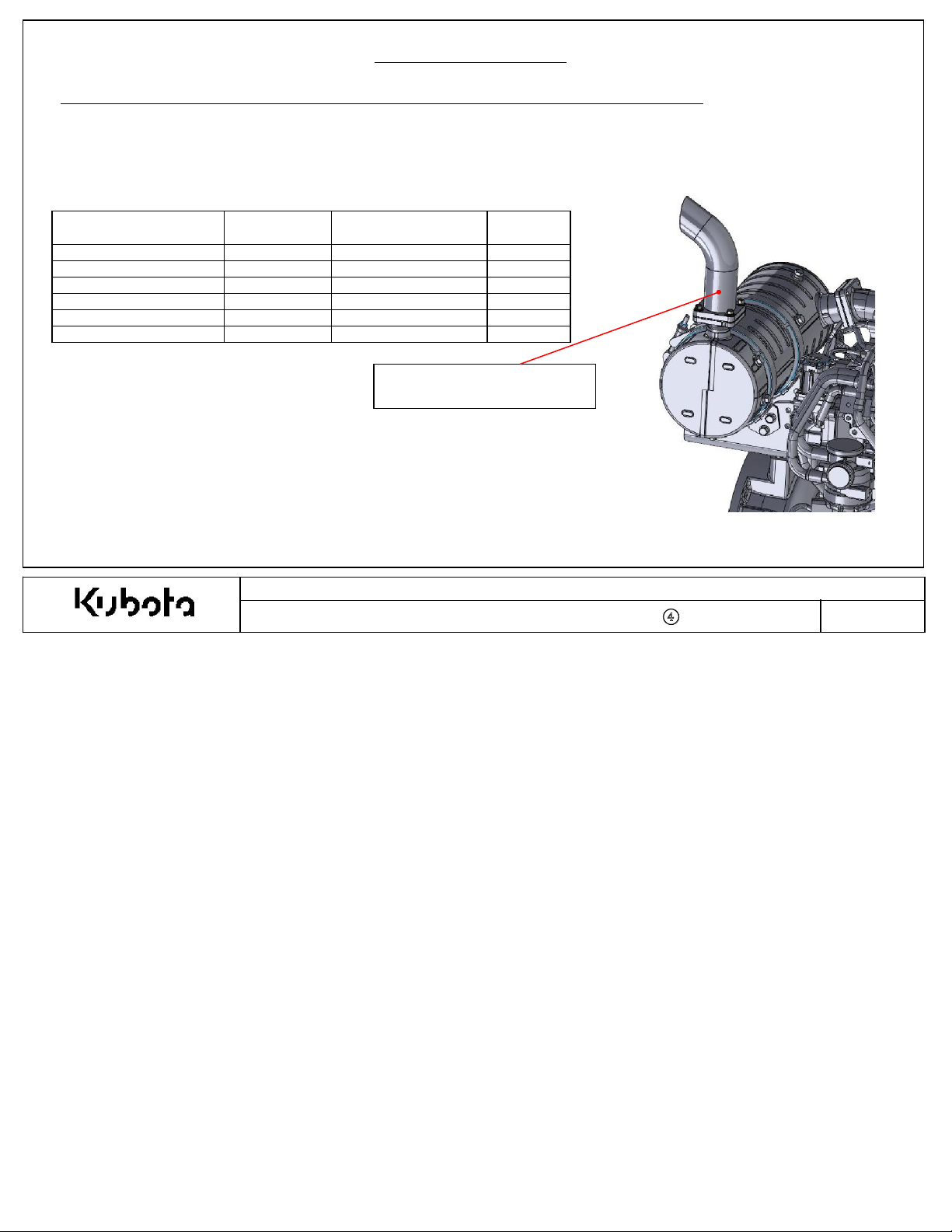

1-1. Ex

1-1-1. Ex

haust System S

haust System S

Exhaust

A

system m

n example of exhaust

upp

1. Exhaust System

ly

upply for

eans the layout of all parts from the exhaust manifold to the exhaust exit.

KEA S

tandard CRS-DOC Engines

system is show

N

o.1 : Diesel Oxi

n below.

dation Cata

lyst (DOC)

N

o.4 : Tail Pi

N

o.3 : Bolt

N

o.2 : Gasket

pe

Kubota Emissi

Document Number : KEA-S

on-R

elated Installation Instructions

TD-03-CRS-DOC-

001

-

④

Page No

.

6

supplied

1J497- 1810△ 1 D1803- CR- TIE4 Engine Code: 1J497- 10000 , 1J478- 10000

1J807- 1810△ 1 D1803- CR- TIE4 Engine Code: 1J497- 20000

1J808- 1810△ 1 V2403- CR- TIE4 All V2403- CR- TIE4 Models

M8 x 1.25mm ISO 8.8

Meet t he back pressure and flange requirements.

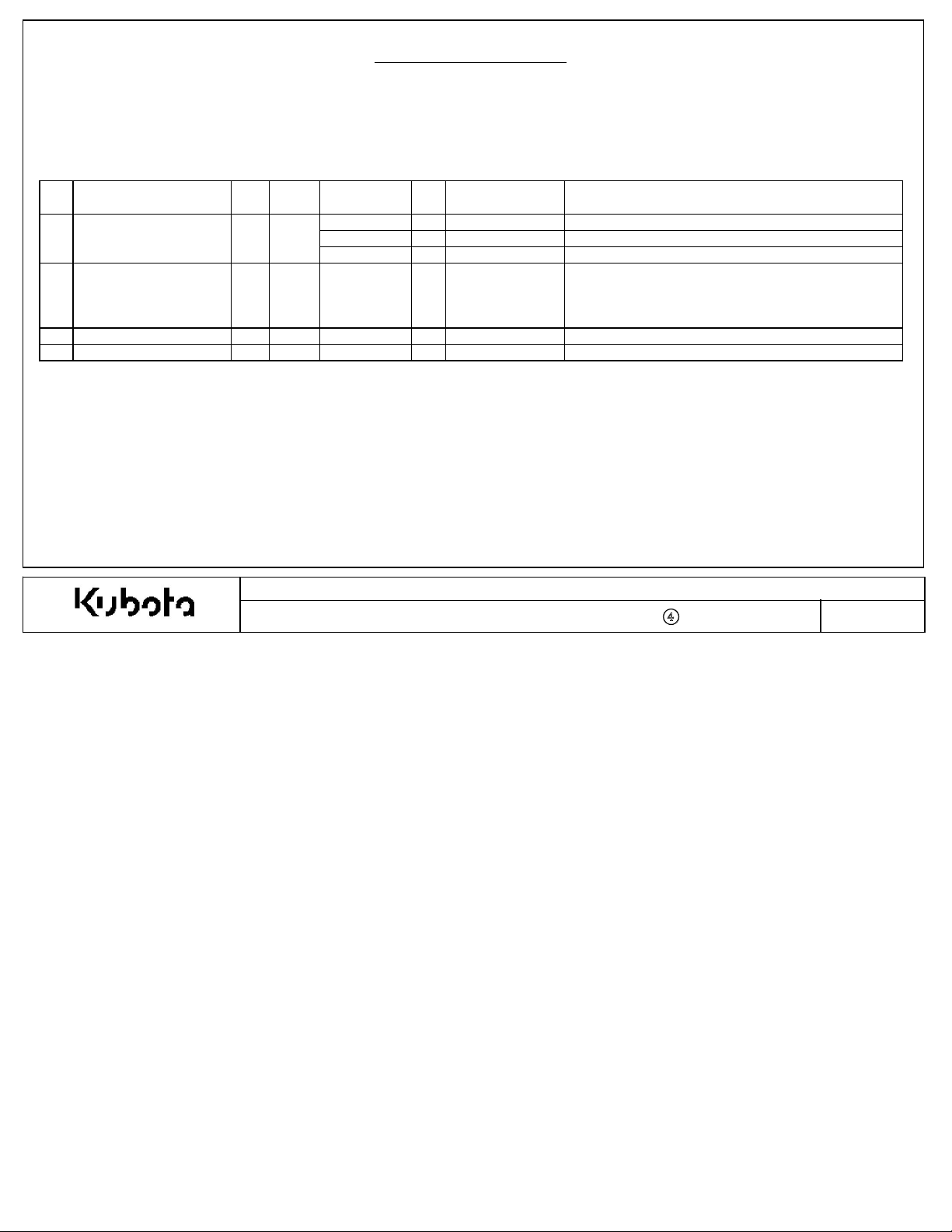

1. Exhaust System

K

ubota supplies the following parts as shown below, these parts must be used in the exhaust

FEA supplied parts must meet the installation instruction requirements.

system

Append

ix 5

.

No. Part Name FEA

Diesel Oxidation Catalyst1

2 Gasket

3 Bolt

4 Tail Pipe

N

ote: Part numbers / assemblies for item #1, Diesel Oxi

○

○

Kubota

○

○

KBT Part No. Q'ty Engine Model Remarks

Qty: 1 Gasket supplied with engine.

17326- 1223△ 1 All 03 Series

Qty: 3 Gaskets are required for remote DOC installation.

(See page 12- 13 f or remote DOC installation details)

- 4

- -

dation Cata

Kubota Emissi

Document Number : KEA-S

lys

t, vary based on the base engine.

on-R

elated Installation Instructions

TD-03-CRS-DOC-

001

-

④

Page No

.

7

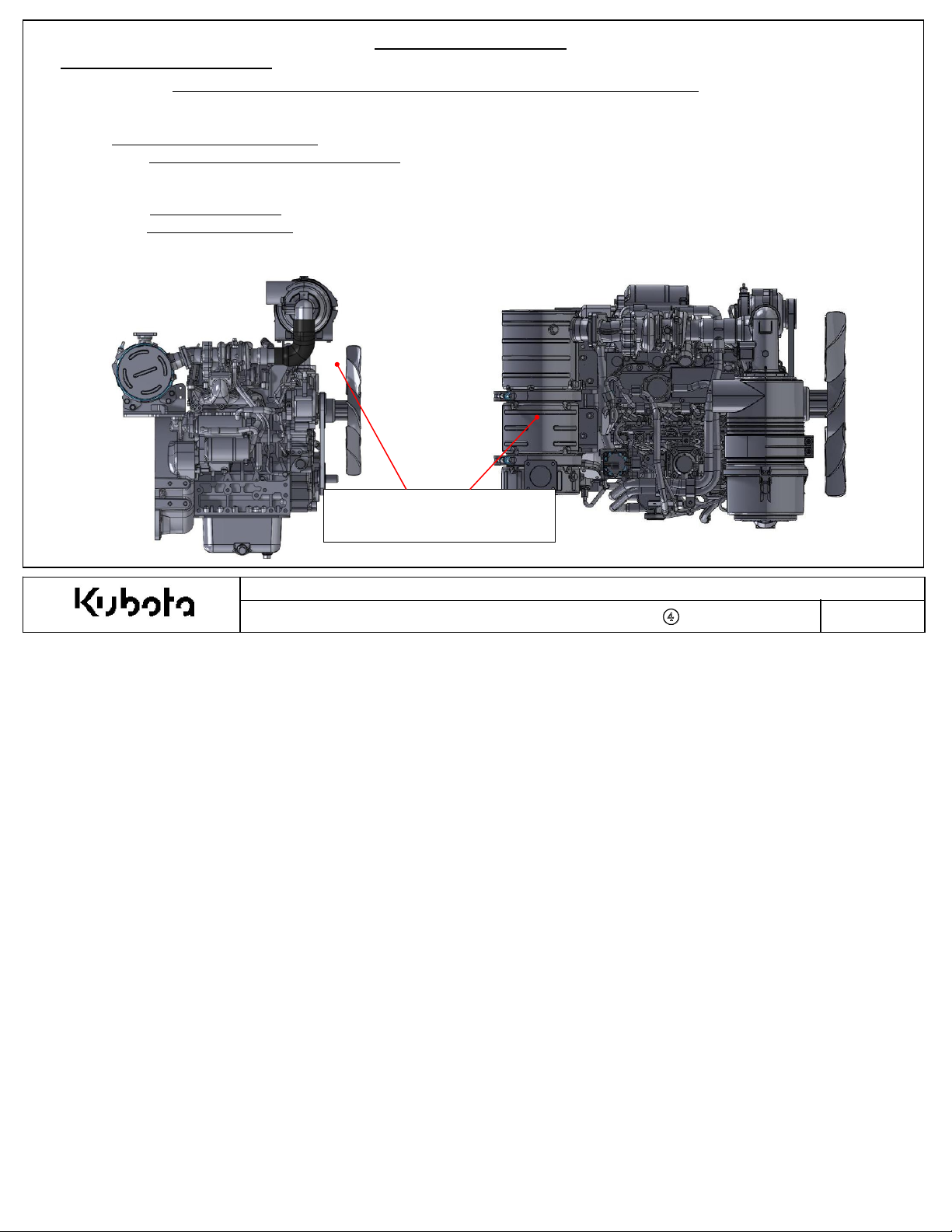

1-2. Ex

haust System

Layout

DOC (Diesel Oxidation Cata

Incorrect DOC inst

allation will cause emission

1-2-1. DOC Installation Options:

A

. Standard DOC Installation Position: T

K

ubota production fa

cility as

the standard configuration. Kubota recommends to keep the DOC in this

factory location.

B. DOC Outlet

C. Remote

It is

critical

Angle: C

Mount DOC: Certai

hanging the DOC outlet angle is acceptable. See following pages.

n app

to follow the instructions outlined in this installation manual to guarantee e

1. Exhaust System

lyst)

Installation for

he DOC is installed onto the top side of the f

lications will r

KEA CRS-DOC S

non-comp

equire for the DOC to be relocated.See following pages.

tandard Engines

liance and/or damage to the DOC

lyw

heel housing at the

missi

on compliance.

Append

ix 5

.

DOC (Diesel Oxidation Cata

Factory

Document Number : KEA-S

Location

Kubota Emissi

lyst)

on-R

elated Installation Instructions

TD-03-CRS-DOC-

001

-

④

Page No

.

8

Industrial

Industrial

BG

Industrial

Industrial

BG

1. Exhaust System

Append

ix 5

1-2-1.A Factory Mounted Installation Position (DOC): Ex

Back pressur

Measurem

Engine Model 10 Digit Code Maximum Back Pressure Remarks

D1803- CR- TIE4B- KEA- 1 1J497- 10000 50 mm Hg

D1803- CR- TIE4B- KEA- 2 1J497- 20000 50 mm Hg

D1803- CR- TIE4BG- KEA- 1 1J478- 10000 40 mm Hg

V2403- CR- TIE4B- KEA- 1 1J498- 10000 50 mm Hg

V2403- CR- TIE4B- KEA- 2 1J498- 20000 50 mm Hg

V2403- CR- TIE4BG- KEA- 1 1J488- 10000 40 mm Hg

e of exhaust tail pipe at full load, rated speed condition must be according to table below.

ent point of back pressure of exhaust

system is within 1” (25.4 mm) of the DOC outlet.

Back Pressure Measurement

Location

haust Back Pressure Check

Kubota Emissi

Document Number : KEA-S

on-R

elated Installation Instructions

TD-03-CRS-DOC-

001

-

④

Page No

.

9

1. Exhaust System

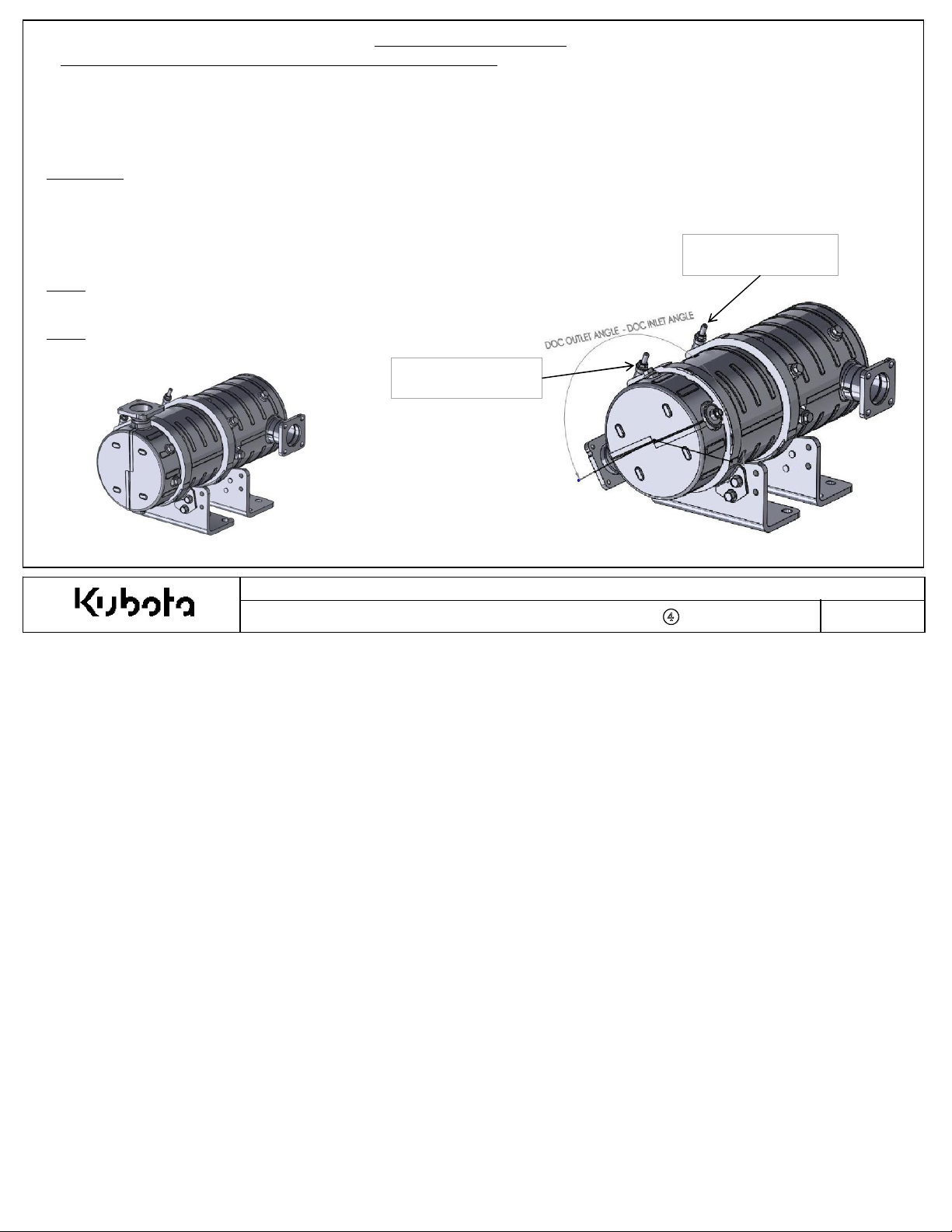

1-2-1.B DOC Outlet Angle Adjustment Proc

1.Kubota recommends to keep the DOC outlet angle in the standard position, but certain app

2.Adjusting the DOC outlet angle is acceptable to meet the installation requirements of the machine.

•Installati

•Angle adjustment must be completed only 1 time (to min

•Angle adjustment must be completed before customers run the engine(to min

on instructions must be carefu

lly

followed to ensure e

edure (Option)

missi

imize risk

of clamp breakage).

on compliance.

imize risk

lications will r

of clamp deterioration due to heat).

equire adjustment.

Append

ix 5

Procedure

STEP

STEP

STEP

STEP

STEP

N

ote 1: It is NOT allowed to adjust the DOC inlet portion of the DOC.

Only

N

ote 2: Any exhaust gas leakage or failures due to incorrect modification is not

cover

:

1: Loosen DOC band clamp at DOC outlet position and remove DOC outlet portion.

2: Replace gasket with new parts. Refer to

3: Ori

ent the DOC outlet to the de

4: Tighten Band clamp nut to 16-20 Nm.

5: Start engine and conf

the DOC outlet position can be adjusted.

ed under standard/e

irm

missions warr

sir

that there are no exhaust leaks.

anty.

STANDARD DOC CONFIGURATIO

ed angle

illustr

ated parts

(similar

lis

to image to the right).

Loosen This DOC

B

and Clamp

N

Kubota Emissi

Document Number : KEA-S

t for gasket P/N.

A

DJUSTED DOC OUTLET ANGLE

on-R

elated Installation Instructions

TD-03-CRS-DOC-

001

-

④

Do NOT

DOC B

Loosen This

and Clamp

Page No

.

10

1. Exhaust System

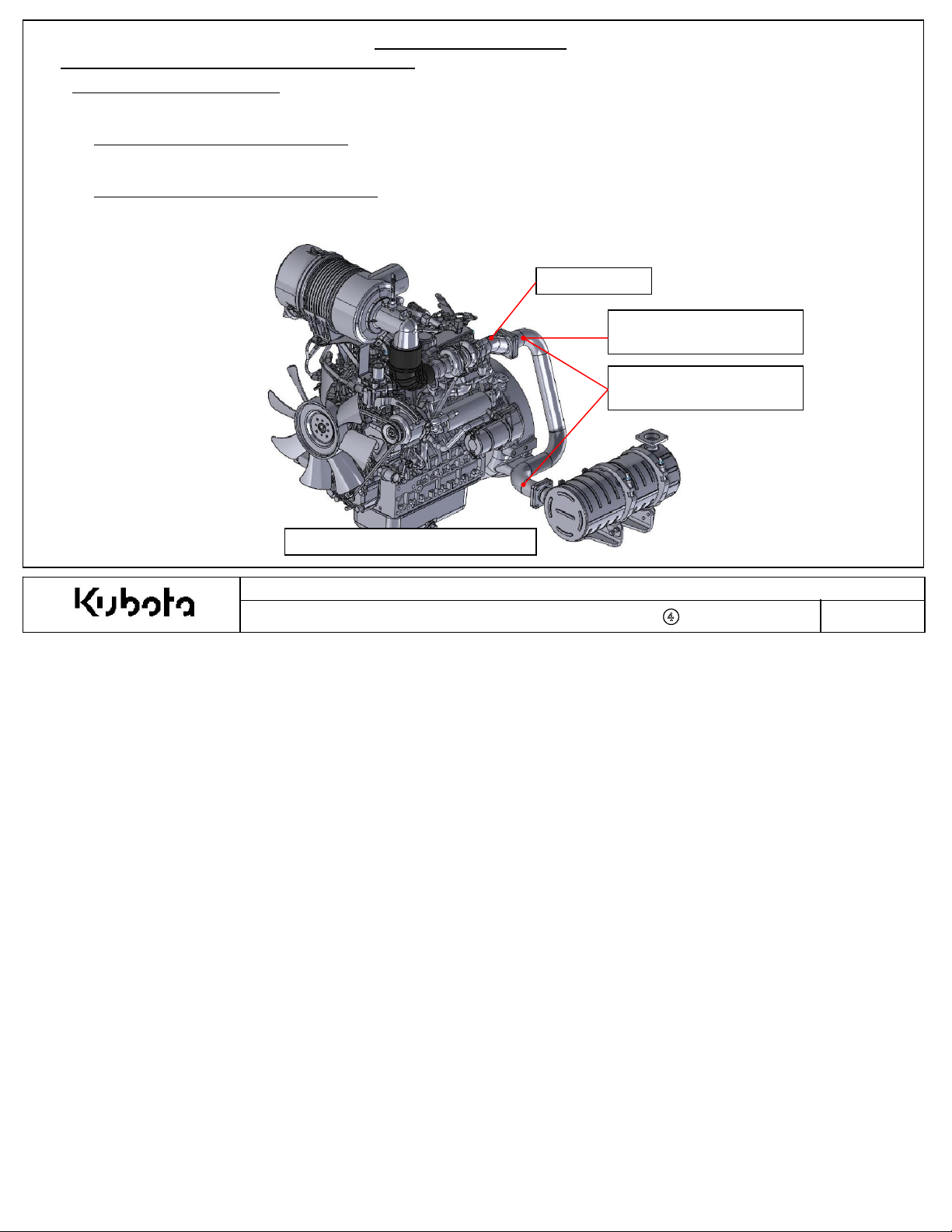

1-2-1.C Remote Mounting the DOC (Option)

Rem

ote DOC Installation Option

Certai

n app

lications will r

equire for the DOC to be relocated.See below installation

criteri

Append

ix 5

a.

1.Exhaust Backpr

A.T

outlet must be less than 113

essure Requirement:

he ma

ximum allowabl

e exhaust back pressure for the complete exhaust

mmH

2.Exhaust Temperature Drop Requireme

A. T

he ma

ximum allowabl

r

ated speed full load condition. Ex

e temperature drop across the intermediate exhaust pipe must be less than 25 deg. C at the

EXAMPLE REMOTE MO

system measur

ed at the muffler flange

g. The back pressure must be measured at the rated speed full load condition.

nt:

haust pipe insulation may be required and is recommended to meet this requirement.

M

uffler Flange

Measurem

Exhaust Back Pressur

Measurem

ent Location for

e

ent Location for

Exhaust Temperature (∆T)

UNT DOC

Kubota Emissi

on-R

elated Installation Instructions

Document Number : KEA-S

TD-03-CRS-DOC-

001

-

④

Page No

.

11

1. Exhaust System

1-2-1.C Remote Mounting the DOC (Option)

Remote DOC Installation Option Continued…

Append

ix 5

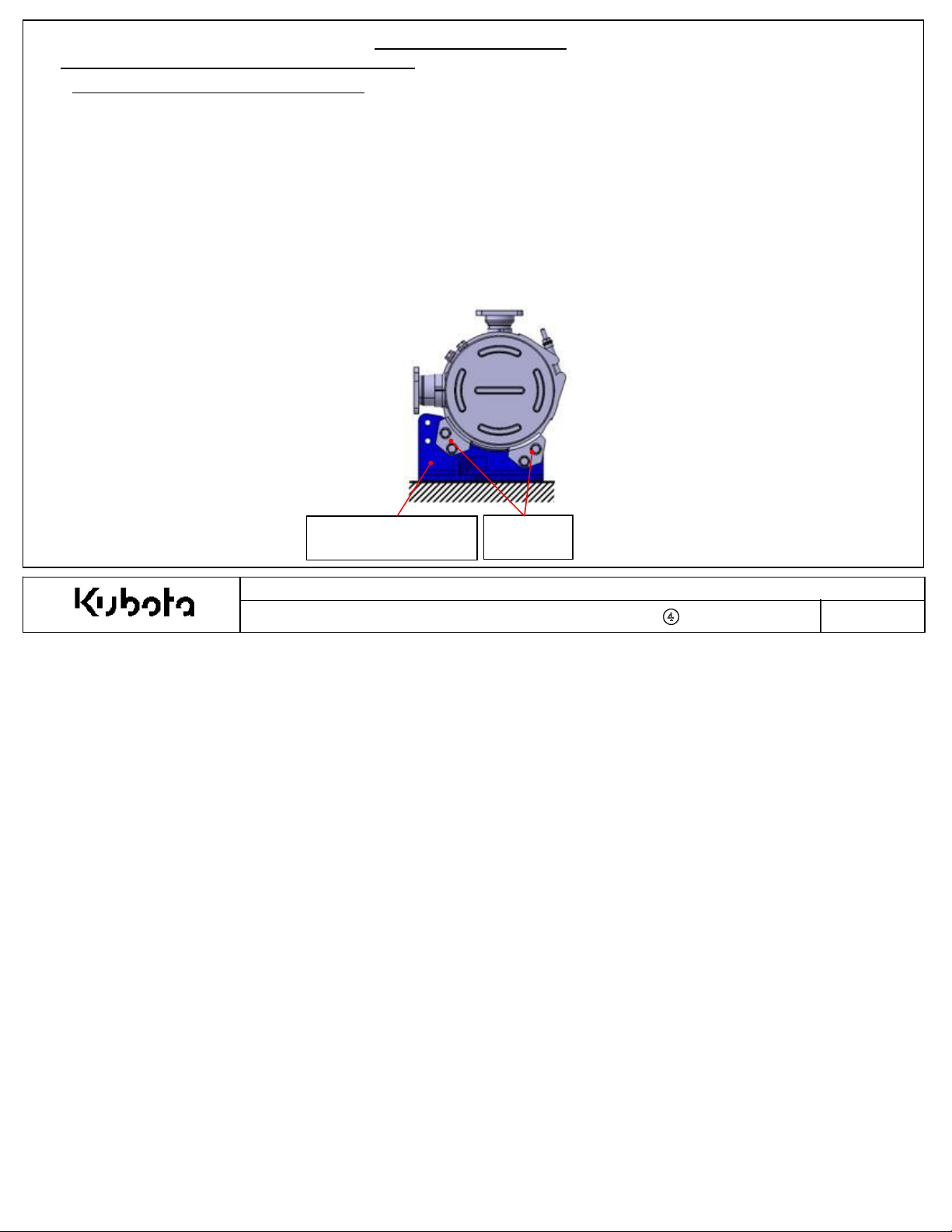

3. Other Inst

A

. Intermediate pipe for remote DOC (from turbo-out to DO

B.T

he muffler flange must not be removed from the engine. The intermediate exhaust pipe must connect to the outlet of the

m

uffler flange.

C.T

he intermediate exhaust pipe and flexible coupling must not leak exhaust gases during operation.

D.New m

remov

E.Ti

ghtening torque for the muffler flange outlet and DOC inlet M8 fasteners is 24-27

F.Reloc

G

. It is strongly recommended to use the Kubota supplied DOC mounting brackets (shown below in blue).

H.DOC incli

allation Requirements for Remotely Installed DOC

C-inlet) must incl

ude a flexible portion.

uffler flange outlet gasket, DOC inlet gasket, studs, and nuts on muffler flange outlet are required when DOC is

ed from engine for remote installation. Refer to the

ated DOC needs to be mounted without exce

illustr

ssive strain/l

ated parts

oad on V-

lis

t for the correct replacement part numbers.

N·m

.

band clamps.

nation angle must follow the required installation angles defined in the next page.

K

ubota Supplied DOC

M

ounting Brackets

V-band

Clamps

Kubota Emissi

Document Number : KEA-S

on-R

elated Installation Instructions

TD-03-CRS-DOC-

001

-

④

Page No

.

12

Append

ix 5

1-2-1.C Remote Mounting the DOC (Option)

4. Other Inst

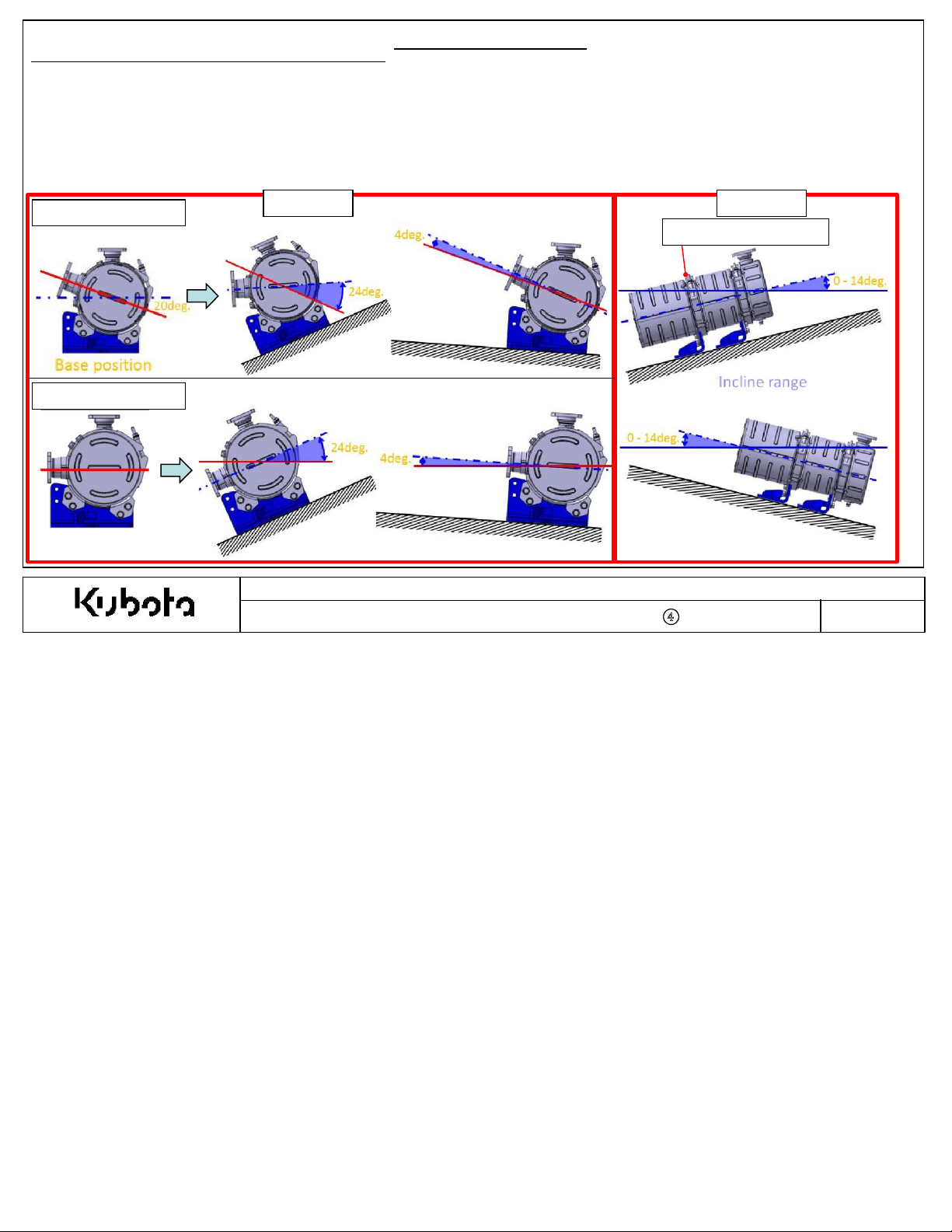

A.DOC incli

B.T

C.T

D

1803

V

2403

he DOC inlet band clamp cannot be loosened or modified in any way.

he DOC can only be in

-CR-TIE4B-***

-CR-TIE4B-***

allation Requirements for Remotely Installed DOC

nation angle must be installed according to the angles defined below.

cli

ned according to option #1 or option #2, not the combination.

I.Option #1: Rotate the DOC about the DOC cente

i.Please note the required installation angle

II.Option #2: In

cli

ne the DOC up to +/-14 deg.

Option #1

1. Exhaust System

rli

ne a

xis

.

limits

below

(view

ed from DOC inlet side

Option #2

DOC

Inlet Band Clamp

)

Base position

Kubota Emissi

Document Number : KEA-S

on-R

elated Installation Instructions

TD-03-CRS-DOC-

001

-

④

Page No

.

13

1. Exhaust System

Append

ix 5

1-3 DOC

(Diesel Oxidation Cata

lyst)

Installation

Criteria {Applies for engine mounted or remote mounted DOC}

1.DOC vibration:

-Accelerati

-Vibrati

on/

Displacem

ent must not exceed the

on must be checked during the app

licati

limits prescri

on review.

bed in the app

licati

on review form.

2. The DOC shall not support mounting loads from adjacent or mated components (tail pipe/intermediate pipe):

- Check DOC

tail pipe vibration during app

licati

on review to ensure it

will

not damage the DOC during long term operation.

-

Intermediate exhaust pipe for remote mount DOC may require support brackets.

3. Pleas

4. OEM Tail Pi

e note that the DOC

- Check surr

ounding component temperatures during the app

pe Requirements:

ski

n temperature can reach about 250

° C

licati

:

on review.

- FEA supplied bolts:

- Fl

ange bolts: M8 x 1.25, strength cla

- Ti

ghtening torque; 24-27

N·m

ssificati

on is ISO

8.8

- Tail Pipe Flange:

- Fl

ange th

- Fl

atness of the flange face is ma

ickness is 8mm or mor

e.

ximum

0.1mm.

-Surface finish of the flange face is 3.2Ra.

5. Intermediate Ex

-Accelerati

app

-Vibrati

haust Pi

licati

on review form.

on/

Displacem

pe Vibrati

on: for remote mounted DO

ent must not exceed the

on must be checked during the app

licati

C

limits prescri

on review.

bed in the

Kubota Emissi

Document Number : KEA-S

on-R

elated Installation Instructions

TD-03-CRS-DOC-

001

-

④

Page No

.

14

Loading...

Loading...