Kubota D1803-CR-TIE4, V2403-CR-TIE4, V3800-CR-TIE4, V3307-CR-TIE4, V2607-CR-TIE4 Operator's Manual

OPERATOR'S MANUAL

KUBOTA

DIESEL ENGINE

MODELS

V2403-CR-TIE4

V2607-CR-TIE4

V3307-CR-TIE4

V3800-CR-TIE4D1803-CR-TIE4

1ABACCJAP0070 1ABAHABAP0070 1ABADBMAP0230

1J778-8915-6

READ AND SAVE THIS BOOK

California Proposition 65

Engine exhaust, some of its constituents,

WARNING

certain vehicle components and fluids,

contain or emit chemicals known to the

State of California to cause cancer and birth

defects or other reproductive harm.

ENGLISH

FOREWORD

You are now the proud owner of a KUBOTA Engine. This engine is a

product of KUBOTA quality engineering and manufacturing. It is made

of fine materials and under a rigid quality control system. It will give

you long, satisfactory service. To obtain the best use of your engine,

please read this manual carefully. It will help you become familiar with

the operation of the engine and contains many helpful hints about

engine maintenance. It is KUBOTA's policy to utilize as quickly as

possible every advance in our research. The immediate use of new

techniques in the manufacture of products may cause some small

parts of this manual to be outdated. KUBOTA distributors and dealers

will have the most up-to-date information. Please do not hesitate to

consult with them.

This Operator's Manual should be considered a permanent part of the

engine and should remain with the engine when it is resold.

This symbol, the industry's "Safety Alert Symbol", is used throughout

this manual and on labels on the machine itself to warn of the

possibility of personal injury. Read these instructions carefully. It is

essential that you read the instructions and safety regulations before

you attempt to assemble or use this unit.

DANGER :

WARNING :

CAUTION :

IMPORTANT :

NOTE :

SAFETY FIRST

Indicates an imminently hazardous situation which,

if not avoided, will result in death or serious

injury.

Indicates a potentially hazardous situation which,

if not avoided, could result in death or serious

injury.

Indicates a potentially hazardous situation which,

if not avoided, could result in minor or moderate

injury.

Indicates that equipment or property damage

could result if instructions are not followed.

Gives helpful information.

CONTENTS

SAFE OPERATION ..................................................................................................1

SERVICING OF THE ENGINE .................................................................................... 1

NAMES OF PARTS ..................................................................................................... 2

PRE-OPERATION CHECK .......................................................................................... 5

BREAK-IN................................................................................................................. 5

DAILY CHECK..........................................................................................................5

OPERATING THE ENGINE .........................................................................................6

STARTING THE ENGINE (NORMAL) ......................................................................6

COLD WEATHER STARTING ................................................................................. 7

STOPPING THE ENGINE ........................................................................................7

CHECKS DURING OPERATION .............................................................................7

Radiator cooling water (Coolant) ...................................................................................... 7

Oil pressure lamp ............................................................................................................. 8

Charge lamp.....................................................................................................................8

Fuel .................................................................................................................................. 8

Color of exhaust ............................................................................................................... 8

Immediately stop the engine if;......................................................................................... 8

AIR FLOW SENSOR ................................................................................................8

Air cleaner-mounted type ................................................................................................. 8

Inlet hose pipe-mounted type ........................................................................................... 8

PRECAUTIONS ON GENERATOR-EQUIPPED ENGINE.......................................8

MAINTENANCE ...........................................................................................................9

SERVICE INTERVALS ........................................................................................... 10

DAILY CHECKS .....................................................................................................14

Checking of engine oil level............................................................................................ 14

Checking of fuel level ..................................................................................................... 15

Checking of coolant level ............................................................................................... 16

Anti-freeze ...................................................................................................................... 17

Checking of fan belt........................................................................................................ 18

REGULAR CHECKS AND MAINTENANCE WORK .................................................. 19

EVERY 50 SERVICE HOURS................................................................................19

Checking of fuel pipes and clamp bands........................................................................ 19

Draining of water separator ............................................................................................ 19

EVERY 100 SERVICE HOURS.............................................................................. 20

Cleaning of air cleaner element...................................................................................... 20

Adjustment of fan belt tension ........................................................................................ 20

EVERY 200 SERVICE HOURS.............................................................................. 21

Checking of radiator hoses and clamp bands ................................................................ 21

Checking of intake air line .............................................................................................. 21

EVERY 250 SERVICE HOURS.............................................................................. 21

Checking of radiator hoses and clamp bands ................................................................ 21

Precaution at overheating .............................................................................................. 21

Cleaning of air cleaner element...................................................................................... 21

Adjustment of fan belt tension ........................................................................................ 22

Checking of intake air line .............................................................................................. 23

EVERY 400 SERVICE HOURS.............................................................................. 23

Changing of engine oil.................................................................................................... 23

ENGLISH

ENGLISH

CONTENTS

Replacement of oil filter cartridge ................................................................................... 23

Replacement of fuel filter cartridge................................................................................. 24

EVERY 500 SERVICE HOURS.............................................................................. 24

Changing of engine oil.................................................................................................... 24

Replacement of oil filter cartridge ................................................................................... 24

Replacement of fuel filter cartridge................................................................................. 25

Cleaning of water separator ........................................................................................... 25

Removal of sediment in fuel tank ................................................................................... 25

Cleaning of water jacket (radiator interior) ..................................................................... 25

Replacement of fan belt ................................................................................................. 25

EVERY 800 SERVICE HOURS.............................................................................. 25

Checking of valve clearance .......................................................................................... 25

EVERY 1000 SERVICE HOURS............................................................................ 25

Checking of valve clearance .......................................................................................... 25

EVERY 1500 SERVICE HOURS............................................................................ 26

Checking of injector tip ................................................................................................... 26

Checking of EGR cooler................................................................................................. 26

Changing of oil separator element ................................................................................. 26

Checking of PCV valve (Positive Crankcase Ventilation valve) ..................................... 26

EVERY 3000 SERVICE HOURS............................................................................ 26

Checking of turbo-charger .............................................................................................. 26

Checking of EGR System............................................................................................... 26

ANNUAL SERVICING ............................................................................................27

Replacement of air cleaner element............................................................................... 27

Checking of EGR piping ................................................................................................. 27

Checking of intake air line .............................................................................................. 27

Checking of exhaust manifold for cracks or gas leak and for looseness or damage .... 27

BIENNIAL SERVICING .......................................................................................... 27

Replacement of rubber piping related oil separator ....................................................... 27

Replacement of intake air line and suction air pressure takeout rubber piping.............. 27

Replacement of boost sensor pressure rubber piping.................................................... 27

Replacement of EGR cooler rubber piping..................................................................... 27

Replacement of water rubber piping .............................................................................. 27

Replacement of lubricant rubber piping.......................................................................... 27

Changing of radiator coolant (L.L.C.) ............................................................................. 27

Remedies for quick decrease of coolant ........................................................................ 28

Replacement of radiator hoses and clamp bands .......................................................... 28

Replacement of fuel pipes and clamp bands ................................................................. 28

Replacement of intake air line ........................................................................................ 28

Replacement of fan belt ................................................................................................ 28

CARRIAGE AND STORAGE .....................................................................................29

CARRIAGE .............................................................................................................29

STORAGE ..............................................................................................................29

TROUBLESHOOTING ...............................................................................................30

SPECIFICATIONS .....................................................................................................32

SAFE OPERATION

1SAFE OPERATION

Careful operation is your best assurance against an accident. Read and understand this

section carefully before operating the engine. All operators, no matter how much

experience they may have, should read this and other related manuals before operating

the engine or any equipment attached to it. It is the owner's obligation to provide all

operators with this information and instruct them on safe operation.

Be sure to observe the following for safe operation.

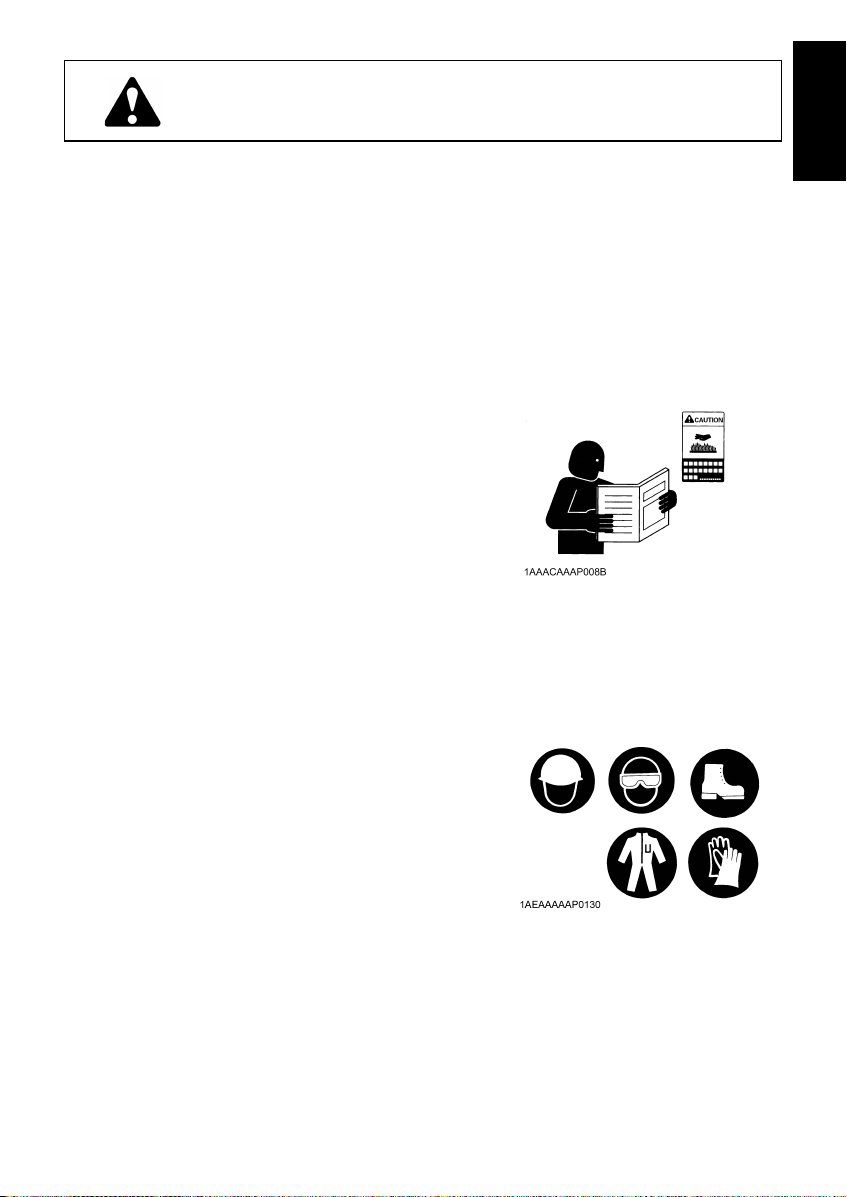

OBSERVE SAFETY INSTRUCTIONS

1.

A Read and understand carefully this "OPERATOR'S

MANUAL" and "LABELS ON THE ENGINE" before

attempting to start and operate the engine.

A Learn how to operate and work safely. Know your

equipment and its limitations. Always keep the engine in

good condition.

A Before allowing other people to use your engine, explain

how to operate and have them read this manual before

operation.

A DO NOT modify the engine. UNAUTHORIZED

MODIFICATIONS to the engine may impair the function

and/or safety and affect engine life. If the engine does not

perform properly, consult your local Kubota Engine

Distributor first.

2. WEAR SAFE CLOTHING AND PERSONAL PROTECTIVE EQUIPMENT (PPE)

A DO NOT wear loose, torn or bulky clothing around the

machine that may catch on working controls and

projections or into fans, pulleys and other moving parts

causing personal injury.

A Use additional safety items-PPE, e.g. hard hat, safety

protection, safety goggles, gloves, etc., as appropriate or

required.

A DO NOT operate the machine or any equipment attached

to it while under the influence of alcohol, medication, or

other drugs, or while fatigued.

A DO NOT wear radio or music headphones while

operating the engine.

ENGLISH

SAFE OPERATION2

3. CHECK BEFORE STARTING & OPERATING THE ENGINE

ENGLISH

A Be sure to inspect the engine before operation. Do not

operate the engine if there is something wrong with it.

Repair it immediately.

A Ensure all guards and shields are in place before

operating the engine. Replace any that are damaged or

missing.

A Check to see that you and others are a safe distance

from the engine before starting.

A Always keep the engine at least 3 feet (1 meter) away

from buildings and other facilities.

A DO NOT allow children or livestock to approach the

machine while the engine is running.

A DO NOT start the engine by shorting across starter

terminals. The machine may start in gear and move. Do

not bypass or defeat any safety devices.

4. KEEP THE ENGINE AND SURROUNDINGS CLEAN

A Be sure to stop the engine before cleaning.

A Keep the engine clean and free of accumulated dirt,

grease and trash to avoid a fire. Store flammable fluids in

proper containers and cabinets away from sparks and

heat.

A Check for and repair leaks immediately.

A DO NOT stop the engine without idling; Allow the engine

to cool down, first. Keep the engine idling for about 5

minutes before stopping unless there is a safety problem

that requires immediate shut down.

5. SAFE HANDLING OF FUEL AND LUBRICANTS -KEEP AWAY FROM FIRE

A Always stop the engine before refueling and/or

lubricating.

A DO NOT smoke or allow flames or sparks in your work

area. Fuel is extremely flammable and explosive under

certain conditions.

A Refuel at a well ventilated and open place. When fuel

and/or lubricants are spilled, refuel after letting the

engine cool down.

A DO NOT mix gasoline or alcohol with diesel fuel. The

mixture can cause a fire or severe engine damage.

A Do not use unapproved containers e.g. buckets, bottles,

jars. Use approved fuel storage containers and

dispensers.

3SAFE OPERATION

6. EXHAUST GASES & FIRE PREVENTION

A Engine exhaust fumes can be very harmful if allowed to

accumulate. Be sure to run the engine in a well ventilated

location and where there are no people or livestock near

the engine.

A The exhaust gas from the muffler is very hot. To prevent

a fire, do not expose dry grass, mowed grass, oil or any

other combustible materials to exhaust gas. Keep the

engine and muffler clean at all times.

A To avoid a fire, be alert for leaks of flammable

substances from hoses and lines. Be sure to check for

leaks from hoses or pipes, such as fuel and hydraulic

fluid by following the maintenance check list.

A To avoid a fire, do not short across power cables and

wires. Check to see that all power cables and wirings are

in good condition. Keep all electrical connections clean.

Bare wire or frayed insulation can cause a dangerous

electrical shock and personal injury.

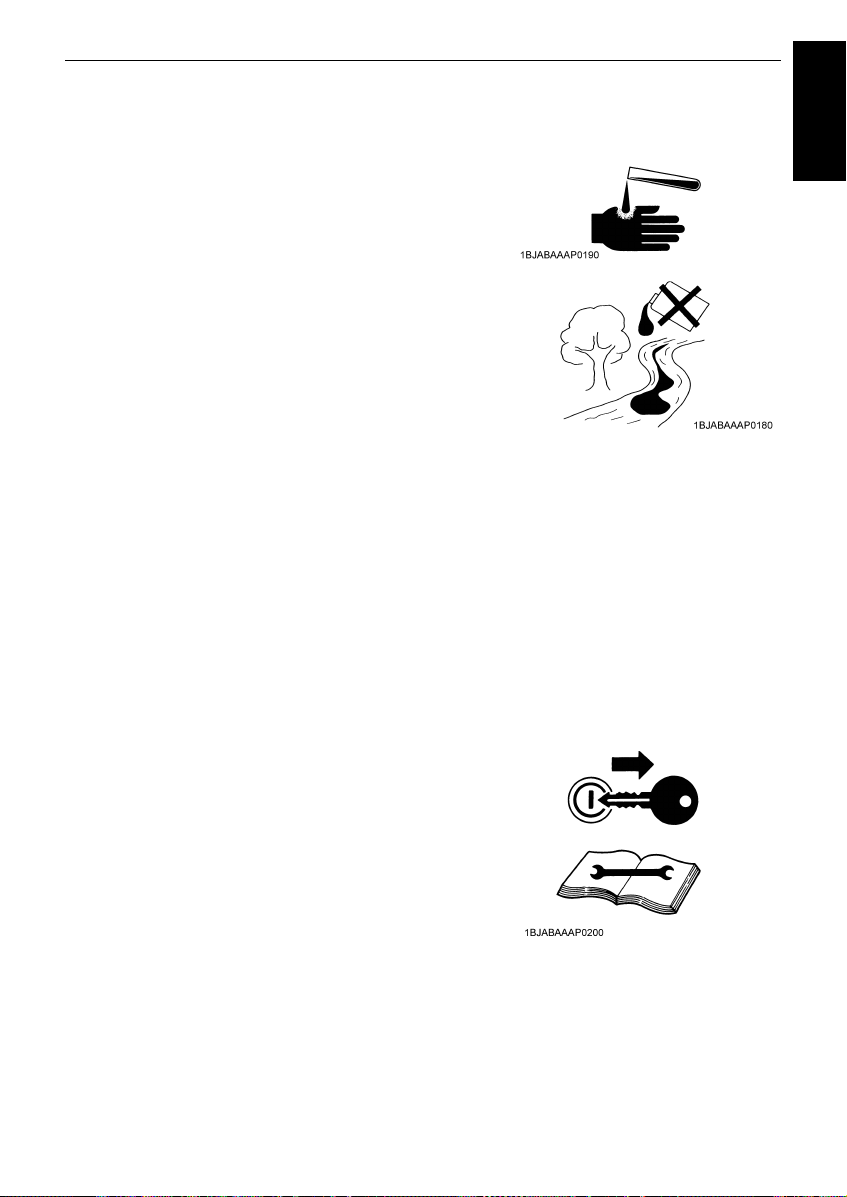

7. ESCAPING FLUID

A Relieve all pressure in the air, the oil and the cooling

systems before disconnecting any lines, fittings or

related items.

A Relieve all pressure in any system before disconnecting

any lines, fittings, or related items.

DO NOT check for pressure leaks with your hand. High

pressure oil or fuel can cause personal injury.

A Escaping fluid under pressure has sufficient force to

penetrate skin causing serious personal injury.

A Fluid escaping from pinholes may be invisible. Use a

piece of cardboard or wood to search for suspected

leaks: do not use hands and body. Use safety goggles or

other eye protection when checking for leaks.

A If injured by escaping fluid, see a medical doctor

immediately. This fluid can produce gangrene or severe

allergic reaction.

ENGLISH

SAFE OPERATION4

8. CAUTIONS AGAINST BURNS & BATTERY EXPLOSION

ENGLISH

A To avoid burns, be cautious of hot components, e.g.,

exhaust piping, turbo-charger, EGR system, radiator,

hoses, engine body, coolants, engine oil, etc. during

operation and after the engine has been shut off.

A DO NOT remove the radiator cap while the engine is

running or immediately after stopping. Otherwise hot

water will spout out from the radiator. Wait until the

radiator is completely cool to the touch before removing

the cap. Wear safety goggles.

A Be sure to close the coolant drain valve, secure the

pressure cap, and fasten the pipe band before operating.

If these parts are taken off, or loosened, it will result in

serious personal injury.

A The battery presents an explosive hazard. When the

battery is being charged, hydrogen and oxygen gases

are extremely explosive.

A DO NOT use or charge the battery if its fluid level is below

the LOWER mark.

Otherwise, the component parts may deteriorate earlier

than expected, which may shorten the service life or

cause an explosion. Immediately, add distilled water until

the fluid level is between the UPPER and LOWER marks.

A Keep sparks and open flames away from the battery,

especially during charging. DO NOT strike a match near

the battery.

A DO NOT check the battery charge by placing a metal

object across the terminals. Use a voltmeter or

hydrometer.

A DO NOT charge a frozen battery. There is a risk of

explosion. When frozen, warm the battery up to at least

16 C (61 F).

9. KEEP HANDS AND BODY AWAY FROM ROTATING PARTS

A Be sure to stop the engine before checking or adjusting

the belt tension and cooling fan.

A Keep your hands and body away from rotating parts,

such as the cooling fan, V-belt, fan drive pulley or

flywheel. Contact with rotating parts can cause severe

personal injury.

A DO NOT run the engine without safety guards. Install

safety guards securely before operation.

5SAFE OPERATION

10. ANTI-FREEZE & DISPOSAL OF FLUIDS

A

Anti-freeze is poisonous. If it is swallowed, seek immediate

medical help. Do NOT make a person throw up unless told

to do so by poison control or a health care professional. Use

standard first aid and CPR for signs of shock or cardiac

arrest. Call your local Poison Control Center or your local

emergency number for further assistance.

A

Wear rubber gloves to avoid personal injury, when you treat

anti-freeze. In case of contact with skin, wash it off

immediately.

A

DO NOT mix different types of Anti-freeze. The mixture can

produce a chemical reaction causing harmful substances.

Use approved or genuine KUBOTA Anti-freeze.

A

Be mindful of the environment and the ecology. Before

draining any fluids, determine the correct way to dispose of

them. Observe the relevant environmental protection

regulations when disposing of oil, fuel, coolant, brake fluid,

filters and batteries.

A

When draining fluids from the engine, place a suitable

container underneath the engine body.

A

DO NOT pour waste onto the ground, down a drain, or into

any water source. Dispose of waste fluids according to

environmental regulations.

11. CONDUCTING SAFETY CHECKS & MAINTENANCE

A When inspecting the engine or servicing, place the

engine on a large flat surface. DO NOT work on anything

that is supported ONLY by lift jacks or a hoist. Always use

blocks or the correct stands to support the engine before

servicing.

A Disconnect the battery from the engine before

conducting service. Put a "DO NOT OPERATE!" tag on

the key switch to avoid accidental starting.

A To avoid sparks from an accidental short circuit always

disconnect the battery's ground cable (-) first and

reconnect it last.

A Be sure to stop the engine and remove the key when

conducting daily and periodic maintenance, service and

cleaning.

A Check or conduct maintenance after the engine, coolant,

muffler, or muffler cover have cooled off completely.

A Always use the appropriate tools and fixtures. Verify that

they are in good condition before performing any service

work. Make sure you understand how to use them before

service.

A Use ONLY correct engine barring techniques for

manually rotating the engine. DO NOT attempt to rotate

the engine by pulling or prying on the cooling fan and Vbelt. This practice can cause serious personal injury or

premature damage to the cooling fan and belt.

ENGLISH

SAFE OPERATION6

A Replace fuel pipes and lubricant pipes with their hose

clamps every 2 years or earlier whether they are

damaged or not. They are made of rubber and age

ENGLISH

gradually.

A Keep a first aid kit and appropriate type fire extinguisher

handy at all times.

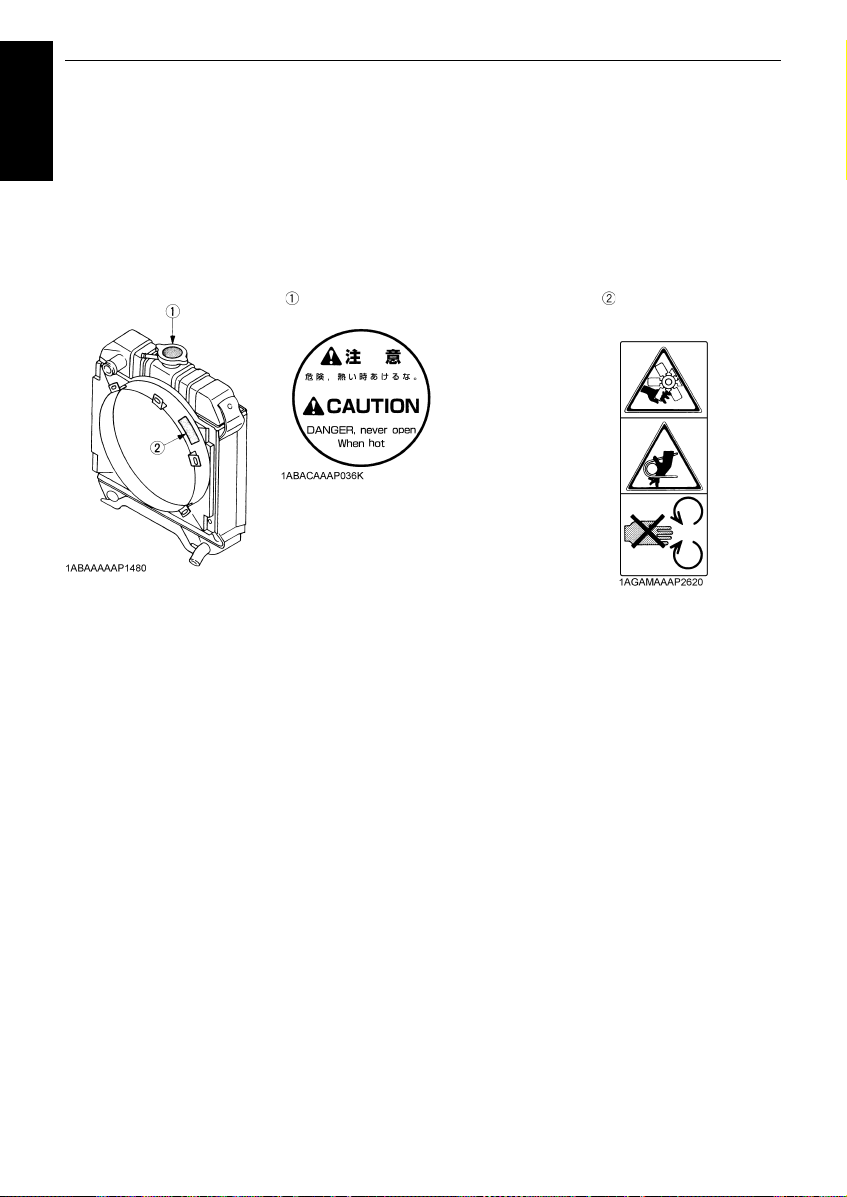

12. WARNING AND CAUTION LABELS

Part No.19077-8724-1 or 16667-8724-1

(55mm in diameter) (37mm in diameter)

Part No.TA040-4957-1

Do n ot get you r hands c lose

to engine fan and fan belt.

13. CARE OF WARNING AND CAUTION LABELS

1. Keep warning and caution labels clean and free from obstructing material.

2. Clean warning and caution labels with soap and water, dry with a soft cloth.

3. Replace damaged or missing warning and caution labels with new labels from your local

KUBOTA Dealer.

4. If a component with warning and caution label(s) affixed is replaced with a new part, make

sure the new label(s) is (are) attached in the same location(s) as the replaced component.

5. Mount new warning and caution labels by applying to a clean dry surface and pressing any

bubbles to the outside edge.

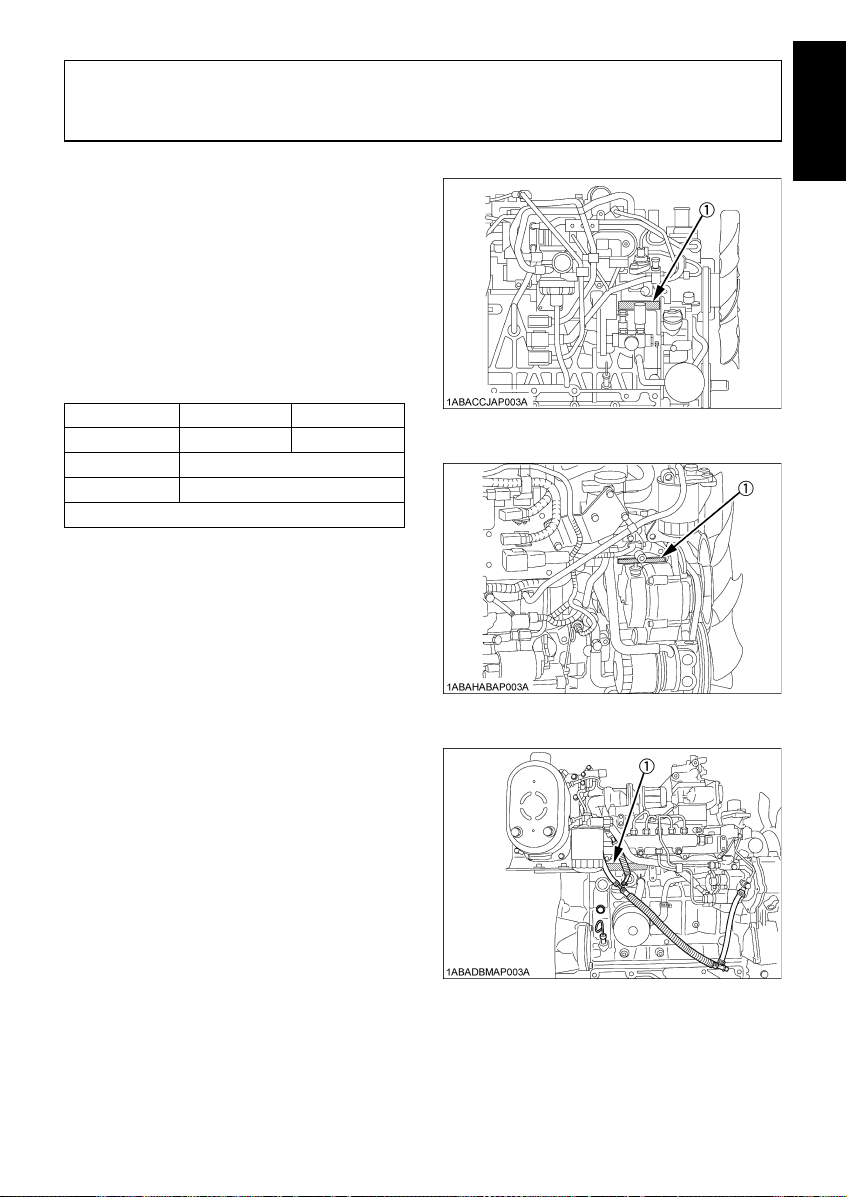

SERVICING OF THE ENGINE

1SERVICING OF THE ENGINE

Your dealer is interested in your new engine and has the

desire to help you get the most value from it. After reading

this manual thoroughly, you will find that you can do some

of the regular maintenance yourself.

However, when in need of parts or major service, be sure

to see your KUBOTA Dealer.

For service, contact the KUBOTA Dealership from which

you purchased your engine or your local KUBOTA

Dealer.

When in need of parts, be prepared to give your dealer

the engine serial number.

Locate the serial number now and record them in the

space provided.

Type Serial No.

Engine

Date of Purchase

Name of Dealer

(To be filled in by purchaser)

[D1803-CR-TIE4, V2403-CR-TIE4]

ENGLISH

(1) Engine serial number

[V2607-CR-TIE4, V3307-CR-TIE4]

(1) Engine serial number

[V3800-TIE4]

(1) Engine serial number

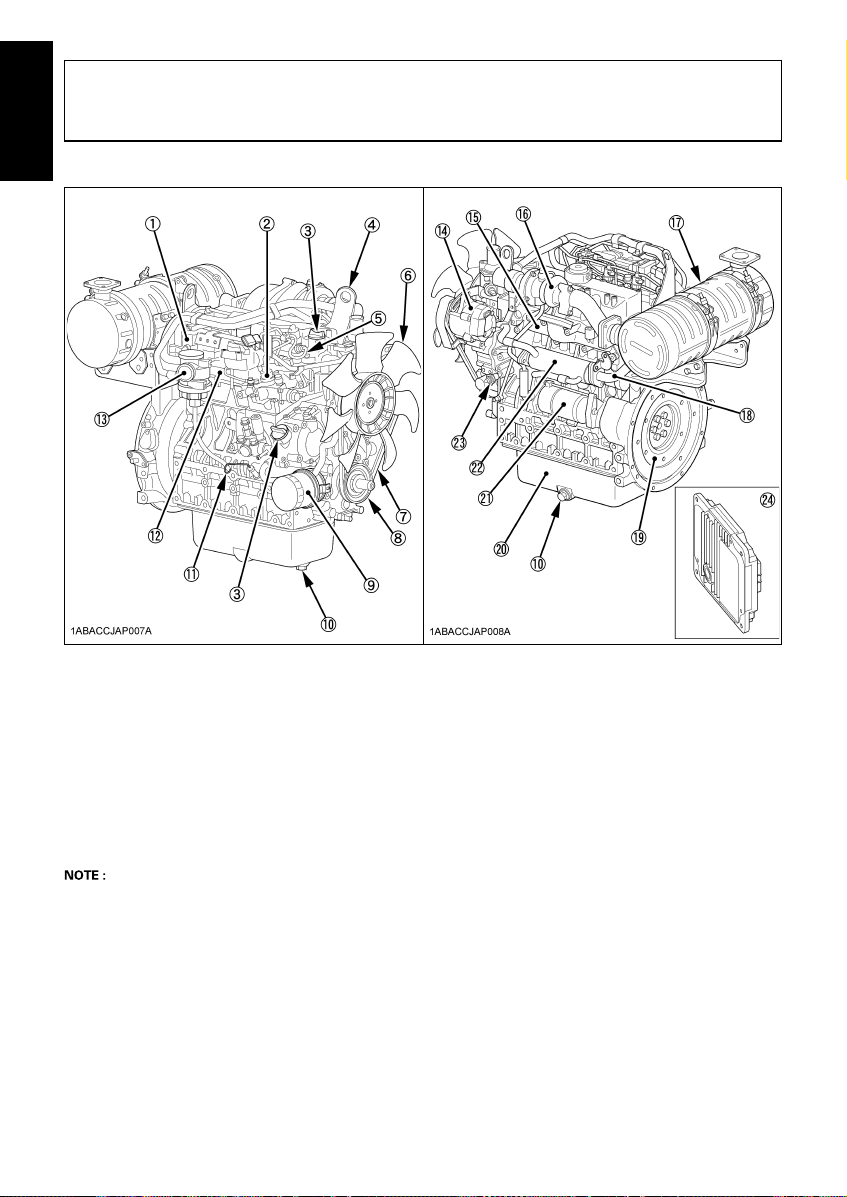

2 NAMES OF PARTS

NAMES OF PARTS

ENGLISH

[D1803-CR-TIE4, V2403-CR-TIE4]

(1) EGR valve

(2) Supply pump

(3) Oil filler plug

(4) Engine hook

(5) Rail

(6) Cooling fan

(7) Fan belt

(8) Fan drive pulley

(9) Oil filter cartridge

(10) Oil drain plug

(11) Oil level gauge

(12) Intake manifold

A (24) ECU (Engine Control Unit) is not connected to the engine in the figure above.

(13) Oil separator

(14) Alternator

(15) Exhaust manifold

(16) Turbo-charger

(17) DOC (Diesel Oxidation Catalyst)

(18) EGR pipe

(19) Flywheel

(20) Oil pan

(21) Starter

(22) EGR cooler

(23) Oil pressure switch

(24) ECU (Engine Control Unit)

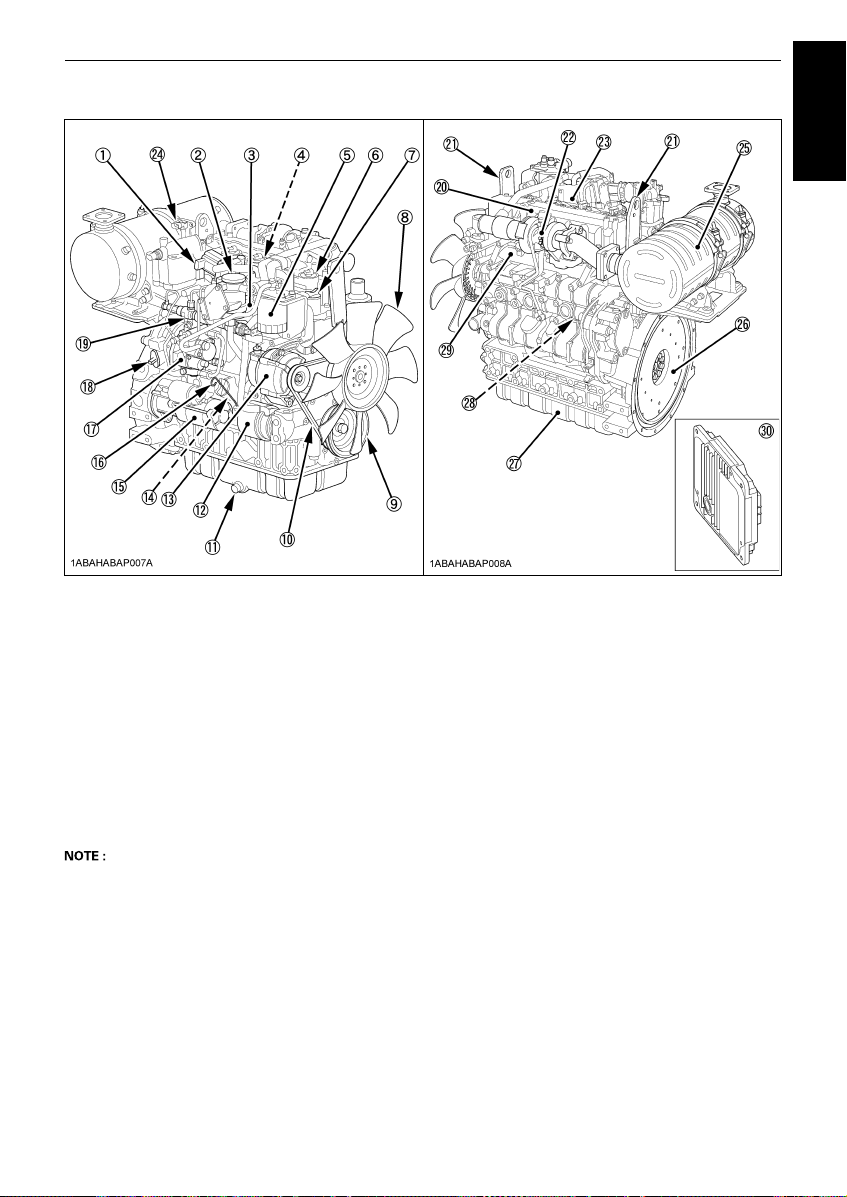

[V2607-CR-TIE4, V3307-CR-TIE4]

3NAMES OF PARTS

ENGLISH

(1) EGR valve

(2) Oil separator

(3) Intake manifold

(4) Glow plug

(5) Fuel filter cartridge

(6) Injector

(7) Oil filler plug

(8) Cooling fan

(9) Fan drive pulley

(10) Fan belt

(11) Oil drain plug

(12) Oil filter cartridge

(13) Alternator

(14) Oil pressure switch

(15) Starter

A (30) ECU (Engine Control Unit) is not connected to the engine in the figure above.

(16) Oil level gauge

(17) Supply pump

(18) NE sensor

(19) Rail

(20) Head cover

(21) Engine hook

(22) Turbo-charger

(23) EGR cooler

(24) Boost sensor

(25) DOC (Diesel Oxidation Catalyst)

(26) Flywheel

(27) Oil pan

(28) G sensor

(29) Exhaust manifold

(30) ECU (Engine Control Unit)

Loading...

Loading...