Page 1

B2301,B2601

WORKSHOP MANUAL

TRACTOR

KiSC issued 11, 2014 A

Page 2

TO THE READER

This Workshop Manual tells the servicing personnel about the mechanism, servicing and

maintenance of the B2301 and B2601. It contains 4 parts: "Information", "General", "Mechanism"

and "Servicing".

Information

This section primarily contains information below.

• Safety First

• Safety Decal

• Specifications

• Dimensions

General

This section primarily contains information below.

• Engine Identification

• Model Identification

• General Precautions

• Maintenance Check List

• Check and Maintenance

• Special Tools

Mechanism

This section contains information on the structure and the function of the unit. Before you continue

with the subsequent sections, make sure that you read this section.

Refer to the latest version of Workshop Manual (Code No. 9Y021-01870 / 9Y021-18200) for the

diesel engine / tractor mechanism that this workshop manual does not include.

Servicing

This section primarily contains information below.

• Troubleshooting

• Servicing Specifications

• Tightening Torques

• Checking, Disassembling and Servicing

All illustrations, photographs and specifications contained in this manual are of the newest

information available at the time of publication.

KUBOTA reserves the right to change all information at any time without notice.

Since this manual includes many models, information or illustrations and photographs can show

more than one model.

November, 2014

© KUBOTA Corporation 2014

KiSC issued 11, 2014 A

Page 3

I INFORMATION

KiSC issued 11, 2014 A

Page 4

CONTENTS

1. SAFETY FIRST .............................................................................................................................. I-1

2. SAFETY DECALS .......................................................................................................................... I-4

3. SPECIFICATIONS.......................................................................................................................... I-7

4. TRAVELING SPEEDS.................................................................................................................... I-8

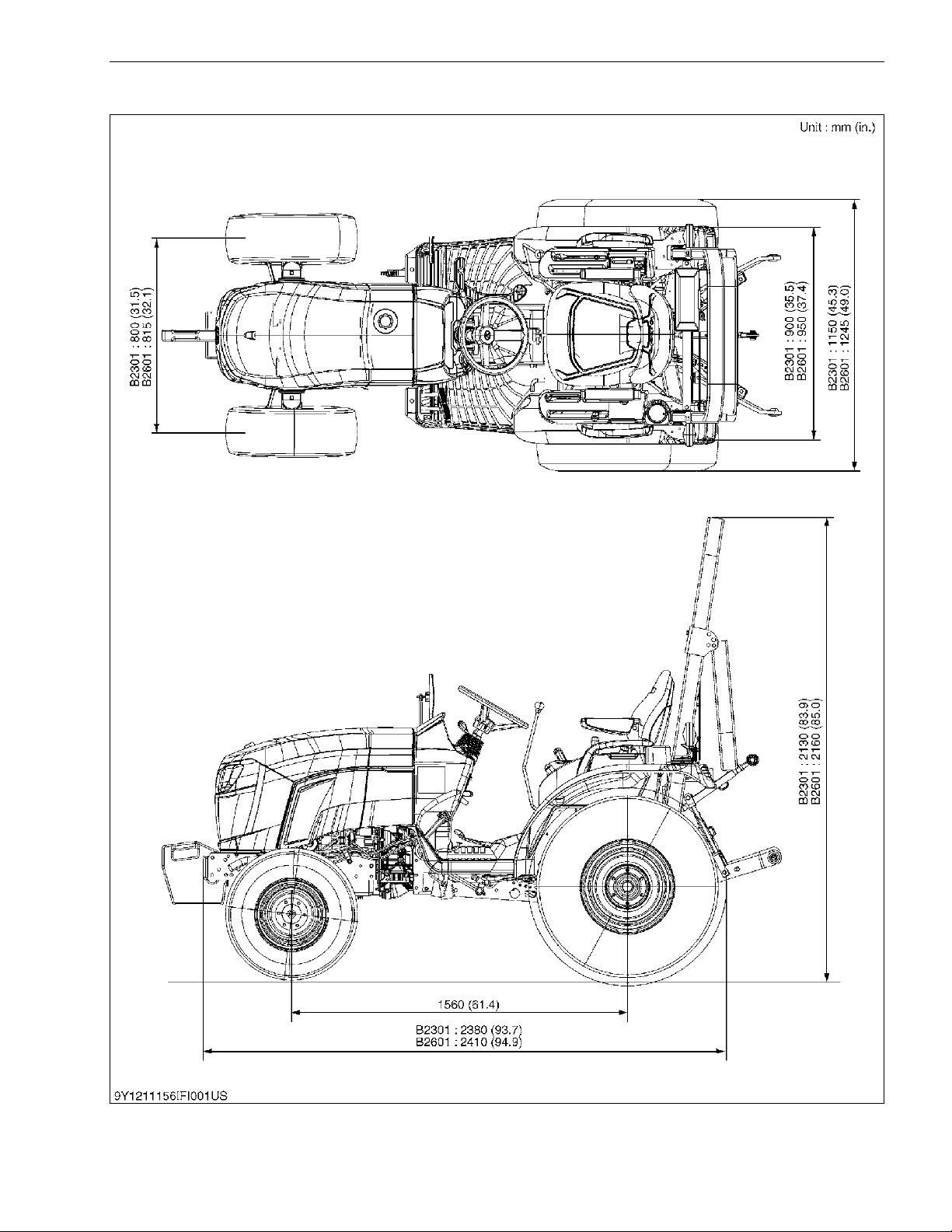

5. DIMENSIONS ................................................................................................................................. I-9

INFORMATION

KiSC issued 11, 2014 A

Page 5

INFORMATION

B2301, B2601, WSM

I-1

1. SAFETY FIRST

WSM000001INI0001US1

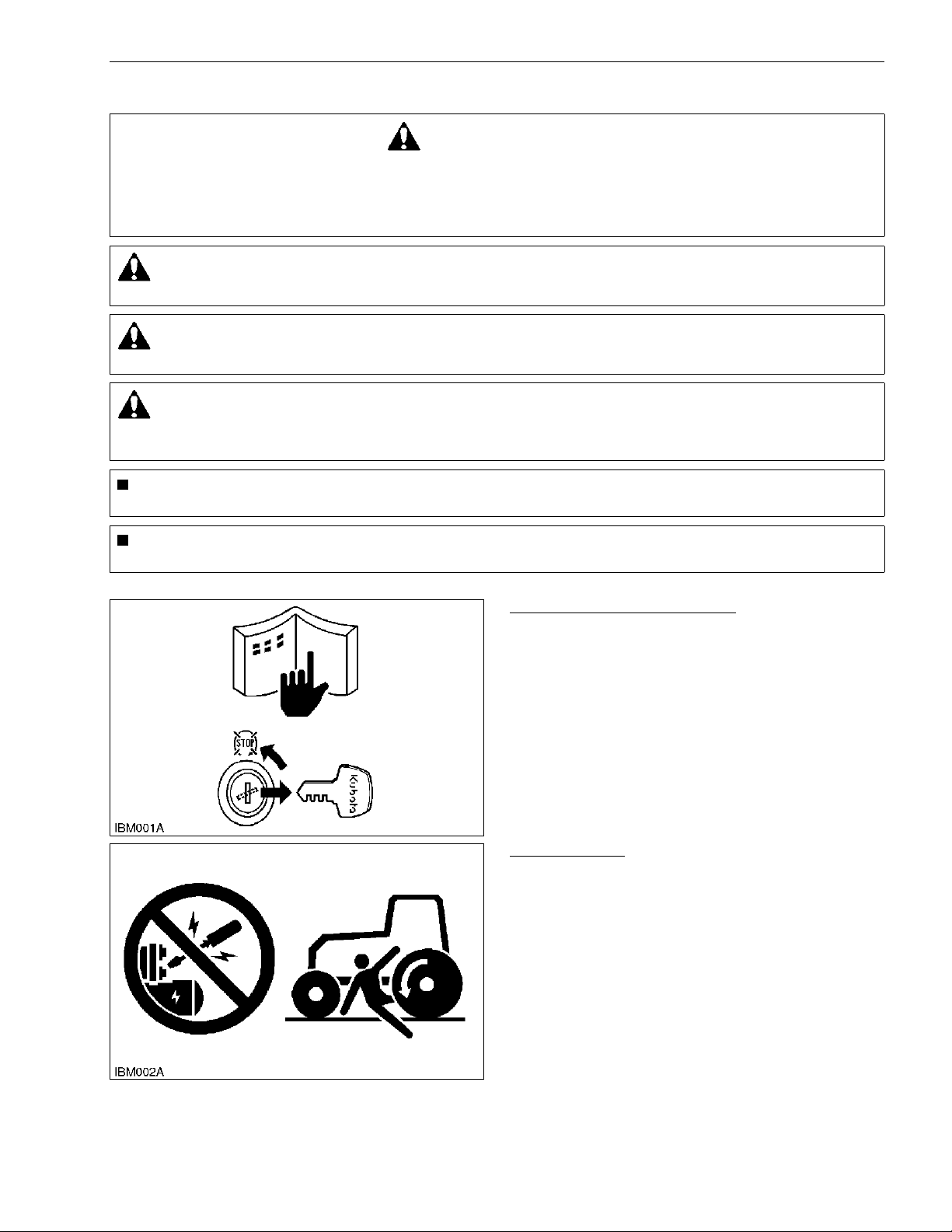

BEFORE YOU START SERVICE

• Read all instructions and safety instructions in this

manual and on your machine safety decals.

• Clean the work area and machine.

• Park the machine on a stable and level ground, and

set the parking brake.

• Lower the implement to the ground.

• Stop the engine, then remove the key.

• Disconnect the battery negative cable.

• Hang a "DO NOT OPERATE" tag in the operator

station.

WSM000001INI0010US0

START SAFELY

• Do not do the procedures below when you start the

engine.

– short across starter terminals

– bypass the safety start switch

• Do not alter or remove any part of machine safety

system.

• Before you start the engine, make sure that all shift

levers are in neutral positions or in disengaged

positions.

• Do not start the engine when you stay on the ground.

Start the engine only from operator's seat.

WSM000001INI0015US0

SAFETY FIRST

• This symbol, the industry's "Safety Alert Symbol", is used throughout this manual and on labels on the

machine itself to warn of the possibility of personal injury. Read these instructions carefully.

• It is essential that you read the instructions and safety regulations before you try to repair or use this

unit.

DANGER

• Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

WARNING

• Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION

• Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate

injury.

IMPORTANT

• Indicates that equipment or property damage could result if instructions are not followed.

NOTE

• Gives helpful information.

KiSC issued 11, 2014 A

Page 6

INFORMATION

B2301, B2601, WSM

I-2

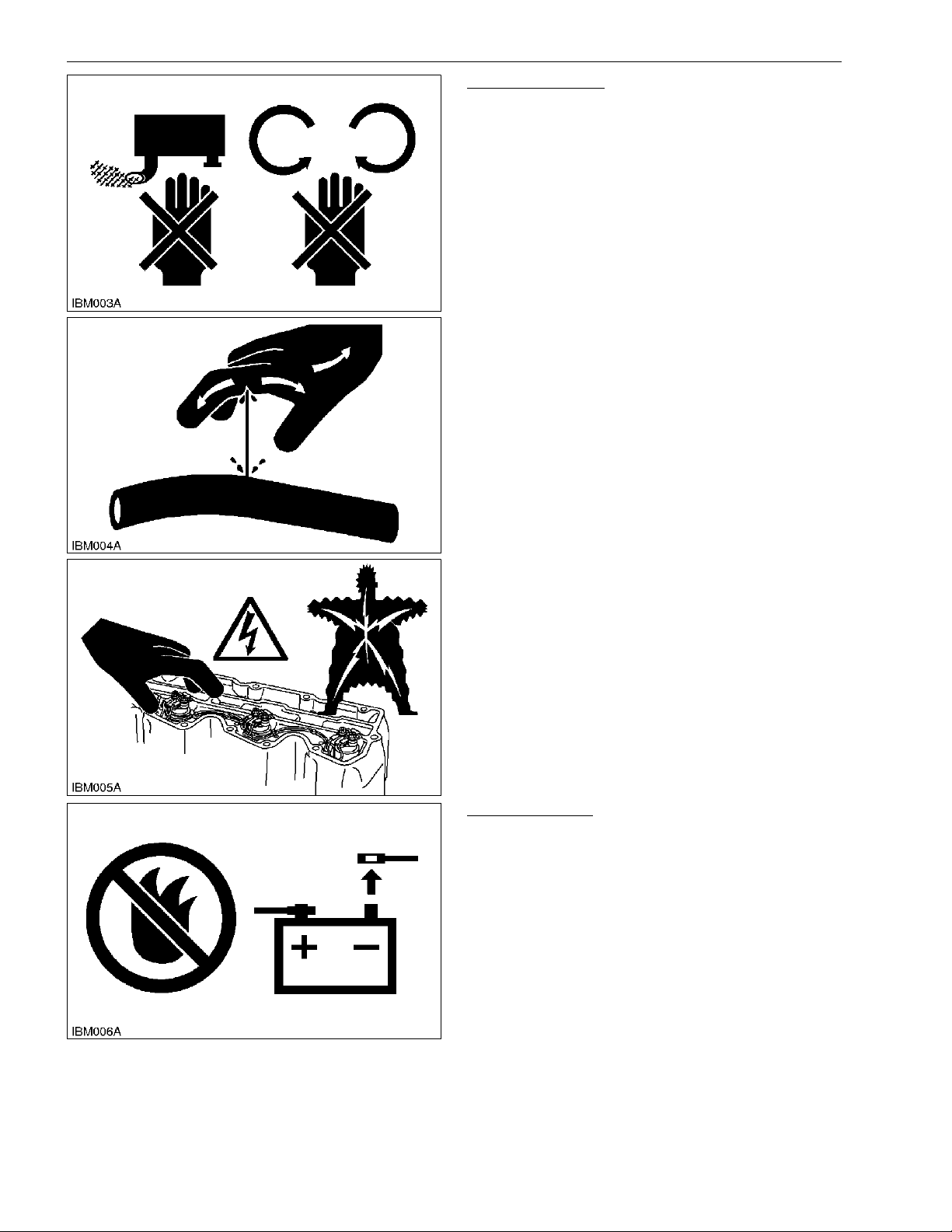

OPERATE SAFELY

• Do not use the machine after you consume alcohol

or medication or when you are tired.

• Put on applicable clothing and safety equipment.

• Use applicable tools only. Do not use alternative

tools or parts.

• When 2 or more persons do servicing, make sure

that you do it safely.

• Do not operate below the machine that only a jack

holds. Always use a safety stand to hold the

machine.

• Do not touch the hot parts or parts that turn when the

engine operates.

• Do not remove the radiator cap when the engine

operates, or immediately after it stops. If not, hot

water can spout out from the radiator. Only remove

the radiator cap when it is at a sufficiently low

temperature to touch with bare hands. Slowly loosen

the cap to release the pressure before you remove it

fully.

• Released fluid (fuel or hydraulic oil) under pressure

can cause damage to the skin and cause serious

injury. Release the pressure before you disconnect

hydraulic or fuel lines. Tighten all connections before

you apply the pressure.

• Do not open a fuel system under high pressure.

The fluid under high pressure that stays in fuel lines

can cause serious injury. Do not disconnect or repair

the fuel lines, sensors, or any other components

between the fuel pump and injectors on engines with

a common rail fuel system under high pressure.

• Put on an applicable ear protective device (earmuffs

or earplugs) to prevent injury against loud noises.

• Be careful about electric shock. The engine

generates a high voltage of more than DC100 V in

the ECU and is applied to the injector.

WSM000001INI0012US0

PREVENT A FIRE

• Fuel is very flammable and explosive under some

conditions. Do not smoke or let flames or sparks in

your work area.

• To prevent sparks from an accidental short circuit,

always disconnect the battery negative cable first

and connect it last.

• The battery gas can cause an explosion. Keep the

sparks and open flame away from the top of battery,

especially when you charge the battery.

• Make sure that you do not spill fuel on the engine.

WSM000001INI0005US0

KiSC issued 11, 2014 A

Page 7

INFORMATION

B2301, B2601, WSM

I-3

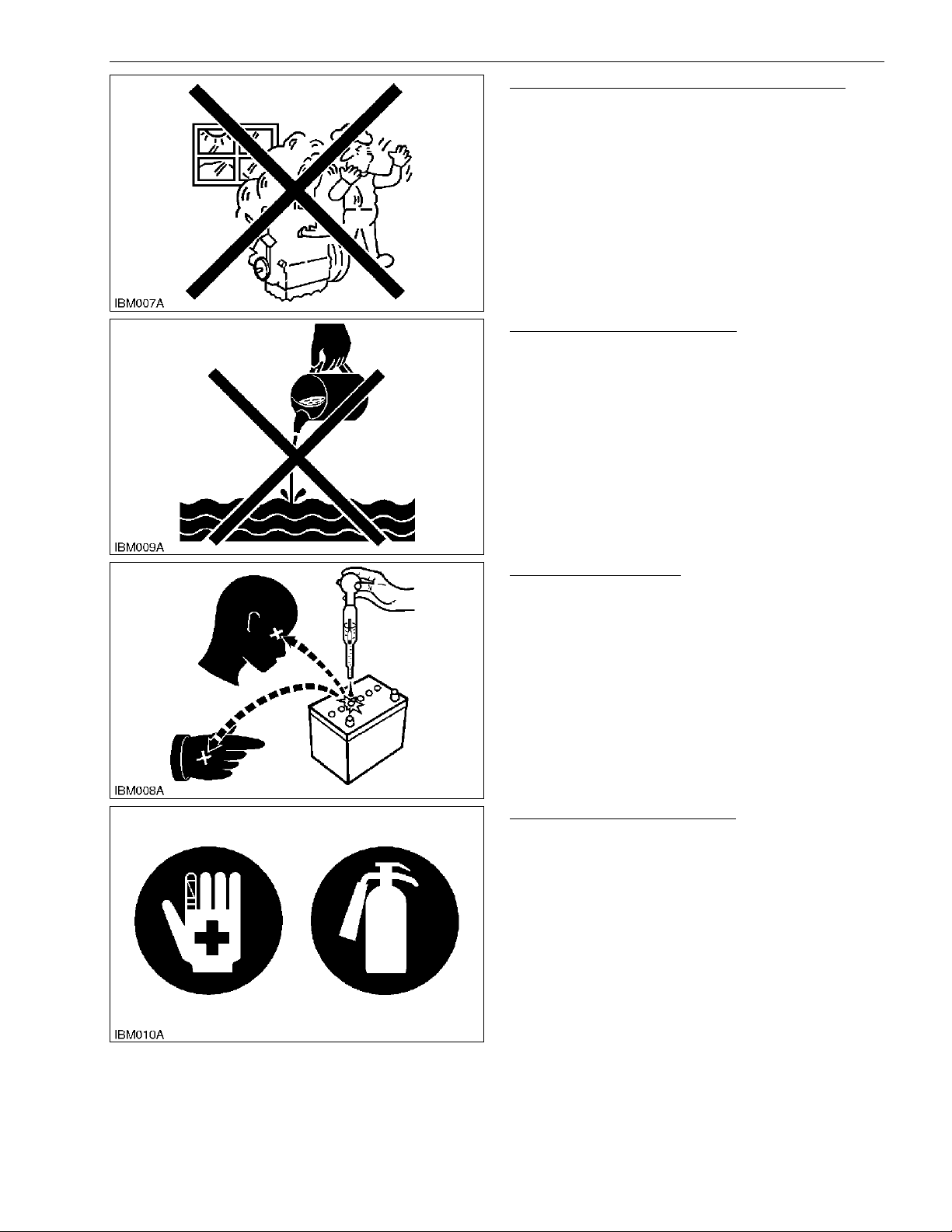

KEEP A GOOD AIRFLOW IN THE WORK AREA

• If the engine is in operation, make sure that the area

has good airflow. Do not operate the engine in a

closed area. The exhaust gas contains poisonous

carbon monoxide.

WSM000001INI0006US0

DISCARD FLUIDS CORRECTLY

• Do not discard fluids on the ground, down the drain,

into a stream, pond, or lake. Obey related

environmental protection regulations when you

discard oil, fuel, coolant, electrolyte and other

dangerous waste.

WSM000001INI0007US0

PREVENT ACID BURNS

• Keep electrolyte away from your eyes, hands and

clothing. Sulfuric acid in battery electrolyte is

poisonous and it can burn your skin and clothing and

cause blindness. If you spill electrolyte on yourself,

clean yourself with water, and get medical aid

immediately.

WSM000001INI0008US0

PREPARE FOR EMERGENCIES

• Keep a first aid kit and fire extinguisher ready at all

times.

• Keep the emergency contact telephone numbers

near your telephone at all times.

WSM000001INI0009US0

KiSC issued 11, 2014 A

Page 8

INFORMATION

B2301, B2601, WSM

I-4

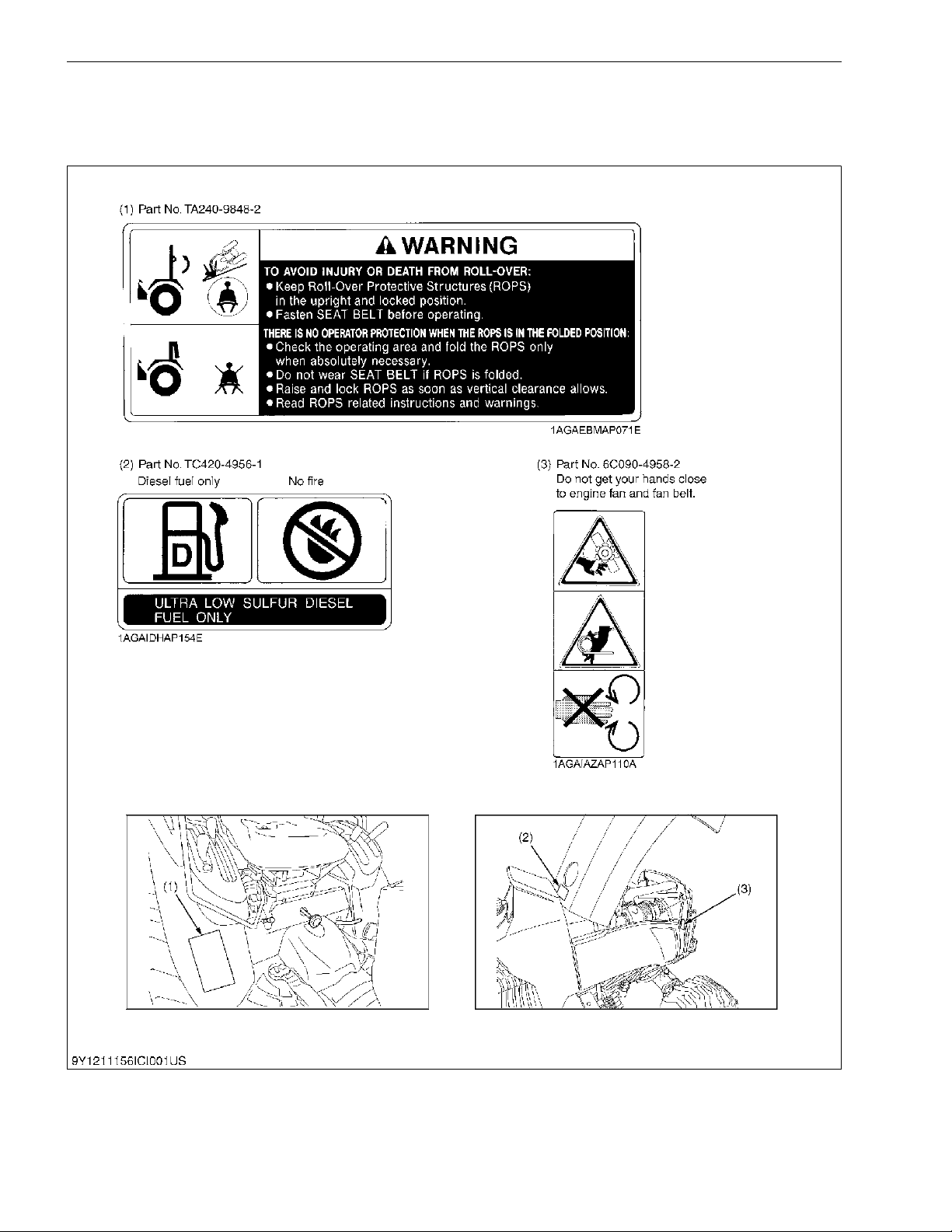

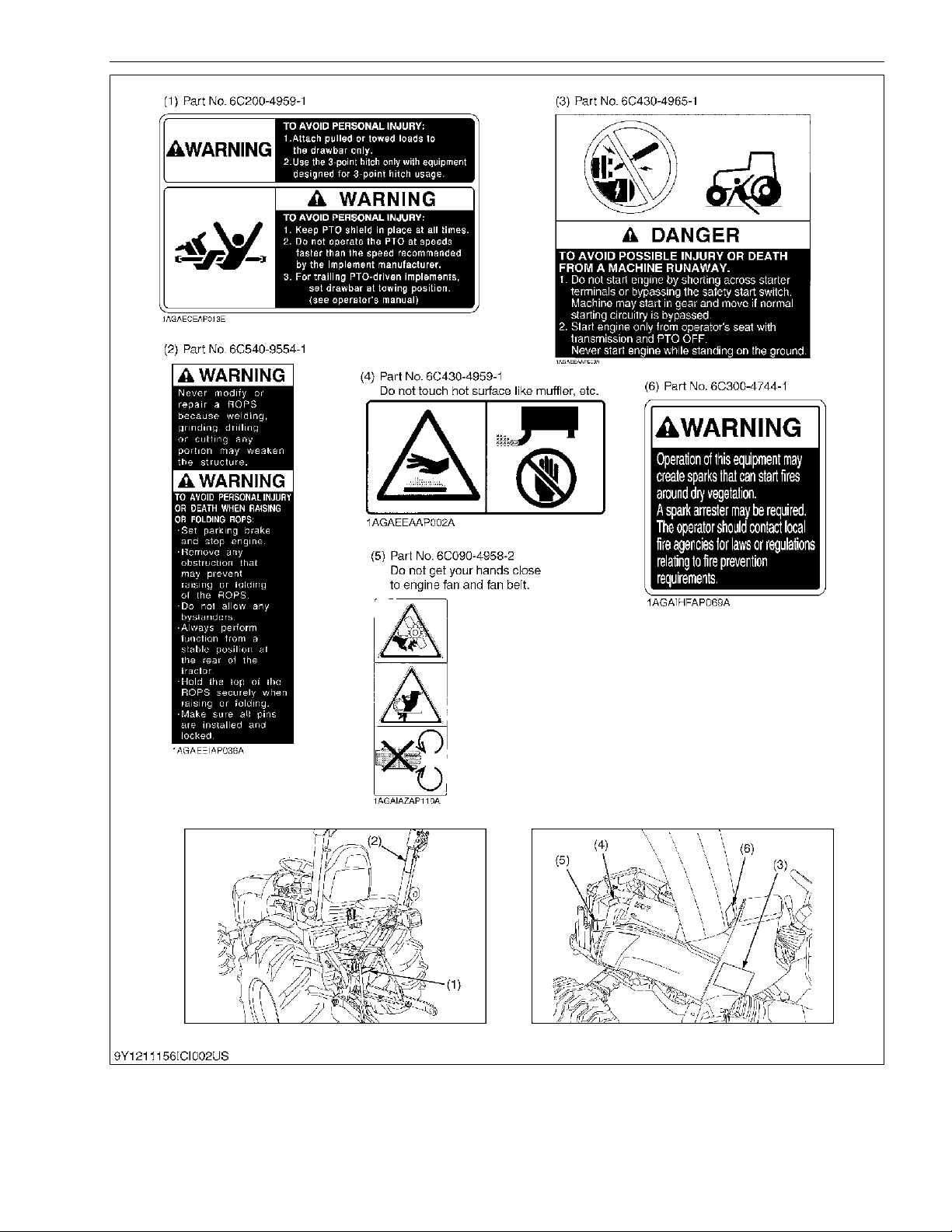

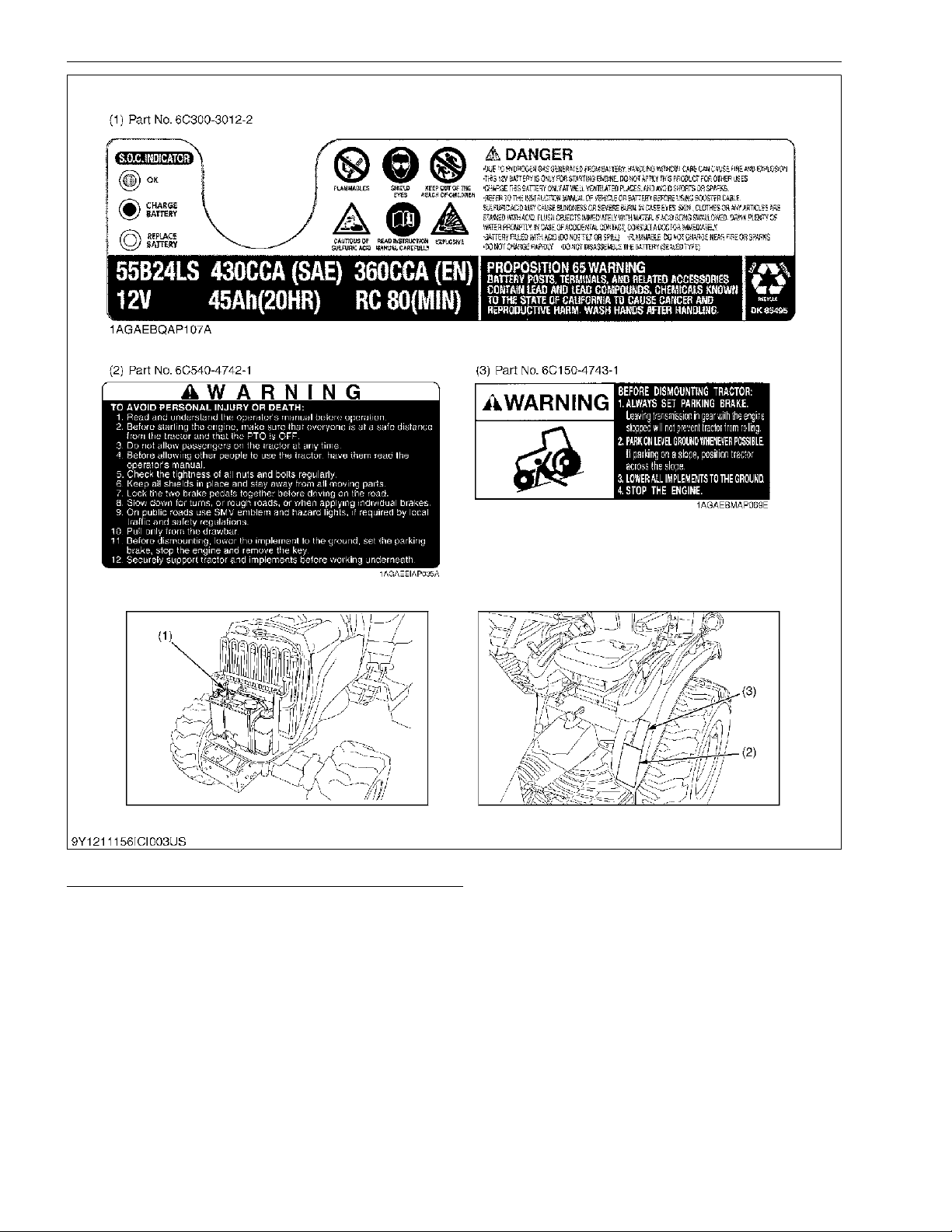

2. SAFETY DECALS

The following safety decals are installed on the machine. If a decal becomes damaged, illegible or is not

on the machine, replace it. The decal part number is listed in the parts list.

WSM000001INI0013US0

9Y1211156INI0004US0

KiSC issued 11, 2014 A

Page 9

INFORMATION

B2301, B2601, WSM

I-5

9Y1211156INI0005US0

KiSC issued 11, 2014 A

Page 10

INFORMATION

B2301, B2601, WSM

I-6

9Y1211156INI0006US0

CARE OF DANGER, WARNING AND CAUTION LABELS

1. Keep danger, warning and caution labels clean and free from obstructing material.

2. Clean danger, warning and caution labels with soap and water, dry with a soft cloth.

3. Replace damaged or missing danger, warning and caution labels with new labels.

4. If a component with danger, warning and caution label(s) affixed is replaced with new part, make sure new label(s)

is (are) attached in the same location(s) as the replace component.

5. Mount new danger, warning and caution labels by applying on a clean dry surface and pressing any bubbles to

outside edge.

9Y1211156INI0007US0

KiSC issued 11, 2014 A

Page 11

INFORMATION

B2301, B2601, WSM

I-7

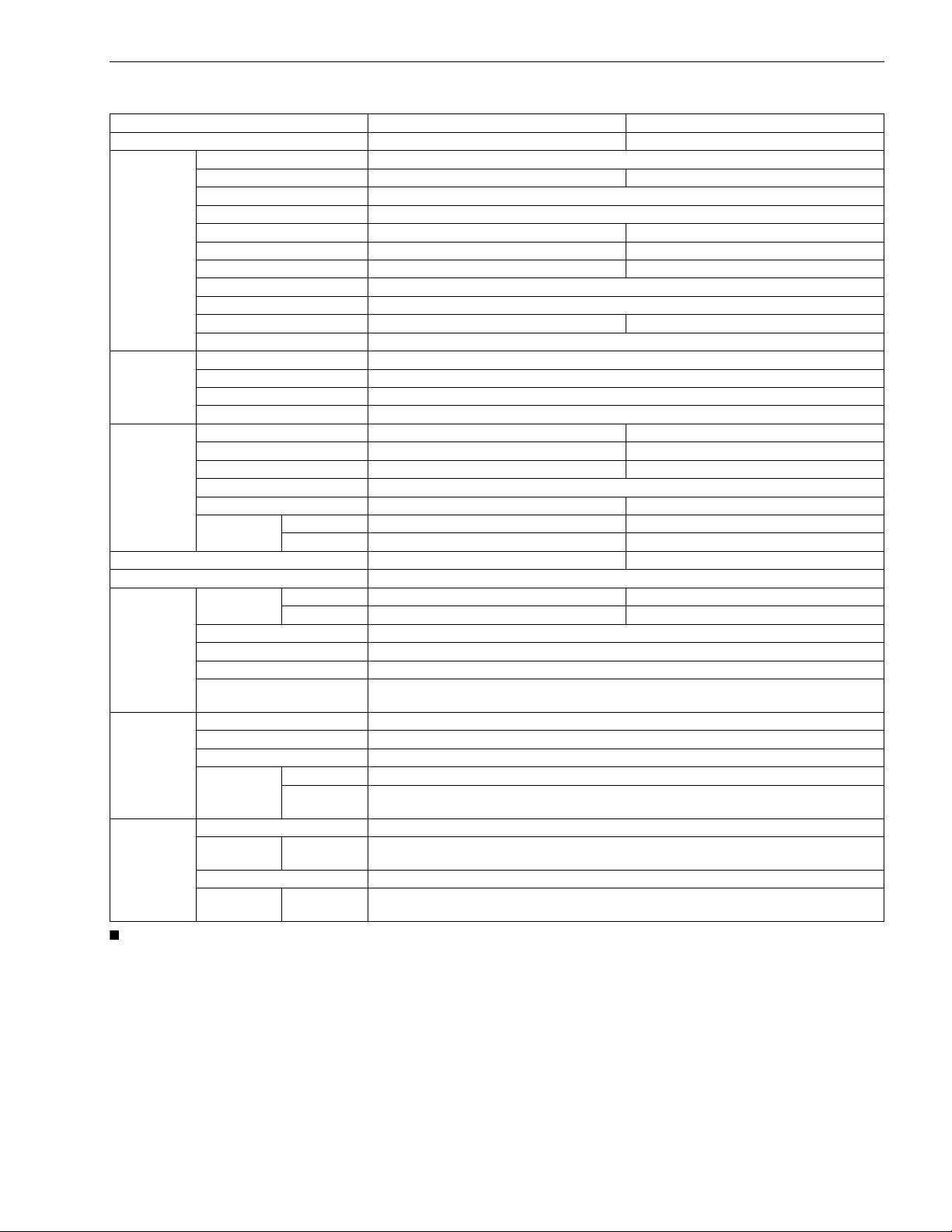

3. SPECIFICATIONS

NOTE

• * Manufacturer's estimate

The company reserves the right to change the specifications without notice.

9Y1211156INI0001US0

Model B2301 B2601

PTO power *1 17.5 kW (13.0 HP) 19.5 kW (14.5 HP)

Engine

Maker KUBOTA

Model D1005-E4-D32 D1105-E4-D32

Type E-TVCS. Liquid-cooled, 3-cylinder diesel

Number of cylinders 3

Bore and stroke 76 × 73.6 mm (3.0 × 2.9 in.) 78 × 78.4 mm (3.1 × 3.1 in.)

Total displacement 1001 cc (61.1 cu.in.) 1123 cc (68.5 cu.in.)

Engine gross power *1 22 kW (16.4 HP) 25.5 kW (19.0 HP)

Rated revolution 2800 min

-1

(rpm)

Low idling revolution 1000 to 1100 min

-1

(rpm)

Maximum torque 60 N·m (6.1 kgf· m, 44 lbf·ft) 71 N·m (7.2 kgf·m, 52 lbf·ft)

Battery 12 V, RC: 80 min, CCD: 430 A

Capacities

Fuel tank 23 L (6.1 U.S.gals, 5.1 Imp.gals)

Engine crankcase (with filter) 3.1 L (3.3 U.S.qts, 2.7 Imp.qts)

Engine coolant 3.8 L (4.0 U.S.qts, 3.3 Imp.qts)

Transmission case 15 L (4.0 U.S.gals, 3.3 Imp.gals)

Dimensions

Overall length (without 3P) 2380 mm (93.7 in.) 2410 mm (94.9 in.)

Overall width (min. tread) 1150 mm (45.3 in.) 1245 mm (49.0 in.)

Overall height 2130 mm (83.9 in.) 2160 mm (85.0 in.)

Wheel base 1560 mm (61.4 in.)

Minimum ground clearance 305 mm (12.0 in.) 325 mm (12.8 in.)

Tread

Front 800 mm (31.5 in.) 815 mm (32.1 in.)

Rear 900 mm (35.5 in.) 950 mm (37.4 in.)

Weight 710 kg (1566 lbs) 740 kg (1632 lbs)

Clutch Not applicable

Traveling

system

Tires

Front 6-12 7-12

Rear 9.5-16 11.2-16

Steering Hydraulic type power steering

Transmission HST (3 range)

Brake Wet disk type

Minimum turning radius (with

brake)

2.1 m (6.9 feet)

Hydraulic unit

Hydraulic control system Position Control Valve

Pump capacity 31.4 L/min (8.3 gals/min)

3-point hitch SAE Category 1

Max. lift force

At lift points 820 kg (1808 lbs)

24 in. behind

lift point

640 kg (1411 lbs)

PTO

Rear-PTO SAE 1-3/8, 6 splines

PTO / Engine

speed

540 min

-1

(rpm) / 2768 min-1 (rpm)

Mid-PTO USA No.5 (KUBOTA 10-tooth) involute spline

PTO / Engine

speed

2500 min

-1

(rpm) / 2753 min-1 (rpm)

KiSC issued 11, 2014 A

Page 12

INFORMATION

B2301, B2601, WSM

I-8

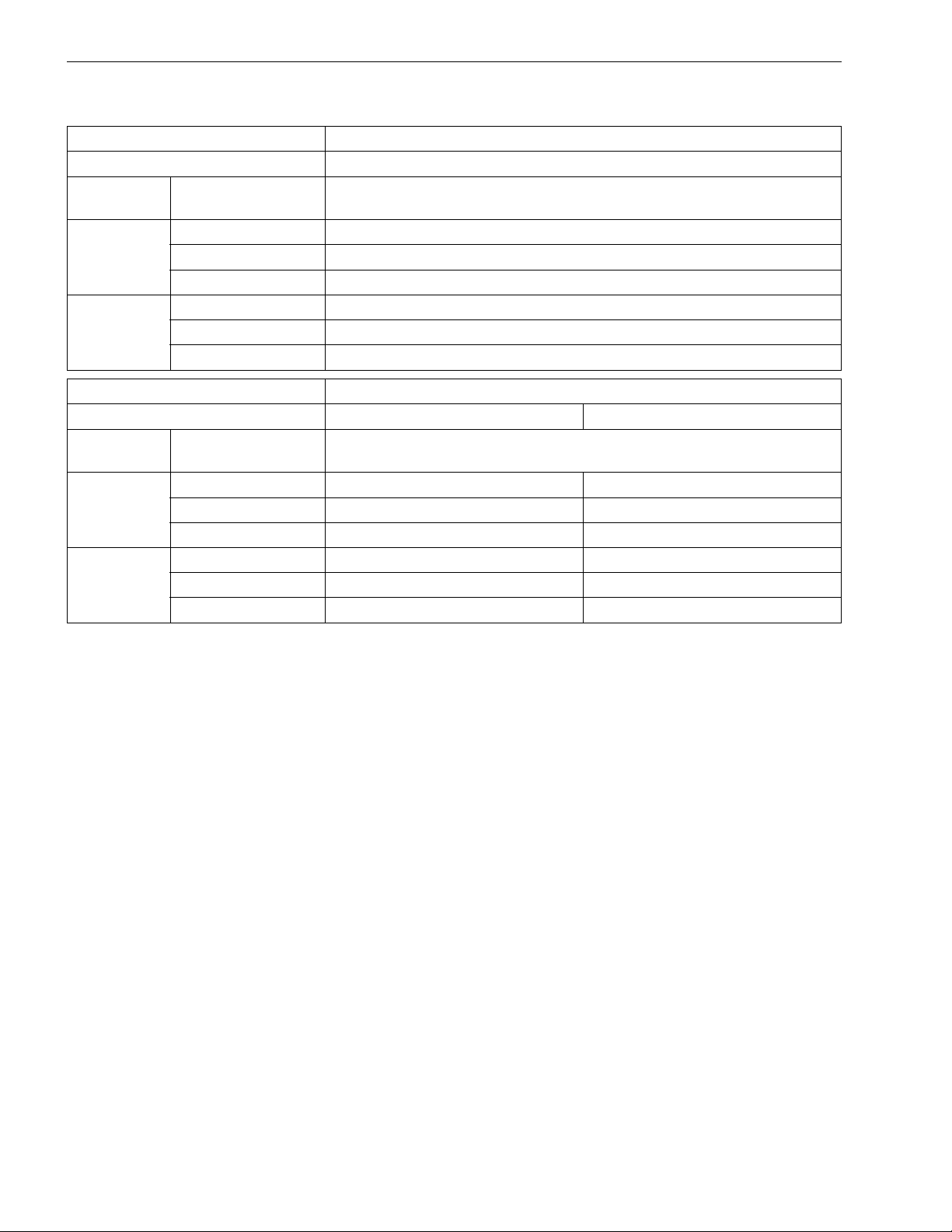

4. TRAVELING SPEEDS

(At rated engine rpm)

The company reserves the right to change the specification without notice.

9Y1211156INI0002US0

Model B2301HSD

Tire size (Rear) 9.5-16 Farm / 33 × 12.5-15 Turf / 12-16.5 Industry

Range gear shift

lever

km/h (mile/h)

Forward

Low 0 to 5.6 (0 to 3.5)

Middle 0 to 8.8 (0 to 5.5)

High 0 to 19.1 (0 to 11.8)

Reverse

Low 0 to 4.2 (0 to 2.6)

Middle 0 to 6.6 (0 to 4.1)

High 0 to 14.3 (0 to 8.9)

Model B2601HSD

Tire size (Rear) 11.2-16 Farm 33 × 12.5-15 Turf / 12-16.5 Industry

Range gear shift

lever

km/h (mile/h)

Forward

Low 0 to 6.0 (0 to 3.7) 0 to 5.6 (0 to 3.5)

Middle 0 to 9.5 (0 to 5.9) 0 to 8.8 (0 to 5.5)

High 0 to 20.4 (0 to 12.7) 0 to 19.1 (0 to 11.8)

Reverse

Low 0 to 4.5 (0 to 2.8) 0 to 4.2 (0 to 2.6)

Middle 0 to 7.1 (0 to 4.4) 0 to 6.6 (0 to 4.1)

High 0 to 15.3 (0 to 9.5) 0 to 14.3 (0 to 8.9)

KiSC issued 11, 2014 A

Page 13

INFORMATION

B2301, B2601, WSM

I-9

5. DIMENSIONS

9Y1211156INI0003US0

KiSC issued 11, 2014 A

Page 14

G GENERAL

KiSC issued 11, 2014 A

Page 15

CONTENTS

1. TRACTOR IDENTIFICATION ....................................................................................................... G-1

2. GENERAL PRECAUTIONS.......................................................................................................... G-2

3. HANDLING PRECAUTIONS FOR ELECTRICAL PARTS AND WIRING .................................... G-3

[1] WIRING .................................................................................................................................. G-3

[2] BATTERY ............................................................................................................................... G-5

[3] FUSE ...................................................................................................................................... G-5

[4] CONNECTOR ........................................................................................................................ G-5

[5] HANDLING OF CIRCUIT TESTER ........................................................................................ G-6

[6] COLOR OF WIRING ..............................................................................................................G-7

4. LUBRICANTS, FUEL AND COOLANT......................................................................................... G-8

5. TIGHTENING TORQUES ........................................................................................................... G-11

[1] GENERAL USE SCREWS, BOLTS AND NUTS .................................................................. G-11

[2] STUD BOLTS ....................................................................................................................... G-11

[3] METRIC SCREWS, BOLTS AND NUTS .............................................................................. G-12

[4] AMERICAN STANDARD SCREWS, BOLTS AND NUTS WITH UNC OR UNF

THREADS ............................................................................................................................ G-12

[5] PLUGS ................................................................................................................................. G-12

6. MAINTENANCE CHECK LIST ................................................................................................... G-13

7. CHECK AND MAINTENANCE ................................................................................................... G-15

[1] DAILY CHECK...................................................................................................................... G-15

[2] CHECK POINTS OF EVERY 50 HOURS ............................................................................ G-19

[3] CHECK POINTS OF EVERY 100 HOURS .......................................................................... G-21

[4] CHECK POINTS OF EVERY 200 HOURS .......................................................................... G-25

[5] CHECK POINTS OF EVERY 400 HOURS .......................................................................... G-28

[6] CHECK POINT OF EVERY 800 HOURS ............................................................................. G-30

[7] CHECK POINT OF EVERY 1500 HOURS ........................................................................... G-30

[8] CHECK POINT OF EVERY 3000 HOURS ........................................................................... G-30

[9] CHECK POINT OF EVERY 1 YEAR .................................................................................... G-30

[10]CHECK POINTS OF EVERY 2 YEARS ............................................................................... G-31

[11]OTHERS............................................................................................................................... G-33

8. SPECIAL TOOLS ................................................................................................................

....... G-35

[1]

SPECIAL TO

OLS FOR ENGINE .......................................................................................... G-35

[2] SPECIAL TOOLS FOR TRACTOR ...................................................................................... G-42

9. TIRES ......................................................................................................................................... G-45

[1] TIRE PRESSURE................................................................................................................. G-45

[2] WHEEL ADJUSTMENT........................................................................................................ G-46

(1) Front Wheels .................................................................................................................. G-46

(2) Rear Wheels................................................................................................................... G-48

[3] BALLAST.............................................................................................................................. G-50

10. IMPLEMENT LIMITATIONS ....................................................................................................... G-52

GENERAL

KiSC issued 11, 2014 A

Page 16

GENERAL

B2301, B2601, WSM

G-1

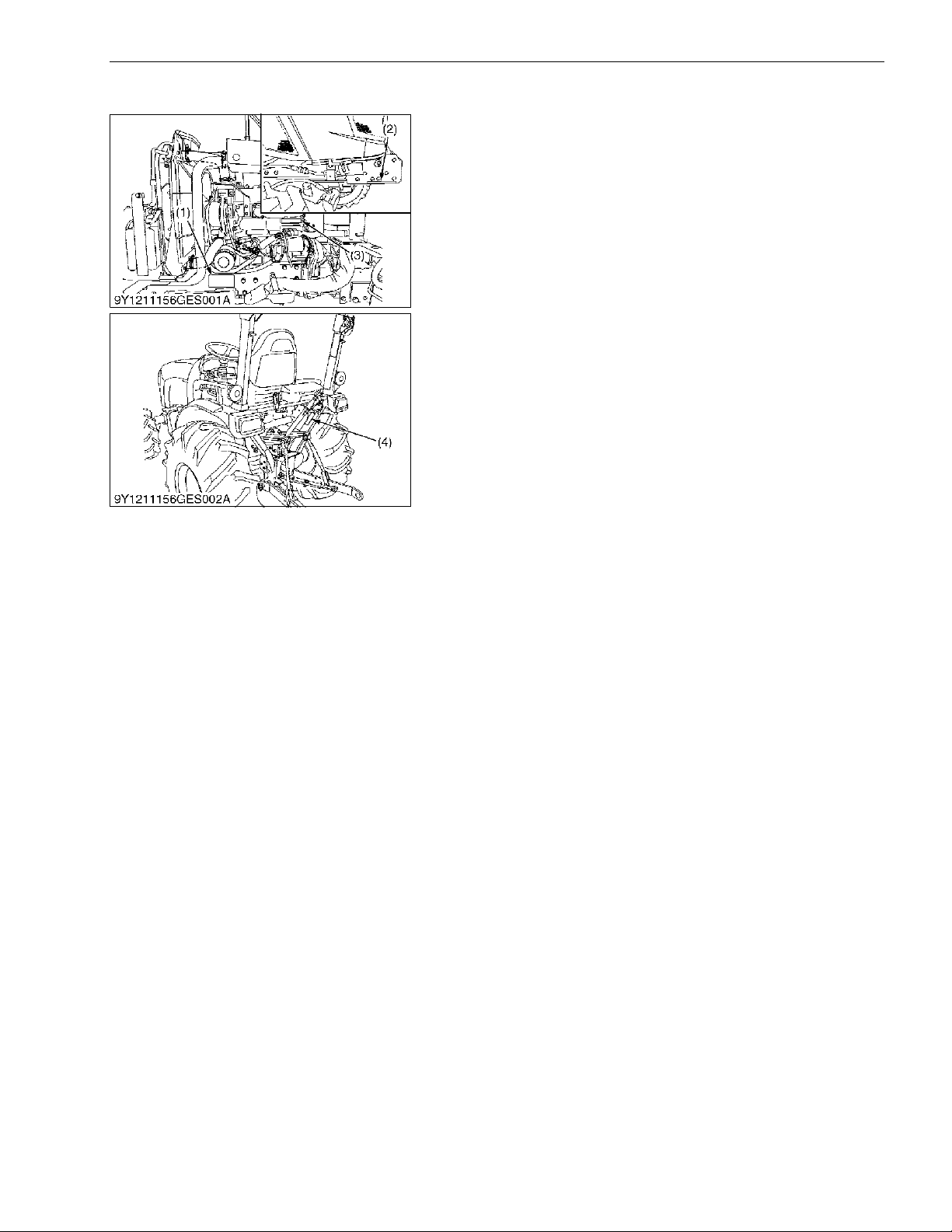

1. TRACTOR IDENTIFICATION

When contacting your local KUBOTA distributor, always specify

engine serial number, tractor serial number and hour meter reading.

9Y1211156GEG0001US0

(1) Tractor Identification Plate

(2) Tractor Serial Number

(3) Engine Serial Number

(4) ROPS Identification Plate

(ROPS Serial Number)

KiSC issued 11, 2014 A

Page 17

GENERAL

B2301, B2601, WSM

G-2

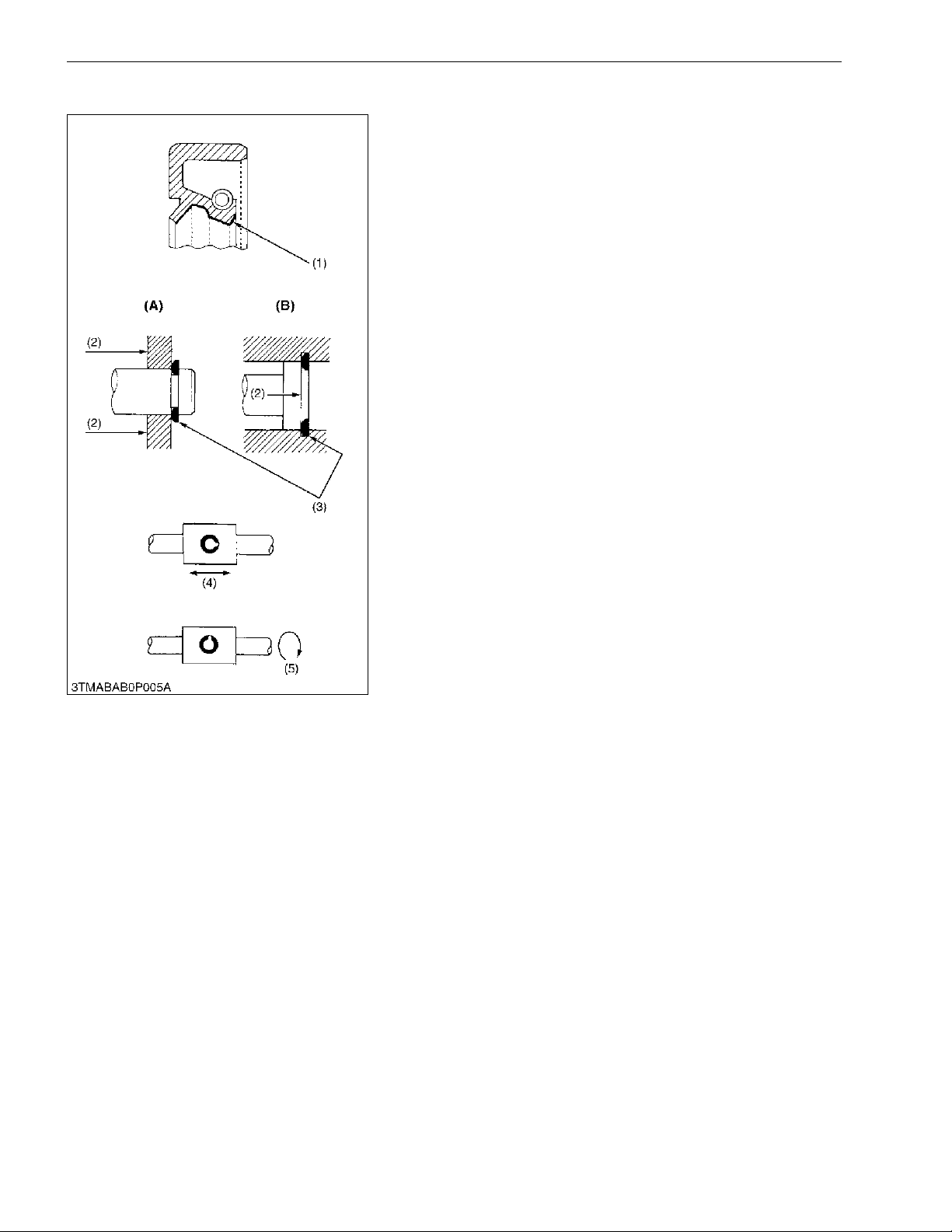

2. GENERAL PRECAUTIONS

• When you disassemble, carefully put the parts in a clean area

to make it easy to find the parts. You must install the screws,

bolts and nuts in their initial position to prevent the reassembly

errors.

• When it is necessary to use special tools, use KUBOTA special

tools. Refer to the drawings when you make special tools that

you do not use frequently.

• Before you disassemble or repair machine, make sure that you

always disconnect the ground cable from the battery first.

• Remove oil and dirt from parts before you measure.

• Use only KUBOTA genuine parts for replacement to keep the

machine performance and to make sure of safety.

• You must replace the gaskets and O-rings when you assemble

again. Apply grease (1) to new O-rings or oil seals before you

assemble.

• When you assemble the external or internal snap rings, make

sure that the sharp edge (3) faces against the direction from

which force (2) is applied.

• When inserting spring pins, their splits must face the direction

from which a force is applied. See the figure left side.

• To prevent damage to the hydraulic system, use only specified

fluid or equivalent.

• Clean the parts before you measure them.

• Tighten the fittings to the specified torque. Too much torque can

cause damage to the hydraulic units or the fittings. Not sufficient

torque can cause oil leakage.

• When you use a new hose or pipe, tighten the nuts to the

specified torque. Then loosen (approx. by 45 °) and let them be

stable before you tighten to the specified torque (This is not

applied to the parts with seal tape).

• When you remove the two ends of a pipe, remove the lower end

first.

• Use two pliers in removal and installation. One to hold the stable

side, and the other to turn the side you remove to prevent twists.

• Make sure that the sleeves of flared connectors and tapers of

hoses are free of dust and scratches.

• After you tighten the fittings, clean the joint and apply the

maximum operation pressure 2 to 3 times to check oil leakage.

WSM000001GEG0106US0

(1) Grease

(2) Force

(3) Sharp Edge

(4) Axial Force

(5) Rotating Movement

(A) External Circlip

(B) Internal Circlip

KiSC issued 11, 2014 A

Page 18

GENERAL

B2301, B2601, WSM

G-3

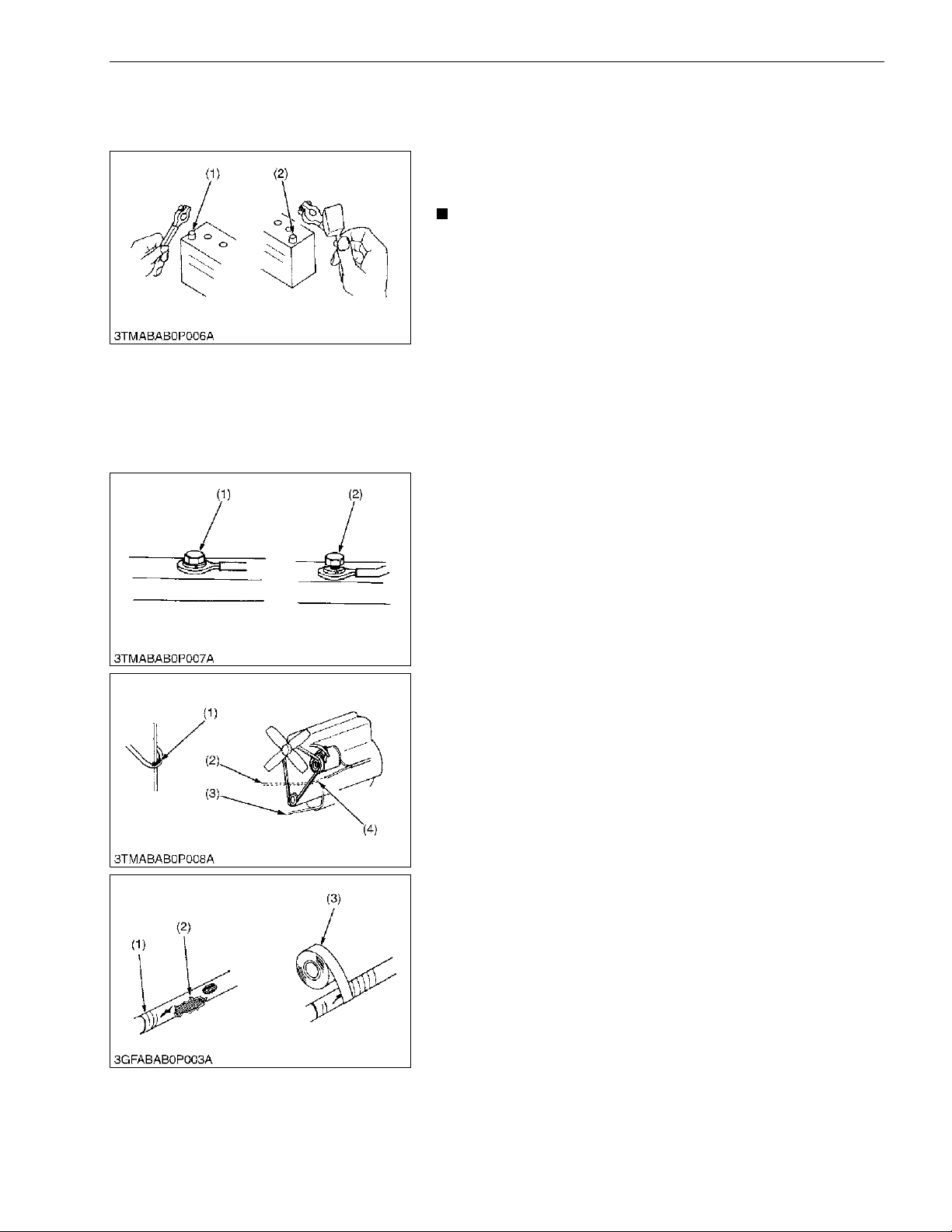

3. HANDLING PRECAUTIONS FOR ELECTRICAL PARTS AND WIRING

To ensure safety and prevent damage to the machine and

surrounding equipment, obey the following precautions in handling

electrical parts and wiring.

IMPORTANT

• Check electrical wiring for damage and loosened

connection every year. To this end, educate the customer

to do his or her own check and at the same time

recommend the dealer to perform periodic check for a fee.

• Do not try to modify or remodel any electrical parts and

wiring.

• When removing the battery cables, disconnect the negative

cable first. When installing the battery cables, connect the

positive cable first.

WSM000001GEG0062US0

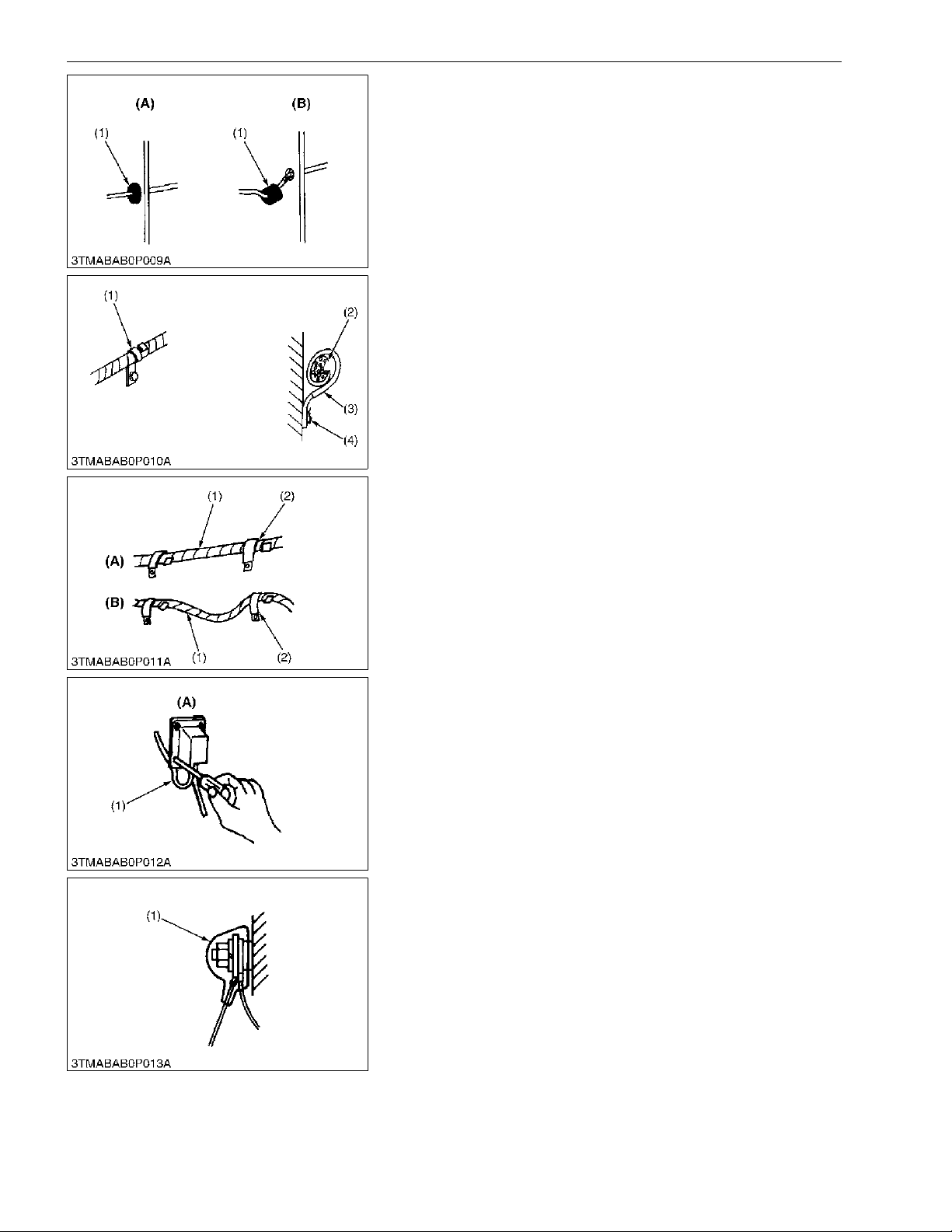

[1] WIRING

• Securely tighten wiring terminals.

WSM000001GEG0063US0

• Do not let wiring contact dangerous part.

WSM000001GEG0064US0

• Repair or change torn or aged wiring immediately.

WSM000001GEG0065US0

(1) Negative Terminal (2) Positive Terminal

(1) Correct

(Securely Tighten)

(2) Incorrect

(Loosening Leads to Faulty Contact)

(1) Dangerous Part (Sharp Edge)

(2) Wiring (Incorrect)

(3) Wiring (Correct)

(4) Dangerous Part

(1) Aged

(2) Torn

(3) Insulating Vinyl Tape

KiSC issued 11, 2014 A

Page 19

GENERAL

B2301, B2601, WSM

G-4

• Securely insert grommet.

WSM000001GEG0066US0

• Securely clamp, being careful not to damage wiring.

WSM000001GEG0067US0

• Clamp wiring so that there is no twist, unnecessary sag, or

excessive tension, except for movable part, where sag be

required.

WSM000001GEG0068US0

• In installing a part, be careful not to get wiring caught by it.

WSM000001GEG0069US0

• After installing wiring, check protection of terminals and

clamped condition of wiring.

WSM000001GEG0070US0

(1) Grommet (A) Correct

(B) Incorrect

(1) Clamp

(Wind Clamp Spirally)

(2) Wire Harness

(3) Clamp

(4) Welding Dent

(1) Wiring

(2) Clamp

(A) Correct

(B) Incorrect

(1) Wiring (A) Incorrect

(1) Cover

(Securely Install Cover)

KiSC issued 11, 2014 A

Page 20

GENERAL

B2301, B2601, WSM

G-5

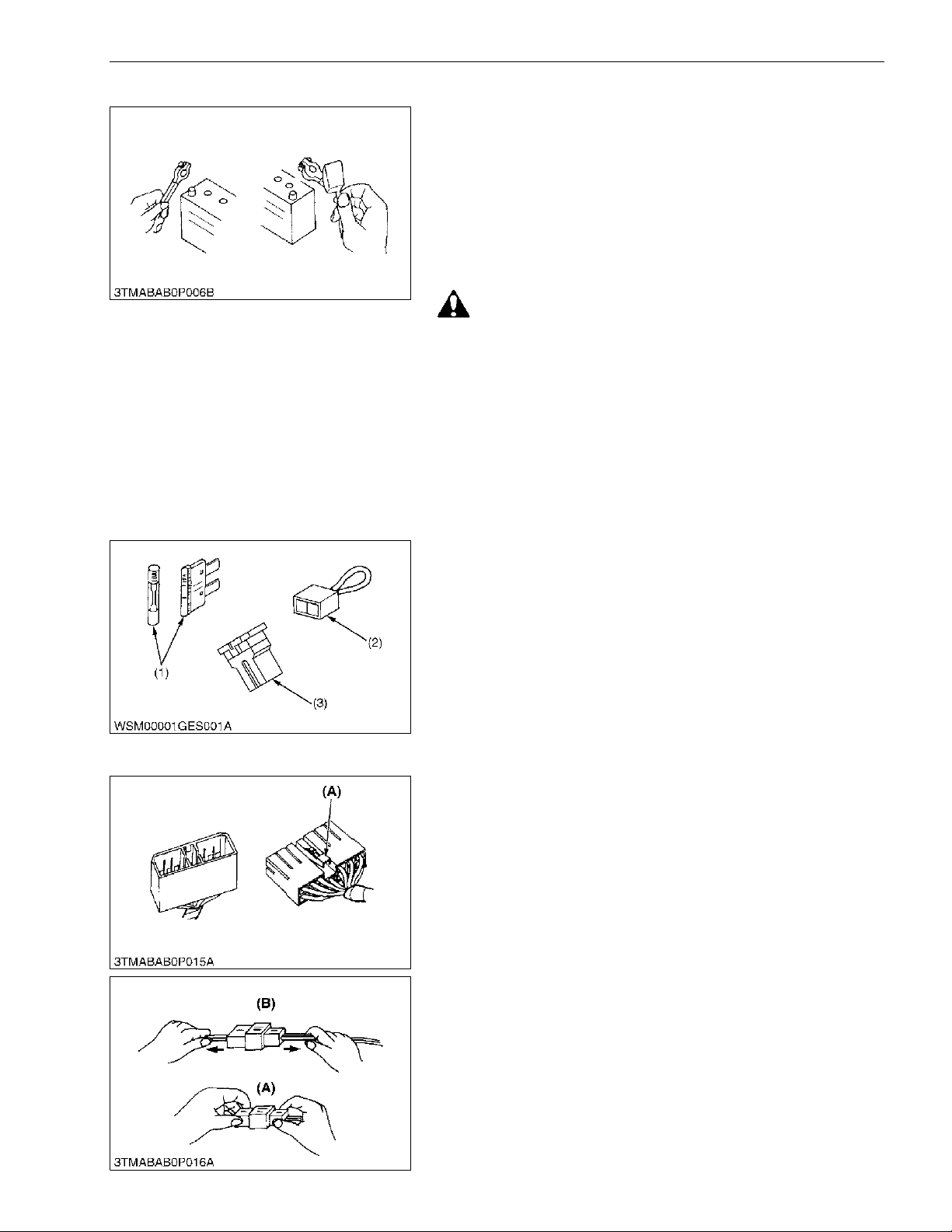

[2] BATTERY

• Be careful not to confuse positive and negative terminal posts.

• When you remove battery cables, disconnect negative cable

first. When you install battery cables, check for polarity and

connect positive cable first.

• Do not install any battery with capacity other than is specified

(Ah).

• After you connect cables to battery terminal posts, apply high

temperature grease to them and securely install terminal covers

on them.

• Do not allow dirt and dust to collect on battery.

DANGER

To avoid serious injury or death:

• Be careful not to let battery liquid spill on your skin and

clothes. If contaminated, wash it off with water

immediately.

• Before you recharge the battery, remove it from the

machine.

• Before you recharge, remove cell caps.

• Recharge in a well-ventilated place where there is no open

flame nearby, as hydrogen gas and oxygen are formed.

WSM000001GEG0071US0

[3] FUSE

• Use fuses with specified capacity.

Neither too large nor small capacity fuse is acceptable.

• Never use steel nor copper wire in place of fuse.

• Do not install working light, radio set, etc. on machine which is

not provided with reserve power supply.

• Do not install accessories if fuse capacity of reserve power

supply is exceeded.

WSM000001GEG0072US0

[4] CONNECTOR

• For connector with lock, push lock to separate.

WSM000001GEG0073US0

• In separating connectors, do not pull wire harnesses.

• Hold connector bodies to separate.

WSM000001GEG0074US0

(1) Fuse

(2) Fusible Link

(3) Slow Blow Fuse

(A) Push

(A) Correct (B) Incorrect

KiSC issued 11, 2014 A

Page 21

GENERAL

B2301, B2601, WSM

G-6

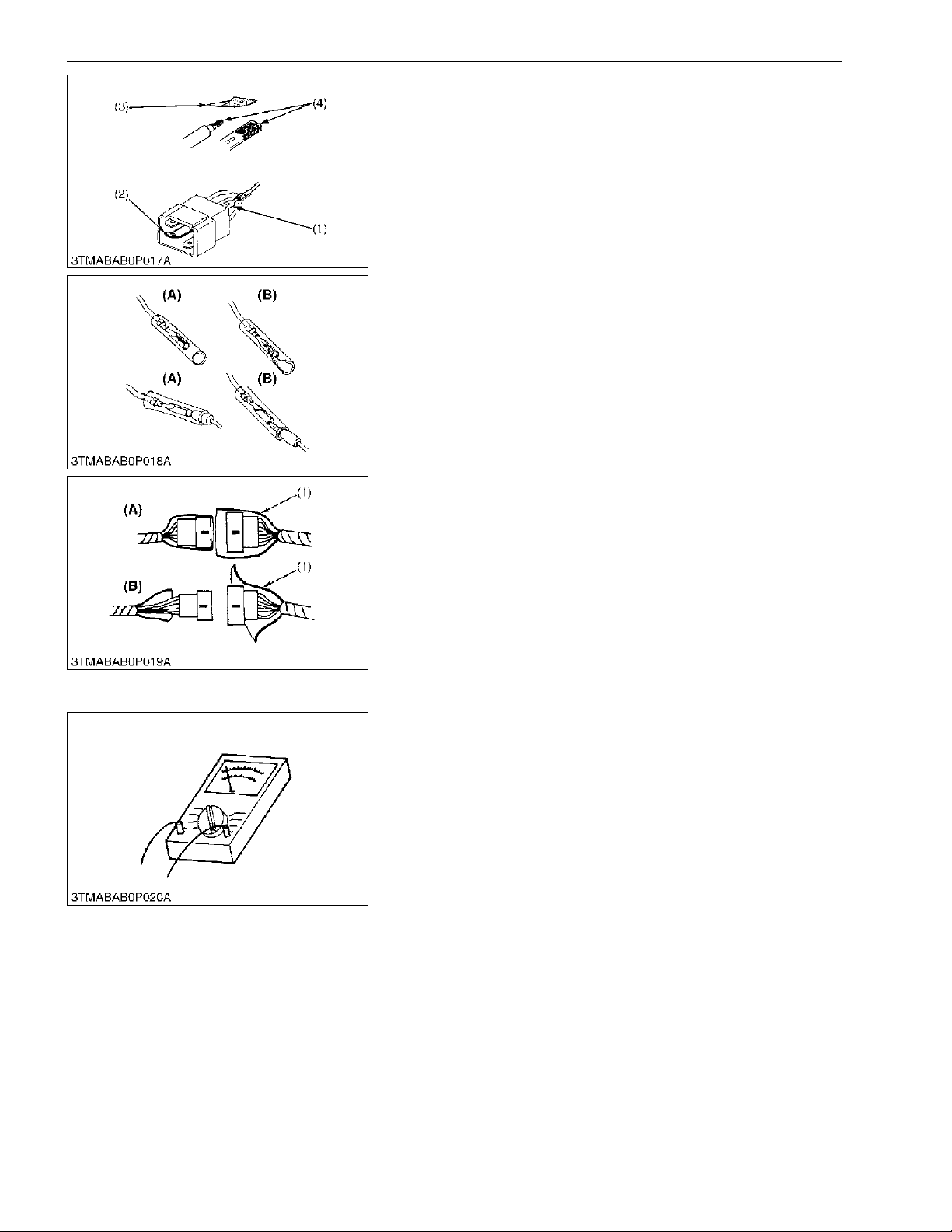

• Use sandpaper to remove rust from terminals.

• Repair deformed terminal. Make sure that there is no terminal

being exposed or displaced.

WSM000001GEG0075US0

• Make sure that there is no female connector being too open.

WSM000001GEG0076US0

• Make sure that plastic cover is large enough to cover whole

connector.

WSM000001GEG0077US0

[5] HANDLING OF CIRCUIT TESTER

• Use tester correctly following manual provided with tester.

• Check for polarity and range.

WSM000001GEG0078US0

(1) Exposed Terminal

(2) Deformed Terminal

(3) Sandpaper

(4) Rust

(A) Correct (B) Incorrect

(1) Cover (A) Correct

(B) Incorrect

KiSC issued 11, 2014 A

Page 22

GENERAL

B2301, B2601, WSM

G-7

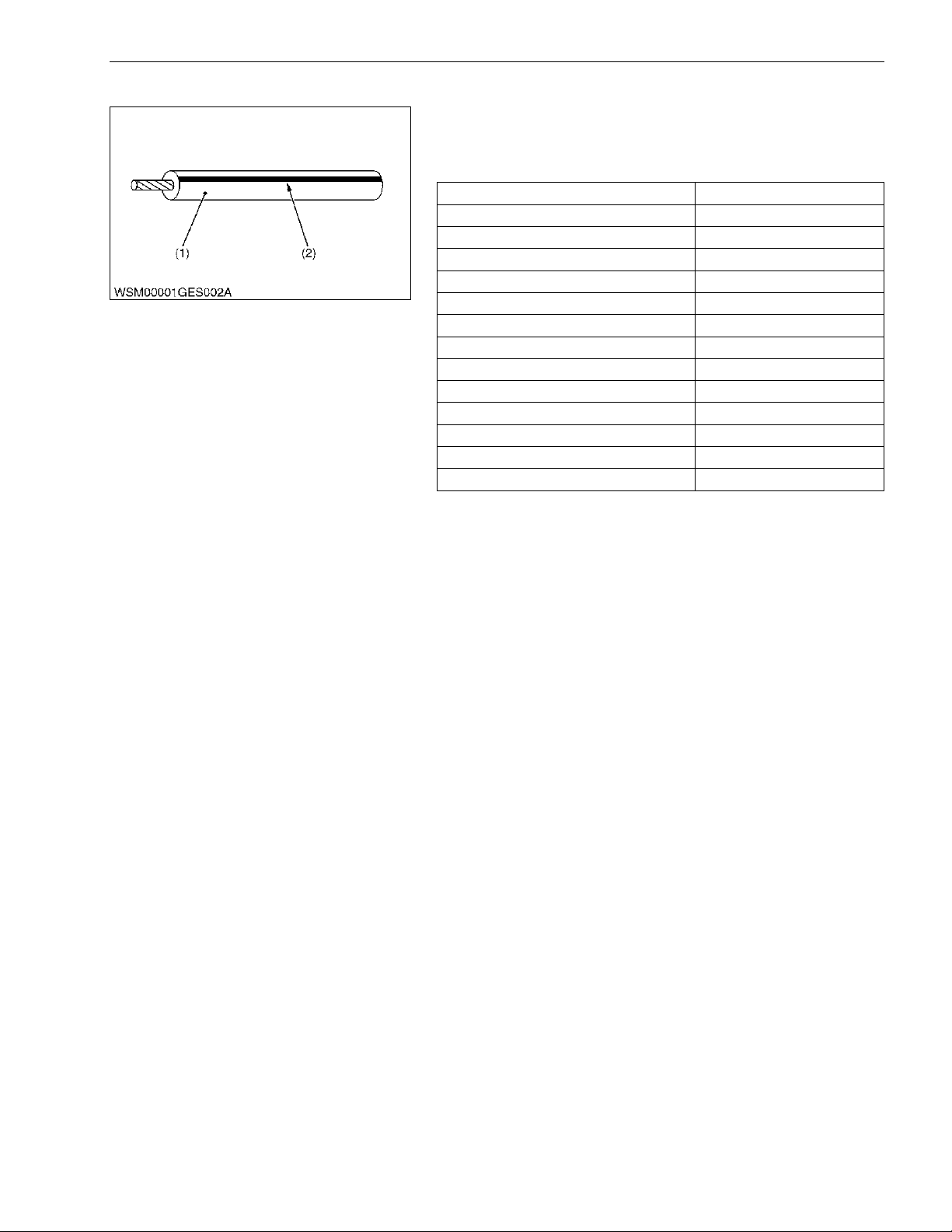

[6] COLOR OF WIRING

• Colors of wire are specified to the color codes.

• This symbol of "/" shows color with stripe(s).

(An example)

Red stripe on white color: W/R

WSM000001GEG0079US0

Color of wiring Color code

Black B

Brown Br

Green G

Gray Gy or Gr

Blue L

Light Green Lg

Orange Or

Pink P

Purple Pu or V

Red R

Sky Blue Sb

White W

Yell ow Y

(1) Wire Color (2) Stripe

KiSC issued 11, 2014 A

Page 23

GENERAL

B2301, B2601, WSM

G-8

4. LUBRICANTS, FUEL AND COOLANT

NOTE

• *KUBOTA UDT or SUPER UDT fluid --- KUBOTA original transmission hydraulic fluid

9Y1211156GEG0002US0

No. Place

Capacity

Lubricants, fuel and coolant

B2301 B2601

1 Fuel tank

23 L

6.1 U.S.gals

5.1 Imp.gals

• No. 2-D diesel fuel

• No. 1-D diesel fuel if temperature

is below –10 °C (14 °F)

2

Coolant (with recovery

tank)

3.8 L

4.0 U.S.qts

3.3 Imp.qts

Fresh clean soft water with

anti-freeze

3

Engine crankcase

(with filter)

3.1 L

3.3 U.S.qts

2.7 Imp.qts

Engine oil: Refer to next page

• Above 25 °C (77 °F)

SAE30, SAE10W-30 or 15W-40

• −10 to 25 °C

(14 to 77 °F)

SAE20, SAE10W-30 or 15W-40

• Below −10 °C (14 °F)

SAE10W-30

4 Transmission case

15 L

4.0 U.S.gals

3.3 Imp.gals

KUBOTA SUPER UDT-2 fluid*

5 Front axle case

3.5 L

3.7 U.S.qts

3.1 Imp.qts

KUBOTA SUPER UDT-2 fluid* or

SAE80 - SAE90 gear oil

Greasing No. of greasing point Capacity Type of grease

6

Top link 1

Until grease

overflows

Multipurpose

type grease

NLGI-2 or

NLGI-1

(GC-LB)

Lift rod [RH] 1

Brake pedal 1

Battery terminal 2

Moderate

amount

KiSC issued 11, 2014 A

Page 24

GENERAL

B2301, B2601, WSM

G-9

NOTE

<For North American market>

Engine Oil

• Oil used in the engine should have an American Petroleum Institute (API) service classification and

Proper SAE Engine Oil according to the ambient temperatures as shown above :

• Refer to the following table for the suitable API classification engine oil according to the engine type (with

internal EGR, external EGR or non-EGR) and the fuel (low-sulfur or high-sulfur fuel).

EGR: Exhaust Gas Re-circulation

• The CJ-4 engine oil is intended for DPF (Diesel Particulate Filter) type engines, and cannot be used on

this tractor.

Fuel

• Cetane number of 45 minimum. Cetane number greater then 50 is preferred, especially for temperatures

below −20 °C (−4 °F) or elevations above 1500 m (5000 ft).

• Diesel fuels specified to EN 590 or ASTM D975 are recommended.

• No.2-D is a distillate fuel of lower volatility for engine in industrial and heavy mobile service. (SAE J313

JUN87)

Transmission oil

• KUBOTA Super UDT-2: For an enhanced ownership experience, we highly recommend Super UDT-2 to be

used instead of standard hydraulic/transmission fluid.

Super UDT-2 is a proprietary KUBOTA formulation that delivers superior performance and protection in

all operating conditions.

Regular UDT is also permitted for use in this machine.

Indicated capacities of water and oil are manufacturer's estimate.

Fuel used

Engine oil classification (API classification)

Oil class of engines except external EGR Oil class of engines with external EGR

Ultra Low Sulfur Fuel

[< 0.0015 % (15 ppm)]

CF, CF-4, CG-4, CH-4 or CI-4

CF or CI-4

(Class CF-4, CG-4 and CH-4 engine oils

cannot be used on EGR type engines)

except external EGR With external EGR

Models B2301 / B2601 –

KiSC issued 11, 2014 A

Page 25

GENERAL

B2301, B2601, WSM

G-10

<For other than North American market>

Engine Oil

• Oil used in the engine should have an American Petroleum Institute (API) service classification and

Proper SAE Engine Oil according to the ambient temperatures as shown above :

• With the emission control now in effect, the CF-4 and CG-4 lubricating oils have been developed for use

of a low-sulfur fuel on on-road vehicle engines. When an off-road vehicle engine runs on a high-sulfur

fuel, it is advisable to employ the "CF or better" lubricating oil with a high Total Base Number (TBN of 10

minimum).

• Refer to the following table for the suitable API classification engine oil according to the engine type (with

internal EGR, external EGR or non-EGR) and the fuel (low-sulfur or high-sulfur fuel).

EGR: Exhaust Gas Re-circulation

• The CJ-4 engine oil is intended for DPF (Diesel Particulate Filter) type engines, and cannot be used on

this tractor.

Fuel

• Cetane number of 45 minimum. Cetane number greater then 50 is preferred, especially for temperatures

below −20 °C (−4 °F) or elevations above 1500 m (5000 ft).

• If diesel fuel with sulfur content greater than 0.5 % (5000 ppm) sulfur content in used, reduce the service

interval for engine oil and filter by 50 %.

• NEVER use diesel fuel with sulfur content greater than 0.05 % (500 ppm) for EXTERNAL EGR type engine.

• DO NOT use diesel fuel with sulfur content greater than 1.0 % (10000 ppm).

• Diesel fuels specified to EN 590 or ASTM D975 are recommended.

• No.2-D is a distillate fuel of lower volatility for engine in industrial and heavy mobile service. (SAE J313

JUN87)

Transmission oil

• The oil used to lubricate the transmission is also used as hydraulic fluid. To insure proper operation of

the hydraulic system and to complete lubrication of the transmission, it is important that a multi-grade

transmission fluid is used in this system. We recommend the use of KUBOTA UDT or SUPER UDT fluid

for optimum protection and performance.

Do not mix different brands together.

Indicated capacities of water and oil are manufacturer's estimate.

9Y1211156GEG0003US0

Fuel used

Engine oil classification (API classification)

Oil class of engines except external EGR Oil class of engines with external EGR

High Sulfur Fuel

[≥ 0.05 % (500 ppm)]

CF

(If the "CF-4, CG-4, CH-4, or CI-4"

lubricating oil is used with a high-sulfur

fuel, change the lubricating oil at shorter

intervals. (approximately half))

–

Low Sulfur Fuel

[(< 0.05 % (500 ppm)]

or Ultra Low Sulfur

Fuel [< 0.0015 %

(15 ppm)]

CF, CF-4, CG-4, CH-4 or CI-4

CF or CI-4

(Class CF-4, CG-4 and CH-4 engine oils

cannot be used on EGR type engines)

except external EGR With external EGR

Models B2301 / B2601 –

KiSC issued 11, 2014 A

Page 26

GENERAL

B2301, B2601, WSM

G-11

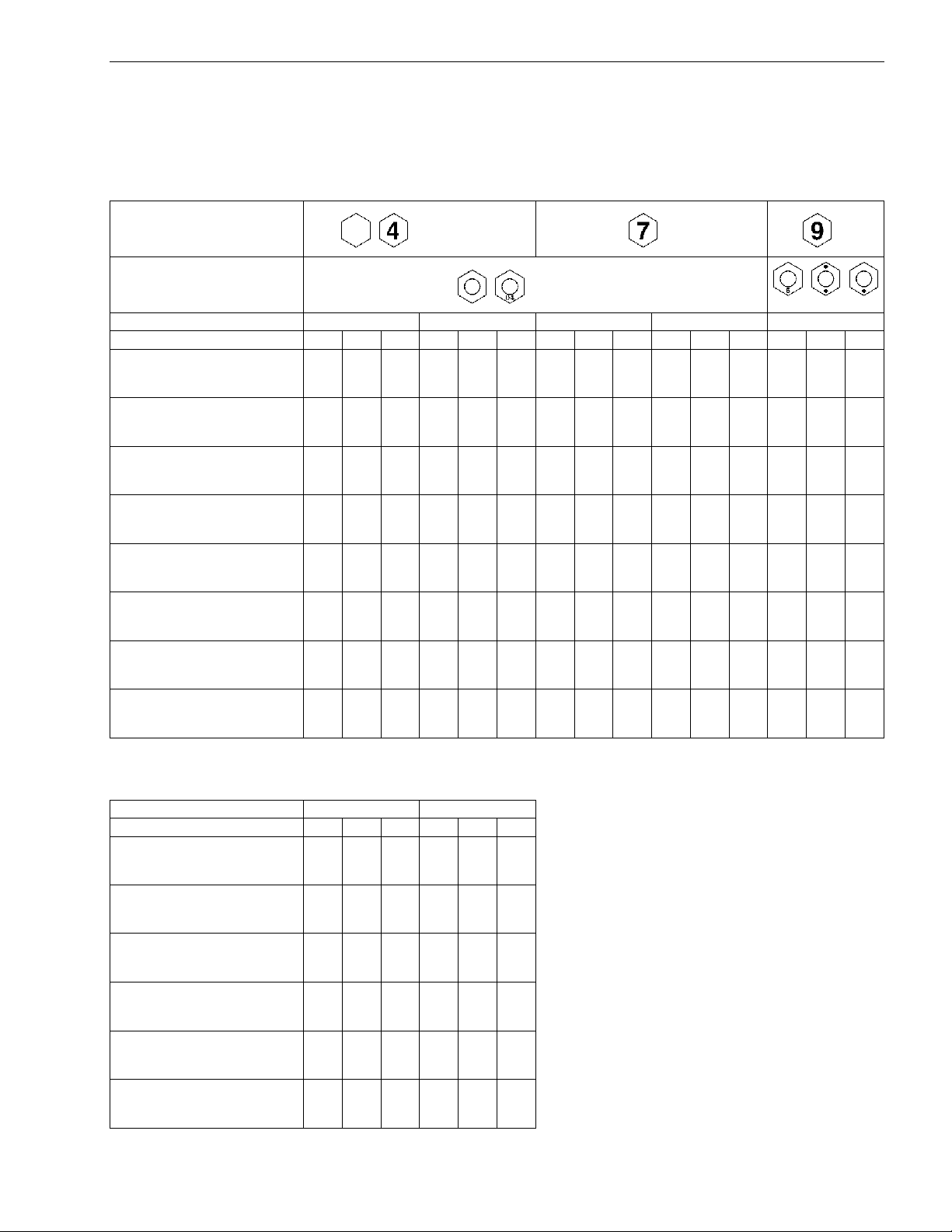

5. TIGHTENING TORQUES

Tighten screws, bolts and nuts whose tightening torques are not specified in this Workshop Manual

according to the table below.

WSM000001GEG0116US0

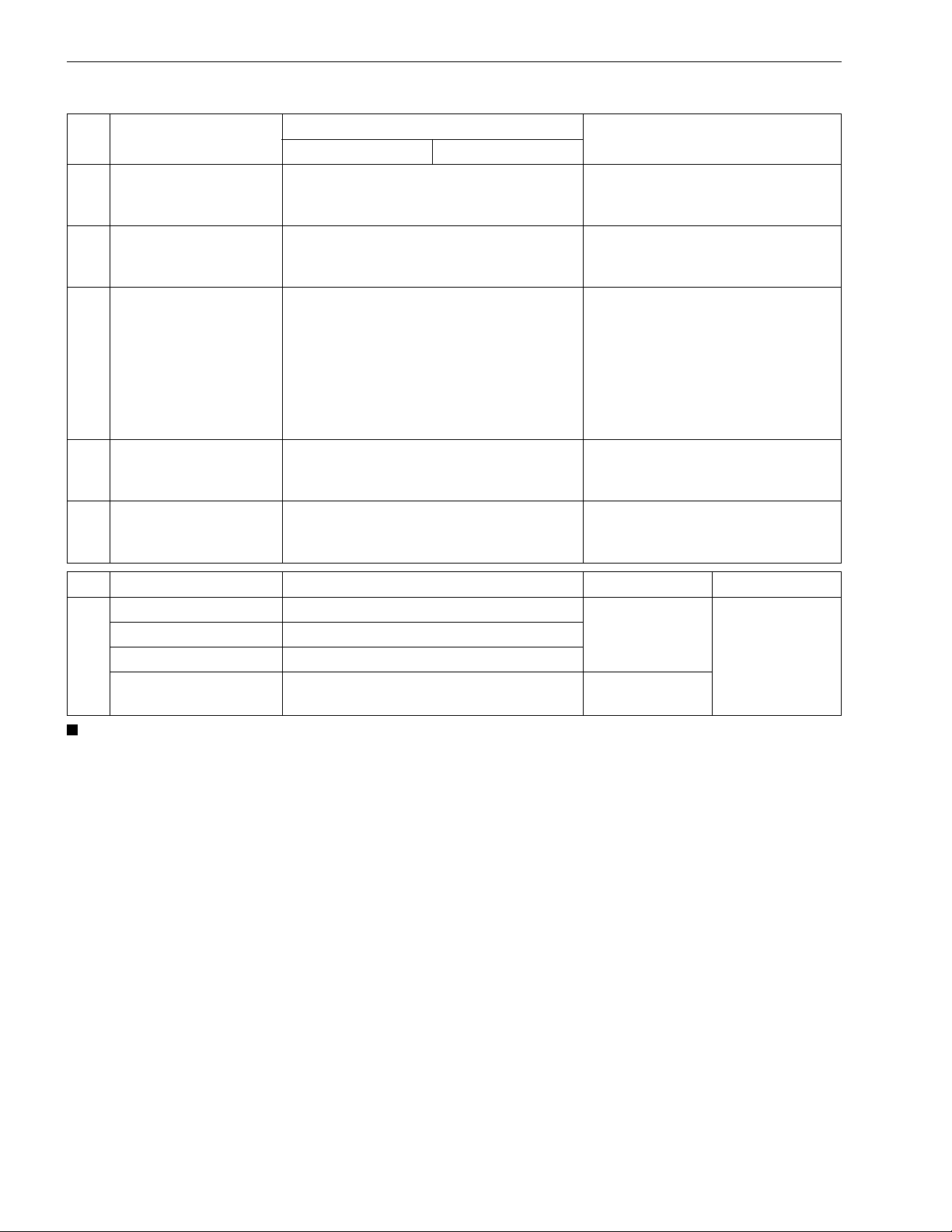

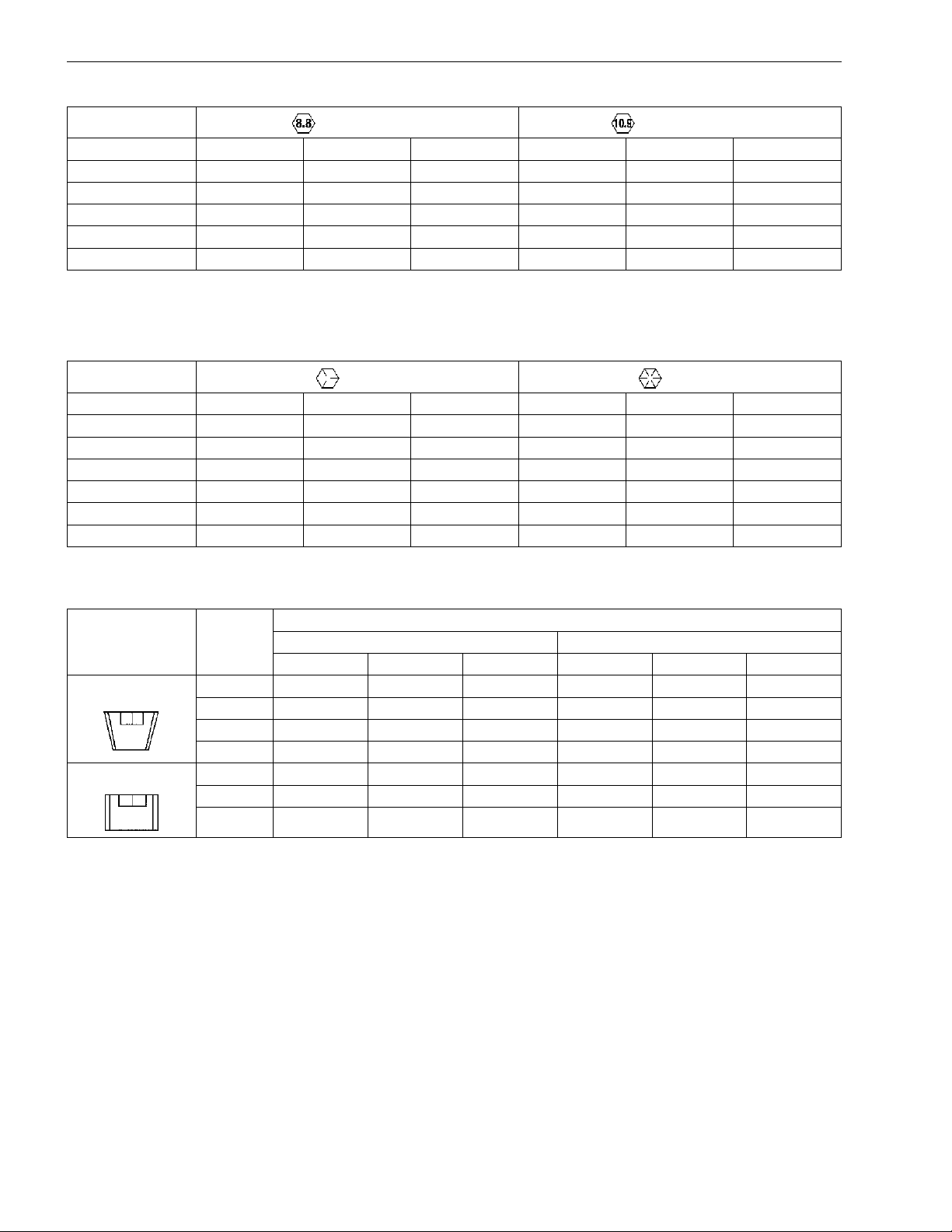

[1] GENERAL USE SCREWS, BOLTS AND NUTS

WSM000001GEG0117US0

[2] STUD BOLTS

WSM000001GEG0002US0

Indication on top of bolt

No-grade or 4T 7T 9T

Indication on top of nut

No-grade or 4T

6T

Material of opponent part Ordinariness Aluminum Ordinariness Aluminum Ordinariness

Unit N·m kgf·m lbf·ft N·m kgf·m lbf·ft N·m kgf·m lbf·ft N·m kgf·m lbf·ft N·m kgf·m lbf·ft

M6

7.9

to

9.3

0.80

to

0.95

5.8

to

6.8

7.9

to

8.8

0.80

to

0.90

5.8

to

6.5

9.81

to

11. 2

1.00

to

1.15

7.24

to

8.31

7.9

to

8.8

0.80

to

0.90

5.8

to

6.5

12.3

to

14.2

1.25

to

1.45

9.05

to

10.4

M8

18

to

20

1.8

to

2.1

13

to

15

17

to

19

1.7

to

2.0

13

to

14

24

to

27

2.4

to

2.8

18

to

20

18

to

20

1.8

to

2.1

13

to

15

30

to

34

3.0

to

3.5

22

to

25

M10

40

to

45

4.0

to

4.6

29

to

33

32

to

34

3.2

to

3.5

24

to

25

48

to

55

4.9

to

5.7

36

to

41

40

to

44

4.0

to

4.5

29

to

32

61

to

70

6.2

to

7.2

45

to

52

M12

63

to

72

6.4

to

7.4

47

to 53–––

78

to

90

7.9

to

9.2

58

to

66

63

to

72

6.4

to

7.4

47

to

53

103

to

117

10.5

to

12.0

76.0

to

86.7

M14

108

to

125

11. 0

to

12.8

79.6

to

92.5

–––

124

to

147

12.6

to

15.0

91.2

to

108

–––

1

67

to

196

17.0

to

20.0

123

to

144

M16

167

to

191

17.0

to

19.5

123

to

14

1

–––

197

to

225

20.0

to

23.0

145

to

166

–––

260

to

304

26.5

to

31.0

192

to

224

M18

246

to

284

25.0

to

29.0

181

to

209

–––

275

to

318

28.0

to

32.5

203

to

235

–––

344

to

402

35.0

to

41.0

254

to

296

M20

334

to

392

34.0

to

40.0

246

to

289

–––

368

to

431

37.5

to

44.0

272

to

318

–––

491

to

568

50.0

to

58.0

362

to

419

Material of opponent part Ordinariness Aluminum

Unit N·m kgf·m lbf·ft N·m kgf·m lbf·ft

M8

12

to

15

1.2

to

1.6

8.7

to

11

8.9

to

11

0.90

to

1.2

6.5

to

8.6

M10

25

to

31

2.5

to

3.2

18

to

23

20

to

25

2.0

to

2.6

15

to

18

M12

30

to

49

3.0

to

5.0

22

to 3631 3.2 23

M14

62

to

73

6.3

to

7.5

46

to 54–––

M16

98.1

to

112

10.0

to

11. 5

72.4

to

83.1

–––

M18

172

to

201

17.5

to

20.5

127

to

148

–––

KiSC issued 11, 2014 A

Page 27

GENERAL

B2301, B2601, WSM

G-12

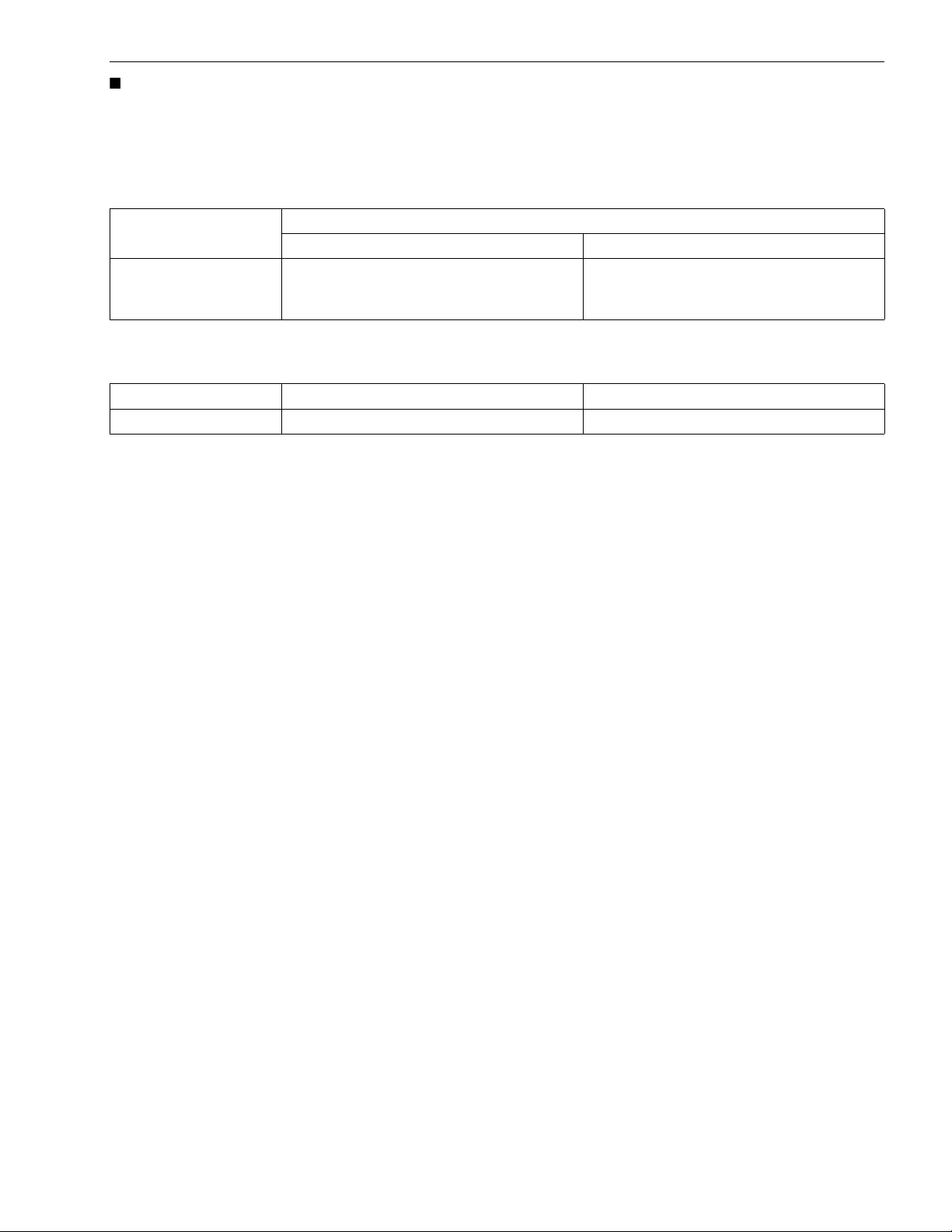

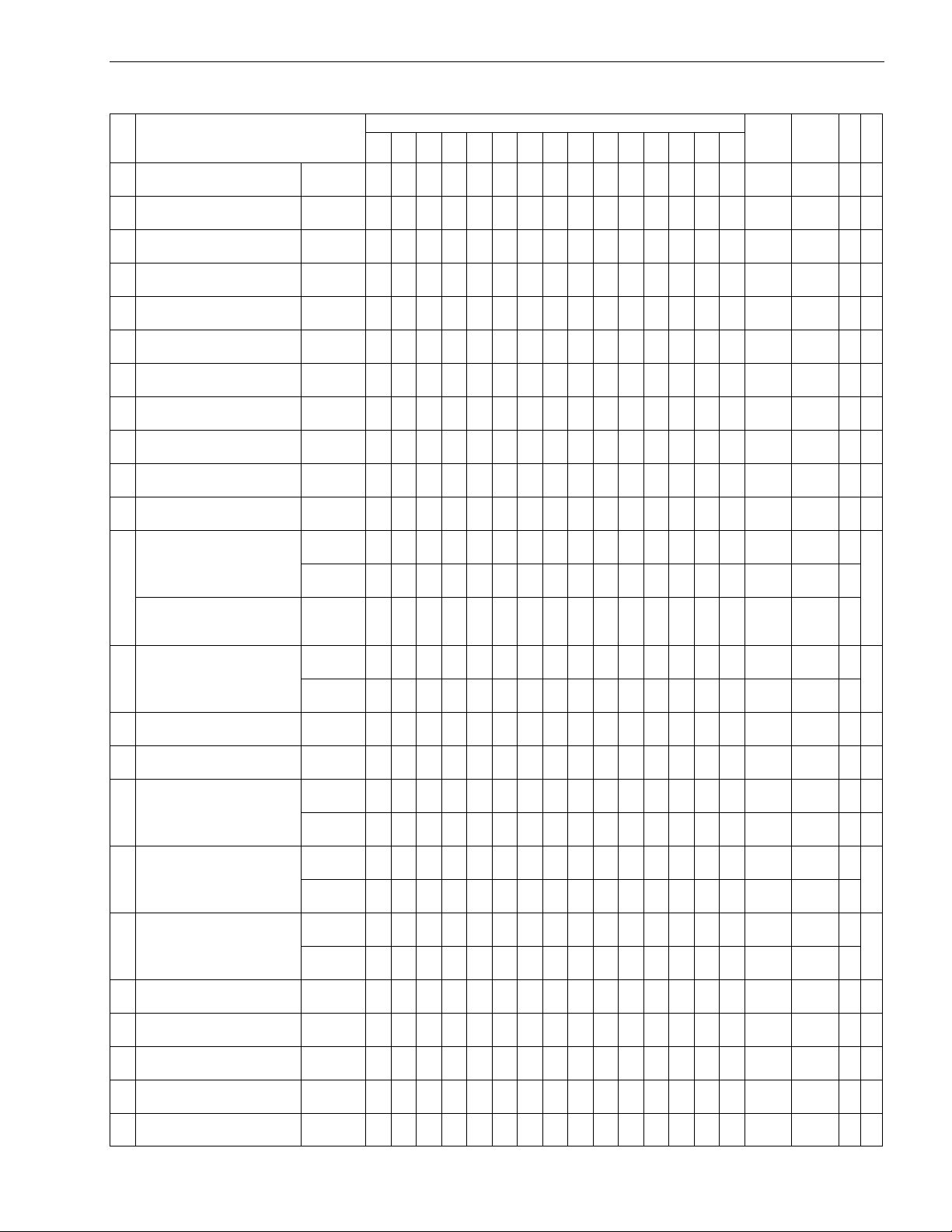

[3] METRIC SCREWS, BOLTS AND NUTS

WSM000001GEG0003US0

[4] AMERICAN STANDARD SCREWS, BOLTS AND NUTS WITH

UNC OR UNF THREADS

WSM000001GEG0008US0

[5] PLUGS

WSM000001GEG0005US0

Grade

Property class 8.8 Property class 10.9

Unit N·m kgf·m lbf·ft N·m kgf·m lbf·ft

M8 24 to 27 2.4 to 2.8 18 to 20 30 to 34 3.0 to 3.5 22 to 25

M10 48 to 55 4.9 to 5.7 36 to 41 61 to 70 6.2 to 7.2 45 to 52

M12 78 to 90 7.9 to 9.2 58 to 66 103 to 117 10.5 to 12.0 76.0 to 86.7

M14 124 to 147 12.6 to 15.0 91.2 to 108 167 to 196 17.0 to 20.0 123 to 144

M16 197 to 225 20.0 to 23.0 145 to 166 260 to 304 26.5 to 31.0 192 to 224

Grade

SAE GR.5 SAE GR.8

Unit N·m kgf·m lbf·ft N·m kgf·m lbf·ft

1/4 11.7 to 15.7 1.20 to 1.60 8.63 to 11.5 16.3 to 19.7 1.67 to 2.00 12.0 to 14.6

5/16 23.1 to 27.7 2.36 to 2.82 17.0 to 20.5 33 to 39 3.4 to 3.9 25 to 28

3/8 48 to 56 4.9 to 5.7 36 to 41 61 to 73 6.3 to 7.4 45 to 53

1/2 110 to 130 11.3 to 13.2 81.2 to 95.8 150 to 178 15.3 to 18.1 111 to 131

9/16 150 to 178 15.3 to 18.1 111 to 131 217 to 260 22.2 to 26.5 160 to 191

5/8 204 to 244 20.8 to 24.8 151 to 179 299 to 357 30.5 to 36.4 221 to 263

Shape Size

Material of opponent part

Ordinariness Aluminum

N·m kgf·m lbf·ft N·m kgf·m lbf·ft

Tapered screw

R1/8 13 to 21 1.3 to 2.2 9.4 to 15 13 to 19 1.3 to 2.0 9.4 to 14

R1/4 25 to 44 2.5 to 4.5 18 to 32 25 to 34 2.5 to 3.5 18 to 25

R3/8 49 to 88 5.0 to 9.0 37 to 65 49 to 58 5.0 to 6.0 37 to 43

R1/2 58.9 to 107 6.00 to 11.0 43.4 to 79.5 59 to 78 6.0 to 8.0 44 to 57

Straight screw G1/4 25 to 34 2.5 to 3.5 18 to 25 – – –

G3/8 62 to 82 6.3 to 8.4 46 to 60 – – –

G1/2 49 to 88 5.0 to 9.0 37 to 65 – – –

KiSC issued 11, 2014 A

Page 28

GENERAL

B2301, B2601, WSM

G-13

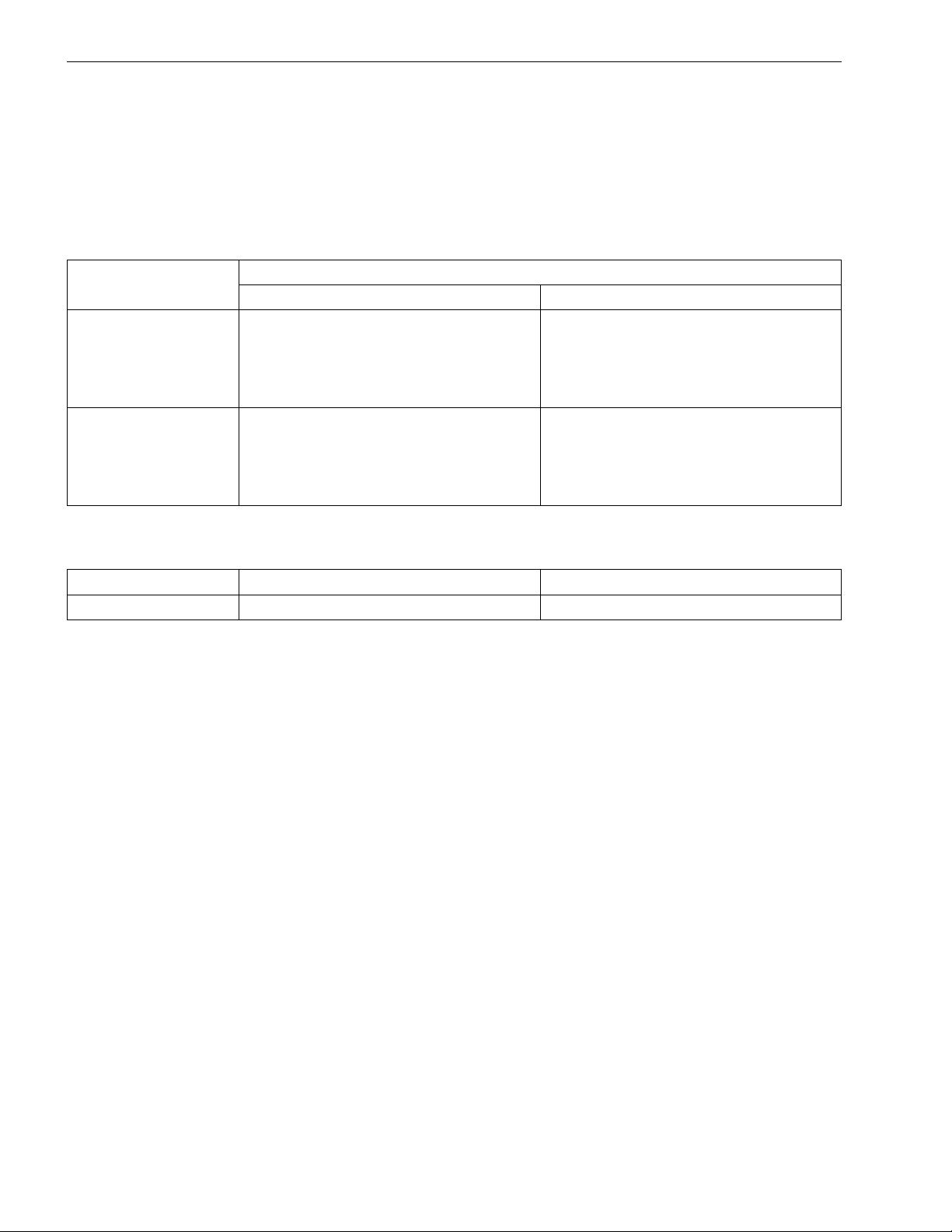

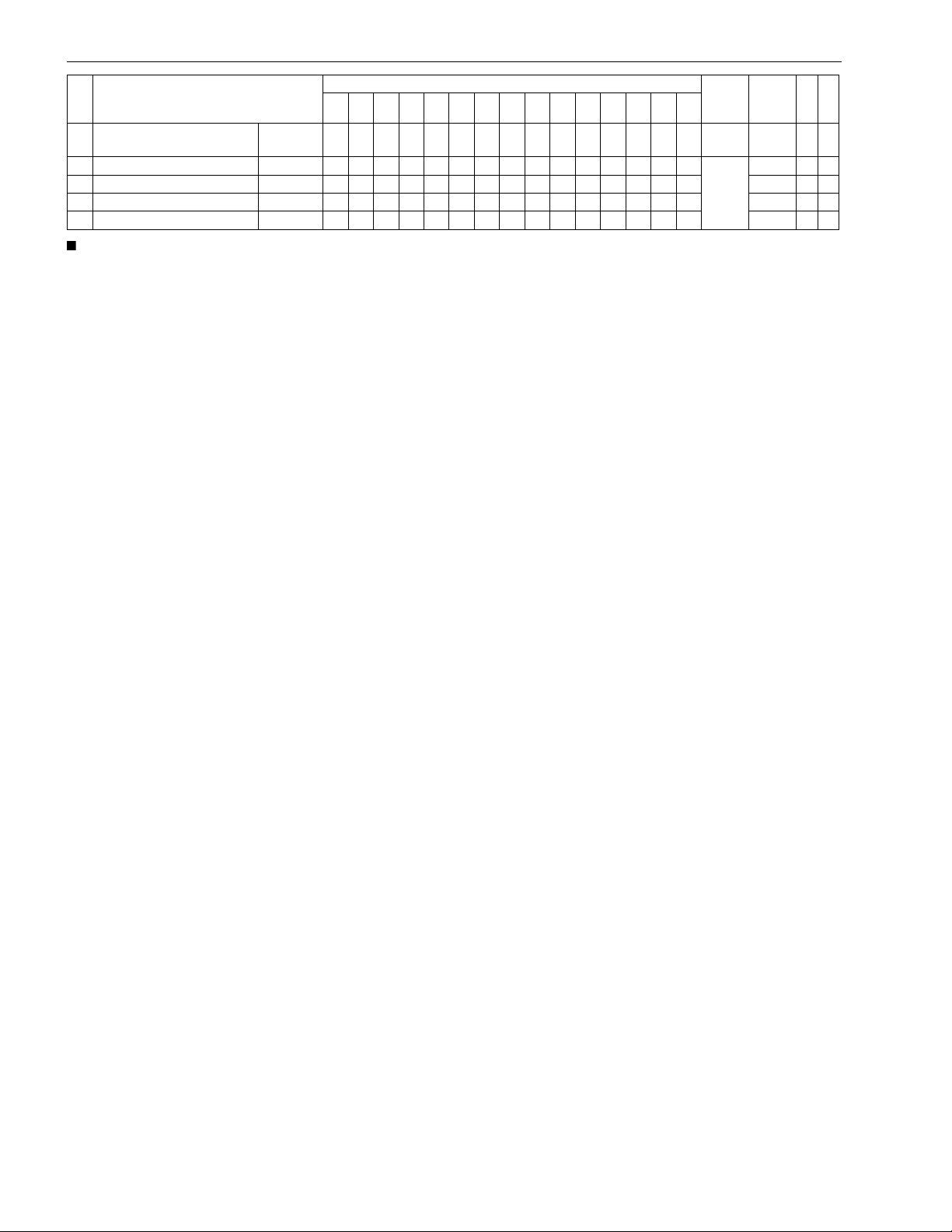

6. MAINTENANCE CHECK LIST

No. Item

Indication on hour meter

Interval

Refer-

ence

page

50 100 150 200 250 300 350 400 450 500 550 600 650 700 800

1 Engine oil Change

every

200 Hr

G-26

2 Engine oil filter Replace

every

200 Hr

G-25

3 Transmission oil filters [HST] Replace

every

200 Hr

G-26

4 Hydraulic oil filter Replace

every

400 Hr

G-29

5 Transmission fluid Change

every

400 Hr

G-28

6 Front axle case oil Change

every

400 Hr

G-29

7 Front axle pivot Adjust

every

400 Hr

G-30

8 Engine start system Check

every

50 Hr

G-19

9 Greasing –

every

50 Hr

G-20

10 Wheel bolt torque Check

every

50 Hr

G-20

11 Battery condition Check

every

100 Hr

G-21 *4

12

Air cleaner element [Double

element type]

Primary element

Clean

every

100 Hr

G-23 *1

@

Replace

every 1

year

G-30 *2

Air cleaner element [Double

element type]

Secondary element

Replace

every 1

year

G-30

13 Fuel filter element

Clean

every

100 Hr

G-24

@

Replace

every

400 Hr

G-30

14 Fan belt Adjust

every

100 Hr

G-24

15 Brake Adjust

every

100 Hr

G-25

16 Radiator

hose and clamp

Check

every

200 Hr

G-27

Replace

every 2

years

G-33

17 Fuel line

Check

every

100 Hr

G-25

@

Replace

every 2

years

G-33 *3

18 Intake air line

Check

every

200 Hr

G-27

@

Replace

every 2

years

G-33 *3

19 Toe-in Adjust

every

200 Hr

G-28

20 Engine valve clearance Adjust

every

800 Hr

G-30

21

Fuel injection nozzle injection

pressure

Check

every

1500 Hr

G-30 @

22 Injection pump Check

every

3000 Hr

G-30 @

23 Cooling system Flush

every 2

years

G-31

KiSC issued 11, 2014 A

Page 29

GENERAL

B2301, B2601, WSM

G-14

IMPORTANT

• The jobs indicated by must be done after the first 50 hours of operation.

*1 Air cleaner should be cleaned more often in severe dusty conditions.

*2 Every year or after 6 cleanings.

*3 Replace only if necessary.

*4 When the battery is used for less than 100 hours per year, check the fluid level annually.

• The items listed above (@ marked) are registered as emission related critical parts by KUBOTA in the U.S.EPA nonroad emission

regulation. As the engine owner, you are responsible for the performance of the required maintenance on the engine according to

the above instruction.

Please see the Warranty Statement in detail.

9Y1211156GEG0004US0

24 Coolant Change

every 2

years

G-31

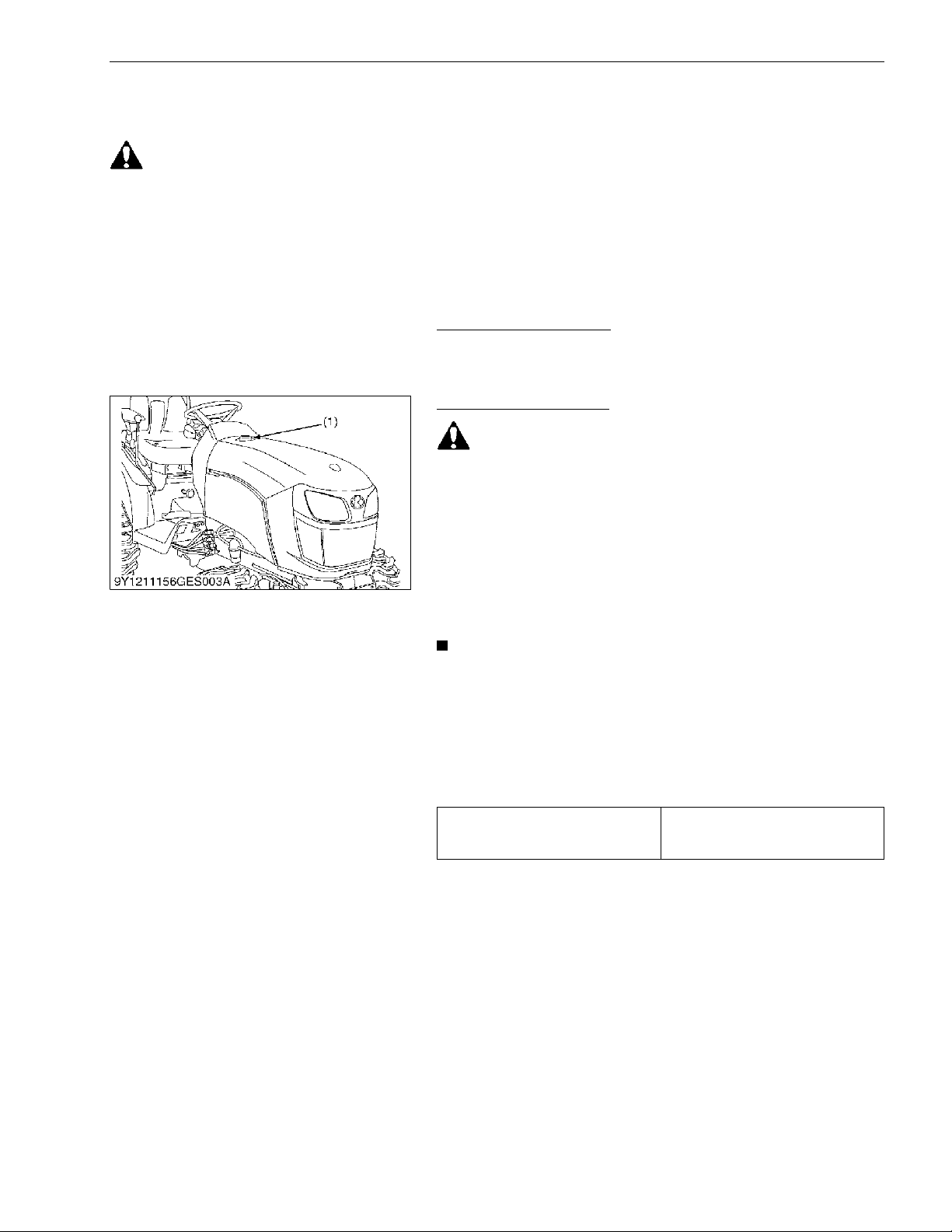

25 Fuel system Bleed

Service

as re-

quired

G-33

26 Clutch housing water Drain G-33

27 Fuse Replace G-34

28 Light bulb Replace G-34

No. Item

Indication on hour meter

Interval

Refer-

ence

page

50 100 150 200 250 300 350 400 450 500 550 600 650 700 800

KiSC issued 11, 2014 A

Page 30

GENERAL

B2301, B2601, WSM

G-15

7. CHECK AND MAINTENANCE

[1] DAILY CHECK

WARNING

To avoid personal injury or death:

Take the following precautions when checking the tractor.

• Park the machine on firm and level ground.

• Set the parking brake.

• Lower the implement to the ground.

• All residual pressure of the hydraulic system released.

• Stop the engine and remove the key.

9Y1211156GEG0005US0

Walk Around Inspection

1. Look around and under the tractor for such items as loose bolts,

trash build-up, oil or coolant leaks, broken or worn parts.

9Y1211156GEG0006US0

Checking and Refueling

WARNING

To avoid personal injury or death:

• Do not smoke while refueling.

• Be sure to stop the engine before refueling.

1. Turn the key switch to "ON", check the amount of fuel by fuel

gauge.

2. Fill fuel tank when fuel gauge shows 1/4 or less fuel in tank.

3. Use grade No.2-Diesel fuel at temperatures above −10 °C

(14 °F).

Use grade No.1-Diesel fuel at temperatures below −10 °C

(14 °F).

IMPORTANT

• Do not permit dirt or trash to get into the fuel system.

• Be careful not to let the fuel tank become empty, otherwise

air will enter the fuel system, necessitating bleeding before

next engine start.

• Be careful not to spill during refueling. If you should spill,

wipe it off at once, or it may cause a fire.

• To prevent condensation (water) accumulation in the fuel

tank, fill the tank before parking overnight.

9Y1211156GEG0007US0

Fuel tank capacity

23 L

6.1 U.S.gals

5.1 Imp.gals

(1) Fuel Tank Cap

KiSC issued 11, 2014 A

Page 31

GENERAL

B2301, B2601, WSM

G-16

Checking Engine Oil Level

WARNING

To avoid personal injury:

• Be sure to stop the engine before checking the oil level.

1. Park the machine on a flat surface.

2. Check engine oil before starting the engine or 5 minutes or more

after the engine has stopped.

3. To check the oil level, draw out the dipstick, wipe it clean,

replace it, and draw it out again. Check to see that the oil level

lies between the two notches.

If the level is too low, add new oil to the prescribed level at the

oil inlet.

IMPORTANT

• When using an oil of different maker or viscosity from the

previous one, remove all of the old oil.

Never mix two different types of oil.

• If oil level is low, do not run engine.

9Y1211156GEG0008US0

Checking Transmission Fluid Level

1. Park the machine on a flat surface, lower the implement and

shut off engine.

2. To check the oil level, draw out the dipstick, wipe it clean,

replace it, and draw it out again. check to see that the oil level

lies within the cross hatched area.

If the level it too low, add new oil to the prescribed level at the

oil inlet.

IMPORTANT

• If oil level is low, do not run engine.

9Y1211156GEG0009US0

Checking Coolant Level

WARNING

To avoid personal injury or death:

• Do not remove radiator cap while coolant is hot. When cool,

slowly rotate cap to the first stop and allow sufficient time

for excess pressure to escape before removing the cap

completely.

1. Check to see that the coolant level is between the "FULL" and

"LOW" makes of recovery tank.

2. When the coolant level drops due to evaporation, add soft water

only up to the full level.

In case of leakage, add anti-freeze and soft water in the

specified mixing ratio up to the full level.

IMPORTANT

• If the radiator cap has to be removed, follow the caution

above and securely retighten the cap.

• Use clean, fresh soft water and anti-freeze to fill the

recovery tank.

9Y1211156GEG0010US0

(1) Oil Inlet

(2) Dipstick

A: Oil level is acceptable within this

range.

(1) Oil Inlet

(2) Dipstick

A: Oil level is acceptable within this

range.

(1) Recovery Tank A: "FULL"

B: "LOW"

KiSC issued 11, 2014 A

Page 32

GENERAL

B2301, B2601, WSM

G-17

Cleaning Evacuator Valve

1. Open the evacuator valve to get rid of large particles of dust and

dirt.

9Y1211156GEG0011US0

Cleaning Grill and Radiator Screen

WARNING

To avoid personal injury or death:

• Be sure to stop the engine and remove the key before

removing the screen.

1. Check front grill and side screens to be sure they are clean of

debris.

2. Detach the screen and remove all foreign material and clean the

front of radiator completely.

IMPORTANT

• Grill and screen must be clean from debris to prevent

engine from overheating and to allow good air intake for

the air cleaner.

9Y1211156GEG0012US0

Checking Brake Pedal

1. Inspect the brake pedals for free travel, and smooth operation.

2. Adjust if incorrect measurement is found.

9Y1211156GEG0013US0

Checking Gauges, Meter and Easy Checker™

1. Inspect the instrument panel for broken gauge(s), meter(s) and

Easy Checker™.

2. Replace if broken.

9Y1211156GEG0014US0

Checking Head Light, Hazard Light etc.

1. Inspect the light for broken bulbs and lenses.

2. Replace if broken.

9Y1211156GEG0015US0

Checking Seat Belt and ROPS

1. Always check condition of seat belt and ROPS attaching

hardware before operating tractor.

2. Replace if damaged.

9Y1211156GEG0016US0

(1) Evacuator Valve

(1) Radiator Screen (A) "DETACH"

KiSC issued 11, 2014 A

Page 33

GENERAL

B2301, B2601, WSM

G-18

Checking and Cleaning of Electrical Wiring and Battery Cables

WARNING

To avoid personal injury or death:

• A loosened terminal or connector, or damaged wire may

affect the performance of electrical components or cause

short circuits. Leakage of electricity could result in a fire

hazard, a dead battery or damage to electrical components.

• Replace damaged wires or connections promptly.

• If a fuse blows soon after replacement, DO NOT USE A

LARGER THAN RECOMMENDED FUSE OR BYPASS THE

FUSE SYSTEM.

• Many wiring connections are protected by waterproof

plugs, plug and unplug these connections carefully and

make sure they are sealed correctly after assembly.

• Accumulation of dust, chaff or spilled fuel deposits around

the battery, electrical wiring, engine or exhaust system are

a fire hazard.

CLEAN THESE AREAS BEFORE STARTING WORK.

To avoid premature electrical malfunctions DO NOT APPLY

high pressure water directly to battery, wiring, connectors,

electrical components or instrument panel.

Inspect the following regularly:

1. Check wiring for chafed or cracked insulation.

2. Check wiring harness clamps. Replace if necessary.

3. Check connectors and terminals for looseness, contamination

or overheated (discolored) connectors.

4. Check instrument panel for correct operation of switches and

gauges.

9Y1211156GEG0017US0

Checking Movable Parts

1. If any of the movable parts, such as levers and pedals, is not

smoothly moved because of rust or anything sticky, do not

attempt to force it into motion.

In the above case, remove the rust or sticky thing, and apply oil

lor grease on the relevant spot.

Otherwise, the machine may get damaged.

9Y1211156GEG0018US0

KiSC issued 11, 2014 A

Page 34

GENERAL

B2301, B2601, WSM

G-19

[2] CHECK POINTS OF EVERY 50 HOURS

Checking Engine Start System

WARNING

To avoid personal injury or death:

• Do not allow anyone near the tractor while testing.

• If the tractor does not pass the test do not operate the

tractor.

• Detach an implement before testing.

Preparation before testing.

1. Sit on operator's seat.

2. Set the parking brake and stop the engine.

3. Shift the range gear shift lever to "NEUTRAL" position.

4. Place the speed control pedal in "NEUTRAL" position.

5. Shift the PTO clutch lever to "OFF" position.

Test: Switch for the speed control pedal.

1. Depress the speed control pedal.

2. Turn the key to "START" position.

3. The engine must not crank.

Test: Switch for the PTO clutch lever.

1. Place the speed control pedal in "NEUTRAL" position.

2. Shift the PTO clutch lever to "ON" position.

3. Turn the key to "START" position.

4. The engine must not crank.

Test: Switches for the operator's seat and the PTO clutch

lever.

1. Sit on the operator's seat.

2. Start the engine.

3. Shift the PTO clutch lever to "ON" position.

4. Release the parking brake.

5. Stand up. (Do not get off the machine.)

6. The engine must shut off after approximately 1 second.

9Y1211156GEG0019US0

(1) Range Gear Shift Lever

(2) PTO Clutch Lever

(3) Speed Control Pedal

(4) Operator's Seat

KiSC issued 11, 2014 A

Page 35

GENERAL

B2301, B2601, WSM

G-20

Lubricating Grease Fittings

1. Apply a small amount of multipurpose grease to the following

points every 50 hours:

If you operated the machine in extremely wet and muddy

conditions, lubricate grease fittings more often.

9Y1211156GEG0020US0

Checking Wheel Mounting Nuts Tightening Torque

WARNING

To avoid personal injury or death:

• Never operate tractor with a loose rim, wheel or axle.

• Any time bolts and nuts are loosened, retighten to

specified torque.

• Check all bolts and nuts frequently and keep them tight.

1. Check wheel bolts and nuts regularly especially when new. If

they are loose, tighten them as follows.

9Y1211156GEG0021US0

(1) Grease Fitting (Brake Pedals)

(2) Grease Fitting (Top Link)

(3) Grease Fitting (Lifting Rod, Right)

(4) Battery Terminals

Tightening torque

Front wheel mounting nut

78 to 90 N·m

8.0 to 9.1 kgf·m

58 to 66 lbf·ft

Rear wheel mounting nut

145 to 150 N·m

14.8 to 15.2 kgf·m

107 to 110 lbf·ft

(1) Front Wheel Mounting Nut (2) Rear Wheel Mounting Nut and Bolt

KiSC issued 11, 2014 A

Page 36

GENERAL

B2301, B2601, WSM

G-21

[3] CHECK POINTS OF EVERY 100 HOURS

Checking Battery Condition

DANGER

To avoid the possibility or battery explosion:

For the refillable type battery, follow the instructions below.

• Do not use or charge the refillable type battery if the fluid

level is below the LOWER (lower limit level) mark.

Otherwise, the battery component parts may prematurely

deteriorate, which may shorten the battery's service life or

cause an explosion. check the fluid level regularly and add

distilled water as required so that the fluid level is between

the UPPER and LOWER levels.

WARNING

To avoid personal injury or death:

• Never remove the battery cap while the engine is running.

• Keep electrolyte away from eyes, hands and clothes. If you

are spattered with it, wash it away completely with water

immediately and get medical attention.

• Keep open sparks and flames away from the battery at all

times. Hydrogen gas mixed with oxygen becomes very

explosive.

• Wear eye protection and rubber gloves when working

around battery.

1. Mishandling the battery shortens the service life and adds to

maintenance costs.

2. The original battery is maintenance free, but needs some

servicing.

3. If the battery is weak, the engine will be difficult to start and the

lights will be dim. It is important to check the battery periodically.

How to read the indicator

Check the battery condition by reading the indicator.

9Y1211156GEG0022US0

The factory-installed battery is of non-refillable type. If the

indicator turns white, do not charge the battery but replace

it with new one.

State of indicator display

Green

Specific gravity of electrolyte and quality of electrolyte

are both in good condition.

Black Needs charging battery.

White Needs replacing battery.

(1) Battery (2) Indicator

KiSC issued 11, 2014 A

Page 37

GENERAL

B2301, B2601, WSM

G-22

Battery Charging

WARNING

To avoid personal injury or death:

• When the battery is being activated, hydrogen and oxygen

gases in the battery are extremely explosive. Keep open

sparks and flames away from the battery at all times,

especially when charging the battery.

• When charging the battery, ensure the vent caps are

securely in place. (if equipped)

• When disconnecting the cable from the battery, start with

the negative terminal first.

When connecting the cable to the battery, start with the

positive terminal first.

• Never check battery charge by placing a metal object

across the posts.

Use a voltmeter or hydrometer.

1. To slow charge the battery, connect the battery positive terminal

to the charger positive terminal and the negative to the negative,

then recharge in the standard fashion.

2. A boost charge is only for emergencies. It will partially charge

the battery at a high rate and in a short time.

When using a boost-charged battery, it is necessary to recharge

the battery as early as possible.

Failure to do this will shorten the battery's service life.

3. The battery is charged if the indicator display turns green from

black.

4. When exchanging an old battery into new one, use battery of

equal specification shown in table 1.

Tab le 1

Direction for Storage

1. When storing the tractor for long periods of time, remove the

battery from tractor, adjust the electrolyte to the proper level and

store in a dry place out of direct sunlight.

2. The battery self-discharges while it is stored.

Recharge it once every three months in hot seasons and once

every six months in cold seasons.

9Y1211156GEG0023US0

Battery

Typ e

Volt (V)

Capacity

at 5 H.R.

Reserve

at (min.)

Cold

Cranking

Amps (A)

Normal

Charging

Rate (A)

55B24L

(S)-MF

12 36 80 430 4.5

(1) Battery

KiSC issued 11, 2014 A

Page 38

GENERAL

B2301, B2601, WSM

G-23

Cleaning Air Cleaner Primary Element [Double Element Type]

WARNING

To avoid personal injury or death:

• Be sure to stop the engine and remove the key before

cleaning air filter element.

1. Remove the air cleaner cover and primary element.

2. Clean the primary element:

a) When dry dust adheres to the element, blow compressed air

from the inside, turning the element. Pressure of

compressed air must be under 205 kPa (2.1 kgf/cm

2

,

30 psi).

b) When carbon or oil adheres to the element, soak the

element in detergent for 15 minutes then wash it several

times in water, rinse with clean water and dry it naturally.

After element is fully dried, inspect inside of the element

with a light and check if it is damaged or not.

3. Replace air cleaner primary element:

Once yearly or after every sixth cleaning, whichever comes first.

NOTE

• Check to see if the evacuator valve is blocked with dust.

IMPORTANT

• The air cleaner uses a dry element, never apply oil.

• Do not run the engine with filter element removed.

• Be sure to refit the cover with the arrow ↑ (on the cover)

upright. If the cover is improperly fitted, evacuator valve

will not function and dust will adhere to the element.

• Do not touch the secondary element except in cases where

replacing is required.

(See "Replacing Air Cleaner Primary Element and

Secondary Element" in "EVERY 1 YEAR".)

Evacuator Valve

Open the evacuator valve once a week under ordinary

conditions - or daily when used in a dusty place - to get rid of large

particles of dust and dirt.

9Y1211156GEG0025US0

(1) Secondary (Safety) Element

(2) Primary Element

(3) Cover

(4) Evacuator Valve

KiSC issued 11, 2014 A

Page 39

GENERAL

B2301, B2601, WSM

G-24

Cleaning Fuel Filter

WARNING

To avoid personal injury or death:

• Stop the engine and remove the key before checking fuel

lines and fuel filter.

• Check the fuel lines periodically. The fuel lines are subject

to wear and aging. Fuel may leak out onto the running

engine, causing a fire.

• Protect your hands when using kerosene to clean

components.

This job should not be done in the field, but in a clean place.

1. Loosen and remove the filter bowl, and rinse the inside with

kerosene.

2. Take out the element and dip it in the kerosene to rinse.

3. After cleaning, reassemble the fuel filter, keeping out dust and

dirt.

4. Bleed the fuel system. (See "SERVICE AS REQUIRED".)

IMPORTANT

• When the fuel filter bowl has been removed, fuel stops

flowing from the fuel tank. If the fuel tank is almost full,

however, the fuel will flow back from the fuel return pipe to

the fuel filter. Before checking, make sure the fuel tank is

less than half-full.

• If dust, dirt or water enters the fuel system, the fuel pump

and injection nozzles are subject to premature wear. To

prevent this, be sure to clean the fuel filter bowl and

element periodically.

9Y1211156GEG0026US0

Adjusting Fan Belt Tension

WARNING

To avoid personal injury or death:

• Be sure to stop engine before checking belt tension.

1. Stop the engine and remove the key.

2. Apply moderate thumb pressure to belt between pulleys.

3. If tension in incorrect, loosen the dynamo mounting bolts and,

using a lever placed between the dynamo and the engine block,

pull the dynamo out until the deflection of the belt falls within

acceptable limits.

4. Replace fan belt if it is damaged.

9Y1211156GEG0027US0

(1) Fuel Filter Bowl

(2) Filter Bracket

(3) O-ring

(4) FIlter Element

(5) O-ring

(A) Loosen

(B) Tighten

Fan belt tension Factory specification

A deflection of between

7.0 to 9.0 mm

(0.28 to 0.35 in.) when the

belt is pressed in the

middle of the span.

(1) Bolt (A) Check the belt tension

(B) To Tighten

KiSC issued 11, 2014 A

Page 40

GENERAL

B2301, B2601, WSM

G-25

Adjusting Brake Pedal

WARNING

To avoid personal injury or death:

• Stop the engine and chock the wheels before checking

brake pedal.

1. Release the parking brake.

2. Slightly depress the right and left brake pedals and measure

free travel at the top of pedal stroke.

3. If adjustment is needed, turn the lock nut and adjust nut, adjust

free travel.

4. Retighten the lock nut.

9Y1211156GEG0028US0

Checking Fuel Line

1. Check to see that all line and hose clamps are tight and not

damaged.

2. If hoses and clamps are found worn or damaged, replace or

repair them at once.

NOTE

• If the fuel line is removed, be sure to properly bleed the fuel

system.

9Y1211156GEG0029US0

[4] CHECK POINTS OF EVERY 200 HOURS

Replacing Engine Oil Filter

WARNING

To avoid personal injury or death:

• Be sure to stop the engine before changing the oil filter

cartridge.

• Allow engine to cool down sufficiently, oil can be hot and

can burn.

1. Remove the oil filter.

2. Put a film of clean engine oil on the rubber seal of the new filter.

3. Tighten the filter quickly until it contacts the mounting surface.

Tighten filter by hand an additional 1/2 turn only.

4. After the new filter has been replaced, the engine oil normally

decreases a little. Make sure that the engine oil does not leak

through the seal and be sure to check the oil level on the

dipstick. Then, replenish the engine oil up to the prescribed

level.

IMPORTANT

• To prevent serious damage to the engine, use only a

KUBOTA genuine filter.

9Y1211156GEG0030US0

Proper brake pedal free travel

30 to 40 mm (1.2 to 1.5 in.) on the

pedal

Keep the free travel in the right and left

brake pedals equal.

(1) Lock Nut (Both Sides)

(2) Turnbuckle (Both Sides)

A: Free Travel

(1) Fuel Hoses (2) Hose Clamps

(1) Engine Oil Filter

KiSC issued 11, 2014 A

Page 41

GENERAL

B2301, B2601, WSM

G-26

Changing Engine Oil

WARNING

To avoid personal injury or death:

• Be sure to stop the engine before changing the oil.

• Allow engine to cool down sufficiently, oil can be hot and

can burn.

1. To drain the used oil, remove the drain plug at the bottom of the

engine and drain the oil completely into the oil pan.

All the used oil can be drained out easily when the engine is still

warm.

2. After draining reinstall the drain plug.

3. Fill with the new oil up to the upper notch on the dipstick.

9Y1211156GEG0031US0

Replacing Transmission Oil Filter [HST]

WARNING

To avoid personal injury or death:

• Be sure to stop the engine before changing the oil filter

cartridge.

• Allow engine to cool down sufficiently, oil can be hot and

can burn.

1. Place the oil pan underneath the transmission oil filter and

remove the filter.

Do not remove the hydraulic oil filter. Otherwise, the oil comes

out.

2. Put a film of clean transmission oil on the rubber seal of the new

filter.

3. Quickly tighten the filter until it contacts the mounting surface,

then, with a filter wrench, tighten it an additional 1 turn only.

4. After the new filter has been replaced, fill the transmission oil up

to the upper limit on the dipstick.

5. After running the engine for a few minutes, stop the engine and

check the oil level again, add oil to the prescribed level.

6. Make sure that the transmission fluid doesn't leak past the seal

on the filter.

IMPORTANT

• To prevent serious damage to the hydraulic system, use

only a KUBOTA genuine filter.

• Do not operate the tractor immediately after changing the

transmission fluid.

Run the engine at medium speed for a few minutes to

prevent damage to the transmission.

9Y1211156GEG0032US0

Oil capacity with filter

3.1 L

3.3 U.S.qts

2.7 Imp.qts

(1) Oil Inlet

(2) Dipstick

(3) Drain Plug (Both Sides)

A: Oil level is acceptable within this

range

(1) Transmission Oil Filter [HST]

(2) Oil Inlet

(3) Dipstick

A: Oil level is acceptable within this

range

KiSC issued 11, 2014 A

Page 42

GENERAL

B2301, B2601, WSM

G-27

Checking Intake Air Line

1. Check to see that hoses and hose clamps are tight and not

damaged.

2. If hoses and clamps are found worn or damaged, replace or

repair them at once.

9Y1211156GEG0033US0

Checking Radiator Hose and Hose Clamp

WARNING

To avoid personal injury or death:

• Be sure to stop the engine and remove the key before

checking radiator hose and clamp.

• Allow engine and coolant to cool down sufficiently before

checking.

Check to see if radiator hoses are properly fixed every

200 hours of operation or six months, whichever comes first.

1. If hose clamps are loose or water leaks, tighten bands securely.

2. Replace hoses and tighten hose clamps securely, if radiator

hoses are swollen, hardened or cracked. Replace hoses and

hose clamps every 2 years or earlier if checked and found that

hoses are swollen, hardened or cracked.

Precaution at Overheating

Take the following actions in the event the coolant temperature

is nearly or more than the boiling point, what is called "Overheating".

1. Stop the machine operation in a safe place and keep the engine

unloaded idling.

2. Don't stop the engine suddenly, but stop it after about 5 minutes

of unloaded idling.

3. Keep yourself well away from the machine for further 10

minutes or while the steam blown out.

4. Checking that there gets on danger such as burn, get rid of the

causes of overheating according to the manual, see

"Troubleshooting" section, and then, start again the engine.

9Y1211156GEG0034US0

(1) Hose (2) Hose Clamp

(1) Radiator Hose (2 Hoses) (2) Clamp (4 Clamps)

KiSC issued 11, 2014 A

Page 43

GENERAL

B2301, B2601, WSM

G-28

Adjusting Toe-in

1. Park tractor on a flat place.

2. Turn steering wheel so front wheels are in the straight ahead

position.

3. Lower the implement, lock the park brake and stop the engine.

4. Measure distance between tire beads at front of tire, hub height.

5. Measure distance between tire beads at rear of tire, hub height.

6. Front distance should be 0 to 10 mm (0 to 0.39in.) less than rear

distance. If not, adjust tie-rod length.

Adjusting procedures

1. Loosen the tie-rod nut.

2. Turn the tie-rod to adjust the rod length until the proper toe-in

measurement is obtained.

3. Retighten the tie-rod nut.

9Y1211156GEG0035US0

[5] CHECK POINTS OF EVERY 400 HOURS

Changing Transmission Fluid

WARNING

To avoid personal injury or death:

• Allow engine to cool down sufficiently, oil can be hot and

can burn.

1. To drain the used oil, remove the drain plug at the bottom of the

transmission case and drain the oil completely into the oil pan.

2. After draining reinstall the drain plug.

3. Fill with new KUBOTA SUPER UDT fluid up to the upper notch

on the dipstick.

4. After running the engine for a few minutes, stop it and check the

oil level again; add oil to prescribed level.

5. Properly dispose of used oil.

IMPORTANT

• If the 3-point hitch can not be raised by setting the

hydraulic control lever to the UP position after long term

storage or when changing the transmission oil, turn

steering wheel to the right and left several times to bleed air

from the system.

• Do not operate the tractor immediately after changing the

transmission fluid.

9Y1211156GEG0037US0

(1) Tie-rod Nut

(2) Tie-rod

(A) Wheel-to-wheel distance at rear

(B) Wheel-to-wheel distance at front

(C) "FRONT"

Oil capacity

15 L

4.0 U.S.gals

3.3 Imp.gals

(1) Oil Inlet

(2) Dipstick

(3) Drain Plug

(4) Drain Plug (Both Sides)

A: Oil level is acceptable within this

range

KiSC issued 11, 2014 A

Page 44

GENERAL

B2301, B2601, WSM

G-29

Replacing Hydraulic Oil Filter

WARNING

To avoid personal injury or death:

• Be sure to stop the engine before changing the oil filter

cartridge.

• Allow engine to cool down sufficiently, oil can be hot and

can burn.

1. Remove the drain plugs at the bottom of the transmission case

and drain the oil completely into the oil pan.

2. After draining reinstall the drain plugs.

3. Remove the oil filter.

4. Put a film of clean transmission oil on the rubber seal of the new

filter.

5. Quickly tighten the filter until it contacts the mounting surface,

then tighten it by hand an additional 1/2 turn only.

6. After the new filters have been replaced, fill the transmission oil

up to the upper notch on the dipstick.

7. After running the engine for a few minutes, stop the engine and

check the oil level again, add oil to the prescribed level.

8. Make sure that the transmission fluid does not leak past the seal

on the filter.

IMPORTANT

• To prevent serious damage to the hydraulic system, use

only a KUBOTA genuine filter.

9Y1211156GEG0038US0

Changing Front Axle Case Oil

1. Park the tractor on a firm, flat and level surface.

2. To drain the used oil, remove the right and left drain plugs and

filling plug at the front axle case and drain the oil completely into

the oil pan.

3. After draining, reinstall the drain plugs.

4. Fill with new oil up to the upper notch on the dipstick.

IMPORTANT

• After ten minutes, check the oil level again; add oil to

prescribed level.

5. After filling, reinstall the filling plug.

6. Properly dispose of used oil.

9Y1211156GEG0039US0

(1) Drain Plug

(2) Drain Plug (Both Sides)

(3) Transmission Oil Filter

(4) Oil Inlet

(5) Dipstick

A: Oil level is acceptable within this

range.

Oil capacity

3.5 L

3.7 U.S.qts

3.1 Imp.qts

(1) Filling Plug with Dipstick

(2) Drain Plug

A: Oil level is acceptable within this

range.

KiSC issued 11, 2014 A

Page 45

GENERAL

B2301, B2601, WSM

G-30

Adjusting Front Axle Pivot [4WD]

WARNING

To avoid personal injury or death:

• Park the tractor on a flat place.

• Lower the implement, lock the parking brake and stop the

engine.

1. If the front axle pivot pin adjustment is not correct, front wheel

vibration can occur causing vibration in the steering wheel.

Adjusting procedure

1. Loosen the lock nut, and tighten the adjusting screw so that the

oscillating load is 50 to 100 N (5.1 to 10.2 kgf, 11.2 to 22.5 lbf).

(If the adjusting screw is tightened, loosened and retightened,

apply liquid gasket to its tip.)

2. Retighten the lock nut.

9Y1211156GEG0040US0

Replacing Fuel Filter Element

• See page G-24.

9Y1211156GEG0041US0

[6] CHECK POINT OF EVERY 800 HOURS

Adjusting Engine Valve Clearance

• See page 1-S13.

9Y1211156GEG0042US0

[7] CHECK POINT OF EVERY 1500 HOURS

Checking Fuel Injection Nozzle Injection Pressure

• See page 1-S19.

9Y1211156GEG0043US0

[8] CHECK POINT OF EVERY 3000 HOURS

Checking Injection Pump

• See page 1-S30.

9Y1211156GEG0044US0

[9] CHECK POINT OF EVERY 1 YEAR

Replacing Air Cleaner Primary Element and Secondary

Element

• See page G-23.

IMPORTANT

• To prevent serious damage to the engine, use only a

KUBOTA genuine filter.

9Y1211156GEG0046US0

(1) Adjusting Screw (2) Lock Nut

KiSC issued 11, 2014 A

Page 46

GENERAL

B2301, B2601, WSM

G-31

[10] CHECK POINTS OF EVERY 2 YEARS

Flushing Cooling System and Changing Coolant

WARNING

To avoid personal injury or death:

• Do not remove radiator cap while coolant is hot. When cool,

slowly rotate cap to the first stop and allow sufficient time

for excess pressure to escape before removing the cap

completely.

1. Stop the engine, remove the key and let it cool down.

2. To drain the coolant, disconnect the radiator hose (engine side)

and remove the radiator cap. The radiator cap must be removed

to completely drain the coolant.

3. After all coolant is drained, close the drain plug.

4. Fill with clean water and cooling system cleaner.

5. Follow directions of the cleaner instruction.

6. After flushing, fill with clean water and anti-freeze until the

coolant level is just below the radiator cap. Install the radiator

cap securely.

7. Fill with coolant up to the "FULL" mark on the recovery tank.

8. Start and operate the engine for few minutes.

9. Stop the engine, remove the key and let cool.

10. Check coolant level of recovery tank and add coolant if

necessary.

11. Properly dispose of used coolant.

IMPORTANT

• Do not start engine without coolant.

• Use clean, fresh water and anti-freeze to fill the radiator and

recovery tank.

• When the anti-freeze is mixed with water, the anti-freeze

mixing ratio must be less than 50 %.

• Securely tighten radiator cap. If the cap is loose or

improperly fitted, water may leak out and the engine could

overheat.

(To be continued)

Coolant capacity (with recover tank)

3.8 L

4.0 U.S.qts

3.3 Imp.qts

(1) Radiator Hose

(2) Radiator Cap

(3) Recovery Tank

A: FULL

B: LOW

KiSC issued 11, 2014 A

Page 47

GENERAL

B2301, B2601, WSM

G-32

(Continued)

Anti-Freeze

WARNING

To avoid personal injury or death:

• When using antifreeze, put on some protection such as

rubber gloves (Antifreeze contains poison.).

• If it is swallowed, seek immediate medical help.

Do NOT make a person throw up unless told to do so by

poison control or a health care professional. Use standard

first aid and CPR for signs of shock or cardiac arrest. Call

your local Poison Control Center or your local emergency

number for further assistance.

• When antifreeze comes in contact with the skin or clothing,