Page 1

KUBOTA CORPORATION

29-9 HONGO 3-CHOME,BUNKYO-KU,TOKYO 1 13-0033,JA PA N

To ensureproper operation of the centrifuge, be sure to read this manual

carefull

y

before operatingit.

Also

,

keepthis manual handyso thatyou can refer to it at anytime.

■

Theprodu cts beingindicated in this Instructionmanual are designed f or opera tors carr

yingexp

ert knowl edge and theseprodu cts are to be used bythesequalified operators observingthe indicatedprecau tions fo r respectivepurposes.

For

p

ersons lackingnecessaryexpert knowl edge,theseproduce s maybe difficult to useproperlyandevendanger maybe consequent upon the use.

When the aforesaid

p

erson s la ckingthe necessaryexpert knowl edgeareusin

g

theseproducts,do so und er a

p

prop

riate supervision andguidance of thequali-

fied o

p

erat orspossessingthe necessaryexpert knowl edge.

NOTE

INSTRUCTION

and

SERVICE MANUAL

[40Page

s

]

F3024 1106

■

Don

otdis

tributethismanu

a

lwithinth

e

U.S

.A.,Mexi

co,Canada

andAustralia

as the Product s ad verti sed in th e manual shall n ot be distributed in the U. S.A.

,

Mexico,Canada an d Austra li a.

TABLE-TOP CENTRIFUGE

May2005,PrintedinJapan

For infor mation ad ded or modifie d afte r June 2005

,

p

le ase contactyour local dealer.

Page 2

WARRANTY

Kubota Corporation ("Kubota") warrants that the instrument covered by this warranty shall be

free from defects in material and workmanshi

p

under normal use. Kubota will repair or replace,

free of all char

ges,

the instrument which, within one (1) year after delivery or fifteen (15) months

after shi

pping,

whichever comes earlier is proved to the satisfaction of Kubota to have been

defective at the time of deliver

y, p

rovided that it does not fall unde r the exceptions and conditions

s

p

ecified in this warranty. Such exception and conditions include, but are not limited to, failure

due to natural wear and tear

,

accident, negligence, alteration, repair, or operation in a manner not

p

rescribed in the Instruction Manual supplied with the instrument. The foregoing expresses

Kubotas sole warrant

y

with respect to the instrument.

THIS WARRANTY IS MADE IN LIEU OF ANY AND AL L OTHER WARRANTIES AND ALL

IMPLIED WARRANTIES OF MERCHANT ABILITY AND FITNESS FOR A PARTICULAR

PURPOSE ARE HEREBY DISCLAIMED AND EXCLUDED.

Kubota and its authorized dealers will not be liable for an

y

consequential damages, loss or

ex

p

ense arising from the improper use of the instrument. Kubota will not honor any other

warrant

y,

which may be given, by its representative or dealer or otherwise which is different from

the warrant

y g

iven hereunder. This warranty is not assignable and is operative only in favor of the

original customer to whom this warranty is originally delivered.

Use of Model 2420

Model 2420 can be used for

prep

rocessing in in-vitro analysis, which breaks down blood or urine

samples containing plasmas or cells. Accordingly, it is not designed to connect directly to a

p

atient's body.

Do not use the centrifu

g

e for separation of any hazardous material (explosive, chemically active,

or

g

anic, or radiation containing material, or material contaminated by pathogenic microorganisms

)

or oil.

Co

pyrig

ht

C

1995 KUBOTA Manufacturing Corporati on

Page 3

■“

Serious in

jury

" is defined as injuries such as loss of eyesight, burn ( high / low temperature ),

electric shock

,

fracture of bone, poisoning causing aftereffects, or any ot her injuries requiring a

lon

g

-term medical treatment at hospital.

■“

Non-fatal in

jury

" is defined as burns, electric shock, or any other injuries which does not

re

q

uire long-term medical treatment at hospital. "Property damage" is defined as expansion

dama

g

e related to damage to equipment or other properties.

Safety Instructions

The centrifuge and the manual indicate important information i n ord er t o ensure safe

o

p

eration of the centrifuge and to prevent physic al injurie s an d property damages.

Be sure to under

st and the mea

nings of the following indi

cations and follow the

instructions.

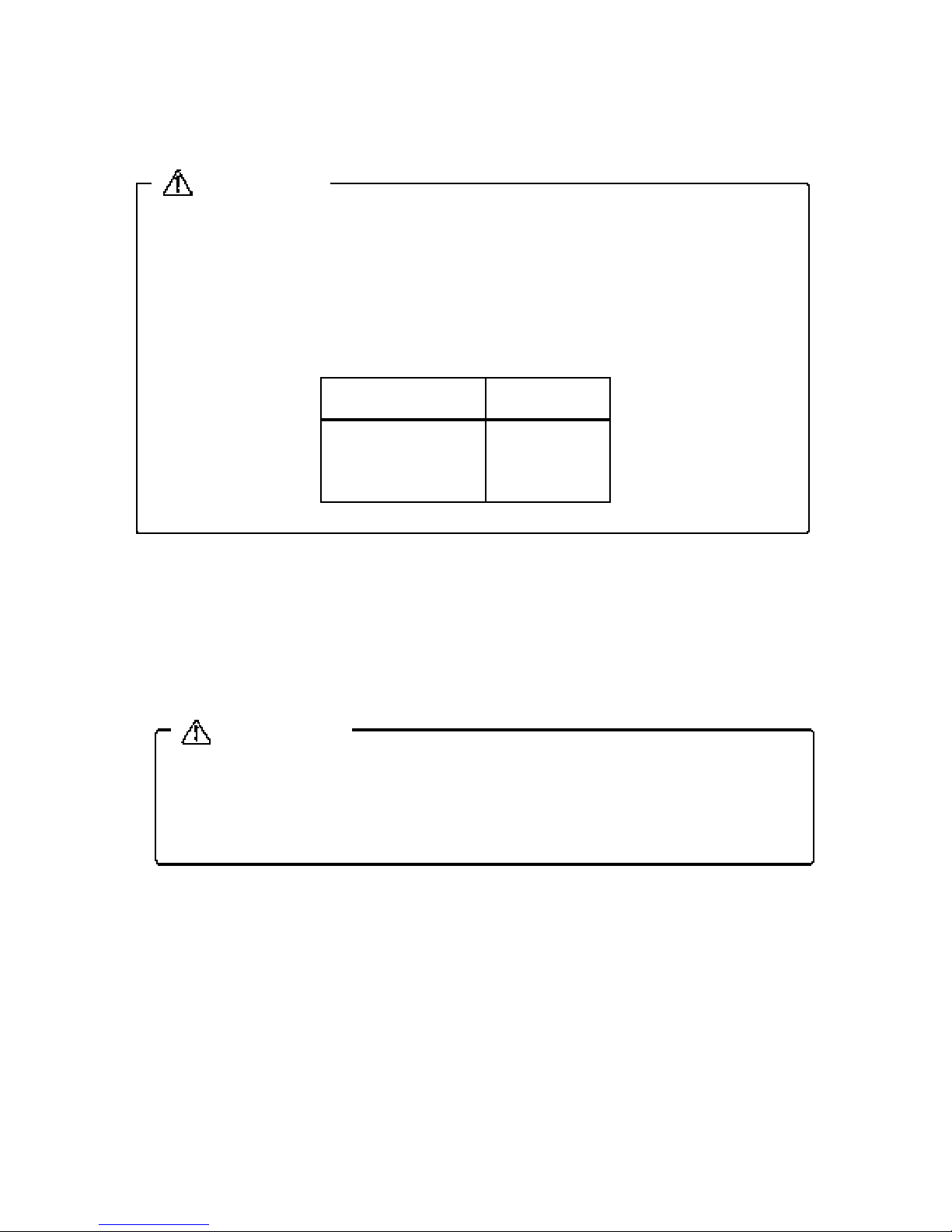

2. Explanation of pictorial marks

1. Ex

p

lanation of indication marks

WARNING

CAUTION

Indication Meanin

g

It is a possibility of serious accident resulting in

death or seriou s in

jury

.

It is a

p

ossibility of accident resulting in sl ight or

non-fatal in

jury

or property damage.

Pictorial marks Meanin

g

Indi cate s prohibition (things you must not do).

Details are shown near the mark

,

using illustration or

sentenc es.

Indi cate s com

p

ulsion (things you have to do).

Details are shown near the mark

,

using illustration or

sentenc es.

Indicates caution

,

warning and danger.

Details are shown near the mark

,

using illustration or

sentenc es.

This label indicates the risk of el ectric shock.

Touchin

g

this attached part wi ll cause an electric shock.

This label indicates a hot section.

Touchin

g

this attached part wi ll cause an burn.

Indicates that the

p

ower is on.

It is indicated o n the

p

ower switch and the circuit breaker.

Indicates that the

p

ower is off.

It is indicated o n the

p

ower switch and the circuit breaker.

Page 4

pag

e

Safety Instr uctions

General Notes

・・・・・・・・・・・・・・・・・・・・・・Ⅰ

Usabl e Rotor

・・・・・・・・・・・・・・・・・・・・・・・Ⅳ

Life ti me of rotors

・・・・・・・・・・・・・・・・・・・Ⅳ

Number of times allowed for

autoclavin

g

of rotor

・・・・・・・・・・・・・・・・Ⅴ

Section 1.

Com

p

onent Name and Explanation

1-1.Appe ar ance・・・・・・・・・・・・・・・・・・・・・ 1-1

1-2.Control Panel ・・・・・・・・・・・・・・・・・・・ 1-2

Section 2.

Installation and Power Su

pply

2-1.Unpacking・・・・・・・・・・・・・・・・・・・・・・ 2-1

2-2.

Place of Installation

・・・・・・・・・・・・・・2-1

2-3.

Movement of centrifuge

・・・・・・・・・・・2-1

2-4.

Power Requirement

・・・・・・・・・・・・・・・ 2-2

2-5.

Groundin

g

・・・・・・・・・・・・・・・・・・・・・・ 2-3

Section 3. Operation

3-1.

Cautions of Operation

・・・・・・・・・・・・・3-1

3-2.

Operation

・・・・・・・・・・・・・・・・・・・・・ 3-1

3-3.

Opening and Closi ng the lid

・・・・・・・・ 3-4

[1]

Turning on the power and opening

the lid

・・・・・・・・・・・・・・・・・・・・・・・・・ 3-4

[2] Opening the lid during power failure・ 3-4

[3] Closing the lid・・・・・・・・・・・・・・・・・・ 3-5

3-4.Setting the Speed・・・・・・・・・・・・・・・・・ 3-6

[1] Setting the speed by the rpm・・・・・・・ 3-6

[2] Setting the speed by the centrifugal

for c e( × g)・・・・・・・・・・・・・・・・・・・・ 3-7

page

3-5.

Setting the Timer

・・・・・・・・・・・・・・・・3- 8

3-6.

Setting the ac ce lera tion ・ deceleration

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・3- 9

3-7.

Saving the Memor

y

・・・・・・・・・・・・・・3-10

[1]

Saving the Memor

y

・・・・・・・・・・・・・3-10

[2]

Memory cancellation

・・・・・・・・・・・・ 3-10

3-8.

Setting the Function

・・・・・・・・・・・・・3-11

[1]

Setting the Rotation Radius

・・・・・・・3-12

[2]

Setting the “ SLOW" deceleration

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・3-13

[3]Setting the Sound that informs

the end of the operation・・・・・・・・・・ 3-14

[4]Reverse of setting order of

the Speed and the Timer ・・・・・・・ 3-15

[5]Settin g the Remin der alarm・・・・・・・3-16

[6]Settin g the Indicators for

the end of the operation ・・・・・・・3-17

3-9.Calculating Centrifugal For ce・・・・・・3-18

3- 10.

Allow able lo ad and

Reduced maximum speed

・・・・・・3-18

Section 4. Service

4- 1.

Daily Inspection

・・・・・・・・・・・・・・・・・4-1

4- 2.

Monthly In spections

・・・・・・・・・・・・・4-2

4- 3.

Annual Inspection

・・・・・・・・・・・・・・・4-2

4- 4.

Cleaning and Sterilization

・・・・・・・・・4-3

[1]

Cleaning the cha mber interior

・・・・・・4-3

[2]

Cleaning the rotor, buckets and

tube rack

・・・・・・・・・・・・・・・・・・・・・・4-4

[3]Sterilization of rotor, buckets and

tube rack ・・・・・・・・・・・・・・・・・・・・・・ 4-4

4- 5.Greasing・・・・・・・・・・・・・・・・・・・・・・・4-5

4- 6.Inspection of Circuit Protector ・・・・・4-6

4- 7.Using the Photoelectric Tachometer Port

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・4-7

Table of Contents

Page 5

4- 8.Spare Parts Supply・・・・・・・・・・・・・・4- 8

4- 9.

Ma nufacturer requirements at Repair

or Maintenance

・・・・・・・・・・・・・・・・4- 8

4- 10.

Product Preparation When R et urning

Units for Repair or for Other Reasons

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・4- 9

Contaminant Elimination Certificate

・・・・・・・・・・・・・・・・・・・・・・・・・・・・4-10

Section 5. Troubleshootin

g

5-1.

Alarm Indicators

・・・・・・・・・・・・・・・・・ 5-1

E0

・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 5-1

C1

・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 5-2

C2

・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 5-2

C3

・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 5-2

C4・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 5-2

C5・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 5-2

5-2.Error Indicators・・・・・・・・・・・・・・・・・・ 5-3

E1・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 5-3

E2・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 5-3

E3・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 5-3

E4・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 5-4

E6・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 5-4

E7・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 5-4

5-3. Troubleshooting・・・・・・・・・・・・・・・・・ 5-5

Section 6. Rotor

6-1.

Mounting RS-240 Rotor

・・・・・・・・・・6- 1

6-2.

Mounting RS-1004 Rotor

・・・・・・・・・6- 2

6-3.

Mounting RMP-23 Rotor

・・・・・・・・・6- 3

6-4.

RS-240 Swinging Buc ket Rotor

・・・・6- 4

[1]

Spec if ic ati on

・・・・・・・・・・・・・・・・・・6- 4

[2]

Setting Bu ckets

・・・・・・・・・・・・・・・・6- 6

[3]

Tube distribution me thod

・・・・・・・・・6- 6

[4]

Cushions / Adapter

・・・・・・・・・・・・・6- 7

6-5.

RS-1004 Swinging Buc ket Rotor

・・・6-10

[1]

Spec if ic ati on

・・・・・・・・・・・・・・・・・・6-10

[2] Se tting Bu ckets ・・・・・・・・・・・・・・・・6-11

[3] Tub e distribution method・・・・・・・・・6-11

[4] Standard accessories ・・・・・・・・・・・・6-11

6-6. RMP-23 Swinging Bucket Rotor・・・6-12

[1]

Spec if ic ati on

・・・・・・・・・・・・・・・・・・6-12

[2]

Check the tru nnion pin

・・・・・・・・・・・ 6-13

[3]

Setting Buckets

・・・・・・・・・・・・・・・・6-13

[4]

Distribution of samples

・・・・・・・・・・6-14

[5]

Setting plate

・・・・・・・・・・・・・・・・・・・6-14

[6]

Allowable weight of plate

・・・・・・・・6-15

[7]

Standard accessories

・・・・・・・・・・・・ 6-15

Section 7. Specifications

7-1.

Centrifuge

・・・・・・・・・・・・・・・・・・・・・・7-1

7-2.

Sta ndar d Ac ce ssories

・・・・・・・・・・・・・7-1

Section 8. Parts List

8-1.Recommended Spare Parts・・・・・・・・・8-1

Page 6

Ⅰ

Do notper for m d ry-heat or autoclave sterilization with tem

p

era-

ture s hi

g

her t han t hose speci fi ed.

O

the

rwi

se,

theroto

rm

aydet

erio

-

ra te and cause an acci den t.

(2)

Maximum s

p

eed

(4)

Hazardous material

General Notes

Since large electrical and mechanical energies arepresent on th e centrifugeandrotor

,

reasonable care is required for their handling.

Otherwise

,

failure mayoccur resultinginpropertydamages or fatalphysical injuries.

In order to

p

revent them from ha

p

p

enin

g

,

be sure to follow the instructiongiven below.

Be sure to follow them.

(1)

Maxi mum l oad

WARNING

(5)

While the centrifugeisinoper ati on

(6)L

id

Do not exceed the maximum load

of rotor and bucket.

The rotor or bucket used be

y

ond

the allowable load level can be

d

amaged,

therebycausing

ana

c

-

cident.

Kee

p

the rotor and bucket speed

below the maximum s

p

eed.

Excessive speed maycause dama

g

etotherotor,bucket and the

centrifuge. Th e m aximum speed

de

p

ends on the rotor and bucket

strength.

Do not modif

y

,

nor use unspeci-

fied

p

arts.

Unautho

riz

e

dre

trofit

ofthecent

ri-

fu

ge,

rotororbucket,or use of un authorizedparts for them can result in accidents.

Whilethe centrifu

g

eisin operation

,

do no t st and clo ser t han 30 cm t o

avoid asecondaryac cident .

Do not o

p

en the lid when the rotor

is spinning.

Ph

y

sical contact with the spinnin

g

rotor or bucket maycause serious

in

jury

.

(9)

D

amaged,corrode

d

,

ru sted or de for med

(8)

Rotor and drive shaft durin

g

rotation

Do n ot to uch r otor and d ri ve sh aft

durin

g

the rotation.

Physical contact with the spinnin

g

rotor or drive s haf t maycause

serious i njury.

Di

scontinueuse

oftheeq

uipment

when its rotor or the buckets

found to have been damaged

,

corroded,ru ste d or d ef orme d.

Otherwise failure mayoc cur.

(7)

Sterilization

Do notput anyhazard ous ma ter ial(explosive,chemical lyactive

,org

anic,or radiation containin

g

material,or mater ia l c on tam in ate d

b

y

p

athogenic microorganisms)as

asample of the centrifuge and do

n

otplaceit

closerthan30cmt

o

avoid a secondaryaccident

sho

uld

thecent

rif

ugeac

cid

ent

ally

rotate and contact the material.

(3)

Modification

and

unspe

c

ifi

edp

art

s

Page 7

Gro

unding

Installation

WARNING

Do not connect theground cabl e

to the followin

g

p

laces:

1. Gas

pipingExp

losion or fire mayoccur.

2. Ground cable of li

g

htnin

g

Cond uctor,or telephone cable.

El ec tr ic sho ck ma

y

occur in the

case of li

g

htening.

A clearance of 30 cm minimum

must b e

p

rovided around the cen-

tr ifu

g

e.

If the centrifu

g

eisdrivenintoun-

c

ontrolle

drota

tionsduetoafa

il-

ur e

,

secondarydamagecanresult

from ener

g

y

absor bed bythe rota-

ti on.

Do not install the centrifu

g

eonan

inclined

,

sli

p

pery

,

or unstab le su r-

f

ace

.

Violent vibration ma

y

occur.

Ensure that the

g

round cable is

connected to the

g

roundingtermi-

n

a

l.

This

p

recaution must be strictl

y

observed to avoid accidents due

to electric shocks or leaka

g

e.

Installation

CAUTION

3. Waterpipes

Do not install the centrifu

g

einaplace

wi

t

hhighhumidi

ty(rela

tivehumidity85%

or above).

L

e

akoraccid

entmayocc

u

r.

Do not install the centrifu

g

einaplace

with

p

oor ventilation.

Otherwise inside tem

p

erature of the cen-

trifu

g

emayrise,resultingin accidents.

D

ono

tinstallthecent

rif

ugeinadust

y

p

lace.

Do not install the centrifu

g

eina

p

lace where the temperature is

below 10

or over 40 .

A

placewiththe

ambienttemp

era

-

ture be

y

ond 40 can introduce

undesira

blebuild-upofheatinsid

e

the centrifuge and aplace under

10

can cause the centrifuge

malfunction and

,

as the r esult,ac-

cidents.

Lifetime of rotors

Use of rotors be

y

ond the lifetime

ma

y

lead to breakage of the rotor.

If the rotor is used continuousl

y

even after the lifetime of the rotor

has ex

p

ired,should the rotorget

dama

g

ed an accident mayoccur.

Cit

y

waterpipes maynot be

ade

q

uate as aground since it

ma

y

consist ofplasticpiping.

Page 8

CAUTION

F

ast

enaroto

r

Toxic or radioactive substances etc.

Bucket

T

ubera

c

k

)

Cushion

Cleanin

g

Cautionplate

Wh

enc

ent

rif

u

ging

ofsubst

a

n-

ce s c onta minat ed wi t h

p

atho-

g

enic bacteria,or toxic or radio-

active substances

,

al waysuse

containers that are

p

athogenic

bacteri a

,

toxic substance or ra-

di atio n

p

roof.

O

the

rwi

se,

inf

ections

,int

oxic

a

-

tion or radioactive ex

p

osu re a c-

cid

ent

smayocc

u

r.

Do not use deter

g

ents exceed-

in

g

the rangeofpH5-8orchlor-

ine deter

g

ents for washin

g

p

ur-

p

oses.

Corr osion ma

y

damagetherotor

and bucket resultin

g

in damage

to the centrifu

g

e.

R

e

place

thecu

shio

nwhenth

e

g

lass orplastic tube is cracked.

If the cushion with

g

lass frag-

mentcuttoitisused

,

the tube is

easil

y

cracked.

Ke e

p

the load(of the sample

,

bucket,etc.)balanced.

If an a

p

prop

riate balance is not

p

rovided,unexpected accidents

can r esu lt f rom a da ma

g

ed r otor

or cen trifu

g

e.

Use the same t

y

p

e of tube racks.

The wron

g

arrangement will

cause imbalance and resultin

g

in

dama

g

etorotor,bucket or the

centrifu

g

e.

Ensure that the rotor i s fi rml

y

fastened to the drive shaft.

If not

p

ositivelyheld inplace

,

the rotor or centrifugecanbe

dama

ged,

therebycausingacc i-

dents.

Thesamet

y

p

e buckets must be

p

rovidedtoeveryrotoryoke.

If not

p

ositivelyheld i nplace,the

rotororcentrifu

g

e can be dam-

a

ged,

therebycausingaccidents.

Do not remove the caution

p

lates.

When a caution

p

late becomes

di rt

y

,

blurred orpeeled off,re-

p

lace it with a new one(caution

p

lates are available at charge).

Balance of sample

Page 9

Ⅳ

Use of rotors beyond the lifetime may lead to breakage of the rotor.

If the rotor is used continuousl

y

even after the lifetime of rotors has expired, should

the rotor

g

et damaged, the main unit of the centrifuge suddenly may start to rotate;

this could result in an accident causin

g

injury or death.

WARNING

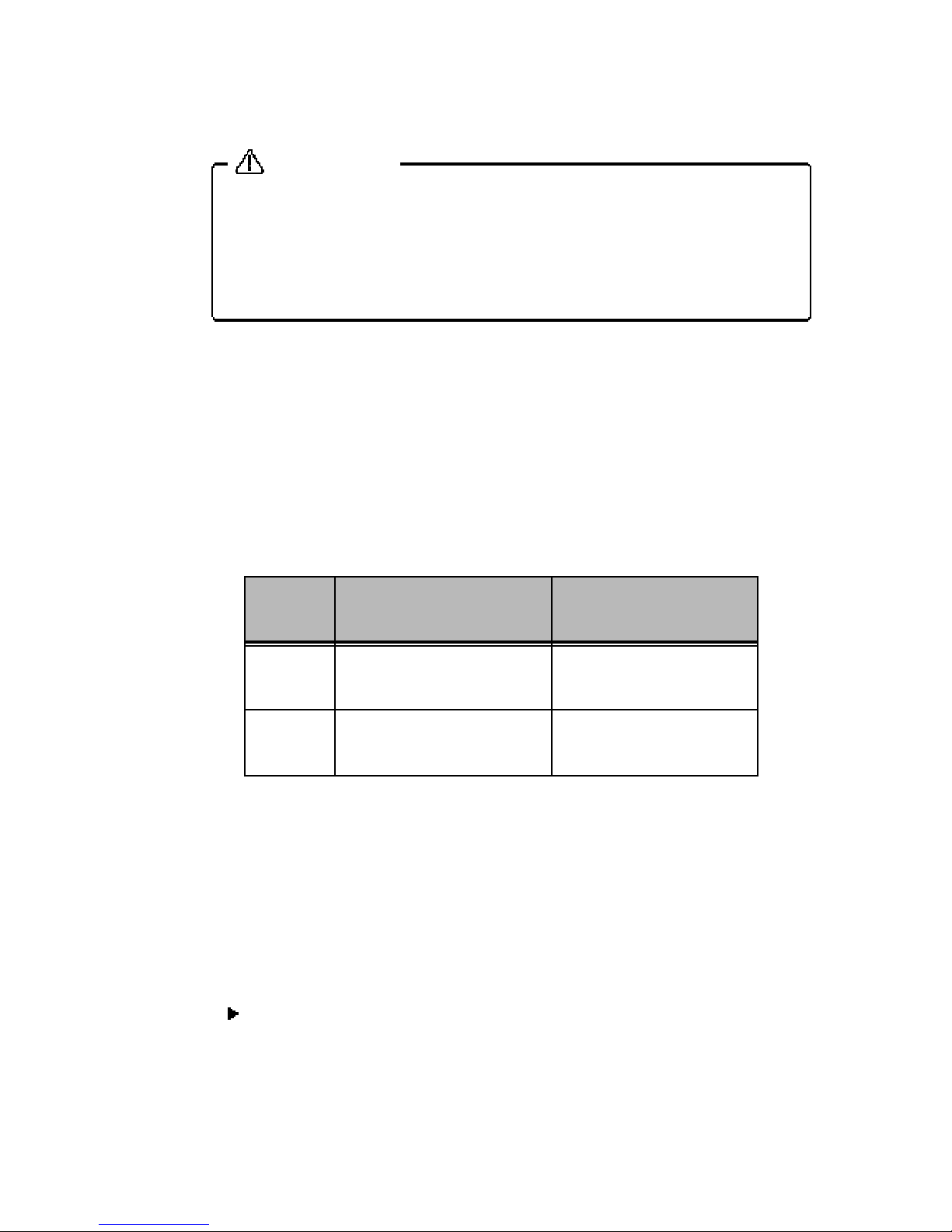

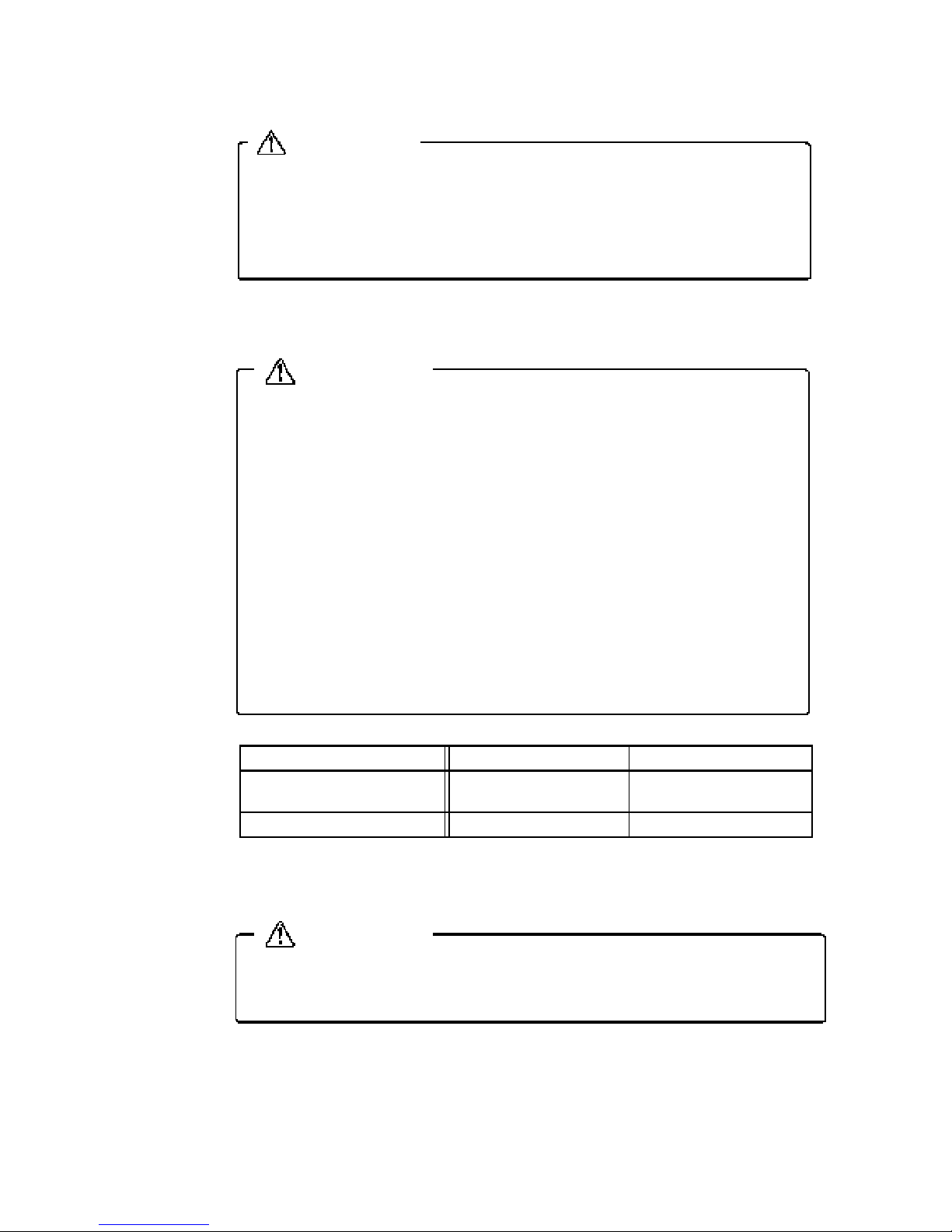

Usable Rotor

Lifetime of rotors

Lifetime of rotors is 7 years after the delivery.

When 7 years have passed after the delivery, discon tin ue operation of the centrifuge to replace the

rotor with a new one.

Earlier re

p

lacement, however, is required if any corrosion, lowered strength, flaw or deform due to

incorrect o

p

eration is detected on the rotor.

In such cas e, contact

y

our local dealer and be sure to have the rotor checked before reusing it.

WARNING

(1)

Do not use an

y

rotors other than those speci fied in (2) below.

If rotors other th an thos e s

p

ecif ied are used, the rotors may be broken, resulting in

a serious accident.

(2)

The rotors that can mount as of Ma

y

2005 are as follows:

This information is sub

j

ect to addition or change.

For information after June 2005

, p

lease contact your local dealer.

Swinging Bucket Rotor Plate Rotor

RS-240

RS-1004

RMP-23

Page 10

Stop the use of the rotor immedi ately when it is used beyond the number of

times allowed for autoclavin

g

. Otherwise, the rotor may deteriorate by the heat

g

enerated by autoclaving, res ul ting in deformation or destruction.

Should the rotor

g

et damaged, the main unit of t he centrifuge suddenly may

start to rotate

;

this could result in an accident causing injury or death.

WARNING

Ⅴ

Number of times allowed for autoclaving of rotor

The number of times allowed for autoclavi ng of each rotor should be deemed as follows.

When the followin

g

conditions has been met, discontinue operation of the centrifuge to

re

p

lace the rotor with a new part.

Earlier re

p

lacement, however, is required if any corrosion, lowered strength, flaw or deform

due to wron

g op

eration is detected on the rotor. In such case, contact your local dealer and

be sure to have the rotor checked before reusin

g

it.

[1]

Number of times allowed for autoclaving and temperature of rotor

[2]

Recording autoclave

After each autoclave proces s, be sure to record the following

(1)

to

(3)

to control how

man

y

times the autoclave is executed.

(1)

Date

(2)

Tem

p

erature of autoclave

(3)

Time of autoclave

You can take advantage of using the “Autoclave record table” attached to

the rotor instruction manual.

Rotor Tem

p

erature of autoclave

Number of times

allowed for autoclavin

g

RMP-23 121

℃

50 times

RS-1004

121

℃

100 times

Page 11

S

T

A

R

T

S

T

O

P

T

I

M

E

m

i

n

s

e

c

S

P

E

E

D

1

0

0

rp

m

1

0

0

g

M

E

M

O

R

Y

1

2

3

A

C

C

D

E

C

F

U

N

C

T

IO

N

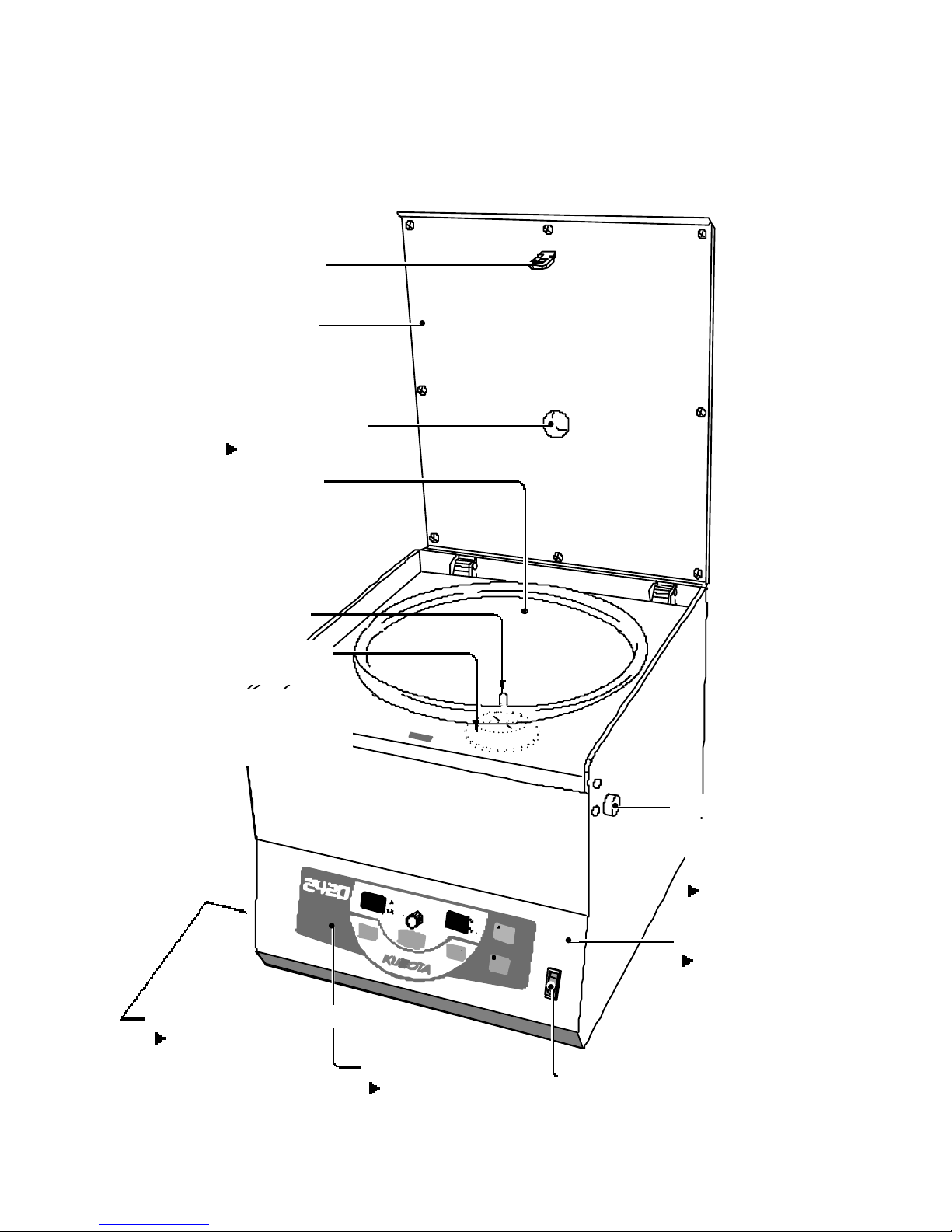

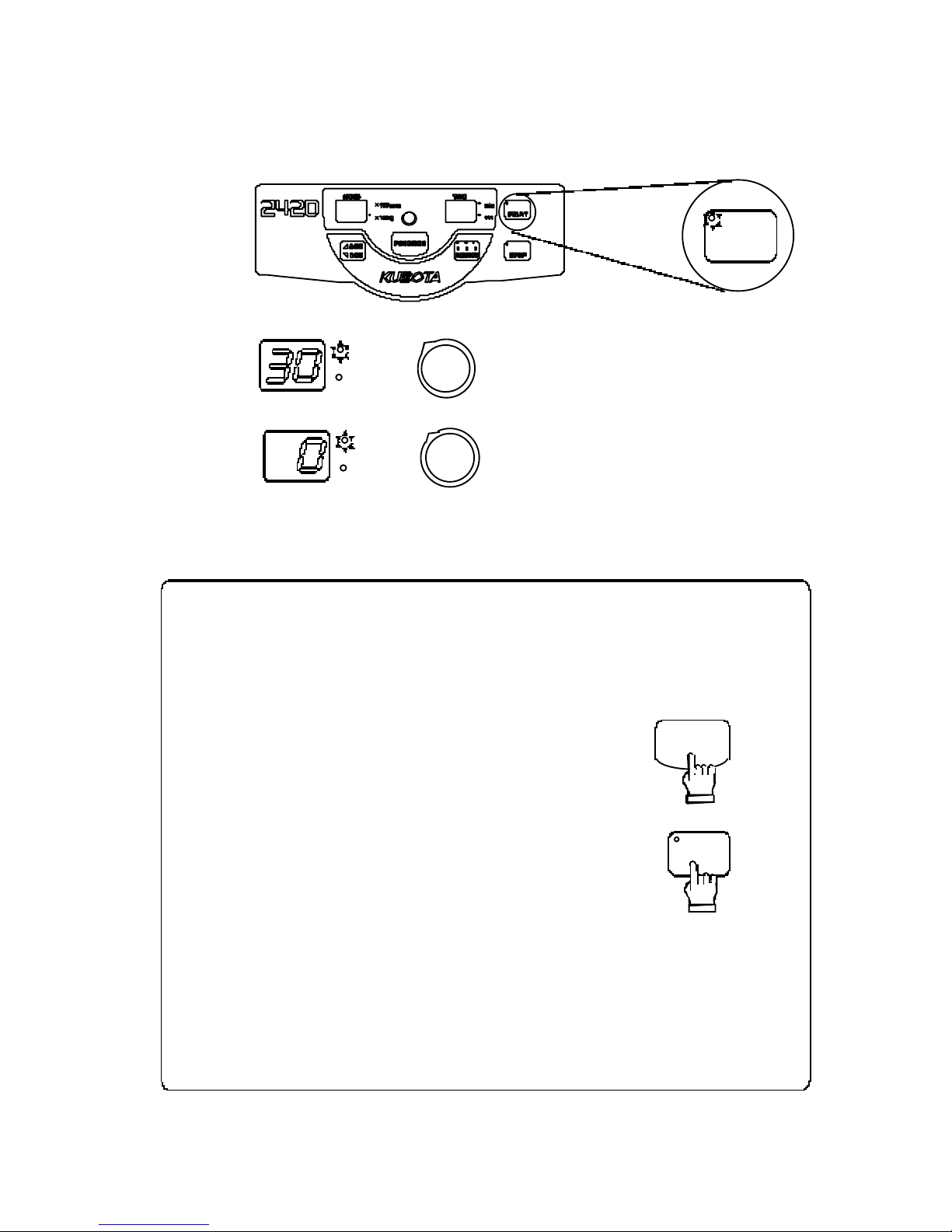

1-1

“

POWER"switch

Drive Shaft

Control panel

Chamber

Front co ver

Hook

Refer to Page 1-2.

Refer to Page 3-5.

Refer to Page 3-4.

The lid opens when it i s

p

ushed during the operation

stop with the power on.

Lid

Tachometer port

Refer to Page 4-7.

“

OPEN”button

Refer to Page 3-4.

Lid extre me release ca

p

Bucket intervention

p

revention plate

This plate prevents the touch of

the b ucket .

Do not remove this pla te, when

y

ou remove the rotor.

Section 1

Component Name and Explanation

1 - 1.

A

pp

earance

Page 12

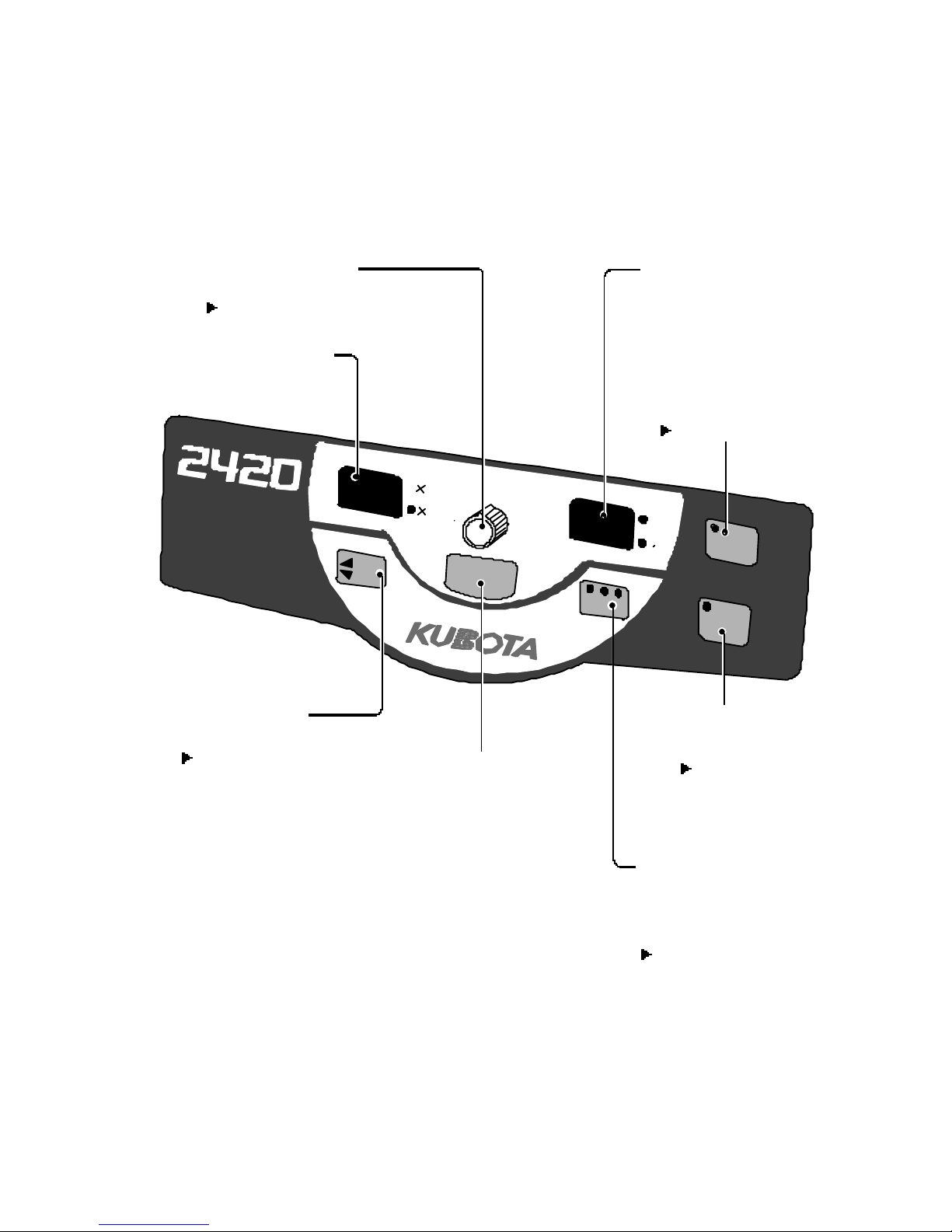

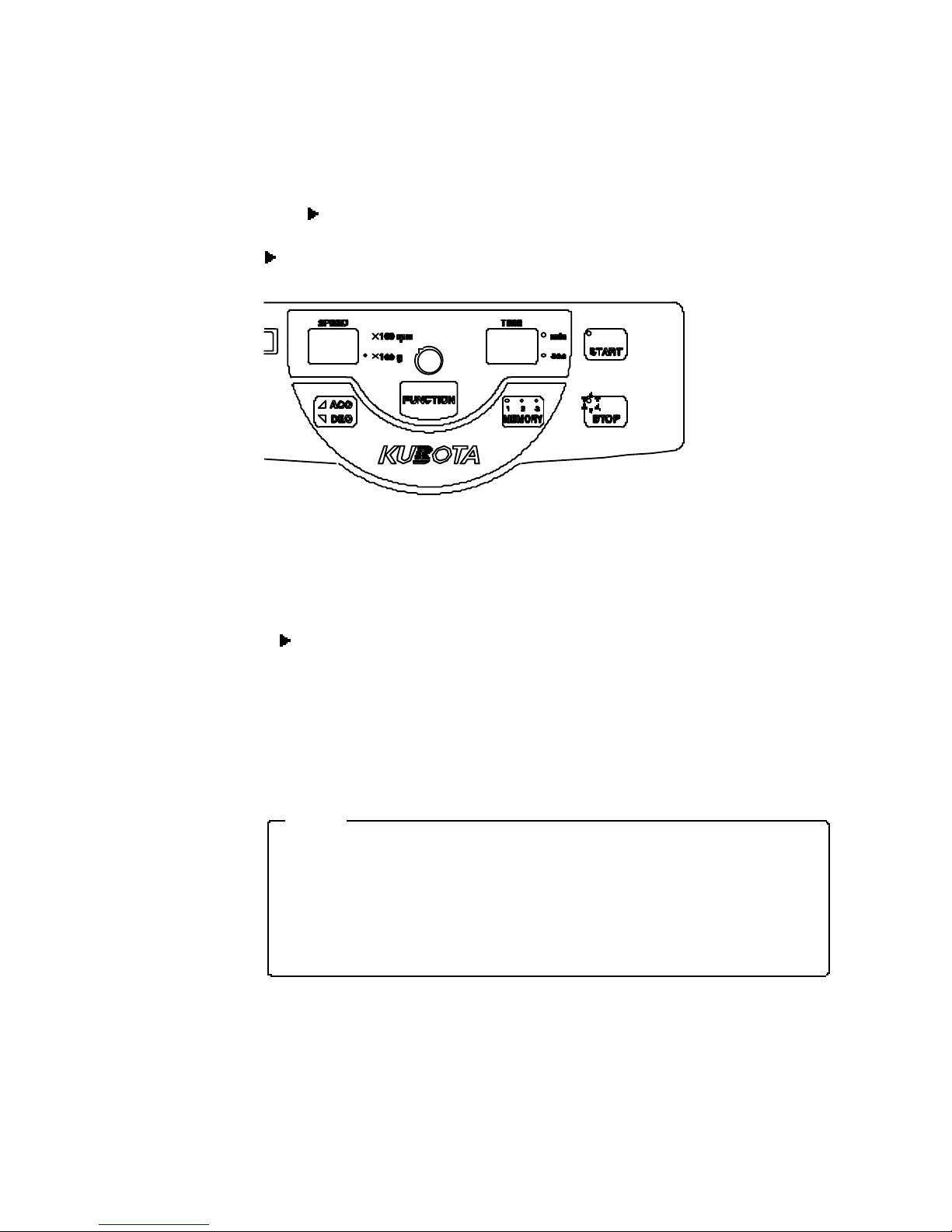

1-2

1-2.

Control Panel

Section1 Component Name and Explanation

S

T

A

R

T

S

T

O

P

T

I

M

E

m

i

n

s

e

c

S

P

E

E

D

1

0

0

r

p

m

1

0

0

g

M

E

M

O

R

Y

1

2

3

A

C

C

D

E

C

F

U

N

C

T

I

O

N

When this key is pressed

the operation will be

started.

“

START" ke

y

“

TIME" dis

play

“

STOP"ke

y

Press this key to

discontinue operation.

“

ACC / DEC" ke

y

“

FUNCTION" ke

y

This key allow the selection

of saved programs.

Pre s sing the key will light

the lamp.

MEMORY selection ke

y

“

SPEED" dis

play

“

SPEED/TIME"kno b

Refer to Page 3-10.

Refer to Page 3-2.

(

Setting the speed, RCF and time.

)

Refer to Page 3-9.

Refer to Page 3-2.

(

To change for ACC and DEC.

)

Refer to Page 3-6.

(

To c hange for speed /

RCF and time.

)

(Sp

eed / R CF

)

Page 13

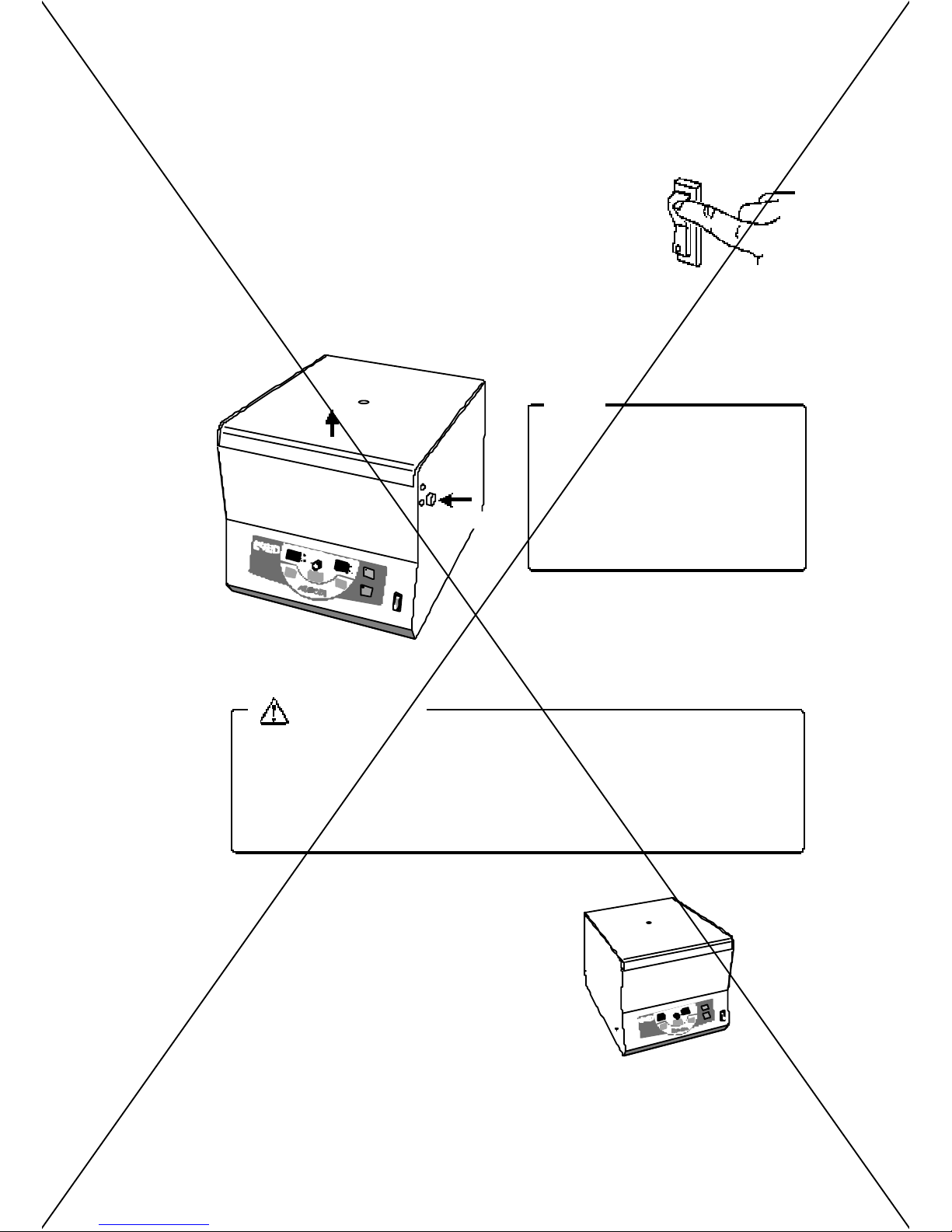

2-1

Contd. o

n next

page

.

●

Never move the centrifu

g

e while the rotor is rotating or while the rotor is

attached to the centrifuge. Otherwise, the drive shaft may become bent

or the rotor and the bucket ma

y

com e o ff, res ulting in an a ccident or

damage to the centrifuge.

●

Ensure that rotor and bucket are removed from the centrifu

g

e and that

the power cord is disconnected from the wall socket.

●

Movin

g

the position of the centrifuge while the power is t urned on may

cau se e le ctrificati on acciden t or functi on al fail ure of the centrifuge.

WARNING

When installing this centrifuge, keep 3meters or more away from AM radio.

Noise

g

enerated by this centrifuge causes the sound of AM radio deteriorated.

A clearance of 30 cm minimum mus t be provided around the centrifuge.

If the centrifu

g

e is driven into uncontrolled rotations due to a failure, secondar

y

damage can result from energy absorbed by the rotation.

WARNING

Do not install the centrifuge on an inclined, slippery, or unstable surface.

Violent vibration ma

y

occur.

CAUTION

Section 2

Installation and Power Su

pply

2-1.

Unpackin

g

When the centrifuge is taken out of a corrugated carton box, check the following.

(1)

U

p

on receiving th e cen tri fuge, examine it for any visible damage caused during

trans

p

ortation.

If an

y

is found, contact the dealer immediately.

(2)

Confirm that all the accessories listed in

[

7 - 2. Standard Accessories] are included with

t he deliver

y

. Refer to page 7-1.

2-2.

Place of installation

2-3.

Movement of centrifuge

Page 14

2-2

■

When movin

g

the centrifuge, lift up the bottom of the centrifuge

body by two or more persons using equal f orces to move the

cent

rif

uge to the desired place

.

■

Do not dro

p

the centrifuge, othe rwise damage or injury may occur.

CAUTION

Prepare a power supply that meets the following conditions.

1. The

p

ower supply voltage must be the same as that indicated on the

name

p

late o f the centrifuge and the voltage va riation m ust be wi thin

the ran

ge g

iven in Table 2-1.

2. The current ca

p

acity must be more than giv en in Ta ble 2-1.

3. In connectin

g

the cord, install a knife switch or circuit breaker of given

value in Table 2-1.

When the centrifu

g

e is connected to an outlet by means of a plug, use

a 3-

p

in plug with a ground terminal.

4. Use sin

g

le-phase power.

5. The outlet m ust have a

g

round terminal and its ground resistance must

be les s than 100 ohm.

Table 2-1 Rated Voltage, Cu rrent and Acceptable Voltage Range and Current Requirement

WARNING

●

The

p

ower cable alone should be connected to the plug socket.

●

Do not use a branched

plug

socket, which may cause overheating or fire.

WARNING

Rated Voltage 100-115V 200-240V

Acceptable Voltage Range 90V to 126V 180V to 264V

Current requirement 8A 5A

2-4.

Power Requirement

Section 2 Installation and Power Suppl

y

Page 15

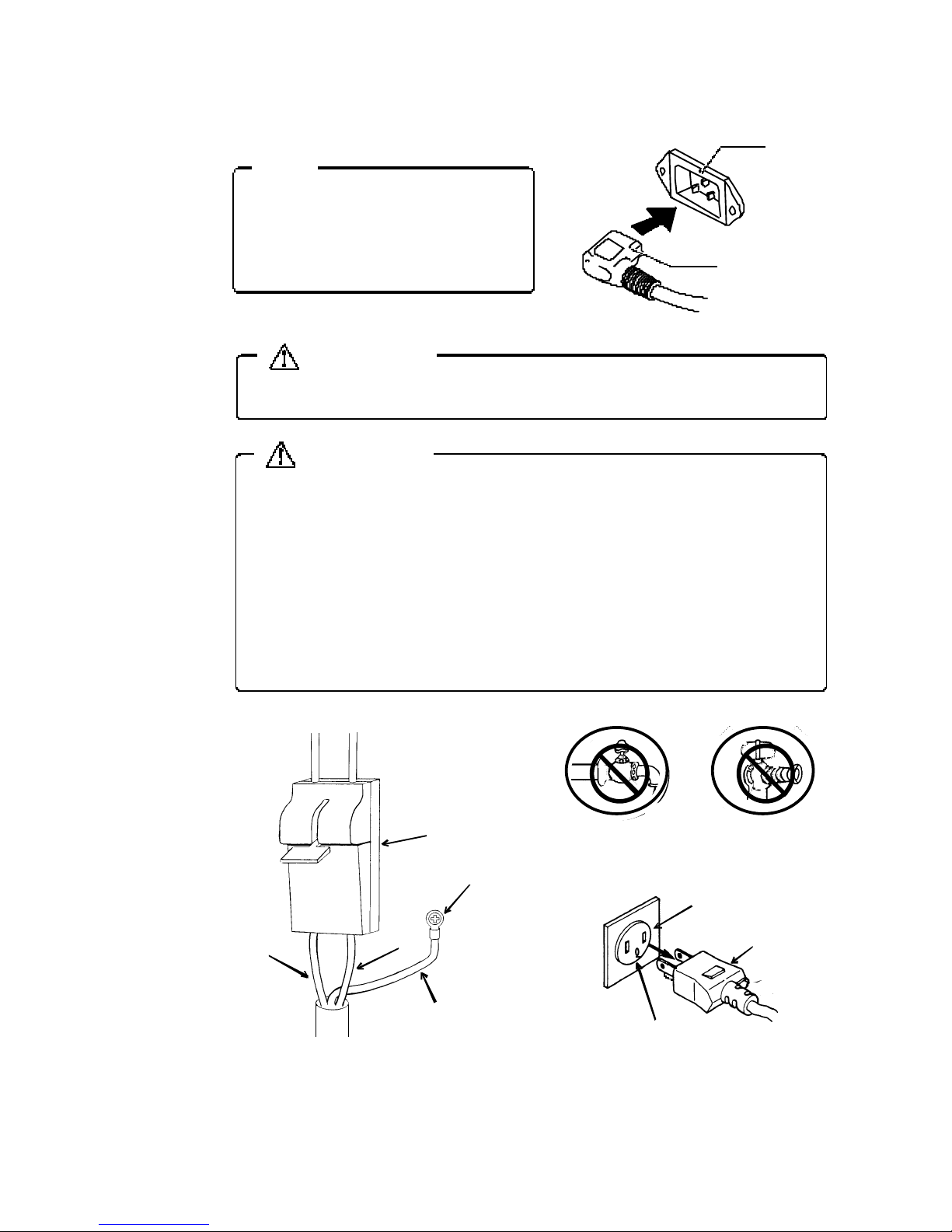

2-3

Power plu

g

Inle

t

When using the cent rifuge for the

first time

, plug

the power cabl e on

the centrifuge into the inlet on the

back of the centrif u

g

e.

NOT E

Ensure that the ground wire is connected to t he grounding terminal.

WARNING

Do not connect the ground cable to the following pla ces:

1. Gas

piping

Ex

p

losion or fire may occur.

2. Ground cable of the li

g

htning conductor, or telephone cable. Electric

shock ma

y

occur in case of thunderbolt.

3. Water

pip

es

Cit

y

water pipes may not be adequate as a ground since it may be

connected to

p

lastic pipework.

WARNING

2-5.

Grounding

Section 2 Installation and Power Suppl

y

Plug Socket

Power plu

g

Ground terminal

Ground wire

(

Gree n- and -yellow stripe

p

attern

)

Ground terminal

Kni fe switch

Power

(White

)

Power

(

Bla ck

)

water pipes

Gas pipin

g

Page 16

3-1

If the lid is not closed properly the

cent

rif

uge is not able to start

.

Make sure the lid is closed firml

y

.

NOT E

Install the rotor after checking if the

"Bucket intervention

p

revention plate" is

installed on the drive shaft.

Refer to page 1-1.

NOT E

Press the "SPEED/TIME" knob to check the "centrifugal force" of the set

s

p

eed or "speed" of the set centrifugal force.

NOT E

Contd. o

n next

page

.

When using this centrifuge, observe t he contents o f th e Sect io n "Ge neral

Note s" be ing described in the f ront part of this document and the

p

recaut ions give n in respective sections.

Section 3

Operation

3-1.

Cautions of Operation

3-2.

Operation

Operation 1. Turn on the “POWER" switch

.

O

p

eration 2.After the “STOP” lamp on the control pan e l l ights, press the “OPEN” button.

O

p

eration 3. Mount the rotor on the drive shaft.

Refer to Section 6.

O

p

eration 4.

For swin

ging

bucket rotor, mount bu ckets on the rotor .

O

p

eration 5. Place the sample in the rotor or buckets

.

Refer to Section 6.

O

p

eration 6. Close the lid firmly.

O

p

eration 7. Proceed to operation 9 when operating with the same setting values as before.

O

p

eration 8. Set the respective parameters.

・

Set to re

q

uired speed. Refer to page 3-6.

・

Set to re

q

uired time. Refer to page 3-8.

・

Set brakin

g

force during deceleration and acceleration speed with the“ACC/DEC”

ke

y

Refer to page 3-12.

●

When the memor

y

has been saved, press the selection key.

Refer to page 3-10.

Page 17

3-2

min

sec

min

sec

(1) When

y

ou want to change the setting (speed, RCF, time) during the operation.

Press the“FUNCTION" ke

y

1 or 2 times on the control panel after changing the

settin

g

, and the flashing of the display is stopped.

The o

p

eration becomes s hifted to the setting that have

been chan

g

ed.

START

STOP

(2)

When you want to halt operation, Press the“STOP" key

on the control

p

anel.

There is the sound and the rotor will come to a halt.

In case that the o

p

eration is stopped before the en d of the period set by the

timer and is resumed

,

the operation period after resumption is the remai ned

p

eriod of the operation.

If the knob is

p

ressed before resumption of operation, the operation period

returns to the ori

g

inal ly set period.

FUNCTION

Operation 9. Press th e“START"key.

“

Pi

p

"sound and lamp on th e“START" key lights.

Value on the “TIME” dis

play

starts decrea-

sin

g

.

When the value becomes 0

,

the centrifuge

automaticall

y

decelerates and stops.

O

p

eration 10.

***

In the followin

g

case

***

Sect ion 3 Operation

Page 18

3-3

NOTE

When the rotor has sto

pped,

the“STOP" l amp flashes and an sound that informs the end of

the o

p

eration is issued.

●

The “Sound that informs the end of the o

p

eration” can be selected from the 5 kinds +

So un d n one.

Refer to page 3-14.

●

The “Alarm Indicat ors” to show the end of the o

p

eration can be selected from the 5

kinds.

Refer to page 3-17.

O

p

eration 11. Press the“OPEN" button to open the lid.

“

STOP” lam

p

remains lit.

O

p

eration 12. Remove the sample.

Refer to page 3-16.

O

p

eration 13. If the centrifuge is to be used again, retu rn to Operation 5.

Operation 14. After finishing use of the centrifuge, turn "OFF" the "POWER" switch to turn off

the

p

ower s upply, leaving the lid i n opened state.

If the power is turned off while a memory being called up and is

then turned on a

g

ain, the same memory as di splayed before the

p

ower cut will be calle d up and displayed.

Ex. : Turn off the power while“MEMORY 2” called up. Turn on the power,

the“MEMORY 2” ke

y

lamp will light and the parameter stored under

“

MEMORY 2” ke

y

will be displayed.

Sect ion 3 Opera tion

Page 19

3-4

The lid is locked in following

cases and

will not

open eve

n if

the

〈

OPEN〉 button is pressed.

・

When the rotor is spinning.

・

When there is a power failure

or the

p

ower is turned off.

Do not open the lid while the rotor is spinning.

When a

p

ower failure occurs during operation of the centrifuge, the rotor

will naturall

y

decele rate to stop its rotation. If the lid is unlocked forcibly

before the rotor sto

ps,

the person can be entangled in the rotor, resulting

in a s erious in

jury

or death.

WARNING

S

T

A

R

T

S

T

O

P

T

IM

E

m

i

n

s

e

c

SP

E

E

D

10

0

r

p

m

1

0

0

g

M

EM

O

R

Y

1

2

3

A

C

C

D

E

C

FU

N

C

T

IO

N

“

OPEN” button

Open

NOTE

3-3.

Opening and Closing the lid

[1] Tu rning on the power and opening the l id

(1)

Turn on the the “POWER" switch to turn the

p

ower on.

The“POWER" switch locates on the front side

p

anel of

the centrifu

g

e.

(2)

The〈STOP〉 lam

p

on the control panel will be lit.

(3)

Press in

g

the〈OPEN〉 button the lid can be opened.

[2] Opening the lid during power failure

(1)

Turn off the “POWER” switch.

(2)

By using a flat-blade screwdriver, remove the lid

extreme release ca

p

on the lower part of the left

si de of the un it.

While pulling the string straight, push “OPEN”

button.

(

Do not pull the string too strong.)

Then t he lid o

p

ens.

Sect ion 3 Oper atio n

Strin

g

S

TA

RT

S

TO

P

T

IM

E

S

PE

ED

F

UN

CTI

ON

Page 20

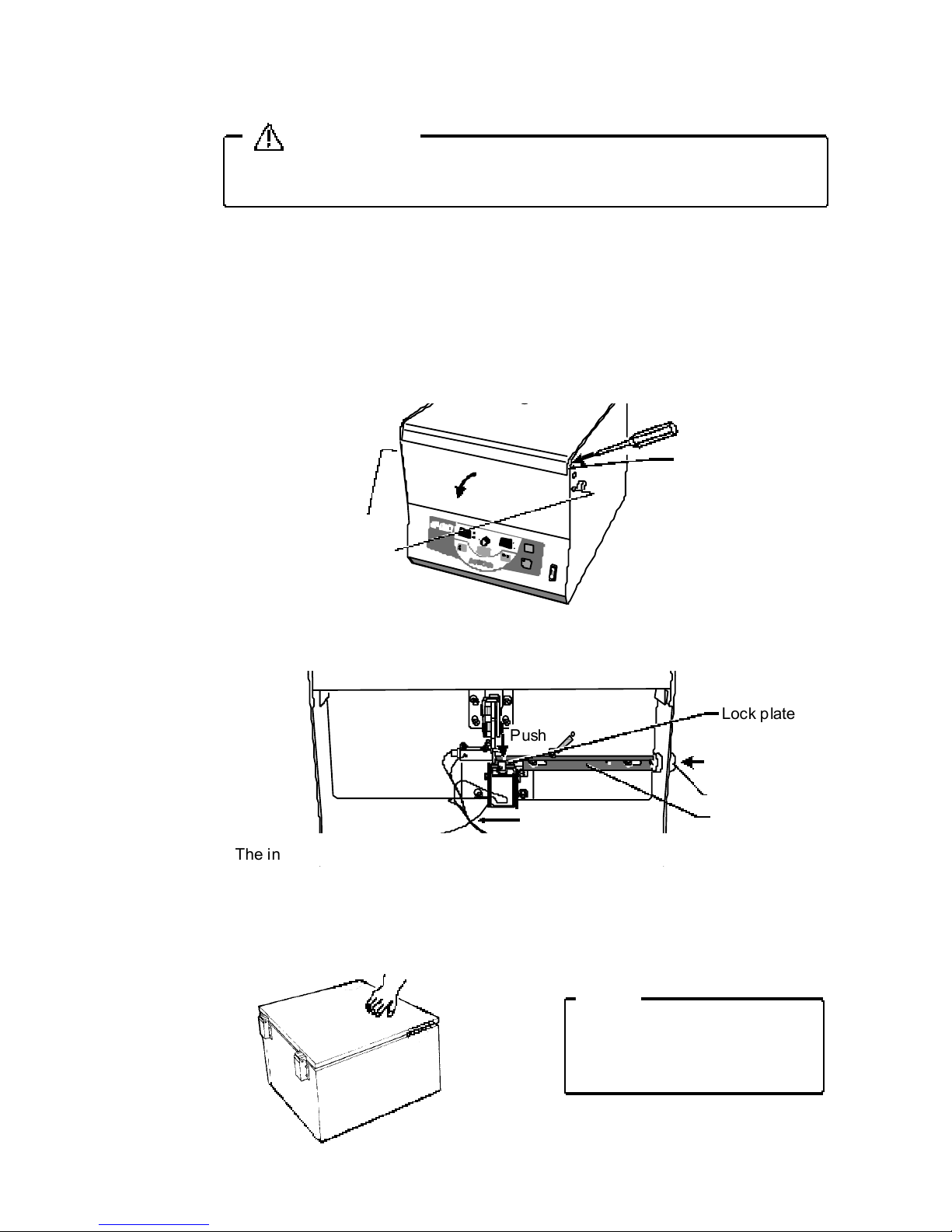

3-5

The lid can be closed even

when th ere is a

p

ower failure

or the power is turned off

.

NOT E

For prevention of electric shock, wait at least 5 minutes before opening the

front lid.

◆

If the lid extreme release ca

p

string is cut

WARNING

(1)

Turn off the “POWER" switch.

(2)

Remove the

p

ower s upply plug from the outlet.

(3)

When more than 5 minutes hav e

p

assed after turning off th e power, remo ve the 2

screws on the left and the ri

g

ht si des of the centrifuge.

(4)

Insert a minus driver into the clearance between the front cover and the centri fu

g

e, and

tu rn the fr on t cover over

g

ently to the front side.

(5)

Press the “OPEN” button while holdin

g

down the lock plate.

The lid o

p

ens after the lid lock has been released.

[3] Closing the lid

Close the lid by pressing the front center of the li d by hands.

Press the lid securel

y

and lock it.

Sect ion 3 Oper atio n

S

T

A

R

T

S

TO

P

T

I

M

E

m

i

n

s

ec

S

PE

E

D

1

0

0

rp

m

1

0

0

g

M

E

MO

R

Y

1

2

3

A

C

C

D

E

C

F

U

N

C

TI

ON

Screws

(

two

)

Space

Minus driver

Lock plate

Push

The inside of t he centrifuge

Strin

g

(

When the string is cut, it can be fixed by

tying the ends.

)

Push

“

OPEN” button

Connection stick

Page 21

3-6

TIME

SPEED

10 0rpm

×

10 0

g

×

FUNCTION

10 0rpm

×

10 0

g

×

10 0rpm

×

10 0

g

×

10 0rpm

×

10 0

g

×

FUNCTION

min

sec

10 0rpm

×

10 0

g

×

SPEED

SPEED

SPEED

SPEED

●

The centrifuge can be started with the speed on the "SPEED" display,

even i f the dis

play

of val ue is flashing.

●

When

y

ou want to change the setting during the operation, press the

“

FUNCTION" ke

y

2 times on the control panel after changing the

settin

g,

and the flashing of the display is stopped.

The o

p

eration becomes s hifted to the setting that have been changed.

●

The setting order of the speed and the timer can be changed.

Refer to page 3-15.

NOT E

3-4.

Setting the Speed

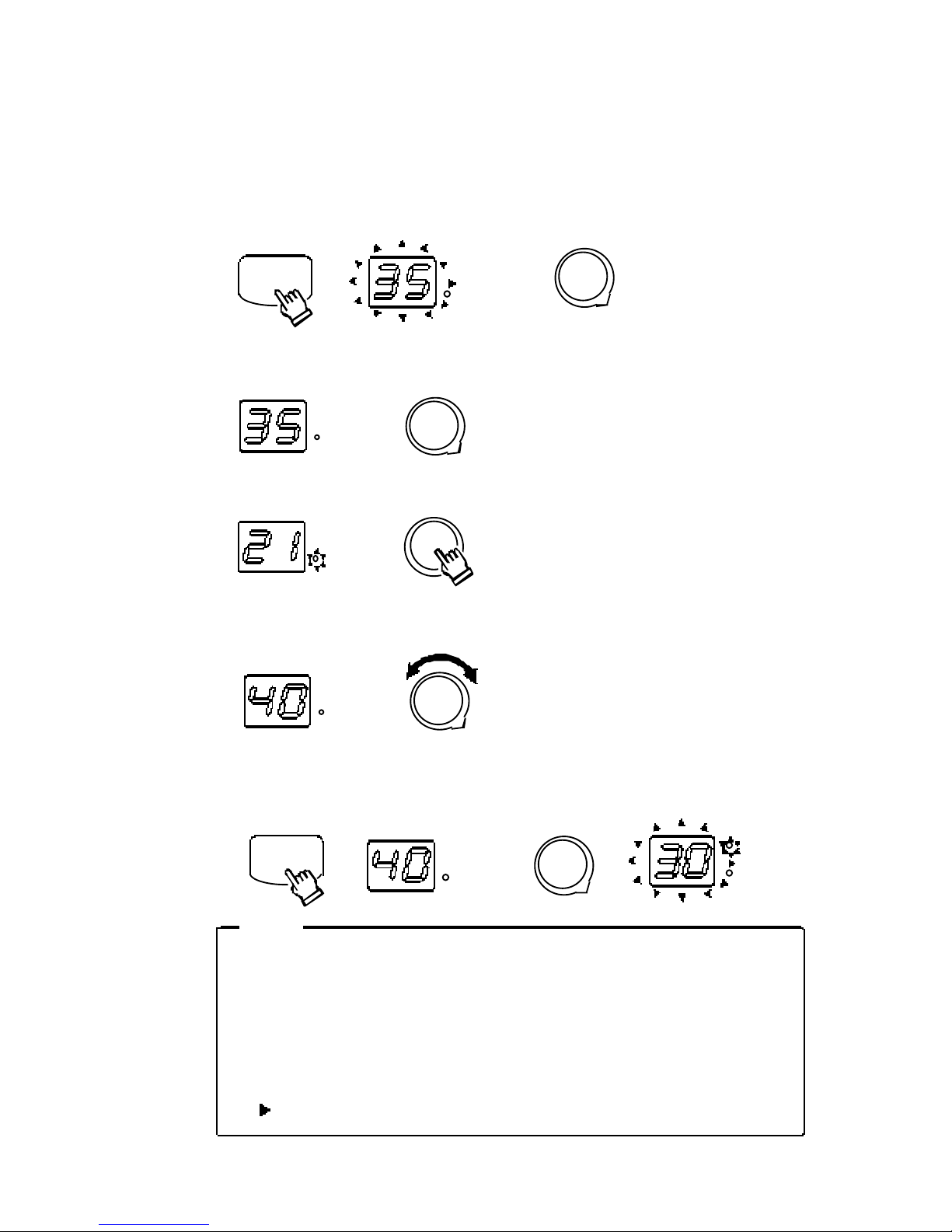

[1] Setting the speed by the rpm

(1)

Press the“FUNCTION” ke

y

.

The“SPEED” dis

play

flashes and indicates the current setting.

(2)

Check if the

〈×

100

g

〉

lamp turned off.

①

When the

〈×

100

g

〉

lamp is off

・・・・・・・・・・・・・・・・・

Proceed to the Procedure

(3)

.

②

When the

〈×

100

g

〉

lam

p

is on

・・・・・・・・・・・・・・・・・・

Press the“SP EED/TIME”

knob and th e

〈×

100

g

〉

lam

p

turns off.

Proceed to the Procedure

(3)

.

(3)

Turn the“SPEED/TIME” knob to set t o re

q

uir ed speed.

The s

p

eed ca n be se t 100 rpm intervals.

(4)

When continuin

g

on to time setting, press the “FUNCTION” key.

The “SPEED” dis

play

stops flashing and the “TIME” display starts to flash.

(

Timer setting status

)

Sect ion 3 Operation

Page 22

3-7

TIME

10 0rpm

×

10 0

g

×

FUNCTION

10 0rpm

×

10 0

g

×

10 0rpm

×

10 0

g

×

1 00rpm

×

10 0

g

×

FUNCTION

min

sec

10 0rpm

×

10 0

g

×

SPEED

SPEED

SPEED

SPEED

SPEED

NOT E

●

The centrifuge can be started with the speed on the "SPEED" display,

even i f the dis

play

of val ue is flashing.

●

When

y

ou want to change the setting during the operation, press the

“

FUNCTION" ke

y

2 times on the control panel after changing the

settin

g,

and the flashing of the display is stopped.

The o

p

eration becomes s hifted to the setting that have been changed.

●

The setting order of the speed and the timer can be changed.

Refer to page 3-15.

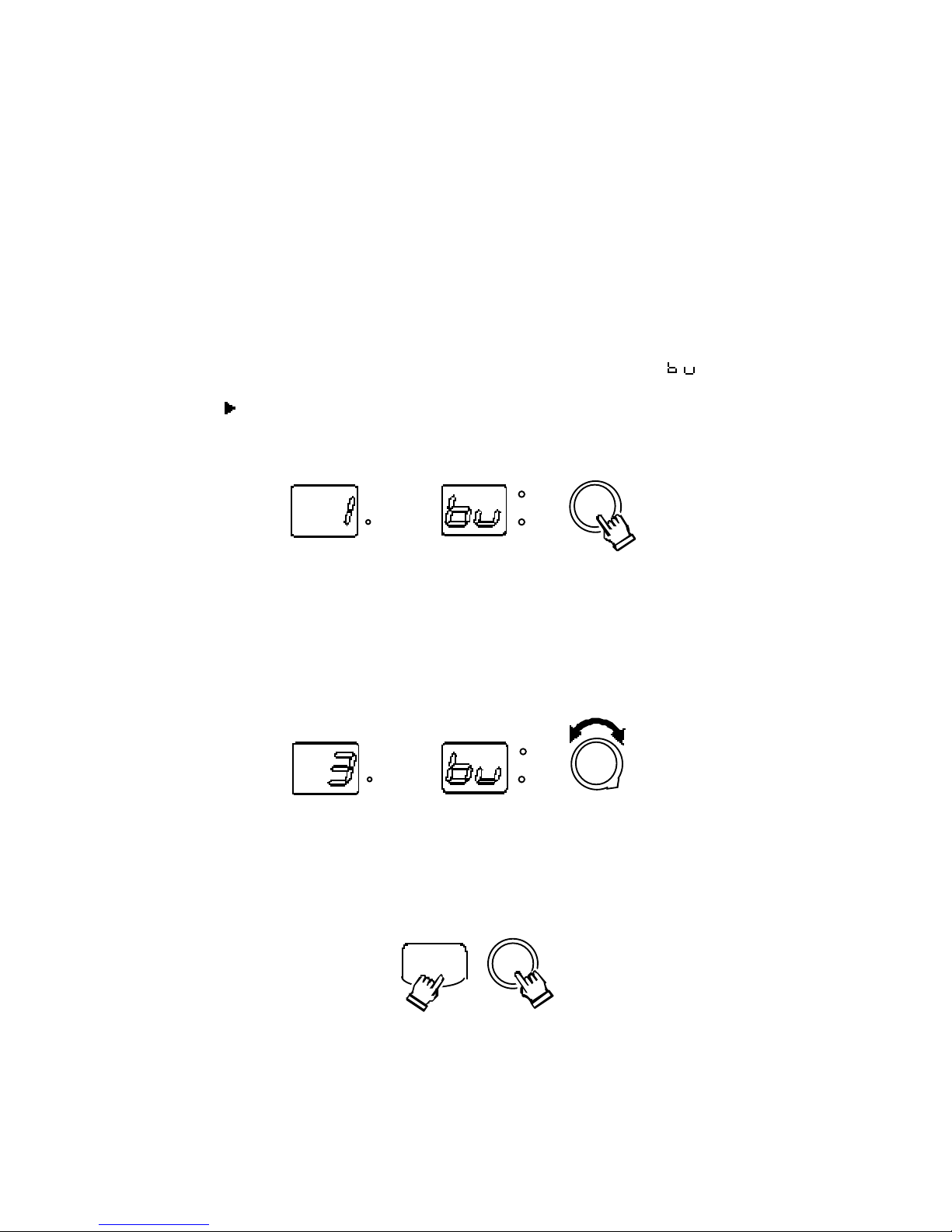

[2]

Setting the speed by the centrifugal fo rce

(

×

g)

(1)

Press the“FUNCTION” key.

The“SPEED” dis

play

flashes and indicates the current setting.

(2)

Check if the

〈×

100

g

〉

lamp turned on.

①

When the

〈×

100

g

〉

lamp is on

・・・・・・・・・・・・・・

Proceed to the Procedure

(3)

.

②

When the

〈×

100

g

〉

lam

p

is off

・・・・・・・・・・・・・・

Press the“SP EED/TIME” knob

and the

〈×

100

g

〉

lamp turns

on.

Proceed to the Procedure

(3)

.

(3)

Turn the“SPEED/TIME” knob to set t o re

q

uir ed centrif ugal force reading.

Indications on the“SPEED” dis

play

are at 100

×

g

intervals.

(4)

When continuin

g

on to time setting, press the “FUNCTION” key.

The “SPEED” dis

play

stops flashing and the “TIME” display starts to flash.

(

Timer setting status

)

Sect ion 3 Opera tion

Page 23

3-8

min

sec

min

sec

FUNCTION

NOT E

●

In case that the operation is stopped before the end of the period set by the

timer and is resumed

,

the operation period after resumption is the remained

p

eriod of the operation.

If the "SPEED/TIME" knob is

p

ressed before resumption of operation, the

o

p

eration period returns to the origina lly set period.

●

The centrifu

g

e can be started at the time when th e setting value is flashing at

"TIME" dis

play

.

●

When

y

ou want to change the setting during the operation, press the

“

FUNCTION" ke

y

on the control panel af ter changing the setting, and the

flashin

g

of the display is stopped.

The o

p

eration becomes s hifted to the setting that have been changed.

●

The s

p

eed and the timer can be set in this sequence or vice versa.

As for the chan

g

e of the setting, please refer to page 3-15.

3-5.

Setting the Timer

(1)

Press ing the "FUNCTION" key 2 times, the“TIME” display flashes and indicates the

current settin

g

.

The timer is able to be set u

p

.

(2)

Press in

g

“

SP EE D /TI M E" k no b chan

g

es the settable range of centrifuging time as des-

cribed below. Set to the ran

g

e as requir ed.

Factor

y

default, the range is set minutes

.

③

HOLD

It will continuall

y op

erate regard les s of

the timer. When set to hold

,

both "min"

and "sec" lam

p

will be turn off.

(3)

Turnin

g

the“SPEE D/TI ME" knob changes

the indication on the dis

play

.

Set to the time re

q

uired.

(4)

Press“START" ke

y

on the control pan el .

The o

p

eration will be started.

When started

,

the display will diminish and stop at point 0.

Sect ion 3 Operation

②

Setting second s

①

Settin

g

minute s

Settable range 1-99 minutes

Setting unit 1 minute

Settable ran

g

e 1-99 seconds

Settin

g

unit 1 second

min

sec

min

sec

min

sec

Page 24

3-9

ACC

DEC

ACC

DEC

ACC

DEC

ACC

DEC

ACC:RAPID(

“

RAPID

”

acceleration

)

DEC:RAPID

(

“

RAPID”deceleration

)

ACC:RAPID

(

“

RAPID”acceleration

)

DEC:SLOW

(

“

SLOW” deceleration

)

ACC:SLOW

(

“

SLOW”acceleration

)

DEC:RAPID

(

“

RAPID”deceleration

)

ACC:SLOW

(

“

SLOW”acceleration

)

DEC:SLOW

(

“

SLOW”deceleration

)

On

Off

It changes to the SL OW characte ristic

from RAPID at 1

000rp

m.

Natural deceleration

1000rpm

N

[Ex.]

SPEED

RAPID

decele ration

SL O W

acceleration

RAPID

acceleration

SLOW

decel eration

You can set the natural deceleration startin

g sp

eed N.

Refer to page 3-13.

NOTE

TIME

3-6.

Setting the acceleration・deceleration

When blowing-up of samples is feared, adjust the acceleration and the

decel eration settin

g

b

y p

ressin

g

the“ACC/DEC” ke

y

Sect ion 3 Opera tion

Page 25

3-10

The paramet ers necessary for operation (speed, RCF, time, acceleration /

decel eration

,

etc.) can be stored as programs with MEMORY 1~3 keys.

NOTE

MEMORY

123

FUNCTION

About 3 seconds

MEM ORY

12

3

FUNCTION

ACC

DEC

Even if the power is turned o ff, the paramet ers set at the time of power off

remain stored.

The last settin

g

is displayed and can be operated.

NOTE

3-7.

Saving the Memory

Saving the set ting value enables operation with the same setting

value re

p

eatedly.

[1] Saving the Memory

(1)

Set the respective parameters.

Refer to the followin

g pag

e for the setting meth od .

[3-4.

Settin

g

the speed

]

Refer to Page 3-6.

[3-5.

Settin

g

the timer

]

Refer to Page 3-8.

[3-6.

Settin

g

the acceleration・deceleration] Refer to Page 3-9.

(2)

Press in

g

“FUNCTION” key, the s etting is settled.

(3)

Press in

g

"MEMORY" key, the lamp is lit, and choose

the lam

p

number you wa nt to save.

(4)

Kee

p p

ressing “FUNCTION” key until the buzzer

sounds.

(

Abou t 3 seconds)

(5)

Stored memories can be easil

y

recalled by press ing the

a

pprop

riate memory selection key.

[2]

Memory cancellation

Pressing the “Function” key or the “ACC/DEC” key, the normal setting mode

will be selected.

①

Pressin

g

the “Function” key.

The chan

g

e for speed / centrifugal force or time.

②

Pressin

g

the “ACC/DEC” key.

The chan

g

e for ACC a n d DEC.

Sect ion 3 Operation

Page 26

3-11

FUNCTION

100rpm

×

100 g

×

min

sec

SP EE D

TIME

100rpm

×

100 g

×

min

sec

SP EE D

TIME

100rpm

×

100 g

×

min

sec

SP EE D TIME

100rpm

×

100 g

×

min

sec

SP EE D TIME

100rpm

×

100 g

×

min

sec

SP EE D

TIME

100rpm

×

100 g

×

min

sec

SP EE D

TIME

100rpm

×

100 g

×

min

sec

SP EE D TIME

NOTE

The memor

y

lamp turns off temporarily, when you set the function while

settin

g

the memory operation in Model 2420. The lamp is lighted after the

settin

g

.

3-8.

Setting the Function

As fo r th is product the following setting is produced.

Choose the item

y

ou want to set up, and pres s "SPEED/ TIME" knob .

The

pag

e where the content is written is referred to.

(1)

Press in

g

the "SPEED/TIME" knob while holding

down the "FUNCTION" ke

y

.

(2)

The used number of times of the

centrifu

g

e is displayed.

[Ex.] 186 times

(3)

Settin

g

the Rotation Radius

Refer to Page 3-12.

[

Ex.]146 mm

(4)

Settin

g

the "SLOW" deceleration.

Refer to Page 3-13.

[

Ex.]300r

p

m

(5)

Settin

g

the Sound that informs the

en d of the o

p

eration.

Refer to Page 3-14.

[

Ex.]1

(6)

Reverse of settin

g

order of the

S

p

eed and the Timer.

Refer to Page 3-15.

[

Ex.]0

(7)

Settin

g

the Reminder alarm.

Refer to Page 3-16.

[

Ex.]ON

(8)

Settin

g

the Indicators for the end of

the o

p

eration.

Refer to Page 3-17.

[

Ex.]1

■

After settin

g

any one of the above, please return the display to the previous indication of

"SP EED" and "TIME".

To do ab ove

, p

ress the "SPEED/TIME" knob while holding down the "FUNCTION" key.

Sect ion 3 Opera tion

Page 27

3-12

FUNCTION

The rotation radius ca n not be stored in the memory, when th e power

su

pply

is turned off without returning the display to the previous

indication.

NOT E

100rpm

×

10 0

g

×

min

sec

SPEED TIME

10 0rpm

×

10 0

g

×

mi n

sec

SPEED

TIME

3 digit s 2 digit s 1 digit

[

Ex.]The rotation radius is 146 mm.

3 digit s

2 digit s

1 digit

FUNCTION

[1]

Setting the Rotation Radius

To obtain more accurate centrifugal force, adjust the rotation radius to that of the rotor

buckets.

Factor

y

default : 146 mm

.

(1)

Press ing the “SPEED/TIME” knob while holding

down the “FUNCTION” ke

y

.

The used number of times of the centrifu

g

e is displayed.

(2)

Press in

g

the "SPEED/TIME" knob several times and let indicate " " on the left side of

the “SPEED” dis

play

.

The “SPEED” and “TIME”dis

play

indicates the current setting.

Unit : mm

Refer to Page 3-11.

(3)

Turn the“SP EED/TIME” knob to set to the rotation radius of the rotor bucket to be

used for o

p

eration.

The ran

g

e is set from 5 0 to 150 mm

.

(4)

Press the “SPEED/TIME” knob while holdin

g

down the “FUNCTION" key.

The dis

play

returns to the previous Speed and Time indication after the setting (rotation

radius

)

is saved.

Sect ion 3 Operation

Page 28

3-13

100rpm

×

10 0

g

×

min

sec

SPEED TIME

10 0rpm

×

10 0

g

×

min

sec

SPEED TIME

FUNCTION

[2]

Setting the "SLOW" deceleration

The characteristics have become as shown in the graph.

You can set the natural deceleration startin

g sp

eed N by the following method.

Factor

y

default, it is set as 0 rpm

.

The settin

g

ra nge of "N" i s from 0 t o 4,000 rpm.

(1)

Press in

g

the "SPEED/TIME" knob while holding down the "FUNCTION" key.

The used number of times of the centrifu

g

e is displayed.

(2)

Press in

g

the "SPEED/TIME" knob several times and let indicate " "on the "TIME"

dis

play

.

The "SPEED" dis

play

indicates the current setting of the natural deceleration speed.

Unit : r

p

m

Refer to Page 3-11.

[

Ex.] Settin

g

is the 0 rpm.

(3)

Turn the "SPEED/TIME" knob to set the natural deceleration speed.

The settin

g

ra nge of "N" i s from 0 t o 4,000 rpm.

[

Ex.]Settin

g

the 300 rpm.

(4)

Press the "SPEED/TIME" knob wh ile holdin

g

down the "FUNCTION" key.

The dis

play

returns to the previous Speed and Time indication after the setting ( Natural

deceleration s

p

eed) is saved.

Sect ion 3 Opera tion

N

1000

N

1000

(A )N =

1,000 rpm or more

(B )N =

1,000 rpm or less

rpm

rpm

speed

It changes t o the SL OW

characteristi c from RAPID

at 100 0rpm.

RAPID

Natural

deceleration

SLOW

TIME

TIME

speed

RAPID

Natural

deceleration

Page 29

3-14

10 0rpm

×

10 0

g

×

min

sec

SPEED

TIME

10 0rpm

×

10 0

g

×

min

sec

SPEED

TIME

FUNCTION

[3]

Setting the Sound that informs the end of the operation

The

“

Sound that informs the end of the operation” can be selected from the 5

kinds + Sound none.

Use this function to identif

y

each “Sound that informs the end of the operation” when

y

ou use more than one centrifuges.

Factor

y

default : [1

]

(1)

Press in

g

the "SPEED/TIME" knob while holding down the "FUNCTION" key.

The used number of times of the centrifu

g

e is displayed.

(2)

Press in

g

the "SPEED/TIME" knob several times and let indicate " " on the "TIME"

dis

play

. The "SPEED" display indicates the current setting of the sound that informs.

Refer to Page 3-11.

[

Ex.]The “Sound that informs the end of the operation” 1.

(3)

Turn the "SPEED/TIME" knob to chan

g

e the "Sound that informs the end of the oper ation".

Press in

g

the "FUNCTION" key makes the selected buzzer sound once.

The "Sound that informs the end of the o

p

eration" can be selected from 1, 2,3, 4,

5 of 5 kinds + 0

(

Sound none).

(4)

Then,

p

ress the "SPEED/TIME" knob while holding down the "FUNC TION" key.

The dis

play

returns to the previo us Speed and Time indication after the setting ( S oun d

that informs the end of the o

p

eration) is saved.

Sect ion 3 Operation

Page 30

3-15

10 0rpm

×

10 0

g

×

mi n

sec

SPEED TIME

10 0rpm

×

10 0

g

×

min

sec

SPEED TIME

FUNCTION

Numbers Content s

0

「

Speed / RCF

」→「

Timer

」

1

「

Timer

」→「

S

p

eed / RCF

」

[4]

Reverse of setting order of the Speed and the Timer

The setting order of the speed and the timer can be reversed.

This function is useful when

y

ou often operate the centrifuge by changing the

timer onl

y

.

Factor

y

default : [0

]

(1)

Press in

g

the "SPEED/TIME" knob while holding down the "FUNCTION" key.

The used number of times of the centrifu

g

e is displayed.

(2)

Press in

g

the "SPEED/TIME" knob several times and let indicate " " on the "TIME"

dis

play

. Th e " SPEED" d isplay indicates the current s etting of the number (see the figure

below

)

.

Refer to Page 3-11.

[Ex.]Numbers 0

(3)

Turn the " SPEED/TIME" knob to chan

g

e the number.

(4)

Press the "SPEED/TIME" knob wh ile holdin

g

down the "FUNCTION" key.

The dis

play

returns to the previo us Speed and Time indication after the setting (Numbers)

is saved.

Sect ion 3 Opera tion

Page 31

3-16

10 0rpm

×

1

00 g

×

min

sec

SPEED TIME

10 0rpm

×

10 0

g

×

min

sec

S

PEED

TIME

FUNCTION

Reminder alarm

“

SPEED” dis

play

.

○

×

[5]

Setting the Reminder alarm

The alarm reminds the u ser every minute when samples are left in side the

centrifu

g

e after completion of the operation.

The reminder alarm

g

oes off when opening the lid or performing some operations.

Factor

y

default : [ON

]

(1)

Press in

g

the "SPEED/TIME" knob while holding down the "FUNCTION" key.

The used number of times of the centrifu

g

e is displayed.

(2)

Press in

g

the "SPEED/TIME" knob several times and let indicate " " on the "TIME"

dis

play

.Th e "SP EED" display indicates the current setting of the reminder on or off.

(

see the figure below

)

Refer to Page 3-11.

[Ex.]Reminder alarm : ON

(3)

Turn the " SPEED/TIME" knob to chan

g

e the number.

[Ex.]Reminder alarm : OFF

(4)

Press the "SPEED/TIME" knob wh ile holdin

g

down the "FUNCTION" key.

The dis

play

returns to the previous Speed and Time indication after the setting (reminder

on or off

)

is saved.

Sect ion 3 Operation

Page 32

3-17

10 0rpm

×

10 0

g

×

min

sec

SPEED TIME

10 0rpm

×

10 0

g

×

min

sec

SPEED

TIME

FUNCTION

Numbers

“

SPEED” and “TIME” displa

y

0

After [Setting value] lights

、[0]

lights

1

After [Setting value] flashin

g

、[0]

flashin

g

2

[8 8][8 8]

flashin

g

3

[--][- -]

flashin

g

4

[E ][nd]

flashin

g

[6]

Setting the Indicators for the end of the operation

Completion of the operation is indicated not only with an alarm but also with the

"SPEED" and "TIME" dis

play

s.

The "Alarm Indicators" can be selected from the 5 kinds.

Factor

y

default : [1] (see the figure below).

(1)

Press in

g

the "SPEED/TIME" knob while holding down the "FUNCTION" key.

The used number of times of the centrifu

g

e is displayed.

(2)

Press in

g

the "SPEED/TIME" knob several times and let indicate " " on the "TIME"

dis

play

. The "SPEED" display indicates the current setting of the n um ber (see the figure

below

)

. Refer to Page 3-11.

[Ex.]Number : 1

(3)

Turn the " SPEED/TIME" knob to chan

g

e the number.

(4)

Press the "SPEED/TIME" knob wh ile holdin

g

down the "FUNCTION" key.

The dis

play

returns to the previo us Speed and Time indication after the setting (Numbers)

is saved.

Sect ion 3 Opera tion

Page 33

3-18

Allowable load (gram

)

Actual load (gram

)

Reduced maximum speed(rpm

)=

Maximum speed(rpm

)×

Do not ex

ceed the ma

ximum

speed and the allowable load o

f r

otor and

bucket.

An excessive s

p

eed or overload may cause a damage to the rotor, bucket

and the cent

rif

uge

.

If the load exceeds the limit

,

reduce the maximum speed as shown in the

formula 3-2 and set the actual speed below the reduced maximum speed.

[

formula 3-2

]

As for rotation radius, please refer the page 6-4, 6-5, 6-10 and 6-12. The

maximu m cen trifu

g

al force being indicated in the said pages is calculate by

substitutin

g

the maximum radius of gyration of the rotor for the radius of

gy

ration of each rotor (cm) and by rounding the first digit above the decimal

p

oint of the calculation result.

B

y

setting the rotation radius, an accurate speed and centrifugal force can be

switched. Factor

y

default at the time of delivery is 14.6 cm.

Refer to page 3-12.

(1)

When the gravity of sample is 1.2 or higher or when a speci al tube is used

,

check t he allowable loa d of the rotor and bucke t.

(2)

Regarding allowable load on rotors and buckets at the maximum speed refer to the

appropriate Specification Table for rotor in use.

(3)

The allowable load includes t he weight of sample, cushions, adaptors, tubes, caps,

and racks. (The weight of bucket is not included in the allowable load.

)

WARNING

NOT E

3-9.

Calculating Centrifugal Force

You can readily calculate the centrifugal force by as signing the Rotation Radius and speed

in the followin

g eq

uation:

Please refer to the Nomo

grap

h for Centrifugal Force Calculation at the last page of this

man ual.

3-10.

Allowable load and Reduced maximum speed

Sect ion 3 Operation

entri fugal force RCF

(

×

g

)

= 11.18

×

S

p

eed N(rpm

)

1000

2

×

Rotation Radius R

(cm)

[

formula 3-1

]

Page 34

4-1

If any abnormality is found during routine daily inspections, discontinue

centrifu

g

e operation, use the "POWER" switch to turn the machine OFF,

disconnect the

p

ower cable, attach "DO NOT USE" labels to the rotor and the

outside of the centrifu

g

e, and contact your nearest deal er to request a c entrifuge

ins

p

ection before resuming operation of the equipment.

If the centrifu

g

e is used after discovering any abnormality, an accident could

occur,

p

ossibly leading to serious damage or accidents involving physica l injury.

WARNING

Checkpoint Action taken

Check whether the rotor knob

and rotor lockin

g

nut are

prop

erly tight.

Reti

g

hten, if either of these is loose. For details, refer

to "Mountin

g

the Rotor" in the rotor instruction

manual. Refer to Section 6.

To inspect, mount buckets on

the swinging bucket rotor

when it is sto

pped,

and lift up

the buckets manually.

If the buckets do not move smoothl

y

and freely, clean

the bucket grooves and trunnion pins of the rotor yoke

using alcohol. Contact your local dealer and make an

a

pp

ointment fo r an authorized i nspection if t hese

p

arts fail to operate smoothly even after lubricant has

been a

pp

lied. Refer to Page 4-5.

Check carefull

y

for any

cracks

,

evidence of corrosion

,

rust or deformation on the

rotor and bucke ts.

Do not use the rotor or buckets if an

y

cracks,

corrosion, rust or deformations are found. Contact

y

our local dealer for an inspection.

Check that no forei

g

n material

or water is present in the

chamber.

Remove an

y

foreign m a terial or water b e fo re

operating the centrifuge.

Check that the lid is hook.

If the lid lock does not work

,

discontinue operation of

the centrifuge. Contact your nearest dealer for a

centrifuge inspection.

Check that the screws fixin

g

the lid hinges are not loose.

If the screws fixin

g

the lid hinge ar e loose or have

been removed, the lid may come off when the buckets

are thrown off and the broken pieces may cause injur

y

to the persons in the vicinity of the centrifuge. If the

lid hinge is not fixed firmly, stop centrifuge

operation. Stop operation promptly and contact

y

our

loca l de aler for inspe ction.

Check the nut of the trunnion

p

in (RMP-23) is not

loosen ed.

If the trunnion

p

in is loosened, contact your local

d e al er fo r in spection.

Check that t he

g

rounding wire

is cor rectly connected.

Refer to Page 2- 3 .

Check that all knobs,

displays, lamps and switches

o

p

erate correctly.

If an

y

do not operate correctly, contact your local

d e al er fo r an in spection.

Refer to Page 1-1 and 1-2.

Check that the centrifu

g

e is

p

laced horizontally.

Refer to

page

2-1.

Section 4

Service

4-1.

Daily Inspection

Page 35

4-2

WARNING

Perform a monthly careful inspection of the rotor appearance. Check for

an

y

deformation or damage, inc luding the interior and bottom of the holes.

If an

y

abnormality whatsoever is found , there may be significant damage or

corrosion of the rotor that could lead to serious dama

g

e or accidents

involvin

g phy

sical injury. Stop operation a t once, put "DO NOT USE" labels

on the rotor an d centrifu

g

e lid, and contact your local deal er to arrange for

authorized service.

Motor S

p

eed control

Rotor and b ucket Imbalanc e

lid Electric current

Chamber Insulat ion

S

p

eed meter Install the centrifuge

Timer

4-2.

Monthly Inspections

[1]

Ins

p

ect the rotor

[2]

Clean the rotor and buckets

Remove the rotor from the shaft, and clean it.

Refer to Page 4-3.

[3]

Clean the chamber interior

Refer to Page 4-3.

4- 3.

Annual Inspection

Annual Inspection (fee required

)

For the following inspection i tems, please call your local deal er and set up an

a

pp

ointment for a periodical inspection.

Sect ion 4 Ser vice

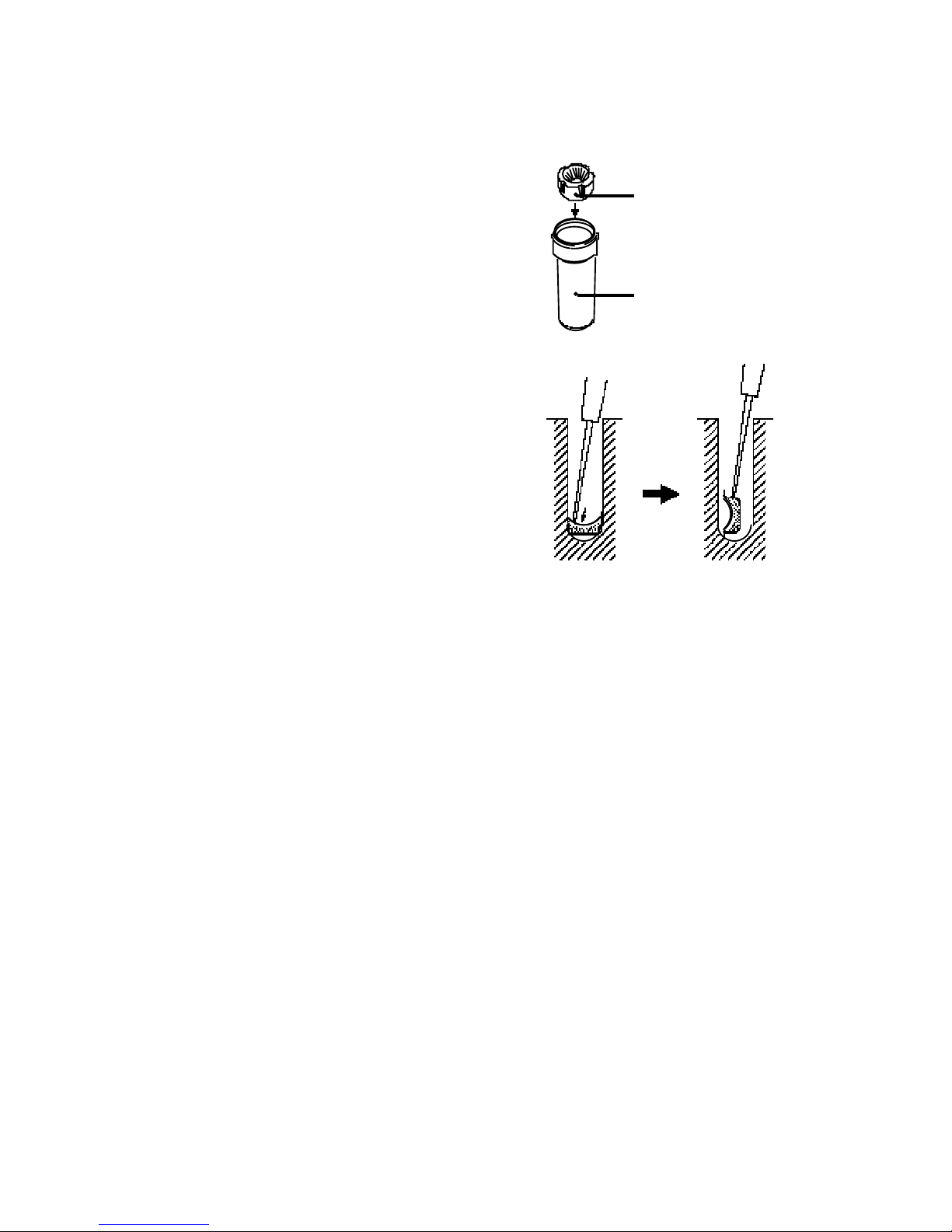

Page 36

4-3

Contd. on next page.

Consult with your nearest dealer prior to attempting any cleaning procedure for

the rotor, bu ckets, or tube rack that is n ot s

p

ecifically recommended in this

manual. Certain cleanin

g

methods or cleaning agents may cause corrosion and

then breaka

g

e leading to serious damage or accidents involving physical injury.

WARNING

4-4.

Cleaning and Sterilization

[1]

Cleaning the chamber interior

The chamber i s made of stainless steel (SUS304) but may rust if sample spillage

contai nin

g

sal t (NaCl) or chlorinated chemicals (Cl) is allowed to remain.

After u sin

g

the centrifuge, follow the method below (1) when wiping the inside of

the chamb er and cleani n

g

the surfaces.

(1)

Cleaning and rust prevention

Cleaning the chamber interior according to the following procedure will he lp

p

reve nt rust.

1

)Wip

e off any di rt or res idu e usi ng a cloth moistened with a small quantity of a neutral

deter

g

ent.

2

)Wip

e away any detergent residue using a cloth dampened with water, and then dry the

inside of the chamber.

3

)

To prevent rust, we recommend the use of common anti-rust agents (such as CRC-556)

onl

y

if such will not affect the samples being centrifuged.

Wi

p

e the dirt off using a cloth containing a small quantity of neutral detergent.

(2)

If rust is

p

resent

Superficial rust can be removed by using a mild solution of sodium bicarbonate

(

NaHCO3, bica rbonate of soda, baking so da).

1

)

Moisten a paper towel with a little water, apply some bicarbonate of soda, and then rub the

area where rustin

g

has occurred.

2

)

After removing the rust with the bicarbonate of soda, follow the above procedure (1) and

clean the chamber interior usin

g

a neut ral detergent followed by a thorough wiping with

p

lain water. Make sure that such cleaning is especially thorough, so that all traces of the

bicarbonate of soda are rem ove d .

[

NOTE

]

Under no circumstances should an

y

rust inside the chamber be removed by using

sand

pap

er or abrasive agents, since if the interior surfaces are scratched, this will

onl

y

increase the likelihood of additional rust developing.

Sect ion 4 Servi ce

Page 37

4-4

Do not al low any spilt samples to remain on any surfaces, otherwise rust

or corrosion ma

y

occur. Also, if sample spillage is left between the rotor

and shaft, later detachment of the rotor may become pro blematic.

WARNING

Do not heat the rotor, buckets, or tube rack above 100℃ for sterilizatio n

or disinf ection

purp

ose s.

Al

so, do not use an autoclave for dry heat ste

rilization, since ex

cessive

heat ma

y

deleteriously affect the strength of the rotor, buckets, or tube

rack, r

esulting

in break

age of the rotor, buckets, or tube rack, causing

seri ou s dama

g

e or accidents involving physical injury.

Yet

,

You can conduct up to 50 times of autoclave sterilizations of the

RMP-23 rotor and bu cket at 121 ℃ and 100 times of autoclave sterilizations

of the RS-1004 rotor and bucket at 121 ℃.

Do not use deter

g

ents exceeding a pH range of 5 - 8, or chlorinated

deter

g

ents normally used for washing.

Corrosion ma

y

damage the rotor, bucket, or tube rack, resulting in damage

to the centrifu

g

e that may lead to serious ad ditional damage or accidents

involvin

g phy

sica l injury.

CAUTION

NOT E

[2]

Cleaning the rotor, buckets and tube rack

1)If s ample spillage has occurred, remove the rotor, buckets, and tube rack from the

centrifu

g

e, and wash the affected items with a neutral detergent and warm water.

Then rinse the items with the distilled water and thorou

ghly

dry them before use.

2

)

If water has accumulated inside the rotor, place the rotor with its bottom side up and allow

it to dr

y

completely.

3

)

If a sample has spilled onto the drive shaft, wipe it off using a cloth moistened wi th a

small amount of a neutral deter

g

ent and then clean away all detergent traces using a cloth

moistened with water. Then, dr

y

the surfaces completely before using the machine.

[3]

Sterilization of rotor, buckets and tube rack

To disinfect the rotor, buckets, or tu be r ack, a 70% ethanol solution, or ultraviolet

radiation, is recommended.

Sect ion 4 Servi ce

Page 38

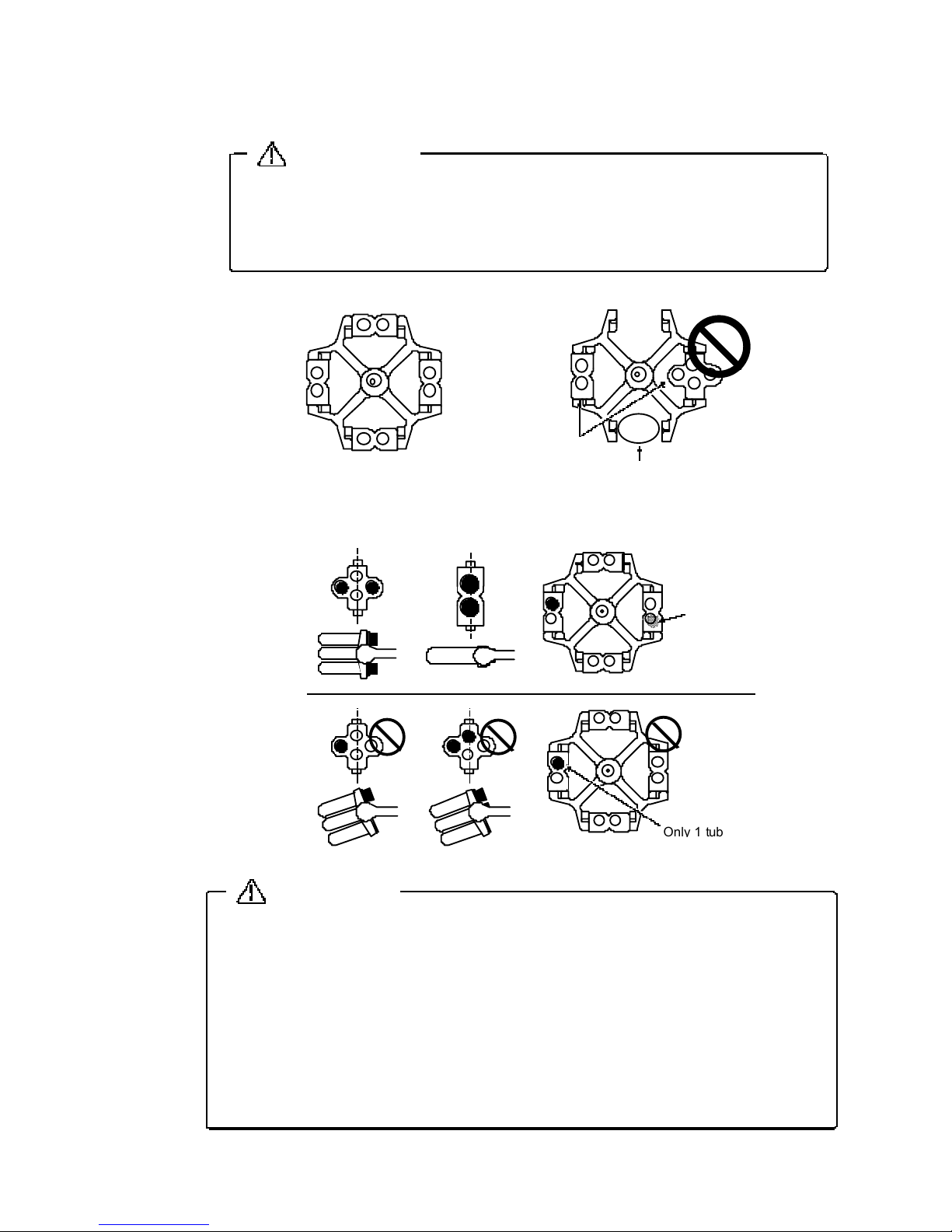

4-5

Roto r yoke

Tr

u

nnion pin

1)If the buckets do not swing up smoothly as the rotor is spun up to

s

p

eed, apply the attached grease to the section A shown in sketch

belo

w. The

buckets should then s

wing up sm

oothly

.

2

)Wip

e off any dirt or congealed material before applying fresh grease,

usin

g

alcohol or acetone.

3

)

If the buckets do not swing up properly after applying the grease,

contact

y

our local dealer for an inspection.

4

)

When the provided grease is used up, purchase replacement grease of

the followin

g

code number from your nearest local dealer.

Be careful to maintain lubrication by ensuring that a proper amount of grease is

p

resent in all bucket grooves (section "A" in th e schemat ic diagram below). A

lack of

g

re ase m ay allow violent vibration to occur, resulting in damage to the

centrifu

g

e.

CAUTION

NOTE

Apply the

attached

g

rease

A

Rotor Grease code No.

RMP-23

RS-1004

S70284

4-5.

Greasing

Sect ion 4 Serv ice

Page 39

4-6

Circuit protector

4-6.

Inspection of Circuit Protector

The circuit protector is automatically activated when the electric circuit failure or

overcurrent occur.

In such a case, the white portion of th e circuit protector, located at the bottom left on the

rear side of the centrifu

g

e, will stick out.

Recover

y p

rocedure is as follows :

(1)

Turn off the power s witch.

(2)

After the rotor s to

p

s completely, open the lid and check the rotor, following

the

p

rocedure given in [3 - 3. Opening and Closing the lid 2. Opening the lid during