Kubota B01 Series, 1KB01PR, 1KB01ST Owner's Manual

1 of 29

INSTALLATION & OWNER

’S MANUAL

Kubota B01

Premium Cab p/n: 1KB01PR

Standard Cab p/n: 1KB01ST

Fits Tractor Models: B2301 and B2601

(*=Not including accessories)

Premium Cab Shown with Optional Front and Rear LED Work Lights

Available Options:

1. Front LED Work Lights (P/N: 9LEDW4)

2. Rear LED Work Lights (P/N: 9LEDW3)

3. Strobe Light (P/N: 9LEDS2)

4. Dome light (P/N 9LEDD14)

5. Heater (P/N: 9PH20S62)

6. Switch Panel (P/N: 9PSF1)

7. Side View Mirrors (P/N: 9PM5)

9. Rear View Mirror (P/N: 9PM3)

8. Rear Wiper (P/N: 9PWK85F)

Note: Front wiper (P/N: 9PWK110) is supplied with premium cab kit only.

Approximate Installation Time *

Experienced Dealer Technician – 3.5 Hours

Average Dealer Technician – 4.5 Hours

Do-It-Yourself – 5.5 Hours

Approximate Product Specifications

Floorboard to Roof Height: 62 inches

Weight: 290 lbs. (Premium), 221 lbs. (Standard)

Cab Width: 41 inches

Rev. D, 07/12/2019

p/n: IM-1KB01PR

The contents of this envelope are the property of the owner. Leave with the owner when installation is complete.

While this cab kit was designed to fit on the vehicle(s) listed above, manufacturing tolerances and vehicle

assembly may affect cab fitment. It is the responsibility of the cab installer to check all vehicle pedals and

levers for full functionality and, as required, adjust the cab fitment to prevent any interference of the cab

components with the travel of pedals or levers.

2 of 29

TABLE OF CONTENTS

WARNINGS, TIPS, & REQUIRED TOOLS ...................................................... 3

CAB INSTALLATION .................................................................................. 4-20

CAB FEATURES & OPERATION ............................................................. 21-22

CARE AND MAINTENANCE ......................................................................... 22

SWITCHED POWER WIRING HARNESS SCHEMATIC ............................... 23

SERVICE PARTS .................................................................................... 24-27

OPTIONAL ACCESSORIES ......................................................................... 28

BOLT TORQUE SPECIFICATIONS .............................................................. 29

3 of 29

Curtis cabs feature an assembly of parts designed for your vehicle which require adjustment

and alignment of components to accommodate vehicle variations and provide proper weather

protection. For accurate installation, proper operation, and years of satisfaction, please read

and understand the installation and owner’s manual fully prior to installing the cab.

From all of us at Curtis, we thank you for choosing our product.

HELPFUL HINTS:

• Refer to parts diagram found in the service parts section of this manual to help

identify parts during the assembly process.

• To assist with the cab installation, leave all fasteners loose for later adjustment

unless otherwise specified.

• Read and understand all instructions before beginning.

• Apply a silicone sealant to seal any minor gaps that may occur due to vehicle

variations.

• Use caution to avoid damaging the factory installed threaded inserts or weld

nuts. Begin the thread engagement by hand to avoid or correct potential cross

threading.

• Make sure the areas where the supplied self-adhesive hook Velcro will be

applied are clean and dry and at room temperature for best adhesion.

• Before installing parts with factory installed rubber, make sure the rubber is fully

installed onto the parts for proper fit and sealing.

• Plastic washers have been supplied to provide a weather seal under the heads

of some exterior bolts. The plastic washer should be installed under each bolt

head directly against the outside cab surface. Care should be taken not to over

tighten the fasteners and damage the plastic washer.

driver and passenger.

Curtis accessory weights are listed in product

add additional weight to the base vehicle. All

Curtis Cabs, blades and general accessories

ADDED

WEIGHT

brochures. Deduct the accessory's total weight

from the vehicle's rated capacity and never

exceed the vehicle's rated capacity including

Exposure to Carbon Monoxide

can Cause illness, serious injury or

death. Never operate vehicle if suspicio us of Carbon Monox-

ide. Inspect exhaust system for le aks monthly. Leaks can

result from loose connections, c orrosion, cracks or other

damage to the exhaust manifold. If leaks are found, repair or

replace exhaust system. Do not us e vehicle until repair or

• Set of Standard and Metric Sockets (3/8” Drive)

• 3/8” Drive Ratchet and Long Drive Extension

• Set of Standard and Metric Open End Wrenches

• Set of Standard and Metric Allen Wrenches

• #2 and #3 Phillips Head Screwdrivers

• Torque Wrench

• Rubber Mallet or Plastic Dead Blow Hammer

• Center Punch

• Awl

• Test light or Volt Meter

• Drill/Driver

• 3/8” and 7/32” Drill Bits

• #2 and #3 Phillips Head Bit

• Utility Knife

• Pair of Scissors

• Shears

• Grease

• C-Clamps

• Silicone Sealant

WARNINGS, TIPS, & REQUIRED TOOLS

TOOLS REQUIRED:

GENERAL INFORMATION BEFORE YOU START

fastener

plastic

washer

cab

surface

CAB INSTALLATION

4 of 29

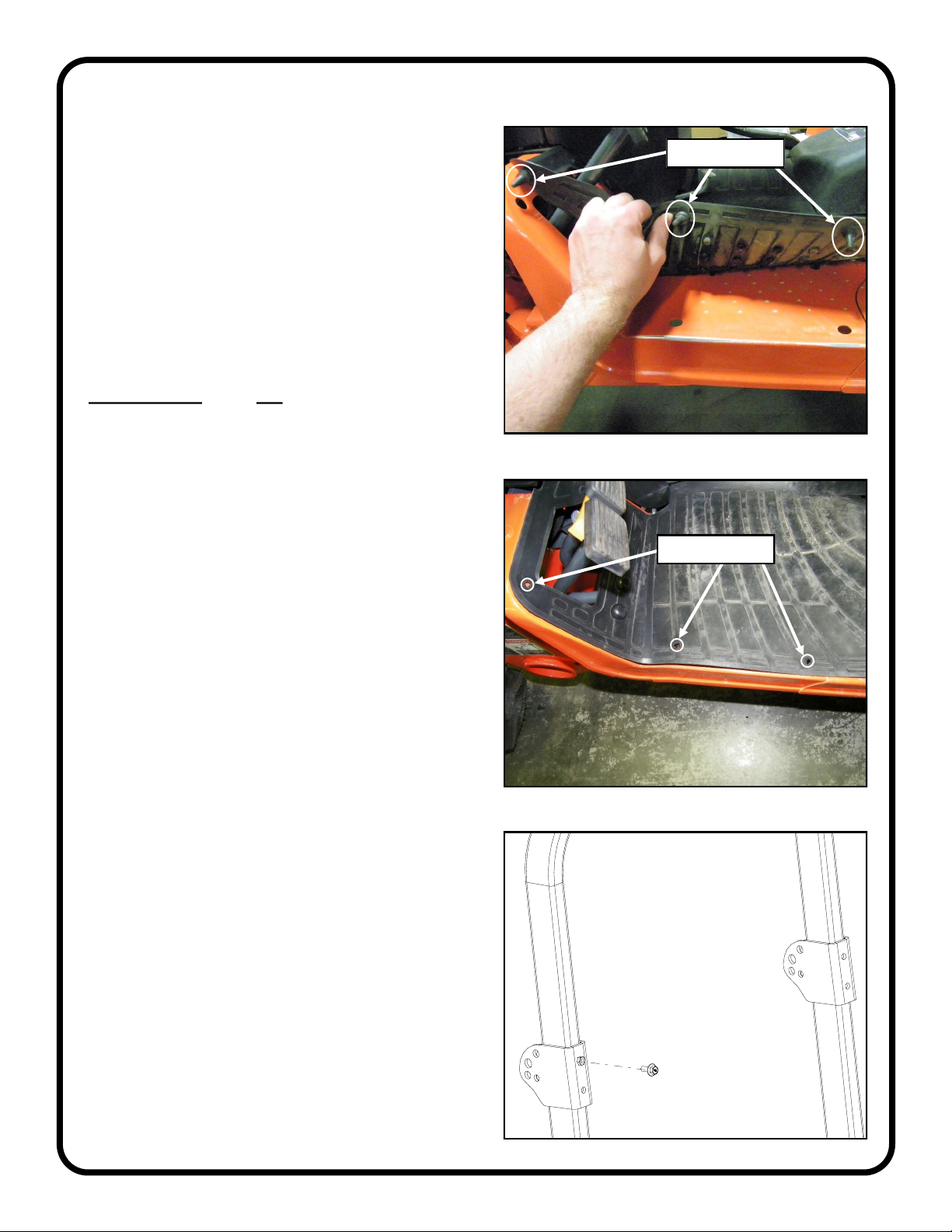

STEP 1: (VEHICLE PREP)

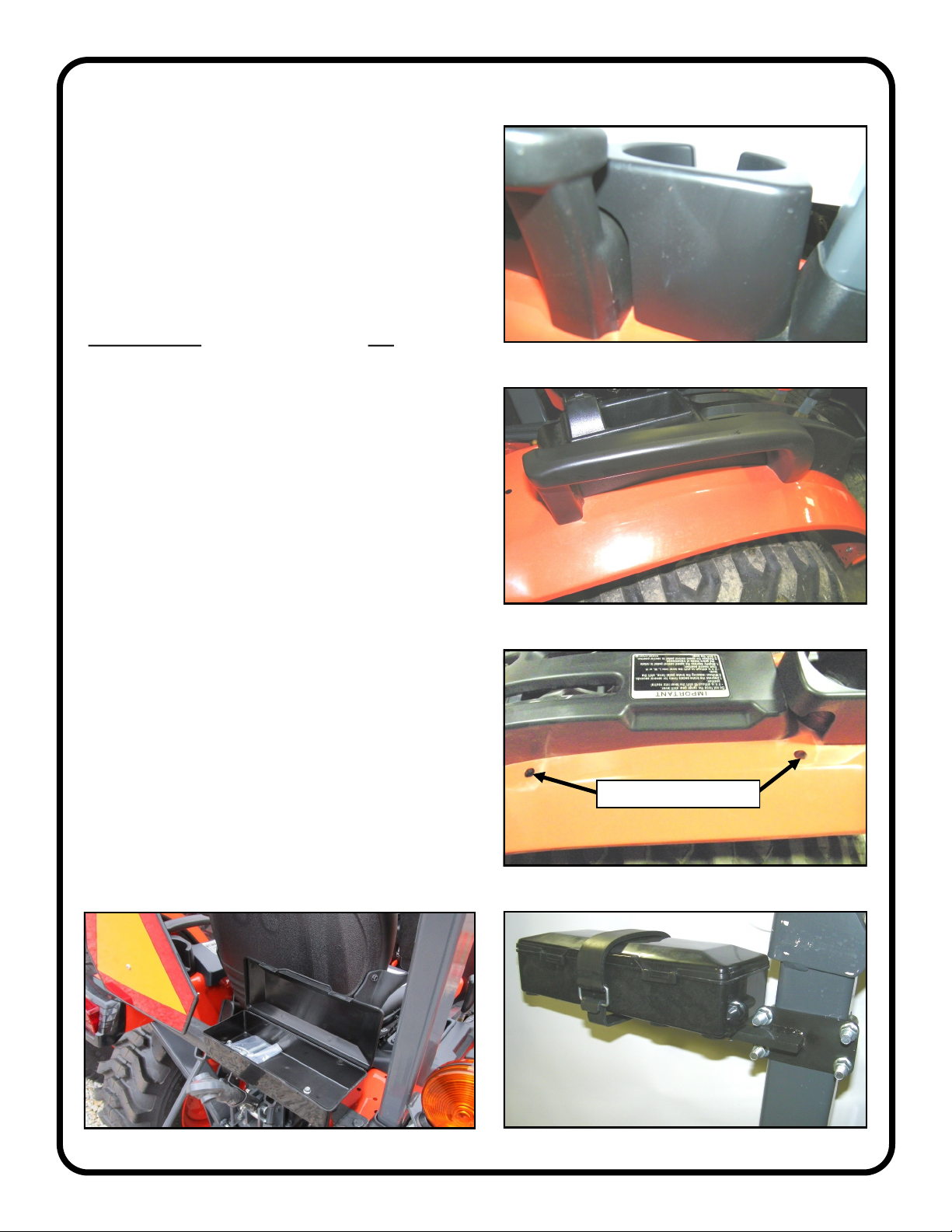

1.1 Per figure 1.1, remove and discard the cup holder

found on the top left fender.

1.2 Per figure 1.2, remove and discard the left and right

fender handles.

1.3 Install the hardware listed below into the exposed

handle mounting holes found on the vehicle’s left and

right fender. See fig 1.3.

Hardware Used Qty

5/16-18 X 3/4 Flange Head Cap Screw 4

5/16 Plastic Washer 4

5/16-18 Flange Nut 4

1.4 For TLB Models Only:

• Per figure 1.4, remove tool box and mount found on

the right side of the ROPS (Rollover Protective

Structure) and discard.

1.5 For non-TLB Models Only:

• Per figure 1.5, remove tool box, SMV (slow moving

vehicle) sign and SMV mounting bracket and

hardware found on the vehicle rear cross brace and

discard.

Fig. 1.1 (cup holder - left fender)

Fig. 1.4 (tool box and mount)

Fig. 1.2 (fender handle - right)

Fig. 1.5 (tool box, SMV sign and mount - rear cross brace)

Fig. 1.3 (left fender)

install hardware here

CAB INSTALLATION

5 of 29

STEP 1: (VEHICLE PREP cont’d.)

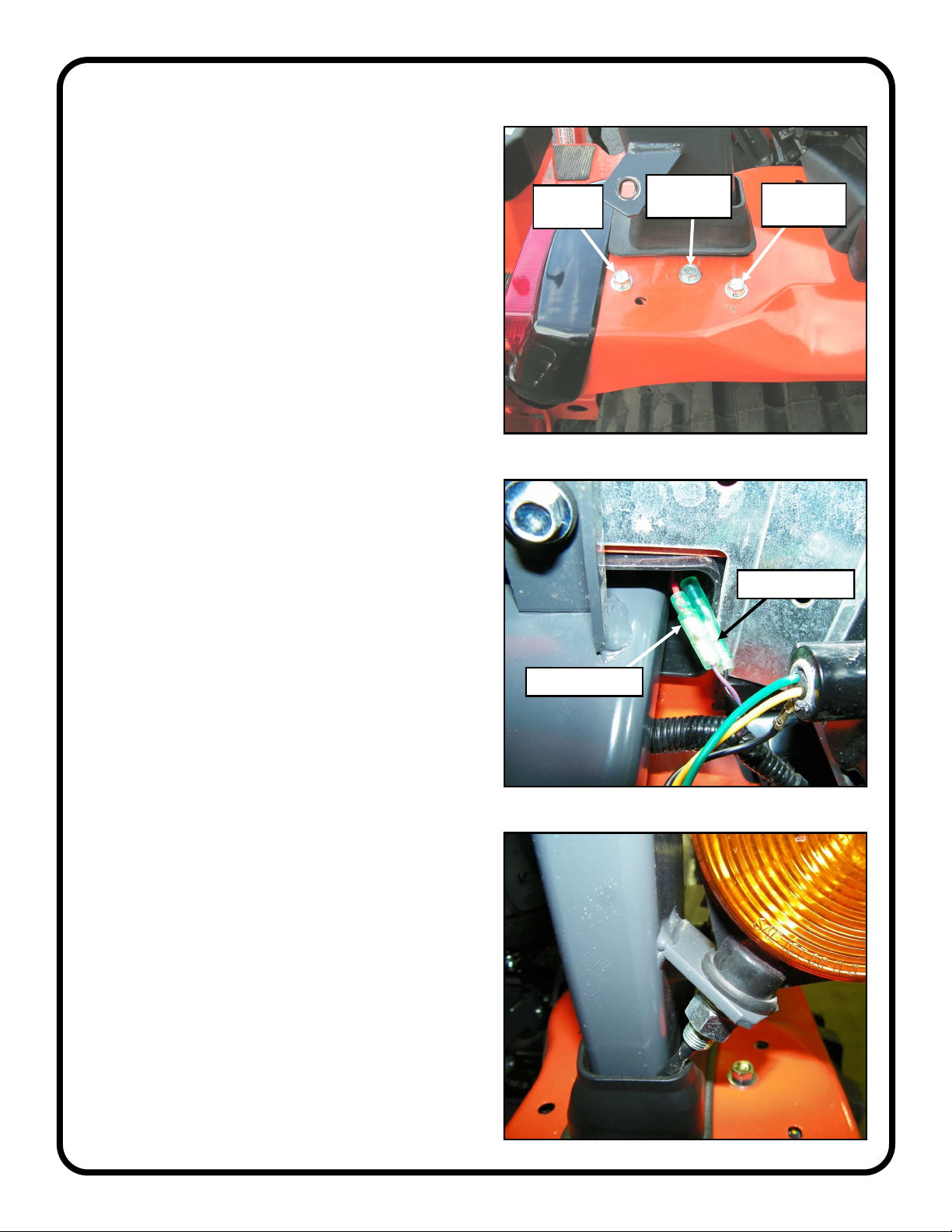

1.6 Per figure 1.6, remove and discard the middle piece

of hardware found on the fenders near the ROPS. If the

vehicle includes the hardware closest to the seat,

remove and discard.

1.7 Per figures 1.7a and 17.b, disconnect all signal light

wires and remove the (2) signal lights from the vehicle

and set aside for reuse.

Fig. 1.7a (signal light wires - under the left fender)

Fig. 1.7b (signal light mount - right)

disconnect wire

disconnect wire

Fig. 1.6 (fender hardware - right)

discard this

hardware

discard this

hardware

leave

installed

CAB INSTALLATION

6 of 29

Fig. 1.10 (right side view of ROPS)

STEP 1: (VEHICLE PREP cont’d.)

1.8 Peel up both the right and left sides of the rubber

mat. Using a utility knife, remove the (3) outer tabs on

both sides of the mat for a total of (6) tabs. See fig 1.8.

Re-install both sides of the mat in place.

1.9 Using an awl, feel for the (6) outer holes of the

rubber mat and punch holes thru the mat. Drill (6) holes

(3/8” diameter) thru the rubber mat. See fig 1.9.

1.10 Remove the ROPS adjustment knob found on the

right side of the ROPS. Replace with metric hardware

provided. See fig. 1.10.

Hardware Used Qty

M10 X 25 FHCS 1

Fig. 1.9 (rubber mat with holes)

Fig. 1.8 (underside of floor mat - left floorboard)

3/8” holes

remove tabs

CAB INSTALLATION

7 of 29

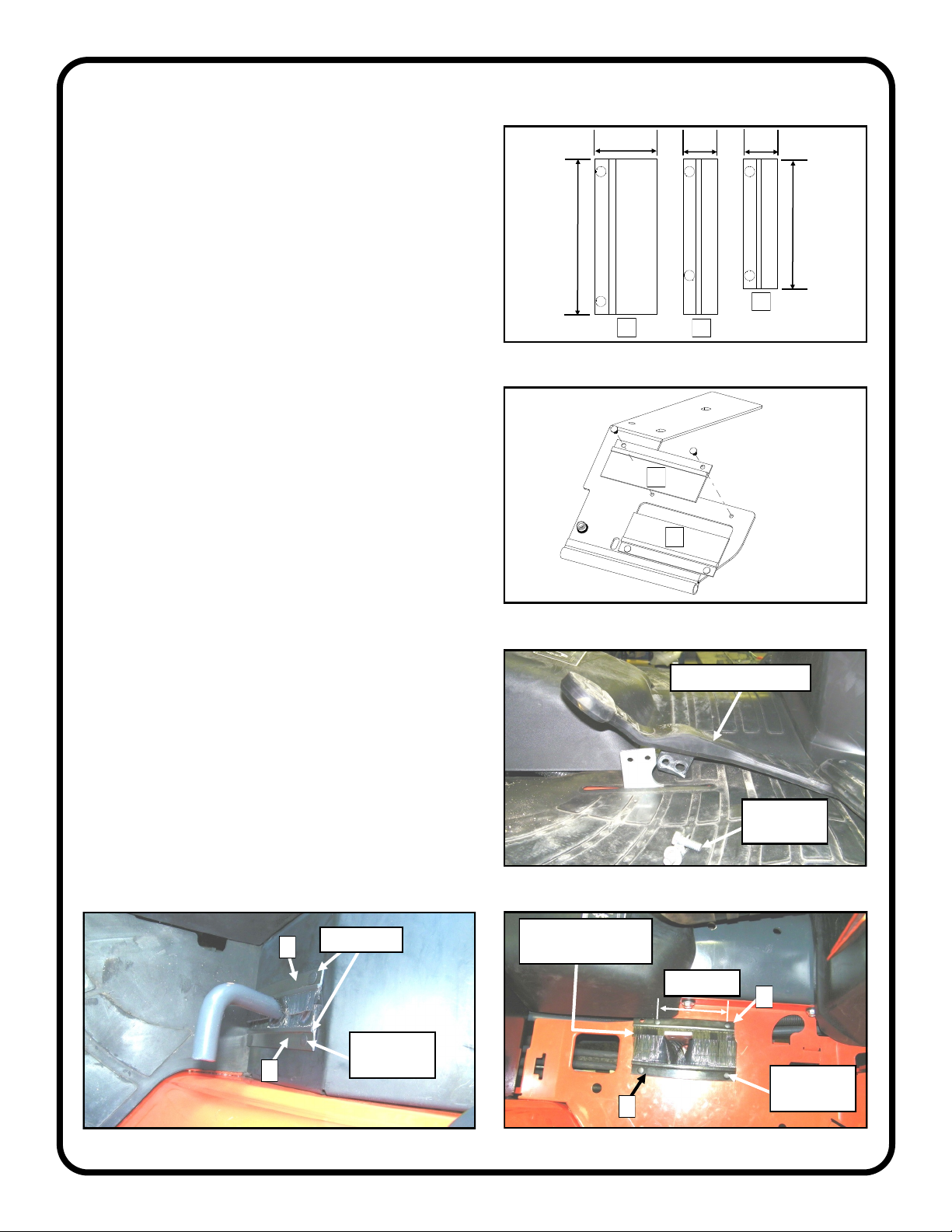

STEP 2: (SEAL KIT)

Seal Kit is included on Premium Cabs only.

Note: the flattest side of the flex brush should face

down for best fit and finish. Bristles to butt up against

each other with NO gaps or overlap unless otherwise

stated. When drilling, do not press down too hard.

Denting or puckering may occur if too aggressive.

2.1 Install (2) 6” long flex brushes (item “A” in fig 2.1a)

to the underside of the left floorboard mount, using (4)

plastic tree clips. See figures 2.1a and 2.1b. Note: the

(2) brushes on the floorboard mount do overlap.

2.2 Remove the hardware from forward/rev pedal, set

aside the pedal and hardware. See fig. 2.2. Peel back

rubber mat.

2.3 Per figures 2.1a and 2.3, install flex brushes as

shown on the right floorboard (one “A” brush and one

“B” brush). Using the hole pattern in the flex brush as a

guide, drill two holes per side (7/32” diameter) thru the

sheet metal floorboard. Note: It is recommended that a

spare piece of metal is placed behind where you are

drilling to ensure no damage is done to the vehicle.

2.4 Per figures 2.1a and 2.4, install flex brushes as

shown around the differential lock lever found on the

left fender (two “C” brushes). Using the hole pattern in

the flex brush as a guide, drill two holes per side (7/32”

diameter) thru the sheet metal fender.

2.5 Re-install the right side of the rubber mat in place

and remount the forward/rev pedal.

Fig. 2.1b (underside of left floorboard mount)

Fig. 2.2 (forward/rev pedal - right floorboard)

Fig. 2.3 (flex brush installation - forward/rev pedal)

Fig. 2.4 (flex brush installation - differential lock pedal)

drill 2 holes

per brush

5” brushes

drill 2 holes

per brush

4” spacing

bristles to butt up

against each other

A

Fig. 2.1a (3 flex brush sizes included in seal kit)

A

A

A

B

C

C

mounting

hardware

forward/rev pedal

B

C

6”

5”

2.4”

1.3” 1.3”

CAB INSTALLATION

8 of 29

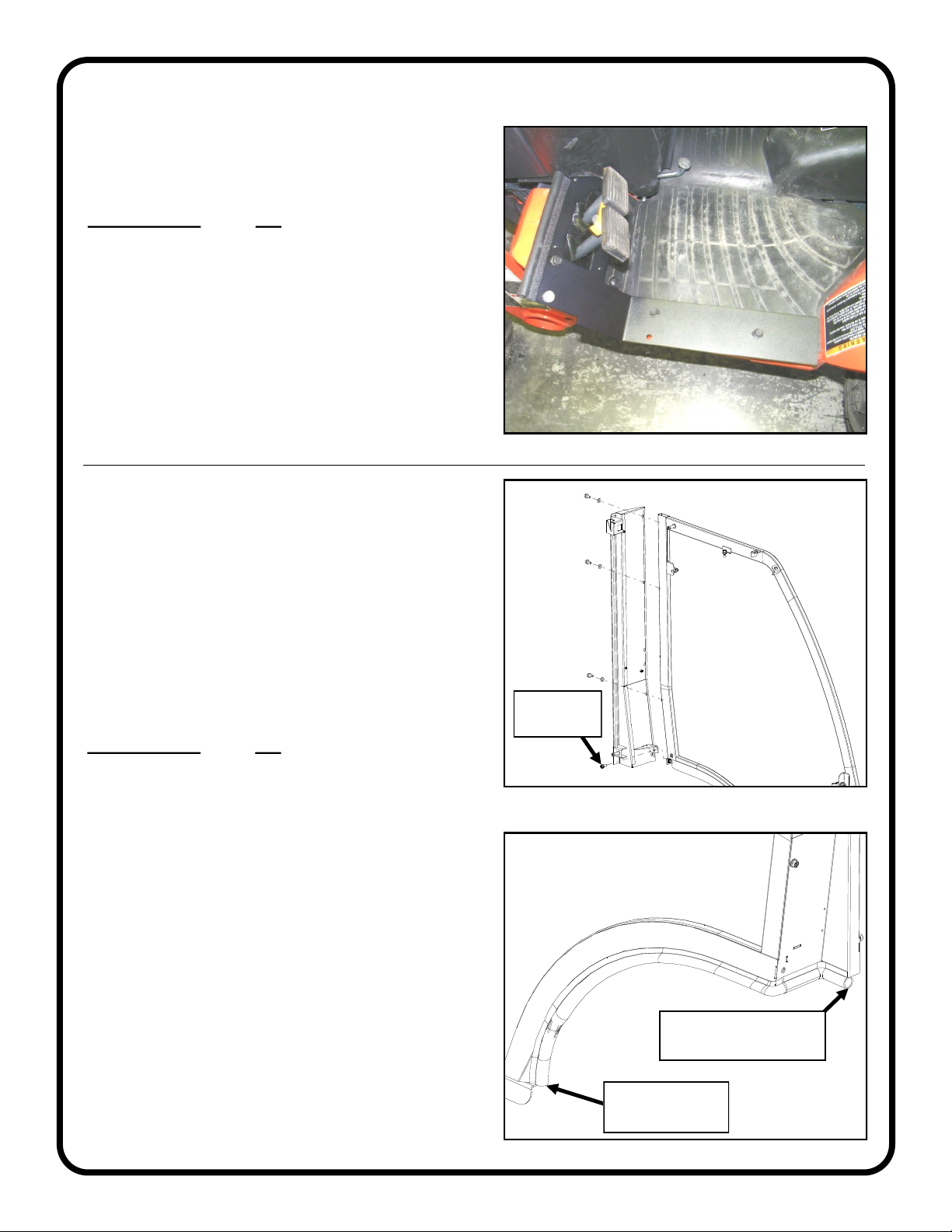

STEP 3: (FLOOROARD MOUNTS)

3.1 Using the hardware listed below, install the left and

right floorboard mounts per fig. 3.1.

Hardware Used Qty

5/16-18 X 1 FHCS 6

5/16-18 Flange Nut 6

Fig. 3.1 (left floorboard mount installation)

Fig. 4.2 (rear leg to sideframe - left)

Fig. 4.3 (1” round bulb rubber installed - left)

STEP 4: (SIDEFRAMES/REAR LEGS)

For Premium Cab only.

If installing a standard cab, proceed to step 5 on the

next page.

4.1 For ease of handling, temporarily remove the doors

from the sideframes. Make sure to also remove the (4)

hinge washers and set aside for reuse.

4.2 Using hardware listed below, bolt the left rear leg to

the left sideframe and then right rear leg to the right

sideframe. See fig. 4.2.

Hardware Used Qty

5/16-18 X 3/4 FHCS 8

5/16 Plastic Washer 6

4.3 Starting at the floorboard of the left sideframe,

install the 1” round rubber provided onto the sideframe,

continue up the sheetmetal edge of the sideframe and

then onto the rear leg. Cut the rubber flush with the

inside rear flange of the rear leg. See fig. 4.3.

Note: Use a rubber mallet or plastic dead blow hammer

as needed to secure the rubber onto the sideframe and

rear leg.

start 1” round bulb

rubber here

cut rubber flush with

inside edge of rear leg

no washer

required

CAB INSTALLATION

9 of 29

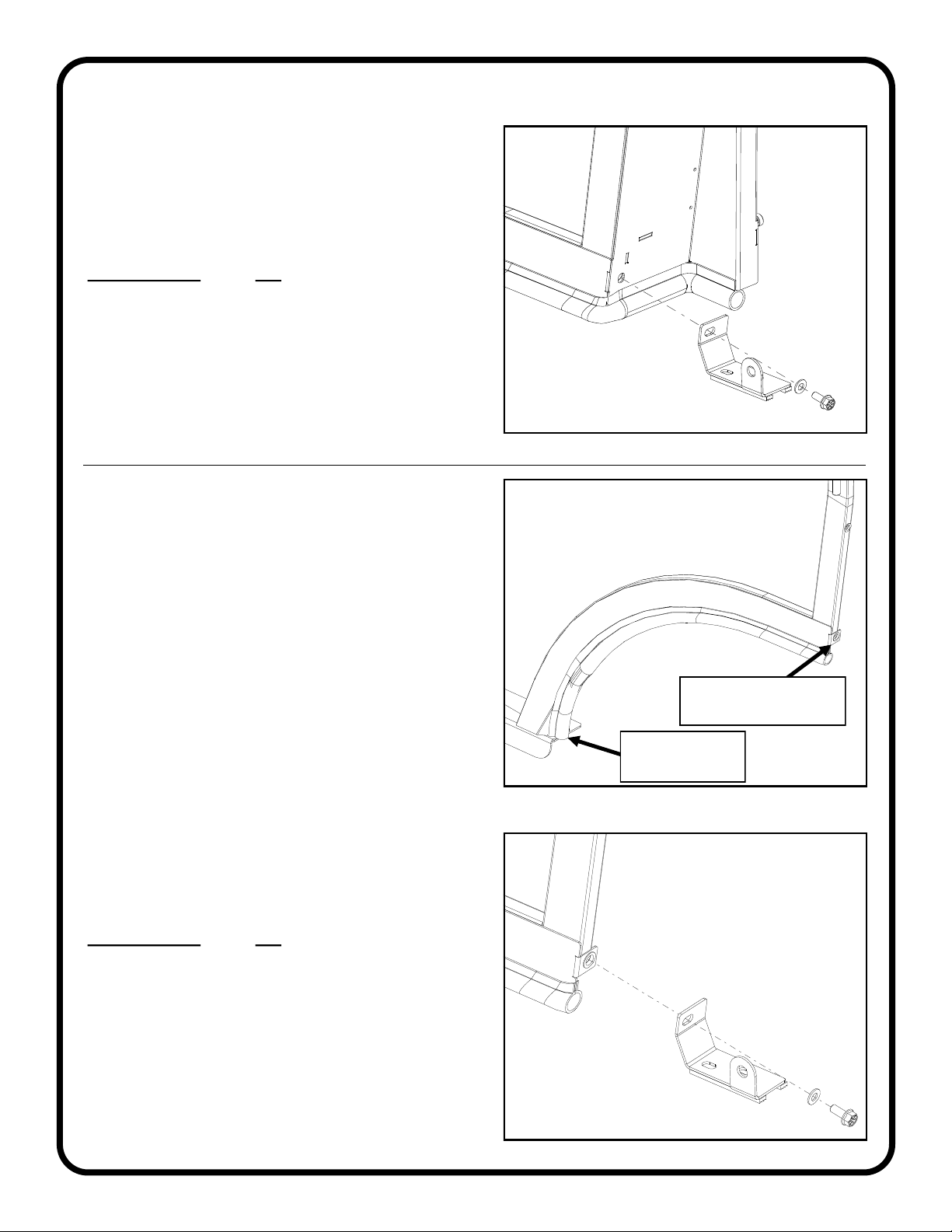

STEP 4: (SIDEFRAMES/REAR LEGS

cont’d.)

4.4 Using hardware listed below, bolt the left fender

bracket to the left sideframe/rear leg. Making sure to

fully tighten hardware down. See fig. 4.4. Repeat the

process for the right fender bracket.

Hardware Used Qty

5/16-18 X 3/4 FHCS 2

5/16 Plastic Washer 2

Fig. 4.4 (fender bracket installation - left)

Fig. 5.3 (fender bracket onto sideframe tab - left)

STEP 5: SIDEFRAMES

For Standard Cab only.

If installing a premium cab, proceed to step 6 on the

next page.

5.1 For ease of handling, temporarily remove the doors

from the sideframes. Make sure to also remove the (4)

hinge washers and set aside for reuse.

5.2 Starting at the floorboard of the left sideframe,

install the 1” round rubber provided onto the sideframe,

continue up the sheetmetal edge of the sideframe. Cut

the rubber flush with the inside rear flange of the fender

contour. See fig. 5.2.

Note: Use a rubber mallet or plastic dead blow hammer

as needed to secure the rubber onto the sideframe and

rear leg.

5.3 Using hardware listed below, bolt the left fender

bracket to the left sideframe tab. Making sure to fully

tighten hardware down. See fig. 5.3. Repeat the

process for the right fender bracket.

Hardware Used Qty

5/16-18 X 3/4 FHCS 2

5/16 Plastic Washer 2

Fig. 5.2 (1” round bulb rubber installed - left)

start 1” round bulb

rubber here

cut rubber flush with

back edge of sideframe

Loading...

Loading...