KTM 390 Duke 2013 Owner's Manual

REPAIR MANUAL 2013

390 Duke 2014 COL

390 Duke EU

390 Duke AUS

390 Duke MAL

Art. no. 3206167en

INTRODUCTION 1

INTRODUCTION

It is important that you read this repair manual carefully and completely before the start of work.

This vehicle can only fulfill the demands placed on it in the long run if the specified service work is performed regularly by qualified

experts.

The repair manual was written to correspond to the most current state of this model series. We reserve the right to make changes in

the interest of technical advancement without, at the same time, updating this repair manual.

We shall not provide a description of general workshop methods. Likewise, safety rules that apply in a workshop are not specified here.

It is assumed that repair work will be performed by a fully trained mechanic.

All specifications are non-binding. KTM Sportmotorcycle AG specifically reserves the right to modify or delete technical specifications, prices, colors, forms, materials, services, designs, equipment, etc., without prior notice and without specifying reasons, to adapt

these to local conditions, as well as to stop production of a particular model without prior notice. KTM accepts no liability for delivery

options, deviations from illustrations and descriptions, as well as misprints and other errors. The models portrayed partly contain special equipment that does not belong to the regular scope of supply.

© 2013 KTM-Sportmotorcycle AG, Mattighofen Austria

All rights reserved

Reproduction, even in part, as well as copying of all kinds, is permitted only with the express written permission of the copyright

owner.

ISO 9001(12 100 6061)

According to the international quality management standard ISO 9001, KTM uses quality assurance processes that lead

to the maximum possible quality of the products.

Issued by: TÜV Management Service

KTM-Sportmotorcycle AG

5230 Mattighofen, Austria

TABLE OF CONTENTS 2

TABLEOF CONTENTS

1 MEANS OF REPRESENTATION ..................................... 5

1.1 Symbols used ................................................... 5

1.2 Formats used.................................................... 5

2 SAFETY ADVICE........................................................... 6

2.1 Repair Manual .................................................. 6

2.2 Safety advice .................................................... 6

2.3 Degrees of risk and symbols............................... 6

2.4 Work rules ........................................................ 6

3 IMPORTANT INFORMATION ......................................... 7

3.1 Guarantee, warranty .......................................... 7

3.2 Operating and auxiliary substances ..................... 7

3.3 Spare parts, accessories .................................... 7

3.4 Figures ............................................................ 7

4 SERIAL NUMBERS ...................................................... 8

4.1 Chassis number/type label ................................. 8

4.2 Key number...................................................... 8

4.3 Engine number ................................................. 8

5 MOTORCYCLE ............................................................. 9

5.1 Raising the motorcycle with the rear wheel

stand ............................................................... 9

5.2 Taking the motorcycle off of the rear wheel

stand ............................................................... 9

5.3 Raising the motorcycle with the front wheel

stand ............................................................... 9

5.4 Taking the motorcycle off of the front wheel

stand ............................................................. 10

5.5 Raising the motorcycle with the work stand ....... 10

5.6 Removing the motorcycle from the work stand ... 11

5.7 Starting.......................................................... 12

5.8 Starting the motorcycle to make checks ............ 13

6 FORK, TRIPLE CLAMP ............................................... 14

6.1 Cleaning the dust boots of the fork legs............. 14

6.2 Removing fork legs.......................................... 14

6.3 Installing the fork legs ..................................... 15

6.4 Disassembling the fork legs.............................. 16

6.5 Checking the fork legs ..................................... 18

6.6 Assembling the fork legs.................................. 19

6.7 Removing the lower triple clamp....................... 21

6.8 Installing the lower triple clamp ....................... 23

6.9 Checking the steering head bearing play............ 26

6.10 Adjusting the steering head bearing play ........... 26

7 HANDLEBAR, CONTROLS........................................... 28

7.1 Checking the play in the throttle cable.............. 28

7.2 Adjusting the play in the throttle cable.............. 28

7.3 Checking the clutch lever play.......................... 28

7.4 Adjusting the clutch cable play ........................ 29

8 SHOCK ABSORBER, SWINGARM ................................ 30

8.1 Adjusting the spring preload of the shock

absorber......................................................... 30

8.2 Removing the shock absorber ........................... 30

8.3 Installing the shock absorber............................ 30

8.4 Removing the spring........................................ 31

8.5 Installing the spring ........................................ 31

9 EXHAUST.................................................................. 33

9.1 Removing the exhaust manifold........................ 33

9.2 Installing the exhaust manifold ........................ 34

9.3 Removing the main silencer ............................. 35

9.4 Installing the main silencer.............................. 36

10 AIR FILTER ............................................................... 37

10.1 Removing the air filter ..................................... 37

10.2 Installing the air filter...................................... 37

11 FUEL TANK, SEAT, TRIM ........................................... 38

11.1 Opening the filler cap...................................... 38

11.2 Closing the filler cap ....................................... 38

11.3 Removing the seat .......................................... 38

11.4 Mounting the seat........................................... 39

11.5 Removing the passenger seat ........................... 39

11.6 Mounting the passenger seat............................ 39

11.7 Removing the fuel tank cover ........................... 39

11.8 Installing the fuel tank cover............................ 42

11.9 Removing the fuel tank.................................... 44

11.10 Installing the fuel tank .................................... 45

11.11 Removing the front spoiler ............................... 47

11.12 Fitting front spoiler ......................................... 47

11.13 Dismounting the front fender ........................... 48

11.14 Installing the front fender ................................ 48

11.15 Checking the fuel pressure............................... 48

11.16 Changing the fuel filter.................................... 49

11.17 Replacing the fuel pump ................................. 51

12 WHEELS ................................................................... 52

12.1 Checking the tire air pressure........................... 52

12.2 Checking the tire condition .............................. 52

12.3 Checking the brake discs ................................. 53

12.4 Front wheel .................................................... 53

12.4.1 Removing the front wheel ............................ 53

12.4.2 Installing the front wheel ............................. 53

12.4.3 Removing the brake disc of the front brake.... 54

12.4.4 Installing the brake disc of the front brake .... 54

12.5 Rear wheel ..................................................... 55

12.5.1 Removing the rear wheel ............................. 55

12.5.2 Installing the rear wheel .............................. 55

12.5.3 Removing the brake disc of the rear brake ..... 56

12.5.4 Installing the brake disc of the rear brake...... 56

12.5.5 Checking the chain tension.......................... 57

12.5.6 Adjusting the chain tension ......................... 57

12.5.7 Checking the chain, rear sprocket, and

engine sprocket .......................................... 58

12.5.8 Cleaning the chain...................................... 59

12.5.9 Checking the rear hub rubber dampers.......... 60

13 WIRING HARNESS, BATTERY..................................... 61

13.1 Removing the battery ...................................... 61

13.2 Installing the battery ....................................... 61

13.3 Disconnecting the negative cable of the

battery ........................................................... 62

13.4 Reconnecting the negative cable of the

battery ........................................................... 62

13.5 Recharging the battery .................................... 62

13.6 Checking the charging voltage .......................... 63

13.7 Changing the fuses of individual power

consumers...................................................... 64

14 BRAKE SYSTEM ........................................................ 65

14.1 Checking the front brake linings ....................... 65

14.2 Changing the front brake linings....................... 65

14.3 Checking the brake fluid level of the front

brake ............................................................. 67

14.4 Adding front brake fluid................................... 67

14.5 Changing the front brake fluid.......................... 68

14.6 Checking the rear brake linings ........................ 69

14.7 Changing the rear brake linings ........................ 70

14.8 Checking the free travel of foot brake lever ........ 71

14.9 Adjusting the free travel of the foot brake

lever .............................................................. 72

14.10 Checking the rear brake fluid level.................... 72

TABLE OF CONTENTS 3

14.11 Adding rear brake fluid .................................... 73

14.12 Changing the rear brake fluid ........................... 73

15 LIGHTING SYSTEM, INSTRUMENTS ........................... 75

15.1 Setting kilometers or miles............................... 75

15.2 Adjusting the shift speed RPM 1 ...................... 75

15.3 Adjusting the shift speed RPM 2 ...................... 75

15.4 Setting the time.............................................. 76

15.5 Resetting the service interval display ................ 76

15.6 Checking the headlight setting ......................... 76

15.7 Adjusting the headlight range........................... 77

15.8 Changing the parking light bulb........................ 78

15.9 Changing the headlight bulb ............................ 79

16 ENGINE .................................................................... 81

16.1 Removing the engine....................................... 81

16.2 Installing the engine........................................ 85

16.3 Disassembling the engine ................................ 90

16.3.1 Preparations............................................... 90

16.3.2 Draining the engine oil ................................ 90

16.3.3 Removing the chain securing guide .............. 90

16.3.4 Removing the valve cover............................. 91

16.3.5 Removing the spark plug ............................. 91

16.3.6 Removing the clutch cover........................... 91

16.3.7 Setting the engine to ignition top dead

center........................................................ 92

16.3.8 Removing the timing chain tensioner............ 93

16.3.9 Removing the camshaft............................... 93

16.3.10 Removing the cylinder head ......................... 94

16.3.11 Removing the piston ................................... 95

16.3.12 Removing the starter motor.......................... 95

16.3.13 Removing the timing chain .......................... 95

16.3.14 Removing the water pump wheel .................. 96

16.3.15 Removing the alternator cover ...................... 96

16.3.16 Removing the rotor...................................... 97

16.3.17 Removing the starter drive ........................... 97

16.3.18 Removing the balancer shaft drive wheel....... 98

16.3.19 Removing the gear position sensor................ 98

16.3.20 Removing the suction pump......................... 99

16.3.21 Removing the spacer................................. 100

16.3.22 Removing the clutch cage.......................... 100

16.3.23 Removing the primary gear ........................ 101

16.3.24 Removing the force pump.......................... 102

16.3.25 Removing the shift shaft............................ 103

16.3.26 Removing the shift drum locating............... 103

16.3.27 Removing the locking lever ........................ 103

16.3.28 Removing the oil filter ............................... 103

16.3.29 Removing the left engine case.................... 104

16.3.30 Removing the shift rails............................. 105

16.3.31 Removing the shift drum ........................... 105

16.3.32 Removing the shift forks............................ 106

16.3.33 Removing the transmission shafts............... 106

16.3.34 Removing the balancer shaft...................... 106

16.3.35 Removing the crankshaft ........................... 106

16.4 Work on individual parts ................................ 107

16.4.1 Work on the left section of the engine

case ........................................................ 107

16.4.2 Work on the right section of the engine

case ........................................................ 108

16.4.3 Changing the shaft seal ring of the water

pump ...................................................... 108

16.4.4 Checking the radial play of the lower

conrod bearing ......................................... 109

16.4.5 Changing the conrod bearing...................... 110

16.4.6 Changing the balancer shaft bearing........... 111

16.4.7 Work on the cylinder head ......................... 112

16.4.8 Checking the cylinder head........................ 113

16.4.9 Checking the pivot point of the

camshafts ................................................ 113

16.4.10 Checking/measuring the cylinder................ 114

16.4.11 Checking the piston ring end gap ............... 114

16.4.12 Checking/measuring the piston................... 115

16.4.13 Checking the piston/cylinder mounting

clearance ................................................. 115

16.4.14 Checking the oil pump .............................. 115

16.4.15 Checking the oil pressure regulator valve..... 116

16.4.16 Checking the clutch .................................. 117

16.4.17 Checking the shift mechanism ................... 118

16.4.18 Preassembling the shift shaft ..................... 119

16.4.19 Disassembling the main shaft .................... 119

16.4.20 Dismantling the countershaft ..................... 120

16.4.21 Checking the transmission......................... 120

16.4.22 Assembling the main shaft......................... 121

16.4.23 Assembling the countershaft...................... 122

16.4.24 Checking the timing assembly.................... 124

16.4.25 Changing the stator................................... 124

16.4.26 Checking the electric starter drive .............. 125

16.4.27 Checking the freewheel ............................. 126

16.5 Assembling the engine .................................. 126

16.5.1 Installing the crankshaft............................ 126

16.5.2 Installing the balancer shaft....................... 126

16.5.3 Installing the transmission shafts ............... 127

16.5.4 Installing the shift forks............................. 127

16.5.5 Installing the shift drum ............................ 127

16.5.6 Installing the shift rails ............................. 127

16.5.7 Installing the left engine case .................... 128

16.5.8 Installing the oil filter................................ 129

16.5.9 Installing the locking lever ......................... 129

16.5.10 Installing the shift drum locating................ 130

16.5.11 Installing the shift shaft ............................ 130

16.5.12 Installing the oil pump .............................. 130

16.5.13 Installing the primary gear ......................... 131

16.5.14 Installing the clutch cage .......................... 132

16.5.15 Installing the spacer.................................. 133

16.5.16 Installing the suction pump ....................... 134

16.5.17 Installing the gear position sensor .............. 135

16.5.18 Installing the balancer shaft drive wheel ..... 135

16.5.19 Installing the starter drive.......................... 136

16.5.20 Installing the rotor .................................... 137

16.5.21 Installing the alternator cover..................... 137

16.5.22 Installing the water pump cover.................. 137

16.5.23 Installing the timing chain ......................... 138

16.5.24 Installing the starter motor......................... 138

16.5.25 Installing the piston .................................. 138

16.5.26 Installing the cylinder head........................ 140

16.5.27 Installing the camshafts ............................ 141

16.5.28 Installing the timing chain tensioner........... 141

16.5.29 Checking the valve clearance ..................... 142

16.5.30 Adjusting the valve clearance ..................... 143

16.5.31 Installing the clutch cover ......................... 143

16.5.32 Installing the spark plug ............................ 144

16.5.33 Installing the valve cover ........................... 144

16.5.34 Installing the chain securing guide ............. 145

16.5.35 Installing the oil screen ............................. 145

16.5.36 Removing the engine from the engine

assembly stand......................................... 146

TABLE OF CONTENTS 4

17 SHIFT MECHANISM ................................................. 147

17.1 Adjusting the shift lever................................. 147

18 WATER PUMP, COOLING SYSTEM ............................ 148

18.1 Draining the coolant...................................... 148

18.2 Filling/bleeding the cooling system ................. 148

18.3 Checking the antifreeze and coolant level ........ 149

18.4 Checking the coolant level ............................. 150

19 LUBRICATION SYSTEM............................................ 152

19.1 Oil circuit..................................................... 152

19.2 Checking the engine oil level.......................... 152

19.3 Checking the engine oil pressure .................... 152

19.4 Changing the engine oil and oil filter,

cleaning the oil screen................................... 154

19.5 Adding engine oil.......................................... 155

20 IGNITION SYSTEM................................................... 156

20.1 Alternator - checking the stator winding .......... 156

21 TECHNICAL DATA.................................................... 157

21.1 Engine ......................................................... 157

21.2 Engine tolerance, wear limits ......................... 157

21.3 Engine tightening torques .............................. 158

21.4 Capacities .................................................... 159

21.4.1 Engine oil ................................................ 159

21.4.2 Coolant.................................................... 159

21.4.3 Fuel ........................................................ 159

21.5 Chassis ........................................................ 159

21.6 Electrical system........................................... 160

21.7 Tires............................................................ 160

21.8 Fork............................................................. 160

21.9 Shock absorber ............................................. 160

21.10 Chassis tightening torques ............................. 161

22 CLEANING/PROTECTIVE TREATMENT....................... 163

22.1 Cleaning the motorcycle ................................ 163

22.2 Checks and maintenance steps for winter

operation...................................................... 164

23 STORAGE................................................................ 165

23.1 Storage ........................................................ 165

23.2 Preparing for use after storage........................ 165

24 SERVICE SCHEDULE ............................................... 166

24.1 Service schedule........................................... 166

25 WIRING DIAGRAM ................................................... 168

25.1 Page 1 of 9 .................................................. 168

25.2 Page 2 of 9 .................................................. 170

25.3 Page 3 of 9 .................................................. 172

25.4 Page 4 of 9 .................................................. 174

25.5 Page 5 of 9 .................................................. 176

25.6 Page 6 of 9 .................................................. 178

25.7 Page 7 of 9 .................................................. 180

25.8 Page 8 of 9 .................................................. 182

25.9 Page 9 of 9 .................................................. 184

26 SUBSTANCES ......................................................... 186

27 AUXILIARY SUBSTANCES ........................................ 187

28 SPECIAL TOOLS ...................................................... 189

29 STANDARDS ........................................................... 198

INDEX ............................................................................ 199

1 MEANS OF REPRESENTATION 5

1.1 Symbols used

The meaning of specific symbols is described below.

Indicates an expected reaction (e.g. of a work step or a function).

Indicates an unexpected reaction (e.g. of a work step or a function).

Indicates a page reference (more information is provided on the specified page).

Indicates information with more details or tips.

Indicates the result of a testing step.

Denotes a voltage measurement.

Denotes a current measurement.

Denotes a resistance measurement.

1.2 Formats used

The typographical formats used in this document are explained below.

Proprietary name Identifies a proprietary name.

®

Name

Brand™ Identifies a trademark.

Identifies a protected name.

2 SAFETY ADVICE 6

2.1 Repair Manual

Read this Repair Manual carefully and thoroughly before beginning work. It contains useful information and tips that will help you

repair and maintain your vehicle.

This manual assumes that the necessary special KTM tools and KTM workplace and workshop equipment are available.

2.2 Safety advice

A number of safety instructions need to be followed to operate the vehicle safely. Therefore, read this manual carefully. The safety

instructions are highlighted in the text and are referred to at the relevant passages.

Info

The vehicle has various information and warning labels at prominent locations. Do not remove information/warning labels. If

they are missing, you or others may not recognize dangers and may therefore be injured.

2.3 Degrees of risk and symbols

Danger

Identifies a danger that will immediately and invariably lead to fatal or serious permanent injury if the appropriate measures

are not taken.

Warning

Identifies a danger that is likely to lead to fatal or serious injury if the appropriate measures are not taken.

Caution

Identifies a danger that may lead to minor injuries if the appropriate measures are not taken.

Note

Identifies a danger that will lead to considerable machine and material damage if the appropriate measures are not taken.

Warning

Identifies a danger that will lead to environmental damage if the appropriate measures are not taken.

2.4 Work rules

Special tools are necessary for certain tasks. The tools are not contained in the vehicle but can be ordered under the number in parentheses. E.g.: bearing puller (15112017000)

During assembly, non-reusable parts (e.g. self-locking screws and nuts, seals and seal rings, O-rings, pins, lock washers) must be

replaced by new parts.

In some instances, a thread locker (e.g. Loctite®) is required. The manufacturer instructions for use must be followed.

After disassembly, clean the parts that are to be reused and check them for damage and wear. Change damaged or worn parts.

After you complete the repair or service work, check the operating safety of the vehicle.

3 IMPORTANT INFORMATION 7

3.1 Guarantee, warranty

The work prescribed in the service schedule must be carried out by an authorized KTM workshop only and confirmed in the customer's

Service & Warranty Booklet and in the KTM dealer.net; otherwise, all warranty claims will be void. No warranty claims can be considered for damage resulting from manipulations and/or alterations to the vehicle.

Additional information on the guarantee or warranty and the procedures involved can be found in the Service & Warranty Booklet.

3.2 Operating and auxiliary substances

Warning

Environmental hazard Improper handling of fuel is a danger to the environment.

– Do not allow fuel to get into the ground water, the ground, or the sewage system.

Use the operating and auxiliary substances (such as fuel and lubricants) as specified in the manual.

3.3 Spare parts, accessories

Only use spare parts and accessories approved and/or recommended by KTM. KTM accepts no liability for other products and any

resulting damage or loss.

The current KTM PowerParts for your vehicle can be found on the KTM website.

International KTM Website: http://www.ktm.com

3.4 Figures

The figures contained in the manual may depict special equipment.

In the interest of clarity, some components may be shown disassembled or may not be shown at all. It is not always necessary to disassemble the component to perform the activity in question. Please follow the instructions in the text.

4 SERIAL NUMBERS 8

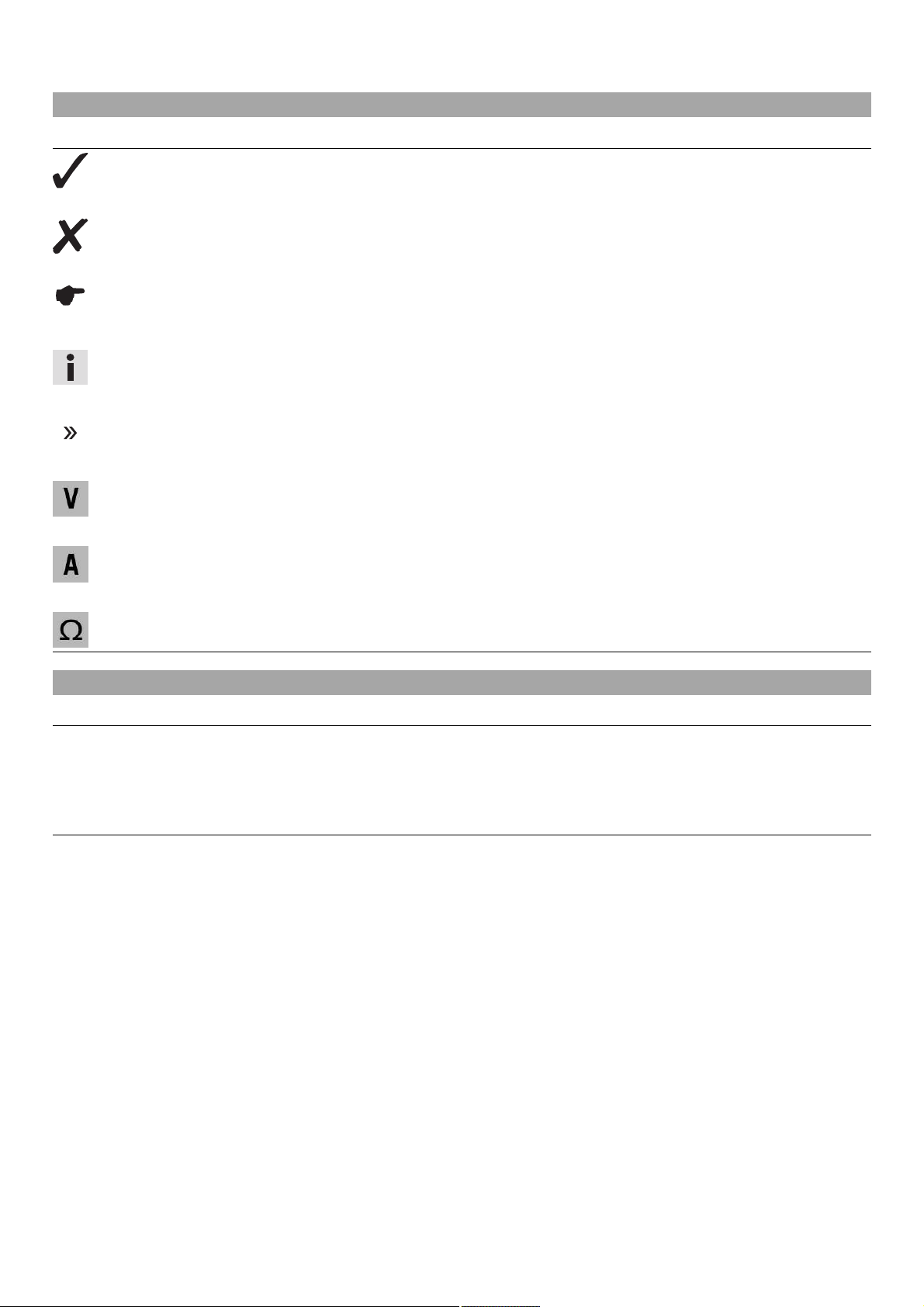

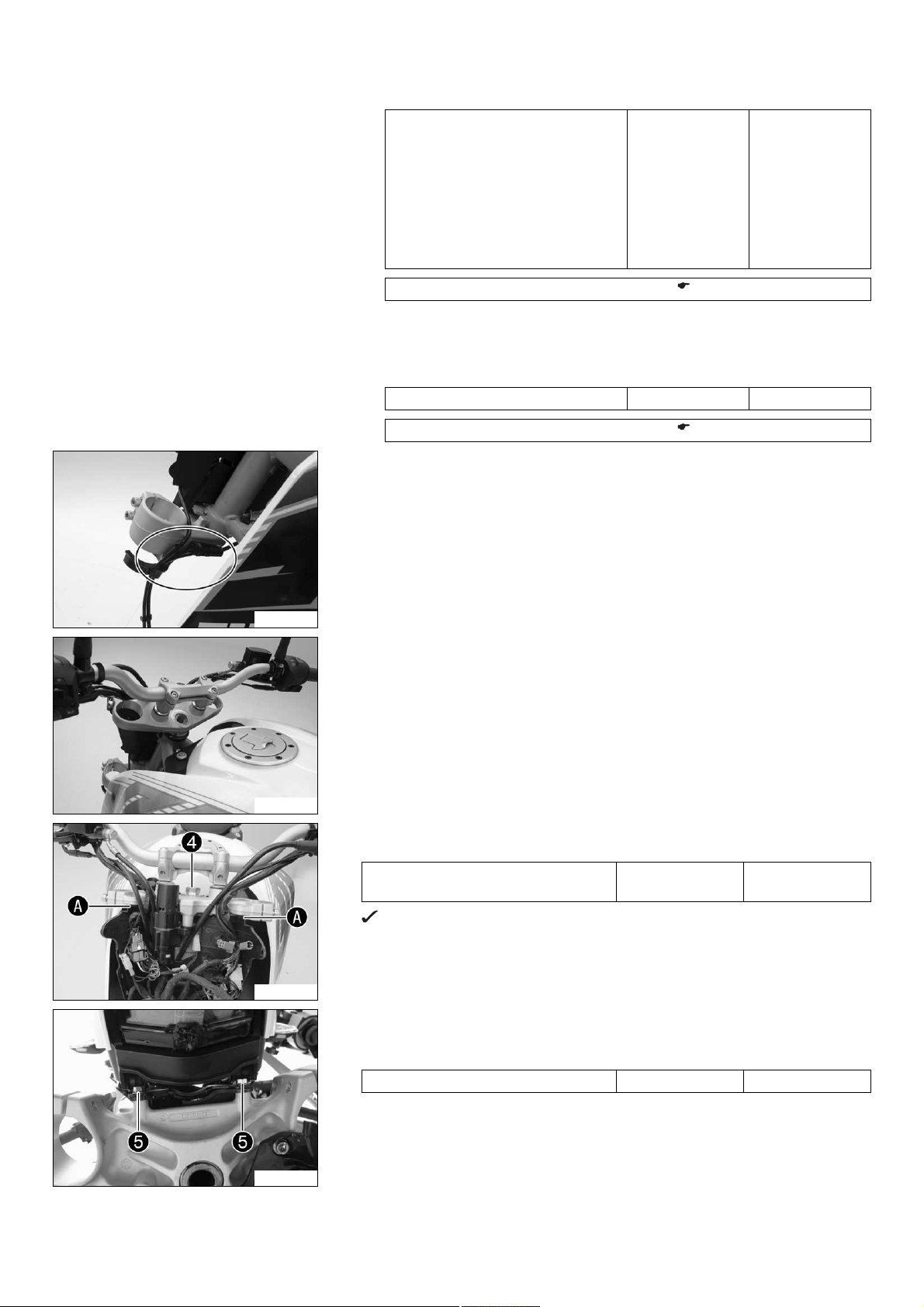

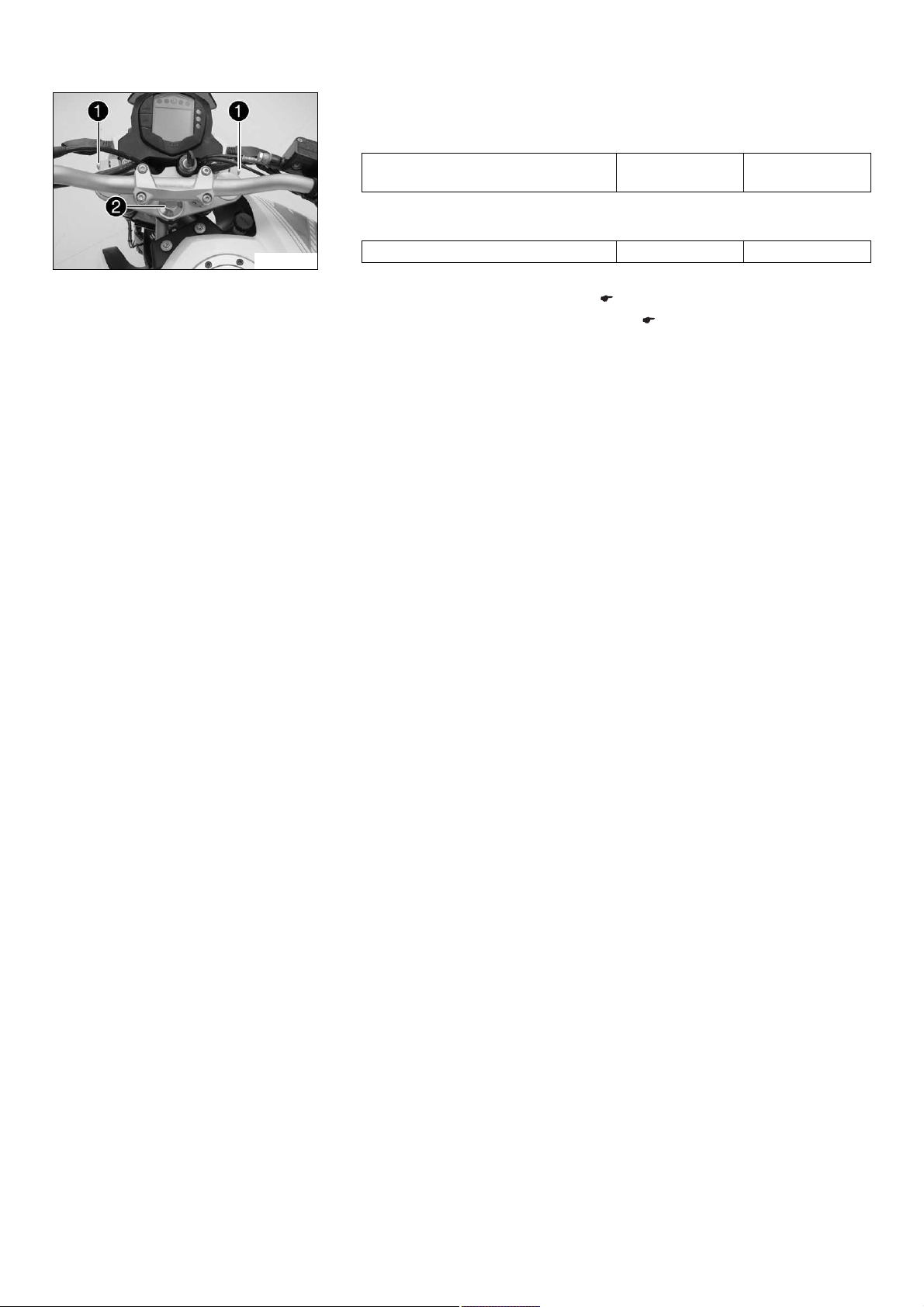

4.1 Chassis number/type label

The chassis number 1 is stamped on the right of the steering head.

The type label 2 is on the right of the frame behind the steering head.

101877-10

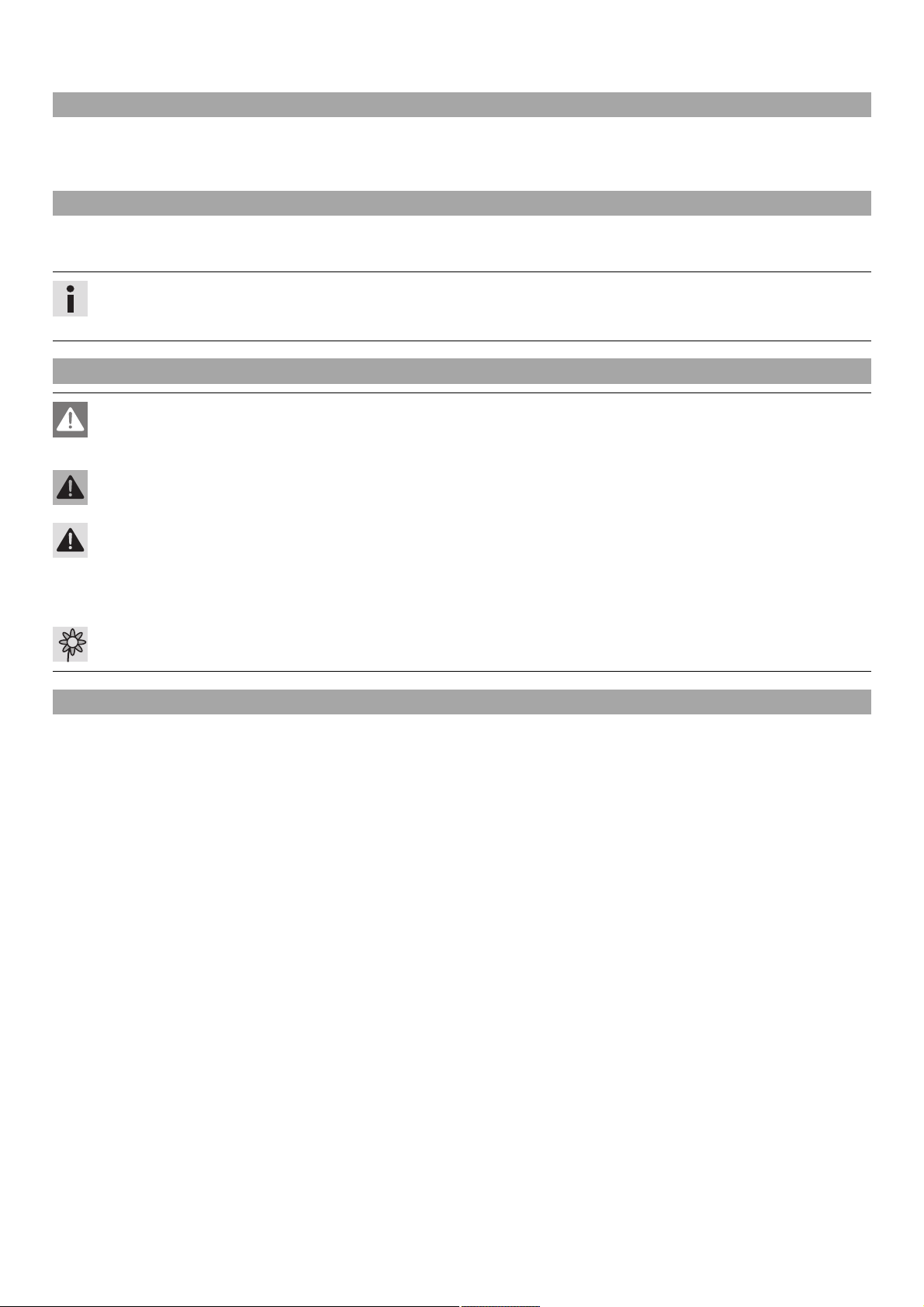

4.2 Key number

The key number 1 can be found on the KEYCODECARD.

Info

You need the key number to order a spare key. Keep the KEYCODECARD in a safe

place.

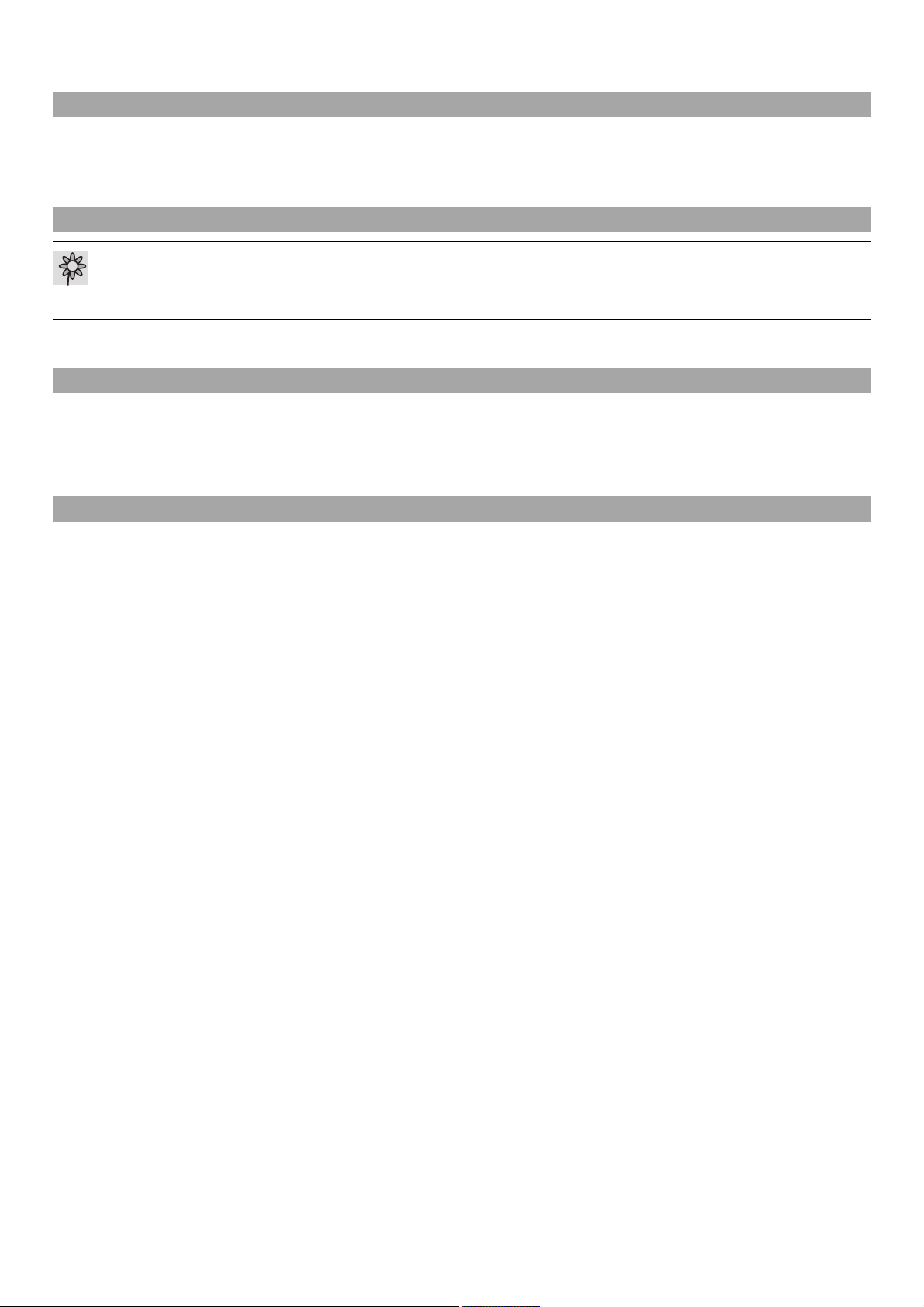

4.3 Engine number

B00755-10

The engine number 1 is stamped on the left side of the engine under the engine

sprocket.

101876-10

5 MOTORCYCLE 9

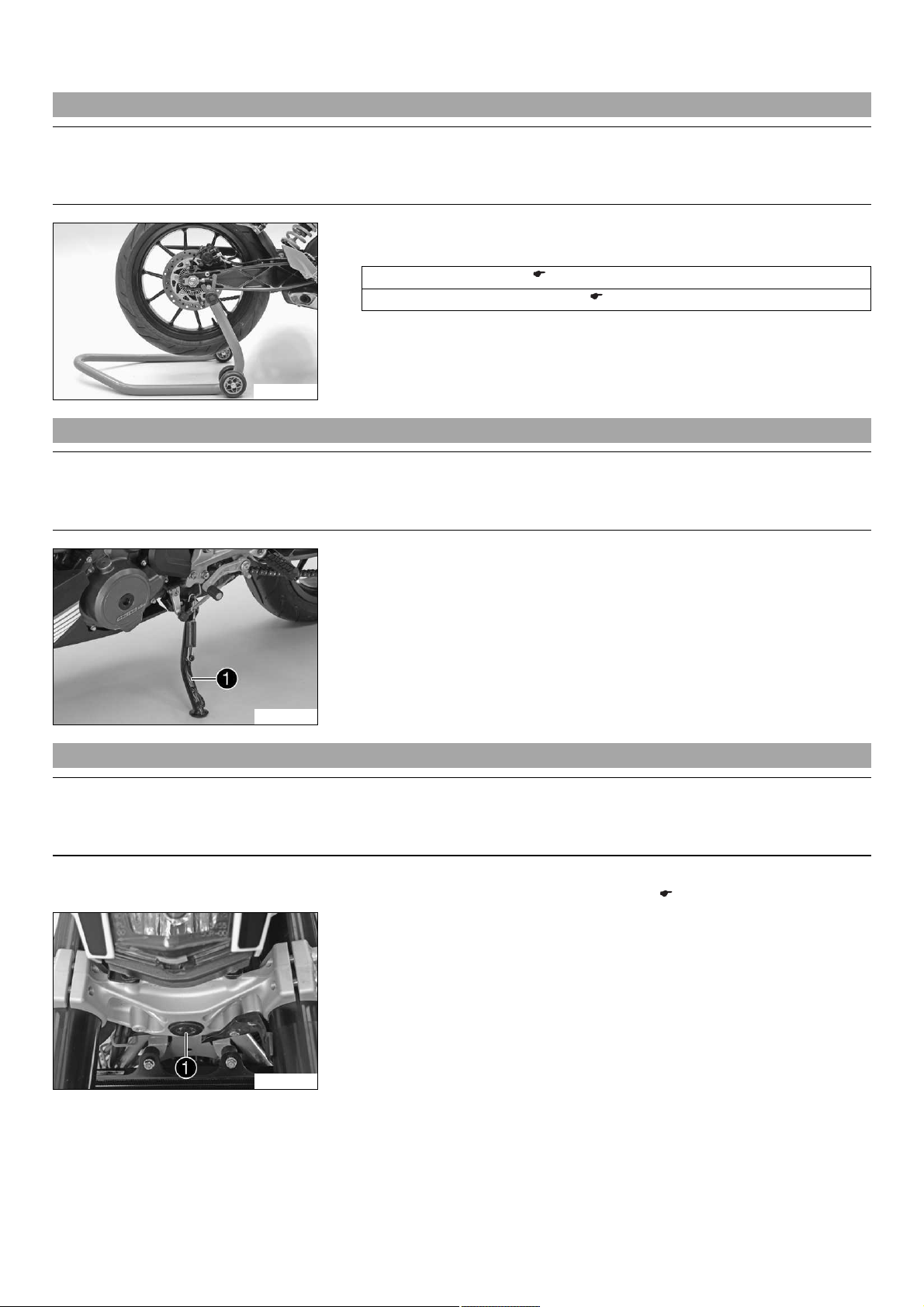

5.1 Raising the motorcycle with the rear wheel stand

Note

Danger of damage The parked vehicle may roll away or fall over.

– Always place the vehicle on a firm and even surface.

– Mount the support of the wheel stand.

– Insert the adapter in the rear wheel stand.

Adapter (61029055130) ( p. 190)

Rear wheel stand (61029055400) ( p. 191)

– Stand the motorcycle upright, align the lifting gear with the swingarm and the

adapters, and lift the motorcycle.

B01387-01

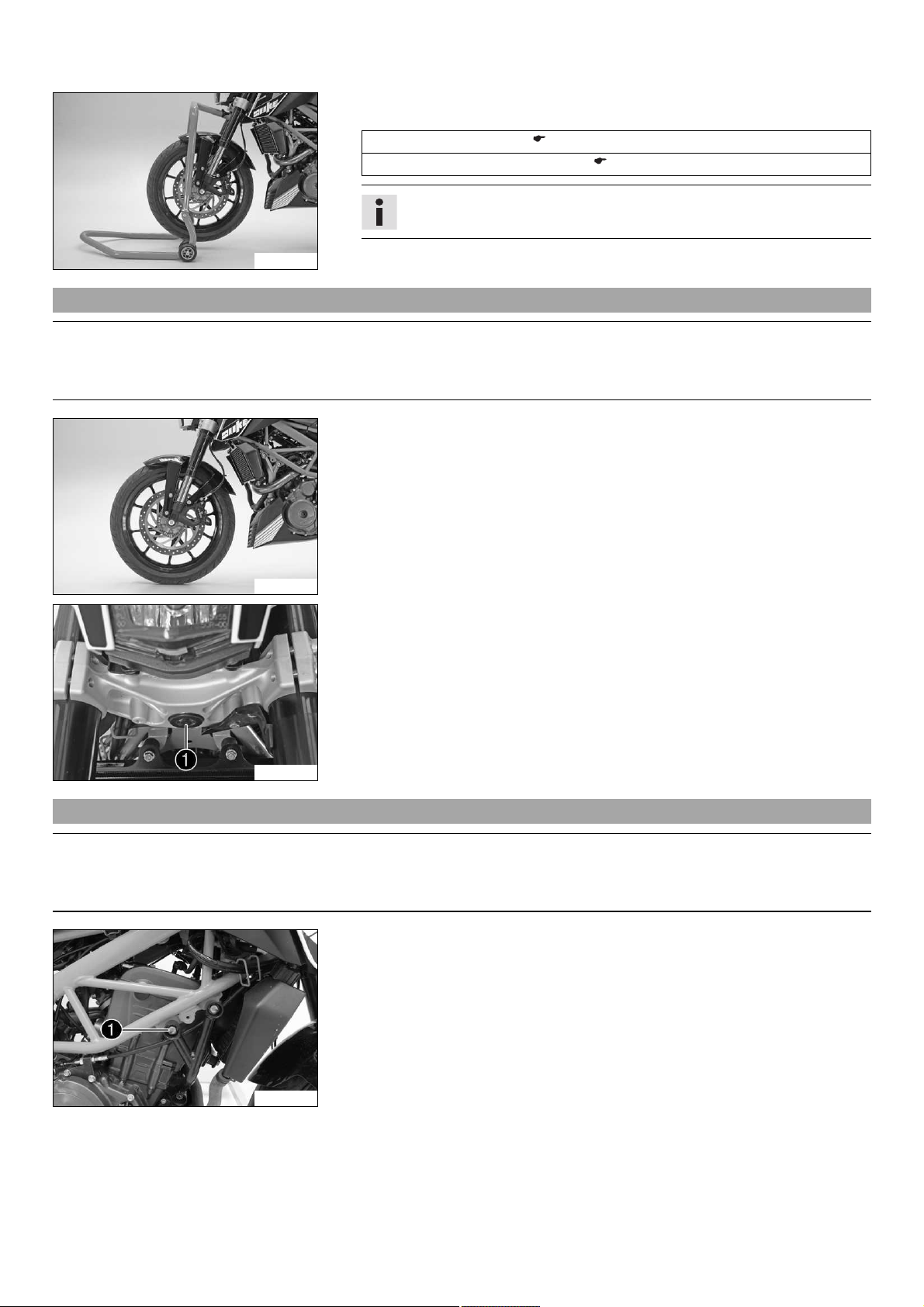

5.2 Taking the motorcycle off of the rear wheel stand

Note

Danger of damage The parked vehicle may roll away or fall over.

– Always place the vehicle on a firm and even surface.

– Secure the motorcycle against falling over.

– Remove the rear wheel stand and lean the vehicle on the side stand 1.

– Remove the support of the wheel stand.

101884-10

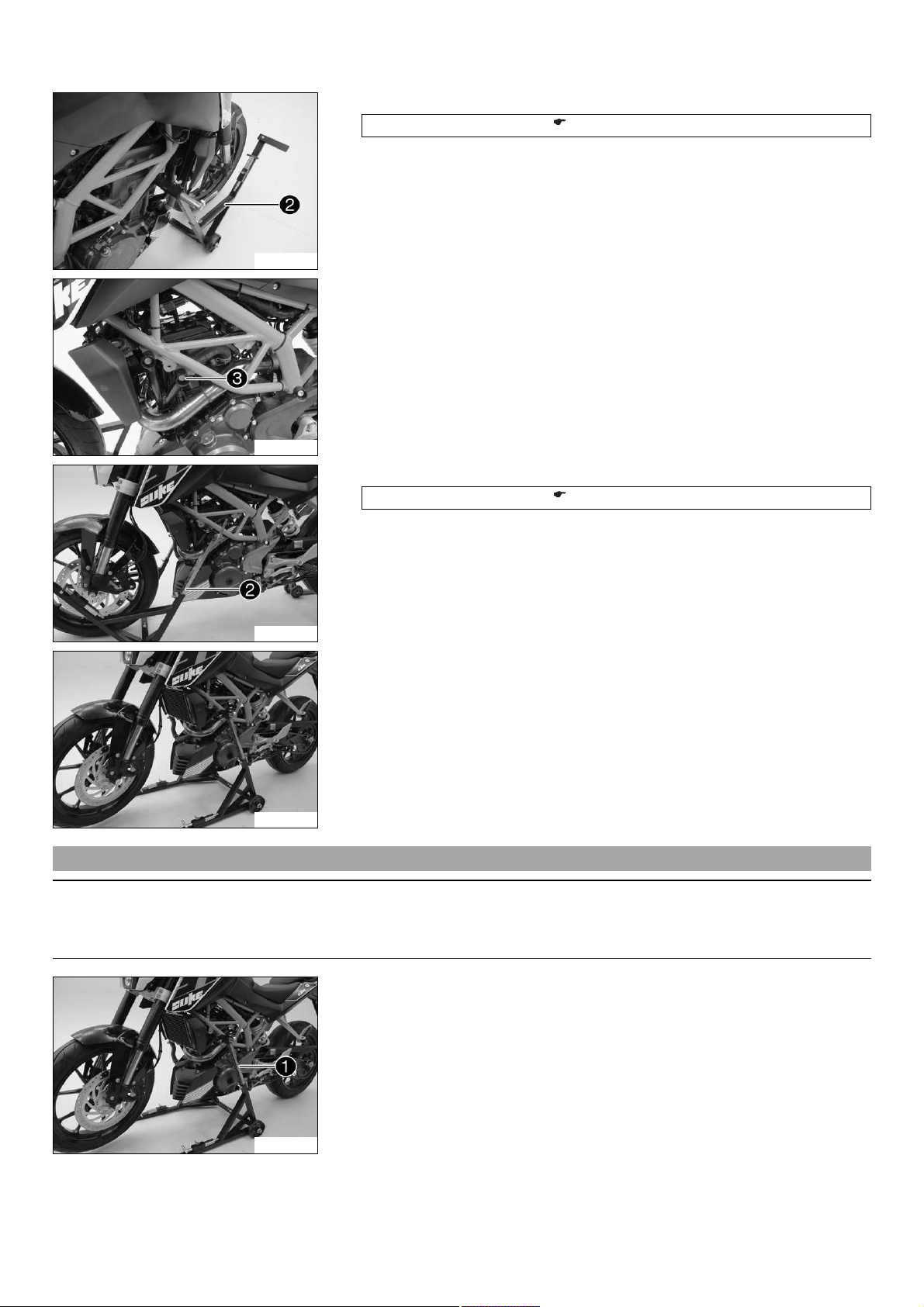

5.3 Raising the motorcycle with the front wheel stand

Note

Danger of damage The parked vehicle may roll away or fall over.

– Always place the vehicle on a firm and even surface.

Preparatory work

– Raise the motorcycle with the rear wheel stand. ( p. 9)

Condition

– Remove cap 1.

101887-10

5 MOTORCYCLE 10

– Move the handlebar to the straight-ahead position. Attach the lifting gear to the

steering stem.

Adapter (61029955620) ( p. 191)

Front wheel stand (61029055500) ( p. 191)

Info

Always raise the rear of the motorcycle first.

101888-01

– Raise the front of the motorcycle.

5.4 Taking the motorcycle off of the front wheel stand

Note

Danger of damage The parked vehicle may roll away or fall over.

– Always place the vehicle on a firm and even surface.

– Secure the motorcycle against falling over.

– Remove the front wheel stand.

101889-01

– Mount cap 1.

101887-10

5.5 Raising the motorcycle with the work stand

Note

Danger of damage The parked vehicle may roll away or fall over.

– Always place the vehicle on a firm and even surface.

– Remove screw 1.

308227-10

5 MOTORCYCLE 11

– Mount special tool 2 on the right side of the vehicle.

Work stand (62529055000) ( p. 192)

308228-10

– Remove screw 3.

308229-10

– Mount special tool 2 on the left side of the vehicle.

Work stand (62529055000) ( p. 192)

308230-10

– Position the motorcycle upright, align the special tool and raise the motorcycle.

308231-10

5.6 Removing the motorcycle from the work stand

Note

Danger of damage The parked vehicle may roll away or fall over.

– Always place the vehicle on a firm and even surface.

– Secure the motorcycle against falling over.

– Remove special tool 1.

308231-11

5 MOTORCYCLE 12

– Mount and tighten screws 23.

Guideline

Screw, engine bearer on frame M8 30 Nm

(22.1 lbf ft)

308232-10

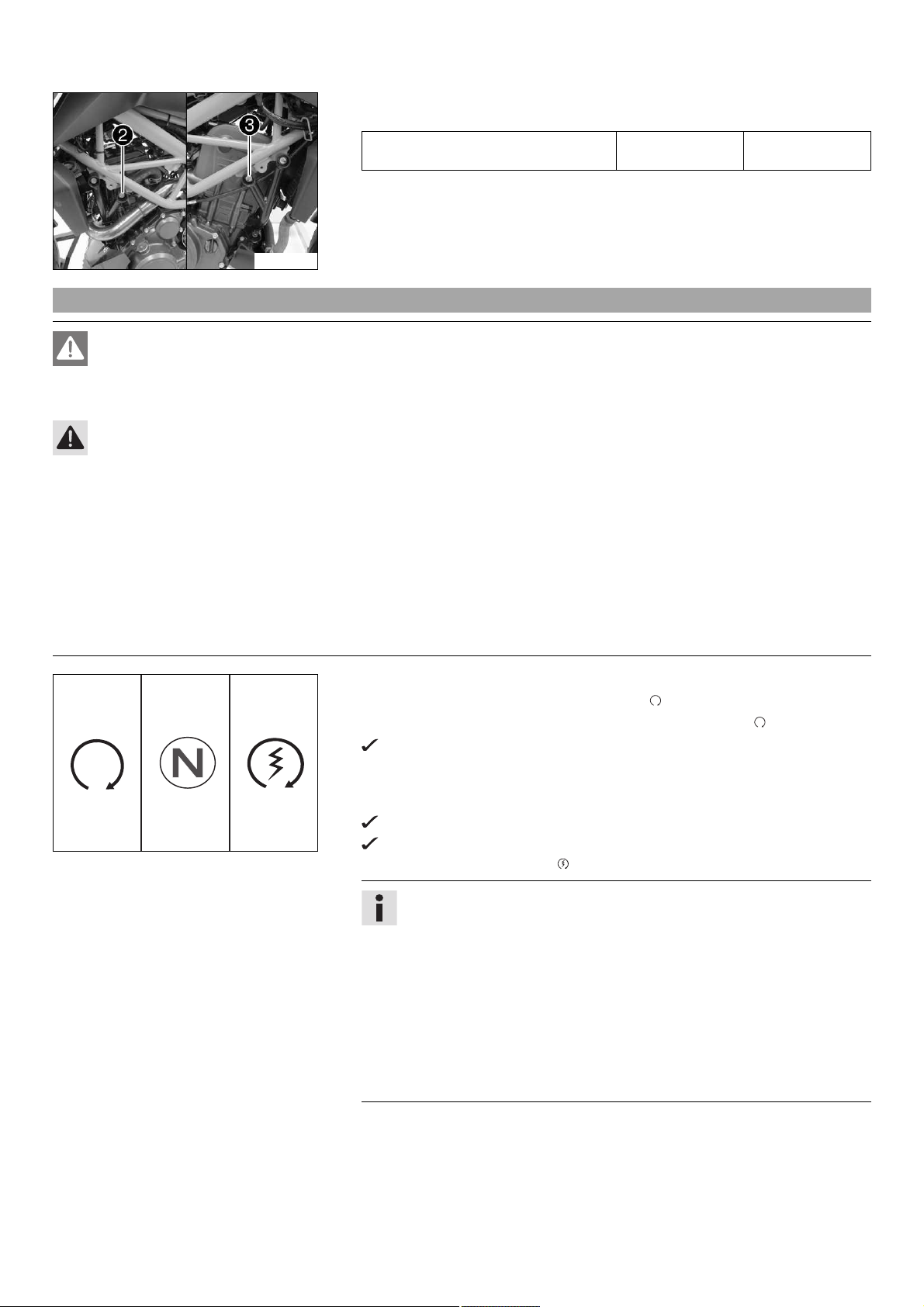

5.7 Starting

Danger

Danger of poisoning Exhaust gases are toxic and inhaling them may result in unconsciousness and/or death.

– When running the engine, always make sure there is sufficient ventilation, and do not start or run the engine in an enclosed

space without an effective exhaust extraction system.

Caution

Danger of accidents If the vehicle is operated with a discharged battery or without a battery, electronic components and safety

equipment may be damaged.

– Never operate the vehicle with a discharged battery or without a battery.

Note

Engine failure Unfiltered intake air has a negative effect on the service life of the engine.

– Never ride the vehicle without an air filter since dust and dirt can get into the engine and result in increased wear.

Note

Engine failure High engine speeds in cold engines have a negative effect on the service life of the engine.

– Always warm up the engine at low engine speeds.

– Sit on the vehicle, take the weight off of the side stand, and move up all the way.

– Turn the emergency OFF switch to the position .

– Switch on the ignition by turning the ignition key to the position .

After you switch on the ignition, you can hear the fuel pump working for about

two seconds. The function check of the combination instrument is run at the

same time.

– Shift gear to neutral.

The green idling speed indicator lamp N lights up.

B00782-10

– Press the electric starter button .

The ABS warning lamp lights up and goes back out after starting off.

Info

Do not press the electric starter button until the combination instrument

function check is finished.

When starting, DO NOT open the throttle. If you open the throttle during the

starting procedure, fuel is not injected by the engine management system

and the engine cannot start.

Press the starter for a maximum of 5 seconds. Wait for a least 5 seconds

before trying again.

This motorcycle is equipped with a safety starting system. You can only start

the engine if the transmission is in neutral or if the clutch is pulled when a

gear is engaged. If the side stand is folded out and you shift into gear and

release the clutch, the engine stops.

5 MOTORCYCLE 13

Switching off ABS

KTM recommends riding with ABS at all times. However, situations may arise in

which ABS is not advantageous.

Condition

Vehicle stationary, engine running.

– Press the 1 button for 3 – 5 seconds.

The ABS warning lamp starts flashing; ABS is deactivated.

401685-15

5.8 Starting the motorcycle to make checks

Danger

Danger of poisoning Exhaust gases are toxic and inhaling them may result in unconsciousness and/or death.

– When running the engine, always make sure there is sufficient ventilation, and do not start or run the engine in an enclosed

space without an effective exhaust extraction system.

Info

Press the starter for a maximum of 5 seconds. Wait for a least 5 seconds before trying again.

B00782-10

– Turn the emergency OFF switch to the position .

– Shift gear to neutral.

– Switch on the ignition by turning the ignition key to the position .

– Press the electric starter button .

Info

Do not open the throttle.

6 FORK, TRIPLE CLAMP 14

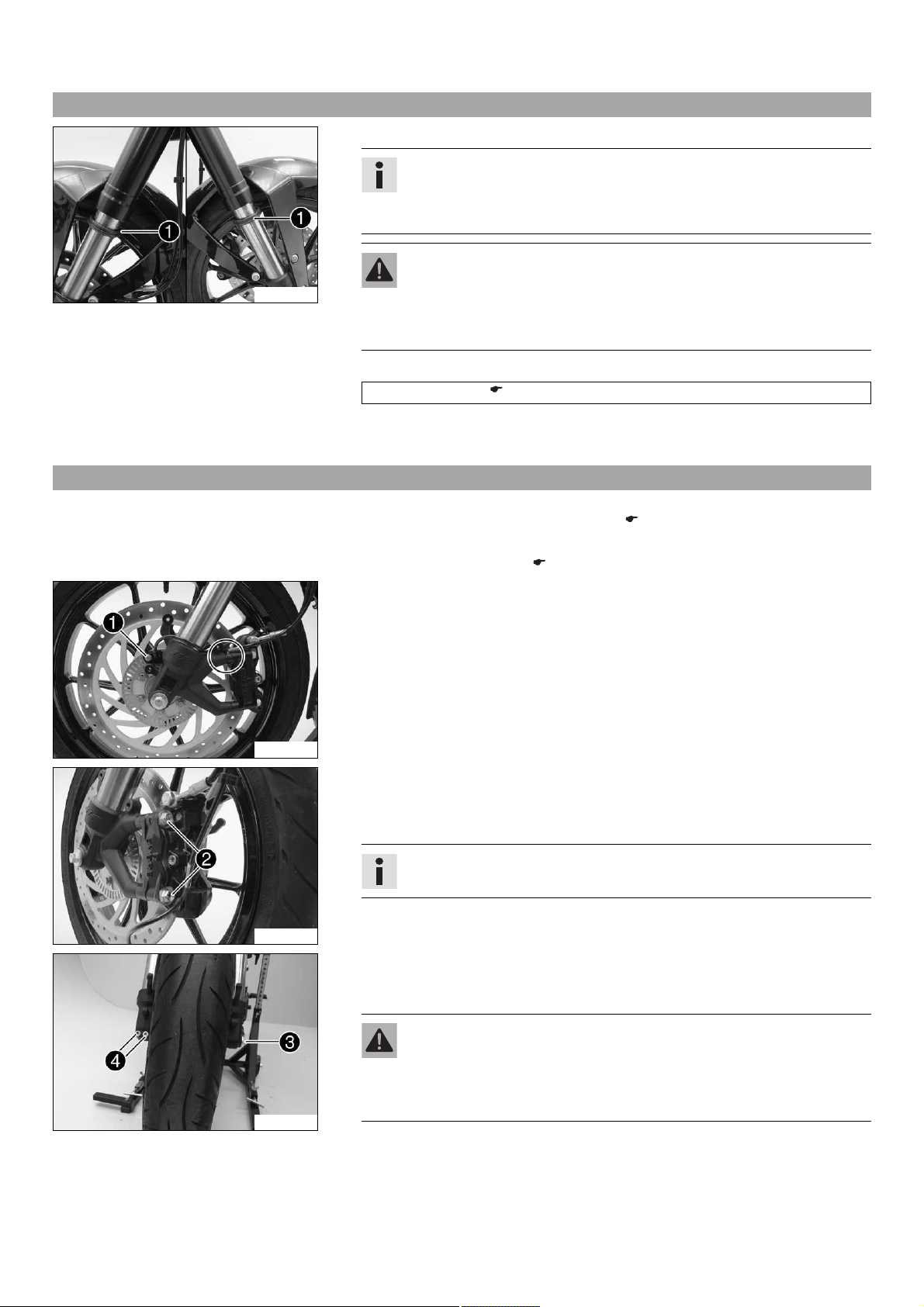

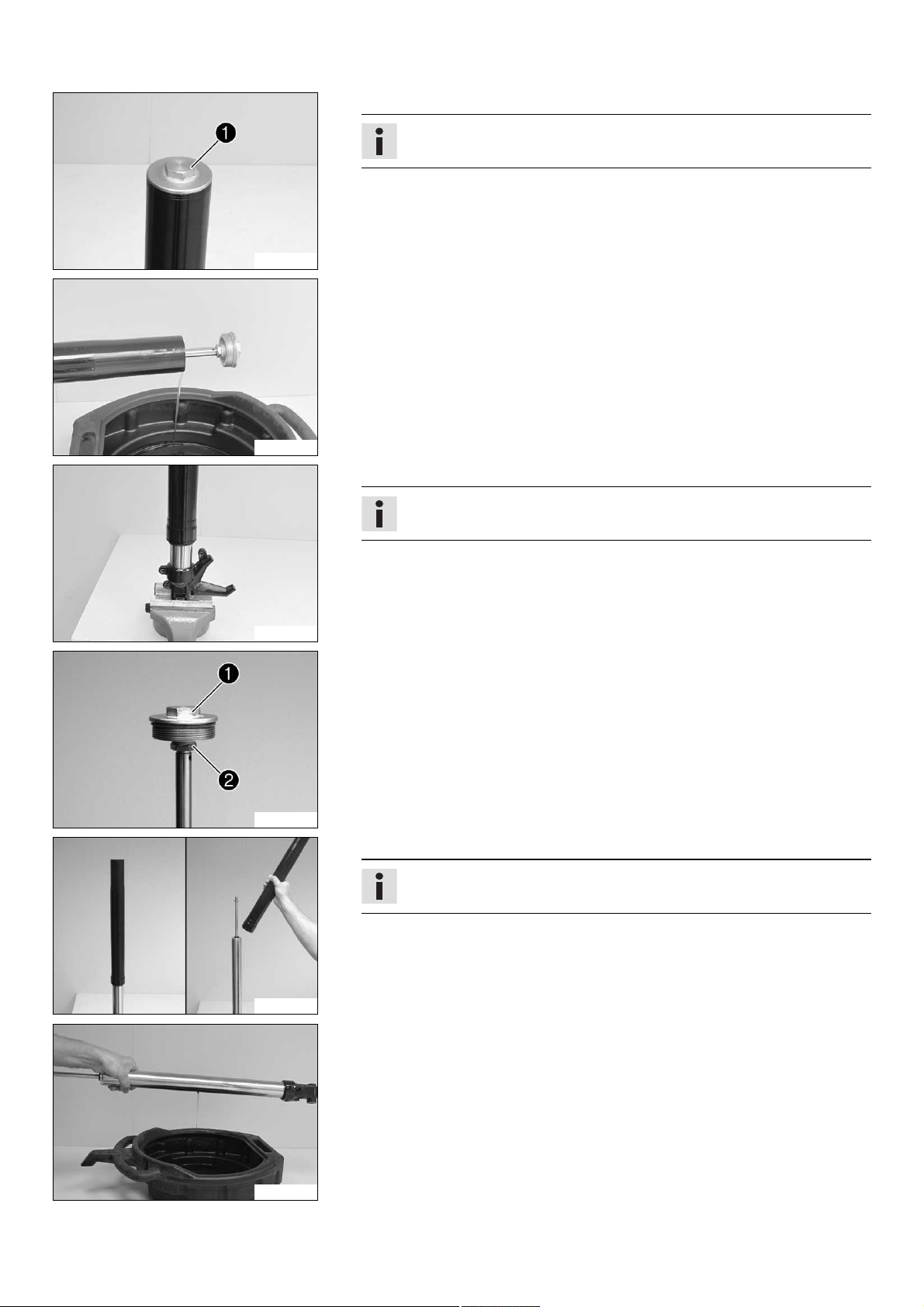

6.1 Cleaning the dust boots of the fork legs

– Push dust boot 1 of both fork legs downwards.

Info

The dust boots should remove dust and coarse dirt particles from the fork

tubes. Over time, dirt can penetrate behind the dust boots. If this dirt is not

removed, the oil seals behind can start to leak.

Warning

308233-10

– Clean and oil the dust boots and inside fork tube of both fork legs.

– Press the dust boots back into their normal position.

– Remove excess oil.

6.2 Removing fork legs

Preparatory work

– Raise the motorcycle with the work stand. ( p. 10)

– Tie the rear of the vehicle down.

– Dismount the front fender. ( p. 48)

Main work

– Remove screw 1.

– Remove the cable binder.

– Pull off the ABS sensor and hang it to one side.

Danger of accidents Reduced braking efficiency due to oil or grease on the

brake discs.

– Always keep the brake discs free of oil and grease, and clean them with

brake cleaner when necessary.

Universal oil spray ( p. 188)

308235-10

308236-10

308237-10

– Remove screws 2.

– Press back the brake linings with a light lateral tilting of the brake caliper on the

brake disc. Pull the brake caliper carefully back from the brake disc and hang it to

one side.

Info

Do not pull the hand brake lever when the brake caliper has been removed.

– Loosen screws 3 and screw 4.

– Unscrew screw 3 about six turns and press your hand on the screw to push the

wheel spindle out of the axle clamp. Remove screw 3.

Warning

Danger of accidents Reduced braking effect caused by damaged brake

discs.

– Always lay the wheel down in such a way that the brake discs are not

damaged.

– Holding the front wheel, withdraw the wheel spindle. Take the front wheel out of

the fork.

6 FORK, TRIPLE CLAMP 15

– Loosen screws 5. Remove the fork legs from the bottom.

308238-10

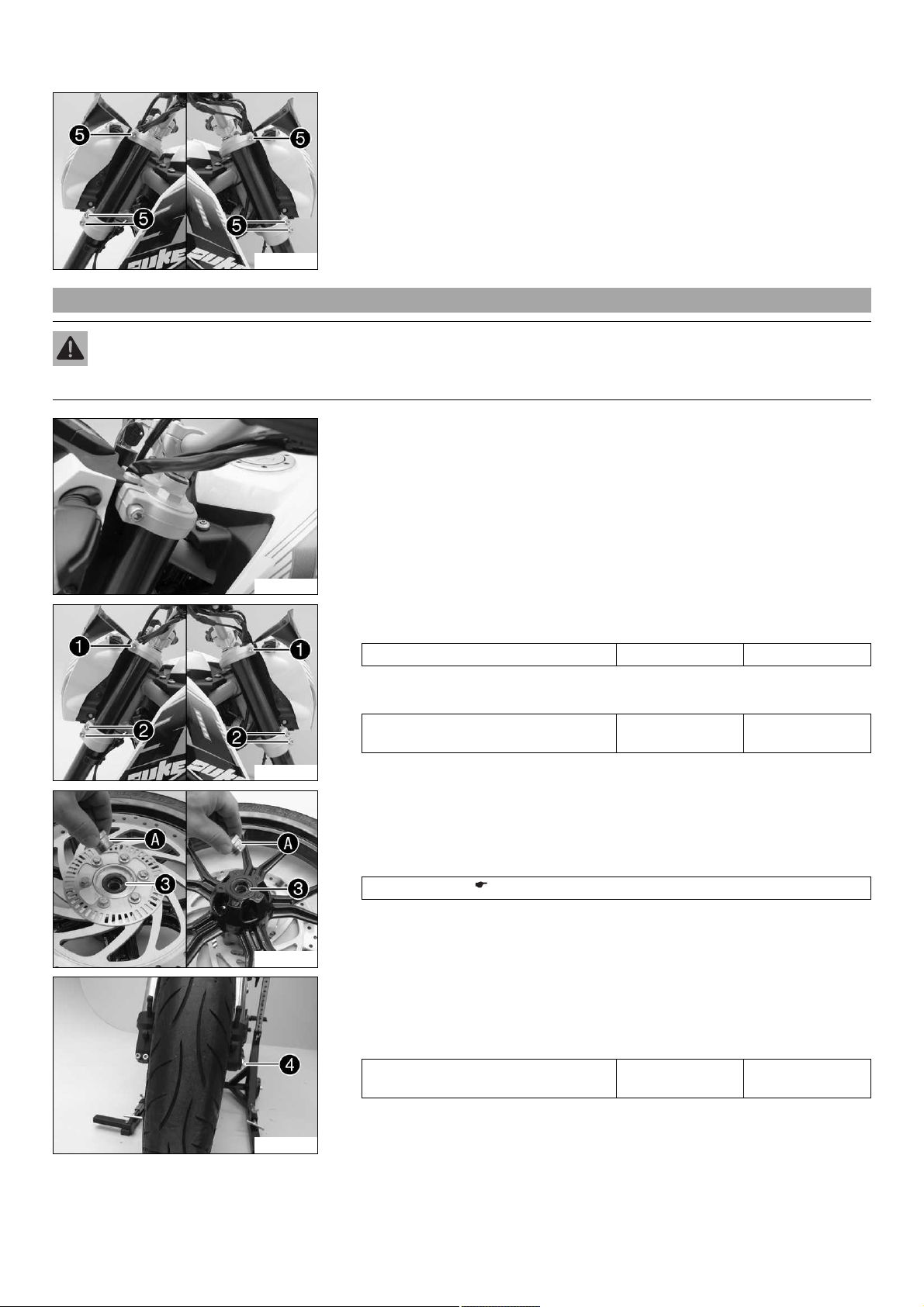

6.3 Installing the fork legs

Warning

Danger of accidents Modifications to the suspension settings can seriously alter the vehicle's ride behavior.

– Following modifications, ride slowly at first to get the feel of the new ride behavior.

Main work

– Push the fork legs into the triple clamps.

– Align the fork legs in the required position using the fork rings.

308239-10

308238-11

308240-10

– Tighten screws 1.

Guideline

Screw, top triple clamp M8 11 Nm (8.1 lbf ft)

– Tighten screws 2.

Guideline

Screw, bottom triple clamp M8 15 Nm

(11.1 lbf ft)

– Check the wheel bearing for damage and wear.

» If the wheel bearing is damaged or worn:

– Change the wheel bearing.

– Clean and grease the shaft seal rings 3 and contact surfaces A of the spacers.

Long-life grease ( p. 187)

– Clean screw 4 and the wheel spindle.

– Lift the front wheel into the fork, position it, and insert the wheel spindle.

– Mount and tighten screw 4.

Guideline

Screw, front wheel spindle M8 30 Nm

(22.1 lbf ft)

308237-11

6 FORK, TRIPLE CLAMP 16

– Position the brake calipers and check that the brake linings are seated correctly.

– Mount screws 5 but do not tighten yet.

– Operate the hand brake lever repeatedly until the brake linings are in contact with

the brake disc and there is a pressure point. Fix the hand brake lever in the activated position.

The brake calipers straighten.

– Tighten screws 5.

Guideline

308236-11

Screw, front brake caliper M8x1 27 Nm

(19.9 lbf ft)

– Remove the fixation of the hand brake lever.

– Unload the rear of the vehicle.

– Remove the motorcycle from the work stand. ( p. 11)

– Position the ABS sensor.

– Mount and tighten screw 6.

Guideline

Screw, wheel speed sensor holder M6 8 Nm (5.9 lbf ft)

– Route the cable and secure with a cable binder.

Loctite®243™

308235-11

308241-10

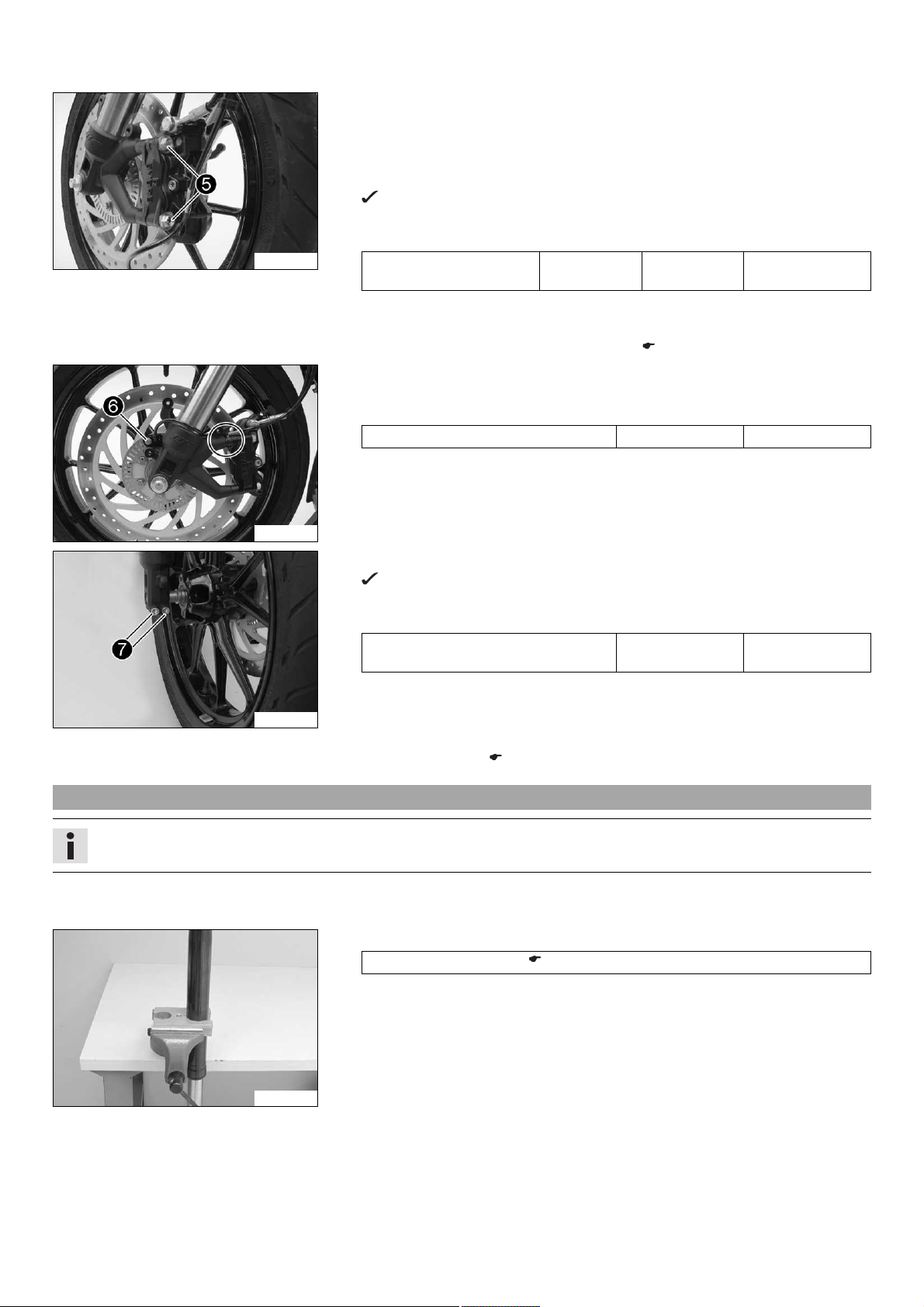

6.4 Disassembling the fork legs

Info

These operations are the same on both fork legs.

– Pull the front brake and compress the fork powerfully a few times.

The fork legs straighten.

– Tighten screws 7.

Guideline

Screw, fork stub M8 15 Nm

(11.1 lbf ft)

Finishing work

– Install front fender. ( p. 48)

Condition

The fork legs have been removed.

– Clamp the fork leg in the area of the lower triple clamp.

Clamping stand (T612S) ( p. 197)

201505-10

6 FORK, TRIPLE CLAMP 17

– Loosen the screw cap 1.

Info

The screw cap cannot be removed yet.

201506-10

– Empty the fork oil.

201507-10

– Release the fork leg and clamp it with the fork stub.

201508-10

201509-10

Info

Use soft jaws.

– Push the outer tube downward.

– Hold screw cap 1. Loosen nut 2. Remove the screw cap.

– Detach the outer tube from the inner tube.

Info

Place a container underneath to catch any oil that may run out.

201510-10

201511-10

– Unclamp the inner tube. Drain the oil.

6 FORK, TRIPLE CLAMP 18

– Clamp the outer tube in the area of the lower triple clamp.

Clamping stand (T612S) ( p. 197)

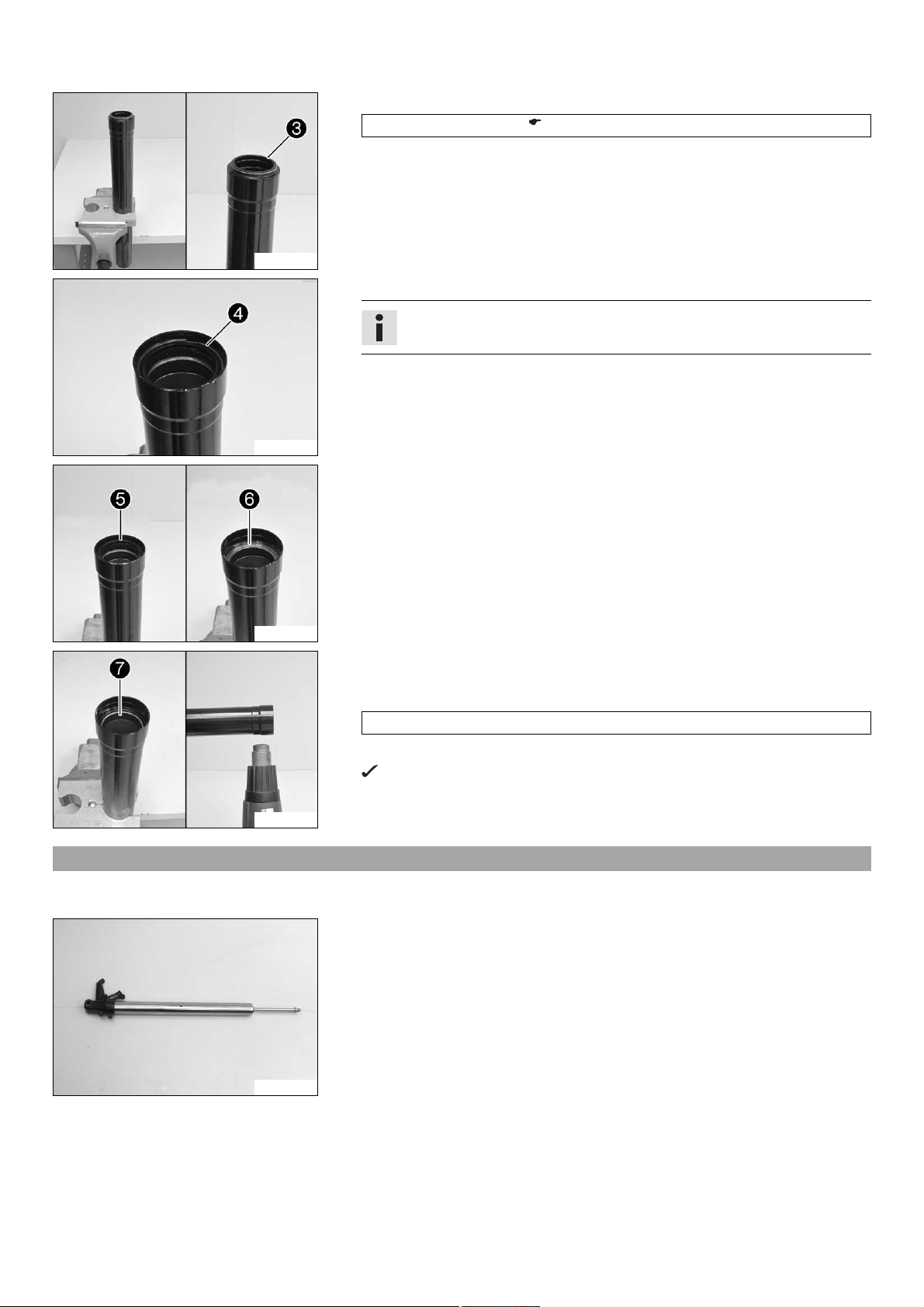

– Remove dust boot 3.

201512-10

– Remove lock ring 4.

Info

The lock ring has a beveled end where a screwdriver can be applied.

201513-10

– Remove seal ring 5. Remove support ring 6.

201514-10

201515-10

6.5 Checking the fork legs

– Unclamp the outer tube.

– Heat up the outer tube in the area of sliding bushing 7.

Guideline

50 °C (122 °F)

– Strike the lower edge of the outer fork tube on a wooden board.

Sliding bushing 7 must fall out of its seat.

Condition

The fork legs have been disassembled.

– Check the inner tube and the axle clamp for damage.

» If damage is found:

– Change the fork leg.

201516-10

6 FORK, TRIPLE CLAMP 19

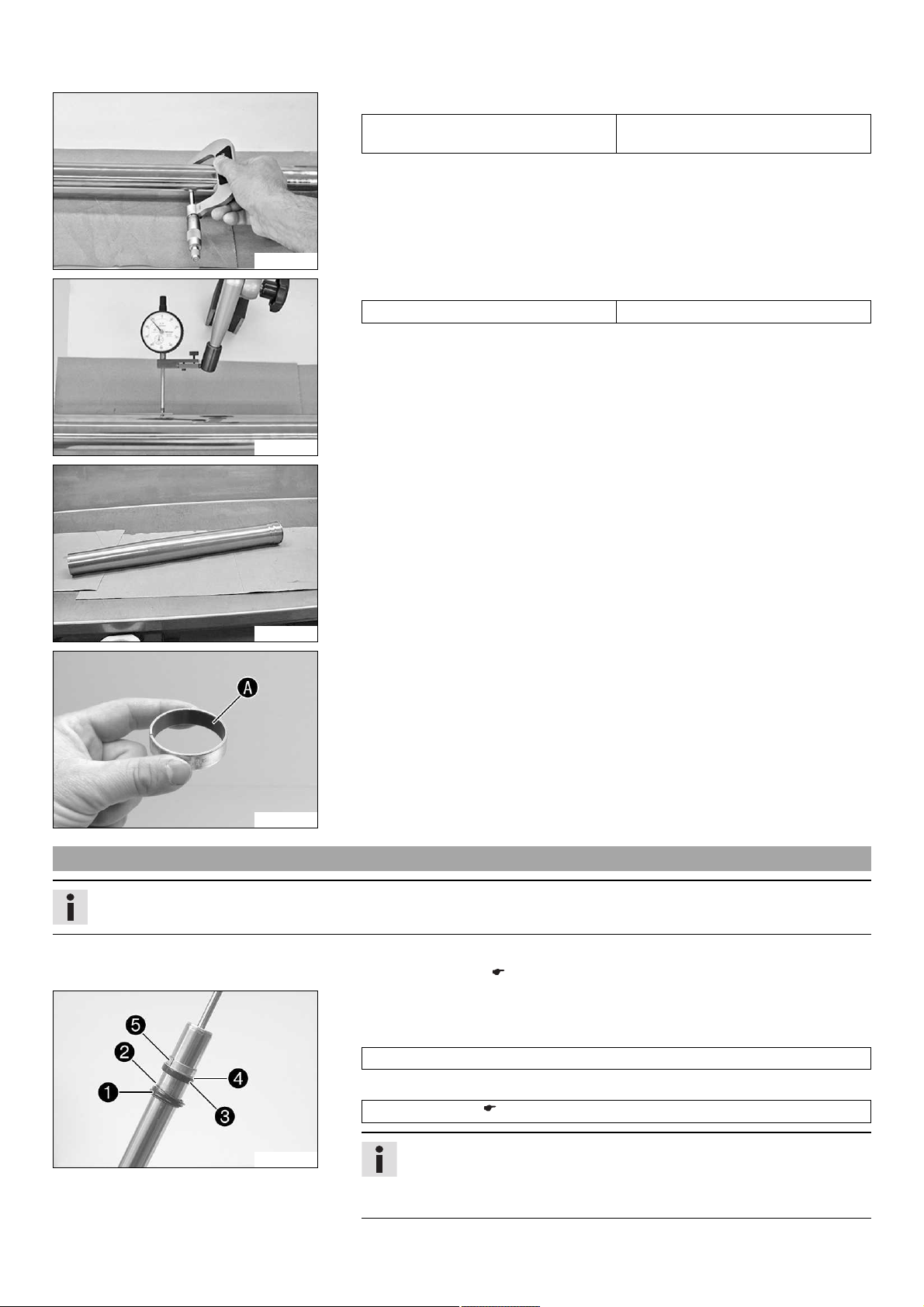

– Measure the outside diameter of the inner tube in several places.

External diameter of inner tube 42.975… 43.005 mm (1.69193…

1.69311 in)

» If the measured value is less than the specified value:

– Change the fork leg.

200684-10

– Measure the run-out of the inner tube.

Run-out of inner tube ≤ 0.20 mm (≤ 0.0079 in)

» If the measured value is greater than the specified value:

– Change the fork leg.

200685-10

– Check the outer tube for damage.

» If damage is found:

– Change the fork leg.

200632-10

201517-10

6.6 Assembling the fork legs

Info

These operations are the same on both fork legs.

– Check the surface of the sliding bushings.

» If the dark layer A is worn off:

– Change the fork leg.

Preparatory work

– Check the fork legs. ( p. 18)

Main work

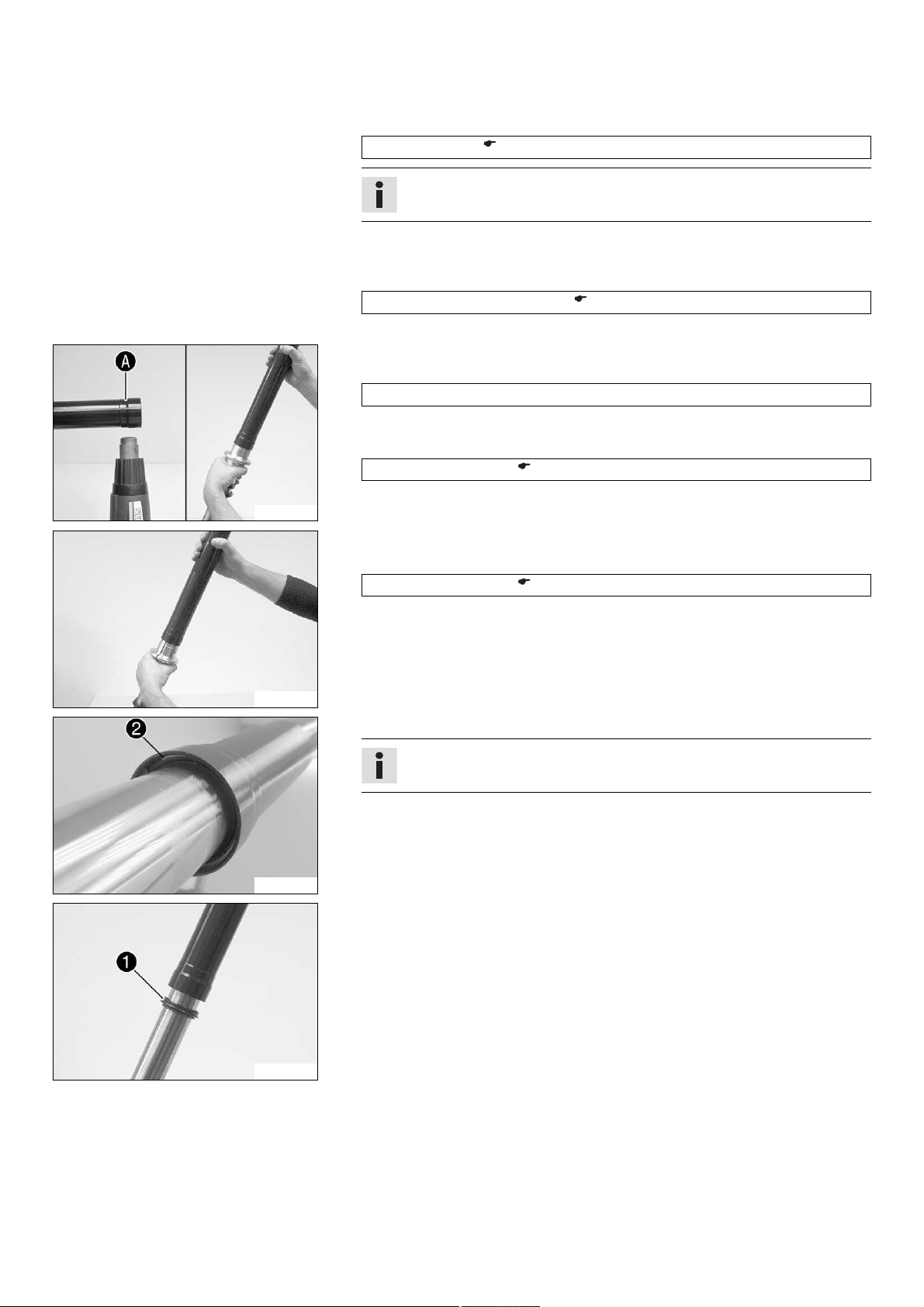

– Clamp in the inner tube with the axle clamp.

Guideline

Use soft jaws.

202092-10

– Grease and slide on dust boot 1.

Lubricant (T511) ( p. 187)

Info

Always change the dust boot, lock ring, seal ring, and support ring.

Install the dust boot with the sealing lip and spring expander facing downward.

6 FORK, TRIPLE CLAMP 20

– Slide on lock ring 2.

– Grease and slide on seal ring 3.

Lubricant (T511) ( p. 187)

Info

Mount with the sealing lip facing down and the open side facing up.

– Slide on support ring 4.

– Sand the edges of sliding bushing 5 with 600-grit sandpaper, then clean and

grease.

Fork oil (SAE 4) (48601166S1) ( p. 186)

– Slide on sliding bushing 5.

– Warm up the outer tube in the lower sliding bushing area A.

Guideline

50 °C (122 °F)

– Slide the outer tube onto the inner tube.

– Hold the sliding bushing with the longer shoulder of the special tool.

Mounting tool (T528S) ( p. 197)

– Push the sliding bushing all the way into the outer tube.

202093-10

– Position the support ring.

– Hold the seal ring with the shorter shoulder of the special tool.

202094-10

202095-10

Mounting tool (T528S) ( p. 197)

– Push the seal ring and support ring all the way into the outer tube.

– Mount lock ring 2.

Info

The lock ring must engage audibly.

– Install dust boot 1.

202096-10

6 FORK, TRIPLE CLAMP 21

– Mount screw cap 6 onto the piston rod.

Info

Nut 7 must be turned all the way down.

– Hold the screw cap and tighten the nut.

Guideline

Nut, piston rod on screw cap M12x1 30 Nm

(22.1 lbf ft)

202097-10

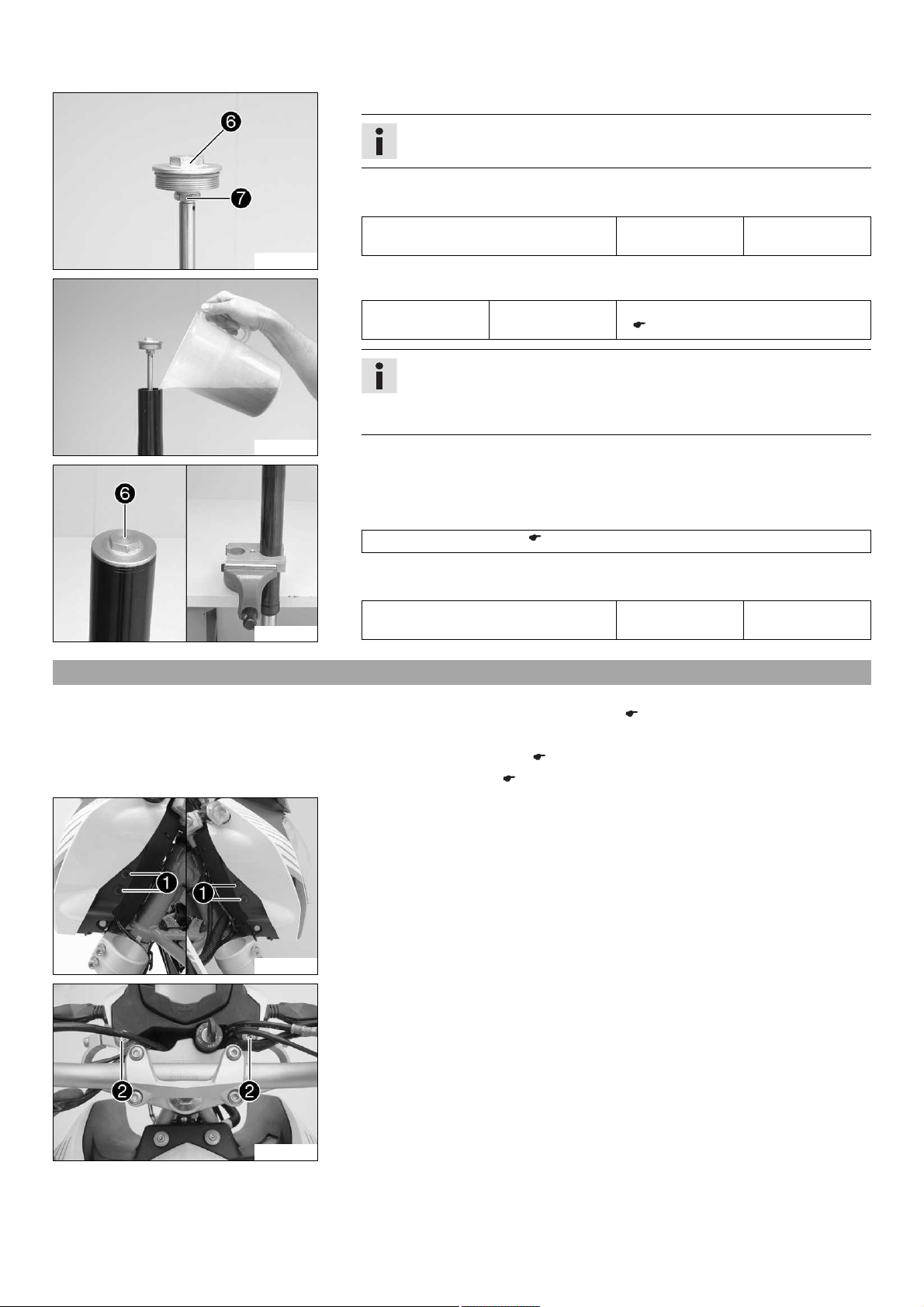

– Fill it with fork oil.

201523-10

201522-10

6.7 Removing the lower triple clamp

Fork oil 450 ml

(15.21 fl. oz.)

Fork oil (SAE 4) (48601166S1)

( p. 186)

Info

If it should be impossible to add the full quantity of oil, close the screw cap

of the outer tube, unclamp the fork and bounce a number of times. Then

add the remaining quantity.

– Push the outer tube upward.

– Mount screw cap 6.

– Unclamp the fork leg in the area of the lower triple clamp.

Clamping stand (T612S) ( p. 197)

– Tighten the screw cap.

Guideline

Screw cap on outer tube M47x1.5 30 Nm

Preparatory work

– Raise the motorcycle with the work stand. ( p. 10)

– Tie the rear of the vehicle down.

– Dismount the front fender. ( p. 48)

– Remove the fork legs. ( p. 14)

Main work

– Remove expanding rivets 1.

(22.1 lbf ft)

308242-10

308243-10

– Remove screws 2.

– Lift the headlight mask slightly and swing forward.

6 FORK, TRIPLE CLAMP 22

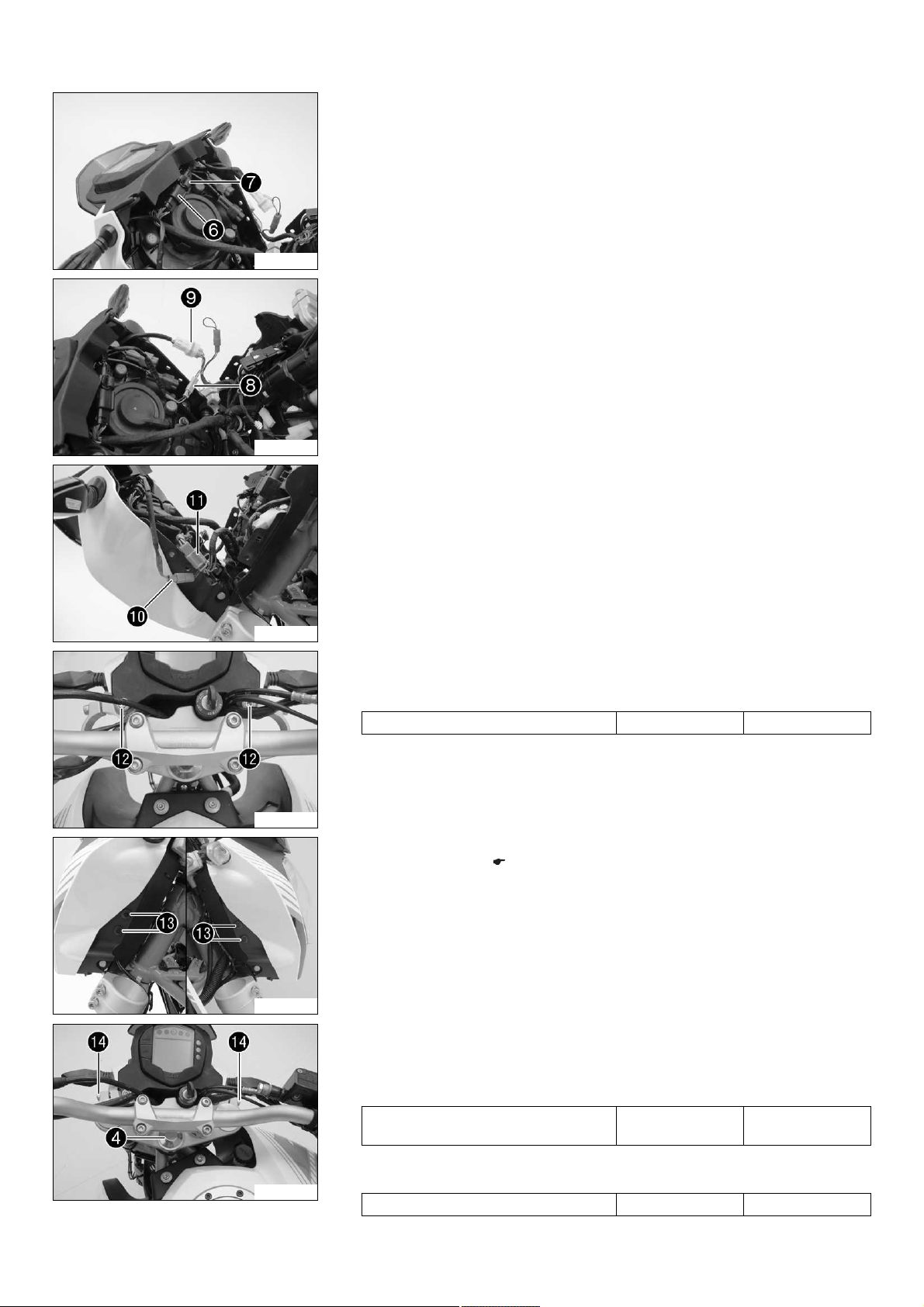

– Detach connectors 3 and 4.

308244-10

– Detach connectors 5 and 6.

308245-10

– Remove the connector holder.

– Disconnect connector 7.

308246-10

308247-10

308248-10

– Remove the combination instrument.

– Remove screws 8.

– Remove the headlight mask.

– Remove screw 9.

308249-10

6 FORK, TRIPLE CLAMP 23

– Remove the upper triple clamp with the handlebar and set aside.

Info

Protect the vehicle and its attachments from damage by covering them.

308251-10

– Expose the cable.

308252-10

– Remove nut bk.

Castle nut wrench; ½" drive (90129050100) ( p. 195)

308253-10

308254-10

6.8 Installing the lower triple clamp

308254-11

– Remove washer bl.

– Remove steering head bearing bm.

– Remove the lower triple clamp with the steering stem.

Main work

– Clean the bearing and sealing elements, check for damage, and grease.

High viscosity grease ( p. 187)

– Insert the lower triple clamp with the steering stem.

– Mount the upper steering head bearing 1.

– Mount washer 2 with the cut-out facing downward.

Alternative 1

A new steering head bearing is used.

– Mount and tighten nut 3.

308253-11

6 FORK, TRIPLE CLAMP 24

Guideline

Nut, steering head M30x1 Step 1

50 Nm

(36.9 lbf ft)

2nd stage

(loosen, counterclockwise)

2 turns

Step 3

5 Nm (3.7 lbf ft)

Castle nut wrench; ½" drive (90129050100) ( p. 195)

Alternative 2

The steering head bearing is used again.

– Mount and tighten nut 3.

Guideline

Nut, steering head M30x1 5 Nm (3.7 lbf ft)

Castle nut wrench; ½" drive (90129050000) ( p. 195)

– Secure the cable in the bracket.

308252-10

308251-10

308250-10

– Position the upper triple clamp with the handlebar.

– Mount screw 4 with the washer but do not tighten it yet.

Guideline

Screw, top steering head M16x1.5 52 Nm

(38.4 lbf ft)

Holding lugs A reach into the drilled holes.

– Position the headlight mask.

– Mount and tighten screw 5.

Guideline

Screw, headlight mask M6 11 Nm (8.1 lbf ft)

308248-11

6 FORK, TRIPLE CLAMP 25

– Position the combination instrument.

– Plug in connector 6.

– Mount the connector holder 7.

308246-11

– Plug in connectors 8 and 9.

308245-11

– Plug in connectors bk and bl.

308244-11

308243-11

308242-11

– Fold the headlight mask up.

– Mount and tighten screws bm.

Guideline

Screw, headlight mask M6 11 Nm (8.1 lbf ft)

– Mount expanding rivets bn on both sides.

– Install the fork legs. ( p. 15)

– Loosen screws bo.

– Using a plastic hammer, tap lightly on the upper triple clamp to avoid strains.

– Tighten screw 4.

Guideline

Screw, top steering head M16x1.5 52 Nm

(38.4 lbf ft)

308255-10

– Tighten screws bo.

Guideline

Screw, top triple clamp M8 11 Nm (8.1 lbf ft)

6 FORK, TRIPLE CLAMP 26

Finishing work

– Check that the wiring harness, throttle cables, and brake line have the necessary

freedom of movement and are correctly routed.

– Check the steering head bearing play. ( p. 26)

– Remove the motorcycle from the work stand. ( p. 11)

6.9 Checking the steering head bearing play

Warning

Danger of accidents Unstable vehicle handling from incorrect steering head bearing play.

– Adjust the steering head bearing play without delay.

Info

If the bike is ridden with play in the steering head bearing, the bearing and the bearing seats in the frame can become damaged with time.

Preparatory work

– Raise the motorcycle with the work stand. ( p. 10)

Main work

– Move the handlebar to the straight-ahead position. Move the fork legs to and fro in

the direction of travel.

No play should be noticeable in the steering head bearing.

» If there is noticeable play present:

– Adjust the play of the steering head bearing. ( p. 26)

–

Move the handlebar to and fro over the entire steering range.

400738-11

The handlebar must be able to move easily over the entire steering range. No

resting locations should be noticeable.

» If click positions are noticeable:

– Adjust the play of the steering head bearing. ( p. 26)

– Check the steering head bearing and change if necessary.

Finishing work

– Remove the motorcycle from the work stand. ( p. 11)

6.10 Adjusting the steering head bearing play

Preparatory work

– Raise the motorcycle with the work stand. ( p. 10)

Main work

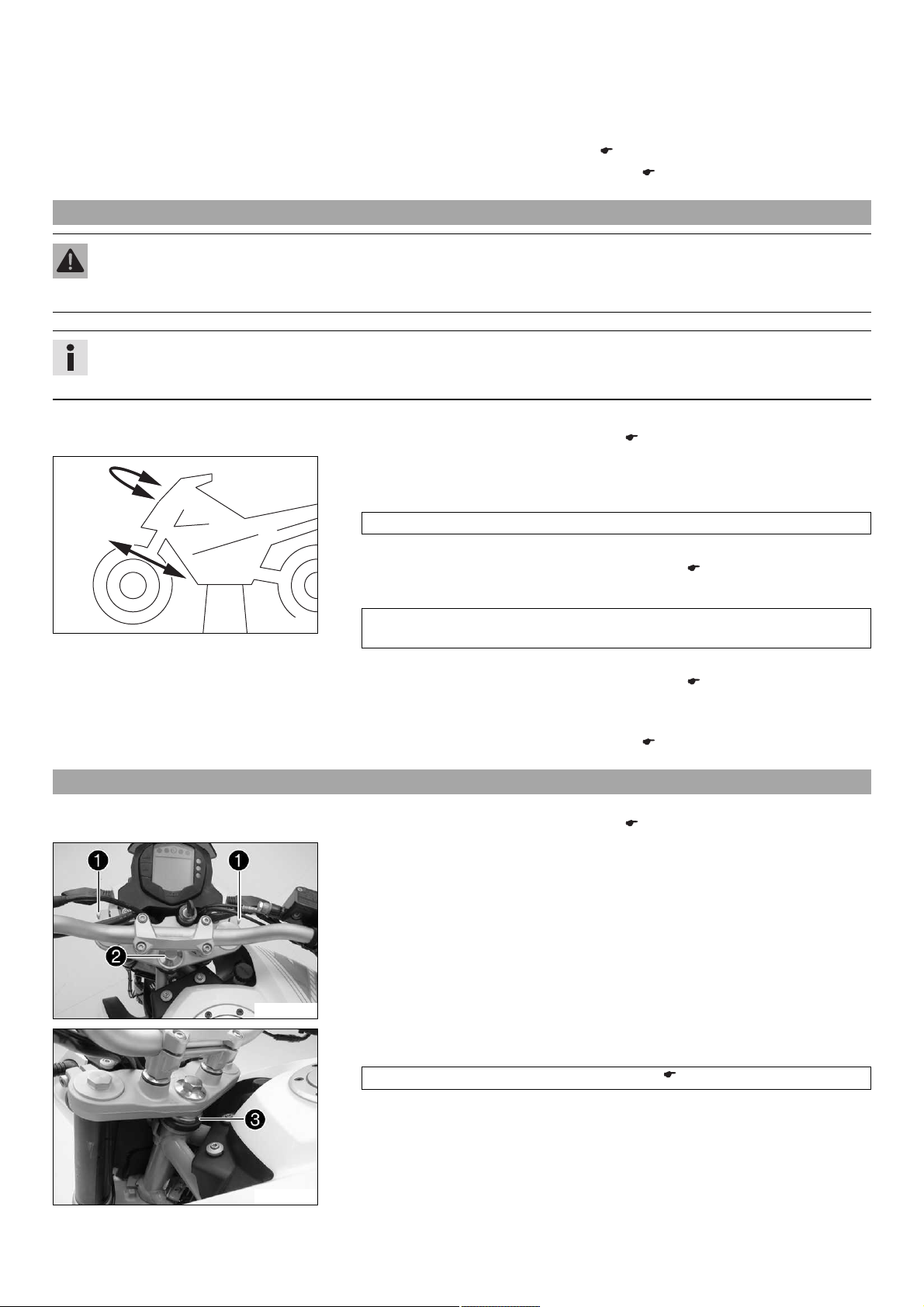

– Loosen screws 1.

– Loosen screw 2.

308256-10

308257-10

– Tighten nut 3 with the special tool until there is no play in the steering head bear-

ing.

Key for steering head bearing (90129051000) ( p. 195)

6 FORK, TRIPLE CLAMP 27

– Using a plastic hammer, tap lightly on the upper triple clamp to avoid strains.

– Tighten screw 2.

Guideline

Screw, top steering head M16x1.5 52 Nm

(38.4 lbf ft)

– Tighten screws 1.

Guideline

308256-10

Screw, top triple clamp M8 11 Nm (8.1 lbf ft)

Finishing work

– Check the steering head bearing play. ( p. 26)

– Remove the motorcycle from the work stand. ( p. 11)

7 HANDLEBAR, CONTROLS 28

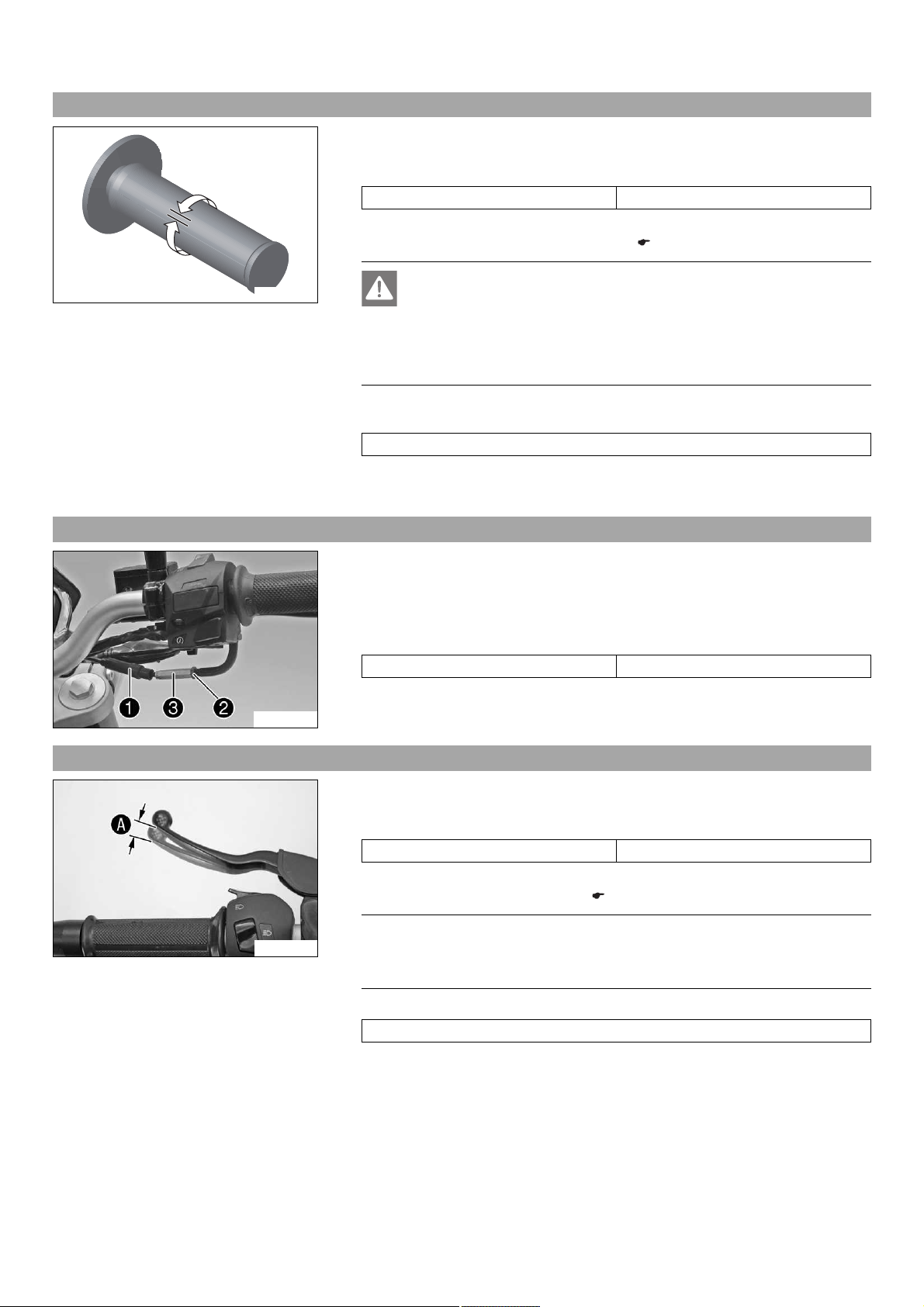

7.1 Checking the play in the throttle cable

– Check the throttle grip for smooth operation.

– Move the handlebar to the straight-ahead position. Move the throttle grip back-

wards and forwards to ascertain the play in the throttle cable.

Throttle cable play 3… 5 mm (0.12… 0.2 in)

» If the throttle cable play does not meet specifications:

– Adjust the play in the throttle cable. ( p. 28)

Danger

400192-10

– Start the engine and let it run idle. Move the handlebar to and fro over the entire

Danger of poisoning Exhaust gases are toxic and inhaling them may result

in unconsciousness and/or death.

– When running the engine, always make sure there is sufficient ventila-

tion, and do not start or run the engine in an enclosed space without an

effective exhaust extraction system.

steering range.

The idle speed must not change.

» If the idle speed changes:

– Check the throttle cable routing.

7.2 Adjusting the play in the throttle cable

– Move the handlebar to the straight-ahead position.

– Push back sleeve 1.

– Loosen lock nut 2.

– Adjust the play in the throttle cable by turning adjusting screw 3.

Guideline

Throttle cable play 3… 5 mm (0.12… 0.2 in)

– Tighten lock nut 2.

B00728-10

– Slide on sleeve 1.

7.3 Checking the clutch lever play

– Check the clutch lever for smooth operation.

– Move the handlebar to the straight-ahead position. Lightly pull the clutch lever and

ascertain the clutch lever play A.

Clutch lever play 1… 3 mm (0.04… 0.12 in)

» If the clutch lever play does not meet specifications:

Note

101914-10

Clutch damage If there is no play on the clutch lever, the clutch will begin to slip.

– When operating the motorcycle, always check the clutch lever play.

– Adjust the clutch cable play. ( p. 29)

– Move the handlebar to and fro over the entire steering range.

The clutch lever play must not change.

» If the clutch lever play changes:

– Check the routing of the clutch cable.

Loading...

Loading...