Page 1

Repair manual KTM 250 / 300 / 380 Art No 3206004 -E

250/300/380 SX,MXC,EXC

REPAIR MANUAL

ENGINE

KTM SPORTMOTORCYCLE AG

5230 Mattighofen

Austria

www.ktm.at

Page 2

Page 3

REPAIR

MANUAL

ENGINE

250 - 380

SX,MXC,EXC

Page 4

Page 5

1 SERVICE-INFORMATIONS

2 GENERAL INFORMATION

3 REMOVING AND REFITTING ENGINE

4 DISASSEMBLING THE ENGINE

5

SERVICING ON INDIVIDUAL COMPONENTS

6 ASSEMBLING THE ENGINE

7 ELECTRICAL

8 TROUBLE SHOOTING

9 TECHNICAL SPECIFICATIONS

10 PERIODIC MAINTENANCE SCHEDULE

11 WIRING DIAGRAMS

12

13

14

15

16

Page 6

Page 7

Repair manual KTM 250 / 300 / 380 Art No 3206004 -E

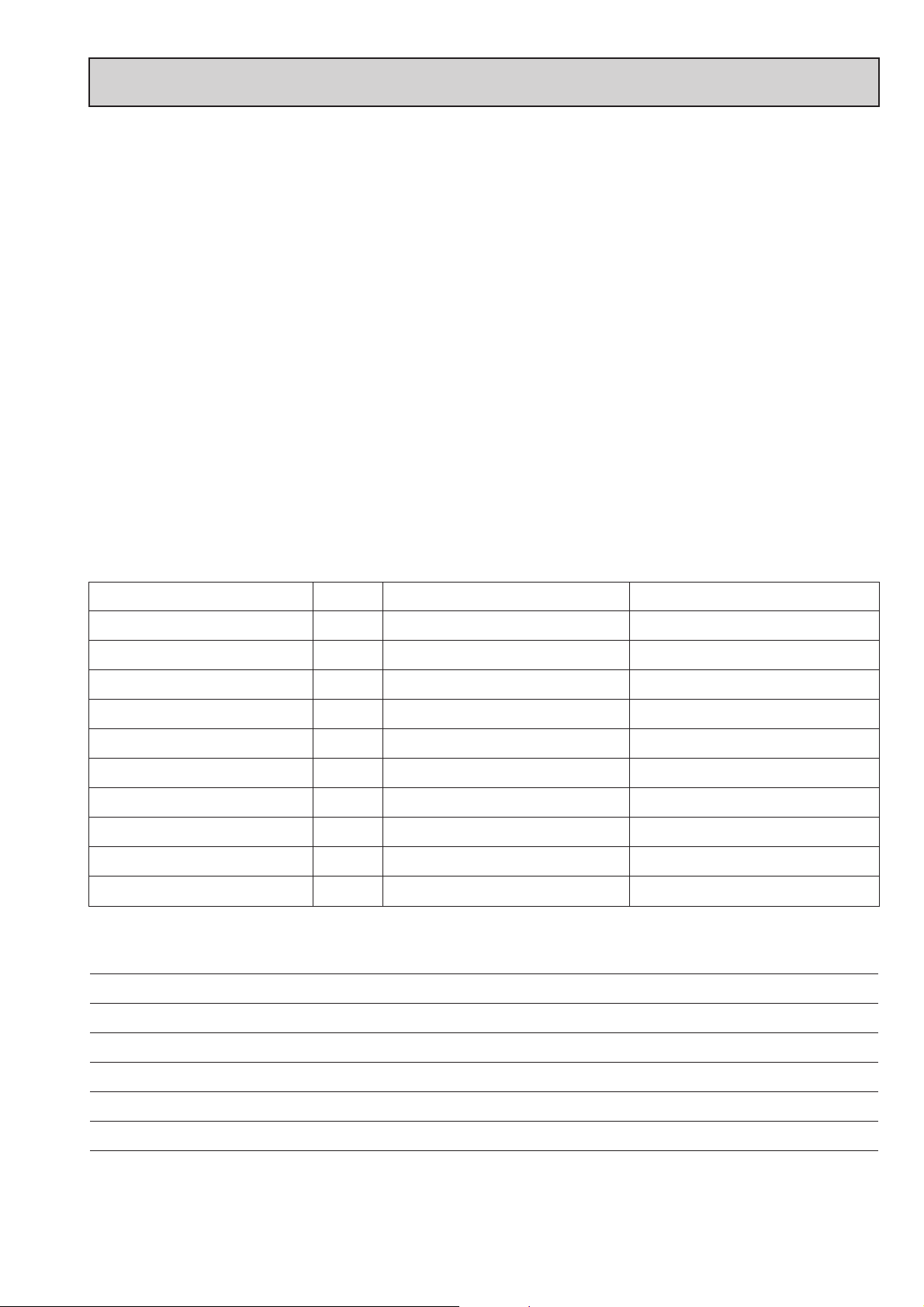

Remove page (s) Replace by page (s) Insert page (s) after page

2-1 to 2-4 2-1C to 2-6C

3-4 3-4C

4-1 to 4-9 4-1C to 4-8C

5-1 5-1C

5-4 5-4C / 5-5C

5-13 to 5-14 5-13C to 5-14C

7-1 7-1C 7-5C to 7-10C

9-1 9-1C 9-37C to 9-42C

10-1 10-1C 10-6C to 10-8C

11-1 11-1C 11-14C to 11-16C

IMPORTANT INFORMATION/UPDATING INSTRUCTIONS

To be able to continue using the existing loose-leaf repair instructions, simply print the following

pages and insert them in the existing repair instructions:

14-20, 26, 28-36, 37, 41, 42, 50, 51, 67, 72-77, 83, 121-126, 127, 134-136,

137, 151-153

KTM REPAIR MANUAL IN LOOSE-LEAF FORM

STORING THE REPAIR MANUAL IN THE BINDER

– Put the index into the binder.

– Put the front page of the repair manual (210x297 mm) into the transparent pocket provided for

this purpose on the outside of the binder.

– Put the spine label (170x45 mm) into the transparent pocket provided for this purpose on the

spine of the binder.

– Put the summary list of contents (150x297 mm) into the transparent pocket provided for this

purpose on the inside of the binder or insert this page on the beginning of the manual.

– Then insert the individual chapters of the manual between the sheets of the index according to

the page number printed in the right bottom corner of each page.

Example: page no. 3-5 3 = chapter 3 5 = page 5

All pages with a page number that begins with the digit 3, for example, must be put under the

index heading „Chapter 3“.

– Index sheets that have not been marked with a certain chapter are for your personal convenience.

The respective headings can be entered in the list of contents.

Page 8

Page 9

EXPLANATION - UPDATING

Edition 11/2002

Repair manual KTM 250 / 300 / 380 Art No 3206004 -E

3.205.63-E Repair Manual 250 / 300 / 380 SX, MXC, EXC

Basicversion Modelyear 1999

(Engine number with first digit “9“)

11/1998

3.205.87-E Updating of Rep.Manual 3.205.63-E

Modelyear 2000

(Engine number with first digit “0“)

2/2000

3.210.02-E Updating of Rep.Manual 3.205.63-E

Modelyear 2001/2002

(Engine number with first digit “1“)

(Engine number with first digit “2“)

3/2001

3.206.004-E Updating of Rep.Manual 3.205.63-E

Modelyear 2003

(Engine number with first digit “3“)

11/2002

Modification / Updating:

Technical Specification,

Periodic Maintenance Schedule, Wiring Diagrams

Page 10

Page 11

INTRODUCTION

This repair manual offers extensiv repair-instructions and is an up-to-date version that describes the

latest models of the series. However, the right to modifications in the interest of technical

improvement is reserved without updating the current issue of this manual.

A description of general working modes common in work shops has not been included. Safety rules

common in the work shop have also not been listed. We take it for granted that the repairs are made

by qualified profesionally trained mechanics.

Read through the repair manual before beginning with the repair work.

WARNING

STRICT COMPLIANCE WITH THESE INSTRUCTIONS IS

ESSENTIAL TO AVOID DANGER TO LIFE AND LIMB.

!

CAUTION

!

NON-COMPLIANCE WITH THESE INSTRUCTIONS CAN LEAD TO

DAMAGE OF MOTORCYCLE COMPONENTS OR RENDER

MOTORCYCLES UNFIT FOR TRAFFIC !

„NOTE” POINTS OUT USEFUL TIPS.

Use only ORIGINAL KTM SPARE PARTS when replacing parts.

The KTM high performance engine is only able to meet user expectations if the maintenance work is

performed regularly and professionally.

KTM Austria’s certificate of achievement for its quality system ISO 9001 is the beginning of an on

going total reengineered quality plan for a brighter tomorrow.

KTM Sportmotorcycle AG

5230 Mattighofen, Austria

All design and assembly modification rights reserved.

C

by KTM SPORTMOTORCYCLE AG, AUSTRIA All rights reserved

Page 12

Page 13

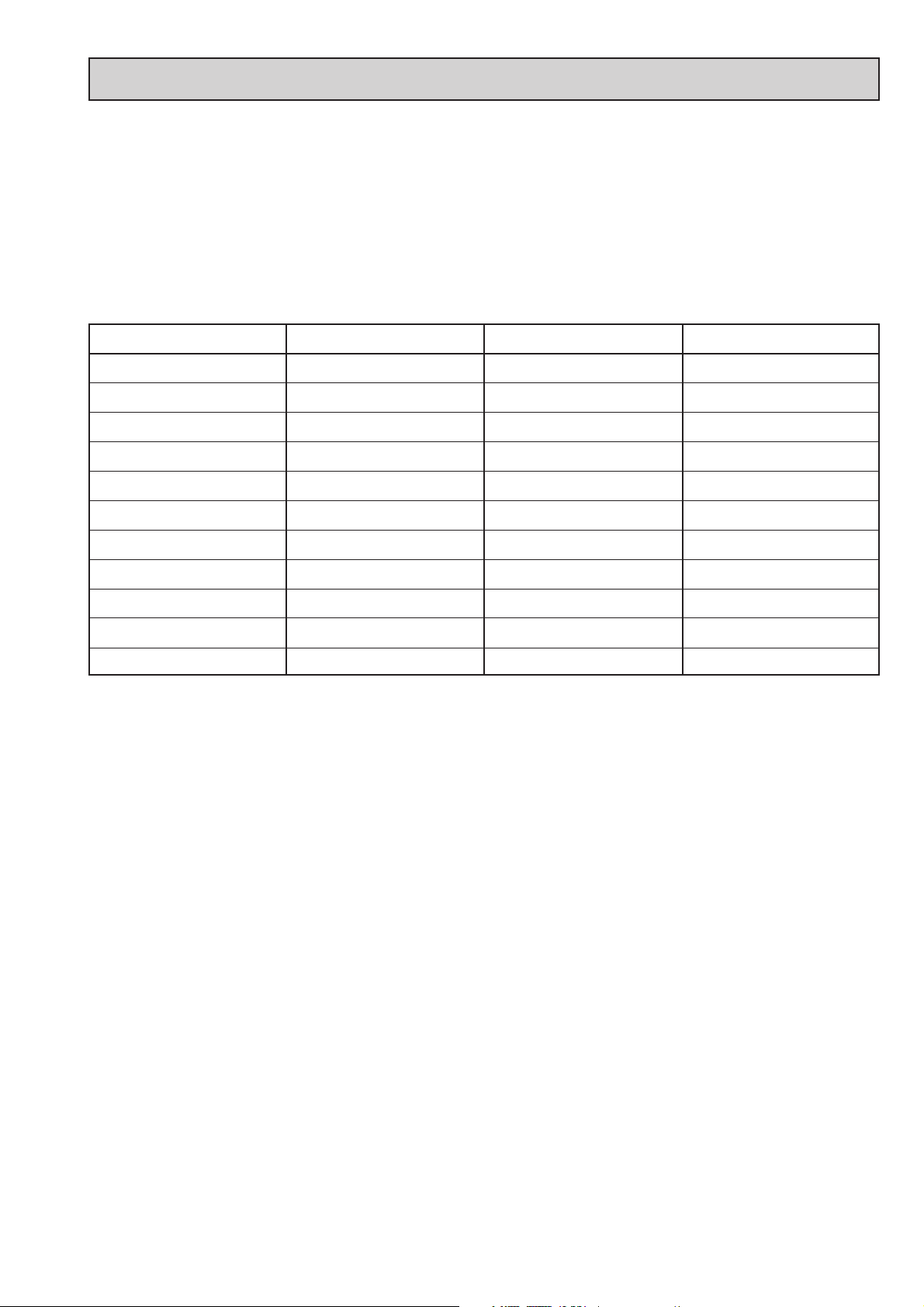

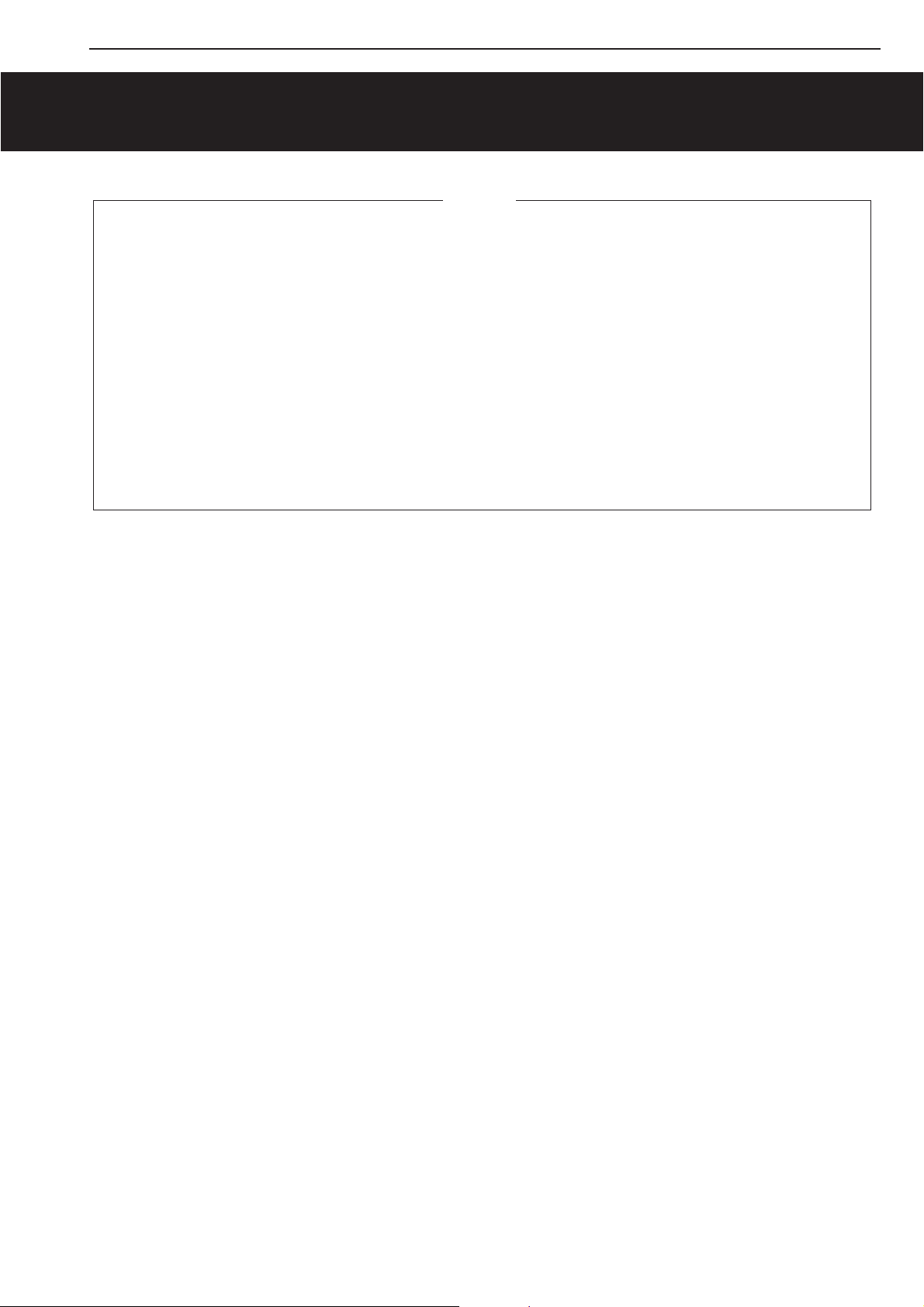

REPLY FAX FOR REPAIR MANUALS

We have made every effort to make our repair manuals as accurate as possible but it is always possible for

a mistake or two to creep in.

To keep improving the quality of our repair manuals, we request mechanics and shop foremen to assist us

as follows:

If you find any errors or inaccuracies in one of our repair manual – whether these are technical errors,

incorrect or unclear repair procedures, tool problems, missing technical data or torques, inaccurate or

incorrect translations or wording, etc. – please enter the error(s) in the table below and fax the completed

form to us at 0043/7742/6000/5349.

NOTE to table:

– Enter the complete item no. for the repair manual in column 1 (e.g.: 3.210.66-E).

You will find the number on the cover page or in the left margin on each right page of the manual.

– Enter the corresponding page number in the repair manual (e.g.: 5-7c) in column 2.

– Enter the current text (inaccurate or incomplete) in column 3 by quoting or describing the respective

passage of the text. If your text deviates from the text contained in the repair manual, please write your

text in German or English if possible.

– Enter the correct text in column 4.

Your corrections will be reviewed and incorporated in the next issue of our repair manual.

Item no. of repair manual Page Current text Correct text

Additional suggestions, requests or comments on our Repair Manuals (in German or English):

Name mechanic/shop foreman Company/work shop

Page 14

Repair manual 250 / 300 / 380 Art Nr 3206004 -E

OPERATING RANGES OF THE CARBURETOR . . . . . . . . . . . . . . . . . . .2-2

CARBURETOR ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

CHECKING OF THE SETTING OF THE TVC SYSTEM . . . . . . . . . . . . . .2-4

BLEEDING OF THE HYDRAULIC CLUTCH . . . . . . . . . . . . . . . . . . . . .2-4

SPECIAL TOOLS - ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

STORAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

INDEX

2-1C

GENERAL INFORMATION

2

Page 15

Page 16

Repair manual KTM 250 / 300 / 380 Art No 3206004 -E

2-2C

main jet

jet needle

jet needle

air control screw

idle adjusting screw

idle jet

throttle valve

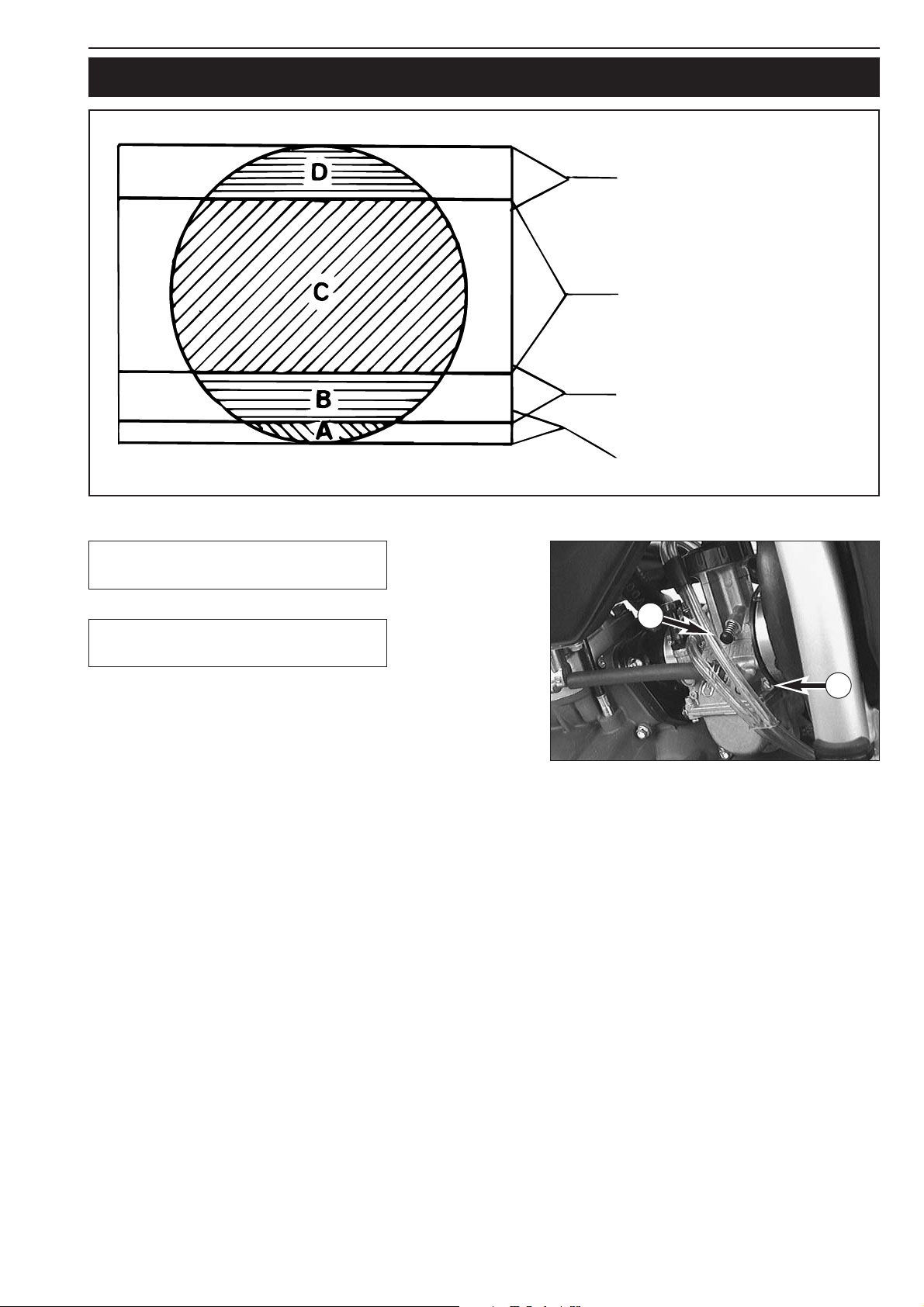

Idling range A

Operation with closed throttle valve. This range is influenced by the position of the air control screw 1 and the idle adjusting screw

2. Only make adjustments when the engine is hot.

To this end, slightly increase the idling speed of the engine by means of the idle adjusting screw. Turning it clockwise produces a

higher idling speed and turning the screw counterclockwise produces a lower idling speed. Create a round and stable engine speed

using the air control screw (basic position of the air control screw = open by 1.5 turns). Then adjust to the normal idling speed by

means of the idle adjusting screw.

Opening up B

Engine behavior when the throttle opens. The idle jet and the shape of the throttle valve influences this range. If, despite good

idling-speed and part-throttle setting, the engine sputters and smokes when the throttle is fully opened and develops its full power

not smoothly but suddenly at high engine speeds, the mixture to the carburetor will be too rich, the fuel level too high or the float

needle is leaking.

Part-throttle range C

Operation with partly open throttle valve. This range is only influenced by the jet needle (shape and position). The optimum

part-throttle setting is controlled by the idling setting in the lower range and by the main jet in the upper range. If the engine runs

on a four-stroke cycle or with reduced power when it is accelerated with the throttle partly open, the jet needle must be lowered by

one notch. If then the engine pings, especially when accelerating under full power at maximum engine revs, the jet needle should

be raised.

If these faults should occur at the lower end of the part throttle range at a four-stroke running, make the idling range leaner; if the

engine pings, adjust the idling range richer.

Full throttle range D

Operation with the throttle fully open (flat out). This range is influenced by the main jet and the jet needle. If the porcelain of the

new spark plug is found to have a very bright or white coating or if the engine rings, after a short distance of riding flat out, a larger

main jet is required. If the porcelain is dark brown or black with soot the main jet must be replaced by a smaller one.

mixture too rich:

too much fuel in proportion to air

mixture too lean:

not enough fuel in proportion to air

1

2

OPERATING RANGES OF THE CARBURETOR

Page 17

2-3C

Carburetor adjustment

Basic information on the original carburetor setting

The original carburetor setting was adapted for an altitude of approx. 500 meters (1600 ft.) above sea level, and the ambient

temperature of approx. 20° C (68° F), mainly for off-road use and central European premium-grade fuel (ROZ 95 MOZ). Mixing

ratio 2-stroke motor oil : super fuel 1:40 – 1:60.

Basic information on a change of the carburetor setting

Always start out from the original carburetor setting. Essential requirements are a clean air filter system, air-tight exhaust system and

an intact carburetor. Experience has shown that adjusting the main jet, the idling jet and the jet needle is sufficient and that changes

of other parts of the carburetor will not greatly affect engine performance.

RULE OF THUMB:

high altitude or high temperatures

➞ choose leaner carburetor adjustment

low altitude or low temperatures

➞ choose richer carburetor adjustment

WARNING

–O

NLY USE PREMIUM

-GRADE GASOLINE ROZ 95 MIXED WITH HIGH-GRADE TWO-STROKE ENGINE OIL. OTHER TYPES OF GASOLINE CAN CAUSE ENGINE

FAILURE

, AND USE OF SAME WILL VOID YOUR WARRANTY.

–O

NLY USE HIGH-GRADE 2-STROKE ENGINE OIL OF KNOWN BRANDS.

–N

OT ENOUGH OIL OR LOW

-GRADE OIL CAN CAUSE EROSION OF THE PISTON. USING TOO MUCH OIL, THE ENGINE CAN START SMOKING AND FOUL THE

SPARK PLUG

.

–I

N THE CASE OF A LEANER ADJUSTMENT OF THE CARBURETOR PROCEED CAUTIOUSLY

. ALWAYS REDUCE THE JET SIZE IN STEPS OF ONE NUMBER TO AVOID

OVERHEATING AND PISTON SEIZURE

.

NOTE: If despite a changed adjustment the engine does not run properly, look for mechanical faults and check the ignition system.

Basic information on carburetor wear

As a result of engine vibrations, throttle valve, jet needle, and needle jet are subjected to increased wear. This wear may cause

carburetor malfunction (e.g., overly rich mixture). Therefore, these parts should be replaced after 10000 kilometers (6000 miles).

Explanation - Example

Compared to the needle N 85 A, the jet needle N 85 C is two steps leaner

in the range from the closed position of the throttle to 1/4 throttle.

Otherwise, there are not differences.

!

CAUTION

!

W

HEN CHANGING THE JET NEEDLE, MAKE SURE THAT YOU USE THE CORRECT NEEDLE

TYPE

(N 85 ,NOZ OR N3). THE TECHNICAL DATASHEET TELLS YOU WHICH JET

NEEDLE CAN BE USED FOR WHICH MODEL

.

N 85 C

0

–1/4 – –

jet needle throttle valve open effect

N 85 A

N 85 B 0

–1/4 –

N 85 C 0

–1/4 – –

N 85 D 0

–1/4 – – –

N 85 E 0

–1/4 – – – –

NOZ C

NOZ D 0

–1/4 –

NOZ E 0

–1/4 – –

NOZ F 0

–1/4 – – –

NOZ G 0

–1/4 – – – –

NOZ H 0

–1/4 – – – – –

NOZ I 0

–1/4 – – – – – –

NOZ J 0

–1/4 – – – – – – –

N3CG

N3CH 0

–1/4 –

N3CW 0

–1/4 – –

Page 18

Repair manual KTM 250 / 300 / 380 Art No 3206004 -E

2-4C

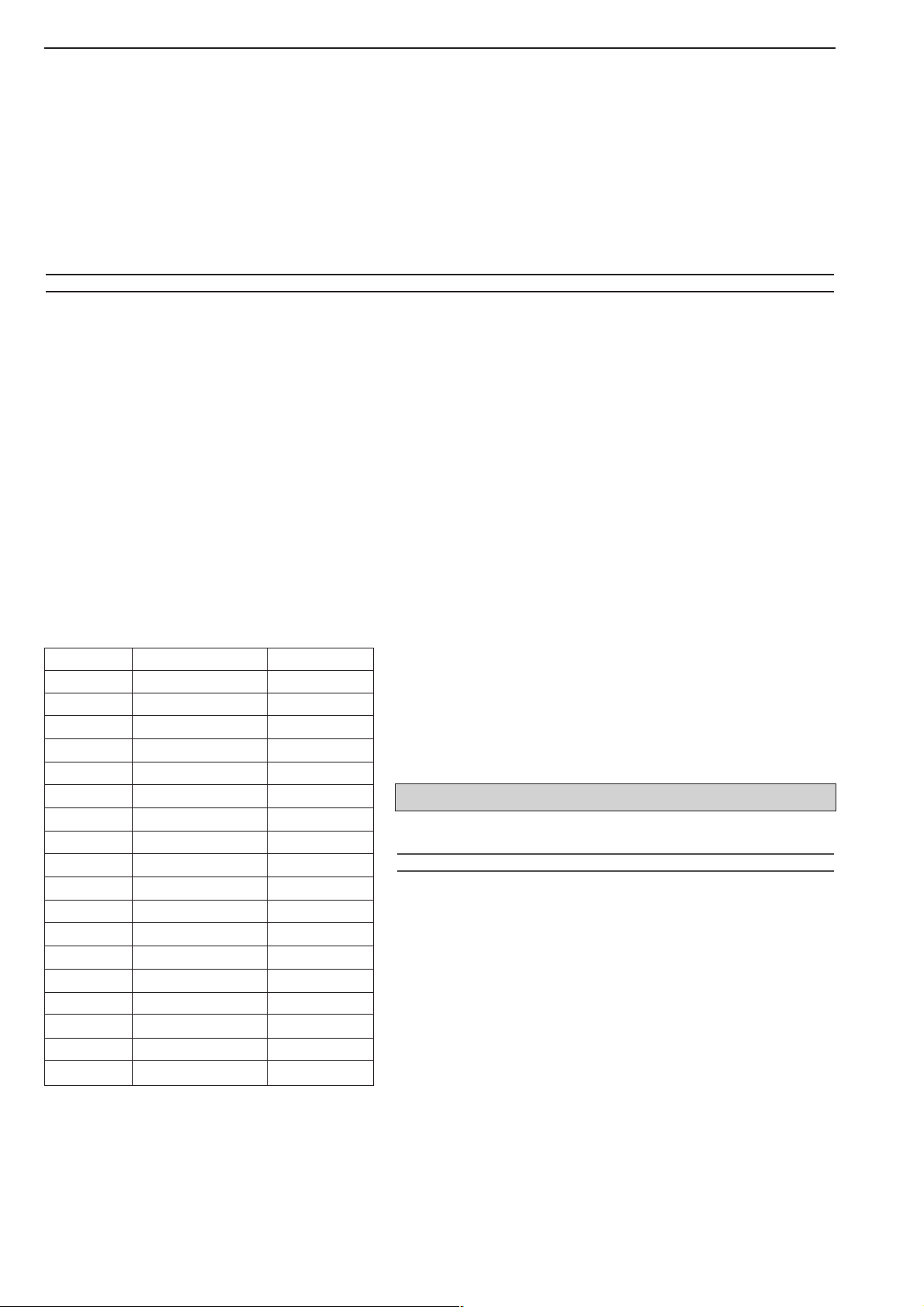

Checking the setting of the TVC system

The function of the TVC system is checked with the engine running.

This test checks the start of advance and the end of advance.

– For this, remove the left control cover.

– Connect a rev counter (either to the ignition cable or to the blue/white

cable in the electronics box, depending on the rev counter design).

– Start engine, accelerate gently and observe when the TVC system

starts to advance (tooth segment creeps upwards).

– If necessary, turn the adjusting screw

1.

NOTE: Twisting the adjusting screw in delays the commencement of

adjustment by the TVC system, twisting the adjusting screw out means

that the TVC system will perform the adjustment earlier.

Bleeding of the hydraulic clutch

–Take off cover together with rubber bellows.

– At the slave cylinder of the clutch, remove the bleeder nipple

2. It its

place, mount the bleeder syringe

3 which is filled with SAE 10

hydraulic oil.

– Refill oil, until oil is discharged from the bore

4 of the master cylinder

in a bubble-free state. Make sure that the oil does not overflow.

!

CAUTION

!

–HAVING COMPLETED THE BLEEDING PROCEDURE, YOU HAVE TO VERIFY THAT THE

OIL LEVEL IN THE MASTER CYLINDER IS CORRECT

.

– KTM

USES BIODEGRADABLE HYDRAULIC OIL FOR THE HYDRAULIC CLUTCH

CONTROL

. NEVER MIX BIODEGRADABLE HYDRAULIC OILS WITH MINERAL OILS.

–ALWAYS USE BIODEGRADABLE HYDRAULIC OIL SAE 10 TO FILL UP THE MASTER

CYLINDER

. NEVER REFILL WITH MINERAL HYDRAULIC OIL OR BRAKE FLUID.

1

start of advance end of advance

250 Model 1999 5400 U/min 7550 U/min

250 from Modell 2000 on 5000 U/min 7000 U/min

300 up to Modell 2000 5300 U/min 7750 U/min

300 from Modell 2001 on 5900 U/min 7750 U/min

380 5200 U/min 7200 U/min

2

3

4

Page 19

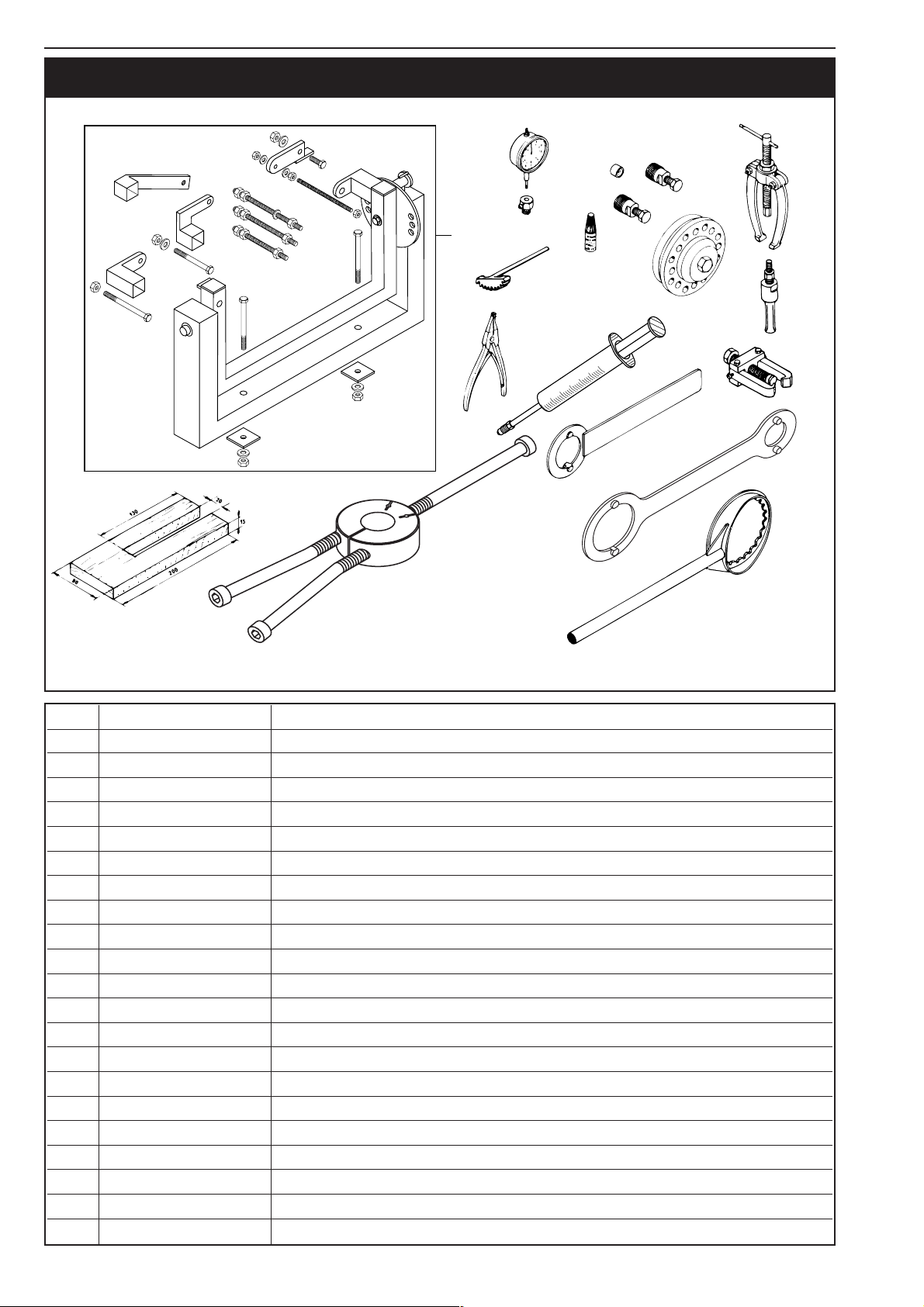

2-5C

Fig. Part no. Description

1 560.12.001.000 Universal engine work stand

3 546.29.003.000 Clutch holder

4 560.12.004.000 Gear wheel segment

5 546.29.009.044 Magneto extractor M 27x1 Kokusan

66 276 807 Magneto extractor M 26x1,5 SEM

7 510.12.011.000 Circlip plier

8 544.12.012.000 Holding spanner for flywheel SEM

9 584.29.037.040 Mounting tool inner ring NJ 207

9 584.29.037.043 Mounting tool inner ring NJ 207

10 510.12.016.000 Protection cap

11 546.29.012.100 Holding spanner for flywheel Kokusan

13 501.12.013.000 Dial gauge 0-10 mm

14 501.12.030.000 Dial gauge support

16 6 899 785 Loctite 243 blue 6 ccm

17 151.12.017.000 Bearing puller

18 151.12.018.100 Internal bearing puller 18-23 mm

18 151.12.018.000 Internal bearing puller 12-16 mm

18 151.12.018.200 Internal bearing puller 5-7 mm

19 546.29.027.000 Clutch rivetting tool

25 0276 179 000 Extractor primary gear

26 503.29.050.000 Vent springe for hydraulic clutch

SPECIAL TOOLS – ENGINE 250 / 300 / 380

13

14

1

7

9

16

4

26

10

8

5

19

6

11

17

18

25

3

Page 20

Repair manual KTM 250 / 300 / 380 Art No 3206004 -E

2-6C

Should you wish to make a pause over a longer space of time, please observe the following instructions:

– Clean motorcycle thoroughly (see chapter: CLEANING)

– Change engine oil (old engine oil contains aggressive contaminants).

– Check antifreeze and amount of cooling liquid.

– Let the engine warm up again, close fuel cock and wait until the engine dies off by itself. In this way the carburetor jets are prevented

from becoming resin- clogged by the old fuel.

– Remove spark plug and fill in approx. 5 ccm of engine oil into the cylinder through the opening. Actuate kick-starter 10 times in order

to distribute the oil onto the cylinder walls and mount the spark plug.

– Let fuel flow out of tank into an appropriate container.

– Correct tire pressure.

– Lubricate bearing points of the control levers, footrests, etc. as well as the chain.

– The storage place should be dry and not be subjected to too big temperature fluctuations.

– Cover the motorcycle with an air permeated tarp or blanket. Do not use non airtight materials as a possible humidity might not be

able to escape and thereby cause corrosion.

!

CAUTION

!

I

T WOULD BE VERY BAD TO LET THE ENGINE RUN FOR A SHORT TIME DURING THE STORAGE PERIOD. THE ENGINE WOULD NOT GET WARMED UP ENOUGH AND

THE THUS DEVELOPED STEAM WOULD CONDENSE DURING THE COMBUSTION PROCESS AND CAUSE THE VALVES AND EXHAUST TO RUST

.

USE AFTER A PERIOD OF STORAGE

– Fill up the tank with fresh fuel.

– Check the motorcycle as before each start (see driving instructions)

–Take a short, careful test ride first.

NOTE: Before you put your motorcycle away for the winter, you should check all parts for their function and wear. Should any service

jobs, repairs, or any refitting be necessary, you should have them carried out during the off-season (lower workload at mechanics'

shops). This way, you can avoid the long waiting times at your shop at the beginning of the next biking season.

STORAGE

Clean your motorcycle regularly in order to maintain the beauty of its plastic surfaces.

The best manner would be to use warm water that has been mixed with a normal brand-name washing detergent and a sponge.

The hard dirt can be removed before washing with the help of a soft water jet.

!

CAUTION

!

NEVER CLEAN YOUR MOTORCYCLE WITH A HIGH-PRESSURED CLEANER OR A HIGH-PRESSURED WATER JET. THE WATER COULD OTHERWISE RUN INTO THE

ELECTRICAL COMPONENTS

, CONNECTORS, SHEATHED CABLES, BEARINGS, CARBURETOR, ETC. AND CAUSE DISTURBANCES OR LEAD TO A PREMATURE

DESTRUCTION OF THESE PARTS

.

– Before cleaning with water, plug the exhaust pipe to prevent water ingress.

–You should use normal brand-name detergents to clean the motorcycle. Especially dirty parts should also be cleaned with the help

of a paint brush.

–After the motorcycle has been rinsed with a soft water jet, it should be dried by air pressure and a cloth. Then take a short drive until

the engine has reached the working temperature and also use the brakes. By warming these components, the residual water can

evaporate from inaccessable parts of the engine and the brakes.

– Slide back the protective covers on the handlebar-mounted instruments so that any water that may have seeped into this part of the

motorcycle is allowed to evaporate.

–After the motorcycle has cooled down, oil and grease all the gliding bearing parts. Treat the chain with a chain spray.

–To prevent failures in the electric system, you should treat the ignition lock, the emergency OFF switch, the short circuit button, the

light switch and the socket connectors with contact spray.

CLEANING

In the event that the motorcycle is also used in winter and on roads where one has to expect salt spraying, you will have to take

precautions against the aggressive road salt.

– clean the motorcycle thoroughly and let it dry after each ride

–treat the engine, carburetor, swing arm, and all other bare or galvanized parts (except for brake discs) with a wax-based anti-corro-

sion agent.

WARNING

K

EEP THE ANTI-CORROSION AGENT FROM GETTING INTO CONTACT WITH THE BRAKE DISCS, OTHERWISE THIS WILL SIGNIFICANTLY REDUCE THE BRAKING POWER

.

!

CAUTION

!

A

FTER RIDES ON SALTED ROADS, CLEAN MOTORCYCLE THOROUGHLY WITH COLD WATER AND LET IT DRY WELL.

CONSERVATION FOR WINTER OPERATION

Page 21

Page 22

Repair manual 250 / 300 / 380 Art No 3206004 -E

REMOVING AND REFITTING ENGINE

REMOVING THE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

REFITTING THE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

INDEX

3-1C

3

Page 23

Page 24

Repair manual KTM 250 / 300 / 380 Art No 3206004 -E

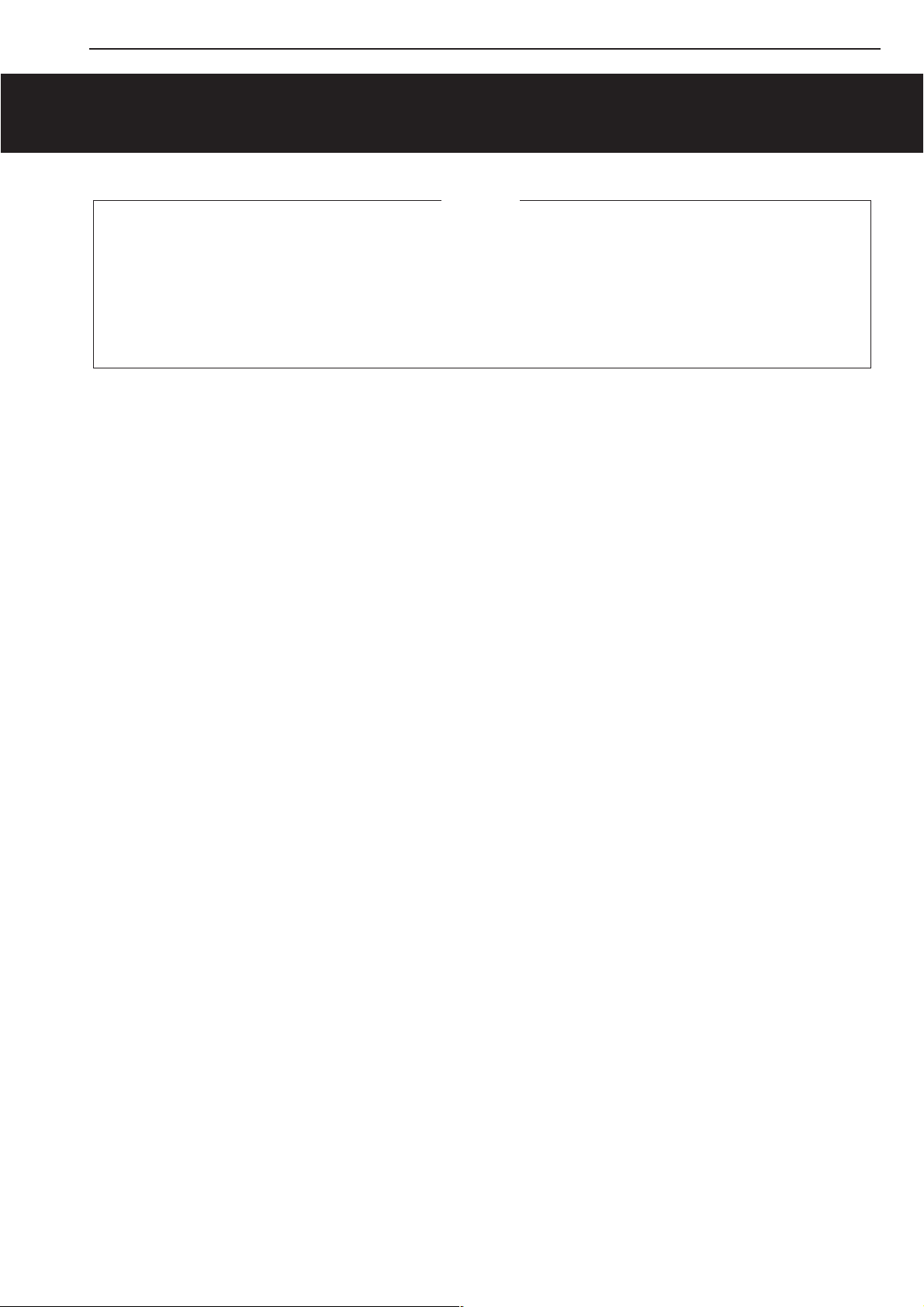

Dismounting the engine

– Clean motorcycle thoroughly.

–Prop up motorcycle on an appropriate stand.

– Remove seat, right side paneling, and tank with spoilers.

– Dismount exhaust system.

– Drain coolant, and disconnect radiator hoses from engine.

– Dismount engine strut

1.

– Disconnect plug-and-socket connector of ignition system and spark-

plug connector.

– Remove sprocket cover

2 and chain.

– Remove footbrake cylinder cover

3.

– Disengage and remove spring

4.

3-2C

1

2

3

4

Page 25

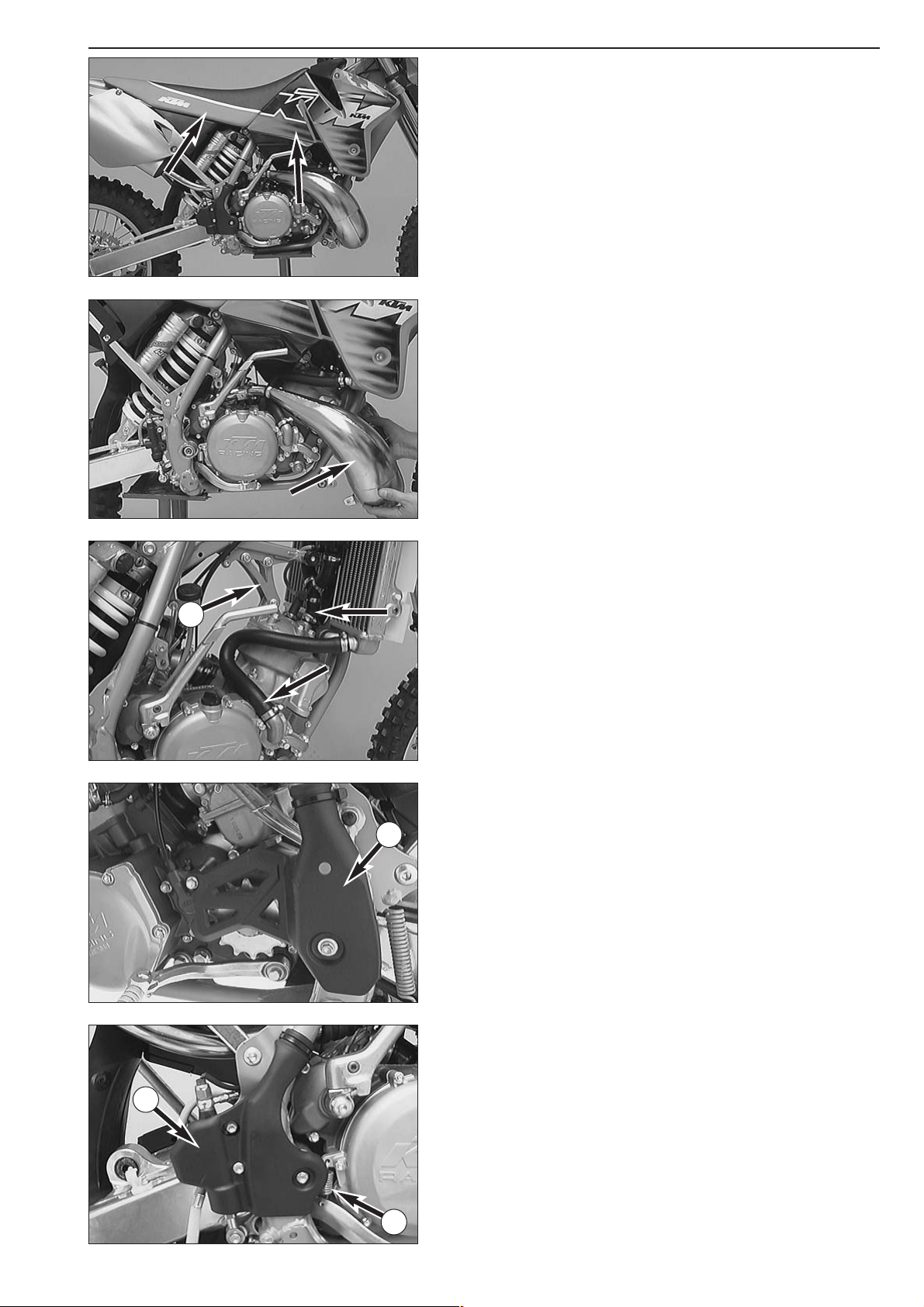

– Loosen the 3 screws, and remove intermediate flange chamber 1 of

KTC system together with O-ring.

– Remove engine fastening screw

2.

– Remove cable ties and loose the cable of ignition from frame.

– Loosen both hose clamps, and pull caburetor out of carburetor

connection boot and intake flange.

– Remove transmission-oil drain plug

3 together with sealing ring, and

drain the transmission oil.

– Remove the 2 screws

4, and dismount clutch slave cylinder.

!

CAUTION

!

D

O NOT ACTUATE THE CLUTCH LEVER WITH THE CLUTCH SLAVE CYLINDER

DISMOUNTED

.

– Remove engine fastening screw

5.

– Remove hexagon nut of swingarm pivot

6.

– Remove swingarm pivot, and pull swing arm backward out of the

frame so as to make lifting the engine out of the frame easier.

– Lift engine out of frame.

NOTE: Cylinder head and cylinder can be dismounted even if the engine

remains mounted. Likewise, work on clutch, primary drive, gearshift

mechanism, and ignition system can be carried out.

3-3C

1

3

5

2

4

4

6

Page 26

Repair manual KTM 250 / 300 / 380 Art No 3206004 -E

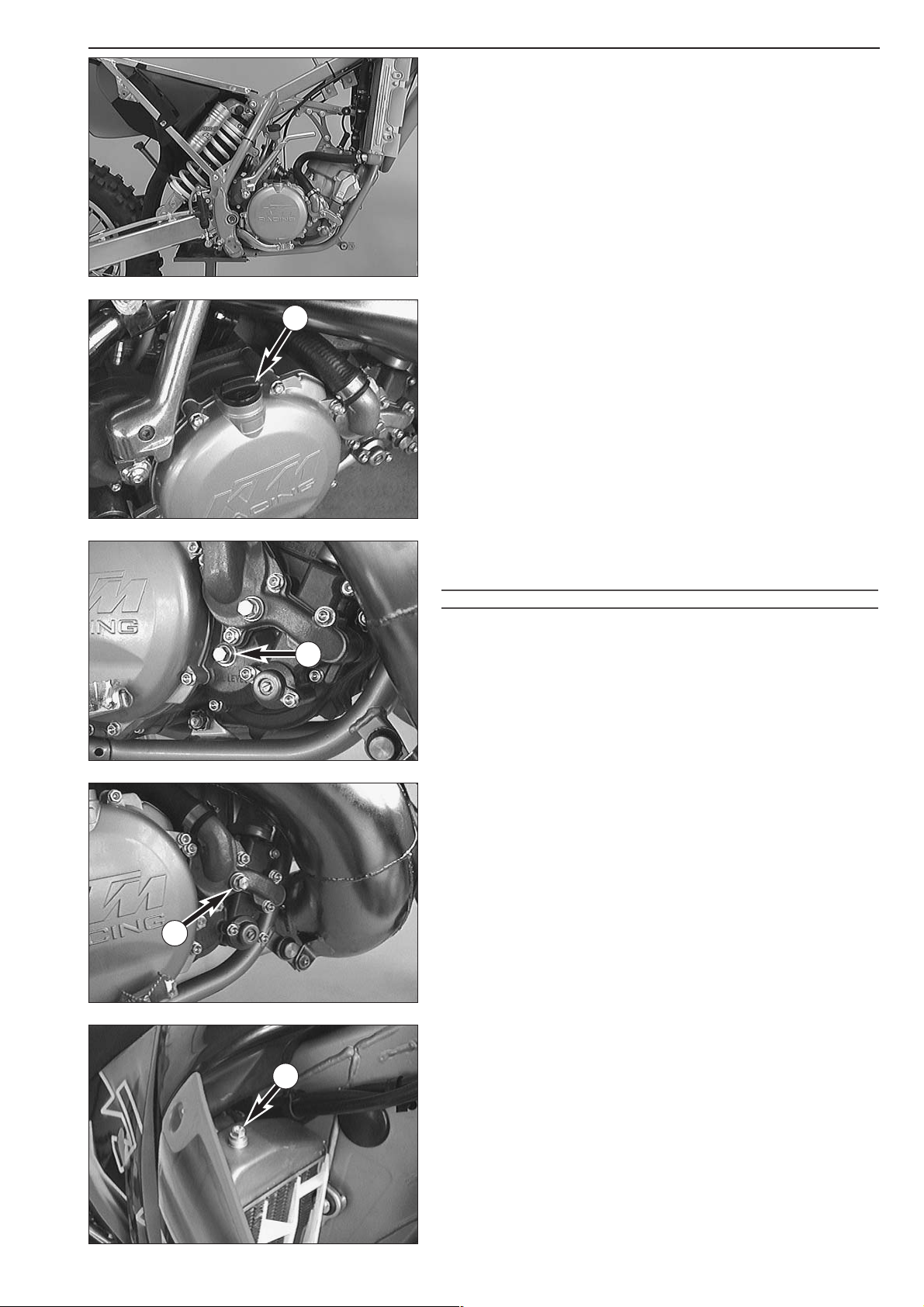

Refitting the engine

–To install the engine, reverse the steps for removing the engine.

Filling in of transmission oil:

– Remove the plug 1 and top up with engine oil 15W-50 (i. e.

MOTOREX TOP SPEED 4T).

– In order to check the transmission oil level the control screw

2 on the

clutch cover is to be removed. Oil should just barely escape from the

inspection opening when the motorcycle is in an upright position.

!

CAUTION

!

T

RANSMISSION AND CLUTCH WILL BE SUBJECT TO AXCESSIVE WEAR AND TEAR, IF YOU

USE TOO LITTLE OR LOW GRADE OIL

. USE ONLY HIGH-GRADE OIL (I.E. MOTOREX

TOP SPEED 4T).

Filling in of cooling liquid:

– Make sure that the drain screw 3 is fastened.

– Pour approx. 0.50 litres (0.13 US gallons) coolant into the system.

40% coolant : 60% water

– Remove the screw 4 on the right radiator and tilt the motorcycle to

the right approx. 30 degree angle.

– Now add cooling liquid until it emerges free of bubbles at the right

radiator. Then immediately mount the screw so that no more air can

enter the right radiator.

– Return the motorcycle to its original position and top up the left

radiator until the coolant can be seen approx. 10 mm (0.4 in) above

the radiator fins.

3-4C

4

2

3

1

Page 27

Page 28

Repair manual 250 / 300 / 380 Art No 3206004 -E

DISASSEMBLING THE ENGINE

DRAINING GEAR OIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

DISMOUNTING OF SPROCKET AND SHIFT LEVER . . . . . . . . . . . . . . .4-2

DISMOUNTING OF CYLINDER HEAD, CYLINDER AND PISTON . . . . .4-2

DISMOUNTING OF CLUTCH COVER . . . . . . . . . . . . . . . . . . . . . . . .4-3

DISMOUNTING OF PRESSURE CAP AND CLUTCH DISCS . . . . . . . . . .4-4

DISMOUNTING OF THE PRIMARY DRIVE . . . . . . . . . . . . . . . . . . . . .4-4

DISMOUNTING OF KICKSTARTER . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

DISMOUNTING OF THE SHIFT LOCK . . . . . . . . . . . . . . . . . . . . . . . .4-5

DISMOUNTING OF IGNITION COVER . . . . . . . . . . . . . . . . . . . . . . .4-5

DISMOUNTING OF THE IGNITION (KOKUSAN) . . . . . . . . . . . . . . . . .4-6

DISMOUNTING OF THE IGNITION (SEM) . . . . . . . . . . . . . . . . . . . . .4-6

DISMOUNTING OF INTAKE FLANGE AND REED VALVE HOUSING . . .4-7

PARTING OF ENGINE HOUSING HALVES . . . . . . . . . . . . . . . . . . . . . .4-7

DISMOUNTING OF GEARSHIFT MECHANISM AND TRANSMISSION . .4-7

DISMOUNTING OF THE CRANKSHAFT . . . . . . . . . . . . . . . . . . . . . . .4-8

INDEX

4-1C

4

Page 29

Page 30

4-2C

Repair manual KTM 250 / 300 / 380 Art No 3206004 -E

– Cleaning the engine thoroughly.

– Clamp the engine into the workstand.

– Remove the kickstarter together with the distance bushing behind.

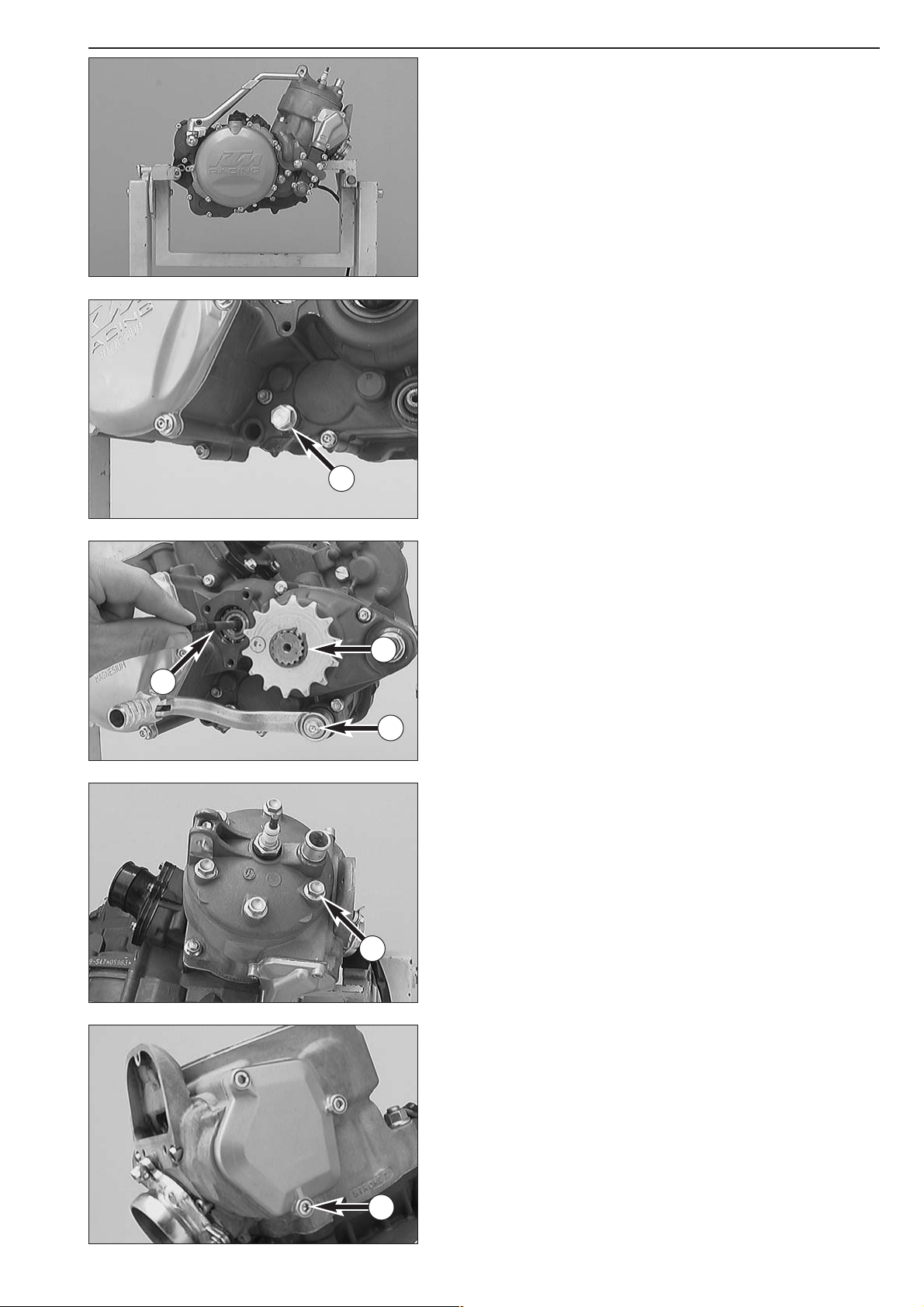

Draining gear oil

NOTE: The transmission oil should already be drained when the engine is

dismounted. Otherwise, the transmission oil will leak out of the drive

shaft following the removal of the slave cylinder of the clutch.

– Unscrew plug

1, allowing oil to drain.

Dismounting of sprocket and shift lever

– Remove circlip 2 from countershaft using circlip pliers. Slide off engine

sprocket, distance bushing and O-ring.

– Undo the screw

3 and remove the shift lever.

– Pull out the clutch push rod

4 from drive shaft.

Dismounting of cylinder head, cylinder and piston

– Unscrew the 6 collar screws 5 and remove cylinder head and the two

O-rings.

– Undo the screws

6 and remove the left control cover together with

the gasket.

1

2

3

4

5

6

Page 31

4-3C

– Undo the screws 1 and remove the right control cover.

– Remove the securing clip of the ball socket

2 and unhook the ball

socket

3 from the adjusting lever.

– Remove gasket of the control cover.

– Remove the 4 collar nuts

4 on cylinder base and remove cylinder.

– Cover the crankcase.

– Place piston on wooden jig and remove both piston pin locking pins.

– Expel piston pin from piston without exerting undue force. Use a

suitable mandrel if necessary.

– Remove piston and piston pin needle-bearing from conrod eye.

– Remove the cylinder base gaskets.

!

CAUTION

!

THE PISTON PIN MUST NEVER BE FORCED OUT WITH A PUNCH. THIS WOULD DAMAGE

THE CONROD BEARING

.

Dismounting of clutch cover

– Remove collar screws and clutch cover including gasket.

NOTE: The water pump cover

6, the outer cover 5 and the cover lid 7

do not need to be removed. The water pump and the centrifugal timer

remain in the clutch cover.

1

2

3

4

5

6

7

Page 32

4-4C

Repair manual KTM 250 / 300 / 380 Art No 3206004 -E

Dismounting of pressure cap and clutch discs

– Loosen collar screws 1 in diagonally opposite sequence to prevent

wedging of discs as springs expand.

– Remove collar screws, springs and spring retainers.

–Take pressure cap and disc package out of outer clutch hub.

–Take thrust bearing 2 off the drive shaft.

Dismounting of the primary drive

– Block the primary gear with the gear wheel segment 3 (see

illustration).

– Undo the hexagon nut (LH thread) and remove it together with the

detent edged ring.

– Release the lock washer of the inner clutch hub.

– Connect clutch holder

4 to inner clutch hub and loosen hexagon nut

(see illustration).

– Remove clutch holder.

– Remove inner clutch hub and outer clutch hub together with bearing

from main shaft.

– Pulling the primary gear

5 and the distance bushing 6 off the

crankshaft.

NOTE: The primary gear and the outer clutch hub belong together.

Always replace both together!

1

2

3

4

5

6

Page 33

4-5C

Dismounting of kickstarter

– Remove circlip 1 and kickstarter intermediate gear.

– Carefully release collar screw

2 kickstarter spring is tensioned, release

tension on kickstarter spring and unhook spring hanger.

!

CAUTION

!

C

AREFULLY RELEASE THE KICKSTARTER SPRING

! DANGER OF INJURY!

–Take the complete kickstarter shaft out of the housing.

–Take care of the stop disc, which could stay in the housing.

Dismounting of the shift lock

–Press the sliding plate 3 back with a screw driver so it no longer

engages with the driver for the shaft roller, at the same time remove

shift shaft from the housing.

NOTE: Watch the stop disc which remains in the housing.

– Remove allan head screw

4 and take driver for roller 5 and locking

piece

6 from the shift roller.

NOTE: From model 2002 driver for roller

5 and locking piece 6 are

made of aluminium.

NOTE: Disassemble locating lever only if the engine case must be

replaced.

– Remove screw

7 and locking lever with spring and bush.

Dismounting of ignition cover

– Undo the 5 screws and remove the ignition cover together with the

gasket.

1

2

3

4

5

6

7

Page 34

4-6C

Repair manual KTM 250 / 300 / 380 Art No 3206004 -E

Dismounting of the ignition (Kokusan)

– Hold the flywheel with the holding spanner 1 and undo the collar nut.

– Put the protection cover on the crankshaft thread, twist in the flywheel

extractor and remove the flywheel.

– Undo the 3 screws

2 and remove the stator together with the base

plate.

Dismounting of the ignition (SEM)

– Hold the flywheel with the special tool and undo the collar nut.

– Place protective cap on crankshaft thread.

–Twist in the flywheel extractor and remove the flywheel.

– Loosen the 3 collar screws 3, and take base plate with stator out of

the casing.

1

2

3

Page 35

4-7C

Dismounting of intake flange and reed valve housing

– Remove the 5 collar screws 1.

– Remove intake flange and reed valve housing.

Parting of engine housing halves

–Top ignition-gear upwards and remove all 11 housing screws.

– Loosen the 2 engine fixtures on the engine work stand.

– Lift left-hand housing half with suitable tools by on the bosses

provided, or part with a few light plastic mallet blows against the

countershaft from the right-hand housing half.

!

CAUTION

!

L

EVERING APART WITH A SCREW DRIVER OR SIMILAR TOOL MUST BE AVOIDED, SINCE

THE SEAL FACES ARE EASILY DAMAGED

.

NOTE: Watch gear shaft stop discs

2 to prevent them sticking to inside

of housing.

Dismounting of gearshift mechanism and transmission

–Take the two stop discs 2 off the transmission shafts.

– Pull the 2 pressure springs 3 out of the shift rails.

3

1

2

2

Page 36

4-8C

Repair manual KTM 250 / 300 / 380 Art No 3206004 -E

– Pull out the shift rails and swing the shift forks aside.

– Pull the shift roller out of the bearing seat.

– Remove the shift forks.

NOTE: During disassembly, watch out for the shift rollers

1 on the

driving pins of the shift forks. They may remain in the shift roller.

Although the counter shaft shift forks are identical they should be refitted

in the same position as before if reused. Therefore mark accordingly upon

removal.

– Remove the 2 pressure springs

2 from the engine case.

– Pull the drive shaft together with the countershaft out of the bearing

seats.

– Remove 1

st

-gear idler gear 3 with needle cage and the two stop discs

from the engine case.

Dismounting the crankshaft

– Pull crankshaft from the bearing seat (if necessary, use a plastic

hammer and tap carefully on the crankshaft journal).

– Remove O-ring from crankshaft.

– Clean all parts and check for wear, replace if necessary.

NOTE: When an engine is completely overhauled it is recommended that

all gaskets, shaft seal rings and O-rings are renewed.

1

2

2

3

Page 37

Repair manual 250 / 300 / 380 Art No 3206004 -E

SERVICING ON INDIVIDUAL COMPONENTS

WORKING ON THE RIGHT-HAND HOUSING HALF . . . . . . . . . . . . . .5-2

WORKING ON THE LEFT-HAND HOUSING HALF . . . . . . . . . . . . . . . .5-3

CRANKSHAFT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

CRANKSHAFT WEBS – MEASURE OUTER DIMENSION . . . . . . . . . . . .5-4

PISTON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

PISTON RING END GAP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

CHECKING CYLINDER FOR WEAR . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

RECOATED CYLINDER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

NIKASIL COATING OF CYLINDER . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

CYLINDER EXHAUST CONTROL SYSTEM . . . . . . . . . . . . . . . . . . . . .5-6

CYLINDER PREASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

EXHAUST CONTROL, CLUTCH COVER . . . . . . . . . . . . . . . . . . . . . . .5-8

PREASSEMBLY OF CLUTCH COVER . . . . . . . . . . . . . . . . . . . . . . . . .5-8

REED VALVE HOUSING, INTAKE FLANGE . . . . . . . . . . . . . . . . . . . . .5-9

CLUTCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

REPLACE OUTER CLUTCH HUB . . . . . . . . . . . . . . . . . . . . . . . . . . .5-11

SHIFT MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-12

PREASSEMBLY OF SHIFT SHAFT . . . . . . . . . . . . . . . . . . . . . . . . . . .5-12

IGNITION (KOKUSAN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-13

SPARK PLUG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-13

CHECK STATOR AND PULSE GENERATOR (KOKUSAN) . . . . . . . . . . .5-13

IGNITION (SEM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-14

CHECK STATOR (SEM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-14

TRANSMISSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-15

ASSEMBLY MAINSHAFT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-15

ASSEMBLY COUNTERSHAFT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-16

KICKSTARTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-17

ASSEMBLE OF KICKSTARTER SHAFT . . . . . . . . . . . . . . . . . . . . . . . .5-17

INDEX

5-1C

5

Engine housing

NOTE: Read through the following section before commencing work. Then determine the assembly sequence so that the engine

housing halves only need to be heated up once before replacing the bearings.

Having first removed the dowels, in order to expel the bearings or remove them with light mallet blows, the housing halves must be

placed on a suitably large plane surface, supporting the whole of the sealing surface without damaging it. A wooden panel is best

used as a base.

Bearings or shaft seal rings should not be hammered into their seats. If no suitable press is available, use a suitable mandrel and

hammer them in with great care. Cold bearings will practically drop into their seats at an engine housing temperature of approx.

150° C.

After cooling, should the bearings fail to lock in the bore, they are bound to rotate after warming. In that event the housing must

be replaced.

Page 38

Page 39

Repair manual KTM 250 / 300 / 380 Art No 3206004 -E

Working on the right-hand housing half

– Remove all shaft seal rings and use an oven to heat the casing half to

approx. 150°C.

Grooved ball bearing of crankshaft

1

Press old grooved ball-bearing inwards. Press in new ball bearing to the

stop. The open side of the ball cage must be towards the bottom

(outside) of the case.

Grooved ball bearing of main shaft

2

Press in new ball bearing from inside up to the stop.

!

CAUTION

!

DO NOT USE FORCE WHEN PRESSING THE GROOVED BALL BEARING AGAINST THE

RETAINING BRACKET

3 TO AVOID A BENDING OF THE BRACKET

, WHICH WOULD RESULT

IN EXCESSIVE AXIAL PLAY OF THE MAINSHAFT

.

Grooved ball bearing of countershaft

4

Press in new grooved ball bearing from downward to the stop. The open

side of the ball cage must be face inwards.

Grooved ball bearing of the shift roller

5

Remove retaining screws A and press bearing inwards. Press in new ball

bearing from inside to the stop and secure retaining screws with Loctite

243.

Needle bushing of the shift shaft

6

Press old needle bushing inwards, press in new needle bushing flush from

the outside.

Grooved ball bearing of centrifugal timer

7

The bearings usually fall out of their seat of their own accord by knocking

the housinq half on a plane piece of wood when the housing has a

temperature of 150° C. If necessary use a 6 mm internal bearing extractor

and guide hammer (see illustration). Press in new grooved ball bearing to

the stop.

Bearing bolt kickstarter intermediate gear

8

Experience has shown that it is never necessary to replace the bearing

bolt. It is not recommended to mount a used bearing bolt in a new

housing half, as it is practically impossible to remove it without causing

damage.

Kickstarter release plate

9

When replacing the release plate, secure the flat-head screws with Loctite

243.

Crankshaft seal ring

bk

Press in new shaft seal ring from the outside, with sealing lip facing

inward, until flush.

Stop screw kickstarter

bl

When mounting the stop screw, it must be secured with Loctite 243. Do

not forget new copper seal ring.

Retaining bracket

3

When replacing the retaining bracket, the two collar screws are to be

secured with Loctite 243.

– Finally check clear passage of the crankshaft ball bearing lubrication

bore

S.

5-2C

1

2

3

4

5

6

7

8

9

10

A

A

7

S

11

Page 40

Working on the left-hand housing half

– Remove all shaft seal rings and use an oven to heat the casing half to

approx. 150°C.

Crankshaft roller bearing

1

Press old roller bearing inwards, press in new ball bearing to the stop with

the open side of ball cage downwards (outside). The inner ring on the

crankshaft must also be renewed (see paragraph about crankshaft).

Needle bearing of drive shaft

2

Press old grooved ball bearing inward, press new grooved ball bearing

from the inside up to the stop.

Grooved ball bearing of countershaft

3

Press old ball bearing inwards, press in new ball bearing to the stop from

inside.

Grooved ball bearing of shift roller

4

Ball bearing falls out of its seat of its own accord when housing half has

been heated to approx. 150° C.

If necessary, knock housing half on a plane piece of wood. Press in new

grooved ball bearing to the stop.

Needle bushing of shift shaft

5

Remove shaft seal ring and press old needle bushing inwards. Press in

new needle bushing from the outside to the collar

D.

Crankshaft seal ring

6

Press in new crankshaft seal ring from the outside, with sealing lip facing

inwards. The seal ring is 1 mm (0.04 in) lower than the upper edge ot the

collar (see sketch).

Counter shaft seal ring

7

Press in the new shaft seal ring, until it is flush with machined surface.

Shift shaft seal ring

8

Press in the new shaft seal ring, until it is flush with machined surface.

When housing half has cooled off, check to see that the bearings are

tight.

– Finally check clear passage of the crankshaft roller bearing lubrication

bore

S.

5-3C

1

2

3

4

5

6

7

8

6

S

5

1 mm (0.04 in.)

D

Page 41

Repair manual KTM 250 / 300 / 380 Art No 3206004 -E

Crankshaft

– When replacing the roller bearing, the inner crankshaft ring must also

be renewed.

– Heat special tool 584.29.037.040 on a heating pad up to approx.

150°C and slip it on the inner ring immediately. Press the special tool

together tightly so as to obtain a good heat transfer and pull the inner

ring off the crankshaft.

–To mount the new inner ring, heat the special tool again to approx.

150°C, engage the inner ring and slip it on the crankshaft journal

immediately.

!

CAUTION

!

N

EVER CLAMP THE CRANKSHAFT WITH A STUD OR WEB IN THE VICE, AND NEVER TRY

TO KNOCK THE BEARING INNER RING FREE

. THE CRANKSHAFT WEBS MAY BE

COMPRESSED AND THE CONROD PLUG AND BEARING MAY BE DAMAGES

, THEREBY

MAKING THE CRANKSHAFT UNUSABLE

.

NOTE: Distance adjustment of the main bearings is not requested.

Crankshaft webs – measure outer dimension

Crankshaft webs – measure outer dimension with a sliding caliper as

illustrated.

Crankshaft webs – outer dimension = 60 mm ± 0.05 mm

Piston

If a used piston is to remain in service then the following should be

checked:

1. Piston running surface: Check for pressure marks (seizing marks) minor

friction marks can be removed with a fine abrasive stick.

2. Piston ring grooves: The piston rings must not get jammed in the

grooves. For cleaning the grooves, use an old piston ring or abrasive

paper (grain size 400).

3. The piston ring locating pins must be firmly seated in the piston and

must not be worn out.

4. Check piston rings for wear and check end gap.

Piston ring end gap

– Insert piston ring into the cylinder and adjust. Piston ring must be

approx. 10 mm (1/2 inch) from top of cylinder.

– The end gap

B can now be checked with a feeler gauge.

Piston ring end gap: max. 0.40 mm (0.015 in)

NOTE: If the end gap is greater check piston and cylinder for wear. If

piston and cylinder wear are within the permitted tolerance limits, replace

the piston ring.

5-4C

Page 42

Checking cylinder for wear

Measure diameter of cylinder approx. 10 mm (0.4 in.) below top of

cylinder edge. Check diameter in several corresponding places to see if

cylinder in worn oval.

Recoated cylinder

NOTE: If the cylinder diameter is larger than e.g. 66.360 mm the cylinder

must be regenerated or replaced.

For reconditioning of the old cylinder all exhaust control components

must be removed. The intermediate flange

1 remains with the cylinder.

The piston size is stamped into the bottom of the piston.

Nikasil coating of cylinder

Nikasil is the brand name for a cylinder coating process, developed by the

piston manufacturer Mahle. The name is derived from the two materials

used in this process - a nickel layer into which the particularly hard silicon

carbide is inbedded.

The main advantages of the Nikasil coating are:

● excellent heat dissipation and thus better power output

● low wear

● low weight of the cylinder.

NOTE: The worn coating can be regenerated at low cost provided that

the cylinders running surface is flawless.

5-5C

1

Engine Cylinder Ø Piston size

250

67,500 - 67,512 1

67,513 - 67,525 2

300

72,000 - 72,012 1

72,013 - 72,025 2

380

78,000 - 78,012 1

78,013 - 78,025 2

250 66,340 - 66,350 1

starting with the 2000 mod

66,351 - 66,360 2

300 71,940 - 71,950 1

starting with the 2000 mod

71,951 - 71,960 2

10mm

x

y

Page 43

Repair manual KTM 250 / 300 / 380 Art No 3206004 -E

Cylinder exhaust control system

Dismantle and clean all exhaust control components, check for signs of wear and damage.

Control rollers

1 – Check clearance of bearings. Remove oil-derived deposits.

Check toothing of control rollers for signs of wear.

Gear segments

2 – Check toothing of gear segments and control rollers for signs of wear.

Bearing sleeves

3 – Check bearing sleeves of the control flap for play and easy operation.

Control flap

4 – Clean the control flap. The control flap must not graze inside the exhaust port.

Silicon O-rings

5, 8 + 9 – Check silicon O-rings of control flap and control rollers for signs of wear. Renew if necessary.

5-6C

Cylinder preassembly

– Mount silicon O-rings (16x2 mm) 5 on control rollers and grease.

– Place control rollers

1 in cylinder and mount retaining brackets 6;

secure flat-head screws

7 with Loctite 243.

1

1

2

2

3

3

4

5

5

9

9

6

6

7

7

8

18

19

10

11

12

13

14

8

16

17

6 6

7

7

only 250

Page 44

– Place preassembled control flap in cylinder, engage gear segments in

control rollers in such a manner that, when the control flap is ,open

(pivoted right to the top), the markings of the gear segments and the

gear rollers coincide. Please check that the two control rollers do not

block the cross-section of the port when the control flap is open.

– Coat sealing surface thinly with silicon and mount intermediate flange

bs with 4 O-rings (11,3x2,4 mm).

– Mount exhaust flange

bt and spring hangers. If you are dealing with

a throttled version, do not forget the exhaust throttle.

– Finally check smooth running of exhaust control system.

NOTE: It must be possible to push adjusting lever

bl further upwards

against the spring force.

5-7C

16

17

–Mount and grease silicon O-rings (15x1,50 mm) 9 on control flap and grease.

– Slightly grease the bearing sleeves 3 and plug them on the control flap.

– Mount toothed segments

2 (the toothed segment with the cylindrical pin has to be mounted on the right side).

– On the right-hand side, mount bearing bushing

bk with collar outside, adjusting lever bl with ball head on outside, overload

spring

bm with short leg on outside and spring sleeve bn to control flap.

– Coat allan head screw

bo with Loctite 243 and screw up about 5 revolutions, hook the short leg of the overload spring on to the

cylinder pin (see illustration) and tighten the allan head screw.

– On the left side, mount the stop plate

8. Apply Loctite 243 to the threads of the two screws bq + br, and mount them.

–Turn control rollers

1 in cylinder in such a way that ports are completely open and no edges protrude.

14

13

12

11

10

2

3

9

4

9

3

2

8

16

17

11

Page 45

Repair manual KTM 250 / 300 / 380 Art No 3206004 -E

Exhaust control, clutch cover

– Remove screws 1 and take off the bearing support.

–Take cup tappet

2, adjusting spring 3 and auxiliary spring 4 out of

clutch cover.

–Take off water pump cover, remove allen head screw

6 and take off

water pump wheel

7.

– The centrifugal timer

8 can be pulled out of the bearing.

– Clean all parts and check for signs of wear.

Check play and easy operatability of the adjusting lever in the bearing

9.

Check pin

A of adjusting lever for wear.

Check linkage ball heads

bk for clearance.

Remove circlip

bl and check axial bearings bm and washers for signs of

wear.

If the water pump shaft seal ring

bn is replaced, it should be coated with

Loctite 243 on the outside.

Check grooved ball bearing

bo for clearance.

Preassembly of clutch cover

–Grease water pump shaft seal ring bn and mount centrifugal timer 8.

– Fit adjusting spring

3, auxiliary spring 4 and cup tappet 2 in the

clutch cover.

– Fit bearing support with control lever and linkage. Secure both screws

1 with Loctite 243.

– Mount water pump wheel

7, coat screw 6 with Loctite 243 and

mount with washer.

– Mount dowels of the water pump cover.

– Position gasket and fix water pump cover with 5 collar screws. The

two screws mounted at the dowels must each be provided with one

copper gasket.

5-8C

1

1

6

7

LOCTITE 243

LOCTITE 243

LOCTITE 243

1

9

2

3

10

11

12

4

6

7

13

14

8

A

Page 46

Reed valve housing, intake flange

NOTE: Reed paddles 1 gradually lose tension through operation,

resulting in power loss. Damaged or worn reed paddles must be replaced.

If the reed sealing surfaces

2 of the reed valve housing are also

damaged, replace the complete reed valve housing.

!

CAUTION

!

SECURE ALL SCREWS OF THE REED VALVE HOUSING WITH

LOCTITE 243.

Velocity insert

3

Check for firm mounting and for signs of damage.

Intake flange

4

Check for cracks and other signs of damage.

5-9C

1

2

1

3

4

LOCTITE 243

LOCTITE 243

Page 47

Repair manual KTM 250 / 300 / 380 Art No 3206004 -E

Clutch

Thrust bearing 1 check for wear

Push rod

2 Check for wear. Minimum length: 199 mm (new: 199.80 mm)

Clutch springs

3

New spring length 42,5 mm / 1.7 in (new 43 mm / 1.73 in). Replace all 6 springs if applicable.

9 Lining discs

4

Minimum thickness 2.60 mm (0.102 in) / new disc 2.70 mm (0.106 in). Discs must be plane; there must be minimum spacing of

13.50 mm (0.531 in) between starting surfaces.

8 Steel discs

5

Must be plane, check for mechanical damage.

Inner clutch hub

6

Check contact surfaces of steel discs on the inner clutch hub, maximum 0.50 mm (0.02 in) indentations.

Pressure cap

7

Check contact surfaces A between lining disc and pressure cap for signs of mechanical damage and score marks.

Outer clutch hub

8

Check start surfaces of clutch discs on for wear. If indentations exceed 0.50 mm (0.02 in), replace outer clutch hub (see below).

Check inner ring

9 and needle cage bk for wear.

5-10C

13,5 mm

1

A

2

3

4

5

6

11

13

14

12

7

8

B

10

9

LOCTITE 242

Page 48

5-11C

Replace outer clutch hub

– Drill open the clutch rivets bl in area of retaining bracket bm and

remove parts.

– Check 8 absorbing elements

bn for signs of mechanical damage,

replace all 8 where applicable.

!

CAUTION

!

THE ABSORBING ELEMENTS ARE WIDER THAN THE PRIMARY GEAR CROWN

. TO ENSURE

THAT THE OUTER CLUTCH HUB

8 AND RETAINING BRACKET ARE POSITIONED DIRECTLY

ON THE PRIMARY GEAR CROWN

bo, THE PARTS MUST BE HELD IN POSITION UNDER

TENSION WITH THE CLUTCH RIVETTING TOOL

C WHILE RIVETING.

11

12

11

13

C

14

12

8

C

Page 49

Repair manual KTM 250 / 300 / 380 Art No 3206004 -E

5-12C

Shift mechanism

Shift forks 1

Check shift fork blades A and shift roller driving pin B for signs of wear.

Shift roller

2

Check shift grooves for wear.

Check position of shift roller in grooved ball bearings

3.

Slide plate

4

Check slide plate at meshing points C for wear.

Check return surface

D for wear (renew, if strongly notched).

Check that guide pin

E is securely fixed and check for wear.

Sliding guides

Check sliding guides (excess between guide pin and shift quadrant not to

be more than 0.7 mm / 0.03 in).

Grooved ball bearings

3

Check grooved ball bearings for easy movement.

Shift mechanism

Assemble shift mechanism (see below) and check free play between slide

plate

4 and shift quadrant 5. Free play should be 0.40 - 0.80 mm (0.016

- 0.032 in).

Preassembly of shift shaft

– Fix shift shaft in vice at shorter end (use covered clamps).

– Mount slide plate

4 with guide pins downwards, hook guide pins into

shift quadrant

5.

– Mount pressure spring

6.

– Slide on spring guide

7, slide on return spring 8 with offset end

upwards over the spring guide and lift offset end over bolt

9 (see

illustration).

–Mount the stop disc

bk (14x30x1 mm).

0,40 -

0,80 mm

9

LOCTITE 243

LOCTITE 243

LOCTITE 243

LOCTITE 243

1

1

2

3

3

4

D

E

C

6

7

8

10

5

1

A

B

Page 50

Ignition (Kokusan)

General information

The measurements described below will only reveal severe problems. Coil

short circuits leading to weak ignition sparks or low generator output,

respectively, can only be detected with the help of an ignition test bench.

In the case of malfunction always check the cables and the plug and

socket connections of the ignition system first.

Make sure to select the correct measuring range when performing

measurements.

Spark plug

– Set the electrode distance.

Electrode distance: 0.60 mm (0.024 in)

Insulator

Check for cracks and fissures.

!

CAUTION

!

A

LWAYS USE A SPARK PLUG WITH RESISTOR. OTHERWISE PROBLEMS CAN OCCUR IN

THE

CDI UNIT.

Check stator and pulse generator (Kokusan)

Use an ohmmeter to perform the following measurements:

NOTE: The measuring must be performed at a temperature of 20° C.

Otherwise significant deviations must be expected.

Replace the stator if the measured values deviate significantly from the

setpoint values.

5-13C

Ignition Measure Cable colours Resistance

2K-1 Pulser coil red – green 100 Ω 15%

Exciter

black/red – red/white

24 Ω 15%

2K-2 Pulser coil red – green 100 Ω 15%

Exciter

black/red – red/white

24 Ω 15%

Charge coil ground – yellow 0,74 Ω 15%

2K-3 Pulser coil red – green 100 Ω 15%

Exciter

black/red – red/white

12.7 Ω 15%

Charge coil ground – yellow 0.65 Ω 15%

white – yellow 0.16 Ω 15%

2K-4 Pulser coil red – green 100 Ω 15%

Exciter

black/red – red/white

24 Ω 15%

Charge coil yellow – yellow 0.65 Ω 15%

Kokusan 2K-1/2K-4

Kokusan 2K-2

Kokusan 2K-3

2K-1

2K-2

2K-3

2K-4

Page 51

Repair manual KTM 250 / 300 / 380 Art No 3206004 -E

Ignition (SEM)

General information

The measurements described below will only reveal severe problems. Coil

short circuits leading to weak ignition sparks or low generator output,

respectively, can only be detected with the help of an ignition test bench.

In the case of malfunction always check the cables and the plug and

socket connections of the ignition system first.

Make sure to select the correct measuring range when performing

measurements.

Spark plug

– Set the electrode distance.

Electrode distance: 0.60 mm (0.024 in)

Insulator

Check for cracks and fissures.

!

CAUTION

!

A

LWAYS USE A SPARK PLUG WITH RESISTOR. OTHERWISE PROBLEMS CAN OCCUR IN

THE

CDI UNIT.

Check stator (SEM)

Perform the following measurements with an ohmmeter.

NOTE: The measuring must be performed at a temperature of 20° C.

Otherwise significant deviations must be expected.

Replace the stator if the measured values deviate significantly from the

setpoint values.

5-14C

+

Pole – Pole Resistance

black red 1,7 kΩ

black green 165 Ω 20 Ω

green red 1,7 kΩ

yellow yellow 1,0 Ω

SEM K11

110 mm

LOCTITE 243

Page 52

5-15C

Transmission

Secure mainshaft or countershaft in the vice (using soft jaw-covers).

Remove gears and check the following for wear:

– Needle bearing

– Mainshaft and countershaft pivot points including idler gears

– Shift dogs and gear wheels

–Tooth faces of all gears

–Tooth profile of mainshaft and countershaft and correspondending

gears

– Easy operation of gear-change

Carefully clean components and replace damaged components.

NOTE: Always place circlips with sharp edge facing the components

secured, ensuring that they are not overexpanded (use special pliers).

Check that after any repair of the transmission, circlips should axially not

move more than 0.20 mm (0.006 in) and must not seize between stop

discs.

Assembly mainshaft

– Fix mainshaft in vice with toothed end upwards (use covered clamps).

– Oil all parts before assembly.

– Mount the split needle cage

1 on mainshaft, push 5th idler gear 2

over it with collar downwards.

– Place internally toothed stop disc

3 (22.4x25.7x32.0x1.5 mm) in

position and mount circlip

4 (25x1.64 mm) with sharp edge upwards.

– Place 3

rd sliding gear

5 in position with shift groove downwards,

mount circlip

6 (25x1.64 mm) with sharp edge downwards and

internally toothed stop disc

7 (22.4x25.7x32.0x1.5 mm)

– Mount the split needle cage

8, 4th

idler gear

9 with shift dogs

downwards 2

nd gear bk with collar downwards and stop disc bl

(20.2x33x1.5 mm).

– Finally check all gears for easy running.

1

5

6

7

8

9

10

11

2

3

4

Page 53

Repair manual KTM 250 / 300 / 380 Art No 3206004 -E

5-16C

Transmission

Secure mainshaft or countershaft in the vice (using soft jaw-covers).

Remove gears and check the following for wear:

– Needle bearing

– Mainshaft and countershaft pivot points including idler gears

– Shift dogs and gear wheels

–Tooth faces of all gears

–Tooth profile of mainshaft and countershaft and correspondending

gears

– Easy operation of gear-change

Carefully clean components and replace damaged components.

NOTE: Always place circlips with sharp edge facing the components

secured, ensuring that they are not overexpanded (use special pliers).

Check that after any repair of the transmission, circlips should axially not

move more than 0.20 mm (0.006 in) and must not seize between stop

discs.

Assembly countershaft

– Fix countershaft in vice with toothed end (use covered clamps).

– Oil all parts before assembly.

– Push stop disc

1 (26x40x1,5 mm) onto countershaft.

–Mount 3

rd idler gear 2 with shift dog recesses upwards and circlip 3

(25x2 mm) with sharp edge upwards.

–Mount 5

th sliding gear

4 with shift groove downwards, stop disc 5

(22,2x33x1,5 mm), needle cage 6, 1st free gear 7 with shift dog

recesses downwards and stop disc

8 (17,2x34x1,5 mm) with collar

upwards on the countershaft.

– Remove countershaft from vice and fix again with toothed end

upwards.

–Mount 4

th sliding gear 9 with shift dog upwards, stop disc bk

(28,2x40x1,5 mm), needle cage bl, 2nd idler gear bm with shift dog

recesses downwards and stop disc

bn (25,7x40x1,5 mm).

– Finally check all gears for easy running.

7

8

5

6

4

3

2

1

9

10

11

12

13

Page 54

Kickstarter

Starter gear 1

Check clearance of starter gear.

Starter intermediate gear

2

Check clearance of starter intermediate gear.

Locking pawl

3

Check for signs of wear and damage.

Kickstarter shaft

4

Check for signs of wear and damage.

For changing the locking pawl, press bearing needle

9 out of the

kickstarter shaft.

Assemble of kickstarter shaft

– Fix the kickstarter shaft 4 in a vice with the toothed end upwards (use

covered vice clamps).

– Mount ratchet spring

5 on kickstarter shaft as shown in the

illustration.

– Place needle cage

6 in position, push starter gear 1 over it, pressing

locking pawl

3 inwards so that starter gear passes smoothly over it.

– Hook legs of the starter spring

7 into driving hub 8, push both

together on the starter shaft, hook starter spring leg into kickstarter

shaft bore

A.

– Release kickstarter shaft, and fix stop disc

bk with a small amount of

grease on the kickstarter shaft.

5-17C

A

5

3

1

2

3

5

6

8

7

10

4

9

LOCTITE 243

LOCTITE 243

LOCTITE 648

Page 55

Repair manual 250 / 300 / 380 Art No 3206004 -E

ASSEMBLING THE ENGINE

CRANKSHAFT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

TRANSMISSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

ASSEMBLING THE ENGINE HOUSING . . . . . . . . . . . . . . . . . . . . . . . .6-3

MOUNTING SHIFT MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4

MOUNTING KICKSTARTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4

MOUNT PRIMARY DRIVE AND CLUTCH . . . . . . . . . . . . . . . . . . . . . .6-5

MOUNTING CLUTCH DISCS AND PRESSURE CAP . . . . . . . . . . . . . . .6-6

MOUNTING CLUTCH COVER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-6

MOUNTING PISTON AND CYLINDER . . . . . . . . . . . . . . . . . . . . . . . .6-7

ADJUSTING DIMENSION „X“ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-7

ADJUSTING CONTROL FLAP (DIMENSION „Z“) . . . . . . . . . . . . . . . .6-8

MOUNTING STEERING COVERS . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-9

MOUNTING CYLINDER HEAD . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-9

MOUNTING REED VALVE HOUSING AND INTAKE FLANGE . . . . . . . .6-9

MOUNTING ENGINE SPROCKET . . . . . . . . . . . . . . . . . . . . . . . . . . .6-10

MOUNTING THE IGNITION (KOKUSAN) . . . . . . . . . . . . . . . . . . . . .6-10

MOUNTING THE IGNITION (SEM) . . . . . . . . . . . . . . . . . . . . . . . . .6-11

ADJUSTING IGNITION POINT (SEM) . . . . . . . . . . . . . . . . . . . . . . . .6-11

MOUNTING IGNITION COVER . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-11

MOUNTING STARTING LEVER AND SHIFT LEVER . . . . . . . . . . . . . .6-11

INDEX

6-1C

6

Page 56

Page 57

Repair manual KTM 250 / 300 / 380 Art No 3206004 -E

– Secure the right-hand housing half in the engine work stand.

Crankshaft

– Insert crankshaft from above through grooved ball bearing and push

carefully as far as stop.

!

CAUTION

!

W

HEN PUSHING IN CRANKSHAFT, MAKE SURE CONROD IS FACING CYLINDER.

Transmission

–Grease the driving pins of the shift forks and mount the shift rollers 1.

– Fix the lower stop disc on the countershaft with a small amount of

grease.

– Mount drive shaft together with countershaft, and insert them into the

bearings as far as they will go.

– Shift fork 2 with driving pin A in the middle belongs to the mainshaft.

–Mount the two other shift forks

3 at the countershaft, using the

marks applied before disassembly for better orientation.

!

CAUTION

!

U

SED SHIFT FORKS SHOULD BE MOUNTED IN THE SAME SLIDING GEAR AS BEFORE.

W

ATCH AT THE MARKINGS FROM DISMANTLING

.

– Attach the shift forks to the sliding gears, and insert shift roller into the

grooved ball bearing.

–Attach the shift forks to the shift roller.

!

CAUTION

!

W

HEN ATTACHING THE SHIFT FORKS, MAKE SURE THAT THE SHIFT DRUMS DO NOT

SLIDE OFF THE SHIFT FORKS

.

6-2C

1

2

A

3

Page 58

– Fix the 4 pressure springs 1 with ample amounts of grease in the

gearshift rails.

– Oil gearshift rails and insert them into the gearshift forks (short

gearshift rail toward drive shaft). Insert gearshift rails into the casing

bores as far as they will go.

NOTE: It must now be possible to gently turn gear shafts.

– Slide stop disc

2 (20.2x 33x1.5 mm) on the drive shaft, and stop disc

3 (25.7x40 x1.5 mm) on the countershaft.

Assembling the engine housing

– Remove engine fastener from engine work stand.

– Check that both dowels are in proper place in right-hand housing and

that transmission shaft stop discs have been mounted.

– Apply light coat of grease to sealing surfaces of the housing and

position new gasket.

–Grease shaft seal rings in left-hand half and place left-hand half in

position.

– Position screws and tighten with 8 Nm (6 ft.lb).

– Gently knock crankshaft with plastic hammer and check easy running

of shafts.

– Fix engine in work stand.

6-3C

1

2

3

M6 x ...

45

45

45

45

45

45

60

60

60

60

45

Page 59

Repair manual KTM 250 / 300 / 380 Art No 3206004 -E

Mounting shift mechanism

– Place locating spring with bent leg upwards into engine housing.

– Insert collar sleeve into spring with collar upwards.

– Coat collar screw

1 with Loctite 243.

– Insert locating lever

2 with roll upwards and fix all parts with collar

screw.

– Hook locking spring

3 to lever. The other end of the retaining spring

must abut the casing nose

B.

– Mount roller locking device 4 (plastic part) to shift roller. Ensure that

the flat parts are not in the middle. Pull locking lever from shift roller.

– Mount driver for shift roller

5.

– Coat allan head screw

6 with Loctite 243 and mount.

NOTE: From model 2002 on driver for roller

5 and locking piece 4 are

made of aluminium.

–Grease assembled shift shaft and push into bearings together with

stop disc until slide plate contacts driver for shaft roller.

– Now squeeze, and push shift shaft in to the stop.

– Check that legs of return spring surround both left and right side of

housing nose

A.

–Mount the foot shift lever and shift through all gears. When shifting

through the gears, turn the countershaft. Then remove the foot shift

lever.

Mounting kickstarter

– Place spacing washer on the stop face an place preassembled

kickstarter shaft in bearing bore in such a way that the locking pawl is

outside the release plate.

NOTE: If the kickstarter shaft is mounted correctly, the visible end of the

starter spring must point forward (see photo).

– Hook spring hanger

7 to starter spring, coat screw 9 with

Loctite 243, tighten starter spring approx. 90° clock-wise and fix

spring pawl with allan head screw.

– Adjust starter spring so that the distance to the kickstarter shaft is the

same all around.

– Place starter intermediate gear

8 with the high collar (see sketch)

showing towards the engine casing on to the bearing.

– Slip on stop disc (17.2x25x1 mm) and mount circlip with the sharp

edge showing upwards.

6-4C

1

2

3

4

5

6

A

7

8

9

B

LOCTITE 243

Page 60

Mount primary drive and clutch

–Grease crankshaft seal ring.

– Put the oiled O-ring (25x1.50 mm) onto the crankshaft and mount the

distance bushing with the chamfer facing the crank web.

– Insert woodruff key into crankshaft.

– Place primary gear

1 onto crankshaft with collar downwards.

– Put the inner ring onto the main shaft with the collar facing

downwards, then mount the oiled needle cage

2.

– Mount outer clutch hub and stop disc

3.

– Apply Loctite 243 to the thread of the main shaft.

– Mount inner clutch hub, new lock washer and hexagon nut to main

shaft.

– Position clutch holder

4 and tighten hexagon nut with 100 Nm

(74 ft.lb.).

– Remove the clutch holder and secure the hexagon nut by bending

both brackets of the lock washer upwards.

– Apply Loctite 243 to thread of the crankshaft.

– Fit locking washer and hexagon nut (left hand thread) by hand.

– Block primary drive with gear segment

5 and tighten primary gear

hexagon nut with 150 Nm (110 ft.lb.).

– Remove gear segment and check easy running of primary drive by

turning crankshaft.

6-5C

1

2

3

4

5

Page 61

Repair manual KTM 250 / 300 / 380 Art No 3206004 -E

Mounting clutch discs and pressure cap

–Oil the thrust bearing 1, and slide it over the drive shaft.

– Oil lining discs before mounting.

– Beginning with one lining disc, mount alternately 9 lining discs (≠ 2.70

mm / 0.10 in) and 8 intermediate discs (≠ 1.20 mm / 0.047 in), with

a lining disc forming the final layer upwards.

– Place pressure cap into position; fit clutch springs, spring retainer and

collar screws.

–Tighten the collar screws crosswise. Do not apply more than 6 Nm (4.5

ft.lb.) to prevent damaging of the threads in the inner clutch hub.

Mounting clutch cover

– Check whether both dowels are mounted in clutch cover or engine

housing.

–Grease kickstarter shaft seal ring and position clutch cover gasket.

Secure gasket with a little grease.

– Carefully position preassembled clutch cover and press into place,

turning crankshaft so that centrifugal timer can engage in the primary

gear.

– Fit collar screws (see sketch for screw lengths) and tighten with 8 Nm

(6 ft.lb.).

– Then check easy running of all shafts.

NOTE: If the clutch cover cannot be mounted, verify whether or not the

kickstarter spring has been positioned correctly.

6-6C

M6x ...

70

70

70

70

30

30

30

30

30

30

30

45

1

Page 62

Mounting piston and cylinder

– Before assembly, oil all parts thoroughly at the sliding points.

– Insert needle bearing in conrod eye, mount piston (arrow on piston

head shows direction for exhaust duct).

– Mount piston pin and wire circlips with open side showing downwards

(see sketch).

– Mount cylinder base gaskets.

– Place piston on selfmade wooden stand and position piston ring.

– Place on preassembled cylinder, remove wooden stand and tighten

cylinder down crosswise, using two nuts.

Adjusting dimension „X“

Dimension „X“ is the dimension from upper edge of piston to upper edge

of cylinder with cylinder under low tension and piston in TDC position.

The dimension „X“ should be adjusted extremely carefully by inserting

cylinder base gaskets of suitable thicknesses.

!

CAUTION

!

I

F THE DIMENSION „X“ IS TOO LARGE, THE COMPRESSION RATIO WILL BE REDUCED

AND THE ENGINE LOOSES POWER

. ON THE OTHER HAND, IF THE DIMENSION „X“ IS

TOO SMALL

,

THE ENGINE WILL PING AND OVERHEAT.

– Set the piston to TDC, and apply a sliding gage or straight-edge to the

cylinder. Now, check the distance between the piston's upper edge

and the sliding gage. This distance should be from 0 mm to 0.10 mm

at the most. It can be corrected, if necessary, by adding or removing

of cylinder-base gaskets.

!

CAUTION

!

T

HE PISTON MUST NOT PROTRUDE BEYOND THE CYLINDER'S UPPER EDGE.

– Mount the 2 remaining collar nuts at the cylinder base, and tighten

each of the 4 collar nuts to 35 Nm (27 ft.lb.).

6-7C

Dimension „X“ = 0 mm

+ 0,1 mm

X

Page 63

Repair manual KTM 250 / 300 / 380 Art No 3206004 -E

Adjusting control flap (dimension “Z“)

Note: Dimension “Z“ is the distance from the lower edge of the control

flap to the upper edge of the cylinder, as measured in the centre of the

exhaust port.

– Undo the screws of the stop plate (left side of the cylinder)

1 and 2

and apply Loctite 243 to the threads. Then mount both screws but do

not tighten them yet.

– Set preselected value on depth gauge and fix.

–Swifel control flap upwards and hold depth gauge into cylinder as

shown in the illustration.

– Control flap must rest against depth gauge.

– Allow bump plate

3 to rest against retaining bracket 4.

– Secure bump plate fastening screws

1 and 2.

– Remove depth gauge.

– Having tightened the screws

1 + 2, you have to check the dimension

"Z" again and correct it, if necessary.

–Press linkage of control flap 5 down-wards as far as stop and press

ball socket 6 onto ball of adjusting lever.

When pressing ball socket do not:

● pull the linkage too far up (max. 1 mm / 0.04 in).

● swivel control flap upwards.

– Adjust linkage length if necessary.

–To do so, loosen counter nut

7 and turn ball socket accordingly.

– Retighten counter nut.

– Once adjustments are completed, remove ball socket once again and

fit gasket for control cover.

– Refit ball socket and fit safety device

8.

6-8C

1

2

3

4

5

6

7

8

control

flap

250 Model 1999 : 48,0 mm

+ 0,2 / - 0,6 mm

250 Model 2000 : 50,5 mm

+ 0,2 / - 0,6 mm

250 ab Model 2001 : 49,5 mm

+ 0,2 / - 0,6 mm

300 : 46,0 mm

+ 0,2 / - 0,6 mm

380 : 50,5 mm

+ 0,2 / - 0,6 mm

Page 64

Mounting steering covers

–Mount the right-hand control cover 1, and fix it with 3 screws.

– Place gasket in position and fix left-hand steering cover

2 on cylinder.

Mounting cylinder head

– Clean cylinder and cylinder head sealing surface, place O-rings in

grooves.

– Mount cylinder head with water nozzle on the exhaust side.

– Oil the collar nuts at threads and contact faces.

–Mount the collar screws with new copper gaskets and tighten them

crosswise, taking three turns to achieve the total tightening torque of

35 Nm (25 ft.lb.).

– In first stage, only tighten until slight resistance is felt.

Mounting reed valve housing and intake flange

– Place reed valve housing with velocity insert in inlet duct and fix intake

flange with the 5 collar screws.

6-9C

1

2

Page 65