Rip-Cut

OWNER’S MANUAL

GUIDE D’UTILISATION

MANUAL DEL PROPIETARIO

ITEM# KMA2675

ARTÍCULO# KMA2675

™

www.kregtool.com

SAVE THESE INSTRUCTIONS

Safety Guidelines

• Before using the Rip-Cut™, read, understand, and follow the

safety warnings and operation instructions included with this

product and provided by your saw manufacturer. Keep all

guards and safety devices in place.

• Wear proper eye, ear, and respiratory protection when operating

your saw.

• Use a sharp blade designed for the type of material you

are cutting.

• Always disconnect your saw from power before making

adjustments to the saw or Rip-Cut™.

• Check the cursor alignment before you cut.

• Ensure that the saw blade will not contact the edge guide

during the cut.

• Do not attempt a cut when any part of the Rip-Cut™ interferes

with the operation of the saw blade guard.

Parts:

A 1

Edge Guide

• Make sure both the workpiece and the cutoff piece are

fully supported.

• Adjust the saw so the blade protrudes ⅛" [3mm] through the

workpiece during the cut.

• Keep your hands away from the saw blade during operation.

• Do not use excessive force when cutting. Maintain a steady

and controlled pace.

• Maintain your tools and accessories. Check for misalignment

or binding of moving parts, loose fasteners, broken parts, and

any other condition that may affect safe operation. If an unsafe

condition is discovered, correct it before use.

G 2

Machine screws

B 2

C 1

D 2

E 2

F 1

Self-Tapping Screws

Rail

Set Screws

Base-plate clamps

Sled

H 2

I 1

J 1

K 1

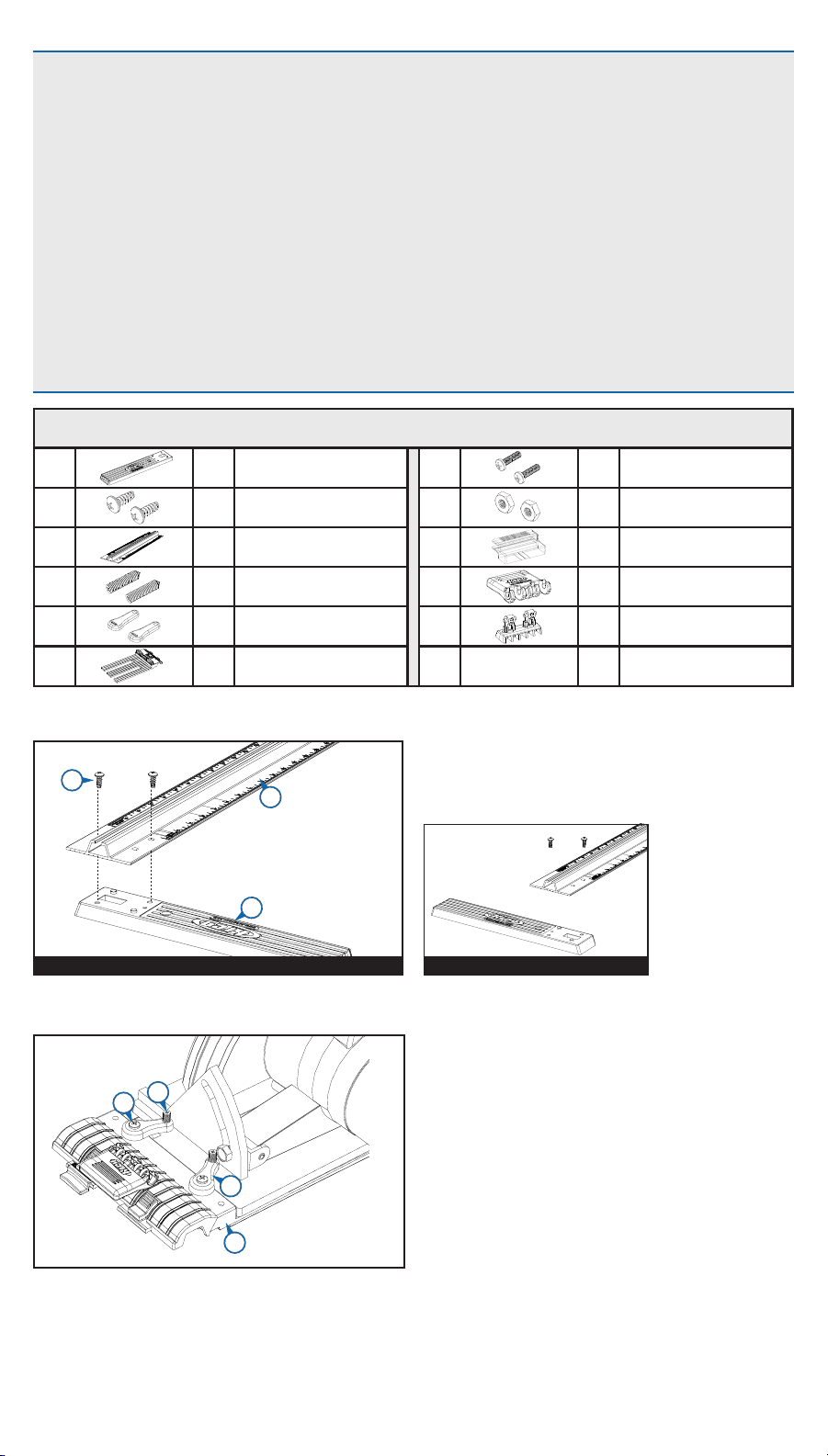

Step 1: Connect the Edge Guide to the Rail

Remove the clear tape covering the recess in the edge guide (A),

B

C

A

Right-hand operation Left-hand operation

remove the two self-tapping screws (B), and use them to secure

the edge guide to the rail (C). Orient the edge guide for right-hand

or left-hand operation as shown.

Step 2: Mount your Circular Saw on the Sled

Loosen the set screws (D) in the base-plate clamps (E) so

your saw base plate can slide under them. With your saw

D

G

E

F

disconnected from power, position it on the sled (F) with the

front of the saw base plate against the step at the front of

the sled. For saws with the blade on the left-hand end of the

motor, center the blade in the left sled slot. For saws with the

blade on the right-hand end of the motor, center the blade

in the right sled slot. To accommodate different saw base-

plate congurations, there are two holes for attaching each

base-plate clamp to the sled. For the most secure clamping,

choose the holes that provide widest spacing allowed by your

saw. The clamps can be oriented at an angle. To relocate a

clamp, loosen the machine screw (G) to free the hex nut (H)

in the recess in the bottom of the sled. Relocate the clamp,

position the hex nut in the corresponding recess, and tighten

the machine screw. Tighten the set screws onto the saw base

plate. Make sure the set screws are tight enough to securely

hold your saw, but do not over tighten. Make sure the saw

blade guard operates freely.

Hex nuts

Cursor

Handle

Wedge

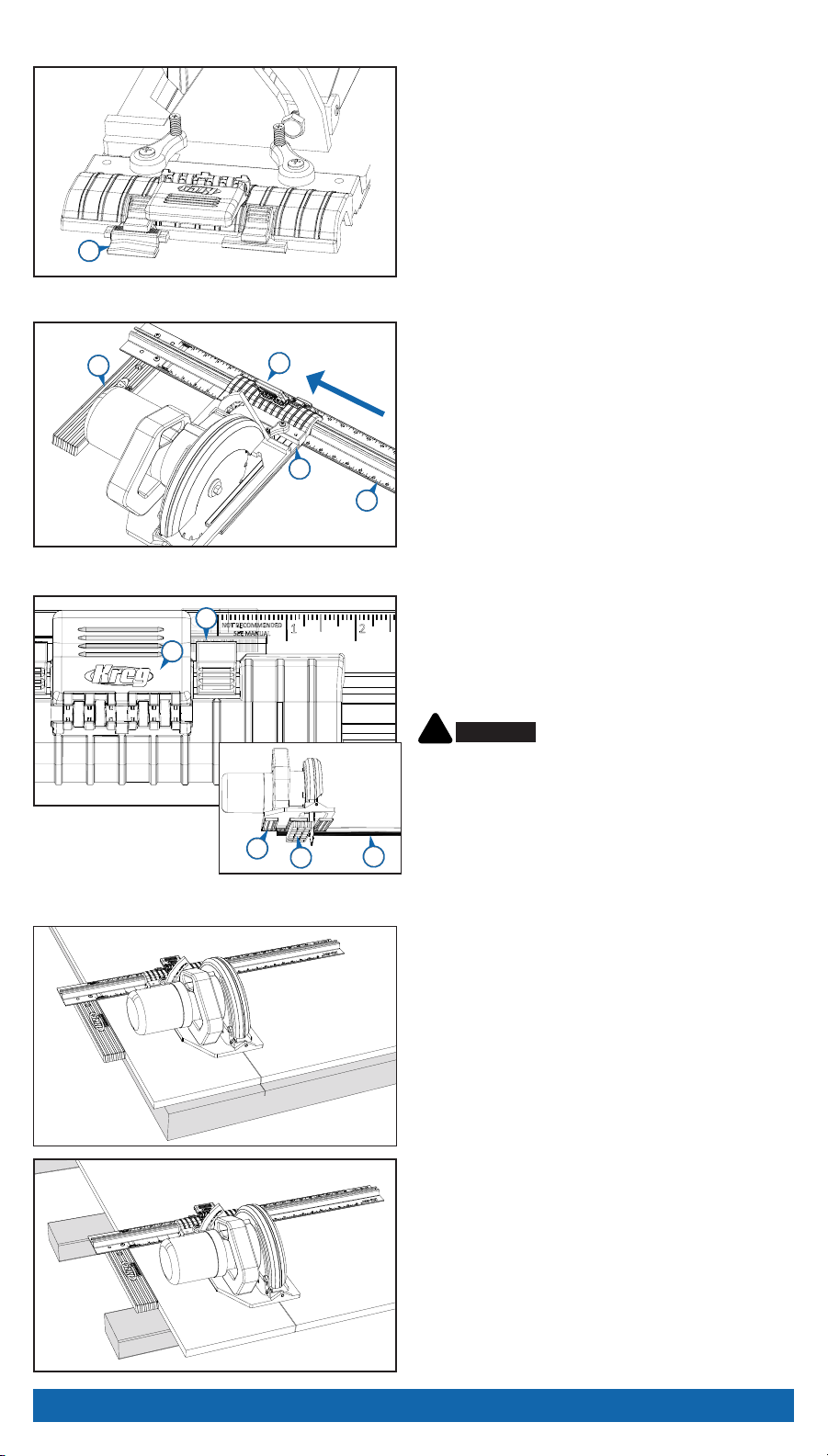

Step 3: Check the Position of the Cursor

There are two positions for the cursor (I) that correspond to

the two sled slots. If the cursor is not in the same position as

the saw blade, press down on the cursor lock, slide the cursor

out of the holder and reinstall it in the other holder.

I

Step 4: Slide the Sled onto the Rail

With your saw clamped to the sled (F), raise the handle (J) to the

A

J

F

C

upright position and slide the sled onto the rail (C), inserting the

wedge (K) into the rail channel. The sled “forks” and the edge guide

(A) should extend from the same edge of the rail.

Step 5: Align the Pointer and Determine the Narrowest Cut

I

J

Rotate the saw blade guard up and slide the sled (F) along

the rail (C) until the blade just touches the edge guide (A).

Lock the sled in place by pressing down on the handle (J).

The handle does not need to be completely horizontal to lock

securely. Press down on the cursor lock and align the cursor

(I) with the zero mark on the rail scale.

Using your Rip Cut

WARNING

!

On the scale, the area between zero and 1" [25mm] is marked

Not Recommended, See Manual. On most saws, the edge

guide interferes with blade-guard operation on cuts of less

than 1" [25mm], so these cuts should not be attempted.

After aligning the cursor, verify the minimum safe cut width

F

A

™

by moving the sled away from the edge guide until the blade

C

guard functions without interference.

1) With the saw mounted on the sled, adjust the depth of cut so

the blade will protrude ⅛" [3mm] through the workpiece

during the cut.

2) Release the wedge lock and slide the sled along the rail

until the cursor aligns with the desired dimension on the

scale. Engage the wedge lock.

3) Completely support the workpiece and cutoff with 2x4s or

2" [50mm]-thick rigid foam insulation laid at on the oor.

4) Connect your saw to power. With one hand on the edge

guide and the other holding the saw, press the edge guide

against the edge of your workpiece and make your cut,

moving the edge guide and saw forward at the same speed

throughout the entire cut. When making narrow cuts, make

sure the hand holding the edge guide does not contact

the blade.

www.kregtool.com • 800.447.8638

CONSERVEZ CES INSTRUCTIONS

Consignes de sécurité

• Avant d’utiliser le Rip-Cut™, veuillez lire, comprendre et

respecter les avertissements de sécurité ainsi que le mode

d’emploi inclus avec ce produit et fournis par le fabricant de

votre scie. Laissez tous les protecteurs et les dispositifs de

sécurité en place.

• Portez toujours des protecteurs appropriés pour les yeux et

les oreilles lorsque vous utilisez la scie.

• Utilisez une lame coupante conçue pour le matériau que

vous coupez.

• Débranchez toujours la scie de la source d’alimentation

avant d’apporter des ajustements à la scie ou au Rip-Cut™.

• Vériez l’alignement du curseur avant de commencer

la coupe.

• Assurez-vous que la lame de la scie n’entre pas en

contact avec le guide de rebord durant la coupe.

• Ne tentez pas d’effectuer une coupe si une partie du

Rip-Cut™ empêche le fonctionnement du protège-lame

de la scie.

Pièces :

A 1

Guide de rebord

• Assurez-vous que la pièce travaillée et celle qui est

coupée reposent entièrement sur la surface de travail.

• Réglez la scie pour que la lame dépasse la pièce

travaillée de 3 mm (1/8 po) durant la coupe.

• Tenez vos mains à distance de la lame de la scie pendant

la coupe.

• N’appliquez pas une pression excessive lors de la coupe.

Maintenez une allure constante et stable.

• Entretenez vos outils et vos accessoires. Inspectez les

pièces mobiles pour vous assurer qu’elles ne sont pas

désalignées, enrayées, mal xées, brisées ni dans un état

pouvant nuire au fonctionnement sécuritaire de l’outil. Si

vous constatez que l’outil n’est pas sécuritaire,

réparez-le avant de l’utiliser.

G 2

Vis à métaux

B 2

C 1

D 2

E 2

F 1

Vis autotaraudeuses

Rail

Vis de calage

Pinces de la plaque de base

Chariot

H 2

I 1

J 1

K 1

Étape 1 : Raccordez le guide de rebord au rail

Retirez le ruban transparent couvrant le renfoncement du guide de rebord

B

C

A

Utilisation de la main droite Utilisation de la main gauche

(A), retirez les deux vis autotaraudeuses (B), et utilisez-les pour xer le

guide de rebord au rail (C). Orientez le guide de rebord pour qu’il puisse

être utilisé de la main gauche ou de la main droite tel qu’il est illustré.

Étape 2 : Installez votre scie circulaire sur le chariot

Desserrez les vis de calage (D) des pinces de la plaque de base (E)

de manière à ce qu’il soit possible de glisser la semelle de la scie

dessous. En vous assurant que votre scie n’est pas branchée sur une

D

G

E

F

source d’alimentation, placez-la sur le chariot (F) de façon à ce que

le devant de sa semelle s’appuie contre la marche située à l’avant du

chariot. Si la lame de votre scie est située du côté gauche du moteur,

centrez-la dans la fente gauche du chariot. Si la lame de votre scie

est située du côté droit du moteur, centrez-la dans la fente droite du

chariot. Les pinces de la plaque de base sont munies de deux trous

de xation permettant différents réglages de la semelle de la scie sur

le chariot. Pour la xation la plus sécuritaire possible, sélectionnez

les trous offrant le plus grand espacement permis par votre scie. Les

pinces peuvent être placées en angle. Pour changer la position des

pinces, desserrez la vis à métaux (G) pour libérer l’écrou hexagonal (H)

situé dans le renfoncement de la partie inférieure du chariot. Changez

la position de la pince, placez l’écrou hexagonal dans le renfoncement

correspondant et serrez la vis à métaux. Serrez les vis de calage sur la

semelle de la scie. Assurez-vous que les vis de calage retiennent votre

scie de façon sécuritaire, mais ne serrez pas trop fort. Assurez-vous

que le protège-lame fonctionne librement.

Écrous hexagonaux

Curseur

Poignée

Cale

Étape 3 : Vériez la position du curseur

Le curseur (I) peut être réglé de deux façons différentes, qui

correspondent aux deux fentes du chariot. Si le curseur n’est pas

dans la même position que la lame de la scie, appuyez sur le verrou

du curseur, glissez le curseur hors du support et réinstallez-le dans

l’autre support.

I

Étape 4 : Glissez le chariot sur le rail

En vous assurant que votre scie est bien xée au chariot (F), levez la poignée

(J) en position verticale et glissez le chariot sur le rail (C) tout en insérant la

A

J

F

C

cale (K) dans la rainure du rail. Les « fourches » du chariot et le guide de

rebord (A) devraient se prolonger à partir du même rebord du rail.

Étape 5 : Alignez le pointeur et choisissez la plus petite coupe

I

J

Tournez le protège-lame de la scie vers le haut et glissez le chariot (F)

le long du rail jusqu’à ce que la lame efeure le guide de rebord (A).

Fixez le chariot en place en appuyant sur la poignée (J). Il n’est pas

nécessaire que la poignée soit complètement à l’horizontale pour être

xée de façon sécuritaire. Appuyez sur le verrou du curseur et alignez

le curseur (I) à la marque du zéro de l’échelle du rail.

Utilisation du Rip Cut

AVERTISSEMENT

!

Sur l’échelle, il est écrit Not Recommended (non recommandé) sur

la zone située entre le zéro et 1 po (25 mm), consultez le guide

d’utilisation. Sur la plupart des scies, le guide de rebord empêche le

bon fonctionnement du protège-lame lors de coupes de moins de

1 po (25 mm). Évitez donc d’effectuer des coupes de cette dimension.

F

A

™

Une fois le curseur aligné, vériez que la largeur minimale de coupe

sécuritaire est respectée en éloignant le chariot du guide de rebord

C

jusqu’à ce que le protège-lame fonctionne correctement.

1) Une fois la scie montée sur le chariot, ajustez la profondeur de la

coupe pour que la lame dépasse de la pièce travaillée de

3 mm (1/8 po) durant la coupe.

2) Déverrouillez le système de serrage et glissez le chariot le long du

rail jusqu’à ce que le curseur s’aligne avec la dimension désirée sur

l’échelle. Enclenchez le système de serrage.

3) Assurez-vous que la pièce travaillée et la partie coupée sont

entièrement soutenues à l’aide de planches de 2 x 4 ou d’un isolant

en mousse rigide d’une épaisseur de 50 mm (2 po) placé sur le sol.

4) Branchez votre scie sur l’alimentation électrique. Avec une main

sur le guide de rebord et l’autre sur la scie, appuyez le guide de

rebord contre le bord de votre pièce travaillée et coupez en avançant

le guide de rebord et la scie à la même vitesse sur toute la longueur

de la pièce. Lorsque vous coupez des pièces étroites, assurez-vous

que la main tenant le guide de rebord n’entre pas en contact avec

la lame.

www.kregtool.com • 800.447.8638

GUARDE ESTAS INSTRUCCIONES

Pautas de seguridad

• Antes de usar la Rip-Cut™, lea, comprenda y respete las

advertencias de seguridad y las instrucciones de

funcionamiento que se incluyen con este producto y que el

fabricante de su sierra le proporciona. Mantenga todos los

dispositivos de seguridad y los protectores en su lugar.

• Use protección adecuada para los ojos, los oídos y el sistema

respiratorio cuando utilice la sierra.

• Utilice una hoja alada y diseñada para el tipo de material que

está cortando.

• Siempre desconecte la sierra de la fuente de alimentación

antes de realizar ajustes a la sierra o a la Rip-Cut™.

• Verique el alineamiento del cursor antes de realizar el corte.

• Asegúrese de que la hoja de la sierra no entre en contacto

con la guía de bordeado durante el corte.

• No intente cortar cuando alguna parte de la Rip-Cut™

interera con el funcionamiento del protector de la hoja

de la sierra.

Piezas:

A 1

Guía de bordeado

• Asegúrese de que tanto la pieza de trabajo como la pieza

que corta cuenten con soporte por completo.

• Ajuste la sierra de modo que la hoja sobresalga 3 mm

(1/8 pulg) por la pieza de trabajo durante el corte.

• Mantenga las manos alejadas de la hoja de la sierra durante

el funcionamiento.

• No ejerza demasiada fuerza cuando realice cortes. Mantenga

un ritmo estable y controlado.

• Dé mantenimiento a sus herramientas y accesorios. Revise

si hay desalineación o adhesión de piezas móviles, si hay

sujetadores sueltos, piezas rotas, así como cualquier otra

condición que pueda afectar la operación segura. Si descubre

una condición insegura, corríjala antes de continuar.

G 2

Tornillos para metal

B 2

C 1

D 2

E 2

F 1

Tornillos autorroscantes

Riel

Tornillos de jación

Abrazaderas de la placa de

la base

Deslizador

H 2

I 1

J 1

K 1

Paso 1: Conecte la guía de bordeado al riel

Retire la cinta transparente que cubre la ranura en la guía de bordeado

B

C

A

Funcionamiento con la mano derecha Funcionamiento con la mano izquierda

(A), retire los dos tornillos autorroscantes (B) y úselos para asegurar

la guía de bordeado al riel (C). Oriente la guía de bordeado para

funcionamiento con la mano derecha o izquierda, como se muestra.

Paso 2: Instale su sierra circular sobre el deslizador

Desajuste los tornillos de jación (D) en las abrazaderas de la placa

de la base (E) de modo que la placa de la base de su sierra pueda

deslizar debajo de las abrazaderas. Asegúrese de que su sierra

D

G

E

F

no esté conectada a la alimentación; colóquela sobre el deslizador

(F) con la parte frontal de la placa de la base de la sierra pegada al

desnivel de la parte frontal del deslizador. Para sierras con la hoja en

el extremo de la mano izquierda del motor, centre la hoja en la ranura

izquierda del deslizador. Para sierras con la hoja en el extremo de

la mano derecha del motor, centre la hoja en la ranura derecha del

deslizador. Para acomodar diferentes conguraciones de placas de

base de sierra, hay dos oricios para jar cada abrazadera de la placa

de la base al deslizador. Para obtener la sujeción más segura, escoja

los oricios que brinden el mayor espaciamiento que su sierra permita.

Las abrazaderas se pueden orientar con ángulo. Para reubicar una

abrazadera, desajuste el tornillo para metal (G) para liberar la tuerca

hexagonal en la ranura en la parte inferior del deslizador. Reubique la

abrazadera, coloque la tuerca hexagonal en la ranura correspondiente

y apriete el tornillo para metal. Apriete los tornillos de jación en la

placa de la base de la sierra. Asegúrese de que los tornillos de jación

estén lo sucientemente apretados para sujetar de forma rme su

sierra, pero no los apriete demasiado. Asegúrese de que el protector

de la hoja de la sierra funcione libremente.

Tuercas hexagonales

Cursor

Manija

Cuña

Paso 3: Verique la posición del cursor

Hay dos posiciones para el cursor (I) que corresponden a las dos

ranuras del deslizador. Si el cursor no está en la misma posición

que la hoja de la sierra, presione sobre el seguro del cursor, deslice

este último para retirarlo del soporte y vuelva a instalarlo en el otro

soporte.

I

Paso 4: Deslice el deslizador en el riel

Sujete su sierra al deslizador (F), levante la manija (J) hasta la posición

vertical y deslice el deslizador en el riel (C), insertando la cuña (K) en la

A

J

F

C

canaleta del riel. El deslizador “se bifurca” y la guía de bordeado (A) debe

extenderse desde el mismo borde del riel.

Paso 5: Alinee el puntero y determine el corte más estrecho

I

J

Gire la protección de la hoja de la sierra y desplace el deslizador (F)

por el riel (C) hasta que la hoja toque a penas la guía de bordeado

(A). Bloquee el deslizador en su lugar presionando sobre la manija

(J). La manija no necesita estar completamente horizontal para

bloquear con seguridad. Presione sobre el seguro del cursor y alinee

el cursor (I) con la marca cero en la escala del riel.

Uso de la Rip Cut

ADVERTENCIA

!

En la escala, el área entre cero y 25 mm (1 pulg) está marcada

“Not Recommended, See Manual” (no se recomienda, consultar el

manual). En la mayoría de las sierras, la guía de bordeado interere

con el funcionamiento del protector de la hoja en cortes de menos de

25 mm (1 pulg), por lo que no debe intentar estos cortes. Después de

F

A

™

alinear el cursor, verique el ancho mínimo para un corte seguro, para

esto mueva el deslizador lejos de la guía de bordeado hasta que el

C

protector de la hoja funcione sin interferencia.

1) Con la sierra instalada sobre el deslizador, ajuste la profundidad de

corte, modo que la hoja sobresalga 3 mm (1/8 pulg) por la pieza de

trabajo durante el corte.

2) Libere el seguro de la cuña y deslice el deslizador por el riel hasta

que el cursor se alinee con la dimensión deseada sobre la escala.

Active el seguro de la cuña.

3) Dé soporte completo a la pieza de trabajo y a la pieza que va a

contar con maderas 2x4 o con aislamiento de espuma rígida de

50 mm (2 pulg) de grosor de forma horizontal sobre el piso.

4) Conecte su sierra a la alimentación eléctrica. Con una mano en

la guía de bordeado y la otra sujetando la sierra, presione la guía

de bordeado hacia el borde de su pieza de trabajo y haga el corte,

moviendo la guía de bordeado y la sierra hacia delante a la misma

velocidad en todo el corte. Cuando haga cortes estrechos, asegúrese

de que la mano que sujeta la guía de bordeado no toque la hoja.

www.kregtool.com • 800.447.8638

www.kregtool.com

Logo on white, gray

or any lighter shade

when printing color

Logo on Pantone

2945 or any darker

shade when printing

color

Logo on white

or light shade when

printing grayscale

KREG TOOL COMPANY

CUSTOMER SERVICE

800.447.8638

Huxley, Iowa

SERVICE À LA CLIENTÈLE

1 800 447-8638

SERVICIO AL CLIENTE

800.447.8638

NK8217

Version 1 - 2/2014

Loading...

Loading...