Precision Router-Table

Insert Plate

INSTALLATION INSTRUCTIONS

Item # PRS3034

[Fits Triton TRA001 and MOF001, all Porter-Cable 7500 series*]

Item # PRS3036

[Fits Bosch 1617, Porter-Cable 690 and 890 series]

Item # PRS3038

[Not drilled]

*Lock-down screw holes and countersinks must be

enlarged for Porter-Cable 7500-series routers.

See the section Before you start in these instructions.

R

Tools Required:

• Phillips Screwdriver

• Masking Tape

• Double-faced Tape

• Drill press

• Drill Bits, Countersink Bit

• Router, top-bearing pattern bit

www.kregtool.com • 800.447.8638

Parts:

• Insert Plate

• (3) Reducing Rings: 1", 13⁄16" (guide bushing), 2⅝"

• Ring Wrench

• (4) ¼-20 x 1¾" fl athead machine screws (lock-down screws)

• ¼-20 x ¾" set screw

• Brass starting pin

• ⅛" hex wrench

• Router-base mounting screws (pre-drilled insert plates only)

WARNING: This product contains one or more chemicals known

to the State of California to cause cancer and birth defects or

other reproductive harm. Wash hands after handling.

NK8090

Version 1 - 4/2013

1.

Precision Insert Plate Installation

Before you start...

These instructions show you how to mount your router on the Kreg Precision Router-Table Insert Plate and

install the insert plate in a shop-built router table. There are two installation methods:

• Create an opening with a rabbeted edge that accepts the insert plate.

• Create a straight-sided opening and install Kreg Precision Router Table Insert Plate Levelers

(item# PRS3040, sold separately).

The section Drill the Insert Plate applies to the undrilled PRS3038 insert plate. The PRS3034 and PRS3036

insert plates are pre-drilled to accept most Triton, Bosch, and Porter-Cable routers. For these plates, simply

fasten your router base to the insert plate using the screws provided with the plate. The PRS3034 insert plate

is pre-drilled for the ¼-20 fl athead machine screws used to mount Triton routers. Porter-Cable 7500-series

routers have the same hole pattern, but use 5/16-18 machine screws. To use a PRS3034 insert plate with

Porter-Cable 7500-series routers, enlarge the router-mounting holes and countersinks to accommodate the

larger machine screws.

Drill the Insert Plate. (PRS3038 only)

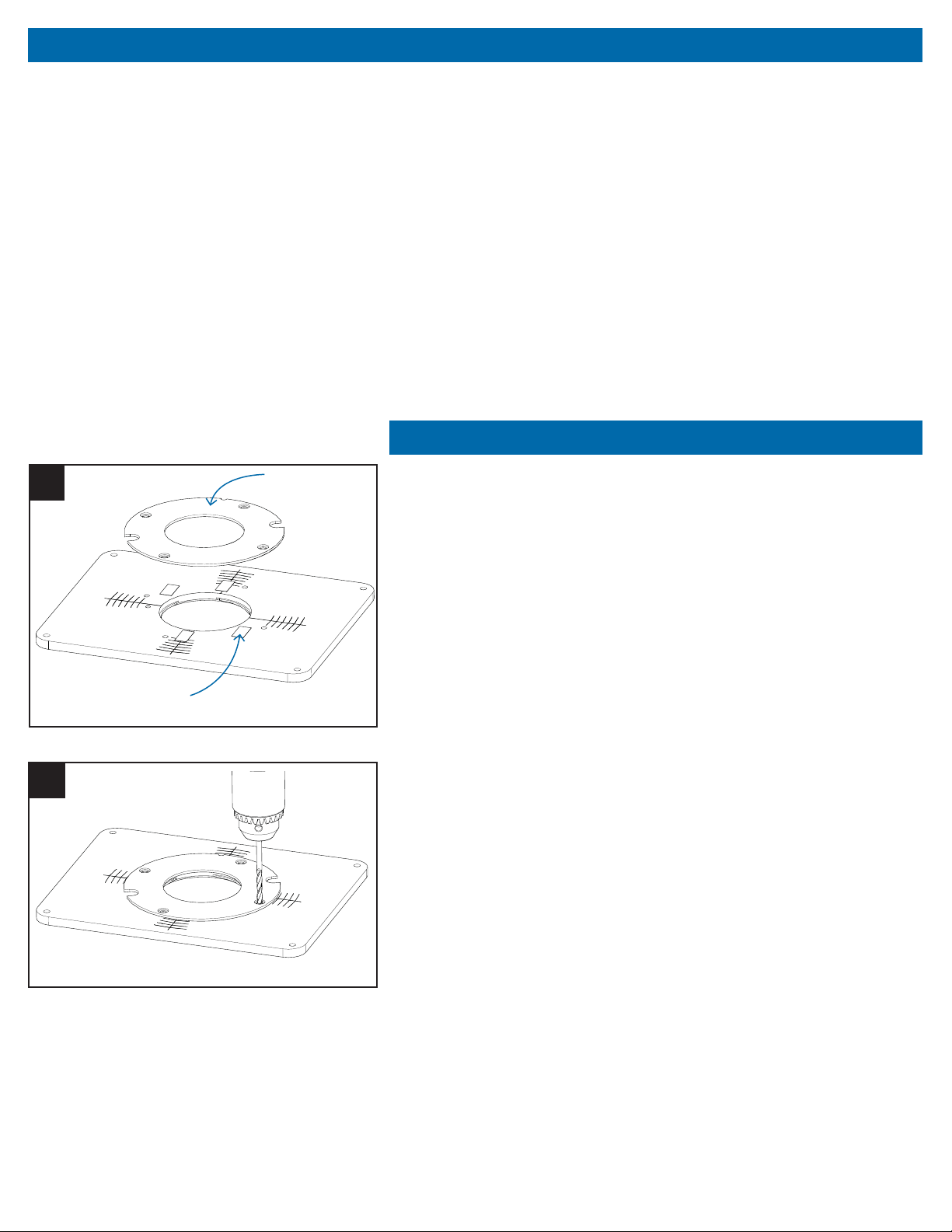

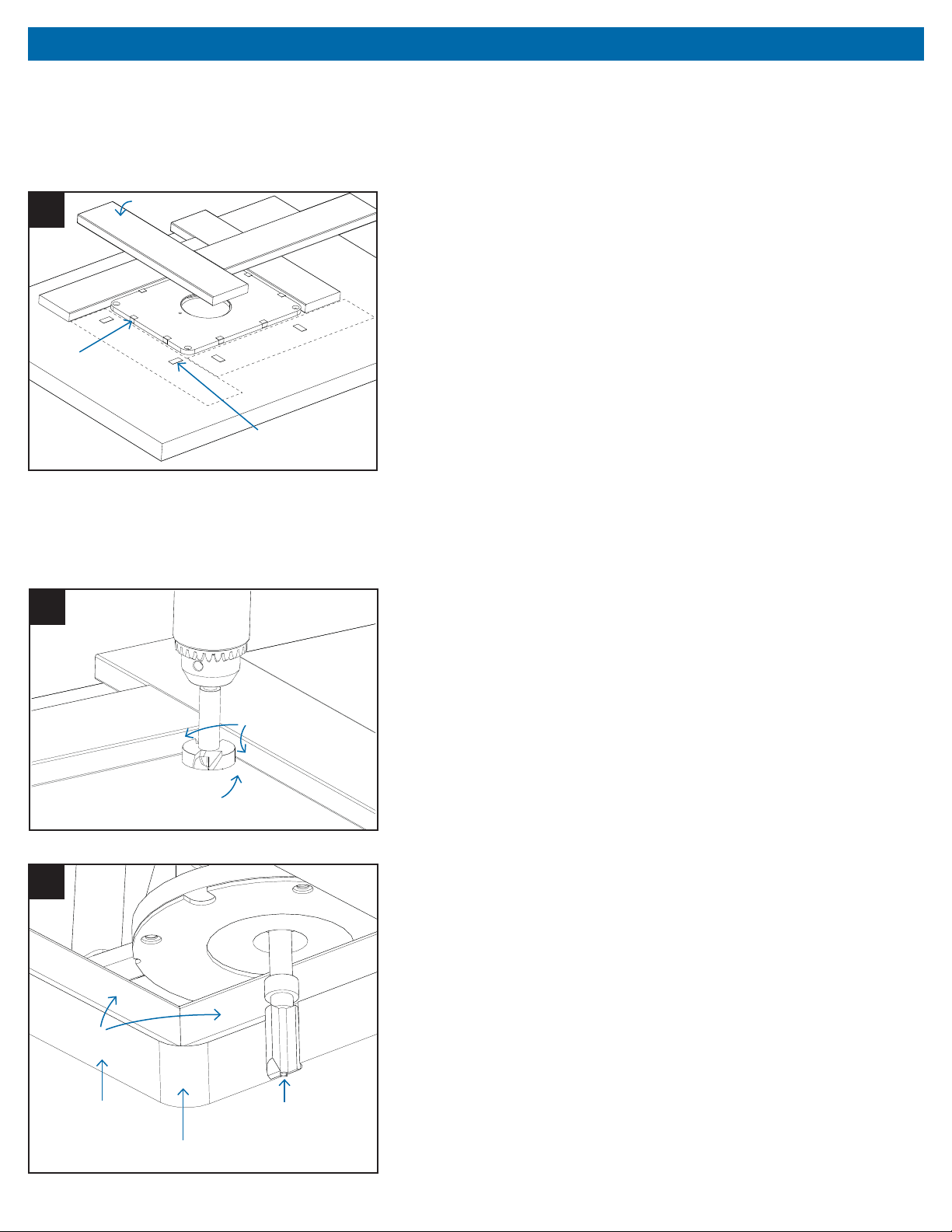

A

Double-faced tape

B

Router sub-base

1. Place the insert plate on your workbench with the target

pattern facing up. Remove the sub-base from your router

and select a drill bit that fi ts the mounting holes. If your router

is equipped with a built-in lift system, also select a bit that

fi ts the lift-access hole. Apply several small pieces of doublefaced tape to the sub-base. Center the sub-base on the

insert-plate, using the target pattern as a guide [Drawing A].

Keep in mind where you want the router controls positioned.

Make sure that none of the holes you are about to drill align

with the threaded hole for the starting pin. Press the subbase fi rmly onto the insert plate.

2. Place a scrapwood backer board under the insert plate

and securely clamp the insert plate and backer to your drillpress table. Using the holes in the sub-base as guides,

drill holes in the insert plate [Drawing B]. With the holes

drilled, remove the sub-base from the insert plate. Flip the

insert plate over and countersink the mounting holes so the

mounting-screw heads sit slightly below the plate surface

when tightened. Store the router sub-base in a convenient

place. You will need it when you remove your router from the

router table for hand-held routing.

C

3

⁄8"

Precision Insert Plate Installation

3

1

⁄

4

"

3

1

⁄

4

"

Router table top

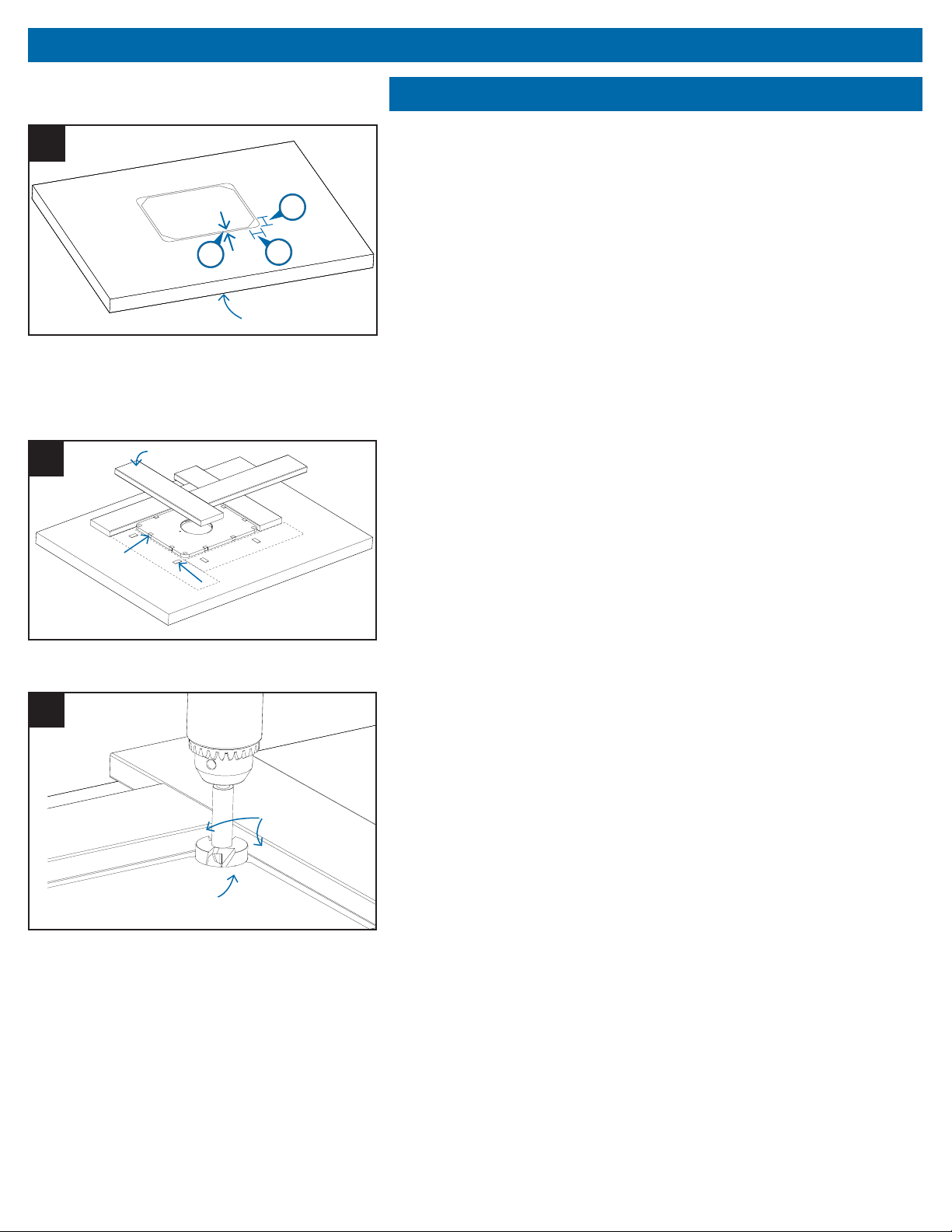

2.

Form the insert-plate opening in your router table top

Rabbeted opening method

1. Position the insert plate on your router table top, squaring the

plate with the table. Trace around the plate with a pencil. Remove

the plate. To form areas to anchor the four ¼-20 x 1 ¾" fl athead

machine screws (lock-down screws) that secure the insert plate to

the router table top, draw 45° lines across each corner of the outline

to form triangles with 1 ¾"-long legs [Drawing C]. Draw lines ⅜"

inside and parallel to the traced insert-plate outline.

D

E

Masking

tape shim

Drill 1½" hole

⅜" deep

Routing guide

Double-faced tape

Drill bit

touches guides

2.

To provide clearance for installing and removing the insert plate,

adhere strips of masking tape to all four edges of the plate. Then

apply small pieces of double-faced tape to one face. (Use just

enough tape to keep the plate in place. Too much tape will make

the plate hard to remove later.) Reposition the insert plate on your

router table top and fi rmly press it into place.

3.

Cut four ¾ x 3½ x 15½" scrapwood routing guides. Apply double-

faced tape and adhere the routing guides to the router table top

with the edges against the masking tape strips on the insert plate

edges [Drawing D]. Remove the plate. Chuck a 1½" Forstner bit

into your drill press. Drilling test holes in the area of the router-table

top you’ll remove for the insert plate, set the drilling depth to ⅜".

With the edge of the bit just touching the inside faces of the routing

guides, drill a ⅜"-deep hole into the router-table top at each corner

[Drawing E].

4. Drill a blade-start hole inside the pencil lines. With the outside

edge of your jigsaw base riding on the routing guides and the inside

edge supported by a ¾"-thick scrapwood block, cut just inside the

lines, leaving the ⅜"-wide area inside the insert-plate outline as well

as the triangular areas at each corner.

3.

Precision Insert Plate Installation

F

Radius corner formed by

Forstner bit

Routing Guides

5. Chuck a top-bearing pattern bit with a ¾" cutting length into your

router. Adjust the cutting depth to the thickness of the insert plate

plus the routing guide. Make test cuts in scrap stock to ensure that

the cut depth exactly matches the thickness of the insert plate. Rout

the perimeter rabbet and the corner triangles in several passes until

the pattern-bit guide bearing runs smoothly against the edges of

the routing guides [Drawing F]. Be sure to stop routing along each

side where the ¾"-radius corners formed by the drilled holes meet

the routing guides. Carefully remove one routing guide and test-fi t

the insert plate in the opening. If the rabbet is too shallow, replace

the guide, adjust the routing depth, and re-rout the rabbet. A toodeep rabbet can be shimmed with tape. When satisfi ed with the fi t,

remove the routing guides.

6.

With the insert plate in place, use the countersunk corner holes

as guides to drill ¼" holes through the triangular corner areas in

the table top. Secure the plate with the lock-down screws and your

own washers and hex nuts or wing nuts. For greater convenience,

remove the insert plate, enlarge the holes in the table top, and

install T-nuts.

Precision Insert Plate Installation

4.

Kreg Precision Router Table Insert Plate Levelers method

Note: This method requires the purchase of Kreg Precision Router Table Plate Levelers (Item # PRS3040) from

your Kreg dealer. These levelers feature eight leveling screws that work with four lock-down screws to keep the

insert plate fl ush with the router-table surface.

G

Masking

tape shim

H

Routing guide

Double-faced tape

Drill bit

touches guides

1. To provide clearance for installing and removing the insert plate,

adhere strips of masking tape to all four edges of the plate. Then

apply small pieces of double-faced tape to one face. (Use just

enough tape to keep the plate in place. Too much tape will make

the plate hard to remove later.) Position the insert plate on your

router table top, squaring the plate with the table, and fi rmly press it

into place.

2. Cut four ¾ x 3½ x 15½" scrapwood routing guides. Apply

double-faced tape and adhere the routing guides to the router table

top with the edges against the masking tape strips on the insert

plate edges [Drawing G]. Remove the plate. Chuck a 1½" Forstner

bit into your drill press. With the edge of the bit just touching the

inside faces of the routing guides, drill a hole all the way through

the router-table top at each corner [Drawing H].

3. Rough-cut the opening with a jigsaw, staying ⅛" inside the

routing guides and cutting from corner hole to corner hole. For best

results, support the inside edge of the jigsaw base with a ¾"-thick

scrapwood block.

Drill 1½" hole all

the way through

I

Routing guides

Router table top

Radius corner formed

by Forstner bit

4. Chuck a top-bearing pattern bit into your router. With the guide

bearing running against the routing guides, rout the edges of the

opening [Drawing I]. Stop routing where the ¾"-radius corners

formed by the drilled holes meet the routing guides. If the thickness

of your router-table top is greater than the reach of your pattern bit,

switch to a bottom-bearing fl ush-trim bit, fl ip over the router-table

top, and fi nish the cut with the fl ush-trim bit guide bearing running

against the surface routed with the pattern bit. Remove the routing

guides.

Pattern bit

5.

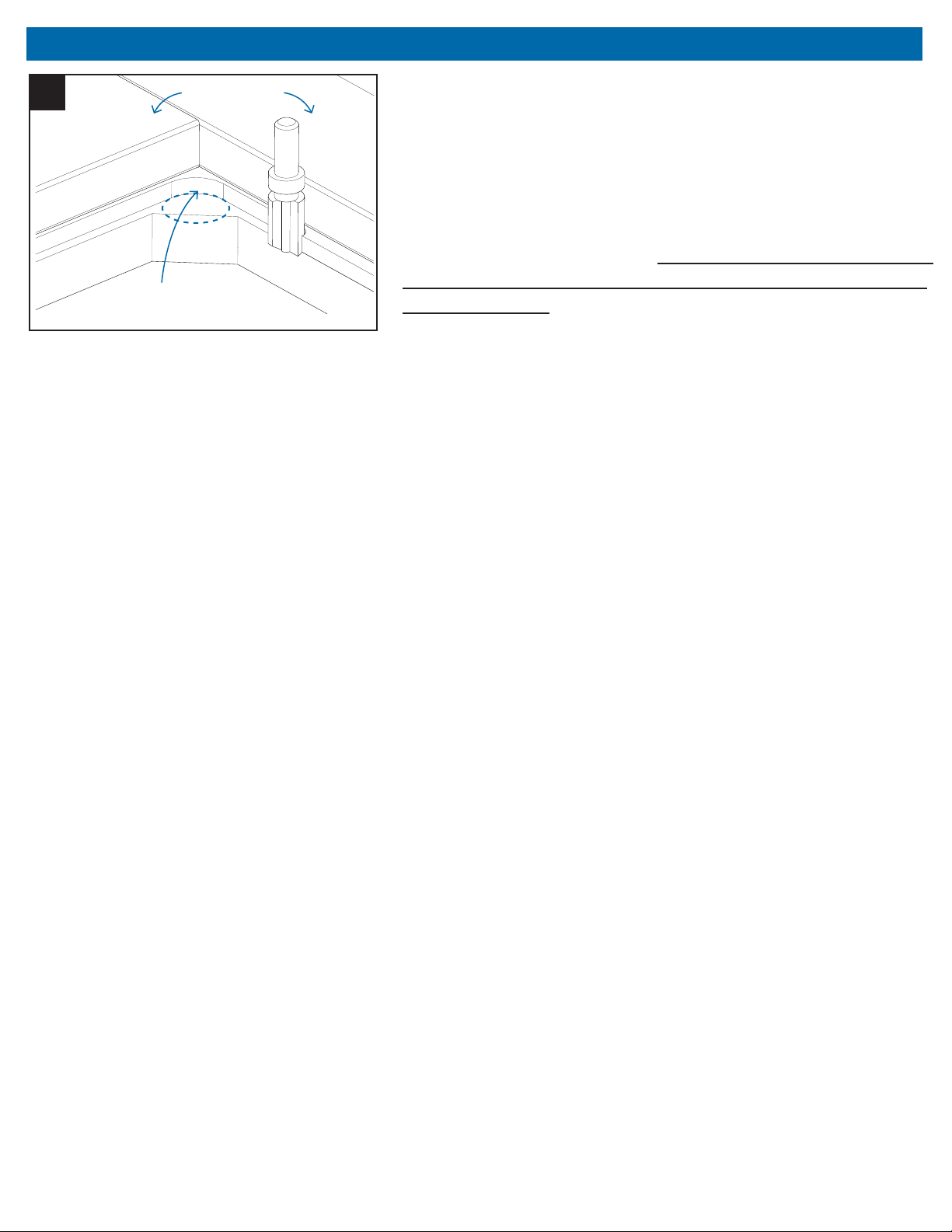

J

Precision Insert Plate Installation

Install the Insert Plate

Rabbeted opening method

1. Attach the router base to the insert plate, using the screws that

were used to attach the sub-base to the router base. Depending

on the thickness of your router sub-base, it may be necessary to

purchase longer screws. Make certain that the screws are long

enough to fully thread into the router base. For fi xed-base routers,

install the motor unit in the router base and install the insert plate,

with router attached, in the table.

2. Drop the four lock-down screws through the countersunk holes in

the insert plate and thread them into the hex nut, wing nut or T-nut.

Tighten the screws.

Kreg Precision Router Table Insert Plate Levelers method

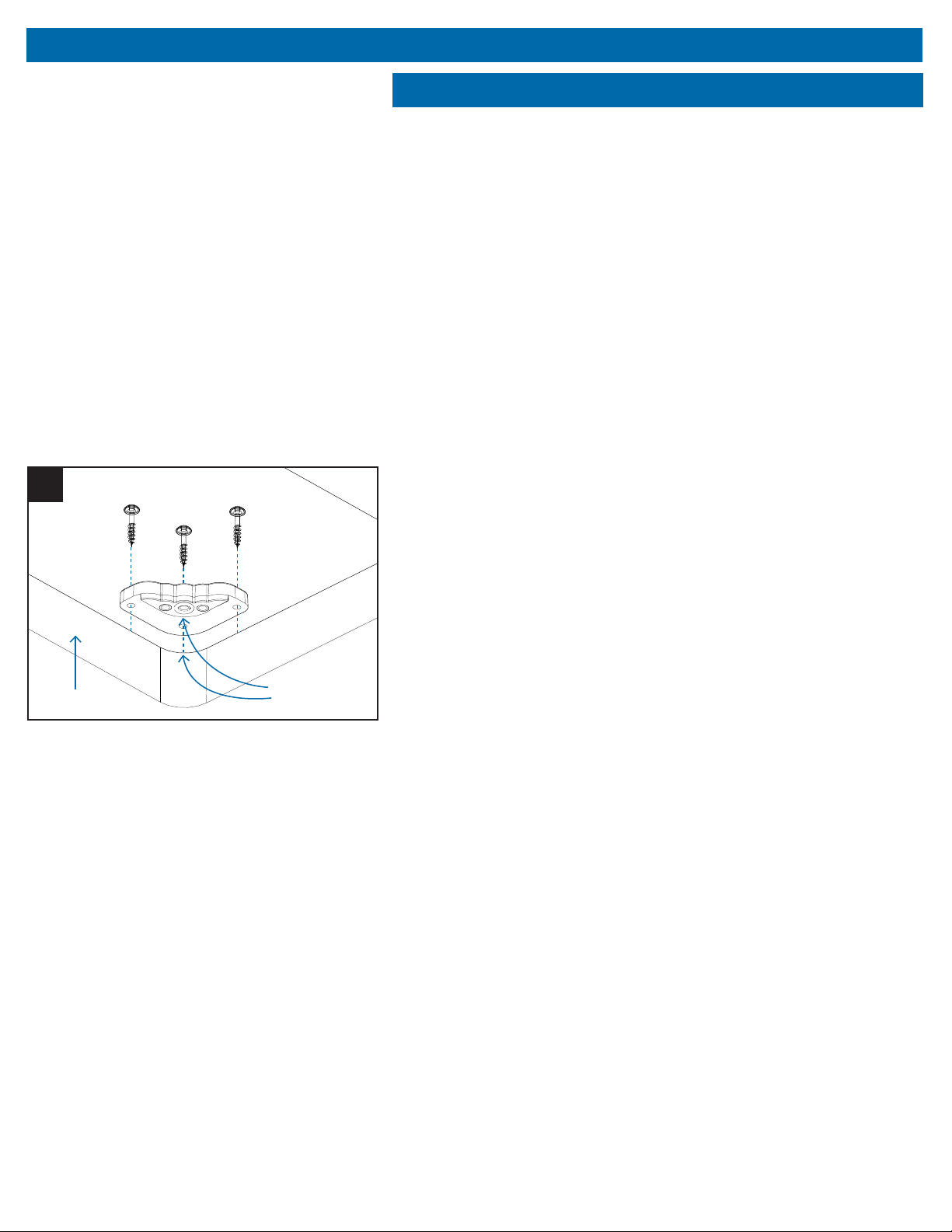

1. With the table top upside down, position an insert-plate leveler

in one corner of the table-top opening, mating the curve on the

raised portion of the leveler with the radius corner of the opening.

Firmly holding the leveler in place and using the three mounting

holes in the leveler fl ange as guides, drill pilot holes into the table

top. Fasten the leveler to the tabletop with three 1¼" coarse-thread

screws provided [Drawing J]. Repeat with the remaining levelers.

Router table top

Mating Curves

Note: The 1¼" coarse-thread screws provided with the levelers

are for use on router table tops with a minimum thickness of 1". For

thinner tops, use your own shorter screws.

2. Using the ⅛" hex wrench, drive a ¼-20 x 1½" socket-head set

screw into each outside hole in each leveler, threading them in

from the bottom until the tips are ⅜" below the table surface.

3. For Kreg PRS3034 and PRS3036 Precision Insert Plates, fasten

the router base to the insert plate using the screws supplied with

the plate. For the Kreg PRS3038 Precision Insert Plate, use the

screws that were used to attach the sub-base to the router base

to attach the router base to the insert plate. Make certain that the

screws are long enough to fully thread into the router base. It may

be necessary to purchase longer screws. For fi xed-base routers,

install the motor unit in the router base.

Precision Insert Plate Installation

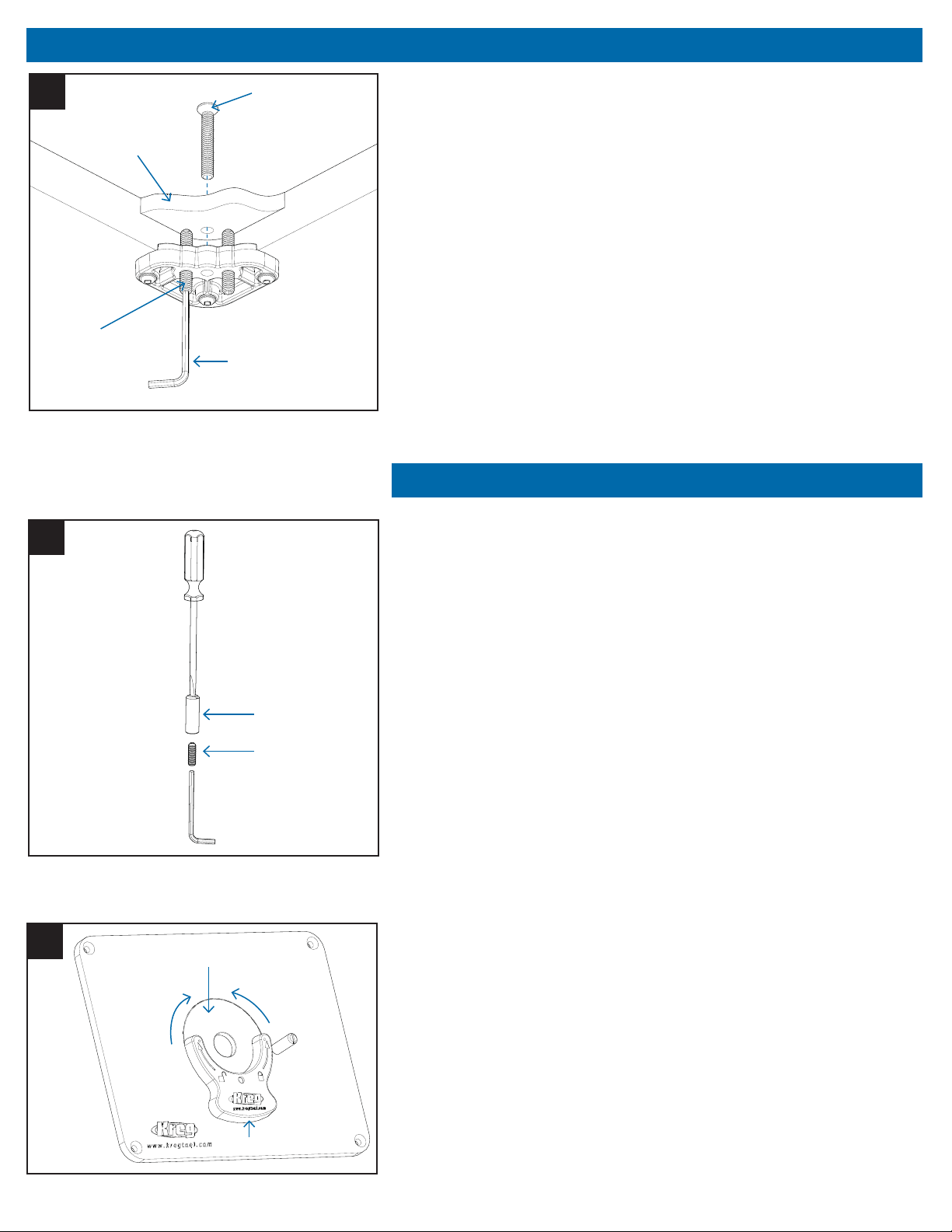

6.

K

Set screw

L

Insert plate

Lock-down screw

Hex wrench

4. Place the insert plate with the router attached in the table-top

opening, resting it on the eight set screws. Using the hex wrench,

adjust the set screws from under the table to align the surfaces of

the plate and the table. Check the alignment with a straight edge.

Make sure all eight set screws are in equal contact with the insert

plate.

5. Thread the four ¼-20 x 1¾" machine screws (lock-down screws)

through the countersunk holes in the insert plate and into the

center hole on each leveler and snug them down [Drawing K].

Some adjustment of the lock-down screws and set screws may be

necessary to fi ne-tune the alignment.

Finishing Up

1. Thread the ¼-20 x ¾" set screw into the bottom of the brass

starting pin using a fl at-blade screw driver and ⅛" hex wrench, until

the two are tightly secured together [Drawing L]. When ready for

use, thread the starting pin assembly into the threaded hole in the

insert-plate and tighten it.

M

Unlock

Reducing ring

Starting pin

Set screw

Lock

2. To install a reducing ring, simply drop it into the insert-plate

opening and turn it by hand until it drops fl ush with the plate

surface. Insert the pegs at the ends of the arms of the ring wrench

into the mating holes in the reducing ring and rotate the ring

counterclockwise [Drawing M]. Rotation of about ⅜" is suffi cient

to lock the ring in place. To remove the ring, turn the wrench

clockwise and lift the ring out of the opening.

Note: The Kreg Precision Insert Plate includes three Level-Lock

reducing rings for fl exibility in matching the size of the insert-plate

opening to the diameter of the router bit in use. The ring with the

rabbeted opening accepts standard universal-style guide bushings,

allowing you to use your router table for pattern routing. A set of

four additional reducing rings plus a blank disk for making a zeroclearance ring is available from your Kreg dealer

(Item #PRS3050).

Wrench

Safety Guidelines

· Failure to follow these rules may result in serious personal injury.

· Woodworking machines are dangerous, and can cause

personal injury if not used properly.

· Completely read the operating manual and safety instructions

for the machine before use. Learn the applications and

limitations of the machine as well as the hazards specifi c to it.

Operating the machine before understanding safe and proper

use could result in serious personal injury.

· Keep all guards and safety devices properly installed while using

the machine.

· Always wear safety glasses.

· Keep hands well away from the rotating bit when operating the

machine. Never overreach.

· Avoid awkward hand positions, where a sudden slip could cause

contact with cutting edges.

· Kickbacks occur when the workpiece binds while being

machined, causing it to twist, jump, and possibly become

airborne. To avoid kickbacks and potential injury, always follow

proper technique, use sharp bits, keep the machine aligned

and maintained properly, and adequately secure and support

the workpiece. To free both hands for tool operation, use clamps

or a vise to hold work when it is practical and safe.

· Turn off the machine before making adjustments. Never adjust

the fence, plate, reducing rings, or any other part of the machine

while it is running.

· Make sure the machine comes to a complete stop before

adjusting the position of a workpiece.

· Ground electric machines. If the machine is equipped with a

three-prong plug, it should only be plugged into a grounded

three-hole electrical outlet. If the proper outlet is not available,

have one installed by a qualifi ed electrician. Never remove the

third prong or modify the provided plug in any way.

· Do not operate the machine in a dangerous or unclean

environment. Do not use the machine in damp or wet locations,

or expose it to rain. Keep the work area well-lit, un-cluttered, and

clean.

· Keep all children and visitors at a safe distance from the work

area. Children and visitors should not operate machinery under

any condition.

· Use the right machine for the task. Never “force” a machine to

do work for which it was not intended. If used properly under

safe conditions, the machine will produce better results in less

time.

· Wear proper apparel. Avoid loose clothing, gloves, neckties,

rings, bracelets, or any other jewelry that could get caught in

moving parts. Wear non-slip footwear and protective hair

covering specifi cally designed as safety gear.

· Secure machinery to prevent tipping or sliding.

· Keep proper footing and balance to avoid slipping or sliding

when you turn on machinery.

· Maintain tools in top condition. For the highest quality and safest

performance, keep bits sharp and clean and machinery properly

maintained. Follow all lubrication and accessory maintenance

practices detailed in the instruction manual.

· Disconnect the machine from electrical power before servicing.

When changing accessories such as bits and clamps, making

any sort of physical assessment of the machine, or when the

motor is being mounted or connected, disconnect the machine

from the power source.

· Check for damaged parts. Before using the machine, make

a careful assessment of all guards and other parts to ensure that

the machine will operate properly and perform as intended.

Check moving parts for alignment, binding, breakage, mounting,

and any other conditions that may affect its operation. A guard or

other part that is damaged should be properly repaired or

replaced as soon as possible, preceding any further use. Do not

use the tool if you are not qualifi ed to make these assessments.

· Never leave a running machine unattended. Always turn off the

machine after operation. Do not leave the tool until it comes to a

complete stop.

· Drugs, alcohol, medication warning: Do not operate machinery

while under the infl uence of drugs, alcohol, or any medications.

· This machinery system is designed only for certain applications.

Kreg Tool strongly recommends that this system NOT be

modifi ed and/or used for any applications other than those

for which it is designed. If you have any questions relative to the

application of the machinery system, DO NOT use the system

until you have written, phoned, or e-mailed Kreg Tool and have

been advised accordingly.

· Make your workshop “child-proof”. Use padlocks, master

switches, or other means necessary to prevent unauthorized

use of machinery.

www.kregtool.com • 800.447.8638

Loading...

Loading...