Precision

Router Table Top

ASSEMBLY INSTRUCTIONS

Item# PRS1020

(

24” x 32”

)

www.kregtool.com • 800.447.8638

Tools Required:

• 5/64” Allen Wrench

• Phillips Head Screwdriver

• Flat Head Screwdriver

• 6” #2 Square Driver

• 1/8” Allen Wrench (Included)

• 3” #2 Square Driver (Included)

RT10116Version 20070701

1.

Precision Router Table Top Assembly

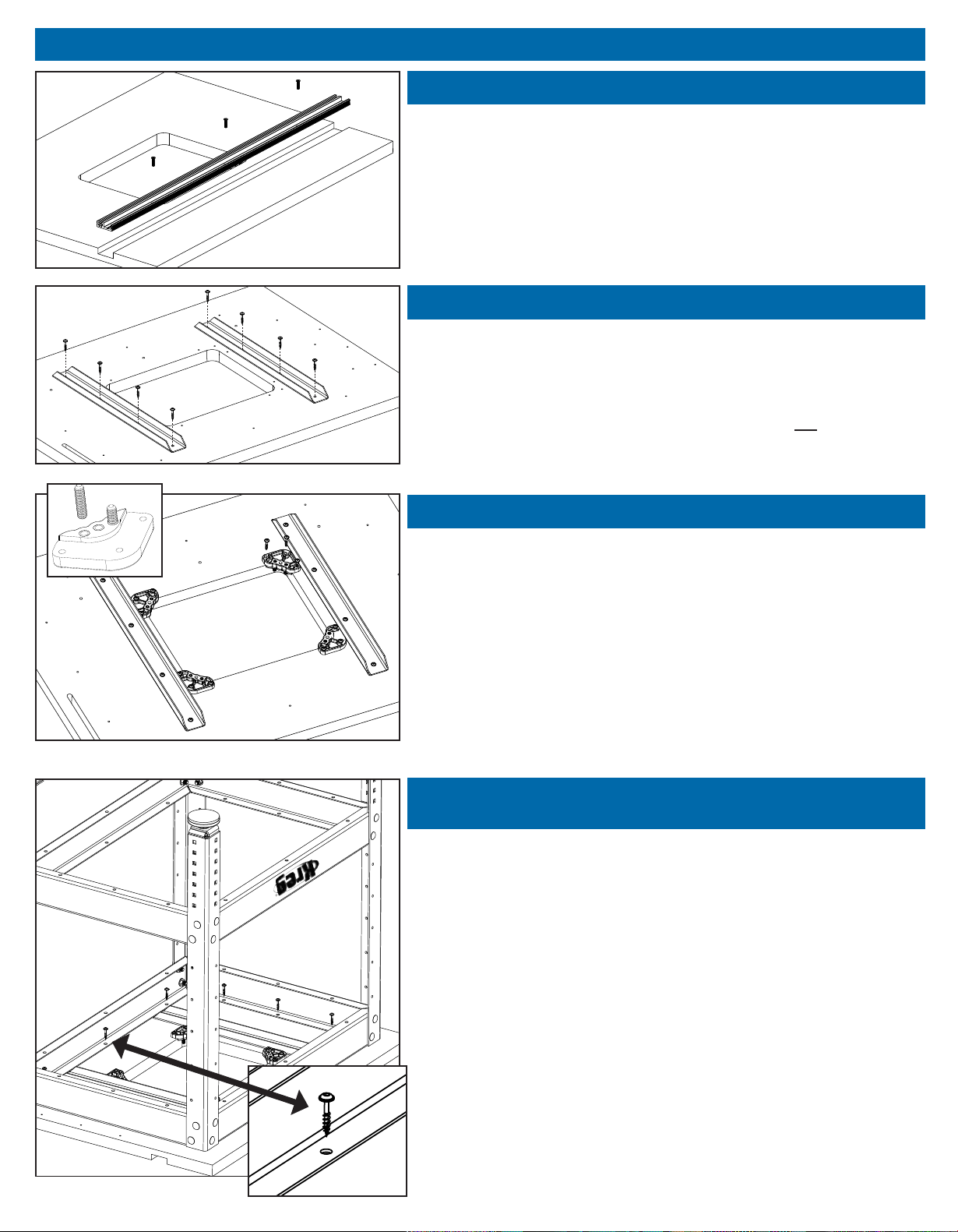

Step 1: Attaching the T-Miter Trak

Your table should have shipped with the T-Miter Track (#3) already inserted

into the slot on the front portion of the router table surface. Begin by aligning

the Trak to the pre-drilled holes and attach with three 10-32 x ¾” Phillips Flat

Head Machine Screws (#15).

Step 2: Mounting the Support Struts to the T able Top

Turn the Router Table top (#2) so it’s face down on the fl oor. Locate the two

Support Struts (#7) and align them to the pre-drilled holes in the bottom of

the Router Table T op. Mount the struts to the top using the eight ¾” Coarse

Thread Screws (#16). Be careful not to over tighten.

Note: To avoid damaging the table’s surface, be sure not to use the

longer 1-1/4” screws (#1 1) on this step.

Step 3: Mounting the Insert Plate Levelers to the T able Top

Use the curved tab on the Insert Plate Levelers (#8) to locate each Leveler

in the corner of the Insert Plate opening and fasten them in to place using

three 1-1/4” coarse thread screws (#11) per leveler. Be careful not to

overtighten.

Thread the eight 1/4-20 x 1-1/2” cup point socket set screws (#10) into the

two holes as shown, and thread about half way in.

Note: These Insert Plate Levelers will be used in Step 6 to mount and

level the Precision Router Table Insert Plate.

Step 4: Mounting the Router T able Top to the Kreg

Universal Steel Stand

For proper mounting and alignment purposes, it’s best to leave the Router

Table Top (#2) face down on the fl oor . T urn the Universal Steel Stand upside

down and align the four rails with the pre-drilled holes on the bottom side of the

Table Top. The Kreg logo, located on the front of the stand should be located

on the same side and parallel to the T -Miter Track opening on the Router Table

Top. Once the table is positioned correctly, use a 6” #2 Square driver bit and

twelve ¾” Coarse Screws (included with the Universal Steel Stand) to secure

the two together, being careful not to over tighten.

Note: The included hardware was intended for use with the Kreg Universal Steel Stand. If you are working with another stand, be sure to doublecheck your hardware sizes to ensure that the screws do not puncture the

surface of the top when tightened. Also be sure to leave the 6” slotted

opening on the table’s surface free from obstruction.

Precision Router Table Top AssemblyPrecision Router Table Top Assembly

2.

Step 5: Mounting the router to the Insert Plate

PLEASE NOTE:

All routers are different. When aligning the router’s base plate to

the bull’s-eye template and Insert Plate, take into consideration all of

the controls you will need access to when the router is suspended

below the plate during operation. Plan your installation completely

and adjust the router orientation accordingly. The router handles do

not need to be square with the table or plate for proper operation, so

easy access to the on/off switch and other controls should be your

#1 priority when attaching the router to the Insert Plate.

Begin by locating the 3/8” phenolic Insert Plate (#1) and placing it face

down on your workbench. The Kreg Logo on the Insert Plate should not

be visible. Take the clear Plastic Template and place the edge marked

“FRONT” towards the front edge of the insert plate. Align the template

so that the Start Pin Hole marking and the bull’s-eye line up perfectly with

the Insert Plate. Once positioned correctly, securely tape the template into

place.

In a later step, you will be duplicating your router’s base plate holes into

your Insert Plate so that you can connect your router directly to the Insert

Plate. First, you must determine the correct size of the holes to drill in

your Insert Plate. Remove the base plate from your router and fi nd the bit

that fi ts just inside of the base plate’s holes.

Now, center your base plate on the concentric rings of the bull’s-eye

template. Keep in mind what position you want the router in when it’s

suspended from the table and make certain the base is rotated to refl ect

that position. For instance, it’s best to have the lock on the router base,

and the controls on the router motor, toward the front of the table, or as

easily accessible as possible.

Note: If your router is equipped with a built-in lift system, you will need to

drill the appropriate holes through the insert plate at this time to gain access

to the system and make adjustments to the bit depth of your router after

it’s been mounted to the insert plate. Once again, use your router base

plate to choose the appropriate size drill bit needed for these holes. VERY

IMPORTANT – When positioning your base plate for drilling, make sure that

none of the holes you are about to drill line up over the pre-drilled Start Pin

Hole in the insert plate.

Once you have the base plate from your router aligned where you want it

on the template, use heavy duty masking tape to secure your base plate

to the bull’s-eye template. Tape on at least four sides of your base plate to

ensure a strong and secure hold.

Whether you use a drill press or hand drill, we recommend you place a

scrap piece of wood under the insert plate. This will reduce blowouts as

you drill through the insert plate. It’s easiest to do this operation on a drill

press so the holes are perfectly square to the insert. If you must drill it by

hand, be careful to keep the holes straight. Before drilling, securely clamp

the insert plate to your bench or drill press to hold it secure and reduce the

chance of the material moving as you drill.

After the holes are drilled, remove the base plate & template. Flip the

insert plate over and use an 82 degree countersink bit to countersink each

hole so the head of the screws sit at fl ush or slightly below the plate’s

surface when tightened down. Be very careful not to over drill these holes,

as their depth will directly affect the quality of your routing surface.

3.

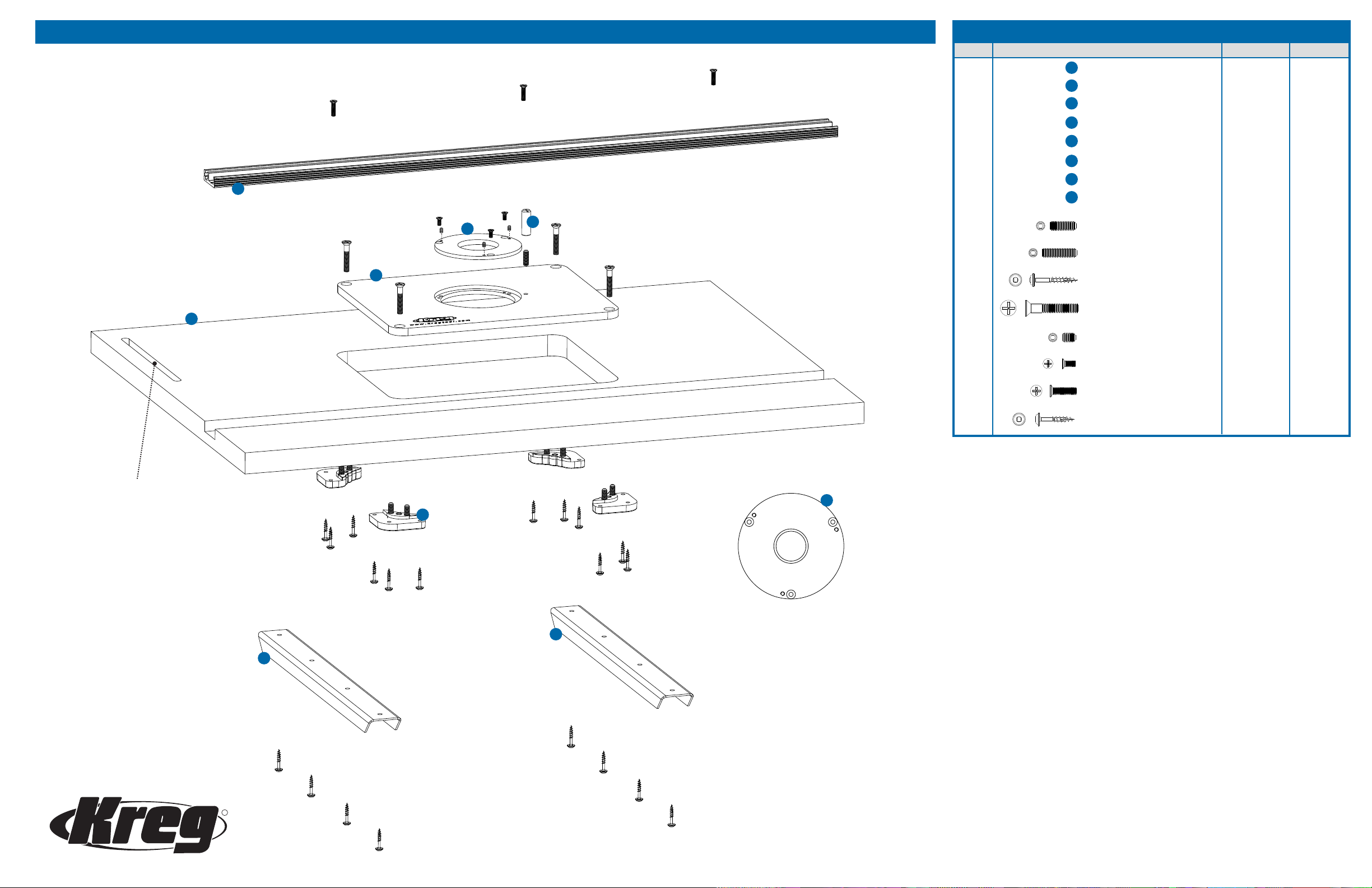

Precision Router Table Top Exploded Parts Diagram

Item# Description Part# Quantity

1 Phenolic Insert Plate RT10101 1

2 Table Top RT10102 1

3 T-Miter Track RT10103 1

4 2” Reducing Ring RT10107 1

5 1-13/64” Reducing Ring RT10106 1

6 Brass Starting Pin RT10108 1

7 Support Strut RT10171 2

C

8 Insert Plate Leveler RT10100 4

A

B

C

D

E

F

G

H

Hardware

4.

Slot to attach Kreg

Precision Router

Table Fence.

D

A

B

H

F

E

9 1/4-20 x 3/4” Set Screw DK1522 1

10 1/4-20 x 1-1/2” Set Screw RT10111 8

11 1-1/4 Coarse Screw SML-C125 12

12 1/4-20 x 1-3/4” Flat Head MS RT10112 4

13 8-32 x 1/4” Set Screw RT10110 6

14 8-32 x 5/16” Flat Head MS RT10109 3

15 10-32 x 3/4” Flat Head MS DK1547 3

16 3/4” Coarse Screw RT10192 8

G

G

2

5.

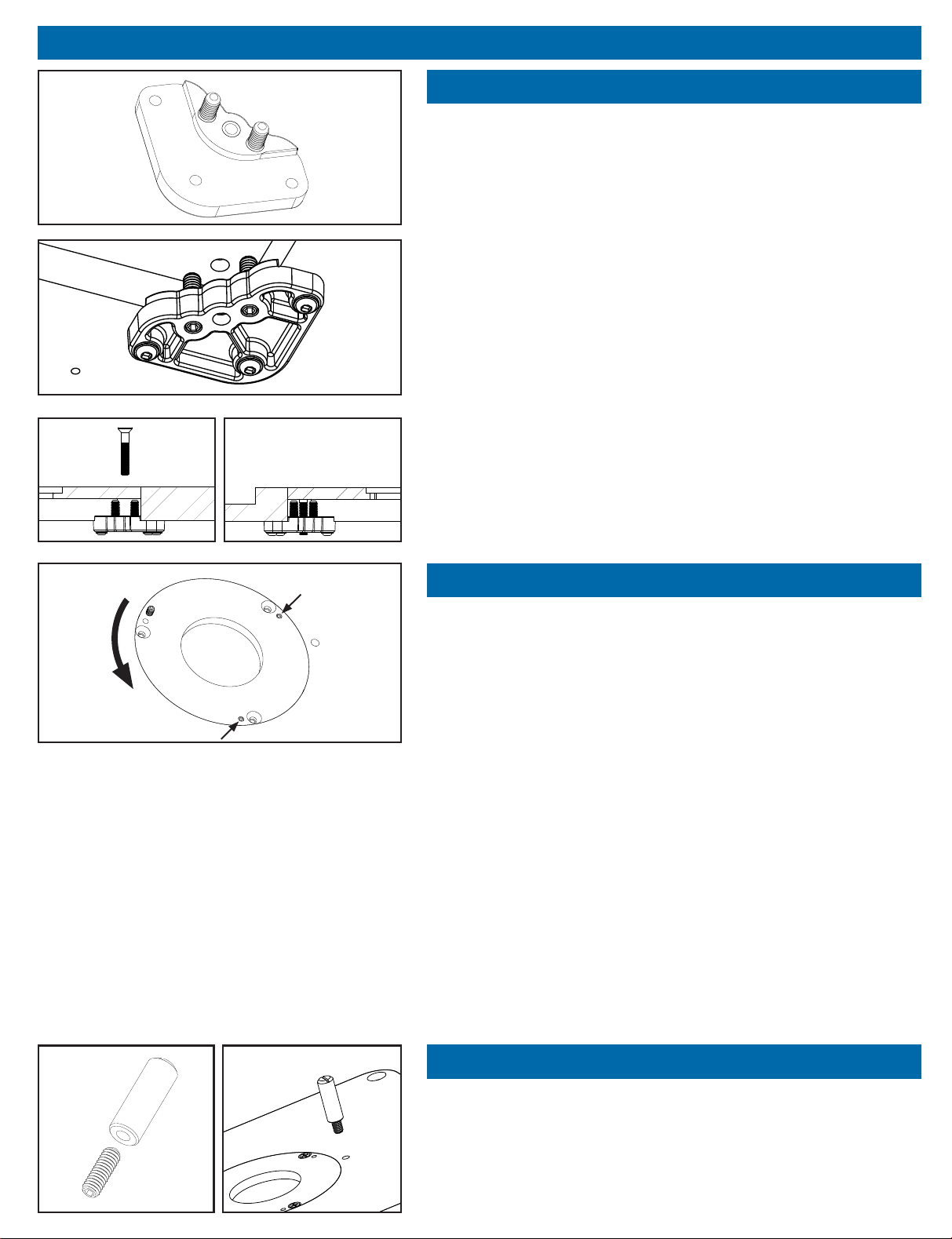

Step 6: Leveling the Insert Plate to the Opening

The unique design of the Precision Insert Plate Levelers (#8) and

adjustable leveling screw system applies pressure to both sides of

the Insert plate so that – once locked in – the Insert Plate stays fl ush

regardless of the weight applied. The 8 Leveling Screws and 4 LockDown screws work together to keep the Insert Plate fl ush with the router

table surface at all times.

Set the eight ¼-20 x 1-½” Cup Point Socket Set Screws (#10) to

aproximately the same height and lay the Insert Plate into the opening.

The Insert Plate should be resting on the eight adjustable Set Screws.

Using the 1/8” Allen Wrench (included), adjust the set screws from the

bottom side of the Insert Plate, being careful to adjust each screw the

same distance as the other. Adjust the Insert Plate as close as possible

to fl ush with the surface of the router table top and run your fi nger along

the perimeter of the Insert Plate to check that all edges are fl ush with the

router table top.

Thread the four ¼-20 x 1-3/4” Phillips Flat Head Machine Screw (#12)

(Lock-Down Screws) through the countersunk holes into the center hole

on each leveler and snug down. Run your fi nger along the perimeter

of the Insert Plate again to check that all edges are fl ush with the router

table top. Some loosening or tightening of the lock down screws might be

necessary to help adjust the reducing ring and hold it securely in place.

Step 7: Installing & Leveling the Reducing Rings

Note: We recommend adjusting both reducing rings at this time. This will

save time later as you change which reducing ring you want to use, and

also reduces the possibility of losing the second set of small Flat Point

Socket Set Screws. After you have leveled one reducing ring, remove it

and level the other.

Insert three 8-32 x ¼” Flat Point Socket Set Screws (#13) into reducing

ring’s threaded holes, using a 5/64 Allen Wrench as shown. Place the

reducing ring into the Insert Plate opening and rotate counter-clockwise

until the set screws fall into the corresponding holes. Adjust the set

screws until the reducing ring is perfectly level with the Insert Plate.

Secure the reducing ring by threading the 8-32 x 5/16” Phillips Flat Head

Machine Screws (#14) into their holes and tightening snuggly.

As you tighten down the reducing ring, some additional adjustment

under tension may be necessary. Adjust each set screw as needed to

bring the reducing ring fl ush with the insert plate. Some loosening or

tightening of the lock down screws might be necessary to help adjust

the reducing ring and hold it securely in place. By leveling the reducing

rings while force is applied in both directions, the rings will stay fl ush

regardless of the weight applied, providing a more level and secure work

surface.

Step 8: Installing the Starting Pin

Thread the ¼-20 x ¾” Cut Point Socket Set Screw into the bottom of the

Brass Starting Pin using a fl at head screw driver and a 1/8” allen wrench,

until the two are secured tightly together. Insert the Starting Pin assembly

into the Insert Plate Start Pin Hole and thread in until tight.

* For more information on how to use the starting pin, please see page 6.

In Use: Starting Pin

The starting pin included with your router table is useful when routing

curves. It supports the edge of your work piece and allows you to gently

ease your work into the router bit. It should only be used with router bits

that have a bearing.

Start with your work piece touching the starter pin, but not in contact with

the router bit. Ease the material into the cutter and make contact with

the ball bearing on the bit.

6.

Once you’ve made solid contact with the ball bearing you can ease off of

the starting pin and allow the work piece to glide along the bit’s bearing.

Loading...

Loading...