R

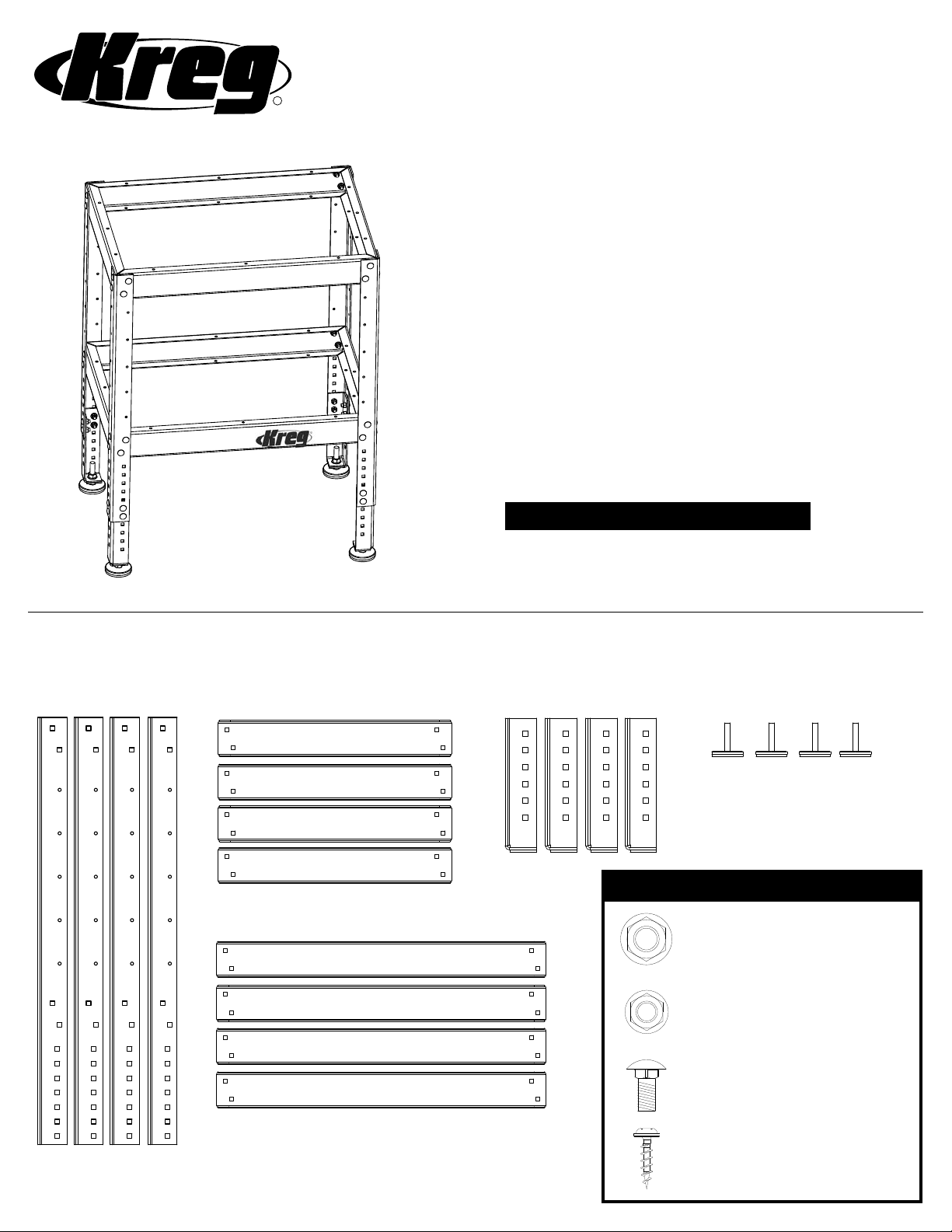

Universal Steel Stand

ASSEMBLY INSTRUCTIONS

Item# KRS1030

Tools Required:

• Square

• 1/2” Socket wrench & extension

• (2) 3/4” Open-end or adjustable wrenches

• Phillips head driver bit

www.kregtool.com • 800.447.8638

Please call us at 800-447-8638

with any questions regarding the

assembly of this stand.

NK7563

Rev B

5/2010

Parts Identifi cation:

Legs (4)

Short Stretcher (4)

Long Stretcher (4)

Height Adjusters (4)

Levelers (4)

Hardware

1/2” Hex Flange Nuts (8)

5/16” Hex Flange Nuts (50)

5/16” Carriage Bolts (50)

3/4” Wood Screws (20)

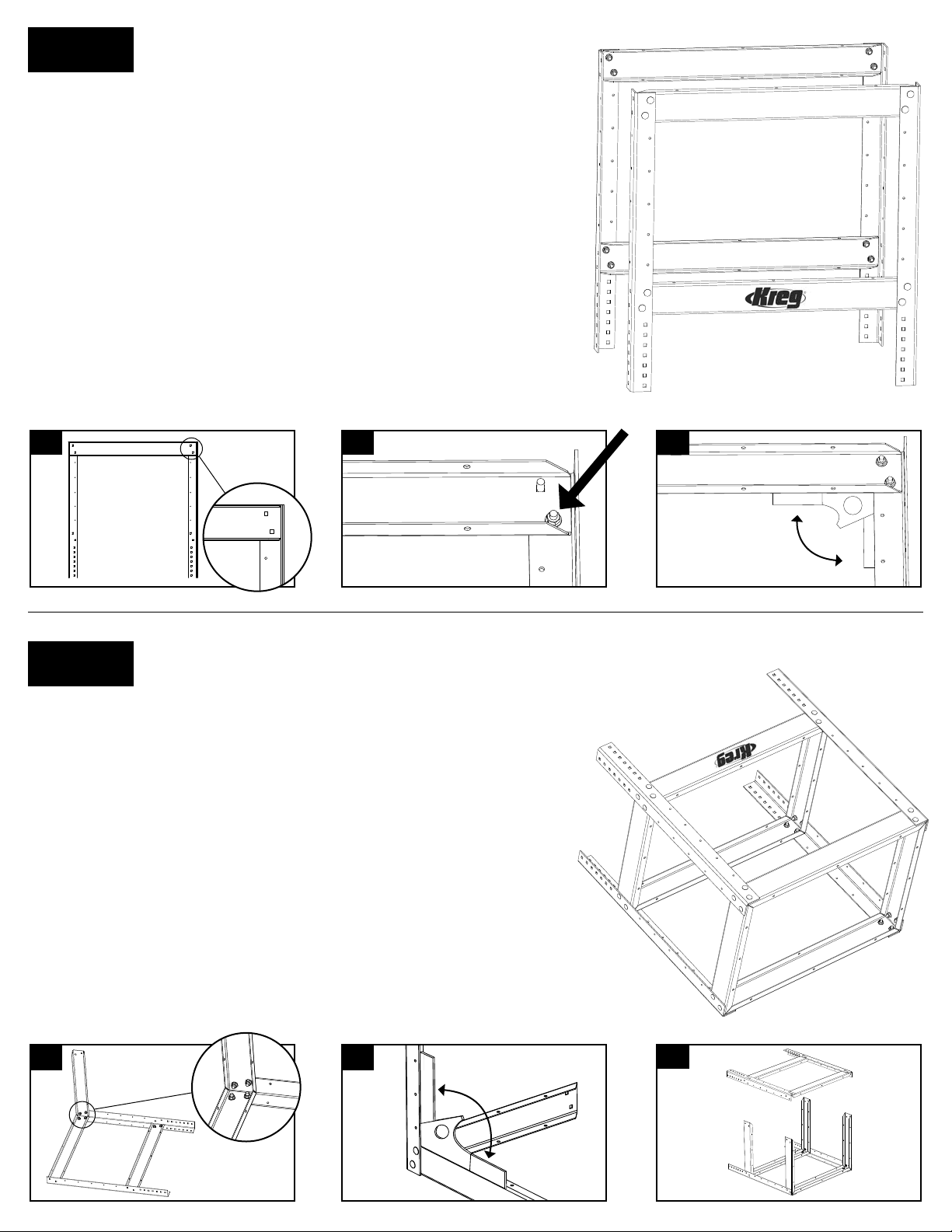

Step 1

Constructing Side Assemblies:

In this step you will be joining four (4) Long Stretchers and four (4) Legs to construct two

separate side-assemblies. Special Note: One of your Long Stretchers includes a Kreg logo.

Y ou may choose where you would like this stretcher to be positioned.

Begin by laying two (2) Legs fl at on your work surface. Each Long Stretcher has two

staggered holes at each end which correspond to two sets of staggered holes on the Legs

(one at the top of the leg, and the other directly above the height adjustment holes). Take a

Long Stretcher and lay it on top of the Leg with the corresponding holes lined up, as shown

in image A. Insert the carriage bolts (from the underside/outside of the assembly) into the

holes and thread the fl ange nuts onto the bolts, as shown in image B. After both carriage

bolts are inserted into the correct holes and the nuts are started, use a square to bring the

legs and stretchers to a 90 degree angle as shown in image C, and begin to tighten the

fl ange nuts. Maintain a strict right angle, as the sturdiness of your table will depend on it.

Once the fl ange nuts are tightened suffi ciently, repeat this step for the remaining Long

Stretcher, to create the fi rst side-assembly. Once the fi rst side assembly is complete, you

may begin assembling the second side assembly in the same way .

A. B. C.

Step 2

Joining Side Assemblies:

In this step you will be joining the two side assemblies that you assembled in Step 1,

using the four (4) Short Stretchers.

Begin by laying one of the side-assemblies fl at on your work surface. Each Short

Stretcher has 2 staggered holes at both ends which correspond to two sets of

staggered holes on the Legs. These holes are directly adjacent to the holes you used

for connecting the Long Stretchers to the Legs. Take the Short Stretcher, line up the

holes, insert the carriage bolts into the correct holes, and thread the fl ange nuts onto

the bolts, as shown in image A. Use your square, as shown in image B, to bring

the leg and stretcher to a 90 degree angle. Begin to tighten the fl ange nuts while

maintaining a strict right angle, as before.

Step 1 Final Assembly

Shown

0

90

Once the fl ange nuts are tightened suffi ciently, repeat this process for the three

remaining Short Stretchers. After this is complete, the four Short Stretchers will be

extending vertically from the side-assembly. Next, position the second side-assembly

on top of the Short Stretchers, as shown in image C, and line up the corresponding

holes. Insert the carriage bolts and tighten the fl ange nuts while maintaining strict 90

degree angles, just as before.

A. B.

0

90

Step 2 Final Assembly

Shown

C.

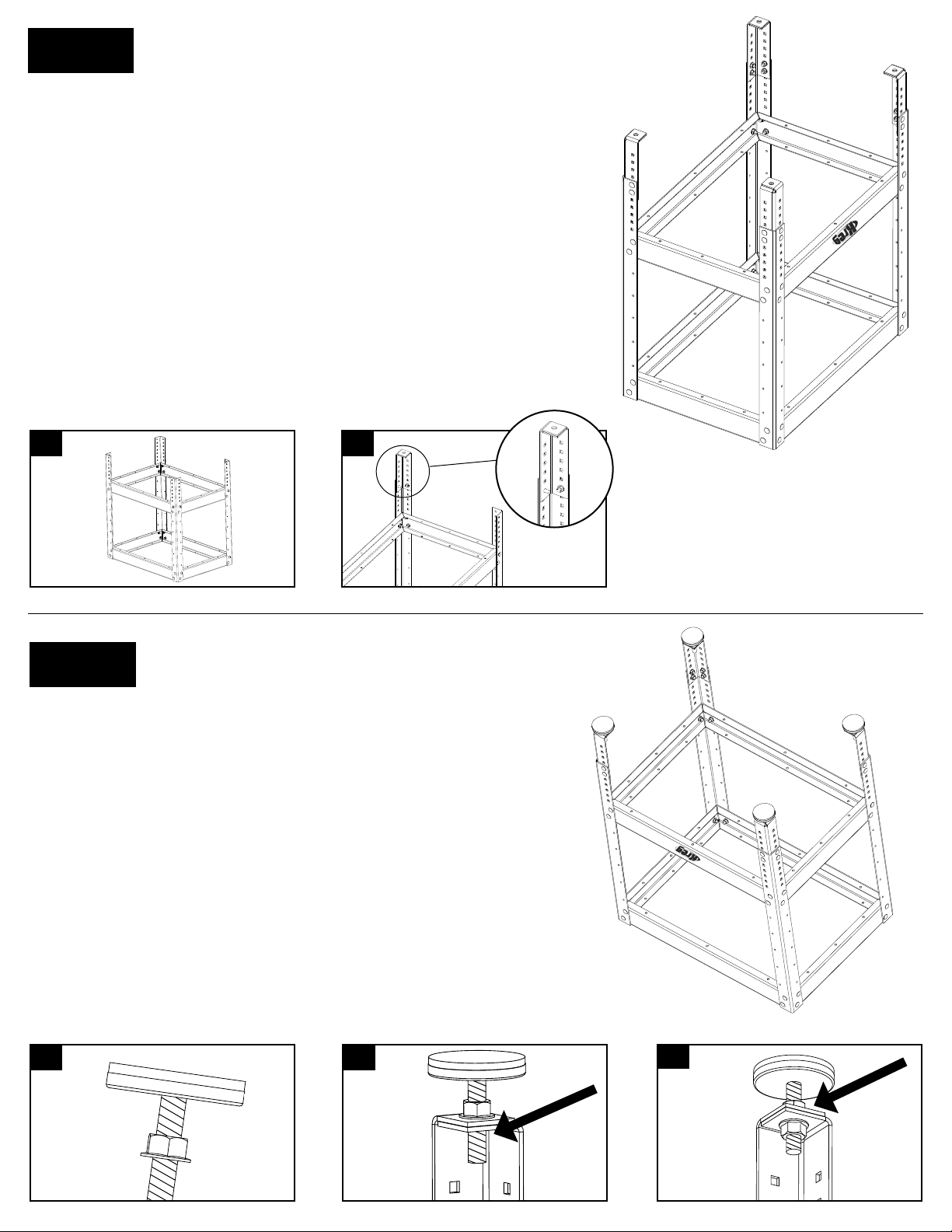

Step 3

Installing Height adjusters:

In this step you will be adding the Height Adjusters to the bottom of each Leg.

Place the Steel Stand face-down on your work surface so that all four legs are pointed

up in the air, and are easily accessible, as shown in image A. Place the height

adjuster into the base of the Leg, with the squared end at the bottom of the stand, as

shown in image B. Each Height Adjuster has several holes that allow you to fi ne

tune your stand height for optimum working conditions. After you have determined

the correct spacing, line up the holes appropriately, insert the four carriage bolts, and

begin to thread the fl ange nuts onto the bolts.

Once the fl ange nuts are tightened suffi ciently, repeat this process for the three

remaining Height Adjusters. After this is complete, you will be ready to install the 4

levelers at the base of the Height Adjusters.

A. B.

Step 4

Installing Levelers:

In this step you will be adding the Levelers to the bottom of each Height Adjuster.

Rotate one fl ange nut onto the Leveler stud, and thread it down until it is approximately

one inch from the base of the leveler foot, as shown in image A. Then, place the

Leveler Stud through the opening in the bottom of the Height Adjuster, as shown in

image B. Thread the second fl ange nut onto the Leveler stud, and tighten to lock the

Leveler into place on the Height Adjuster, as shown in image C.

Once the fl ange nut is tightened suffi ciently, and the Leveler is locked into place,

repeat this process on the remaining three (3) Levelers. After all three Levelers are

locked into place, it is a good idea to position the stand right-side-up and test it for

level. Based on your readings, you can adjust the Levelers to compensate for any

discrepancies in the stand or on your fl oor. Simply loosen the two fl ange nuts on the

leveler you wish to adjust, make your small height adjustment, and retighten the nuts

into place. Repeat as necessary.

Step 3 Final Assembly

Shown

Step 4 Final Assembly

Shown

A. B.

C.

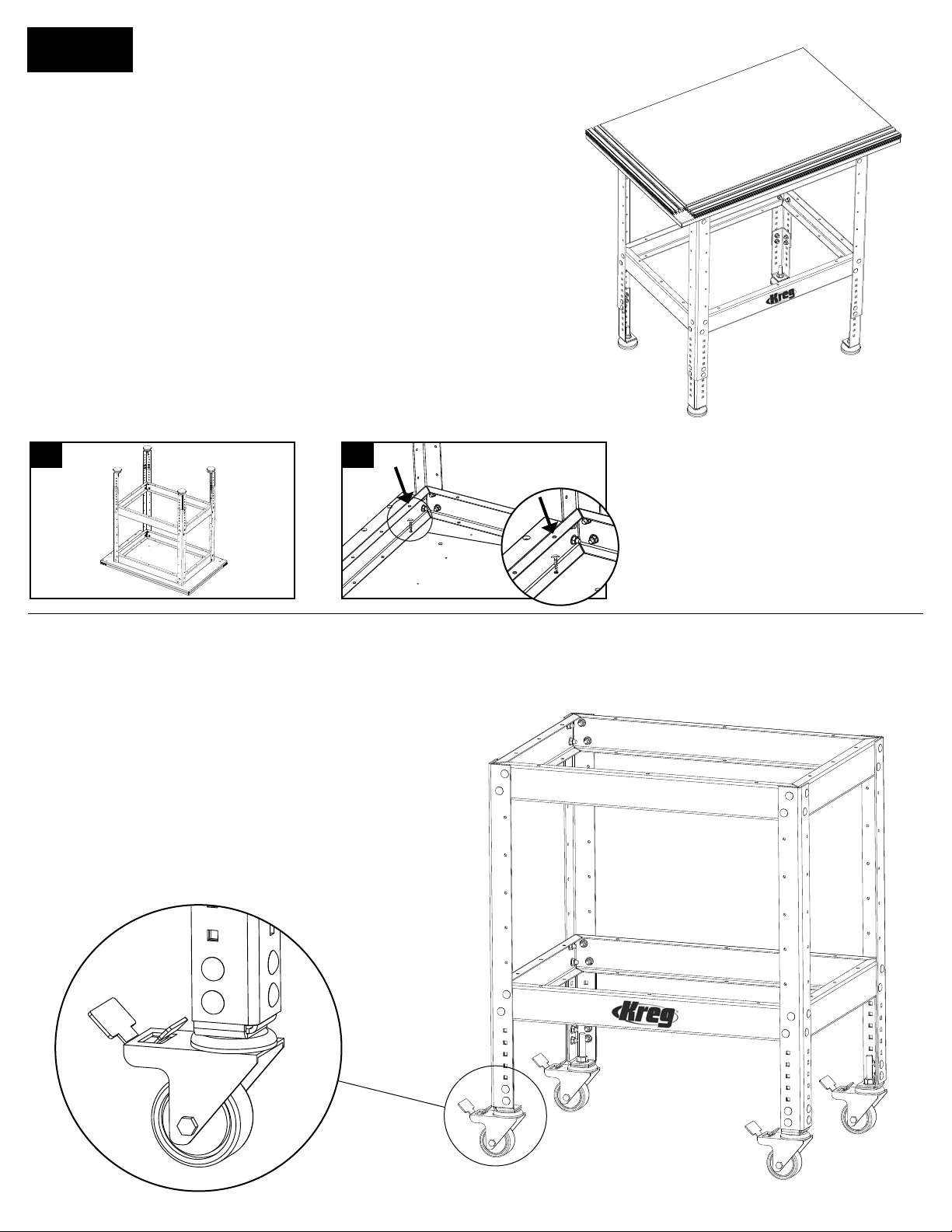

Step 5

Joining Table Top to Stand:

In this step you will be joining the Universal Steel Stand to a Kreg or other table-top of

your choice.

Place the table face-down on your work surface, and have someone help you fl ip the

stand on top of it, as shown in image A. Once the stand is centered, and all edges have

equal overhang on parallel edges, you may begin securing the two together using ¾”

wood screws (not included) and a corresponding driver, as shown in image B.

All Kreg table-top solutions come with pre-drilled holes at their base, which align with

holes in the stand. These tables-tops can be attached to the Universal Steel Stand

using the included ¾” screws. Please reference specifi c table-top instructions for

further detail. For more information on Kreg table tops, visit www.kregtool.com.

A. B.

Step 5 Final Assembly

Shown

Mobilize your stand...

Add true mobility to your Universal Steel Stand with our

Heavy-Duty Casters. Built to last and perform, these

casters feature a dual locking mechanism that won’t

roll OR pivot once engaged, resulting in an extremely

stable work station.

Item#

KRS3090

Loading...

Loading...