Kreg KKS-KBKSYS User Manual

See the entire system of

8-2009 NK7514B

KLAMP SYSTEMTM COMPONENTS at:

WWW.KREGTOOL.COM

This manual is intended

for use with:

• Large Bench Klamp

• Klamp Plate

TM

TM

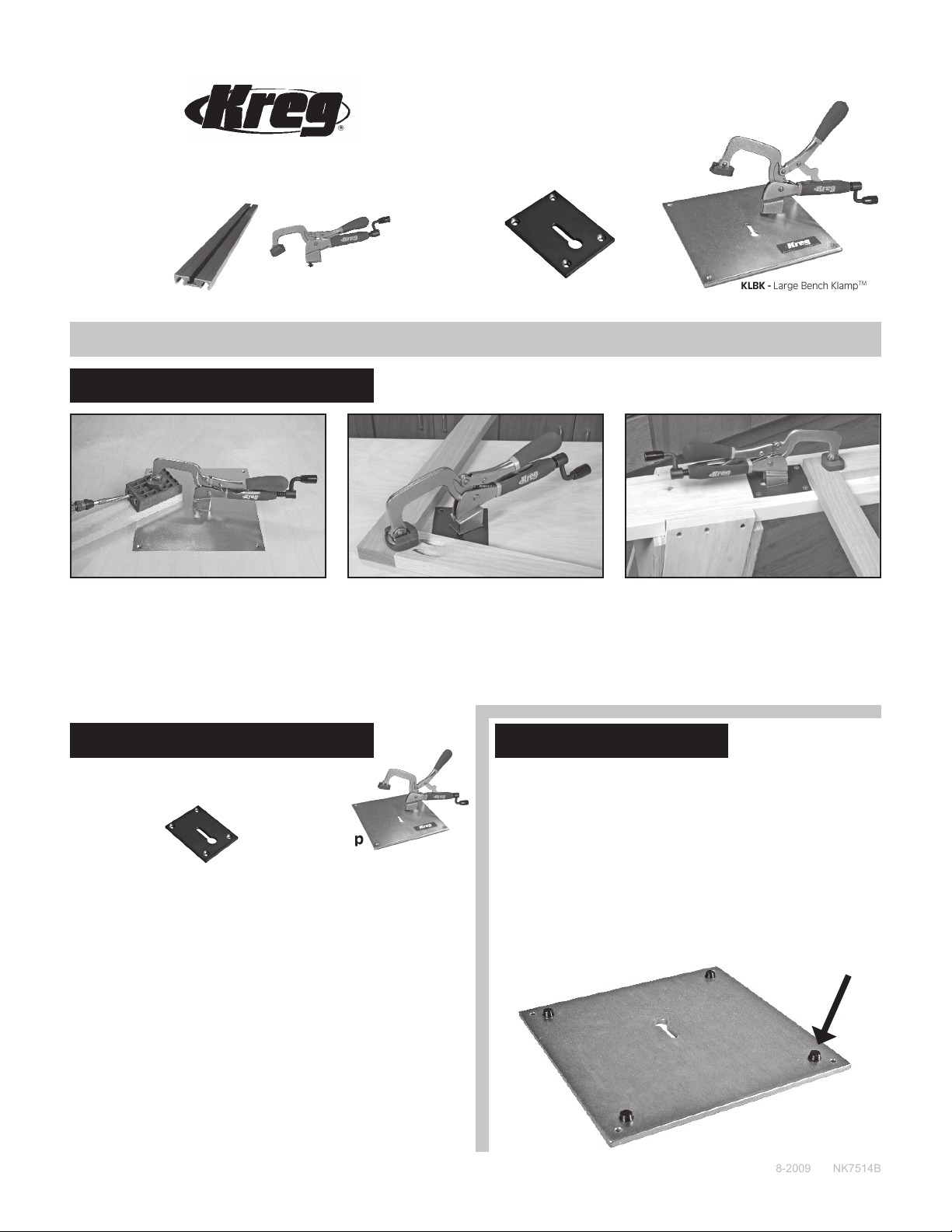

Practical Uses

Hold Pocket-Hole Jigs in place.

Firmly clamp your Pocket-Hole Jig to its

workpiece. Learn more about PocketScrew Joinery at www.kregtool.com.

KBK-IP - Klamp Plate

Frame construction.

Perfectly flush joints, every time!

Great for edge-banding, joining miters,

sanding, routing, and many other

frame construction processes.

TM

KLBK - Large Bench Klamp

Sawhorse hold down.

Rout into a sawhorse for an extremely

mobile clamping station. Great for

clamping roofing-steel, vinyl siding, or

framing stock on the job site.

TM

Product Features/Specs

Klamp Plate

Item# KBK-IP

•3” x 4” plate

•1/4” thick Anodized Aluminum

•Hardware Included

Rigid aluminum clamping

hub routs easily into any

workbench, drill-press,

or sawhorse. Allows for

quick-attach and release

of Bench KlampTM, and

360o clamping wherever

you need it most! Expand

your work area with 2 or

3 Klamp PlatesTM on the

same workbench.

Large

Bench Klamp

Item# KLBK

•10” square plate

•Zinc plated, 1/4” thick steel

•Hardware Included

Rigid steel clamping

surface routs into any

workbench and can be

used independently on

the job-site. Allows for

quick-attach and release of

Bench KlampTM, and 360o

clamping wherever you

need it most! Bring your

clamp to your work, not

the other way around.

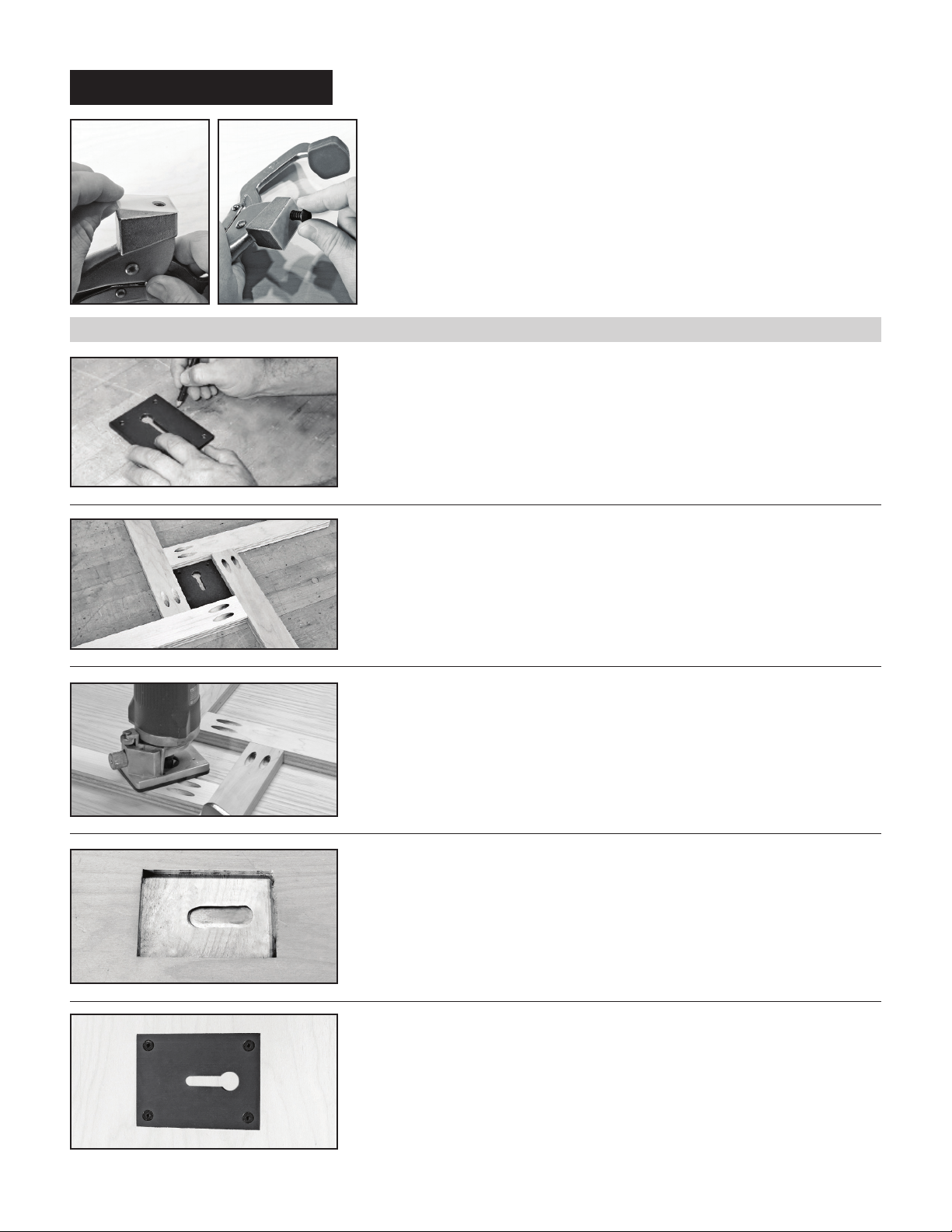

Large Bench Klamp Only

Rubber Bumpers

When not routed into a workbench, the Large Bench Klamp

requires the use of rubber bumpers to elevate the base

from the work surface. This allows the Bench Klamp’s

anchoring screw to slide and rotate freely. The bumpers

can be installed to the bottom-side of the Large Bench

Klamp. First, mark a point on each corner, roughly 1” from

each side, as shown in the picture below. Then, remove the

protective coating on each rubber bumper, and place over

your mark. An exact placement is not essential. Allow

several minutes for glue compund to cure.

(Bottom-side of plate shown)

Installation Instructions

Prepare the Bench Klamp

1)

Begin by separating the Plastic Glide Pad from its paper backing. Then, carefully center and adhere

the pad to the base of the Bench Klamp™. Any part of the pad which extends beyond the Bench

Klamp™’s base may be trimmed off, using a scissors. This Pad protects the anodized aluminum of

the plate, from the steel Klamp.

Once finished with the pad, insert the Anchoring Screw into the base of the Bench Klamp. Start with

the Anchoring Screw roughly ½ of the way in, and test it on the Klamp Plate/KLBK. The goal is for

the Anchoring Screw to “slip-fit” into the key-hole of the Klamp Plate/KLBK. If the connection is too

tight, the Bench Klamp will not be able to move freely across the key-hole. If the connection is too

loose, you may get vibrations and imperfect clamping results. Once you have the Anchoring Screw

positioned to your liking, allow a minute for the Thread Locking Compound to cure.

TM

(The following steps are for recessed mounting only)

Determine Location for Installation

2)

The Klamp Plate is uniquely designed to offer you a clamping solution where other clamps simply

can not go. Consider placing the Klamp Plate/KLBK in the center of your workbench. Once you

have determined a good location, position the plate accordingly, and mark around it with a pencil.

This will be your guide for routing later on.

Construct a Routing Template

3)

It’s necessary to construct a template for accurate routing of your workbench. Make sure that you

use 4 pieces of stock with identical thickness, so that your routing depth will be true and without

discernable variation. Begin by placing the Klamp Plate on a work surface, and positioning your 4

pieces around it, as shown in the image to the left. Align the 4 pieces around the plate, snuggly.

Join them together using Pocket-Screw Joinery, or any other technique you are comfortable with.

Begin Routing

4)

Clamp, screw, or nail your template to the workbench, over the pencil marks that you made

earlier. Remember to keep your clamps clear of the router’s intended path. Set the flush trim

bit depth to the thickness of the Klamp Plate/KLBK, plus the thickness of the template you have

constructed. Starting slightly more shallow than intended is highly recommended, as you can

always rout deeper, but it’s very difficult to replace wood that you have already removed. If this

does happen, paper or wood shims can be added to raise the effective height once again. Use

a wood chisel to remove the remnant wood from the corners. When this step is complete, you

should be left with a space in your workbench identical to the size of the plate you are installing.

5)

Key-Hole Routing

Because the Anchoring Screw protrudes below the Klamp Plate when inserted, you must rout an

additional space below the Key-Hole for smooth operation. Place the plate into the newly routed

surface on your workbench and use a pencil to outline the Key-Hole onto the workbench. Use a

Forstner or Spade style drill-bit to rout an additional ¼” of material below the Key-Hole. Use a

wood chisel to finish, if necessary. Place the plate into the completed workbench, and ensure

that the Bench Klamp is able to move freely across the key-hole.

6)

Finishing Touch

Drill pilot holes and use wood screws to install the Klamp Plate/KLBK in solid wood and plywood

surfaces of 1-½” and thicker. Drill appropriately sized holes and use machine screws, washers and

nuts in all particle board and MDF installations, as well as solid wood and plywood surfaces of less

than 1-½” in thickness.

Loading...

Loading...