Kreg Jig® Jr.

User Manual

Manual del usuario

Guide d’utilisation

www.kregjig.com

www.kregjig.com

Introduction Introduction

Our hope is that your Kreg Jig® Jr. opens up a

whole new world of project possibilities for you.

We’ve made every effort to make the it as fun

and easy-to-use as possible. Along with this

user manual, here are several other resources

you may fi nd helpful along the way.

kregjig.com

Your online resource for everything “Kreg.” Whether

you can’t remember how to make a particular joint,

need to order some more self-tapping screws, or just

want to see what kind of accessories are available for

your jig... this is where you’ll fi nd it.

Woodsmith

Kreg Tool Company is a proud sponsor of the popular

Woodworking TV Show, “The Woodsmith Shop.”

Instead of focusing on larger projects, the Woodsmith

Shop focuses on tips, techniques, and woodshop

fundamentals. It’s a great way to learn the basics

and take your projects to the next level. Learn more

at www.woodsmithshop.com.

2

CLUB

Kreg Club

As a member of the Kreg Club, you’ll be the fi rst to receive

all new tips, tricks and project ideas... sent right to your

inbox. As a valued Kreg customer, you’ll also receive

exclusive offers and product sneak-previews based on the

Kreg products you already own. Just sit back and let the

information come to you! Sign up today at www.kregjig.com.

• Tips/Tricks

• Project Plans

• Product Updates

• Exclusive Offers

• Product “Sneak Peaks”

• Much More...

800-447-8638

www.kregjig.com

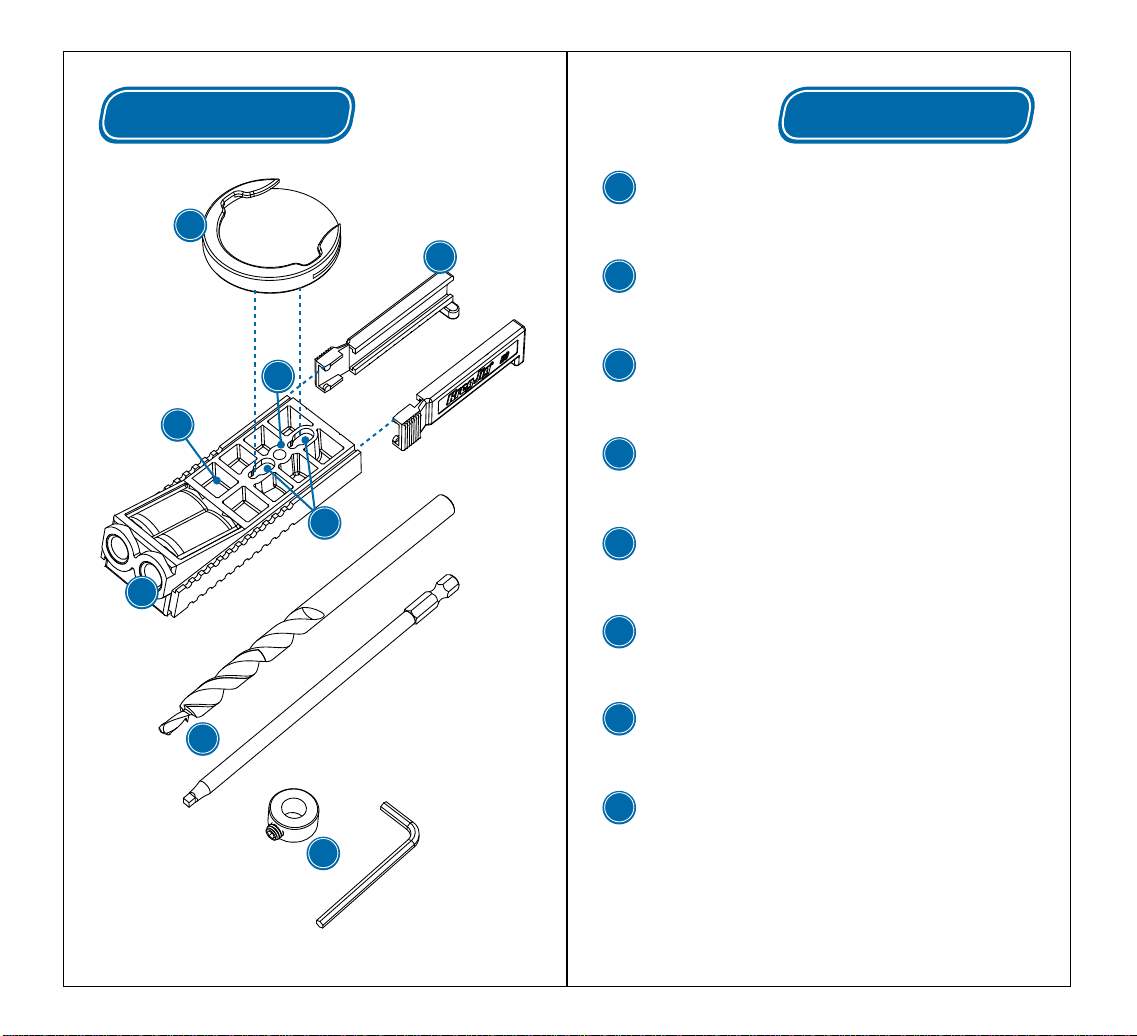

Components Components

A

Clamp Pad Adapter:

This simple adapter snaps onto the back of the jig, allowing

A

C

E

D

F

B

Kreg Face Clamps to be attached for faster drilling and

superior repeatability.

B

Drill Guide:

This two-hole drill guide helps keep your drilling stroke

straight and true. Features 2 lifetime-guaranteed hardened

steel ‘cores.’

C

Easy-Press™ Positioning Sliders:

These two removable positioning sliders allow you to

compensate for workpiece thickness adjustments with a

simple press of your thumb.

D

Wood-Chip Release Holes:

Two holes at the base of each hardened steel core allow

wood chips to escape, easing the drill stroke and improving

the lifetime of your drill bit.

E

Mounting Hole:

For tight applications where a clamp won’t reach, the jig can

be secured to the workpiece using a wood screw through

this small hole.

F

Clamp Adapter Holes:

For high-speed repeatable applications, these two holes

secure the Clamp Pad Adapter in place for use with Kreg

Face Clamps.

800-447-8638

G

Depth Collar | Allen Wrench:

H

G

The Depth Collar can be set at predetermined lengths along

the drill bit and locked in place with the Allen Wrench to set

the bit’s maximum plunge depth.

H

#2 Square Driver | 3/8” Stepped Drill Bit:

These two uniquely designed Kreg bits feature long-lasting

durable steel and are specialized for use with the

®

and Kreg Joinery™.

Kreg Jig

www.kregjig.com

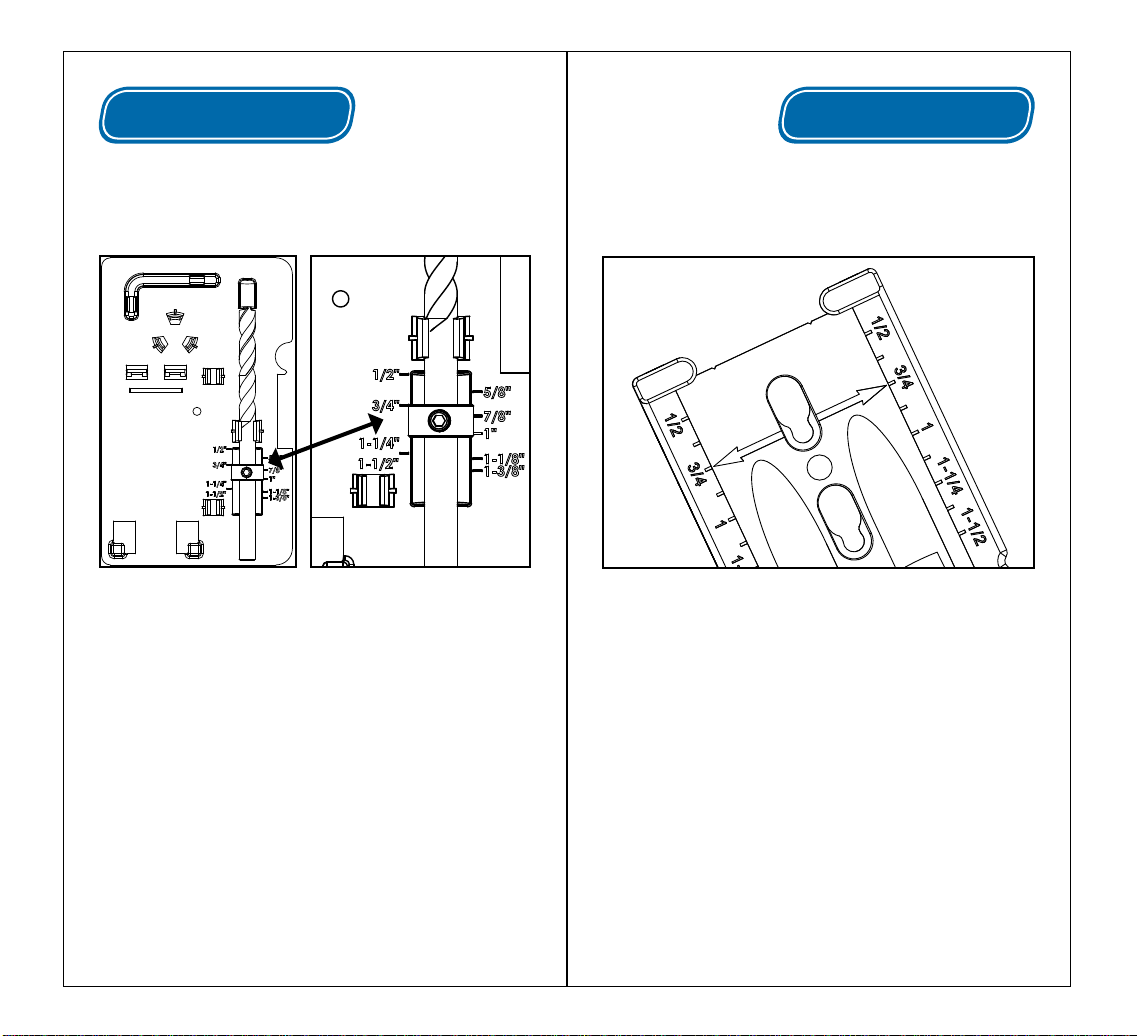

Jig Settings Jig Settings

To create the strongest joint possible, you’ll need to set your

jig to match the thickness of your workpiece. The

Kreg Jig

For 3/4” material, place the step of the bit as far forward as it will go

and tighten the depth collar at the 3/4” marking.

®

Jr. makes this easy, in just two simple steps!

To get the right Pocket-Hole depth, you’ll fi rst have to

adjust the position of the Depth Collar on the Drill Bit. The

collar prevents the your drill from plunging too far into the

workpiece, so its position is essential.

Begin by placing the bit inside the Depth Setting Gauge

found inside of the Kreg Jig

®

Jr.’s case. Place the step of

the bit as far forward as it will go, then slide the Depth

Collar onto the shank of the bit until it reaches the marking

which matches your workpiece thickness, as shown. Lock

the Depth Collar fi rmly into place with the included Allen

Wrench.

To ensure the exit-point of your screw is at the center of the

workpiece for the strongest joint possible, you’ll also need to

adjust the Positioning Sliders on either side of the Kreg Jig

Positioning Sliders shown set for 3/4” thick material.

®

Jr.

On the bottom of each Positioning Slider there are markings

which represent different material thicknesses. Press

each slider with your thumb and slide it until the marking

which matches the thickness of your workpieces comes into

alignment with the large arrows on the bottom of the jig, as

shown.

800-447-8638

www.kregjig.com

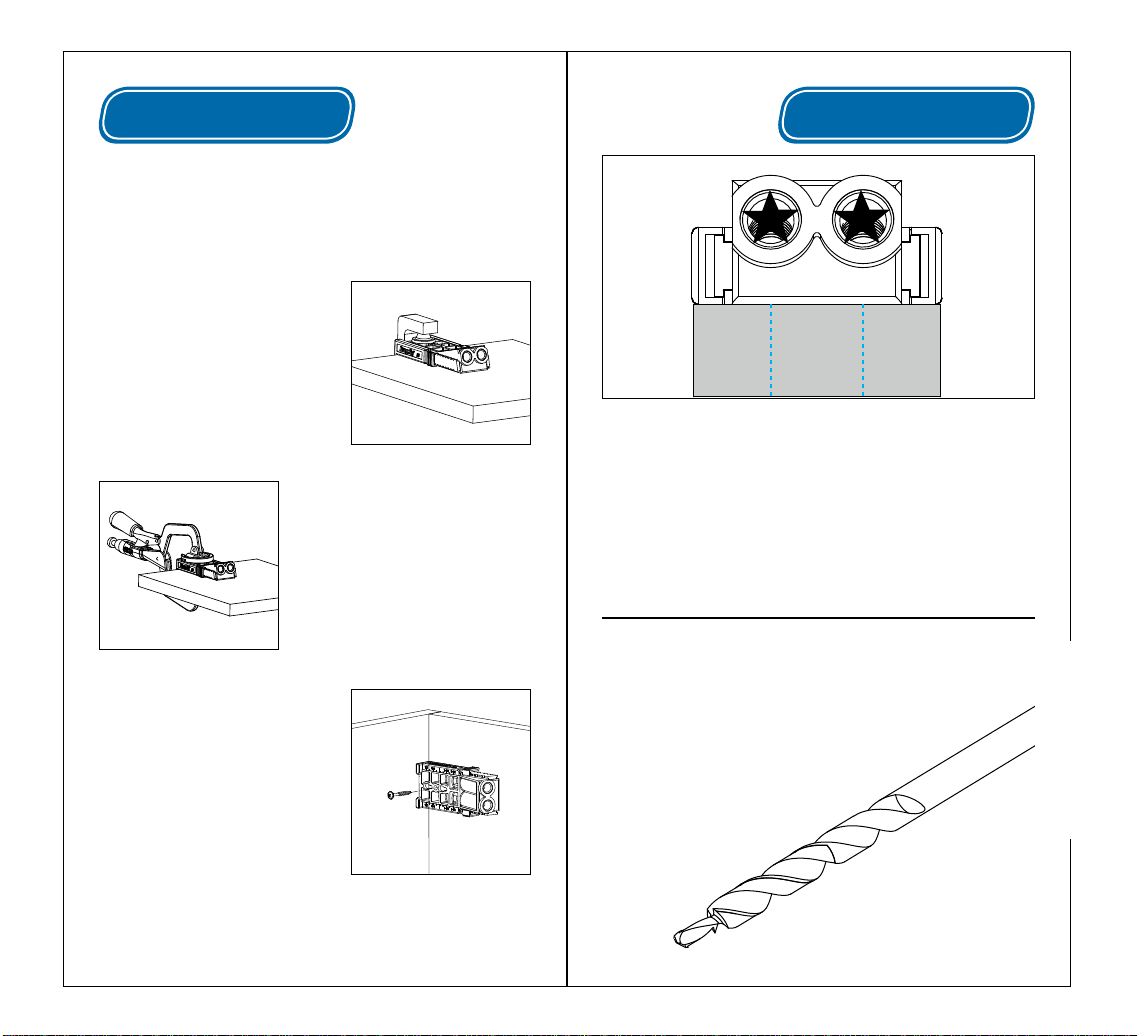

Clamping Drilling

With the Kreg Jig

®

Jr. properly set to match the thickness of

your workpiece, you’re ready to clamp the jig in place and

start drilling. Depending on the type of work you’re doing,

you’ve got several options:

For the majority of applications

any simple bar clamp or c-clamp

you have lying around will work

just fi ne to keep the jig clamped

tightly to the workpiece while you

drill your Pocket-Holes.

With the included Clamp Pad

Adapter, the Kreg Jig

®

Jr. can

be connected directly to any one

of our Face Clamps when you

need to take your work on the

road or just get faster and more

repeatable Pocket-Holes.

In certain tight situations where

the use of a clamp is not

possible, the Kreg Jig

®

Jr. can

also be secured in place with

a common wood screw driven

through the Mounting Hole on

the top of the jig.

Along with the Jig settings, another important part of

getting the strongest possible Kreg Joint™ is to space your

Pocket-Holes evenly across the workpiece. Your Kreg Jig

®

Jr. features a 2-hole Drill Guide which lets you drill holes in

narrow stock without having to reposition the jig.

For panels we recommend placing the fi rst Pocket-Hole

roughly 2 inches away from the exposed edge of the panel,

and every 6” after that.

®

Included with your Kreg Jig

Jr. is a stepped drill bit

designed specifi cally for use with Kreg Joinery™. While

the large part of the drill actually creates the “pocket”, the

narrow tip drills the guide hole for the screw. When

you drill your fi rst hole, place the bit about an

inch inside of the Drill Guide, bring the drill

up to full speed, and plunge the bit

smoothly and consistently into the

workpiece.

800-447-8638

www.kregjig.com

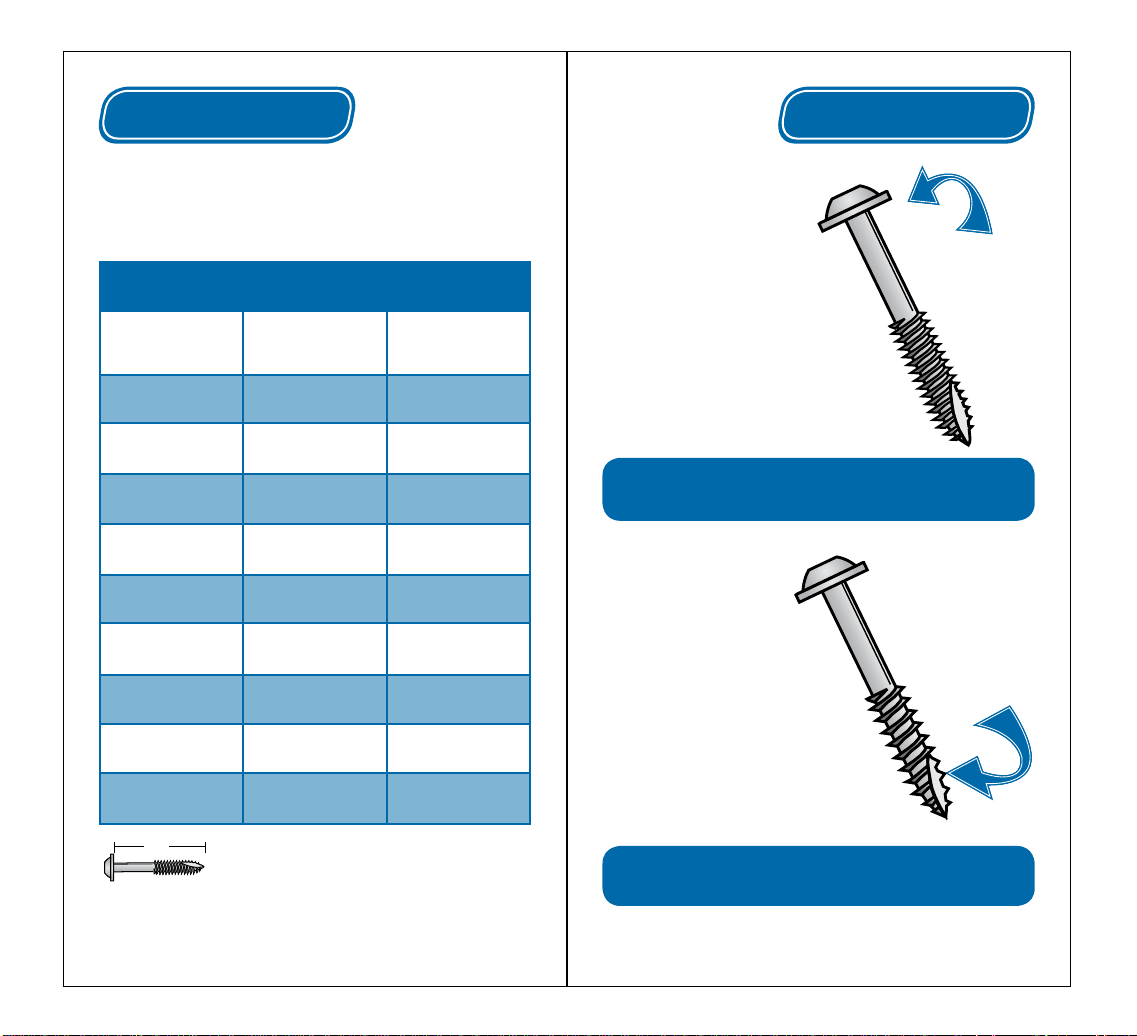

Choosing a Screw Choosing a Screw

Kreg offers a complete line of specialized screws for every

workpiece size and type. Use this graph to fi nd the correct

screw. All are available online, at www.kregjig.com or at

your local authorized Kreg dealer.

Screw Selection / Kreg Jig® Setting Chart

Material

Thickness

1

⁄2” (12 mm)

5

⁄8” (16 mm) 1” (25 mm)

3

⁄4” (19 mm) 11⁄4” (32 mm)

Screw

Length

1” (25 mm)

Kreg Jig

Setting

1

⁄2” Marking

5

⁄8” Marking

3

⁄4” Marking

®

Fine Thread

Fine thread screws are

recommended for hardwoods as

they reduce the chance of the

material splitting when driven.

Use in woods such as:

• Ash • Oak • Maple • Walnut • Hickory • Cherry • Mahogany • Birch

Deep Square Drive

improves driver

engagement and

reduces the

possibility of

cam-out.

7

⁄8” (22 mm) 11⁄2” (38 mm)

1

1” (25 mm) 1

1

⁄8” (29 mm) 11⁄2” (38 mm) 11⁄8” Marking

1

1

⁄4” (32 mm) 2” (51 mm) 11⁄4” Marking

1

3

⁄8” (35 mm) 2” (51 mm) 13⁄8” Marking

1

1

⁄2” (38 mm) 21⁄2” (64 mm) 11⁄2” Marking

1

11⁄4”

*Note: Screw length is measured from bottom of

the head to the tip of the screw

⁄2” (38 mm) 1” Marking

800-447-8638

7

⁄8” Marking

Self-Tapping

Auger point

eliminates the

need to drill a

Coarse Thread

pilot hole.

Due to a signifi cantly larger

thread diameter, coarse thread

screws offer a much stronger

hold in composite materials such

as MDF and plywood.

Use in woods such as:

• Pine • Cedar • Basswood • Poplar • Plywood • Melamine• Particle Board

www.kregjig.com

Introducción Introducción

Nuestro deseo es que con su Kreg Jig® Jr . descubra

un mundo nuevo lleno de posibilidades para sus

proyectos. Hicimos todo a nuestro alcance para que

sea lo más divertido y fácil de usar posible. Junto con

este manual del usuario, encontrará otros recursos

que quizá sean útiles para la construcción.

kregjig.com

Su recurso en línea para todo lo que sea “Kreg”. Si no

puede recordar cómo fabricar una junta en particular,

necesita pedir algunos tornillos autorroscantes, o sólo

desea ver qué tipo de accesorios hay disponibles

para su plantilla para taladrar, aquí es dónde lo

encontrará.

Woodsmith

Kreg Tool Company se enorgullece de ser el

patrocinador del famoso programa de televisión de

carpintería The Woodsmith Shop. En lugar de centrarse

en proyectos más grandes, el programa The Woodsmith

Shop hace hincapié en los consejos, las técnicas y los

conceptos básicos de la compra de madera. Es una

excelente manera de aprender los conceptos básicos y

hacer que sus proyectos tengan más categoría. Para más

información, visite www.woodsmithshop.com.

800-447-8638

2

CLUB

Club Kreg

Como miembro del Club Kreg, será el primero en recibir

todos los consejos, trucos e ideas de proyectos más recientes

en su correo electrónico. Como un valioso cliente de Kreg,

también recibirá exclusivas ofertas y vistas previas de

productos basadas en los productos Kreg que ya conoce.

¡Póngase cómodo y deje que le llegue información!

Regístrese hoy en www.kregjig.com.

• Consejos/trucos

• Planos de proyectos

• Actualizaciones de productos

• Ofertas exclusivas

• Vistas previas de productos

• Mucho más...

www.kregjig.com

Componentes Componentes

A

Adaptador de la almohadilla de la abrazadera:

Este simple adaptador se encaja en la parte posterior de

la plantilla, permitiendo instalar las abrazaderas Kreg Face

A

C

E

D

F

B

H

G

800-447-8638

Clamp para un taladrado más rápido y repetibilidad superior.

B

Guía de taladro:

Esta guía de taladro de dos orifi cios permite que el

taladrado se mantenga recto y aplomado. Trae 2 “núcleos”

en acero endurecido garantizados de por vida.

C

Correderas de posicionamiento Easy-Press™:

Estas dos correderas de posicionamiento desmontables le

permiten compensar los ajustes de grosor de la pieza de

trabajo con una simple presión del pulgar.

D

Orifi cios de liberación de astillas de madera:

Los dos orifi cios de la base de cada núcleo de acero

endurecido permiten el escape de las astillas de madera,

facilitando el taladrado y mejorando la vida útil de la broca

para taladro.

E

Orifi cio de montaje:

Para aplicaciones con poco espacio en que no llegan las

abrazaderas, la plantilla se puede fi jar a la pieza de

trabajo con un tornillo para madera a través de este

pequeño orifi cio.

F

Orifi cios del adaptador de la abrazadera:

Para aplicaciones repetibles a alta velocidad, estos dos orifi cios

fi jan el adaptador de la almohadilla de la abrazadera para

poder usarlo con abrazaderas Kreg Face Clamp.

G

Anillo de profundidad y llave Allen:

El anillo de profundidad se puede ajustar a longitudes

predeterminadas a lo largo de la broca para taladro y

se puede bloquear con una llave Allen para establecer la

profundidad máxima de penetración de la broca.

H

Broca cuadrada #2 |

Broca escalonada de forma cónica de 3/8”

Estas dos brocas Kreg de diseño exclusivo están hechas de

acero de larga duración y su uso específi co es con Kreg

®

y Kreg Joinery™.

Jig

www.kregjig.com

Confi guración de la plantilla Confi guración de la plantilla

Para crear la junta más fuerte que sea posible, deberá

colocar la plantilla para taladrar de manera que coincida

con el grosor de su pieza de trabajo. El juego Kreg Jig

®

Jr.

lo hace simple y en tan sólo dos pasos.

Para el material de 19 mm de grosor, coloque la escala hasta donde va

a llegar y ajuste el anillo de profundidad en la marca de 19 mm.

Para obtener la correcta profundidad de las cavidades

ocultas, primero deberá ajustar el anillo de profundidad

en la broca para taladro. El anillo impide que el taladro

perfore demasiado profundo en la pieza de trabajo, así

que su posición es esencial.

Comience por colocar la broca en el interior del calibrador

de confi guración de profundidad en el interior de la

caja del Kreg Jig

®

Jr. Coloque la escala de la broca

tan adelante como llegue; luego, deslice el anillo de

profundidad en el vástago de la broca hasta que llegue a

la marca que coincide con el grosor de su pieza de trabajo,

como se muestra. Bloquee bien el anillo de profundidad en

su lugar con la llave Allen que viene incluida.

Para asegurar que el punto de salida del tornillo sea en el

centro de la pieza de trabajo para crear la junta más fuerte

posible, deberá ajustar las correderas de posicionamiento en

ambos lados de Kreg Jig

Las correderas de posicionamiento se muestran confi guradas para

los materiales de 19 mm de grosor.

®

Jr.

En la parte inferior de cada corredera de posicionamiento

hay marcas que representan diferentes grosores de

material. Presione cada corredera con el pulgar y deslícela

hasta que la marca que coincide con el grosor de su pieza

de trabajo se alinee con las fl echas grandes de la parte

inferior de la plantilla, como se muestra.

800-447-8638

www.kregjig.com

Sujeción Perforación

®

Con la plantilla Kreg Jig

el grosor de su pieza de trabajo, está listo para sujetar la

plantilla y comenzar a taladrar. Dependiendo del tipo de

trabajo que realice, tendrá varias opciones:

Para la mayoría de las

aplicaciones, servirá cualquier

simple abrazadera de barra o

de presión en C para mantener

la plantilla bien sujeta en la

pieza de trabajo mientras

perfora los orifi cios ocultos.

En ciertas situaciones de poco

espacio en que no se puede

usar abrazaderas, la plantilla

Kreg Jig

®

Jr. se puede fi jar con

un tornillo común para madera a

través del orifi cio de montaje de

la parte superior de la plantilla.

Jr. correctamente alineada con

Con el adaptador de la

almohadilla de la abrazadera,

la plantilla Kreg Jig® Jr. se

puede conectar directamente

a cualquiera de las cuatro

abrazaderas Face Clamp cuando

necesite trasladar el trabajo o

perforar orifi cios ocultos más

rápidos y repetibles.

Junto con la confi guración de la plantilla, otra parte importante

de crear la junta Kreg Joint™ más fuerte posible es que entre

las cavidades ocultas haya espacios parejos en la pieza de

trabajo. El juego Kreg Jig

®

Jr. tiene una guía de taladro de

tres orifi cios que le permite hacer esto en piezas de trabajo

estrechas sin tener que cambiar de posición la plantilla.

Para los paneles, recomendamos colocar la primera cavidad

oculta aproximadamente a 5,1 cm del borde expuesto del

panel y en intervalos de 15,2 cm después de eso.

La plantilla Kreg Jig

®

Jr. incluye una broca escalonada

de forma cónica diseñada específi camente para su uso

con Kreg Joinery™. La parte grande de la broca crea el

orifi cio oculto; las brocas estrechas guían el orifi cio

para el tornillo. Al perforar el primer orifi cio,

coloque la broca aproximadamente a 2,5

cm de la guía de taladro, aumente

completamente la velocidad del

taladro e inserte la broca en

forma suave y constante

en la pieza de

trabajo.

800-447-8638

www.kregjig.com

Elección de un tornillo. Elección de un tornillo.

Kreg ofrece una línea completa de tornillos especiales para

cada tipo y tamaño de pieza de trabajo. Utilice este gráfi co para hallar el tornillo correcto. Todos están disponibles

en línea en www.kregjig.com o en el vendedor de Kreg

autorizado de su área local.

Cuadro de elección de tornillos y

confi guración de Kreg Jig

Grosor

del material

1

⁄2” (12 mm)

5

⁄8” (16 mm) 1” (25 mm)

3

⁄4” (19 mm) 11⁄4” (32 mm)

Largo

del tornillo

1” (25 mm)

®

Posición del

Kreg Jig

1

⁄2” marca

5

⁄8” marca

3

⁄4” marca

Roscado fi no

Los tornillos de rosca fi na están

recomendados para maderas

duras ya que reducen las

probabilidades de que el material

se rasgue al ser introducidos.

Utilice en maderas como:

• Fresno • Roble • Arce • Nogal • Nogal americano • Cerezo

• Caoba • Abedul

Los tornillos de

cabeza cuadrada

para profundidad

mejoran el agarre

del atornillador y

reducen la

posibilidad

de que el

atornillador

se deslice

hacia

afuera.

7

⁄8” (22 mm) 11⁄2” (38 mm)

1” (25 mm) 11⁄2” (38 mm) 1” marca

11⁄8” (29 mm) 11⁄2” (38 mm) 11⁄8” marca

11⁄4” (32 mm) 2” (51 mm) 11⁄4” marca

13⁄8” (35 mm) 2” (51 mm) 13⁄8” marca

11⁄2” (38 mm) 21⁄2” (64 mm) 11⁄2” marca

11⁄4”

*Aviso: El largo del tornillo se mide desde la parte

inferior de la cabeza hasta la punta del tornillo.

800-447-8638

7

⁄8” marca

Roscado de

ángulo grande

Debido a su diámetro

signifi cativamente mayor, los

La punta de barrena

de los tornillos

autorroscantes elimina

la necesidad de hacer

un agujero guía.

tornillos con roscas de ángulo

grande ofrecen una mucho mejor

sujeción en materiales compuestos

como tableros de fi bra de densidad

media (MDF, por sus siglas en inglés) y

contrachapado.

Utilice en maderas como:

• Pino • Cedro • Tilo americano • Álamo • Madera contrachapada

• Melamina • Panel de aglomerado

www.kregjig.com

Introduction Introduction

Nous espérons que votre Kreg Jig® Jr . vous donnera

accès à un nouveau monde de possibilités et de

projets. Nous nous sommes efforcés de le rendre

aussi amusant et facile à utiliser que possible.

Vous trouverez ci-dessous des outils qui, en plus

de ce guide d’utilisation, pourraient vous être

utiles pendant la réalisation de votre projet.

kregjig.com

Il s’agit de votre ressource en ligne pour tout ce qui

concerne Kreg. Que ce soit pour savoir comment faire

un joint en particulier, pour commander quelques vis

autotaraudeuses de plus ou simplement pour voir quels

types d’accessoires sont offerts pour votre gabarit, vous

trouverez sur ce site la réponse à toutes vos questions.

Woodsmith

Kreg Tool Company est un fi er commanditaire de la

célèbre émission télévisée sur le travail du bois « The

Woodsmith Shop ». Au lieu de se concentrer sur des

projets à grand déploiement, « The Woodsmith Shop »

donne des conseils, présente des techniques et explique

les principes fondamentaux d’un atelier de menuiserie.

C’est une bonne façon d’apprendre les rudiments de la

menuiserie et d’amener vos projets au niveau supérieur.

Pour obtenir plus de renseignements, rendez-vous sur le

site www.woodsmithshop.com.

800-447-8638

2

CLUB

Kreg Club

Les membres du Kreg Club sont les premiers à recevoir tous

les nouveaux conseils, astuces et idées de projet directement

par courriel. À titre de client important de Kreg, vous

recevrez également des offres et des avant-goûts exclusifs,

selon les produits Kreg que vous possédez déjà. Vous n’avez

absolument rien à faire pour obtenir cette information!

Inscrivez-vous aujourd’hui même sur le site www.kregjig.com.

• Conseils et astuces

• Plans de projet

• Nouvelles sur les produits

• Offres exclusives

• Avant-goût des nouveaux produits

• Et bien plus encore

www.kregjig.com

Composants Composants

A

Adaptateur de tampon :

Cet adaptateur simple se fi xe à l’arrière du gabarit et

permet d’utiliser les serre-joints Kreg Face Clamps pour

A

C

E

D

F

B

percer plus rapidement des trous identiques.

B

Guide-foret :

Ce guide-foret à deux trous vous permet de percer des

trous droits et précis. Il est fait d’acier durci garanti à vie.

C

Coulisseaux d’ajustement Easy-Press™ :

Ces coulisseaux amovibles vous permettent de régler le

gabarit selon l’épaisseur des pièces sur lesquelles vous

travaillez d’une simple pression du pouce.

D

Trous d’évacuation des copeaux :

Deux trous au bas des guide-forets d’acier assurent

l’évacuation des copeaux de bois, ce qui facilite le perçage

et accroît la durée de vie de votre foret.

E

Trou de montage :

Pour les travaux en espace restreint, lorsque le serre-joint ne

peut pas être utilisé, le gabarit peut être fi xé à la pièce à

l’aide d’une vis par ce petit trou.

F

Trous pour l’adaptateur de tampon :

Ces deux trous permettent de fi xer l’adaptateur de tampon

en vue d’utiliser les serre-joints Kreg Face Clamps afi n de

percer rapidement plusieurs trous identiques.

800-447-8638

G

H

G

Collier de profondeur et clé Allen :

Le collier de profondeur peut être placé à des longueurs

prédéterminées le long du foret et être verrouillé à l’aide

de la clé Allen afi n de régler la profondeur de pénétration

maximale du foret.

H

Tournevis carré nº 2 et

foret étagé de 3/8 po :

Ces deux embouts Kreg de conception exclusive sont faits

d’acier robuste et durable et sont spécialement conçus pour

être utilisés avec les outils Kreg Jig

®

et Kreg Joinery™.

www.kregjig.com

Réglages du gabarit Réglages du gabarit

Pour obtenir les joints les plus solides possible, il est

nécessaire de régler votre gabarit de manière à ce qu’il

corresponde à l’épaisseur de votre pièce. Le Kreg Jig

®

Jr.

permet de le faire facilement, en deux étapes seulement!

Pour une pièce de ¾ po, placez l’échelon du foret le plus loin possible vers

l’avant et serrez le collier de profondeur au niveau de la marque de ¾ po.

Pour que vos trous en angle aient la bonne profondeur, il est

nécessaire de régler la position du collier de profondeur sur

le foret. Ce collier empêche la perceuse de pénétrer trop

profondément dans la pièce; sa position est donc essentielle.

Placez d’abord le foret dans le calibre de réglage de

la profondeur qui se trouve dans le boîtier du Kreg Jig®

Jr. Placez l’échelon du foret le plus loin possible vers

l’avant, puis faites glisser le collier de profondeur sur le

foret jusqu’à la marque correspondant à l’épaisseur de la

pièce, tel qu’il est illustré. Bloquez le collier de profondeur

solidement en place avec la clé Allen fournie.

Pour vous assurer que le point de sortie de la vis est au centre

de la pièce, afi n que le joint soit le plus solide possible, il est

aussi nécessaire de régler les coulisseaux d’ajustement de

chaque côté du Kreg Jig

Coulisseaux réglés pour des pièces de ¾ po d’épaisseur.

®

Jr.

Au fond de chaque coulisseau, des marques indiquent

différentes épaisseurs de pièce. En appuyant avec le

pouce, faites glisser chacun des coulisseaux jusqu’à ce que

la marque correspondant à l’épaisseur de votre pièce soit

alignée sur les grandes fl èches au fond du gabarit, comme

sur l’illustration.

800-447-8638

www.kregjig.com

Blocage Perçage

Une fois que le Kreg Jig

®

Jr. est réglé à l’épaisseur de votre

pièce, vous pouvez le placer sur la pièce et commencer à

percer. Vous avez plusieurs options, selon le projet que vous

réalisez :

Dans la plupart des cas, tout

serre-joint à barre ou en C

ordinaire conviendra pour fi xer

solidement le gabarit à la pièce

pendant que vous percez vos

trous en angle.

Avec l’adaptateur de tampon

fourni, le Kreg Jig

®

Jr. peut

être rattaché directement à nos

serre-joints Face Clamps si vous

devez emporter votre projet à

l’extérieur ou simplement pour

percer plus rapidement des trous

à angle identiques.

Dans les cas où il est impossible

d’utiliser un serre-joint, le Kreg

®

Jig

Jr. peut aussi être fi xé sur

la pièce à l’aide d’une vis à

bois ordinaire par le trou de

montage situé sur le dessus du

gabarit.

En plus de bien régler le gabarit, il est important, pour obtenir les

joints les plus solides possible, de répartir les trous en angle de

façon régulière sur la surface de la pièce. Le Kreg Jig

®

comprend

un guide-foret à deux trous qui permet de percer des trous dans

des pièces de faible largeur sans avoir à déplacer le gabarit.

Pour les panneaux, nous recommandons de placer le premier trou

à environ 5 cm de l’extrémité du côté apparent du panneau et les

autres trous à une distance de 15 cm les uns des autres.

Un foret étagé conçu spécialement pour être utilisé avec

l’ensemble Kreg Joinery™ est fourni avec votre Kreg Jig

®

Jr. La partie plus large du foret crée le trou en angle,

tandis que la partie plus fi ne crée le trou pour la vis.

Au moment de percer le premier trou, insérez

le foret 2,5 cm à l’intérieur du guideforet, réglez la perceuse à la vitesse

maximale et percez la pièce d’un

mouvement constant, sans

à-coups.

800-447-8638

www.kregjig.com

Kreg vous offre une gamme complète de vis adaptées pour

les pièces de tous les types et de tous les formats. Utilisez

le tableau suivant pour choisir la bonne. Elles sont toutes

offertes en ligne, sur le site www.kregjig.com ou chez votre

détaillant Kreg autorisé.

1

®

®

⁄2 po

Sélection de vis et réglage du Kreg Jig

Épaisseur

de la pièce

1

⁄2 po (12 mm)

5

⁄8 po (16 mm) 1 po (25 mm) MARQUE 5⁄8 po

3

⁄4 po (19 mm) 11⁄4 po (32 mm) MARQUE 3⁄4 po

7

⁄8 po (22 mm) 11⁄2 po (38 mm) MARQUE 7⁄8 po

Longueur

de la vis

1 po (25 mm)

Réglage du

Kreg Jig

MARQUE

Choisir le bon type de visChoisir le bon type de vis

Un carré conducteur

profond permet de

mieux guider la vis

et de réduire les

risques de rejet.

Filetage fi n

Les vis à fi letage fi n sont

recommandées pour les bois durs,

car elles réduisent les risques que

le bois se fende lorsqu’il est percé.

Utilisez-les avec les types de bois suivants :

• Le frêne • Le chêne • L’érable • Le noyer • L’hickory • Le cerisier

• L’acajou • Le bouleau

1

1 po (25 mm) 1

1

⁄8 po (29 mm) 11⁄2 po (38 mm) MARQUE 11⁄8 po

1

1

⁄4 po (32 mm) 2 po (51 mm) MARQUE 11⁄4 po

1

3

⁄8 po (35 mm) 2 po (51 mm) MARQUE 13⁄8 po

1

1

1

⁄2 po (38 mm) 21⁄2 po (64 mm) MARQUE 11⁄2 po

11⁄4”

*Remarque : La longueur de la vis est calculée du

bas de la tête jusqu’au bout de la vis.

⁄2 po (38 mm) MARQUE 1 po

800-447-8638

La pointe de tarière

autotaraudeuse

vous évite d’avoir

à percer un trou

Filetage normal

En raison de leur diamètre

beaucoup plus grand, les vis à

fi letage normal offrent une prise

bien plus solide pour les matériaux

composites tels que les panneaux

MDF et de contreplaqué.

Utilisez-les avec les types de bois suivants :

• Le pin • Le cèdre • Le tilleul d’Amérique • Le peuplier

• Le contreplaqué • La mélamine • Les panneaux de particules

www.kregjig.com

d’essai.

Welcome to the Kreg Jig® family.

800-447-8638

NK7716

Bienvenido a la familia de Kreg Jig®.

Bienvenue dans la famille Kreg Jig®.

Loading...

Loading...