Kreg Jig® K5

User Guide

www.kregtool.com

Introduction

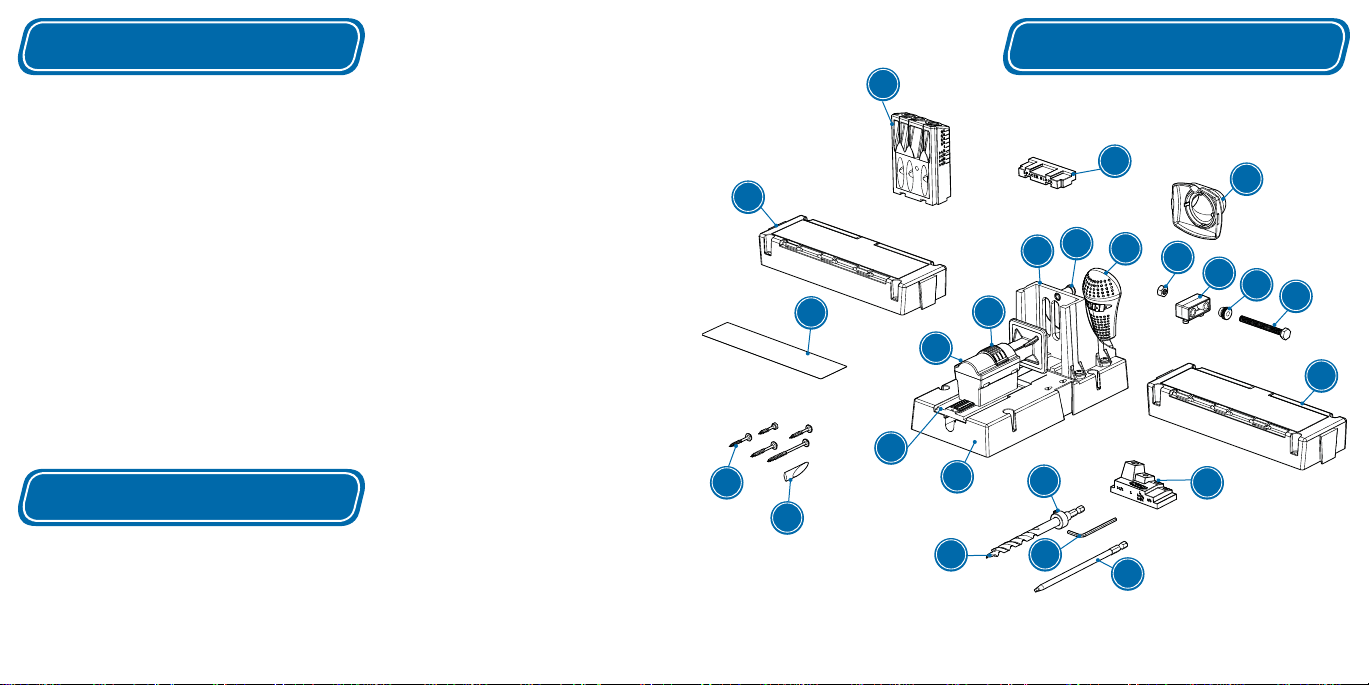

Parts

Owning a Kreg Jig® opens up new project possibilities. This Guide shows

you how to adjust your jig and drill pocket holes. You may fi nd the following

resources helpful:

Kreg Online: To view videos of the Kreg Jig® K5 in use, order more pocket-

hole screws, or view accessories available for your jig, go to kregtool.com.

Kreg Owner’s Community: Sign up as a member, create your own page, view

other members’ projects, post photos of your projects, view how-to videos, and

participate in forums by going to kregjig.ning.com.

Kreg YouTube Channel: For project, product, and how-to videos, visit

youtube.com/user/kregtoolcompany.

Kreg on Facebook: Connect with Kreg on Facebook to share your projects and

to get inspiration from our fans and friends at facebook.com/kregJig.

Assembly

Your Kreg Jig® K5 is almost ready to use right out of the box. Apply the screwlength selection guide label to the inside of one extension lid. Place the jig on

your workbench and fi t the dovetail keys on the extensions into the dovetail

slots in the base. The jig and extensions feature holes for mounting to a board.

G

S

T

D

E

V

A

W

I

For a complete listing of repair parts, see the

Kreg Jig® K5 manual at www.kregtool.com.

U

R

H

B

F

C

O

N

P

Q

S

J

L

K

M

www.kregtool.com 800-447-8638

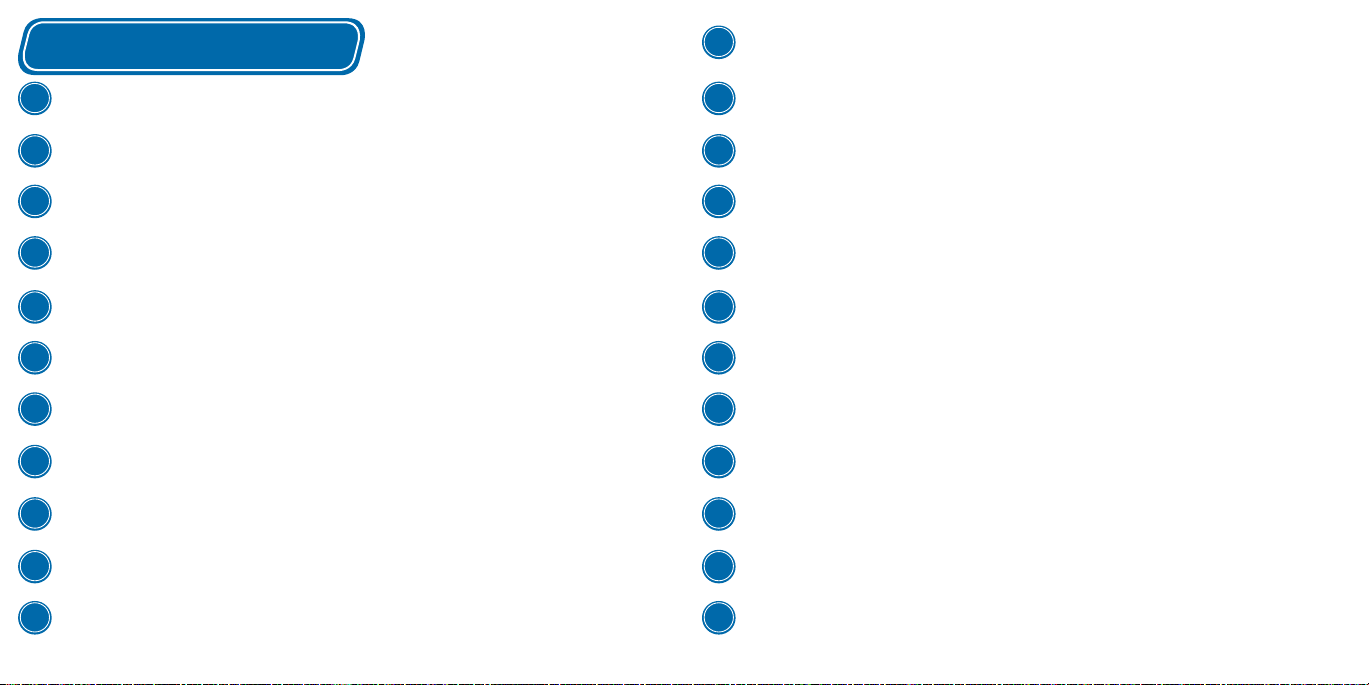

Parts

A

Base:

Features four holes for securing the jig to a work bench or auxiliary base.

Drill-guide socket:

B

Accepts all Kreg drill guides: Micro, Standard (included), and HD

Toggle handle:

C

Operates workpiece clamping mechanism.

Clamp assembly:

D

Powerful internal spring applies clamping pressure.

Stop-collar setting block

L

Ensures proper positioning of the stop collar on the drill bit.

Driver bit:

M

#2 square-drive bit 6" long.

Workpiece stop:

N

Stop snaps into keyhole slots in the base.

O

Workpiece stop fi ne-adjustment nut:

¼-20 nut fi ts into hex recess in workpiece stop.

P

Knurled nut:

Nylon knurled nut acts as jam nut to fi x the position of the fi ne-adjustment screw.

Ratchet plate:

E

Provides clamp-assembly adjustment.

F

Ratchet release:

Disengages clamp assembly from ratchet plate.

G

Standard drill guide:

Features marks for positioning the guide for different workpiece thicknesses.

Locking pin:

H

Spring-loaded pin locks the drill guide into the drill-guide socket at the selected setting.

Step bit:

I

Simultaneously drills a pilot hole and clearance hole, forming a bearing shoulder for the screw head.

Stop collar:

J

Controls drilling depth.

Hex wrench

K

For the stop-collar set screw.

Fine-adjustment screw:

Q

¼-20 x 2 ½" Nylon bolt threads into nut to provide no-slip fi ne adjustment.

Vacuum port:

R

Accepts a 1¼" shop vacuum hose for effi cient chip removal, swivels side to side.

Extensions:

S

Provide support for wide workpieces and storage for bits and accessories.

Screw-length selection guide:

T

Apply this self-adhesive label to the inside of an extension lid for easy reference.

Spacer block:

U

In repair applications, positions the drill guide for drilling pocket holes in ¾"-thick material

Pocket-screw sample pack:

V

Contains 10 each of the fi ve most often used screws.

Pocket-hole plug sample pack

W

Contains fi ve paint-grade wood plugs.

www.kregtool.com 800-447-8638

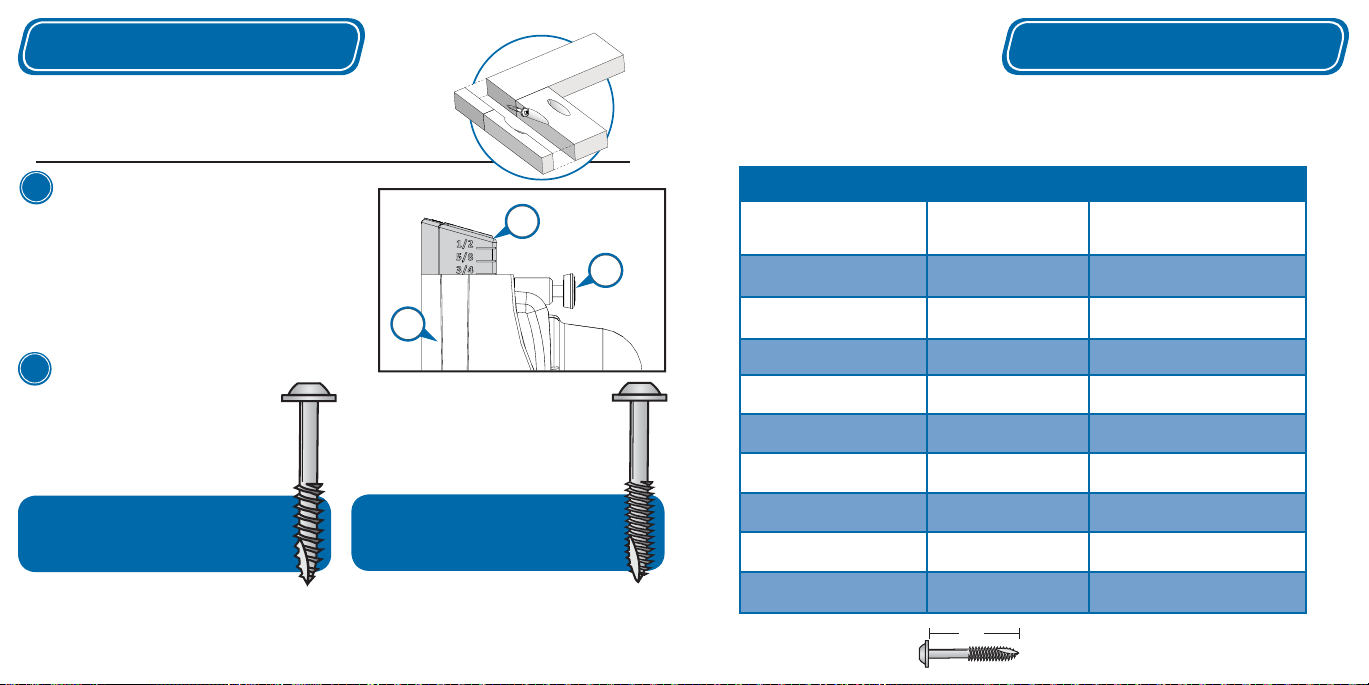

Settings

Settings

To create strong joints, you’ll set your jig to match the

thickness of the workpiece and the length of the screw.

The Kreg Jig® makes this easy, in just four simple steps:

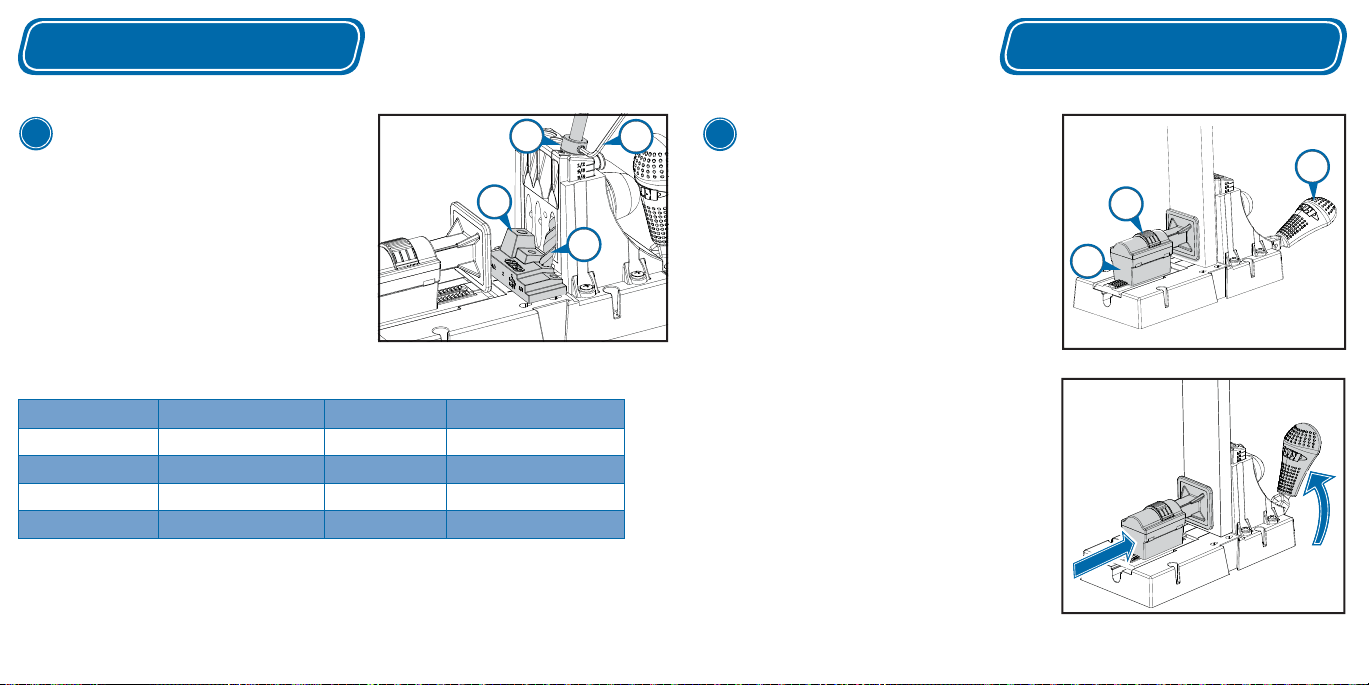

1

Set the Drill Guide

For a strong joint, the screw should exit at the center

of the workpiece. To adjust the pocket-hole position,

G

retract the spring-loaded drill-guide locking pin (H).

Then raise or lower the drill guide (G) until the mark

H

on the side of the guide that matches the thickness of

the workpiece is even with the top of the guide socket

(B). Release the locking pin.

Choose a Screw

2

Coarse Thread

Due to the large diameter and thread

pitch, our #8 coarse-thread screws offer

a strong hold in softwoods and composite

materials.

Use in woods such as:

• Pine • Cedar • Basswood • Poplar

• Plywood • Melamine • Particle Board

All Kreg pocket screws have a deep square drive that improves driver engagement and reduces the possibility of

cam-out. Self-tapping auger point eliminates the need to drill a pilot hole.

B

Fine Thread

Because the smaller diameter and thread

pitch of our #7 fi ne-thread screws reduce

the chance of splitting the material, we

recommend them for hardwoods.

Use in woods such as:

• Ash • Oak • Maple • Walnut • Hickory

• Cherry • Mahogany • Birch

Kreg offers a complete line of pocket screws for every workpiece thickness and type.

Use this chart to select the correct screw length. All Kreg pocket screws are available

at your Kreg dealer or online at www.kregtool.com.

Screw Selection / Kreg Jig® Setting Chart

Setting

1

⁄2" Mark

5

⁄8" Mark

3

⁄4" Mark

7

⁄8" Mark

®

www.kregtool.com 800-447-8638

Material

Thickness

1

⁄2" (12 mm)

5

⁄8" (16 mm) 1" (25 mm)

3

⁄4" (19 mm) 11⁄4" (32 mm)

7

⁄8" (22 mm) 11⁄2" (38 mm)

1" (25 mm) 1

1

⁄8" (29 mm) 11⁄2" (38 mm) 11⁄8" Mark

1

1

⁄4" (32 mm) 2" (51 mm) 11⁄4" Mark

1

3

1

⁄8" (35 mm) 2" (51 mm) 13⁄8" Mark

1

⁄2" (38 mm) 21⁄2" (64 mm) 11⁄2" Mark

1

Screw

Kreg Jig

Length

3

⁄4" (19 mm)

1

⁄2" (38 mm) 1" Mark

11⁄4"

*Note: Screw length is measured from bottom of

the head to the tip of the screw

Settings

Settings

3

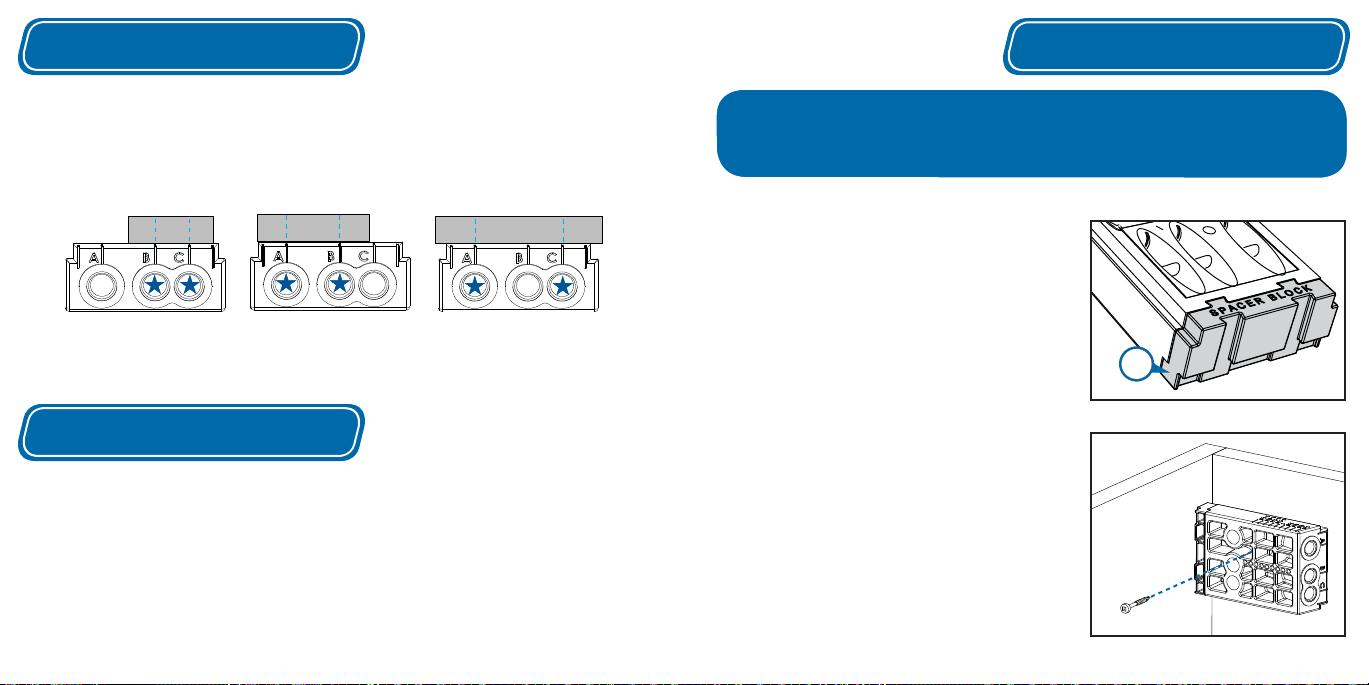

Position the Stop Collar

Place the stop-collar setting block (L) on the jig base in

front of the drill guide. Slide the step bit (I) into one of

the drill guide bushings and drop the pilot tip into the

hole in the block that corresponds to the length of the

screw you’ll be using. With the step bit shoulder resting

on the block, slide the stop collar (J) onto the drive-end

of the bit so it rests on the drill guide. Tighten the stop

collar set screw with the hex wrench (K).

Example: 3⁄4" board, 11⁄4" screw

J

L

Using the Stop-Collar Setting Block

Drill Guide & Bit Material Thickness Screw Length Setting Block Step

Micro* ½"

Micro* & Standard

Standard

Standard & HD*

*optional accessories

⅝" - 1⅛" 1", 1¼", 1½" 1", 1¼", 1½"

1¼" - 1⅜"

1½"2½"2½"

¾" ¾"

2" 2"

Adjust the Clamp Assembly

K

I

4

Press down on the ratchet release (F) and slide the

clamp assembly (D) all the way back. Position the

workpiece against the drill guide. Move the toggle

handle (C) to the full-down (clamped) position.

Slide the clamp assembly forward until the pad

contacts the workpiece. (You’ll hear the adjustment

mechanism clicking.)

Holding the clamp assembly against the workpiece,

raise the toggle handle until you hear the adjustment

mechanism click two times. Place the workpiece

against the drill guide and move the toggle handle

to the clamped position. Check to make sure the

workpiece is securely held in place. If needed,

raise the toggle handle one more click. The clamp

assembly is now positioned so the internal spring

applies suffi cient pressure to secure the workpiece

when the toggle handle is in the full-down position.

C

F

D

Example: 3⁄4" board

www.kregtool.com 800-447-8638

Pocket-Hole Placement

Repair Applications

Spacing pocket holes evenly across the workpiece is an important part of getting a strong joint. The

Kreg Jig® features a three-hole drill guide that allows you do this in a variety of workpiece widths

without the need to reposition the workpiece after drilling each hole. Use the guide below to determine how to position your workpiece for drilling pocket holes.

1" to 2" Wide Material 2" to 3" Wide Material 3" to 4" Wide Material

Use B and C Guides Use A and B Guides Use A and C Guides

For wide parts such as panels, we recommend placing the fi rst pocket hole 2" from the

panel edge and every 6" on center after that.

Drilling Pocket Holes

Before turning on the drill, slide the bit into the drill guide until the tip of the bit touches

the workpiece. Withdraw the bit about ¼". Turn on the drill, make sure it is running at full

speed, and feed the bit into the workpiece. Always run variable-speed or multi-speed

drills at the fastest speed. A shop vacuum connected to the vacuum port quickly removes

the wood chips and the hole can be drilled in one motion. When not using a shop vacuum,

remove the vacuum port, and while drilling the pocket hole, partially withdraw the bit

several times to clear the chips. Stop drilling when the stop collar contacts the drill guide.

Wait until the drill stops rotating to withdraw the bit from the drill guide.

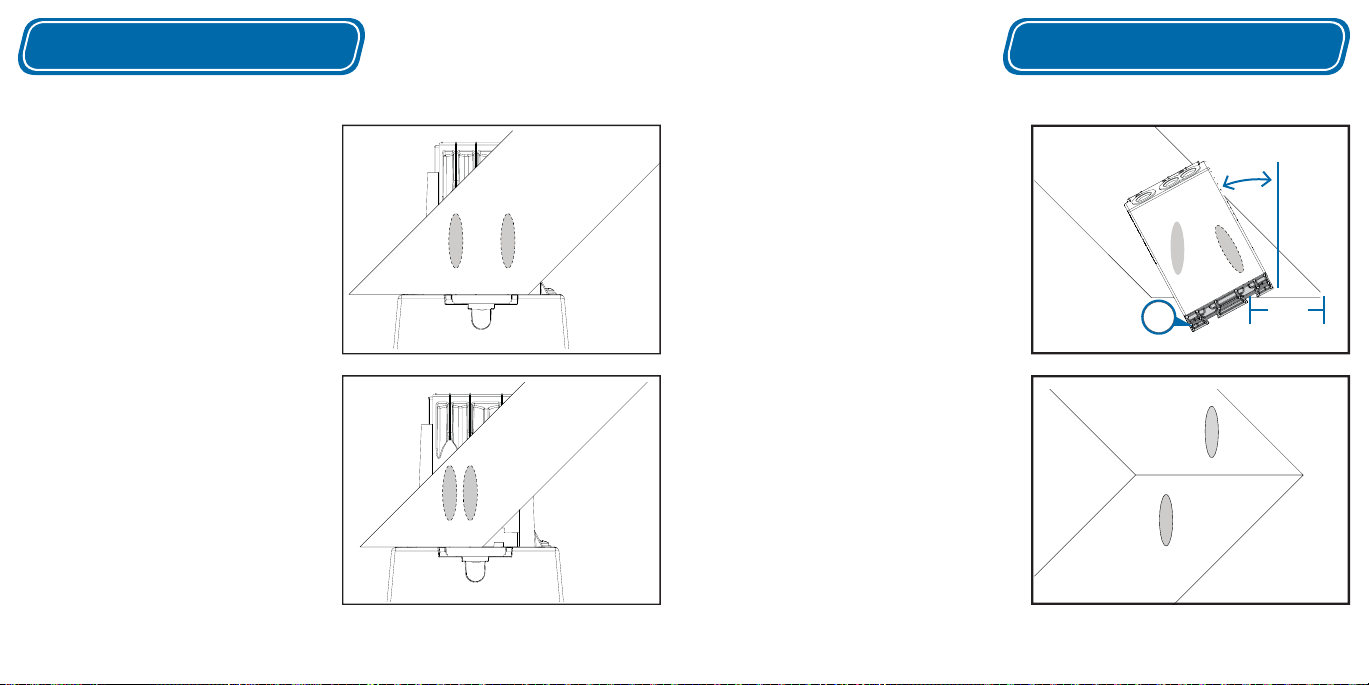

For repair applications, remove the drill guide from the drill guide socket

and clamp it directly to the workpiece.

For ½"-thick material, align the bottom of the drill

guide with the edge of the part to be drilled. For

thicker stock, attach one or more spacer blocks (U)

to the drill guide. Each spacer block accommodates

an additional ¼" in material thickness. For example,

¾"-thick material requires one spacer block, 1"-thick

material requires two blocks, and 1¼" material requires three blocks. One spacer block is included with

your Kreg Jig®. Additional blocks are available.

When using the drill guide separately in a repair

application, remember to set the stop collar, and

fi rmly secure the drill guide to the workpiece with a

bar clamp, C-clamp, or Kreg face clamp. In situations

where using a clamp is not possible, you may screw

the drill guide directly to the workpiece, as shown.

U

www.kregtool.com 800-447-8638

Tips Tips

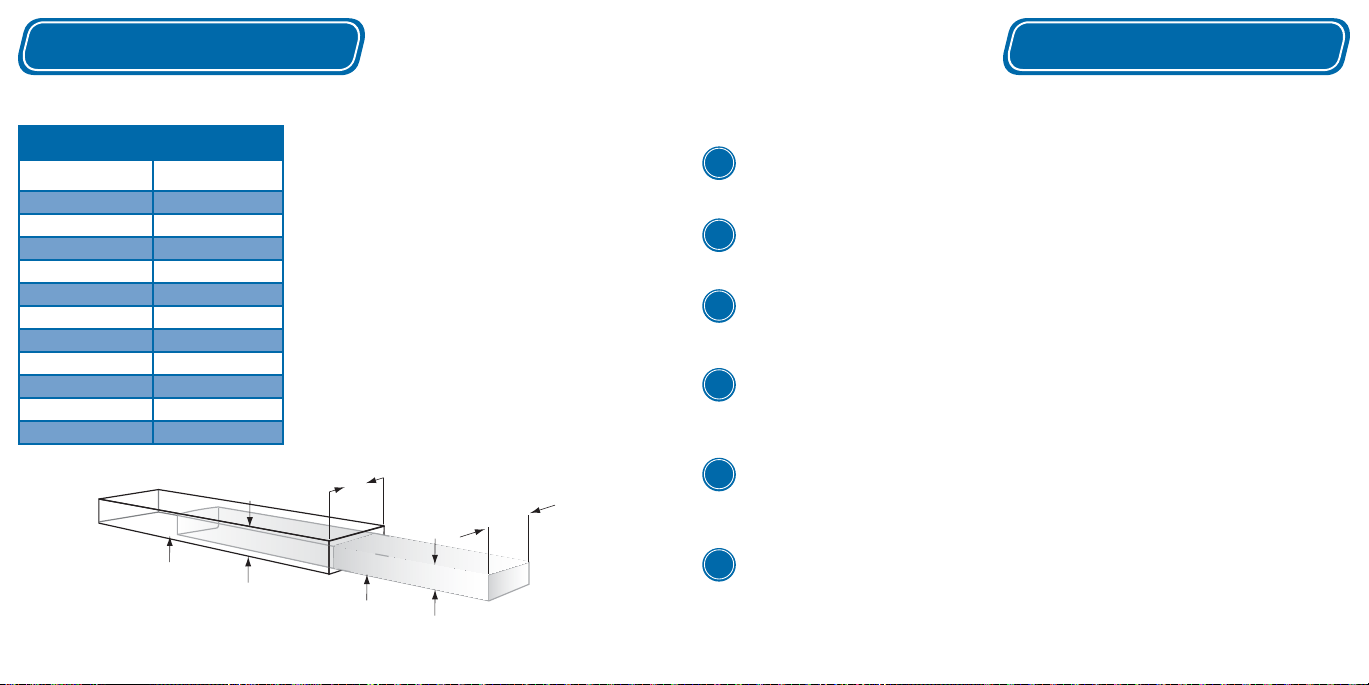

Mitered Corners

For boards at least 3" wide, pocket holes

drilled with the “A” and “C” guides both

fi t entirely on the face of the board. In

this situation, simply position the mitered

workpiece on the jig, clamp it in place, and

drill.

For boards at least 23/8" wide, pocket

holes drilled with the “B” and “C” guides

both fi t entirely on the face of the board.

In this situation, simply position the mitered

workpiece on the jig, clamp it in place, and

drill.

T o position a pocket screw close to the miter

“toe” on a wide workpiece or to position a

second pocket screw on a narrow workpiece

and still have the hole entirely on the face of

the part, drill the pocket hole closest to the

miter heel with the drill guide in the drill guide

socket. Remove the guide from the socket. F or

¾"-thick stock, attach a spacer block (U) to

the drill guide. Position the drill guide with the

spacer-block end 1½" from the miter toe, and

then angle the drill guide away fr om the toe

at a 30-degree angle. Clamp the drill guide

in place and drill the pocket hole.

Y ou also can drill one pocket hole on each

side of a miter joint rather than drilling both

holes on the same side.

30°

U

11⁄2"

www.kregtool.com 800-447-8638

Tips

Tips

Common Board Sizes

Nominal Size Actual Size

1x2

1x3

1x4

1x6

1x8

2x2 1

2x4 1

2x6 1

2x8 1

4x4 3

6x6 5

Nominal

Ý[Ý

3

⁄4" x 11⁄2"

3

⁄4" x 21⁄2"

3

⁄4" x 31⁄2"

3

⁄4" x 51⁄2"

3

⁄4" x 71⁄4"

1

⁄2" x 11⁄2"

1

⁄2" x 31⁄2"

1

⁄2" x 51⁄2"

1

⁄2" x 71⁄4"

1

⁄2" x 31⁄2"

1

⁄2" x 51⁄2"

Nominal Size vs. Actual Size

At a lumber yard or home center you’ll see

labels on lumber such as “1x6” and “2x4.” These

“nominal” sizes once described the dimensions of

rough-cut lumber before it w as milled to fi nished or

actual size. Actual size is always less than nominal

size.

The board-thickness marks on your Kreg Jig refer

the actual thickness of the board. For example, a

1x4 is actually ¾" thick, so you’ll set your jig to the

¾" mark.

Ý

òÝ

Ý

òÝ

Actual

òÝ[òÝ

6 Tips to Reduce Wood Splitting

Test Pieces

1

Test the joint with scrap pieces cut from the same stock as your fi nal workpiece.

Make sure you’re using Kreg Screws

2

Kreg screws feature sharp, self-tapping tips that slice through the wood fi bers.

Use the Right Screw Type

3

Use fi ne-thread screws in hardwood. These #7 screws displace less wood than the #8 coarse-

thread screws used for softwood, plywood, MDF, and particleboard.

4

Screw it In, Back it Out

Drive the screw half-way in, back it out to clear excess wood fi bers from the hole, and then

drive the screw all the way in.

5

Reduce Friction

Apply bee’s wax or other lubricant to the screw to reduce the friction as the screw enters the

workpiece.

Clamp Correctly

6

Center the pads of your Kreg Face Clamp™ on the joint line with the large clamp pad on the face

side (opposite the pocket holes) of the joint. Adjust the clamp to apply enough pressure to keep the

workpieces fl ush and stable but not so tight to make clamping and unclamping diffi cult.

www.kregtool.com 800-447-8638

Features

Optional Accessories

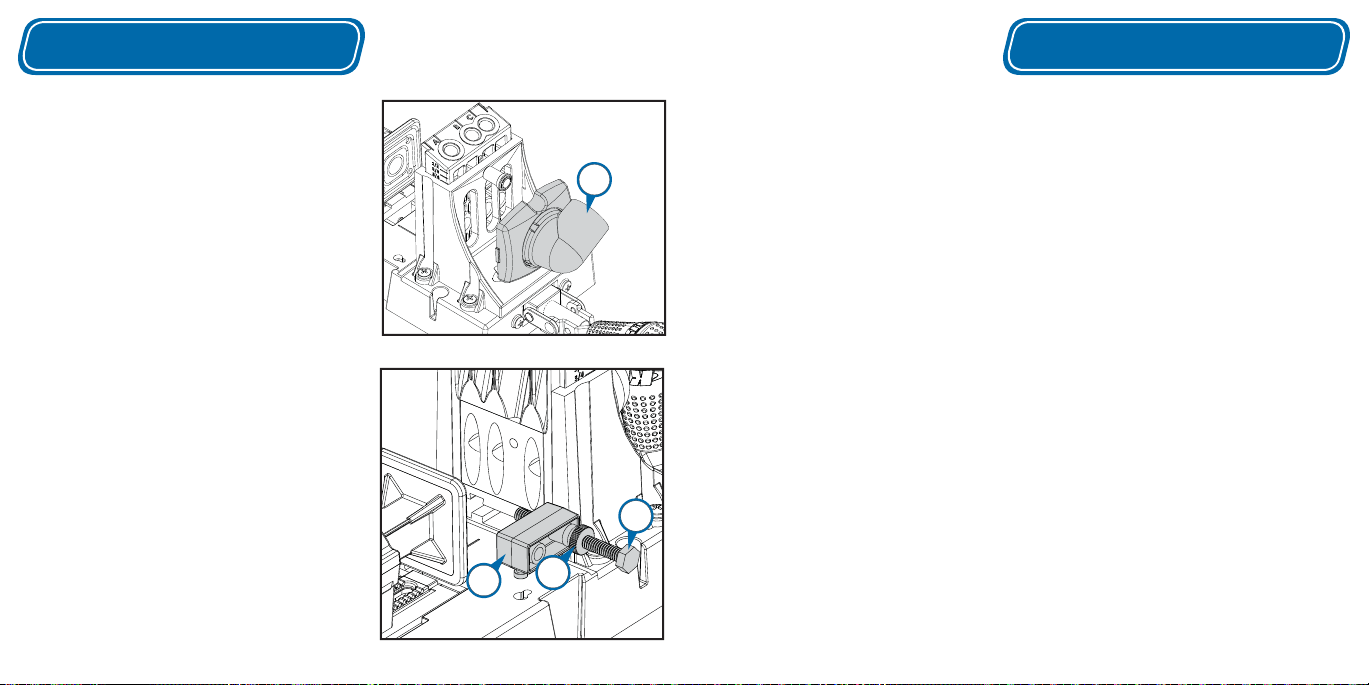

Vacuum Port

This chip-collection attachment (R) snaps into place on

the back of the drill guide socket. The port accepts any

standard 1¼" vacuum hose and conveniently swivels

from side to side. In addition to helping keep your

work area clean, effi cient chip removal speeds drilling

time and reduces heat build-up, extending the life of

your drill bit.

Workpiece Stops

For repetitive pocket-hole drilling operations, the

stop(N) snaps into keyhole slots in the base. To install,

drop the pegs on the bottom of the stop into the large

end of the keyhole slots and slide the stop toward the

front of the jig. For precise pocket-hole placement,

press a steel nut (O) into one of the hexagonal

recesses in the stop. Thread a knurled (P) nut onto each

nylon bolt (Q) and thread the bolt into the nut from

the opposite side of the stop. The nut and bolt work

together to provide easy adjustment and the knurled

nut locks the bolt in position.

Available from your Kreg dealer or online at www.kregjig.com

Micro Pocket™ Drill Guide Item# KJMICRODGB

R

With a hole diameter 25% smaller than our standard pocket hole, the Micro Pocket™ Drill Guide

lets you create compact pocket holes in small projects, thin stock, and tight repair applications. Kit

includes drill guide, drill bit, and stop collar.

Kreg Jig® HD Item# KJHD

Designed for use with “2-by” material, this heavy-duty system features #14 x 2 ½" pocket scre ws.

Kreg Jig® Portable Base Item# KPDGB

This base accepts Micro, Standard, and HD drill guide blocks for go-anywhere pocket hole drilling.

It is particularly useful for large panels or assemblies that would be diffi cult to clamp into a bench-

mounted jig. Built-in cams secure the Portable Base to your Kreg Face Clamp

™

.

Kreg Face Clamps™

Item# KHC-PREMIUM (3" reach), Item# KHC-LARGE (6" reach), Item# KHC-XLARGE (10" reach)

With a choice of 3"-, 6"-, and 10" reach, there’s a Kreg Face Clamp™ that meets your needs.

Q

N

P

Quick Change Kit Item# QUIK-KIT

Switch from drilling pocket holes to driving pocket-hole screws in seconds. The kit includes a quickchange chuck, #2 square-drive bit, hex-shank drill bit, and stop collar.

Drill Guide Spacer Blocks Item# KDGADAPT

Spacer blocks attach to the end of your Standard Drill Guide when used in a repair application. The

Guide alone accommodates ½"-thick material. Each block compensates for an additional ¼" thickness. Set

includes three blocks.

www.kregtool.com 800-447-8638

Notes

Kreg Jig® K5

Guide de l’utilisateur

www.kregtool.com 800-447-8638

Introduction

Pièces

Détenir un outil Kreg Jig® vous donnera accès à de nouvelles possibilités en matière

de projets. Ce guide vous montrera comment régler v otre g abarit et comment

percer des trous en angle. Les ressources suivantes pourraient v ous être utiles:

Kreg en ligne : pour visionner des vidéos montrant le Kreg Jig® K5 en

utilisation, pour commander des vis pour perçage à angle ou pour voir les

accessoires offerts pour votre gabarit, visitez le site kregtool.com.

Communauté des propriétaires de Kreg : inscrivez-vous en tant que membre,

créez votre propre page, regardez les projets des autres membres, affi chez

les photos de vos projets, visionnez des vidéos d’instructions et participez à des

forums en vous rendant au kregjig.ning.com.

Kreg YouTube Channel: chaîne YouTube Kreg : pour des projets, des produits

et des vidéos d’instructions, visitez le site youtube.com/user/kregtoolcompany.

Kreg sur Facebook : prenez contact avec Kreg sur Facebook afi n de partager vos

projets et de vous inspirer de nos admirateurs et amis sur face book.com/kregJig .

Assemblage

Votre Kreg Jig® K5 est presque prêt à être utilisé dès que vous le sortez de la boîte.

Suivez les instructions fi gurant sur l’étiquette de sélection concernant la longueur

des vis. Celle-ci se trouve à l’intérieur du couv ercle de l’une des rallong es. Placez le

gabarit sur votre établi et fi xez les clés à queue d’aronde sur les r allonges situées

à l’intérieur des rainures en queue d’aronde de la base. Le gabarit et les r allonges

présentent des trous permettant de les installer à un panneau.

G

S

B

T

F

D

E

V

A

J

W

I

Pour voir la liste complète des pièces de rechange,

consultez le manuel du Kreg Jig® K5 au www.kregtool.com.

K

U

R

H

C

O

N

P

Q

S

L

M

www.kregtool.com 800-447-8638

Pièces

A

Base :

possède quatre trous pour fi xer le gabarit à un établi ou à une base auxiliaire.

Support du guide-foret :

B

convient à tous les guide-forets Kreg : micro, standard (inclus) et HD.

Poignée articulée :

C

permet de faire fonctionner le mécanisme de serrage de la pièce travaillée.

Serre-joint :

D

ressort interne puissant qui exerce une pression de serrage.

Plaque à cliquet :

E

permet de régler le serre-joint.

F

Dégagement à cliquet :

dégage le serre-joint de la plaque à cliquet.

G

Guide-foret standard :

présente des marques permettant de positionner le guide pour les différentes épaisseurs de pièces travaillées.

Goupille d’arrêt :

H

goupille à ressort permettant de fi xer le guide-foret au support du guide-foret et au réglage sélectionné.

Foret :

I

perce simultanément un avant-trou et un trou de passage , f ormant ainsi un épaulement pour la tête de la vis.

Collet de butée :

J

permet de défi nir la profondeur du perçage.

Clé hexagonale :

K

pour la vis de calage du collet de butée.

Bloc d’appui du collet de butée :

L

assure le positionnement approprié de la bague de profondeur sur le foret.

Embout :

M

embout de vissage carré no 2 de 6 po.

Butée de pièce :

N

s’enclenche dans les encoches en trou de serrure de la base.

O

Écrou de réglage fi n de la butée de pièce :

écrou de ¼-20 qui s’insère dans la cale de soutien de la butée de pièce.

P

Écrou moleté :

écrou moleté en nylon qui agit en tant que contre-écrou pour fi xer la position de la vis de réglage fi n.

Vis de réglage fi n :

Q

boulon en nylon de ¼-20 x 2 ½ po qui se visse dans l’écrou pour assurer un réglage fi n qui ne glisse pas.

Port pour aspirateur :

R

convient à un tuyau d’aspirateur d’atelier de 1¼ po pour un nettoyage effi cace des copeaux.

Pivote d’un côté à l’autre.

Rallonges :

S

permettent de supporter de grandes pièces et offrent un espace de rangement pour les forets et les accessoires.

Guide de sélection de la longueur des vis :

T

collez cette étiquette autoadhésive à l’intérieur du couvercle de l’une des rallonges pour vous y

référer facilement.

Bloc-espaceur :

U

lorsque vous effectuez des réparations, placez le guide-foret pour percer des trous en angle dans

des matériaux de ¾ po d’épaisseur.

Ensemble d’échantillons de vis pour perçage à angle :

V

contient 10 de chacune des cinq vis les plus utilisées.

Ensemble d’échantillons de bouchons pour trous en angle :

W

contient cinq bouchons de bois à peindre.

www.kregtool.com 800-447-8638

Réglages

Réglages

Pour obtenir des joints solides, vous devez régler votre

gabarit de manière à ce qu’il corresponde à l’épaisseur de

votre pièce et à la longueur de la vis. Le Kreg Jig® permet

de le faire facilement; en quatre étapes seulement :

1

Fixez le guide-foret

Pour un joint solide, la vis devrait sortir au centre de

la pièce travaillée. Pour régler la position du trou en

angle, rétractez la goupille d’arrêt (H) du guide-foret

à ressort. Ensuite, soulevez ou abaissez le guide-foret

(G) jusqu’à ce que la marque se trouvant sur le côté

de celui-ci et qui correspond à l’épaisseur de la pièce

travaillée soit au même niveau que le dessus du support

du guide-foret (B). Relâchez la goupille d’arrêt.

Choisissez une vis

2

Vis à fi let normal

En raison de leur grand diamètre et de

leur grand pas de fi letage, nos vis à fi let

normal no 8 offrent une prise solide sur les

bois résineux et les matériaux composites.

Utilisez-les avec les types de bois suivants :

• Pin • Cèdre • Tilleul d’Amérique

• Peuplier • Contreplaqué • Mélamine

• Panneaux de particules

Toutes les vis pour perçage à angle Kreg ont un carré conducteur profond permettant de mieux les guider et de

réduire les risques de rejet. La pointe de tarière autotaraudeuse vous évite d’avoir à percer un avant-trou.

B

Vis à fi let fi n

En raison de leur diamètre et de leur pas

de fi letage plus petits, nos vis à fi let fi n no 7

réduisent les risques de fendre le matériau. Nous

recommandons de les utiliser avec les bois francs.

Utilisez-les avec les types de bois suivants :

• Frêne • Chêne • Érable • Noyer

• Hickory • Cerisier • Acajou • Bouleau

G

H

Kreg vous offre une gamme complète de vis pour perçage à angle pour toutes les

épaisseurs et tous les types de pièces travaillées. Utilisez le tableau suivant pour

choisir la bonne longueur de vis. Toutes les vis pour perçage à angle Kreg sont

offertes chez votre détaillant Kreg ou en ligne sur le site www.kregtool.com.

Sélection des vis/Tableau de réglage du Kreg Jig

Épaisseur

du matériau

12 mm (1/2 po) 25 mm (1 po) Marque de 1/2 po

16 mm (5/8 po) 25 mm (1 po) Marque de 5/8 po

19 mm (3/4 po) 32 mm (1 1/4 po)

22 mm (7/8 po) 38 mm (1 1/2 po) Marque de 7/8 po

25 mm (1 po) 38 mm (1 1/2 po) Marque de 1 po

29 mm (1 1/8 po) 38 mm (1 1/2 po) Marque de 1 1/8 po

32 mm (1 1/4 po) 51 mm (2 po) Marque de 1 1/4 po

35 mm (1 3/8 po) 51 mm (2 po) Marque de 1 3/8 po

38 mm (1 1/2 po) 64 mm (2 1/2 po) Marque de 1 1/2 po

Longueur

de la vis

11⁄4 po

Réglage du

Kreg Jig

Marque de 3/4 po

*Remarque : La longueur de la vis est calculée du

bas de la tête au bout de la vis

®

®

www.kregtool.com 800-447-8638

Réglages

Réglages

3

Placez le collet de butée

Placez le bloc d’appui du collet de butée (L) à la

base du gabarit, en avant du guide-foret (I). Glissez

le foret dans un des trous du guide-foret et placez

l’embout-guide dans le trou du bloc qui correspond à la

longueur de la vis que vous utiliserez. Tout en reposant

l’épaulement du foret sur le bloc, glissez le collet de

butée (J) sur la tête du foret afi n que celui-ci repose

sur le guide-foret. Serrez la vis de calage du collet de

butée à l’aide de la clé hexagonale (K).

Exemple : panneau de 3/4 po, vis de 1 1/4 po

J

L

Utilisation du bloc d’appui du collet de butée

Guide-foret

et foret

Micro* ½ po

Micro* et standard

Standard

Standard et HD* 1½ po 2 ½ po 2 ½ po

*Accessoires en option

Épaisseur

du matériau

⅝ po – 1⅛ po

1¼ po – 1⅜ po

Longueur

de la vis

¾ po ¾ po

1 po, 1 ¼ po, 1 ½ po 1 po, 1 ¼ po, 1 ½ po

2 po 2 po

Réglage du

bloc d’appui

Ajustez le serre-joint

K

I

4

Appuyez sur le mécanisme de dégagement à cliquet

(F) et glissez complètement le serre-joint (D) à

l’arrière. Placez la pièce travaillée contre le guideforet. Placez la poignée articulée (C) complètement

vers le bas (position de serrage). Glissez le serrejoint vers l’avant jusqu’à ce que le tampon entre en

contact avec la pièce travaillée. (Vous entendrez un

déclic provenant du mécanisme de réglage.)

En maintenant le serre-joint contre la pièce

travaillée, levez la poignée articulée jusqu’à ce

que vous entendiez deux déclics provenant du

mécanisme de réglage. Placez la pièce travaillée

contre le guide-foret et la poignée articulée à la

position de serrage. Assurez-vous que la pièce

travaillée est fermement maintenue en place. Au

besoin, soulevez la poignée articulée un déclic plus

haut. Le serre-joint est maintenant placé de façon

à ce que le ressort interne exerce suffi samment de

pression pour fi xer la pièce travaillée lorsque la

poignée articulée est complètement vers le bas.

C

F

D

Exemple : planche de 3/4 po

www.kregtool.com 800-447-8638

Emplacement des trous en angle

Il est important de répartir également les trous en angle sur la surface de la pièce travaillée pour

obtenir des joints solides. Le Kreg Jig® comprend un guide-foret à trois trous qui vous permet de

le faire sur différentes largeurs de pièces travaillées sans avoir à les déplacer après avoir percé

chaque trou. Utilisez le guide ci-dessous pour déterminer comment positionner la pièce travaillée

lorsque vous percez des trous en angle.

Matériaux d’une largeur

de 1 po à 2 po

Utilisez les guides B et C

Matériaux d’une largeur

de 2 po à 3 po

Utilisez les guides A et B

Matériaux d’une largeur

de 3 po à 4 po

Utilisez les guides A et C

Pour les pièces larges comme les panneaux, nous v ous recommandons de placer le premier tr ou en

angle à 2 po de l’extrémité du panneau et les autres à une distance de 6 po les uns des autres.

Perçage des trous en angle

Avant de mettre en marche la perceuse, glissez le foret dans le guide-foret jusqu’à ce

que le bout du foret touche la pièce travaillée. Retirez le foret d’environ 6,35 mm. Mettez

la perceuse en marche et assurez-vous qu’elle fonctionne à pleine vitesse, puis faites

pénétrer le foret dans la pièce travaillée. Faites toujours fonctionner à pleine vitesse les

perceuses à vitesse variable ou à plusieurs vitesses. Un aspirateur d’atelier branché sur le

port pour aspirateur permet de retirer les copeaux de bois et vous pouvez ainsi percer un

trou d’un seul mouvement. Si vous n’utilisez pas un aspirateur d’atelier, retirez le port pour

aspirateur. Lorsque vous percez un trou en angle, enlevez partiellement le foret plusieurs

fois pendant que vous effectuez la tâche afi n d’enlever les copeaux. Cessez de percer

lorsque le collet de butée entre en contact avec le guide-foret. Attendez que la perceuse

cesse de tourner avant d’enlever le foret du guide-foret.

Pour effectuer des réparations

Lorsque vous effectuez des réparations, enlevez le guide-foret du support

du guide-foret et fi xez-le directement à la pièce travaillée.

Pour les matériaux d’une épaisseur de ½ po, alignez

le bas du guide-foret au bord de la pièce à percer.

Pour les pièces plus épaisses, fi xez un ou plusieurs

blocs-espaceurs (U) au guide-foret. Chaque blocespaceur augmente l’épaisseur des pièces que vous

pouvez utiliser de ¼ po. Par exemple, pour un matériau d’une épaisseur de ¾ po, vous devez utiliser un

bloc-espaceur, pour un matériau de 1 po, vous aurez

besoin de deux et pour un matériau de 1 ¼ po, vous

aurez besoin de trois. Un bloc-espaceur est inclus avec

votre Kreg Jig

sont offerts.

Lorsque vous utilisez seulement le guide-foret pendant

que vous effectuez des réparations, n’oubliez pas de

régler le collet de butée, puis de vous assurer que le

guide-foret est bien fi xé sur la pièce travaillée au

moyen d’un serre-joint à barre, d’un serre-joint en C

ou d’un serre-joint Face Clamp de Kreg. Dans certains

cas, lorsque l’utilisation d’un serre-joint est impossible,

vous pouvez aussi visser le guide-foret directement sur

la pièce travaillée, tel qu’il est illustré.

®

. Des blocs-espaceurs supplémentaires

U

www.kregtool.com 800-447-8638

Conseils Conseils

Coins à onglet

Pour les planches d’une épaisseur d’au

moins 3 po, les trous en angle percés

avec le guide A et le guide C s’ajustent

tous les deux entièrement à la surface

de la planche. Dans cette situation, fi xez

simplement la pièce travaillée à onglet

au gabarit, serrez-la pour la maintenir en

place, puis percez.

Pour les planches d’une épaisseur d’au

moins 2 ⅜ po, les trous en angle percés

avec le guide B et le guide C s’ajustent

tous deux entièrement à la surface de

la planche. Dans cette situation, fi xez

simplement la pièce travaillée à onglet

au gabarit, serrez-la pour la maintenir en

place, puis percez.

Pour fi xer une vis pour perçage à angle près

de la « pointe » de l’onglet sur une pièce

travaillée large ou pour fi xer une seconde vis

pour perçage à angle sur une pièce travaillée

étroite, tout en g ardant le trou complet sur la

surface de la pièce, percez le trou en angle le

plus près possible de la pointe de l’onglet à

l’aide du guide-foret du support du guideforet. Retirez le guide du support. P our les

pièces d’une épaisseur de ¾ po, fi xez un

bloc-espaceur (U) au guide-foret. Positionnez

le guide-foret avec l’extrémité du blocespaceur à 1 ½ po de la pointe de l’onglet,

puis placez le guide-foret loin de la pointe

à un angle de 30°. Serrez le guide-foret en

place et percez le trou en angle.

Vous pouv ez aussi percer un trou en angle

de chaque côté d’un joint à onglet au lieu

de percer les deux trous du même côté.

30°

U

1 1⁄2 po

www.kregtool.com 800-447-8638

Conseils

Conseils

Dimensions standard

des planches

Dimensions

nominales

1x2

1x3

1x4 3/4 po x 3 1/2 po

1x6 3/4 po x 5 1/2 po

1x8 3/4 po x 7 1/4 po

2x2 1 1/2 po x 1 1/2 po

2x4 1 1/2 po x 3 1/2 po

2x6 1 1/2 po x 5 1/2 po

2x8 1 1/2 po x 7 1/4 po

4x4 3 1/2 po x 3 1/2 po

6x6 5 1/2 po x 5 1/2 po

Dimensions

réelles

3/4 po x 1 1/2 po

3/4 po x 2 1/2 po

Dimensions

nominales

(2 x 4)

Dimensions nominales et

dimensions réelles

Dans les parcs à bois débités ou dans les centres

de rénovation, vous pouvez v oir des étiquettes sur

le bois d’œuvre indiquant des dimensions comme

1x6 ou 2x4. Ces dimensions « nominales » ont déjà

servi à indiquer les dimensions du bois d’œuvre

coupé grossièrement, avant qu’il ne soit fraisé pour

être fi ni ou pour obtenir sa dimension réelle. Les

dimensions réelles sont toujours plus petites que les

dimensions nominales

Les marques pour mesurer l’épaisseur de la planche

sur votre Kreg Jig sont celles de l’épaisseur réelle

de la planche. Par ex emple, une planche 1x4 a

en fait une épaisseur de 3/4 po. V ous devez alors

régler votre gabarit à la marque de 3/4.

4 po

3½ po

2 po

1½ po

Dimensions réelles

(1½ po x 3½ po)

6 conseils pour éviter de fendre les planches

Effectuez des tests

1

Testez le joint à l’aide de retailles du même matériau que celui de votre pièce travaillée.

Assurez-vous d’utiliser des vis Kreg

2

Les vis Kreg sont munies de bouts pointus et autotaraudeurs qui fendent les fi bres du bois.

Utilisez le bon type de vis

3

Utilisez des vis à fi let fi n pour le bois franc. Ces vis no 7 déplacent moins de bois que les vis à fi let

normal no 8 utilisées pour les bois résineux, le contreplaqué, le MDF et les panneaux de particules.

4

Insérez la vis dans un mouvement de va-et-vient

Insérez la vis à moitié et retirez-la pour enlever l’excédent de fi bres de bois du trou, puis

insérez-y complètement la vis.

5

Faites en sorte de diminuer la friction

Appliquez de la cire d’abeille ou tout autre lubrifi ant sur la vis pour diminuer la friction au

moment de l’insérer dans la pièce travaillée.

Serrez correctement

6

Centrez les tampons de votre serre-joint Face Clamp™ de Kreg sur la ligne de joint avec le grand

tampon sur la face avant (à l’opposé des trous en angle) du joint. Réglez le serrage afi n de vous

assurer qu’il y a une pression suffi sante pour garder les pièces trav aillées de niveau et stables , mais

pas trop pour éviter que le serrage et le desserrage soient diffi ciles.

www.kregtool.com 800-447-8638

Caractéristiques

Accessoires en option

Port pour aspirateur

Ce dispositif qui enlève les copeaux (R) s’enclenche à

l’arrière du support du guide-foret. Le port convient

à tous les tuyaux d’aspirateur standard de 1 ¼ po. Il

pivote facilement d’un côté à l’autre. En plus d’aider

à garder votre aire de travail propre, enlever les

copeaux vous permet de percer plus rapidement et de

réduire la chaleur, prolongeant ainsi la durée de vie

de votre foret.

Butées de pièce

Pour les travaux répétitifs de perçage de trous en

angle, la butée de pièce (N) s’insère dans les encoches

en trou de serrure de la base. Pour l’installer, faites

passer les taquets au bas de la butée de pièce dans

la grande extrémité des encoches en trou de serrure,

puis glissez la butée de pièce vers l’avant du gabarit.

Pour placer précisément un trou en angle, insérez un

écrou en acier (O) dans une des alvéoles hexagonales

de la butée de pièce. Vissez un écrou moleté (P) sur

chaque boulon en nylon (Q), puis vissez le boulon dans

l’écrou du côté opposé de la butée de pièce. L’écrou et

le boulon fonctionnent ensemble de manière à offrir un

réglage facile, puis les écrous moletés fi xent le boulon

en place.

Offerts par votre détaillant Kreg ou en ligne sur le site www.kregjig.com

Micro Pocket™ Drill Guide Article# KJMICRODGB

Le guide-foret Micro Pocket™ vous permet de percer des trous en angle 25 % plus petits que nos

R

trous en angle standard. Vous pouvez ainsi créer de petits trous en angle pour les petits projets, les

pièces minces et les réparations dans des endroits diffi ciles d’accès. L’ensemble inclut un guide-foret,

un foret et un collet de butée.

Kreg Jig® HD Article# KJHD

Conçu pour être utilisé avec les pièces de bois de 2 po d’épaisseur , ce système r obuste comprend des vis

pour perçage à angle no 14 de 2 ½ po.

Kreg Jig® Portable Base Article# KPDGB

Cette base convient aux supports de guide-foret micro, standard et HD pour percer des trous

en angle sur n’importe quelle surface. Elle est particulièrement utile pour les grands panneaux

et ensembles qui seraient diffi ciles à serrer à l’aide d’un gabarit monté sur une table. Les cames

intégrées fi xent la base portative à votre serre-joint Face Clamp™ de Kreg.

Kreg Face Clamps™

Article #KHC-PREMIUM (portée de 3 po), Article# KHC-LARGE (portée de 6 po),

Article# KHC-XLARGE (portée de 10 po)

Avec un choix de 3 po, 6 po et 10 po, il y a un serre-joint Face Clamp™ de Kreg qui convient à v os besoins.

Quick Change Kit Article# QUIK-KIT

Q

N

P

Passez du perçage de trous en angle au vissage de vis pour perçage en angle en quelques

secondes. L’ensemble inclut un mandrin à changement rapide, un embout de vissage carré no 2, un

foret hexagonal et un collet de butée.

Drill Guide Spacer Blocks Article# KDGADAPT

Les blocs-espaceurs se fi xent à l’e xtrémité de votre guide-f oret standard lorsque v ous l’utilisez pour effectuer

des réparations. Le guide-foret seul convient aux matériaux d’une épaisseur de ½ po. Chaque blocespaceur augmente l’épaisseur des pièces de ¼ po. L’ensemble inclut tr ois blocs.

www.kregtool.com 800-447-8638

Remarques

Kreg Jig® K5

Guía para el usuario

www.kregtool.com 800-447-8638

Introducción

Piezas

Tener un Kreg Jig® abre un mundo nuevo lleno de posibilidades para sus

proyectos. Esta guía muestra cómo ajustar la plantilla y las cavidades ocultas

del taladro. Es posible que los siguientes recursos le sean útiles:

Kreg en línea: Para videos sobre el uso de la Kreg Jig® K5, pedir más tornillos

para cavidades ocultas o ver los accesorios disponibles para la plantilla, vaya

a kregtool.com.

Comunidad de propietarios de Kreg: Inscríbase como miembro, cree su propia

página, vea los proyectos de otros miembros, publique fotos de sus proyectos,

vea videos instructivos y participe en foros visitando kregjig.ning.com.

Canal de YouTube de Kreg: Para conocer proyectos, productos y ver videos

instructivos, visite youtube.com/user/kregtoolcompany.

Kreg en Facebook: Conéctese con Kreg en Facebook para compartir sus proyectos

y obtener inspiración de nuestros amigos y fans en facebook.com/kregJig .

Ensamblaje

La Kreg Jig® K5 viene casi lista para usar después de sacarla de la caja.

Aplique la etiqueta de guía de selección del largo de los tornillos en el interior

de una tapa de extensión. Coloque la plantilla en el banco de trabajo y

ajuste las llaves con cola de milano de las extensiones en las ranuras con cola

de milano de la base. La plantilla y las extensiones cuentan con orifi cios para

montaje en tabla.

G

S

H

B

T

F

D

E

V

A

J

W

I

Para ver la lista completa de piezas de repuesto, consulte el

manual de la Kreg Jig® K5 en www.kregtool.com.

K

U

R

C

O

N

P

Q

S

L

M

www.kregtool.com 800-447-8638

Piezas

A

Base:

Cuenta con cuatro orifi cios para asegurar la plantilla en un banco de trabajo o base auxiliar.

Dado de la guía del taladro:

B

Acepta todas las guías de taladro Kreg: Micro, estándar (incluida) y HD

Palanca:

C

Opera la pieza de trabajo del mecanismo de sujeción.

Ensamble de la abrazadera:

D

Un potente resorte interno aplica presión de sujeción.

Placa del trinquete:

E

Proporciona el ajuste del ensamble de la abrazadera.

F

Liberación del trinquete:

Desconecta el ensamble de la abrazadera de la placa del trinquete.

G

Guía de taladro estándar:

Cuenta con marcas de ubicación de la guía para los diferentes tipos de grosor de las piezas de trabajo.

Pasador de fi jación:

H

Un pasador activado por resorte fi ja la guía del taladro en el dado de la guía del taladro con el

ajuste seleccionado.

Broca escalonada:

I

Perfora un orifi cio guía y un orifi cio de distancia simultáneamente, formando un reborde de

rodamiento para la cabeza del tornillo.

Anillo de detención:

J

Controla la profundidad de taladrado.

Llave hexagonal

K

Para el tornillo de fi jación del anillo de detención.

Bloque de ajuste para el anillo de detención:

L

Garantiza la posición adecuada del anillo de profundidad de la broca para taladro.

Punta de destornillador:

M

Punta de destornillador cuadrada #2 de 6 pulg de largo.

Tope de la pieza de trabajo:

N

El tope se encaja en las ranuras con forma de cerradura de la base.

O

Tuerca de ajuste preciso para el tope de la pieza de trabajo:

La tuerca de ¼-20 se encaja en la ranura hexagonal del tope de la pieza de trabajo.

P

Tuerca moleteada:

La tuerca moleteada de nailon funciona como una contratuerca para fi jar la posición del tornillo de

ajuste preciso.

Tornillo de ajuste preciso:

Q

El perno de nailon de ¼-20 x 2 ½ pulg se enrosca en la tuerca para brindar un ajuste preciso antideslizante.

Puerto de aspiración:

R

Admite una manguera de aspiradora industrial de 1¼ pulg para una eliminación efi ciente de las

astillas y gira de lado a lado.

Extensiones:

S

Proporciona soporte para piezas de trabajo anchas y almacenamiento para brocas y accesorios.

Guía de selección del largo de los tornillos:

T

Aplique esta etiqueta autoadhesiva en el interior de una tapa de extensión para una referencia fácil.

Bloque separador:

U

En reparaciones, ubica la guía del taladro para taladrar las cavidades ocultas en material grueso de ¾ pulg.

Paquete de muestra de tornillos ocultos:

V

Contiene 10 de los cinco tornillos que se utilizan con más frecuencia.

Paquete de muestra de tapones para cavidades ocultas:

W

Contiene cinco tapones de madera para pintura.

www.kregtool.com 800-447-8638

Ajustes

Ajustes

Para crear uniones fuertes, debe confi gurar la plantilla

para taladrar de manera que coincida con el grosor de la

pieza de trabajo y el largo del tornillo. La Kreg Jig® lo hace

simple y en tan solo cuatro pasos sencillos:

1

Ajuste la guía del taladro

Para una unión fuerte, el tornillo debe salir en el centro

de la pieza de trabajo. Para ajustar la posición de la

G

cavidad oculta, retraiga el pasador de fi jación accionado

por resorte de la guía del taladro (H). Luego, levante o

baje la guía del taladro (G) hasta que la marca en el

H

lado de la guía que coincide con el grosor de la pieza de

trabajo quede pareja con la parte superior del dado de

la guía (B). Suelte el pasador de fi jación.

2

Elija un tornillo

Rosca gruesa

Debido al gran diámetro y al paso de

rosca, nuestros los tornillos de rosca gruesa

#8 ofrecen un fuerte agarre en materiales

compuestos y de madera suave.

Rosca fi na

Debido al diámetro más pequeño y a paso

de rosca nuestros tornillos de rosca fi na #7

reducen la posibilidad de partir el material,

los recomendamos para maderas duras.

Utilice en maderas como:

• Pino • Cedro • Tilo americano • Álamo

• Madera contrachapada • Melamina

• Paneles de aglomerado

Todos los tornillos para cavidades ocultas de Kreg tienen una cabeza con ranura cuadrada profunda que mejora el

agarre y reduce la posibilidad de deslizamiento hacia afuera. La punta de barrena de los tornillos autorroscantes

elimina la necesidad de taladrar un orifi cio guía.

B

Utilice en maderas como:

• Fresno • Roble • Arce • Nogal

• Nogal americano • Cerezo

• Caoba • Abedul

Kreg ofrece una línea completa de tornillos para cavidades ocultas para cada tipo y

grosor de pieza de trabajo. Utilice este gráfi co para seleccionar el largo correcto de

los tornillos. Todos los tornillos para cavidad oculta de Kreg están disponibles en su

concesionario Kreg o en línea en www.kregtool.com.

Gráfi co de selección de tornillos y ajustes de Kreg Jig

Grosor

del material

12 mm (1⁄2")

5

⁄8")

16 mm (

19 mm (3⁄4") 32 mm (11⁄4") Marca de 3⁄4"

7

22 mm (

⁄8") 38 mm (11⁄2")

25 mm (1") 38 mm (11⁄2") Marca de 1"

1

29 mm (1

32 mm (1

35 mm (1

38 mm (1

⁄8") 38 mm (11⁄2") Marca de 11⁄8"

1

⁄4") 51 mm (2") Marca de 11⁄4"

3

⁄8") 51 mm (2") Marca de 13⁄8"

1

⁄2") 64 mm (21⁄2") Marca de 11⁄2"

Largo

del tornillo

1")

25 mm (

25 mm (1")

11⁄4"

Ajuste

de Kreg Jig

Marca de

Marca de 5⁄8"

Marca de 7⁄8"

*Nota: El largo del tornillo se mide desde la parte

inferior de la cabeza hasta la punta del tornillo.

®

®

1

⁄2"

www.kregtool.com 800-447-8638

Ajustes

Ajustes

3

Ubicación del anillo de detención

Coloque el bloque de ajuste del collar de detención (L)

en la base de la plantilla frente a la guía del taladro.

Deslice la broca escalonada hacia uno de los conectores

de la guía del taladro y coloque la punta guía en el

orifi cio del bloque que corresponde al largo del tornillo

que usará. Con la broca escalonada (I) apoyada en el

bloque, deslice el anillo de detención hacia el extremo

con empalme de la broca, de forma que se apoye en la

guía del taladro. Apriete el tornillo de fi jación del anillo

de detención (J) con la llave hexagonal (K).

Uso del bloque de ajuste para el anillo de

detención

Guía y broca

de taladro

Micro* ½"

Micro* y estándar

Estándar

Estándar y HD*

*Accesorios opcionales

Grosor

del material

⅝" - 1⅛" 1", 1¼", 1½" 1", 1¼", 1½"

1¼" - 1⅜"

1½"2½"2½"

del tornillo

J

L

I

Ejemplo: Tabla de 3⁄4 pulg, tornillo de 11⁄4 pulg

Largo

Escalón del bloque de

ajuste

¾" ¾"

2" 2"

Ajuste del ensamble de la abrazadera

K

4

Presione hacia abajo la liberación del trinquete

(F) y deslice el ensamble de la abrazadera (D)

completamente hacia atrás. Ubi que la pieza de

trabajo contra la guía del taladro. Mueva la palanca

(C) a la posición completamente hacia abajo (sujeta).

Deslice el ensamble de la abrazadera hacia adelante

hasta que la almohadilla entre en contacto con la

pieza de trabajo. (Escuchará un "clic" del mecanismo

de ajuste.)

Sostenga el ensamble de la abrazadera contra la

pieza de trabajo, levante la palanca hasta que

escuche el "clic" del mecanismo de ajuste dos veces.

Coloque la pieza de trabajo contra la guía del

taladro y mueva la palanca a la posición de sujeción.

Verifi que que la pieza de trabajo esté sujeta en su

lugar de forma segura. De ser necesario, levante la

palanca hasta escuchar un "clic" más. El ensamble de

la abrazadera ahora está ubicado de forma que el

resorte interno aplica sufi ciente presión para asegurar

la pieza de trabajo cuando la palanca está en la

posición completamente hacia abajo.

C

F

D

Ejemplo: Tabla de 3⁄4 pulg

www.kregtool.com 800-447-8638

Ubicación de las cavidades ocultas

Separar las cavidades ocultas de manera uniforme a lo largo de la pieza de trabajo es importante

para obtener una unión fuerte. La juego Kreg Jig® cuenta con una guía de taladro de tres orifi cios

que le permite hacer esto en una variedad de anchos de piezas de trabajo sin la necesidad

de cambiar de posición la pieza de trabajo después de taladrar cada orifi cio. Utilice la guía a

continuación para determinar cómo fi jar la pieza de trabajo para taladrar cavidades ocultas.

Reparaciones

Para hacer reparaciones, retire la guía de taladro del dado de la guía de

taladro y fíjelo directamente en la pieza de trabajo.

Material ancho de 1 a 2 pulg

Uso de las guías B y C

Para piezas anchas, como los paneles, recomendamos colocar la primera cavidad oculta a 2 pulg

del borde del panel y en intervalos de 6 pulg después de eso.

Material ancho de 2 a 3 pulg

Uso de las guías A y B

Material ancho de 3 a 4 pulg

Uso de las guías A y C

Taladrado de cavidades ocultas

Antes de usar el taladro, deslice la broca en la guía de taladro hasta que la punta de la broca

toque la pieza de trabajo. Retire la broca alrededor de 6,35 mm. Encienda el taladro, asegúrese de

que esté funcionando a máxima velocidad y acerque la broca a la pieza de trabajo. Siempre utilice

taladros de velocidad variable o con varias velocidades en su potencia más rápida. Una aspiradora

industrial conectada al puerto de aspiración elimina rápidamente las astillas de madera y el orifi cio

se puede taladrar en un solo movimiento. Cuando no utilice una aspiradora industrial, quite el puerto

de aspiración y mientras taladra la cavidad oculta, retire parcialmente la broca varias veces para

quitar las astillas. Deje de taladrar cuando el anillo de detención haga contacto con la guía de

taladro. Espere hasta que el taladro deje de girar para retirar la broca de la guía de taladro.

Para material con un grosor ½ pulg, alinee la parte

inferior de la guía de taladro con el borde de

la parte que va a taladrar. Para materiales más

gruesos, coloque más bloques separadores (U) en la

guía de taladro. Cada bloque separador agregar

¼ pulg adicionales para el grosor del material.

Por ejemplo, un material con un grosor de ¾ pulg

requiere un bloque separador, un material con un

grosor de 1 pulg requiere dos bloques separadora y

un material con un grosor de 1¼ pulg requiere tres

bloques. Se incluye un bloque separador con la Kreg

®

Jig

. Hay bloques adicionales disponibles.

Cuando utilice la guía de taladro por separado

en las reparaciones, recuerde ajustar el anillo de

detención y asegurar fi rmemente la guía de taladro

en la pieza de trabajo con una abrazadera de

barra, abrazadera en C o una abrazadera face

clamp de Kreg. En determinadas situaciones, cuando

no puede utilizarse una abrazadera, puede atornillar

la guía de taladro directamente a la pieza de

trabajo, como se muestra.

U

www.kregtool.com 800-447-8638

Sugerencias Sugerencias

Esquinas a inglete

Para tablas que tienen al menos 3

pulg de ancho, las cavidades ocultas

taladradas con las guías “A” y “C” encajan

completamente en la parte frontal de la

tabla. En esta situación, simplemente ubique

la pieza de trabajo con inglete en la

plantilla, utilice la abrazadera para fi jarla

en el lugar y taladre.

Para tablas que tienen al menos

2 3/8 pulg de ancho, las cavidades ocultas

taladradas con las guías “B” y “C” encajan

completamente en la parte frontal de

la tabla. En esta situación, simplemente

ubique la pieza de trabajo con inglete en

la plantilla, utilice la abrazadera para

fi jarla en el lugar y taladre.

Para colocar un tornillo de cavidad oculta

junto al “pie” del inglete en una pieza

de trabajo o para colocar un segundo

tornillo de cavidad oculta en una pieza

de trabajo delgada y aún tener el orifi cio

completamente en la parte frontal de la

pieza, taladre el orifi cio de cavidad oculta

lo más cercano al talón del inglete con la

guía de taladro en el dado de la guía

de taladro. Retire la guía del dado. Para

materiales con un grosor de ¾ pulg, coloque

un bloque separador (U) en la guía de

taladro. Coloque la guía de taladro con el

extremo del bloque separador a 1½ pulg

del pie del inglete y luego coloque la guía

de taladro en ángulo de 30 grados lejos

del pie. Use una abrazadera para fi jar la

guía de taladro en su lugar y taladre una

cavidad oculta.

T ambién puede taladr ar una cavidad oculta

en cada lado de la junta a inglete en lugar

de taladrar ambos orifi cios en el mismo

lado.

30°

U

11⁄2

pulg

www.kregtool.com 800-447-8638

Sugerencias

Sugerencias

Tamaños comunes

de tablas

Tamaño Nominal Tamaño real

1x2

1x3

1x4

1x6

1x8

2x2 1

2x4 1

2x6 1

2x8 1

4x4 3

6x6 5

Nominal

Ý[Ý

3

⁄4" x 11⁄2"

3

⁄4" x 21⁄2"

3

⁄4" x 31⁄2"

3

⁄4" x 51⁄2"

3

⁄4" x 71⁄4"

1

⁄2" x 11⁄2"

1

⁄2" x 31⁄2"

1

⁄2" x 51⁄2"

1

⁄2" x 71⁄4"

1

⁄2" x 31⁄2"

1

⁄2" x 51⁄2"

Ý

Tamaño nominal vs. tamaño real

En un almacén de madera o tienda para el hogar

verá etiquetas en la madera como “1x6” y “2x4”.

Estos tamaños “nominales” alguna vez describieron

las dimensiones de la madera con corte áspero,

antes de que fuese aserrada a su tamaño fi nal o

real. El tamaño real es siempre menor que el tamaño

nominal.

Las marcas del grosor de la tabla en la Kreg Jig se

refi eren al grosor real de la tabla. Por ejemplo, una

madera de 1x4 tiene en verdad ¾ pulg de grosor,

por lo que debe ajustar la plantilla en la marca de

¾ pulg.

Ý

òÝ

òÝ

Real

òÝ[òÝ

6 consejos para reducir el resquebrajamiento de la madera

Pruebe las piezas

1

Pruebe la junta con piezas de desecho cortadas del mismo material de la pieza de trabajo fi nal.

Asegúrese de usar tornillos Kreg

2

Los tornillos Kreg tienen puntas afi ladas y autorroscante que cortan a través de las fi bras de madera.

3

Use el tipo de tornillo adecuado

Use tornillos de rosca fi na para madera dura. Estos tornillos de #7 corta menos madera que

los tornillos de rosca gruesa #8 utilizados para madera suave, madera contrachapada, fi bra

de densidad media (MDF) y panel de aglomerado.

Coloque el tornillo y retírelo

4

Introduzca el tornillo hasta la mitad, sáquelo y limpie el exceso de fi bras de madera del

orifi cio y luego introduzca el tornillo completamente.

5

Reduzca la fricción

Aplique cera de abejas u otro lubricante en el tornillo, para reducir la fricción a medida que

se introduce en la pieza de trabajo.

6

Fíjelo con una abrazadera correctamente

Centre las almohadillas de la Face Clamp™ de Kreg en la línea de junta con la almohadilla de

la abrazadera grande en el lado frontal de la junta (opuesto a las cavidades ocultas). Regule la

abrazadera para aplicar sufi ciente presión para mantener las piezas de trabajo al ras y estables,

pero no tan fi rmes de modo que difi culten fi jación con abrazadera y su liberación.

www.kregtool.com 800-447-8638

Características

Accesorios opcionales

Puerto de aspiración

Este accesorio para la recolección de astillas (R) se

encaja en la parte posterior del dado de la guía

de taladro. El puerto admite cualquier manguera de

aspiradora industrial estándar de 1¼ pulg y gira

prácticamente de lado a lado. Además de ayudar

a mantener su área de trabajo limpia, la eliminación

efi ciente de astillas acelera el tiempo de taladrado y

reduce la generación de calor, lo que extiende la vida

útil de su broca para taladro.

Topes de la pieza de trabajo

Para operaciones repetitivas de taladrado de

cavidades ocultas, el tope (N) se encaja en las ranuras

con forma de cerradura de la base. Para instalarlo,

coloque las espigas de la parte inferior del tope en

el extremo más grande de las ranuras con forma de

cerradura y deslice el tope hacia la parte frontal de

la plantilla. Para colocar la cavidad oculta de manera

precisa, presione una tuerca de acero (O) en una

de las ranuras hexagonales del tope. Enrosque una

tuerca moleteada (P) en cada perno de nailon (Q) y

enrosque el perno en la tuerca del lado opuesto del

tope. La tuerca y el perno funcionan en conjunto para

proporcionar un ajuste fácil y la tuerca moleteada fi ja

el perno en la posición.

Disponibles en su concesionario Kreg o en línea en www.kregjig.com

Micro Pocket™ Drill Guide Artículo# KJMICRODGB

Con un diámetro de orifi cio un 25% más pequeño que nuestras cavidades ocultas estándar, la guía

R

de taladro Micro Pocket™ le permite crear una cavidades ocultas compactas en proyectos pequeños,

materiales delgados y reparaciones estrechas. El kit incluye la guía de taladro, la broca de taladro y

el anillo de detención.

Kreg Jig® HD Artículo# KJHD

Diseñado para utilizarse con materiales “2-by”, este sistema para trabajo pesado cuenta con tornillos de

cavidad oculta de #14 x 2 ½".

Kreg Jig® Portable BaseArtículo# KPDGB

Esta base acepta bloques para guías de taladro micro, estándar y HD para taladrar cavidades

ocultas donde sea. Es particularmente útil para paneles o ensambles grandes que serían difíciles

de fi jar con abrazadera en un plantilla montada en banco. Las levas integradas aseguran la base

portátil en la Face Clamp™ de Kreg.

Kreg Face Clamps™

Artículo# KHC-PREMIUM (alcance de 7,62 cm), Artículo# KHC-LARGE (alcance de 15,24 cm),

Artículo# KHC-XLARGE (alcance de 25,4 cm)

Con opciones de 7,62 cm, 15,24 cm y 25,4 cm de alcance, encontrará una Face Clamp™ Kreg que

satisfaga sus necesidades.

Q

N

P

Quick Change Kit Artículo# QUIK-KIT

Cambie de taladrar cavidades ocultas a insertar tornillos de cavidad oculta en segundos. El kit

incluye un portabrocas de cambio rápido, una punta de destornillador cuadrada #2, una broca para

taladro con vástago hexagonal y un anillo de detención.

Drill Guide Spacer Blocks Artículo# KDGADAPT

Los bloques separadores se fi jan en el extremo de la guía de taladr o estándar cuando se utiliza en una

reparación. La guía por sí sola sirve para materiales con un grosor de ½ pulg. Cada bloque compensa un

grosor adicional de ¼ pulg. El conjunto incluye tres bloques.

www.kregtool.com 800-447-8638

Notas Notas

www.kregtool.com 800-447-8638

Safety Guidelines

• Read this manual and these safety guidelines. Learn the applications and limitations of the tool as well as the

hazards specifi c to it. Operating the tool before understanding safe and proper use could result in personal injury.

• Always wear e y e, hearing, and respiratory protection specifi cally designed and certifi ed as safety equipment.

• The drill bit is sharp. Handle with care.

• Avoid awkward hand positions where a sudden slip could cause contact with the rotating bit.

• Properly secure your workpiece before drilling.

• Follow your drill manufacturer’s safety guidelines.

• Do not operate this tool or any machinery while under the infl uence of drugs, alcohol, or medications.

• Do not allow familiarity gained from frequent use of your tools to replace safe work practices. A moment of

carelessness is suffi cient to cause severe injury.

Warning

This product contains one or more chemicals known to the State of California to cause cancer and birth defects or other

reproductive harm. Wash hands after handling.

Consignes de sécurité

• Lisez attentivement ce manuel et ces consignes de sécurité. Assurez-vous de connaître le fonctionnement et les restrictions de l’outil

ainsi que les risques potentiels liés à son utilisation. Le fait d’utiliser cet outil sans comprendre la méthode sécuritaire et adéquate

peut entraîner des blessures graves.

• Portez toujours des lunettes de sécurité, des protecteurs auditifs et un dispositif de protection des voies respiratoires spécialement

conçus et certifi és comme équipement de sécurité.

• Le foret est pointu. Soyez prudent lorsque vous le manipulez.

• Évitez de placer les mains à un endroit où elles risquent d’entrer en contact avec la mèche si la pièce travaillée glisse soudainement.

• Fixez correctement votre pièce travaillée avant de la percer.

• Suivez les consignes de sécurité du fabricant de votre perceuse.

• N’utilisez pas cet outil ou aucun autre appareil lorsque vous êtes sous l’effet de drogues, d’alcool ou de médicaments.

• L’habitude liée à une utilisation fréquente de vos outils ne remplace pas une méthode de travail sécuritaire. Il suf fi t d’être

négligent une fraction de seconde pour causer de graves blessures.

Avertissement

Cet article contient un ou plusieurs produits chimiques reconnus par l’État de la Californie comme étant la cause de cancers,

d’anomalies congénitales et d’autres problèmes liés aux fonctions reproductrices. Lavez-vous les mains après l’av oir manipulé.

Pautas de seguridad

• Lea este manual y estas pautas de seguridad. Conozca las aplicaciones y las limitaciones de la herramienta, además de sus

peligros específi cos. La operación de la herramienta antes de comprender su utilización segura y adecuada puede causar

lesiones personales.

• Siempre utilice protección para los oídos, la respiración y lentes de protección diseñados y certifi cados específi camente como equipos

de seguridad.

• La broca para taladro es afi lada. Manipule con cuidado.

• Evite las posiciones de manos incómodas donde un resbalón repentino podría provocar el contacto con la broca giratoria.

• Asegure adecuadamente la pieza de trabajo antes de taladrar.

• Siga las pautas de seguridad del fabricante del taladro.

• No opere esta herramienta o cualquier maquinaria bajo los efectos de drogas, alcohol o medicamentos.

• No permita que la familiaridad obtenida por el uso de herramientas remplace las prácticas de un trabajo seguro. Un momento

de descuido es sufi ciente para causar lesiones graves.

Advertencia

Este producto contiene una o más sustancias químicas reconocidas por el estado de

California como causantes de cáncer, defectos congénitos u otros daños en el aparato

reproductivo. Lávese las manos después de manipularlo.

800-447-8638

Version 2 - 9/2013

NK8104

Loading...

Loading...