Quick-Start Guide

Guía de inicio rápido

Guide de démarrage

www.kregtool.com

www.kregtool.com

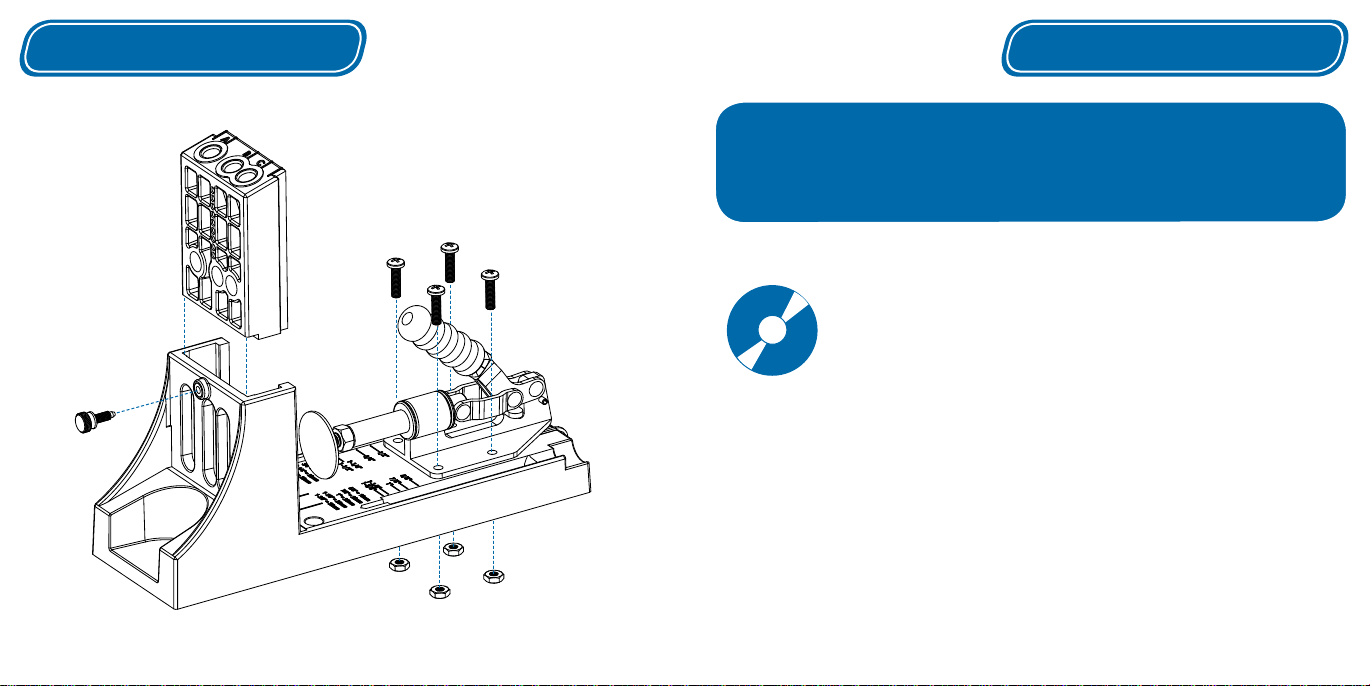

Assembly

Introduction

Our hope is that your Kreg Jig® opens up a whole new world of project

possibilities for you. We’ve made every effort to make the Kreg Jig® as fun

and easy-to-use as possible. Along with this Quick-Start Guide, here are

several other resources you may fi nd helpful along the way.

SkillBuilder™ DVD:

information you’ll need to start building (and keep building)

with your new Kreg Jig®. Once you’ve mastered the skills on this

DVD, you’ll be ready to build just about anything!

Kregtool.com: Your online resource for everything “Kreg.” Whether you can’t

remember how to make a particular joint, need to order some more selftapping screws, or just want to see what kind of accessories are available for

your jig... this is where you’ll fi nd it.

Woodsmith: Kreg Tool Company is a proud sponsor of the popular

Woodworking TV Show, “The Woodsmith Shop.” Instead of focusing on

larger projects, the Woodsmith Shop focuses on tips, techniques, and

woodshop fundamentals. Currently airing on many public television

stations across the country. Learn more at www.woodsmithshop.com.

800-447-8638 www.kregtool.com

Start here! This DVD includes all the

A

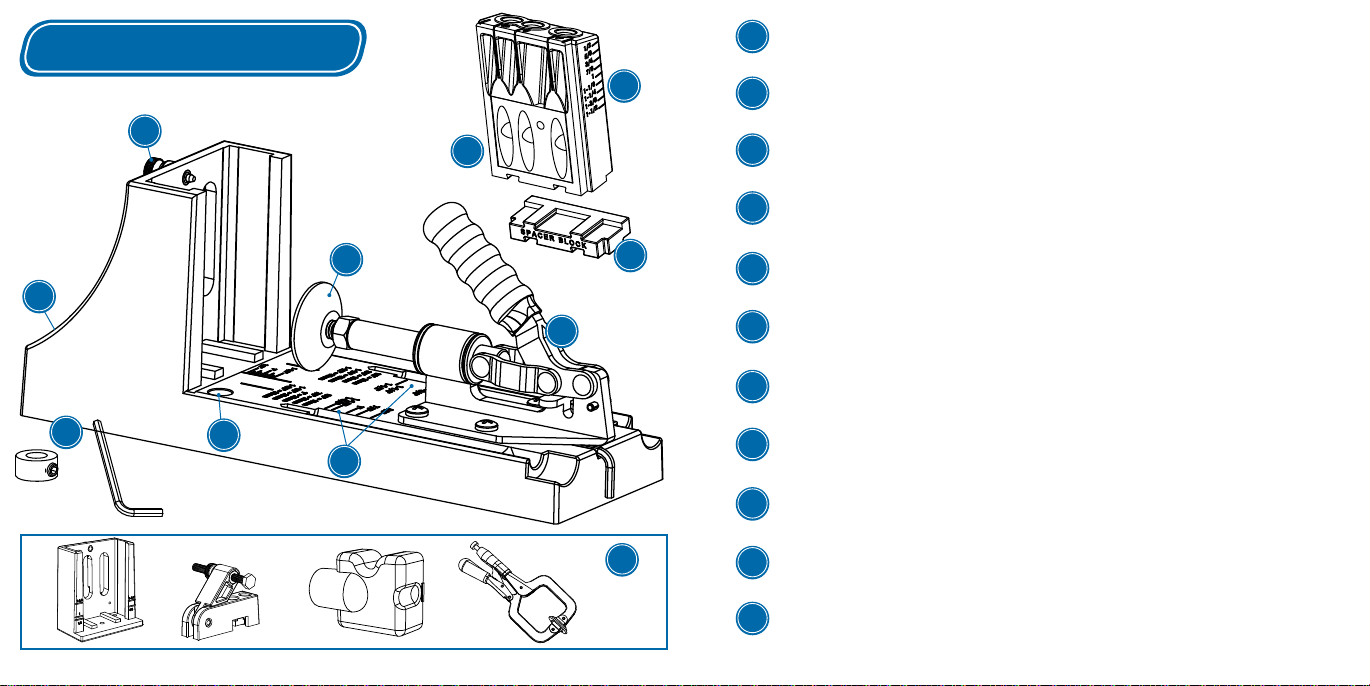

Parts

D

Toggle Clamp:

Secures workpieces while drilling Pocket-Holes. Use fi rm pressure to lock in place.

Clamp Pad:

B

Rotate clockwise or counter-clockwise to compensate for workpiece thickness.

G

Drill Guide:

C

B

H

F

A

I

E

J

K

800-447-8638 www.kregtool.com

C

The “core” of the Kreg Jig®. Can be used in the Kreg Jig® or removed for repair applications.

Drill Guide Adjustment Markings:

D

Markings indicate the Drill Guide’s height setting. Match with workpiece thickness.

Screw Holes (4):

E

To minimize movement during use, secure the jig to your workbench using 4 wood screws.

F

Clamping Recess:

For a less permanent solution, clamp your jig to your workbench with a Bar or C-Clamp.

G

Drill Guide Pin:

Locks Drill Guide into place while adjusting height for different material thicknesses.

Drill Guide Spacer Block:

H

For repair applications. Each spacer compensates for an additional ¼” in material thickness.

Depth Collar / Allen Wrench:

I

Sets the maximum plunge depth of drill. Use Allen Wrench to lock into place on the bit.

Depth Setting Gauge:

J

Helps you fi nd the correct Depth Collar setting for varying workpiece thicknesses.

Master Systems Components

K

Parts unique to the Kreg Jig® Master System. Detailed information on components pages.

Settings

2

Drill Guide Adjustment

To create the strongest joint possible, you’ll need

to set your jig to match the thickness of your

®

workpiece. The Kreg Jig

makes this easy, in just

three simple steps!

1

Depth Collar Adjustment

To get the right Pocket-Hole depth, you’ll have to

adjust the position of the collar on the drill bit. Place

your bit inside the Depth Setting Gauge on the Kreg

Jig®, with the step of the bit at the marking which

matches your workpiece thickness, as shown. Slide the

Depth Collar towards the jig base and lock it in place

with the included Allen Wrench.

For 3/4” material, place the step of the bit

800-447-8638 www.kregtool.com

at the 3/4” marking and tighten depth collar.

To ensure the exit-point of your screw is near

the center of the workpiece, (for the strongest

joint possible) you’ll need to adjust position of

your Pocket-Hole by raising or lowering the

Drill Guide’s height to match your workpiece

thickness. Loosen the Drill Guide Pin, lift the

Drill Guide until the correct mark is showing

just above the jig body, and re-tighten the pin.

3

Clamp Pad Adjustment

For a fi rm hold on the workpiece, you may

have to adjust the position of the clamp pad.

To do so, release the lock-nut, rotate the clamp

pad in or out, and test the hold by depressing

the toggle. Repeat this process until you get a

secure hold on the workpiece. Then, re-tighten

the lock-nut.

Settings

Drill Guide shown set for 3/4” material.

Release lock-nut, adjust clamp pad

position, test hold, and re-tighten lock-nut.

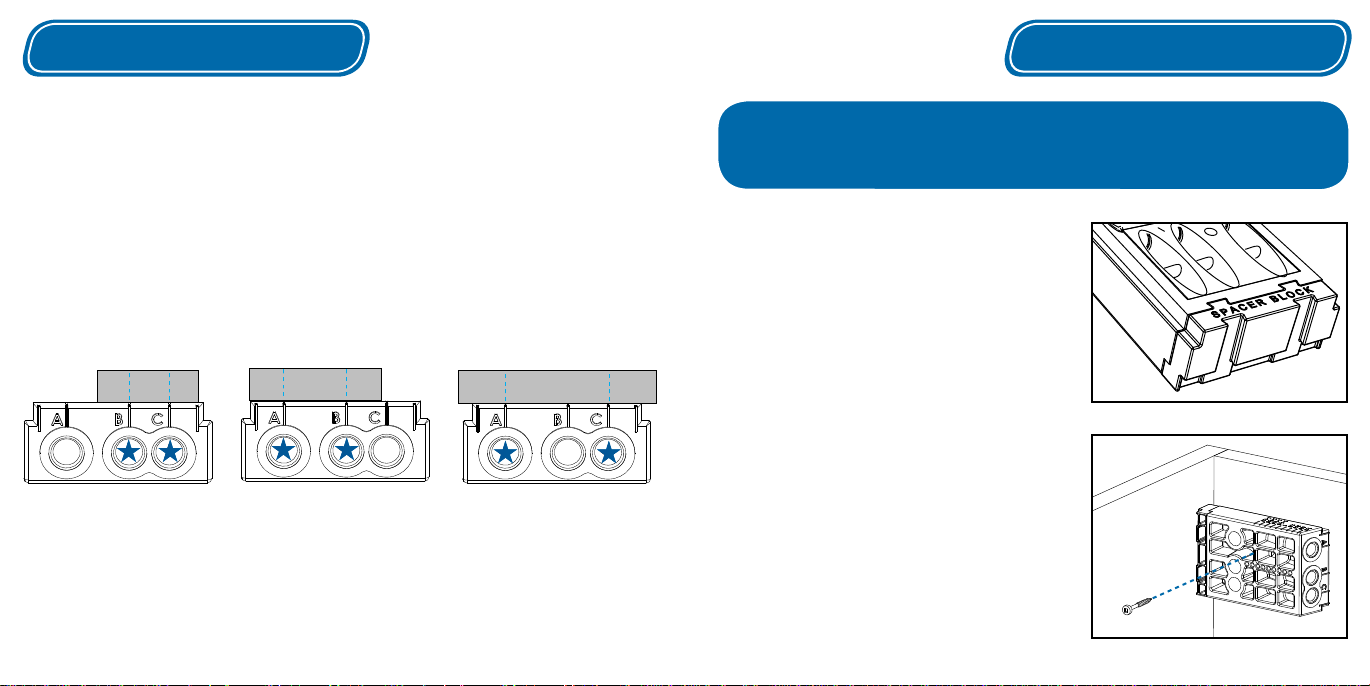

Pocket-Hole Placement

Repair Applications

Along with the Kreg Jig® Settings, another important part of getting the

strongest possible Kreg Joint is to space your Pocket-Holes evenly across

the workpiece. Your Kreg Jig® features a patented 3-hole Drill Guide

which lets you do this in a wide variety of workpiece widths without the

For repair applications, the Drill Guide can be removed completely

from the benchtop base, and taken directly to the problem joint

serving as a ‘mobile Kreg Jig®’.

need to reposition the workpiece after each hole is drilled. Use the guide

below to determine how to best clamp your workpiece and drill your

Pocket-Holes.

1” to 2”

Wide Material

Use B and C Holes Use A and B Holes Use A and C Holes

2” to 3”

Wide Material

3” to 4”

Wide Material

For panels, we recommend placing the fi rst Pocket-Hole roughly 2 inches

away from the exposed edge of the panel, and every 6” after that. When

When you bring the bottom of the Drill Guide to the

edge of the joint for a repair, the jig is set correctly

to center a screw in

larger stock, you’ll need to compensate with the

included Spacer Block. Each Spacer Block you add,

compensates for another ¼” in material size. For

3

⁄4” material, use 1 block. For 1” material, use 2

blocks, etc.

Additional blocks can be purchased from your local

Kreg Dealer.

In repair applications, when using the Drill Guide

separately, remember that you still have to set the

Depth Collar and ensure that the Drill Guide is

fi rmly secured to the workpiece using a bar clamp

or c-clamp. In certain situations where the use of a

clamp is not possible, you may also screw the Drill

Guide directly to the workpiece, as shown.

1

⁄2” material. If the joint uses

drilling panels, you can use any of the Drill Guide’s three holes.

800-447-8638 www.kregtool.com

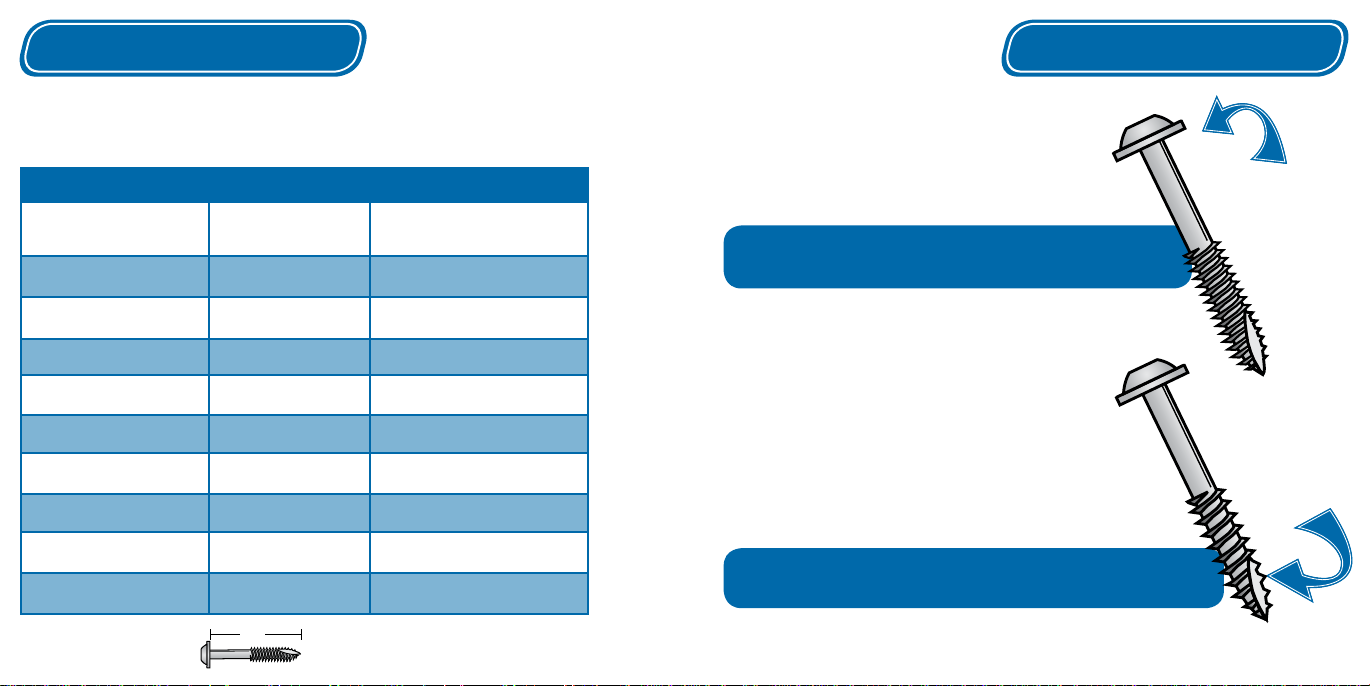

Choosing a Screw

Kreg offers a complete line of specialized screws for every workpiece size

and type. Use this graph to fi nd the correct screw. All are available online,

at www.kregtool.com or at your local authorized Kreg dealer.

Screw Selection / Kreg Jig® Setting Chart

Material

Thickness

1

⁄2” (12 mm)

Screw

Length

3

⁄4” (19 mm)

Kreg Jig

1

⁄2” Marking

®

Setting

Choosing a Screw

Fine Thread

Fine thread screws are recommended for

hardwoods as they reduce the chance of the

material splitting when driven.

Use in woods such as:

• Ash • Oak • Maple • Walnut • Hickory • Cherry • Mahogany • Birch

Deep Square Drive

improves driver

engagement and

reduces the

possibility of

cam-out.

5

⁄8” (16 mm) 1” (25 mm)

3

⁄4” (19 mm) 11⁄4” (32 mm)

7

⁄8” (22 mm) 11⁄2” (38 mm)

1” (25 mm) 1

1

⁄8” (29 mm) 11⁄2” (38 mm) 11⁄8” Marking

1

1

⁄4” (32 mm) 2” (51 mm) 11⁄4” Marking

1

3

1

⁄8” (35 mm) 2” (51 mm) 13⁄8” Marking

1

⁄2” (38 mm) 21⁄2” (64 mm) 11⁄2” Marking

1

800-447-8638 www.kregtool.com

1

⁄2” (38 mm) 1” Marking

11⁄4”

*Note: Screw length is measured from bottom of

the head to the tip of the screw

5

⁄8” Marking

3

⁄4” Marking

7

⁄8” Marking

Coarse Thread

Due to a signifi cantly larger thread diameter,

coarse thread screws offer a much stronger hold

in composite materials such as MDF

and plywood.

Use in woods such as:

• Pine • Cedar • Basswood • Poplar • Plywood • Melamine• Particle Board

Self-Tapping

Auger point

eliminates the

need to drill a

pilot hole.

Tips

Tips

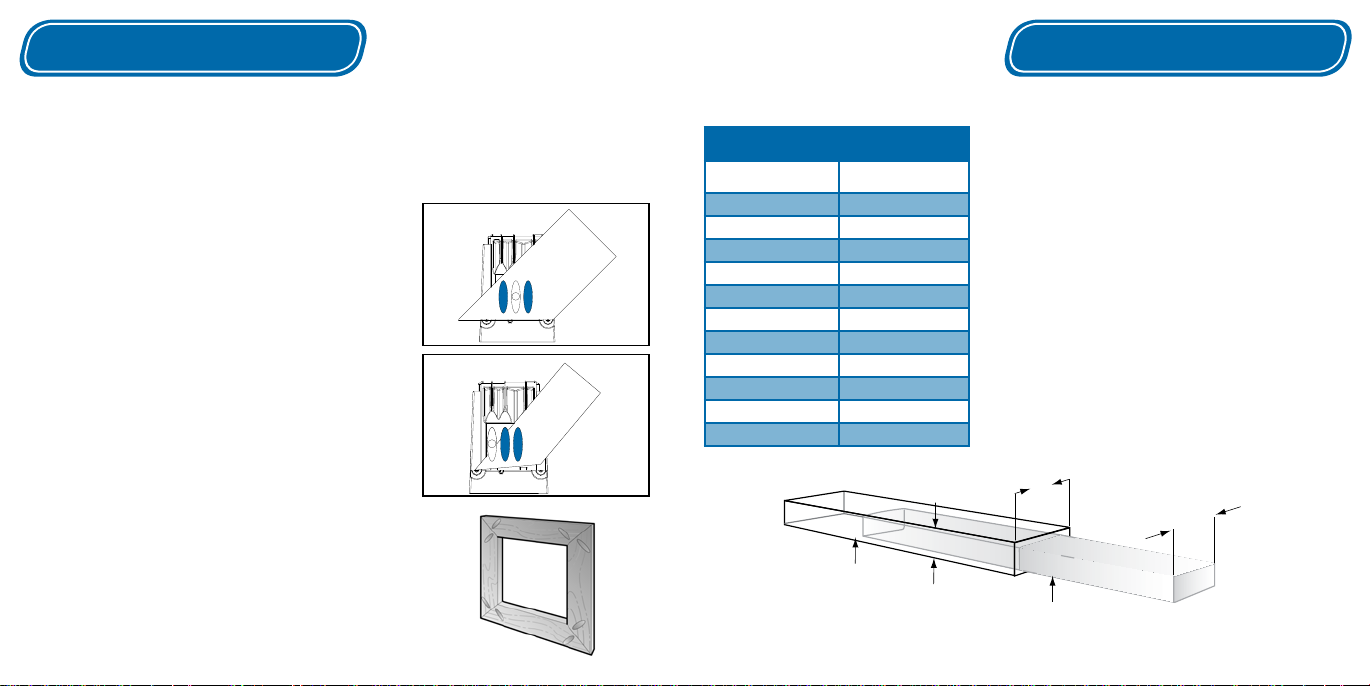

Mitered Corners

There are several ways to join mitered pieces with your Kreg Jig®. Depending on the

width of the boards, choose the method best for you.

For wider boards, simply place the mitered joint on the

jig, clamp it down and drill as normal.

Base

For more narrow boards, you may need to raise the

heel of the miter off of the base to get your pockets in

the correct space.

Heel raised off

base of jig

®

For creating mitered corners with the Kreg Jig

, we

generally recommend at least 3” wide boards. For smaller

stock, it may be helpful to place one Pocket-Hole on either

side of the joint, instead of two holes on one side.

Base

Common Board Sizes

Nominal Size Actual Size

1x2

1x3

1x4

1x6

1x8

2x2 1

2x4 1

2x6 1

2x8 1

4x4 3

6x6 5

Nominal

(2˝ x 4˝)

3

⁄4” x 11⁄2”

3

⁄4” x 21⁄2”

3

⁄4” x 31⁄2”

3

⁄4” x 51⁄2”

3

⁄4” x 71⁄4”

1

⁄2” x 11⁄2”

1

⁄2” x 31⁄2”

1

⁄2” x 51⁄2”

1

⁄2” x 71⁄4”

1

⁄2” x 31⁄2”

1

⁄2” x 51⁄2”

Nominal Size vs. Actual Size

When you look at the labels on boards at the

home store or woodworking store, you may see

simple sizes like “1x6” or “2x4.” That’s the ‘nominal’

size of the board, which describes the board’s

dimensions before it was machined to fi nished size.

The fi nished size, known as the ‘actual’ size, will be

slightly less.

The markings on your Kreg Jig® refer to the ‘actual’

size of your boards. If you buy a “1x4” at the

store, but measure it at home and it’s actually ¾”

thick, set your jig and depth collar to their ¾”

settings before drilling.

4˝

3½˝

2˝

1½˝

Actual

(1½˝ x 3½˝)

800-447-8638 www.kregtool.com

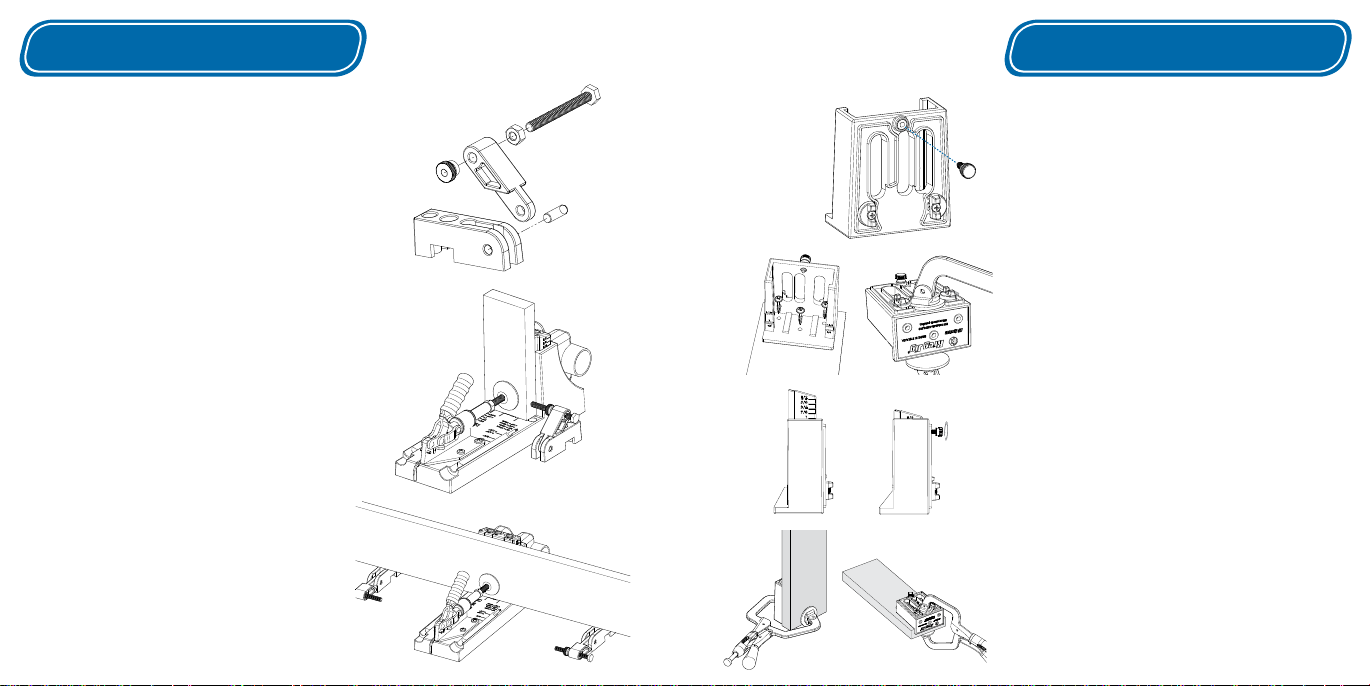

Tips Additional Components

For more detailed instructions, please

visit us online at www.kregtool.com.

6 Tips to Reduce Wood Splitting

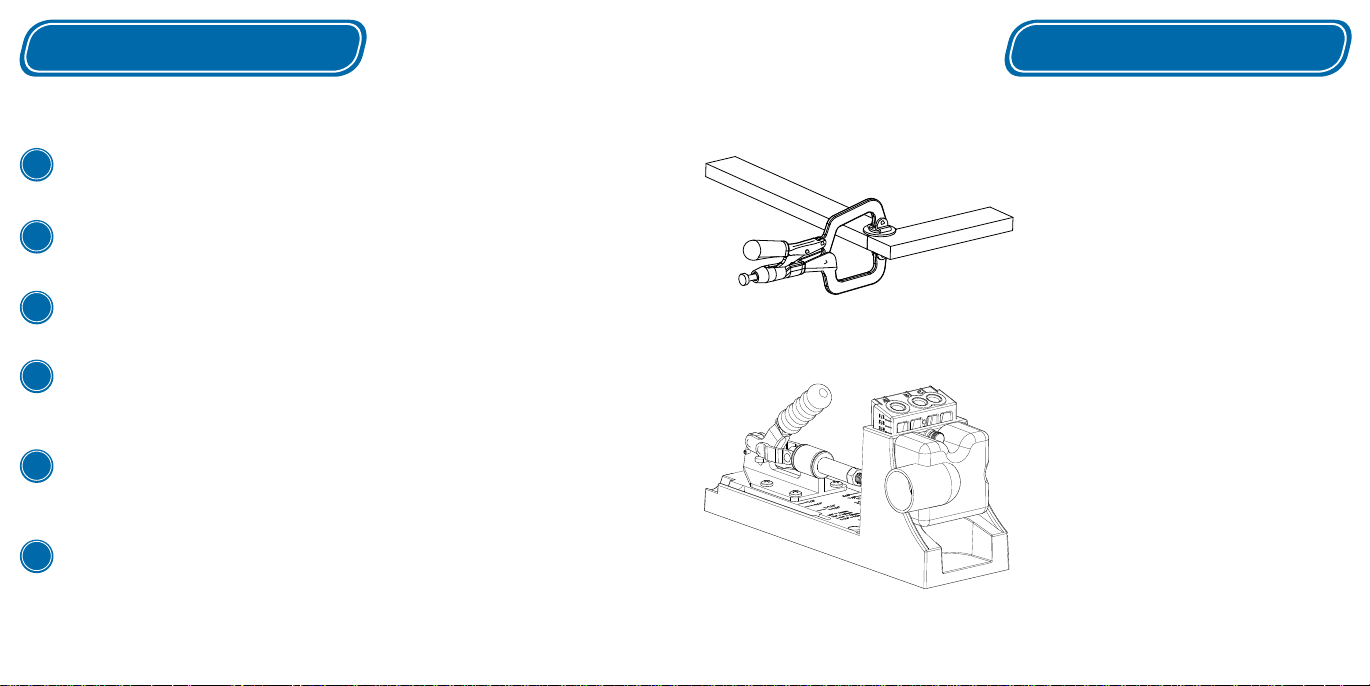

Face Clamp

Test Pieces

1

Test the joint with some scrap workpieces cut from the same stock as your fi nal workpiece.

Make sure you’re using Kreg Screws

2

Kreg screws have several features designed to limit/eliminate wood splitting in your joints.

Use Fine Thread Screws in Hardwood

3

Coarse Thread screws displace more wood thanks to a more aggressive thread pattern.

Screw it In, Back it Out

4

By driving your screw half way in, back out, and then in again, you’ll reduce excess wood in the

hole and reduce the chance for splitting.

Reduce Friction

5

By applying some bee’s wax or other lubricant to the screw, you’ll reduce the friction of the

screw entering the workpiece.

Clamp, Clamp, Clamp

6

Correctly clamping your joints reduce workpiece movement/vibration, both of which can cause splitting.

800-447-8638 www.kregtool.com

Perfectly fl ush Kreg JointsTM, in no time.

For the best results, place the Face Clamp™

on the joint directly over the center of the

joint line. Make sure the large pad of the

clamp is on the face side of the joint (opposite

the Pocket-Holes) to keep the workpieces

perfectly fl ush. Clamp fi rmly to reduce the

possibility for workpiece movement.

Dust Collection Attachment

Keep a clean shop.

This simple attachment is a real time saver. It

snaps easily into place on the back of your

jig providing compatibility with any standard

1-1/4” vacuum hose. In addition to a clean

shop, it also provides faster/easier drill

strokes and extends the life of your drill bit.

TM

For more detailed instructions, please

visit us online at www.kregtool.com.

Additional ComponentsAdditional Components

Material Support Stop

Repeatable Pocket-Holes.

The Material Support Stop serves two great

purposes. Supporting long stock on either

side of the jig, and providing the ability to

drill consistent repeatable Pocket-Holes, at

equal distances.

To use the Material Support Stop as a

repeatable stop, simply screw the stop to the

work surface at your chosen distance from

the jig and fi ne-tune the arm to the exact

distance desired.

To use the Material Support Stop to support

your workpiece, simply swing the stop arm

out of the way and slide the workpiece into

position.

* This kit includes one Material Support Step

800-447-8638 www.kregtool.com

Portable Base

Work from anywhere. Connect the brass pin to

the Portable Base.

Prepare the Portable Base for use by either

screwing it to your work surface, or securing it to

a Kreg Face Clamp™.

Match the markings on the side of the Drill Guide

to the thickness of your workpiece.

Clamp each workpiece securely to your jig and

your workspace before drilling.

Assemblage

Introduction

Nous espérons que votre Kreg Jig® vous donnera accès à un nouveau monde

de possibilités et de projets. Nous nous sommes efforcés de rendre le Kreg Jig

aussi amusant et facile à utiliser que possible. Vous trouverez ci-dessous des

outils qui, en plus du guide de démarrage, pourraient vous être utiles pendant la

réalisation de votre projet.

Le DVD SkillBuilder™ :

dont vous avez besoin pour commencer à construire (et pour continuer à le faire)

avec votre nouveau Kreg Jig®. Une fois que vous aurez maîtrisé les techniques

expliquées sur le DVD, vous pourrez construire presque n’importe quoi!

Le site Kregtool.com : Il s’agit de votre ressource en ligne pour tout ce qui concerne

Kreg. Que vous le consultiez pour savoir comment faire un joint en particulier, pour

commander quelques vis autotaraudeuses de plus ou simplement pour voir quels types

d’accessoires sont offerts pour votre gabarit, vous y trouverez la réponse à toutes vos

questions.

Woodsmith : Kreg Tool Company est un fi er commanditaire de la populaire émission

télévisée sur le travail du bois « The Woodsmith Shop ». Au lieu de se concentrer sur des

projets à grand déploiement, « The Woodsmith Shop » donne des conseils, présente des

techniques et explique les principes fondamentaux d’un atelier de menuiserie. L’émission

est actuellement diffusée par plusieurs stations de télévision publiques. Pour obtenir plus de

renseignements, rendez-vous sur le site www.woodsmithshop.com.

800-447-8638 www.kregtool.com

1-800-447-8638

Ça commence ici! Ce DVD comprend toute l’information

®

A

Pièces

D

G

B

F

I

E

J

800-447-8638 www.kregtool.com

1-800-447-8638

C

H

A

K

Serre-joint articulé :

Il maintient les pièces en place pendant que vous percez des trous en angle. Appuyez fermement sur

le serre-joint pour le bloquer.

Tampon du serre-joint :

B

Il peut pivoter dans le sens des aiguilles d’une montre ou dans le sens contraire pour s’adapter à

l’épaisseur des pièces.

Guide-foret :

C

Le « noyau » du Kreg Jig®. Il peut être utilisé avec le Kreg Jig® ou être retiré pour effectuer

des réparations.

Marques de réglage du guide-foret :

D

Les marques indiquent la hauteur à laquelle le guide-foret est réglé. Elles correspondent à l’épaisseur

de la pièce.

Trous de vis (4) :

E

Pour diminuer les mouvements du gabarit pendant que vous l’utilisez, fi xez-le sur l’établi en utilisant

4 vis à bois.

F

Fraisure de blocage :

Pour une solution temporaire, fi xez le gabarit sur l’établi en utilisant une barre ou un serre-joint en C.

G

Broche à guide-foret :

Elle maintient le guide-foret en place et permet d’en régler la hauteur en fonction de l’épaisseur des

différents matériaux.

Bloc-espaceur du guide-foret :

H

Il sert à effectuer des réparations. Chaque bloc-espaceur augmente l’épaisseur des pièces de 6,35 mm.

Collier de profondeur et clé hexagonale :

I

Ils permettent de régler la profondeur de pénétration maximale de la mèche. Utilisez la clé

hexagonale pour maintenir le foret en place.

Calibre de réglage de la profondeur :

J

Il vous aide à déterminer l’emplacement adéquat du collier de profondeur en fonction de l’épaisseur

des différentes pièces.

Composants du système de base :

K

Des renseignements détaillés sur les pièces uniques au système Kreg Jig® de base se trouvent dans la

section « Composants ».

Réglages

2

Réglage du guide-foret

Pour obtenir les joints les plus solides possible, vous

devrez régler votre gabarit de manière à ce qu’il

corresponde à l’épaisseur de la pièce avec laquelle vous

travaillez. Le Kreg Jig

®

permet de le faire facilement, en

seulement trois étapes!

1

Réglage du collier de profondeur

Pour que vos trous en angle aient la bonne

profondeur, il est nécessaire de régler la position

du collier sur le foret. Placez le foret dans le calibre

de réglage de la profondeur sur le Kreg Jig® en

mettant l’échelon du foret au niveau de la marque

correspondant à l’épaisseur de la pièce, tel qu’il est

illustré. Faites glisser le collier de profondeur vers la

base du gabarit et maintenez-le en place avec la

clé hexagonale fournie.

Pour une pièce de 1,91 cm, placez le foret au niveau de

800-447-8638 www.kregtool.com

1-800-447-8638

la marque de ¾ po et serrez le collier de profondeur.

Pour vous assurer que le point de sortie de

la vis est près du centre de la pièce (pour

que le joint soit le plus solide possible), il est

nécessaire de régler la position du gabarit de

perçage à angle en élevant ou en abaissant

la hauteur du guide-foret de façon à ce

qu’elle corresponde à l'épaisseur de la pièce.

Desserrez la vis de blocage du guide-foret,

soulevez le guide-foret jusqu'à ce que la

bonne marque se trouve juste au-dessus du

gabarit et resserrez-la.

3

Réglage du tampon

Pour que la pièce reste stable, vous devrez

peut-être régler la position du tampon. Pour

ce faire, desserrez l’écrou de blocage, faites

pivoter le tampon vers l’intérieur ou l’extérieur

et testez la prise en relâchant la pression du

serre-joint articulé. Répétez ces étapes jusqu’à

ce que la pièce soit solidement en place.

Ensuite, serrez à nouveau l’écrou de blocage.

Réglages

Le guide-foret illustré est réglé pour des

pièces de 1,91 cm d’épaisseur.

Desserrez l’écrou de blocage, réglez la

position du tampon, testez la solidité de la

prise et serrez à nouveau l’écrou de blocage.

Emplacement des trous en angle

Pour effectuer des réparations

En plus de bien régler le Kreg Jig®, il est important, pour obtenir les joints les plus

solides possible, de répartir les trous en angle également sur la surface de la pièce.

Le Kreg Jig® comprend un guide-foret à trois trous breveté qui vous permet de le

faire sur des pièces de tailles variées sans avoir à déplacer quoi que ce soit après

avoir percé chaque trou. Utilisez le guide ci-dessous pour déterminer la meilleure

façon de maintenir la pièce en place et de percer des trous en angle.

Pièces d’une

largeur de

2,54 cm à 5,08 cm

Utilisez les trous B et C Utilisez les trous A et B Utilisez les trous A et C

Pour les panneaux, nous recommandons de placer le premier trou à environ 5,08 cm

de l’extrémité du côté apparent du panneau et les autres à une distance de 15,24 cm

les uns des autres. Lorsque vous faites des trous dans les panneaux, vous pouvez utiliser

n’importe lequel des trois trous du guide-foret.

800-447-8638 www.kregtool.com

1-800-447-8638

Pièces d’une

largeur de

5,08 cm à 7,62 cm

Pièces d’une

largeur de

7,62 cm à 10,16 cm

Lorsque vous effectuez des réparations, le guide-foret peut être retiré

complètement du socle pour table de travail et devenir un « Kreg Jig®

mobile » à utiliser directement sur le joint qui pose problème.

Lorsque vous placez le bas du guide-foret sur le

bord d’un joint pour effectuer une réparation, le

gabarit est réglé de manière à ce que la vis arrive

au centre d’une pièce de 1,27 cm. Si le joint est fait

sur une plus grande pièce, il est nécessaire d’utiliser

le bloc-espaceur fourni. Chaque bloc-espaceur

augmente l’épaisseur des pièces de 6,35 mm. Pour

une pièce de 1,91 cm, utilisez un bloc. Pour des

pièces de 2,54 cm, utilisez deux blocs, etc.

Vous pourrez vous procurer des blocs additionnels

auprès de votre détaillant Kreg local.

Pendant que vous effectuez des réparations, lorsque

vous utilisez le guide-foret seulement, n’oubliez pas

que vous devez tout de même régler le collier de

profondeur et vous assurer que le guide-foret est

bien fi xé sur la pièce au moyen d’un serre-joint à

barre ou d’un serre-joint en C. Dans certains cas,

lorsque l’utilisation d’un serre-joint est impossible,

vous pouvez aussi visser le guide-foret directement

sur la pièce, tel qu’il est illustré.

Choisir le bon type de vis

Choisir le bon type de vis

Kreg vous offre une gamme complète de vis spécialisées pour les pièces de tous les types

et de tous les formats. Utilisez le tableau suivant pour choisir la bonne. Elles sont toutes

offertes en ligne, sur le site www.kregtool.com ou chez votre détaillant Kreg autorisé.

Filetage fi n

Les vis à fi letage fi n sont recommandées pour

Sélection de vis et réglage du Kreg Jig

Épaisseur

de la pièce

1

⁄2 po (12 mm)

Longueur

de la vis

3

⁄4 po (19 mm)

®

Réglage du

Kreg Jig

MARQUE

®

1

⁄2 po

les bois durs puisqu’ils réduisent les risques

que le bois se fende lorsqu’il est percé.

Utilisez-les avec les types de bois suivants :

• Le frêne • Le chêne • L’érable • Le noyer • L’hickory • Le cerisier

• L’acajou • Le bouleau

5

⁄8 po (16 mm) 1 po (25 mm)

3

⁄4 po (19 mm) 11⁄4 po (32 mm) MARQUE 3⁄4 po

7

⁄8 po (22 mm) 11⁄2 po (38 mm) MARQUE 7⁄8 po

1 po (25 mm) 1

1

⁄8 po (29 mm) 11⁄2 po (38 mm) MARQUE 11⁄8 po

1

1

1

⁄4 po (32 mm) 2 po (51 mm) MARQUE 11⁄4 po

3

⁄8 po (35 mm) 2 po (51 mm) MARQUE 13⁄8 po

1

1

⁄2 po (38 mm) 21⁄2 po (64 mm) MARQUE 11⁄2 po

1

800-447-8638 www.kregtool.com

1-800-447-8638

1

⁄2 po (38 mm) MARQUE 1 po

11⁄4 po

*Remarque : La longueur de la vis est calculée du

bas de la tête jusqu’au bout de la vis.

MARQUE

5

⁄8 po

Filetage normal

En raison de leur diamètre beaucoup plus grand,

les vis à fi letage normal offrent une prise bien

plus solide pour les matériaux composites tels

que les panneaux MDF et de contreplaqué.

Utilisez-les avec les types de bois suivants :

• Le pin • Le cèdre • Le tilleul d’Amérique • Le peuplier • Le contreplaqué

• La mélamine • Les panneaux de particules

Un carré conducteur

profond permet de

mieux guider la vis

et de réduire les

risques de rejet.

La pointe de

tarière autota-

raudeuse élimine

le besoin de

percer un trou

d’essai.

Conseils

Conseils

Dimensions standard

Coins à onglet

Le Kreg Jig® vous permet de raccorder des pièces à onglet de plusieurs façons. Choisissez

la méthode optimale en fonction de la largeur de vos

planches.

Pour les planches larges, fi xez simplement le joint à

onglet au gabarit et percez normalement.

Base

Pour les planches étroites, il est possible que vous ayez

à soulever le talon de l’onglet de la base pour ajuster

l’emplacement des cavités.

®

Pour créer des coins à onglet à l’aide du Kreg Jig

nous vous recommandons d’utiliser des planches d’une

,

Base

largeur d’au moins 3 po. Pour les matériaux de petite

taille, il peut être préférable de percer un seul trou en

angle d’un côté ou de l’autre du joint.

800-447-8638 www.kregtool.com

1-800-447-8638

Talon soulevé

de la base du

gabarit

des planches

Dimensions

nominales

1x2

1x3

1x4

1x6

1x8

2x2 11⁄2 po x 11⁄2 po

2x4 11⁄2 po x 31⁄2 po

2x6 11⁄2 po x 51⁄2 po

2x8 11⁄2 po x 71⁄4 po

4x4 31⁄2 po x 31⁄2 po

6x6 51⁄2 po x 51⁄2 po

Dimensions

3

⁄4 po x 11⁄2” po

3

⁄4 po x 21⁄2 po

3

⁄4 po x 31⁄2 po

3

⁄4 po x 51⁄2 po

3

⁄4 po x 71⁄4 po

Dimensions

nominales

(2 po x 4 po)

réelles

Dimensions nominales et

dimensions réelles

Les étiquettes des planches indiquent parfois des

dimensions simplifi ées, par exemple 1x6 ou 2x4.

Il s’agit des dimensions « nominales », soit les

dimensions de la planche avant son usinage. Les

dimensions « réelles », soit les dimensions une fois

l’usinage terminé, sont légèrement inférieures aux

dimensions nominales.

Les indications sur le Kreg Jig

dimensions réelles des planches. Si vous achetez

une planche portant l'indication « 1x4 » et qu’elle

mesure en fait 3/4 po d’épaisseur, réglez le

gabarit et le collier de profondeur à 3/4 po avant

de commencer le perçage.

po

4

2

po

1½

po

Dimensions réelles

(1 1/2 po x 3 1/2 po)

®

sont basées sur les

3½

po

Conseils

Pour obtenir des instructions plus

détaillées, veuillez visiter notre site

Web au www.kregtool.com.

Composants additionnels

Six conseils pour éviter de fendre les planches

Effectuez des tests

1

Testez le joint à l’aide de retailles du matériau que vous utilisez.

Assurez-vous d’utiliser des vis Kreg

2

Les vis Kreg sont conçues pour réduire les risques de fendillement du bois des joints.

Utilisez des vis à fi let fi n pour le bois franc

3

Les vis à gros fi let déplacent davantage de bois.

Insérez la vis d’un mouvement de va-et-vient

4

En insérant la vis à moitié et en la retirant pour ensuite l’insérer de nouveau, vous réduirez les

accumulations de bois dans le trou et vous diminuerez les risques de fendillement.

Faites en sorte de diminuer la friction

5

En appliquant un peu de cire d’abeille ou tout autre lubrifi ant sur la vis, vous diminuerez la

friction au moment de l’insérer dans la planche.

Fixez vos joints

6

Une fi xation adéquate des joints empêche la pièce de se déplacer ou de vibrer, réduisant ainsi les

risques de fendillement.

800-447-8638 www.kregtool.com

1-800-447-8638

Des joints Kreg parfaitement lisses,

en très peu de temps.

Pour de meilleurs résultats, placez le serre-joint

Face Clamp™ directement au centre de la ligne

de joint. Assurez-vous que le grand tampon

du serre-joint est sur la face avant du joint

(contrairement aux trous en angle) afi n que les

pièces demeurent parfaitement lisses. Fixez le tout

fermement afi n d’éviter que les pièces bougent.

Dispositif de dépoussiérage

Préservez la propreté de votre atelier.

Ce dispositif facile à utiliser permet d’économiser

du temps. Il se place facilement à l’arrière de

votre gabarit et convient aux tubes d’aspiration

standard de 3,18 cm de diamètre. En plus de

vous permettre de préserver la propreté de

votre atelier, il accélère et facilite le perçage et

augmente la durée d’utilisation de vos forets.

Face Clamp

TM

Composants additionnels

Pour obtenir des instructions plus

détaillées, veuillez visiter notre site

Web au www.kregtool.com.

Composants additionnels

Cale de soutien

pour des trous en angle identiques.

La cale de soutien joue deux rôles

importants : elle permet de maintenir en

place les pièces longues et de percer

des trous en angle identiques espacés

uniformément.

Pour percer des trous espacés

uniformément, vissez simplement la cale

de soutien à la surface de travail, à la

distance désirée du gabarit, et réglez le

bras à la distance exacte.

Pour soutenir une pièce longue, pivotez

simplement le bras de la cale de façon à

éviter qu’il vous gêne et glissez la pièce

en place.

* Cet ensemble inclut une cale de soutien.

800-447-8638 www.kregtool.com

1-800-447-8638

Socle portatif

Le socle portatif permet de travailler n’importe

où. Raccordez la vis de blocage en laiton au socle

portatif.

Pour utiliser le socle portatif, vissez-le à votre

surface de travail ou fi xez-le à un serre-joint Face

Clamp™ de Kreg.

Réglez le guide-foret de façon à ce que

les indications sur son côté correspondent à

l’épaisseur de votre pièce.

Fixez fermement chaque pièce à votre gabarit et

à votre surface de travail avant de commencer à

percer.

Ensamblaje

Introducción

Nuestro deseo es que con su Kreg Jig® descubra un mundo nuevo lleno de

posibilidades para sus proyectos. Hicimos todo a nuestro alcance para que

Kreg Jig® sea lo más divertido y fácil de usar posible. Junto con esta guía

de inicio rápido, encontrará otros recursos que quizá sean útiles para la

construcción.

DVD SkillBuilder™: Comience por aquí. Este DVD incluye toda la

información que necesitará para comenzar a construir (y seguir

construyendo) con su nuevo Kreg Jig

las habilidades que se muestran en este DVD, estará listo para

construir casi todo.

Kregtool.com: Su recurso en línea para todo lo que sea “Kreg”. Si no puede

recordar cómo fabricar una junta en particular, necesita pedir algunos tornillos

autorroscantes, o sólo desea ver qué tipo de accesorios hay disponibles para su

plantilla para taladrar… aquí es dónde lo encontrará.

Woodsmith: Kreg Tool Company se enorgullece de ser el patrocinador del

famoso programa de televisión de carpintería The Woodsmith Shop. En lugar

de centrarse en proyectos más grandes, el programa The Woodsmith Shop hace

hincapié en los consejos, las técnicas y los conceptos básicos de la compra de

madera. Actualmente, el programa se ve en diversas estaciones de televisión

públicas en todo el país. Infórmese más en www.woodsmithshop.com.

®

. Una vez que haya dominado

800-447-8638 www.kregtool.com

A.

Partes

D

G

B

F

I

E

J

800-447-8638 www.kregtool.com

C

H

A

K

Abrazadera de palanca:

Fija las piezas de trabajo mientras taladra orifi cios inclinados. Aplique presión fuerte para

bloquearla en su lugar.

Almohadilla de abrazadera:

B.

Gírela en sentido de las agujas del reloj, o en sentido contrario, para compensar el grosor de la

pieza de trabajo.

Guía de taladro:

C.

El “corazón” del Kreg Jig®. Se puede utilizar en el Kreg Jig® o se l puede retirar para hacer

reparaciones.

Marcas de ajuste de la guía de taladro:

D.

Las marcas indican la confi guración de altura de la guía de taladro. Hágalas coincidir con el grosor

de las piezas de trabajo.

Orifi cios para tornillos (4):

E.

Para reducir al mínimo el movimiento durante el uso, asegure la plantilla para taladrar a su banco

de trabajo con 4 tornillos para madera.

F.

Entrante de pared sujetable:

Para una solución menos permanente, asegure su plantilla para taladrar a su banco de trabajo con

una abrazadera de barra o de presión en C.

G.

Pasador de la guía de taladro:

Bloquea la guía de taladro en su lugar y a la vez regula la altura para los diferentes grosores de

los materiales.

Bloque separador de la guía de taladro:

H.

Para hacer reparaciones. Cada espaciador compensa 6 mm adicionales del grosor de los materiales.

Anillo de profundidad y llave Allen:

I.

El anillo establece la máxima profundidad de penetración del taladro. Utilice la llave Allen para

bloquearlo en su lugar en la broca.

Calibrador de confi guración de profundidad:

J.

Le ayuda a encontrar la correcta confi guración del anillo de profundidad para los distintos grosores

de los materiales.

Componentes del sistema maestro:

K

Piezas exclusivas del sistema maestro Kreg Jig®. Información detallada en las páginas sobre

“Componentes”.

Ajustes

2

Ajuste de la guía de taladro

Para crear la junta más fuerte que sea posible, deberá

colocar la plantilla para taladrar de manera que

coincida con el grosor de su pieza de trabajo. El juego

®

Kreg Jig

1

Ajuste del anillo de profundidad

Para obtener la correcta profundidad de las

cavidades ocultas, deberá ajustar la posición

del anillo en la broca del taladro. Coloque la

broca dentro del calibrador de confi guración de

profundidad en el Kreg Jig® con la escala de la

broca en la marca que coincide con el grosor de

su pieza de trabajo, como se muestra. Deslice

el anillo de profundidad hacia la base de la

plantilla para taladrar y bloquéelo en su lugar

con la llave Allen que viene incluida.

800-447-8638 www.kregtool.com

lo hace simple y en tan sólo tres pasos.

Para el material de 19 mm de grosor, coloque la

escala de la broca en la marca de 3/4” (19 mm)

y ajuste el anillo de profundidad.

Para asegurar que el punto de salida del

tornillo sea cerca del centro de la pieza

de trabajo (para crear la junta más fuerte

posible), deberá ajustar la posición de su

cavidad oculta elevando o bajando la altura

de la guía del taladro para que coincida con

el grosor de su pieza de trabajo. Afl oje el

pasador de la guía de taladro, eleve la guía

de taladro hasta que se muestre la marca

correcta por encima del cuerpo de la plantilla

para taladrar y vuelva a ajustar el pasador.

3

Ajuste de la almohadilla

de abrazadera

Para obtener un buen agarre de la pieza de

trabajo, quizá deba ajustar la posición de la

almohadilla de la abrazadera. Para hacerlo,

libere la tuerca de fi jación, gire la almohadilla

de la abrazadera hacia adentro o hacia afuera

y pruebe el agarre presionando la palanca.

Repita este proceso hasta que obtenga un

agarre seguro de la pieza de trabajo. Luego,

vuelva a ajustar la tuerca de fi jación.

Ajustes

La guía de taladro se muestra confi gurada

para los materiales de 19 mm de grosor.

Libere la tuerca de fi jación, ajuste la posición

de la almohadilla de la abrazadera, pruebe el

agarre y vuelva a ajustar la tuerca de fi jación.

Ubicación de las cavidades ocultas

Reparaciones.

Junto con la confi guración de Kreg Jig®, otra parte importante de crear la junta

Kreg más fuerte posible es que entre las cavidades ocultas haya espacios parejos

en la pieza de trabajo. El juego Kreg Jig® tiene una guía de taladro de tres orifi cios

patentada que le permite hacer esto en piezas de trabajo de diferentes anchos sin

tener que cambiar de posición la pieza de trabajo después de perforar cada orifi cio.

Utilice la guía a continuación para determinar cómo fi jar de la mejor manera su pieza

de trabajo y perforar sus cavidades ocultas.

25 mm a 51 mm

Material ancho

Utilice los orifi cios B y C. Utilice los orifi cios A y B. Utilice los orifi cios A y C.

Para los paneles, recomendamos colocar la primera cavidad oculta aproximadamente

a 51 mm del borde expuesto del panel y en intervalos de 152 mm después de eso.

Cuando se perforan paneles, puede utilizar cualquiera de los tres orifi cios de la guía

de taladro.

800-447-8638 www.kregtool.com

51 mm a 76 mm

Material ancho

76 mm a 101 mm

Material ancho

Para hacer reparaciones, la guía de taladro se puede retirar por

completo de la base del banco y se la puede llevar directamente a la

junta en la que tiene problemas, como un Kreg Jig® portátil.

Cuando lleva la parte inferior de la guía de taladro al

borde de la junta para hacer una reparación, la plantilla

para taladrar se confi gura correctamente para centrar un

tornillo en material de 12 mm de grosor. Si para la junta

utiliza madera de mayor tamaño, deberá compensar

el grosor con el bloque espaciador que viene incluido.

Cada bloque espaciador que agregue, compensa 6 mm

adicionales en el tamaño de los materiales. Para material

de 19 mm, utilice 1 bloque. Para material de 25 mm,

utilice 2 bloques, etc.

Puede comprar más bloques en su distribuidor local Kreg.

En las reparaciones, cuando utilice la guía de taladro por

separado, recuerde que todavía debe confi gurar el anillo

de profundidad y asegurarse de que la guía de taladro

esté fi ja en la pieza de trabajo con una abrazadera de

barra o de presión en C. En determinadas situaciones,

cuando no puede utilizarse una abrazadera, también

puede atornillar la guía de taladro directamente a la

pieza de trabajo, como se muestra.

Elección de un tornillo. Elección de un tornillo.

Kreg ofrece una línea completa de tornillos especiales para cada tipo y tamaño de pieza

de trabajo. Utilice este gráfi co para hallar el tornillo correcto. Todos están disponibles en

línea en www.kregtool.com o en el vendedor de Kreg autorizado de su área local.

Cuadro de elección de tornillos y confi guración de Kreg Jig

Grosor

del material

1

⁄2” (12 mm)

5

⁄8” (16 mm) 1” (25 mm)

3

⁄4” (19 mm) 11⁄4” (32 mm)

7

⁄8” (22 mm) 11⁄2” (38 mm)

1” (25 mm) 1

1

1

⁄8” (29 mm) 11⁄2” (38 mm) 11⁄8” marca

1

1

⁄4” (32 mm) 2” (51 mm) 11⁄4” marca

3

⁄8” (35 mm) 2” (51 mm) 13⁄8” marca

1

1

⁄2” (38 mm) 21⁄2” (64 mm) 11⁄2” marca

1

800-447-8638 www.kregtool.com

Largo

del tornillo

3

⁄4” (19 mm)

1

⁄2” (38 mm) 1” marca

11⁄4”

*Aviso: El largo del tornillo se mide desde la parte

inferior de la cabeza hasta la punta del tornillo.

Confi guración de

Kreg Jig

1

⁄2” marca

5

⁄8” marca

3

⁄4” marca

7

⁄8” marca

®

®

Roscado fi no

Los tornillos de roscado fi no se recomiendan para la

madera dura dado que reducen la posibilidad de

que el material se astille cuando se los atornilla.

Utilice en maderas como:

• Fresno • Roble • Arce • Nogal • Nogal americano • Cerezo

• Caoba • Abedul

Roscado de ángulo grande

Debido al diámetro mucho más grande de la rosca, los

tornillos de roscado de ángulo grande ofrecen un agarre

mucho más fuerte en materiales compuestos como fi bra

de densidad media y madera contrachapada.

Utilice en maderas como:

• Pino • Cedro • Tilo americano • Álamo • Madera contrachapada

• Melamina• Panel de aglomerado

Los tornillos de

cabeza cuadrada

para profundidad

mejoran el agarre

del atornillador y

reducen la

posibilidad

de que el

atornillador

se deslice

hacia

afuera.

La punta de barrena

de los tornillos

autorroscantes elimina

la necesidad de

hacer un agujero

guía.

Consejos Consejos

Tamaño nominal vs. tamaño real

Cuando lee las etiquetas de las tablas en la tienda

de materiales o para trabajos con madera, es

posible que vea tamaños sencillos, como “1x6”

o “2x4”. Se trata de la medida "nominal" de la

tabla, la cual describe el tamaño de la tabla

antes que se procese a su tamaño fi nal. El tamaño

acabado, conocido como el tamaño “real”, es

ligeramente inferior.

Las marcas en su Kreg Jig® se refi eren al tamaño

“real” de sus tablas. Si compra un “1x4” en la

tienda, pero su medida real es 3/4" de grosor,

ajuste su plantilla y el anillo de profundidad al

ajuste de 3/4" antes de taladrar.

4˝

3½˝

2˝

1½˝

Actual

(1½˝ x 3½˝)

Esquinas a inglete

Hay varias maneras de unir piezas con inglete con su Kreg Jig®. Escoja el método que más

le convenga según el ancho de sus tablas.

Para tablas más anchas, sólo coloque la junta con

inglete en la plantilla, sujétela y taladre normalmente.

Base

Para tablas más delgadas, es posible que necesite

elevar el talón del inglete y retirarlo de la base para

que las cavidades estén en el lugar correcto.

Talón elevado

y retirado de

la plantilla

®

Para crear esquinas a inglete con el Kreg Jig

,

normalmente recomendamos al menos tablas de 7,62 cm

de ancho. Para material de menor tamaño, puede ser

útil colocar una cavidad oculta en uno de los lados de la

junta, en lugar de dos orifi cios en un lado.

Base

Tamaños comunes

de tablas

Tamaño

nominal

1x2

1x3

1x4

1x6

1x8

2x2 1

2x4 1

2x6 1

2x8 1

4x4 3

6x6 5

Tamaño

Nominal

(2˝ x 4˝)

real

3

⁄4” x 11⁄2”

3

⁄4” x 21⁄2”

3

⁄4” x 31⁄2”

3

⁄4” x 51⁄2”

3

⁄4” x 71⁄4”

1

⁄2” x 11⁄2”

1

⁄2” x 31⁄2”

1

⁄2” x 51⁄2”

1

⁄2” x 71⁄4”

1

⁄2” x 31⁄2”

1

⁄2” x 51⁄2”

800-447-8638 www.kregtool.com

Consejos

Para instrucciones más detalladas, sírvase

visitarnos en línea en www.kregtool.com.

Componentes adicionales

6 consejos para reducir el resquebrajamiento de la madera

Pruebe las piezas

1

Pruebe la junta con piezas de trabajo de desecho cortadas del mismo material como su pieza

de trabajo fi nal.

Asegúrese de usar tornillos Kreg

2

Los destornilladores de Kreg cuentan con varias características diseñadas para limitar o

eliminar el resquebrajamiento de la madera en las juntas.

Use tornillos de rosca fi na para madera dura

3

Los tornillos de rosca gruesa mueven más madera debido a su diseño de rosca más fuerte.

Coloque el tornillo y retírelo

4

Cuando coloca el tornillo hasta la mitad, lo retira, y lo vuelve a colocar, reduce el exceso de

madera en el orifi cio y reduce el riesgo de resquebrajamiento.

Reduzca la fricción

5

Cuando aplica un poco de cera de abejas o de otro lubricante en el tornillo, reduce la fricción

que genera el mismo cuando ingresa en la pieza de trabajo.

Sujete, sujete, sujete

6

El sujetar correctamente sus juntas reduce el movimiento y vibración de la pieza de trabajo, los cuales

pueden causar resquebrajamiento.

800-447-8638 www.kregtool.com

Nivela perfectamente Kreg JointsTM, sin tardar.

Para mejores resultados, coloque el Face Clamp™

en la junta, directamente sobre el centro de la línea

de junta. Asegúrese de que la almohadilla grande

de la abrazadera se ubique en el lado frontal de

la junta (opuesto a las cavidades ocultas) para

mantener las piezas de trabajo perfectamente

al ras. Coloque la abrazadera fi rmemente para

reducir la posibilidad de que la pieza de trabajo

se mueva.

Dust Collection Attachment

Mantenga su taller limpio.

Este accesorio sencillo permite ahorrar tiempo.

Encaja fácilmente en su sitio en la parte posterior

de su plantilla, lo que brinda compatibilidad con

cualquier manguera de aspiradora estándar de

25,4 a 6,4 mm. Además de contar con un taller

limpio, permite taladrar de forma más rápida y

fácil y extiende la vida útil de la broca.

Face Clamp

TM

Para instrucciones más detalladas, sírvase

visitarnos en línea en www.kregtool.com.

Componentes adicionalesComponentes adicionales

Tope de soporte de material

Cavidades ocultas a repetición.

El tope de soporte de material cumple dos

grandes funciones. Da soporte a material

largo en uno de los lados de la plantilla

y permite taladrar cavidades ocultas

equidistantes, uniformes y a repetición.

Para usar el tope de soporte de material

como un tope a repetición, simplemente

coloque el tope en la superfi cie de trabajo a

la distancia escogida de la plantilla y ajuste

con mucha precisión el brazo a la distancia

exacta deseada.

Para usar el tope de soporte de material

para dar apoyo a la pieza de trabajo,

simplemente deslice y retire el brazo tope

del camino y deslice la pieza de trabajo en

su posición.

* Este kit incluye un tope de soporte de material

800-447-8638 www.kregtool.com

Base portátil

Trabaje en cualquier parte. Conecte el pasador

de latón a la base portátil.

Prepare la base portátil para su uso ya sea

atornillándola a su superfi cie de trabajo o

fi jándola con un Kreg Face Clamp™.

Haga coincidir las marcas en el lado de la guía

de taladro al grosor de su pieza de trabajo.

Sujete cada pieza de trabajo fi rmemente a su

plantilla y a su espacio de trabajo antes de

taladrar.

Drill Guide Markings Notes

Highlight Your Markings

The Adjustment Markings on the K3 and K4 Drill Guide have been molded into the Drill Guide to

eliminate the possibility of them being rubbed off. If you’d like to highlight these markings to make

them easier to read, visit the FAQ section of www.kregtool.com to learn how.

Mettez les marques en évidence

Les marques de réglage des guide-forets K3 et K4 ont été moulées pour éviter qu’elles s’effacent. Si vous

désirez savoir comment les mettre en évidence afi n de faciliter leur utilisation, rendez-vous dans la section

relative aux questions les plus fréquemment posées sur le site www.kregtool.com.

Resalte sus marcas

Las marcas de ajuste en la guía de taladro K3 y K4 se han moldeado en la guía de taladro para eliminar

la posibilidad que se borren. Si desea resaltar dichas marcas para que sean más fáciles de leer, visite

nuestra sección Preguntas frecuentes de www.kregtool.com para saber cómo proceder.

800-447-8638 www.kregtool.com

Safety Guidelines

Always wear proper safety equipment.

Always wear safety goggles.

Drill Bit is sharp. Handle with care.

Follow your drill manufacturer’s safety guidelines.

Properly secure your workpiece before drilling.

Avoid awkward hand positions where a sudden slip could cause contact with the rotating blade.

WARNING: This product contains one or more chemicals known to the State of California to cause cancer

and birth defects or other reproductive harm. Wash hands after handling.

ADVERTENCIA: Este producto contiene una o más sustancias químicas reconocidas por el estado de

California como causantes de cáncer y defectos congénitos u otros daños en el aparato reproductivo.

Lávese las manos después de manipularlo.

AVERTISSEMENT: Ce produit contient au moins un produit chimique reconnu par l’État de la Californie

comme étant la cause de cancers, d’anomalies congénitales et d’autres problèmes liés aux fonctions

reproductrices. Lavez-vous les mains après l’avoir manipulé.

800-447-8638

6/2010 NK3059-Quick Start Guide

Rev C

Loading...

Loading...