4-

®

Kreg Jig

K3 Pocket Hole System

INSTRUCTIONAL MANUAL

4-

Products covered by one or

more of the following patents:

4,955,766

5,676,500

6,481,937

6,726,411

Other patents pending.

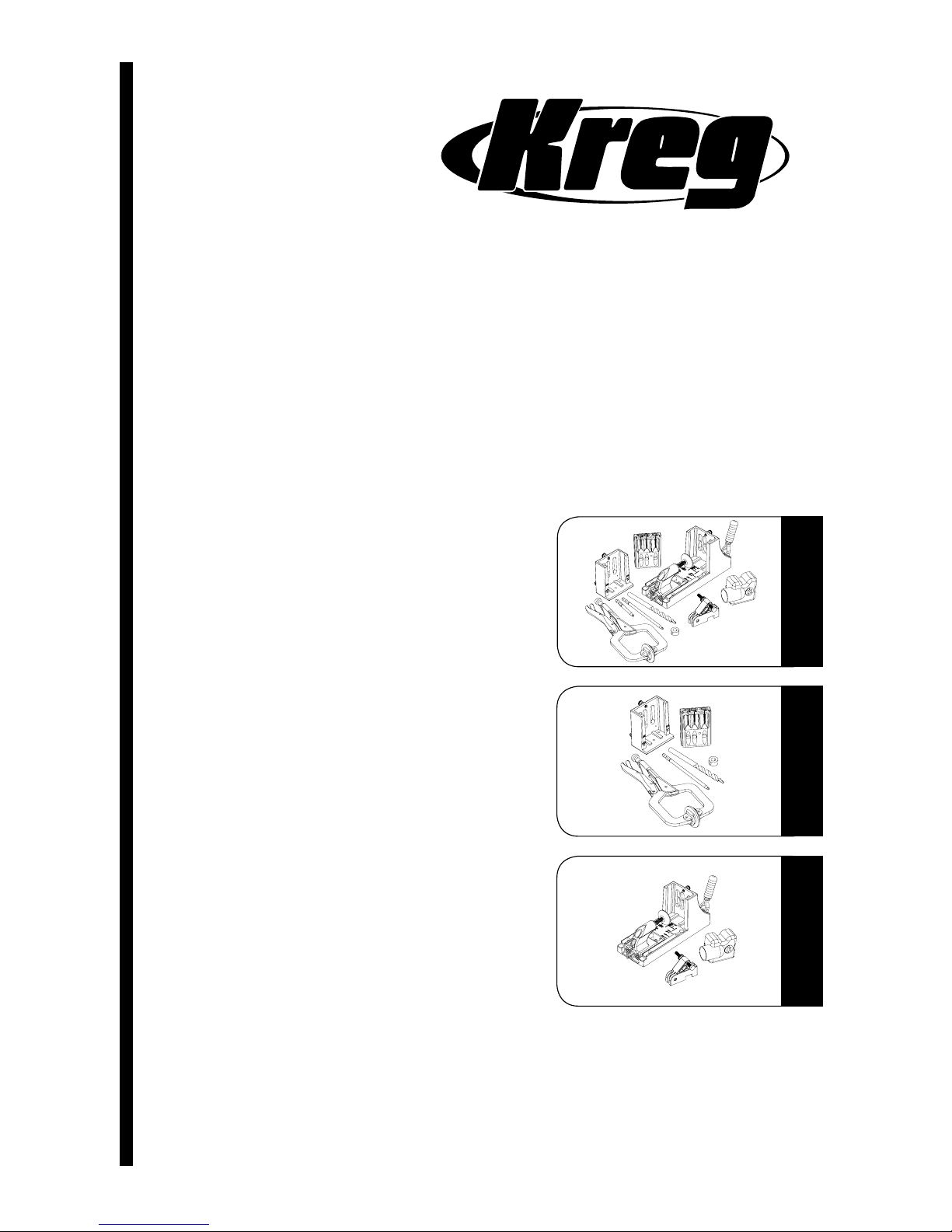

K3 Master System

Item# K3MS

K3 Standard Pack

Item# K3SP

K3 Upgrade Kit

Item# K3UP

The Blue Mark of Quality.

Version 2005701

NK3022

1

Table of Contents

Table of Contents 1

Warnings and Cautions 2

Package Contents 3

Parts Identification 4

Benchtop Base Assembly 5

Portable Base Assembly 6

Quickstart Guide To Building Your First Pocket Hole Joint 7-8

Getting To Know Your K3 System 9-16

4-

Selecting The Correct Screw 17-19

Self-Tapping Screw FAQ’s 20

Face Frames 21-22

Leg and Rail 23-24

Mitered Joints 25-26

Angled Joints/Curves 27-28

Edgebanding 29

Edgejoining 30

Plugging A Pocket Hole 31

General FAQ’s 32-33

Warranty and Contact Information 34

4-

Warnings and Cautions

Thank you for your purchase! Kreg Tool Company is proud to

manufacture top quality tools and accessories that are surpassed only by

our commitment to customer service. If after reviewing this manual you

still have a question or concern that you would like addressed please

visit our website at www.kregtool.com, call 800-447-8638 or email

customerservice@kregtool.com. This manual covers the basics of

pocket hole joinery including the Kreg Jig® K3 Pocket Hole System. In

addition, a joinery guide located towards the back of the manual details the

basics for producing a variety of wood joints utilizing pocket hole joinery.

We offer various educational materials to help you get the most out

of your Pocket Hole tools. In addition to educational videos, we also offer

a plan CD which contains 15 Pocket Hole project plans in a PDF format that

can be printed from your home computer. Video titles include...

• The Pocket Hole Solution to Cabinetmaking

2

• The Pocket Hole Solution to Tables

• The Pocket Hole Solution to Building Your Own Router Table

• The Pocket Hole Solution to Home Improvements

Warnings and Cautions

CAUTION! : Handle drill bit carefully - Like any cutting tool, flutes

of drill bit are extremely sharp.

Never hold a pocket hole jig by hand while drilling holes. Always

secure jig and workpiece to an immovable object before drilling.

Always check drilling depth in scrap material before producing final

pocket holes and driving screws.

Make sure material is securely clamped into jig before drilling.

Always allow drill bit to reach full speed before plunging into the

workpiece.

3

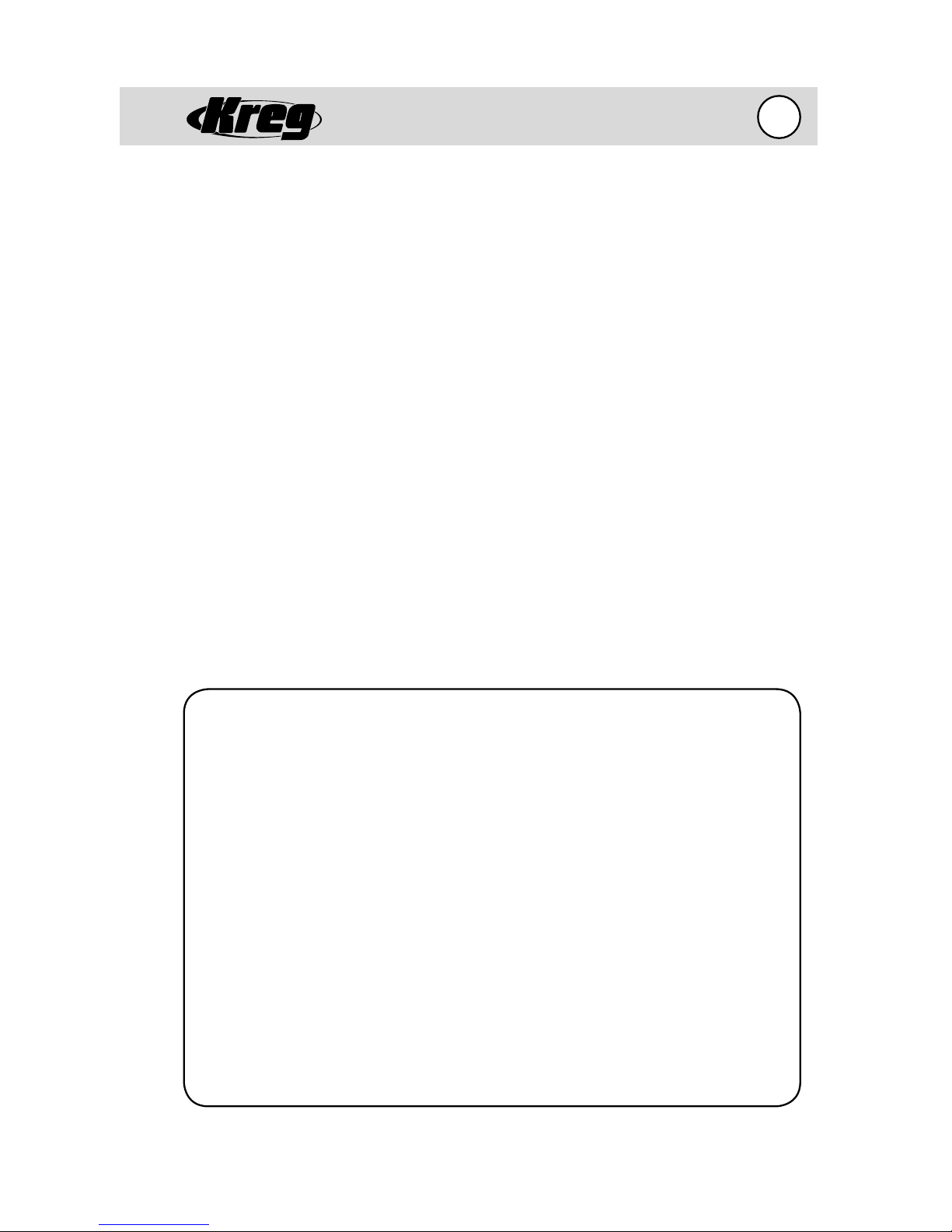

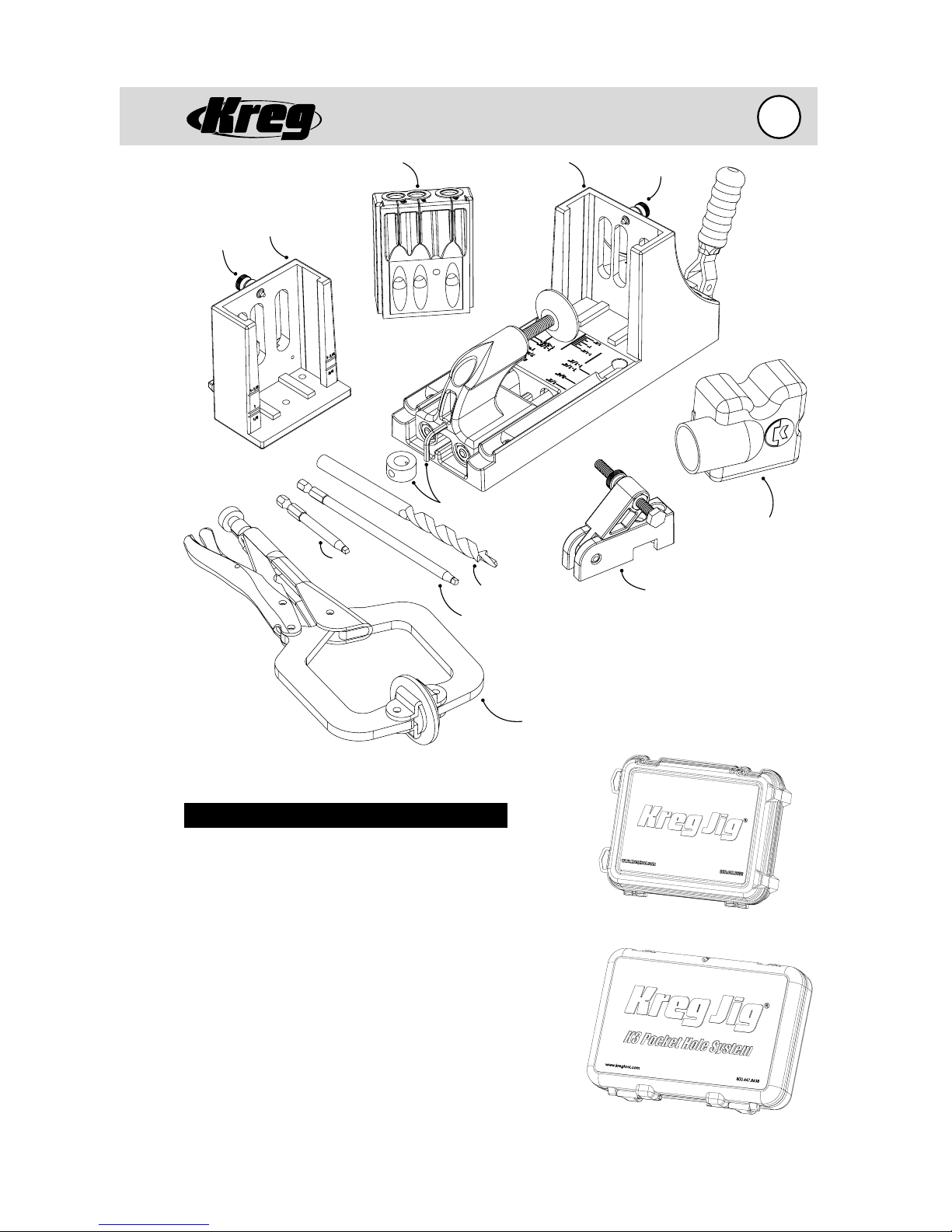

Package Contents

4-

- Indicates what is

included in package.

3/8” Step Drill Bit (KJD)

3”-#2 Square Driver Bit (D3)

6”-#2 Square Driver Bit (D6)

Allen Wrench - 1/8” (AW18)

Depth Collar (KJSC)

Premium Face Clamp (PFC)

Material Support Stop (KJSS)

K3 Upgrade Kit

K3 Standard Pack

K3 Master System

Dust Collection Shroud (NK3005)

Portable Base (NK3036)

K3 Drill Guide Block (NK3003)

Benchtop Base (NK3035)

SPS-C1 Screws

SML-F125 Screws

SML-C125 Screws

SML-C150 Screws

SML-C2 Screws

SML-C250 Screws

Standard Pack Case (NK3031)

Master System Case (NK3023)

4-

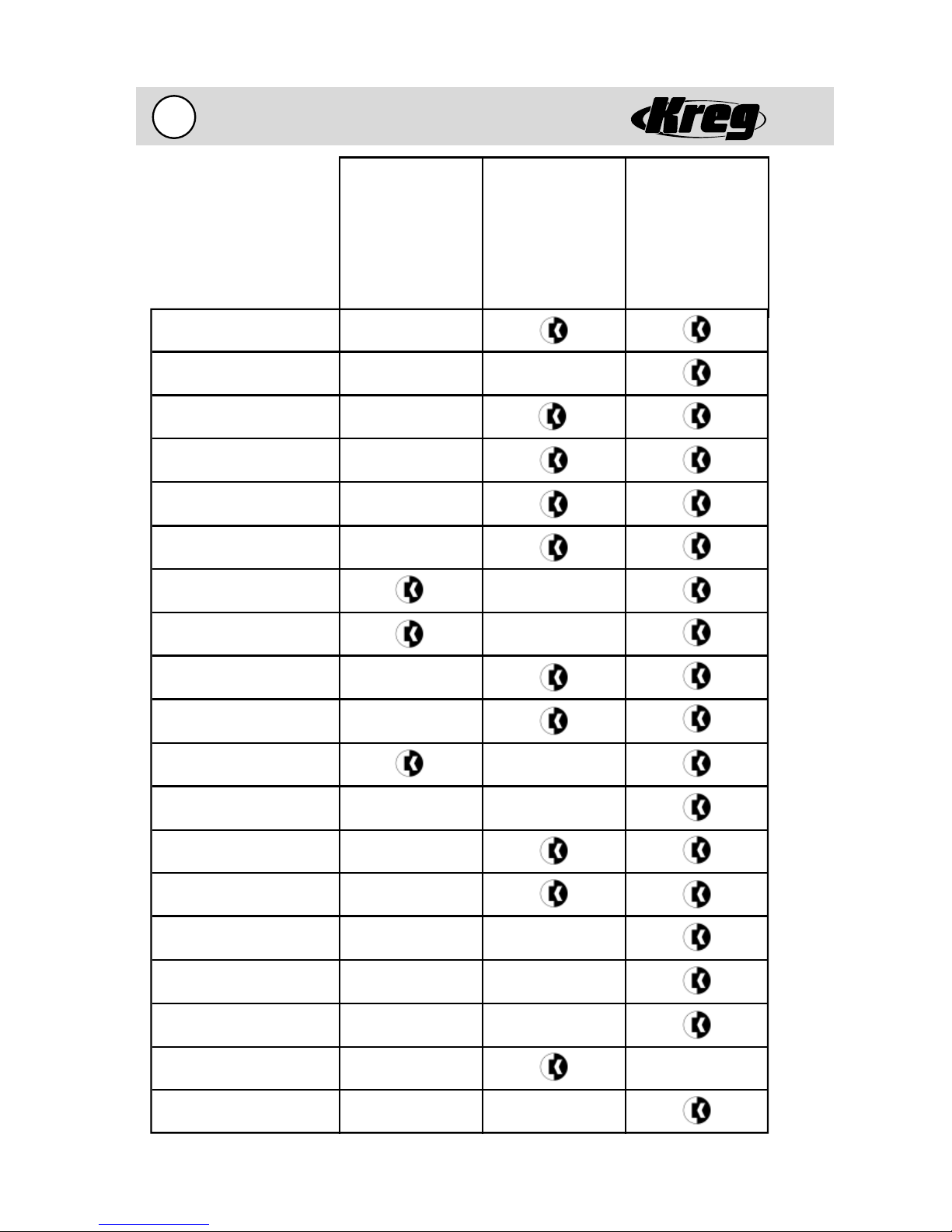

Parts Identifi cation

4

Brass

Index Pin

Portable

Base

K3 Drill Guide Block

3”-#2 Square

Driver Bit

Benchtop

Base

Depth Collar/Allen Wrench

3/8” Step Drill Bit

6”-#2 Square Driver Bit

Brass

Index Pin

Material

Support

Stop

Dust

Collection

Shroud

Part Number Description

KJD .................................

D3 ...................................

D6 ...................................

AW18 .............................

KJSC ................................

PFC .................................

KJSS ................................

NK3005 .........................

NK3009 .........................

NK3036 .........................

NK3003 .........................

NK3035 .........................

NK3031 ..........................

NK3023 .........................

3/8” Step Drill Bit

3”-#2 Square Driver Bit

6”-#2 Square Driver Bit

Allen Wrench - 1/8”

Depth Collar

Premium Face Clamp

Material Support Stop

Dust Collection Shroud

Brass Index Pin

Portable Base

Drill Guide Block

Benchtop Base

Standard Pack Case

Master System Case

Premium

Face Clamp

Standard Pack Case

Master System Case

5

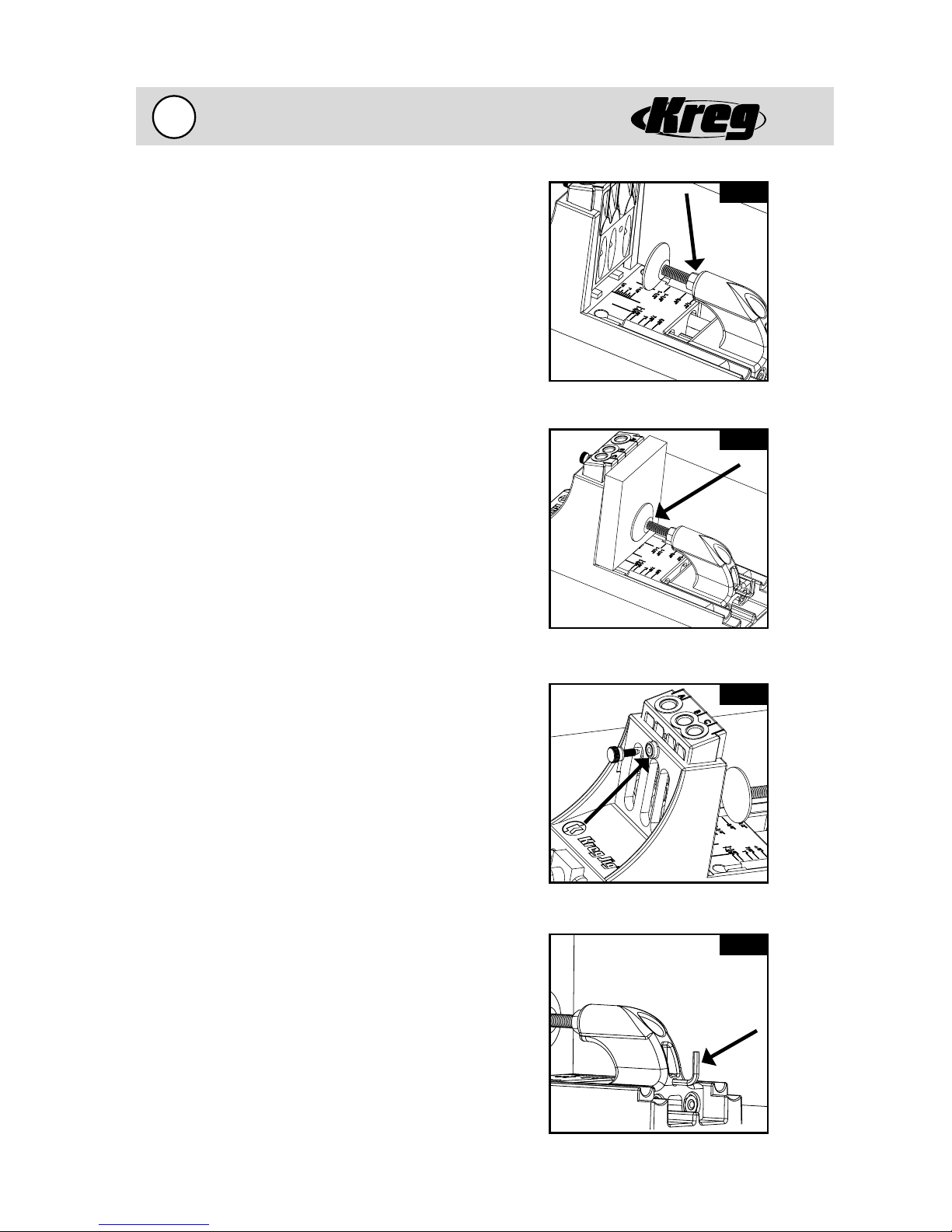

Benchtop Base Assembly

4-

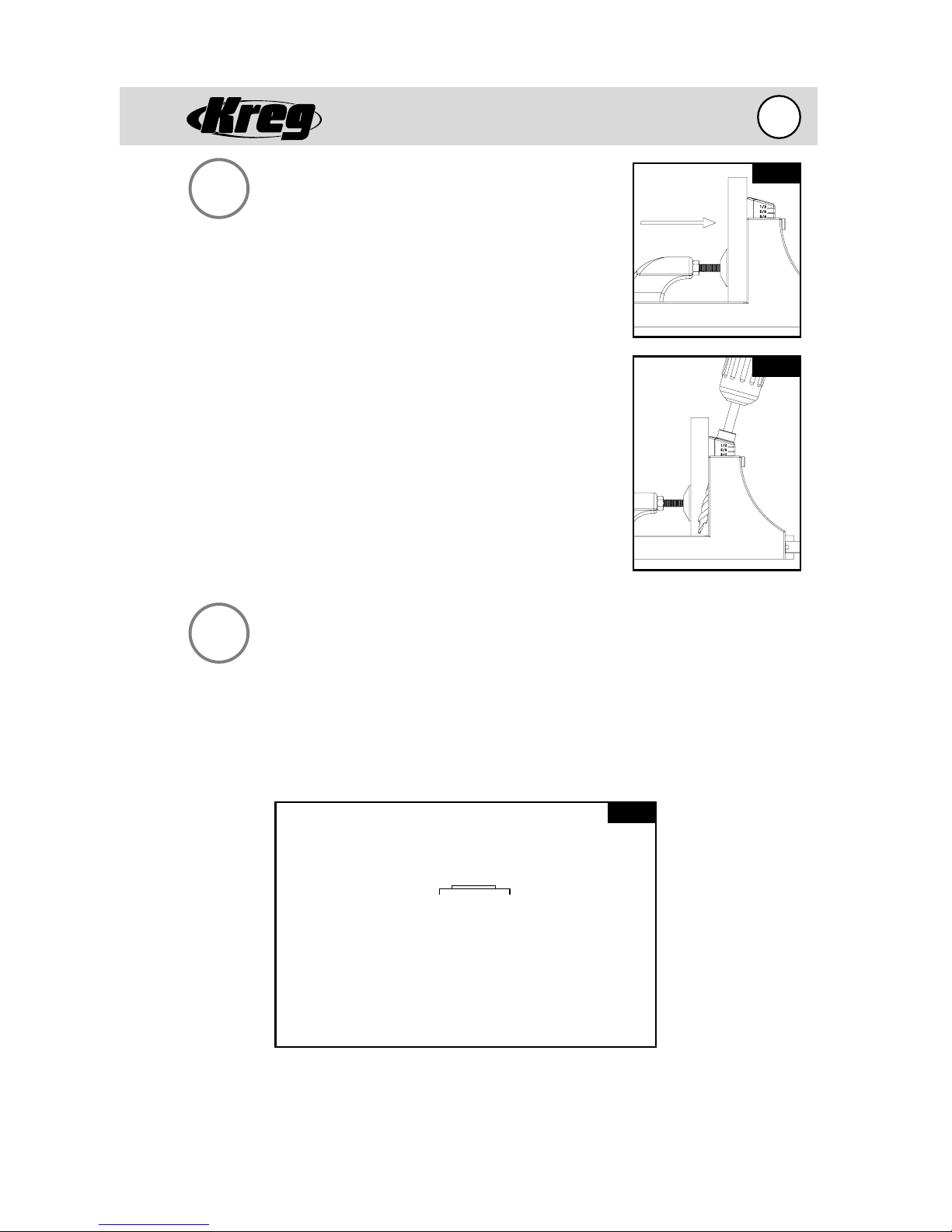

Attach the Clamping Pad (Fig. 5A&B)

1. Attach the Clamping Pad to the Clamp Follower

by simply threading the shaft of the Clamping Pad

into the threaded insert of the Clamp Follower.

2. The position of the Clamping Pad will be

adjusted for the thickness of the material to

be drilled. Proper position of the Clamping Pad

will be outlined in the “Getting to Know Your

K3 System” section.

3. You may notice that the Clamping Pad will

angle slightly upward once the Clamping Pad

is installed into the Clamp Follower. This is the

correct configuration of the Clamping Pad. The

Clamping Pad is angled slightly upward to assist

the clamping mechanism to insure the work

piece is seated tight against the Drill Guide Block

and flush with the Benchtop Base surface.

Attach the Index Pin (Fig. 5C)

1. Thread the Brass Index Pin into the threaded

insert contained in the upright of the

Benchtop Base.

2. Back off the Brass Index Pin so that the rounded

point of the Brass Index Pin is flush with the inside

of the upright surface.

3. The Brass Index Pin will be seated fully when the

Drill Guide Block has been inserted in the opening of

the upright and used to hold the Drill Guide Block

in position prior to clamping.

Fig. 5A

Hex nut on threaded shaft.

Fig. 5B

Clamping Pad clamped against board.

Fig. 5C

Store the Allen Wrench (Fig. 5D)

1. The 1/8” Allen Wrench is used to lock the

Depth Collar in position on the Kreg Jig® Drill

Bit for different depths of pocket holes.

2. The Allen Wrench may be stored either in the

designated location in the case or it can be held

conveniently in the rear of the Clamp Follower.

3. When using the Clamp Follower location be

sure to rotate the right-angled extension of

the Allen Wrench to a clock position between

9 o’clock and 3 o’clock. This will prevent the

Allen Wrench from being accidentally lost when

the Clamp Follower slides across the center rib

in the bottom of the Benchtop Base.

Inserting the Brass Index Pin.

Fig. 5D

Storage for the Allen Wrench.

4-

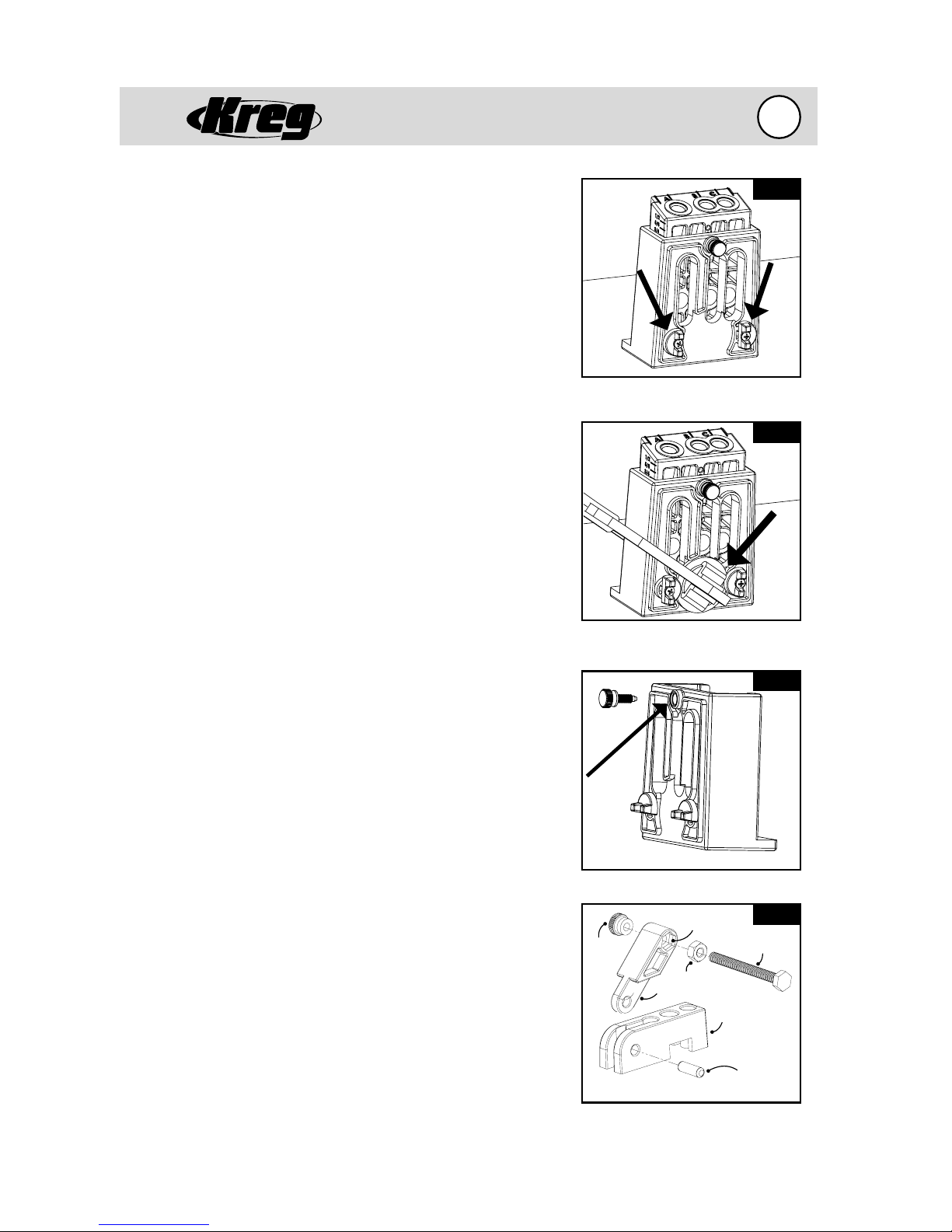

Portable Base Assembly

6

Attach the Locking Tabs (Fig. 6A&B)

1. Align the center-hole of each of the Locking Tabs to

the corresponding mounting hole on the rear vertical

surface of the Portable Base.

2. Insert a #6 x 3/8” screw through center-hole of each

of the Locking Tabs and tighten while still allowing the

Locking Tabs to move freely.

3. The smaller pad of the Premium Face Clamp will be

held in position on the Portable Base by rotating the

Locking Tabs so that they cover the outside surface

of the Premium Face Clamp pad. Proper position of

the Premium Face Clamp will be outlined in the

“Getting to Know Your K3 System” section.

4. You may notice that there are raised ribs on the rear

outside surface of the K3 Portable Base surrounding

the openings used for wood chip ejection. These

raised ribs are provided so that any clamp may be

used to secure the K3 Portable Base and Drill Guide

Block to the material to be drilled.

Attach the Index Pin

(Fig. 6C)

1. Thread the Brass Index Pin into the threaded insert

contained in the upright of the Portable Base.

2. Back off the Brass Index Pin so that the rounded

point of the Brass Index Pin is flush with the inside

of the upright surface.

3. The Brass Index Pin will be seated fully when the Drill

Guide has been inserted in the opening of the upright

and used to hold the Drill Guide Block in position prior

to clamping.

Fig. 6A

Locking Tabs on Portable Base.

Fig. 6B

Locking Tabs holding the Premium

Face Clamp in position.

Fig. 6C

®

Assemble the Kreg Jig

Support/Stop (Fig. 6D)

1. Slide the center tongue of the Support/Stop Arm

between the outside extensions of the Support/Stop

Base and align the pivot hole through all three

surfaces.

2. Insert the Pivot Pin through one outside surface

of the Support/Stop Base and either tap into place

with a mallet or a hammer and a block of wood to

prevent marring the end of the Pivot Pin. Continue

to advance the Pivot Pin until it is fully seated in the

Support/Stop Base and Support/Stop Arm. Push the

1/4”-20 Hex Nut into the side of the Support/Stop

Arm hex recess.

3. Thread the Nylon Stop Bolt from either side through

the Support/Stop Arm into the Hex Nut. Which side

will depend on which side of the Kreg Jig

®

that the

Support/Stop will be used.

4. Thread the Knurled Nylon Lock Nut onto the Nylon

Stop Bolt on the side of the Support/Stop Arm

opposite the Hex Nut. It may be necessary to thread

the Knurled Nylon Lock Nut onto the Nylon Stop Bolt

prior to threading the Nylon Stop Bolt into the Hex

Nut in some applications.

How to insert the Brass Index Pin.

Hex Recess

Knurled

Nylon

Lock

Nut

Support/Stop assembly diagram

Hex Nut

Arm

Fig. 6D

Nylon Bolt

Base

Pivot Pin

7

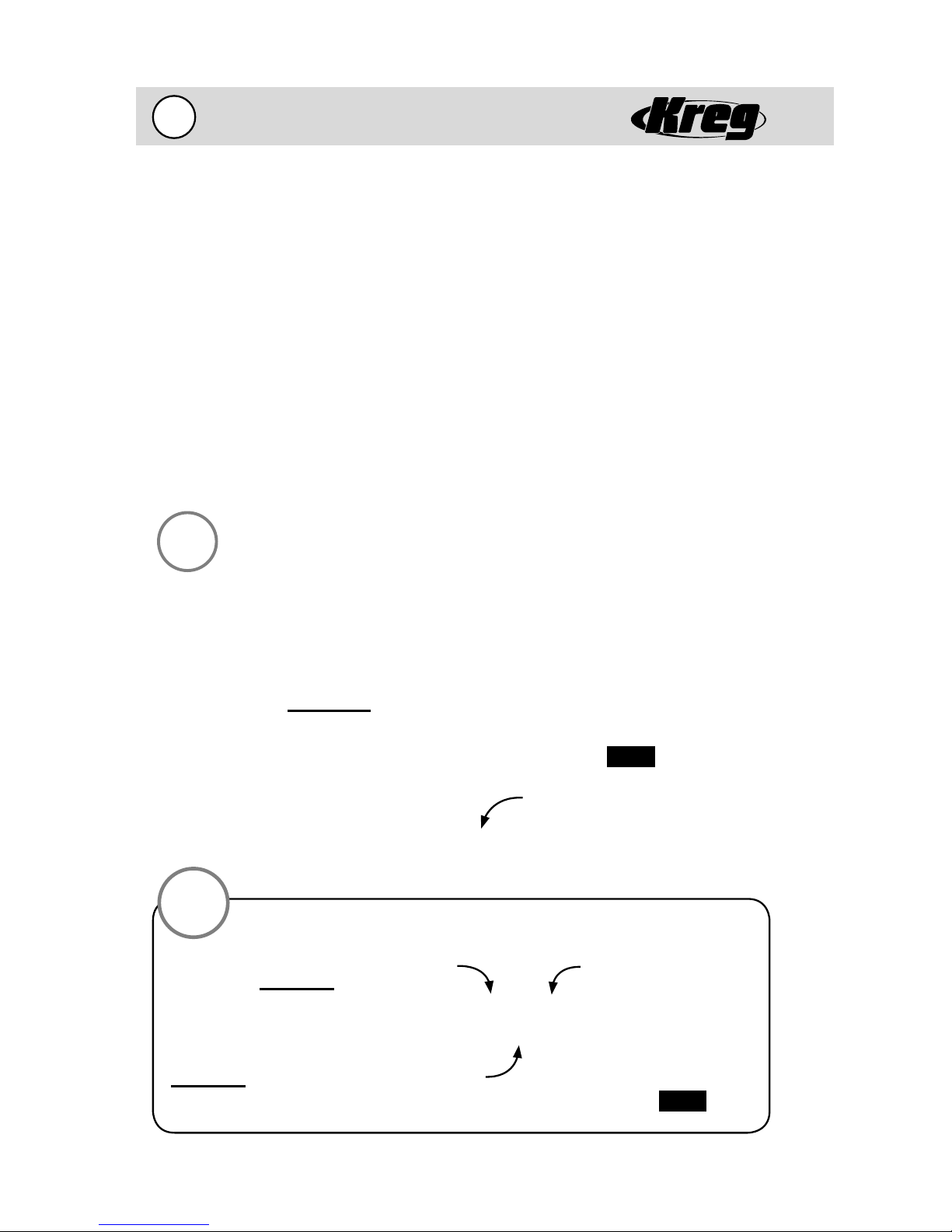

Quick-Start Guide...

To Building Your First Pocket Hole Joint

Ready to jump in and start building? Here is a quick-start guide to

creating your first pocket hole joint.

Before you start... a few Pocket Hole Joinery Facts

• You only need to drill a pocket hole into ONE of the workpieces to be

joined. No pre-drilling of the second workpiece is required with the use

of self-tapping screws.

• The step drill bit forms both a pocket hole for the screw head and a

guide hole for the screw shank in one motion.

• Gluing the joint is optional.

• Simply clamp the two workpieces to be joined to hold flush alignment

and drive the screw.

STEP 1 - Set the drilling depth.

(this example assumes using 3/4” thick material)

1.

4-

(CAUTION! Drill bit fl utes are extremely sharp! Handle with care.)

The first step in creating a pocket hole joint is to set the drilling depth of

your drill bit. Drilling depth is adjusted by changing the location of the depth collar

on the shank of the drill bit. For joining 3/4” thick material, place the depth collar

onto the shank of the drill bit. Use a tape measure to position the depth collar

3-9/16” from the SHOULDER of the drill bit. Tighten the depth collar in this posi-

tion with the Allen Wrench provided.

Fig. 7A

3-9/16”

Shoulder of Drill Bit

TIP

Setting the depth collar

closer to the SHOULDER of

the drill bit will result in less

screw travel into the second

workpiece, moving the depth

collar further from the

SHOULDER of the drill bit will

result in more screw travel.

Deeper Hole

Depth Collar

Shallower Hole

Fig. 7B

4-

Quick-Start Guide Cont.

8

STEP 2 - Prepare wood and

drill the pocket holes.

2.

Prepare your wood by squaring the pieces to be joined

on all edges. Place the drill bit into your drill and tighten

securely. Place one workpiece to be joined onto the base

of the Kreg Jig® K3 as shown in Fig. 8A. Adjust the

clamping pressure of the clamp by turning the clamping

pad to firmly hold the workpiece into the jig. Next,

place the first 1-1/2” of the drill bit into any one of the

three drill guides making sure that the tip does not come

in contact with the workpiece. Bring the drill bit up to full

speed and slowly plunge the drill bit into the drill guide

until the depth collar reaches the top of the guide as

shown in Fig. 8B. Remove drill bit and drill the second hole

in an adjacent drill guide. Once drilling is complete,

unclamp and remove workpiece from jig, gently tapping

the workpiece to remove any remaining wood chips from

the holes you have just created.

Fig. 8A

Fig. 8B

STEP 3 - Drive screws to secure the joint.

3.

At this time, choose the correct screw length for your application. If you are

joining 3/4” material to 3/4” material, a 1-1/4” length screw is suggested. Add glue

to the joint line if desired. If you are joining the two pieces in a flat plane, such as

a frame, position the large pad of the Kreg Premium Face Clamp over the joint line

and clamp with firm pressure to hold them perfectly flush as shown in figure 8C.

Fig. 8C

Joint Line

Face Side

Large Pad

Place the self-tapping screws down into the pocket hole and drive with a cordless drill until tight. Your joint should be tight, flush and extremely strong. If you

encounter any problems, consult our FAQ section that begins on page 32.

9

Getting to Know Y our K3 System

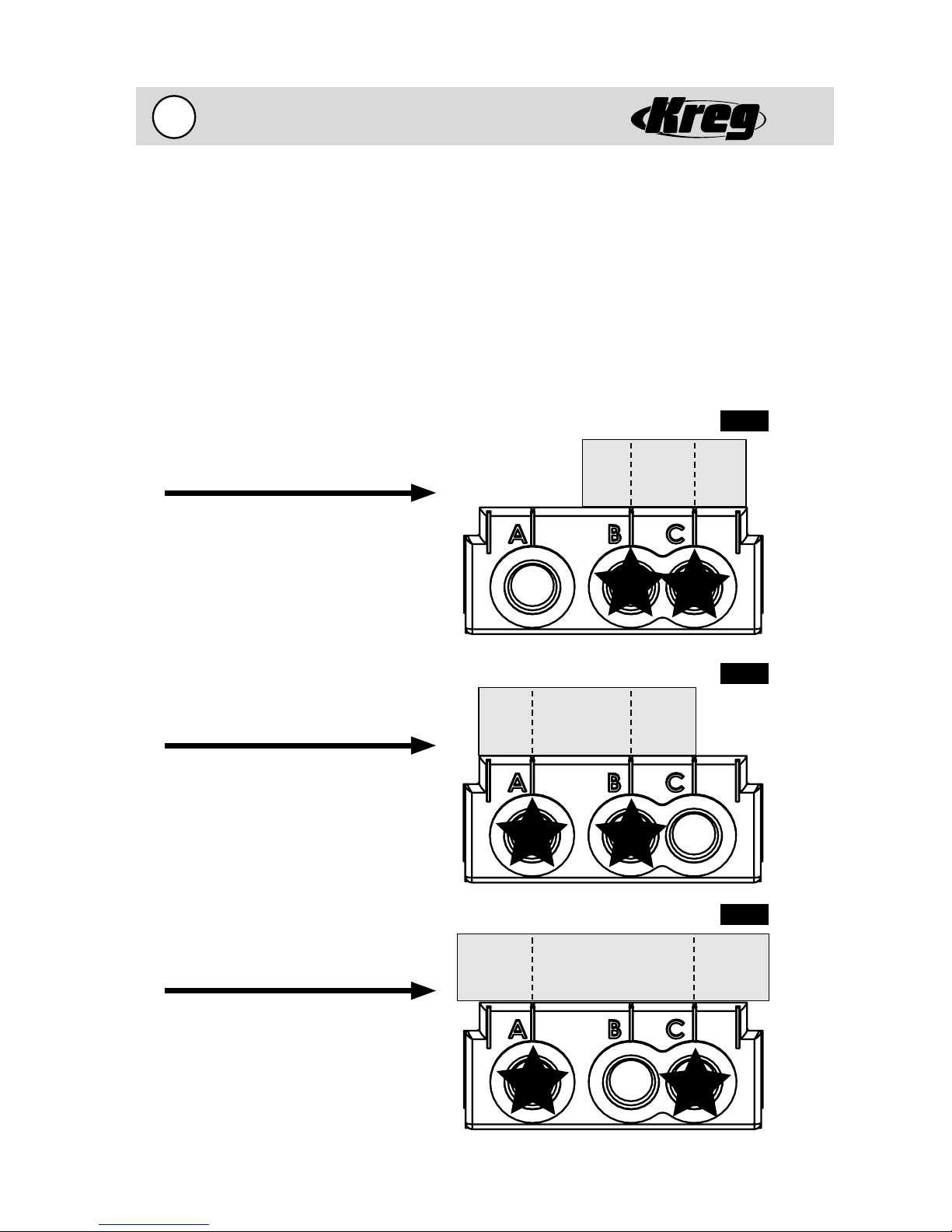

Choosing the Correct 2-Hole Spacing

Spacing pocket holes across the width of a workpiece is important in maximizing the

strength of a joint. When framing most woodworking projects, it is recommended

to place two pocket holes across the width of a rail to keep the workpiece from

twisting once it has been assembled. The patented three-drill guide fixed spacing of

the Kreg Jig® Drill Guide Block makes it extremely easy to place two pocket holes in

a workpiece without having to unclamp and move the workpiece to drill the second

hole. A real timesaver when working with a variety of wood widths. We recommend

using the drill guide spacings indicated below for each rail width. For very wide pieces

such as panels, we recommend placing a pocket hole every 6-8 inches across the

length of the panel. Use any of the three drill guides to form the pocket on panels.

Fig. 9A

Use B & C Spacing

On 1-1/4” to 1-3/4”

Material

4-

Use A & B Spacing

On 1-3/4” to 2-3/4”

Material

Use A & C Spacing

On 2-3/4” to 3-3/4”

Material

Fig. 9B

Fig. 9C

4-

Getting to Know Y our K3 System

10

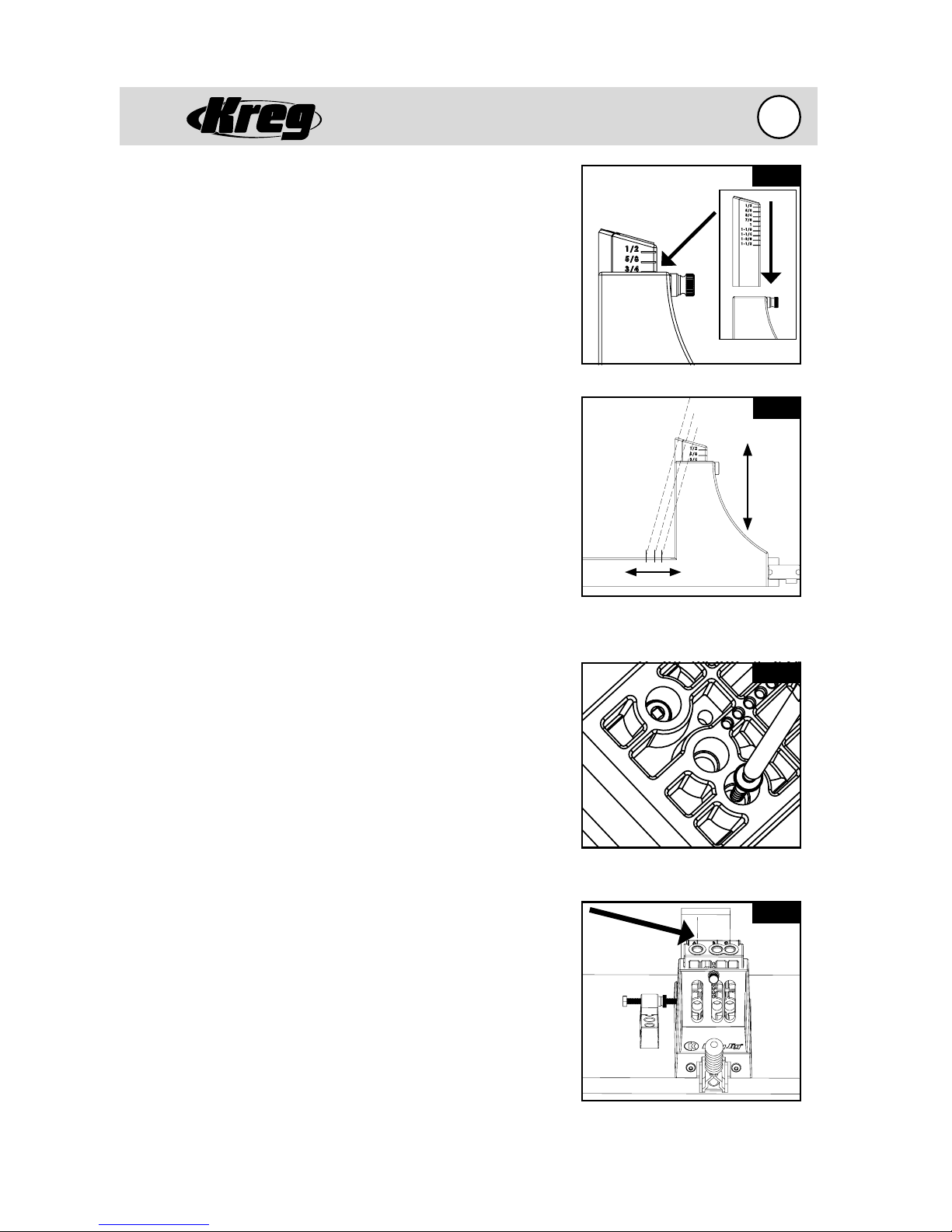

Adjusting the Drill Guide Block (Fig. 10A)

Lines molded into the side of the Drill Guide Block are

labeled with fractional designations that represent

the thickness of the material that is being drilled.

For example if you are drilling a pocket hole in 3/4”

material the line beside the marking of 3/4 is aligned

to the top of either the Benchtop Base opening or

the Portable Base opening.

Moving the Exit Point of the Screw (Fig. 10B)

As the Drill Guide Block of the K3 Kreg Jig® is raised

vertically, the exit point of the screw projects out

further from the base of the jig. The key here is

that the 15 degree drilling angle remains constant.

The result is that as you move the upright to your

desired material thickness setting, the screw will

automatically be aligned to exit on the centerpoint

of the workpiece.

Using the Drill Guide Block Separately (Fig. 10C)

There are times when it is not convenient to use

one of the bases specially designed for the Kreg Jig®

K3; or it is awkward to clamp the Drill Guide Block in

position. For these occasions the Drill Guide Block has

been specially designed to accept two SML head style

screws to hold the Drill Guide Block in position while

drilling the pocket hole.

(CAUTION! You must use the center drill guide

hole (“B”) when peforming this operation.)

Fig. 10A

Drill Guide Block markings.

Fig. 10B

Constant

15 deg.

angle

As the Drill Guide Block is raised,

the exit point of the screw projects

further from the base of the jig.

Fig. 10C

Centerlines on the Drill Guide Block (Fig. 10D)

Markings on the top surface of the Drill Guide Block

designate the centerlines of the three drill guides.

These markings also align with corresponding

markings on the surface of the Benchtop Base.

To place a pocket hole in a specific location, mark a

board with a pencil in the desired location, then align

the pencil mark with the corresponding centerline

marking on the Drill Guide Block or Benchtop Base.

Drive screws into chip extraction

holes to hold jig in position.

Fig. 10D

Pencil mark aligned with centerline

of Drill Guide Block.

Loading...

Loading...