Kreg Jig K2000 ProPack Instruction Manual

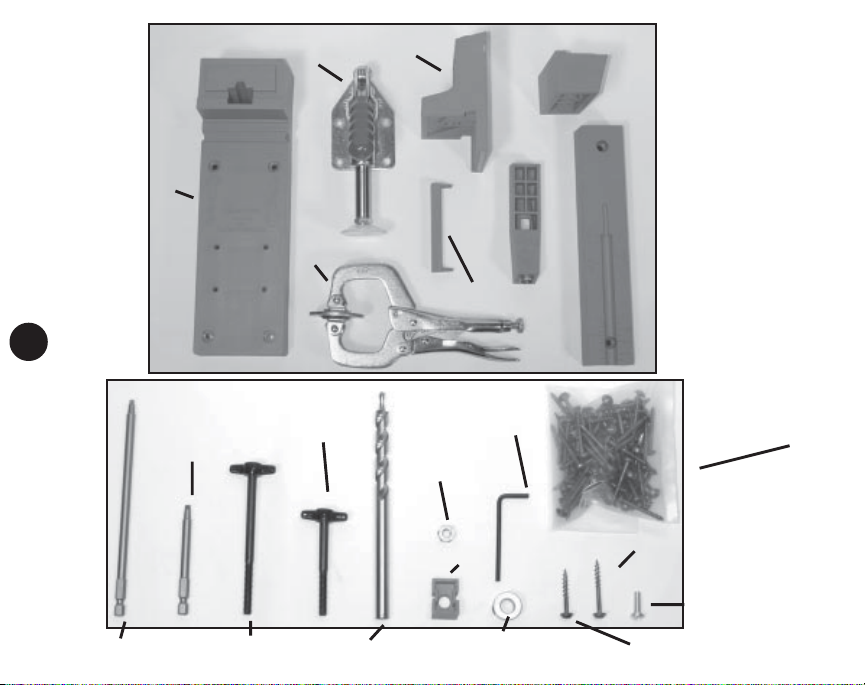

Base

Toggle

Clamp

Upright

1-1/2" Riser block

2

6" Driver

3" Driver

3-3/4" T-bolt

Face clamp

2-1/2" T-bolt

3/8" KJD bit

1/2" Step block

Allen wrench

1/4-20 Hex nut

Nut retainer

Depth collar

(2) Wing supports

Mini Kreg Jig

Sample pack of screws

(4) 1-1/2 Screws

(4) 10-32 x 3/4"

Machine Screws

(4) 1-1/4" Screws

Thank you!!!

Thank you for purchasing the Kreg Jig K2000 ProPack from Kreg Tool Company. For

over a decade, Kreg Tool has worked to make woodworking faster, stronger, and simpler using

pocket hole joinery. The K2000 Kreg Jig you have purchased is loaded with features that make

it the most versatile pocket hole system available.

Kreg Tool welcomes your ideas and comments. To contact us please call 1-800-4478638, or visit our web site at www.kregtool.com. The web site now includes a pocket hole

joinery forum where employees of Kreg Tool and other woodworking enthusiasts can get

together to solve problems and gather useful information.

Important Notice

Before drilling any parts with your Kreg Jig K2000, assemble the upright onto the base

in Position 1, adjust your depth collar for 3/4" material on your drill bit, and drill out each of the

holes. This process will remove blue plastic chips from the drill guide path. The chips are

perfectly normal and occur because of the tight tolerances placed on the drill guides and the path

of the drill bit. Blue chips will continue to be seen for approximately the first 20 holes.

Warranty

The Kreg Jig K2000 comes with a 30 day satisfaction guarantee. If you are unhappy

with the performance of the jig in any way, simply return it within 30 days for a full refund.

Both the K2000 and the Mini Kreg Jig included in this ProPack carry a lifetime warranty on

their hardened steel drill guides.

3

Assembly Instructions

Nut Retainer

Hexagonal recess

Step 2

Step 1

Please follow these simple steps in order to prepare

your Kreg Jig for use. Refer to the photo on page 2 of this

manual for part reference.

1. Step 1, press the hex nut into the hex recess on the bottom

of the jig base. Step 2, then push the plastic nut firmly onto

the ribs to capture the nut as shown in fig. 1.

2. If the toggle clamp is not already assembled, use the 4

machine screws to attach it to the base.

3. Next, you’ll want to screw the base down to a piece of

4

plywood using the four 1-1/2" screws provided. The plywood will serve as a mobile base

that will allow you to easily transport the jig around your work area. Simply clamp the

plywood to your workbench when ready to drill.

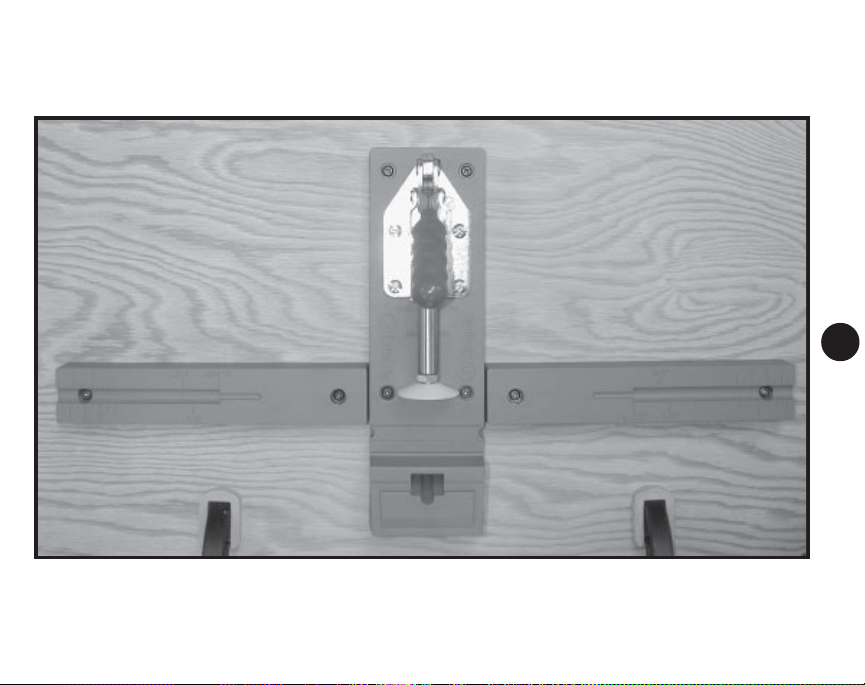

4. Locate the 2 support wings and place them perpendicular to the base so that they appear as

shown at right. Notice that the support wings are positioned to the forward edge of the

1/2" Step Block groove. Positioning them as shown will assure that the groove does not

become filled with wood chips while drilling. Finally, screw the wings tight to the plywood

using the (4) 1-1/4" screws provided. The wing supports serve two purposes: 1. They help

to support panels that are wider than the base of the jig. 2. They incorporate a groove that

is used to help locate the correct depth collar setting.

fig. 1

5

Kreg Jig K2000 Philosophy

Pocket hole joinery has

come a long way in the last

decade. An astounding number

of woodworkers are realizing

what we’ve known for many

years–that the fast, strong, and

simple technique that was

primarily used in face frame

assembly can be utilized in many

different woodworking applications. To better

serve the growing number of woodworkers that

use pocket hole joinery as their main joinery

6

method, Kreg worked to design a pocket hole

tool that easily places pocket holes in their ideal

location. The innovative design of the K2000

has produced a tool that provides three easy

adjustments for working with different thicknesses of material as well as three horizontal

hole spacings to properly place holes in material

of varying widths. In addition, the Mini Kreg

Jig that is included in this ProPack can be used

virtually anywhere. Simply clamp the jig flush to the edge of your workpiece, adjust depth

collar setting, and drill to achieve the Position 1 result. Adjust the distance from the edge of your

workpiece accordingly for thicker or thinner materials and change your depth collar setting.

fig. 2

A

B

C

fig. 3

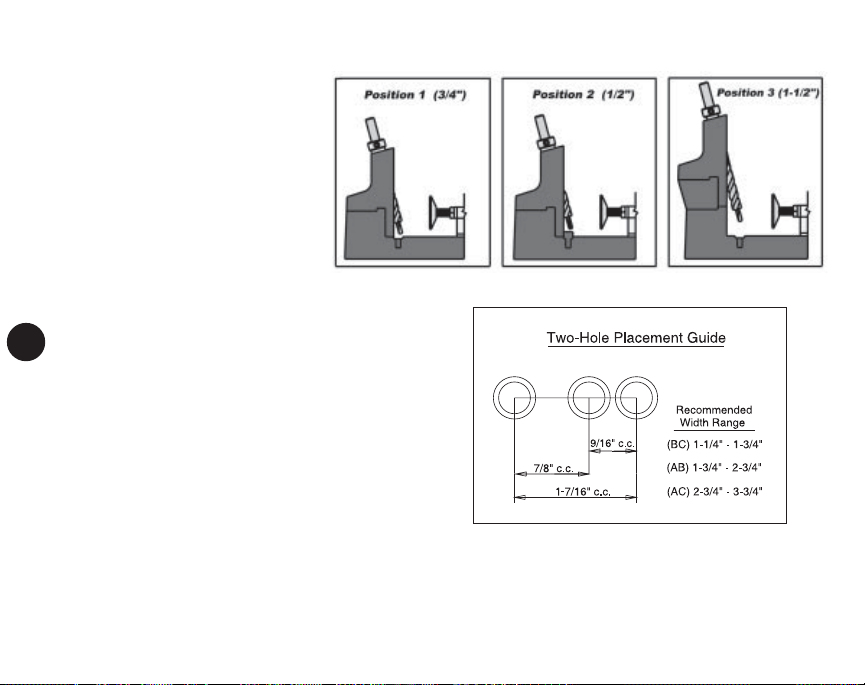

Set-up for Position 1

**Position 1 assumes standard 3/4" thick material using

1-1/4" screw. However, use this position for material ranging

between 3/4" and 1-1/8" in thickness. (You may need to adjust

screw length as material thickness varies.)

1. Set up base and support wings as shown on page 5.

2. Place the upright onto the base and finger tighten

using the 2-1/2" T-Bolt provided until parts are snug.

3. When using 3/4" material, the depth collar can be

set by aligning the step of the drill bit with the

3/4" marking on either wing support. Then use the

allen wrench to tighten the depth collar flush with

the end of the wing support as shown in fig. 5.

This setting leaves approximately 1/8" between the

tip of the bit and the base of the jig. (The depth

collar setting on the wing supports is a standard

setting only. Difference in screw length as well as

material thickness may cause need for adjustment.

Always check your setting before drilling final holes

as shown on page 8, fig. 7.)

4. Depending on which width of material you will be

drilling, either choose the AB, AC, or BC hole

spacings shown in fig. 6. Center the appropriate two

holes over the width of your material.

fig. 4

7

fig. 5

A

B

C

fig. 6

Drilling the Pocket Hole

Because variations in wood thickness and screw length can cause undesired results in

the screw protruding through the final workpiece, always check depth collar setting by testing in

scrap material and adjust depth collar accordingly (as shown in fig. 7). To set the correct

clamping pressure, spin the bumper in or out of the clamp’s barrel until the handle snaps closed

with two fingers of pressure. Once adjusted correctly, tighten the hex nut. Drill the pocket hole

by sliding the bit into the guide allowing the drill to achieve full

speed before pushing into the material. Once the depth collar has

made contact with the top of the drill guide, keep the drill turning at

full speed and withdraw the drill bit from the guide. It is recommended to use a 2000+ RPM corded drill in order to maximize drill

bit life.

8

fig. 7

Assembling the Joint

Self-tapping pocket hole screws eliminate the need to bore an aligning pilot hole in the

mating workpiece, even in hardwoods lik e oak, hick ory and maple. Although other types of

screws may work, pocket hole scre ws greatly reduce splitting and are hardened to nearly eliminate

breakage. We recommend using glue unless the ability to disassemble the joint is desired.

Using the 6" Face Clamp included to align the workpieces, as shown below, ensures

that the joint stays flush as the screws are driven. Place the large washer on the face of the joint,

increase tension, and clamp. The washer will help to keep the face flush if the workpieces are of

slightly different thicknesses, and will also keep the clamp from denting the face of softer materials.

It is strongly recommended to drive the screws using a drill with a clutch. The

clutch allows you to vary how much torque the drill puts on the screws so you don’t have

strip out. Most cordless drills include this feature. If you do not have a drill with a clutch,

you can use a corded drill to drive the screws until they are almost seated, and then finish

driving the screws using a hand driver.

When driving the screws, you may notice a slight separation of the work pieces

before the screw begins to pull them back together. This is normal, but if the gap exceeds

1/4" increase the clamp pressure. The face clamp works well for aligning face frame and

picture frame style joints. For other joints a bar clamp will be useful to keep the

workpieces in position while driving the screws.

A good tip for joining workpieces is to build a grid similar to the one shown in fig.

8. The grid allows you to suspend the joint above the table top

where you can reach it from both sides with the face clamp. The

grid also keeps your tools, screws and glue easily accessible

between the 2x4’s, yet out of the w ay when sliding the frame

around. Make the grid using a sheet of 3/4" plywood cut to any

dimension, with 2x4’s pocket-holed on edge to the sheet. Vary

the spacing of the 2x4’s.

fig. 8

9

Set-up for Position 2

**Position 2 was primarily designed for use with standard 1/2"

thick material. This type of stock is widely used in drawer construction.

To attach workpieces, plan on using 1" screws. You will also want to use

this position for material ranging between 1/2" and 5/8" in thickness.

(You may need to adjust screw length as material thickness varies.)

1. Set up base and support wings as shown on page 5.

2. Press the 1/2" Step Block into place.

3. When using 1/2" material, the depth collar can be

set by aligning the step of the drill bit with the 1/2"

marking on either wing support. Then use the allen

10

wrench to tighten the depth collar flush with the end

of the wing support as shown in fig. 10. This setting

leaves approximately 1/8" between the tip of the bit

and the base of the jig. (The depth collar setting on

the wing supports is a standard setting only. Difference in screw length as well as material thickness may

cause need for adjustment. Always check your setting

before drilling final holes as shown on page 8.)

4. Depending on which width of material you will be

drilling, either choose the AB, AC, or BC hole

spacings shown in fig. 11. Center the appropriate two

holes over the width of your material.

A

fig. 9

fig. 10

B

fig. 11

C

Set-up for Position 3

**Position 3 assumes standard 1-1/2" thick material using

2-1/2" screw. However, use this position for material ranging between

1-1/2" to 2" in thickness. (You may need to adjust screw length as

material thickness varies.)

1. Set up base and support wings as shown on page 5.

2. Locate the 1-1/2" Riser Block from the ProPack case. Press

the Riser Block into position on the base and then assemble

the upright on top of the Riser Block using the 3-3/4"

T-bolt. Finger tighten until all parts become snug.

3. When using 1-1/2" material, the depth collar can be set

by aligning the step of the drill bit with the 1-1/2"

marking on either wing support. Then use the allen

wrench to tighten the depth collar flush with the end of

the wing support as shown in fig. 13. This setting

leaves approximately 3/4" between the tip of the bit and

the base of the jig. (The depth collar setting on the

wing supports is a standard setting only . Dif ference in

screw length as well as material thickness may cause

need for adjustment. Al ways check your setting before

drilling final holes as shown on page 8.)

4. Depending on which width of material you will be

drilling, either choose the AB, A C, or BC hole spacings

shown in fig. 14. Center the appropriate two holes o ver

the width of your material.

A

fig. 12

B

11

fig. 13

C

fig. 14

Choosing the Right Screw

Choosing the right screw is largely a matter of experi-

mentation, however some guidelines do exist.

1. Thread - Our screws are designed so that a fine thread

screw is to be used in hardwoods, and a coarse thread screw

is used in softwoods and composite material (plywood,

particle board, MDF).

2. Length - 1-1/4" is standard length for 3/4" materials. Use

1" screws when working with 1/2" thick material. A 2-1/2"

screw is recommended when working with 1-1/2" thick

12

material. All screws are available in a Sun Seal weather

resistant finish. Call for details.

3. Maxi-loc Screws - The washer head keeps the screw

head from crushing into the bottom of the pocket hole and

seating the screws deeper than desired. Use a coarse thread

washer head when joining any combination of soft materials

like pine, plywood or particle board. Use a fine washer head

screw when the pocket hole is bored in a soft material and

passes into a hard material (i.e., edge-banding or partition to

face frame).

Maxi-Loc Fine

fig. 15

Maxi-Loc Coarse

fig. 16

Applications

With the almost limitless settings and adjustability of the K2000

ProPack, application data has grown tremendously. The following are some

of the most common in use today.

Face Frames

Using pocket hole joinery for face frames is faster and stronger

than conventional methods (dowel, biscuit and even mortise and tenon), and

frees you from having to simultaneously manipulate several bar clamps as

the frame is clamped for glue-up.

Angled Joinery

Using pocket hole joinery to make angles and curves eliminates

difficult clamping set-ups and the expense of specialized clamps. To form

any angle up to 45 degrees, rather than cutting half the desired angle

on both workpieces, the entire angle is cut on the mating workpiece

(right), which provides more distance for the screw. Before drilling

the pocket hole make sure the depth collar is set correctly by checking a piece of scrap.

Cutting the entire miter on only one workpiece makes its

edge longer than the edge of the first workpiece. This o verhang is to

be removed with a jointer, sander, or hand plane. Notice in

fig. 18 that the point of the joint shifts away from the glue-line.

When making face frames assemble your angled stiles first, remove

the overhang, and then complete the face frame. A simple jig, as

pictured at right, makes it easy to screw the workpieces together.

pocket holes

mating work piece

shim

workbench

pocket

holes

fig. 17

overhang

glue-line

shim

height

13

fig. 18

fig. 19

clamp

Curves

The same technique used to form angles is also used for curves,

except a shallower angle between 5 and 15 degrees is typically used as shown

at right. The smaller angle creates a smaller overhang, and a belt sander is

used to smooth the face. This technique can be used for both solid wood and

curved panel work as well.

Beveled Ninety Degree Corners

Trying to join two workpieces, each with 45 degree miters, to form a

90 degree corner is not a good application for the pocket hole joint. However,

a 90 degree change of direction can be accomplished using pocket hole joinery

with the 90 degree bevel joint shown at right. The joint consists of a center

14

workpiece with a 45 degree miter on both edges.

Table Tops and Aprons

When making table tops a bar clamp is helpful to hold the work in

position as the screws are driven.

Edge-Banding Countertops or Shelving

Pocket holes are a great, sometimes overlooked solution for edgebanding countertops and shelving made from either plywood or particle board,

as shown at right.

fig. 20

fig. 21

fig. 22

fig. 23

Mitered Corners

Using pocket hole joinery for a mitered corner eliminates

the need for frustrating and expensive clamps. For narrower frames

a single pocket hole can be used. Cut the miter and rout the rabbet

before boring the pocket holes. Use a face clamp to align the joint

and drive the screws. Notice in the drawing at right that the holes

are not necessarily drilled perpendicular to the joint line. This is

accomplished by lifting one edge of the workpiece off the base of

the jig as shown. This technique is especially helpful when working

with stock less than 2" wide. One inch screws are useful when

making mitered corners.

Window and Door Jam Extensions

A great time saver and something that can easily be

accomplished in the field.

Stairs

Extremely solid stair construction. Pocket holes can be

bored into existing stairs to eliminate squeaks.

fig. 24

fig. 25

15

fig. 26

fig. 27

Post (Leg) and Rail Leg

Table and chair legs are extremely strong and easy to

construct with pocket hole joinery. Cut the miters for the brace after

drilling the pocket holes.

Traditional Style (Framed Cabinets)

Pocket hole joinery can be used for almost every facet of

framed cabinet construction, as shown at right. The traditional

technique calls for making the face frame and case as separate

components, and then fitting the two together, creating substantial

opportunities for error. Because of the strength of pocket hole

joinery, cabinet end-panels and partitions can be attached directly to

the face frame one component at a time making construction much

16

simpler. Also, the strength of pocket hole joinery eliminates the

need for dadoes and rabbets that are usually cut into the face frame

for the partitions and end-panels, making construction easier.

Euro-Style (Frameless) Cabinets

Pocket hole joinery works well for Euro-style (frameless)

cabinetry, as shown at right. Use #SML-C125 (#7 coarse) screws

for greater holding power.

Shelving

Pocket holes work great for shelving with or without

a dado.

fig. 28

fig. 29

fig. 30

Outdoor Applications

The K2000 makes working with dimension material easier than ever. Pocket holes help to

hide the fastener from exposure to the elements. Because water can no longer pool around the head

of the fastener and seep into the core of the wood, the fastener and the wood last much longer.

Project Plans / Videos

To get the most out of your Kreg Jig ProPack, consider purchasing one of our pocket hole

plan sets or instructional videos. The plan sets include step-by-step instructions in a large, easy to

read format that will have you building professional quality projects in no time. Be sure to check

with your local dealer or www.kregtool.com for the most up to date listing of projects av ailable.

17

Mini Kreg Jig

The Mini Kreg Jig is

provided in the ProPack as a

portable companion to the

K2000. Simply clamp the jig

flush to the edge of your

3/4"workpiece, adjust depth

collar setting, and drill to

achieve the Position 1 result as

shown at right. Adjust

accordingly for thicker or

thinner materials and change

your depth collar setting.

18

also incorporates a plug setting

feature into its design. Load

the plug into the groove on the

underside of the jig (1),

position it in the center of the

pocket hole and press into

place (2). Pre-cut pocket hole

plugs are available in a variety

of species from Kreg.

The Mini Kreg Jig

1.

2.

Other Products Available From Kreg Tool

For maximum performance from your Kreg Jig ask your dealer for genuine Kreg tools

and accessories. If there is not a Kreg dealer near you, or your dealer can’t supply you with

genuine Kreg accessories, please call 1-800-447-8638 or visit www.kregtool.com.

Maintenance

Place a drop of oil in hardened steel drill guides when dry, or every 250-500 holes.

Keep your drill bits sharp. It is recommended that you sharpen your bits after

approximately 750-1000 holes. Kreg Tool provides a bit sharpening service for a small fee.

Kreg Tool Company, 201 Campus Drive, Huxley, Iowa 50124

www.kregtool.com

Loading...

Loading...