TM

Deck JigDeck Jig

Concealed Fastening System

Système de fi xations dissimulées

Sistema de sujeción oculto

Quick-Start Guide

Guía de inicio rápido • Guide de démarrage

U.S. Patent #7,044,460

www.kregtool.com

www.kregtool.com 800-447-8638 - customerservice@kregtool.com

Introduction

Congratulations on your purchase of a new Kreg Deck Jig™!

Whether you’re building a deck from scratch or remodeling an existing one, the

Deck Jig™ can help you build a better-looking deck in less time and with less

frustration. We made every effort to make the Deck Jig™ as fun and easy-to-use

as possible. In addition to this Quick-Start Guide, here are three resources you

may fi nd helpful:

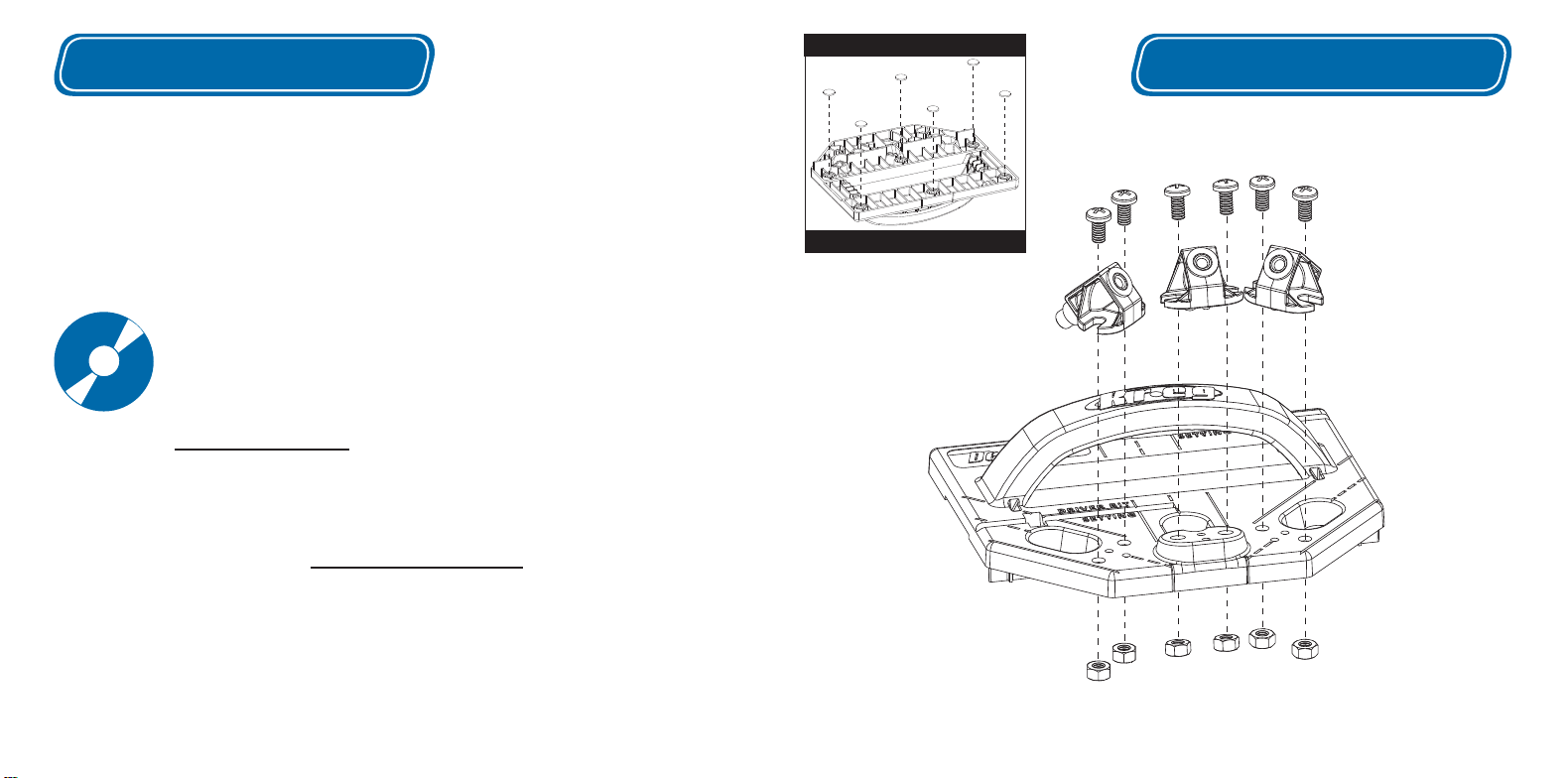

Rubber Feet

Assembly

Includes Four Extra

Instructional DVD: Start Here! This DVD is full of information you’ll

™

need to start building and keep building with the Kreg Deck Jig

.

Follow along as master carpenter Gary Streigler walks you through

the process.

Kreg Website: www.kregtool.com is your online resource for everything Kreg.

Whether you can’t remember a particular step of the process, need to order

another box of specialized Kreg Deck Screws, or just want to see what kind of

accessories are available for your new jig… this is where you’ll fi nd it.

Kreg Owners Community: Visit http://kregjig.ning.com to see what other

™

Kreg Deck Jig

owners are building, get your questions answered in the forums,

and sign up to receive the Kreg Plus Newsletter. Don’t forget to

post photos of your new deck!

www.kregtool.com 800-447-8638 - customerservice@kregtool.com

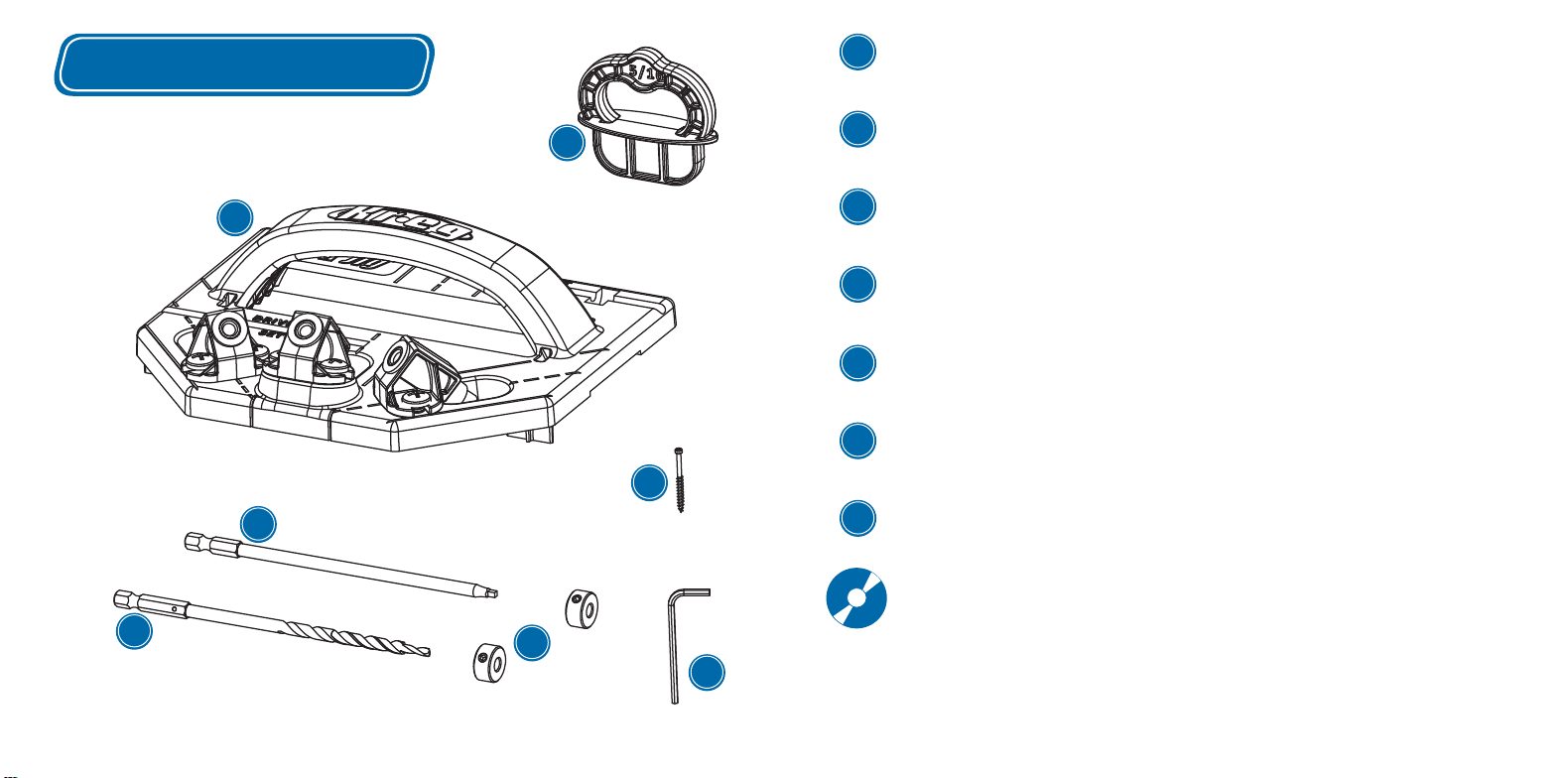

Parts

Kreg Deck Jig

A

B

A

Deck Jig

The core of the system. Allows you to quickly and securely add deck boards to

™

E

D

C

your deck without visible fasteners.

6” Deck Jig™ Drill Bit

B

This specialized stepped bit creates the unique shouldered hole in the deck board for

Kreg Deck Screws.

6” KTX Square Driver Bit

C

The KTX Square Head on this bit ensures optimal driver engagement while driving

your Deck Screws to the proper depth.

D

2” Deck Screws

100 screws 2”-long to get you started. All screws feature our Protec-Kote

rust-resistant coating, self-tapping tip, and KTX square drive.

Spacer Rings

E

Three ¼” rings for standard spacing and three 5/16” rings for stock prone to excess

expansion allow quick deck-board spacing.

F

Stop Collars

Stop Collars for your drill and driver bits guarantee precise drilling depth and screw placement.

For non-grooved decking, use the gauges on the Deck Jig™ to correctly position them.

G

Allen Wrench

Use the wrench to lock the Stop Collars in the correct position on the drill and driver bits.

™

™

Instructional DVD (Not shown)

Follow along as Master Carpenter Gary Streigler walks you through the basics, tips,

and tricks for using the Kreg Deck Jig™.

F

G

2-5/8” Deck Screws (Not included)

These longer screws are designed especially for fastening 1 ½”-thick deck boards

(2x4s and 2x6s).

www.kregtool.com 800-447-8638 - customerservice@kregtool.com

How It Works Operation

The Kreg Deck Jig™ allows you to drill a specialized hole at

the optimum angle necessary to secure your deck boards

to the deck joists. The hole is created by a stepped (or

shouldered) drill bit that drills the pocket hole and screw pilot

hole in one simple motion. The depth of the hole is controlled

by a Stop Collar.

The Kreg Deck Jig™ also guides the deck screws so they

follow the exact path necessary for a strong connection, and

so you don’t over-drive or under-drive them. With the Drill

Guide aligned with the pilot hole, insert a screw into the Drill

Guide, ensure that the screw is correctly positioned to enter

the pilot hole, and drive it until the Driver Stop Collar contacts

the Drill Guide.

IMPORTANT!

Driving your screws without using

the Stop Collar and the Deck Jig™

can cause over-driving, which results

in a joint with signifi cantly reduced

strength and the potential for

excessive moisture build-up on the

screw head.

Stop Collars

Before drilling your fi rst hole, position the Stop Collars on both the drill bit and driver bit. The drill-bit Stop

Collar controls hole depth and where the hole “shoulder” stops the screw. The driver-bit Stop Collar prevents

over-driving the screws and ensures that they are driven to the proper depth for the strongest possible joint and

minimum exposure to the elements.

Setting the Stop Collar on your Deck Jig™ Drill Bit & Driver Bit:

Non-Grooved Decking

Place shoulder of bit at line.

Drill Bit

For non-grooved decking from 3/4” to 1-1/2” thick

fastened with 2” or 2-5/8” long deck screws, use the

recessed Drill Bit Setting Gauge built into the Deck

Jig™. Secure the Stop Collar with the included

Allen wrench.

Tip – Check your Stop Collar settings from time to time

to ensure they are still correctly positioned.

Driver Bit

For non-grooved decking from 3/4” to 1-1/2” thick

fastened with 2” or 2-5/8” long deck screws, use

the recessed Driver Bit Setting Gauge built into

the Deck Jig™. Secure the Stop Collar with the

included Allen wrench.

www.kregtool.com 800-447-8638 - customerservice@kregtool.com

Operation Operation

Setting the Stop Collar on your Deck Jig™ Drill Bit & Driver Bit:

Grooved Decking

Drill Bit

For grooved decking, use the end of a deck board

as a gauge and slide the Deck Jig™ Drill Bit into

the center drill guide, extending it from the bottom

of the guide until the drill bit shoulder is even with

the bottom of the groove. Holding the drill bit in this

position, slide the Stop Collar onto the bit until the

collar rests against the Drill Guide. Secure the Stop

Collar with the Allen wrench.

Tip – Check your Stop Collar settings from time to time

to ensure they are still correctly positioned.

Driver Bit

For grooved decking, use the end of a deck board

as a gauge and slide the Deck Jig™ Driver Bit into

the center drill guide, extending it from the bottom

of the guide until the tip of the driver bit is even with

the bottom of the groove. Holding the driver bit in

this position, slide the Stop Collar onto the driver

until the collar rests against the drill guide. Secure

the Stop Collar with the Allen wrench.

Screw Placement

Test-drive a deck screw into a scrap of grooved

decking. The bottom of the screw head should bear

against the bottom lip of the groove. There should

not be any of the screw shank exposed, but the

head should not be buried. (Burying the screw head

in the bottom lip of the groove reduces the amount

of material needed to prevent the screw from

pulling through the decking and could cause the

lip to split.) Make any necessary adjustment to the

position of the Driver Bit Stop Collar

Spacer Rings

There are two sizes of Spacer Rings, 5/16” and 1/4”,

included with your Deck Jig™. These Spacer Rings

help you create consistent spaces between deck

boards. Building your deck with 1/4” minimum spaces

allows debris to fall through for a clean deck, and more

importantly, ensures adequate air movement to reduce

moisture buildup. If your decking material is prone to a

high rate of expansion and contraction, we recommend

using the 5/16” Spacer Rings as this helps maintain

proper spacing even after signifi cant expansion.

Tip – Be sure to check your decking manufacturer’s

spacing recommendations

www.kregtool.com 800-447-8638 - customerservice@kregtool.com

Operation

Hole Placement

Locating screw holes for maximum joint strength depends on several factors. Use the suggestions on the

following pages as a guide.

Operation

Board to Board Splice

When securing a splice centered on a

joist, use the End Drill Guides. For ¾”- to

1 1/8”-thick deck boards fastened with

2”-long Kreg Deck Screws, align the end

of the Deck Jig™ with the splice.

Using 2-5/8” long Kreg Deck Screws Using 2-5/8” long Kreg Deck Screws

For 1 ½”-thick deck boards fastened with

2 ⅝”-long Kreg Deck Screws, position the

end of the jig ½” from the splice.

1/2”

End of Board (obstructed)

When securing the end of a ¾”- to

1 1/8”-thick deck board with a 2”-long

Kreg Deck Screw where the Deck Jig™

cannot protrude beyond the end of the

board (wall obstruction), align the end of

the jig with the end of the board and use

the End Drill Guide.

For a 1 ½”-thick deck board fastened

with a 2 ⅝”-long Kreg Deck Screw,

position the end of the jig ½” from the

end of the board.

Wall

Wall

1/2”

www.kregtool.com 800-447-8638 - customerservice@kregtool.com

Operation

Hole Placement

Operation

End of Board (un-obstructed)

When securing the end of a deck board

to a perimeter joist with either 2”-long

Kreg Deck Screws or 2 ⅝”-long Kreg

Deck Screws where the Deck Jig™ can

protrude beyond the end of the board

(no wall obstruction), use the Center Drill

Guide, centering it on the thickness of

the joist.

Long Edge of Board

(un-obstructed)

Most decking-to-joist joints will be

unobstructed, and you’ll drill and drive

screws through the edges of the deck

boards and into the joists. For these

joints, use the Center Drill Guide,

centering it on the joists.

Long Edge of Board (obstructed)

Where the edge of the deck board is

against a wall, or along the outside of the

deck where, for appearance, you don’t

want to see the angled holes, do not use

the jig. Instead, “face screw” the board by

drilling pilot holes and driving Kreg Deck

Screws through the deck board from the

top face.

Long Edge of Board

(45° Decking)

When securing a deck board that crosses

the joist at a 45° angle, position the Center

Drill Guide at the intersection of the joist and

deck board, using the dashed line on the jig

as a guide. Then drill and drive the screw.

Face Screw

www.kregtool.com 800-447-8638 - customerservice@kregtool.com

Choosing a Deck

The Kreg Deck Jig™ works with almost any type of decking material. Here are the characteristics of some of

the most popular types of decking:

• ACQ – “Green Treat” is one of the most affordable types of decking material, and is usually made from pine. This

material commonly suffers from shrinking/swelling/splitting and won’t last as long as many other types of decking.

• Composite Material – Composite decking is usually made from a combination of wood fi bers and

plastic. It is more expensive than pine, but lasts much longer and is less prone to shrinking/swelling/splitting.

We recommended using composite decking material.

• Exotic Hardwoods – Exotic woods, such as Ipe, are much harder and denser than pine. Because

of this, they last longer, look better, and cost more. Exotic woods still require periodic treatment to prevent

discoloration and water damage.

Note: The Kreg Deck Jig™ works with grooved and non-

grooved stock. For 4/4 to 5/4 (¾”- to 1 ⅛”-thick)

material, fasten with 2”-long Kreg Deck Screws.

To fasten 1 ½”-thick material, use 2 5/8”-long

Kreg Deck Screws.

non-grooved

grooved

Deck Screws

Protec-Kote™ - Three anti-corrosion layers protect against rusting in a wide variety of decking applications.

Perfect for use with ACQ treated lumber.

Stainless - For even more protection, choose stainless. Stainless steel screws provide the best long-term

resistance to corrosion and protects your investment when using premium decking.

Multi-Function

Kreg Deck Screws are designed specifi cally for use with the Kreg Deck Jig™, a high-quality concealed-

fastening system. These screws also can be used for simple face-screwing on a variety of outdoor projects.

Oculto

Concealed

KTX Square Drive

Solid driver engagement.

Flat Bottom Head

Won’t split the workpiece.

Protec-Kote

Perfect for treated lumber.

305 Stainless Steel

Ultimate rust protection.

No bending. No breaking.

Visible

Face-Screw

™

Case-Hardened Steel

No bending. No breaking.

Self-Tapping Tip

Faster and easier driving.

www.kregtool.com 800-447-8638 - customerservice@kregtool.com

Welcome to the Kreg Jig® family.

NK7746B-Deck Jig™ Quick Start Guide

Bienvenido a la familia de Kreg.

Bienvenue dans la famille Kreg.

Loading...

Loading...