Kreg DB55 User Manual

R

FOREMAN

INSTRUCTIONAL MANUAL

DB55 Pneumatic/DB110 Electric Models

R

Item# DB110

Item# DB55

Electric Foreman

Pneumatic Foreman

Patents pending.

6/2010 DB5305

Rev C

1.

Table of Contents

Congratulations on choosing a Kreg Foreman Semi-Automatic Pocket-Hole Machine!

Be sure to read the instructions and the safety warnings completely before using this machine.

Table of Contents

TABLE OF CONTENTS 1

SAFETY GUIDELINES 2-6

ASSEMBLY INSTRUCTIONS - DB110 7

ASSEMBLY INSTRUCTIONS - DB55 8

DB110 (Electric Model) 9-12

General Operations/Maintenance 9

Adjusting the EZ DB Fence 10

Adjusting the Drill Bit Depth Stop/Clamping Pad Height 11

Swing Stops/Changing the Drill Bit 12

DB55 (Pneumatic Model) 13-16

General Operations/Maintenance 13

Adjusting the EZ DB Fence 14

Adjusting the Drill Bit Depth Stop/Clamping Cylinder Height/Automatic Lubricator 15

Swing Stops/Changing the Drill Bit 16

Warranty 17

Notes 18

R

Attention:

As with all machinery, there are certain hazards involved with operation and use of the machine. Using

the machine with respect and caution will considerably lessen the possibility of personal injury. However, if

normal safety precautions are overlooked or ignored, personal injury to the operator may result.

This machine was designed for specifi c applications only. Kreg strongly recommends that this

machine NOT be modifi ed and/or used for any application other than for which it was designed. If

you have any questions relative to its application, DO NOT use the Machine until you have written

Kreg Tool and we have advised you.

Symbols:

!

Caution,

refer to manual

Earth Ground

Connection

P

Indicates the PHASE (HOT)

wire from the powersource

wire from the powersource

N

Indicates the NEUTRAL

Make sure all power sources have been disconnected

from this machine before opening the electrical box.

R

Safety Guidelines

2.

ATTENTION! - PLEASE READ BEFORE USE!

Note: The following is updated information for users of the Foreman Pneumatic machines. Please read

and follow the directions in order for your new machines to work and function correctly .

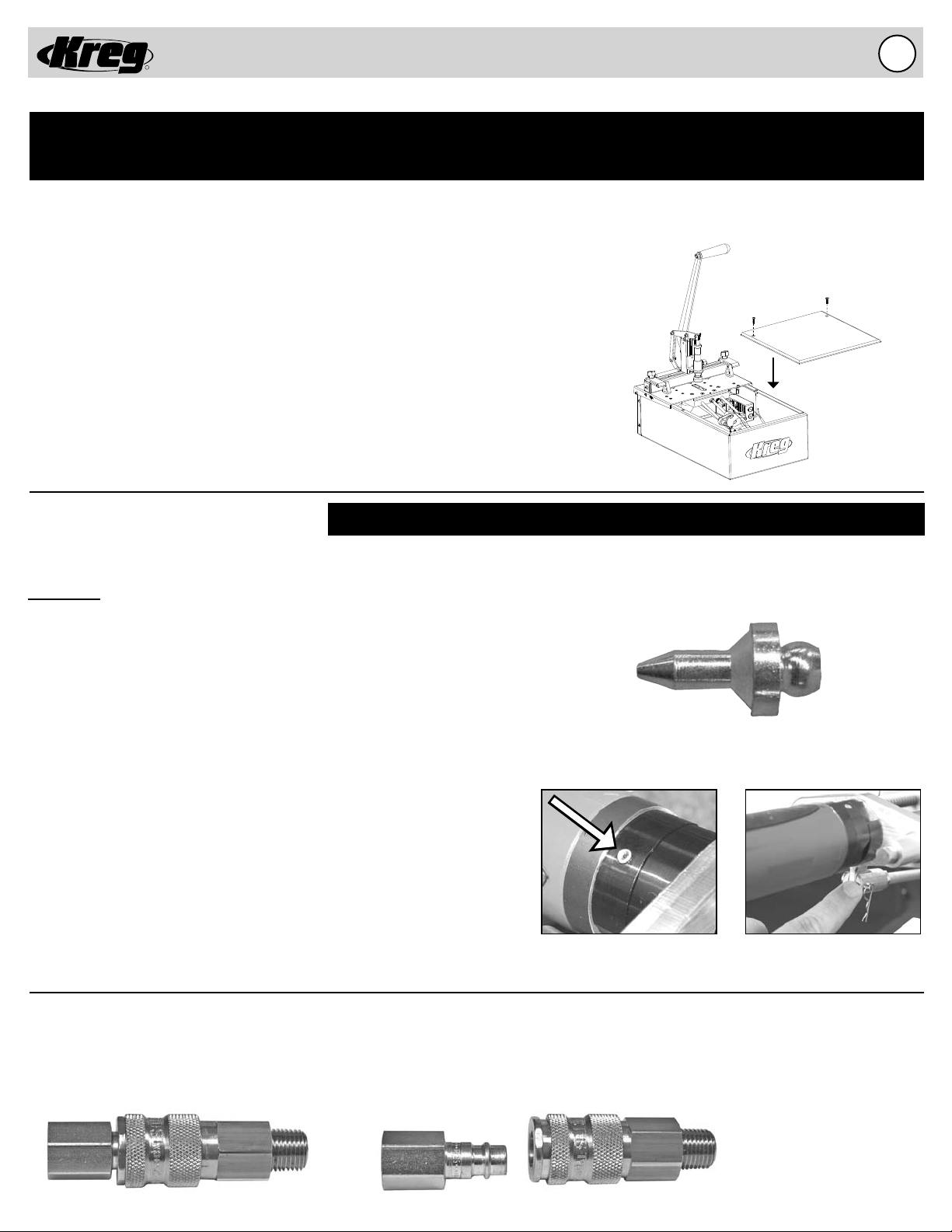

Acrylic Top Must Be Secured (DB55 & DB110)

Do not operate this machine without the acrylic top positioned correctly

and secured with the two provided lock-down screws. Running the

machine without the top in place and properly secured increases your

chance of injury and is not recommended under any circumstance. Make

sure all power sources have been disconnected from this machine before

removing the acrylic top.

Grease Zerk (DB55 ONLY)

NOTE: Grease zerk is provided so you can grease the front part of the drill (Planetary Gear). Insert zerk in

grease gun, with Extreme Pressure Moly-Graph Multi-Purpose Grease., grease gear with a couple of pumps

MONTHLY.

1. Disconnect the machine from the air supply.

2. Remove the Black Acrylic Top to gain access to the inside of the machine.

3. Disconnect the air supply line from the Air Motor by pushing in the collar on

the inlet fitting of the Air Motor and simultaneously pull out the tubing.

4. Lift the Tool Plate as it pivots on the hinges till the Safety Latch

engages to hold the Tool Plate in position.

5. Remove the Clevis and Cotter Pin from the Connecting Rod to

disconnect the Connecting Rod from the Drill Motor Mounting Block.

6. Remove the Drill Motor and Motor Mount assembly and grease it.

NOTE:

according to the “MAINTENANCE” section of this manual.

7. Re-install the Drill Motor and Motor Mount assembly on the Guide Rods.

8. Connect the Clevis and Cotter Pin through the Connecting Rod

and Drill Motor Mounting Block.

9. Lift the Tool Plate to disengage the Safety Latch and lower the Tool Plate

into position.

10. Make sure the air supply line for the Air Motor is free of debris

then connect the air supply line to the Air Motor by pushing in the

tubing until it seats in the inlet fitting of the Air Motor.

11. Place the Black Acrylic Top back on the machine.

If you can’t get to your grease zerk, please follow the instructions below.

Now is a good time to clean and lubricate the Guide Rods

WARNING! - Disconnect all air supply before working on machine.

Grease Zerk fi tting

included with machine.

Insert the Grease Zerk fitting

here on the motor.

Removing Clevis and Cotter Pin

from the Connecting Rod.

High Flow Air Fitting (DB55 ONLY)

It is very important to make sure you use the high fl ow fi tting provided with your machine, this fi tting is necessary to get the

correct volume of air to the machine for use. It is also important not to restrict air fl ow anywhere else coming to the machine.

To make sure you are getting the maximum amount of air to the machine, we don’t recommend using a hose extension.

Safety Guidelines

3.

Warnings:

• Do not operate this machine without the acrylic top securely fastened into place using the provided lock-down screws.

Doing so will ncrease your chances of injury or death.

• Woodworking machines are dangerous, and can cause personal injury if not used properly.

• Read safety instructions and operating instructions for your machine completely, before using products. Using this

system before understanding its safe and proper use could result in serious injury to the operator.

• Failure to follow these rules may result in serious personal injury.

• For your own safety, read the instruction manual before operating the tool. Learn the tool’s application and limitations

as well as the specifi c hazards distinctive to it.

• Keep all guards and safety devices in proper place while using these products.

• Always wear safety glasses.

• Keep hands well away from the pneumatic clamp and rotating bit when operating the machine.

• Avoid awkward hand positions, where a sudden slip could cause contact with the rotating bit. Never reach under the

pneumatic clamp pad with either hand to hold down the workpiece.

• As with all machinery, there are certain hazards involved with the operation and use of the machine. Using the machine

with respect and caution will considerably lessen the possibility of personal injury. However, if normal safety

precautions are overlooked or ignored, personal injury to the operator may result.

R

• This system was designed for certain applications only. Kreg strongly recommends that this system NOT be modifi ed

and/or used for any application other than for which it was designed. If you have any questions relative to its

application, DO NOT use the machine until you have written, phoned, or e-mailed Kreg Tool and have been advised

accordingly.

• Be aware of kickbacks. Kickbacks occur when the workpiece binds-up while being drilled, causing it to twist, jump, and

possibly become airborne. To avoid kickbacks (and potential injury) always use sharp drill bits, keep the machine aligned

and maintained properly, and adequately secure/support the workpiece.

• Turn machine off before adjusting. Never adjust the fence, swing stop, clamping cylinder, depth stop, drill bit, or any

other part of the machine while it is running.

• Wait for the machine to stop. Make sure the drill comes to a complete stop before adjusting the workpiece or

workpiece-angle.

• Ground electric machines. If your machine is equipped with a three-prong plug, it should be plugged into a three-hole

electrical receptacle only. If the proper outlet is not available, have one installed by a qualifi ed electrician before use.

Never remove the third prong, and never modify the provided plug in any way.

• Remove adjusting keys and wrenches. Be sure to check that all adjusting keys and wrenches are removed from the

machine before turning it on.

• Don’t operate in a dangerous or unclean environment. Don’t use power tools in damp or wet locations, or expose them

to rain. Keep work area well-lit, un-cluttered, and clean.

• Keep children and visitors away. All children and visitors should be kept a safe distance from the work area, and should

not operate the machine under any condition.

• Make your workshop “child-proof”. Use padlocks, master switches, or any other means necessary to make your work

area safe for children.

• Use the right tool. Never ‘force’ the tool to do work for which it was not intended. If used properly, the tool will

produce better results in less time, under safer conditions.

• Wear proper apparel. No loose clothing, gloves, neckties, rings, bracelets, or any other jewelry that could possibly

get caught in moving parts. Non-slip footwear is highly recommended, as is protective hair covering. Remember

to always use safety glasses, specifi cally designed as safety wear.

R

Safety Guidelines

Warnings:

• Secure the workpiece. Use clamps or a vise to hold work when it is practical and safe. Using the proper tool may

allow you to free both hands for tool operation. Also, be sure to never overreach.

• Secure your tools. In the event of the machine tipping or sliding, it is always recommended to secure your tools to

the machine, or in another safe location, during use.

• Keep the proper footing and balance. Ensure that you are in no danger of slipping or sliding once you turn the

machine on. Once again, non-slip footwear is highly recommended.

• Maintain tools in top condition. Keep tools sharp, clean, and properly maintained for the highest quality and safest

performance. Remember to properly follow all lubrication and accessory maintenance practices, as detailed in this

Instruction Manual.

• Disconnect tool before servicing. When changing accessories such as bits, clamps, etc., making any sort of physical

assessment of the tool, or when motor is being mounted/connected, remember to disconnect the machine from

its power source. This will reduce the possibility of accidentally engaging the machine.

• Use recommended accessories only. Use of any additional accessories (add-ons) is strictly at your own risk. This

machine was designed with only the use of Kreg certifi ed parts in mind. Use of uncertifi ed accessories may be

hazardous.

4.

• Avoid accidental starting. Make sure power switch is positioned at “OFF” and that no one is located near the

machine, before plugging in the power cord.

• Never stand on the machine. Serious injury could occur if the machine is tipped or if the cutting tool is contacted.

Do not stand on top of the machine for any reason.

• Check for damaged parts. Before use of the machine, a careful assessment of all guards and other parts should

be made to ensure that it will operate properly, and perform as intended. Check for alignment of moving parts,

binding of moving parts, breakage of parts, mounting, and any other conditions that may affect its operation. A

guard or other part that is damaged should be properly repaired or replaced as soon as possible, preceding any

additional use. Do not use the machine if you are not qualifi ed to make these sorts of assessments.

• Never leave a running machine unattended. Always turn the machine’s power “OFF” after operation. Do not leave

the tool until it comes to a complete stop.

• Drugs, alcohol, medication warning. Do not operate tool while under the infl uence of drugs, alcohol, or any

medications.

• USE PROPER EXTENSION CORD. Make sure your extension cord is in good condition. When using an extension cord,

be sure to use one heavy enough to carry the current your product will draw. An undersized cord will cause a drop

in line voltage resulting in loss of power and overheating.

WARNING: This product contains one or more chemicals known to the State of California to cause cancer and birth

defects or other reproductive harm. Wash hands after handling.

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains

chemicals known to the State of California to cause cancer and birth defects or other reproductive harm.

Some examples of these chemicals are:

- lead from lead-based paints,

- crystalline silica from bricks and cement

and other masonry products,

- arsenic and chromium from chemically

treated lumber.

Your risk from exposure to these chemicals varies, depending on how often you do this type of work. To reduce your

exposure, work in a well-ventilated area and with approved safety equipment, such as dust masks that are specially

designed to fi lter out microscopic particles.

WARNING: The wire of this product contains chemicals known to the State of California to cause cancer and birth

defects or other reproductive harm. Wash hands after handling.

Safety Guidelines

5.

Avertissements :

• Les machines à travailler le bois sont dangereuses et peuvent causer des blessures corporelles s’ils ne sont pas utilisées

correctement.

• Lisez complètement les consignes de sécurité et le mode d’emploi de la machine avant d’utiliser les produits. Utiliser ce

système avant d’en comprendre son utilisation correcte et sécuritaire peut causer des blessures graves à l’opérateur.

• Ne pas se conformer à ces règles peut entraîner des blessures corporelles graves.

• Pour votre propre sécurité, lisez le manuel de l’utilisateur avant d’utiliser l’outil. Prenez connaissance des applications et

des limites de l’outil, de même que des dangers spécifi ques qui lui sont propres.

• Laissez tous les dispositifs de sécurité à leur place lorsque vous utilisez ces produits.

• Portez toujours des lunettes de sécurité.

• Gardez les mains loin de la pince pneumatique et de l’embout rotatif lorsque vous utilisez la machine.

• Évitez de placer vos mains de façon incommode, où elles pourraient glisser soudainement et entrer en contact avec

l’embout rotatif. Ne passez jamais une main sous la plaque de la pince pneumatique pour maintenir en place la pièce.

• Comme pour tout équipement, l’utilisation de la machine comporte certains risques. Utiliser la machine avec respect

et prudence diminue considérablement les risques de blessures corporelles. Toutefois, ne pas tenir compte ou ignorer

les précautions d’usage peut entraîner des blessures corporelles à l’opérateur.

R

• Ce système a été conçu pour certaines applications seulement. Il est fortement recommandé par Kreg de NE PAS

modifi er et/ou utiliser ce système pour des applications autres que celles pour lesquelles il a été conçu. Si vous avez

des questions concernant son application, N’UTILISEZ PAS la machine avant d’avoir écrit, appelé ou contacté par

courriel Kreg Tool et que vous ayez été conseillé relativement à ces questions.

• Méfi ez vous des rebonds. Il y a rebond lorsque la pièce se coince pendant qu’on la perce; elle se tord, saute et peut

possiblement être projetée. Afi n d’éviter les rebonds (et des blessures potentielles), utilisez toujours des forets bien

aiguisés, entretenez bien la machine et maintenez son alignement, et fi xez ou supportez bien la pièce.

• Éteignez la machine avant d’effectuer des ajustements. N’ajustez jamais le guide, le dispositif anti oscillation, le cylin dre de

serrage, la butée de profondeur de mortaise, le foret ou tout autre élément de la machine pendant qu’elle est en marche.

• Attendez l’arrêt complet de la machine. Assurez vous que le foret soit complètement arrêté avant d’ajuster la pièce ou

l’angle de la pièce.

• Mettez les machines électriques à la terre. Si la machine est munie d’une fi che à trois broches, elle doit uniquement être

branchée à une prise de courant à trois trous. S’il n y a pas de prise adéquate disponible, faites en installer une par un électricien

qualifi é avant usage. N’enlevez jamais la troisième broche et ne modifi ez jamais la fi che fournie en au cune façon.

• Enlevez les clavettes de calage et les clés de réglage. Assurez vous qu’il ne reste aucune clavette de calage ou clé de

réglage avant d’allumer la machine.

• N’utilisez pas le produit dans des environnements dangereux ou sales. N’utilisez pas d’outils électriques dans des en

droits humides et ne les exposez pas à la pluie. Gardez l’espace de travail bien éclairé, rangé et propre.

• Maintenez les enfants et les visiteurs à l’écart. Tous les enfants et les visiteurs doivent demeurer à une distance sécuri

taire de l’espace de travail et ne doivent en aucun cas utiliser la machine.

• Ayez un atelier « à l’épreuve des enfants ». Utilisez des cadenas, des interrupteurs principaux ou tout autre moyen

nécessaire pour que votre espace de travail soit sécuritaire pour les enfants.

• Utilisez les outils adéquats. Ne « forcez » jamais un outil à effectuer un travail pour lequel il n’a pas été conçu. Si l’outil

est utilisé correctement, vous obtiendrez de meilleurs résultats en moins de temps et dans des conditions sécuritaires.

• Portez des habits adéquats. Pas de vêtement ample, de gant, de cravate, de bague, de bracelet ou autres bijoux

pouvant se prendre dans des pièces mobiles. Le port de chaussures à semelle antidérapante est fortement

recommandé, de même qu’une coiffure antiscalp. Souvenez vous de toujours porter des lunettes de sécurité

spécialement identifi ées en tant qu’accessoire de sécurité.

Loading...

Loading...