Kreg Accu-Cut KMA2700 Owner's Manual

Accu-Cut

™

Owner’s Manual

Guide d’utilisation

Manual del propietario

NK9191

Version 2 - 06/2017

www.kregtool.com • 800.447.8638

Item# KMA2700

Article KMA2700

Artículo # KMA2700

Saw not included

General Safety Guidelines

!

WARNING When using electric tools, always follow the safety precautions below to reduce the risk of re, electric shock,

and personal injury. Read all these instructions before attempting to operate this product. SAVE THESE INSTRUCTIONS.

• Before using the Accu-Cut™, read, understand, and follow the safety

warnings and operation instructions included with this product and provided

by your saw manufacturer. Keep all guards and safety devices in place.

• Wear proper eye, ear, and respiratory protection when operating your saw.

• Use a sharp blade designed for the type of material you are cutting.

• Always disconnect your saw from power before making adjustments

to the saw or Accu-Cut™.

• Wipe the guide strips with a damp cloth and remove dust and debris

from the workpiece before positioning the track on the workpiece.

• The Accu-Cut™ is designed for use with both tracks joined together.

Do not attempt a cut using only one track section without rst clamping

the track section to the work piece.

• Ensure that the saw blade will not contact the aluminum track during the cut.

• Do not attempt a cut when any part of the Accu-Cut™ interferes with

the operation of the saw blade guard.

• Fully support both the workpiece and the cutoff piece to prevent

binding and kickback.

• Adjust the depth of cut so the saw blade protrudes ⅛″ [3mm] through

the workpiece during the cut.

• Keep your hands away from the saw blade during operation.

• Secure your workpiece to ensure it doesn’t move during the cut.

• Do not use excessive force when cutting. Maintain a steady

and controlled pace.

• Allow the saw blade to come to a complete stop before removing the

saw/sled assembly from the track.

• Do not leave unattended saw resting on the track or starting block.

• Maintain your tools and accessories. Check for misalignment or binding of

moving parts, loose fasteners, broken parts, and any other condition that may

affect safe operation. If an unsafe condition is discovered, correct it before use.

Parts

A 2

Tracks

I 2

Base-plate Clamps

B 4

Guide Strips

(Pre-Installed)

J 1

Indexing Stop

C 2

Connector Bars

K 3

Machine Screws

D 8

Set Screws

L 3

Hex Nuts

E 1

Starting Block

M 1

Indicator Clip

F 1

Filler Strip

N* 1

Cursor

G 1

Sled

O* 1

Wedge

H 2

Set Screws

P* 1

Handle

*Part functional only on Kreg Rip-Cut™.

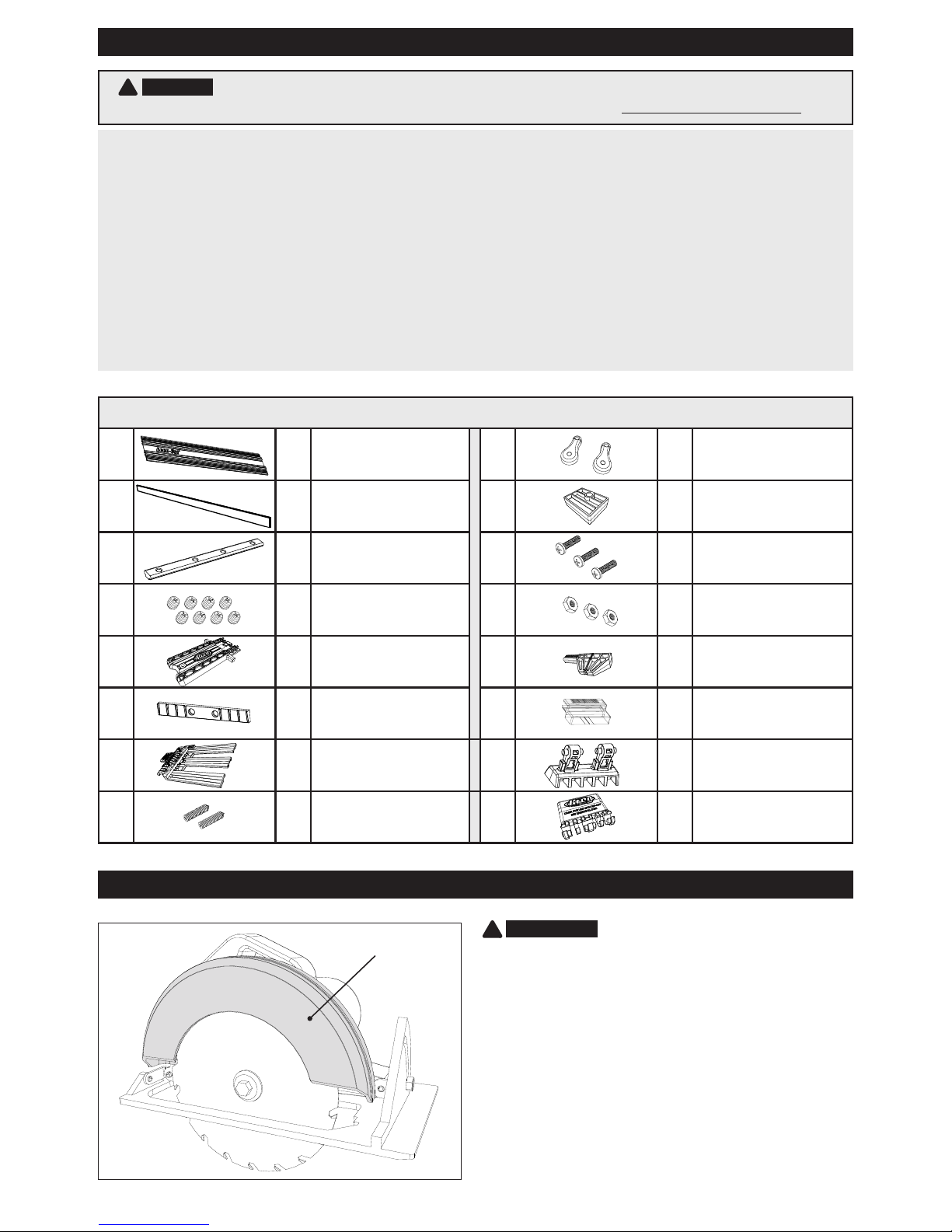

Upper blade guard

Before You Begin

Welcome to the Kreg Accu-CutTM!

With your new Accu-CutTM, you are sure to have a

lifetime of quality cutting experience. The Accu-Cut is

designed to work best with circular saws that have

a metallic upper blade guard. Saws with a plastic

upper blade guard may allow excessive deection

between the blade and the base plate causing

undesirable results when paired with the Accu-CutTM.

Please check the upper blade guard on your circular

saw. If your upper blade guard is plastic, Kreg

recommends not using this circular saw with the

Accu-CutTM.

!

ATTENTION

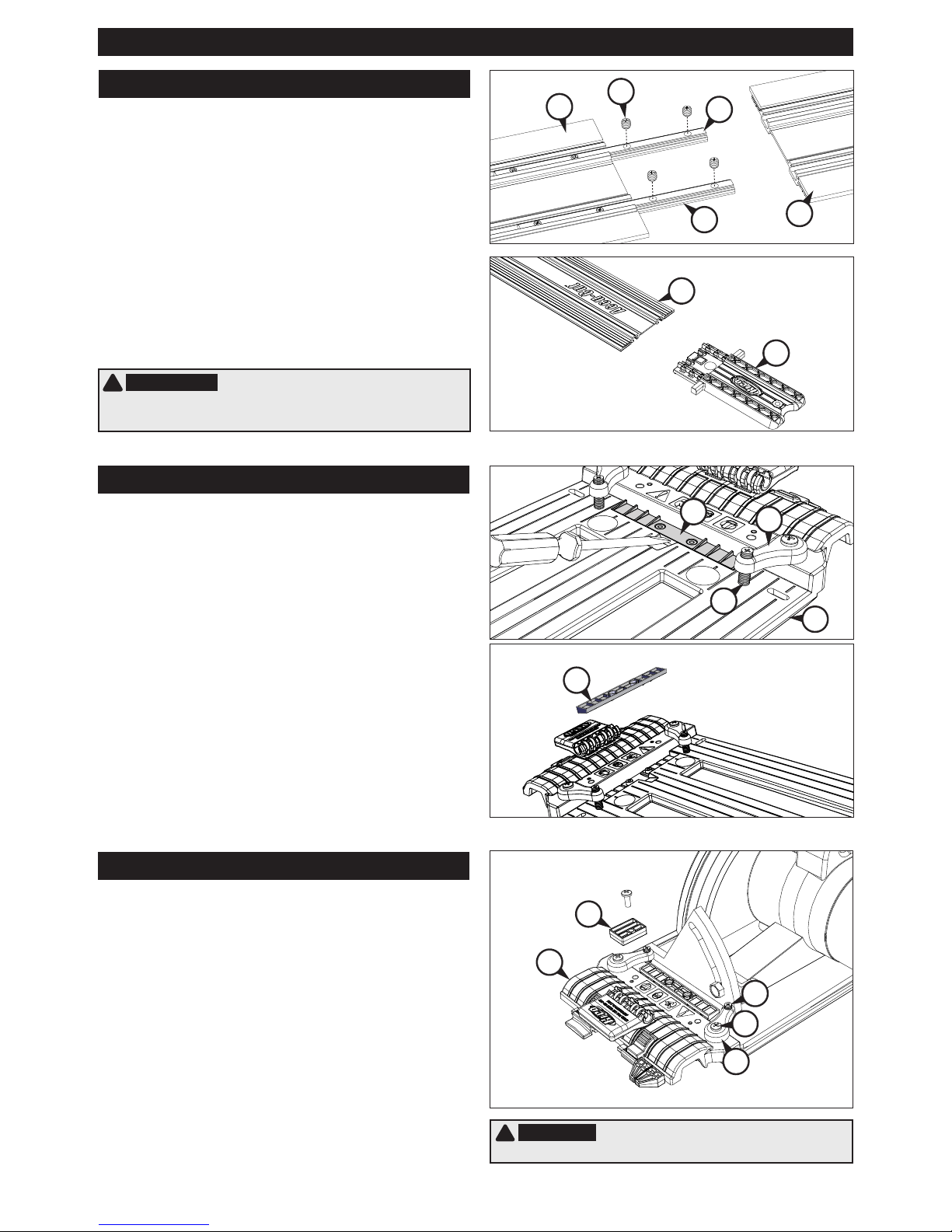

1

Turn the two tracks (A) upside down (black faces

of the guide strips up). Slide the connector bars

(C) halfway into the T-slots in the rst track at the end

with the indicator arrows on the top face and tighten

the set screws (D). Slide the second track onto the

connector bars so the indicator arrows on the top face

align with those on the rst track section. Tightly hold

the two tracks together and tighten the remaining set

screws. Slide the starting block (E) into the T-slots at

the end of one track.

Assemble the track

D

C

C

E

A

A

A

I

H

G

I

K

H

G

J

F

F

!

ATTENTION The tracks can be taken apart for storage.

If you disassemble the tracks, align the indicator arrows on the

top faces of the tracks when reassembling them.

!

WARNING Disconnect the saw from power before

mounting it on the sled.

2

The ller strip (F) on the sled (G) is shipped with

the angled ribs facing up. These ribs support a

saw base with an angled leading edge, keeping the

saw base at on the sled when the set screws (H) in

the base-plate clamps (I) are tightened. For a saw

base with a at leading edge, lift the ller strip from

the sled recess with the tip of a screwdriver, turn

it over to expose the at face, and press it into the

recess.

3

Remove the indexing stop (J) from the sled (G).

Loosen the set screws (H) in the base-plate

clamps (I) and slide your saw base plate under them.

Position the saw on the sled with the front of the saw

base plate against the step at the front of the sled. For

saws with the blade on the left-hand end of the motor,

center the blade in the left sled slot. For saws with the

blade on the right-hand end of the motor, center the

blade in the right sled slot. To accommodate different

saw base-plate congurations, there are two holes for

attaching each base-plate clamp to the sled. For the

most secure clamping, choose the holes that provide

widest spacing allowed by your saw. The clamps can

be oriented at an angle. Tighten the set screws onto the

saw base plate just enough to hold the saw in place.

Assembly

Orient the Filler Strip

Mount your Circular Saw on the Sled

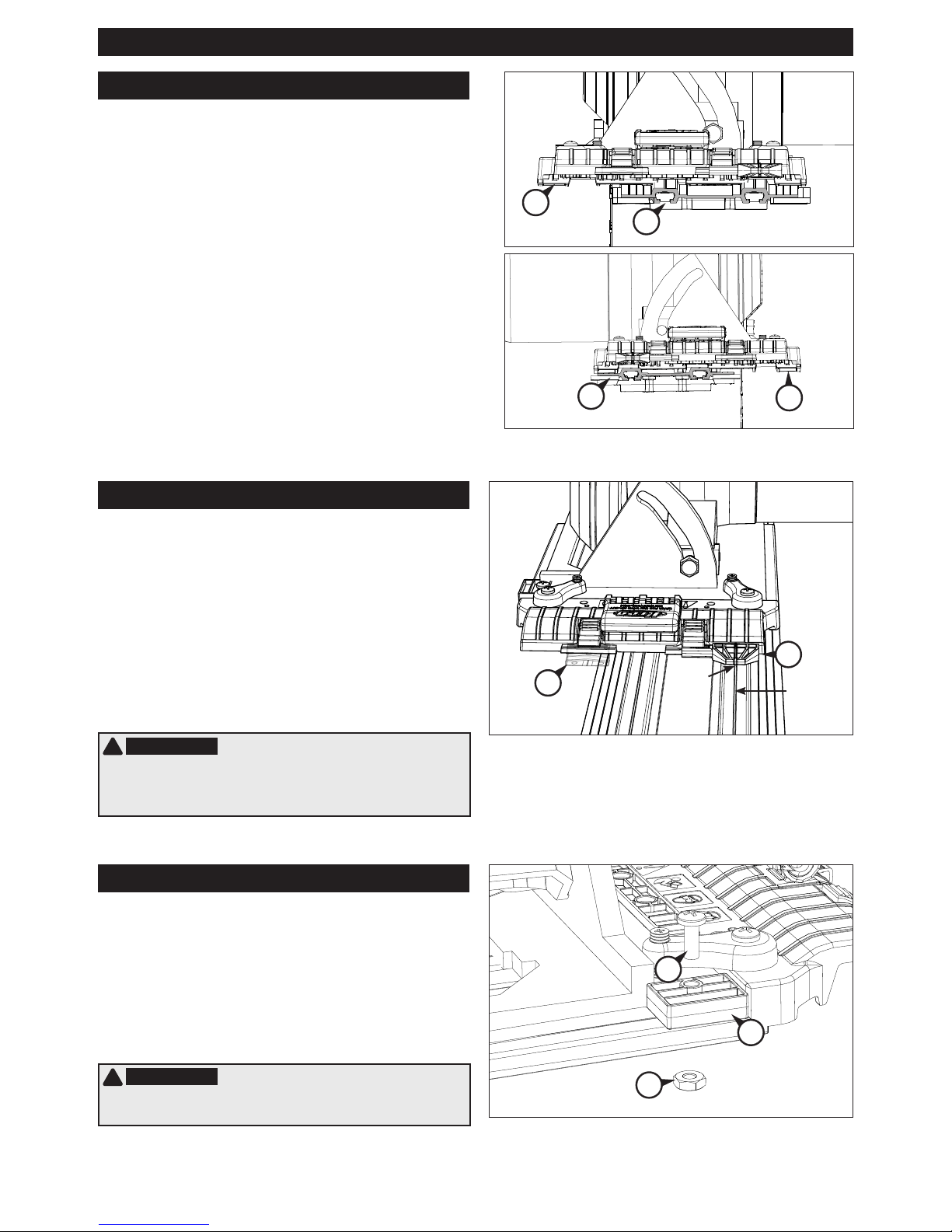

5

There are two positions on the sled for the

indicator clip (M) and cursor (N*) that correspond

to the two sled slots. Position the cursor in the holder

in front of the saw blade and the indicator clip in

the other holder. To switch indicator clip and cursor

positions, press down on the holder locks, slide

the indicator clip and cursor out of the holders and

reinstall each one in the other holder. For ease in

positioning the saw/sled assembly on the starting

block, align the notch at the front of the indicator clip

with the groove in the track rail.

Assembly

Check the Position of the Indicator Clip and Cursor

*

6

The indexing stop (J) allows you to remove the

saw from the sled assembly and then re-mount it

in exactly the same position without having to re-trim

the guide strip. Place the indexing stop against the

side of the saw base and secure it to the sled with

the machine screw (K) and nut (L). For maximum

positioning exibility, the sled is slotted and the

indexing stop can be rotated 180°.

Reinstall the Indexing Stop

N*

K

J

L

M

Groove

Notch

!

ATTENTION When mounting a different saw on the sled

repeat Steps 2-6. When installing a different blade in the saw,

repeat Step 4.

!

ATTENTION The sled assembly is equipped with

features only functional on the Kreg Rip-Cut™. Additional steps,

found in the Rip-Cut™ manual, are required to calibrate this sled

for use on the Rip-Cut™.

*The cursor is functional only on the Rip-Cut™.

A

A

G

G

4

There are three grooves in the bottom of the sled

(G). For a saw with the blade in the right-hand

sled slot, the center and left grooves ride on the track

(A) rails. For a saw with the blade in the left-hand sled

slot, the center and right grooves ride on the track rails.

Position the saw/sled assembly on the starting block,

engaging the appropriate sled grooves. Loosen the

base-plate clamp (I) set screws (H) enough to slide the

saw side to side. Align the saw so the blade will shave

about 1⁄32″ [.8mm] off the guide strip. (You’ll trim the

guide strip later for zero-offset positioning of the track.)

Tighten the base-plate clamp set screws enough to

securely hold the saw, but do not over tighten. Make

sure the saw blade guard operates freely.

Align the Saw/Sled Assembly on the Track

Using your Accu-Cut™

Using your Accu-Cut™

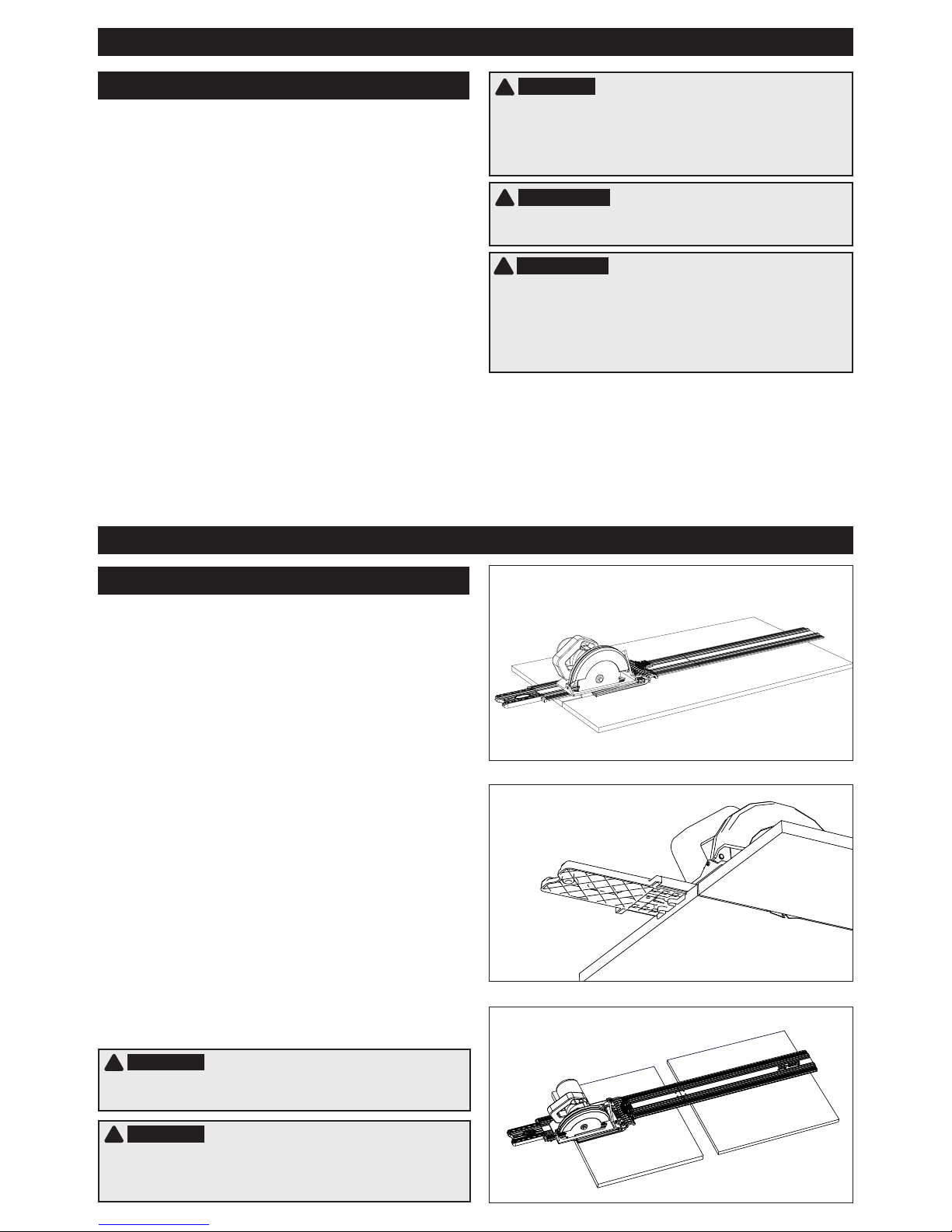

7

The tracks (A) are supplied with the guide strips

(B) already installed. The guide strips grip the

workpiece surface to ensure the track does not move

during use. When properly trimmed, the guide strips

allow you to align the edge of the strip with the cutline

and provide zero-clearance support next to the blade

to minimize chip-out.

To allow positioning the edge of the guide strip on

the workpiece cutline (zero offset), position and fully

support the track on a 48″ [1219mm]-long scrap

workpiece with the edge stop on the bottom of the

starting block against the edge of the workpiece.

Position the saw/sled assembly on the starting block

using the indicator clip to ensure proper alignment

and engage the track rails. Adjust the depth of cut

so the blade will protrude ⅛″ [3mm] through the

workpiece during the cut. With the blade clear of the

workpiece, turn on the saw. Applying light downward

pressure on the saw and maintaining a steady,

controlled pace, trim the guide strip and workpiece

along the entire length of the track. Turn off the saw

and allow the blade to stop before removing the saw/

sled assembly from the track.

Trim the Guide Strip

!

ATTENTION Always wipe the guide strips with a

damp cloth and remove dust and debris from the workpiece

before positioning the track.

1

For the best results, install a 40-tooth blade on

your saw

2

Mark the cutline on your workpiece. Position

the track with the edge of the guide strip on

the cutline and the starting block edge stop against

the edge of the workpiece. Always make cuts with

the workpiece under the track and the waste to the

outside.

3

Place the saw/sled assembly on the starter

block, using the indicator clip to align the sled

with the track. Adjust the depth of cut so the blade will

protrude ⅛″ [3mm] through the workpiece during the

cut.

4

Connect your saw to power. With both hands on

the saw and the blade clear of the workpiece,

turn on the saw. Applying light downward pressure on

the saw and maintaining a steady, controlled pace,

make the cut. Turn off the saw and allow the blade to

stop before removing the saw/sled assembly from the

track.

!

WARNING Completely support the workpiece and

cutoff with 2x4s or [2″] [50mm]-thick rigid foam insulation laid

at on the oor.

!

WARNING When more than 12″ of the end of the track

opposite the starter block extends beyond the workpiece,

support the protruding end of the track with an auxiliary

surface that it is ush with the workpiece.

!

WARNING The wedge lock is functional only on the

Kreg Rip-Cut™. To avoid interference with the operation of

the Accu-Cut™, raise the wedge (O*) by pushing the handle

(P*) forward and down. Make sure the handle is in this

position whenever using the Accu-Cut™.

!

ATTENTION Should the zero-offset guide strip

become worn or damaged, remove the starting block from

the track and install it on the other end. Perform the trimming

operation on the second guide strip. When the guide strips

are no longer usable, contact Kreg Customer Service or

www.kregtool.com to purchase replacements.

Assembly

Loading...

Loading...