Page 1

KRAMER ELECTRONICS LTD.

USER MANUAL

MODEL:

85 0

Pattern Generator

P/N: 2900-300033 Rev 2

Page 2

Page 3

850 – Contents

i

Contents

1 Introduction 1

2 Getting Started 2

2.1 Achieving the Best Performance 2

2.2 Safety Instructions 2

2.3 Recycling Kramer Products 3

3 Overview 4

3.1 Defining the 850 DisplayPort Pattern Generator 4

4 Connecting the 850 6

4.1 Connecting a PC 7

5 Operating the 850 Pattern Generator 11

5.1 Operating the 850 Using the Front Panel Buttons 12

5.2 Operating the 850 Using the Control Application 13

6 Technical Specifications 21

7 Communication Parameters 22

8 Serial Protocol 23

8.1 Command Format 23

8.2 Device Response 23

8.3 Commands 24

Figures

Figure 1: 850 Pattern Generator Front Panel 4

Figure 2: 850 Pattern Generator Rear Panel 5

Figure 3: Connecting the 850 Pattern Generator 6

Figure 4: Found New Hardware Wizard Window 8

Figure 5: File Location Selection Window 9

Figure 6: Insert Disk Window 10

Figure 7: Connection Method Window 13

Figure 8: Connection Error Message 14

Figure 9: Controller Software Main Window 15

Figure 10: The Menu Bar 16

Figure 11: About 16

Figure 12: User Defined Resolution Window–Standard Tab 17

Figure 13: User Defined Resolution Advanced Window–Additional Tab 18

Figure 14: User Defined Resolution Advanced Window–Timing Parameters Tab 19

Figure 15: User Defined Resolution Advanced Window–EDID Tab 20

Page 4

850 - Introduction

1

1

1 Introduction

Welcome to Kramer Electronics! Since 1981, Kramer Electronics has been

providing a world of unique, creative, and affordable solutions to the vast range of

problems that confront the video, audio, presentation, and broadcasting

professional on a daily basis. In recent years, we have redesigned and upgraded

most of our line, making the best even better!

Our 1,000-plus different models now appear in 11 groups that are clearly defined

by function: GROUP 1: Distribution Amplifiers; GROUP 2: Switchers and Matrix

Switchers; GROUP 3: Control Systems; GROUP 4: Format/Standards Converters;

GROUP 5: Range Extenders and Repeaters; GROUP 6: Specialty AV Products;

GROUP 7: Scan Converters and Scalers; GROUP 8: Cables and Connectors;

GROUP 9: Room Connectivity; GROUP 10: Accessories and Rack Adapters and

GROUP 11: Sierra Products.

Congratulations on purchasing your Kramer MultiTOOLS® 850 DisplayPort Pattern

Generator, which is ideal for the following typical applications:

As a diagnostic tool in AV setups

Testing and adjusting flat panel LCD displays, projectors, plasmas and

DisplayPort cables

Testing the refresh rates of LCD displays by using the motion patterns

Page 5

2

850 - Getting Started

2 Getting Started

We recommend that you:

Unpack the equipment carefully and save the original box and packaging

materials for possible future shipment

Review the contents of this user manual

Use Kramer high performance, high resolution cables

Go to http://www.kramerelectronics.com/support/product_downloads.asp

to check for up-to-date user manuals, application programs, and to

check if firmware upgrades are available (where appropriate).

2.1 Achieving the Best Performance

To achieve the best performance:

Use only good quality connection cables (we recommend Kramer high-

performance, high-resolution cables) to avoid interference, deterioration in

signal quality due to poor matching, and elevated noise levels (often

associated with low quality cables)

Do not secure the cables in tight bundles or roll the slack into tight coils

Avoid interference from neighboring electrical appliances that may adversely

influence signal quality

Position your Kramer 850 DisplayPort Pattern Generator away from

moisture, excessive sunlight and dust

This equipment is to be used only inside a building. It may only be

connected to other equipment that is installed inside a building.

2.2 Safety Instructions

Caution:

There are no operator serviceable parts inside the unit

Warning:

Use only the Kramer Electronics input power wall

adapter that is provided with the unit

Warning:

Disconnect the power and unplug the unit from the wall

before installing

i

!

!

Page 6

850 - Getting Started

3

3

2.3 Recycling Kramer Products

The Waste Electrical and Electronic Equipment (WEEE) Directive 2002/96/EC

aims to reduce the amount of WEEE sent for disposal to landfill or

incineration by requiring it to be collected and recycled. To comply with the

WEEE Directive, Kramer Electronics has made arrangements with the

European Advanced Recycling Network (EARN) and will cover any costs of

treatment, recycling and recovery of waste Kramer Electronics branded

equipment on arrival at the EARN facility. For details of Kramer’s recycling

arrangements in your particular country go to our recycling pages at

http://www.kramerelectronics.com/support/recycling/.

Page 7

4

850 - Overview

3 Overview

The 850 is a high performance, DisplayPort video test pattern generator. It can

generate 32 preset patterns at 16 popular, predefined, computer and HD video

resolutions and seven user-defined resolutions, including several unique patterns

incorporating motion.

In particular, the MultiTOOLS® 850 features:

A DisplayPort output

Five dual-function and two single-function control buttons

A two-digit 7 segment display

An onboard EPROM that saves the last setting

3.1 Defining the 850 DisplayPort Pattern Generator

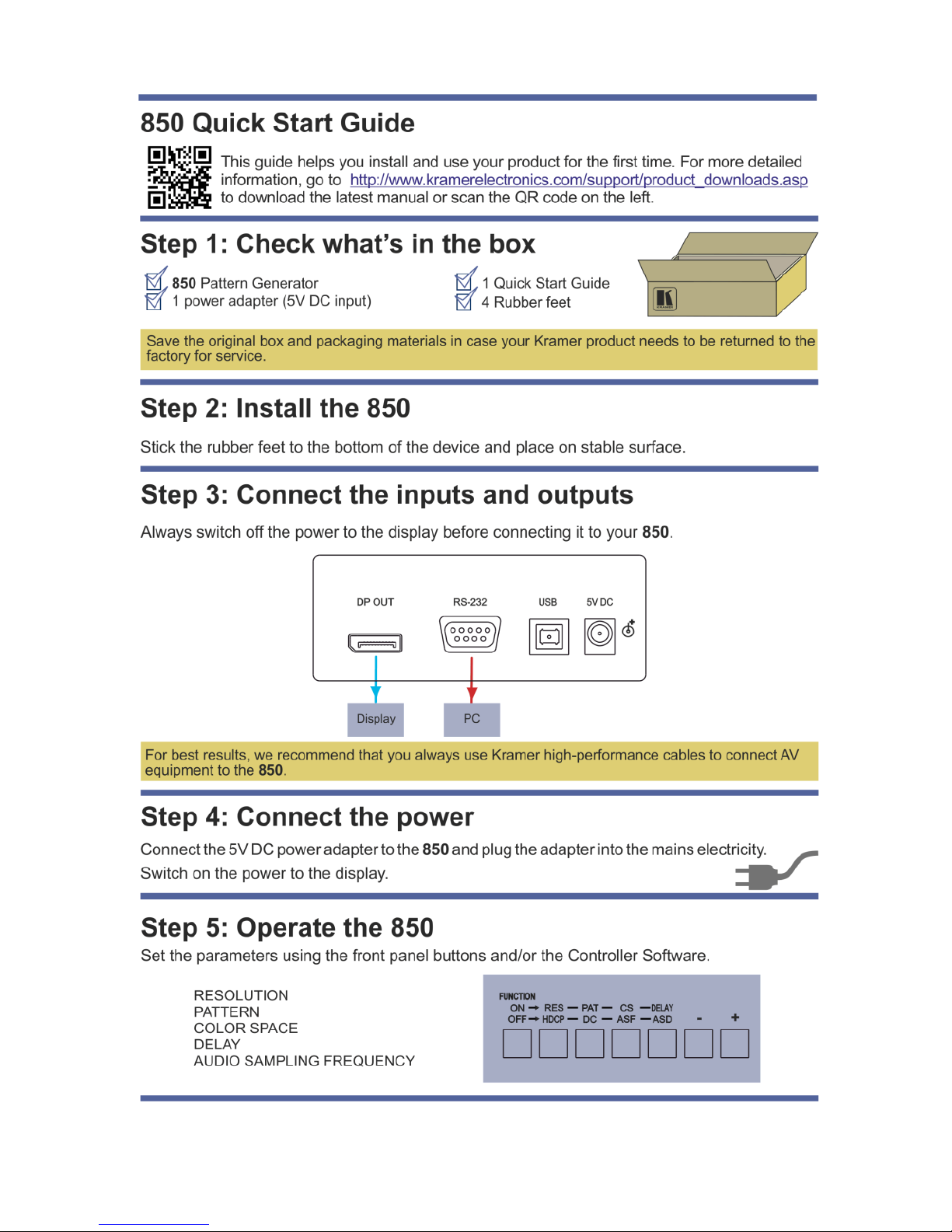

Figure 1 defines the front panel of the 850.

Figure 1: 850 Pattern Generator Front Panel

850 Front Panel Features

#

Feature

Function

1

FUNCTION

Buttons

ON/OFF

Press to toggle between the top row and bottom row functions.

Button LED lights when on.

When on, the top row of functions are enabled (RES, PAT, CS and

Delay). When off, the bottom row of functions (HDCP, DC, ASF

and ASD) are enabled (see Section 5.1)

2

RES/HDCP

Press to select either the Resolution (when the ON/OFF button is

on) or HDCP functions (when the ON/OFF button is off)

3

PAT/DC

Press to select either the Pattern (when the ON/OFF button is on)

or Color Depth functions (when the ON/OFF button is off)

Page 8

850 - Overview

5

5

850 Front Panel Features

#

Feature

Function

4

CS/ASF

Press to select either the Color Space (when the ON/OFF button is

on) or Audio Sample Frequency functions (when the ON/OFF

button is off)

5

DELAY/ASD

Press to select either the Delay (when the ON/OFF button is on) or

Audio Sample Data functions (when the ON/OFF button is off)

6

2-digit 7-segment Display

Indicates the current setting. The display flashes if there is a

problem communicating with the display, for example, if the display

does not support HDCP or does not support the selected resolution

7

ON LED

Lights red when the device receives power

8

– Button

Press to step down through the list of available values

9

+ Button

Press to step up through the list of available values

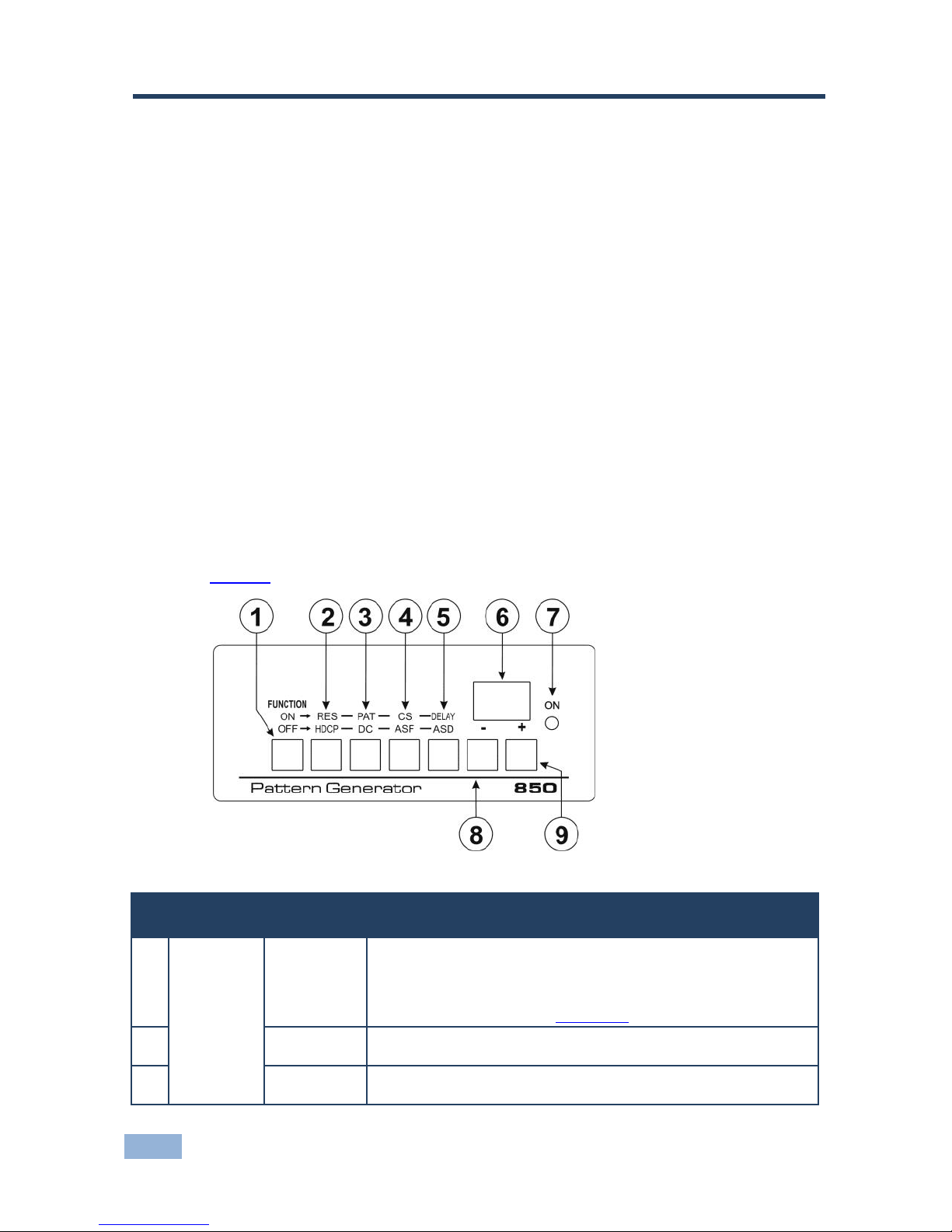

Figure 2 defines the rear panel of the 850.

Figure 2: 850 Pattern Generator Rear Panel

850 Rear Panel Features

#

Feature

Function

10

DP OUT Connector

Connect to the DisplayPort acceptor (see Section 4)

11

RS-232 9-pin D-sub

Connector

Connect to the serial port on a PC for remote control (see

Section 4.1.1)

12

USB Connector

Connect to a USB port on a PC for remote control

13

5V DC Connector

Connect to the power adapter

Page 9

6

850 - Connecting the 850

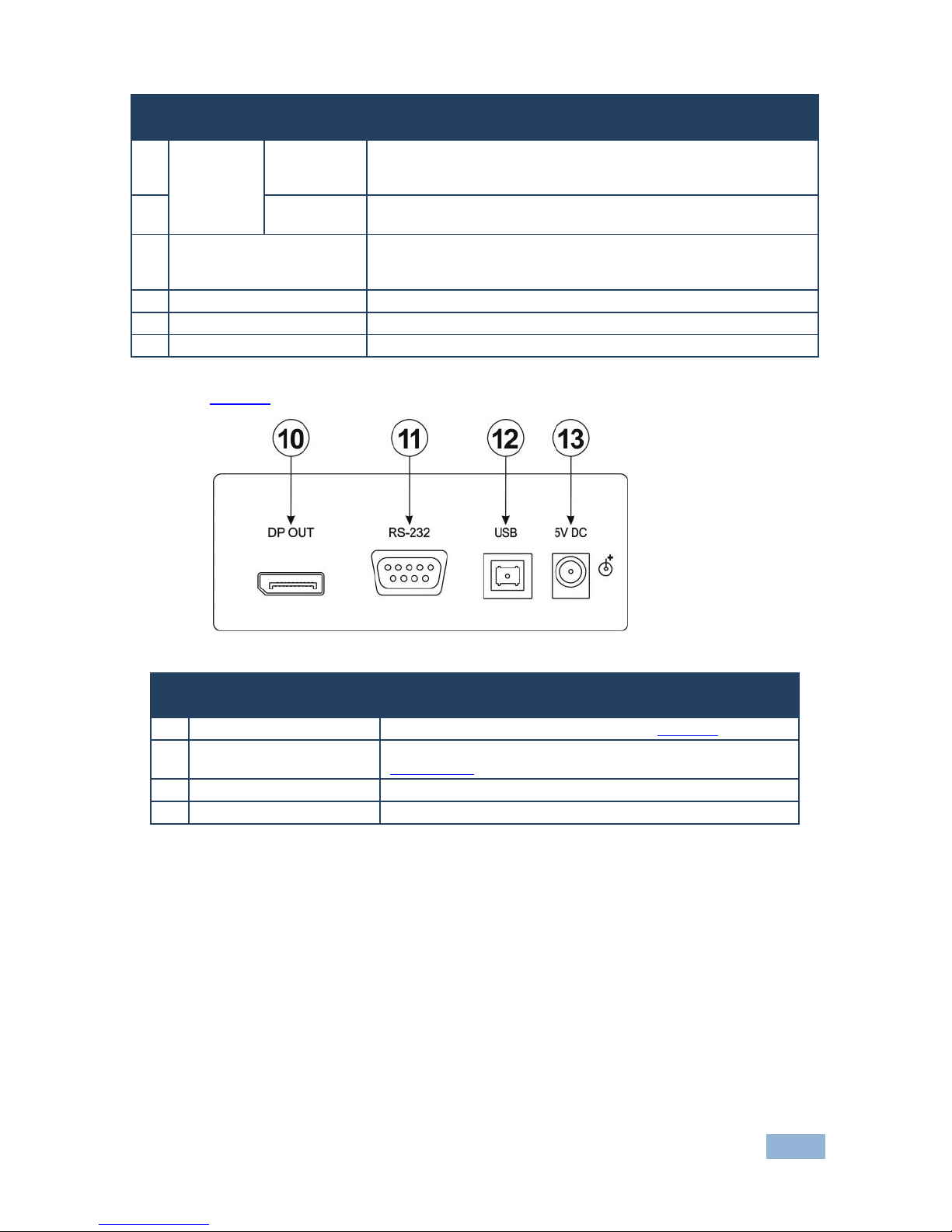

4 Connecting the 850

Always switch off the power to any device before connecting it to your

850. After connecting your 850, connect its power and then switch on

the power to the device.

To connect the 850 as illustrated in the example in Figure 3:

1. Connect the DP OUT connector to a DisplayPort acceptor (for example, a

flat panel LCD display).

2. Optional—connect a PC to control the 850 via the RS-232 or USB port.

3. Connect the power adapter to the 5V DC socket and to the mains electricity.

Figure 3: Connecting the 850 Pattern Generator

!

Page 10

850 - Connecting the 850

7

7

4.1 Connecting a PC

You can connect to the 850 via the RS-232 serial and via the USB port.

4.1.1 Connecting a PC via the RS-232 Serial Port

You can connect to the 850 via an RS-232 connection using, for example, a PC.

Note that a null-modem adapter/connection is not required.

To connect to the product via RS-232:

Connect the RS-232 9-pin D-sub rear panel port on the product unit via a

9-wire straight cable (only pin 2 to pin 2, pin 3 to pin 3, and pin 5 to pin 5

need to be connected) to the RS-232 9-pin D-sub port on your PC

4.1.2 Connecting a PC via the USB Port

To connect the 850 via a USB port you must download and install the USB driver

and 850 Control application.

Note: The driver only works on 32-bit systems.

To install the USB driver and Control Application:

1. Navigate to the Kramer Electronics Web site

(http://www.kramerelectronics.com) and search for the product 850.

2. Click on the Downloads tab.

3. Download the 850 Windows USB Driver.

4. Download the 850 Control Application to a designated folder on your

computer.

5. Extract the compressed USB driver file to your designated folder.

Two files are extracted, a .inf and a .sys file.

6. Connect the USB cable between your computer and the 850.

7. Connect the power supply to the 850.

Page 11

8

850 - Connecting the 850

8. After a few seconds the Found New Hardware message appears as shown

in Figure 4.

Figure 4: Found New Hardware Wizard Window

9. Click on the No, not this time radio button.

10. Click Next.

11. Select Install from a list or specific location (Advanced) as shown in

Figure 5.

Page 12

850 - Connecting the 850

9

9

Figure 5: File Location Selection Window

12. Click Next.

13. Select Search for the best driver in these locations.

14. Check Include this location in the search. Browse to your previously

designated folder.

15. Click Next.

16. Select the file atm6124.inf

17. The warning This driver is not digitally signed! appears.

18. Click Next.

19. Ignore the warning. Click Continue Anyway.

20. In the Insert disk window, click OK as shown in Figure 6.

Page 13

10

850 - Connecting the 850

Figure 6: Insert Disk Window

21. Select the file atm6124.sys and click Open.

The driver installs and a success message is displayed. The USB driver has

been successfully installed and you can install the 850 Control Application.

22. Navigate to the designated folder to which you downloaded the Control

Application.

23. Double-click the file setup.exe from this folder or from the distribution media

included with the 850.

The Control Application has been successfully installed.

Page 14

850 - Operating the 850 Pattern Generator

11

11

5 Operating the 850 Pattern Generator

The 850 can be operated using the front panel buttons (see Section 5.1) and the

850 Control Application (see Section 5.2).

The 850 Control Application is available as a free download from

http://www.kramerelectronics.com).

The following output video resolutions are supported.

Resolution Values

#

Resolution

#

Resolution

1

VGA 640 x 480 @60Hz

13

2048 x 1536 @60

2

SVGA 800 x 600 @60Hz

14

1856 x 1392 @60

3

XGA 1024 x 768 @60Hz

15

2560 x 1440 @60

4

1280 x 720 @60Hz

16

2560 x 1600 @60

5

1280 x 1024 @60

17

User defined

6

WSXGA+ 1680 x 1050 @60Hz

18 7 SXGA 1280 x 1024 @75Hz

19 8 HD 1920 x 1080 @60Hz

20 9 WUXGA 1920 x 1200 @60Hz

21

10

UXGA 1600 x 1200 @60Hz

22

11

2048 x 1280 @60

23

12

2048 x 1152 @60

24

Output native resolution

The following video patterns are supported.

Pattern Values

#

Pattern

#

Pattern

1

100% Color bar

17

Square

2

75% Color bar

18

White dot

3

Gray bar

19

Alternate pixels

4

Red screen

20

White HScroll

5

Green screen

21

White VScroll

6

Blue screen

22

Multiburst

7

Yellow screen

23

Vertical split

8

Cyan screen

24

Horizontal split

9

Magenta screen

25

Red ramp

10

Gray screen

26

Green ramp

11

White screen

27

Blue ramp

12

RGB ramp

28

Bounce

13

Black screen

29

Window

14

Crosshatch black

30

White border

15

Crosshatch green

31

Target circle

16

Crosshatch blue

32

Moving ball

Page 15

12

850 - Operating the 850 Pattern Generator

The following video and audio output options are supported.

Output Settings

Parameter

Front Panel

Values

Delay

Delay

Sets the delay before changes are implemented

HDCP

HDCP

On, Off

Color Space

CS

RGB, YUV 444, YUV 422, Auto

Color Depth

DC

24 bit, 30 bit, 36 bit, Auto

Audio Sample

ASF

44kHz, 48kHz, 88kHz, 96kHz, 176kHz, 192kHz, Auto

Audio Bit

ASD

16 bit, 20 bit, 24 bit, Auto

5.1 Operating the 850 Using the Front Panel Buttons

To activate the top row of functions (RES, PAT, CS and DELAY):

Press the Function ON/OFF button (the button LED lights)

To activate the bottom row of functions (HDCP, DC, ASF and ASD):

Press the Function ON/OFF button again (the button LED no longer lights)

To select a function and modify the value, for example, to select a specific

pattern:

1. Press the Function button.

The button lights to indicate the top row of functions (ON) is active.

2. Press the PAT/DC button.

The button lights to indicate that the Pattern function is active.

3. Press the + or – button to cycle through the list of available patterns until the

required pattern is displayed on the 7-segment display.

Note: The display flashes if there is a problem communicating with the display, for

example, the display does not support HDCP or does not support the selected

resolution.

Page 16

850 - Operating the 850 Pattern Generator

13

13

5.2 Operating the 850 Using the Control Application

The 850 Control Application is a PC-based program which lets you program and

control the device.

To use the 850 Control Application you must download and install the USB driver

and the 850 Control Application.

Note: The USB driver is not supported by Windows 64 bit systems.

5.2.1 Connecting to the Device

To connect to the device:

1. Run the Control Application by clicking Start > Programs > Kramer

Electronics > 850.

2. Click the Connect button.

The Connection Method window is displayed as shown in Figure 7.

Figure 7: Connection Method Window

3. Select the required connection method (via a serial or USB connection) by

clicking the relevant radio button.

4. For a serial connection, select the required Com port from the drop-down

list.

5. For a USB connection, select the required USB device from the drop-down

list.

To view an up-to-date list of available USB ports, press the Refresh Ports

button.

Page 17

14

850 - Operating the 850 Pattern Generator

Note: If the drop-down list shows No USB Devices, then either you have not

installed the USB driver (see Section 4.1.2) or the installation was not successful.

6. Click Connect.

If the connection is not successful, a Timeout error message appears as

shown in Figure 8. If the connection is successful, the main window shown

in Figure 9 appears.

Figure 8: Connection Error Message

5.2.2 Controller Software Main Window

The Controller Software Main Window is shown in Figure 9.

Page 18

850 - Operating the 850 Pattern Generator

15

15

Figure 9: Controller Software Main Window

850 Controller Software Main Window

#

Feature

Function

1

CONNECT Button

Press to connect to a device (see Section 5.2.1)

2

Resolutions

COMMON Buttons

Press to select a pre-configured output resolution

3

USER DEFINED

Buttons

Press to select a pre-configured output resolution

4

User Defined Resolution Edit

Buttons

Press to edit the relevant user defined output resolution

5

Patterns Buttons

Press to select an output pattern

6

Output Settings Buttons

Press to modify the output settings:

Delay—Sets the delay before changes are implemented

HDCP—HDCP, No HDCP

Color Space—RGB, YUV 444, YUV 422, Auto

Color Depth—24 bit, 30 bit, 36 bit, Auto

Audio Sample—44kHz, 48kHz, 88kHz, 96kHz, 176kHz, 192kHz,

Auto

Audio Bit—16 bit, 20 bit, 24 bit, Auto

7

Status of Connected Display

Information on the currently connected display

8

Status of Output

Information on the currently selected output settings

Page 19

16

850 - Operating the 850 Pattern Generator

850 Controller Software Main Window

#

Feature

Function

9

EDID Info

Click on Get EDID Info from the menu bar to display EDID

information from the connected display. If there is no display

connected, random data is displayed

5.2.3 The Menu Bar

Figure 10: The Menu Bar

There are four functions available from the menu bar:

Device Reset—Resets the device to factory default settings

Get EDID Info—Reads EDID data from an attached display device

About—Displays the current software version number, (see Figure 11)

Check for updates—Checks that the current software version is the latest

version available

Figure 11: About

Page 20

850 - Operating the 850 Pattern Generator

17

17

5.2.4 Editing User Defined Resolutions

To edit a user defined resolution:

1. Click the required user defined resolution edit button .

The User Defined Window appears with the CEA 861 Standard Tab

selected as shown in Figure 12.

Figure 12: User Defined Resolution Window–Standard Tab

2. In the Label field, enter the required label for the button.

3. Click one of the resolutions to select the required resolution.

4. Click OK to save the resolution settings or click the Additional button to edit

the aspect ratio and specific resolution.

The Additional Tab is displayed as shown in Figure 13.

Page 21

18

850 - Operating the 850 Pattern Generator

Figure 13: User Defined Resolution Advanced Window–Additional Tab

5. Select the required aspect ratio and resolution.

6. Click OK to save the additional parameters or click the Advanced button to

edit the timing parameters and EDID values.

The Advanced Window appears with the Timing Parameters tab selected

as shown in Figure 14.

Page 22

850 - Operating the 850 Pattern Generator

19

19

Figure 14: User Defined Resolution Advanced Window–Timing Parameters Tab

7. Edit or select the required resolution timing values, such as, Pixel Clock and

Digital Sync.

8. Click OK to accept the changes or click on the EDID tab to edit the EDID

values.

The EDID tab is displayed as shown in Figure 15.

Page 23

20

850 - Operating the 850 Pattern Generator

Figure 15: User Defined Resolution Advanced Window–EDID Tab

9. Edit the EDID values as required.

10. Click OK to save the values.

5.2.5 To Read EDID Information

To read EDID information:

Click Get EDID Info on the menu bar.

The EDID of the display connected to the 850 is read and shown under

EDID Info. If there is no display connected to the 850, random data is

displayed, (see Figure 9).

Page 24

850 - Technical Specifications

21

21

6 Technical Specifications

OUTPUT:

1 DisplayPort connector

CONTROL:

Five dual-function and two single function front panel buttons,

Remote control via USB on a USB connector and RS-232 on a

9-pin D-sub connector

POWER SOURCE:

5V DC, 670mA

OPERATING

TEMPERATURE:

0° to +40°C (32° to 104°F)

STORAGE

TEMPERATURE:

-40° to +70°C (-40° to 158°F)

HUMIDITY:

10% to 90%, RHL non-condensing

DIMENSIONS:

10.7cm x 10.0cm x 4.4cm (4.2" x 3.9" x 1.7”) W, D, H

WEIGHT:

0.4kg (0.88lbs) approx.

ACCESSORIES:

Power supply

OPTIONS:

RK-1 Universal rack adapter

Specifications are subject to change without notice at http://www.kramerelectronics.com

Page 25

22

850 - Communication Parameters

7 Communication Parameters

RS-232

Baud Rate:

9600

Data Bits:

8

Stop Bits:

1

Parity:

None

Page 26

850 - Serial Protocol

23

23

8 Serial Protocol

The 850 can be controlled via the serial port using the commands described in this

section.

8.1 Command Format

Commands must be in the following format:

0xEB, address, command, length of data, data 1,…, data n, checksum

where the following table describes the command components.

Command

Component

Description

0xEB

Fixed command start byte

address

Device address. This is always 0x90 for the 850

command

Command to be sent (see Section 8.3)

length of data

How many bytes sent/received (from data 1 to data n)

data 1, data n

One or more command variables within the range 0x01 to 0xFA and excluding 0xEB

checksum

Optional—Checks whether the sending/receiving frame is valid.

Check sum = Address + Command + Data length + Data 1+…+Data n

For example, EBH, 90H, 01H, 01H, F3H, 85H

Check sum = 90H + 01H + 01H + F3H = 185H

Note: The checksum gets the low 8 bits, for example, if the check sum = EBH, then check sum =

14H

8.2 Device Response

The device responds as follows:

0xEB, 0x90, command, 0x01, answer, check sum

where answer is one of the values described in the following table.

Command

Component

Description

0xF1

Either:

–the device received the wrong address and returns no response

–the device gets information about Errors and Alarms

0xF2

The data is out of range. The command is not executed

0xF3

The device is currently controlled by the buttons. The command is not executed

0xF7

The data length is incorrect. The command is not executed

0xFC

The data is out of range. The command is not executed

Page 27

24

850 - Serial Protocol

8.3 Commands

The commands listed below are supported by the 850.

Note: The checksum is required at the end of the send/receive command as

shown in Section 8.1. If a checksum is not included in a sent command, the device

will not respond.

8.3.1 Get Device Address and Software Version

Command

Send/Receive

Data

0x00

0xEB, 0x00, 0x00, 0x01, 0xXX, checksum

0xEB, [address], 0x00, 0x02, [version], 0x00,

checksum

0xXX can be any data except 0xEB

8.3.2 Set Output Encryption or Decryption

Command

Send/Receive

Data

0xE3

0xEB, 0x00, 0xE3, 0x01, data1, checksum

0xEB, address, 0xE3, 0x01, 0xFA, checksum

data1:

0 = encryption

1 = decryption

8.3.3 Get Device Status

Command

Send/Receive

Data

0xE4

0xEB, address, 0xE4, 0x01, 0x00, checksum

0xEB, address, 0xE4, 0x08, data1, ....., data8,

checksum

data1: reserved

data2: reserved

data3: output encryption status:

0 = encryption

1 = decryption

data4: reserved

data5: reserved

data6: reserved

data7: reserved

data8: reserved

Page 28

850 - Serial Protocol

25

25

8.3.4 Set Output Status

Command

Send/Receive

Data

0xE6

0xEB, address, 0xE6, 0x02, data1, data2,

checksum

0xEB, address, 0xE6, 0x01, 0xFA,

checksum

data 1:

0x00: reserved

0x01: RESOULTION_INDEX

0x02: PATTERN_INDEX

0x03: DEEPCOLOR_MODE

0x04: COLORSPACE_MODE

0x05: reserved

0x06: AUDSAMPLE_INDEX

0x07: AUDBIT_INDEX

0x08: AUDCHANNEL_INDEX

0x09: BITRATE_INDEX

0x0A: OUT_LANE_INDEX

0x0B: OUT_ENHFRAMING_INDEX

0x0C: OUT_DELAY

0x0D: training

data 2:

reserved

from 0x00 to 0x17. (24 Resolutions)

from 0x00 to 0x1f. (32 Patterns)

0 = auto, 0x18 = 24bit, 0x1e = 30bit, 0x24 = 36bit

0 = auto, 1 = RGB444, 2 = YUV444, 3 = YUV422

reserved

0 = auto, 1 = 44k, 2 = 48k, 3 = 88k, 4 = 96k, 5 = 176k, 6 =

192k

0 = auto, 0x10 = 16bit, 0x14 = 20bit, 0x18 = 24bit

0 = auto, 1 = turn off, 2 = 2 channels, ……, 8 = 8 channels

0 = auto, 1 = 1.62G, 2 = 2.7G

0 = auto, 1 = 1 channel, 2 = 2 channels, 4 = 4 channels

0 = auto, 1 = not supported, 2 = supported

0 = 0ms, 1 = 200ms, 2 = 400ms, 3 = 600ms, 4 = 800ms, 5

= 1000ms

0 = training again

8.3.5 Get Output Status

Command

Send/Receive

Data

0xE7

0xEB, address, 0xE7, 0x01, 0x00, checksum

0xEB, address, 0xE7, 0x0E, data1,… data14,

checksum

Data1: FOLLOWENCRY_MONITOR;

0 = decryption, 1 = encryption

Data2: RESOULTION_INDEX;

from 0x00 to 0x17 (24 resolutions)

Data3: PATTERN_INDEX;

from 0x00 to 0x1f (32 patterns)

Data4: DEEPCOLOR_MODE;

0 = auto, 0x18 = 24bit, 0x1e = 30bit, 0x24 = 36bit

Data5: COLORSPACE_MODE;

0 = auto, 1 = RGB444, 2 = YUV444, 3 = YUV422

Data6: reserved

Data7: AUDSAMPLE_INDEX;

0 = auto, 1 = 44k, 2 = 48k, 3 = 88k, 4 = 96k, 5 = 176k,

6 = 192k

Data8: AUDBIT_INDEX;

0 = auto, 0x10 = 16bit, 0x14 = 20bit, 0x18 = 24bit

Data9: AUDCHANNEL_INDEX;

0 = auto, 1 = turn off, 2 = 2channels …..,8 = 8channels

Data10: BITRATE_INDEX;

0 = auto, 1 = 1.62G, 2 = 2.7G

Data11: OUT_LANE_INDEX;

0 = auto, 1 = 1, 2 = 2, 4 = 4 (channels)

Data12: OUT_ENHFRAMING_INDEX

0 = auto, 1 = not supported, 2 = supported.

Data13: OUT_DELAY;

0 = 0ms, 1 = 200ms, 2 = 400ms, 3 = 600ms, 4 = 800ms,

5 = 1000 (ms)

Data14: training result;

0 = fail, 1 = succeed

Page 29

26

850 - Serial Protocol

8.3.6 Get Output Status when the Device is in Auto Mode

Command

Send/Receive

Data (Auto Setup)

Data (Not

Auto Setup)

0xE7

0xEB, address, 0xE7, 0x01, 0x01, checksum

0xEB, address, 0xE7, 0x08, data1, ……,

data8, checksum

data1: Deep Color:

0x18 (24bit), 0x1E (30bit), 0x24 (36bit)

Setup value

data2: Color Space:

1 = RGB444, 2 = YUV444,

3 = YUV422

Setup value

data3: Audio sample:

1 = 44k, 2 = 48k, 3 = 88k, 4 = 96k, 5 =

176k, 6 = 192k

Setup value

data4: Audio bit:

0x10 (16), 0x14 (20), 0x18 (24)

Setup value

data5: Audio channel number

If setup is auto: 2-8

channels

If setup is not auto:

setup value

data6: Bit Rate

If setup is auto:

1=1.62G, 2=2.7G

If setup is not auto:

setup value

data7: Lane Number

If setup is auto: 1,

2, 4

If setup is not auto:

setup value

data8: Enhanced Framing

If setup is auto:

1=Not support,

2=Support

If setup is not auto:

setup value

8.3.7 Get Monitor Status

Command

Send/Receive

Data

0xE8

0xEB, address, 0xE8, 0x01, 0x00, checksum

0xEB, address, 0xE8, 0x08, data1, ……,

data8, checksum

data1: reserved

data2: reserved

data3: reserved

data4: monitor type (0 = DVI, 1 = HDMI)

data5: monitor HDCP status. (0 = no HDCP support, 1 =

HDCP supported)

data6: monitor Deep Color status (24/30/36)

data7: Load status. (0 = no HPD, 1=HPD)

data8: reserved

8.3.8 Set Monitor Status

Command

Send/Receive

Data

0xE9

0xEB, address, 0xE9, 0x01, 0x00, checksum

0xEB, address, 0xE9, 0x08, data1, ……,

data8, checksum

data1: monitor Color Space status: 0 = RGB, 1 = YUV422, 2

= YUV444, 3 = YUV444+422

data2: reserved

data3: reserved

data4: monitor Bit Rate status: 1 = 1.62G, 2 = 2.7G

data5: monitor Lane status: 1, 2, 4

data6: monitor Enhanced framing status: 1 = Not support, 2

= Support

data7: reserved

data8: reserved

Page 30

850 - Serial Protocol

27

27

8.3.9 Set Detailed Timing for User-defined Resolution

Command

Send/Receive

Data

0xEA

0xEB, address, 0xEA, 0x26, [block index],

[perform immediately], data1H_4bits,

data1L_4bits, data2H_4bits, data2L_4bits, ……,

data17H_4bits, data17L_4bits, data18H_4bits,

data18L_4bits, checksum

0xEB, address, 0xEA, 0x01, 0xFA, checksum

1. [block index]: From 0 to 7

Note: 7 is the preferred timing of the monitor, so it is

preferable to use 0 to 6

2. [perform immediately]: 1 = switch to the user-defined

resolution immediately, 0 = save the user-defined

resolution but do not switch

3. “H_”: high bits

4. “L_”: low bits

5. “data nH_4bits” and “data nL_4bits”: As, 0xfa apart to

0x0f and 0x0a

6. The 18 data are the detailed timing of the EDID.

Example 1: 1600*1200*60 VESA DMT-10

Frame of Command as: EB 90 EA 26 00 00 04 08 03 0F

04 00 03 00 06 02 0B 00 03 02 04 00 04 00 0C 00 01 03

00 00 06 0F 01 03 01 01 00 00 00 00 01 0E (00)

Example 2: 720p

Frame of Command as: EB 90 EA 26 00 00 00 01 01 0D

00 00 07 02 05 01 0D 00 01 0A 02 00 06 0E 02 08 05 05

00 00 07 0E 08 08 04 02 00 00 00 00 01 0A (00)

8.3.10 Get Detailed Timing for the User-defined Resolution

Command

Send/Receive

Data

0xEA

0xEB, address, 0xEA, 0x01, data1, checksum

0xEB, address, 0xEA, 0x26, block index, 00,

data1H_4bits, data1L_4bits, data2H_4bits,

data2L_4bits, ……, data17H_4bits,

data17L_4bits, data18H_4bits, data18L_4bits,

checksum

data1: From 0 to 7

8.3.11 Setting a Predefined Resolution as a User-defined Resolution

Command

Send/Receive

Data

0xEA

0xEB, address, 0xEA, 0x03, data1, data2, data3,

checksum

0xEB, address, 0xEA, 0x01, 0xFA, checksum

data1: block index: from 0 to 7

data2: perform immediately: 0 = save the user-defined

resolution but do not switch, 1 = switch to the userdefined resolution immediately

data3: predefined resolution number, from 0 to 35

8.3.12 Get the Monitor EDID

Command

Send/Receive

Data

0xFD

0xEB, address, 0xFD, 0x02, 0x03, 0x00,

checksum

0xEB, address, 0xFD, 0x12, 0x03, [group num],

data1H_4bits, data1L_4bits, data2H_4bits,

data2L_4bits, ……, data7H_4bits, data7L_4bits,

data8H_4bits, data8L_4bits, checksum

[group num]: from 0 to 0x3f. Each group has 8 bytes of

EDID data

When sending the command, there are 64 groups for 512

bytes of EDID data

Page 31

28

850 - Serial Protocol

8.3.1 Get the Monitor DPCD

Command

Send/Receive

Data

0xFD

0xEB, address, 0xFD, 0x02, 0x05, data1, (check

sum)

0xEB, address, 0xFD, 0x12, 0x05, [data num],

data1H_4bits, data1L_4bits, data2H_4bits,

data2L_4bits, ……, data7H_4bits, data7L_4bits,

data8H_4bits, data8L_4bits, (check sum)

data1:

0: Receiver Capability Field

1: Link Configuration Field

2: Link / Sink Status Field

3: Source Device Specific Field

4: Sink Device Specific Field

5: Branch Device Specific Field

6: Sink Control Field

[data num]: from 0 to 0x1f. Every group has 8 bytes

DPCD data

When sending the command, there are 32 groups for 256

bytes of DPCD data

8.3.2 Reset Device

Command

Send/Receive

0xED

0xEB, address, 0xED, 0x04, 0x03, 0x01, 0x02, 0x07, checksum

0xEB, address, 0xED, 0x01, 0xFA, checksum

Page 32

850 - Serial Protocol

29

29

Page 33

For the latest information on our products and a list of Kramer distributors,

visit our Web site where updates to this user manual may be found.

We welcome your questions, comments, and feedback.

Web site: www.kramerelectronics.com

E-mail: info@kramerel.com

P/N:

2900-300033

Rev:

2

!

SAFE TY WARNI NG

Disconnect the unit from the power

supply before opening and servicing

Loading...

Loading...