Page 1

Auto Refkeratometer

Operations Manual

RB-525-B04

Page 2

INTRODUCTION

This manual contains information on correct handling and operational procedures as well as safety

consideration pertinent to KW-2000

Before carrying out measurement and/or adjustment, read the instructions thoroughly so that effective

operation is ensured. As this constitutes an important reference and user guide, keep it on hand at all times.

NOTE

The information contained in this manual is subject to change without notice.

While reasonable efforts have been made in the preparation of this document to ensure its accuracy,

you should contact your local distributor immediately, if any quarries arise due to editorial errors or

omissions etc.

If you find any imperfect collating or missing pages, contact your local distributor for replacement.

SAFETY CONSIDERATION

KW-2000 is a Class I, Type B medical instrument as well as LED Class 2 product.

This instrument complies with Medical Device Directive 93/42/EEC.

A great deal of consideration has gone into the design and manufacturing of this instrument with regard to

its operational ease, the patient's safety and well-being as well as to the reliability of the product.

For safer and more effective use, however, follow the points described in this manual.

This instrument is designed for professional use.

~ General Definitions of Safety Symbols ~

Personal injury or physical damage may occur when this warning

CAUTION

LED Class 2 Product

NOTE

is ignored.

General warning. Caution. Risk of danger.

Denotes general ban or prohibition.

General mandatory action.

Caution of invisible LED radiation.

Avoid exposure to beam.

Indicated inside of the device.

This device is an LED class 2 product.

Additional information which is important to the text or is

useful/convenient to know.

RB-525-B041

Page 3

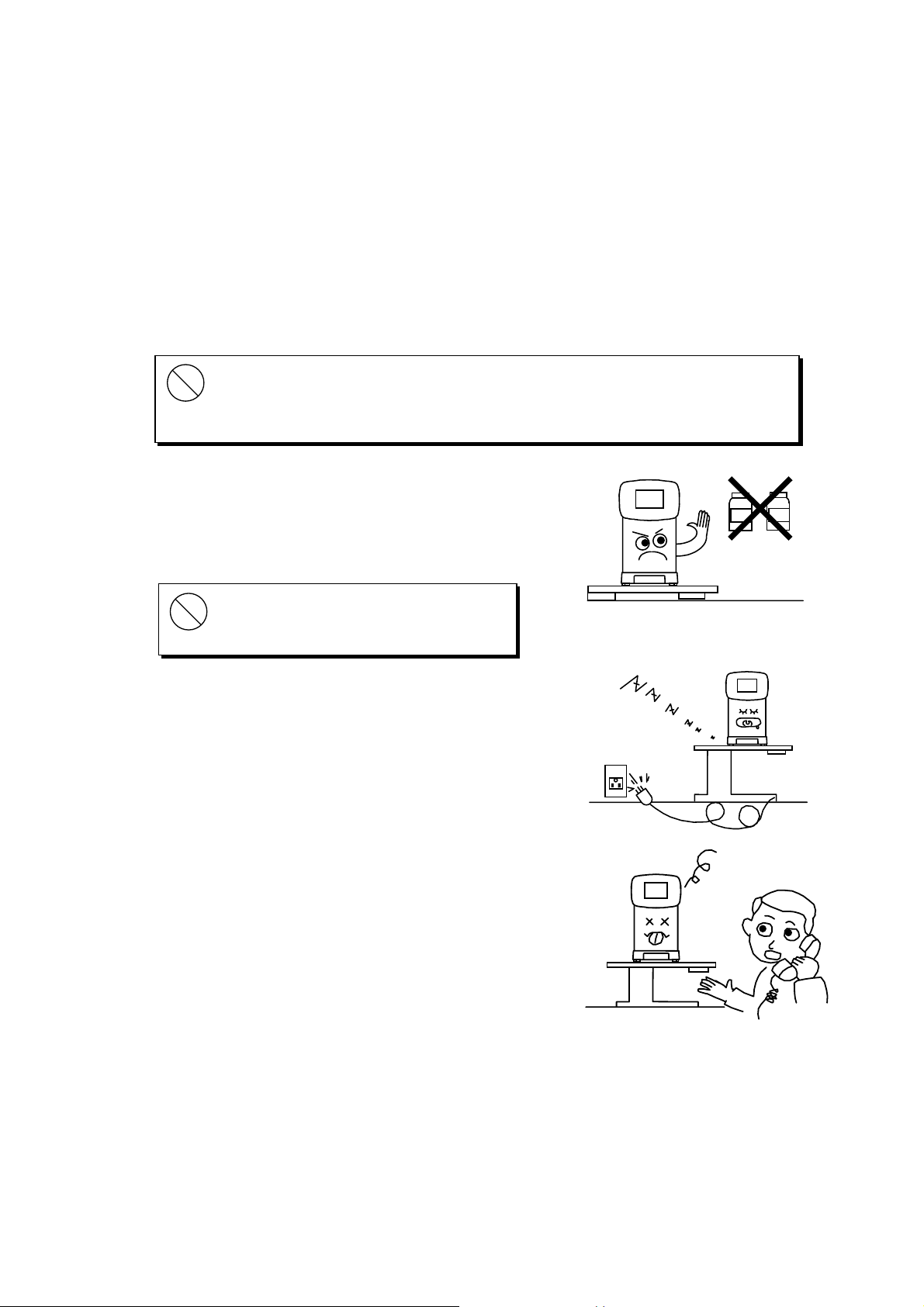

CAUTION

Always take great care when operating KW-2000. Malfunction or damage to the instrument could

occur.

Cut the power immediately if malfunction occurs during operation. Damage to the equipment or

personal injury will result. Consult your dealer, if repair work needs to be carried out.

At no time attempt to remodel or disassemble KW-2000. Damage to the instrument or personal injury

will result.

As KW-2000 is a precision optical instrument, operations must be carried out at all times by

experienced, authorized personnel. Damage to the equipment or personal injury will result.

Avoid installation near TV or radio. The reception can be disturbed by electrical noise. Follow the

manual for the proper installation.

Never remove the plug from the outlet if your hands are wet. Electric shock or personal injury could

result.

Make sure the power cord is not damaged. Fire or electric shock may occur.

Do not touch the optical parts. Measurement accuracy will be adversely affected.

The power cord must be firmly connected to an electrical ground (safety ground) at the power outlet.

Personal injury may result form electric shock, etc.

If the instrument fails to work properly, you should not try to repair the fault. Consult your dealer

immediately.

The instruction in this manual ensures correct operations.

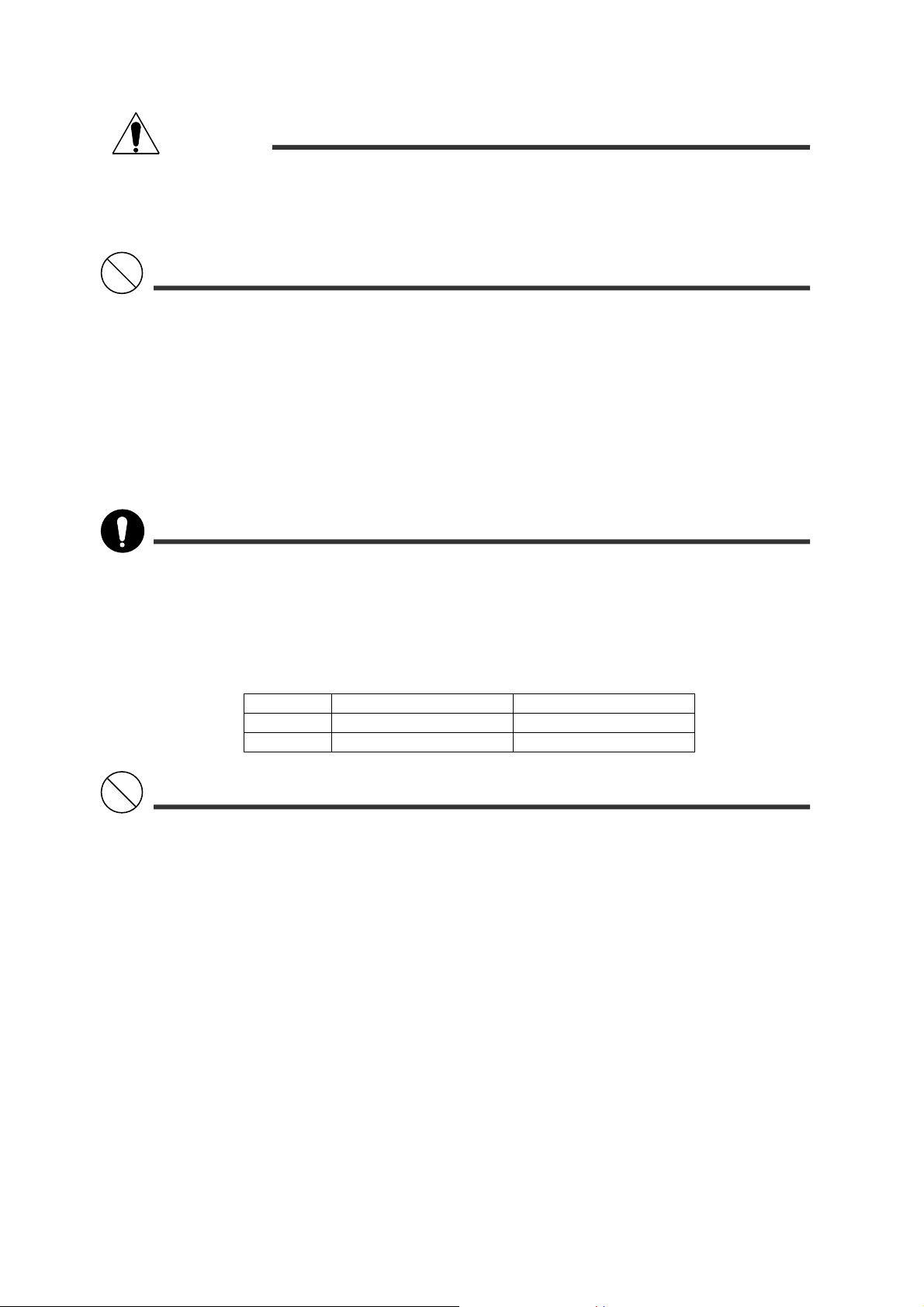

Observe the following environmental conditions for used and storage. Avoid dew condensation at all

time.

Temperature Relative humidity

Use +10°C to +40°C 30% to 85%

Storage –10°C to +60°C below 70%

Avoid the following conditions for storage and use of the instrument.

Where noxious gases or air pollutants are present.

Where dust and grit may occur.

Where oil fumes or greasy substances are emitted.

Where there are atmospheric concentrations of salt.

Near gas generation areas and places where dust accumulates.

Keep in a secure, stable situation. Do not expose to strong vibrations (areas of seismic activity) and

sudden shocks (this includes transportation) etc.

Where there is an inclination of more than 10 degrees.

Where voltage from the power sources rises or falls sharply during loading.

Where fluctuations in the voltage of the power source occurs.

Direct contact with sunlight.

If the instructions above are not followed, damage to the equipment or personal injury will ensue.

RB-525-B042

Page 4

Contents

Introduction............................................................................................................................. 1

Safety Consideration............................................................................................................... 1

Contents.................................................................................................................................. 2

Accessories............................................................................................................................. 4

1. Parts Identification............................................................................................................ 5

2. Conveyance and Handling Procedure ............................................................................. 6

3. Installation Environment................................................................................................... 6

4. Safeguard Summary........................................................................................................ 7

5. Preparation....................................................................................................................... 8

5.1 Setting ...........................................................................................................................................8

5.2 Applying Power .............................................................................................................................9

5.3 Standby.......................................................................................................................................10

5.4 Switch Function............................................................................................................ ...............11

6. Measurement................................................................................................................. 12

6.1 Measurement Flow......................................................................................................................12

6.2 Alignment ....................................................................................................................................13

6.3 Measurement Results .................................................................................................................14

6.4 Print Out......................................................................................................................................15

6.5 Kerato-Peripheral Measurement.................................................................................................16

6.6 IOL Measurement........................................................................................................................18

6.7 Menu Screen Setting...................................................................................................................19

6.7.1 Each Item Description....................................................................................................20

6.7.2 Optional Functions .........................................................................................................23

6.8 Auto Start Function......................................................................................................................27

6.9 Data Screen Function..................................................................................................................29

6.10 Power Saving Function .............................................................................................................30

6.11 Output Terminal.........................................................................................................................30

7. Tips for Effective Measurement......................................................................................31

8. Error Messages.............................................................................................................. 32

9. Contact Lens: Base Curve Measurement...................................................................... 33

10. Troubleshooting............................................................................................................. 34

11. Storage and Maintenance.............................................................................................. 35

11.1 Reloading Printer Paper............................................................................................................35

11.2 Fuse Replacement....................................................................................................................36

11.3 Storage......................................................................................................................................36

11.4 Confirmation of Measurement Accuracy...................................................................................37

11.5 Periodical Inspection and Maintenance ....................................................................................37

12. Specifications................................................................................................................. 38

RB-525-B043

Page 5

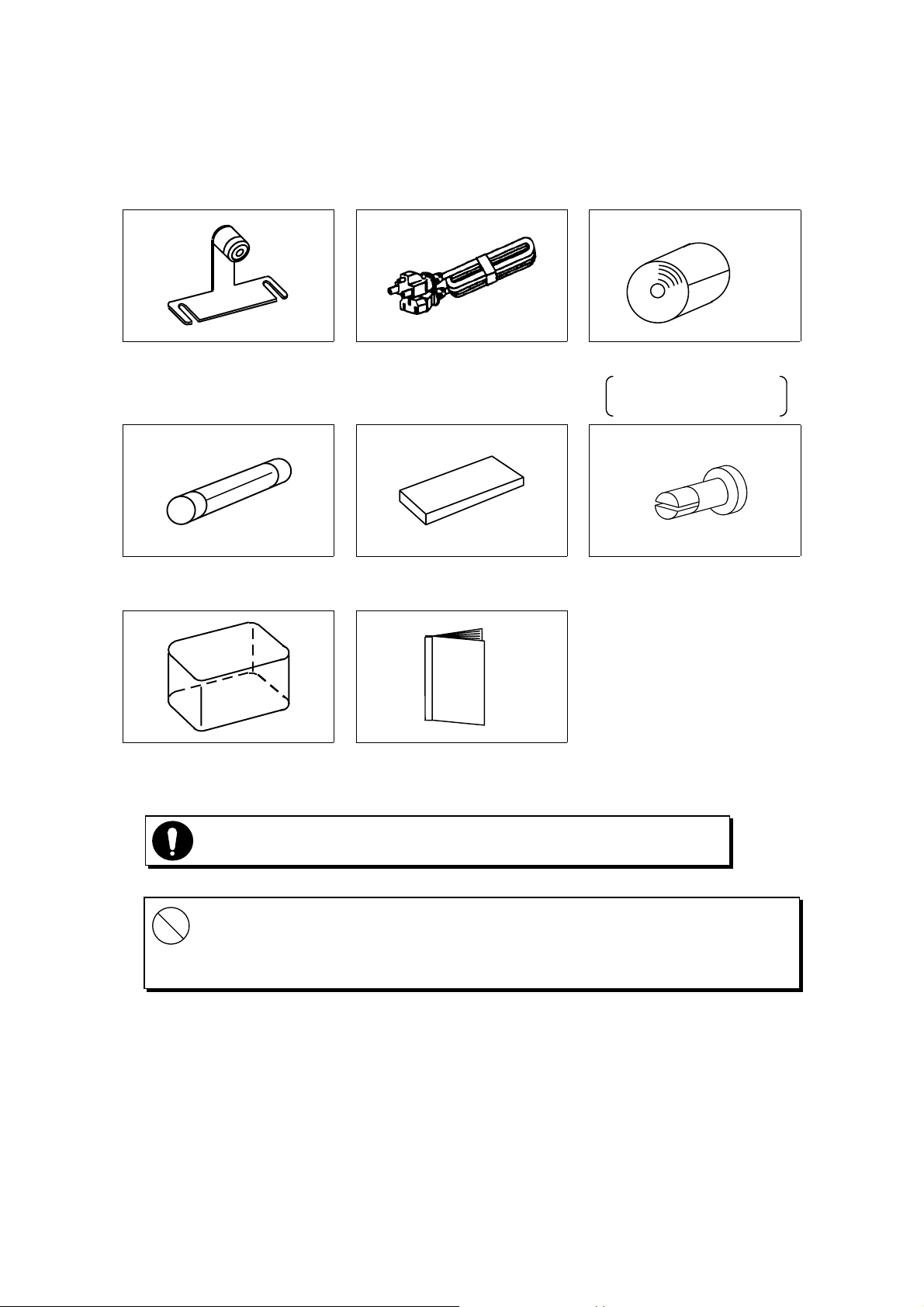

Accessories

Model eye: 1

(with a contact lens holder)

Fuse: 2

(T2A 250V)

Dustproof cover: 1 Operations manual: 1

Power cord: 1

(2.5m)

Pack of chin rest liners: 1

(1,000 sheets)

Printer paper role: 3

(width 57mm)

Two packed and o ne

installed into the body

Chine rest liner pin: 2

Use accessories specified by us to avoid any malfunction or failure.

Extra care should be taken for storage of a model eye. Avoid where the lens of the

model eye may be damaged as well as any dusty or humid/steamy environments.

Avoid direct sunlight, humidity and high temperature when storing printer paper

which is a thermal paper.

RB-525-B044

Page 6

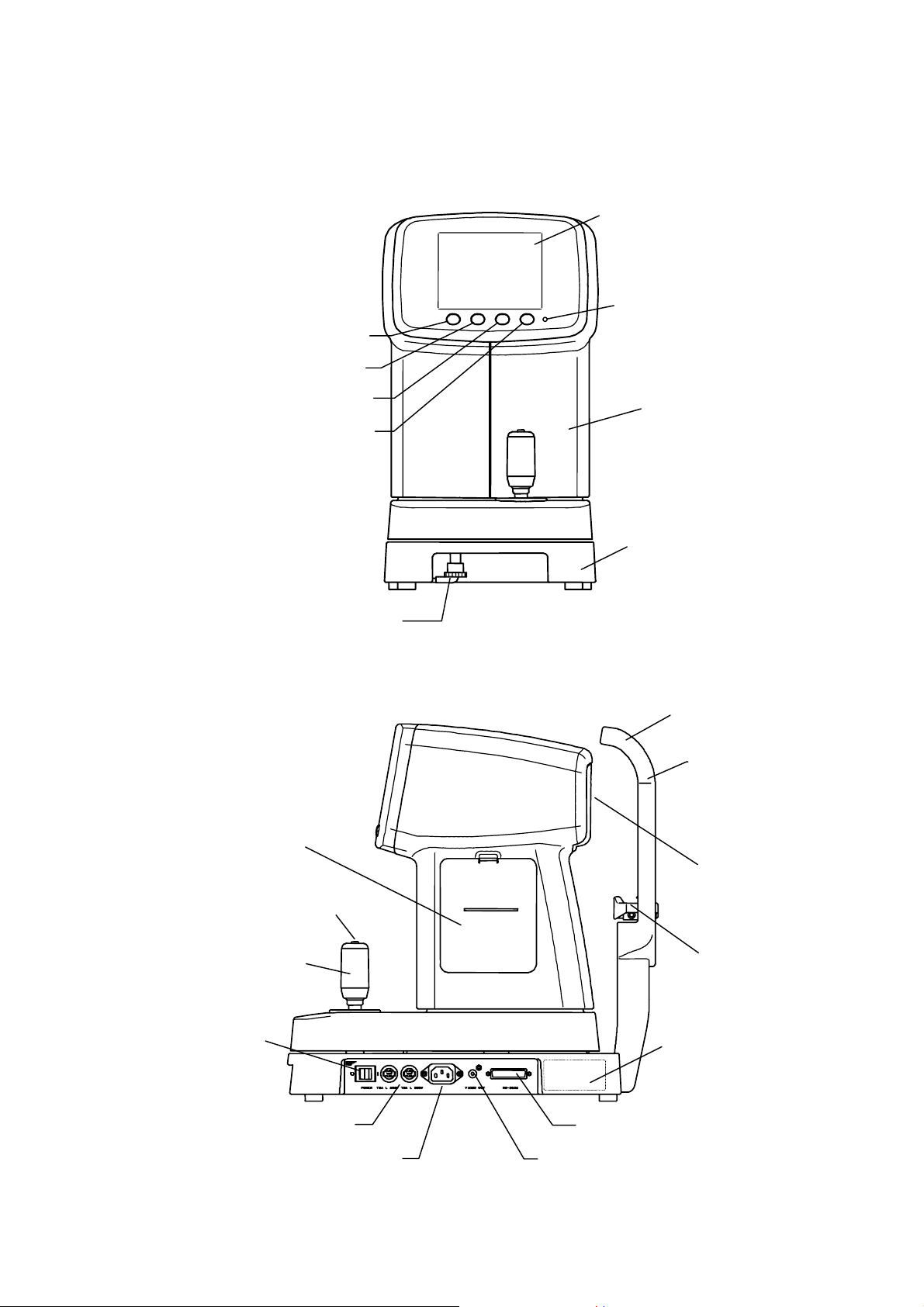

1. Parts Identification

y

IOL switch

Measurement mode selection switch

LCD monitor

Power indicator

Menu switch

Print switch

Anti-sliding lock

Printer

Bod

Base

Head rest

Eye mark

View window

Measurement start switch

Joystick

Power switch

Fuse holder

Power plug connector

External interface connector

External monitor output terminal

Chin rest

Rating plate

RB-525-B045

Page 7

2. Conveyance and Handling Procedure

When transporting the instrument, make sure that the body has been securely locked.

Center the body onto the base so that their edges are aligned. Push down the lock while turning right until

both body and base are firmly fixed to each other.

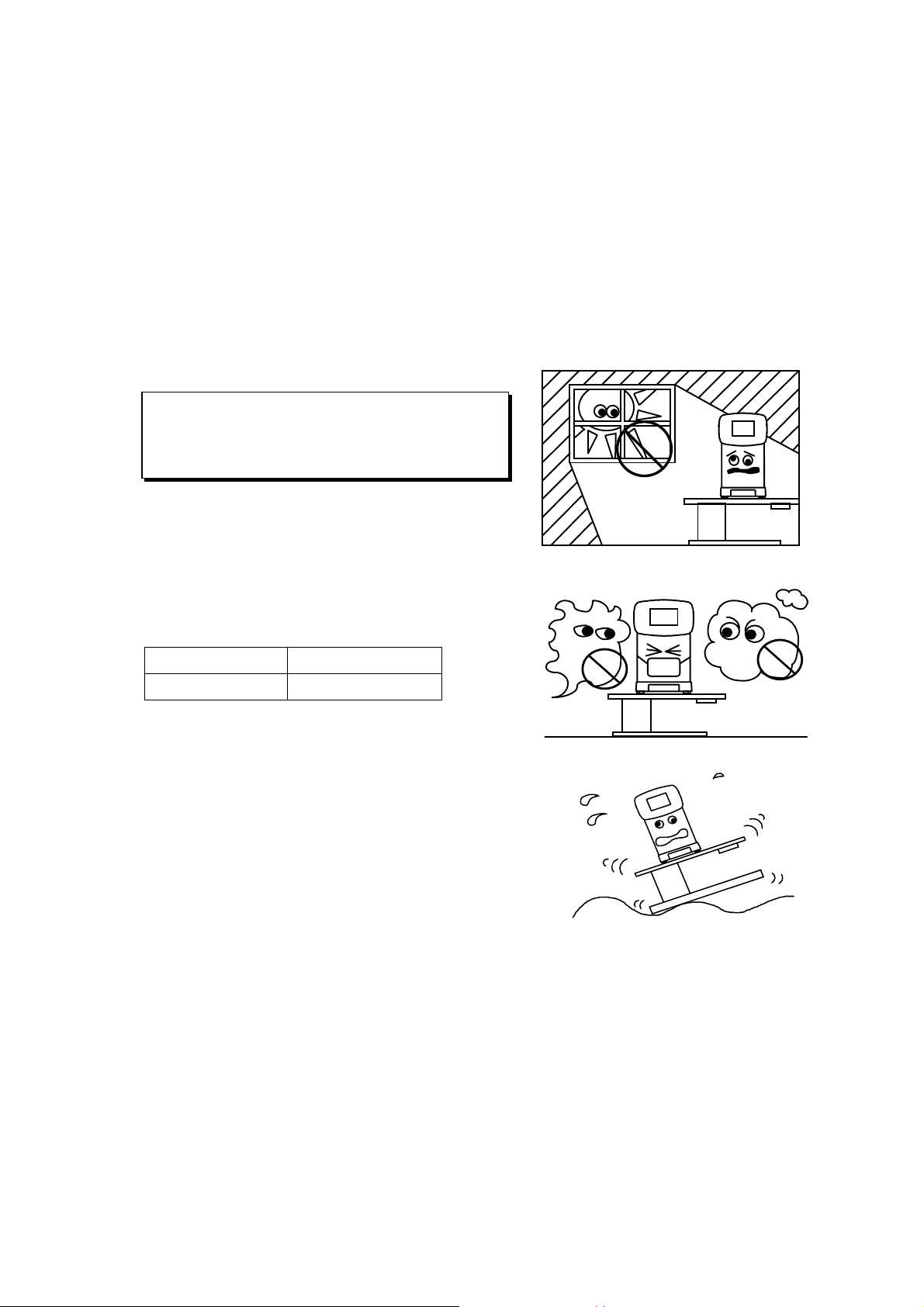

3. Installation Environment

1) Do not expose the instrument's view window directly to the sunlight or bright lighting from other

sources.

Great care should be taken and avoid that the

examinee is exposed to strong light or glare. The

pupil will contract too much for measurement to

be carried out.

2) Do not operate in places where either dust or rubbish

accumulates. Environment with extremes in heat and

humidity should also be avoided.

Always follow the environmental requirements below

for installation.

Temperature

Relative Humidity

3) Keep away from inflammable or explosive gases as

well as storage areas housing medical supplies and

chemicals.

+10 °C ~ – 40°C

30 % ~ 85 %

Gases

Dust

4) Avoid installing where dew condensation may

accumulate. Also, avoid where the radical temperature

changes may occur.

5) Keep away from sites that may experience strong

vibrations or sudden shocks.

6) Malfunction is likely to occur if the instrument is improperly stabilized or accidentally overturns.

To prevent internal/external damage caused by sudden impact, set the instrument on a solid and

secure surface. Do not store in high, 'out of reach' places.

RB-525-B046

Page 8

4. Safeguard Summary

1. KW-2000 is a precision optical instrument. Always handle with care and avoid dropping it

accidentally.

2. Ensure that the instrument is properly grounded when connected to the power source.

3. Do not touch the optical parts with fingers and be sure to avoid dust, as their measuring accuracy

could be adversely affected and incorrect values may result.

When dust or fingerprints appear on the optical part, use a soft cloth to wipe off

the build-up. In case that the build-up is hard to remove, absolute alcohol is

recommended. Take great care when cleaning these parts as they are particularly

sensitive and fragile.

4. If the surfaces of the measuring unit and main unit including

the control panel are dirty, gently wipe with a dry cloth. For

hard to remove stains, a damp cloth or neutral cleanser is

recommended.

Avoid using organic solvents that will

damage the water based paint finish of the

instrument.

5. Clean the chin rest and head rest with the neutral cleanser.

For disinfecting them, especially where the examinee may

contact, hydrogen peroxide (Oxydol) is recommended.

6. If the instrument is not used for any length of time, remove

the power cord from the outlet.

7. When not in use, protect the instrument with a supplied

dustproof cover.

8. When the instrument fails to function properly, never

attempt to perform internal service or adjustment. Contact

your nearest registered agent, distributor or retail outlet.

Benzene

Thinner

RB-525-B047

Page 9

5. Preparation

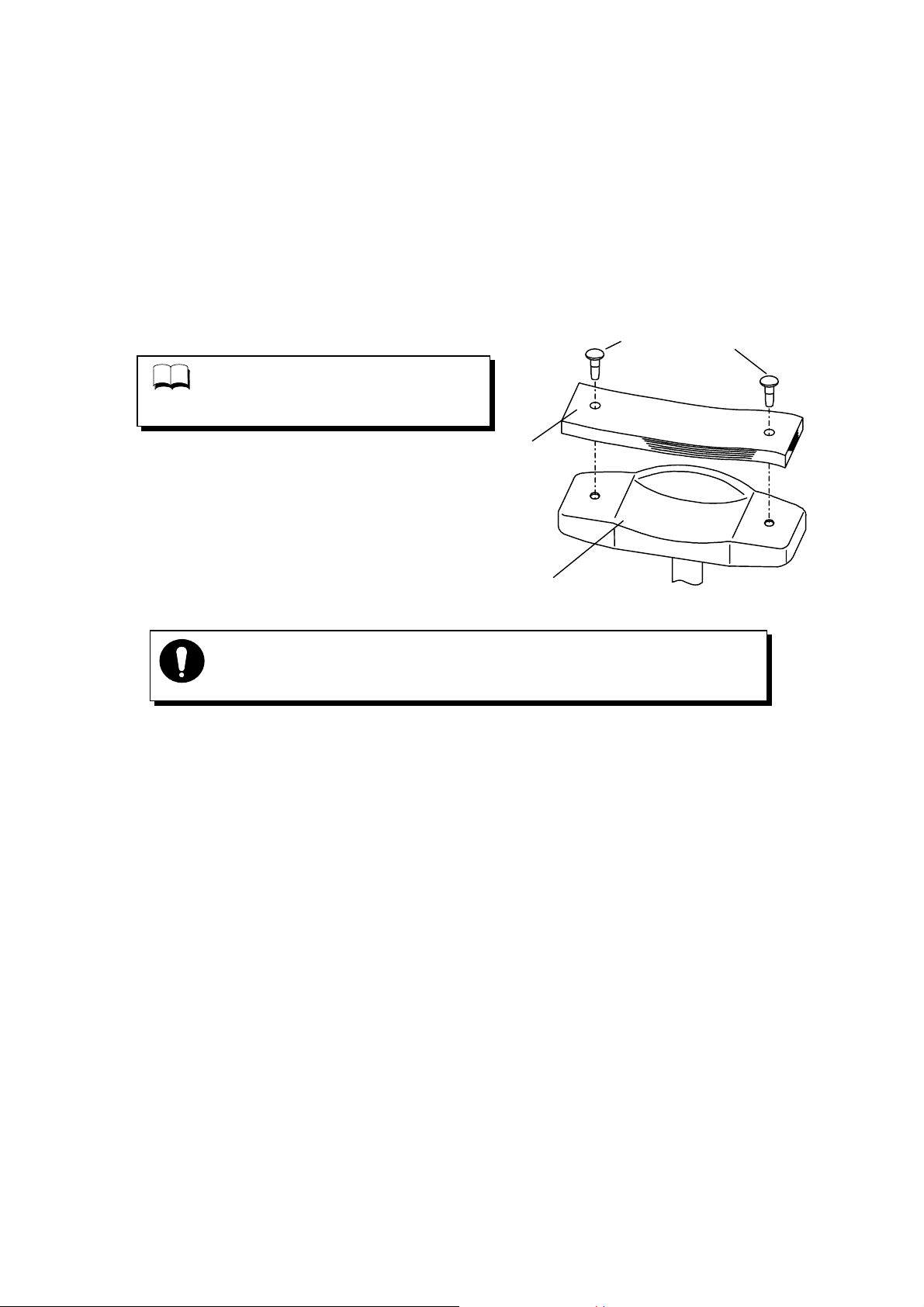

5.1 Setting

(1) Set a roll of printer paper in the printer. Refer to '11.1 Reloading Printer Paper' for the procedure.

(2) Set and fix the chin rest liners with the chin rest liner pins on the chin rest.

Refer to the figure on the right.

Chin Rest Liner Pins

For sanitary consideration, disposing

NOTE

a sheet of the used chin rest liners after

every measurement is recommended.

Chin Rest Liners

Chin Rest

Always use the chin rest liners following above.

For sanitary consideration, disinfecting the chin rest with Oxydol is

recommended.

RB-525-B048

Page 10

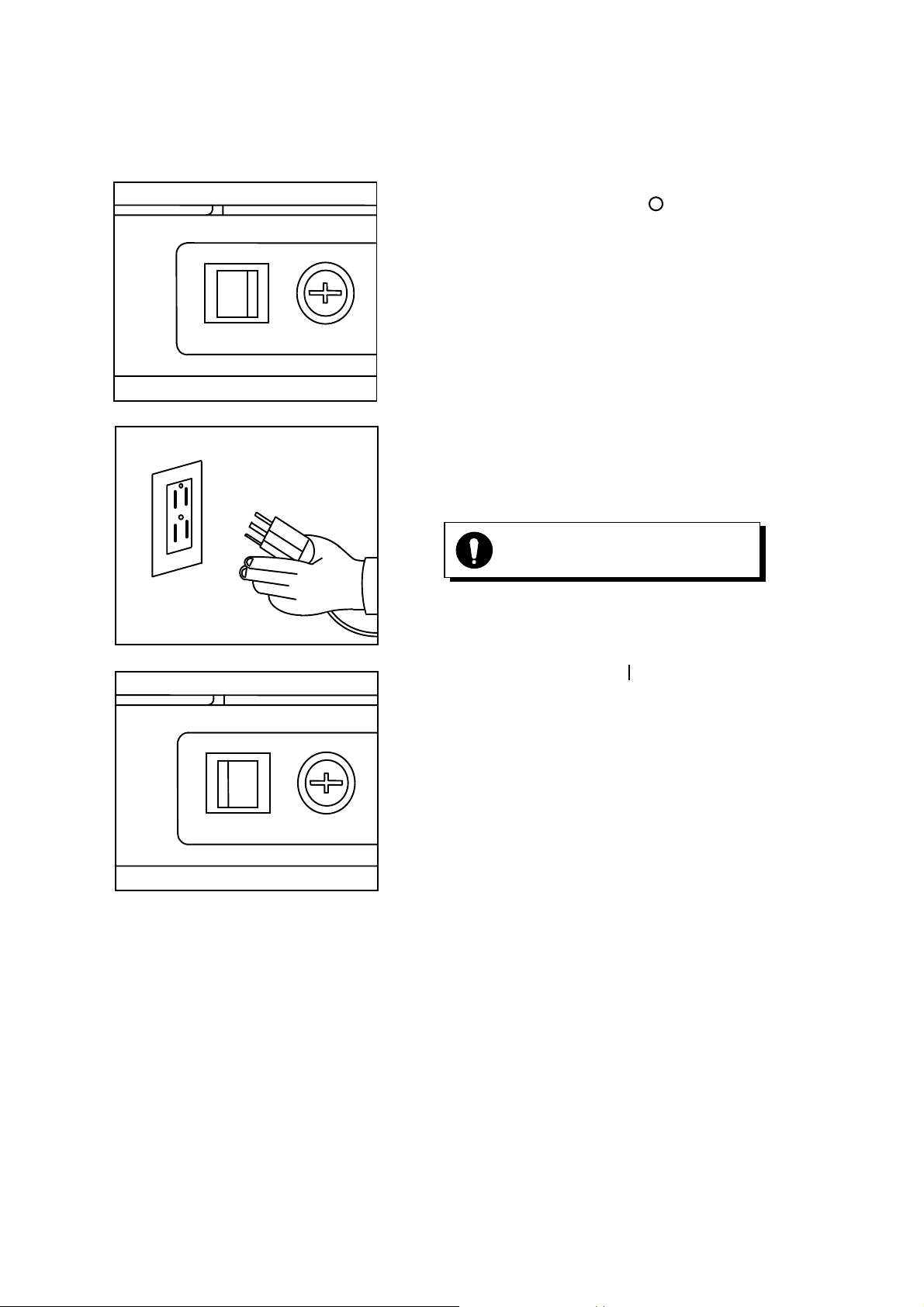

5.2 Applying Power

(1) Confirm that the power is 'OFF' ( ).

O

POWER

I

T 2A 250V

(2) Insert the power cord into the instrument's power plug

connector. Then insert the plug into a general-purpose

outlet.

(3) Turn the power switch 'ON' ( ).

Always make sure that the cable is

grounded.

O

POWER

I

T 2A 250V

RB-525-B049

Page 11

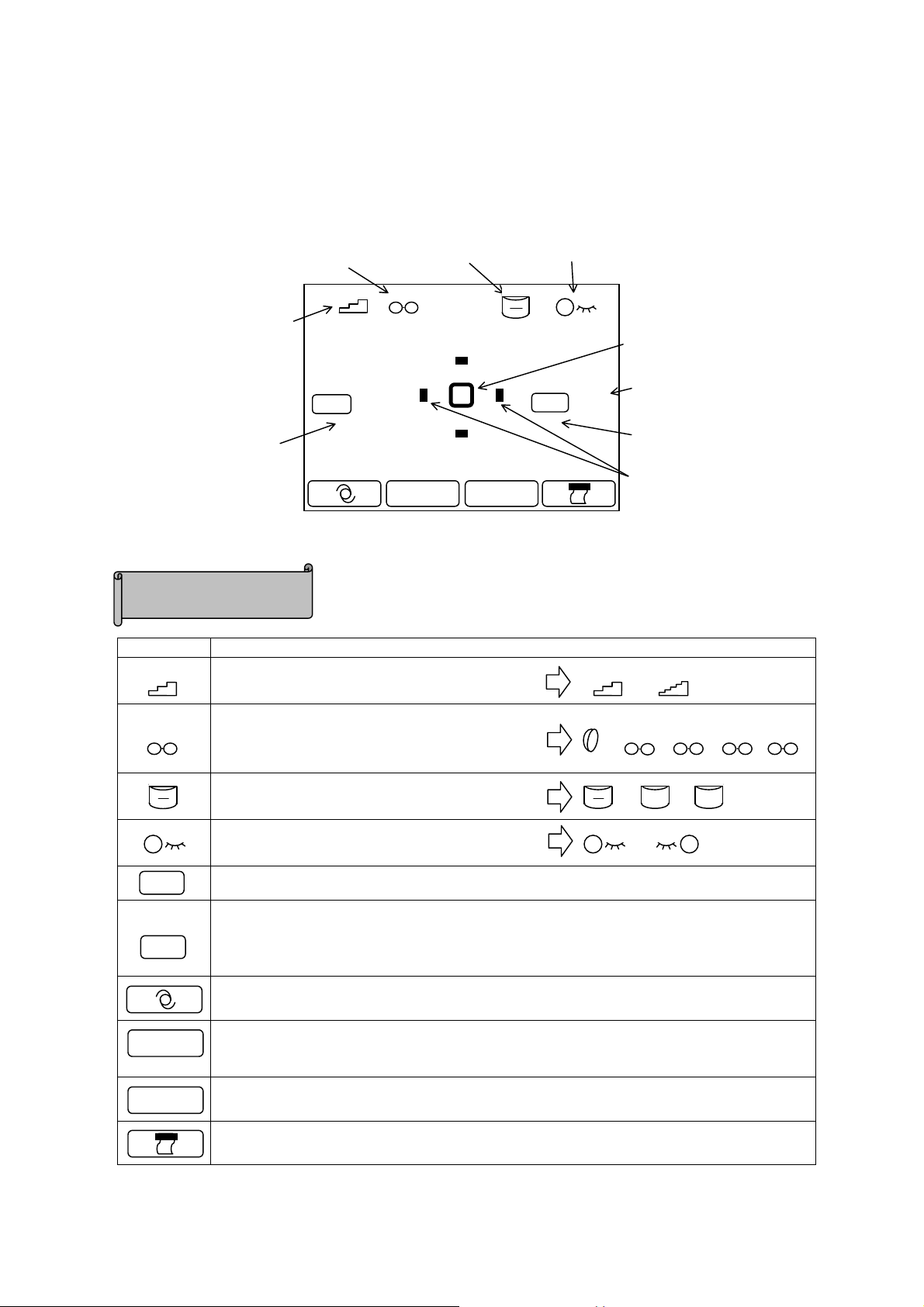

5.3 Standby

f

When the power is turned on, the screen as shown below appears on the LCD monitor, which is ready to

take measurements.

Vertex distance

Increment o

measurement values

Refraction data

display area

Icon Description

Cylindrical mark

( 0 )

12

R

/

K MENU

0.25

Ref.

(Normal measurement)

Eye selection indication

0 )

(

Ker.

Icon Description

0.25 0.25

Indicates increment of refraction data.

Reticle mark

Number of

measurement

Keratometry data

display area

Minimum pupil

diameter measurable

0.12

12 10 1513.512

Indicates corneal vertex distance.

Selection is available among 0, 10, 12, 13.5

and 15mm.

Indicates a mark for a cylindrical value.

Indicates an eye currently measured.

Ref.

Refractive measurement result is displayed in this area. Indicated values are S, C, and A.

Keratometry result is displayed in this area.

Indicated values are R1, R2, and A.

Ker.

K1, K2 and KC can be also indicated when the setting of KERATO in the menu screen is

changed.

Shifts to IOL measurement mode.

Measurement mode is switched. There are four measurement modes: Ref/Kerato

R

K

/

continuous measurement, Ref single measurement, Kerato single measurement, and

measurement corneal periphery.

MENU

Shifts to MENU screen.

Displays the measurement result on the screen and prints it out.

+ ±

RB-525-B0410

Page 12

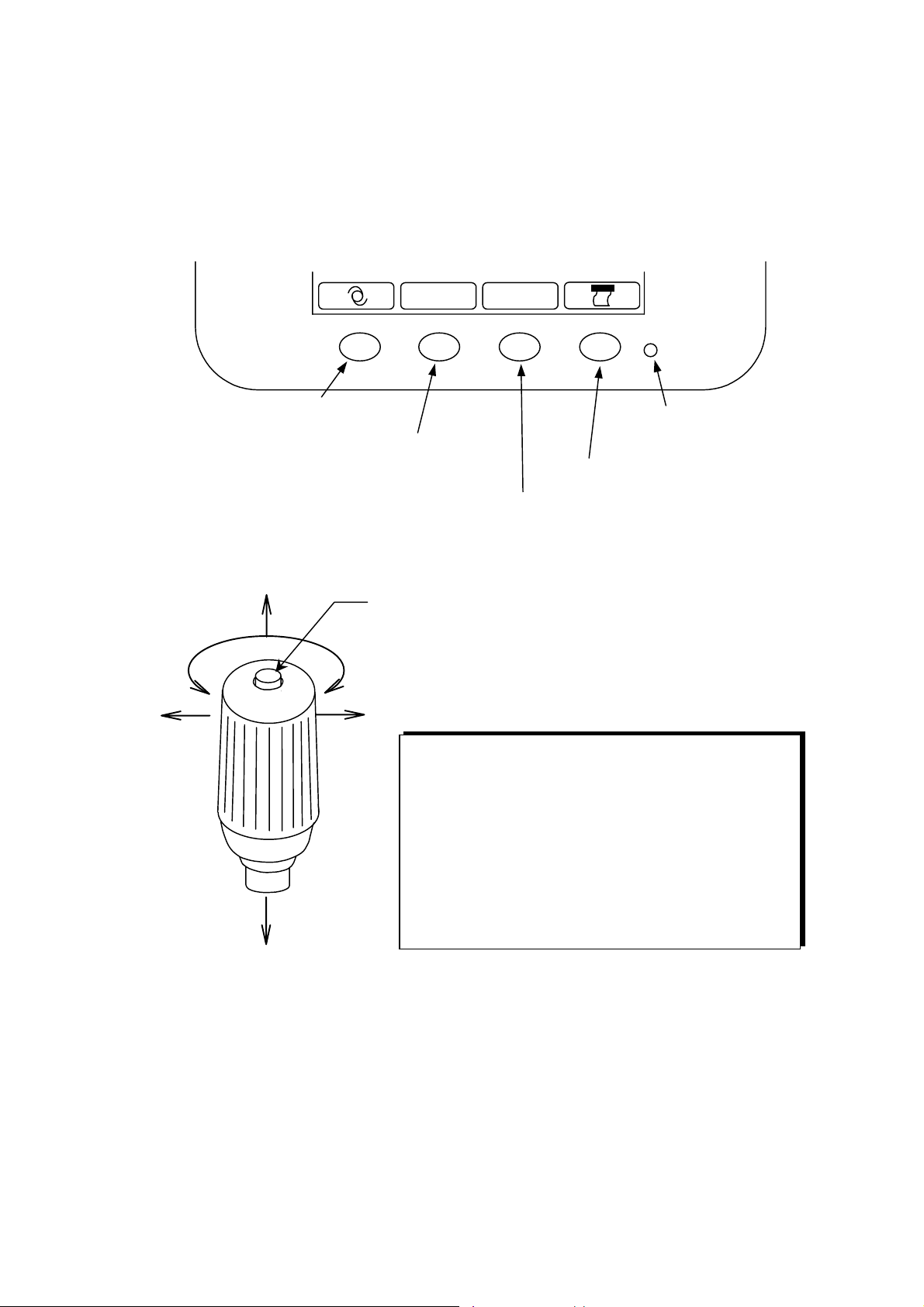

5.4 Switch Function

Operating switches below a LCD monitor correspond to the icons displayed on the bottom of the screen.

For normal measurement, each icon functions as below.

/

R

K MENU

Down

Left

IOL switch

Measurement mode selection switch

Forward

Measurement start switch: starts the measurement.

Up

Right

Backward

Operation of Joystick

• Forward: the body moves toward an examinee.

• Backward: the body moves toward an operator.

• Right/Left: the body moves to the right or left

respectively.

• The measurement unit moves up when the joystick

is rotated to the right, and moves down when rotated

to the left.

Power indicator

(It blinks when the saving

function is activated.)

Print switch

Menu switch

RB-525-B0411

Page 13

6. Measurement

6.1 Measurement Flow

(1) Rotate an anti-sliding lock clockwise to release it.

(2) Have the examinee place his/her chin on the chin rest and his/her forehead against the head rest.

Then, have him/her see a target.

Uncomfortable posture may cause fatigue to the examinee during measurement.

Vertically adjust the optical table or the chair to avoid that.

NOTE

(3) Check from the side and adjust the chin rest so that the examinee's eye level is in line with the eye

mark.

(4) When the eye appears on LCD monitor, carry out alignment for correct measurement.

Refer to '6.2 Alignment' for detail procedure.

NOTE

(5) Press the measurement start switch when the alignment mark reaches a center of the reticle mark, and

take measurement.

KW-2000 incorporates a high-speed continuous me asurement function.

To us the function, set DAT CLEARS (S) for OFF in MENU screen and keep pressing

NOTE

the measurement start switch during measurement.

RB-525-B0412

Page 14

6.2 Alignment

(1) Operate a joystick to bring a center of the subject eye onto a

reticle mark. When the subject eye is focused on, a kerato

ring appears.

If the eyelid is over the kerato ring, urge the

examinee to open the eye bigger .

NOTE

0.25

( 0 )

Kerato ring

R

12

/

K MENU

(

0 )

Ker.Ref.

(2) Keeping the reticle mark in the center of the subject eye, try

to focus the subject eye, and then, an alignment mark ( )

will appear.

Then, operate the joystick to bring the alignment mark ( )

into the center of the reticle mark.

(3) Keeping the alignment mark ( )in the center of the reticle

mark, focus on the subject eye and press the measurement

start switch.

(For auto measurement, measurement will automatically

start once the focus on the eye is achieved.)

Alignment mark

( 0 )

R

12

/

0.25

Reticle mark

0.25

12

( 0 )

K

MENU

0 )

(

Ker.Ref.

0 )

(

Ker.Ref.

NOTE

/

R

When focus is achieved, the kerato ring will become the thinnest.

K

MENU

RB-525-B0413

Page 15

6.3 Measurement Results

(

)

K

( 1 )

R

12

/

630

K MENU

R

(

1 )

er.

R1 7 . 8 5

R2 7 . 7 4

A90

Keratometry measurement result

Radi us of Cu rvat ure(m axim um)

Radi us of Cu rvat ure(m i nmum )

Axis An g le

Refr act i ve measure me nt re sult

Spherical value

Cylindrica l value

Axis angle

Pupillary Distance

Near p upillary distance

0.25

Ref.

S-4.75

C-0.25

A90A90

PD=67 NP D= 2

※ PC result is indicated after both right and left eyes are measured. The order of the eye to be measured is

not important.

NPD is indicated when some value is set in 'W-D (cm)' of menu screen only.

RB-525-B0414

Page 16

6.4 Print Out

Normally you can print out the measurement result by pressing PRINT switch after the measurement.

(The icon of PRINT switch in the monitor turns into blue during printing.)

A maximum of ten data is recorded for each eye and the most reliable among them is indicated as an

optimum value. The optimum value is indicated when each eye is measured over three times only.

The printout format, ALL, ECONO and OFF, can be set on the MENU screen.

∗

ALL : prints out a maximum of ten refractive data for each eye.

Optimum values only are printed out for the others except for the refractive data.

∗

ECONO : prints out only optimum values of all measurement data.

∗

OFF : prints out no data.

Regardless of the setting of the printout format, the measurement data stored in memory will be cleared

when the measurement start switch is pressed following the PRINT switch.

Sample printout when PRINT FORM is set for ALL

Message area

Refractive data

Keratometry data

Refractive data

Keratometry data

Pupillary distance

No. 00001

NAME

2002 11 20 14:29

VD=12

<R> SPH CYL AX

- 4.75 -0.25 62

- 4.75 -0.00

- 4.75 -0.00

----------------------------------------

- 4.75 -0.00

<R> mm D AX

R1 7.59 44.50 120

R2 7.57 44.50 30

AVE 7.58 44.50

CYL 0.00

<L> SPH CYL AX

- 4.50 -0.75 90

- 4.50 -0.75 90

- 4.50 -0.75 89

----------------------------------------

- 4.50 -0.75 90

<L> mm D AX

R1 7.59 44.50 120

R2 7.57 44.50 30

AVE 7.58 44.50

CYL 0.00

PD = 64

MODEL KW-2000(V1.00)

Date and time display

Right eye data

Opt imum value

indicated when

each eye is

measured more

than three times.

Left eye data

Sample printout

when PRINT FORM is set for

No. 00001

NAME

2002 11 20 14:29

VD=12

<R> SPH CYL AX

- 4.75 -0.00

<R> mm D AX

R1 7.59 44.50 120

R2 7.57 44.50 30

AVE 7.58 44.50

CYL 0.00

<L> SPH CYL AX

- 4.50 -0.75 90

<L> mm D AX

R1 7.59 44.50 120

R2 7.57 44.50 30

AVE 7.58 44.50

CYL 0.00

PD = 64

MODEL KW-2000(V1.00)

※Message area

You can print out registered characters in the range of 22 characters/line x 2 in the message area.

For registration, refer to

'6.7.2 Option Function: I. Message Input Function'

.

RB-525-B0415

Page 17

6.5 Kerato-Peripheral Measurement

P.K

MENU

KW-2000 incorporates a function to measure not only a center but also peripheries of a cornea.

Operation

(1) Press a measurement mode selection switch to switch over to P.K. mode.

P.K. measurement screen will appear and a 'measurement guiding mark' which indicates the

measurement position will appear on the top of the screen.

NOTE

Measurement guiding mark

R

P.K.

Measurement position:

Normally measurement is taken in the

following order: C→S→I→N.

C (Central): center

S (Superior): top

T (Temporal): temple side

I (Inferior): bottom

N (Nasal): nasal side

.

P.K. target selection switch

Measurement Guiding Mark

A measurement guiding mark changes its color and state to signal the measu rement

position and the end of measurement. Each color and state means as follows.

No color: where have not been measured yet.

Blue : where is going to be measured.

Light blue: where measurement is complete.

(2) Measure the center following the kerato measurement

procedure.

When the measurement is complete, the center of the

measurement guiding mark changes from blue to light

blue, and the next measurement position becomes blue.

Always start to measure from the center.

NOTE

However, it is not necessary when the

center is already measured in R/K mode or

Kerato mode.

Next measurement position (blue)

R

P.K.

P.K.

MENU

RB-525-B0416

Page 18

(3) Measure the corneal periphery.

(

)

Have the examinee look at the fixation target that is

illuminating. A measurement position in the guiding

Position already measured

Next measurement position

blue

mark is indicated in blue. Carry out alignment and

press the measurement switch.

When the measurement is completed, the guiding mark

R

changes blue to light blue and the next measurement

position becomes blue.

P.K.

For peripheral measurement, align the

NOTE

alignment mark to the center of the reticle

mark, not to the center of pupil.

H 7.55 V 7.51

P.K.

MENU

(4) Complete the peripheral measurement for all four positions. When it is completed, all positions of the

measurement guiding mark will turn to light blue.

Proceed to measure the other eye according to the procedure above.

When you wish to measure some position again, use P.K. target selection switch to

NOTE

move the cursor to the position you wish to measure.

When you can not take any data, or you do not need all data of the peripheral

measurement, you can skip some position using P.K. target selection switch.

In such a case, the result of the position measured only is displayed. The center,

however, must be measured all the time.

Printout Sample of P.K. Measurement

<R> mm D AX

R1 7.59 44.50 120

R2 7.57 44.50 107

AVE 7.58 44.50

CYL 0.00

Peripheral

T 7.66− H 7.55 −N 7.71

Measurement Result

V H AVE

e 0.554 0.396 0.475

<L> mm D

S 7.84

|

V 7.51

|

I 7.84

Data of Corneal Center only

When R/K or Kerato

measurement is also taken,

only optimum values are

printed.

Average of Vertical and

Horizontal Eccentrici ties

Horizontal Eccentrici t y

Vertical Eccentricity

RB-525-B0417

Page 19

6.6 IOL Measurement

KW-2000 has the function to measure the IOL (intraocular lens) implanted eye.

When measuring the IOL implanted eye, press IOL switch on the front panel of the body to activate the

function.

At this time, the icon for IOL switch as well as S, C, and A on the LCD monitor turns to purple.

( 0 )

R

12

/

K

MENU

0.25

S

C

A

IOL mode measurement screen

【

In IOL measurement mode, the IO L switch icon, S,

C, and A change to purple.

IOL measurement mode will be cancelled:

① when IOL switch is pressed again;

② when the measurement mode is switched to either K mode or P.K. mode;

③ when the data is printed out;

④ when the eye to be measured is switched from right to left or vice versa;

⑤ when the power is turned off.

R

No. 00001

NAME

(

0 )

Ker.Ref.

】

Measurement results of IOL measurement mode

are marked with 'IOL' on the left of each data.

2002 08 20 14:29

VD=12

<R> SPH CYL AX

IOL - 4.75 -0.00

IOL - 4.50 -0.25 60

IOL - 4.50 -0.25 131

----------------------------------------

- 4.50 -0.25 60

<L

Printout sample

【

】

If IOL mode is not set when IOL implanted eye is measured, error message may appear and

measurement may fail.

NOTE

RB-525-B0418

Page 20

6.7 Menu Screen Setting

Standard measurement mode is preset to be ready to use. However, you can easily alter the setting if

necessary.

To enter the menu screen, press a menu switch below the LCD monitor.

【Menu Screen】

STAR T MANUAL AUTO3 AUTO5

REF NORMAL QUICK( 3)

STEP 0.25 0.12

VD(mm) 0 10 12 13.5 15

CYL

KERA TO RADIUS DIOPT

PRINT FORM ALL ECONO OFF

PRINT OUT TOP BOTTOM

DATA SCREEN ON OFF

W-D(cm) OFF 30 35 40 45

TARGET LIGH T BRIGHT NORMAL DARK

SCREEN ADJ.

+

−

〉〉〉〉〉〉〉〉〉〉〉〉〉〉〉〉〉〉〉〉〉

±

SAVE(min.) OFF 3 5 10

BUZZER HIGH LOW OFF

DATA CLEAR(s) OFF 1 2 3

OPTION MESSAGE No. RS232C

DATE FORM YMD DMY MDY

DATE 2002/11/20

TIME 14:29:22

the First Screen the Second Screen

Change of Switch Function

Each switch function will change when you enter the menu screen.

Follow the icons indicated on the bottom of the screen, which corresponds to each

switch (see below).

The cursor moves downward on each setting menu.

The cursor moves upward on each setting menu.

Selection of the item in each setting menu. The cursor moves to the right.

Completion of the setting and return to the measurement screen.

RB-525-B0419

Page 21

6.7.1 Each Item Description

【The First Screen】

START Selects how to start measurement. Refer to '6.8 Auto Start Function' for detail.

MANUAL:

Measurement is taken every time the measurement switch is

pressed.

AUTO 3 :

Measurement is automatically started when the measurement

requirements are met. Three measurements are continuously

taken for each eye and automatically printed out when the

measurement is over.

AUTO 5 :

Measurement is automatically started when the measurement

requirements are met. Five measurements are continuously

taken for each eye and automatically printed out when the

measurement is over.

REF Selects refractive measurement manner.

NORMAL:

One measurement when the measurement start switch is pressed

once.

QUICK :

A set number of measurements are continuously taken when the

measurement start switch is pressed once. A maximum of ten

measurements is available.

A target moves only for the first measurement for the

continuous measurement. The target does not move after the

second measurement.

The setting of this item is invalid when START is set for either "AUTO 3" or " AUTO 5".

NOTE

STEP Selects the increment for refractive measurement.

VD(mm) Selects corneal vertex distance.

CYL Selects the sign for cylindrical value.

KERATO Selects the display unit for kerato measurement.

RADIUS : a radius of corneal curvature

DIOPT : a corneal refractive power

PRINT FORM Select printout format. Refer to '6.4 Print Out' for detail.

ALL

ECONO

OFF

: prints all data. (A maximum of ten data for each eye.)

: prints the optimal values only.

: no printouts.

PRINT OUT Selects direction of data printed out.

RB-525-B0420

Page 22

DATA SCREEN Measurement results stored in memory are displayed on the screen. Refer to '6.8

Data Screen Function' for detail.

ON :

OFF :

All measurement results are displayed on the screen.

No measurement results are displayed on the screen.

W-D(cm) Sets near work distance. When measurement is taken with this item set, a near

pupillary distance is automatically computed and indicated on the screen as well

as on the printout.

This function is activated only when refractive measurement is taken.

NOTE

TARGET LIGHT Sets the brightness of the target.

BRIGHT :

NORMAL :

DARK :

for brightening the target.

normal setting.

for darkening the target.

SCREEN ADJ. Brightness of a LCD monitor is adjusted or altered.

Switch functions will change in this item as below.

NOTE

•

(K・R>R>K>P.K.switch): makes the monitor brighter.

•

(IOL switch) : makes the monitor darker.

When you finish adjusting or altering, move the cursor to any other items except for

"SCREEN ADJ.", using or switch.

【The Second Screen】

SAVE(min.) Selects switchover time (in minute) to activate power saving function.

BUZZER Sets volume of buzzer at measurement.

HIGH : turns volume up.

LOW : turns volume down.

OFF : no buzzer.

DATA CLEAR(S) Sets the condition for clearing measurement data. (The unit is second.)

The measurement data can be cleared from memory when the measurement start

switch is pressed for the time set.

If this item is set for OFF, the measurement data is not cleared and continuous

measurement is taken when the measurement start switch is pressed.

RB-525-B0421

Page 23

OPTION Selects and sets optional functions. Refer to '6.7.2 Optional Function' for detail.

MESSAGE:

No. :

RS232C :

shifts to the screen for registering message.

shifts tot he screen for setting examinee's number.

shifts to the screen to set RS232C transmission parameters.

DATE FORM Selects display form of date.

YMD: year/month/ date

DMY: date/year/month

MDY: month/date/year

DATE Sets and corrects date.

TIME Sets and corrects time.

If you wish to correct date or time, move the cursor to the number you wish to change.

Month

Year

Date

2002/11/20

14:29:22

Hour

Minute

S

witch Functions will change in this item as below.

NOTE

•

•

: Increases the number.

: Decreases the number.

When you complete all settings or changes, press or switch to move the cursor to

any items other than TIME. Then, press switch to return the measurement mode.

Second

RB-525-B0422

Page 24

6.7.2 Optional Functions

Phone012(345)678

When you select the function you wish to set in '

screen.

【

Each Option Screen and Description

I. Message Input Function

Input

cursor

A

ABCDEFGHIGKLMNOPQRST

Cursor

UVWXYZabcdefghijklm

nopqrstuvwxyz012345

6789!"&'()*+<,‑./:;=

Move the cursor to the right.

Move the cursor to the left.

】

END

SET

Move the input cursor to any

given position in the input area.

Set the character.

OPTION

' of Menu screen, you can enter each option

When this function, you can print out registered

messages in the range of 22 characters/line x 2 lines.

When you select this menu, the screen on the

left will appears, and function of each switch

will change as shown on the left.

ABCOPTICI AN

Phone012( 345)678

ABCDEFGHIGKLMNOPQRST

UVWXYZabcdefghijklm

nopqrstuvwxyz012345

6789!"&'()*+<,‑./:;=

8

ABCOPTICIAN

No. :00001

NAME

2002 11 20 14:29

<R> SPH CYL AX

- 4.75 -0.25 62

〔

Print out sample

- 4.50 -0.25 60

END

SET

〕

(1) With or switch, select the

character you wish to input and confirm with

switch.

Then, the input cursor moves to the next input area

to be ready for the next input.

When you need to change the character

NOTE

already inputted, press switch to

move the input cursor to the character you

wish to input. Then, you can write over.

(2) When the setting is completed, move the input

cursor to 'END' and press switch to go

SET

back to the menu screen.

SET

RB-525-B0423

Page 25

II. No. Function

R

K

MENU

You can set or change the examinee's number, and select whether the number is displayed on the screen

and whether the number is printed out.

When you select this menu, the screen below will appear and function of each switch

will change as following.

Sets or changes the examinee's

number.

Selects print out setting of

examinee's number.

OFF: no print out.

ON : prints out the number.

Selects monitor display setting

of examinee's number.

OFF: no display

ON : displays on the screen

Move the cursor to select the item

you wish to change.

No.SET 00001 RESET

PRINT OFF ON

DISPLAY OFF ON

+

Set the examinee's number.

Return switch to return to

the measurement mode.

Move the cursor to the r ight and left to

choose the setting within each item.

Resetting Examinee's Number

When you wish to reset the examinee's number, move the cursor to RESET of No.SET

NOTE

and press the measurement start switch.

(1) Move the cursor to the item you wish to set/change

No.SET 00001 RESET

PRINT OFF ON

DISPLAY OFF ON

with switch and execute with

switch.

(2) When you complete the setting, press

switch to go back to the Menu screen

【Screen when DISPLAY is set to ON】 【Print out when PRINT is set to ON】

( 0 )

12

/

Ker.Ref.

00001

( 0 )

Examinee's

number

No. 00001

NAME

2002 11 20 14:29

VD=12

<R> SPH CYL AX

- 4.75 -0.25 62

- 4.75 -0.00

- 4.75 -0.00

----------------------------------------

- 4.75 -0.00

0.25

RB-525-B0424

Page 26

III. RS232C Setting Function

t

BAUDRATE 9600

BAUDRATE 9600

CHARACTER 8

PARITY NONE

STOPBIT 1

Move the cursor downward

o select the item you wish to

change.

Change the setting of the item selected.

The display changes every time the switch is

pressed. Press the ret urn switch at any give n

setting.

【Each Item Description】

1. BAUDRATE : selection of a transmission rate for a serial interface.

With this function, you can send the measure ment data

to an external computer through an interface. The data is

sent using ASCII CODE.

When you select this menu, the screen on the left

will appear and function of each switch will change

as shown.

Return switch to go back the

measurement mode.

BAUDRATE option Standard setting

38400bps

19200bps

9600bps

○

4800bps

2400bps

2. CHARACTER : selection of data bit

CHARACTER option Standard setting

8

7

3. PARITY : selection of transmission data check.

PARITY option Standard setting

EVEN

ODD

NONE

4. STOP BIT : selection of code to terminate data output.

STOP BIT option Standard setting

2

1

○

○

○

RB-525-B0425

Page 27

BAUDRATE 9600

67812345

516

81920

5

345

876

910

CHARACTER 8

PARITY EVEN

PARITY NONE

STOPBIT 1

【Connection method】

(1) Move the cursor to the item you wish to set/change with

switch and execute with switch.

(2) When the setting is completed, press

switch to go back to the menu screen.

KW-2000

1

2

1

14

Connection

D-Sub25pin D-Sub9pin

TXD 2 2 RXD

RXD 3 3 TXD

DSR 6 4 DTR

SG (GND) 7 5 SG (GND)

DTR 20 6 DSR

PC

Connect with a cross cable.

D-Sub25pin

Male

11 1312

1

17

21222324 2

D-Sub9pin

Female

Use a shield type of cable for the connection cable in order to protect the output

NOTE

data from noise.

※ If you have any inquiries about changes in transmission parameters and/or detail

connections, please direct them to the relevant agent or distributor.

RB-525-B0426

Page 28

6.8 Auto Start Function

KW-2000 incorporates Auto Start Function.

This function starts measuring automatically when alignment meets the measurement requirement, and

also prints out automatically when the measurement of both eyes completes.

When Auto Start Function is activated, measurement is always taken according

NOTE

to the setting of START regardless of REF setting in the menu screen.

START MANUAL AUTO3 AUTO5

REF NORMAL QUICK( 3)

STEP 0.25 0.12

VD(mm) 0 10 12 13.5 15

CYL

KERATO RADIUS DIOPT

PRINT FO R M ALL ECONO O F F

PRINT OUT TOP BOTTOM

DATA SCREEN ON OFF

W-D(cm) OFF 30 35 40 45

TARGET LIGHT B RIGHT NORMAL DARK

SCREEN ADJ.

0.25

( 0 )

0.25

+

−

〉〉〉〉〉〉〉〉〉〉〉〉〉〉〉〉〉〉〉〉〉

12

/

R

12

AUTO

K

AUTO

±

MENU

Ker.Ref.

(1) When you wish to measure with auto start function,

select 'AUTO3' or 'AUTO5' in 'START' of the Menu

screen

(2) Then, press switch to go back to the

measurement screen.

(3) Auto Start mode is activated when 'AUTO' and arrows

below 'AUTO' appear on the top of the screen (see on

the left).

You can start measurement from either right or left eye.

0 )

(

(4) Carry out alignment. Measurement will automatically

start when alignment is achieved.

For alignment, refer to '6.2 Alignment'.

NOTE

( 0 )

/

R

K

MENU

The arrow to urge the

shift flashes.

(

Ker.Ref.

0 )

When the measurement of one eye finishes, an arrow on

either left or right side you have measured will

disappear. In addition, an arrow to urge the shift to the

other eye will appear and flash in the center of the

screen.

The operator shifts the body of the unit to the

NOTE

eye which has not measured according to the

arrow.

When the body is shifted, the arrow flashing in

the center of the screen will disappear.

(5) Measure the other eye in the same manner.

RB-525-B0427

Page 29

(6) After both eyes are measured, the arrow will disappear and the measurement result will be

automatically printed out.

The data printed out depends on the setting of print out format.

NOTE

When the data screen is set for 'ON', the screen changes to display all optimal

values after both eyes are measured.

(7) If you wish to continue to measure with auto start function, realignment is necessary.

When you wish to cancel auto start function, change the setting of 'START' back

NOTE

to 'MANUAL' in the menu screen.

RB-525-B0428

Page 30

6.9 Data Screen Function

R) SPH

CYL

AX

AX

Data screen function allows you to check measurement results saved in the memory on the screen.

Displaying measurement data on the screen

START MANUAL AUTO3 AUTO5

REF NORMAL QUICK( 3)

STEP 0.25 0.12

VD(mm) 0 10 12 13.5 15

CYL

KERATO RADIUS DIOPT

PRINT FORM ALL ECONO OFF

PRINT OUT TOP BOTTOM

DATA SCREEN ON OFF

W-D(cm) OFF 30 35 40 45

TARGET LIGHT BRIGHT NORMAL DARK

SCREEN ADJ.

** RIGHT**

- 4.75 - 0.25 62

- 4.75 0.00

- 4.75 0.00

- 4.75 0.00

- 4.75 0.00

- 4.75 - 0.25 62

- 4.75 0.00

- 4.75 0.00

- 4.75 0.00

- 4.75 0.00

- 4.75 0.00

+

−

〉〉〉〉〉〉〉〉〉〉〉〉〉〉〉〉〉〉〉〉〉

PRESS START SW ‑>

±

mm D

R1) 7.59 44.50 120

R2) 7.57 44.50 107

AVE 7.58 44.50

CYL 0.00

S 7.58 T 7.66

V 7.51 H 7.55

I 7.84 N 7.71

e(ver) 0.554

e(hol) 0.396

e(ave) 0.475

RETURN

(1) Select 'ON' in 'DATA SCREEN' of the Menu screen.

When 'DATA SCREEN' is 'ON', the setting

of 'PRINT FORM' is invalid (see '6.7.1 Each

NOTE

Item Description'.

(2) After the measurement, press switch, and

the data screen will appear as shown on the left.

'I' mark will be indicated on the left side of

each refractive data as shown below when

NOTE

you measure with IOL measurement mode.

Example: SPH CYL AX

I - 4.75 - 0.25 62

(3) Displaying the data on the screen, press switch to change over the display as below.

All data of right eye

(RIGHT)

All data of left eye

(LEFT)

Refractive data

(REF)

(4) When you wish to print out the measurement data, press switch again.

(5) Press the measurement start switch to go back to the measurement screen.

Representative data

(ECONO)

RB-525-B0429

Page 31

6.10 Power Saving Function

Power saving function will start operating when switch operation is suspended with the power on.

(The switchover time (in minute) can be selected at 'SAVE' on the mode selection screen. )

To return to the measurement mode, press any switch (any switch on the front panel or the measurement

start switch).

Measur ement Mode

Power Indicator (PW) ON

Leave idling f or a set ting time

Power Saving Condition

Power Indicator (PW) flashing

Pr es s any switc h

Return to Measurement Mode

Power Indicator (PW) ON

6.11 Output Terminal

Video Terminal

This terminal outputs an NTSC video signal.

If you connect an external monitor such as a portable TV or similar unit to KW-2000 with pin plug (video)

cable, you can observe and check the same image that appears on the internal monitor screen of KW-2000

simultaneously.

RB-525-B0430

Page 32

7. Tips for Effective Measurement

(1) Do not allow external light to directly penetrate the room.

(2) Fluctuation of values during measurement may occur if the examinee looks something other than the

target. Urge the examinee to concentrate on the target set in front.

(3) Talk to the examinee in a relaxed and friendly manner, so as to allay any fear or doubt they may have.

(4) Inappropriate height of a chin rest or a chair will cause the examinee fatigue. Adjust the (optional)

instrumental table to establish the most comfortable and convenient position for the examinee.

(5) When the eyelash or eyelid interfere measurement, error will occur in measurement. Urge the

examinee to keep his/her eye wide open.

(6) Tear residue or eye mucus, etc. trapped on the corneal surface may cause measurement errors. Check

the surface with LCD monitor, and if you see something moving when the examinee blinks, remove it

before measurement.

(7) When the pupil of the eye to be examined is smaller than the minimum pupil diameter measurable,

correct measurement will be impossible. When the pupil is too small to take correct measurement,

make the surroundings (room) or the target darker to allow the pupil to dilate as much as possible.

(8) If the examinee's head moves during measurement, AXIS value will be adversely affected.

RB-525-B0431

Page 33

8. Error Messages

KW-2000 automatically evaluates measurement condition or result and indicates error messages if it is

invalid. Error messages also appear when abnormality is detected in its operational system.

When any error message appears, always check the system with a supplied model eye. If it appears when

no abnormality in system is detected, check the measured eye for eye disease or problem.

Message Cause/Explanation Corrective Action

RETRY

SPH OVER

CYL OVER

Motor fault.

EEPROM fault.

Printer head up

lever.

Printer head heat

over.

Printer cutter fault.

Failed to capture eye image because

the examinee blinks or moves during

measurement or the examined eye has

an eye disease.

Exceeded spherical measurement

range (–25D to +25D). (when VD =

0 )

Exceeded cylindrical measurement

range (0 to ±10D) .

Detected abnormality in motor control

system.

Failed to initialize.

Printer head is up. Close the printer head.

Printer head is overheated.

A paper jam occurred at a printer

cutter or the printer cutter did not

move for some reason.

Realign precisely and take measurement

again. Consult your dealer immediately if

the message reappear.

Do not try to repair by yourself.

Cut the power and turn it back on. Consult

your dealer immediately if the message

reappear.

Do not try to repair by yourself.

Cut the power and stop using until the head

cools off. Consult your dealer immediately

if the message reappear.

Do not try to repair by yourself.

Always cut the power, and check on the

paper jam.

If the message reappears without the paper

jam, consult your dealer immediately.

Do not try to repair by yourself.

Paper empty.

No printer paper.

Set the printer paper.

See '11.1 Reloading Printer Paper.'

RB-525-B0432

Page 34

9. Contact Lens: Base Curve Measurement

You can measure a base curve of a hard contact lens with KW-2000.

To do so, attach a contact lens onto a contact lens holder of the model eye as following.

(1) Put a small amount of water on a concave side of the contact lens holder.

(2) Place the contact lens so that its convex side faces the holder.

Contact Lens Hold er

Model Eye

Contact Lens

(3) Confirm the contact lens is firmly adhered to the holder and does not slip down, set the model eye

unit to measure.

RB-525-B0433

Page 35

10. Troubleshooting

If there are any malfunction found, refer to the table below to take appropriate measures.

CAUTION

Symptom Causes and Measures

The monitor and power indicator are not

turned on.

Fuse is blown when the power switch is

turned on.

The monitor display suddenly disappears.

The main body can not be moved in a

horizontal direction.

The moving parts such as a joystick are not

moving appropriately.

The apparatus does not print out.

Never disassemble, modify or repair the instrument.

Personal injury may result from electric shock.

• The power cord may be not properly connected. Make

sure to connect it securely.

• Fuse may be blown. If so, replace it to the new one.

• Contact your local distributor immediately.

• The saving function may be activated.

Press any switch to deactivate the saving function.

• Anti-sliding lock may be locked. Unscrew the lock

under the base.

• Do not force to move the part. Contact your local

distributor or service person.

• Check the papers being set. Reload them if the papers

are out.

• PRINT FORM in the MENU screen may be set for

OFF. Change the setting.

The printer papers come out but no printing.

The date setting becomes inaccurate.

Contact your local distributor immediately if the situation does not improve even when the measures

mentioned above are taken.

• The printer paper may be set in a wrong direction. Set

the paper properly.

• The battery inside the apparatus may be dead. Keep the

power on for 24 hours to recharge it.

RB-525-B0434

Page 36

11. Storage and Maintenance

11.1 Reloading Printer Paper

1) Remove a printer cover and take a printer paper shaft

out.

2) Lift a printer cutter part and pull up a head-up lever.

3) Set a roll of printer paper, paying attention to direction

of the paper rolled up.

The loose end of the paper should be drawn

NOTE

forward in a counterclockwise direction.

4) Insert the loose end of the paper behind a rubb er roller.

Press print switch more than one second to feed the

paper out.

Printer cutter part

Printer cutter part

Head-up lever

Knurl

Never pull the paper out.

NOTE

Pulling the paper may cause the paper

output incorrectly or jammed.

5) Draw the paper through the printer cutter slot and

lower the head-up lever and the printer cutter back to

the original positions.

6) Draw the paper a cutter slot of a printer cover and

reattach the printer cover to complete the procedure.

Always use the specified printer paper only.

The paper other than the specified one may

cause a paper jam or fade in printing.

Rubber roller

RB-525-B0435

Page 37

11.2 Fuse Replacement

When replacing a fuse, unplug the power cord from the unit

CAUTION

When a fuse is blown, remove a fuse holder at the side of a main unit for replacement.

Pushing the fuse holder, rotate it in the direction of the arrow below and you can remove it.

Fuse Holder

before removing the fuse holder.

You may be in danger of electric shock if you remove the fuse

holder without unplugging the power cord.

Fuse

Rotate the holder counterclockwise.

11.3 Storage

(1) Points to be checked for long-term storage

Turn the power switch OFF.

Remove the power cord from the outlet.

Lower the optical unit to the bottom (original position).

Secure the body with the anti-sliding screw lock.

Put a dustproof cover on the optical unit.

(2) Notes on storage environment

Avoid storage under the following conditions.

Where dust accumulates.

Where water may get on the unit.

Where temperature and humidity are high.

Where sunlight directly contacts.

Unstable and/or high place.

Always use the specified fuse (T2A 250V).

NOTE

Always follow the environment conditions below for storage.

Environmental Conditions

Temperature Relative Humidity

−10℃ ~ +60℃ below 70%

Always check above whenever you store or do not use KW-2000 for a long time.

When you reuse the instrument after long-term storage, operate according to instruction in

' 5. Preparation.'

RB-525-B0436

Page 38

11.4 Confirmation of Measurement Accuracy

It is extremely important to check operation and accuracy of the instrument using a supplied model eye.

We recommend you to check accuracy periodically.

When the measurement result of the model eye falls anywhere within the tolerance listed below,

measurement should be considered reliable and accurate. When the result exceeds the tolerance, contact

your dealer immediately.

Model Eye Data

SPH CYL R

Indicated value ±0.25 0 ±0.25 Indicated value ±0.03

※Precise value of the supplied model eye is indicated on the model eye stand (VD =12).

Model eye

Note for setting of model eye

NOTE

Remove a contact lens holder cap and set a model eye, checking it is not inclined in any

directions.

When the model eye is inclined, CYL value can not be correctly measured.

Set the model eye at the position where an alignment mark is located inside a reticle

mark and good focusing is achieved.

When conditions above have been satisfied, proceed to measurement.

11.5 Periodical Inspection and Maintenance

To prevent malfunction and accidents and maintain the performance and reliability of the product, it is

recommended to request your distributor for the periodical inspection and maintenance once a year.

The periodical inspection and maintenance include inspection of the function and performance of the

product, and cleaning, adjustment and replacement of consumable parts if necessary.

RB-525-B0437

Page 39

12. Specifications

Sphere (S)

Cylinder (C)

Axis (A)

Sphere

Measurement Accuracy

Cylinder

Radius of

Corneal Curvature

Keratometry Measurement Range

Vertex Distance 0, 10, 12, 13.5, 15mm

Minimum Pupil Diameter

PD Measurement Measurement range 85mm (step: 1mm)

Measurement Time

Printer Thermal line printer with automatic cutter (paper width 57mm)

Internal Monitor 5.6 inch LCD monitor (color)

Shifting Range for Sliding Body

Vertical Adj. Range for Chin Rest

Dimensions

Weight approx. 15kg

Data Output

Power Source

Consumption 80VA

Power Saving Function

Corneal

Refraction

Cylinder

Axis

φ2.3 mm

Refractive measurement

Keratometry measurement

back/forth ±17mm right/left ±43mm up/down ±17.5 mm

±30mm

245 mm (W)×422 mm (D)×429 mm (H)

RS232C interface

Video Terminal

100〜240V

50/60Hz

OFF,3,5,10min.(switchable)

-25〜+25D

0〜±10D

0〜180º

between −10〜+10D : ±0.25D

beyond ±10 : ±0.5D

±0.25D

5.0〜10.0mm

33.75〜67.5D

0〜±9D

0〜180°

(step: 0.12/0.25D)

(step: 0.12/0.25D)Refractive Measurement Range

(step: 1°)

(step: 0.01mm)

(step: 0.12/0.25D)

(a refractive index of cornea:

n = 1.3375)

(step: 1°)

approx. 0.07 sec.

approx. 0.07 sec.

Production Year

The second digit of serial number represents a production year of each instrument. The serial number is

indicated on the nameplate that is on the side of body. See below.

92AG0103

This number is the last digit of the production year.

In this example, the production year is 2002.

RB-525-B0438

Page 40

Life Science Division

p

No.4-14, 3-chome, Nihonbashi-Honcho, Chuo-ku, Tokyo 103-8433, Japan

Phone: 81(3) 3279-7312

Facsimile: 81(3) 3245-1109

Manufacturer

RyuSyo Industrial Co., Ltd.

Kagawa Factory

958 Ikeuchi, Konan-cho,

Kagawa-gun, Kagawa 761-1494 JAPAN

20001 So. Vermont Ave. Torrance,

CA 90502, U.S.A.

Phone: 1(310) 327-1913

Facsimile: 1(310) 327-4177

EU Re

resentative

Immermannstrasse 65A 40210

Dusseldorf F.R. Germany

Phone:19 (211) 35-3444/45/46

Facsimile: 49(211) 161952

Printed on recycled paper.

RB-525-B04

Prepared: 2002. 12. 4

Loading...

Loading...