Page 1

VSBC-32

Combined VMEbus System Controller and

Serial Communications Controller Board

Manual ID 21168, Rev. Index 04

Jul 00

The product described in this manual is

in compliance with all ap plied CE standards.

Page 2

General VSBC-32

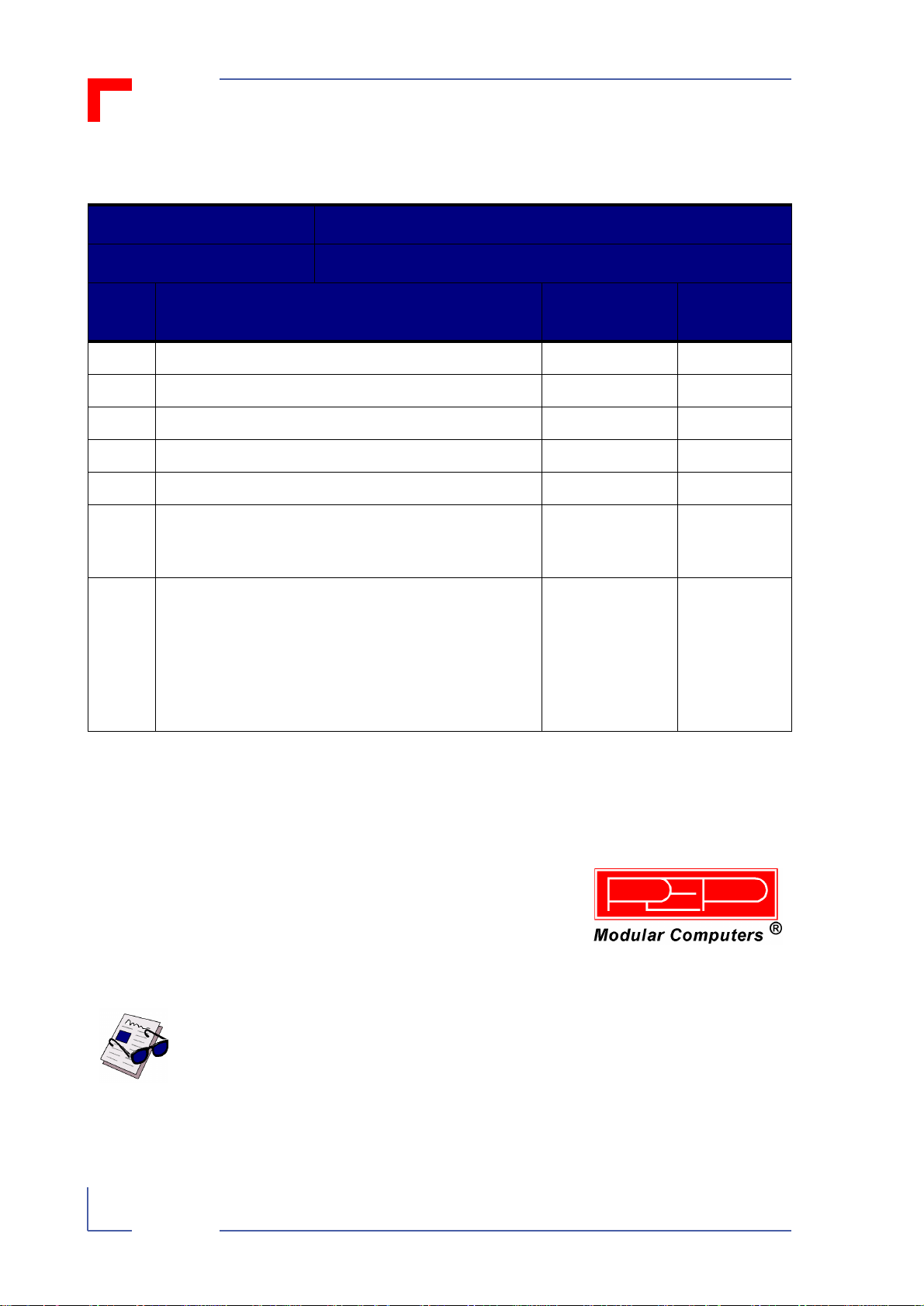

Revision History

Manual/Product Title: VSBC-32

Manual ID Number: 21168

Rev.

Index

0100 Initial Issue 00/1 Aug 95

0200 General corrections 00/2 D ec 95

0201 J9 default setting chan ged 00/2 Nov 96

0300 General corrections and new manual structure 01 Dec 96

0301 New Preface 01 Aug 98

0311 Improvement to Fig. 2.1.3. In Appendices, correc-

04 Information of Er rata S heets 0100 _1/2 in tegra ted,

Brief Description of Ch anges Board Index

01 Sept 98

tions to flash a ddres ses on pag es MEM-2 to

MEM-4, page MEM-5 replaced.

01 Ju ly 00

adequate manual structure , new mem ory piggybacks mentioned, desc riptio n of co mbi ned sys tem

and communications con troller fuc ntionality,

function-related board diagrams, cohere nt terminology (e.g. proce ssor and bo ard varia nt names)

etc. Appendices mod ified, upda ted, reduced .

Date of

Issue

Imprint

Copyright © 2000 PEP Modular Computers GmbH. All rights

reserved. This manual may not be c opied, photocopied, reproduced, translated or converted to any electronic or machinereadable form in whole or in part without prior written approval of

PEP Modular Computers GmbH.

Disclaimer:

PEP Modular Computers GmbH rejects any liability for the cor-

rectnesss and completeness of this manual as well as its suitability for any part icular purpo se.

This manual was realized by: TPD/Engineering, PEP Modular Computers GmbH.

ID 21168, Rev. 04Page ii © 2000 PEP Modular Computers GmbH

Page 3

VSBC-32 Contents

Contents

Preface

Preface ..................................................................................................................... ix

Proprietary Note ....................................................................................................... ix

Trademarks .............................................................................................................. ix

Explanation of Symbols ..................... .... ..... .............................................................. x

For Your Safety ........................................................................................................ xi

High Voltage Safety Instructions .............................................................................. xi

Special Handling and Unpacking Instructions .......................................................... xi

General Instructions on Usage ............................................................................... xii

Two Year Warranty ................................................................................................ xiii

Chapt

Chapter

1. Introduction ................................................................................................. 1 - 3

1.1 System Overview .................................................................................. ..... 1 - 3

1.2 Board Overview ........................................................ ..... ............................ 1 - 4

1.2.1 Board-Specific Information ................................................................. 1 - 4

1.2.2 Board Variants ......................................... ..................................... ..... 1 - 4

1.2.3 Board Connectivity and Interface Expandib ility ............... ..... .............. 1 - 5

1.2.4 Memory Piggybacks ........................................................................... 1 - 6

1.2.5 System-Relevant Information ............................................................. 1 - 6

1.3 Board Diagrams ...................................... ................................ ..... .............. 1 - 8

1

1

1.3.1 System-Level Functional Block Diagram ........................................... 1 - 8

1.3.2 Frontpanels ........................................................................................ 1 - 9

1.3.3 Board Layouts .................................................................................. 1 - 10

1.4 Technical Specifications .......................................................................... 1 - 12

ID 21168, Rev. 04 Page iii© PEP Modular Computers GmbH

Page 4

VSBC-32 Contents

1.5 Applied Standards ............... .... ..... ................................. .... ....................... 1 - 14

1.5.1 CE Compliance ................................................................................. 1 - 14

1.5.2 Mechanical Compliance ................................................................... 1 - 14

1.5.3 Environmental Tests ......................................................................... 1 - 14

1.6 Related Publications ............................. ..... ................................. .... ......... 1 - 15

1.6.1 VMEbus/CXC Systems/Boards ........................................................ 1 - 15

1.6.2 Manufacture rs’ Component Documentation ............................ ..... .... 1 - 15

Chapter

2. Functional Description ................................................................................ 2 - 3

2.1 General Information ................................................................................... 2 - 3

2.2 Specifics ..................................................................................................... 2 - 4

2.2.1 System Control Functionality .............................................................. 2 - 4

2.2.2 Memory Configurations ...................................................................... 2 - 5

2.2.3 DMA Channels ................................................................................... 2 - 6

2.2.4 Serial Communications Control .......................................................... 2 - 7

2.3 Functional Block Diagram ........................................................................ 2 - 10

2.4 Board Interfaces ....................................................................................... 2 - 11

2.4.1 Serial I/O Interfaces .......................................................................... 2 - 11

2.4.2 Piggyback Interface Connectors for Serial Interface Piggybacks ..... 2 - 12

2.4.3 Memory Piggyba ck Interface Conne ctors ......... ................................ 2 - 12

2.4.4 EPROM DIP Sockets ............................................. .... ..... .................. 2 - 12

2.4.5 Background Debug Mode Interface Connector ................................ 2 - 13

2

2.4.6 VMEbus Backplane Interface ........................................................... 2 - 13

2.4.7 CXC Mezzanine Inte rface ..... ..... .... ................................. ..... ............. 2 - 14

2.5 VSBC-to-VSBC-32 System Upgrading .................................................... 2 - 15

2.6 Special Board Functions .......................................................................... 2 - 18

2.6.1 Real-Time Clock ...................................... .... ..... ................................ 2 - 18

2.6.2 EEPROM .......................................................................................... 2 - 18

2.6.3 PLL Operation Mode ........................................................................ 2 - 18

2.6.4 Tick Generator .................................................................................. 2 - 18

2.6.5 Bus Error Timers .............................................................................. 2 - 19

ID 21168, Rev. 04Page iv © PEP Modular Computers GmbH

Page 5

VSBC-32 Contents

2.6.6 Watchdog Timer ............................................................................... 2 - 20

2.6.7 Reset Sources ................................................................................. 2 - 20

2.6.8 “Slot 1” Detection ............................................................................. 2 - 20

2.7 Frontpanel Functions ............................................................................... 2 - 21

2.8 RTC and SRAM Data Retention .............................................................. 2 - 21

2.9 Address Decoder ........................................................... .......................... 2 - 23

2.9.1 Basic Structure ................................................................................. 2 - 23

2.9.2 Boot Decoding ................................................................................. 2 - 23

Chapter

3. Installation .................................................................................................. 3 - 3

3.1 Hardware Installation ................................................................................. 3 - 3

3.1.1 External Serial Interface Module ........................................................ 3 - 4

3.2 Software Installation ................................................. ..... ............................ 3 - 4

Chapter

4. Configuration .............................................................................................. 4 - 3

4.1 Hardware Configuration .. ..... ................................. .... ................................. 4 - 3

4.1.1 Wire Jumpers ..................................................................................... 4 - 3

4.1.2 Solder Jumpers .................................................................................. 4 - 4

4.2 Software Configuration ...................... ..... ................................ ..... .............. 4 - 5

4.2.1 Address Map ......................... ..... ........................................................ 4 - 5

3

4

4.2.2 Board Control/Status Re giste r .......................... ................................. 4 - 6

4.2.3 VMEbus Control/Status Register ..................................................... 4 - 7

4.2.4 VMEbus Interrupt Mask Register ................................ .... ..... .............. 4 - 8

ID 21168, Rev. 04 Page v© PEP Modular Computers GmbH

Page 6

VSBC-32 Contents

Appx.

A. Memory Piggybacks ................................................................................... A - 3

A.1 General ..................................................................................................... A - 3

A.2 DM600 ...................................................................................................... A - 4

A.2.1 Board Layout and Jumper Location ................................................... A - 4

A.2.2 Jumper Description and Flash Addresses ......................................... A - 4

A.3 DM601 ...................................................................................................... A - 5

A.3.1 Board Layout and Jumper Location ................................................... A - 5

A.3.2 Jumper Description and Flash Addresses ......................................... A - 5

A.4 DM602 ...................................................................................................... A - 6

A.4.1 Board Layout and Jumper Location ................................................... A - 6

A.4.2 Jumper Description and Flash Addresses ......................................... A - 6

A.5 DM603 ...................................................................................................... A - 7

A.5.1 Board Layout and Jumper Location ................................................... A - 7

A.5.2 Jumper Description and Flash Addresses ......................................... A - 7

A

A.6 DM604 ...................................................................................................... A - 8

A.6.1 Board Layout and Jumper Location ................................................... A - 8

A.6.2 Jumper Description and Flash Addresses ......................................... A - 8

A.7 DM605 ...................................................................................................... A - 9

A.7.1 Board Layout and Jumper Location ................................................... A - 9

A.7.2 Jumper Description and Flash Addresses ......................................... A - 9

ID 21168, Rev. 04Page vi © PEP Modular Computers GmbH

Page 7

VSBC-32 Contents

Appx.

B. Serial Interface Piggybacks ........................................................................ B - 3

B.1 General ...................................................................................................... B - 3

B.2 SI-10B2 ..................................................................................................... B - 4

B.2.1 Specifications ..................................................................................... B - 4

B.2.2 Front Panel View ........................ ..... ................................................... B - 4

B.3 SI-10B5 ..................................................................................................... B - 5

B.3.1 Specifications ..................................................................................... B - 5

B.3.2 Front Panel View and Pinout .............. ..... ................................. .... ..... B - 5

B.4 SI-10BT ..................................................................................................... B - 6

B.4.1 Specifications ..................................................................................... B - 6

B.4.2 Front Panel View, Jumper Layout, and Pinouts ................................. B - 6

4.2.1 SI-10BT Jumper Settings ....................................... ............................ B - 7

B.5 SI-PB232 .................................................................. ................................. B - 8

B.5.1 Front Panel View and Pinout .............. ..... ................................. .... ..... B - 8

B

B.6 SI-PB485-ISO .................................... ..... ................................................... B - 9

B.6.1 Specifications ..................................................................................... B - 9

B.6.2 Front Panel View, Jumper Layout, and Pinout ................................... B - 9

B.6.3 SI-PB485-ISO Jumper Settings ....................................................... B - 10

Appx.

C. CXC ............................................................................................................ C - 3

C.1 CXC Address Ranges ............................................................................... C - 3

C.2 CXC Generic Pinouts ................................................................................ C - 5

C.3 CPU Pinout Cross Reference .................................................................... C - 6

C.4 Timing ........................................................................................................ C - 7

C.5 CXC Backplanes ....................................................................................... C - 8

C

ID 21168, Rev. 04 Page vii© PEP Modular Computers GmbH

Page 8

VSBC-32 Contents

Appx.

D. OS-9 Cabling ............................................................................................. D - 3

D.1 OS-9 System – Terminal ........................................................................... D - 3

D.1.1 Software (XON/XOFF) or No Handshake .......................................... D - 3

D.1.2 Hardware Handshake (Set Terminal to CTS/DTR Handshake) ........ D - 4

D.2 OS-9 System – PC .................................................................................... D - 5

D.2.1 Software (XON/XOFF) or No Handshake .......................................... D - 5

D.2.2 Hardware Handshake (Select RTS/CTS Handshake on the PC Side) D - 7

D.3 OS-9 System – Modem ............................................................................. D - 9

D.4 OS-9 System – OS-9 System .................................. ..... .......................... D - 10

D.4.1 Software (XON/XOFF) or No Handshake ........................................ D - 10

D.4.2 Ha rd ware Handshake ..................................................... ..... ............ D - 11

D

ID 21168, Rev. 04Page viii © PEP Modular Computers GmbH

Page 9

VSBC-32 Preface

Preface

ID 21168, Rev. 04 Page vii© PEP Modular Computers GmbH

Page 10

This page was intentionally left blank.

ID 21168, Rev. 04Page viii © PEP Modular Computers GmbH

Page 11

VSBC-32 Preface

Preface

Proprietary Note

This document contains information proprietary to

copied or transmitted by any means, disclosed to others or stored in any retrieval system or

media, without the prior written consent of

rized agents.

The information contained in this document is, t o the best of our knowledge, entirely correct .

However,

quences thereof, nor for any liability arising from the use or application of any circuit, product,

or example shown in this document.

PEP Modular Computers reserve the right to change, modify, or improve this document or the

product described herein, as seen fit by

PEP Modular Computers

cannot accept liability for any inaccuracies, or the conse-

PEP Modular Computers GmbH

PEP Modular Computers

PEP Modular Computers

or one of its autho-

without further notice.

. It may not be

Trademarks

PEP Modular Computers

marks owned by

document may include names, company logos and trademarks, which ar e registered trademarks and, therefore, proprietary to their respective owners.

PEP Modular Computers GmbH

, the

PEP

logo and, if occurring in this manual, “CXM” are trade

, Kaufbeuren (Germany). In addition, this

ID 21168, Rev. 04 Page ix© PEP Modular Computers GmbH

Page 12

VSBC-32 Preface

Explanation of Symbols

CE Conformity

This symbol indicates that the product described in this manual

is in compliance with all applied CE standards. Please refer

also to the section “Applied Standards” in this manual.

Caution, Electric Sh ock!

This symbol and title warn of hazards due to electrical shocks

(> 60V) when touching products or parts of them. Failure to

observe the precautions indicated and/or prescribed by the law

may endanger your life/health and/or result in damage to your

material.

Please refer also to the section “High Voltage Safety Instructions” on the f ollowing page.

Warning, ESD Sensitive Dev ice!

This symbol and title inform that electronic boards and their

components are sensitive to static electricity. Therefore, care

must be taken during all ha ndling operat ions and ins pections of

this product, in order to ensure product integrity at all times.

Please read also the section “Special Handling and Unpacking

Instructions” on the following page.

Warning!

This symbol and title emphasize points which, if not fully understood and tak en into cons ider ation b y the read er, may endanger

your health and/or result in damage to your material.

Note...

This symbol an d title emph asi ze aspe cts the rea der sh ould read

through carefully for his or her own advantage.

PEP Advantage

This symbol and title emphasize advantages or positive aspects

of a product an d/or proce dure.

ID 21168, Rev. 04Page x © PEP Modular Computers GmbH

Page 13

VSBC-32 Preface

For Your Safety

Your new

to ensure the renown electrical sa fety requirements. I t was also designed for a long fault-free

life. However, the life expectancy of your product can be drastically reduced by improper treatment during unpacking and installation. Therefore, in the interests of your own safety and of

the correct operation of your new

ing guidelines.

PEP

product was developed and tested carefully to provide all features necessary

PEP

product, you are requested to conform with the follow-

High Vol tage Safety Instructions

Warning!

All operations on this de vice must be carried out by sufficiently

skilled personnel only.

Caution, Electric Sh ock!

However, serious electrical shock hazards exist during all

installation, repair and maintenance operations with this product. Therefore, always unplug the power cable to avoid exposure to hazardous voltage.

Before installing your new

PEP

product into a system always

ensure that your ma ins power is switched off. This applies al so

to the installation of piggybacks.

Special Handling and Unpacking Instructions

ESD Sensitive Devic e!

Electronic boards and their components are sensitive to static

electricity. Therefore, care must be taken during all handling

operations and inspections of this product, in order to ensure

product integrity at all times.

• Do not handle this product out of its protective enclosure while it is not used for operational

purposes, unless it is otherwise protected.

• Whenever possible, unpack or pack this product only at EOS/ESD safe work stations.

Where safe work stations are not guaranteed, it is importa nt for the user to be electri-cally

discharged before touching the product with his/her hands or tools. This is most easily

done by touching a metal part of your system housing.

• It is particularly important to observe standard anti-static precautions when changing piggybacks, ROM devices, jumper settings etc. If the product contains batteries for RTC or

memory back-up, ensure that the board is not placed on conductive surfaces, including

anti-static plastics or sponges. They can cause short circuits and damage the batteries or

tracks on the board.

ID 21168, Rev. 04 Page xi© PEP Modular Computers GmbH

Page 14

VSBC-32 Preface

General Instructions on Usage

• In order to maintain

any way. Changes or modifications to the device, which are not explicitly approved by

Modular Computers

as a special handling instruction, will void your warranty.

• This device should only be installed in or connected to systems that fulfill all necessary

technical and specific environmental requirements. This applies also to the operational

temperature range of the specific board version, which must not be exceeded. If batteries

are present, their temperature restrictions must be taken into account.

• In performing all necessary installation and application operations, please, follow only th e

instructions supplied by the present manual.

• Keep all the original packaging material for future storage or warranty shipments. If it is

necessary to store or ship the board please re-pack it as nearly as possible in the manner

in which it was delivered.

• Special care is necessary when handling or unpacking the product. Please, consult the

special handling and unpacking instruction on the following page of this manual.

PEP’s

product warranty, this product must not be altered or modified in

and described in this manual or received from

PEP

Technical Support

PEP

ID 21168, Rev. 04Page xii © PEP Modular Computers GmbH

Page 15

VSBC-32 Preface

Two Year Warranty

PEP Modular Computers

HARDWARE

granted or implied by anyone on behalf of

written consent of

WARRANTY

PEP Modular Computers

PEP Modular Computers

manufacturing and material defects for a period of 24 consecutive months from the date of

purchase. This warranty is not transferable nor extendible to cover any other users or longterm storage of the product. It does not cover products which have been modified, altered or

repaired by any other party than

more, any product which has been, or is suspected of being damaged as a result of negligence, improper use, incorrect handling, servicing or maintenance, or which has been

damaged as a result of excessive current/voltage or temperature, or which has had its serial

number(s), any other markings or parts thereof altered, defaced or removed will also be

excluded from this warranty.

If the customer’s eligibility for warranty has not been voided, in the event of any claim, he may

return the product at the earliest possible convenience to the original place of purchase,

together with a copy o f the original document of purchase, a full description of the application

the product is used on and a description of the defect. Pack the product in such a way as to

ensure safe transportation (see our safety instructions).

PEP

provides for repair or replacement of any part, as sembly or sub-assembly at their own

discretion, or to refund the original cost of purchase, if appropriate. In the event of repair,

refunding or replacement of any part, the ownership of the removed or replaced parts reverts

to

PEP Modular Computers

guarantee to cover the repaired or replaced items, will be transferred to cover the new or

repaired items. Any extensions to the original guarantee are considered gestures of goodwill,

and will be defined in the “Repair Report” issued by

grants the original purchaser of

as described in the following. However, no other warranties that may be

PEP

are valid unless the consumer has the express

.

warrants their own products, excluding software, to be free from

PEP Modular Computers

, and the remaining part of the original guarantee, or any new

PEP

PEP

products a

or their authorized agents. Further-

with the repaired or replaced item.

TWO YEAR LIMITED

PEP Modular Computers

rectly from any warr anty claim, other than the above specified repair, replacement or refunding. In particular, all claims for damage to any system or process in which the product was

employed, or any loss incurred as a result of the product not functioning at any given time, are

excluded. The extent of

original purchase price of the item for which the claim exists.

PEP Modular Computers

respect to its products’ reliability, fitness, quality, marketability or ability to fulfil any particular

application or purpose. As a result, the products are sold “as is,” and the responsibility to

ensure their suitability for any given task rem ains that of the purchaser. In no event will

be liable for direct, indirect or consequential damages resulting from the use of our hardware

or software products, or documentation, even if PEP were advised of the possibility of s uch

claims prior to the purchase of the product or during any period since the date of its purchase.

Please remember that no

make any modification or addition to the above specified terms, either verbally or in any other

form, written or electronically transmitted, without the company’s consent.

will not accept liability for any further claims resulting directly or indi-

PEP Modular Computers

issues no warranty or representation, either explicit or implicit, with

liability to the customer shall not exceed the

PEP

PEP Modular Computers

employee, dealer or agent is authorized to

ID 21168, Rev. 04 Page xiii© PEP Modular Computers GmbH

Page 16

This page was intentionally left blank.

ID 21168, Rev. 04Page xiv © PEP Modular Computers GmbH

Page 17

VSBC-32 Introduction

Introduction

Chapter

1

ID 21168, Rev. 04 Page 1 - 1© PEP Modular Computers GmbH

Page 18

This page was intentionally left blank.

ID 21168, Rev. 04Page 1 - 2 © PEP Modular Computers GmbH

Page 19

VSBC-32 Introduction

1. Introduction

1.1 System Overview

The

PEP Modular Computers

VMEbus architecture. In addition, some products also support the CXC and/or

Enhanced CXC (eCXC) local mezzanine interface standards which represent a streamlined variant of the VMEbus standard itself. Thus a wide range of I/O functions for industrial applications are supplied. Some of the major advantag es of the VMEbus standard

are:

• internationally accepted VITA standards (VMEbus, CXC, eCXC);

• broad range of available VMEbus solutions

• scalable processor performance

In addition, in combination with (e)CXC technology the VMEbus equipment offers the

following advantages:

product described in this chapter operates with the

• lower costs and optimized reliability thanks to reduced design complexity;

• compact I/O sub-systems thanks to easier I/O wiring.

For detailled information concerning the VMEbus and (e)CXC standards, please consult

the VMEbus and CXC Specifications which are available via the

Trade Association (VITA): http://www.vita.com

Many system-relevant features that are specific for VMEbus systems can be found in

the ANSI/VITA VME64 Standard and in the VITA/

despite its name, applies also to VMEbus MPI carriers.

The VME64 Standard includes the following information:

• VMEbus Specification

• Signal Lines, Bus Modules, Typical Operation

• Electrical Specifications

• Mechanical Specifications

The CXC MPI Specification includes the following information:

• Mechanical dimensions

• Electrical specifications

• Interface description

• ID Byte assignment

With reference to the (e)CXC aspects of mixed VMEbus+CXC systems please refer

PEP

also to the

CXC Reference Manual.

.

PEP

CXC MPI Specification which,

VMEbus International

ID 21168, Rev. 04 Page 1 - 3© PEP Modular Computers GmbH

Page 20

VSBC-32 Introduction

1.2 Board Overview

1.2.1 Board-Specific Information

The VSBC-32(E) is a 3U (Enhanced) CXC combined system and communications controller board that can operate in either a VMEbus or a mixed VMEbus+CXC environment. The board is based on the Motorola Quad Integrated Communications Controller

“QUICC” MC68(EN)360. Therefore, it is particularly suitable for system control functions

within applications with communications requirements. Depending on the controller chip

used, there are two board variants with different CPU frequencies. The board’s external

interfacing consists of a twin RS232 interface connector, which can be extended by

means of a variety of seria l interface piggybacks and/or external seri al interface modules. Other piggybacks provide DRAM/ flash memory.

Some of the outstanding features of the product described in this manual are:

• VMEbus system and communications controller board

• Both VMEbus and eCXC connectivity

• Master/slave system controller functionality

• 32-bit Motorola MC68(EN)360 integrated CPU and communications controller

• 25Hz or 33Hz CPU frequency

• CPU on-chip background debugging

• 1, 4, 16, 32 or 64 MB DRAM

• 0, 0.5, 1, 2 or 4 MB flash memory

• 256kB or 1 MB SRAM

• 2kbit serial EEPROM

• 256kB or 1MB DIP (flash) EPROM

• Real-time clock (backed-up)

• Six different communication standards possible:

• Serial I/O (RS232, RS485; RS422 on request)

• Ethernet (10Base2, 10Base5 or 10BaseT Ethernet)

• Up to six frontpanel serial interface connectors

• Compatibility with external serial interface module CXM-SIO3

• Reset and Abort control (frontpanel buttons)

• Halt, watchdog and general-purpose status indicators (frontpanel LED’s)

• OS-9 and VxWorks

®

drivers

1.2.2 Boar d Variants

Two basic variants of the VSBC-32(E) with different processors are available. Depending on the controller chip used and the SRAM size, there are four vari ants o f the VSBC32(E) system and serial communications controller board. The distinctive features of the

variants are listed in the following

• Ethernet capability

• CPU frequency

• SRAM size

The following basic board variants are available:

• VSBC-32: MC68360 processor, no Ethernet control capability.

• VSBC-32E: MC68EN360 processor, Ethernet control capability.

ID 21168, Rev. 04Page 1 - 4 © PEP Modular Computers GmbH

Page 21

VSBC-32 Introduction

The MC68EN360 processor is also available with two different clock rates:

• 25MHz

• 33MHz (this variant is again supplied with either 256kB or 1MB SRAM ).

The below described frontend connectivity and interface expandibility are common to all

board variants.

1.2.3 Board Connectivity and Interface Expandibility

The VSBC-32(E) mainboard is provided with the following standard connectors:

• Non-optoisolated RS232 serial interface (two RJ45 connectors, on frontpanel)

• One set of piggyback inter face connectors for serial interface (SI) piggybacks

(three 7-pin row male connectors)

• One set of memory piggyback interface connectors

(two 50-pin row female connectors)

• Two sets of (flash) EPROM DIP sockets

(two 32-pin row female sockets)

• Background debug mode (BDM) interface (one 12-pin row male connector)

• VMEbus backplane interface

(one 96-pin DIN 41612, style C male connector)

• Enhanced CXC mezzanine interface

(one 96-pin DIN 41612, style C male connector)

In addition, the mainboard external interfacing is usually integrated by one o f the follow ing piggyback-mounted frontpanel interface options (serial interface piggybacks). The

kinds of piggyback that can be used depend on the mainboard variant.

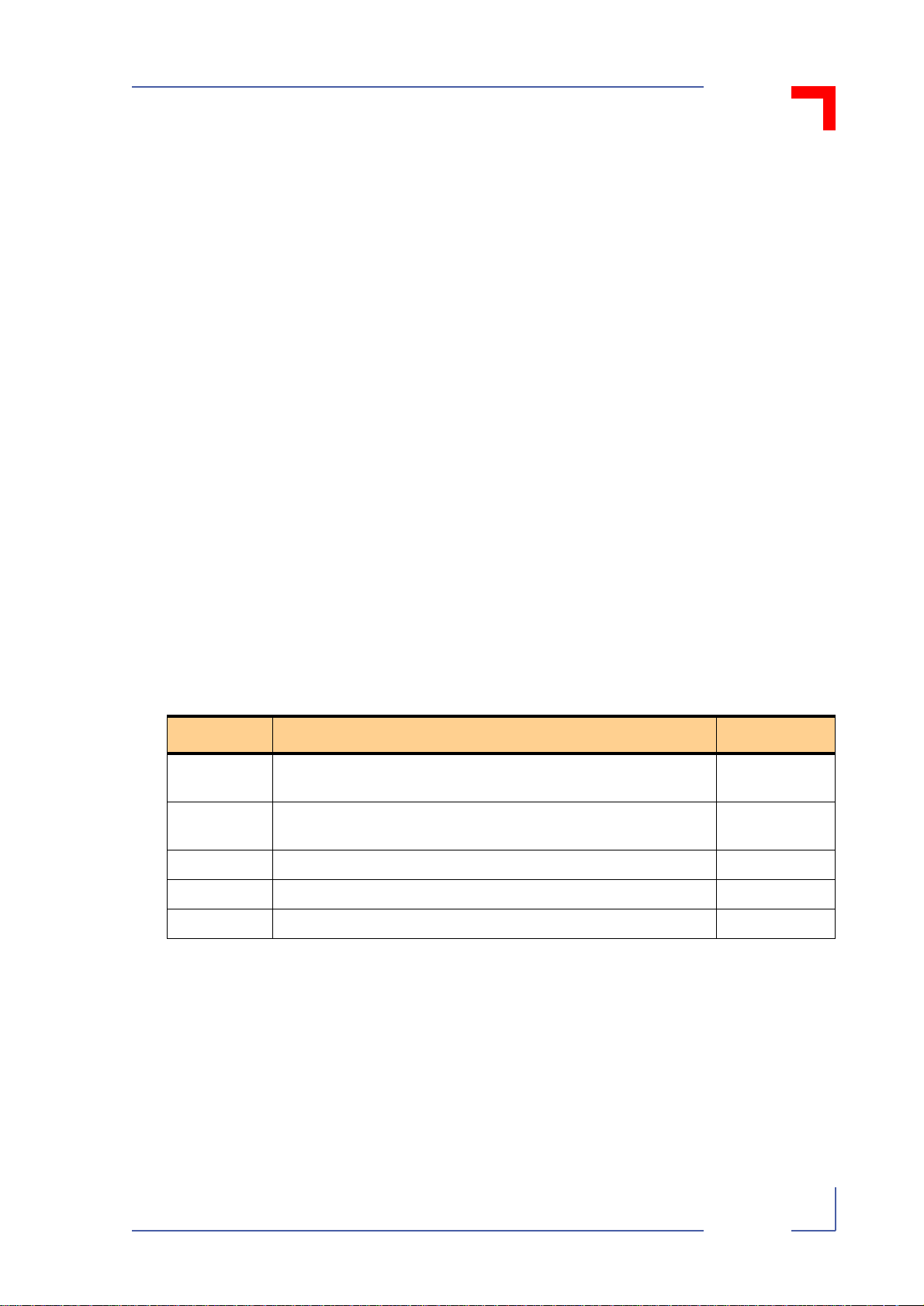

Table 1-1: Serial Interface Piggy backs

Piggyback Description Board Variant

SI-PB232 Non-optoisolated RS232 serial interface (two RJ45 connectors)

SI-PB485-ISO Optoisolated RS485 serial interface (one 9-pin female DSUB connector)

SI-10B2 10Base2 Ethernet interface (one RG58 coaxial connector) VSBC-32E

SI-10B2 10Base2 Ethernet interface (one RG58 coaxial connector) VSBC-32E

SI-10BT 10BaseT Ethernet interface (one RJ45 con nector) VSBC-32E

VSBC-32,

VSBC-32E

VSBC-32,

VSBC-32E

Applications requiring further communication interfaces may be upgraded by means of

an external CXM-SIO3 serial interface module which provides the following interface

extension possibilities:

• RS232 serial interface connectors (non-optoisolated)

• Serial interface piggyback ports

• Serial communications piggyback port

ID 21168, Rev. 04 Page 1 - 5© PEP Modular Computers GmbH

Page 22

VSBC-32 Introduction

Maximum one CXM-SIO3 module can be controlled by a VSBC-32(E) board. The CXMSIO3 module provides access to internal communication signals of the base board that

are transferred to the module via the CXC bus.

For a detailled list and description of the frontpanel interface and serial interface/communication piggybacks please refer to the “Serial Interface Piggybacks” appendix of this

manual as well as to the CXM-SIO3 user’s manual and its “Serial Communications Piggybacks” appendix respectively.

1.2.4 Memory Piggybacks

The VSBC-32(E) mainboard is not provided with any on-board DRAM/flash. These are

provided by special memory pig gybacks (DM60x). By means of these piggybacks the

following memory configurations are possible:

• ≤64MB of DRAM

• ≤4MB of flash/EPROM

For a detailled description of the memor y piggybacks please refer to the “Mem ory Pig-

gybacks” appendix of this manual.

1.2.5 System-Relevant Information

System Configuration

Up to twenty-one VSBC-32(E) boards can be installed in a VMEbus 3U rack. Please

refer to the description of the VMEbus backplane connector in the Functional Description chapter of this manual. If used as a system controller, the board should be always

installed in the system slot.

If a CXM-SIO3 or a CXM-SCSI module is used in combination with the VSBC-32(E), the

module can be “sandwiched” with the controller, Communication between the controller

and the I/O module being acchieved via the VSBC-32(E)’s on-board CXC connector.

Master/Slave Functionality

The VSBC-32(E) is a combined system and communications controller boar d provided

with both a VMEbus backplane interface which can operate both as a VMEbus master

and slave simultaneously. Thanks to this feature all twenty-one VSBC-32(E) boards

possible in a VMEbus system can operate as VMEbus masters while at the same time

sixteen of them can act as VMEbus slaves. The VSBC-32(E) VMEbus master/slave (or

neither) operation is a function of the application software.

Bootstrap Loader

Via the VSBC-32(E) frontend serial interface connectors the flash memory of the

board’s memory piggyback can be re-programmed by means of the Bootstrap Loader

which is delivered already installed in the D M60x memory piggy backs. This standalone

software has the capability of loading flash memory from Motorola S-records or from

any absolute address. If the downloaded image does not work pr operly, the Bootstrap

ID 21168, Rev. 04Page 1 - 6 © PEP Modular Computers GmbH

Page 23

VSBC-32 Introduction

Loader can be re-entered, the memory c ontents analyzed and a further programming

cycle initiated.

Warn in g!

To avoid damaging of your Bootstrap Loader and, consequently,

leaving your board unusable, please read the separate Bootstrap

Loader manual before re-setting the flash contents of your VSBC32 board.

Operating Systems

The VSBC-32(E) can operate under the following operating systems:

• OS-9

• VxWorks

Drivers are available for both operating systems.

Porting to other operating systems on request.

®

ID 21168, Rev. 04 Page 1 - 7© PEP Modular Computers GmbH

Page 24

VSBC-32 Introduction

(

y)

1.3 Board Diagrams

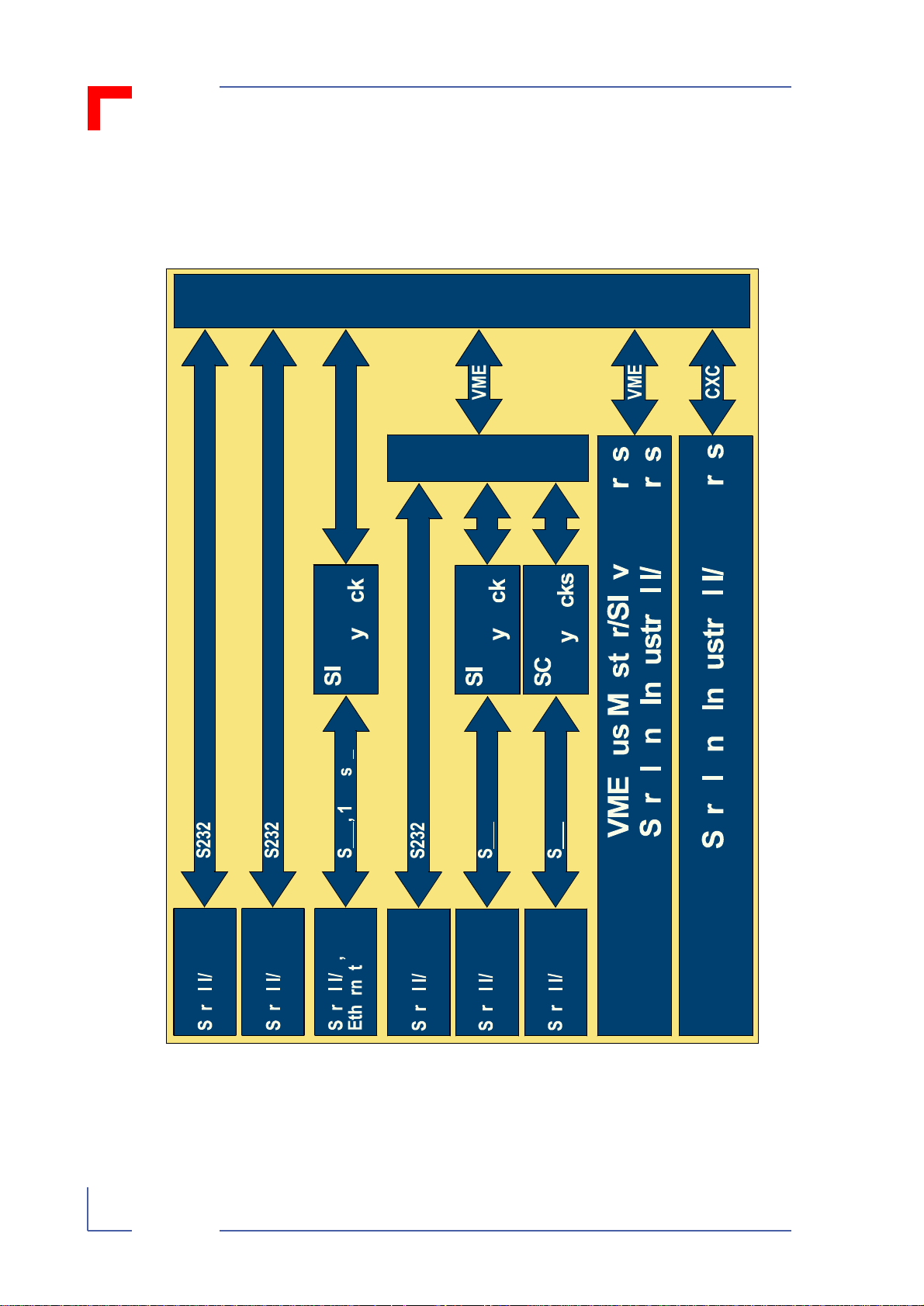

1.3.1 System-Level Functional Block Diagram

Figure 1-1: VSBC-32(E) System-Level Functional Block Diagram

VSBC-32 Mainboard (Master)

CXM-SIO3

*

Legend:

RS__[I]: RS232 non-optoisolated or RS485 optoisolated

10Base_: 10Base2 or 10Ba se5 or 10Base T Ethernet

* Serial I/O or Ethernet

Ethernet with VSBC-32E onl

ID 21168, Rev. 04Page 1 - 8 © PEP Modular Computers GmbH

Page 25

VSBC-32 Introduction

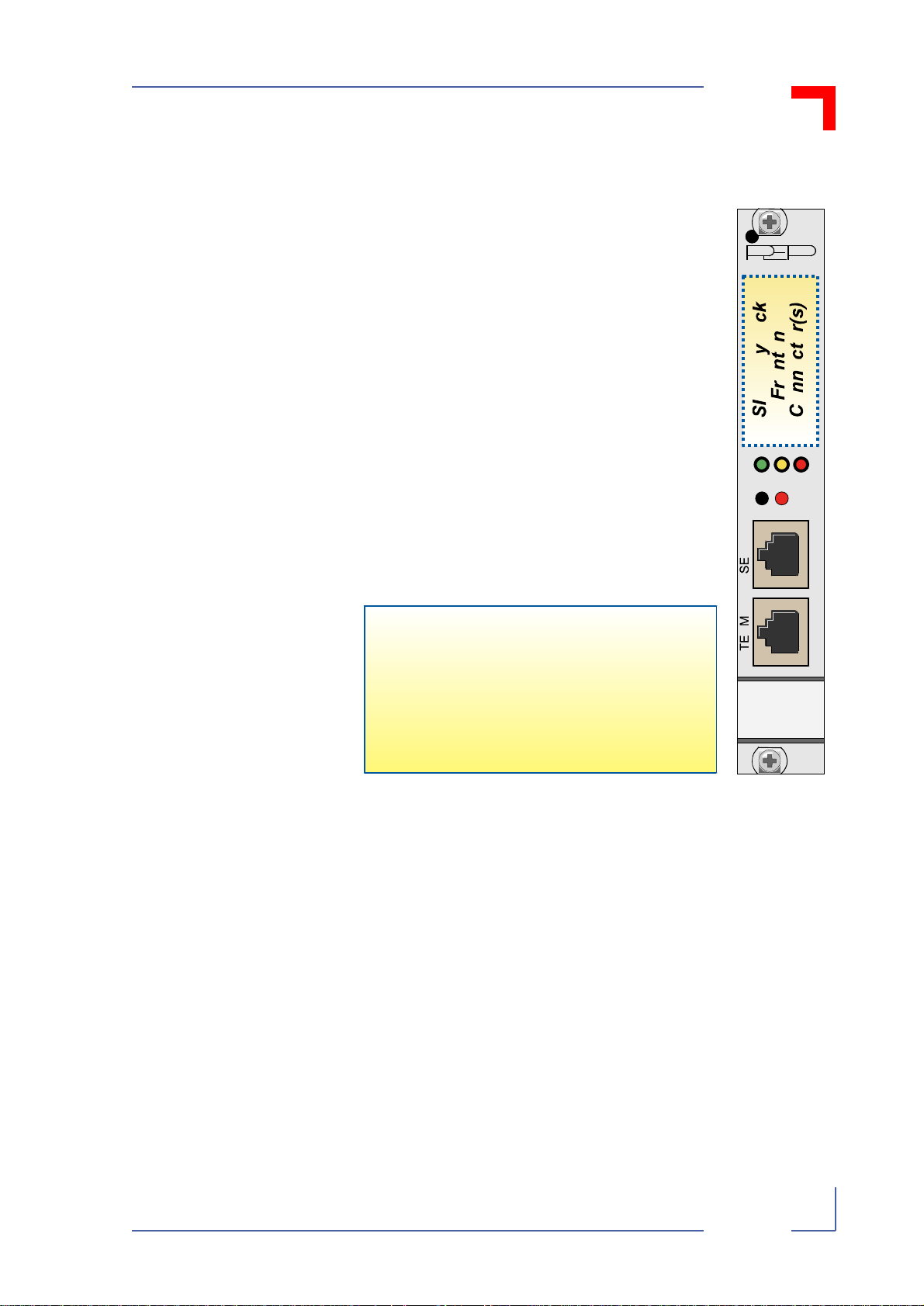

1.3.2 Frontpanels

Figure 1-2: VSBC-32 (E)

Frontpanel

LED’s:

• Green (“U”): General purpose

• Yellow (“W”): Watchdog

• Red (“H”): Halt

UWH

Pushbuttons:

• RST (left): Re set

• AB (right): Abort

RST AB

SI Piggyback Frontend Connector(s):

The additional frontend connector(s)

depend(s) on the type of serial interface

piggyback insta lled in combination with

the VSBC-32(E) mainboard. For any

details, please refer to the “Serial Interface Piggybacks” appendix in this manual.

VSBC-32

ID 21168, Rev. 04 Page 1 - 9© PEP Modular Computers GmbH

Page 26

VSBC-32 Introduction

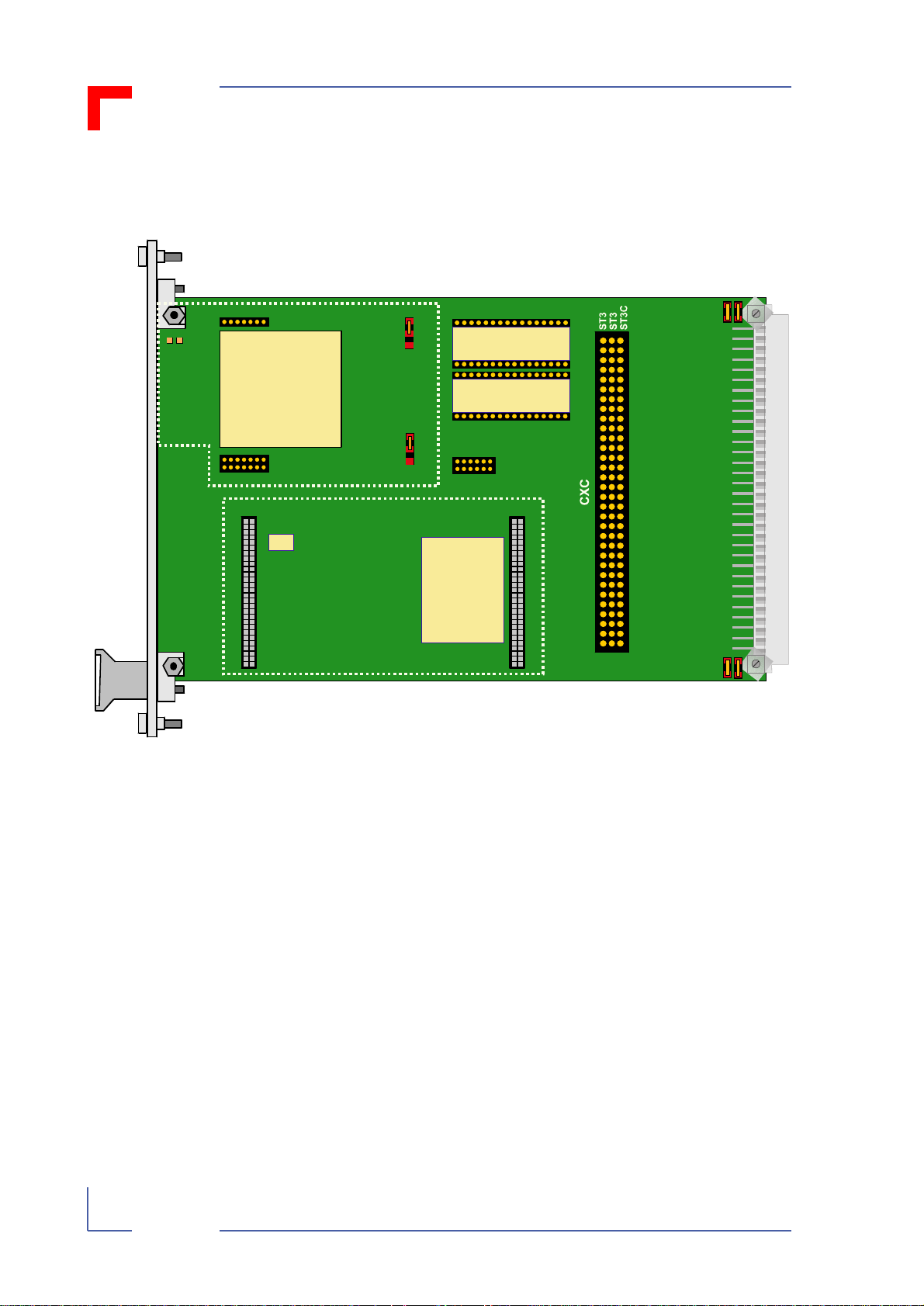

1.3.3 Board Layouts

Figure 1-3: VSBC-32(E) Board Diagram (front)]

J11J12

J6

17

ST2A

CPU / Serial

Communications

Controller

ST2B

ST2C

17

SI Piggyback

17 32

3

1

J14

2

FLASH/EPROM

(Upper Data)

116

17 32

FLASH/EPROM

(Lower Data)

116

3

1

J13

2

BDM

712

16

BU3

1492

EEPROM

SRAM

50

FLASH/EPROM:

Upper Data: D8-D15, even Byte addresses

Lower Data: D0-D7, odd Byte addre sses

BDM: Background Debug Mode.

Memory Piggyback

BU4

1492

50

J9J10

ID 21168, Rev. 04Page 1 - 10 © PEP Modular Computers GmbH

Page 27

VSBC-32 Introduction

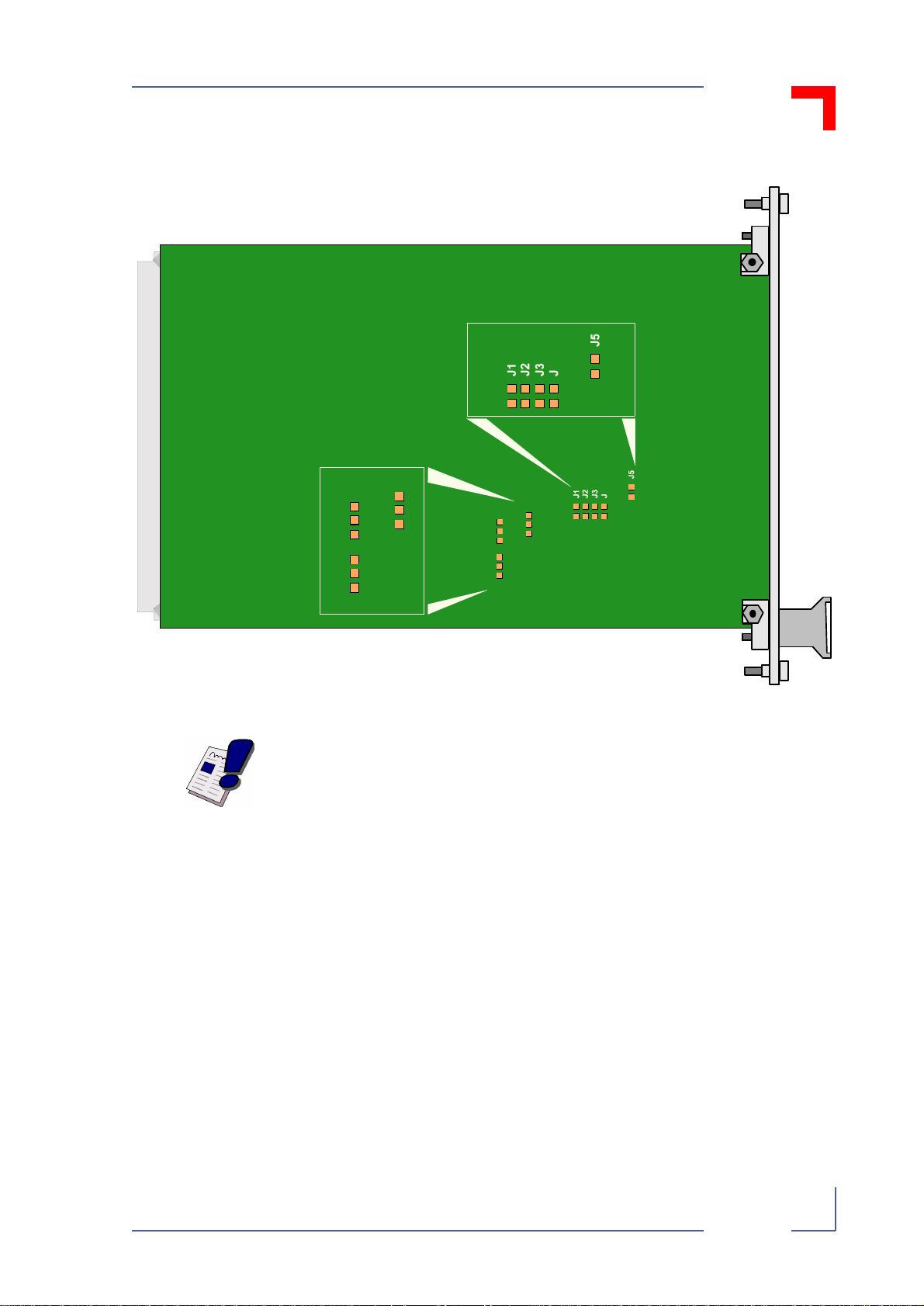

Figure 1-4: VSBC-32(E) Board Diagram (reverse)]

J11

J7

3

3

1

1

2

2

3

1

2

J8

J11

J7

3

3

1

1

2

2

3

1

2

J8

JUMPERS MAGNIFIED

Warn in g!

Solder jumpers are factory-set. To avoid possible damage to your

equiment, please do not alter them.

ID 21168, Rev. 04 Page 1 - 11© PEP Modular Computers GmbH

Page 28

VSBC-32 Introduction

1.4 Technical Specifications

Table 1-2: VSBC-32(E) Technical Specification (Sheet 1 of 3)

VSBC-32(E) Specifica tion

Board Variants

Combined CPU/Serial

Communica tio ns Co ntro lle r

On-Board Memory

Memory on Piggybacks

VMEbus Master/Slave

Functionality

Interrupt Control

• VSBC-32 : MC68360 processor,

• VSBC-32E: MC68EN360 processor

• MC68360: 25 MHz, no Ethernet capability

• MC68EN360: 25MHz or 33 MHz, Ethernet capability

CPU performance: Equivalent to Motorola CPU32

Serial I/O perfo rm.: RISC, 14 de dicate d D MA ch anne ls

• S RAM 256kB or 1MB (dual-p orte d,

backed-up by mean s of Gold -Cap s)

Note:

1MB with VSBC-32E only.

• EEPROM 2 kbit (serial); 1 kbit available

for applications

• Flash/EPROM 256kB or 1MB DIP EPROM/flash,

16-bit access

Minimum access ti me - 120n s

• DRAM 1, 4, 16 or 32 MB, 32-bit access

• F lash 0, 0.5, 1, 2 or 4 MB, 3 2-bit acc ess

• Mas ter A 24:D16 /D8, arbit ration , AM codes

• Slave A24:D16, dual-port RAM, mailbox IRQ

7-level CXC/VME IRQ handler, maskable via CXC/VME interrupt mask register; system vectors:

• ACFAIL* (via VME)Level 7 autovectored

• A bort Level 7 au tovect ored

• Tick Level 6 autovect ored

• M ailbox IR Q Level 5 autovect ored, mas kable

• SYSFAIL* Level 3 autovectored

16 on-board inte rrupt ers; level s/v ectors pro gramm able

Programmable Timers

Special Fun ction s

• Tick: Periodic-interrupt timer

• Watchdog: 512ms time-out for reset

• On-board bus error:8µs

• Ge neral-purp ose: 4*16 bit or 2*32 bit

Real-time cloc k (back ed-up):

• Date (year, month, week, day)

• Time (hour, minute, second)

2kbit serial EEPRO M:

• 1kbit for board specific data (serial number, IP address etc.)

• 1k bit for ap plicati on purpos es

DMA: 2 additional independent channels

(transfers between DRAM, FLASH, VME and CXC)

ID 21168, Rev. 04Page 1 - 12 © PEP Modular Computers GmbH

Page 29

VSBC-32 Introduction

Table 1-2: VSBC-32(E) Technical Specification (Sheet 2 of 3)

VSBC-32(E) Specification

Communication Standards

Mainboard Connectivity

Interface Ex pandib ility

• S erial I/ O (RS232, RS4 22, RS48 5)

• Ether net (VSBC-32E only)

• N on-op tois ola ted RS 232 se ria l int erfac e

(two RJ12 connectors, on frontpanel)

• One set of piggyback interface connectors for serial interface (SI) pig gyba cks (t wo 13-pi n ro w fe /male conn ect ors)

• One set of memory piggyback interface connectors

(two 50-pin row fe /m ale co nnec tors )

• B ackgroun d debug mode (BDM) interfa ce

(one 12-pin r ow m ale conn ector)

• VMEbus backplane interface

(one 96-pin D IN 41612, sty le C mal e co nnec tor)

• Enhanced CXC mezzanine interface

(one 96-pin D IN 41612, sty le C mal e co nnec tor)

Serial interface pi ggybac ks:

• SI-PB232: non-optoisolated RS232 serial interface

(two RJ45 connectors)

• SI-PB485-ISO: optoisolated RS485 serial interface

(two RJ45 connectors)

• S I-10B2: 10Base2 Ethernet int erface

(one RG58 coaxial connector)

• S I-10B5: 10Base5 Ethernet int erface

(one 15-pin DSUB female connector)

• S I-10BT: 10B aseT Et herne t in terfac e

(one RJ45 connector)

Note:

SI-10B_ with VSBC-32E only.

Front-End Functions

Data Retention

Power Supply

External serial interface modules:

• C XM-SIO3 Up to one modu le.

Pushbuttons:

• R eset but ton

• A bort button

LED’s:

• R ed: Halt

• Yellow Watchdog

• Gr een Gene ral purpo se

Short-term backu p (RTC and SRAM):

Via on-board gold-cap. Typ. 2µA/3V -> 150 hours

Long-term backup:

Via VME 5V stand-by line; automatic switching between 5V

stand-by and intern al gold -cap. Typ. 30µA/3V

Typically: 5V

With SI-PB5B: 12V

ID 21168, Rev. 04 Page 1 - 13© PEP Modular Computers GmbH

Page 30

VSBC-32 Introduction

Table 1-2: VSBC-32(E) Technical Specification (Sheet 3 of 3)

VSBC-32(E) Specifica tion

Power Consumption

Temperature Ranges

Humidity

Dimensions

Weight

• VSBC-32 : typ. 3.0W

• VSBC-32E: typ. 3.5W

Operation:

0° C to 70 °C (standard)

-40°C to +85°C (extended)

Storage:

-55°C to +125°C

0..95%, non-condensing

4HP/3U Eurocard (100mm x 160mm)

Mainboard: 130g

Serial inte rfac e pigg ybac k: 20..30g

Memory piggyb ack: 30g

1.5 Applied Standards

1.5.1 CE Com pliance

The

PEP Modular Computers’

ments of the following CE-relevant standards:

VMEbus and (e)CXC systems comply with the require-

• Emission EN50081-1

• Immission EN50082-2

• Electrical Safety EN60950

1.5.2 Mechanical Compliance

• Mechanical Dimensions IEEE 1101.10

1.5.3 Environmental Tests

• Vibration IEC68-2-6

• Permanent Shock IEC68-2-29

• Single Shock IEC68-2-27

ID 21168, Rev. 04Page 1 - 14 © PEP Modular Computers GmbH

Page 31

VSBC-32 Introduction

1.6 Related Publications

1.6.1 VMEbus/CXC Systems/Boards

• ANSI/VITA: VME64 Draft Specification 1-1994, Rev. 1.9

• VITA: CXC Specification, Rev. 2.0

•

PEP Modular Computers

•

PEP Modular Computers

•

PEP Modular Computers

•

PEP Modular Computers

1.6.2 Manufacturers’ Component Documentation

• Motorola: MC68EN360 Quad Integrated Communications Controller User’s Manual

• EM Microelectronic:V 3021 1-Bit Real- Time Clock Datasheet

• XICOR:X25C02 SPI Serial EEPROM Datasheet

CXC MPI Draft Specification, Rev. 3.1 (ID 12190)

CXC Reference Manual, ID 05263

CXM-SIO3 Manual (ID 14411)

CXM-SCCI Manual (ID 03545)

ID 21168, Rev. 04 Page 1 - 15© PEP Modular Computers GmbH

Page 32

This page was intentionally left blank.

ID 21168, Rev. 04Page 1 - 16 © PEP Modular Computers GmbH

Page 33

VSBC-32 Functional Description

Functional Description

Chapter

2

ID 21168, Rev. 04 Page 2 - 1© PEP Modular Computers GmbH

Page 34

This page was intentionally left blank.

ID 21168, Rev. 04Page 2 - 2 © PEP Modular Computers GmbH

Page 35

VSBC-32 Functional Description

2. Functional Description

2.1 General Information

The VSBC-32(E) is a 3U VMEbus combined system and communications controller

board based on the Motorola Quad Integrated Communications Controller “QUICC”

MC68(EN)360. Depending on the controller chip used and the SRAM size, there are

four board variants with different characteristics. The following table provides an overview of the various VSBC-32(E) board variants.

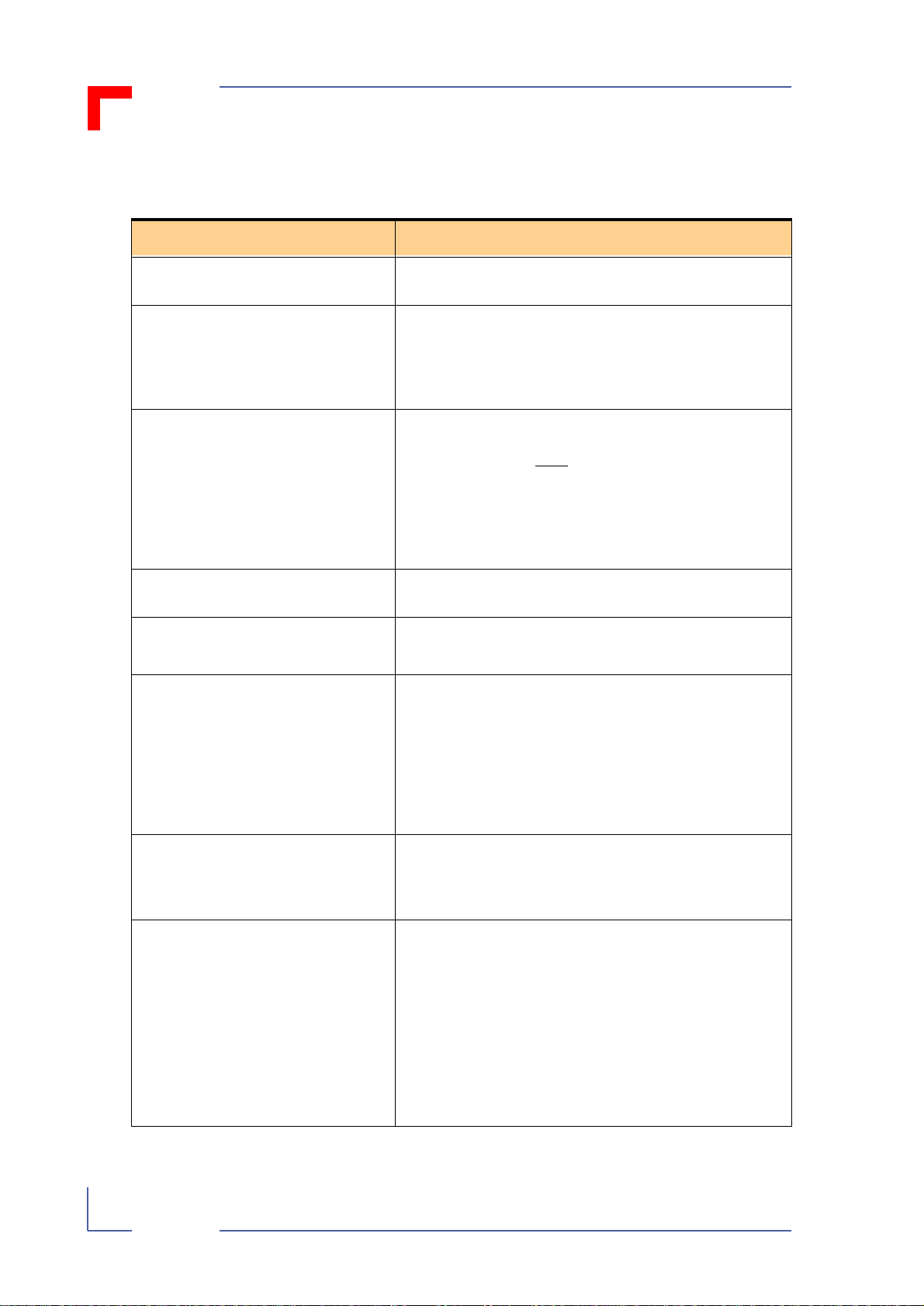

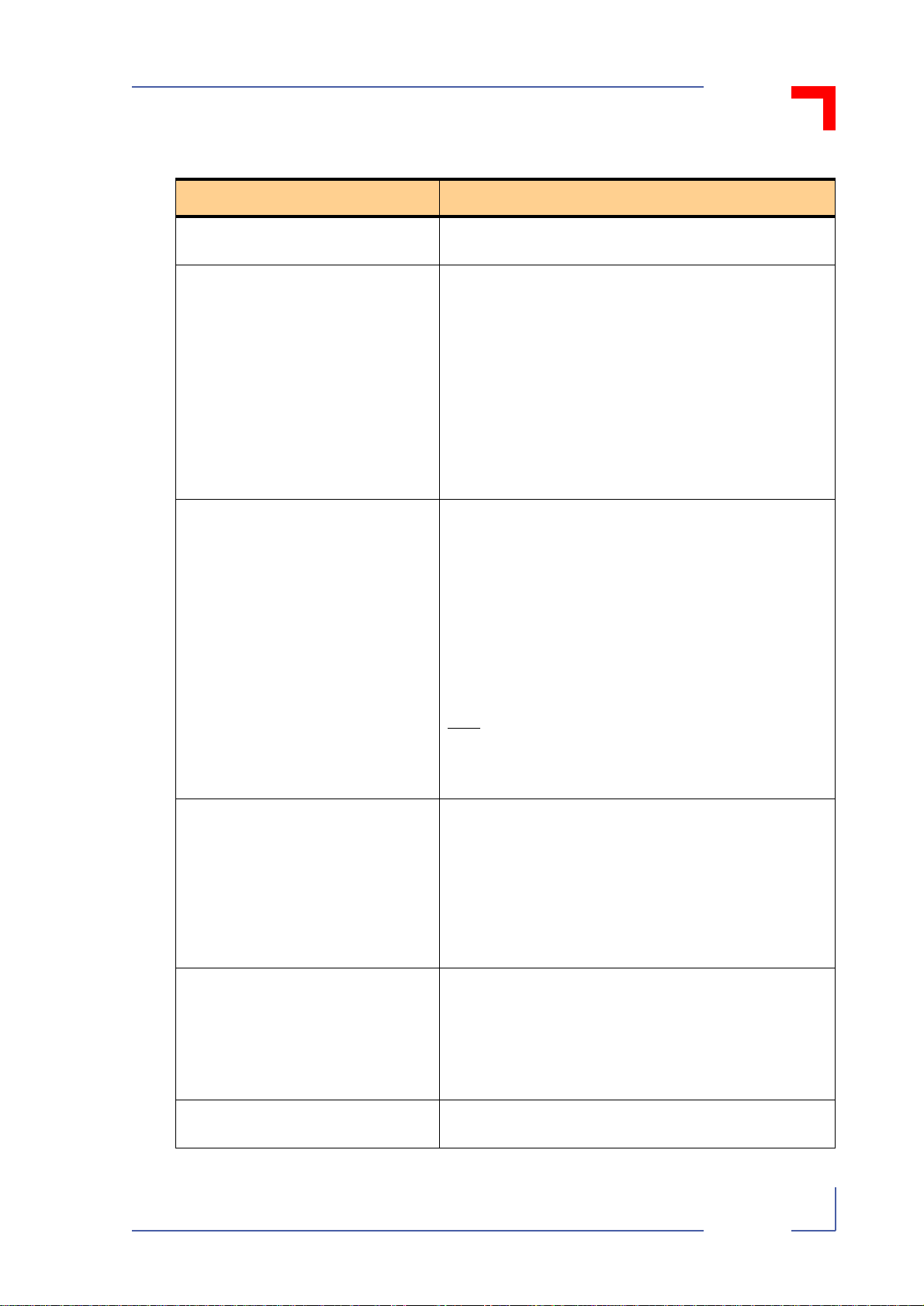

Table 1-1: VSBC-32(E) Board Variants

Board Name Proc esso r

VSBC-32

MC68360 — 25MHz 256kB

Ethernet

Capabilit y

+

VSBC-32E

MC68EN360

+

+

Being the MC68(EN)360 a CPU and serial communications contr oller, it is particularly

suitable for system control functions within applications with communications requirements such as LAN, WAN or fieldbusses (CAN, LON, PROFIBUS).

In fact, both the VSBC-32 and the VSBC-32E allow for a wide range of serial interfaces

based on the MC68(EN)360 controller which is able to handle up to six seri al communications channels. The channels can be configured in the following way:

• Two service / debug interface connectors (SMC interface, RxD/ TxD, RS232 only)

• Four full modem interface connectors / multiprotocol channels (SCC interfaces).

Thus, the VSBC-32(E) mainboard comes complete with two non-optoisolated RS232

external interfaces which are located on the lower half of the front panel. However, the

external serial interfacing can be extended by means of a variety of serial interface (SI)

piggybacks and/or a CXM-SIO3 type external serial interface module. This external module can be either “sandwiched” with the controller or placed to the right of the VSBC-32(E).

In the first case, communication between the controller and the I/O module is acchieved

via the VSBC-32(E)’s on-board CXC connector, in the second case via the VMEbus.

Processor

Frequency

25MHz 256k B

33MHz 256k B

33MHz 1MB

SRAM Size

As the CXM-SIO3 can be used again as a carrier for various serial interface (SI) and

serial communications (SC) piggy backs, the VSBC- 32/CXM-SIO3 tandem r epresents a

really powerful and versatile sytem control and serial communications control set.

Together with the two service/debug interfaces, a maximum of three (four with the serial

interface piggyback fitted) completely configured serial interfaces are available for the

base board. Three (two with serial interface piggy back fitted) serial interfaces may be

configured via the VMEbus where three of the four full modem Interfaces are routed.

The VSBC-32(E) allows also a significant variety of memory configurations, mainly

DRAM and flash memory located on special memory piggybacks, add-on flash/EPROM

on DIP s ockets, battery backed-up SRAM and EEPROM.

ID 21168, Rev. 04 Page 2 - 3© PEP Modular Computers GmbH

Page 36

VSBC-32 Functional Description

2.2 Specifics

2.2.1 System Control Functionality

Under the aspect of system control the on-chip 32-bit CPU core of the Motorola

MC68(EN)360 provides system integration at different processor frequencies. The processor core acts essentially as a Motorola CPU32 microprocessor operating at 25MHz or

33MHz without cache memory. In addition, the MC68(EN)360 offers background debugging via the on-chip “Background Debug Mode” which allows direct communication with

the CPU.

To act as a system controller, the VSBC-32(E) is provided with arbiter, system clock

driver, power monitor with system reset driver, IACK daisy chain driver and 7-level

VMEbus interrupt controller.

Arbitration is single-level FAIR (compare VME64 Specification Rule 3.14/Observation

3.17). If the VSBC-32(E) is used as a system controller and consequently placed in the

VMEbus backplane’s system slot, a special detection function provided by the board

makes any “slot 1” jumper setting superfluous. The VSBC-32(E) also provides a bus

monitor for the VMEbus.

Interrupt Control

The interrupt control logic of the MC68(EN)360 processes internal interrupt requests

alongside with external autovectored interrupt requests and a “mailbox” interrupt request

from the VMEbus control/status register. The interrupt control logic is built up using the

processor’s internal interrupt control and an external IRQ7 interrupt handler.

Internal requests are related to all interrupt requests caused by the controller sources,

including the processor’s system integration functions (watchdog timer, periodic interrupt timer) and the communications processor module (RISC controller, timers, DMA’s,

SCC’s etc.).

In order to avoid conflicts regarding the different interrupt levels, it is recommended to

use IRQ level 4 for the MC68(EN)360 CPU internal requests and IRQ level 6 for the

MC68(EN)360 serial controller internal requests.

In addition, external interrupt sources can generate autovectored interrupts and an

external VMEbus master may require an interrupt by setting a “mailbox” IRQ in the

VMEbus control/status register.

For any detailled information as well as a complete list of the Motorola

controller signals please refer to the relating Data Sheet.

®

MC68(EN)360

ID 21168, Rev. 04Page 2 - 4 © PEP Modular Computers GmbH

Page 37

VSBC-32 Functional Description

Table 2-2: External Autovector and Mailbox Interrupts

Source Interrupt Source Interrupt Type

ABORT / ACFAIL MC68(EN)360, pin IRQ7 Aut ovecto r 7

Reserved MC68 (EN)36 0, p in IRQ6 Aut ovec tor 6

Mailbox IRQ MC68(EN)360, pin IRQ5 Autovector 5

Reserved MC68 (EN)36 0, p in IRQ4 Aut ovec tor 4

SYSFAIL MC68(EN)360, pi n IRQ3 Autov ector 3

Reserved MC68 (EN)36 0, p in IRQ2 Aut ovec tor 2

Reserved MC68 (EN)36 0, p in IRQ1 Aut ovec tor 1

Mailbox Pendi ng Bit P_IR Q5 Control/stat us r egiste r

2.2.2 Memory Configurations

The VSBC-32(E) allows a significant variety of memory configurations. The special

DRAM/flash piggybacks (DM60x), for instance, allows the user to take advantage of the

on-board programming facility to produce low cost upgrades by simply overwriting existing stored data. This memory can be configured with different memory options allowing

remarkable flexibility when customizing memory requirements for real-time applications.

The DM60x piggybacks provide between 1MB and 64MB o f DRAM with 32-bit access

and up to 4MB of +5V flash memory. In addition, a set of DIP sockets located on the

VSBC-32(E) mainboard allows the installation of an additional 1MB of flash/EPROM.

Both memory devices can be used for bootstrapping. The selection of the boot memory

is achieved by hardware jumpering.

Note...

Physically the DM60x piggybacks provide up to 64MB of DRAM.

However, the IUC-32(E) mainboard envisages addre ssing for up to

two memory banks of 6 4MB each.

Exchange and retention of system relevant data from the VMEbus to the CPU/DMA and

viceversa is provided by means of 256kB or 1MB of a 16-bit wide dual-ported SRAM

which is backed-up using Gold Caps. Both the VMEbus users and the on-board CPU

have access to the SRAM memory.

Note...

The upper 8kB of dual-ported SRAM are accessed by the

VMEbus, the lower 8kB a re reserved for mailbox interru pts.

Configuration data are stored in a 2kbit EEPROM. 1kbit is used for factory-specific configuration purposes, and 1kbit is available for application-specific configuration data.

ID 21168, Rev. 04 Page 2 - 5© PEP Modular Computers GmbH

Page 38

VSBC-32 Functional Description

ggy

A schematic overview of all possible memory c onfigurations is given in the fi gure on the

next page.

Figure 2-1: VSBC-32 Memory Configuration Variants

VSBC-32

MC68360

25MHz

VSBC-32E

MC68EN360

25MHz

33MHz

CPU Options

SRAM

256kB

SRAM

256kB

or

SRAM

1MB

2kbit EEPROMRTC

CPU/Serial

Comm.

Controller

Flash

or

EPROM

(256kB or

1 MB)

Memory Pi

- 1MB DRAM + 0 or 1 MB Flash EPROM

- 4MB DRAM + 1,2 or 4 MB Flash EPROM

- 8MB DRAM + 1,2 or 4 MB Flash EPROM

- 16MB DRAM + 1,2 or 4 MB Flash EPROM

- 32MB DRAM + 0.5,1 or 2 MB Flash EPROM

- 64MB DRAM + 1,2 or 4 MB Flash EPROM

backs

SRAM

DRAM

+

Flash

Mainboard

2.2.3 DMA Channels

Two independent channels are provided by the MC68(EN)360 controller chip and can

be used by applications requiring data transfer between VMEbus modules (as well as

CXC modules, if present), DRAM, flash memory and dual-ported SRAM.

Memory-to-memory transfers with the DMA’ s of the MC68(EN)360 are possible with any

combination of on-board and VMEbus addresses.

ID 21168, Rev. 04Page 2 - 6 © PEP Modular Computers GmbH

Page 39

VSBC-32 Functional Description

2.2.4 Serial Communications Control

Under the aspect of serial communications control, a major advantage of the

MC68(EN)360 serial communications controller cor e SIM60 is its compatibility with all

important communication standards. A detailled description of all control functions is

provided on the following pages alongside with a comprehensive list of the possible

serial interface piggybacks and their connectors.

For the mainboard interface connector pinouts refer also to the “Board Interfaces” section of this chapter. For a description and pinouts of the connectors of the serial interface/communication piggybacks as well as of the CXM-SIO3 frontpanel interface

connectors please refer instead to the “SI Piggy backs” appendix of this manual as well

as to the CXM-SIO3 user’s manual and its “Serial Communications Piggybacks” appendix respectively.

Communication Standards and Protocols

Six communication standards are available on the VSBC-32(E):

• Serial I/O (RS232, RS485; RS422)

• Ethernet (10Base2, 10Base5, 10BaseT)

Serial communications using the RS232 standard are available on the VSBC-32(E)

mainboard frontpanel as well as on a dedicated piggy back to be connected to its SI

Interface. In addition, RS232 communication is possible via a CXM-SIO3 external serial

interface module. Communications using the PROFIBUS protocol are supported by an

optoisolated, half-duplex RS485 serial I/O interface implemented on a dedicated piggy back to be connected to the SI Interface of either the VSBC-32(E) or the external serial

interface module. RS422 is not commonly available on the VSBC-32(E) but can be supplied by

The MC68(EN)360 processor is specified to support also a full set of IEEE 802.3/Ethernet CSMA/CD media access control and channel interface functions. Since the controller requires an external interface adapter and transceiver function, the Ethernet

interface can be adapted to all standard Ethernet functions, such as 1 0Base T, 10Base5

and 10Base2 via a piggyback connected to the SI Interface on the VSBC-32(E).

PEP Modular Computers

on special request.

Note...

The CXC bus does not support a 12V power supply. Therefore,

the 10Base5 Et hernet piggyback SI-10B5 ca nnot be used on the

IUC-32(E) controller bo ard.

Serial I/O Channelling

The VSBC-32(E) mainboard is provided with TxD and RxD signals by the controller’s

SMC1 and SMC2 channels and supply RS232 interface software handshake (XON/

XOFF) capability. They are configured as service/debug connectors by default.

All full modem interfaces located on the piggybacks and/or CXM-SIO3 external serial

interface module supply RxD, TxD, RTS, CTS, CD, DTR and RCLK/TCLK. Two of the

full modem interfaces can be configured on the piggyback interface with a variety of

ID 21168, Rev. 04 Page 2 - 7© PEP Modular Computers GmbH

Page 40

VSBC-32 Functional Description

ggy

y

serial interface (SI) piggybacks (RS232, RS485, Ethernet). The SCC1 channel of the

MC68(EN)360 provides the interface to the ser ial interface (SI) piggyback installed on

the VSBC-32(E). All other channels of the controller (SCC2, SCC3 and SCC4) are

ported to the CXC interface except for the SI-PB232 piggyback which has on-board

additional control provided by the SCC4 channel through the piggyback interface for

serial interface piggybacks.

Thanks to the fact that three out of four SCC channels ar e routed to the CXC interface

connector, also an CXM-SIO3 external serial i nterface module can be installed in the

system, which therefore becomes a sort of “privileged” serial I/O extension of the VSBC32(E) board itself. In addition to two non-optoisolated RS232 serial interface connectors

the external serial interface module supports again a serial interface piggyback and up

to three serial communications piggy backs with the relating interfacing options. Maximum one CXM-SIO3 module can be cont rolled by an VSBC-32(E) board.

Figure 2-2: MC68(EN)360 Serial Communication Channeling

MC68(EN)360

Rx and Tx onl

SCC2

SCC3

SCC4

SCC1

SMC2SMC1

}

}

RS232

RS232

CXC Interface:

RS232, RS432, RS485

Ethernet (10Base2,

10Base5, 10BaseT)

SI Pi

Interface:

RS232, RS432, RS485

Ethernet (10Base2,

10Base5, 10BaseT)

back

Note...

The serial channel SCC4 is routed to both the piggyback interface for serial interface p iggyb acks a nd th e CXC and c an be used

by either one or the other, not both at the same time.

ID 21168, Rev. 04Page 2 - 8 © PEP Modular Computers GmbH

Page 41

VSBC-32 Functional Description

Depending on whether the piggyback interface for serial interface (SI) piggybacks is

configured as an Ethernet port (board versions with Ethernet piggyback) or not, the

serial interfaces channels of the VSBC-32(E) can assume the functions described in the

following figure.

Figure 2-3: VSBC-32(E) Serial Interface Channel Configurations

Port

Service/Debug 1 SMC1 Main board, upper RJ12

Service/Debug 2 SMC2 Main board, lowe r RJ12

Ethernet

Full MODEM 1

Full MODEM 2 SCC2 External serial inte rface module

Full MODEM 3 SCC3 External serial inte rface module

Full MODEM 4 SCC4

Legend:

Board versions with Ethernet port

Board versions without Ethernet port

Independent of Ethernet configuration

1

SCC4 is not used by any of the Ethernet piggybacks. With these piggybacks, SCC4 can be used on the C XC bus.

Serial Communicati on

Channel

SCC1 Mainboard, serial in terface pig gyback

Interface Location

External serial i nterface module

Mainboard or

Serial interface piggyback or

External serial i nterface module

1

ID 21168, Rev. 04 Page 2 - 9© PEP Modular Computers GmbH

Page 42

VSBC-32 Functional Description

* S i l I/O PROFIBUS ( Eth t)

2.3 Functional Block Diagram

Figure 2-4: VSBC-32 Board-Level Functional Block Diagram

System Controller

Subordinbate CPU Control Functions

System

Controller Core

Subordinbate CPU Memory Functio ns

Memory

Piggyback

Serial Communications Controller

SMC1 SMC2 SCC1 SCC4 SCC3 SCC2

CXC B u s

CXM-SIO3

CXC

Controller Logic

VMEbus

VMEbus

*

Legend:

RS___: RS232 non-optoisolated or RS485 optoisolated

10Base_:10Base2 or 10Base5 or 10BaseT Ethernet

ID 21168, Rev. 04Page 2 - 10 © PEP Modular Computers GmbH

Page 43

VSBC-32 Functional Description

Fi

f

2.4 Board Interfaces

The following section provides a description of the mainboard interface connector

pinouts. For a detailled list and description of the connectors of the serial interface/communication piggybacks and of the frontpanel interface connectors please refer to the “SI

Piggybacks” appendix of this manual a s well as to the CXM-SIO3 user’s manual and its

“Serial Communications Piggyba cks” appendix respectively.

2.4.1 Serial I/O Interfaces

The mainboard RJ12 RS232 frontpanel connectors BU7 and BU8 of the VSBC-32(E) are provided with TxD and RxD signals by the controller’s

SMC1 and SMC2 channe ls and supply RS232

interface software handshake (XO N/XOFF) capability. They are configured as service/debug connectors by default.

The pinouts of the RJ12 connectors are shown in

the following table.

Table 2-3: Pinouts of the Mainboard Serial Interface Connectors BU7/BU8

Pin Pinouts

1N/C

2GND

3TxD

4RxD

gure 2-5: Orientation o

the VSBC-32(E) Mainboard

Serial Interfaces

1

SMC1

6

1

SMC2

6

5N/C

6N/C

N/C = Not connected.

ID 21168, Rev. 04 Page 2 - 11© PEP Modular Computers GmbH

Page 44

VSBC-32 Functional Description

2.4.2 Piggy back Interface Connectors for Serial Interface Piggybacks

The VSBC-32(E) is equipped with a set of piggyback interface connectors for serial

interface (SI) piggybacks (three 7-pin row male connectors). The pinout of these piggyback interface connectors includes all signals for serial I/O (RS232), PROFIBUS

(RS485) and Ethernet (10BaseT, 10Base5, 10Base2) communication.

Note...

Although physically all piggybac ks fit on bott basic board variant s

(IUC-32 and IUC-32E), the MN68360 processor of the IUC-32

variant does not support Ethernet communication. Therefore,

Ethernet piggybacks should be used only on the IUC-32E board

variants.

For a detailled description of the pinouts of these piggyback interface connectors please

refer to the VITA/

PEP Modular Computers

CXC MPI Specification.

2.4.3 Memory Piggyback Interface Connectors

The VSBC-32(E) is equipped with a set of memory piggyback interface connectors (two

50-pin row female connectors). The pinout of these piggyback interface connectors

includes all signals for t he con nection of u p to 128M B of DR AM and up to 4 MB o f flash

EPROM.

For a detailled description of the pinouts of these piggyback interface connectors please

refer to the VITA/

PEP Modular Computers

CXC MPI Specification.

2.4.4 EPROM DIP Sockets

The VSBC-32(E) is equipped with two sets of (flash) EPROM DIP sockets (two 32-pin

row female sockets). The pinout of th es e DIP s oc kets includes all signals for the connection of up to 1MB of SRAM.

ID 21168, Rev. 04Page 2 - 12 © PEP Modular Computers GmbH

Page 45

VSBC-32 Functional Description

2.4.5 Background Debug Mode Interface Connector

The VSBC-3 2(E ) is equipped wi t h a b ackground debu g mode (BDM) in terface connector

(one 12-pin row male connector). This connector allows an external debugger to be

interfaced to the MC68(EN)360 for controlling purposes. The interface connector is

specified by Motorola.

The pinouts of the BDM interface connector are shown in the following table. For any

further details, please refer to the Motorola MC68(EN)360 User ’s Manual.

Table 2-4: BDM Interface Connector Pinouts

Pin Signal Pin Signal

1GND 2CLKO1

3 DS* 4 BERR*

5 GND 6 BKPT * / DSCL K

7GND 8FREEZE

9 RESETH* 10 IFETCH / DSI

11 VCC 12 IPIPE0 / DSO

2.4.6 VMEbus Backplane Interface

The VSBC-32(E) is equipped with a VMEbus backplane interface connector.

The board is provided with a complete ma ster inter face f or the VMEbus backplane con-

nector. The VMEbus master interface consists of a VMEbus arbiter, requester, system

controller and buffers for data/address/control signals. Simultaneously, the VSBC-32(E)

can act as a VMEbus slave, as it is provided with a slave interface which consists of a

programmable board address decoder, a dual-ported SRAM access and a mailbox

interrupt controller.

To act as a system controller, the VSBC-32(E) is provided with arbiter, system clock

driver, power monitor with system reset driver, IACK daisy chain driver and 7-level

VMEbus interrupt controller.

Arbitration is single-level FAIR (compare VME64 Specification Rule 3.14/Observation

3.17) on BR3*. If the VSBC-32(E) is used as a system controller, a special detection

function provided by the board, which is also readable within the VMEbus control/status

register, makes any “slot 1” jum per setting superfluous. The VMEbus int erru pt acknowledgement is controlled via a daisy chain driver that is supplied with the board. IACK* is

connected via the VMEbus backplane for IACKIN* of the system slot.

The signals SYSCLK* and SYSRES* can be routed from on-board to the VMEbus

through the use of jumpers, leaving to the VMEbus user instead of the system controller

the initiative of generating these signals. SYSFAIL* generates a maskable on-board

autovectored level-3 interrupt (please refer also to the section System Control Functionality (Interrupt Control) of this chapter), whereas ACFAIL* generates a non-maskable

on-board level-7 interrupt.

ID 21168, Rev. 04 Page 2 - 13© PEP Modular Computers GmbH

Page 46

VSBC-32 Functional Description

The VSBC-32(E) also provides a bus monitor for the VMEbus. A 128µs bus error timer

monitors the cycle le ngths of the VMEb us data tra ns fer and generate s a V MEbus BERR*

signal on timeout. This timer is enabled and disabled via the VMEbus control/status register which conta ins a lsao a timeout statu s bit in order to ide ntify th e bus e rrors g enerate d

by the bus monitor.

Exchange and retention of system relevant data from the VMEbus to the CPU/DMA and

viceversa is provided by means of 256kB or 1MB of a 16-bit wide dual-ported SRAM

which is backed-up using Gold Caps. Both the VMEbus users and the on-board CPU

have access to the SRAM memory (upper 8kB, i.e. even Byte addresses).

Note...

The dual-ported SRAM cannot be accessed through its own

VMEbus interface. A bus monitor timeout would result due to the

fact that any access by the VMEbus to the DPRAM would be

blocked as long as the VSBC-32(E) is bu s master.

An external VMEbus master may interrupt the VSBC-32(E) by setting P_IRQ5 (“mailbox

interrupt pending”) in the VMEbus control/status register. Seen from the VMEbus, the

address of this dual-ported register is identical to the base address of the dual-ported

SRAM (lower 8kB, i.e. odd Byte addresses).

Note...

All bits of the VMEbus control/status register can be read from

the VMEbus, but only th e bit P_IRQ5 is read /write.

For a complete map of the VMEbus control/status register please refer to the relating

section in the Configuration chapter of this manual.

For any general VMEbus information including generic pinouts please refer to Appendix

B of the ANSI/VITA VME64 Specification.

2.4.7 CXC Mezzanine Interface

The VSBC-32(E) is equipped with a CXC mezzanine interface connector.

CXC and eCXC both contain a 16-bit data bus, seven address lines and eight decoded

chip select lines. In total, there are eight control signals (CXC_CS0...CXC_CS7). The

base address of the CXC can be programmed via the CS5 line of the MC68(EN)360.

The main difference between the two VITA standards is the amount of address space

available for peripheral devices:

• CXC: 8*256Bytes (overall length: 0x400H, 1024Bytes actually av ailable)

• eCXC: 8*16MB (overall length: 0x1000 000, 16MB actually available)

Furthermore, the (e)CXC contains a 4-IRQ capability (4 edge-sensitive interrupt

requests), DMA capability (1 channel, DREQ + DACK), serial ports (3 channels, Full

MODEM) and a set of parallel port signals. These special CXC functions are based on

the MC68(EN)360 controlle r reso urc es.

ID 21168, Rev. 04Page 2 - 14 © PEP Modular Computers GmbH

Page 47

VSBC-32 Functional Description

For general CXC information, including generic pinouts and a comparison of the

MC68(EN)360 and the MC68302 CPU pinouts on the CXC, please refer to the “CXC”

appendix attached to this manual, the

or to the CXC Specification.

2.5 VSBC-to-VSBC-32 System Upgrading

In the following the porting information required by customers w anting to upgrade their

VSBC-based systems to an VSBC-32 based one is supplied.

The VMEbus/CXC ports SER1, SER2 and SER3 of the MC68302 are equivalent to

ports SCC2, SCC3 and SCC4 respectively on the MC68(EN)360 controller chip.

With regard to special VMEbus/CXC capabilities, the VMEbus/CXC pinout on the

VSBC-32(E) has been developed to provide maximum compatibi lity between the standard VMEbus/CXC functions. In addition, all signals are available in order to configure

two time division multiple xed channels via the VMEb us/CXC (ISDN, PCM, GCI and so on).

PEP Modular Computers

CXC Reference Manual

Multifunction pins with incompatible functions with regard to the MC68302 and

MC68(EN)360, which are called “user-defined” in the generic CXC Specification, are not

part of the VSBC-32(E) VMEbus or CXC specification.

Although the SMCs are configured on the mainboard, these ports are also integrated on

the VMEbus/CXC because of possible ISDN applications where SMCs can be integrated and other protocols supported by the M C 68(EN) 3 60.

Note...

If the RCLK2 signal (VMEbus/CXM pin C16) is required, jumper

J4 (24MHz clock) must be opened and the serial drivers delivered by

PEP Modular Computers

must be modified.

ID 21168, Rev. 04 Page 2 - 15© PEP Modular Computers GmbH

Page 48

VSBC-32 Functional Description

Table 2-5: IUC/IUC- 32 Por tin g Information (Sheet 1 of 2)

CXC

Function

IRQ_1 A1 Yes PC0 —

IRQ_2 A2 Yes PC1 —

IRQ_3 A3 Yes PC2 —

IRQ_4 A4 Yes PC3 —

DMA_ACK C2 Yes PB5 —

DMA_REQ C3 Yes PB4 —

SER1_RCLK B1 Yes PA8 —

SER1_TCLK B2 Yes PA10 —

SER1_TXD B4 Yes PA3 —

SER1_RXD B10 Yes PA2 —

SER1_RTS B5 Yes PB13 —

SER1_DTR A13 Yes PB17 —

SER1_CTS B13 Yes PC6 —

SER1_CD B14 Yes PC7 —

SER2_RCLK C16 Yes PA13 Cannot be used if J4 is set 3

Pin

MC68302

HW

Comp.

MC68(EN)

360

Port

Comment

See

Note

SER2_TCLK C15 Yes PA12 —

SER2_TXD C17 Yes PA5 —

SER2_RXD C18 Yes PA4 —

SER2_RTS C12 Yes PB14 —

SER2_DTR A11 Yes PB16 —

SER2_CTS C13 Yes PC8 —

SER2_CD C11 Yes PC9 —

SER3_RCLK C6 Yes PA15 Not usable if SI piggyback uses SCC4 4

SER3_TCLK C5 Yes PA14 —

SER3_TXD C8 Yes PA7 Not usable if SI piggyback uses SCC4 4

Legend:

1 Reserved Pin: On a standard VSBC-32 board, this signals is used for UART ports at BU7 and BU8.

2 Reserved Pin: On a standard VSBC-32 board, this signal is used for SPI to which the EEPROM is already con-

nected. PB0 is chip select of the EEPROM.

3 Reserved Pin: On PA13, a 24 MHz clock signal is routed via jumper J4. This signal is alw ays needed for PEP

standard software (serial drivers).

4 Dual Functioning Pin: This signal is routed both to the mainboard’s interface for serial interface piggybacks

(ST5C) and the CXC backplane connector and can be used by either one or the other, but not both at the same

time. Due to this, a conflict exists if the SCC4 port is to be used with the SI232 piggyback and CX C boards

(such as CXM-SIO3), as both boards access this port. The SCC4 port can, therefore, not be used at the same

time by serial interface piggybacks and CXC boards.

ID 21168, Rev. 04Page 2 - 16 © PEP Modular Computers GmbH

Page 49

VSBC-32 Functional Description

Table 2-5: IUC/IUC-32 Porting Information (Sheet 2 of 2)

CXC

Function

SER3_RXD C9 Yes PA6 Not usab le if SI pi ggyba ck use s SCC 4 4

SER3_RTS B7 Yes PB15 Not usable if SI pi ggyba ck u ses SC C4 4

SER3_DTR A12 Yes PB9 Not usable if SI piggyback uses SCC4 4

SER3_CTS B16 Yes PC10 Not u sab le if SI pi ggyba ck u ses SC C4 4

SER3_CD B8 Yes PC11 Not usable if SI piggyback uses SCC4 4

User-Defined

Pin

A5 No PB0

A6 No PB1

A8 No PB2

A9 No PB3

A10 No PB8 See MC68360 User Manual

B11 No PB10 Used on board SMC2 (Transmit) 1

C1 No PB6 Used on board SMC1 (Transmit) 1

MC68302

HW

Comp.

MC68(EN)

360

Port

Comment

Used on board SPI SEL for EEPROM.

Cannot be used on CXC

SPI Clk: can be used if an ‘SPI SEL’

other than PB0 is used.

SPI TxD: can be used if an ‘SPI SEL’

other than PB0 is used.

SPI RxD: can be used if an ‘SPI SEL’

other than PB0 is used.

See

Note

2

C4 No PB11 Used on board SMC2 (Receive) 1

C10 No PB7 Used on board SMC1 ( Recei ve) 1

Legend:

1 Reserved Pin: On a standard VSBC-32 board, this signals is used for UART ports at BU7 and BU8.

2 Reserved Pin: On a standard VSBC-32 board, this signal is used for SPI to which the EEPROM is already con-

nected. PB0 is chip select of the EEPROM.

3 Reserved Pin: On PA13, a 24 MHz clock s ignal is routed via jumper J 4. This signal is al ways needed for PEP

standard software (serial drivers).

4 Dual Functioning Pin: This signal is routed both to the mainboard’s interface for serial interface piggybacks

(ST5C) and the CXC backplane connector and can be used by either one or the other, but not both at the same

time. Due to this, a conflict exists if the SCC4 port is to be used with the SI232 piggyback and CXC boards