Page 1

VMP3

PowerPC CPU Board

for VME Applications

Manual ID: 29230, Rev. Index 01

27 July, 2005

USER GUIDE

®

The product described in this manual is

in compliance with all applied CE standards.

P R E L I M I N A R Y

29230.01.UG.VC.050727/091404

Page 2

Preface VMP3

Revision History

Publication Title: VMP3: PowerPC CPU Board for VME Applications

ID Number: 29230

Rev.

Index

01 User Guide initial issue 27 Jul, 2005

Brief Description of Changes Date of Issue

Imprint

Kontron Modular Computers GmbH may be contacted via the following:

MAILING ADDRESS TELEPHONE AND E-MAIL

Kontron Modular Computers GmbH +49 (0) 800-SALESKONTRON

Sudetenstraße 7 sales@kontron.com

D - 87600 Kaufbeuren Germany

For further information about other Kontron Modular Computers products, please visit our

Internet web site: www.kontron.com

P R E L I M I N A R Y

Copyright

Copyright © 2005 Kontron Modular Computers GmbH. All rights reserved. This manual may

not be copied, photocopied, reproduced, translated or converted to any electronic or machinereadable form in whole or in part without prior written approval of Kontron Modular Computers.

GmbH.

Disclaimer:

Kontron Modular Computers GmbH rejects any liability for the correctness and

completeness of this manual as well as its suitability for any particular purpose.

Page ii © 2005 Kontron Modular Computers GmbH ID 29230, Rev. 01

29230.01.UG.VC.050727/091404

Page 3

VMP3 Preface

Table of Contents

Revision History .........................................................................................................ii

Imprint ........................................................................................................................ii

Copyright ....................................................................................................................ii

Table of Contents ......................................................................................................iii

List of Tables .............................................................................................................ix

List of Figures ......................................................................................................... xiii

Proprietary Note .......................................................................................................xv

Trademarks ..............................................................................................................xv

Environmental Protection Statement ........................................................................xv

Explanation of Symbols .......................................................................................... xvi

For Your Safety ...................................................................................................... xvii

High Voltage Safety Instructions ........................................................................ xvii

Special Handling and Unpacking Instructions ................................................... xvii

General Instructions on Usage ............................................................................. xviii

Two Year Warranty ..................................................................................................xix

Chapter

1. Introduction .................................................................................................. 1 - 3

1.1 Board Overview ....................................................................................... 1 - 4

1.1.1 Board Introduction .......................................................................... 1 - 4

1.1.2 Board Specific Information .............................................................. 1 - 4

1.2 System Relevant Information .................................................................. 1 - 5

1.2.1 System Configuration ..................................................................... 1 - 5

1.2.2 Operating Software ......................................................................... 1 - 5

1.3 Board Diagrams ...................................................................................... 1 - 5

1.3.1 Application System Interfacing ....................................................... 1 - 6

1.3.2 System Level Interfacing ................................................................ 1 - 7

1.3.3 Board Layout .................................................................................. 1 - 8

1.4 Technical Specifications ........................................................................ 1 - 11

1.5 Applied Standards ................................................................................. 1 - 13

1.6 Related Publications ............................................................................. 1 - 14

1

P R E L I M I N A R Y

29230.01.UG.VC.050727/091405

ID 29230, Rev. 01 © 2005 Kontron Modular Computers GmbH Page iii

Page 4

Preface VMP3

Chapter

2. Functional Description .................................................................................2 - 3

2.1 General Information .................................................................................2 - 3

2.2 Board-Level Interfacing Diagram .............................................................2 - 4

2.3 EB8541 E²Brain™ Module Interfaces ......................................................2 - 6

2.3.1 System Interface .............................................................................2 - 6

2.3.2 System Interface Extension ............................................................2 - 6

2.3.3 Communications Interface ..............................................................2 - 6

2.3.4 Communications Interface Extension ..............................................2 - 7

2.4 VMP3 Board Interfaces ............................................................................2 - 8

2.4.1 J10 – VME Interface ........................................................................2 - 8

2.4.2 J5A/B – Dual Gigabit Ethernet Interface .......................................2 - 10

2.4.3 J6 – Fast Ethernet Interface ..........................................................2 - 11

2.4.4 J7 Terminal Interface .....................................................................2 - 12

2.4.5 J8 JTAG/Debug Interface ..............................................................2 - 13

2

2.4.6 J9 PCI Expansion Interface ...........................................................2 - 14

2.4.7 J11 I/O Expansion Interface ..........................................................2 - 16

2.4.8 J12 In-System-Programming Interface .........................................2 - 19

Chapter

3

P R E L I M I N A R Y

3. Installation ....................................................................................................3 - 3

3.1 Hardware Installation ...............................................................................3 - 3

3.1.1 Safety Requirements .......................................................................3 - 3

3.1.2 Installation Procedures ....................................................................3 - 4

3.1.3 Removal Procedures .......................................................................3 - 4

3.2 Software Installation ................................................................................3 - 5

Page iv © 2005 Kontron Modular Computers GmbH ID 29230, Rev. 01

29230.01.UG.VC.050727/091405

Page 5

VMP3 Preface

Chapter

4. Configuration ............................................................................................... 4 - 3

4.1 Board Address Map ................................................................................ 4 - 3

4.2 Board Control Registers .......................................................................... 4 - 4

4.2.1 Board ID Register ........................................................................... 4 - 4

4.2.2 Software Compatibility ID ............................................................... 4 - 4

4.2.3 Memory Configuration Register ...................................................... 4 - 5

4.2.4 Control Register .............................................................................. 4 - 6

4.2.5 Event Register ................................................................................ 4 - 6

4.2.6 Interrupt Configuration Register ...................................................... 4 - 8

4.2.7 Device Interrupt Pending Register .................................................. 4 - 8

4.2.8 Watchdog Control Register ............................................................. 4 - 9

4.2.9 Board Logic / Revision Register ................................................... 4 - 11

4.2.10 Serial Interrupt Pending 1 Register ............................................... 4 - 12

4.2.11 Serial Interrupt Pending 2 Register ............................................... 4 - 12

4

4.2.12 Serial Interrupt Mask 1 Register ................................................... 4 - 12

4.2.13 Serial Interrupt Mask 2 Register ................................................... 4 - 13

4.2.14 Serial Interrupt Polarity 1 Register ................................................ 4 - 13

4.2.15 Serial Interrupt Polarity 2 Register ................................................ 4 - 13

4.2.16 Device Disable Register ............................................................... 4 - 14

4.2.17 Delay Timer Control/Status Register ............................................ 4 - 14

4.3 UART Registers Address Mapping ....................................................... 4 - 16

4.3.1 UART A (SER1) ............................................................................ 4 - 16

4.3.2 UART B (SER2) ............................................................................ 4 - 17

4.3.3 UART C (SER3) ............................................................................ 4 - 18

4.3.4 UART D (SER4) ............................................................................ 4 - 19

4.4 Real-time Clock ..................................................................................... 4 - 20

4.5 IRQ Routing .......................................................................................... 4 - 22

4.6 CompactFlash ....................................................................................... 4 - 23

4.7 EEPROM ............................................................................................... 4 - 23

4.8 Digital Temperature Sensor, LM75 ........................................................ 4 - 23

P R E L I M I N A R Y

4.9 Ethernet PHY Addresses ...................................................................... 4 - 23

29230.01.UG.VC.050727/091405

ID 29230, Rev. 01 © 2005 Kontron Modular Computers GmbH Page v

Page 6

Preface VMP3

Chapter

5. NetBootLoader .............................................................................................5 - 3

5.1 General Operation ...................................................................................5 - 3

5.2 NetBootLoader Interfaces ........................................................................5 - 3

5.2.1 MC1 (Abort) Signal ..........................................................................5 - 4

5.2.2 TERM Serial Interface .....................................................................5 - 4

5.2.3 SER0 Serial Interface ......................................................................5 - 4

5.2.4 Ethernet Port FCC1 (FE) Interface ..................................................5 - 4

5.3 NetBootLoader Functions ........................................................................5 - 5

5.3.1 NetBootLoader Control ...................................................................5 - 5

5.3.2 System Status Monitoring ...............................................................5 - 6

5.3.3 Network Accessing ..........................................................................5 - 6

5.3.4 FLASH Operation ............................................................................5 - 7

5.3.5 Motorola S-Records ........................................................................5 - 8

5.4 Operating the NetBootLoader ..................................................................5 - 8

5

5.4.1 Initial Setup .....................................................................................5 - 8

5.4.2 Accessing the NetBootLoader .........................................................5 - 8

5.4.3 NetBootLoader Configuration ..........................................................5 - 9

5.4.4 telnet Login ....................................................................................5 - 11

5.4.5 FLASH Operations ........................................................................5 - 11

5.4.6 Updating the NetBootLoader .........................................................5 - 14

P R E L I M I N A R Y

5.4.7 Updating With an Image Loaded Via an ftp Server .......................5 - 14

5.4.8 Uploading a FLASH Area ..............................................................5 - 14

5.5 Plug and Play .........................................................................................5 - 15

5.6 Porting an Operating System to the CPU Board ...................................5 - 15

5.7 Commands ............................................................................................5 - 16

Chapter

6. System Considerations ................................................................................6 - 3

6

6.1 Thermal Design Considerations ..............................................................6 - 3

Page vi © 2005 Kontron Modular Computers GmbH ID 29230, Rev. 01

29230.01.UG.VC.050727/091405

Page 7

VMP3 Preface

6.1.1 Thermodynamics Terminology ....................................................... 6 - 3

6.1.2 System Environment ...................................................................... 6 - 4

6.2 Heat Sinks ............................................................................................... 6 - 5

6.3 Power Considerations ............................................................................. 6 - 5

6.3.1 System Power ................................................................................. 6 - 5

6.3.2 VMP3 Voltage Ranges .................................................................... 6 - 5

6.3.3 Backplane Requirements ................................................................ 6 - 6

6.3.4 Power Supply Units ........................................................................ 6 - 6

6.3.5 Power Consumption of the VMP3 ................................................... 6 - 7

6.4 Start-Up Current of the VMP3 ................................................................. 6 - 8

Annex

A. WDOG Functionality ....................................................................................A - 3

Annex

B. VMP1-IO1 Module .......................................................................................B - 3

B.1 Overview .................................................................................................B - 3

B.2 Board Interfaces ......................................................................................B - 3

B.2.1 PCI Expansion Connector ..............................................................B - 3

B.2.2 PMC Interface .................................................................................B - 3

B.2.3 Power Supply ..................................................................................B - 3

B.3 Board Layout ...........................................................................................B - 4

B.4 VMP1-IO1 Front Panel ............................................................................B - 5

B.5 Technical Specifications ..........................................................................B - 6

A

B

P R E L I M I N A R Y

B.6 Board Installation .....................................................................................B - 7

B.7 Pinouts ....................................................................................................B - 9

B.7.1 Jn1 (CON4) Pin Assignment ...........................................................B - 9

B.7.2 Jn2 (CON5) Pin Assignment .........................................................B - 10

B.8 Jumper Setting ...................................................................................... B - 11

29230.01.UG.VC.050727/091406

ID 29230, Rev. 01 © 2005 Kontron Modular Computers GmbH Page vii

Page 8

Preface VMP3

Annex

C. VMP1-HDD1 Module .................................................................................. C - 3

C.1 Board Description ................................................................................... C - 3

C

P R E L I M I N A R Y

Page viii © 2005 Kontron Modular Computers GmbH ID 29230, Rev. 01

29230.01.UG.VC.050727/091406

Page 9

VMP3 Preface

List of Tables

1-1 System Relevant Information ................................................................... 1 - 5

1-2 VMP3 Main Specifications ..................................................................... 1 - 11

1-3 Applied Standards ................................................................................. 1 - 13

1-4 Related Publications .............................................................................. 1 - 14

2-1 System Interface Signal Types ................................................................ 2 - 6

2-2 System Interface Extension Signal Types ................................................ 2 - 6

2-4 Communications Interface Extension Signal Type ................................... 2 - 7

2-3 Communications Interface Signal Types .................................................. 2 - 7

2-5 Pinout of J10 Connector .......................................................................... 2 - 9

2-6 Pinouts of J5A and J5B Based on the Implementation .......................... 2 - 10

2-7 Pinout of J6 ............................................................................................ 2 - 11

2-8 Pinout of J7 ............................................................................................ 2 - 12

2-9 Pinout of J8 ............................................................................................ 2 - 13

2-10 JTAG/Debug Signal Descriptions ........................................................... 2 - 13

2-11 Pinout of J9 ............................................................................................ 2 - 15

2-12 Pinout of J11 .......................................................................................... 2 - 16

2-13 LPC Interface Signal Description ........................................................... 2 - 17

2-14 CAN Interface Signal Type and Description ........................................... 2 - 18

2-15 High Speed Serial Interface Signal Type and Description ..................... 2 - 18

4-1 Board Address Map ................................................................................. 4 - 3

4-2 Board ID Register .................................................................................... 4 - 4

4-3 Software Compatibility ID ......................................................................... 4 - 4

4-4 Memory Configuration Register ............................................................... 4 - 5

4-5 Control Register ....................................................................................... 4 - 6

4-6 Event Register ......................................................................................... 4 - 7

4-7 Interrupt Configuration Register ............................................................... 4 - 8

P R E L I M I N A R Y

4-8 Device Interrupt Pending Register ........................................................... 4 - 9

4-9 Watchdog Control Register .................................................................... 4 - 10

4-10 Board Logic / Revision Register ............................................................. 4 - 11

4-11 Serial Interrupt Pending 1 Register ........................................................ 4 - 12

4-12 Serial Interrupt Pending 2 Register ........................................................ 4 - 12

4-13 Serial Interrupt Mask 1 Register ............................................................ 4 - 12

29230.01.UG.VC.050727/091406

ID 29230, Rev. 01 © 2005 Kontron Modular Computers GmbH Page ix

Page 10

Preface VMP3

4-14 Serial Interrupt Mask 2 Register ............................................................. 4 - 13

4-15 Serial Interrupt Polarity 1 Register ......................................................... 4 - 13

4-16 Serial Interrupt Polarity 2 Register ......................................................... 4 - 13

4-17 Device Disable Register ......................................................................... 4 - 14

4-18 Delay Timer Control/Status Register ..................................................... 4 - 15

4-19 UART A General Register Set ................................................................ 4 - 16

4-20 UART A Baud Rate Register Set ............................................................ 4 - 16

4-21 UART A Enhanced Register Set ............................................................ 4 - 16

4-22 UART B General Register Set ................................................................ 4 - 17

4-23 UART B Baud Rate Register Set ............................................................ 4 - 17

4-24 UART B Enhanced Register Set ............................................................ 4 - 17

4-25 UART C General Register Set ................................................................ 4 - 18

4-26 UART C Baud Rate Register Set ........................................................... 4 - 18

4-27 UART C Enhanced Register Set ............................................................ 4 - 18

4-28 UART D General Register Set ................................................................ 4 - 19

4-29 UART D Baud Rate Register Set ........................................................... 4 - 19

4-30 UART D Enhanced Register Set ............................................................ 4 - 19

4-31 Register Map RTC M41T81 .................................................................... 4 - 20

4-32 IRQ Routing ............................................................................................ 4 - 22

4-33 CompactFlash Register .......................................................................... 4 - 23

5-1 NetBootLoader Control Commands ......................................................... 5 - 5

5-2 System Status Monitoring Commands ..................................................... 5 - 6

5-3 tftp/ftp Server Commands ......................................................................... 5 - 7

5-4 FLASH Operation Commands .................................................................. 5 - 7

P R E L I M I N A R Y

5-5 Motorola S-Records Commands .............................................................. 5 - 8

6-1 Thermodynamics Terminology as Relating to the VMP3 .......................... 6 - 3

6-2 Absolute Maximum Rating ....................................................................... 6 - 5

6-3 DC Operational Input Voltage Range ....................................................... 6 - 6

6-4 Input Voltage Characteristics .................................................................... 6 - 7

6-5 Power Consumption with 256 MB Memory .............................................. 6 - 8

B-1 VMP1-IO1 Specifications ........................................................................ B - 6

B-2 Jn1, 32-bit PCI ......................................................................................... B - 9

B-3 Jn2, 32-bit PCI ....................................................................................... B - 10

B-4 IO1 Jumper Settings for Different Module Positions .............................. B - 11

Page x © 2005 Kontron Modular Computers GmbH ID 29230, Rev. 01

29230.01.UG.VC.050727/091407

Page 11

VMP3 Preface

C-1 Pinout of the PMC Connectors ................................................................ C - 4

C-2 IDE Hard Disk Drive Connector Pinout .................................................... C - 5

29230.01.UG.VC.050727/091407

ID 29230, Rev. 01 © 2005 Kontron Modular Computers GmbH Page xi

P R E L I M I N A R Y

Page 12

Preface VMP3

This page has been intentionally left blank.

P R E L I M I N A R Y

Page xii © 2005 Kontron Modular Computers GmbH ID 29230, Rev. 01

29230.01.UG.VC.050727/091407

Page 13

VMP3 Preface

List of Figures

1-1 VMP3 Application System Interfacing Diagram ....................................... 1 - 6

1-2 VMP3 System Level Interfacing Diagram ................................................ 1 - 7

1-3 VMP3 Board (Front View Without E²Brain™ Module) ............................. 1 - 8

1-4 VMP3 Board (Front View With E²Brain™ Module) .................................. 1 - 8

1-5 VMP3 Board (Rear View) ......................................................................... 1 - 9

1-6 VMP3 Board (Rear View with Optional CompactFlash Socket) ............... 1 - 9

1-7 VMP3 Front Panels (4HP Standard and 6HP with CompactFlash) ....... 1 - 10

2-1 VMP3 Board Level Interfacing ................................................................. 2 - 5

2-2 J10 - VME Connector ............................................................................... 2 - 8

2-3 J5A/B - Dual Gigabit Ethernet Connector .............................................. 2 - 10

2-4 J6 - Fast Ethernet Connector ................................................................. 2 - 11

2-5 J7 - TERM Connector ............................................................................ 2 - 12

2-6 J8 - JTAG/Debug Connector .................................................................. 2 - 13

2-7 J9 PCI Expansion Connector ................................................................. 2 - 14

2-8 J11 I/O Expansion Connector ................................................................ 2 - 16

2-9 J12 In-System-Programming Connector ................................................ 2 - 19

5-1 Flash Addressing Scheme - VMP3 ........................................................ 5 - 12

A-1 WDOG Functional States ......................................................................... A - 4

B-1 Board Layout (Front View) ....................................................................... B - 4

B-2 VMP1-IO1 Front Panel ............................................................................. B - 5

B-3 Installation Diagrams ............................................................................... B - 8

C-1 VMP1-HDD1 Module with Hard Disk Drive Attached ............................... C - 3

P R E L I M I N A R Y

29230.01.UG.VC.050727/091407

ID 29230, Rev. 01 © 2005 Kontron Modular Computers GmbH Page xiii

Page 14

Preface VMP3

This page has been intentionally left blank.

P R E L I M I N A R Y

Page xiv © 2005 Kontron Modular Computers GmbH ID 29230, Rev. 01

29230.01.UG.VC.050727/091407

Page 15

VMP3 Preface

Proprietary Note

This document contains information proprietary to Kontron Modular Computers GmbH. It may

not be copied or transmitted by any means, disclosed to others, or stored in any retrieval

system or media without the prior written consent of Kontron Modular Computers GmbH or one

of its authorized agents.

The information contained in this document is, to the best of our knowledge, entirely correct.

However, Kontron Modular Computers GmbH cannot accept liability for any inaccuracies or the

consequences thereof, or for any liability arising from the use or application of any circuit,

product, or example shown in this document.

Kontron Modular Computers GmbH reserves the right to change, modify, or improve this

document or the product described herein, as seen fit by Kontron Modular Computers GmbH

without further notice.

Trademarks

Kontron Modular Computers GmbH, the PEP logo and, if occurring in this manual, “CXM” are

trade marks owned by Kontron Modular Computers GmbH, Kaufbeuren (Germany). In addition, this document may include names, company logos and trademarks, which are registered

trademarks and, therefore, proprietary to their respective owners.

Environmental Protection Statement

This product has been manufactured to satisfy environmental protection requirements where

possible. Many of the components used (structural parts, printed circuit boards, connectors,

batteries, etc.) are capable of being recycled.

Final disposition of this product after its service life must be accomplished in accordance with

applicable country, state, or local laws or regulations.

P R E L I M I N A R Y

29230.01.UG.VC.050727/091407

ID 29230, Rev. 01 © 2005 Kontron Modular Computers GmbH Page xv

Page 16

Preface VMP3

Explanation of Symbols

CE Conformity

This symbol indicates that the product described in this manual is in

compliance with all applied CE standards. Please refer also to the

section “Applied Standards” in this manual.

Caution, Electric Shock!

This symbol and title warn of hazards due to electrical shocks (> 60V)

when touching products or parts of them. Failure to observe the precautions indicated and/or prescribed by the law may endanger your

life/health and/or result in damage to your material.

Please refer also to the section “High Voltage Safety Instructions” on

the following page.

Warning, ESD Sensitive Device!

This symbol and title inform that electronic boards and their components are sensitive to static electricity. Therefore, care must be taken

during all handling operations and inspections of this product, in

order to ensure product integrity at all times.

Please read also the section “Special Handling and Unpacking

Instructions” on the following page.

Warning!

This symbol and title emphasize points which, if not fully understood

and taken into consideration by the reader, may endanger your health

and/or result in damage to your material.

Note...

This symbol and title emphasize aspects the reader should read

P R E L I M I N A R Y

through carefully for his or her own advantage.

Page xvi © 2005 Kontron Modular Computers GmbH ID 29230, Rev. 01

29230.01.UG.VC.050727/091407

Page 17

VMP3 Preface

For Your Safety

Your new Kontron product was developed and tested carefully to provide all features necessary

to ensure its compliance with electrical safety requirements. It was also designed for a long

fault-free life. However, the life expectancy of your product can be drastically reduced by

improper treatment during unpacking and installation. Therefore, in the interest of your own

safety and of the correct operation of your new Kontron product, you are requested to conform

with the following guidelines.

High Voltage Safety Instructions

Warning!

All operations on this device must be carried out by sufficiently skilled

personnel only.

Caution, Electric Shock!

Before installing your new Kontron product into a system always

ensure that the mains power is switched off. This applies also to the

installation of piggybacks.

Serious electrical shock hazards can exist during all installation,

repair and maintenance operations with this product. Therefore,

always unplug the power cable and any other cables which provide

external voltages before performing work.

Special Handling and Unpacking Instructions

ESD Sensitive Device!

Electronic boards and their components are sensitive to static electricity. Therefore, care must be taken during all handling operations

and inspections of this product, in order to ensure product integrity at

all times.

Do not handle this product out of its protective enclosure while it is not used for operational

purposes unless it is otherwise protected.

P R E L I M I N A R Y

Whenever possible, unpack or pack this product only at EOS/ESD safe work stations. Where

a safe work station is not guaranteed, it is important for the user to be electrically discharged

before touching the product with his/her hands or tools. This is most easily done by touching a

metal part of your system housing.

It is particularly important to observe standard anti-static precautions when changing piggybacks, ROM devices, jumper settings etc. If the product contains batteries for RTC or memory

back-up, ensure that the board is not placed on conductive surfaces, including anti-static plastics or sponges. They can cause short circuits and damage the batteries or conductive circuits

on the board.

29230.01.UG.VC.050727/091408

ID 29230, Rev. 01 © 2005 Kontron Modular Computers GmbH Page xvii

Page 18

Preface VMP3

General Instructions on Usage

In order to maintain Kontron’s product warranty, this product must not be altered or modified in

any way. Changes or modifications to the device, which are not explicitly approved by Kontron

Modular Computers GmbH and described in this manual or received from Kontron’s Technical

Support as a special handling instruction, will void your warranty.

This device should only be installed in or connected to systems that fulfill all necessary

technical and specific environmental requirements. This applies also to the operational

temperature range of the specific board version, which must not be exceeded. If batteries are

present their temperature restrictions must be taken into account.

In performing all necessary installation and application operations, please follow only the

instructions supplied by the present manual.

Keep all the original packaging material for future storage or warranty shipments. If it is

necessary to store or ship the board please re-pack it as nearly as possible in the manner in

which it was delivered. In the event that the original packaging material is not available for

storage or warranty shipments, packaging which complies with the standards indicated in

section 1.8 may be used to ensure the proper protection of this product.

Special care is necessary when handling or unpacking the product. Please, consult the special

handling and unpacking instruction on the previous page of this manual.

P R E L I M I N A R Y

Page xviii © 2005 Kontron Modular Computers GmbH ID 29230, Rev. 01

29230.01.UG.VC.050727/091408

Page 19

VMP3 Preface

Two Year Warranty

Kontron Modular Computers GmbH grants the original purchaser of Kontron’s products a TWO

YEAR

LIMITED HARDWARE WARRANTY as described in the following. However, no other warranties

that may be granted or implied by anyone on behalf of Kontron are valid unless the consumer

has the express written consent of Kontron Modular Computers GmbH.

Kontron Modular Computers GmbH warrants their own products, excluding software, to be free

from manufacturing and material defects for a period of 24 consecutive months from the date

of purchase. This warranty is not transferable nor extendible to cover any other users or longterm storage of the product. It does not cover products which have been modified, altered or

repaired by any other party than Kontron Modular Computers GmbH or their authorized agents.

Furthermore, any product which has been, or is suspected of being damaged as a result of negligence, improper use, incorrect handling, servicing or maintenance, or which has been damaged as a result of excessive current/voltage or temperature, or which has had its serial

number(s), any other markings or parts thereof altered, defaced or removed will also be excluded from this warranty.

If the customer’s eligibility for warranty has not been voided, in the event of any claim, he may

return the product at the earliest possible convenience to the original place of purchase, together with a copy of the original document of purchase, a full description of the application the

product is used on and a description of the defect. Pack the product in such a way as to ensure

safe transportation (see our safety instructions).

Kontron provides for repair or replacement of any part, assembly or sub-assembly at their own

discretion, or to refund the original cost of purchase, if appropriate. In the event of repair, refunding or replacement of any part, the ownership of the removed or replaced parts reverts to

Kontron Modular Computers GmbH, and the remaining part of the original guarantee, or any

new guarantee to cover the repaired or replaced items, will be transferred to cover the new or

repaired items. Any extensions to the original guarantee are considered gestures of goodwill,

and will be defined in the “Repair Report” issued by Kontron with the repaired or replaced item.

Kontron Modular Computers GmbH will not accept liability for any further claims resulting

directly or indirectly from any warranty claim, other than the above specified repair,

replacement or refunding. In particular, all claims for damage to any system or process in which

the product was employed, or any loss incurred as a result of the product not functioning at any

given time, are excluded. The extent of Kontron Modular Computers GmbH liability to the

customer shall not exceed the original purchase price of the item for which the claim exists.

Kontron Modular Computers GmbH issues no warranty or representation, either explicit or

implicit, with respect to its products’ reliability, fitness, quality, marketability or ability to fulfil any

particular application or purpose. As a result, the products are sold “as is,” and the responsibility

to ensure their suitability for any given task remains that of the purchaser. In no event will

Kontron be liable for direct, indirect or consequential damages resulting from the use of our

hardware or software products, or documentation, even if Kontron were advised of the

possibility of such claims prior to the purchase of the product or during any period since the

date of its purchase.

P R E L I M I N A R Y

Please remember that no Kontron Modular Computers GmbH employee, dealer or agent is

authorized to make any modification or addition to the above specified terms, either verbally or

in any other form, written or electronically transmitted, without the company’s consent.

29230.01.UG.VC.050727/091408

ID 29230, Rev. 01 © 2005 Kontron Modular Computers GmbH Page xix

Page 20

Preface VMP3

This page has been intentionally left blank.

P R E L I M I N A R Y

Page xx © 2005 Kontron Modular Computers GmbH ID 29230, Rev. 01

29230.01.UG.VC.050727/091408

Page 21

VMP3 Introduction

Chapter 1

1

Introduction

29230.01.UG.VC.050727/091408

ID 29230, Rev. 01 © 2005 Kontron Modular Computers GmbH Page 1 - 1

P R E L I M I N A R Y

Page 22

Introduction VMP3

This page has been intentionally left blank.

P R E L I M I N A R Y

Page 1 - 2 © 2005 Kontron Modular Computers GmbH ID 29230, Rev. 01

29230.01.UG.VC.050727/091408

Page 23

VMP3 Introduction

1. Introduction

The VMP3 is a comprehensive computing platform which brings together the latest advances

in computing technology in a board designed for maximum performance, flexibility, and versatility within a rugged compact format.

The VMP3 is designed to accept the E²Brain™ module EB8541 as its core processor unit. This

module which is based on the MPC8541E PowerPC CPU – a highly integrated microprocessor

containing a PowerPC e500 core – provides a very comprehensive set of system and communications interfaces.

In addition to the standard VME system interface, the VMP3 incorporates a PCI extension interface for a full range of PCI peripherals, two Gigabit Ethernet interfaces, one Fast Ethernet

interface, high speed serial connectivity, an optional CompactFlash socket, and an IO extension interface which provides optional high speed serial as well as CAN interfacing, LPC interfacing, and an external I²C interface. For board logic and CPU test and debugging there is a

JTAG interface.

The VMP3 employs an OS-independent boot loader that enables the loading of any PowerPC

enabled operating system. This boot loader makes an update of the Flash contents and automatically downloads from Flash to SDRAM before booting the OS. For performance reasons

the OS is started from the DDR-SDRAM.

The power of the board is greatly enhanced by means of the PCI expansion connector which

makes it possible to cascade one or two additional VMP1-IO1 modules onto the board resulting

in a total package of up to 14HP. Both VMP1-IO1 modules may be used to carry PMC modules.

Given the wide range of PMC modules now available, this feature affords the user a very wide

range of options. Additionally, one can substitute a module designed to provide an even greater

range of PCI peripherals in place of either of the IO1 modules. These features enable, for example, the connection of the widest range of system I/O components such as various field busses and Ultra 2 SCSI, to name just a few. The complete range of expansion possibilities is thus

made available to the user by the VMP3.

P R E L I M I N A R Y

29230.01.UG.VC.050727/091408

ID 29230, Rev. 01 © 2005 Kontron Modular Computers GmbH Page 1 - 3

Page 24

Introduction VMP3

1.1 Board Overview

1.1.1 Board Introduction

The VMP3 is a VME PowerPC-based single-board computer specifically designed for use in

highly integrated platforms with solid mechanical interfacing for a wide range of industrial environment applications.

Some of the VMP3’s outstanding features are:

• PowerPC MPC8541E Power QUICC III (e500 core)

• 32 kB data cache

• 32 kB instruction cache

• 256 kB L2 cache

• up to 256 MB DDR-I-SDRAM, 64-bit, 264 MHz with ECC support

• up to 64 MB onboard Flash

• onboard PCI bus with expansion connector

• a Fast Ethernet interface

• two Gigabit Ethernet interfaces

• one serial terminal interface

• an IO extension interface for optional interfacing:

• up to five high speed serial I/O’s (RS232, RS422/485)

• a CAN interface

• an LPC interface

• an I²C interface

• optional CompactFlash socket (6 or 10 HP versions)

• programmable watchdog timer

• programmable hardware delay timer

• real-time clock

• optional versions for PCI expansion

• PCI-to-VME Bridge

• compliance with VITA VME-Specification ANSI / IEEE STD1014-1987 / IEC 821 and 297

1.1.2 Board Specific Information

Major board components of the VMP3 are:

P R E L I M I N A R Y

• EB8541 E²Brain™ computer core module

• Tundra Universe II PCI-to-VME bridge (VME A24 / D16 operation)

• CPLD logic device

• Fast Ethernet interface

• Gigabit Ethernet interfaces

• Interfacing connectors for:

• VME-bus

• Fast Ethernet

• Gigabit Ethernet (2)

• serial Terminal (RJ45)

• PCI-bus expansion

• I/O expansion

• Test and Programming (2)

• Abort and Reset switches

• Monitor and Control (MC) LEDs

• BrainCAP™ heat sink for VMP3

Page 1 - 4 © 2005 Kontron Modular Computers GmbH ID 29230, Rev. 01

29230.01.UG.VC.050727/091408

Page 25

VMP3 Introduction

1.2 System Relevant Information

The following system relevant information is general in nature but should still be considered

when developing applications using the VMP3.

Table 1-1: System Relevant Information

SUBJECT INFORMATION

System Configuration The VMP3 operates onboard with a PCI system clock frequency of 33.

System Controller The VMP3 provides first slot detection, therefore it can be the system con-

troller.

Application Interfacing The application interfacing to the VMP3 must comply with the specifications

set forth in this manual.

1.2.1 System Configuration

System configuration is solely a function of the application, however, when implementing applications, precautions must be taken to ensure that the signals of the VMP3 are properly terminated in accordance with the specifications set forth in this manual. For this reason it will be

necessary for system integrators to ensure proper signal conditioning for their applications before interfacing with the VMP3. In addition, it is imperative that signal interference be kept to a

minimum.

1.2.2 Operating Software

The VMP3 is supplied with appropriate operating system and board support software for board

operation.

1.3 Board Diagrams

The following diagrams provide additional information concerning board functionality and component layout.

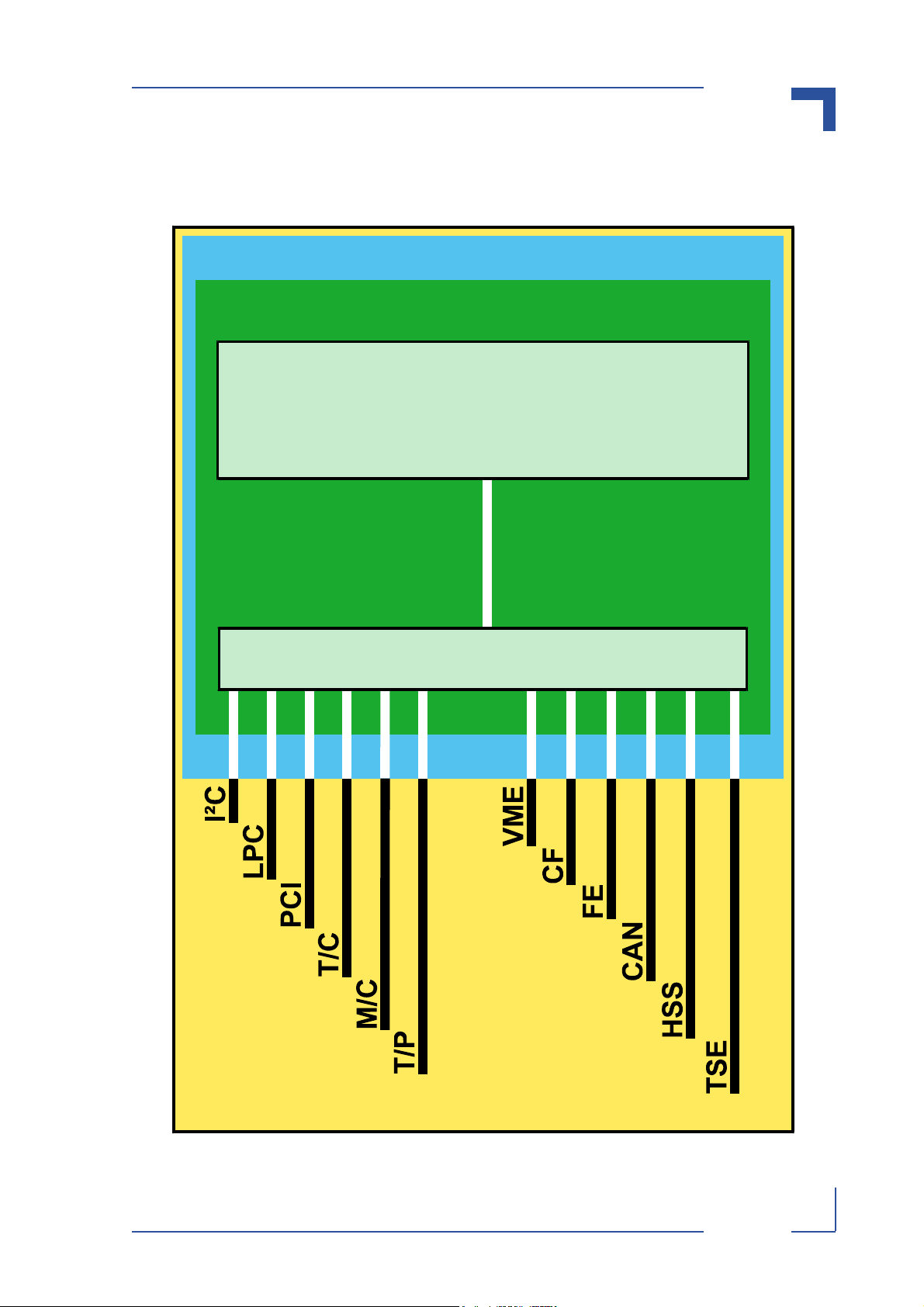

LEGEND FOR FIGURE 1-2:

CAN Communications Area Network

CF CompactFlash

FE Fast Ethernet

HSS High Speed Serial

I²C Inter-Integrated Circuit

LPC Low Pin Count

M/C Monitor and Control

PCI Peripheral Component Interface

T/C Terminal/Console (Serial Interface)

T/P Test/Programming

TSE Gigabit Ethernet (Three Speed Ethernet)

P R E L I M I N A R Y

29230.01.UG.VC.050727/091408

ID 29230, Rev. 01 © 2005 Kontron Modular Computers GmbH Page 1 - 5

Page 26

Introduction VMP3

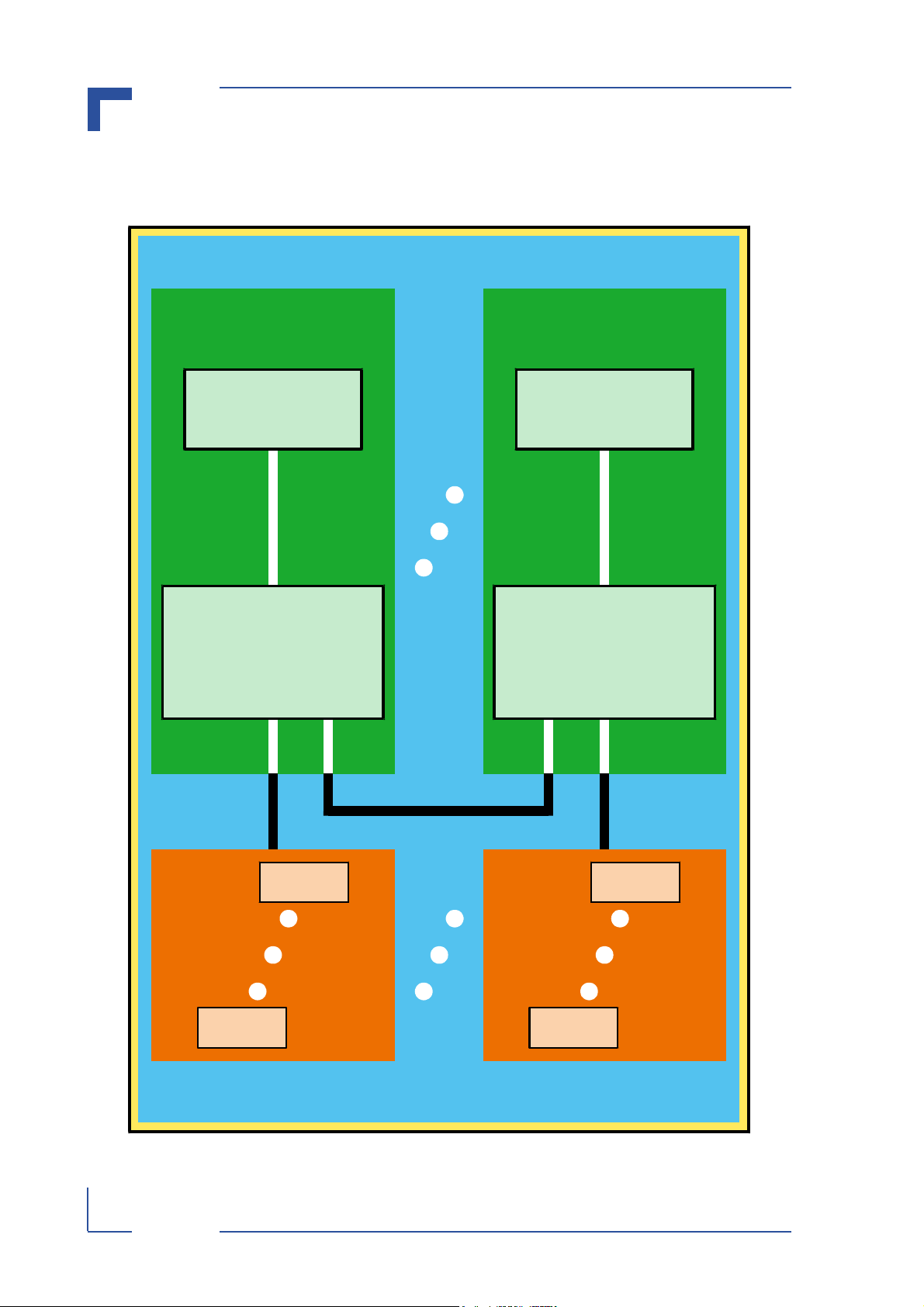

1.3.1 Application System Interfacing

Figure 1-1: VMP3 Application System Interfacing Diagram

Application System (AS)

VMP3 VMP3

EB8541E

Board

Interfacing

P R E L I M I N A R Y

AS

Processes

EB8541E

Board

Interfacing

AS

Processes

Page 1 - 6 © 2005 Kontron Modular Computers GmbH ID 29230, Rev. 01

29230.01.UG.VC.050727/091408

Page 27

VMP3 Introduction

1.3.2 System Level Interfacing

Figure 1-2: VMP3 System Level Interfacing Diagram

VMP3 System

VMP3

EB8541E E²Brain Module

VMP3 Interfaces

P R E L I M I N A R Y

29230.01.UG.VC.050727/091408

ID 29230, Rev. 01 © 2005 Kontron Modular Computers GmbH Page 1 - 7

Page 28

Introduction VMP3

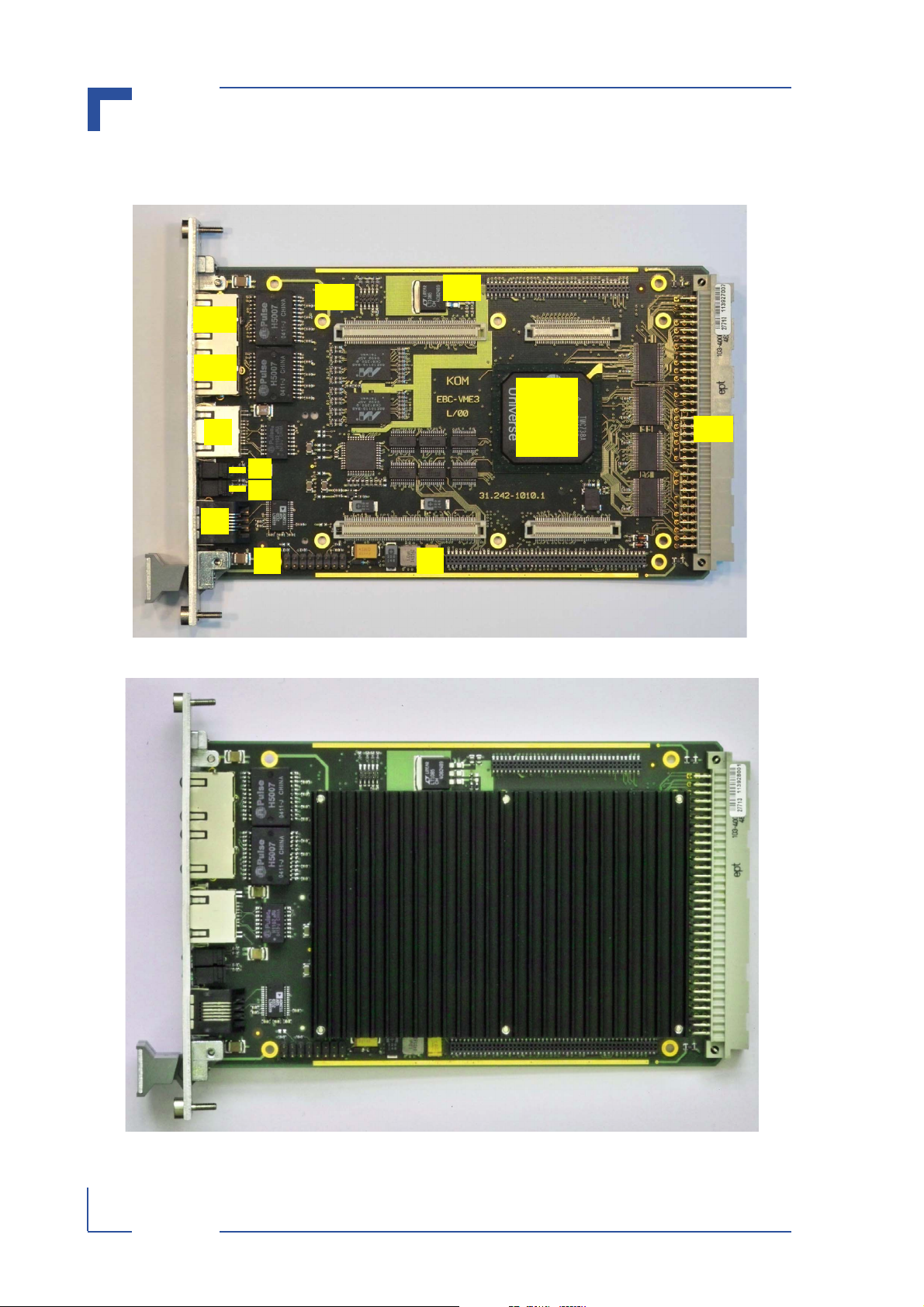

1.3.3 Board Layout

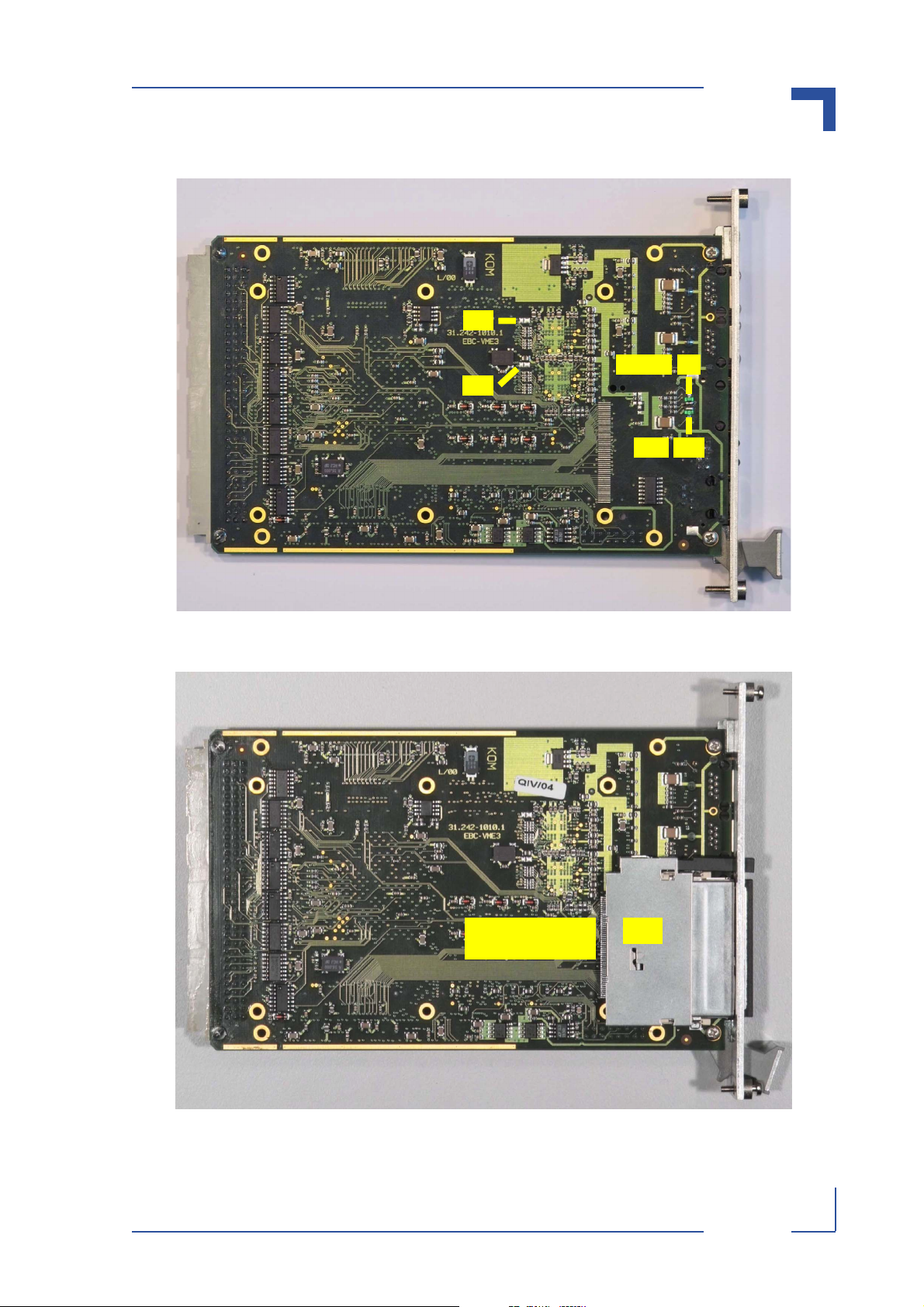

Figure 1-3: VMP3 Board (Front View Without E²Brain™ Module)

J12

J11

J5A

J5B

PCI

to

J6

D1

D2

VME

Bridge

J7

J8 J9

Figure 1-4: VMP3 Board (Front View With E²Brain™ Module)

J10

P R E L I M I N A R Y

Page 1 - 8 © 2005 Kontron Modular Computers GmbH ID 29230, Rev. 01

29230.01.UG.VC.050727/091408

Page 29

VMP3 Introduction

Figure 1-5: VMP3 Board (Rear View)

JP1

SPEED

JP2

Figure 1-6: VMP3 Board (Rear View with Optional CompactFlash Socket)

D7

D11ACT

29230.01.UG.VC.050727/091414

ID 29230, Rev. 01 © 2005 Kontron Modular Computers GmbH Page 1 - 9

CompactFlash

Socket

P R E L I M I N A R Y

J13

Page 30

Introduction VMP3

Figure 1-7: VMP3 Front Panels (4HP Standard and 6HP with CompactFlash)

P R E L I M I N A R Y

Page 1 - 10 © 2005 Kontron Modular Computers GmbH ID 29230, Rev. 01

29230.01.UG.VC.050727/091416

Page 31

VMP3 Introduction

1.4 Technical Specifications

Table 1-2: VMP3 Main Specifications

VMP3 Specifications

Processor Motorola MPC8541E Integrated Processor PowerPC, e500 core

Cache Structure 32 KB instruction cache and 32 KB data cache; L2 cache: 256 KB

On Chip Controllers Coherency Module, DDR-SDRAM, OCeaN switch fabric, Local Bus, FCC, TSEs,

Security Engine

Main Memory Soldered DDR-SDRAM: up to 256 MB, 64-bit, 264 MHz with ECC

Watchdog Watchdog generates exception condition: system reset, NMI, or cascading

RTC Real-time clock, backed up via VME auxiliary power (+5VSTDBY)

Processor and Related

BPCC E²Brain™ Board Process/Communications Controller: controls Local Bus

interfacing, provides LPC interface and monitor and control functions

SRAM 1 MB soldered, 512k x 16, optionally backed up via auxiliary power (+5VSTDBY)

EEPROM (I²C) 64 kBit soldered, serial access

Memory

Flash Minimum of 4 MB and up to 64 MB soldered

Peripheral

VME ANSI/VITA 1-1994 for VME, approved April 10.1995

Support for A24:D16/8 master and A24:D16/8 slave interface

PCI On-chip controller, 32-bit, 33 MHz, PCI System Master

LPC Low Pin Count sub-set, 8-bit IO and memory space access, realized in BPCC

I²C On-chip, message interface, full master/slave

CF CompactFlash, optional (PIO mode)

Fast Ethernet One 10baseT, 100baseTX, FCC integrated in MPC8541E, Intel PHY: LXT 972

Gigabit Ethernet Two three speed Ethernet (TSE): 10/100/1000 Mbit GMII (Marvell PHY: 88E1011)

CAN Controller Area Network interface (Philips SJA1000)

External Interfaces

Serial Ports Terminal and Console:

Two serial ports: RS232: TERM1 (Terminal on front panel)

TTL: TERM2 (Console on I/O expansion)

High Speed Serial:

Four ports, full modem : SER1 (on I/O expansion)

(Local Bus) : SER2 (on I/O expansion)

(Support for RS485 direction control) : SER3 (on I/O expansion)

: SER4 (on I/O expansion)

P R E L I M I N A R Y

JTAG/Debug JTAG/Debug interface for MPC8541E emulation probe

T/P

In-System

Programming

Interfaces

29230.01.UG.VC.050727/091419

ID 29230, Rev. 01 © 2005 Kontron Modular Computers GmbH Page 1 - 11

In-System-Programming interface for the VMP3 CPLD logic device

Page 32

Introduction VMP3

Table 1-2: VMP3 Main Specifications (Continued)

VMP3 Specifications

LEDs Six LEDs:

One general pupose (USER)

One Watchdog (WD)

M/C

Interfaces

Switches Two puch buttons: Reset and Abort

Connectors VME connector, 96-pin

Two Ethernet Activity/Link

Two Ethernet Speed

Onboard connectors: 1 x RJ12 for RS232; 2 x RJ45 for GigaEthernet; 1 x RJ45 for

Fast Ethernet

PCI expansion connector: Samtec FLE-150-01-G-DV

I/O expansion connector: Samtec FLE-136-01-G-DV

Power Consumption Source: 5 V: consumption: 10.85 watts @ 800 MHz (Ethernet not connected)

Temperature Range Operational: 0ºC to +60ºC Standard

-40ºC to +85ºC E2 (on request)

General

Climatic Humidity 93% relative humidity at 40°C, non-condensing

Dimensions 160 mm L x 100 mm W x 4HP H (minimum height)

Board Weight 300 g (4HP); 447 g (8HP)

Storage: -55ºC to +125ºC

The maximum height of the VMP3 is a function of the BrainCAP™ options as well

as the other possible optional interfaces.

P R E L I M I N A R Y

Page 1 - 12 © 2005 Kontron Modular Computers GmbH ID 29230, Rev. 01

29230.01.UG.VC.050727/091420

Page 33

VMP3 Introduction

1.5 Applied Standards

The Kontron Modular Computers’ VMP3 board complies with the requirements of the following

standards:

Table 1-3: Applied Standards

COMPLIANCE TYPE STANDARD TEST LEVEL

CE Emission EN55022

EN61000-6-3

Immission EN55024

EN61000-6-2

Electrical Safety EN60950 --

Mechanical Mechanical Dimensions IEEE 1101.10 --

Transport and Storage IEC 61131-2 --

Environmental and

Health Aspects

Vibration (sinusoidal) IEC60068-2-6 10 - 300 [Hz] / 5 [g] / 1 [oct / min]

Shock IEC60068-2-27 30 [g]

Bump IEC60068-2-29 15 [g]

--

--

10 [cycles / axis]

3 [axis: x, y, z]

9 [ms]

3 [shocks per direction]

5 [s] recovery time

6 [directions, ±x, ±y, ±z]

11 [ms]

500 [shocks per axis]

1 [s] recovery time

3 [axis: x, y, z]

29230.01.UG.VC.050727/091420

ID 29230, Rev. 01 © 2005 Kontron Modular Computers GmbH Page 1 - 13

Vibration, broad-band

random (digital control)

and guidance

Climatic Humidity IEC60068-2-78 93% RH at 40°C, non-condensing

IEC60068-2-64 20 - 2000 [Hz] / 3.5 [g RMS]

30 [min.] test time / axis

3 [axis: x, y, z]

P R E L I M I N A R Y

Page 34

Introduction VMP3

1.6 Related Publications

Table 1-4: Related Publications

ISSUED BY DOCUMENT

PCI PCI-SIG PCI Local Bus Specification, R.2.2

VME ANSI/VITA 1-1994 for VME

LPC Intel® Intel® Low Pin Count (LPC) Interface Specification,

Rev. 1.1

I²C Philips I2C-BUS SPECIFICATION, Rev. 2.1

E²Brain Kontron Modular Computers E²Brain™ Module Specification, Rev. 01

P R E L I M I N A R Y

Page 1 - 14 © 2005 Kontron Modular Computers GmbH ID 29230, Rev. 01

29230.01.UG.VC.050727/091420

Page 35

VMP3 Functional Description

Chapter 1

2

Functional Description

29230.01.UG.VC.050727/091420

ID 29230, Rev. 01 © 2005 Kontron Modular Computers GmbH Page 2 - 1

P R E L I M I N A R Y

Page 36

Functional Description VMP3

This page has been intentionally left blank.

P R E L I M I N A R Y

Page 2 - 2 © 2005 Kontron Modular Computers GmbH ID 29230, Rev. 01

29230.01.UG.VC.050727/091420

Page 37

VMP3 Functional Description

2. Functional Description

The following chapters present more detailed, board level information about the VMP3

E²Brain™ High Performance PowerPC Processor VME board whereby the board components

and their basic functionality are discussed in general.

2.1 General Information

The VMP3 is comprised basically of the EB8541 E²Brain™ module and the EBC-VME3 carrier

board.

The EB8541 E²Brain™ module consists of the following:

• a Motorola MPC8541E Integrated Processor, Power QUICC III with a PPC e500 core

• a Board Process/Communications Controller (BPCC)

• System and Communications interfacing to the EBC-VME3 for:

•I²C bus

• LPC bus

• PCI bus

• CompactFlash (CF) interface

• Terminal and Console (T/C) serial interfacing

• Monitor and Control (M/C) interfacing

• Test and Programming (T/P) interfacing

• High Speed Serial (HSS) communications

• Communications Area Network (CAN) bus

• Fast Ethernet (FE)

• Gigabit Ethernet (TSE)

• Memory elements:

• Main memory DDR-I-SDRAM, soldered

• Soldered SRAM, backed-up using an auxiliary power line

• Soldered FLASH

• Serial EEPROM

• a BrainCAP™ heat sink for the EB8541

• Software

• Operating system

• Board support package

• Boot strap loader (NetBootLoader)

P R E L I M I N A R Y

The EB8541 carrier board, EBC-VME3, consists of the following:

• a Tundra Universe II PCI-to-VME bridge and VME-bus connector for VME-bus system

interfacing

• PHYs, magnetics, and connectors for Gigabit Ethernet interfacing

• magnetics and connector for Fast Ethernet interfacing

• a Terminal connector for serial interfacing

• a PCI expansion connector for PCI peripheral interfacing

• an I/O expansion connector for additional system and communications interfacing

• two test and programming connectors for JTAG and ISP logic interfacing

• switches and LEDs for Monitor and Control interfacing

• an optional CompactFlash socket for Type I and II CF cards

29230.01.UG.VC.050727/091420

ID 29230, Rev. 01 © 2005 Kontron Modular Computers GmbH Page 2 - 3

Page 38

Functional Description VMP3

2.2 Board-Level Interfacing Diagram

The following figure demonstrates the interfacing structure between the internal processing elements of the EBC-VME3 and other major VMP3 module components. Where system elements have common interfacing they are grouped into a block. Interfacing common to only one

element of a block is indicated with a direct connecting line. The interfacing lines are shown in

white where they are on board and in black for board external interfacing.

LEGEND FOR FIGURE 2-1

AB Abort

ACT Activity

CAN Communications Area Network

CI Communications Interface

CIE Communications Interface Extension

CF CompactFlash

FE Fast Ethernet

HSS High Speed Serial

I²C Inter-Integrated Circuit

LPC Low Pin Count

MAG Magnetics

M/C Monitor/Control

PCI Peripheral Component Interface

PHY PHY

RST Reset

SI System Interface

SIE System Interface Extension

T/C Terminal/Console (Serial Interface)

T/P Test/Programming

P R E L I M I N A R Y

VME BUFs VME buffers

TSE Three Speed Ethernet

VME VME

WD Watchdog

Page 2 - 4 © 2005 Kontron Modular Computers GmbH ID 29230, Rev. 01

29230.01.UG.VC.050727/091420

Page 39

VMP3 Functional Description

Figure 2-1: VMP3 Board Level Interfacing

VMP3

EB8541 E²Brain Computer Core Module

SI

SI

PCI

PCI-BUS

PCI

-to-

VME

LPC

I²C

M/C

LED

USER

LED

VME

BUFs

WD

SW

AB

SW

RST

VME

J9

J11

J10 J7

M/C

CPLD

J12

ISP

M/C

T/C T/P

J8

CI

CI

MAG

J6

FE

LED

Activity

LED

Speed

CAN

HSS

J11

CIE

CIE

TSE1

PHY

LED

ACT

LED

Speed

MAG

J5B

TSE2

PHY

LED

ACT

LED

Speed

MAG

J5A

SIE

SIE

CF

* optional

*

J13

29230.01.UG.VC.050727/091420

ID 29230, Rev. 01 © 2005 Kontron Modular Computers GmbH Page 2 - 5

P R E L I M I N A R Y

Page 40

Functional Description VMP3

2.3 EB8541 E²Brain™ Module Interfaces

The following sections provide a very brief description of the interfacing between the E²Brain™

module and the EBC-VME3 board.

2.3.1 System Interface

As the name implies, this interface provides the basic application connection functionality required to integrate the EB8541 E²Brain™ module as the high performance core of the VMP3.

The System Interface is realized using a 140-pin, HIROSE FX8C-140P-SV connector. The following table provides an overview of the signal types and a brief description of the interfacing

realized on this connector.

Table 2-1: System Interface Signal Types

SIGNAL TYPE DESCRIPTION

POWER VMP3 E²Brain™ module input power, grounds, battery backup power, PCI

signaling voltage V(I/O)

MONITOR AND CONTROL (M/C) Control signals for E²Brain™ module operation, configuration, and addi-

tional GPIO interfacing

TEST AND PROGRAMMING (T/P) JTAG/Debug signals for Emulator interfacing

TERMINAL AND

CONSOLE (T/C)

I2C One I2C standard interface for low speed, serial, inter-chip communica-

LPC One LPC standard interface for (GP)IOs and simple memory interfacing

PCI One PCI standard interface for PCI-bus interfacing

Two 2-wire serial interfaces:

RxD1/TxD1: Used by the boot loader during startup as a terminal interface;

once the system has been booted, is available as general purpose serial interface (Terminal)

RxD2/TxD2: general purpose serial interface (Console)

tions

2.3.2 System Interface Extension

The System Interface Extension is realized using an 80-pin, HIROSE FX8C-80P-SV connector,

P R E L I M I N A R Y

and it is used to provide CPU architecture specific system interfaces.

In the case of the VMP3, a CompactFlash interface is made available on the System Interface

Extension.

Table 2-2: System Interface Extension Signal Types

SIGNAL TYPE DESCRIPTION

COMPACTFLASH One CompactFlash interface (true IDE mode)

POWER VMP3 E²Brain™ module input power and grounds

2.3.3 Communications Interface

The Communications Interface Connector is used to provide a set of standard communications

interfaces. In the case of the VMP3, there are three types of interfaces provided: four high

speed serial interfaces, one CAN interface, and one Fast Ethernet interface.

Page 2 - 6 © 2005 Kontron Modular Computers GmbH ID 29230, Rev. 01

29230.01.UG.VC.050727/091420

Page 41

VMP3 Functional Description

Table 2-3: Communications Interface Signal Types

SIGNAL TYPE DESCRIPTION

High Speed Serial (HSS) Four high speed serial interfaces

Fast Ethernet One Fast Ethernet 10/100 Mbps interface

CAN One standard CAN interface

2.3.4 Communications Interface Extension

The Communications Interface Extension is realized using a 140-pin, HIROSE FX8C-140P-SV

connector. The following table provides an overview of the signal types and a brief description

of the interfacing realized on this connector.

Table 2-4: Communications Interface Extension Signal Type

SIGNAL TYPE DESCRIPTION

GIGABIT ETHERNET Two Gigabit Ethernet interfaces (10/100/1000 Mbps, GMII)

29230.01.UG.VC.050727/091420

ID 29230, Rev. 01 © 2005 Kontron Modular Computers GmbH Page 2 - 7

P R E L I M I N A R Y

Page 42

Functional Description VMP3

2.4 VMP3 Board Interfaces

The following sections provide a specific information regarding the application interfaces available with the EBC-VME3 board.

2.4.1 J10 – VME Interface

The VME interface is based on the TUNDRA UNIVERSE II Bridge which includes the following

features required for 3U VME systems.

• A24/A16 addressing modes capability

• D16/D8 data transfer capability

• Automatic First-Slot-Detection

• Single level BR3 arbitration release-when-done

option

• FAIR VMEbus arbitration option

• ACFAIL NMI option

• SYSFAIL IRQ option

• System controller functions (SYSCLK, Bus

monitor, Power monitor)

• Compatibility with Kontron 3U VME system

addressing schemes

• Compatibility with Kontron VME backplane

design and feature set

• Compatibility with Kontron backplane transceiver

logic

The following figure and table provide pinout and signal

information for this interface.

Figure 2-2: J10 - VME Connector

PINROWS

C B A

1

P R E L I M I N A R Y

32

Page 2 - 8 © 2005 Kontron Modular Computers GmbH ID 29230, Rev. 01

29230.01.UG.VC.050727/091420

Page 43

VMP3 Functional Description

Table 2-5: Pinout of J10 Connector

PIN PINROW A PINROW B PINROW C

1 D00 BBSY D08

2 D01 BCLR D09

3D02 ACFAIL D10

4 D03 BG0IN D11

5 D04 BG0OUT D12

6 D05 BG1IN D13

7 D06 BG1OUT D14

8 D07 BG2IN D15

9 GND BG2OUT GND

10 SYSCLK BG3IN SYSFAIL

11 GND BG3OUT BERR

12 DS1 BR0 SYSRESET

13 DS0 BR1 LWORD

14 WRITE BR2 AM5

15 GND BR3 A23

16 DTACK AM0 A22

17 GND AM1 A21

18 AS AM2 A20

19 GND AM3 A19

20 IACK GND A18

21 IACKIN NC A17

22 IACKOUT NC A16

23 AM4 GND A15

24 A07 IRQ7 A14

25 A06 IRQ6 A13

26 A05 IRQ5 A12

27 A04 IRQ4 A11

28 A03 IRQ3 A10

29 A02 IRQ2 A09

30 A01 IRQ1 A08

31 -12V +5VSTDBY +12V

32 +5V +5V +5V

P R E L I M I N A R Y

29230.01.UG.VC.050727/091421

ID 29230, Rev. 01 © 2005 Kontron Modular Computers GmbH Page 2 - 9

Page 44

Functional Description VMP3

2.4.2 J5A/B – Dual Gigabit Ethernet Interface

This connector provides two three speed Ethernet (TSE1 and TSE2) interfaces (10/100/1000

mega-bit operation) for application communications interfacing. This is a dual RJ45 connector

with LEDs to indicate the status of the links.

The following figure and table provide pinout and signal information for this interface.

Figure 2-3: J5A/B - Dual Gigabit Ethernet Connector

LED OPERATION:

ACTSPEEDACTSPEED

J5A

J5B

TSE2 TSE1

8 1 8

Table 2-6: Pinouts of J5A and J5B Based on the Implementation

1

ACT OFF: link not active

GREEN: link active

GREEN BLINKING: activity on link

SPEED OFF: 10 Mbps

GREEN: 100 Mbps

YELLOW: 1000 Mbps

MDI / Standard Ethernet Cable

10BASE-T 100BASE-TX 1000BASE-T 10BASE-T 100BASE-TX 1000BASE-T

I/O SIGNAL I/O SIGNAL I/O SIGNAL I/O SIGNAL I/O SIGNAL I/O SIGNAL

O TX+ O TX+ I/O BI_DA+ 1 IRX+IRX+I/OBI_DB+

O TX- O TX- I/O BI_DA- 2 I RX- I RX- I/O BI_DB-

I RX+ I RX+ I/O BI_DB+ 3 O TX+ O TX+ I/O BI_DA+

----I/OBI_DC+4 ----I/OBI_DD+

----I/OBI_DC-5 ----I/OBI_DD-

I RX- I RX- I/O BI_DB- 6 O TX- O TX- I/O BI_DA-

----I/OBI_DD+7 ----I/OBI_DC+

----I/OBI_DD-8 ----I/OBI_DC-

Note ...

The Gigabit PHYs on the VMP3 support automatic MDI/MDIX crossover at all

P R E L I M I N A R Y

speeds of operation. Therefore both standard as well as crossed Ethernet

cables can be used with these interfaces.

PIN

MDIX / Crossed Ethernet Cable

Page 2 - 10 © 2005 Kontron Modular Computers GmbH ID 29230, Rev. 01

29230.01.UG.VC.050727/091422

Page 45

VMP3 Functional Description

2.4.3 J6 – Fast Ethernet Interface

This connector provides a single Fast Ethernet interface (10/100 mega-bit operation) for application communications interfacing. This is a single RJ45 connector without link status LEDs.

Link status LEDs for this interface are located on the bottom side of the EBC-VME3 board.

The following figure and table provide pinout and signal information for this interface.

Figure 2-4: J6 - Fast Ethernet Connector

LED OPERATION:

Speed

Activity

8 1

Table 2-7: Pinout of J6

Activity OFF: link not active

GREEN: link active

GREEN BLINKING: activity on link

Speed OFF: 10 Mbps

GREEN: 100 Mbps

PIN SIGNAL DESCRIPTION

1 TX+ Transmit data +

2 TX- Transmit data -

3 RX+ Receive data +

4 Terminated Bob-Smith termination

5 Terminated Bob-Smith termination

6 RX- Receive data -

7 Terminated Bob-Smith termination

9 Terminated Bob-Smith termination

P R E L I M I N A R Y

29230.01.UG.VC.050727/091422

ID 29230, Rev. 01 © 2005 Kontron Modular Computers GmbH Page 2 - 11

Page 46

Functional Description VMP3

2.4.4 J7 Terminal Interface

The VMP3 provides one serial interface for supporting a terminal port (TERM1). This interface

is realized using one of the MPC8541E on-chip UARTs, and as such provides only a two wire

interface without hardware handshake signals.

The connector J7 provides interfacing to the TERM1 port. This port can also be used as a low

speed solution for firmware updating. The signal levels on this connector are RS232 compliant.

The UART itself is a 16550 type UART.

The following figure and table provide pinout and signal information for the TERM1 interface.

Figure 2-5: J7 - TERM Connector

6 1

Table 2-8: Pinout of J7

PIN SIGNAL

1NC

2GND

3TxD1

4RxD1

5NC

6NC

P R E L I M I N A R Y

Page 2 - 12 © 2005 Kontron Modular Computers GmbH ID 29230, Rev. 01

29230.01.UG.VC.050727/091423

Page 47

VMP3 Functional Description

2.4.5 J8 JTAG/Debug Interface

This Test and Programming interface supports JTAG/Debug operations. This interface can be

used for connecting hardware emulators and debuggers (e.g. BDM, COP, …). It is comprised

of a set of ten signals whereby some are common to both interfaces and some are dedicated

to only one.

The following figure and tables provide pinout and signal information for this connector.

Figure 2-6: J8 - JTAG/Debug Connector

15

1

216

Table 2-9: Pinout of J8

SIGNAL PIN PIN SIGNAL

TDO 1 2 NC

TDI 3 4 TRST

(pulled to +3.3V with 10 kΩ)56EMU_VCC

TCK 7 8 CHKSTP_IN (pulled to +3.3V with 10 kΩ)

TMS 9 10 NC

SRST 11 12 NC

HRST 13 14 NC

CHKSTP_OUT (pulled to +3.3V with 10 kΩ)15 16GND

Table 2-10: JTAG/Debug Signal Descriptions

TCK Test Clock in for JTAG and emulator/debugger

TDI Test Data In for JTAG and emulator/debugger

TDO Test Data Out JTAG and emulator/debugger

TMS Test Mode Select, input for JTAG and emulator/debugger

TRST Test Reset, input for JTAG and emulator/debugger

HRST Hard Reset, emulator/debugger hard reset input

SRST Soft Reset, emulator/debugger reset input

CHKSTP_IN Checkstop input

CHKSTP_OUT Checkstop output

EMU_VCC Reference Voltage of the JTAG/DEBUG core

29230.01.UG.VC.050727/091424

ID 29230, Rev. 01 © 2005 Kontron Modular Computers GmbH Page 2 - 13

SIGNAL DESCRIPTION

P R E L I M I N A R Y

Page 48

Functional Description VMP3

2.4.6 J9 PCI Expansion Interface

The PCI Expansion connector provides the possibility to mount several transition boards above

the VMP3 for adding special functionality which is not provided on the VMP3 main board or on

the VME bus. All the PCI signals of the onboard PCI bus are routed to this connector, so that

a complete PCI bus is provided on this connector. In addition, almost the same number of

ground and power pins (3.3V and 5V) as are on a PCI or PMC connector are provided.

Examples of transition boards are:

• PMC carrier

• IO board with Graphic interface, SCSI, etc.

Figure 2-7: J9 PCI Expansion Connector

1 99

P R E L I M I N A R Y

1002

Page 2 - 14 © 2005 Kontron Modular Computers GmbH ID 29230, Rev. 01

29230.01.UG.VC.050727/091424

Page 49

VMP3 Functional Description

Table 2-11: Pinout of J9

SIGNAL PIN PIN SIGNAL SIGNAL PIN PIN SIGNAL

GND 1 2 SCL (I2C) AD17 51 52 AD16

RST# 3 4 +3.3V C/BE2 53 54 +5V

+3.3V 5 6 CLK1 GND 55 56 FRAME#

CLK2 7 8 GND IRDY# 57 58 GND

GND 9 10 NC +3.3V 59 60 TRDY#

INTB# 11 12 INTA# DEVSEL# 61 62 NC

INTD# 13 14 INTC# GND 63 64 STOP#

+5V 15 16 GNT1# LOCK# 65 66 +3.3V

GNT2# 17 18 +5V PERR# 67 68 +5V

+3.3V 19 20 NC SERR# 69 70 GND

GND 21 22REQ1# +5V 71 72PAR

REQ2# 23 24 GND C/BE1 73 74 AD15

+5V 25 26NC AD14 75 76+3.3V

AD31 27 28 AD30 GND 77 78 AD13

AD29 29 30 +5V AD12 79 80 AD11

GND 31 32AD28 AD10 81 82GND

AD27 33 34 AD26 GND 83 84 AD9

AD25 35 36 GND AD8 85 86 C/BE0

+3.3V 37 38 AD24 AD7 87 88 +5V

C/BE3 39 40 SDA (I2C) +3.3V 89 90 AD6

AD23 41 42 +3.3V AD5 91 92 AD4

GND 43 44 AD22 AD3 93 94 GND

AD21 45 46 AD20 NC 95 96 AD2

AD19 47 48 GND AD1 97 98 AD0

+5V 49 50 AD18 +12V 99 100 -12V

P R E L I M I N A R Y

29230.01.UG.VC.050727/091425

ID 29230, Rev. 01 © 2005 Kontron Modular Computers GmbH Page 2 - 15

Note...

The PCI signalling voltage is 5V on this connector.

Page 50

Functional Description VMP3

2.4.7 J11 I/O Expansion Interface

The I/O Expansion connector provides additional capability for LPC, TERM2, M/C, CAN, and

HSS/UART interfacing. All signals on this connector are at TTL levels which means that they

will require additional signal conditioning prior to interfacing to VMP3 external devices.

Figure 2-8: J11 I/O Expansion Connector

72

2

71 1

Table 2-12: Pinout of J11

SIGNAL PIN PIN SIGNAL SIGNAL PIN PIN SIGNAL

+BAT (see Note) 1 2 GND SER4_RI 37 38 SER4_RTS

MC4 3 4 LPC_CLK SER3_CD 39 40 SER4_DSR

LAD1 5 6 +3V3 SER3_RXD 41 42 GND

+5V 7 8 LAD0 SER3_CTS 43 44 SER3_DTR

LAD3 9 10 LAD2 SER3_RI 45 46 SER3_TXD

PCI_RST 11 12 GND +3V3 47 48 SER3_RTS

TXD2 13 14 LFRAME SER2_CD 49 50 SER3_DSR

RXD2 15 16 +5V SER2_RXD 51 52 GND

GND 17 18 SERIRQ GND 53 54 SER2_DTR

CAN1_RX1 19 20 +3V3 SER2_CTS 55 56 SER2_TXD

CAN1_RX0 21 22 CAN1_TX1 SER2_RI 57 58 SER2_RTS

GND 23 24 CAN1_TX0 +5V 59 60 SER2_DSR

P R E L I M I N A R Y

CAN2_RX1 25 26 +5V SER1_CD 61 62 +3V3

CAN2_RX0 27 28 CAN2_TX1 SER1_RXD 63 64 SER1_DTR

GND 29 30 CAN2_TX0 GND 65 66 SER1_TXD

SER4_CD 31 32 GND SER1_CTS 67 68 SER1_RTS

SER4_RXD 33 34 SER4_DTR SER1_RI 69 70 SER1_DSR

SER4_CTS 35 36 SER4_TXD +3V3 71 72 +5V

Note...

+BAT = 3.2V is derived from the 5V standby (is not regulated)

Page 2 - 16 © 2005 Kontron Modular Computers GmbH ID 29230, Rev. 01

29230.01.UG.VC.050727/091425

Page 51

VMP3 Functional Description

2.4.7.1 LPC Interface

One Low Pin Count (LPC) interface for supporting simple IOs, simple static memory devices,

and IO controllers is available via the I/O Expansion interface.

The controller is completely integrated in the BPCC and offers a 8-bit data access port to devices which use LPC IO or memory access protocols. I/O and memory area are selected using

different address spaces.

The I/O address space is 64 kByte in size, whereas the memory area offers 16 MByte address

space. DMA is not supported by this interface.

In addition, a serial IRQ controller is also implemented in the BPCC, controlling and collecting

the serial LPC IRQs and converting and processing them to IRQs for the CPU.

The serial IRQ controller is realized according to the “Serialized IRQ Support for PCI Systems”

Specification, Rev. 6.0, Sept. 1, 1995

The following table provides a listing of the LPC interface signals and a brief description.

Table 2-13: LPC Interface Signal Description

SIGNAL DESCRIPTION

LAD[0:3] Multiplexed Command, Address, and Data lines

LFRAME# Indicates start of a new cycle, termination of broken cycle

LPCCLK 33 MHz clock

SERIRQ Serialized IRQ, optional for peripherals that need interrupt

2.4.7.2 Terminal Interface

A second serial interface for supporting a terminal port and a low speed communications interface (TERM2) for firmware updating is provided on this connector. This interface is realized using one of the MPC8541E on-chip UARTs, and, as such, provides only a two wire interface

without hardware handshake signals.

Note...

The corresponding serial signals on the VMP3 are TTL logic level signals.

Therefore, the transceivers for RS232 must be provided by the carrier board.

WARNING!

The signal level on the receive lines must not exceed 3.3V. Transients and signal levels higher than 3.3V may damage the VMP3 board.

P R E L I M I N A R Y

29230.01.UG.VC.050727/091426

ID 29230, Rev. 01 © 2005 Kontron Modular Computers GmbH Page 2 - 17

Page 52

Functional Description VMP3

2.4.7.3 CAN Interface

To provide field bus support, there are signals available to implement a CAN bus interface

(Philips SJA 1000) via the J11 connector. The signals provided are at 5V TTL voltage levels

and must be adapted to the CAN bus levels through the use of appropriate CAN transceivers

on the carrier board.

Table 2-14: CAN Interface Signal Type and Description

SIGNAL DESCRIPTION

CAN1_TX[0:1] Transmit data output driver

CAN1_RX[0:1] Receive data input channel

Note...

For more information concerning interfacing of the SJA 1000 to the CAN PHY,

refer to the Philips Application Note: AN97076 or the datasheet of the PCA

82C250 CAN controller interface.

2.4.7.4 High Speed Serial Interfaces

Four, full modem, serial ports (SER1, 2, 3, and 4) are available on the I/O expansion connector.

Eight signals per port are provided to realize asynchronous high speed serial links interfaced

using dedicated controlling/handshaking. The VMP3 uses DUARTs (EXAR XR 16C2850 or

XR16L2750) which are 16550 compatible and provide hardware handshaking support for

RS485 operation.

Table 2-15: High Speed Serial Interface Signal Type and Description

SIGNAL DESCRIPTION

SERn_TXD Transmit data output

SERn_RXD Receive data input

SERn_RTS Request to send output

P R E L I M I N A R Y

SERn_CTS Clear to send input