Page 1

VMOD-2/VMOD-2D

VModular Industrial I/O Module

for VMEbus Applications

Manual ID 03139, Rev. Index 0200 of 12/10/97

Page 2

This page was intentionally left blank.

Man. ID 03139, Rev. Index 0200

Page 3

VMOD-2/VMOD-2D

Preface

Preface

Revision History ............................................................. 0-6

For Your Safety.............................................................. 0-5

Special Handling and Unpacking Instructions 0-5

HV Safety Instructions 0-6

Two Years Warranty ...................................................... 0-7

Table of Contents........................................................... 0-8

Warning!

The first index (PCB layout 00) of VMOD-2 was designed for

improved noise immunity (via multi-layer shielding) and as such

have insufficient clearance around the piggybacks I/O pins and the

50-way external interface connectors pins to ensure the 2.5kV

breakdown isolation specified by certain piggybacks. Use index 01

or higher for such applications, or take additional measures to be

taken to ensure syste m/user safety.

12/10/97

Page 0 - #Man. ID 03139, Rev. Index 0200

Page 4

VAR Product Name

R

EVISION HISTOR

Y

Manual/Product Title:

VMOD-2/VMOD-2D

Manual ID Number:

03139

Rev.

Index

Brief Description of Changes

PCB Index

Date of

Issue

Revision History

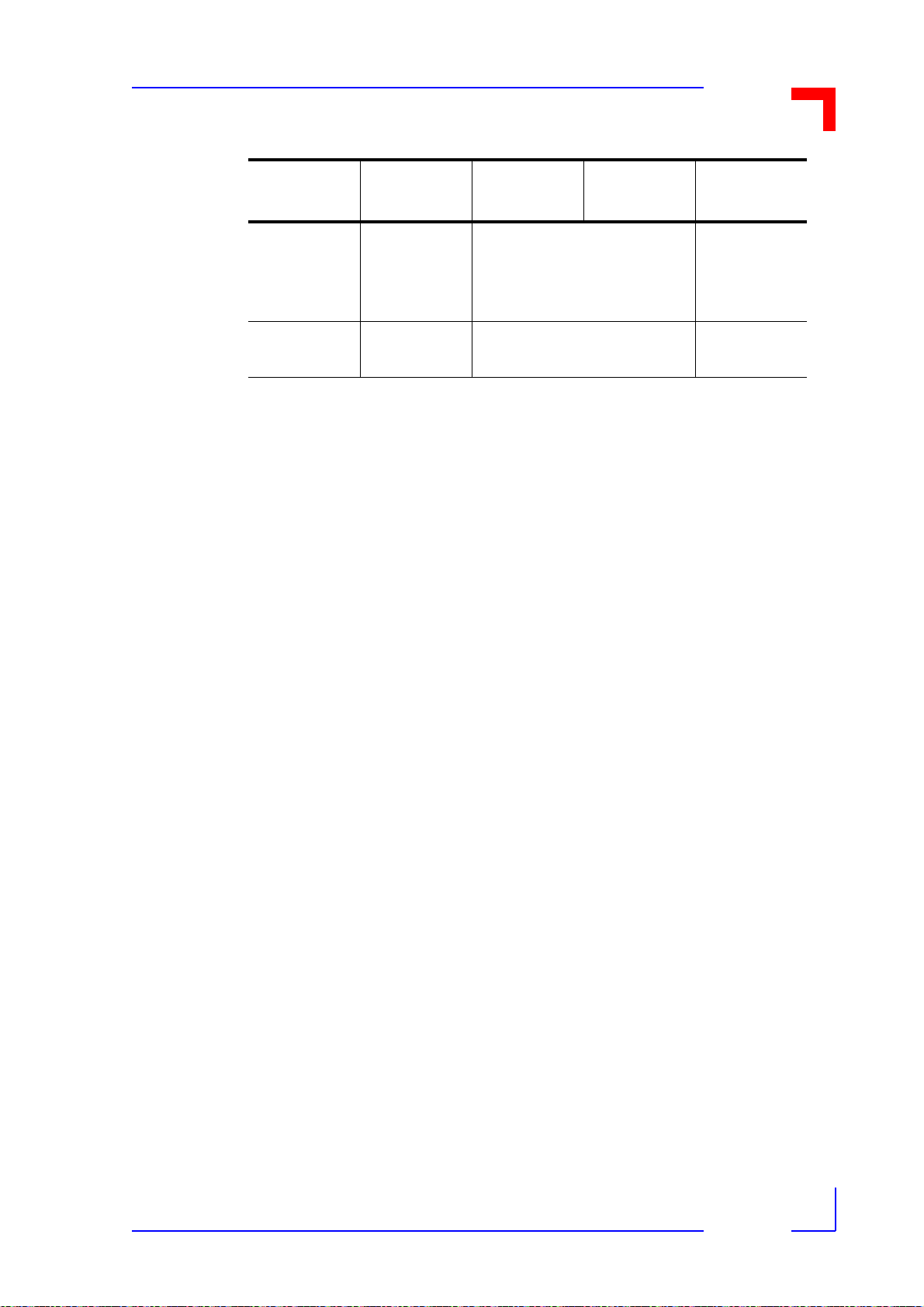

0100 Initial Issue 01 01 Feb. 1992

0101 Changes to Address Range in 2.4 01 01 July 1994

0200 Standard Preface, New Numbering System 01 01 Dec. 1997

Preface

This document contains proprietary information of

copied or transmitted by any means, passed to others, or stored in any retrieval system or

media, without the prior consent of

The information in this document is, to the best of our knowledge, entirely correct. However,

PEP Modular Computers

thereof, nor for any liability arising from the use or application of any circuit, product, or example shown in this document.

PEP Modular Computers reserve the right to change, modify, or improve this document or the

product described herein, as seen fit by

cannot accept liability for any inaccuracies, or the consequences

PEP Modular Computers

PEP Modular Computers

PEP Modular Computers

or its authorized agents.

without further notice.

. It may not be

12/10/97

Page 0 - #Man. ID 03139, Rev. Index 0200

Page 5

VAR Product Name

Preface

For your safety

PEP

This

can be drastically reduced by improper treatment during unpacking and installation. Therefore, in the interest of your own safety and of correct operation of your new PEP product,

please take care of the following guidelines:

product is carefully designed for a long, fault-free life. However, its life expectancy

Before installing your new

power mains. This applies also to installing piggybacks.

In order to maintain

in any way. Changes or mo difications to the device, which are not explicitly approved by

PEP Modular Computers

Support as a special handling instruction, will voi d your warranty.

This device should only be installed in or connected to systems that fulfill all necessary

technical and specific environmental requirements. This applies also to the operational

temperature range of the specific board version, which must not be exceeded. If batteries are present, their temperature re strictions must be taken into account.

In performing all necessary installation and application operations, please, follow only

the instructions supplied by the present manual.

Keep all the original packaging material for future storage or warranty shipments. If it is

necessary to store or ship the board, please, re-pack it in the original way.

PEP’s

PEP

product into a system, please, always switch off your

product warranty, please, do not alter or modify this product

and described in this manual or received from

PEP

Technical

Special Handling and Unpacking Instructions

Electronic boards are sensitive to static electricity. Therefore, care must be taken during all

handling operations and inspections wi th this produ ct, in order to ensure pro duct integrit y at all

times.

Do not handle this product out of its protective enclosure while it is not being worked

with, or unless it is otherwise protected.

Whenever possible, unpack or pack this product only at EOS/ESD safe work stations.

Where safe work stations are not guaranteed, it is important for the user to be electri-

cally discharged before touching the product with his/her hands or tools. This is most

easily done by touching a metal part of your system housing.

Particularly, observe standard anti-static precautions when changing piggybacks, ROM

devices, jumper settings etc. If the product contains batteries for RTC or memory backup, ensure that the board is not placed on conductive surfaces, including anti-static

plastics or sponges. They can cause short circuits and damage the batteries or tracks

on the board.

12/10/97

Page 0 - #Man. ID 03139, Rev. Index 0200

Page 6

VAR Product Name

Safety Instructions for High Voltages

This chapter of the safety instructions appli e s to HV appli ances (> 60 V) only.

Preface

Your new

to ensure the reknown electrical safety requirements. However, serious electrical shock hazards exist during all installation, repair and maintenance operations with this product. Therefore, always unplug the power cable to avoid exposure to hazardous voltage.

All operations on this device have to be carried out by sufficiently skilled personnel only.

PEP

product was developed and tested carefully to provide all features necessary

12/10/97

Page 0 - #Man. ID 03139, Rev. Index 0200

Page 7

VAR Product Name

Two Years Warranty

Preface

Preface

PEP Modular Computers

HARDWARE

be granted or implied by anyone on behalf of

expressed written consent of

PEP Modular Computers

manufacturing and material defects for a period of 24 consecutive months from the date of

purchase. This warranty is not transferable nor extendible to cover any other users or longterm storage of the product. It does not cover products which have been modified, altered or

repaired by any other party than

more, any product which has been, or is suspected of being damaged as a result of negligence, unproper use, incorrect handling, servicing or maintenance, or which has been

damaged as a result of excessive current/voltage or temperature, orwhich has had its serial

number(s), any other markings or parts thereof altered, defaced or removed will also be

excluded from this warranty.

If the customer’s eligibility for warranty has not been voided, in case of any claim, he may

return the product at the earliest possible convenience to the original place of purchase,

together with a copy of the original document of purchase, a full description of the application

the product is used on and a description of the defect. Pack the product in such a way as to

ensure safe transportation (see our safety instructions).

PEP

provides for repair or replacement of any part, assembly or sub-assembly at their own

discretion, or to refund the original cost of purchase, if appropriate. In the event of repair,

refunding or replacement of any part, the ownership of the removed or replaced parts reverts

PEP Modular Computers

to

guarantee to cover the repaired or replaced items, will be transferred to cover the new or

repaired items. Any extensions to the original guarantee are considered gestures of goodwill,

and will be defined in the “Repair Report” issued by

WARRANTY

grants the original purchaser of

as described in the following. However, no other warranties that may

PEP

PEP Modular Computers

warrants their own products, excluding software, to be exempt of

PEP Modular Computers

, and the remaining part of the original guarantee, or any new

PEP

products a

are valid unless the consumer has the

.

or their authorized agents. Further-

PEP

with the repaired or replaced item.

TWO YEARS LIMITED

PEP Modular Computers

rectly from any warranty claim, other than the above specified repair, replacement or refunding. Particularly, all claims for damage to any system or process in which the product was

employed, or any loss incurred as a result of the produc t not functi oning at any given time, are

excluded. The extent of

original purchase price of the item for which the claim exist.

PEP Modular Computers

respect to its products, reliability, fitness, quality, marketability or ability to fulfil any particular

application or purpose. As a result, the products are sold “as is,” and the responsibility to

ensure their suitabilit y for an y given t ask r emain s of the purch aser. I n no eve nt wil l

ble for direct, indirect or consequential damages resulting from the use of our hardware or

software products, or documentation, even if PEP were advised of the possibility of such

claims prior to the purchase of the product or during any period since the date of its purchase.

Please remember that no

make any modification or addition to the abovespecified terms, either verbally or in any other

form written or electronically trans mitted, without the company’s consent.

will not accept liability for any further claims resulting directly or indi-

PEP Modular Computers

issues no warranty or representation, either explicit or implicit, with

PEP Modular Computers

liability to the customer shall not exceed the

PEP

be lia-

employee, dealer or agent i s author ize d to

12/10/97

Page 0 - #Man. ID 03139, Rev. Index 0200

Page 8

VAR Product Name

g

g

g

g

gg

Chapter

Chapter

1. Introduction...............................................................1-1

1.1 Product Overview................................................. 1-1

1

1

Preface

1.2 Orderin

1.3 Glossary of Terms................................................ 1-2

1.4 Hazards................................................................ 1-2

1.5 VMOD-2 Specifications........................................ 1-3

1.6 VMOD-2 Board Overview .................................... 1-4

1.7 Advanta

PepCard 1-5

1.7 Advanta

PepCard 1-5

1.8 Functional Block Dia

1.9 Related Publications ............................................ 1-7

1.10Pi

Information............................................ 1-1

es and Features of the VMOD-2

es and Features of the VMOD-2

ram ................................... 1-6

yback Selection Assistance.......................... 1-7

Chapter

2. Functional Description..............................................2-1

2.1 VMOD-2 Address Map......................................... 2-1

2.2 VMEbus Interrupts ............................................... 2-3

2.3 External "Local" Reset Input .............................. 2-5

2.4 ID Byte ................................................................. 2-8

2.5 VMOD/VMOD-2 Connector Location s and

Pin-Outs............................................................... 2-9

12/10/97

2

Page 0 - #Man. ID 03139, Rev. Index 0200

Page 9

VAR Product Name

g

g

g

g

g

Preface

Chapter

3. Configuration............................................................3-1

3.1 Jumper Location s and Functions......................... 3-1

3.2 Fittin

Chapter

4. Installation .............. .. ... ................ ... ................. .. .......4-1

4.1 VMEbus Connection............. .. .. ........................... 4-1

4.2 Installin

4.2 IChronolo

4.4 Connectin

3

Piggybacks...... .. ... ................. .. ................. . 3-7

4

the VMOD-2.......................................... 4-1

ical Installation Procedure.................. 4-2

the External Devices......................... 4-3

4.5 Front Panel Functions.......................................... 4-4

4.6 Trouble-shootin

VMEbus System.................................................. 4-5

4.7 General Remarks on the Use of Your System..... 4-6

for VMOD-2/VMOD and

12/10/97

Page 0 - #Man. ID 03139, Rev. Index 0200

Page 10

VAR Product Name

Preface

Annex

System Configuration Record........................................ A-1

Annex

VMOD-2 Board Layout................................................... B-1

Annex

VMOD-2 Schematics ..................................................... C-1

A

B

C

12/10/97

Page 0 - #Man. ID 03139, Rev. Index 0200

Page 11

VMOD-2/VMOD-2D

Product Overview

Product Overview

1.1 Product Overview.................................................................. 1-1

1.2 Ordering Information............................................................ .. 1-1

1.3 Glossary of Terms................................................................. 1-2

1.4 Hazards................................................................................. 1-2

1.5 VMOD-2 Specifications......................................................... 1-3

1.6 VMOD-2 Board Overview...................................................... 1-4

1.7 Advantages and Features of the VMOD-2 PepCard............. 1-5

Chapter

1

1.7.1 Features of the VMOD-2 Module.................................. 1-5

1.7 Advantages and Features of the VMOD-2 PepCard............. 1-5

1.8 Functional Block Diagram ..................................................... 1-6

1.9 Related Publications.............................................................. 1-7

1.10 Piggyback Selection Assistance............................................ 1-7

1.10.1 VMOD/VMOD-2 Piggybacks Overview........................ 1-8

12/15/97

Page 1 - 1Man. ID 03139, Rev. Index 0200

Page 12

VMOD-2/VMOD-2D

Product

Description

Order No.

Product Overview

1. Introduction

1.1 Product Overview

VMOD-2 is a "User Configurable" Industrial I/O module with the ability to fit any two (identical

or different) standard sized VMOD piggybacks. Each fitted piggyback shares half of the front

panel's 50-way connector allowing a flat-ribbon cable to be easily routed to either one or two

end devices. The VMOD-2 may not only be used with all existing (VMOD) piggybacks, but will

also accept the future generation of enhanced piggybacks, which may use the additional signal lines only provided on the VMOD-2.

Upgrade paths/Compatibility. The original VMOD is no longer available and if ordered will

automatically be replaced with the new VMOD-2. The VMOD-2 can be used as a direct

replacement for any application using an older style VMOD. Full electro-mechanical compatibility (and acceptance of the existing piggyback int erfaces) is guaranteed.

The VMOD-2 may be used as a direct replacement for an y existing VMOD and will accept the

fitted piggybacks from that existing VMOD without any modification. (See also special note

below)

A VMOD may be used in place of the new VMOD-2 with the loss of some new features, and

then only with piggybacks developed up to the end of 1990. Any enhanced piggybacks which

need additional signals from the VMOD-2 will not work on the old VMOD. To identify which

piggybacks are only suit able f or use on the VMOD-2 loo k for a f our digit o rder number suc h as

the PB-BIT has. i.e. 5230-11. Any and all piggybacks with three digit numbers 523-xx, will

function with both VMOD and VMOD-2 modules alike.

1.2 Ordering Information

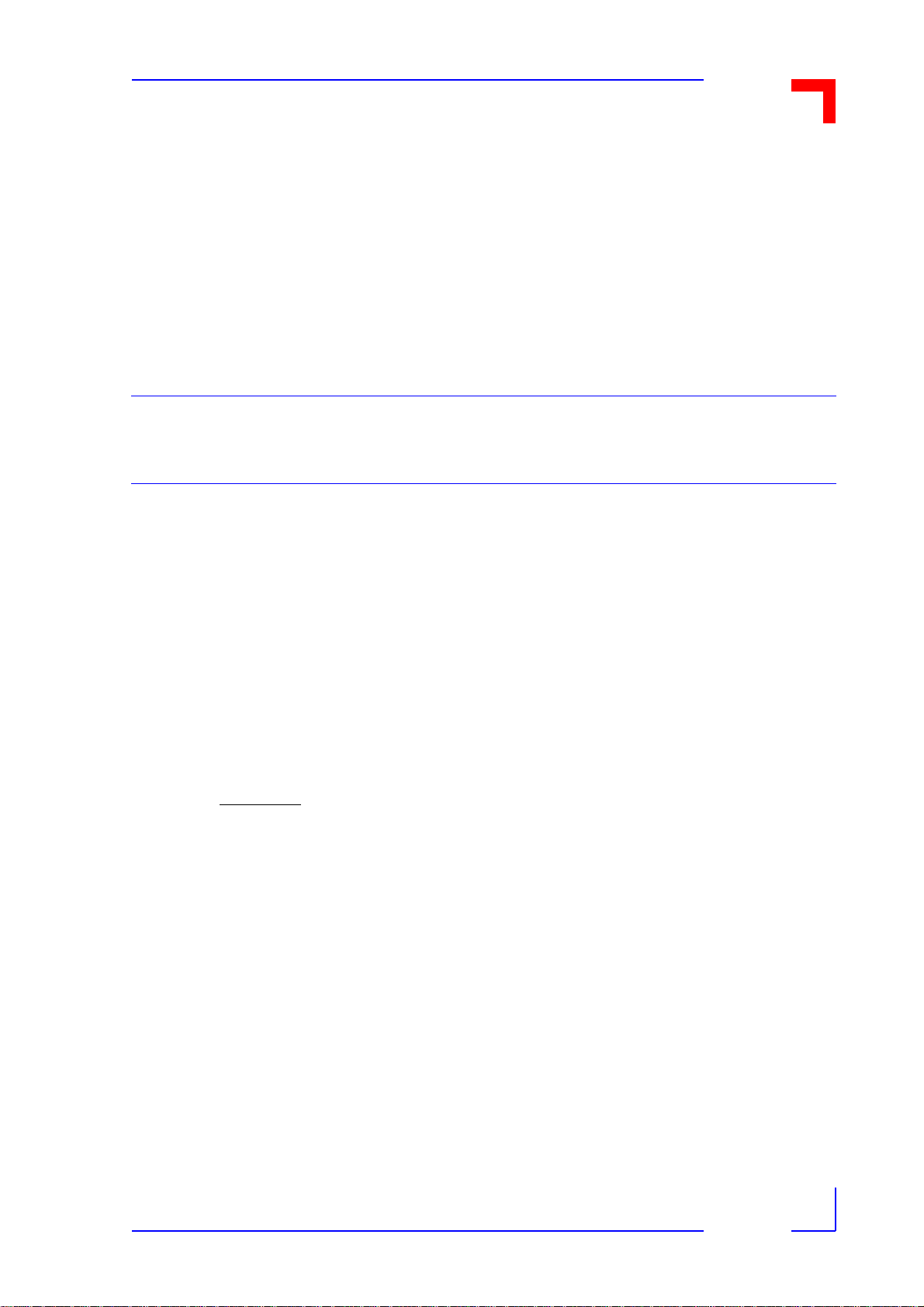

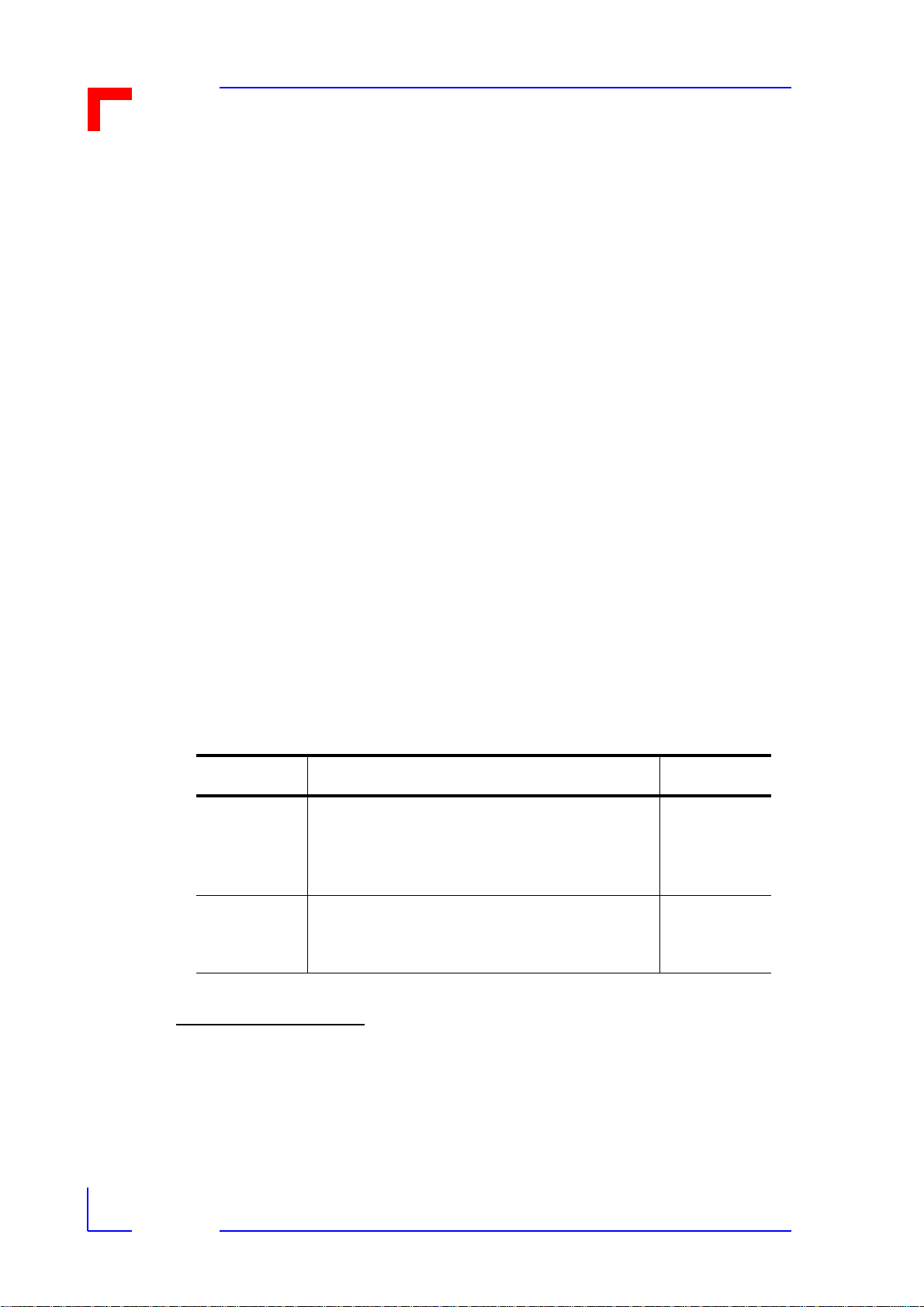

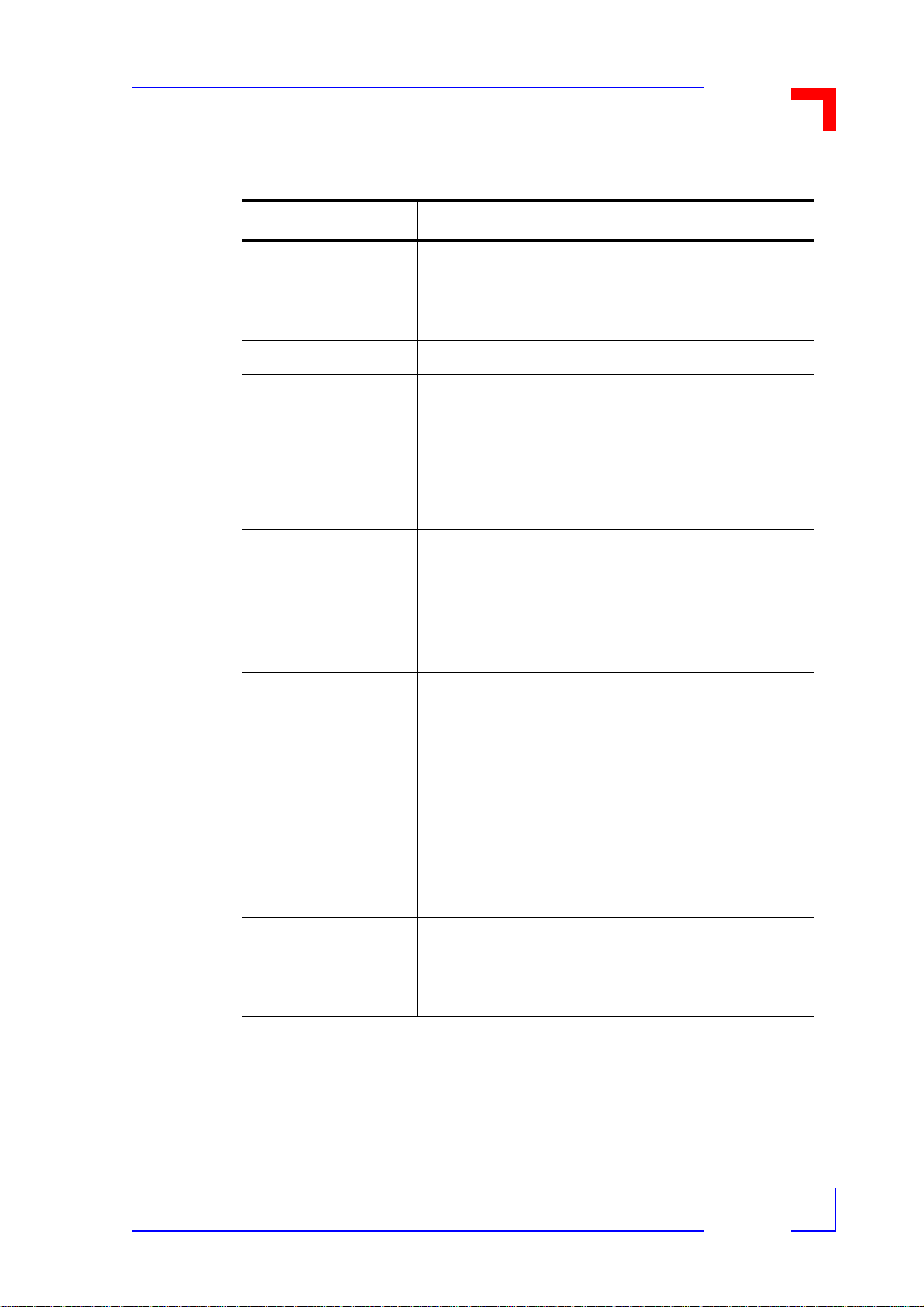

Table 1-1: VMOD-2 Ordering Information

VMOD-2 VMEbus industrial I/O interface module with

latching 50 pin front panel connector, but

without the additional on-board 50 pin

header.

VMOD-2 VMEbus industrial I/O interface module with

the 50 pin flat ribbon on-board header only.

(the 50-pin front panel connector is omitted)

5230-0

5230-1

12/15/97

Special Note! Caution!

VMOD-2 boards with an index 00 offe r increased inter-board shielding by

using tight-routed ground and V cc planes in their multi-layer layout. This

will compromise the 2.5 kV breakdow n isolation offered by many VMODpiggybacks. If the 2.5 kV fault isolation is important for the application,

Page 1 - 2Man. ID 03139, Rev. Index 0200

Page 13

VMOD-2/VMOD-2D

AB#

PBx

PCB

PSU

please use a VMOD-2 with a board index of 01 upwards since this will

have an increased galvanic isolation gap around the 50-way external

interface and 26-way piggyback I/O pin areas.

Product Overview

1.3 Glossary of Terms

This is a brief description of some of the abbreviations used throughout this manual.

Table 1-2: Abbreviations

Address Block number (used in some tables in this

manual to signify a 256 byte wide address block chosen out of a maximu m permis sible 32 ad dresse s)

Piggyback (where x is the location "A" or "B")

Printed Circuit Board

Power Supply Unit

1.4 Hazards

The VMOD-2 can be fitted with one or two piggybacks carrying voltages classed as dangerous (i.e. over 50V dc). These are usually powered by external devices and therefore are not

powered subject to the status of the VMEbus systems power switch. This can result in a

VMOD/VMOD-2 being removed from a powered-down rack with an external device still connected and presenting its voltage to the solder-side of both the VMOD/VMOD-2 and the back

of the respective piggyback. A typical example is the PB-REL an eight relay SPST switching

module, which can in certain circumstances present an unsuspecting user with up to 175V dc

when pulling out (or installing) a VMOD-2 with the external powered interface leads connected. (For continued fault isolation to 2. 5 kV use a VMOD-2 of index 01 or higher).

12/15/97

Page 1 - 3Man. ID 03139, Rev. Index 0200

Page 14

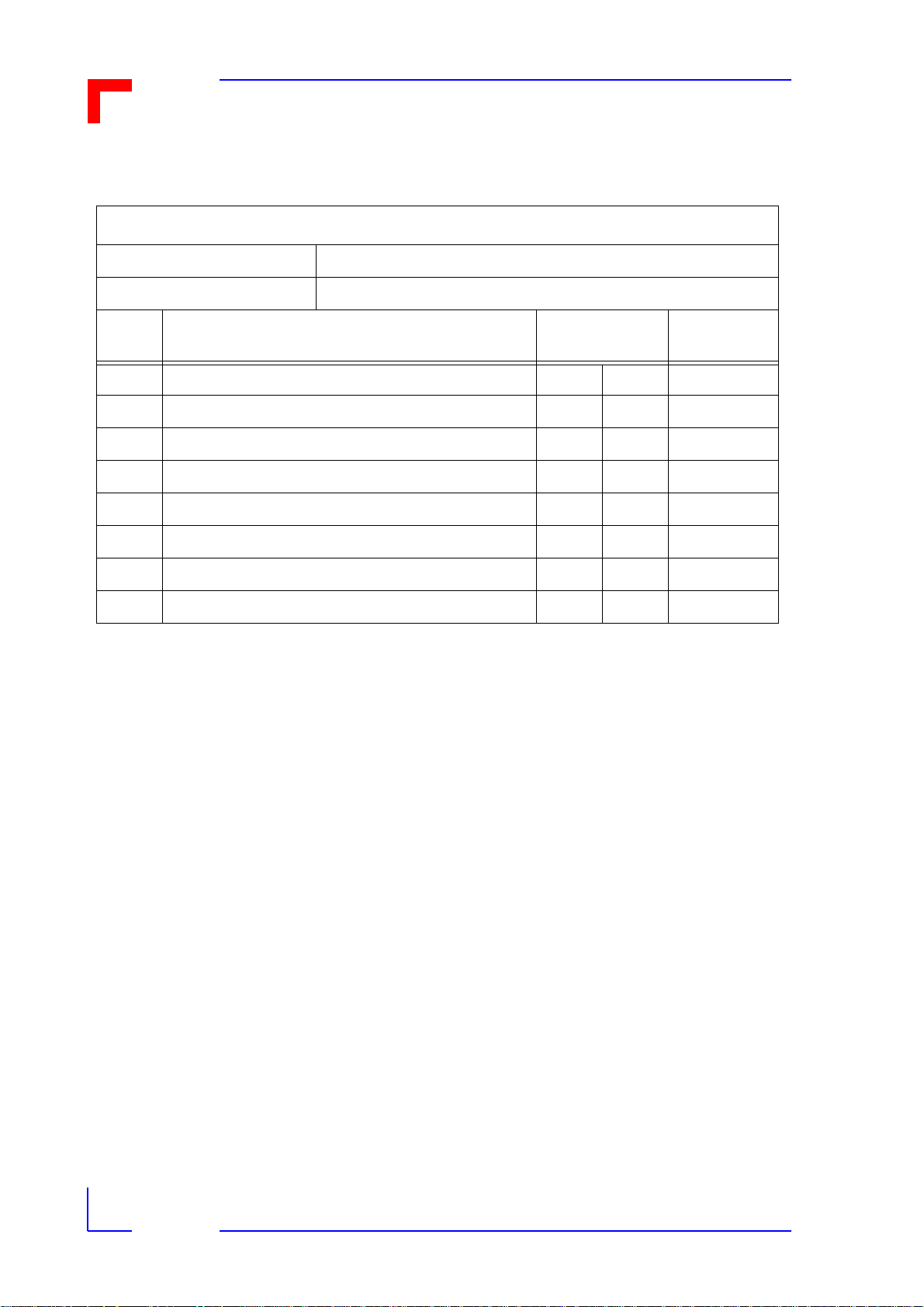

VMOD-2/VMOD-2D

Figure 1-1: VMOD-2 Hazard Example (PB-REL)

Product Overview

26-pin

ST 2

Connector

8 x SPDT

Relays

GAL &

Interface

Logic ICs

This end towards

front of VMOD

Caution!

enclosed area

carries your

externally

connected

voltages and

may present

shock hazar d

Caution!

When using Piggybacks w ith external interfaces or supplies carrying Voltages higher than 50V dc ensure that the solder pins on the rear side of

the PB-xxx and the VMOD to which it fits, are not acc essible (cannot be

accidently touched) during use. These pins can be under power all the

time the external interfaces are connected, when powered,

even when VMOD-2/VMEbus is no t powered!

12/15/97

Page 1 - 4Man. ID 03139, Rev. Index 0200

Page 15

VMOD-2/VMOD-2D

VMOD-2

Specification

1.5 VMOD-2 Specifications

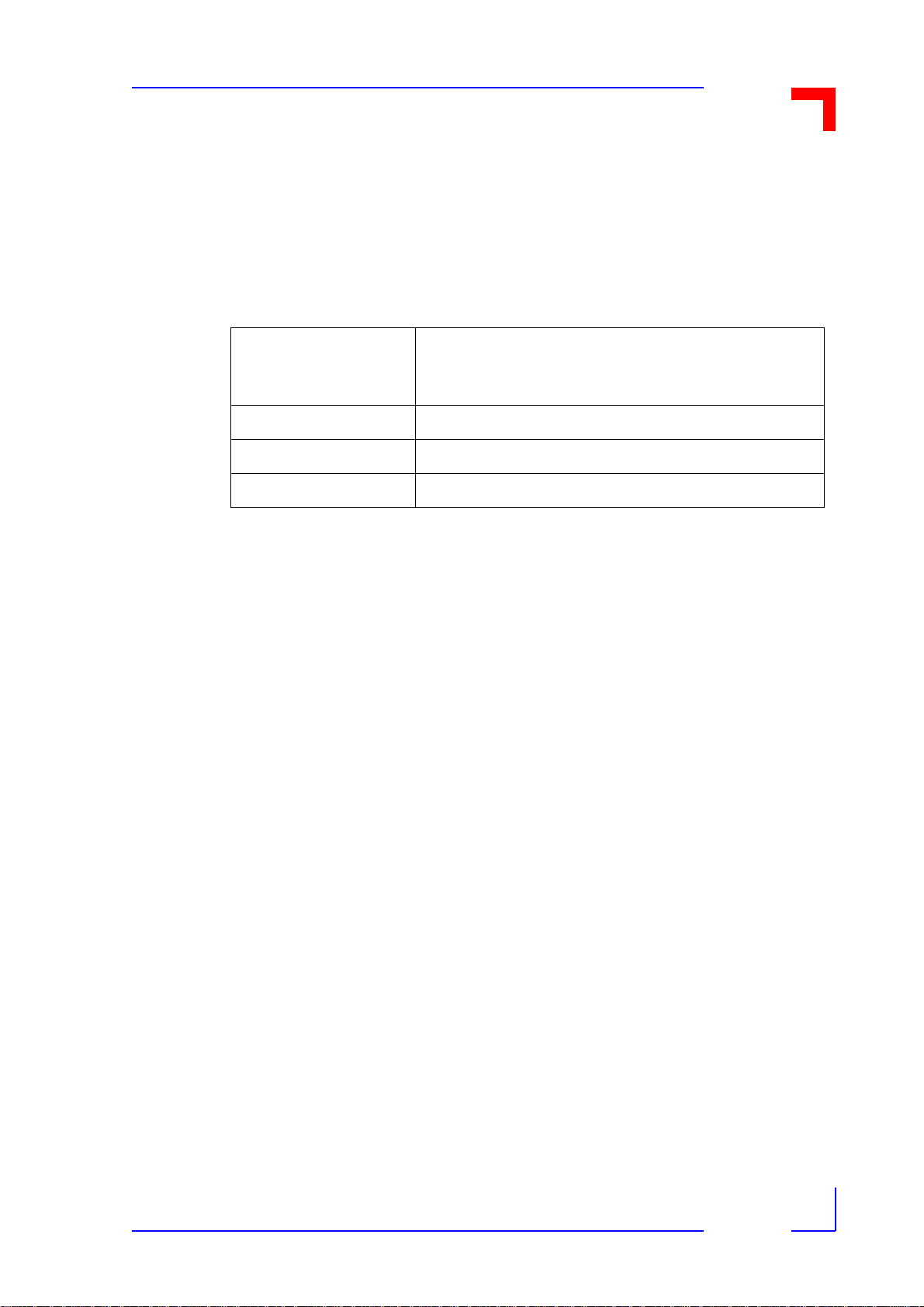

Table 1-3: VMOD-2 Specifications

External Interface 50-way flat band cable connector (upper half and

VMEbus Interface A24:D8/16, A16:D8/16 Slave

VME Address Range Occupies 256 Bytes or 8 KBytes, A1....A11 to each

Interrupt Requester Single-level , IRQ 1-7. Jumper selectable. Two

Product Overview

lower half used by respective piggyback position)

only accessible via the addition of VMOD/VMOD-2

piggyback (s) to the desired interface standard

piggyback. Base Address jumper selectable.

lines for interrupt request, one per Piggyback. Interrupt vector generated by piggybacks, or by jumper

settings on VMOD-2.

External Reset Inputs Pins 25 and 26 of front-panel connector may be

used to connect a NC (Normally clo sed) push- button reset switc h, or fo r the crea tion of an "Emergency-Stop" loop, or for automatic detection of

disconnection of interface. This facility may be disabled via jumper setting.

Power Requirements +5V DC (±5%), 140 mA, excluding additional piggy-

backs demands

Temperature Range

- Operating

- Storage

Operating Humidity 5 - 95% (non-condensing)

Board Size Single-height Eurocar d 100 x 160 mm (4 x 61/4 ")

VMOD to Piggyback

Connectors (VME

side)

- 0° to +70°C (standard)

- -40° to +85°C (extended, subject to fitted piggy back/-s)

- -55° to +85°C

A triple-row (to/from VMOD's VME side) per pigg yback location. Providing Address, Data and necessary control line interfaces to selected PB type(s)

fitted.

12/15/97

Page 1 - 5Man. ID 03139, Rev. Index 0200

Page 16

VMOD-2/VMOD-2D

VMOD-2

Specification

Table 1-3: VMOD-2 Specifications

Product Overview

VMOD to Piggyback

Connectors (User

side)

VMEbus Connecto r DIN 41612 style C, 96-p in

Front Panel Width 4 TE (20.3 mm)(1 slot)

Front Panel Connec -

tor

Piggybacks General See respective piggyback's manual for exact speci-

Piggyback Size Width: 48 mm(1 7/8 inches)

A double-row (to/from user I/O side) set of connectors per piggyback location. These connectors are

galvanically isolated for 2.5 kV (not on index 00

however) from the rest of the VMOD-2 circuits and

are selected to their respective function according

to actual piggyback(s) fitted.

50-pin male ribb on cable header with ret ain/ejec t

latches. Alternatively, no front connector, but a 50pin on-board header (without retain/eject latches

where interfaces are to be kept internal to rack/

equipment.

fications.

Length: 100 mm(3 15/16 inches)

Depth: 12 mm (1/2 inch)

Mechanical/Electrical Interface

Temperature Range:

- Operatin g

- Storage

Held by either Two sets of twin row header pins, or

a triple-row and double-row set of headers, providing all necessary communication paths and a

mechanical mounting method.

- 0° to +70° C (standard)

- -40° to +85° (extended, for some piggybacks)

- typically -55° to +85°C

12/15/97

Page 1 - 6Man. ID 03139, Rev. Index 0200

Page 17

VMOD-2/VMOD-2D

1.6 VMOD-2 Board Overview

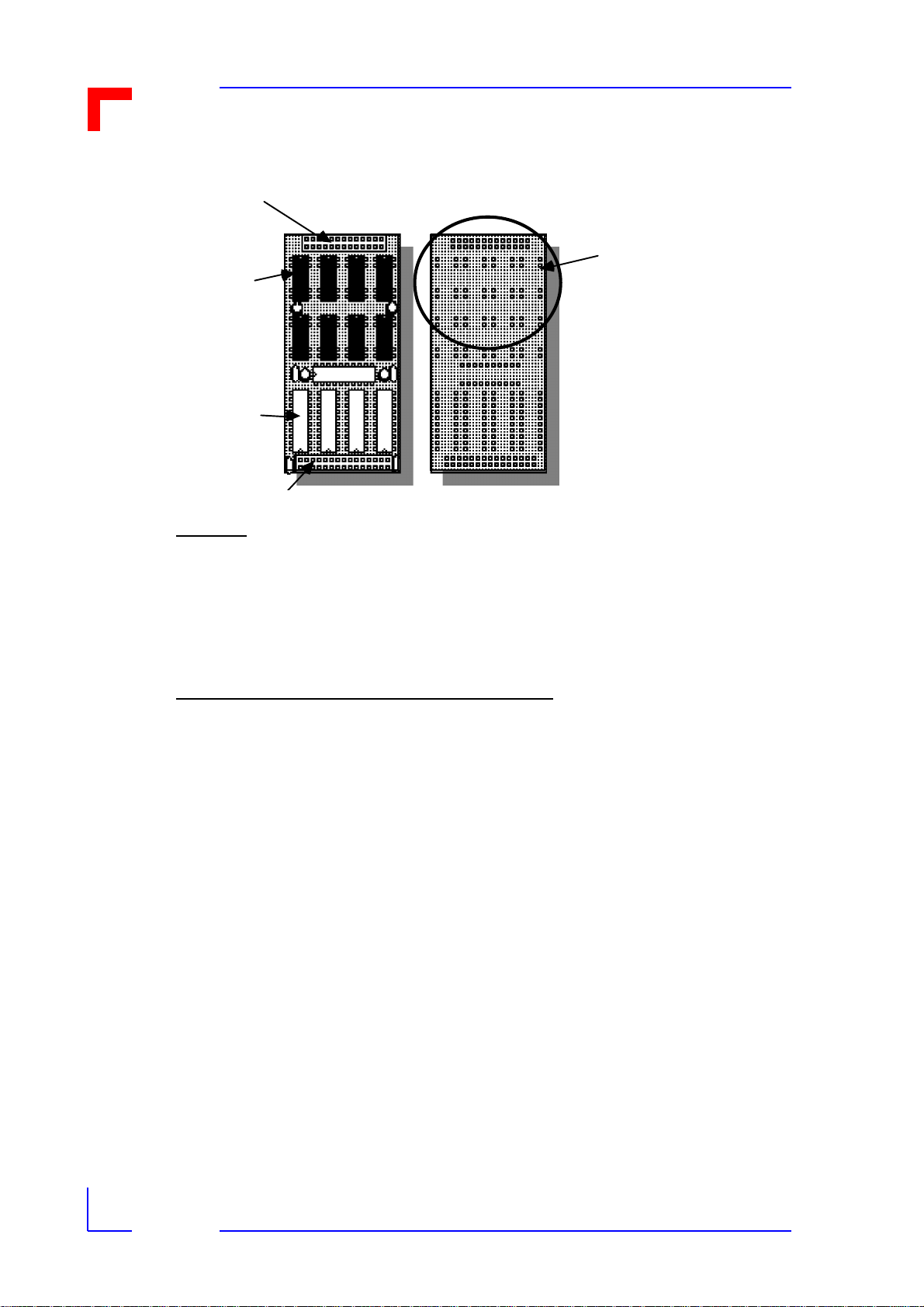

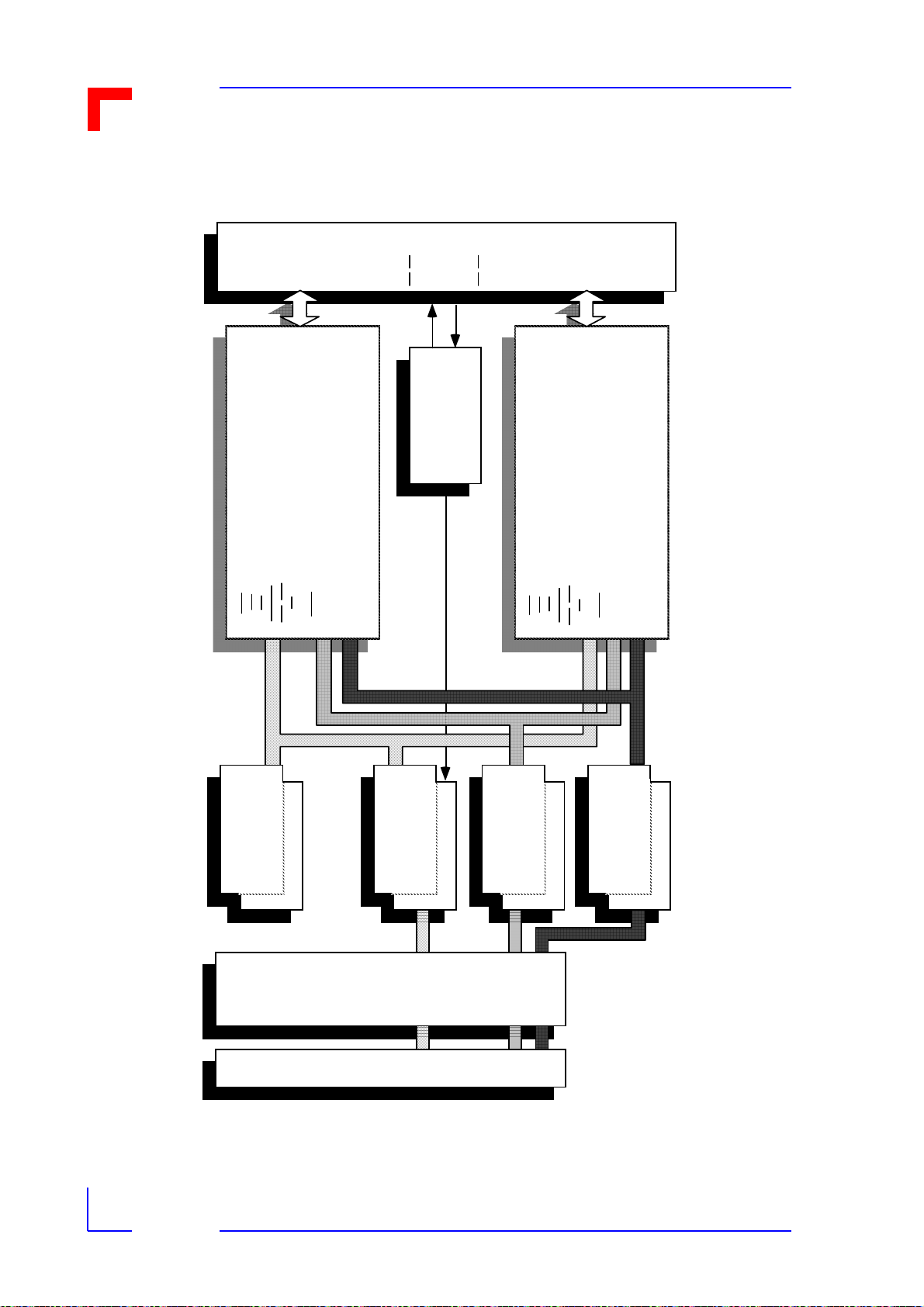

Figure 1-2: VMOD-2 Board Overview

Product Overview

Loc al Rese t

Enable/Disable

Jum pe r (B20)

50-way front

panel connecto r

— or —

26-way, 2-row

pig gyback s oc ket

Pig gyback A

Up per Loc a ti on

on VM O D -2

Pig gyback B

Lower Location

on VM O D -2

50 -way on-

boar d h eade r

VM Ebu s interface

logic in S MD device s

30/45-wa y 2/3-row

pig gyback s oc ket

Jum pers

B01

B19

96-way VME bus

c onn ec tor (P1, J1)

The VMOD-2 is a simple low-cost product designed for maximum flexibility while keeping the

single-height, single-slot modular concept of the PepCard. To ensure user/system security

against fault conditions is maintained with and when using opto-isolated piggybacks, the

VMOD-2 has a large area of unpopulated board space under the front half of both piggyback

locations. This unused area is part of the VMOD-2's Galvanic isolation (see special note on

page 1-1) and no additional wiring should be routed to/from component s in the rear-most area

of the VMOD-2 and the component groups (connectors) at the front of the VMOD-2. A "localReset" logic line is however routed to the three-p in j umper near the 50- pin fr ont pane l conne ctor, but this follows distancing and opto-isolation rules to ensure that the galvanic capability of

the opto-isolated piggybacks is not compromised.

The VMOD-2 is shown above with both the 50-way front panel connector and the 50-way onboard header. It can only be ordered with one or the other. Further the VMOD-2 is shown with

the two piggyback locations occupied, which is how the majority of users employ their

VMOD's, but is delivered without any piggybacks, these items being added to the above illustration to help see where the connectors and piggybacks are to be found /used.

Each of the two piggybacks are fitted so their 26-way connector pins fit into the correspondi ng

26-way socket-holes provided for each piggyback location. The rear connectors pins will then

fit into the correct rows of the 30/45-way sockets regardless of whether the piggyback has a

30-pin or 15-pin connector.

All the jumpers, with the exception of B20 (local reset), are to be found at the back end of the

VMOD-2 in several small groups. Jumper B01 is an "L" shaped group of three-pins nearest

the top edge of the board, and the rest are consecutively numbered progressing down the

VMOD-2 until the last (Jumper B19) is reached nearest the bottom of the board. The function

12/15/97

Page 1 - 7Man. ID 03139, Rev. Index 0200

Page 18

VMOD-2/VMOD-2D

of these jumpers, and a detailed illustration of their locations and pin-numbering, are to be

found in chapter 3 of this manual.

The remaining components on this simple low-cost industrial base board are in CMOS SMD

logic and GALs to ensure reduced power consumption/thermal generation over it's predecessor.

Product Overview

1.7 Advantages and Features of the VMOD-2 PepCard

The VMOD-2 is an improved version of the original VMOD, which was designed with a major

objective in mind: to provide a low cost and easy to implement user configurable I/O interface

for industrial interface applications and/or space-savings in many different customer applications.

This result is a maximized choice of design flexibility. The VMOD-2 provides a very costeffective solution, with quick and easy implementat ion, and fu ll compatibil ity with the ex tensive

range of existing VMOD-piggybacks and the ability to accept the planed "enhanced" piggybacks of the second generation.

With the flexibility offered by the VMOD-2 and the exi sting range of indust rial I/O modules, you

are able to configure many complex and usually very intense interfaces, in a very quick and

compact way. This may be especially important when needing to add interfaces to an already

existing system, or where when using other products several additional slots or a larger rack/

sub-frames or additional power supplies/cooling, were needed/used with their financial overhead.

Now with the VMOD-2 you may replace several of these existing cards, or external interface

boxes, with a single VMOD-2, fitted with two piggybacks containing the desired interfaces,

and also offering the added feature of a local res et input.

1.7.1Features of the VMOD-2 Module

Features of the VMOD-2 are:

* Widest possible range of base address selection to allow up to thirty-two VMOD-2's to

be used in any one system. (Prev iou sly onl y eight origi nal VMOD's coul d be fi tt ed due to

their fixed base addresses).

* Each piggyback location now supports 11 address lines. (A1...A11 to each piggyback).

* Each piggyback location now has 8/16-bit Databus lines. (D0..D15 to each piggyback).

* Galvanic Isolation between each interface and to the VMOD-2's VMEbus circuitry

depending upon the piggybacks fitted.

* External Reset facility, can be used to cause "local-reset" of the VMOD-2's piggybacks.

* Two Individually configurable piggyback locations, with board ID byte for remote (soft-

ware) configuration identity checking.

* Compact size, VMOD-2 plus two piggybacks containing your chosen interface circuitry,

are all contained within standard single-height, single-slot PepCard dimensions. Choice

of interface connector options, so where needed the connection method can be kept

internal, i.e. via a 50-pin on-board connector.

* Easy maintenance (i.e. swap-and-test, reduce service down-time)

12/15/97

Page 1 - 8Man. ID 03139, Rev. Index 0200

Page 19

VMOD-2/VMOD-2D

Hardware Features:

* Full electro/mechanical compatibility with the existing VMOD piggybacks and with the

very latest VMOD-2 enhanced piggybacks.

* All necessary VMEbus lines are made available to each of the piggybacks.

* 2.5 kV Galvanic VME to external isolation (not on index 00 boards), and PB to PB inter-

faces supporting opto-isolated piggybacks and the opto-isolated external "local" reset

input circuits.

* Extended temperature ver sions of bot h the VMOD-2 and many of the currentl y availab le

piggybacks, allowing combinations suitable for harsh industrial environments to be con-

figured.

Product Overview

12/15/97

Page 1 - 9Man. ID 03139, Rev. Index 0200

Page 20

VMOD-2/VMOD-2D

1.8 Functional Block Diagram of the VMOD-2

Figure 1-3: Functional Block Diagram

50-way E xternal Interface(s)

Pi ns

25 & 26

Piggyback

F itte d

Acco rdin g

Type

Use r

I/O

To

Disable Jumper

In put Log ic &

Pins 27...50 for Upper Piggyback Pins 01...24 for Low er Piggyback

Extern a l Rese t

Product Overview

Piggyback

F itte d

Acco rdi ng

Type

Use r

I/O

To

Must be ord ered

an d fitted

UDTACK1

INTA1

CS1

INT 1

Local/PB

Control

Logic

(Lower Location)

Op ti on a l Ex tra

IDS 0 / ID S1

IAS

Control

Piggyback "B"

PB I. D . dat a

ID 0...15

IA 1...11

RESET

CLK

Address

Data

In terrupt Control

IRQ* Driver

Logic and

VMEbus

Local Reset

I/O Control

Logic

Must be ord ered

an d fitted

UDTACK0

INTA0

INT 0

CS0

Dec odi ng and

P iggyba ck Select

Address

(Upper Location)

Op ti on a l Ex tra

IDS 0 / ID S1

IAS

Piggyback "A"

ID 0...15

PB I. D . dat a

IA 1...11

RESET

CLK

Driver

Data Latch

Data

12/15/97

Including...

IACK*

DS1*

IRQ1*. . .7*

IA CKOUT*

LWORD*

IACKIN*

AM0...5

SYSRESET*

WRITE*

DS0*

AS*

Co ntro l

SYSCLK*

96-way VMEbus Interface Conne ctor

Ad d ress

Data

A24/A16: D16/D8

Sla ve VM Ebus

Interface

Page 1 - 10Man. ID 03139, Rev. Index 0200

Page 21

VMOD-2/VMOD-2D

Product Overview

1.9 Related Publications

For more information regarding the VMEbus, please refer to:

* The VMEbus Specification, Revision C.1.

For details regarding the VMOD-piggybacks (or VMOD-2-piggybacks) , please refer to the

respective products User's Manual.

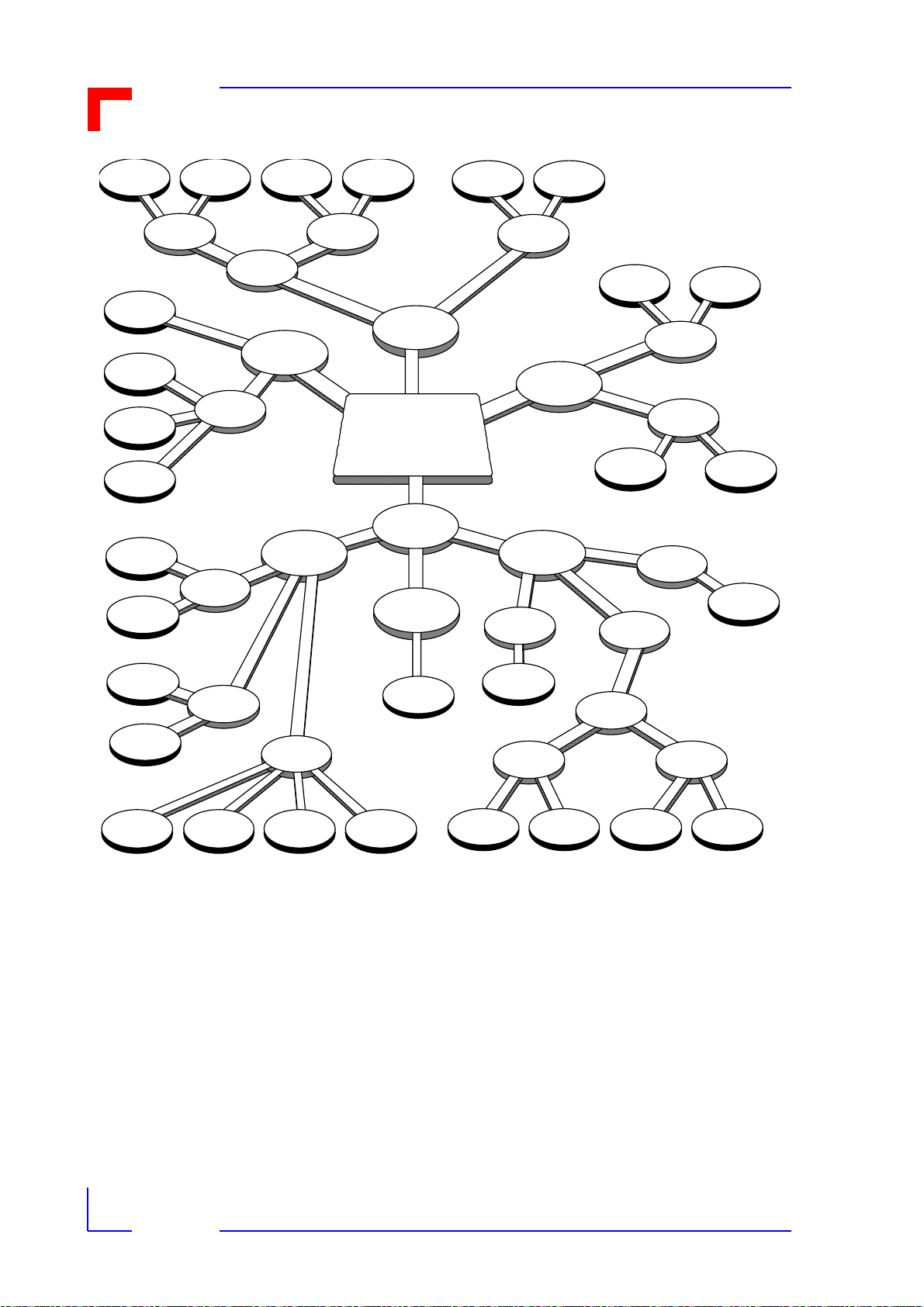

1.10Piggyback Selection Assistance

As there are so many different types of piggyback available for the VMOD-2, and many offer

different options such as common ground or Vcc for their inputs, etc. the following selection

help chart has been provided. It may be used in conjunction with the piggyback overview table

on the next page. The prototyping piggyback is not shown in this figure.

All grey edged "coins" are decisions or group titles, all black edged coins are actual product

names and order numbers.

12/15/97

Page 1 - 11Man. ID 03139, Rev. Index 0200

Page 22

VMOD-2/VMOD-2D

Figure 1-4: Piggyback Selection Chart

PB-DAC

fo r 0 -10 V

523-11

PB-DAC

fo r 0 - 8 . 1 92 V

523-11/1

PB-DAC2

for 4-20 mA

523-17

PB-DAC2

for 0-20 mA

523-17/1

ADC for

Voltage

523-28

Product Overview

ADC for

Curren t

523-28/1

8 x SPDT

8 Re lays

PB -R EL

523-26

5V

PB-STP

523-22/ 1

12V

PB-STP

523-22/ 2

24V

PB-STP

523-22

PB- CI O 20ch.

Change of State

523-19

PB- CI O 18ch.

Change of State

523-19/1

PB-DIN

for 5V (TT L )

523-14

PB- D IN2

for 12V-60V dc

523-24

DAC for

Voltage

Stepper

Moto r

Control

Change of

Stat e

Digi tal In

D to A

Converter

Industr ial

Control and

Swit c hing

In put

Counter

input

DAC2 for

Curren t

VMOD-2 piggyback

location (one of t wo) for

which an appropriate

Piggyback is sought

Analog

Digital

Output

PB-DOUT

for 5 -80V dc

523-25

A to D

Converter

Communications

I/O

(Select Volt age)

5V dc (TTL)

PB-DIO

CVcc in/CG ou t

523-13/ 1

PB-DIO2

for Cmn

Vcc In

PB -B IT

at 12 MHz

523 0 -1 1

PB -S IO4

non-isolated

523-15

Select

common mo d e

24V dc

BITBUS™

Cont roller

Serial I/O

4 x RS232C

5 - 80V dc

PB-DIO3

for Cmn

Gnd In

PB -B IT

at 16.67 MHz

5230-11/1

PB -S IO4

opt o-is o late d

523-15/1

PB- D IO4

C.G in /OCCE

523-27

PB-CNT

for 5V inputs

523-12/ 1

PB-CNT

fo r 1 2 V in pu t s

523-12/ 2

PB-CNT

fo r 1 5 V in pu t s

523-12/ 3

PB-CNT

fo r 2 4 V in pu t s

523-12

PB- D IO2

for Cmn Gnd out

523-16

PB- D IO2

fo r C mn Vc c o u t

523-16/ 1

PB- D IO3

for Cmn Gnd out

523-23

PB- D IO3

fo r C mn Vc c o u t

523-23/ 1

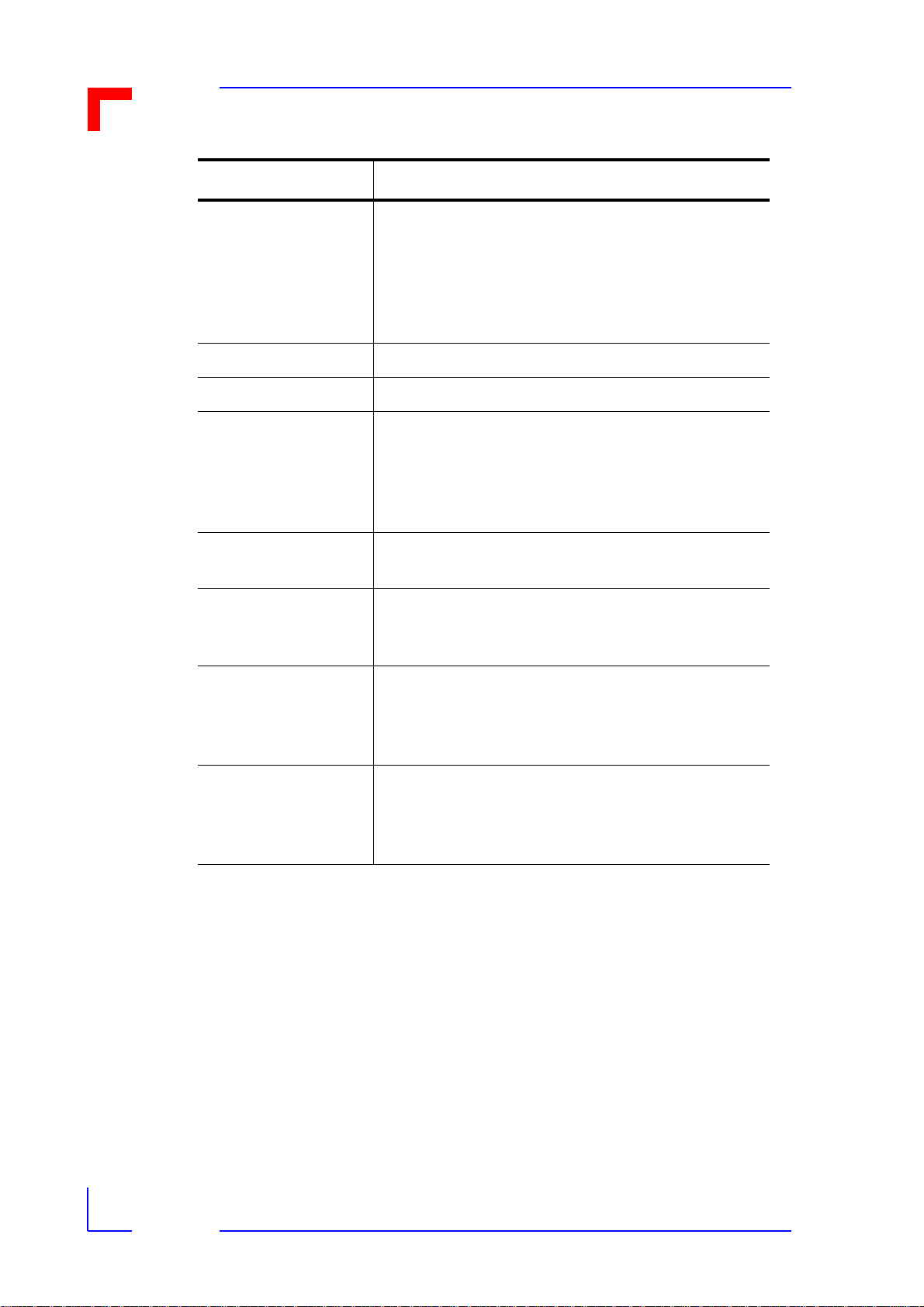

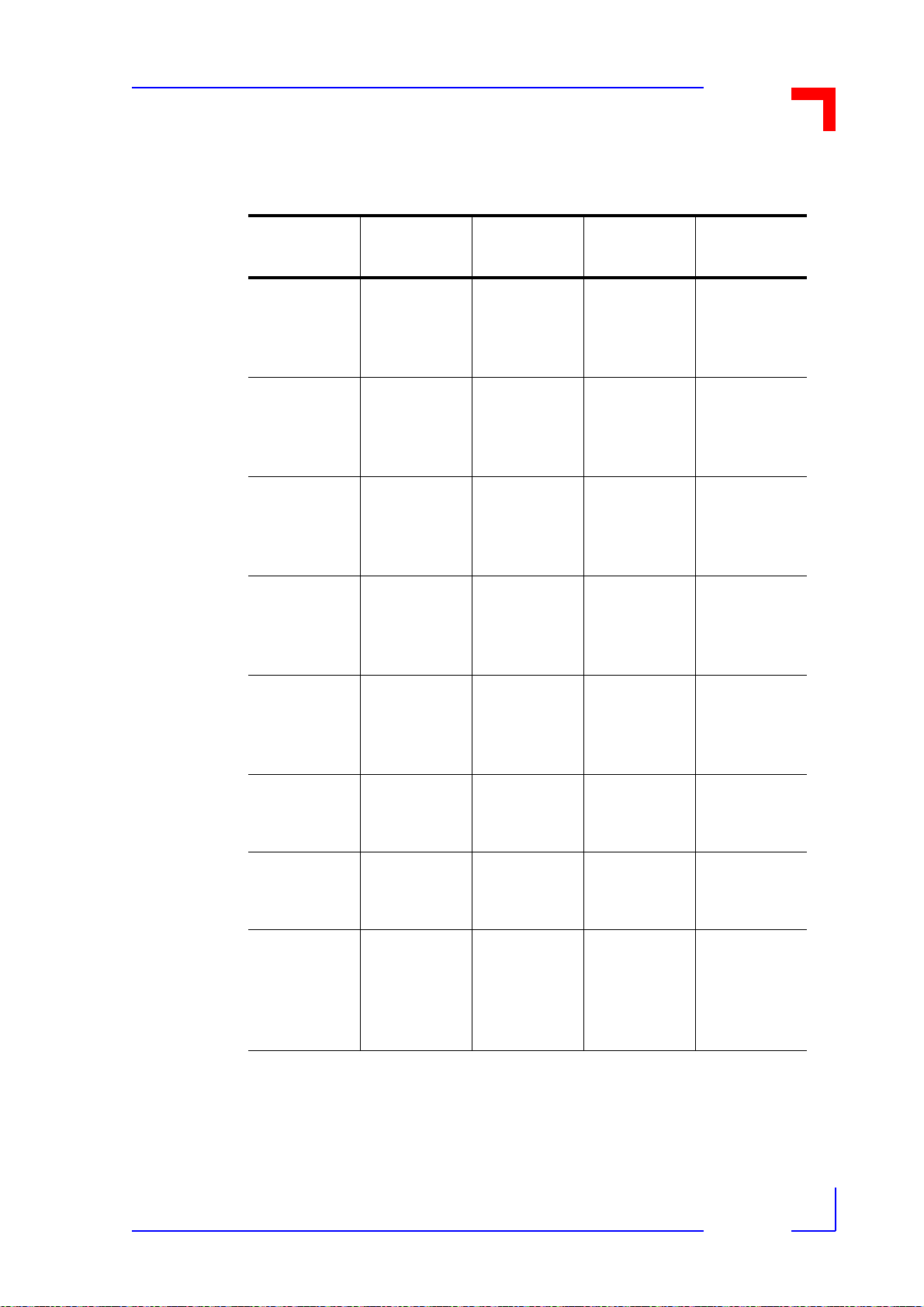

1.10.1VMOD/VMOD-2 Piggybacks Overview

Your VMOD-2 can accept any two piggybacks from those listed in the following table. Some

of the piggybacks have several different versions to allow their precise adaptation to your target application. i.e. The PB-DIO2 is av ailabl e with i t's outpu ts in a common gr ound o r common

Vcc mode. The differences are sh own by ital ics, braces and bracket s showing what char acte r-

12/15/97

Page 1 - 12Man. ID 03139, Rev. Index 0200

Page 23

VMOD-2/VMOD-2D

PB-Name

Brief

Description

Ch. @ V In

Ch. @ V

Out

Order #

istic is different in each order number type. The body text (normal) applies to all versions of

that piggyback type.

Table 1-4: Piggyback Overview

Product Overview

PB-DIO 20 Ch. Digi-

tal I/O with

68230 and

24-bit timer

PB-DIO2 20 Ch. Digi-

tal I/O with

68230 and

24-bit timer

PB-DIO3 20 Ch. Digi-

tal I/O with

68230 and

24-bit timer

PB-DIO4 16 Ch. High

Voltage Digital I/O

PB-DIN 20 Ch. Digi-

tal Input

68230 and

24-bit timer

10 ch. at 5V

/10mA opto,

Cmn Vcc

10 ch. 24V /

5mA opto,

Cmn Vcc

10 ch. 24V /

5mA opto,

Cmn Gnd

8 ch.12 to

80V / 5mA

opto CG in

pairs

20 ch. 24V

(5V) 10mA

opto CV

10 ch. at 5V/

10mA opto,

Cmn Ground

10 ch. 24V/

100mA opto,

CG (CV)

10 ch. 24V/

100mA opto,

CG (CV)

8 ch 5 to

80V/500mA

opto OC CE

in pairs

- 523-14

523-13/1

523-16

(523-16/1)

523-23

(523-23/1)

523-27

(523-14/1)

PB-DIN2 1 2 Ch. Hi-V

Digital Input

PB-DOUT 12 Ch. High

Voltage Digital Output

PB-CIO 20 Ch.

"Change of

State"

Z8536

Inputs

12 individual ch.s 12

to 60V 5mA

- 12 individ-

20 (18) CV

ch.s opto

24V/7.5mA

-523-24

ual ch.s 5 to

80V/500mA

(2 independant ch.

24V/5mA

opto)

523-25

523-19

(523-19/1)

12/15/97

Page 1 - 13Man. ID 03139, Rev. Index 0200

Page 24

VMOD-2/VMOD-2D

PB-Name

Brief

Description

Ch. @ V In

Ch. @ V

Out

Order #

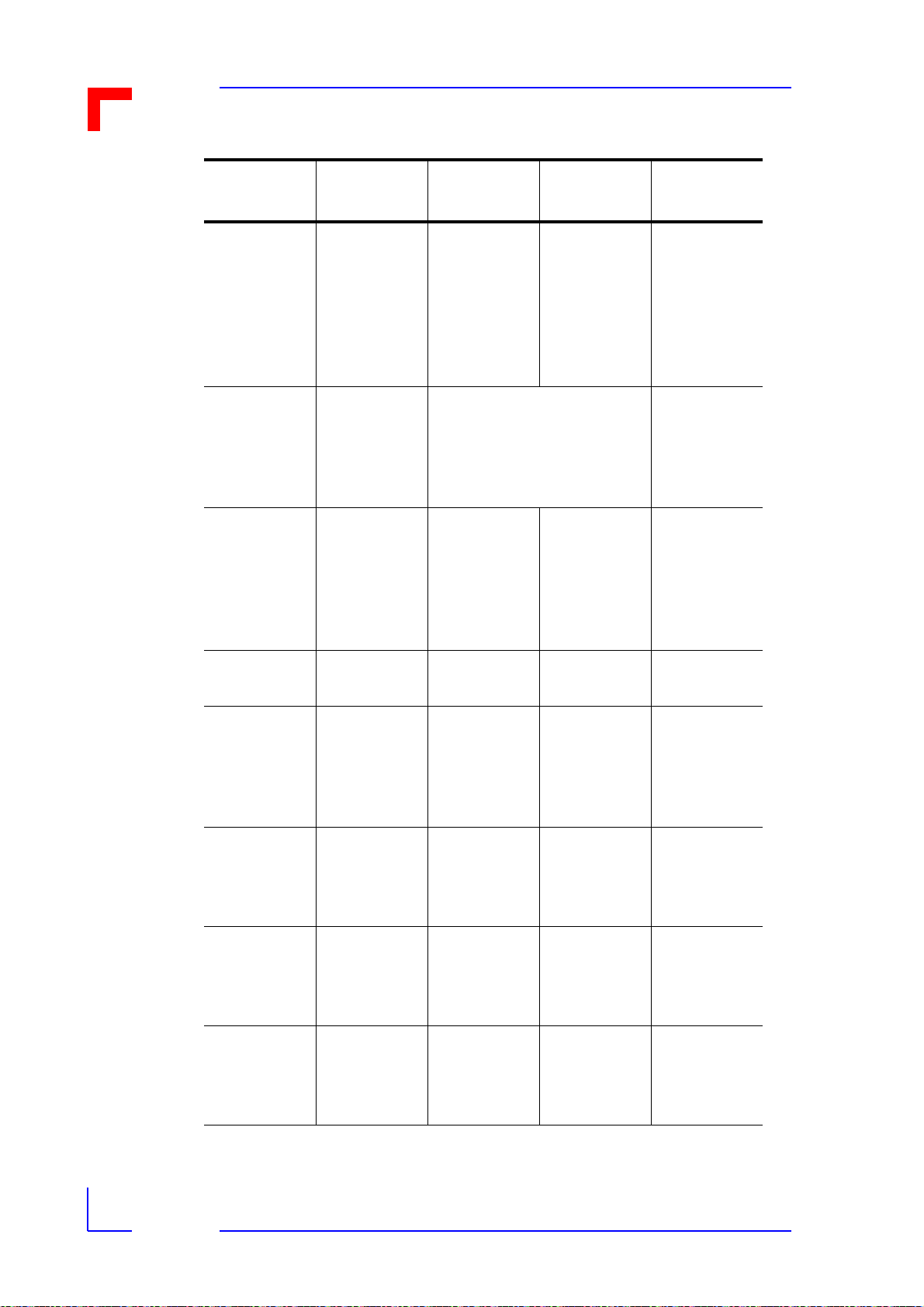

Table 1-4: Piggyback Overview

Product Overview

PB-CNT 2x32-bit or

4x16-bit

Counter, @

500 kHz

max. input

speeds.

PB-SIO4 Quad Serial

I/O 68681

RS232 +

RTS and

CTS

PB-STP Single Axis

multi-mode

Stepper

Motor Controller.

PB-REL Eight SPDT

Relays

2/4 opto-isolated

counter

inputs, 24V/

5mA (5V/

10mA)

[12V] {15V}

4 x RS232, non-opto (optoisolated)

6 control

lines @

24V (5V )

[12V ] /

11mA optoisolated

- 8 x galv.-

- 523-12

10 lines / 1

Axis 24V

(5V) [12V]

8mA optoisolated

isolated

(523-12/1)

[523-12/2]

{523-12/3}

523-15

(523-15/1)

523-22

(523-22/1)

[523-22/2]

523-26

PB-DAC 4 ch 12-bit D

to A Converter

(10µs )

PB-DAC2 4 ch 12-bit D

to A Converter

(10µs )

PB-ADC 4 ch 12-bit D

to A Converter

(10µs )

PB-ADC-2 8 ch 10-bit A

to D Converter

(16µs)

-4ch. 010V±10V

(0-

8.192V±8.1

92V)

- 4ch. 4-20

mA (0-20

mA)

8 ch. 010V±10V

8 ch. 0-20

mA

- 523-28

523-11

(523-11/1)

523-17

(523-17/1)

523-28/1

12/15/97

Page 1 - 14Man. ID 03139, Rev. Index 0200

Page 25

VMOD-2/VMOD-2D

PB-Name

Brief

Description

Ch. @ V In

Ch. @ V

Out

Order #

Table 1-4: Piggyback Overview

Product Overview

PB-BIT BITBUS™

Communications Controller

PB-PRM Prototyping User definable I/O accord-

CG = Common Ground, CV = Common Vcc, opto = optoisolated, and OC CE =

open colector-common emitter.

* = PB-BIT is not suited for use with the original VMOD. BITBUS is a registered

trademark of the Intel corporation.

80C152A. 12 (16.67)

MHz. (2.4 Mbaud Sync.)

1.5 Mbaud self-clocked. 2 x

1 KByte FIFO

ing to your own design

5230-11*

(5230-11/1)*

523-18

12/15/97

Page 1 - 15Man. ID 03139, Rev. Index 0200

Page 26

This page was intentionally left blank.

Man. ID 03139, Rev. Index 0200

Page 27

VMOD-2/VMOD-2D

Functional Description

Functional Description

2.1 VMOD-2 Address Map.......................................................... 2-1

2.1.1 Selection of the Address Block Widths......................... 2-2

2.1.2 Address Range of the VMOD-2.................................... 2-2

2.2 VMEbus Interrupts................................................................. 2-3

2.2.1 Interrupt Generation on the VMOD-2............................ 2-3

2.2.2 Interrupt Level Setting................................................... 2-3

2.2.3 Interrupt Vector Options................................................ 2-3

Chapter

2

2.2.4 Interrupt Vector Setting................................................. 2-4

2.2.5 Interrupt Vector Setting Examples................................ 2-4

2.3 External "Local" Reset Input ................................................ 2-5

2.4 ID Byte................................................. .... ..... ......................... 2-8

2.5 VMOD/VMOD-2 Connector Locations and Pin-Outs............. 2-9

2.5.1 VMOD-2 (VMOD/VME End) Piggyback Connector

BU1/0.................. ..... ............................ ..... .... ..... ......... 2-10

2.5.2 VMOD-2 External Interface Connectors BU2a and

BU2b................... ..... ............................ ..... .... ..... ......... 2-11

2.5.3 Pin Outs of the VMOD Front Panel Connector with Two

VMOD-2s............................................. ..... .... ..... ......... 2-13

12/15/97

Page 2 - 1Man. ID 03139, Rev. Index 0200

Page 28

VMOD-2/VMOD-2D

Functional Description

2. Functional Description

The VMOD-2 is a very simple and compact Modular Base-board accepting any two VMODPiggyback sub-modules for user-configurable I/O in any VMEbus system. It is better suited for

use in conjunction with other VMOD-2's in a VMEbus system than the original VMOD, which

only had eight different ba se addresses. This cha pter will descr ibe the " physic al" in ter faces of

the VMOD-2, and the function of the external "local" reset interfaces.

Although this manual contains references to some VMOD piggybacks, you are asked to refer

to the piggyback's own user manuals for comprehensive and up to date information regarding

the individual piggyback products.

The VMOD-2 is designed to function as a slave module (any slot other than slot 1) in any 3U

or 6U VMEbus system. in 6U (double-height) systems it is fitted in the upper backplane connector (P1, J1).

2.1 VMOD-2 Address Map

The VMOD-2 is addressed by setting appropriate jumpers for each selectable Address-line

and/or the setting of an address modifier jumper (B03) to specify the desired addressing

mode. A further jumper B16 can be set to provide increased address block widths when using

the VMOD-2 with newer piggybacks using the additional address lines A7...A11. The first piggyback (upper location) is always available at the base address and the second piggyback

(lower location) is available at base address plus either offset $80/$81 or $1000/$1001, subject to selected address block widths.

All existing "VMOD" (523-xx) piggybacks use the address l ines A1.. .A6. Any new 5230-xx piggybacks (VMOD-2 only types) use not only the address lines A1...A6, but als o A7...A11 which

are provided on the VMOD-2 only.

Remember!

Any existing and/or new piggybacks with a "523-" order number, can be

used on either an original VMOD or a VMOD-2, and when used on a

VMOD-2 may be used in either 256 Byte or 8 KB yte address block widths.

Any new piggybacks with a "5230-" order number (only suitable for

VMOD-2 use) with the address block width of 8 KBytes. A VMOD-2 can

have a mix of old and new piggybacks fitted provided the address block

width is set for the increased 8 K Byte addressing mode, i.e. jumper B16

must be set.

Via the address offsets, the user can address specific piggyback devices (i.e. SCCs) by writing to the selected VMOD-2's base address plus an offset of the appropriate value (see specific piggyback user's manual).

Example of offsets where two PB-RELs are fitted to VMOD-2.

12/15/97

Page 2 - 2Man. ID 03139, Rev. Index 0200

Page 29

VMOD-2/VMOD-2D

Configuration for base add ress rang e $FE2400 to $FE24F F

Addressing piggyback (i.e. PB-REL) fitted in location A (the upper position on VMOD-2)

Functional Description

• VMOD-2 BASE ADDRESS+$41= PB-REL's ID Vector (read only)

• VMOD-2 BASE ADDRESS+$01= PB-REL's 8-bit output port Register

(read/write)

Addressing piggyback (i.e. PB-REL) fitted in location B (the lower position on VMOD-2)

• VMOD-2 BASE ADDRESS+$C1/$1041* = PB-REL's ID Vector (read

only)

• VMOD-2 BASE ADDRESS+$81/$1001* = PB-REL's 8-bit output port

Register (read/write)

* Actual offset for lower piggyback is subject to the setting of jumper B16 and could be $10xx

if a 5230-xx piggyback is fitt ed in to the up per pi ggyb ack locat ion, and jumper B16 is set . I. e. 8

KByte address width is required.

Table 2-1: Default Setting of the VMOD-2 Base Address

VMOD-2 Jumpers B02 B12 B13 B14 B15 B16 Base Address

Default Settings Set Set Open Set Set Open $FE2400

Address Lines A15 A14 A13 A12 A11 in

256

Byte

block

A jumper set results in the related address line being assigned a logical low (0) function.

2.1.1Selection of Address Block Widths

As mentioned in the preceding section, an important aspect regarding the use of the VMOD-2

is the option of block size selection, which must be taken into consideration when using the

VMOD-2 in certain configurations and/or applications.

When using the VMOD-2 to replace an existing VMOD (as a one-to-one direct replacement),

the VMOD-2 should be set to the narrower address range of 256 Bytes by opening the jumper

B16. This ensures that the VMOD-2 presents an address width of only 256 Bytes identical to

the old VMOD, and uses offsets of $01 and $80 for the two piggyback locations.

No new "5230-xx" piggybacks should be added to the VMOD-2 when used as a replacement

for an older VMOD since when jumper B16 is open the enhanced (5230-xx) piggybacks will

not have the use of additional address lines A7...A11 and will not therefore function correctly.

Where using existing piggybacks and a VMOD-2 to substitute an older style VMOD, we rec-

12/15/97

Page 2 - 3Man. ID 03139, Rev. Index 0200

Page 30

VMOD-2/VMOD-2D

Jumper B16 Setting

Set

Open

ommend the jumper B16 is removed, which will ensure that your software will address both

piggybacks correctly without any need of modification.

Functional Description

Table 2-2:Address Block Widths According to Jumper B16 Setting

VMOD-2's Address Block Width 8 KByte 256 Byte

Upper Piggybacks add ress offset $00/$01 $00/$01

Lower Piggybacks add ress offset $1000/$100 1 $80/$81

Address lines available t o piggy-

backs

Special note!

The user's manuals for various piggybacks currently in existence, will

continue to give details of their address offsets based on the 256 Byte

address block spacing as described above. You can of course use the

new 8 KByte spacing with all "523-xx" piggybacks, by simply increasing

the offset from $80/$81 to $1000/$1001 for p iggyback location B .

A1.....A11 A1....A6

2.1.2Address Range of the VMOD-2

Using the address widths given before, you are able to select from either thirty-two 256 Byte

wide addresses, or from eight 8 KByte wide addresses,. i.e. your system can have 32 or eight

VMOD-2s fitted subject to your address configurations. The address selection is acheived by

decoding the state of five jumpers, B2, B12, B13, B14 a nd B15. Where a jumper Set returns a

logical 0 for the respective address line and a jumper Open returns a logical 1 for the respective address line.

A full listing with all address setting permutations is given in section 3.1.6.

2.2 VMEbus Interrupts

2.2.1Interrupt Generation on the VMOD-2

Each piggyback on the VMOD-2 is able to request/generate interrupts between levels 1 to 7.

However the VMOD-2 will only be set for one level of interrupt for use on the VMEbus.

For each request from pigg ybacks , I NT0* for pi ggyback lo cati on "A " and I NT1* f or " B", t here is

an acknowledge signal, INTA0* and INTA1* respectively. If two simultaneous interrupts are

detected, the one which is first will disable any handling of the other until its been dealt with

itself.

2.2.2Interrupt Level Setting

As mentioned above the user can set his VMOD-2 to use any IRQ level from 1 to 7 as appropriate to his VMEbus systems application. The selection of these levels is subject to the set-

12/15/97

Page 2 - 4Man. ID 03139, Rev. Index 0200

Page 31

VMOD-2/VMOD-2D

Dumb

Dumb

Dumb

Dumb

Dumb

Dumb

Int Fixed

Int Fixed

Int Progr

Int Progr

Int Progr

Int Progr

Int Progr

Int Progr

Int Progr

Int Progr

ting of three jumpers B17, B18 and B19, where when all three are set the IRQ from the

VMOD-2 is disabled. See section 3.1 (jumper configuration) for detailed settings.

Functional Description

2.2.3Interrupt Vector Options

The user can select between several different ways to use his VMOD-2's Interrupt Vectors as

the VMOD-2 is provided with a jumper (B1) with three different possibilities. See section 3.1

(jumper configuration) for detailed settings.

1). Vector can be generated by either or both piggybacks, if these pig gybacks are intel ligent

enough. Most are.

2). Vector can be generated by the VMOD-2, using preset jumper coding, where non-intelli gent piggybacks are being fitted. In thi s mode a furt her opt ion to as sig n both piggyb acks

the same vector is provided by the setting of a three-pin jumper B11.

3). Vector can be generated by the lower piggyback ("B") and derived from jumper settings

on the VMOD-2 for a non-intelligent pi ggyba ck fitted into the up per pi ggyba ck ("A") loc ation.

The features of some piggybacks you may wish to use on your VMOD-2 are:

Table 4-3: Possible Piggybacks for VMOD-2

PB-DAC D to A converter piggyback

PB-DAC-2 D to A converter piggyback

PB-DIN2 Digital input piggyback

PB-DIO4 Digital I/O piggyback

PB-DOUT Digital output piggyback

PB-REL Octo-Relay piggyback

PB-ADC A to D converter piggyback

PB-CNT Counter piggyback

PB-BIT BITBUS™ communications piggy-

back

PB-CIO Counter/I/O piggyback

PB-DIN Digital Input piggyback

PB-DIO Digital I/O piggyback

PB-DIO-2 Digital I/O piggyback

12/15/97

PB-DIO-3 Digital I/O piggyback

PB-SIO4 Quad serial piggyback

PB-STP Digital I/O piggyback

Dumb = no on-piggyback vector generation ability .

Page 2 - 5Man. ID 03139, Rev. Index 0200

Page 32

VMOD-2/VMOD-2D

Interrupt Vector Bit

Jumper Numbers

Example Setting # 1

Upper PBs Vector

Lower PBs Vecto r

Example Setting # 2

Upper PBs Vector

Lower PBs Vecto r

Example Setting # 3

Upper PBs Vector

Lower PBs Vecto r

Int Fixed = Vector is pre-fixed on-board the piggyback

Int Progr = programmable vector on piggyback

Functional Description

2.2.4Interrupt Vector Setting

As described before, the user can set his VMOD-2's Interrupt Vectors as appropriate to his

VMOD-2/Piggyback configurations needs. The selection of these vectors is subject to the

binary code of bits D0.. .D7 as derived by the setting of jumpers B11 to B4 respective ly. B11 is

a three-pin type and can provide an identical or different vector for the two piggybacks. Three

examples are given below where jumper B1 must be set to 1-2 to use these vectors.

Table 2-4: Interrupt Vector Selection

D7 D6 D5 D4 D3 D2 D1 D0

B04 B05 B06 B07 B08 B09 B10 B11

Open Open Open Open Set Open Set 1-3*

F4

F5

Open Open Open Open Set Open Set 1-2*

F4

F4

Open Open Open Open Set Open Set Open

F5

F5

* = If jumper B11 is set for 1-3, D0 will return a "0" for piggyback "A" and a "1" for

piggyback "B".

When jumper B11 is set to 1-2 the vector of both piggyback locations "A" and "B"

will be the same (so D0 = 0).

When jumper B11 is open the vector of both piggyback locations "A" and "B" will

also be the same (but D0 = 1).

12/15/97

Page 2 - 6Man. ID 03139, Rev. Index 0200

Page 33

VMOD-2/VMOD-2D

#

Configuration

Vector

Modes

B1 Settings

B4...B11

Settings

Functional Description

2.2.5Interrupt Vector Setting Examples

The following examples are provided to help VMOD-2 users to quickly understand when and

how to set his VMOD-2's Interrupt Vectors as appropriate to his VMOD-2/Piggyback configurations needs.

Table 2-5: Interrupt Vector Configuration Examples

1). Two "intelligent" pi ggyback s

(both able to generate interrupt vectors) are fitted to the

VMOD-2 to use their own generated vecto rs.

2). Two "Dumb" piggybacks

(both unable to gener ate

interrupt vectors) are fitted to

the VMOD-2 and ne ed

VMOD-2's set vectors.

3). One "intelligent" and one

"Dumb" piggyb ack are to be

fitted to the VMOD-2 and the

user wants th e intell igent pi ggyback to use it's on-board

"Intelligent" vector generation

in combination with "Dumb"

jumper coding.

Use Piggyback Generated Vectors

Use VMOD-2

Jumper set

Vectors

Use the

"Dumb" piggyback in

upper location, and fit

the "intelligent" one in

lower location.

2.3 External "Local" Reset Input

Jumper B1 is

left open.

B1 is to be

set to 1-2.

B1 is to be

set to brid ge

pins 1-3.

Jumpers

B4...B11 ar e not

decoded and can

be left in any setting.

Jumpers

B4...B11 are set

for appropriate

byte coding.

Jumpers

B4...B11 are set

for desired vector

code to be

assigned when

piggyback "A"

makes an IRQ.

A new feature of the VMOD-2 is the ability to cause a "local" reset to the on-board pi ggybacks

from two (previously unused) pins on the front panel connector. These pins accept external

voltages between +5V min. and +48V max, across each VMOD-2.

Set jumper B20 to 1-2 if an external reset facility is n ot required.

The principals of the local reset input circuit are, that an opto-coupler is monitored for an

external presence of current i n through pin 26 and out to ground via pin 25 of the 50-way connector. If the flow of current is interrupted at any time, e.g. by disconnection of connectors,

pressing a stop button, etc., the "local" reset is act ivated.

This facility may be enabled by setting the three- pin B20 jumper (li nking jumper pins 1-3). Otherwise the VMOD-2 is delivered with this jumper set to 1-2, which is particularly important

when using the VMOD-2 to replace an existing VMOD and not wanting to modify cables.

12/15/97

Page 2 - 7Man. ID 03139, Rev. Index 0200

Page 34

VMOD-2/VMOD-2D

Functional Description

The External Reset is limited to the VMOD-2 and it's piggybacks, and will not reset the VMEbus unless your application software demands it to. I.e. via the polling of an output register to

detect a "reset" state.

Special note!

There can be occasions when spurious interrupts are caused with the use

of the "local" reset facility.

This can happen when a VMOD-2 IR Q is cleared by the local re set before

the VMEbus system h as had a chance to clear the interrupt itself.

The two-pins (25 and 26) of the 50-way front panel connector, can be used to detect the following external events;

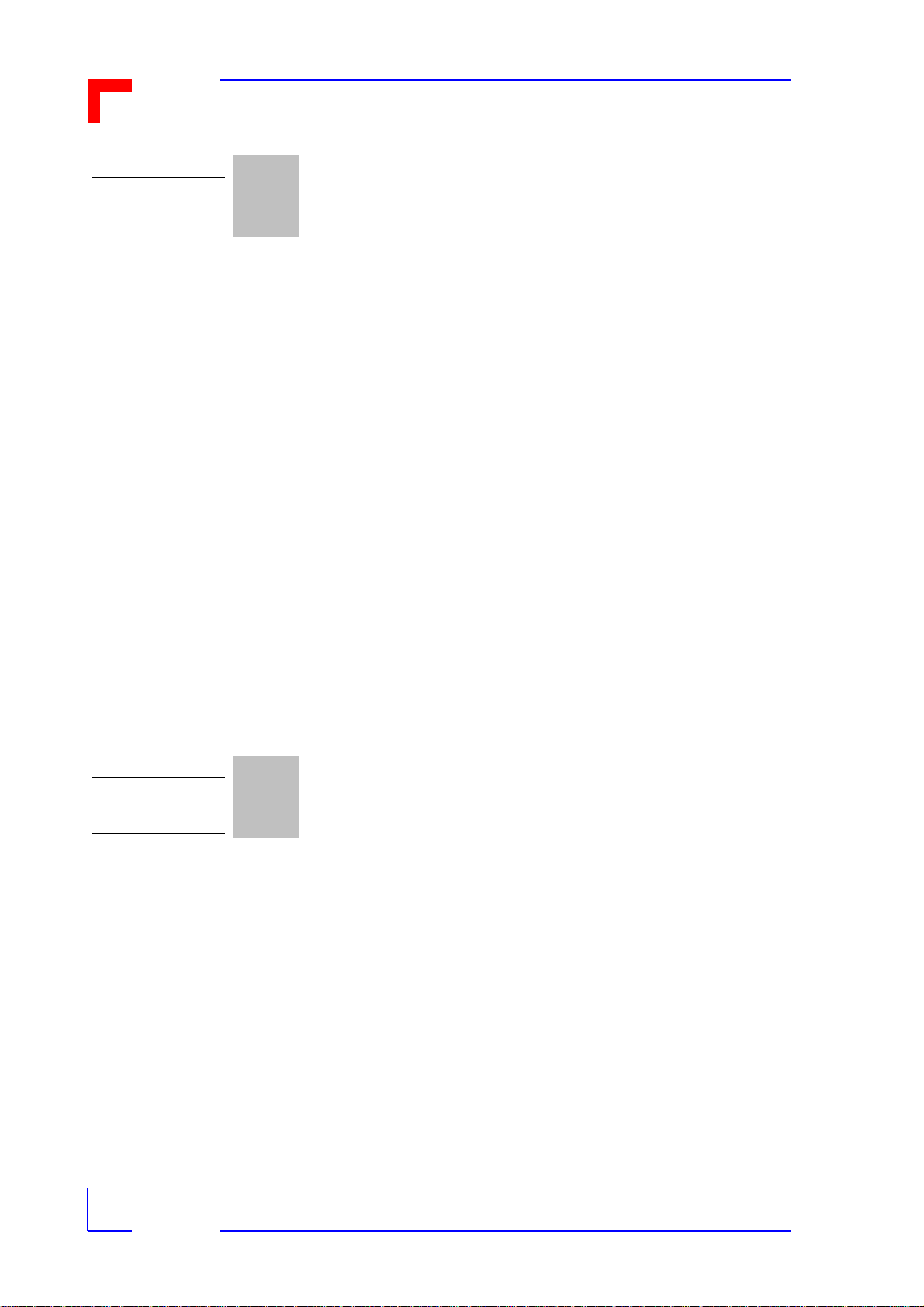

Figure 2-1: External Reset Connection — Example 1

1).

VM OD

2

Bre a ki ng ei th er of t hese connectors

causes a local reset to the VMOD-2

Detect breaking of any intermediate connectors between VMOD -2 and exte rnal

device.

Machin e

Vcc

Upper

pig gybac k

0V or

Lower

pig gybac k

In this kind of mode their two wires are

joined to Vcc and Gnd at the furth est end.

Gnd

12/15/97

Page 2 - 8Man. ID 03139, Rev. Index 0200

Page 35

VMOD-2/VMOD-2D

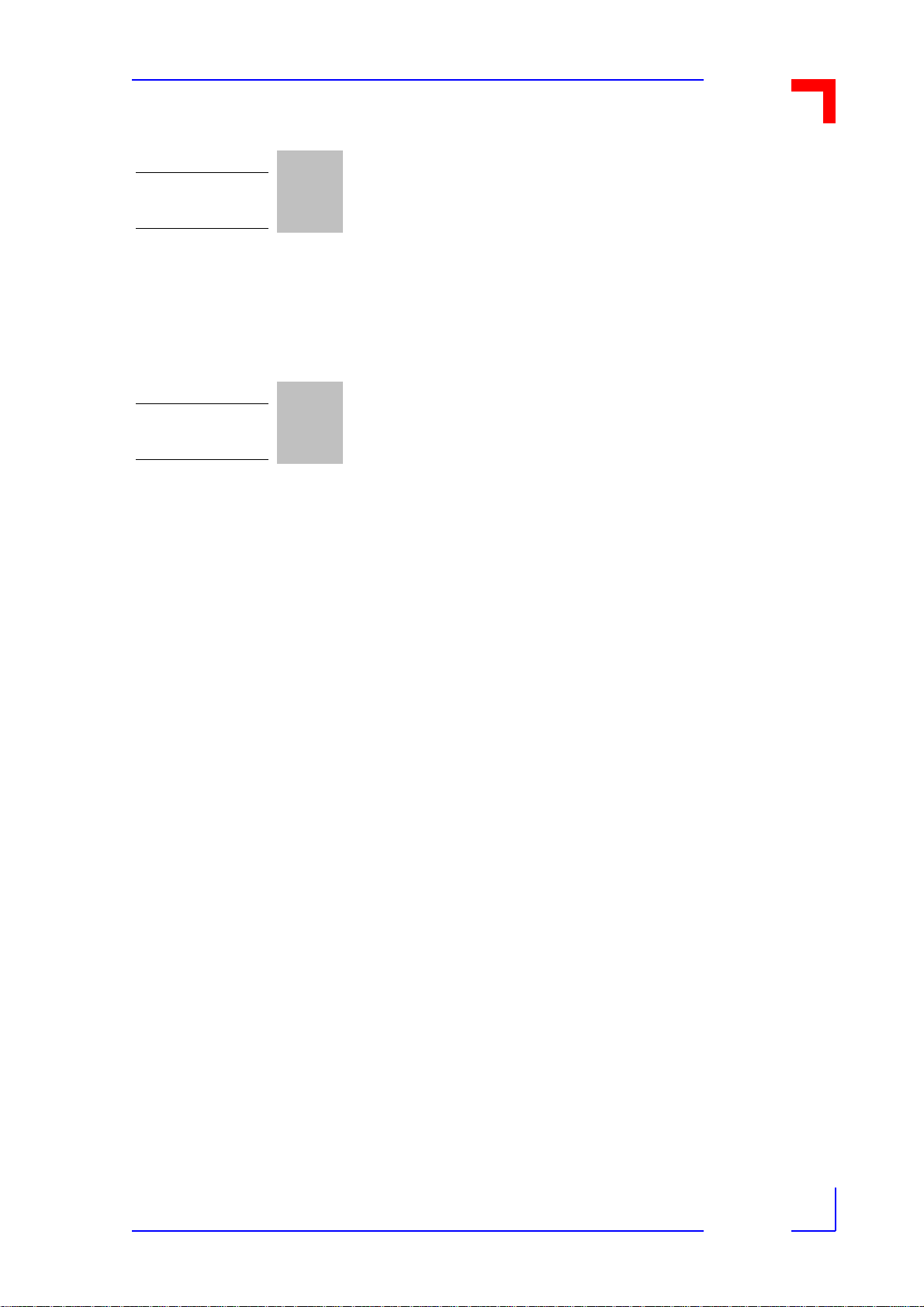

Figure 2-2: External Reset Connection — Example 2

Functional Description

2).

VM OD

2

Sa fety cage door holding N O switch

clo sed . Openin g do o r ( switch) will

cause a local reset to the V MO D-2

Detect the opening of safety-cage doors of

any external device under VMO D-2's control.

Machin e

Vcc

Upper

pig gybac k

0V or

Lower

pig gybac k

The two wires are at tached through "NO"

terminals of the switch, which automatically

opens when the doo r becomes "Uns afe"

(opened).

Gnd

12/15/97

Page 2 - 9Man. ID 03139, Rev. Index 0200

Page 36

VMOD-2/VMOD-2D

Figure 2-3: External Reset Connection — Example 3

Functional Description

3).

VM OD

2

Pr essin g eith er of these but t o n s w ill

cause a local reset to the V MO D-2

Machine

Upper

pig gybac k

Lower

pig gybac k

Vcc

0V or

Gnd

Pseudo "emergen cy stop" bu tton chain for

manual intervent ion, i.e. during mot or control applicatio n develop ment.

In this kind of mo de the ir two w ires bein g

daisy chained thr ough sever al NC

switches, and joined to Vcc and Gnd at the

most distant end.

12/15/97

Page 2 - 10Man. ID 03139, Rev. Index 0200

Page 37

VMOD-2/VMOD-2D

Figure 2-4: External Reset Connection — Example 4

Functional Description

4).

Machine #2

Pin-26

Pin-25

Upper

pig gybac k

Vcc

Reset

Logic

Machine #1

0V or

VM OD

2

I f mach in e 2's reset lo g ic turns reset loop su pply

off, or bu tton p re ssed bo t h V M OD- 2s will reset

VM OD

2

Lower

pig gybac k

Gnd

To synchronize the reset of two (or mo re)

VMOD-2s (see voltage notes on next

page).

The two wires ar e daisied throug h two

VMOD-2s and the NC switch/logic before

being joined to Vcc and Gnd at th e most

distant end.

Note: in example #4, the applied Vcc from machine #2 must be at least

+10V to work the two V MOD-2s co nnec ted in series, Th is doe s not inclu de

p.d. on length of lea ds, connector con tact resistance, etc.

2.4 ID Byte

An extremely important feature of the VMOD-2 is the ability to "ask it" per software what piggybacks are on board. Remembering that once configured and fitted one VMOD-2 is indistinguishable from others configured differently. Via this built-in identification feature you can

interrogate the VMOD-2 to return an ID for each of the fitted piggybacks, and if this is integrated into your application software, may be used to check that any given tasks is valid for

the fitted piggyback before execution.

The VMOD-2 can be tested per software in order to determine what type of piggybacks is fitted. If jumper B16 is not set it is offset $7F (location A) and offset $FF (location B), with

jumper B16 set it is $107F (location A) and $10FF (location B). Where our "example" VMOD2 fitted with two PB-RELs, would return a "$FC" Byte for both locations.

12/15/97

Page 2 - 11Man. ID 03139, Rev. Index 0200

Page 38

VMOD-2/VMOD-2D

$EE

$EF

$F0

$F1

$F1

$F2

$F3

$F4

$F5

$F7

$F8

$F9

$FB

$FC

$FD

$FE

Some ID Bytes you may come across when interrogating your VMOD-2 for it's configuration

are:

Functional Description

Table 2-6: ID Bytes

PB-BIT BITBUS™ Commun ications pi ggyback

PB-DIO4 Digital I/O piggyback

PB-CNT Counter piggyback

PB-DAC D to A converter piggyback

PB-DAC-2 D to A converter piggyback

PB-DIO Digital I/O piggyback

PB-DIN Digital Input piggyback

PB-ADC A to D converter piggyback

PB-CIO Counter/I/O piggyback

PB-SIO4 Quad serial piggyback

PB-DOUT Digital Output pi ggyback

PB-DIN2 Digital Input piggyback

PB-DIO-2 Digital I/O piggyback

PB-REL Octo-Relay piggyback

PB-DIO-3 Digital I/O piggyback

PB-STP Digital I/O piggyback

As piggybacks are being continually added to the VMOD-2 range, we recommend you check

each employed VMOD/VMOD-2 piggyback's user manual for pr eci se infor mation re gardi ng its

individual ID Byte assignment.

BITBUS is a registered Trademark of the Intel corporation

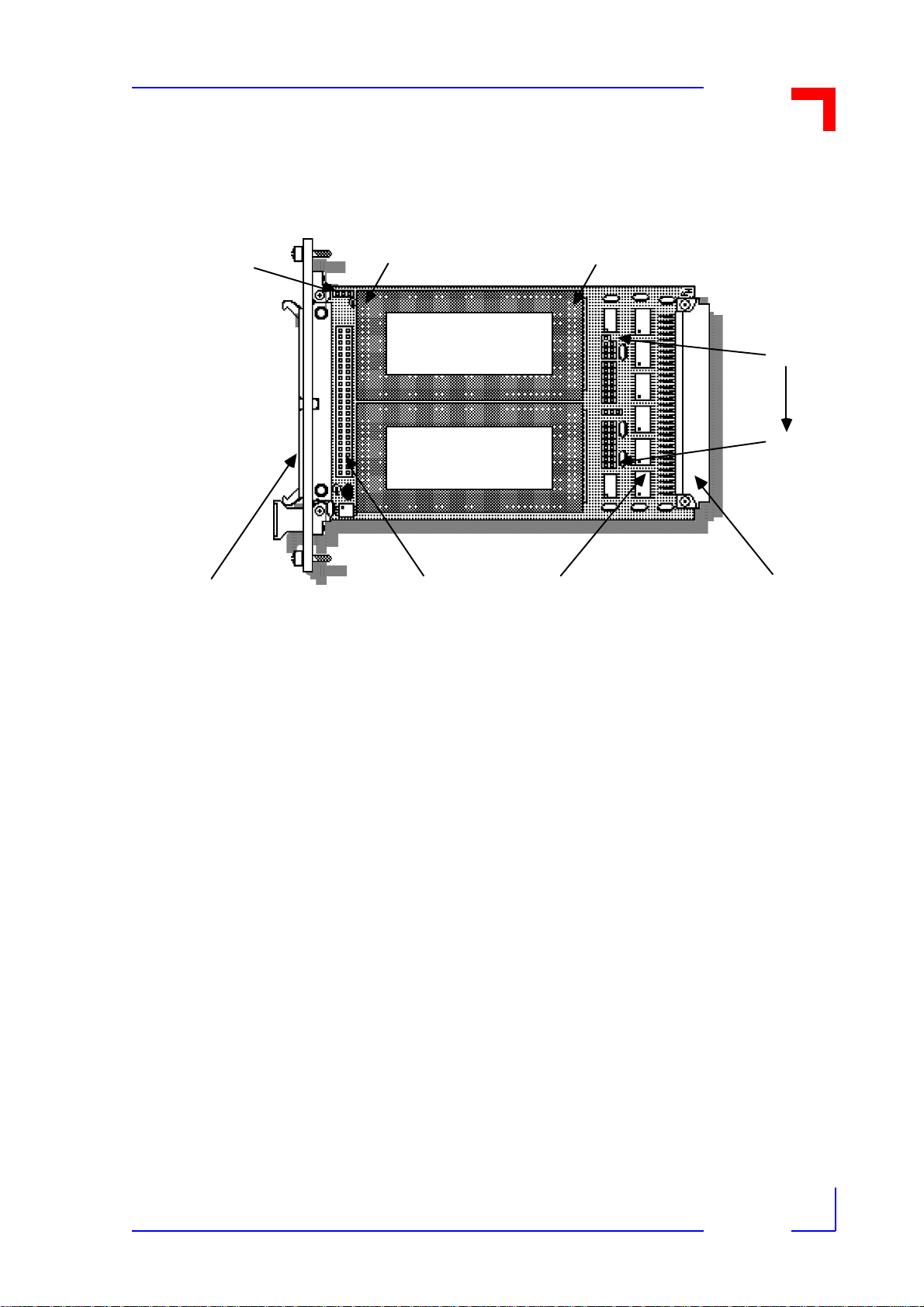

2.5 VMOD/VMOD-2 Connector Locations and Pin-outs

This section serves to give an overview of the piggyback interface connectors at both the

VMOD-2's VMEbus end and the VMOD-2's (piggyback's) external I/O. Figure 2.4 shows an

example configuration where two piggybacks are to be fitted to your VMOD-2, the first fits in

the upper position (Position A), and the second, is fitted in the lower (B) position. This section

commences with the two header type connectors (BU1a/BU1b and BU0a/BU0b) of the

VMOD-2 which directly interface to the selected piggyback's ST1 and (where 3-row/45-pin

interfaces are used) ST0 pin rows.

The lower case letters in the socket numbers refer to which piggyback location the connector

is used for, i.e. BU1a is socket 1 for piggyback location A. An illustration giving details of all

the VMOD-2's connectors is given below.

12/15/97

Page 2 - 12Man. ID 03139, Rev. Index 0200

Page 39

VMOD-2/VMOD-2D

Caution!

When using the VMOD/VMOD-2 with any piggyback, take care to note

that the terms ST1 and ST 2 used in the piggybacks user's manual and

circuit diagrams, refer to the connectors of the Piggyback and equate to

their Plug 1 and Plu g 2 (ST from the German word "Stecker") these fit to

BU1a and BU2a or BU1b and BU2b (BU = "Buchse" = Socket) on the

VMOD/VMOD-2.

This is very important as the VMO D/VMOD-2 also have Plugs called ST1

(VMEbus connector) and ST2 (50-way header) which have no direct relationship to those of the piggybacks circuit diagrams as attached to the

piggyback user's m anual.

Look for the front connector overview in each VMOD-piggybacks user's

manual, before making any interfa ce leads/connections, a nd use with due

caution, especially where high external voltages or unprotected external

supplies are to be co nnected.

Functional Description

Figure 2-5: Overview of VMOD-2's Connector Locations

BU2a 26-way, 2-row

p i g g y bac k socke t for

upp e r piggyback

ST3 front p anel

connector (50-w a y)

— or —

ST 2 on- b oard

50-way header

BU2b 26-way, 2-row

p i g g y bac k socke t for

lower piggyback

BU1 a/BU0a 30/45-way

2/ 3 - row upper

pig gybac k s ocket

BU1 b/BU0b 30/45-way

2/3-r ow lower

pig gybac k s ocket

2.5.1VMOD-2's (VMOD/VME End) Piggyback Connector BU1/0

ST 1 VMOD -2's

VM E bus 96-way

connector (P1, J1)

12/15/97

The front two-rows of the three-row 30/45-pin sockets (BU1 and/or BU0) are used

by all VMOD/VMOD-2 piggybacks. Some piggyback's, having three-row headers,

also use the third row, BU0a or BU0b. The use of the third row does not however

define a piggyback as being only suitable for use on the VMOD-2, as the original

VMOD also had these third rows, and several existing VMOD-piggybacks use signals on the third row which are found on both the VMOD and the VMOD-2. Previously unused pins in the third row (BU0) are now fully utilized by the VMOD-2 and

Page 2 - 13Man. ID 03139, Rev. Index 0200

Page 40

VMOD-2/VMOD-2D

BU1 Connector

BU0 Connector

Signal

Pin #

Pin #

Signal

Pin #

Signal

to help see which pins are only on the VMOD-2, we have shown these additional

lines in bold/italics.

Functional Description

Table 2-7:

+5V (Vcc) 2 1 GND 1 GND

-12V 4 3 +12V 2 IA8

CLK 6 5 R /W* 3 IA9

UDTACK

n*

CSn* 10 9 INTAn* 5 IA11

IA71211INTn*6 IDS1*

IDS0*1413ID77 ID15

IAS* 16 15 ID6 8 ID14

IA61817ID59 ID13

IA5 20 19 ID4 10 ID12

VMOD/VMOD-2

8 7 RESET* 4 IA10

BU1/0 Connector Pin-Outs

IA4 22 21 ID3 11 ID11

IA32423ID212ID10

IA22625ID113ID9

IA12827ID014ID8

+5V (Vcc) 30 29 GND 15 GND

Notes:

1). All signals marked with an "*" are Active Low.

2). Lower case "n" used with some signal lines above is for the location identifier 0 or 1, where 0 = signal for upper piggyback location and 1 = lower piggyback location.

3). ±12V is only needed by some piggybacks, and will only be available if your

VMEbus backplane is connected to a PSU capable of supplying such voltages.

4). The orientation of the pin-number columns in the above connector overview

(and that of the connector overview on the next page) rel ates to the pin- positions of the VMOD-2 when viewed as shown in figure 2.5 on the preceding

page. I.e. their pin number 1s are top-right.

12/15/97

Page 2 - 14Man. ID 03139, Rev. Index 0200

Page 41

VMOD-2/VMOD-2D

VMOD-2 50-Way ST2/ST3 Pins as Used When a Selected Piggyback is

Fitted into the BU2 for Upper Location (A)

BU2 Pin #

VMOD-2 50-Way Pins Used When Piggyback is

Fitted into the BU2 for Lower Location (B)

Remember!

If any of the piggybacks you wish to use need any of the signals shown

bold/italic above (i.e. a 5230-xx typ e), a VMOD-2 set for an 8 KByte wide

address area must be used. Any piggyback not needing these additional

lines can be used on the VMOD-2 in either a 256 Byte or 8 KByte address

width setting.

Functional Description

2.5.2VMOD-2 External Interface Connectors BU2a and BU2b

The twenty-six pin double row sockets are totally isolated from the remaining circuits of the

VMOD-2, and only connect the input/output side of the respective piggybacks 26-pin I/O

header directly to the upper or lower half of the 50-way VMOD-2 front panel connector.

The actual pins used are subject to the design of the piggyback, but the pin interconnections

between the two BU2 connectors and the 50-way front panel connector will always be the

same. To determine what pin -s your si gnals wi ll a ppear on when using any re ady made pigg yback, please see the piggyback's user manual which will give precise details of the external

interfaces for use in both l ocations. If fault-tracing or designing your own piggybacks, the relationship of the respective piggyback locations (inputs/outputs) to the external connector is as

given in the table below.

Table 2-8: ST2/ST3 Connector Pin-Outs

50 24 2 1 24 50

47 21 4 3 22 48

45 19 6 5 20 46

43 17 8 7 18 44

41 15 10 9 16 42

39 13 12 11 14 40

37 11 14 13 12 38

359 16151036

337 18178 34

315 20196 32

293 22214 30

271 24232 28

49 23 26 25 23 49

12/15/97

Page 2 - 15Man. ID 03139, Rev. Index 0200

Page 42

VMOD-2/VMOD-2D

Caution!

The term "ST2" on th e schematics at the back of any pigg yback manuals,

refer only to the ST-2 conn ector of the actual pigg yback (which plugs into

the above BU2) not to the VM OD-2's ST2. Ta ke care not to confuse these

when making connections to your VMOD-2 front pane l.

Remember also that the pin-outs change when swapping the previously

fitted piggybacks around or replacing them with different types. This is

also true when mov ing several differently configure d VMOD-2's around in

your VMEbus system, where the external appearance of one VMOD-2 is

indistinguishable from any other.

Please refer to resp ective piggy backs use r's manu al for the ex act p in-outs

which are presented to the external equipment (the VMOD's 50-way

header) when such a p iggyback is fitted.

Functional Description

12/15/97

Page 2 - 16Man. ID 03139, Rev. Index 0200

Page 43

VMOD-2/VMOD-2D

Figure 2-6: VMOD-2 and VMOD-Piggyback Connector Overview

Functional Description

VMOD-2's ST2 (on-boar d)

50-way Header

Pin 50

Eve n

pins

Pin 2

VMOD

2

Pin 49

VMOD-2's ST3

Front Pa ne l

Connector

(50-Wa y )

Odd

pins

Pin 1

VMOD-2's two 26-way

Headers BU2a (upper)

BU2b (lowe r )

Position A

Fitted PB-REL

Position B

VMOD -2's two 30/45- way

Heade r BU1/0a (uppe r PB)

BU1/0b (lower PB location)

VMOD's ST1

VMEbus

Connector

(96-Wa y )

PB's ST2

Short

Connector

(26-Way)

26

Even

Pins

2

PB's ST1

PB-REL

(rea dy for fi tti n g)

PB's ST2 a nd ST1

25

Odd

Pins

1

pin distribution as

seen from th e PB's

component si de.

!

Rem ember t he PB's

ST2 pin numbers

have nothi ng to do

with the VMOD-2

ST2's (user I/O) pins.

30

Even

Pins

2

Long

Connector

(30-Way)

29

Odd

Pins

1

12/15/97

Page 2 - 17Man. ID 03139, Rev. Index 0200

Page 44

VMOD-2/VMOD-2D

Functional Description

2.5.3Pin Outs of the VMOD's Front Panel Connector with two VMOD-2s

The respective half of the VMOD-2's front panel 50-way connector (pins 1...24 for lower posi-

tion and pins 27.....50 for upper) assume the relationship of the piggybacks (as fitted to

VMOD-2) signals as routed from their ST2 (via the BU2a or BU2b) through connections as

shown in table 2.5.2 on previous page.

The connector's pins 25 and 26 a re u sed as an exter nal res et (or emergency s top loop ) on the

VMOD-2, and were left "not used" on the original VMOD.

An option to have the VMOD-2 with no front panel connector, but rather a 50-way header

behind a blank front panel will provide an identical pin-out to the standard 50-way front panel

connector, and is provided for applications where the flat band cabl e is to be routed internally,

or where an alternative front panel is to be fitted and used. Take care to note that the 50-way

header is unpolarized, and can be accidently missconnected if the flat-ribbon connector is

turned upside-down.

Figure 2-7: VMOD Front Panel Connector

Eve n p ins

Pin 50

Pin 2

VMOD

2

O dd pins

Pin 49

Pin 1

12/15/97

Note.

In systems having more than one connector of this type, or when using

several VMOD-2s with different piggybacks, it is advisable to put one or

two drops of colored paint on the back of the connector and on the front

panel of the VMOD-2 to which it was ma de for. The connector splits virtually in half (pins 1...24 and 27 to 50) for connection to the re spective piggybacks location behind it. Pins 25 and 26 are used by the "local reset"

Page 2 - 18Man. ID 03139, Rev. Index 0200

Page 45

VMOD-2/VMOD-2D

PB Name

and

Direction*

Signal*

VMOD Front (50-Way)

Pin #s

Piggyback

Position

PB ST2

Pins

input circuits where such feature is desired and thus enabled.

Table 2-9: VMOD-2 Front Panel Connector Pin-Outs

Functional Description

50 Upper (A) 1, 2

49 Upper (A) 25, 26

48 Upper (A) 3

47 Upper (A) 4

46 Upper (A) 5

45 Upper (A) 6

44 Upper (A) 7

43 Upper (A) 8

42 Upper (A) 9

41 Upper (A) 10

40 Upper (A) 11

39 Upper (A) 12

38 Upper (A) 13

37 Upper (A) 14

36 Upper (A) 15

35 Upper (A) 16

34 Upper (A) 17

33 Upper (A) 18

32 Upper (A) 19

31 Upper (A) 20

30 Upper (A) 21

12/15/97

29 Upper (A) 22

28 Upper (A) 23

27 Upper (A) 24

26 Reset GND

Page 2 - 19Man. ID 03139, Rev. Index 0200

Page 46

VMOD-2/VMOD-2D

PB Name

and

Direction*

Signal*

VMOD Front (50-Way)

Pin #s

Piggyback

Position

PB ST2

Pins

Table 2-9: VMOD-2 Front Panel Connector Pin-Outs

Functional Description

25 Reset +

Vcc

24 Lower (B) 1, 2

23 Lower (B) 25, 26

22 Lower (B) 3

21 Lower (B) 4

20 Lower (B) 5

19 Lower (B) 6

18 Lower (B) 7

17 Lower (B) 8

16 Lower (B) 9

15 Lower (B) 10

14 Lower (B) 11

13 Lower (B) 12

12 Lower (B) 13

11 Lower (B) 14

10 Lower (B) 15

09 Lower (B) 16

08 Lower (B) 17

07 Lower (B) 18

06 Lower (B) 19

05 Lower (B) 20

04 Lower (B) 21

12/15/97

03 Lower (B) 22

02 Lower (B) 23

01 Lower (B) 24

An identical table with appropriate signal names ready added, is to be found in

each piggyback manual.

Page 2 - 20Man. ID 03139, Rev. Index 0200

Page 47

This page was intentionally left blank.

Man. ID 03139, Rev. Index 0200

Page 48

VMOD-2/VMOD-2D

Configuration

3.2 Fitting Piggybacks

Detailed descriptions on how to fit and use each piggyback is given in their respective user's

manuals.

After fitting, please look under the fitted piggyback to ensure that every pin of it's front 26-pin

connector is in a socket hole. If any holes are not occupied or any pins are left without a hole,

there is a strong possibility that the piggyback is the wrong-way round and/or displaced in pin

number/height.

For many piggybacks the last 15-pin row of 30/45-pin socket holes (connector nearest the

VMEbus interface end of VMOD-2) will not be used. It is easier to see that all is well by checking the 26-pin interface at the front end first.

Pin-outs of the front panel 50-way connector will change according to the piggybacks fitted

and if they are used in the upper or lower locations. Again ple a se refer to the individual piggyback's user's manuals before making any interface cables.

12/15/97

Page 3 - 13Man. ID 03139, Rev. Index 0200

Page 49

VMOD-2/VMOD-2D

RQ Level

Wanted

B17

B18

B19

Local Reset

Enabled

Disabled

see note

below

Configuration

3.1.7Jumpers B17...B19 Setting Interrupt Level

The VMOD-2 user can set the three jumpers B17, B18 a nd B19 to us e any IRQ level from 1 to

7 as appropriate to his VMEbus systems application. When all three jumpers are set the IRQ

from the VMOD-2 is disabled.I

Table 3-10: IRQ Level selection

None Set Set Set

IRQ1* Set Set Open (Default)

IRQ2* Set Open Set

IRQ3* Set Open Open

IRQ4* Open Set Set

IRQ5* Open Set Open

IRQ6* Open Open Set

IRQ7* Open Open Open

3.1.8Jumper B20 Enable/Disable "Local" Reset Input

The VMOD-2 user can take advantage of an external signal which when utilized will allow the

two piggybacks to be "reset" whenever certain external conditions occur. The external twowire signal is input onto pins 25 and 26 of the 50-way external interface, where the wiring and

use of these two lines are as described in section 2.3.

Table 3-11: Local Reset Enable/Disable

Jumper B20 1-3 1-2 Open

Note.

Jumper B20 must be set to either 1-2 or 1-3. B20 left open is not allowed.

If this jumper is left totally open (neither pin con nected to pin 1) the logic

is floating and may cause spurious resets or other unpredictable problems.

12/15/97

Page 3 - 12Man. ID 03139, Rev. Index 0200

Page 50

VMOD-2/VMOD-2D

B16

AB Size

Address

Block #s

B2 A15

B12 A14

B13 A13

B14 A12

B15 A11

Address Range

From ... To

Table 3-9: Address Width (B16) and Range (B2 and B12...15) Selections

Open 2 56 Byte AB #3 1 Open Open Open Open Set $FE F4 00 $ FE F4 FF

Open 2 56 Byte AB #3 2 Open Ope n Open Open Open $FE FC 00 $FE FC FF

Set 8 KByte AB#01..04 Set Set Set x x $FE 00 00 $FE 1F FF

Set 8 KByte AB#05..08 Set Set Open x x $FE 20 00 $FE 3F FF

Set 8 KByte AB#09..12 Set Open Set x x $FE 40 00 $FE 5F FF

Set 8 KByte AB#13..16 Set Open Open x x $FE 60 00 $FE 7F FF

Set 8 KByte AB#17..20 Open S et Set x x $FE 80 00 $FE 9F FF

Set 8 KByte AB#21..24 Open S et Open x x $FE A0 00 $FE BF FF

Configuration

Set 8 KByte AB#25..28 Open Open Set x x $FE C0 00 $FE DF FF

Set 8 KByte AB#29..32 Open Open Open x x $FE E0 00 $FE FF FF

12/15/97

x = B14 and B15 can be left at any setting when using 8 KByte address block widths. Default Setting bold/italic

Page 3 - 11Man. ID 03139, Rev. Index 0200

Page 51

VMOD-2/VMOD-2D

B16

AB Size

Address

Block #s

B2 A15

B12 A14

B13 A13

B14 A12

B15 A11

Address Range

From ... To

Table 3-9: Address Width (B16) and Range (B2 and B12...15) Selections

Open 2 56 Byte AB #16 Set Open O pen O pen Op en $FE 7C 00 $FE 7C FF

Open 2 56 Byte AB #17 Open Set Se t Set Set $FE 84 00 $FE 84 FF

Open 2 56 Byte AB #18 Open Set Se t Set Open $FE 8C 00 $F E 8C FF

Open 2 56 Byte AB #1 9 Open Set Set Op en Set $FE 94 00 $FE 94 FF

Open 2 56 Byte AB #20 Open Set Se t Open Ope n $FE 9C 00 $ FE 9C FF