Page 1

VM62(A) / VM42(A) User’s Manual Preface

VM62(A) / VM42(A)

Intelligent Universal Controller Modules

for Stand-Alone and VMEbus

Manual Order No. 3368

User’s Manual

Issue 3

Unpacking and Special Handling Instructions

This PepCard product is carefully designed for a long and fault-free life; nonetheless, its life expectancy can be drastically

reduced by improper treatment during unpacking and installation.

Observe standard anti-static precautions when changing piggybacks, ROM devices, jumper settings, etc. If the product

contains batteries for RTC or memory back-up, ensure that the board is not placed on conductive surfaces, including antistatic plastics or sponges. These can cause shorts and damage to the batteries or tracks on the board.

When installing the board, switch off the power mains to the chassis. Do not disconnect the mains as the ground

connection prevents the chassis from static voltages, which can damage the board as it is inserted.

Furthermore, do not exceed the specified operational temperature ranges of the board version ordered. If batteries are

present, their temperature restrictions must be taken into account.

Keep all of the original packaging material for future storage or warranty shipments. If it is necessary to store or ship the

board, re-pack it as it was originally packed.

May 17, 1996 © 1995 PEP Modular Computers Page 0-1

Page 2

Preface VM62(A) / VM42(A) User’s Manual

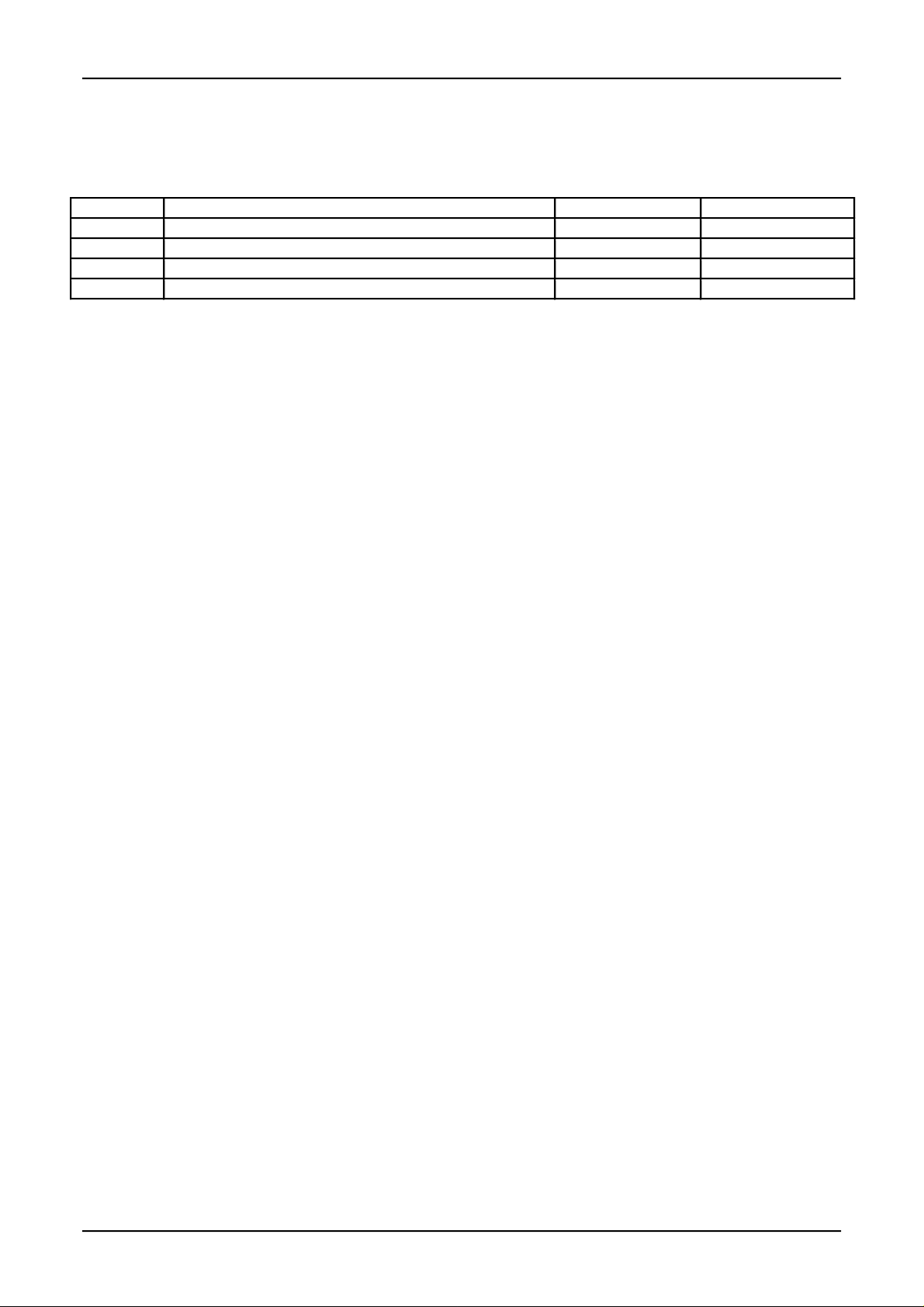

R EVISION HISTORY

VM62(A) / VM42(A) User’s Manual

Issue Brief Description of Changes PCB Index Date of Issue

1 Issue 1 01-01/2 March, 1995

2 General Corrections throughout Manual 01-01/4 June, 1995

2.0.1 Correction of Figure 3.2.0.1 (Jumper Layout Solder Side) 01-01/4 July, 1995

3 Updated for board index 02 02 December, 1995

This document contains proprietary information of PEP Modular Computers. It may not be copied or transmitted by

any means, passed to others, or stored in any retrieval system or media, without the prior consent of PEP Modular

Computers or its authorized agents.

The information in this document is, to the best of our knowledge, entirely correct. However, PEP Modular

Computers cannot accept liability for any inaccuracies, or the consequences thereof, nor for any liability arising from

the use or application of any circuit, product, or example shown in this document.

PEP Modular Computers reserve the right to change, modify, or improve this document or the product described

herein, as seen fit by PEP Modular Computers without further notice.

Page 0-2 © 1995 PEP Modular Computers May 17, 1996

Page 3

VM62(A) / VM42(A) User’s Manual Preface

PEP Modular Computers® Two Year Limited Warranty

We grant the original purchaser of PEP products the following hardware and system warranty. No other warranties that

may be granted or implied by anyone on behalf of PEP are valid unless the consumer has the express written consent of

PEP Modular Computers.

PEP Modular Computers warrants their own products (excluding software) to be free from defects in workmanship

and materials for a period of 24 consecutive months from the date of purchase. This warranty is not transferable nor

extendible to cover any other consumers or long term storage of the product.

This warranty does not cover products which have been modified, altered, or repaired by any other party than

PEP Modular Computers or their authorized agents. Furthermore, any product which has been, or is suspected of

being damaged as a result of negligence, misuse, incorrect handling, servicing or maintenance; or has been damaged as a

result of excessive current/voltage or temperature; or has had its serial number(s), any other markings, or parts thereof

altered, defaced, or removed will also be excluded from this warranty.

A customer who has not excluded his eligibility for this warranty may, in the event of any claim, return the product at

the earliest possible convenience, together with a copy of the original proof of purchase, a full description of the

application it is used on, and a description of the defect; to the original place of purchase. Pack the product in such a way

as to ensure safe transportation (we recommend the original packing materials), whereby PEP undertakes to repair or

replace any part, assembly or sub-assembly at our discretion; or, to refund the original cost of purchase, if appropriate.

In the event of repair, refund, or replacement of any part, the ownership of the removed or replaced parts reverts to

PEP Modular Computers, and the remaining part of the original guarantee, or any new guarantee to cover the

repaired or replaced items, will be transferred to cover the new or repaired items. Any extensions to the original guarantee

are considered gestures of goodwill, and will be defined in the "Repair Report" returned from PEP with the repaired or

replaced item.

Other than the repair, replacement, or refund specified above, PEP Modular Computers will not accept any liability

for any further claims which result directly or indirectly from any warranty claim. We specifically exclude any claim for

damage to any system or process in which the product was employed, or any loss incurred as a result of the product not

functioning at any given time. The extent of PEP Modular Computers liability to the customer shall not be greater

than the original purchase price of the item for which any claim exists.

PEP Modular Computers makes no warranty or representation, either express or implied, with respect to its

products, reliability, fitness, quality, marketability or ability to fulfill any particular application or purpose. As a result,

the products are sold "as is," and the responsibility to ensure their suitability for any given task remains the purchaser's.

In no event will PEP be liable for direct, indirect, or consequential damages resulting from the use of our hardware or

software products, or documentation; even if we were advised of the possibility of such claims prior to the purchase of, or

during any period since the purchase of the product.

Please remember that no PEP Modular Computers employee, dealer, or agent are authorized to make any

modification or addition to the above terms, either verbally or in any other form written or electronically transmitted,

without consent.

May 17, 1996 © 1995 PEP Modular Computers Page 0-3

Page 4

Preface VM62(A) / VM42(A) User’s Manual

TABLE OF CONTENTS

Page

1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1 Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Figure 1.2.0.1: VM62(A)/VM42(A) Configuration Options . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 1.4.0.1: CPU Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

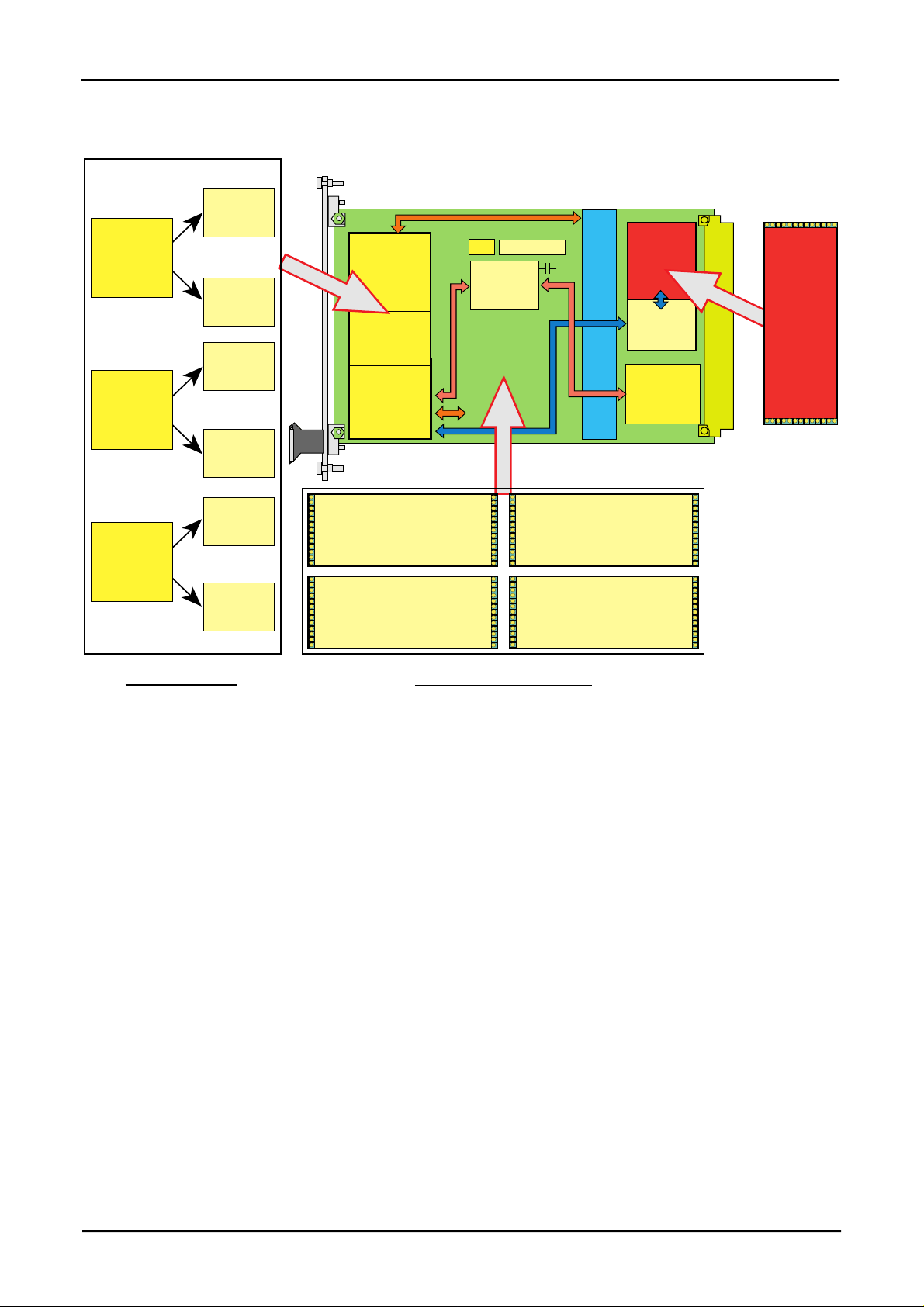

Figure 1.4.0.2: MC68EN360 Intelligent Controller Schematic . . . . . . . . . . . . . . . . . . . . . . . 7

1.5 Related Publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2. Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

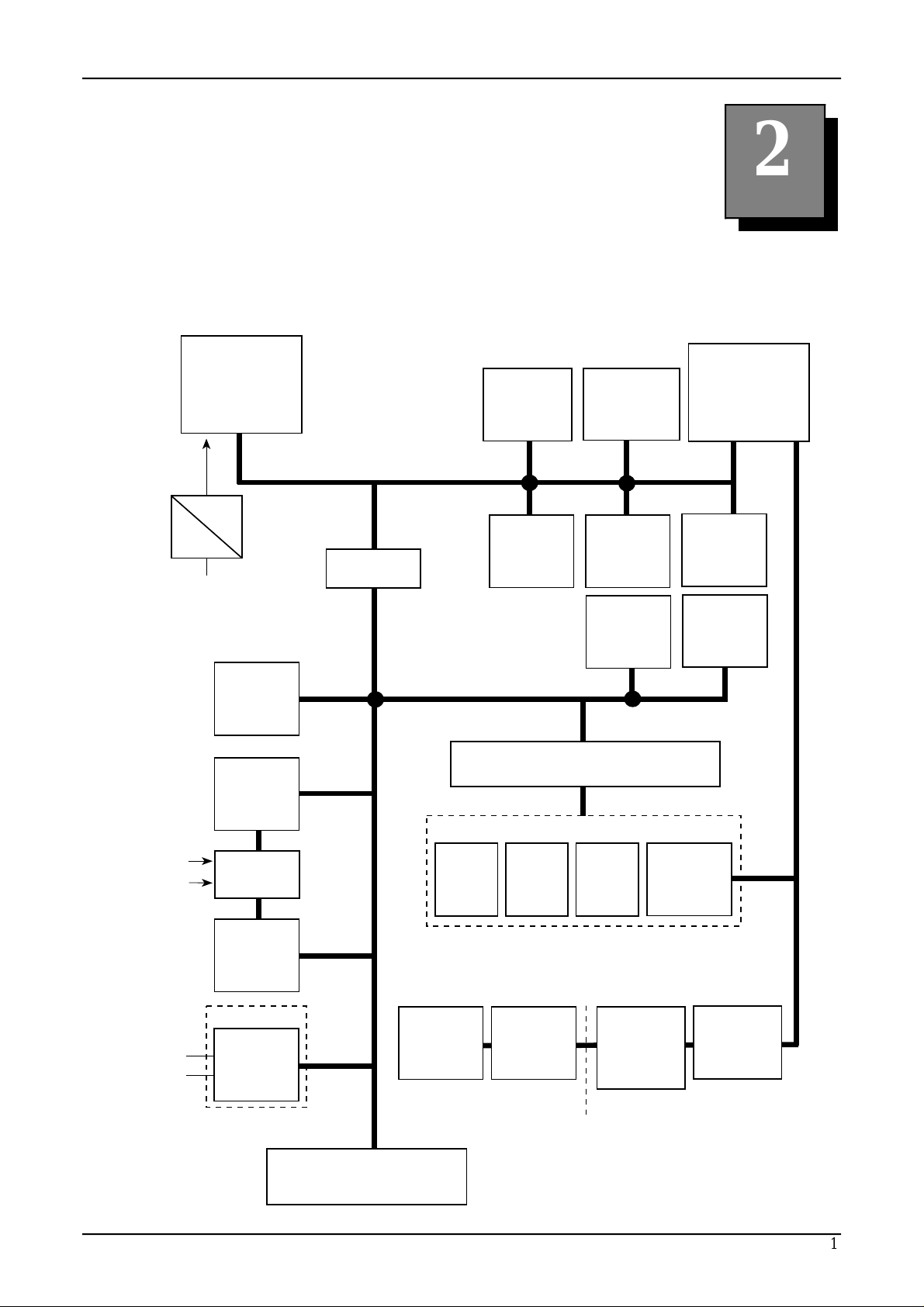

Figure 2.0.0.1: VM62(A) / VM42(A) Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.1 The 68EN360 (QUICC) on the VM62(A) / VM42(A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.2 Address Decoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.2.1 Basic Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.2.2 Boot Decoding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.2.3 Primary Address Decoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2.4 Secondary Address Decoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2.5 Address Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 2.2.5.1: VM62(A) / VM42(A) Address Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2.6 DMA Transfers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3 VMEbus Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3.1 System Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3.2 Dual-Ported SRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3.3 Mailbox Interrupt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3.4 VMEbus Control / Status Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4 Interrupt Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4.1 Internal Requests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4.2 External Autovector Requests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4.3 VME Interrupt Mask Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.5 I/O Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.5.1 Ethernet Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.5.2 Serial Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 2.5.2.1: MC68EN360 Intelligent Controller Schematic . . . . . . . . . . . . . . . . . . . . . . . 9

2.5.3 CXC Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 2.5.3.1: CXC Pinouts using the 68(EN)360 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 2.5.3.2: Further Explanation of 68(EN)360 Mnemonics . . . . . . . . . . . . . . . . . . . . . . . 15

2.5.4 AutoBahn Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.6 Special Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.6.1 Real-Time Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.6.2 EEPROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.6.3 TICK Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.6.4 On-board Bus Error Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.6.5 VME Bus Error Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 8

2.6.6 Watchdog Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 2.6.6.1: Watchdog LED Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.6.7 First Slot Detection (FSD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.6.8 Board Control/Status Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.6.9 Reset Sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Page 0-4 © 1995 PEP Modular Computers May 17, 1996

Page 5

VM62(A) / VM42(A) User’s Manual Preface

2.7 Front Panel Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 2.7.0.1: LED Port and Button Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.7.1 RESET Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.7.2 ABORT Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.7.3 LED Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.8 Data Retention for RTC and SRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.9 Register Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3. Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Table 3.0.0.1: VM62(A) / VM42(A) Default Jumper Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

3.1 Jumper Description (Component Side) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Figure 3.1.0.1: VM62(A) / VM42(A) Jumper Layout (Component Side) . . . . . . . . . . . . . . . . 2

3.1.1 Jumper J1: VME-SYSCLK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3.1.2 Jumper J2: VME-SYSRES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3.1.3 Jumper J8: VME Boot (VBOOT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3.1.4 Jumper J9: AutoBahn Boot (ABOOT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3.1.5 Jumper J14: Connection of Protective and Signal GND . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3.2 Jumper Description (Solder Side) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 3.2.0.1: VM62(A) / VM42(A) Jumper Layout (Solder Side) . . . . . . . . . . . . . . . . . . . . 4

3.2.1 Jumpers J3, J4 and J5: CPU (Bus) Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.2.2 Jumper J6: 24 MHz Clock (Communications Clock) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.2.3 Jumper J7: CPU Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.2.4 Jumper J10: Serial EEPROM Write Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.2.5 Jumpers J11 and J12: SRAM Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.2.6 Jumpers J131 - J134: Processor Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4. Memory Piggybacks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1 DM600 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

4.1.1 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 4.1.1.1: DM600 Jumper Layout (Component Side) . . . . . . . . . . . . . . . . . . . . . . . . . . 1

4.2 DM601 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

4.2.1 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Figure 4.2.1.1: DM601 Jumper Layout (Component Side) . . . . . . . . . . . . . . . . . . . . . . . . . . 2

4.3 DM602 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

4.4 DM603 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

4.4.1 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Figure 4.4.1.1: DM603 Jumper Layout (Component Side) . . . . . . . . . . . . . . . . . . . . . . . . . . 3

May 17, 1996 © 1995 PEP Modular Computers Page 0-5

Page 6

Preface VM62(A) / VM42(A) User’s Manual

5. Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1 Main Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 5.1.0.1: Main Board Connector Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

5.1.1 VMEbus Connector (ST1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

5.1.2 CXC Connector (ST3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

5.2 Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

5.2.1 Standard RS232 Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 5.2.1.1: Standard Front Panel Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

5.2.2 Ethernet 10Base2 (SI-10B2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 5.2.2.1: SI-10B2 Front Panel Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

5.2.3 Ethernet AUI / 10Base5 (SI-10B5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 5.2.3.1: SI-10B5 Front Panel Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5.2.4 Serial RS232 Interface (SI-PB232) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 5.2.4.1: SI-PB232 Front Panel Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5.2.5 Ethernet 10BaseT (SI-10BT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 5.2.5.1: SI-10BT Front Panel Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.2.6 PROFIBUS Interface (SI-PBPRO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 5.2.6.1: SI-PBPRO Front Panel Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6. Software Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.1 Initializing the 68EN360 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

6.2 Initialising the Cache . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Appendix Controller eXtension Connector

Appendix OS-9 Cabling

Page 0-6 © 1995 PEP Modular Computers May 17, 1996

Page 7

VM62(A) / VM42(A) User’s Manual Chapter 1 Introduction

1

1. INTRODUCTION

1.1 Product Overview

The computer user today requires high performance to meet high expectations. At the same time, the mass of data that

has to be processed is dramatically increasing, for instance the data that a modern graphic user interface generates.

Additionally, there is a further demand on the communications ability and multi-functionality of the computer.

The VM62(A)/VM42(A) meets all the above requirements, combining high computational performance with excellent

communication ability via the AutoBahn™ Spanceiver™ chip.

A combination of the high performance CPU (Motorola MC68060 or 68040) and the Quad Integrated Communications

Controller chip, the Motorola MC68EN360 or QUICC, not only enables a pure computation performance from

approximately 35 MIPS to over 100 MIPS, but dispenses with the usual restrictions associated with communications

over serial interfaces. Communication tasks are dealt with by the QUICC chip, freeing the CPU from such timeconsuming chores. Fieldbus protocol, such as PROFIBUS, are also handled by the QUICC. In addition, the QUICC,

used together with PEP’s expanding CXC interface is ideally suited for communication tasks extending from 6 serial

interfaces over LAN to WAN (X.25, ISDN) applications. The ‘EN’ version of the QUICC also supports Ethernet on 2

channels (only one usable on the VM42(A)/VM62(A) using PEP standard software).

The various I/O interfaces are realised using piggybacks attached to the main board. Five options are at the moment

available. They are:

• Ethernet 10Base 2;

• Ethernet 10Base 5 (AUI);

• Ethernet 10BaseT;

• 2 * RS232 serial interfaces;

• PROFIBUS interface (RS485, isolated, half duplex, 2 wires).

PEP’s AutoBahn technology has solved one of the major problems that exist in information technology - data transfer

over the various bus systems. Normally the data transfer rate over a bus system is below the data transfer capability of a

modern CPU chip. The AutoBahn chip (the Spanceiver MC100SX1451) allows transfer rates of up to 100 Mbyte/sec

over the VMEbus using the VMEbus lines SERA and SERB.

PEP has also developed a cost-effective VMEbus backplane series that support AutoBahn, called VBP4A, in 7, 12 and 15

slot options. These backplanes allow direct connection of the main power supply, hence reducing cabling costs

dramatically.

A CXM-SIO3 module is available in order to make all three serial interfaces that are available on the CXC accessible on

the VM62(A)/VM42(A). This is achieved by using RS232, SC-xxx or SI-xxx interfaces. For more details, please refer to

the CXM-SIO3 user’s manual.

AutoBahn ™ and Spanceiver ™ are trademarks of PEP Modular Computers.

May 17, 1996 © 1995 PEP Modular Computers Page 1-1

Page 8

Chapter 1 Introduction VM62(A) / VM42(A) User’s Manual

1.2 Ordering Information

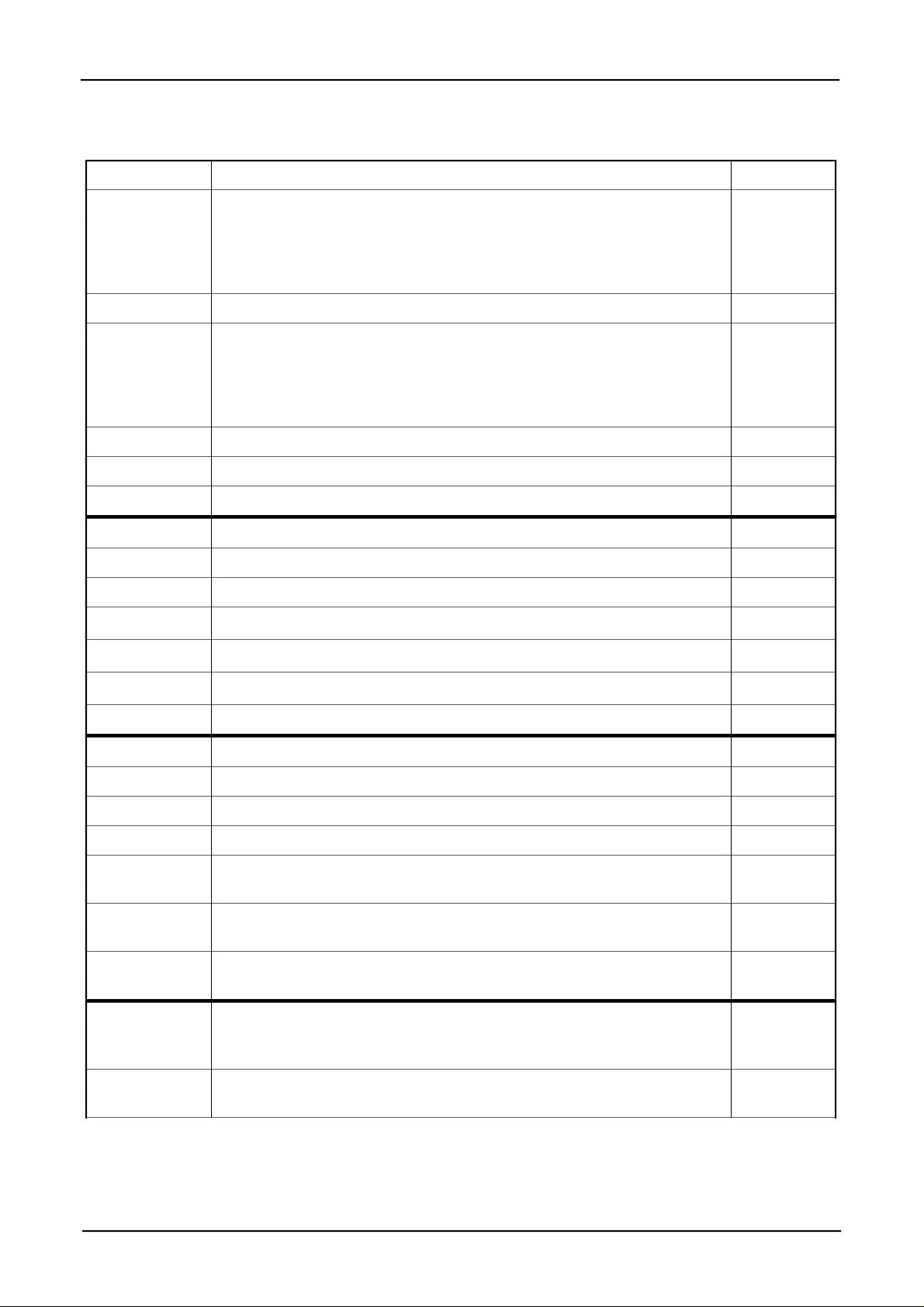

Name Description Order No

VM62-BASE VMEbus single board computer comprising MC68060 @ 50 MHz,

MC68EN360 @ 25 MHz, 256 kByte dual-ported SRAM (with Gold Cap for

backup), configured for use with the AutoBahn interface piggyback, up to 6

serial interfaces (2 available on the front panel as RS232 and an additional 4

divided between the CXC interface and SI-Interface), CXC Interface, PEPbug.

VM62-BASE Same as order no. 12349 but with 1 MByte dual-ported SRAM 12350

VM42-BASE VMEbus single board computer comprising MC68040 @ 33 MHz,

MC68EN360 @ 33 MHz, 256 kByte dual-ported SRAM (with Gold Cap for

backup), configured for use with the AutoBahn interface piggyback, 6 serial

interfaces (2 available on the front panel as RS232 and an additional 4 divided

between the CXC interface and SI-Interface), CXC Interface, PEPbug.

VM42-BASE Same as order no. 12344 but with 1 MByte dual-ported SRAM 12345

VM42-BASE Same as order no. 12344 but with MC68040V @ 33 MHz (3.3-V technology) 12346

VM42-BASE Same as order no. 12346 but with 1 MByte dual-ported SRAM 12347

DM600 Memory piggyback with 4 MByte DRAM and 1 MByte Flash EPROM 11852

DM600 Memory piggyback with 4 MByte DRAM and 4 MByte Flash EPROM 11853

DM601 Memory piggyback with 16 MByte DRAM and 1 MByte Flash EPROM 11854

DM601 Memory piggyback with 16 MByte DRAM and 4 MByte Flash EPROM 11855

DM602 Memory piggyback with 1 MByte DRAM and 1 MByte Flash EPROM 12765

12349

12344

DM603 Memory piggyback with 32 MByte DRAM and 512 kByte Flash EPROM 13027

DM603 Memory piggyback with 32 MByte DRAM and 2 MByte Flash EPROM 13627

SI-10B2 10Base2 (Thin) Ethernet (cheapernet) interface with RG58 (coax) connector 9925

SI-10B5 10Base5 (AUI) Ethernet interface piggyback with 15-pin D-Sub connector 9924

SI-10BT 10BaseT (Twisted pair) Ethernet interface piggyback with RJ45 connector 9926

SI-DUMMY Front panel only fitted when no SI piggyback required 12351

SI-PB232 Serial interface piggyback for 2 RS232 connections (Modem interface) with 2

RJ45 connectors

SI-PB232-ISO Serial interface piggyback for 1 RS232 optoisolated connection with 1 RJ45

connector (Available in 1996 if requested)

SI-PBPRO RS485 optoisolated interface piggyback for 2 wire half-duplex (PROFIBUS)

connection with 9-pin D-Sub connector

MP-AB100 AutoBahn interface piggyback complete with all control logic, 128 kByte 32-

bit fast SRAM as buffer for AutoBahn data transfer with Spanceiver MC

100SX1451 of 50/100 MByte/s

CABLE-VM42-

232

3 meter RS232 Serial Interface cable for VM42(A) / VM62(A) with 9-pin

female D-Sub (PC pinout) to RJ12 connector

11850

11851

9927

9923

12383

Page 1-2 © 1995 PEP Modular Computers May 17, 1996

Page 9

VM62(A) / VM42(A) User’s Manual Chapter 1 Introduction

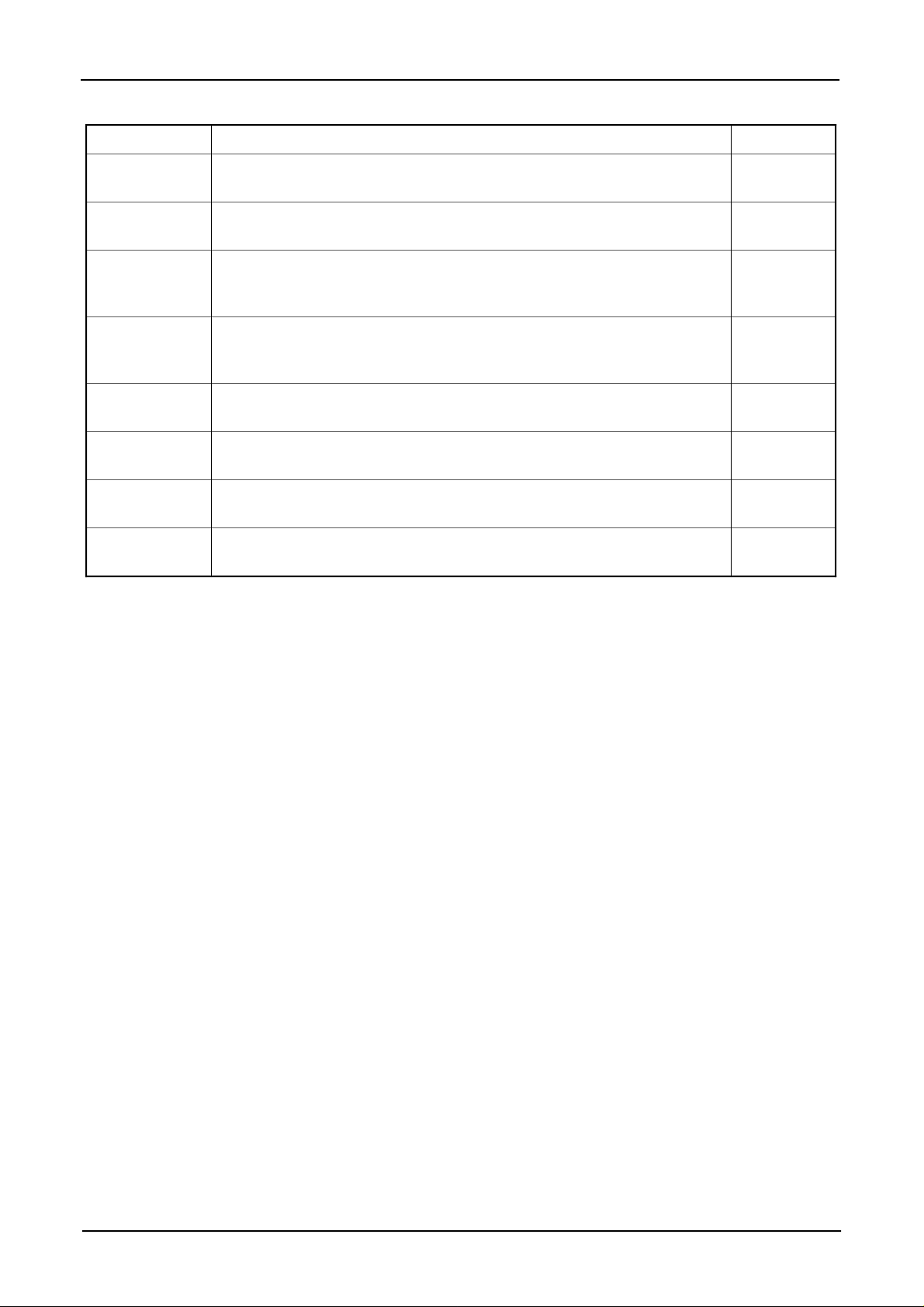

Name Description Order No

CXM-SIO3-1 CXM module with 3 RJ45 connected RS232 ports for use with a CXC

backplane

CXM-SIO3-1 CXM module with 3 RJ45 connected RS232 ports, compatible for direct

connection to a CPU board

CXM-SIO3-2 CXM module with 2 RJ45 connected SC piggyback ports and one SI

piggyback interface, no front panel (delivered with SC piggyback) for use with

a CXC backplane

CXM-SIO3-2 CXM module with 2 RJ45 connected SC piggyback ports and one SI

piggyback interface, no front panel (delivered with SC piggyback), compatible

for direct connection to a CPU board

CXM-SIO3-3 CXM module with 3 RJ45 connected SC piggyback ports for use with a CXC

backplane

CXM-SIO3-3 CXM module with 3 RJ45 connected SC piggyback ports, compatible for direct

connection to a CPU board

CXM-SIO3-4 CXM module with 3 15-pin D-Sub connected SC piggyback ports, 8TE front

panel for use with a CXC backplane

CXM-SIO3-4 CXM module with 3 15-pin D-Sub connected SC piggyback ports, 8TE front

panel, compatible for direct connection to a CPU board

TBD

13692

TBD

13693

TBD

13694

TBD

13695

Each VM62(A)/VM42(A) comes complete with 2 RS232 serial interfaces situated on the lower half of the front panelThese interfaces are provided with TxD and RxD signals by the SMC1 and SMC2 channels of the ‘QUICC’ controller.

The SCC1 channel of the ‘QUICC’ provides the interface to one of the available SI-xxx piggybacks. All other channels

(SCC2, SCC3 and SCC4) of the ‘QUICC’ are ported to the CXC interface except for the SI-PB232 piggyback which has

on-board additional control provided by the SCC4 channel through the SI Interface.

As mentioned above, a CXM-SIO3 module is available in order to make all the serial interfaces accessible on the

VM62(A)/VM42(A). For more details, please refer to the CXM-SIO3 user’s manual.

Important: The VM62(A)/VM42(A) must be ordered with a memory module (DM60x) and a front

panel interface piggyback module (SI-xxx).

May 17, 1996 © 1995 PEP Modular Computers Page 1-3

Page 10

Chapter 1 Introduction VM62(A) / VM42(A) User’s Manual

Figure 1.2.0.1: VM62(A)/VM42(A) Configuration Options

SRAM

VM42(A)

MC68040

@ 33 MHz

MC68EN360

@ 33 MHz

VM42(A)

MC68040V

@ 33 MHz

MC68EN360

@ 33 MHz

256 kByte

OR

SRAM

1 MByte

SRAM

256 kByte

OR

SRAM

1 MByte

68EN360

* Ethernet

* 6 serial I/O

* Timers

* Watchdog

Companion Mode

VM62(A)

MC68060

@ 50 / 66MHz

VM42(A)

MC68040(V)

MC68040

@ 33 MHz

RTC

dual-ported

SRAM

DRAM

FLASH

1 kbit EEPROM

+

MP

interface

(optional)

Spanciever

CXC Interface

Dual-ported

SRAM

128 kByte

VMEbus

* System

controller

* Master/slave

interface

VMEbus

Optional MP

Interface Piggyback

VM62(A)

MC68060

@ 50/66 MHz

MC68EN360

@ 25 /33MHz

CPU Options

SRAM

256 kByte

OR

SRAM

1 MByte

Optional Memory Piggyback

with

1 MByte DRAM

1 MByte FLASH

Optional Memory Piggyback

with

16 MByte DRAM

1 or 4 MByte FLASH

Memory Piggybacks

Optional Memory Piggyback

with

4 MByte DRAM

1 or 4 MByte FLASH

Optional Memory Piggyback

with

32 MByte DRAM

512 kByte or 2 MByte FLASH

Page 1-4 © 1995 PEP Modular Computers May 17, 1996

Page 11

VM62(A) / VM42(A) User’s Manual Chapter 1 Introduction

1.3 Specifications

Main CPU

I/O Controller

Memory

DRAM

FLASH

SRAM

EEPROM

VMEbus Interface

A24:D16/D8

Arbitration

AM Codes

MC68060 66 or 50 MHz (3.3V)

MC68040 33 or 25 MHz

MC68040V 33 or 25 MHz (3.3V)

MC68LC040 33 or 25 MHz

MC68EN360, 25 or 33MHz used in companion mode

1, 4, 16 or 32 Mbyte

0.5, 1, 2, or 4 MByte

1 MByte or 256 kByte (dual-ported, backed-up using Gold-Caps)

2 kbit (serial); 1 kbit available for applications

Master and slave with optional AutoBahn Interface (100 MBytes/sec)

Single level (BR3*), release-when-done daisy-chain

Standard Superv./User Prog./Data HEX 39/3A/3D/3E

User Defined HEX 10-17/18-1F

Short I/O HEX 29/2D

System controller functions

• Automatic First Slot Detection (FSD)

• SYSRES* (disabled by jumper)

• SYSCLK* (disabled by jumper)

• ACFAIL*

• SYSFAIL*

• Power monitor

• Bus monitor (programmable)

• VME IRQ mask register

A24:D16

Dual-port SRAM

1 Mailbox IRQ

Interrupt Control

7 Level VME IRQ Handler,

maskable via VME IRQ mask

register

System vectors

* Available for Index 02 boards or later.

Slave

1 Mbyte window, software programmable base (1 out of 16 addresses)

Lower 8kBytes of the SRAM area

ACFAIL* -> Level 7 autovectored

ABORT -> Level 7 autovectored

TICK -> Level 6 autovectored

SYSFAIL* -> Level 3 autovectored (maskable)

Mailbox IRQ -> Level 5 autovectored

AutoBahn IRQ 2 -> Level 2 autovectored

AutoBahn IRQ 1 -> Level 1 autovectored

16 on-board Interrupters, Levels / Vectors programmable

*

May 17, 1996 © 1995 PEP Modular Computers Page 1-5

Page 12

Chapter 1 Introduction VM62(A) / VM42(A) User’s Manual

I/O Ports

Serial

Mezzanine Interface

Timers

RISC controller (in the 68EN360) with 14 dedicated DMA channels

4*multiprotocol SCCs up to 8 MBaud

with one (two) supporting IEEE 802.3/Ethernet up to 10 Mbit/s

10Base5, 10Base2 or 10BaseT

2*UARTs RS232 (XON/XOFF) RS232 up to 120 kBaud

4 independent baud rate generators

CXC Interface

- 16 bit asyncronous data transfer with 4 IRQs,

independent DMA channel

- 3 serial interfaces

TICK

General Purpose

Watchdog

Special Functions

Real-time clock (backed-up)

Serial EEPROM

DMA

Front Panel Functions

Data Retention

Short term backup for RTC and

SRAM via on-board Gold-Cap

Periodic Interrupt Timer, programmable

4*16 bit or 2*32 bit, programmable

512 ms time-out for reset, programmable

Date (year, month, week, day)

Time (hour, minute, second)

1 kbit for board specific data (serial number, Internet address, etc.)

+ 1 kbit for application purposes

2 independent channels (supports single and dual address transfers

between all offboard locations including DRAM, FLASH,

AutoBahn memory, CXC and VME)

RESET button

ABORT button

HALT LED (red)

Watchdog LED (yellow)

General purpose LED (green)

Typ. 2µA/3V -> 50 hours

Long term backup via VME 5V

Stby line

Power Requirements

VM62 /66 MHz

VM62 /50 MHz

VM42 /33 MHz (68040)

VM42 /25 MHz 3.3V (68040V)

Temperature Range

Operating Humidity

Board Size

VMEbus Connector

Front panel width

Page 1-6 © 1995 PEP Modular Computers May 17, 1996

Dependent on the battery installed on the system 5V Stby.

Automatic switching between 5V Stby and internal Gold-Cap

Typ. 30µA/3V

To be defined

5 W with DM600 and SITB5 fitted

7W with DM600 and SITB5 fitted

4 W with DM600 and SITB5 fitted

Standard 0 - 70˚C

Optionally E2 -40˚C to +85˚C

0 to 95% non-condensing

Single height Eurocard 100*160 mm

DIN 41612 style C, 96 contacts, P1 connector

4 TE, 1 slot

Page 13

VM62(A) / VM42(A) User’s Manual Chapter 1 Introduction

1.4 Features

CPU Options

The Table below illustrates the capabilities of the available CPUs. The 68060 processors operating at 50 MHz deliver up

to 100 MIPs while the 68040 processors operating at 33 MHz give performances up to 35 MIPs.

Table 1.4.0.1: CPU Configuration

Processor Product CPU MMU FPU Supply

MC68040 VM42(A) √ √ √ 5V

MC68LC040

MC68040V VM42(A) √ √ 3.3V

MC68060 VM62(A) √ √ √ 3.3V

*

VM42(A) √ √ 5V

MC68EC060

planned project

*

68EN360

25/33 MHz - the ‘QUICC’ chip used in ‘companion mode’ is tightly coupled to the CPU. Working as an I/O and system

controller, it provides all the necessary interfaces, timers and clocks etc. in addition to the DRAM memory controller.

Serial Channels

Six are provided by the ‘QUICC’ - Two SMC channels are ported to the front panel and the remaining four SCC channels

may be optionally configured as shown below.

Figure 1.4.0.2: MC68EN360 Intelligent Controller Schematic

Mask E71M required.

MC68EN360

VM62(A)

SCC2

SCC3

SCC4

SCC1

}

}

√

SI-Interface

3.3V

CXC Interface

SI-Piggyback

Interface

}

SMC2SMC1

2x RS232 with

Rx and Tx only

May 17, 1996 © 1995 PEP Modular Computers Page 1-7

Memory

Piggyback

Page 14

Chapter 1 Introduction VM62(A) / VM42(A) User’s Manual

Ethernet Interface (SI-10B2, SI-10B5, SI-10BT)

Three different piggybacks complete with all the associated control logic are available providing 10Base5, 10Base2 or

10BaseT interfaces.

Note

The SI-10B5 piggyback requires an external +12V power source to operate.

Fieldbus Interface (SI-PBPRO)

This is a fully optoisolated RS485 (PROFIBUS) interface piggyback with a 9-pin D-Sub connector.

RS232 Serial Interface

Two piggybacks are available with RJ45 connectors for MODEM compatible communication.

AutoBahn Interface (MP-AB100)

This is realised via a piggyback containing all the necessary control logic, 128 kByte high speed SRAM (10 ns) as a

memory buffer between the processor and the AutoBahn chip (MC 100SX1451) for communication on the high speed

serial data lines over pins b21 and b22 of the VMEbus.

DMA Channels

2 independent channels are provided by the ‘QUICC’ chip and can be used by applications requiring data transfer between

CXC-modules, DRAM, FLASH memory, dual-ported SRAM and AutoBahn memory buffers. This memory can be

configured with different memory options allowing tremendous flexibility when customising memory requirements for

real-time applications.

DRAM/FLASH

This memory, complete with a 32 bit data wide access bus is placed on a piggyback with addressing capability for up to

two memory banks of 64 MByte each. On-board +5V FLASH memory provides the latest ROM technology allowing the

user to take advantage of the on-board programming facility to produce low cost upgrades by simply overwriting existing

stored data.

SRAM

This is a dual-ported battery-backed (Gold-Cap) memory area with a 16 bit data wide access bus. Users of the VMEbus

and the on-board CPU both have access to this memory. The lower 8 kByte are reserved for the location monitor.

EEPROM

Although a 2 kbit EEPROM is provided on-board, 1 kbit has been pre-programmed with PEP production data (boot info,

Ethernet registration, etc) leaving the remaining 1 kbit for user application code. A write protect jumper prevents

accidental erasure.

Page 1-8 © 1995 PEP Modular Computers May 17, 1996

Page 15

VM62(A) / VM42(A) User’s Manual Chapter 1 Introduction

1.5 Related Publications

VITA

VMEbus Specifications Revision C1

MPI: Modpack and CXC Specification from PEP (Version 1.5 or later)

Motorola

M68060 Microprocessors User’s Manual

M68040 Microprocessors User’s Manual

MC68EN360 Quad Integrated Communications Controller User’s Manual

AutoBahn Spanceiver Data Sheet

EM Microelectronic

V3021 1 Bit Real Time Clock Data Sheet

XICOR

X25C02 SPI Serial EEPROM Data Sheet

May 17, 1996 © 1995 PEP Modular Computers Page 1-9

Page 16

VM62(A) / VM42(A) User’s Manual Chapter 2 Functional Description

2

2. FUNCTIONAL DESCRIPTION

Figure 2.0.0.1: VM62(A) / VM42(A) Block Diagram

CPU

68(LC)040

68040V

33 / (40) MHz

68060

50 / 66 / (80) MHz

3.3V

5V

Serial

EEPROM

Real-Time

Clock

Address/

Data/

Control

BUSSIZER

SPI

1 Bit

1 Bit

32 Bit 32 Bit

DRAM

1/4/16/32 MB

IRQ

Handler

CXC (Serial / Parallel / DMA Port)

16 Bit

FLASH

0.5/1/2/4 MB

Clock

Logic

Status/

Control

Logic

8 Bit

68EN360

Companion

Mode

25/33/(40) MHz

Reset

Logic

Watchdog

optional

On board Gold-Cap

VME 5V Stdby

b21

b22

Backup

Logic

Dual-Port

SRAM

256/1MB

70ns

optional

AutoBahn

Interface

autoswitchover

16 Bit

32 Bit

VMEbus Interface

Master / Slave

Serial

I/O User

Spec

SCC2

Serial

I/O

RS232

SMC1

16 Bit

Serial

I/O User

Spec

SCC3

Serial

I/O

RS232

SMC2

Standard I/O Additional I/O

Serial

I/O User

Spec

SCC4

Front Panel

10Base2/5/T

RS485

RS232 ISo

2*RS232

SCC1 SCC4

SCSI

(DMA)

LED

Functions

May 17, 1996 © 1995 PEP Modular Computers Page 2-1

Page 17

Chapter 2 Functional Description VM62(A) / VM42(A) User’s Manual

2.1 The 68EN360 (QUICC) on the VM62(A) / VM42(A)

Motorola’s MC68EN360 is a 32 bit high performance communication controller, combining powerful peripheral

functions with system integration functions and an on-chip microprocessor core (CPU32+).

On the VM62(A) / VM42(A), the on-chip CPU core is disabled and replaced with a more powerful external CPU, the

MC68040 or MC68060. The 68EN360 operates as a slave to the CPU in so-called ‘Companion Mode’. In this mode, the

68EN360 provides complete I/O functionality. The DMA channels can still obtain ownership of the CPU’s system bus

and therefore all on-chip DMA channels can address the whole of the address space. Moreover, important functions for

system integration, such as memory controller, clock generation, interrupt controller etc. are available in this mode,

meeting the requirements for the initialisation of the 68EN360, described later in this manual.

The programming of the 68EN360 begins by determining the block of on-chip RAM and registers via the MBAR

register. This register is located at a fixed address and can only be accessed in CPU space.

2.2 Address Decoder

2.2.1 Basic Structure

The address decoder of the VM62(A) / VM42(A) consists of two basic parts. A primary address decoder pre-decodes the

select signals for the processor data bus (in front of the bussizer) and for the I/O data bus (behind the bussizer). With

reference to initial boot cycles, the primary address decoder passes or enables a secondary address decoder stage. The

secondary address decoder stage is realised using the programmable chip slect logic of the MC68EN360. The 8 outputs of

the 68EN360 chip select logic are used for the base addresses of the various memory and I/O address ranges.

2.2.2 Boot Decoding

Due to the fact that the default boot memory used by the VM62(A) / VM42(A) is FLASH memory, which is completely

reprogrammable, a special boot decoder is provided. The boot memory is jumper selectable, the user having the choice

between FLASH (default), VMEbus memory or the on-board AutoBahn Interface. The boot decoder redirects the physical

address range 0H to 1000000H from either FLASH (DM60x), VMEbus or MP piggyback, providing the selected boot

memory is initially accessed.

Note

VMEbus boot memory must be located at VME base address 0H in Standard Supervisor Program/Data

address space.

Page 2-2 © 1995 PEP Modular Computers May 17, 1996

Page 18

VM62(A) / VM42(A) User’s Manual Chapter 2 Functional Description

2.2.3 Primary Address Decoder

The primary address decoder generates the following select signals.

CS_360 Secondary address decoder (68EN360, DRAM, FLASH)

CS_VME VMEbus address range

CS_AUT AutoBahn Interface address range

CS_BSS Bussizer address range (VME, SRAM, AutoBahn, I/O)

BERR_0 Reserved address range (Bus Error)

EN_BSS 68EN360 DMA address range

IACK Interrupt Acknowledge Cycle

2.2.4 Secondary Address Decoder

The secondary address decoder is built by the 68EN360 chip select logic and is therefore programmable. The outputs are

used as base address selects, as shown below.

68EN360 Chip Select Connected to

CS0 FLASH

CS1 DRAM

CS2 VME via 68EN360 DMA

CS3 AutoBahn Interface

CS4 SRAM

CS5 CXC

CS6 RTC

CS7 Control / Status Registers

May 17, 1996 © 1995 PEP Modular Computers Page 2-3

Page 19

Chapter 2 Functional Description VM62(A) / VM42(A) User’s Manual

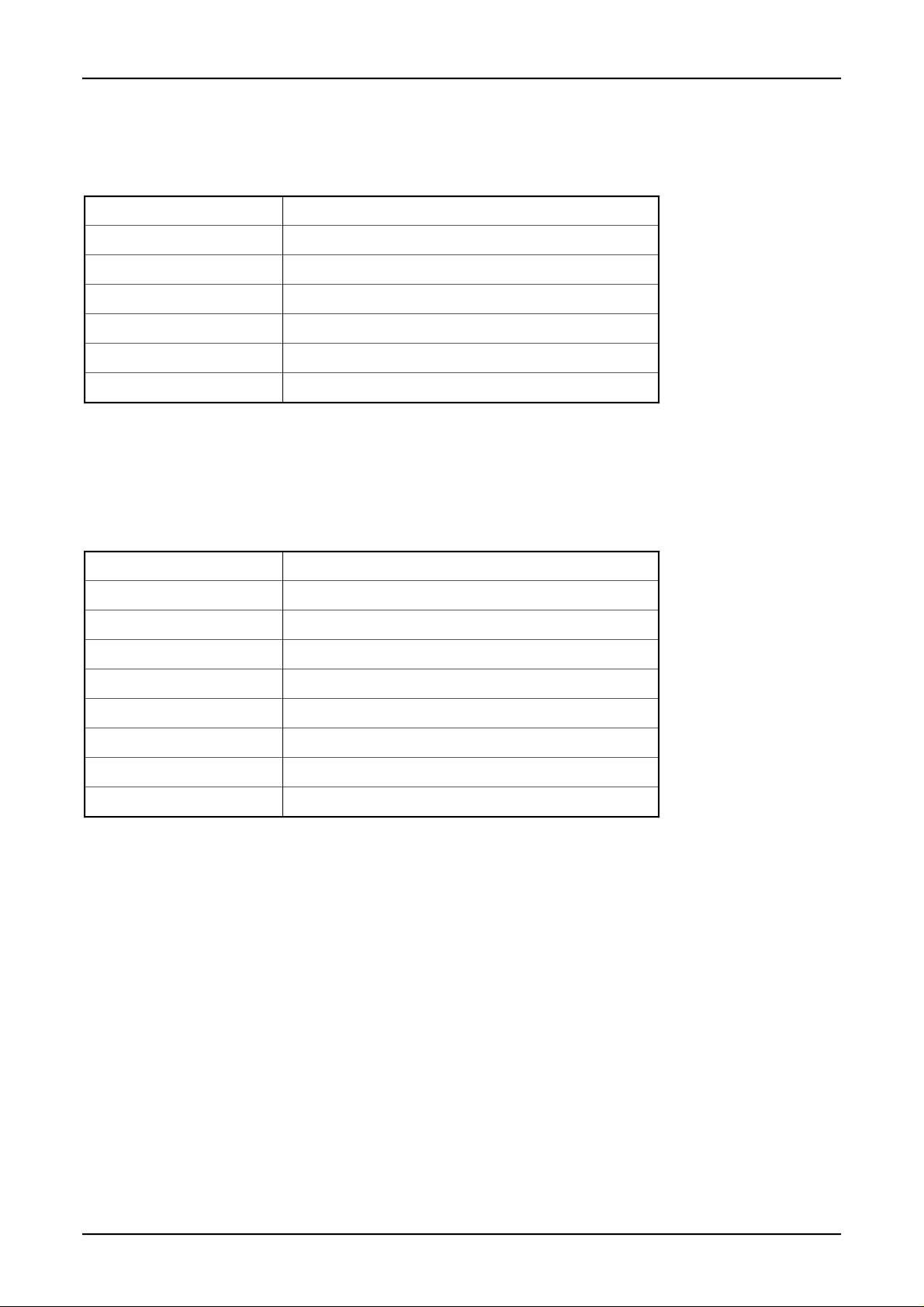

2.2.5 Address Map

The VM62(A) / VM42(A) address map shown in the Table below is based on the recommended default initialisation of

the 68EN360 chip select logic.

Figure 2.2.5.1: VM62(A) / VM42(A) Address Map (PEP Default)

Address (Hex) Device

00 xx xx xx

04 xx xx xx

07 00 0x xx

09 xx xx xx

0A xx xx xx

0B xx xx xx

0C xx xx xx

0D xx xx xx

1x xx xx xx

2x xx xx xx

3x xx xx xx

4x xx xx xx

5x xx xx xx

6x xx xx xx

82 xx xx xx

83 xx xx xx

85 00 xx xx

87 xx xx xx

87 xx xx xx

9x xx xx xx

Ax xx xx xx

Bx xx xx xx

C0 xx xx xx

C4 xx xx xx

C7 xx xx xx

CA xx xx xx

CB F7 0x xx

CC xx xx xx

CD 00 00 01

CD 00 00 05

CD 00 00 07

Dx xx xx xx

Ex xx xx xx

Fx xx xx xx

DRAM (68EN360’s CS1)

FLASH (68EN360’s CS0)

Reserved, 68EN360 internal RAM / register

DMA AutoBahn (CS3)

Reserved, mirrored 68EN360’s CS4

Reserved, mirrored 68EN360’s CS5

Reserved, mirrored 68EN360’s CS6

Reserved, mirrored 68EN360’s CS7

Reserved (BERR_0)

Reserved (BERR_0)

Reserved (BERR_0)

MP interface (CS_AUT)

Reserved (BERR_0)

Reserved (BERR_0)

The following address area is non-cachable serialised.

VMEbus (CS_VME), user-defined AM code

VMEbus (CS_VME), user-defined AM code

VMEbus (CS_VME), short I/O AM code

VMEbus (CS_VME), user-defined AM code

DMA-VME, 68EN360’s CS2

Reserved (BERR_0)

Reserved (BERR_0)

Reserved (BERR_0)

Reserved, mirrored DRAM

Reserved, mirrored FLASH

Reserved, 68EN360 internal RAM / register

68EN360’s CS4, SRAM

68EN360’s CS5, CXC

68EN360’s CS6, RTC

68EN360’s CS7+1, VME IRQ MASK register

68EN360’s CS7+5, VME control / status register

68EN360’s CS7+7, board control / status register

Reserved (BERR_0)

Reserved (BERR_0)

Reserved (BERR_0)

Note

In order to determine the base of the 68EN360’s internal memory map, the module base address register

(MBAR) must be set. The location of this register is fixed in the address area Supervisor CPU Space at

3FF00H. For more information, please refer to the Software Configuration chapter in this manual.

Page 2-4 © 1995 PEP Modular Computers May 17, 1996

Page 20

VM62(A) / VM42(A) User’s Manual Chapter 2 Functional Description

2.2.6 DMA Transfers

Memory to memory transfers with the 68EN360 DMAs are possible with any combination of on-board and VME

addresses. In order to achieve address compatibility between CPU/VME and DMA/VME transfers, it is recommended that

the initialisation of CS2 be initialised to the standard VME address space as described in the Software Configuration

chapter in this manual.

2.3 VMEbus Interface

The VM62(A) / VM42(A) has a complete master interface for the P1, J1 VMEbus connector. It consists of a VMEbus

arbiter, requester, system controller and buffers for data/address/control signals. In addition, the VM62(A) / VM42(A)

provides a VMEbus slave interface which consists of a programmable board address decoder, a dual-ported RAM and a

mailbox interrupt controller.

2.3.1 System Controller

The VM62(A) / VM42(A) can act as a VME system controller with arbiter, system clock driver, power monitor with

system reset driver, IACK daisy chain driver and 7-level VMEbus interrupt controller.

Arbitration is single level FAIR1 on BR3*. If the VM62(A) / VM42(A) is used as system controller it has to be placed

in slot 1 of the VMEbus backplane (furthermost left slot). There is no jumper setting necessary, as the board provides a

‘first slot detection’ function which is also readable within the VME control / status register. The IACK daisy chain

driver is supplied by connecting the IACKIN* and IACKOUT* line. IACK* is connected via the VMEbus backplane for

IACKIN* of slot 1.

VME SYSCLK* and SYSRES* can be routed from on-board using jumpers, leaving the choice of generating these

signals by the system controller to the user. SYSFAIL* generates a maskable on-board autovectored interrupt (see also

External Autovector Requests). ACFAIL* generates a non-maskable autovector level 7 interrupt (NMI) in the same way

as the ABORT button. When an ACFAIL* NMI is detected, it can be differentiated from an ABORT by reading bit 1 of

the Board Control/Status Register (bit 1 is set to ‘1’ for ACFAIL*). If this is the case, the CPU should stay in the IRQ

service routine and save any important data to non-volatile memory.

The VM62(A) / VM42(A) also provides a bus monitor for the VMEbus. A 128µs timeout timer monitors VMEbus data

transfer cycle lengths and generates a VMEbus BERR* signal for error termination. This timer is enabled/disabled via the

VME control / status register which also supplies a timeout status bit in order to identify bus errors generated by the bus

monitor.

2.3.2 Dual-Ported SRAM

The VM62(A) / VM42(A) provides on-board SRAM of either 256 kByte or 1 Mbyte. The SRAM is 16- bit wide and

dual-ported between the CPU/DMA and VME, accessible through an on-board arbiter. Read-Modify-Write cycles (TAS

instruction used for semaphores) are supported in any direction. The location of the dual-ported SRAM as seen from the

VME is programmable via the VME control / status register. There are 16 different base addresses possible that are all

located in the VME standard supervisor / user data space. Enable / disable is selected using a separate bit.

Note

The lower 8 kBytes of dual-ported SRAM should not be accessed from the VME because this area is

reserved for mailbox interrupts.

1

FAIR according to VME 64 Specifications, Rule 3.14 and Observation 3.17.

May 17, 1996 © 1995 PEP Modular Computers Page 2-5

Page 21

Chapter 2 Functional Description VM62(A) / VM42(A) User’s Manual

2.3.3 Mailbox Interrupt

An external VMEbus master may interrupt the VM62(A) / VM42(A) by setting P_IRQ5 (pending mailbox IRQ) in the

VME control / status register. The address of this dual-ported register seen from VME is identical to the base address of

the dual-ported SRAM, occupying the lower 8 kBytes (odd byte addresses) of the dual-ported SRAM.

Setting P_IRQ5 generates an autovector 5 interrupt on the CPU. Typically, the on-board CPU resets P_IRQ5 during the

processing of the corresponding interrupt service routine.

Note

Although every odd address of the 8k block of the VME control / status register can be accessed from

VME, only the P_IRQ5 bit can be set. All other bits are write protected from the VME. As the

P_IRQ5 bit is located at bit 7 within the register, it can be directly used as a semaphore because readmodify-write (TAS instruction) is supported.

2.3.4 VMEbus Control / Status Register

Address: CS7 + $5 PEP Default Address $CD 00 00 05

Format: Byte

Access: read / write

Value after HW reset: see table

CS7 + $5

P_IRQ5 FSDEN_BERR2EN_DPR

BADR2BADR3 BADR1 BADR0

Register Description

Name Value Reset (HW) Reset PEP (SW) Description

Slot 1 Other Slot 1 Other

P_IRQ5

1 0 0 0 0 Pending mailbox IRQ

bit 7

EN_DPR

bit 6

1 0 0

Value

stored in

EEPROM

Value

stored in

EEPROM

Dual-port RAM (including mailbox

IRQ) for VME requester enabled. Base

address fixed through BADRx bits

EN_BERR2

bit 5

FSD

bit 4

BADR3

- BADR0

bits 3 - 0

1 0 0 1 0 Enable bus monitor timer, all VME

cycles, timeout after 128µs

1 1 0 1 0 VMEbus ‘First Slot Detection’ flag,

system controller

0 0

Value

stored in

EEPROM

Value

stored in

EEPROM

VME address location of dual-ported

RAM. Equivalent to VME address lines

A23 - A20, programmable from $0 - $F

in 1 Mbyte windows, enabled with

EN_DPR. See Table on next page.

01234567

Page 2-6 © 1995 PEP Modular Computers May 17, 1996

Page 22

VM62(A) / VM42(A) User’s Manual Chapter 2 Functional Description

BADR [3 .. 0] VME Board Base Address

0000

0001

0010

0011

0100

0101

0110

0111

1000

1001

1010

1011

1100

1101

1110

1111

$00 00 00

$10 00 00

$20 00 00

$30 00 00

$40 00 00

$50 00 00

$60 00 00

$70 00 00

$80 00 00

$90 00 00

$A0 00 00

$B0 00 00

$C0 00 00

$D0 00 00

$E0 00 00

$F0 00 00

2.4 Interrupt Control

The interrupt control logic processes internal interrupt requests (68EN360), together with external requests (VME) and

external autovectored interrupt requests. The interrupt control logic is built up using the 68EN360 internal interrupt

controlling and a 7-level VMEbus interrupt handler with the corresponding mask register.

2.4.1 Internal Requests

Internal requests are related to all interrupt requests caused by the 68EN360 sources, including the 68EN360 system

integration functions (watchdog timer, periodic interrupt timer) and the communication processor module (RISC

controller, timers, DMAs, SCCs and so on). For more information, please refer to the 68EN360 User’s Manual.

In order to avoid conflicts regarding interrupt levels, it is recommended to use IRQ level 4 for 68EN360 CPU internal

requests and IRQ level 6 for 68EN360 SIM60 internal requests.

Note

The 4 IRQ lines specified by CXC are supplied by the 68EN360 Port C lines and are therefore also

processed as internal requests (PC0, 1, 2, 3).

2.4.2 External Autovector Requests

Some 68EN360 external interrupt sources are routed to the IRQ lines of the 68EN360 and generated as autovectored

interrupts. Care must be taken that the relevant 68EN360 register is initialised with respect to the wiring (see also the

Software Configuration chapter in this manual).

Source 68EN360 Pin Autovector

ABORT / ACFAIL IRQ7 7

TICK IRQ6 6

Mailbox IRQ IRQ5 5

SYSFAIL IRQ3 3

AutoBahn IRQ2 IRQ2 2

AutoBahn IRQ1 IRQ1 1

May 17, 1996 © 1995 PEP Modular Computers Page 2-7

Page 23

Chapter 2 Functional Description VM62(A) / VM42(A) User’s Manual

2.4.3 VME Interrupt Mask Register

Address: CS7 + $1 PEP Default Address $CD 00 00 01

Format: Byte

Access: read / write

Value after HW reset:0

Value after PEP SW initialization: Value of EEPROM

01234567

CS7 + $1

Register Description

Name Value Description

EN_IRQx 1 Enable VME IRQx where x = 1 to 7

SYSFAIL 1 Enable VME SYSFAIL IRQ autovector 3

EN_IRQ7 EN_IRQ4EN_IRQ5EN_IRQ6

EN_IRQ2EN_IRQ3 EN_IRQ1 SYSFAIL

Page 2-8 © 1995 PEP Modular Computers May 17, 1996

Page 24

VM62(A) / VM42(A) User’s Manual Chapter 2 Functional Description

2.5 I/O Ports

2.5.1 Ethernet Port

The MC68EN360 is specified to support a full set of IEEE 802.3/Ethernet CSMA/CD media access control and channel

interface functions. Since the 68EN360 requires an external interface adapter and transceiver function, the Ethernet port

can be adapted to all standard Ethernet functions, such as 10BaseT, 10Base5 and 10Base2 via a piggyback connected to the

SI Interface on the VM62(A) / VM42(A).

2.5.2 Serial Ports

The VM62(A) / VM42(A) provides 6 serial ports based on the 68EN360 communications processor. The ports can be

configured in the following way:

• 2 * service / debug ports (SMC port / RxD / TxD only RS232);

• 4 * full MODEM ports / multiprotocol channels (SCC ports).

The service / debug ports are configured as default on the VM62(A) / VM42(A). These ports supply RxD/TxD RS232

Interfaces software handshake (XON/XOFF) capability. The full MODEM ports supply RxD, TxD, RTS, CTS, CD,

DTR and RCLK/TCLK. Two of the full MODEM ports can be configured on the SI Interface with a variety of SI

Modules (RS232/RS485, isolated/non-isolated and so on). Together with the two service/debug ports, a maximum of

three (four) completely configured serial ports are available for the base board. Three (two) serial ports may be configured

via the CXC where three of the four full MODEM Interfaces are routed.

Figure 2.5.2.1: MC68EN360 Intelligent Controller Schematic

CXC Interface

SCC2

SCC3

}

}

Rx and Tx only

SI-Interface

SI-Piggyback

Interface

MC68EN360

}

SCC4

SCC1

SMC2SMC1

2x RS232 with

Memory

Piggyback

Note

The serial channel SCC4 is routed to both the SI Interface and the CXC and can only be used by one or

the other and not both at the same time.

May 17, 1996 © 1995 PEP Modular Computers Page 2-9

Page 25

Chapter 2 Functional Description VM62(A) / VM42(A) User’s Manual

The Ethernet port can be configured via the SI Interface with 10BaseT, 10Base5 or 10Base2 SI Modules. The following

configurations are therefore possible for the serial ports.

Versions with Ethernet Port

Port 68EN360 Resource Configured via

Service/Debug 1 SMC1 Base board, upper RJ12

Service/Debug 2 SMC2 Base board, lower RJ12

Ethernet SCC1 Base board, SI Module

Full MODEM 2 SCC2 CXC Module

Full MODEM 3 SCC3 CXC Module

Full MODEM 4 SCC4 CXC Module

*

The 10BaseX Modules do not make use of SCC4 and, therefore, can be used on the CXC.

Versions without Ethernet Port

Port 68EN360 Resource Configured via

*

Service/Debug 1 SMC1 Base board, upper RJ12

Service/Debug 2 SMC2 Base board, lower RJ12

Full MODEM 1 SCC1 Base board, SI Module

Full MODEM 2 SCC2 CXC Module

Full MODEM 3 SCC3 CXC Module

Full MODEM 4 SCC4 Base board, SI Module or CXC Module

*

Can only be used once.

*

2.5.3 CXC Interface

The Controller Extension Connector (CXC) is a local mezzanine interface. The CXC contains a 16-bit data bus, 7 address

lines and 8 decoded chip select lines. In total, there are 8 control signals. The base address of the CXC can be programmed

via the CS5 line of the 68EN360. The 8 CXC chip selects (CXC_CS0 - CXC_CS7) occupy 256 Bytes each and have an

address length of 400H (512 Bytes).

Furthermore, the CXC contains 4 IRQ capability (4 edge sensitive IRQs), DMA capability (1 channel, DREQ + DACK),

serial ports (3 channels, Full MODEM) and a set of parallel port signals. These special CXC functions are based on the

68EN360 resources.

For general CXC information, including generic pinouts and a comparison of the 68(EN)360 and 68302 CPU pinouts on

the CXC, please refer to the CXC Specification User’s Manual and the CXC Appendix attached to this manual.

Page 2-10 © 1995 PEP Modular Computers May 17, 1996

Page 26

VM62(A) / VM42(A) User’s Manual Chapter 2 Functional Description

Table 2.5.3.1: CXC Pinouts using the 68(EN)360

Pin Row A

Signals

1 PC0/_RTS1/L1ST1 PA8/CLK1/BRGO1/L1RCLKA/TIN1 PB6/SMTXD1/_DONE1

2 PC1/_RTS2/L1ST2 PA10/CLK3/BRGO2/L1TCLKA/TIN2 PB5/BRGO2/_DACK1

3 PC2/_RTS3/_L1RQB/L1ST3 GND PB4/BRGO1/_DREQ1

4 PC3/_RTS4/_L1RQA/L1ST4 PA3/TXD2 PB11/SMRXD2/L1CLKOA

5 PB0/_SPISEL/_RRJCT1 PB13/_RTS2/L1ST2 PA14/CLK7/BRGO4/TIN4

6 PB1/SPICLK/_RSTRT2 GND PA15/CLK8/_TOUT4/L1TCLKB

7 VCC PB15/_RTS4/_L1RQA/L1ST4 VCC

8 PB2/SPIMOSI(SPITXD)/_RRJCT2 PC11/_CD4/_L1RSYNCA PA7/TXD4/L1RXDA

9 PB3/SPIMISO(SPIRXD)/BRGO4 GND PA6/RXD4/L1TXDA

10 PB8/_SMSYN1/_DREQ2 PA2/RXD2 PB7/SMRXD1/_DONE2

11 PB16/BRGO3/STRBO PB10/SMTXD2/L1CLKOB PC9/_CD3/_L1RSYNCB

12 PB9/_SMSYN2/_DACK2 GND PB14/_RTS3/_L1RQB/L1ST3

13 PB17/_RSTRT1/STRBI PC6/_CTS2 PC8/_CTS3/_L1TSYNCB/SDACK2

14 VCC PC7/_CD2/_TGATE2 VCC

15 _CS-CXC (CS5 of 68360) GND PA12/CLK5/BRGO3/TIN3

16 _AS PC10/_CTS4/_L1TSYNCA/_SDACK1 PA13/

17 R/_W _SYSR PA5/TXD3/L1RXDB

18 _UDS GND PA4/RXD3/L1TXDB

19 _LDS _EDTACK VCC

20 VCC 16MHz CLOCK _CXC-CS2

21 A1 GND _CXC-CS3

22 A2 _CXC-CS0 _CXC-CS4

23 A3 _CXC-CS1 _CXC-CS5

24 A4 GND _CXC-CS6

25 A5 A6 _CXC-CS7

26 VCC A7 VCC

27 D0 GND D10

28 D1 D6 D11

29 D2 D7 D12

30 D3 GND D13

31 D4 D8 D14

32 D5 D9 D15

Row B

Signals

Row C

Signals

CLK6/_TOUT3/L1RCLKB/BRGCLK2

May 17, 1996 © 1995 PEP Modular Computers Page 2-11

Page 27

Chapter 2 Functional Description VM62(A) / VM42(A) User’s Manual

CXC

Function

IRQ_1 a1 Yes PC0

IRQ_2 a2 Yes PC1

IRQ_3 a3 Yes PC2

IRQ_4 a4 Yes PC3

CXC

Function

DMA_ACK c2 Yes PB5

DMA_REQ c3 Yes PB4

CXC

Function

SER1_RCLK b1 Yes PA8

Pin Nr. 68302 HW

Compatible

Pin Nr. 68302 HW

Compatible

Pin Nr. 68302 HW

Compatible

68(EN)360

Port

68(EN)360

Port

68(EN)360

Port

Comment

Comment

Comment

SER1_TCLK b2 Yes PA10

SER1_TXD b4 Yes PA3

SER1_RXD b10 Yes PA2

SER1_RTS b5 Yes PB13

SER1_DTR a13 Yes PB17

SER1_CTS b13 Yes PC6

SER1_CD b14 Yes PC7

CXC

Function

SER2_RCLK c16 Yes PA13 Cannot be used if J6 is set

SER2_TCLK c15 Yes PA12

SER2_TXD c17 Yes PA5

SER2_RXD c18 Yes PA4

SER2_RTS c12 Yes PB14

Pin Nr. 68302 HW

Compatible

68(EN)360

Port

Comment

See note 3

SER2_DTR a11 Yes PB16

SER2_CTS c13 Yes PC8

SER2_CD c11 Yes PC9

Page 2-12 © 1995 PEP Modular Computers May 17, 1996

Page 28

VM62(A) / VM42(A) User’s Manual Chapter 2 Functional Description

CXC

Function

SER3_RCLK c6 Yes PA15 Not usable if SI Module uses SCC4

SER3_TCLK c5 Yes PA14

SER3_TXD c8 Yes PA7 Not usable if SI Module uses SCC4

SER3_RXD c9 Yes PA6 Not usable if SI Module uses SCC4

SER3_RTS b7 Yes PB15 Not usable if SI Module uses SCC4

SER3_DTR a12 Yes PB9 Not usable if SI Module uses SCC4

SER3_CTS b16 Yes PC10 Not usable if SI Module uses SCC4

SER3_CD b8 Yes PC11 Not usable if SI Module uses SCC4

Pin Nr. 68302 HW

Compatible

68(EN)360

Port

Comment

See note 4

See note 4

See note 4

See note 4

See note 4

See note 4

See note 4

CXC

Function

user defined a5 No PB0 Used on board SPI SEL for

Pin Nr. 68302 HW

Compatible

a6 No PB1 SPI Clk: can be used if an ‘SPI SEL’

a8 No PB2 SPI TxD: can be used if an ‘SPI SEL’

a9 No PB3 SPI RxD: can be used if an ‘SPI

a10 No PB8 See 68360 User Manual

b11 No PB10 Used on board SMC2 (Transmit)

c1 No PB6 Used on board SMC1 (Transmit)

c4 No PB11 Used on board SMC2 (Receive)

c10 No PB7 Used on board SMC1 (Receive)

68(EN)360

Port

Comment

EEPROM. Cannot be used on CXC

See note 2

other than PB0 is used.

other than PB0 is used.

SEL’ other than PB0 is used.

See note 1

See note 1

See note 1

See note 1

May 17, 1996 © 1995 PEP Modular Computers Page 2-13

Page 29

Chapter 2 Functional Description VM62(A) / VM42(A) User’s Manual

Notes

Reserved Pins

1) On a standard VM62(A)/VM42(A) board, these signals are already used for UART ports at BU7 and BU8.

2) On a standard VM62(A)/VM42(A) board, these signals are used for SPI to which the EEPROM is already

connected. PB0 is chip select of the EEPROM.

3) On PA13, a 24 MHz clock signal is routed via jumper J6. This signal is always needed for PEP standard

software (serial drivers).

Dual Functioning Signal Pins

4) These signals are routed both to the base board SI Interface connector (ST5C) and the CXC connector and can

only be used by one or the other and not both at the same time.

Due to this, a conflict exists if the SCC4 port is to be used with the SI232 piggyback and CXC boards (such as

CXM-SIO3), as both boards access this port. The SCC4 port can, therefore, not be used at the same time by SI

piggybacks and CXC boards.

The CXC ports SER1, SER2 and SER3 are equivalent to ports SCC2, SCC3 and SCC4 resp. on the 68xx360.

With regard to special CXC capabilities, the CXC pinout on the VM62(A) / VM42(A) has been developed to provide

maximum compatibility between the standard CXC functions. In addition, all signals are available in order to configure 2

time division multiplexed channels via the CXC (ISDN, PCM, GCI and so on). Multi-function pins with incompatible

functions with regard to the 68302 and 68EN360 (called user defined in the generic CXC specification) are not part of the

VM42(A) / VM62(A) CXC specification.

Although the SMCs are configured on the base board, these ports are also integrated on the CXC. This is because of

possible ISDN applications where SMCs can be integrated and other protocols supported by the 68EN360.

Note

If the RCLK2 signal (CXM pin c16) is required, jumper J6 (24 MHz clock) must be opened and the

serial drivers delivered by PEP modified.

Page 2-14 © 1995 PEP Modular Computers May 17, 1996

Page 30

VM62(A) / VM42(A) User’s Manual Chapter 2 Functional Description

Table 2.5.3.2: Further Explanation of 68(EN)360 Mnemonics

Group Signal Name Mneumonic Function

SCC Receive Data RXD4-RXD1 Serial receive data input to the SCCs (I)

Transmit Data TXD4-TXD1 Serial transmit data output from the SCCs (O)

Request to Send _RTS4-_RTS1 Request to send outputs indicate that the SCC is ready

to transmit data (O)

Clear to Send _CTS4-_CTS1 Clear to send inputs indicate to the SCC that data

transmission may begin (I)

Carrier Detect _CD4-_CD1 Carrier detect inputs indicate that the SCC should begin

reception of data (I)

Receive Start _RSTRT1 This output from SCC1 identifies the start of a receive

frame. Can be used by an Ethernet CAM to perform

address matching (O)

Receive Reject RRJCT1 This input to SCC1 allows a CAM to reject the current

Ethernet frame after it determines the frame address did

not match (I)

Clocks CLK8-CLK1 Input clocks to the SCCs, SMCs, SI, and the baud rate

IDMA DMA Request _DREQ2-

_DREQ1

DMA Acknowledge _DACK2-

_DACK1

DMA Done _DONE2-

_DONE1

TIMER Timer Gate _TGATE2-

_TGATE1

Timer Input TIN4-TIN1 Time reference input to the timer that allows it to

Timer Output _TOUT4-

_TOUT1

SPI SPI Master-In

Slave-Out

SPI Master-Out

Slave-In

SPI Clock SPICLK Output clock from the SPI master (O); input clock to

SPIMISO Serial data input to the SPI master (I); serial data

SPIMOSI Serial data output from the SPI master (O); serial data

generators (I)

A request (input) to an IDMA channel to start an

IDMA transfer (I)

An acknowledgement (output) by the IDMA that an

IDMA transfer is in progress (O)

A bidirectional signal that indicates the last IDMA

transfer in a block of data (I/O)

An input to a timer that enables/disables the counting

function (I)

function as a counter (I)

Output waveform (pulse or toggle) from the timer as a

result of a reference value being reached (O)

output from an SPI slave (O)

input to an SPI slave (I)

the SPI slave (I)

SPI Select _SPISEL SPI slave select input (I)

SMC SMC Receive Data SMRXD2-

SMRXD1

SMC Transmit Data SMTXD2-

SMTXD1

SMC Sync _SMSYN2-

_SMSYN1

May 17, 1996 © 1995 PEP Modular Computers Page 2-15

Serial data input to the SMCs (I)

Serial data output from the SMCs (O)

SMC syncronization signal (I)

Page 31

Chapter 2 Functional Description VM62(A) / VM42(A) User’s Manual

Group Signal Name Mneumonic Function

SI SI Receive Data L1RXDA,

L1RXDB

SI Transmit Data L1TXDA,

L1TXDB

SI Receive Clock L1RCLKA,

L1RCLKB

SI Transmit Clock L1TCLKA,

L1TCLKB

SI Transmit Sync

Signals

SI Receive Sync

Signals

IDL Interface

Request

SI Output Clock L1CLKOA,

SI Data Strobes L1ST4-L1ST1 Serial data strobe outputs can be used to gate clocks to

L1TSYNCA,

L1TSYNCB

L1RSYNCA,

L1RSYNCB

L1RQA, L1RQB IDL interface request to transmit on the D channel.

L1CLKOB

Serial input to the Time Division Multiplexed (TDM)

channel A or channel B

Serial output from the TDM channel A or channel B

Input receive clock to TDM channel A or channel B

Input transmit clock to TDM channel A or channel B

Input transmit data sync signal to TDM channel A or

channel B

Input receive data sync signal to TDM channel A or

channel B

Output from the SI

Output serial data rate clock. Can output a data rate

clock when the input clock is 2x the data rate

external devices that do not have a biult-in Time Slot

Assigner (TSA)

BRG Baud Rate Generator

Out 4-1

BRG Input Clock CLK2, CLK6 Baud rate generator input clock from which BRG will

PIP Port B 15-0 PB15-PB0 PIP Data I/O Pins

Strobe Out STRBO This input causes the PIP output data to be placed on

Strobe In STRBI This input causes data on the PIP data pins to be

SDMA SDMA

Acknowledge 2-1

2.5.4 AutoBahn Interface

In preparation

BRGO4-BRGO1 Baud rate generator output clock allows baud rate

generator to be used externally

derive the baud rates

the PIP data pins

latched by the PIP as input data

_SDACK2_SDACK1

SDMA output signals used in RISC receiver to mark

fields in the Ethernet receive frame

Page 2-16 © 1995 PEP Modular Computers May 17, 1996

Page 32

VM62(A) / VM42(A) User’s Manual Chapter 2 Functional Description

2.6 Special Functions

2.6.1 Real-Time Clock

The RTC (V3021 3-wire serial interface) is a 1-bit device which is accessible over the CS6 of the 68EN360. Its

timekeeping features include :-

• seconds, minutes, hours, day of month, month, year, week day and week number in BCD format.

• leap year and week number correction

• standby supply smaller than 1µA

See also the Software Configuration chapter in this manual and the V3021 data sheet.

2.6.2 EEPROM

The serial EEPROM is a 1-bit device which is accessible over the SPI Interface (3-wire Interchip) of the 68EN360. The

first half of the EEPROM (1 kbit) is reserved for factory data, including Board ID codes, Internet/Ethernet addresses, boot

information etc. The second half of the EEPROM is available for the user. See also the Software Configuration chapter in

this manual.

For more information on the EEPROM, please refer to the XICOR X25C02 data sheet.

2.6.3 TICK Generator

The 68EN360 internal Periodic Interrupt Timer is used by the PEP real-time operating system as TICK generator.

For more information please refer to the 68EN360 User’s Manual.

2.6.4 On-board Bus Error Timer

The VM62(A) / VM62(A) provides an on-board bus error timer. An 8µs timeout timer monitors the cycle lengths of data

transfers to and from locations beyond the bussizer, including on-board I/O, CXC, SRAM, AutoBahn and some VME.

After a timeout occurs, it generates an on-board BERR signal for error termination. This timer is enabled/disabled via the

board control/status register, which also supplies a timeout status bit in order to identify bus errors generated by the onboard bus error timer.

There are four cases of bus error.

Cause Timeout Enable / Disable possible

Reserved address BERR0

On-board BERR1

VME BERR2

Chip selects 68EN360

100ns

8µs

128µs

programmable

None

Yes, set in board control register

Yes, set in VMEbus control register

Yes, set in 68EN360 register

May 17, 1996 © 1995 PEP Modular Computers Page 2-17

Page 33

Chapter 2 Functional Description VM62(A) / VM42(A) User’s Manual

Note

During VMEbus cycles, the on-board bus error timer is reset as soon as the VM62(A) / VM42(A) gains

VMEbus ownership. This means that the time gap between a VMEbus request and the starting of the

VMEbus cycle is monitored by the on-board BERR timer. VMEbus cycles themselves are monitored

by the separate VMEbus BERR timer (BUS monitor).

2.6.5 VME Bus Error Timer

The VM62(A) / VM42(A) also provides a bus monitor for the VMEbus. A 128µs timeout timer monitors VMEbus data

transfer cycle lengths and generates a VMEbus BERR* signal for error termination. This timer is enabled/disabled via the

VME control/status register which also supplies a timeout status bit in order to identify bus errors generated by the bus

monitor.

2.6.6 Watchdog Timer

A 512ms watchdog timer triggers the on-board and VME system reset generator at timeout. Once enabled via the board

control/status register, the watchdog timer cannot be reset by software. It must be re-triggered via the corresponding bit in

the board control/status register periodically within the timeout period. ‘Watchdog timer running’ is a status that is

displayed by the yellow front panel LED.

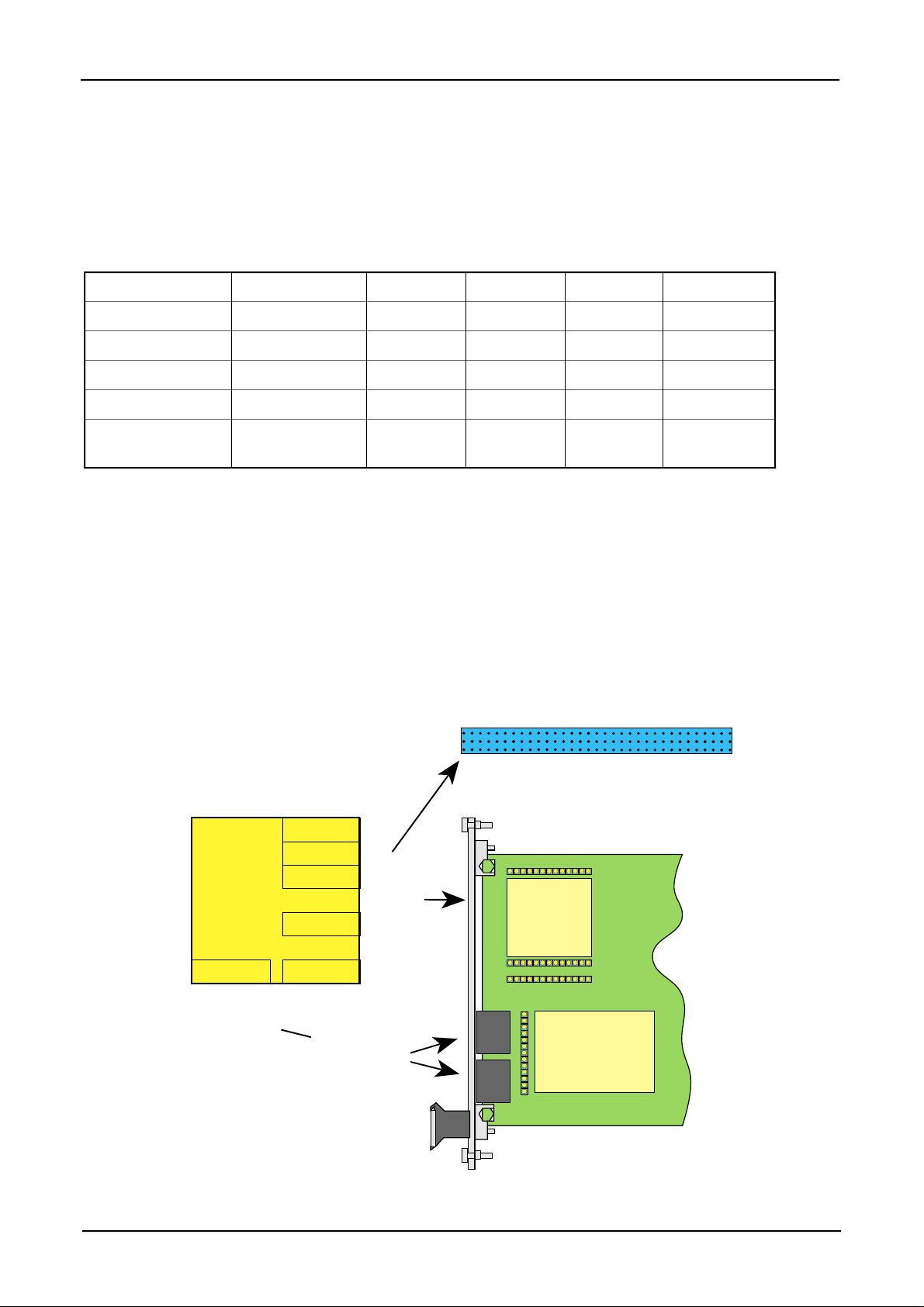

Figure 2.6.6.1: Watchdog LED Location

Watchdog LED

Yellow

W

2.6.7 First Slot Detection (FSD)

The VM62(A)/VM62(A) detects during power-up whether the CPU in use is positioned in the far left slot of the system.

This is achieved using a 100k pull-down resistor at the BG3IN* pin.

BG3IN* low = system controller (far left slot)

BG3IN* high = no system controller

This information can be read from the VMEbus Control/Status register and is valid until the next power down of the

system.

Page 2-18 © 1995 PEP Modular Computers May 17, 1996

Page 34

VM62(A) / VM42(A) User’s Manual Chapter 2 Functional Description

2.6.8 Board Control/Status Register

Address: CS7 + $7 PEP Default Address $CD 00 00 07

Format: Byte

Access: read / write

Value after HW reset:0

01234567

CS7 + $7

Register Description

Name Value Access Description

WDG

bit 7

BERR2

bit 6

BERR1

bit 5

EN_WDG

bit 4

TR_WDG

bit 3

WDG EN_WDGBERR1BERR2

Read/Write Set by watchdog timer when timout has been reached. Used

to differentiate between resets caused by the watchdog and

resets caused by the reset button

(power up resets can be identified within the 68EN360)

Read/Write Set by VMEbus BUS monitor when timeout has been

reached. Used to identify BERR caused by this timer (see

also VMEbus Control/Status register)

Read/Write Set by on-board bus error timer when timeout has been

reached. Used to identify BERR caused by this timer

1 Read/Write Enable the watchdog timer. It can only be set once, and

remains enabled until the next reset

1 Read/Write Triggers the watchdog timer. Watchdog timeout = 512ms

EN_BERR1TR_WDG ACFAIL LED_G

EN_BERR1

bit 2

ACFAIL

bit 1

LED_G

bit 0

1 Read/Write Enables the on-board bus error timer. It also monitors all on-

board I/O cycles, including the time from the VMEbus

request to the VMEbus grant. Timeout = 8µs

1 Read/Write VME ACFAIL signal latched when active in order to

distinguish a level 7 NMI from an ABORT or ACFAIL

1 Read/Write Enables the green ‘general purpose’ front panel LED

Note

Information may be lost if the user writes to bit 7.

May 17, 1996 © 1995 PEP Modular Computers Page 2-19

Page 35

Chapter 2 Functional Description VM62(A) / VM42(A) User’s Manual

2.6.9 Reset Sources

Reset Source Identification

Push button No

SYSRES* VME No

Watchdog WDG bit on-board (Board Control/Status Register)

Power monitor (4.65V) Inside the 68EN360

2.7 Front Panel Functions

Figure 2.7.0.1: LED Port and Button Location

Watchdog LED

Yellow

General Purpose

Green

W

UH

RESET Switch ABORT Switch

RST AB

CPU HALT or RESET

Red

2.7.1 RESET Button

A RESET button is fitted to the front panel to avoid false operation. The RESET button triggers the on-board system reset

generator, as well as the VME if jumper J2 is set.

2.7.2 ABORT Button

Together with the RESET button, an ABORT button is also fitted to the front panel. The ABORT button generates a level

7 IRQ (non-maskable interrupt) which is used for debugging purposes. In this case, bit 1 of the Board Control/Status

Register is not set (remains ‘0’).

2.7.3 LED Port

The front panel LED port consists of three LEDs with the following functions:

Red LED CPU in HALT or RESET status

Yellow LED Watchdog timer running status

Green LED General purpose, set via board control/status register

The green LED is free to be used by the customer. It is set by the software during startup when the 68EN360 is initialized.

Page 2-20 © 1995 PEP Modular Computers May 17, 1996

Page 36

VM62(A) / VM42(A) User’s Manual Chapter 2 Functional Description

2.8 Data Retention for RTC and SRAM

Short term data retention for RTC and SRAM is gained with two Gold-Caps, each with a value of 0.22 Farad. In contrast

to Lithium cells, Gold-Caps do not require servicing. This short term backup is intended for short power failures or for

reconfiguring systems. An empty Gold-Cap needs approximately three hours to charge up, with backup times dependant on

the temperature, memory size and memory manufacturer tolerances. A well charged Gold-Cap provides a minimum of 10

hours backup time.