Page 1

Kontron Carrier Grade Server

TIGH2U

Product Guide

December 2009

Rev. 1.2

Page 2

Legal Lines and Disclaimers

Copyright © 2009, Kontron AG. All Rights Reserved.

All data is for information purposes only and not guaranteed for legal purposes. Information has been carefully checked and is

believed to be accurate; however, no responsibility is assumed for inaccuracies. Kontron and the Kontron logo and all other

trademaarks or registed trademarks are the property of their respective owners and are recognized. Specifications are subject to

change without notice.

Kontron Carrier Grade Server TIGH2U

Product Guide, rev.1.2 December 2009

2

Page 3

Contents—TIGH2U Server

Contents

1Introduction..............................................................................................................8

1.1 About this Manual ...............................................................................................8

1.1.1 Manual Organization.................................................................................8

1.2 What Your Server Includes ...................................................................................9

1.3 Product Accessories .............................................................................................9

1.4 Additional Information and Software .................................................................... 10

2Features..................................................................................................................11

2.1 Server Components........................................................................................... 13

2.2 Back Panel ....................................................................................................... 14

2.3 Front Panel....................................................................................................... 15

2.4 Rear Panel Ethernet Ports...................................................................................18

2.5 SAS Front Panel (SFP) Board .............................................................................. 18

2.5.1 SFP Board Features ................................................................................ 18

2.6 Telco Alarms Manager Board...............................................................................18

2.6.1 TAM Board Features ............................................................................... 19

2.7 Server Board Connector and Component Locations ................................................ 19

2.8 Hard Disk Drives ............................................................................................... 20

2.9 Riser Card Assembly.......................................................................................... 21

2.9.1 Full-Height PCI-X/PCIe Riser Card.............................................................21

2.9.2 Low-Profile PCIe Riser Card ..................................................................... 21

2.10 Power Supply.................................................................................................... 22

2.11 System Cooling................................................................................................. 22

2.11.1 CPU 1 and Memory Cooling Area .............................................................. 23

2.11.2 CPU 2 and Chipset Cooling Area ...............................................................23

2.11.3 PCI Cooling Area .................................................................................... 23

2.11.4 Hard Disk Drive and Power Supply Cooling................................................. 23

2.11.5 Fan Speed Control.................................................................................. 23

2.11.6 Cooling Summary................................................................................... 24

2.12 Hardware Requirements..................................................................................... 24

2.12.1 Processor .............................................................................................. 24

2.12.2 Memory ................................................................................................ 24

3 Server Component Installations and Upgrades ........................................................25

3.1 Before You Begin............................................................................................... 25

3.1.1 Tools and Supplies Needed ...................................................................... 25

3.1.2 System References................................................................................. 25

3.2 General Installation Procedures........................................................................... 25

3.2.1 Removing the Front Bezel........................................................................ 25

3.2.2 Installing the Front Bezel......................................................................... 26

3.2.3 Removing the Chassis Cover.................................................................... 26

3.2.4 Installing the Chassis Cover..................................................................... 27

3.2.5 Removing the Processor Air Duct.............................................................. 28

3.2.6 Installing the Processor Air Duct............................................................... 29

3.3 Hot-Swappable Component Installation Procedures................................................ 30

3.3.1 Installing or Replacing a Hard Drive ..........................................................30

3.3.1.1 Removing a Hard Drive Tray....................................................... 30

3.3.1.2 Attaching a Hard Drive to the Drive Tray...................................... 31

3.3.2 Replacing a Power Supply........................................................................ 32

3.3.2.1 Removing the Power Supply Module ............................................ 33

3.3.2.2 Installing a Power Supply Module ................................................ 33

3.3.2.3 Installing or Replacing a DC Power Supply.................................... 34

3.3.2.4 Grounding a DC-Powered System................................................ 34

December 2009 Product Guide, rev.1.2

3

Kontron Carrier Grade Server TIGH2U

Page 4

TIGH2U Server—Contents

3.4 Internal System Component Configuration and Installation Procedures .....................34

3.4.1 Configuring Jumpers on the Server Board ..................................................34

3.4.1.1 Configuration Jumpers ...............................................................35

3.4.1.2 BIOS Select Jumper...................................................................36

3.4.1.3 DCD/DSR Signal Select Jumper...................................................37

3.4.2 Configuring Memory DIMMs......................................................................37

3.4.2.1 Memory RASUM Features ...........................................................39

3.4.2.2 Supported Memory....................................................................39

3.4.2.3 DIMM Population Rules and Supported DIMM Configurations ...........40

3.4.2.4 Non-Mirrored Mode Minimum Configuration...................................41

3.4.2.5 Non-Mirrored Mode Memory Upgrades..........................................42

3.4.2.6 Mirrored Mode Memory Configuration...........................................42

3.4.2.7 DIMM Sparing Mode Memory Configuration...................................43

3.4.2.8 Single Branch Mode Sparing ......................................................43

3.4.2.9 Dual Branch Mode Sparing..........................................................43

3.4.3 Installing DIMMs.....................................................................................44

3.4.4 Removing Memory DIMMs........................................................................45

3.4.5 Adding or Replacing a Processor ...............................................................46

3.4.5.1 ESD and Processor Handling Precautions ......................................46

3.4.5.2 Removing a Processor................................................................47

3.4.5.3 Installing a New Processor..........................................................48

3.4.5.4 Installing the Heat Sink..............................................................50

3.4.6 Other Installation and Upgrade Options .....................................................50

3.5 Installing the Server into a Rack ..........................................................................50

3.5.1 Connecting the Power Cord ......................................................................50

3.5.2 Equipment Rack Precautions ....................................................................51

4 Optional Component Installations ............................................................................52

4.1 Before You Begin ...............................................................................................52

4.1.1 Tools and Supplies Needed.......................................................................52

4.1.2 System References .................................................................................52

4.1.3 Cable Routing Reference..........................................................................53

4.2 Installing or Replacing a PCI Add-in Card ..............................................................53

4.2.1 Riser Card Options..................................................................................54

4.2.2 Removing the PCI Riser Card Assembly......................................................56

4.2.3 Removing an Add-in Card from the Riser Card Assembly ..............................57

4.2.4 Installing an Add-in Card in the Riser Card Assembly ...................................58

4.2.5 Installing the PCI Riser Card Assembly ......................................................59

4.3 Installing an I/O Expansion Module ......................................................................59

4.4 Installing Remote Management Module 2 Components............................................61

4.4.1 Installing the RMM2 NIC Module ...............................................................61

4.4.2 Installing the Remote Management Module 2..............................................62

4.5 Installing an Embedded USB Solid-State Drive.......................................................62

4.6 Installing Hardware RAID 5 Components...............................................................65

4.6.1 Installing the RAID Activation Key and the RAID DIMM ................................66

4.6.2 Installing the RAID Smart Battery .............................................................67

4.7 Installing an Optical Device.................................................................................69

4.7.1 Removing the Optical Device Filler Panel ....................................................69

4.7.2 Installing a New Optical Device.................................................................71

5 Server Component Replacements.............................................................................73

5.1 Before You Begin ...............................................................................................73

5.1.1 Tools and Supplies Needed.......................................................................73

5.1.2 System References .................................................................................73

5.1.3 Cable Routing Reference..........................................................................73

5.2 Replacing the Fan Assemblies..............................................................................74

5.2.1 Removing the CPU Fan Assembly..............................................................75

Kontron Carrier Grade Server TIGH2U

Product Guide, rev.1.2 December 2009

4

Page 5

Contents—TIGH2U Server

5.2.2 Replacing the CPU Fans in the Bracket ...................................................... 76

5.2.3 Installing the CPU Fan Assembly............................................................... 77

5.2.4 Removing the PCI Fan Assembly .............................................................. 78

5.2.5 Replacing the PCI Fans in the Fan Bracket ................................................. 81

5.2.6 Installing the Fan Assembly ..................................................................... 82

5.3 Replacing the TAM Board.................................................................................... 83

5.3.1 Removing the TAM Board ........................................................................ 84

5.3.2 Removing the LED Light Pipe Assembly .....................................................87

5.3.3 Installing the TAM Board ......................................................................... 88

5.4 Replacing the SAS Front Panel Board ................................................................... 89

5.4.1 Removing the Front Panel Board............................................................... 89

5.4.2 Installing the Front Panel Board ............................................................... 92

5.5 Replacing the Removable Drive Bay Assembly and the SAS Backplane Board............. 93

5.5.1 Removing the Drive Bay Assembly............................................................ 93

5.5.2 Removing the SAS Backplane Board from the Drive Bay Assembly ................ 94

5.5.3 Installing a New SAS Backplane Board ...................................................... 95

5.5.4 Installing the Drive Bay Assembly............................................................. 96

5.6 Replacing the Power Distribution Assembly ........................................................... 97

5.6.1 Removing the Power Distribution Board..................................................... 97

5.6.2 Installing the Power Distribution Board...................................................... 99

5.7 Replacing the Server Board .............................................................................. 100

5.7.1 Removing the Server Board................................................................... 100

5.7.2 Installing the Server Board .................................................................... 103

5.8 Replacing the CMOS Battery on the Server Board ................................................ 104

6 Server Utilities ...................................................................................................... 106

6.1 Using the BIOS Setup Utility ............................................................................. 106

6.1.1 Starting Setup ..................................................................................... 106

6.1.2 If You Cannot Access Setup ................................................................... 106

6.1.3 Setup Menus ....................................................................................... 106

6.2 Upgrading the BIOS......................................................................................... 107

6.2.1 Preparing for the Upgrade ..................................................................... 108

6.2.1.1 Recording the Current BIOS Settings......................................... 108

6.2.1.2 Obtaining the Upgrade............................................................. 108

6.2.2 Updating the BIOS ............................................................................... 108

6.3 Clearing the CMOS .......................................................................................... 108

6.4 Clearing the Password...................................................................................... 109

6.5 BMC Force Update Procedure ............................................................................ 109

7 Troubleshooting .................................................................................................... 110

7.1 Resetting the System....................................................................................... 110

7.2 Problems Following Initial System Installation ..................................................... 110

7.2.1 First Steps Checklist ............................................................................. 110

7.3 Hardware Diagnostic Testing............................................................................. 111

7.3.1 Verifying Proper Operation of Key System Lights ...................................... 111

7.3.2 Confirming the Operating System Load ................................................... 111

7.4 Specific Problems and Corrective Actions............................................................ 112

7.4.1 Power Light does not Light .................................................................... 112

7.4.2 No Characters Appear on Screen ............................................................ 112

7.4.3 Characters are Distorted or Incorrect ...................................................... 112

7.4.4 Ctrl-G Option is not available to Configure RAID ....................................... 113

7.4.5 System Cooling Fans do not Rotate Properly ............................................ 113

7.4.6 Cannot Connect to a Server................................................................... 113

7.4.7 Diagnostics Pass but the Connection Fails ................................................ 113

7.4.8 The Controller Stopped Working When an Add-in Adapter was Installed....... 113

7.4.9 The Add-in Adapter Stopped Working Without Apparent Cause................... 114

December 2009 Product Guide, rev.1.2

5

Kontron Carrier Grade Server TIGH2U

Page 6

TIGH2U Server—Contents

7.4.10 System Boots When Installing a PCI Card ................................................114

7.4.11 Problems with Newly Installed Application Software...................................114

7.4.12 Problems with Application Software that Ran Correctly Earlier..................... 114

7.4.13 Devices are not Recognized under Device Manager (Windows* OS) ............. 115

7.4.14 Hard Drive(s) are not Recognized ...........................................................115

7.5 LED Information ..............................................................................................115

7.6 BIOS Error Messages........................................................................................ 116

7.6.1 BIOS POST Beep Codes ......................................................................... 117

8 Warranty ...............................................................................................................118

Kontron Carrier Grade Server TIGH2U

Product Guide, rev.1.2 December 2009

6

Page 7

Revision History—TIGH2U Server

Revision History

Date Revision Description

September 2007 001 Initial release; rev 0.5

November 2007 002 Gold release

April 2008 003

December 2009 004

Minor edits for SRA posting. Primarily grammar ed

with Intel Z-U130 Value Solid State Drive.

Kontron version: Changed Intel Z-U130 Value Solid State Drive to SMART Embedded USB

Sol

id-State Drive

its. Replaced SysCon board text and art

December 2009 Product Guide, rev.1.2

7

Kontron Carrier Grade Server TIGH2U

Page 8

Introduction—TIGH2U Server

1 Introduction

1.1 About this Manual

Thank you for purchasing and using the Kontron Carrier Grade Server TIGH2U.

This manual is for trained system technicians who are responsible for troubleshooting, upgrading, and

maintaining this server. This document provides a brief overview of the features of the system, a list

of accessories or other components you may need, troubleshooting information, and instructions on

how to add and replace components on the TIGH2U Server.

Note: Always be sure to check the Support web site at http://us.kontron.com/ for the latest

version of this manual.

1.1.1 Manual Organization

Chapter 2 provides a brief overview of the TIGH2U Server. In this chapter, you will find a list of the

server board features, chassis features, illustrations of the product, and product diagrams to help you

identify components and their locations.

Chapter 3 provides instructions on adding and replacing hot-swappable and standard components

such as processors and memory DIMMs. Use this chapter for step-by-step instructions and diagrams

for installing or replacing components.

Chapter 4 provides instructions on adding optional components such as PCI add-in cards, I/O

expansion modules, hardware RAID 5 components, and optical devices. Use this chapter for step-bystep instructions and diagrams for installing components.

Chapter 5 provides instructions on replacing components such as fans, boards, the drive bay

assembly, and the battery. Use this chapter for step-by-step instructions and diagrams for replacing

components.

Chapter 6 provides instructions on using the utilities that are shipped with the board or that may be

required to update the system. This includes how to navigate through the BIOS (Basic Input/Output

System) setup screens, how to perform a BIOS update, and how to reset the password or CMOS

(Complementary Metal Oxide Semiconductor). Information about the specific BIOS settings and

screens is available in the

Intel® Server Board S5000PAL/S5000XAL Technical Product Specification.

Chapter 7 provides troubleshooting information. In this chapter, you will find BIOS error messages

and POST (Power-on Self Test) code messages. You will also find suggestions for performing

troubleshooting activities to identify the source of a problem.

December 2009 Product Guide, rev.1.2

11

Kontron Carrier Grade Server TIGH2U

Page 9

TIGH2U Server—Introduction

1.2 What Your Server Includes

Your Kontron Carrier Grade Server TIGH2U includes the following components:

•One Intel® Server Board T5000PAL

• One 2U chassis

• Six internal hard disk drive trays in a removable drive bay assembly. A SAS backplane board is

attached to the rear of the drive bay assembly.

• A riser card assembly for PCI-X* and PCI Express* (PCIe*) add-in cards

• DC or AC power subsystem: one hot-swappable PSU and power distribution board (PDB). You

must order a second power supply for a redundant system.

• Four dual-rotor fan assemblies for cooling the processor(s), DIMM(s), PCI slot(s), power supply

modules, and other internal components

• SAS front panel (SFP) board

• Telco Alarms Manager (TAM) board

• Internal cables and connectors

See Chapter 3 for initial system installation and configuration instructions. See Chapter 4 for optional

component installation and configuration instructions.

1.3 Product Accessories

You may need or want to purchase one or more of the following items for your server as spares or for

more processing power:

• Quad-Core Intel® Xeon® processor 5400 series and appropriate heat sink(s)

• DDR2-667 FBD ECC memory DIMM(s) (system maximum = 32 Gbytes)

• SAS hard disk drives (system maximum = six HDDs)

• 0.5-inch slim-line optical drive

• PCI-X* or PCIe* add-in cards

• Additional AC or DC power supply for redundancy and hot-swapping

•Intel® Remote Management Module 2 (Intel® RMM2) and RMM2 NIC module

• I/O expansion module for dual-GbE or 4xSAS external drive support

• SMART Embedded USB Solid-State Drive

For information about the accessories, memory, processors, and third-party hardware that have been

tested and can be used with your system, and for ordering information, see the accessories and

spares list on

http://us. kontron.com/support/

Kontron Carrier Grade Server TIGH2U

Product Guide, rev.1.2 December 2009

12

Page 10

Introduction—TIGH2U Server

1.4 Additional Information and Software

For more technical information about this product or information about the accessories that can be

used with this TIGH2U Server, see

http://us.kontron.com/support. This site also contains information

about:

• In-depth technical information about the server board included with this server, including BIOS

settings and chipset information

• The latest product information

• Accessories or other server products

• Hardware (peripheral boards, add-in cards) and operating systems that have been tested with

this product

• DIMMs that have been tested with this product

• The power budget for this product

• Software to manage your server

• Diagnostics testing software

• Firmware and BIOS updates

•System drivers

December 2009 Product Guide, rev.1.2

13

Kontron Carrier Grade Server TIGH2U

Page 11

TS000342

Features—TIGH2U Server

2Features

This chapter briefly describes the main features of the Kontron Carrier Grade Server TIGH2U. This

chapter provides a diagram of the product, a list of the server features, and diagrams that show the

location of important components and connections.

Figure 1 shows the Kontron Carrier Grade Server TIGH2U.

Figure 1. K

ontron Carrier Grade Server TIGH2U

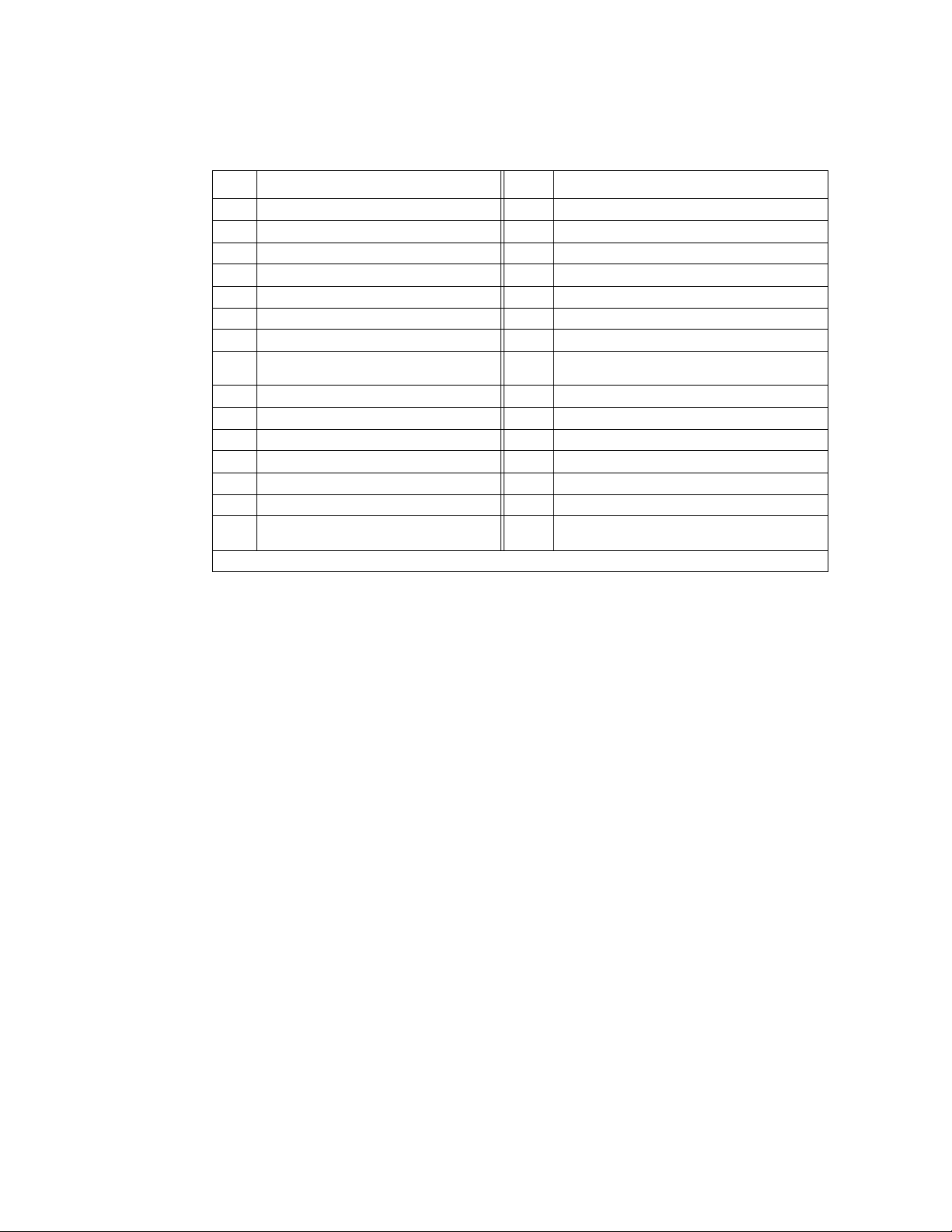

Tab le 1 summarizes the major features of the server system.

Table 1. K

December 2009 Product Guide, rev.1.2

ontron Carrier Grade Server TIGH2U Features

Feature Description

Compact, high-density

syst

em

Configuration flexibility One- or two-way capability in low-profile and cost / v

Serviceability Rear access to hot-swappable power supplies

Rack-mount server with a height of 2U (3.45 inches, 8.9 cm) and a depth of

20.0 inches (50.8 cm)

Stand-alone system

Supports up to two Quad-Core Intel

Front access to hot-swappable SAS disk drives

Front access to optical drive

Ability to swap the entire drive bay as a unit

11

®

Xeon® processor 5400 series †

Kontron Carrier Grade Server TIGH2U

alue-effective packaging

Page 12

Table 1. Kontron Carrier Grade Server TIGH2U Features (Continued)

Feature Description

Availability Two hot-swappable 600 W power supplies in a redundant (1+1) configuration

Disk subsystem configurable as hardware or software RAID

Memory sparing and memory mirroring configurations supported

Manageability Remote management

Emergency management port (serial and LAN)

IPMI 2.0 compliant

Remote diagnostics support

Optional SMART Embedded USB Solid-State Drive

Optional Intel® Remote Management Module 2 (Intel® RMM2) providing GCM

support

Upgradeability and

investment protection

System-level scalability Supports up to 32 Gbytes FBDIMM memory in non-mirrored mode

Front panel Switches:

I/O Front panel:

Internal connection options Internal connectors/headers:

Add-in card support One full-height riser slot supporting 2U PCI-X and PCIe add-in cards

† For a list of compatible processors, see http://us.kontron.com/support/.

Supports up to two Quad-Core Intel® Xeon® processor 5400 series †

Multi-generational chassis

Intel® 64 architecture support

Supports up to 16 Gbytes FBDIMM memory in mirrored mode

Supports up to two Quad-Core Intel® Xeon® processor 5400 series †

Two full-height / full-length x4 PCI Express* (PCIe)* slots

One full-height / full-length 64-bit x 133 MHz PCI-X* slot

Two low-profile / half-length x4 PCI Express slots

Six internal hot-swappable 2.5-nch SAS disk drives

One optical drive (optional)

•Power switch

• Reset switch

• NMI switch

•ID switch

• Serial B port (RJ45)

•USB 2.0 port

• One 44-pin ATA/100 connector (power and I/O) for optical drive

•One Intel® Remote Management Module 2 (Intel® RMM2) connector

•One Intel® I/O Expansion Module (optional) supporting either:

- a dual GbE NIC Intel® connection

- an external x4 SAS drive

One low-profile riser slot supporting PCIe add-in cards

LEDs / Relays:

• Telco critical alarm fault LED / relay

• Telco major alarm fault LED / relay

• Telco minor alarm fault LED / relay

• Telco power alarm fault LED / relay

•ID LED

•NIC activity LED

•Main power LED

•HDD activity LED

Rear panel:

• Dual PS/2 ports for keyboard and mouse

• Serial B port (RJ45)

• Two USB 2.0 ports

•Intel® RMM2 NIC 100 Mbps management

port

• Two RJ45 NIC connectors for 10 / 100 /

1000 Mbps connections

• Video connector

• Alarms connector

TIGH2U Server—Features

Kontron Carrier Grade Server TIGH2U

Product Guide, rev.1.2 December 2009

12

Page 13

TS000343

F

A

B

J

K

C

D

E

G

H

L

I

Note: View with fan ducting removed.

Features—TIGH2U Server

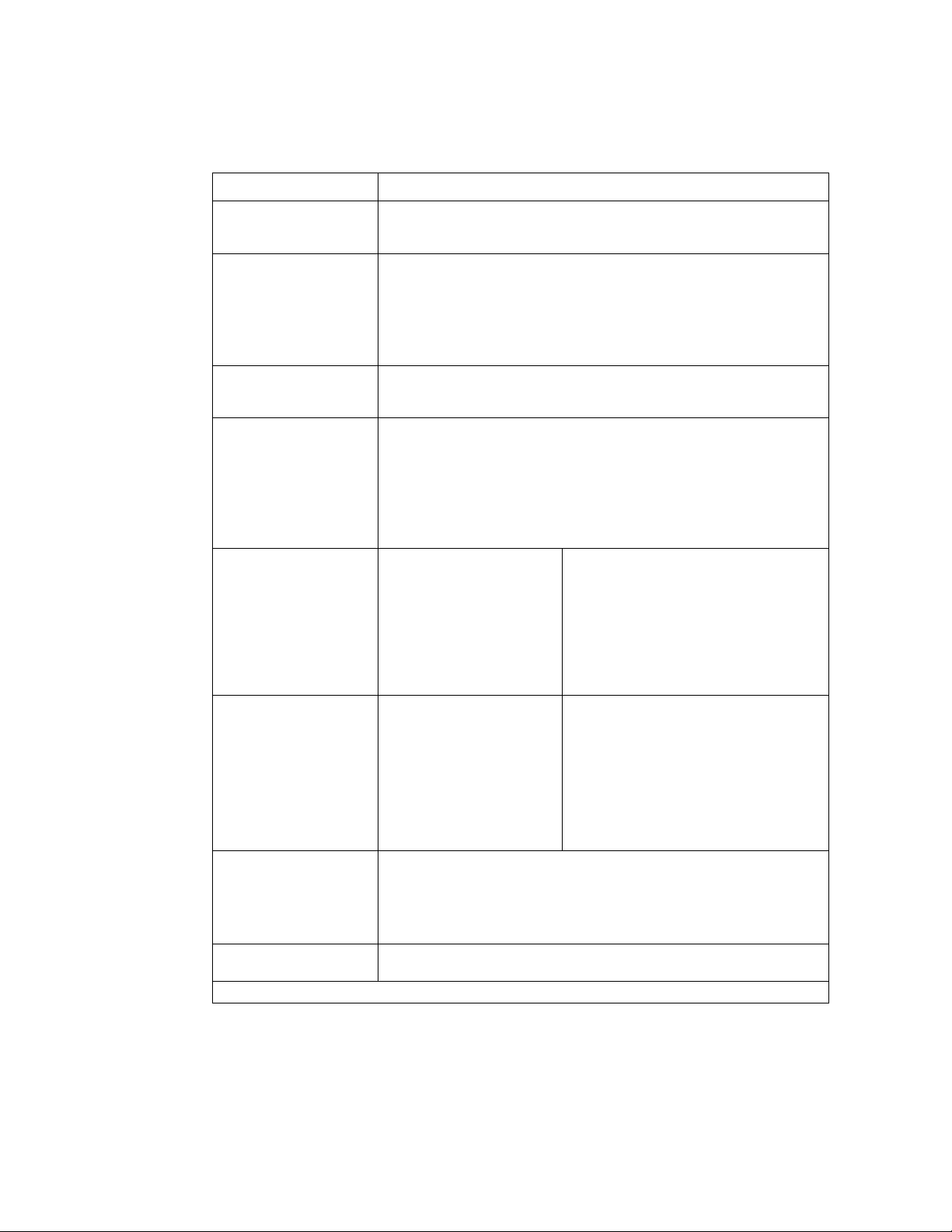

2.1 Server Components

Figure 2 shows the TIGH2U Server with top cover and front bezel removed to show the internal

components. The components are listed on the next page.

Figure 2. Carrier Grade Server TIGH2U Components

December 2009 Product Guide, rev.1.2

Item Description Item Description

A Optical drive (optional) G System fans

Power supply cage (contains one power

B

s

upply module with provision for an optional

second module)

Provision for PCI-X* and

C

(PCIe*) full-height and full-length add-in

cards

Riser card assembly (containing riser cards

D

fo

r both full-height and low-profile add-in

cards)

Provision for two PCI Express low-profile

E

ad

d-in cards

®

F Intel

Server Board T5000PAL L

PCI Express*

H SAS front panel (SFP) board

TAM board (behind front panel)

Note: Th

I

J RJ45 COM2 and USB port 2 connectors

K Control panel and status indicators

Hot-swappable SAS 2.5-inch disk drives (up

to

six)

Kontron Carrier Grade Server TIGH2U

13

e bracket on which the TAM board

is installed can also include an

optional SMART Embedded USB

Solid-State Drive, which provides

local memory storage

Page 14

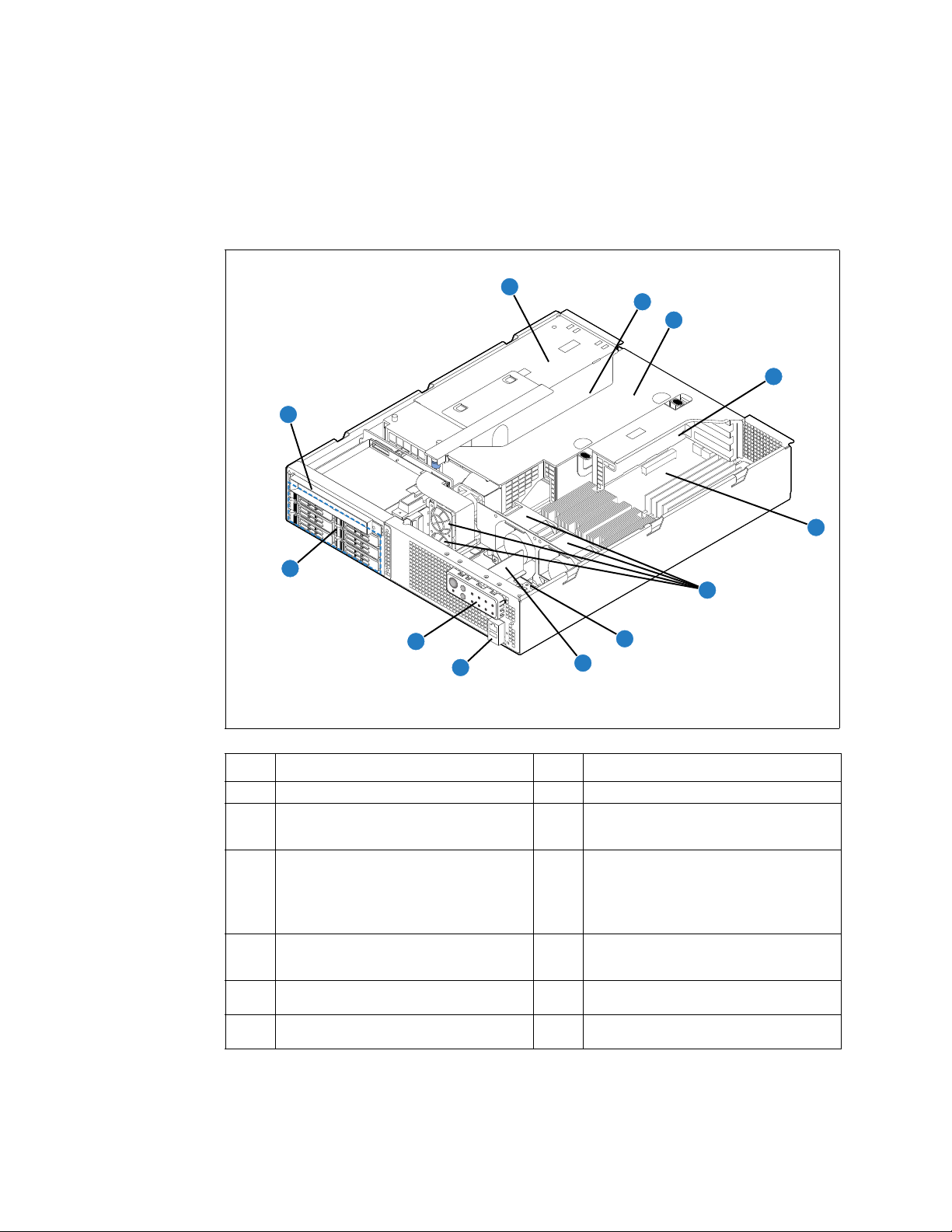

2.2 Back Panel

TS000354

01

L

K

G F

J

I

H

A

D

E

B

C

N

M

Figure 3 shows the back panel of the TIGH2U Server.

Figure 3. Rear View

Item Description Item Description

Low-profile PCI Express add-in cards

A

(or filler panels)

Full-height PCI-X/PCI Express add-in cards (or

B

filler pane

C Ground studs (used for DC-input system) J GbE NIC #2 connector ††††

D Power supply 2 slot; filler panel shown K GbE NIC #1 connector ††††

E Power supply 1 † L RJ45 serial port connector

F RMM2 NIC connector (optional) †† M PS/2 keyboard and mouse connectors

G I/O expansion module connector (optional) ††† N Alarms connector

†In Figure 3, the power supply shown is an AC-input modul

†† If an RMM2 NIC is not present, a fi

††† May be either an external SAS port connector or Gigabit Etherport port connector. If neither of the

optional m

†††† The GbE ports are only designed to pass intra-building lightn

cabling, which must be grounded at both ends.

ls)

ller panel occupies this space.

odules is installed, a filler panel occupies this space.

TIGH2U Server—Features

H USB 0 and USB 1 port connectors

I Video connector

e. DC-input modules are also available.

ing surge when used with shielded

Kontron Carrier Grade Server TIGH2U

Product Guide, rev.1.2 December 2009

14

Page 15

TS000345

Alarms

Status

ID ONNIC

CRT MNR PWRMJR

A

C B

Features—TIGH2U Server

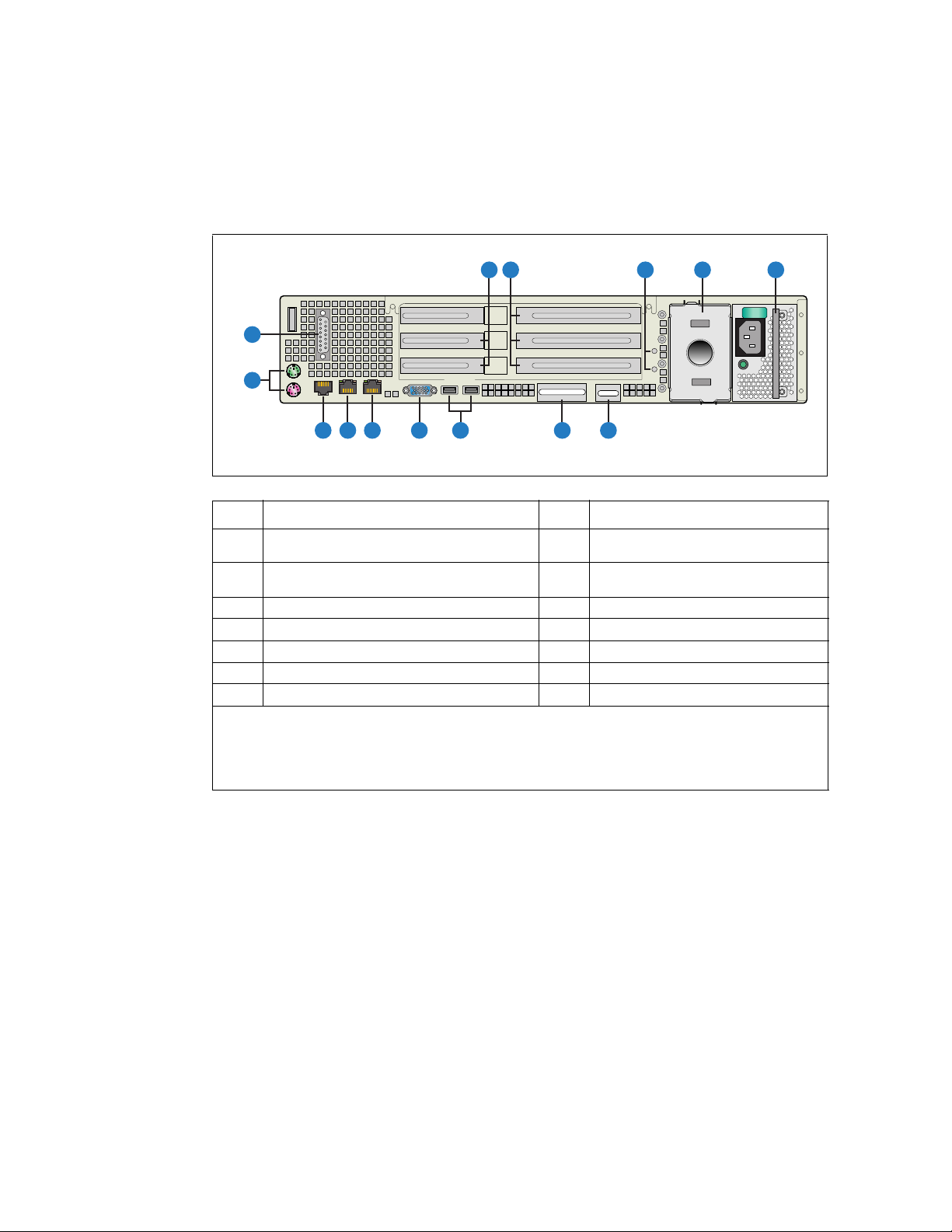

2.3 Front Panel

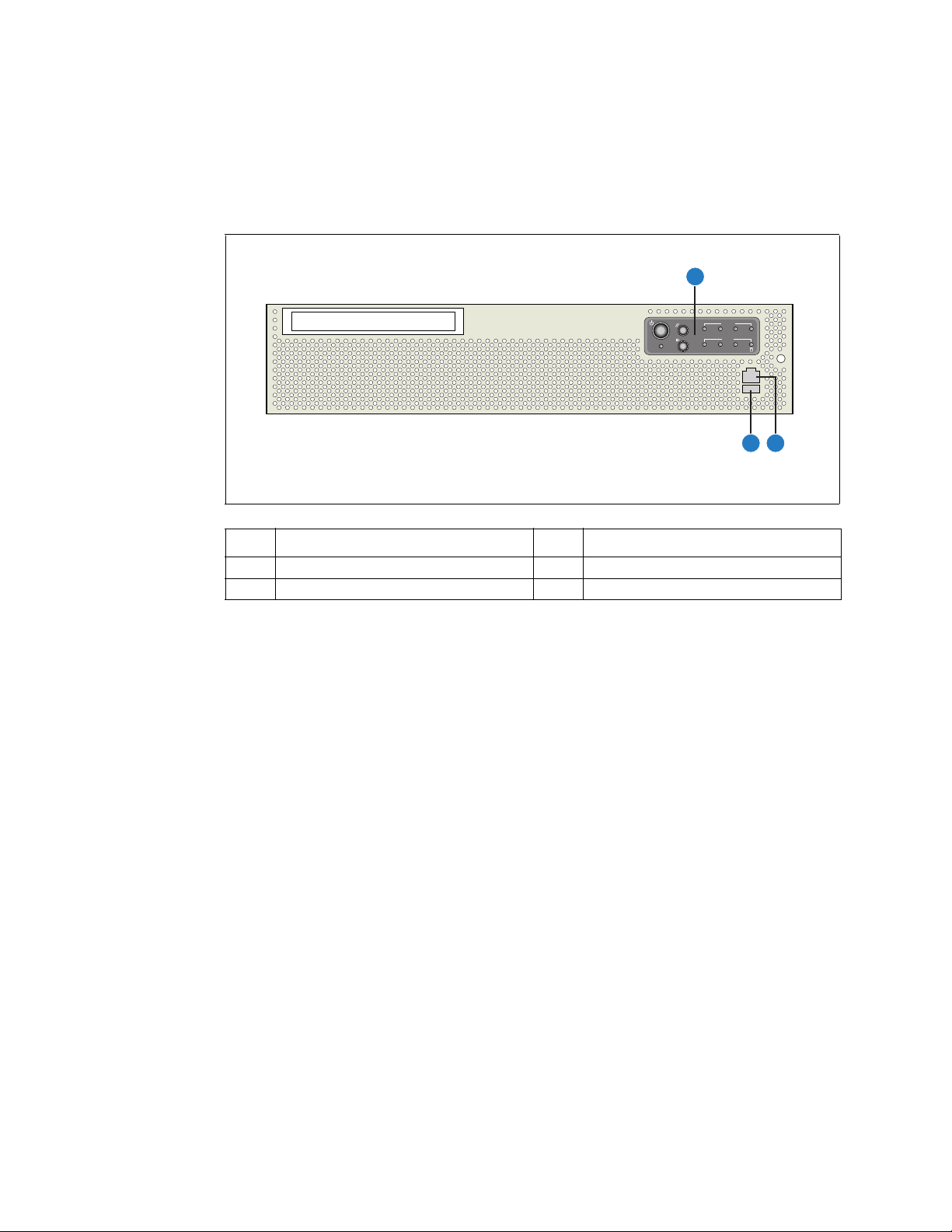

Figure 4 shows the front panel of the TIGH2U Server with the bezel installed.

Figure 4. Front View (Bezel Installed)

Item Description Item Description

A Front panel control switches and status LEDs C USB port

B COM port

December 2009 Product Guide, rev.1.2

15

Kontron Carrier Grade Server TIGH2U

Page 16

TIGH2U Server—Features

Alarms

Status

ID ONNIC

CRT MNR PWRMJR

TS000346

A B C

DEK HJ GI F

L

M

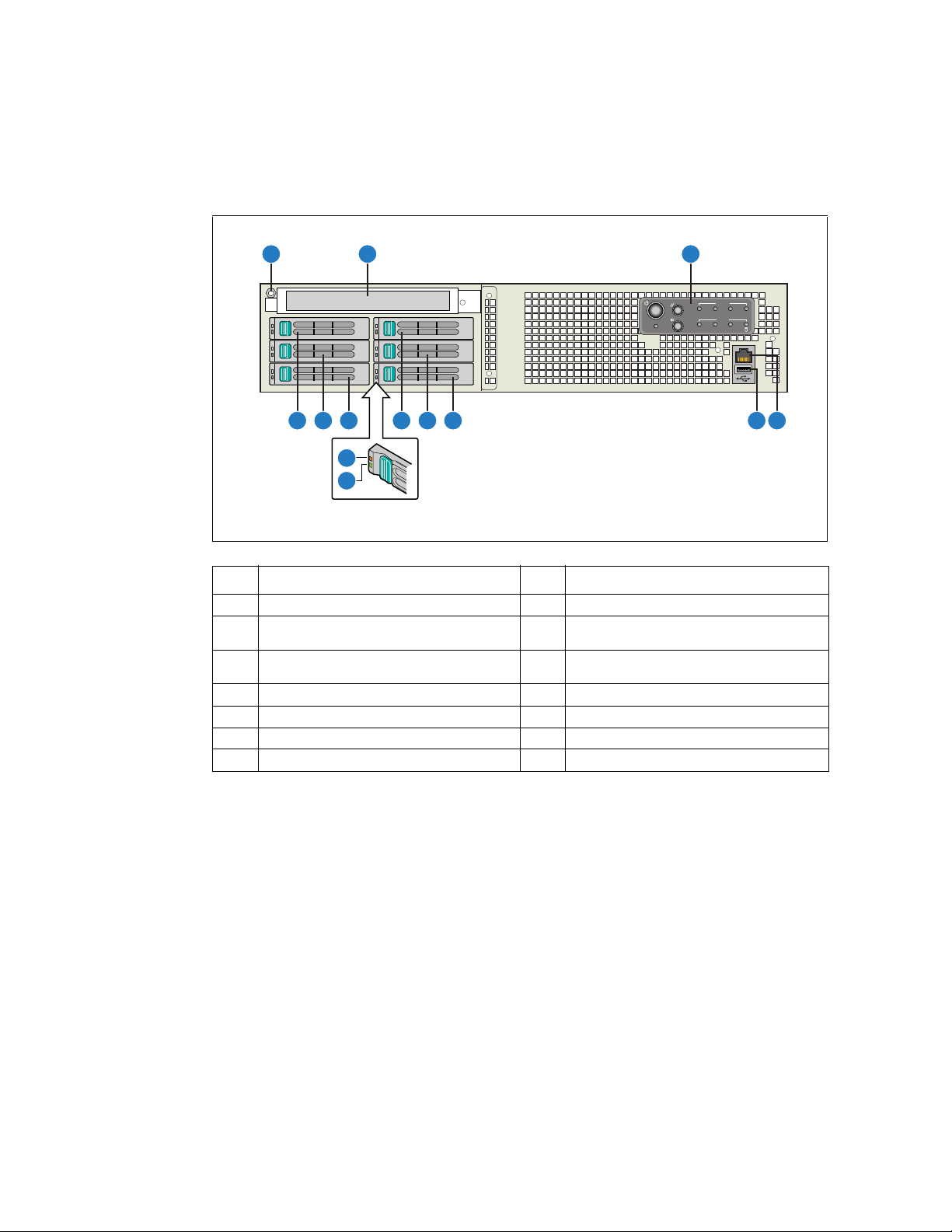

Figure 5 shows the front panel of the TIGH2U Server with the bezel removed. The components are

listed on the next page.

Figure 5. Front View (Bezel Removed)

Item Description Item Description

A Anti-static connection point H Hard drive bay 4

Optical drive (optional) or filler panel if no

B

driv

e is installed

Front panel control switches and status LEDs

C

(See Figure 6 for details)

D Front panel serial port connector (RJ45) K Hard drive bay 5

E USB port 2 connector L Drive fault indicator (one per hard drive)

F Hard drive bay 0 M Drive activity indicator (one per hard drive

G Hard drive bay 2

I Hard drive bay 1

J Hard drive bay 3

Kontron Carrier Grade Server TIGH2U

Product Guide, rev.1.2 December 2009

16

Page 17

Alarms

Status

ID ONNIC

CRT MNR PWRMJR

A B E F G H

C D I J K L

TS000347

Features—TIGH2U Server

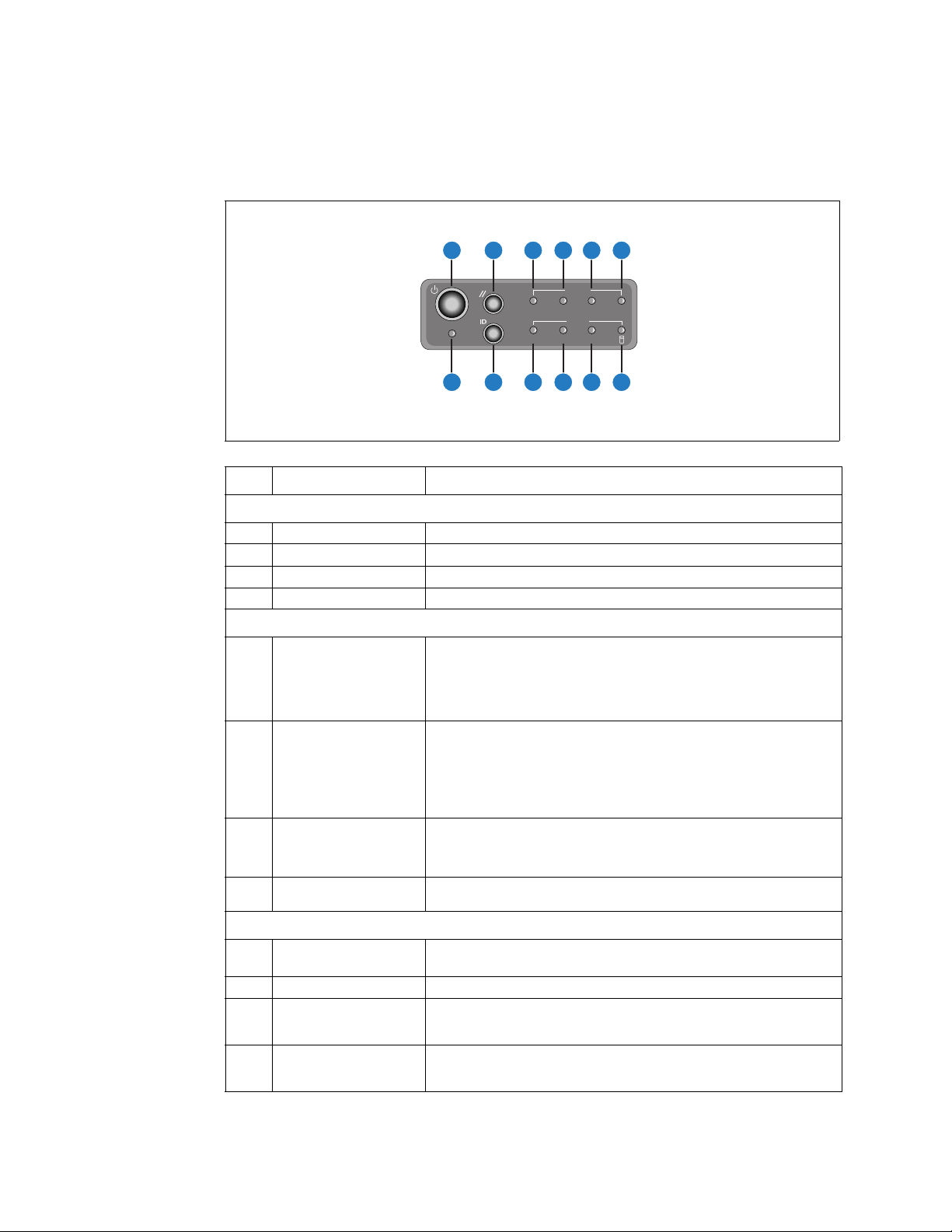

Figure 6 shows the control panel.

Figure 6. Control Panel

December 2009 Product Guide, rev.1.2

Item Feature Description

Front Panel Switches

A Power switch Toggles the system power

B Reset switch Resets the system

C NMI switch (pin hole) Asserts NMI to the server board

D ID switch Toggles the system ID LED on / off

Front Panel Alarm LEDs and Relays

The Critical alarm LED can be either amber (default) or red (set with an

FRUSD

R update). When continuously lit, indicates a Critical System Fault

E Critical (amber or red)

F Major (amber or red)

occurred. A critical system fault is an error or event that has a fatal

system impact. In this case, the system cannot continue to operate. An

example is the loss of a large section of memory, or other corruption. The

front panel critical alarm relay is engaged.

The Major alarm LED can be either amber (default) or red (set with an

R update). When continuously lit, indicates a Major System Fault

FRUSD

occurred. A major system fault is an error or event that has discernible

impact to the system operation. In this case, the system can continue to

operate, but in a degraded fashion (reduce performance or with the loss

of non-fatal features). An example is the loss of a mirrored disk. The front

panel major alarm relay is engaged.

When continuously lit, indicates a Minor System Fault occurred. A minor

ystem fault typically has little impact to the system operation. An

G Minor (amber)

H Power (amber)

s

example is a correctable ECC error. The front panel minor alarm relay is

engaged.

When continuously lit, indicates a Power System Fault occurred. The front

panel power alarm rela

y is engaged.

Front Panel Status LEDs

I System ID LED (white)

Indicates system identity

This LED can be toggled remotely or by front panel ID switch

J NIC activity LED (green) Indicates NIC activity when lit

When continuously lit, indicates the pres

K Main power LED (green)

HDD activity / fault LED

L

een / amber)

(gr

power in the server. The LED turns off when the main output power from

the power supply is turned off or if the power source is disrupted.

Indicates HDD activity when green or an HDD fault when amber. This is an

agg

regated indication for all hard drives in the system (up to six). Each

hard disk contains its own activity and fault indicators.

17

ence of power supply DC output

Kontron Carrier Grade Server TIGH2U

Page 18

TIGH2U Server—Features

2.4 Rear Panel Ethernet Ports

The TIGH2U Server has two GbE NIC ports that are mounted on the server board and accessible from

the rear of the chassis. Additional rear-accessible GbE NIC ports can be added by using full-height

PCI-X/PCIe add-in cards or low-profile PCIe add-in cards.

A dual GbE I/O option module is available. This module adds two RJ45, 1 Gigabit Ethernet ports

accessible on the rear panel. The GbE NIC ports are intended to be installed with shielded cabling that

is grounded at both ends of the cable.

The possible configurations of full-height PCI-X/PCIe add-in cards are in Tabl e 2 on page 21 and the

possible configurations of low-profile PCIe add-in cards are in Tab le 3 on page 21.

Warning: The intra-building port(s) of the equipment or subassembly is suitable for connection to

intra-building or unexposed wiring or cabling only. The intra-building port(s) of the

equipment or subassembly MUST NOT be metallically connected to interfaces that

connect to the OSP or its wiring. These interfaces are designed for use as intra-building

interfaces only (Type 2 or Type 4 ports as described in GR-1089-CORE, Issue 4) and

require isolation from the exposed OSP cabling. The addition of Primary Protectors is

not sufficient protection to connect these interfaces metallically to OSP wiring.

2.5 SAS Front Panel (SFP) Board

The SAS Front Panel (SFP) board adds SAS support and provides support for hardware RAID 0, 1, 10,

and 5, and software RAID 0, 1, and 10. This board is located on the floor of the chassis between the

front panel and the two 80 mm fans.

2.5.1 SFP Board Features

The TIGH2U Server SFP board has the following features:

• One RS-232 front panel port

• One USB2.0 front panel port

• One USB2.0 interface to local memory storage

• One flex cable connection to the SAS backplane to support the interface to six independent 2.5inch SAS hard drives

• One socket for a DDR2 mini-DIMM that provides data caching for hardware RAID

• One connector for the Intel® RAID Smart Battery that allows the contents of the DDR2 mini-DIMM

to be preserved if power falls below specifications.

• Four fan connectors to provide power, control, and monitoring for the four cooling fans

• Four fan fault LEDs (for diagnostics purposes only, not visible on front panel)

2.6 Telco Alarms Manager Board

The Telco Alarms Manager (TAM) board adds LEDs and power functions to the front of the server

chassis. It also uses a cable to provide an alarms function with fault relays to the back of the chassis.

This board is located over the top of the SFP board between the front panel and the two 80 mm fans.

Kontron Carrier Grade Server TIGH2U

Product Guide, rev.1.2 December 2009

18

Page 19

TS000277

K

L

J

Q P O NR M

BB

CC

AA

Z

Y

X

W

T

U

S

BA ED F HGC

I

V

Features—TIGH2U Server

2.6.1 TAM Board Features

The TIGH2U Server TAM board has the following features:

• Four switches to control power on, reset,

• One system ID LED that can be controlled remotely

NMI, and the system ID LED

or by the system ID switch

• Two system activity LEDs that indicate power-on and NIC activity

• One hard drive / fault LED that indicates activity or faults for any of the six HDDs

• Four system fault LEDs that indicate critical, major, minor, and power system fault status

• Four system fault relays for external critical, major, minor, and power fault indicators

• One connector to interface with the SFP board

• One connector to route the contacts of the four system fault relays to a connector at the back of

the chassis

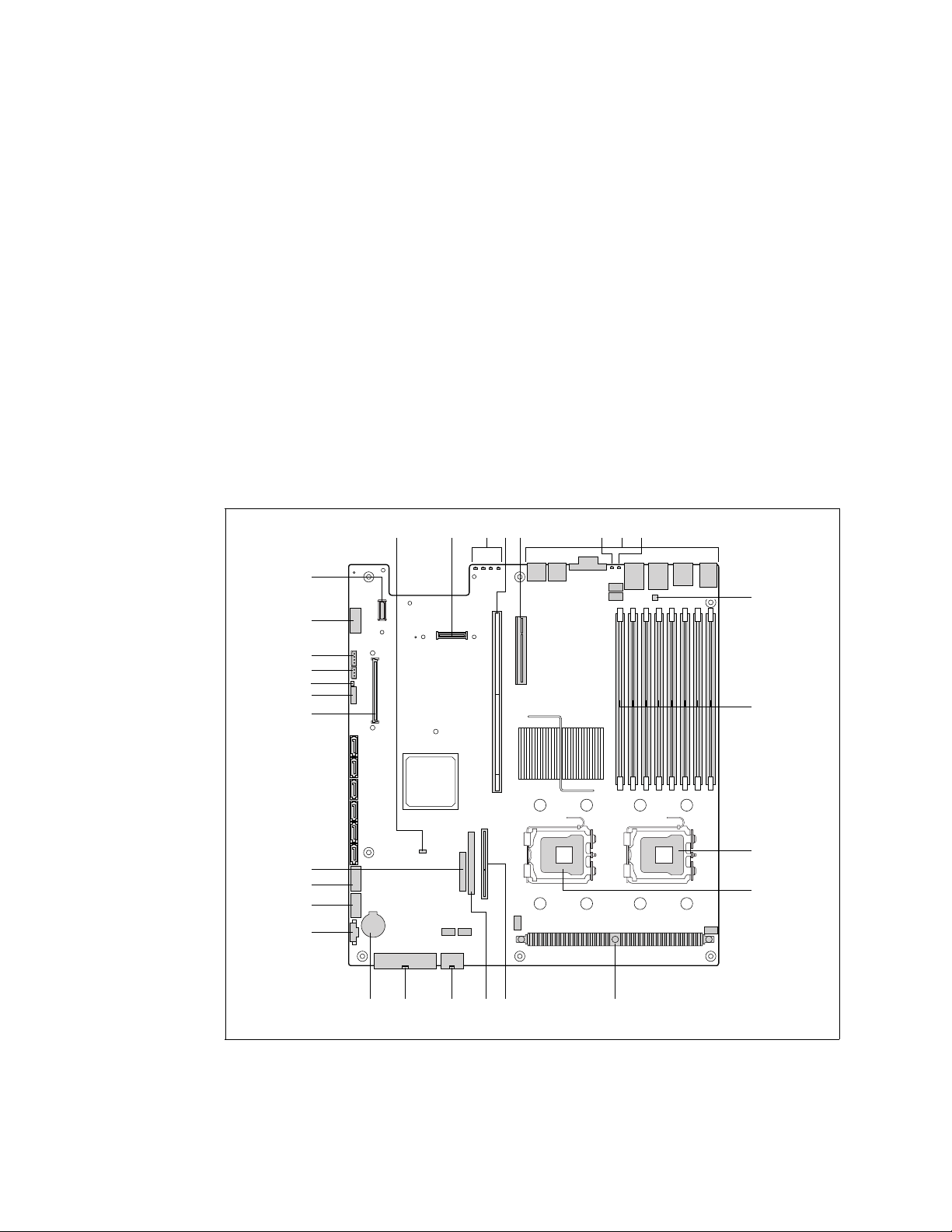

2.7 Server Board Connector and Component Locations

Figure 7 shows the locations of connectors and components on the T5000PAL Server Board.

Figure 7. Intel® Server Board T5000PAL Layout

December 2009 Product Guide, rev.1.2

19

Kontron Carrier Grade Server TIGH2U

Page 20

TIGH2U Server—Features

Description Description

A BIOS Bank Select Jumper P CPU Power Connector

B I/O Module Option Connector Q Main Power Connector

C POST Code Diagnostic LEDs R Battery

®

D Intel

E PCI Express Riser Slot – Low-profile T Dual Port USB 2.0 Header

F System Identification LED - Blue U Serial Port Connector

G External I/O Connectors V SSI 24-pin Control Panel Header

H Status LED – Green/Amber W

I Serial ‘B’ Port Configuration Jumper X System Recovery Jumper Block

J FBDIMM Sockets Y Chassis Intrusion Switch Header

K CPU #1 Connector Z 3-pin IPMB Header

L CPU #2 Connector AA Intel

M Voltage Regulator Heat Sink BB Serial ‘A’ Header

N Bridge Board Connector CC Intel

O

Note: In Figure 7, connectors shown but not called out are “not used”.

Adaptive Slot – Full-height S Power Supply Management Connector

®

Intel

Remote Management Module 2 (Intel®

RMM) Connector

®

Local Control Panel Header

®

RMM2 NIC Connector

ATA-100 Optical Drive Connector

(power and I/O)

2.8 Hard Disk Drives

The TIGH2U Server chassis supports up to six 2.5-inch SAS drives in hot-swappable hard drive tray

assemblies at the front of the chassis.

For information on how to install these drives, see Section 3.3.1, “Installing or Replacing a Hard

Drive”.

Note: The

Drives can consume up to 17 W of power each. Drives must be specified to run at a maximum

ambient temper

TIGH2U Server does not support all SAS hard drives. For a list of validated hard

drive manufacturers and hard drive types, see the Tested Hardware and Operating

Systems List (THOL) at

http://us.kontron.com/support/

ature of 45° C.

ntron Carrier Grade Server TIGH2U

Ko

Product Guide, rev.1.2 December 2009

20

Page 21

Features—TIGH2U Server

2.9 Riser Card Assembly

The Carrier Grade Server TIGH2U incorporates a PCI riser assembly that supports installation of PCIX and PCI Express add-in boards. The assembly includes two riser cards that connect into the Intel

®

Server Board S5000PAL.

• One of the riser card slots facilitates installing PCI-X* and PCI Express* add-in cards.

• The second riser card slot facilitates installing low-profile PCIe add-in cards.

See Section 4.2, “Installing or Replacing a PCI Add-in Card” on page 53, for instructions describing

how to install a PCI-X or PCIe add-in card. After the

add-in cards are installed, the riser assembly is

plugged back into the system and the I/O brackets of all the add-in cards are accessible through the

rear panel of the server chassis.

2.9.1 Full-Height PCI-X/PCIe Riser Card

The PCI-X/PCIe riser card plugs into the super slot on the server board. For PCI-X add-in cards, the

super slot riser card implements a 64-bit PCI-X slot with bus speeds of 66 MHz, 100 MHz, or 133 MHz.

F

or PCIe cards, the super slot has eight PCIe lanes which can be used for a single x8 add-in card or

for one or two x4 or x1 add-in cards. See Tabl e 2 for the supported configurations. For detailed

information about the pinouts and electrical specifications, see the K

TIGH2U Technical Product Specification.

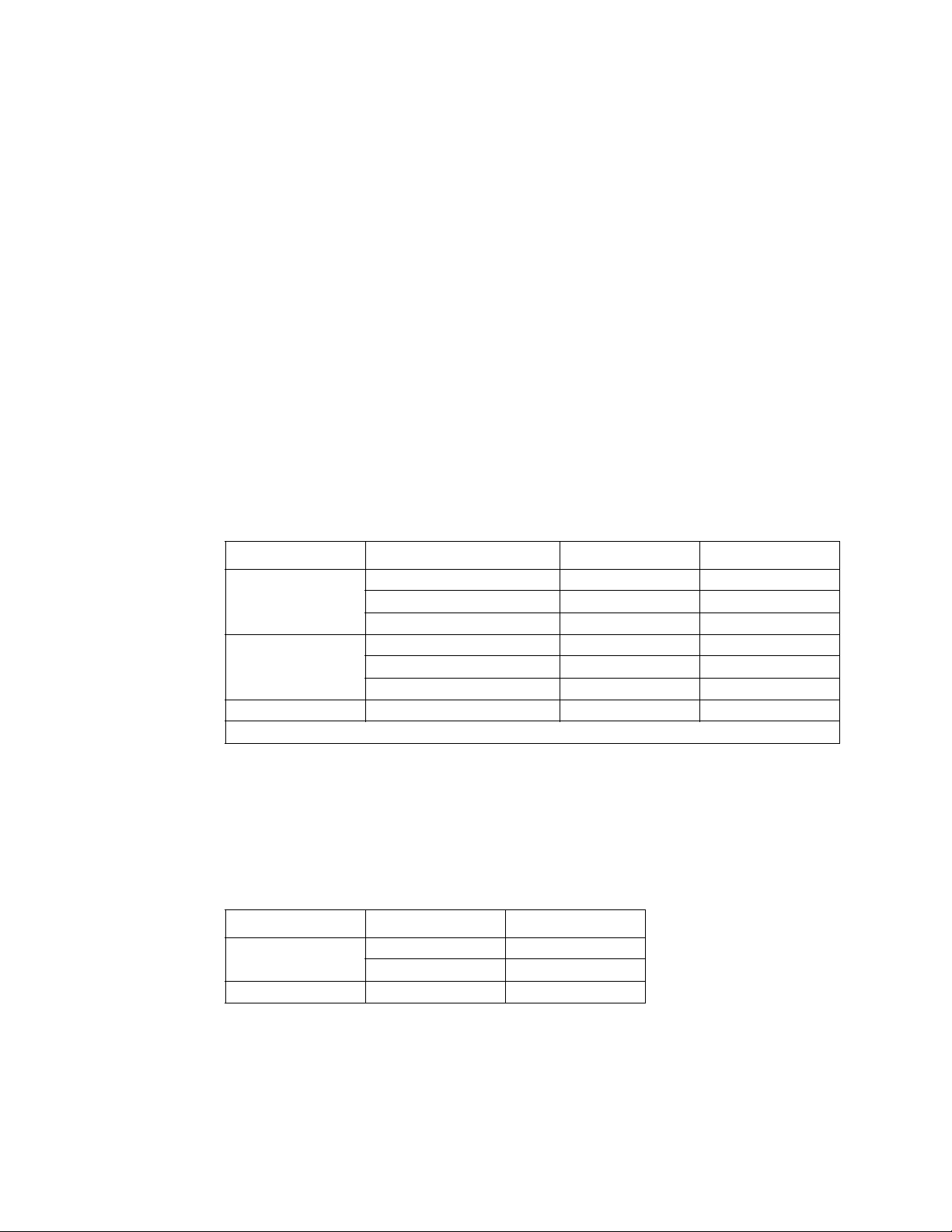

Table 2. Full-Height Riser Card Configurations and Throughput

Configuration Bottom Slot Middle Slot Top Slot

PCI-X † – –

One add-in card

Two a d d - in cards

Three add-in cards PCI-X † x4 PCIe x4 PCIe

Note: † U

p to 133 MHz bus speed

– x8 or x4 PCIe –

– – x4 PCIe

PCI-X † x8 or x4 PCIe –

PCI-X † – x4 PCIe

– x4 PCIe x4 PCIe

ontron Carrier Grade Server

2.9.2 Low-Profile PCIe Riser Card

The low-profile PCIe riser card plugs into the server board and supports the connection of low-profile

PCIe add-in cards only. The low-profile PCIe riser card implements two ×4 link interfaces. Up to two

low-profile PCIe add-in cards can be installed. See Tabl e 3 for the supported configurations. For

detailed information about the pinouts and electrical specifications, see the Ko

Server TIGH2U Technical Product Specification.

Table 3. Low-Profile PCI Add-in Card Configuration

Configuration Lower Slot Upper Slot

One add-in card

Two a d d - in cards x4 PCIe x4 PCIe

December 2009 Product Guide, rev.1.2

x4 PCIe

21

s and Throughput

x4 PCIe

ntron Carrier Grade

Kontron Carrier Grade Server TIGH2U

Page 22

TIGH2U Server—Features

A

B

TS000419

2.10 Power Supply

The power subsystem has a power distribution board (PDB) and up to two hot-swap power supply

modules capable of operating in redundant mode. A power supply filler panel for the empty power

supply site is supplied for systems without redundancy.

The power supply is rated for 600 W output capability in full AC (or

DC) input voltage range.

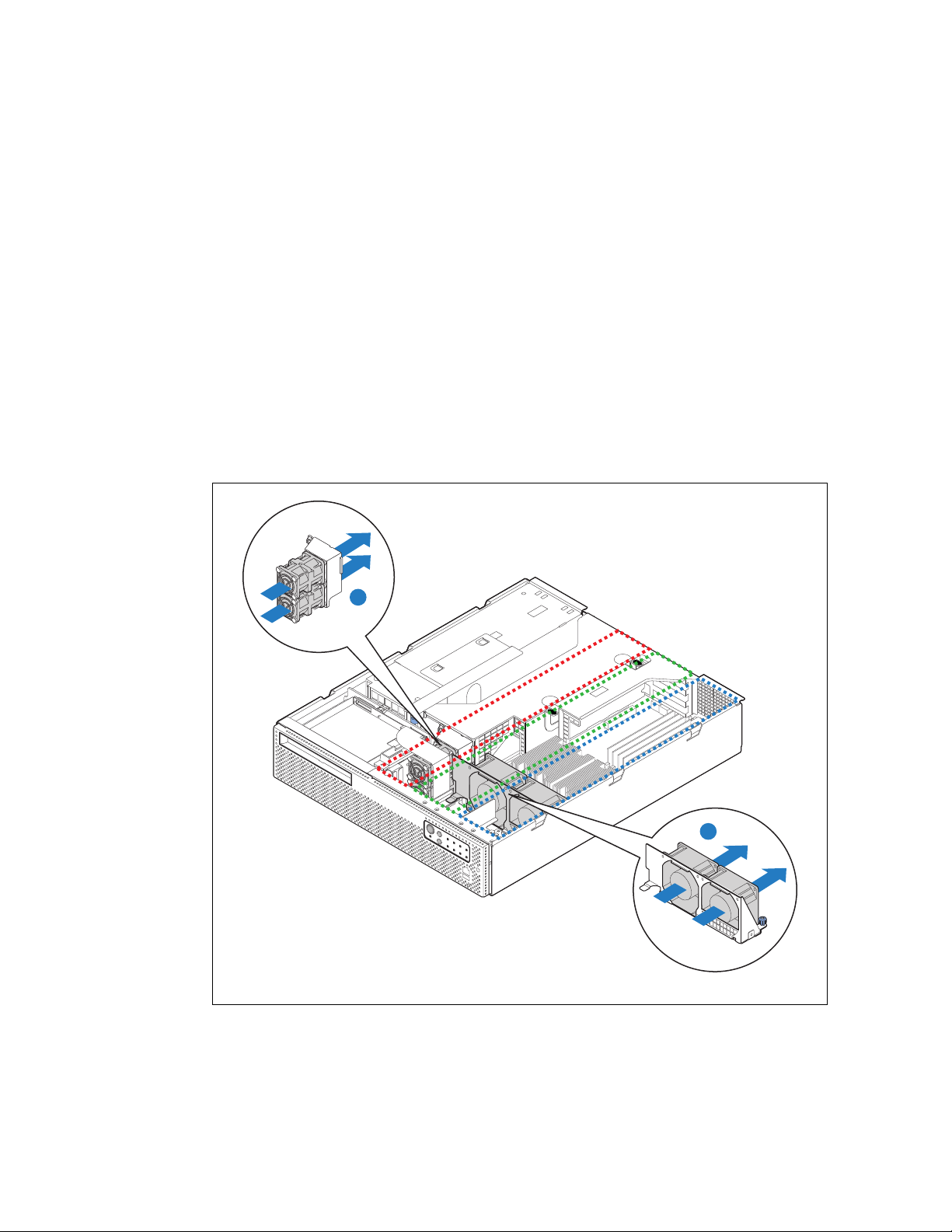

2.11 System Cooling

There are three cooling areas (domains) in the TIGH2U Server system:

• Domain 1 - CPU 1 and memory; see area outlined in blue in Figure 8

• Domain 2 - CPU 2, chipset, and any low-profile PCIe add-in cards; see

Figure 8

• Domain 3 - any full length PCI-X or PCIe add-in cards; see area outlined in red in Figure 8

Letter A in the following figure calls out the

PCI fans. Letter B calls out the CPU fans.

Figure 8. System Cooling Areas

area outlined in green in

Kontron Carrier Grade Server TIGH2U

Product Guide, rev.1.2 December 2009

22

Page 23

Features—TIGH2U Server

2.11.1 CPU 1 and Memory Cooling Area

One of the system’s large fans provides cooling for domain 1, outlined in blue in Figure 8. This fan

facilitates the flow of air through the front bezel over the SF

P, through the fan, and over the server

board, CPU 1, memory, and ultimately out through the rear of the chassis.

2.11.2 CPU 2 and Chipset Cooling Area

One of the system’s large fans provides cooling for domain 2, outlined in green in Figure 8. This fan

facilitates the flow of air through the front bezel over the SF

P, through the fan, and over the server

board, CPU 2, chipset and any low-profile PCIe add-in cards, and ultimately out through the rear of

the chassis.

2.11.3 PCI Cooling Area

The two 40 × 40 × 56 mm dual-rotor fans (A in Figure 8) facilitate the flow of air through the front

bezel, through the fans, over the server board and any full-length PCI-X or PCIe add-in cards, and

ultimately ou

t through the rear of the chassis.

2.11.4 Hard Disk Drive and Power Supply Cooling

Fans that are integrated into the PSUs provide the airflow to cool the hard disk drives. The airflow is

adequate even with a single PSU installed as long as a filler panel is installed in the other PSU slot.

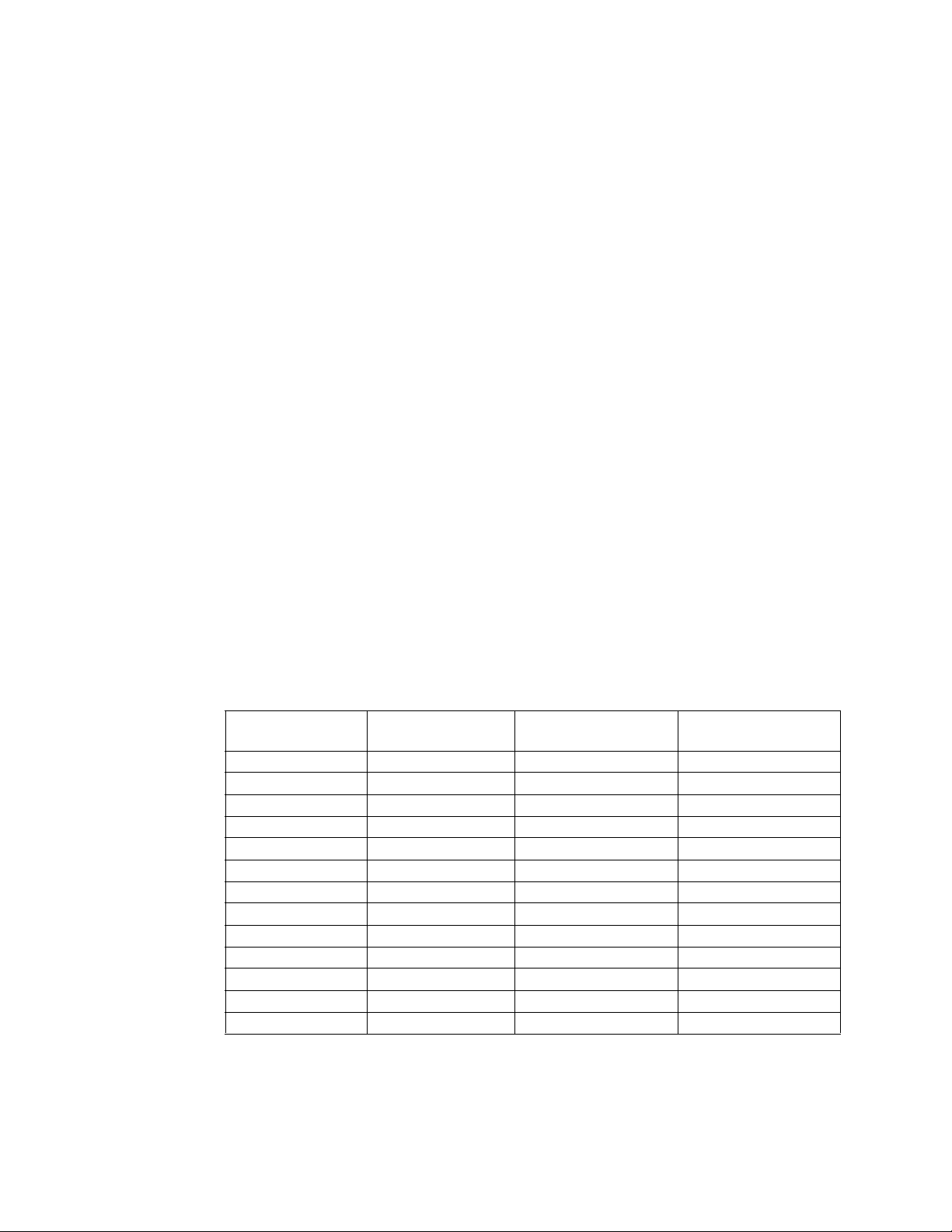

2.11.5 Fan Speed Control

The server board contains Pulse Width Modulation (PWM) circuits, which control the 12 VDC fan

voltage to provide quiet operation when system ambient temperature is low and there are no fan

failures. There is one PWM circuit for each cooling domain, resulting in one PWM being connected to

each of the two 80 × 38 mm fans and the other PWM connected to the two dual-rotor 56 × 40 mm

fans. Based on the ambient temperature, monitored by the front panel sensor, the fan speeds (PWM

duty cycle) are set per Tab le 4.

Table 4. Fan Speed Settings

Temperature (°C)

0 - 28 46 46 46

29 47 47 47

30 48 48 48

31 53 53 53

32 58 58 58

33 63 63 63

34 68 68 68

35 73 73 73

36 78 78 78

37 84 84 84

38 89 89 89

39 95 95 95

40 100 100 100

CPU1 Fan

PWM DC (%)

CPU2 Fan

PWM DC (%)

PCI Fans

PWM DC (%)

December 2009 Product Guide, rev.1.2

23

Kontron Carrier Grade Server TIGH2U

Page 24

TIGH2U Server—Features

2.11.6 Cooling Summary

The four-fan cooling subsystem of the TIGH2U Server is sized to provide cooling for:

• Up to two server board processors

• Up to 32 Gbytes of FBDIMM memory

• Up to six SAS hard drives

• Up to five PCI add-in cards consuming a maximum of 25 W for each full-height

PCI-X / PCIe add-in cards and 10 W for each low-profile PCIe add-in card

The cooling subsystem meets acoustic and thermal requirements at the lower fan speed settings. At

the higher fan speed settings, thermal requirements are met for the maximum ambient

temperatures, but acoustic requirements are not met.

2.12 Hardware Requirements

To avoid integration difficulties and possible board damage, your system must meet the requirements

outlined below. For a list of qualified components, see

Software”.

2.12.1 Processor

Section 1.4, “Additional Information and

The server board accommodates two Quad-Core Intel® Xeon® processor 5400 series. For a list of the

currently supported processors, see the product support page at:

http://us.kontron.com/support/

2.12.2 Memory

The memory controller hub (MCH) on the T5000PAL server board accommodates four channels of

fully buffered DIMM (FBDIMM) memory. Each channel can support up to two dual-ranked FBDIMM

DDR2 DIMMs. FBDIMM memory channels are organized into two branches for support of RAID 1

(mirroring). See

population rules and instructions for installing DIMMs in the sockets on the server board.

Section 3.4.2, “Configuring Memory DIMMs” for detailed information about

Kontron Carrier Grade Server TIGH2U

Product Guide, rev.1.2 December 2009

24

Page 25

Server Component Installations and Upgrades—TIGH2U Server

3 Server Component Installations and Upgrades

3.1 Before You Begin

Before working with your server product, pay close attention to the safety instructions provided in this

manual. See

Warning: Electrostatic discharge (ESD) and ESD protection: ESD can damage disk drives,

3.1.1 Tools and Supplies Needed

Appendix A, “Safety Information”.

boards, and other parts. Perform the procedures in this chapter at an ESD workstation.

If one is not available, provide some ESD protection by wearing an antistatic wrist strap

attached to chassis ground (any unpainted metal surface) on your server when

handling parts.

• #1 and #2 Phillips (cross-point) screwdrivers (or interchangeable tip screwdriver with #1 and #2

Phillips bits)

• Personal grounding device such as an anti-static wrist strap and a grounded conductive pad

3.1.2 System References

All references to left, right, front, top, and bottom assume that you are facing the front of the server,

as it would be positioned for normal operation.

3.2 General Installation Procedures

The following sections present general installation and removal procedures that are required before

removing or installing internal components that are not hot-swappable.

3.2.1 Removing the Front Bezel

Remove the front bezel to

• Install or remove hard drives or an optical device

• Access the front-panel serial port and USB connectors

• Observe the individual HDD activity/fault indicators

• Install or remove the optional Intel® RAID Smart Battery

December 2009 Product Guide, rev.1.2

Kontron Carrier Grade Server TIGH2U

25

Page 26

TIGH2U Server—Server Component Installations and Upgrades

Note: The front bezel can be removed while the server power is on.

1. Disconnect the cables from the front panel USB port and / or serial port connectors.

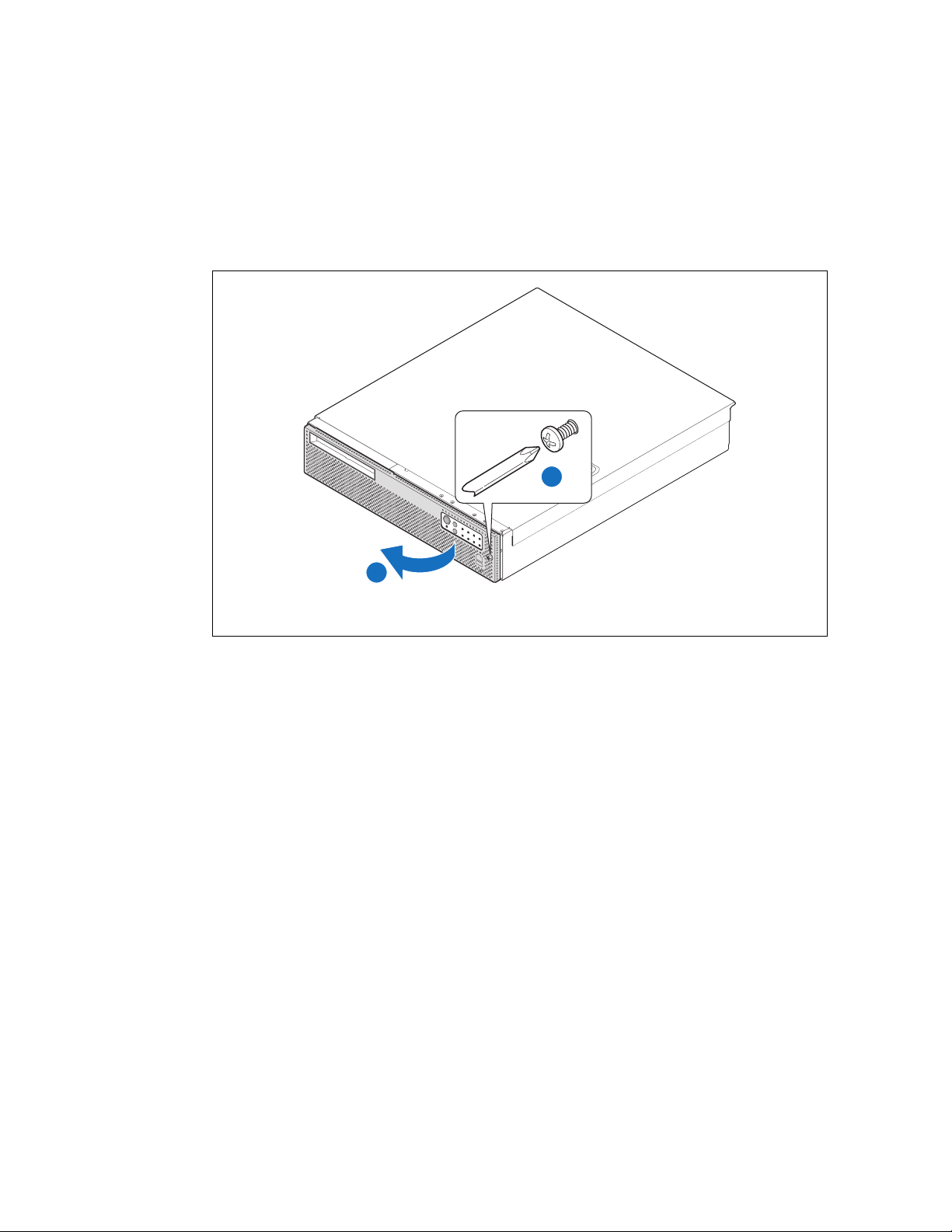

2. Loosen the bezel retention screw from the right side. (“A”)

3. Rotate the bezel outward as shown and remove. (“B”)

Figure 9. Removing the Front Bezel

A

B

TS000423

3.2.2 Installing the Front Bezel

1. Align the four tabs on the left side of the bezel with the slots in the front panel and then rotate the

free end of the bezel to the closed position.

2. Snap the front bezel into place and tighten the screw at the right edge of the bezel (if used).

3. Re-connect the serial port and USB cables if they are used.

3.2.3 Removing the Chassis Cover

The TIGH2U Server must be operated with the top cover in place to ensure proper cooling. You will

need to remove the top cover to add or replace components inside of the server that are not hotswappable from the front or rear panels.

Caution: 5

Before removing the top cover, power down the server system

the power cable.

Note: A

1. Observe the safety and ESD precautions in Appendix A, “Safety Information”.

2. Turn off all peripheral devices connected

3. Disconnect the power cord(s).

V standby power is present inside the chassis whenever the PSU(s) are connected to

a source of power.

and unplug all peripheral devices and

non-skid surface or a stop behind the server may be needed to prevent the server

from sliding on your work surface.

to the server. Turn off the server.

Kontron Carrier Grade Server TIGH2U

Product Guide, rev.1.2 December 2009

26

Page 27

B

A

TS000422

Server Component Installations and Upgrades—TIGH2U Server

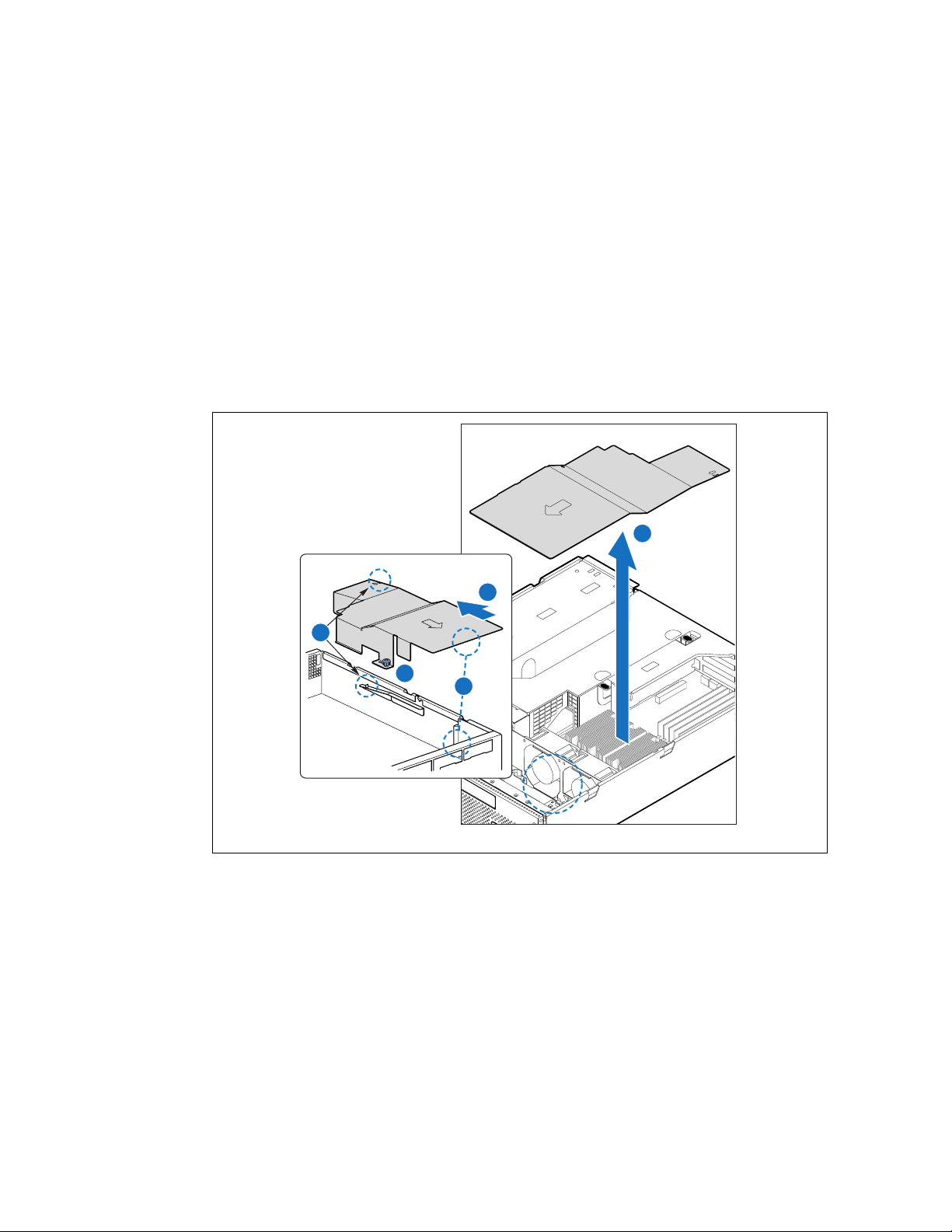

4. Remove the shipping screw at the left side, near the rear.

5. While holding the blue button at the top of the chassis in

stops.

6. Lift the cover straight up to remove it from the server.

Figure 10. Removing the Chassis Cover

(“A”), slide the top cover back until it

3.2.4 Installing the Chassis Cover

1. Place the cover over the chassis so that the side edges of the cover sit just inside the chassis side

walls, with the front of the cover with about 1/8-inch (3-mm) gap showing between the chassis

cover and the sheet-metal at the front of the chassis.

2. Press down slightly on the chassis cover behind the

peripheral area and slide the cover forward

until it clicks into place.

3. Install the shipping screw if tooled entry is required or if the system will be shipped.

4. Reconnect all peripheral devices and the power cord(s).

Caution: This unit must be operated with the top cover installed to ensure proper cooling.

December 2009 Product Guide, rev.1.2

Kontron Carrier Grade Server TIGH2U

27

Page 28

TIGH2U Server—Server Component Installations and Upgrades

TS000273

A

B

C

E

D

3.2.5 Removing the Processor Air Duct

The air duct must be removed to access the processors, memory DIMMs, CPU fan assembly, the SFP

board, or the inside of the front panel. The processor air duct is required for proper airflow within the

chassis. Be sure the air duct is in place before installing the chassis cover.

1. Power down the server system and unplug all pe

2. Remove the chassis cover. For instructions, see Section 3.2.3, “Removing the Chassis Cover”.

3. Loosen the captive fastener on the left side of the air duct. (“A”)

4. Slide the duct several millimeters toward t

The front edge will disengage from the front panel. (“C”)

The metal tab at the rear will release. (“D”)

5. Lift the air duct straight up and remove it from the chassis. (“E”)

Figure 11. Removing the Processor Air Duct

ripheral devices and the AC power cable.

he rear panel until it stops. (“B”)

Kontron Carrier Grade Server TIGH2U

Product Guide, rev.1.2 December 2009

28

Page 29

TS000467

E

C

B

A

D

Server Component Installations and Upgrades—TIGH2U Server

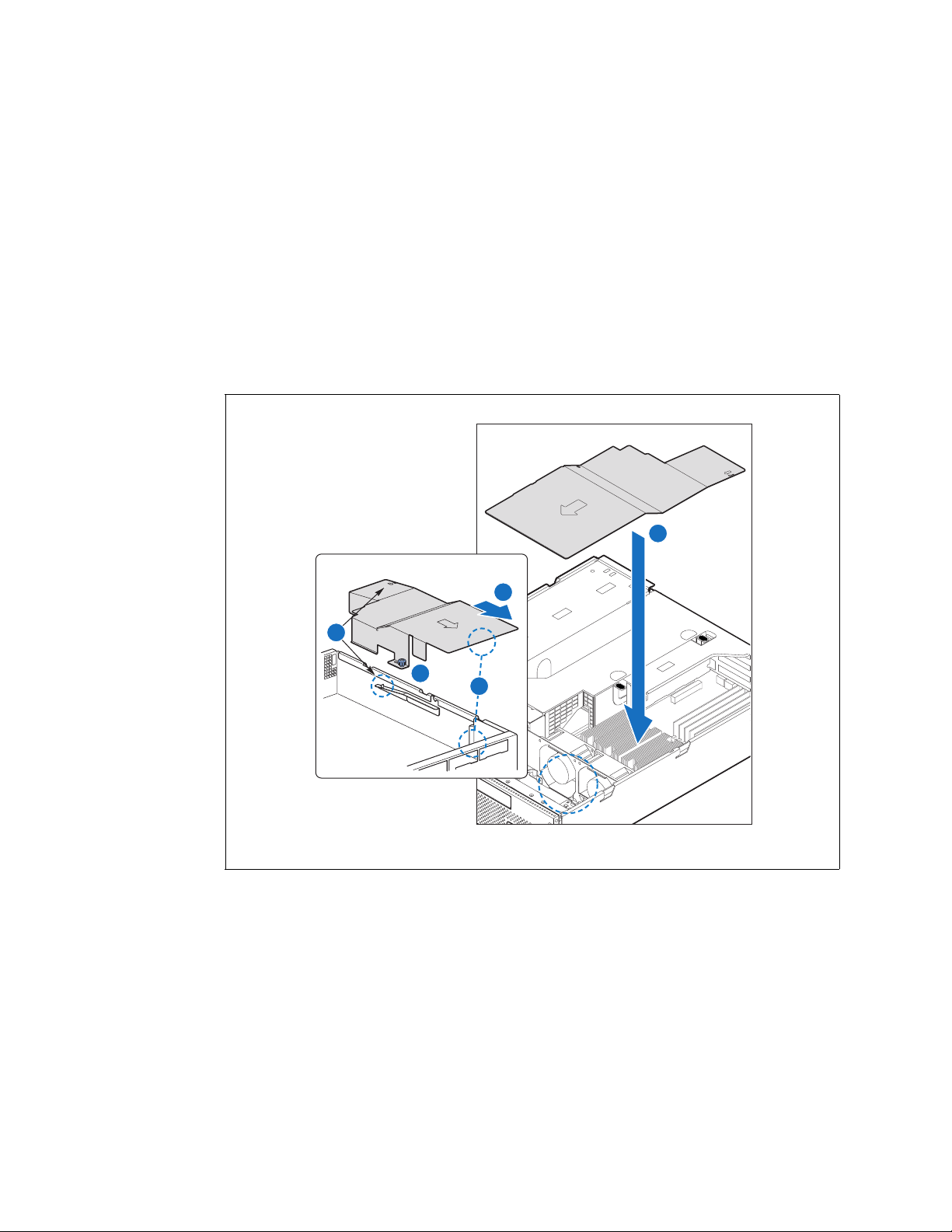

3.2.6 Installing the Processor Air Duct

1. Place the processor air duct over the processor sockets and fan assembly, using caution to make

sure you do not pinch any cables beneath the edges of the air duct. (“A”)

The top of the installed air duct should be flush with the top surface

assembly.

The front of the air duct should line up with the metal tab. (“B”)

2. Slide the air duct forward until it is flush with the front panel. (“C”)

3. Ensure that the rear of the air duct is fastened to the metal tab on the chassis. (“D”)

4. Tighten the captive fastener. (“E”)

5. Replace the chassis cover if you have completed all work inside of the chassis.

Figure 12. Installing the Processor Air Duct

of the PCI riser card

December 2009 Product Guide, rev.1.2

Kontron Carrier Grade Server TIGH2U

29

Page 30

TIGH2U Server—Server Component Installations and Upgrades

TS000274

54

32

10

A

3.3 Hot-Swappable Component Installation Procedures

The following components are hot-swappable and do not require powering down the system or

removing the chassis cover:

• Hard disk drives

• AC and DC power supplies (if power redundancy is a

3.3.1 Installing or Replacing a Hard Drive

Up to six hot-swappable SAS drives can be installed in your TIGH2U Server. You must remove the

front bezel to add or replace a hard drive in one of the six drive bays.

vailable)

Caution: If y

The Carrier Grade Server TIGH2U does not support all SAS hard drives. To see a list of validated

manufacturers and hard drive types, see the Tested Hardware and Operating System List (THOL) at :

http://us.kontron.com/support/

Click on Downloads and then Compatability Matrix.

ou install fewer than six hard drives, the empty bays must have drive trays with

baffles in them to maintain proper system cooling.

3.3.1.1 Removing a Hard Drive Tray

1. Remove the front bezel. For instructions, see Section 3.2.1, “Removing the Front Bezel”.

2. Select the drive bay where you want to install the d

green button to open the lever. (“A”)

Note: If y

3. Pull the drive tray assembly out of the chassis.

Figure 13. Removing a Drive Tray

ou will have fewer than six drives installed, drive bay 0 must be used first, then

drive bay 1, and so forth.

rive and remove the drive tray by pressing the

Kontron Carrier Grade Server TIGH2U

Product Guide, rev.1.2 December 2009

30

Page 31

AF000810

A

B

Server Component Installations and Upgrades—TIGH2U Server

3.3.1.2 Attaching a Hard Drive to the Drive Tray

1. If a drive is already installed (that is, if you are replacing the drive), remove it by unfastening the

four screws that attach it to the drive tray. (“A”)

Figure 14. Removing a Hard D

rive from the Drive Tray

A

TS000219

2. Install the new drive in the drive tray and secure the drive with the four screws provided with the

drive tray. (Figure 15, “A” and “B”)

Figure 15. Installing a Hard Drive in the Drive Tray

December 2009 Product Guide, rev.1.2

Kontron Carrier Grade Server TIGH2U

31

Page 32

TIGH2U Server—Server Component Installations and Upgrades

A

TS000275

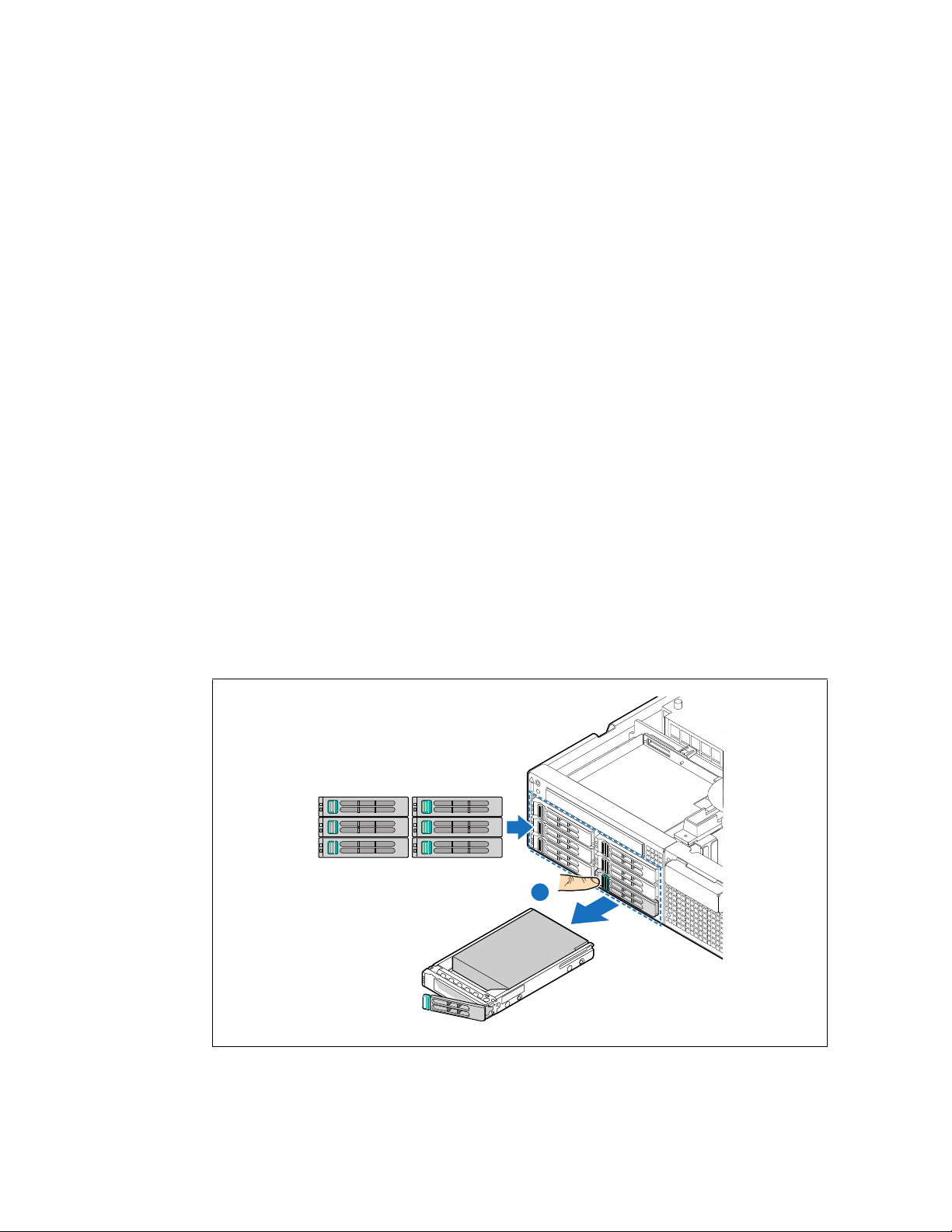

3. With the drive tray locking lever fully open, push the hard drive tray into the drive bay in the

chassis until it stops. (Figure 16, “A”)

4. Press the lever until it snaps shut to secure the drive in the bay.

5. Replace the front bezel.

Figure 16. Inserting a New SAS Drive Assembly

3.3.2 Replacing a Power Supply

Caution: Your server does not have a redundant power supply unless you have purchased the

optional second power supply. If there is no second supply, before replacing the power

supply you must first take the server out of service, turn off all peripheral devices

connected to the system, turn off the system by pressing the power button, and unplug

the power cord(s) from the system or wall outlet.

To maintain hot-swap capability, make sure that

in both chassis slots before replacing (hot-swapping) a power supply module.

The TIGH2U Server supports th

Kontron Carrier Grade Server TIGH2U

Product Guide, rev.1.2 December 2009

32

e use of either AC (Figure 17, “C”) or DC (“D”) power supply modules.

there is an active power supply module

Page 33

Server Component Installations and Upgrades—TIGH2U Server

3.3.2.1 Removing the Power Supply Module

1. Check the status LED to determine which power supply has failed and disconnect the appropriate

power cable. (Figure 17, “A”)

2. Press and hold the green safety lock downw

3. Grasp the handle (“B”) and pull the power supply module from the chassis.

Figure 17. AC and DC Power Supplies

ard to disengage the power supply module.

AC PS DC PS

A

C

B

3.3.2.2 Installing a Power Supply Module

1. Slide the power supply module into the chassis slot until it clicks into place.

2. Make sure the power supply is fully inserted by pulling on

the power supply will not slide out without pressing the green safety lock.

the handle. When correctly installed,

D

B

TS000424

December 2009 Product Guide, rev.1.2

Kontron Carrier Grade Server TIGH2U

33

Page 34

TIGH2U Server—Server Component Installations and Upgrades

Strip Wire 0.625"

(16mm)

Min. Wire

14 AWG

C

A

B

#2 Phillips*

Screwdriver

3.3.2.3 Installing or Replacing a DC Power Supply

1. Slide open top of male connector to reveal screw holes. ("A")

2. Strip the wire insulation as shown.

Note minimum wire gauge. ("B")

Insert each wire all the way and tighten

to 24 in-lb (2.7 N-m) torque. ("C")

Figure 18. DC Power In Male Connector Configuration

3.3.2.4 Grounding a DC-Powered System

The DC chassis provides two #10-32 threaded studs for chassis enclosure grounding. A single 90º

standard barrel, two-hole, compression terminal lug with 5/8-inch pitch suitable for a #14-10 AWG

conductor (such as the Thomas & Betts* terminal lug, p/n 256-31426-141) must be used for proper

safety grounding. See “C” in Figure 3 for the location of the ground studs.

A crimping tool may be needed to secure the terminal lug to the grounding cable.

3.4 Internal System Component Configuration and Installation Procedures

Note: The procedures in this section assume that you have powered down the server and

removed the chassis cover as described in Section 3.2,“General Installation

Procedures”.

3.4.1 Configuring Jumpers on the Server Board

The jumpers are located on the T5000PAL server board, which is in the rear right section of the

Carrier Grade Server TIGH2U chassis. To configure the jumpers on the server board, you must first

remove the chassis cover, the processor air duct (see Section 3.2.5, “Removing the Processor Air

Duct”), and the PCI riser card assembly (see Section 4.2.2, “Removing the PCI Riser Card Assembly”

on page 56). All other components installed on the server board can remain in place.

Kontron Carrier Grade Server TIGH2U

Product Guide, rev.1.2 December 2009

34

Page 35

Server Component Installations and Upgrades—TIGH2U Server

3.4.1.1 Configuration Jumpers

The server board has several 2-pin and 3-pin jumper blocks (see Figure 19) that can be used to

configure, protect, or recover specific features of the serv

denoted by “*” or “ ”.

er board. Pin 1 on each jumper block is

Figure 19. Recovery Jumper Bl

ocks (J1D1, J1D2, J1D3)

Tab le 5 defines the jumper positions and identifies the default configuration of each jumper.

Table 5. Recovery Jumpers

Jumper Name Pins What happens at system reset…

J1D1: BMC Force Update

J1D2: Password Clear

J1D3: CMOS Clear

1-2 BMC Firmware Force Update Mode – Disabled (D

2-3 BMC Firmware Force Update Mode – Enabled

1-2

2-3

1-2

2-3

These pins should have a jumper in plac

(Default)

If these pins are jumpered, administr

cleared at the next system reset. These pins should not be jumpered

for normal operation.

These pins should have a jumper in plac

(Default)

If these pins are jumpered, the CMOS settings will be cleared at the

ne

xt system reset. These pins should not be jumpered for normal

operation.

e for normal system operation.

ator and user passwords will be

e for normal system operation.

efault)

December 2009 Product Guide, rev.1.2

Kontron Carrier Grade Server TIGH2U

35

Page 36

TIGH2U Server—Server Component Installations and Upgrades

3.4.1.2 BIOS Select Jumper

The jumper block at J3H1, located to the left of the SSI control panel header (see Figure 20), is used

to select which BIOS image the system will boot to. Pin 1 on the jumper is identified with a “ ”.

Figure 20. BIOS Select Jumper (J3H1)

Tab le 6 gives the possible configuration options. This jumper should only be moved if you wish to

force the BIOS to boot to the secondary bank, which

may hold a different version of the BIOS.

Table 6. BIOS Select Jumper

Pins What happens at system reset…

1-2 Force BIOS to bank 0

2-3 System is configured for normal operation (D

efault)

The rolling BIOS feature of the server board automatically alternates the boot BIOS to the secondary

bank if the BIOS image in the primary bank is corrupted or cannot boot.

Note: When pe

rforming a BIOS update procedure, the BIOS select jumper must be set to its

default position (pins 2-3).

Kontron Carrier Grade Server TIGH2U

Product Guide, rev.1.2 December 2009

36

Page 37

Server Component Installations and Upgrades—TIGH2U Server

3.4.1.3 DCD/DSR Signal Select Jumper

Note: This jumper affects the rear panel serial port only.

Various serial port concentrators may require either the DCD (Data Carrier Detect) or DSR (Data

ignal Ready) signal on Pin 7 of the RJ45 connector. To allow support for either of these two serial

S

port configuration standards, a jumper block (J8A3) located directly behind the rear RJ45 serial port

(see Figure 21) must be configured appropriately according to the desired standard:

• For configurations that are compatible with Cisco serial concentrators and require a DSR signal,

the ju

mper block must be configured with the serial port jumper over pins 3 and 4. This is the

factory-installed default setting for this jumper.

• For configurations that are compatible with many

DCD signal, the jumper block must be configured with the serial port jumper over pins 1 and 2.

Pin 1 on the jumper is identified by “ ”.

Figure 21. BIOS Select Jumper (J3H1)

modems and other serial devices that require a

3.4.2 Configuring Memory DIMMs

The memory DIMM sockets are located on the T5000PAL server board at the rear right portion of the

TIGH2U Server chassis. See Figure 22 for the location of the DIMM sockets. The silkscreen on the

board for the DIMMs displays DIMMA1, DIMMA2, DIM

MA3, DIMMB1, DIMMB2 and DIMMB3, starting

from the inside (left side) of the server board. DIMMB3 is the socket closest to the outside edge of the

server board.

The Memory Controller Hub (MCH) on the T5000PAL serv

er board provides for four channels of Fully

Buffered DIMM (FB-DIMM) memory. Each channel can support up to two Dual Ranked FB-DIMM DDR2

DIMMs. FB-DIMM memory channels are organized into two branches for support of RAID 1

(mirroring). The MCH can support up to 8 DIMMs for a maximum memory size of 32 Gbytes of

physical memory in non-mirrored mode and 16 Gbytes of physical memory in a mirrored

configuration.

For DDR2 533 FB-DIMM memory, the read bandwidth for each FB-DIMM channel is 4.25 Gbytes/s,

whi

ch gives a total read bandwidth of 17 Gbytes/s for four FB-DIMM channels. This provides 8.5

Gbytes/s of write memory bandwidth for four FB-DIMM channels.

For DDR2 667 FBDIMM memory, the read bandwidth for each FBDIMM channel is 5.3 Gbytes/s, which

gi

ves a total read bandwidth of 21 GBytes/s for four FBDIMM channels. This provides 10.7 Gbytes/s of

write memory bandwidth for four FBDIMM channels.

December 2009 Product Guide, rev.1.2

Kontron Carrier Grade Server TIGH2U

37

Page 38

TIGH2U Server—Server Component Installations and Upgrades

TS000270

DIMM D2

DIMM D1

DIMM C2

DIMM C1

DIMM B2

DIMM B1

DIMM A2

DIMM A1

Branch 0

MCH

Channel A

Channel B

Channel D

Channel C

Branch 1

The total bandwidth is based on read bandwidth, so the total bandwidth is 17 Gbytes/s for DDR2 533

FBDIMMs and 21.0 Gbytes/s for DDR2 667 FB-DIMMs.

On the T5000PAL server board, a pair of channels becomes a branch where Branch 0 consists of

channels A and B, and Branch 1 consists of channels C and D. FBD memory channels are organized

into two branches for support of RAID 1 (mirroring).

Figure 22. DIMM Sockets and Channels

To boot the system, the system BIOS on the server board uses a dedicated I2C bus to retrieve the

DIMM information needed to program the MCH memory registers. Tab le 7 provides the I

for each DIMM socket.

2

Table 7. I

Kontron Carrier Grade Server TIGH2U

Product Guide, rev.1.2 December 2009

38

C Addresses for Memory Module SMB

Device Address

DIMM A1 0xA0

DIMM A2 0xA2

DIMM B1 0xA0

DIMM B2 0xA2

DIMM C1 0xA0

DIMM C2 0xA2

DIMM D1 0xA0

DIMM D2 0xA2

2

C addresses

Page 39

Server Component Installations and Upgrades—TIGH2U Server

3.4.2.1 Memory RASUM Features

The MCH supports several memory Reliability, Availability, Serviceability, Usability, and Manageability

(RASUM) features. These features include the Intel

®

x4 Single Device Data Correction (Intel® x4

SDDC) for memory error detection and correction, memory scrubbing, retry on correctable errors,

memory built in self test, DIMM sparing, and memory mirroring. See the In

tel® S5000 Series

Chipsets Server Board Family Datasheet for more information about these features.

3.4.2.2 Supported Memory

The server board supports up to eight DDR2-533 or DDR2-667 Fully Buffered DIMMs (FBD memory).

The following tables show the maximum memory configurations supported using the specified

memory technology.

Table 8. Maximum Eight-DIMM Sy

DRAM Technology

x8 Single Rank

256 Mbit 1 GB 2 GB

512 Mbit 2 GB 4 GB

1024 Mbit 4 GB 8 GB

2048 Mbit 8 GB 16 GB

Table 9. Maximum Eight-DIMM System Memory Configuration - x4 Dual Rank

DRAM Technology

x4 Dual Rank

256 Mbit 4 GB 8 GB

512 Mbit 8 GB 16 GB

1024 Mbit 16 GB 32 GB

2048 Mbit 16 GB 32 GB

stem Memory Configuration - x8 Single Rank

Maximum Capacity

Mirrored Mode

Maximum Capacity

Mirrored Mode

Maximum Capacity

Non-Mirrored Mode

Maximum Capacity

Non-Mirrored Mode

Note: DDR2 DIMMs that are not fully buffered are not supported. See

http://www.cmtlabs.com/

mbSearchResults.asp?sManuf+Kontron&sMem=FBDIMM

&sMN=S50000PHB&oSubmit=

Search

for a list of supported memory.

December 2009 Product Guide, rev.1.2

Kontron Carrier Grade Server TIGH2U

39

Page 40

TIGH2U Server—Server Component Installations and Upgrades

3.4.2.3 DIMM Population Rules and Supported DIMM Configurations

DIMM population rules depend on the operating mode of the memory controller, which is determined

by the number of DIMMs installed. DIMMs must be populated in pairs. DIMM pairs are populated in

the following DIMM socket order:

1. A1 and B1

2. C1 and D1

3. A2 and B2

4. C2 and D2

DIMMs within a given pair must be identical with respect to size, speed, and organization. However,

DIMM capacities

can be different between different DIMM pairs.

For example, a valid mixed-DIMM configuration may have:

• 512 Mbyte FBDIMMs installed in DIMM sockets A1 and B1

• 1 Gbyte FBDIMMs installed in DIMM sockets C1 and D1

The supported DIMM configurations for the T5000PAL server board are in Tab le 10.

Table 10. Supported DIMM Configurations

Branch 0 Branch 1

Channel A Channel B Channel C Channel D

DIMM A1 DIMM A2 DIMM B1 DIMM B2 DIMM C1 DIMM C2 DIMM D1 DIMM D2

Y (0)

Y

Mirroring: Y = Yes. Indicates that configuration

ts memory mirroring.

= Supported and validated configur

populated.

= Supported, not validated configuration; socket is

pulated.

po

= Socket is not populated.

ation; socket is

suppor

Sparing: Y(x) = Yes. Indicates that configuration

ports memory sparing, where x is one of the

sup

following:

• 0: Sparing supported on Branch 0 only

• 1: Sparing supported on Branch 1 only

• 0,1: Sparing supported on both branches

Mirroring

Possible

Sparing

Possible

Y (0)

Y Y (0, 1)

The following restrictions apply:

• Single channel mode is only tested and supported

with a 512 Mbyte x8 FBDIMM installed in DIMM

socket A1.

• The supported memory configurations must me

• For best performance, the number of DIMMs instal

et the population rules defined above.

led should be balanced across both memory

branches. For example: a four-DIMM configuration performs better than a two-DIMM

configuration and should be installed in DIMM sockets A1, B1, C1, and D1. An eight-DIMM

configuration performs better than a six-DIMM configuration.

• Although mixed DIMM capacities between channels is supported,

Kontron does not validate

DIMMs in mixed-DIMM configurations.

Kontron Carrier Grade Server TIGH2U

Product Guide, rev.1.2 December 2009

40

Page 41

Server Component Installations and Upgrades—TIGH2U Server

3.4.2.4 Non-Mirrored Mode Minimum Configuration

The server board can be operated with only one DIMM. For better system performance, Kontron

recommends that at least two DIMMs be installed.

Figure 23 shows the recommended minimum DIMM memory configuration. Populated DIMM sockets

are shown in grey.

Figure 23. Recommended Minimum Two-DIMM Memory Configuration

Note: The server board supports single DIMM mode operation. Kontron will only validate and

support this configuration with a single 512 MB x8 FBDIMM installed in DIMM socket

A1.

December 2009 Product Guide, rev.1.2

Kontron Carrier Grade Server TIGH2U

41

Page 42

TIGH2U Server—Server Component Installations and Upgrades

3.4.2.5 Non-Mirrored Mode Memory Upgrades

The minimum memory upgrade increment is two DIMMs per branch. The DIMMs must cover the same

socket position on both channels. DIMM pairs must be identical with respect to size, speed, and

organization. DIMMs that cover adjacent socket positions do not need to be identical.

When adding two DIMMs to the configuration shown in Figure 23, the DIMMs should be populated in

DIMM sockets C1 and D1 as shown in Figure 24. Populated DIMM sockets are shown in grey.

Figure 24. Recommended Four-DIMM Configuration

Functionally, DIMM sockets A2 and B2 could also have been populated instead of DIMM sockets C1

and D1. However, the system will not achieve equivalent performance. Figure 24 shows the supported

DIMM configuration that is recommended because it allows both memory branches from the MCH to

operate independently and simultaneously. FBD bandwidth is doubled when both branches operate in

parallel.

3.4.2.6 Mirrored Mode Memory Configuration

When operating in mirrored mode, both branches operate in lock step. In mirrored mode, branch 1

contains a replica of the data in branch 0. The minimum DIMM configuration to support memory

mirroring is four DIMMs, populated as shown in Figure 24. All four DIMMs must be identical with

respect to size, speed, and organization.