» User’s Guide «

www.kontron.com

Kontron SYMKLOUD MS2900 Platform

Document revision 1.5

2

www.kontron.com

User’s Guide

» Table of Contents «

1 User Information .............................................................................................................................. 5

1.1 Kontron User Documentation .................................................................................................................................. 5

1.2 Copyright Notice ...................................................................................................................................................... 5

1.3 Quality Standards ..................................................................................................................................................... 5

1.4 Warranty ................................................................................................................................................................... 5

1.5 Technical Support .................................................................................................................................................... 5

2 About this Guide ............................................................................................................................... 6

3 SYMKLOUD MS2900 Safety Information ........................................................................................... 7

3.1 General Safety Warnings and Cautions .................................................................................................................... 7

3.2 General Power Safety Warnings and Cautions ......................................................................................................... 7

3.3 DC Power Supply Safety ............................................................................................................................................ 8

3.4 Rack Installation Safety ........................................................................................................................................... 8

3.4.1 Elevated Operating Ambient Temperature ..................................................................................................... 9

3.4.2 Reduced Air Flow ............................................................................................................................................. 9

3.4.3 Mechanical Loading ........................................................................................................................................ 9

3.4.4 Circuit Overloading ......................................................................................................................................... 9

3.4.5 Reliable Earth-Grounding ............................................................................................................................... 9

4 The SYMKLOUD MS2900 Platform ...................................................................................................10

4.1 Feature Summary ................................................................................................................................................... 11

4.2 Block Diagram ........................................................................................................................................................ 12

4.3 System Components ............................................................................................................................................... 12

4.3.1 Chassis Front Panel ....................................................................................................................................... 12

4.3.1 MS2900 Hot-Swappable Components .......................................................................................................... 14

4.3.2 System Control Panel .................................................................................................................................... 14

4.3.3 MSH8900 Hub Modules ................................................................................................................................. 16

4.3.4 System Fans................................................................................................................................................... 17

4.3.5 Chassis Rear Panel ........................................................................................................................................ 18

4.3.6 Processor Nodes ............................................................................................................................................ 19

4.3.7 Uplink/Stacking Module ............................................................................................................................... 20

4.3.8 Power Supply Units ....................................................................................................................................... 21

4.4 Supported Operating Systems ............................................................................................................................... 25

4.5 Mechanical Specifications ..................................................................................................................................... 25

4.5.1 Physical Dimensions ..................................................................................................................................... 25

4.5.2 Shipping Weights .......................................................................................................................................... 26

4.5.3 Rack Mounting Equipment ............................................................................................................................ 27

4.5.4 Environmental Specifications ....................................................................................................................... 28

3

www.kontron.com

User’s Guide

4.5.5 Regulatory Specifications ............................................................................................................................. 29

4.5.6 CE Mark .......................................................................................................................................................... 29

4.5.7 Waste Electrical and Electronic Equipment Directive (WEEE Directive) ...................................................... 29

5 Platform Management ....................................................................................................................30

5.1 System Manager & System Monitor ....................................................................................................................... 30

5.1.1 Platform Health Monitoring ......................................................................................................................... 31

5.2 Management Subsystems ...................................................................................................................................... 31

5.2.1 Platform Management .................................................................................................................................. 31

5.2.2 Cooling and Thermal Management ............................................................................................................... 32

5.2.3 Power ............................................................................................................................................................. 34

5.3 Buttons, Connectors and LEDs ............................................................................................................................... 35

5.3.1 LED Indicators ............................................................................................................................................... 35

5.3.2 Cable Connections......................................................................................................................................... 39

4

www.kontron.com

User’s Guide

» Table of Figures «

Figure 1: Earth Ground Lug Location .................................................................................................................................... 7

Figure 2: DC Power Supply Connector Polarity ...................................................................................................................... 8

Figure 3: Integrated Software and Hardware Components ................................................................................................ 10

Figure 4: MS2900 System Block Diagram ............................................................................................................................ 12

Figure 5: Front View ............................................................................................................................................................. 13

Figure 6: System Control Panel ........................................................................................................................................... 14

Figure 7: Hot-Swappable hub module ................................................................................................................................. 16

Figure 8: Hot-Swappable System Fan Module ..................................................................................................................... 17

Figure 9: Rear View .............................................................................................................................................................. 18

Figure 10: Hot-Swappable Processor Nodes ....................................................................................................................... 19

Figure 11: Hot-Swappable Uplink Module .......................................................................................................................... 20

Figure 12: Hot-Swappable Power Supplies ......................................................................................................................... 21

Figure 13: Attaching Slide Rails for Rear Mounting ............................................................................................................ 27

Figure 14: Main Page Overview ............................................................................................................................................ 30

Figure 15: Air Path Through the System .............................................................................................................................. 33

Figure 16: Front and Rear Panel LEDs ................................................................................................................................. 35

Figure 17: Rear Uplink Ports ................................................................................................................................................ 39

Figure 18: RJ-45 to DB-9 Console Adapter ......................................................................................................................... 39

5

www.kontron.com

User’s Guide

1 User Information

1.1 Kontron User Documentation

This document provides information about products from Kontron and/or its subsidiaries. No warranty of suitability, purpose, or

fitness is implied. While every attempt has been made to ensure that the information in this document is accurate, the

information contained within is supplied “as-is” and it is subject to change without notice.

For the circuits, descriptions and tables indicated, Kontron assumes no responsibility as far as patents or other rights of third

parties are concerned.

1.2 Copyright Notice

Copyright © 2016 Kontron America Inc.

All rights reserved. No part of this document may be reproduced, transmitted, transcribed, stored in a retrieval system, or

translated into any language or computer language, in any form or by any means (electronic, mechanical, photocopying,

recording, or otherwise), without the express written permission from Kontron.

1.3 Quality Standards

Kontron is certified to ISO 9000 Quality Standards.

1.4 Warranty

This Kontron product is warranted against defects in material and workmanship for the warranty period from the date of

shipment. During the warranty period, Kontron will at its discretion decide to repair or replace defective products.

Within the warranty period, the repair of products is free of charge as long as warranty conditions are observed.

The warranty does not apply to defects resulting from improper or inadequate maintenance or handling by the buyer,

unauthorized modification or misuse, operation outside of the product’s environmental specifications or improper installation or

maintenance.

Kontron will not be responsible for any defects or damages to other products not supplied by Kontron that are caused by a fau lty

Kontron product.

1.5 Technical Support

Technicians and engineers from Kontron and/or its subsidiaries are available for technical support. We are committed to making

our product easy to use and will help you use our products in your solutions.

Please consult our web site (www.kontron.com) for the latest product documentation, utilities, drivers, and support contacts.

6

www.kontron.com

User’s Guide

2 About this Guide

The

Kontron SYMKLOUD MS2900 Platform User’s Guide

the features of the platform and provides links and references to other documents in the set for more detailed information about

all the system components.

The topics covered in this User’s Guide are:

» Safety information

» Feature summary and block diagram

» Component overview

» Physical specifications

» Environmental and regulatory specifications

» System management – thermal, power, cables and connectors

For more detailed information on these topics or additional features of the MS2900 platform, see all the available

documentation and drivers on the Kontron web site http://www.kontron.com/

is the central manual in the MS2900 documentation set. It covers all

7

www.kontron.com

User’s Guide

3 SYMKLOUD MS2900 Safety Information

Caution! The SYMKLOUD MS2900 Platform is ESD sensitive equipment. Users must observe precautions for handling

electrostatic discharge sensitive devices. Also review the following safety instructions before you handle the equipment.

WARNING

pay close attention to the safety information in this section. Assembly instructions in this guide must be followed to ensure and

maintain compliance with existing product certifications and approvals. Use only the described, regulated components specified

in this guide. Use of other products/components will void the CSA certification and other regulatory approvals of the product and

will most likely result in non-compliance with product regulations in the region(s) in which the product is sold.

Read all caution and warning statements in this section before performing any of the instructions elsewhere in this guide or other

SYMKLOUD MS2900 platform documentation.

:

Although you may be using this guide or another resource as a reference, before working with SYMKLOUD products,

3.1 General Safety Warnings and Cautions

WARNING: To prevent a fire or shock hazard, do not expose this product to rain or moisture. The chassis should not be exposed to

dripping or splashing liquids and no objects filled with liquids should be placed on the chassis cover.

CAUTION: The MS2900 switch and the processor nodes inside the MS2900 system contain CR2032-type lithium batteries. There

is a risk of explosion if the batteries are replaced by an incorrect type.

Dispose of used batteries according to the battery manufacturer’s instructions.

3.2 General Power Safety Warnings and Cautions

NOTE: This equipment operates over the marked voltage and frequency range without requiring manual setting of any selector

switches.

WARNING: The power button on the system does not turn off system power. To remove power from the system, you must unplug

each power cord from the wall outlet or the power supply.

CAUTION: This unit usually has more than one power supply cord. Disconnect all power supply cords before servicing to avoid

electric shock.

CAUTION: Equipment must be connected to protective earth ground with a minimum 6 AWG cable using the supplied double lug

terminal.

Figure 1: Earth Ground Lug Location

CAUTION: Installation of this product must be in accordance with national wiring codes and conform to local regulations. Different

types of line cord sets may be used for connections to the mains supply circuit and must comply with the electrical code

requirements of the country of use.

CAUTION: The AC power supply plug is intended to serve as a power disconnect device. The socket outlet must be installed near

the equipment and must be easily accessible.

8

www.kontron.com

User’s Guide

Pin (Input)

Name

Description

1

Vin+

Input positive

2

Vin-

Input negative

3

PE

Ground

3.3 DC Power Supply Safety

WARNING: An MS2900 platform equipped with DC power must be installed in a restricted access area. This equipment when

powered by DC current must be protected by a listed branch circuit protector with a maximum 50 A rating. The DC source must be

electrically isolated from any hazardous AC source by double or reinforced insulation.

WARNING: The DC power supply does not have polarity markings. Use the supplied DC power mating connector with a wire and

polarities as shown in Figure 2

Figure 2: DC Power Supply Connector Polarity

Use 8 AWG wires at a minimum for connection to the DC power source

NOTE: the DC power supply is reverse polarity protected by internal diodes and will not operate at all if wired incorrectly.

WARNING: This equipment is designed to permit connecting the earth grounded conductor on the DC supply circuit to the earth

grounding conductor on the equipment (MS2900 DC-equipped version only).

To make this connection, all of the following conditions must be met:

1. This equipment must be connected either directly to the DC supply system grounding electrode conductor or to a

bonding jumper from a grounding terminal bar or bus to which the DC supply system earth grounding electrode is

connected.

2. This equipment must be located in the same immediate area (such as adjacent cabinets) as any other equipment that

has a connection between:

a. the same DC supply circuit’s earth-grounded conductor and the earth-grounding conductor, and also

b. at the point of grounding for the DC system. The DC system cannot be grounded anywhere else.

3. The DC power supply source must be located within the same premises as the equipment.

4. The grounded circuit conductor between the DC source and the grounding electrode conductor’s point of contact

cannot be used for switching or disconnecting devices.

3.4 Rack Installation Safety

The following sections cover important guidelines and considerations for safely installing this equipment in a cabinet or rack.

9

www.kontron.com

User’s Guide

3.4.1 Elevated Operating Ambient Temperature

If this equipment is installed in a closed or multi-unit rack assembly, the operating ambient temperature of the rack environment

may be greater than room ambient. Therefore, be careful to install the equipment in an environment that is compatible with the

maximum ambient temperature (TMA=55oC) specified by the manufacturer.

3.4.2 Reduced Air Flow

When installing this equipment in a rack, do not compromise the amount of air flow required for safe operation.

3.4.3 Mechanical Loading

When mounting this equipment in a rack, be careful not to create a hazardous condition by loading the equipment unevenly.

The system comes with rear mounting flanges already in place on both sides of the chassis. Rails that fit in these flanges also

come in the box

NOTE: Because the heaviest components in the chassis, i.e., the processor nodes and power supplies, are in the rear, using the

slide rails and L-brackets for rear mounting is strongly recommended. This method will provide the most stable and secure

cabinet/rack installation.

For information about installing the MS2900 system in a rack, see Section 4.5.3: Rack Mounting Equipment.

3.4.4 Circuit Overloading

When connecting this equipment to the supply circuit, be sure not to overload the circuits, as this can adversely affect overcurrent

protection and the supply wiring. Check the supply equipment nameplate ratings when addressing this concern.

3.4.5 Reliable Earth-Grounding

Always maintain reliable grounding of rack-mounted equipment. Particular attention should be given to supply connections other

than direct connections to the branch circuit (e.g. when using power strips).

10

www.kontron.com

User’s Guide

4 The SYMKLOUD MS2900 Platform

This chapter describes the main features of the Kontron MS2900 platform. It provides an overview and block diagram of the

product, a list of the platform features, and also covers the mechanical, environmental, and regulatory specifications.

The Kontron SYMKLOUD MS2900 Platform is a fully integrated cloud computing infrastructure platform that uses a modular

hardware and software design to provide excellent performance, energy savings, and ease of system management. The MS2900

platform supports high-availability features such as hot-swappable hubs (for the switch/ShMC), processor nodes, fans, and

power supplies. The platform scales from one to nine processor nodes per system to multiple stacked systems in a cabinet/rack.

The MS2900 platform also includes integrated System Monitor software and specialized management software/firmware for

individual components such as the switch(es), etc. Figure 3 illustrates the flexible integrated features for this cloud computing

solution.

Figure 3: Integrated Software and Hardware Components

11

www.kontron.com

User’s Guide

Feature

Description

Hardware Layer

Hardware Platform

Ruggedized modular platform design

2U height, 21 inches deep

Up to nine hot-swappable processor modules

One or two hot-swappable hubs

Up to two hot-swappable rear uplink modules

Redundant management ports

Five hot-swappable fans for front to back

cooling

Dual redundant AC or DC hot-swappable power

supplies

Processor Node options

(for each processor node)

Many configurable options exist across the various Processor

Nodes available for the Symkloud platform (Single- or Dual-CPU,

up to 32GB memory, GbE or 10G backplane Ethernet, on-board

storage, etc.)

See the Ordering Guide for a complete list of available Node

models and options, or refer to the manual of the specific MSP

node for more details.

Power Supplies

two hot-swappable power supply units (AC or DC), 12 VDC

output, 80 PLUS® silver or better efficiency

Fans

Five hot-swappable and redundant fans for uninterrupted frontto-back cooling

Switching Interface

Up to two hot-swappable MSH8900 hubs

(See the

MSH8900 Hub Module User’s Guide

for more

information.)

Network Interfaces

High uplink capacity;

4x 10GbE ports, SFP+ (front or rear)

8x 1GbE ports, RJ-45

Management interface

2x 1GbE ports, RJ-45

2x serial port, RJ-45

Software Layer

System Management

System Monitor

Dedicated System Manager

Remote management for diagnostics and AMT provisioning

One-click updates for streamlined maintenance

Switch Management

Integrated BMC with IPMI and KVM

Switch Web GUI

Support

Product life cycle support for 5 – 7 years

Compliance/Regulatory

Meets the following environmental, safety, and EMC

requirements:

EN 300 019 (meets)

Telcordia GR-63 (designed to meet)

Telcordia SR-3580 level 3 (designed to meet)

Telcordia GR-1089 (designed to meet)

EN 300 386 (meets)

IEC/EN/CSA/UL 60950-1 (meets) FCC Part 15 (meets)

(**Some limitations may apply, depending on the configuration)

4.1 Feature Summary

Table 1 lists the key features of the MS2900 platform.

For up-to-date details of available Nodes, power supplies and other configurable options, please refer to the Symkloud Ordering

Guide.

Table 1: Key Features

12

www.kontron.com

User’s Guide

4.2 Block Diagram

Figure 4 is the block diagram, which shows the internal connections among the components as well as how signals are routed.

Figure 4: MS2900 System Block Diagram

*Dual connectors to the backplane fabric interface have one 10GbE connector and one 1GbE connector each.

4.3 System Components

The modular design of the MS2900 platform makes all of the key system components hot-swappable, whether accessible from

the front or rear external chassis panel.

4.3.1 Chassis Front Panel

Figure 5 shows the features and accessible components on the MS2900 system front panel.

13

www.kontron.com

User’s Guide

Component

Description

1

Management 1GbE RJ-45 port (Switch/ShMC 1)

(Marked “MNGT” on the Hub 1 faceplate)

2

Serial Console RJ-45 port (Switch/ShMC 1)

3

SFP+ stacking port (Switch/ShMC 1)

(Marked ‘’1’’ on the Hub 1 faceplate)

4

10GbE SFP+ uplink port (Switch/ShMC 1)

(Marked ‘’2’’ on the Hub 1 faceplate)

5

Quad GbE RJ-45 ports (Switch/ShMC 1)

(Marked “3”, “4”, “5”, and “6” on the Hub 1 faceplate)

6

Management GbE RJ-45 port (Switch/ShMC 2)

(Marked “MNGT” on the Hub 2 faceplate)

7

Console RJ-45 port (Switch/ShMC 2)

8

SFP+ stacking port (Switch/ShMC 2)

(Marked ‘’1’’ on the Hub 2 faceplate)

9

10GbE SFP+ uplink port (Switch/ShMC 2)

(Marked ‘’2’’ on the Hub 2 faceplate)

10

Quad GbE RJ-45 ports (Switch/ShMC 2)

(Marked “3”, “4”, “5”, and “6” on the Hub 2 faceplate)

Figure 5: Front View

14

www.kontron.com

User’s Guide

ID

Description

Location

Quantity

Hub

MSH8900 hub module

Front

2

Fan

Fan module

Front

5

Hub Uplink

Uplink module

Rear

2

Node

Node module

Rear

9

PSU

Power supply unit

Rear

2

Feature

Description

1

Power button

2

Power LED (green)

3

ESD connection

4

Minor alarm LED (amber)

5

Major alarm LED (red)

6

Critical alarm LED (red)

7

Chassis ID LED (blue)

4.3.1 MS2900 Hot-Swappable Components

Table 2: Hot-Swappable Components

4.3.2 System Control Panel

The control panel is the main health and status interface for the whole platform. Figure 6 shows the features on the control panel.

Figure 6: System Control Panel

Chassis Power Button functionality

15

www.kontron.com

User’s Guide

Current State

Short Press

Long press (>4 seconds)

Power OFF

(Standby)

Chassis is

powered.

PWR Led off and

ID Led ON (Blue)

Power on “Active” and “Stand-By” hub.

PWR Led will start to blink during the transition.

“Active” hub waits 30 seconds for switch to be up

and running.

“Active” Hub sends power on command to all nodes.

Once all nodes and hubs reach the M4 State (power

on) the PWR Led is turned on (green).

Nothing happens

Power ON

Chassis is

powered

PWR Led ON

(green) and ID

Led OFF.

“Active” Hub sends graceful shutdown to all nodes.

PWR Led will start to blink during the transition to the

“Power Off” state.

Wait for all nodes in the chassis to reach the M1

State (power off).*

Send graceful shutdown to “Stand-By” hub.

Perform graceful shutdown of “Active” hub.

Hub sends immediate power off command to all

nodes.

Hub Sends immediate power off to “Stand-By” hub.

Power off “Active” hub.

Once all nodes and hubs reach the M1 State (power

off) the PWR Led is turned off.

Power State

Transition

Nothing happens

Nothing happens

*Note: The node’s BMC waits up to 5 minutes for the OS to shut down the CPU engine before forcing a power off.

16

www.kontron.com

User’s Guide

4.3.3 MSH8900 Hub Modules

The MS2900 platform supports two hot-swappable hub modules installed from the front of the chassis. Each Hub modules

includes both a Shelf Manager (ShMC) module and an Ethernet Switch (with 24x GbE + 4x 10GbE and associated PHYs).

The Hub 1 module is installed by default with the system. The Hub 2 module is optional. Adding a second hub gives the platform

the following configurable capabilities:

» ShMC function: active-standby

» Switch function: active-active

Figure 5 shows the locations of the hubs on the front panel and the I/O connections on both Hub 1 and Hub 2 faceplates.

Figure 9, “Rear View” shows the location of the uplink connections on the rear panel of the chassis. The 10GbE uplink ports can

be used for high-speed connections to switch/ShMC Hub 1 and switch/ShMC Hub 2 instead of the front panel 10GbE ports.

The main functions of the hub modules are:

» Chassis shelf manager functions such as fans controls, system monitoring and reporting

» Web interface and IPMI 2.0 management

» Redundancy and hot-swap management

» Power management

» One-click updates

» Stacking support

» Chassis switching functions among all system components

Figure 7 shows the location on the chassis front panel of the hot-swappable hub modules.

Figure 7: Hot-Swappable hub module

NOTE: See the

for detailed information about this subsystem

Kontron SYMKLOUD MSH8900 Hub Module User’s Guide

on the Kontron web site at http://www.kontron.com/

.

17

www.kontron.com

User’s Guide

4.3.4 System Fans

There are five hot-swappable system fans on the MS2900 platform. Each fan module consists of a single 60x60x38mm fan, its

housing, lock, and status LED. Figure 8 shows the location of the system fans on the chassis front panel.

For information about cooling and thermal management within the MS2900 platform, see Section 5.2.2, “Cooling and Thermal

Management“.

Figure 8: Hot-Swappable System Fan Module

18

www.kontron.com

User’s Guide

Feature

Description

1

Rear-Uplink ports (with 2x MSU8900)

- Hub 2 Uplink ports (top): port 1 stacking, port 2 uplink

- Hub 1 Uplink ports (bottom): port 1 stacking, port 2 uplink

2

Up to nine processor subsystem nodes, slots 1 – 9

NOTES: 1) Slots 7 and 9 have one 10GbE port, see lines 5 and 6

2) Unpopulated slots ship with blank filler modules

3 & 4

AC or DC power supply unit (PSU 1 & 2)

5 & 6

Slots 7 & 9; with 3x GbE and 1x 10GbE ports

4.3.5 Chassis Rear Panel

Figure 9 shows the features and accessible components on the rear panel of the chassis.

Figure 9: Rear View

19

www.kontron.com

User’s Guide

4.3.6 Processor Nodes

Up to nine processor nodes can be installed in the rear of the chassis. Figure 9, “Rear View” shows the node numbering. Filler

modules are used in all slots that do not have processor nodes installed.

Figure 10 shows a hot-swappable processor node being removed from the chassis rear panel.

Figure 10: Hot-Swappable Processor Nodes

NOTE: See the

Guide

The MS2900 platform provides one internal 10GbE connection to each slot 7 (from Hub 1) & slot 9 (from Hub 2) (when used with

10G-enabled nodes). See Figure 9, “Rear View” for these slot locations.

Kontron SYMKLOUD MSP8000/MSP8001 Processor Node User’s Guide

on the Kontron web site at www.kontron.com for detailed information about this subsystem

or the

MSP8020 Processor Node User’s

.

20

www.kontron.com

User’s Guide

4.3.7 Uplink/Stacking Module

The MS2900 platform provides for two optional uplink/stacking modules, one for each hub, accessible from the rear panel of the

chassis. Figure 11 shows the location of the two slots (one for each hub). If a slot is not used for an uplink module, there is a

blank filler module in the slot.

Figure 11: Hot-Swappable Uplink Module

The key features of the uplink module are:

» Two SFP+ cages

» Status LEDs

» Electrically hot swappable

NOTE: When using optical SFP+ modules in Uplink Modules, the chassis alignment bracket may prevent easily pulling or closing

the SFP+ release clamp. Pulling out the whole Uplink Module to release the SFP+ module is suggested.

21

www.kontron.com

User’s Guide

4.3.8 Power Supply Units

The MS2900 platform provides two bays for hot-swappable power supply units (PSUs), either AC or DC. Two PSUs ship with the

platform. Figure 12 shows the location of the power supply units at the rear of the chassis.

NOTE: Read the power safety warnings in Sections 3.2 and 3.3 before handling the power supply units.

Figure 12: Hot-Swappable Power Supplies

See section 5.2.3 for information about the MS2900 platform power requirements.

The key features of the power supply units are:

» Hot-swappable

» PMBus

22

www.kontron.com

User’s Guide

Description

Input Voltage

Range

Power

(W)

Quantity

Subtotal

(W)

AC power supply module (1100W)

90-264 VAC

1080

1

2

2160

DC power supply module (1100W)

40-72 VDC

10801 2 2160

AC power supply module (1300W)2

90-264 VDC

13001

2

2600

AC power supply module (1500W)3

85-264 VAC

15001 2 3000

Ambient Temperature (C)

Vin(VAC) / T (°C)

25

30

35

40

45

50

Vin (V

AC

)

90

1100W

984

984

984

900

900

825

1300W

960

960

960

960

960

936

1500W

1260

1260

1260

1260

1160

1075

115

1100W

1080

1080

1080

1080

1080

1005

1300W

1080

1080

1080

1080

1080

1008

1500W

1500

1500

1500

1500

1500

1300

120

1100W

1080

1080

1080

1080

1080

1005

1300W

1300

1200

1200

1080

1069

1068

1500W

1500

1500

1500

1500

1500

1400

180

1100W

1080

1080

1080

1080

1080

1005

1300W

1300

1300

1300

1200

1200

1164

1500W

1500

1500

1500

1500

1500

1400

The MS2900 supports up to two (2) redundant AC or DC power supplies. The rated power output of these PSUs is directly related

to the Voltage input and the ambient temperature.

Power Supply

1

Subject to temperature and input voltage de-rating

2

A 12 Amps cable rated 105°C must be used to limit de-rating

3

A 15 Amps cable rated 105°C must be used to limit de-rating

Output Power (Watts) as a function of ambient temperature and AC input voltage (de-rating)

23

www.kontron.com

User’s Guide

Ambient Temperature (C)

Vin(VAC) / T (°C)

25

30

35

40

45

50

Vi

n

(V

AC

)

40V-72V

1100W

1080

1080

1080

1080

1080

924

Output Power (Watts) as a function of ambient temperature and DC input voltage (de-rating)

24

www.kontron.com

User’s Guide

Description

Max. Input

Current (A)

PSU Receptacle Type

Mating Cable Description

1100W AC power

supply module

13A

IEC60320-C14

A cable with C13 plug rated at

105°C must be used.

1300W AC power

supply module

12A

IEC60320-C14

A cable with C13 plug rated at

105°C must be used.

1500W AC power

supply module

15A

IEC60320-C16

A cable with C15 plug rated at

105°C must be used.

AC Power Supply Inlet

Power Supply Connector

25

www.kontron.com

User’s Guide

Chassis

Measurements (mm

[in])

Notes

Depth

533,4 mm [21 in]

Body

580,2 mm [22.8 in]

Total with front handle (19 mm [0.75 in]) and rear power supply handles

(27,8 mm [1.1in])

Width

449 mm MAX [17.6 in]

Body

483,4 mm MAX [19 in]

Overall width: front/mid mounting brackets included (2x 17,2 mm [0.7 in])

465.5 mm [18.3 in]

Between rack mounting points

Height

88.1 mm MAX [3.5 in]

Body

Side clearance

76.2 mm [3 in]

Between rack mounting points

Front clearance

100 mm [4 in]

Recommended

Rear clearance

150 mm [6 in]

Recommended

4.4 Supported Operating Systems

The MS2900 platform supports most major OS distributions. Refer to the processor node User’s Guide that covers the processor

node and CPU model used on your platform for a list of supported OS versions. Kontron continuously improves and extends the

product documentation set for this platform. The latest documentation covering supported operating systems will be made

available on the Kontron web site (www.kontron.com).

4.5 Mechanical Specifications

The MS2900 chassis is a modular 19-inch rack-mount unit that is 2U x 21 in. deep. The system has brackets and rails to support

front or middle solid rack/cabinet mounting as well as adjustable rear mounting.

4.5.1 Physical Dimensions

This table shows the height, width, and depth measurements for the chassis.

26

www.kontron.com

User’s Guide

Descriptions

Weight (kg)

Weight (lbs)

System weight - with fan modules only

12.1

26.6

System packaging

1.94

4.3

MSP8000/MSP8001 – typical processor node (with CPU and DIMM)

0.880

1.9

MSP8020 – typical processor node (with CPU and DIMM, without HDD)

1.08

2.4

MSH8900 hub

0.64

1.4

MSU8700 uplink module

0.30

0.7

AC power supply

1.34

2.95

DC power supply

1.34

2.95

Node carrier (bare sled - for unused slots)

0.36

0.80

Hub filler panel

0.14

0.3

Uplink module filler panel

0.04

0.09

Fan module

0.30

0.7

Generic DIMMs (2)

0.02

0.04

Solid State Drive (SSD)

0.15

0.3

4.5.2 Shipping Weights

The following table shows the weights of all components in both kilograms and pounds.

27

www.kontron.com

User’s Guide

4.5.3 Rack Mounting Equipment

The MS2900 platform comes with both front and rear mounting attachments. The front of the chassis has brackets attached on

each side for fastening the system in a cabinet/rack. These brackets can also be mounted on the chassis center of mass for midmount applications. The system also comes with two slide rails to enable mounting at the rear of the cabinet/rack and an

optional set of longer slide rails can be ordered for cabinets deeper than 24 inches.

NOTE: Because the heaviest components in the chassis (i.e. the processor nodes and power supplies) are in the rear, rear

mounting using the slide rails and L-brackets is required, unless you must use the center mounting method. Using both front and

rear mounting provides the most stable and secure cabinet/rack installation.

For installing the slide rails, the system has rear mounting flanges already in place on both sides of the chassis. No screws are

needed; just slide the rails between the flanges with the L-bracket facing the rear of the chassis. See Figure 13.

Once the rails are installed on the MS2900 system, you will need four screws to fasten the rails to the rack posts. Depending on

the width of the cabinet or rack you are using, the grounding lug on the left rear side of the chassis may make this a tight fit. If the

chassis doesn’t slide in easily, you may have to tilt or wiggle the chassis to get it into the rack. If that doesn’t work, you can

remove the grounding lug by unscrewing the two fasteners and re-attaching the lug from the rear of the cabinet/rack once you

have the chassis in place. See Figure 13.

Figure 13: Attaching Slide Rails for Rear Mounting

28

www.kontron.com

User’s Guide

Environment

Specification

Temperature, operating

-5ºC to +55ºC (23º F to 131º F)

(some limitations may apply, depending on the configuration)

Temperature, non-operating

-40º C to +85º C (-40º F to 185º F)

Temperature, operating (high altitude)

Up to 61ºC for altitude compensation at 6,000 ft (1800 m)

1ºC rise per 1000 ft

Humidity, operating

This product meets a test profile based on GR-63, ETSI EN 300 019-2-3 Class 3.1E, ETSI

EN 300 019-2-2 Class 2.3, and ETSI EN 300 019-2-1 Class 1.2

5% to 93%, non-condensing at 40ºC

Humidity, non-operating

5% to 93%, non-condensing at 40º C (104º F)

Altitude/pressure, operating

Testing done at sea level; ambient temperature is increased 1ºC per 1,000 ft to reflect the

altitude effect on cooling

-300 m to 4,000 m at aisle-ambient 40ºC

(May require cooling above 1,800 m)

Altitude/pressure, non-operating

-300 m to 14,000 m

Vibration, operating

This product meets operational swept sine vibration

Test profile based on GR-63, clause 5.4.2, and ETSI EN 300 019-2-3, class 3.2

5 Hz to 200 Hz @ 0.2g

This product meets operational random vibration

Test profile based on ETSI EN 300 019-2-3, class 3.2

5 Hz to 10 Hz @ +12 dB/oct (slope up)

10 Hz to 50 Hz @ 0.02 m2/s3 (0.0002 g2/Hz (flat)

50 Hz to 100 Hz @ -12 dB/oct (slope down)

30 minutes per each of three axes

Vibration, non-operating

This product meets transportation and storage swept sine vibration

Test profile based on ETSI EN 300 019-2-1, class 1.2

5 Hz to 200 Hz @ 0.2g

This product meets transportation and storage random vibration

Test profile based on GR-63, clause 5.4.3, and ETSI EN 300 019-2-2, class 2.3

5 Hz to 20 Hz @ 1m2/s3 (0.01 g22/Hz) (flat)

20 Hz to 200 Hz @ -3 dB/oct (slope down)

30 minutes per each of three axes

Shock, operating

This product meets operational shock standards

Test profile based on ETSI EN 300 019-2-3, class 3.2

11 ms half sine, 3g, three shocks in each direction

Shock, non-operating

This product meets transportation and storage half sine shock

Test profile based on ETSI EN 300 019-2-2, class 3.2

6 ms half sine, 18g, 100 shocks in each direction

Drop/free fall

This product meets Bellcore GR-63, section 5.3

Packaged = 1,000 mm, six surfaces, three edges, and four corners

Unpackaged = 100 mm, two sides and two bottom corners

Electrostatic discharge (ESD)

This product meets 8kV Contact, 15 kV Air Discharge using IEC61000-4-2 Test Method.

Acoustic

Designed to meet GR-63 and EN 300 753

RoHS

This product is designed to meet China RoHS Phase 1 (self-declaration and labeling)

This product complies with EU directive 2002/96/EC (WEEE)

This product complies with RoHS directive 2011/65/EU

4.5.4 Environmental Specifications

The MS2900 Platform meets the following environmental tests and standards:

29

www.kontron.com

User’s Guide

USA/Canada

This product meets all requirements of UL/CSA 60950-1

Europe

This product complies with the Low Voltage Directive, EC Council Directive 2006/95/EC

and EN 60590-1

International

This product meets IEC 60950-1

USA/Canada

This product meets all requirements of FCC Part 15 and GR-1089.

Europe

This product complies with the Electromagnetic Compatibility Directive, EC Council

Directive 2004/108/EC and ETSI EN 300 386, EN 55022, and EN 55024.

International

CISPR 22 Class A and CISPR 24

4.5.5 Regulatory Specifications

The MS2900 platform meets the following regulatory tests and standards:

Safety Compliance

Electromagnetic Compatibility

4.5.6 CE Mark

The CE marking on this product indicates that it is in compliance with the European Union safety, EMC and RoHS requirements.

4.5.7 Waste Electrical and Electronic Equipment Directive (WEEE Directive)

This product contains electrical or electronic materials. If not disposed of properly, these materials may have potential adverse

effects on the environment and human health. The presence of this logo on the product means it should not be disposed of as

unsorted waste and must be collected separately.

To find out how to properly dispose of this product, please contact your customer service representative.

30

www.kontron.com

User’s Guide

5 Platform Management

This chapter covers the MS2900 software/firmware that enables monitoring and upgrading the subsystem components.

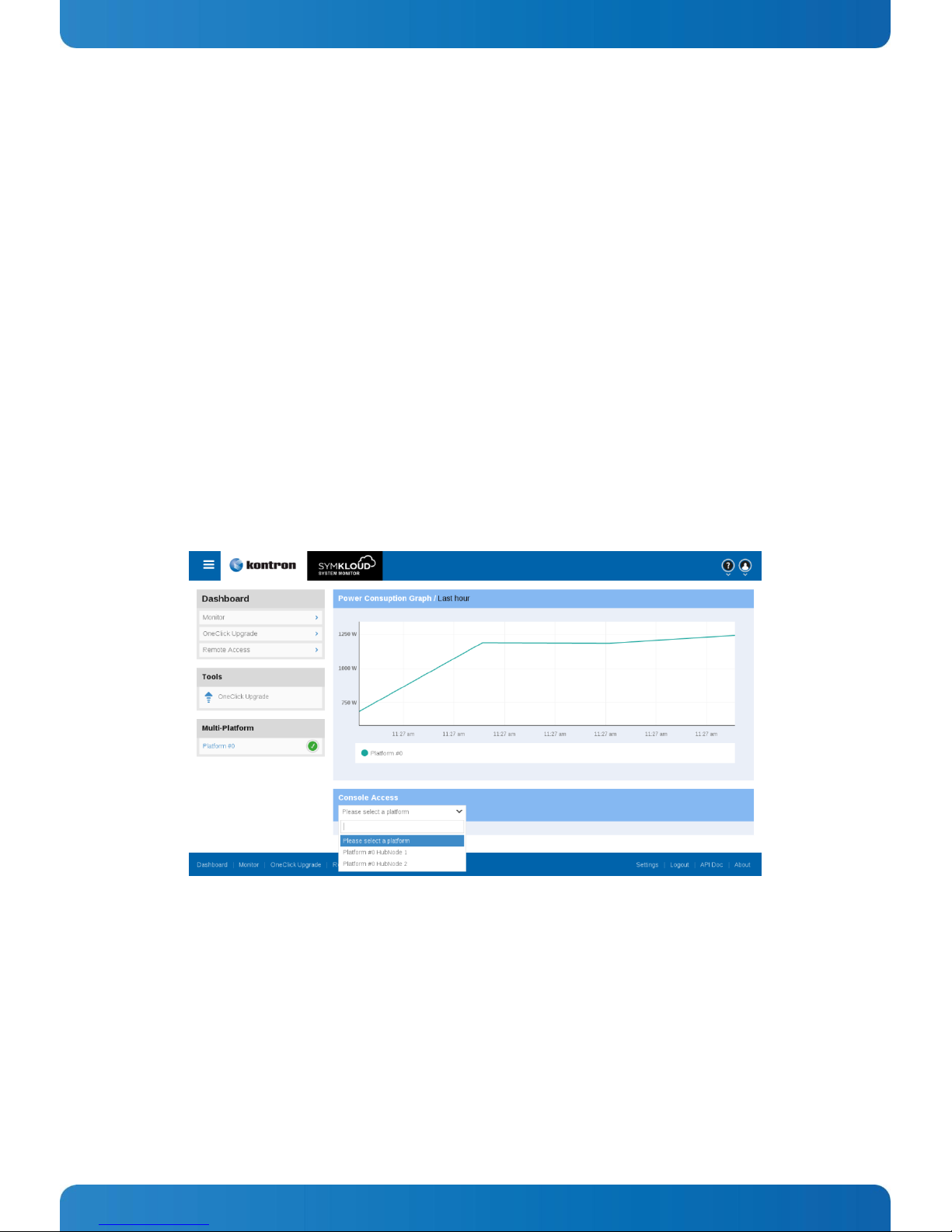

5.1 System Manager & System Monitor

The SYMKLOUD Shelf Manager hosts a monitoring, management and maintenance application called System Manager. The

functions of the System Manager are available through an API or a web interface. The System Monitor is the web interface also

hosted by the Shelf Manager. It provides a graphical representation of the features provided by System Manager's API.

The key features of the System Monitor are:

» Monitor system health

» System Maintenance (One-Click firmware upgrades)

» Access to switch configuration page

» Access to node KVM

NOTE: See the

this application

Kontron System Monitor User’s Guide

.

on the Kontron web site (www.kontron.com) for detailed information about

Figure 14: Main Page Overview

31

www.kontron.com

User’s Guide

“Chassis Health” Sensor State

Alarm Level

01h Healthy

No alarm (all alarm leds off)

02h Informational fault

No alarm (all alarm leds off)

03h Minor fault

Minor (MNR) led on (amber)

04h Major fault

Major (MJR) led on (red)

05h Critical fault

Critical (CRT) led on (red)

5.1.1 Platform Health Monitoring

Each node BMC and hub ShMC of the MS2900 platform implements a set of component “Health Status”. The “Health Sensor” of

each component aggregates the state of local sensors. The list of sensors for the nodes and hubs usually includes critical

voltage, temperature and discrete sensors. Please consult the associated User Guide for a detailed list of sensors members of

this aggregate for a specific node or hub.

Additionally ShMCs on the hub have a “Chassis Health” sensor. This sensor is an aggregation of all the “Health Status” sensors

of each component of the platform. The state of this sensor is replicated on the system control panel CRT, MJR and MNR LEDs.

The most critical “Health Status” sensor reading is displayed by the LEDs.

Here are the “Health Status” vs LEDs status reading table:

5.2 Management Subsystems

The MS2900 management software addresses all major subsystems within the platform, including platform management (IPMI),

cooling/thermal management, and power management.

5.2.1 Platform Management

The platform management subsystem is based on features of the Integrated Baseboard Management Controller (iBMC). This

subsystem consists of communication buses, sensors, system BIOS, and server management firmware. The platform

management subsystem also supports standard IPMI features as well as other features that are not part of IPMI. The supported

features are listed below.

IPMI 2.0 Features

» Baseboard Management Controller (BMC)

» IPMI Watchdog timer

» Messaging support, including command bridging and user/session support

» Chassis device functionality, including power/reset control and BIOS boot flags support

» Event receiver device: the BMC receives and processes events from other platform subsystems

» Field Replaceable Unit (FRU) inventory device functionality: the BMC supports access to system FRU devices using IPMI

FRU commands

» System Event Log (SEL) device functionality: the BMC supports and provides access to a SEL

» Sensor Data Record (SDR) repository device functionality: the BMC supports storage and access of system SDRs

» Sensor device and sensor scanning/monitoring: the BMC provides IPMI management of sensors and polls sensors to

monitor and report system health.

32

www.kontron.com

User’s Guide

» IPMI interfaces: host interfaces include System Management Software (SMS) with receive message queue support and

Server Management Mode (SMM)

IPMB Interface

» LAN interface that supports the IPMI-over-LAN protocol (RMCP, RMCP+)

» Serial-over-LAN (SOL)

» ACPI state synchronization: the BMC tracks ACPI state changes that are provided by the BIOS

» BMC self-test: the BMC performs initialization and run-time self-tests and makes results available to external entities

Non-IPMI Features

The integrated BMC also supports the following non-IPMI features:

» Fault Resilient Booting (FRB): FRB2 is supported by the Watchdog timer functionality

» Limited number of system resets for fan speed control

» Platform Environment Control Interface (PECI) thermal management support

» Memory thermal management

» Power supply unit management

Support for the power supply unit sensor: the BMC handles power-good dropout conditions

» Front panel management: the ShMC controls the system status LED and chassis ID LED

The chassis ID LED is turned on using an IPMI command

» Address Resolution Protocol (ARP): the BMC sends and responds to ARPs (supported on embedded NICs)

» Dynamic Host Configuration Protocol (DHCP): the BMC performs DHCP (supported on embedded NICs)

» Embedded web server

New Manageability Features

The SYMKLOUD MS2900 platform also offers some new features:

» Support for embedded web server UI in Basic Manageability feature set (i.e., fan monitoring, software upgrade, node

health/presence)

» Management support for PMBus rev1.2-compliant power supplies

5.2.2 Cooling and Thermal Management

MS2900 Airflow Path

The MS2900 platform cooling scheme is a front-to-back push configuration. Air is pushed into the chassis by the fans at the

front. Air then passes through the backplane assembly and is channeled into the node bays where it exits the system through the

node carrier grills. Figure 15 shows this air path.

33

www.kontron.com

User’s Guide

Figure 15: Air Path Through the System

This cooling push configuration pressurizes the system. With this configuration, dust can only enter the system by the fan inlet.

34

www.kontron.com

User’s Guide

Description

Power (W)

Quantity

Subtotal

(W)

MSH8900 Hub (without SFP+ modules)

15 2 30

MSU8700 Uplink Module (without SFP+ modules)

4 2 8

SFP+ Optical Module

0.7 2 1.4

60x60x38 Fan Module

33 5 165

MSP8020 Processor Node Module

82 9 738

Total power consumption (W)

9431

5.2.3 Power

Power consumption while running a stressed transcoding application (on MSP8020 Processor Nodes)

1

Measured with a stressed transcoding application; 25°C ambient temperature

35

www.kontron.com

User’s Guide

5.3 Buttons, Connectors and LEDs

This section covers the user-accessible connectors, cable requirements, and LED definitions.

5.3.1 LED Indicators

Figure 16 shows the locations of all MS2900 platform LEDs and the table explains the LED functions.

Figure 16: Front and Rear Panel LEDs

36

www.kontron.com

User’s Guide

LED State Definitions

Front Panel LEDs

Chassis/Control Panel

Color(s)

Description

Chassis ID LED

Blue

OFF

Whole chassis is ready to be pulled off-line

OR

All nodes are OFF (No payload) = On, blue

All nodes are on, payload power is on = Off

Power LED

Green

OFF

All nodes ON, payload power = On, green

Power state transition in progress (Power On or Power Off) =

Blinking, green

All nodes OFF, no payload power = Off

Alarm LEDs

(CRT, MJR, MNR)

MNR: Amber

MJR: Red

CRT: Red

OFF

Alarm = On

Alarm Description:

Minor fault (MNR): The system is not at risk and still runs within

its specifications.

Major fault (MJR): The system is at risk and requires immediate

attention. Major faults can be normal if the system in high stress

conditions, but should never be repetitive and permanent.

Critical fault (CRT): The system is at risk and requires immediate

action. A device might have already failed.

See section 5.1.1 for more details.

No alarm = Off

Hub 1 and Hub 2

Color(s)

Description

ID LED

Blue

OFF

Only management power is present = On, blue

ID command is active = Blinking, blue

Payload power is present = Off

Power/Active LED

Green

OFF

Payload power is on = On, green

Hub hosts active shelf manager = On, green

Hub hosts the inactive shelf manager = Blinking green

Payload power removed = Off

Status LED

Amber

OFF

Hub “not healthy”, needs attention = On, amber (default)

Hub transitioning when power button pressed

(clean shutdown request) = Blinking, amber

Hub operating under normal conditions = Off

37

www.kontron.com

User’s Guide

LED State Definitions

1Gbe RJ-45 (Quad/Management)

Color(s)

Description

LED1 Link Status/Activity

Green

OFF

Link established = On, green

Activity = Blinking, green

No link, no activity = Off

LED2 Link Speed

Green

Amber

OFF

Link speed 1 Gbit = On, green

Link speed 10 Mbit, 100 Mbit = On, amber

No link = Off

10GbE SFP+ Stacking,

10GbE SFP+ Uplink

Color(s)

Description

LED1

Green

OFF

Link established = On, green

Activity = Blinking, green

No link, no activity = Off

LED2

Amber

OFF

Fault = On, amber

Normal conditions, no fault = Off

Fan ID/Status

Color(s)

Description

LED

Amber

OFF

Maintenance needed = On, amber

Fan ID command active = Blinking, amber

Normal operating condition = Off

Back Panel LEDs

Hub Uplink

Color(s)

Description

LED1

Green

OFF

Link established = On, green

Activity = Blinking, green

No link, no activity = Off

LED2

Amber

OFF

Fault = On, amber

Normal conditions, no fault = Off

Processor Node

Color(s)

Description

Status LED

Red/Amber

OFF

Node not healthy, needs attention = On, red

Node in transition, power button pressed =

Blinking, amber

Node operating normally = Off

38

www.kontron.com

User’s Guide

LED State Definitions

Power LED

Green

OFF

Node on, payload present = On, green

Node in standby state (S3/S4 sleep state) =

Blinking, green

Node is off (no payload) = Off

ID LED

Blue

OFF

Management power on, but no payload = On, blue

Command active = Blinking, blue

Node is on or on standby (payload present) = Off

Power Supply

Color(s)

Description

AC/DC Input Status

Green

OFF

Line within range = On, green

Line under voltage = Off

DC Output

Yellow

Green

Both Yellow/Green

12V or Vsb1 out of regulation = On, yellow

Over temperature shutdown = On, yellow

Output over voltage = On, yellow

Regulation normal operation = On, green

Hot-Standby mode = Blinking, yellow 25%,

green 75%

Over temperature warning = Blinking, yellow 75%,

green 25%

Minor fan regulation error = Blinking, yellow 50%,

green 50%

1

Vsb – Standby Output (3V3)

39

www.kontron.com

User’s Guide

5.3.2 Cable Connections

The MS2900 platform provides I/O connections from both the front and rear of the chassis. In the front of the chassis there is a

10GbE SFP+ uplink port, a 10GbE SFP+ stacking port, and four 1GbE RJ-45 LAN ports for each hub. For the location of the front

panel ports, see Figure 5, “Front View.”

Rear Uplink modules provide the option of redirecting 10GbE/Stacking (per hub) to the rear.

Figure 17 shows the location of the two 10GbE uplink ports and two 10GbE stacking ports (one of each for each switch/ShMC

hub).

Figure 17: Rear Uplink Ports

For each hub there is also front panel access to an RJ-45 serial console port and a management RJ-45 Ethernet port. The

MS2900 platform ships with an RJ-45 to DB-9 serial adapter (included in the box – see Figure 18). This adapter can be used with

an RJ-45 cable to connect devices with a DB-9 serial port to the MS2900 via either hub RJ-45 console port (See Figure 5, “2” or

“7”).

Figure 18: RJ-45 to DB-9 Console Adapter

40

www.kontron.com

User’s Guide

Europe, Middle East & Africa

Lise-Meitner-Str. 3-5

86156 Augsburg

Germany

Tel.: +49 (0) 821 4086-0

Fax: +49 (0) 821 4086 111

info@kontron.com

North America

14118 Stowe Drive

Poway, CA 92064-7147

USA

Tel.: +1 888 294 4558

Fax: +1 858 677 0898

info@us.kontron.com

Asia Pacific

1~2F, 10 Building, No. 8

Liangshuihe 2nd Street,

Economical & Technological

Development Zone,

Beijing 100176, P.R.China

Tel.: + 86 10 63751188

Fax: + 86 10 83682438

info@kontron.cn

e.

Corporate Offices

Loading...

Loading...