Page 1

USER GUIDE

www.kontron.com // 1

KBox A-103

Doc. User Guide, Rev. 3.0

Doc. ID: 1057-0976

Page 2

KBox A-103 – User Guide, Rev. 3.0

This page has been intentionally left blank

www.kontron.com // 2

Page 3

KBox A-103 – User Guide, Rev. 3.0

KBOX A

-103 - USER GUIDE

Disclaimer

Kontron would like to point out that the information contained in this user guide may be subject to alteration,

particularly as a result of the constant upgrading of Kontron products. This document does not entail any guarantee

on the part of Kontron with respect to technical processes described in the user guide or any product characteristics

set out in the user guide. Kontron assumes no responsibility or liability for the use of the described product(s),

conveys no license or title under any patent, copyright or mask work rights to these products and makes no

representations or warranties that these products are free from patent, copyright or mask work right infringement

unless otherwise specified. Applications that are described in this user guide are for illustration purposes only.

Kontron makes no representation or warranty that such application will be suitable for the specified use without

further testing or modification. Kontron expressly informs the user that this user guide only contains a general

description of processes and instructions which may not be applicable in every individual case. In cases of doubt,

please contact Kontron.

This user guide is protected by copyright. All rights are reserved by Kontron. No part of this document may be

reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any language or computer

language, in any form or by any means (electronic, mechanical, photocopying, recording, or otherwise), without the

express written permission of Kontron. Kontron points out that the information contained in this user guide is

constantly being updated in line with the technical alterations and improvements made by Kontron to the products

and thus this user guide only reflects the technical status of the products by Kontron at the time of publishing.

Brand and product names are trademarks or registered trademarks of their respective owners.

©2018 by Kontron S&T AG

Kontron S&T AG

Lise-Meitner-Str. 3-5

86156 Augsburg

Germany

www.kontron.com

www.kontron.com // 3

Page 4

KBox A-103 – User Guide, Rev. 3.0

Intended Use

THIS DEVICE AND ASSOCIATED SOFTWARE ARE NOT DESIGNED, MANUFACTURED OR INTENDED FOR USE

OR RESALE FOR THE OPERATION OF NUCLEAR FACILITIES, THE NAVIGATION, CONTROL OR

COMMUNICATION SYSTEMS FOR AIRCRAFT OR OTHER TRANSPORTATION, AIR TRAFFIC CONTROL, LIFE

SUPPORT OR LIFE SUSTAINING APPLICATIONS, WEAPONS SYSTEMS, OR ANY OTHER APPLICATION IN A

HAZARDOUS ENVIRONMENT, OR REQUIRING FAIL-SAFE PERFORMANCE, OR IN WHICH THE FAILURE OF

PRODUCTS COULD LEAD DIRECTLY TO DEATH, PERSONAL INJURY, OR SEVERE PHYSICAL OR

ENVIRONMENTAL DAMAGE (COLLECTIVELY, "HIGH RISK APPLICATIONS").

You understand and agree that your use of Kontron devices as a component in High Risk Applications is entirely at

your risk. To minimize the risks associated with your products and applications, you should provide adequate design

and operating safeguards. You are solely responsible for compliance with all legal, regulatory, safety, and security

related requirements concerning your products. You are responsible to ensure that your systems (and any Kontron

hardware or software components incorporated in your systems) meet all applicable requirements. Unless otherwise

stated in the product documentation, the Kontron device is not provided with error-tolerance capabilities and cannot

therefore be deemed as being engineered, manufactured or setup to be compliant for implementation or for resale as

device in High Risk Applications. All application and safety related information in this document (including application

descriptions, suggested safety measures, suggested Kontron products, and other materials) is provided for reference

only

.

www.kontron.com // 4

Page 5

KBox A-103 – User Guide, Rev. 3.0

Revision History

Revision Brief Description of Changes Date of Issue Author/

Editor

1.0 Initial Issue 2016-Jan-27 MK

2.0 New Corporate Design; legal and safety information

updated, BIOS chapter reworked, Linux note added, pinout of GPIO header added, COM port configuration

information added, errors corrected

3.0 CE Directives and Standards updated 2018-Sep-27 MK

2017-Aug-03 MK

Terms and Conditions

Kontron warrants products in accordance with defined regional warranty periods. For more information about

warranty compliance and conformity, and the warranty period in your region, visit http://www.kontron.com/termsand-conditions.

Kontron sells products worldwide and declares regional General Terms & Conditions of Sale, and Purchase Order

Terms & Conditions. Visit http://www.kontron.com/terms-and-conditions

.

For contact information, refer to the corporate offices contact information on the last page of this user guide or visit

our website CONTACT US.

Customer Support

Find Kontron contacts by visiting: http://www.kontron.com/support.

Customer Service

As a trusted technology innovator and global solutions provider, Kontron extends its embedded market strengths into

a services portfolio allowing companies to break the barriers of traditional product lifecycles. Proven product

expertise coupled with collaborative and highly-experienced support enables Kontron to provide exceptional peace of

mind to build and maintain successful products.

For more details on Kontron’s service offerings such as: enhanced repair services, extended warranty, Kontron

training academy, and more visit http://www.kontron.com/support-and-services/services

.

Customer Comments

If you have any difficulties using this user guide, discover an error, or just want to provide some feedback, contact

Kontron support

revised user guide on our website.

. Detail any errors you find. We will correct the errors or problems as soon as possible and post the

www.kontron.com // 5

Page 6

Symbols

V) when touching

. Failure to observe the precautions indicated and/or

This symbol and title inform that the electronic boards and their components are sensitive

to static electricity. Care must therefore be taken during all handling operations and

The following symbols may be used in this user guide

DANGER indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

WARNING indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

NOTICE indicates a property damage message.

CAUTION indicates a hazardous situation which, if not avoided,

may result in minor or moderate injury.

Electric Shock!

This symbol and title warn of hazards due to electrical shocks (> 60

products or parts of products

prescribed by the law may endanger your life/health and/or result in damage to your

material.

KBox A-103 – User Guide, Rev. 3.0

ESD Sensitive Device!

inspections of this product in order to ensure product integrity at all times.

HOT Surface!

Do NOT touch! Allow to cool before servicing.

Laser!

This symbol inform of the risk of exposure to laser beam and light emitting devices (LEDs)

from an electrical device. Eye protection per manufacturer notice shall review before

servicing.

This symbol indicates general information about the product and the user guide.

This symbol also indicates detail information about the specific product configuration.

This symbol precedes helpful hints and tips for daily use.

www.kontron.com // 6

Page 7

KBox A-103 – User Guide, Rev. 3.0

For Your Safety

Your new Kontron product was developed and tested carefully to provide all features necessary to ensure its

compliance with electrical safety requirements. It was also designed for a long fault-free life. However, the life

expectancy of your product can be drastically reduced by improper treatment during unpacking and installation.

Therefore, in the interest of your own safety and of the correct operation of your new Kontron product, you are

requested to conform with the following guidelines.

High Voltage Safety Instructions

As a precaution and in case of danger, the power connector must be easily accessible. The power connector is the

product’s main disconnect device.

Warning

All operations on this product must be carried out by sufficiently skilled personnel only.

Electric Shock!

Before installing a non hot-swappable Kontron product into a system always ensure that

your mains power is switched off. This also applies to the installation of piggybacks. Serious

electrical shock hazards can exist during all installation, repair, and maintenance operations

on this product. Therefore, always unplug the power cable and any other cables which

provide external voltages before performing any work on this product.

Earth ground connection to vehicle’s chassis or a central grounding point shall remain

connected. The earth ground cable shall be the last cable to be disconnected or the first

cable to be connected when performing installation or removal procedures on this product.

Special Handling and Unpacking Instruction

ESD Sensitive Device!

Electronic boards and their components are sensitive to static electricity. Therefore, care

must be taken during all handling operations and inspections of this product, in order to

ensure product integrity at all times.

Do not handle this product out of its protective enclosure while it is not used for operational purposes unless it is

otherwise protected.

Whenever possible, unpack or pack this product only at EOS/ESD safe work stations. Where a safe work station is not

guaranteed, it is important for the user to be electrically discharged before touching the product with his/her hands

or tools. This is most easily done by touching a metal part of your system housing.

It is particularly important to observe standard anti-static precautions when changing piggybacks, ROM devices,

jumper settings etc. If the product contains batteries for RTC or memory backup, ensure that the product is not placed

on conductive surfaces, including anti-static plastics or sponges. They can cause short circuits and damage the

batteries or conductive circuits on the product.

www.kontron.com // 7

Page 8

KBox A-103 – User Guide, Rev. 3.0

Lithium Battery Precautions

If your product is equipped with a lithium battery, take the following precautions when replacing the battery.

Danger of explosion if the battery is replaced incorrectly.

Replace only with same or equivalent battery type recommended by the manufacturer.

Dispose of used batteries according to the manufacturer’s instructions.

General Instructions on Usage

In order to maintain Kontron’s product warranty, this product must not be altered or modified in any way. Changes or

modifications to the product, that are not explicitly approved by Kontron and described in this user guide or received

from Kontron Support as a special handling instruction, will void your warranty.

This product should only be installed in or connected to systems that fulfill all necessary technical and specific

environmental requirements. This also applies to the operational temperature range of the specific board version

that must not be exceeded. If batteries are present, their temperature restrictions must be taken into account.

In performing all necessary installation and application operations, only follow the instructions supplied by the

present user guide.

Keep all the original packaging material for future storage or warranty shipments. If it is necessary to store or ship

the product then re-pack it in the same manner as it was delivered.

Special care is necessary when handling or unpacking the product. See Special Handling and Unpacking Instruction.

Quality and Environmental Management

Kontron aims to deliver reliable high-end products designed and built for quality, and aims to complying with

environmental laws, regulations, and other environmentally oriented requirements. For more information regarding

Kontron’s quality and environmental responsibilities, visit http://www.kontron.com/about-kontron/corporateresponsibility/quality-management.

Disposal and Recycling

Kontron’s products are manufactured to satisfy environmental protection requirements where possible. Many of the

components used are capable of being recycled. Final disposal of this product after its service life must be

accomplished in accordance with applicable country, state, or local laws or regulations.

WEEE Compliance

The Waste Electrical and Electronic Equipment (WEEE) Directive aims to:

Reduce waste arising from electrical and electronic equipment (EEE)

Make producers of EEE responsible for the environmental impact of their products, especially when the product

become waste

Encourage separate collection and subsequent treatment, reuse, recovery, recycling and sound environmental

disposal of EEE

Improve the environmental performance of all those involved during the lifecycle of EEE

Environmental protection is a high priority with Kontron.

Kontron follows the WEEE directive

www.kontron.com // 8

You are encouraged to return our products for proper disposal.

Page 9

KBox A-103 – User Guide, Rev. 3.0

Table of Contents

Symbols ................................................................................................................................................................................................................. 6

For Your Safety ................................................................................................................................................................................................... 7

High Voltage Safety Instructions .................................................................................................................................................................. 7

Special Handling and Unpacking Instruction ............................................................................................................................................ 7

Lithium Battery Precautions .......................................................................................................................................................................... 8

General Instructions on Usage ..................................................................................................................................................................... 8

Quality and Environmental Management ................................................................................................................................................ 8

Disposal and Recycling .................................................................................................................................................................................... 8

WEEE Compliance.............................................................................................................................................................................................. 8

Table of Contents............................................................................................................................................................................................... 9

List of Tables ...................................................................................................................................................................................................... 11

List of Figures .................................................................................................................................................................................................... 12

1/ General Safety Instructions for IT Equipment ......................................................................................................................... 14

1.1. Electrostatic Discharge (ESD) ................................................................................................................................................................ 16

1.1.1. Grounding Methods ................................................................................................................................................................................ 16

1.2. Instructions for the optional Lithium Battery .................................................................................................................................. 16

2/ Electromagnetic Compatibility ..................................................................................................................................................... 17

2.1. Electromagnetic Compatibility (EU) .................................................................................................................................................... 17

2.2. FCC Statement (USA) ............................................................................................................................................................................... 17

2.3. 5.3. EMC Compliance (Canada) ............................................................................................................................................................. 17

3/ Shipment and Unpacking ................................................................................................................................................................ 18

3.1. Unpacking .................................................................................................................................................................................................... 18

3.2. Scope of Delivery ...................................................................................................................................................................................... 18

3.2.1. Standard ................................................................................................................................................................................................... 18

3.2.2. Optional Parts ........................................................................................................................................................................................ 18

3.2.3. Optional System Extension ................................................................................................................................................................ 18

3.3. Type Label and Product Identification ............................................................................................................................................... 19

4/ System Overview .............................................................................................................................................................................. 20

4.1. RTC ................................................................................................................................................................................................................. 21

4.1.1. RTC Buffer Time ...................................................................................................................................................................................... 21

4.1.2. Setting the RTC ...................................................................................................................................................................................... 22

4.2. 7.2. System Expansion Capabilities ................................................................................................................................................... 23

4.2.1. System Expansion via SATA Interface ........................................................................................................................................... 23

4.2.2. System Expansion via mSATA Interface ...................................................................................................................................... 23

4.2.3. System Expansion via Mini PCI Express® (mPCIe) Card Interfaces (with SIM card socket) ....................................... 23

4.3. Block Diagram of the KBox A-103 ...................................................................................................................................................... 25

4.4. Front Side ................................................................................................................................................................................................... 26

4.4.1. X101 - Power Input Connector .......................................................................................................................................................... 27

4.4.2. 7.4.2. Controls and LED Indicators ................................................................................................................................................. 27

4.4.3. X102/X103 - Ethernet Connectors (ETH) ..................................................................................................................................... 28

4.4.4. X105 - USB 3.0 ....................................................................................................................................................................................... 28

4.4.5. X107/X108 - USB 2.0 ........................................................................................................................................................................... 28

4.4.6. X109 - DisplayPort ............................................................................................................................................................................... 28

4.4.7. X110 – Serial Port COM 1..................................................................................................................................................................... 28

4.4.8. X204 - Serial Port COM 2 (Option) ................................................................................................................................................. 28

4.4.9. X206 - Serial Port COM 3 (Option) ................................................................................................................................................. 28

www.kontron.com // 9

Page 10

KBox A-103 – User Guide, Rev. 3.0

4.4.10. X205 - FIELDBUS Interface (Option) ............................................................................................................................................ 29

4.4.11. X207 - VGA Interface Connector .................................................................................................................................................... 29

4.5. Left and Right Side View ....................................................................................................................................................................... 30

4.6. Top and Bottom Side View ................................................................................................................................................................... 30

4.7. Rear Side View ........................................................................................................................................................................................... 31

4.7.1. Rear Side View of the KBox A-103 with Vertical Mounting Bracket ...................................................................................... 31

4.7.2. Rear Side View of the KBox A-103 as Desktop Unit or with Wallmount Bracket ............................................................ 32

4.7.3. DIN Rail Clip (Option) ........................................................................................................................................................................... 33

4.7.4. WiFi/WLAN (Option) ........................................................................................................................................................................... 33

4.7.5. GPIO Interface (Option) ...................................................................................................................................................................... 33

4.8. Internal View ............................................................................................................................................................................................. 34

4.8.1. Integrated SMARC-sXBTi Module ................................................................................................................................................... 35

4.8.2. SATA Interface ...................................................................................................................................................................................... 35

4.8.3. mSATA Socket ....................................................................................................................................................................................... 35

4.8.4. Expansion Slots for mPCIe Cards ................................................................................................................................................... 35

5/ Accessing internal Components .................................................................................................................................................. 36

5.1. Opening and Closing the KBox A-103 ................................................................................................................................................. 37

5.1.1. Access Cover ........................................................................................................................................................................................... 38

5.1.2. Serial Port COM2 (X204) Configuration for RS422 or RS485 via DIP Switches ............................................................... 39

5.1.3. Serial Port COM 3 (X206) Configuration of the Serial Port COM 3 ......................................................................................... 41

5.1.4. Optional GPIO Port ................................................................................................................................................................................ 42

5.1.5. Installing an mPCIe Mini Card ........................................................................................................................................................... 42

5.1.6. Installing an mSATA SSD .................................................................................................................................................................... 43

5.1.7. Installing the SIM Card ........................................................................................................................................................................ 43

5.1.8. BIOS Recovery Jumper ........................................................................................................................................................................ 44

5.1.9. Replacing the optional Lithium Battery ......................................................................................................................................... 44

6/ Thermal Considerations ................................................................................................................................................................. 45

6.1. Available Processors............................................................................................................................................................................... 45

6.2. Convection Cooling ................................................................................................................................................................................. 45

6.3. Minimum System Clearance ................................................................................................................................................................ 45

6.4. Maximum Temperatures ...................................................................................................................................................................... 45

6.5. Third Party Components ....................................................................................................................................................................... 45

7/ Installation Instructions ................................................................................................................................................................. 46

7.1. System Mounting ..................................................................................................................................................................................... 47

7.2. DC Power Connection ............................................................................................................................................................................. 48

7.2.1. Cabling ...................................................................................................................................................................................................... 48

8/ Starting Up........................................................................................................................................................................................... 49

8.1. Connecting to DC Main Power Supply ............................................................................................................................................... 49

8.2. Operating System and Hardware Component Drivers ............................................................................................................... 50

9/ Maintenance and Cleaning ............................................................................................................................................................. 51

10/ Technical Specifications ................................................................................................................................................................. 52

10.1. Mechanical Specifications ................................................................................................................................................................... 53

10.1.1. Mechanical Specifications of the KBox A-103 as Desktop ..................................................................................................... 53

10.1.2. Mechanical Specifications of the KBox A-103 with Vertical Mounting Plate .................................................................. 54

10.1.3. Mechanical Specifications of the KBox A-103 Wall/Table Mounting Brackets ............................................................. 55

10.2. Environmental Specifications............................................................................................................................................................ 56

10.3. CE Directives and Standards ............................................................................................................................................................... 57

11/ Standard Interfaces – Pin Assignments ................................................................................................................................... 58

11.1.1. (X101) Power Input Connector .......................................................................................................................................................... 58

www.kontron.com // 10

Page 11

KBox A-103 – User Guide, Rev. 3.0

11.1.2. (X102 as ETH 1 and X103 as ETH 2) Ethernet Connectors ....................................................................................................... 58

11.1.3. (X105) USB 3.0 Port ............................................................................................................................................................................. 59

11.1.4. (X107, X108) USB 2.0 Port .................................................................................................................................................................. 59

11.1.5. (X109) DisplayPort ............................................................................................................................................................................... 59

11.1.6. (X110) Serial Interface COM 1 (RS232) ........................................................................................................................................... 60

11.1.7. (X204) Serial Interface COM 2 (RS232) ......................................................................................................................................... 60

11.1.8. (X204) Serial Port COM 2 (RS422/RS485) configured as RS485 (2-Wire Mode) S, half duplex ............................... 61

11.1.9. (X204) Serial Port COM 2 (RS422/RS485) configured as RS485 (4-Wire Mode), full duplex, (Bus-Master) ....... 61

11.1.10. (X204) Serial Port COM 2 (RS422/RS485) configured as RS422 (4-Channel Mode) ................................................. 62

11.1.11. (X206) Serial Port COM 3 (RS422/RS485) configured as RS485 (4-Wire Mode), full duplex, (Bus-Master) ..... 63

11.1.12. (X206) Serial Port COM 3 (RS422/RS485) configured as RS485 (2-Wire Mode), half duplex ................................. 63

11.1.13. (X206) Serial Port COM 3 (RS422/RS485) configured as RS422 (8-Channel Mode) full duplex ............................ 64

11.1.14. (X207) VGA Port .................................................................................................................................................................................. 64

12/ uEFI BIOS .............................................................................................................................................................................................. 65

12.1. Starting the uEFI BIOS ........................................................................................................................................................................... 65

12.2. Setup Menus ............................................................................................................................................................................................ 66

12.2.1. Main Setup Menu ................................................................................................................................................................................ 67

12.2.2. Advanced Setup Menu ...................................................................................................................................................................... 70

12.2.3. Security Setup Menu ......................................................................................................................................................................... 80

12.2.4. Boot Setup Menu ................................................................................................................................................................................ 82

12.2.5. Exit Setup Menu .................................................................................................................................................................................. 83

12.3. The uEFI Shell .......................................................................................................................................................................................... 84

12.3.1. Basic Operation of the uEFI Shell ................................................................................................................................................... 84

12.4. uEFI Shell Scripting ............................................................................................................................................................................... 85

12.4.1. Startup Scripting ................................................................................................................................................................................. 85

12.4.2. Create a Startup Script ..................................................................................................................................................................... 85

12.4.3. Examples of Startup Scripts ........................................................................................................................................................... 85

12.5. Firmware Update ................................................................................................................................................................................... 86

12.5.1. Updating Procedure............................................................................................................................................................................ 86

Appendix A: List of Acronyms ..................................................................................................................................................................... 87

About Kontron .................................................................................................................................................................................................. 88

List of Tables

Table 1: DIP1, DIP2 and DIP3 settings for serial communication type ............................................................................................ 40

Table 2: DIP4 setting in order to activate or deactivate the termination resistor ..................................................................... 40

Table 3: DIP5, DIP6, DIP7 and DIP8 settings in order to set the needed Timeout and min. baud rate ................................. 40

Table 4: J46 settings forCOM 3 RS485 and RS422 modes (factory settings are in bold letters) .......................................... 41

Table 5: Pin assignments of internal and external GPIO connector ............................................................................................... 42

Table 6: Technical Specifications ............................................................................................................................................................... 52

Table 7: Mechanical Specifications............................................................................................................................................................ 53

Table 8: Environmental Specifications..................................................................................................................................................... 56

Table 9: CE Directive ........................................................................................................................................................................................ 57

Table 10: Electrical Safety.............................................................................................................................................................................. 57

Table 11: EMC ...................................................................................................................................................................................................... 57

Table 12: (X101) Power Input Connector .................................................................................................................................................. 58

Table 13: (X102, X103) Ethernet Connectors ........................................................................................................................................... 58

Table 14: (X105) USB 3.0 Port ....................................................................................................................................................................... 59

Table 15: (X107, X108) USB 2.0 Port ........................................................................................................................................................... 59

Table 16: (X109) DisplayPort ........................................................................................................................................................................ 59

Table 17: (X110) Serial Interface COM 1 (RS232) .................................................................................................................................... 60

www.kontron.com // 11

Page 12

KBox A-103 – User Guide, Rev. 3.0

Table 18: (X204) Serial Interface COM 2 (RS232) ................................................................................................................................. 60

Table 19: (X204) Serial Port COM 2 (RS422/RS485) configured as RS485 (2-Wire Mode) S, half duplex ......................... 61

Table 20: (X204) Serial Port COM 2 (RS422/RS485) configured as RS485 (4-Wire Mode), full duplex, Bus-Master ... 61

Table 21: (X204) Serial Port COM 2 (RS422/RS485) configured as RS422 (4-Channel Mode) ............................................. 62

Table 22: (X204) Serial Port COM 2 (RS422/RS485) configured as RS485 (4-Wire Mode), full duplex, Bus-Master .. 63

Table 23: (X206) Serial Port COM 3 (RS422/RS485) configured as RS485 (2-Wire Mode), half duplex ........................... 63

Table 24: (X206) Serial Port COM 3 (RS422/RS485) configured as RS422 (8-Channel Mode) full duplex ...................... 64

Table 25: (X207) VGA Port............................................................................................................................................................................. 64

Table 26: Navigation Hot Keys Available in the Legend Bar.............................................................................................................. 65

Table 27: Main Setup Menu Sub-screens ................................................................................................................................................ 68

Table 28: Advanced Setup menu Sub-screens and Functions .......................................................................................................... 71

Table 29: Security Setup Menu Functions ............................................................................................................................................... 80

Table 30: Boot Setup Menu Functions ..................................................................................................................................................... 82

Table 31: Save and Exit Setup Menu Functions ..................................................................................................................................... 83

Table 32: List of Acronyms (Example) ...................................................................................................................................................... 87

List of Figures

Figure 1: Type Label.......................................................................................................................................................................................... 19

Figure 2: RTC buffer time diagram .............................................................................................................................................................. 21

Figure 3: Bottom side view ........................................................................................................................................................................... 24

Figure 4: Right side view ............................................................................................................................................................................... 24

Figure 5: Front side view config. with vertical mounting plate ........................................................................................................ 24

Figure 6: Left side view .................................................................................................................................................................................. 24

Figure 7: Top side view .................................................................................................................................................................................. 24

Figure 8: Rear side view ................................................................................................................................................................................ 24

Figure 9: Block Diagram of the KBox A-103 ............................................................................................................................................ 25

Figure 10: KBox A-103 – Front View ........................................................................................................................................................... 26

Figure 11: X101 - 24VDC power input connector .................................................................................................................................... 27

Figure 12: Detail - Power button and PWR LED and HDD LED .......................................................................................................... 27

Figure 13: X205 - Optional FIELDBUS interface ..................................................................................................................................... 29

Figure 14: Right side of the KBox A-103 system .................................................................................................................................... 30

Figure 15: Left side of the KBox A-103 system ....................................................................................................................................... 30

Figure 16: Top side of the KBox A-103 system ....................................................................................................................................... 30

Figure 17: Bottom side of the KBox A-103 system ................................................................................................................................ 30

Figure 18: Rear side of the KBox A-103 system with vertical mounting plate ............................................................................. 31

Figure 19: Rear side of the KBox A-103 without optional WLAN and GPIO (shown as desktop unit) .................................. 32

Figure 20: Rear side of the KBox A-103 with optional WLAN and GPIO (shown with vertical/horizontal mounting

brackets) ............................................................................................................................................................................................................ 32

Figure 21: DIN rail clip ..................................................................................................................................................................................... 33

Figure 22: WLAN (WiFi) antenna ................................................................................................................................................................ 33

Figure 23: KBox A-103 - internal view (without cover) ....................................................................................................................... 34

Figure 24: Opening the access cover of the KBox A-103 .................................................................................................................... 37

Figure 25: Inside of the access cover ........................................................................................................................................................ 38

Figure 26: DIP1-DIP8 switches (shown with factory settings) ........................................................................................................ 39

Figure 27: DIP-Switch (SW1) with DP1 to DP8 for RS422/RS485 serial communication settings (for COM 2) ................ 39

Figure 28: Locked SIM card socket (without SIM card) ....................................................................................................................... 43

Figure 29: Unlocked and opened SIM card socket ................................................................................................................................ 43

Figure 30: Mini SIM card ................................................................................................................................................................................ 43

Figure 31: Inserted SIM card into the card holder of the SIM socket .............................................................................................. 43

Figure 32: Closed and locked SIM card socket with inserted SIM card ........................................................................................ 43

Figure 33: J49 in open (default) and closed position ........................................................................................................................... 44

Figure 34: Restricted area for mounting around KBox A-103 (desktop side view with antenna) ........................................ 47

Figure 35: Restricted area for mounting around KBox A-103 (front view with vert./horiz. mounting brakets) ............. 47

Figure 36: Phoenix power plug terminal .................................................................................................................................................. 48

Figure 37: Dimensions: Front as desktop ................................................................................................................................................ 53

www.kontron.com // 12

Page 13

KBox A-103 – User Guide, Rev. 3.0

Figure 38: Dimensions: Front side with antennas and wall/table mounting brackets ........................................................... 53

Figure 39: Dimensions: Left side ................................................................................................................................................................ 54

Figure 40: Dimensions: Rear side with vertical mounting plate ..................................................................................................... 54

Figure 41: Dimensions: Detail key hole ..................................................................................................................................................... 54

Figure 42: Dimensions: Top side (with wall/table mounting brackets) ....................................................................................... 55

Figure 43: Dimensions: front side (with wall/table mounting brackets) ..................................................................................... 55

Figure 44: Detail mounting slide hole (wall/table mounting brackets) ....................................................................................... 55

Figure 45: Main Setup Menu Initial Screen.............................................................................................................................................. 67

Figure 46: Advanced Setup Menu Initial Screen .................................................................................................................................... 70

Figure 47: Security Setup Menu Initial Screen ....................................................................................................................................... 80

Figure 48: Boot Setup Menu Initial Screen .............................................................................................................................................. 82

Figure 49: Save and Exit Setup Menu Initial Screen ............................................................................................................................. 83

www.kontron.com // 13

Page 14

KBox A-103 – User Guide, Rev. 3.0

1/ General Safety Instructions for IT Equipment

Please read this chapter carefully and take careful note of the instructions, which have been

compiled for your safety and to ensure to apply in accordance with intended regulations. If

the following general safety instructions are not observed, it could lead to injuries to the

The product has been built and tested according to the basic safety requirements for low voltage (LVD) applications

and has left the manufacturer in safety-related, flawless condition. To maintain this condition and also to ensure safe

operation, the operator must not only observe the correct operating conditions for the product but also the following

general safety instructions:

The product must be used as specified in the product documentation, in which the instructions for safety for the

product and for the operator are described. These contain guidelines for setting up, installation and assembly,

maintenance, transport or storage.

The on-site electrical installation must meet the requirements of the country's specific local regulations.

If a power cable comes with the product, only this cable should be used. Do not use an extension cable to connect

the product.

To guarantee that sufficient air circulation is available to cool the product, please ensure that the ventilation

openings are not covered or blocked. If an air filter is provided, this should be cleaned regularly. Do not place the

system close to heat sources or damp places. Make sure the system is well ventilated.

operator and/or damage of the product; in cases of nonobservance of the instructions

Kontron is exempt from accident liability, this also applies during the warranty period.

Only devices or parts which fulfill the requirements of SELV circuits (Safety Extra Low Voltage) as stipulated by

IEC 60950-1 may be connected to the available interfaces.

Before opening the device, make sure that the device is disconnected from the mains.

Switching off the device by its power button does not disconnect it from the mains. Complete disconnection is

only possible if the power cable is removed from the wall plug or from the device. Ensure that there is free and

easy access to enable disconnection.

The device may only be opened for the insertion or removal of add-on cards (depending on the configuration of

the system). This may only be carried out by qualified operators.

If extensions are being carried out, the following must be observed:

All effective legal regulations and all technical data are adhered to.

The power consumption of any add-on card does not exceed the specified limitations.

The current consumption of the system does not exceed the value stated on the product label.

Only original accessories that have been approved by Kontron can be used.

Please note: safe operation is no longer possible when any of the following applies:

The device has visible damages.

The device is no longer functioning.

In this case the device must be switched off and it must be ensured that the device can no longer be operated.

www.kontron.com // 14

Page 15

KBox A-103 – User Guide, Rev. 3.0

Additional safety instructions for DC power supply circuits

To guarantee safe operation of devices with DC power supply voltages larger than 60 volts DC or a power

consumption larger than 240 VA, please observe that:

the device is set up, installed and operated in a room or enclosure marked with “RESTRICTED ACCESS”, if

there are no safety messages on product as safety signs and labels on the device itself.

no cables or parts without insulation in electrical circuits with dangerous voltage or power should be

touched directly or indirectly

a reliable protective earthing connection is provided

a suitable, easily accessible disconnecting device is used in the application (e.g. overcurrent protective

device), if the device itself is not disconnectable

a disconnect device, if provided in or as part of the equipment, shall disconnect both poles simultaneously

interconnecting power circuits of different devices cause no electrical hazards

A sufficient dimensioning of the power cable wires must be selected – according to the maximum electrical

specifications on the product label – as stipulated by EN60950-1 or VDE0100 or EN60204 or UL508 regulations.

The devices do not generally fulfill the requirements for "centralized DC power systems“ (UL 60950-1, Annex

NAB; D2) and therefore may not be connected to such devices!

www.kontron.com // 15

Page 16

KBox A-103 – User Guide, Rev. 3.0

1.

2.

3.

4.

1.

2.

3.

4.

5.

6.

7.

8.

1.1. Electrostatic Discharge (ESD)

A sudden discharge of electrostatic electricity can destroy static-sensitive devices or microcircuitry.

Therefore proper packaging and grounding techniques are necessary precautions to prevent damage. Always take the

following precautions:

Transport boards in ESD-safe containers such as boxes or bags.

Keep electrostatic sensitive parts in their containers until they arrive at the ESD-safe workplace.

Always be properly grounded when touching a sensitive board, component, or assembly.

Store electrostatic-sensitive boards in protective packaging or on antistatic mats.

1.1.1. Grounding Methods

By adhering to the guidelines below, electrostatic damage to the device can be avoided:

Cover workstations with approved antistatic material. Always wear a wrist strap connected to workplace. Always

use properly grounded tools and equipment.

Use antistatic mats, heel straps, or air ionizers for more protection.

Always handle electrostatically sensitive components by their edge or by their casing.

Avoid contact with pins, leads, or circuitry.

Turn off power and input signals before inserting and removing connectors or connecting test equipment.

Keep work area free of non-conductive materials such as ordinary plastic assembly aids and Styrofoam.

Use only field service tools which are conductive, such as cutters, screwdrivers, and vacuum cleaners.

Always place drives and boards PCB-assembly-side down on the foam.

1.2. Instructions for the optional Lithium Battery

If ordered, your KBox A-103 is equipped with an optional lithium battery. For the replacement of this battery please

observe the instructions described in section 5.1.9 “Replacing the optional Lithium Battery”.

Danger of explosion when replacing with wrong type of battery. Replace only with the same

or equivalent type recommended by the manufacturer. The lithium battery type must be UL

recognized.

Do not dispose of lithium batteries in general trash collection. Dispose of the battery

according to the local regulations dealing with the disposal of these special materials, (e.g.

to the collecting points for dispose of batteries).

www.kontron.com // 16

Page 17

KBox A-103 – User Guide, Rev. 3.0

2/ Electromagnetic Compatibility

For detailed information refer to section 10.3 “CE Directives and Standards”.

2.1. Electromagnetic Compatibility (EU)

This product is intended only for use in industrial areas. The most recent version of the EMC guidelines (EMC Directive

2014/30/EU) and/or the German EMC laws apply. If the user modifies and/or adds to the equipment (e.g. installation

of add-on cards) the prerequisites for the CE conformity declaration (safety requirements) may no longer apply.

Warning!

This is a class A product. In domestic environment this product may cause radio interference in which case the user

may be required to take adequate measures.

This is a class A product. In domestic environment this product may cause radio interference

in which case the user may be required to take adequate measures.

2.2. FCC Statement (USA)

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of

the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to

radio communications. Operation of this equipment in residential area is likely to cause harmful interference in which

case the user will be required to correct the interference at his own expense.

2.3. 5.3. EMC Compliance (Canada)

The method of compliance is self-declaration to Canadian standard ICES-003:

(English): This Class A digital apparatus complies with the Canadian ICES-003.

(French): Cet appareil numérique de la class A est conforme à la norme NMB-003 du Canada.

www.kontron.com // 17

Page 18

KBox A-103 – User Guide, Rev. 3.0

3/ Shipment and Unpacking

Please check that your package is complete, and contains the items below (according to the ordered unit

configuration). If you discover damaged or missing items, please contact your dealer.

3.1. Unpacking

Proceed as follows to unpack the unit:

1. Remove packaging.

2. Do not discard the original packaging. Keep it for future relocation.

3. Check the delivery for completeness by comparing it with your order.

4. Please keep the associated paperwork. It contains important information for handling the unit.

5. Check the contents for visible shipping damage.

6. If you notice any shipping damage or inconsistencies between the contents and your order, please contact

Kontron for help and information.

3.2. Scope of Delivery

3.2.1. Standard

KBox A-103 (corresponding to the ordered system configuration)

POWER-SUBCON PSC 1,5/ 3-F, 3-pin plug

General Safety Instructions for IT Equipment

3.2.2. Optional Parts

internal 2.5" SATA SSD

mSATA (MO-300) card

Mini PCIe cards

Two brackets for wall/table mounting

Vertical mounting plate for control cabinet mounting

DIN rail mounting clip

Rubber feet (self-adhesive)

3.2.3. Optional System Extension

COM 2: configured as RS232 or RS422/RS485 via adapter module

COM 3: configured as RS422/RS485

Fieldbus: PROFIBUS via mPCIe module

WiFi: via mPCIe module

GPIO: via adapter cable

www.kontron.com // 18

Page 19

KBox A-103 – User Guide, Rev. 3.0

3.3. Type Label and Product Identification

The type label (product name, serial number) of your KBox A-103 system are located on the access cover of the

device (refer to Figure 1 and Figure 14 pos. 1).

Figure 1: Type Label

www.kontron.com // 19

Page 20

KBox A-103 – User Guide, Rev. 3.0

Standard front panel:

Standard baseboard and system expansion capabilities:

4/ System Overview

The KBox A-103 expands the Kontron line of computers - KBox Series. It is a highly scalable and flexible industrial

computer. The scalability performance is achieved through the use of the Computer-on-Module SMARC-sXBTi. This is

based on Intel's Bay Trail platform and is available in different variants.

Refer to the information and technical data in the user manual of the installed SMARC-sXBTi

Module.

The KBox A-103 hardware system configuration and the robust construction with excellent mechanical stability offer

the superior qualities of a computer designed for operation in harsh industrial environment. It is a fanless system

with a compact U-shaped aluminum chassis with cooling fins. The systems hardware configuration depends also on

installation position of the KBox A-103 (refer to subsection 4.7.1 and 4.7.2).

The rated voltage of the mains (+24VDC) can be found on the type label. The type label is located at the bottom side

of the device. The KBox A-103 may be optionally factory-equipped with an mPCIe WLAN card for three antennas or a

mPCIe card for FIELDBUS communication. As storage media for your KBox A-103 system, you may choose the

implementation of a 2.5" SSD (Solid State Drive) or/and of an mSATA SSD card. Further information about the

configuration of the KBox A-103 can be found on our web site www.kontron.com by selecting the product.

The user’s manual of the installed SMARC-sXBTi Module can be downloaded from our web

page http://www.kontron.com

. Search for the name of the installed module.

The KBox A-103 offers maintenance-free operation. That means it operates without battery, fans and rotating

storage device (HDD's). The system flexibility is a result of the basic design concept of the KBox A-103:

by use of a prime carrier board which provides the SMARC-sXBTi (SXVV) module and a set of standard IO

interfacing

a comprehensive set of optionally available IOs and devices.

The following interfaces are available with the KBox A-103:

24VDC input power (X101)

2x Gigabit Ethernet (X102, X103)

1x USB 3.0 (X105)

2x USB 2.0 (X107, X108)

DisplayPort (X109)

COM 1 (X110)

COM 2 (X204), optional

COM 3 (X206), optional

Fieldbus (X205), optional

VGA (X207)

Power button PWR and power LED

SSD or/and mSATA drive status LED

1x SATA connector (J16) and SATA power connector (J12)

1x mSATA (J17)

2x mPCIe (one for FIELDBUS expansion (J27 slot) and the second one for WLAN expansion (J37 slot)

1x SIM card socket (J40) only with the corresponding mPCIe card installed in the onboard J37 slot.

1x GPIO connector on the rear side of the system

www.kontron.com // 20

Page 21

KBox A-103 – User Guide, Rev. 3.0

The device is designed to be operated in:

Vertical position: (KBox A-103 configuration with vertical mounting plate) mounted inside a control cabinet or

Vertical/horizontal: wall mounted (KBox A-103 configuration with wall mounting brackets) or

Horizontal position: KBox A-103 as desktop unit (equipped with the supplied rubber feet) or

Vertical/horizontal: KBox A-103 DIN Rail mounting (with DIN Rail mounting clip)

When powering on the KBox A-103, make sure that the cooling fins of the chassis (Figure 15,

Figure 16 and Figure 17, pos. 6) are not obstructed (covered) by any objects.

To provide sufficient heat dissipation by the cooling of the device, do not cover the cooling

fins of the

KBox A-103. Do not place any objects on the device. When installing the system, please note

the clearance recommendation in the section 7.1 “System Mounting”.

Please observe that the expansion of your system with an mPCIe WLAN card (and the

corresponding antennas) and/or GPIO port, allows you to use the KBox A-103 only as

desktop unit or equipped with brackets for vertical/horizontal wall/table mounting.

The KBox A-103 equipped with an mPCIe WLAN card with the corresponding antennas

and/or GPIO port is not possible to operate vertical mounting in a control cabinet.

4.1. RTC

The KBox A-103 comprises a chipset external RTC. This RTC is connected to the SMBus of the processor module. A RTC

of type RV-8564 or compatible is used. To provide a valid date and time when no power is connected to the KBox A103, the RTC is equipped with a goldcap buffer.

4.1.1. RTC Buffer Time

The RTC buffer time is depending of the ambient temperature.

If the time is not valid this is indicated by a status bit in the RTC registers. For details see the RV-8564 application

manual.

Figure 2: RTC buffer time diagram

www.kontron.com // 21

Page 22

KBox A-103 – User Guide, Rev. 3.0

To get the maximum buffer time it is necessary to have the system a certain time powered

on. This ensures that the buffer capacitors are fully loaded.

The buffer time depends on the ambient temperature and on how long the box is connected

to its power supply.

4.1.2. Setting the RTC

During startup, the uEFI performs a comparison of chipset clock and external RTC and sets the chipset clock

accordingly if the RTC time is valid. Further it is possible to set the time manually by accessing the RTC over the

SMBus.

www.kontron.com // 22

Page 23

KBox A-103 – User Guide, Rev. 3.0

4.2. 7.2. System Expansion Capabilities

4.2.1. System Expansion via SATA Interface

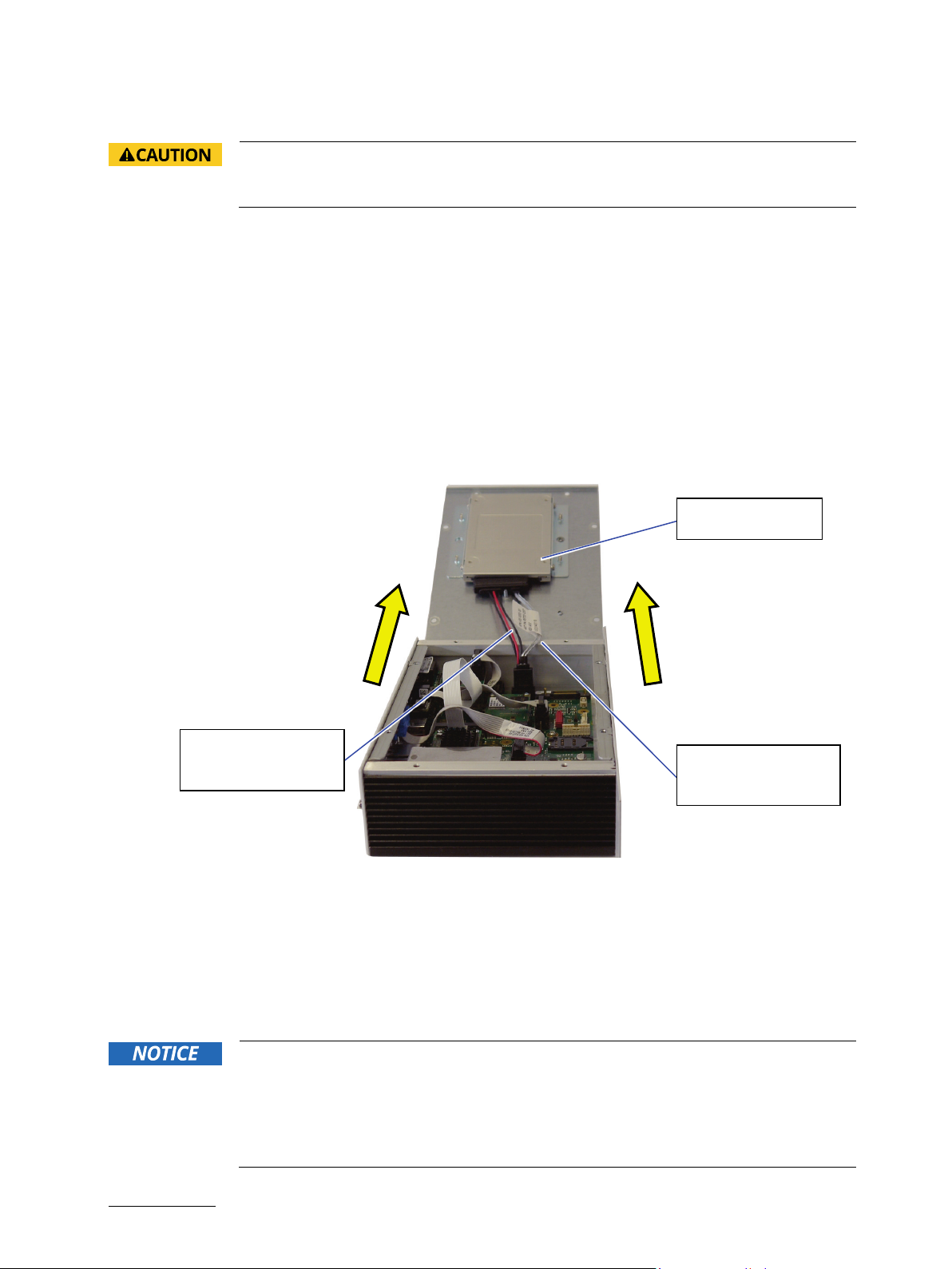

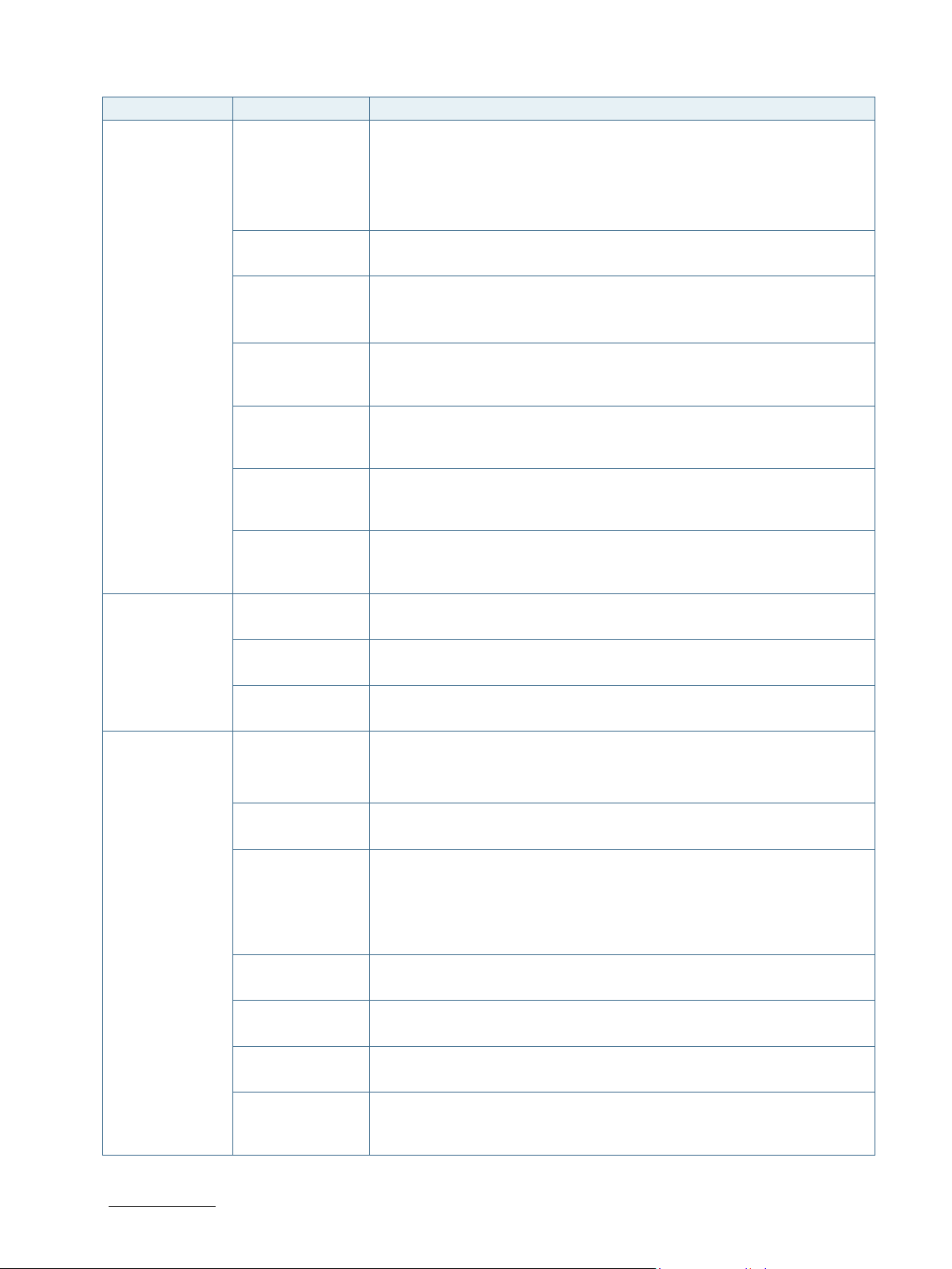

The baseboard comes with an onboard SATA interface connector and corresponding power connector (Figure 23, pos.

19 and pos. 20). You can expand your KBox A-103 with a 2.5" SATA SSD drive.

4.2.2. System Expansion via mSATA Interface

The baseboard comes with an onboard mSATA interface connector (Figure 23, pos. 17). You can expand your KBox A103 with an mSATA SSD drive.

4.2.3. System Expansion via Mini PCI Express® (mPCIe) Card Interfaces (with SIM card socket)

There are two mPCIe interfaces (J27 and J37) on the baseboard of the KBox A-103 (Figure 23, pos. 11 and pos. 16).

These interface connectors are intended to be used for the system expansion as follows:

J27: to install an mPCIe PROFIBUS card (Figure 23, pos. 11)

J37: to install an mPCIe WLAN card or an mPCIe modem adapter card (Figure 23, pos. 16) for the onboard SIM card

reader socket (Figure 23, pos. 6).

If a customer requires one of these system expansions or both, it must be so stipulated

when ordering, as the device must be installed at the factory.

If an mPCIe WLAN card is installed into your KBox A-103, the SIM card slot is not functional.

4.2.3.1. System Expansion via SIM Socket

The baseboard comes with an onboard socket for a SIM card (Figure 23, pos. 6).

In order to use the SIM card reader functionality, a corresponding mPCIe modem card must be installed to the mPCIe

slot (Figure 23, pos. 16) of your KBox A-103.

If an mPCIe modem adapter card (and SIM card) is installed into your KBox A-103, the WLAN

function is no longer usable.

www.kontron.com // 23

Page 24

KBox A-103 – User Guide, Rev. 3.0

Figure 3: Bottom side view

Figure 7: Top side view

Figure 8: Rear side view

Figure 4: Right side view

Figure 5: Front side view config. with

vertical mounting plate

Figure 6: Left side view

www.kontron.com // 24

Page 25

4.3. Block Diagram of the KBox A-103

Figure 9: Block Diagram of the KBox A-103

KBox A-103 – User Guide, Rev. 3.0

www.kontron.com // 25

Page 26

4.4. Front Side

X101

24VDC

X103

ETH 2

X102

ETH1

X105

USB 3.0

X107/X108

USB 2.0

X110

COM 1

X109

Power

Button

X204

X205

X206

X207

PWR LED

HDD LED

Figure 10: KBox A-103 – Front View

DisplayPort

KBox A-103 – User Guide, Rev. 3.0

COM 2

FIELDBUS

COM 3

VGA

www.kontron.com // 26

Page 27

KBox A-103 – User Guide, Rev. 3.0

Prerequisite:

Pin 1

Pin 2

Pin 3

3

4.4.1. X101 - Power Input Connector

The 3-pin connector (X101, Figure 10) provides the power connection of the KBox A-103 to the appropriate DC main

power supply. For pin assignments refer to the subsection 11.1.1.

The external cable connector is a Phoenix PSC 1,5/ 3-M, 3-pin plug with an SCT-D-SUB 9-KG housing. This power plug

is delivered along with the KBox A-103. Please observe the section 8.1 “Connecting to DC Main Power Supply”. The

mating connector is a Phoenix PSC 1,5/ 3-F connector.

Figure 11: X101 - 24VDC power input connector

Pin Signal Name

1 +24 VDC (input)

2 Functional Earth

3 0V (input)

4.4.2. 7.4.2. Controls and LED Indicators

Figure 12: Detail - Power button and PWR LED and HDD LED

1

Power Button Press this button (Figure 10) to turn the system on or off. Please observe the setting options

for the power button in the BIOS-Setup.

Power LED

(green)

HDD Activity LED

(yellow)

The power LED (marked PWR, Figure 10 and Figure 12, pos. 2) lights up green if the system

powered on.

The system must be attached by means of the power cord to an appropriate mains (DC).

The HDD LED (marked HDD, Figure 10 and Figure 12, pos. 3) indicates hard disk (SSD/mSATA)

activity.

Even when the system is turned off via the power button there is still a standby voltage on

the baseboard. The unit is only completely disconnected from the DC mains, when the power

is removed.

2

1 Power button

2 Power LED (PWR), green

3 HDD LED, yellow

www.kontron.com // 27

Page 28

KBox A-103 – User Guide, Rev. 3.0

4.4.3. X102/X103 - Ethernet Connectors (ETH)

These connectors (X102 as ETH 1 and X103 as ETH 2, Figure 10) are Gigabit Ethernet 10/100/1000 Mbit/s, IEEE 1588

capable interfaces. The connectors are standard 8-pin RJ45 type connectors with status LEDs:

Activity/link: green = link up; green blinking = activity.

Speed: off, green, yellow (10/100/1000 MBit/s).

For pin assignment refer to subsection 11.1.2.

4.4.4. X105 - USB 3.0

The KBox A-103 provides one USB 3.0/2.0 interface. This connector (X105, Figure 10) allows connection of USB 3.0 or

USB 2.0 compatible device to the system. For pin assignment refer to subsection 11.1.3.

4.4.5. X107/X108 - USB 2.0

The KBox A-103 provides two USB 2.0/1.1 interfaces. These connectors (X107/X108, Figure 10) allow connection of

USB-compatible devices to the system. For pin assignment refer to subsection 11.1.4.

4.4.6. X109 - DisplayPort

This is a DisplayPort compliant interface realized using a standard DisplayPort connector. An external (digital) display

can be connected to the DisplayPort connector (X109, Figure 10). For pin assignment refer to subsection 11.1.5.

As the SMARC module does not support DP++ (dual-mode DisplayPort) only active converter

cables can be used together with the KBox A-103. Active adapters use additional chips to

make the conversion inside the adapter, regardless of whether the source supports DP++.

4.4.7. X110 – Serial Port COM 1

This interface (X110, Figure 10) is provided as a 9-pin D-SUB connector; it is RS232 configured and allows the

connection of a serial peripheral. For pin assignment refer to subsection 11.1.6.

4.4.8. X204 - Serial Port COM 2 (Option)

This interface (X204, Figure 10) is provided as a 9-pin D-SUB and allows the connection of a serial peripheral. It is

designed to support RS232 serial communication or can be factory configured for RS422/RS485 serial

communication via an adapter module. The RS422/RS485 modes can be configured via an on-board DIP switch (SW1)

on the RS422/485 adapter.

For configuration of COM 2 refer to 5.1.2 “Serial Port COM2 (X204) Configuration for RS422 or RS485 via DIP Switches”.

For pin assignment of COM 2 refer to the chapters 11.1.7 to 11.1.10.

In RS-422/485 mode, the termination of this port is configurable via DIP switch (see chapter

5.1.2, “Serial Port COM2 (X204) Configuration for RS422 or RS485 via DIP Switches”).

4.4.9. X206 - Serial Port COM 3 (Option)

This interface (X206, Figure 10) is provided as a 9-pin D-SUB (female) and allows the connection of a serial peripheral.

It is designed to support RS422/RS485 serial communication and can be configured via onboard jumper J46

(Figure 23, pos. 3). The serial onboard header for COM 3 is J44 (Figure 23, pos. 5).

For configuration of COM 3 refer to 5.1.3 “Serial Port COM 3 (X206) Configuration of the Serial Port COM 3”.

For pin assignment of COM3 refer to the chapters 11.1.11 to 11.1.3.

www.kontron.com // 28

Page 29

The optional interface (FIELDBUS) on the front side of the KBox A-103

This port has no internal termination. If necessary, it has to be terminated externally.

4.4.10. X205 - FIELDBUS Interface (Option)

Figure 13: X205 - Optional FIELDBUS interface

(X205, Figure 10) must be ordered separately.

To expand KBox A-103 with an interface for FIELDBUS

communication, the FIELDBUS additional card will be installed

always into the second mPCIe slot on the bottom of the baseboard.