Page 1

AM4901

MicroTCA™ Carrier Hub

Single, Full-size AMC Form Factor

Doc. ID: 1022-5813, Rev. 1.0

September 19, 2008

User Guide

P R E L I M I N A R Y

Page 2

Preface AM4901

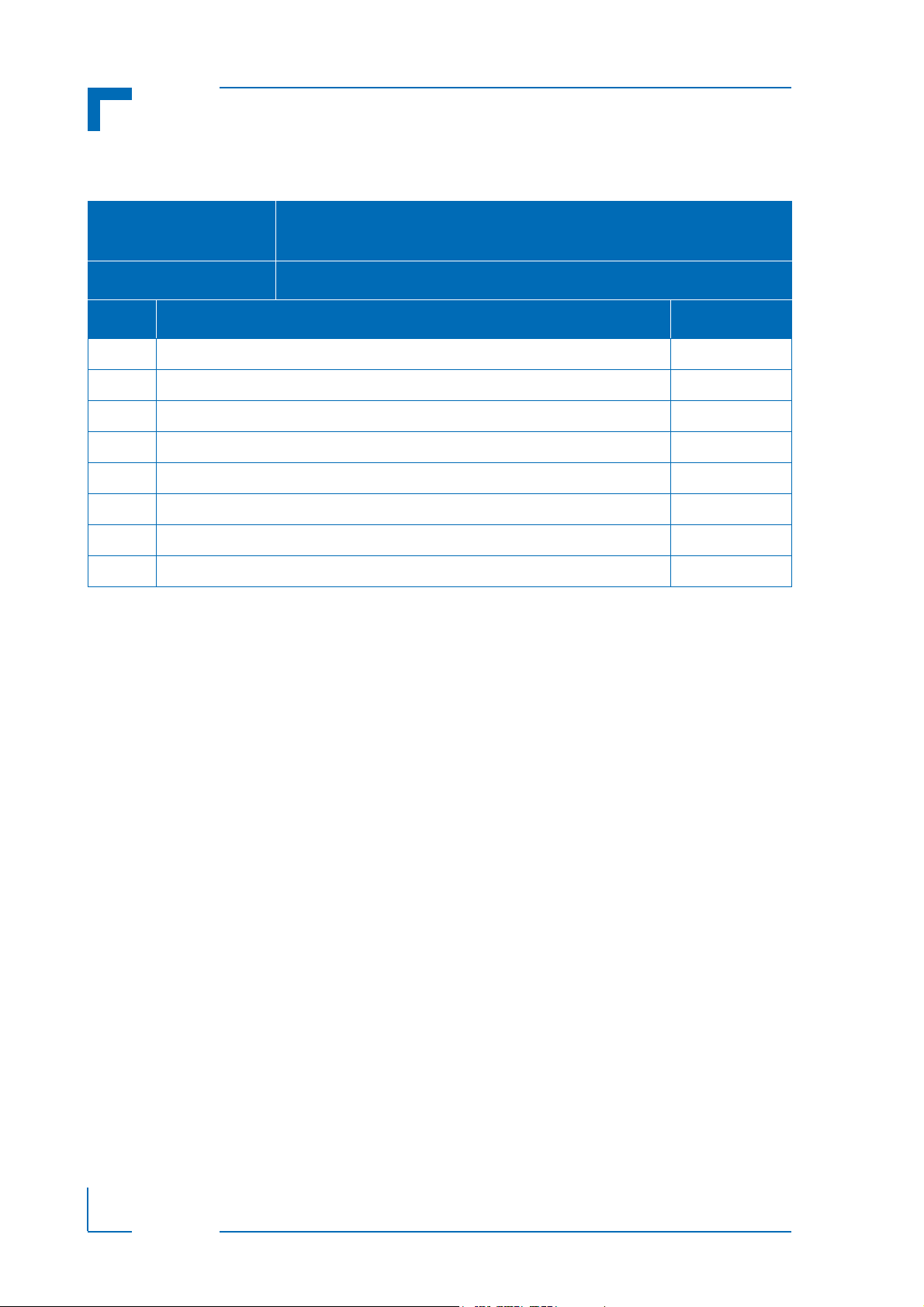

Revision History

Publication Title:

Doc. ID: 1022-5813

Rev. Brief Description of Changes Date of Issue

1.0 Initial issue Sep 19, 2008

AM4901: MicroTCA™ Carrier Hub

Single, Full-size AMC Form Factor

Imprint

Kontron Modular Computers GmbH may be contacted via the following:

MAILING ADDRESS TELEPHONE AND E-MAIL

Kontron Modular Computers GmbH +49 (0) 800-SALESKONTRON

Sudetenstraße 7 sales@kontron.com

D - 87600 Kaufbeuren Germany

For further information about other Kontron products, please visit our Internet web site:

P R E L I M I N A R Y

www.kontron.com

Disclaimer

Copyright © 2008 Kontron AG. All rights reserved. All data is for information purposes only and

not guaranteed for legal purposes. Information has been carefully checked and is believed to

be accurate; however, no responsibility is assumed for inaccuracies. Kontron and the Kontron

logo and all other trademarks or registered trademarks are the property of their respective owners and are recognized. Specifications are subject to change without notice.

Page ii ID 1022-5813, Rev. 1.0

Page 3

AM4901 Preface

Table of Contents

Revision History .........................................................................................................ii

Imprint ........................................................................................................................ii

Disclaimer ..................................................................................................................ii

Table of Contents ...................................................................................................... iii

List of Tables ............................................................................................................ vii

List of Figures ...........................................................................................................ix

Proprietary Note ........................................................................................................xi

Trademarks ...............................................................................................................xi

Environmental Protection Statement .........................................................................xi

Explanation of Symbols ...........................................................................................xii

For Your Safety ....................................................................................................... xiii

High Voltage Safety Instructions ......................................................................... xiii

Special Handling and Unpacking Instructions .................................................... xiii

General Instructions on Usage ........................................................................... xiv

Two Year Warranty ...................................................................................................xv

1. Introduction ............................................................................. 1 - 3

1.1 MicroTCA™ System Overview ................................................................ 1 - 3

1.2 Board Overview ....................................................................................... 1 - 3

1.2.1 Board Introduction .......................................................................... 1 - 3

1.2.2 Board-Specific Information ............................................................. 1 - 4

1.3 System Relevant Information .................................................................. 1 - 5

1.4 Board Diagrams ...................................................................................... 1 - 5

1.4.1 Functional Block Diagram ............................................................... 1 - 5

1.4.2 Front Panel ..................................................................................... 1 - 7

1.4.3 Board Layouts ................................................................................. 1 - 8

1.5 Technical Specification ............................................................................ 1 - 9

1.6 Standards .............................................................................................. 1 - 11

1.7 Related Publications ............................................................................. 1 - 11

2. Functional Description ........................................................... 2 - 3

P R E L I M I N A R Y

2.1 MCMC and Fabric [A] Switch .................................................................. 2 - 3

2.1.1 MicroTCA™ Carrier Management Controller (MCMC) ................... 2 - 3

ID 1022-5813, Rev. 1.0 Page iii

Page 4

Preface AM4901

2.1.2 Fabric [A] Switch .............................................................................2 - 3

2.2 Board Interfaces ......................................................................................2 - 4

2.2.1 Front Panel LEDs ............................................................................2 - 4

2.2.2 Module Handle ................................................................................2 - 6

2.2.3 General Purpose DIP Switch ..........................................................2 - 7

2.2.4 Debug Interface ...............................................................................2 - 7

2.2.5 Serial Ports ......................................................................................2 - 7

2.2.5.1 Management Serial Port .........................................................2 - 7

2.2.5.2 MCH Cross-Over Channel Interface .......................................2 - 8

2.2.6 Ethernet Interfaces ..........................................................................2 - 8

2.2.6.1 Management Ethernet Interface (10Base-T) ..........................2 - 8

2.2.6.2 Uplink Ethernet Port (1000Base-T) .........................................2 - 9

2.2.7 MCMC Reset ...................................................................................2 - 9

2.3 MCH Interconnection .............................................................................2 - 10

2.3.1 Fabric Interface .............................................................................2 - 10

2.3.2 IPMB-L Interface ...........................................................................2 - 10

2.3.3 Inter-MCH IPMB-L Interface ..........................................................2 - 10

2.3.4 IPMB-0 Interface ...........................................................................2 - 10

2.3.5 MCH Update Channel Interface .................................................... 2 - 11

2.3.6 MCH Cross-Over Channel Interface .............................................2 - 11

2.3.7 MCH PWR_ON Interface .............................................................. 2 - 11

2.3.8 JTAG Interface ..............................................................................2 - 11

2.3.9 Pinout of MCH Card-edge Connector J1 ......................................2 - 11

P R E L I M I N A R Y

3. Installation ................................................................................ 3 - 3

3.1 Safety Requirements ...............................................................................3 - 3

3.2 Module Handle Positions .........................................................................3 - 4

3.3 Hot Swap Procedures ..............................................................................3 - 5

3.3.1 Hot Swap Insertion ..........................................................................3 - 5

3.3.2 Hot Swap Extraction ........................................................................3 - 6

4. Configuration / Power / Thermal ............................................ 4 - 3

4.1 Configuration ...........................................................................................4 - 3

Page iv ID 1022-5813, Rev. 1.0

Page 5

AM4901 Preface

4.1.1 DIP Switch Configuration ................................................................ 4 - 3

4.1.1.1 Firmware Update Configuration ............................................. 4 - 3

4.2 Power Considerations ............................................................................. 4 - 4

4.2.1 AM4901 Input Voltage Ranges ....................................................... 4 - 4

4.2.2 Power Requirements ...................................................................... 4 - 4

4.2.2.1 Payload Power ....................................................................... 4 - 4

4.2.2.2 Payload and Management Voltage Ramp .............................. 4 - 4

4.2.2.3 Management Power Consumption ......................................... 4 - 5

4.2.3 Payload Power Consumption of the AM4901 ................................. 4 - 5

4.2.4 IPMI FRU Payload Power Consumption ......................................... 4 - 5

4.2.5 Payload Start-Up Current of the AM4901 ....................................... 4 - 5

4.3 Thermal Considerations .......................................................................... 4 - 6

4.3.1 Thermal Monitoring ......................................................................... 4 - 6

4.3.1.1 Placement of the Temperature Sensor ................................... 4 - 6

P R E L I M I N A R Y

ID 1022-5813, Rev. 1.0 Page v

Page 6

Preface AM4901

This page has been intentionally left blank.

P R E L I M I N A R Y

Page vi ID 1022-5813, Rev. 1.0

Page 7

AM4901 Preface

List of Tables

1-1 System Relevant Information ................................................................... 1 - 5

1-2 AM4901 Main Specifications .................................................................... 1 - 9

1-3 Standards ............................................................................................... 1 - 11

1-4 Related Publications .............................................................................. 1 - 11

2-1 Module Management LEDs Function ....................................................... 2 - 4

2-2 Carrier Management LED 0 Function ...................................................... 2 - 5

2-3 Carrier Management LEDs 13..1 Function .............................................. 2 - 5

2-4 Module Handle Positions ......................................................................... 2 - 6

2-5 DIP Switch Functions ............................................................................... 2 - 7

2-6 Serial Connector J2 Pinout ...................................................................... 2 - 7

2-7 Ethernet Connector J3 Pinout .................................................................. 2 - 8

2-8 Gigabit Ethernet Connector J4 Pinout ..................................................... 2 - 9

2-9 Pinout of MCH Card-edge Connector J1 ............................................... 2 - 12

2-10 JTAG Pins Description ........................................................................... 2 - 16

4-1 DIP Switch Functions ............................................................................... 4 - 3

4-2 Firmware Update Configuration ............................................................... 4 - 3

4-3 DC Operational Input Voltage Ranges ..................................................... 4 - 4

4-4 AM4901 Payload Power Consumption .................................................... 4 - 5

P R E L I M I N A R Y

ID 1022-5813, Rev. 1.0 Page vii

Page 8

Preface AM4901

This page has been intentionally left blank.

P R E L I M I N A R Y

Page viii ID 1022-5813, Rev. 1.0

Page 9

AM4901 Preface

List of Figures

1-1 AM4901 Functional Block Diagram .......................................................... 1 - 6

1-2 AM4901 Front Panel ................................................................................ 1 - 7

1-3 AM4901 Board Layout (Top View) ........................................................... 1 - 8

1-4 AM4901 Board Layout (Bottom View) ...................................................... 1 - 8

2-1 Front Panel LEDs ................................................................................... 2 - 4

2-2 Module Handle Positions ....................................................................... 2 - 6

2-3 Serial Connector J2 ................................................................................. 2 - 7

2-4 Ethernet Connector J3 ............................................................................. 2 - 8

2-5 Gigabit Ethernet Connector J4 ................................................................. 2 - 9

3-1 Module Handle Positions ........................................................................ 3 - 4

4-1 DIP Switch ............................................................................................... 4 - 3

4-2 Board Temperature Sensor Placement (AM4901 Top View) ................... 4 - 6

P R E L I M I N A R Y

ID 1022-5813, Rev. 1.0 Page ix

Page 10

Preface AM4901

This page has been intentionally left blank.

P R E L I M I N A R Y

Page x ID 1022-5813, Rev. 1.0

Page 11

AM4901 Preface

Proprietary Note

This document contains information proprietary to Kontron. It may not be copied or transmitted by any means, disclosed to others, or stored in any retrieval system or media without the

prior written consent of Kontron or one of its authorized agents.

The information contained in this document is, to the best of our knowledge, entirely correct.

However, Kontron cannot accept liability for any inaccuracies or the consequences thereof, or

for any liability arising from the use or application of any circuit, product, or example shown in

this document.

Kontron reserves the right to change, modify, or improve this document or the product

described herein, as seen fit by Kontron without further notice.

Trademarks

This document may include names, company logos and trademarks, which are registered

trademarks and, therefore, proprietary to their respective owners.

Environmental Protection Statement

This product has been manufactured to satisfy environmental protection requirements where

possible. Many of the components used (structural parts, printed circuit boards, connectors,

batteries, etc.) are capable of being recycled.

Final disposition of this product after its service life must be accomplished in accordance with

applicable country, state, or local laws or regulations.

P R E L I M I N A R Y

ID 1022-5813, Rev. 1.0 Page xi

Page 12

Preface AM4901

Explanation of Symbols

Caution, Electric Shock!

This symbol and title warn of hazards due to electrical shocks (> 60V)

when touching products or parts of them. Failure to observe the precautions indicated and/or prescribed by the law may endanger your

life/health and/or result in damage to your material.

Please refer also to the section “High Voltage Safety Instructions” on

the following page.

Warning, ESD Sensitive Device!

This symbol and title inform that electronic boards and their components are sensitive to static electricity. Therefore, care must be taken

during all handling operations and inspections of this product, in

order to ensure product integrity at all times.

Please read also the section “Special Handling and Unpacking

Instructions” on the following page.

Warning!

This symbol and title emphasize points which, if not fully understood

and taken into consideration by the reader, may endanger your health

and/or result in damage to your material.

Note ...

This symbol and title emphasize aspects the reader should read

through carefully for his or her own advantage.

P R E L I M I N A R Y

Page xii ID 1022-5813, Rev. 1.0

Page 13

AM4901 Preface

For Your Safety

Your new Kontron product was developed and tested carefully to provide all features necessary to ensure its compliance with electrical safety requirements. It was also designed for a

long fault-free life. However, the life expectancy of your product can be drastically reduced by

improper treatment during unpacking and installation. Therefore, in the interest of your own

safety and of the correct operation of your new Kontron product, you are requested to conform

with the following guidelines.

High Voltage Safety Instructions

Warning!

All operations on this device must be carried out by sufficiently skilled

personnel only.

Caution, Electric Shock!

Before installing any piggybacks or carrying out maintenance operations always ensure that your mains power is switched off.

Serious electrical shock hazards can exist during all installation,

repair and maintenance operations with this product. Therefore,

always unplug the power cable and any other cables which provide

external voltages before performing work.

Special Handling and Unpacking Instructions

ESD Sensitive Device!

Electronic boards and their components are sensitive to static electricity. Therefore, care must be taken during all handling operations

and inspections of this product, in order to ensure product integrity at

all times.

Warning!

This product has gold conductive fingers which are susceptible to contamination. Take care not to touch the gold conductive fingers of the

MCH Card-edge connector when handling the board.

Failure to comply with the instruction above may cause damage to the

board or result in improper system operation.

P R E L I M I N A R Y

Do not handle this product out of its protective enclosure while it is not used for operational purposes unless it is otherwise protected.

Whenever possible, unpack or pack this product only at EOS/ESD safe work stations. Where

a safe work station is not guaranteed, it is important for the user to be electrically discharged

before touching the product with his/her hands or tools. This is most easily done by touching a

metal part of your system housing.

ID 1022-5813, Rev. 1.0 Page xiii

Page 14

Preface AM4901

It is particularly important to observe standard anti-static precautions when changing piggybacks, ROM devices, jumper settings etc. If the product contains batteries for RTC or memory

backup, ensure that the board is not placed on conductive surfaces, including anti-static plastics or sponges. They can cause short circuits and damage the batteries or conductive circuits

on the board.

General Instructions on Usage

In order to maintain Kontron’s product warranty, this product must not be altered or modified in

any way. Changes or modifications to the device, which are not explicitly approved by Kontron

and described in this manual or received from Kontron’s Technical Support as a special handling instruction, will void your warranty.

This device should only be installed in or connected to systems that fulfill all necessary technical and specific environmental requirements. This applies also to the operational temperature

range of the specific board version, which must not be exceeded. If batteries are present, their

temperature restrictions must be taken into account.

In performing all necessary installation and application operations, please follow only the instructions supplied by the present manual.

Keep all the original packaging material for future storage or warranty shipments. If it is necessary to store or ship the board, please re-pack it as nearly as possible in the manner in which

it was delivered.

Special care is necessary when handling or unpacking the product. Please consult the special

handling and unpacking instruction on the previous page of this manual.

P R E L I M I N A R Y

Page xiv ID 1022-5813, Rev. 1.0

Page 15

AM4901 Preface

Two Year Warranty

Kontron grants the original purchaser of Kontron’s products a TWO YEAR LIMITED HARDWARE

WARRANTY

implied by anyone on behalf of Kontron are valid unless the consumer has the express written

consent of Kontron.

Kontron warrants their own products, excluding software, to be free from manufacturing and

material defects for a period of 24 consecutive months from the date of purchase. This warranty is not transferable nor extendible to cover any other users or long-term storage of the

product. It does not cover products which have been modified, altered or repaired by any

other party than Kontron or their authorized agents. Furthermore, any product which has

been, or is suspected of being damaged as a result of negligence, improper use, incorrect

handling, servicing or maintenance, or which has been damaged as a result of excessive current/voltage or temperature, or which has had its serial number(s), any other markings or

parts thereof altered, defaced or removed will also be excluded from this warranty.

If the customer’s eligibility for warranty has not been voided, in the event of any claim, he may

return the product at the earliest possible convenience to the original place of purchase,

together with a copy of the original document of purchase, a full description of the application

the product is used on and a description of the defect. Pack the product in such a way as to

ensure safe transportation (see our safety instructions).

as described in the following. However, no other warranties that may be granted or

Kontron provides for repair or replacement of any part, assembly or sub-assembly at their own

discretion, or to refund the original cost of purchase, if appropriate. In the event of repair,

refunding or replacement of any part, the ownership of the removed or replaced parts reverts

to Kontron, and the remaining part of the original guarantee, or any new guarantee to cover

the repaired or replaced items, will be transferred to cover the new or repaired items. Any

extensions to the original guarantee are considered gestures of goodwill, and will be defined

in the “Repair Report” issued by Kontron with the repaired or replaced item.

Kontron will not accept liability for any further claims resulting directly or indirectly from any

warranty claim, other than the above specified repair, replacement or refunding. In particular,

all claims for damage to any system or process in which the product was employed, or any

loss incurred as a result of the product not functioning at any given time, are excluded. The

extent of Kontron liability to the customer shall not exceed the original purchase price of the

item for which the claim exists.

Kontron issues no warranty or representation, either explicit or implicit, with respect to its

products’ reliability, fitness, quality, marketability or ability to fulfil any particular application or

purpose. As a result, the products are sold “as is,” and the responsibility to ensure their suitability for any given task remains that of the purchaser. In no event will Kontron be liable for

direct, indirect or consequential damages resulting from the use of our hardware or software

products, or documentation, even if Kontron were advised of the possibility of such claims

prior to the purchase of the product or during any period since the date of its purchase.

Please remember that no Kontron employee, dealer or agent is authorized to make any modification or addition to the above specified terms, either verbally or in any other form, written or

electronically transmitted, without the company’s consent.

P R E L I M I N A R Y

ID 1022-5813, Rev. 1.0 Page xv

Page 16

Preface AM4901

This page has been intentionally left blank.

P R E L I M I N A R Y

Page xvi ID 1022-5813, Rev. 1.0

Page 17

AM4901 Introduction

Chapter 1

1

Introduction

ID 1022-5813, Rev. 1.0 Page 1 - 1

P R E L I M I N A R Y

Page 18

Introduction AM4901

This page has been intentionally left blank.

P R E L I M I N A R Y

Page 1 - 2 ID 1022-5813, Rev. 1.0

Page 19

AM4901 Introduction

1. Introduction

1.1 MicroTCA™ System Overview

The MicroTCA™ Carrier Hub (MCH) described in this manual is based on the Micro

Telecommunications Computing Architecture (MicroTCA™ or µTCA™) defined by the

PCI Industrial Computer Manufacturers Group (PICMG®). The main advantages of

MicroTCA™ include high throughput, multi-protocol support, hot swappability, high scalability,

and integrated system management. For further information regarding the MicroTCA™

standard and its use, please consult the complete Micro Telecommunications Computing

Architecture Base Specification.

The Kontron MCH cards can be integrated into MicroTCA™ backplanes providing them with superior processing power and maximum design options. To learn more about the outstanding

features and advantages of Kontron MicroTCA™ systems, please contact Kontron or visit the

Kontron web site.

1.2 Board Overview

1.2.1 Board Introduction

The AM4901 is a MicroTCA™ Carrier Hub (MCH) implemented in the form factor of a Single,

Full-size Advanced Mezzanine Card (AMC) Module with a single tongue. It combines the

control and management infrastructure and the interconnect fabric resources needed to support up to twelve AMC modules, up to two cooling units and up to four power modules in a

MicroTCA™ system. The MCH’s design is based on the NXP® LPC2368 microcontroller and

the Broadcom BCM5396 Gigabit Ethernet switch.

The NXP® LPC2368 microcontroller includes a 16-bit/32-bit, 70 MHz, ARM7 CPU with integrated 512 kB Flash, 58 kB SRAM, I²C busses for IPMB usage, and an Ethernet interface. On

the AM4901, this microcontroller serves as the MicroTCA™ Carrier Management Controller

(MCMC) with electronic keying (E-Keying) support.

The Broadcom BCM5396 Gigabit Ethernet switch uses 14 SerDes/SGMII ports and combines

all functions of a high-speed base fabric including packet buffer, Media Access Controllers, address management and a non-blocking switch controller.

The AM4901 itself is hot swappable and uses E-Keying to provide hot swap capability for the

FRUs installed in a MicroTCA™ system, such as AMCs, cooling units and power modules, thus

enabling them to be replaced, monitored and controlled without having to shut down the MicroTCA™ system. Furthermore, it is able to monitor and control several onboard temperature

conditions of the FRUs, their board voltages and their power supply status, manage hot swap

operations, reboot them, etc.

P R E L I M I N A R Y

The AM4901 supports one standard RS-232 serial port, one Gigabit Ethernet uplink port for

fabric interconnection and one Ethernet port for carrier management as well as a variety of

high-speed interconnect topologies to the MicroTCA™ system, such as 12 SerDes connections in the Gigabit Ethernet Fabric [A], one additional SerDes connection for the MCH update

channel, 12 IPMB-L interfaces, two IPMB-0 interfaces, one Inter-MCH IPMB-L interface and

one cross-over channel interface.

ID 1022-5813, Rev. 1.0 Page 1 - 3

Page 20

Introduction AM4901

1.2.2 Board-Specific Information

Due to the comprehensive features of the AM4901, such as high-performance switching fabric

and flexible interconnect topologies, this MCH provides a highly scalable solution not only for

a wide range of telecom and data network applications, but also for highly integrated industrial

environment applications with solid mechanical interfacing.

Some of the AM4901's outstanding features are:

• NXP® LPC2368 microcontroller (MCMC):

• 16-bit /32-bit, 70 MHz ARM7 CPU

• 512 kB Flash

• 58 kB SRAM

• Ethernet interface

•IPMI

• Watchdog timer

• I²C busses for IPMB usage

• Broadcom BCM5396 Gigabit Ethernet switch:

• 14 SerDes/SGMII ports

• Non-blocking full-wire speed

• Low latency

• Unmanaged layer 2 switch

• Automatic address learning and aging

• 256 kB on-chip packet buffer

• Low power consumption

• MCH interconnection:

• 12 Gigabit Ethernet SerDes connections in Fabric [A]

• One MCH update channel (SerDes)

• 12 IPMB-L interfaces

• One Inter MCH IPMB-L interface

• One I²C to Carrier FRU

• Two IPMB-0 interfaces

• One MCH cross-over channel

• Full hot swap support

• One Gigabit Ethernet port on front I/O for Fabric [A] uplink

• One Ethernet port on front I/O for management purposes

P R E L I M I N A R Y

• One serial port on front I/O (RS-232)

• JTAG interface for debugging and manufacturing purposes

• 14 Carrier Management LEDs

• Standard temperature range: -5°C to + 55°C

• Single, Full-size AMC form factor module with a single tongue (tongue 1)

• Designed to be compliant with the following specifications:

• PICMG AMC.0, Advanced Mezzanine Card Specification R2.0

• PICMG MTCA.0 Micro Telecommunications Computing Architecture R1.0

• IPMI - Intelligent Platform Management Interface Specification, v1.5

Page 1 - 4 ID 1022-5813, Rev. 1.0

Page 21

AM4901 Introduction

1.3 System Relevant Information

The following system relevant information is general in nature but should still be considered

when developing applications using the AM4901.

Table 1-1: System Relevant Information

SUBJECT INFORMATION

Hardware Requirements The AM4901 can be installed on any MicroTCA™ backplane that supports the fol-

lowing MCH interconnection:

• Fabric [A]

• 12 Gigabit Ethernet SerDes ports

• MCH update channel

• One Gigabit Ethernet SerDes port

• MCH cross-over channel

• Serial interface shifted to M-LVDS

For further information on the MCH interconnection, refer to section 2.3, “MCH

Interconnection”.

1.4 Board Diagrams

The following diagrams provide additional information concerning board functionality and

component layout.

1.4.1 Functional Block Diagram

The following figure shows the block diagram of the AM4901.

P R E L I M I N A R Y

ID 1022-5813, Rev. 1.0 Page 1 - 5

Page 22

Introduction AM4901

Health

Hot Swap

Out-of-Service

I²C Hub

1 to 12

MCMC

LPC2368

Temp.

Sense

MCH Tongue 1

12V Payload Power

Mag.

RS-232

EEP

IPMB-L[1..12]

3.3V Mgmt. Power

FRU Data

Hot Swap Switch

SER

I

2

C

IPMB-0[A]

IPMB-0[B]

I

2

C (Carrier FRU)

Ethernet / Fabric [A]

Switch

BCM5396

12 +1 LEDs

12 +1 Link/Activity

12x

1000Base-Bx

1000Base-Bx

update

Channel

h

Front Panel

XOVER

Inter-MCH IPMB-L

SER

RxD/TxD

I

2

C

JTAG

Debug

Con

JTAG

SerDes

Port14

LED

DATA

Mag.

Ethernet GPIO

Port 13

PLD

PHY

PHY

RJ-45

2 LED

RJ-45

DC/DC and

LDO

MDC1/MDIO1

JTAG

EN

TTL

LVDS

I

2

C

I

2

C

I

2

C

I

2

C

I

2

C

12

SGMII

12

Port1..12

SerDes

GPIO

JTAG

RJ-45

2 LED

I

2

C

Expan.

HUB_EN[1:12]

Indicates Input Source

1 LED

Figure 1-1: AM4901 Functional Block Diagram

P R E L I M I N A R Y

ront Reset Switc

Page 1 - 6 ID 1022-5813, Rev. 1.0

Page 23

AM4901 Introduction

13

1..12

0

0

AM4901

1

6

7

13

12

Module Management LEDs

• LED1 (red): Out-of-Service LED

• LED2 (red/green/amber): Health LED

• HS LED (blue): The hot swap indicator provides basic feedback to the

user on the hot swap state of the module. The HS LED

states are off, short blink, long blink, and on.

Carrier Management LEDs

• CMLED13 (green): Link signal from MCH update channel or MCMC

• CMLED12..1 (green): Link signal from the AMC SerDEs ports or the MCMC

• CMLED0 (green): Indicates the input source for the CMLED13..1 (Fabric [A]

or MCMC)

Connectors/Switch

• Serial Connector

• Ethernet Connector

• MCMC Reset Switch

For further information about the LEDs used on the AM4901, refer to section 2.2.1, “Front Panel

LEDs”.

1.4.2 Front Panel

Figure 1-2: AM4901 Front Panel

ID 1022-5813, Rev. 1.0 Page 1 - 7

P R E L I M I N A R Y

Page 24

Introduction AM4901

J1

1

85

J3

J2

J4

GbE

Switch

MCU

J6

1

Fast Eth.

Logic

PHY

GbE

PHY

Mag.

Mag.

J1

86

170

ON

SW3

FWU CONF

1

2

1.4.3 Board Layouts

Figure 1-3: AM4901 Board Layout (Top View)

Figure 1-4: AM4901 Board Layout (Bottom View)

P R E L I M I N A R Y

Page 1 - 8 ID 1022-5813, Rev. 1.0

Page 25

AM4901 Introduction

1.5 Technical Specification

Table 1-2: AM4901 Main Specifications

FEATURES SPECIFICATIONS

MCMC NXP® LPC2368 microcontroller

• 16-bit / 32-bit, 70 MHz ARM7 CPU

• 512 kB Flash

• 58 kB SRAM

• One Ethernet connection to the management uplink port (J3) on the

front panel via Remote Monitoring and Control Protocol (RMCP)

• IPMI

• Watchdog timer

• I²C busses for IPMB usage

• Command line interface

Fabric [A] Broadcom BCM5396 Gigabit Ethernet switch

• 16 SerDes / SGMII ports, only 14 ports are used on the AM4901:

• 12 ports connected to the Fabric [A]

• 1 port connected to the MCH update channel

• 1 port connected to the fabric uplink port (J4) on the front panel

Microcontroller and Ethernet Switch

• Non-blocking

• Low latency

• Unmanaged layer 2 switch

• Automatic address learning and aging

• 256 kB on-chip packet buffer

• Low power consumption

Tongue 1 • 12 Gigabit Ethernet SerDes connections in the Fabric [A]

• One MCH update channel (SerDes)

• 12 IPMB-L interfaces

• One Inter MCH IPMB-L interface

• One I²C to Carrier FRU

• Two IPMB-0 interfaces

MCH Interconnection

Front Panel

Connectors

Onboard Connector

Connectors

MCH card-edge

Connector

DIP Switch One onboard DIP switch consisting of two switches for Firmware update

Switches

MCMC Reset Switch One MCMC hardware reset switch on the front panel

• One MCH cross-over channel

• One serial port with RS-232 signaling level on the RJ-45 connector J2

• One Gigabit Ethernet port on the RJ-45 connector J4

• One Ethernet port on the RJ-45 connector J3

• One JTAG connector J6

• One 170-pin MCH card-edge connector J1

(FWU) configuration

P R E L I M I N A R Y

ID 1022-5813, Rev. 1.0 Page 1 - 9

Page 26

Introduction AM4901

Table 1-2: AM4901 Main Specifications (Continued)

FEATURES SPECIFICATIONS

Module Management

LEDs

• LED1 (red): Out-of-Service LED

• LED2 (red/green/amber): Health LED

• HS LED (blue): The hot swap indicator provides basic feed-

back about the hot swap state of the module.

The HS LED states are off, short blink, long

blink, and on.

LEDs

Carrier Management

LEDs

• CMLED13 (green): Link signal from MCH update channel or the

MCMC

• CMLED12..1 (green): Link signal from the AMC SerDEs ports or

the MCMC

• CMLED0 (green): Indicates the input source for the

CMLED13..1 (Fabric [A] or MCMC)

MCMC • IPMI integrated in the NXP® LPC2368 microcontroller

• The MCMC receives the relevant IPMI events from the AMC modules

and carries out IPMI commands such as monitoring several onboard

temperature conditions, board voltages and the power supply status,

and managing hot swap operations

• The MCMC is accessible via a local IPMB (IPMB-L) bus, the serial port

IPMI

Hot Swap Full hot swap capability via E-Keying:

or the Ethernet port

• Hot swap capability of the AM4901 MCH

• Hot swap capability for the installed AMC modules

• Hot swap capability for the installed power modules and cooling units

Power Consumption See Chapter 4.2, “Power Considerations” for details.

Temperature Range Operational: -5 °C to +55 °C

Storage: -40 °C to +70 °C

Mechanical Single, Full-size AMC form factor

General

Dimensions 181.5 mm x 73.5 mm x 28.95 mm

Board Weight 100 grams

P R E L I M I N A R Y

Page 1 - 10 ID 1022-5813, Rev. 1.0

Page 27

AM4901 Introduction

1.6 Standards

The Kontron MCH boards comply with the requirements of the following standards.

Table 1-3: Standards

COMPLIANCE TYPE STANDARD TEST LEVEL

CE Emission EN55022

EN61000-6-3

EN300386

Immission EN55024

EN61000-6-2

EN300386

Electrical Safety EN60950-1 --

Mechanical Mechanical Dimensions IEEE 1101.10 --

Environmental and

Health Aspects

Vibration

(sinusoidal, operating)

Shock (operating) EN300019-2-3

Climatic Humidity IEC60068-2-78 93% RH at 40°C, non-condensing

WEEE Directive 2002/96/EC Waste electrical and electronic equipment

GR-63-CORE

EN300019-2-3

IEC61131-2

IEC60068-2-6

IEC61131-2

IEC60068-2-27

--

--

5-150 [Hz] frequency range

1 [g] acceleration

1 [oct/min] sweep rate

10 sweeps/axis

3 directions: x,y,z

15 [g] acceleration

11 [ms] pulse duration

3 shocks per direction

5 [s] recovery time

6 directions, ±x, ±y, ±z

RoHS Directive 2002/95/EC Restriction of the use of certain

hazardous substances in electrical and

electronic equipment

1.7 Related Publications

The following publications contain information relating to this product.

Table 1-4: Related Publications

PRODUCT PUBLICATION

MicroTCA™ PICMG® MTCA.0 Micro Telecommunications Computing Architecture R1.0, July 6,

2006

AMC PICMG® AMC.0, Advanced Mezzanine Card Specification R2.0

IPMI IPMI - Intelligent Platform Management Interface Specification, v1.5

All Kontron products Product Safety and Implementation Guide, ID 1021-9142

P R E L I M I N A R Y

ID 1022-5813, Rev. 1.0 Page 1 - 11

Page 28

Introduction AM4901

This page has been intentionally left blank.

P R E L I M I N A R Y

Page 1 - 12 ID 1022-5813, Rev. 1.0

Loading...

Loading...