Page 1

User Guide

AM4311

Document Revision: 1.0

Issue Date: 28 July, 2009

Document ID: TECHNICAL_REFERENCE_MANUAL_AM4311

Page 2

Revision History

Rev. Index Brief Description of Changes Date of Issue

0.5 Initial Issue 26 June, 2009

1.0 Updated Issue. Minor changes in Chapter 2 28 July, 2009

Imprint

Kontron AG may be contacted via the following:

North America EMEA

Kontron Canada, Inc. Kontron Modular Computers GmbH

4555 Ambroise-Lafortune Sudetenstrasse 7

Boisbriand, Québec 87600 Kaufbeuren

J7H 0A4 Canada Germany

Tel: (450) 437-5682 +49 (0) 8341 803 333

(800) 354-4223

Fax: (450) 437-8053 +49 (0) 8341 803 339

E-mail: support@ca.kontron.com support-kom@kontron.com

Visit our site at: www.kontron.com

Disclaimer

© 2009 Kontron AG, an International Corporation. All rights reserved.

The information in this user's guide is provided for reference only. Kontron does not assume any liability

arising out of the application or use of the information or products described herein. This user's guide maycontain or reference information and products protected by copyrights or patents and does not convey any

license under the patent rights of Kontron, nor the rights of others.

Kontron is a registered trademark of Kontron AG. All trademarks, registered trademarks, and trade names

used in this user's guide are the property of their respective owners. All rights reserved. This user's guide

contains information proprietary to Kontron. Customers may reprint and use this user's guide in other publications. Customers may alter this user's guide and publish it only after they remove the Kontron name,

cover, and logo.

Kontron reserves the right to make changes without notice in product or component design as warranted by

evolution in user needs or progress in engineering or manufacturing technology. Changes that affect the

operation of the unit will be documented in the next revision of this user's guide.

Page ii AM4311 User Guide

Page 3

Table of Contents

Table of Contents

Revision History........................................................................................................ ii

Imprint .................................................................................................................. ii

Disclaimer............................................................................................................... ii

Before You Begin ...................................................................................................... vii

When Working Inside a Computer.................................................................................. viii

Advisory Conventions ................................................................................................. ix

Safety Instructions.................................................................................................... x

Special Handling and Unpacking Instructions .................................................................. xi

Unpacking .......................................................................................................... xi

Powering up the System ......................................................................................... xi

Adapter Cables ..................................................................................................... xii

Storing the Boards ................................................................................................ xii

General Instructions on Usage ..................................................................................... xiii

Regulatory Compliance Statements ............................................................................... xiv

Two Year Warranty..................................................................................................... xv

1. Introduction........................................................................................... 2

1.1 Board Overview............................................................................................. 2

1.2 Board Diagrams............................................................................................ 2

1.2.1 Functional Block Diagram ........................................................................ 2

1.2.2 Front Panel .......................................................................................... 3

1.3 Technical Specifications ................................................................................. 5

1.3.1 General ............................................................................................... 5

1.3.2 AMC LEDs ............................................................................................. 5

1.3.3 Operating Voltages................................................................................. 5

1.3.4 Operation Power.................................................................................... 5

1.3.5 Temperature ......................................................................................... 5

1.3.6 Humidity ............................................................................................. 5

1.3.7 Altitude............................................................................................... 5

1.3.8 Vibration ............................................................................................. 6

1.3.9 Schock ................................................................................................ 6

1.3.10 Safety ................................................................................................. 6

1.3.11 Electromagnetic Compatibility .................................................................. 6

1.3.12 MTBF .................................................................................................. 6

1.4 Standards Compliance.................................................................................... 7

1.5 Related Publications...................................................................................... 7

Page iii AM4311 User Guide

Page 4

Table of Contents

2. Functional Description ............................................................................... 9

2.1 Uplink Infrastructure ....................................................................................... 9

2.2 MMC........................................................................................................... 10

2.3 Board Sensors .............................................................................................. 10

2.3.1 Sensor List ........................................................................................... 10

2.3.2 OEM sensor types and OEM sensor event/reading types ................................... 12

2.3.3 Sensor Thresholds .................................................................................. 15

2.4 Board FRU Information .................................................................................. 15

2.4.1 Structure and Functionality...................................................................... 15

2.4.2 Board Specific FRU Data .......................................................................... 15

2.5 OEM Commands ............................................................................................ 16

2.5.1 Kontron-specific OEM commands .............................................................. 16

2.5.2 Board-specific OEM commands ................................................................. 22

2.5.3 Configuring Port Settings......................................................................... 26

3. Installation............................................................................................ 29

3.1 Safety Requirements...................................................................................... 29

3.2 Module Handle Positions ................................................................................ 30

3.3 Hot Swap Procedures ..................................................................................... 31

3.3.1 Hot Swap Insertion................................................................................. 31

3.3.2 Hot Swap Extraction ............................................................................... 33

Page iv AM4311 User Guide

Page 5

List of Tables

List of Tables

Table 1-1: Blue LED State .......................................................................................... 3

Table 1-2: OOS LED State ........................................................................................... 3

Table 1-3: Health LED State........................................................................................ 4

Table 1-4: Related Publications................................................................................... 7

Table 2-1: Port Mapping ............................................................................................9

Table 2-2: Default Port Assignment ..............................................................................9

Table 2-3: Sensor List AM4311 .................................................................................. 10

Table 2-4: OEM Sensor List AM4311............................................................................ 12

Table 2-5: Temperature Sensor Thresholds [°C]............................................................. 15

Table 2-6: Voltage Sensor Thresholds.......................................................................... 15

Table 2-7: Kontron-specific OEM Command Overview ...................................................... 16

Table 2-8: Board-specific OEM Command Overview ......................................................... 22

Table 3-1: Module Handle Positions ........................................................................... 31

Page v AM4311 User Guide

Page 6

List of Figures

List of Figures

Figure 1-1: AM4311 Functional Block Diagram................................................................2

Figure 1-2: AM4311 Front Panel ..................................................................................3

Figure 3-1: Module Handle Positions .......................................................................... 30

Page vi AM4311 User Guide

Page 7

Preface

Before You Begin

Before handling the board, read the instructions and safety guidelines on the following pages to prevent

damage to the product and to ensure your own personal safety. Refer to the "Advisories" section for advisory conventions used in this user's guide, including the distinction between Warnings, Cautions and Notes.

• Always use caution when handling/operating the computer. Only qualified, experienced, authorized

electronics service personnel should access the interior of the computer. The power supplies produce

high voltages and energy hazards, which can cause bodily harm.

• Use extreme caution when installing or removing components. Refer to the installation instructions in

this user's guide for precautions and procedures. If you have any questions, please contact Kontron

Technical Support

WARNING

High voltages are present inside the chassis when the unit’s power

cord is plugged into an electrical outlet. Turn off system power,

turn off the power supply, and then disconnect the power cord from

its source before removing the chassis cover. Turning off the system

power switch does not remove power to components.

Page vii AM4311 User Guide

Page 8

When Working Inside a Computer

Before taking covers off a computer, perform the following steps:

• Turn off the computer and any peripherals.

• Disconnect the computer and peripherals from power sources or subsystems to prevent electric shock

or system board damage. This does not apply to when hot-swapping parts.

• Disconnect telephone or telecommunications lines from the computer.

In addition, take note of these safety guidelines when appropriate:

• To help avoid possible damage to system boards, wait five seconds after turning off the computer before removing a component, removing a system board, or disconnecting a peripheral device from the

computer.

• When you disconnect a cable, pull on its connector or on its strain-relief loop, not on the cable itself.

Some cables have a connector with locking tabs. If you are disconnecting this type of cable, press in on

the locking tabs before disconnecting the cable. As you pull connectors apart, keep them evenly

aligned to avoid bending any connector pins. Also, before connecting a cable, make sure both connectors are correctly oriented and aligned.

Preface

CAUTION

Do not attempt to service the system yourself, except as explained in

this user’s guide. Follow installation and troubleshooting instructions closely.

Page viii AM4311 User Guide

Page 9

Advisory Conventions

This symbol and title indicate potential damage to hardware and tells

you how to avoid the problem.

Electric Shock

This symbol and title warn of hazards due to electrical shocks (> 60V)

when touching products or parts of them. Failure to observe the precautions indicated and/or prescribed by the law may endanger your

life/health and/or result in damage to your material.

This symbol and title emphasize points which, if not fully understood

and taken into consideration by the reader, may endanger your

health and/or result in damage to your material.

Preface

CAUTION

CAUTION

WARNING

ESD Sensitive Device

This symbol and title inform that electronic boards and their components are sensitive to static electricity. Therefore, care must be taken

during all handling operations and inspections of this product, in

order to ensure product integrity at all times.

Please read also the section “Special Handling and Unpacking

Instructions”.

Note...

This symbol and title emphasize aspects the reader should read through carefully for his or her own advantage.

CE Conformity

This symbol indicates that the product described in this manual is in

compliance with all applied CE standards. Please refer also to the section “Regulatory Compliance Statements” in this manual.

Page ix AM4311 User Guide

Page 10

Preface

Safety Instructions

Your new Kontron product was developed and tested carefully to provide all features necessary to ensure its

compliance with electrical safety requirements. It was also designed for a long fault-free life. However, the

life expectancy of your product can be drastically reduced by improper treatment during unpacking and

installation. Therefore, in the interest of your own safety and of the correct operation of your new Kontron

product, you are requested to conform with the following guidelines.

WARNING

All operations on this device must be carried out by sufficiently

skilled personnel only.

WARNING

Do not connect a switch port to a telephone line.

WARNING

For installation in a Hot-Plug system, observe the safety instructions specific to the system. Read the relevant documentation.

CAUTION

Electric Shock

High voltages are present inside the chassis when the unit’s power

cord is plugged into an electrical outlet. Turn off system power, turn

off the power supply, and then disconnect the power cord from its

source before removing the chassis cover. Turning off the system

power switch does not remove power to components.

Caution, Laser Light!

Laser light from fiber-optic transmission cables and components can damage

your eyes. The laser components plugged into the switch are Class 1 laser components. Class 1 laser is considered incapable of producing damaging radiation levels during normal operation or maintenance.

To avoid damaging your eyes and to continue safe operation in case of abnormal

circumstances:

• Never look directly into the outlets of fiber-optic transmission components

or fiber-optic cables with unprotected eyes.

• Never allow fiber-optic transmission path to operate until all the connections have been made.

• Always fit protective plugs to any unused ports of the switch.

Page x AM4311 User Guide

Page 11

Special Handling and Unpacking Instructions

ESD Sensitive Device

This symbol and title inform that electronic boards and their components

are sensitive to static electricity. Therefore, care must be taken during

all handling operations and inspections of this product, in order to

ensure product integrity at all times.

Unpacking

Follow these recommendations while unpacking:

• Remove all items from the box. If any items listed on the purchase order are missing, notify Kontron

customer service immediately.

• Inspect the product for damage. If there is damage, notify Kontron customer service immediately.

• Keep all the original packaging material for future storage or warranty shipments. If it is necessary to

store or ship the board please re-pack it as nearly as possible in the manner in which it was delivered.

Preface

Do not handle this product out of its protective enclosure while it is not used for operational purposes unless

it is otherwise protected.

Whenever possible, unpack or pack this product only at EOS/ESD safe work stations. Where a safe work station is not guaranteed, it is important for the user to be electrically discharged before touching the product

with his/her hands or tools. This is most easily done by touching a metal part of your system housing.

It is particularly important to observe standard anti-static precautions when changing mezzanines, ROM

devices, jumper settings etc. If the product contains batteries for RTC or memory back-up, ensure that the

board is not placed on conductive surfaces, including anti-static plastics or sponges. They can cause short

circuits and damage the batteries or conductive circuits on the board.

Powering up the System

Before any installation or setup, ensure that the board is unplugged from power sources or subsystems.

If you encounter a problem, verify the following items:

• Make sure that all connectors are properly connected.

• Verify your boot devices.

• If the system does not start properly, try booting without any other I/O peripherals attached, including

AMC adapters.

Page xi AM4311 User Guide

Page 12

Preface

Make sure your system provides the minimum DC voltages required at the board's slot, especially if DC power

is carried by cables.

If you are still not able to get your board running, contact our Technical Support for assistance.

Adapter Cables

Because adapter cables come from various manufacturers, pinouts can differ. The direct crimp design

offered by Kontron allows the simplest cable assembly. All cables are available from Kontron Sales Department.

Storing the Boards

Electronic boards are sensitive devices. Do not handle or store device near strong electrostatic, electromagnetic, magnetic or radioactive fields.

Page xii AM4311 User Guide

Page 13

Preface

General Instructions on Usage

In order to maintain Kontron’s product warranty, this product must not be altered or modified in any way.

Changes or modifications to the device, which are not explicitly approved by Kontron AG and described in

this manual or received from Kontron’s Technical Support as a special handling instruction, will void your

warranty.

This device should only be installed in or connected to systems that fulfill all necessary technical and specific environmental requirements. This applies also to the operational temperature range of the specific

board version, which must not be exceeded. If batteries are present their temperature restrictions must be

taken into account.

Page xiii AM4311 User Guide

Page 14

Preface

Regulatory Compliance Statements

FCC Compliance Statement for Class B Devices

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generated, uses and can radiate radio frequency energy

and, if not installed and used in accordance with the instructions may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or television reception, which can be determined

by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more

of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experience radio/TV technician for help.

WARNING

This is a Class B product. If not installed in a properly shielded enclosure and used in accordance with this User's Guide, this product may

cause radio interference in which case users may need to take additional measures at their own expense.

Safety Certification

All Kontron equipment meets or exceeds safety requirements based on the IEC/EN/UL/CSA 60950-1 family of

standards entitled, "Safety of information technology equipment." All components are chosen to reduce

fire hazards and provide insulation and protection where necessary. Testing and reports when required are

performed under the international IECEE CB Scheme. Please consult the "Kontron Safety Conformity Policy

Guide" for more information.

CE Certification

The product described in this user's guide was tested in a representative system and is found to be compliant

with the CE marking requirements. For computer systems to remain CE compliant, only CE-compliant parts

may be used. Maintaining CE compliance also requires proper cable and cabling techniques. Although Kontron offers accessories, the customer must ensure that these products are installed with proper shielding to

maintain CE compliance. Kontron does not offer engineering services for designing cabling systems. In addition, Kontron will not retest or recertify systems or components that have been reconfigured by customers.

Page xiv AM4311 User Guide

Page 15

Preface

Two Year Warranty

Kontron AG grants the original purchaser of Kontron’s products a TWO YEAR LIMITED HARDWARE WARRANTY as

described in the following. However, no other warranties that may be granted or implied by anyone on

behalf of Kontron are valid unless the consumer has the express written consent of Kontron AG.

Kontron AG warrants their own products, excluding software, to be free from manufacturing and material

defects for a period of 24 consecutive months from the date of purchase. This warranty is not transferable

nor extendible to cover any other users or long-term storage of the product. It does not cover products

which have been modified, altered or repaired by any other party than Kontron Modular Computers GmbH or

their authorized agents. Furthermore, any product which has been, or is suspected of being damaged as a

result of negligence, improper use, incorrect handling, servicing or maintenance, or which has been damaged as a result of excessive current/voltage or temperature, or which has had its serial number(s), any

other markings or parts thereof altered, defaced or removed will also be excluded from this warranty.

If the customer’s eligibility for warranty has not been voided, in the event of any claim, he may return the

product at the earliest possible convenience to the original place of purchase, together with a copy of the

original document of purchase, a full description of the application the product is used on and a description

of the defect. Pack the product in such a way as to ensure safe transportation (see our safety instructions).

Kontron provides for repair or replacement of any part, assembly or sub-assembly at their own discretion, or

to refund the original cost of purchase, if appropriate. In the event of repair, refunding or replacement of

any part, the ownership of the removed or replaced parts reverts to Kontron Modular Computers GmbH, and

the remaining part of the original guarantee, or any new guarantee to cover the repaired or replaced items,

will be transferred to cover the new or repaired items. Any extensions to the original guarantee are considered gestures of goodwill, and will be defined in the “Repair Report” issued by Kontron with the repaired or

replaced item.

Kontron Modular Computers GmbH will not accept liability for any further claims resulting directly or indirectly from any warranty claim, other than the above specified repair, replacement or refunding. In particular, all claims for damage to any system or process in which the product was employed, or any loss incurred as

a result of the product not functioning at any given time, are excluded. The extent of Kontron Modular Computers GmbH liability to the customer shall not exceed the original purchase price of the item for which the

claim exists.

Kontron Modular Computers GmbH issues no warranty or representation, either explicit or implicit, with

respect to its products’ reliability, fitness, quality, marketability or ability to fulfil any particular application

or purpose. As a result, the products are sold “as is,” and the responsibility to ensure their suitability for any

given task remains that of the purchaser. In no event will Kontron be liable for direct, indirect or consequential damages resulting from the use of our hardware or software products, or documentation, even if Kontron

were advised of the possibility of such claims prior to the purchase of the product or during any period since

the date of its purchase.

Please remember that no Kontron Modular Computers GmbH employee, dealer or agent is authorized to make

any modification or addition to the above specified terms, either verbally or in any other form, written or

electronically transmitted, without the company’s consent.

Page xv AM4311 User Guide

Page 16

Introduction

Chapter

1

Page 1 AM4311 User Guide

Page 17

Introduction

1

MUX

A

0

A

1

A

4

A

9

A

11

A

10

SFP Transc

2

SFP Transce

3

4

C0

C1

C2

C3

A

20

B0

B1

B2

B3

A0A

1

A2A3A

8

1. Introduction

The Advanced Mezzanine Card (AMC) described in this manual operates with the Advanced Telecommunications Computing Architecture (AdvancedTCA® or ATCA) and the Micro Telecommunications Computing Architecture (MicroTCA or uTCA) defined by the PCI Industrial Computer Manufacturers Group (PICMG). The main

advantages of AdvancedTCA include high throughput, multi-protocol support, high-power capability, hot

swappability, high scalability, and integrated system management. For further information regarding the AdvancedTCA/MicroTCA standards and their use, please consult the complete AdvancedTCA specification or visit

the PICMG web site.

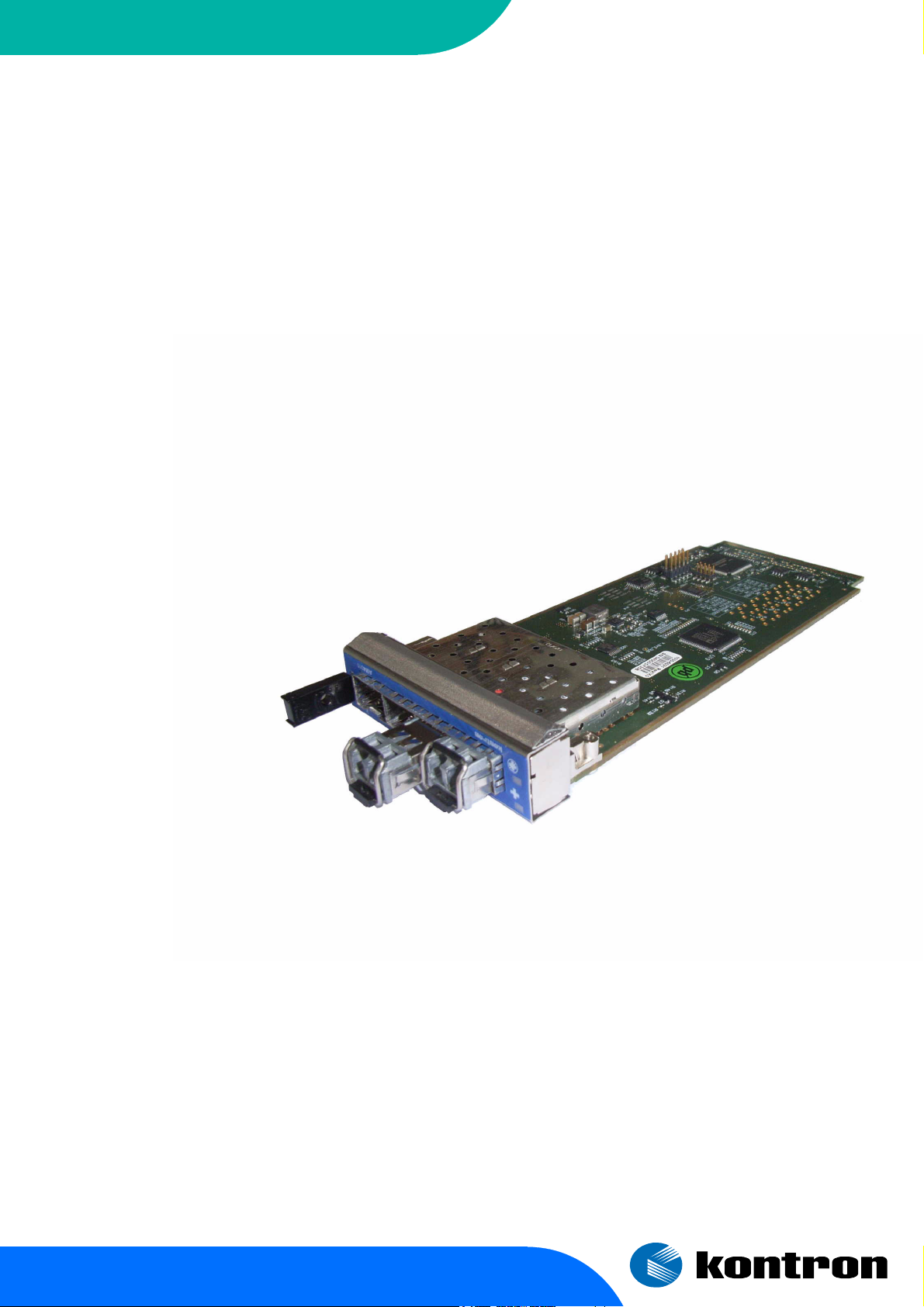

1.1 Board Overview

The AM4311 is a PIGMG AMC.0 R1.0 compliant Advanced Mezzanine Card with 4x 1000Base-X SFP modules.

The main application of this module is to direct-connect GbE ports from an AMC connector of an AMC carrier

or a μTCA system to the front. The AM4311 selects 4 of 8 GbE ports from the Carrier. It can be used in μTCA as

well as ATCA environments.

1.2 Board Diagrams

The following diagram provides additional information concerning board functionality and component layout.

1.2.1 Functional Block Diagram

The following figure shows the block diagram of the AM4311.

Figure 1-1: AM4311 Functional Block Diagram

SFP Transceiver Cage Port

eiver Cage Port

iver Cage Port

SFP Transceiver Cage Port

The Uplink Infrastructure supports 4x 1000Base-X SFP uplink ports which are connected via a MUX to 8 AMC

ports.

MC Port

MC Port

MC Port

MC Port

MC Port

MC Port

MC Port

MC Port

Page 2 AM4311 User Guide

Page 18

Introduction

1.2.2 Front Panel

Figure 1-2: AM4311 Front Panel

1.2.2.1 Hot Swap LED (Blue LED)

The AM4311 board supports a blue Hot Swap LED mounted on the front panel. This LED indicates when it is

safe to remove the Module. The on-board MMC drives this LED to indicate the hot swap state but is controlled

by the carriers IPMC or the MicorTCA carrier manager.

The following states are possible:

Table 1-1: Blue LED State

LED state Description

Solid Off (0 % on) FRU activation in progress / FRU active

Solid On (100 % on) FRU inactive

Short Blink (10 % on) FRU deactivation request / FRU deactivation in progress

Long Blink (90 % on) FRU activation request

1.2.2.2 Out-Of-Service (OOS) LED (LED1)

The AM4311 supports a green Activity LED mounted on the front panel. The position of this LED is near the

bottom handle beside the health LED.

Table 1-2: OOS LED State

LED state Description

ON while executing the boot-block application

OFF when starting execution of the IPMI firmware.

Blinking while boot-block application is flashing a new IPMI firmware

Page 3 AM4311 User Guide

Page 19

Introduction

1.2.2.3 Health LED (LED2)

The AM4311 Switch Board supports a Health LED mounted on the front panel. This sensor is built from an aggre-

gation of critical sensors of the MMC. In normal condition, the Health error sensor is not asserted and the

LED is green indicating normal operation. If the sensor i

The following states are possible.

Table 1-3: Health LED State

LED state Description

ON normal st ate when board is in operation, and all sensors related are in range.

Off payload is off

Amber switched to AMBER when the payload is on and at least one sensor is out of range.

s asserted for any reason, the LED is set to amber.

Page 4 AM4311 User Guide

Page 20

1.3 Technical Specifications

1.3.1 General

• Mechanical: Single, Mid-size AMC form factor

• Dimensions: 180.6 mm x 73.5 mm

•Board Weight: 100 g

1.3.2 AMC LEDs

• LED0 (blue) Ready for Hot Swap

• LED1 (red/green/yellow) Out of Service LED

• LED2 (green/amber/red) Healthy LED

1.3.3 Operating Voltages

• Management: 3.0V/3.6V

•Payload: 10VDC to 14VDC

Introduction

1.3.4 Operation Power

• Management 0.5W

• Payload 4.0W max.

1.3.5 Temperature

This board is designed for operation from 0 °C to 60°C inlet air temperature.

•Air Flow: 20 CFM

• Operating: 0 °C to +60 °C

• Non-Operating: -40 °C to +85 °C

1.3.6 Humidity

The board is designed to meet Bellcore GR63, Section 4.1

• Operating: 15%-90% (non-condensing) at 0°C to 55°C

• Non-Operating: 5%-95% (non-condensing) at -40°C to 70°C

1.3.7 Altitude

The board is designed to meet the following requirements:

• Operating: 4000 m (13123 ft), may require additional cooling above

1800m (5905ft)

• Non-Operating: 15000 m (49212 ft)

Page 5 AM4311 User Guide

Page 21

Introduction

1.3.8 Vibration

The board is designed to meet the following requirements according to IEC 60068-2-6, Bellcore GR-63, Section 4.4 and MIL-STD-810E, Method 514:

• Operating

• 5Hz to 100Hz: 1G @ 0.25 Octave/minute

• 100HZ to 500Hz: 1G @ 1 Octave/minute

• 5Hz @ 0.01 g2 /Hz to 20 Hz @ 0.02 g2 /Hz (slope up)

• 20Hz to 500 Hz @ 0.02 g2 /Hz (flat)

• 3.13 g RMS, 10 minutes per axis for all 3 axes

• Non-Operating

• 5Hz to 50Hz: 0.5G @ 0.1 Octave/minute

• 50Hz to 500Hz: 3G @ 0.25 Octave/minute

1.3.9 Schock

The board is designed to meet the following requirements IEC 60068-2-27 and MIL-STD-810E, Method 516:

• Operating: 30G/11 ms half sine

• Non-Operating: 50G, 170 inches/second trapezoidal

1.3.10 Safety

CB report to IEC 60950-1, complies with EN/CSA/UL 60950-1.

1.3.11 Electromagnetic Compatibility

The board is designed to meet or exceed the following specifications/requirements (assuming an adequate

carrier/chassis):

• CFR 47, FCC Part 15, Subpart B

• Telcordia GR-1089-Core-Issue 3 and SR-3580 Issue 2

• EMC Directive 89/336/EEC (Europe)

• EN55022 (Europe)

• EN55024 (Europe)

• EN61000-4-2 + A1 + A2

• EN61000-4-3 + A1

• EN300 386 V1.3.3, Electro Magnetic Compatibility (EMC) Requirements for Public Telecommunication

Network Equipment; Electromagnetic Compatibility (EMC) Requirements.

1.3.12 MTBF

MTBF is >170,000h@40°C, calculations based on Bellcore/Telcordia SR-332.

Page 6 AM4311 User Guide

Page 22

1.4 Standards Compliance

This board is compatible to the following standards:

• AMC.0 R2.0 Advance Mezzanine Card Base Specification

• AMC.2 R1.0 AMC Gigabit Ethernet

•IPMI v1.5

• IEEE 802.3

The AM4311 is RoHS compliant.

1.5 Related Publications

The following publications contain information relating to this product.

Table 1-4: Related Publications

PRODUCT PUBLICATION

MicroTCA™

AMC PICMG® AMC.0, Advanced Mezzanine Card Specification R1.0

IPMI IPMI - Intelligent Platform Management Interface Specification, v1.5

All Kontron products Product Safety and Implementation Guide, ID 1021-9142

PICMG® MTCA.0 Micro Telecommunications Computing Architecture R1.0,

July 6,2006

Introduction

PRODUCT PUBLICATION

Page 7 AM4311 User Guide

Page 23

Functional Description

Chapter

2

Page 8 AM4311 User Guide

Page 24

Functional Description

2. Functional Description

2.1 Uplink Infrastructure

The Uplink Infrastructure supports 4x 1000Base-X SFP uplink ports which are connected via a MUX to 8 AMC

ports.

The quad-lane 2:1 switch consists of four multiplexers and four demulti-plexers, one per lane. Each port is a

4-lane link, and each lane runs up to a 3.2 Gbps data rate independent of the other lanes. The lanes are

switched independently by setting control bits using an IPMI OEM command, according to Table 2.1.

The SFP Transceiver cages are designed according SFP MSA.

Table 2-1: Port Mapping

SFP Port Control Bit

0 1

SFP1 AMC P0 AMC P11

SFP2 AMC P1 AMC P10

SFP3 AMC P20 AMC P9

SFP4 AMC P4 AMC P8

The IMPI OEM command to change the port mapping is described in Section 2.5.2.2 "OEM Set Control State".

This segmentation allows several combinations for specific usage. Configuration of all possible variation is

described in Section 2.5.3 "Configuring Port Settings".

Examples include:

AT8904M

• Base-Interface access on AMC port 0 and 1.

• Fabric-Interface access on AMC port 4 or 8.

AT8404M

• Base-Interface access on AMC port 0.

• Fabric-Interface link aggregation on AMC port P8, P9, P10 and P11

The default port assignment is listed in Table 2-2.

Table 2-2: Default Port Assignment

SPF Port Port

SFP1 AMC P0

SFP2 AMC P1

SFP3 AMC P9

SFP4 AMC P8

Page 9 AM4311 User Guide

Page 25

Functional Description

2.2 MMC

The IPMI (Intelligent Platform Management Interface) consists of the FWUM (Firmware Upgrade Manager)

and the MMC (Module Management Controller).

The FWUM controls the MMC firmware update. Two EEPROM banks are connected to the FWUM, one for the old

firmware image and one for the new image. During an update, the new firmware image will be programmed

in one of the two EEPROMs. This new image is then programmed into the MMC under control of the FWUM. If

the MMC does not start correctly with the new image, the old image of the other EEPROM will be programmed

in the MMC.

2.3 Board Sensors

The Management Controller includes many sensors for voltage or temperature monitoring and various others

for pass/fail type signal monitoring.

Every sensor is associated with a Sensor Data Record (SDR). Sensor Data Records contain information about

the sensors identification such as sensor type, sensor name, sensor unit. SDRs also contain the configuration of a specific sensor such as thresholds, hysteresis, event generation capabilities, etc. that specify the

sensor’s behavior. Some fields of the sensor SDR are configurable through IPMI v1.5 command and are set to

a built-in initial value.

Module sensors that have been implemented are listed in the sensor list below.

2.3.1 Sensor List

The sensor number is the number which identifies the sensor e.g. when using the IPMI command “Get Sensor

Reading”. Please note that ‘ipmitool’ accepts sensor numbers in decimal (e.g. ‘10’) or hexadecimal (e.g.

‘0xa’) notation.

Please note that the IPMI tool ‘ipmitool’ displays for command ‘ipmitool sdr list’ the contents of the sensor

data record repository (SDRR) of the whole rack if the SDRR is generated. The generation of the SDRR has

always to be done new after adding or subtracting any board to or from the rack.

For OEM (Kontron) specific sensor types and reading types in the following table, please refer to the next

chapter.

Table 2-3: Sensor List AM4311

ID Num ID string Sensor Type Code Event Type Code / Event Offsets

0 Xx B1:AM4311 NA (FRU Device Locator

Record)

1 0 B1:IPMI Info-1 C0h (OEM Kontron)

2 1 B1:IPMI Info-2 C0h (OEM Kontron)

3 2 B1:FRU Agent C5h (OEM Kontron FRU

Info Agent State)

0Ah (Discrete)

Offset 6: transition to Degraded

Offset 8: Install Error

Page 10 AM4311 User Guide

Page 26

Functional Description

Table 2-3: Sensor List AM4311 (Continued)

ID Num ID string Sensor Type Code Event Type Code / Event Offsets

4 3 B1:Module-

HotSwap

5 4 B1:IPMBL State C3h (OEM Kontron) 6Fh (Senso r Specif ic)

6 5 B1:Temp-Center 01h (Temperature) 01h (Threshold Based)

7 6 B1:Temp-Outlet 01h (Temperature) 01h (Threshold Based)

8 7 B1:Temp-Inlet 01h (Temperature) 01h (Threshold Based)

9 8 B1:Vcc 3.3V 02h (Voltage) 01h (Threshold Based)

10 9 B1:Vcc 3.3V SUS 02h (Voltage) 01h (Threshold Based)

11 10 B1:Vcc 12V 02h (Voltage) 01h (Threshold Based)

12 11 B1:Pres SFP-1 25h (Entity Present) 6Fh (Sensor specific)

13 12 B1:Pres SFP-2 25h (Entity Present) 6Fh (Sensor specific)

14 13 B1:Pres SFP-3 25h (Entity Present) 6Fh (Sensor specific)

F2h (Module Hot Swap) 6Fh (Sensor Specific)

Offset 0: Module Handle Closed

Offset 1: Module Handle Opened

Offset 2: Quiesced

Offset 3: Backend Power Failure

Offset 4: Backend Power Shutdown

Refer to AMC.0 R2.0 Section 3.6.6 Module Hot

Swap Sensor.

Offset 0: IPMB-A disabled, IPMB-B disabled

Offset 1: IPMB-A enabled, IPMB-B disabled

Offset 2: IPMB-A disabled, IPMB-B enabled

Offset 3: IPMB-A enabled, IPMB-B enabled

Sensor is only readable when Payload Power is on.

Sensor is only readable when Payload Power is on.

Sensor is only readable when Payload Power is on.

Sensor is only readable when Payload Power is on.

Offset 0: Entity Present

Offset 1: Entity Absent

Offset 2: Entity Disabled

Sensor is only readable when Payload Power is on.

Offset 0: Entity Present

Offset 1: Entity Absent

Offset 2: Entity Disabled

Sensor is only readable when Payload Power is on.

Offset 0: Entity Present

Offset 1: Entity Absent

Offset 2: Entity Disabled

Sensor is only readable when Payload Power is on.

Page 11 AM4311 User Guide

Page 27

Functional Description

Table 2-3: Sensor List AM4311 (Continued)

ID Num ID string Sensor Type Code Event Type Code / Event Offsets

15 14 B1:Pres SFP-4 25h (Entity Present) 6Fh (Sensor specific)

Offset 0: Entity Present

Offset 1: Entity Absent

Offset 2: Entity Disabled

Sensor is only readable when Payload Power is on.

16 15 B1:Health Error 24h (Platform Alert) 03h (Generic Discrete)

Offset 0: no critical sensors asserted

Offset 1: one or multiple critical sensors are

asserted

See table: Health Sensor list for details.

17 16 B1:MMC Reboot 24h (Platform Alert) 03h (Generic Discrete)

Offset 0: State Deasserted

Offset 1: State Asserted

18 17 B1:Ver change 2Bh (Version Change)

2.3.2 OEM sensor types and OEM sensor event/reading types

Table 2-4: OEM Sensor List AM4311

Sensor Type

C0h 03h Standard

Event/Reading

type Code

IPMI Discrete

Sensor Specific

Offset

Internal Management Controller firmware

diagnostic

Internal error condition

Event Trigger

Page 12 AM4311 User Guide

Page 28

Table 2-4: OEM Sensor List AM4311 (Continued)

Functional Description

Sensor Type

C3h OEM Kontron

IPMI-L Link

Event/Reading

type Code

6Fh Standard

IPMI sensor specific

Sensor Specific

Offset

02h

03h

Event Trigger

IPMB-L Disable

Event Data 2: always 0

Event Data 3:

bit[7:3]: always 0

bit [2:0]:

0h = no failure

1h = Unable to drive clock HI

2h = Unable to drive data HI

3h = Unable to drive clock LO

4h = Unable to drive data LO

5h = clock low timeout

6h = Under test (the IPM Controller is attempting

to determine who is causing a bus hang)

7h = Undiagnosed Communication Failure

IPMB-L Enable

Event Data 2: always 0

Event Data 3:

bit[7:3]: always 0

bit [2:0]:

0h = no failure

1h = Unable to drive clock HI

2h = Unable to drive data HI

3h = Unable to drive clock LO

4h = Unable to drive data LO

5h = clock low timeout

6h = Under test (the IPM Controller is attempting

to determine who is causing a bus hang)

7h = Undiagnosed Communication Failure

Page 13 AM4311 User Guide

Page 29

Table 2-4: OEM Sensor List AM4311 (Continued)

Functional Description

Sensor Type

C5h OEM Kontron

FRU Info Agent

Event/Reading

type Code

6Fh Standard

IPMI sensor specific

Sensor Specific

Offset

06h

08h

Event Trigger

Transition to degraded

Event Data 2 is used a bit flag error

Bit 7: unspecifiedError

Bit 6: notPresentError

Bit 5: multirecHeaderError

Bit 4: multirecDataError

Bit 3: timeout error

Bit 2: ipmcError

Bit 1: fruDataError

Bit 0: commonHeaderError

Event Data 3 is used a bit flag error

Bit 7: reserved

Bit 6: reserved

Bit 5: SetPortState Not Supported

Bit 4: SetPortState Error

Bit 3: reserved

Bit 2: reserved

Bit 1: reserved

Bit 0: Match Error, Not in single link matches

Install Error

Event Data 2 is used a bit flag error

Bit 7: unspecifiedError

Bit 6: notPresentError

Bit 5: multirecHeaderError

Bit 4: multirecDataError

Bit 3: timeout error

Bit 2: ipmcError

Bit 1: fruDataError

Bit 0: commonHeaderError

Event Data 3 is used a bit flag error

Bit 7: SetClockState Not Supported

Bit 6: SetClockState Error

Bit 5: SetPortState Not Supported

Bit 4: SetPortState Error

Bit 3: Clock Internal Mismatch

Bit 2: Clock Match Error, Not a single clock matches

Bit 1: Internal mismatch

Bit 0: Match Error, Not in single link matches

Page 14 AM4311 User Guide

Page 30

2.3.3 Sensor Thresholds

Following tables show sensor thresholds for temperature, voltage and current sensors.

Table 2-5: Temperature Sensor Thresholds [°C]

Functional Description

SENSOR Number / ID string

ID=5: B4:Temp-Center - - 15 25 59 60 70

ID=6: B4:Temp-Outlet - - 15 25 59 60 70

ID=7: B4:Temp-Inlet - - - - - 60 70

Lower

critical

Lower

non criti-

cal

Normal

min

Nominal

Normal

max

Upper non

critical

Upper

critical

Table 2-6: Voltage Sensor Thresholds

SENSOR Number / ID string

ID=8: B4:Board 3.3V 3.037 3.139 3.154 3.300 3.446 3.460 3.562

ID=9: B4:Board 3.3VSUS 3.037 3.139 3.154 3.300 3.446 3.460 3.562

ID=10: B4:Board 12V 10.561 10.797 10.856 11.977 13.157 13.216 13.452

Lower

critical

Lower

non criti-

cal

Normal

min

Nominal

Normal

max

Upper non

critical

Upper

critical

2.4 Board FRU Information

This FRU information contains the IPMI defined Board and Product Information areas that hold the part

number and serial number of the board and the Multirecord Information Area that contains the PICMG

defined Point to Point Information records.

The Internal Use Area is preallocated to 256 bytes and is free for customer use. This FRU information

responds to FRU ID #0, which is the ID for the MMC.

2.4.1 Structure and Functionality

The Management Controller provides 4 kB non-volatile storage space for FRU information.

Full low level access to read or write a module’s FRU Information is provided by regular IPMI FRU Device commands. Please be careful when writing FRU information directly using standard IPMI commands because

there is no write protection. Damaging the FRU Information e.g. may confuse a shelf management software

which uses the FRU data.

2.4.2 Board Specific FRU Data

Supported are the following FRU data areas and data fields:

FRU Board Info Area

• Board Mfg: Kontron

• Board Product: AM4311

• Board Serial: 0400057367

Page 15 AM4311 User Guide

Page 31

• Board Part Number: S1500

• Board FRU ID: FRU-S1500-00

FRU Product Info Area

• Product Manufacturer: Kontron

• Product Name: AM4311

• Product Part Number: S1500

• Product Version: 00

• Product Serial: 0400057367

• Product Asset Tag: 0000000000

• Product FRU ID: FRU-S1500-00

2.5 OEM Commands

2.5.1 Kontron-specific OEM commands

All Kontron-specific OEM commands are listed in Table 2-7 below.

Functional Description

Table 2-7: Kontron-specific OEM Command Overview

Command Name NetFn LUN Command Number MMC Requirement

OemApGetFirmwareSysUpTime 3 3Eh 03h YES

OemApSetNvParam 3 3Eh 05h YES

OemApFpgaWriteRead__ 3 3Eh 08h YES

OemApFormatStorage 3 3Eh 09h YES

OemApSetSdrLocatorString 3 3Eh 0Ah YES

OemApSetSerialNumber 3 3Eh 0Bh YES

OemApGetSerialNumber 3 3Eh 0Ch YES

OemApSetManufacturingDate 3 3Eh 0Dh YES

OemApGetManufacturingDate 3 3Eh 0Eh YES

OemApSetNvData 3 3Eh 0Fh YES

OemApGetNvData 3 3Eh 10h YES

OemApSetDeviceGuid 3 3Eh 11h NO

Page 16 AM4311 User Guide

Page 32

2.5.1.1 OEM Get Firmware SysUp Time

Command Name NetFn LUN Command Number

OemApGetFirmwareSysUpTime 3 3Eh 03h

Byte Num Data Field

Request Data 1 Pass Code 0: ~’K’

2 Pass Code 1: ~’o’

3 Pass Code 2: ~’n’

4 Pass Code 3: ~’t’

Response Data 1 Completion Code

2…5 System Up-Time in Seconds

Functional Description

2.5.1.2 OEM Set NV Param

Command Name NetFn LUN Command Number

OemApSetNvParam 3 3Eh 05h

Byte Num Data Field

Request Data 1 Pass Code 0: ~’K’

2 Pass Code 1: ~’o’

3 Pass Code 2: ~’n’

4 Pass Code 3: ~’t’

5 Command flags:

[7..2] – reserved

[1] – is Set

[0] – is Cold Reset Required

6 Operation mode:

[7..5] – reserved

[4] – ipmbMode

[3..1] – reserved

[0] – controller mode

7 KCS SMS IRQ

Response Data 1 Completion Code

Page 17 AM4311 User Guide

Page 33

2.5.1.3 OEM FPGA Write/Read

Command Name NetFn LUN Command Number

OemApFpgaWriteRead__ 3 3Eh 08h

Byte Num Data Field

Request Data 1 Pass Code 0: ~’K’

2 Pass Code 1: ~’o’

3 Pass Code 2: ~’n’

4 Pass Code 3: ~’t’

5 Register Address

6 Read Count

7Write Data

8Write Mask

Response Data 1 Completion Code

2…n Read Data

Functional Description

2.5.1.4 OEM Format Storage

Command Name NetFn LUN Command Number

OemApFormatStorage 3 3Eh 09h

Byte Num Data Field

Request Data 1 Pass Code 0: ~’K’

2 Pass Code 1: ~’o’

3 Pass Code 2: ~’n’

4 Pass Code 3: ~’t’

Response Data 1 Completion Code

Page 18 AM4311 User Guide

Page 34

2.5.1.5 OEM Set SDR Location String

Command Name NetFn LUN Command Number

OemApSetSdrLocatorString 3 3Eh 0Ah

Byte Num Data Field

Request Data 1 Pass Code 0: ~’K’

2 Pass Code 1: ~’o’

3 Pass Code 2: ~’n’

4 Pass Code 3: ~’t’

5…7 Manufacturer ID

8…9 Product ID

10…25 Device ID Str ing

Response Data 1 Completion Code

Functional Description

2.5.1.6 OEM Set Serial Number

Command Name NetFn LUN Command Number

OemApSetSerialNumber 3 3Eh 0Bh

Byte Num Data Field

Request Data 1 Pass Code 0: ~’K’

2 Pass Code 1: ~’o’

3 Pass Code 2: ~’n’

4 Pass Code 3: ~’t’

5…20 Serial Number String

Response Data 1 Completion Code

Page 19 AM4311 User Guide

Page 35

2.5.1.7 OEM Get Serial Number

Command Name NetFn LUN Command Number

OemApGetSerialNumber 3 3Eh 0Ch

Byte Num Data Field

Request Data 1 Pass Code 0: ~’K’

2 Pass Code 1: ~’o’

3 Pass Code 2: ~’n’

4 Pass Code 3: ~’t’

Response Data 1 Completion Code

2…16 Serial Number String

Functional Description

2.5.1.8 OEM Set Manufacturing date

Command Name NetFn LUN Command Number

OemApSetManufacturingDate 3 3Eh 0Dh

Byte Num Data Field

Request Data 1 Pass Code 0: ~’K’

2 Pass Code 1: ~’o’

3 Pass Code 2: ~’n’

4 Pass Code 3: ~’t’

5…7 Manufacturing Date

Response Data 1 Completion Code

2.5.1.9 OEM Get Manufacturing date

Command Name NetFn LUN Command Number

OemApGetManufacturingDate 3 3Eh 0Eh

Page 20 AM4311 User Guide

Page 36

Byte Num Data Field

Request Data 1 Pass Code 0: ~’K’

2 Pass Code 1: ~’o’

3 Pass Code 2: ~’n’

4 Pass Code 3: ~’t’

Response Data 1 Completion Code

2…4 Manufacturing Date

2.5.1.10 OEM Set NV date

Command Name NetFn LUN Command Number

OemApSetNvData 3 3Eh 0Fh

Functional Description

Byte Num Data Field

Request Data 1 Pass Code 0: ~’K’

2 Pass Code 1: ~’o’

3 Pass Code 2: ~’n’

4 Pass Code 3: ~’t’

5NV Data Param ID

6…N RAW Data

Response Data 1 Completion Code

2.5.1.11 OEM Get NV Data

Command Name NetFn LUN Command Number

OemApGetNvData 3 3Eh 10h

Page 21 AM4311 User Guide

Page 37

Byte Num Data Field

Request Data 1 Pass Code 0: ~’K’

2 Pass Code 1: ~’o’

3 Pass Code 2: ~’n’

4 Pass Code 3: ~’t’

5NV Data Param ID

Response Data 1 Completion Code

2…N RAW Data

2.5.1.12 OEM Set Device GUID

Command Name NetFn LUN Command Number

OemApSetDeviceGuid 3 3Eh 11h

Functional Description

Byte Num Data Field

Request Data 1 Pass Code 0: ~’K’

2 Pass Code 1: ~’o’

3 Pass Code 2: ~’n’

4 Pass Code 3: ~’t’

5…20 Device GUID

Response Data 1 Completion Code

2.5.2 Board-specific OEM commands

The board-specific OEM commands are listed in Table 2-8 below.

Table 2-8: Board-specific OEM Command Overview

Command Name NetFn LUN Command Number MMC Requirement

OemApGetReleaseInfo 30h 3 - OEM2 01h YES

CmdSetControlState 3Eh 0 - BMC 20h YES

CmdGetControlState 3Eh 0 - BMC 21h YES

CmdGetSfpData 30h 3 - OEM2 10h YES

Page 22 AM4311 User Guide

Page 38

2.5.2.1 OEM Get Release Information

Command Name NetFn LUN Command Number

OemApGetReleaseInfo 3Eh 3 - OEM2 01h

Byte Num Data Field

Request Data 1 Pass Code 0: ~’S’

2 Pass Code 1: ~’1’

3 Pass Code 2: ~’5’

4 Pass Code 3: ~’0’

5 Pass Code 4: ~’0’

Response Data 1 Completion Code

2...6 Release TAG

7…12 Subrelease TAG

13…20 Release Date

Functional Description

Example

ipmitool -t 0x80 -b 7 -l 3 raw 0x30 0x1 0xac 0xce 0xca 0xcf 0xcf

e.g. returned data:

48 45 41 44 00 4e 2f 41 00 00 00 59 59 59 59 4d 4d 44 44

Page 23 AM4311 User Guide

Page 39

2.5.2.2 OEM Set Control State

Command Name NetFn LUN Command Number

CmdSetControlState 3Eh 0 - BMC 20h

Byte Num Data Field

Request Data 1 Control ID

0 – SFP#1

1 – SFP#2

2 – SFP#3

3 – SFP#4

2 Control State

Control Number 0: SFP#1

0 – AMC port 0

1 – AMC port 11

Control Number 1: SFP#2

0 – AMC port 1

1 – AMC port 10

Control Number 2: SFP#3

0 – AMC port 20

1 – AMC port 9

Control Number 3: SFP#4

0 – AMC port 4

1 – AMC port 8

Control Number 4: Loopback

0..7 – Loopback Mode

Bit [2] – AD8159 LB_C Pin 65 state

Bit [1] – AD8159 LB_B Pin 66 state

Bit [0] – AD8159 LB_A Pin 67 state

Default value is 00h (loopback mode disabled).

Response Data 1 Completion Code

Functional Description

Each SFP can separately be switched to one of the mentioned AMC ports.

Example 1: Configure SFP1 (Control ID 0) to port 11 (Control State 1)

ipmitool –t 0x7a –b 7 raw 0x3e 0x20 0x0 0x1

Example 2: Configure SFP2 (Control ID 1) to port 1 (Control State 0)

ipmitool –t 0x7a –b 7 raw 0x3e 0x20 0x1 0x0

Page 24 AM4311 User Guide

Page 40

2.5.2.3 OEM Get Control State

Command Name NetFn LUN Command Number

CmdGetControlState 3Eh 0 - BMC 21h

Byte Num Data Field

Request Data 1 Control ID

0 – SFP#1

1 – SFP#2

2 – SFP#3

3 – SFP#4

4 - Loopback Mode

Response Data 1 Completion Code

00h – valid

CCh – parameter out of range

D5h – when payload is not applied

2 Control State

Control ID 0: SFP#1

0 – AMC port 0

1 – AMC port 11

FFh – override jumper JP6 (7-8) asserted

Control ID 1: SFP#2

0 – AMC port 1

1 – AMC port 10

FFh – override jumper JP6 (5-6) asserted

Control ID 2: SFP#3

0 – AMC port 20

1 – AMC port 9

FFh – override jumper JP6 (3-4) asserted

Control ID 3: SFP#4

0 – AMC port 4

1 – AMC port 8

FFh – override jumper JP6 (1-2) asserted

Control ID 4: Loopback

0..7 – Loopback Mode

Bit [2] – AD8159 LB_C Pin 65 state

Bit [1] – AD8159 LB_B Pin 66 state

Bit [0] – AD8159 LB_A Pin 67 state

Functional Description

Example:

Module in AMC bay B1 (IPMB-L address 0x7a), ipmitool invokes on carrier (AT8404)

ipmitool –t 0x7a –b 7 raw 0x3e 0x21 <0|1|2|3>

ipmitool –t 0x7a –b 7 kontron boot get <0|1|2|3>

Page 25 AM4311 User Guide

Page 41

2.5.2.4 OEM Get SFP Data

Command Name NetFn LUN Command Number

CmdGetSfpData 30h

Byte Num Data Field

Request Data 1 Pass Code 0: ~’S’

2 Pass Code 1: ~’1’

3 Pass Code 2: ~’5’

4 Pass Code 3: ~’0’

5 Pass Code 4: ~’0’

6 0 – SFP#1

1 – SFP#2

2 – SFP#3

3 – SFP#4

7Offset

8Count

Response Data 1 Completion Code

D5h – when payload is not applied

CEh – when SFP is not present

C9h – when maximum count is exceeded, or when invalid SFP ID

2 Count n returned DATA bytes

3 .... n DATA bytes

Functional Description

Example:

Module in AMC bay B1 (IPMB-L address 0x7a), ipmitool invokes on carrier (AT8404)

ipmitool -t 0x7a -b 7 -l 3 raw 0x30 0xa0 0xac 0xce 0xca 0xcf 0xcf <ID><OFFSET><COUNT>

2.5.3 Configuring Port Settings

The port settings can be configured using the ipmitool on Kontron ATCA AMC carrier board

ipmitool <IPMB-ADDRESS> <IPMB-CHANNEL> raw <NETFN> <CMD-ID> [CMD-DATA]

IPMB-ADDRESSES:

AMC slot A1: 0x72

AMC slot A2: 0x74

AMC slot A3: 0x76

AMC slot A4: 0x78

Page 26 AM4311 User Guide

Page 42

AMC slot B1: 0x7a

AMC slot B2: 0x7c

AMC slot B3: 0x7e

AMC slot B4: 0x80

# Configure SFP1 (Control ID 0) to port 0 (Control State 0)

ipmitool -t 0x7a -b 7 raw 0x3e 0x20 0x0 0x0

# Configure SFP1 (Control ID 0) to port 11 (Control State 1)

ipmitool -t 0x7a -b 7 raw 0x3e 0x20 0x0 0x1

# Configure SFP2 (Control ID 1) to port 1 (Control State 0)

ipmitool -t 0x7a -b 7 raw 0x3e 0x20 0x1 0x0

# Configure SFP2 (Control ID 1) to port 10 (Control State 1)

ipmitool -t 0x7a -b 7 raw 0x3e 0x20 0x1 0x1

# Configure SFP3 (Control ID 2) to port 20 (Control State 0)

ipmitool -t 0x7a -b 7 raw 0x3e 0x20 0x2 0x0

Functional Description

# Configure SFP3 (Control ID 2) to port 9 (Control State 1)

ipmitool -t 0x7a -b 7 raw 0x3e 0x20 0x2 0x1

# Configure SFP4 (Control ID 3) to port 4 (Control State 0)

ipmitool -t 0x7a -b 7 raw 0x3e 0x20 0x3 0x0

# Configure SFP4 (Control ID 3) to port 8 (Control State 1)

ipmitool -t 0x7a -b 7 raw 0x3e 0x20 0x3 0x1

Page 27 AM4311 User Guide

Page 43

Installation

Chapter

3

Page 28 AM4311 User Guide

Page 44

Installation

3. Installation

The AM4311 has been designed for easy installation. However, the following standard precautions, installation procedures and general information must be observed to ensure proper installation and to preclude

damage to the board, other system components, or injury to personnel.

3.1 Safety Requirements

The following safety precautions must be observed when installing or operating the AM4311. Kontron

assumes no responsibility for any damage resulting from failure to comply with these requirements.

WARNING

MCH modules require, by design, a considerable amount of force in

order to (dis)engage the module from/in the MicroTCA™ backplane connector. For this reason, when inserting or extracting the module, apply

only as much force as required to preclude damage to either the module’s handle or the front panel.

DO NOT push on the module handle to seat the module in the backplane

connector. Do not use the module handle as a grip to handle the board

outside of the chassis slot.

Use of excessive force, bending or rotation of the module handle will

result in damage to the handle or the module’s locking mechanism.

Kontron disclaims all liability for damage to the module or the system

as a result of failure to comply with this warning.

ESD Equipment

This AMC board contains electrostatically sensitive devices. Please observe the necessary precautions to avoid damage to your board:

• Discharge your clothing before touching the assembly. Tools must be discharged before use.

• Do not touch components, connector-pins or traces.

• If working at an anti-static workbench with professional discharging equipment, please do not omit to use it.

WARNING

This product has gold conductive fingers which are susceptible to contamination. Take care not to touch the gold conductive fingers of the

AMC Card-edge connector when handling the board.

Failure to comply with the instruction above may cause damage to the

board or result in improper system operation.

WARNING

Be careful when inserting or removing the AM4311. The SFP cages have

sharp edges which might lead to injuries.

Page 29 AM4311 User Guide

Page 45

Caution, Laser Light!

Laser light from fiber-optic transmission cables and components can damage your

eyes. The laser components plugged into the switch are Class 1 laser components.

Class 1 laser is considered incapable of producing damaging radiation levels during

normal operation or maintenance.

To avoid damaging your eyes and to continue safe operation in case of abnormal circumstances:

• Never look directly into the outlets of fiber-optic transmission components or fiber-optic cables with unprotected eyes.

• Never allow fiber-optic transmission path to operate until all the connections

have been made.

• Always fit protective plugs to any unused ports of the switch.

3.2 Module Handle Positions

Installation

At the front panel, the AM4311 provides a module handle for module extraction for securing the module in

the chassis and actuating the hot swap switch.

The module handle supports a three-position operation.

Figure 3-1: Module Handle Positions

Page 30 AM4311 User Guide

Page 46

Table 3-1: Module Handle Positions

Module Handle Position Function

Locked When the AM4311 is installed, the module handle is pushed in the

“Locked” position and the following actions result:

• The module is locked in the chassis

• The hot swap switch is actuated

Hot Swap When an extraction process of the AM4311 is initiated, the mod-

ule handle is pulled in the “Hot Swap” position and the following

actions result:

• The module is locked in the chassis

• The hot swap switch is deactuated

Unlocked When the module handle is pulled to the “Unlocked” position, the

AM4311 can be fully extracted and the following actions result:

• The module is unlocked in the chassis

• The hot swap switch is deactuated

Installation

Note...

For normal operation, the module handle must be in the “Locked” position

3.3 Hot Swap Procedures

The AM4311 is designed for hot swap operation. Hot swapping allows the coordinated insertion and extraction of modules without disrupting other operational elements within the system.

The procedures contained in this section are also applicable for “non-operating systems” with the exception

of indications and functions which require power to be applied.

3.3.1 Hot Swap Insertion

To insert the MCH module proceed as follows:

1. Ensure that the safety requirements indicated in Section 3.1 are observed.

WARNING

Failure to comply with the instruction above may cause damage to

the board or result in improper system operation.

Page 31 AM4311 User Guide

Page 47

Installation

2. Ensure that the module is properly configured for operation in accordance with the application requirements before installation.

WARNING

Care must be taken when applying the procedures below to ensure

that neither the AM4311 nor other system boards are physically damaged by the application of these procedures.

3. Ensure that the module handle is in the “Unlocked” position.

4. Using the front panel as a grip, carefully insert the module into the slot designated by the application

requirements until it makes contact with the backplane connector.

5. Apply pressure to the front panel until the module is properly seated in the backplane connector. This

may require a considerable amount of force. Apply pressure only to the front panel, not the module

handle. During seating in the connector, there is a noticeable “snapping” of the board into the connector. When the board is seated it should be flush with the system front panel.

In the case of a running system, the following occurs:

• The BLUE HS LED turns on.

When the module is seated, the module management power is applied and the BLUE HS LED turns

on. (No payload power is applied at this time).

6. Connect all external interfacing cables to the module as required and ensure that they are properly secured.

7. Push the module handle in the “Locked” position. When the module handle is in the “Locked” position,

the module is locked and the hot swap switch is actuated.

In the case of a running system, the following occurs:

• The BLUE HS LED turns off.

The power module now enables the payload power for the MCH.

8. The MCH module is now operating.

Page 32 AM4311 User Guide

Page 48

3.3.2 Hot Swap Extraction

To extract the MCH module proceed as follows:

1. Ensure that the safety requirements indicated in Section 3.1 are observed.

2. Pull the module handle in the “Hot Swap” position.

When the module handle is in the “Hot Swap” position, the extraction process of the module is initiated and the following occurs:

• The BLUE HS LED displays short blinks. When the power module IPMI controller receives the handle

opened event, it sends a command to the MCMC with a request to perform short blinks of the BLUE

HS LED.

This indicates that the MCH is waiting to be deactivated.

Once the MCH receives the permission to continue the deactivation, all used ports are disabled.

• The BLUE HS LED turns on.

The Intelligent Platform Management Controller on the power module disables the module's payload power and the BLUE HS LED is turned on.

Now the module is ready to be safely extracted.

3. Pull the module handle in the “Unlocked” position.

Installation

4. Disconnect any interfacing cables that may be connected to the module.

5. Disengage the module from the backplane connector by pulling on the module handle. This may require

a considerable amount of force.

6. Using the front panel as a grip, remove the module from the chassis.

7. Dispose of the module as required.

Page 33 AM4311 User Guide

Loading...

Loading...