Page 1

» User Guide «

AM4024(E)

Doc. ID: 1056-0032, Rev. 1.0

Date: July 18, 2014

D R A F T — F O R I N T E R N A L U S E O N L Y

The pulse of innovation

Page 2

User Guide

AM4024(E)

Revision History

Revision Brief Description of Changes Date of Issue

1.0 Initial issue 18-Jul-2014

Imprint

Kontron Europe GmbH may be contacted via the following:

MAILING ADDRESS TELEPHONE AND E-MAIL

Kontron Europe GmbH +49 (0) 800-SALESKONTRON

Lise-Meitner-Straße 3-5 sales@kontron.com

86156 Augsburg, Germany

For further information concerning other Kontron products, please visit our Internet website:

www.kontron.com.

Disclaimer

Copyright © 2014 Kontron AG. All rights reserved. All data is for information purposes only and not

guaranteed for legal purposes. Information has been carefully checked and is believed to be accurate;

however, no responsibility is assumed for inaccuracies. Kontron and the Kontron logo and all other

trademarks or registered trademarks are the property of their respective owners and are recognized.

Specifications are subject to change without notice.

www.kontron.com

D R A F T — F O R I N T E R N A L U S E O N L Y

2

Page 3

User Guide

AM4024(E)

Warranty

This Kontron product is warranted against defects in material and workmanship for the warranty period

from the date of shipment. During the warranty period, Kontron will at its discretion decide to repair

or replace defective products.

Within the warranty period, the repair of products is free of charge as long as warranty conditions are

observed.

The warranty does not apply to defects resulting from improper or inadequate maintenance or handling

by the buyer, unauthorized modification or misuse, operation outside of the product’s environmental

specifications or improper installation or maintenance.

Kontron will not be responsible for any defects or damages to other products not supplied by Kontron

that are caused by a faulty Kontron product.

Proprietary Note

This document contains information proprietary to Kontron. It may not be copied or transmitted by any

means, disclosed to others, or stored in any retrieval system or media without the prior written consent

of Kontron or one of its authorized agents.

The information contained in this document is, to the best of our knowledge, entirely correct. However, Kontron cannot accept liability for any inaccuracies or the consequences thereof, or for any liability

arising from the use or application of any circuit, product, or example shown in this document.

Kontron reserves the right to change, modify, or improve this document or the product described herein, as seen fit by Kontron without further notice.

Trademarks

This document may include names, company logos and trademarks, which are registered trademarks

and, therefore, proprietary to their respective owners.

Environmental Protection Statement

This product has been manufactured to satisfy environmental protection requirements where possible.

Many of the components used (structural parts, printed circuit boards, connectors, batteries, etc.) are

capable of being recycled.

Final disposition of this product after its service life must be accomplished in accordance with applicable country, state, or local laws or regulations.

www.kontron.com

D R A F T — F O R I N T E R N A L U S E O N L Y

3

Page 4

User Guide

AM4024(E)

Contents

Revision History ..........................................................................................................2

Imprint .....................................................................................................................2

Disclaimer ..................................................................................................................2

Warranty ....................................................................................................................3

Proprietary Note ..........................................................................................................3

Trademarks ................................................................................................................3

Environmental Protection Statement ................................................................................3

Contents ....................................................................................................................4

Tables .......................................................................................................................8

Figures .................................................................................................................... 10

1 Introduction ...................................................................................... 11

1.1 Board Overview .......................................................................................... 11

1.2 System Expansion Capabilities ....................................................................... 11

1.2.1 SATA Flash Module (Optional) ........................................................................ 11

1.2.2 RTC Backup Battery Module (Optional) ............................................................. 11

1.3 System Relevant Information......................................................................... 12

1.4 Board Diagrams.......................................................................................... 12

1.4.1 Functional Block Diagrams ............................................................................ 13

1.4.2 Front Panel ............................................................................................... 15

1.4.3 Board Layout ............................................................................................. 16

1.5 Technical Specification ................................................................................ 17

1.6 Standards ................................................................................................. 21

1.7 Related Publications.................................................................................... 22

2 Functional Description ......................................................................... 23

2.1 Processor and Chipset.................................................................................. 23

2.1.1 Integrated Processor Graphics Controller ......................................................... 24

2.2 Memory .................................................................................................... 24

2.3 Watchdog Timer.......................................................................................... 24

2.4 Battery..................................................................................................... 24

2.5 Flash Memory............................................................................................. 25

2.5.1 SPI Boot Flash for uEFI BIOS .......................................................................... 25

2.5.2 SATA Flash Module ...................................................................................... 25

2.6 Trusted Platform Module 1.2.......................................................................... 25

2.7 Board Interfaces......................................................................................... 25

2.7.1 Front Panel LEDs......................................................................................... 25

2.7.1.1 Module Management LEDs and Hot Swap LED .................................................... 25

2.7.1.2 User-Specific LEDs...................................................................................... 26

2.7.2 Module Handle ........................................................................................... 27

D R A F T — F O R I N T E R N A L U S E O N L Y

www.kontron.com

4

Page 5

User Guide

AM4024(E)

2.7.3 Debug Interface ......................................................................................... 28

2.7.4 USB Interface ............................................................................................ 28

2.7.5 Serial Ports ............................................................................................... 29

2.7.6 Mini DisplayPort ......................................................................................... 30

2.7.7 SATA Interfaces .......................................................................................... 30

2.7.8 PCI Express ............................................................................................... 30

2.7.9 Gigabit Ethernet Interfaces .......................................................................... 30

2.8 AMC Interconnection ................................................................................... 31

2.8.1 Fabric Interface.......................................................................................... 31

2.8.2 Synchronization Clock Interface ..................................................................... 34

2.8.3 System Management Interface ....................................................................... 34

2.8.4 JTAG Interface ........................................................................................... 34

2.8.5 Module Power Interface................................................................................ 34

2.8.6 AMC Card-edge Connector J1 ......................................................................... 34

2.8.6.1 Pinout of AMC Card-edge Connector J1 on the AM4024 ........................................ 35

2.8.6.2 Pinout of AMC Card-edge Connector J1 on the AM4024E ...................................... 38

3 Configuration..................................................................................... 41

3.1 DIP Switch Configuration.............................................................................. 41

3.1.1 DIP Switch SW2 .......................................................................................... 41

3.2 System Write Protection ............................................................................... 42

3.3 AM4024(E)-Specific Registers........................................................................ 42

3.3.1 Write Protection Register (WPROT) .................................................................. 42

3.3.2 Reset Status Register (RSTAT) ........................................................................ 43

3.3.3 Board ID High-Byte Register (BIDH)................................................................ 44

3.3.4 Geographic Addressing Register (GEOAD) ......................................................... 44

3.3.5 Watchdog Timer Control Register (WTIM) ......................................................... 45

3.3.6 Board ID Low-Byte Register (BIDL) ................................................................. 46

3.3.7 LED Configuration Register (LCFG) .................................................................. 46

3.3.8 LED Control Register (LCTRL) ......................................................................... 47

3.3.9 General Purpose Output Register (GPOUT)......................................................... 48

4 Power Considerations .......................................................................... 49

4.1 AM4024(E) Voltage Ranges ........................................................................... 49

4.2 Carrier Power Requirements .......................................................................... 49

4.2.1 Module Management Power ........................................................................... 49

4.2.2 Payload Power............................................................................................ 49

4.2.3 Power Sequencing for Unmanaged Systems ....................................................... 50

4.3 Power Consumption..................................................................................... 50

4.4 Payload Power Consumption of Accessories ....................................................... 52

4.5 IPMI FRU Payload Power Consumption ............................................................. 52

D R A F T — F O R I N T E R N A L U S E O N L Y

5 Thermal Considerations ........................................................................ 53

5.1 Operational Limits for the AM4024(E).............................................................. 54

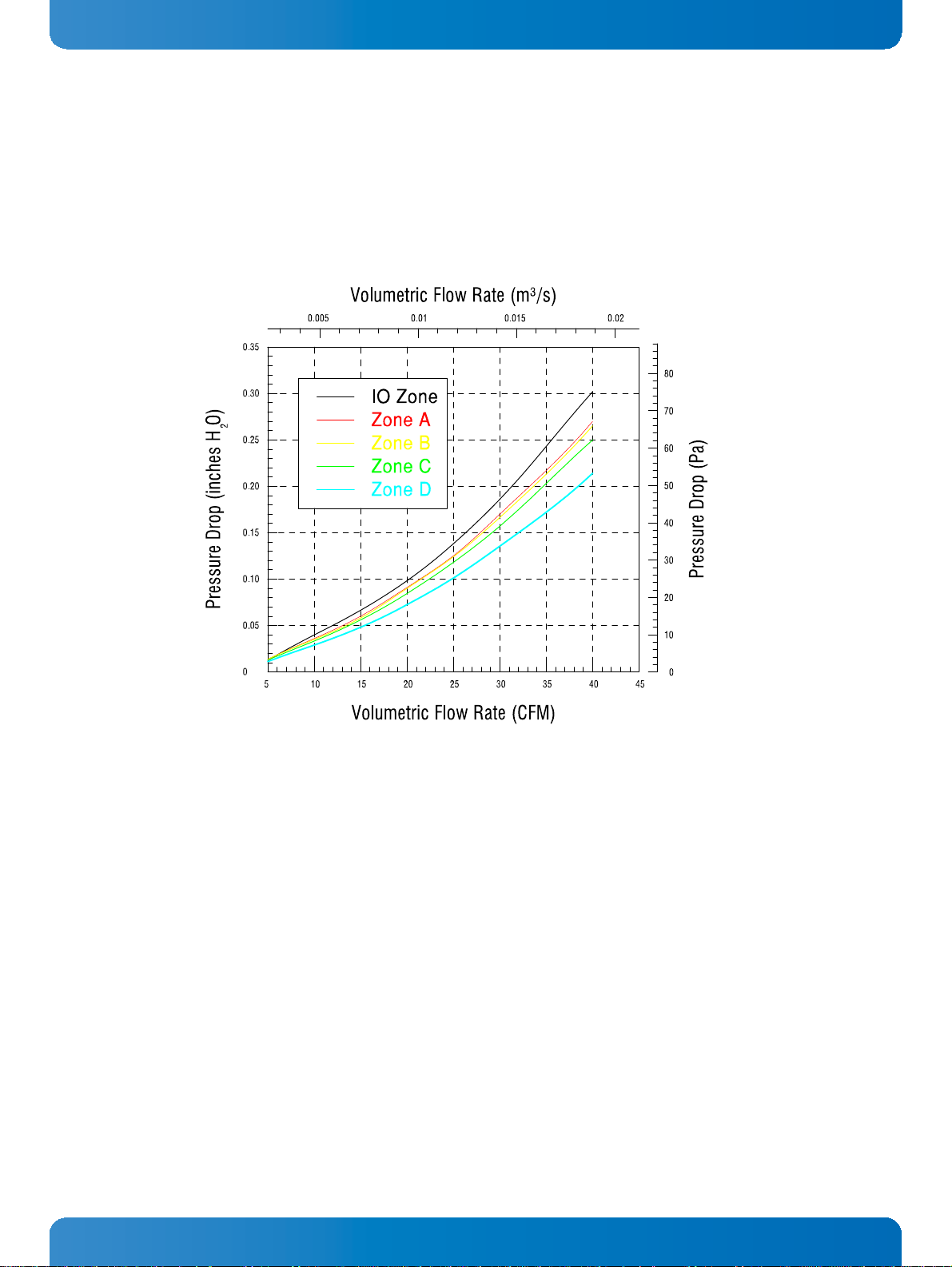

5.1.1 Airflow Impedance ...................................................................................... 56

5.1.2 Airflow Paths ............................................................................................. 57

www.kontron.com

5

Page 6

User Guide

AM4024(E)

6 SATA Flash Module............................................................................... 59

6.1 Technical Specifications ............................................................................... 59

6.2 SATA Flash Module Layout............................................................................. 59

7 RTC Backup Battery Module ................................................................... 60

7.1 Technical Specifications ............................................................................... 60

7.2 RTC Backup Battery Module Layout.................................................................. 60

8 Installation ....................................................................................... 61

8.1 Safety ...................................................................................................... 61

8.2 General Instructions on Usage ....................................................................... 61

8.3 Board Installation ...................................................................................... 62

8.3.1 Hot Swap Insertion ..................................................................................... 62

8.3.2 Hot Swap Removal ...................................................................................... 63

8.4 Installation of Peripheral Devices ................................................................... 64

8.4.1 SATA Flash Module Installation ...................................................................... 64

8.4.2 RTC Backup Battery Module Installation ........................................................... 64

9 uEFI BIOS .......................................................................................... 65

9.1 Starting the uEFI BIOS ................................................................................. 65

9.2 Setup Menus.............................................................................................. 66

9.2.1 Main Setup Menu ........................................................................................ 66

9.2.2 Advanced Setup Menu .................................................................................. 67

9.2.3 Security Setup Menu .................................................................................... 67

9.2.3.1 Remember the Password ............................................................................... 68

9.2.4 Boot Setup Menu ........................................................................................ 68

9.2.5 Exit Setup Menu ......................................................................................... 68

9.3 The uEFI Shell ............................................................................................ 69

9.3.1 Introduction, Basic Operation ....................................................................... 69

9.3.1.1 Entering the uEFI Shell ................................................................................ 69

9.3.1.2 Exiting the uEFI Shell .................................................................................. 69

9.3.2 Kontron-Specific uEFI Shell Commands ............................................................ 70

9.4 uEFI Shell Scripting..................................................................................... 71

9.4.1 Startup Scripting ........................................................................................ 71

9.4.2 Create a Startup Script ................................................................................. 71

9.4.3 Examples of Startup Scripts........................................................................... 72

9.4.3.1 Execute Shell Script on Other Harddrive ........................................................... 72

9.4.3.2 Enable Watchdog ........................................................................................ 72

9.4.3.3 Handling the Startup Script in the SPI Boot Flash ............................................... 72

9.5 Firmware Update ........................................................................................ 73

9.5.1 Updating the uEFI BIOS ................................................................................ 73

9.5.1.1 uEFI BIOS Fail-Over Mechanism ...................................................................... 73

9.5.1.2 Updating Procedure .................................................................................... 73

9.5.1.3 uEFI BIOS Recovery ..................................................................................... 74

9.5.1.4 Determining the Active Flash......................................................................... 74

9.5.2 Updating the IPMI Firmware .......................................................................... 74

D R A F T — F O R I N T E R N A L U S E O N L Y

www.kontron.com

6

Page 7

User Guide

AM4024(E)

9.5.2.1 IPMI Rollback Mechanism ............................................................................. 74

9.5.2.2 Determining the Active IPMI Firmware Image .................................................... 74

9.5.2.3 Updating Procedure .................................................................................... 74

10 IPMI Firmware .................................................................................... 75

10.1 Overview................................................................................................... 75

10.2 IPMI Firmware and KCS Interface Configuration ................................................. 75

10.3 Supported IPMI and ATCA Commands ............................................................... 76

10.3.1 Standard IPMI Commands ............................................................................ 76

10.3.2 AdvancedTCA and AMC Commands ................................................................... 79

10.4 Firmware Identification................................................................................ 80

10.4.1 Get Device ID Command ............................................................................... 80

10.5 Board Control Extensions ............................................................................. 81

10.5.1 SPI Boot Flash Selection—uEFI BIOS Failover Control .......................................... 81

10.5.2 uEFI BIOS Boot Order Selection ...................................................................... 81

10.5.3 Set Control State (SPI Boot Flash Selection, Boot Order Selection) ......................... 82

10.5.4 Get Control State (SPI Boot Flash Selection, Boot Order Selection)......................... 83

10.6 Sensors Implemented on the AM4024(E) .......................................................... 83

10.6.1 Sensor List ................................................................................................ 84

10.7 Sensor Thresholds....................................................................................... 86

10.8 OEM Event/Reading Types ............................................................................. 87

10.9 IPMI Firmware Code..................................................................................... 88

10.9.1 Firmware Upgrade....................................................................................... 88

10.9.2 IPMI Firmware and FRU Data Write Protection .................................................... 88

10.10 LAN Functions............................................................................................ 89

10.11 E-Keying................................................................................................... 89

10.11.1 AMC Module Configuration Options ................................................................. 89

10.11.1.1 Default of AMC Configuration Settings ............................................................. 90

10.11.1.2 Forced AMC Port Activation/ Deactivation......................................................... 90

10.11.1.3 PCI Express Speed Selection .......................................................................... 90

10.11.1.4 Forced FCLKA/ PCI Express Reference Clock Configuration .................................... 91

10.11.1.5 Fail-Safe Mode ........................................................................................... 91

www.kontron.com

D R A F T — F O R I N T E R N A L U S E O N L Y

7

Page 8

User Guide

AM4024(E)

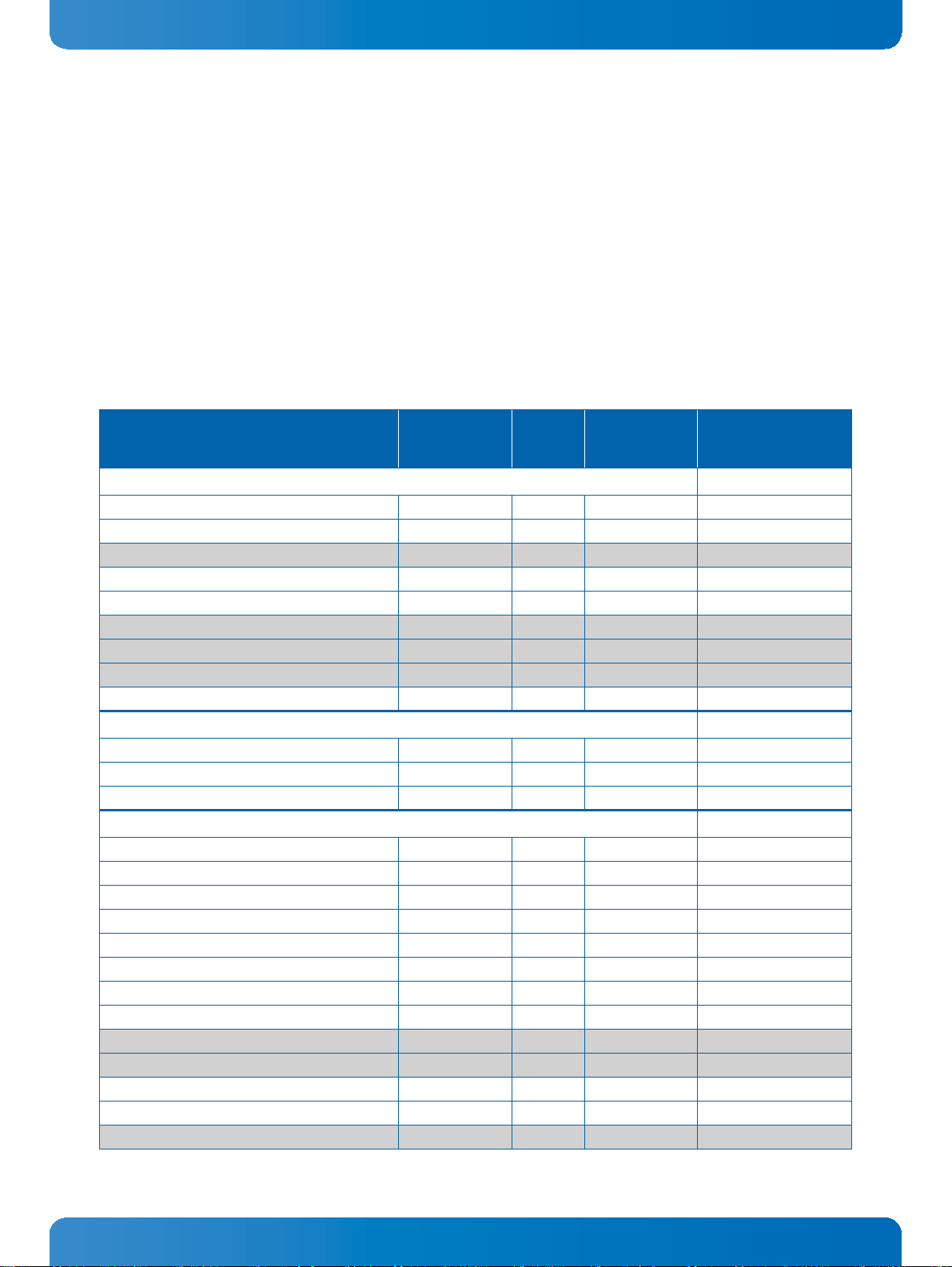

Tables

1 System Relevant Information ................................................................................ 12

2 AM4024(E) Main Specifications ............................................................................. 17

3 Standards ........................................................................................................ 21

4 Related Publications ........................................................................................... 22

5 Features of the Processors Supported on the AM4024(E) ............................................. 23

7 User-Specific LEDs’ Functions ............................................................................... 26

6 Module Management and Hot Swap LEDs’ Functions ................................................... 26

8 POST Code Sequence ........................................................................................... 27

9 POST Code Example ............................................................................................. 27

10 Module Handle Positions ..................................................................................... 28

11 Serial Port Connector J11 (COMA) Pinout ................................................................. 29

12 Gigabit Ethernet Controller Port Mapping for the AM4024 ............................................ 31

13 Gigabit Ethernet Controller Port Mapping for the AM4024E .......................................... 31

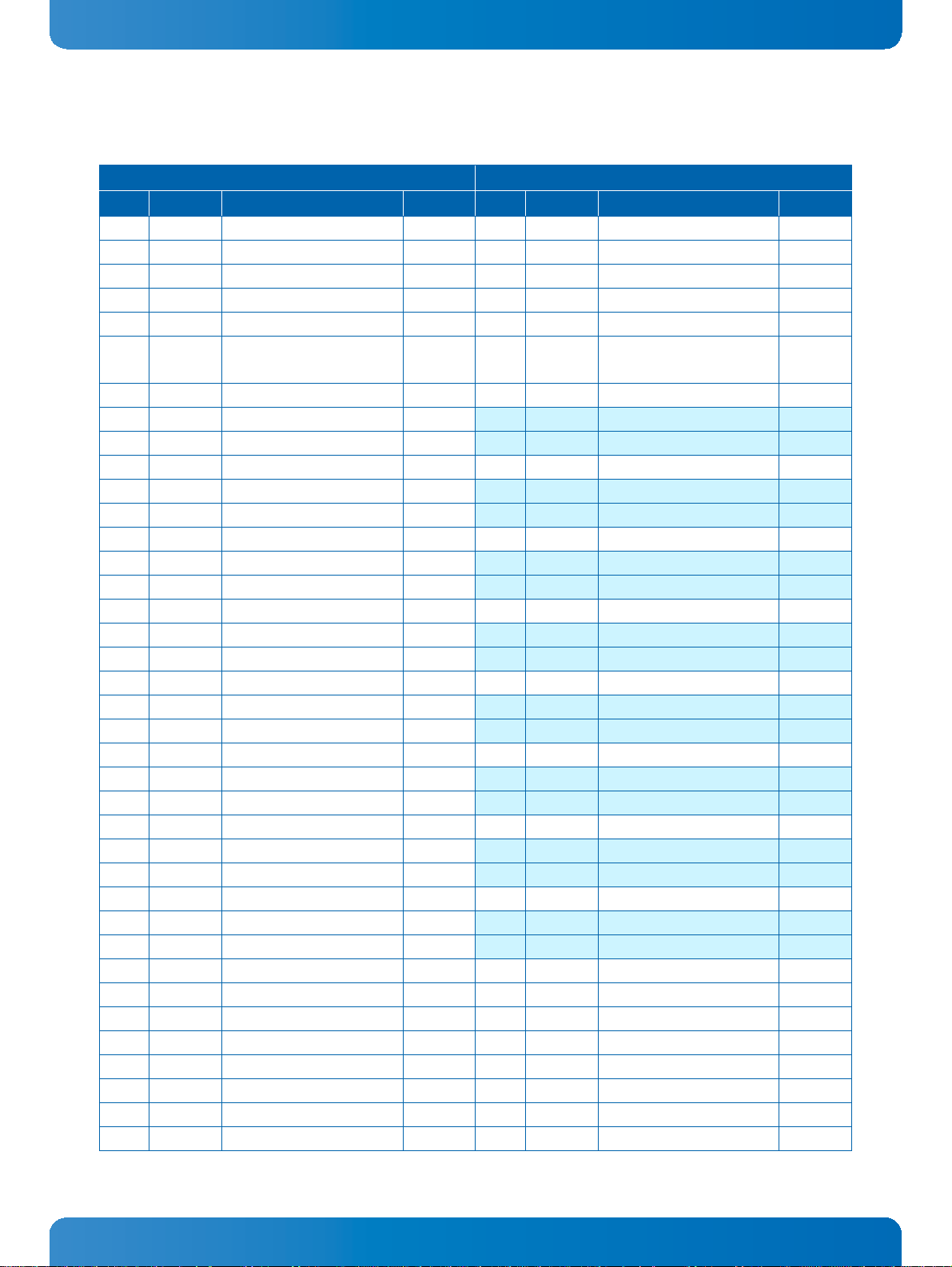

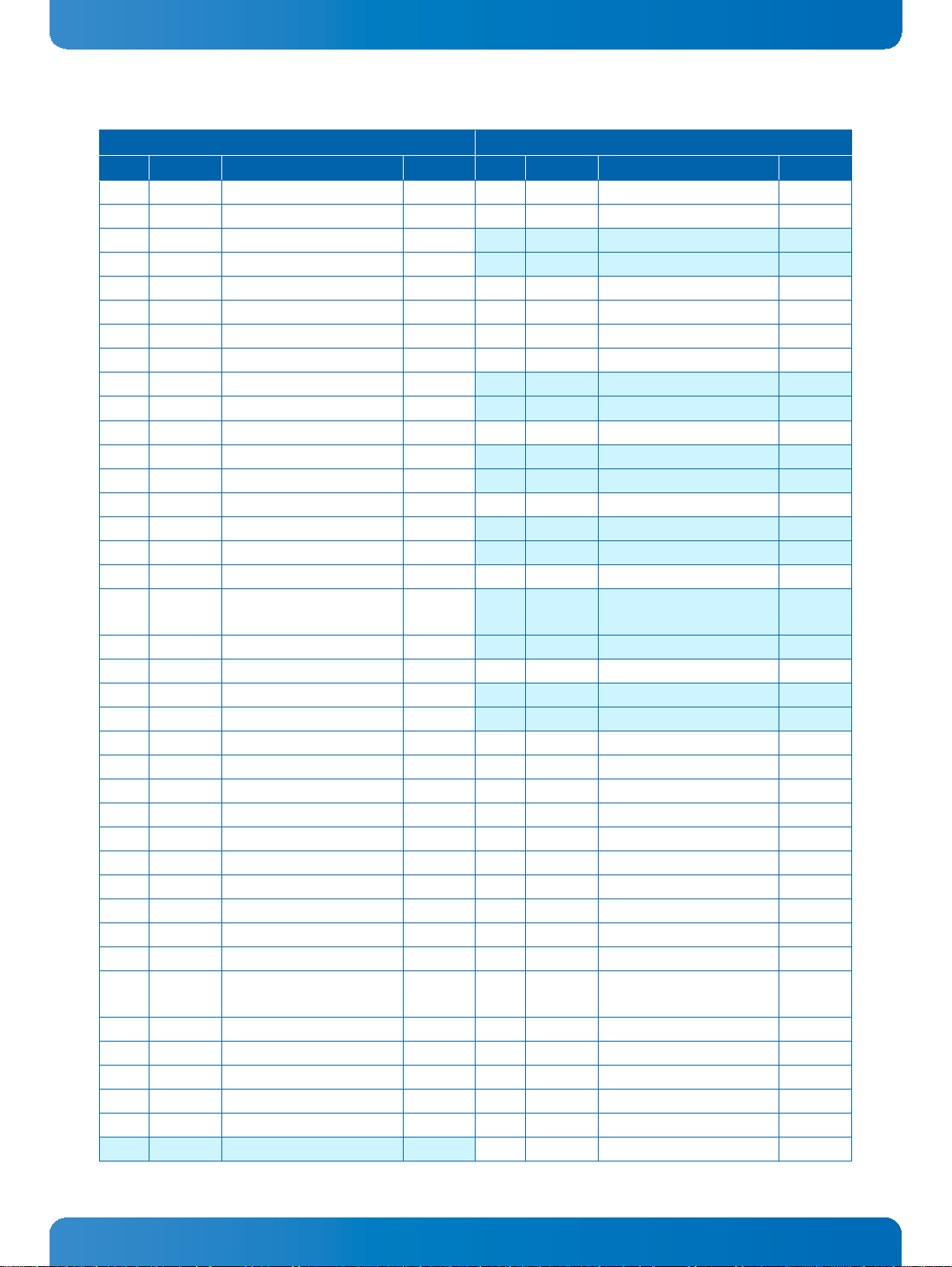

14 Pinout of AMC Card-edge Connector J1 on the AM4024 ................................................ 35

15 Reserved Pin’s Description ................................................................................... 37

16 Extended Options Region Single-Ended Pins’ Description ............................................ 37

17 Single-Ended GPO Pins’ Description ........................................................................ 37

18 Pinout of AMC Card-edge Connector J1 on the AM4024E .............................................. 38

19 Reserved Pin’s Description ................................................................................... 40

20 Extended Options Region Single-Ended Pins’ Description ............................................ 40

21 Single-Ended GPO Pins’ Description ........................................................................ 40

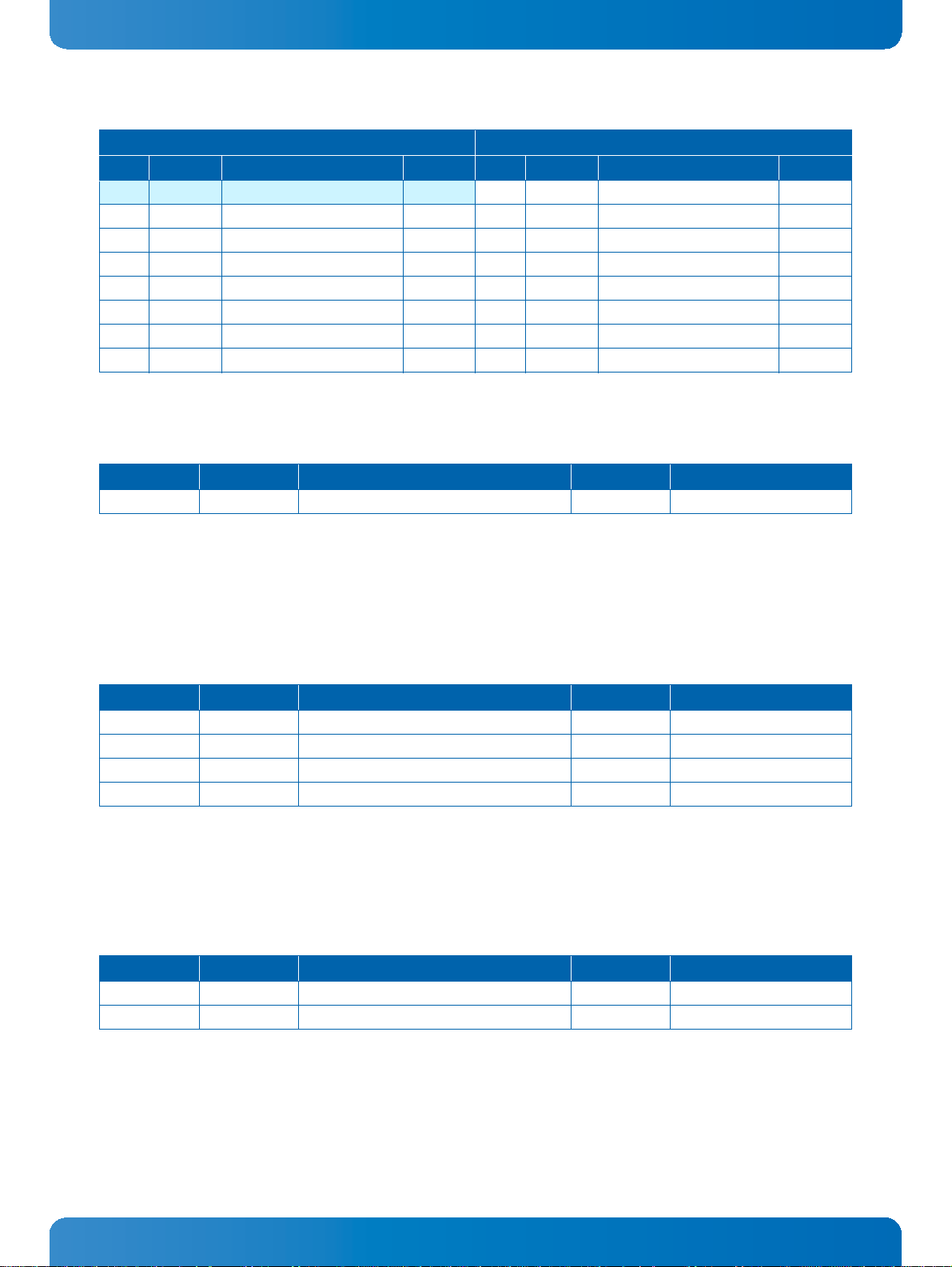

22 DIP Switch SW2 Functionality ................................................................................ 41

23 Fail-Safe AMC Fabric Configuration ......................................................................... 41

24 AM4024(E)-Specific Registers ............................................................................... 42

25 Write Protection Register (WPROT) ......................................................................... 42

26 Reset Status Register (RSTAT) ............................................................................... 43

27 Board ID High-Byte Register (BIDH) ....................................................................... 44

28 Geographic Addressing Register (GEOAD) ................................................................ 44

29 Watchdog Timer Control Register (WTIM) ................................................................. 45

30 Board ID Low-Byte Register (BIDL) ........................................................................ 46

31 LED Configuration Register (LCFG) ......................................................................... 46

32 LED Control Register (LCTRL) ................................................................................ 47

33 General Purpose Output Register (GPOUT) ................................................................ 48

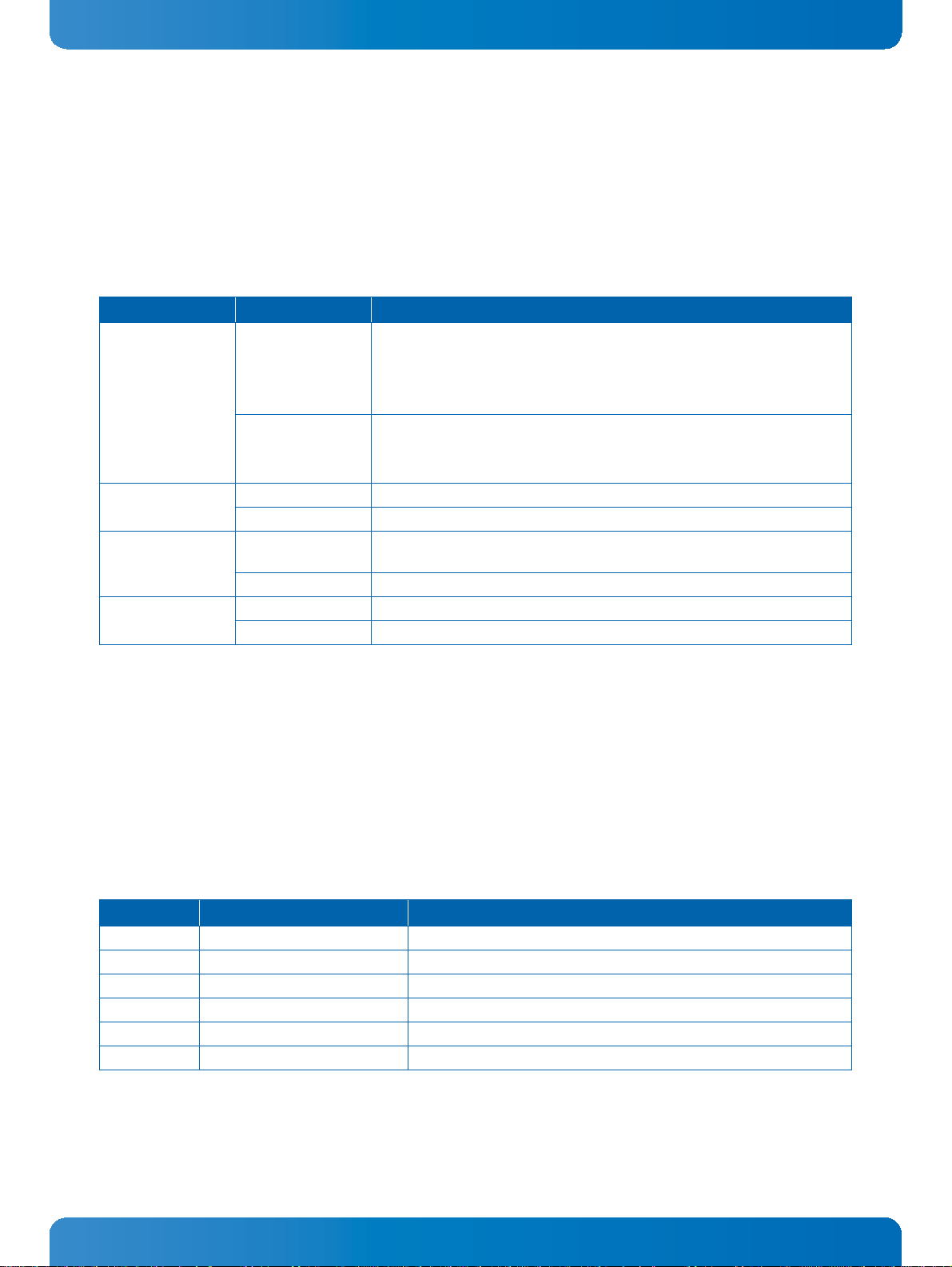

34 DC Operational Input Voltage Range ....................................................................... 49

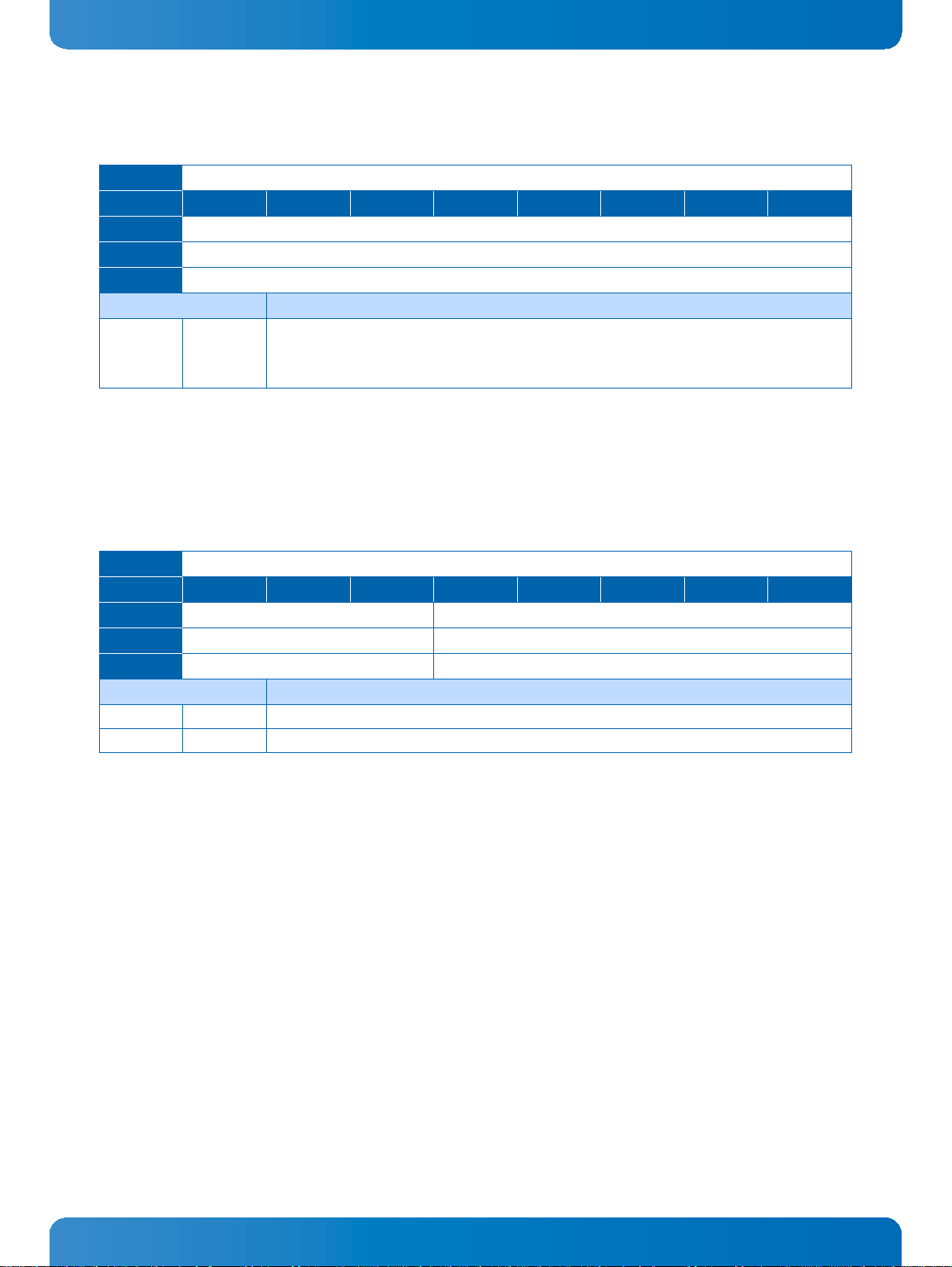

35 AM4024(E) Power Consumption ............................................................................. 51

36 Power Consumption of AM4024(E) Accessories .......................................................... 52

37 IPMI FRU Payload Power Consumption ..................................................................... 52

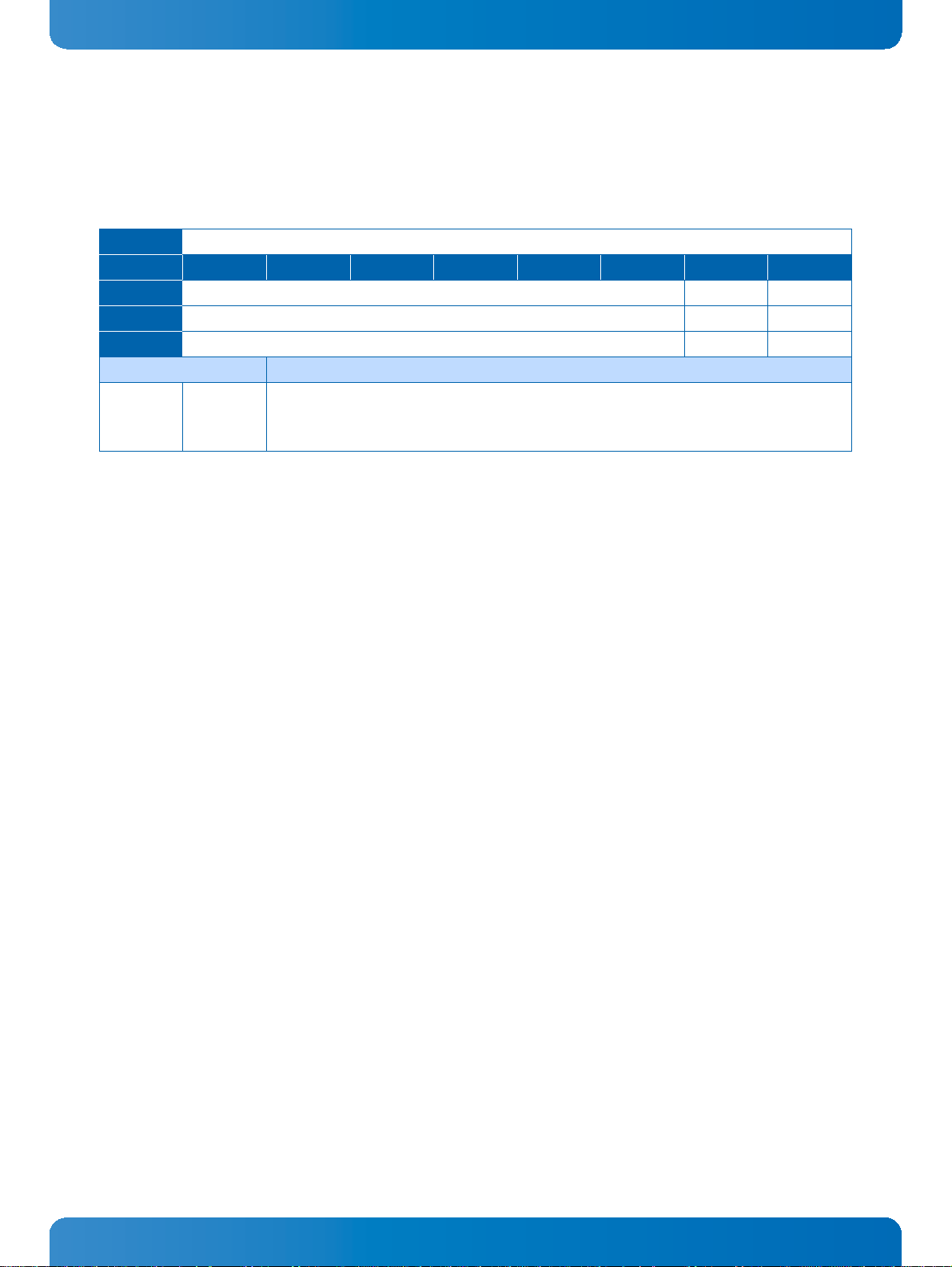

38 AM4024(E) Airflow Impedance by Zone [N/m²] ......................................................... 57

39 AM4024(E) Airflow Impedance by Zone [inches H2O] .................................................. 57

40 Deviation of the Airflow Rate on the AM4024(E) ........................................................ 58

41 SATA Flash Module Main Specifications ................................................................... 59

42 RTC Backup Battery Module Main Specifications ........................................................ 60

43 Navigation ....................................................................................................... 65

44 Main Setup Menu Sub-Screens and Functions ............................................................ 66

45 Advanced Setup Menu Sub-Screens and Functions ..................................................... 67

D R A F T — F O R I N T E R N A L U S E O N L Y

www.kontron.com

8

Page 9

User Guide

AM4024(E)

46 Security Setup Menu Functions .............................................................................. 67

47 TPM Configuration Sub-Screen .............................................................................. 67

48 Boot Priority Order ............................................................................................. 68

49 Exit Setup Menu Functions ................................................................................... 68

50 Kontron-Specific uEFI Shell Commands ................................................................... 70

www.kontron.com

D R A F T — F O R I N T E R N A L U S E O N L Y

9

Page 10

User Guide

AM4024(E)

Figures

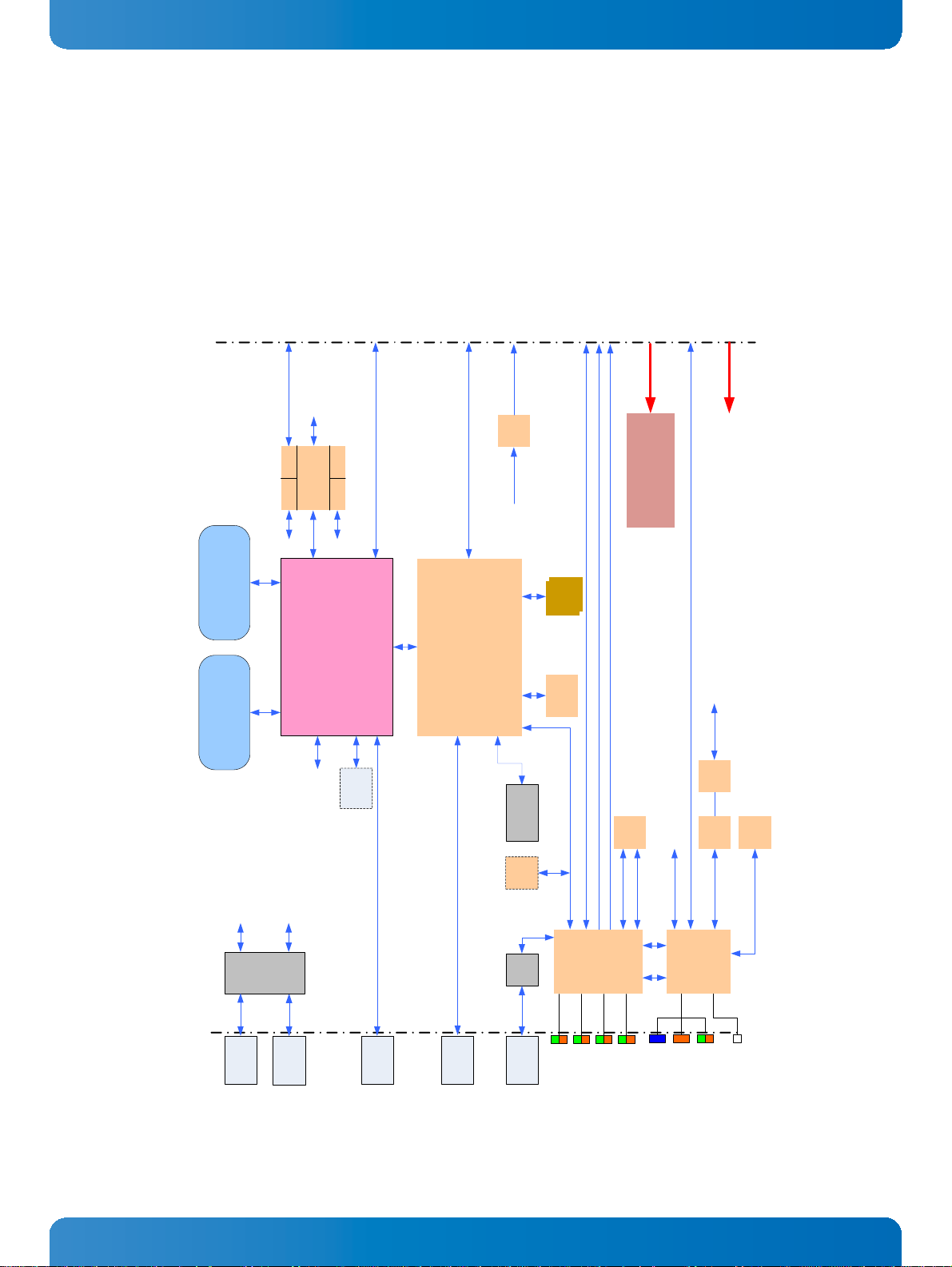

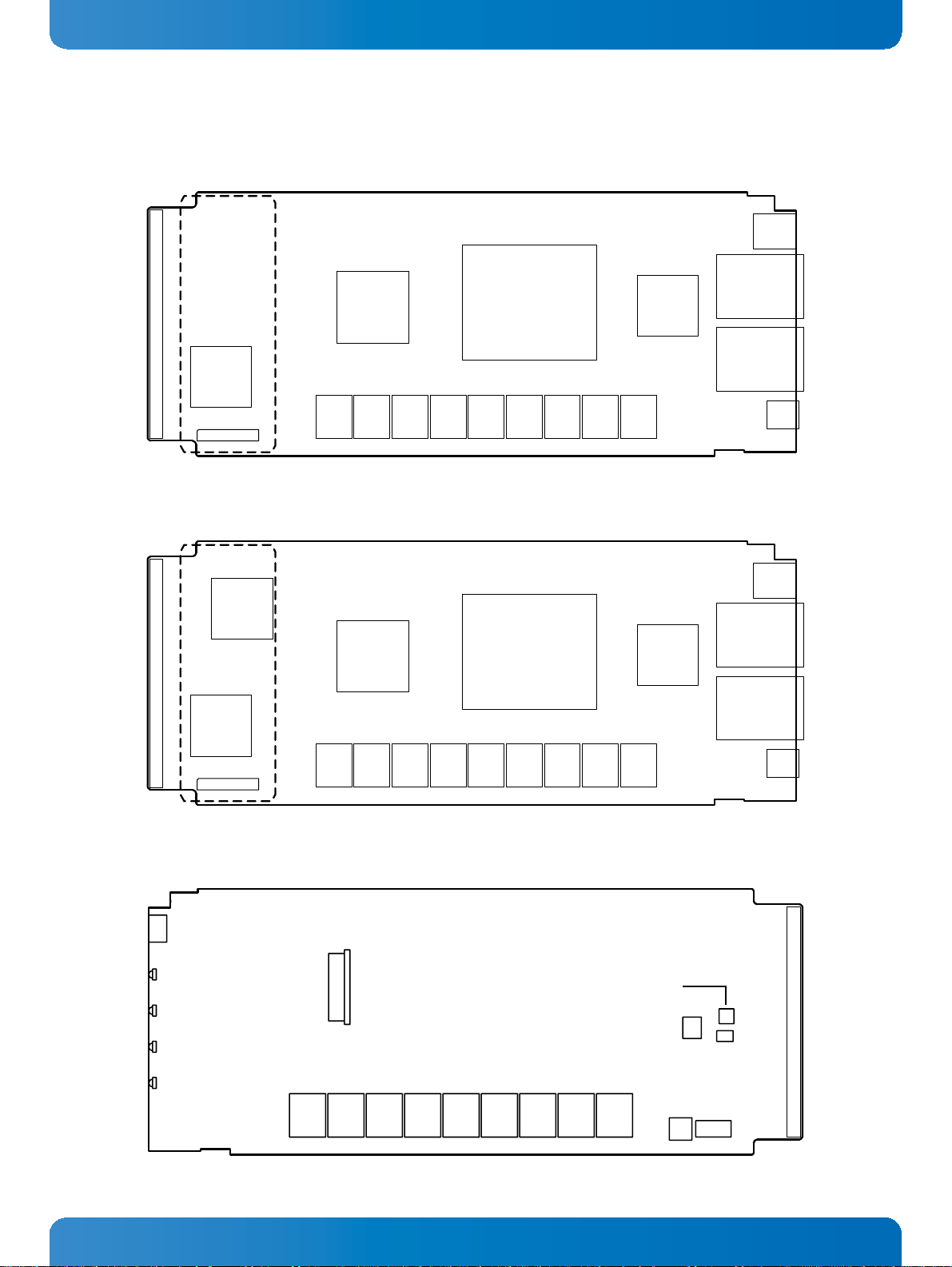

1 AM4024 Functional Block Diagram ........................................................................ 13

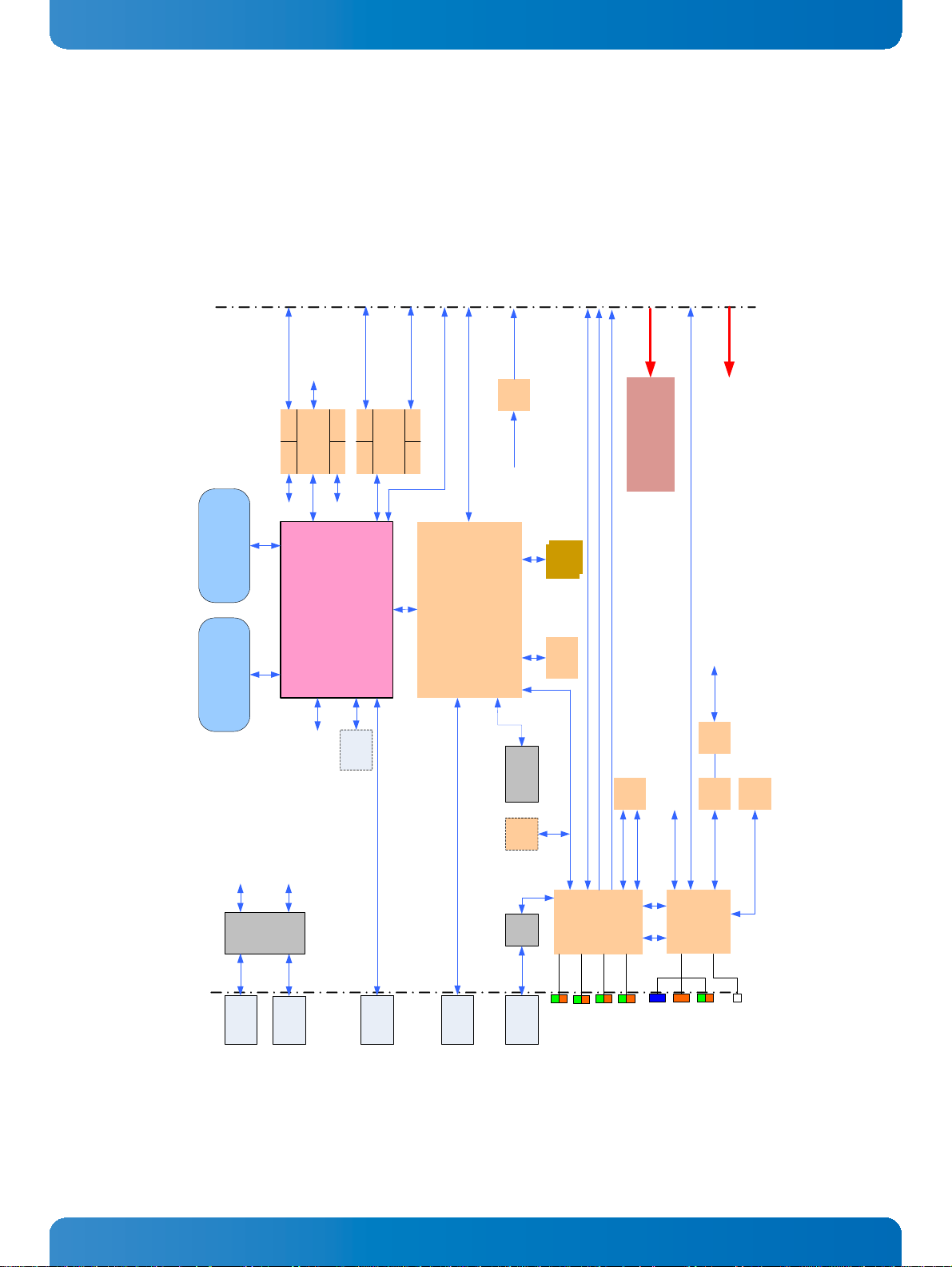

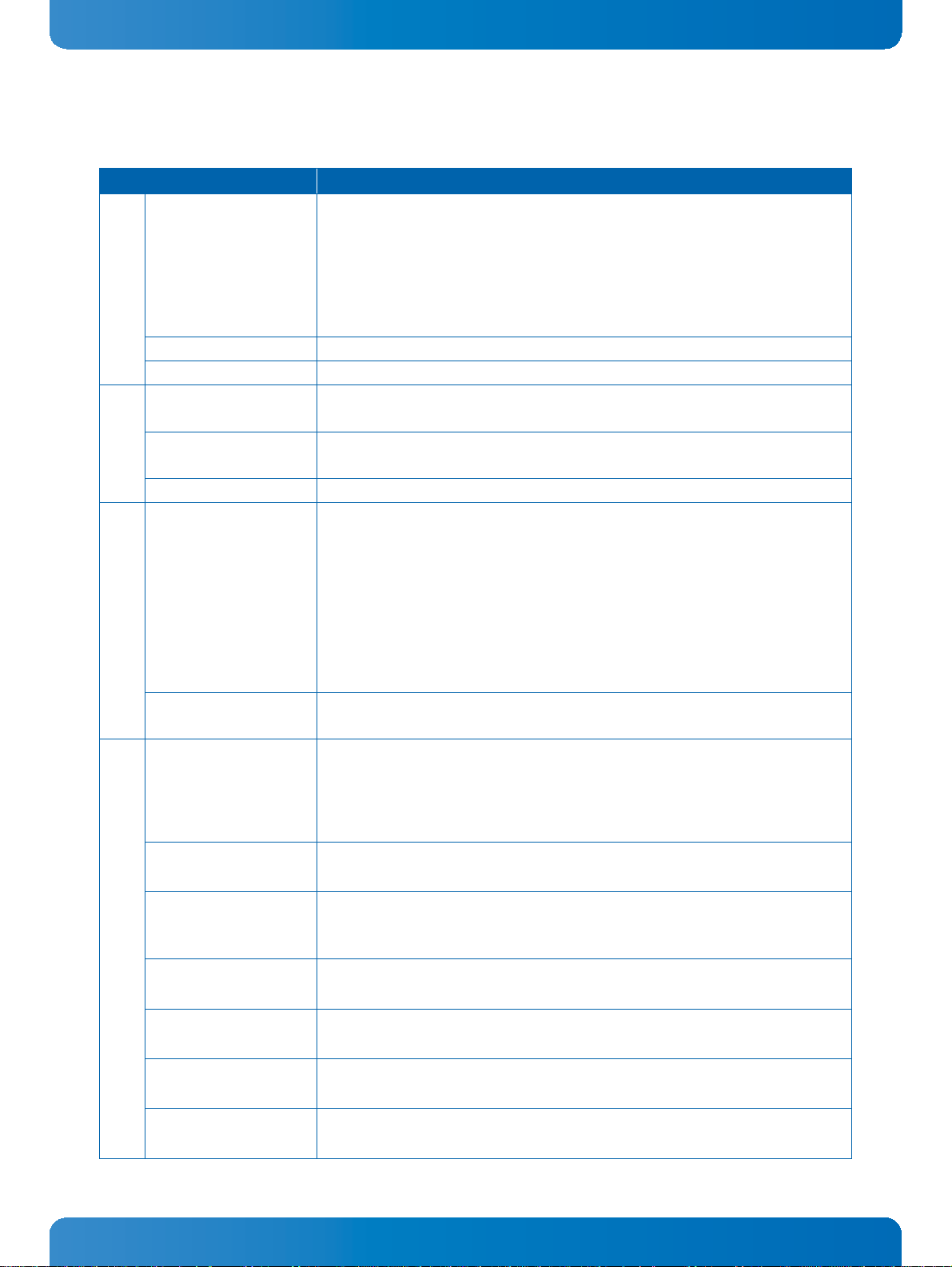

2 AM4024E Functional Block Diagram ....................................................................... 14

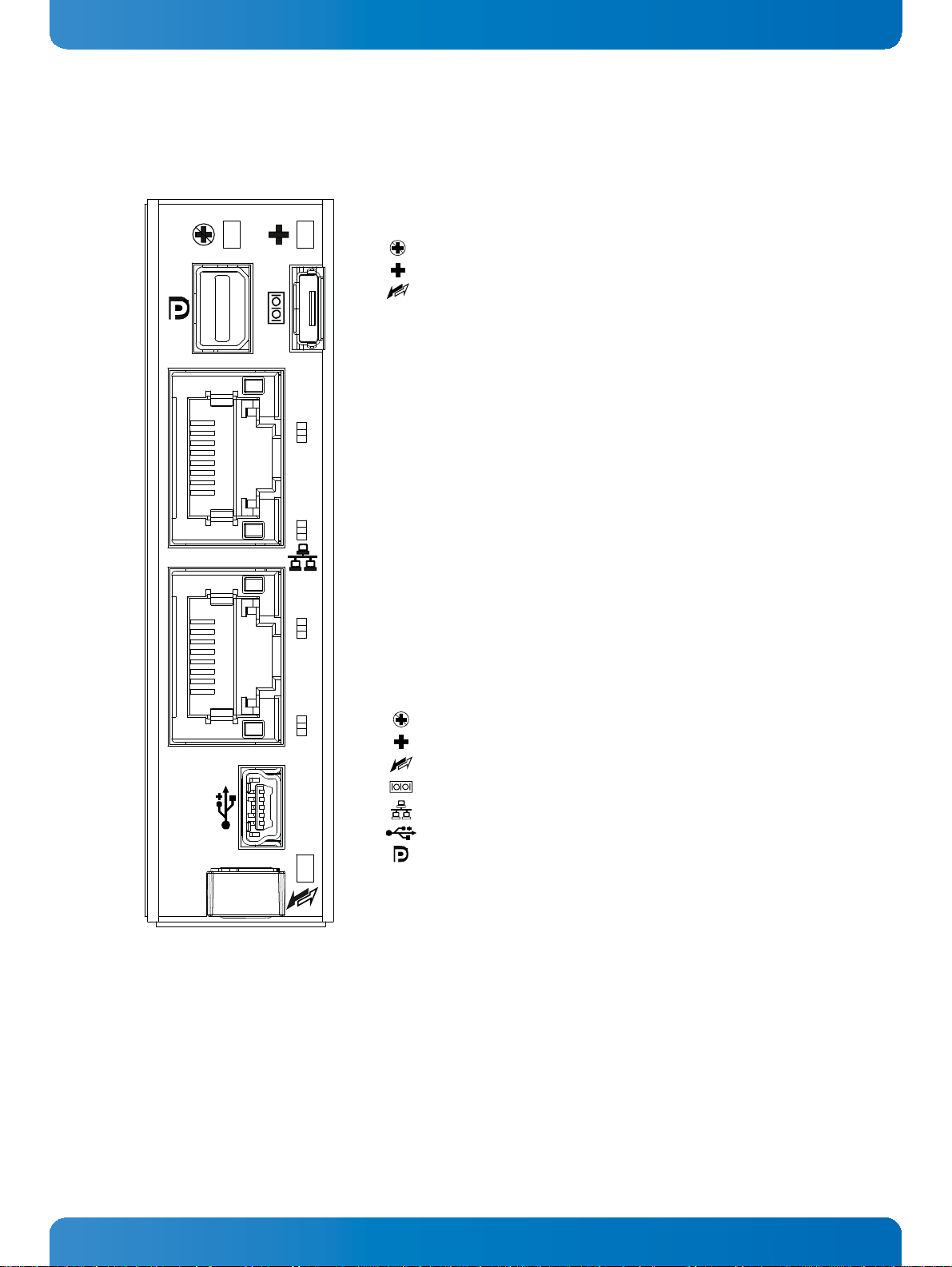

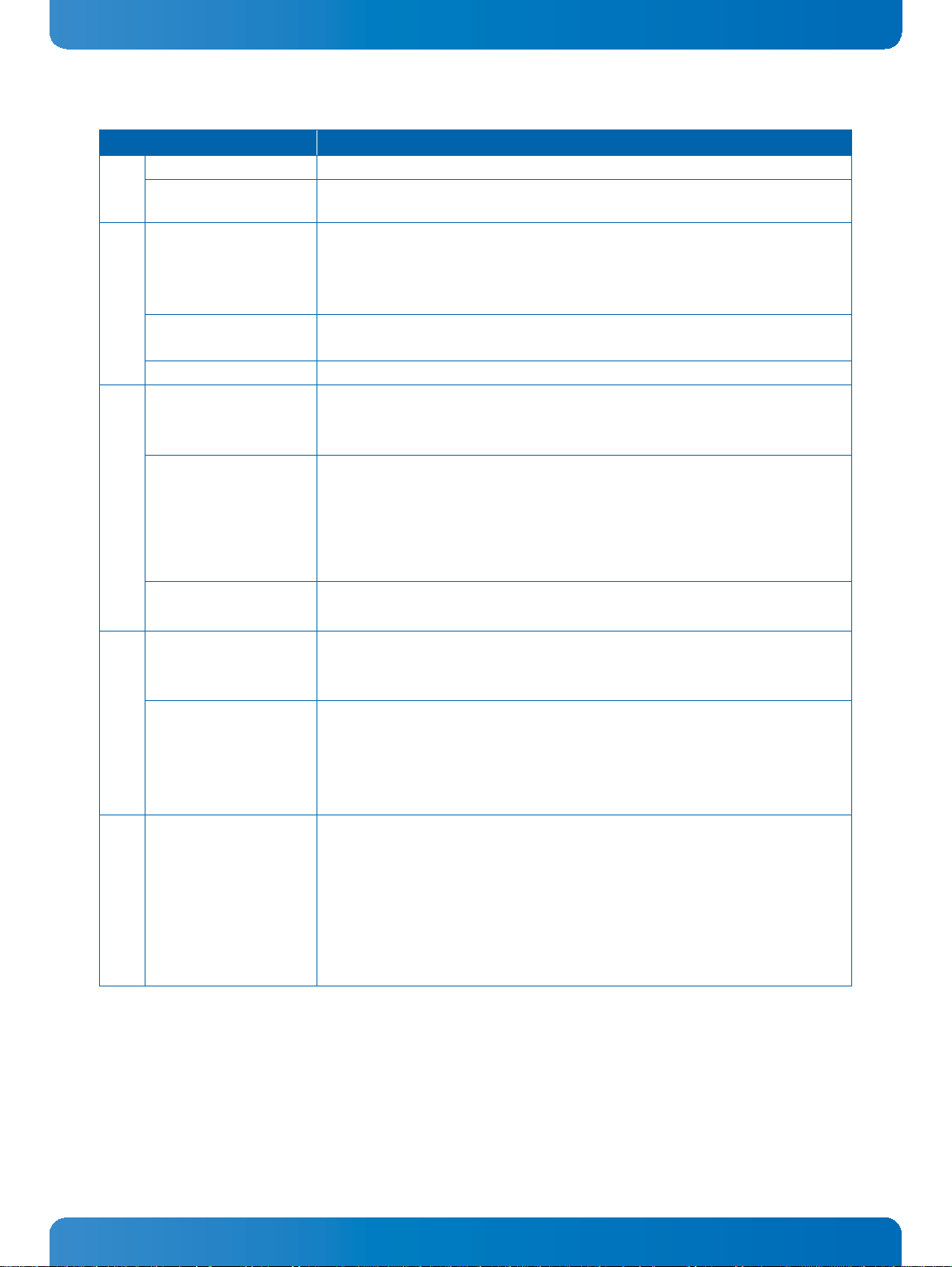

3 AM4024(E) Front Panel ...................................................................................... 15

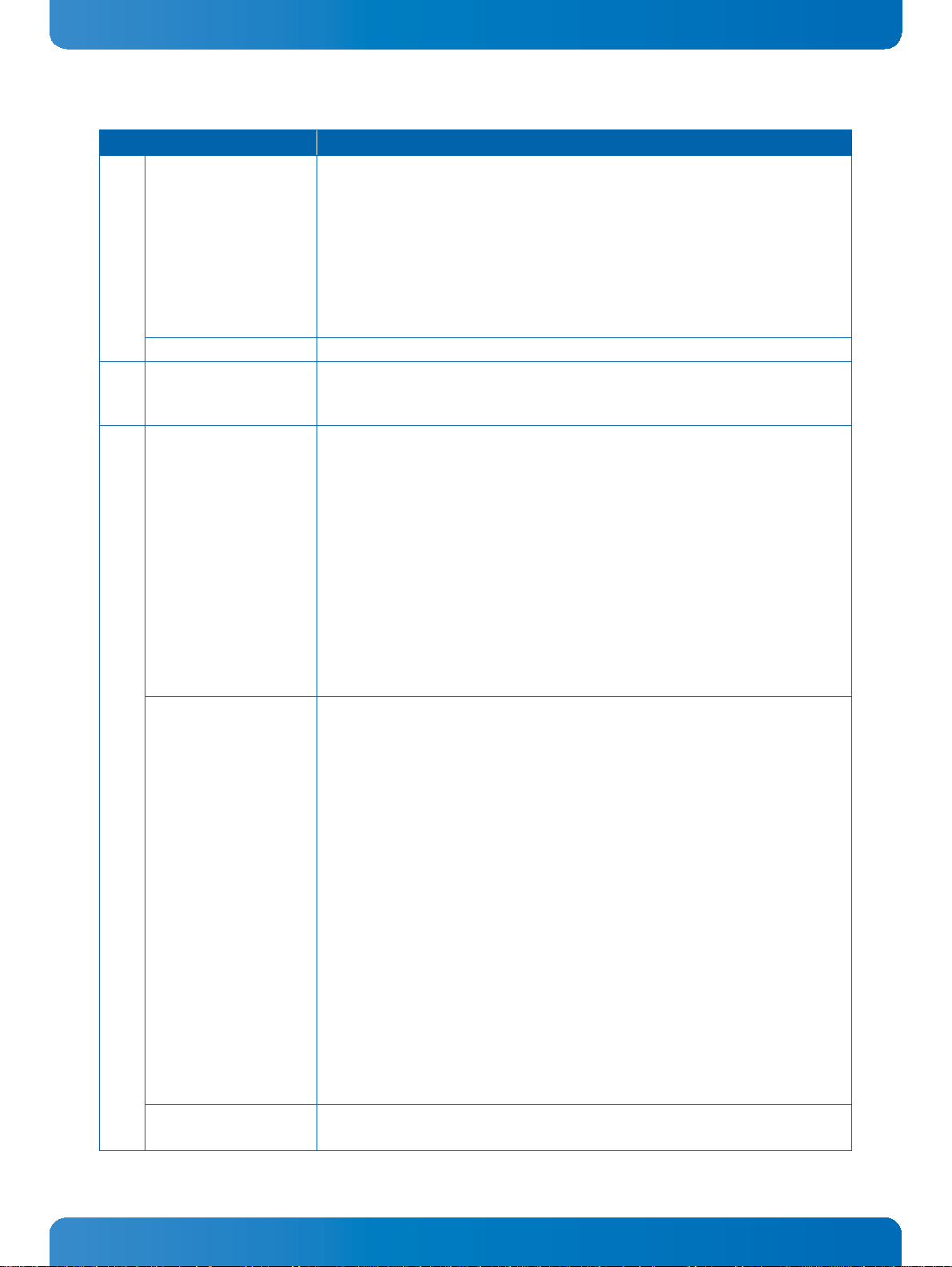

4 AM4024 Board Layout (Top View) .......................................................................... 16

5 AM4024E Board Layout (Top View) ........................................................................ 16

6 AM4024(E) Board Layout (Bottom View) ................................................................. 16

7 Module Handle Positions .................................................................................... 27

8 Adapter for Mini USB Type A to USB Type A Connector ................................................ 29

9 Serial Port Connector J11 (COMA) ......................................................................... 29

10 AM4024(E) Port Mapping .................................................................................... 33

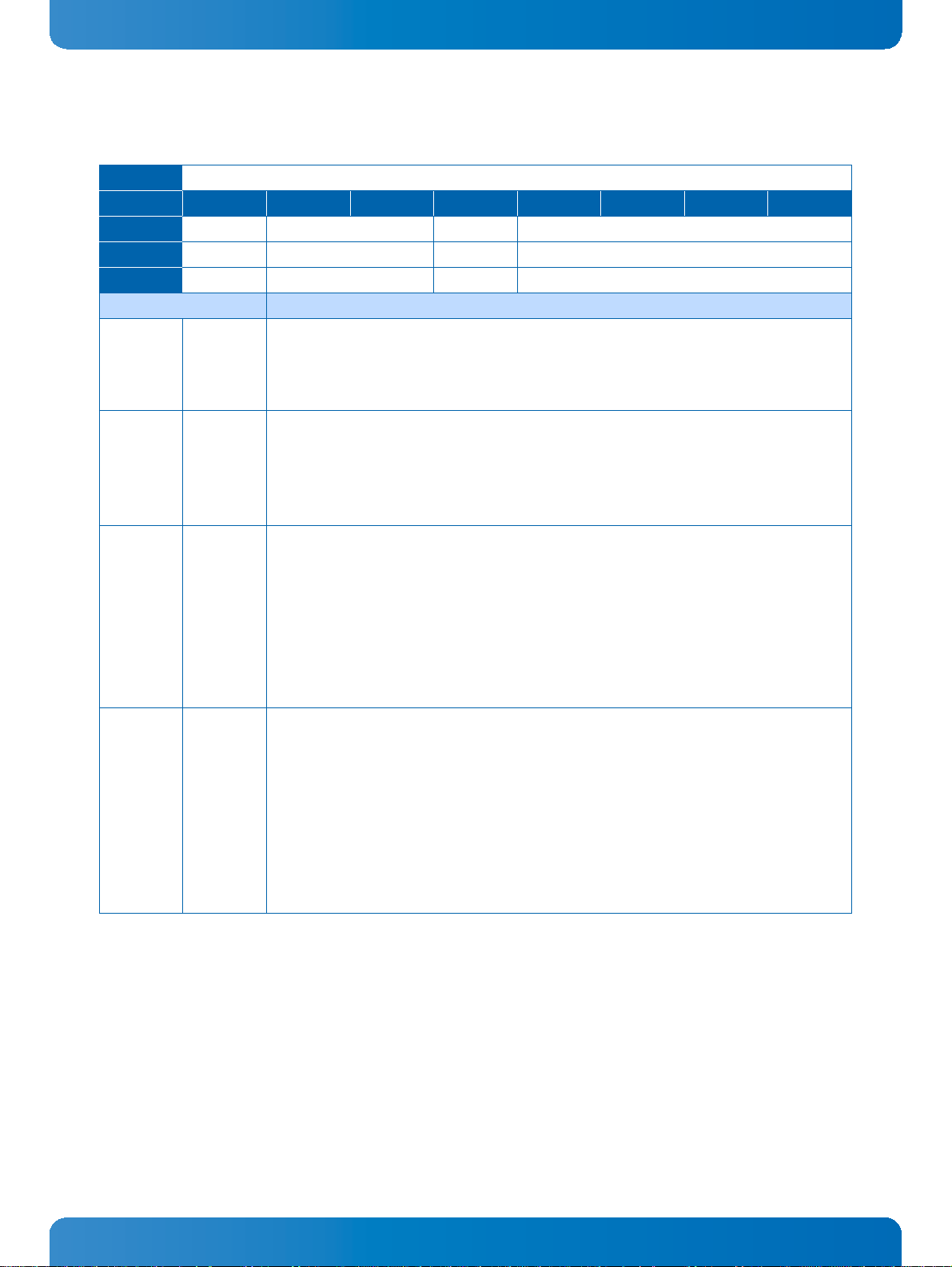

11 AM4024(E) with i7-4860EQ (SV), 1.8 GHz ............................................................... 54

12 AM4024(E) with i7-4700EQ (SV), 2.4 GHz ............................................................... 54

13 AM4024(E) with i5-4402EQ (LV), 1.6 GHz ............................................................... 55

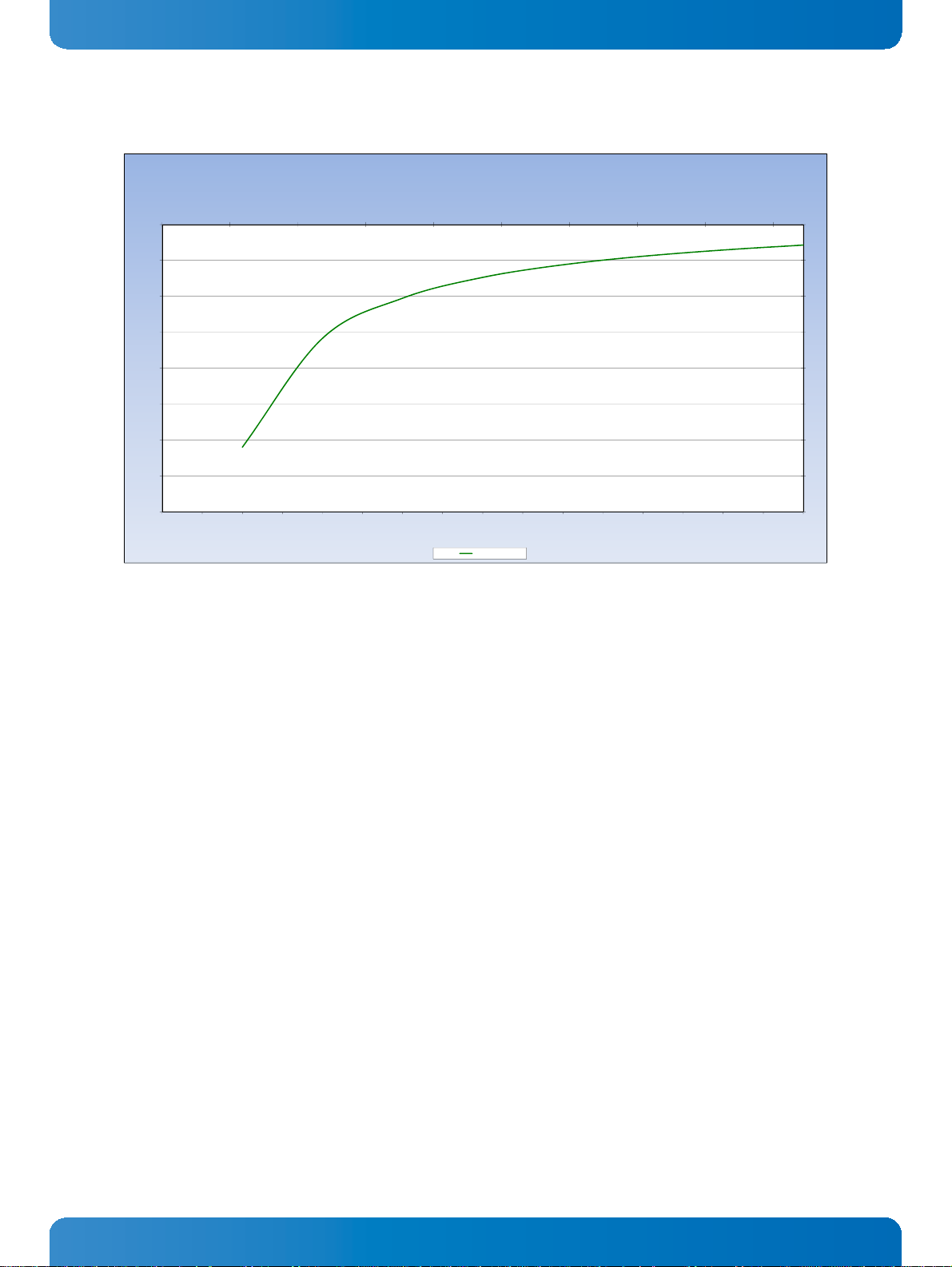

14 AM4024(E) Airflow Impedance ............................................................................. 56

15 Thermal Zones of the AM4024(E) Module ................................................................ 57

16 SATA Flash Module Layout (Bottom View) ............................................................... 59

17 RTC Backup Battery Module Layout (Top and Bottom Views) ........................................ 60

www.kontron.com

D R A F T — F O R I N T E R N A L U S E O N L Y

10

Page 11

1 Introduction

1.1 Board Overview

User Guide

AM4024(E)

The AM4024(E) is a highly integrated CPU board implemented as a Single Mid-size Advanced Mezzanine

Card (AMC) for ATCA and MicroTCA applications. The design is based on the 4

i5/i7 processor platform combined with the mobile Intel® QM87 Chipset.

The AM4024(E) supports up to 16 GB dual-channel Double Data Rate (DDR3) memory with Error Checking and Correction (ECC) running at 1600 MHz. Up to two Intel® I350 Quad Gigabit Ethernet controllers

(providing up to 8 GbE ports) are directly connected to the processor via x4 PCI Express 3.0 interfaces,

thus ensuring a maximum data throughput between processor and memory. The AM4024(E) can be optionally equipped with up to 64 GB of SLC NAND flash memory via a SATA Flash module.

The AM4024(E) supports a comprehensive set of interconnecting capabilities. On the front panel, the

AM4024(E) comes with a broad set of I/O interfaces, such as 2x Gigabit Ethernet, DisplayPort, COM, and

USB, allowing for a convenient bring-up process during the application development process. A variety

of high-speed interconnect ports to the backplane, such as up to 8 Gigabit Ethernet ports, PCI Express,

and SATA, ensures a wide range of possible application use cases for the AM4024(E).

The processor and the memory are soldered on the AM4024(E) which results in a higher MTBF value and

a significant advantage for the cooling concept. The careful design and selection of high-temperatureresistant components together with the elaborated heat sink design ensure high product reliability.

A front panel design according to the PICMG® MTCA.1 specification (on project request) provides shock

and vibration resistance in demanding environmental conditions.

th

generation Intel® Core™

The AM4024(E) is an ideal platform for high-performance computing and multi-processor systems in

general. In the communication market the AM4024(E) perfectly serves for media server, gateway applications as well as in test solutions for networking equipment. In particular, the Core™ i7 with integrated Intel® HD Graphics 4600/5200 provides a significant performance boost for video streaming/

transcoding and IPTV applications.

The AM4024(E) is offered with various Board Support Packages including Windows, VxWorks and Linux

operating systems. For further information concerning the operating systems available for the

AM4024(E), please contact Kontron.

1.2 System Expansion Capabilities

1.2.1 SATA Flash Module (Optional)

The SATA Flash module provides up to 64 GB of SLC NAND flash memory. For further information on the

SATA Flash module, refer to Chapter 6.

1.2.2 RTC Backup Battery Module (Optional)

The RTC Backup Battery module provides backup-power for the RTC via two soldered, parallel-connected 3V lithium batteries. For further information on the RTC Backup Battery module, refer to Chapter 7.

D R A F T — F O R I N T E R N A L U S E O N L Y

www.kontron.com

11

Page 12

User Guide

AM4024(E)

1.3 System Relevant Information

The following system relevant information is general in nature but should still be considered when developing applications using the AM4024(E).

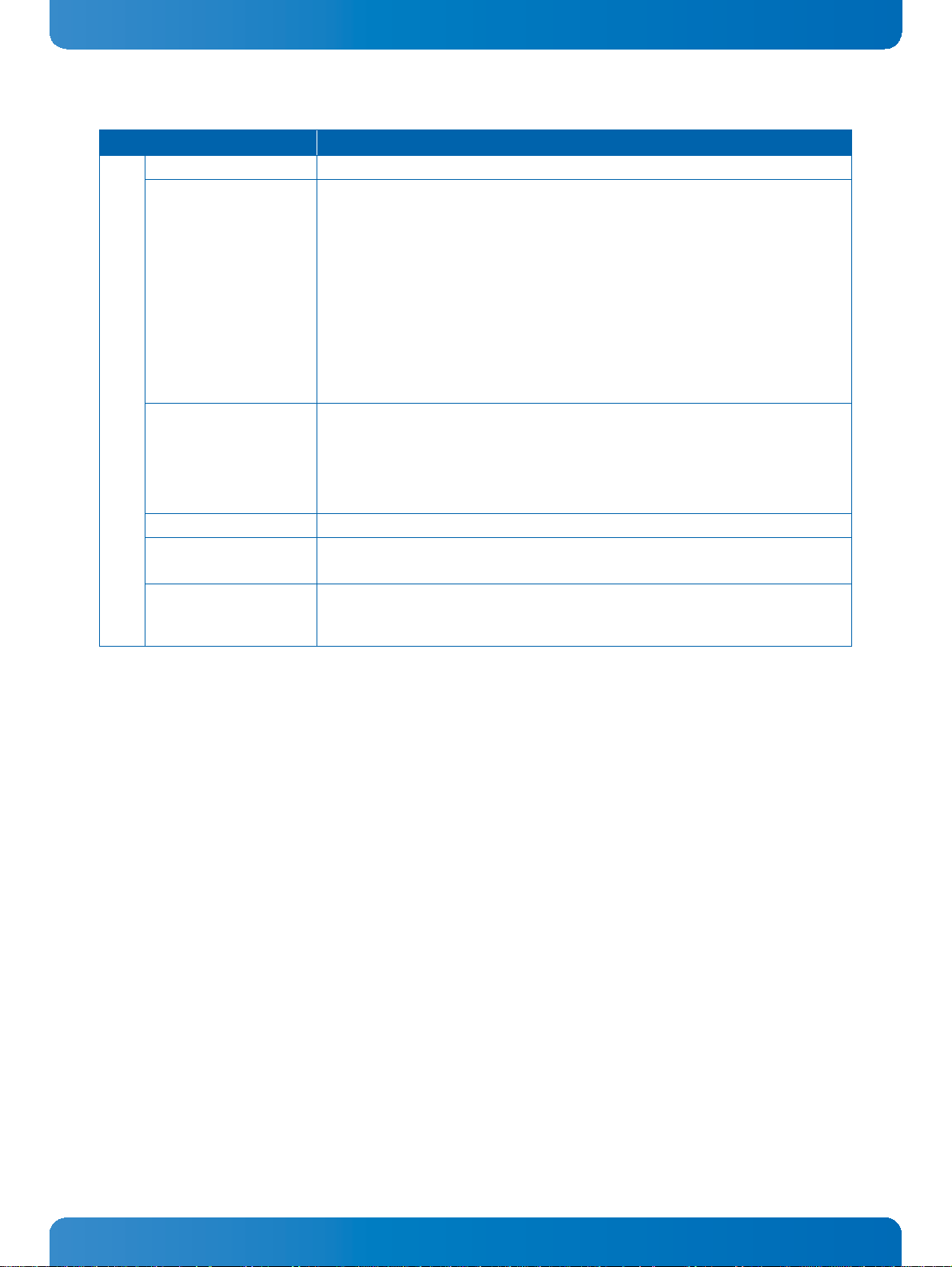

Table 1: System Relevant Information

SUBJECT INFORMATION

Hardware Requirements The AM4024(E) can be installed on any AMC-supporting carrier board or MicroTCA

backplane with the following AMC Card-edge connector port mapping:

AM4024:

» Common Options Region ports 0-1:

» Two Gigabit Ethernet SerDes ports

» Common Options Region ports 2-3:

» Two Serial ATA ports

» Fat Pipes Region ports 4-7:

» One x4 PCI Express interface

» Extended Options Region port 14-16:

» One Serial port

» One Debug port

»Two GPOs

»Clock:

» PCI Express reference clock, FCLKA

AM4024E:

» Common Options Region ports 0-1:

» Two Gigabit Ethernet SerDes ports

» Common Options Region ports 2-3:

» Two Serial ATA ports

» Fat Pipes Region ports 4-7:

» One x4 PCI Express interface

» Fat Pipes Region ports 8-11:

» Four Gigabit Ethernet SerDes ports

» Extended Options Region port 14-16:

» One Serial port

» One Debug port

»Two GPOs

»Clock:

» PCI Express reference clock, FCLKA

PCI Express Configuration The AM4024(E) supports the PCI Express root complex configuration.

Operating Systems The AM4024(E) is offered with various Board Support Packages including Windows,

VxWorks and Linux operating systems. For further information concerning the operat-

ing systems available for the AM4024(E), please contact Kontron.

1.4 Board Diagrams

The following diagrams provide additional information concerning board functionality and component

layout.

www.kontron.com

12

D R A F T — F O R I N T E R N A L U S E O N L Y

Page 13

1.4.1 Functional Block Diagrams

Intel®

4

th

Core™ i7

Intel®

QM87

Front Panel

Health

Hot Swap

Out-of-Service

POST Code /

Debug

Front Panel LEDs

FPGA

Board

Control

MMC

Temp.

Sense

AMC

Connector

Port No.

0 - 1

12V payload

14

IPMB-L

COMA

COMA

COMA

COMA

Ext. Opt. R e g .

SPI

SFF

XDP

Debug

EEP

64 kB

I

2

C

I

2

C

2 - 3

15

I

2

C

Debug

Debug

3.3V management

power

LPC

Hot Swap Switch

DDR3L

Bank A soldered

DDR3L

Bank B soldered

DDR3 DDR3

DMI

Single

UART

USB 2.0

DMI

LPC SMBus SPI

USB 2.0

PCIe

RS-

232

2x 1 GbE SerDes

2x SATA 6 Gb/s

SATA

x4 PCIe

Mini

Display

Port

Display

Port

DDI

xBus

NC-SI

NC-SI

To GbE controller

SATA

Flash

4 MB

SPI

LPC

SATA

Flash

Module

Onboard Power Supplies

DC/DC etc.

16

GPO

GPO

TPM

PECI

Quad GbE

Intel® I350

SERDES

SERDES

COPPER

COPPER

GbE

Dual

Mag.

GbE

RJ-45

RJ-45

x4 PCIe

Fat Pipe Reg.4 - 7

PCIe

Clock

Mux

FCLKA

PCIe clk

PCIe

Micro-

USB

Mini-USB

type-A

AMC temp. sensor

AMC temp. sensor

PECI

Common Opt. Reg.

Common Opt. Reg.

SPI Boot

Flashes

(standard/

recovery)

XDP

Intel® I350 (c opper)

Intel® I350 (c opper)

GbE

(front)

User

EE-PROM

Figure 1: AM4024 Functional Block Diagram

User Guide

AM4024(E)

www.kontron.com

D R A F T — F O R I N T E R N A L U S E O N L Y

13

Page 14

Figure 2: AM4024E Functional Block Diagram

Intel®

4

th

Core™ i7

Intel®

QM87

Front Panel

Health

Hot Swap

Out-of-Service

POST Code /

Debug

Front Panel LEDs

FPGA

Board

Control

MMC

Temp.

Sense

AMC

Connector

Port No.

0 - 1

12V payload

14

IPMB-L

COMA

Fat Pipe Reg.

COMA

COMA

COMA

Ext. Opt. Reg.

SPI

SFF

XDP

Debug

EEP

64 kB

I

2

C

I

2

C

2 - 3

15

I

2

C

Debug

Debug

3.3V management

power

LPC

Hot Swap Switch

DDR3L

Bank A soldered

DDR3L

Bank B soldered

DDR3

PCIe

DDR3

DMI

Single

UART

USB 2.0

DMI

LPC SMBus SPI

USB 2.0

PCIe

RS-

232

2x 1 GbE SerDes

2x SATA 6 Gb/s

SATA

x4 PCIe

8 - 9

Mini

Display

Port

Display

Port

DDI

xBus

NC-SI

NC-SI

To GbE controller

SATA

Flash

4 MB

SPI

LPC

SATA

Flash

Module

Onboard Power Supplies

DC/DC etc.

TPM

x4 PCIe

PECI

Quad GbE

Intel® I350

SERDES

SERDES

COPPER

COPPER

Quad GbE

Intel® I350

SERDES

SERDES

COPPER

COPPER

2x 1 GbE SerDes

2x 1 GbE SerDes

10 - 11 Fat Pipe Reg.

GbE

Dual

Mag.

GbE

RJ-45

RJ-45

x4 PCIe

Fat Pipe Reg.4 - 7

PCIe

Clock

Mux

FCLKA

PCIe clk

PCIe

Micro-

USB

Mini-USB

type-A

AMC temp. sensor

AMC temp. sensor

PECI

Common Opt. Reg.

Common Opt. Reg.

SPI Boot

Flashes

(standard/

recovery)

XDP

Intel® I350 (copper)

Intel® I350 (copper)

GbE

(front)

GPO

GPO

16

User

EE-PROM

User Guide

AM4024(E)

www.kontron.com

D R A F T — F O R I N T E R N A L U S E O N L Y

14

Page 15

1.4.2 Front Panel

SPEED

A

3

2

1

0

AM4024

B

SPEED

ACT

ACT

Module Management LEDs

LED1 (red): Out-of-Service LED

LED2 (red/green/amber): Health LED

HS (blue): Hot Swap LED

User-Specific LEDs

ULED3 (red/green): AMC port 0 Ethernet link status

(green) + POST Code

ULED2 (red/green): AMC port 1 Ethernet link status

(green) + POST Code

ULED1 (red/green): SATA channels active (green) + POST

Code

ULED0 (red/green): POST Code

Note: If the ULEDs3..0 are blinking red or remain lit,

a failure is indicated.

Integral Ethernet LEDs

ACT (green): Network Link/Activity

SPEED (green): Network Speed

Legend

Out-of-Service LED

Health LED

Hot Swap LED

Serial Port Connector

Gigabit Ethernet Connector

USB Connector

DisplayPort Connector

Figure 3: AM4024(E) Front Panel

User Guide

AM4024(E)

www.kontron.com

D R A F T — F O R I N T E R N A L U S E O N L Y

15

Page 16

1.4.3 Board Layout

Intel® Core™ i7

Intel®

QM87

85

1

33

34

1

2

J1

J5

J4

J2

J3

J7

Logic

DDR3L Memory

Intel®

I350

SATA Flash

Module/

Battery Module

Intel® Core™ i7

Intel®

QM87

85

1

33

34

1

2

J1

J5

J4

J2

J3

J7

Logic

DDR3L Memory

Intel®

I350

(2nd)

Intel®

I350

(1st)

SATA Flash

Module/

Battery Module

86

170

J1

ULED 0

ULED 1

ULED 2

ULED 3

J11

J10

4321

ON

SW2

Air Temperature Sensor

DDR3L Memory

1

Figure 4: AM4024 Board Layout (Top View)

User Guide

AM4024(E)

Figure 5: AM4024E Board Layout (Top View)

Figure 6: AM4024(E) Board Layout (Bottom View)

www.kontron.com

D R A F T — F O R I N T E R N A L U S E O N L Y

16

Page 17

1.5 Technical Specification

Table 2: AM4024(E) Main Specifications

FEATURES SPECIFICATIONS

CPU

Processor & Chipset

Graphics Controller High-performance 3D graphics controller integrated in the processor

PCH Intel® QM87 Chipset

Main Memory Up to 16 GB, dual-channel DDR3L SDRAM memory with ECC running at 1600 MHz

Flash Memory Two 16 MB SPI boot flash chips for two separate uEFI BIOS images

Memory

EEPROM EEPROM with 64 kbit

Gigabit Ethernet Up to two Intel® I350 Quad Gigabit Ethernet PCI Express bus controllers with

The AM4024(E) supports the following 4

» Quad-core Intel® Core™ i7-4860EQ (SV), 1.8 GHz, 6 MB L3 cache, GT3e, Intel®

Iris™ Pro Graphics 5200

» Quad-core Intel® Core™ i7-4700EQ (SV), 2.4 GHz, 6 MB L3 cache, GT2, Intel®

HD Graphics 4600

» Dual-core Intel® Core™ i5-4402EQ (LV), 1.6 GHz, 3 MB L3 cache, GT2, Intel®

HD Graphics 4600

(soldered)

Up to 64 GB SLC NAND flash via an onboard SATA Flash module (SSD)

advanced management features such as serial redirection over LAN:

AM4024:

» Two interfaces routed to the front I/O connectors

» Two interfaces routed to the AMC Card-edge connector

th

generation processors:

User Guide

AM4024(E)

AM4024E:

» Two interfaces routed to the front I/O connectors

Onboard Controller

Serial One 16550-compatible UART routed either to the front I/O (RS-232 signaling) or

Gigabit Ethernet Common Options Region ports 0-1:

Serial ATA Common Options Region ports 2-3:

PCI Express Fat Pipes Region ports 4-7:

Debug Interface Extended Options Region port 14:

AMC Interconnection

Serial Interface Extended Options Region port 15:

GPO Extended Options Region port 16:

Clock Clock (FCLKA):

» Six interfaces routed to the AMC Card-edge connector

the AMC Card-edge connector (TTL level)

» Two Gigabit Ethernet SerDes ports

Fat Pipes Region ports 8-11 (AM4024E):

» Four Gigabit Ethernet SerDes ports

» Two Serial ATA ports (6 Gb/s)

» One x4 PCI Express interface conf igured as root complex only and operating

up to 8.0 GT/s

» One Debug port

» One Serial port (COMA, TTL signaling)

»Two GPOs

» PCI Express clock reference output to the host system

D R A F T — F O R I N T E R N A L U S E O N L Y

www.kontron.com

17

Page 18

Table 2: AM4024(E) Main Specifications (Continued)

FEATURES SPECIFICATIONS

DIP Switch One DIP switch, SW2, for board configuration

Hot Swap One Hot Swap switch

Switches

Front Panel Connectors

Onboard Connector One extension connector, J7, for either a Serial ATA Flash module or an RTC Backup

Connectors

AMC Card-edge Connector One 170-pin AMC Card-edge connector

Module Management LEDs

User-Specific LEDs

LEDs

Ethernet LEDs

Watchdog Timer Software-configurable, two-stage Watchdog with programmable timeout ranging

System Timer The Intel® QM87 Chipset contains three 8254-style counters which have fixed uses

Timer

Thermal Management CPU and board overtemperature protection is provided by:

Sys. Management

One Serial port (COMA) with RS-232 signal level on a 5-pin micro-AB USB connector, J11

One 20-pin mini DisplayPort connector, J5

Two Gigabit Ethernet ports on RJ-45 connectors with integrated magnetics, J3 and J4

One USB 2.0 port on a 5-pin, mini USB type A connector, J2

Battery module

» LED1 (red): Out-of-Service LED

» LED2 (red/green/amber): Health LED

» HS LED (blue): Hot swap LED

» ULED3 (red/green): AMC port 0 Ethernet link status,

» ULED2 (red/green): AMC port 1 Ethernet link status,

» ULED1 (red/green): SATA channels active (green) + POST code

» ULED0 (red/green): POST code

» Act (green): Network Link / Activity

» Speed (green/yellow): Network speed

from 125 ms to 4096 s in 16 steps

Serves for generating IRQ or hardware reset

In addition to the three 8254-style counters, the Intel® QM87 Chipset includes

eight individual high-precision event timers that may be used by the operating

system. They are implemented as a single counter each with its own comparator

and value register.

» Temperature sensors integrated in the 4

» Up to four digital thermal sensors for monitoring the processor cores, one

sensor for each core

» One digital thermal sensor for monitoring the graphics core

» One digital thermal sensor for monitoring the package die temperature

» One onboard air temperature sensor for monitoring the board temperature

» Specially designed heat sink

(green) + POST code

(green) + POST code

th

gen. Intel® Core™ i7/i5 processor:

User Guide

AM4024(E)

www.kontron.com

D R A F T — F O R I N T E R N A L U S E O N L Y

18

Page 19

Table 2: AM4024(E) Main Specifications (Continued)

FEATURES SPECIFICATIONS

Module Management

Controller

IPMI

Hot Swap The AM4024(E) has full hot swap capability.

TPM Trusted Platform Module (TPM) 1.2 for enhanced hardware- and software-based

Security

uEFI BIOS Phoenix SecureCore Tiano™ (SCT) BIOS firmware based on the uEFI Specification and

IPMI Firmware IPMI firmware providing the following features:

Software

Operating Systems There are various operating systems available for the AM4024(E). For further

NXP® ARM7 microcontroller with 512 kB firmware flash and automatic rollback

strategy

The MMC carries out IPMI commands such as monitoring several onboard tempera-

ture conditions, board voltages and the power supply status, and managing hot

swap operations.

The MMC is accessible via a local IPMB (IPMB-L) and one host Keyboard Controller

Style Interface (KCS)

One MMC system EEPROM for FRU data and f irmware private data

data and system security

the Intel Platform Innovation Framework for EFI:

» Serial console redirection via serial port

» LAN boot capability for diskless systems (standard PXE)

» Automatic fail-safe recovery in case of a damaged image

» Non-volatile storage of setting in the SPI boot flash (battery only required for

the RTC)

» Compatibility Support Module (CSM) providing legacy BIOS compatibility

based on Phoenix SCT3

» Command shell for diagnostics and configuration

» uEFI Shell commands executable from mass storage device in a pre-OS envi-

ronment (open interface)

» MMC support in the command shell

» Keyboard Controller Style (KCS) interface

» IPMB-L interface for out-of-band management and sensor monitoring

» IPMI over LAN (IOL) and Serial over LAN (SOL) support

» Sensor Device functionality with configurable thresholds for monitoring

board voltages, CPU state, board reset, etc.

» FRU Inventory functionality

» IPMI Watchdog functionality (power-cycle, reset)

» Board monitoring and control extensions:

» Graceful shutdown support

» uEFI BIOS fail-over control: selection of the SPI boot flash (standard/re-

covery)

» Field-upgradable IPMI firmware:

» via the KCS, IPMB or IOL interfaces

» Download of firmware does not break the currently running firmware or

payload activities

» Two flash banks with rollback capability: manual rollback or automatic in case

of upgrade failure

» E-Keying (AMC ports and clock in accordance with the AMC.0 R2.0 specifica-

tion)

information, please contact Kontron.

User Guide

AM4024(E)

D R A F T — F O R I N T E R N A L U S E O N L Y

www.kontron.com

19

Page 20

Table 2: AM4024(E) Main Specifications (Continued)

FEATURES SPECIFICATIONS

Power Consumption See Chapter 4 for details.

Temperature Range Operational: -5°C to +55°C Standard (depending on processor version and air-

Storage: -40°C to +70°C Without hard disk and without battery

Note: When the RTC Backup Battery Module is installed, refer to the opera-

tional specifications of this module as this determines the storage tem-

perature of the AM4024(E). (See "RTC Backup Battery Module" below.)

Note: When additional components are installed, refer to their operational

specifications as this will influence the operational and storage tem-

perature of the AM4024(E).

RTC Backup Battery Mod-

General

ule (on request)

Climatic Humidity 93% RH at 40 °C, non-condensing (acc. to IEC 60068-2-78)

Dimensions Dimensions of the AM4024(E) without retention screws on front panel:

Board Weight 280 grams

Special battery mezzanine module with up to two batteries connected in parallel;

uses the J7 connector for interfacing with the AM4024(E)

Temperature ranges:

Operational: - 5°C to + 55°C

Storage: -30°C to + 60°C

Mid-size: 181.5 mm x 73.5 mm x 18.96 mm

The above-mentioned board weight refers to the AM4024(E) without extension

modules such as the SATA Flash module or the RTC Backup Battery module.

User Guide

AM4024(E)

flow in the system)

www.kontron.com

D R A F T — F O R I N T E R N A L U S E O N L Y

20

Page 21

1.6 Standards

The AM4024(E) complies with the requirements of the following standards.

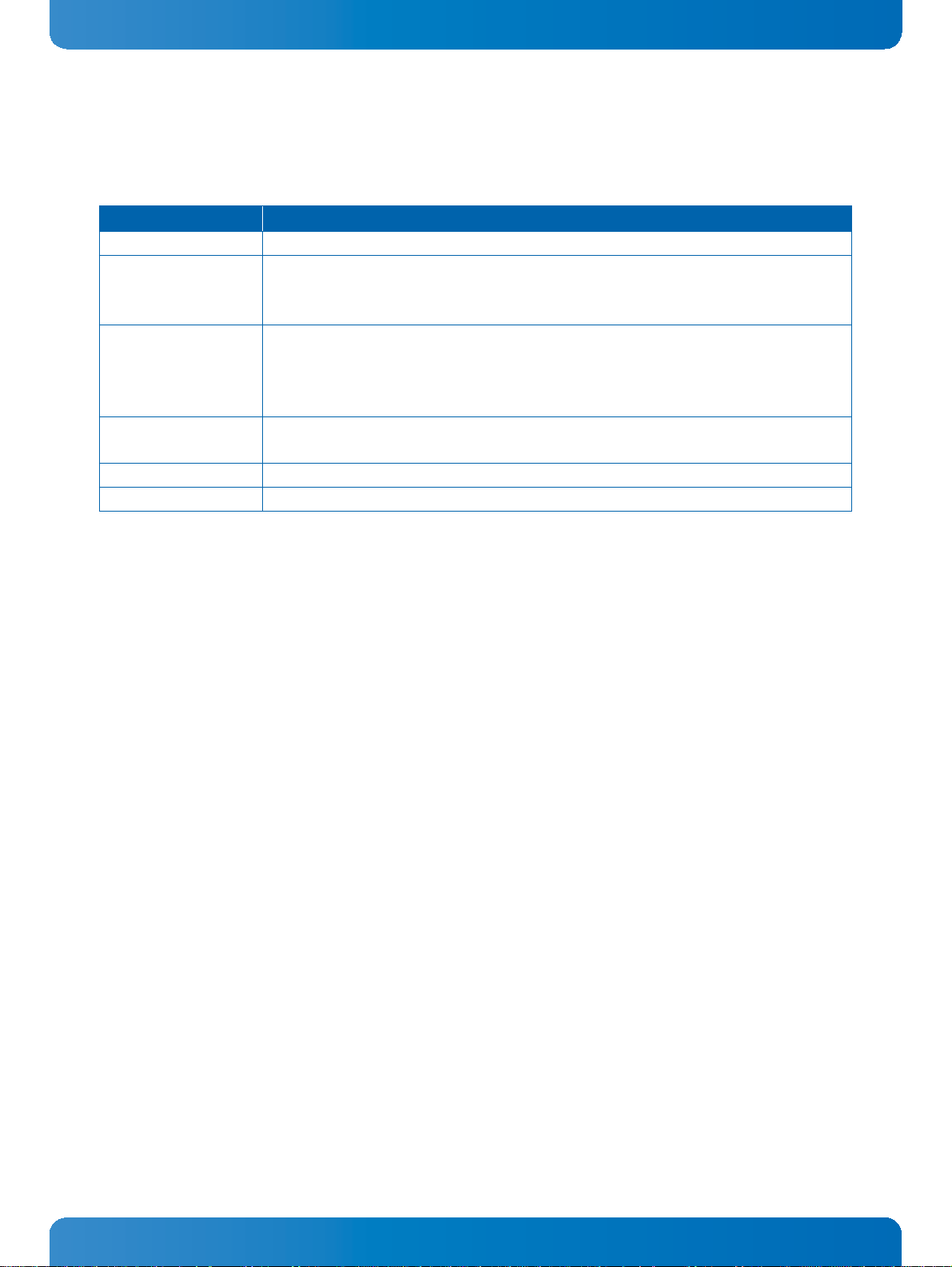

Table 3: Standards

TYPE ASPECT STANDARD TEST LEVEL

CE Emission EN55022, EN61000-6-3, EN300386 --

Immission EN55024, EN61000-6-2, EN300386 --

Electrical Safety EN60950-1 --

Mechanical Mechanical Dimensions IEEE 1101.10 --

Environmental and

Health Aspects

Climatic Humidity IEC60068-2-78 93% RH at 40 °C,

non-condensing

(see note below)

WEEE Directive 2002/96/EC Waste electrical and electronic

equipment

RoHS 2 Directive 2011/65/EU Restriction of the use of certain

hazardous substances in electri-

cal and electronic equipment

Vibration

(sinusoidal, operating)

Shock (operating) EN300019-2-3

GR-63-CORE

EN300019-2-3

IEC61131- 2

IEC60068-2-6

IEC61131- 2

IEC60068-2-27

5-150 [Hz] frequency range

1 [g] acceleration

1 [oct/min] sweep rate

10 sweeps/axis

3 directions: x, y, z

15 [g] acceleration

11 [ms] pulse duration

3 shocks per direction

5 [s] recovery time

6 directions, ±x, ±y, ±z

User Guide

AM4024(E)

Note: Boards without conformal coating must not be exposed to a change of temperature which

can lead to condensation. Condensation may cause irreversible damage, especially when

the board is powered up again.

Kontron does not accept any responsibility for damage to products resulting from destructive environmental testing.

Please contact Kontron for assistance prior to performing further environmental testing of

the AM4024(E).

www.kontron.com

21

D R A F T — F O R I N T E R N A L U S E O N L Y

Page 22

User Guide

AM4024(E)

1.7 Related Publications

The following publications contain information relating to this product.

Table 4: Related Publications

PRODUCT PUBLICATION

ATCA PICMG® 3.0 R3.0, AdvancedTCA® Base Specification, March 24, 2008

MicroTCA PICMG® MTCA.0 R1.0, Micro Telecommunications Computing Architecture Base Specifica-

tion, July 6, 2006

PICMG® MTCA.1 R1.0, Air Cooled Rugged MicroTCA Specification, March 19, 2009

AMC PICMG® AMC.0 R2.0, Advanced Mezzanine Card Base Specification, Nov. 15, 2006

PICMG® AMC.1 R2.0, PCI Express™ on AdvancedMC™, Oct. 8, 2008

PICMG® AMC.2 R1.0, Ethernet Advanced Mezzanine Card Specification, March 1, 2007

PICMG® AMC.3 R1.0, Advanced Mezzanine Card Specification for Storage, Aug. 25, 2005

IPMI IPMI - Intelligent Platform Management Interface Specification, v2.0 Document Revision

1.0, February 12, 2004

Platform Firmware Unified Extensible Firmware Interface (uEFI) specification, version 2.1

All Kontron Products Product Safety and Implementation Guide, ID 1021-9142

www.kontron.com

D R A F T — F O R I N T E R N A L U S E O N L Y

22

Page 23

User Guide

AM4024(E)

2 Functional Description

2.1 Processor and Chipset

The AM4024(E) supports the Intel® Core™ i7-4860EQ, the Intel® Core™ i7-4700EQ (SV), and the Intel®

Core™ i5-4402EQ processors in combination with the mobile Intel® QM87 Chipset.

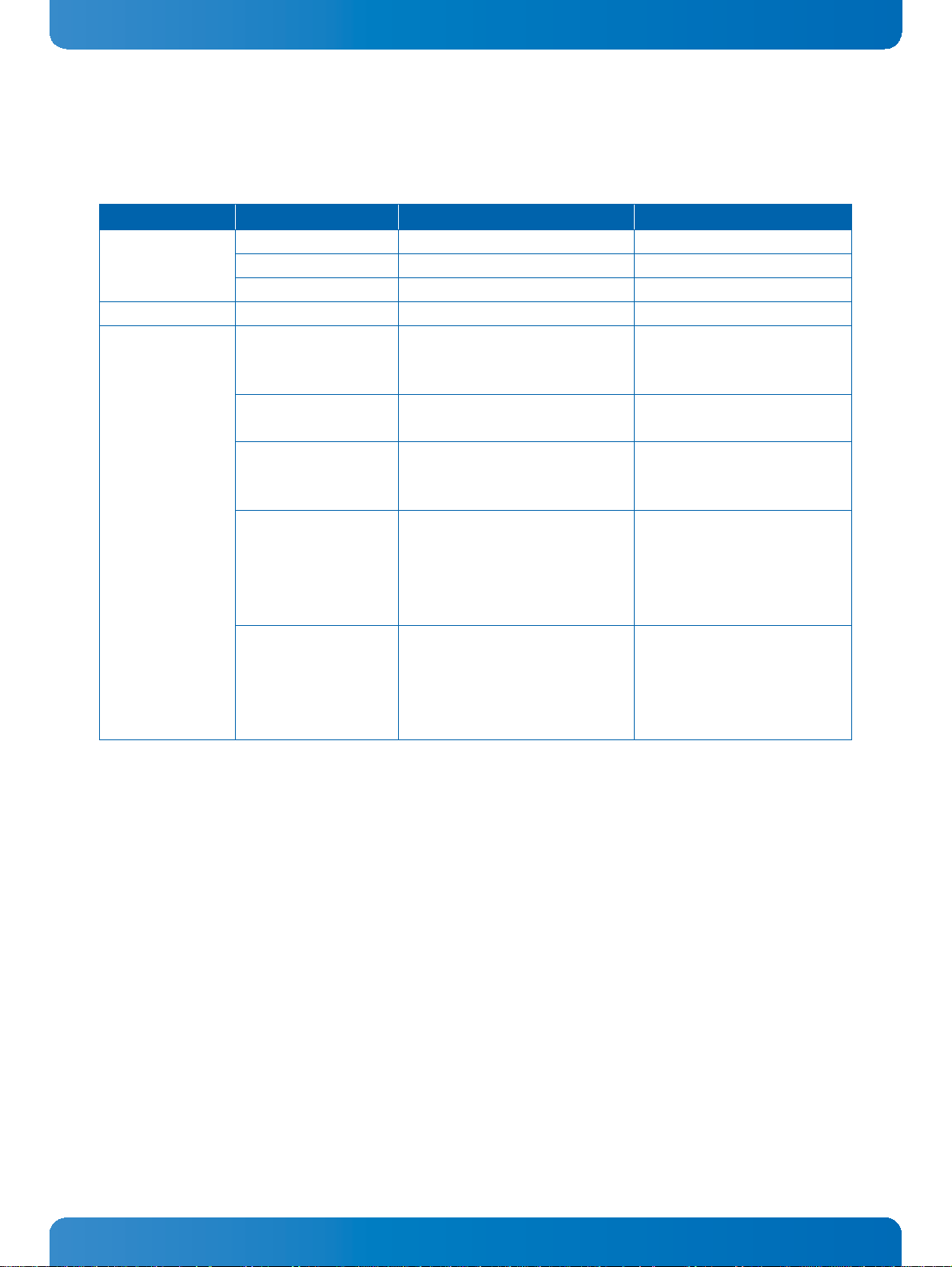

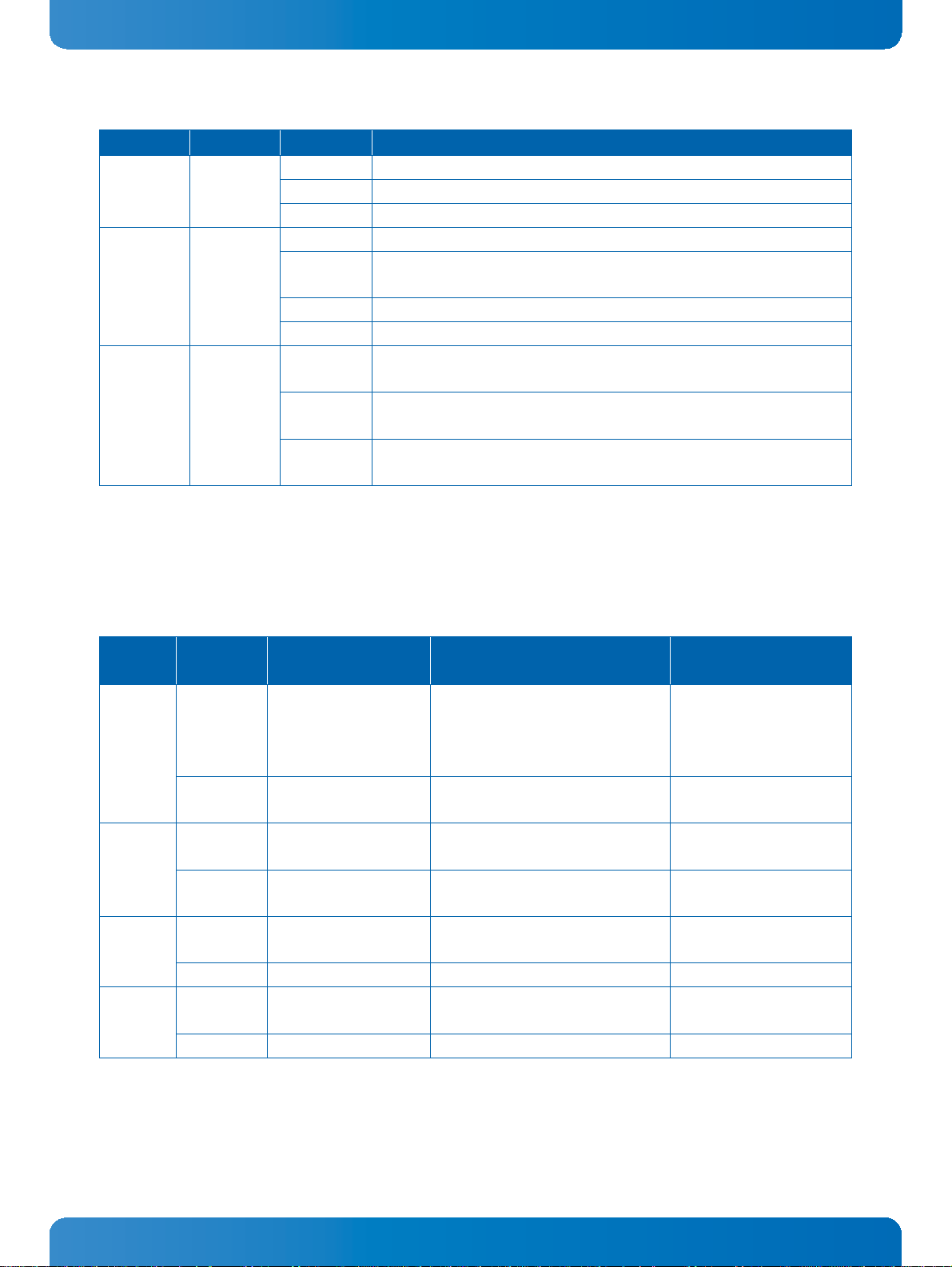

Table 5: Features of the Processors Supported on the AM4024(E)

FEATURE Intel® Core™ i7-4860EQ

(SV), 1.8 GHz

Processor Cores four four two

Processor Base Frequency (HFM) 1.8 GHz 2.4 GHz / 1.7 GHz 1.6 GHz

Maximum Turbo Frequency 3.2 GHz 3.4 GHz 2.7 GHz

LFM 800 MHz 800 MHz 800 MHz

Hyper-Threading supported supported supported

SpeedStep® supported supported supported

L1 cache per core 64 kB 64 kB 64 kB

L2 cache per core 256 kB 256 kB 256 kB

L3 cache 6 MB 6 MB 3 MB

On-package cache up to 128 MB -- --

DDR3L Memory up to 16 GB / 1600 MHz up to 16 GB / 1600 MHz up to 16 GB / 1600 MHz

Graphics Intel® Iris™

Pro Graphics 5200

Graphics Base Frequency 750 MHz 400 MHz 400 MHz

Graphics Max. Dynamic Frequency 1.0 GHz 1.0 GHz 900 MHz

Graphics Execution Units 40 20 20

Configurable Thermal Design Power -- cTDP --

Power Limit Reduction Power Limit Reduction -- Power Limit Reduction

Thermal Design Power 47 W 47 W / 37 W 25 W

Intel® Core™ i7-4700EQ

(SV), 2.4 GHz

Intel® HD Graphics 4600 Intel® HD Graphics 4600

Intel® Core™ i5-4402EQ

(LV), 1.6 GHz

Note: The Intel® Core™ i7-4700EQ processor supports the cTDP-Down mode to 37 W. The maxi-

mum power consumption of the Intel® Core™ i7-4860EQ and Intel® Core™ i5-4402EQ processors can be reduced to approx. 10 W using the Power Limit Reduction feature. This

feature can be configured via the kBoardConfig uEFI Shell command. For information on

this command, refer to the Chapter 9, uEFI BIOS.

For further information about the processors used on the AM4024(E), please visit the Intel website.

For further information concerning the suitability of other Intel processors for use with the

AM4024(E), please contact Kontron.

www.kontron.com

23

D R A F T — F O R I N T E R N A L U S E O N L Y

Page 24

User Guide

AM4024(E)

2.1.1 Integrated Processor Graphics Controller

th

The 4

with up to 40 execution units delivering high-performance 3D, 2D graphics capabilities. The

AM4024(E) uses one display interface of the integrated processor graphics controller and supports resolutions up to 3840 x 1160 pixels @ 60 Hz through DisplayPort and up to 1920 x 1200 pixels @ 60 Hz

using DVI.

gen. Intel® Core™ i7/i5 processor includes a highly integrated processor graphics controller

2.2 Memory

The AM4024(E) supports a soldered, dual-channel (144-bit), Double Data Rate (DDR3) memory with Error Checking and Correcting (ECC) running at 1600 MHz (memory error detection and reporting of 1bit and 2-bit errors and correction of 1-bit failures). The available memory configuration can be either

8 GB or 16 GB.

However, when the internal graphics controller is enabled, the amount of memory available to applications is less than the total physical memory in the system. For example, the chipset’s Dynamic Video

Memory Technology dynamically allocates the proper amount of system memory required by the operating system and the application.

2.3 Watchdog Timer

The AM4024(E) provides a Watchdog timer that is programmable for a timeout period ranging from 125 ms

to 4096 s in 16 steps.

The Watchdog timer provides the following modes of operation:

»Timer-only mode

» Reset mode

» Interrupt mode

» Dual-stage mode

In dual-stage mode, a combination of both interrupt and reset is generated if the Watchdog is not serviced.

2.4 Battery

The AM4024(E) does not have any provisions for an onboard battery for backup of the RTC. There is,

however, an optional mezzanine module available which does provide battery-powered backup for the

RTC. The RTC Backup Battery module uses the J7 connector for interfacing with the AM4024(E). If this

module is required, the J7 interface is not available for the SATA Flash module. Refer to Chapter 7 for

further information on this module.

www.kontron.com

D R A F T — F O R I N T E R N A L U S E O N L Y

24

Page 25

User Guide

AM4024(E)

2.5 Flash Memory

The AM4024(E) provides flash interfaces for the uEFI BIOS and the SATA Flash module.

2.5.1 SPI Boot Flash for uEFI BIOS

The AM4024(E) provides two 16 MB SPI boot flashes for two separate uEFI BIOS images, a standard SPI

boot flash and a recovery SPI boot flash. The fail-over mechanism for the uEFI BIOS recovery can be

controlled via the DIP switch SW2, switch 2. The SPI boot flash includes hardware write protection functionality, which can be configured via the uEFI BIOS. If write protection is enabled, the SPI boot flash

cannot be written to.

Note: The uEFI BIOS code and settings are stored in the SPI boot flashes. Changes made to the

uEFI BIOS settings are available only in the currently selected SPI boot flash. Thus, switching over to the other SPI boot flash may result in operation with different uEFI BIOS code

and settings.

2.5.2 SATA Flash Module

The AM4024(E) supports up to 64 GB flash memory in combination with an optional SATA Flash module.

The SATA Flash module uses the J7 connector for interfacing with the AM4024(E). If this module is required, the J7 interface is not available for the The RTC Backup Battery module. Refer to Chapter 6 for

further information on this module.

2.6 Trusted Platform Module 1.2

The AM4024(E) supports the Trusted Platform Module (TPM) 1.2. TPM1.2 is a security chip specifically

designed to provide enhanced hardware- and software-based data and system security. TPM1.2 is

based on the Atmel AT97SC3204 security controller and stores sensitive data such as encryption and

signature keys, certificates and passwords, and is able to withstand software attacks to protect the

stored information.

2.7 Board Interfaces

2.7.1 Front Panel LEDs

T

he

AM4024(E)

Specific LEDs can be configured via two onboard registers (see Chapter 3.3.7, LED Configuration Register, and Chapter 3.3.8, LED Control Register).

is equipped with three Module Management LEDs and four User-Specific LEDs. The User-

2.7.1.1 Module Management LEDs and Hot Swap LED

The Module Management LEDs (LED0 and LED1) show the software status of the MMC. The Hot Swap LED

(HS LED) indicates when the board may be extracted. It can be switched on or off by software and may

be used, for example, to indicate that the shutdown process is finished and the board is ready for extraction.

www.kontron.com

25

D R A F T — F O R I N T E R N A L U S E O N L Y

Page 26

Table 6: Module Management and Hot Swap LEDs’ Functions

LED COLOR STATE FUNCTION

LED1

(Out-of-

Service LED)

LED2

(Health

LED)

HS LED Blue Off Module in normal operation

Red Off MMC running (default)

On MMC out of service or in reset state

Blinking MMC firmware upgrade

Green/

Amber/Red

Off Payload is off; module is not powered

Green Module is healthy (normal operation) and all related sensors are within

the specified range

Amber Payload is on and at least one sensor is out of range

Red Reserved

Do not extract the module.

Blinking Module hot swap in progress

Module is not ready for extraction.

On a) Module ready for hot swap extraction, or

b) Module has just been inserted in a powered system

User Guide

AM4024(E)

Note: The status of the Module Management LEDs may be temporarily overwritten by the PICMG-

defined “Set FRU LED State” command to implement, for example, a lamp test.

2.7.1.2 User-Specific LEDs

Table 7: User-Specific LEDs’ Functions

LED COLOR FUNCTION

DURING POWER-UP

ULED3 Red Power failure -- Processor overtemperature

Green -- uEFI BIOS POST bit 3 and bit 7 AMC port 0 Ethernet link

ULED2 Red Clock failure Processor overtemperature

Green -- uEFI BIOS POST bit 2 and bit 6 AMC port 1 Ethernet link

ULED1 Red Hardware reset -- Processor overtemperature

Green -- uEFI BIOS POST bit 1 and bit 5 SATA channels active

ULED0 Red uEFI BIOS boot failure -- Processor overtemperature

Green -- uEFI BIOS POST bit 0 and bit 4 --

FUNCTION DURING BOOT-UP

(POST code enabled)

FUNCTION

AFTER BOOT-UP

above 125°C (blinking) /

Processor overtemperature

above 100°C (on)

signal status

above 125°C (blinking)

signal status

above 125°C (blinking)

above 125°C (blinking)

D R A F T — F O R I N T E R N A L U S E O N L Y

www.kontron.com

26

Page 27

User Guide

Locked

Hot Swap

Unlocked

AM4024(E)

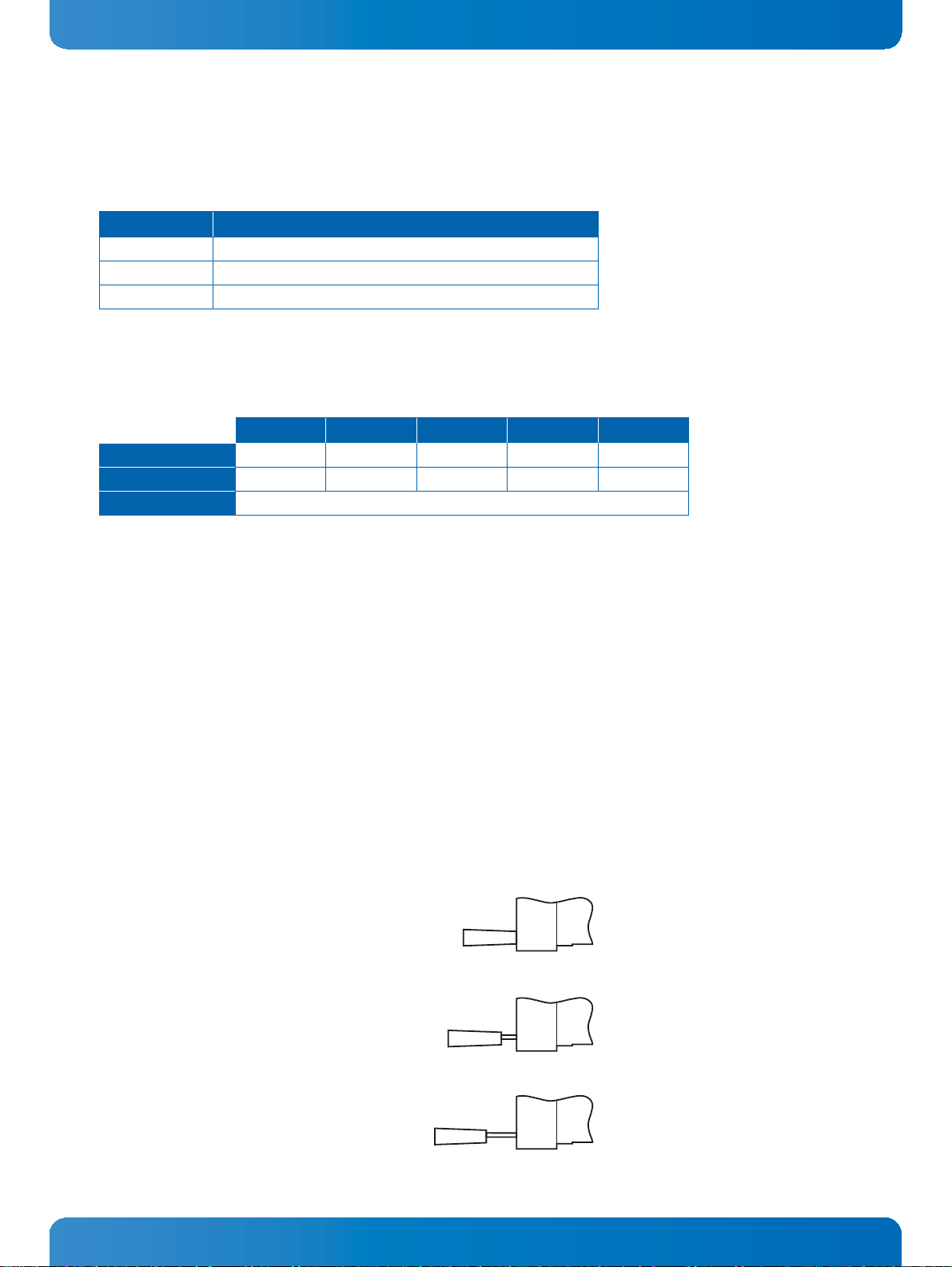

How to Read the 8-Bit POST Code

Due to the fact that only 4 LEDs are available and 8 bits must be displayed, the POST code output is

multiplexed on the User-Specific LEDs.

Table 8: POST Code Sequence

STATE GENERAL PURPOSE LEDs

0 All ULEDs are OFF; start of POST sequence

1 High nibble

2 Low nibble; state 2 is followed by state 0

The following is an example of the User-Specific LEDs’ operation with POST configuration enabled (see

also Table 8).

Table 9: POST Code Example

ULED3 ULED2 ULED1 ULED0 RESULT

HIGH NIBBLE off (0) on (1) off (0) off (0) 0x4

LOW NIBBLE off (0) off (0) off (0) on (1) 0x1

POST CODE 0x41

Note: Under normal operating conditions, the User-Specific LEDs should not remain lit during

boot-up. They are intended to be used only for debugging purposes. In the event that a

User-Specific LED lights up during boot-up and the AM4024(E) does not boot, please contact Kontron.

If all User-Specific LEDs flash red on and off at regular intervals, they indicate that the

processor junction temperature has reached a level beyond which permanent silicon damage may occur. Once activated, the overtemperature event remains latched until a cold restart of the AM4024(E) is undertaken (all power off and then on again).

2.7.2 Module Handle

At the front panel, the AM4024(E) provides a handle for module extraction as well as for securing the

module in the carrier/ chassis and actuating the hot swap switch. The module handle supports a threeposition operation.

Figure 7: Module Handle Positions

www.kontron.com

D R A F T — F O R I N T E R N A L U S E O N L Y

27

Page 28

User Guide

AM4024(E)

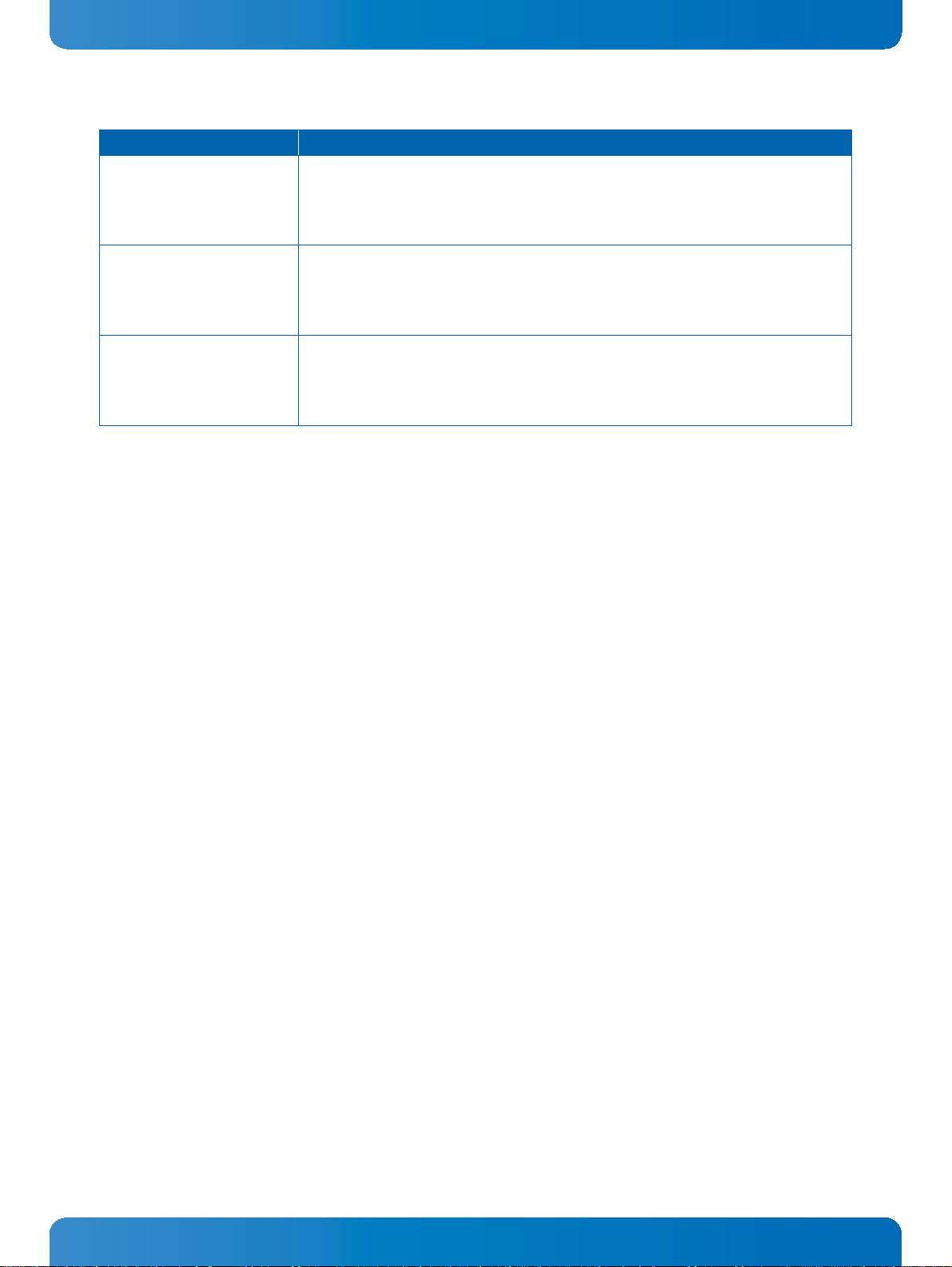

Table 10: Module Handle Positions

MODULE HANDLE POSITION FUNCTION

Locked When the AM4024(E) is installed, the module handle is pushed in the “Locked” posi-

tion and the following actions result:

» The module is locked in the carrier /chassis.

» The hot swap switch is actuated.

Hot Swap When an extraction process of the AM4024(E) is initiated, the module handle is pulled

in the “Hot Swap” position and the following actions result:

» The module is locked in the carrier /chassis.

» The hot swap switch is deactuated.

Unlocked When the module handle is pulled to the “Unlocked” position, the AM4024(E) can be

fully extracted and the following actions result:

» The module is unlocked in the carrier /chassis.

» The hot swap switch is deactuated.

Note: For normal operation, the module handle must be in the “Locked” position.

2.7.3 Debug Interface

The AM4024(E) provides several onboard options for hardware and software debugging, such as:

» Four bicolor debug ULEDs for signaling hardware failures and uEFI BIOS POST code

» One optional, small form factor extended debug port (SFF XDP processor JTAG) connector,

J10, to facilitate debug and uEFI BIOS software development

» One JTAG interface connected to the AMC Card-edge connector for debugging and manufac-

turing purposes

2.7.4 USB Interface

The AM4024(E) provides one

high-speed, full-speed and low-speed capable

USB 2.0 host port implemented as one standard, 5-pin, Mini USB, type A connector, J2, on the front panel. This connector allows standard USB peripheral devices to be connected to the AM4024(E) via an adapter for Mini USB

type A to USB type A connectors.

The following figure illustrates the adapter required for connecting standard USB devices to the

AM4024(E). For further technical or ordering information on this adapter, please contact Kontron.

www.kontron.com

D R A F T — F O R I N T E R N A L U S E O N L Y

28

Page 29

Figure 8: Adapter for Mini USB Type A to USB Type A Connector

Figure 9: Serial Port Con. J11 (COMA)

5

1

Table 11: Serial Port Con. J11 (COMA) Pinout

PIN SIGNAL FUNCTION I/O

1 RTS# Request to send O

2RXD Receive data I

3TXD Transmit data O

4 CTS# Clear to send I

5 GND Signal ground --

User Guide

AM4024(E)

2.7.5 Serial Ports

The AM4024(E) supports one serial port, COMA, fully compatible with the 16550 UART controller. COMA

is implemented as a serial RS-232 interface available on a 5-pin USB Micro-AB connector, J11, on the

front panel.

The COMA interface includes receive and transmit signals as well as additional signals for handshaking

mode. Data transfer rates up to 115.2 kB/s are supported.

The COMA interface can be routed to the AMC port 15 in the Extended Options Region of the AMC Cardedge Connector as TTL 3.3 V signal level. In this event, the COMA port includes only receive and transmit signals.

The following figure and table provide pinout information on the serial port connector J11.

To connect standard serial devices to the AM4024(E)

is required. For further technical or ordering information on this adapter, please contact Kontron.

www.kontron.com

,

a specially designed serial adapter from Kontron

D R A F T — F O R I N T E R N A L U S E O N L Y

29

Page 30

User Guide

AM4024(E)

2.7.6 Mini DisplayPort

The AM4024(E) provides one DisplayPort interface implemented as a 20-pin standard Mini DisplayPort

connector, J5, on the front panel for connection to a DisplayPort/DVI monitor. To connect a monitor

with standard DisplayPort connector or a standard DVI connector to the AM4024(E), an adapter is required.

2.7.7 SATA Interfaces

The AM4024(E) provides three SATA ports:

» One SATA 6 Gb/s port routed to the J7 connector, which is used to connect the SATA Flash

module

» Two SATA 6 Gb/s ports connected to the AMC ports 2-3 in the Common Options Region of the

AMC Card-edge Connector

2.7.8 PCI Express

The AM4024(E) provides one x4 PCI Express 3.0 interface operating at up to 8.0 GT/s. The PCI Express

interface operates as root complex only and is routed to the AMC interconnection, Fat Pipes Region,

ports 4-7.

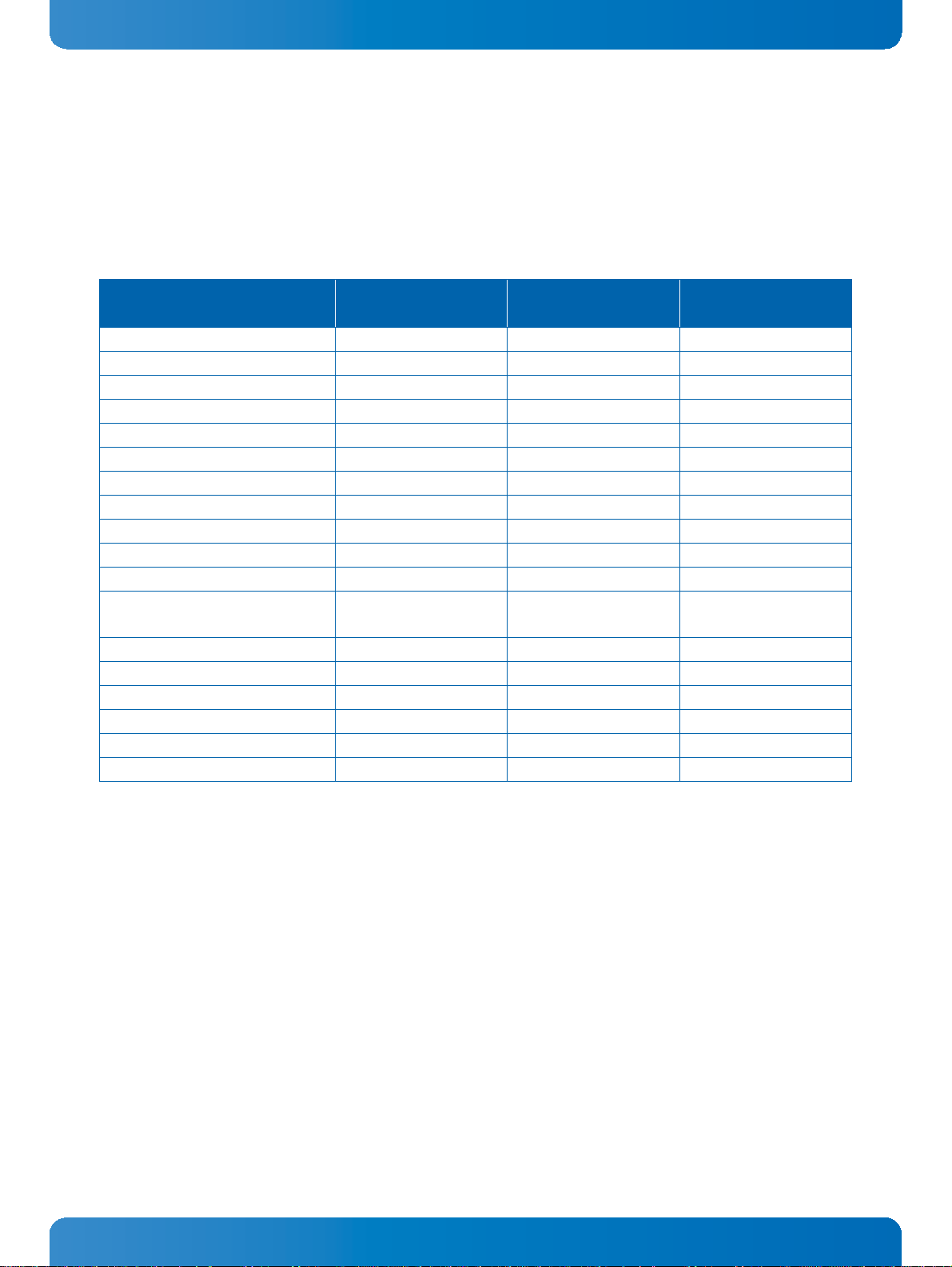

2.7.9 Gigabit Ethernet Interfaces

The AM4024 provides four Gigabit Ethernet interfaces using one Intel® I350 Gigabit Ethernet controller. Two Gigabit Ethernet copper ports (1000BASE-TX) are connected to the RJ-45 front panel connectors, J3 and J4, and two Gigabit Ethernet SerDes ports are routed to the AMC ports 0-1 in the Common

Options Region of the AMC Card-edge Connector. On the AM4024, the two Gigabit Ethernet copper ports

and the two Gigabit Ethernet ports in the Common Options Region (AMC ports 0 and 1) support IPMI

over LAN (IOL) and Serial over LAN (SOL) via the Intel® I350 Gigabit Ethernet controller which is connected to the Network Controller Sideband Interface (NC-SI).

The AM4024E provides eight Gigabit Ethernet interfaces using two Intel® I350 Gigabit Ethernet controllers. Two Gigabit Ethernet copper ports (1000BASE-TX) are connected to the RJ-45 front panel connectors, J3 and J4, two Gigabit Ethernet SerDes ports are routed to the AMC ports 0-1 in the Common

Options Region, and four Gigabit Ethernet SerDes ports are routed to the AMC ports 8-11 in the Fat Pipes

Region of the AMC Card-edge Connector. On the AM4024E, the two Gigabit Ethernet copper ports and

the two Gigabit Ethernet ports in the Common Options Region (AMC ports 0 and 1) support IPMI over

LAN (IOL) and Serial over LAN (SOL) via the 1st Intel® I350 Gigabit Ethernet controller which is connected to the Network Controller Sideband Interface (NC-SI).

The Boot from LAN feature is also supported on all Ethernet ports.

www.kontron.com

D R A F T — F O R I N T E R N A L U S E O N L Y

30

Page 31

Table 12: Gigabit Ethernet Controller Port Mapping for the AM4024

ETHERNET CONTROLLER PORT MAPPING IPMI Channel (IOL/SOL)

1st Intel® I350, port 0 AMC port 0 1

1st Intel® I350, port 1 AMC port 1 2

1st Intel® I350, port 2 Front I/O connector J3 (GbE B) 3

1st Intel® I350, port 3 Front I/O connector J4 (GbE A) 4

Table 13: Gigabit Ethernet Controller Port Mapping for the AM4024E

ETHERNET CONTROLLER PORT MAPPING IPMI Channel (IOL/SOL)

1st Intel® I350, port 0 AMC port 0 1

1st Intel® I350, port 1 AMC port 1 2

1st Intel® I350, port 2 Front I/O connector J3 (GbE B) 3

1st Intel® I350, port 3 Front I/O connector J4 (GbE A) 4

2nd Intel® I350, port 0 AMC port 8 --

2nd Intel® I350, port 1 AMC port 9 --

2nd Intel® I350, port 2 AMC port 10 --

2nd Intel® I350, port 3 AMC port 11 --

User Guide

AM4024(E)

2.8 AMC Interconnection

The AM4024(E) communicates with the carrier board or the MicroTCA backplane via the AMC Card-edge

connector, which is a serial interface optimized for high-speed interconnects. The AMC Card-edge connector supports a variety of fabric topologies divided into five functional groups:

» Fabric interface

» Synchronization clock interface

» System management interface

» JTAG interface

» Module power interface

The following sections provide detailed information on these interfaces.

2.8.1 Fabric Interface

The Fabric interface is the real communication path and comprises 20 high-speed ports providing

point-to-point connectivity for module-to-carrier and module-to-module implementations. The highspeed ports are separated in three logical regions as follows:

» Common Options Region

» Fat Pipes Region

» Extended Options Region

D R A F T — F O R I N T E R N A L U S E O N L Y

The AM4024(E) port mapping is described below and illustrated in Figure 10.

www.kontron.com

31

Page 32

AM4024:

» Common Options Region:

» Ports 0-1: Two Gigabit Ethernet SerDes ports

» Ports 2-3: Two Serial ATA ports

» Fat Pipes Region:

» Ports 4-7: One x4 PCI Express interface operating as root-complex only

» Extended Options Region:

» Port 14: One debug port

» Port 15: One serial port

» Port 16: Two GPOs

AM4024E:

» Common Options Region:

User Guide

AM4024(E)

» Ports 0-1: Two Gigabit Ethernet SerDes ports

» Ports 2-3: Two Serial ATA ports

» Fat Pipes Region:

» Ports 4-7: One x4 PCI Express interface operating as root-complex only

» Ports 8-11: Four Gigabit Ethernet SerDes ports

» Extended Options Region:

» Port 14: One debug port

» Port 15: One serial port

» Port 16: Two GPOs

www.kontron.com

D R A F T — F O R I N T E R N A L U S E O N L Y

32

Page 33

Figure 10: AM4024(E) Port Mapping

User Guide

AM4024(E)

Port No.

TCLKA

TCLKB not used not used

FCLKA PCIe Reference Clock (output) PCIe Reference Clock (output)

0

1

2

3

Basic Connector

Extended Connector

4

5

6

7

8

9

10

11

12

13

14

15

TCLKC/D TCLKC / 2 x GPO TCLKC/ 2 x GPO

17

18

19

20

Standard Port Mapping

AMC

Clocks

Common

Options

Region

Fat

Pipes

Region

Extended Options

Region

AM4024

Port Mapping

TCLKA (input) TCLKA (input)

GbE-0 GbE-0

GbE-1 GbE-1

SATA-A (6Gb/s) SATA-A (6Gb/s)

SATA-B (6Gb/s) SATA-B (6Gb/s)

1 x4 PCIe 1 x4 PCIe

not used

not used not used

not used not used

Debug / not used Debug / not used

Serial (COMA) Serial (COMA)

not used not used

not used not used

not used not used

not used not used

AM4024E

Port Mapping

GbE-8

GbE-9

GbE-10

GbE-11

www.kontron.com

D R A F T — F O R I N T E R N A L U S E O N L Y

33

Page 34

User Guide

AM4024(E)

2.8.2 Synchronization Clock Interface

On the AM4024(E), two PCI Express reference clock configurations are supported in accordance with

the PCI Express Base Specification Revision 3.0 as follows:

» AM4024(E) uses local PCI Express reference clock, and AMC (input) clock (FCLKA) is disabled.

In this configuration, the clock spread spectrum modulation must be disabled.

» AM4024(E) uses local PCI Express reference clock, and AM4024(E) generates PCI Express ref-

erence clock to the AMC Card-edge connector (FCLKA)

The PCI Express reference clock configurations can be set via the uEFI BIOS kBoardConfig command,

option AMCFclka.

2.8.3 System Management Interface

The system management interface is a port from the module to the carrier via the Local Intelligent Platform Management Bus (IPMB-L). The Module Management Controller uses this port for the communication with the carrier Intelligent Platform Management Controller (IPMC). The IPMB-L is a multimaster I²C bus.

2.8.4 JTAG Interface

JTAG support is provided on the AMC Card-edge connector. The JTAG interface is supported for vendor

product test and logic update.

On the AM4024(E), the FPGA JTAG port is connected to the AMC JTAG port.

2.8.5 Module Power Interface

The module power interface provides the management power (MP) and payload power (PWR). These two

supply voltages must have power-good indicators so that the system management can detect boot sequence events and nominal operating conditions.

The AM4024(E) operates with payload power in the range of 10.8 V to 13.2 V, and with management

power of 3.3 V ± 5%.

The board supports removal and insertion in a powered slot as required by the AMC.0 specification.

2.8.6 AMC Card-edge Connector J1

The AMC Card-edge connector is a high-speed serial interface with 170 pins. The following table provides the pinout of the AMC Card-edge connector J1. The shaded table cells indicate signals that are

not used on the AM4024(E).

D R A F T — F O R I N T E R N A L U S E O N L Y

Note: When handling the board, take care not to touch the gold conductive fingers of the AMC

Card-edge connector. Failure to comply with the instruction above may cause damage to

the board or result in improper system operation.

www.kontron.com

34

Page 35

User Guide

AM4024(E)

2.8.6.1 Pinout of AMC Card-edge Connector J1 on the AM4024

Table 14: Pinout of AMC Card-edge Connector J1 on the AM4024

BASIC SIDE (COMPONENT SIDE 1) EXTENDED SIDE (COMPONENT SIDE 2)

PIN SIGNAL FUNCTION DRIVEN BY PIN SIGNAL FUNCTION DRIVEN BY

1 GND Logic Ground - 170 GND Logic Ground -

2 PWR Payload Power Carrier 169 TDI JTAG Test Data Input Carrier

3 PS1# Presence 1 AMC 168 TDO JTAG Test Data Output AMC

4 MP Management Power Carrier 167 TRST# JTAG Test Reset Input Carrier