Konica Minolta MULTI GLOSS 268, UNI GLOSS 60A, UNI GLOSS 60CT, UNI GLOSS 60S Instruction Manual

Page 1

Instruction Manual

Betriebsanleitung

Mode d´emploi

MULTI GLOSS 268

UNI GLOSS 60

MULTI GLOSS 268A

UNI GLOSS 60A

UNI GLOSS 60CT

UNI GLOSS 60S

Instruction Manual

Page 2

1

Instruction Manual

Patent pending

260 023 933 E 1609

MULTI GLOSS 268A

UNI GLOSS 60A

UNI GLOSS 60CT

UNI GLOSS 60S

Page 3

2

Page 4

3

Table of content

Table of content

1. Safety Symbols ......................................................................................6

2. Safety Precautions .................................................................................7

3. Notes on Use...........................................................................................8

4. System description .............................................................................. 13

5. Power supply........................................................................................ 14

5.1 Power supply battery-operated ............................................................ 14

5.2 Changing the battery ............................................................................. 15

5.3 External power supply........................................................................... 15

6. Controls ................................................................................................. 16

7. Getting started ...................................................................................... 18

7.1 Turning on the unit and measuring ....................................................... 18

7.2 Navigation ............................................................................................... 19

7.3 Change names/numbers ....................................................................... 20

7.4 Overview of main menu ......................................................................... 21

8. Calibrate ............................................................................................... 22

8.1 Autodiagnosis ........................................................................................ 22

8.2 Calibrate ................................................................................................. 23

8.2.1 Gloss ........................................................................................... 23

8.2.2 Change cal.values ....................................................................... 24

8.2.3 Status ........................................................................................... 25

8.2.4 Scale Gloss ................................................................................. 25

8.3 Calibrating standards ............................................................................ 26

8.4 Checking standard ................................................................................ 26

9. Measurement techniques .................................................................... 27

9.1 Paints and varnishes, plastics and similar materials ......................... 27

9.2 Anodized aluminum and other metal surfaces .................................... 28

10. Measurement Modes ........................................................................... 29

10.1 Sample mode ......................................................................................... 29

Page 5

4

Table of content

10.2 Statistics ................................................................................................ 30

10.2.1 Number of measurements .......................................................... 31

10.2.2 Display ......................................................................................... 31

10.2.3 Exit block ...................................................................................... 33

10.2.4 Delete block ................................................................................. 33

10.2.5 Delete measurement .................................................................. 33

10.3 Continuous ............................................................................................. 34

10.4 Basic mode ............................................................................................ 35

11 Geometry ..............................................................................................36

11.1 Geometry selection ............................................................................... 36

12. Memory ................................................................................................. 37

12.1 Memory................................................................................................... 37

12.2 Select memory ....................................................................................... 37

12.3 Create memory ...................................................................................... 38

12.4 Delete memory....................................................................................... 38

12.5 Display memory ..................................................................................... 38

13. Difference measurement and Pass/Fail ............................................ 40

13.1 Difference ............................................................................................... 40

13.2 Measure standard ................................................................................. 40

13.3 Select standard ..................................................................................... 41

13.4 Create standard ..................................................................................... 42

Define standard .............................................................................................. 42

13.5 Change standard ................................................................................... 43

13.6 Delete standard ..................................................................................... 43

14. Setup ..................................................................................................... 44

14.2 Date/Time ............................................................................................... 44

14.3 Beeper .................................................................................................... 44

14.4 Display time ............................................................................................ 44

14.5 Language................................................................................................ 45

14.6 Info .......................................................................................................... 45

15. Interface ................................................................................................ 46

16. Standards..............................................................................................47

17. Specifications ....................................................................................... 48

Page 6

5

Table of content

18. Accessories ........................................................................................... 49

19. Errors and warning messages ............................................................ 50

20. Cleaning and maintenance ................................................................ 52

21. Copyright .............................................................................................. 53

Page 7

6

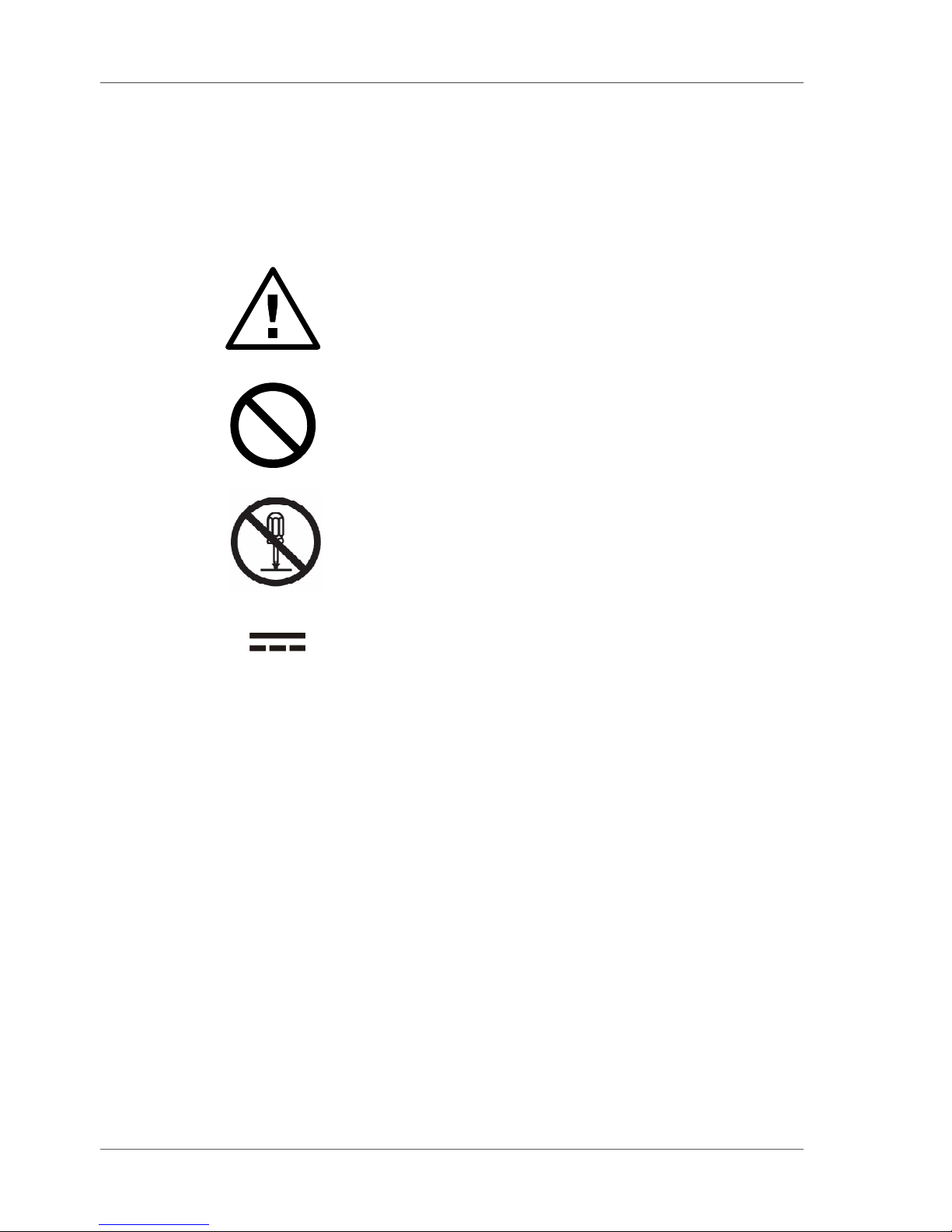

1. Safety Symbols

The following symbols are used in this manual and

the instrument to prevent accidents which may

occur as a result of incorrect use of the instrument.

• Denotes a sentence regarding a safety warning

or note. Read the sentence carefully to ensure

safe and correct use.

• Denotes a prohibited operation. The operation

must never been performed

• Denotes a prohibited operation. Never

disassemble the instrument.

• This symbol indicates direct current (DC).

Notes on this manual

• Copying or reproduction of all or any part of the

contents of this manual without permission of the

manufacturer is strictly prohibited.

• The contents of this manual are subject to

change without prior notice.

• Every effort has been made in the preparation of

this manual to ensure the accuracy of its

contents. However, should you have any

questions or find any errors, please contact the

store where you purchased the instrument.

• The manufacturer will not accept any

responsibility for consequences arising from the

use of the instrument.

Safety Symbols

Page 8

7

2. Safety Precautions

To ensure correct use of this instrument, read the following points carefully and

adhere to them. After you have read this manual, keep it in a safe place where

it can be referred to anytime a question arises. If you pass this instrument to

somebody else, make sure to include these instructions.

Safety Precautions

Do not use the instrument in

places where flammable or

combustible gases (gasoline

etc.) are present. Doing so may cause fire.

Do not disassemble or modify

the instrument or the Power

supply. Doing so may cause a

fire or electric shock.

Take special care not to allow

liquid or metal objects to enter

the instrument. Doing so may

cause a fire or electric shock. Should liquid

or metal objects enter the instrument,

disconnect the Power supply from the AC

outlet immediately, and contact the store

where you purchased the instrument.

The instrument should not be

operate if it is damaged, or if

smoke or odd smells occur.

Doing so may result in a fire. In such

situations, remove the battery and/or

immediately disconnect the USB interface

cable, and contact the company where you

purchased the instrument.

CAUTION (Failure to adhere to the following points may result in injury

or in damage to the instrument or other property)

Do not use batteries other

than those specified. When

installing batteries in the

instrument, make sure that they are correctly

oriented according to the (+) and (-) marks.

Failure to adhere to these instructions may

cause batteries to explode or leakage of

electrolytes, resulting in fire, injury or air

pollution.

Only devices that meet the

requirements for low-voltage

safety can be connected to the

USB interface.

WARNING (Failure to adhere to the following points

may result in death or serious injury.)

Do not dispose of batteries in

fire, short the terminals, apply

heat to them, or disassemble

them. Also, do not recharge them. Doing so

may cause explosion or heat generation,

resulting in fire or injury.

Do not touch the battery with wet

hands. Doing so may cause

electric shock.

Page 9

8

Notes on Use

3. Notes on Use

• The measurement unit consists of sensitive

precision optical and electronic parts.

Do not drop it. Protect it from being bumped or

jostled.

• Do not hold the unit by the measurement

aperture. You should not allow any foreign

objects to get into this opening.

• Do not expose the unit to direct sunlight for

extended periods of time. Do not store it in a hot

or dusty environment. The case that comes with

the unit offers the best protection when the unit

is being stored.

• Avoid prolonged high relative humidity and do not

allow condensation to form.

• Protect the measuring unit from moisture,

chemicals and corrosive vapors.

• The holder and the unit housing are resistant to a

number of solvents. However, we cannot

guarantee resistance to all chemicals. You

should therefore use a soft, moist cloth for

cleaning. For clean excessive dirt and dust, use

ethanol or cleaning alcohol.

Do not use any acetone!

• If you will not be using the measuring unit for an

extended period of time, remove the battery to

prevent it from leaking in the unit and thus

potentially causing damage.

Page 10

9

Notes on Use

• Do not replace the internal backup battery

yourself. Contact the nearest authorized service

facility to replace the backup battery.

• If the instrument is subjected to strong static

electricity, the display may become blank. If this

occurs, wait for the power to be automatically

switched off, and then switch the power on

again.

• Do not perform any repairs on the unit yourself.

The unit must be opened by trained professions

only. Please contact our customer service

department in such cases.

• Do not use accessories other than those

specified by KONICA MINOLTA INC.

• Pollution degree 2: Use it in areas where there is

no metal dust and no possibility of condensation.

• Do not use at altitudes of higher than 2000m.

Additional information on use:

• Make sure that the instrument, accessories and

used battery are either disposed of or recycled

correctly in accordance with local laws and

regulations.

Page 11

10

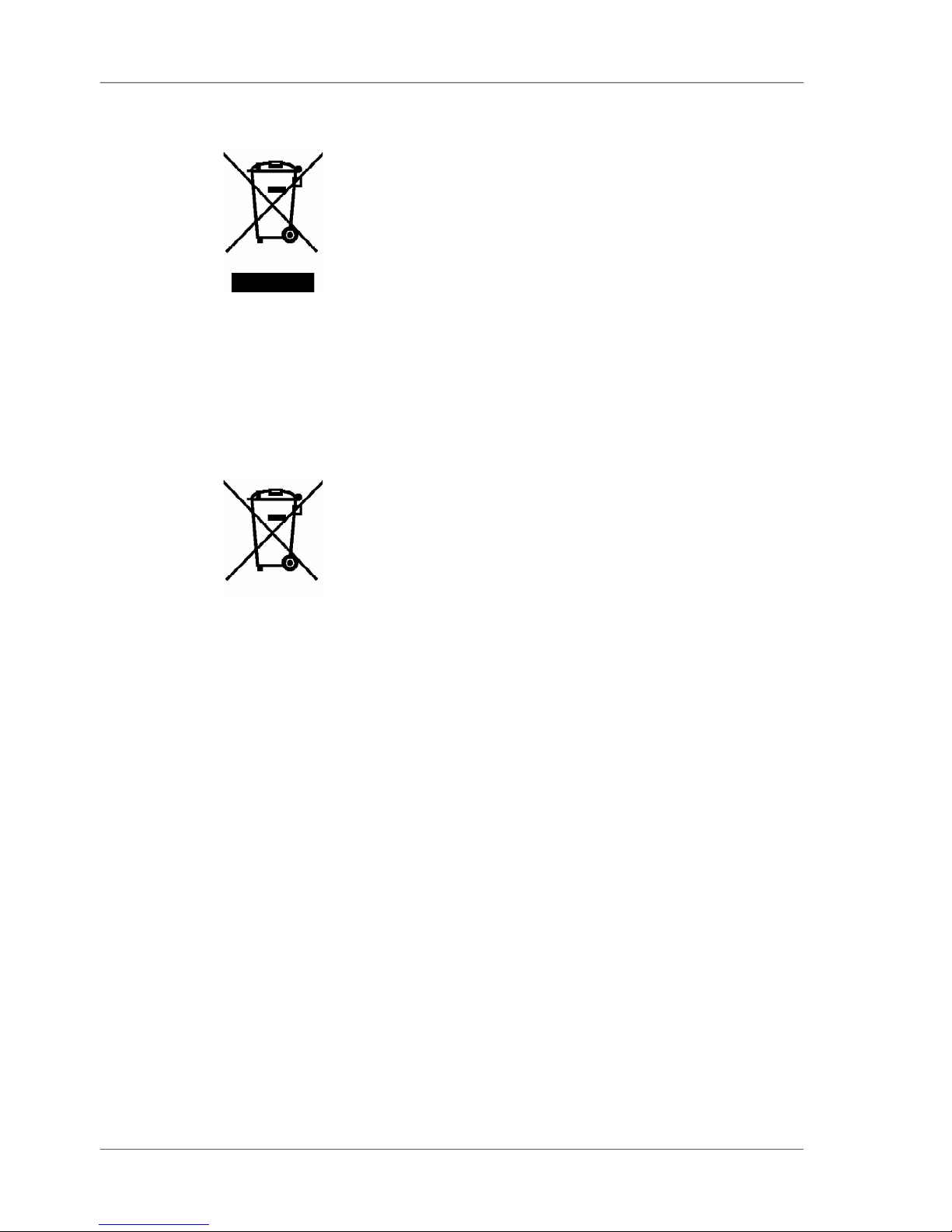

For EU member states only:

This symbol means: Do not dispose of this product

together with your household waste.

Please refer to the information of your local

community or contact our dealers regarding the

proper handling of end-of-life electric and electronic

equipment.

Recycling of this product will help to conserve

natural resources and prevent potential negative

consequences for the environment and human

health caused by inappropriate waste handling.

For EU member states only:

This symbol on the batteries or on the packaging

indicates that the batteries provided with this

product shall not be disposed of as unsorted

municipal waste. If chemical symbol Cd, Hg or Pb

is placed beneath the symbol, the symbol means

that the battery or accumulator has a heavy metal

content that exceeds a certain concentration level.

By contributing to the collection and recycling of

waste batteries, you will help to reduce potential

effects on the environment and human health that

could otherwise arise from inappropriate waste

handling.

In case of products that require a permanent

connection with incorporated batteries for safety,

performance, medical or data integrity reasons, the

batteries are not readily removable and are not

intended to be replaced and disposed of separately

from the products by end users. These types of

batteries will be separated by recyclers during the

treatment phase of the products as required under

the WEEE Directive 2002/96/EC.

For all other batteries, please refer to the section in

the instruction manual on how to remove the

batteries from the products safely and take the used

batteries to the applicable collection point, in

Notes on Use

Page 12

11

accordance with your national legislation and the

Directive 2006/66/EC.

For more detailed information about recycling of

products or batteries, please contact your local

municipality, collection/recycling services or shops

where you purchased the product.

For China only

Notes on Use

Page 13

12

System description

4. System description

Measurement units of the portable glossmeter

family can be used to determine the gloss level of

paint coatings, plastics, ceramics and metal

surfaces.

Light is directed at the surface of the sample at a

defined angle and the reflected light is measured

photoelectrically (reflectometer).

Depending on the typical gloss level of the test

object, reflectometers that direct light onto the

surface at different angles (geometry) can be used.

Measurement units are equipped with standard

geometries of 20°, 60° or 85°. All three of these

geometries are integrated into the three angle units.

Functions described in this manual in terms of

geometry selection are only available with the three

angle device.

In addition to measuring individual gloss values, it is

also possible to record, save and statistically

evaluate series of measurements consisting of up to

999 values.

The operate button and scroll wheel are used to

control the system. System operation is supported

by display messages (autodiagnosis and error

messages).

The measurement unit conforms to the standards

ISO 2813, ASTM D 523, ASTM D 2457, DIN 67530

and ISO 7668, JIS Z 8741 (excluding 60°S)

Page 14

13

Comes complete with:

Measurement device

Protective holder with integrated calibration tile

Traceable certificate

USB-cable

Quick user guide and Safety instructions

Battery

Carrying case.

Additionaly, Software and Operating manual can be

downloaded from the support section of the

instrument suppliers website.

System description

Page 15

14

Power supply

5. Power supply

Before operating the instrument for the first time,

please read the operating instructions and pay

attention to the Safety Precautions in Chapter 2.

Unpack the device and check to make certain all

pieces have been included with delivery (for scope of

delivery, see section System description).

5.1 Power supply battery-operated

The battery must be placed in the measuring unit for

operation service. The device runs on one AA 1.5-V

alkaline or 1.2-V NiMH rechargeable battery.

Use only alkaline batteries or NiMH

rechargeables (AA /LR6)!

Depending on the exact brand, the capacity of each

battery is sufficient for about 4.000 measurements.

When the battery voltage falls below the required

minimum voltage in the course of operation, the

following message appears on the display

Battery low!

To ensure that the unit is always ready for operation,

it is recommended to have a spare battery handy,

especially when performing measurements in the

field.

Page 16

15

Power supply

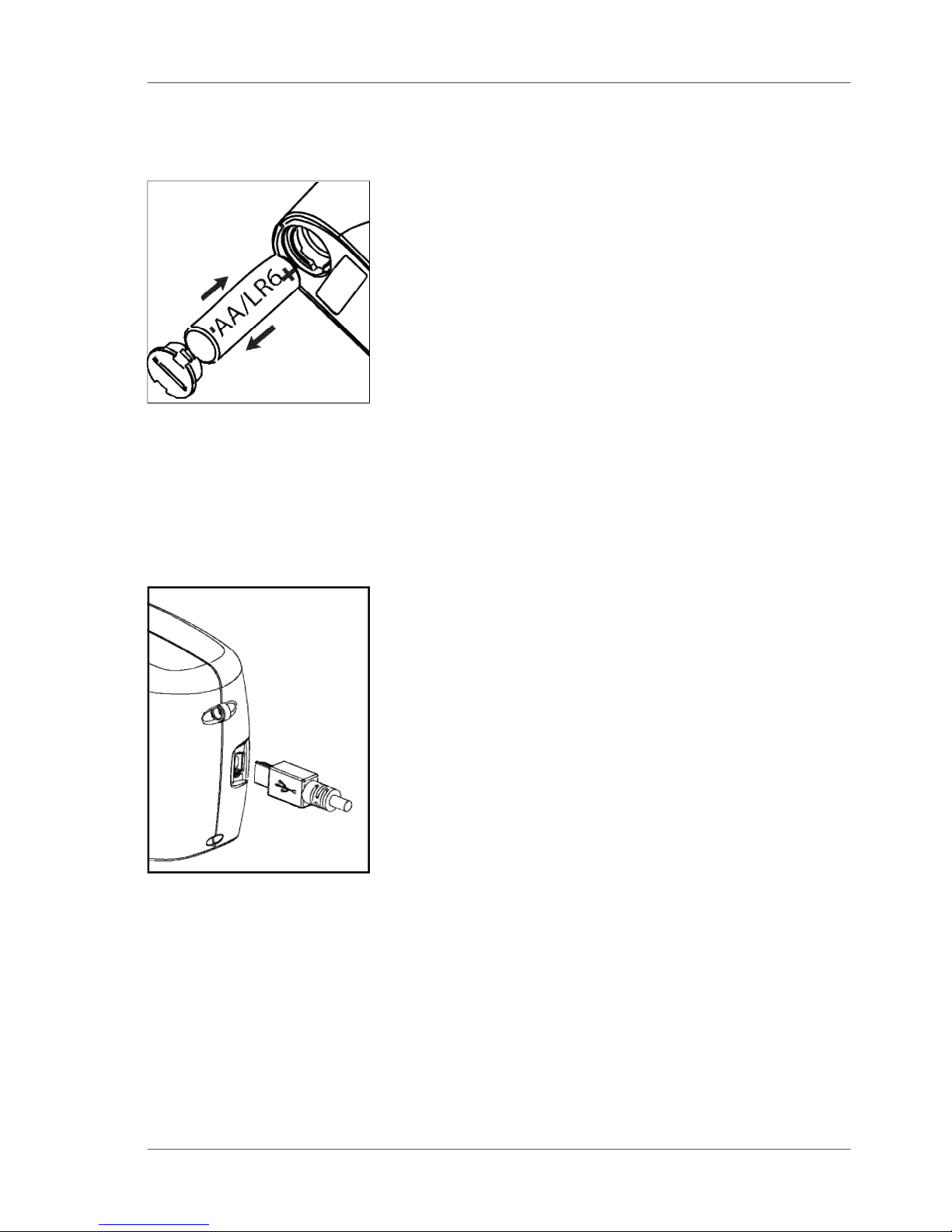

5.2 Changing the battery

To insert or change the battery open the battery

compartment. The easiest way to do this is by

turning the cover with a coin one-eighth of a rotation

to the left. Turn the device back around and allow

the old battery and the battery compartment cover

to slide into your hand.

Insert the new battery with the positive (top) end first

into the battery compartment and set the battery

compartment cover in place again. Lock the cover

by turning it one-eighth of a rotation to the right.

5.3 External power supply

The instrument can be operated and supplied at a

computer via USB-port. For the connection to the

PC use the USB- cable included in the delivery.

Please refer to the chapter Interface for installation

of the required software and drivers.

For power supply specification note the technical

data.

Changing the battery

Page 17

16

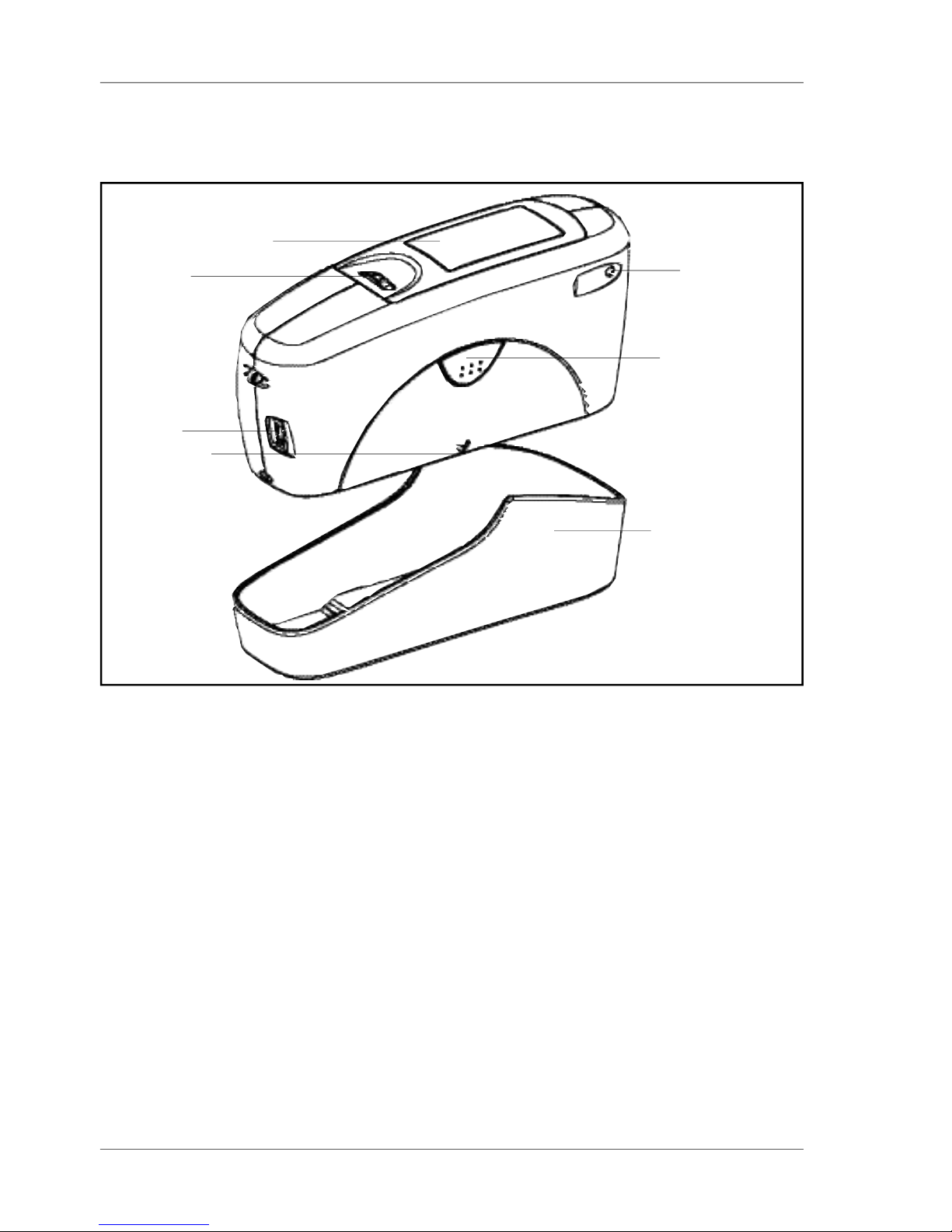

Controls

Measurement unit and protective holder

1 Mode scroll wheel: used to turn the unit on and for menu selection

2 Display for user guidance and displaying measurement values

3 Signal lamp:

green: measurement active

red: error

4 Operate button: used to activate measurements

5 Protective holder with integrated calibration standard

6 Mark for the measurement aperture

7 USB interface for connecting to a PC

1

2

4

3

6

7

5

6. Controls

Page 18

17

Controls

The basic system consists of the measuring device

and the protective holder.

The protective holder is used for calibration and to

store the measurement unit. Calibration is

performed inside the holder automatically at the

touch of a button. The gloss standard required for

this purpose is kept in the holder and is positioned

in such a manner that calibration is always

performed at the same point.

When the device is turned on inside the holder, it

performs a self-test (autodiagnosis).

If you will not be using the measuring unit, please

store it in the protective holder. In this way the

measurement optics are protected from dirt and

dust and the calibration standard is always readily

available.

The operate button and scroll wheel are used to

control the system. Pressing the wheel turns the

unit on and causes a menu to be displayed. All

settings within the menus are made by turning and

pressing the wheel.

Pressing the operate button starts measurements or

performs functions that are displayed. In addition,

you can return from the various menus to mode with

the operate button. System operation is supported

by an autodiagnosis test, comments and error

messages. Measurement values and comments

appear in the display.

Page 19

18

Getting started

7. Getting started

7.1 Turning on the unit and measuring

To turn on the unit, press the mode scroll wheel.

Information on the date and last certification appears

in the display. If the device was turned on in its

holder, the autodiagnosis test is performed (see the

section on Calibration).

Then the unit switches into the last measurement

mode to be selected.

Pressing operate initiates measurements.

The display of measurement results on the screen

may be broken down into the following elements:

A: When Difference measurement is turned on,

the name of the standard that is selected is

displayed here.

B: If Memory is selected, the memory area that

is selected appears at the top left and for

C: the sample name (block name).

D: If Statistics or Continuous is turned on, the

number of measurements performed or selected is

displayed here.

The measurement values appear in the lower part of

the display area. The size of the numbers depends

on whether Statistics or Difference measurement

has been activated and on the number of geometries

displayed. Depending on the measurement mode, a

header line also appears for the measurement

values.

Page 20

19

Getting started

7.2 Navigation

All control functions are controlled by the mode

scroll wheel. Pressing the wheel causes a menu to

appear in the display. Turning the wheel allows you

to move the black mark to the desired function and

to select or activate it by pressing the wheel.

What functions are displayed in the menu depends

on the settings in the main menu. The main menu is

the “central” level and can always be reached

quickly.

Certain rules apply within the menus to make it

easier to navigate:

A black triangle to the right of a function indicates

that selecting this function will take you to a submenu.

A check mark on the right indicates that the function

in question has been activated.

You can use the arrow at the top right to switch the

display back by one level.

Arrows pointing up or down indicate that there are

other menu options above or below the part of the

menu that is visible. To reach these menu options,

simply turn the scroll wheel in the direction in which

the arrow is pointing.

You can quickly switch back from the menus to the

measurement display by using the operate button.

In some cases this button also has another

function, but that will be indicated in the display (for

example Confirm -> operate).

Page 21

20

Getting started

7.3 Change names/numbers

For some functions, you can enter or change the

date or name. The arrow pointing upward marks the

position that can be changed. To change the

character, turn the scroll wheel. When you press the

wheel, the arrow jumps to the next character.

After you have adjusted the last character or

number, confirm your input by pressing the wheel.

When you enter the name, the arrow jumps to the

first character. This allows you to correct any

inadvertent incorrect entries. You can confirm the

name in these menus at any time with the operate

key.

Page 22

21

Getting started

Measurement without statistical evaluation.

Multiple measurement with statistics.

Continuous measuring with adjustable interval.

Measuring without statistics, saving and difference.

Reactivates all menues and functions when Basic

mode was activated.

Memory functions:

Turn saving on/off.

Select memory area from list.

Enter up to 50 memory areas.

Delete memory content or memory name.

Recall of memory content (use scroll wheel).

Settings for difference mode:

Turn difference measurement on/off.

Measure a standard.

Select standard (if saved).

Enter up to 50 standards and limits for Pass/Fail.

Delete individual standards.

Enter/change limit values for Pass/Fail.

The following can be used together simultaneously:

Mode

Sample mode

Statistics

Continous

Basic mode

Advanced mode

Geometry

Memory

Memory

Select memory

Create memory

Delete memory

Display memory

Difference

Difference

Measure standard

Select standard

Create standard

Delete standard

Changestandard

Calibration

Setup

Calibrate, change cal. values, GU - % scale.

Date/Time, Beeper, Display time, Language, Info

7.4 Overview of main menu

Select geometry.

• Memory with: Sample mode, Statistics, Continuous

• Difference with: Sample mode, Statistics

Page 23

22

Calibrate

8. Calibrate

The holder with the integrated glass standard is

used for calibration. Always keep the measurement

unit in the holder. This protects the measurement

optics and ensures that the standard is always at

hand.

If you have several devices of this type, you must

put the unit in the holder which belongs to the unit

(see the serial number).

Make certain that the standard is clean and

there are no cracks on it.

When you place the device in the holder, make

certain that it ships firmly into place.

8.1 Autodiagnosis

Whenever you turn on the device in the holder, it first

performs a self-test. During this test, any changes in

the measurement signal are tested against saved

calibration data. This allows for a long-term calibration

so that a new calibration is required only about once a

week. Beyond that, calibration is only necessary if

there are significant weather changes (see under 8.2).

It is recommended that you perform the self-test in the

holder regularly (every day).

The autodiagnosis generally takes about 2 seconds.

“Please clean standard” or “Please test standard”

may be displayed. For more information on

cleaning, see Chapter 20.

A message will appear in the display informing you

that the autodiagnosis has been completed

successfully.

In some cases, the system may suggest that you

repeat the calibration. The reason for this may be

changed ambient conditions. It is also possible,

however, that the standard still has small amounts

of residue left over from cleaning. This problem can

generally be alleviated by cleaning with a dry optical

cleaning cloth.

Page 24

23

Calibrate

8.2 Calibrate

You should recalibrate the device if ambient

conditions have changed. This applies especially

when changing location if major changes in

temperature and relative humidity may be expected

as a result (for example inside/outside).

When moving from cold areas to warm areas, there

is a danger of condensation. For this reason, after

there has been a change in ambient conditions, you

should wait for an appropriate amount of time to

allow the optical components to adjust before

calibrating and using the unit.

Use the path shown on the left side to reach the

Calibrate menu option.

8.2.1 Gloss

To begin calibration, press the scroll wheel.

The calibration process is performed automatically

for all three geometries. The saved calibration values

of the standard appear in the display.

The unit then returns to the selection menu

Calibration.

Page 25

24

8.2.2 Change cal.values

The gloss values of the calibration standard in the

holder included with delivery are saved in the

measuring device. During automatic calibration, this

data is assigned to the standard in the holder.

In some cases it will be necessary to enter data for

a new calibration standard, for example if the

previous standard has been damaged or scratched.

To ensure exact calibration, only original

standards from the manufacturer should be

used.

You can use the path shown on the right side to

reach the Change cal.values menu option.

At three angle units, a selection menu will appear

for geometries. Select the desired geometry and

press the scroll wheel.

A warning message appears. You can cancel this

process by pressing the operate button.

If you press the scroll wheel, you will continue with

the process of changing calibration values.

In the next display you can enter new calibration

values.

Calibrate

Page 26

25

8.2.4 Scale Gloss

You can use the Scale menu option to switch back

and forth between Gloss Units and Reflectance (see

the Section on Practical measuring suggestions).

Move the mark to the desired entry and press mode.

A check mark identifies the Scale that is selected.

After you switch the Scale, the unit must not be

recalibrated.

Calibrate

After you have entered the new value, a warning

message appears again in the display. You can

again abort the process with operate.

If you confirm the new value by pressing the scroll

wheel, the value will be accepted.

After you have changed all necessary values, you

should recalibrate the measurement device as

usual.

8.2.3 Status

This menu item provides you with information on the

calibration status of the unit.

In particular, you can check here whether the saved

calibration values match those of the holder. The

display also indicates if an error message was

generated as a result of the last autodiagnosis or

calibration. If this has happened, further information

is available under Section Errors and warning

messages.

Page 27

26

Calibrate

8.3 Calibrating standards

To ensure exact calibration, only original standards

from the manufacturer should be used.

These are calibrated against tested primary

standards. Their surface must not be touched and

must be protected against scratches. Due to

environmental influences, however, the values of

standards can change over the course of time even

if they are handled gently. For this reason, you

should have the calibration standards tested by the

manufacturer at regular intervals (we recommend

annually).

8.4 Checking standard

We recommend the regular use of a separate test

standard for control of test equipment. The

frequency of this verification depends on the

conditions of usage (for example monthly). The

gloss standards are integrated into an aluminum

guide in which the measurement device is

positioned exactly. Perform the measurement as

you would normally, for example in Basic mode. The

displayed measurement value must not deviate from

the value printed on the standard by more than one

unit. Otherwise you should check whether there is

dirt and dust on the high gloss standard in the

holder or test standard. If cleaning and recalibration

do not offer any improvement, please get in touch

with our Customer Service.

Page 28

27

Measurement techniques

9. Measurement techniques

In accordance with the standard, the reflectometer

value is related to a black glass standard at a

defined index of refraction (generally 1.567) which is

thus equal to 100 units.

Reflectometers are differentiated by the angle of

incidence of the illuminating mechanism.

Geometries are set in the standards at 20°, 60° and

85°.

9.1 Paints and varnishes, plastics and similar materials

The various geometries are distinguished according

to their fields of application as follows:

Semi-gloss surfaces are measured at an angle of

incidence of 60° and should fall within a range from

10 to 70 gloss units.

Highly reflective surfaces with measurement values

exceeding 70 units in the 60° geometry should be

measured at 20°.

On the other hand, matte surfaces with less than 10

gloss units (at 60°) should be measured at the 85°

geometry.

Page 29

28

Measurement techniques

9.2 Anodized aluminum and other metal surfaces

The measuring unit is equipped with an extended

measuring range for measuring samples with a very

high reflectance.

The reflectance of non-metallic surfaces increases

with the angle of incidence. The reflective properties of

metals do not always behave in this manner. Because

of double reflection, the light is partially reflected on

the coating and partially on the metal underneath. For

a complete understanding of the reflective properties

of such surfaces, it is recommended to measure them

at all geometries.

In addition to the reference to a black glass standard

(gloss units), it is also common in the area of metals

to relate the reflectometer value to the amount of

irradiated light and to express it as a % (reflectance).

You can select this in the Scale menu.

Notes

Proper measurements are only possible on level

surfaces.

Measurements on dirty, scratched or otherwise

distorted areas of the test specimen are not meaningful except as a way of determining the degree of such

imperfections by means of a gloss measurement.

Since it cannot be assumed that the gloss capacity is

not constant over the entire surface of the test

specimen, the reflectometer value can be measured

at several different places and the standard deviation

can be determined.

If the sample exhibits structures or directionally

dependent gloss properties, the structural features

and the direction of the incident light should be

specified for the measurement in the test report.

Samples that must be measured several times over

the course of an examination (for example weathering

samples) should be marked accordingly to ensure

that the measurement is made at the same point

during repeated tests.

Page 30

29

10. Measurement Modes

You can select different types of measurement in

the Mode menu. The mode that is activated is

identified by a check mark.

10.1 Sample mode

Single measurements can be performed without

statistical evaluation in Sample mode.

The results can be saved and compared with a

standard (refer to Memory or Difference).

When Memory is turned on, a name is suggested

after every measurement. You can confirm this

name directly or change it.

If you would like to delete the last measurement,

press the scroll wheel and select the appropriate

menu item.

Measurement Modes

Page 31

30

10.2 Statistics

You can make multiple measurements with each

sample in Statistics mode. These measurements

will be evaluated statistically and displayed.

The results can be saved and compared with a

standard. These functions must be previously

activated (refer to Memory or Difference).

Measurement Modes

When Memory is turned on, a name is suggested

after all measurements of a sample (block). You can

confirm this name directly or change it.

When the Statistics function is turned on, additional

functions are available depending on the context

after you press the scroll wheel.

Page 32

31

Measurement Modes

10.2.1Number of measurements

You can adjust the number of measurements per

sample or per block with this option, from 2 - 99.

You can find this value in the measurement display

by looking for “n=” after the forward slash. The

number of measurements (which increases by one

each time a measurement is performed) appears

before the slash.

10.2.2Display

In the Statistics measurement display, you can

assign the following data freely to three columns:

Value:

Last value to be measured

Mean value:

Arithmetic mean of the sample (block).

Maximum:

Highest measurement value of the sample

Minimum:

Lowest measurement value of the sample

Range:

The difference between the maximum and minimum

value.

Page 33

32

Measurement Modes

Std. Dev.:

The standard deviation of the sample

Difference*:

The difference between the sample and a target

value.

Pass/Fail*:

Pass is displayed if the sample value falls within the

specified limits, or Fail if it falls outside.

Off:

Turns off the display of the selected column.

* To be able to use these functions, a standard must

be measured, created or selected. In particular, a

limit value must be defined.

Page 34

33

Measurement Modes

10.2.3Exit block

This function terminates the block before it reaches

the required number of measurements n. It is useful

if you have selected a high number of

measurements for n, for example in the case of

large samples.

If Save is turned on, a display appears to enter a

block name for the sample.

10.2.4Delete block

This function deletes the current block.

10.2.5Delete measurement

This function deletes the last measurement value.

Page 35

34

Measurement Modes

10.3 Continuous

You can use this function to perform up to 99

measurements at an adjustable measurement

interval. This is helpful when you are covering large

samples and you want to evaluate the homogeneity

of the surface.

Activate Continuous under Mode from the Main

menu.

A screen appears for starting a new sequence.

To start the measurement, press operate. The unit

now performs measurements up to 99 times at the

set interval. Measurement values are shown in the

display after each measurement.

You can interrupt the continuous measurement by

pressing the operate button (hold it down briefly).

The number of measurements, the mean value, the

minimum and the maximum appear in the display.

The Pause symbol on the left side indicates that

you can continue the sequence, therefore press the

operate button.

To end the sequence, press mode.

For starting a new sequence, press operate again

If saving is activated, a screen appears at start of a

new sequence, which allows to enter a sample

name.

Page 36

35

Measurement Modes

The measuring interval can be changed before a

sequence is started. Therefore press the mode

wheel to open the Continuous submenu.

The longest measurement interval possible is 9

seconds, the shortest 0 seconds for continous

measuring.

10.4 Basic mode

The selection options are limited to the most

essential in Basic mode. This also greatly simplifies

operation in this mode.

You can select geometry and perform calibration. In

addition, all functions in the Setup menu item are

available.

Basic mode is useful if you want to interrupt a

series of measurements and quickly perform some

other measurements in the middle without leaving

the series of measurements.

Once these other measurements are complete, you

can use

to return to the point where you interrupted the

series of measurements.

Page 37

36

11 Geometry

In this menu, you can select the geometry for the

gloss measurement.

11.1 Geometry selection

Choose Gloss Geometry from the Geometry menu.

You can choose between the representation of one,

two or all three geometries in the display.

The currently set angle combination is indicated in

the Geometry menu by a check mark.

Select the desired combination with the scroll wheel

and then confirm by pressing mode.

When Save is turned on, switching the geometry

automatically causes the program to switch to the

appropriate predefined area of memory.

Geometry

Page 38

37

12. Memory

To save measurement values, you must activate the

Memory function before measuring or else select or

create a memory. Up to 999 measurements can be

stored. A fixed memory area is already created for

each geometry or combination (e.g. M60°). These

memory areas cannot be deleted. A total of 50

memory areas can be created.

The Memory function can be used for sample mode,

Statistics and Continuous measurements. The

layout of the memory is such that the measurement

mode and the standard can be changed within a

memory area, but not the geometry.

12.1 Memory

You can use this function to turn saving on or off. A

check mark indicates if the function has been

activated.

Turning on Memory automatically selects the area

in memory that is predefined for the currently set

geometry (for example M20°60°).

When you press operate to start a reading, you are

asked to enter a name for this memory.

12.2 Select memory

All available areas of memory are listed in this

menu, beginning with the one that is predefined.

The number of measurements saved for each area in

memory is shown on the right.

Select the appropriate memory area with the scroll

wheel and activate the selection by pressing mode.

This automatically turns on Save and switches the

geometry if necessary (if the selected memory area

is defined for other geometries than what was

previously set).

Memory

Page 39

38

12.3 Create memory

Users can set up their own memory areas with this

function. Select the required geometry before you

activate this function. Then you must enter the

name of a memory area. You can confirm the

suggested name directly with the operate button or

change it with the scroll wheel. After you confirm,

Save is automatically turned on.

12.4 Delete memory

This menu lists all memory areas that have been

created with the number of values stored in each

one.

Use the scroll wheel to move the mark to the

memory area you would like to delete and press the

wheel.

A menu appears in which you can decide whether

you would like to delete just the content of the

memory area or the entire memory area.

For pre-defined memory areas, you can only delete

the measurement values.

12.5 Display memory

You can transfer data that has been saved to a PC

via the interface. The values can also be shown in

the display at any time.

The “Display memory” function opens a menu in

which all memory areas that have been created are

listed. Select the desired area of memory with the

scroll wheel.

Memory

Page 40

39

Memory

The values of the first measurement appear in the

display. The sample name is displayed in the

highlighted field.

Turning the wheel switches the display to the next

sample with its corresponding values.

Which values are displayed in the columns (for

example mean value, min., max.) depends on the

display currently selected for Statistics.

Page 41

40

Difference measurement and Pass/Fail

13. Difference measurement and Pass/Fail

You can compare the readings of samples with the

value of a previously measured or saved standard.

For saved standards, you can also display whether

the test specimen falls within the limits (Pass) or

outside (Fail).

Up to 50 standards can be saved. They are stored in

a separate area of memory. For each geometry you

can determine:

- A target value

- Maximum and minimum for Pass/Fail,

see Create standard or Change standard.

13.1 Difference

You can use this menu option to turn Difference

measurement on or off. A check mark indicates if

the function is active.

When you turn on Difference, the last standard to be

used is automatically selected.

If no standard is available, choose the function

“Measure standard“ or “Create standard“ to

continue.

13.2 Measure standard

We recommend to perform several readings on the

standard with Statistics turned on.

Memory must be activated to store the measured

standard. Otherwise it will be temporary hold until

another standard is measured.

Activate “Measure standard” and perform the

measurement with operate. With memory on, a

window appears after the last reading where you can

enter the standard’s name.

If you inadvertently select a name that has already

been used, a message will appear in the display

and the arrow will jump back to the first position of

the name.

Page 42

41

The measured standard values are saved as the

target values. At the same time, Difference

measurement is turned on and the measured

standard is activated. If you want to define limit

values additionally , you can use the “Change

standard” function.

For measuring the samples continue by pressing

operate. The display shows the sample values and

difference to the target.

The Measure standard function can also be reached

directly from the measurement screen by pressing

mode.

If you want to compare samples without saving the

standard, use the Difference mode with Memory

switched off. A measured standard will be kept

temporary then, until you measure another one.

13.3 Select standard

To select an existing standard, use the arrow to

move the mark to Select standard and then press

the wheel.

The first standard appears in the display. The target

value, minimum and maximum are displayed. For

values that are not defined, 0.0 or 2000 is displayed.

The name of the standard appears inverted at the

top right.

Turning the scroll wheel causes the next standard to

be displayed.

When you have selected the desired standard in the

display, activate it by pressing on the wheel.

A reference to the selected data will appear in the

display.

To start Difference measurement press “operate“.

Difference measurement and Pass/Fail

Page 43

42

Difference measurement and Pass/Fail

13.4 Create standard

Standards can also be saved by entering the target

and limit values with the scroll wheel. Move the

mark to “Create standard” and activate the function.

A display appears in which you must assign a name

for the new standard. If you inadvertently select a

name that has already been used, a message will

appear to this effect and the marker arrow will jump

back to the first position of the name. Confirm the

name with the operate button.

In the next step you can define the target and limit

values of your standard.

Define standard

With the three angle device, a menu first appears in

which you can select the geometry.

After that, the menu appears for selecting the target

value, minimum and maximum.

Select the desired variable and press on the scroll

wheel.

Now you can adjust the corresponding value.

After the last number is activated, the display jumps

back to the previous menu.

In this manner you can enter additional target and/or

limit values for the standard one after the other if

need be. After the entries are complete, Difference

measurement is turned on with the new standard.

Page 44

43

Difference measurement and Pass/Fail

13.5 Change standard

You can use this function to change target values

and limit values of saved standards. You can also

use it to define limit values subsequently (for

example for a measured standard). Use the scroll

wheel to move the mark to Change standard and

press the wheel.

All standards are listed one after the other in the

following menu. Select the desired standard and

press the scroll wheel.

In the next step you can define the target and limit

values as described above.

13.6 Delete standard

Use the selection wheel to move the mark to Delete

standard in the Difference menu and then press the

wheel.

The Delete standard menu appears. All saved

standards are listed in this menu.

If there are more standards than can be shown in

the display, arrows on the right edge of the display

will point to additional standards.

Use the scroll wheel to move the mark to the

desired standard and press the wheel.

The standard to be deleted is listed again in the

display. Confirm by pressing the mode scroll wheel.

The unit then reverts to the previous menu.

Page 45

44

14. Setup

You can make general settings in the Setup menu,

for example Language or Display time.

14.2 Date/Time

The unit contains an integrated clock. This makes

the date and time of the measurement available for

data transfer to a PC. The date and time are not lost

even when the battery is changed. If you would like

to change the time setting, use the scroll wheel to

move the mark to Date/Time and then press mode.

The display for setting the date and time appears.

14.3 Beeper

You can use this menu option to turn the beeper on

or off. Use the scroll wheel to move the mark to

Beeper and press the wheel.

When the beeper is turned on, a check mark

appears at the end of the line.

14.4 Display time

To save electricity, the unit automatically turns off

after a certain amount of time. You can determine

this time yourself with Display time.

Setup

Page 46

45

Setup

14.5 Language

You can use this menu to select the display

language.

Use the scroll wheel to move the mark to the

desired language and press the wheel.

14.6 Info

You can use this menu option to find the following

information:

• Catalog No.

• Serial No.

• Version number of the firmware

• Date of the last calibration

• Date of the last certification

Page 47

46

Interface

15. Interface

The measurement device is equipped with a USB

interface that allows direct communication with a

PC.

For data transfer use the USB cable included with

delivery. Measurement data can be transferred into

the gloss software, which is available for download

from the support section of the instrument suppliers

website. The data are displayed immedeately in a

test report with trend graph.

Page 48

47

Standards

16. Standards

ISO 2813 Paints and varnishes - Determination of specular

gloss of non-metallic paint films at 20°, 60° and 85°

ASTM D 523 Standard Test Method for Specular Gloss

ASTM D 2457 Standard Test Method for Specular Gloss of Plastic

Films and Solid Plastics

DIN 67530 Reflektometer als Hilfsmittel zur Glanzbeurteilung an

ebenen Anstrich- und Kunststoffoberflächen

(Reflectometer as a means for gloss assessment of

plane surfaces of paint coatings and plastics)

JIS Z 8741 Method of Measurement for Specular Glossiness

ISO 7668 Anodized aluminium and aluminium alloys -

Measurement of specular reflectance and specular

gloss at angles of 20°, 45°, 60° or 85°.

Page 49

48

Specifications

17. Specifications

Model MULTI GLOSS 268A UNI GLOSS 60A

UNI GLOSS 60CT

UNI GLOSS 60S

Measurement geometry 20°, 60°, 85° 60°

Size of measurement 20°: 10 x 10mm 60°A, CT: 9 x 15mm

spot 60°: 9 x 15mm 60°S: 2 x 4mm

85°: 5 x 38mm

Standard compliance ISO 2813, ASTM D 523, ASTM D 2457, DIN 67 530

and ISO 7668, JIS Z 8741 (excluding 60° S)

Measurement range 20°: 0.0 ~2,000 GU

60°: 0.0 ~1,000 GU 60°: 0.0 ~1,000 GU

85°: 0.0 ~ 160 GU

Resolution 0 ~99.9 GU: 0.1 GU100~2 000 GU: 1 GU

Repeatability 0.0~99.9 GU: 0.2 GU

100~2,000 GU: 0.2% of reading

60°CT: 0~19.9 GU: 0.1 GU

Inter-instrument 0.0~99.9 GU: 0.5 GU100~2,000 GU: 0.5% of reading

agreement 60°CT: 0~19.9 GU: 0.2 GU

Memory 999 measurements with date and time

Difference measurement Memory for 50 standards

Battery performance Approx. 4,000 measurements (when using 1.5 V

AA(R6) size alkaline battery)

Measurement time 0.5 seconds / geometry

Auto power off 10~99 seconds selectable

Languages English, Spanish, German, French, Italian,

Japanese, Russian, Polish, Portuguese, Turkish

Measurement mode Normal mode (Sample mode, Statistics,

Continuous, Basic mode), Difference mode

Interface USB 2.0

Operation temperature/ 15 to 40°C relative humidity max. 85% (at 35°C)

humidity range with no condensation

Storage temperature/ -10 to 60°Crelative humidity max. 85% (at 35°C)

humidity range with no condensation

Power 1.5 V AA(R6) size alkaline battery, or via USB-port of PC

Size 155(W) × 73(H) × 48(D) mm

Weight 400 g

Page 50

49

18. Accessories

Model MULTI GLOSS 268A UNI GLOSS 60A

UNI GLOSS 60CT

UNI GLOSS 60S

Standard accessories Calibration holder TRI Calibration holder 60°A

(High gloss tile) Calibration holder 60°CT

Calibration holder 60°S

(High gloss tile)

USB-cable

Carrying case

Gloss Data Software

(Downloadable from internet; 2 licenses)

1.5 V AA(R6) size alkaline battery

Optional accessories Checking standard TRI Checking standard 60°A

(High and 3 semi gloss tiles

Checking standard 60°CT

20, 60, 85°)

Checking standard 60°S

(High and semi gloss tile)

Checking standard Mirror

(

High and

3

semi gloss

tiles 20, 60, 85°)

Note: The accessories described in this document are subject to change without notice.

Accessories

Page 51

50

Errors and warning messages

19. Errors and warning messages

Memory full Transfer the content of memory to a PC and then

delete the contents of memory.

Reference memory full A maximum of 50 references can be saved. It may

be necessary to delete old references.

You will also find an error number for the following messages in the Calibration/

Status menu to provide support for diagnostics:

Tolerance Generally occurs only with major changes in

Error 01 climatic or weather conditions. The deviation was

successfullycompensated for by calibration and

correct measurements are still possible. You should

still recalibrate the device as soon as it is operating

in normal climatic conditions again. However if a

change in climate cannot be considered as the

cause of the problem, you should check whether the

standard is clean.

Please call Service Autodiagnosis has determined an impermissible

Service (invalid) deviation in the measurement signal

that cannot be remedied by recalibrating.

Error 02 Generally occurs when there is a significant amount

of dirt or dust on the standard or optics. First try to

clean the standard. You should only have the optics

cleaned by our Customer Service department, for

example as part of a yearly recertification.

Error 03 Defect in the electronics or operating error. First

check whether the standard is clean and whether

the device is properly snapped into the holder.

Error 04 Defect in the lamp or electronics.

Error 05 Defect in the electronics.

Please observe the instructions on cleaning standards in the section on

Calibration.

Page 52

51

Errors and warning messages

Fluctuations in measurement values

Was the same point on

the sample used for all

measurements?

Yes. It may help to test

the calibration with an

additional standard if

one is available.

Calibration correct:

Is the test surface

completely even and

does the measuring

device have good

contact with the

sample?

Yes: Device defective

No. Check how high the deviations are on

the sample itself.

Calibration not correct:

Recalibrate and clean the standard if

necessary.

No:

In this case, major deviations are possible.

Please contact our Customer Service

department.

Do not attempt to make any repairs yourself! If a malfunction occurs on your

measuring device, our Customer Service department will be happy to help you

as quickly as possible.

Page 53

52

20. Cleaning and maintenance

• Do not insert any objects into the measurement

aperture for cleaning. The instrument could get

damaged - affecting a proper and safe operation.

• The instrument housing is resistant to a number

of solvents, but cannot be guaranteed to withstand

all chemicals. You should therefore use a soft,

moist cloth for cleaning. For cleaning excessive dirt,

use ethanol or cleaning alcohol. Do not use any

acetone!

• Cleaning standards

The accuracy of the measurement can be

significantly impacted by using dirty or damaged

standards.

Since the surfaces of the standards are highly

sensitive, cleaning must be undertaken with great

care.

To clean standards, use a new lint-free cloth, dust-

free lens paper or an optical cloth.

Apply only slight pressure as you clean and make

certain there are no large particles stuck in the cloth

that could damage the surface. Do not use any

acetone!

For dirt that is difficult to remove, use an optical

cloth dipped in liquid. Then wipe the surface with a

dry optical cloth.

Exact calibration is not possible unless the

standard is in perfect condition. If the condition of

the standard seems doubtful

because of its appearance or measurement errors,

we will be happy to check it for you.

Cleaning and maintenance

Page 54

53

21. Copyright

Copyright

Page 55

260 023 933 E 1609

Loading...

Loading...