Konica Minolta DI620PE, MICROPRESS SERVER M500-2, MICROPRESS SERVER CII, MICROPRESS SERVER 062, MICROPRESS SERVER M500 User Manual

Di620PE

CF911PE

Operator’s Manual

Using the Printer Properly

To ensure optimum performance of the printer, follow the precautions listed below.

• Never place a heavy object on the printer.

• Never subject the printer to shocks.

• Never open any doors or turn the printer off while the printer is making prints.

• Never bring any magnetized object near the printer.

• Never use flammable sprays, liquids or gases near the printer.

• Never modify the printer, as a fire or electrical shock could result.

• Never remove any panel or cover which is secured. The printer contains high voltage

components which can cause electrical shock.

• Never tamper with the laser mechanism in laser-equipped models, as blindness or

other injury may result.

• Never drop paper clips, staples or other small pieces of metal through the vents or

other openings in the printer, as a fire or electrical shock can result.

• Never place containers of liquid on the printer. If liquids get inside the printer, they

can cause fire or electrical shock. If a piece of metal or any liquid gets inside the

printer, immediately turn the printer off, unplug the power cord and call your technical

representative. A fire or electrical shock can result if the printer remains plugged in or

is operated after metal or liquid gets inside.

• Never leave the printer running if it becomes unusually hot, or if smoke or an unusual

odor or noise is detected. Should any of these conditions occur, immediately turn the

printer off, unplug the power cord and call your technical representative. A fire or

electrical shock can result if the printer remains plugged in under any of these

conditions.

• Always insert the power plug all the way into the outlet.

• Always make sure that the outlet is visible, clear of the printer or printer cabinet.

• Always provide good ventilation when making a large number of continuous prints.

• Never pull on the power cord, and always hold the plug when unplugging the power

cord. A damaged cord could result in a fire or cause an electrical shock.

• Never unplug the power cord with a wet hand, as it could cause an electrical shock.

• Always unplug the power cord before moving the printer. Moving the printer with the

power cord plugged in can damage the cord resulting in a fire or causing an electrical

shock.

• Always unplug the power cord when the printer is not going to be used for a long time.

• Never place a heavy object on the power cord, or pull or bend it, as a fire or electrical

shock can result.

• Always ensure that the printer does not sit on or ride on the power cord or

communications cable of other electrical equipment, as malfunctioning equipment or

a fire could result.

• Always ensure that the power cord or communications cable of other electrical

equipment does not become wedged into the printer mechanism, as malfunctioning

equipment or a fire could result.

i

Di620PE Operator’s Manual

ii

Using the Printer Properly

• Always use the correct power voltage, as improper voltage can cause a fire or

electrical shock.

• Never use a multiple outlet adapter, as a fire or electrical shock can result.

• Should the power cord become damaged, immediately turn the printer off, unplug the

power cord and call your technical representative. A damaged cord can result in a fire

or cause an electric shock.

• If an extension cord is needed, use one with a greater rated capacity than the

maximum power requirements of the printer. The use of an extension cord that falls

short of supporting the maximum power requirements can result in overheating or a

fire.

• Always unplug the printer whenever anything unusual is observed during operation.

Make sure that the outlet is nearby and clear of the printer and furniture.

=Locate the Printer in a Well Ventilated Room=

A negligible amount of ozone is generated during normal operation of this printer. An

unpleasant odor may, however, be created in poorly ventilated rooms during extensive

printer operations. For a comfortable, healthy and safe operating environment, it is

recommended that the room be well ventilated.

=Placer le l’appareil dans une pièce largement ventilée=

Une quantité d’ozone négligeble est dégagée pendant le fonctionnement du l’appareil

quand celui-ci est utilisé normalement. Cependant, une odeur désagréable peut être

ressentie dans les pièces dont l’aération est insuffisante et lorsqu’une utilisation

prolongée du l’appareil est effectuée. Pour avoir la certitude de travailler dans un

environnement réunissant des conditions de confort, santé et de sécurité, il est

préférable de bien aérer la pièce ou se trouve le l’appareil.

Di620PE Operator’s Manual

iii

Safety Precautions

Safety Information

This is a digital printer which prints by means of a laser. There is no possibility of danger from the laser,

provided the printer is operated according to the instructions in this manual.

Since radiation emitted by the laser is completely confined within protective housing, the laser beam

cannot escape from the machine during any phase of user operation.

This printer is certified as a Class 1 laser product. This means the printer does not produce hazardous

laser radiation.

LUOKAN 1 LASERLAITE

KLASS 1 LASER APPARAT

CAUTION: The use of controls, adjustments or performance of procedures other than those

specified in this manual may result in hazardous radiation exposure. Because of this, we strongly

recommend that you operate your printer only as described in this documentation.

For United States Users:

Laser Safety

This printer is certified as a Class 1 Laser product under the U.S. Department of Health and Human

Services (DHHS) Radiation Performance Standard according to the Radiation Control for Health

and Safety Act of 1968. This means that the printer does not produce hazardous laser radiation.

CDRH Regulations

The Center for Devices and Radiological Health (CDRH) of the U.S. Food and Drug

Administration implemented regulations for laser products on August 2, 1976. Compliance is

mandatory for products marketed in the United States. The label shown below indicates compliance

with the CDRH regulations and must be attached to laser products marketed in the United States.

WARNING:

specified in this manual may result in hazardous radiation exposure.

Internal Laser Radiation

Maximum Radiation Power: 15mW × 2 diodes

Wave Length: 780nm

Use of controls, adjustments or performance of procedures other than those

Di620PE Operator’s Manual

iv

Safety Precautions

For European Users:

WARNING:

specified in this manual may result in hazardous radiation exposure.

This is a semiconductor laser. The maximum power of the laser diode is 15mW and the

wavelength is 780nm. (Two provided.)

Use of controls, adjustments or performance of procedures other than those

For Denmark Users:

ADVARSEL

Usynlig laserstråling ved åbning, når sikkerhedsafbrydere er ude af funktion.

Undgå udsættelse for stråling.

Klasse 1 laser produkt der opfylder IEC825 sikkerheds kravene.

For Finland, Sweden Users:

VAROITUS

Laitteen käyttäminen muulla kuin tässä käyttöohjeessa mainitulla tavalla saattaa altistaa

käyttäjän turvallisuusluokan 1 ylittävälle näkymättömälle lasersäteilylle.

VARNING

Om apparaten används på annat sätt än i denna bruksanvisning specificerats, kan användaren

utsättas för osynlig laserstrålning, som överskrider gränsen för laserklass 1.

For Norway Users:

ADVERSEL

Dersom apparatet brukes på annen måte enn spesifisert i denne bruksanvisning, kan brukeren

utsettes for unsynlig laserstråling som overskrider grensen for laser klasse 1.

Dette en halvleder laser. Maksimal effeckt till laserdiode er 15mW og bølgelengde er 780nm.

Di620PE Operator’s Manual

Laser Safety Label

A laser safety label is attached to the outside of the printer as shown below.

For Europe

For United States

v

Safety Precautions

1155O698CB

4115O003AA

1155O699EB

The Manufacturer’s Name Plate is affixed at the position illustrated above.

Please write down the Model Name and Serial No. of your printer here.

Model:

Serial No.

Di620PE Operator’s Manual

vi

Regulatory Information

For United States Users:

WA R N I N G

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

The design and production of this unit conforms to FCC Regulations, and any changes or modifications

must be registered with the FCC and are subject to FCC control. Any changes made by the purchaser or

user without first contacting the manufacturer will be subject to penalty under FCC regulations.

FCC-F01

For Canada Users:

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

IC-F03

Di620PE Operator’s Manual

vii

Regulatory Information

For European Users:

Thank you for choosing Minolta.

This operator's manual explains how to operate the printer and replenish its supplies. It also gives some

troubleshooting tips as well as general precautions to be observed when operating the printer.

To ensure the best performance and effective use of your printer, read this manual carefully until you

familiarize yourself thoroughly with its operation and features. After you have read through the manual,

keep it for ready reference.

Please use this manual as a quick and handy reference tool for immediately clarifying any questions

which may arise.

CE Marking (Declaration of Conformity)

We declare under our sole responsibility that the printer and options to which this declaration relates is in

conformity with the specifications below. This declaration is valid for the area of the European Union

(EU) only.

Product Type Console Type Printer

Product Name Di620PE

Options FN-3, FN-102, FN-502, C-304, C-304L, D-102, DT-103, Hard Disk Drive Kit

Accessories 16 MB Memory

Standards Safety *2 : EN 60 950 / 1992 (A1, A2, A3, A4)

(Safety of information technology equipment, including electrical business

equipment)

EN 60825/1992 (A11:1996)

(Safety of laser products-Part 1: Equipment classification, requirements

and users guide)

EMC *1 : EN 55 022 (Class B) / 1994 (A1, A2)

(Limits and method for measurement of radio disturbance characteristics of

information technology equipment (ITE))

EN61000-3-2 / 1995

(Electromagnetic compatibility (EMC) - Part 3: Limits, Section 2: Limits

for harmonic current emissions (equipment input current 16A per phase))

EN61000-3-3 / 1995

(Electromagnetic compatibility (EMC) - Part 3: Limits, Section 3:

Limitation of voltage fluctuations and flicker in low-voltage supply

systems for equipment with rated current 16A)

EN 50 082-1 / 1992

(Electromagnetic compatibility - Generic immunity standard

Part 1: Residential, commercial and light industry)

IEC 801-2 / 1991 (Electrostatic discharge requirement)

IEC 801-3 / 1984 (Radiated electromagnetic field requirement)

IEC 801-4 / 1988 (Electrical fast transient / burst requirement)

Notes : *1) EMC performance: This product was designed for operation in a typical

office environment.

*2) First year of labeling according to EC-directive 73/23/EEC and 93/68/

EEC: 98

3) This product was designed for operation in a typical office environment.

EC Directives Safety : 73 / 23 / EEC and 93 / 68 / EEC

EMC : 89 / 336 / EEC and 93 / 68 / EEC

<

=

<

=

Di620PE Operator’s Manual

viii

Technical Support

For United States and Canada Users:

Thank you for choosing Minolta quality. For over 30 years Minolta has been a leader on the forefront of

office equipment technology and service. Our desire has always been to bring you highly reliable

products. We pledge to continue to provide you, our customer, with our state of the art equipment, as well

as full customer service for all our products. We look forward to a long healthy relationship with you and

our company. If you have any questions or comments about Minolta, our product or service, please let us

know. Our fax number is 800-237-8087 (for U.S.A. and Canada). Thank you again.

This operator’s manual explains how to operate the printer and replenish its supplies. It also gives some

troubleshooting tips as well as general precautions to be observed when operating the printer.

To ensure the best performance and effective use of your printer, read this manual carefully until you

familiarize yourself thoroughly with it’s operation and features. After you have read through the manual,

keep it ready for reference.

Please use this manual as a quick and handy reference tool for immediately clarifying any questions

which may arise.

MC-F01

Di620PE Operator’s Manual

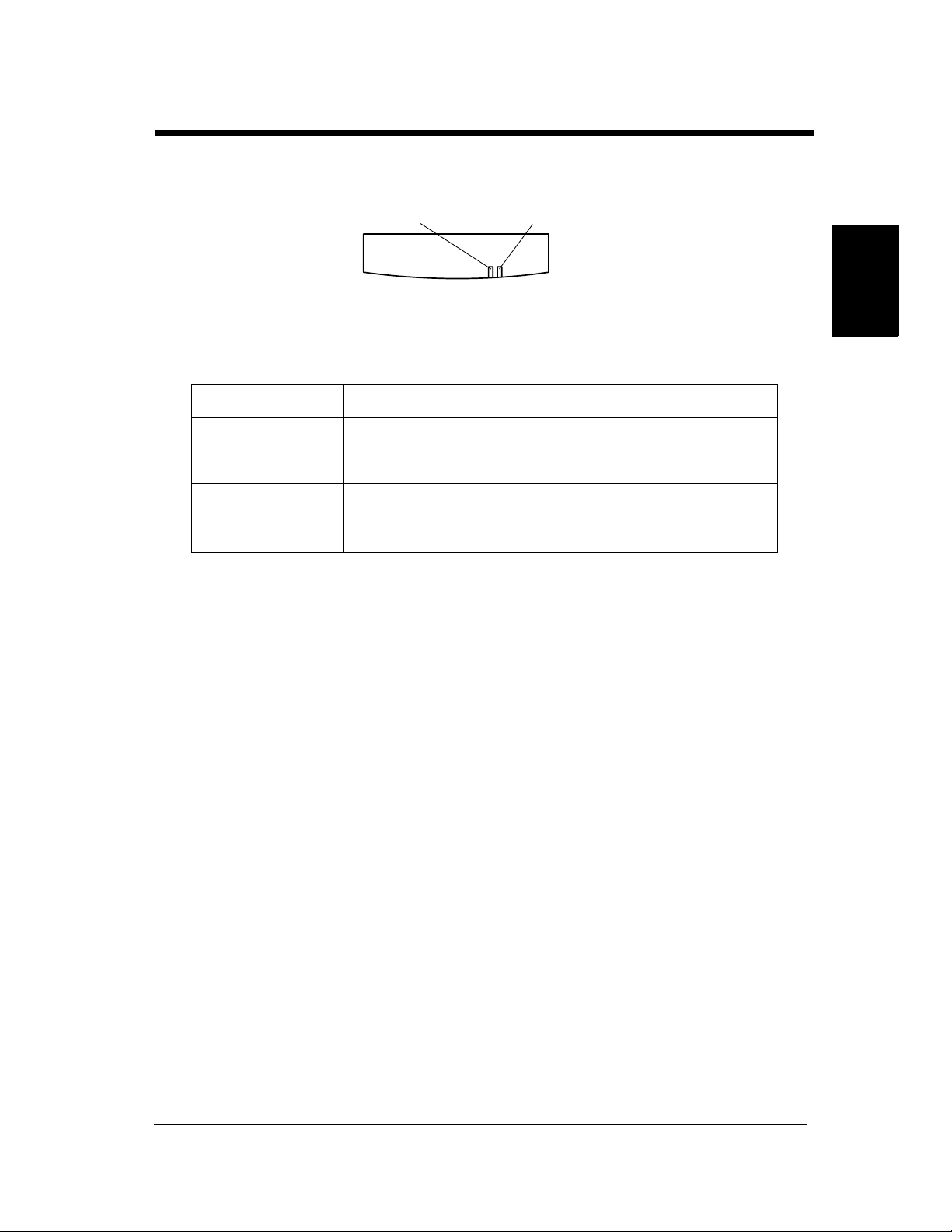

Terms and Symbols for the Type of document and Paper

A few special terms and symbols are used in this manual to designate types of paper. This page explains

about these terms and symbols.

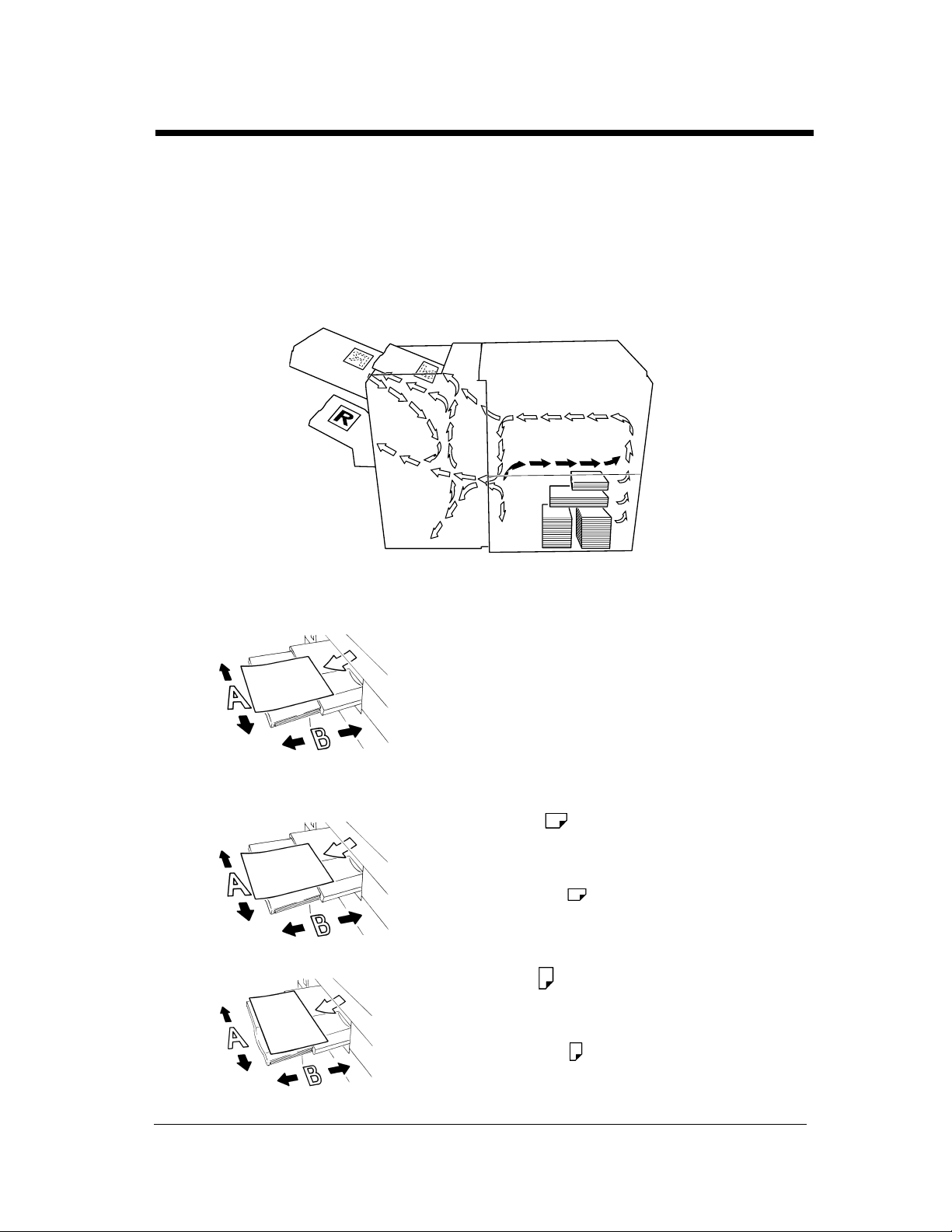

Feeding Direction (paper path)

In this printer system, paper is taken up from the right-hand side of the printer and fed through the printer

toward the left-hand side, face up onto the Tray. In the figure below, the direction in which the paper is

fed, as indicated by the arrow, is called the “feeding direction.”

ix

“Width” and “Length”

1139O1610A

Terms and Symbols Used

1139O1610A

4115O002AA

When we talk about the size of the document or

paper, we call side A “width” and side B “length.”

A: Width

B: Length

<Lengthwise >

When the document or paper has a “length” longer

than its “width,” we call it “lengthwise” and use

symbol “L” or “ .”

<Crosswise >

Di620PE Operator’s Manual

When the document or paper has a “length” shorter

than its “width,” we call it “crosswise” and use

symbol “C” or “ .”

1139O1620A

x

Contents

Using the Printer Properly .................................................................................. i

Safety Precautions .............................................................................................iii

Regulatory Information .....................................................................................vi

Technical Support ...........................................................................................viii

Terms and Symbols for the Type of Originals and Paper ................................. ix

Chapter 1 Safety Notes

1. Installing the Printer

Installation Site ...............................................................................................1-2

Power Source ..................................................................................................1-2

Space Requirements ........................................................................................1-2

2. Precautions for Use

Operating Environment ...................................................................................1-3

Using the Printer Properly ..............................................................................1-3

Moving the Printer ..........................................................................................1-3

Care of Printer Supplies ..................................................................................1-3

Note on Making Multiple Prints .....................................................................1-4

Legal Restrictions on Printing ........................................................................1-4

Chapter 2 Getting to Know Your Printer

1. System Overview

System Overview ............................................................................................2-2

2. Printer Parts and Accessories

Outside the Printer ..........................................................................................2-3

Printer Accessories .........................................................................................2-5

Precautions When Using a Finisher ................................................................2-6

Inside the Printer .............................................................................................2-7

3. Turning ON and OFF

Turning ON and OFF ......................................................................................2-8

When the unit is turned ON ............................................................................2-8

Chapter 3 Printing Procedure

1. Printing & Function Settings

Printing & Function Settings ..........................................................................3-2

2. Basic Printing Overview

Manual Feed Tray ...........................................................................................3-3

3. Selecting the Finishing

Selecting the Finishing Function ....................................................................3-5

Auto Dual Function ......................................................................................3-12

Note on Stapling ...........................................................................................3-14

Chapter 4 When a Message Appears

1. When the Message “The current Paper Tray is empty.” Appears

Adding paper ...................................................................................................4-2

2. When the Message “Replenish Toner.” Appears

Replacing the Toner Bottle .............................................................................4-6

3. When the Message “The Staple Cartridge is empty.” Appears

Replacing the Staple Cartridge .......................................................................4-8

4. When the Message “A paper misfeed has been detected.” Appears

Misfeed Location Displays ...........................................................................4-12

Di620PE Operator’s Manual

Misfeed Clearing Procedures ....................................................................... 4-14

5. When a Staple Misfeed Occurs

Clearing the Staple Misfeed ......................................................................... 4-30

6. What Does Each Message Mean?

What does each message mean? ................................................................... 4-32

Chapter 5 Troubleshooting

1. When This Type of Print is Produced

When this type of print is produced ............................................................... 5-2

2. The Printer is not Functioning as Designed

The printer is not functioning as designed ..................................................... 5-3

Chapter 6 Miscellaneous

1. Specifications

Specifications ................................................................................................. 6-2

2. Care of the Printer

Cleaning ......................................................................................................... 6-7

3. Function Combination Matrix

Function combination matrix ......................................................................... 6-8

Conditions for Combined Functions .............................................................. 6-8

4. Description of Paper Size Table

Description of paper size table ....................................................................... 6-9

Index

xi

Contents

About this Manual

Di620PE Operator’s Manual

Chapter 1

1-1

Safety Notes Chapter 1

Safety Notes

Di620PE Operator’s Manual

1-2

1. Installing the Printer

Installation Site

To ensure utmost safety and prevent possible malfunction of the printer, install it in a location which

Chapter 1

meets the following requirements.

◆ A place away from a curtain or the like that may catch fire and burn easily.

◆ An area where there is no possibility of being splashed with water or other types of liquid.

◆ An area free from direct sunlight.

◆ A place out of the direct air stream of an air conditioner, heater, or ventilator.

Safety Notes

◆ A well-ventilated place.

◆ A dry place.

◆ A dust-free location.

◆ An area not subject to undue vibration.

◆ A stable and level location.

◆ A place where ammonia or other organic gas is not generated.

◆ A place which does not put the operator in the direct stream of exhaust from the printer.

◆ A place which is not near any kind of heating device.

Power Source

The power source voltage requirements are as follows:

◆ Use a power source with little voltage fluctuation.

Voltage Fluctuation : Within ± 10% (for U.S.A. and Canada)

Specified voltage ± 10% (For EU)

Frequency Fluctuation : Within ± 0.3% (for U.S.A. and Canada)

Specified voltage ± 10% (For EU)

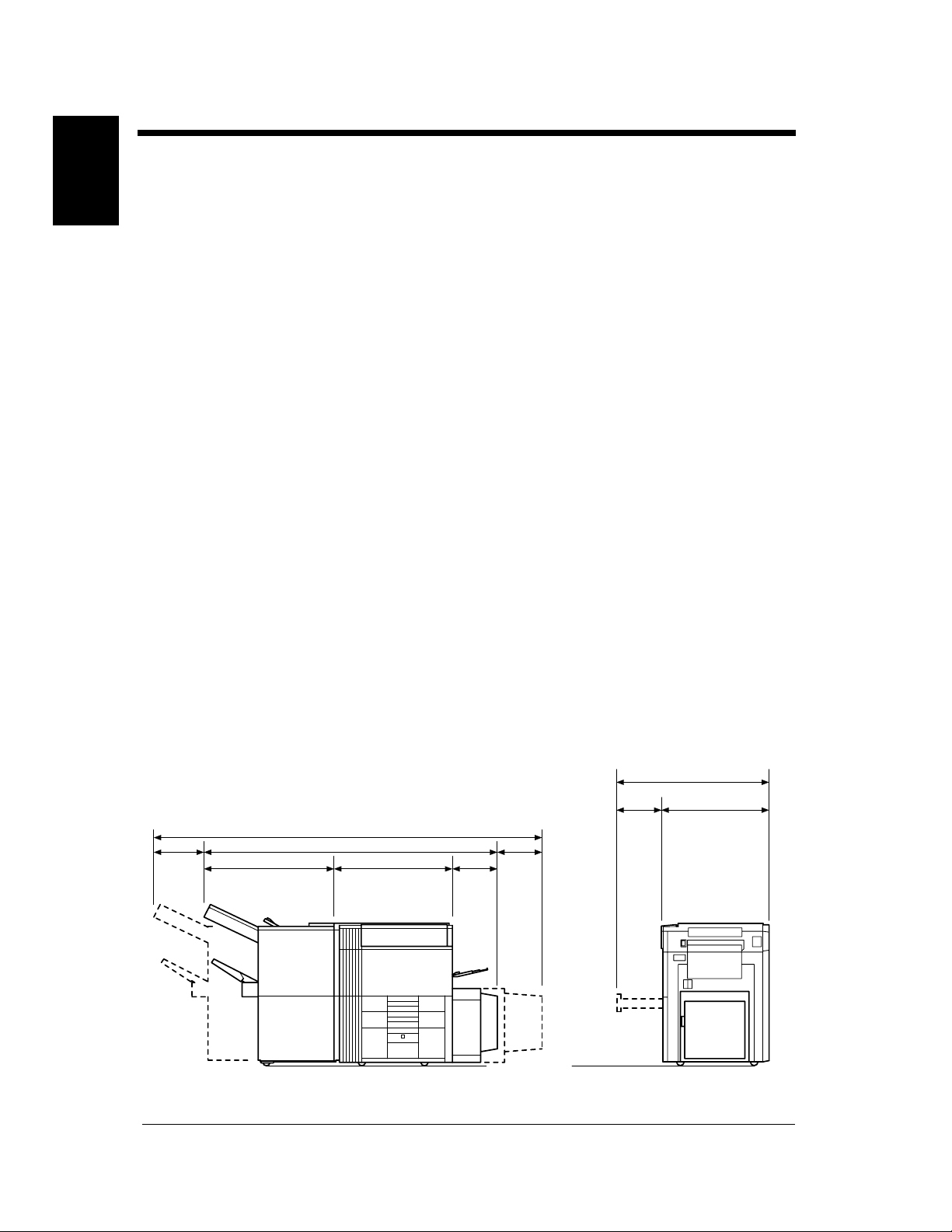

Space Requirements

To ensure easy printer operation, supply replacements, and service maintenance, adhere to the

recommended space requirements detailed below. Allow a clearance of 150mm (6″) or more at the back

of the printer as there is a ventilation duct.

1323 (52)

500

230 (9)

931 (36-3/4)

2831 (111-1/2)

2071 (81-1/2)

735 (29)

405

(11-1/2)

(19-3/4)

530

(16-3/4)

823 (32-1/2)

<With FN-3 and C-304L mounted>

Di620PE Operator’s Manual

4115O004AA

Unit: Metric (Inch)

2. Precautions for Use

Operating Environment

The operating environmental requirements of the printer are as follows:

Temperature : 10°C to 32°C (50°F to 90°F) with a fluctuation of 10°C (18°F) per hour.

Humidity : 15% to 85% with a fluctuation of 10% per hour.

Using the Printer Properly

To ensure optimum performance of the printer, follow the precautions listed below.

◆ NEVER place a heavy object on the printer or subject the printer to shocks.

◆ NEVER open any doors, or turn OFF the printer while the printer is making prints.

◆ NEVER bring any magnetized object or use flammable sprays near the printer.

◆ NEVER remodel the printer, as a fire or electrical shock could result.

◆ ALWAYS insert the power plug all the way into the outlet.

◆ ALWAYS make sure that the outlet is visible, clear of the printer or printer cabinet.

◆ ALWAYS provide good ventilation when making a large number of continuous prints.

NOTE

= Locate the Printer in a Well Ventilated Room =

A negligible amount of ozone is generated during normal operation of this printer. An unpleasant odor

may, however, be created in poorly ventilated rooms during extensive printer operations. For a

comfortable, healthy, and safe operating environment, it is recommended that the room be well

ventilated.

1-3

Safety Notes Chapter 1

REMARQUE

= Placer le Pappareil dans une pièce largement ventilée =

Une quantité d'ozone négligable est dégagée pendant le fonctionnement du l’apparil quand celui-ci

est utilisé normalement. Cependant, une odeur désagréable peut être ressentie dans les pièces dont

l'aération est insuffisante et lorsque une utilisation prolongée du l’apparil est effectuée. Pour avoir la

certitude de travailler dans un environnement réunissant des conditions de confort, santé et de

sécurité, il est préférable de bien aérer la pièce ou se trouve le l’apparil.

Moving the Printer

If you need to transport the printer over a long distance, consult your Technical Representative.

Care of Printer Supplies

Use the following precautions when handling the printer supplies (toner, paper, etc.).

◆ Store the paper, toner, and other supplies in a place free from direct sunlight and away from any heating

apparatus. Keep them in a dry, cool, clean environment.

◆ Store paper, which has been removed from its wrapper but not loaded into the drawer, in a sealed plastic

bag in a cool, dark place.

◆ Keep supplies out of the reach of children.

◆ If your hands become soiled with toner, wash them with soap and water immediately.

Di620PE Operator’s Manual

1-4

2. Precautions for Use

Note on Making Multiple Prints

If the fusing temperature drops excessively during a multi-print cycle, there is a possibility that the

Chapter 1

printing speed will be reduced. The printing speed will automatically return to normal when the fusing

temperature rises enough to ensure good fusing performance.

Legal Restrictions on Printing

Certain types of documents must never be copied by the printer for the purpose or with the intent to pass

Safety Notes

copies of such documents off as the original. The following is not a complete list but is meant to be used

as a guide to responsible printing.

Financial Instruments

• Personal Checks

• Travelers Checks

• Money Orders

• Certificates of Deposit

• Bonds or other Certificates of Indebtedness

• Stock Certificates

Legal Documents

• Food Stamps

• Postage Stamps (canceled or uncanceled)

• Checks or Drafts drawn by Government Agencies

• Internal Revenue Stamps (canceled or uncanceled)

•Passports

• Immigration Papers

• Motor Vehicle Licenses and Titles

• House and Property Titles and Deeds

General

• Identification Cards, Badges, or Insignias

• Copyrighted Works without permission of the copyright owner

In addition, it is prohibited under any circumstances

Art without permission of the copyright owner.

When in doubt about the nature of a document, consult with legal counsel.

Di620PE Operator’s Manual

to print domestic or foreign currencies or Works of

Chapter 2

2-1

Chapter 2Getting to Know Your Printer

Getting to Know Your Printer

Di620PE Operator’s Manual

2-2

1. System Overview

System Overview

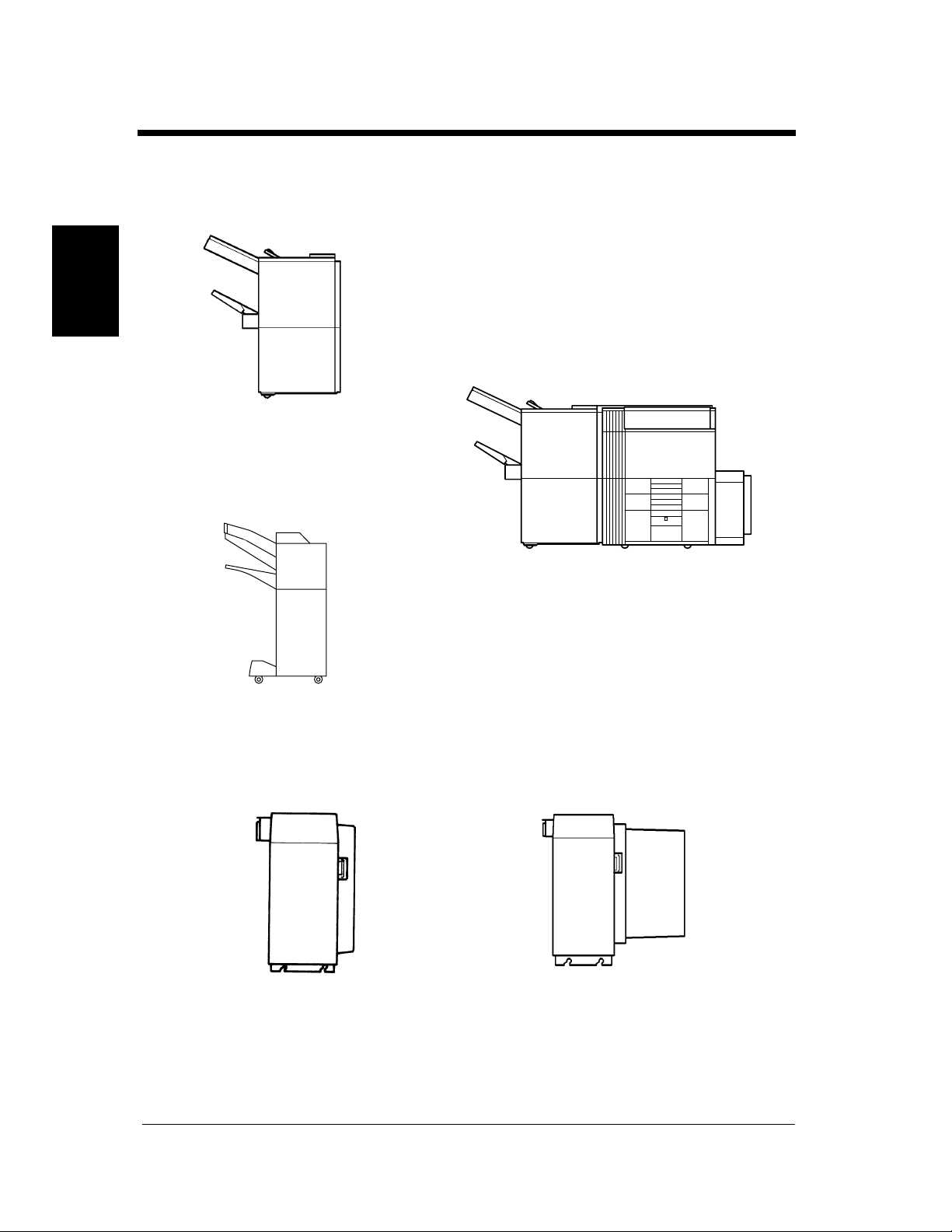

The following overview presents the printer and the available options with a brief explanation of the

function of each. Refer to the separate manual “Print Station Manager Reference Manual”.

Chapter 2

1155O014AA

Finisher FN-3 <Option>

Permits sorting, grouping, sort-stapling,

punching or folding of prints.

Getting to Know Your Printer

1155O730AA

Finisher FN-102 <Option>

Permits sorting, grouping, sort-stapling or

punching of prints.

1134O005AA

Large Capacity Cassette C-304 <Option>

Holds up to 3,400 sheets of A4C, LetterC

paper (80g/m

2

, 20 lbs.).

4115O005AA

1155O721AA

Large Capacity Cassette C-304L <Option>

Holds up to 3,400 sheets of A4L or A4C,

LegalL, LetterL or LetterC, paper (80g/m

2

,

20 lbs.).

Di620PE Operator’s Manual

2. Printer Parts and Accessories

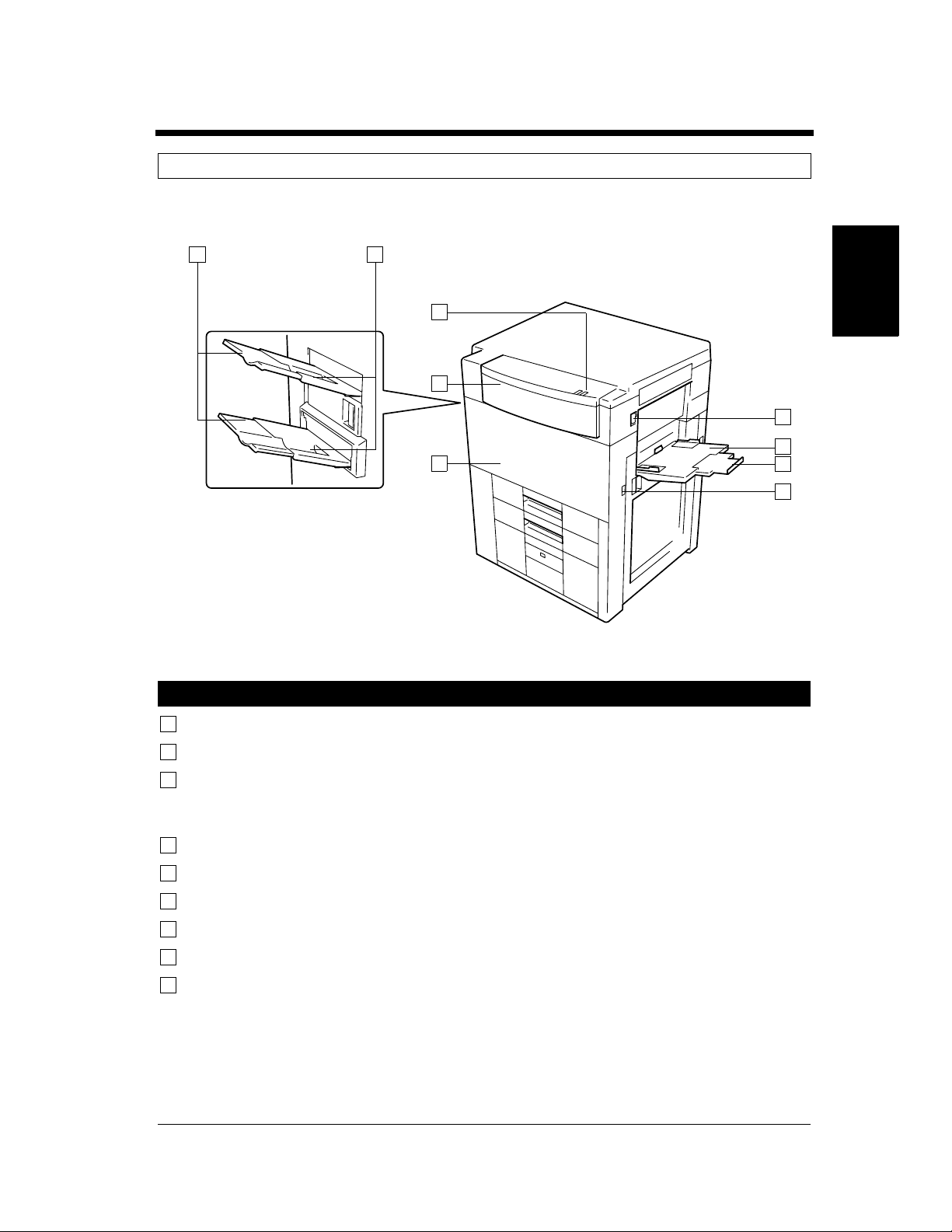

Outside the Printer

1 2

2-3

5

4

3

Printer

1

Exit Tray Extender : Slide this extender out when making prints on large-size paper.

2

Exit Tray : Holds prints fed out of the printer. (Option)

Chapter 2Getting to Know Your Printer

6

7

8

9

4115O006AA

3

Front Door : Open to clear a paper misfeed. ☞p. 4-12

Closing the Front Door after a misfeed has been cleared will turn the

misfeed warning message on the control panel OFF.

4

Upper Front Door : Open to replace the Toner Bottle. ☞p. 4-6

5

Indicator : Green means “Ready”, red means “Paper Misfeed”.

6

Power Switch : Use to turn the pirnter ON and OFF. ☞p. 2-8

7

Manual Feed Tray : Use for manual feeding of paper into the printer. ☞p. 3-3

8

Extender : Slide this extender out to make prints on large-size paper.

9

Total Counter : Shows the total number of prints made so far.

Di620PE Operator’s Manual

2-4

2. Printer Parts and Accessories

Chapter 2

Getting to Know Your Printer

13

10

11

12

Drawers of the Printer

10

Tray 1 : Holds up to 550 sheets of paper. ☞p. 4-2

11

Tray 2 : Holds up to 550 sheets of paper. ☞p. 4-3

It can accommodate paper of different sizes.

12

Tray 3 : Holds up to 2,700 sheets of paper. ☞p. 4-4

13

Paper Descent Key : Press before sliding the drawer out of the printer.

4115O007AB

Di620PE Operator’s Manual

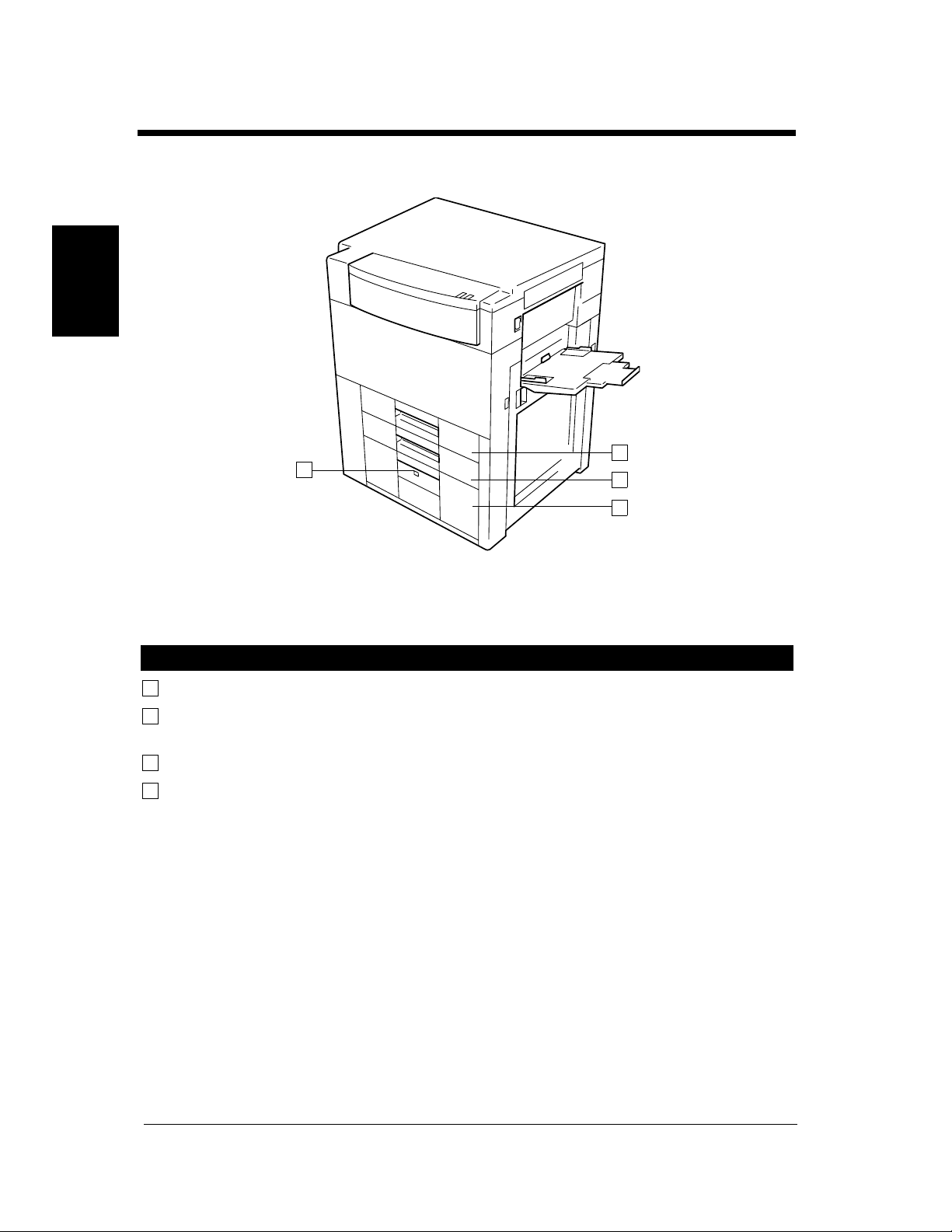

Printer Accessories

1 2 3

8

2-5

2. Printer Parts and Accessories

Chapter 2Getting to Know Your Printer

4

5

7

4115O008AB

6

FN-3 LCC C-304

11

14

15

10

12

13

9

16

1155O732AB

1155O734AB

FN-102 LCC C-304L

Di620PE Operator’s Manual

2-6

2. Printer Parts and Accessories

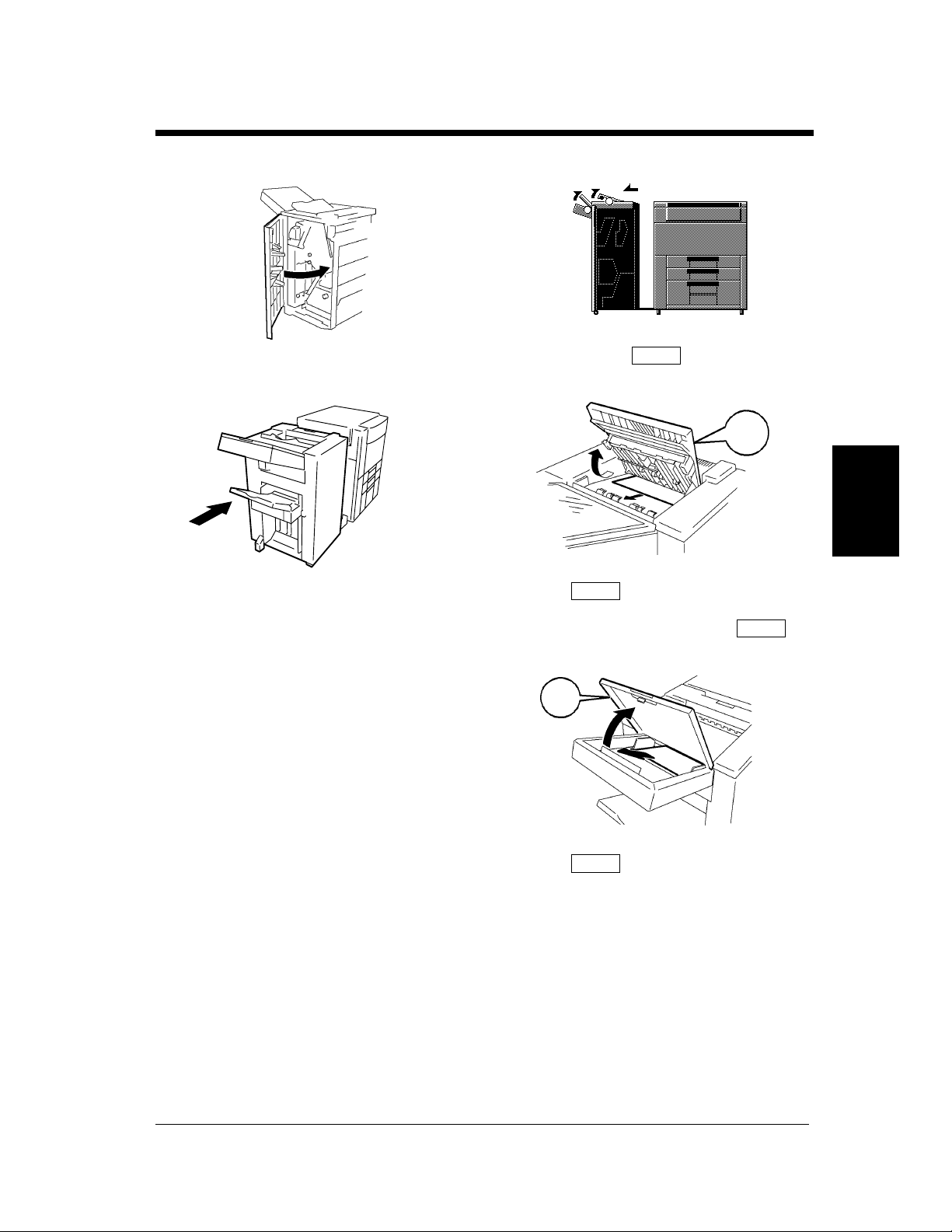

Finisher FN-3

1

Manual Staple Tray : Open to load documents for manual stapling or to clear a paper misfeed.

Cover

2

Top Offset Tray : Receives sorted print sets or grouped print stacks.

3

Grip : Grasp and press here to slide the Finisher away from the printer to clear a

misfeed or other service job.

Finisher Door : Open to replace the Staple Cartridge. ☞p. 4-8

7

Chapter 2

Open to clear a paper misfeed. ☞p. 4-12

Bottom Offset Tray : Receives sorted/stapled print sets or grouped print stacks.

8

Precautions When Using a Finisher

Do not place an

object here.

Getting to Know Your Printer

1155O720AA

NEVER place an object under the Bottom

Offset Tray or Elevator Tray. Anything that is

placed under the Bottom Offset Tray or

Elevator Tray can interfere with the tray when

it lowers after a print set has been fed onto it,

which results in a malfunction.

CAUTION

Do not stack more than 2000 sheets of

paper on the Finisher’s Elevator Tray or risk

damaging the elevator mechanism.

Large Capacity Cassette C-304

Lock Release Lever : Use to unlock the Cassette from the printer for clearing a misfed sheet of

4

paper or other service job.

5

Paper Plate Descent Key : Press to lower the paper plate.

6

Cassette Door : Open to add paper or clear a misfed sheet of paper.

Finisher FN-102

9

Elevator Tray : Receives sorted paper by shifting.

10

Top Offset Tray : Receives plain paper or exclusive paper fed out.

11

Misfeed Clearing Guide : Open to clear misfed paper.

12

Stapler Cover : Open to replace the staple cartridge.

13

Lock Release Lever : Hold to slide the Finisher away from the printer.

Large Capacity Cassette C-304L

14

Lock Release Lever : Use to unlock the Cassette from the printer for clearing a misfed sheet of

paper or other service job.

15

Paper Plate Descent Key : Press to lower the paper plate.

16

Cassette Door : Open to add paper or clear a misfed sheet of paper.

Di620PE Operator’s Manual

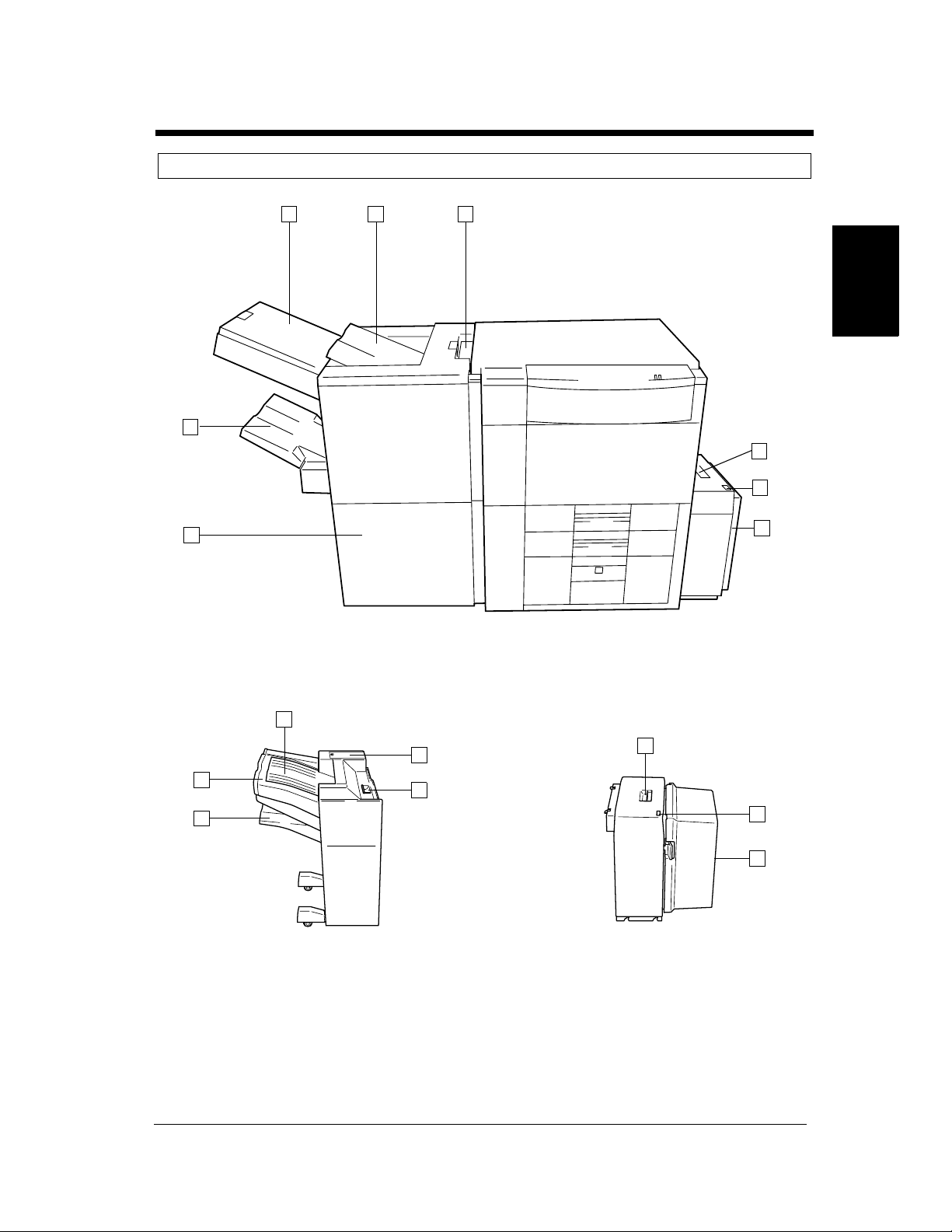

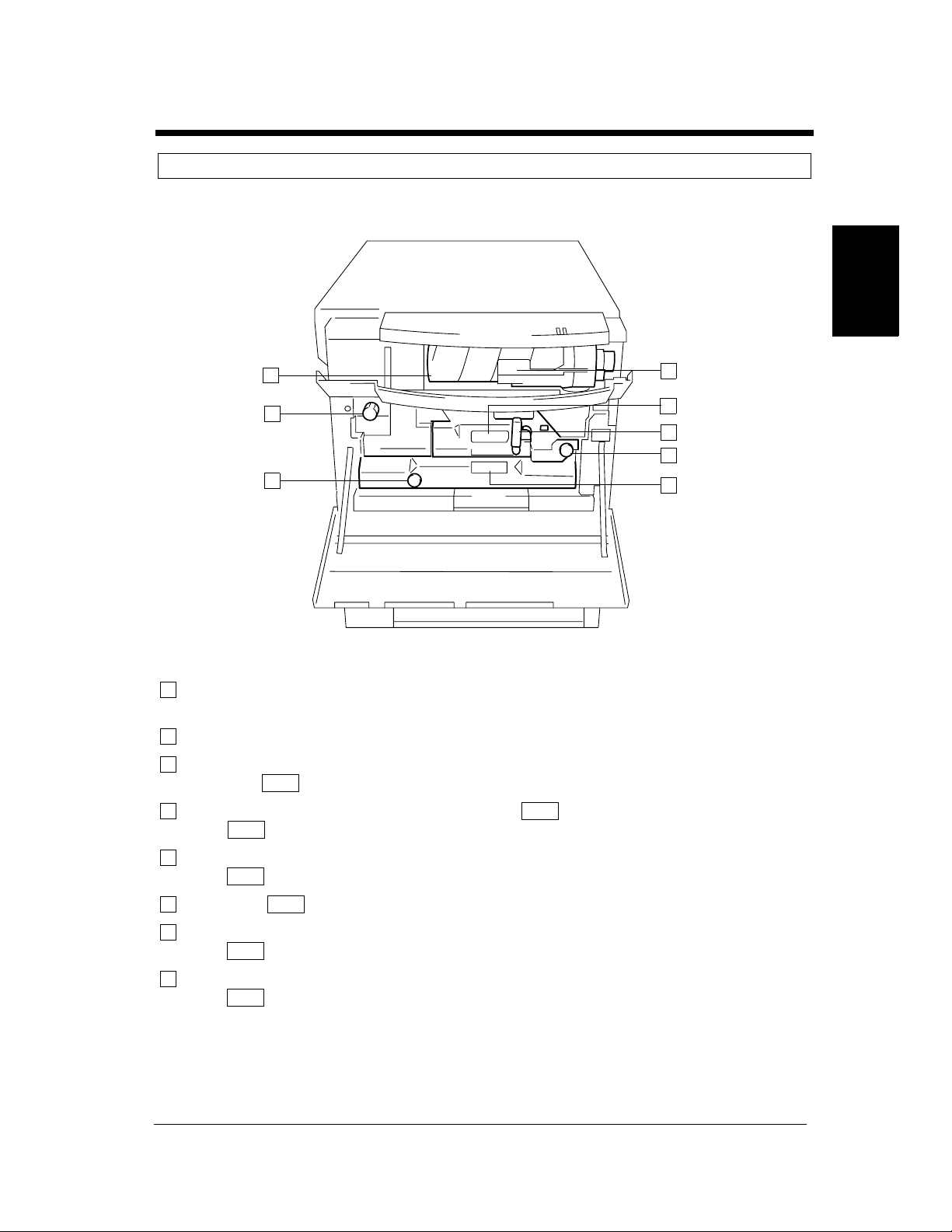

Inside the Printer

2-7

2. Printer Parts and Accessories

Chapter 2Getting to Know Your Printer

1

8

7

Toner Bottle : Contains Toner. Replace it with a new one when the warning message

1

M1

M5

D2

D1

M7

M4

M3

4115O009AB

2

3

4

5

6

tells you to. ☞p. 4-6

Toner Bottle Holder : Swing open to replace the Toner Bottle. ☞p. 4-6

2

Misfeed Removal : Use to clear a misfed sheet of paper. ☞p. 4-14

3

Guide Unit

Misfeed Removal : Press down to pull out the Unit. ☞p. 4-14

4

Lever

M5

M5

M4

Misfeed Removal : Use to clear a misfed sheet of paper. ☞p. 4-14

5

Knob

Duplex Unit : Slide out to clear a sheet of paper misfed in the Duplex Unit. ☞p. 4-16

6

Misfeed Removal : Use to clear a misfed sheet of paper. ☞p. 4-14

7

Knob

Misfeed Removal : Turn to clear a misfed sheet of paper. ☞p. 4-14

8

Knob

M3

D2

D1

M1

Di620PE Operator’s Manual

2-8

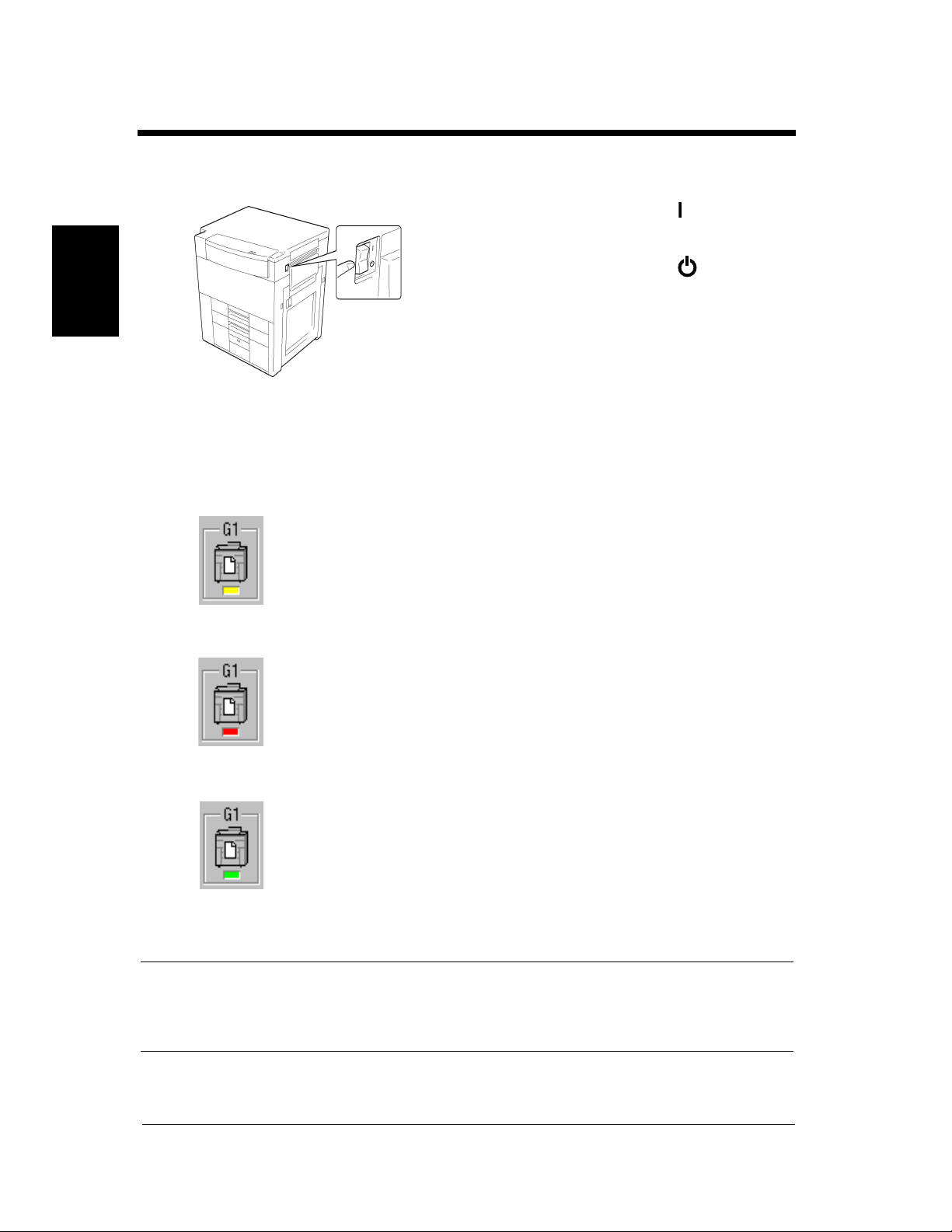

3. Turning ON and OFF

Turning ON and OFF

• Turning the Printer ON:

Press the Power Switch to the (ON) position.

• Turning the Printer OFF:

Press the Power Switch to the (OFF)

position.

Chapter 2

4115O050AB

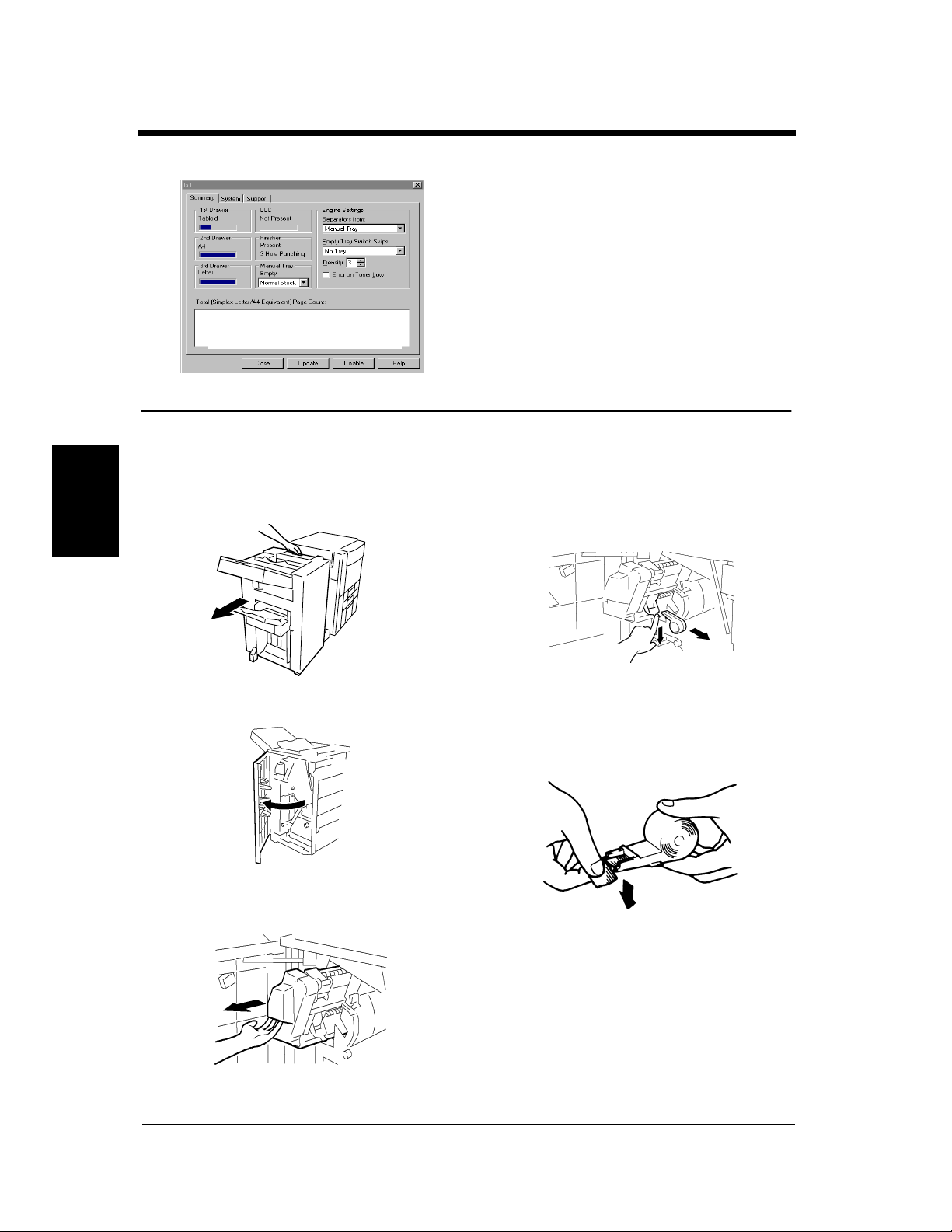

When the unit is turned ON

The printer icon on the print station manager screen changes as follows when the power is turned ON.

(1) While the printer is performing a self-test operation during warm-up, or is off-line, busy or in sleep

mode, the icon will turn yellow. The power indicator (green) on the panel will be blinking.

Getting to Know Your Printer

(2) If a printer system error occurs, the icon will turn red. The error indicator (red) on the panel will be

blinking.

• Click this icon to display any current error messages on the

Summary page of the printer driver screen.

• If the icon is red with black stripes, the Di620PE is powered

off.

(3) When the printer enters the print-ready state, the icon will turn light green. The power indicator

(green) on the panel will be on.

• If the icon is dark green, the PlintLink is powered off or the

interface is disconnected.

However, the printing operation cannot be performed even if data from the computer is sent at this time.

A warm-up time of approximately seven minutes (at a room temperature of 20ºC (68ºF)) is required

before printing can be performed.

NOTE

If the fusing temperature drops excessively during a multi-print cycle, there is a possibility that the

printing speed will be reduced. The printing speed will automatically return to normal when the fusing

temperature rises enough to ensure good fusing performance.

Di620PE Operator’s Manual

Panel Indicator

2-9

3. Turning ON and OFF

Power Indicator Error Indicator

Green Red

4115O057AA

Indicator Meaning

Power Indicator ON: Print engine is in the ready state.

Blinking: warming up.

Slow Blinking: Power save mode.

Error Indicator ON: Printing error, fatal error, paper misfeed, something that

prevents printing has occured.

Blinking: Maintenance call.

Chapter 2Getting to Know Your Printer

Di620PE Operator’s Manual

2-10

3. Turning ON and OFF

Chapter 2

Getting to Know Your Printer

Di620PE Operator’s Manual

Chapter 3

3-1

Chapter 3Printing Procedure

Printing Procedure

Di620PE Operator’s Manual

3-2

1. Printing & Function Settings

Printing & Function Settings

Refer to the following manuals for the procedure about printing and/or function settings.

◆ PrintStation Manager Reference Manual

◆ PrintStation Manager Configuration Reference Manual

◆ Raster Image Processor Reference Manual

◆ MicroSpool Reference Manual

◆ MicroSpool Configuration Reference Manual

Chapter 3

Printing Procedure

Di620PE Operator’s Manual

2. Basic Printing Overview

2

Manual Feed Tray

• Use the Manual Feed to make prints on paper not loaded in any tray, or to print onto OHP

transparencies, thick paper, or any other special paper.

• When using the Manual Feed Tray, you can load multiple sheets of paper.

• The setting of paper size is needed for manual feed printing.

• Manual Feed cannot be used for a reserved job.

Paper that Can be Used for Manual Feed Tray

◆ Types of Paper

• Plain paper (weighing 60 g/m

• Thick paper (weighing 91 g/m

• Recycled paper, OHP transparencies

◆ Paper Size

• Max. Size : A3, 11-3/4″

• Minimum Size : A6, 4″

◆ Capacity of the Manual Feed Tray

• Plain paper, Recycled paper⋅⋅⋅Up to 50 sheets

• Plain paper (once-copied paper)⋅⋅⋅Up to 20 sheets

• Thick paper, OHP transparencies⋅⋅⋅Up to 20 sheets

×

5-3/4″

2

to 90 g/m2, 16lbs. to 24 lbs.)

2

to 157 g/m2, 24-1/4 lbs. to 41-3/4 lbs.)

×

17″

3-3

Chapter 3Printing Procedure

Using the Intelligent Manual Feed Tray

Swing down the Manual Feed Tray and insert

1

a neat stack of paper into the tray until it

stops.

*Slide the Tray Extender out when using

large-size paper.

1075O025AB

Slide the Paper Guide Plate to the size of the

paper.

1075O024AB

NOTES

• The paper should be loaded no higher than

the ▼ (Max. Level Indicator).

• Before inserting, fan the paper stack well if

you are using OHP transparencies.

• Correct any curl if you are using thick paper.

• For making prints on thick paper or OHP

transparencies, the following functions cannot

be used: Staple, Hole Punch, Folding Options.

• The paper will be printed on the side facing

up.

Di620PE Operator’s Manual

3-4

3. Selecting the Finishing

In the following, we explain about different finishing functions and setting procedures.

For more infomation on finishing function settings and options, please refer to the PrintStation Manager

Reference Manual.

Staple

<Only when the Finisher is mounted>

• This function is effective when making multiple

printings of a multipage document. Prints are

sorted or grouped into complete sets of the jobs

and then stapled.

• Only when the Finisher FN-3 is mounted, this

feature is efficient for stapling document sets

after making prints.

Chapter 3

1151O108AA

Hole Punch

<Only when the Finisher is mounted>

• Holes are punched in the print sets or stacks for

filing. It can be combined with Non-Sort, Sort,

Printing Procedure

Group or Staple.

Folding

Di620PE Operator’s Manual

1149O398EA

<Only when the Finisher FN-3 is mounted>

• This function allows you to fold prints.

You have a choice of folding options, either

Crease, Half-Fold or Z-fold.

1155O031AA

Selecting the Finishing Function

Sort/Group

Select the desired finishing function.

1

Refer to the printer driver manual

(PrintStation Manager Reference Manual)

for a detailed description of the setting

procedures and setting items.

NOTES

• When the Finisher FN-102 is installed, prints

are fed out in a sawtooth manner in Sort or

Group mode.

• When the Finisher FN-3 is installed, sorted

sets and grouped stacks are separated by a

separator page.

• When a Finisher is not installed, sorted sets

and grouped stacks are separated by a

separator page.

3-5

3. Selecting the Finishing

Useful Tips

• Shift Sorting

The sorted print sets are stacked in the same

direction, but in a sawtooth manner by

shifting the tray to the front or rear for each

set.

Chapter 3Printing Procedure

1166O033AB

• Shift Grouping

The grouped print stacks are stacked in the

same direction, but in a sawtooth manner by

shifting the tray to the front or rear for each

stack.

1166O035AB

Di620PE Operator’s Manual

3-6

3. Selecting the Finishing

Hole Punch

Select the desired finishing function.

1

Refer to the printer driver manual

(PrintStation Manager Reference Manual)

for a detailed description of the setting

procedures and setting items.

NOTES

• The size of the paper for Hole Punch is

11″×17″L, LegalL, LetterL, LetterC, A3L,

A4L and A4C only.

• Hole Punch is not possible in the Interrupt

mode.

• When making prints in the Hole Punch Mode,

Chapter 3

Printing Procedure

make sure of the correct document

orientation.

<Only when the Finisher FN-3 is mounted>

• The number of punch holes can be changed

between “2-Hole” and “3-Hole” by using the

Knob located inside the Finisher.

*When changing the setting for the number of

holes to be made, be sure the marks are

aligned.

Useful Tips

• If you do not select a hole-punching position,

the printer automatically sets the Hole Punch

position according to the document

orientation illustrated below.

On Screen

On Screen

Print

1155O789EA

Print

1155O790EA

• When making prints from either the 11″×17″

or LegalL, A3L or B4L size, the printer

automatically specifies the hole punching

position as shown below.

On Screen

Print

Knob

1155O723AA

Pull out Knob: 2-Hole

Push in Knob: 3-Hole

*The number of punch holes can be graphically

identified on the Display.

1155O791EA

Di620PE Operator’s Manual

Staple

You have a choice of the following two

stapling types.

4115O054CA

*When you touch a stapling key, the finisher

is automatically set into the Sort mode.

3-7

3. Selecting the Finishing

Chapter 3Printing Procedure

Useful Tip

Paper size: A3L to A4, 11″×17L″ to Letter

Number of sheets: 2 to 50

Kinds of Paper: Plain paper, Recycled paper

Di620PE Operator’s Manual

3-8

3. Selecting the Finishing

Manual Staple

<Only with the Finisher FN-3>

Open the Manual Staple Tray Cover.

1

Chapter 3

Align the sheets of paper neatly.

2

Printing Procedure

1155O033AA

1134O039AA

Slide the Paper Guide Plate to the size of the

4

paper.

1155O034AA

NOTE

Make sure that the Paper Guide Plates are in

touch with the edge of the paper stack.

Close the Manual Staple Tray Cover.

5

Insert a neat stack of papers face down into

3

the Staple Tray.

1155O036AB

NOTES

• Make sure of the stapling position and press

the paper stack against the end bracket.

• Up to 50 sheets of plain paper can be stapled.

After you hear the mechanism stop, select

6

the desired stapling type on the Finisher

Panel.

1155O035AA

1155O037AA

Di620PE Operator’s Manual

You have a choice of the following three

stapling positions.

Press . This staples the paper stack or

7

set.

3-9

3. Selecting the Finishing

Chapter 3Printing Procedure

4115O055CA

1155O038AA

Useful Tip

This feature is useful for stapling document sets

after making prints.

Open the Manual Staple Tray Cover and

8

remove the stapled paper stack.

1155O760AA

Close the Manual Staple Tray Cover.

9

Di620PE Operator’s Manual

3-10

3. Selecting the Finishing

Folding

<Only with the Finisher FN-3>

<Crease>

Crease makes a crease in the print at its center

before it is fed out.

1155O039AA

Sizes of paper that can be loaded:

Chapter 3

NOTE

Even if Staple is previously set to a corner or side position, the setting of Crease automatically cancels

this setting and reselects a center stapling position.

A3L, B4L, A4L, 11″×17″L, LetterL

Make sure to select the correct stapling function

when making prints with the Crease function if

you want to make a stapled print set.

<Half-Fold>

Half-Fold folds the print in two at its center with

the print surface on the outside.

Printing Procedure

ex.) A3→A4,

11

″×17″

→

Letter

1155O041AA

You can produce a document that looks like below

by combining this function with Staple and Hole

Punch.

Sizes of paper that can be loaded: 11″×17″L, A3L,

B4L

*The finished print size has a length half that of

Number of sheets: 2~10

the paper loaded in the printer.

NOTE

Even if Staple is previously set to a corner or center position, the setting of Half-Fold automatically

cancels this setting and reselects a side stapling position.

1155O640EA

Di620PE Operator’s Manual

3. Selecting the Finishing

<Z-Fold>

Z-Fold folds the print into three parts with the

print surface inside as shown below.

→

ex.) 11″×17

A3→A4

Sizes of paper that can be loaded: 11″×17″L, A3L

*The finished print size has a length half that of

the paper loaded in the printer.

″

Letter,

1155O043AA

1155O642EA

Number of sheets: 2~10.

NOTES

• Even if screen settings are made to make 2-sided prints, the prints to be Z-Folded will be 1-sided.

• Even if Staple is previously set to center position, the setting of Z-Fold automatically cancels this

setting and reselects a side stapling position.

3-11

Chapter 3Printing Procedure

Di620PE Operator’s Manual

3-12

3. Selecting the Finishing

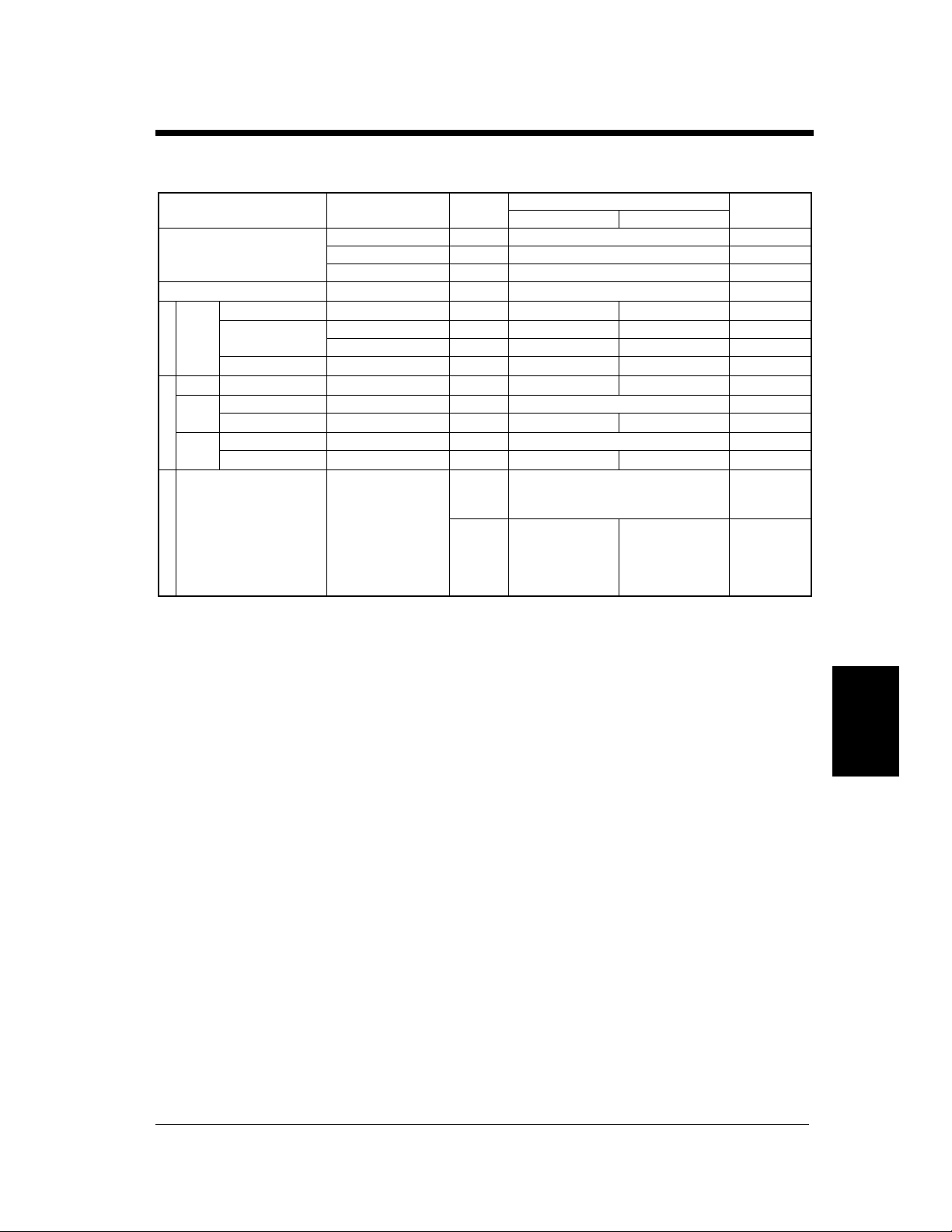

Auto Dual Function

Auto Dual Function in Finishing Mode

<Only when the Finisher FN-3 is mounted>

Though the Top Offset Tray can hold only up to 100 sheets, the Auto Dual function permits making prints

of up to 2,100 sheets.

Inch Areas

Chapter 3

Sort

Group

Staple

Printing Procedure

Crease

HalfFold

Folding

ZFold

Non-Sort

Sort

Group

Crisscross Sort

Corner

Side

Center

Staple

Non-Sort, Sort,

Group

Staple

Non-Sort, Sort,

Group

Staple

Paper Size

LetterC

11 by 17L, LegalL,

LetterL

5.5 by 8.5L,

5.5 by 8.5C

LetterL, LetterC

11 by 17L to Letter

LetterC

11 by 17L, LegalL,

LetterL

11 by 17L, LetterL

11 by 17L, LetterL

11 by 17L

11 by 17L

11 by 17L

11 by 17L

To p

Offset

Tray

100 sheets

100 sheets

100 sheets

100 sheets

- 100 sets or 1000 sheets -

- - 200 sets or 2000 Sheets

- - 200 sets or 1000 Sheets

- - 100 sets or 1000 sheets

- - 100 sets or 1000 sheets

10 sheets

-

10 sheets

-

Corner Staple 2-Point Staple

Bottom Offset Tray

2000 sheets (no staple)

1000 sheets (no staple)

-

1000 sheets (no staple)

50 sheets (no staple)

- 100 sheets

50 sheets (no staple)

100 sheets 100 sheets

Di620PE Operator’s Manual

Metric Areas

3-13

3. Selecting the Finishing

Non-Sort

Sort

Group

Crisscross Sort

Sort

Group

Staple

Crease

HalfFold

Folding

ZFold

Non-Sort, Sort,

Non-Sort, Sort,

Corner

Side

Center

Staple

Group

Staple

Group

Staple

Paper Size

A4C

A3L, B4L, A4L

A5L, A5C, A6L

A4L, A4C

A3L to A4

A4C

A3L, B4L, A4L

A3L to A4L

A3L to A4L

A3L to B4L

A3L to B4L

A3L

A3L

To p

Offset

Tra y

100 sheets

100 sheets

100 sheets

100 sheets

- 100 sets or 1000 sheets -

- - 200 sets or 2000 Sheets

- - 200 sets or 1000 Sheets

- - 100 sets or 1000 sheets

- - 100 sets or 1000 sheets

10 sheets

-

10 sheets

-

Corner Staple 2-Point Staple

Bottom Offset Tray

2000 sheets (no staple)

1000 sheets (no staple)

1000 sheets (no staple)

50 sheets (no staple)

- 100 sheets

50 sheets (no staple)

100 sheets 100 sheets

NOTE

When the Finisher FN-102 is mounted, the Auto Dual Function is not available.

-

Chapter 3Printing Procedure

Auto Dual Function in Stapling

If a stapling sequence is attempted and the number of sheets is greater than the stapling capacity, Stapling

is automatically canceled and the Finisher is set into the Sort or Group mode, sorting or grouping prints

using the Auto Dual function (but no stapling action takes place).

Di620PE Operator’s Manual

3-14

3. Selecting the Finishing

Note on Stapling

When prints are made using the stapling function, the stapled print sets may not be neatly stacked on the

tray or may even fall off the tray unless certain conditions are met regarding the number of prints to be

stapled and the number of print sets to be made. Use the following table as guide when making prints.

Print Set Capacity

Chapter 3

No. of Prints Stapled

2 prints 200 sets

3 to 5 prints 150 sets

6 to 10 prints 100 sets

11 to 20 prints 70 sets

21 to 30 prints 53 sets

31 to 40 prints 45 sets

41 to 50 prints 40 sets

When Finisher FN-102 is Mounted

A3L to A4

, 11″×17″L

to Letter

Printing Procedure

Di620PE Operator’s Manual

4-1

Chapter 4

When a Message Appears

Chapter 4When a Message Appears

Di620PE Operator’s Manual

4-2

Ma.

1. When the Message “The current Paper Tray is empty.” Appears

When the tray currently selected for use runs out

of paper, the message shown on the left appears.

The current print cycle is interrupted and you

cannot start a new print cycle. The blinking

drawer has run out of paper.

Adding paper

Tray 1

Slide out Tray 1.

1

Chapter 4

Load the paper stack into the Tray so that its

2

front side faces down.

When a Message Appears

The current Paper Tray is empty.

1075O101DA

Add paper by using the following procedure.

Slide the Tray back in.

3

1161O095DA

1161O009AA

NOTE

The paper should be loaded no higher than the

▼ (Max. Level Indicator).

Ma.

1145O555KA

Di620PE Operator’s Manual

Tray 2

Ma.

4

4-3

1. When the Message “The current Paper Tray is empty.” Appears

Slide out Tray 2.

1

Slide the Edge Guides in the direction of the

2

arrow to suit the paper size.

1161O096DA

1161O097DA

Slide the Tray back in.

1161O104DA

Chapter 4When a Message Appears

Load the paper stack into the Tray so that its

3

front side faces down.

1161O099DA

NOTE

The paper should be loaded no higher than the

▼ (Max. Level Indicator).

Ma.

1145O555KA

Di620PE Operator’s Manual

4-4

r

y

Ma.

1. When the Message “The current Paper Tray is empty.” Appears

Tray 3

Press the Paper Descent Key and then slide

1

the Tray out.

Indication of the Paper Descent Key

Steady Light:

Tray 3 has run out of paper when a Tray

other than the 3rd is currently selected fo

1136O146AA

Chapter 4

1136O145AA

2

use.

Blinking Light

:

Tray 3 has run out of paper when the Tra

3 is currently selected for use.

Load the paper stack into the right half of the

tray, front side face down. Press the leading

edge of the paper stack tightly up against the

right side of the Tray.

1075O049BA

Load another paper stack into the left half of

3

the Tray, front side face down. Press the

leading edge of the paper stack tightly up

against the left side of the Tray.

1161O108DA

NOTE

The paper should be loaded no higher than the

▼ (Max. Level Indicator).

Ma

1161O150AA

Slide the Tray back in and press the Paper

4

Descent Key.

When a Message Appears

1075O052BA

1161O106DA

NOTE

The paper should be loaded no higher than the

▼ (Max. Level Indicator).

Ma.

1145O555KA

Di620PE Operator’s Manual

Large Capacity Cassette

Ma.

3

4-5

1. When the Message “The current Paper Tray is empty.” Appears

Holding the Door Lock Release Lever, open

1

the Cassette Door.

1134O055AA

When adding paper to a partially loaded Cassette,

press the Paper Plate Descent Key to lower the

Paper Plate before opening the Cassette Door.

1134O031AA

Place the paper stack onto the Paper Plate so

2

that its front side faces up.

NOTES

• Make sure that the leading edge of the paper

stack is pressed tightly up against the Guide

Plate on the take-up side of the Cassette.

• The paper should be loaded no higher than

the ▼ (Max. Level Indicator).

Ma.

1145O555KA

Close the Cassette Door.

Chapter 4When a Message Appears

1134O033AA

* This causes the Paper Plate to rise

automatically.

Di620PE Operator’s Manual

NOTE

The Paper Plate may not ascend if the Cassette

Door is not closed completely. Be sure to close

the Door completely.

1134O054AA

4-6

2. When the Message “Replenish Toner.” Appears

The message shown on the left appears when

toner is soon running out. You can still make

prints, but the image density will become lighter

and lighter. It is recommended therefore that you

replace the Toner Bottle as soon as possible.

Replenish Toner

When toner has run out, the message shown on

the left appears and you can no longer start a new

print cycle. Replace the Toner Bottle with a new

one by following the procedure given below.

Chapter 4

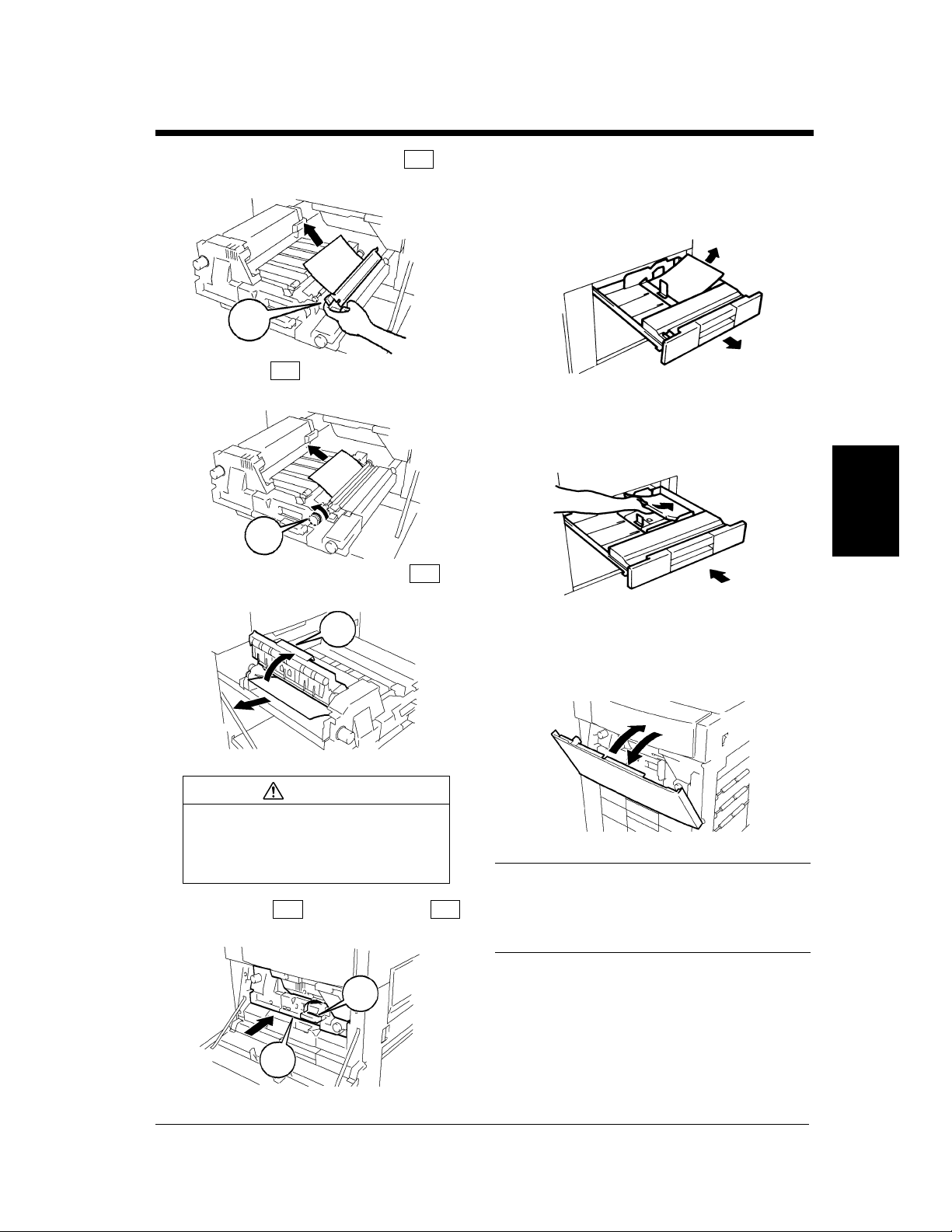

Replacing the Toner Bottle

Swing down the Upper Front Door.

1

When a Message Appears

Swing open the Toner Bottle Holder and pull

2

out the used Toner Bottle.

4115O013CA

4115O045AA

Tap a new Toner Bottle against a desk or

3

other hard surface four to five times. Then,

turn the Toner Bottle upside down and tap it

in the same way again.

1075O229AA

Di620PE Operator’s Manual

1075O054AA

4-7

7

2. When the Message “Replenish Toner.” Appears

Shake the new Toner Bottle well and turn it

4

over lengthwise five times.

1075O266AA

With the “UP” marking on top, insert the

5

Bottle into position.

Check that the marking on the Bottle is

aligned with the marking on the Toner

Bottle Holder.

4115O046AA

Swing the Toner Bottle Holder closed and

close the Front Door.

1075O059AA

NOTES

• Use ONLY the specified toner for this printer.

Using any other toner could result in trouble.

• Do not throw away, but keep, the used Toner

Bottle which will be collected by your Tech.

Rep.

• Be careful not to drop the Toner Bottle from a

1 m or more height. It may cause damage to

the Toner Bottle.

• When the Front Door is closed, the printer

automatically starts replenishing the supply of

toner. During this period, do not attempt to

turn OFF the Power Switch or open the Front

Door.

Chapter 4When a Message Appears

Pull the seal off the Toner Bottle.

6

Ton er R ep le n i s he r

Use the Toner Replenisher function available

from the User Mode if the image is light

immediately after the Toner Bottle has been

replaced with a new one.

1075O058AA

Di620PE Operator’s Manual

4-8

3. When the Message “The Staple Cartridge is empty.” Appears

The message shown on the left appears when the

staples are running out.

Replace the Staple Cartridge with a new one by

following the procedure given below.

Replenish Toner

Replacing the Staple Cartridge

<Only when the Finisher FN-3 is mounted>

While pressing down the Staple Cartridge

4

Lever, pull the Staple Cartridge out of its

port.

Chapter 4

Holding the Finisher Lock Release Lever,

1

slide the Finisher away from the printer.

4115O014AA

Open the Finisher Front Door.

2

When a Message Appears

1155O067AA

Slide out the Staple Unit.

3

1155O068AA

Pull the staple sheet about 3 cm out of the

5

new Staple Cartridge and break off that

portion.

1155O069AA

1136O012AA

Di620PE Operator’s Manual

4-9

8

9

10

3. When the Message “The Staple Cartridge is empty.” Appears

NOTE

Check that no portion of the staple sheet hangs

out of the cartridge. Break off any portion of the

sheet that hangs out of the cartridge.

1134O076AA

Insert the new Staple Cartridge until it clicks

6

into position.

1155O070AA

Push the Staple Unit back in and close the

7

Finisher Front Door.

Slide the Finisher back against the printer.

4115O015AA

Test the stapler by placing a sheet of paper

into the Manual Staple Tray (see p. 3-8).

Press the key.

Chapter 4When a Message Appears

1155O038AA

Remove the sheet of paper to check that it

has been properly stapled.

* If no staples are evident, repeat the procedure

from the beginning.

Di620PE Operator’s Manual

1155O071AA

1155O644AC

NOTES

• Replace the Staple Cartridge only after you

are prompted to do that by the message.

Removing the Staple Cartridge before then

will result in stapling trouble.

• After a new Staple Cartridge has been

installed, be sure to run a test-stapling

sequence to ensure that staples are properly

driven into the paper.

4-10

3. When the Message “The Staple Cartridge is empty.” Appears

<Only when the Finisher FN-102 is mounted>

Press and turn the knob and open the cover at

1

the rear of the Finisher.

Pull the Stapler Unit out of the well.

2

Chapter 4

While pressing down the green lever, pull out

3

the Staple Cartridge.

1155O766AA

1166O127AA

Remove the empty staple clip from the

4

Staple Cartridge.

Load a new staple clip into the Staple

5

Cartridge and carefully peel off the Seal.

Insert the Staple Cartridge into the Stapler

6

Unit until it clicks into place.

1166O129AA

1166O161AD

When a Message Appears

Di620PE Operator’s Manual

1166O128AA

Align the arrows and firmly push the Stapler

7

Unit down into the well.

1166O130AB

1166O131AB

Press and turn the Knob to lock the cover.

8

1155O767AA

NOTES

• Replace the Staple Cartridge only after you

are prompted to do that by the message.

Removing the Staple Cartridge before then

will result in stapling trouble.

4-11

3. When the Message “The Staple Cartridge is empty.” Appears

Chapter 4When a Message Appears

Di620PE Operator’s Manual

4-12

4. When the Message “A paper misfeed has been detected.” Appears

If a paper misfeed occurs during a print cycle, the

message shown on the left appears and that

particular print cycle is stopped in the middle of

operation.

Clear the misfed sheet of paper according to the

procedure given below.

4115O016CA

Misfeed Location Displays

Different procedures are used to clear a misfed sheet of paper depending on the location. First, isolate the

location, then clear the misfeed according to the procedure applicable to the misfeed occurring at that

particular location. A blinking dot “ ” indicates that there is a misfeed at that location. A lit dot “ ”

indicates that there might be a sheet of paper stopped at that location.

When a misfeed occurs, the error indicator (red) on the printer’s front panel will light. This light will go

out whenever the front door is opened.

Chapter 4

Copier p. 4-14

4115O017AA 4115O018AA 4115O019AA 4115O020AA 4115O021AA

When a Message Appears

Duplex Unit p. 4-16

Di620PE Operator’s Manual

4115O020AA4115O023AA4115O022AA

4-13

4. When the Message “A paper misfeed has been detected.” Appears

Large Capacity Cassette p. 4-18 Intelligent Manual Feeding Tray p. 4-19

4115O024AA

Finisher FN-3 p. 4-20

4115O025AA 4115O026AA 4115O027AA 4115O028AA

4115O029AA 4115O030AA 4115O031AA 4115O032AA

Finisher FN-102 p. 4-28

4115O019AA

Chapter 4When a Message Appears

4115O033AA 4115O034AA

Di620PE Operator’s Manual

4115O035AA

4115O036AA

4-14

M5

4. When the Message “A paper misfeed has been detected.” Appears

Misfeed Clearing Procedures

Printer

Chapter 4

Open the Misfeed Clearing Guide ,

1

pull out the sheet of paper.

L1

Open the Left Door.

2

Open the Front Door.

3

L1

1155O558AB

1155O076AA

Open the Right Door.

6

Turning Knob , pull out the sheet of

7

paper.

M2

Close the Right Door.

8

M2

1155O079AA

1155O080AA

Turn Knob to feed the sheet of paper.

9

When a Message Appears

4115O047AA

Turning Knob , pull out the sheet of

4

paper. Then turn Knob to return any

paper to the Duplex Unit.

Close the Left Door.

5

M1

D1

D1

M1

1155O078AA

Lower the Lever and slide out the

10

M3

M3

1155O081AA

M4

Unit.

M4

M5

1155O082AA

Di620PE Operator’s Manual

4-15

15

16

17

18

4. When the Message “A paper misfeed has been detected.” Appears

Raising Misfeed Clearing Guide ,

11

remove the sheet of paper.

M6

Turn Knob and remove the sheet of

12

paper.

Opening Misfeed Clearing Guide ,

13

remove the sheet of paper.

M7

M7

M6

1155O083AA

1155O085AA

M8

Close the Front Door.

Slide out the Tray being used and take out

the paper stack left in it.

1075O068AA

Reload the paper stack and slide the Tray

into the printer.

Chapter 4When a Message Appears

1075O069AA

M8

CAUTION

The area around the Fusing Unit is

very hot. Do not touch anything but

the paper to prevent you from

getting burned.

Slide in the Unit and raise the

14

Lever back up again.

M5 M4

M4

M5

To reset the paper misfeed indication on the

Panel, open and close the Front Door.

1155O084AA

4115O048AA

Useful Tip

After the paper misfeed has been cleared, the

printer automatically resumes a print cycle

without the Start Command.

1155O086AA

Di620PE Operator’s Manual

4-16

4. When the Message “A paper misfeed has been detected.” Appears

Duplex Unit

Chapter 4

Open the Left Door.

1

Open the Front Door.

2

Turning Knob , pull out the sheet of

3

paper. Then turn Knob to return any

paper to the Duplex Unit.

M1

D1

1155O076AA

4115O047AA

Turning Knob , pull out the sheet of

6

paper.

M2

Close the Right Door.

7

Slide out Duplex Unit .

8

Raising Misfeed Clearing Guide ,

9

remove the sheet of paper.

M2

D2

D2

1155O080AA

1155O089AA

D3

When a Message Appears

Close the Left Door.

4

Open the Right Door.

5

Di620PE Operator’s Manual

D1

M1

1155O078AA

1155O079AA

D3

Raising Misfeed Clearing Guide ,

10

remove the sheet of paper.

D4

1155O090AA

D4

1155O091AA

4-17

4. When the Message “A paper misfeed has been detected.” Appears

Raising Misfeed Clearing Guide ,

11

remove the sheet of paper.

Slide Duplex Unit back into the

12

printer.

Close the Front Door.

13

D2

D2

D5

D5

1155O092AA

Chapter 4When a Message Appears

1155O093AA

Useful Tip

After the paper misfeed has been cleared, the

printer automatically resumes a print cycle

without the Start Command.

Di620PE Operator’s Manual

4-18

4. When the Message “A paper misfeed has been detected.” Appears

Large Capacity Cassette

Chapter 4

Press the Paper Descent Key.

1

1134O031AA

Holding the Door Lock Release Lever, open

2

the Cassette Door and remove the sheet of

paper.

1134O027AA

Remove the sheet of paper.

5

Slide the Cassette back against the printer.

6

1134O029AA

1134O030AA

Close the Cassette Door.

3

When a Message Appears

1134O033AA

Press the Lock Release Lever and slide the

4

Cassette away from the printer.

1134O028AA

Di620PE Operator’s Manual

Intelligent Manual Feed Tray

Unload the paper stack from the Manual

1

Feed Tray and open the Right Door.

Pull out the sheet of paper from the Paper

2

Take-Up Section. Then, close the Right

Door.

4-19

4. When the Message “A paper misfeed has been detected.” Appears

1075O071AB

Chapter 4When a Message Appears

Place the paper stack back on the tray.

3

To reset the paper misfeed indication on the

4

Touch Panel, open and close the Front Door.

1155O087AA

1075O073AA

Di620PE Operator’s Manual

4115O048AA

4-20

4. When the Message “A paper misfeed has been detected.” Appears

Finisher FN-3

<When the following dots are lit:>

4115O037AA

Holding the Finisher Lock Release Lever,

1

slide the Finisher away from the printer.

Close the Misfeed Clearing Guide and

4

tighten the screws.

Open the Finisher Front Door.

5

1155O067AA

Chapter 4

When a Message Appears

Opening Misfeed Clearing Guide ,

2

remove the sheet of paper.

FN1

Loosen two screws, open the Misfeed

3

Clearing Guide and remove the sheet of

paper.

4115O014AA

FN1

1155O406AA

Raising Misfeed Clearing Guide ,

6

remove the sheet of paper.

FN3

FN2

FN2

FN4

Turn Knob to feed the sheet of paper.

7

Open Misfeed Clearing Guide .

8

FN3

1155O407AA

1155O408AA

Di620PE Operator’s Manual

1155O700AA

FN4

1155O409AA

4-21

13

14

4. When the Message “A paper misfeed has been detected.” Appears

Remove the sheet of paper and close Misfeed

9

Clearing Guide .

Turn Knobs and to feed the

10

sheet of paper.

FN7

FN6

FN4

FN7

FN4

FN6

1155O410AA

1155O411AA

Close the Finisher Front Door.

1155O645AA

Slide the Finisher back against the printer.

4115O015AA

Chapter 4When a Message Appears

Pinching the lever of Misfeed Clearing

11

Guide , open .

Remove the sheet of paper and close .

12

FN5

FN5

FN5

FN5

1155O412AA

FN5

1155O413AA

Di620PE Operator’s Manual

4-22

FN5

4. When the Message “A paper misfeed has been detected.” Appears

<When the following dots are lit:>

Holding the Finisher Lock Release Lever,

1

slide the Finisher away from the printer.

Chapter 4

Open the Finisher Front Door.

2

4115O038AA

4115O014AA

Remove the sheet of paper and close

4

FN8

.

Turn Knobs and to feed the

5

sheet of paper.

Pinching the lever of Misfeed Clearing

6

Guide , open .

FN7 FN6

FN7

FN6

FN5

FN8

1155O415AA

1155O411AA

When a Message Appears

Pinching the lever of Misfeed Clearing

3

Guide , open .

Di620PE Operator’s Manual

FN8 FN8

FN8

1155O067AA

1155O414AA

FN5

Remove the sheet of paper and close .

7

FN5

1155O412AA

FN5

1155O413AA

4-23

1

2

FN9

3

4

FN10

4. When the Message “A paper misfeed has been detected.” Appears

Close the Finisher Front Door.

8

Slide the Finisher back against the printer.

9

1155O645AA

4115O015AA

<When the following dots are lit:>

4115O039AA

Open Exit Tray and remove the

sheet of paper.

Close .

FN9

FN9

Chapter 4When a Message Appears

1155O424AA

Open Manual Staple Tray Cover

and remove the sheet of paper.

FN10

Close .

FN10

1155O425AA

Di620PE Operator’s Manual

4-24

4. When the Message “A paper misfeed has been detected.” Appears

<When the following dots are lit:>

Holding the Finisher Lock Release Lever,

1

slide the Finisher away from the printer.

Chapter 4

Open the Finisher Front Door.

2

4115O040AA

4115O014AA

Turn Knob to feed the sheet of

4

paper.

Open Misfeed Clearing Guide .

5

Remove the sheet of paper and close Misfeed

6

Clearing Guide .

FN2

FN2

FN4

FN4

1155O408AA

FN4

1155O409AA

When a Message Appears

Raising Misfeed Clearing Guide ,

3

remove the sheet of paper.

FN3

Di620PE Operator’s Manual

1155O067AA

FN3

1155O407AA

FN4

Turn Knobs and to feed the

7

sheet of paper.

FN7 FN6

FN7

FN6

1155O410AA

115 5O4 11AA

4-25

11

12

13

4. When the Message “A paper misfeed has been detected.” Appears

Pinching the lever of Misfeed Clearing

8

Guide , open .

Remove the sheet of paper and close

9

FN5 FN5

FN5

FN5

.

FN5

1155O412AA

1155O413AA

Check to see if a sheet of paper is left in the

Finisher. If any is visible, perform step 10

once again.

1155O719AA

NOTE

Sliding out Paper Folding Unit with a

sheet of paper left inside could result in a

malfunction.

Open Misfeed Clearing Guide .

PF2

FN4

Chapter 4When a Message Appears

Turn Knobs and together five

10

turns to feed the sheet of paper.

FN2 PF1

FN2

PF1

1155O408AA

1155O416AA

FN4

1155O409AA

Remove the sheet of paper and close Misfeed

Clearing Guide .

FN4

FN4

1155O410AA

Di620PE Operator’s Manual

4-26

4. When the Message “A paper misfeed has been detected.” Appears

Chapter 4

Turn Knobs and to feed

14

the sheet of paper.

Pinching the lever of Misfeed Clearing

15

Guide , open .

Remove the sheet of paper and close .

16

FN7 FN6

FN7

FN6

1155O411AA

FN5 FN5

FN5

1155O412AA

FN5

Opening Misfeed Clearing Guide ,

18

remove the sheet of paper.

PF3

Raise Misfeed Clearing Guide .

19

PF4

Turning Knob , remove the sheet of

20

paper and then lower Misfeed Clearing

Guide .

PF4

PF1

PF3

1155O418AA

PF4

1155O419AA

When a Message Appears

Slide out Paper Folding Unit .

17

Di620PE Operator’s Manual

FN5

PF2

PF2

1155O413AA

1155O417AA

PF4

Opening Misfeed Clearing Guide ,

21

remove the sheet of paper.

PF5

PF1

1155O420AB

PF5

1155O421AA

4-27

4. When the Message “A paper misfeed has been detected.” Appears

Opening Misfeed Clearing Guide ,

22

remove the sheet of paper.

PF6

Slide Paper Folding Unit back into

23

the printer.

PF2

PF2

PF6

1155O423AA

Chapter 4When a Message Appears

1155O422AA

Close the Finisher Front Door.

24

Slide the Finisher back against the printer.

25

1155O645AA

4115O015AA

Di620PE Operator’s Manual

4-28

4. When the Message “A paper misfeed has been detected.” Appears

Finisher FN-102

Chapter 4

Holding the Finisher Lock Release Lever,

1

slide the Finisher away from the printer.

If “Hole Punch” has been set, turn the Hole

2

Punch Adjustment Dial ten times upward.

Remove the sheet of paper.

4115O041AA

Open Misfeed Clearing Guide and

4

remove the sheet of paper.

Open Misfeed Clearing Guide and

5

remove the sheet of paper.

FN3

1155O740AA

FN4

1155O741AA

1155O739AA

Open Misfeed Clearing Guide .

3

When a Message Appears

CAUTION

Metallic parts inside Misfeed

Clearing Guide are very hot.

Do not touch anything but the

paper to prevent you from getting

burned.

FN2

FN2

1166O168AA

Raise Misfeed Clearing Guide and

6

remove the sheet of paper.

Close Misfeed Clearing Guide until

7

it clicks into position.

FN5

1155O742AA

FN5

1155O743AA

Di620PE Operator’s Manual

4-29

12

13

14

15

4. When the Message “A paper misfeed has been detected.” Appears

Open Misfeed Clearing Guide and

8

remove the sheet of paper.

Open Misfeed Clearing Guide at the

9

right side of the Finisher.

Remove the sheet of paper.

10

FN9

FN7

1155O744AC

1155O745AB

Close Misfeed Clearing Guide .

Open Misfeed Clearing Guide .

Remove the sheet of paper and close Misfeed

Clearing Guide .

FN1

FN2

1166O172AA

FN1

1166O173AA

Chapter 4When a Message Appears

Close Misfeed Clearing Guide .

11

Di620PE Operator’s Manual

1155O746AC

1166O174AA

FN7

Slide the Finisher back against the printer.

1155O747AA

4115O049AA

4-30

5. When a Staple Misfeed Occurs

Clearing the Staple Misfeed

<Only when the Finisher FN-102 is mounted>

4115O042CA

If a staple misfeed occurs, the message shown on

the left appears.

Clear the staple misfed according to the procedure

given below.

Chapter 4

When a Message Appears

Open Misfeed Clearing Guide .

1

Remove the sheet of paper and close Misfeed

2

Clearing Guide .

Press and turn the knob to open the cover at

3

the rear of the Finisher.

FN1

FN1

1166O174AA

1166O173AA

Pull the Stapler Unit out of the well.

4

While pressing down the green lever, pull out

5

the Staple Cartridge.

Push up the guide of the Staple Cartridge and

6

pull out one staple sheet.

1166O127AA

1166O128AA

Di620PE Operator’s Manual

1155O766AA

1166O177AA

Return the guide back to its original position.

7

Insert the Staple Cartridge into the Stapler

8

Unit until it clicks into place.

4-31

5. When a Staple Misfeed Occurs

1166O178AA

Chapter 4When a Message Appears

1166O130AB

Align the arrows and firmly push the Stapler

9