Page 1

User Manual

Minolta MicroPress System Software Release 6

www.minoltaeurope.com

The essentials of imaging

Page 2

Page 3

User Manual

PrintStation Manager

www.minoltaeurope.com

The essentials of imaging

Page 4

Page 5

Copyright © 1995–2001 T/R Systems, Inc.

All Rights Reserved

Reproduction, adaptation, or translation without prior written permission is prohibited, except as allowed

under the copyright laws.

The information contained in this document is subject to change without notice. T/R Systems makes no

warranty of any kind with regard to this material, including, but not limited to, the implied warranties of

merchantability and fitness for a particular purpose. T/R Systems shall not be liable for errors contained

herein or for incidental or consequential damage in connection with the furnishing, performance, or use

of this material.

T/R Systems, MicroPress, M@estro, e-Ticket, MicroImager and other T/R Systems' product names are

registered trademarks or trademarks of T/R Systems, Inc. in the United States and other countries.

Portions of this product were created using LEADTOOLS © 1991-2001, LEAD Technologies, Inc. ALL

RIGHTS RESERVED.

Portions hereof include TextBridge® OCR Copyright © Xerox Corporation. ALL RIGHTS RESERVED.

LZW data compression technology licensed under U.S. Patent No. 4,558,302

Some ICC Profiles created using software under License from Monaco Systems, Inc.

Portions Copyright © 2001 URW++. All Rights Reserved

Imaging Technology provided under License by AccuSoft Corporation. ImageGear© 1996-2001 by

AccuSoft Corporation. All Rights Reserved.

All other company and product names are registered trademarks or trademarks of their respective owners in the United States and other countries.

The following marks are used in this manual:

Indicates precautions that must be observed to prevent possible personal injury or damage

to equipment or malfunctioning of software.

Indicates notes and memos containing additional or detailed information.

Indicates useful tips.

Page 6

Page 7

Table of Contents

What is PrintStation Manager™? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

PrintStation and Virtual Engine Naming Convention. . . . . . . . . . . . . . . . . . . . . . . . . . 2

The PrintStation Manager Main Screen Display . . . . . . . . . . . . . . . . . . 2

Job List Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Job List Fields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Job Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Display Jobs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

PrintStation Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Virtual Engine Status Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

UnArchive Job File(s)… . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Exit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Virtual Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Pause or Resume a Virtual Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Resuming a Paused Virtual Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Resynch Jobs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Forms… . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Multi Page Forms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Letterhead. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Engine Defaults… . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Virtual Engine Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Media Saving Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Job Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Finishing Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Finishing Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

TRueColor.... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

B&W Engine Balance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Job . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Info... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Job Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Finishing Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

062 Finishing Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Output Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Page Range Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Margin Offsets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Brightness/Contrast. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Color Adjust. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

ColorCurves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Default ColorCurves and Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Job Parsing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Chapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Page Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Annotations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Finishing Setup, Settings and Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Preview…. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Edit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

iii

Page 8

Lock/Unlock... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Hold/Suspend . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Move... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Delete . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Abort . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Merge… . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Archive... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Apply Form…. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Mail Merge… . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Center Pages… . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Image Editing... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

OCR... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Imposition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Insert/Delete Pages… . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Numbering… . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Re-order Pages… . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Scale & Rotate… . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Rotate Pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Send To . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Tumble . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Job Ticket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Assign Job Ticket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Edit/View Job Ticket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Delete Job Ticket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Print Job Ticket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Toolbar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Status Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

System Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

System Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Accounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Scripting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Script Toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Notifications… . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Find… . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

AutoScript . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Archive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Preview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

TRueEdit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Enable Remote Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

BAT Object Registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Engine Status Dialogs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

iv

Page 9

PrintStation 024-Specific Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Jam Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Unit Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Miscellaneous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Feed Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Non-Standard Paper Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Browser. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Covers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Tab Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Engine Density . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Engine Exposure Adjust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Engine Margin Offsets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Color Insertion Tray. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

OPC Connected Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

OPC Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Custom PJL Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

e-PSM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

PSM Functionality Available in e-PSM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

PSM Functionality Not Available in e-PSM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Glossary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

v

Page 10

vi

Page 11

What is PrintStation Manager™?

”

PrintStation Manager (PSM) is an application that groups multiple PrintStations™/PrintLinks™ so they appear and function as a single high-speed printer. This Virtual Engine (VE)

system lets you customize printer configurations based on printing requirements. Using multiple Virtual Engines allows printing multiple jobs simultaneously. PSM’s Electronic Collator

and job parser (job manager) evenly distributes jobs between PrintStations grouped in the

Virtual Engine. PrintStations can have several VE configurations, so the MicroPress® ships

with default VE configurations.

Features

PSM has many built-in features (e.g., drag-and-drop to move files between Virtual Engines,

one-click duplexing).

Optional features* include:

• Imposition – See “Imposition” on

page 29

• Document Merge – See “Merge…” on

page 23

• Forms – See “Apply Form…” on

page 24

• Image Manipulation (not available on

PrintStation 312) – See “Brightness/

Contrast” on page 17 See “Color

Adjust” on page 18

• TRueColor™ (Print Test Calibrate in

prior versions) – See “TRueColor...” on

page 10

• Scripting – See “Scripting” on page 38

• Job Ticketing – See “Job Ticket” on

page 35

• Page Numbering – See “Numbering…

on page 31

• Annotations – See “Annotations” on

page 21

• Image Editing – See “Image Editing...”

on page 27

•OCR – See “OCR...” on page 28

• PDF Archive – See “Archive...” on

page 24

• e-PSM™ – See “e-PSM” on page 58

• Job Parsing – See “Job Parsing” on

page 19

• TRueEdit™ – See “Edit” on page 21

Note: You must purchase each optional feature and get a new license number from your Micro-

Press dealer. If you haven’t purchased an option, you will see a yellow key and “grayed out” or

unavailable controls. Some features may not be available for all PrintStations.

To enter licensing information, select Help

button (or run the PSM Configuration™ software).

ÎAbout... from the menu, then click the Licensing

1

Page 12

PrintStation and Virtual Engine Naming Convention

PrintStation/Virtual Engine names are a letter and a number. The letter indicates the PrintStation type; the number is an increment of 1-12, reflecting the quantity of the PrintStation type.

• A – PrintStation 312

• B – PrintStation 024

•C – PrintLink Cii

• D – PrintStation LaserJet 5Si

• E – PrintStation DesignJet CP

• F – PrintStation 040

• G – PrintLink 062

• H – PrintStation LaserJet 8000

• J – PrintStation DesignJet 1000

• K – PrintStation 070

• M – PrintStation 065

• N – PrintStation 085r

• O – PrintStation 036k

Example: A MicroPress with four 024s would have PrintStations named B1, B2, B3, and B4.

A virtual engine using B1 and B2 would be named B12.

• P – PrintStation 2525t

• Q – PrintStation 070r

• R – PrintStation 080t

• S – PrintStation 0110i

• T – PrintStation 075m

• U – PrintStation 832m

• V – PrintStation 2020m

• W – PrintStation 624m

•Z – OPC

• AB – PrintStation 060c

• AC – PrintStation 085c

• AD – PrintStation 5050c

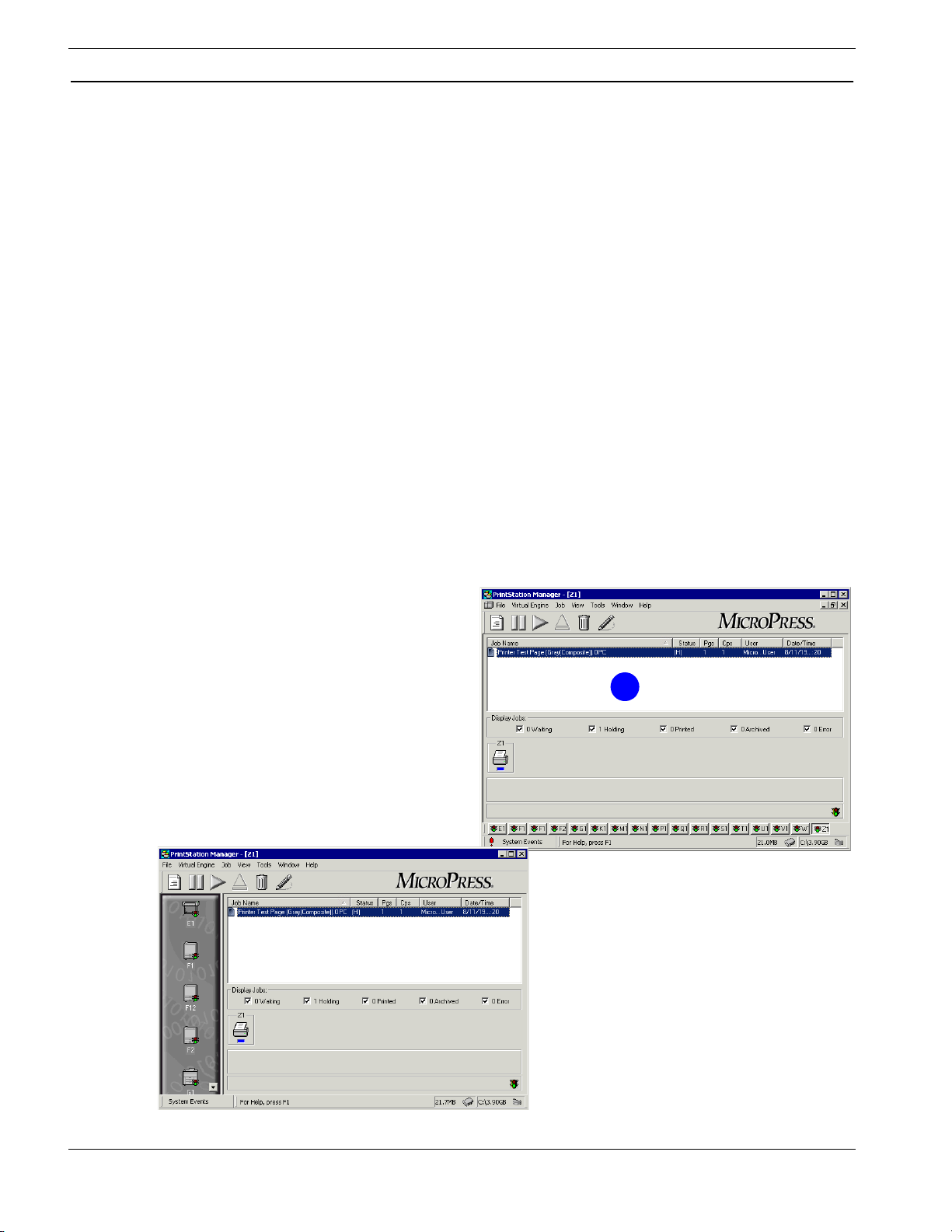

The PrintStation Manager Main Screen Display

The main screen allows access to:

• The Virtual Engines within the PrintStation Manager

• Print jobs and job attributes

• The Toolbar for PrintStation and job

control

The graphic (right) shows the default

view.

Use the Options dialog to enable an

alternate view (below). See “Options” on

page 41.

1

2

Page 13

Job List Window

When details view is active, the Job List window ([1] on above graphic) gives detailed job

information. To enable this view, select Virtual EngineÎView Job Details from the menu.

Note: An * in front of the number of pages in the job means the job is set to print some sequence of pages other

than the first page to the last (e.g., odd pages only).

You can also set the Job List Window to display job names only. Select Virtual EngineÎ

View Job Name from the menu.

Job List Fields

The following table describes the columns in the Job List window. A small arrow head in a

column header indicates the list is sorted by that field. The direction of the arrow indicates

ascending or descending order.

Field/Control Description

Job Name The name of the job to print and job icon.

Job Status The current state of the job.

Pages The number of pages contained in the job. A “?” will display as a job is loading into the

PrintStation Manager.

Copies The number of times the job will be printed.

User The user or the name of the user’s workstation.

Date/Time When the PrintStation Manager received the job.

The checked selection in the ViewÎSort By menu indicates the current field that jobs are

sorted by. Sort by a particular field by clicking on the column header. Clicking again will

reverse the sort order. Jobs are initially sorted in ascending order.

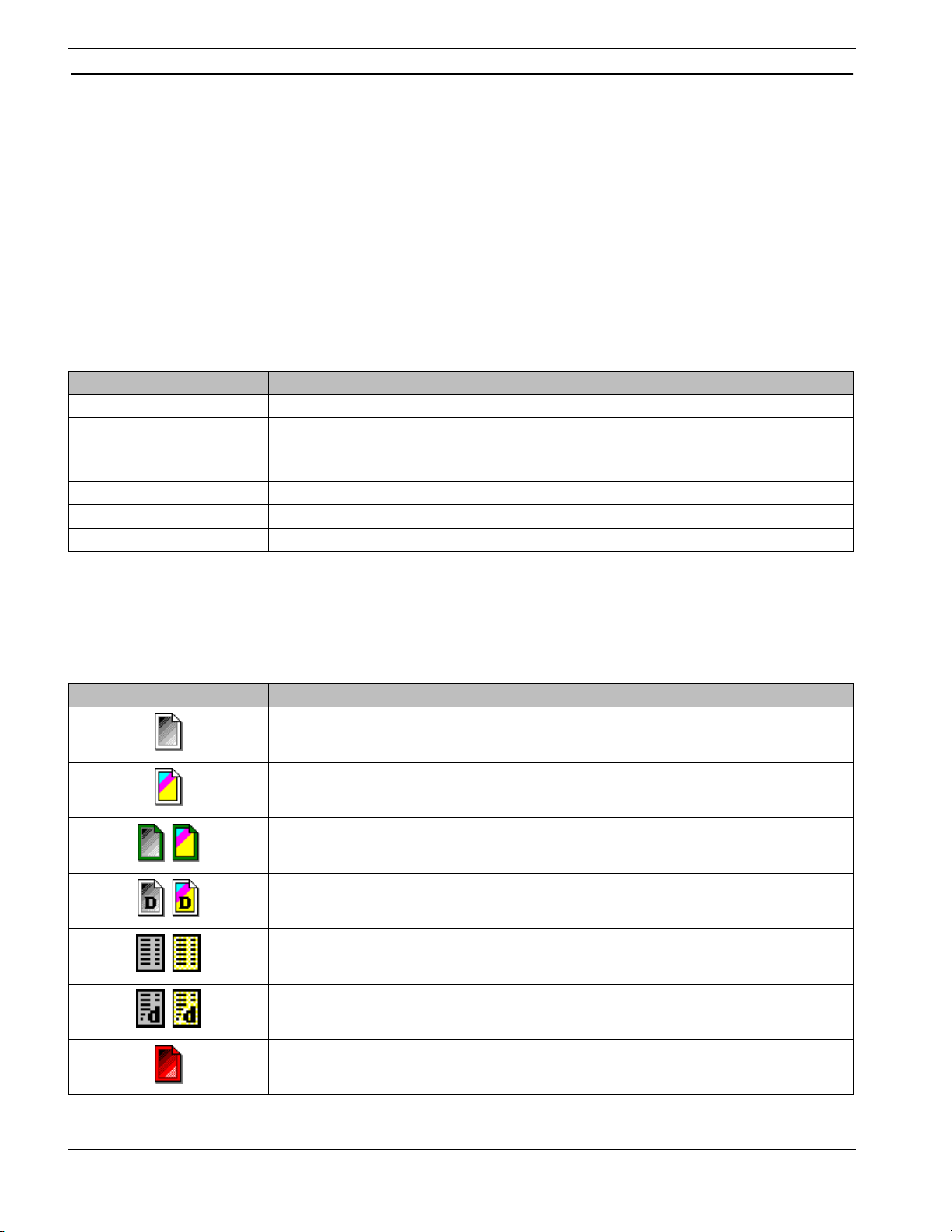

Job Icons

This table describes the job icons.

Job Icon Description

B&W standard – Displays for standard B&W jobs in the Waiting, Holding, Suspended, or

Printed state.

Color standard – Displays for standard color jobsin the Waiting, Holding Suspended, or

Printed state.

Printing (B&W, Color) – When a job is printing the icon is highlighted in green.

Duplex (B&W, Color) – A duplexed job.

Form (B&W, Color) – Indicates a job was Merged with a Form.

Combination (B&W, Color) – Indicates job is both Duplex and a Form.

Error – Indicates job has errored.

3

Page 14

Job Icon Description

Tab – Indicates job contains tab pages

Display Jobs

When you select a job type, all jobs of that

type will display in the Job List Window.

Click the box beside each job type to

include it in the Job List. The number beside each job type is the number of jobs of that type.

Note: The number of each current job type will display regardless of whether the job type is selected.

This table describes various states in which jobs can display in the status column.

Field/Control Description

Waiting W: waiting to be printed.

Holding H: holding to print later.

Printed P: printed successfully.

Archived A: archived with Auto Archive.

Error E: printing error has occurred.

This table describes other job status indicators not listed in the Display Jobs check box area.

Status Indicates

>> Printing

P! Job stack moved to another PrintStation.

-B- Job is busy, usually during archiving.

S Currently printing. Clicking Hold/Suspend button stops printing.

°L Job locked with password.

PrintStation Button

PrintStation buttons located inside the Virtual Engine window alert you to common PrintStation conditions that can cause image defects or print job errors.

Clicking on a PrintStation button opens the PrintStation window and allows access to PrintStation Summary or PrintStation Systems information for a specific PrintStation.

PrintStation status is indicated by various colors. This table describes various PrintStation

button colors.

The PrintStation Icon

Light Displays

Black

Bright Green

Flashing Bright Green A job is printing without error, or toner is low.

Dark Green

Yel lo w

Flashing Yellow A Job is printing, but a caution is indicated.

Red

Flashing Red A printer is paused for “work and turn” pages for manual duplexing.

When

The PSM is starting up.

A printer is idle and ready.

No communication exists between the PSM and a PrintStation.

Paper out or conditions may be developing that will result in problems with image quality.

User intervention is needed before printing can continue.

4

Page 15

The PrintStation Icon

Light Displays

Disabled

Blue

Paper Out

Toner Low/Out

When

A PrintStation is disabled.

A device’s status cannot be determined. Currently, blue used only by OPC VE. See “OPC

Connected Devices” on page 56.

PrintStation has used last sheet of paper in selected paper source (some PrintStations

display which paper tray is empty).

• Paper Out with Yellow Light: Auto Tray Switch enabled and a paper tray is empty; however, printing may continue with use of another paper tray.

• Paper Out with Red Light: one or all paper trays are empty and printing stops.

Toner low. PrintStation button displays which toner cartridge is low.

Paper Jam

Paper jam. Always displays along with a red light. Click the engine button for information on

the paper jam location and jam resolution.

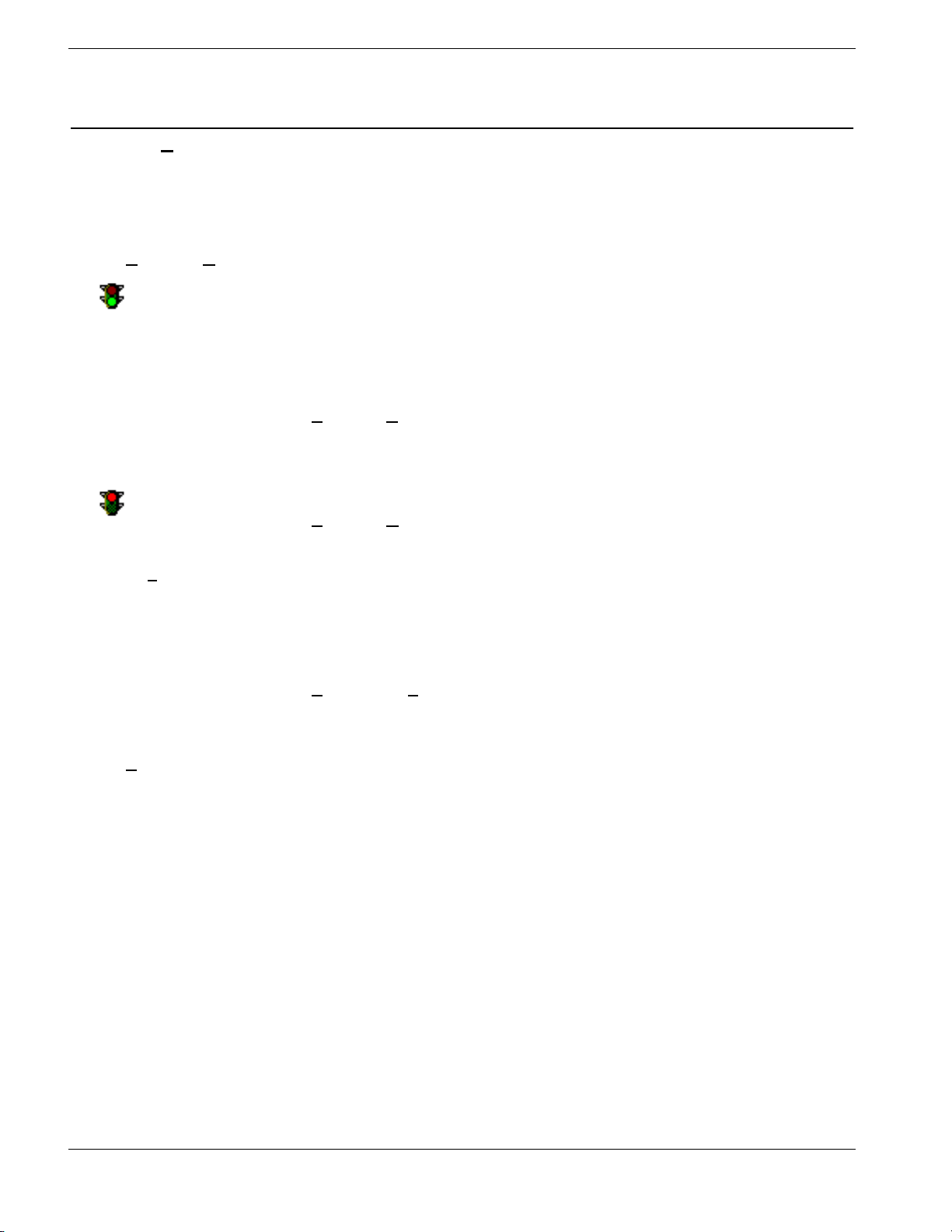

Virtual Engine Status Bar

The Virtual Engine Status Bar displays the name and status of the job printing and has also

has a Pause/Resume button. Icons indicate status:

Status Bar Indicates

Printing

Forms

Paused

Archiving/Unarchiving

Menus

File

Use the File menu selections to UnArchive jobs and Exit the PSM.

nArchive Job File(s)…

U

Use UnArchive Job File(s) to decompress archived files and return the file to PSM format.

1 Select the Virtual Engine to receive the archived file.

2 Select F

ileÎUnArchive Job File(s) from the menu.

3 Select the file to be unarchived. Click OK to decompress the file and place it in the

active Virtual Engine Job List.

Note: UnArchiving an older version PSM job will update to the current PSM version.

Exit

To exit PSM:

Select FileÎExit from the menu.

Note: PSM saves status of current jobs before closing.

Caution: Make sure all active jobs have completed processing before shutting down the PSM. If you shut down

the PSM while jobs are printing, a program error will result. To avoid having to reboot the server, select CTRL-

5

Page 16

ALT-DEL to launch the Task Manager. Open the Processes tab in the Task Manager, select psm.exe from the list

of active processes, then click End Process.

Virtual Engine

Virtual Engine menu options affect the selected Virtual Engine (VE). Which features are

active depends on the MicroPress configuration. The TRueColor feature is active only if the

VE contains a color capable PrintStation. The following sections describe the Virtual Engine

menu options.

P

ause or Resume a Virtual Engine

This option prevents or starts print activity on the active VE (but does not affect a currently

printing job). When the Pause/Resume light is green, the Virtual Printer is ready to print;

when it red, the Virtual Printer is paused and will not print. All jobs selected to print will display as a Wait (W) status in the Status column of the Job List window until the VE is resumed.

To pause a VE:

1 Select a VE.

2 Select Virtual E

continue to send jobs that will be held until the VE is resumed).

Resuming a Paused Virtual Engine

1 Select a paused Virtual Engine.

2 Select Virtual E

3 Virtual Engine activity resumes.

ngineÎPause from the menu to halt printing from the VE (users can

ngineÎResume from the menu.

ynch Jobs

Res

The Resynch Jobs feature lets you refresh and update the Job List window. This is especially

useful if a job file is copied into a PrintStation Manager spool directory. The updated job will

display after Resynch Jobs has refreshed the PrintStation Job List window.

1 Select a Virtual Engine.

2 Select Virtual E

ngineÎResynch from the menu.

3 The Job List window will refresh, and any jobs copied to the Virtual Engine’s Spool

Directory are added to the display.

F

orms…

Use the Forms option to print data from one job as an overlay onto another job. This provides

a more efficient way of printing multiple copies of a job that contains both common and

unique text or graphics. To print a form more efficiently, send it with fixed image information

(common text and graphics) to be processed through MicroSpool, the MicroPress RIP, and

then to the PSM only once. Next, configure the job as a form for that Virtual Engine to merge

the job with the form information. You can also set the forms print option from Macintosh or

PC workstations using the MicroPress drivers.

Multi Page Forms

A form can have one or more pages and be merged with unique text documents containing

any number of pages (e.g., 10 pages of unique text or variable data to be merged with a 5page form). Forms can be repeated so that each page of the unique text document will be

merged with the appropriate page of the form. Click the Repeat Form button to merge a 5-

page form with a 10-page document. The PSM merges pages 1-5 of the form with pages1-5

of the unique text document, and then the 5-page form is repeated with the next 5 pages

(pages 6-10) of the unique text document.

6

Page 17

Letterhead

The Forms option makes printing jobs with letterhead more efficient as it eliminates the need

to change or reload the paper tray with pre-printed letterhead. If the forms option is turned off

at the PSM, you can still set it from the workstation to override default options in PSM. However, if the current form in the PSM is “No Form”, the job set this way will fail because no form

has been added for use.

Warning: When using the Form feature in the PSM, the following Job Settings must match to achieve the desired

output:

• Bit Depth (Contone/BiLevel/Monochrome): Both the Form and the file to be overlaid must come

through the same Virtual Printer.

• Horizontal and Vertical Resolution Settings

If these Job Settings do not match, the job will print without the form, and an error message will be generated in

the system log.

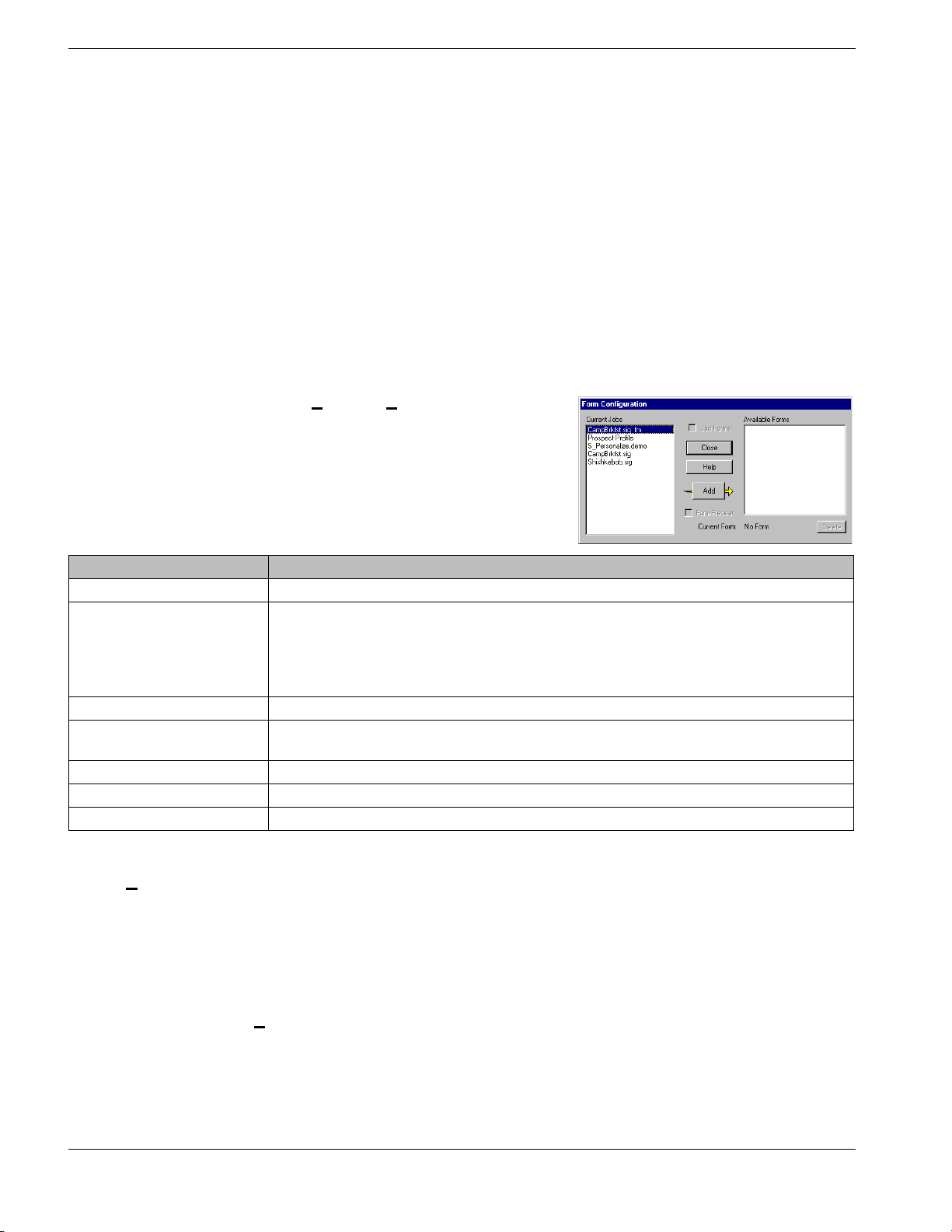

To use the Forms Setup option:

1 Select a Virtual Engine.

2 Select Virtual E

ngineÎForms to open the

Form Configuration dialog.

Note: To open the Form Setup dialog, pressing

[Ctrl]+[F].

Field Description

Current Jobs Displays all current jobs for the active Virtual Engine (VE).

Use Forms Prints the form as an overlay for every job sent to the VE. The current form is highlighted

under Available Forms and listed next to Current Form . If this box is not checked, the

selected form will not print unless the job itself has specified “Use Form.”

Note: Before the “Use Forms” option is available, a job must first be selected to be used as a

form from the Current Jobs field. “Add” it to the list of Available Forms.

Add Copies the job selected from the Current Jobs field to the Available Forms field.

Form Repeat Repeats a form so that each page of a specific document will be merged with the

appropriate page of the form.

Current Form Displays currently selected form.

Available Forms Selects a form for use as a printed overlay for every job sent to the VE.

Delete Removes selected form from the Available Forms list.

3 Click Close to apply the Form Setup.

ngine Defaults…

E

The Virtual Engine Default Settings dialog may contain several option categories (e.g., Virtual Engine Defaults and Job Defaults), depending on engine type. The next section

describes each default type.

To access the Engine Defaults dialog:

1 Right-click the Virtual Engine's task bar button on the PSM main dialog.

2 Select E

ngine Defaults.

7

Page 18

Virtual Engine Defaults

Virtual Engine Defaults control the behavior of all jobs printed from a VE and can be overridden by the workstation sending the job. The available defaults may vary by engine type.

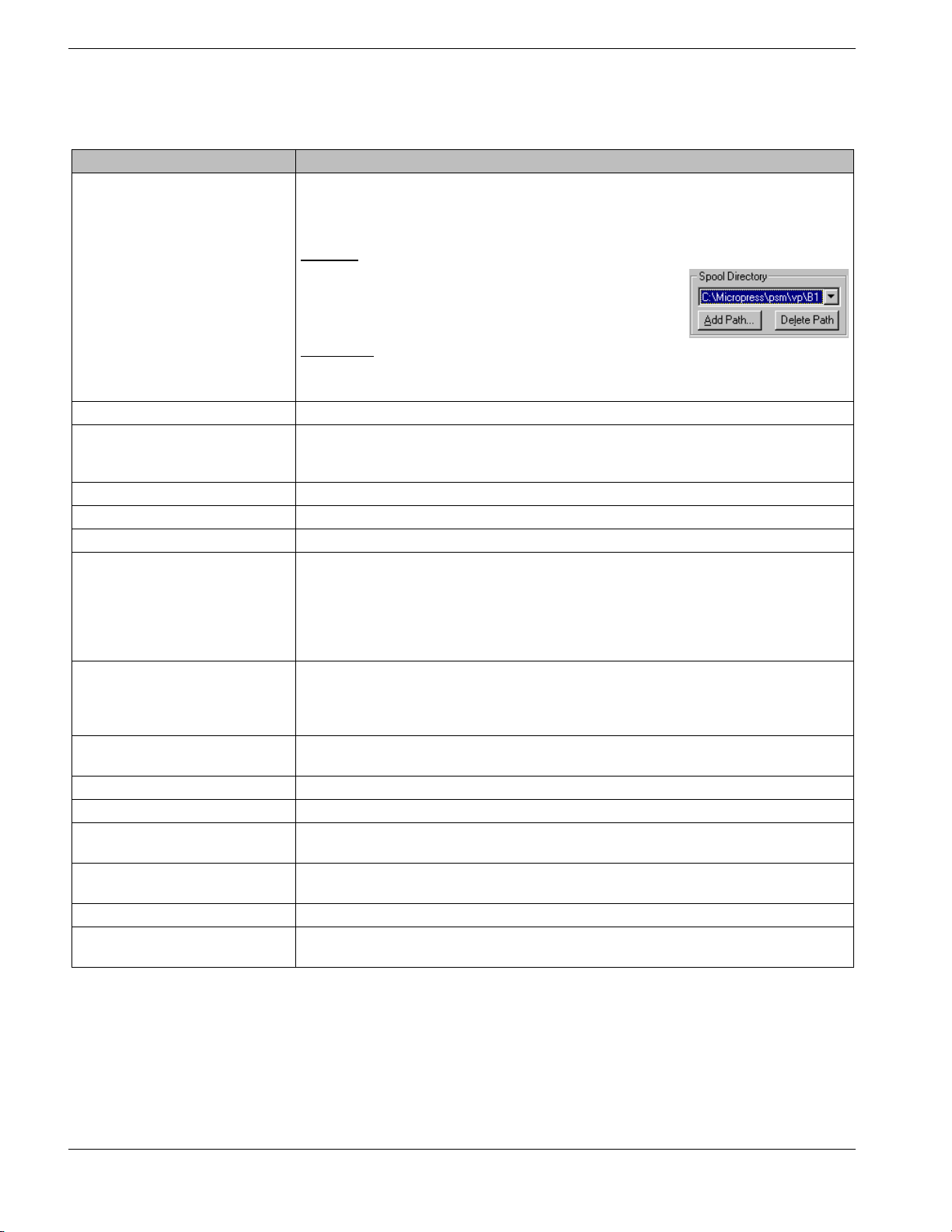

Field/Control Description

Spool Directory The directory containing the PSM job files for the currently selected Virtual Engine. If

multiple Spool Directories are specified for the Virtual Engine, they may be selected

from the drop down lists.

To modify the Spool Directory:

Add Path

1 Click the Add Path button.

2 Navigate to the desired directory.

3 Click on the directory to select it.

4 Click OK to add the path.

Delete Path

1 From the drop down list, select the path to delete.

2 Click the Delete Path button.

Form Setup Forms option is used to print data from one job as an overlay onto another job.

Custom PJL

(Printer Job Language)

Hold Incoming Jobs Holds all incoming jobs until they are manually selected to print.

Keep Printed Jobs Saves jobs after printing.

Print Job Separators Prints a marked separator page at the end of each job.

Use Manual Tray for Separators Keeps paper for Separators in the Manual Tray. Select this option to use paper of a

Write Through Allows an incoming job to print as the RIP is processing it. Note: If Write Through is

Delete Color Pages When enabled, will delete color pages from jobs coming into the VE. Black and White

Print Color Pages Only For color engines – enable to print only the color pages in a job.

Print Color Inserts For Black and White engines – enable to put an insert sheet in place of a color page.

Step and Repeat Enables placing copies of a page across the width of the media as many times as

SafePrint Determines whether a page or job can be printed on the media remaining. See “Output

Print Quality Chooses the appropriate balance of print speed vs. quality. See Output Options.

Margin Offsets Changes the margin size and expands the print area of the page reducing the amount

(OPC VE) Permits advanced control of printer/finisher functionality. You must know

what commands the printer accepts; obtain this information from the manufacturer.

See “Custom PJL Support” on page 57.

different size and/or color for Job and/or Copy Separators. If you do not select this

option, the system checks the manual tray first. If no paper is loaded into the manual

tray, the currently selected input tray is used. Note: This does not apply to a duplex job

on a PrintStation 312 because it would use one of the pages from the job as a

separator; therefore, the separator will have to come from the manual tray.

selected and a job starts coming in, the PSM will use only one PrintStation of a Virtual

Engine to print until the entire job has been received. This guarantees correct collation.

For the LaserJet 8000, if Stapling is enabled, Write Through will be ignored.

pages will be retained.

possible. See “Media Saving Features” on page 9.

Options” on page 14.

of media waste. See “Page Range Settings” on page 16.

8

Page 19

Media Saving Features

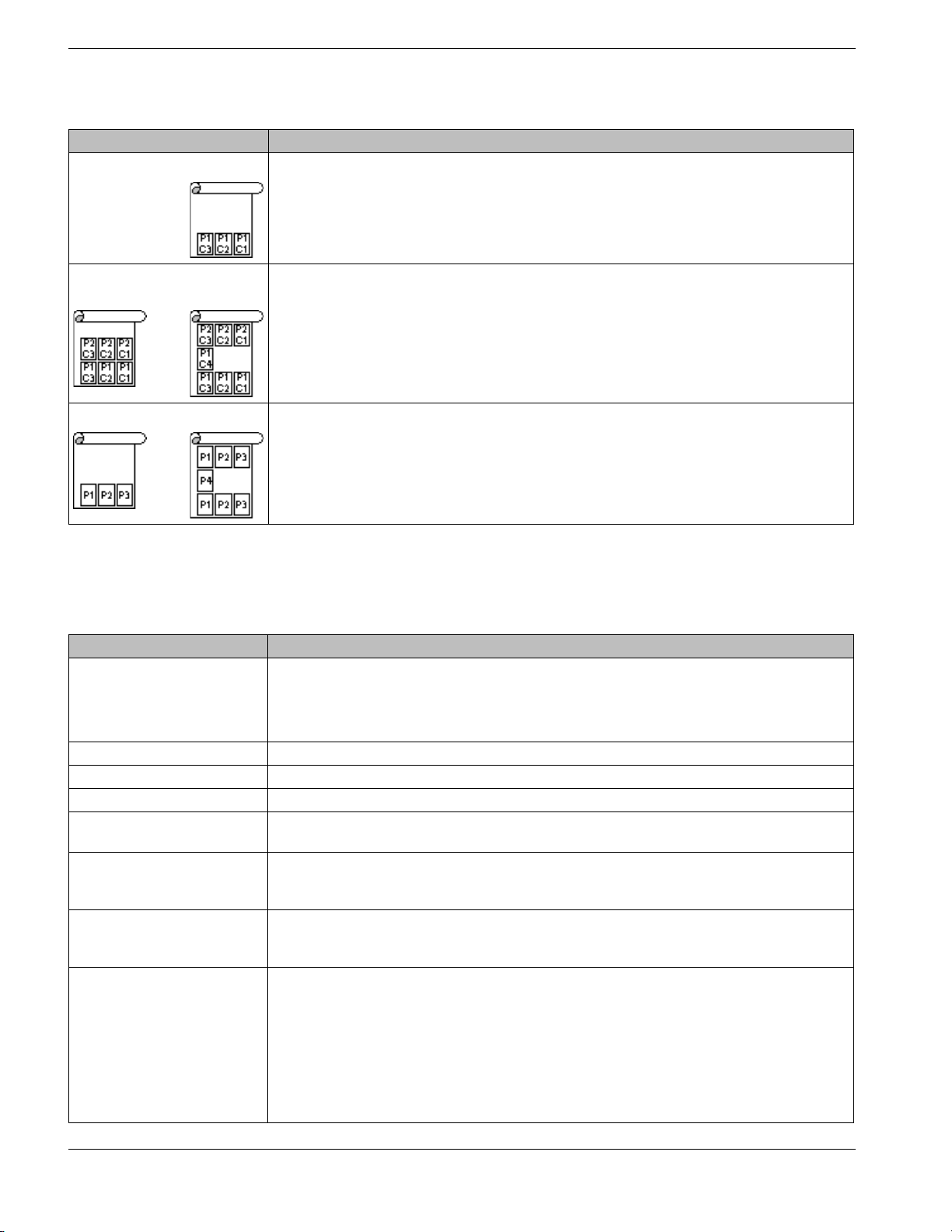

The following features apply to the DesignJets (P=Page; C=Copy).

Feature Description

Step and Repeat Use to print multiple copies of a job. Places copies of a page across the width of the media

as many times as possible.

Step and Repeat with

Gather Collate

FillWidth Use FillWidth to print multiple page jobs. As in the case with Step and Repeat with Gather

Using Step and Repeat with Gather Collate keeps the copies of pages together.

If all of the pages will not fit across the width as seen in the right-side graphic, a blank area

on the media may occur.

Collate, there may be an area of unused media if all of the pages will not fit across the

width.

Job Defaults

When sending jobs from a workstation, you can choose specific job settings to override the

Virtual Engine’s Job Defaults. The available defaults may vary by engine type.

Field/Control Description

Gloss Level Sets the job Gloss Level for the entire job. Available levels:

• Low: use for jobs containing text only (Matte/Satin finish)

• Standard: use for jobs containing both text and images

• High: use for jobs containing images only (Heavy sheen)

Feed Tray Selects paper tray from which paper will be fed.

Duplex Prints double-sided pages.

Print Copy Separators Prints a slip sheet after printing each copy of a job.

Quality Print Mode Improves registration and gives better image quality. Note: Quality Print Mode will

decrease PrintStation output speed.

Empty Tray Switch Enables a print job to automatically switch another paper feed tray when the selected tray

runs out of paper. Works only if the paper size is the same in both trays. The 062 will not

switch to the Manual tray when Empty Tray Switch is on.

Auto Select Allows a PrintStation to check all trays for the paper size specified in the job. In the case of

Letter, which is defaulted to APS from Tray 1 only, the PrintStation will not check all trays for

Letter unless Empty Tray Switch is enabled.

Gather Collate / Group Prints all page 1s, then all page 2s, for off-line electronic/manual collation.

f you have selected the collate option from a print dialog and also select the

Note: I

group option, the group option will have no effect. Here’s why: When you select

collate with mulitple copies from the print driver, the driver assumes that the print-

er has no storage capability and will send each page in the expected output order.

For example, two copies of a five-page job will be treated as a single 10-page job

(1,2,3,4,5,1,2,3,4,5). Thus, the group option will have have no effect since the job

amounts to one copy in the PSM.

9

Page 20

Field/Control Description

Parse on Copy Keeps multi-page documents together when sent to multiple engines. See “Output Options”

on page 14.

Reverse Order Causes the job to print and stack in the correct order. If the output device is a “face up”

printer jobs will stack in reverse order.

Split After n Pages Splits large jobs into smaller sections.

Interpret Image As Select the orientation of incoming jobs. This is not the paper feed direction but the actual

orientation of the job page contents. Orientation being either Landscape (top of the image is

along the long edge of the paper) or Portrait (top of the image is toward the short edge of

the paper)

Archive Jobs Older Than x Sets the PSM to automatically archive jobs in the (H) or (P) state that have not been printed

for the specified amount of time.

Jog Copies When the stacker is used with multiple copies, Jog Copies will offset each set of copies.

Stapling Set Stapling options.

Punching Toggles punching on or off.

Folding Sets Folding options.

Trim Cut page “creep” from a folded booklet.

Booklet Maker Folds or Folds and Staples job to create a booklet

Cover Inserter Add Cover – Insert a cover page pulled from the cover inserter. Some engines may insert a

cover page(s) to be pulled from the Cover Inserter while others may assign a Media Type

for the cover page(s).

Insert Color Pages Prints black-and-white pages and leaves color pages blank rather than printing them as

grayscales (i.e., if using black-and-white/color splitting).

Toner Saving Mode Uses the selected engine’s toner saving mode to reduce toner coverage.

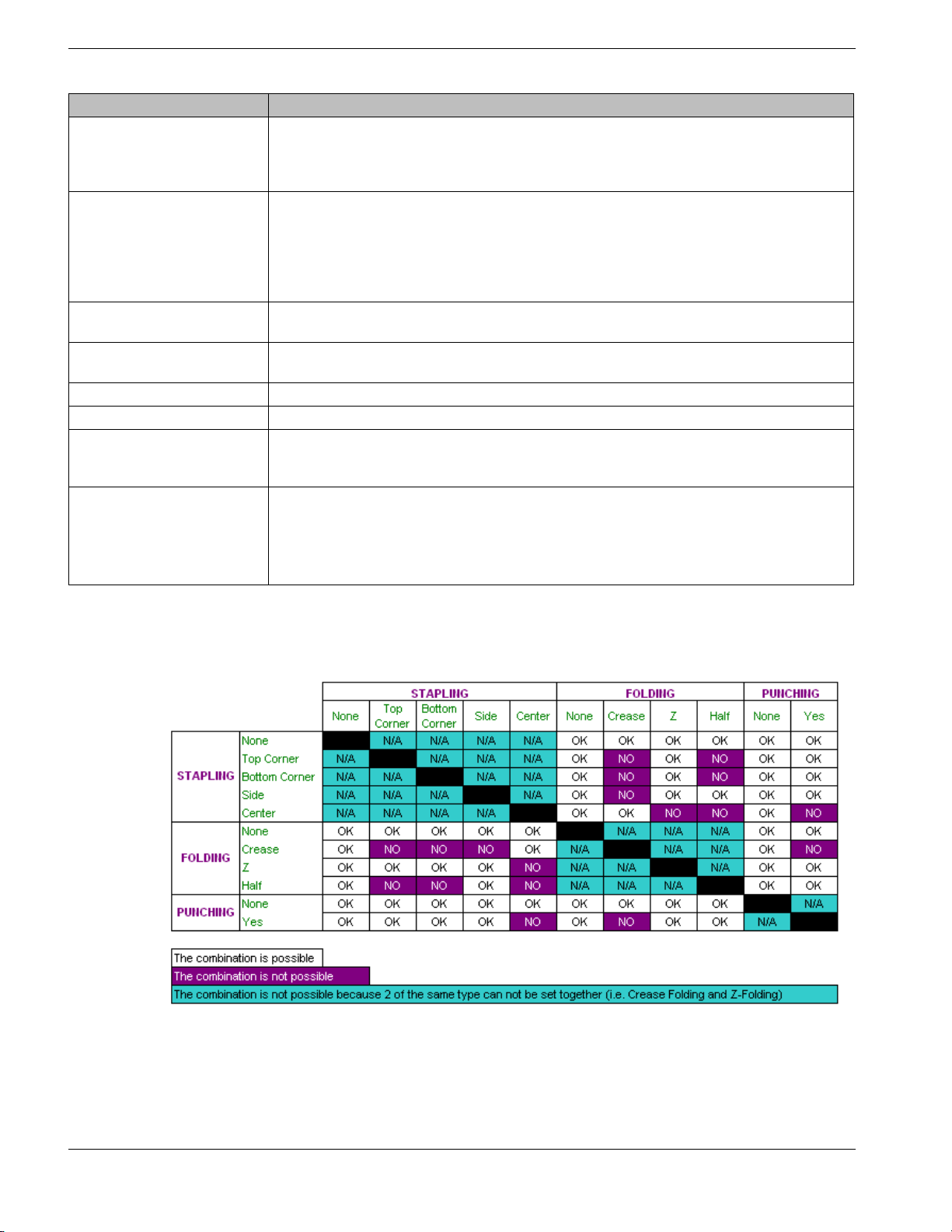

Finishing Defaults

The following options set up the finishing parameters for the PrintStation 624m.

Field/Control Description

Base Configuration File XML (eXtensible Markup Language) file contains configuration data for the finisher. PSM

reads the file and populates the Finishing Configuration dialogs accordingly. See “Finishing

Configuration” on page 10.

Customize Finishing Displays the Finishing Configuration dialogs if the Base Configuration file has been loaded.

Finishing Configuration

Note: You can access the Finishing Configuration dialogs from the Engine Defaults or the Job Information dialog.

From the Engine Defaults dialog, the settings affect every job coming into the VE. From the Job Information dialog

(“Info...” on page 11), settings apply to individual jobs.

Dialog Description

Finishing Setup Checking items on this dialog populates the Finishing Settings dialog accordingly.

Finishing Settings Selections on the Finishing Setup dialog and the Base Configuration File determine the

settings on this dialog.

Finishing Summary Displays current configuration as set on the Finishing Setup and Settings dialogs.

Selections available in the Finishing Selected list determine the selections available in the

Option Selected list.

TRueColor...

10

TRueColor activates the optional

Gamma Calibration software and prints a Gamma Target.

For more information about calibration, see the TRueColor User Guide.

1 Select the Virtual Engine.

Page 21

2 Select Virtual EngineÎTRueColor from the menu.

Note: A Key Code is necessary to activate the optional functionality of TRueColor. Contact your MicroPress

dealer for more information.

B&W Engine Balance

B&W Engine Balance sends the MonoTune test target to the output devices connected to

the currently selected VE.

1 Select the Virtual Engine.

2 Select Virtual E

3 Follow the directions on the test target to make adjustments to the PrintStation.

Job

The Job Menu Bar gives immediate access to frequently used commands.

I

nfo...

The Job Information dialog consists of several tab pages displaying setup options for Job

Settings, Page Settings, job parsing, etc. The dialog’s title bar displays the job name and file

size. Selections may vary based on engine type. This section describes each page.

• Job Settings: displays information about the whole job. You can view or change many

global job settings.

ngineÎB&W Engine Balance from the menu.

Note: When bit depth or job resolution is identical in either the horizontal or vertical direction for any page in the

job, the exact resolution will be displayed. If it differs in either direction for all pages in the job, an asterisk displays

beside the resolution number. When both directions differ, two asterisks will display instead of a number in the title

bar. To view the individual resolution of each page, see the Page Settings tab.

• Output Options: displays various printing options. See “Output Options” on page 14.

• Finishing Options: finishing options vary depending on the output device. Options

may include Folding, Punching, Stapling, etc. See “Finishing Options” on page 12.

• Margin Offsets: options for adjusting margin offsets. See “Page Range Settings” on

page 16.

• Brightness/Contrast: options for adjusting Image brightness and contrast for the job.

See “Brightness/Contrast” on page 17.

• Color Adjust: controls for setting C, M, and Y levels, and for choosing a ColorCurve

Calibration Set. See “Color Adjust” on page 18 and “ColorCurves” on page 18.

• Parsing: displays a graphic depicting how the job is parsed and how to combine the

output of each PrintStation for a collation. See “Job Parsing” on page 19.

• Chapters: used for grouping pages into sections. See “Chapters” on page 19.

• Page Settings: displays information about individual pages in print jobs. See “Page

Settings” on page 20.

• Annotations: options for adding/viewing comments. See “Annotations” on page 21.

• Finishing Setup, Finishing Settings, Finishing Summary: configures functionality

for the finisher. See “Finishing Configuration” on page 10.

11

Page 22

• Page Range Settings: set and view settings, such as Media Types, Feed Trays, Paper

Sizes, and Subset Stapling for pages and groups of pages within a job. See “Page

Range Settings” on page 16.

To open the Info window:

1 Select a job from the Job List Window of the active VE.

2 Select J

Note: Click Reparse only if something changes on the Job Settings (e.g., number of copies, available print

engines).

obÎInfo from the menu.

Job Information dialogs may vary based on PrintStation/PrintLink type. Two types of messages may be displayed: Warnings (yellow!) and Errors (red!). Warning message jobs will

print, though perhaps with undesirable results. A job with an Error message will not print.

Attempting to do so will immediately puts the job in an error state.

Job Settings

Use the Job Settings tab to set up print options (i.e., number of copies, job name). The document paper size is also displayed but cannot be changed because it is set in the generating

application.

Note: Paper sizes B1–B6 referred to in this manual are JIS unless otherwise noted.

Field/Control Description

Copies Number of copies to print.

Print Range • All Pages - Prints every page in the job.

• Page Range - Prints specific pages in the job.

• Chapters - Prints the selected chapters.

• Odd + Even - Prints odd AND even pages for the specified range.

• Odd - Prints odd pages only.

• Even - Prints even pages only.

Reverse Order Causes job to print in the opposite order. For the 040, Reverse Order is not available if

Duplex (Output Options) is on.

Job Name Current job name (can modified directly).

User Name Network name of the workstation that sent the job. “NoName” displays if user name is not

indicated in the print job.

Paper Paper size for the job.

Calculate Toner Coverages Click Calculate in the Toner panel of the Job Settings or Page Settings tab to calculate the

toner coverage on all pages of selected job. Note: Selected paper size in the workstation

application may not match the paper size in the feed tray if Auto Select (Output Options,

Engine Defaults) is not on. If this happens, the job will print anyway.

Finishing Options

This dialog displays the available features if Finishing is available and will vary depending on

engine/finisher type. Some features may become unavailable when other features are

selected. This is to ensure proper operation of the engine/finisher.

12

Note: A job containing both long edge feed landscape and any orientation short edge feed may require that the

long edge feed be tumbled.

Page 23

Field/Control Description

Interpret Image As Select the orientation of incoming jobs. This is not the paper feed direction but the actual

orientation of the job page contents. Orientation being either Landscape (top of the image is

along the long edge of the paper) or Portrait (top of the image is toward the short edge of

the paper)

Stapling The possible stapling locations will be displayed. The page graphic on the dialog will

change to show how the job will be affected by the stapling location.

Note for 060c: To determine stapling position, look at the engine from the front. Portrait

Corner Stapling places the staple on the trailing edge corner closest to the back of the

engine (farthest away from you). Landscape Corner Stapling places the staple on the

trailing edge corner closest to the front of the engine (closest to you).

Punching The possible punching locations will be displayed. The page graphic on the dialog will

change to show how the job will be affected by the punching location.

Folding The possible folding locations will be displayed. The page graphic on the dialog will change

to show how the job will be affected by the folding method.

Jog Copies When the stacker is used with multiple copies, Jog Copies will offset each set of copies

Trim Cut page “creep” from a folded booklet.

Insert Covers Insert a cover page pulled from the cover inserter. Some engines may insert a cover

page(s) to be pulled from the Cover Inserter while others may assign a Media Type for the

cover page(s).

Booklet Maker Folds or Folds and Staples job to create a booklet. For some engines additional features

are available for producing booklets:

• Front – Produces an outside cover. Media may be selected from a specific location.

• Centerfold – Produces an insert for the inside center of the booklet. Media may be

selected from a specific location.

062 Finishing Rules

Some Finishing Options depend on other options (i.e., paper size, Copy Separators). This

table lists the combinations of options and availability for the 062 FN-3 Finisher.

13

Page 24

Options

Location

Paper

Staple Punch Fold

Corner LEF SEF Center LEF SEF Half Crease Z

Tabloid

SEF

Letter

SEF

Letter LEF •• •

Legal SEF •••*

Invoice

SEF

A3 SEF ••••

A4 SEF • •••*

A4 LEF •• •

A5 SEF

B4 SEF ••••

B5 SEF ••••

B5 LEF •• •

SEF=Short Edge Feed, LEF=Long Edge Feed, *=Unable to 3 hole punch on Short Edge

• •• ••••

• •••* •

Output Options

Output Options let you set and view job settings (i.e., paper source, duplexing, and copy separators). The table below describes the output options.

Field/Control Description

Feed Tray Select the paper source.

Pages Differ - will display when pages within a job are printed from different trays.

Destination Selects output tray for the printed job.

Reverse Order Causes the job to print and stack in the opposite order.

Media Type The type of media in the input tray (transparency, letterhead, bond, etc.)

Jog Copies Offsets each set of copies when the stacker is used with multiple copies.

Fast Print Enables the Cii to print at 6 pages per minute. Works only with Letter and A4 size paper

and may not be used with the manual feed tray, duplex jobs, or Pages Differ. Note: Some

engines connected to the PrintLink Cii will ignore Fast Print if Duplex is selected.

Manual Tray Increase

Transfer

Quality Print Mode Improves registration and image quality.

Modifies amount of toner applied for getting:

• uniform toner transfer on the second side of manual feed duplex jobs

• uniform toner transfer on single sided jobs of heavy stock

• increased toner density on single sided jobs with normal paper stock

Note: This option is available only for the Cii. The manual tray must be selected.

14

Page 25

Field/Control Description

Gloss Level Sets the job Gloss Level for the entire job.

•Low

• Standard

•High

Parse on Copy Keeps multi-page documents together when sent to multiple engines.

Print Inserts After selecting where to insert sheets within a job, Print Inserts can be used to toggle the

feature on or off. If the check box is active, the job has insert sheets that will print. If sheets

have been inserted but you don’t want to print them, uncheck this box ( insert sheets will

not print but you do not have to remove them from the job). If this check box is disabled,

there are no Insert Sheets in this job to print. Checking Insert Sheet After This Page on

ANY page will toggle on tthe job option Print Inserts.

Gather Collate / Group Prints all page 1s, then all page 2s, for off-line electronic/manual collation.

f you have selected the collate option from a print dialog and also select the

Note: I

group option, the group option will have no effect. Here’s why: When you select

collate with mulitple copies from the print driver, the driver assumes that the print-

er has no storage capability and will send each page in the expected output order.

For example, two copies of a five-page job will be treated as a single 10-page job

(1,2,3,4,5,1,2,3,4,5). Thus, the group option will have have no effect since the job

amounts to one copy in the PSM.

Duplex Prints double-sided pages.

For PrintStation 312: one side must be printed first, then turn the pages 180° and place

the pages back in the feed tray. Press “On Line” button on the front of the PrintStation to put

the engine back on line (Work and Turn). For the 040, Duplex is not available if Reverse

Order (Job Settings) is on.

Copy Separators Prints a slip sheet after each copy prints.

Empty Tray Switch Enables a print job to automatically switch to another paper feed tray when the selected

tray runs out of paper. Works only if the paper size is the same in both trays.

Auto Select

Special Handling Select this option to issue a special handling alert dialog to any user who attempts to print

Print Quality Chooses the appropriate print quality from the following choices:

SafePrint Determines whether a page or job can print on the media remaining in the DesignJet CP.

Staple Turns Stapling on or off. Stapling is not available on the HP 8000 for Legal size paper.

Sort Used with Gather Collate to group sets of copies.

Print Color Pages Only For color engines – enable to print only the color pages in a job.

Print Color Inserts For Black and White engines – enable to put an insert sheet in place of a color page.

Media Convert Job to Default Media Types – Selects a Media Type from the Media Catalog for

Tab Options • Print Tabs Only – Print only the tab pages within a job.

Allows the PrintStations to look in other paper trays when the selected paper tray contains the

wrong size paper. This item is a feed tray for the PrintLink 062.

the job. The alert dialog will prompt the user to perform any special handling the job

requires (e.g., must be printed on the corporate letterhead or on red 60# card stock or

watermarked “Confidential”; etc.) before processing.

• Best - the highest possible quality at the lowest speed (600X600 dpi)

• Normal - good combination of image quality and speed (300X300 dpi)

• Fast - job is printed at the highest speed with lower quality (300X300 dpi)

• SafePrint On Page - checks to see if the first page of the job can be printed

• SafePrint On Job - checks to see if the entire job can be printed

• No SafePrint - do not use SafePrint

Note: SafePrint will issue a warning if there is not enough media remaining to print the job or

page. The initial paper length must be set in order for SafePrint to function correctly.

each page in the job based on the paper size of each page.

• Print No Tabs – Print the job only with none of the tab pages.

15

Page 26

Field/Control Description

Print & Hold Job One copy of the job will print and then be put on Hold. Also known as Proofing.

Hold Jobs The job will be put in Hold status when it comes into the PSM and will not be printed.

Toner Saving Decreases toner coverage for producing a draft copy.

Character Mode Enable when printing jobs containing text to produce sharper characters.

Photo Mode Enable when printing jobs containing graphics to produce smoother gradients.

Page Range Settings

Set and view settings, such as Media Types, Feed Trays, Paper Sizes, and Subset Stapling

for pages and groups of pages within a job.

Field/Control Description

View Select • None – (default) None of the following views will be displayed. None will be selected each

time the Page Range Settings page is closed and re-opened.

• Media/Feed Tray View – Display and assign Media Types or Feed Trays to individual

pages or groups of pages within a job. If the Feed Tray is set to Auto Select on the Job

Settings tab, the Media Types drop down menu will be available. If set to a tray, the Media

Types drop down menu will not be available and instead the Feed Tray drop down menu

will be available.

• Paper Size View – Display Paper Sizes associated with individual pages or groups of

pages within a job.

• Subset Stapling View – Display and assign stapling to groups of pages within a job.

• Insert Color Page View – Display Insert Color Pages associated with individual pages or

groups of pages within a job.

Begin Page The first page of a Media/Feed Tray or Subset Stapling group.

End Page The last page of a Media/Feed Tray or Subset Stapling group.

Apply Commit changes to the job.

Subset Staple Enable/

Disable

Feed Tray Assign a Feed Tray to a page or group of pages within a job.

Media Type Assign a Media Type to a page or group of pages within a job.

List View Displays each page or group of pages within a job and the features associated with them.

Turn stapling on or off for a group of pages.

16

Margin Offsets

The settings on the Margin Offsets page affect the placement of data on each page for the

entire job.

Note: PrintLink 5050c – This engine will accept only positive margin offset values.

Note: PrintLink Cii – It is only possible to combine Fast Print and Margin Offsets if the offset

is the same for all pages of a job.

Page 27

Note: PrintLink 624m – Margin Offsets on this dialog are combined with the offsets on the

Engine Margin Offsets dialog, see “Engine Margin Offsets” on page 56.

Field/Control Description

Margin Offset Top and Left margin settings for Odd and Even pages.

Units – Pixels, Inches, or mm.

DesignJet:

Roll Media TE LE

•Smaller

•Normal

• Extended

Smaller only available for the DesignJet CP.

Sheet Media TE LE

•Smaller

•Normal

• Extended

Example 1:

You need to print a job as portrait on an A4 page. The

paper in the drawer is LEF and the page was imaged

LEF

as LEF. On the Margin Offsets dialog the paper is displayed as portrait. The only valid margins will be -Top

and +Left. The top margin is actually the LEF right margin and the left margin is the LEF top margin.

SEF

To make the point more clear; if the paper size was

297mm x 210mm and 0.0mm was entered for the top

margin and 0.0mm for the left margin the actual margins would be:

TM = 0, BM = 210

LM = 0, RM = 297

Example 2:

The paper is 297x210. -25.4mm for the top margin and 12.7mm for the left margin was

entered, the actual margins would be:

TM = 12.7, BM = 222.7

-25.4 was entered which means 25.4 is added to the left margin. The actual margins (in pixels) would be:

LM = 25.4, RM = 322.1

If +25.4 for the top margin were entered, this would move the right +25.4, which is -25.4 for

the left, which is < 0. This is not permissible.

LEF=Long Edge Feed

• TM=Top Margin, BM=Bottom Margin, LM=Left Margin, RM=Right Margin

Top margin

Left margin

Top margin

Left margin

Brightness/Contrast

Brightness/Contrast sliders modify the lightness / darkness of an entire job or a selected

page or page range without having to re-RIP the job or start over from the application software.

Note: Image Adjust—The contrast slider adjusts contrast. For example, a contrast setting of .5 will reduce contrast by 50%. A setting of 1.5 will increase contrast by 50%. A contrast setting of 1 equates to NO CHANGE. The

brightness slider adjusts job brightness in 1% increments. For example, a brightness setting of +20 increases

brightness by 20%. –20 reduces brightness by 20%.

Note: 624m—The settings are not in percentage. See also “Engine Density” on page 55

Field/Control Description

Image Adjust • Brightness – Each increment is equivalent to a 1% change.

• Contrast – Each increment represents a 10% change.

17

Page 28

Field/Control Description

Black • Include – All color planes will be adjusted.

• Exclude – Only the Cyan, Magenta and Yellow planes will be adjusted.

• Only – Only the Black (K) plane will be adjusted.

Color Adjust

These sliders modify the color cast or hue of an entire job or a selected page or page range

without having to re-RIP the job or start over from the application software.

The table below describes the options.

Field/Control Description

Color Adjust Controls Adjusts amount of Cyan, Magenta, Yellow for the selected job.

ColorCurve Calibration Set Shows the currently selected ColorCurve Calibration Set. ColorCurve (.CLR) files may be

chosen from this list.

Edit Curve Graphically Display, Edit and Save ColorCurve Calibration Sets.

Image Adjust • Adjust the Sharpness, Brightness, and Contrast of the job.

•Black:

Include – All color planes will be adjusted.

Exclude – Only the Cyan, Magenta and Yellow planes will be adjusted.

Only – Only the Black (K) plane will be adjusted.

ColorCurves

ColorCurves complete the color adjustment flexibility of PostRipped files by allowing you to

create custom color reproduction curves and apply them to a job. Once created, a ColorCurve is available to all color jobs in the PSM and can be saved and loaded on other Micro-

Press installations.

Click Edit Curve button to open the ColorCurve dialog. If you selected a ColorCurve in the

ColorCurve Calibration Set box, the curve will be displayed for editing. Otherwise, select

FileÎOpen… to select a curve.

ColorCurve allows changes to be made to 4 curves (Cyan, Magenta, Yellow, Black). The bottom axis represents the original job color density (input) from 0 to 100%. The vertical axis

represents the printed job color density (output) from 0 to 100%. When a curve or a point on

a curve has higher output values than input values (the curve is above the 1:1 reference

line), the printed job will increase in density according to the percentage(s). When the curve

is below the 1:1 line, the printed job density will decrease. Change the curve shape by selecting and dragging a curve point with the mouse.

Note: ColorCurves provide additional color adjustment control. Color adjustment refers to the practice of altering

color according to customer preference. Use color calibration (Gammatic) and color matching (ICC Profile Processor) prior to printing to ensure the best possible rendering before adjustments are made

Field/Control Description

Color selection Chooses the color curve to display.

Input, Output, Ratio Displays the input percentage, output percentage, and the percent difference respectively

between the original and the printed job at any given point.

Undo Clears last change made to the curves.

Status bar Shows the curve being displayed/edited.

18

Page 29

Default ColorCurves and Definitions

ColorCurve Definition

Linear This selection does not directly change output, but rather serves as a starting point from

which the user can create a custom curve.

Light-10%

Light-15%

Light-25%

Light-35%

Dark+10%

Dark+15%

Dark+25%

Dark+35%

HighContrast-8%+8%

HighContrast-15%+15%

LowContrast+8%-8%

LowContrast+15%-15%

HighKey0+8%

HighKey0%+14%

HighKey-4%0%

HighKey-4%+8%

HighKey-4%+14%

LowKey+8%0%

From the curve’s 50% point, the dot is decreased (-) by the % shown. 0% and 100% are

unchanged.

From the curve’s 50% point, the dot is increased (+) by the % shown. 0% and 100% are

unchanged.

Dot is decreased (-) or increased (+) by the amounts shown at the 25% and 75% curve

locations respectively.

The 0%, 50% and 100% curve locations remain unchanged.

Job Parsing

This dialog shows how the pages of a job are distributed to the PrintStations within the Virtual

Engine. MicroPress uses the Electronic Collator to efficiently divide the print job into Job

Stacks (a set of instructions for pages designated for a specific PrintStation to print). Use this

dialog to interpret how the job was divided across the available PrintStations. The Part Info

field displays where the PrintStation will pause when printing duplex jobs and whether even

or odd pages will be printed, where separator sheets will be inserted, number of copies, and

errors. If Job Parsing has not been licensed, the option will not be available and only one

engine will be available. See “Output Options” on page 14.

1 Click on a Printer to display the parsing information for that PrintStation. The Part Info

field displays the job instructions.

2 Click OK. Note:

another PrintStation. See “System Errors” on page 37.

In the event of a printing error, the Job Stack could be automatically “moved” to

Chapters

This dialog is used to combine groups of contiguous pages within a job. Once the groups of

pages (Chapters) are added, you can apply options to them.

To s et up Chapters for a job:

1 Double-click on the job in the PSM Virtual Engine window.

2 Select the Chapters tab.

3 Click Add to create a Chapter.

4 Change the suggested Chapter Name if necessary. Subsequent chapter names will

be "Chapter" incremented by one.

5 Select the page range to include in the Chapter. One chapter may not contain a page

that is also in another chapter. Click OK.

6 Repeat Steps 3-5 as needed.

Notes: For more Chapters features, see “Page Settings” on page 20 and “Numbering…” on page 31.

19

Page 30

If you select multiple chapters then change a setting, the name of the feature to display in green. This is a temporary indicator showing that changes will be made only to this setting in all the selected chapters.

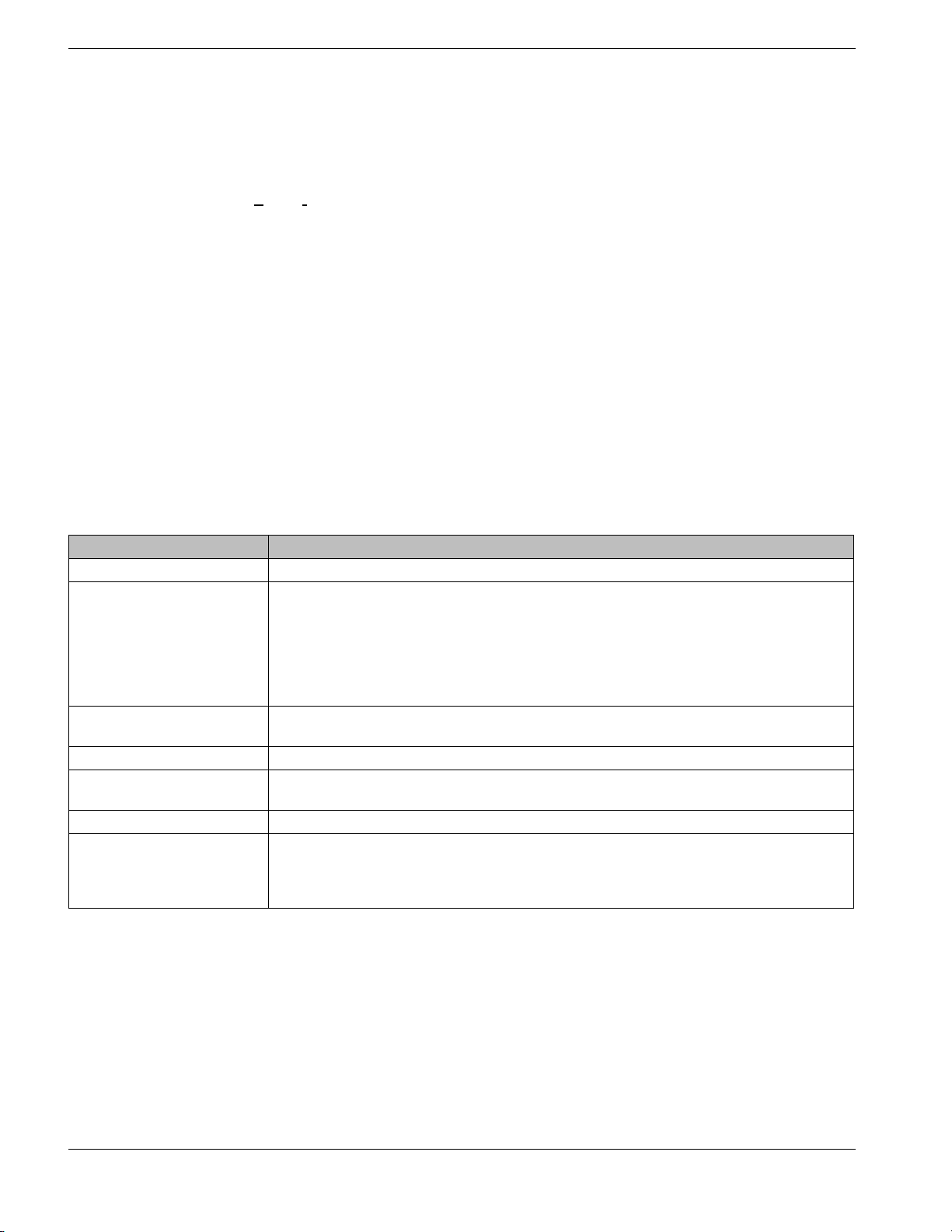

Field/Control Description

Print Marked Chapters Only Prints marked (consecutive) only.

Insert Sheet After Last Page Inserts a blank page after the last page in the selected chapter.

Note: The insert sheet is not applied to the chapter but is a separate page added after the

chapter. Thus, deleting a chapter with an insert page will not delete the insert sheet. The

insert sheet will remain unless you manually delete it.

Simplex Page Lock Prevents a page from having anything printed on its back and from being printed on the

back of another page. Applies the feature to all pages in the chapter. See “Page Settings”

on page 20.

Feed Tray Selects the paper tray from which the paper will be fed.

Destination Selects the output tray for the job.

Margin Offset Adjusts the Top and Left margins for each page .

Add Includes a page or group of contiguous pages as a chapter.

Delete Removes a chapter.

Page Settings

Use this dialog to view or apply print options to individual pages of the selected job.

Note: Double-click on a job, then click on the Page Settings tab to display the Page Settings.

Field/Control Description

Page Number Chooses the page number to apply print options to.

Insert Sheet After This Page Causes an additional blank page to be printed after the selected page. The blank page will

be pulled from the same location as Job and Copy Separators.

Feed Tray Selects the paper tray from which the paper will be fed.

Destination Selects the output tray for the printed job.

Gloss Set the job Gloss Level for the selected page (Low, Standard, High). Note: You can set the

Gloss Level (312 only) for all pages in a job on the Job Settings tab.

Simplex Page Lock Prevents a page from having anything printed on its back and from being printed on the

back of another page.

End Staple Set Allows groups of pages within a multi-page job to be stapled for output devices supporting

the feature.

Note: It is not recommended to set End Staple Set for a range of less than 2 physical pages;

End Staple Set will be ignored if Stapling is set to “None” on the Finishing tab; only one type of

stapling per job is allowed. Both “Top Corner” and “Side” cannot be used within the same job,

for example.

Toner Calculate Click Calculate in the Toner section of the Job Settings or Page Settings tab to calculate the

toner coverage on all pages of the selected job.

Note: The Calculate Toner option on the Job Settings dialog box

displays the toner coverage for individual pages within the job.

When a number (#%) displays, the toner coverage has been calculated. When “0%” displays, the toner coverage is less than 0.5%.

When “-%” displays, the toner coverage has not been calculated.

Margin Offset Adjusts the Top and Left margins for each page.

Lock Page Prevents global changes to the document’s margin settings from affecting the selected

page.

20

Page 31

Annotations

Use this dialog to enter comments about individual pages in a job. You can search for a word

or phrase in any annotation using the Find feature in the Tools menu. Use the Page Number

control to view each page of the job.

Finishing Setup, Settings and Summary

Please refer to the section “Finishing Configuration” on page 10 for information on these dia-

logs.

Preview…

Use this feature to preview a page of the job.

1 Select a job in the Job List window.

2 Select J

obÎPreview. The Preview dialog is accessible

from various dialogs within PSM.

Field/Control Description

Feed Direction Indicates the direction the paper will feed into the PrintStation.

Navigation buttons Goes to the beginning, end, previous or next page.

Page Displays the page currently being viewed. Enter a page number to go to that page.

Orientation Arrows

More Detail

B&W PrintStations

Use the controls to rotate the preview image to the desired orientation.

Clarifies the preview image.

Edit

Opens the TRueEdit application for manipulating PSM jobs and adding tabs. Refer to the

TRueEdit manual for more information.

/Unlock...

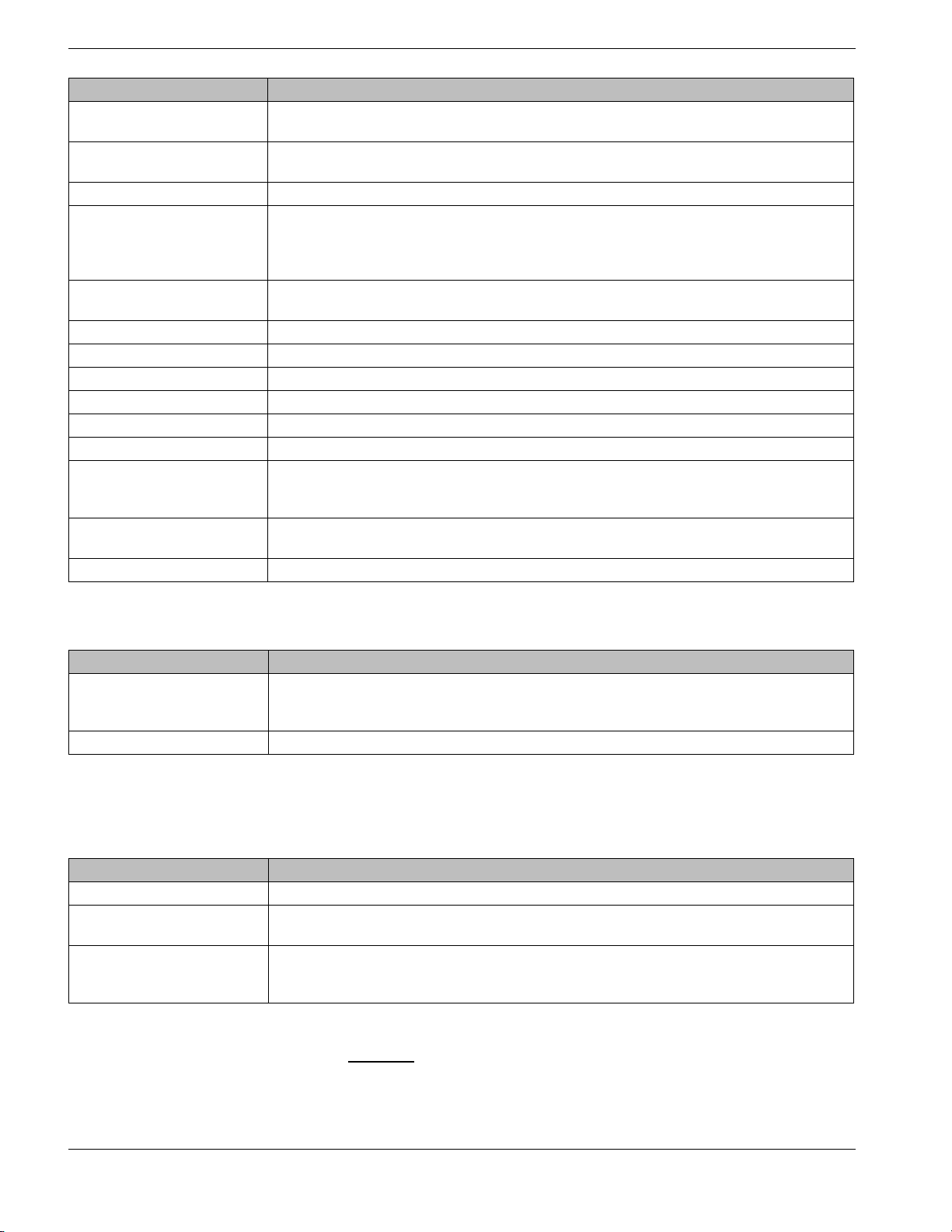

Lock

Use the Lock/Unlock feature to add password protection to PSM jobs.

Note: A password protected job is not accessible from any MicroPress application. If an attempt

is made to access a password protected job, a dialog will be displayed informing the user that

the job is locked.

Locking a job

1 Right-click on the job to lock, then select Lock

/Unlock...

2 Enter the password for the job in the Enter New Password box.

3 Enter the password again in the Confirm New Password box.

4 Click OK to apply the password, click OK again to close the notifi-

cation dialog. A small key will be appear to the left of the job

21

Page 32

name.

Unlocking a job

1 Right-click on the job to unlock, then select Lock

/Unlock...

2 Enter the password assigned to the job in the dialog box that is displayed.

3 Click OK to unlock the job.

H

old/Suspend

Use the Hold/Suspend option to set a selected job (not currently printing) to a Hold state. The

job will remain in a Hold state until you release it manually.

To place a job on Hold:

1 Select the VE that lists the job to be put on hold, then select the job from the Job List

Window.

2 Select JobÎÎÎÎHold/Suspend from the menu.

3 The status column displays H for the selected job, and the job is held for printing at a

later time.

To release the suspended job, select the job, then select Print.

P

rint

Use the Print Job option to take a selected job or jobs from the Job List Window from a Hold,

printed, or error state, and send it to the PrintStation.

To place a job in a printing state:

1 Select the VE that lists the job to print, then select the job from the Job List Window.

2 Select J

obÎPrint from the menu.

3 The status column of the Job List Window for the selected job displays >> if there is no

other job already printing. If another job is printing, the status column of the job the

user selected will display W; the job will print after all jobs ahead of it have printed.

M

ove...

Use the Move Job option to move a selected job from one VE to another. Moving a job will

change the printing parameters for the job.

not

To move a job to another Virtual Engine:

1 Select the VE that lists the job to move, then select the job from the Job List Window.

2 Select J

obÎMove from the menu.

3 Select a Virtual Engine.

4 Click OK. The selected job moves to the chosen VE destination.

Note: You cannot use this option to move a grayscale job from the 5050c to either the 060c or the 085c because

the resolutions differ (5050c jobs are ripped at 400 dpi, 8 bits per pixel, whereas 060c and 085c jobs are ripped at

600 dpi, 1 bit per pixel).

Note: Dragging a job into a LaserJet 5Si VE halts printing. When the file finishes copying, the job resumes printing.

Delete

To remove a job from the PSM:

1 Select the VE that lists the job to delete, then select the job from the Job List Window.

2 Select J

obÎDelete from the Job Menu.

3 The job will be removed from the PrintStation Manager Job List window.

22

Page 33

Abort

Use the Abort Job option to cancel a currently printing job.

To cancel a print job:

1 Select the VE that is currently printing the job to abort.

2 Select J

obÎAbort.

3 The job currently printing is canceled and displays an Error (E) status.

Warning: The printer may output one or two pages after the job is aborted due to PrintStation limitations. It is best

to wait until the PrintStation has stopped before proceeding.

Merge…

Use the Merge Job option to combine existing documents, in whole or in part, into a new job.

To merge jobs:

1 Select the VE that has the files listed to be merged.

2 Select J

obÎMerge from

the menu.

3 Select a job from the Cur-

rent Jobs list. You can

select multiple jobs.

4 Type the Page Range for

the selected job to be

added.

5 Click Add button. The

New Document Order list

displays the selected document.

Note: Double-click a job in the New Document Order window to display the Edit Page Range dialog.

6 Repeat steps 4—6 until all the documents to be merged are selected.

7 Select a job in the New Document Order list. You can arrange jobs in the New Docu-

ment Order list to place them in the order in which they will be printed.

8 Click Move Up, Move Down, or Remove.

9 Type the name of the merged document in the New Job Name field.

10 If the Merge As Chapters box is checked,

each job added will be treated as an individual

chapter. When you use this feature, another

dialog (see graphic) will open when you click

OK. You can edit the chapter names here. If a

chapter has an odd number of pages, a blank

page will be printed at the end, and the job will

be printed duplex if Insert blank page after

odd paged chapters for duplexing is

checked.