Page 1

SERVICE MANUAL

Models

FS-110/FS-210

JANUARY 2004

CSM-FS110

KONICA MINOLTA BUSINESS SOLUTIONS U.S.A., INC.

Page 2

Page 3

FS-110/FS-210

SERVICE MANUAL

JANUARY 2004

Used on Konica Models

7155/7165/FORCE 65/7255/7272

Page 4

IMPORTANT NOTICE

Because of the possible hazards to an inexperienced

person servicing this equipment, as well as the risk of

damage to the equipment, Konica Minolta Business

Solutions U.S.A., Inc. strongly recommends that all

servicing be performed by Konica-trained service technicians only.

Changes may have been made to this equipment to

improve its performance after this service manual was

printed. Accordingly, Konica Minolta Business Solutions U.S.A., Inc., makes no representations or warranties, either expressed or implied, that the information contained in this service manual is complete or

accurate. It is understood that the user of this manual

must assume all risks or personal injury and/or damage to the equipment while servicing the equipment for

which this service manual is intended.

Corporate Publishing Department

© 2004, KONICA MINOLTA BUSINESS SOLUTIONS U.S.A., INC.

All rights reserved.

Printed in U.S.A.

Page 5

CONTENTS

CONTENTS

SAFETY AND IMPORTANT WARNING ITEMS

Refer to the 7155/7165/7255/7272 service manual

on page.................................................................S-1

1. OUTLINE

FS-110/FS-210 PRODUCT SPECIFICATIONS ........1-1

CRO SS SE CTION DIAGRAM....................... .... ..... .. .1- 4

DRIVE SYSTEM DIAGRAM......................................1-5

[1] Paper Conve y ance Drive...........................1-5

[2] Stacke r Drive......................................... .... .1- 6

[3] Staple Drive.................................... .... ... .... .1-7

[4] Tray D riv e........................... .. ..... ..... .... ... .... .1- 8

[5] Folding Drive............................................. .1- 9

PAPER CONVEYANCE PATH................................1-10

[1] Paper Conve yance Path..........................1-10

[2] Non-S o r t M o d e.........................................1-1 1

[3] Sort, and Group Modes............................1-12

[4] Sub-tray Mode..........................................1-13

[5] Staple Mode..................................... .. ..... .1 -1 4

[6] Bookle t Mode............................ ..... .... ... ...1 -16

[7] Three -fo ld in g Mode..................................1-1 7

2. UNIT EXPLANATION

EXTE RNAL S E CTION.................. ..... ....... ....... ..... .....2 -1

[1] Composition............................ .. ..... .... ..... .. .2- 1

[2] Mech a nism......................... ..... .... ... .... ..... ...2 - 1

CON V E YANC E SECT ION............... .... ....... ....... ....... .2-2

[1] Composition............................ .. ..... .... ..... .. .2- 2

[2] Mech a nism......................... ..... .... ... .... ..... ...2 - 3

[3] M701 (FNS Conveyance) Control ..............2-6

[4] M712 (gate drive) Control...........................2-7

[5] SD70 5 (by - p a ss g a te ) C o n tr ol....................2-7

[6] M702 (shift) Control....................................2-8

[7] M707 (paper exit roller) Control..................2-9

[8] SD704 (paper exit opening solenoid)

Contro l................................ ..... .. ..... .... ..... .2 -11

[9] M708 (paper exit opening) Control...........2-12

[10] M721 (sub-tray paper exit) Control...........2-13

MAIN TRAY SEC TION.................................... .. ..... .2 -1 4

[1] Composition............................ .... ..... .. ..... .2 -1 4

[2] Mech a nism........................... ..... .. ..... ..... .. .2 -1 4

[3] M703 (tray up/down) Control....................2-15

STAC KER S E CTION.................. ....... ..... ....... ....... ...2 -1 7

[1] Composition............................ .... ..... .. ..... .2 -1 7

[2] Mech a nism........................... ..... .. ..... ..... .. .2 -1 8

[3] M705 (alignment/U) Control .....................2-21

[4] M716 (alignment/L) Control

(FS-21 0 o n ly)............. .... ....... ....... ....... ..... .2-2 2

[5] M718 (folding stopper) Control

(FS-210 only)...........................................2-23

[6] M713 (stacker entrance) Control..............2-25

2 UNIT EXPL A NATION 1 OUTLINE3 DIS./ASSEMBLY

MODEL MANUAL REVISED EDITION DATE PAGE METHOD

7155/7165/7255/7272

SERVICE MANUAL Dec. 2003

- REPLACEMENT

Page 6

1 OUTLINE2 UNIT EXPL A NATION3 DIS./ASSEMBLY

STAPLER SECTION................................. .. ..... .... ..2-27

[1] Com p osition........ ..... ..... .... ... .... ..... ..... .... ..2-27

[2] Mechanism.............................................. 2-28

[3] Staple r Movement C o n tro l.......................2-30

[4] Staple Contro l................... ..... ..... .... ... .... ..2-32

FOLDING/THREE-FOLDING SECTION

(FS-2 10 ONLY ).............................. ....... ....... ....... ....2-35

[1] Com p osition........ ..... ..... .... ... .... ..... ..... .... ..2-35

[2] Mechanism.............................................. 2-36

[3] M719 (folding knife) Control .................... 2-37

[4] M720 (folding conveyance) Control......... 2-38

[5] SD706 (three-folding gate) Control.......... 2-39

3. DISASSEMBLY/ASSEMBLY

EXTERNAL SE CTION.......................... ..... .... ... .... ....3-1

[1] Removing and Reinstalling the Booklet

Tray (FS-210 only)..................................... 3-1

[2] Removing and Reinstalling the Top

Cove r/1................................ .... ... .... ..... .. ....3-1

[3] Removing and Reinstalling the Top

Cove r/2................................ .... ... .... ..... .. ....3-2

[4] Removing and Reinstalling the Side

Cove r....................................... ... .... ..... .. ....3-2

[5] Removing and Reinstalling the Front

Door.................... ..... ..... .. ..... .... ... .... ..... .. ....3-3

[6] Removing and Reinstalling the Rear

Cove r....................................... ... .... ..... .. ....3-3

[7] Removing and Reinstalling the Main

Tray................................................... .. .... ..3-4

[8] Removing and Reinstalling the Main Paper

Exit Opening Cover................................... 3-5

[9] Removing and Reinstalling the Booklet Paper

Exit Opening Cover................................... 3-5

CONVEYANCE SECTION........................................ 3-6

[1] Replacing the Paper Exit Roller

(Sponge Roller) ......................................... 3-6

[2] Replacing the Intermediate Conveyance Roll-

er (Sp o n ge Ro ller).....................................3-7

[3] Removing and Reinstalling the Paper Exit

Open in g U n it... .... ....... ..... ....... ....... ..... ...... ..3-8

MAIN TRA Y SEC TION....................................... .... ..3-9

[1] Replacing the Tray Up/down Motor

(M703)....................................................... 3-9

[2] Repla cin g th e U p /D o wn Wire.................... 3-9

STACKER S ECTION............................................ ..3-13

[1] Removing and Reinstalling the Stacker Unit

Cove r....................................... ... .... ..... .. ..3-13

[2] Removing and Reinstalling the Stacker

Unit...................................... .... ... .... ..... ....3-13

STAPLER SECTION................................. .. ..... .... ..3-15

[1] Removing and Reinstalling the Stapler Unit

Cove r....................................... ... .... ..... .. ..3-15

[2] Removing and Reinstalling the Clincher.. 3-16

[3] Removing and Reinstalling the Stapler ... 3-17

Page 7

SAFETY WARNINGS

[1] Modifications Not Authorized by

Konica Minolta

Konica Minolta equipment is renowned for their high

reliability. This reliability is achieved through high-quality

design and a solid service network.

Unauthorized modifications involve a high risk of degrading performance and safety. Such modifications are therefore strictly prohibited. The points listed below are not

exhaustive, but they illustrate the reasoning behind this

policy.

PROHIBITED ACTIONS :

(1) Using extension cables or a different power cord

than specified by Konica Minolta.

(2) Using other fuses than specified by Konica

Minolta. Safety will not be assured, leading to a

risk of fire and injury.

(3) Disabling fuses or bridging fuse terminals with

wire, metal clips, solder or similar. (This applies

also to thermal fuses.)

(4) Removing air filters (except for replacement).

(5) Disabling relay functions (such as wedging pa-

per between relay contacts, etc.).

(6) Disabling safety functions (interlocks, safety cir-

cuits, etc.). Safety will not be assured, leading to

a risk of fire and injury.

(7) Performing actions to equipment not described

in the instruction manual or the service hand-

book.

(8) Using parts other than specified by Konica

Minolta.

[2] Checkpoints When Performing On-

site Service

Konica Minolta equipment is extensively tested before

shipping, to ensure that all applicable safety standards

are met, in order to protect the customer and customer

engineer from the risk of injury. However, in daily use, any

electrical equipment may be subject to parts wear and

eventual failure. In order to maintain safety and reliability,

the customer engineer must perform regular safety checks.

(3) Be sure to disconnect the power cord of the

equipment from the AC outlet.

Simply turning off the power switch is not sufficient, because paper feed units or other electrical equipment may be powered also when the

power switch is turned off.

(4) Proceed with special care when performing op-

eration checks or adjustment while the unit is

powered. When carrying out operation checks or

adjustment while external covers are removed,

the risk of electrical shock exists when touching

parts which carry high voltage or electrical charge.

The risk of injury exists when touching moving

parts such as gears or chains.

2. Safety Checkpoints

The following list is not exhaustive, but it includes actions

which must be carried out at every on-site service.

CAUTION:

(1) Check external covers and the frame for sharp

edges, burrs, or nicks.

(2) Check external covers and hinges for loosening

or damage.

(3) Check wiring for squeezing or damage.

(4) Check power cord for insulation problems (con-

ductor must not be exposed).

(5) Check power cord and cable ties etc. for loosen-

ing from frame.

WARNING:

(1) Verify that the equipment is properly grounded. If

a problem is detected, establish a proper ground

connection.

(2) Connecting the ground lead to an improper point

such as listed below results in a risk of explosion

and electric shock.

Unsuitable ground points:

- Gas pipe

- Lightning rod

- Telephone line ground

- Plastic water pipe or water pipe or faucet that

has not been approved by authorities for

grounding use

1. Advance Preparation for Safety Checks

CAUTION:

(1) Wear clothing that facilitates work and is de-

signed for safety.

(2) Carry out all procedures carefully to prevent in-

jury.

3. Description of Safety Checks

CAUTION:

(1) Before performing safety check work, read all

relevant documentation (service handbook, technical notices, etc.) and proceed according to the

prescribed procedure, using only the prescribed

tools. Do not carry out any adjustments not

described in the documentation.

Page 8

(2) If the power cord is damaged, replace it only with

the specified power cord. If the power cord insulation has been damaged and there are exposed

sections, short- circuits and overheating may

occur, leading to a serious fire risk.

(3) Do not route the power cord so that it can be

stepped on or pinched. Otherwise overheating

may occur, leading to a serious fire risk.

(4) When disconnecting any cables, always grasp

the connector and not the cable (especially in the

case of AC and high-voltage leads).

(5) Carefully remove all toner remnants from electri-

cal parts, electrodes, etc.

(6) Make sure that wiring cannot come into contact

with sharp edges, burrs, or other pointed parts.

(7) Double-check to make sure that all screws, com-

ponents, wiring, connectors, etc. that were removed for safety check maintenance have been

reinstalled in the original location. (Pay special

attention to forgotten connectors, pinched cables,

forgotten screws, etc.)

(8) When installation and preventive maintenance,

verify that the power cord has been securely

plugged into the AC outlet. Contact problems

may lead to increased resistance, overheating,

and the risk of fire.

WARNING:

Before disassembling or adjusting the equipment, make sure that the power cord has been

disconnected.

[4] Measures to Take in Case of an

Accident

(1) If an accident has occurred, the distributor who has

been notified first must immediately take emergency

measures to provide relief to affected persons and to

prevent further damage.

(2) If a report of a serious accident has been received

from a customer, an on-site evaluation must be

carried out quickly and Konica Minolta must be

notified.

(3) To determine the cause of the accident, conditions

and materials must be recorded through direct onsite checks, in accordance with instructions issued

by Konica Minolta.

(4) For reports and measures concerning accidents,

consult your superior, and follow the regulations set

in "Standards for the Control Program for Measures

Against Electrical Equipment Accidents".

[5] Conclusion

(1) Safety of users and customer engineers depends

highly on accurate maintenance and administration.

Therefore, safety can be maintained by the appropriate by the proper daily service work conducted by the

customer engineer.

(2) When performing service, equipment on the site

must be tested for safety. The customer engineer

must verify the safety of parts and ensure appropriate management of the equipment.

[3]

Handling of Materials for Servicing

CAUTION: Alcohol-based and acetone- based

cleaners are highly flammable and

must be handled with care. When

using these materials for cleaning

parts, observe the following precau-

tions.

(1) Disconnect the power cord from the AC outlet.

(2) Use only a small amount of cleaner at a time and

take care not to spill any liquid. If this happens,

immediately wipe it off.

(3) Perform cleaning only in an environment where

sufficient ventilation is assured. Breathing large

quantities of organic solvents can lead to discomfort.

(4) Do not replace the cover or turn the unit on before

any solvent remnants on the cleaned parts have

fully evaporated.

Page 9

1

OUTLINE

1 OUTLINE

Page 10

1 OUTLINE

Blank page

Page 11

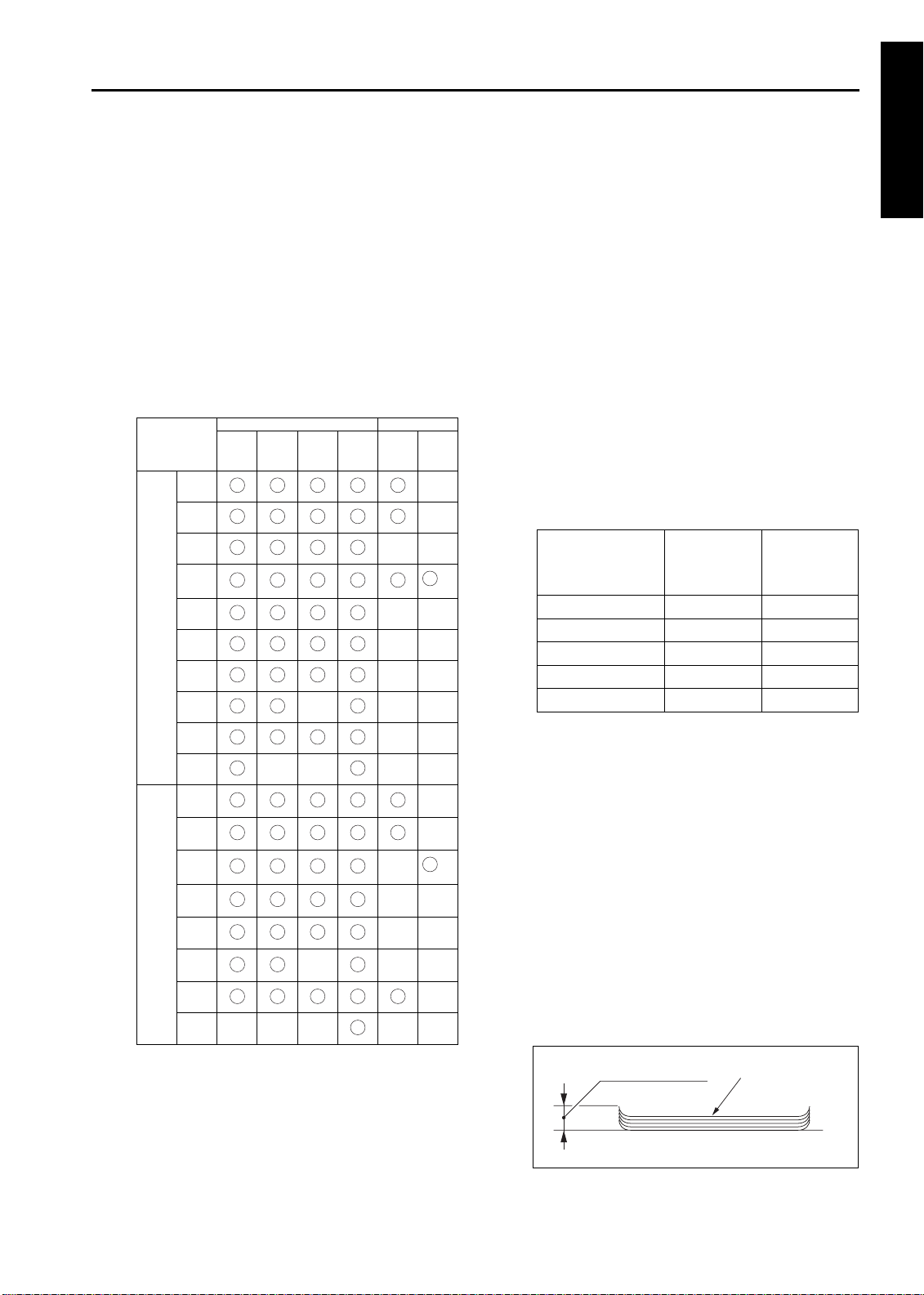

FS-110/FS-210 PRODUCT SPECIFICATIONS

FS-110/FS-210

[1] T ype

FS-110:

Finishing device with offset collation (sort and

group), stapling, and sub-tray eject features.

FS-210:

Finishing device with offset collation (sort and

group), stapling, sub-tray eject, booklet (stitchand-fold), and three-folding features.

[2] Functions

T ype of Paper:

Same as the main body

Paper Size:

A3

B4

F4R

A4R

A/B

A4

standards

B5R

B5

A5R

FS-110/210 FS-210 only

Non-

Sort/

Sta-

sort

group

ple

Sub-

tray

Book-

let

Three

-folding

*1

2

Paper Stacking Capacity (80g/m

or 20lbs):

Sub-tray exit mode:

Maximum 200 sheets (same-size sheets only)

Non-Staple, Group, and Offset modes:

Maximum 1500 sheets (A3, B4, F4R, 11 x 17,

and 8.5 x 14)

Maximum 3000 sheets (A4, A4R, B5, B5R,

8.5 x 11, and 8.5 x 11R)

Maximum 500 sheets (A5, A5R, B6R, 5.5 x 8.5,

and 5.5 x 8.5R)

Note: For FS-210, the maximum stacking

capacity is 2500 sheets for A4, A4R, B5,

B5R, 8.5 x 11, and 8.5 x 11R paper .

Staple Mode:

Maximum 1000 sheets (paper must be the

same size)

Main-Tray Capacity

Original pages

A3, 11 x 17,

A5, and 5.5 x

8.5

Other paper

types

2 to 9 50 stacks 100 stacks

10 to 20 50 stacks 50 stacks

21 to 30 30 stacks 30 stacks

31 to 40 25 stacks 25 stacks

41 to 50 20 stacks 20 stacks

1 OUTLINE

A5

B6R

11 x

17

8.5 x

14

By

inch

8.5 x

11R

8.5 x

11

5.5 x

8.5R

5.5 x

8.5

Wide

Other

*1

*1 The position of the stopper must be changed

when using paper with different size.

Booklet Mode (FS-210 only):

• Stitch-and-fold

20 booklets with 5 sheet s folded each. 15

booklets in case of small size paper (A4R/

8.5 x 11R ). One booklet with 6 sheets folded

is taken as two and more booklets.

• Folding

33 booklets with 3 or less sheets folded each

25 booklets in case of small size paper

(A4R/8 .5 x 11R).

• Three-folding

Tray capacity is a maximum of 50 individual

folded s h e e ts .

Paper curling:

10mm or less

Amount of curl

Paper (5 sheets)

1-1

Page 12

FS-110/FS-210

1 OUTLINE

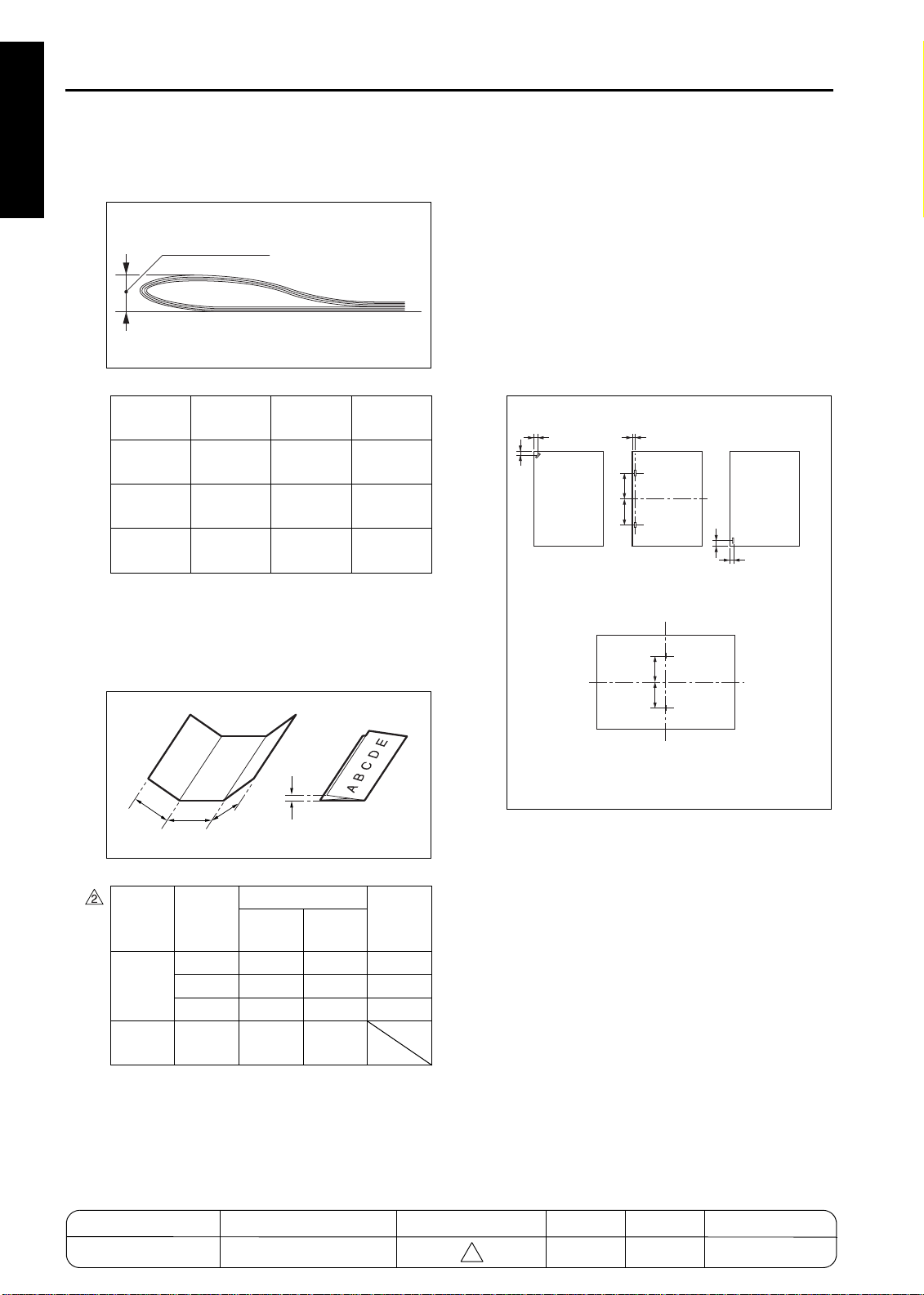

Height of folding in the booklet mode (FS210

only):

(80g/m2 or 20lbs)

Height of folding

Original

pages

0 to 5

6 to 10

11 to 20

A3, 11 x 17

25mm or

less

50mm or

less

Not

specified*

B4,

8.5 x 14

25mm or

less

50mm or

less

Not

specified*

A4R,

8.5 x 11R

25mm or

less

Not

specified*

Not

specified*

* The height of folding may be larger after exit,

[3] Staple Mode

Number of sheets to be stapled:

50 sheets or less (the height must be 5mm or

less when using 80g/m

Positions for stapling:

A = 8.5mm

B = 8.5mm

C = 60mm

D = 8.5mm

E = 14mm

F = 60mm

A

B

Single staple

(rear)

3mm

±

3mm

±

3mm

±

3mm

±

3mm

±

3mm

±

D

CC

T wo staples

2

or 20lbs quality paper)

E

Single staple

D

(front)

although the booklet must be folded with ease

manually.

Width (a, b and c) and height (h) in the threefolding mode:

FF

h

a

Width/

height

Width

Height h

c

b

Measure-

ments

Nominal values

A4R

8.5 x 11R

a 95mm 89.4mm

b 101mm 95mm

c 101mm 95mm

25mm

or less

25mm

or less

Allow-

ance

2mm

±

2mm

±

2mm

±

Note: Measurements must be made using a

single sheet.

Amount of sort offsetting:

30mm (after sorting and grouping)

Booklet mode (stitch-and-fold)

(FS-210 only)

Staple capacity:

5000 staples/cartridge

MODEL MANUAL REVISED EDITION DATE PAGE METHOD

7155/7165/7255/7272

SERVICE MANUAL Dec. 2003

1-2

2

1-2 REPLACEMEN T

Page 13

FS-110/FS-210

[4] Booklet Mode (FS-210 only)

Stitch-a n d -fo ld:

Maximum 20 sheets (when using 80g/m

20lbs quality paper)

Maximum 19 sheets (when using 80g/m

20lbs qualit y paper) + one sheet ( 200g/m

45lbs quality paper)

Foldin g :

Maximum 3 sheets (when using 80g/m

20lbs quality paper)

[5] Three-folding Mode (FS-210 only)

Num b e r of three-f o ld in g :

Maximum 3 sheets (when using 80g/m

20lbs quality paper)

However, special paper cannot be used.

[6] Option

PI-110

(Cover sheet feeder)

PK-110

(Puncher)

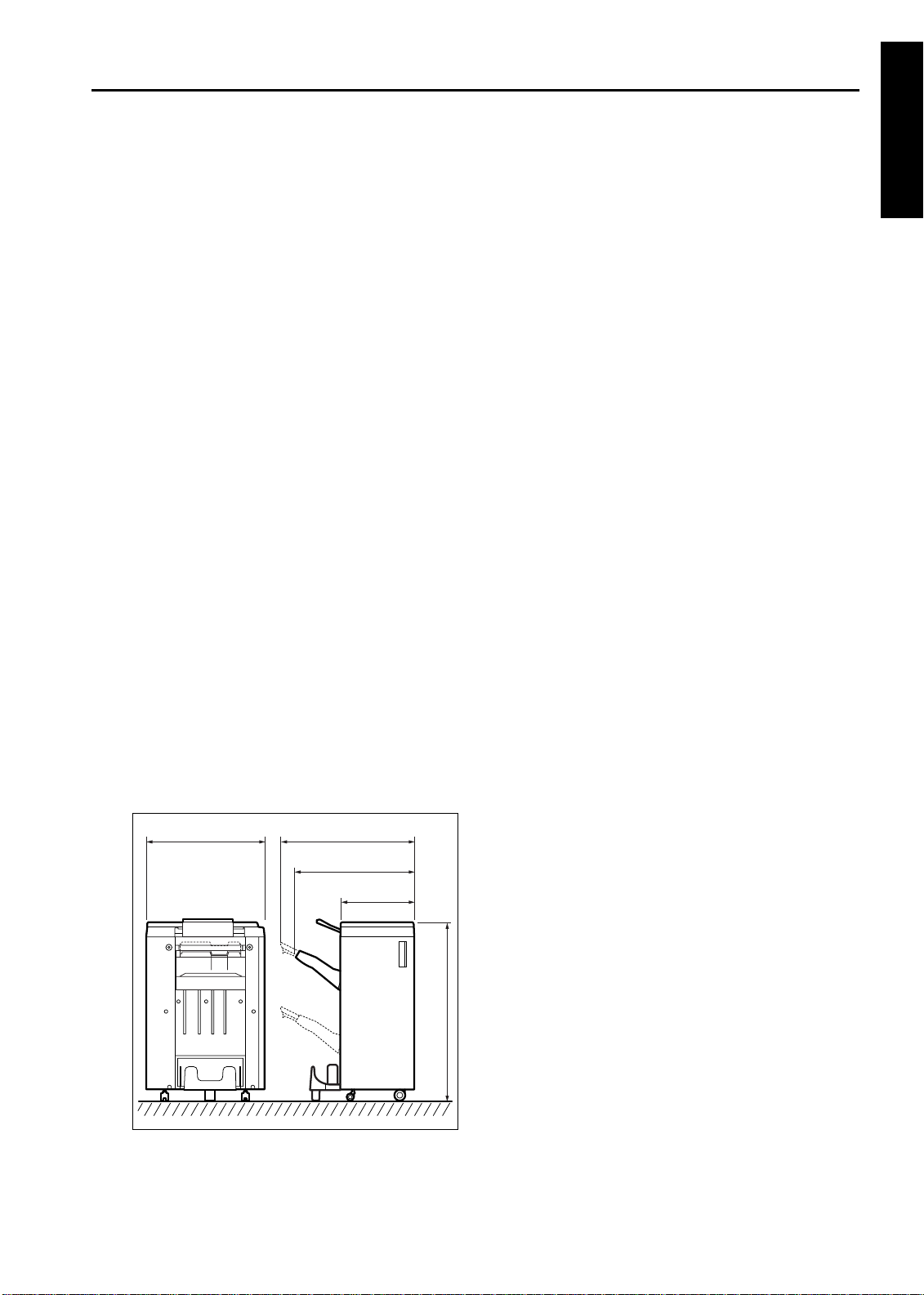

[7] Machine Specifications

Power source:

24V, 5VDC (supplied from the main body)

Maximum power consump tion:

100V A

Weight:

FS-110: Approx. 55kg

FS-210: Approx. 65kg

Extern a l Dimen s io n s :

2

2

2

2

2

or

or

or

or

or

[8] Maintenance

Maintenance procedures:

Same as the main body

Service life:

Same as the main body

[9] Operating Environment

T emperature:

10 to 30

Humidity:

10 to 80% RH

Note: The information herein may be subject to

change for improvement without notice.

C (50 °F to 86°F)

°

1 OUTLINE

741656

(tray extended)

656

(tray closed)

410

990

1-3

Page 14

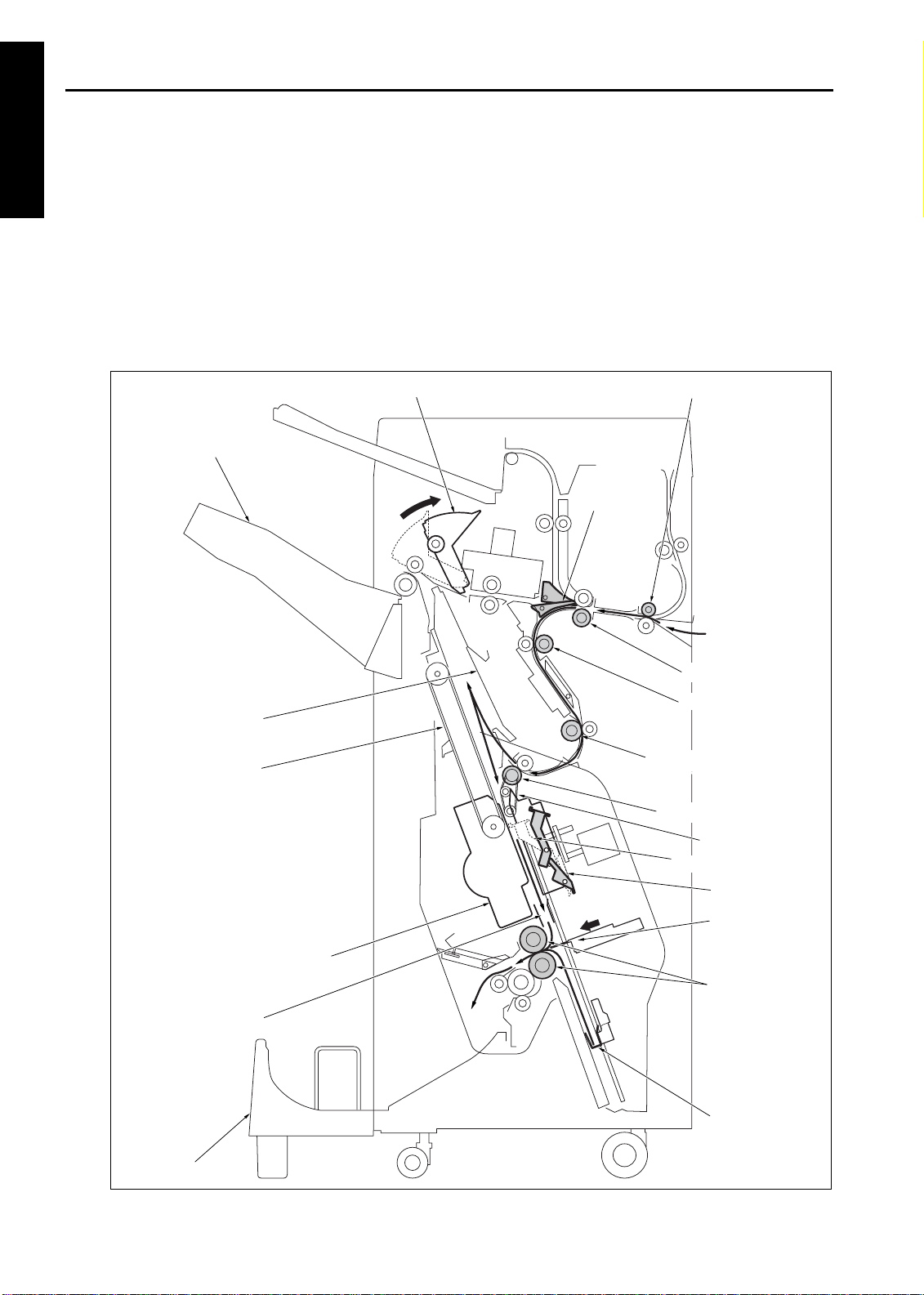

FS-110/FS-210

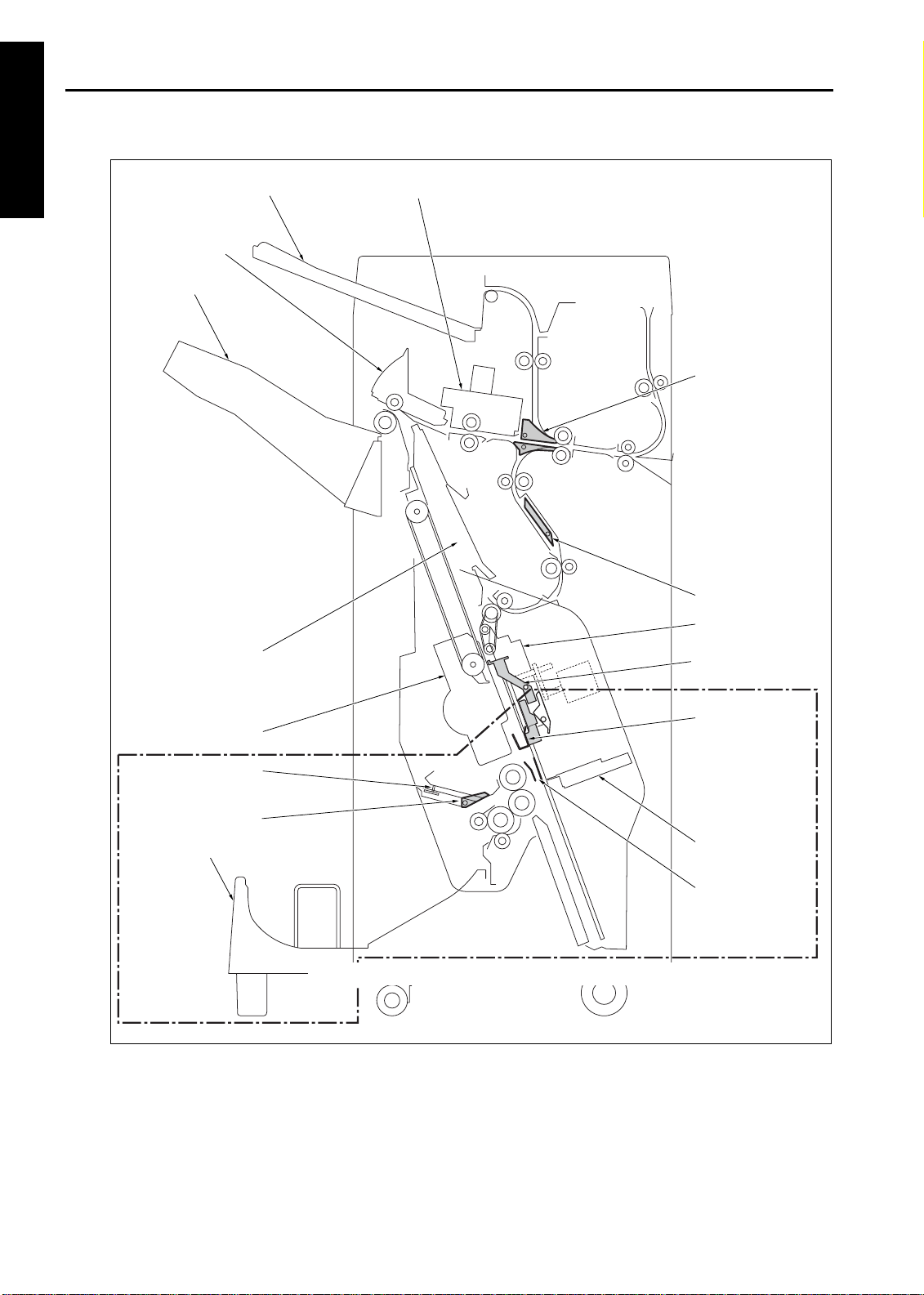

CROSS SECTION DIAGRAM

1 OUTLINE

Sub-tray

Paper exit

opening unit

Main tray

Shift unit

Gate

Alignment plate/U

Stapler

Three-folding

stopper

Three-folding gate

Booklet tray

Bypass gate

Clincher

Flat-stapling stopper

Booklet stopper

Folding knife

Alignment plate/L

Components in the region enclosed by the dotted line represent those of FS-210.

1-4

Page 15

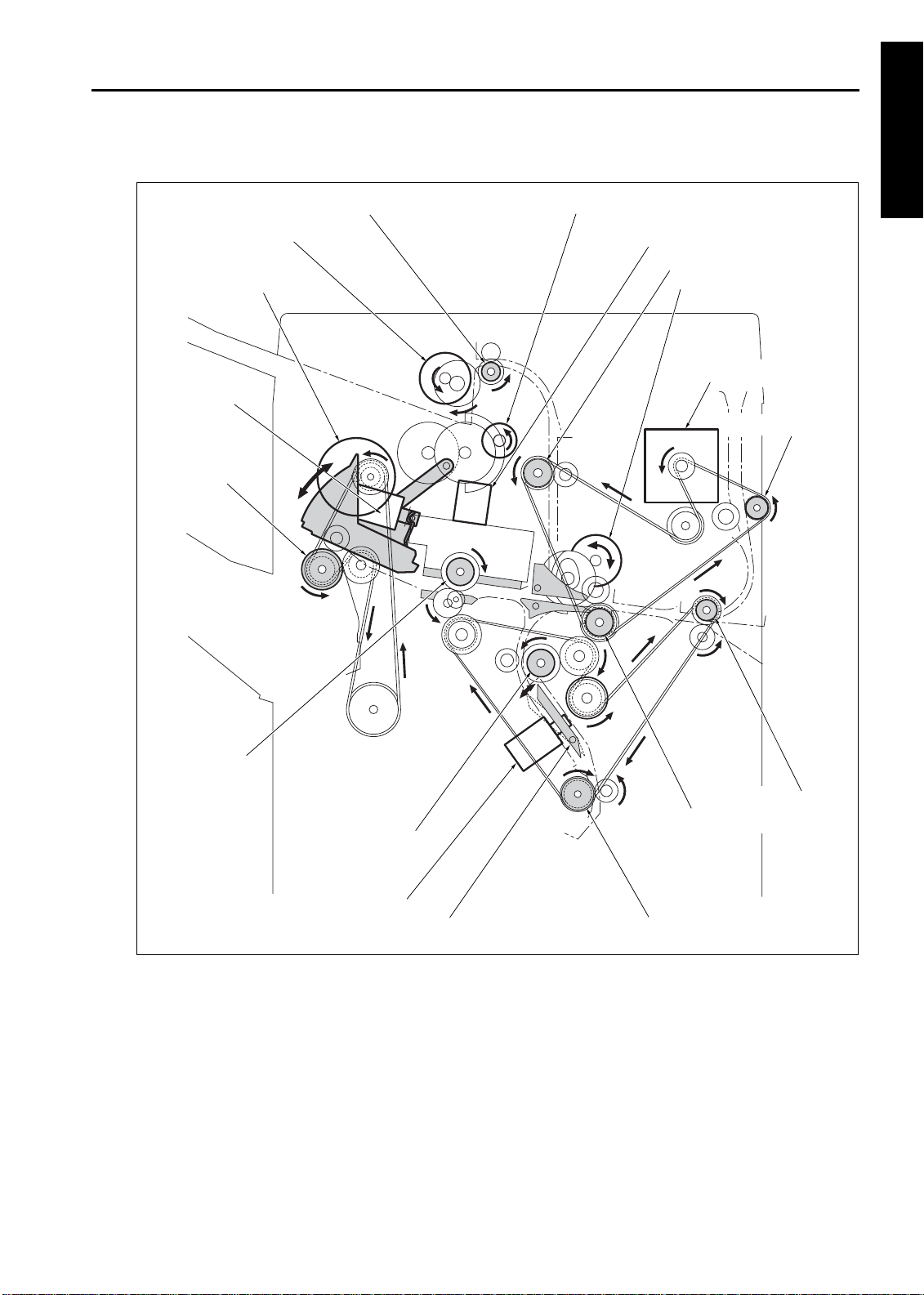

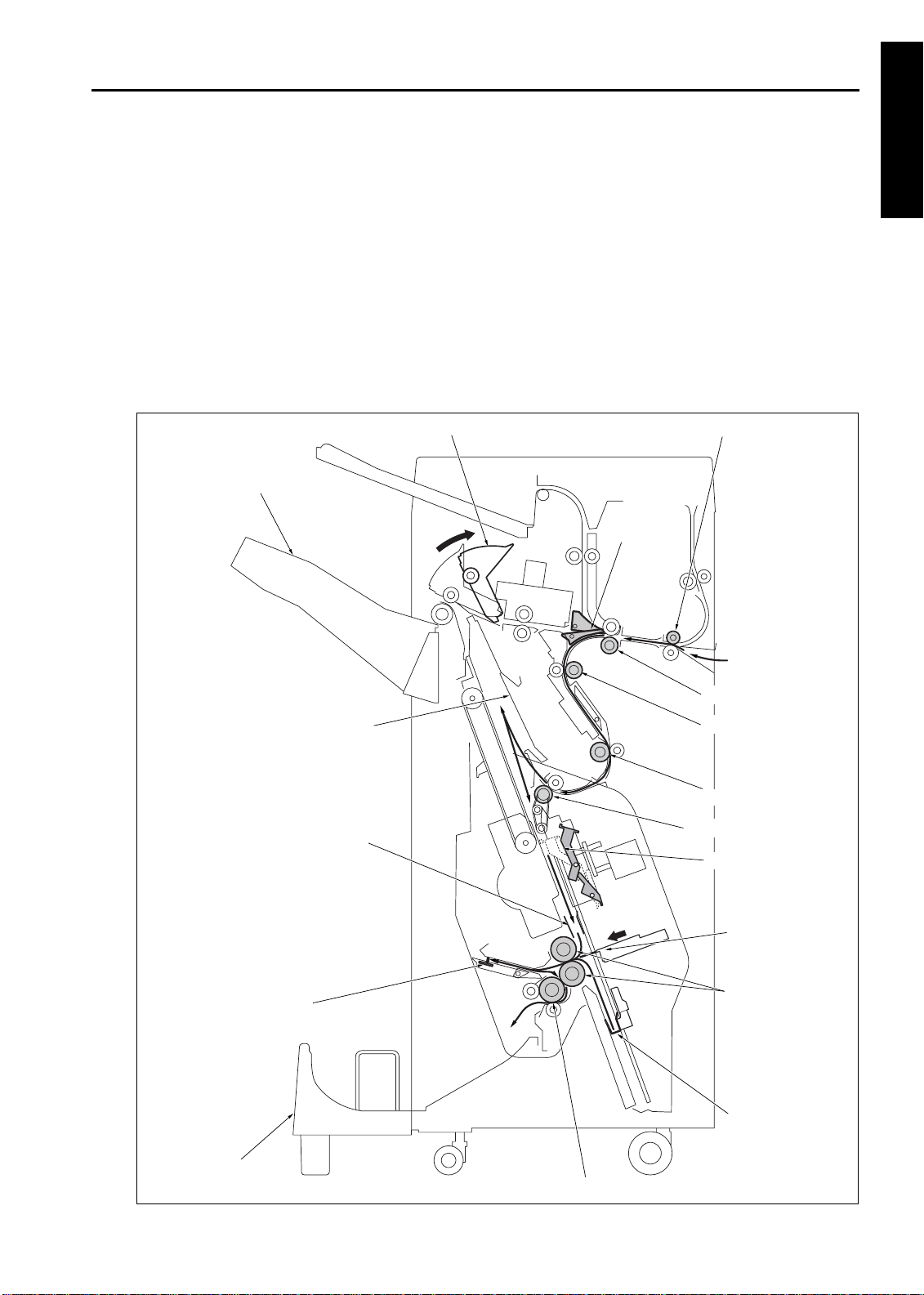

DRIVE SYSTEM DIAGRAM

FS-110/FS-210

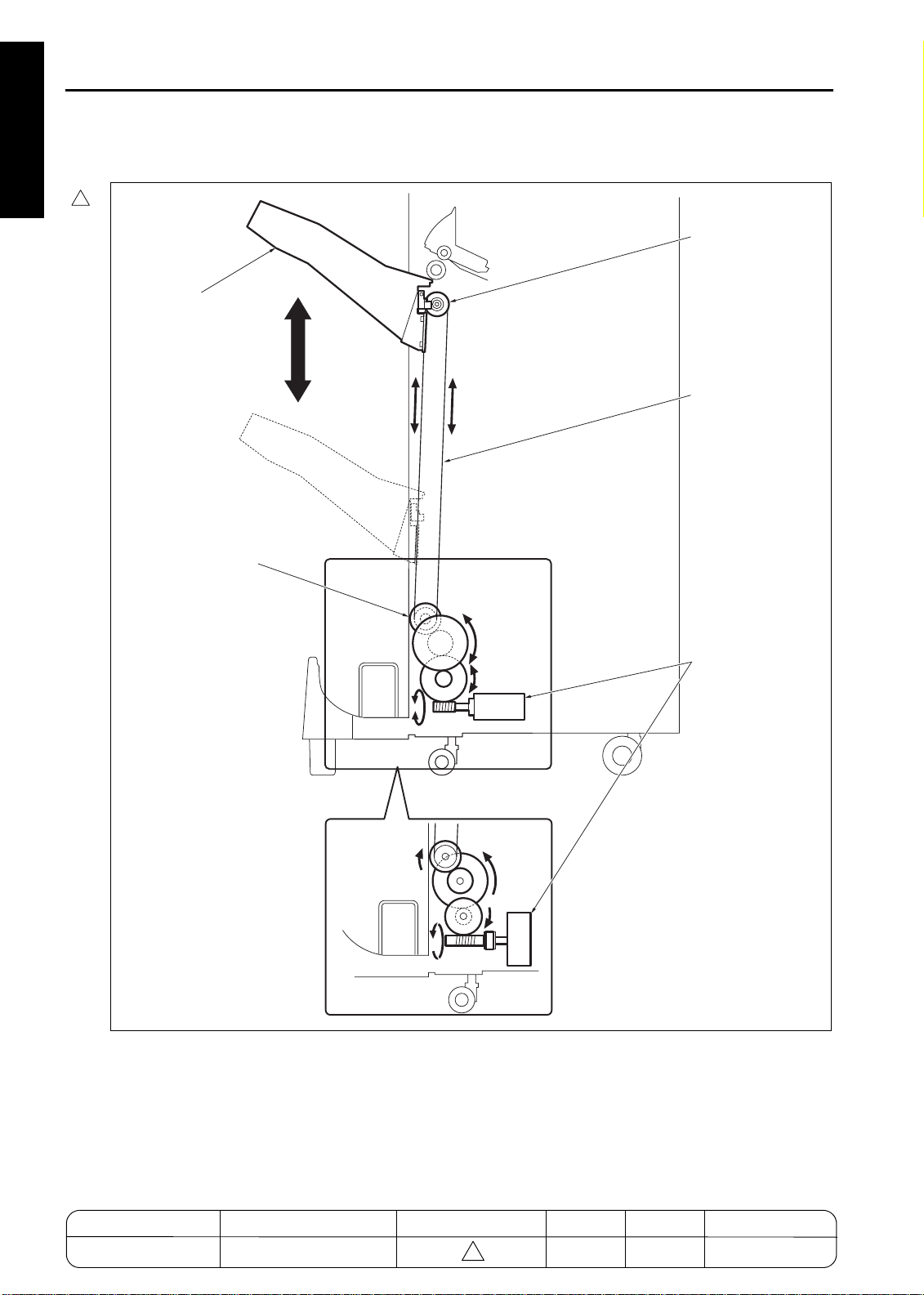

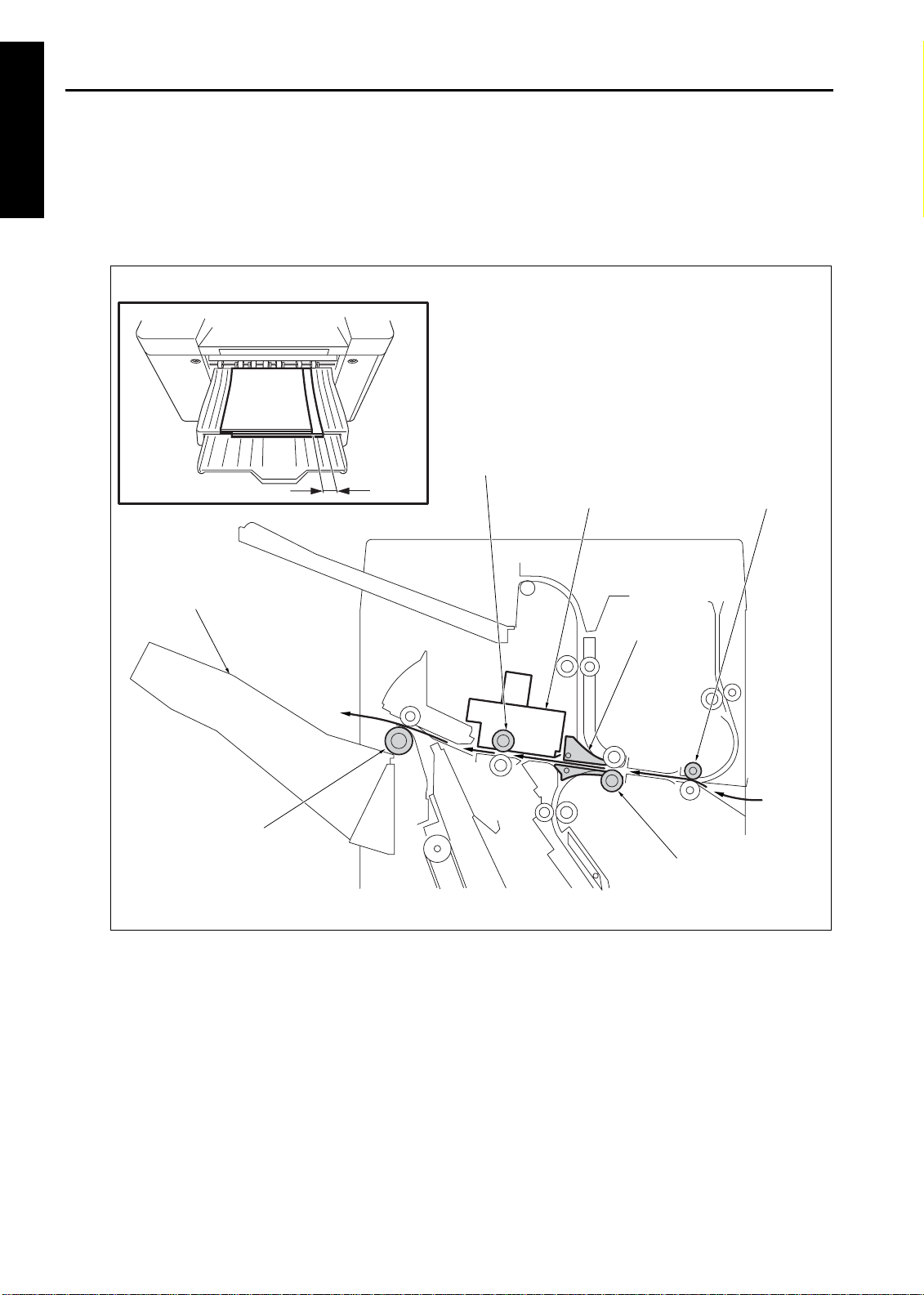

[1] Paper Conveyance Drive

Sub-tray paper exit roller

Sub-tray paper exit motor (M721)

Paper exit roller motor (M707)

Paper exit opening

SD (SD704)

Paper exit roller

1 OUTLINE

Paper exit opening motor (M708)

Shift motor (M702)

Sub-tray conveyance roller

Gate drive motor (M712)

FNS conveyance motor (M701)

PI conveyance roller

Shift roller

Conveyance roller/B

By-pass gate SD (SD705)

By-pass gate

Entrance roller

Conveyance roller/A

Intermediate conveyance roller

1-5

Page 16

FS-110/FS-210

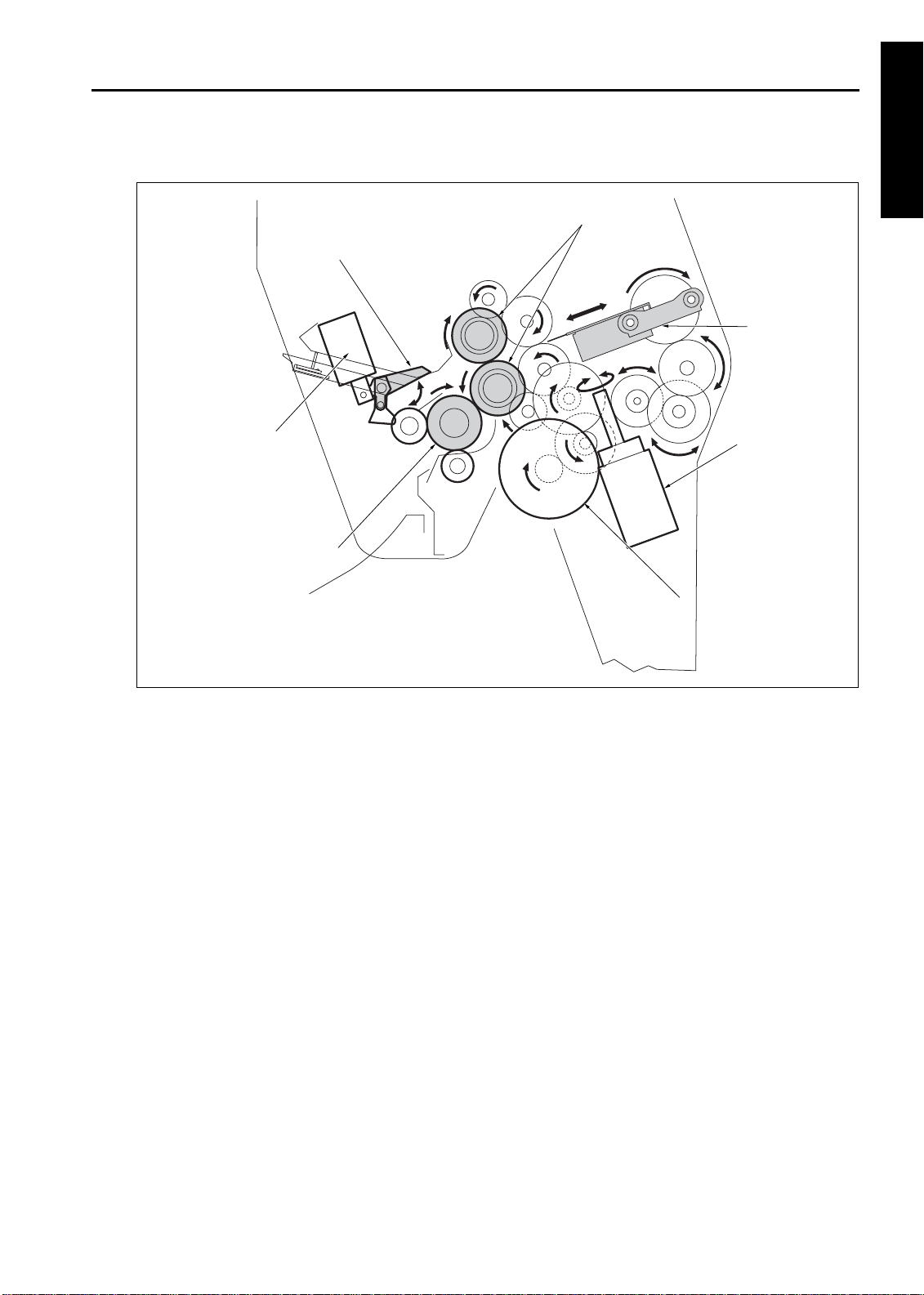

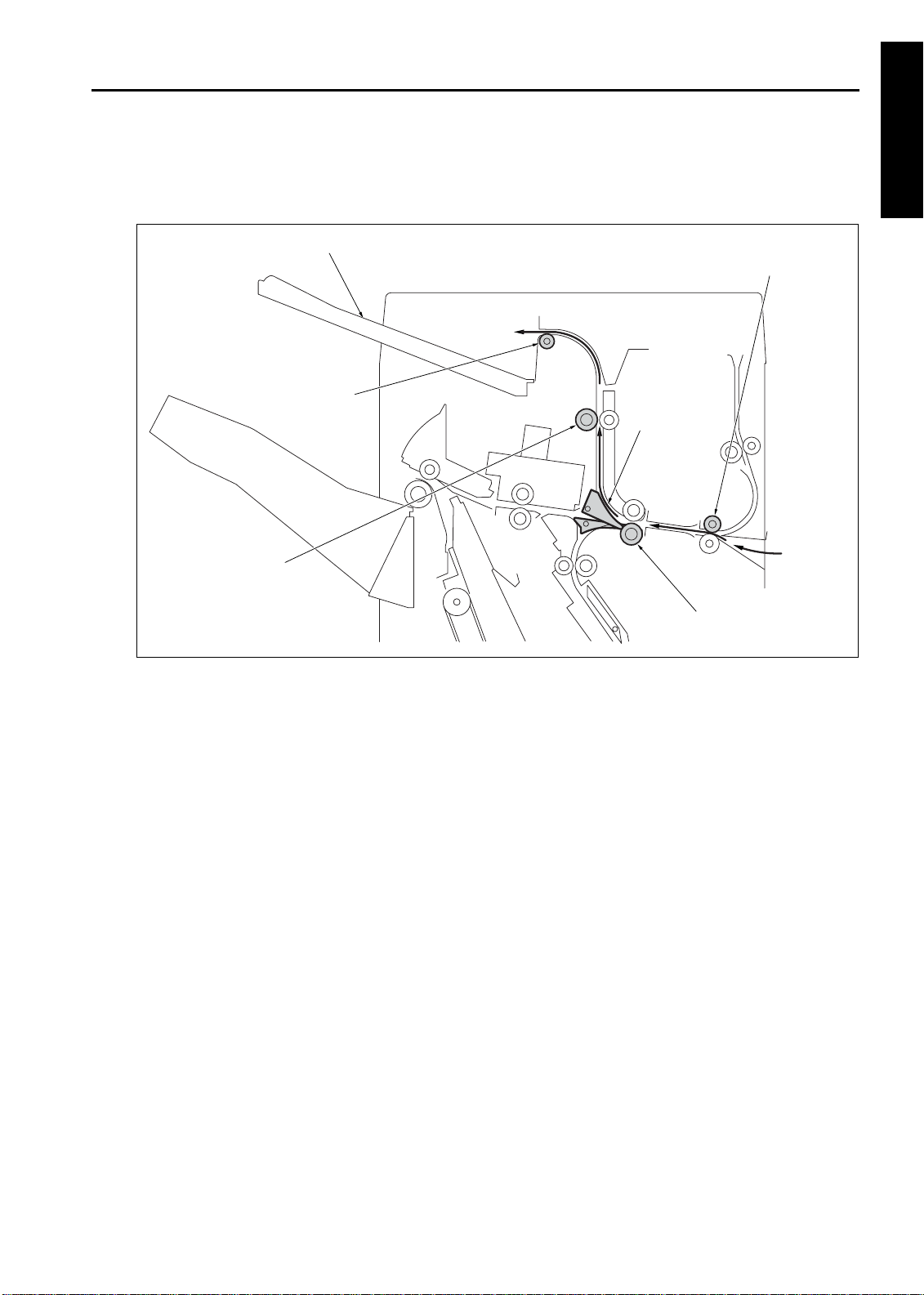

[2] Stacker Drive

1 OUTLINE

Alignment plate/U

Paper exit arm

From paper exit roller motor (M707)

Alignment motor/U (M705)

Stacker entrance motor

(M713)

Stacker entrance roller

Flat-stapling stopper

Alignment motor/L (M716)

Alignment plate/L

Booklet stopper

Stopper motor (M718)

1-6

Page 17

FS-110/FS-210

[3] Staple Drive

Stapler/F

Clincher/F

Stapler/R

Stapler rotation motor (M706)

Stapler

Stapler movement

motor (M711)

1 OUTLINE

Clincher

Clincher/R

Clincher rotation motor

(M704)

1-7

Page 18

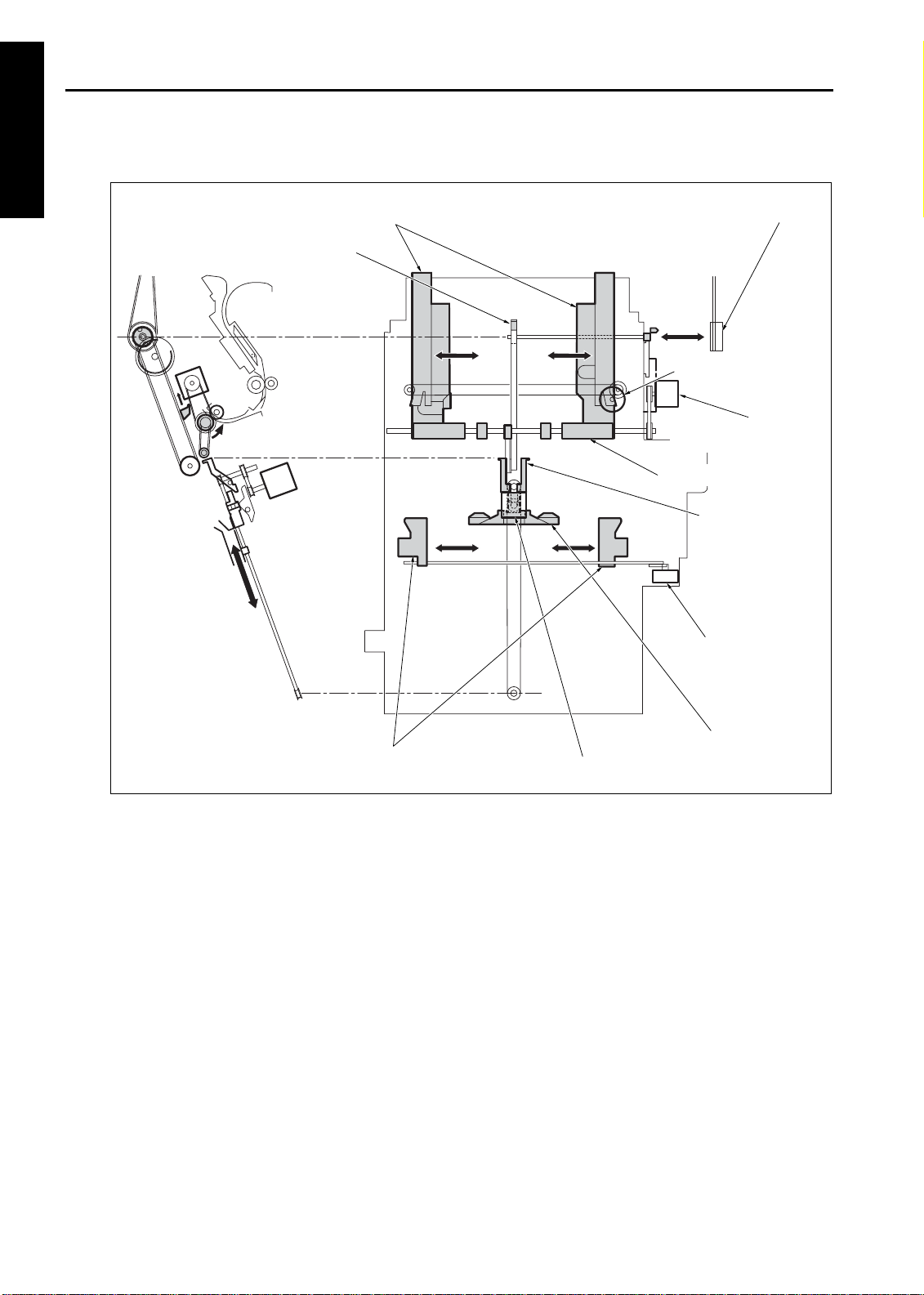

FS-110/FS-210

[4] Tra y Drive

1 OUTLINE

2

Up/down pulley/U

Main tray

Up/down wire

Up/down pulley/L

Old type

Tray up/down motor

(M703)

New type

fs2101001

MODEL MANUAL REVISED EDITION DATE PAGE METHOD

7155/7165/7255/7272

SERVICE MANUAL Dec. 2003

1-8

2

1-8 REPLACEMEN T

Page 19

FS-110/FS-210

[5] Folding Drive

Three-folding gate SD

(SD706)

Three-folding roller

1 OUTLINE

Folding roller

Three-folding gate

Folding knife

Folding knife motor

(M719)

Folding conveyance motor

(M720)

1-9

Page 20

FS-110/FS-210

PAPER CONVEYANCE PATH

[1] Paper Conveyance Path

1 OUTLINE

The finisher (FNS) consists of five paper paths, as shown in the diagram below.

Sheets are turned over by the main body's exit page inverter, and then passed to the FNS.

The FNS has two paper entrance connections: one from the main body, and the other from PI-110 (optional).

Sub-tray

PI-110

Main tray

Booklet tray

2

3

1

1

3

5

2

3

54

5

4

Main body

4

5

Paper conveyance path Finishing mode

1

112

3

4

5

Non-sort, sort, and group modes

Sub-tray mode

Staple mode

Booklet mode (FS-210 only)

Three-folding mode (FS-210 only)

1-10

Page 21

FS-110/FS-210

[2] Non-Sort Mode

In the non-sort mode, the gate is set to the position to carry paper to the main tray. Each sheet, delivered from

the main body, is carried to the main tray through the gate.

Entrance roller

Main tray

Gate

Paper exit roller

Conveyance roller/A

1 OUTLINE

1-11

Page 22

FS-110/FS-210

[3] Sort, and Group Modes

1 OUTLINE

In the sort and group modes, the gate is set to the position to carry paper to the main tray. Each sheet, delivered from the main body, is conveyed to the main tray while the sheet is shifted by 30mm to the r ear. The

shift roller of the shift unit performs the shift action. In the sort mode, even pages are offset. In the group mode,

even numbered copies are offset.

30mm

Shift roller

Shift unit

Entrance roller

Main tray

Paper exit roller

Gate

Conveyance roller A

1-12

Page 23

FS-110/FS-210

[4] Sub-tray Mode

In the sub-tray mode, the gate is set to the position to carry paper to the sub-tray. Each sheet, delivered

from the main body, is delivered to the sub-tray

Sub-tray paper exit roller

Sub-tray conveyance roller

1 OUTLINE

Sub-tray

Entrance roller

Gate

Conveyance roller/A

1-13

Page 24

FS-110/FS-210

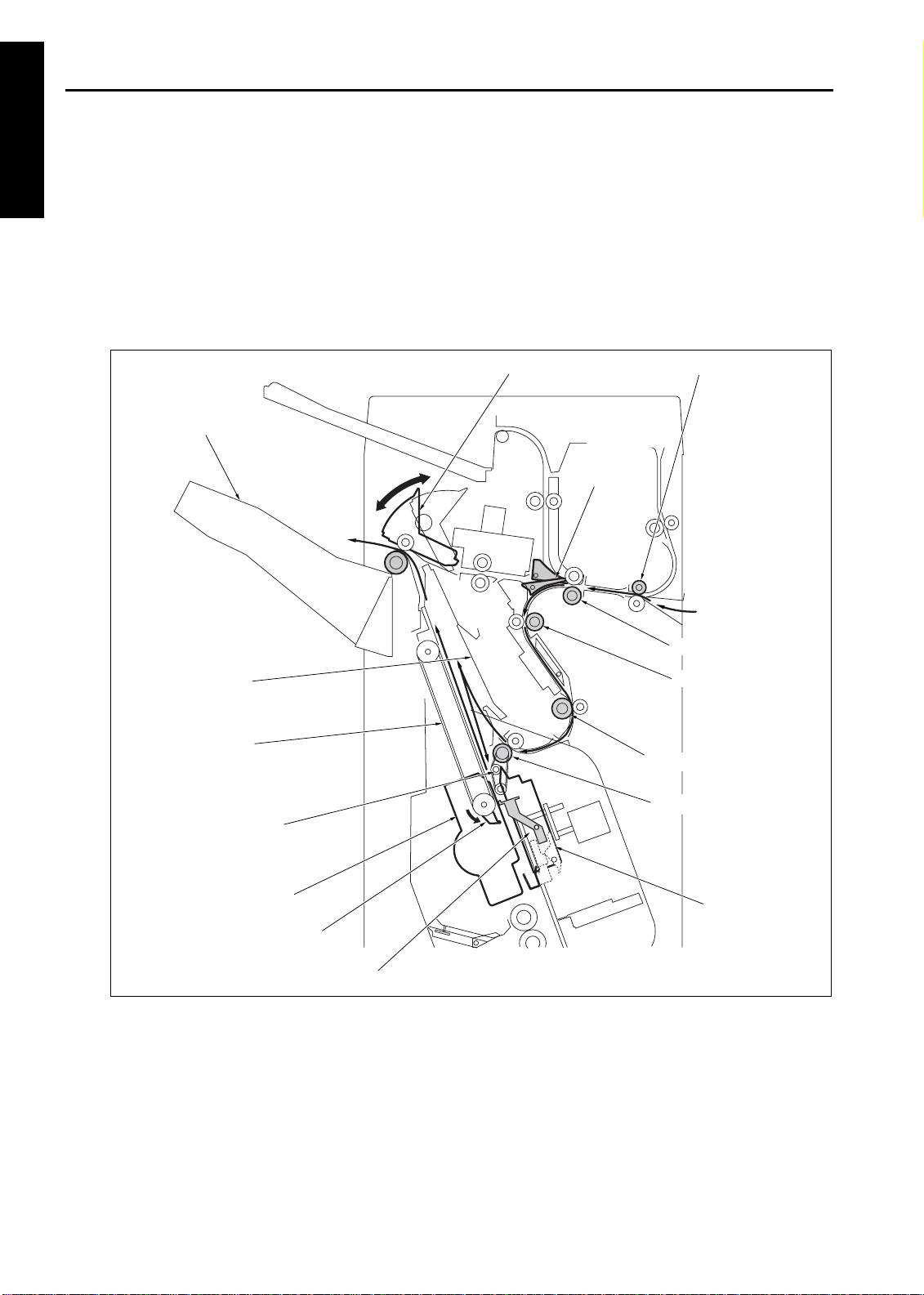

[5] Staple Mode

1 OUTLINE

For sheets of all size except A4, B5, and 8.5 x 11:

(1) The gates are set to the position to carry paper to the stacker.

(2) If paper is larger than A4R, the paper exit opening will open.

(3) Each sheet is carried to the flat-stapling stopper and its vertical position (feeding direction) is adjusted.

(4) The horizontal position (widthwise direction) of each sheet is adjusted by the alignment plate/U.

(5) When all necessary sheets are stacked, they are stapled with the stapler and the clincher.

(6) The set of stapled sheets is delivered by the paper exit arm to the main tray.

(7) Steps (3) through (6) are repeated for each set of sheets to be stapled.

Main tray

Alignment plate/U

Paper exit belt

Swing belt

Paper exit opening unit

Gate

Intermediate conveyance roller

Entrance roller

Conveyance roller/A

Conveyance roller/B

Stacker entrance roller

Stapler

Paper exit arm

Flat-stapling stopper

Clincher

1-14

Page 25

FS-110/FS-210

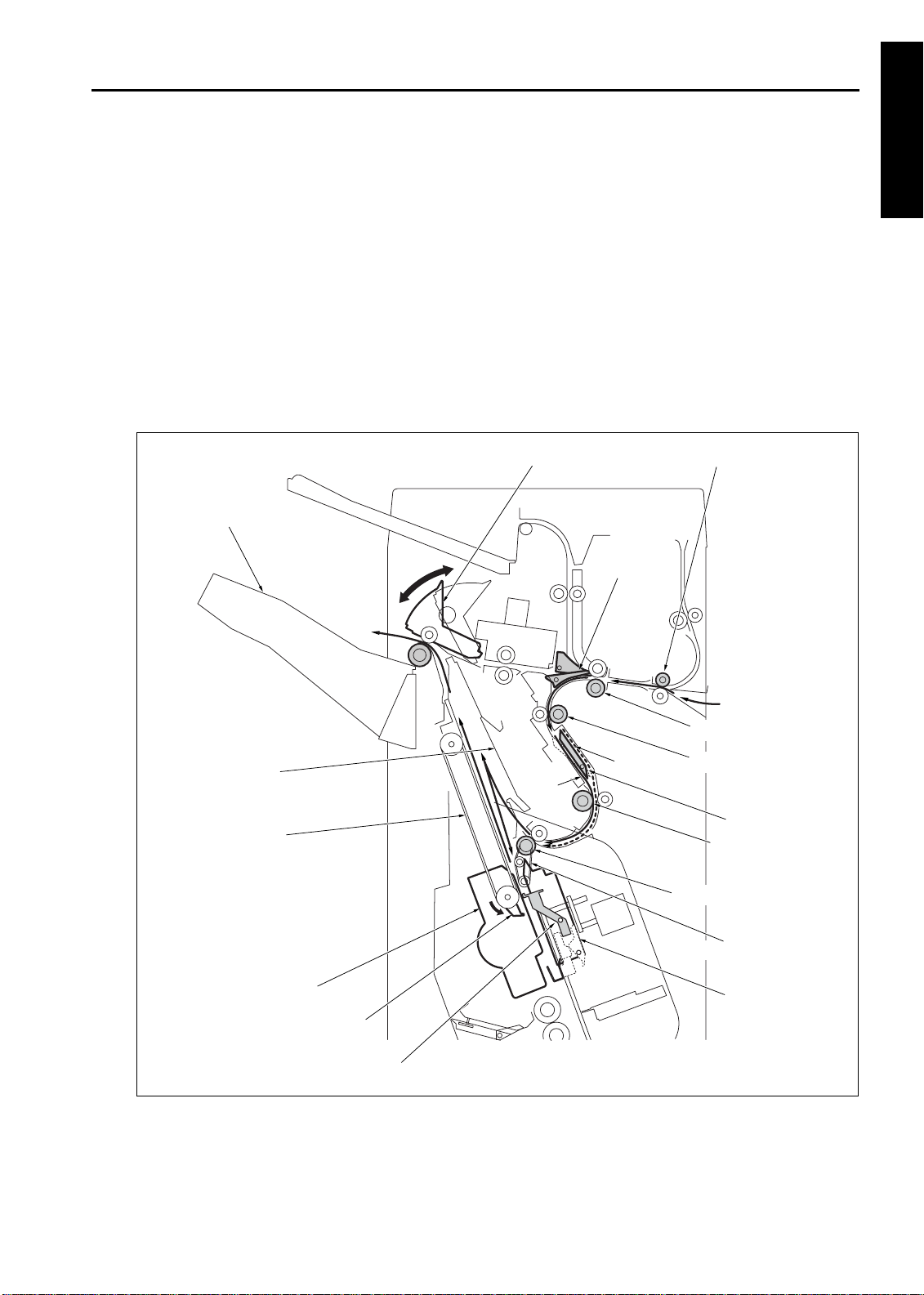

For sheets of A4, B5, and 8.5 x 11:

(1) The first set is stapled and delivered to the main tray in the same manner as sheets of all size except A4,

B5, and 8.5 x 11.

(2) As the front of t he f i r st set i s bei ng di schar ged, t he st ac ker ent r ance r ol l er st ops and t he by- pass gat e

opens. The first sheet of the second set (and subsequent sets) is conveyed to the stacker entrance.

(3) The by-pass gate closes, and a second sheet is l aid over the fi rst sheet which is f ixed by the st acker

entrance roller.

(4) When the front of the first set has been delivered, the stacker entrance roller starts to rotate. The first and

second sheets are conveyed to the stacker.

(5) The alignment plate/U lines up each sheet in the widthwise direction.

(6) When all sheets are stacked, they are stapled with the stapler and the clincher.

(7) The set of stapled sheets is delivered by the paper exit arm to the main tray.

(8) Steps (2) through (7) are repeated for each set of sheets.

Paper exit opening unit

Main tray

Gate

Entrance roller

1 OUTLINE

Alignment plate/U

Paper exit belt

Stapler

Paper exit arm

Flat-stapling stopper

Second

sheet

First sheet

Conveyance roller/A

Conveyance roller/B

By-pass gate

Intermediate

conveyance roller

Stacker entrance roller

Intermediate conveyance

roller

Clincher

1-15

Page 26

FS-110/FS-210

[6] Booklet Mode

1 OUTLINE

(1) The gates are set to the position to carry paper to the stacker.

(2) The paper exit opening opens.

(3) The booklet stopper lowers t o the sti tch- and-fol d positi on. The fl at-s tapli ng stopper i s rel eased as the

booklet stopper lowers.

(4) The paper is conveyed to the booklet stopper to line up sheets in the lengthwise direction.

(5) The alignment plate/U and alignment plate/L line up each sheet in the widthwise direction.

(6) When the stitch-and-fold mode is selected, the sheets are stapled by the stapler and the clincher.

(7) The booklet stopper lowers to the folding position for setting the paper to the folding position.

(8) The folding knife and the folding roller fold the sheets, which are delivered to the booklet tray.

Main tray

Alignment plate/U

Paper exit belt

Paper exit opening unit

Entrance roller

Gate

Conveyance roller/A

Conveyance roller/B

Intermediate conveyance

roller

Stacker entrance roller

Swing belt

Flat-stapling stopper

Clincher

Alignment plate/L

Booklet tray

Folding knife

Stapler

Folding roller

Booklet stopper

1-16

Page 27

FS-110/FS-210

[7] Three-folding Mode

(1) The gates are set to the position to carry paper to the stacker.

(2) The paper exit opening opens.

(3) The booklet stopper lowers t o the sti tch-and- fol d positi on. The fl at-s tapli ng stopper i s rel eased as the

booklet stopper lowers.

(4) The paper is conveyed to the booklet stopper to line up in the lengthwise direction.

(5) The alignment plate/U and the alignment plate/L line up each sheet in the widthwise direction.

(6) The booklet stopper lowers to the first folding position, and the sheet is set to the first folding position.

(7) The folding knife and the folding roller perform the first folding, and the paper is conveyed toward the three-

folding stopper.

(8) The three-folding stopper curls the sheet, and the second folding is made by drawing it to the three-folding

roller. The three-folded sheet is delivered to the booklet tray.

Paper exit opening unit

Main tray

Gate

Entrance roller

1 OUTLINE

Alignment plate/U

Alignment plate/L

Three-folding stopper

Booklet tray

Conveyance roller/A

Conveyance roller/B

Intermediate conveyance roller

Stacker entrance roller

Flat-stapling stopper

Folding knife

Folding roller

Booklet stopper

Three-folding stopper

1-17

Page 28

1 OUTLINE

Blank page

Page 29

2

UNIT EXPLANATION

2 UNIT EXPL A NATION

Page 30

2 UNIT EXPL A NATION

Blank page

Page 31

EXTERNAL SECTION

[1] Composition

FS-110/FS-210

Main paper exit cover

Main tray

Rear cover

Booklet paper exit cover

(FS-210 only)

Booklet tray

(FS-210 only)

[2] Mechanism

Mechanism Method

Jam removal*1 Through the rotation of

roller(s) and the opening/closing operation of the guide

plates.

Sub-tray

Top cover/1

Top cover/2

Front door

Side cover

2 UNIT EXPL A NATION

*1 Jam removal

When a jam occurs in the conveyance secti on,

open the front door, turn the convey ance rol ler,

open the guide plates, and remove the jammed

paper.

When a jam occurs in the stacker section, open

the front door, draw out the stacker section,

rotate the fol ding roller, open the gui de plates,

and remove the jammed paper.

2-1

Page 32

FS-110/FS-210

CONVEYANCE SECTION

[1] Composition

Sub-tray full PS (PS719)

Shift unit

Shift roller

Paper exit opening unit

2 UNIT EXPL A NATION

Main tray paper exit PS

(PS706)

Main tray paper exit roller

Sub-tray paper exit PS (PS701)

PI conveyance roller

Gate

Entrance roller

FNS entrance PS

(PS704)

Conveyance roller/A

Conveyance roller/B

By-pass gate

Intermediate conveyance roller

Conveyance section

2-2

Page 33

FS-110/FS-210

[2] Mechanism

Mechanism Method

Gate switching*1 Driven by the stepping

motor/cam.

By-pass gate*2 Solenoids

Shift mechanism

of the shift unit*3

Open/close of

paper exit opening*4

Paper exit opening

nip*5

*1 Gat e S witching

The two gates (/U and /L) switch the paper path

to three direct ions: the sub-tr ay, the main tray,

and the stacker secti on. The upper and lower

gates (/U and /L) ar e driven by the gate cam,

which is driven by the gate drive motor (M712).

Gate HP PS (PS716)

Crank mechanism

Crank mechanism

Pressure rollers driven by

solenoid.

Gate drive motor (M712)

The gate cam consists of two cams (/U and /L) on

the same shaft. The position of the cams determines the paper path.

To sub-tray

Gate/U

Gate/L

To stacker section

Gate HP PS (PS716)

Cam/U

Cam/L

Sub-tray paper exit

Stacker section

paper exit

2 UNIT EXPL A NATION

Gate/U

Main tray paper exit

Gate cam

To main tray

Gate/L

2-3

Page 34

FS-110/FS-210

*2 By-pass Gate

2 UNIT EXPL A NATION

The by-pass gate is l ocated on the path t o the

stacker. This gate changes the conveyance path

of the next sheet while the stapling is being performed, saving time and improving performance.

This gate is used for small size papers (A4, B5,

and 8.5 x 11). The gate changes the feeding

direction of the second sheet so that it is laid over

the first sheet. The first and second sheets will be

conveyed to the stacker simultaneously.

The by-pass gate SD (SD705) drives the bypass gate.

First paper of the second and

subsequent sets

First paper of the second

and subsequent sets

By-pass gate

*3 Shift Mecha n is m of the S h ift Unit

The FNS conveyance motor (M701) drives the

shift rol ler, conveying the paper forward t o the

main tra y.

While the paper is conveyed to the main tray, the

shift motor (M702) rotates to activate the crank

mechanism. This mechanism moves the shift

moving section (including the shift roller) by

300mm toward the rear, which also moves the

paper and then it is delivered.

The shift HP PS (PS718) detects t he s hift position.

To main tray

Fixed section

Shift HP PS (PS718)

Shift moving section

Shift motor

(M702)

Shift roller

Crank arm

From FNS conveyance

motor (M701)

By-pass gate SD (SD705)

Second paper of the second

and subsequent sets

Second paper of

the second and

subsequent sets

By-pass gate SD (SD705)

First paper of the second

and subsequent sets

By-pass gate

Shift HP PS (PS718)

Fixed

section

Shift moving section

Position for straight

Paper exit

Shift motor (M702)

Shift roller

Crank shaft

Position for offset

(shift) paper exit

2-4

Page 35

FS-110/FS-210

*4 Op e n /c lo s e o f Paper E x it Open in g

When paper is conveyed to the stacker, and it is

larger than B5R in t he vertical length ( feeding

direction) , it does not fi t the paper exit opening.

This mechanism addresses this problem by

opening the paper exit opening from the start of

copying until the completion of stapling.

Paper exit opening unit

To main tray

Paper exit opening HP PS (PS712)

Crank arm

Paper exit opening

motor (M708)

The paper exit opening motor (M708) rotates to

activate the cr ank mechanism, lif ting t he paper

exit opening unit. The paper exit opening opens.

*5 Pap e r Exit Op e n in g Nip

Because the rotati onal speed of the paper exit

roller is slower than that of the conveyance roller,

the nip is in the released position except during

the paper exit action. When a sheet of paper

reaches the paper exi t opening, t he paper exit

opening solenoid (SD704) activates the nip

roller. The roller nips the sheet to deli ver t o the

main tra y.

Paper exit opening unit

Paper exit opening SD

To main tray

Nip moving section (Paper exit guide assembly)

(SD704)

Nip roller

Main tray paper exit PS

(PS706)

2 UNIT EXPL A NATION

Paper exit

opening unit

Close position

Crank shaft

Paper exit opening

motor (M708)

Paper exit opening HP PS (PS712)

Open position

Position when the

nip is not active.

Nip roller

Nip moving

section

Position when the

nip is active.

Paper exit opening SD

(SD704)

Main tray paper exit

roller

2-5

Page 36

FS-110/FS-210

[3] M701 (FNS Conveyance) Control

24V

24V

DRV A

DRV A

DRV B

DRV B

5V

PS704 IN

GND

24V-IN

5V

2 UNIT EXPL A NATION

SGND

PGND

PGND

FGND

MTXD

SGND

MCTS

MRXD

SGND

MRTS

M701 (FNS conveyance) operation is performed

by the 24V DC motor and controlled by the FNS

CB (FNS Control Board).

The related signals is PS704 (FNS Entrance).

1. Operation

a. Interlock control

FNS paper conveyance drive control is initiated

by the ON signal from the main body' s START

button. If MS701 (int er lock) i s OFF at t his t i me,

however, the finisher transmits an error signal to

the main body's PRCB and does not begin thi s

control.

b. M701 (FNS conveyance) control

When the position of the START button is ON,

and the paper exit speed is high, ON from PS37

(main body paper exit) sets the speed to low, and

ON from PS704 (FNS entrance) sets the speed

to high after a predefined time peri od. For the

main tray paper exi t operation, PS704 det ects

the end of the paper, and, after a predefined time

period, the speed mode swit ches to medium to

match the paper exit speed of the FNS. Then,

after a predefined time, the mode returns to the

high speed to prepare for the next conveyance of

paper.

24VDC IN

5V

SGND

PGND

PGND

SRXD

SGND

SRTS

STXD

SGND

SCTS

FNS CBMAIN BODY

M701

PS704

2. Signals

a. Input signals

(1) SRXD (Main body to FNS CB)

Serial data line; transmits the operating status of

the main body's CB to the FNS CB.

(2) SCTS (Main body to FNS CB)

Acknowledgment signal, sent from the main

body to the FNS, allowing the FNS to send data

to the main body.

(3) 24V-IN (MS701 to FNS CB)

Interlock signal:

[H]: Front cover is closed.

[L]: Front cover is open.

(4) PS704 IN (PS704 to FNS CB)

Signal indicating whether the paper passes

through the entrance. The front and rear ends of

the paper are detected.

[H]: Paper does not exists.

[L]: Paper exist.

b. Output signals

(1) S RTS (FNS C B to Ma in b o d y )

Acknowledgment signal, sent from the FNS to

the main body, allowing the main body to send

data to the FNS.

(2) S T X D (FNS CB to Main bo d y )

Serial data line; transmits the operating status of

the FNS to the main body's CB.

(3) M701 DRV A, A

Pulse signal to drive/control the Phase A of M701

(4) M701 DRV B, B

Pulse signal to drive/control the Phase B of M701

(FNS CB to M701)

(FNS CB to M701)

2-6

Page 37

FS-110/FS-210

[4] M712 (gate drive) Control

24V

M712 DRV A

M712 DRV A

M712 DRV B

M712 DRV B

M712 (gate drive) perf orms the paper conveyance path switching between the sub-tray, main

tray or stacker section. The FNS CB (FNS control board) controls the operation of M712.

The related signal is PS716 (gate HP).

1. Operation

M712 (gate drive) is activated by the FNS operation signal from the main body, selecting one of

the three positions depending on the paper exit

destinations: the sub-tray (home position), main

tray or stacker. However, when the current paper

exit destination is the sub-tray, M712 is not activated (it is already in the home position).

After the operation, M712 returns to i ts home

position based on PS716 (gate HP).

2. Signals

a. FNS CB input signals

(1) PS716 IN (PS716 to FNS CB)

Signal relating to the gate home position

[H]: HP

[L]: Non -H P

b. FNS CB output signals

(1) M712 DRV A, A

Pulse signal to drive/control the Phase A of M712

(2) M712 DRV B, B

Pulse signal to drive/control the Phase B of M712

(FNS CB to M712)

(FNS CB to M712)

24V

5V

PS716 IN

SGND

FNS CBMAIN BODY

M712

PS716

[5] SD705 (by-pass gate) Control

24V

SD705 DRV

5V

PS704 IN

GND

FNS CBMAIN BODY

SD705 (by-pass gate) only oper ates for small

size papers (A4, B5 or 8.5 x 11). The FNS CB

(FNS control board) controls SD705.

The related signal is PS704 (FNS entrance).

1. Operation

(1) Fir st s e t:

While the sheets of the first set are being pr ocessed, SD705 (by-pass gate) does not operate.

(2) Second set:

The stapling operation for the first set is activated, and, after a predefined time, SD705 (bypass gate) is activated to pull the first sheet of the

second set toward the by-pass.

SD705 stops it operation when a predefined time

has elapsed since PS704 (FNS entrance)

detected the rear end of the first sheet of the second set.

SD705 does not operate when the second and

subsequent sheets of the second set are processed.

(3) Third and subsequent sets:

PS704 (FNS entrance) detects t he rear end of

the last sheet of the second set. Then, af ter a

predefined ti me, SD705 (by-pass gate) is acti vated to pull the first sheet of the third set toward

the by-pass.

SD705 stops it operation when a predefined time

has elapsed since PS704 (FNS entrance)

detected the rear end of the first sheet of the third

set.

SD705 does not operate when the second and

subsequent sheets of t he third and subsequent

sets are processed.

SD705

PS704

2 UNIT EXPL A NATION

2-7

Page 38

FS-110/FS-210

2. Signals

a. FNS CB output signals

(1) PS705 DRV (FNS CB to SD705)

Signal to drive/control the SD705.

[H]: SD705 is ON.

[L]: SD705 is OFF.

2 UNIT EXPL A NATION

[6] M702 (shift) Control

24V

M702 DRV

5V

PS704 IN

GND

5V

PS718 IN

GND

FNS CBMAIN BODY

M702 (shift) performs the paper offset operation

in the sort or group mode.

The FNS CB (FNS control board) controls M702.

The related signal s are PS704 (FNS entrance)

and PS718 (shift HP).

1. Operation

In the sort or group mode, PS704 (FNS

entrance) detects the rear end of the paper. After

a predefined time period, M702 (shift) operates.

Its rotati on trigger s the shift (travel) of the shif t

moving section. The shift roller, rotated by M701

(FNS conveyance), carries t he paper while the

shift operation is being performed.

The completion of the shift operation is detected

by the change of PS718 (shi ft HP) signal , f rom

OFF to ON, and then M702 is deactivated.

After a predefined time period has elapsed since

M702 was deactivated, it is activated again.

M702 stops when PS718 (shift HP) signal

changes from ON to OFF. This operation allows

the shift moving section to return to its original

position to wait for the next paper to be shifted.

This sequence of acti ons is repeated for each

sheet to achieve offsetting of paper.

M702

PS704

PS718

2-8

Page 39

FS-110/FS-210

2. Signals

a. FNS CB input signals

PS718 IN (PS718 to FNS CB)

Signal relating to the shift position

[L] to [H]: S tra ig h t position

[H] to [L]: S h ift p o s itio n

b. FNS CB output signals

(1) M702 DRV (FNS CB to M702)

Signal to drive/control M702.

[L]: M702 ON

[H]: M702 OFF

[7] M707 (paper exit roller) Control

5V

M707 P/S

M707 CLK

M707 F/R

M707 LD

PGND

PGND

24V

24V

5V

PS704 IN

GND

5V

PS706 IN

GND

5V

PS709 IN

GND

5V

PS712 IN

GND

FNS CBMAIN BODY

M707

PS704

2 UNIT EXPL A NATION

PS706

PS709

PS712

M707 (paper exit roller) drives the main tray

paper exit rol ler and the paper exit bel t of the

stacker section.

The FNS CB (FNS control board) controls M707.

The related signals are PS704 (FNS entrance),

PS706 (main tray paper exit), PS709 (paper exit

belt HP), and PS712 (paper exit opening HP).

1. Operation

a. Straight, sort, and group modes

When PS704 (FNS entrance) detects the l eading edge of the paper, M707 starts to rotate at a

high speed. When PS704 has detected the trailing edge of the paper and a predefined time

period has elapsed, the rotation of M707

changes to low. Then the paper delivery action is

performed.

When PS706 (main tray paper exit) has detected

the trailing edge of the paper (preparation for the

next paper conveyance) and a predefi ned time

period has elapsed, the rotation speed of M707

returns to h ig h .

When PS704 has detected the last paper and a

predefined time period has elapsed, M707

cease s to ro ta te .

2-9

Page 40

FS-110/FS-210

b. Staple mode (for papers whose length in the

feeding direction is smaller than B5R)

The FNS operation signal from the main body

lets M707 (paper exit roller) rotate. When PS709

(paper exit belt HP) signal has changed from

OFF to ON and a predefined time period has

elapsed, M707 stops. The paper exit arm moves

to the staple mode HP.

When the stapling operation has been completed, M707 rotates to drive the paper exit belt

of the stacker section. This action allows the

paper exit arm to lift the paper to the level of the

2 UNIT EXPL A NATION

paper exit roller, which delivers it to the main tray.

When PS709 detects the change in signal, from

OFF to ON, M707 stops.

c. Staple mode (other than those above)

The FNS operation signal from the main body

lets M707 (paper exit roller) rotate. When PS709

(paper exit belt HP) signal has changed from

OFF to ON and a predefined time period has

elapsed, M707 stops. The paper exit arm moves

to the staple mode HP.

When paper other than those described above is

used, the paper exit opening is open. The paper

exit opening i s closed by M708 upon t he completion of stapling. When PS712 (paper exit

opening HP) detects that the paper exit opening

has been closed, M707 starts r otating to dri ve

the paper exit arm. This allows the paper exit arm

to lift the paper to the level of the paper exit roller,

which delivers it to the main tray .

When PS709 detects the change in signal, from

OFF to ON, M707 stops.

d. Folding and stitch-and-fold modes

The FNS operation signal from the main body

lets M707 (paper exit roller) counter-rotate.

When PS709 (paper exit belt HP) signal has

changed from OFF to ON, M707 stops. The

paper exit arm moves to the booklet mode HP.

When the stapling operation has completed, the

paper is moved to the f olding position. At this

stage, the paper exit arm will not operate. This is

because the paper exit arm may come into contact with the paper, which is waiting for a process

at the folding position

e. Three-folding mode

The FNS operation signal from the main body

lets M707 (paper exit roller) counter-rotate.

When PS709 (paper exit belt HP) signal has

changed from OFF to ON, M707 stops. The

paper exit arm moves to the booklet mode HP.

When the paper alignment has been completed,

M707 (paper exit roller) counter-rotates helping

the paper to be carried to the three-folding position. When PS709 signal has changed from OFF

to ON, M707 stops.

2-10

Page 41

FS-110/FS-210

2. Signals

a. FNS CB input signals

(1) PS706 IN (PS706 to FNS CB)

Signal relating to the main tray paper exit.

[L]: Paper does not exist.

[H]: Paper exists.

(2) PS709 IN (PS709 to FNS CB)

Signal relating to the paper exit belt HP

[L]: Paper exit belt is not at the HP.

[H]: Paper exit belt is at the HP.

(3) PS712 IN (PS712 to FNS CB)

Signal relating to the paper exit opening HP

[L]: Paper exit opening is open.

[H]: Paper exit opening is close.

(4) M707 LD (M707 to FNS CB)

Signal relating to the rotation speed of M707

[L]: Operating at a specified rotation speed.

[H]: Operating at a speed other than a specified

rotation speed.

b. FNS CB output signals

(1) M707 P/S (FNS CB to M707)

Signal relating to rotation/stop of M707

[L]: M707 ON

[H]: M707 OFF

(2) M707 CLK (FNS CB to M707)

Signal relating to the clock for controlling the

rotation speed of M707

(3) M707 F/R (FNS CB to M707)

Signal to control the rotation direction of M707

[L]: CCW

[H]: CW

[8] SD704 (paper exit opening solenoid)

Control

24V

SD704 DRV

5V

PS704 IN

GND

5V

PS706 IN

GND

FNS CBMAIN BODY

SD704 (paper exit opening) drives the nip moving section. This solenoid al lows the ni p paper

exit roll er to fir mly contact the main tr ay paper

exit roll er for nipping the paper. The FNS CB

(FNS control board) controls the operation of

SD704.

The related signal s are PS704 (FNS entrance)

and PS706 (main tray paper exit).

1. Operation

a. SD704 ON

(1) Straight, sort, and group modes:

When PS704 (FNS entrance) has detected the

rear end of the paper, and a predefined time

period has elapsed, SD704 is activated (ON).

(2) Staple mode:

When the stapling operation has been completed and a predefined time period has elapsed,

SD704 is activated (ON) for nipping the paper.

b. SD704 OFF

In each mode, when PS706 (main tray paper

exit) has detect ed the paper and a predefined

time period has elapsed, SD704 is deactivat ed

(OFF).

SD704

PS704

PS706

2 UNIT EXPL A NATION

2. Signals

a. FNS CB output signals

(1) SD704 DRV (FNS CB to SD704)

Signal to drive/control SD704

[L]: SD704 ON

[H]: SD 7 0 4 O FF

2-11

Page 42

FS-110/FS-210

[9] M708 (paper exit opening) Control

24V

SD708 DRV

5V

PS712 IN

GND

5V

PS729 IN

GND

5V

PS729 IN

2 UNIT EXPL A NATION

MAIN BODY

In the staple (when the length of the paper in the

feeding direction is larger than B5R), booklet, or

three-fol ding mode, M708 (paper exit opening)

drives the open/close operation of the paper exit

opening through the link mechanism.

The FNS CB (FNS control board) controls the

operation of M708.

The related signals are PS712 (paper exit opening HP), PS725 (folding exit), and PS729 (folding

full PS) .

GND

5V

GND

FNS CB

M708

PS712

PS725

PS729

LED729

When PS712 (paper exit opening HP) detect s

the position closed, M708 stops.

2. Signals

a. FNS CB output signals

(1) M708 DRV (FNS CB to M708)

Signal to drive/control M708

[L]: M708 ON

[H]: M708 OFF

1. Operation

a. Staple mode (for papers whose length in the

feeding direction is larger than B5R)

The FNS operation signal from the main body

lets M708 (paper exit opening) rotate, causing

the paper exit opening to be opened.

Upon completion of the stapling operation, M708

(paper exit openi ng) rotates again to star t the

closing operation of the paper exit opening.

When PS712 (paper exit opening HP) detects

the closed position, M708 stops.

The steps above are repeated for each set of the

sheets that will be stapled .

b. Folding, stitch-and-fold, and three-folding

modes

The ON signal from the main body's ST ART button lets M708 (paper exit opening) rotate, causing the paper exit opening to be opened.

When PS725 (folding paper exit) or PS729 (folding full PS) has detected the trailing edge of the

last sheet, and a predefined time period has

elapsed since then, M708 again r otat es t o st ar t

the closing oper ation of the paper exit opening.

2-12

Page 43

FS-110/FS-210

[10] M721 (sub-tray paper exit) Control

24V

PS701 IN

PS704 IN

PS719 IN

FNS CBMAIN BODY

24V

M721

5V

PS701

GND

5V

PS704

GND

5V

PS719

GND

M721 DRV A

M721 DRV A

M721 DRV B

M721 DRV B

M721 (sub-tray paper exit), controlled by the

FNS CB (FNS control board), drives the sub-tray

paper exit roller.

The related signal s are PS701 (sub-tary paper

exit), PS704 (FNS entr ance), and PS719 (subtray full).

2. Signals

a. FNS CB input signals

(1) PS701 IN (PS701 to FNS CB)

Signal indicating the existence of the paper at the

location of the sub-tray paper exit sensor.

[L]: Paper does not exist.

[H]: Paper exists.

(2) PS719 IN (PS719 to FNS CB)

Signal indicating the sub-tray full

[L]: Sub- tra y fu ll

[H]: Sub -tra y n o t fu ll

b. FNS CB output signals

(1) M721 DRV A, A

Pulse signal to drive/control the Phase A of M721

(2) M721 DRV B, B

Pulse signal to drive/control the Phase B of M721

(FNS CB to M721)

(FNS CB to M721)

2 UNIT EXPL A NATION

1. Operation

a. M721 (sub-tray paper exit) Control

M721 (sub-tray paper exit) starts its high-speed

rotation when PS701 (sub-tray paper exit)

detects the leading edge of the paper.

When PS704 (FNS entrance) has detected the

trailing edge of the paper and a predefined time

period has elapsed si nce then, the rotation of

M721 changes to low.

When PS701 detects the trailing edge of the

paper and a predefined time period has elapsed,

M721 stops.

b. Sub-tray full detection

When the papers ejected to sub- tray reach to

specified height, PS719 (sub-tray full) turns ON,

and FNS transmits "sub-tray full" information to

the main body.

When the main body receives it, the message is

displayed on the operation panel.

2-13

Page 44

FS-110/FS-210

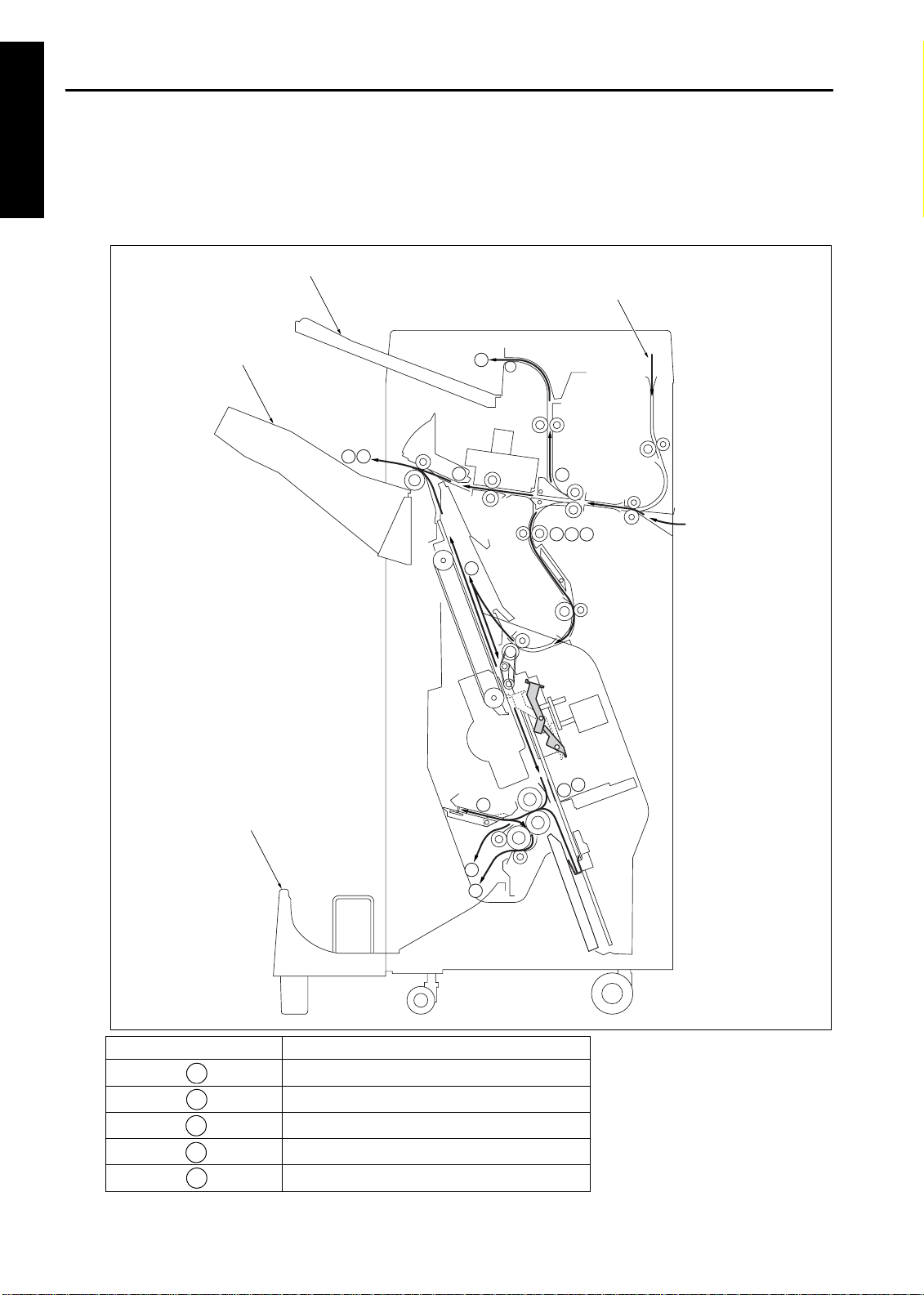

MAIN TRAY SECTION

[1] Composition

2

Main tray

Upper up/down pulley

2 UNIT EXPL A NATION

Up/down pulley/L

Old type

Stapler paper exit upper limit PS

(PS707)

Tray upper limit PS (PS702)

Counter reset PS (PS715)

Tray lower limit PS (PS703)

Tray up/down motor (M703)

Timing belt

New type

Tray up/down motor (M703)

fs2102001

[2] Mechanism

Mechanism Method

Main tray up/down*1 Wire drive

Paper detection*2 Photo sensor

*1 Main Tray Up/Do w n

The tray up/down motor (M703) and the worm

gear installed on the motor shaft perform the

winding operation of the up/down wire. The rotation direct ion of the motor shaft deter mines the

moving direction of the main tray, i.e. rise or fall.

If the up/down pul ley/L rotates cl ockwise seen

from the front, the main tray rises. Otherwise, the

main tra y fa lls .

2

In old type, a brush motor is used for M703 but in

new type brushless motor and ti ming belt are

used to enhance the silence effectiveness.

*2 Paper Detection

The distance between the top surface of the piled

sheets on the main tray (the top surface of the

main tray if there's no sheet on the tray) and the

paper exit opening is monitored using t he tray

upper limit PS (PS702) and the stapler paper exit

upper limit PS (PS707). This distance is kept constant to avoid misalignment of delivered sheets.

The counting program, bui lt i n the FNS, count s

the number of delivered sheets on the main tray

during continuous copying. When the total number of delivered sheets reaches a maximum (values are predefined depending on type/size of

paper), the copying operation is suspended.

However, when some delivered sheets are

removed, the main tray is raised and the counter

reset PS is activated. This resets the current

sheet counter. This enables limitless delivery.

The tray lower limit PS (PS703) detects the bottom of the main tr ay. The number of deliver ed

sheets on the main tray i s not counted by the

software counter during non-continuous copying. PS703 is used for the limitation of the number.

MODEL MANUAL REVISED EDITION DATE PAGE METHOD

7155/7165/7255/7272

SERVICE MANUAL Dec. 2003

2-14

2

2-14 REPLACEMENT

Page 45

FS-110/FS-210

[3] M703 (tray up/down) Control

2

M703 DRV_F

M703 DRV_R

24V

24V

PGND

PGND

M703 H/L

M703 LD

M703 F/R

M703 CLK

M703 CONT

M703 SGND

M703 5V

5V

PS702 IN

GND

5V

PS703 IN

GND

5V

PS706 IN

GND

5V

PS707 IN

GND

5V

PS715 IN

GND

FNS CBMAIN BODY

Old type

M703

New type

M703

PS702

PS703

PS706

PS707

PS715

FS1102002

1. Operation

a. Non-sort, sort, and group modes

According to the FNS oper at ion signal from the

main body, M703 (tray up/down) elevates the

main tray until PS702 (tray upper limit) responds

(ON).

When PS706 (main tray paper exit) detect s the

paper, M703 lowers the tray. When the signal

from PS702 has changed to OFF, and a predefined time peri od has elapsed, M703 raises

the tray again. M703 stops with PS702 signal

ON.

b. Staple m o d e

When M707 (paper exit roller) has started rotating and a predefined t ime period has elapsed,

M703 (tray up/down) lowers t he main tray. The

rotation of M703 is reversed to raise the main

tray when PS706 (main tray paper exit) detects

the trail ing edge of t he paper st ack on the tr ay.

M703 stops when the signal from PS707 (stapler

paper exit upper limit) changes from ON to OFF.

2 UNIT EXPL A NATION

M703 (tray up/down) rai ses or lowers t he main

tray by a normal or reverse rotation. The FNS CB

(FNS control board) controls the operation of

M703.

The related signals are PS702 (tray upper limit),

PS703 (tray lower limit), PS707 (stapler exit

upper limit) , PS715 (count er r eset ) , and PS706

(main tray paper exit).

MODEL MANUAL REVISED EDITION DATE PAGE METHOD

7155/7165/7255/7272

SERVICE MANUAL Dec. 2003

2-15

2

2-15 REPLACEMENT

Page 46

FS-110/FS-210

2. Signals

a. FNS CB input signals

(1) PS702 IN (PS702 to FNS CB)

Signal relating to the main tray upper limit position

[L]: Non-upper limit position

[H]: Upper limit position

(2) PS703 IN (PS703 to FNS CB)

Signal relat i ng t o t he main tr ay l ower l i mit posi tion

[L]: Non- lo w e r lim it p o s itio n

[H]: Lower limit p o s itio n

(3) PS707 IN (PS707 to FNS CB)

2 UNIT EXPL A NATION

Signal relating to the main tray upper limit position in the staple mode

[L]: Upper limit position

[H]: Non-upper limit position

(4) PS715 IN (PS715 to FNS CB)

Signal relating to the counter reset

[L]: Non-counter reset position

[H]: Counter reset position

(5) M703LD (M703 to FNSCB)

2

Rotation speed detect ion speed of M703 (New

type only)

b. FNS CB output signals

(1) M703 DRV_F (FNS CB to M703)

Signal to drive/control the normal rotation of

M703 (Old type)

(2) M703 DRV_R (FNS CB to M703)

Signal to drive/control the reverse rotation of

M703 (Old type)

(3) M703 CONT (FNSCB to M703)

2

Rotation/stop control signal (New type only)

[L]: M703 ON

[H]: M703 OFF

(4) M703 CLK (FNSCB to M703)

2

Rotation speed control clock signal of M703

(New type only)

(5) M703 F/R (FNSCB to M703)

2

Rotation direction control signal (New type only)

[L]: M703 Counterclockwise

[H]: M703 Clockwise

MODEL MANUAL REVISED EDITION DATE PAGE METHOD

7155/7165/7255/7272

SERVICE MANUAL Dec. 2003

2-16

2

2-16 REPLACEMENT

Page 47

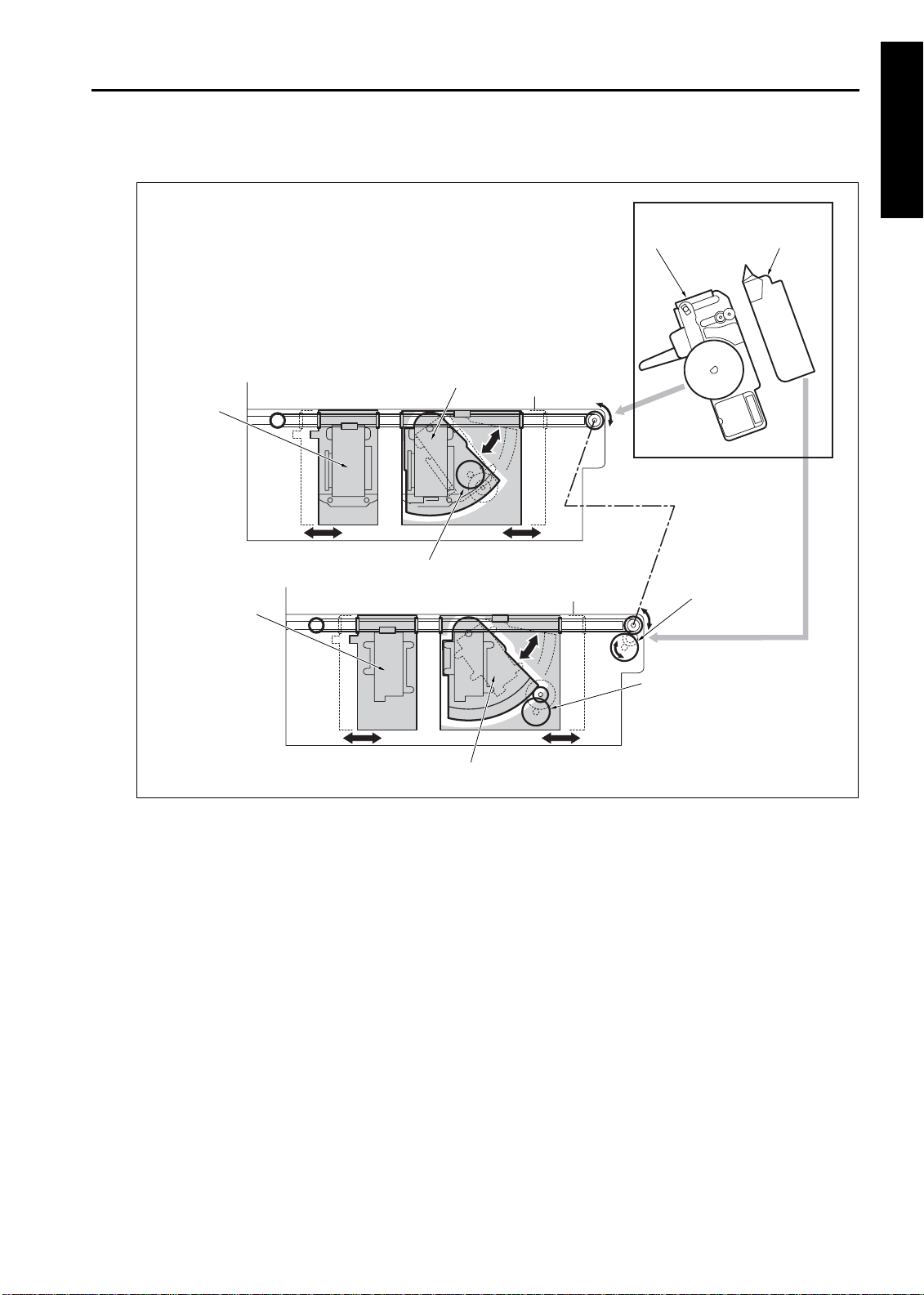

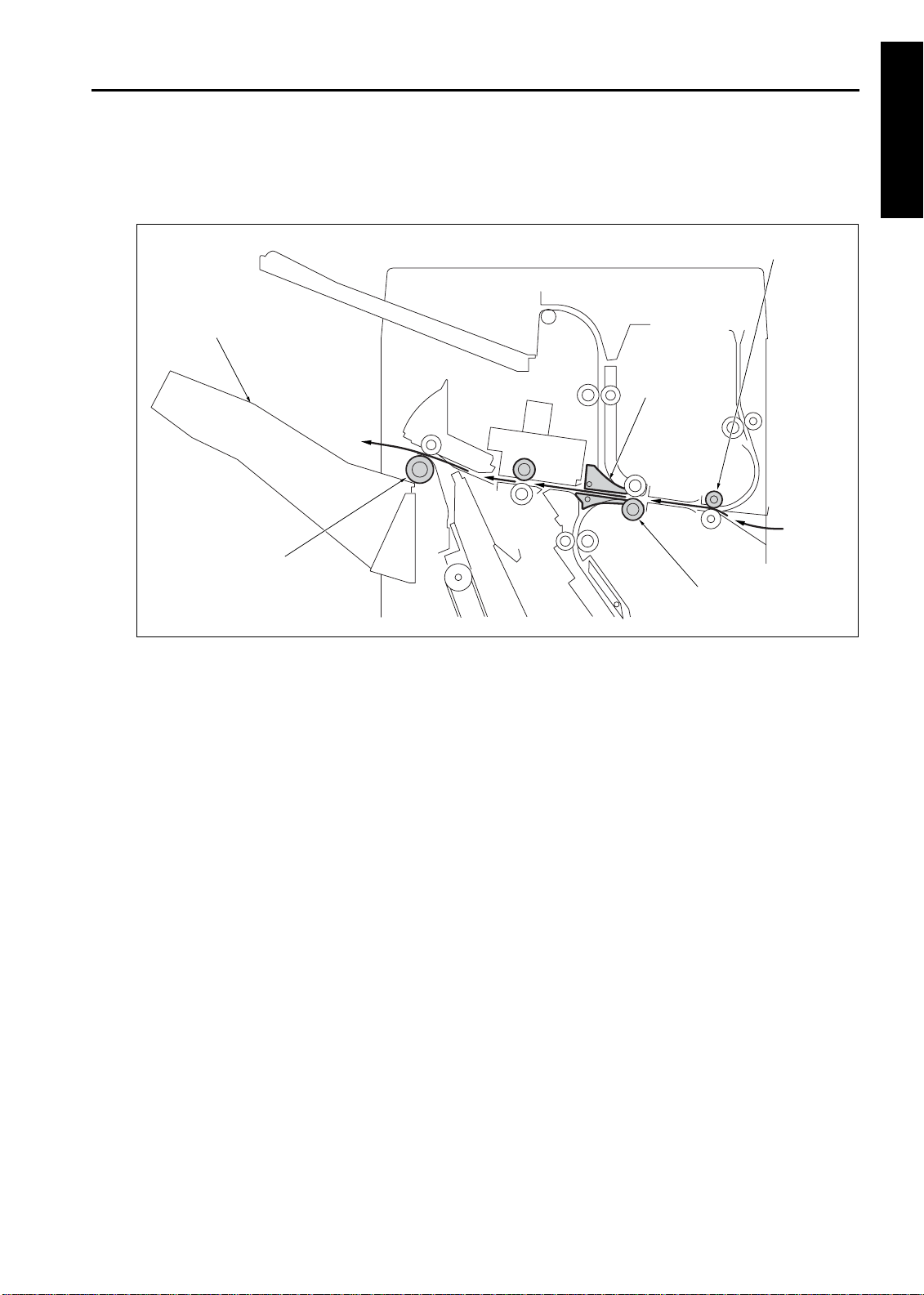

STACKER SECTION

[1] Composition

FS-110/FS-210

Paper exit arm

Paper exit belt

Stacker no paper PS (PS720)

Stacker entrance PS (PS705)

Swing belt

Flat-stapling stopper

Alignment plate/U

Alignment HP PS/U (PS708)

Coupling pin

Paper exit belt HP PS (PS709)

Stacker entrance motor (M713)

Alignment motor/U (M705)

2 UNIT EXPL A NATION

Stacker entrance roller

Folding stopper motor (M718)

Alignment HP PS/L

(PS724)

Folding stopper

HP PS (PS723)

Booklet stopper

Alignment motor/L

(M716)

Alignment plate/L

FS-210 only

2-17

Page 48

FS-110/FS-210

[2] Mechanism

Stack*1 Corrugation roller

Paper exit belt*2 Timing belt driven by

Booklet stopper*3 Driven by timing belt

2 UNIT EXPL A NATION

Paper alignment/U*4 Stepping motor

Paper alignment/L*5 Stepping motor

*1 Stack

The stacker section features a compact component design using the stack with an inclination of

70 degrees. The corrugation r oll er is employed

for the sta cker en trance roller , wh ich facilita tes a

smooth paper delivery to the stacker. The paper

sinks under its own weight into the stacker, of

which lower end is supported by the swing belt.

Mechanism Method

Swing belt + own

weight

coupling connection

using stepping motor

(the flat stapling stopper is released by the

interlocking mechanism)

Paper

Stacker entrance motor

(M713)

*2 Pap e r E x it B e lt

The paper exit arm delivers the paper to the main

tray in the staple mode, or to the folding section

in the three-folding mode. The paper exit arm is

driven by the paper exit belt, which is in turn

driven by the paper exit roller motor (M707)

through the coupling connection.

The paper exit belt HP PS (PS709) detect s t he

home position of the paper exit arm.

Paper exit roller motor

(M707)

Coupling pin

Paper exit belt HP PS

(PS709)

Paper exit arm

Paper exit belt

Stacker no paper PS

(PS720)

70 degrees

Stacker entrance PS

(PS705)

Swing belt

2-18

Page 49

FS-110/FS-210

*3 Booklet Stopper (FS210 only)

The folding stopper motor (M718) oper ates t he

booklet stopper.

The folding stopper HP PS (PS723) detects the

home position of the booklet stopper. The booklet stopper is interlocked with the flat-stapling

stopper. When the booklet stopper is at its home

position, the fl at-st apli ng stopper is i n the posi tion to support t he paper by t he pr essure of the

spring. With thi s configuration, stapl ing is performed in the staple mode.

Paper

Booklet stopper

Flat-stapling stopper

Folding stopper

Spring

Stopper HP PS (PS723)

motor (M718)

Spring

When the booklet stopper l owers, the flat-stapling stopper is released via the link mechanism.

The booklet stopper catches the paper that falls.

Release

Paper

Booklet stopper

Flat-stapling stopper

Spring

One flat-stapling stopper is fixed on each of two

clinchers (R and F). When the two clinchers

move away from each other, the two stoppers

also become remote.

2 UNIT EXPL A NATION

Flat-stapling stoppers

Clincher/R

Clincher/F

2-19

Page 50

FS-110/FS-210

*4 Paper Alignment/U

In the staple (flat-stapling) mode, the paper

alignment plate/U (front and rear) oscillate to

align the sheets.

The oscillation of the paper alignment plate/U is

achieved by the normal and reverse rotations of

the alignment motor/ U (M705). The alignment

HP PS/U (PS708) detects the home positi on of

the paper alignment plate/U.

*5 Paper Alignment/L (FS-210 only)

In the stitch-and-fold, folding, three-folding

modes, both the paper alignment plate/U and the

2 UNIT EXPL A NATION

paper alignment plate/L oscillate to align the

sheets.

The oscillation of the paper alignment plate/L is

achieved by the normal and reverse rotations of

the alignment motor/L (M716). The alignment

HP PS/L (PS724) detects the home positi on of

the paper alignment plate/L.

2-20

Page 51

[3] M705 (alignment/U) Control

24V

M705 DRV A

M705 DRV A

M705 DRV B

M705 DRV B

24V

24V

M705 DRV A

M705 DRV A

M705 DRV B

M705 DRV B

FS-110/FS-210

M705

In the staple, folding, stitch-and-fold, three-folding modes, the widthwise alignment operation of

the paper carried into the stacker section is performed by the alignment plate/U. The space

between the two alignment pl at es/ U extends or

shrinks by means of the rotat ion of the M705

(alignment/U). The FNS CB (FNS control board)

controls the oper ation of M705 thr ough the RB

(relay board).

The related signals are PS705 (stacker

entrance) and PS708 (alignment HP/U).

1. Operation

The FNS operation signal fro m the main body

lets M705 (alignment/U) rotate so that the space

between the two alignment plates/U will become

narrower. The rotation of M705 stops when t he

plates reach their waiting positions that provide a

little wider space for the paper to be accommodated.

When PS705 (stacker entrance) has det ected

the trail ing edge of the paper and a predefi ned

time period has elapsed, the alignment plates/U

horizontally oscillate to align the paper. The

oscillatio n is pro vided by the normal and reverse

rotations of M705. This paper alignment action is

repeated each time a sheet of paper is fed.

PS705 IN

PS708 IN

FNS CB RBMAIN BODY

5V

PS705 IN

GND

5V

PS708 IN

GND

PS705

PS708

2. Signals

a. FNS CB input signals

(1) P S 7 0 5 IN (PS7 0 5 to RB to F N S CB)

Signal relat ing to the detec tion of t he paper by

the stacker entrance sensor

[L]: Paper not detected

[H]: Paper detected

(2) P S 7 0 8 IN (PS7 0 8 to RB to F N S CB)

Signal relating to the detection of the home position of the alignment plate/U

[L]: Not in th e h o me pos itio n

[H]: In the h o me pos ition

b. FNS CB output signals

(1) M705 DRV A, A

Pulse signal to drive/control the Phase A of M705

(2) M705 DRV B, B

Pulse signal to drive/control the Phase B of M705

(FNS CB to RB to M705)

(FNS CB to RB to M705)

2 UNIT EXPL A NATION

2-21

Page 52

FS-110/FS-210

[4] M716 (alignment/L) Control (FS-210 only)

2 UNIT EXPL A NATION

M718 DRV A

M718 DRV A

M718 DRV B

M718 DRV B

24V

24V

M716 DRV A

M716 DRV A

M716 DRV B

M716 DRV B

5V

PS705 IN

GND

5V

PS724 IN

GND

M716

PS705

PS724

MAIN BODY

In the folding, stitch-and-fold, three-folding

modes, the widthwise alignment operation of the

paper carried into the stacker section is performed by the alignment plate/L. The space

between the two alignment pl ates/L ext ends or

shrinks by means of the rotation of M716 (alignment/L ).

The FNS CB (FNS control board) controls the

operation of M716 through the RB (relay board).

The related signals are PS705 (stacker

entrance) and PS724 (alignment HP/L).

1. Operation

The FNS operation signal from the main body

lets M716 (alignment/L) rotate so that the space

between the two alignment plates/L will become

narrower. The rotation of M716 stops when t he

plates reach their waiting positions that provide a

little wider space for t he paper to be accommodated.

When PS705 (stacker entrance) has detect ed

the rear end of the paper and a predefined time

period has elapsed, the alignment plates/L horizontally oscillate to align the paper. The oscillation is provided by the normal and reverse

rotations of M716. This paper alignment action is

repeated each time a sheet of paper is fed.

FNS CB

RB

2. Signals

a. FNS CB input signals

(1) PS724 IN (PS724 to RB to FNS CB)

Signal relating to the detection of the home position of the alignment plate/L

[L]: Not in the home position

[H]: In the home position

b. FNS CB output signals

(1) M716 DRV A, A

Pulse signal to drive/control the Phase A of M716

(2) M716 DRV B, B

Pulse signal to drive/control the Phase B of M716

(FNS CB to R B to M716)

(FNS CB to R B to M716)

2-22

Page 53

[5] M718 (folding stopper) Control (FS-210 only)

24V

M718 CLK

M718 RESET

M718 F/R

M718 CONT

24V

24V

M718 DRV A

M718 DRV A

M718 DRV B

M718 DRV B

FS-110/FS-210

M718

MAIN BODY

M718 (folding stopper) moves the booklet stopper. The link mechanism releases the f lat-stapling stopper when the booklet stopper comes

down.

The FNS CB (FNS control board) controls t he

operation of M718 through the RB (relay board).

The signals (or sensor s) rel at ed to thi s component include PS723 (folding stopper HP), PS725

(folding paper exit) and PS729 (folding full PS).

1. Operation

a. Folding mod e

The FNS operation signal fro m the main body

lets M718 (folding stopper) drive to lower the

booklet stopper. The booklet stopper comes

down to the appropriat e al i gnment posi t i on t hat

fits the size of the paper to be handled.

When the last sheet has been aligned, M718

rotates to lo wer it to the fo ld in g p o s itio n .

When the folding has been complet ed and the

traili ng edge of the set has been detected by

PS725 (folding paper exit ), M718 is activated.

The booklet stopper is raised to t he paper-si ze

specific position. The machine waits for the

sheet of the next set.

b. Stitch-and -fo ld mode

The FNS operation signal fro m the main body

lets M718 (folding stopper) drive to lower the

booklet stopper. The booklet stopper comes

down to the appropriat e st i tch- and-f ol d posi t ion

that fits the size of the paper.

PS723 IN

PS725 IN

FNS CB

5V

PS723 IN

GND

5V

PS725 IN

GND

RB

PS723

PS725

When the stapling has been completed,M718

rotates to lower the paper to the folding position.

When the folding has been complet ed and the

traili ng edge of the set has been detected by

PS725 (folding paper exit ), M718 is activated.

The booklet stopper is rai sed to the paper- size

specific position. The machine waits for the

sheet of the next set.

c. Three-folding mode

The FNS operation signal from the main body

lets M718 (folding stopper) drive to lower the

booklet stopper. The booklet stopper comes

down to the appropri at e al i gnment posi t i on t hat

fits the size of the paper.

When the last sheet has been aligned, M718

operate s to low er it to the first folding position for

three-folding.

When the folding has been complet ed and the

traili ng edge of the set has been detected by

PS729 (folding ful l PS), M718 is acti vated. The

booklet stopper is raised to the paper-size specific position. The machine waits for the sheet of

the next set.

2 UNIT EXPL A NATION

2-23

Page 54

FS-110/FS-210

2. Signals

a. FNS CB input signals

(1) PS723 IN (PS723 to RB to FNS CB)

Signal relating to the detection of the booklet

stopper's home position

[L]: Not in the home position

[H]: In the home position

(2) PS725 IN (PS725 to RB to FNS CB)

Signal relating to the detection of the paper at the

folding paper exit position

[L]: Paper not detected

[H]: Paper detected

b. FNS CB output signals

2 UNIT EXPL A NATION

(1) M718 CLK (FNS CB to RB)

Signal relating to the clock for controlling the

rotation speed of the M718

(2) M718 RESET (FNS CB to RB)

Reset signal for the M718

(3) M718 F/R (FNS CB to RB)

Signal to control the rotation direction of the

M718

[L]: CCW

[H]: CW

(4) M718 CONT (FNS CB to RB)

Signal to activate or deactivate the M718

[L]: M718 ON

[H]: M718 OFF

c. RB output signals

(1) M718 DRV A, A

Pulse signal to drive/control the Phase A of

M718

(2) M718 DRV B, B

Pulse signal to drive/control the Phase B of

M718

(RB to M718)

(RB to M718)

2-24

Page 55

[6] M713 (stacker entrance) Control

24V

M713 CLK

M713 RESET

M713 CONT

24V

24V

M713 DRV A

M713 DRV A

M713 DRV B

M713 DRV B

FS-110/FS-210

M713

PS705 IN

PS725 IN

PS704 IN

MAIN BODY

FNS CB

M713 (stacker entrance) drives the stacker

entrance roll er and the swing belt . These components are responsible for conveying the paper

to the stacker, aligni ng the paper r ear end, and

controlling the timing for stapling.

The FNS CB (FNS control board) controls t he

operation of M713 through the RB (relay board).

The related signal s are PS704 (FNS entrance),

PS705 (stacker entrance) , and PS725 (folding

paper exit).

1. Operation

a. Staple mode (for sheets of all paper sizes

except A4, B5, and 8.5 x 11 = without by-pass

feature)

The FNS operation signal fro m the main body

lets M713 (stacker ent r ance) start to rot at e at a

high-speed.

When PS705 (stacker entrance) has det ected

the rear end of t he paper, the rot at ion speed of

M713 changes to low, conveying the paper

slowly to the st acker. Then, after a predefined