Konica Minolta FS-113 User Manual

SERVICE MANUAL

MODEL

FS-113

Finisher Unit

NOVEMBER 2002

CSM-FS113

FS-113

SERVICE MANUAL

Used On Model 7145

November 2002

IMPORTANT NOTICE

Because of the possible hazards to an inexperienced

person servicing this equipment, as well as the risk of

damage to the equipment, Konica Business Technologies strongly recommends that all servicing be

performed by Konica-trained service technicians only.

Changes may have been made to this equipment to

improve its performance after this service manual was

printed. Accordingly, Konica Business Technologies,

Inc., makes no representations or warranties, either

expressed or implied, that the information contained

in this service manual is complete or accurate. It is

understood that the user of this manual must assume

all risks or personal injury and/or damage to the

equipment while servicing the equipment for which

this service manual is intended.

Corporate Publishing Department

© 2002, KONICA BUSINESS TECHNOLOGIES, INC.

All rights reserved.

Printed in U.S.A.

CONTENTS

CONTENTS

SAFETY AND IMPORTANT WARNING ITEMS

Refer to the 7145 service manual on page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-1

I OUTLINE

1. FS-113 PRODUCT SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

2. PARTS IDENTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1- 5

3. CROSS-SECTIONAL VIEW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

4. DRIVE SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 7

5. ELECTRICAL COMPONENTS LAYOUT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

II UNIT EXPLANATION

1. PAPER TRANSPORT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

1.1 Paper Transport Mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

(1) Entrance Section Paper Transport Mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

(2) 1st Tray Paper Transport Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

(3) Finisher Tray Paper Transport Mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

(4) Elevator Tray Paper Transport Mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

1.2 Paper Switchback Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

1.3 Roller/Rolls Spacing Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

(1) Storage Roller/Rolls Spacing Mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

(2) Exit Roller/Rolls Spacing Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2. PUNCH MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 8

3. FINISHER TRAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

3.1 Paper Aligning Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

(1) Aligning Plate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1 1

(2) Paddles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2- 1 2

4. STAPLING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 3

4.1 Stapling Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

4.2 Stapling Unit Moving Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

4.3 Staple Sheet Empty Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

5. ELEVATOR TRAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

5.1 Elevator Tray Ascent/Descent Mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

5.2 Elevator Tray Shifting Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

I OUTLINE

II UNIT EXPLANATIONIII DIS./ASSEMBLY

III DISASSEMBLY/ASSEMBLY

1. DISASSEMBLY/ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

1.1 Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

1.2 Removal of the Exterior Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

1.3 Removal of the Punch Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

1.4 Removal of the Stapling Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

iii

CONTENTS

I OUTLINE

II UNIT EXPLANATIONIII DIS./ASSEMBLY

Blank page

iv

FS-113 PRODUCT SPECIFICATIONS

I OUTLINE

1. FS-113 PRODUCT SPECIFICATIONS

A. Type

Finishing device with the offset sorting (sort and group), stapling and punching functions.

B. Functions

I OUTLINE

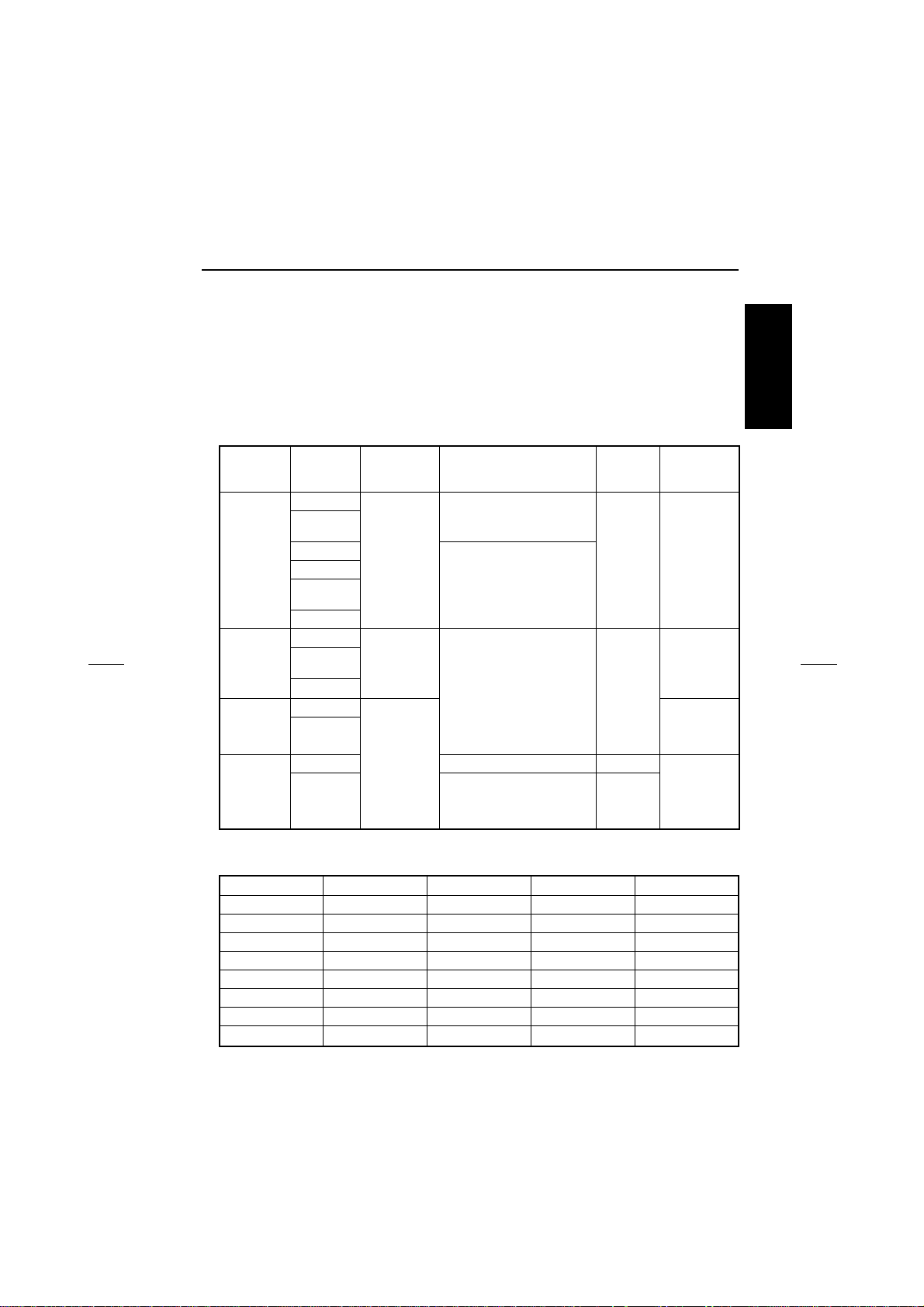

Maximum loadage

Mode Paper type Weight

Non-sort Plain paper

Recycled

paper

Thick paper

OHP

Blueprint

master

Postcard

Non-sort/

Sort/Group

Staple Plain paper

Punch Plain paper 250 sheets 1st tray —

Plain paper

Recycled

paper

Thick paper

Recycled

paper

Recycled

paper

50 to 130g/m

13 ~ 34lbs

50 to 130g/m

13 ~ 34lbs

60 to 90g/m

16 to 24lbs

* Limited only to the same size

2

250 sheets

20 sheets

2

3000 sheets: Smaller than

A4R, 8.5 x 11R

1500 sheets: Larger than B4,

8.5 x 14

2

3000 sheets: Smaller than

A4R, 8.5 x 11R

1500 sheets: Larger than B4,

8.5 x 14

(80g/m

2

or 20lbs)

Paper exit

tray

1st tray —

Elevator

tray

Elevator

tray

No. of sheets

to be stapled

50 sheets

(80g/m2 or

20lbs)

For metric area

Non-sort Sort/Group Staple Punch (4 holes)

A3 !!!!

B4 !!!!

F4 !!!

A4R !!!

A4 !!!!

B5R !!!

B5 !!!!

A5R !

—

1-1

FS-113 PRODUCT SPECIFICATIONS

For inch area

11 x 17 !!!!!

8.5 x 14 !!!!

8.5 x 11R !!!!

I OUTLINE

8.5 x 11 !!!!!

5.5 x 8.5R !

5.5 x 8.5 !

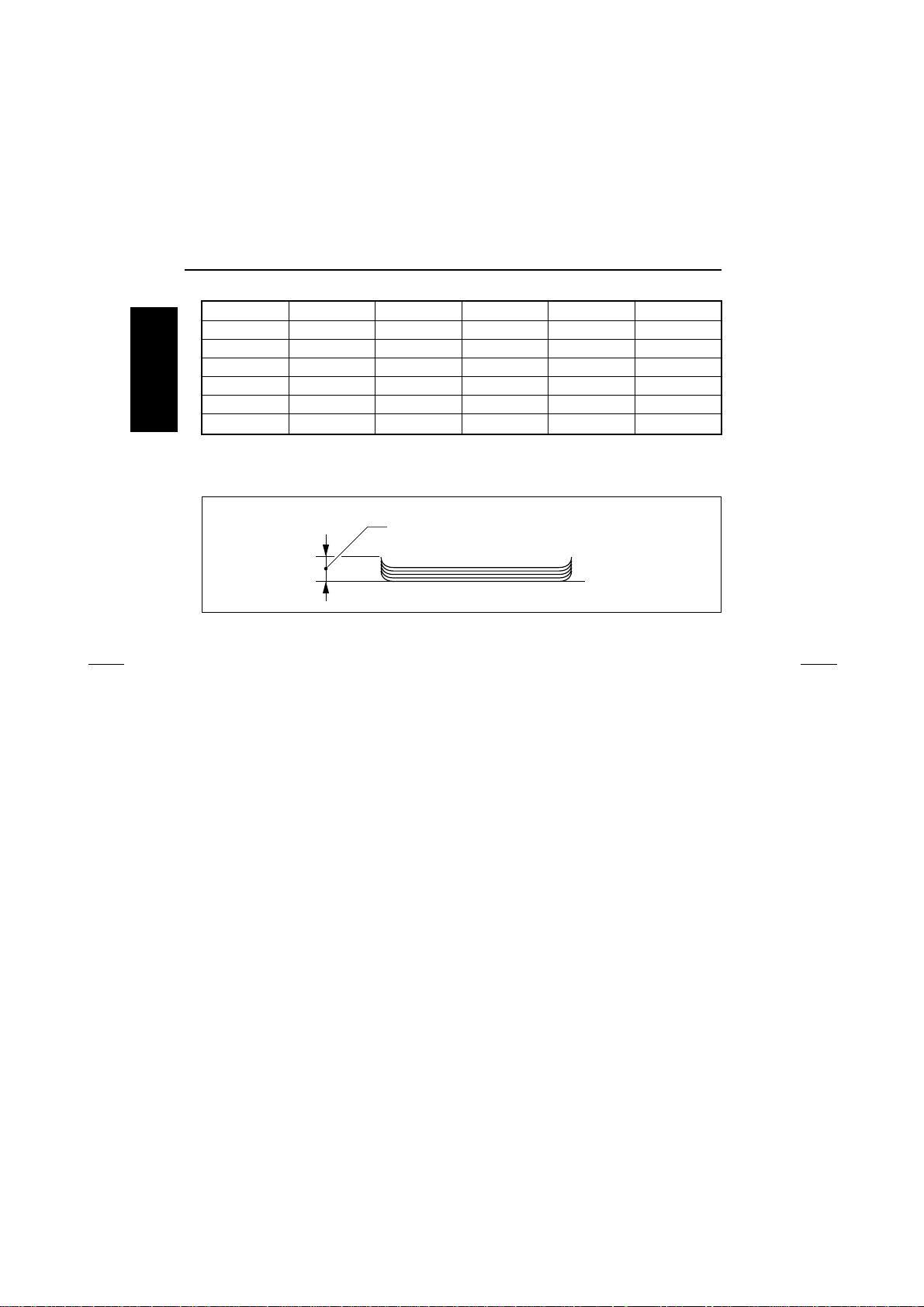

Amount of curling in paper (5 sheets):h= 10mm or less

Amount of sort offsetting (during sorting/grouping):

No. of sheets to be stapled: 50 sheets, max.

No. of staples contained in cartridge: 5000 staples/cartridge

Stapling position: A = 12.1 ± 4mm (when the paper width is 297mm), 45°

Non-sort Sort/Group Staple Punch (2 holes) Punch (3 holes)

h

30mm

2

(80g/m

or 20lbs high quality paper with thickness less

than 5mm)

6.0 ± 4mm (when the paper width is 279mm), 28°

B = 12.1 ± 4mm (when the paper width is 297mm), 45°

16.2 ± 4mm (when the paper width is 279mm), 28°

C = 6.0 ± 4mm (when the paper width is 182 to 216mm)

D = 6.5 ± 4mm (when the paper width is 182 to 216mm)

E = 6.0 ± 4mm

F = 158.0 ± 4mm

1-2

FS-113 PRODUCT SPECIFICATIONS

A

B

D

C

E

F

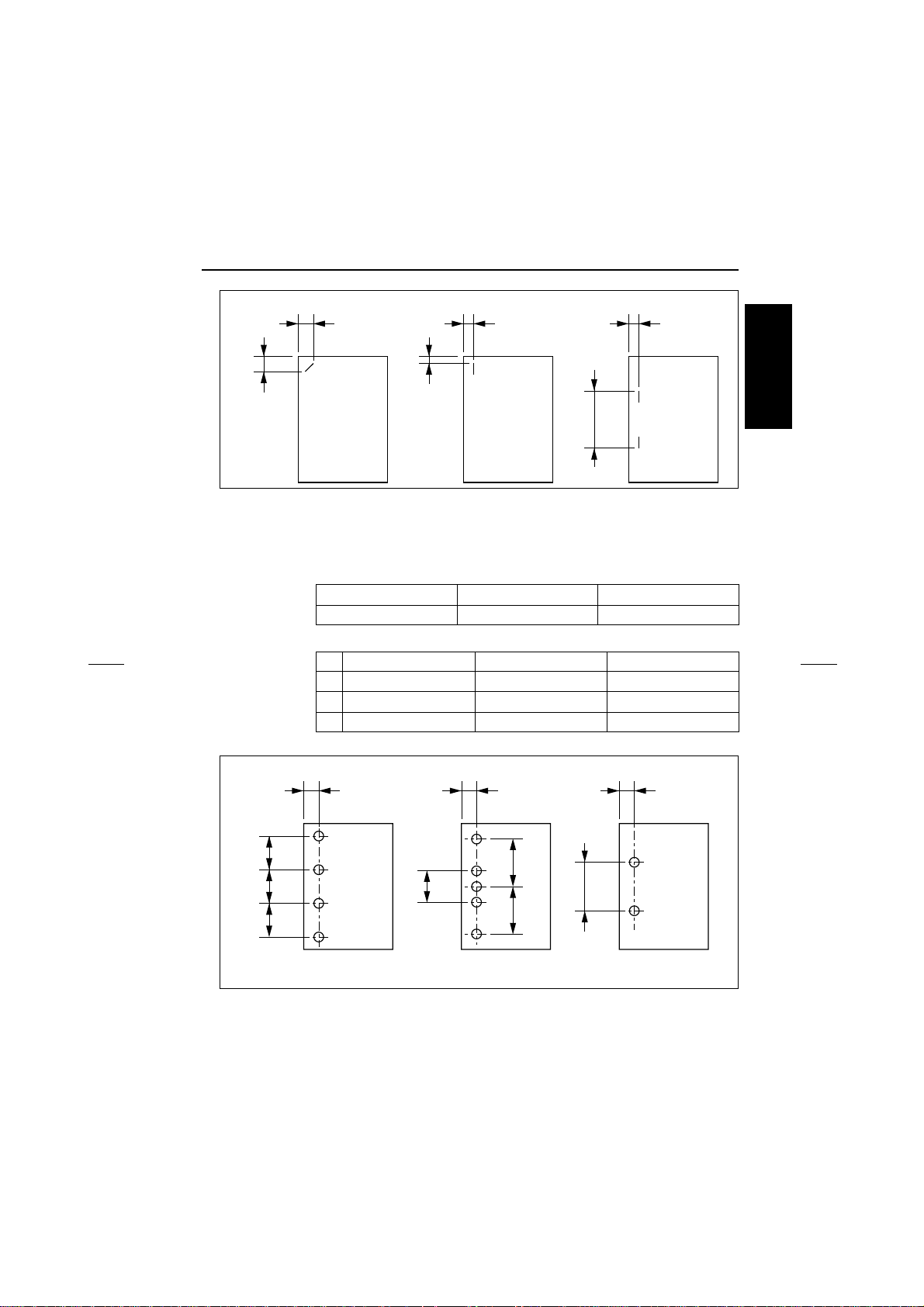

Number of holes (For metric area): 4 holes

Number of holes (For inch area): 2 holes and 3 holes (Automatic switchover)

Number of holes (For Japan): 2 holes

Hole diameter 4 holes 2 holes and 3 holes 2 holes

φ 6 ± 0.5mm φ 8 ± 0.5mm φ 7 ± 0.5mm

Hole position 4 holes 2 holes and 3 holes 2 holes

A 11 ± 3mm 9.5 ± 3mm 13 ± 3mm

B 80 ± 1mm 70 ± 1mm 80 ± 1mm

C — 108 ± 1mm —

I OUTLINE

A

B

B

B

B

4 holes 2 holes and 3 holes 2 holes

A

C

B

C

1-3

A

FS-113 PRODUCT SPECIFICATIONS

C. Machine data

Power source: 24VDC ± 10% (supplied from the main body through RU-

Power consumption: M axim um 63VA

I OUTLINE

Weight: Approx. 39.2kg

Dimensions: 538mm (W) x 978.6mm (D) x 637mm (H)

D. Maintenance and life

Maintenance: Same as the main body

Machine service life: Same as the main body

E. Operating environment

Temperature: 10°C to 30°C (50°F to 86°F)

Humidity: 10% RH to 80% RH

Note:

• The information herein may be subject to change for improvement without notice.

101)

5VDC ± 10% (generated inside the FNS)

1-4

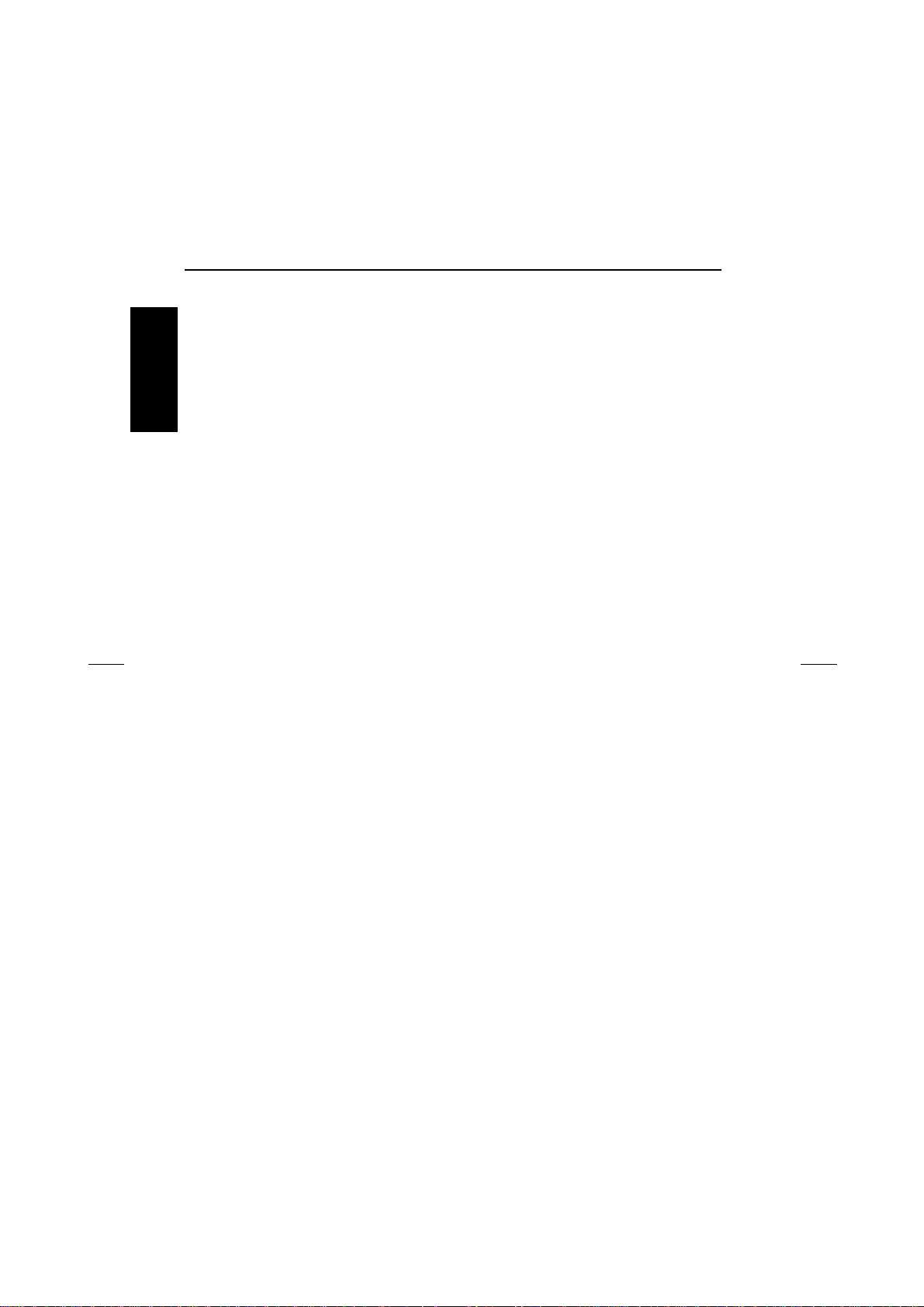

2. PARTS IDENTIFICATION

PARTS IDENTIFIC AT I O N

1

2

I OUTLINE

6

3

5

4

4643M001AA

1. 1st Tray

2. Upper Cover

3. Upper Front Cover

4. Lower Front Cover

5. Elevator Tray

6. Rear Cover

1-5

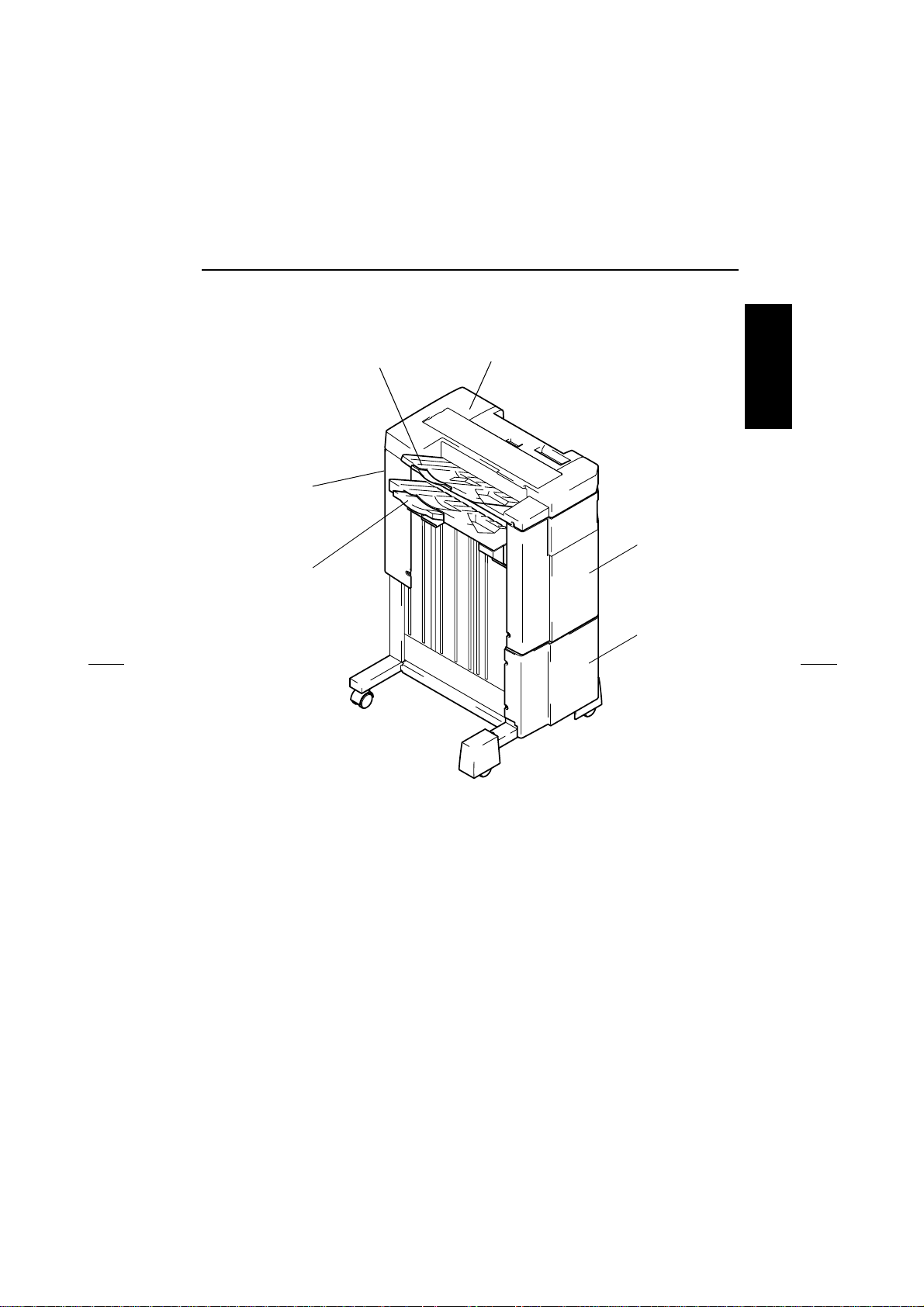

CROSS-SECTIONAL VIEW

3. CROSS-SECTIONAL VIEW

2

1

3

4

I OUTLINE

12

11

1. 1st Tray Exit Roll

2. 1st Tray Exit Roller

3. Upper Path Transport Roller

4. Upper Path Transport Roll

5. Entrance Roller

6. Entrance Roll

7

9

8

10

4643M002AA

7. Lower Path Transport Roll

8. Lower Path Transport Roller

9. Storage Roller

10. Storage Roll

11. Exit Roller

12. Exit Roll

5

6

1-6

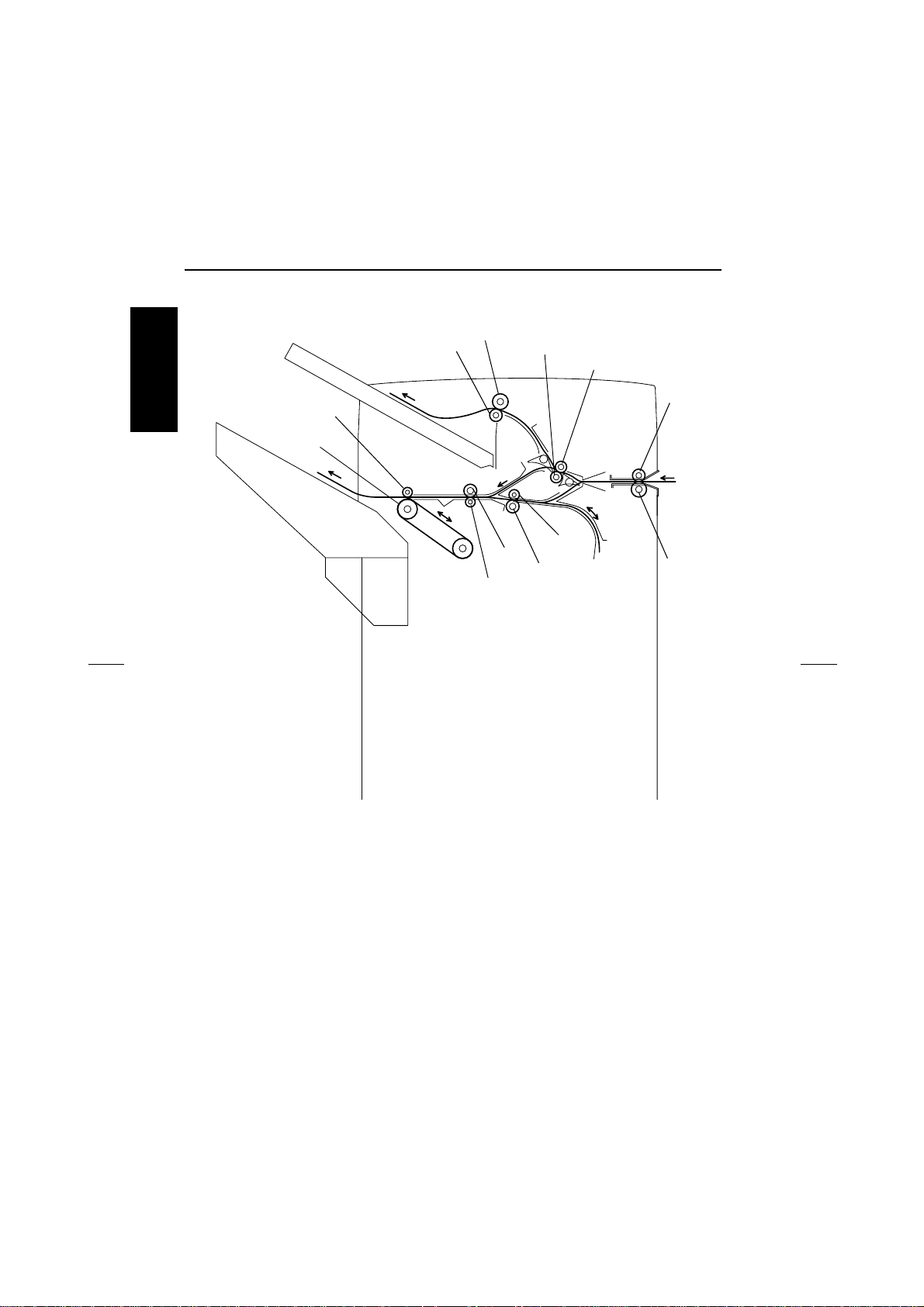

4. DRIVE SYSTEM

CD Aligning

Motor (M5)

Stapling Unit

Moving Motor (M6)

Lower Paddle Motor (M9)

Hole Position

Selector Motor (M14):

U.S.A. and Canada

DRIVE SYSTEM

I OUTLINE

Shift Motor (M8)

Upper Entrance Motor (M4)

Lower Entrance Motor (M2)

Exit Roller/Rolls

Spacing Motor (M13)

Upper Paddle

Motor (M15)

Exit Motor (M3)

4643M003AC

Elevator Motor (M7)

Entrance Motor (M1)

Punch Motor (M11)

Storage Roller/Rolls

Spacing Motor (M12)

4643M004AA

1-7

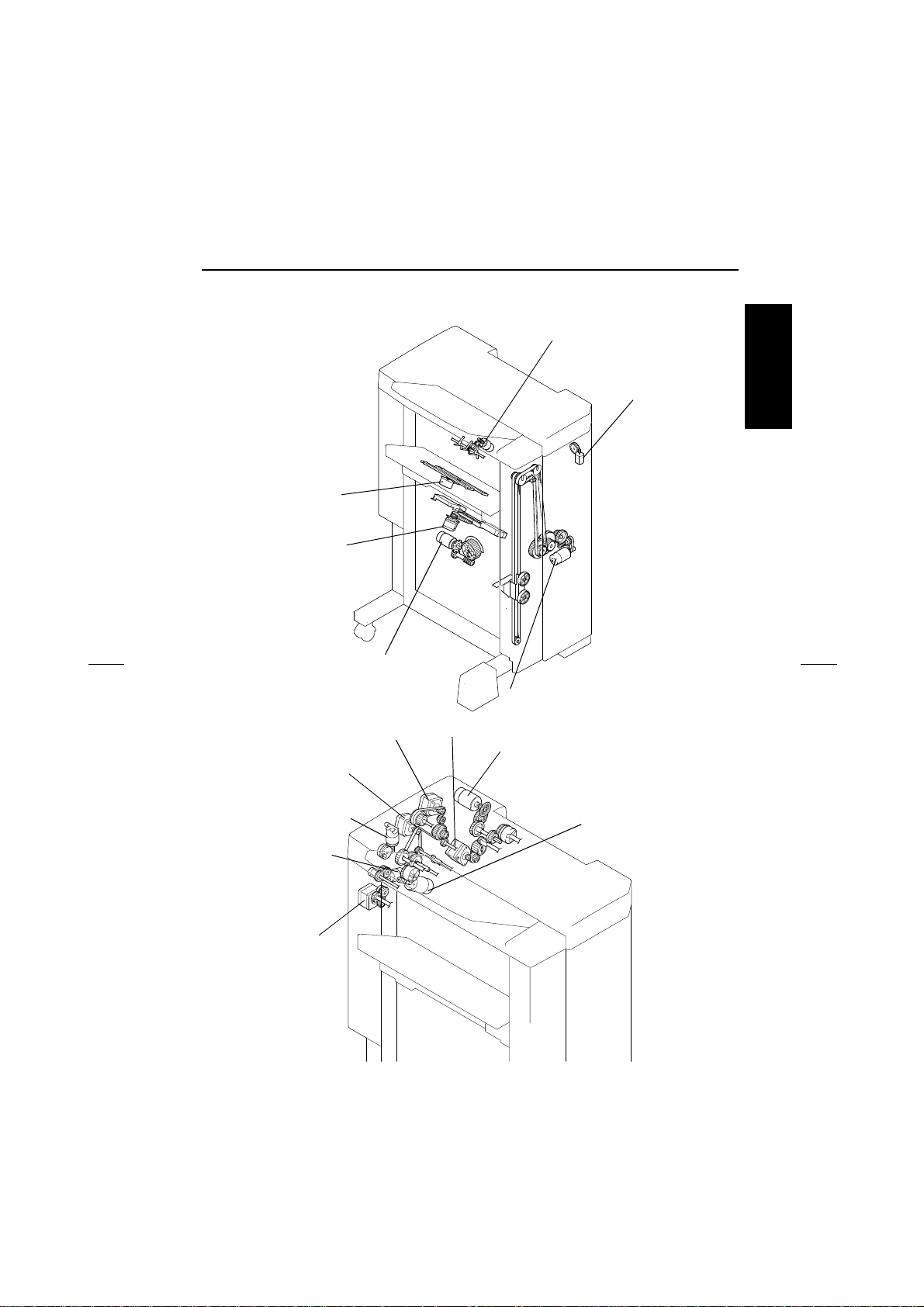

ELECTRICAL COM PONENTS LAYOUT

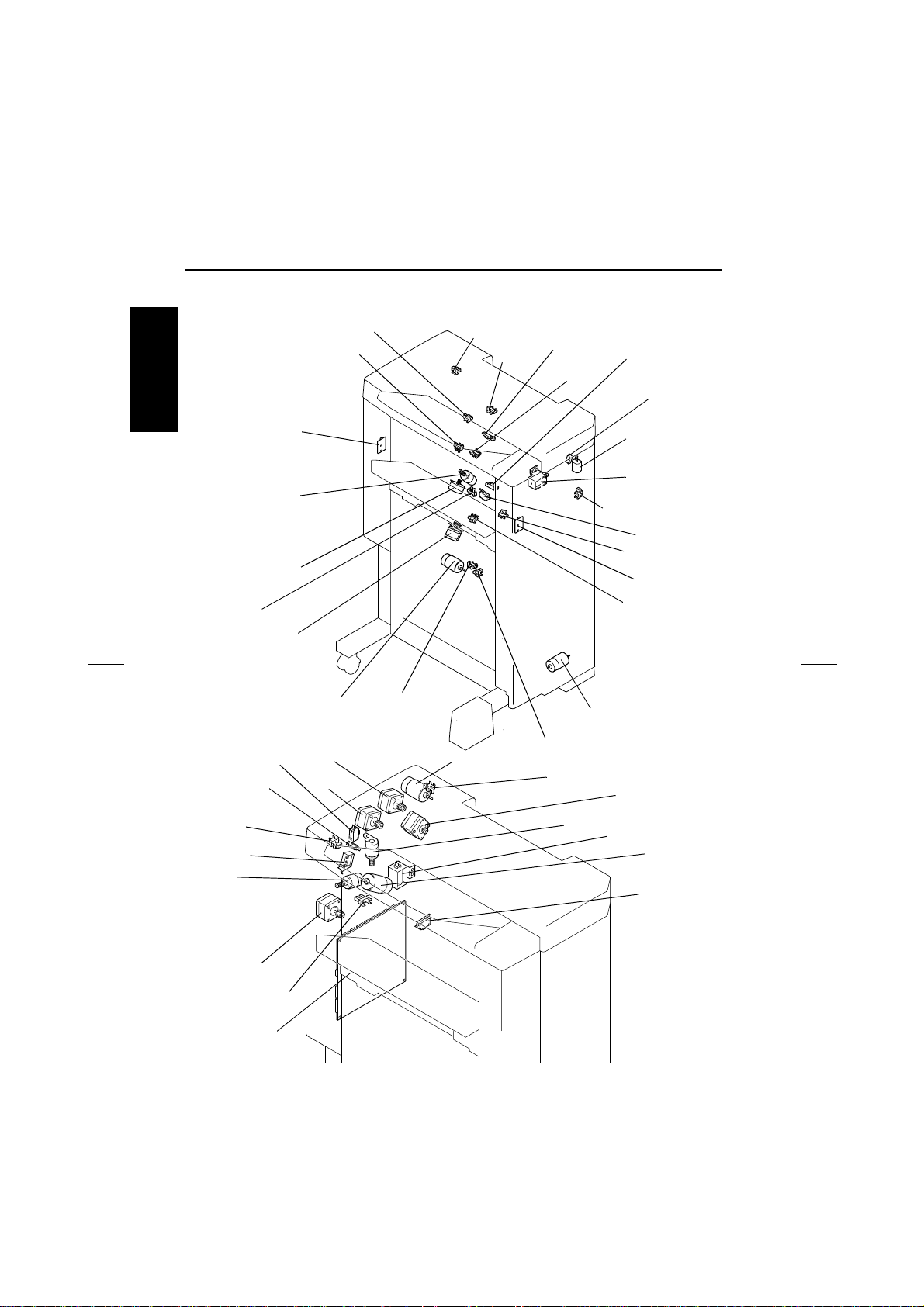

5. ELECTRICAL COMPONENTS LAYOUT

I OUTLINE

PC8

PC13

PWB-D

M9

M5

M6

S3

M4

M2

M8

PC4

PC6

PC11

M11

PC18

PC1

PC2

PC10

PC15

PC3

PC5

S4:U.S.A. and

Canada

M14:U.S.A. and

Canada

SL2

PC17

S2

PC9

PWB-C

PC14

M7

4643M005AC

M1

PC7

M15

SL3

M3

PWB-A

PC12

1-8

M13

SL1

M12

S1

4643M006AA

ELECTRICAL CO MPONENTS LAYO UT

Symbol Name Symbol Name

PWB-A Control Board PC1 1st Tray Exit Sensor

PWB-C Elevator Tray Upper Limit Sensor

LED

PC2 Lower Entrance Sensor

PC3 Storage Sensor

PWB-D Elevator Tray Upper Limit Sensor PQPC4 Upper Entrance Sensor

PC5 Finisher Tray Paper Detecting Sen-

sorM1 Entrance Motor

M2 Lower Entrance Motor PC6 1st Tray Full Detecting Sensor

M3 Exit Motor PC7 Elevator Tray Full Detecting Sensor

M4

M5

Upper Entrance Motor

CD Aligning Motor

PC8 Elevator Tray Paper Detecting Sen-

sor

M6 Stapling Unit Moving Motor PC9 CD Aligning Home Position Sensor

M7 Elevator Motor PC10 Shift Home Position Sensor

M8 Shift Motor PC11 Shift Motor Pulse Sensor

M9

M11

Lower Paddle Motor

Punch Motor

PC12 Storage Roller Home Position Sen-

sor

M12 Storage Roller/Rolls Spacing Motor PC13 Exit Roller Home Position Sensor

M13 Exit Roller/Rolls Spacing Motor PC 14 Staple Home Position Sensor

M14 Hole Position Selector Motor PC15 Punch Motor Pulse Sensor

M15 Upper Paddle Motor PC17 Front Door Detecting Sensor

SL1 Upper/Lower Entrance Switching

Solenoid

SL2 1st Tray Entrance Selecting Sole-

noid

PC18 Upper Cover Detecting Sensor

S1 Set Switch

S2 Elevator Tray Upper Limit Switch

S3 Elevator Tray Lower Limit Switch

SL3 Upper Paddle Solenoid S4 Hole Punch Position Switch

I OUTLINE

1-9

ELECTRICAL COM PONENTS LAYOUT

I OUTLINE

Blank page

1-10

PAPER TRANSPO RT

II UNIT EXPLANATION

1. PAPER TRANSPORT

1.1 Paper Transport Mechanism

(1) Entrance Section Paper Transport Mechanism

• The Entrance Roller is turned to transport the paper into the Finisher as the Entrance Motor

is energized.

Entrance Motor (M1)

Entrance Roller

Paper

4643M007AD

CONTROL SIGNAL Energized Deenergized WIRING DIAGRAM

M1 PWB-A PJ9A-1~-4 Pulse output 3-B

II UNIT EXPLANATION

2-1

PAPER TRANSPO RT

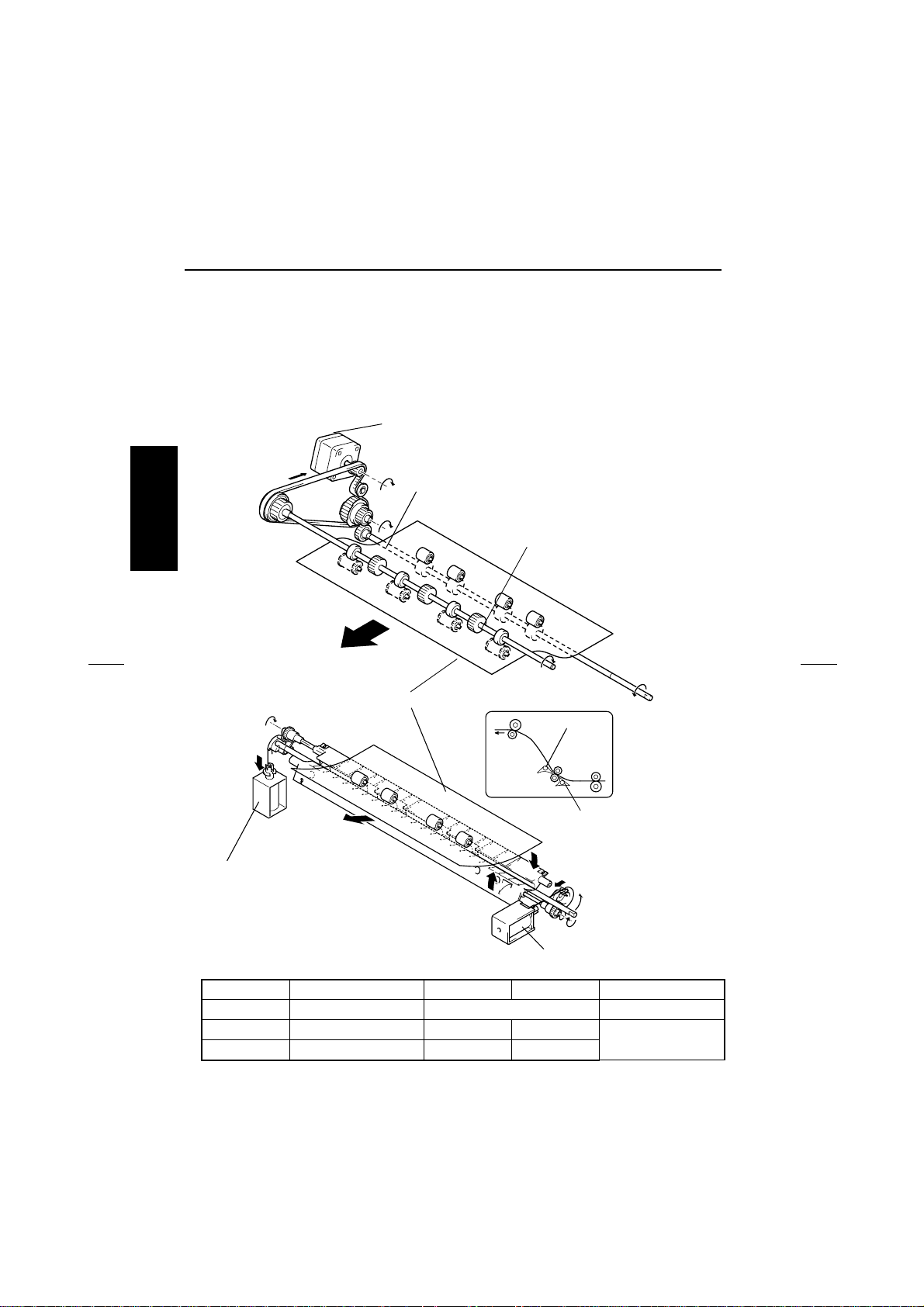

(2) 1st Tray Paper Transport Mechanism

• Paper transport to the 1st Tray takes place when the Finisher is in the Non-Sort mode.

• The Upper Path Transport Roller and 1st Tray Exit Roller turn to transport the paper into the

1st Tray as the motor is energized.

• The 1st Tray Entrance Selecting Solenoid and Upper/Lower Entrance Switching Solenoid are

energized to select the paper path into the 1st Tray.

II UNIT EXPLANATION

Upper Entrance Motor (M4)

Upper Path Transport Roller

Paper

1st Tray Exit Roller

SL2

4643M008AB

SL1

Upper/Lower Entrance

Switching Solenoid (SL1)

1st Tray Entrance Selecting Solenoid (SL2)

CONTROL SIGNAL Energized Deenergized WIRING DIAGRAM

M4 PWB-A PJ9A-5~-8 Pulse output 3-B

SL1 PWB- A PJ18A -2 L H

SL2 PWB- A PJ18A -4 L H

2-2

4643M011AE

7-E

PAPER TRANSPO RT

(3) Finisher Tray Paper Transport Mechanism

• Paper transport to the Finisher Tray takes place when the Finisher is in the Staple mode.

• As the Lower Entrance Motor is energized, the Storage Roller turns to transport the paper

toward the exit direction.

• By turning the Exit Motor backward, paper is transported onto the Finisher Tray.

• Either the upper paper path or lower paper path is used depending on the copy mode to

transport the paper onto the Finisher Tray.

• The upper paper path is selected when the Upper/Lower Entrance Switching Solenoid is

energized, while the 1st Tray Entrance Selecting Solenoid is deenergized.

• The lower paper path is selected when the Upper/Lower Entrance Switching Solenoid is

deenergized.

Lower Entrance Motor (M2)

Finisher Tray

Storage Roller

Lower Path Transport Roller

Paper

II UNIT EXPLANATION

Exit Motor (M3)

1st Tray Entrance Selecting Solenoid (SL2)

Upper/Lower Entrance Switching Solenoid (SL1)

4643M009AG

CONTROL SIGNAL Energiz ed Deenergized WIRING DIAGRAM

M2 PWB-A PJ9A-9~-12 Pulse output 3-A

2-3

PAPER TRANSPO RT

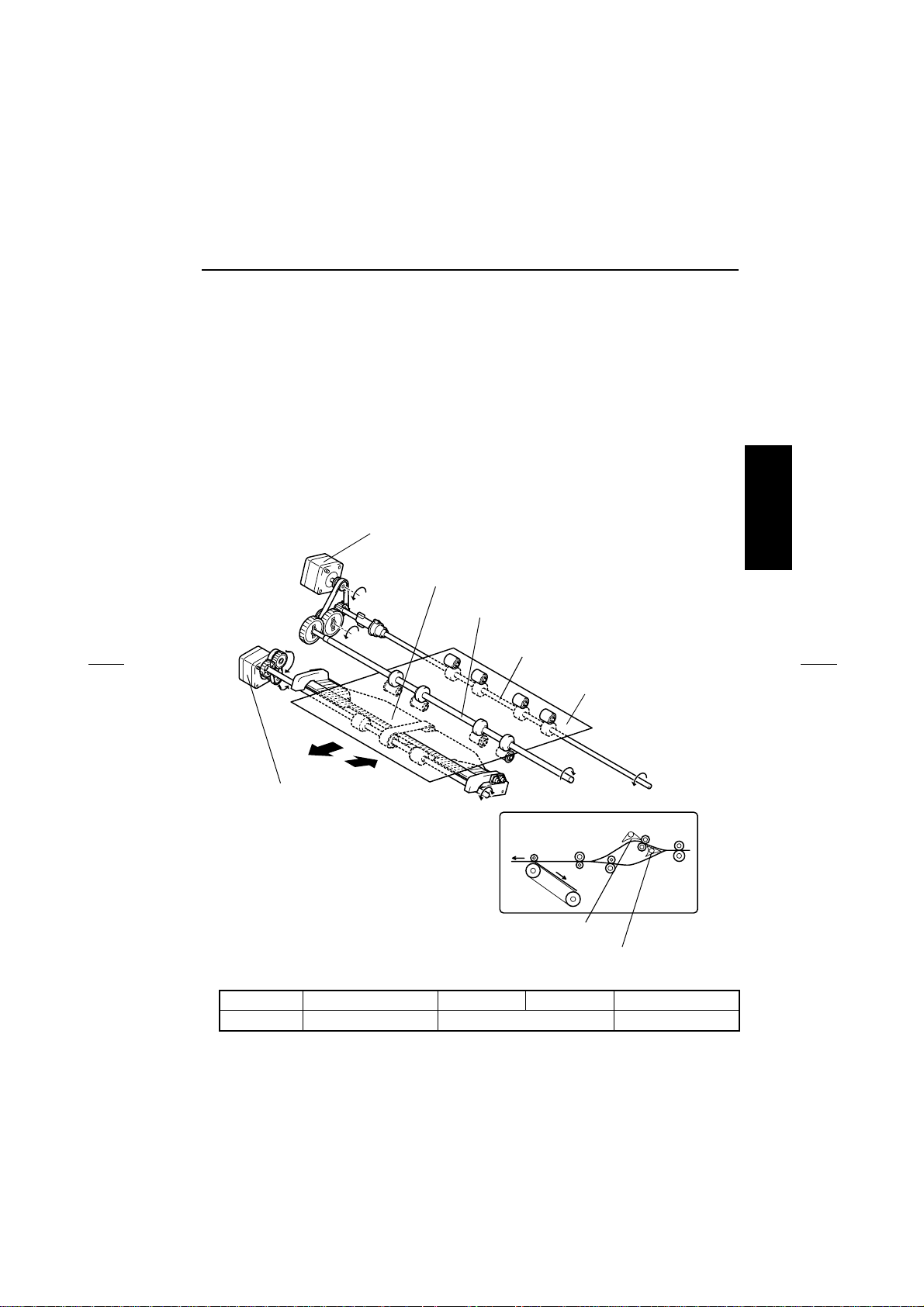

(4) Elevator Tray Paper Transport Mechanism

• As the motor is energized, the Exit Roller turns to transport the paper into the Elevator Tray.

• Either the upper paper path or lower paper path is used depending on the copy mode to

transport the paper into the Elevator Tray.

• The upper paper path is selected when the Upper/Lower Entrance Switching Solenoid is

energized, while the 1st Tray Entrance Selecting Solenoid is deenergized.

• The lower paper path is selected when the Upper/Lower Entrance Switching Solenoid is

deenergized.

II UNIT EXPLANATION

Exit Motor (M3)

Finisher Tray

Exit Roller

Paper

Elevator Tray

4643M010AF

1st Tray Entrance Selecting Solenoid (SL2)

Upper/Lower Entrance Switching Solenoid (SL1)

4643M012AD

CONTROL SIGNAL E nergized Deenergized W IR ING DIAG RAM

M3 PWB-A PJ8A-1~-4 Pulse output 2-A

2-4

PAPER TRANSPO RT

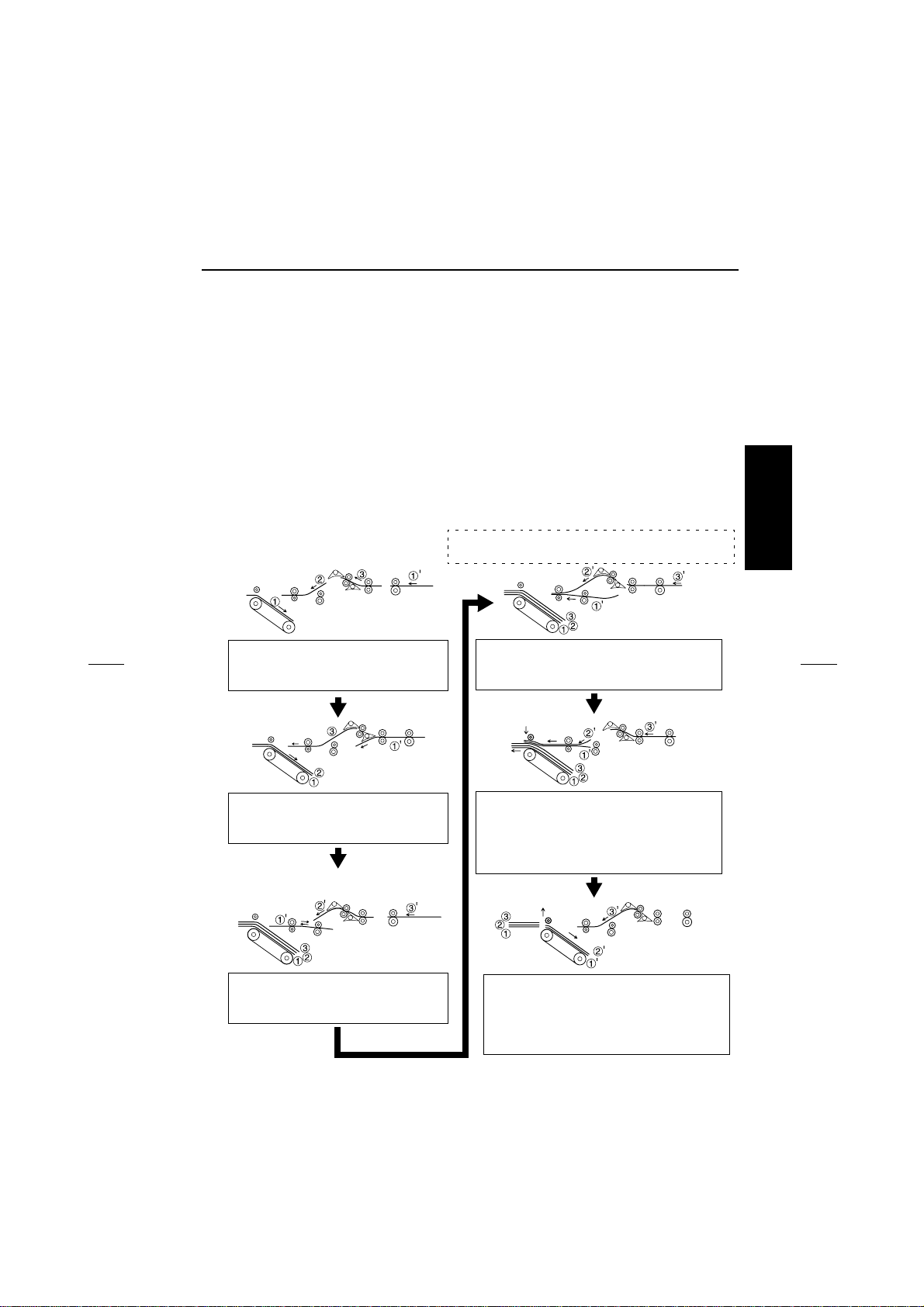

1.2 Paper Switchback Mechanism

• When the last paper of the 1st copy set is transported onto the Finisher Tray during a multicopy cycle in the Sort Staple mode, the 1st paper of the subsequent copy sets, which is to be

next transported, undergoes a switchback sequence. The paper for the switchback is transported via the lower paper path.

• The 2nd paper of the 2nd copy set is placed over the paper which has undergone the switchback sequence. After the 1st copy set has been fed into the Elevator Tray, the 1st and 2nd

sheets of paper of the 2nd copy set are together transported onto the Finisher Tray.

• The switchback sequence of the paper is performed by turning the motor backward, which

turns the Lower Path Transport Roller and Storage Roller backward.

• The sheet of paper to be transported next to the one subjected to the switchback sequence is

transported via the upper paper path.

<3 A4R originals for 2 copy sets>

➀, ➁, ➂

➀

: Sheets of paper for the 1st copy set

’, ➁’, ➂’: Sheets of paper for the 2nd copy set

II UNIT EXPLANATION

4643M027AD

The sheets of paper for the 1st copy

are transported via the upper paper

path onto the Finisher Tray.

4643M031AH

The 1st sheet of paper of the 2nd copy

set is transported via the lower paper

path.

4643M028AG

The 1st sheet of paper of the 2nd copy

set undergoes the switchback

sequence.

4643M029AG

The 1st and 2nd sheets of paper of the 2nd

copy set are transported together, one on

top of the other.

4643M030AH

The Exit Rolls are pressed against the Exit

Roller to feed the sheets of paper of the 1st

copy set out. At the same time, the 1st and

2nd sheets of paper of the 2nd copy set are

transported toward the exit.

4643M032AE

When the 1st copy set is fed out, the Exit

Roller starts turning backward to transport

the 1st and 2nd sheets of paper of the 2nd

copy set to the Finisher Tray . The Exit Rolls

leave the Exit Roller.

2-5

PAPER TRANSPO RT

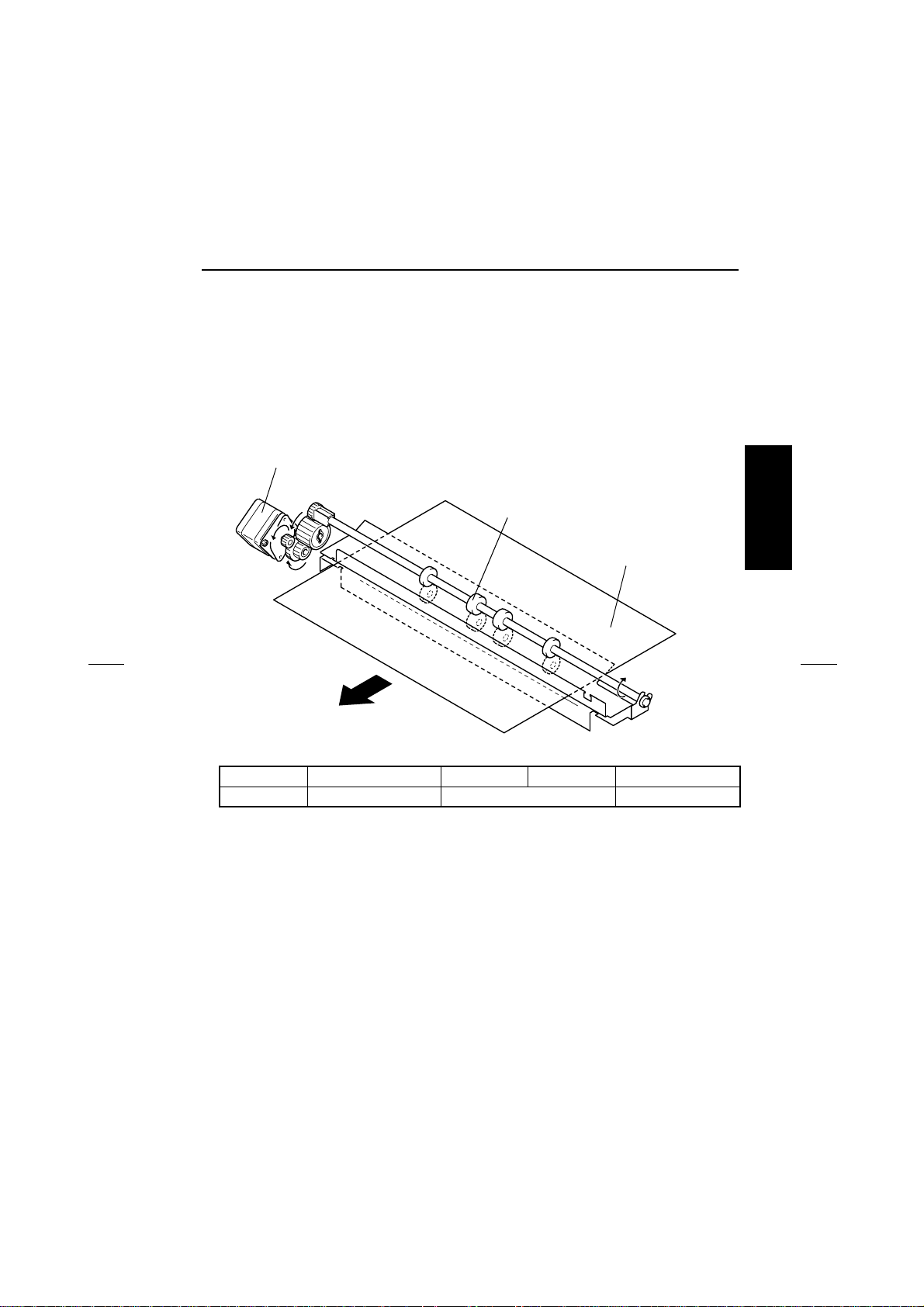

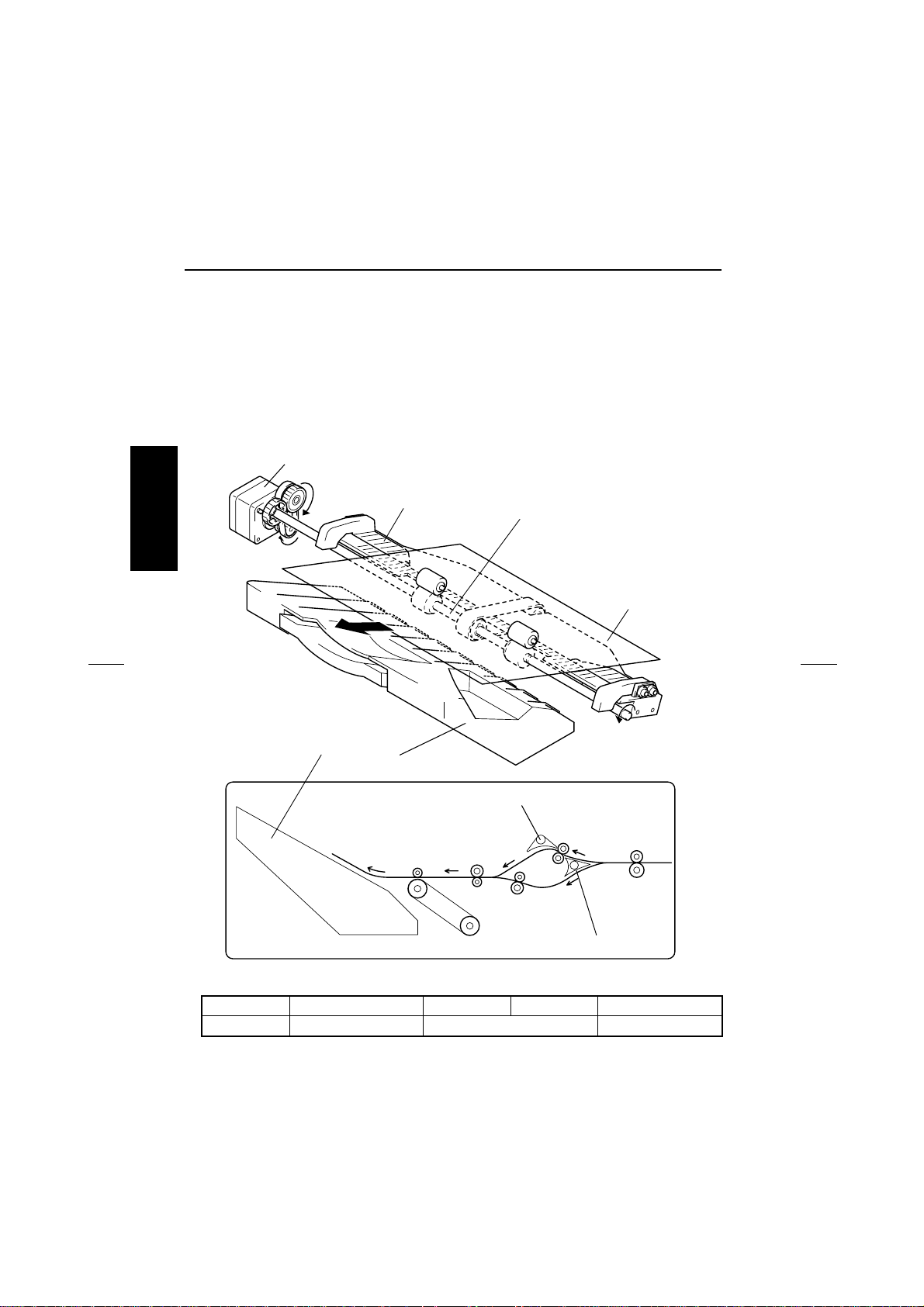

1.3 Roller/Rolls Spacing Mechanism

(1) Storage Roller/Rolls Spacing Mechanism

• While in continuous copying in the Sort Staple mode, the Storage Roller stops once when the

switchback of the 1st paper after the 2nd copy is completed. However, when the paper size is

larger than 217mm, the 2nd paper reaches the Storage Roller. So, the Storage Roller is

raised up to be separated from the Storage Roll.

• After the 2nd paper stops, the Storage Roller goes down and convey 2 sheets that are put

one over another onto the process tray.

• The separation of the Storage Roller is made by rotating the cam through the drive of the

motor and moving the lever to right and left.

(2) Exit Roller/Rolls Spacing Mechanism

• Paper needs to be temporarily transported to the Finisher Tray in the Staple mode, which

II UNIT EXPLANATION

makes it necessary to raise the Exit Rolls to provide a given clearance from the Exit Roller.

• After the stapling sequence has been completed, the Exit Rolls are lowered and pressed

against the Exit Roller so that the paper can be fed out.

• The Exit Rolls are spaced from the Exit Roller as a lever is moved to the right and left by the

corresponding motor.

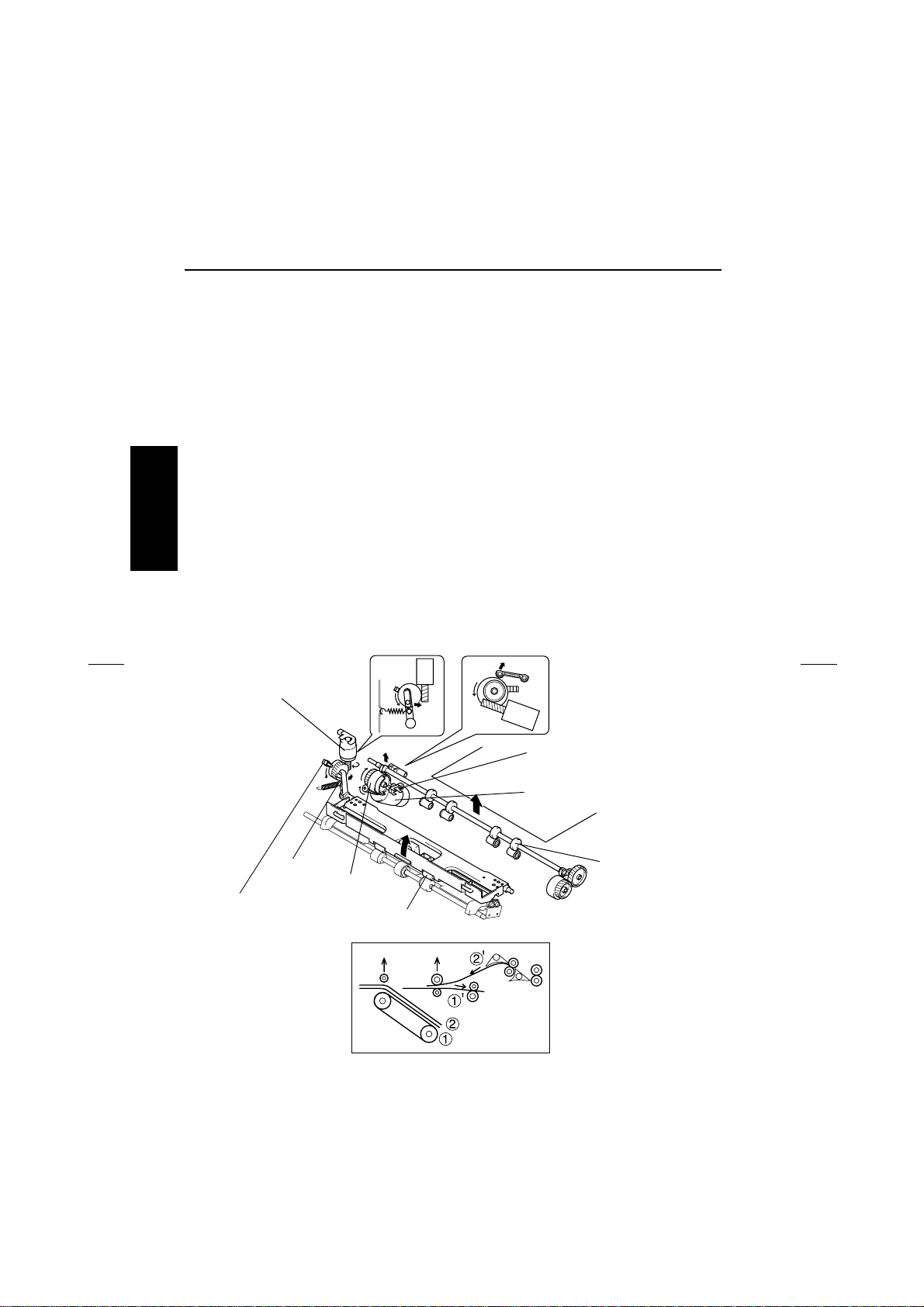

Exit Roller/Rolls

Spacing Motor (M13)

Lever

Exit Rolls Home Position

Sensor (PC13)

Cam

Exit Rolls

Storage Roller Home

Position Sensor (PC12)

Storage Roller/Rolls

Spacing Motor (M12)

Storage Roller

4643M013AE

4643M033AD

2-6

PAPER TRANSPO RT

CONTROL SIGNAL Energized Deenergized WIRING DIAGRAM

M12 PWB-A PJ8A-6 Pulse outpu t L 2-A

M13 PWB-A PJ16A-2 H L 7-D

II UNIT EXPLANATION

2-7

Loading...

Loading...