Page 1

SERVICE MANUAL

Models

FS-111/FS-211

JANUARY 2004

CSM-FS111/211

KONICA MINOLTA BUSINESS SOLUTIONS U.S.A., INC.

Page 2

Page 3

FS-111/211

SERVICE MANUAL

JANUARY 2004

Used on Konica Models

7085/FORCE 85: FS-111/211

7255/7272: FS-111

Page 4

IMPORTANT NOTICE

Because of the possible hazards to an inexperienced

person servicing this equipment, as well as the risk of

damage to the equipment, Konica Minolta Business

Solutions U.S.A., Inc. strongly recommends that all

servicing be performed by Konica-trained service technicians only.

Changes may have been made to this equipment to

improve its performance after this service manual was

printed. Accordingly, Konica Minolta Business Solutions U.S.A., Inc., makes no representations or warranties, either expressed or implied, that the information contained in this service manual is complete or

accurate. It is understood that the user of this manual

must assume all risks or personal injury and/or damage to the equipment while servicing the equipment for

which this service manual is intended.

Corporate Publishing Department

© 2004, KONICA MINOLTA BUSINESS SOLUTIONS U.S.A., INC.

All rights reserved.

Printed in U.S.A.

Page 5

CONTENTS

CONTENTS

SAFETY AND IMPORTANT WARNING ITEMS

Refer to the 7155/7165/7255/7272 Service Manual

1. OUTLINE

FS-111/FS-211 PRODUCT SPECIFICATIONS ...... 1-1

CENTER CROSS SECTION ................................... 1-3

DRIVE SYSTEM DIAGRAM .................................... 1-4

[1] Paper Conveyance Drive ............................ 1-4

[2] Stacker Drive .............................................. 1-5

[3] Folding Drive (FS-211 only) ........................ 1-6

PAPER CONVEYANCE PROCESS ....................... 1-7

[1] Paper Conveyance Process ....................... 1-7

[2] Non-Sort Mode............................................ 1-8

[3] Sort, Group Mode ....................................... 1-9

[4] Sub-tray Mode .......................................... 1-10

[5] Staple Mode .............................................. 1-11

[6] Booklet Mode (FS-211 only) ..................... 1-13

2. UNIT EXPLANATION

EXTERNAL SECTION ............................................ 2-1

[1] Composition ................................................ 2-1

[2] Mechanisms ................................................ 2-1

CONVEYANCE SECTION ...................................... 2-2

[1] Composition ................................................ 2-2

[2] Mechanisms ................................................ 2-3

[3] M1 (FNS Conveyance) Control ................... 2-7

[4] Gate Control................................................ 2-9

[5] M13 (Stacker Entrance) Control ............... 2-12

[6] M5 (Alignment Plate/Upper) Control ......... 2-14

[7] M15 (Alignment Plate/Lower) Control

(FS-211 only) ............................................ 2-15

[8] M2 (Roller Shift) Control ........................... 2-16

[9] M7 (Paper Exit Roller) Control .................. 2-17

[10] SD4 (Paper Exit Opening) Control ............ 2-19

[11] M8 (Paper Exit Opening) Control .............. 2-20

STAPLER UNIT ..................................................... 2-21

[1] Composition .............................................. 2-21

[2] Mechanisms .............................................. 2-22

[3] Stapler Control .......................................... 2-26

MAIN TRAY UNIT ................................................. 2-30

[1] Composition .............................................. 2-30

[2] Mechanisms .............................................. 2-30

[3] Main Tray Up/Down Control...................... 2-31

FOLDING UNIT (FS-211 ONLY) ........................... 2-32

[1] Composition .............................................. 2-32

[2] Mechanisms .............................................. 2-33

[3] Folding-Unit Control .................................. 2-34

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

3. DISASSEMBLY/ASSEMBLY

EXTERNAL SECTION ............................................ 3-1

[1] Removing and Reinstalling

the Rear Cover............................................ 3-1

[2] Removing and Reinstalling

the Front Cover ........................................... 3-1

[3] Removing and Reinstalling

the Top Cover ............................................. 3-1

Page 6

CONTENTS

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

[4] Removing and Reinstalling

the Paper Exit Cover ................................... 3-2

[5] Removing and Reinstalling

the Main Tray .............................................. 3-2

[6] Removing and Reattaching

the Front Side Cover ................................... 3-3

[7] Removing and Reinstalling

the Paper Exit Stopper Plate ....................... 3-3

PAPER FEED UNIT ................................................ 3-5

[1] Replacing a Paper Exit Roller

(Sponge Roller) ........................................... 3-5

[2] Removing and Reinstalling

the Paper Exit Unit/Shift Unit ...................... 3-5

[3] Removing and Reinstalling

the Stacker/Stapler Unit .............................. 3-8

STAPLER UNIT ..................................................... 3-11

[1] Exchanging the clincher (FS-211 only) ..... 3-11

[2] Removing and Reinstalling a Stapler

(For FS-111) ............................................. 3-12

[3] Removing and Reinstalling a Stapler

(For FS-211) ............................................. 3-12

MAIN TRAY SECTION .......................................... 3-14

[1] Removing and Reinstalling

the Up-Down Stay ..................................... 3-14

[2] Exchanging the Up-Down Wire ................. 3-14

FOLDING UNIT (FS-211 ONLY) ........................... 3-16

[1] Removing and Reinstalling

the Folding Unit ......................................... 3-16

[2] Removing and Reinstalling

the Adjustment Cover ............................... 3-17

Page 7

SAFETY WARNINGS

[1] Modifications Not Authorized by

Konica Minolta

Konica Minolta equipment is renowned for their high

reliability. This reliability is achieved through high-quality

design and a solid service network.

Unauthorized modifications involve a high risk of degrading performance and safety. Such modifications are therefore strictly prohibited. The points listed below are not

exhaustive, but they illustrate the reasoning behind this

policy.

PROHIBITED ACTIONS :

(1) Using extension cables or a different power cord

than specified by Konica Minolta.

(2) Using other fuses than specified by Konica

Minolta. Safety will not be assured, leading to a

risk of fire and injury.

(3) Disabling fuses or bridging fuse terminals with

wire, metal clips, solder or similar. (This applies

also to thermal fuses.)

(4) Removing air filters (except for replacement).

(5) Disabling relay functions (such as wedging pa-

per between relay contacts, etc.).

(6) Disabling safety functions (interlocks, safety cir-

cuits, etc.). Safety will not be assured, leading to

a risk of fire and injury.

(7) Performing actions to equipment not described

in the instruction manual or the service hand-

book.

(8) Using parts other than specified by Konica

Minolta.

[2] Checkpoints When Performing On-

site Service

Konica Minolta equipment is extensively tested before

shipping, to ensure that all applicable safety standards

are met, in order to protect the customer and customer

engineer from the risk of injury. However, in daily use, any

electrical equipment may be subject to parts wear and

eventual failure. In order to maintain safety and reliability,

the customer engineer must perform regular safety checks.

(3) Be sure to disconnect the power cord of the

equipment from the AC outlet.

Simply turning off the power switch is not sufficient, because paper feed units or other electrical equipment may be powered also when the

power switch is turned off.

(4) Proceed with special care when performing op-

eration checks or adjustment while the unit is

powered. When carrying out operation checks or

adjustment while external covers are removed,

the risk of electrical shock exists when touching

parts which carry high voltage or electrical charge.

The risk of injury exists when touching moving

parts such as gears or chains.

2. Safety Checkpoints

The following list is not exhaustive, but it includes actions

which must be carried out at every on-site service.

CAUTION:

(1) Check external covers and the frame for sharp

edges, burrs, or nicks.

(2) Check external covers and hinges for loosening

or damage.

(3) Check wiring for squeezing or damage.

(4) Check power cord for insulation problems (con-

ductor must not be exposed).

(5) Check power cord and cable ties etc. for loosen-

ing from frame.

WARNING:

(1) Verify that the equipment is properly grounded. If

a problem is detected, establish a proper ground

connection.

(2) Connecting the ground lead to an improper point

such as listed below results in a risk of explosion

and electric shock.

Unsuitable ground points:

- Gas pipe

- Lightning rod

- Telephone line ground

- Plastic water pipe or water pipe or faucet that

has not been approved by authorities for

grounding use

1. Advance Preparation for Safety Checks

CAUTION:

(1) Wear clothing that facilitates work and is de-

signed for safety.

(2) Carry out all procedures carefully to prevent in-

jury.

3. Description of Safety Checks

CAUTION:

(1) Before performing safety check work, read all

relevant documentation (service handbook, technical notices, etc.) and proceed according to the

prescribed procedure, using only the prescribed

tools. Do not carry out any adjustments not

described in the documentation.

Page 8

(2) If the power cord is damaged, replace it only with

the specified power cord. If the power cord insulation has been damaged and there are exposed

sections, short- circuits and overheating may

occur, leading to a serious fire risk.

(3) Do not route the power cord so that it can be

stepped on or pinched. Otherwise overheating

may occur, leading to a serious fire risk.

(4) When disconnecting any cables, always grasp

the connector and not the cable (especially in the

case of AC and high-voltage leads).

(5) Carefully remove all toner remnants from electri-

cal parts, electrodes, etc.

(6) Make sure that wiring cannot come into contact

with sharp edges, burrs, or other pointed parts.

(7) Double-check to make sure that all screws, com-

ponents, wiring, connectors, etc. that were removed for safety check maintenance have been

reinstalled in the original location. (Pay special

attention to forgotten connectors, pinched cables,

forgotten screws, etc.)

(8) When installation and preventive maintenance,

verify that the power cord has been securely

plugged into the AC outlet. Contact problems

may lead to increased resistance, overheating,

and the risk of fire.

WARNING:

Before disassembling or adjusting the equipment, make sure that the power cord has been

disconnected.

[4] Measures to Take in Case of an

Accident

(1) If an accident has occurred, the distributor who has

been notified first must immediately take emergency

measures to provide relief to affected persons and to

prevent further damage.

(2) If a report of a serious accident has been received

from a customer, an on-site evaluation must be

carried out quickly and Konica Minolta must be

notified.

(3) To determine the cause of the accident, conditions

and materials must be recorded through direct onsite checks, in accordance with instructions issued

by Konica Minolta.

(4) For reports and measures concerning accidents,

consult your superior, and follow the regulations set

in "Standards for the Control Program for Measures

Against Electrical Equipment Accidents".

[5] Conclusion

(1) Safety of users and customer engineers depends

highly on accurate maintenance and administration.

Therefore, safety can be maintained by the appropriate by the proper daily service work conducted by the

customer engineer.

(2) When performing service, equipment on the site

must be tested for safety. The customer engineer

must verify the safety of parts and ensure appropriate management of the equipment.

[3]

Handling of Materials for Servicing

CAUTION: Alcohol-based and acetone- based

cleaners are highly flammable and

must be handled with care. When

using these materials for cleaning

parts, observe the following precau-

tions.

(1) Disconnect the power cord from the AC outlet.

(2) Use only a small amount of cleaner at a time and

take care not to spill any liquid. If this happens,

immediately wipe it off.

(3) Perform cleaning only in an environment where

sufficient ventilation is assured. Breathing large

quantities of organic solvents can lead to discomfort.

(4) Do not replace the cover or turn the unit on before

any solvent remnants on the cleaned parts have

fully evaporated.

Page 9

1

OUTLINE

1 OUTLINE

Page 10

1 OUTLINE

Blank page

Page 11

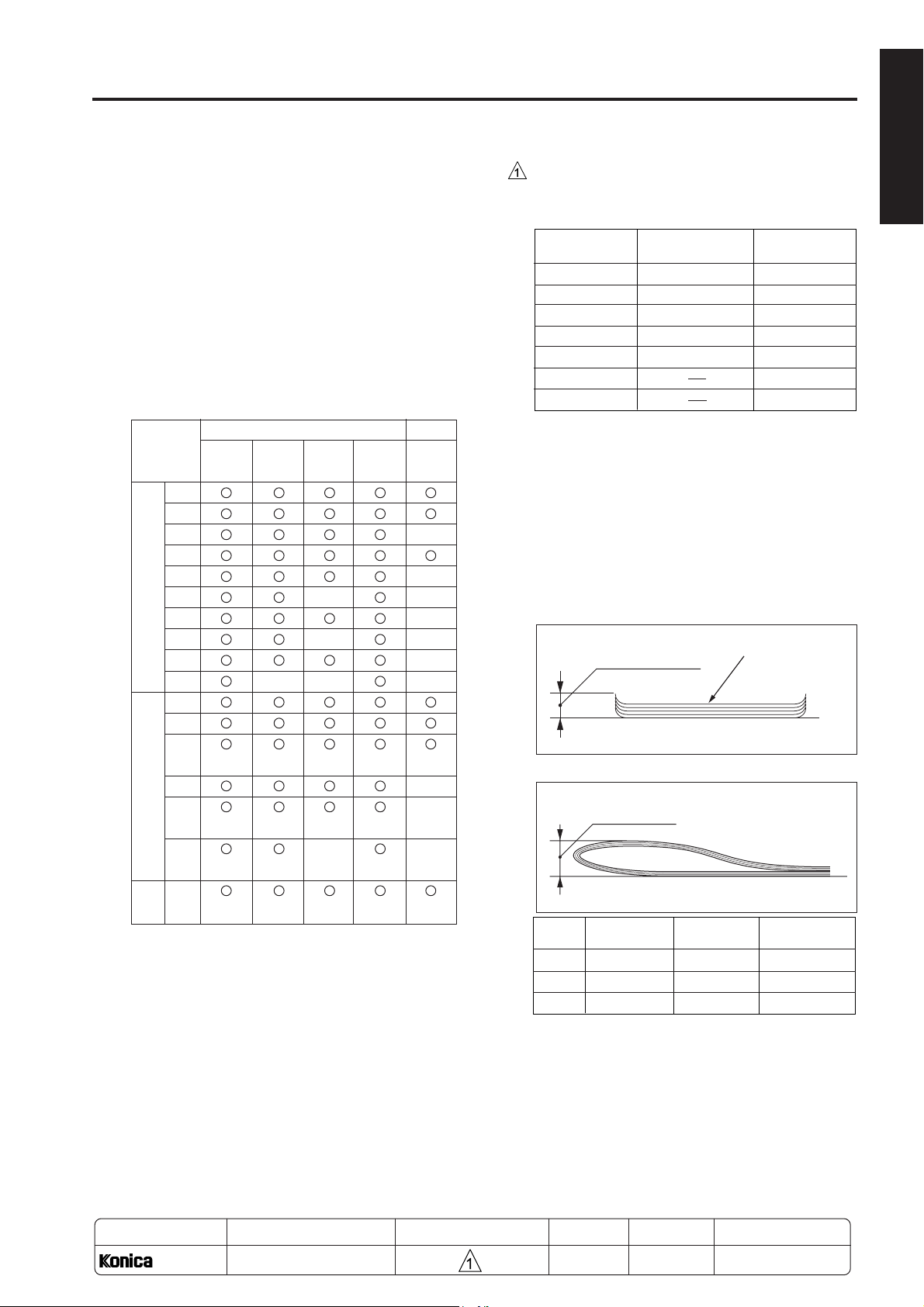

FS-111/FS-211 PRODUCT SPECIFICATIONS

Folded

Pages

A3, 11x17

0 to 5

11 to 16

6 to 10

25mm or less

Not specified*

50mm or less

A4R, 8.5x11R

25mm or less

Not specified*

B4, 8.5x14

25mm or less

50mm or less

Not specified*

Not specified*

Original Main-tray

capacity Pages

A3, 11x17

Other paper types

2 to 9

41 to 50

31 to 40

21 to 30

10 to 20

100 (50) stacks

50 stacks

20 stacks

25 stacks

30 stacks

50 stacks

50 stacks

30 stacks

25 stacks

20 stacks

51 to 60

61 to 100

15 stacks

10 stacks

*

FS-111 only

( ) A5, 5.5x8.5 only

*

*

FS-111/FS-211

[1] Type

FS-111: Finishing device implementing offset

collation (sort,group), stapling, and

sub-tray eject

FS-211: Finishing device implementing offset

collation(sort,group), stapling, sub-tray

eject (booklet), stapling-and-folding,

and folding

[2] Functions

Type of Paper: Same as the main body.

Paper Size:

FS-111/211

Non sort Sort/ Staple Sub-tray Booklet

group

A3

B4

F4

A4R

A4

A/B

B5R

Stan-

B5

dard

A5R

A5

B6R

11x17

8.5x14

8.5x

11R

By

8.5x11

inch

5.5x

8.5R

5.5x

8.5

Wide

paper

FS-211only

Staple Mode:

Maximum 1000 sheets (same-size

sheets only)

Booklet Mode (FS-211 only):

• Stapling-and-folding

20 booklets of 5 folded sheets each (20 pages/

booklet; eq. to 400 pages)

• Folding

33 booklets of 3 folded sheets each (12 pages/

booklet; eq. to 396 pages)

Paper curling: Maximum 10mm

Copy paper (5 sheets)

Amount of Curll

Booklet-mode folding level (FS-211 only)

(80g/m2 or 20 lbs)

Height of folding

1 OUTLINE

Paper Stacking Capacity (80g/m2 or 20 lbs):

Sub-tray exit mode:

Maximum 200 sheets (same-size

sheets only)

Non-Staple, Sort, and Group modes:

Maximum 1500 sheets (A3, B4, F4,

11x17, 8.5x14)

MODEL

7075/7085

Maximum 3000 sheets (A4, A4R, B5,

B5R, 8.5x11, 8.5x11R)

Maximum 500 sheets (A5, A5R, B6R,

5.5x8.5, 5.5x8.5R)

MANUAL

SERVICE HANDBOOK

REVISED EDITION DATE

1 - 1

* The height of folding may be larger after exit,

although the booklet must be folded with ease

manually along the line once made by folding.

Amount of sort offsetting

30mm (after sorting and grouping)

METHOD

REPLACEMENT

Apr. 2003

PAGE

1-1

Page 12

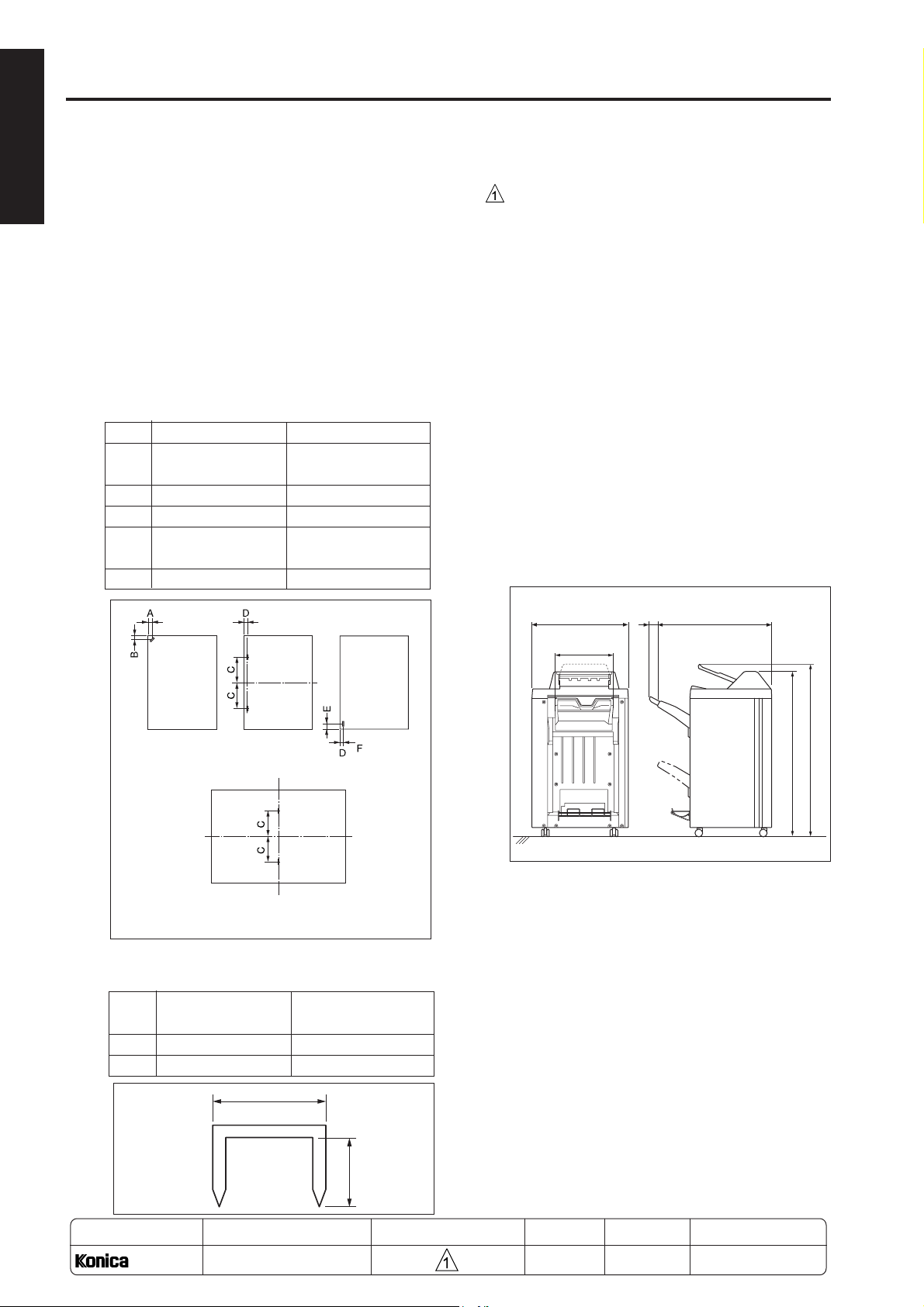

FS-111/FS-211

1 OUTLINE

[3] Staple Mode

Number of sheets to be stapled:

FS-111: 50 sheets maximum (the length in the

FS-211: 50 sheets maximum

Staple position:

A 9.0mm±3mm 8.5mm±3mm

B 9.0mm±3mm 8.5mm±3mm

C 82.5mm±3mm 82.5mm±3mm

D 9.0mm±3mm 8.5mm±3mm

E 15.0mm±3mm 14.0mm±3mm

paper feed direction is 400 mm or more)

100 sheets maximum (except for paper

mentioned above in parentheses)

* The height must be 10 mm or less when

using 80g/m2 or 20 lbs quality paper.

* The height must be 5 mm or less when

using 80g/m2 or 20 lbs quality paper.

FS-111 FS-211

(adjustment possible) (adjustment possible)

(adjustment possible) (adjustment possible)

[4] Booklet Mode (FS-211 only)

Stapling-and-fold:

Maximum 20 sheets (80g/m2 or 20 lbs paper)

Maximum 19 sheets (80g/m2 or 20 lbs paper)

+1 sheet (200g/m2 or 45 lbs paper)

Folding:

Maximum 3 sheets (80g/m2 or 20 lbs paper)

[5] Option

PI-108 (Cover sheet feeder)

[6] Machine Data

Power Source:

24 VDC, 5 VDC (supplied from the main body)

Maximum Power

Consumption: 100VA

Weight:

FS-111: Approx. 65kg

FS-211: Approx. 80kg

External Dimensions:

656 85

781

(unit: mm)

Single staple

(rear)

Booklet mode (stitch-and-fold)

Two staples Single

(FS-211 only)

Staple capacity: 5000 staples/cartridge

Binding Staples:

FS-111 FS-211

(Binding staples for 100 sheets) (Binding staples for 50 sheets)

A 13.5mm 12.0mm

B 13.2mm 8.0mm

A

staple

(front)

367

1095

[7] Maintenance

Maintenance: Same as the main body.

Service Life: Same as the main body.

[8] Machine Operating Environment

Temperature: 10 to 30½C (50½F to 86½F)

Humidity: 10 to 80% RH

Note: The information herein may subject to change

for improvement without notice.

1151

MODEL

7075/7085

MANUAL

SERVICE HANDBOOK

B

REVISED EDITION DATE

1 - 2

Apr. 2003

PAGE

1-2

METHOD

REPLACEMENT

Page 13

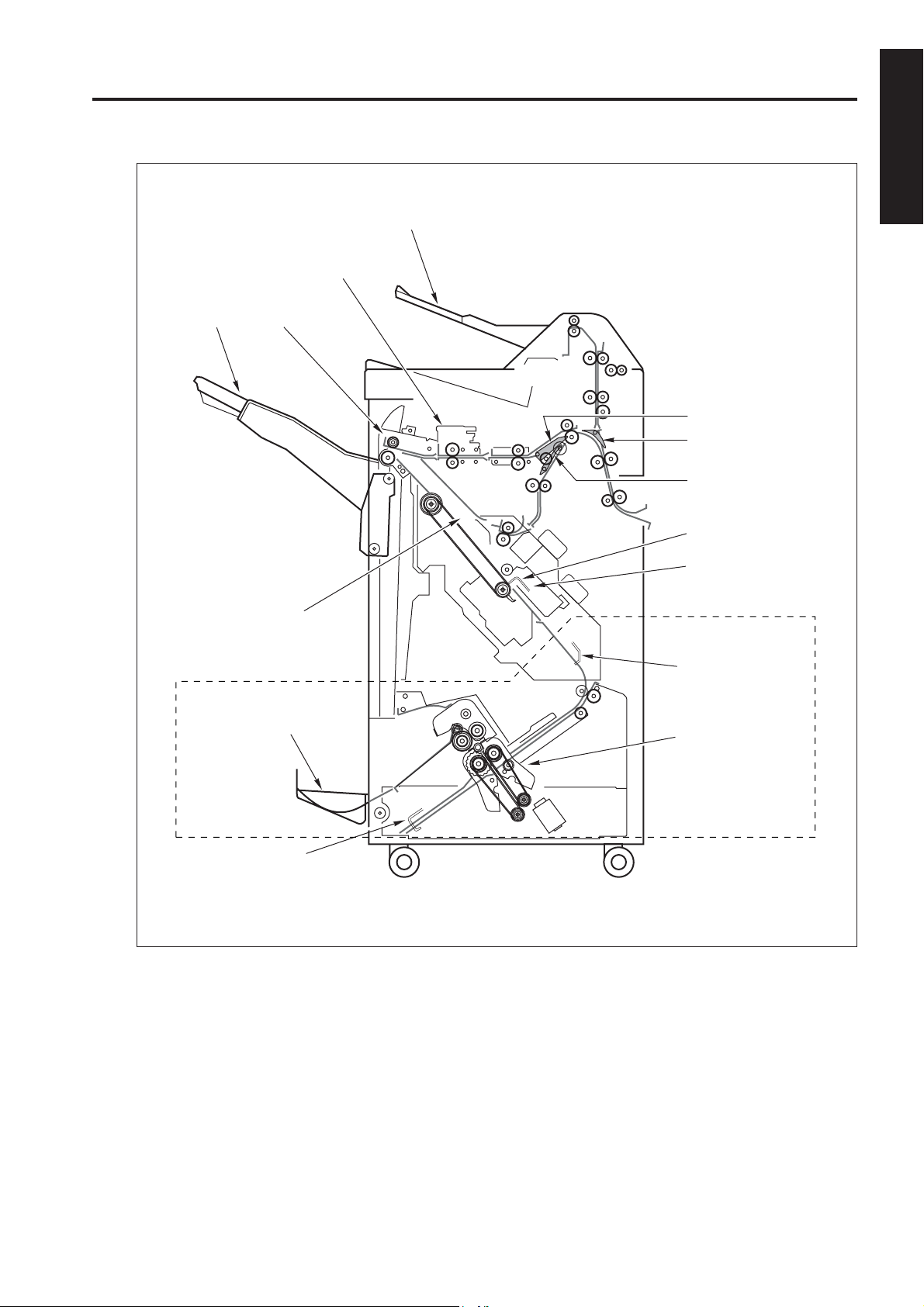

CENTER CROSS-SECTION

Sub-tray

Shift unit

FS-111/FS-211

1 OUTLINE

Main tray

Paper exit unit

Stacker unit

Booklet tray

Gate

Sub-tray gate

By-pass gate

Flat-stapling stopper

Stapler unit

Stapling and

folding stopper

Folding unit

Folding stopper

Area within dotted lines:

FS-211 only

1 - 3

Page 14

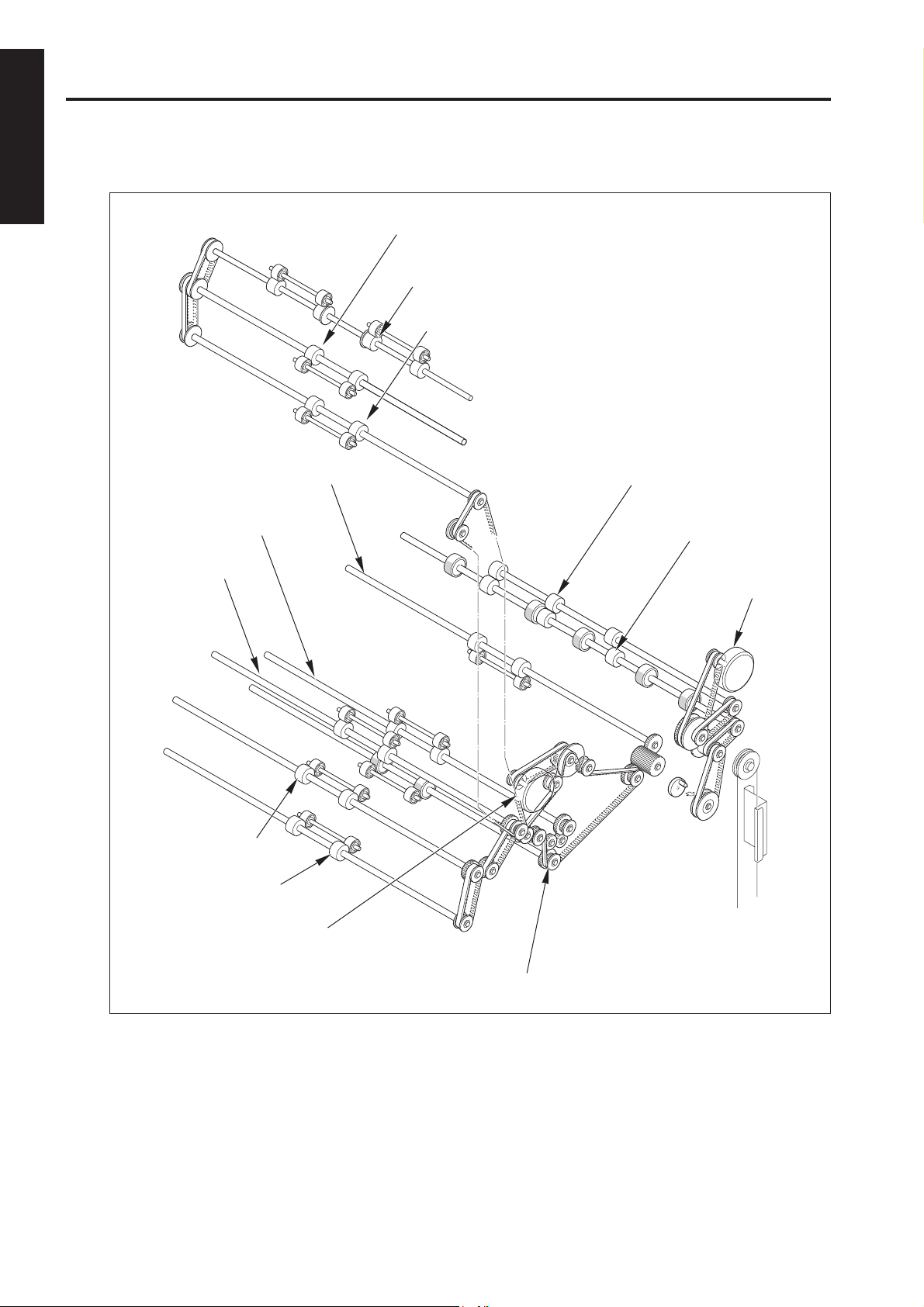

FS-111/FS-211

DRIVE SYSTEM DIAGRAM

1 OUTLINE

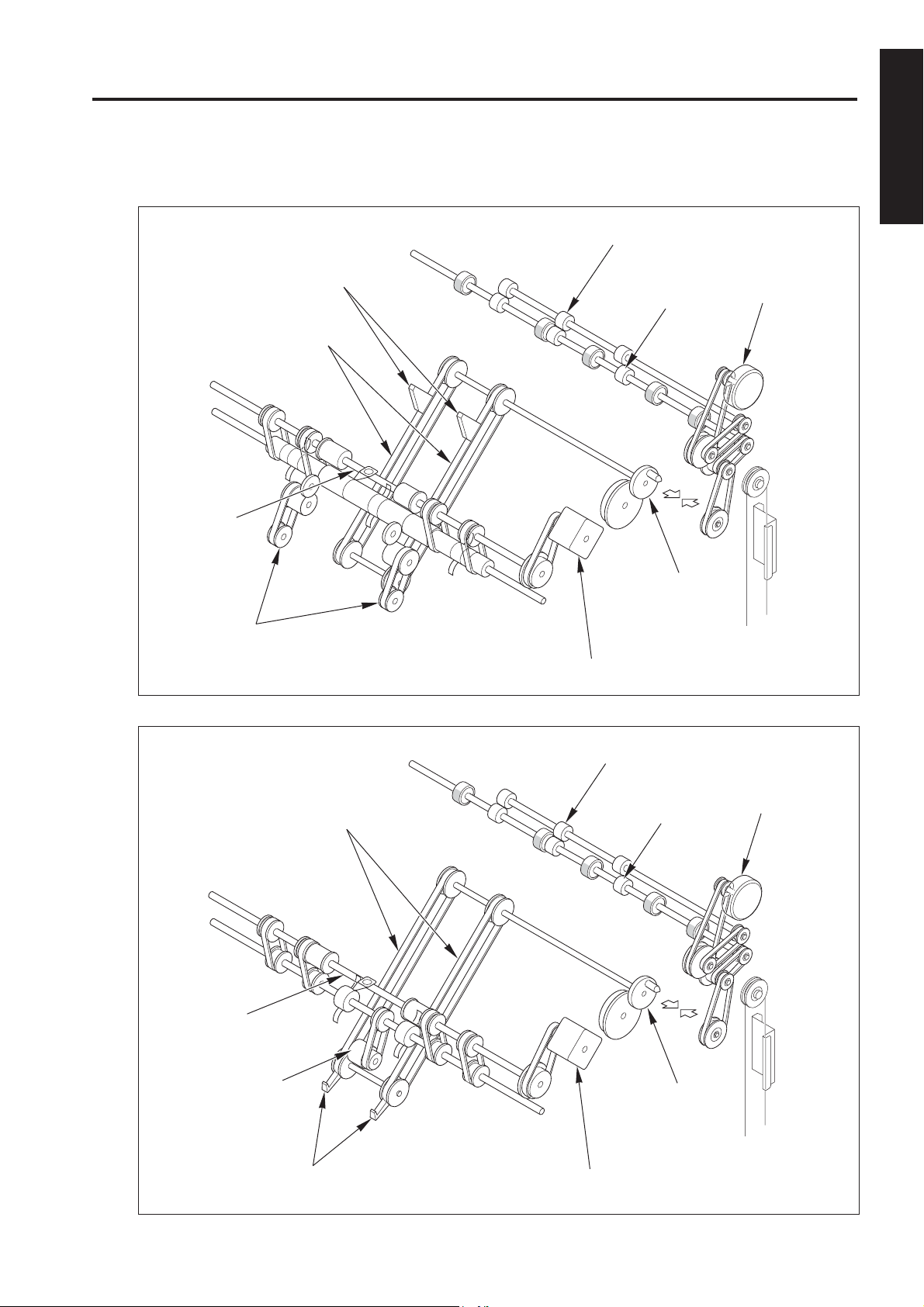

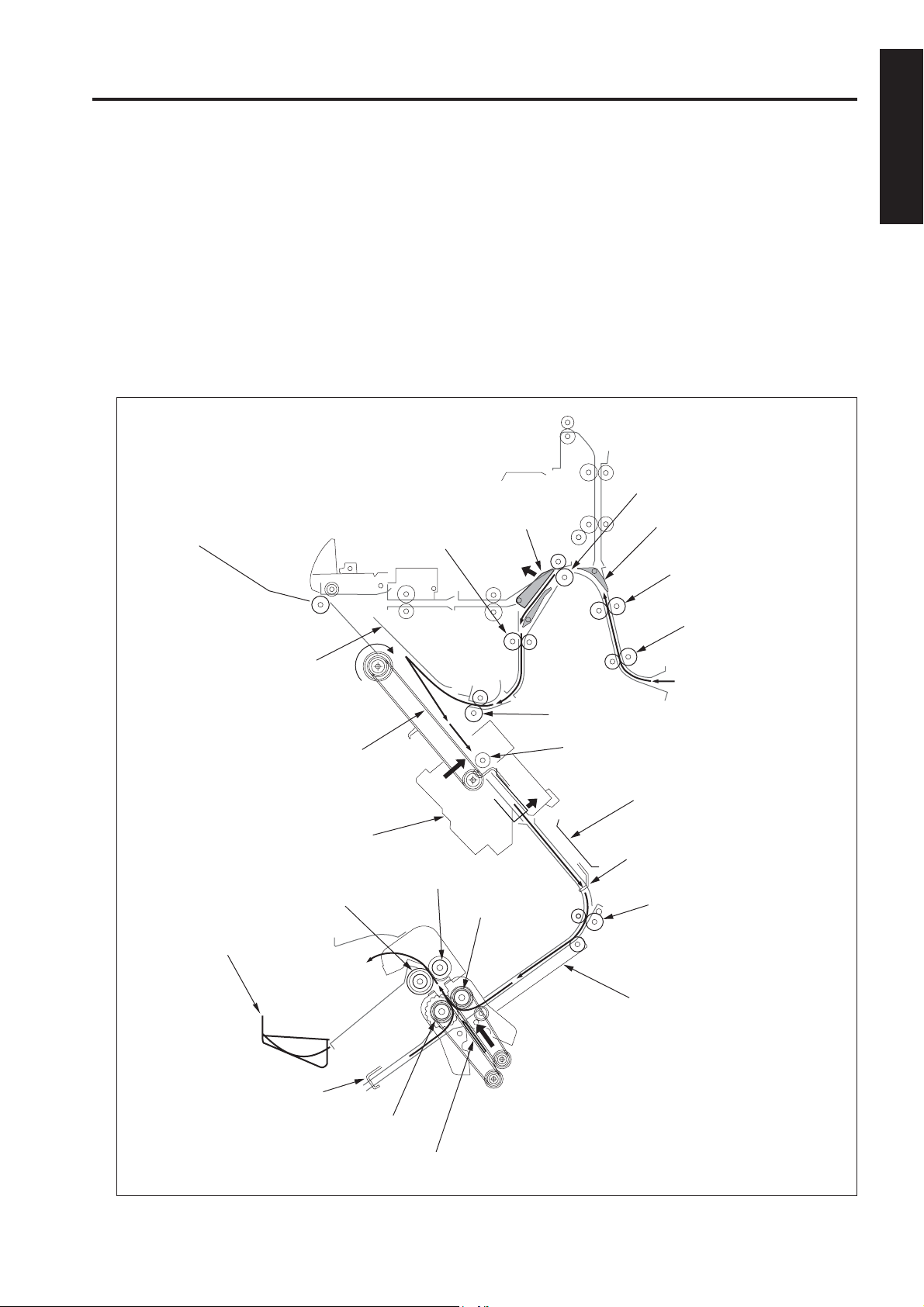

[1] Paper Conveyance Drive

Sub-tray paper exit roller (B)

Sub-tray paper exit roller (C)

Sub-tray paper exit roller (A)

Conveyance slide shaft

Conveyance roller (D)

Conveyance roller (C)

Conveyance roller (B)

Conveyance roller (A)

Nip paper exit roller

Paper exit roller

Paper exit roller

motor (M7)

FNS conveyance motor

(M1)

Intermediate conveyance roller

1 - 4

Page 15

FS-111/FS-211

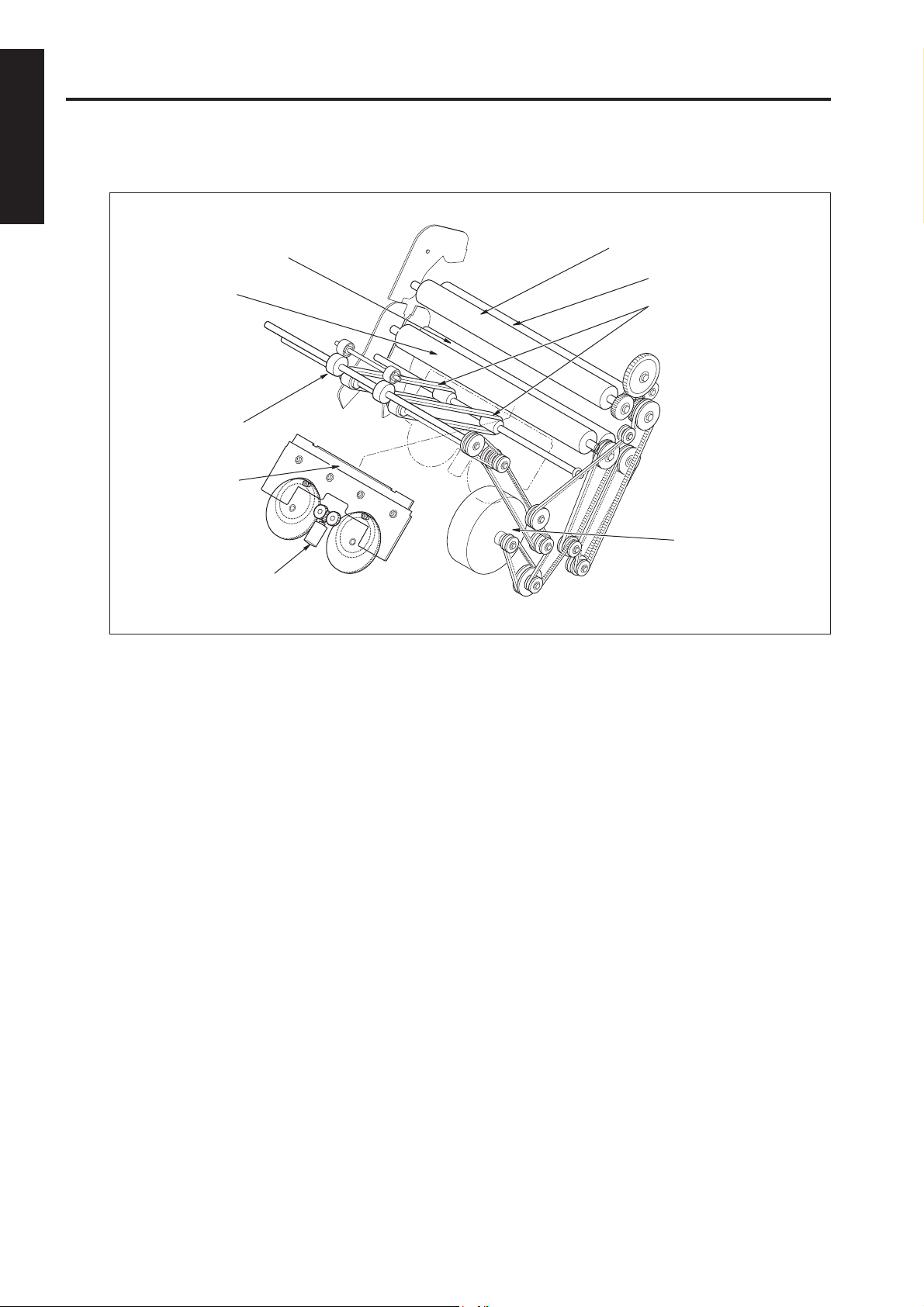

[2] Stacker Drive

(FS-111)

Stacker entrance

roller

Paper exit arms

Paper exit belts

Nip paper exit roller

Paper exit roller

Coupling

1 OUTLINE

Paper exit roller

motor (M7)

Swivel roller

(FS-211)

Stacker

entrance roller

Paper exit belts

Stacker entrance motor (M13)

Nip paper exit roller

Paper exit roller

Paper exit roller

motor (M7)

Swivel roller

Paper exit arms

Coupling

Stacker entrance motor (M13)

1 - 5

Page 16

FS-111/FS-211

1 OUTLINE

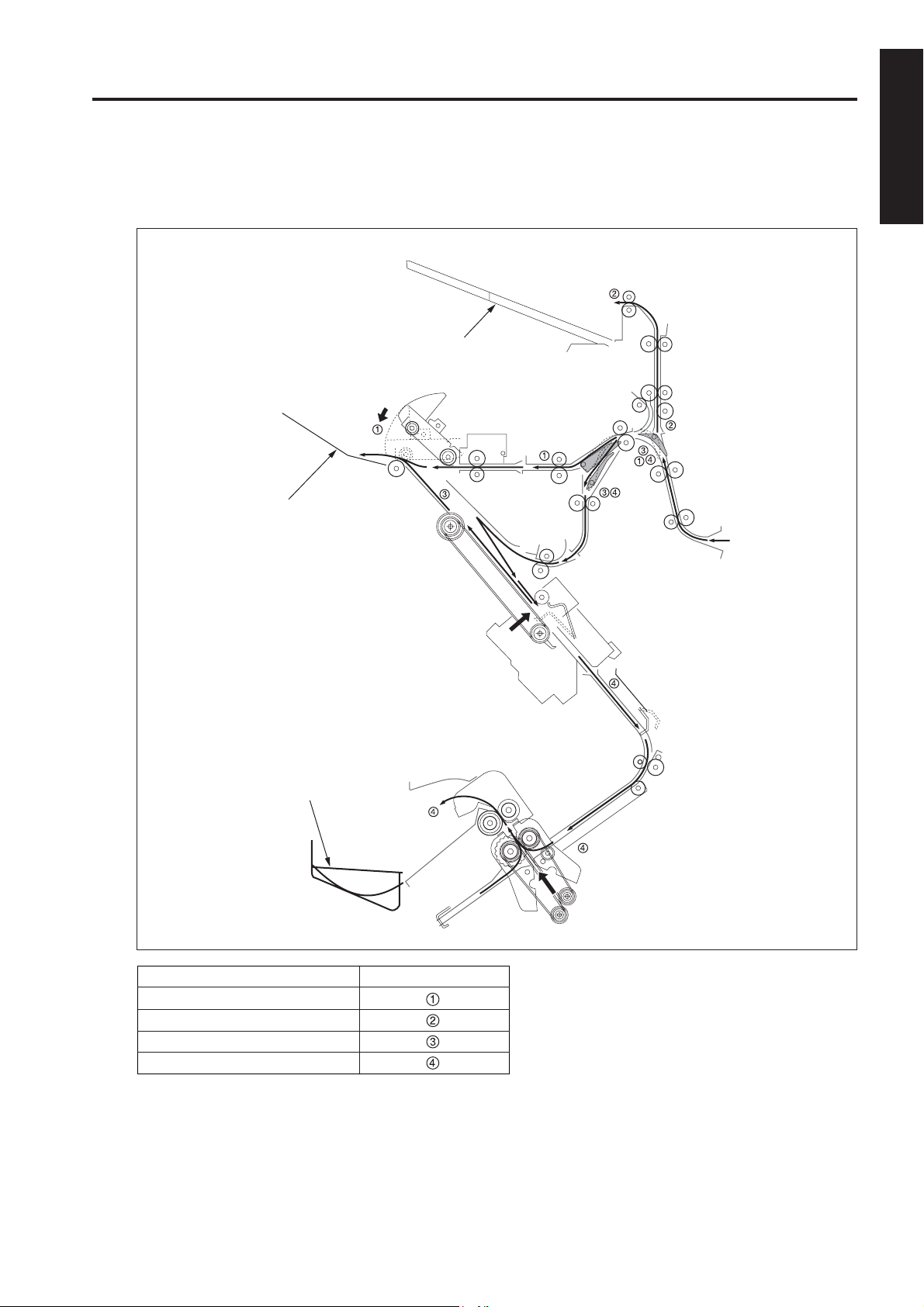

[3] Folding Drive (FS-211 only)

Folding roller (B)

Folding roller (A)

Folding conveyance

roller

Folding knife

Folding knife motor

(M19)

Pressure roller (A)

Pressure roller (B)

Folding conveyancebelts

Folding conveyance

motor (M20)

1 - 6

Page 17

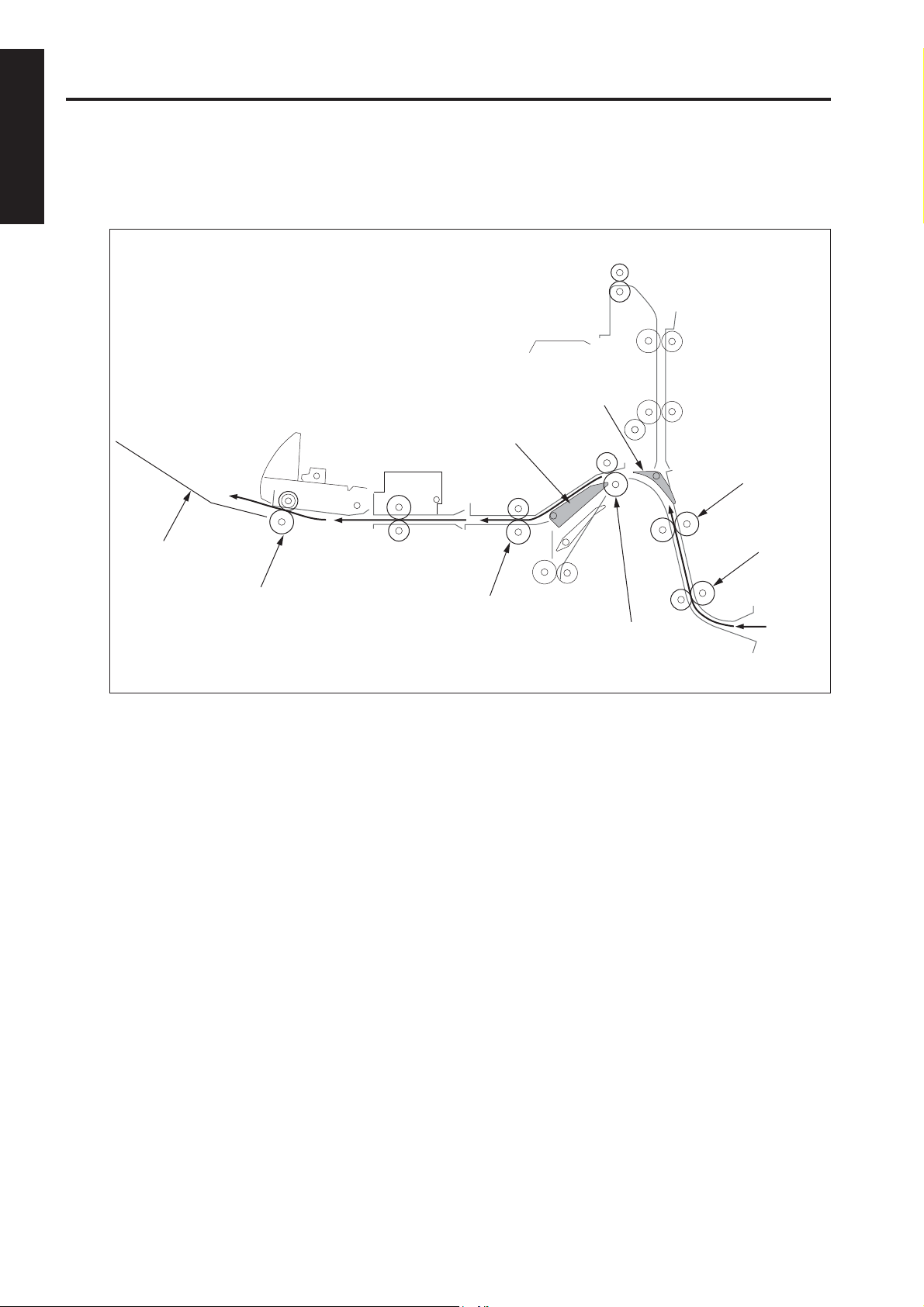

PAPER CONVEYANCE PROCESS

FS-111/FS-211

[1] Paper Conveyance Process

The FNS (finisher) provides four paper paths, as shown in the diagram below.

Face-up and face-down inversion is handled by at the main-body side by the main body’s exit page inverter.

Sub-tray

Main tray

1 OUTLINE

Booklet tray

Finishing mode

Sort, Group, Non-sort mode

Sub-tray mode

Staple mode

Booklet mode (FS-211 only)

Paper Conveyance Paths

1 - 7

Page 18

FS-111/FS-211

1 OUTLINE

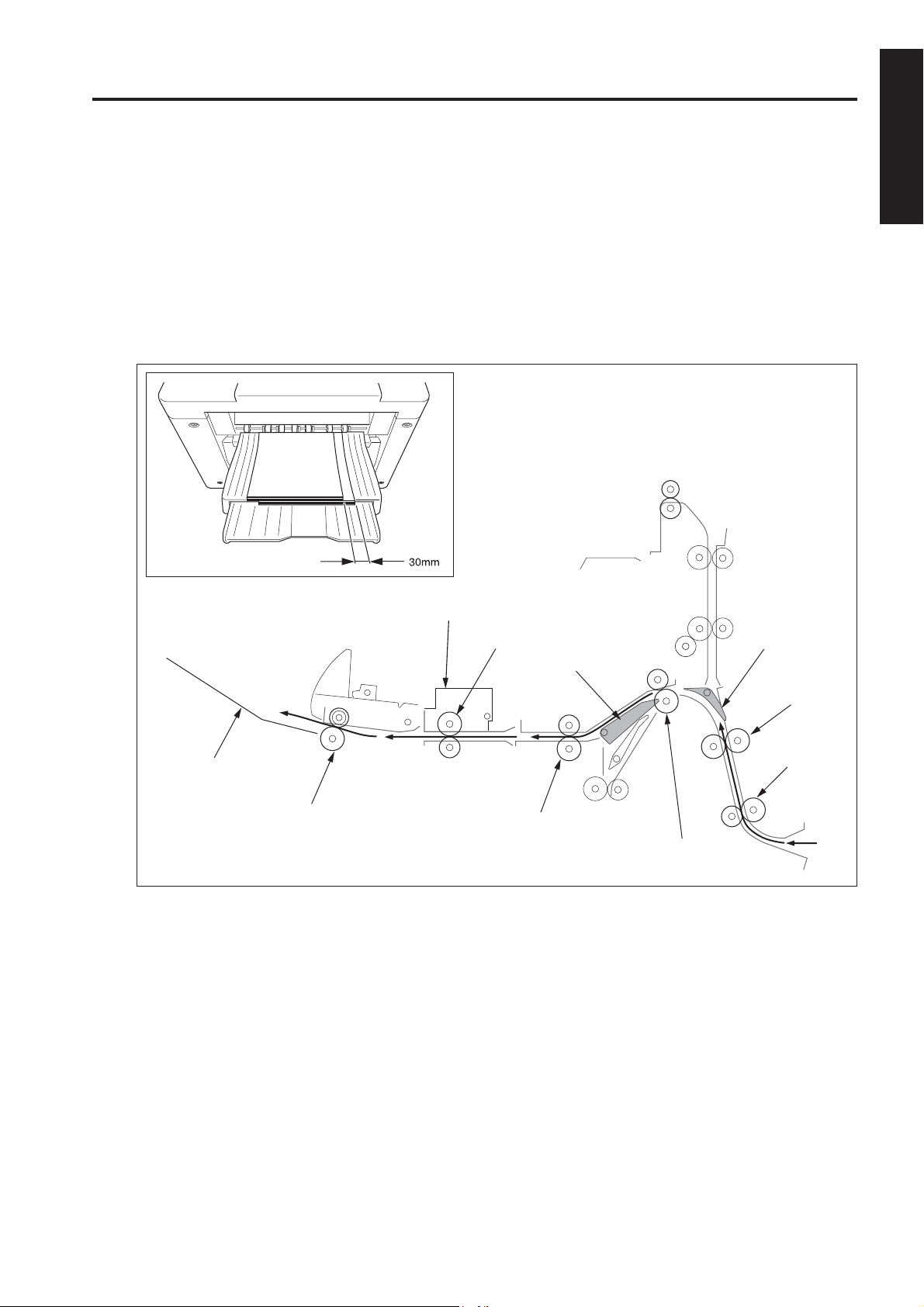

[2] Non-Sort Mode

Exit to main tray

A paper exited from the main body is conveyed and exited to the main tray.

Main tray

Sub-tray gate

Gate

Conveyance roller (B)

Conveyance

roller (A)

Paper exit roller

Conveyance roller (D)

Conveyance roller (C)

1 - 8

Page 19

FS-111/FS-211

[3] Sort, Group Mode

Exit to main tray

Paper exited from the main body is conveyed and exited to the main tray. This mode has an off-set function

that allows each page of the even-numbered sets to be exited with the paper shifted 30mm to the rear.

Off-set Function

(1) The odd-numbered pages are exited to the main tray with the image side face down.

(2) The even-numbered pages are shifted 30mm to the rear by the conveyance slide shaft of the shift unit and

then exited to the main tray.

Shift unit

1 OUTLINE

Main tray

Paper exit roller

Conveyance slide shaft

Gate

Conveyance roller (D)

Sub-tray gate

Conveyance

roller (B)

Conveyance

roller (A)

Conveyance roller (C)

1 - 9

Page 20

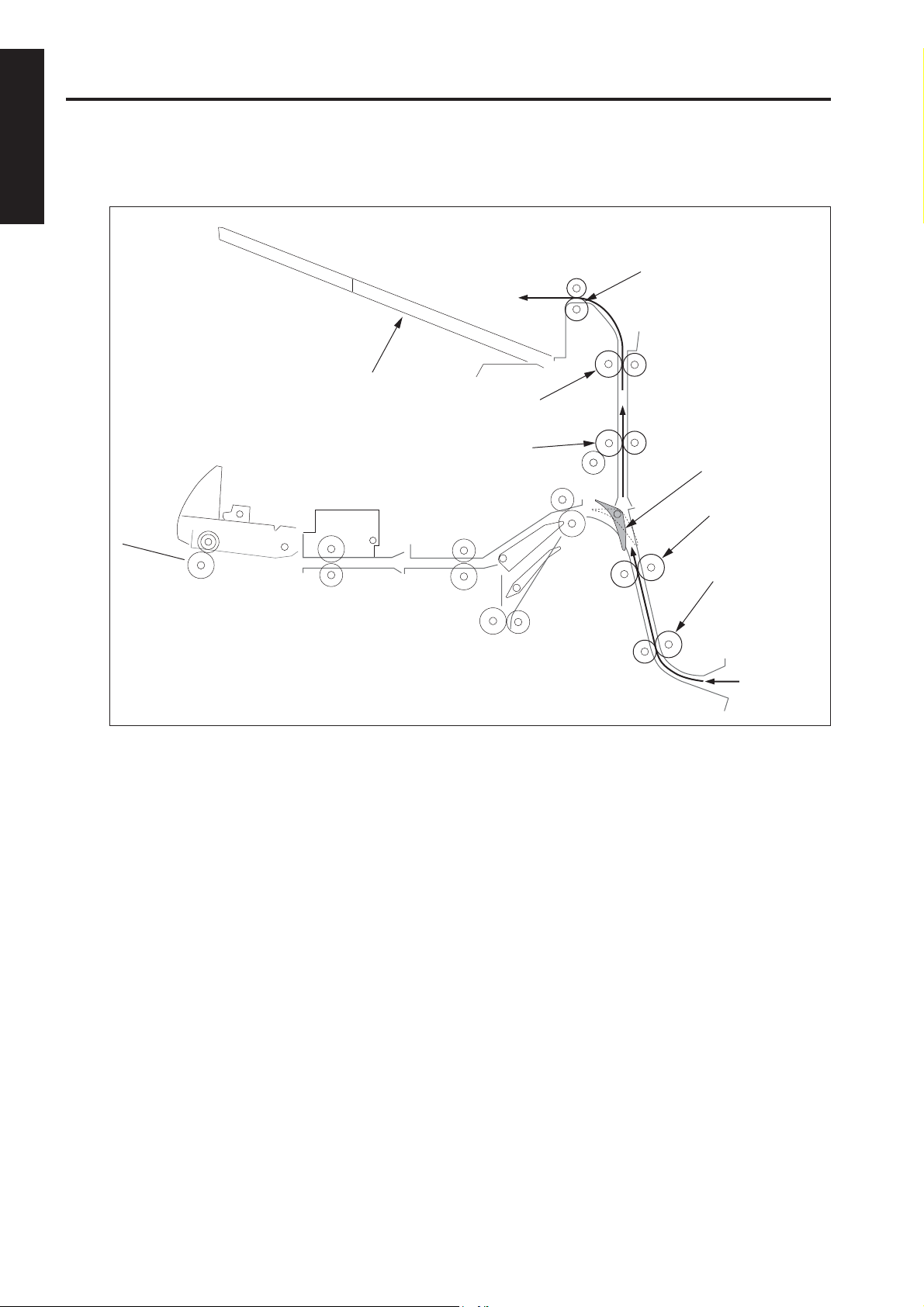

FS-111/FS-211

1 OUTLINE

[4] Sub-tray Mode

The sub-tray gate opens. Paper exited from the main body is conveyed and exited to the sub-tray.

Sub-tray paper exit roller (C)

Sub-tray

Sub-tray paper exit roller (B)

Sub-tray paper exit roller (A)

Sub-tray gate

Conveyance roller (B)

Conveyance roller (A)

1 - 10

Page 21

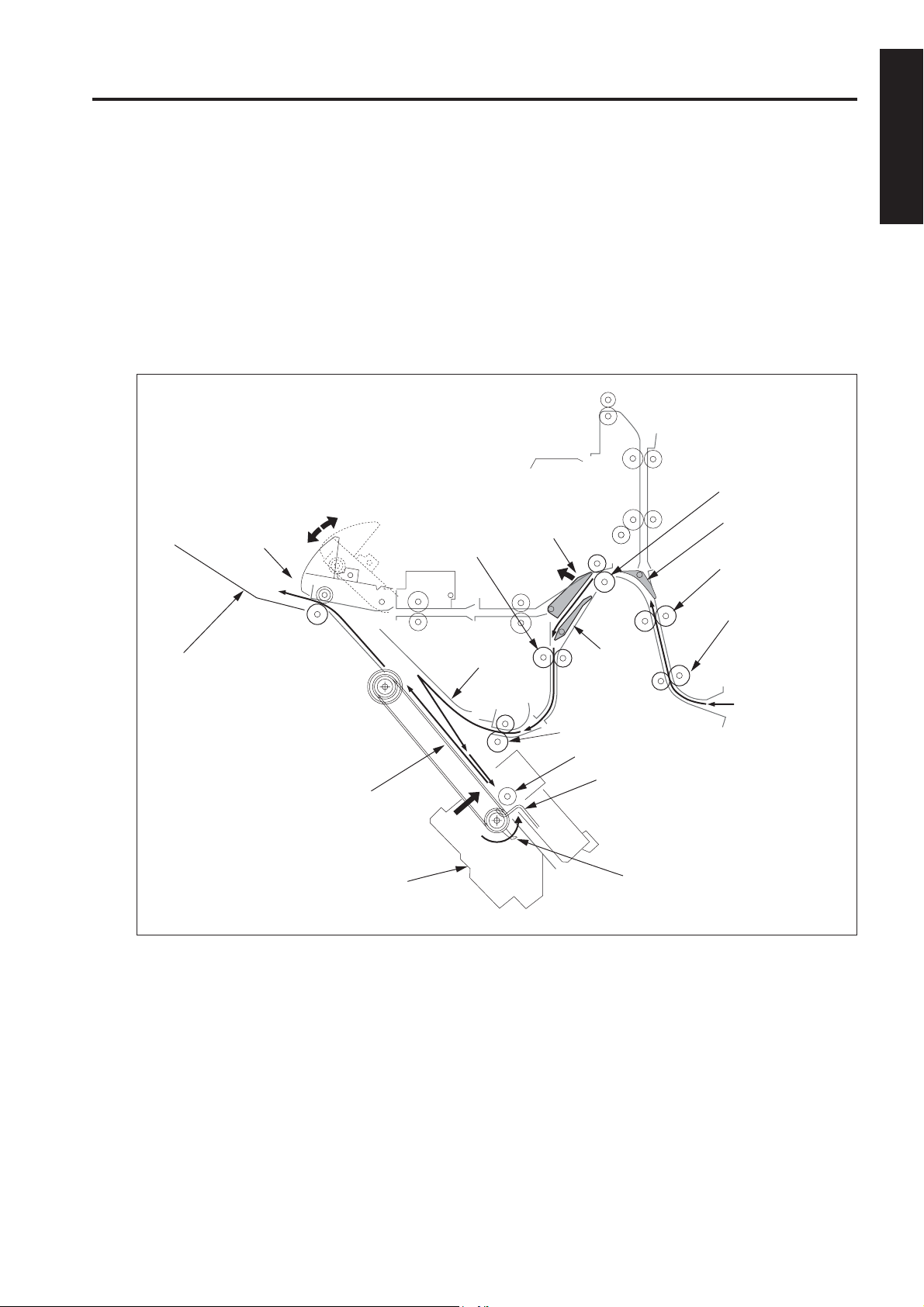

FS-111/FS-211

[5] Staple Mode

(1) The gate switches to the staple mode.

(2) For A4R paper and above, the paper exit opening opens.

(3) The first set of paper is conveyed and stacked.

1) The stacker section roller sends the paper to the flat-stapling stopper and the paper is lined up in the

lengthwise direction.

2) The upper alignment plate lines up paper in the widthwise direction.

3) Paper is stapled.

4) The first set is conveyed by the paper exit arm and exited to the main tray.

Conveyance roller (C)

Paper exit

First stapled set

opening

Intermediate

conveyance roller

Gate

Sub-tray gate

Conveyance roller (B)

Conveyance roller (A)

1 OUTLINE

Main tray

Paper exit belt

Stapler unit

Alignment plate

/upper

By-pass

gate

Stacker entrance

roller

Swivel roller

Flat-stapling stopper

Paper exit arm

1 - 11

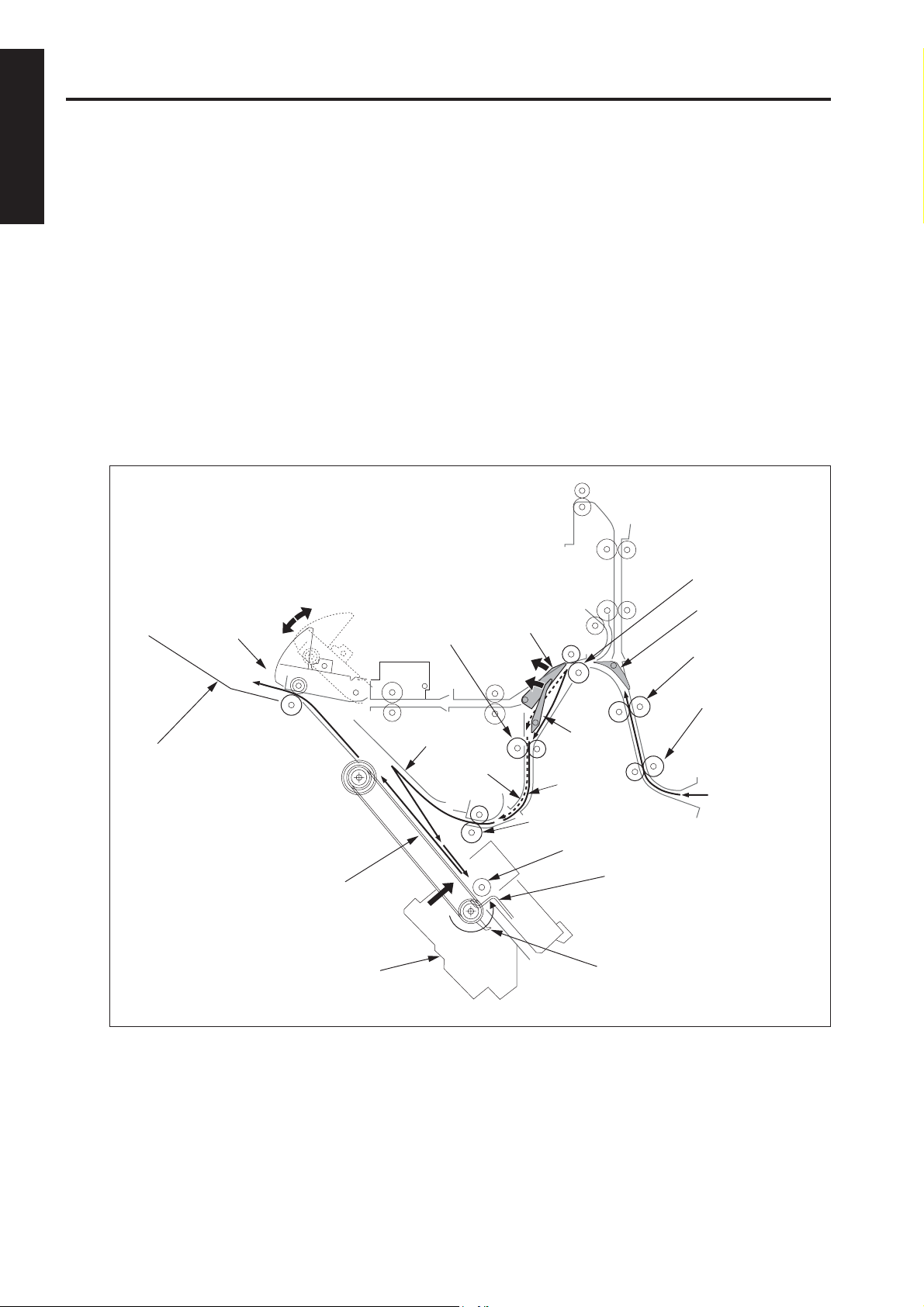

Page 22

FS-111/FS-211

1 OUTLINE

(4) The second and subsequent sets of paper are conveyed and stacked.

1) The first page stops in the stacker entrance with the by-pass gate opened. The stacker entrance

roller stops to wait for the previous stack to be exited.

2) The by-pass gate is closed and the second page is stacked on top of the first.

3) Once the previous stack has exited, the stack entrance roller rotates and the first and second pages

are simultaneously sent to the stacker.

* The above steps (1) to (3) are for paper to a maximum of A4 size.

4) The stacker section roller sends the paper to the flat-stapling stopper and the paper is lined up in

the lengthwise direction.

5) The upper alignment plate lines up paper in the widthwise direction.

6) When all paper is conveyed to the stacker, the paper is stapled.

7) The second and subsequent sets are conveyed by the paper exit arm and the paper is exited to

the main tray.

Paper exit opening

Conveyance roller (C)

Second stapled set

Intermediate

conveyance roller

Gate

Sub-tray gate

Conveyance roller (B)

Main tray

Paper exit belt

Stapler unit

Alignment

plate/upper

Second sheet

Conveyance roller (A)

By-pass

gate

First

sheet

Stacker entrance roller

Swivel roller

Flat-stapling stopper

Paper exit arm

1 - 12

Page 23

FS-111/FS-211

[6] Booklet Mode (FS-211 only)

(1) The gate switches to the staple mode.

(2) The paper exit opening opens.

(3) The paper is conveyed and stacked.

(4) The stacker section roller sends the paper to the stapling-and-folding stopper and the paper is lined up in the

lengthwise direction.

(5) The upper and lower alignment plate lines up paper in the widthwise direction.

(6) If stapling-and-folding has been selected, staple the stack.

(7) Release the stapling-and-folding stopper and convey the stack to the folding unit by the paper exit belt.

(8) Convey the stack up to the folding stopper, fold it with the folding knife, and eject to the booklet tray.

Conveyance roller (C)

Intermediate

conveyance roller

Gate

Sub-tray gate

Conveyance roller (B)

1 OUTLINE

Upper alignment plate

Paper exit belt

Stapler unit

Pressure roller (B)

Booklet tray

Pressure roller (A)

Folding roller (A)

Conveyance roller (A)

Stacker entrance roller

Swivel roller

Alignment plate/lower

Stapling and folding stopper

Folding conveyance roller

Folding conveyance belt

Folding stopper

Folding roller (B)

Folding knife

1 - 13

Page 24

FS-111/FS-211

1 OUTLINE

Blank page

1 - 14

Page 25

2

UNIT EXPLANATION

2 UNIT EXPLANATION

Page 26

2 UNIT EXPLANATION

Blank page

Page 27

EXTERNAL SECTION

[1] Composition

Sub-tray

FS-111/FS-211

Paper exit cover

Top cover

Main tray

Rear cover

Paper exit stopper plate

Booklet tray

(FS-211 only)

[2] Mechanisms

Mechanism

Jam pmrocessing *1

*1 Jam processing

To remove a jamming paper in the convey

ance unit, open the front cover, rotate the con

veyance roller, then open each guide plate.

To remove a jamming paper in the stapler unit,

open the front cover, then pull out the stapler

section.

To remove a jamming paper in the folding unit,

open the front cover, rotate the conveyance roller,

then open the guide plate.

Method

Roller rotation

Guide plate open/close

2 UNIT EXPLANATION

Front cover

Front side cover

Conveyance unit

Stapler unit

Folding unit

2 - 1

Page 28

FS-111/FS-211

CONVEYANCE SECTION

[1] Composition

Sub-tray

paper exit roller (C)

Sub-tray

paper exit roller (B)

Sub-tray

paper exit roller (A)

2 UNIT EXPLANATION

Conveyance roller (B)

Conveyance roller (A)

Conveyance roller (C)

Intermediate

conveyance roller

FS-111/FS-211 Rear View

Deceleration roller

FNS conveyance motor (M1)

Conveyance slide shaft

Paper exit roller motor

(M7)

Nip paper exit roller

Paper exit roller

(Sponge roller)

Conveyance roller (D)

Stacker entrance motor

(M13)

Stacker entrance roller

Paper exit belt

Folding

conveyance roller

Folding conveyance belt

Folding conveyance

motor (M20)

Area within dotted lines: FM-211 only

Folding roller (A)

Pressure roller (A)

Pressure roller (B)

Folding roller (B)

2 - 2

Page 29

FS-111/FS-211

[2] Mechanisms

Mechanism

Paper conveyance

*1

Path switching *2

Shift mechanism of

the shift unit *3

Stacker unit *4

Stapler paper exit

*5

Sub-tray

exit *6

Folding *7

*1 Paper Conveyance

Paper conveyance is carried out by conveyance

rollers (A), (B), (C), and (D); the intermediate conveyance roller; the conveyance slide shaft; and

sub-tray paper exit rollers (A), (B), and (C). These

components are driven by the FNS conveyance

motor (M1) by means of a timing belt.

Stacking is implemented by the stacker entrance

roller and the swivel roller. These rollers are

driven by the stacker entrance motor (M13) by

means of a timing belt.

Method

Motor + roller

Gate /sub-tray

Gate/by-pass

Gate + solenoid

Roller shift

FS-111: Stapler and

clincher combined

FS-211: Stapler and

clincher separated

Paper exit belt + roller

Deceleration roller re

lease

Folding knife

*2 Paper Path Switching

Gate

Sub-tray paper exit

solenoid (SD2)

By-pass

solenoid (SD5)

Sub-tray gate

By-pass gate

Gate solenoid

(SD1)

Path switching is carried out by the gate, the subtray gate, and the by-pass gate. Each of these is

controlled by the ON/OFF action of a corresponding solenoid: the gate solenoid (SD1), the subtray paper exit solenoid (SD2), and the by-pass

solenoid (SD5), respectively.

*3 Shift Unit Sort Shift Operation

(1) Paper entering the shift unit is fed toward the

paper exit direction by the action of the slide

shaft.

(2) Driving by the roller shift motor (M2) causes the

linkage to shift the slide shaft and paper 30mm

toward the rear.

Link mechanism

2 UNIT EXPLANATION

Ejection to the main tray (following staple

processing) is implemented by the stacker paper exit belt arm and the paper exit roller. These

components are driven by the paper exit motor

(M7).

Ejection to the booklet tray is implemented by

the folding conveyance roller, the folding conveyance belt, the folding knife, folding rollers A and

B, and pressure rollers A and B. The folding knife

is driven by the folding knife motor (M19). The

conveyance belt, folding rollers, and pressure

rollers are driven by the folding conveyance motor (M20) by means of a timing belt.

Paper exit

direction

Slide shaft

Roller shift motor

(M2)

Slide shaft

Link mechanism

Roller shift motor

(M2)

30mm towards the direction

of the rear side

2 - 3

Page 30

FS-111/FS-211

*4 Stacker Unit a. Paper Alignment (Staple Mode (Flat Stapling))

Sheets conveyed into the stacker are aligned by

the oscillation of the (front and rear) alignment

plates/upper. The alignment plates/upper are

driven by the alignment plate/upper motor (M5).

b. Paper Alignment (Booklet Mode (FS-211 only))

Sheets conveyed into the stacker are aligned by

the movement of the (front and rear) alignment

Alignment

plate/

2 UNIT EXPLANATION

upper

Paper exit

belts

Paper exit arms

Paper exit

belts

Alignment

plate/upper

motor

(M5)

Alignment plate/

upper

plates/upper and the (front and rear) alignment

plates/lower. The alignment plates/upper are

driven by the alignment plate motor/upper (M5);

the alignment plates/lower are driven by the alignment plate motor/lower (M15). The stapling-andfolding stopper is moved by the stapling-and-folding stopper motor (M14) and is released by the

stapling-and-folding stopper release motor (M17).

Stapling and

folding stopper

release motor

(M17)

Stapling and folding stopper

Alignment plate/lower

FS-211 Only

Stapling and folding

stopper motor (M14)

Alignment

plate/lower

Alignment plate motor/lower

(M15)

c. Paper Exiting to the main tray

Stapled paper is sent to the paper exit by the

paper exit arm. The paper exit belt is driven by

the paper exit-roller motor (M7).

d. Feeding to the Folding Unit (FS-211 only)

The stapling-and-folding stopper release motor

(M17) releases the stapling-and-folding stopper

and feeds the paper into the folding unit.

2 - 4

Page 31

FS-111/FS-211

*5 Paper Exit Opening Unit c. Pressure of the Paper Exit Roller

The paper exit roller turns more slowly than the

Paper exit opening solenoid

(SD4)

Paper exit opening

Nip roller

Paper exit opening

motor (M8)

conveyance rollers (A, B, C, and D), and remains

unengaged by the nip roller except during ejection.

When paper reaches the paper exit opening, the

paper exit roller is engaged by the nip roller and

the paper is ejected to the main tray. Engagement and release is controlled by the paper exit

opening solenoid (SD4).

a. Staple Mode and Booklet Mode Operation for

Paper Sizes A4R and Above

Because paper of this size juts out from the

stacker, the paper exit opening is held open from

the start of copying until the completion of stapling.

b. Paper Exit of the Staple Mode (Flat Stapling)

Upon completion of stapling, the paperr exit

closes, and the paper is grasped and ejected to

the main tray. The opening and closing of the

paper exit is controlled by the paper exit opening

motor (M8).

Paper exit opening motor

(M8)Paper exit opening

Open

Close

Paper exit opening

solenoid (SD4)

Paper exit opening

Main tray

Paper

exit roller

Conveyance

roller (D)

Conveyance

roller (B)

Conveyance roller (C)

Conveyance roller (A)

Nip roller

2 UNIT EXPLANATION

2 - 5

Paper exit roller

Paper exit opening solenoid

(SD4)

Page 32

FS-111/FS-211

*6 Sub-tray

Exit paper is conveyed to the sub-tray via the subtray paper exit rollers (A), (B) and (C) during the

sub-tray mode. In this mode, the deceleration

roller lowers when the sub-tray deceleration solenoid (SD6) turns ON; then the paper is nipped

between the sub-tray deceleration solenoid and

the sub-tray paper exit roller (C) rotating at a low

speed, and the conveyance speed of the exiting

paper decelerates.

2 UNIT EXPLANATION

Sub-tray deceleration solenoid (SD6)

Deceleration roller

*7 Folding by the Folding Unit (FS-211 only)

Paper is conveyed to the folding stopper by the

action of the folding conveyance roller and the

folding conveyance belts, and is then folded by

the action of the folding knife and the folding rollers. The folding conveyance roller, the folding

conveyance belts, the folding rollers, and the

pressure roller are driven by the folding conveyance motor (M20). The folding stopper motor

(M18) drives the folding stopper. The folding knife

motor (M19) drives the folding knife.

Folding conveyance

motor (M20)

Folding rollers

Folding stopper

motor (M18)

Folding paper-end

stopper

Folding knife

Folding

conveyance belts

Folding knife

2 - 6

Folding knife

Paper

Folding knife motor

(M19)

Page 33

FS-111/FS-211

[3] M1 (FNS Conveyance) Control

MS1

SGND

PGND

PGND

MAIN BODY

24V

24V-IN

5V

M_TXD

SGND

M_REQ

SGND

M_ACK

SGND

M_RXD

SGND

S_REQ

SGND

S_ACK

SGND

FNS CB

M1 (FNS conveyance) drives paper conveyance (if

main-tray exit) and paper exit (if sub-tray exit) by means

of conveyance rollers (A), (B), (C), (D), conveyance

slide shaft and the sub-tray paper paper exit roller (A),

(B), (C). M1 is controlled by the FNS CB (FNS control

board).

H/L

CONT

CLK

F/R

24V

24V

PGND

PGND

GND

GND

24V

DRV

GND

5V

LD

5V

IN

5V

IN

5V

IN

M1

PS1

PS4

SD6

PS207

1. Operation

a. Interlock

FNS paper-conveyance drive control is initiated

by the ON signal from the main body START

button. If MS1 (interlock) is OFF at this time, however, the finisher transmits an error signal to the

main body CB and does not begin control.

b. PS207 (paper exit cover open/close detection)

control

As mentioned above, FNS paper-conveyance

drive control is initiated by the ON signal from

the main body START button. But if PS207 (paper exit cover open/close detector) is [H] at this

time (paper exit cover is open), the FNS transmits an error signal to the main body CB and

does not begin control.

c. M1 (FNS conveyance) control

(1) Main tray paper exit operation

M1 is set ON by the ON signal of the START

button and goes OFF a preset time interval after

PS4 (FIN entrance passage) detects the trailing

edge of the final copy paper.

(2) Sub-tray paper exit operation

SD6 (sub-tray deceleration) turns ON a predefined time after PS4 detects the trailing edge of

the paper, and the deceleration roller is stuck with

pressure to the sub-tray exit roller (C). Thus the

speed of ejecting paper is reduced.

SD6 then turns OFF a predefined time after PS1

(sub-tray paper exit) detects the trailing edge of

the paper.

2 UNIT EXPLANATION

2 - 7

Deceleration roller

Sub-tray

paper exit roller (B)

Sub-tray

M1 (FNS conveyance)

Sub-tray paper

exit roller (A)

Sub-tray paper exit

roller (C)

PS1 (Sub-tray

paper exit)

Sub-tray

Conveyance

roller (B)

PS4

(FNS

entrance

passage)

Conveyance roller (A)

Page 34

FS-111/FS-211

2. Signals

a. Input signals

(1) TXD (Main body CB to FNS CB)

Serial data line; transmits operating status of the

main body’s CB to the FNS CB.

(2) DTR (Main body CB to FNS CB)

Request to send signal from the main body to the

FNS.

(3) RTS (Main body CB to FNS CB)

Transmission acknowledgment signal from the

main body to the FNS.

2 UNIT EXPLANATION

(4) 24V IN (MS1 to FNS CB)

Outputs +24V if MS1 (interlock) is ON. The power

is supplied to all loads on the FNS side.

(5) PS207 IN (PS207 to FNS CB)

Inputs [L] when the sub-tray paper paper exit

cover is closed.

(6) PS4 IN (PS4 to FNS CB)

Comes ON and inputs [L] when paper passes

through the FNS inlet.

(7) M1PLL (M1 to FNS CB)

Monitors rotation status of M1 (FNS conveyance).

[L] is input when M1 reaches the specified speed.

(8) IN (PS1 to FNS CB)

Turns ON when the paper passes through the

paper exit opening of the sub-tray, and inputs [L].

b. Output signals

(1) TXD (FNS CB to Main body CB)

Serial data line; transmits FNS operating status

to the main body’s CB.

(2) RTS (FNS CB to Main body CB)

Request to send signal from the FNS to the main

body.

(3) DTR (FNS CB to Main body CB)

Transmission acknowledgment signal from the

FNS to the main body.

(4) M1 CONT (FNS CB to M1)

M1 drive control signal.

[H]: OFF

[L]: ON

(5) M1 BRK (FNS CB to M1)

Rotation speed control gain switching signal of

M1.

[H]: High speed rotation

[L]: Low speed rotation

(6) M1 CLK (FNS CB to M1)

Reference clock signal for controlling the speed

of M1.

(7) M1 F/R (FNS CB to M1)

M1 direction signal.

[H]: Clockwise

[L]: Counterclockwise

(8) DRV (FNS CB to SD6)

Drive signal of SD6 (sub-tray deceleration).

[H]: OFF

[L]: ON

2 - 8

Page 35

FS-111/FS-211

[4] Gate Control

DRV

24V

DRV

MS1

SGND

PGND

PGND

MAIN BODY

24V

24V-IN

5V

M_TXD

SGND

M_REQ

SGND

M_ACK

SGND

M_RXD

SGND

S_REQ

SGND

S_ACK

SGND

FNS CB

24V

DRV

24V

GND

GND

GND

GND

5V

IN

5V

IN

5V

IN

5V

IN

The paper conveyance path is switched by the ON/

OFF switching of SD1 (gate), SD2 (sub-tray paper

exit), and SD5 (by-pass), which are switched ON/OFF

by the FNS CB (FNS control board).

SD1

SD2

SD5

PS4

PS5

PS6

PS50

1. Operation

PS5 (Stacker conveyance

passage)

PS50

(Sub-tray

full)

PS6 (Paper

exit 1)

SD1

(Gate)

a. Main-tray Paper Exit Operation (Sort, Group,

and Non-Sort modes)

Paper moves through the shift unit and paper

exits to the main tray, passing through the subtray gate and the gate. As both these gates direct the paper toward the shift-unit side by default, SD2 and SD1 remain OFF.

b. Stacker conveyance operation (Staple mode)

Paper moves through the stacker unit to the main

tray, passing the sub-tray gate, the gate, and the

by-pass gate. As the sub-tray gate is already set

to the stacker side, SD2 remains OFF.

(1) ON timing for SD1

SD1 comes on when the START button ON

signal is received, setting the gate to the stacker

side. The FNS stands by for paper conveyance to

begin.

(2) Conveyance of paper sizes other than A4 and B5

The gates direct the paper into the stacker. SD5

remains OFF, as paper moves without by-pass

toward the stacker entrance roller.

(3) Conveyance of A4 and B5 paper (first paper of

second and subsequent sets)

SD5 comes ON a preset time period after PS4

(FNS entrance passage) detects the trailing edge

of the final paper of the preceding set. This

switches the by-pass gate to the by-pass side, so

that the first paper of the new set is carried to that

side.

PS1 (Sub-tray

paper exit)

SD2

(Sub-tray

paper exit)

PS4

(FNS ent-

rance

passage)

SD5

(By-pass)

Stacker

entrance roller

2 UNIT EXPLANATION

2 - 9

Page 36

FS-111/FS-211

(4) Conveyance of A4 and B5 paper (second and

subsequent papers of second and subsequent

sets)

SD5 turns OFF a preset time period after PS4

(FNS entrance passage) detects the trailing edge

of the first sheet of the current set, closing the bypass gate. The second sheet moves directly

(without by-pass), together with the first paper, to

the stacker entrance roller.

SD5 remains off for the third and subsequent

sheets of the set, which move without by-pass to

2 UNIT EXPLANATION

the stacker.

(5) OFF timing for SD1 (gate)

SD1 turns OFF a preset time period after PS6

(paper exit-1) detects the final stapled set.

c. Stacker conveyance operation (Booklet mode)

(FS-211 only)

Paper moves through the stacker unit to the folding unit, passing the sub-tray gate, the gate, and

the by-pass gate. As the sub-tray gate is already

set to the stacker side, SD2 (sub-tray paper exit)

remains off.

(1) ON timing for SD1

SD1 turns ON when the START button ON signal

is received, setting the gate to the stacker side.

The FNS stands by for paper conveyance to

begin.

(2) The gates direct the paper to the stacker. SD5

remains OFF, as paper moves without by-pass

toward the stacker entrance roller.

(3) OFF timing for SD1

SD1 turns OFF a preset time period after PS6

detects the final stapled set.

d. Sub-tray paper exit operation

SD2 turns ON when the START button ON signal is received, setting the sub-tray gate to the

sub-tray side. SD2 turns OFF a preset time period after PS4 detects the final sheet.

e. Sub-tray full detection

When the papers ejected to sub-tray reach to

specified height, PS50 (sub-tray full) turns ON,

and FNS transmits "sub-tray full" signal to the

main body.

When the main body receives it, the message is

displayed on the operation panel.

Finishing

Sort, Group, and Non-Sort modes

Staple mode, sizes A4,

B5

( ) is for sizes other

than A4, B5

Booklet mode (FS-211 only)

Sub-tray mode

First paper of

2nd or

subsequent set

Others

SD1

OFF

ON

ON

ON

OFF

SD2

OFF

OFF

OFF

OFF

ON

SD5

OFF

ON

(OFF)

OFF

OFF

OFF

2 - 10

Page 37

2. Signals

a. Input signals

(1) PS5 IN (PS5 to FNS CB)

Turns ON ([L]) when paper passage is detected

at the stacker entrance.

(2) PS6 IN (PS6 to FNS CB)

Turns ON ([L]) when paper passage is detected

at the main-tray paper paper exit.

(3) IN (PS50 to FNS CB)

Turns ON ([L]) when sub-tray full is detected.

b. Output signals

(1) SD1 DRV (FNS CB to SD1)

SD1 drive control signal.

[H]: OFF

[L]: ON

(2) SD2 DRV (FNS CB to SD2)

SD2 drive control signal.

[H]: OFF

[L]: ON

(3) SD5 DRV (FNS CB to SD5)

SD5 drive control signal.

[H]: OFF

[L]: ON

FS-111/FS-211

2 UNIT EXPLANATION

2 - 11

Page 38

FS-111/FS-211

[5] M13 (Stacker Entrance) Control

24V

DRVA

DRVA

DRVB

DRVB

24V

M13

2 UNIT EXPLANATION

RB

FS-211 only

M13 (stacker entrance) drives the stacker entrance

roller and the swivel roller, thereby carrying out the

following functions: conveyance of paper to the

stacker; paper alignment; and adjustment of staple

waiting time. M13 is controlled by the FNS CB (FNS

control board) via the RB (relay board)(FS-211) or

directly (FS-111).

MS1

SGND

PGND

PGND

MAIN BODY

24V

M13 DRVA

M13 DRVA

M13 DRVB

M13 DRVB

24V

24V

24V-IN

5V

M_TXD

SGND

M_REQ

SGND

M_ACK

SGND

M_RXD

SGND

S_REQ

SGND

S_ACK

SGND

1. Operation

5V

FNS CB

GND

GND

24V

DRVA

DRVA

DRVB

DRVB

24V

IN

5V

IN

PS4

PS5

M13

FS-111 only

Conveyance to the stacker varies according to

paper size: one method is used for A4 and B5,

another is used for all other sizes.

PS4

(FNS entrance passage)

PS5 (Stacker conveyance

passage)

2 - 12

PS6 (Paper exit 1)

M13 (Stacker

entrance)

Flat-stapling stopper

Stapling and

folding stopper

Stacker

entrance roller

Swivel roller

Page 39

FS-111/FS-211

a. Conveyance to the stacker (sizes other than

A4 or B5)

(1) M13 (stacker entrance) ON timing

M13 is turned ON by the START button ON

signal, and begins with high speed rotation. M13

then switches to low speed rotation a preset time

period after PS5 (stacker conveyance passage)

detects the trailing edge of the paper.

M13 then returns to high speed rotation a preset

period after PS5 detects the trailing edge of the

paper. This action is repeated as necessary to

transport all papers to be stacked into the stacker.

(2) M13 OFF timing

M13 goes OFF a preset time period after PS5

detects the trailing edge of the final paper set.

b. Conveyance to the stacker (A4 and B5 sizes)

(1) First set

Paper for the first set to be stapled is conveyed in

the same way as other paper sizes.

(2) First paper of second and subsequent sets

M13 turns OFF a preset time period after PS4

(FNS entrance passage) detects the trailing edge

of the first paper for the second or subsequent

set, and the paper moves into the by-pass. This

prevents paper from moving into the stacker

while stapling of the previous set is still in progress.

(3) Second and subsequent papers of second and

subsequent sets

M13 resumes low speed rotation a preset time

period after PS4 detects the trailing edge of the

second paper of the set. This causes the first and

second papers to move together (one atop the

other) into the stacker. M13 switches to rapid

rotation a preset time period after PS5 detects the

trailing edge of the first and second papers, so

that it is ready to handle the third paper of the set

when it arrives from the main body. Third and

subsequent papers for the set are then conveyed

in the same way as the papers in the first set.

c. Paper alignment (trailing-edge alignment)

For operation in staple mode:

The swivel roller adjusts the position of each

paper (one paper at a time) within the stacker.

For operation in booklet mode (FS-211 only): The

stapling & folding stopper is moved and set into

appropriate position. The swivel roller adjusts the

position of each paper (one paper at a time).

2. Signals

a. Output signals

(1) DRV A, A, B, B (FNS CB to M13:FS-111)

(FNS CB to RB to M13:FS-211)

M13 drive signal.

2 UNIT EXPLANATION

2 - 13

Page 40

FS-111/FS-211

[6] M5 (Alignment Plate/Upper) Control

PS 8IN

5V

IN

GND

24V

24V

DRVA

2 UNIT EXPLANATION

DRVA

DRVB

DRVB

FS-211

M5 (alignment plate/upper) aligns the paper widthwise

in the stacker by opening and closing the alignment

plates/upper. M5 is controlled by the FNS CB (FNS

control board) via the RB (relay board)(FS-211) or

directly (FS-111).

M5

PS8

PS5

MS1

24V

5V

SGND

PGND

PGND

MAIN BODYRB

M5 DRVA

M5 DRVA

M5 DRVB

M5 DRVB

5V

IN

GND

5V

IN

GND

24V

24V

DRVA

DRVA

DRVB

DRVB

24V-IN

M_TXD

SGND

M_REQ

SGND

M_ACK

SGND

M_RXD

SGND

S_REQ

SGND

S_ACK

SGND

FNS CB

Alignment

plate/upper

PS5

(Stacker

conveyance

passage)

FS-111

M5 (Alignment plate/upper)

2. Signals

a. Input signals

(1) IN (PS8 to FNS CB:FS-111)

(PS8 to RB to FNS CB:FS-211)

Detects signal of the alignment plate/upper HP.

[L] indicates the alignment plate/upper is at HP.

b. Output signals

(1) DRV A ,A, B, B (FNS CB to M5:FS-111)

(FNS CB to RB to M5:FS-211)

M5 drive signals.

1. Operation

At initial operation, the alignment plates/upper are

stationary at the ON position of PS8 (alignmentplate/upper HP).

A specified time period after PS5 (stacker conveyance passage) detects the paper trailing edge,

M5 begins rotation so as to close the plates. After another specified interval it opens the plates.

This cycle repeats for each paper.

2 - 14

Page 41

[7] M15 (Alignment Plate/Lower) Control (FS-211 only)

FS-111/FS-211

5V

PS24

M15

PS24IN

GND

24V

24V

DRVA

DRVA

DRVB

DRVB

PS24IN

M15 (alignment plate/lower) aligns the stapling-andfolding position by opening and closing the alignment

plates/lower.

M15 is controlled by the FNS CB (FNS control board)

via the RB (relay board).

1. Operation

At start-up, the alignment plates/lower are stationary at the ON position of PS24 (alignmentplate/lower HP). A specified time period after PS5

(stacker conveyance passage) detects the paper trailing edge, M15 begins rotation so as to

close the plates. After another specified interval

it opens the plates. This cycle repeats for each

paper.

M15 DRVA

MS1

SGND

PGND

PGND

MAIN BODY

24V

M15 DRVA

M15 DRVB

M15 DRVB

24V-IN

5V

5V

SGND

PGND

PGND

M_TXD

SGND

M_REQ

SGND

M_ACK

SGND

M_RXD

SGND

S_REQ

SGND

S_ACK

SGND

FNS CBRB

GND

Alignment

plate/upper

M5

(Alignment

plate/upper)

M15

(Alignment plate/lower)

2. Signals

a. Input signals

(1) PS24 IN (PS24 to RB to FNS CB)

Detects signal of the alignment plate/lower HP.

[L] indicates the alignment plate/lower is at HP.

b. Output signals

(1) DRV A, A, B, B (FNS CB to RB to M15)

M15 drive signals.

5V

IN

PS5

2 UNIT EXPLANATION

PS5

(Stacker

conveyance

passage)

Alignment

plate/lower

2 - 15

Page 42

FS-111/FS-211

[8] M2 (Roller Shift) Control

24V

24V-IN

5V

M_TXD

SGND

M_REQ

SGND

M_ACK

SGND

M_RXD

SGND

S_REQ

SGND

S_ACK

SGND

FNS CB

MS1

SGND

PGND

PGND

2 UNIT EXPLANATION

MAIN BODY

When running in Sort or Group mode, the FNS carries

out shifting of paper. Shifting is driven by M2 (roller

shift), which is controlled by the FNS CB (FNS control

board).

1. Operation

If operation is in sort or group mode, M2 (roller

shift) turns ON a predetermined time period after PS4 (FNS entrance passage) detects the trailing edge of a paper that needs to be shifted.

Rotation of M2 starts shifting of the conveyance

slide shaft, while rotation of M1 (FNS conveyance) causes the shaft to turn, so that shifting

and conveyance occur simultaneously.

PS18 (roller-shift HP) turns ON when the conveyance slide shaft has been fully shifted, causing M2 to turn OFF.

A specified time period after PS4 turns OFF, M2

turns ON and returns the conveyance slide shaft

to its original position. PS18 turns OFF when the

conveyance slide shaft has returned all the way,

causing M2 to turn OFF again.

This operation is repeated as necessary to shift

paper as it moves toward the exit roller.

24V

DRV

GND

GND

5V

IN

5V

IN

M2

PS4

PS18

M2 (Roller shift)

Conveyance

slide shaft

Paper exit roller

2. Signals

a. Input signals

(1) IN (PS18 to FNS CB)

Detect signal of roller shift position.

[L] to [H]: Front position

[H] to [L]: Rear position

b. Output signals

(1) DRV (FNS CB to M2)

M2 drive signal.

[H]: ON

[L]: OFF

PS18 (Roller

shift HP)

PS4

(FNS

entrance

passage)

2 - 16

Page 43

[9] M7 (Paper Exit Roller) Control

FS-111/FS-211

PS9IN

5V

GND

IN

FS-211

PS9

MS1

MAIN BODY

FS-111

24V

SGND

PGND

PGND

5V

The paper exit belt ejects paper from the stacker, while

the paper exit roller ejects the paper from the FNS to

the main tray. M7 (paper exit roller) drives both the

belt and the roller. M7 is controlled by the FNS CB

(FNS control board) via RB (Relay board)(FS-211) or

directly (FS-111).

1. Operation

a. Sort, Group, and Non-Sort modes

M7 starts turning when PS4 (FNS entrance passage) detects the leading edge of a paper.

M7 turns OFF when PS10 (paper exit 2) detects

paper exit of the paper, unless an FNS start signal has already been received from the main

body.

5V

IN

SGND

24V-IN

M_TXD

SGND

M_REQ

SGND

M_ACK

SGND

M_RXD

SGND

S_REQ

SGND

S_ACK

SGND

PS6 (Paper exit 1)

Paper exit

roller

(Sponge roller)

5V

P/S

CLK

H/L

LD

PGND

PGND

24V

24V

F/R

5V

IN

GND

5V

IN

GND

FNS CBRB

M7

PS4

2 UNIT EXPLANATION

PS10

M7

(Paper exit roller)

PS10 (Paper exit 2)

PS9 (Paper exit belt HP)

Paper exit belt

Paper exit

arm

b. Staple mode (flat stapling)

M7 starts rotating when stapling is finished, and

stops when PS9 (paper exit-belt HP) turns ON.

c. Booklet mode

M7 starts rotating in reverse when stapling is finished, and stops when PS9 turns ON.

2 - 17

Page 44

FS-111/FS-211

2. Signals

a. Input signals

(1) IN (PS9 to FNS CB : FS-111)

(PS9 to RB to FNS : FS-211)

Turns ON ([L]) when the paper exit belt is in HP.

(2) IN (PS10 to FNS CB)

Turns ON ( [L]) when paper passage is detected

at the FNS paper exit.

(3) LD (M7 to FNS CB)

M7 (Paper exit roller) rotational status detection

signal. This signal becomes [L] when M7 reaches

2 UNIT EXPLANATION

the specified speed.

b. Output signals

(1) P/S (FNS CB to M7)

M7 drive control signal.

[H]: OFF

[L]: ON

(2) CLK (FNS CB to M7)

M7 rotating speed control clock signal.

(3) H/L (FNS CB to M7)

M7 rotating speed control gain switching signal.

[H]: low speed

[L]: High speed

(4) F/R (FNS CB to M7)

M7 rotation direction control signal.

[H]: Counterclockwise

[L]: Clockwise

2 - 18

Page 45

FS-111/FS-211

[10] SD4 (Paper Exit Opening) Control

5V

IN

FNS CB

GND

GND

GND

5V

IN

5V

IN

SD4

MS1

SGND

PGND

PGND

MAIN BODY

24V

DRV

24V

24V-IN

5V

M_TXD

SGND

M_REQ

SGND

M_ACK

SGND

M_RXD

SGND

S_REQ

SGND

S_ACK

SGND

SD4 (paper exit opening) controls engagement by the

nip paper exit roller. SD4 is controlled by the FNS CB

(FNS control board).

1. Operation

When ejection is not in progress, a gap is maintained between the nip paper exit roller and the

paper exit roller so as to prevent paper jams at

the paper exit.

At time of ejection, however, SD4 turns ON, inclining the nip paper exit roller against the paper

exit roller so that the gap is closed.

a. SD4 ON timing

(1) Sort, Group, and Non-Sort modes

SD4 turns ON a preset time period after PS10

(paper exit 2) detects the leading edge of the

paper.

(2) Staple mode

SD4 turns ON a preset time period after completion of stapling.

PS6

PS10

PS12

b. SD4 OFF timing

(1) Sort, Group, and Non-Sort modes

SD4 turns OFF a preset time period after PS10

detects the trailing edge of the paper.

(2) Staple mode

SD4 turns OFF a preset time period after PS6

(paper exit 1) detects the trailing edge of the

paper set.

Conveyance roller (B)

PS6 (Paper exit 1)

Nip paper

exit roller

SD4

(Paper exit

opening)

PS10 (Paper

Conveyance

roller (C)

exit 2)

Conveyance roller (D)

Paper exit roller

(Sponge roller)

PS4 (FNS entrance

passage)

Conveyance roller (A)

2. Signals

a. Input signals

(1) PS12 IN (PS12 to FNS CB)

Detects open/closed state of the paper exit opening.

[H] ∅ [L]: Closed

[L] ∅ [H]: Open

b. Output signals

(1) SD4 DRV (FNS CB to SD4)

SD4 (paper exit opening) drive control signal.

[H]: OFF

[L]: ON

2 UNIT EXPLANATION

2 - 19

Page 46

FS-111/FS-211

[11] M8 (Paper Exit Opening) Control

24V

24V-IN

5V

M_TXD

SGND

M_REQ

SGND

M_ACK

SGND

M_RXD

SGND

S_REQ

SGND

S_ACK

SGND

FNS CB

MS1

SGND

PGND

PGND

2 UNIT EXPLANATION

MAIN BODY

M8 (paper exit opening) opens and closes the paper

exit by means of a linkage mechanism. M8 is controlled

by the FNS CB (FNS control board).

1. Operation

If large paper (the length in the paper feed

direction is 217 mm or more) is being stapled,

M8 turns ON when the START button ON signal

is received, causing the paper exit to open.

Upon completion of stapling, the stapling-completed signal from the FNS CB causes the paper

exit to close, and the stapled set is exited.

The status of the paper exit opening is detected

by PS12 (paper exit opening).

24V

DRV

GND

5V

IN

M8

PS12

When print

starts

When paper conveying to stacker

When paper

exit to the main

tray

Staple

(large paper)

Staple

(small paper)

Off-set

Booklet

Open

Closed

Closed

Open

Open

Closed

Open

2. Signals

a. Input signals

(1) PS12 IN (PS12 to FNS CB)

Detects open/closed state of the paper exit opening.

[H] to [L]: Closed

[L] to [H]: Open

b. Output signals

(1) M8 DRV (FNS CB to M8)

M8 drive control signal.

[H]: ON

[L]: OFF

Closed

Closed

Closed

Open

Paper exit

M8 (Paper exit opening)

PS12

(Paper exit

opening)

2 - 20

Page 47

STAPLER UNIT

[1] Composition

Stapler (F)

FS-111/FS-211

FS-111

Stapler movement motor (M11)

Flat-stapling stopper

Stapling and folding

stopper HP PS (PS23)

Stapling and

folding stopper

motor (M14)

Clincher (F)

Flatstapling stopper

Stapling and

folding stopper

release motor

(M17)

Stapler (R)

2 UNIT EXPLANATION

Stapler rotation motor (M4)

FS-211

Stapler movement motor (M11)

Cincher (R)

Flat-stapling stopper

Stapler rotation motor (M4)

Stapling and folding stopper

Stapler (R)

Stapler rotation HP PS (PS14)

2 - 21

Stapler movement

HP PS (PS11)

Stapler (F)

Page 48

FS-111/FS-211

[2] Mechanisms

Mechanism

Staple mode *1

Stopper *2

2 UNIT EXPLANATION

(FS-211 only)

Stapling operation

*3

Method

FS-111:

Single staple (front/rear)

Two staples (flat)

FS-211:

Single staple (front/rear)

Two staples (flat)

Two staples (stapling and

folding)

Flat-stapling stopper

Staple-and-folding stopper

FS-111:

Stapler and clincher

combined

FS-211:

Stapler and clincher

separated

*1 Staple mode

a. Single staple (front or rear)

The stapler movement motor (M11) moves only

the stapler (F and R)(FS-111) or both the stapler

(F and R) and clincher (F and R)(FS-211) to the

stapling position.

When the stapling position is at the back, the stapler rotation motor (M4) rotates only the stapler

(R)(FS-111) or both the stapler (R) and clincher

(R)(FS-211) to the stapling position.

Only the stapler (FS-111) or both the stapler and

clincher (FS-211) staple the paper aligned by the

stacker.

FS-111

Stapler rotation motor (M4)

Stapler movement motor (M11)

Stapler movement motor

(M11)

Stapler rotation motor (M4)

FS-211

2 - 22

Page 49

FS-111/FS-211

b. Tow staples (flat-stapling)

The stapler movement motor (M11) moves only

the staplers (F and R)(FS-111) or both the staplers (F and R) and clinchers (F and R)(FS-211)

to the stapling positions.

Only the staplers (F and R)(FS-111) or both the

staplers (F and R) and clinchers (F and R)(FS-

211) staple the paper aligned by the stacker at

two positions simultaneously.

Stapler rotation

motor (M4)

FS-111

c. Two staples (stapling and folding) (FS-211 only)

Stapler (F), stapler (R), clincher (F), and clincher

(R) move into position.

Paper is transported to the stapling-and-folding

stopper, and then aligned by the action of the

upper and lower alignment plates. The paper is

then stapled in two locations.

Stapler (F) and clincher (F) are driven by the stapler movement motor (M11). Stapler (R) and

clincher (R) are driven by M11 and the stapler

rotation motor (M4).

Stapler movement motor (M11)

Clincher (R)

Stapler rotation

motor (M4)

Stapling and

folding stopper

motor

(M14)

Stapler (R)

2 UNIT EXPLANATION

Stapler movement motor (M11)

Stapler movement motor

(M11)

Stapler rotation motor (M4)

Stapler (F)

Clincher (F)

FS-211

Stapling and folding stopper

release motor (M17)

2 - 23

Page 50

FS-111/FS-211

*2 Operation of the Flat-stapling and Stapling-

and-folding Stopper (FS-211 only)

The flat-stapling stopper is held set while the stapling-and-folding stopper unit is at home position. The flat-stapling stopper is released by a

spring when the stapling-and-folding stopper unit

is moved out of home position by the action of

the stapling-and-folding stopper motor (M14).

Stapling and folding

stopper HP PS (PS23)

2 UNIT EXPLANATION

Spring

Staple position

Flat-stapling stopper

For stapling-and-folding operation: Paper is transported up to the stapling-and-folding stopper for

stapling. When stapling is completed, M17 releases the stopper and the paper set moves to

the folding unit. Setting and releasing of the stopper is repeated for each paper set.

Return of the staple paper-end stopper to home

position resets the flat-stapling stopper.

Stapling and

folding stopper

motor (M14)

Stapling and

folding

stopper unit

Stapling and

folding stopper

Staple position

When the stapling-and-folding stopper unit has

moved into the predetermined position, it is set

in place by the stapling-and-folding stopper release motor (M17).

Stapling and folding stopper release motor (M17)

Stapling and folding stopper

Released

Set

2 - 24

Page 51

FS-111/FS-211

*3 Stapling Operation

a. FS-111

The stapler motor/F (M24) and stapler motor/R

(M22) in the stapler (F and R) run to inject a staple

in order to bend it into the shape of the clincher.

Rotation control of the motors M24 and M22 are

exerted by the stapler HP PS/F (PS34) and stapler HP PS/R (PS31).

The cartridge detection PS/F (PS36) and cartridge PS/R (PS39) detect presence and improper loading of a cartridge.

Staple detection PS/F (PS37) and staple detection PS/R (PS40) detect presence of staples in

the cartridge.

After staples are charged, M24 and M22 run until the stapler ready PS/F (PS38) and stapler

ready PS/R (PS41) are turned ON by staples,

thus preventing blank stapling.

Stapler (F, R)

Stapler motor/

F (M24)

Stapler motor/

R (M22)

The cartridge-R detection switch (SW1) and the

cartridge-F detection switch (SW3) detect presence

(and correct setting) or absence (or improper

setting) of the respective staple cartridges. The

staple detection/R switch (SW2) and the staple detection/F switch (SW4) come ON when the amount

of staples in the respective cartridge runs low.

Eject staple.

Clincher

Stapler

Clincher

Bend staple.

Close staple.

Stapler

2 UNIT EXPLANATION

Staple

detection

PS/F

(PS37)

Staple

detection

PS/R

(PS40)

Stapler ready

PS/F (PS38)

Stapler ready

PS/R (PS41)

Cartridge detection

PS/F (PS36)

Cartridge detection

PS/R (PS39)

b. FS-211

Each stapler houses a stapler motor, and each

clincher houses a clincher motor. Motors the

stapler motor/F(M24) and the stapler motor/R

(M22) eject the staples, while motors the clincher

motor/F (M23) and the clincher motor/R (M21)

bend the staples.

The timing for staple clinching is controlled by

stapler-internal sensors the clincher-timing PS/

R (PS32) and the clincher-timing PS/F (PS35).

Switching ON of PS32 and PS35 causes motors

M21 and the within the clinchers motor (M23) to

operate, initiating the clinch action.

Stapler HP PS/R (PS31)

Stapler HP PS/F (PS34)

Clincher timing PS/R (PS32)

Clincher timing PS/F (PS35)

Staple detection

SW/R (SW2)

Staple detection

SW/F (SW4)

Stapler (F, R)

Cartridge detection SW/R (SW1)

Cartridge detection SW/F (SW3)

Clincher (F, R)

Clincher HP PS/R (PS30)

Clincher HP PS/F (PS33)

Clincher motor/R (M21)

Clincher motor/F (M23)

Stapler motor/R

(M22)

Stapler motor/F

(M24)

2 - 25

Page 52

FS-111/FS-211

[3] Stapler Control

PS31

PS32

SW1

SW2

M22

2 UNIT EXPLANATION

PS30

M21

PS34

PS35

SW3

SW4

M24

PS33

M23

FS-211

5V

PS31IN

GND

5V

PS32IN

GND

5V

5V IN

5V

5V IN

M22DRV F

M22DRV R

5V

PS30IN

GND

M21DRV F

M21DRV R

5V

PS34IN

GND

5V

PS35IN

GND

5V

5V IN

5V

5V IN

M24DRV F

M24DRV R

5V

PS33IN

GND

M23DRV F

M23DRV R

PS24

/RESET

SPCH

SNCH

/SHOME

/READY

/BUSY

/CLRREQ

/START

/CLR

SPCH

SNCH

/SHOME

/RESET

SPCH

SNCH

/SHOME

/READY

/BUSY

/CLRREQ

/START

/CLR

SPCH

SNCH

/SHOME

5V

PS24IN

GND

(FS211 ONLY)

RB

/READY

/BUSY

/CLRREQ

/READY

/BUSY

/CLRREQ

PS21IN

PS23IN

PS24IN

GND

GND

24V

24V

DRVA

DRVA

DRVB

DRVB

24V

24V

DRVA

DRVA

DRVB

DRVB

24V

24V

DRVA

DRVA

DRVB

DRVB

12V

DRV

PS21IN

GND

PS23IN

GND

R/RESET

R/START

R/CLR

F/RESET

IN

IN

5V

IN

PS11

5V

IN

PS14

M4

M11

M14

M17

5V

PS21

5V

PS23

MS1

24V

SGND

PGND

PGND

MAIN BODY

F/START

M4 DRVA

M4 DRVA

M4 DRVB

M4 DRVB

24V

M11 DRVA

M11 DRVA

M11 DRVB

M11 DRVB

M14 DRVA

M14 DRVA

M14 DRVB

M14 DRVB

M17_12V

M17 DRV

5V

PS11 SIG

SGND

5V

PS14 SIG

SGND

24V

M4 DRV

24V

24V

DRVA

DRVA

DRVB

DRVB

24V-IN

5V

M_TXD

SGND

M_REQ

SGND

M_ACK

SGND

M_RXD

SGND

S_REQ

SGND

S_ACK

SGND

FNS CB

F_HOME

F_CD

F_LS

F_READY

SGND

STR_F_DRV1

STR_F_DRV1

R_HOME

R_CD

R_LS

R_READY

SGND

STR_F_DRV1

STR_F_DRV1

5V

5V

PS34IN

GND

PS36IN

GND

PS37IN

GND

PS38IN

GND

M24 DRVF

M24 DRVR

PS31IN

GND

PS39IN

GND

PS40IN

GND

PS41IN

GND

M22 DRVF

M22 DRVR

5V

PS34

5V

PS36

5V

PS37

5V

PS38

M24

5V

PS31

5V

PS39

5V

PS40

5V

PS41

M22

FS-111

M11 (stapler movement) and M4 (stapler rotation)

move staplers (FS-111) or the staplers and clinchers

(FS-211) into position in accordance with the selected

stapling mode. Once in position, the stapler(s) execute

stapling. A stapling cycle is detected by ON-OFF-ON

activation of the various stapler and clincher homeposition sensors; specifically: PS31 (stapler HP/R),

PS34 (stapler HP/F), PS30 (clincher HP/R), and PS33

(clincher HP/F). Operation is controlled by the FNS

CB (FNS control board) via the RB (relay board)(FS-

211) or directly (FS-111).

1. Operation

a. Single-staple movement control (front)

M11 turns ON when the main body issues the

START button ON signal, moves the staplers

(FS-111) or the staplers and clinchers (FS-211)

to the predetermined positions, and then stops.

When single-staple mode is completed, M11

moves the staplers (FS-111) or the staplers and

clinchers back to the ON position of PS11 (stapler movement HP) and then stops.

2 - 26

Page 53

FS-111/FS-211

b. Single staple movement control (rear)

M11 (stapler movement) and M4 (staple rotation)

turn ON when the main body issues the START

button ON signal, move the staplers (FS-111) or

the staplers and clinchers (FS-211) to the predetermined positions, and then stop. When single-staple mode is completed, M11 and M4 move

the stapler or the staplers and clinchers back to

the PS11 (stapler movement HP) and PS14 (stapler rotation HP) ON positions, and then stop.

c. Two staplers movement control

M11 and M4 come ON when the main body issues the START button ON signal, move the staplers (FS-111) or the staplers and clinchers (FS-

211) to the predetermined positions, and then

stops. When two-staple mode is completed, M11

and M4 moves the staplers and clinchers (FS-

211) back to the ON position of PS11 (stapler

movement HP) and then stops.

d. Control of the stapling-and-folding stopper

(stapling & folding) (FS-211 only)

On receipt of the START button ON signal, the

stapling-and-folding stopper is moved and set into

position. M14 (stapling-and-folding stopper)

moves the stopper into position, and M17 (stapling-and-folding stopper release) sets it. When

stapling action is completed, M17 releases the

stopper and the papers move to the folding unit.

Setting and releasing of the stopper is repeated

for each paper set.

When PS25 (folding paper exit) detects exiting

of the final paper set, M14 returns the stopper to

its home position. Arrival at home position is detected by PS23 (stapling-and-folding stopper HP).

e. Control of the stapler paper-end stopper

(folding) (FS-211 only)

On receipt of the START button ON signal, the

stapling-and-folding stopper is moved and set

into position. M14 moves the stopper into position, and M17 sets it.

A preset period after PS5 (stacker conveyance

passage) detects the final paper set, M17 releases the stopper and the papers move to the

folding unit. Setting and releasing of the stopper

is repeated for each paper set.

A preset period after PS25 detects the passage