Page 1

SERVICE MANUAL

Model

FS-109

NOVEMBER 2000

CSM-FS109

KONICA BUSINESS TECHNOLOGIES, INC.

Page 2

Page 3

FS-109

SERVICE MANUAL

NOVEMBER 2000

Used on Konica Model

7045

Page 4

IMPORTANT NOTICE

Because of the possible hazards to an inexperienced

person servicing this equipment, as well as the risk of

damage to the equipment, Konica Business Technologies strongly recommends that all servicing be performed by Konica-trained service technicians only.

Changes may have been made to this equipment to

improve its performance after this service manual was

printed. Accordingly, Konica Business Technologies,

Inc., makes no representations or warranties, either

expressed or implied, that the information contained in

this service manual is complete or accurate. It is understood that the user of this manual must assume all risks

or personal injury and/or damage to the equipment while

servicing the equipment for which this service manual

is intended.

Corporate Publications Department

© 2000, KONICA BUSINESS TECHNOLOGIES, INC.

All rights reserved.

Printed in U.S.A.

Page 5

CONTENTS

OUTLINE

FS-109 PRODUCT SPECIFICATIONS ............................1

CENTER CROSS-SECTIONAL VIEW ............................. 3

DRIVE SYSTEM DIAGRAM ............................................. 4

Paper Conveyance System Drive .............................4

Stapler Unit System Drive......................................... 4

UNIT EXPLANATION

EXTERNAL SECTION......................................................5

Composition ..............................................................5

CONVEYANCE SECTION ...............................................6

Composition ..............................................................6

Mechanisms .............................................................. 6

Conveyance Motor (M801) Control...........................9

Conveyance Drum (M807) Control .........................10

Tray Up/Down (M804) Control ................................ 11

PAPER EXIT/STAPLER UNIT SECTION....................... 13

Composition ............................................................13

Mechanisms ............................................................ 13

Paper Alignment Control.........................................15

Paper Exit (M805) Control ......................................16

Paper Stacking Control ........................................... 17

Stapler Movement (M806) Control..........................18

Stapler Control ........................................................18

OTHER CONTROL FUNCTIONS ..................................20

Power-on Operation................................................20

CONTENTS

DISASSEMBLY/ASSEMBLY

DISASSEMBLY AND REASSEMBLY ............................21

Replacing the Tray 2/3 Paper Exit Roller Unit ........ 21

Raising and Lowering the Tray ...............................21

Removing and Reinstalling Tray 2/3 ....................... 22

Removing and Reinstalling the External Covers ....22

Removing and Reinstalling the Lift Wire................. 23

Replacing the Stapler Cartridge..............................25

Removing and Reinstalling the Stapler Unit ........... 25

DIAGRAMS

ELECTRICAL PARTS LAYOUT .....................................27

CONNECTOR LAYOUT ................................................. 28

TIMING CHARTS ........................................................... 29

OVERALL WIRING DIAGRAM....................................... 31

iii

Page 6

CONTENTS

This page left blank intentionally.

iv

Page 7

SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

Installation Environment

Safety considerations usually are directed toward

machine design and the possibility of human error. In

addition, the environment in which a machine is operated must not be overlooked as a potential safety

hazard.

Most electrical equipment is safe when installed in a

normal environment. However, if the environment is

different from what most people consider to be normal, it is conceivable that the combination of the

machine and the room air could present a hazardous

combination. This is because heat (such as from

fusing units) and electrical arcs (which can occur

inside switches) have the ability to ignite flammable

substances, including air.

When installing a machine, check to see if there

is anything nearby which suggests that a potential hazard might exist. For example, a laboratory

might use organic compounds which, when they

evaporate, make the room air volatile. Potentially dangerous conditions might be seen or smelled. The

presence of substances such as cleaners, paint thinners, gasoline, alcohol, solvents, explosives, or similar items should be cause for concern.

If conditions such as these exist, take appropriate

action, such as one of the following suggestions.

effect may be caused by altering any aspect of the

machine’s design. Such changes have the potential

of degrading product performance and reducing

safety margins.

For these reasons, installation of any modification not

specifically authorized by Konica Business Machines

U.S.A., Inc., is strictly prohibited.

The following list of prohibited actions is not all-inclusive, but demonstrates the intent of this policy.

• Using an extension cord or any unauthorized

power cord adapter.

• Installing any fuse whose rating and physical size

differs from that originally installed.

• Using wire, paper clips, solder, etc., to replace or

eliminate any fuse (including temperature fuses).

• Removing (except for replacement) any air filter.

• Defeating the operation of relays by any means

(such as wedging paper between contacts).

• Causing the machine to operate in a fashion other

than as it was designed.

• Making any change which might have a chance

of defeating built-in safety features.

• Using any unspecified replacement parts.

• Determine that the environment is controlled

(such as through the use of an exhaust hood) so

that an offending substance or its fumes cannot

reach the machine.

• Remove the offending substance.

• Install the machine in a different location.

The specific remedy will vary from site to site, but the

principles remain the same. To avoid the risk of injury

or damage, be alert for changes in the environment

when performing subsequent service on any machine, and take appropriate action.

Unauthorized Modifications

Konica copiers have gained a reputation for being

reliable products. This has been attained by a combination of outstanding design and a knowledgeable

service force.

The design of the copier is extremely important. It is

the design process that determines tolerances and

safety margins for mechanical, electrical, and electronic aspects. It is not reasonable to expect individuals not involved in product engineering to know what

General Safety Guidelines

This copier has been examined in accordance with

the laws pertaining to various product safety regulations prior to leaving the manufacturing facility to

protect the operators and service personnel from

injury. However, as with any operating device, components will break down through the wear-and-tear of

everyday use, as will additional safety discrepancies

be discovered. For this reason, it is important that the

technician periodically performs safety checks on the

copier to maintain optimum reliability and safety.

The following checks, not all-inclusive, should be

made during each service call:

CAUTION: Avoid injury. Ensure that the copier is

disconnected from its power source before continuing.

• Look for sharp edges, burrs, and damage on all

external covers and copier frame.

• Inspect all cover hinges for wear (loose or broken).

• Inspect cables for wear, frays, or pinched areas.

v

Page 8

SAFETY PRECAUTIONS

• Ensure that the power cord insulation is not damaged (no exposed electrical conductors).

• Ensure that the power cord is properly mounted

to the frame by cord clamps.

• Check the continuity from the round lug (GND) of

the power cord to the frame of the copier -- ensure

continuity. An improperly grounded machine can

cause an electrically-charged machine frame.

Safeguards During Service Calls

Confirm that all screws, parts, and wiring which are

removed during maintenance are installed in their

original positions.

• When disconnecting connectors, do not pull the

wiring, particularly on AC line wiring and high

voltage parts.

• Do not route the power cord where it is likely to

be stepped on or crushed.

• Carefully remove all toner and dirt adhering to any

electrical units or electrodes.

• After part replacement or repair work, route the

wiring in such a way that it does not contact any

burrs or sharp edges.

• Do not make any adjustments outside of the

specified range.

Applying Isopropyl Alcohol

Care should be exercised when using isopropyl alcohol, due to its flammability. When using alcohol to

clean parts, observe the following precautions:

• Remove power from the equipment.

• Use alcohol in small quantities to avoid spillage

or puddling. Any spillage should be cleaned up

with rags and disposed of properly.

• Be sure that there is adequate ventilation.

• Allow a surface which has been in contact with

alcohol to dry for a few minutes to ensure that the

alcohol has evaporated completely before applying power or installing covers.

Summary

It is the responsibility of every technician to use professional skills when servicing Konica products. There

are no short cuts to high-quality service. Each copier

must be thoroughly inspected with respect to safety

considerations as part of every routine service call.

The operability of the copier, and more importantly,

the safety of those who operate or service the copier,

are directly dependent upon the conscientious effort

of each and every technician.

Remember...when performing service calls, use good

judgement (have a watchful eye) to identify safety

hazards or potential safety hazards that may be present, and correct these problem areas as they are

identified -- the safety of those who operate the copier

as well as those who service the copier depend on it!

vi

Page 9

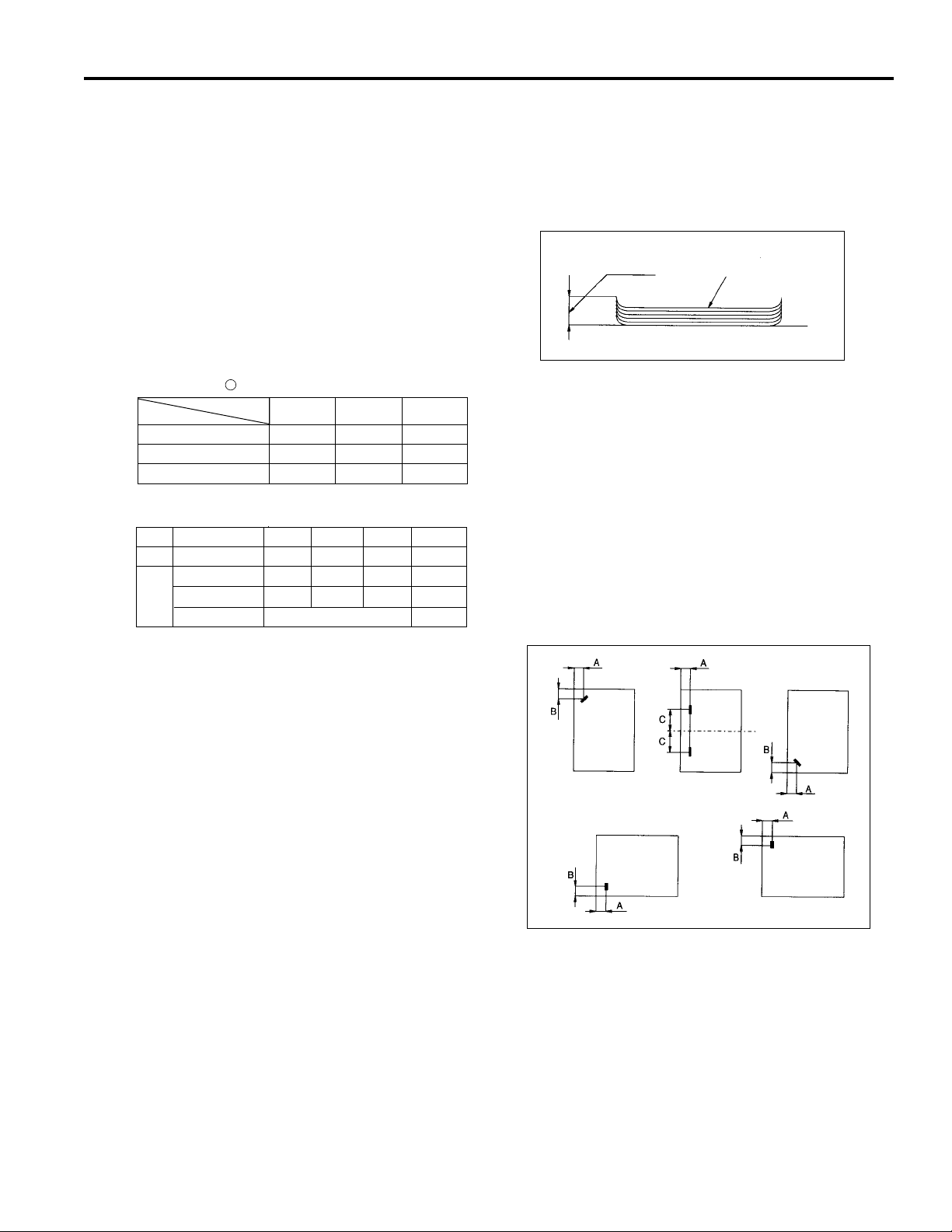

FS-109 PRODUCT SPECIFICATIONS

FS-109

Type

Type: Natural inverting type, Multi-

tray finisher

Functions

Kinds of

copy paper: Same as main body

Copy Paper

size: 8.5 x 11, 8.5 x 11R/11 x 17R /

8.5 x 14R

Modes

Mode

Through mode

Offset mode

Staple mode

Sheet capacity

Tray

Through mode

Tray 1

Through mode

Tray 2,

Offset mode

Tray 3

Staple mode

: Available ✕ : Not availab le

Tray

Tray 1

Mode

●

✕

✕

Small sizes

100

300

–

25 sets (Note)

Middle sizes Large sizes

100

700

700

Tray 2

●

●

●

100

300

300

Tray 3

●

●

●

Special paper

10

–

–

–

Paper weight

Tray 1: 13 - 53 lb.

Tray 2/3: 16 - 35 lb.

Copy paper

curling: 10 mm maximum

Curling

Copy paper (5 sheets)

Offset amount: 30 mm (offset/group mode)

Stapler Kit

No. of

copies

stapled : 50 maximum (22 lb. fine quality

paper, thickness 5 mm max)

Staple

position: A = 8 mm (±3 mm adjustable)

B = 10 mm (±3 mm adjustable)

C = 90 mm (±4 mm adjustable)

Stapler

capacity: 5000 staples/cartridge

Note1: The above numbers apply for same-size

paper (22 lb., standard paper) stacked

continuously.

Note2: Small sizes: 5.5 x 8.5R

Middle sizes: 8.5 x 11, 8.5 x 11R

Large sizes: 11 x 17R, 8.5 x 14R

Special paper: Other than standard paper

(thin paper, thick paper,

blueprint master

OHP film etc.)

Note3: The maximum capacity (500 or 300

sheets) should not be exceeded.

1

Page 10

FS-109

Particulars of Machine

Power

source:

Max. power

consumption: 100 VA

Weight: Approximately 81 lb. (with pedestal)

Machine

dimensions: Width 10.4 in.

24 V DC / 5 V (supplied from main body)

Depth 23.6 in.

Height 24.5 in.

Maintenance and Life

Maintenance: Same as the main body

Operating Environment

Temperature: 50°F to 86°F

Humidity: 10% to 80% RH

Note: The contents of this manual may be changed

without prior notice.

2

Page 11

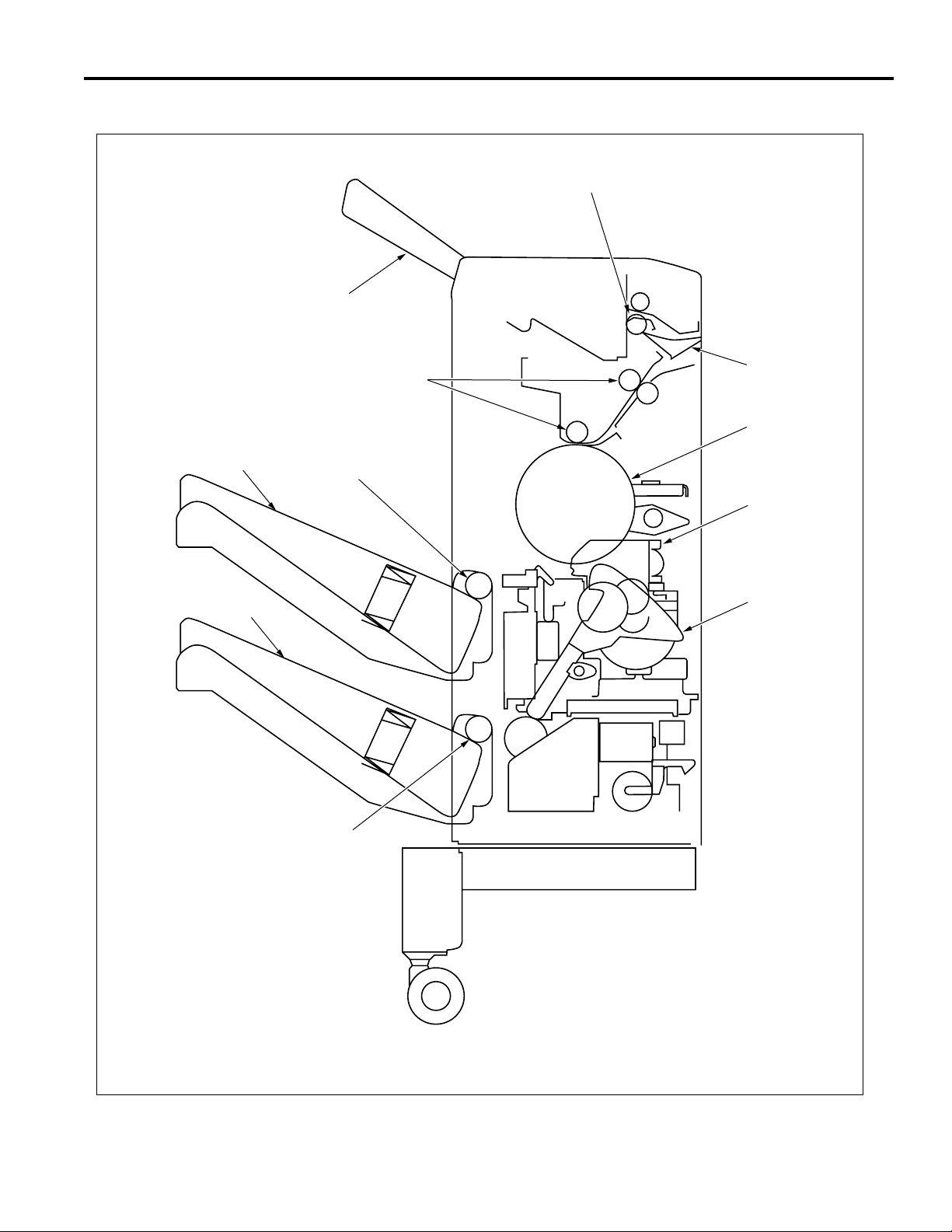

CENTER CROSS-SECTIONAL VIEW

Paper exit roller

Tray 1

FS-109

Tray 2

Tray 3

Conveyance rollers

Switching gate

Conveyance drum

Paper exit roller (A)

Stapler unit

Exit lever

Paper exit roller (A)

3

Page 12

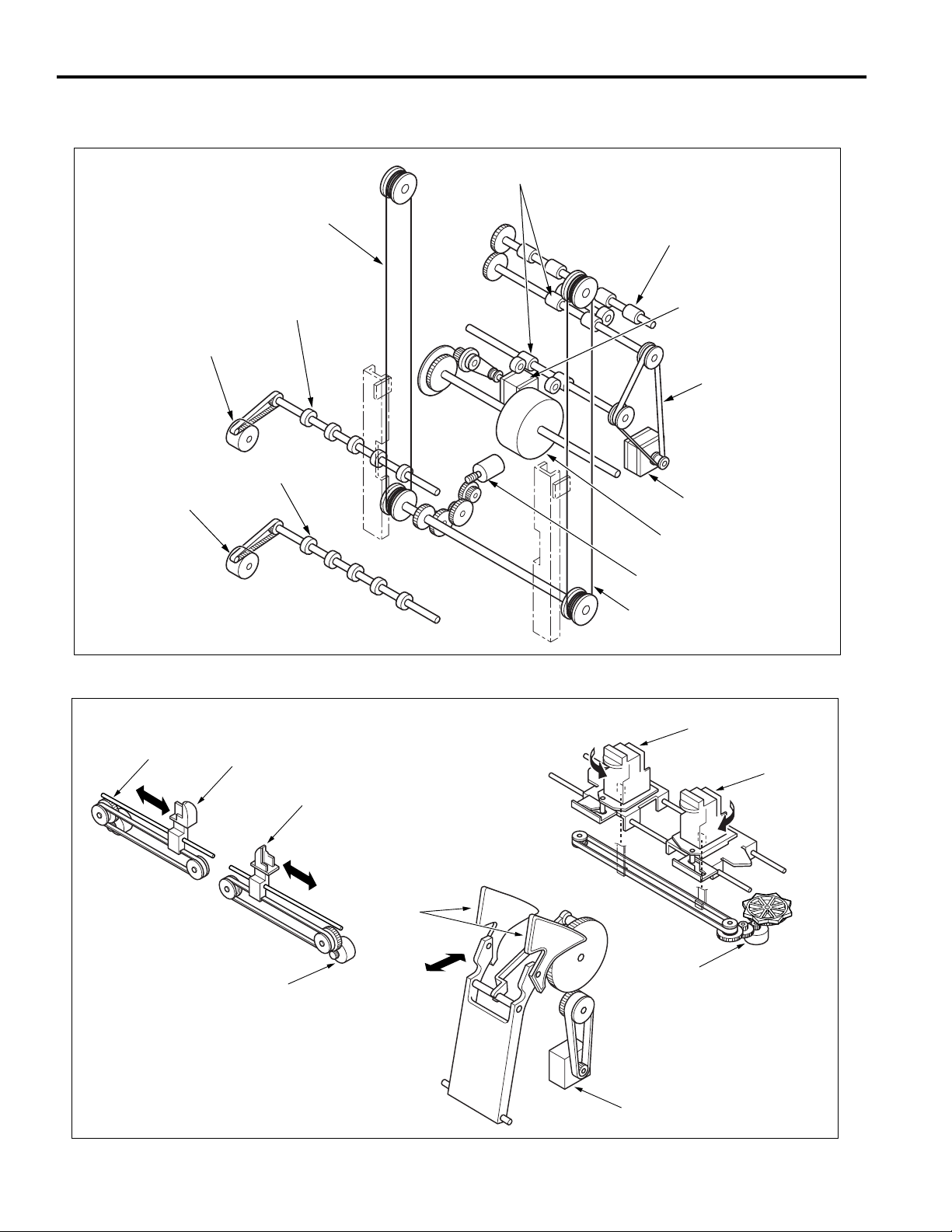

FS-109

DRIVE SYSTEM DIAGRAM

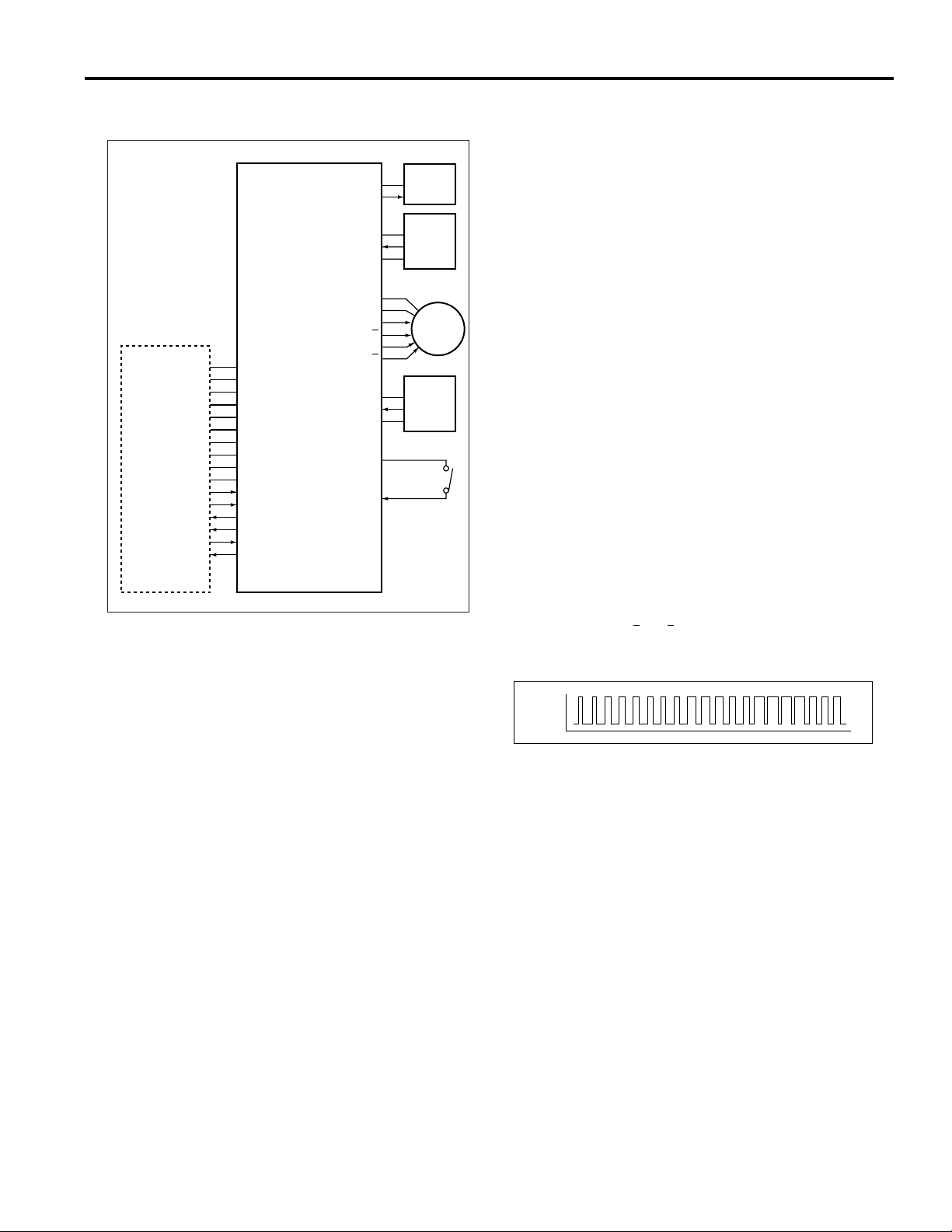

Paper Conveyance System Drive

Conveyance rollers

Tray 2 motor (M810)

Tray 3 motor (M811)

Lift wire (rear)

Paper exit roller (A)

Paper exit roller (A)

Paper exit roller

Conveyance

drum drive motor (M807)

Timing belt

Conveyance motor (M801)

Conveyance drum

Tray up/down motor (M804)

Lift wire (front)

Stapler Unit System Drive

Alignment motor

(rear)(M808)

Alignment plate

(rear)

Alignment plate

(front)

Alignment motor

(front)(M809)

Stapler unit (rear)

Stapler unit (front)

Exit lever

Stapler movement

motor (M806)

Paper exit motor (M805)

4

Page 13

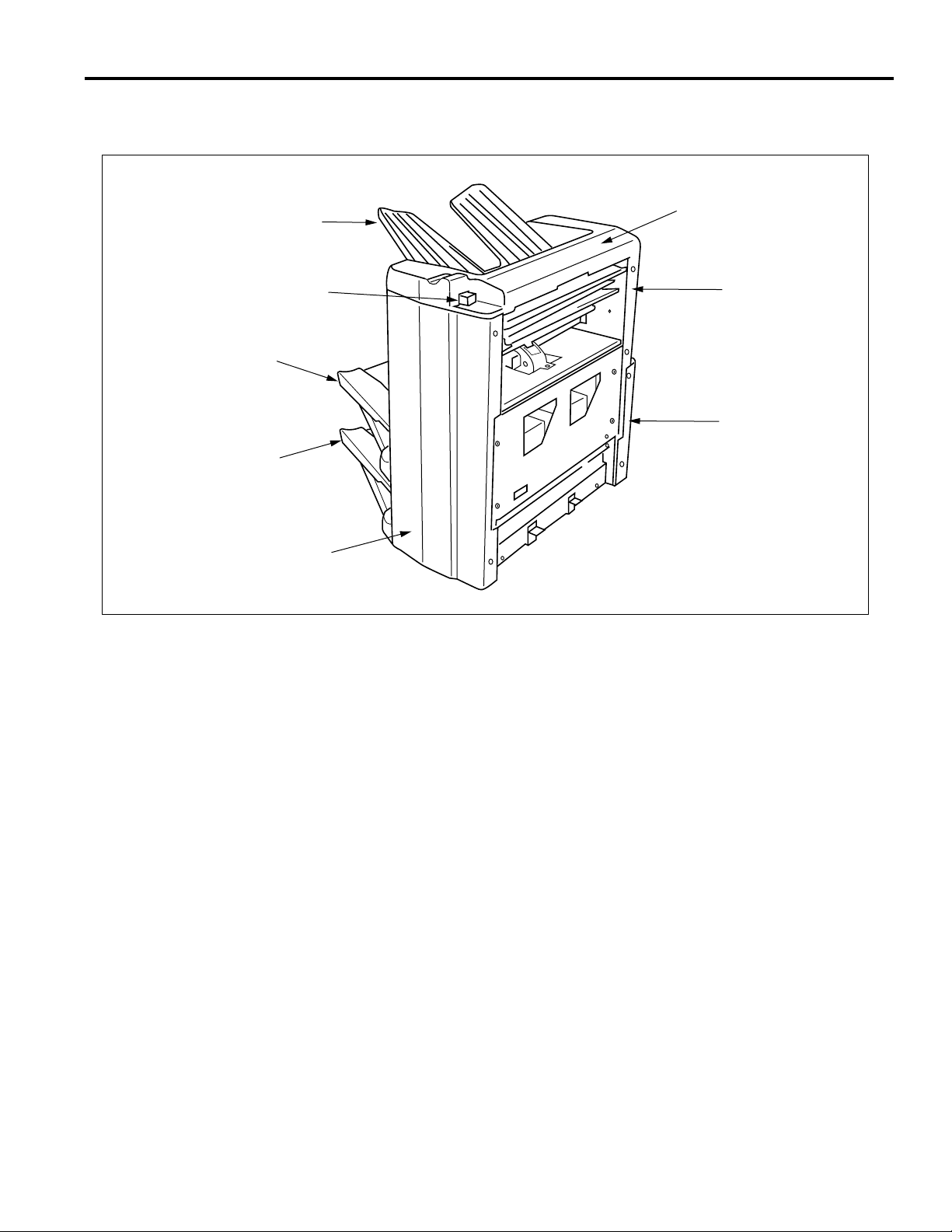

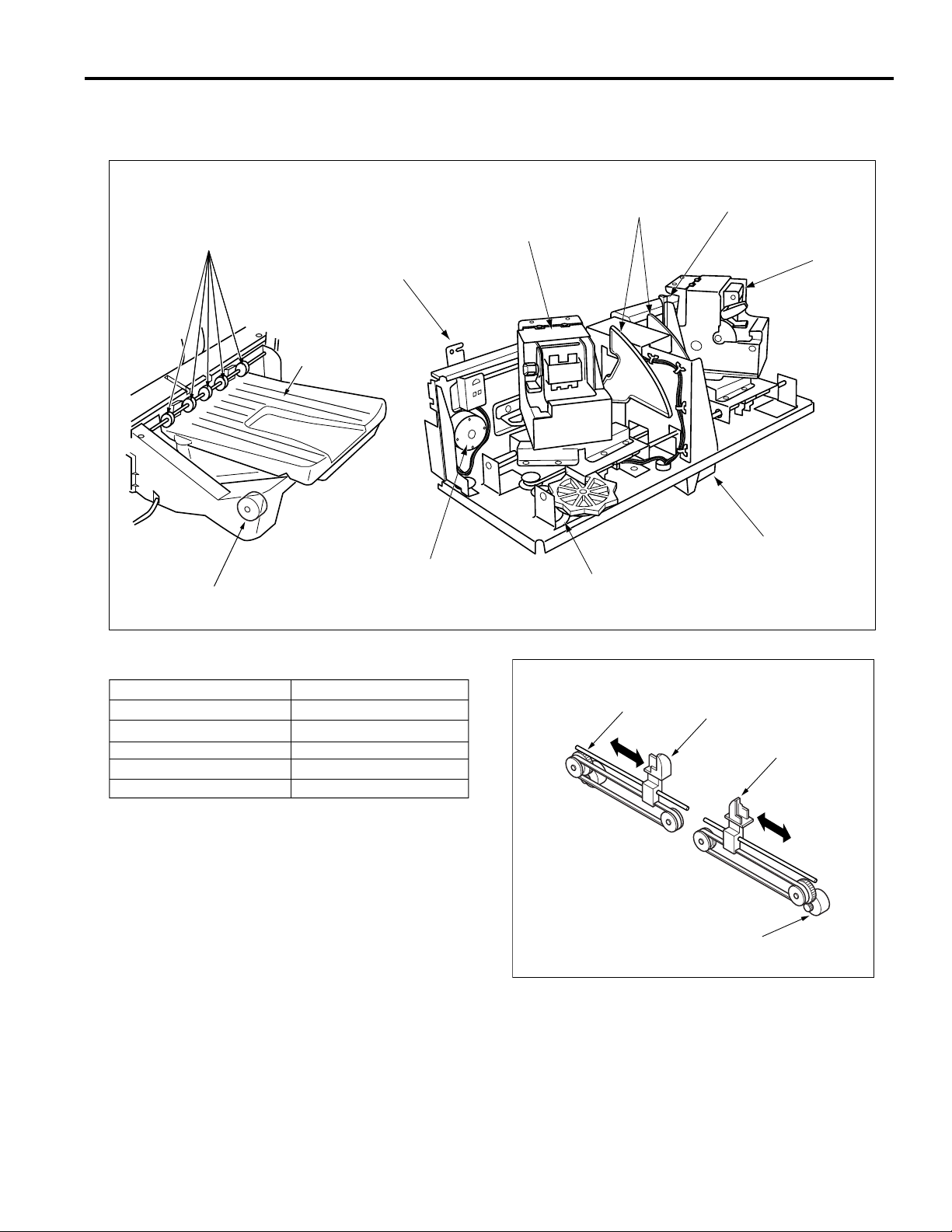

EXTERNAL SECTION

Composition

FS-109

Tray 1

Release lever

Tray 2

Tray 3

Front cover

Top cover

Upper rear cover

Rear cover

5

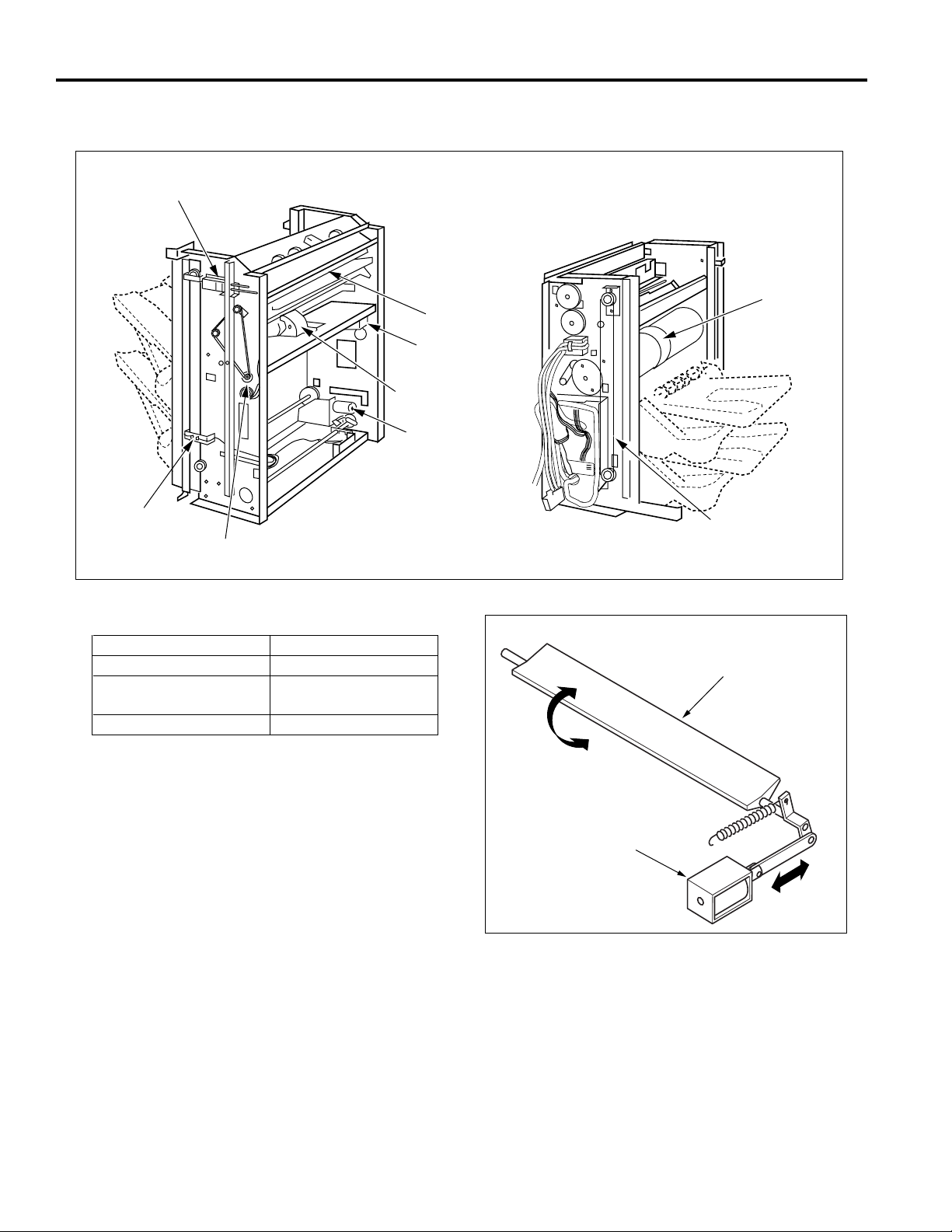

Page 14

FS-109

CONVEYANCE SECTION

Composition

Gate SD

Lift wire

Mechanisms

Mechanisms Methods

Paper path switching *1

Paper conveyance *2

Tray lift (up/down) *3

Conveyance motor

Switching gate

Conveyance roller

Conveyance drum

Wire drive (Lift wire)

Switching gate

Conveyance

drum motor

Conveyance

drum

Tray up/down

motor

Conveyance

drum

Lift wire

Switching gate

*1: Paper path switching

The paper exited from the fixing unit in the main body

passes through the switching gate which sends it to

tray 1 or tray 2/3. The switching gate is operated by

the on/off state of the gate SD (SD801).

Gate SD

6

Page 15

FS-109

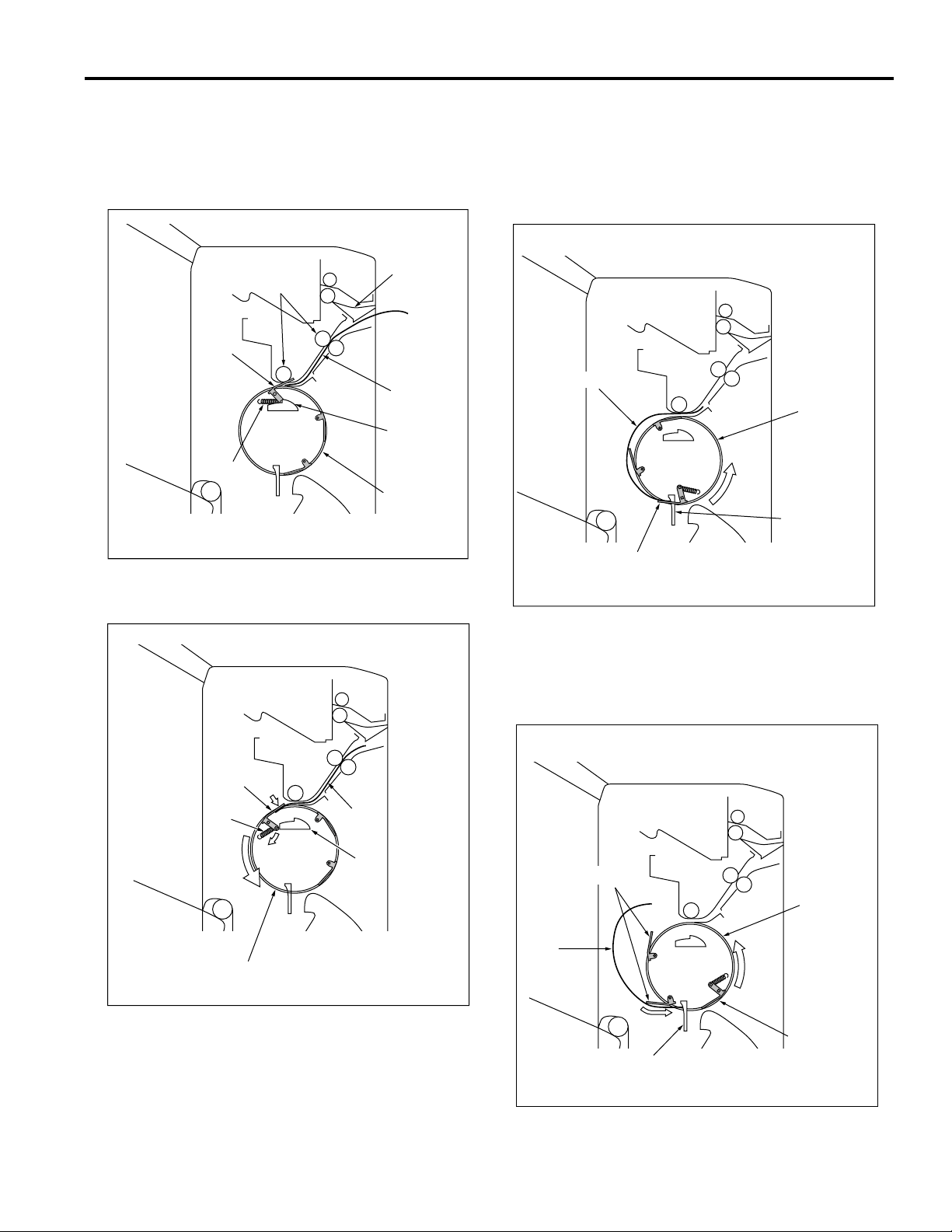

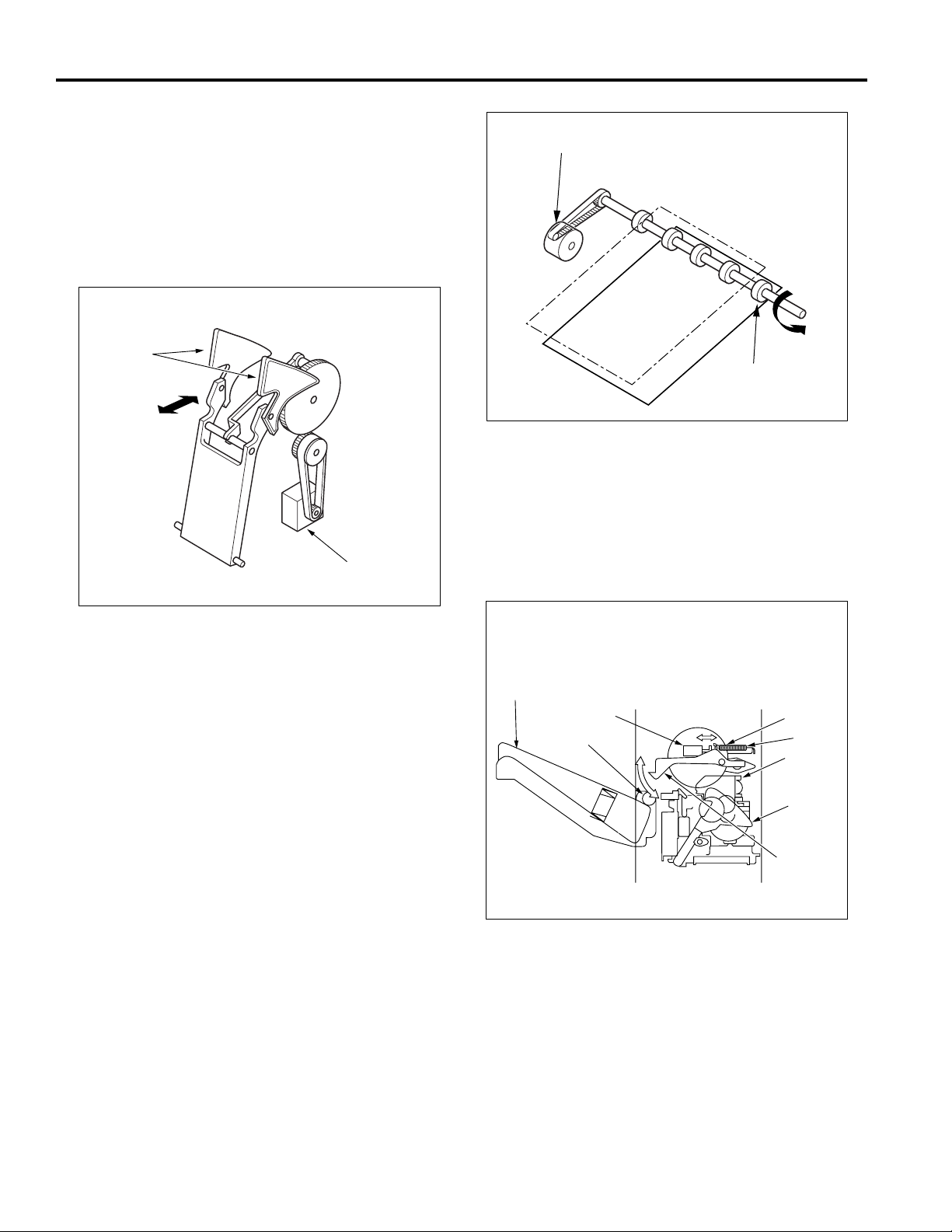

*2: Paper Conveyance

When the paper has been switched to tray 2/3 by the

switching gate, the conveyance roller conveys it to

the conveyance drum until it enters the grip plate on

the circumference of the drum.

Switching

Conveyance

rollers

Grip plate

Spring

gate

Paper

Cam

Conveyance

drum

When the rotation speed of the drum increases, the

paper is pushed out and separated from the

conveyance drum. When the grip plate on the

conveyance drum reaches the paper exit position,

the paper hits a stopper and is separated from the

grip plate.

Paper

Conveyance

drum

Stopper

The grip plate closes due to the force of a cam and

spring arrangement and grasps the paper.

Grip plate

Spring

Conveyance drum

Paper

Cam

Grip plate

Behind the grip plate on the drum circumference,

there are two alignment plates. When these reach

the paper exit position, their own weight causes them

to open, and the rubber section at the plate tip aligns

the paper against the stopper.

Alignment plates

Conveyance

drum

Paper

Grip plate

Stopper

7

Page 16

FS-109

The grip plate and alignment plates on the

conveyance drum do not use electrical control, they

operate only through the rotation of the drum. (The

grip plate is driven by the drum via a cam

arrangement, and the alignment plates are driven by

the centrifugal force and their own weight.)

The conveyance drum and conveyance rollers are

controlled electrically by conveyance drum motor

(M807) and conveyance motor (M801).

*3: Tray lift

The paper exit position for the paper sent to tray 2/3

is fixed. Switching between tray 2 and tray 3 is

carried out by changing the tray position with the tray

lift (up/down) mechanism.

The tray lift mechanism is driven by the tray up/down

motor (M804) whose driving force is transmitted to the

tray by a wire arrangement.

Lift wire

Tray 2

Tray up/down motor

Tray 3

8

Page 17

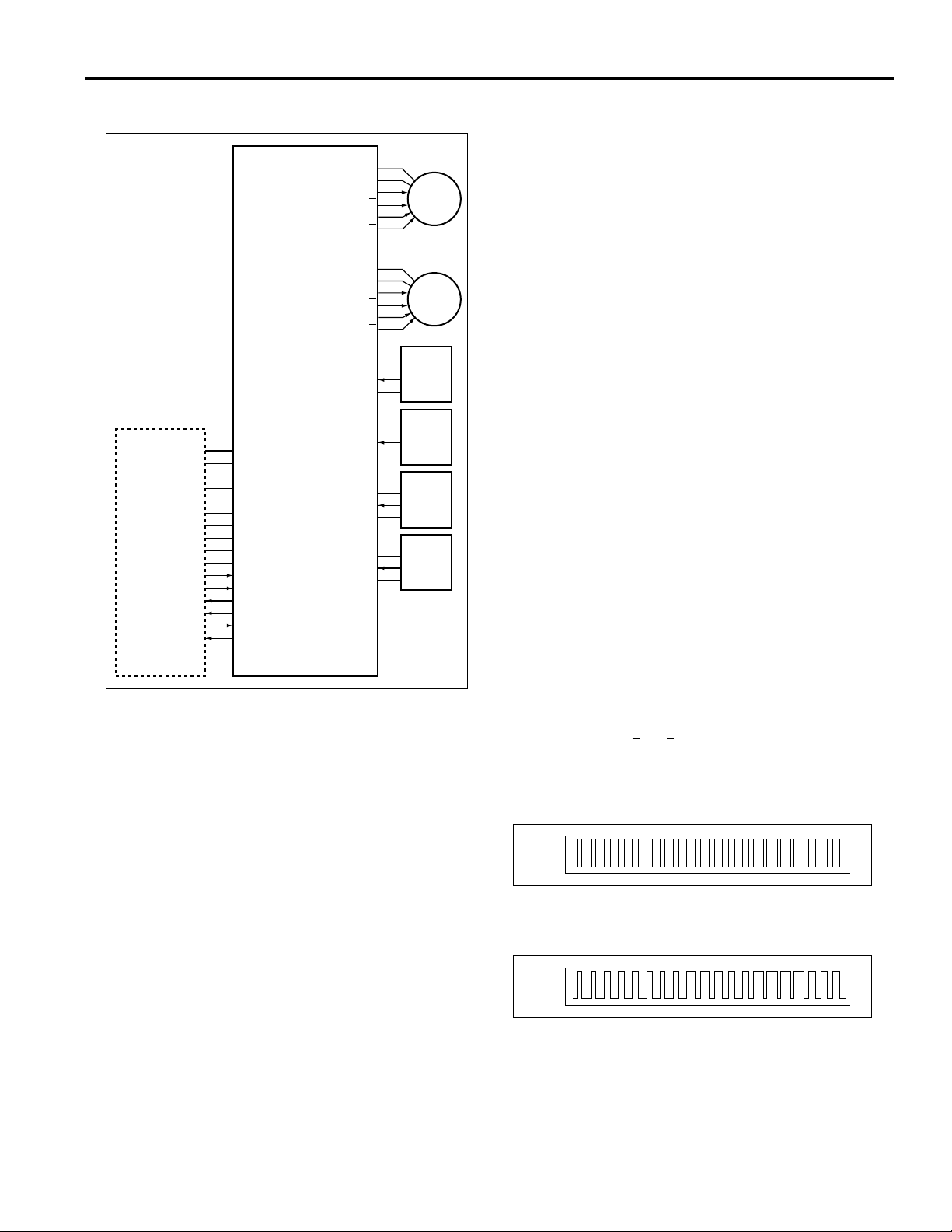

FS-109

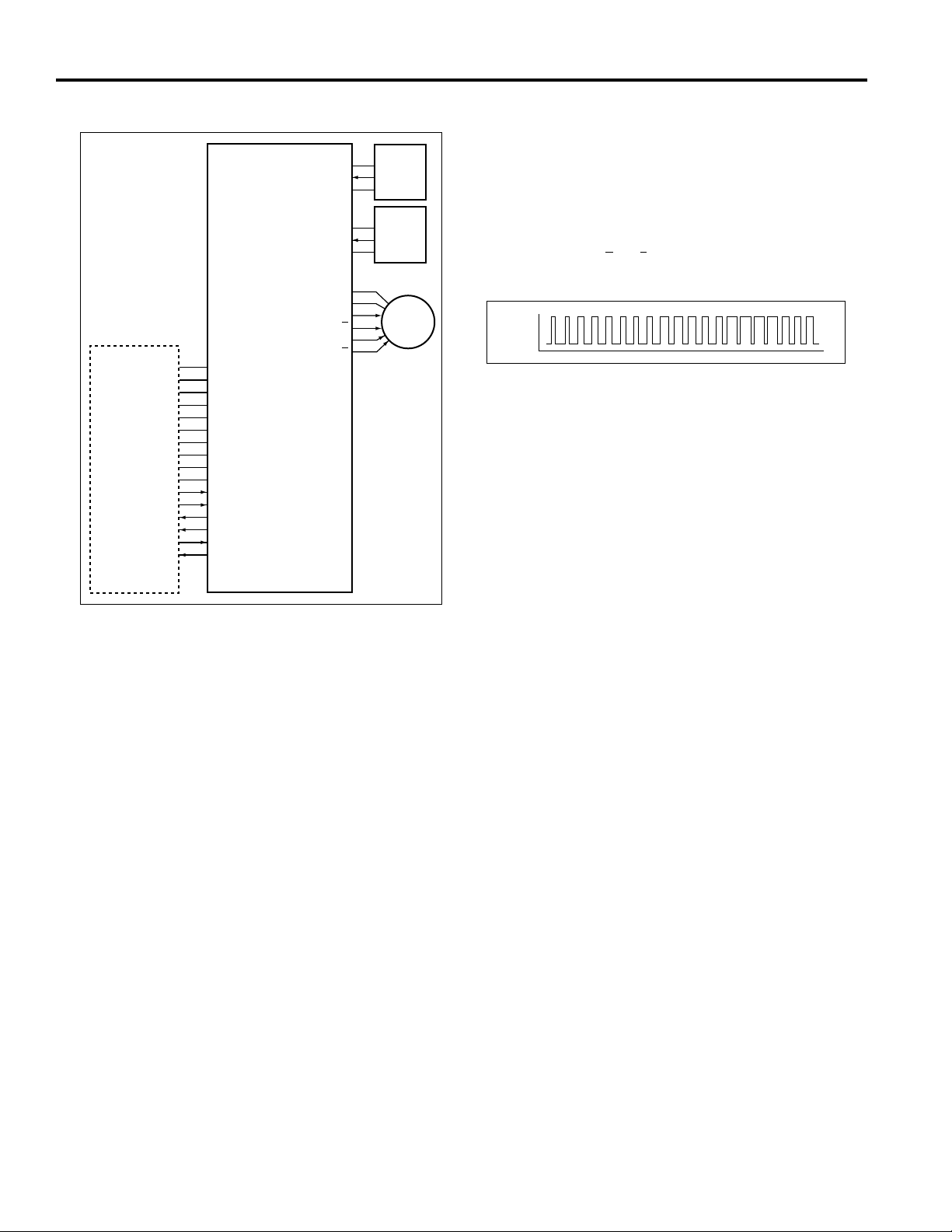

Conveyance Motor (M801) Control

24V

SD801 DRV

VCC

PS803IN

GND

24V

24V

M801 DRVA

M801 DRVA

M801 DRVB

SGND

SGND

PGND

PGND

PGND

M TxD

M REQ

M ACK

MAIN BODY

5V

5V

24V

24V

24V

S ACK

M RxD

S REQ

FNSCB

M801 DRVB

VCC

PS802IN

GND

24VOUT

24VIN

SD801

PS803

M801

PS802

MS801

2. Signals

a. Input signals

(1) PS802IN (PS802 to FNSCB)

Paper detection signal at the paper exit section

entrance of the tray 2 and tray 3 side.

[L]: Paper is not detected

[H]: Paper is detected

(2) PS803IN (PS803 to FNSCB)

Paper detection signal at the paper exit section

entrance of the tray 1.

[L]: Paper is not detected

[H]: Paper is detected

(3) 24VIN (MS801 to FNSCB)

Power supply line for various loads. When finisher is

in mechanical contact with main body, 24 V DC is

supplied to finisher.

(4) M TxD (MAIN BODY to FNSCB)

Serial data line for transmitting operation status

information from control board in main body to

finisher.

(5) M REQ (MAIN BODY to FNSCB)

Send request signal from main body to finisher.

(6) M ACK (MAIN BODY to FNSCB)

Send enable signal from main body to finisher.

Paper exit conveyance takes place as a result of the

transmission of the drive force of motor M801

(conveyance) to the paper exit rollers and conveyance

rollers. The paper conveyance path is switched between

tray 1 or tray 2/3 by solenoid SD801 (gate).

M801 and SD801 are controlled by the FNSCB (FNS

control board).

1. Operation

a. Gate switching operation

Normally, SD801 is OFF and the gate allows paper to

exite to tray 2/3. When tray 1 is selected as the paper

exit tray, SD801 goes ON, the gate is switched, and

the paper is conveyed to tray 1.

b. Conveyance operation

M801 is turned ON and OFF in conjunction with the

copy operation of the main body. During operation of

the main body, the M801 rotates constantly, enabling

paper conveyance at any time.

When paper has been conveyed to tray 2/3, the

status of the PS802 (drum entrance) and main body

PS1 (paper exit) causes the M801 to be switched

from low speed to high speed. The high-speed

activation signal and the rotation speed depend on

the paper size.

b. Output signals

(1) M801 DRV A, A, B, B (FNSCB to M801)

M801 ON/OFF drive signal

24V

0V

(2) SD801 DRV (FNSCB to SD801)

SD801 ON/OFF drive signal

[L]: SD801 ON

[H]: SD801 OFF

(3) M RxD (FNSCB to MAIN BODY)

Serial data line for transmitting operation status information

from finisher to main body CB (control board).

(4) S REQ (FNSCB to MAIN BODY)

Send request signal from finisher to main body.

(5) S ACK (FNSCB to MAIN BODY)

Send enable signal from finisher to main body.

9

Page 18

FS-109

Conveyance Drum (M807) Control

VCC

PS801IN

GND

VCC

PS802IN

GND

24V

24V

M807 DRVA

M807 DRVA

M807 DRVB

SGND

SGND

5V

5V

PGND

PGND

PGND

24V

24V

24V

M TxD

M REQ

M ACK

S ACK

M RxD

S REQ

M807 DRVB

PS801

PS802

M807

2. Signals

a. Input signal

(1) PS801IN (PS801 to FNSCB)

Encoder slit detection signal

[L]: Slit is not detected

[H]: Slit is detected

b. Output signal

(1) M807 DRV A, A, B, B (FNSCB to M807)

M807 ON/OFF drive signal

24V

0V

MAIN BODY

FNSCB

The paper that has been sent to tray 2/3 is exited into the

respective tray by the conveyance drum. The conveyance

drum is driven by M807 (conveyance drum) which is

controlled by the FNSCB (FNS control board).

1. Operation

a. Conveyance operation

When PS802 (drum entrance) detects the leading

edge of the paper and goes ON, M807 is turned ON

after the specified time, and the conveyance drum

starts to rotate.

To convey one sheet of paper, the M807 is switched

through a predetermined sequence of three speeds.

When the conveyance drum reaches the standby

position, the motor is switched OFF.

During this time, the drum makes one revolution

which includes gripping, conveying, and releasing

the paper.

b. M807 speed control

When the conveyance drum rotation pulses reach a

predetermined number, the rotation speed is

changed.

10

Page 19

FS-109

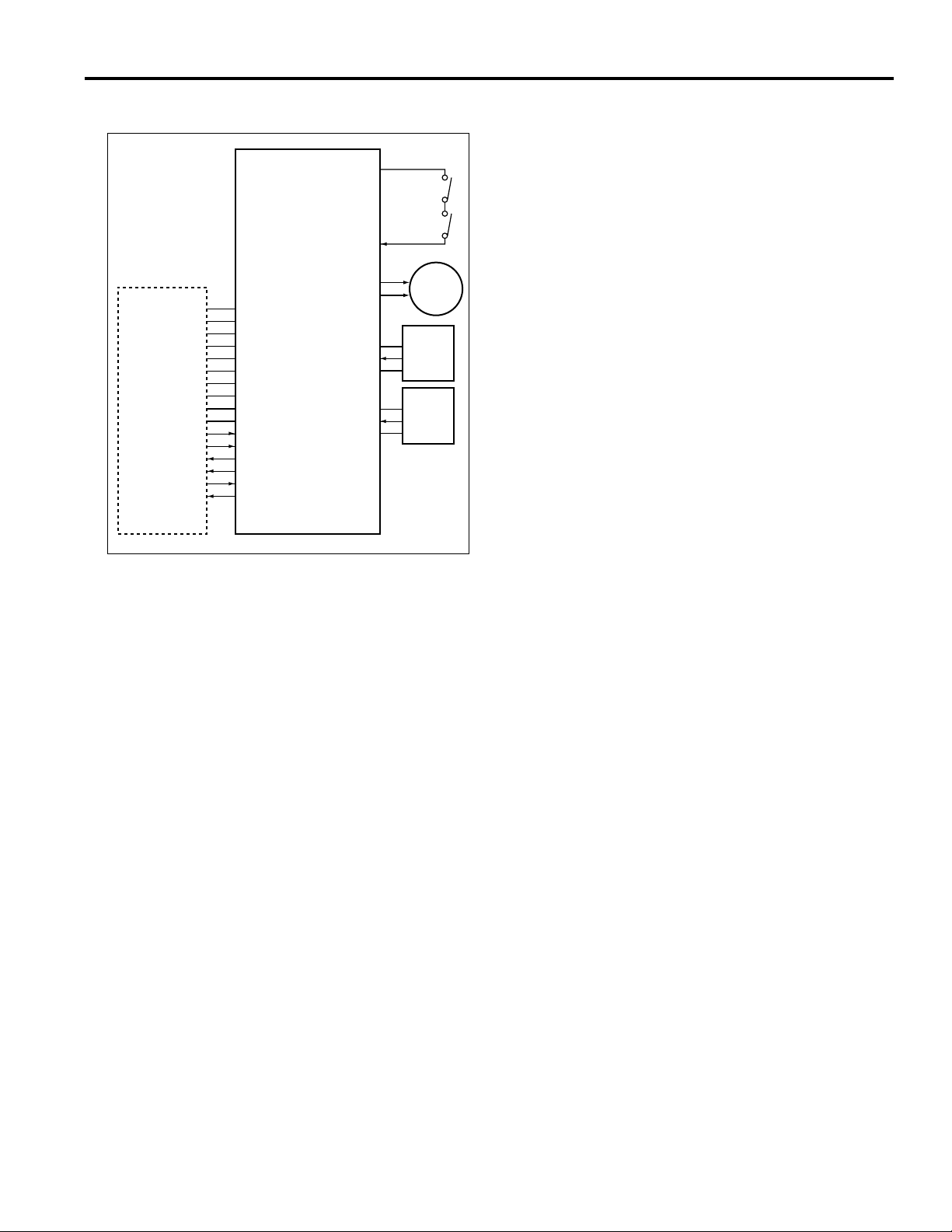

Tray Up/Down (M804) Control

24VOUT

MS802

MS803

24VIN

M804 DRV 1

SGND

SGND

PGND

PGND

PGND

M TxD

M REQ

M ACK

MAIN BODY

5V

5V

24V

24V

24V

S ACK

M RxD

S REQ

FNSCB

M804 DRV 2

VCC

PS805IN

GND

VCC

PS806IN

GND

The paper exit position of the conveyance drum is always

fixed, and tray switching is carried out by raising or

lowering tray 2/3.

The up/down motion is achieved by transmitting the

driving force of motor M804 (tray up/down) to the lift wires

connected to each tray. This operation is controlled by the

FNSCB (FNS control board).

M804

PS805

PS806

1. Operation

Normally, the paper exit position of the conveyance

drum is aligned with tray 2. Therefore no lift operation

is carried out when tray 2 is selected.

a. Upward movement

When tray 3 is selected as paper exit tray and PS806

(traylower limit) is ON, M804 (tray up/down) goes ON

(forward rotation). Tray 2 and tray 3 are then raised

simultaneously.

When the upward movement causes tray 2 to switch

PS805 (tray upper limit) to ON, M804 goes OFF and

the upward movement stops. Tray 3 is now aligned

with the paper exit position of the conveyance drum.

b. Downward movement

When tray 2 is selected as paper exit tray and PS805

is ON, M804 goes ON (reverse rotation). Tray 2 and

tray 3 are then lowered simultaneously.

When the downward movement causes tray 3 to

switch PS806 to ON, M804 goes OFF and the

upward movement stops. Tray 2 is now aligned with

the paper exit position of the conveyance drum.

c. Tray squeeze prevention

During tray upward or downward movement, if a

foreign object is caught between the tray and the

finisher unit, MS802 (up/down (upper)) or MS803

(up/down (lower)) will mechanically go OFF, causing

the power supply line of M804 to be cut off.

11

Page 20

FS-109

2. Signals

a. Input signals

(1) PS805IN (PS80 to FNSCB)

Tray 2 upper limit detection signal.

[L]: Upper limit is not detected

[H]: Upper limit is detected

(2) PS806IN (PS806 to FNSCB)

Tray 3 lower limit detection signal.

[L]: Lower limit is not detected

[H]: Lower limit is detected

(3) 24VIN (MS802/MS803 to FNSCB)

Power supply line for M804 (tray up/down). Forcibly

interrupted when a foreign object is caught between

tray and finisher unit.

b. Output signal

(1) M804 DRV 1, 2 (FNSCB to M804)

M804 drive signals.

M804 rotation direction is controlled by switching the

current direction of these two signals.

State M804 DRV 1 M804 DRV 2

Upward movement

Downward movement

Stop

L

L

H

L

H

H

12

Page 21

PAPER EXIT/STAPLER UNIT SECTION

Composition

FS-109

Paper exit rollers (A)

Tray 2 motor

Tray 3 motor

Alignment plate (front)

Tray 2/3

Stapler unit (front)

Alignment motor (front)

Exit levers

Stapler movement motor

Stopper

Stapler

unit (rear)

Paper exit motor

Mechanisms

Mechanisms Methods

Paper alignment *1

Paper exit *2

Paper stacking *3

Stapler unit movement

Staple accident prevention *4

*1: Paper alignment

The paper being conveyed by the conveyance drum

is aligned by the alignment plates. Separately driven

guides are provided for front and rear, to allow

independent movement and asymmetrical operation

in shift mode.

The alignment plates are driven by the alignment motor

(front) (M809) and alignment motor (rear) (M808).

Separate guides for front and rear

Exit lever

Paper exit roller (A)

Stapler unit movement motor

Shutter cover

Alignment motor (rear)

Alignment plate (rear)

Alignment plate (front)

Alignment motor (front)

13

Page 22

FS-109

Exit levers

*2: Paper exit

The paper being supplied by the conveyance drum is

conveyed to the stapling position, regardless of

whether stapling will be carried out or not. If stapling

is enabled, the stapled stack is exited to tray 2 or 3

after stapling. If stapling is not enabled, each sheet is

exited individually to tray 2 or 3.

This movement is performed by the exit levers which

are driven by the paper exit motor (M805).

Paper exit motor

Tray 2 motor

Tray 3 motor

Paper exit roller (A)

*4: Staple accident prevention

A shutter cover is provided to prevent the user from

inadvertently inserting a finger etc. into the stapler. The

shutter cover is driven by the shutter SD (SD802) which

is ON during stapler operation and during stapler unit

movement. The shutter cover blocks the clearance

between the paper exit tray and the stapler unit.

*3: Paper stacking

A spring arrangement in the bottom of tray 2 and tray

3 lifts the bottom plate up, so that it always is in direct

contact or not more than 3 mm away from the paper

exit roller assembly.

[ Operation in through mode ]

The paper is stacked on the tray by the movement of

the exit lever and the rotation of the paper exit roller

(A) of each tray.

When the paper exit roller (A) turns, the tip of the

paper is grasped by the rollers and is stacked under

the rollers.

[ Operation in offset mode ]

The paper is offset by the alignment plates (front/

rear), and is stacked on the tray by the movement of

the exit lever and the rotation of the paper exit roller

(A) of each tray.

By repeating this action, the tip of the paper is

grasped by the rollers and is stacked under the

rollers.

Tray 2

Shutter SD

Paper exit roller (A)

Conveyance

drum

Spring

Stapler

unit

Exit lever

Shutter

cover

14

Page 23

FS-109

24V

0V

24V

0V

Paper Alignment Control

24V

24V

M808 DRV A

M808 DRV A

M808 DRV B

M808 DRV B

24V

24V

M809 DRV A

M809 DRV A

M809 DRV B

M809 DRV B

5VDC

PS815IN

GND

5VDC

SGND

SGND

PGND

PGND

PGND

M TxD

M REQ

M ACK

MAIN BODY

5V

5V

24V

24V

24V

S ACK

M RxD

S REQ

FNSCB

PS816IN

GND

5VDC

PS802IN

GND

5VDC

PS804IN

GND

The paper exited by the conveyance drum is aligned on

the center of the respective exit tray by the alignment

plates driven by the M808 (alignment (rear)) and M809

(alignment (front)). M808 and M809 are controlled by the

FNSCB (FNS control board).

1. Operation

a. Non-shift alignment operation

The alignment plate (front) and alignment plate (rear)

work symmetrically, with the tray center serving as

the reference point. The guides repeat the alignment

and release pattern. The rotation direction of M809

and M808 is therefore always opposite.

The ON timing of M809 and M808 is referenced to

the ON/OFF state of PS802 (drum entrance) or

PS804 (paper through detect). Which sensor is used

depends on the paper size.

M808

M809

PS815

PS816

PS802

PS804

b. Shift alignment operation

During the first alignment operation, the alignment

plate (front) and alignment plate (rear) are front and

rear symmetric with respect to operation as

reference with the center of the tray and paper is

exited.

During the next alignment operation, the alignment

plate (front) and alignment plate (rear) are not front

and rear symmetric with respect to operation as

reference with the center of the tray and paper is

exited at the position shift to the first copy.

From now on, these operation are repeated.

The ON/OFF timing of M809 and M808 is the same

as that of the non-shift alignment operation.

c. Staple mode operation

In staple mode, M809 and M808 perform release

operation after stapling is completed. The ON/OFF

timing is based on the OFF timing of the stapler motor

that last completed a stapling operation (M802 or M803).

2. Signals

a. Input signals

(1) PS815IN (PS815 to FNSCB)

Home position detection signal for alignment plate

(front).

[L]:Alignment plate is not in home position

[H]:Alignment plate is in home position

(2) PS816IN(PS816 to FNSCB)

Home position detection signal for alignment plate (rear).

[L]:Alignment plate is not in home position

[H]:Alignment plate is in home position

b. Output signals

(1) M808 DRV A, A, B, B (FNSCB to M808)

M808 ON/OFF drive signal

(2) M809 DRV A, A, B, B (FNSCB to M809)

M809 ON/OFF drive signal

15

Page 24

FS-109

Paper Exit (M805) Control

24V

24V

M805 DRV A

M805 DRV A

M805 DRV B

SGND

SGND

PGND

PGND

PGND

M TxD

M REQ

M ACK

MAIN BODY

5V

5V

24V

24V

24V

S ACK

M RxD

S REQ

FNSCB

M805 DRV B

VCC

PS813IN

GND

VCC

PS804IN

GND

When the alignment or stapling operation is completed, the

paper is pushed out to tray 2 or tray 3 by the exit levers. The

levers are driven by M805 (paper exit) via a set of gears.

Operation is controlled by the FNSCB (FNS control board).

M805

PS813

PS804

2. Signals

a. Input signal

(1) PS813IN (PS813 to FNSCB)

Home position detection signal for exit lever.

[L]: Exit lever is not in home position

[H]: Exit lever is in home position

b. Output signal

(1) M805 DRIVE A, A, B, B (FNSCB to M805)

M805 ON/OFF drive signal

24V

0V

1. Operation

a. Non-stapling mode operation

The drive gear for the exit levers is controlled using

the home position detected by PS813 (paper exit

motor HP).

When PS804 (paper through) detects the paper

leading edge and goes ON, M805 goes ON for the

specified time and drives the exit levers. This causes

PS813 to go OFF.

The exit levers are connected to the circumference of

the drive gear. Within one rotation of the gear, the

paper is pushed out (forwarding motion) and

returned to the standby position (return motion).

When PS813 goes ON, the exit levers have returned

to the standby position and M805 is turned OFF.

b. Stapling mode operation

In stapling mode, when the stapler motor (M802 or

M803) that has last finished to operate goes OFF,

M805 goes ON for the specified time and drives the

exit levers. Other operations are the same as for nonstapling mode.

16

Page 25

FS-109

24V

0V

24V

0V

Paper Stacking Control

24V

24V

M810 DRV A

M810 DRV A

M810 DRV B

M810 DRV B

24V

24V

M811 DRV A

M811 DRV A

M811 DRV B

SGND

SGND

PGND

PGND

PGND

M TxD

M REQ

M ACK

MAIN BODY

5V

5V

24V

24V

24V

S ACK

M RxD

S REQ

FNSCB

M811 DRV B

VCC

PS807IN

GND

VCC

PS809IN

GND

The paper exited to tray 2 or tray 3 is placed on top of the

paper exit rollers of the respective tray. The drive force of

motor M810 (tray 2) or M811 (tray 3) is used to operate the

rollers and stack the paper on the tray.

M810 and M811 operation is controlled by the FNSCB

(FNS control board).

M810

M811

PS807

PS809

b. Tray auto-switching control

When copying is carried out with tray 2 or tray 3

specified as output tray and the specified tray

becomes full, causing PS807 or PS809 to become

ON, the output tray is automatically switched to the

other tray.

This operation is also valid if tray 1 is specified as the

output tray. The output tray will be switched to tray 2

or tray 3. Normally, tray 2 will be selected. If it is full,

tray 3 will be selected. Switching from tray 2 or tray 3

to tray 1 is not possible.

2. Signals

a. Input signals

(1) PS807IN (PS807 to FNSCB)

Tray 2 stack-full detection signal

[L]: Stack full condition not detected

[H]: Stack full condition detected

(2) PS809IN (PS809 to FNSCB)

Tray 3 stack-full detection signal

[L]: Stack full condition not detected

[H]: Stack full condition detected

b. Output signals

(1) M810 DRV A, A, B, B (FNSCB to M810)

M810 ON/OFF drive signal

(2) M811 DRV A, A, B, B (FNSCB to M811)

M811 ON/OFF drive signal

1. Operation

a. Paper stacking control

When M805 (paper exit) goes ON, M810 (tray 2) or

M811 (tray 3) are set to ON after the specified time.

When M805 goes OFF, M810 or M811 are set to OFF

after the specified time. While the motor is ON, the

rollers of the tray are driven and the paper that was

placed on the rollers is stacked.

The stacking section of the tray is pushed up by a

spring. When the maximum allowable number of sheets

has been stacked, the stacking section contacts the

bottom of the tray and PS807 (tray 2 full-stack detect) or

PS809 (tray 3 full-stack detect) goes ON.

When PS807 or PS809 are ON, no copy operation

will be carried out when the respective tray is

selected.

17

Page 26

FS-109

Stapler Movement (M806) Control

24V

24V

M806 DRV A

M806 DRV A

M806 DRV B

SGND

SGND

PGND

PGND

PGND

M TxD

M REQ

M ACK

MAIN BODY

5V

5V

24V

24V

24V

S ACK

M RxD

S REQ

FNSCB

M806 DRV B

VCC

PS814IN

GND

24V

24VIN

The position of the stapler units at the front and rear with

respect to the paper is adjusted using the driving force of

the M806(stapler movement). Operation of M806 is

controlled by the FNSCB (FNS control board).

1. Operation

Normally, the stapler units are stationary, positioned so

that the stapling is carried out parallel to the paper

edge. This position is detected by PS814 (stapler unit

HP).

When the stapling position is changed according to a

command from the main body, M806 goes ON and

the two stapler units at the front and rear are moved

simultaneously. The M806 OFF timing is controlled

using the number of drive step from when PS814

went OFF.

M806

PS814

MS804

Stapler Control

M802 DRV 1

M802 DRV 2

VCC

PS820IN

PS821IN

PS822IN

GND

M803 DRV 1

M803 DRV 2

VCC

PS817IN

PS818IN

PS819IN

GND

SGND

SGND

PGND

PGND

PGND

M TxD

M REQ

M ACK

MAIN BODY

5V

5V

24V

24V

24V

S ACK

M RxD

S REQ

FNSCB

24VOUT

24VIN

24V

SD802 DRV

Stapling is carried out by driving M802 (stapler (rear)) and

M803 (stapler (front)). Operation of M802 and M803 is

controlled by the FNSCB (FNS control board).

The maximum number of sheets for stapling and the

operation to be carried out when the number is exceeded

can be set with 25 mode of the main body. For details,

refer to the adjustment section of the main body

M802

M803

MS804

SD802

2. Signals

a. Input signals

(1) PS814IN (PS814 to FNSCB)

Home position detection signal for stapler unit

[L]: Stapler unit is in home position

[H]: Stapler unit is not in home position

(2) 24VIN (MS804 to FNSCB)

Power supply line for M802 (stapler (rear)), M803

(stapler (front)), and M806. Forcibly interrupted when

the shutter is raised.

b. Output signal

(1) M806 DRV A, A, B, B (FNSCB to M806)

M806 ON/OFF drive signal

24V

0V

18

Page 27

FS-109

1. Operation

a. Stapling operation

M803 (stapler (front)) goes ON when the last paper

alignment operation is completed, and goes OFF

when PS817 (stapler HP (front)) goes ON.

This causes the front side of the paper to be stapled.

When stapling at two locations is carried out, M802

(stapler (rear)) goes ON after the specified time,

measured from the point when M803 goes ON. It

goes OFF when PS820 (stapler HP (rear)) goes ON.

b. Shutter control

During stapler unit movement and during stapling

operation, the SD802 (shutter) is ON, causing the

shutter to block the clearance between the paper exit

tray and the stapler unit.

c. No-staple detection

The front and rear stapler units are each equipped

with a PS818, PS821 (no stapler (front), (rear)).

When staples have run out and the no staple

condition is detected, a message is shown on the

display of the main body.

2. Signals

a. Input signals

(1) PS817IN (stapler unit (front) to FNSCB)

Home position detection signal for M803

[L]: Home position is detected

[H]: Home position is not detected

(2) PS818IN (stapler unit (front) to FNSCB)

Stapler unit (front) no-staple detection signal.

[L]: No-staple condition is detected

[H]: No-staple condition is not detected

(3) PS820IN (stapler unit (rear) to FNSCB)

Home position detection signal for M802

[L]: Home position is detected

[H]: Home position is not detected

(4) PS821IN (stapler unit (rear) to FNSCB)

Stapler unit (rear) no-staple detection sensor signal

[L]: No-staple condition is detected

[H]: No-staple condition is not detected

(5) PS819IN (stapler unit (front) to FNSCB)

[L]: stapler unit (front) tion is detected

[H]: No-staple condition is not detected

(6) PS822IN (stapler unit (rear) to FNSCB)

stapler unit (rear) no-staple sensor signal at the

stapling position.

[L]: No-staple condition is detected

[H]: No-staple condition is not detected

b. Output signals

(1) M802 DRV 1, 2 (FNSCB to stapler unit (rear))

M802 drive signals.

M802 rotation direction is controlled by switching the

current direction of these two signals.

(2) M803 DRV 1, 2 (FNSCB to stapler unit (front))

M803 drive signals.

M803 rotation direction is controlled by switching the

current direction of these two signals.

(3) SD802 DRV (FNSCB to SD802)

SD802 ON/OFF drive signal.

[L]: SD802 ON

[H]: SD802 OFF

19

Page 28

FS-109

OTHER CONTROL FUNCTIONS

Power-on Operation

When the main body SW2 (sub power) is set to ON,

the finisher performs the following initialization

sequence.

1. SD802 (shutter) goes ON and the shutter cover closes.

2. M808 (alignment (rear)) and M809 (alignment (front))

go ON and the alignment plates (front/rear) perform

home position search.

3. M807 (conveyance drum) goes ON and the conveyance drum performs home position search.

4. M806 (stapler movement) goes ON and the stapler unit

moves to the standby position.

5. SD802 goes OFF and the shutter cover opens.

6. M805 (paper exit) goes ON and the exit lever is driven

for one operation.

7. Lower limit position detection for tray 2 and tray 3 is

carried out. If PS806 (tray lower limit) does not go ON,

M804 (tray up/down) goes ON, causing tray 2 and tray

3 to move downward.

20

Page 29

DISASSEMBLY AND REASSEMBLY

FS-109

Caution: Be sure that the power cord of the

main body is unplugged from the

power outlet.

Replacing the Tray 2/3 Paper Exit Roller

Unit

Before replacing the paper exit roller unit for tray 3,

move tray 2 to the top. (See 2. "Raising and

Lowering the Tray".)

a. Procedure

(1) Remove the two set screws, and remove the connector

cover.

Set screws

Connector cover

Raising and Lowering the Tray

a. Raising procedure

(1) Start the main body in the 47 mode while referring to the

main body manual (Field Service volume).

(2) Enter the following codes.

Input/output check code: 70

Multi code: 16

Note: Finalize each entered code by pressing

the P button

(3) Press the Start button, and the tray starts to rise. When

the tray reaches the position at which you wish to stop

it, press the Stop/Clear button.

b. Lowering procedure

(1) Start the main body in the 47 mode while referring to

main body manual (Field Service volume).

(2) Enter the following codes.

Input/output check code: 70

Multi code: 15

Note: Finalize each entered code by pressing

the P button.

(3) Press the Start button, and the tray starts to fall. When

the tray reaches the position at which you wish to stop

it, press the Stop/Clear button.

(2) Remove the left and right stop rings and bearings, then

remove the paper exit roller unit.

Stop ring

Paper exit roller unit

Bearing

(3) Install the new roller unit in the opposite sequence to

removal.

Stop ring

Bearing

21

Page 30

FS-109

Removing and Reinstalling Tray 2/3

a. Procedure

(1) Remove the two set screws, and remove the connector

cover.

(2) Disconnect the two connectors (CN728 and 751: Tray

2 / CN729 and 752: Tray 3).

(3) Remove the set screw, and remove the stopper.

Set screw

Stopper

Connector

(CN 728)

Connector

(CN 751)

(4) Remove the four set screws at the front, then remove

the tray in the direction of the arrow.

Removing and Reinstalling the External

Covers

a. Procedure

(1) Remove the four set screws

(2) Remove the five set screws

(3) Remove the three set screws C , then remove the

upper rear cover.

(4) Remove the set screw

(5) Remove the four set screws

Release lever

Set screw

Set

screws

D

E

, then remove the front cover.

A

, then remove the rear cover.

B

, then remove the release lever.

D

, then release the top cover.

E

Top cover

Set screws

E

Set screws

Upper rear

cover

Set

screws

C

Set

screws

B

Rear cover

Set screws

Tray

Set screws

(5) Reinstall tray 2/3 in the opposite sequence to removal.

Front cover

Set screws

Rear cover

Set screws

(6) Reinstall the external covers in the opposite sequence

to removal.

B

Set screws

A

A

Front cover

22

Page 31

FS-109

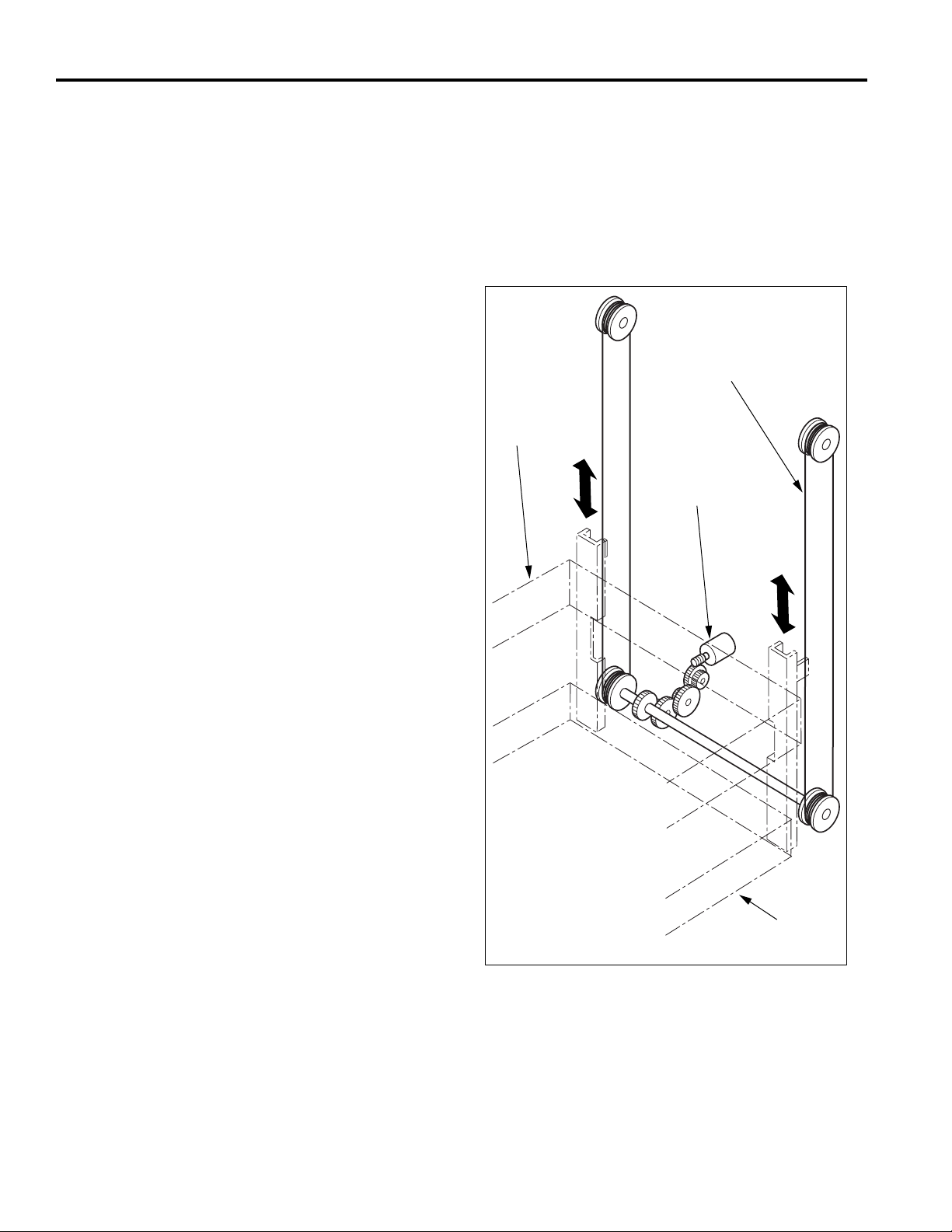

Removing and Reinstalling the Lift Wire

a. Procedure

(1) Remove the tray 2 and tray 3.

(2) Remove the external covers.

Note: The lift wire must be removed (and

installed) first on the front side and then on

the rear side.

(3) Remove the two set screws, then release the wire

fastening bracket (front).

(4) Loosen the two set screws, then release the pulley

tensioning plate (front).

(5) Remove the E ring of the lower pulley (front).

(6) Remove the lower pulley (front), then remove the lift

wire (front).

(7) Attach the metal ball of the lift wire to the inside of the

lower pulley (front) and pass the pulley onto the shaft.

The end of the wire attached to the pulley must be the

short end as seen from the wire fastening bracket.

Note: When installing the lower pulley (front)

onto the shaft, align the pin on the shaft

with the lower pulley (front).

(8) Wind the lift wire five turns around the lower pulley

(front) and then hook the wire onto the upper pulley

(front).

Note: Wind the wire clockwise as seen from the

front.

(9) Route the lift wire from the upper pulley (front) back

down to the lower pulley (front) and wind it one turn in

clockwise direction around the pulley. Then attach the

metal ball at the end of the wire to the side of the lower

pulley (front).

(10) Attach the E ring to secure the lower pulley (front).

Pulley tensioning plate (rear)

Metal ball

(winding start)

Metal ball (winding end)

Set screws

Wire fastening bracket

Metal ball (winding end)

Set screws

Wire fastening bracket (rear)

Lower pulley (rear)

1 turn

5 turn

Upper pulley (rear)

Lift wire

Pin

Shaft

Pulley tensioning plate (front)

Upper pulley (front)

Set screws

Lift wire

Wire fastening bracket (front)

Set screws

E ring

Lower pulley (front)

Metal ball

(winding end)

5 turn 1 turn

Metal ball (winding start)

23

Metal ball (winding start)

Page 32

FS-109

(11) Pull the pulley tensioning plate (front) up until a tension

of 2.3 kg is achieved, then fasten the plate with the two

set screws.

Note: Use a tension gauge or similar when

fastening the pulley tensioning plate, to

assure that the specified tension value is

achieved.

Specification: 2.3 kg

Tension gauge

Set

screws

Pulley

tensioning

plate (front)

Lift wire

(19) Install the tray 2 and move its position in the vertical

direction so that the tray is flush with the lower limit

detection plate. Then permanently secure the wire

fastening brackets (front) and (rear) which were

provisionally fastened previously.

Note: To check the flush condition, use a metal

ruler or other suitable tool on both the front

and the rear side.

Lower limit detection plate

Tray 2

Metal scales

(12) Provisionally fasten the two set screws of the wire

fastening bracket (front).

(13) Remove the lift wire on the rear side in the same way as

described in steps (3) through (6).

(14) Attach the metal ball of the lift wire to the inside of the

lower pulley (rear) and pass the pulley onto the shaft.

The end of the wire attached to the pulley must be the

short end as seen from the wire fastening bracket.

Note: When setting the lower pulley (rear) onto

the shaft, align the pin on the shaft with the

lower pulley (rear).

(15) Wind the lift wire five turns around the lower pulley

(rear) and then hook the wire onto the upper pulley

(rear).

Note: Wind the wire counterclockwise as seen

from the front.

(16) Route the lift wire from the upper pulley (rear) back

down to the lower pulley (rear) and wind it one turn in

counterclockwise direction around the pulley. Then at

tach the metal ball at the end of the wire to the side of

the lower pulley (rear).

(17) Attach the E ring to secure the lower pulley (rear).

(18) Fasten the pulley tensioning plate (rear) and wire

fastening bracket (rear) as described in steps (11) and

(12).

24

Page 33

FS-109

Replacing the Stapler Cartridge

a. Procedure

(1) Push the release lever to remove the finisher from the

main body.

(2) Push the release levers of the stapler units down and

remove the stapler cartridges.

Release lever

Release lever

Stapler cartridge

Stapler

cartridge

Removing and Reinstalling the Stapler

Unit

a. Procedure

(1) Remove the set screw (one each), then remove the

alignment plate (front) and alignment plate (rear).

Alignment

plate

(front)

Alignment

plate

(rear)

Set screws

Lower limit

detection plate

Film

(3) Push the new stapler cartridge all the way in, until it is

locked in the stapler unit.

(2) Remove the four set screws, then remove the stapler

unit cover (lower).

(3) Disconnect the three connectors (CN705, 706 and

707) on the FNSCB FNS control board and also the

connector (CN726) on the tray up-down motor.

(4) Remove the four set screws, then pull the stapler unit

out.

Caution: Take care not to bend the film on the

exit side during re-installation.

Top cover

Stapler unit

Set screws

Set

screws

Stapler unit

cover (lower)

Set screws

Set screws

25

Page 34

FS-109

(5) Turn the stapler unit gear, then open the stapler unit

(front) and stapler unit (rear) towards the outside.

(6) Remove the two set screws each, then remove the

connector cover of each stapler unit.

Set screws

Stapler unit (rear)

Stapler unit (front)

Set

screws

Connector

cover

Stapler unit movement gear

Connector

cover

Set

screws

(7) Remove the two set screws each, then remove the

stapler unit (front) and stapler unit (rear).

(8) Disconnect the connector (CN745, CN746) from each

stapler unit.

(9) Remove the two set screws, then remove the stapler

unit.

Set screws

Stapler chassis

Stapler unit

(10) Reinstall the stapler unit in the opposite sequence to

removal.

Set screws

Connector

(CN745)

Set screws

Stapler unit (front) Stapler unit (rear)

Connector

(CN746)

26

Page 35

FS-109 ELECTRICAL PARTS LAYOUT DRAWING

PS819

PS803

MS802

Up-down MS (upper)

PS801

Drum position detect PS

Tray 1 paper exit detect PS

FNSCB

FNS control board

PS802

Drum entrance PS

PS809

Tray 3 full-stack detect PS

PS817

Stapler HP (front) PS

PS820

Stapler HP (rear) PS

PS804

Paper through detect PS

PS807

Tray 2 full-stack detect PS

M810

Tray 2 motor

M811

Tray 3 motor

M806

Stapler movement motor

No-staple (front) (lead edge) PS

PS822

No-staple (rear) (lead edge) PS

PS818

No-staple (front) PS

PS821

No-staple (rear) PS

M805

Paper exit motor

DIAGRAMS

PS805

Tray upper limit

PS

M801

Conveyance

motor

MS803

Up-down MS (lower)

PS806

Tray lower limit PS

SD801

Gate SD

MS801

Inter lock MS

M809 Alignment motor (front)

M807

Conveyance drum

motor

SD802

Shutter SD

MS804

Stapler safety MS

M804

Tray up/down motor

PS812

Stapler no paper

PS815

Alignment motor

(front) HP PS

PS

PS813

Paper exit motor

HP PS

M803

Stapler motor (front)

M808

Alignment motor (rear)

PS816

Alignment motor (rear) HP PS

M802

Stapler motor (rear)

PS814

Stapler unit HP PS

27

Page 36

DIAGRAMS

FS-109 CONNECTOR LAYOUT DRAWING

730 (W:2 PIN)

756 (BK:8 PIN)

736 (W:3 PIN)

759 (W:3 PIN)

749 (W:9 PIN)

757(BK:8 PIN)

761 (BK:8 PIN)

737 (W:3 PIN)

401 (GY:16 PIN)

750

(W:12 PIN)

753

(W:6 PIN)

734 (W:3 PIN)

754 (W:2 PIN)

721 (W:6 PIN)

733 (W:3 PIN)

726

(BK:2 PIN)

724 (W:6 PIN)

763

(W:3 PIN)

724 (W:6 PIN)

744 (W:3 PIN)

760 (W:3 PIN)

751 (W:3 PIN)

723 (W:6 PIN)

727 (W:6 PIN)

725 (W:6 PIN)

743 (W:3 PIN)

741 (W:3 PIN)

740 (W:3 PIN)

746 (W:13 PIN)

742 (W:3 PIN)

745 (W:13 PIN)

722

(W:6 PIN)

729(W:6 PIN)

751 (BK:3 PIN)

728 (W:6 PIN)

752 (W:3 PIN)

(W:10 PIN)

752 (W:3 PIN)

28

702 (W:6 PIN)

701

711

(W:2 PIN)

709

(W:2 PIN)

FNSCB

704 (W:28 PIN)

703 (W:24 PIN)706 (W:15 PIN)

713

(GY:30 PIN)

712

(W:15 PIN)

710

(W:3 PIN)

707

(W:24 PIN)

705 (W:24 PIN)

Page 37

TIMING CHART

FS-109 TIMING CHART

8.5x11, SORT MODE, 3 SHEETS, 3 SETS

(sec)

110ms

260ms

320ms

110ms

260ms

320ms

110ms

260ms

70ms 70ms

240ms

200ms

10ms

10ms

10ms

60ms

190ms

60ms

250ms

60ms

8.5x11, 3 SHEETS, 2 PLACES STAPLING,

2 SETS

330ms

280ms

320ms

110ms

260ms

320ms

110ms

260ms

280ms

10ms

10ms

60ms

10ms

330ms

60ms

400ms

100ms

10ms

330ms

280ms

280ms

10ms

60ms

330ms

320ms

110ms

260ms

320ms

110ms

260ms

70ms 70ms

200ms

200ms

210ms

250ms

250ms

320ms

110ms

260ms

70ms 70ms 70ms

250ms

320ms

110ms

260ms

0 1 2 3 4 5 6

29

Page 38

TIMING CHART

FS-109 TIMING CHART

11x17, 3 SHEETS, 3 PLACES STAPLING, 3 SETS

(sec)

280ms

280ms

140ms

140ms

600ms

600ms

10ms

10ms

10ms

10ms

60ms

10ms

650ms

60ms

650ms

60ms

10ms

140ms

650ms

600ms

1 2 3 4 5 6 7 8 9

270ms 280ms

0

30

Page 39

PAPER THROUGH

DETECTSENSOR

DRUM POSITION

DETECT SENSOR

DRUM ENTRANCE

SENSOR

TRAY 1

PAPER EXIT

DETECT SENSOR

TRAY

UPPER LIMIT

SENSOR

TRAY

LOWER LIMIT

SENSOR

TRAY 3

FULL–STACK

DETECT SENSOR

TRAY 2

FULL–STACK

DETECT SENSOR

STAPLER NO

PAPER SENSOR

PAPER EXIT

MOTOR HP SENSOR

STAPLER UNIT HP SENSOR

ALIGNMENT MOTOR

HP (FRONT) SENSOR

ALIGNMENT MOTOR

(REAR) HP

STAPLER (FRONT)

MOTOR

STAPLER HP (FRONT) SENSOR

NO STAPLE (FRONT) SENSOR

FS-109 OVERALL WIRING DIAGRAM

NO STAPLE (FRONT)

(LEAD EDGE) SENSOR

STAPLER (REAR)

MOTOR

STAPLER HP (REAR) SENSOR

NO STAPLE (REAR) SENSOR

NO STAPLE (REAR)

(LEAD EDGE) SENSOR

TRAY UP/DOWN

MOTOR

M804

CN726–1

CN726–2

UL1007#24

UL1007#24

23

24

CN707–A8 M804 DRV1

CN707–A9 M804 DRV2

H

H

1516192021

25314

CN727–2

CN727–5

25314

UL1007#24

5253545556

CN705–B7 24V

CN704–B1 24V

CN704–B2 24V

CN704–B5 M801 DRVA

CN704–B6 M801 DRVA

P

PPP

UL1007#24

UL1007#24

UL1007#24

UL1007#24

PAPER EXIT

MOTOR

M805

CN727–3

CN727–6

CN727–4

UL1007#24

UL1007#24

UL1007#24

UL1007#24

CN705–B10 M805 DRVA

CN705–B11 M805 DRVB

CN705–B9 M805 DRVA

CN705–B8 24V

PPP

CN704–B7 M801 DRVB

CN704–B8 M801 DRVB

22

UL1007#24

UL1007#24

6

CN727–1

6

UL1007#24

57

CN705–B12 M805 DRVB

P

TRAY 2 MOTOR

M810

CN728–5

CN728–6

CN728–1

CN728–3

18

CN753–12

CN753–11

CN753–10

CN753–9

CN753–1

CN753–2

CN753–3

CN753–4

UL1007#26

UL1007#26

UL1007#26

34789

CN704–A7 M810 DRVA

CN704–A4 24V

CN704–A3 24V

PPP

CN704–B3 24V

CN704–B4 24V

PPP

1718232425

UL1007#24

UL1007#24

25314

CN728–2

CN728–4

1314151617

CN753–8

CN753–7

CN753–5

CN753–6

UL1007#26

UL1007#26

UL1007#26

10

CN704–A9 M810 DRVB

CN704–A10 M810 DRVB

CN704–A8 M810 DRVA

P

CN704–B9 M807 DRVA

CN704–B10 M807 DRVA

CN704–B11 M807 DRVB

P

UL1007#24

UL1007#24

UL1007#24

CN704–B12 M807 DRVB

26

UL1007#24

6

TRAY 3 MOTOR

M811

CN729–5

CN729–6

CN729–1

CN729–3

12

CN753–6

CN753–5

CN753–4

CN753–3

CN753–7

CN753–8

CN753–9

CN753–10

UL1007#26

UL1007#26

UL1007#26

UL1007#26

56111213

CN704–A12 M811 DRVA

CN704–A11 M811 DRVA

CN704–A6 24V

CN704–A5 24V

PPP

4647484950

CN762–1

CN763–6

6

CN729–2

CN729–4

7891011

CN753–2

CN753–1

CN753–11

CN753–12

UL1007#26

UL1007#26

14

CN704–A14 M811 DRVB

CN704–A13 M811 DRVB

P

CN705–B1 24V

CN705–B2 24V

CN705–B3 M808 DRVA

CN705–B4 M808 DRVA

PPP

UL1007#26

UL1007#26

UL1007#26

UL1007#26

CN762–4

CN762–5

CN762–3

CN762–2

CN763–5

CN763–4

CN763–3

CN763–2

GATE SOLENOID

SD801

CN730–1

CN730–2

UL1007#26

UL1007#26

2

1

CN704–A1 24V

CN704–A2 SD801 DRV

H

CN705–B5 M808 DRVB

CN705–B6 M808 DRVB

P

51

UL1007#26

UL1007#26

CN762–6

CN763–1

12345

SHUTTER SOLENOID

SD802

CN731–2

CN731–1

1

2

CN748–1

CN748–2CN748–1

CN748–2

UL1007#26

UL1007#26

27

28

CN704–B14 24V

CN704–B13 SD802 DRV

H

CN705–A1 24V

CN705–A3 M809 DRVA

CN705–A2 24V

CN705–A4 M809 DRVA

PPP

3436373839

35

UL1007#26

UL1007#26

UL1007#26

UL1007#26

CN761–1

CN761–2

CN761–3

CN761–4

CN761–5

CN761–6

CN761–5

CN761–4

CN761–3

CN761–2

456

PS804

CN760–1

CN760–2

CN760–3

543

CN763–3

CN760–2

CN763–1CN763–3

CN763–2

CN763–1

UL1007#26

UL1007#26

UL1007#26

424140

CN703–A11 PS804IN

CN703–A12 VCC

CN703–A10 GND

CN705–A7 24V

CN705–A6 M809 DRVB

CN705–A5 M809 DRVB

P

4042434445

UL1007#26

UL1007#26

UL1007#26

CN725–6

CN761–6

CN725–1

CN761–1

132

CN705–A8 24V

CN705–A9 M806 DRVA

CN705–A10 M806 DRVA

PPP

41

UL1007#26

UL1007#26

UL1007#26

CN725–1

CN725–2

CN725–3

CN725–5

CN725–6

CN725–5

CN725–4

CN725–2

PS801

CN732–3

CN732–2

CN732–1

UL1007#26

UL1007#26

UL1007#26

484746

CN703–B5 PS801IN

CN703–B4 GND

CN703–B6 VCC

CN705–A12 M806 DRVB

CN705–A11 M806 DRVB

P

UL1007#26

UL1007#26

CN725–4

CN725–3

PS802

CN733–1

CN733–2

CN733–3

UL1007#26

UL1007#26

UL1007#26

454344

CN703–B1 GND

CN703–B2 PS802IN

CN703–B3 VCC

L

T

OU

V

24

CN711–2

2

UL1015#18

IN

V

24

CN711–1

1

UL1015#18

PS803

CN734–1

CN734–2

CN734–3

CN736–1

UL1007#26

UL1007#26

UL1007#26

UL1007#26

39

37

3635343332

38

CN703–A6 VCC

CN703–A8 PS803IN

CN703–A7 GND

CN703–A9 VCC

L

FNSCB

T

OU

V

24

CN710–2

30

UL1007#22

CN754–1

CN754–2

UL1015#18

UL1015#18

PS805

PS806

CN736–2

CN736–3

CN737–1

CN737–2

UL1007#26

UL1007#26

UL1007#26

UL1007#26

UL1007#26

CN703–A3 VCC

CN703–A2 PS806IN

CN703–A4 GND

CN703–A5 PS805IN

L

H

55

29

UL1007#22

CN755–2

CN755–1

UL1015#18

CN737–3

CN752–1

CN752–2

CN750–5

CN750–6

CN750–1

CN750–2

UL1007#26

UL1007#26

UL1007#26

UL1007#26

31

545352

CN703–A1 GND

CN703–B12 VCC

V IN

24

CN710–1

UL1007#22

UL1015#18

PS809

CN751–1

CN752–3

456

CN750–3

CN750–4

CN750–3

CN750–4

UL1007#26

UL1007#26

UL1007#26

UL1007#26

UL1007#26

51

CN703–B10 GND

CN703–B11 PS809IN

CN703–B9 VCC

L

V IN

V OUT

24

24

CN709–1

CN709–2

1

2

UL1007#18

UL1015#18

PS807

CN751–2

CN751–3

123

CN750–1

CN750–2

CN750–5

CN750–6

UL1007#26

UL1007#26

UL1007#26

50

49

CN703–B8 PS817IN

CN703–B7 GND

L

PS812

CN740–1

CN740–2

CN740–3

789

CN749–8

CN749–7

CN759–1 CN749–9

CN749–3

CN749–2

UL1007#26

UL1007#26

UL1007#26

UL1007#26

UL1007#26

151413

CN706–13 GND

CN706–14 PS812IN

CN706–15 VCC

PS813

CN741–1

CN741–2

CN741–3

456

CN749–6

CN749–5

CN749–4

CN749–6

CN749–5

CN749–4

UL1007#26

UL1007#26

UL1007#26

UL1007#26

UL1007#26

12

10

11

CN706–12 VCC

CN706–10 GND

CN706–11 PS813IN

H

PS814

CN742–1

CN742–2

CN742–3

123

CN749–3

CN749–2

CN759–1

CN749–9

CN749–8

CN749–7

UL1007#26

UL1007#26

UL1007#26

UL1007#26

UL1007#26

789

CN706–7 GND

CN706–8 PS814IN

CN706–9 VCC

L

PS815

PS816

CN743–1

CN743–2

CN743–3

CN744–1

CN744–2

CN744–3

789

789

CN759–3

CN759–2

CN758–3

CN758–2

CN758–2

CN758–1

UL1007#26

UL1007#26

CN706–6 VCC

H

GND

S.

CN701–1

123456789

UL1007#24

CN401–5 S.GND

CN759–1

CN758–1

CN759–3

CN759–2

CN759–1

CN758–3

UL1007#26

UL1007#26

UL1007#26

UL1007#26

UL1007#26

UL1007#26

123

456

CN706–2 PS816IN

CN706–5 PS815IN

CN706–3 VCC

CN706–4 GND

H

GND

GND

GND

V

V

S.

5

5

P.

P.

CN701–4

CN701–5

CN701–2

CN701–3

CN701–6

UL1007#24

UL1007#24

UL1007#24

UL1007#24

UL1007#24

CN401–7 P.GND

CN402–5 P.GND

CN402–1 S.GND

CN401–8 5V

CN402–2 5V

UL1007#26

UL1007#26

CN706–1 GND

.GND

P

CN701–7

UL1007#24

CN402–3 P.GND

M803

CN745–3

CN745–1

CN745–6

1234567

CN756–1

CN756–2

CN756–3

16171920212218

UL1007#26

UL1007#24

UL1007#24

CN707–A1 M803 DRV1

CN707–A4 VCC

CN707–A2 M803 DRV2

V

V

V

_TXD

_REQ

24

24

24

M

M

CN702–2

CN701–8

CN701–9

CN701–10

CN702–1

PPPPP

10111213141516

UL1007#24

UL1007#24

UL1007#24

UL1007#26

UL1007#26

CN401–4 M_TxD

CN401–3 M_REQ

CN401–8 24V

CN402–8 24V

CN402–4 24V

PS817

PS818

PS819

CN745–5

CN745–11

CN745–7

CN745–9

8

CN756–4

CN756–5

CN756–6

CN756–7

CN756–8

59

UL1007#26

UL1007#26

UL1007#26

UL1007#26

UL1007#22

CN707–A3 GND

CN707–A7 PS819IN

CN707–A6 PS818IN

CN707–A5 PS817IN

LLL

_RXD

_ACK

_ACK

_REQ

S

M

M

S

CN702–3

CN702–5

CN702–6

CN702–4

P

UL1007#26

UL1007#26

UL1007#26

UL1007#26

CN402–7 S_ACK

CN401–1 S_RxD

CN402–8 S_REQ

CN401–2 M_ACK

CN746–1

1234567

CN757–1

33323029282831

17

UL1015#18

EARTH

CN100–

MAIN BODY

M802

+5V

CN746–3

CN746–6

CN757–2

CN757–3

UL1007#24

UL1007#24

UL1007#24

CN707–B9 M802 DRV1

CN707–B8 M802 DRV2

CN707–B6 VCC

PS820

PS821

PS822

GND

CN746–9

CN746–7

CN746–11

CN746–5

8

CN757–4

CN757–5

CN757–6

CN757–7

CN757–8

58

UL1007#24UL1007#24

UL1007#24

UL1007#24

UL1007#24

UL1007#22

CN707–B7 GND

CN707–B3 PS822IN

CN707–B4 PS821IN

CN706–B5 PS820IN

LLL

[How to see the diagram]

1.The signals shown reflect levels present

under normal idling conditions with

the main switch turned ON.

2.Wiring symbols in the figure are as follows.

(1) [Symbol]

(2)

Crimp

Signal typs are as follows :

Active high

H

Active low

L

Analog signal

*

Pulse signal

P

V

50-1

Connector

V

Faston

Wire(Violet)

(3) RC is ribbon cable.

(4) Signal flow

The solid black circle ( ) among

the connector symbols ( )

indicates the direction of signal flow.

Example)

5VDC

PS1

Direction of

signal flow

PS1

CB

SGND

CN721–2

CN721–5

CN721–6

CN721–4

M801

ONVEYANCE MOTOR

CN721–3

CN721–1

CN722–2

CN722–5

CN722–6

CN722–4

M807

CONVEYANCE

DRUM MOTOR

CN722–3

CN722–1

CN723–5

CN723–6

CN723–1

CN723–2

CN723–1

CN723–3

CN723–2

CN723–5

CN723–4

CN723–6

M808

ALIGNMENT

MOTOR (REAR)

CN723–4

CN723–3

31

CN724–6

CN724–5

CN724–2

CN724–1

CN724–3

CN724–1

CN724–6

CN724–4

M809

ALIGNMENT

MOTOR (FRONT)

CN724–4

CN724–2

CN724–5

CN724–3

M806

STAPLER

MOVEMENT

MOTOR

MS801

INTER LOCK MS

MS802

UP–DOWN

MS (UPPER)

MS803

UP–DOWN

MS (LOWER)

MS804

STAPLER

SAFETY

MS

Page 40

This page left blank intentionally.

32

Page 41

PARTS CATALOG

Model

FS-109

NOVEMBER 2000

KONICA BUSINESS TECHNOLOGIES, INC.

Page 42

Page 43

How to use this catalog

This parts catalog includes illustrations and part numbers for all replacement parts and assemblies used in this model.

Model-specific parts are identified in the illustrations with reference

numbers. Use the reference number to locate the corresponding part

number on the facing page.

Common hardware items, such as screws, nuts, washers, and pins,

are identified in the illustrations with reference letters. Use the reference

letter to locate the corresponding part number on the hardware listing in

the lower right hand corner of the facing page.

If you know a part number, but don’t know where the part is used, use

the numerical index to determine the page number and reference number for that part. Because some common parts are used in several

places, there may be more than one entry. Refer to the illustrations to

see where the part may be used.

If you know a part’s description, but don’t know where to look to find

the part number, use the alphabetical index to determine likely page and

reference numbers. Then look at the illustrations to determine that you

have identified the correct part. Locate the part number using the listing

on the opposite page.

Retail pricing that appears with the numerical index, while valid when

this catalog was printed, is subject to change without notice. The prices

are only suggested prices and are provided only for reference. Dealers

may determine their own selling prices. For up-to-date pricing, refer to

current Konica price lists or contact the Konica Parts Distribution Center.

How to order parts

Use standard Konica parts ordering procedures to obtain these parts.

For ordering options, contact Konica’s Parts Distribution Center.

When ordering parts, be sure to specify part numbers exactly as listed in

this catalog.

NOTE: Electrical parts may include previously used components.

Model FS-109 Konica Business Technologies, Inc. Page iii

1st Edition November, 2000

Page 44

This page left blank intentionally.

Page iv Konica Business Technologies, Inc. Model FS-109

November, 2000 1st Edition

Page 45

How to use this catalog . . . . . . . . . . . . . . . . . . . . . . . . . iii

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

FS-109 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Alphabetical index . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Numerical index, Retail price list . . . . . . . . . . . . . . . . . . . . 31

Contents

Model FS-109 Konica Business Technologies, Inc. Page 1

1st Edition November, 2000

Page 46

FS-109

Page 2 Konica Business Technologies., Inc. Model FS-109

November, 2000 1st Edition

Page 47

REF. PART NUMBER DESCRIPTION

NO.

1 13LP10050 Support panel/left

2 120H10240 Protect sheet/B

3 13LP48030 Paper exit driving rail/front

4 120H73011 Electrical parts MT plate

5 13LP-9010 FNS control unit

6 13LP90010 FNS wiring/1

7 13LP48040 Paper exit driving rail/rear

8 120H73050 Presser sheet

9 12AR45611 Actuator

10 12QR86010 Interlock switch

11 120H73020 Sensor MT plate

12 120H12080 External MT plate/D

13 120H10030 Bottom plate

14 13LP20050 Carriage cover

15 120H10060 Side cover/right

16 120H10070 Main body fixed plate

17 120H50240 Rear plate

18 25BA10160 Carriage support material/B

19 13LP20130 Carriage support material/A

20 12AR74020 Screw/B

21 13LP20030 Carriage fixed plate

22 120H20040 Carriage rail

23 120H20090 Main body regulating stopper

24 13LP20010 Carriage support plate/front

25 120H20080 Main body stopper

26 120H20020 Carriage support plate/rear

27 120H20060 Carriage fulcrum shaft

28 120H-2050 Connecting plate/front ass’y

29 120H-2060 Connecting plate/rear ass’y

30 120H20070 Carriage stay

31 120H-1160 Main body PS plate ass’y

32 120H12070 External MT plate/C

HARDWARE

REF.

LTR.

a 00Z193181

b 00Z925103

c 00Z194061

d 00Z144062

e 00Z193061

f 00Z184061

g 00Z921303

h 00Z194201

j 00Z921302

k 00Z163081

m 00Z164081

n 00Z192101

p 00Z194201

PART

NUMBER

Model FS-109 Konica Business Technologies., Inc. Page 3

1st Edition November, 2000

Page 48

FS-109

Page 4 Konica Business Technologies., Inc. Model FS-109

November, 2000 1st Edition

Page 49

REF. PART NUMBER DESCRIPTION

NO.

1 13LP48010 Paper exit tray/A

2 13LP48020 Paper exit tray/B

3 13LP80020 FNS motor/1

4 13LP77550 Driving belt/E

5 13LP-4980 Driving roller/A assy

6 13GQ76020 Bearing/A

7 120H48060 Support spring

8 13LP48410 Sensor MT plate

9 12QV85510 Sensor

10 13LP97030 Indication label/A

11 120H12010 Front cover

12 120H12030 Upper plate

13 120H12040 Rear AUX cover

14 120H12020 Rear cover

15 13LP48370 Paper exit driving cover

16 13LP48500 Wiring holding part

HARDWARE

REF.

LTR.

a 00Z253081

b 00Z144082

c 00Z253082

d 00Z183041

e 00Z194061

f 00Z144062

g 00Z670606

PART

NUMBER

Model FS-109 Konica Business Technologies., Inc. Page 5

1st Edition November, 2000

Page 50

FS-109

Page 6 Konica Business Technologies., Inc. Model FS-109

November, 2000 1st Edition

Page 51

REF. PART NUMBER DESCRIPTION

NO.

1 120H10160 Detecting plate/upper

2 120H10230 Switch input material

3 12QV85510 Sensor

4 13LP-4300 Sensor MT plate unit assy

5 120H42240 Stopper part

6 120H42230 Sensor spring/B

7 120H42201 Paper detecting actuator

8 12AR45131 Entrance pressure spring

9 120H42161 RF stay

10 120H48090 Sensor MT plate/A

11 120H73030 Wiring MT base

12 12QR86010 Interlock switch

13 120H12110 Release lever

14 120H10130 Lever MT plate

15 120H10140 Hinge guide plate

16 12AR45650 Stopper part

17 13LP10150 Lever fulcrum shaft

18 120H-1140 Lever release plate/A ass’y

19 13LP10190 Fulcrum shaft/A

20 120H10170 Open-close spring

21 13LP90110 Paper exit wiring/1

22 120H10120 Connecting plate

23 12AR-4590 Rocking part ass’y

24 120H10090 Main body lock plate

25 120H10080 Main body lock shaft

26 120H10210 Paper exit panel/D

27 13LP10200 Support shaft/B

28 120H10180 Paper exit protection cam

29 13LP90100 Paper exit wiring

30 13LP45480 Switch lever

HARDWARE

REF.