Page 1

SERVICE MANUAL

Model

FS-107

SECOND EDITION

NOVEMBER 2000

CSM-FS107

KONICA BUSINESS TECHNOLOGIES, INC.

Page 2

Page 3

FS-107

SERVICE MANUAL

NOVEMBER 2000

SECOND EDITION

Page 4

IMPORTANT NOTICE

Because of the possible hazards to an inexperienced

person servicing this equipment, as well as the risk of

damage to the equipment, Konica Business Technologies strongly recommends that all servicing be performed by Konica-trained service technicians only.

Changes may have been made to this equipment to

improve its performance after this service manual was

printed. Accordingly, Konica Business Technologies,

Inc., makes no representations or warranties, either

expressed or implied, that the information contained in

this service manual is complete or accurate. It is understood that the user of this manual must assume all risks

or personal injury and/or damage to the equipment while

servicing the equipment for which this service manual

is intended.

Corporate Publications Department

© 2000, KONICA BUSINESS TECHNOLOGIES, INC.

All rights reserved.

Printed in U.S.A.

Page 5

CONTENTS

OUTLINE

PRODUCT SPECIFICATIONS......................................... 1

Type ..........................................................................1

Functions .................................................................. 1

Stapler kit ..................................................................2

Machine data ............................................................2

Maintenance .............................................................2

Machine environment ............................................... 2

CENTRAL CROSS SECTION .......................................... 3

DRIVE SYSTEM DIAGRAM .............................................4

Paper conveyance drive ........................................... 4

Stapler unit drive.......................................................5

PAPER CONVEYANCE PATH......................................... 6

Straight mode............................................................ 6

Offset mode/staple mode .......................................... 7

UNIT EXPLANATION

EXTERNAL SECTION ..................................................... 9

Composition ..............................................................9

CONVEYANCE SECTION .............................................10

Composition ............................................................10

Mechanisms ............................................................ 10

Conveyance control ................................................11

Tray up/down control .............................................. 13

PAPER EXIT/STAPLER UNIT ....................................... 15

Composition ............................................................15

Mechanisms ............................................................ 15

Paper alignment control..........................................17

Paper exit control .................................................... 18

Paper stack control .................................................19

Stapler control......................................................... 20

Staple control .......................................................... 2 1

OTHER KINDS OF CONTROL ......................................23

Movement with power on ........................................ 23

Opening and closing motion of the

front door............................................................... 2 3

FS-107

DISASSEMBLY/ASSEMBLY

DISASSEMBLY/ASSEMBLY ...........................................25

Removing and reinstalling of the finisher ..............2 5

Removing and reinstalling of the tray .................... 2 5

Replacing the paper exit roller/A ............................2 6

Removing and reinstalling of the up/down wire ....2 8

Replacing the stapler cartridge .............................. 29

Removing and reinstalling the stapler unit .......... 30

DIAGRAMS

ELECTRICAL PARTS LAYOUT.....................................31

CONNECTOR LAYOUT.................................................33

TIME CHART (8.5X11, SORT MODE, 2 SHEETS/SET

2 SETS)........................................................................ 35

TIME CHART (8.5X11, STAPLE MODE 2 SHEETS,

1 POSITION ................................................................. 3 6

OVERALL WIRING DIAGRAM....................................... 37

iii

Page 6

FS-107

This page left blank intentionally.

iv

Page 7

SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

Installation Environment

Safety considerations usually are directed toward

machine design and the possibility of human error. In

addition, the environment in which a machine is operated must not be overlooked as a potential safety

hazard.

Most electrical equipment is safe when installed in a

normal environment. However, if the environment is

different from what most people consider to be normal, it is conceivable that the combination of the

machine and the room air could present a hazardous

combination. This is because heat (such as from

fusing units) and electrical arcs (which can occur

inside switches) have the ability to ignite flammable

substances, including air.

When installing a machine, check to see if there

is anything nearby which suggests that a potential hazard might exist. For example, a laboratory

might use organic compounds which, when they

evaporate, make the room air volatile. Potentially dangerous conditions might be seen or smelled. The

presence of substances such as cleaners, paint thinners, gasoline, alcohol, solvents, explosives, or similar items should be cause for concern.

If conditions such as these exist, take appropriate

action, such as one of the following suggestions.

effect may be caused by altering any aspect of the

machine’s design. Such changes have the potential

of degrading product performance and reducing

safety margins.

For these reasons, installation of any modification not

specifically authorized by Konica Business Machines

U.S.A., Inc., is strictly prohibited.

The following list of prohibited actions is not all-inclusive, but demonstrates the intent of this policy.

• Using an extension cord or any unauthorized

power cord adapter.

• Installing any fuse whose rating and physical size

differs from that originally installed.

• Using wire, paper clips, solder, etc., to replace or

eliminate any fuse (including temperature fuses).

• Removing (except for replacement) any air filter.

• Defeating the operation of relays by any means

(such as wedging paper between contacts).

• Causing the machine to operate in a fashion other

than as it was designed.

• Making any change which might have a chance

of defeating built-in safety features.

• Using any unspecified replacement parts.

• Determine that the environment is controlled

(such as through the use of an exhaust hood) so

that an offending substance or its fumes cannot

reach the machine.

• Remove the offending substance.

• Install the machine in a different location.

The specific remedy will vary from site to site, but the

principles remain the same. To avoid the risk of injury

or damage, be alert for changes in the environment

when performing subsequent service on any machine, and take appropriate action.

Unauthorized Modifications

Konica copiers have gained a reputation for being

reliable products. This has been attained by a combination of outstanding design and a knowledgeable

service force.

The design of the copier is extremely important. It is

the design process that determines tolerances and

safety margins for mechanical, electrical, and electronic aspects. It is not reasonable to expect individuals not involved in product engineering to know what

General Safety Guidelines

This copier has been examined in accordance with

the laws pertaining to various product safety regulations prior to leaving the manufacturing facility to

protect the operators and service personnel from

injury. However, as with any operating device, components will break down through the wear-and-tear of

everyday use, as will additional safety discrepancies

be discovered. For this reason, it is important that the

technician periodically performs safety checks on the

copier to maintain optimum reliability and safety.

The following checks, not all-inclusive, should be

made during each service call:

CAUTION: Avoid injury. Ensure that the copier is

disconnected from its power source before continuing.

• Look for sharp edges, burrs, and damage on all

external covers and copier frame.

• Inspect all cover hinges for wear (loose or broken).

• Inspect cables for wear, frays, or pinched areas.

v

Page 8

SAFETY PRECAUTIONS

• Ensure that the power cord insulation is not damaged (no exposed electrical conductors).

• Ensure that the power cord is properly mounted

to the frame by cord clamps.

• Check the continuity from the round lug (GND) of

the power cord to the frame of the copier -- ensure

continuity. An improperly grounded machine can

cause an electrically-charged machine frame.

Safeguards During Service Calls

Confirm that all screws, parts, and wiring which are

removed during maintenance are installed in their

original positions.

• When disconnecting connectors, do not pull the

wiring, particularly on AC line wiring and high

voltage parts.

• Do not route the power cord where it is likely to

be stepped on or crushed.

• Carefully remove all toner and dirt adhering to any

electrical units or electrodes.

• After part replacement or repair work, route the

wiring in such a way that it does not contact any

burrs or sharp edges.

• Do not make any adjustments outside of the

specified range.

Applying Isopropyl Alcohol

Care should be exercised when using isopropyl alcohol, due to its flammability. When using alcohol to

clean parts, observe the following precautions:

• Remove power from the equipment.

• Use alcohol in small quantities to avoid spillage

or puddling. Any spillage should be cleaned up

with rags and disposed of properly.

• Be sure that there is adequate ventilation.

• Allow a surface which has been in contact with

alcohol to dry for a few minutes to ensure that the

alcohol has evaporated completely before applying power or installing covers.

Summary

It is the responsibility of every technician to use professional skills when servicing Konica products. There

are no short cuts to high-quality service. Each copier

must be thoroughly inspected with respect to safety

considerations as part of every routine service call.

The operability of the copier, and more importantly,

the safety of those who operate or service the copier,

are directly dependent upon the conscientious effort

of each and every technician.

Remember...when performing service calls, use good

judgement (have a watchful eye) to identify safety

hazards or potential safety hazards that may be present, and correct these problem areas as they are

identified -- the safety of those who operate the copier

as well as those who service the copier depend on it!

vi

Page 9

FS-107 PRODUCT SPECIFICATIONS

Type

Type: Built-in type compact finisher

(multiple trays type)

Option: Finisher tray (FT-107) (Up to

2 trays can be installed)

Functions

Type of paper: Same as the main body

Modes: Straight mode

Offset mode (shift)

Staple mode

Paper size

Straight paper exit: 11 x 17, 8.5 x 14R, 8. 5 x 11,

8.5 x 11R, 8.5 x 5.5, 8.5 x 5.5R

Offset: 11 x 17, 8.5 x 14, 8.5 x 11, 8.5

x 11R, 8.5 x 5.5R

1 position staple: 11 x 17, 8.5 x 14, 8.5 x 11, 8.5

x 11R, 8.5 x 5.5R

2 position staple: 11 x 17, 8.5 x 14, 8.5 x 11, 8.5

x 5.5R

Maximum

Paper capacity: 2 trays: 100 +1000 = 1,100

sheets

3 trays:100 + 100 + 600 =

800 sheets

4 trays:100 x 4 = 400 sheets

Copy

Paper weight: 13 lb. to 53 lb. papers

Stack capacity: (21 lb. high-quality paper)

With 2 standard trays

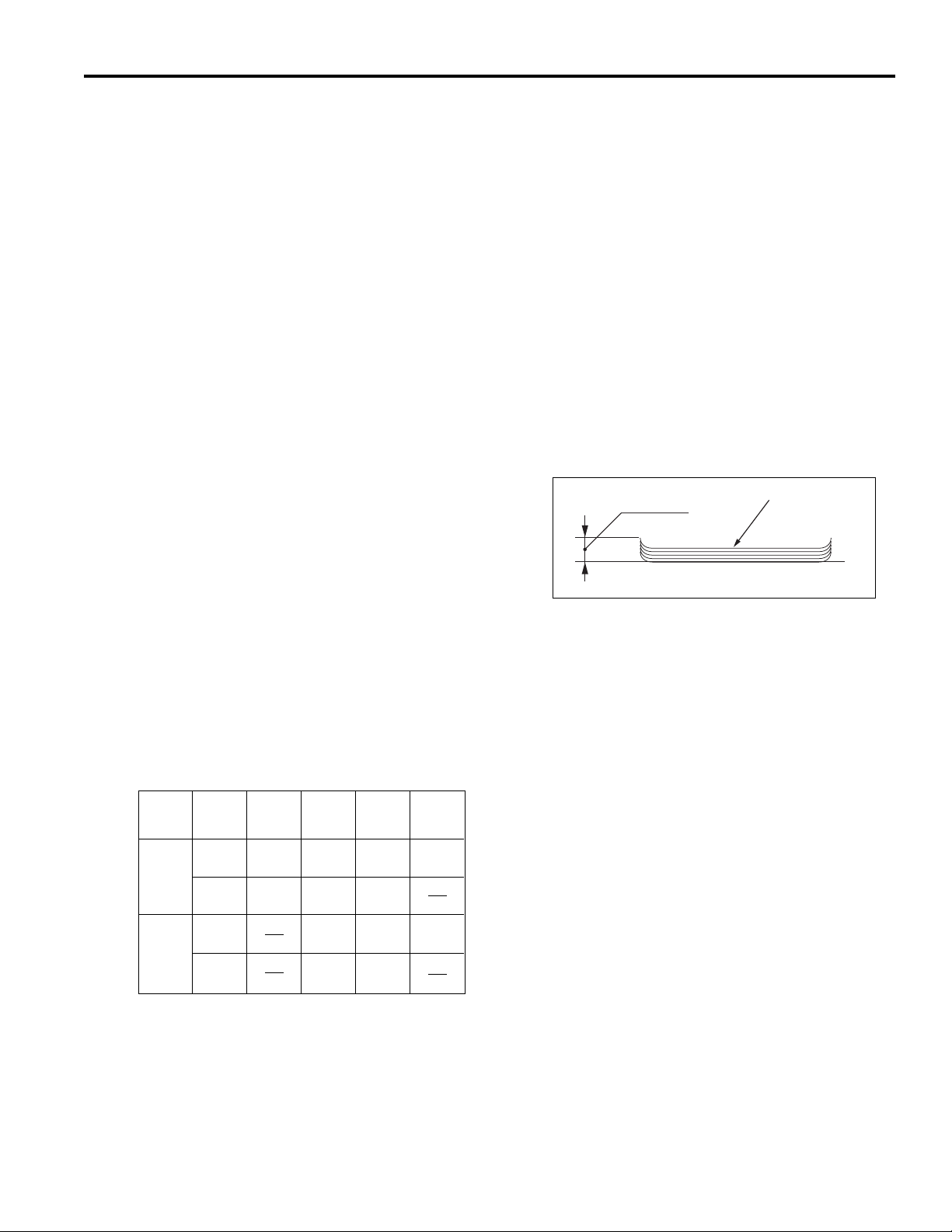

Note 2: The number of stacked sheets in staple

Note 3: Small size: 8.5x5.5R

Note 4: The stacking capacity of the option

Paper curling: Maximum 10mm

Amount of sort

off-setting: 30mm

FS-107

mode must not exceed the stack sheet

capacity for non-staple mode.

Medium size: Everything other than

small size, large size,

special media.

Large size: 8.5x14, 11x17

Special paper: Thin paper (16 lb. or

less), thick paper (over 34

lb.), blueprint masters,

OHP, etc.

conforms to the stacking capacity of tray 1.

Curl

20mm (8.5 x 5.5R)

Five copy sheets

size

100

10

sets

Medium

size

100

sheets

10

sets

1000

sheets

50

sets

Large

size

100

sheets

10

sets

300

sheets

20

sets

Special

media

10

sheets

50

sheets

Small

Non-

Tray 1

staple

sheets

Staple

Non-

Tray 2

staple

Staple

Note 1: The above figures apply only to if stacked

paper is all of the same size.

1

Page 10

FS-107

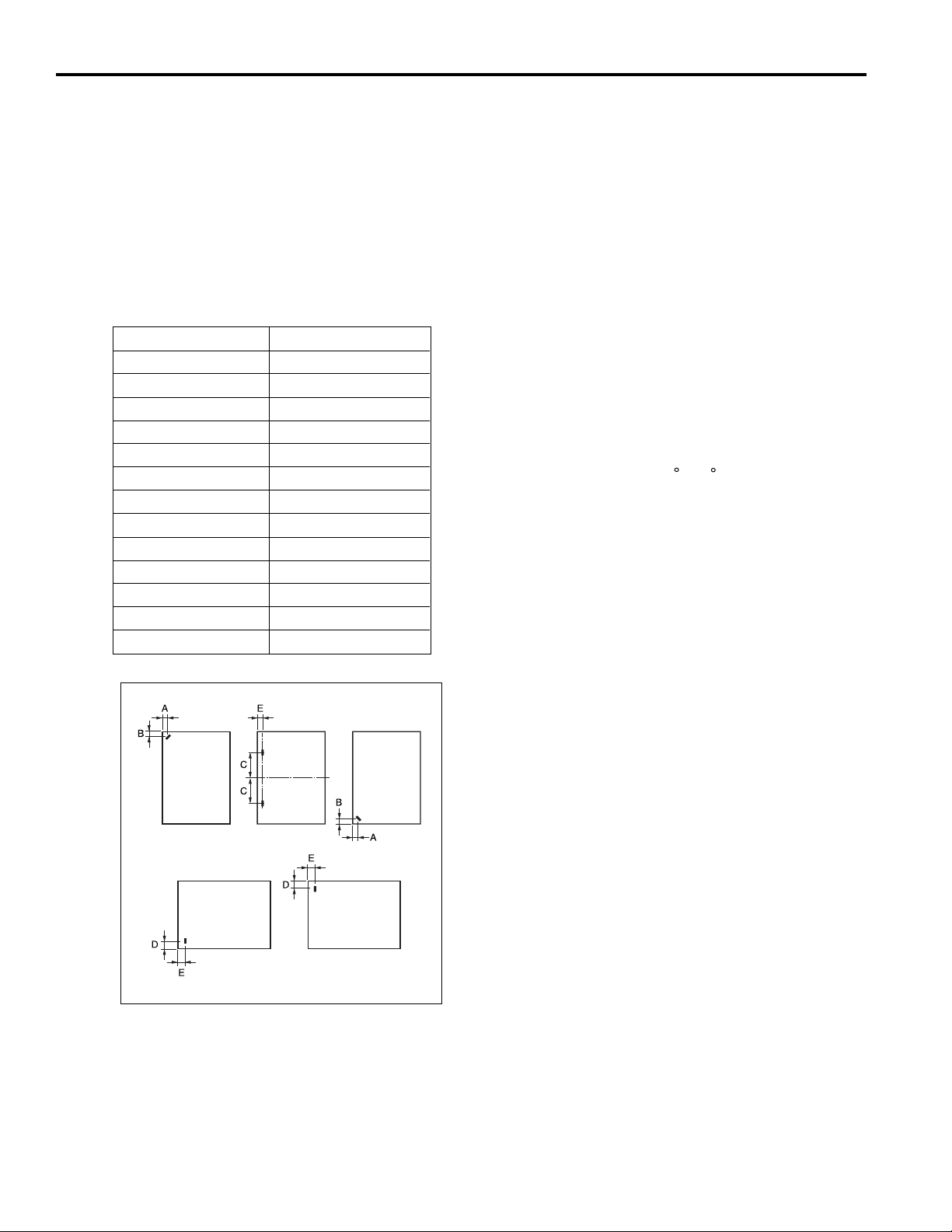

Stapler kit

Staple ability Maximum 50 sheets (with 21

lb. paper, paper thickness

less than 5mm)

Stapler capacity: 5,000 staples/cartridge

Staple position: A = 8.6mm ± 3mm

B = 8.6mm ± 3mm

C = refer to following table

D = 10.5mm ± 3mm

E = 8.0mm ± 3mm

Paper Size

A3/A4

B4/B5

A4R/A5

B5R

A5R

F4 (8 x 13)

F4 (8.125 x 13)

F4 (8.25 x 13)

F4 (8.5 x 13)

11 x 17/8.5 x 11

8.5 x 14/8.5 x 11R

5.5 x 8.5

5.5 x 8.5R

C (mm)

60±4

53±4

90±4

80±4

63±4

90±4

91.5±4

93±4

95±4

52±4

95±4

95±4

60±4

Machine data

Power source: DC24V/5V (supplied from the

main body)

Maximum power

Consumption: Maximum 70VA

Weight: 28.6 lb.

External

dimensions: Length 30.8 in.

Depth 19.8 in.

Height 15.4 in.

Maintenance

Maintenance: Same as the main unit

Machine environment

Temperature: 50 to 86 F

Humidity: 10 to 80%RH

(below condensation-forming

conditions)

Caution: The contents of this service manual may be

changed without notice.

2

Page 11

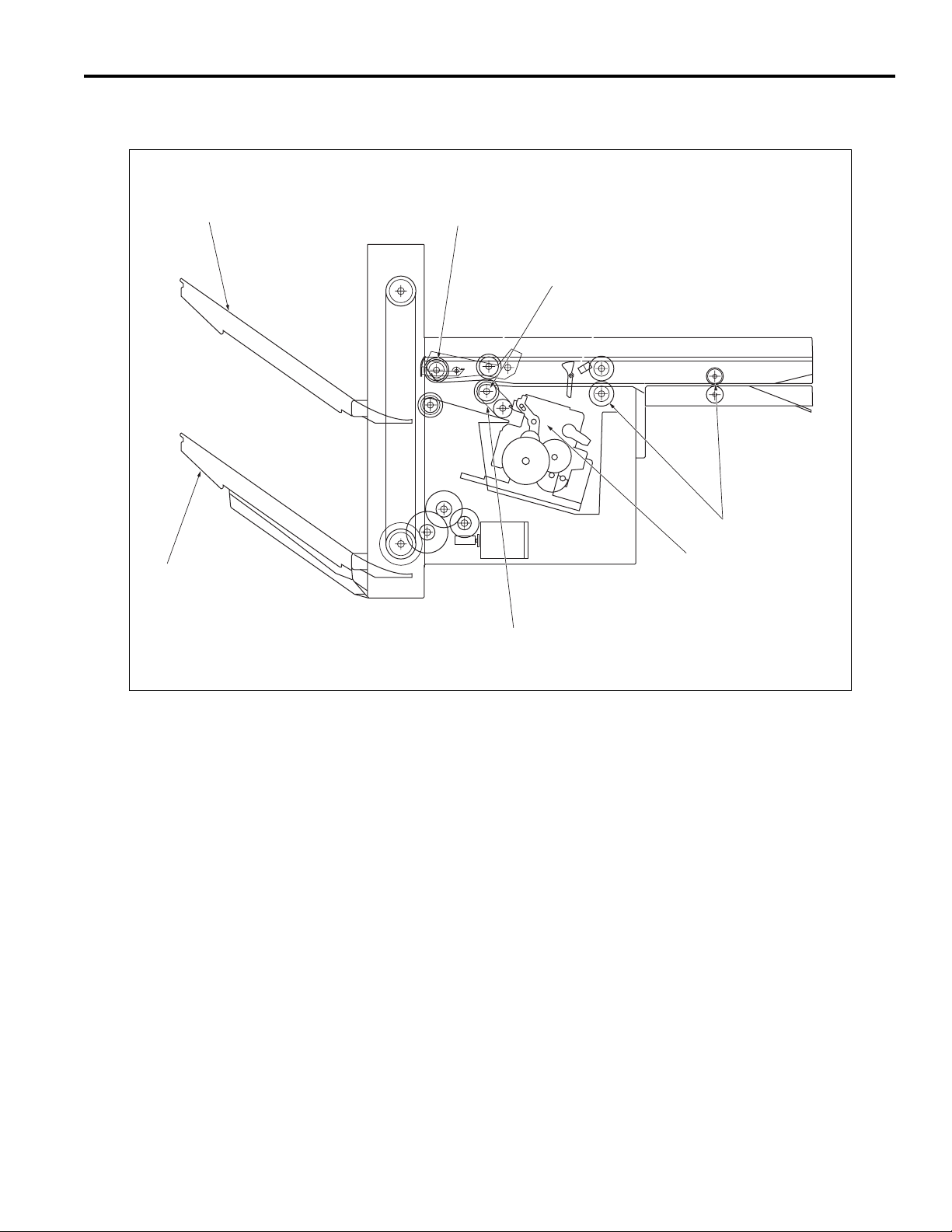

CENTER CROSS SECTION

FS-107

Tray 2

Tray 1

Exit roller/A

Conveyance roller

Conveyance rollers

Stapler unit

Conveyance belt

3

Page 12

FS-107

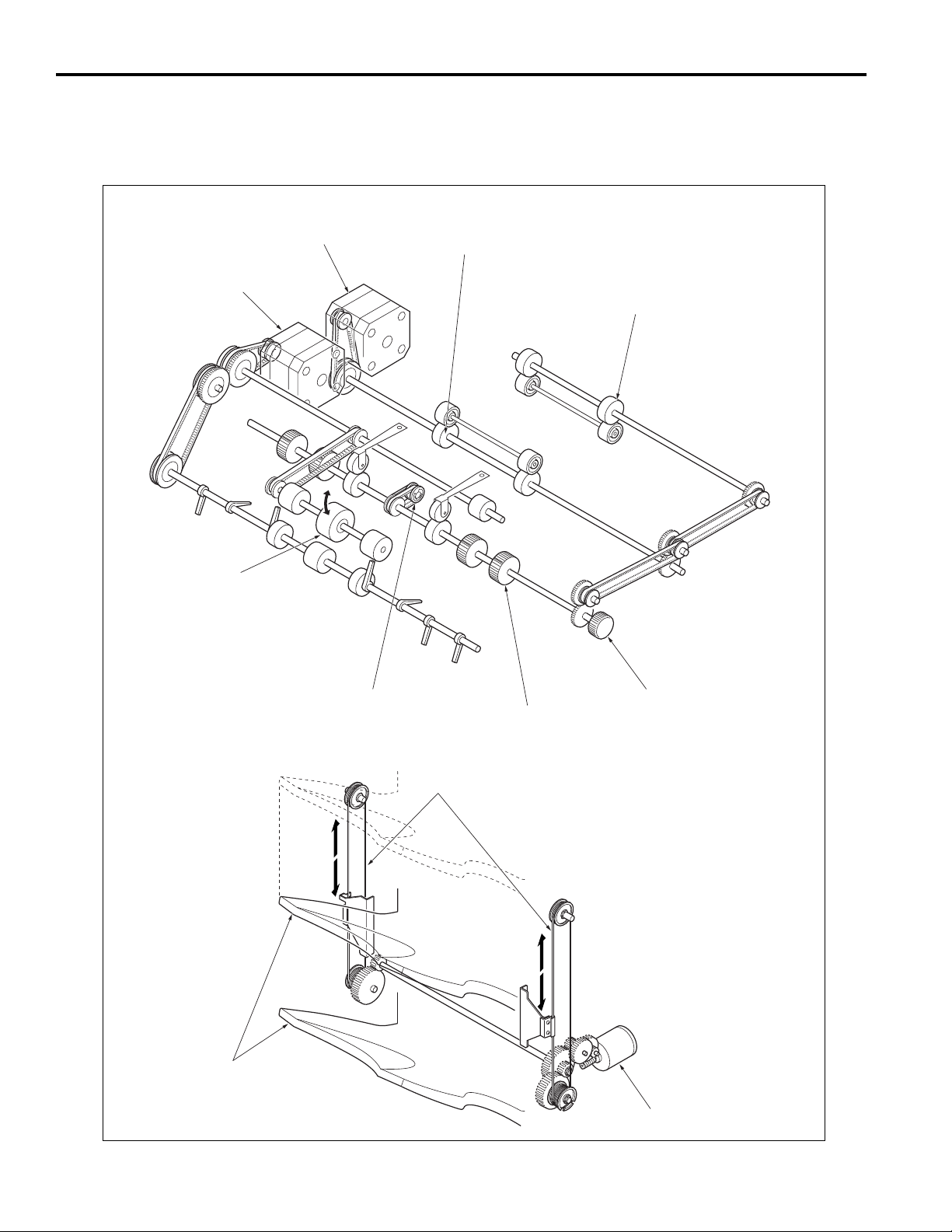

DRIVE SYSTEM DIAGRAM

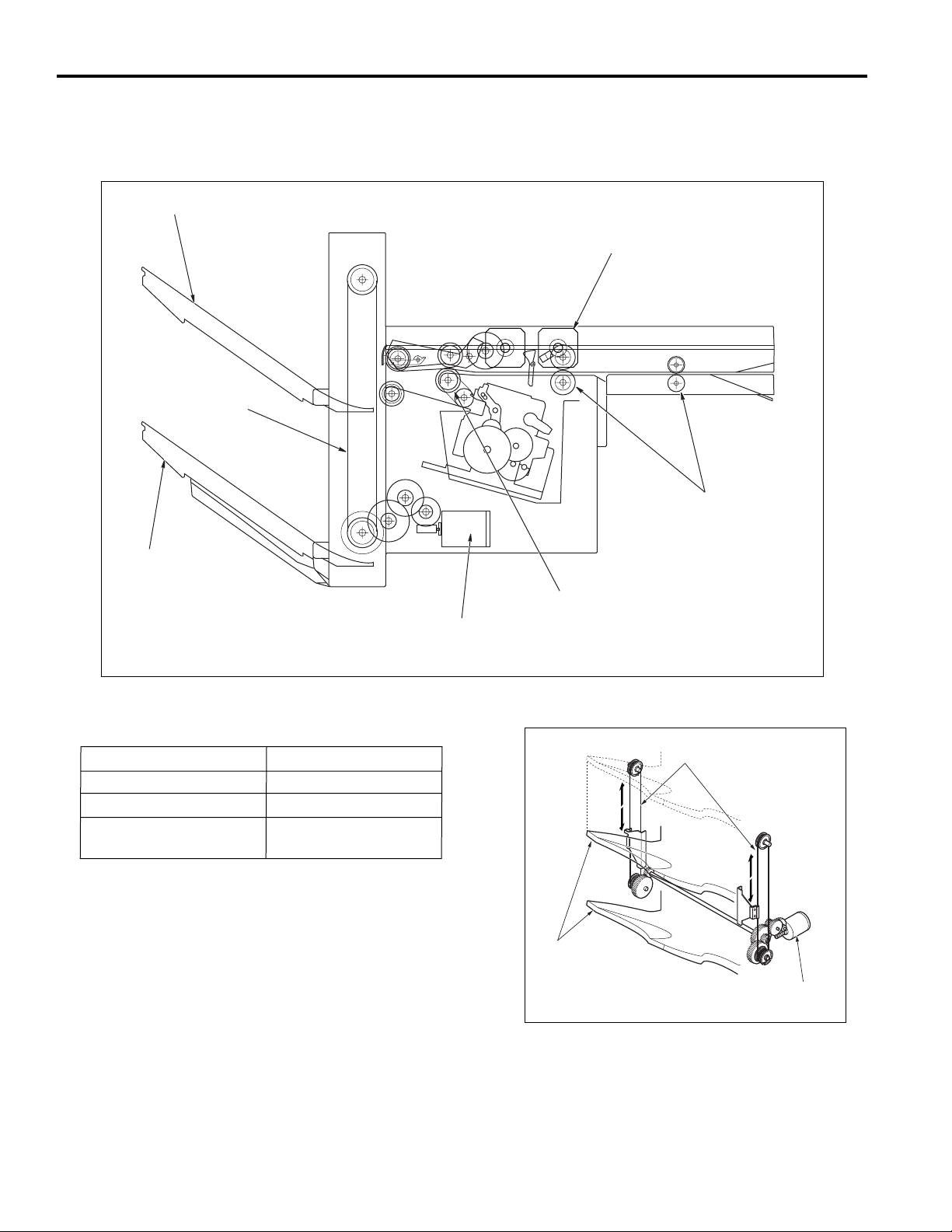

Paper Conveyance Drive

Paper conveyance

motor (M701)

Paper exit motor (M702)

Conveyance roller

Conveyance roller

Exit roller A

Conveyance belt

Paper jam release knob

Conveyance roller

Tray up/down wires

Trays

Tray up/down motor (M706)

4

Page 13

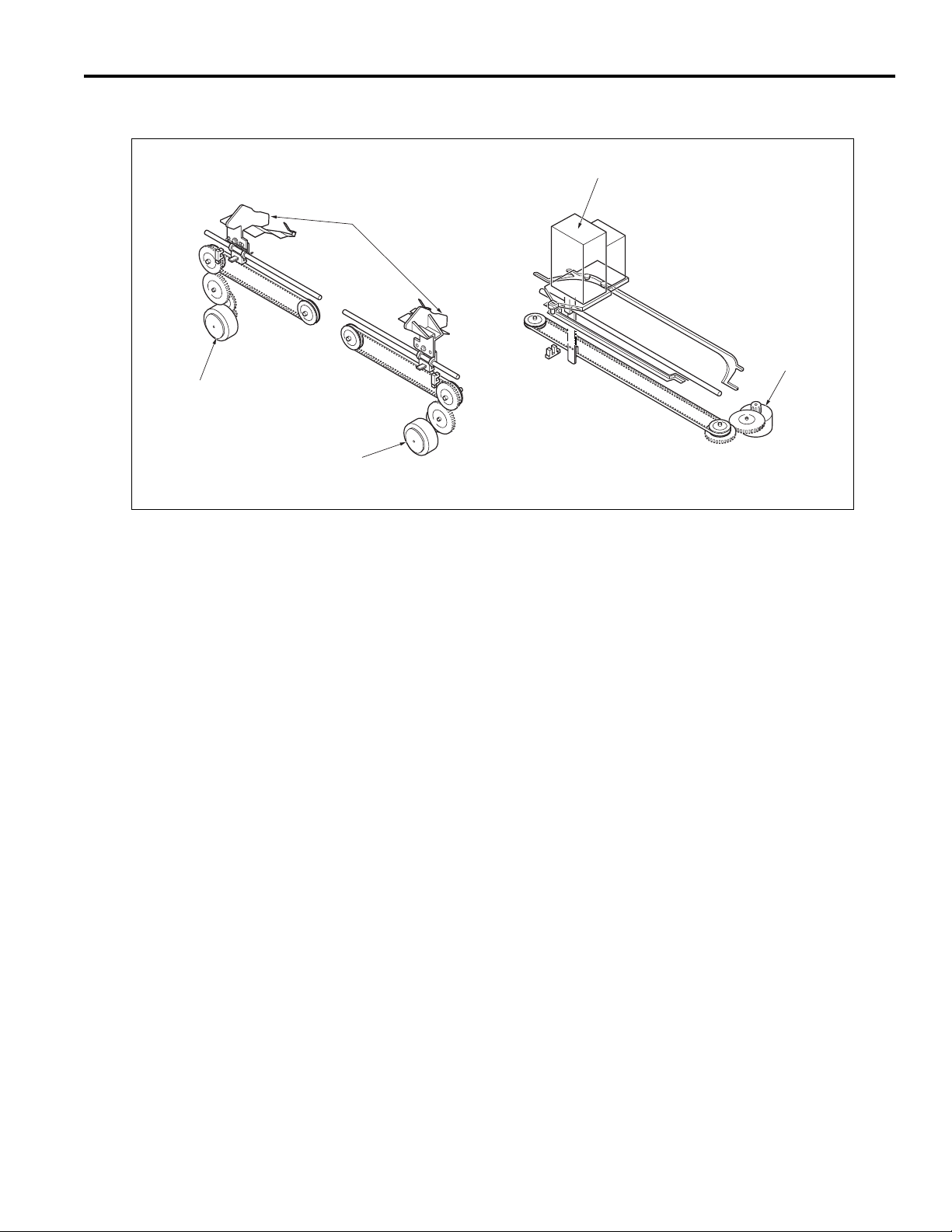

Stapler Unit Drive

Alignment motor

(rear) (M703)

FS-107

Stapler unit

Alignment plates

Stapler shift

motor (M705)

Alignment motor

(front) (M704)

5

Page 14

FS-107

PAPER CONVEYANCE PATH

In the finisher, two different paper conveyance paths are

used, changing by the mode selected.

Straight Mode

In this mode, paper conveyed to the finisher is exited

straight into the tray. (For small size paper, the

operation of OffsetMode/Stapling Mode takes place,

even in the straight paper exit mode.)

6

Page 15

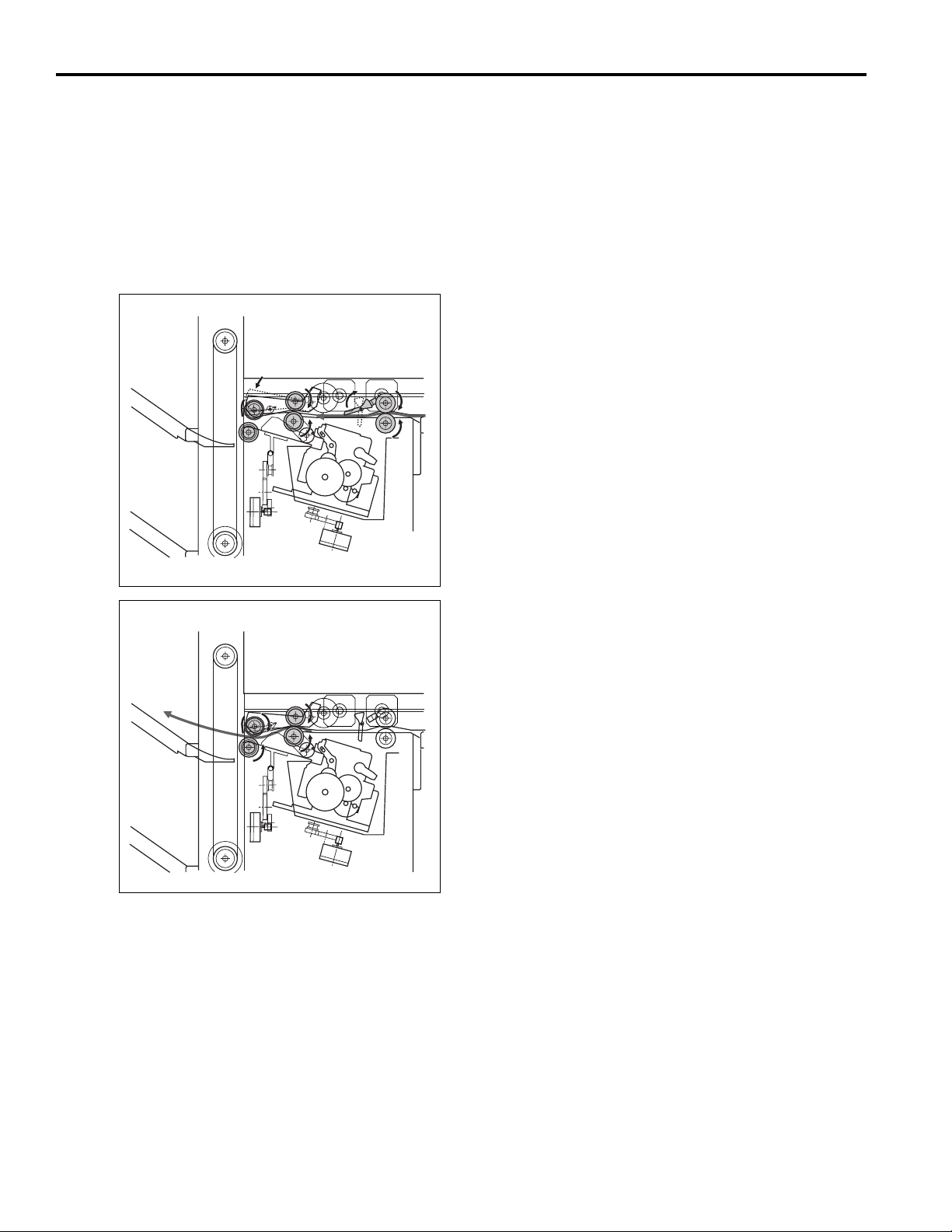

Offset Mode/Staple Mode

In the offset mode or staple mode, paper conveyed

to the finisher is stacked once by the reverse

rotation of the exit roller. In the offset mode, this

stacked paper is offset by the paper alignment

plates. In the staple mode, the paper is stapled. When

the respective process is finished, the paper is exited

to the tray by the exit roller.

Paper exit roller

FS-107

Alignment plate

7

Page 16

FS-107

This page left blank intentionally.

8

Page 17

EXTERNAL SECTION

Composition

FS-107

Front door

Conveyance plate

Paper conveyance cover

Stapler unit

Tray 1

Optional tray 1

(FT-107)

Optional tray 2

(FT-107)

Tray 2

9

Page 18

FS-107

CONVEYANCE SECTION

Composition

Tray 1

Tray up/down wire

Paper conveyance motor (M701)

Conveyance rollers

Tray 2

Mechanisms

Mechanism System

Paper Conveyance Conveyance rollers

Tray Up/Down *1 Wire drive

Tray Up/Down Accident Shutter

Prevention *2

*1 Tray up/down

The paper exit gate position is fixed; switching

between trays is accomplished by changing the

tray position up/down mechanism.

Tray up and down is done by the tray up/down

motor (M706), which the tray up/down wires to

drive the tray up or down.

Conveyance roller

Tray up/down motor (M706)

Tray up/down wires

Trays

Tray up/down

motor (M706)

10

Page 19

FS-107

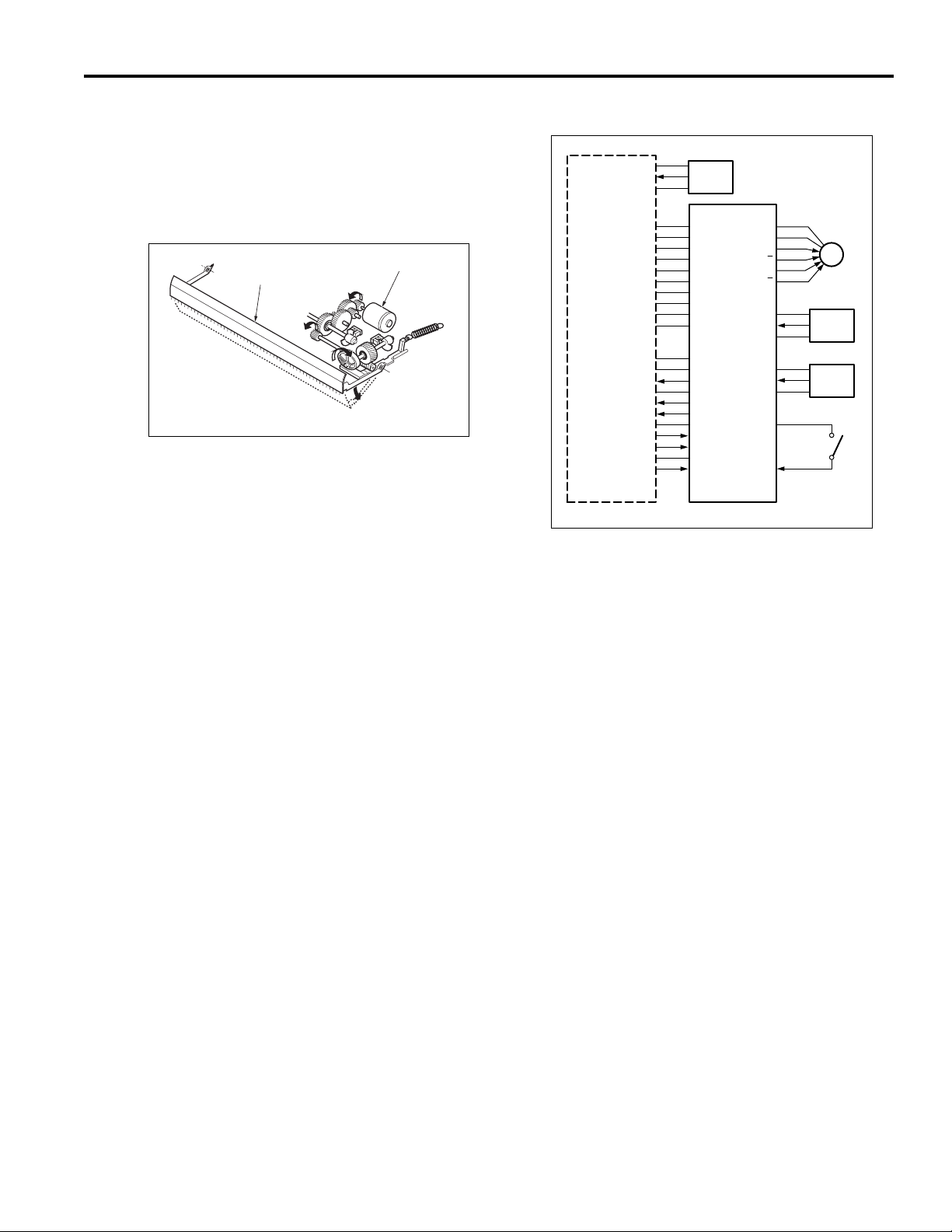

*2 Prevention of tray up/down accident

To prevent the accident insertion of the hand into

the paper exit gate during tray motion up or down,

the paper exit gate is equipped with a shutter. The

shutter is driven by the reverse motion of the

paper pressure motor (M707), closing the paper

exit gate when the tray is in motion.

Shutter

Paper pressure motor (M707)

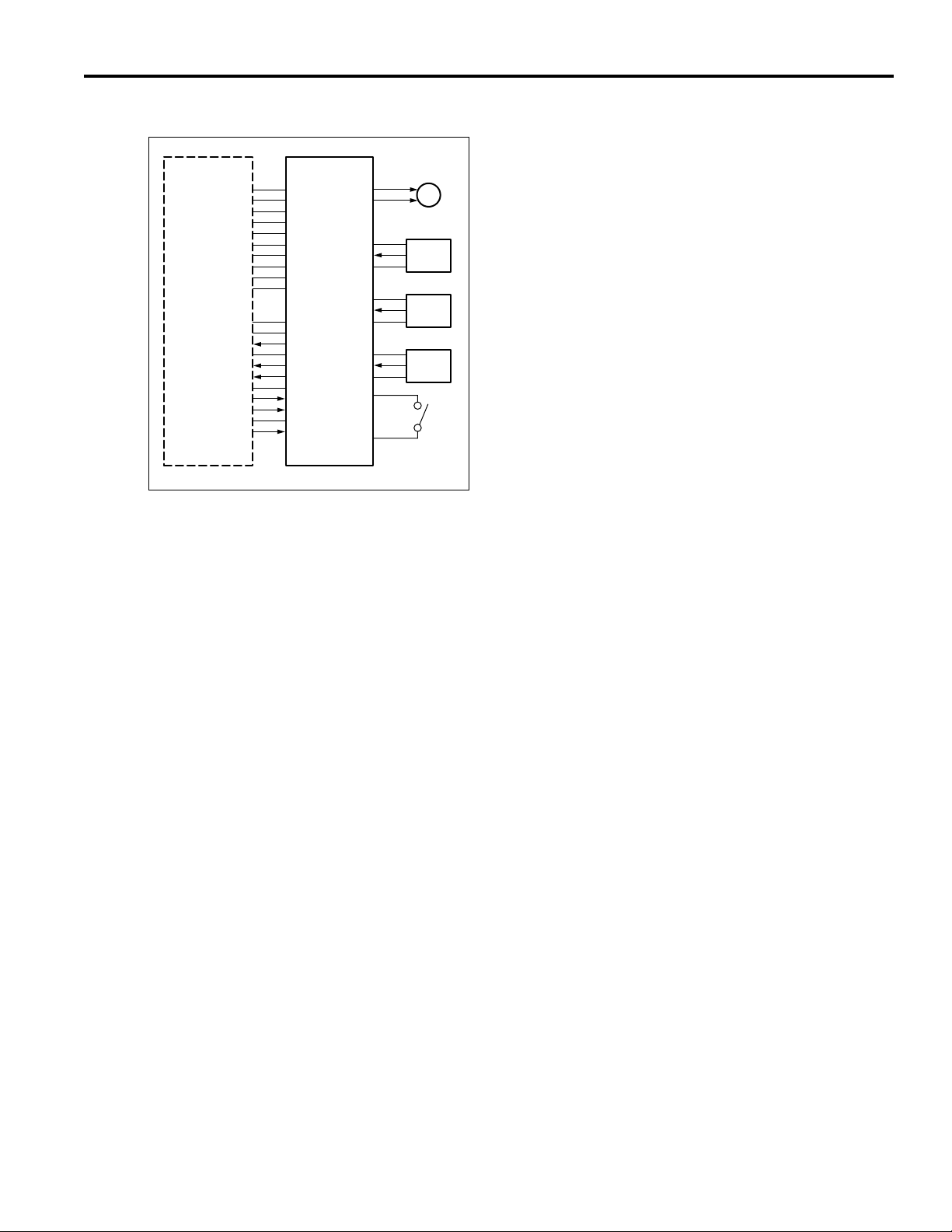

Conveyance Control

5VDC

PS3

SGND

24VDC

24VDC

24VDC

5VDC

5VDC

SGND

SGND

PGND

PGND

PGND

SGND

SGND

M ACK

SGND

S REQ

M RXD

SGND

S ACK

M REQ

SGND

M TXD

MAIN BODY

PS3

M701 OUT A

M701 OUT A

M701 OUT B

M701 OUT B

FS CB

24VDC

24VDC

5VDC

PS702

SGND

5VDC

PS717

SGND

24VDC

MS701

M701

PS702

PS717

MS701

Conveyance is accomplished by the drive force of the

M701 (paper conveyance motor), which is transmitted to

the conveyance rollers. The M701 is linked with the main

body, so that rotation is set to low or high speed according

to the conveyance movement during copying.

The M701 is controlled by the FS CB (FS control board).

Related signals are provided by the PS702 (paper

entrance detect PS), PS717 (conveyance cover open/

close detect PS) and the MS701 (front door switch) and

PS3 (paper exit PS) of the main body.

1. Operation

As paper passes by the PS3 of the main body, the

M701 conveys the paper at a low speed in relation

with the paper exit velocity of the main body. When

the end of the paper passes through the PS3, the

M701 then conveys the paper at high speed. The

M701 again changes to low speed after the specified

period of time when the end of the paper passes

through the PS702, ready to convey the next sheet of

paper.

11

Page 20

FS-107

2. Signals

a. Input signals

(1) PS3 (PS3 -> PRDB)

When the main body paper exit section detection

signal detects paper, [H] is output.

(2) PS702 (PS702 -> FS CB)

Conveyance section paper entrance detection signal

[L]: No paper is present

[H]: Paper is present

(3) PS717 (PS717 -> FS CB)

Conveyance plate opening/closing detection signal

[L]: Conveyance plate open

[H]: Conveyance plate closed

(4) MS701 (MS701 -> FS CB)

Power supply line for each load

When the finisher front door is closed, 24VDC is

supplied to each load.

(5) S ACK (MAIN BODY -> FS CB)

Transmission of OK signal from the main body to the

finisher.

b. Output signals

(1 ) M701 OUTA, M701 OUTA, M701 OUTB, M701

OUT B (FS CB -> M701)

M701 drive control signal

24V

0V

(2) M ACK (FS CB -> MAIN BODY)

Transmission of OK signal from the finisher to the

main body.

(3) S REQ (FS CB -> MAIN BODY)

Transmission of request signal from the finisher to

the main body.

(4) M RXD (FS CB -> MAIN BODY)

Serial data sign sending the movement condition of

the finisher to the main body CB.

(6) M TXD (MAIN BODY -> FS CB)

Serial data sign sending the movement condition of

the main body to the finisher.

(7) M REQ (MAIN BODY -> FS CB)

Transmission of request signal from the main body to

the finisher.

12

Page 21

FS-107

Tray Up/Down Control

24VDC

24VDC

24VDC

5VDC

5VDC

SGND

SGND

PGND

PGND

PGND

SGND

SGND

M ACK

SGND

S REQ

M RXD

SGND

S ACK

M REQ

SGND

M TXD

MAIN BODY

The paper exit position of the FS is fixed, the selected tray

is elevated or lowered to the paper exit position. Control of

the tray up/down is by the M706 (tray up/down motor)

which drives wires which is connected to and moves the

trays up and down.

The M706 is controlled by the FS CB (FS control board).

Related signals are provided by the PS703 (paper exit

detect PS), PS706 (tray lower limit detect PS), PS716

(tray count PS) and the MS702 (shutter switch).

M706 DRIVE 1

M706 DRIVE 2

5VDC

PS706

SGND

5VDC

PS703

SGND

5VDC

PS716

SGND

24VDC

MS702

FS CB

M706

PS706

PS703

PS716

MS702

1. Operations

a. Tray lower limit detection operation

With the sub power swich turnd ON, and the PS706

OFF, the M706 is reversed and the tray is lowered

until the PS706 is turned ON.

b. Tray count operation

One, two, or no optional trays can be installed.

If PS716 goes OFF after the low limit of the tray has

been detected, the machine judges that no optional

trays are installed.

When PS716 is ON, optional tray 1 is in place; in this

condition the M706 rotates normally, raising the tray

one step up until PS716’s detection position where

motion is stopped. Whether PS716 is ON or OFF at

this point determines whether optional tray 2 is in

place or not.

The number of trays is counted by means of a series

of operations.

After the tray count, the default tray that was set in the

key operator mode is set in the exit position.

c. Tray movement operation

If the exit tray has been selected at the LCD, then

when copying starts M706 turns ON and moves the

selected tray so that it sets into the exit position.

The number of times PS703 switches ON and OFF

sets the selected tray into the paper exit position.

d. Shutter switch operation

While the tray is in motion, the shutter, which

prevents the fingers or foreign objects from entering

the paper exit gate, is closed, with MS702 in the ON

position supplying 24VDC to the various loads.

While the tray is being raised or lowered the shutter

is opened and MS702 is OFF, interrupting the flow of

electricity and halting the motion of the FS.

13

Page 22

FS-107

2. Signals

a. Input signals

(1 ) PS706 (PS706 -> FS CB)

Tray lower limit detection signal

[L]: Not at lower limit

[H]: Lower limit

(2 ) PS703 (PS703 -> FS CB)

Paper exit detection signal

[L]: Top face

[H]: Not at top face

(3 ) PS716 (PS716 -> FS CB)

Tray installation detection signal

[L]: No tray

[H]: Tray in position

(4 ) PS702 (PS702 -> FS CB)

The power supply line for each load.

24VDC is supplied to each load when the shutter is

closed.

b. Output signal

(1) M706 DRIVE 1, 2 (FS CD -> M706)

M706 drive control signal

The drive direction of the M706 is controlled by two

signals which change the direction of the electrical

current.

14

Page 23

PAPER EXIT/ST APLER UNIT

Composition

Exit roller/A

Alignment plates

Trays

FS-107

Mechanisms

Mechanism System

Paper Alignment *1 Separate plates for front

and rear

Paper Exit *2 Exit roller/A

Paper Stacking *3 Exit roller/A

Conveyance belt

Stapler Unit Shift *4 Stapler shift motor

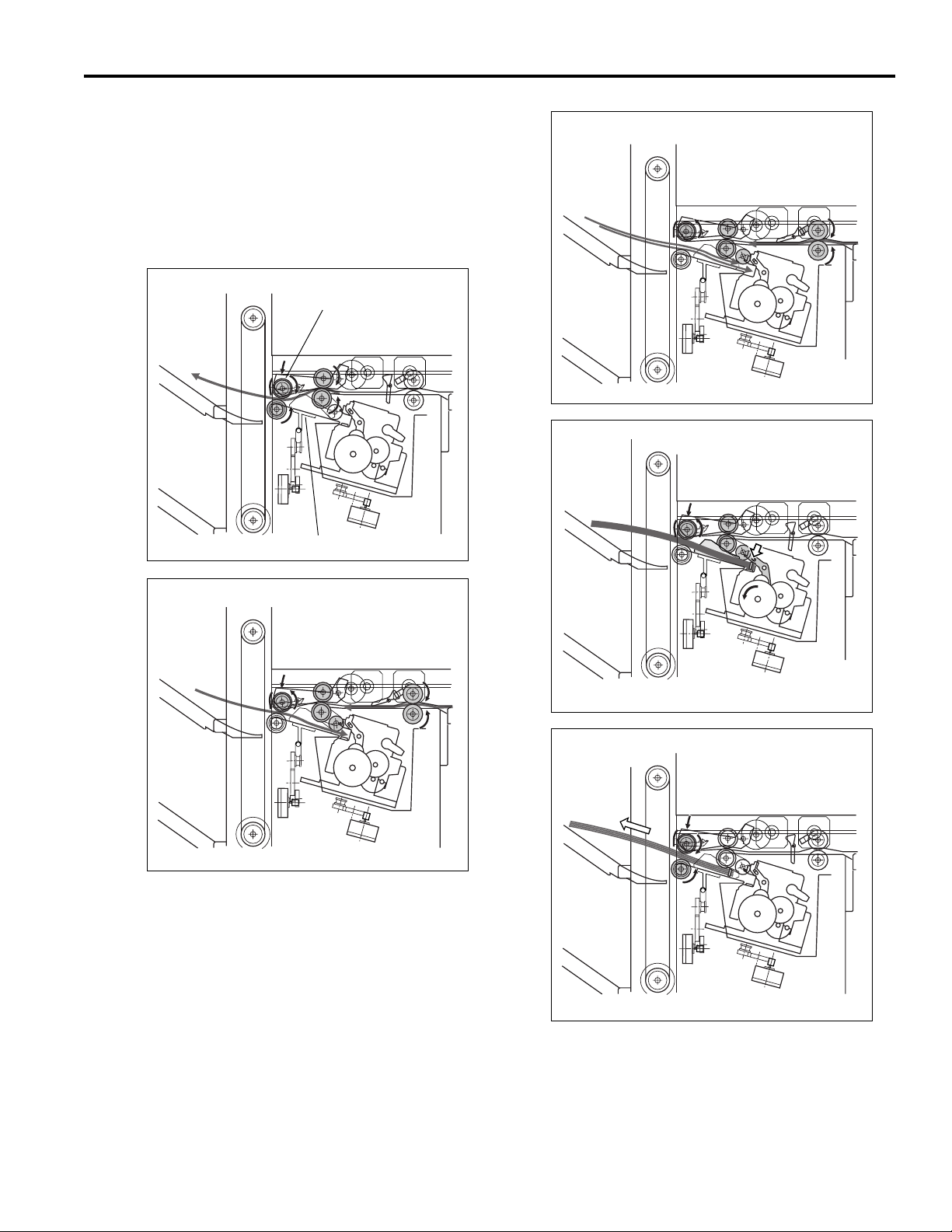

*1 Paper alignment

Paper conveyed to the paper exit gate by the conveyance roller is stacked by reverse rotation of the

paper exit roller/A. The stacked paper is aligned

by the alignment plates. Independently-driven

alignment plates are set on both the front and rear

sides, allowing independent operation at the front

and rear during shift mode. The alignment plates

are driven by alignment motors M704 (front) and

M703 (rear).

Alignment motors

(M703, M704)

Stapler unit

Stapler shift motor (M705)

Alignment plate (rear)

Alignment plate (front)

Alignment motor (rear)

(M703)

Alignment motor (front)

(M704)

15

Page 24

FS-107

*2 Paper exit

In the straight mode, paper conveyed to the paper

exit gate by the conveyance rollers is conveyed to

the tray through paper pressure being applied to

paper exit roller/A by the paper pressure motor

(M707) and the roller being made to run forward.

(Does not apply to small paper sizes.)

In offset mode or staple mode, when the stacked

paper is conveyed, paper pressure being applied

to paper exit roller/A by the paper pressure motor

(M707) and the roller being made to run forward,

all the stacked paper is conveyed into the tray.

Straight mode

Paper exit rollerA

Offset mode/staple mode

*3 Paper stack

In the offset mode or staple mode, paper conveyed to the paper exit gate by the conveyance

rollers is then conveyed to the stack position by

paper exit roller/A running in reverse direction.

The conveyed paper is sent to the stopper by the

friction of the conveyance belt and stacked.

*4 Stapler unit shift

The stapler unit is driven by the stapler shift

motor; the stapler unit is fixed on the staple base

and moved by a belt along a rail. Owing to the

shape of the rail, when the stapler unit is moved to

either the forward or rear positions, the unit

rotates and it is possible to staple slantwise.

When the stapler is set to staple in two locations,

it moves to the first location, puts in the first

staple, then moves to the second location to put

in the second staple.

16

Stapler unit

Rails

Stapler shift motor

(M705)

Belt

Page 25

FS-107

Paper Alignment Control

24VDC

24VDC

24VDC

5VDC

5VDC

SGND

SGND

PGND

PGND

PGND

SGND

SGND

M ACK

SGND

S REQ

M RXD

SGND

S ACK

M REQ

SGND

M TXD

MAIN BODY

FS CB

24VDC

24VDC

M702 OUT A

M702 OUT A

M702 OUT B

M702 OUT B

24VDC

24VDC

M703 OUT A

M703 OUT A

M703 OUT B

M703 OUT B

24VDC

24VDC

M704 OUT A

M704 OUT A

M704 OUT B

M704 OUT B

5VDC

PS702

SGND

5VDC

PS709

SGND

5VDC

PS710

SGND

M702

M703

M704

PS702

PS709

PS710

1. Operations

a. Normal alignment operation

The front and rear alignment plates work in

symmetry to the front and rear based on the center of

the alignment section, alternately aligning and

releasing. To create this symmetrical movement

the M703 and M704 always rotate in opposite

directions.

Every five sheets of the conveyed paper are aligned

and sent on to the paper exit section.

The timing of the M703 and M704 are set to the

starting point by the ON/OFF of the PS702 (paper

entrance detect PS).

b. Offset (shift alignment) operation

The sheets corresponding to odd sets of copies are

fed to the paper exit unit as soon as they have been

aligned normally. (Up to 5 sheets are stacked and

exited.)

During the alignment operation for even sets of

copies, M703 and M704 rotate in the same direction,

shifting the sheets forward from the center. The

aligned sheets are then sent to the paper exit unit.

(Up to 5 sheets are stacked and exited.

During sorting and stapling, paper exited by the

conveyance section is sent to the alignment section by the

M702 (paper exit motor) reverse direction, then aligned by

the alignment plates driven by the M703 (alignment motor,

(rear)) and the M704 (alignment motor, (front)).

The home position of the alignment plates is detected by

the PS709 (alignment plate detect PS (rear)) and the

PS710 (alignment plate detect PS (front)). The FS CB (FS

control board) controls the M702, M703 and M704. The

related signal are passed to the PS702 (paper entrance

detect PS).

c. Staple mode operation

In the staple mode, the M703 and M704 are

released after the stapling action is completed.

The ON/OFF timing of the M703 and M704 is set as

the M702 is turned from OFF to ON, and the PS702 is

turned OFF after the specified period of time.

17

Page 26

FS-107

2. Signals

a. Input signals

(1 ) PS709 (PS709 -> FS CB)

Detection signal of the home position of the

alignment plate (rear)

[L]: Non-home position

[H]: Home position

(2) PS710 (PS710 -> FS CB)

Detection signal of the home position of the

alignment plate (front)

[L]: Non-home position

[H]: Home position

b. Output signals

(1) M702 OUT A, M702 OUT A–, M702 OUT B,

M702 OUT B– (FS CB -> M702)

Drive control signal for M702

Paper Exit Control

5VDC

PS3

SGND

24VDC

24VDC

24VDC

5VDC

5VDC

SGND

SGND

PGND

PGND

PGND

SGND

SGND

M ACK

SGND

S REQ

M RXD

SGND

S ACK

M REQ

SGND

M TXD

MAIN BODY

PS3

FS CB

24VDC

24VDC

M702 OUT A

M702 OUT A

M702 OUT B

M702 OUT B

M707 DRIVE 1

M707 DRIVE 2

M708 DRIVE 1

M708 DRIVE 2

5VDC

PS701

SGND

5VDC

PS702

SGND

5VDC

PS703

SGND

5VDC

PS707

SGND

M702

M707

M708

PS701

PS702

PS703

PS707

24V

0V

(2) M703 OUT A, M703 OUT A–, M703 OUT B,

M703 OUT B– (FS CB -> M703)

Drive control signal for M703

24V

0V

(3) M704 OUT A, M704 OUT A–, M704 OUT B,

M704 OUT B– (FS CB -> M704)

Drive control signal for M704

24V

0V

Papers that have already been aligned or stapled are

exited by the paper exit roller.

A mechanical clutch is connected to M702 (paper exit

motor). A mechanical clutch can convey the forward

direction driving power to the exit roller with certain

movement.

The M702 is responsible for speed control for connection

with the mechanical clutch, for sending the alignment

section at the reversal rotation, and also during the usual

paper exit.

The M702 is controlled by the FS CB (FS control board).

The related signals are M707 (paper pressure motor),

M708 (stapler motor), PS701 (paper pressure PS), PS702

(paper entrance detect PS), PS703 (paper exit detect PS),

and PS707 (no paper detect PS).

18

Page 27

FS-107

1. Operation

During paper exit, both upper and lower exit rollers

are compressed as a consequence of the operation

performed by M707, and that condition is detected by

the ON/OFF state of PS701.

a. Non-staple mode operation

The ON/OFF timing of M702 is such that it turns ON

during the OFF of PS3, and turns OFF during the

OFF of PS702.

After the paper exit tray goes up until PS703 turns

ON, M706 moves the tray up and down in order to

keep the ON state of PS703 during paper exit.

b. Staple mode operation

M702 turns ON a certain time after M708 finishes the

stapling operation and turns OFF.

The subsequent operations are the same as for the

non-staple operation.

2. Signals

a. Input signal

(1) PS701 (PS701 -> FS CB)

Pressure detection signal of the exit paper compressing plate

[L]: Pressure

[H]: Release

Paper Stack Control

24VDC

24VDC

24VDC

5VDC

5VDC

SGND

SGND

PGND

PGND

PGND

SGND

SGND

M ACK

SGND

S REQ

M RXD

SGND

S ACK

M REQ

SGND

M TXD

MAIN BODY

When the stack of the papers on the paper exit tray is full,

a message is put up on the LCD.

During the automatic switching mode of the tray, a

message is not put up on the LCD. The tray located 1 step

below is brought to the paper exit position by a vertical

movement of M706 (tray up/down motor).

The M706 is controlled by FS CB (FS control board).

The related signals are PS702 (paper entrance detect

PS), PS703 (paper exit detect PS), PS704 (tray full-stack

detect PS), PS706 (tray lower limit detect PS), and PS716

(tray count PS).

M706 DRIVE 1

M706 DRIVE 2

5VDC

PS702

SGND

5VDC

PS703

SGND

5VDC

PS704

SGND

5VDC

PS706

SGND

5VDC

PS716

SGND

FS CB

M706

PS702

PS703

PS704

PS706

PS716

b. Output signals

(1) M707 DRIVE 1,2 (FS CB -> M707)

M707 drive control signal

The drive direction of the M707 is controlled by two

signals which change the direction of the electrical

current.

(2) M708 DRIVE 1,2 (FS CB -> M708)

M708 drive control signal

The drive direction of the M708 is controlled by two

signals which change the direction of the electrical

current.

The automatic switching mode of the tray can be

controlled using the 25 modes of the main unit.

19

Page 28

FS-107

1. Operation

a. Up/down operation

When the tip of the paper turns PS702 ON, the tray is

driven down by a certain amount. After the rear of the

paper turns PS702 OFF, M706 turns ON driving the

tray up until PS703 is turned ON.

b. Full-stack detection operation

When a tray other than tray 1 is selected and PS703

is turned ON when PS704 is ON, the paper-full

condition is detected. When tray 1 is selected and

PS 703 is turned ON when PS706 is ON, the paperfull condition is detected.

c. Automatic tray switching operation

When tray 1, optional tray 1, and optional tray 2 are

selected and the paper-full condition is detected,

M706 drives the tray up so that PS703 is turned OFF

and then ON again, and the immediately lower tray is

set at the paper exit position.

When tray 2 is selected and the paper-full condition

is detected, M706 drives the tray down until PS716 is

turned ON, and then up until PS703 is turned ON, set

tray 1 at the paper exit position.

Stapler Control

24VDC

24VDC

24VDC

5VDC

5VDC

SGND

SGND

PGND

PGND

PGND

SGND

SGND

M ACK

SGND

S REQ

M RXD

SGND

S ACK

M REQ

SGND

M TXD

MAIN BODY

M705 (staple shift motor) performs staple displacement

control by moving the stapler unit up to the stapler

operation position.

The home position of the stapler unit is detected by PS708

(stapler unit HP detect PS).

M705 is controlled by FS CB (FS control board).

M705 OUT A

M705 OUT A

M705 OUT B

M705 OUT B

FS CB

24VDC

24VDC

5VDC

PS708

SGND

M705

PS708

2. Signal

a. Input signal

(1) PS704 (PS704 -> FS CB)

Paper-full detection signal

Goes [H] when paper-full condition is detected.

1. Operation

The stapler unit is usually at the home position of the

finisher.

When receiving a command signal from the main

unit, M705 moves the stapler unit to the stapling

position according to paper size and starts the

stapling operation.

After finishing the copy, M705 moves the stapler unit

to its home position.

The M705 OFF timing is controlled by the number of

driving steps after PS708 is turned OFF.

20

Page 29

FS-107

2. Signal

a. Input signal

(1 ) PS708 (PS708 -> FS CB)

Detection signal of the home position of the stapler

unit

[L]: Non-home position

[H]: Home Position

b. Output signal

(1) M705 OUT A, M705 OUT A–, M705 OUT B,

M705 OUT B– (FS CB -> M705)

Drive control signal for M705

24V

0V

Staple Control

24VDC

24VDC

M705 OUT A

M705 OUT A

M705 OUT B

M705 OUT B

M707 DRIVE 1

M707 DRIVE 2

M708 DRIVE 1

M708 DRIVE 2

5VDC

PS701

SGND

5VDC

PS708

SGND

5VDC

PS712

SGND

5VDC

PS713

SGND

FS CB

MAIN BODY

24VDC

24VDC

24VDC

5VDC

5VDC

SGND

SGND

PGND

PGND

PGND

SGND

SGND

M ACK

SGND

S REQ

M RXD

SGND

S ACK

M REQ

SGND

M TXD

In staple mode, stapling is performed using the driving

force of the M708 (stapler motor).

M705

M707

M708

PS701

PS708

PS712

PS713

M708 is controlled by FS CB (FS control board).

The related signals are M705 (stapler shift motor), M707

(paper pressure motor), PS701 (paper pressure PS),

PS708 (stapler unit HP detect PS), PS712 (stapler HP

detect PS), PS713 (no-staple PS), and PS714 (stapler

ready PS).

The maximum number of sheets that can be stapled, and

the operation when stapling is not possible, can be

chosen in the 25 mode of the main body.

21

Page 30

FS-107

1. Operation

a. Stapler operation

After the aligning operation of the last paper, M707 is

turned ON and compresses the paper using the exit

rollers. Then, M708 is turned ON and stapling

begins.

When PS701 is turned OFF, M707 is turned OFF,

PS712 is turned ON, and M708 is turned OFF.

For continuous stapling, M705 is not turned ON, and

the stapler unit waits for the next stapling at the same

position.

In the case of 2 stapling positions, the first staple is

executed and then M705 moves the stapler to the

specified position for the second staple. M708 then

turns ON and executes the second staple. At this

moment, if continuous stapling has been selected,

the stapler unit stops at the immediately previous

stapling position. When the first stapling operation of

the next paper is done, M705 moves the stapler unit

for the second stapling operation.

After the copy is finished, the stapler unit returns to

its home position.

2. Signals

a. Input signals

(1) PS712 (PS712 -> FS CB)

M708 home position detection signal

[L]: Home position

[H]: Non-home position

(2) PS713 (PS713 -> FS CB)

No-staple detection signal of the stapler unit

[L]: With staple

[H]: No staple

(3) PS714 (PS714 -> FS CB)

Detects whether staple is in position for stapling by

stapler unit (whether staple is present at point just

ahead of where it is actually driven from the stapler).

[L]: With staple

[H]: No staple

b. No-staple detection control

The PS713 is equipped to detect the no-staple

condition of the stapler unit. When the staple is not

present, the LCD (display board) of the main unit

shows a message indicating the no-staple condition.

c. Stapler Initial Operation

After replacing the stapler cartridge, M708 is driven

until staples are detected in the PS714, performing

up to a maximum of 16 blank stapling operations,

then the staples are positioned just in front of the

stapling position.

22

Page 31

OTHER CONTROLS

Movement With Power On

When the power is turned ON, the finisher performs

the following initialization operations.

1. M707 turns ON and the paper exit gate pressure

is released.

2. PS708 (stapler unit HP detect PS) detects

whether the stapler unit is on stand-by in home

position.

3. M703 (alignment motor (rear)) and M704 (alignment motor (front)) turn ON and perform a home

position search for the alignment plates (front and

rear).

4. The paper exit gate shutter closes and the tray

count operation takes place.

Opening and Closing Motion of the Front

FS-107

Door

1. In case PS707 is ON, it makes M702 go through a

normal rotation and performs a paper exit operation.

2. M707 turns ON and the paper exit gate pressure is

released.

3. PS708 (stapler unit HP detect PS) detects

whether the stapler unit is on stand-by in home

position.

4. M703 (alignment motor (rear)) and M704 (alignment motor (front)) turn on and perform a home

position search for the alignment plates (front and

rear).

23

Page 32

FS-107

This page left blank intententionally.

24

Page 33

DISASSEMBLY AND ASSEMBLY

FS-107

Caution: Make sure the power plug is

uplugged.

Removal and Reinstalling of the Finisher

(1) Open the front door, then insert a pen, or the like,

into the hole at the bottom of the finisher

Caution: There is a risk of the internal lever

becoming deformed, so do not push it in

hard.

(2) Take out each 2 sets of set screws from the wire

fittings on front and rear.

Set

screws

Wire fittings

(3) Pull out the tray downward from the frame that it is

installed.

Caution 1: Taking out the set screws from the fixed

fittings will make the tray frame fall out.

Caution 2: Take care not to drop the rollers installed

on the tray.

Set

screws

(2) Pull the finisher forward and remove it.

Removal and Reinstalling of the Tray

(1) Take out each 3 sets of set screws and remove

the cover’s front and rear.

Set screws

Cover

(rear)

Set screws

Set screws

Cover

(front)

25

Page 34

FS-107

(4) Install by reversing the removal procedure.

Caution: In case of fixing the tray frame to the fixed

fittings, make sure that the set screws are

fastened so that the tray is horizontal.

(Use the 6 marks at each of the front and

rear as guides for horizontal adjustment.)

Replacing the Paper Exit Roller/A

(1) Remove the finisher from the main body.

(2) Take off 5 lids and 6 set screws and remove the

paper conveyance cover.

Lid

Set screws

Paper conveyance cover

(3) Take out each of the single springs and set screws

and remove the plate spring roller.

Set screws

Plate spring rollers

Spring adjustment

plate

Caution: Do not remove the screws for the spring

adjustment plate.

26

Page 35

FS-107

(4) Remove the E-ring and remove the cam shaft.

Shaft

E-ring

(5) Take out the 2 sets of set screws and remove the

set of 2 plate springs.

Set screws

Plate spring

(8) Remove the 5 E-rings and pull out the shaft from

the paper exit roller/A.

Caution: Be careful to not drop the pin inside the

paper exit roller/A.

Shaft

E-rings

Paper exit

roller/A

Pin

E-rings

Pin

(9) Replace the paper exit roller/A.

(10) Install by reversing the removal procedure.

(6) Take out 1 set screw and remove the plate.

(7) Remove the E-ring that affixes the belt gear, slide

the gear and remove the belt.

Caution: Be careful to not drop the pin inside the

gear.

Set screw

Pin

Plate

E-ring

Belt

27

Page 36

FS-107

Removing/Reinstalling the Up/Down Wire

(1) Take out the 3 sets of set screws and remove the

front cover and rear cover.

(2) Remove the 2 set screws from each of the front

and rear wires and then remove the tray unit.

Caution: Perform the removal/installating of the

front up/down wire before performing the

removal/installating of the rear up/down

wire.

(3) Loosen the 2 set screws and release the pulley

tension plate in front from its fixed position.

(4) Remove the E-ring of the lower pulley (in front).

(5) Remove the lower pulley (in front) and remove the

up/down wire in front.

(6) Attach the metallic ball of the up/down wire on the

inner surface of the lower pulley (in front), and

insert into the shaft. The metallic ball to be set is

the one longer from the wire fitting.

Also, check to see if the gear position at which the

pulley is installed is in line with the opposite side.

Caution: Ensure that the pulley installation gear is

horizontal with respect to the casing.

(7) Wind the up/down wire once around the lower

pulley front) counter-clockwise, and string it to the

upper pulley (front).

(8) Down the up/down wire strung to the upper pulley

(front) to the lower pulley and wind it around 4

times counter-clockwise, and attach the metallic

ball on the end to the side of the lower pulley

(front).

(9) Attach the E-ring and affix the lower pulley (front).

(10) Fasten the 2 set screws while pulling up the pulley

tension plate (front), applying 3kg tension.

Caution: Apply the required amount of tension at

the time of affixing the pulley tension plate

by using such devises as a tension gauge.

Required value: 3kg

Set screws

Pulley tension

plate

28

Page 37

FS-107

(11) Refer to procedures 3 to 6 and remove the up/

down wire on the rear.

(12) Wind the up/down wire once around the lower

pulley (rear) in the clockwise, and string it to the

upper pulley (rear).

(13) Down the up/down wire strung to the upper pulley

(rear) to the lower pulley and wind it around 4

times clockwise, and attach the metallic ball on the

end to the side of the lower pulley (rear).

(14) Attach the E-ring and affix the lower pulley (rear).

(15) Fasten the 2 set screws while pulling up the pulley

tension plate (rear), applying 3kg tension.

Replacing the Stapler Cartridge

(1) Operate the stapler cartridge replacing from the

operation panel. The stapler unit will move and

position itself to the front.

(2) Turn the stapler cartridge replace knob on the

stapler unit.

Stapler unit

Cartridge replace knob

(3) Remove the old cartridge and push a new

cartridge firmly in place.

Stapler

cartridge

29

Page 38

FS-107

Removing/Reinstalling the Stapler Unit

(1) Remove the finisher from the main unit.

(2) Take out the fixing plates of the plate affixing the

stapler unit, from the rear of the finisher unit.

(3) Slide the plate and remove.

(5) Take out the set screw from the unit saddle, slide

out and remove the stapler unit.

Plate

Set screw

Caution: When reinstalling the plate, be sure to in-

sert the plate into the insides of the hooks.

(4) Take out the connector and 1 grounding screw

from the stapler unit.

Ground screw

Ground

Connector

Stapler units

Set screw

(6) Install by reversing the removal procedure.

30

Page 39

FS-107 ELECTRICAL PARTS LAYOUT DRAWING

PS711 Tray upper limit detect PS

PS704 Tray full-stack detect PS

PS703 Paper exit detect PS

PS716 Tray count PS

PS706 Tray lower limit detect PS

M706 Tray up/down motor

FS-107

PS709 Alignment plate

detect PS (rear)

M703 Alignment motor (rear)

M706 Tray up/down motor

M705 Stapler shift motor

PS707 No paper detect PS

PS708 Stapler unit HP

detect PS

M704 Alignment motor (front)

MS701 Front door switch

PS710 Alignment plate

detect PS (front)

FS CB FS control board

31

Page 40

FS-107

M709 Cooling fan motor

PS702 Paper entrance detect PS

PS701 Paper pressure PS

PS705 Shutter PS

MS702 Shutter switch

M707 Paper pressure motor

M702 Peper exit motor

M701 Paper conveyance motor

PS717 Conveyance cover open/close detect PS

PS714 Stapler ready detect PS

PS712 Stapler HP detect PS

M708 Stapler motorPS713 No-staple PS

32

Page 41

FS-107 CONNECTOR LAYOUT DRA WING

CN736 (W:3pin)

CN735 (W:3pin)

CN734 (W:3pin)

CN744 (W:3pin)

CN737 (W:3pin)

CN756 (W:15pin)

FS-107

CN741 (W:3pin)

CN724 (W:6pin)

CN756 (W:15pin)

CN738 (W:3pin)

CN723 (W:6pin)

CN725 (W:6pin)

CN740 (W:3pin)

CN756 (W:15pin)

CN739 (W:3pin)

CN726 (BK:2pin)

CN751 (W:1pin)

33

Page 42

FS-107

CN753 (W:1pin) CN752 (W:3pin)

CN709 (12pin)

CN715 (30pin)

CN706 (2pin)

CN714 (15pin)

CN701 (10pin)

CN712 (2pin)

FS CB

CN711 (2pin)

CN704 (12pin)

CN702 (11pin)

CN713 (3pin)

CN10 (2pin)

CN733 (W:3pin)

CN732 (W:3pin)

CN300 (BK:24pin)

CN708 (8pin)

CN731 (W:3pin)

CN703 (12pin)

CN705 (W:6pin)

CN722 (W:6pin)

CN721 (W:6pin)

CN707 (30pin)

CN734 (W:3pin)

CN730 (BK:2pin)

CN745 (W:3pin)

34

Page 43

FS-107

TIME CHART (8.5X11, SORT MODE, 2 SHEETS/SET, 2 SETS)

01234567 9108

)

sec

(

Time

Item

Exit PSPS3

Symbol

Paper entrance detect PSPS702

140mm/s

600mm/s

Paper

conveyance

No paper detect PS

PS707

motor

M701

140mm/s

600mm/s

Paper exit

M702

35

Stop

motor

Reverse

Shift

Alignment

Alignment

motor

M703,704

F

R

Stapler shift

motor

M705

Pressure

Paper

pressure

M707

Open

motor

Raise

Tray up/down

Lower

motor

M706

Page 44

FS-107

TIME CHART (8.5X11, STAPLE MODE, 2 SHEETS, 1 POSITION)

01234 567 9108

)

sec

(

Time

Item

Exit PSPS3

Symbol

Paper entrance detect PSPS702

140mm/s

600mm/s

No paper detect PS

Paper

conveyance

motor

PS707

M701

140mm/s

600mm/s

Paper exit

M702

Stop

motor

36

Reverse

Shift

Alignment

Alignment

motor

M703,704

F

R

Stapler shift

motor

M705

Pressure

Stapler motor

M708

Paper

Open

pressure

motor

M707

Raise

Tray up/down

Lower

motor

M706

Page 45

FS-107 OVERALL WIRING DIAGRAM

37

[HOW to see the diagram]

1. The signals shown reflect levels present under normal idling

conditions with the main switch turned ON.

2. Wiring symbols in the figure are as follows.

1) @@@@ is Connector

2) @@@is ribbon cable

RC

3. Signal symbols in the figure are as follows .

High active

H

L

Low active

Analog signal

*

Pulse signal

P

Page 46

This page left blank intentionally.

38

Page 47

PARTS CATALOG

Model

FS-107

SEPTEMBER 2002

THIRD EDITION

KONICA BUSINESS TECHNOLOGIES, INC.

Page 48

Page i Konica Business Technologies, Inc. Model FS-107

September, 2002 3rd Edition

Page 49

How to use this catalog

This parts catalog includes illustrations and part numbers for all replacement parts and assemblies used in this model.

Model-specific parts are identified in the illustrations with reference

numbers. Use the reference number to locate the corresponding part

number on the facing page.

Common hardware items, such as screws, nuts, washers, and pins, are

identified in the illustrations with reference letters. Use the reference letter to locate the corresponding part number on the hardware listing in the

lower right hand corner of the facing page.

If you know a part number, but don’t know where the part is used, use

the numerical index to determine the page number and reference number for that part. Because some common parts are used in several

places, there may be more than one entry. Refer to the illustrations to see

where the part may be used.

If you know a part’s description, but don’t know where to look to find

the part number, use the alphabetical index to determine likely page and

reference numbers. Then look at the illustrations to determine that you

have identified the correct part. Locate the part number using the listing

on the opposite page.

Retail pricing that appears with the numerical index, while valid when

this catalog was printed, is subject to change without notice. The prices

are only suggested prices and are provided only for reference. Dealers

may determine their own selling prices. For up-to-date pricing, refer to

current Konica price lists or contact the Konica Parts Distribution Center.

How to order parts

Use standard Konica parts ordering procedures to obtain these parts.

For ordering options, contact Konica’s Parts Distribution Center.

When ordering parts, be sure to specify part numbers exactly as listed in

this catalog.

NOTE: Electrical parts may include previously used components.

Model FS-107 Konica Business Technologies, Inc. Page iii

3rd Edition September, 2002

Page 50

This page left blank intentionally.

Page iv Konica Business Technologies, Inc. Model FS-107

September, 2002 3rd Edition

Page 51

How to use this catalog . . . . . . . . . . . . . . . . . . . . . . . . . iii

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

FS-107 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Alphabetical index . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Numerical index, Retail price list . . . . . . . . . . . . . . . . . . . . 21

Contents

Model FS-107 Konica Business Technologies, Inc. Page 1

3rd Edition September, 2002

Page 52

FS-107

Page 2 Konica Business Technologies., Inc. Model FS-107

September, 2002 3rd Edition

Page 53

REF. PART NUMBER DESCRIPTION

NO.

1 13GQ12040 Paper exit cover/front

2 13GQ10022 Main casing/2

3 13GQ12050 Paper exit cover/rear

4 13GQ45021 Conveyance open-close plate

5 12QV85510 Photosensor

6 13GQ12100 Screw cover

7 13GQ97020 Staple label

8 13GQ12010 Open-close cover

9 12AA12100 Magnet catch/A

10 048645260 Stopper rubber

11 13GQ12020 Side cover

12 13GQ12091 External upper plate

13 13GQ45210 Conveyance pressure spring/A

14 13GQ45860 Conveyance driven roller/B

15 13GQ-4690 Conveyance driven shaft/A assembly

16 13GQ45940 Conveyance guide sheet/A

HARDWARE

REF.

LTR.

a 00Z373082

b 00Z353102

c 00Z354122

d 00Z353081

PART

NUMBER

Model FS-107 Konica Business Technologies., Inc. Page 3

3rd Edition September, 2002

Page 54

FS-107

Page 4 Konica Business Technologies., Inc. Model FS-107

September, 2002 3rd Edition

Page 55

REF. PART NUMBER DESCRIPTION

NO.

1 13GQ48010 Paper exit tray/A

2 13GQ48020 Paper exit tray/B

3 13GQ-4910 Paper exit tray/lower assembly

4 13GQ15091 Up-down wire/front

5 13GQ48310 Support plate/front

6 13GQ48080 Up-down roller

7 13GQ48050 Up-down plate/front

8 13GQ48152 Guide part

9 13GQ48300 Tension pulley

10 13GQ48060 Up-down plate/rear

11 13GQ48070 Up-down pulley

12 090075530 Bearing

13 13GQ77130 Rocking gear/D (Z=30)

14 13GQ77120 Rocking gear/C (Z=15/45)

15 300078010 Pin A

16 13GQ76030 Shaft holder/B

17 13GQ80020 FNS driving motor

18 13GQ48320 Support plate/rear

19 13GQ15101 Up-down wire/rear

20 12QV85510 Photosensor

21 13GQ48180 Mount plate/C

22 13GQ48200 Paper exit standard actuator

23 13GQ-4830 Mount plate/D assembly

24 13GQ-1520 Drive Mount plate/C assembly

25 13GQ77140 Rocking gear/E (Z=15)

26 13GQ-1540 Tension plate/A assembly

27 13GQ-1510 Drive Mount plate/B assembly

HARDWARE

REF.

LTR.

a 00Z670606

b 00Z163061

c 00Z670406

d 00Z254081

e 00Z921930

f 00Z670306

g 00Z353102

h 00Z353081

j 00Z353101

PART

NUMBER

Model FS-107 Konica Business Technologies., Inc. Page 5

3rd Edition September, 2002

Page 56

FS-107

Page 6 Konica Business Technologies., Inc. Model FS-107

September, 2002 3rd Edition

Page 57

REF. PART NUMBER DESCRIPTION

NO.

1 13GQ48250 Positioning actuator/B

2 13GQ76040 Shaft holder/C

3 13GQ76560 Paper exit pulley (Z=22)

4 13GQ48230 Collar/C

5 13GQ48221 Paper exit driving roller/B

6 12QV85510 Photosensor

7 13GQ48260 Detecting part

8 13GQ-4530 Conveyance guide plate/A assembly

9 13GQ45470 Rotary knob

10 322076010 Paper lift-up lever shaft holder

11 13GQ77040 Conveyance driving gear/1 (Z=28)

12 466078010 Pin A

13 13GQ45150 Conveyance driving roller/C

14 13GQ77581 Driving belt/H (L=92)

15 13GQ77020 Conveyance idler gear/1 (Z=18/28)

16 13GQ45480 Collar/A

17 13GQ77540 Driving belt/D (L=129)

18 13GQ77030 Paper exit idler gear (Z=22/33)

19 13GQ77560 Driving belt/F (L=309)

20 13GQ45070 Conveyance driving roller/B

21 13GQ76590 Conveyance auxiliary pulley (Z=22)

22 13GQ76540 Conveyance driving pulley/B (Z-18)

23 13GQ76020 Shaft holder/A

24 13GQ45870 Spring spacer

25 13GQ76580 Conveyance driving pulley/A (Z=24)

26 13GQ80510 Cooling fan motor

27 13GQ77181 Paper exit connecting clutch (Z=28/36)

28 13GQ45060 Conveyance driving roller/A

29 13GQ-4340 FNS motor/Assembly

30 13GQ45620 Hold spring

31 13GQ45820 Conveyance auxiliary roller

32 13GQ77570 Driving belt/G (L=207)

HARDWARE

REF.

LTR.

a 00Z670606

b 00Z193061

c 00Z163061

d 00Z670406

e 00Z921301

f 00Z183251

g 00Z193161

h 00Z353081

PART

NUMBER

Model FS-107 Konica Business Technologies., Inc. Page 7

3rd Edition September, 2002

Page 58

FS-107

Page 8 Konica Business Technologies., Inc. Model FS-107

September, 2002 3rd Edition

Page 59

REF. PART NUMBER DESCRIPTION

NO.

1 13GQ45681 Neutralizing cover

2 13GQ45580 Neutralizing brush

3 13GQ76020 Shaft holder/A

4 13GQ45410 Pressure cam

5 13GQ-4320 Connecting shaft assembly

6 13GQ77090 Rocking gear/A (Z=48)

7 322076010 Paper lift-up lever shaft holder

8 13GQ77230 Rocking gear/C (Z=30)

9 13GQ45690 Detecting arm

10 13GQ45421 Positioning actuator/A

11 13GQ77070 Rocking idler/1 (Z=20/40)

12 12QR86010 Inter lock switch

13 13GQ45780 Detecting spring

14 13GQ45750 Rocking actuator

15 12QV85510 Photosensor

16 55GA77670 Toner supply worm

17 13GQ77080 Rocking idler/2 (Z=20/48)

18 13GQ77220 Rocking gear/B (Z=20)

19 13GQ45761 Mount plate/G

20 13GQ80051 FNS motor/3

21 13GQ45931 Cam positioning spring/D

HARDWARE

REF.

LTR.

b 00Z670406

c 00Z193041

d 00Z252121

e 00Z182641

f 00Z660206

g 00Z163041

h 00Z183081

j 00Z473043

PART

NUMBER

Model FS-107 Konica Business Technologies., Inc. Page 9

3rd Edition September, 2002

Page 60

FS-107

Page 10 Konica Business Technologies., Inc. Model FS-107

September, 2002 3rd Edition

Page 61

REF. PART NUMBER DESCRIPTION

NO.

1 13GQ98040 Cam auxiliary sheet

2 13GQ45430 Paper exit pressure spring

3 13GQ77550 Driving belt/E (L=195)

4 13GQ45490 Collar/B

5 13GQ76550 Paper exit driving pulley/A (Z=12)

6 466078010 Pin A

7 13GQ45090 Paper exit driven roller/A

8 13GQ76010 Paper exit shaft holder

9 13GQ45191 Paper exit driving roller/A

10 13GQ45050 Conveyance rocking plate

11 13GQ45511 Toque limiter

12 454078050 Pin (Cleaner A)

13 13GQ76020 Shaft holder/A

14 13GQ45600 Conveyance auxiliary sheet/A

15 13GQ45450 Adjusting spring

16 13GQ45610 Conveyance auxiliary sheet/B

17 13GQ-4730 Conveyance pressure spring/B assembly

18 13GQ-4700 Conveyance auxiliary sheet/F assembly

19 13GQ45910 Finisher cushion

20 12QR86010 Interlock switch

21 13GQ45301 Spring

21 13GQ45300 Spring

22 12QV85510 Photosensor

HARDWARE

REF.

LTR.

a 00Z670206

b 00Z670406

c 00Z193041

d 00Z353081

PART

NUMBER

Model FS-107 Konica Business Technologies., Inc. Page 11

3rd Edition September, 2002

Page 62

FS-107

Page 12 Konica Business Technologies., Inc. Model FS-107

September, 2002 3rd Edition

Page 63

REF. PART NUMBER DESCRIPTION

NO.

1 13GQ80011 FNS collect motor

2 25AA52090 Stopper sheet

3 12QV85510 Photosensor

4 13GQ60171 Paper detecting actuator

5 13GQ90011 FNS I/F wiring

6 13GQ-6080 Paper regulating plate/rear assembly

7 13GQ60010 Paper regulating plate/front

8 13GQ-6151 Paper positioning plate/front

9 13GQ60051 Paper regulating spring

10 13GQ60220 Paper regulating collar

11 13GQ60211 Detecting spring

12 13GQ-6141 Paper positioning plate/rear assembly

13 13GQ60191 Paper detecting board

14 13GQ-9018 FNS control unit

15 13GQ77010 Regulating gear (Z=28/55)

16 25AA52140 Belt holder/B

17 13GQ77190 Regulating gear/B (Z=22/37)

18 13GQ77160 Regulating idler (Z=64)

19 13GQ77510 Driving belt/A (L=380)

20 13GQ77520 Driving belt/B (L=406)

21 13GQ76510 Idler pulley (Z=28)

22 13GQ10170 Switch plate

23 13GQ60251 Wiring fixed plate

24 12QR86010 Interlock switch

HARDWARE

REF.

LTR.

a 00Z670606

b 00Z670406

c 00Z183061

d 00Z921931

e 00Z670306

f 00Z163061

g 00Z670206

h 00Z660206

j 00Z182081

k 00Z353081

m 00Z353101

PART

NUMBER

Model FS-107 Konica Business Technologies., Inc. Page 13

3rd Edition September, 2002

Page 64

FS-107

Page 14 Konica Business Technologies., Inc. Model FS-107

September, 2002 3rd Edition

Page 65

REF. PART NUMBER DESCRIPTION

NO.

1 120HK0010 Cartridge case

2 * Not used

3 13GQ50090 Oscillate cam

4 13GQ50080 Slide plate

5 13GQ-1220 Cover/Lower assembly

6 13GQ50051 Fixed plate

7 13GQ50070 Driving plate

8 25AA52140 Belt holder/B

9 13GQ77210 Staple driving gear (Z=19/55)

10 12QR77010 Staple driving gear (Z=28/55)

11 13GQ50170 Click part

12 13GQ80031 FNS motor/1

13 13GQ77530 Driving belt/C (L=741)

14 13GQ50230 Fixed block

15 12QRK0011 Staples

16 12QV85510 Photosensor

17 13GQ90101 Relay wiring/2

18 13GQ76570 Idler pulley/2 (Z=19)

19 13GQ10140 Main lock spring

20 13GQ10120 Main lock claw

21 13GQ50120 Wiring cover

22 120H50402 Staple

23 13GQ50110 Staple mount plate

24 13GQ50180 Oscillate collar

25 13GQ50100 Staple board

26 13GQ50271 Fixed part

HARDWARE

REF.

LTR.

a 00Z193061

b 00Z670606

c 00Z670406

d 00Z183061

e 00Z921931

f 00Z163061

g 00Z922410

h 00Z194041

j 00Z353081

k 00Z353102

PART

NUMBER

Model FS-107 Konica Business Technologies., Inc. Page 15

3rd Edition September, 2002

Page 66

Wiring

Page 16 Konica Business Technologies., Inc. Model FS-107

September, 2002 3rd Edition

Page 67

REF. PART NUMBER DESCRIPTION

NO.

1 13GQ90011 FNS I/F wiring

2 13GQ90021 Motor wiring/1

3 13GQ90031 Motor wiring/2

3 13GQ90030 Motor wiring/2

4 13GQ90101 Relay wiring/2

5 13GQ90110 Interlock wiring/1

6 13GQ90061 Sensor wiring/1

Model FS-107 Konica Business Technologies., Inc. Page 17

3rd Edition September, 2002

Page 68

This page left blank intentionally.

Page 18 Konica Business Technologies, Inc. Model FS-107

September, 2002 3rd Edition

Page 69

Alphabetical index

PART PAGE REF.

DESCRIPTION NO. NO.

A

Adjusting spring . . . . . . 11 15

B

Bearing . . . . . . . . . . . 5 12

Belt holder/B . . . . . . . . 13 16

Belt holder/B . . . . . . . . 15 8

C

Cam auxiliary sheet . . . . 11 1

Cam positioning spring/D . 9 21

Cartridge case . . . . . . . 15 1

Click part . . . . . . . . . . 15 11

Collar/A . . . . . . . . . . 7 16

Collar/B . . . . . . . . . . 11 4

Collar/C . . . . . . . . . . 7 4

Connecting shaft assembly 9 5

Conveyance auxiliary pulley

(Z=22) . . . . . . . . . 7 21

Conveyance auxiliary roller 7 31

Conveyance auxiliary sheet/A 11 14

Conveyance auxiliary sheet/B 11 16

Conveyance auxiliary

sheet/F assembly . . . 11 18

Conveyance driven roller/B 3 14

Conveyance driven shaft/A

assembly . . . . . . . . 3 15

Conveyance driving gear/1

(Z=28) . . . . . . . . . 7 11

Conveyance driving pulley/A

(Z=24) . . . . . . . . . 7 25

Conveyance driving pulley/B

(Z=18) . . . . . . . . . 7 22

Conveyance driving roller/A 7 28

Conveyance driving roller/B 7 20

Conveyance driving roller/C 7 13

Conveyance guide plate/A

assembly . . . . . . . . 7 8

Conveyance guide sheet/A . 3 16

Conveyance idler gear/1

(Z=18/28) . . . . . . . 7 15

Conveyance open-close plate 3 4

Conveyance pressure

spring/A . . . . . . . . 3 13

Conveyance pressure

spring/B assembly . . . 11 17

Conveyance rocking plate . 11 10

Cooling fan motor . . . . . 7 26

Cover/Lower assembly . . . 15 5

D

Detecting arm . . . . . . . 9 9

Detecting part . . . . . . . 7 7

Detecting spring . . . . . . 9 13

Detecting spring . . . . . . 13 11

Detecting spring . . . . . . 13 11

PART PAGE REF.

DESCRIPTION NO. NO.

Drive Mount plate/B

assembly . . . . . . . . 5 27

Drive Mount plate/C

assembly . . . . . . . . 5 24

Driving belt/A (L=380) . . . 13 19

Driving belt/B (L=406) . . . 13 20

Driving belt/C (L=741) . . . 15 13

Driving belt/D (L=129) . . . 7 17

Driving belt/E (L=195) . . . 11 3

Driving belt/F (L=309) . . . 7 19

Driving belt/G (L=207) . . . 7 32

Driving belt/H (L=92) . . . . 7 14

Driving plate . . . . . . . . 15 7

E

External upper plate . . . . 3 12

F

FNS I/F wiring . . . . . . . 13 5

FNS I/F wiring . . . . . . . 17 1

FNS collect motor . . . . . 13 1

FNS control unit . . . . . . 13 14

FNS driving motor . . . . . 5 17

FNS motor/1 . . . . . . . . 15 12

FNS motor/3 . . . . . . . . 9 20

FNS motor/Assembly . . . . 7 29

Finisher cushion . . . . . . 11 19

Fixed block . . . . . . . . . 15 14

Fixed part . . . . . . . . . . 15 26

Fixed plate . . . . . . . . . 15 6

G

Guide part . . . . . . . . . 5 8

H

Hold spring . . . . . . . . . 7 30

I

Idler pulley (Z=28) . . . . . 13 21

Idler pulley/2 (Z=19) . . . . 15 18

Interlock switch . . . . . . . 9 12

Interlock switch . . . . . . . 11 20

Interlock switch . . . . . . . 13 24

Interlock wiring/1 . . . . . . 17 5

M

Magnet catch/A . . . . . . . 3 9

Main casing/2 . . . . . . . 3 2

Main lock claw . . . . . . . 15 20

Main lock spring . . . . . . 15 19

Motor wiring/1 . . . . . . . 17 2

Motor wiring/2 . . . . . . . 17 3

PART PAGE REF.

DESCRIPTION NO. NO.

Motor wiring/2 . . . . . . . 17 3

Mount plate/C . . . . . . . . 5 21

Mount plate/D assembly . . 5 23

Mount plate/G . . . . . . . 9 19

N

Neutralizing brush . . . . . 9 2

Neutralizing cover . . . . . . 9 1

O

Open-close cover . . . . . . 3 8

Oscillate cam . . . . . . . . 15 3

Oscillate collar . . . . . . . 15 24

P

Paper detecting actuator . . 13 4

Paper detecting board . . . 13 13

Paper exit connecting clutch

(Z=28/36) . . . . . . . . 7 27

Paper exit cover/front . . . . 3 1

Paper exit cover/rear . . . . 3 3

Paper exit driven roller/A . . 11 7

Paper exit driving pulley/A

(Z=12) . . . . . . . . . 11 5

Paper exit driving roller/A . . 11 9

Paper exit driving roller/B . . 7 5

Paper exit idler gear

(Z=22/33) . . . . . . . . 7 18

Paper exit pressure spring . 11 2

Paper exit pulley (Z=22) . . 7 3

Paper exit shaft holder . . . 11 8

Paper exit standard actuator 5 22

Paper exit tray/A . . . . . . 5 1

Paper exit tray/B . . . . . . 5 2

Paper exit tray/lower

assembly . . . . . . . . 5 3

Paper lift-up lever shaft

holder . . . . . . . . . . 7 10

Paper lift-up lever shaft

holder . . . . . . . . . . 9 7

Paper positioning plate/front 13 8

Paper positioning plate/rear

assembly . . . . . . . . 13 12

Paper regulating collar . . . 13 10

Paper regulating plate/front . 13 7

Paper regulating plate/rear

assembly . . . . . . . . 13 6

Paper regulating spring . . . 13 9

Photosensor . . . . . . . . 3 5

Photosensor . . . . . . . . 5 20

Photosensor . . . . . . . . 7 6

Photosensor . . . . . . . . 9 15

Photosensor . . . . . . . . 11 22

Photosensor . . . . . . . . 13 3

Photosensor . . . . . . . . 15 16

Pin (Cleaner A) . . . . . . . 11 12

Pin A . . . . . . . . . . . . 5 15

Pin A . . . . . . . . . . . . 7 12

Model FS-107 Konica Business Technologies, Inc. Page 19

3rd Edition September, 2002

Page 70

PART PAGE REF.

DESCRIPTION NO. NO.

Pin A . . . . . . . . . . . . 11 6

Positioning actuator/A . . . 9 10

Positioning actuator/B . . . 7 1

Pressure cam . . . . . . . . 9 4

R

Regulating gear (Z=28/55) . 13 15

Regulating gear/B (Z=22/37) 13 17

Regulating idler (Z=64) . . . 13 18

Relay wiring/2 . . . . . . . 15 17

Relay wiring/2 . . . . . . . 17 4

Rocking actuator . . . . . . 9 14

Rocking gear/A (Z=48) . . . 9 6

Rocking gear/B (Z=20) . . . 9 18

Rocking gear/C (Z=15/45) . 5 14

Rocking gear/C (Z=30) . . . 9 8

Rocking gear/D (Z=30) . . . 5 13

Rocking gear/E (Z=15) . . . 5 25

Rocking idler/1 (Z=20/40) . . 9 11

Rocking idler/2 (Z=20/48) . . 9 17

Rotary knob . . . . . . . . 7 9

PART PAGE REF.

DESCRIPTION NO. NO.

S

Screw cover . . . . . . . . . 3 6

Sensor wiring/1 . . . . . . . 17 6

Shaft holder/A . . . . . . . . 7 23

Shaft holder/A . . . . . . . . 9 3

Shaft holder/A . . . . . . . . 11 13

Shaft holder/B . . . . . . . . 5 16

Shaft holder/C . . . . . . . 7 2

Side cover . . . . . . . . . . 3 11

Slide plate . . . . . . . . . . 15 4

Spring . . . . . . . . . . . . 11 21

Spring spacer . . . . . . . . 7 24

Staple . . . . . . . . . . . . 15 22

Staple board . . . . . . . . 15 25

Staple driving gear (Z=19/55) 15 9

Staple driving gear (Z=28/55) 15 10

Staple label . . . . . . . . . 3 7

Staple mount plate . . . . . 15 23

Staples . . . . . . . . . . . 15 15

Stopper rubber . . . . . . . 3 10

Stopper sheet . . . . . . . . 13 2

Support plate/front . . . . . 5 5

Support plate/rear . . . . . 5 18

Switch plate . . . . . . . . . 13 22

PART PAGE REF.

DESCRIPTION NO. NO.

T

Tension plate/A assembly . 5 26

Tension pulley . . . . . . . 5 9

Toner supply worm . . . . 9 16

Toque limiter . . . . . . . . 11 11

U

Up-down plate/front . . . . 5 7

Up-down plate/rear . . . . 5 10

Up-down pulley . . . . . . 5 11

Up-down roller . . . . . . . 5 6

Up-down wire/front . . . . 5 4

Up-down wire/rear . . . . . 5 19

W

Wiring cover . . . . . . . . 15 21

Wiring fixed plate . . . . . 13 23

Page 20 Konica Business Technologies, Inc. Model FS-107

September, 2002 3rd Edition

Page 71

Numerical index

PART PAGE REF.

NUMBER NO. NO.

048645260 3 10

090075530 5 12

120H50402 15 22

120HK0010 15 1

12AA12100 3 9

12QR77010 15 10

12QR86010 9 12

12QR86010 11 20

12QR86010 13 24

12QRK0011 15 15

12QV85510 3 5

12QV85510 5 20

12QV85510 7 6

12QV85510 9 15

12QV85510 11 22

12QV85510 13 3

12QV85510 15 16

13GQ-1220 15 5

13GQ-1510 5 27

13GQ-1520 5 24

13GQ-1540 5 26

13GQ-4320 9 5

13GQ-4340 7 29

13GQ-4530 7 8

13GQ-4690 3 15

13GQ-4700 11 18

13GQ-4730 11 17

13GQ-4830 5 23

13GQ-4910 5 3

13GQ-6080 13 6

13GQ-6141 13 12

13GQ-6151 13 8

13GQ-9018 13 14

13GQ10022 3 2

13GQ10120 15 20

13GQ10140 15 19

13GQ10170 13 22

13GQ12010 3 8

13GQ12020 3 11

13GQ12040 3 1

13GQ12050 3 3

13GQ12090 3 12

13GQ12091 3 12

13GQ12100 3 6

13GQ15091 5 4

13GQ15101 5 19

13GQ45021 3 4

13GQ45050 11 10

13GQ45060 7 28

13GQ45070 7 20

13GQ45090 11 7

13GQ45150 7 13

13GQ45191 11 9

13GQ45210 3 13

13GQ45301 11 21

13GQ45410 9 4

13GQ45421 9 10

13GQ45430 11 2

13GQ45450 11 15

13GQ45470 7 9

13GQ45480 7 16

13GQ45490 11 4

13GQ45511 11 11

13GQ45580 9 2

PART PAGE REF.

NUMBER NO. NO.

13GQ45600 11 14

13GQ45610 11 16

13GQ45620 7 30

13GQ45681 9 1

13GQ45690 9 9

13GQ45750 9 14

13GQ45761 9 19

13GQ45780 9 13

13GQ45820 7 31

13GQ45860 3 14

13GQ45870 7 24

13GQ45910 11 19

13GQ45931 9 21

13GQ45940 3 16

13GQ48010 5 1

13GQ48020 5 2

13GQ48050 5 7

13GQ48060 5 10

13GQ48070 5 11

13GQ48080 5 6

13GQ48152 5 8

13GQ48180 5 21