Page 1

SERVICE MANUAL

MODEL

FS-105

JUNE 1998

CSM-FS105

Page 2

TABLE OF CONTENTS

CONTENTS

SAFETY PRECAUTIONS........................................................v

FS-105

SPECIFICATIONS ................................................................. 1

Type ............................................................................... 1

Functions ....................................................................... 1

Stapler Kit ...................................................................... 1

Machine Data................................................................. 1

Maintenance .................................................................. 1

Operating Environment ................................................. 1

CENTER CROSS SECTION................................................. 3

DRIVE SYSTEM DIAGRAM....................................................4

Paper Conveyance System Drive .................................. 4

Stapler Unit Drive........................................................... 4

EXTERNAL SECTION ........................................................... 5

Construction .................................................................. 5

Disassembly and Reassembly .................................... 5

CONVEYANCE SECTION ..................................................... 8

Construction .................................................................. 8

Mechanisms..................................................................8

Disassembly and Reassembly .................................. 11

Paper Feed Motor (M801) Control ............................... 13

Conveyance Drum (M807) Control ..............................14

Tray Up/Down (M804) Control ..................................... 15

PAPER EXIT/STAPLER UNIT SECTION ............................. 16

Construction ................................................................ 16

Mechanisms................................................................16

Disassembly and Reassembly .................................. 18

Paper Alignment Control ............................................. 20

Paper Exit (M805) Control............................................ 21

Paper Stacking Control ............................................... 22

Stapler Movement (M806) Control............................... 24

Stapler Control .............................................................25

OTHER CONTROL FUNCTIONS ....................................... 27

Power On Operation ....................................................27

DIAGRAMS

ELECTRICAL PARTS LAYOUT DIAGRAM .......................... 28

CONNECTOR LAYOUT DIAGRAM...................................... 29

iii

Page 3

This page left blank intentionally.

iv

Page 4

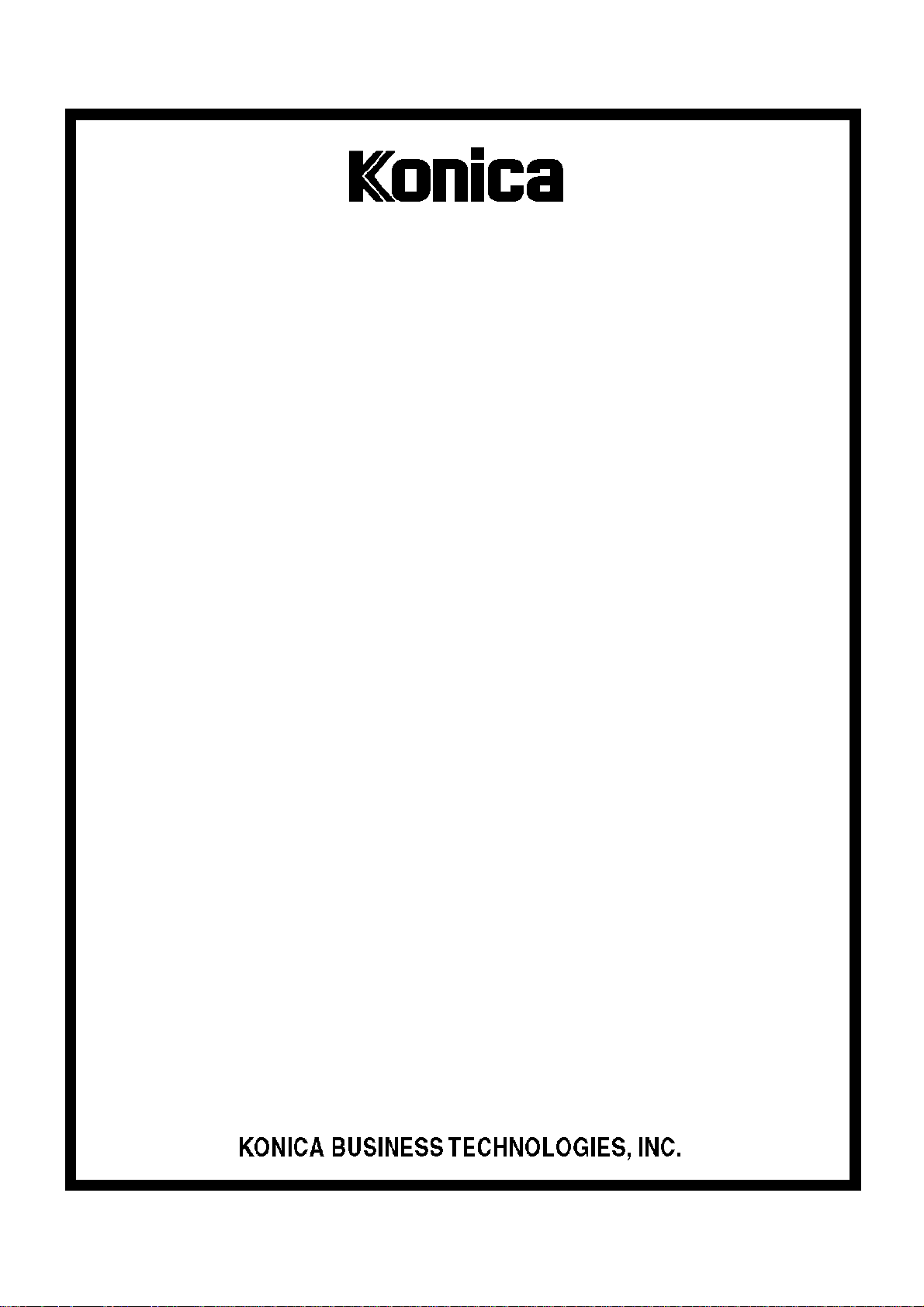

PRODUCT SPECIFICATIONS

FS-105

Type

Type: Drum inverting type, multi-tray

finisher

Functions

Kinds of copy paper: Same as main body

Copy paper size: A11x17R, 8.5x14R, 8.5x11,

8.5x11R, 8.5x5.5, 8.5x5.5R,

5.5x8.5R

Modes : Available ✕ : Not available

Mode

Tray

Tray 1

Through mode

Offset mode

Staple mode

✕

✕

Sheet capacity

Tray

Tray 1

Tray 2,

Tray 3

Mode

Through mode

Through mode

Offset mode

Staple mode

Small sizes

100

300

–

Middle sizes

100

500

500

25 sets (Note)

Large sizes

The above numbers apply for same-size paper (22 lb. ,standard

paper) stacked continuously.

Small sizes : 5.5x8.5R

Middle sizes : 8.5x11, 8.5x11R, 8.5x5.5, 8.5x5.5R

Large sizes : 11x17R, 8.5x14R

Special paper: Other than standard paper (thin paper, thick

paper, blueprint masters, OHP film etc.)

Note: The maximum capacity (500 or 300 sheets) should not

be exceeded.

100

300

300

Tray 3Tray 2

Special paper

10

–

–

–

Stapler Kit

Number of copies that can be stapled together:

50 maximum (22 lb. fine quality paper,

thickness 5 mm maximum)

Staple position:

A = 9 mm (non-adjustable)

B = 10 mm (±3 mm adjustable)

C = 90 mm (±4 mm adjustable)

Stapler capacity:

5000 staples/cartridge

Machine Data

Power source: 24 V DC / 5 V (supplied from main

body)

Max. power consumption:

100 VA (FS-105 only)

Weight: approximately 72 lb. (with base)

Machine dimensions

Unit: inches

21.5

10.4

Paper weight

Tray 1: 14 - 54 lb.

Tray 2/3: 16 - 44 lb.

Copy paper curling: 10 mm maximum

Curling

Copy paper (5 sheets)

Offset amount: 30 mm (offset/group mode)

24.5

23.6

1

Page 5

FS-105

Maintenance

Maintenance: Same as main body

Operating Environment

Temperature: 50°F ~ 91°F

Humidity: 20% to 80% RH

Note: The contents of this manual may be changed without

prior notice.

2

Page 6

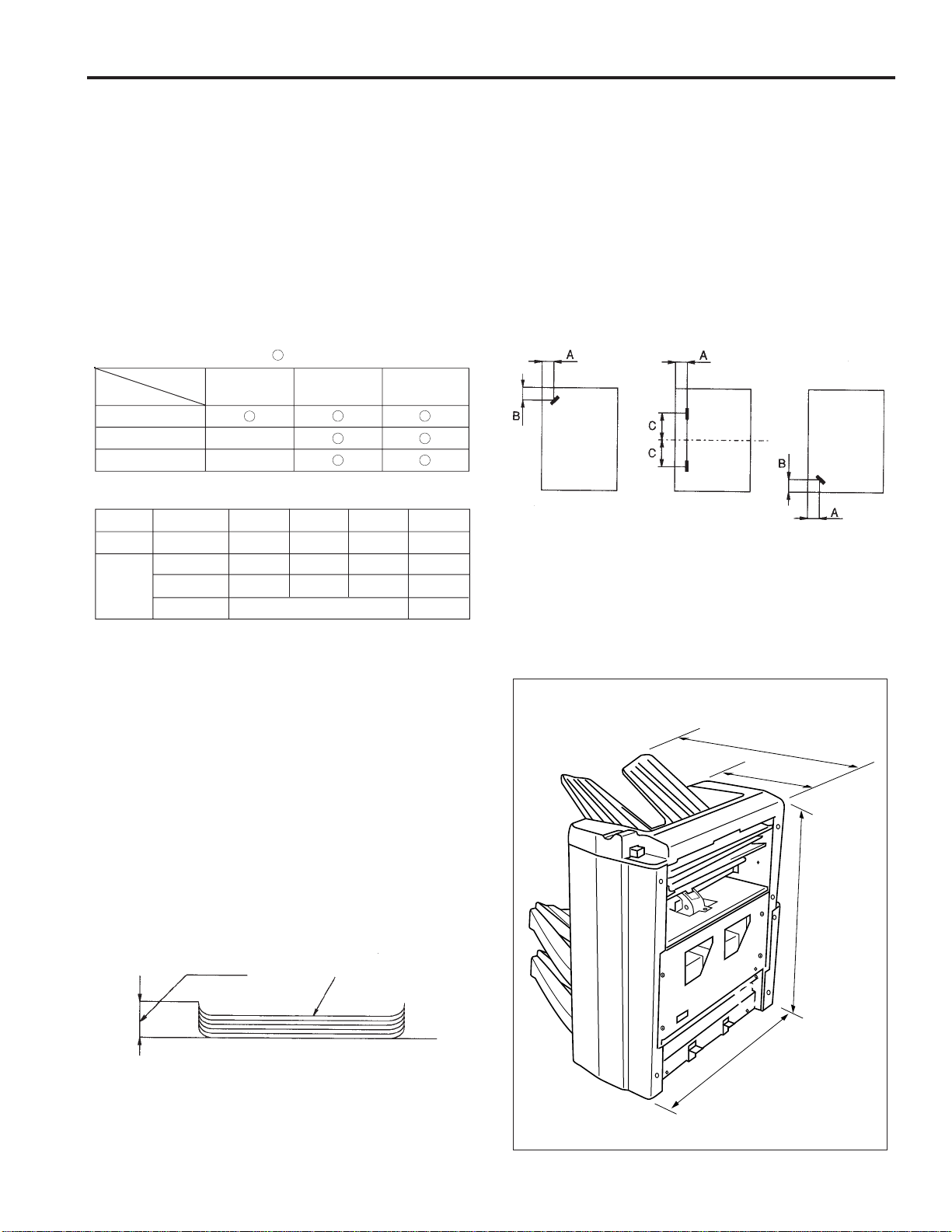

CENTER CROSS-SECTIONAL DRAWING

Paper exit roller

Tray 1

FS-105

Tray 2

Tray 3

Conveyance rollers

Paper exit roller (A)

Switching

guide

Conveyance drum

Stapler unit

Exit lever

Paper exit roller (A)

3

Page 7

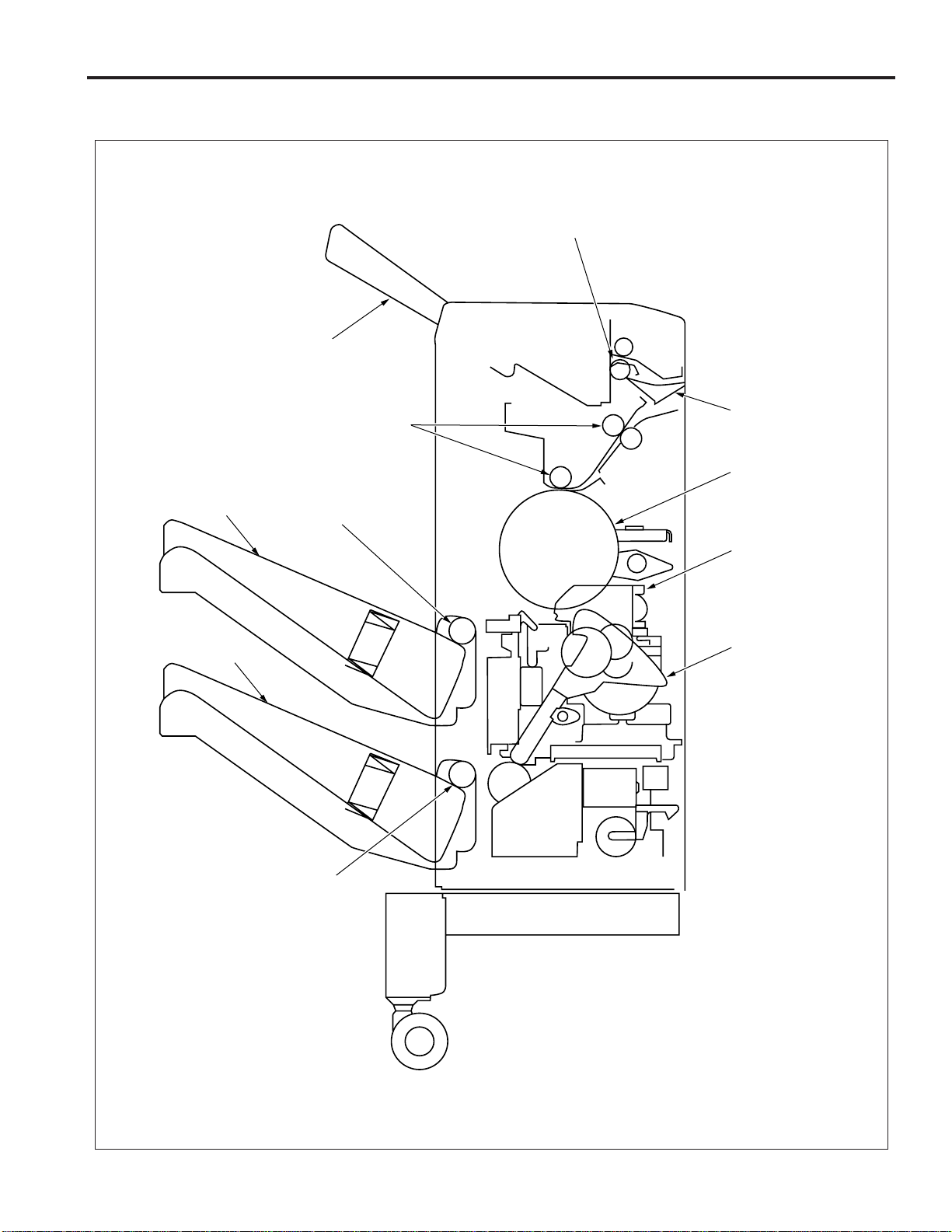

FS-105

DRIVE SYSTEM DRAWING

Paper Conveyance System Drive

Lift wire (rear)

Paper exit roller (A)

Tray 2 motor (M810)

Conveyance rollers

Paper exit roller

Conveyance drum

drive motor (M807)

Timing belt

Tray 3 motor

(M811)

Stapler Unit Drive

Alignment motor

(rear)(M808)

Alignment plate

(rear)

Paper exit roller (A)

Alignment plate

(front)

Paper feed motor

(M801)

Conveyance drum

Tray up/down motor (M804)

Lift wire (front)

Stapler unit (rear)

Stapler unit (front)

Alignment motor

(front)(M809)

Exit lever

Stapler movement

motor (M806)

Paper exit motor

(M805)

4

Page 8

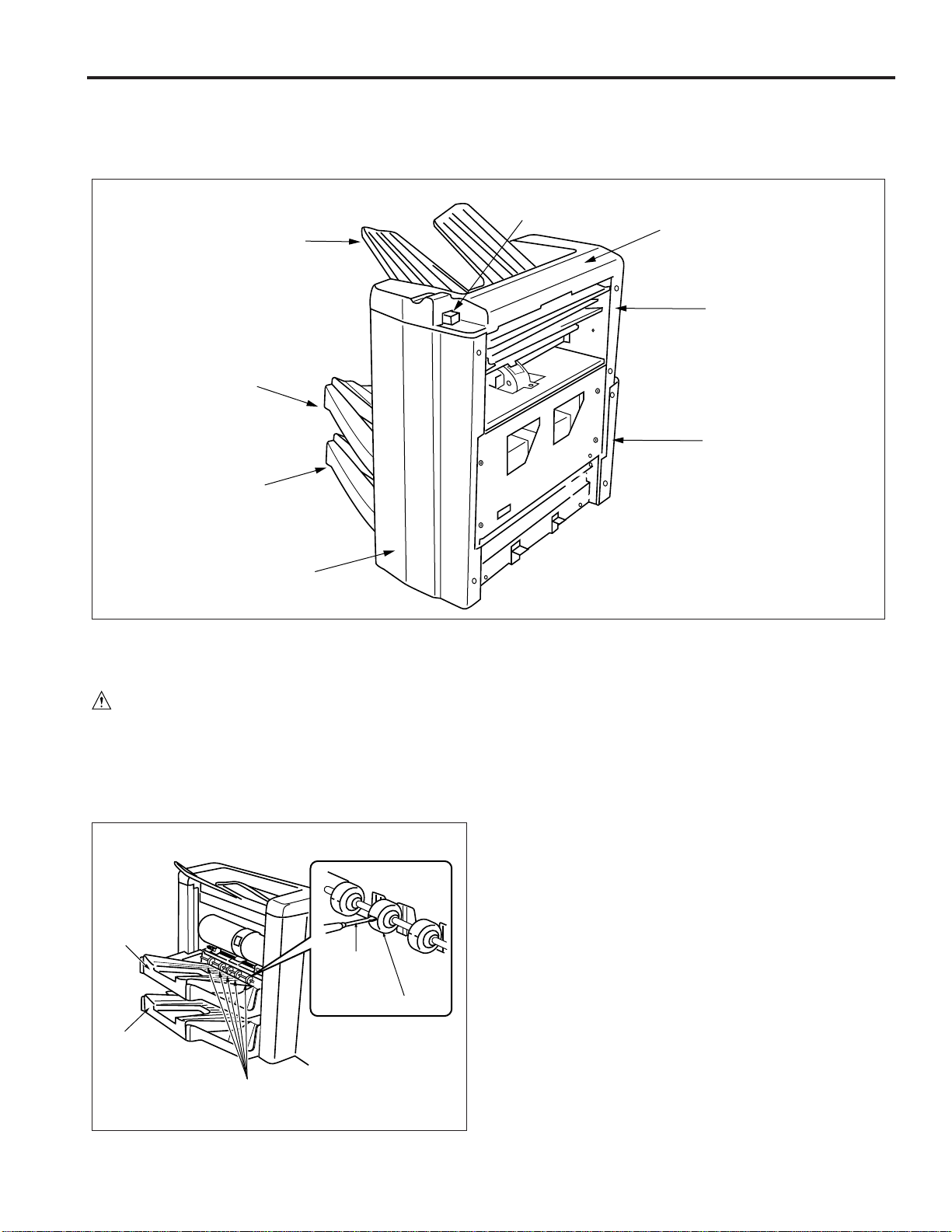

EXTERNAL SECTION

Construction

Tray 1

Tray 2

Tray 3

FS-105

Release lever

Top cover

Upper rear cover

Rear cover

Front cover

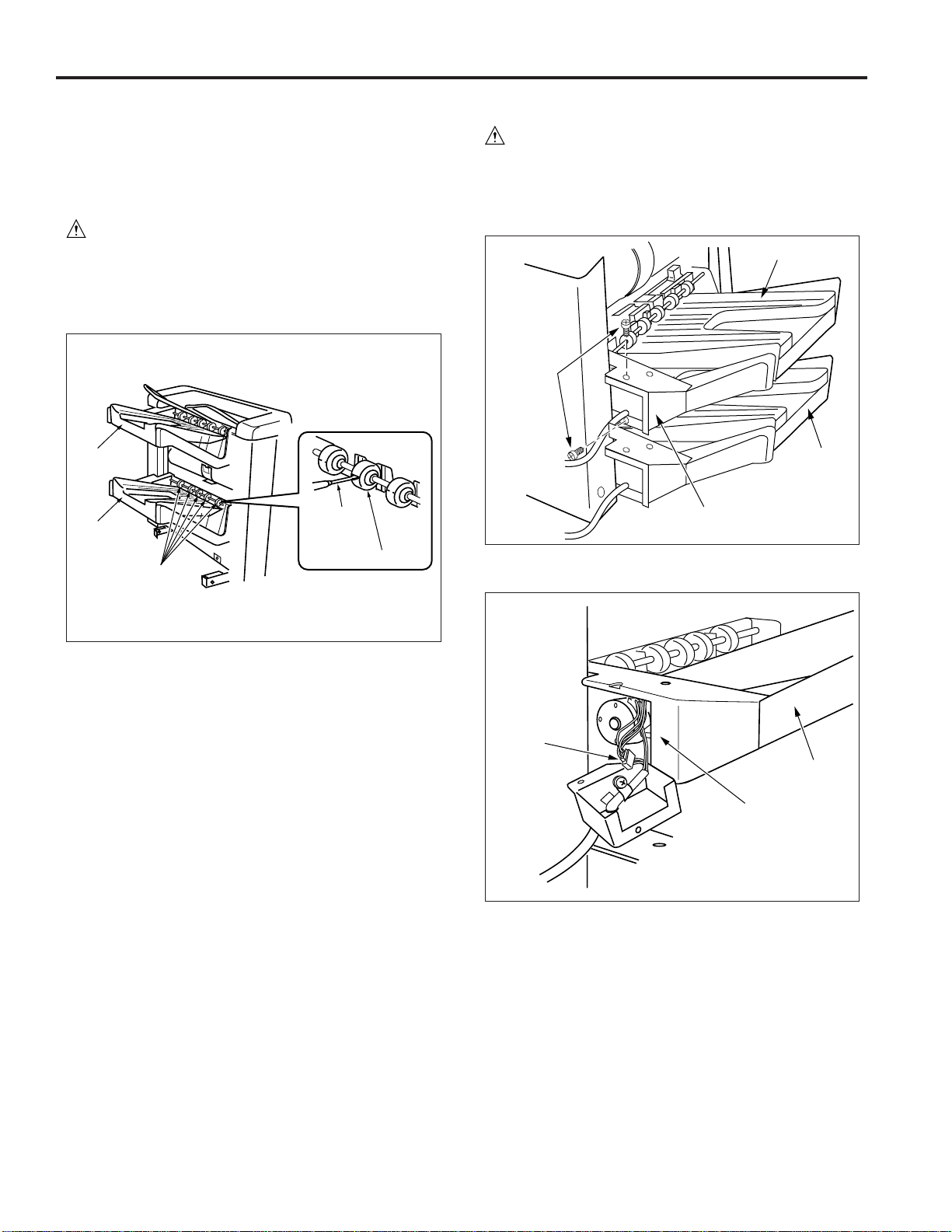

Disassembly and Reassembly

Replacing the paper exit roller (A) (for tray 2)

Caution: Be sure that the power cord has been un-

plugged from the power outlet.

Procedure

(1) Insert a flatbladed screwdriver or similar tool into the joint

of a paper exit roller (A), pry the roller open, and remove

it. Remove all paper exit rollers (A) (5 rollers) in this way.

Tray 2

Flatblade

screwdriver

Paper exit rollers (A)

(2) To install new rollers, snap two roller parts (top and

bottom) onto the exit roller shaft (5 locations).

Tray 3

Paper exit roller (A)

5

Page 9

FS-105

Replacing the paper exit roller (A) (for tray 3)

Procedure

(1) Use the operation panel on the main body to specify tray

3 and raise tray 2 to the topmost position.

(2) Turn the power OFF of the main body and unplug the

power cord from the power outlet.

Caution: Be sure that the power cord has been un-

plugged from the power outlet.

(3) Insert a flatbladed screwdriver or similar tool into the joint

of apaper exit roller (A), pry the roller open, and remove

it. Remove all paper exit roller (A) (5 rollers) in this way.

Tray 2

Tray 3

Paper exit roller (A)

Flatblade

screwdriver

Paper exit rollers (A)

Removing and Reinstalling tray 2

Caution: Be sure that the power cord has been un-

plugged from the power outlet.

Procedure

(1) Remove the two set screws, then remove the connector

cover.

Tray 2

Set screws

Tray 3

Connector cover

(2) Disconnect the two connectors (CN728, CN751).

(4) To install new rollers, snap two roller parts (top and

bottom) onto the exit roller shaft (5 locations).

Connector

(CN728)

Tray 2

Connector

(CN751)

(3) Remove the two set screws, then remove the stopper

bracket (front).

(4) Lift the front side of tray 2 up, then rotate it towards the rear

and remove it.

6

Page 10

FS-105

Stopper bracket

(front)

Set

screws

Tray 3

Tray 2

(5) Reinstall tray 2 in the opposite sequence to removal.

Removing and Reinstalling tray 3

Caution: Be sure that the power cord has been un-

plugged from the power outlet.

Procedure

(1) Remove tray 2.

(2) Remove the two set screws, then remove the connector

cover. (Refer to “Removing and Reinstalling tray 2”.)

(3) Disconnect the two connectors (CN729, CN752). (Refer

to “Removing and Reinstalling tray 2”.)

(4) Remove the two set screws, then remove the stopper

bracket (front). (Refer to “ Removing and Reinstalling tray

2”.)

(5) Lift the front side of tray 3 up, then rotate it towards the rear

and remove it. (Refer to “ Removing and Reinstalling tray

2”.)

(6) Reinstall tray 3 in the opposite sequence to removal.

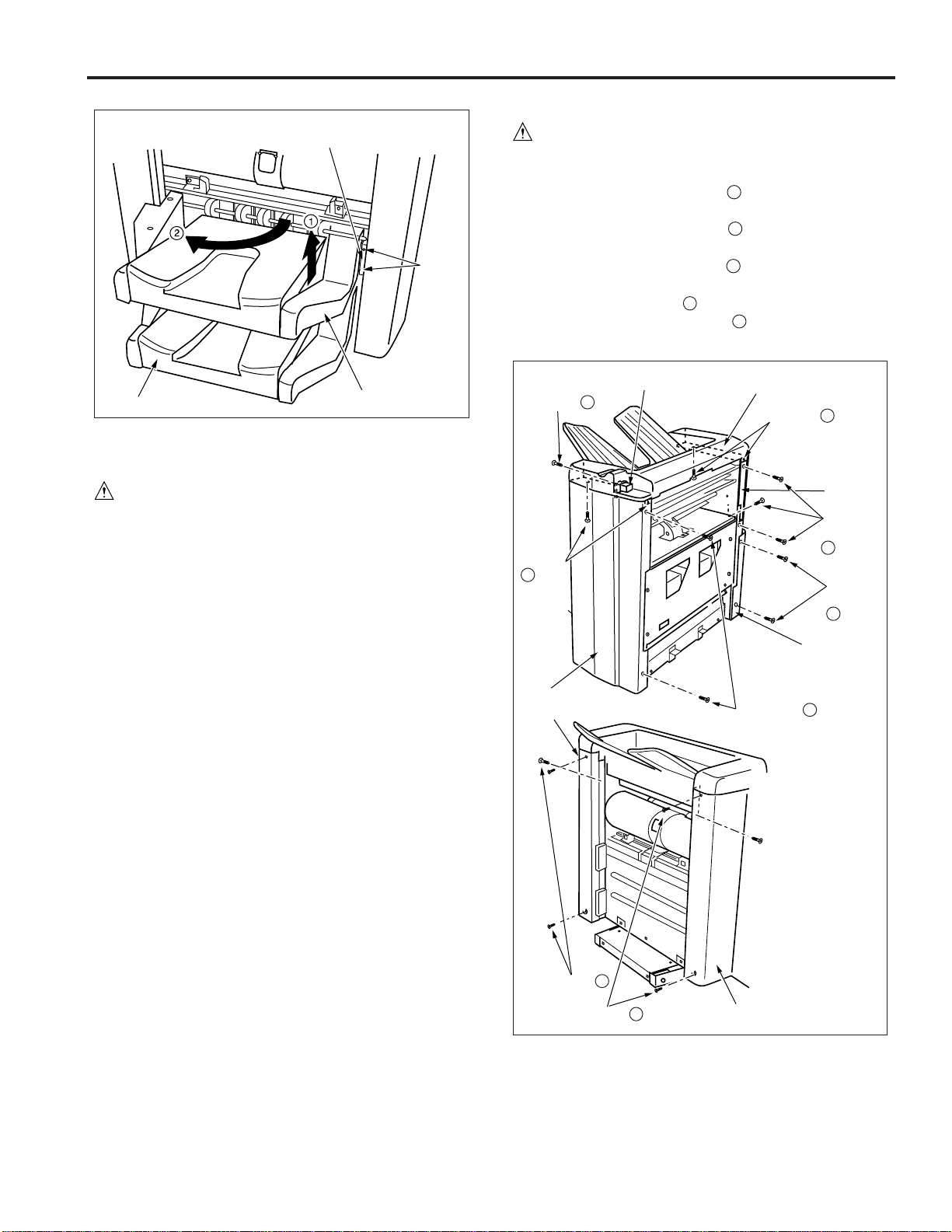

Removing and Reinstalling the external covers

Caution: Be sure that the power cord has been un-

plugged from the power outlet.

Procedure

(1) Remove the four set screws A , then remove the front

cover.

(2) Remove the five set screws B , then remove the rear

cover.

(3) Remove the three set screws C , then remove the upper

rear cover.

(4) Remove the set screw D , then remove the release lever.

(5) Remove the four set screws E , then release the top

cover.

Release lever

Set screw D

Set

screws

E

Front cover

Rear

cover

Top cover

Set screws E

Upper rear

cover

Set

screws

C

Set

screws

B

Rear

cover

Set screws A

Set screws B

Set screws A

Front cover

(6) Reinstall the external covers in the opposite sequence to

removal.

7

Page 11

FS-105

CONVEYANCE SECTION

Construction

Gate solenoid (SD801)

Conveyance

drum

Switching guide

Conveyance

drum drive motor

(M807)

Tray up/down

motor (M804)

Conveyance

drum

Lift wire

Paper feed motor (M801)

Mechanism

Mechanisms

Paper path switching

∗1

Paper conveyance

∗2

Tray lift (up/down)

∗3

∗∗

∗1:Paper path switching

∗∗

The paper exited from the fixing unit in the main body passes

through the switching guide which sends it to tray 1 or tray 2/3.

The switching guide is operated by the on/off state of the gate

solenoid (SD801).

Switching guide

Conveyance roller

Conveyance drum

Wire drive (Lift wire)

Methods

Lift wire

Switching guide

Gate solenoid (SD801)

8

Page 12

FS-105

∗∗

∗2:Paper Conveyance

∗∗

When the paper has been switched to tray 2/3 by the switching

guide, the conveyance roller conveys it to the conveyance

drum until it enters the grip plate on the circumference of the

drum.

Switching

Conveyance

rollers

Grip plate

Spring

guide

Paper

Cam

Conveyance

drum

The grip plate closes due to the force of a cam and spring

arrangement and grasps the paper.

When the rotation speed of the drum increases, the paper is

pushed out and separated from the conveyance drum. When

the grip plate on the conveyance drum reaches the paper exit

position, the paper hits a stopper and is separated from the grip

plate.

Paper

Grip plate

Conveyance

drum

Stopper

Behind the grip plate on the drum circumference, there are two

alignment plates. When these reach the paper exit position,

their own weight causes them to open, and the rubber section

at the plate tip aligns the paper against the stopper.

Grip plate

Spring

Conveyance drum

Paper

Cam

Alignment

plates

Conveyance

drum

Paper

Grip plate

Stopper

The grip plate and alignment plates on the conveyance drum

do not use electrical control, they operate only through the

rotation of the drum. (The grip plate is driven by the drum via

a cam arrangement, and the alignment plates are driven by the

centrifugal force and their own weight.)

The conveyance drum and conveyance rollers are controlled

electrically by the conveyance drum drive motor (M807) and

the paper feed motor (M801).

9

Page 13

FS-105

∗∗

∗3: Tray lift

∗∗

The paper exit position for the paper sent to tray 2/3 is fixed.

Switching between tray 2 and tray 3 is carried out by changing

the tray position with the tray lift (up/down) mechanism.

The tray lift mechanism is driven by the tray up/down motor

(M804) whose driving force is transmitted to the tray by a wire

arrangement.

Lift wire

Tray 2

Tray up/down

motor (M804)

Tray 3

10

Page 14

FS-105

Disassembly and Reassembly

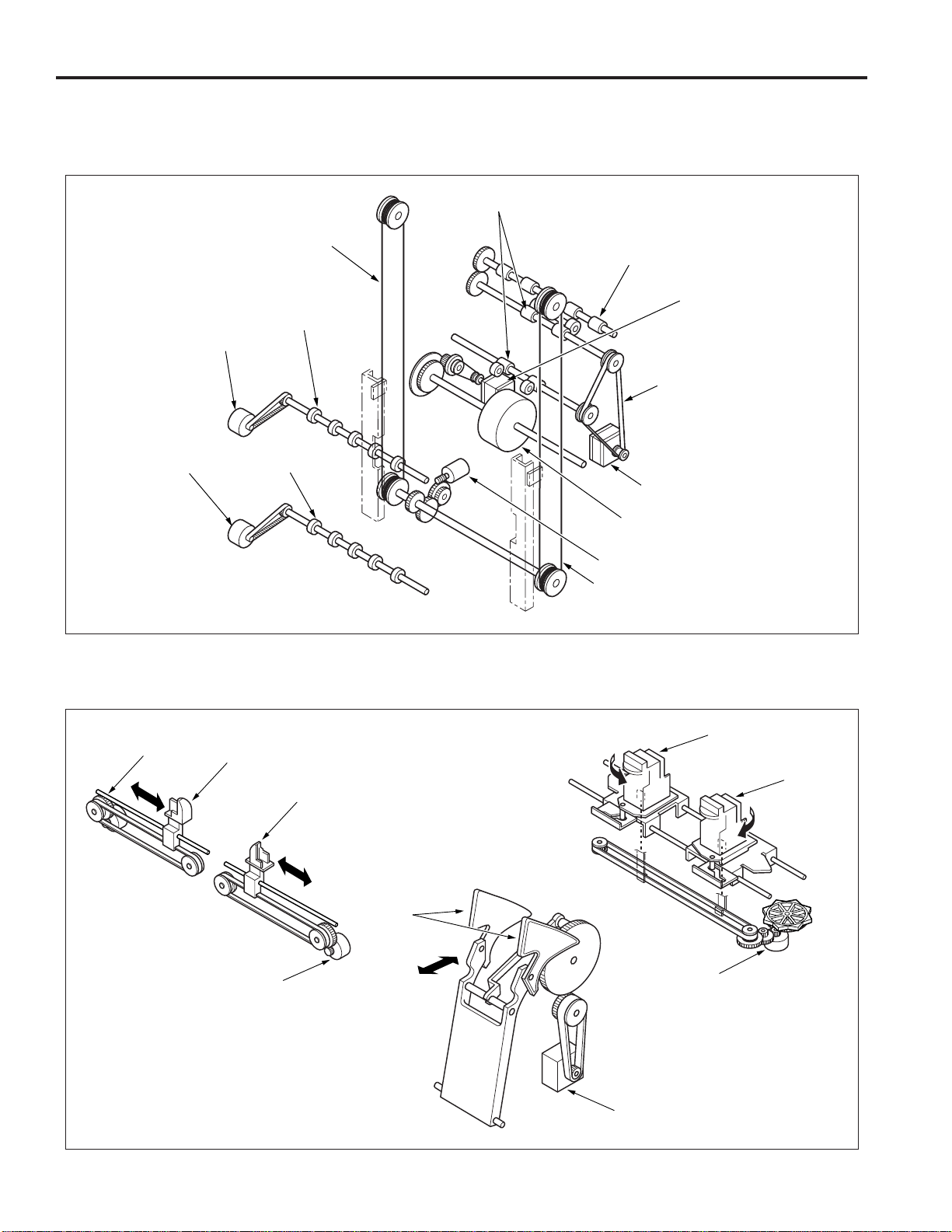

Removing and Reinstalling the lift wire

Caution: Be sure that the power cord has been un-

plugged from the power outlet.

Procedure

(1) Remove tray 2 and tray 3.

(2) Remove the external covers.

Note: The lift wire must be removed (and installed) first on the

front side and then on the rear side.

(3) Remove the two set screws, then release the wire fasten-

ing bracket (front).

(4) Loosen the two set screws, then release the pulley

tensioning plate (front).

(5) Remove the e-ring of the lower pulley (front).

(6) Remove the lower pulley (front), then remove the lift wire

(front).

Set screws

Wire fastening bracket

(7) Attach the metal ball of the lift wire to the inside of the lower

pulley (front) and pass the pulley onto the shaft. The end

of the wire attached to the pulley must be the short end as

seen from the wire fastening bracket.

Note: When installing the lower pulley (front) onto the shaft,

align the pin on the shaft with the lower pulley (front).

(8) Wind the lift wire five turns around the lower pulley (front)

and then hook the wire onto the upper pulley (front).

Note: Wind the wire clockwise as seen from the front.

(9) Route the lift wire from the upper pulley (front) back down

to the lower pulley (front) and wind it one turn in clockwise

direction around the pulley. Then attach the metal ball at

the end of the wire to the side of the lower pulley (front).

(10) Attach the e-ring to secure the lower pulley (front).

Pulley tensioning plate (rear)

Upper pulley (rear)

Lift wire

Pulley tensioning plate (front)

Upper pulley (front)

Metal ball

(winding start)

Metal ball (winding end)

Set screws

Wire fastening bracket (rear)

Lower pulley (rear)

Metal ball (winding end)

1 turn 5 turn

Metal ball (winding start)

Pin

Shaft

Metal ball (winding start)

Set screws

Lift wire

Wire fastening bracket (front)

Set screws

E-ring

Lower pulley (front)

Metal ball

(winding end)

1 turn5 turn

11

Page 15

FS-105

(11) Pull the pulley tensioning plate (front) up until a tension of

2.3 kg is achieved, then fasten the plate with the two set

screws.

Note: Use a tension gauge or similar when fastening the

pulley tensioning plate, to assure that the specified

tension value is achieved.

Specification: 2.3 kg

Tension gauge

Set

screws

Pulley

tensioning

plate (front)

Lift wire

(12) Provisionally fasten the two set screws of the wire fasten-

ing bracket (front).

(13) Remove the lift wire on the rear side in the same way as

described in steps (3) through (6).

(14) Attach the metal ball of the lift wire to the inside of the lower

pulley (rear) and pass the pulley onto the shaft. The end

of the wire attached to the pulley must be the short end as

seen from the wire fastening bracket.

Note: When setting the lower pulley (rear) onto the shaft, align

the pin on the shaft with the lower pulley (rear).

(15) Wind the lift wire five turns around the lower pulley (rear)

and then hook the wire onto the upper pulley (rear).

Note: Wind the wire counterclockwise as seen from the front.

(16) Route the lift wire from the upper pulley (rear) back down

to the lower pulley (rear) and wind it one turn in

counterclockwise direction around the pulley. Then at

tach the metal ball at the end of the wire to the side of the

lower pulley (rear).

(17) Attach the e-ring to secure the lower pulley (rear).

(18) Fasten the pulley tensioning plate (rear) and wire fasten-

ing bracket (rear) as described in steps (11) and (12).

(19) Install the tray 2 and move its position in the vertical

direction so that the tray is flush with the lower limit

detection plate. Then permanently secure the wire fastening brackets (front) and (rear) which were provisionally

fastened previously.

Note: To check the flush condition, use a metal ruler or other

suitable tool on both the front and the rear side.

Lower

limit

detection

plate

Tray 2

Metal scale

12

Page 16

FS-105

Paper Feed Motor (M801) Control

Signals

Input signals

PS802 (PS802 → FS CB)

Paper detection signal at the paper exit section entrance

of the tray 1.

[H]: Paper is detected

[L]: Paper is not detected

PS803 (PS803 → FS CB)

Paper detection signal at the paper exit section entrance

of the tray 2 and tray 3 side.

[H]: Paper is detected

[L]: Paper is not detected

MS801 (MS801 → FS CB)

Power supply line for various loads. When finisher is in

mechanical contact with main body, 24 V DC is supplied

to finisher.

FS RXD (MAIN BODY → FS CB)

Serial data line for transmitting operation status information from control board in main body to finisher.

FS R REQ (MAIN BODY → FS CB)

Send request signal from main body to finisher.

FS T ACK (MAIN BODY → FS CB)

Send enable signal from main body to finisher.

Output signals

M801 DRIVE A, A, B, B (FS CB → M801)

M801 (conveyance) ON/OFF drive signal

Paper exit conveyance takes place as a result of the transmission of the drive force of motor M801 (paper feed) to the paper

exit rollers and conveyance rollers. The paper conveyance

path is switched between tray 1 or tray 2/3 by solenoid SD801

(gate ).

M801 and SD801 are controlled by the FS CB (FS control

board).

Operation

Gate switching operation

Normally, SD801 is OFF and the gate allows paper to exite to

tray 2/3. When tray 1 is selected as the paper exit tray, SD801

goes ON, the gate is switched, and the paper is conveyed to

tray 1.

Conveyance operation

M801 is turned ON and OFF in conjunction with the copy

operation of the main body. During operation of the main body,

the M801 rotates constantly, enabling paper conveyance at

any time.

When paper has been conveyed to tray 2/3, the status of the

PS802 (conveyance drum entrance detect) and main body PS

(paper exit detect sensor) causes the M801 to be switched

from low speed to high speed. The high-speed activation signal

and the rotation speed depend on the paper size.

SD801 DRIVE (FS CB → SD801)

SD801 (gate) ON/OFF drive signal

[L]: SD801 ON

[H]: SD801 OFF

FS TXD (FS CB → MAIN BODY)

Serial data line for transmitting operation status information from finisher to main body control board.

FS T REQ (FS CB → MAIN BODY)

Send request signal from finisher to main body.

FS R ACK (FS CB → MAIN BODY)

Send enable signal from finisher to main body.

13

Page 17

FS-105

Conveyance Drum (M807) Control

Signals

Input signals

PS801 (PS801 → FS CB)

Encoder slit detection signal

[L]: Slit is detected

[H]: Slit is not detected

PS802 (PS802 → FS CB)

Paper detection signal at the exit section entrance of the

tray 1.

[L]: Paper is not detected

[H]: Paper is detected

FS RXD (MAIN BODY → FS CB)

Serial data line for transmitting operation status information from control board in main body to finisher.

FS R REQ (MAIN BODY→ FS CB)

Send request signal from main body to finisher.

FS T ACK (MAIN BODY → FS CB)

Send enable signal from main body to finisher.

Output signals

M807 DRIVE A, A, B, B (FS CB → M807)

M807 (conveyance drum drive) ON/OFF drive signal

The paper that has been sent to tray 2/3 is exited into the

respective tray by the conveyance drum. The conveyance

drum is driven by M807 (conveyance drum drive) which is

controlled by the FS CB (FS control board).

Operation

Conveyance operation

When PS802 (conveyance drum entrance detect) detects the

leading edge of the paper and goes ON, M807 is turned ON

after the specified time, and the conveyance drum starts to

rotate.

To convey one sheet of paper, the M807 is switched through

a predetermined sequence of three speeds. When the conveyance drum reaches the standby position, the motor is switched

OFF.

During this time, the drum makes one revolution which includes

gripping, conveying, and releasing the paper.

M807 speed control

When the conveyance drum rotation pulses reach a predetermined number, the rotation speed is changed.

FS TXD (FS CB → MAIN BODY)

Serial data line for transmitting operation status informa

tion from finisher to main body control board.

FS T REQ (FS CB → MAIN BODY)

Send request signal from finisher to main body.

FS R ACK (FS CB → MAIN BODY)

Send enable signal from finisher to main body.

14

Page 18

FS-105

Tray Up/Down (M804) Control

Tray squeeze prevention

During tray upward or downward movement, if a foreign object

is caught between the tray and the finisher unit, MS802 (up/

down (upper)) or MS803 (up/down (lower)) will mechanically

go OFF, causing the power supply line of M804 to be cut off.

Signals

Input signals

PS805 (PS805 → FS CB)

Tray 2 upper limit detection signal.

[L]: Upper limit is detected

[H]: Upper limit is not detected

PS806 (PS806 → FS CB)

Tray 3 lower limit detection signal.

[L]: Lower limit is detected

[H]: Lower limit is not detected

MS802/MS803 (MS802/MS803 → FS CB)

Power supply line for M804. Forcibly interrupted when a

foreign object is caught between tray and finisher unit.

FS RXD (MAIN BODY → FS CB)

Serial data line for transmitting operation status information from control board in main body to finisher.

FS R REQ (MAIN BODY → FS CB)

Send request signal from main body to finisher.

FS T ACK (MAIN BODY → FS CB)

Send enable signal from main body to finisher.

The paper exit position of the conveyance drum is always fixed,

and tray switching is carried out by raising or lowering tray 2/3.

The up/down motion is achieved by transmitting the driving

force of motor M804 (tray up/down) to the lift wires connected

to each tray. This operation is controlled by the FS CB (FS

control board).

Operation

Normally, the paper exit position of the conveyance drum is

aligned with tray 2. Therefore no lift operation is carried out

when tray 2 is selected.

Upward movement

When tray 3 is selected as paper exit tray and PS806 (tray

lower limit detect) is ON, M804 goes ON (forward rotation).

Tray 2 and tray 3 are then raised simultaneously.

When the upward movement causes tray 2 to switch PS805

(tray upper limit detect) to ON, M804 goes OFF and the upward

movement stops. Tray 3 is now aligned with the paper exit

position of the conveyance drum.

Downward movement

When tray 2 is selected as paper exit tray and PS805 is ON,

M804 goes ON (reverse rotation). Tray 2 and tray 3 are then

lowered simultaneously.

When the downward movement causes tray 3 to switch PS806

to ON, M804 goes OFF and the upward movement stops. Tray

2 is now aligned with the paper exit position of the conveyance

drum.

Output signals

M804 DRIVE 1, 2 (FS CB → M804)

M804 drive signals.

M804 rotation direction is controlled by switching the

current direction of these two signals.

State

Upward movement

Downward movement

Stop

FS TXD (FS CB → MAIN BODY)

Serial data line for transmitting operation status information from finisher to main body control board.

FS T REQ (FS CB → MAIN BODY)

Send request signal from finisher to main body.

FS R ACK (FS CB → MAIN BODY)

Send enable signal from finisher to main body.

M804 DRIVE 1

H

L

H

M804 DRIVE 2

L

H

H

15

Page 19

FS-105

PAPER EXIT/STAPLER UNIT SECTION

Construction

Paper exit rollers (A)

Tray 2 (3) motor

(M810, M811)

Mechanism

Mechanisms

∗1

Paper alignment

∗2

Paper exit

∗3

Paper stacking

Stapler unit movement

∗4

Staple accident prevention

Alignment plate

(front)

Tray 2 (3)

Alignment motor

(front) (M809)

Methods

Separate guides for front and rear

Exit lever

Paper exit roller (A)

Stapler unit movement motor

Shutter cover

Stapler unit

(front)

Exit levers

Stapler movement

motor (M806)

Alignment motor (rear)

(M808)

Alignment plate (rear)

Stopper

Stapler

unit (rear)

Paper exit

motor (M805)

Alignment plate (front)

∗∗

∗1:Paper alignment

∗∗

The paper being conveyed by the conveyance drum is aligned

by the alignment plates. Separately driven guides are provided

for front and rear, to allow independent movement and asymmetrical operation in shift mode.

The alignment plates are driven by the alignment motor (front)

(M809) and alignment motor (rear) (M808).

Alignment motor (front)

(M809)

16

Page 20

∗∗

∗2:Paper exit

∗∗

The paper being supplied by the conveyance drum is conveyed

to the stapling position, regardless of whether stapling will be

carried out or not. If stapling is enabled, the stapled stack is

exited to tray 2 or 3 after stapling. If stapling is not enabled,

each sheet is exited individually to tray 2 or 3.

This movement is performed by the exit levers which are driven

by the paper exit motor (M805).

Exit levers

Paper exit motor

(M805)

FS-105

Tray 2/3 motor

(M810, M811)

Paper exit roller (A)

∗∗

∗4:Staple accident prevention

∗∗

A shutter cover is provided to prevent the user from inadvertently inserting a finger etc. into the stapler. The shutter cover

is driven by the SD802 (shutter solenoid) which is ON during

stapler operation and during stapler unit movement. The

shutter cover blocks the clearance between the paper exit tray

and the stapler unit.

∗∗

∗3:Paper stacking

∗∗

A spring arrangement in the bottom of tray 2 and tray 3 lifts the

bottom plate up, so that it always is in direct contact or not more

than 3 mm away from the paper exit roller assembly.

[ Operation in through mode ]

The paper is stacked on the tray by the movement of the exit

lever and the rotation of the paper exit roller (A) of each tray.

When the paper exit roller (A) turns, the tip of the paper is

grasped by the rollers and is stacked under the rollers.

[ Operation in offset mode ]

The paper is offset by the alignment plates (front/rear), and is

stacked on the tray by the movement of the exit lever and the

rotation of the paper exit roller (A) of each tray.

By repeating this action, the tip of the paper is grasped by the

rollers and is stacked under the rollers.

Tray 2

Paper exit roller (A)

Shutter solenoid

(SD802)

Conveyance

drum

Spring

Stapler

unit

Exit lever

Shutter

cover

17

Page 21

FS-105

Disassembly and Reassembly

Replacing the stapler cartridge

Caution: Be sure that the power cord has been un-

plugged from the power outlet.

Procedure

(1) Push the release lever to remove the finisher from the

main body.

(2) Push the release levers of the stapler units down and

remove the stapler cartridges.

Release lever

Release lever

Stapler

cartridge

(3) Push the new stapler cartridge all the way in, until it is

locked in the stapler unit.

Stapler

cartridge

Removing and Reinstalling the stapler unit

Caution: Be sure that the power cord has been un-

plugged from the power outlet.

Procedure

(1) Remove the set screw (one each), then remove the

alignment plate (front) and alignment plate (rear).

Alignment

plate

(front)

Alignment

plate

(rear)

Lower limit

detection plate

(2) Remove the four set screws, then remove the stapler unit

cover (lower).

(3) Disconnect the six connectors (CN747, CN748, CN749,

CN753, CN754, CN755).

(4) Remove the four set screws, then pull the stapler unit out.

Caution: Take care not to bend the film on the exit side during

reinstallation.

Film

Set screws

Set

screws

Top cover

Stapler unit

Set screws

Internal connectors

(CN747, CN748,

CN749, CN753,

CN754, CN755)

Set screws

Stapler unit cover

(lower)

Set screws

18

Page 22

FS-105

(5) Turn the stapler unit gear, then open the stapler unit

(front) and stapler unit (rear) towards the outside.

(6) Remove the two set screws each, then remove the

connector cover of each stapler unit.

Set screws

Connector

cover

Set

screws

Set

screws

Connector

cover

Stapler

unit (rear)

Stapler unit

(front)

Stapler unit movement gear

(7) Remove the two set screws each, then remove the stapler

unit (front) and stapler unit (rear).

(8) Disconnect the connector (CN745, CN746) from each

stapler unit.

(9) Remove the two set screws, then remove the stapler unit.

Set screws

Stapler chassis

Stapler unit

(10) Reinstall the stapler unit in the opposite sequence to

removal.

Set screws

Connector

(CN745)

Stapler

unit (front)

Set screws

Stapler unit

(rear)

Connector

(CN746)

19

Page 23

FS-105

Paper Alignment Control

The paper exited by the conveyance drum is aligned on the

center of the respective exit tray by the alignment plates driven

by the alignment motor (rear) (M808) and alignment motor

(front) (M809). M808 and M809 are controlled by the FS CB

(FS control board).

Operation

Normal alignment operation

The alignment plate (front) and alignment plate (rear) work

symmetrically, with the tray center serving as the reference

point. The guides repeat the alignment and release pattern.

The rotation direction of M809 and M808 is therefore always

opposite.

The ON timing of M809 and M808 is referenced to the ON/OFF

state of PS802 (conveyance drum entrance detect) or PS804

(paper through detect). Which sensor is used depends on the

paper size.

Shift alignment operation

During the first alignment operation, the alignment plate (front)

and alignment plate (rear) are front and rear symmetric with

respect to operation as reference with the center of the tray and

paper is exited.

During the next alignment operation, the alignment plate (front)

and alignment plate (rear) are not front and rear symmetric with

respect to operation as reference with the center of the tray and

paper is exited at the position shift to the first copy.

From now on, these operation are repeated.

Staple mode operation

In staple mode, M809 and M808 perform release operation

after stapling is completed. The ON/OFF timing is referenced

to the OFF timing of the stapler motor that has last finished to

operate (M802 or M803).

Signals

Input signals

PS802 (PS802 → FS CB)

Paper detection signal at the paper conveyance section

entrance of the tray 2/3.

[L]: Paper is not detected

[H]: Paper is detected

PS804 (PS804 → FS CB)

Paper detection signal at the conveyance drum circumference.

[L]:Paper is not detected

[H]: Paper is detected

PS815 (PS815 → FS CB)

Home position detection signal for alignment plate (rear).

[L]:Alignment plate is not in home position

[H]:Alignment plate is in home position

PS816 (PS816 → FS CB)

Home position detection signal for alignment plate (front).

[L]:Alignment plate is in home position

[H]:Alignment plate is not in home position

FS RXD (MAIN BODY → FS CB)

Serial data line for transmitting operation status information from control board in main body to finisher.

FS R REQ (MAIN BODY → FS CB)

Send request signal from main body to finisher.

FS T ACK (MAIN BODY → FS CB)

Send enable signal from main body to finisher.

20

Page 24

FS-105

Output signals

M808 DRIVE A, A, B, B (FS CB → M808)

M808 (alignment motor (rear)) ON/OFF drive signal

M809 DRIVE A, A, B, B (FS CB → M809)

M809 (alignment motor (front)) ON/OFF drive signal

FS TXD (FS CB → MAIN BODY)

Serial data line for transmitting operation status information from finisher to main body control board.

FS T REQ (FS CB → MAIN BODY)

Send request signal from finisher to main body.

FS R ACK (FS CB → MAIN BODY)

Send enable signal from finisher to main body.

Paper Exit (M805) Control

When the alignment or stapling operation is completed, the

paper is pushed out to tray 2 or tray 3 by the exit levers. The

levers are driven by M805 (paper exit motor) via a set of gears.

Operation is controlled by the FS CB (FS control board).

Operation

Non-stapling mode operation

The drive gear for the exit levers is controlled using the home

position detected by PS813 (paper exit motor HP).

When PS804 (paper through detect) detects the paper leading

edge and goes ON, M805 goes ON for the specified time and

drives the exit levers. This causes PS813 to go OFF.

The exit levers are connected to the circumference of the drive

gear. Within one rotation of the gear, the paper is pushed out

(forwarding motion) and returned to the standby position

(return motion).

When PS813 goes ON, the exit levers have returned to the

standby position and M805 is turned OFF.

21

Page 25

FS-105

Stapling mode operation

In stapling mode, when the stapler motor (M802 or M803) that

has last finished to operate goes OFF, M805 goes ON for the

specified time and drives the exit levers. Other operations are

the same as for non-stapling mode.

Signals

Input signals

PS804 (PS804 → FS CB)

Paper detection signal at the conveyance drum circumference.

[L]: Paper is not detected

[H]: Paper is detected

PS813 (PS813 → FS CB)

Home position detection signal for exit lever.

[L]: Exit lever is not in home position

[H]: Exit lever is in home position

FS RXD (MAIN BODY → FS CB)

Serial data line for transmitting operation status information from control board in main body to finisher.

FS R REQ (MAIN BODY → FS CB)

Send request signal from main body to finisher.

FS T ACK (MAIN BODY → FS CB)

Send enable signal from main body to finisher.

Paper Stacking Control

Output signals

M805 DRIVE A, A, B, B (FS CB → M805)

M805 (paper exit) ON/OFF drive signal

FS TXD (FS CB → MAIN BODY)

Serial data line for transmitting operation status information from finisher to main body control board.

FS T REQ (FS CB → MAIN BODY)

Send request signal from finisher to main body.

FS R ACK (FS CB → MAIN BODY)

Send enable signal from finisher to main body.

The paper exited to tray 2 or tray 3 is placed on top of the paper

exit rollers of the respective tray. The drive force of motor M810

(tray 2) or M811 (tray 3) is used to operate the rollers and stack

the paper on the tray.

M810 and M811 operation is controlled by the FS CB (FS

control board).

Operation

Paper stacking control

When M805 (paper exit) goes ON, M810 or M811 are set to ON

after the specified time. When M805 goes OFF, M810 or M811

are set to OFF after the specified time. While the motor is ON,

the rollers of the tray are driven and the paper that was placed

on the rollers is stacked.

The stacking section of the tray is pushed up by a spring. When

the maximum allowable number of sheets has been stacked,

the stacking section contacts the bottom of the tray and PS 807

(tray 2 stack-full detect) or PS 809 (tray 3 stack-full detect) goes

ON.

When PS807 or PS809 are ON, no copy operation will be

carried out when the respective tray is selected.

22

Page 26

Tray auto-switching control

When copying is carried out with tray 2 or tray 3 specified as

output tray and the specified tray becomes full, causing PS807

or PS809 to become ON, the output tray is automatically

switched to the other tray.

This operation is also valid if tray 1 is specified as the output

tray. The output tray will be switched to tray 2 or tray 3.

Normally, tray 2 will be selected. If it is full, tray 3 will be

selected. Switching from tray 2 or tray 3 to tray 1 is not possible.

Signals

Input signals

PS807 (PS807 → FS CB)

Tray 2 stack-full detection signal

[L]: Stack full condition not detected

[H]: Stack full condition detected

PS809 (PS809 → FS CB)

Tray 3 stack-full detection signal

[L]: Stack full condition not detected

[H]: Stack full condition detected

FS RXD (MAIN BODY → FS CB)

Serial data line for transmitting operation status information from control board in main body to finisher.

FS R REQ (MAIN BODY → FS CB)

Send request signal from main body to finisher

FS T ACK (MAIN BODY → FS CB)

Send enable signal from main body to finisher

FS-105

Output signals

M810 DRIVE A, A, B, B (FS CB → M810)

M810 (tray 2) ON/OFF drive signal

M811 DRIVE A, A, B, B (FS CB → M811)

M811 (tray 3) ON/OFF drive signal

FS TXD (FS CB → MAIN BODY)

Serial data line for transmitting operation status information from finisher to main body control board.

FS T REQ (FS CB → MAIN BODY)

Send request signal from finisher to main body

FS R ACK (FS CB → MAIN BODY)

Send enable signal from finisher to main body

23

Page 27

FS-105

Stapler Movement (M806) Control

FS T ACK (MAIN BODY → FS CB)

Send enable signal from main body to finisher

Output signals

M806 DRIVE A, A, B, B (FS CB → M806)

M806 (stapler movement) ON/OFF drive signal

FS TXD (FS CB → MAIN BODY)

Serial data line for transmitting operation status informa-

tion from finisher to main body control board.

FS T REQ (FS CB → MAIN BODY)

Send request signal from finisher to main body.

FS R ACK (FS CB → MAIN BODY)

Send enable signal from finisher to main body.

The position of the stapler units at the front and rear with

respect to the paper is adjusted using the driving force of the

stapler movement motor (M806). Operation of M806 is controlled by the FS CB (FS control board).

Operation

Normally, the stapler units are stationary, positioned so that

the stapling is carried out parallel to the paper edge. This

position is detected by PS814 (stapler unit HP).

When the stapling position is changed according to a command from the main body, M806 goes ON and the two stapler

units at the front and rear are moved simultaneously. The

M806 OFF timing is controlled using the number of drive step

from when PS814 went OFF.

Signals

nput signals

PS814 (PS814 → FS CB)

Home position detection signal for stapler unit

[L]: Stapler unit is in home position

[H]: Stapler unit is not in home position

MS804 (MS804 → FS CB)

Power supply line for M802 (stapler (front)), M803 (stapler

(rear)), and M806. Forcibly interrupted when the shutter

is raised.

FS RXD (MAIN BODY → FS CB)

Serial data line for transmitting operation status information from control board in main body to finisher

FS R REQ (MAIN BODY → FS CB)

Send request signal from main body to finisher

Revised 10/00

24

Page 28

FS-105

Stapler Control

M803

M803

M802

M802

Stapling is carried out by driving M802 (stapler (front)) and

M803 (stapler (rear)). Operation of M802 and M803 is controlled by the FS CB (FS control board).

The maximum number of sheets for stapling and the operation

to be carried out when the number is exceeded can be set with

25 mode of the main body. For details, refer to the adjustment

section of the main body

Operation

Stapling operation

M802 goes ON when the last paper alignment operation is

completed, and goes OFF when PS817 (stapler HP (front))

goes ON.

This causes the front side of the paper to be stapled.

When stapling at two locations is carried out, M803 goes ON

after the specified time, measured from the point when M803

goes ON. It goes OFF when PS820 (stapler HP (rear)) goes

ON.

M803

M802

No-staple detection

The front and rear stapler units are each equipped with a nostaple sensor (PS818, PS821). When staples have run out

and the no-staple condition is detected, a message is shown

on the display of the main body.

Signals

Input signals

PS817 (stapler unit (front) → FS CB)

Home position detection signal for M803

[L]: Home position is detected

[H]: Home position is not detected

PS818 (stapler unit (front) → FS CB)

Stapler unit (front) no-staple detection signal.

[L]: No-staple condition is detected

[H]: No-staple condition is not detected

PS820 (stapler unit (rear) → FS CB)

Home position detection signal for M802

[L]: Home position is detected

[H]: Home position is not detected

PS821 (stapler unit (rear) → FS CB)

Stapler unit (rear) no-staple detection sensor signal

[L]: No-staple condition is detected

[H]: No-staple condition is not detected

MS804 (MS804 → FS CB)

Power supply line for M802 (stapler (front)), M803 (stapler

(rear)), and M806 (stapler movement). Forcibly inter

rupted when the shutter is raised.

FS RXD (MAIN BODY → FS CB)

Serial data line for transmitting operation status information from control board in main body to finisher.

FS R REQ (MAIN BODY → FS CB)

Send request signal from main body to finisher.

FS T ACK (MAIN BODY → FS CB)

Send enable signal from main body to finisher.

PS819 (Stapler unit (front) → FS CB)

stapler unit (front) no-staple sensor signal at the stapling

position.

[L]: No-staple condition is detected

[H]: No-staple condition is not detected

PS822 (Stapler unit (rear) → FS CB)

stapler unit (rear) no-staple sensor signal at the stapling

position.

[L]: No-staple condition is detected

[H]: No-staple condition is not detected

Shutter control

During stapler unit movement and during stapling operation,

the SD802 (shutter) is ON, causing the shutter to block the

clearance between the paper exit tray and the stapler unit.

25

Revised 10/00

Page 29

FS-105

Output signals

M802 DRIVE 1, 2 (FS CB → stapler unit (front))

M802 drive signals.

M802 rotation direction is controlled by switching the

current direction of these two signals.

M803 DRIVE 1, 2 (FS CB → stapler unit (rear))

M803 drive signals.

M803 rotation direction is controlled by switching the

current direction of these two signals.

SD802 DRIVE (FS CB → SD802)

SD802 (shutter) ON/OFF drive signal.

[L]: SD802 ON

[H]: SD802 OFF

FS TXD (FS CB → MAIN BODY)

Serial data line for transmitting operation status information from finisher to main body control board.

FS T REQ (FS CB → MAIN BODY)

Send request signal from finisher to main body.

FS R ACK (FS CB → MAIN BODY)

Send enable signal from finisher to main body.

Revised 10/00

26

Page 30

OTHER CONTROL FUNCTIONS

Power-on Operation

When the main body SW2 (sub power) is set to ON, the finisher

performs the following initialization sequence.

1. SD802 (shutter) goes ON and the shutter cover closes.

2. M808 (alignment (rear)) and M809 (alignment (front)) go

ON and the alignment plates (front/rear) perform home

position search.

3. M807 (conveyance drum drive) goes ON and the conveyance drum performs home position search.

4. M806 (stapler movement) goes ON and the stapler unit

moves to the standby position.

5. SD802 goes OFF and the shutter cover opens.

6. M805 (paper exit) goes ON and the exit lever is driven for

one operation.

FS-105

7. Lower limit position detection for tray 2 and tray 3 is

carried out. If PS806 (tray lower limit detect) does not go

ON, M804 (tray up/down) goes ON, causing tray 2 and

tray 3 to move downward.

27

Page 31

FS-105

ELECTRICAL PARTS LAYOUT DRAWING

17

24

35

2

9

3

10

16

13

14

30

36

4

27

1

26

5

37

20 23

33

7

34

6

8

11

12

28

32

15

25

Switches and Sensors

1 MS801 Inter lock MS

2 MS802 Up/down MS (UPPER)

3 MS803 Up/down MS (LOWER)

4 MS804 Stapler safety MS

5 PS801 Conveyance drum position detect sensor

6 PS802 Conveyance drum entrance detect sensor

7 PS803 Tray 1 paper exit detect sensor

8 PS804 Paper through detect sensor

9 PS805 Tray upper limit detect sensor

10 PS806 Tray lower limit detect sensor

11 PS807 Tray 2 full-stack detect sensor

12 PS809 Tray 3 full-stack detect sensor

13 PS812 Stapler no paper detect sensor

14 PS813 Paper exit motor HP sensor

15 PS814 Stapler unit HP sensor

16 PS815 Alignment motor (rear) sensor

17 PS816 Alignment motor HP (front) sensor

18 PS817 Stapler HP sensor (front)

19 PS818 No-staple sensor (front)

20 PS819 No-staple (F) (lead edge) sensor

19

22

29

18

21

21 PS820 Stapler HP sensor (rear)

22 PS821 No-staple sensor (rear)

23 PS822 No-staple (R) (lead edge) sensor

Loads

24 M801 Paper feed motor

25 M802 Stapler motor (front)

26 M803 Stapler motor (rear)

27 M804 Tray up/down motor

28 M805 Paper exit motor

29 M806 Stapler movement motor

30 M807 Conveyance drum drive motor

31 M808 Alignment motor (rear)

32 M809 Alignment motor (front)

33 M810 Tray 2 motor

34 M811 Tray 3 motor

35 SD801 Gate solenoid

36 SD802 Shutter solenoid

PCBs and Others

37 FSCB FS control board

28

31

Page 32

CONNECTOR LAYOUT DRAWING

FS-105

736(W:3 PIN)

737(W:3 PIN)

730(W:2 PIN)

721(W:6 PIN)

726

(BK:2 PIN)

735(W:6 PIN)

747(W:12 PIN)

748(W:6 PIN)

749(W:6 PIN)

754(W:9 PIN)

755(W:16 PIN)

725(W:6 PIN)

724(W:6 PIN)

756(BK:8 PIN)

723(W:6 PIN)

727(W:6 PIN)

740(W:3 PIN)

757(BK:8 PIN)

755

(BK:19 PIN)

741(W:3 PIN)

749(BK:6 PIN)

748

(BK:7 PIN)

747

(BK:12 PIN)

753

(BK:8 PIN)

754(BK:9 PIN)

743(W:3 PIN)

401(GY:16 PIN)

722

(W:6 PIN)

729(W:6 PIN)

734(W:3 PIN)

750(BK:3 PIN)

728(W:6 PIN)

750(BK:3 PIN)

733(W:3 PIN)

729(W:6 PIN)

735(W:3 PIN)

739(W:3 PIN)

728(W:6 PIN)

750(BK:3 PIN)

744(W:3 PIN)

738(W:3 PIN)

721(W:6 PIN)

704(W:11 PIN)

703(W:10 PIN)

701(W:11 PIN)

702(W:6 PIN)

708(GY:26 PIN)

746(W:13 PIN)

742(W:3 PIN)

745(W:13 PIN)

706

(GY:16 PIN)

705

(GY:20 PIN)

707

(W:12 PIN)

709(GY:34 PIN)

29

Page 33

FS-105

This page left blank intentionally.

30

Loading...

Loading...