Page 1

Force 85

Network Printing System

Force 85

Page 2

Recycled paper is used for the inside pages of this book.

Konica Force 85

Network Printing System

User's Manual

Page 3

© 2002 by Konica Business Technologies, Inc.

MAINTENANCE AGREEMENT:

The KONICA Force 85 Network Printing System will give you many years of trouble-free service. To ensure

high-quality printing performance and to prevent premature wear or failure of precision parts and components,

schedule periodic cleaning and routine adjustments.

We recommend that you contact your service center to discuss the benefits and advantages of Konica's

Customer Service Maintenance Agreement and to be shown how a maintenance plan can be tailored to your

individual printing needs.

NOTICE:

Konica Business Technologies, Inc. has made every effort to ensure that the information in this manual is

complete and accurate. However, constant efforts are also being made to improve and update the product.

Therefore, Konica Business Technologies, Inc. shall not be liable for errors in this manual or for any consequential

damage resulting from the use of this manual. The information contained herein is subject to change without

notice.

FEDERAL OR STATE STATUTES MAY PROHIBIT THE COPYING OF CERTAIN DOCUMENTS OR

INFORMATION, RESULTING IN FINES OR IMPRISONMENT FOR VIOLATORS.

MANUAL PART NUMBER:

OP-Force85-01

Web Site Address:

http://www.konicabt.com

CORRESPONDENCE:

Correspondence regarding this manual may be mailed to the address shown below.

KONICA BUSINESS TECHNOLOGIES, INC.

CORPORATE PUBLICATIONS

500 DAY HILL ROAD

WINDSOR, CT 06095

Page 4

Contents

Contents

Section 1: Introduction

To the User ..................................................................................................................... 1-2

Features Overview .......................................................................................................... 1-3

Section 2: Safety Information

User Instructions ............................................................................................................. 2-2

Machine Labels ............................................................................................................... 2-3

Label Locations........................................................................................................ 2-3

Regulations ..................................................................................................................... 2-5

FCC Regulations...................................................................................................... 2-5

Canadian Department of Communications Regulations .......................................... 2-5

FDA Regulations...................................................................................................... 2-5

Machine Installation and Power Requirements............................................................... 2-6

Machine Handling and Care............................................................................................ 2-8

Routine Safety................................................................................................................. 2-9

Finisher Capacity Requirements ................................................................................... 2-10

Section 3: Machine Information

Konica Force 85 Overview .............................................................................................. 3-2

Key Operator Functions ........................................................................................... 3-3

Service, Repairs & Supplies .................................................................................... 3-3

Machine Labels........................................................................................................ 3-3

Service Settings ....................................................................................................... 3-4

Machine Configuration .................................................................................................... 3-5

External Machine ..................................................................................................... 3-5

External Machine Call-outs ...................................................................................... 3-6

Internal Machine ...................................................................................................... 3-7

Internal Machine Call-outs ....................................................................................... 3-7

Optional Equipment ................................................................................................. 3-8

Site Requirements......................................................................................................... 3-17

Control Panel Layout..................................................................................................... 3-19

Specifications ................................................................................................................ 3-20

Page 5

Contents

Section 4: Media Information

Main Body Trays ............................................................................................................. 4-2

LT-402 Large Capacity Tray (Option) ............................................................................. 4-3

LT-412 Large Capacity Tray (Option) ............................................................................. 4-3

Automatic Duplex Unit..................................................................................................... 4-4

Multi-Sheet Bypass Tray ................................................................................................. 4-4

FS-111/211 Finisher (Option).......................................................................................... 4-5

FS-111/211 Finisher Primary (Main) Tray................................................................ 4-5

FS-111/211 Finisher Secondary (Sub) Tray ............................................................ 4-5

FS-211 Finisher Booklet Tray .................................................................................. 4-6

PI-108 Cover Sheet Feeder (Option) .............................................................................. 4-7

TU-108 Trimmer Unit (Option) ........................................................................................ 4-7

PU-108 Punching Unit (Option)....................................................................................... 4-7

PZ-108 Punching / Z-Folding Unit (Option)..................................................................... 4-8

Paper Supply Message ................................................................................................... 4-9

Paper Weight Compatibility Chart ................................................................................. 4-10

Section 5: Printing Operations

Introduction ..................................................................................................................... 5-2

Wake Up Screen...................................................................................................... 5-2

Warm Up Screen ..................................................................................................... 5-2

Control Panel .................................................................................................................. 5-3

The Basic Screen............................................................................................................ 5-3

Check Mode Message .................................................................................................... 5-4

Check Screen .......................................................................................................... 5-4

Reservation List .............................................................................................................. 5-5

Screen Display......................................................................................................... 5-5

Help Mode....................................................................................................................... 5-6

Stop Printing.................................................................................................................... 5-7

Change Job Order........................................................................................................... 5-8

Job Deletion .................................................................................................................... 5-9

Previous Job List........................................................................................................... 5-10

Non Complete Job List.................................................................................................. 5-11

Change Setting ............................................................................................................. 5-12

Print Size....................................................................................................................... 5-13

Selecting Paper Type/Size for Multi-Sheet Bypass Tray ....................................... 5-13

Controller Screen .......................................................................................................... 5-14

Auto Low Power Mode .................................................................................................. 5-15

The Counter List............................................................................................................ 5-16

View the Counter List............................................................................................. 5-16

Print the Counter List ............................................................................................. 5-16

Weekly Timer Function ................................................................................................. 5-17

Timer Interrupt ....................................................................................................... 5-17

Page 6

Contents

Section 6: Output Modes

FS-111/211 Finisher Specifications ................................................................................ 6-2

Finisher Type ........................................................................................................... 6-2

Primary (Main) Tray ................................................................................................. 6-2

Secondary (Sub) Tray.............................................................................................. 6-3

Booklet Tray (FS-211 Finisher only) ........................................................................ 6-3

Cover Sheet Feeder................................................................................................. 6-4

Punching Unit........................................................................................................... 6-4

Punching / Z-Folding Unit ........................................................................................ 6-4

Non-Sort Mode Using Primary (Main) Tray..................................................................... 6-5

Sort Mode Using Primary (Main) Tray............................................................................. 6-6

Staple-Sort Mode Using Primary (Main) Tray ................................................................. 6-7

Folding and Stapling & Folding Modes ........................................................................... 6-8

Punch Mode .................................................................................................................... 6-9

Z-Folding Mode ............................................................................................................. 6-10

Trimming Mode ............................................................................................................. 6-11

Cover Sheet Feeder...................................................................................................... 6-12

Manual Finishing ........................................................................................................... 6-13

Output Mode for Machine without Finisher ................................................................... 6-16

Section 7: Web Utilities

To Use Web Utilities........................................................................................................ 7-2

Machine Information Mode.............................................................................................. 7-4

Job Status Mode ............................................................................................................. 7-5

Environment Setup Mode................................................................................................ 7-6

To Set E-Mail Transmission Function ...................................................................... 7-6

To Set E.C.M. Function............................................................................................ 7-7

To Transmit/Edit Machine Setting File ................................................................... 7-13

Section 8 : Maintenance & Supplies

Loading Paper................................................................................................................. 8-2

Paper Indicator......................................................................................................... 8-2

Using the HELP Key ................................................................................................ 8-2

Loading Paper in Tray 1, 2 and 3............................................................................. 8-3

Loading Paper in Multi-Sheet Bypass Tray.............................................................. 8-4

Loading Paper in LCT (LT-402/LT-412)................................................................... 8-5

Loading Tabbed Sheets in Tray 1, 2, or 3................................................................ 8-6

Loading Tabbed Sheets in Multi-Sheet Bypass Tray............................................... 8-7

Loading Tabbed Sheets in LCT (LT-402/LT-412) .................................................... 8-8

Adding Toner................................................................................................................... 8-9

Inserting a New Staple Cartridge into FS-111 Finisher................................................. 8-10

Inserting a New Staple Cartridge into FS-211 Finisher................................................. 8-11

Page 7

Contents

Section 8 : Maintenance & Supplies (continued)

Empty Trash Basket of PU-108/PZ-108 Punching (Z-Folding) Unit.............................. 8-12

Preventive Maintenance................................................................................................ 8-13

Reading the PM Counter ....................................................................................... 8-13

Printing the PM Counter......................................................................................... 8-13

Service, Repairs, Supplies ............................................................................................ 8-14

Clearing Mishandled Paper........................................................................................... 8-15

Jam Location Screen ............................................................................................. 8-15

Printing Hints................................................................................................................. 8-16

Section 9 : Key Operator Mode

To the Key Operator........................................................................................................ 9-2

How to Access the Key Operator Mode................................................................... 9-3

Function Menu Map ........................................................................................................ 9-4

System Initial Setting [1].................................................................................................. 9-6

Date & Time Setting [1]............................................................................................ 9-6

Language Select Setting [2]..................................................................................... 9-8

IP Address Setting [3] .............................................................................................. 9-9

E-Mail Transmission Setting [3] ............................................................................. 9-10

ECM (Electronic Copy Monitor) Function Setting [4]..................................................... 9-12

How to Access the ECM Setting Mode .................................................................. 9-13

E.C.M. Data Edit [1] ............................................................................................... 9-14

E.C.M. All Count Reset [2] ..................................................................................... 9-18

E.C.M. Function Setting [3] .................................................................................... 9-19

Paper Type / Special Size Set [6] ................................................................................. 9-20

Panel Contrast / Key Sound Adjustment [7].................................................................. 9-22

Key Operator Data Setting [8] ....................................................................................... 9-23

Weekly Timer [9] ........................................................................................................... 9-24

How to Access the Weekly Timer Setting Mode .................................................... 9-25

Weekly Timer On/Off Setting [1] ............................................................................ 9-26

Timer Setting [2]..................................................................................................... 9-27

Timer Action On/Off Setting [3] .............................................................................. 9-29

Lunch Hour Off Setting [4] ..................................................................................... 9-31

Timer Interrupt Password Setting [5] ..................................................................... 9-32

Control Panel Adjustment [10] ...................................................................................... 9-33

Tray Auto Select Setting [11] ........................................................................................ 9-34

Power Save Setting [12]................................................................................................ 9-35

Memory Switch Setting [13] .......................................................................................... 9-36

Machine Management List Print [14]............................................................................. 9-39

Call Remote Center [15]................................................................................................ 9-40

Side 2 Lens Adjustment [16] ......................................................................................... 9-41

Finisher Adjustment [17] ............................................................................................... 9-42

Timing Adjustment [21] ................................................................................................. 9-44

Centering Adjustment [22]............................................................................................. 9-45

Key Operator ECM Form .............................................................................................. 9-46

Page 8

Section 1: Introduction

To the User ...........1-2

Features Overview ...........1-3

Introduction 1-1

Page 9

Introduction

To the User

Welcome to the Konica Force 85 Network Printing System, which includes the main body

engine, the print controller, and the optional network interface card. Separate user

documentation is provided with the print controller and the network interface card.

This User's Manual describes the layout of the main body machine configured with both

standard and optional equipment and explains control panel functions and procedures for

all operations. This manual also includes basic engine specifications, and information on

media requirements, maintenance, supplies, safety measures, and troubleshooting tips.

Be sure to read this manual thoroughly before operating the equipment and keep it in a

handy location for the convenience of all users.

Konica is committed to serving you in the best way possible and we welcome your

comments on this manual. If you wish to send us your comments, please use our mailing

address displayed in the front of this book.

1-2 Introduction

Page 10

Introduction

Features Overview

The Konica Force 85 Network Printing System connects the Konica Force 85 main body

engine to the IP-602 Printer Controller, enabling the system to function as a network

printer or print server on the network.

• All-Image Area

Prints completely to the edges of the paper to avoid image loss.

•ATS - Automatic Tray Switching

Automatically switches to another paper tray when a tray becomes empty during a print

job.

•Auto Low Power

Automatically lowers the power after a specified period of printer inactivity.

•Auto Reset

Automatically resets to printer defaults after a specified period of printer inactivity.

•Auto Shut-Off

Automatically shuts off the main power after a specified period of printer inactivity.

• Booklet

Creates letter R or ledger size booklets from letter size originals in duplex mode.

• Chapter

Places chapter pages on the right hand side in duplex mode.

• Combination

Prints a fixed number (2, 4, or 8) of pages onto one sheet of print paper.

• Counter List

Displays on the screen and prints the following data: total counter of the machine and the

date when the counter started.

•Image Shift

Creates or removes a binding margin at the top, bottom, right and left edges (shift amount

from 0 ~ 250mm, in 1mm increments); reduces image to prevent image loss (reduce &

shift amount from 0 ~ 250mm, in 1mm increments).

• Machine Status Confirmation

Displays the current machine status on LCD for confirmation.

Introduction 1-3

Page 11

Introduction

Features Overview (continued)

• Manual Shut-off

Shuts off the main power when pressing [POWER SAVER ON/OFF] key.

• Non Standard Size for Multi-Sheet Bypass Tray

Allows special paper size to be loaded in the Multi-sheet bypass tray and entered using the

touch screen keypad in order to avoid paper misfeed.

• Output mode for Machine with FS-111/211 Finisher Installed:

Non-Sort, Sort, Staple-Sort, and Group modes using the primary (main) tray

Non-Sort Face Down exit, Non-Sort Face Up exit, Group Face Down exit, and

Group Face Up exit modes using the secondary (sub) tray

Folding, Stapling & Folding, and 3-Folding modes using the booklet tray (FS-211

only)

• Output mode for FS-111/211 Finisher with PI-108 Cover Sheet Feeder Installed:

Cover Sheet mode

Manual Staple mode

For details of each output mode, see Section 6: Output Modes.

•Paper Capacity

Total 2,600 sheets, including two 500-sheet trays, a 1,500-sheet tray, and a 100-sheet

Multi-sheet bypass tray.

Total 6,600 sheets, including 4,000-sheet optional large capacity tray.

•Power Saver

Automatically turns off all but nominal power supply after a specified period of printer

inactivity, for optimal efficiency. Power is returned after a brief warm up period by pressing

POWER SAVER ON/OFF] key on the Control panel.

the [

• Proof Print

To ensure correct output before running multiple prints, run a proof print by touching

PROOF PRINT

• Punch Mode for FS-111/211 Finisher with PU-108 Punching Unit Installed:

Punches three holes in output prints.

• Punch / Z-Folding Mode for FS-111/211 Finisher with PU-108 Punching Unit (PZ-108

Punching / Z-Folding Unit) Installed:

Punches three holes in output prints and Z-fold printed sheets.

1-4 Introduction

on the Check Screen.

Page 12

Introduction

Features Overview (continued)

• Repeat Image

Accepts the horizontal image area across the page, and repeats it down the page as many

times as the repeat width setting (10 ~ 150mm) permits, in manual or auto.

•Reverse Image

Reverses the image from black-on-white to white-on-black or vice versa.

• Sheet/Cover Insertion

Inserts up to 30 blank or printed sheets from any tray including the Multi-Sheet Bypass

Tr ay, or inserts blank or printed front and back covers from any tray including the MultiSheet Bypass Tray.

• Stamp

Imprints a stamp onto the print image.

• Staple

Selects the stapling position and number of staples (3 positions).

• STD Size (Special)

Detects standard paper sizes which cannot normally be detected when loaded in a main

body tray or Multi-sheet bypass tray.

•Tab Paper

Prints onto tabbed sheets from tabbed data, allowing the image on the tab part of the

original to be printed on the same part of the tabbed print paper.

•Transparency Interleave

Prints onto transparency film and interleave blank or printed paper for each print data.

•Trimming Mode for FS-211 Finisher with TU-108 Trimmer Unit Installed:

Tr ims the end of folded or stapled & folded booklet.

•Web Utilities

Manages the machine from PC over the internet.

•Weekly Timer

Can be set according to the needs of each work environment. Turns main body power Off/

On daily or weekly, during lunch time, on holidays, and also enables the Timer Interrupt

mode, which allows temporary use of the machine even when the machine is in the daily,

weekly, or holiday Off Mode.

Introduction 1-5

Page 13

Introduction

Features Overview (continued)

•Wide Size Paper

Prints onto paper slightly larger than the specified regular size.

1-6 Introduction

Page 14

Section 2: Safety Information

User Instructions ...........2-2

Machine Labels ...........2-3

Label Locations...............2-3

Regulations ...........2-5

FCC Regulations...............2-5

Canadian Department of Communications Regulations...............2-5

FDA Regulations...............2-5

Machine Installation and Power Requirements ...........2-6

Machine Handling and Care ...........2-8

Routine Safety ...........2-9

Finisher Capacity Requirements .........2-10

Safety Information 2-1

Page 15

Safety Information

User Instructions

The following pages include important safety information, which you must read and

understand before you attempt to operate the machine. If you have any concerns about

safety matters, please contact your service representative. Keep this manual located

permanently with the machine, so that this safety information is readily available.

Machine safety labels are attached to the internal area of the machine. The purpose of

safety labels is to alert you of imminent or potentially hazardous situations or conditions.

Be sure to heed all safety label information. If the safety labels become illegible due to

soilage, etc., please contact your service representative for information about label

replacements. Sample safety labels are shown on the following page.

TO AVOID GETTING BURNED do not touch any part of the machine that you are advised

not to touch by a warning or caution label.

DO NOT REMOVE WARNING OR CAUTION LABELS.

Clean labels as needed to maintain legibility. If any warning or caution label is removed or

becomes illegible from soilage, please contact your service representative for information

about label replacements.

The following standard safety categories are commonly used on product labelling.

DANGER:

Danger indicates an imminent hazardous situation, which, if not avoided, will result

in death or serious injury.

Note:

The DANGER category is not required for this product, and is only included here for general user

information.

WARNING:

Warning indicates a potentially hazardous situation, which, if not avoided, could

result in death or serious injury.

CAUTION:

Caution indicates a potentially hazardous situation, which, if not avoided, may

result in minor or moderate bodily injury.

NOTICE:

Notice provides information on the correct handling or use of the machine to prevent breakage of the

printer or some machine part, etc. It does not indicate concern for personal safety.

2-2 Safety Information

Page 16

Safety Information

Machine Labels

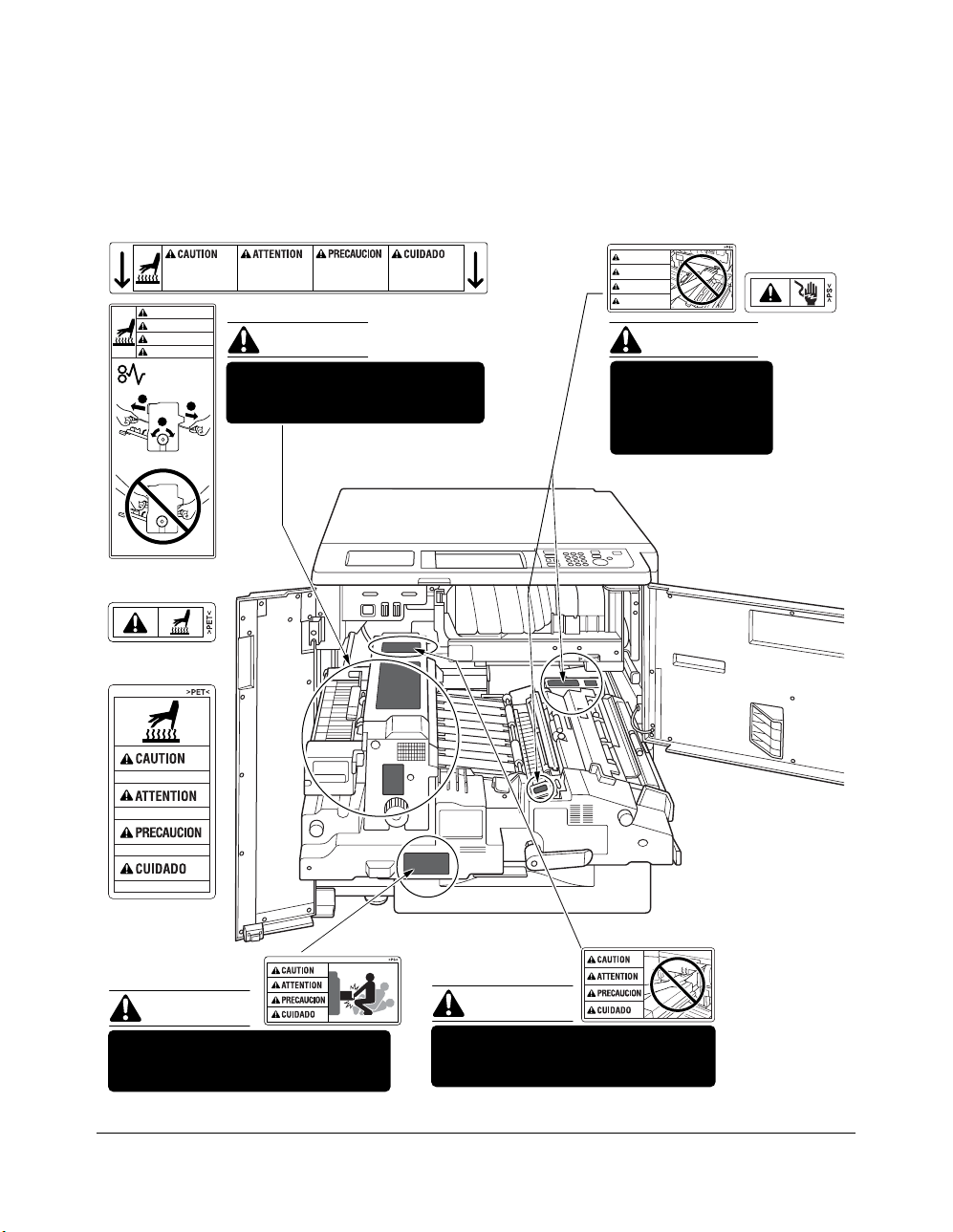

Label Locations

This internal area is very

hot. To avoid getting

burned, DO NOT TOUCH.

CAUTION

ATTENTION

PRECAUCION

CUIDADO

2

2

1

(Top surface of

the fixing unit)

(Inside of

the fixing unit)

High temperature!

Cette zone interne est

très chaude. Pour éviter

de se brûler, NE PAS LA

TOUCHER.

Esta zona interior está

muy caliente. Para no

quemarse NO TOCAR.

Alta temperatura. NÃO

TOQUE nesta área

interior, pois há risco de

queimadura.

(Both sides of the fixing unit)

CAUTION

The fixing unit is very hot.

To avoid getting burned DO NOT

TOUCH.

WARNING

DANGER

ADVERTENCIA

ADVERTÊNCIA

WARNING

This area generates

high voltage. If

touched, electrical

shock may occur. DO

NOT TOUCH!

Température élevée!

¡Temperatura alta!

Alta temperatura!

(Front side of

the fixing unit)

CAUTION

The conveyance fixing unit is heavy.

Use care and draw it out gently;

otherwise you may be injured.

CAUTION

DO NOT put your hand between the

main body and developing fixing

unit; otherwise you may be injured.

Safety Information 2-3

Page 17

Safety Information

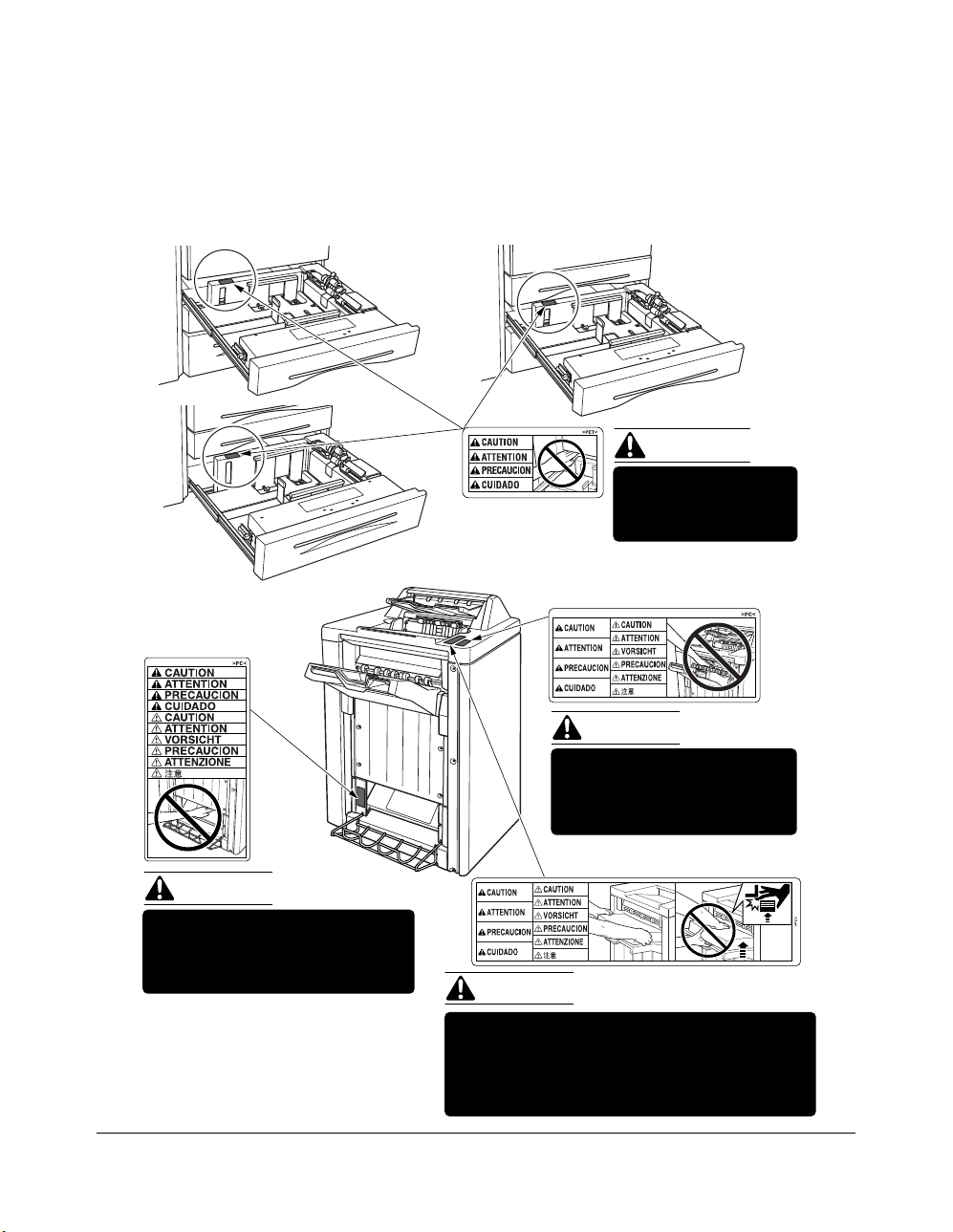

Machine Labels (continued)

Label Locations (continued)

Tray 3

(FS-211 only)

Tray 1

Tray 2

CAUTION

DO NOT put your hand

between the main body

and tray; otherwise you

may be injured.

(FS-111/211)

CAUTION

Use care after opening the

paper exit outlet. DO NOT put

your hand into it; otherwise

you may be injured.

CAUTION

Inside the lower paper exit outlet

is the roller drive unit.

DO NOT put your hand into it;

otherwise you may be injured.

85

2-4 Safety Information

(FS-111/211)

FS-211 Finisher

CAUTION

To avoid injury, DO NOT put your hand on the

top of the printed sheets. Be sure to hold both

sides of the printed sheets when removing them,

and DO NOT leave your hand onto the printed

sheets while the primary (main) tray goes up.

Page 18

Safety Information

Regulations

FCC Regulations

Warning:

it is not installed and used in accordance with the instruction manual, interference with

radio communications may result. This equipment has been tested and found to comply

with the limits for a Class A computing device, pursuant to Subpart B, Part 15, of FCC

rules, which are designed to provide reasonable protection against interference from such

equipment when it is operating in a commercial environment.

Users operating this equipment in a residential area are likely to cause interference, in

which case they may be required to correct the interference at their own expense.

The Konica Force 85 generates, uses, and can radiate radio frequency energy. If

Canadian Department of Communications Regulations

Le présent appareil n’émet pas de bruits radioélectriques dépassant les limites

applicables aux de Classe A prescrites dans le règlement sur la brouillage radioélectrique

édicté par Le Ministère des Communications du Canada.

This equipment does not exceed the Class A limits for radio noise emissions as set out in

the radio interference regulations of the Canadian ICES-003.

FDA Regulations

This Printer is certified as a “Class 1” laser product under the U.S. Department of Health

and Human Service (DHHS) Radiation Performance Standard according to the Radiation

Control for Health and Safety Act of 1968. Since radiation emitted inside this printer is

completely confined within protective housings and external covers, the laser beam cannot

escape during any phase of normal user operation.

Safety Information 2-5

Page 19

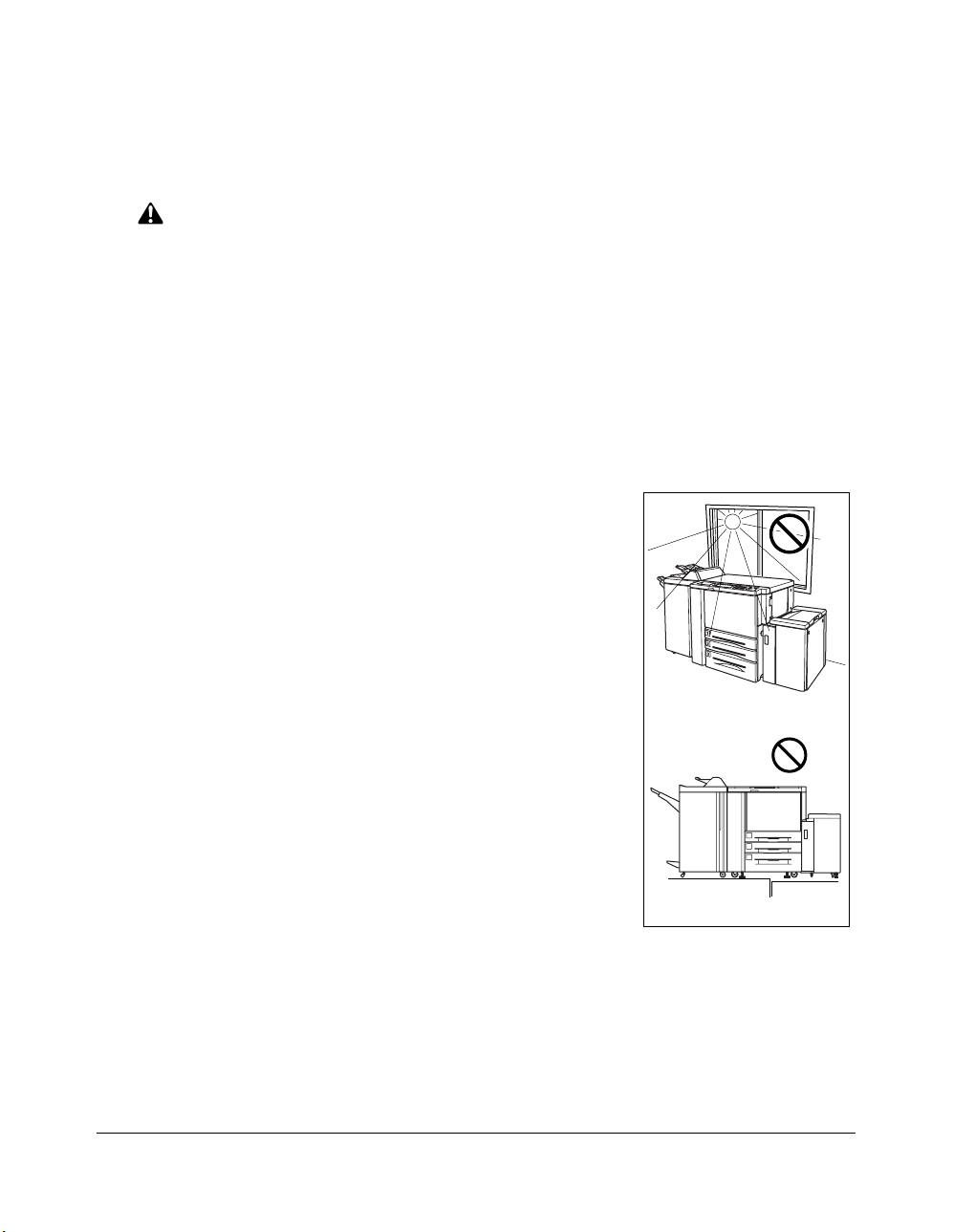

Safety Information

Machine Installation and Power Requirements

CAUTION:

FAILURE TO HEED THE FOLLOWING CAUTIONS MAY RESULT IN BODILY INJURY AND/OR

MACHINE DAMAGE.

❒

FIRE PREVENTION

Install machine away from flammable or volatile materials. Routinely check for abnormal

heat from power cord and/or plug.

❒

SHORT CIRCUIT FROM WATER DAMAGE

Do not install or operate this equipment outdoors near a lake, pond, or river, etc.; and do

not allow the machine to come in contact with splashes of rain, water, or any liquid.

❒

TEMPERATURE AND HUMIDITY

Install the machine away from direct sunlight, heat sources

(stoves, heaters) and cold temperatures (air conditioners).

Avoid any environment that is outside 50°~86°F (10°~30°C),

with 10~80% humidity.

❒

VENTILATION

Do not allow the machine to come in contact with dust or

ammonia gas, or fumes from printing or cleaning solutions,

etc.; otherwise, image quality will be poor. Install the machine

in a well-ventilated area, for comfort; otherwise, an ozone odor

will be detected during large print runs. When in use, the

printer generates ozone in amounts too small to be hazardous

to the human body.

Temperature

❒

VIBRATIONS

If the machine is constantly vibrated or jolted, trouble may

occur. Install the machine on a level, horizontal floor, free from

vibrations.

❒

SPACE ALLOTMENT

Vibration

Install machine in an area with adequate space for performing printer operations, replacing

supply items, and conducting preventive maintenance. See Site Requirements, Section 3.

❒

MACHINE RELOCATION/TRANSPORTATION

Be sure to contact your service representative when moving or transporting the machine.

If you move the machine with the Memory unit installed, machine trouble may be caused

by vibration.

2-6 Safety Information

Page 20

Safety Information

Machine Installation and Power Requirements (continued)

CAUTION:

FAILURE TO HEED THE FOLLOWING CAUTIONS MAY RESULT IN MACHINE DAMAGE,

OVERHEATING, RISK OF ELECTRICAL SHOCK, AND/OR PERSONAL INJURY.

❒

PLUG SOCKET

A plug socket is limited in capacity. Use an exclusive power source for this machine;

otherwise, overheating and/or smoking may occur. The total power consumption of the

main body, plus all peripherals, must not exceed the capacity of the main power supply.

Be sure the socket-outlet is near the equipment and is easily accessible.

❒

PLUG AND CORD (LEAD)

Unless the power plug is firmly inserted into the socket, overheating and/or smoking may

occur. Firmly insert the power cord plug into the electrical outlet before turning on the

printer power switch. If the inserted plug is loose in the socket, disconnect it, and consult

an electrician for repair; do not attempt to operate the machine.

Be sure the socket-outlet is near the equipment and is easily accessible.

A damaged power cord may result in overheating, short circuit or fire. Do not bend, crush,

wind, kick, or strike the cord with any item. Do not roll up the cord. If the main body power

cord is bent or damaged, immediately contact your service representative; do not attempt

to repair it yourself; do not continue to operate the machine.

❒

ADAPTERS AND PLURAL LOADS

Never use adapters and never connect plural loads or a branched socket to one socket

outlet; otherwise, overheating or fire may occur.

❒

EXTENSION CORDS (LEADS)

An extension cord or lead is limited in capacity. Unless the cord or lead has adequate

capacity, smoking and overheating may occur. Should smoking and/or overheating occur,

contact an electrician immediately. If you require further information about power

requirements, power consumption, extension cords, adapters and connectors, please

contact your service representative, and consult your electrician.

Safety Information 2-7

Page 21

Safety Information

Machine Handling and Care

WARNING:

FAILURE TO HEED THE FOLLOWING WARNING MAY RESULT IN DEATH OR SERIOUS INJURY AND/

OR MACHINE DAMAGE.

❒

MACHINE CONTACT

Never touch internal high voltage areas, indicated with a WARNING label.

Never touch the drum surface.

Never put your hand into the developing unit when removing mishandled paper.

CAUTION:

FAILURE TO HEED THE FOLLOWING CAUTIONS MAY RESULT IN MACHINE DAMAGE,

OVERHEATING, AND/OR PERSONAL INJURY.

❒

MACHINE CONTACT

Never touch internal high temperature or magnetism areas, indicated with a CAUTION label.

Never insert your hand into the fixing unit when removing mishandled paper.

Never touch the inside of the main body for any purpose except

removing mishandled paper or adding toner.

Use care when pulling out the conveyance fixing unit.

❒

MACHINE CARE

Do not drop paper clips, staples or other small metallic objects

into the printer, or spill water or any other liquid into the

machine.

Do not use the machine surface to support vases, books, etc.

These items will interfere with the work space and may cause

damage to the machine.

❒

ABNORMAL CONDITIONS

If any abnormal sound, odor, or smoke generates from the

machine, immediately stop using the printer, turn off the main

power switch, disconnect the plug and contact your service

representative.

If a circuit breaker is tripped, or if a fuse blows, stop using the machine and contact an

electrician. If more detailed information is needed regarding the power source or power

consumption of this machine, contact your service representative.

❒

MACHINE MODIFICATION

Do not modify the machine in any way or remove any part or screw. Never attempt to

perform any maintenance function that is not specifically described in this manual. Do not

connect the machine with any options other than those specified.

2-8 Safety Information

Page 22

Safety Information

Routine Safety

CAUTION:

FAILURE TO HEED THE FOLLOWING CAUTIONS MAY RESULT IN MACHINE DAMAGE,

OVERHEATING, AND/OR PERSONAL INJURY.

❒

PERIODIC CHECK

Check for loose connections or excessive heat on power plug, damage to power cord and/

or plug (creased, frayed, scratched or cut, etc.). Be sure the plug is inserted fully, and

ground wire is connected correctly. If any abnormality occurs, do not continue to operate

the machine.

❒

SERVICE MESSAGES

If a service message displays, turn the machine off, disconnect the power cord from the

outlet, and report the condition to your service representative.

❒

TONER

Check to be sure toner in storage is out of the reach of children, or anyone incapable of

using supplies safely. Although toner is nontoxic, do not inhale toner or allow it to come in

contact with eyes. If inhalation or eye contact occurs, immediately consult a physician.

Please refer to the appropriate material safety data sheet for additional toner safety

information.

❒

PAPER

Check paper to be sure it is according to the specifications outlined in Section 4.

• Do not use stapled paper or paper that conducts electricity (silver, carbon, etc.),

otherwise an accident may occur as a result of fire.

•To avoid machine trouble, do not use heat-sensitive paper, paper that conducts

electricity (silver, carbon, etc.), or colored OHP film.

❒

CLEANING MATERIALS

Check the type of cleaning material used on your machine to be sure it is recommended

by Konica. If necessary, check with your service representative. Never use cleaning

materials for purposes other than cleaning, and be sure to keep all cleaning materials out

of the reach of children or anyone who is incapable of using them safely.

❒

POWER SAVER

Use Power Saver mode for short periods of machine inactivity. When not using the

machine for long periods of time, turn power off, unless the weekly timer function is

operating.

❒

DISPOSAL OF THE PRINTER AND ACCESSORIES

Dispose of this printer and accessories according to your local regulations.

Safety Information 2-9

Page 23

Safety Information

Finisher Capacity Requirements

CAUTION:

FAILURE TO HEED THE FOLLOWING CAUTIONS MAY RESULT IN BODILY INJURY AND/OR

MACHINE DAMAGE.

❒

FINISHER PAPER CAPACITY

To prevent paper misfeed, do not exceed the paper capacity of the Finisher.

FS-111/FS-211 Finisher paper weight: 16 lb ~ 24 lb

When the selected print quantity exceeds the maximum paper capacity, remove the

printed sheets from the finisher while the paper is exiting.

Paper capacities below are stated for 20 lb bond unless otherwise indicated.

This Finisher also accepts wide types of the regular sizes stated below.

Finisher FS-111/FS-211

Primary (Main) tray: Non-sort/Sort/Group mode

500 sheets (5.5"x8.5"R)

3,000 sheets (8.5"x11", 8.5"x11"R)

1,500 sheets (11"x17", 8.5"x14")

The Secondary (sub) tray can be unloaded while the Force 85 is running.

Set production is not limited by the capacity of the Secondary (sub) tray.

Primary (Main) tray: Punch mode (machine with PU-108/PZ-108 only)

3,000 sheets (8.5"x11")

1,500 sheets (11"x17")

The Secondary (sub) tray can be unloaded while the Force 85 is running.

Set production is not limited by the capacity of the Secondary (sub) tray.

Primary (Main) tray: Staple-Sort / Staple-Sort + Z-Folding mode

1,000 sheets* (11"x17" ~ 8.5"x11"/R)

* The maximum capacity varies according to the number of prints to be stapled.

See p. 4-5.

When using Z-Folding mode with Staple-Sort mode, the maximum capacity

varies according to the number of Z-folded sheet in one stapled set. See p. 4-8.

Secondary (Sub) tray: Non-sort mode

200 sheets max.

2-10 Safety Information

Page 24

Safety Information

Finisher Capacity Requirements (continued)

CAUTION:

FAILURE TO HEED THE FOLLOWING CAUTIONS MAY RESULT IN BODILY INJURY AND/OR

MACHINE DAMAGE.

❒

FINISHER PAPER CAPACITY (continued)

Booklet tray (FS-211 only)

100 sheets max. (11"x17", 8.5"x14")

(The maximum number of sheets varies, depending on the number of pages in the

booklet and whether Folding or Stapling & Folding is selected. See p. 4-7.)

❒

FS-211 FINISHER BOOKLET MODE OUTLET

Inside the Booklet mode outlet is the roller drive unit. DO NOT put your hand into it when

removing the folded or stapled & folded sheet; otherwise you may be injured.

❒

FS-111/FS-211 FINISHER PAPER EXIT OUTLET

To avoid injury when stapling large size prints, DO NOT put your hand into the open Paper

exit outlet.

❒

FS-111/FS-211 FINISHER PRIMARY (MAIN) TRAY

When printed materials are removed from the primary (main) tray of FS-111/FS-211

Finisher, the tray goes up automatically. To avoid injury, DO NOT put your hand on top of

the printed sheets. Be sure to hold both sides of the printed sheets when removing them,

and DO NOT leave your hand on the printed sheets while the primary tray goes up.

Safety Information 2-11

Page 25

Page 26

Section 3: Machine Information

Konica Force 85 Overview ...........3-2

Key Operator Functions...............3-3

Service, Repairs & Supplies...............3-3

Machine Labels...............3-3

Service Settings...............3-4

Machine Configuration ...........3-5

External Machine...............3-5

External Machine Call-outs...............3-6

Internal Machine...............3-7

Internal Machine Call-outs...............3-7

Optional Equipment...............3-8

Site Requirements .........3-17

Control Panel Layout .........3-19

Specifications .........3-20

Machine Information 3-1

Page 27

Machine Information

Konica Force 85 Overview

The Force 85 Network Printing System provides high quality printing suitable for any IBMcompatible or Macintosh environment. The printer's main body engine works in

conjunction with the new open architecture (NOA) of the print controller to provide a

flexible and modular way of customizing the language interpreter, the I/O and

communication, and the system control. NOA supports a modular based object oriented

system software that enables you to use special software modules developed for

enhancing printing capabilities and/or for adjusting the IP system to meet special

requirements.

The built-in electronic recirculating document handler (ERDH) provides dual access

capability, enabling the printer to receive a job while another job is printing or rasterizing.

This timesaving system allows you to work with optimal efficiency even when the printer is

working at peak capacity.

The advanced finishing system of the Force 85 provides you with the option of sending

print jobs to the output tray face down and in correct order.

The Force 85 printer is perfect for any work environment.

• use it as a non-network printer by connecting it to your PC with standard serial or

parallel port cabling.

• install the optional network interface card and use it as a standard network printer

supporting NetWare, AppleTalk (EtherTalk) or TCP/IP.

• install the Force 85 as a high-end network printer in an AS 400/IBM Host

Environment.

Highlights of the Force 85 include:

• 85 ppm

• 600 dpi

• duplex mode

•3 standard paper trays plus a Multi-sheet bypass tray

• LCT, Finisher and Punching/Z-Folding Unit

3-2 Machine Information

Page 28

Machine Information

Konica Force 85 Overview (continued)

Key Operator Functions

Access to the Key Operator mode may require entry of a key operator password previously

set by your service representative. A Key Operator may make various custom settings that

affect printer functions. We recommend using a password to limit access to the Key

Operator mode to an authorized person.

Service, Repairs & Supplies

Service and repairs should be performed only by an authorized service representative. To

maintain personal safety and to avoid machine damage, never disassemble the machine

for any reason. To ensure optimal printing quality, use only supplies that are recommended

by Konica Business Technologies, Inc. Use the convenient form located at the end of the

Maintenance & Supplies

Machine Labels

Machine labels are affixed to provide quick and easy instructions on loading paper, adding

toner, and clearing mishandled paper. Machine safety labels, affixed to key areas of the

internal machine, provide cautionary information to prevent personal injury or damage to

the equipment. Sample machine safety labels are shown in the

section to record all service, repair, and supply orders.

Safety Information

section.

Machine Information 3-3

Page 29

Machine Information

Konica Force 85 Overview (continued)

Service Settings

Setting changes for the following functions can be made by your service representative.

Finisher-Paper Capacity

In the default condition, the Force 85 will produce unlimited sets. If required, your service

representative can set the printer to stop printing when the number of prints exceeds

specified capacity.

Key Operator Password

Your service representative can set a 4-digit Key operator password to access the Key

Operator Mode Screen.

After this setting is made, a Password Entry Screen will be displayed when Key Operator

mode is selected from the Help Screen. The user or Key Operator will be required to enter

the valid Key Operator password before accessing the Key Operator Mode Screen. It is

recommended that the Key Operator password be noted and kept in a secure place in the

event it is forgotten. Otherwise, you will be required to contact your service representative

to obtain a password.

Weekly Timer

Your service representative can set a 4-digit Weekly timer

key operator to gain access to the Weekly Timer Setting Menu Screen.

After this setting is made, the Weekly Timer Master Key Code Screen will be displayed and

will always require entry of the set Weekly timer master key code to access the Weekly

Timer Setting Menu Screen.

Your service representative can set the weekly timer system to display the Weekly timer

key on the Help Screen which enables you to view Weekly timer settings.

Staple Sheet Capacity

Staple capacity is changeable, and may be set to 45, 40, or 35 by your service

representative.

Notice Message for ADD TONER/ PM CALL

Your service representative can set the printer message area to display “ADD TONER”

when the toner supply is low, or “PM CALL” when preventive maintenance is required.

3-4 Machine Information

master key code

to enable the

Page 30

Machine Information

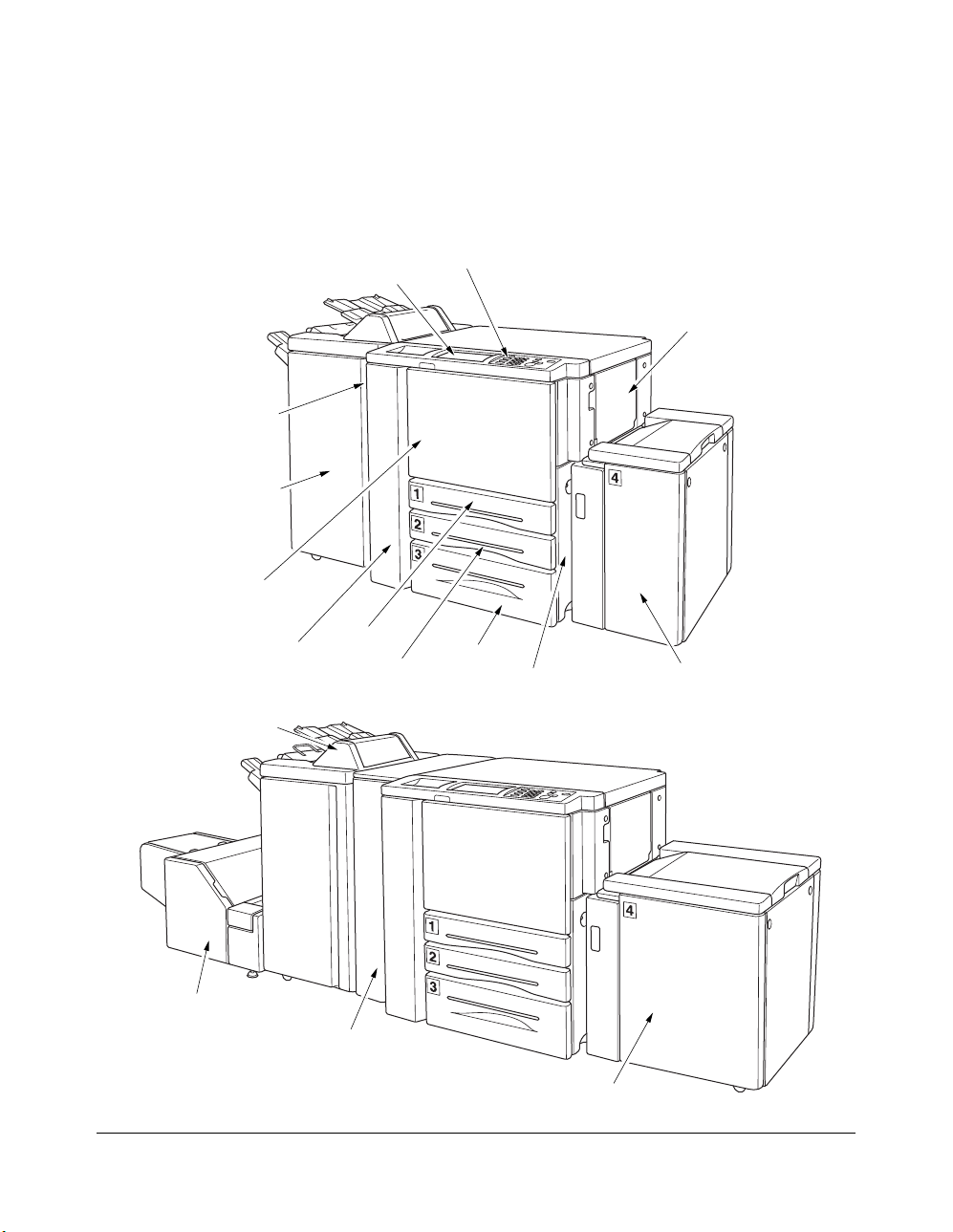

Machine Configuration

External Machine

14 LCD touch screen

13 Power switch

10 FS-111/FS-211

Finisher (option)

8 Front door

15 Control panel

1 Multi-sheet

bypass tray

7 Left door

12 Cover sheet feeder

PI-108 (option)

11 TU-108 Trimmer unit (option)

9 PU-108 Punching unit or

PZ-108 Punching / Z-Folding unit

(option)

6 Tray 1

5 Tray 2

4 Tray 3

3 Right side door

(not shown)

2 Tray 4: Large capacity tray

2 Tray 4: Large capacity tray

LT-402 (option)

LT-412 (option)

Machine Information 3-5

Page 31

Machine Information

Machine Configuration (continued)

External Machine Call-outs

1Multi-sheet bypass tray used for small quantity printing onto plain paper or special

paper.

2Tray 4: Large capacity tray LT-402/LT-412 option holds 4,000 sheets.

3 Right side door opens to allow removal of mishandled paper.

4Tray 3 (universal tray) is user-adjustable and holds 1,500 sheets of either 11"x17"/

8.5"x14"/8.5"x11"R or 5.5"x8.5".

5Tray 2 (universal tray) is user-adjustable and holds 500 sheets of either 11"x17"/

8.5"x14"/8.5"x11"R or 5.5"x8.5".

6Tray 1 (universal tray) is user-adjustable and holds 500 sheets of either 11"x17"/

8.5"x14"/8.5"x11"R or 5.5"x8.5".

NOTE: Tray 1, 2, 3, and LCT are available for loading wide types of the regular sizes specified above.

7 Left side door opens together with the front door to allow removal of mishandled

paper.

8Front door opens to the internal printer to allow clearing of mishandled paper.

9 PU-108 Punching unit (option) punches file holes in the output prints.

PZ-108 Punching / Z-Folding unit (option) punches file holes and/or Z-folds the

output prints.

10 FS-111/211 Finisher (option) sorts, staple-sorts, and groups prints into finished sets.

FS-211 also folds or staples & folds prints into booklet-styled sets.

11 TU-108 Trimmer unit (option) trims the end of booklet.

12 PI-108 Cover sheet feeder (option) loads cover sheet paper and feeds the sheet as

cover.

13 Power switch turns printer power On/Off when pressed.

14 LCD touch screen displays interactive operation screens.

15 Control panel controls printer operations.

3-6 Machine Information

Page 32

Machine Information

Machine Configuration (continued)

Internal Machine

1 Toner cartridge

7 Reset switch

6 Fixing unit

5 Drum unit

2 Toner unit

3 Conveyance fixing

unit

4 Lever A

Internal Machine Call-outs

1Toner cartridge holds toner and is replaced when replenishing toner.

2Toner unit holds the toner supply.

3 Conveyance fixing unit passes the paper through the drum unit, and fuses the toner

onto the print paper, and is to be withdrawn for removal of mishandled paper.

4Lever A can be moved to withdraw the conveyance fixing unit for removal of

mishandled paper.

5 Drum unit forms the print image.

6 Fixing unit fuses the toner onto the print paper.

7 Reset switch used only by service representative turns machine power on/off when

pressed.

Machine Information 3-7

Page 33

Machine Information

Machine Configuration (continued)

Optional Equipment

PI-108 Cover sheet feeder

FS-111 Finisher

VI-602 Video interface kit

MU-401/402 Memory unit

FS-211 Finisher

TU-108 Trimmer unit

3-8 Machine Information

Force 85 main body

IP-602 Printer controller

PS-362 Postscript kit

KN-306 Network Board

PU-108 Punching unit or

PZ-108 Punching / Z-Folding unit

LT-402 Large capacity tray

LT-412 Large capacity tray

Page 34

Machine Information

Machine Configuration (continued)

Optional Equipment (continued)

5 Secondary

(Sub) tray

1 Finisher door

6 Secondary (Sub) tray cover6 Secondary (Sub) tray cover

5 Secondary

(Sub) tray

1 Finisher door

4 Primary

(Main) tray

FS-111 Finisher

4 Primary

(Main) tray

2 Booklet mode outlet

3 Booklet tray

FS-211 Finisher

1 Finisher door opens to the internal Finisher to allow clearing mishandled paper and

replenishing staples.

2 Booklet mode outlet (FS-211 Finisher only) outputs finished printed sets when

selecting Folding mode or Stapling & Folding mode.

3 Booklet tray (FS-211 Finisher only) holds sets output in Folding mode or Stapling &

Folding mode.

4 Primary (Main) tray holds sets output in Non-sort mode, Sort mode (offset), Staple-

sort mode, or Group mode (offset).

5 Secondary (Sub) tray holds sets output in Non-sort mode or Group mode with face

down/up mode.

6 Secondary (Sub) tray cover opens to allow clearing mishandled paper.

Machine Information 3-9

Page 35

Machine Information

Machine Configuration (continued)

Optional Equipment (continued)

1 Upper lever

2 Upper knob

3 Right lever

4 Left lever

5 Stacker unit

6 Stacker unit

handle

6 Stacker unit handle

9 Cartridge housing

9 Cartridge housing

FS-111 Finisher

FS-211 Finisher

1 Upper lever

2 Upper knob

3 Right lever

4 Left lever

5 Stacker unit

6 Stacker unit

handle

7 Lower lever

8 Knob

6 Stacker unit handle

1 Upper lever opens upward to remove mishandled paper.

2 Upper knob can be turned to ease removal of mishandled paper.

3 Right lever opens to remove mishandled paper.

4 Left lever opens to remove mishandled paper.

5 Stacker unit holds stapler, and also holds the device to provide Folding and

Stapling&Folding mode in FS-211.

6 Stacker unit handle withdraws unit to allow removal of mishandled paper and

replacement of staple cartridge.

7Lower lever opens to remove mishandled paper.

8 Knob can be turned to ease removal of mishandled paper.

9 Cartridge housing holds staple cartridge and is to be replaced when supplying

staples.

3-10 Machine Information

Page 36

Machine Information

Machine Configuration (continued)

Optional Equipment (continued)

2 Cover sheet feeder

3 Cover sheet feeder

guide plates

1 Manual finishing

operation panel

1Manual finishing operation panel controls cover sheet feeder operations.

2Cover sheet feeder holds cover sheets for use in cover sheet output mode.

3Cover sheet feeder guide plates hold cover sheets to fix the position.

Machine Information 3-11

Page 37

Machine Information

Machine Configuration (continued)

Optional Equipment (continued)

w LCT left

side door

r LCT paper guides

q LCT top door

e LCT levere LCT lever

y LCT bottom plate

t Paper loading

u Rear stopper

w LCT left

side door

r LCT paper guides

button

q LCT top door

y LCT bottom plate

u Rear stopper

t Paper loading

button

LT-402 Large capacity tray

LT-412 Large capacity tray

1 LCT top door opens to allow paper loading.

2 LCT left side door opens to allow removal of mishandled paper.

3 LCT lever can be moved downward to ease removal of mishandled paper.

4 LCT paper guides hold print paper to fix the position.

5Paper loading button is pressed to lower the bottom plate to allow loading paper.

6 LCT bottom plate goes up automatically when paper supply becomes low, and goes

down when the paper loading button is pressed.

7 Rear stopper fixes the rear end of print paper.

3-12 Machine Information

Page 38

Machine Information

Machine Configuration (continued)

Optional Equipment (continued)

FS-211 Finisher

5 Tr immer stacker cover

4 Tr immer unit tray

1 Front-right cover

2 Front door

3 Tr immer stacker

1Front-right cover opens to allow removal of mishandled paper.

2Front door opens to allow removal of mishandled paper or waste paper.

3Trimmer stacker holds sets output in Trimming mode.

4Trimmer unit tray slides to the left side each time a trimmed booklet is delivered.

5Trimmer stacker cover opens to allow you to take out the finished sets.

NOTE: DO NOT place heavy objects on the trimmer stacker or apply any weight on it, and DO NOT use it for

storage.

Excessive weight applied to the inside or outside of the trimmer stacker will damage the equipment.

Machine Information 3-13

Page 39

Machine Information

Machine Configuration (continued)

Optional Equipment (continued)

1 Tr immer unit knob

3 Tr immer pressure

release lever

2 Tr ash basket

1Trimmer unit knob can be turned to ease removal of mishandled paper.

2Trash basket holds waste paper cut off from the booklets.

3Trimmer pressure release lever opens to allow removal of mishandled paper.

3-14 Machine Information

Page 40

Machine Information

Machine Configuration (continued)

Optional Equipment (continued)

3 Upper lever

1 Punching unit

front door

4 Knob

5 Left lever

6 Tr ash basket

2 Right lever

1 Punching unit front door opens to allow removal of mishandled paper or waste

paper.

2 Right lever opens to allow removal of mishandled paper.

3 Upper lever opens to allow removal of mishandled paper.

4 Knob can be turned to ease removal of mishandled paper.

5 Left lever opens to allow removal of mishandled paper.

6Trash basket holds waste paper punched out.

Machine Information 3-15

Page 41

Machine Information

Machine Configuration (continued)

Optional Equipment (continued)

3 Knob

2 Right lever

1 Punching / Z-Folding

unit front door

4 Handle

5 Left lever

6 Tr ash basket

1 Punching / Z-Folding unit front door opens to allow removal of mishandled paper

or waste paper.

2 Right lever opens to allow removal of mishandled paper.

3 Knob can be turned to ease removal of mishandled paper.

4 Handle can be withdrawn to allow removal of mishandled paper.

5 Left lever opens to allow removal of mishandled paper.

6Trash basket holds waste paper punched out.

3-16 Machine Information

Page 42

Machine Information

Site Requirements

18.7

(475)

34.9

(887)

15.75

(400)

61.4

(1560)

37.4

(950)

Unit: inches (mm)

30.5

(775)

4.7

(120)

3.9

(100)

43.1

(1095)

12.7

(322)

39.0

(990)

21.5

(546)

67.3

(1711)

92.1

(2341)

1

2

3

69.4

(1762)

72.6

(1845)

Force 85

Unit: inches (mm)

72.6

(1845)

30.5

(775)

4.7

(120)

37.4

3.9

(100)

34.9

(887)

11

2

3

15.2

(386)

4

24.8

(630)

39.0

(990)

61.4

(1560)

(950)

Force 85 + FS-111/211 + LT-402

Machine Information 3-17

Page 43

Machine Information

Site Requirements (continued)

5.9

(150)

43.1

(1095)

44.05

(1118)

21.5

(546)

6.9

(174)

34.9

(887)

24.65

(626)

3.9

(100)

39.0

(990)

61.4

(1560)

37.4

(950)

Unit: inches (mm)

30.5

(775)

4.7

(120)

111.35

(2828)

141.8

(3601)

30.45

(773)

72.6

(1845)

Force 85 + FS-211 + PU-108/PZ-108 + TU-108 + LT-412

NOTES:

1 Dimensions are in inches with millimeters included in parentheses.

2 The Finisher main tray of the FS-111/211 Finisher gradually goes down while printed material is output.

DO NOT allow any object to interfere with the operation of the tray on the left side of the Finisher, as interference may cause damage to the Finisher.

3-18 Machine Information

Page 44

Machine Information

Control Panel Layout

124

CHECK

3

HELP

56

COUNTER

11

CLEAR QTY.

START

910

STOP/PAUSE

7

TIMER

POWER SAVER

ON / OFF

8

1 LCD touch screen displays machine and printing status, help information, interactive

screens, and touch keys for selecting all functions.

2 CHECK displays a screen showing all settings that are selected for the current job.

3 MODE switches the machine operation mode.

4 HELP displays a screen with help for the currently selected function, or to access the

Key Operator Mode Screen.

5 Keypad enters numeric values.

6 STOP/PAUSE stops the printing sequence; deletes the stored memory.

7 TIMER lights when the timer function is set.

8 POWER SAVER ON/OFF activates power-saving mode for times when the printer is

inactive, or activates timer interrupt mode when weekly timer function is active.

9 START restarts printing after mishandled paper is cleared or the paper tray is

replenished with paper.

10 CLEAR QTY. allows resetting of print quantity.

11 [P] (counter) displays the Counter Screen or accesses programming modes for

setting special functions.

Machine Information 3-19

Page 45

Machine Information

Specifications

Product Name Konica Force 85 Network Printing System

Engine Type Dual Beam Laser, Electrostatic

Engine Speed 65 pages per minute

Recommended Operating Environment 50°~86°F (10°~30°C); 10~80% RH

Warm Up Approx. 6 min. @68°(20°C); 50% RH

First Print Out Time Approx. 3.3 sec. for 8.5"x11"

Voltage 208 ~ 240V AC14 to 10.6%

Current 17.6A Dedicated line recommended

Frequency 60Hz

Grounding Isolation recommended

Power Consumption Max. 3,840 VA (full option)

Noise Level (full system) Approx. 78 dB (A) or less, during printing

Toner Black, cartridge type

Paper Source Main body trays 1/2/3; 500/500/1,500 sheets

LCT tray 4; 4,000 sheets

Multi-sheet bypass tray; 150 sheets

Tr ay 1/2/3 user adjustable

LCT adjusted by your service representative

Main Body Safety Standard UL 1950; CSA 22.2 No. 950-95

Laser Safety Standard FDA: 21CFR Chapter 1. Subchapter J

3-20 Machine Information

Paper Exit Tray 100 sheets (20 lb)

Paper Weight 16 lb~24 lb bond recommended

(Max. range: 16 lb~110 lb (200 g/m

in duplex mode, 13 lb~15 lb in simplex mode)

OHP sheet, Transparency, Labels, Tab, 3-hole

Radio Interference FCC Rules part 15, sub-part B Class A

ICES 003. issue 3 Class A

Specifications Subject To Change Without Notice

2

thick paper)

Page 46

Machine Information

Specifications (continued)

Machine Weight 569 lb (258.5 kg)

Machine Dimensions Main Body

Options Finisher (FS-111/FS-211)

Cover Sheet Feeder (PI-108)

Tr immer Unit (TU-108)

Punching Unit (PU-108)

Punching / Z-Folding Unit (PZ-108)

Large Capacity Tray (LCT) (LT-402/LT-412)

Image Processor (IP-602)

PostScript Unit (PS-362)

Network Board (KN-306)

Key Counter

+176 lb (80 kg) w/FS-211 Finisher

+143 lb (65 kg) w/FS-111 Finisher

+11 lb (5 kg) w/PI-108 Cover sheet feeder

+77.2 lb (35 kg) w/PU-108 Punching unit

+83.6 lb (38 kg) w/PZ-108 Punching / Z-Folding unit

+66 lb (30 kg) w/LCT (LT-402)

+93 lb (42 kg) w/LCT (LT-412)

Width: 34.9 in. (887 mm)

Depth: 30.5 in. (775 mm)

Height: 39.0 in. (990 mm)

Stapler-Finisher (FS-111/211)

Width: 21.4 in. (544 mm)

Depth: 25.8 in. (656 mm)

Height: 43.1 in. (1095 mm)

Cover Sheet Feeder (PI-108)

Width: 13.0 in. (330 mm)

Depth: 18.0 in. (456 mm)

Height: 4.7 in. (120 mm)

Tr immer Unit (TU-108)

Width: 44.0 in. (1117 mm)

Depth: 23.8 in. (604 mm)

Height: 22.1 in. (562 mm)

Punching Init (PU-108)

Width: 6.7 in. (169 mm)

Depth: 26.0 in. (660 mm)

Height: 36.6 in. (930 mm)

Specifications Subject To Change Without Notice

Machine Information 3-21

Page 47

Machine Information

Specifications (continued)

Automatic Duplex Unit (ADU)

Stapling Finisher (FS-111/211) Power source: Main body

Staple Cartridge 5000 staples/cartridge

Punching / Z-Folding Unit (PZ-108)

Width: 6.7 in. (169 mm)

Depth: 26.0 in. (660 mm)

Height: 36.6 in. (930 mm)

Paper size: 11"x17", 8.5"x14", 8.5"x11", 5.5"x8.5"

Paper weight: 16~45 lb

Non-stack type

Non-sort/Sort/Group mode:

500 sheets 5.5"x8.5"/R

3000 sheets 8.5"x11"/R

1500 sheets 11"x17", 8.5"x14"

Size 11"x17" ~ 5.5"x8.5"R

Staple-sort mode:

1000 sheets*

Size 11"x17" ~ 8.5"x11"/R, 5.5"x8.5"

*Variable according to the number of pages to

be stapled. See p. 4-5 for detail.

Folding/Stapling & Folding mode (FS-211 only):

100 sheets (11"x17", 8.5"x14")

75 sheets (8.5"x11"R, A4R)

Size 11"x17", 8.5"x14", 8.5"x11"R, A4R (8.27" x

11.69", 210 mm x 297 mm)

* The maximum number of sheets varies,

depending on the number of pages in the

booklet and whether Folding or Stapling &

Folding is selected. See p. 4-6~p. 4-7.

Three-Folding mode (FS-211 only):

50 sheets (folding one sheet in three)

Size 8.5"x11"R, A4R (8.27"x11.69", 210 mm x

297 mm)

3-22 Machine Information

Specifications Subject To Change Without Notice

Page 48

Machine Information

Specifications (continued)

Cover Sheet Feeder (PI-108) Power source: Finisher

Tr immer Unit (TU-108) Paper size: 11"x17", 8.5"x14", 8.5"x11"R, A4R

Punching Unit (PU-108) Paper size: 11"x17", 8.5"x11"

Paper size: 11"x17", 8.5"x14", 8.5"x11",

8.5"x11"R, 5.5"x11", 5.5"x11"R, A4, A4R (8.27"

x 11.69", 210 mm x 297 mm)

Paper weight in cover sheet mode: 13 ~ 110 lb

(200 g/m2 thick paper)

Paper weight in manual staple: 16 ~ 24 lb

(8.27" x 11.69", 210 mm x 297 mm)

Paper weight: 16 ~ 45 lb

* One 110 lb cover paper (200 g/m2 thick paper) is

available.

Number of trimmed sheets:

3 sheets max. with Folding mode

16 sheets max. with Stapling&Folding mode

(15 sheets max. when using a thick cover)

Tr immed width: 10 mm max.

Stack capacity: 512 sheets max.

* The maximum number of sheets varies,

depending on the number of pages in the

booklet and whether Folding or Stapling &

Folding is selected. See p. 4-6~p. 4-7.

Power source: supply from outlet

Paper weight: 16 ~ 45 lb

Number of holes: 3 holes

Hole diameter: 0.315" ± 0.020" (8 mm ± 0.5 mm)

Hole pitch: 4.252" ± 0.020" (108 mm ± 0.5 mm)

Weight: 77 lb (35 kg)

Power source: supply from outlet

Specifications Subject To Change Without Notice

Machine Information 3-23

Page 49

Machine Information

Specifications (continued)

Punching / Z-Folding Unit (PZ-108) Paper size: (Punching) 11"x17", 8.5"x11"

(Z-Folding) 11"x17", 8.5"x14"

Paper weight: 16 ~ 45 lb (16 ~ 24 lb for Z-Folding

mode)

(Punching mode)

Number of holes: 3 holes

Hole diameter: 0.315" ± 0.020" (8 mm ± 0.5 mm)

Hole pitch: 4.252" ± 0.020" (108 mm ± 0.5 mm)

(Z-Folding mode)

Folding type: Z-folding for 11"x17", doublefolding for 8.5"x14"

Folded width: 215 mm or less for 11"x17"

261.6 mm or less for 8.5"x14"

Weight: 83.6 lb (38 kg)

Power source: supply from outlet

Large Capacity Tray (LT-402) Paper type: Plain paper (13~110 lb (200 g/m2

thick paper))

Paper size: 8.5"x11", A4

Dimensions: Width 16.9 in (430 mm)

Depth 25.2 in (639 mm)

Height 27.2 in (690 mm)

Weight: 66 lb (30 kg)

Power source: supply from main body

Large Capacity Tray (LT-412) Paper type: Plain paper (13~110 lb (200 g/m2

3-24 Machine Information

thick paper))

Paper size: 11"x17", 8.5"x14", 8.5"x11",

8.5"x11"R, A3, B4, A4, A4R

Dimensions: Width 26.4 in (670 mm)

Depth 25.2 in (639 mm)

Height 27.4 in (695 mm)

Weight: 92.4 lb (42 kg)

Power source: supply from main body

Specifications Subject To Change Without Notice

Page 50

Section 4: Media Information

Main Body Trays ...........4-2

LT-402 Large Capacity Tray (Option) ...........4-3

LT-412 Large Capacity Tray (Option) ...........4-3

Automatic Duplex Unit ...........4-4

Multi-Sheet Bypass Tray ...........4-4

FS-111/211 Finisher (Option) ...........4-5

FS-111/211 Finisher Primary (Main) Tray...............4-5

FS-111/211 Finisher Secondary (Sub) Tray...............4-5

FS-211 Finisher Booklet Tray...............4-6

PI-108 Cover Sheet Feeder (Option) ...........4-7

TU-108 Trimmer Unit (Option) ...........4-7

PU-108 Punching Unit (Option) ...........4-7

PZ-108 Punching / Z-Folding Unit (Option) ...........4-8

Paper Supply Message ...........4-9

Paper Weight Compatibility Chart .........4-10

Media Information 4-1

Page 51

Media Information

Main Body Trays

Paper Size: STD size: 11"x17", F4, 8.5"x14", 8.5"x11", 8.5"x11"R, 5.5"x8.5", A3,

B4, A4, A4R, B5, B5R, A5 (user-adjustable)

STD size (spec.): Detects A4R or F4 instead of 8.5"x11"R, 5.5"x8.5"R

instead of 5.5"x8.5"

Non STD size: Max. 314 mm x 459 mm and min. 210 mm x 140 mm

Wide paper: 11"x17"W, 8.5"x11"W, 8.5"x11"WR, 5.5"x8.5"W, A3W,

B4W, A4W, A4WR, B5W, A5W (user-adjustable)

NOTES: • F4: 8"x13", 203 mm x 330 mm

Paper Weight: General tray: 16~24 lb

NOTE: Paper type setting for each tray can be made in the Key Operator mode. See p. 9-18 ~ p. 9-19.

Paper Capacity: Tray 1/2: 500 sheets 20 lb/ user-adjustable to any standard/wide size

A3: 11.69"x16.54", 297 mm x 420 mm

B4: 10.11"x14.33", 257 mm x 364 mm

A4: 8.27"x11.69", 210 mm x 297 mm

B5: 7.17"x10.11", 182 mm x 257 mm

A5: 5.85"x8.27", 148 mm x 210 mm

• A5 print paper is available in portrait orientation loading only.

• STD size (spec.)/Non STD size/Wide paper setting for each tray can be made in the Key Operator

mode. See p. 9-18 ~ p. 9-19.

Tr ay specified as Thick1: 25~45 lb

Tr ay specified as Thick2: 46~110 lb (200 g/m2 thick paper)

Tr ay specified as Thin: 13~15 lb (simplex mode only)

Tr ay specified as Tab paper: 25~45 lb (simplex mode only)

from 11"x17"/W~5.5"x8.5"/W

Tr ay 3: 1,000 sheets 20 lb/ user-adjustable to any standard/wide size

from 11"x17"/W~5.5"x8.5"/W

2,150 sheets, including 150-sheet Multi-Sheet Bypass Tray

NOTE: Reliability and print quality are not guaranteed for all special papers. Use only paper that is

recommended by Konica.

4-2 Media Information

Page 52

Media Information

LT-402 Large Capacity Tray (Option)

Paper Size: 8.5"x11" fixed (can be changed to the following sizes)

STD size: 8.5"x11", A4 (service-adjustable)

STD size (spec.): cannot be specified

Non STD size: Max. 314 mm x 223 mm and min. 257 mm x 182 mm

Wide paper: 8.5"x11"W, A4W (service-adjustable)

NOTE: Non STD size setting for LCT can be made in the Key Operator mode. See p. 9-18 ~ p. 9-19

.

Paper Weight: 16~24 lb

LCT specified as Thick1: 25~45 lb

LCT specified as Thick2: 46~110 lb (200 g/m2 thick paper)

LCT specified as Thin: 13~15 lb (single-sided print mode only)

LCT specified as Tab paper:25~45 lb (single-sided print mode only)

NOTE: Paper type setting for LCT can be made in the Key Operator mode. See p. 9-18 ~ p. 9-19.

Paper Capacity:

LT-412 Large Capacity Tray (Option)

4,000 sheets 20 lb/ fixed to standard/wide size 8.5"x11"/W or A4/W

6,150 sheets, including three Main body trays and 150-sheet Multi-Sheet

Bypass Tray

Paper Size: 11"x17" fixed (can be changed to the following sizes)

STD size: 11"x17", F4, 8.5"x14", 8.5"x11", 8.5"x11"R, A3, B4, A4, A4R

(service-adjustable)

STD size (spec.): cannot be specified

Non STD size: Max. 314 mm x 459 mm and min. 257 mm x 182 mm

Wide paper: 11"x17"W, F4W, 8.5"x14"W, 8.5"x11"W, 8.5"x11"WR, A3W,

B4W, A4W, A4WR (service-adjustable)

Paper Weight: 16~24 lb

LCT specified as Thick1: 25~45 lb

LCT specified as Thick2: 46~110 lb (200 g/m2 thick paper)

LCT specified as Thin: 13~15 lb (single-sided print mode only)

LCT specified as Tab paper:25~45 lb (single-sided print mode only)

NOTE: Paper type setting for LCT can be made in the Key Operator mode. See p. 9-18~ p. 9-19.

Paper Capacity: 4,000 sheets 20 lb/ fixed to standard/wide size 11"x17"/W, F4/W, 8.5"x14"/W,

8.5"x11"/W, 8.5"x11"R/W, A3/W, B4/W, A4/W, or A4R/W

6,150 sheets, including three Main body trays and 150-sheet Multi-Sheet

Bypass Tray

NOTE: Reliability and print quality are not guaranteed for all special papers. Use only paper that is

recommended by Konica.

Media Information 4-3

Page 53

Media Information

Automatic Duplex Unit

Paper Size: STD size: 11"x17" ~ 5.5"x8.5"

STD size (spec.): 11"x17" ~ 5.5"x8.5"

Wide paper: 11"x17"W ~ 5.5"x8.5"W

NOTE: 5.5"x8.5"/W print paper is available in portrait orientation feeding only.

Paper Weight: 16~110 lb (200 g/m2 thick paper)

Multi-Sheet Bypass Tray

Paper Size: STD size: 11"x17", 8.5"x14", 8.5"x11", 8.5"x11"R, 5.5"x8.5",

5.5"x8.5"R, A3, B4, A4, B5, B5R

STD size (spec.): F4, A4R, A5, A5R

Non STD size: Max. 314 mm x 459 mm and min. 100 mm x 148 mm

Wide paper: 11"x17"W, 8.5"x11"W, 8.5"x11"WR, 5.5"x8.5"W,

5.5"x8.5"WR, A3W, B4W, A4W, A4WR, B5W, B5WR,

A5W, A5WR

Paper Weight: General mode: 16~24 lb

Thick mode: 25~110 lb (200 g/m2 thick paper)

Thin mode: 13~15 lb

Tab paper mode: 25~45 lb

OHP transparencies, labels, hole punch, and rag content can be loaded.