Page 1

FIXING UNIT

FIXING UNIT

Caution:

When disassembling and reassembling

the machine, Be sure the power cord has

been unplugged from the wall outlet.

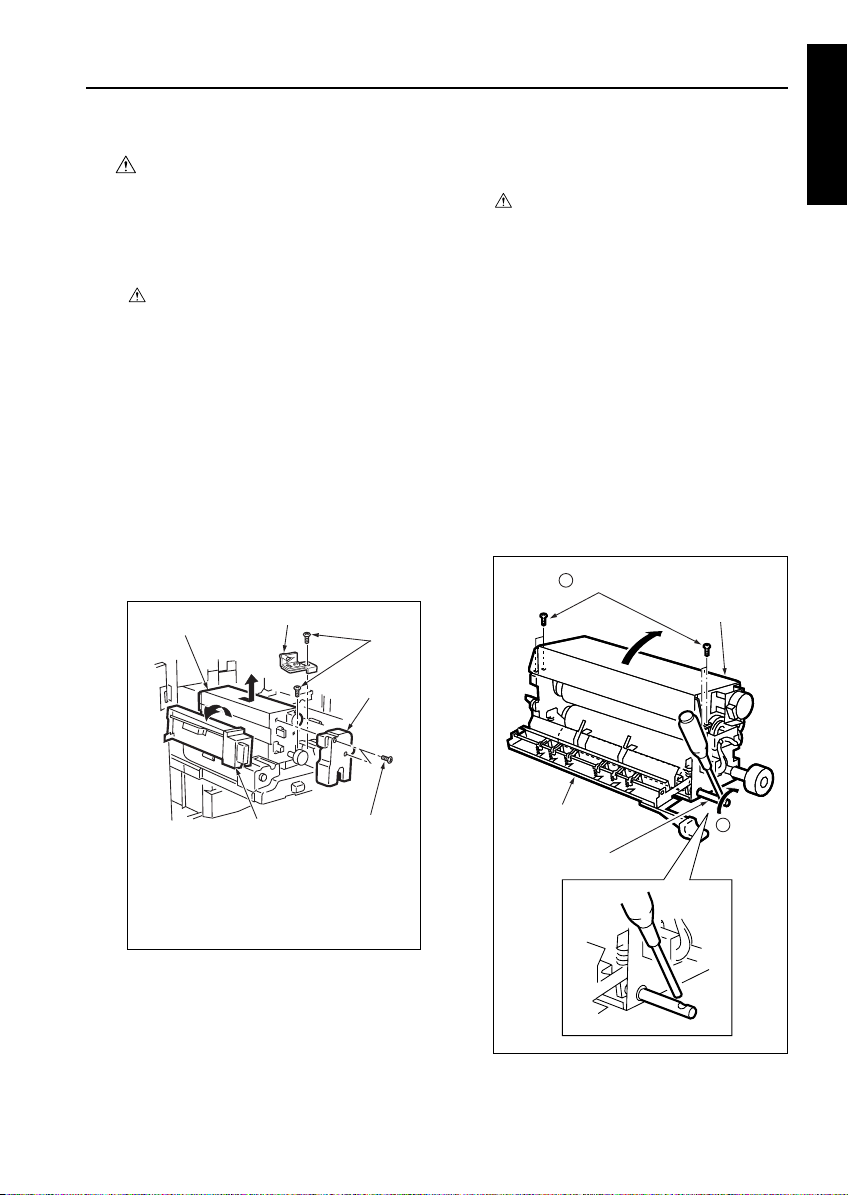

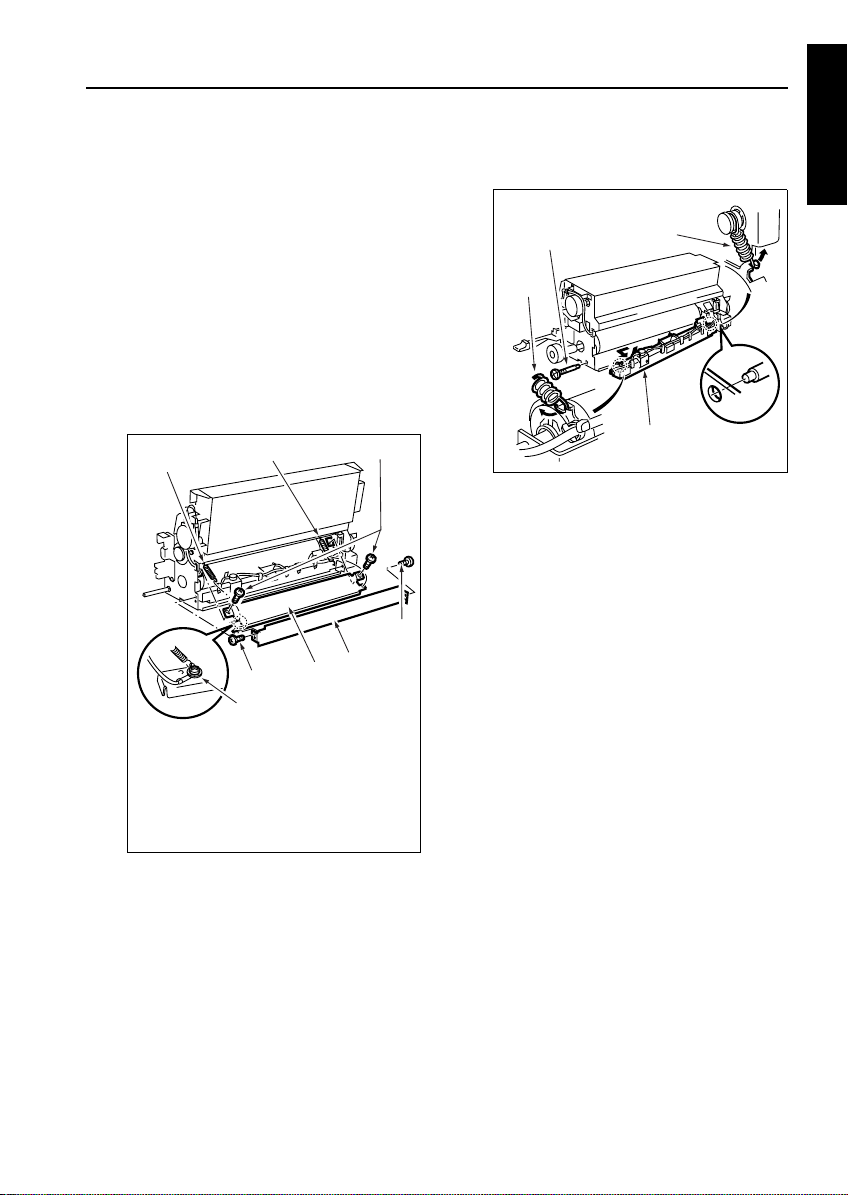

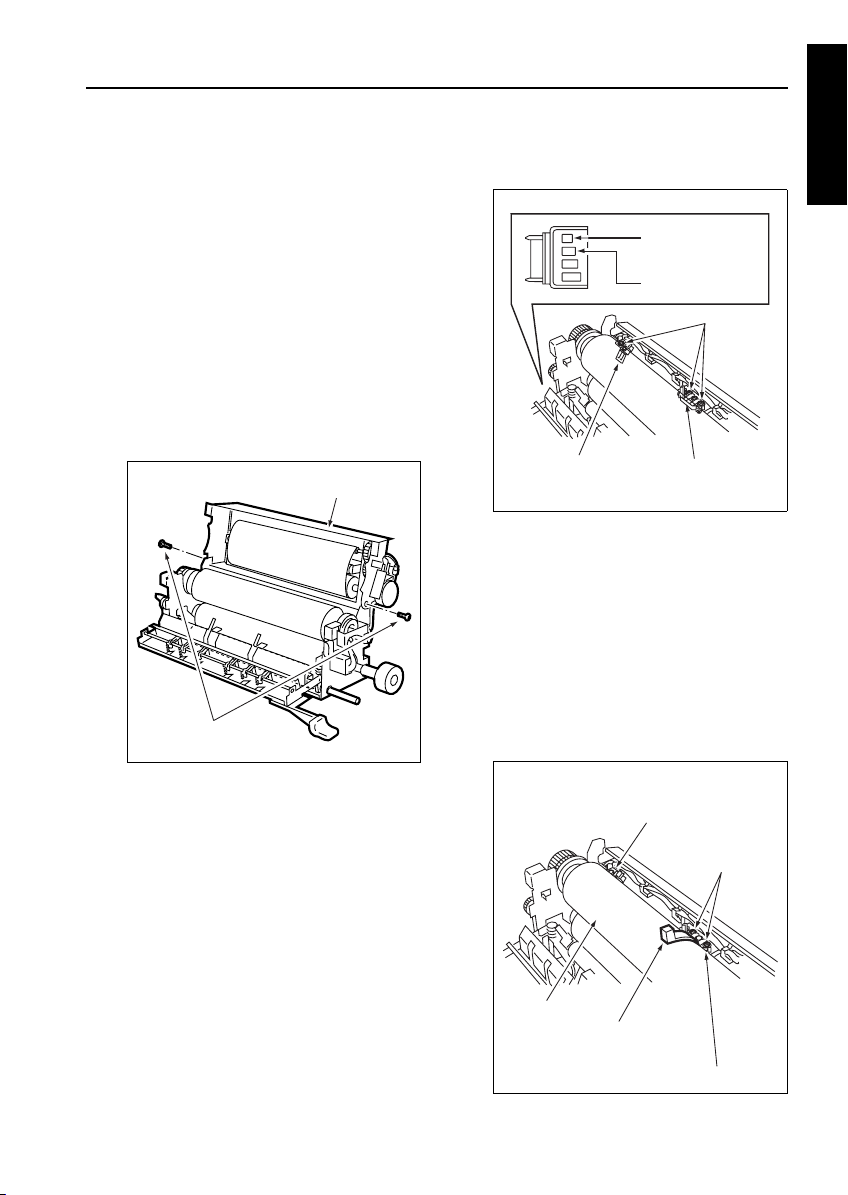

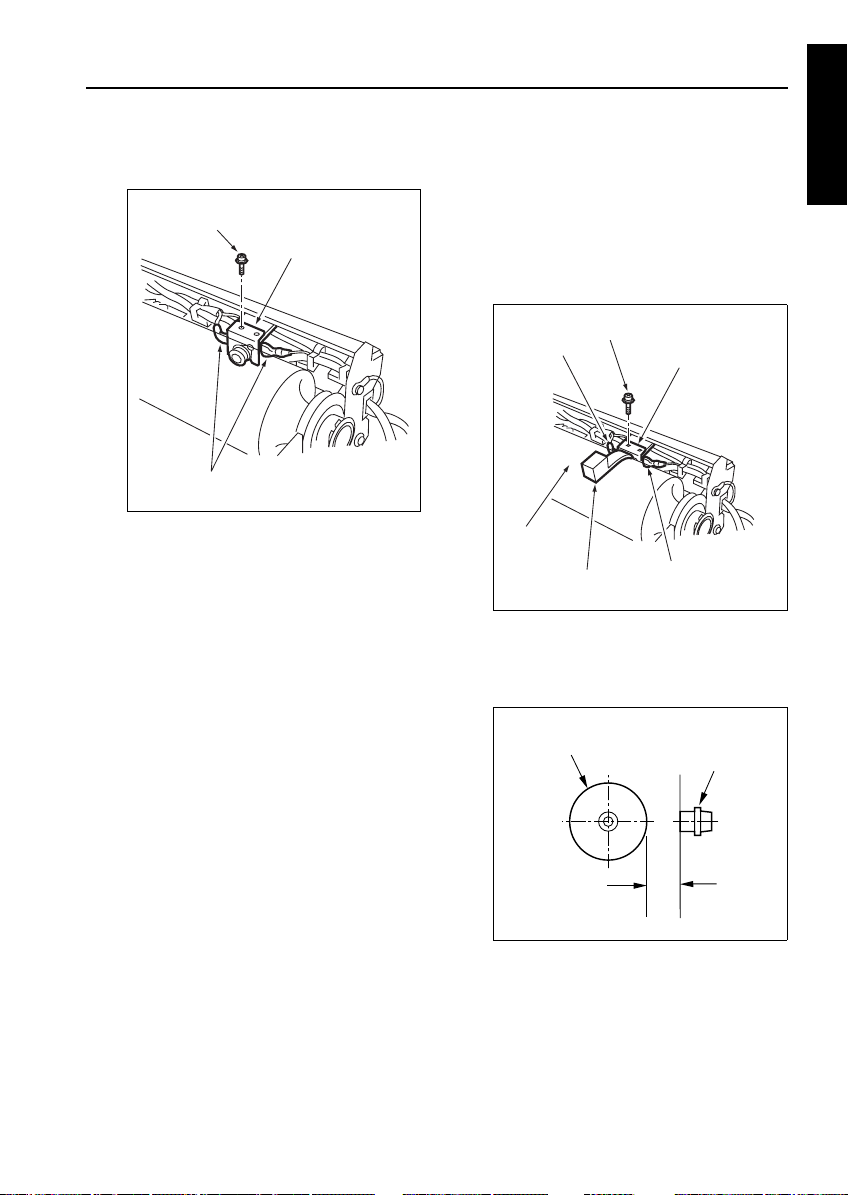

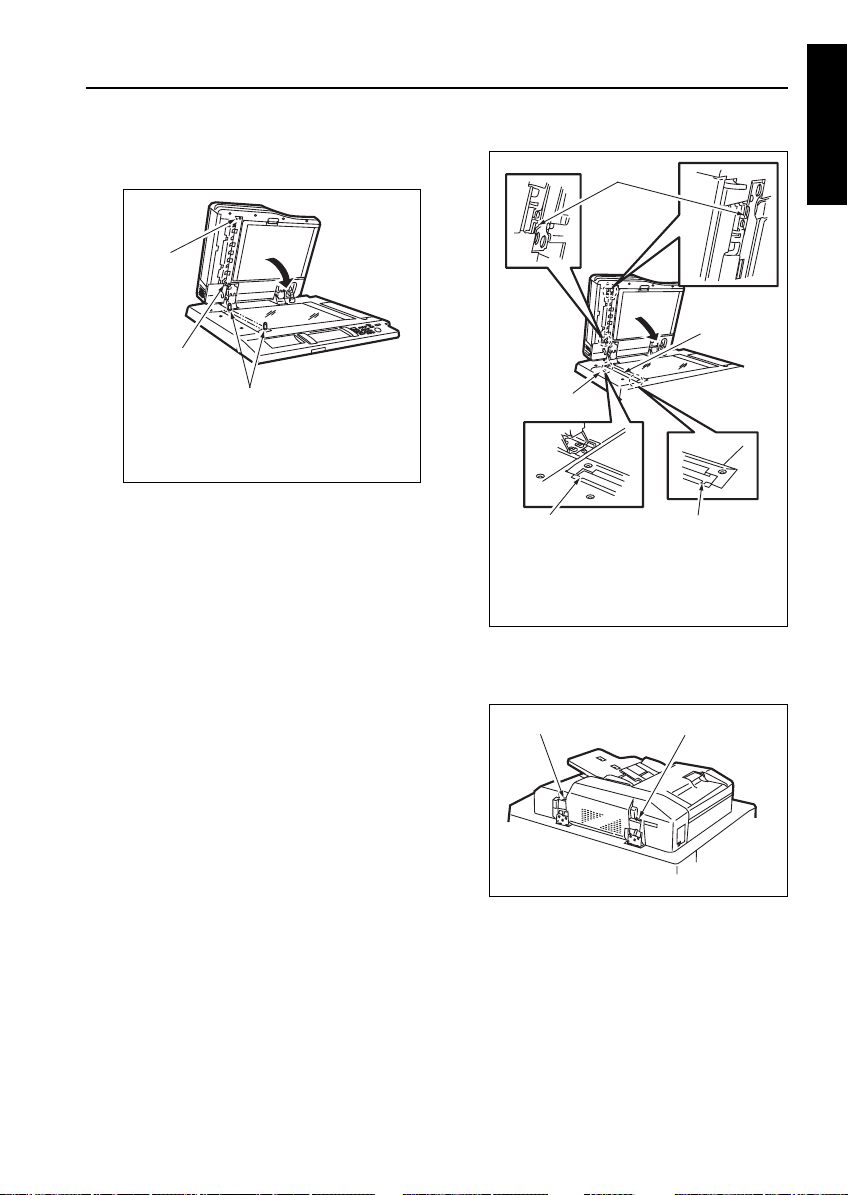

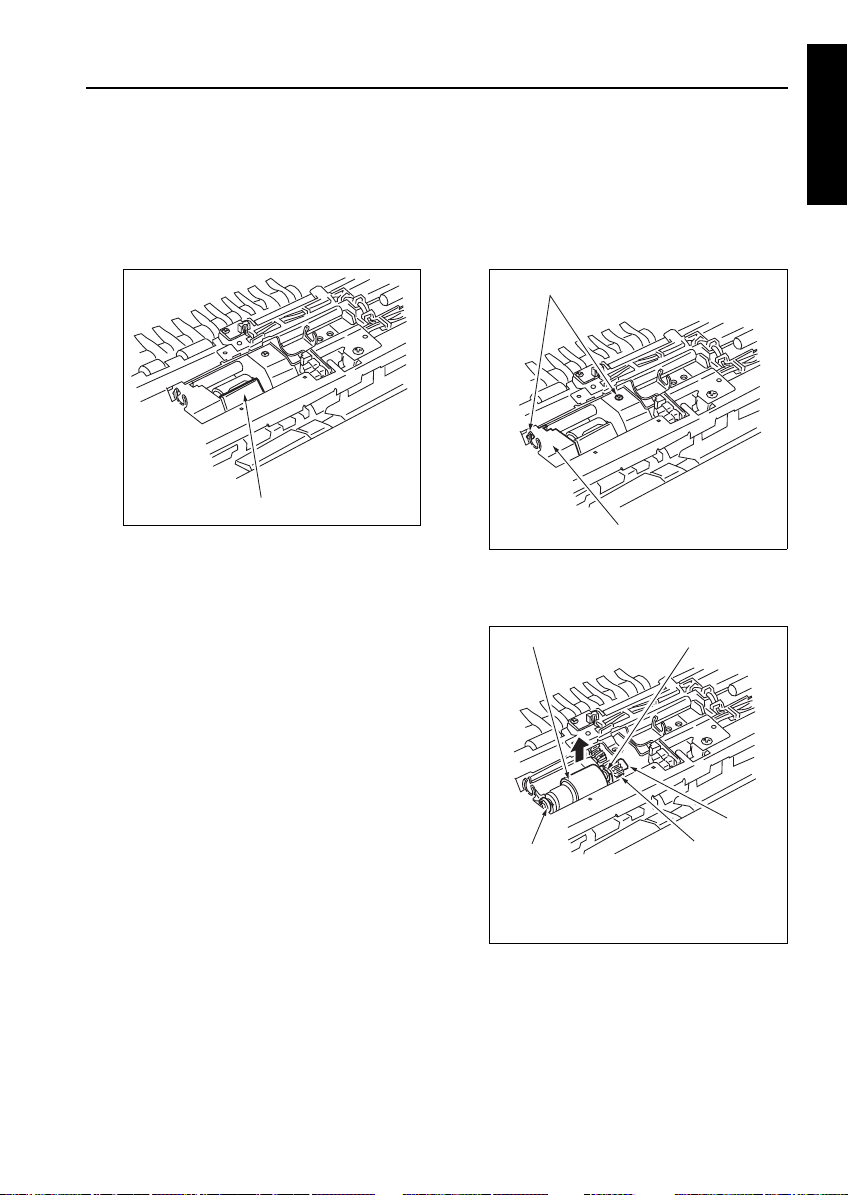

[1] Removing and Reinstalling the Fixing

Unit

Caution: Do not touch the fixing unit

a. Procedure

(1) Draw out the ADU stand. (See “ADU UNIT.”)

(2) Loosen two screws and detach the fixing unit

front cover.

(3) Open the paper reverse/exit unit.

(4) Remove one screw to detach the inlet guide plate

push-down lever.

(5) Remove one screw to draw out the fixing unit.

Then, remove it upward.

immediately after turning OFF

the main switch because it is

very hot and you may suffer

burns. Wait until the fixing

unit has cooled down sufficiently before working on it.

1

2

3

4

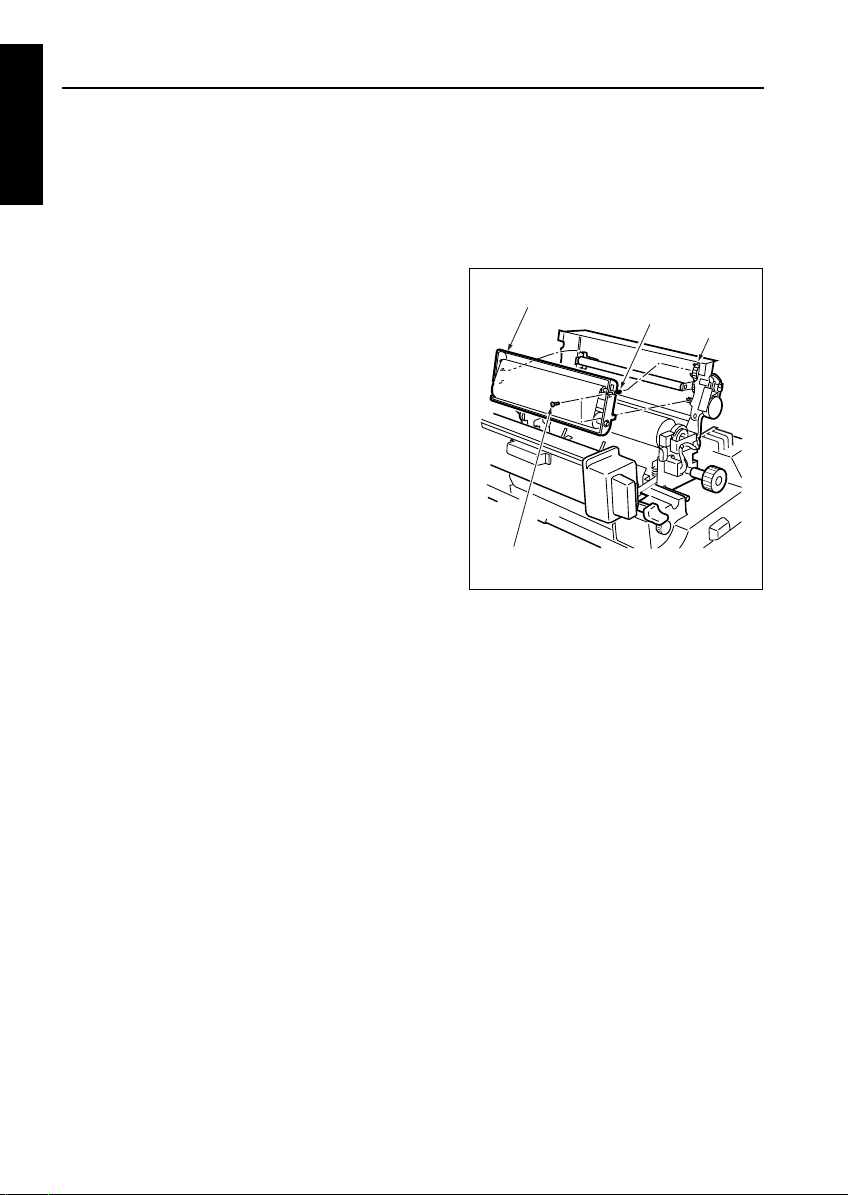

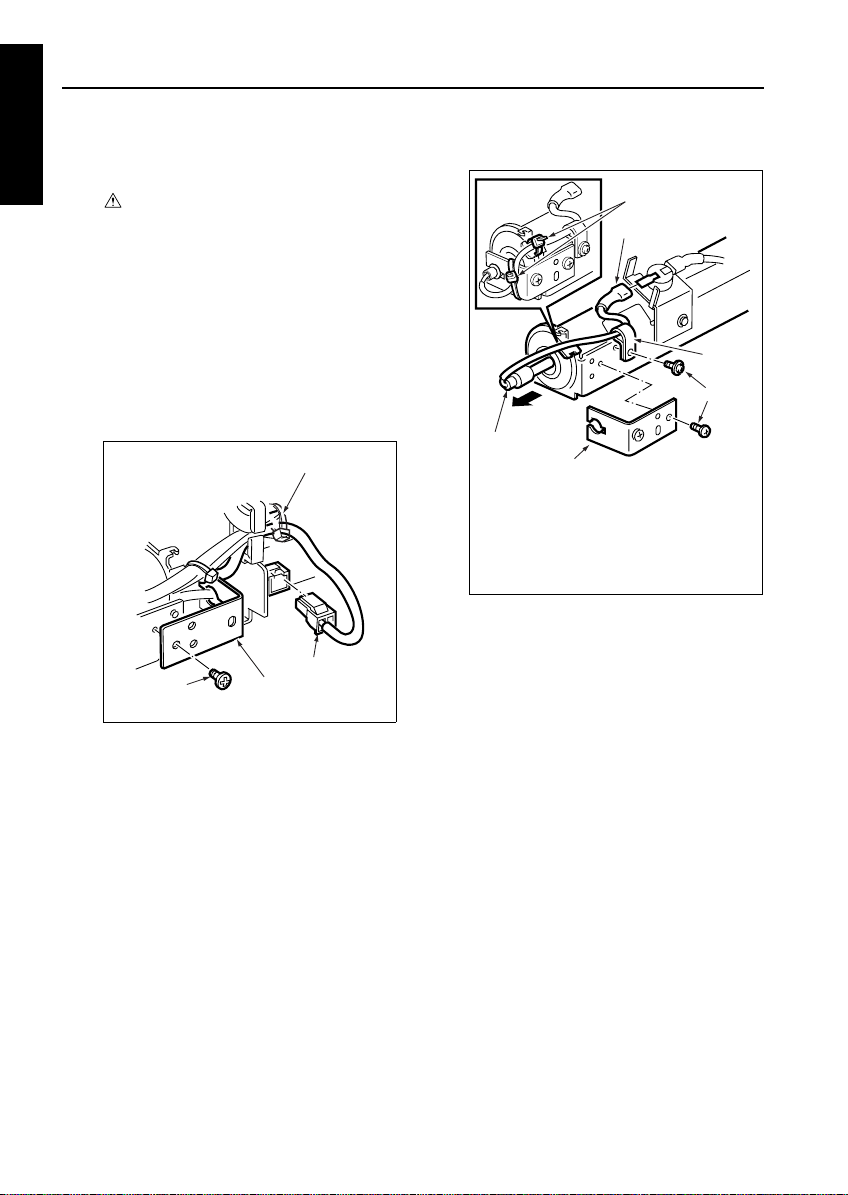

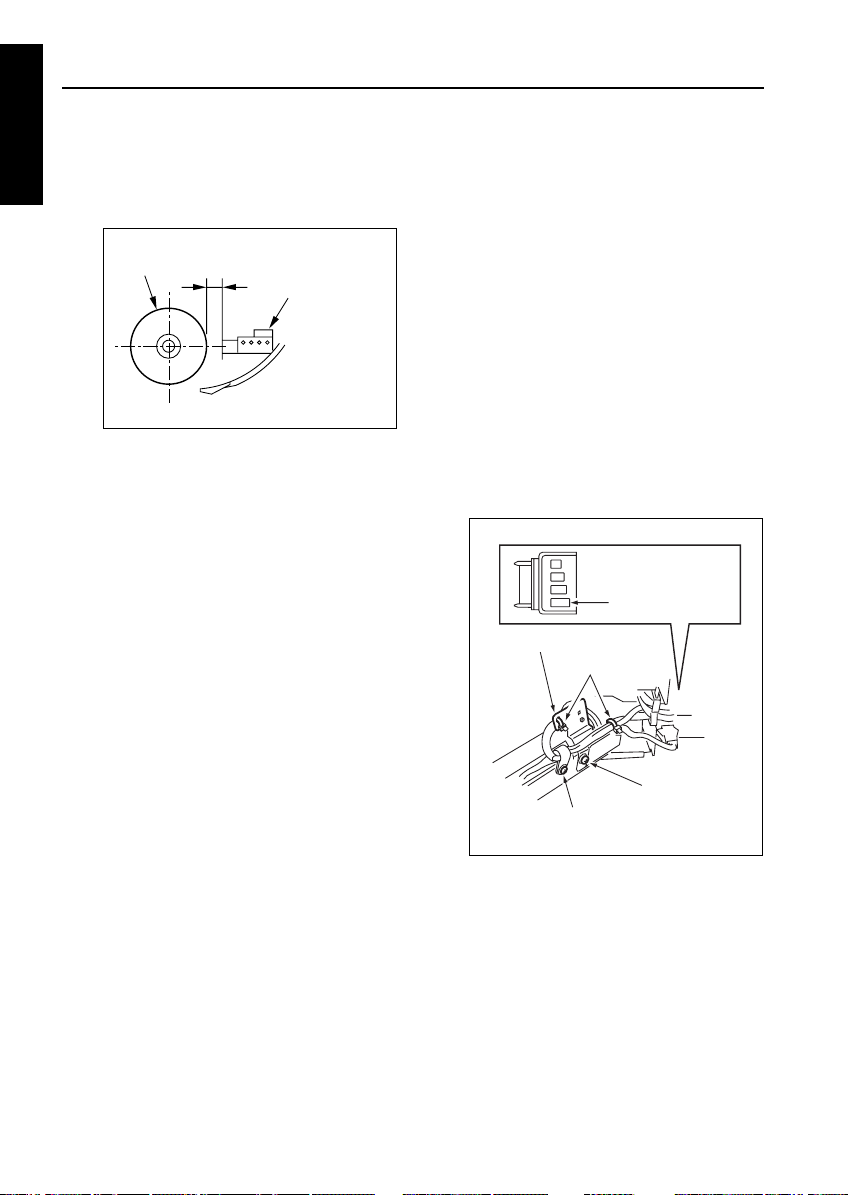

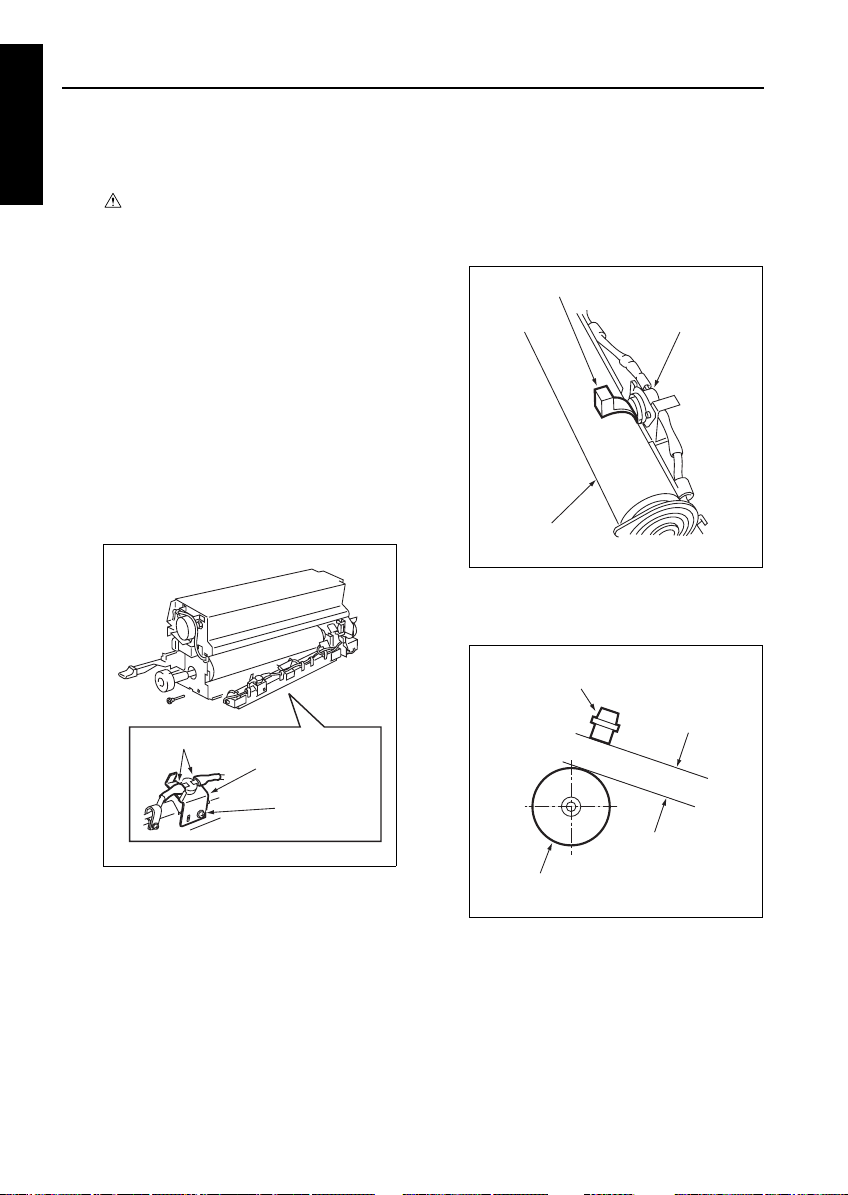

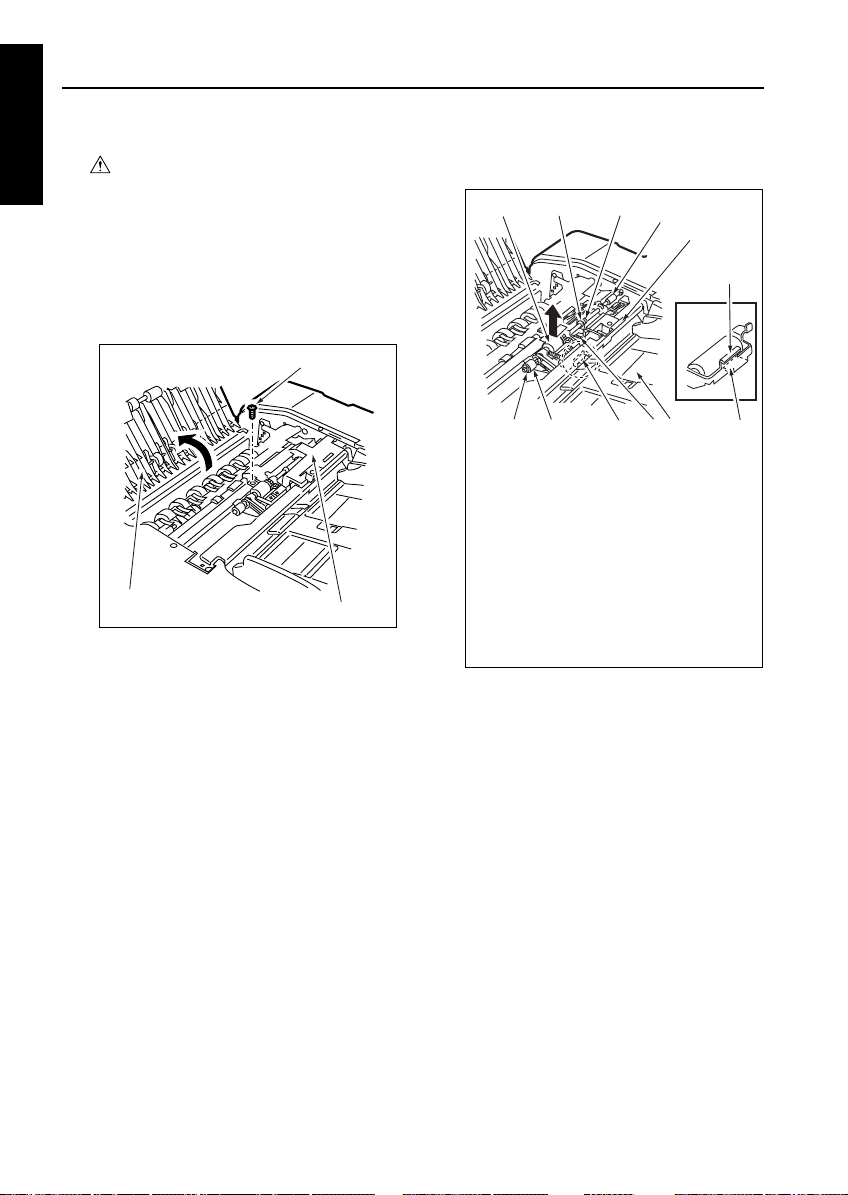

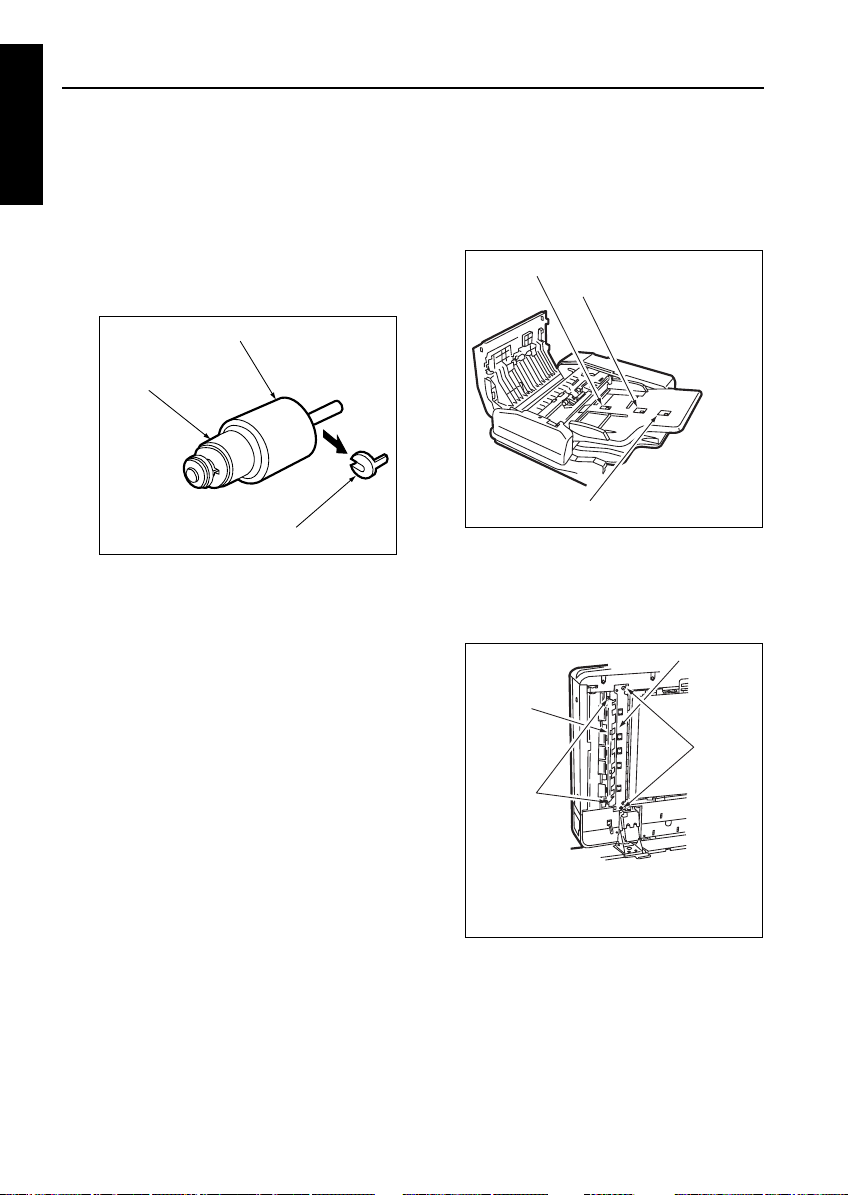

[2] Removing and Reinstalling the Fixing

Unit Top Cover

Caution: Before opening the fixing unit

a. Procedure

(1) Draw out the ADU stand. (See “ADU UNIT.”)

(2) Insert a screwdriver or the like in the hole in the

pressure release shaft and rotate the pressure

release shaft to release pressure.

Caution: Perform pressure release with the fix-

(3) Remove the four screws to open the fixing unit

top cover.

top cover, be sure to rotate the

pressure release shaft clockwise to release the lower roller.

After closing the fixing unit top

cover, be sure to rotate the

pressure release shaft counterclockwise to apply pressure to

the lower roller.

ing unit top cover closed.

2

Remove four screws.

Fixing unit top cover

1 DIS./ASSEMBLY

5

1. Fixing unit

2. Inlet guide plate push-down lever

3. Screws

4. Fixing unit front cover

5. Paper reverse/exit unit (open)

(1) Reinstall the above parts following the removal

steps in reverse.

3

1-O-1

Fixing paper

exit u nit

Pressure release shaft

1

Release

pressure.

Page 2

FIXING UNIT

(4) Close the fixing unit top cover following the open-

1 DIS./ASSEMBLY

ing steps in reverse.

Caution: When the fixing unit top cover has

been closed and secured with the four

screws, pressure must be applied to it

without fail.

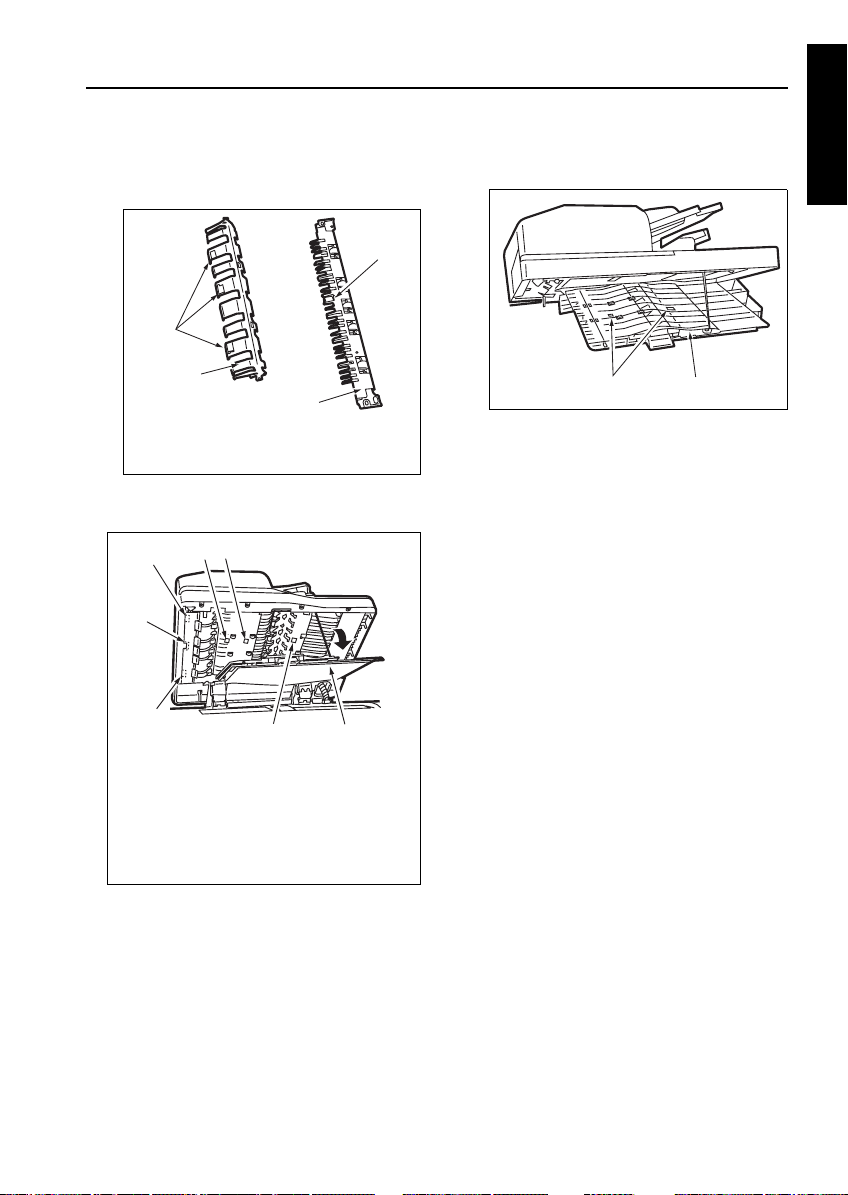

[3] Replacing the Cleaning Web

a. Procedure

(1) Draw out the ADU stand. (See “ADU UNIT.”)

(2) Open the fixing unit top cover.

(3) Remove the two screws to detach the cleaning

web unit.

Cleaning web unit

Screws (2)

(4) Reinstall the above parts following the removal

steps in reverse.

Caution1: When installing the cleaning web,

align the groove in the take-up gear

with the shaft pin on the unit, keeping

its tension.

Caution2: After replacing the cleaning web,

make sure to reset the count value of

the fixing unit cleaning web by “Copy

Count by Parts to be Replaced

(Fixed Parts)” in the 25 mode.

Pin

Gear groove

1-O-2

Page 3

FIXING UNIT

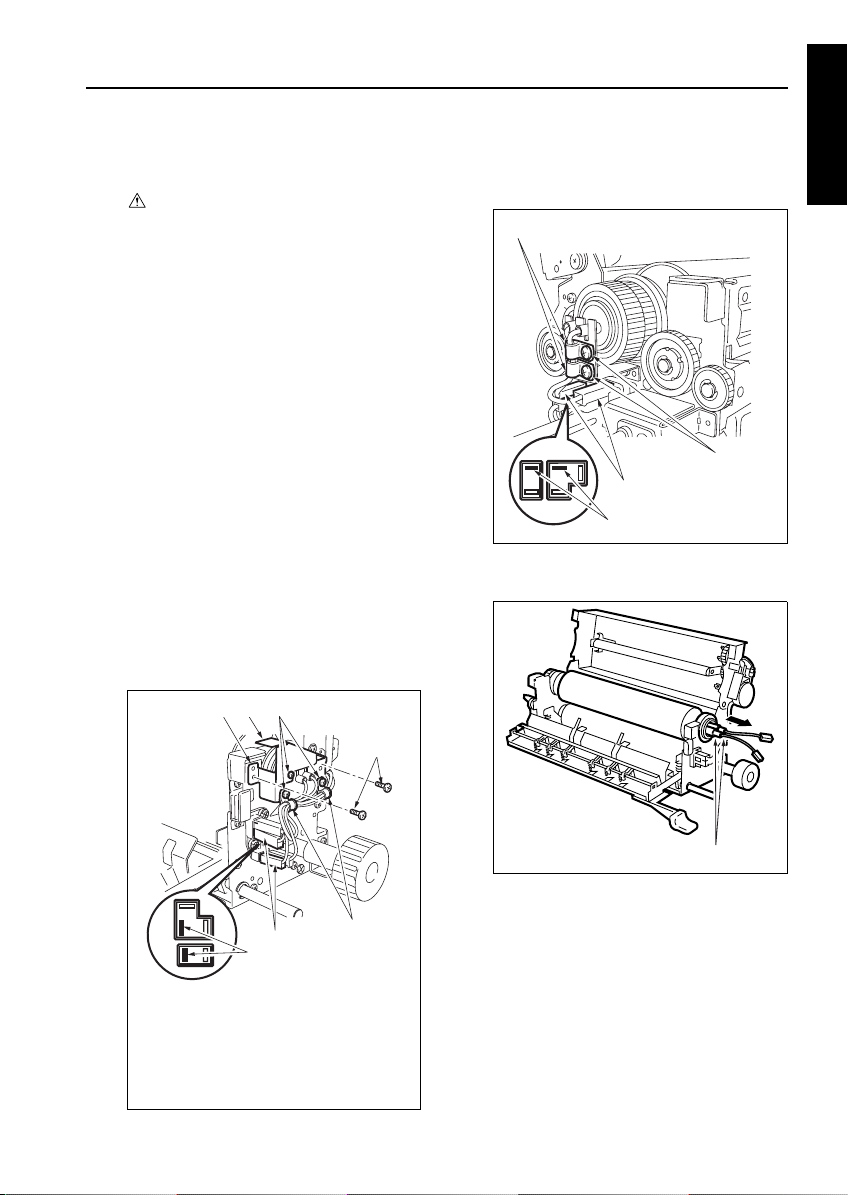

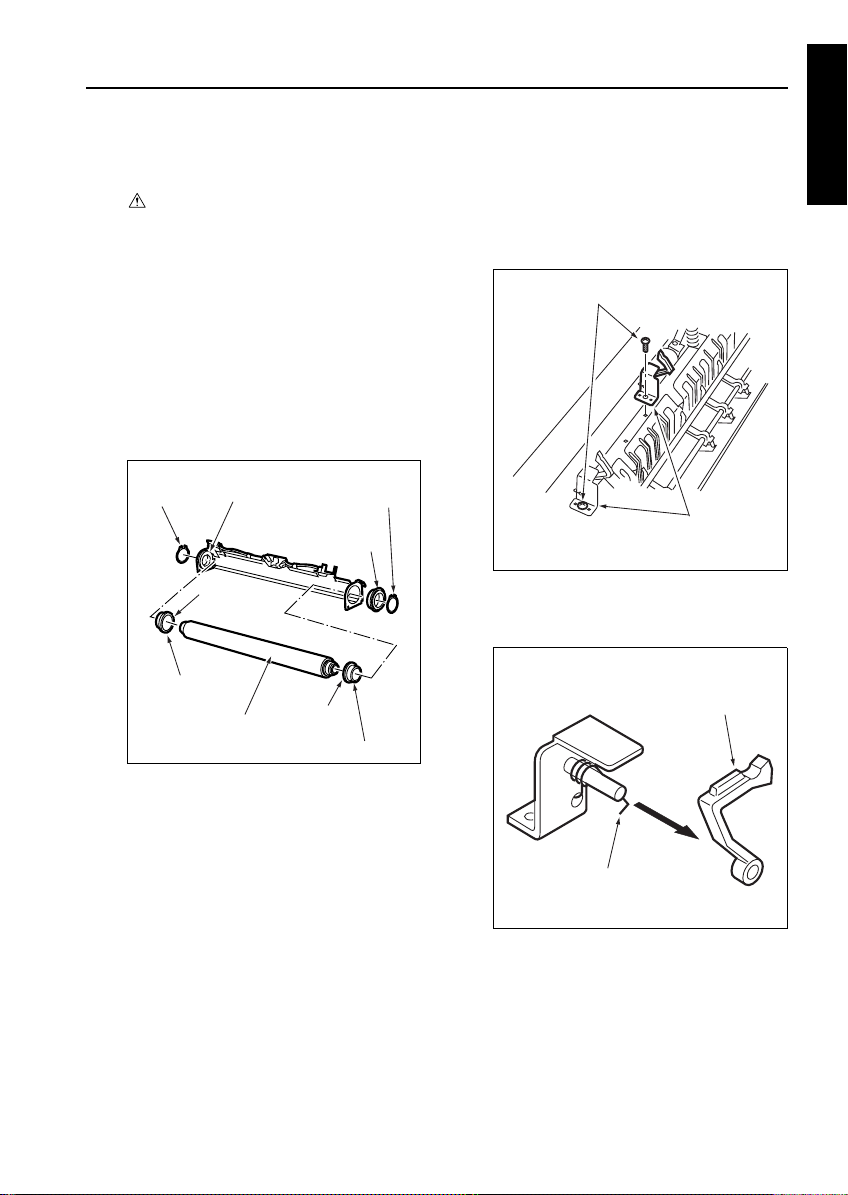

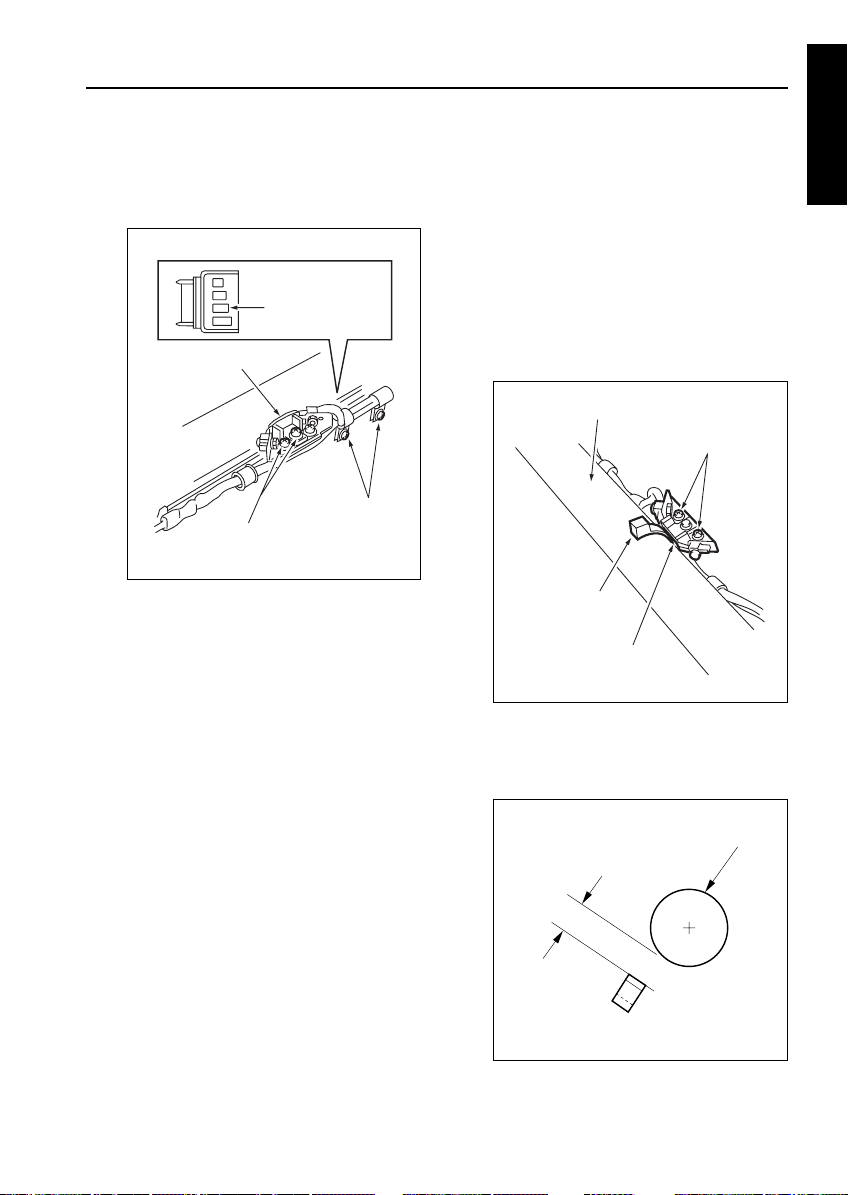

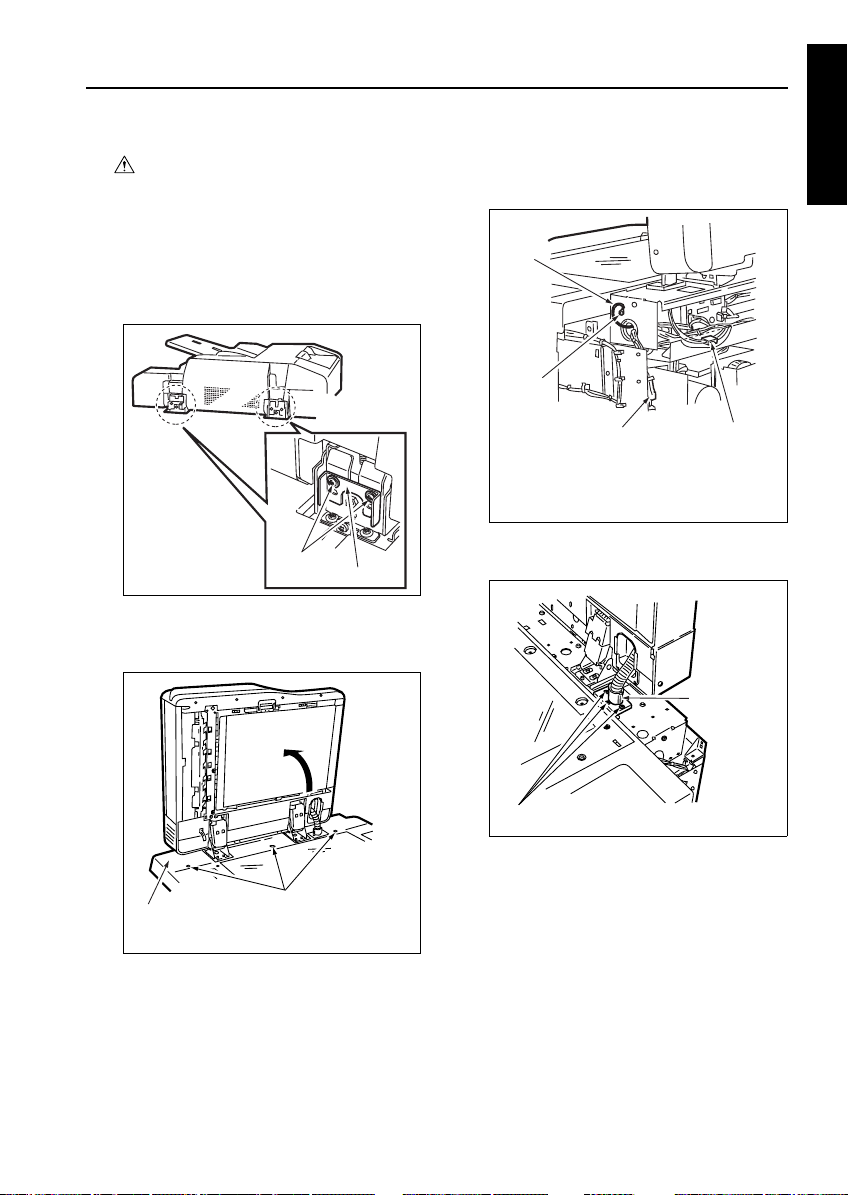

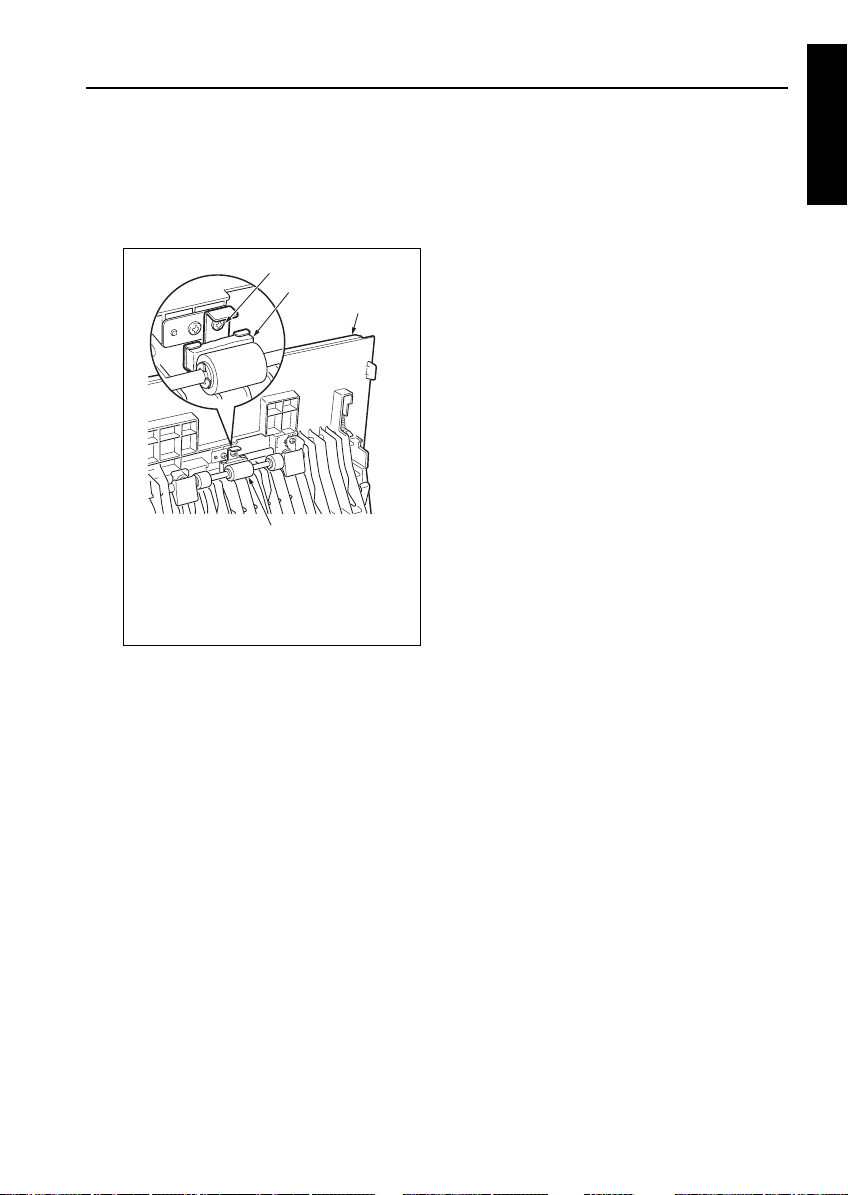

[4] Replacing the Fixing Heater Lamps

(Upper/Roller) (L2, L3)

Caution: Do not touch the fixing heater

Caution1: Install the heater lamp with the

Caution2: The heater lamp should not touch

Caution3: When replacing a heater lamp, be

a. Procedure

(1) Remove the fixing unit from the main body.

(2) Open the fixing unit top cover.

(3) Remove the two screws at the front to detach the

two wire harness clamps.

Caution: Install the wiring clamp screws

(4) Remove one screw and detach the lamp fixing

plate cover.

(5) Remove the two screws to detach the front lamp

fixing plate.

(6) Remove the two Faston terminals.

lamp with bare hands.

maker mark indication side facing

front.

the inner surface of the upper roller.

sure to insert the lamp end in the

lamp terminal securely.

through the lower mounting holes. If

installed through a wrong mounting

hole, the fixing unit front cover cannot

be installed.

3

2

1

(7) Remove the two screws at the back to detach two

wiring harness clamps.

(8) Remove the two Faston terminals at the back.

Wiring harness clamps (2)

Screws (2)

Faston terminals (2)

Faston terminals (remove 2)

(9) Pull out the fixing heater lamps (L2, L3) from the

front side of the fixing upper roller.

1 DIS./ASSEMBLY

5

6

1. Front lamp fixing plate

2. Lamp fixing plate cover

3. Screws

4. Wiring harness clamps

5. Faston terminals (2)

6. Faston terminals (remove)

3

Heater lamps (L2, L3)

(10) Reinstall the above parts following the removal

4

1-O-3

steps in reverse.

Caution: When installing new lamps, pay atten-

tion to their orientation. The size of the

lamp terminal mounting hole in the

front lamp fixing plate is different from

that in the rear lamp fixing plate. The

lamp inserted in the fixing upper roller

in the opposite direction cannot be

secured properly.

Page 4

FIXING UNIT

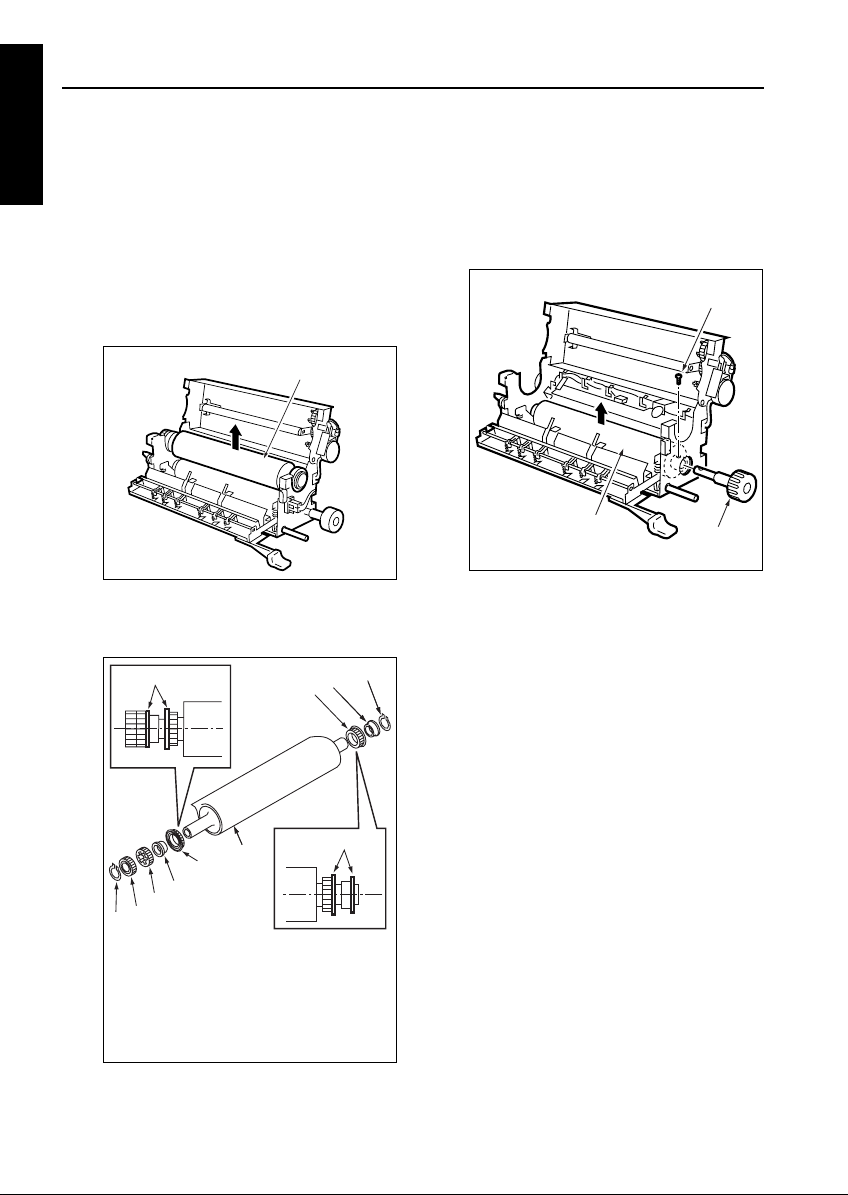

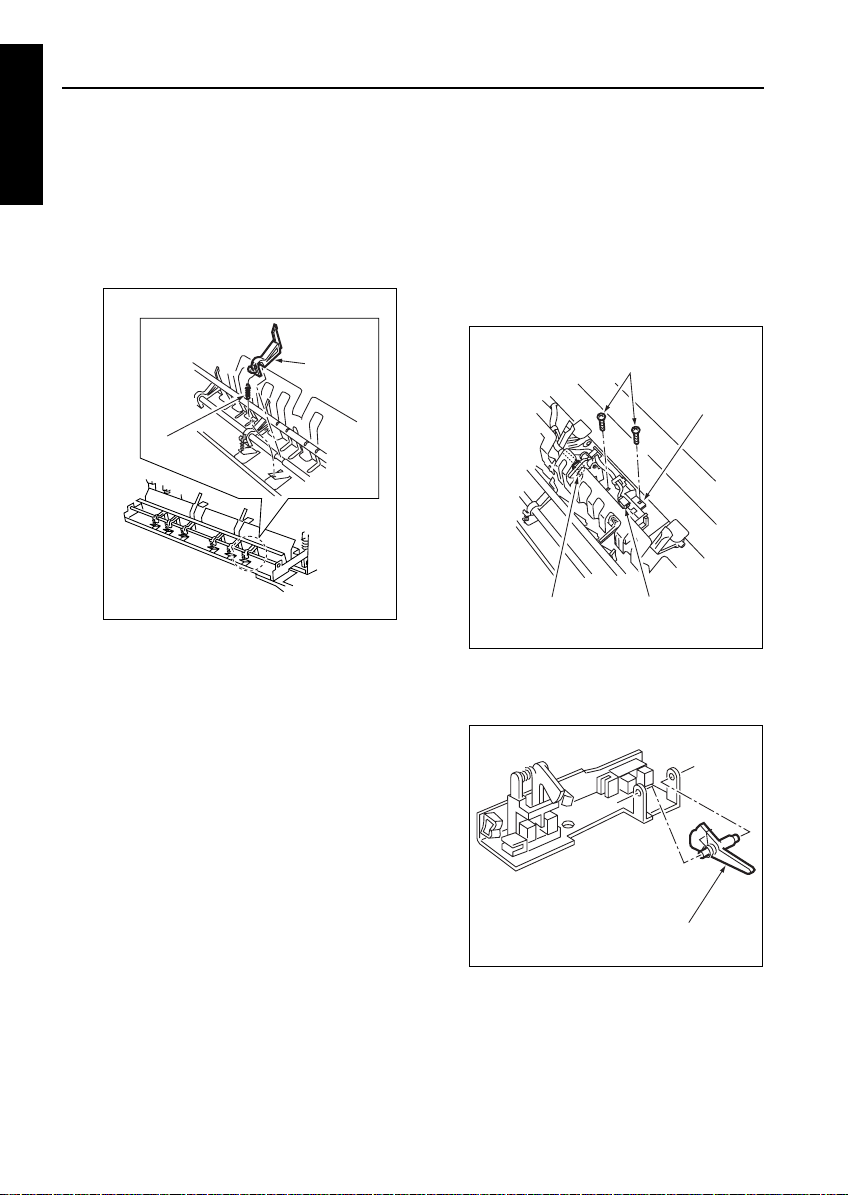

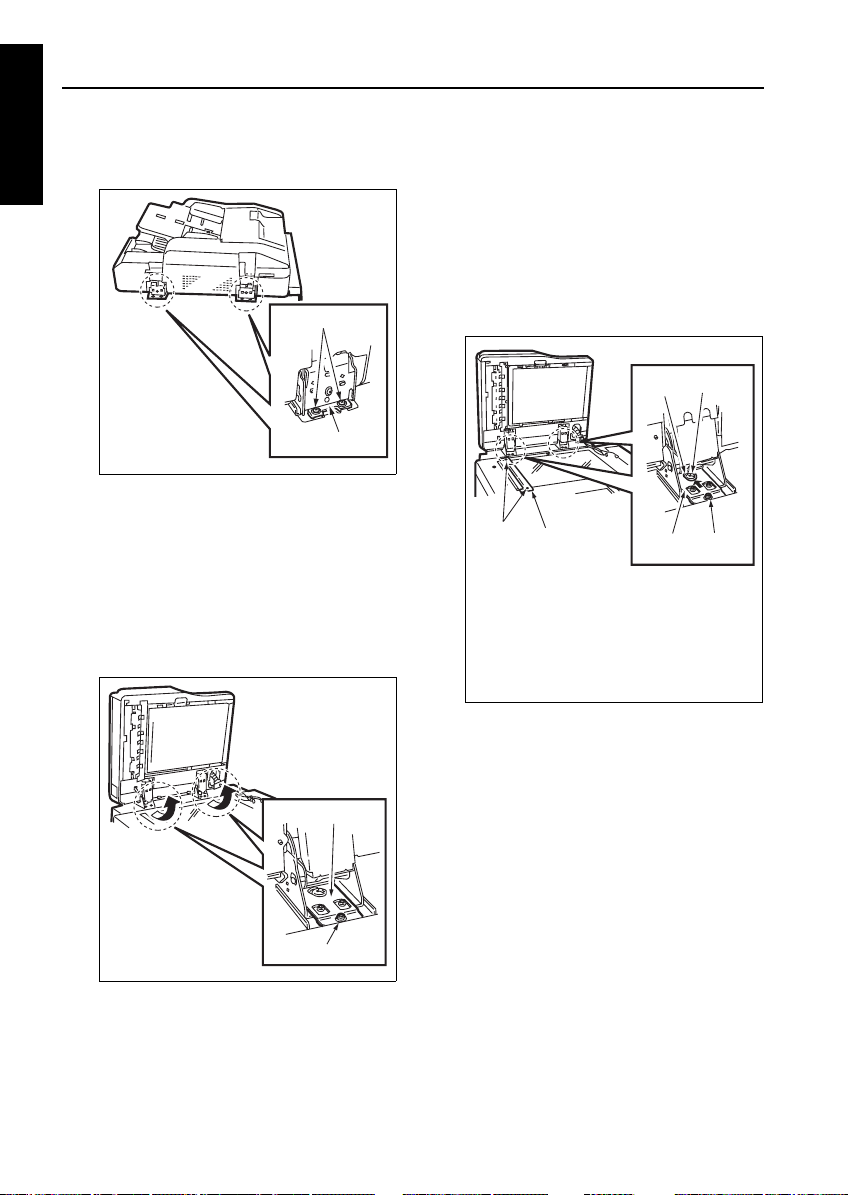

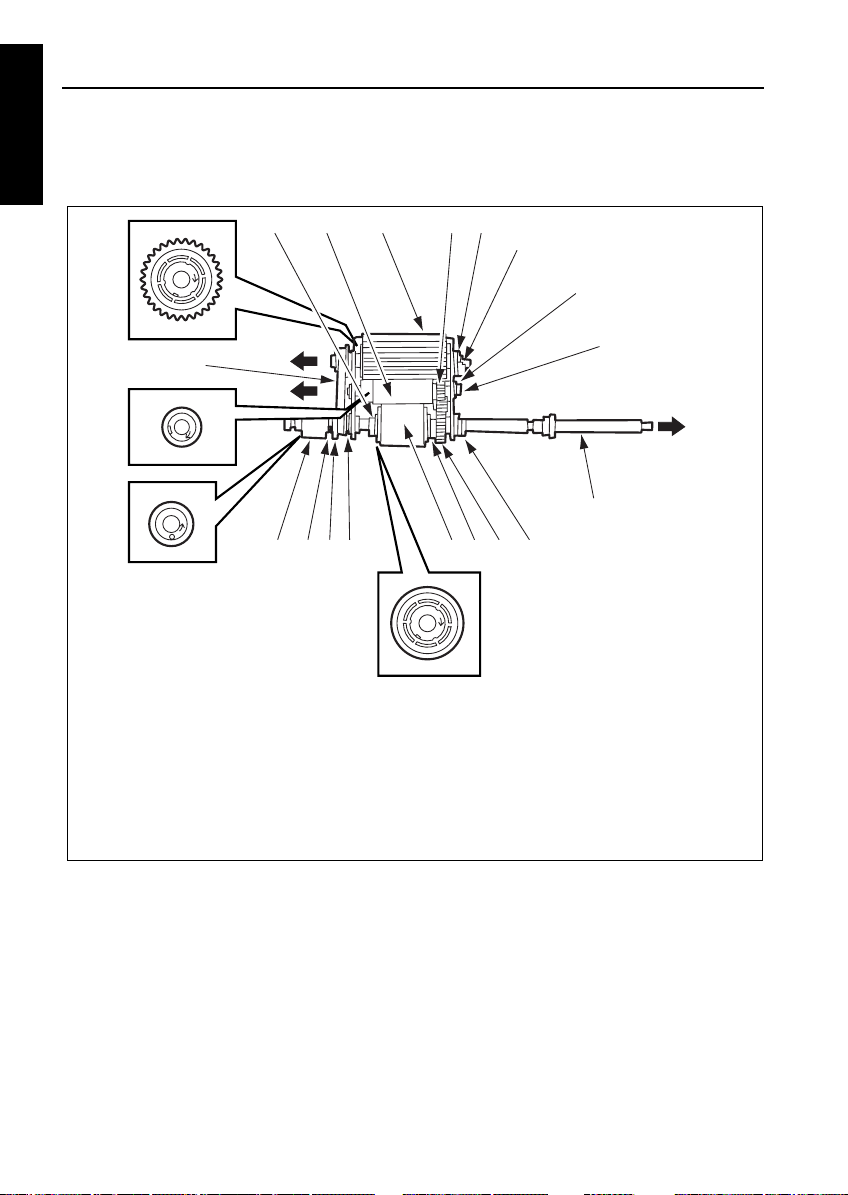

[5] Removing and Reinstalling the Fixing

1 DIS./ASSEMBLY

Upper Roller

a. Procedure

(1) Remove the fixing unit from the main body.

(2) Release the fixing unit lower contact with the

upper roller.

(3) Open the fixing unit top cover.

(4) Remove the fixing upper roller heater lamps (L2,

L3).

(5) Remove the fixing upper roller upward.

Fixing upper roller

(6) Remove the two C-rings, two gears, two bear-

ings, and two insulating sleeves from the fixing

upper roller.

1

2

[6] Removing and Reinstalling the Fixing

Lower Roller

a. Procedure

(1) Remove the fixing upper roller.

(2) Remove one screw to detach the fixing knob.

(3) Remove the fixing lower roller upward.

Screw

Fixing lower roller

(4) Reinstall the above parts following the removal

steps in reverse.

4

3

Fixing knob

5

2

3

6

7

4

1. Collars

2. Bearing

3. Insulating sleeve

4. C-ring

5. Fixing upper roller

6. Gear (iron)

7. Gear (resin)

(1) Reinstall the above parts following the removal

steps in reverse.

1

1-O-4

Page 5

FIXING UNIT

[7] Removing and Reinstalling the Fixing

Heat Roller Assembly

a. Procedure

(1) Remove the fixing unit from the main body.

(2) Remove the two springs and one screw (along

with the ground cable) from the thick paper transport auxiliary plate.

Caution: The front and rear springs are different

(3) Remove the two shoulder screws to detach the

thick paper transport auxiliary plate.

(4) Remove the two screws to detach the fixing

plate.

in size and length. Install them properly.

1

1. Spring (short)

2. Spring (long)

3. Shoulder screws

4. Screw

5. Fixing plate

6. Thick paper transport auxiliary plate

7. Screw/ground wire

2

4

7

6

3

5

4

(1) Remove the two springs and one screw to detach

the fixing heat roller assembly.

Screw

Spring

Caution: When installing the fixing heat roller

assembly, be sure to fit the guide pin in

the guide hole on the rear side.

(2) Reinstall the above parts following the removal

steps in reverse.

Spring

Fixing heat roller

assembly

1 DIS./ASSEMBLY

1-O-5

Page 6

FIXING UNIT

[8] Replacing the Heater Lamp (Heat

1 DIS./ASSEMBLY

roller) (L4)

Caution: Do not touch the fixing heater

Caution: Install the heater lamp (heat roller)

a. Procedure

(1) Remove the fixing heat roller assembly.

(2) Cut the insulating cable tie to disconnect the con-

nector (CN462).

(3) Remove one screw to detach the lamp fixing

plate (rear).

lamp (heat roller)(L4) with bare

hands.

(L4) with the maker mark indication

side facing front.

Cable tie (for heat insulation)

Connector

Screw

Lamp fixing plate (rear)

(6) Remove the heater lamp (L4) from the front side.

1

2

3

4

6

5

1. Cable ties (for heat insulation)

2. Faston terminal

3. Cable clamp (for heat insulation)

4. Screws

Lamp fixing plate (front)

5.

6. Heater lamp (L4)

(1) Reinstall the above parts following the removal

steps in reverse.

Caution: When reinstalling the lamp, pay atten-

tion to its orientation.

(4) Cut two insulating cable ties and remove the

screw securing the cable clamp to remove the

Faston terminal.

(5) Remove one screw to detach the lamp fixing

plate (front).

1-O-6

Page 7

FIXING UNIT

[9] Removing and Reinstalling the Fixing

Heat Roller

Caution: Do not touch the fixing heater

a. Procedure

(1) Remove the fixing heat roller assembly.

(2) Remove the heater lamp (lower) (L4).

(3) Remove the two C-rings and the front bearing to

remove the fixing heat roller.

(4) Remove two insulating sleeves from the fixing

heat roller.

Caution: Reinstall the front and rear insulating

C-ring

Insulating sleeve

lamp (lower)(L4) with bare

hands.

sleeves with the collars facing toward

the fixing heat roller.

Bearing

Bearing

Collar

Fixing heat roller

Collar

Insulating sleeve

C-ring

[10] Removing and Reinstalling the Fixing

Separation Claws (Lower)

a. Procedure

(1) Open the fixing paper exit unit.

(2) Remove the two screws to detach the fixing sep-

aration claws (lower) assembly.

Screws

Fixing separation claws

(lower) assembly

(3) Remove the spring supporting each fixing sepa-

ration claw (lower).

(4) Remove the fixing separation claws (lower).

Fixing separation

claw (lower)

1 DIS./ASSEMBLY

(5) Reinstall the above parts following the removal

steps in reverse.

Spring/lower

(5) Reinstall the above parts following the removal

steps in reverse.

1-O-7

Page 8

FIXING UNIT

[11] Removing and Reinstalling the Fixing

1 DIS./ASSEMBLY

Separation Claws (Upper)

a. Procedure

(1) Open the fixing paper exit unit.

(2) Remove the six springs connected to the fixing

separation claws.

(3) Remove the six fixing separation claws.

Fixing

separation

claws

(upper)

Spring

(4) Reinstall the above parts following the removal

steps in reverse.

[12] Removing and Reinstalling the

Actuator for Fixing Exit PS (PS2)

a. Procedure

(1) Open the fixing paper exit unit.

(2) Disconnect the two connectors (CN464, 465).

(3) Remove one screw to detach the fixing separa-

tion claw (lower) (on the drive side).

(4) Remove the two screws to detach the actuator/

sensor assembly.

Screws

Connectors (CN464)Connectors

(CN465)

(5) Remove the spring from the actuator/sensor

assembly to detach the actuator for fixing exit PS

(PS2).

Actuator/

sensor

assembly

Fixing paper exit

actuator

(6) Reinstall the above parts following the removal

steps in reverse.

1-O-8

Page 9

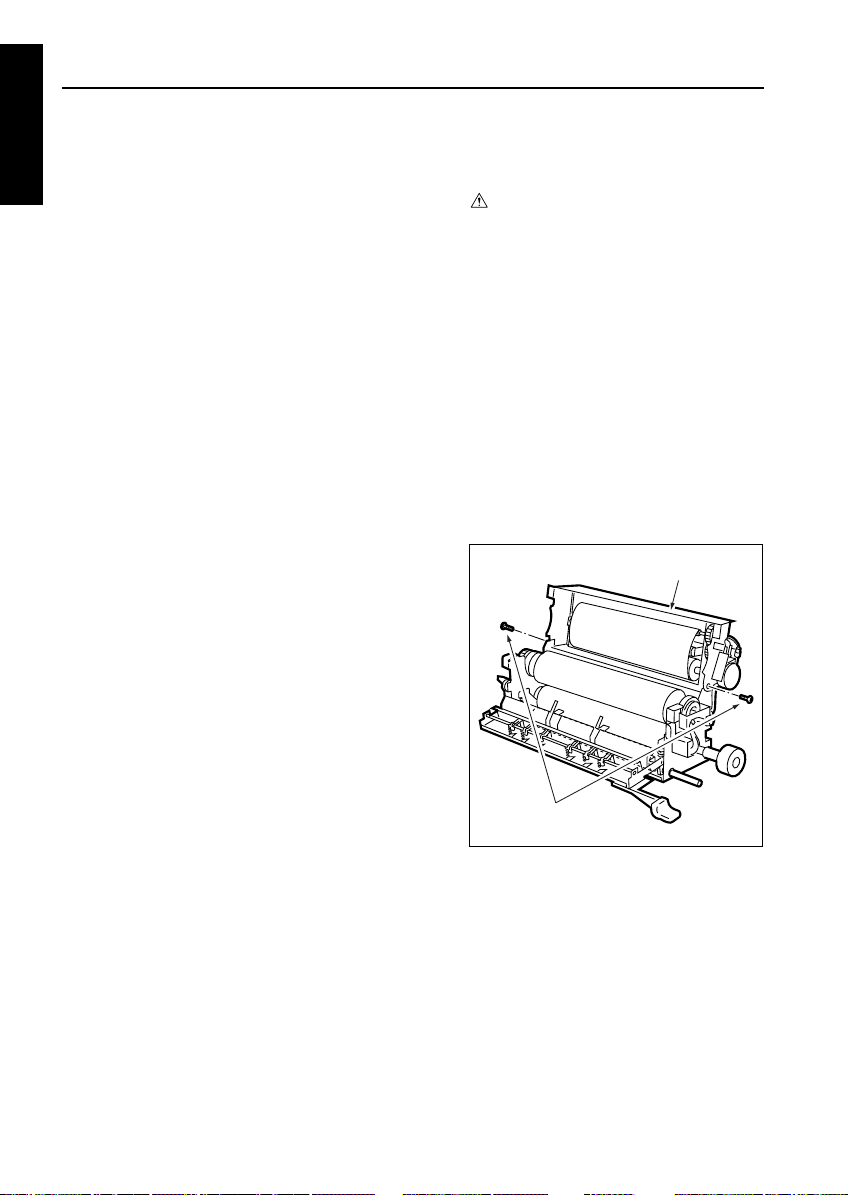

FIXING UNIT

[13] Removing and Reinstalling Fixing

Temperature Sensors 1 and 2

Caution1: After reinstalling fixing temperature

sensor 2, make sure that the sensor

touches the fixing upper roller.

Caution2: Make sure the sensor wires do not

touch the fixing upper roller.

Caution3: When reinstalling fixing temperature

sensor 1, adjust its position using the

positioning jig (4014-5001-01) and

secure it with screws. Be sure to

apply screw lock agent to the screws.

a. Removal procedure

(1) Open the fixing unit top cover.

(2) Remove the two screws to detach the fixing unit

top cover.

Fixing unit top cover (upper)

Screws

(5) Remove one screw (on the fixing plate side) to

detach fixing temperature sensor 2.

Fixing temperature

sensor 1 (CN466)

Fixing temperature

sensor 2 (CN467)

Screws

Fixing temperature

sensor 2

b. Reinstallation procedure

(1) Secure fixing temperature sensor 2 with a screw.

(2) Make sure that fixing temperature sensor 2

touches the fixing upper roller. If they do not

touch each other, be sure to bring the sensor in

touch with the roller.

(3) Set a fixing temperature sensor positioning jig

between fixing temperature sensor 1 and fixing

upper roller, and secure fixing temperature sensor 1 with two screws so that the distance

between the sensor and roller is equal to the

thickness of the jig.

Fixing temperature

sensor 1

1 DIS./ASSEMBLY

(3) Disconnect the two connectors (fixing tempera-

ture sensor 1, CN466; fixing temperature sensor

2, CN467) and release the sensor wires from the

cable guides.

(4) Remove the two screws to detach fixing temper-

ature sensor 1.

1-O-9

The fixing temperature sensor 2 must

contact the fixing upper roller.

Fixing upper

roller

Positioning jig

(4014-5001-01)

Fixing temperature sensor 1

Screws

Page 10

FIXING UNIT

a) Set the distance “a” between the fixing tem-

1 DIS./ASSEMBLY

perature sensor 1 and fixing upper roller so

that it is equal to the thickness of the positioning jig.

Fixing upper roller

Standard value of a: 0.75±0.1 mm

(4) Apply screw lock agent to the two screws secur-

ing fixing temperature sensor 1.

(5) Secure the wires of fusion temperature sensors

1 and 2 in the wire guides, and connect their con-

nectors.

(6) Reinstall other parts following the removal steps

in reverse.

Fixing temperature

sensor 1

a

[14] Removing and Reinstalling Fixing

Temperature Sensors 3 and 4

Caution1: After reinstalling fixing temperature

Caution2: Make sure the sensor wires do not

Caution3: When reinstalling fixing temperature

a. Removal procedure

(1) Remove the fixing heat roller assembly.

(2) Disconnect one connector (CN469), remove the

screw to detach the cable clamp, and cut insulating ties.

(3) Remove one screw (on the fixing plate side) to

remove fixing temperature sensor 4.

sensor 4, make sure that the sensor

touches the fixing heat roller (upper).

touch the fixing heat roller.

sensor 3, adjust its position using the

positioning jig (4014-5002-01) and

secure it with screws. Be sure to

apply screw lock agent to the screws.

Fixing

temperature

sensor 4

Fixing temperature

sensor 4

Cable ties

1-O-10

Screw

Screw/wiring harness clamp

Page 11

FIXING UNIT

(4) Disconnect one connector (CN468) and remove

four screws to detach two wire clamps.

(5) Remove the two screws to detach fixing temper-

ature sensor 3.

Fixing

temperature

sensor 3

Fixing temperature

sensor 3

Screw/wiring

Screws (2)

harness clamps

b. Reinstallation procedure

(1) Secure fixing temperature sensor 4 with a screw.

(2) Make sure that fixing temperature sensor 4

touches the fixing heat roller (upper). If they do

not touch each other, be sure to bring the sensor

in touch with the roller.

(3) Set a fixing temperature sensor positioning jig

between fixing temperature sensor 3 and fixing

heat roller, and secure fixing temperature sensor

3 with two screws so that the distance between

the sensor and roller is equal to the thickness of

the jig.

Fixing heat roller

Screws (two)

Positioning jig

(4014-5002-01)

Fixing temperature

sensor 3

a) Set the distance “a” between the fixing tem-

perature sensor 3 and fixing heat roller so that

it is equal to the thickness of the positioning

jig.

1 DIS./ASSEMBLY

1-O-11

Fixing heat roller

a

Fixing temperature sensor 3

Standard value of a = 0.7±0.1 mm

Page 12

FIXING UNIT

(4) Apply screw lock agent to the two screws secur-

1 DIS./ASSEMBLY

ing fixing temperature sensor 3.

(5) Secure the wires of fixing temperature sensors 3

and 4 with wire clamp and ties, and connect the

connectors.

(6) Reinstall other parts following the removal steps

in reverse.

[15] Removing and Reinstalling the

Thermostat (Upper)

Caution: This is an important safety part.

Be sure to observe the following cautions and steps when

removing or reinstalling.

Caution1: After reinstalling the thermostat

(upper), make sure that its wires do

not touch the fixing upper roller.

Caution2: When reinstalling the thermostat

(upper), adjust its position using the

thermostat PS jig/A (4014-5003-01)

and secure it with screws. Be sure to

apply screw lock agent to the screws.

Make this adjustment with pressure

applied.

a. Removal procedure

(1) Open the fixing unit top cover.

(2) Remove the two screws to detach the fixing unit

top cover.

Fixing unit top cover

1-O-12

Screws (2)

Page 13

FIXING UNIT

(3) Remove one screw and remove two Faston ter-

minals to detach the thermostat.

Screw

Thermostat (upper)

Faston terminals (2)

b. Reinstallation procedure

(1) Connect two Faston terminals to the thermostat

(upper).

(2) Set a thermostat positioning jig between the ther-

mostat (upper) and fixing upper roller, and

secure the thermostat (upper) with one screw so

that the distance between the roller and thermostat equal to the thickness of the jig.

Faston terminal

Fixing upper

roller

Thermostat PS jig/A

(4014-5003-01)

a) Set the distance “a” between the thermostat

(upper) and fixing upper roller so that it is

equal to the thickness of the thermostat PS

jig/A.

Screw

Thermostat (upper)

Faston terminal

1 DIS./ASSEMBLY

Fixing upper roller

Standard value of a = 3.0±0.2 mm

(3) Apply screw lock agent to the screw securing the

thermostat (upper).

(4) Reinstall other parts following the removal steps

in reverse.

1-O-13

Thermostat (upper)

a

Page 14

FIXING UNIT

[16] Removing and Reinstalling the

1 DIS./ASSEMBLY

Thermostat (Lower)

Caution: This is an important safety part.

Be sure to observe the following cautions and steps when

removing or reinstalling.

Caution1: After reinstalling the thermostat

(upper), make sure that its wires do

not touch the fixing heat roller.

Caution2: When reinstalling the thermostat

(upper), adjust its position using the

thermostat PS jig/B (4014-5004-01)

and secure it with screws. Be sure to

apply screw lock agent to the screws.

a. Removal procedure

(1) Remove the fixing heat roller assembly.

(2) Remove two Faston terminals from the thermo-

stat (lower).

(3) Remove one screw to detach the thermostat

(lower).

b. Reinstallation procedure

(1) Set a thermostat PS jig/B between the thermo-

stat (lower) and fixing heat roller, and secure the

thermostat (lower) with one screw so that the distance between the roller and thermostat equal to

the thickness of the jig.

Thermostat PS jig/B (4014-5004-01)

Thermostat (lower)

Fixing heat roller

a) Set the distance “a” between the thermostat

(lower) and fixing heat roller so that it is equal

to the thickness of the thermostat PS jig/B.

Thermostat (lower)

Faston terminal

Thermostat (lower)

a

Screw

Fixing heat roller

Standard: a = 3.0±0.20 mm

(2) Connect two Faston terminals to the thermostat

(lower).

(3) Apply screw lock agent to the screw securing the

thermostat (lower).

(4) Reinstall other parts following the removal steps

in reverse.

1-O-14

Page 15

EXTERNAL SECTION

RADF

Caution:

When disassembling and reassembling

the machine, Be sure the power cord has

been unplugged from the wall outlet.

[1] Removing the RADF

a. Procedure

(1) Remove the rear cover.

(2) Remove two screws to detach the two stoppers.

Screws

(3) Open the RADF to the upright position.

(4) Remove the three screws to detach the top cover

(rear) of the main unit.

Stopper

(5) Remove the screw to disconnect the ground

cable.

(6) Remove the two relay connectors (CN31, CN32).

4

3

21

1. Relay connector (CN32)

2. Relay connector (CN31)

3. Screw

4. Ground cable

(7) Remove the three screws to detach the cable

conduit.

Cable conduit

3 DIS./ASSEMBLY1 DIS./ASSEMBLY

Top cover (rear)

Screws

(8) Draw the cable to the top of the main unit.

Screws

1-P-1

Page 16

RADF

(9) Close the RADF. Remove the two screws to

3 DIS./ASSEMBLY1 DIS./ASSEMBLY

detach each of the two fixing plates (R).

Fixing plate (R)

(10) Open the RADF up to the upright position.

(11) Holding the RADF, remove one screw to detach

each of two fixing plates.

(12) Holding the RADF, remove it from the main unit.

Caution: When the fixing plates (F) are

removed, the RADF may fall down to

the rear side. Be sure to hold the

RADF while performing steps 11 and

12.

Fixing plate (F)

Screws

[2] Reinstalling the RADF

a. Procedure

(1) Place the RADF on the top of the main unit and

loosely secure each of the two fixing plates (F)

with one screw.

Note: The necked hole in the fixing plate (F)

(2) Remove the two screws to detach the original

(3) Following the removal procedure in reverse,

(4) Install two RADF positioning jigs in the mounting

must fit over the guide screw.

stopper plate (left).

4

3

2

1

1. Original stopper plate (left)

2. Screws

3. Necked hole

4. Guide screw

5. Screws (tighten temporarily)

6. Fixing plate (F)

install the cable conduit, two relay connectors

(CN31, CN32), ground cable, and top cover

(rear) of the main unit.

holes of the original stopper plate (left).

6

5

Screw

1-P-2

Page 17

RADF

(5) Close the RADF to mate the reference holes and

RADF positioning jigs.

3

2

1

1. RADF positioning jigs

2. Reference hole (oblong hole)

3. Reference hole (round hole)

(6) Install two screws to secure each of the two fixing

plates (R) following the removal procedure in

reverse.

(7) Open the RADF, install the other screw for each

of the two fixing plates (F), and finally tighten all

the four screws to secure the two fixing plates

(F).

(8) Remove the RADF positioning jigs and install the

original stopper plate (left) with two screws.

(9) Close the RADF and check whether both stopper

pieces on the RADF-side touch the slit glass.

Note: The state of contact between the stopper

pieces and the silt glass can be checked

by looking into the slits in the top cover of

the main unit.

1

2

4

3

1. Stopper piece

2. Slit glass

3. Slit

4. Top cover (middle)

(10) If both stopper pieces do not touch the slit glass

at the same time, make adjustments using

adjusting screws A and B alternately.

Adjusting screws B Adjusting screws A

3

3 DIS./ASSEMBLY1 DIS./ASSEMBLY

(11) Perform steps (9) and (10) repeatedly until the

two stopper pieces touch the slit glass at the

same time.

(12) Install the rear cover of the main unit.

1-P-3

Page 18

RADF

ORIGINAL FEED/CONVEYANCE/EXIT SECTION

3 DIS./ASSEMBLY1 DIS./ASSEMBLY

Caution:

When disassembling and reassembling

the machine, Be sure the power cord has

been unplugged from the wall outlet.

[1] Replacing the Pickup Roller and Con-

veyance Roller Rubber

a. Procedure

(1) Open the Jam access cover.

(2) Remove the screw to detach the sensor cover.

Screws

Jam access cover

(3) Remove the spring.

(4) Remove the two stop rings to slide the bearing

and one-way clutch outward.

(5) Slide the original feed roller unit to the front to

release it from the coupling, then remove it

upward.

Sensor cover

(6) Remove the original feed roller rubber from the

original feed roller.

2

1

389

1. Original feed roller unit

2. Bearing

3. Stop ring

4. Coupling

5. Stay

6. Original feed tray

7. Spring

8. Angled portion

9. One-way clutch

10. Angled portion of original feed roller unit

11. Angled portion of stay

(7) Clean rollers using a blower brush or the like.

(8) Reinstall the original feed roller unit in the

reverse order of the removal procedure.

Note: Caution:Make sure the angled portion of the

original feed roller unit is positioned above the

angled portion of the stay. If the angled portion

of the original feed roller unit is positioned

below the angled portion of the stay, originals

are not fed properly.

3

4

5

10

67

11

1-P-4

Page 19

RADF

[2] Cleaning the Cleaning Pad

a. Procedure

(1) Open the movable cover.

(2) Remove one screw to detach the cleaning pad.

(3) Using a blower brush, clean the cleaning pad.

1

2

4

1. Screw

2. Cleaning pad

3. Movable cover

4. Registration roller

(4) Reinstall the above parts following the removal

steps in reverse.

3

[3] Replacing the Original Feed Roller/

Separation Roller/Auxiliary Separation Roller

a. Procedure

(1) Remove the original feed roller unit.

(2) Remove the one-way clutch.

(3) Remove stop ring (1) to detach gear (1) and belt.

(4) Remove stop ring (2) and pull out shaft (1) to

detach the original feed roller.

(5) Pull the pin for gear (1) and the spacer from shaft

(2).

(6) Remove stop rings (3), (4), and (5) to pull the pin

for gear (2) from shaft (2).

(7) Pull out shaft (2) to detach the separation roller.

(8) Remove stop ring (6) to pull the pin for gear (3)

from shaft (3).

3 DIS./ASSEMBLY1 DIS./ASSEMBLY

1-P-5

Page 20

RADF

(9) Pull out shaft (3) to detach the auxiliary separa-

3 DIS./ASSEMBLY1 DIS./ASSEMBLY

tion roller.

21

18

17 131416 15

1. Stop ring (3)

2. Auxiliary separation roller

3. Original feed roller

4. Gear (3) (with a pin)

5. Shaft (1)

6. Stop ring (2)

7. Stop ring (6)

8. Shaft (3)

9. Shaft (2)

53

4

6

12

1011

10. Stop ring (5)

11. Gear (2) (with a pin)

12. Stop ring (4)

13. Separation roller

14. Spacer

15. Gear (1) (with a pin)

16. Stop ring (1)

17. One-way clutch

18. Belt

7

8

9

(10) Reinstall the original feed roller/separation roller/

auxiliary separation roller in the reverse order of

the removal procedure.

Caution: Make sure the one-way clutch and roll-

ers are oriented properly when reinstalling them.

1-P-6

Page 21

RADF

[4] Cleaning the Paper Separation Rub-

ber

a. Procedure

(1) Remove the original feed roller unit.

(2) Clean the paper separation rubber using a drum

cleaner and cleaning pad.

Paper separation rubber

(3) Reinstall the cleaning roller in the reverse order

of the removal procedure.

[5] Replacing the Double Feed Preven-

tion Roller/Torque Limiter

a. Procedure

(1) Remove the original feed roller unit.

(2) Remove the two screws to detach the auxiliary

roller assembly.

Screws

Auxiliary roller assembly

(3) Remove the stop ring to detach the gear.

(4) Slide the two bearings outward to detach the

double feed prevention roller unit.

1

2

3 DIS./ASSEMBLY1 DIS./ASSEMBLY

1-P-7

2

1. Double feed prevention unit

2. Bearing

3. Stop ring

4. Gear

4

3

Page 22

RADF

(5) Remove the stop ring to detach the double feed

3 DIS./ASSEMBLY1 DIS./ASSEMBLY

prevention roller and torque limiter.

(6) Reinstall the double feed prevention roller and

torque limiter in the reverse order of the removal

procedure.

Note: Make sure the double feed prevention

roller is oriented properly when reinstalling it.

Double feed prevention roller

Torque limiter

Stop ring

[6] Cleaning Photo Sensors/Mirrors for

Photo Sensors

a. Procedure

(1) Close the RADF.

(2) Clean sensors using a blower brush or the like.

PS310 (Original count detection)

PS303 (Original size detection 2)

PS303 (Original size detection 1)

(3) Open the RADF.

(4) Remove the two screws to detach the driven

roller assembly.

(5) Remove the two screws to detach the original

conveyance guide.

1

3

1-P-8

2

2

1. Driven roller assembly

2. Screws

3. Original conveyance guide

Page 23

RADF

(6) Using a blower brush or the like, clean the mirror

on the driven roller assembly and the three mirrors on the original conveyance guide.

1

1

3

1. Mirror

2. Driven roller assembly

3. Original conveyance guide

(7) Open the platen guide.

(8) Clean sensors using a blower brush or the like.

1

7

2

2

6

5

34

1. PS309 (Original reversal detection)

2. PS304 (Reverse jam detection)

3. Platen guide

4. PS313 (Original exit reverse detection)

5. PS312 (Original skew detection 2)

6. PS308 (Original conveyance detection PS)

7. PS311 (original skew detection 1)

(9) Clean the two mirrors on the back of the platen

guide using a blower brush or the like.

Mirrors

(10) Reinstall the photo sensors/mirrors for photo

sensors in the reverse order of the removal pro-

cedure.

Platen guide

3 DIS./ASSEMBLY1 DIS./ASSEMBLY

1-P-9

Page 24

3 DIS./ASSEMBLY1 DIS./ASSEMBLY

Page 25

PAPER FEED SECTION

LCT

Caution:

If LCT is connected to the main body, make

sure that main body power plug is disconnected from the power outlet.

[1] Cleaning the Paper Dust Removing

Brush

a. Procedure

(1) Open the top cover.

(2) Remove six screws to detach the paper feed

cover B.

Top cover

Screws

Paper feed cover B

(3) Insert a flat bladed screwdriver in the cavities (in

two locations) for paper dust removing brush to

release the locking lugs, then remove the paper

dust removing brush.

Paper dust removing brush

[2] Cleaning the LT feed PS (PS106)/LT

first paper feed PS (PS107)

a. Procedure

(1) Looking into the paper exit side of the LCT from

below, and clean sensors through the cavity for

LT feed PS (PS106) and the cavity for LT first

paper feed (PS107) using a blower brush.

Cavity for PS106

Cavity for PS107

Paper exit side

3 DIS./ASSEMBLY1 DIS./ASSEMBLY

Locking lugs

(4) Clean the paper dust removing brush using a

blower brush.

(5) Reinstall the above parts following the removal

steps in reverse.

Cavity

1-Q-1

Page 26

LCT

[3] Removing and Reinstalling the Paper

3 DIS./ASSEMBLY1 DIS./ASSEMBLY

Feed Roller Unit

a. Procedure

(1) Open the top cover.

(2) Remove the spring from the paper feed roller

unit.

Top cover

Spring

Paper feed roller unit

Paper feed roller unit

(3) After removing two stop rings, remove the two

bearings outward to remove the paper feed roller

unit.

Paper feed roller unit

Remove

this

[4] Replacing the Paper Feed Roller Rub-

ber/Feed Roller Rubber

a. Procedure

(1) Remove the paper feed roller unit.

(2) Remove the bearing and paper feed reference

actuator.

Paper feed reference actuator

Bearing

(3) Remove two stop rings.

(4) Remove two bearings outward to detach the

roller section from the roller fitting.

Roller fitting

Stop rings

Bearing

Bearing

Stop ring

(4) Reinstall the above parts following the removal

steps in reverse.

Bearing

Stop ring

Bearing

1-Q-2

Page 27

LCT

(5) Remove the bearing from the opposite side of the

coupling, then remove the paper feed roller from

the shaft.

(6) Remove the stop ring to pull the feed roller from

the shaft.

(7) Remove the rubber from each roller.

4

3

2

1

5

3

6

7

8

1. Paper feed roller

2. Paper feed roller rubber

3. Shaft

4. Coupling

5. Feed roller

6. Feed roller rubber

7. Stop ring

8. Bearing

Paint mark

[5] Replacing the Double Feed Preven-

tion Roller Rubber

a. Procedure

Caution: With the power held on, press the LT

tray down switch (SW100) to move the

up/down plate down to the bottom in

advance.

(1) Remove the paper feed roller unit.

(2) Remove two screws to detach the double feed

prevention roller unit cover.

2

1

3

1. Double feed prevention roller

2. Double feed prevention roller unit cover

3. Screws

3 DIS./ASSEMBLY1 DIS./ASSEMBLY

(8) Reinstall the above parts following the removal

steps in reverse.

Caution1: Make sure rollers and rubber por-

tions are oriented properly when

reinstalling them.

Caution2: Make sure the one-way clutch direc-

tion is correct.

Caution3: Check whether grease or the like is

present on each roller.

1-Q-3

Page 28

LCT

(3) Remove two screws to detach the double feed

3 DIS./ASSEMBLY1 DIS./ASSEMBLY

prevention roller unit.

Caution: When reinstalling the double feed pre-

vention roller unit, tighten the screws

on the rear side first.

Double feed prevention roller unit

(4) Remove two stop rings, fit the shaft into the D-cut

in the fitting, and remove the double feed prevention roller together with the shaft.

Double feed prevention roller

Screws

D-cut

(5) Remove the double feed prevention roller rubber

from the double feed prevention roller.

Pain t mar k

1

2

3

1. Double feed prevention roller

2. Shaft

3. Double feed prevention roller rubber

(6) Reinstall the double feed prevention roller in the

reverse order of the removal procedure.

Caution1: Make sure the double feed preven-

tion roller rubber is oriented properly

when reinstalling it.

Caution2: Check whether scratch or the like is

visible on the pet cover for the drive

gear.

Caution3: Check whether grease or the like is

present on double feed prevention

roller.

Stop rings

1-Q-4

Page 29

LCT

[6] Replacing the LT feed MC (MC101)/LT

first paper feed MC (MC102)

a. Procedure

(1) Open the top cover.

(2) Remove the spring from the paper feed roller

unit.

(3) Remove two screws to detach the top cover.

Top cover

Screws

(4) Remove three screws to detach the clutch

replacement cover.

Clutch replacement cover

Screws

(5) Disconnect two relay connectors (CN765,

CN766) of the clutches.

(6) Remove the stop ring to detach each clutch.

3

2

1

1

5

4

1. Stop ring

2. LT feed MC (MC101)

3. LT first paper feed MC (MC102)

4. Relay connector (CN765)

5. Relay connector (CN766)

(7) Reinstall the above parts following the removal

steps in reverse.

Caution: When installing each MC, make sure

that the stopper of each clutch is on

the predefined position.

3 DIS./ASSEMBLY1 DIS./ASSEMBLY

1-Q-5

Page 30

LCT

[7] Replacing the C-403 Up/Down Wires

3 DIS./ASSEMBLY1 DIS./ASSEMBLY

Caution: With the power held on, press the LT

tray down switch (SW100) to move the

up/down plate down to the bottom in

advance.

a. Procedure

(1) Open the top cover.

(2) Remove the clutch replacement cover.

(3) Remove five screws to detach the right side

cover.

Right side cover

(4) After opening the jam access door, remove six

screws to detach the front cover.

Caution: When removing the front cover, close

the jam access door after removing

the screws.

Jam access door

Screws

Screws

(5) Remove twelve screws to detach the rear cover.

Screw

Screws

Screws

Rear cover

(6) Remove the five relay connectors (CN749,

CN780, CN781, CN782, CN783) to disconnect

the wiring harness from the up/down motor

mounting assembly.

(7) Remove the E-ring to detach the up/down gear.

(8) Pull the pin from the shaft.

(9) Remove the E-ring to detach the bearing.

Screws

Screws

Screws

Right side cover

1-Q-6

Page 31

LCT

(10) Remove three screws to detach the up/down

motor assembly.

3

1

2

4

5

6

7

3

12

8

3

11

9

9

10

1. Up/down motor mounting assembly

2. Relay connector (CN749)

3. Screw

4. Relay connector (CN780)

5. Relay connector (CN781)

6. Relay connector (CN782)

7. Relay connector (CN783)

8. Up/down gear

9. E-ring

10. Pin

11. Bearing

12. Shaft

(11) Replace the up/down wire following the instruc-

tions in “Removing Up/Down Wires’’ and “Installing Up/Down Wires.’’

Caution: Two sets of four up/down wires with

different length, one set at the front

and the other at the back, are used.

Wires with the same length can be

used either at the front or back if they

are used in the same location.

1323.6 mm

Wire A

1250.3 mm

Wire B

769.3 mm

Wire C

661 mm

Wire D

3 DIS./ASSEMBLY1 DIS./ASSEMBLY

1-Q-7

Page 32

LCT

<Removing the Up/Down Wires>

3 DIS./ASSEMBLY1 DIS./ASSEMBLY

Up/down plate

Wire B

Wire A

14.Release the metal

ball to remove wire A.

7.Release the metal ball

to remove wire C.

9.Release the metal ball

to remove wire D.

12.Release the metal

ball to remove wire B.

Wire C

Wire D

6.Remove the E-ring.

8.Remove the pulley.

10.Remove the pulley.

Wire B

Wire A

FRONT

Wire D

Up/down shaft

2.Release the metal ball

to remove wire C.

18.Release the metal ball

to remove wire A.

4.Release the metal ball

to remove wire D.

16.Release the metal

ball to remove wire B.

Wire C

1.Remove the E-ring.

3.Remove the pulley.

5.Remove the pulley.

15.Remove the E-ring,

then remove the pulley

to release wire B.

11.Remove the E-ring,

then remove the pulley

to release wire B.

13.Remove the pulley to

release wire A.

1-Q-8

17.Remove the pulley to

release wire A.

Page 33

<Installing the Up/Down Wires>

Wire B

Wire A

7.Insert wire A in the pulleys, then attach a

metal ball.

15.Insert wire C in the pulleys, then attach a

metal ball.

12.Insert wire D in the pulleys, then attach a

metal ball.

10.Insert wire B in the pulleys, then attach a

metal ball.

Wire C

Wire D

13.Insert wire C in the up/

down shaft, attach a pulley,

and secure the pulley with

an E-ring.

14.Wind wire C around the pulley by 6 turns in such a manner that the wire can be

pulled from over the pulley.

Wire B

Wire A

FRONT

Up/down plate

1.

6.

Insert wire A in

the up/down

shaft, attach pulleys, then pull the

wire A from under

the pulleys.

20.Insert wire B in the pulleys,

then attach a metal ball.

2.Insert wire A in the pulleys, then

attach a metal ball.

17.Insert wire D in the pulleys,

then attach a metal ball.

5.Insert wire B in the pulleys, then

attach a metal ball.

Wire D

Wire C

Up/down shaft

18.Insert wire C in the up/

down shaft, attach a pulley, and secure the pulley

with an E-ring.

19.Wind wire C around the

pulley by 6 turns in su ch a

manner that the wire can

be pulled from over the

pulley.

LCT

3 DIS./ASSEMBLY1 DIS./ASSEMBLY

6 turns

6 turns

11.Insert wire D in the up/down

shaft, attach a pulley, and

wind wire D around the pulley by six turns in such a

manner that the wire can be

pulled from over the pulley.

6 turns

Insert wire B in the up/down

3.

shaft, attach a pulley, and

8.

secure the pulley with E-rings.

d

n

u

m

o

r

f

B

4.

9.

e

r

i

l

w

u

l

P

.

s

y

l

e

1-Q-9

16.Insert wire D in the up/

down shaft, attach a pulley, and wind wire D

around the pulley by six

turns in such a manner

that the wire can be

pulled from over the pul-

-

l

p

u

h

e

t

r

e

ley.

6 turns

Page 34

LCT

(12) After installing the up/down wires, make sure the

3 DIS./ASSEMBLY1 DIS./ASSEMBLY

up/down wires are passed in the grooves in the

pulleys properly and wires do not run on the

sides of the pulleys. Also make sure the up/down

plate can be moved up and down smoothly by

hand.

Caution: If the up/down plate does not move up

(13) Install the up/down wire drive motor assembly,

up/down gear, and relay connectors, following

the removal steps in reverse.

(14) Remove the E-ring to detach the idle gear.

(15) Rotate the remaining paper detection gear until

the round hole in this gear is aligned with the

oblong hole in the up/down motor mounting

assembly.

Caution: Align when the up/down plate is in low-

and down smoothly, reinstall the up/

down wires.

est position.

1

6

1. Up/down motor mounting assembly

2. Remaining paper detection gear

3. Round hole

4. Oblong hole

5. E-ring

6. Idle gear

2

5

[8] Replacing the C-404 Up/Down Wires

a. Procedure

Caution: With the power held on, press the LT

(1) Remove the clutch replacement cover, side

cover (right), front cover, and rear cover following

the steps (1) to (5) in [7] Replacing the C-404 Up/

Down Wires.

(2) Remove the E-ring.

(3) Remove the five screws to detach the gear cover.

(4) Remove the two bearings.

(5) Remove the gear A.

(6) Remove the E-ring to remove gear B.

3

4

(7) Remove the detent pin for gear B from the up/

down pulley shaft.

(8) Remove the E-ring and bearing to remove gear

C.

tray down switch (SW100) to move the

up/down plate down to the bottom in

advance.

E-ring

Bearing

Screws

Bearing

Screw

Screw

Gear cover

Bearing

Gear C

(16) Install the idle gear.

(17) Attach the covers following the removal steps in

reverse.

Caution1: After replacing the up/down wires,

make horizontal and centering

adjustment of the up/down plate.

(Refer to “ADJUSTMENT SECTION.”)

1-Q-10

Gear A

Pin

Gear B

E-ring

E-ring

Up/down pulley shaft

Page 35

LCT

(9) Remove the bearing behind gear C.

(10) Remove the E-ring to remove the up/down gear.

(11) Remove the detent pin for up/down gear from the

up/down pulley shaft.

(12) Remove the E-ring to remove gear D.

(13) Remove the E-ring to remove the remaining

paper detection gear.

(14) Remove four relay connectors (CN780, CN781,

CN782, and CN783) to disconnect the wiring

harness from the up/down motor mounting

assembly.

3

2

1

4

5

12

7

11

10

7

9

1. Remaining paper detection gear

2. Relay connector (CN780)

3. Relay connector (CN781)

4. Relay connector (CN782)

5. Up/down motor mounting assembly

6. Relay connector (CN783)

7. E-ring

8. Bearing

9. Up/down pulley shaft

10. Up/down gear

11. Pin

12. Gear D

8

6

7

(15) Remove the E-ring to remove the bearing.

(16) Remove the six screws to remove the up/down

motor mounting assembly.

Up/down motor mounting assembly

Screws

Bearing

E-ring

(17) Replace the up/down wires following the instruc-

tions in “Removing the Up/Down Wires” and

“Installing Up/Down Wires.”

Caution: Two sets of four up/down wires with

different length, one set at the front

and the other at the back, are used.

Wires with the same length can be

used either at the front or back if they

are used in the same location.

1057.3 mm

Wire A

692.1 mm

Wire B

1321.7 mm

Wire C

1303.1 mm

Screws

3 DIS./ASSEMBLY1 DIS./ASSEMBLY

1-Q-11

Wire D

Page 36

LCT

<Removing the Up/Down Wires>

3 DIS./ASSEMBLY1 DIS./ASSEMBLY

Up/down plate

2.Release the metal ball

to remove wire A.

Wire C

Wire D

Wire C

18.Release the metal ball

to remove wire D.

Wire D

4.Release the metal ball

14.Release the metal

ball to remove wire D.

7.Release the metal ball

to remove wire A.

to remove wire B.

16.Release the metal ball

to remove wire C.

Wire B

9.Release the metal ball

to remove wire B.

12.Release the metal

ball to remove wire C.

Wire A

1.Remove the E-ring.

3.Remove the pulley.

6.Remove the E-ring.

8.Remove the pulley.

10.Remove the pulley.

Wire A

Wire B

11.Remove the E-ring,

FRONT

then remove the pulley

to release wire C.

1-Q-12

Up/down shaft

13.Remove the pulley to

release wire D.

5.Remove the pulley.

15.Remove the E-ring,

then remove the pulley

to release wire C.

17.Remove the pulley to

release wire D.

Page 37

<Installing the Up/Down Wires>

Wire C

Wire D

Wire C

Wire D

7.Insert wire D in the pulleys, then attach a

metal ball.

15.Insert wire A in the pulleys, then attach a metal

ball.

12.Insert wire B in the pulleys, then attach a metal

ball.

10.Insert wire C in the pulleys, then attach a metal

ball.

Wire A

Wire B

13.Insert wire A in the up/down

shaft, attach a pulley, and secure

the pulley with an E-ring.

14.Wind wire A around the pulley by

6 turns in such a manner that the

wire can be pulled from over the

pulley.

6 turns

11.Insert wire B in the up/down shaft,

attach a pulley, and wind wire B around

the pulley by six turns in such a manner

that the wire can be pulled from over

the pulley.

Up/down plate

FRONT

3.

8.

4.

9.

1.

6.

h

s

n

w

o

d

,

s

l

l

ey

u

p

r

f

D

e

i

r

w

.

s

ey

l

l

u

p

h

c

a

t

t

a

,

t

f

a

h

t

m

o

e

t

h

l

l

u

p

n

e

e

t

h

r

e

d

n

u

/

p

u

e

t

h

n

i

D

e

r

i

w

t

r

e

s

I

n

Insert wire C in the up/down

shaft, attach a pulley, and

secure the pulley with E-rings.

-

l

u

p

e

t

h

r

e

n

d

u

m

o

f

r

C

e

r

i

l

w

u

l

P

.

s

y

e

l

20.Insert wire A in the pulleys,

then attach a metal ball.

2.Insert wire D in the pulleys, then

attach a metal ball.

17.Insert wire B in the pulleys,

then attach a metal ball.

5.Insert wire C in the pulleys, then

attach a metal ball.

Wire B

Wire A

Up/down shaft

18.Insert wire A in the up/

down shaft, attach a pulley,

and secure the pulley with

an E-ring.

19.Wind wire A around the

pulley by 6 turns in such a

manner that the wire can be

pulled from over the pulley.

6 turns

16.Insert wire B in the up/

down shaft, attach a pulley,

and wind wire B around the

pulley by six turns in such a

manner that the wire can be

pulled from over the pulley.

6 turns

LCT

3 DIS./ASSEMBLY1 DIS./ASSEMBLY

6 turns

1-Q-13

Page 38

LCT

(18) After installing the up/down wires, check whether

3 DIS./ASSEMBLY1 DIS./ASSEMBLY

they are engaged with the pulleys properly and

whether they do not ride over the pulleys. Next,

move the up/down plate manually to check

whether it moves up and down smoothly.

Caution: If the up/down plate does not move

(19) Install the up/down motor mounting assembly,

relay connectors, remaining paper detection

gear, gear D, and up/down gear following the

removal steps in reverse.

(20) Rotate the remaining paper detection gear until

the round hole in this gear is aligned with the

oblong hole in the up/down motor mounting

assembly.

smoothly, remove the up/down wires

and install them again.

1

2

4

3

1. Remaining paper detection gear

2. Up/down motor mounting assembly

3. Round hole

4. Oblong hole

Caution: Align them when the up/down plate is

at the bottom.

(21) Install gear C.

(22) Attach the other gears, gear cover, and external

covers following the removal steps in reverse.

Caution: After replacing the up/down wires,

make horizontal and centering adjust-

ment of the up/down plate. (Refer to

“ADJUSTMENT SECTION.”)

1-Q-14

Page 39

EXTERNAL SECTION

FN

Caution:

When disassembling and reassembling

the machine, Be sure the power cord has

been unplugged from the wall outlet.

[1] Removing and Reinstalling the Rear

Cover

a. Procedure

(1) Remove the five set screws holding the rear

cover in place, and take off the cover.

Screws

Screws

Rear Cover

(2) Reinstall the rear cover in the opposite sequence

to removal.

[2] Removing and Reinstalling the Front

Cover

a. Procedure

(1) Open the front cover.

(2) Remove the two set screws holding the bottom

hinge in place, and take off the front cover.

[3] Removing and Reinstalling the Top

Cover

a. Procedure

(1) Remove the sub-tray.

(2) Open the paper exit cover.

(3) Remove the two caps.

(4) Open the front cover.

(5) Remove the six set screws holding the top cover

in place, and take off the cover.

Screws

Caps

(6) Reinstall the top cover in the opposite sequence

to removal.

Paper exit cover

Screws

3 DIS./ASSEMBLY1 DIS./ASSEMBLY

Fron t C ove r

(3) Reinstall the front cover in the opposite

sequence to removal.

Screws

Hinge

1-R-1

Page 40

FN

[4] Removing and Reinstalling the Paper

3 DIS./ASSEMBLY1 DIS./ASSEMBLY

Exit Cover

a. Procedure

(1) Remove the top cover.

(2) Remove the two set screws holding the paper

exit cover in place, and take off the paper exit

cover.

Paper exit cover

Screw

(3) Reinstall the paper exit cover in the opposite

sequence to removal.

Screw

[5] Removing and Reinstalling the Main

Tra y

a. Procedure

(1) Remove the rear cover.

(2) Detach the connector and remove the two set

screws holding motor M3 (tray up-down) in place.

Remove M3.

Note: Support the main tray with your hand

when removing M3.

M3 (Tray up-down)

Connector

(3) Remove the two set screws holding the main tray

in place, and lift the main tray up and off.

Screws

Main tray

(4) Reinstall the main tray in the opposite sequence

to removal.

1-R-2

Page 41

FN

[6] Removing and Reattaching the Front

Side Cover

a. Procedure

(1) Remove the two set screws holding the front side

cover in place, and take off the front side cover.

Screws

Front side cover

(2) Reinstall the front side cover in the opposite

sequence to removal.

[7] Removing and Reinstalling the Paper

Exit Stopper Plate

a. Procedure

(1) Remove the following parts.

• Rear cover

• Main tray

• Booklet tray

• Front cover

• Front side cover

(2) Remove the four set screws holding the left and

right up-down covers in place, and remove these

two covers.

Screws

Up-down cover

(3) Remove the two set screws holding the wire bra-

ket in place, and release the lock of the up-down

stay.

Wire bracket Wire bracket

Screws

3 DIS./ASSEMBLY1 DIS./ASSEMBLY

1-R-3

Screws

Up-down stay

Screws

Page 42

FN

(4) Remove eight set screws and take off the front

3 DIS./ASSEMBLY1 DIS./ASSEMBLY

and rear auxiliary side-up-down plates.

3

2

2

1. Front auxiliary side-up-down plate

2. Screws

3. Rear auxiliary side-up-down plate

(5) Remove four set screws and detach the two

plates (front and back plates) at the booklet exit.

Screws

1

2

Screws

(6) Remove thirteen more set screws, and take off

the paper exit stopper plate.

1

3

2

1

1

1

1. Screws

2. Up-down stay

3. Paper exit stopper plate

(7) Remove the up-down stay. (See “Removing and

Reinstalling the Up-Down Stay”.)

(8) Reinstall the stopper in the opposite sequence to

removal. But note the following caution.

Note: Be sure to press down on the up-down

stay while tightening the four screws for

the wire brackets.

Wire bracket Wire bracket

Press down

1

Plate

Plate

1-R-4

Screws

Up-down stay

Screws

Page 43

PAPER FEED UNIT

FN

Caution:

When disassembling and reassembling

the machine, Be sure the power cord has

been unplugged from the wall outlet.

[1] Replacing a Paper Exit Roller

(Sponge Roller)

a. Procedure

(1) Run the copier in mode 47 (code 75-06) to lower

the main tray.

Sponge roller

Main tray

(2) Insert the end of a screwdriver into the slot in the

sponge roller, and twist the screwdriver to pry the

roller off.

Sponge roller

[2] Removing and Reinstalling the Paper

Exit Unit/Shift Unit

a. Procedure

(1) Remove the following parts:

• Rear cover

• Top cover

• Front side cover

• Cover Inserter C (when installing Cover Inserter

C)

(2) Remove the four screws and detach the paper

exit c over.

Paper exit-opening cover

Screw

Screw

Paper exit-opening unit

Screw

Screw

3 DIS./ASSEMBLY1 DIS./ASSEMBLY

(3) Take the two halves of the new sponge roller and

align their indentations with the indentations on

the roller shaft.

(4) Press the two halves of the roller together until

the click into place.

Match

Match

1-R-5

Page 44

FN

(3) Remove the pulley and the belt.

(4) Remove the E-ring, and detach the collar, drive

3 DIS./ASSEMBLY1 DIS./ASSEMBLY

belt, two bearings, and gear.

Drive belt Pulley

E-ring

Collar

Bearing Bearing

Gear

(5) Detach the E-ring and the bearing.

Bearing

E-ring

(6) Open the front cover, and detach the front E-ring

and the bearing.

E-ring

Bearing

(7) Remove the spring.

Spring

Belt

(8) Remove two clamp screws and two ground wire

screws.

(9) Remove the connectors of roller shift motor (M2),

roller shift PS (PS18), paper exit opening SD

(SD4), and paper exit PS/1 (PS6).

(10) Remove one screw and detach the paper exit

PS/2 (PS10) from the unit, then remove the connector.

Note: When detaching the paper exit PS/2

(PS10), beware not to add too much

stress onto the actuator located under

the paper exit PS/2.

1-R-6

Page 45

FN

(11) Remove harnesses from three clamps.

21

6

1. Ground wire screws

2. Harness clamps

3. Connector for the paper exit PS/2 (PS10)

4. Connector for the roller shift motor (M2)

5. Connector for the roller shift HP PS (PS18)

6. Clamp screw

7. Connector for the paper exit PS/1 (PS6)

8. Screw

9. Connector for the paper exit opening sole-

(12) Remove one screw and release the paper exit

opening open/close link.

9

noid (SD4)

8

7

Screw

3

4

6

5

(13) Remove four screws and tilt the shift unit.

Screws

Screw

(14) Lift and detach the paper exit opening unit.

Shift unit

Shift unit

Paper exit opening unit

Screw

3 DIS./ASSEMBLY1 DIS./ASSEMBLY

Paper exit opening open/close link

(15) Remove the shift unit from the paper exit side.

Shift unit

(16) Reinstall the parts by following the removal steps

in reverse.

1-R-7

Page 46

FN

[3] Removing and Reinstalling the

3 DIS./ASSEMBLY1 DIS./ASSEMBLY

Stacker/Stapler Unit

a. Procedure

(1) Open the front cover and pull the stacker/stapler

unit part of the way out.

(2) Remove the two rail-stopper set screws. Then

pull the stacker/stapler unit all of the way out.

Rail stopper screw

Stacker/stapler unit

Rail stopper screw

Rail stopper screw

(3) Remove four set screws holding the cover in

place, and remove the cover. (FN-7 only)

FN-7

Screws

FN-115

Cover

Screws

(4) Remove the two set screws holding the bundle

guide arm to the stacker/stapler unit.

Bundle guide arm

Screws

FN-7

Stacker/stapler unit

Rail stopper screw

1-R-8

Page 47

FN

(5) For FN-115

Remove five relay connectors (FN-115 only).

FN-115

(5) For FN-7

Detach the two connectors from the connector

board at the rear of the stacker/stapler unit.

(FN-7 only)

FN-7

Connectors

Connectors

Connectors

(7) Remove the final two set screws holding the

stacker/stapler unit in place. Remove the

stacker/stapler unit.

Set screw

Screw

Stacker/stapler unit

Set screw

Stacker/stapler unit

Set screw

FN-115

FN-7

3 DIS./ASSEMBLY1 DIS./ASSEMBLY

(6) Remove two screws from each side of the car-

tridge rails to remove the cartridge rails.

Cartridge rails

Screws

Screws

Set screw

(8) Reinstall the stacker/stapler unit in the opposite

sequence to removal.

1-R-9

Page 48

FN

STAPLER UNIT

3 DIS./ASSEMBLY1 DIS./ASSEMBLY

Caution:

When disassembling and reassembling

the machine, Be sure the power cord has

been unplugged from the wall outlet.

[1] Exchanging the clincher (FN-7 only)

a. Procedure

(1) Remove the front cover.

(2) Pull out the stacker/stapler unit by pulling on the

handle.

(3) Remove the two rail-stopper set screws.

Rail stopper screw

Stacker/stapler unit

Rail stopper screw

(4) Remove four set screws holding the cover in

place, and remove the cover.

(5) Detach the connector from the clincher you wish

to replace, and remove the four set screws holding the clincher in place.

Screws

Connector

(6) Lift the clincher up and out.

Clincher

Connector

Cover

Screws

(7) To install the new clincher, carry out the above

sequence in reverse.

(8) Adjust the stapler vertical positioning.

Screws

1-R-10

Page 49

[2] Removing and Reinstalling a Stapler

(For FN-115)

a. Procedure

(1) Open the front cover.

(2) Pull out the stacker/stapler unit by pulling on the

handle.

(3) Remove the cartridge from the stapler.

(4) Detach the two connector (if stapler-R, CN 201

and CN 202; if stapler-F, CN 203 and CN 204).

(5) Remove the set screw holding the stapler unit in

place, and remove the stapler unit.

Screws

(6) Reinstall in the opposite sequence to removal.

FN

3 DIS./ASSEMBLY1 DIS./ASSEMBLY

1-R-11

Page 50

FN

[3] Removing and Reinstalling a Stapler

3 DIS./ASSEMBLY1 DIS./ASSEMBLY

(For FN-7)

a. Procedure

(1) Open the front cover.

(2) Pull out the stacker/stapler unit by pulling on the

handle.

(3) Remove the cartridge from the stapler.

(4) Remove the set screw holding the connector

cover in place, and remove the connector cover.

Screw Connector cover

(5) Detach the stapler connector (if stapler-R, CN-

202; if stapler-F, CN-204), and remove the 4 set

screws holding the stapler in place.

(6) Lift the stapler slightly and remove it.

Stapler Connector Cover

(7) Reinstall in the opposite sequence to removal.

(8) Adjust the stapler vertical positioning.

Screws

Connector

(If stapler-R, connector CN-202

If stapler-F, connector CN-204)

1-R-12

Page 51

MAIN TRAY SECTION

FN

Caution:

When disassembling and reassembling

the machine, Be sure the power cord has

been unplugged from the wall outlet.

[1] Removing and Reinstalling the Up-

Down Stay

a. Procedure

(1) Remove the following parts.

• Rear cover

• Front cover

• Front side cover

• Main tray

(2) With the up-down stay and exit-stopper plate in

contact, remove the exit-stopper plate. (See

“Removing and Reinstalling the Exit Stopper

Plate.”)

(3) Remove the two slide stoppers (removing one

screw at each stopper).

Screws

[2] Exchanging the Up-Down Wire

Caution: The following procedure shows

replacement of the rear wi re. Removal

of the front wire is similar, but relationships are inverted (mirror image).

a. Procedure

(1) Remove the following parts.

• Rear cover

• Front cover

• Front side cover

• Main tray

(2) Remove the four wire-bracket set screws (two

screws at the front wire bracket and two screws

at the rear wire bracket), and take off the updown stay.

Screws

Up- down stay

Wire bracket (front)

(3) Remove the E-ring and the lower up-down pulley,

and remove the wire you are replacing.

Caution: There is a pin located in the inside of

the pulley. Take care to avoid losing

the pin when removing the pulley.

3 DIS./ASSEMBLY1 DIS./ASSEMBLY

Slide stopper

(4) Slide the up-down stay upward to remove it.

Up-down stay

(5) Reinstall the stay in the opposite sequence to

removal.

Wire

E-ring

Lower up-down pulley

1-R-13

Page 52

FN

(4) Move the up-down stay as necessary so that

3 DIS./ASSEMBLY1 DIS./ASSEMBLY

front inner wire (the shorter side from the wire

bracket) is wound twice around the pulley.

Short wire

Two winds

(5) Wind the shorter side of the rear wire (relative to

the wire bracket) twice around the up-down pul-

ley.

(6) Adjust the wire-bracket position so that it is even

with the front wire bracket. Insert the pin, and

then fasten the pulley into place with the E-ring.

(7) Fit the wire onto the upper pulley.

Two w i nd s

E-ring

(9) Press down on the up-down stay and refasten

the four wire-bracket set screws.

V

Wire bracket Wire bracket

Press down

Screws

Up-down stay

Screws

(10) Loosen the two belt-tensioner set screws.

(11) Using a tension gauge or spring balance, pull the

belt tensioner so that tension A is at the value

indicated below. Maintain this tension while

retightening the screws.

Spec value for tension: A = 2.5 ± 0.1kg

A=2.5±01kg

A=2.5±01kg

Upper pulley

(8) Wind the opposite side of the wire (the long side)

from the inside of the up-down pulley toward the

outside, and fix the wire end in place.

Long wire

Wire end

1-R-14

Page 53

FOLDING UNIT (FN-7 ONLY)

FN

Caution:

When disassembling and reassembling

the machine, Be sure the power cord has

been unplugged from the wall outlet.

[1] Removing and Reinstalling the Fold-

ing Unit

a. Procedure

(1) Remove the plate on the fold exit side.

(2) Remove the rear cover.

(3) Remove four set screws at the rear, as illustrated

below.

Screws

(4) Detach three connectors.

Connector

(5) Remove four set screws and detach the two

plates (front and back plates) at the booklet exit.

Screws

Plate

(6) Remove seven set screws at the front.

Pull stacker unit out slightly.

(7) Pull the folding unit out and off.

Note1: Be careful to keep the unit clear of the

up/down wires when removing it.

Note2: Be careful to keep the harness from

catching on the FNS body.

Folding unit

Screws

Plate

3 DIS./ASSEMBLY1 DIS./ASSEMBLY

Connector

Connector

Screws

(8) Reinstall the unit in the opposite sequence to

removal.

Note: When reinstalling the folding unit, take

care to keep the connectors and harness

from getting caught between the unit and

the FNS body.

1-R-15

Page 54

FN

[2] Removing and Reinstalling the

3 DIS./ASSEMBLY1 DIS./ASSEMBLY

Adjustment Cover

a. Procedure

(1) Use a stubby screwdriver to remove the set

screw holding the cover in place, and take the

cover off.

Adjustment Cover

(2) Reinstall the cover in the opposite sequence to

removal.

Screws

1-R-16

Page 55

PAPER FEED UNIT

PI

Caution:

When disassembling and reassembling

the machine, Be sure the power cord has

been unplugged from the wall outlet.

[1] Replacing a Paper-Feed Roller and

Feed Roller

a. Procedure

(1) Remove the cover.

(2) Remove the two stop rings, then shift the bearing

and pulley outward, and remove the feed roller

unit.

1

4

3

1. Stop ring

2. Pulley

3. Paper feed roller

4. Bearing

2

1

3 DIS./ASSEMBLY1 DIS./ASSEMBLY

1-S-1

Page 56

PI

(3) Pull out eighteen stop rings, the bearing, the two

3 DIS./ASSEMBLY1 DIS./ASSEMBLY

actactuators and four shaft of the feed-roller unit

then remove each roller.

1

2

3

4

1

9

5

2

6

5

9

11

1

5

2

6

5

7

8

7

3

4

2

11

2

1

4

5

3

9

10

11

5

8

7

9

7

11

2

2

1. Shaft

2. Stop ring

3. Feed drive belt

4. Pulley

5. Paper feed arm

6. Bearing

(4) Re-install the paper-feed roller and feed roller in

the opposite sequence to removal.

Note: Ensure that the mounting direction of the

rubber is correct.

7. E-ring

8. Actuator

9. Rubber

10. Feed roller

11. Blue mark

1-S-2

Page 57

PI

[2] Replacing the Rubber, Double-Feed

Prevention Roller

a. Procedure

(1) Remove the cover.

(2) Remove the feed-roller unit. Refer to the previ-

ous procedure for instructions on removing the

unit.

(3) Remove the two set screws, Then remove the

plate.

Screw

Plate

Screw

(4) Remove the 3 stop rings, then pull out the shaft,

and remove the double-feed-prevention roller

together with the feed-reverse gear.

1

(5) Remove the rubber from the double-feed-pre-

vention roller.

(6) Re-install the removed parts in the reverse

sequence to removal.

Note: Ensure that the mounting direction of the

rubber is correct.

3 DIS./ASSEMBLY1 DIS./ASSEMBLY

5

1. Stop rings

2. Paint mark

3. Feed reverse gear

4. Double-feed prevention roller

5. Shaft

4

2

3

1-S-3

Page 58

3 DIS./ASSEMBLY1 DIS./ASSEMBLY

Page 59

PAPER FEED UNIT

PI

Caution:

When disassembling and reassembling

the machine, Be sure the power cord has

been unplugged from the wall outlet.

[1] Replacing a Paper-Feed Roller and

Feed Roller

a. Procedure

(1) Remove the cover.

(2) Remove the two stop rings, then shift the bearing

and pulley outward, and remove the feed roller

unit.

1

4

3

1. Stop ring

2. Pulley

3. Paper feed roller

4. Bearing

2

1

3 DIS./ASSEMBLY1 DIS./ASSEMBLY

1-S-1

Page 60

PI

(3) Pull out eighteen stop rings, the bearing, the two

3 DIS./ASSEMBLY1 DIS./ASSEMBLY

actactuators and four shaft of the feed-roller unit

then remove each roller.

1

2

3

4

1

9

5

2

6

5

9

11

1

5

2

6

5

7

8

7

3

4

2

11

2

1

4

5

3

9

10

11

5

8

7

9

7

11

2

2

1. Shaft

2. Stop ring

3. Feed drive belt

4. Pulley

5. Paper feed arm

6. Bearing

(4) Re-install the paper-feed roller and feed roller in

the opposite sequence to removal.

Note: Ensure that the mounting direction of the

rubber is correct.

7. E-ring

8. Actuator

9. Rubber

10. Feed roller

11. Blue mark

1-S-2

Page 61

PI

[2] Replacing the Rubber, Double-Feed

Prevention Roller

a. Procedure

(1) Remove the cover.

(2) Remove the feed-roller unit. Refer to the previ-

ous procedure for instructions on removing the

unit.

(3) Remove the two set screws, Then remove the

plate.

Screw

Plate

Screw

(4) Remove the 3 stop rings, then pull out the shaft,

and remove the double-feed-prevention roller

together with the feed-reverse gear.

1

(5) Remove the rubber from the double-feed-pre-

vention roller.

(6) Re-install the removed parts in the reverse

sequence to removal.

Note: Ensure that the mounting direction of the

rubber is correct.

3 DIS./ASSEMBLY1 DIS./ASSEMBLY

5

1. Stop rings

2. Paint mark

3. Feed reverse gear

4. Double-feed prevention roller

5. Shaft

4

2

3

1-S-3

Page 62

3 DIS./ASSEMBLY1 DIS./ASSEMBLY

Page 63

EXTERNAL SECTION

PU

Caution:

When disassembling and reassembling

the machine, Be sure the power cord has

been unplugged from the wall outlet.

[1] Removing the PU (Puncher)

a. Procedure

(1) Loosen the two screws in the lower part of the

rear cover of the PU, then remove the two screws

in the upper part to remove the rear cover.

(2) Open the front door of the FNS and raise the

paper reception guide lever of the PU to retract

the paper reception guide in the PU.

Paper reception guide lever

(3) Remove the three screws securing the PU to the

main body, draw out the PU, and remove the two

relay connectors (CN95 and CN96) of the PU

from the main body.

Relay connectors (CN96)

Relay connectors (CN95)

3 DIS./ASSEMBLY1 DIS./ASSEMBLY

Screws

(4) Remove the two screws (front side) fixing the PU

and the FNS, and remove two screws (rear side)

fixing the positioning plate.

(5) Pull the lever of the FNS installation stay to

release the fixing the PU and the FNS, and

detach the PU by lifting.

(6) Remove the two relay connectors of the FNS

from the PU.

(7) Reinstall the above parts following the removal

steps in reverse.

Screws (loosen)

Rear cover

1-T-1

Page 64

PU

PUNCH SECTION

[1] Replacing the Punch unit

3 DIS./ASSEMBLY1 DIS./ASSEMBLY

Note: Be sure to unplug the power cords of the

main body and this machine from the wall

outlet.

Note: The following screws should not be

removed. If you do, punching cannot be

done as designed.

Screws that should

not be removed

Screws that should not be removed

Retaining ring that should

not be removed

Punch unit

Retaining ring

that should not

be removed

a. Procedure

(1) Remove the sensor mounting stay by removing a

screw.

Paper mounting stay

Screw

(2) Cut the wiring harness band and disconnect the

relay connector (CN39) upward.

(3) Remove the punch unit by removing four screws.

Punch unit

Wiring harness band

Screws that should not be removed

OK

NG

Screws

Relay connector (CN39)

(4) Reinstall the above parts following the removal

steps in reverse.

Note: When reinstalling, harness the band in

same direction. (see the figure is step (3))

1-T-2

Page 65

PU

[2] Replacing the Punch Clutch (MC1)

Note: The punch unit gear rotates only in the

direction of the arrow.

Never turn it in the direction opposite to

the arrow direction. If you do so, the MC1

(punch clutch) will break.

Caution:

a. Procedure

(1) Remove the punch unit. See "[1] Replacing the

Punch unit."

(2) Remove the punch motor unit by removing two

screws.

(3) Cut the three wiring harness bands and discon-