Page 1

T

User Manual

Di850

www.minoltaeurope.com

he essentials of imaging

Page 2

Table of Contents

1 Introduction

1.1 We Want You to Be a Satisfied Customer ..................................1-1

1.2 Protecting the Environment. . . ....................................................1-2

Takeback and Reutilization.............................................................1-2

What is Energy Star®? ...................................................................1-2

Use of Recycled Paper ...................................................................1-2

1.3 Guide to this Manual.....................................................................1-3

How is this Manual Structured? ...................................................... 1-3

A Brief Explanation of the Conventions

Used in this Manual.........................................................................1-4

A Brief Explanation of Important Concepts

and Symbols ...................................................................................1-5

1.4 Overview of System Features ......................................................1-8

General Features............................................................................1-8

Automatic Features .......................................................................1-12

Finishing Features......................................................................... 1-13

Features that can only be Set Up by a

Service Technician........................................................................ 1-14

WWW-Server Function ................................................................. 1-15

2 Getting to Know Your System

2.1 System Overview ..........................................................................2-1

External System Overview ..............................................................2-1

Internal System Overview ...............................................................2-3

2.2 Options (Accessories)..................................................................2-4

Finisher FN-115/FN-7 .....................................................................2-4

Cover Inserter C for Finisher...........................................................2-7

Large Capacity Cassette (LCC) C-403N/C-404N ........................... 2-8

TMG-2 Trimming Unit (optional for FN-7 Finisher)..........................2-9

PK-3 Hole Punch Unit ................................................................... 2-11

ZK-2 Punch/Z-fold Unit.................................................................. 2-12

Memory Expansions...................................................................... 2-13

Pi8500 Printcontroller....................................................................2-13

Di850 IVZ-1

Page 3

2.3 Safe Working with Your System ............................................... 2-14

Laser Safety ................................................................................. 2-18

Internal Laser Radiation ............................................................... 2-18

Safety Label.................................................................................. 2-20

System serial number ................................................................... 2-22

2.4 Transporting the System ........................................................... 2-23

2.5 Installing the System.................................................................. 2-23

Environmental Requirements ....................................................... 2-23

Installation Site ............................................................................. 2-23

Space required for System ........................................................... 2-24

Storing Supplies ........................................................................... 2-25

2.6 Connecting the System.............................................................. 2-25

Voltage and Frequency Tolerances.............................................. 2-25

2.7 Switching the System on and off .............................................. 2-26

Switching the System on .............................................................. 2-26

Switching the System off .............................................................. 2-27

2.8 Control Panel Keys and Indicators........................................... 2-28

Control Panel................................................................................ 2-28

Indicators and Keys on the Touch Screen.................................... 2-30

2.9 Using the Touch Screen ............................................................ 2-33

2.10 Adding Paper .............................................................................. 2-34

Refilling Trays 1, 2 and 3.............................................................. 2-35

Adding Paper to Paper Tray 4 - C-403N (optional) ..................... 2-37

Adding Paper to Paper Tray 4 - C-404N (optional) ..................... 2-39

Filling the Bypass Tray ................................................................. 2-41

2.11 Adding Toner .............................................................................. 2-43

2.12 Replenishing the Staple Supply................................................ 2-46

Adding Staples for the FN-115 Finisher (optional) ....................... 2-46

Adding Staples for the FN-7 Finisher (optional) ........................... 2-49

2.13 Monitoring the PM Count Time ................................................. 2-52

Viewing the PM Count .................................................................. 2-52

Printing the PM Count .................................................................. 2-53

Closing the PM Count Screen ...................................................... 2-53

2.14 Shutting Down the System ........................................................ 2-54

2.15 Please Observe these Precautions........................................... 2-55

. . . when working with your system.............................................. 2-55

. . . when servicing and repairing the system ............................... 2-55

2.16 Proper Use of Your System ....................................................... 2-56

IVZ-2 Di850

Page 4

3 Initial Steps . . .

3.1 Basic Operator Steps....................................................................3-1

Entering the Number of Copies....................................................... 3-1

Start Cycle....................................................................................... 3-2

Stop Cycle....................................................................................... 3-2

Reset System Settings ....................................................................3-2

3.2 Activating the System...................................................................3-3

Ending Energy Saving Mode...........................................................3-3

Ending Auto Shut Off ...................................................................... 3-3

Interrupting Weekly Timer Mode ..................................................... 3-4

Entering the E.K.C. Password.........................................................3-6

3.3 Placing the Originals on the Original Glass ............................... 3-8

3.4 Feeding Originals Using the EDH.............................................. 3-10

Loading Equal-Sized Originals into the EDH ................................3-11

Loading Single Originals into the EDH (SDF) ...............................3-12

Loading Mixed-Sized Originals into the EDH ................................3-13

Place Z-Folded Originals in the EDH ............................................3-14

3.5 Checking the System Settings...................................................3-15

Changing Settings.........................................................................3-15

Releasing Settings ........................................................................3-17

Processing a Proof Copy ..............................................................3-18

3.6 Reserving Copy Jobs .................................................................3-19

Setting up Reserve Jobs ............................................................... 3-20

Calling up the Status Display ........................................................ 3-21

Status Display Message Definitions.............................................. 3-22

Changing the Order of Reserve Jobs............................................3-23

Deleting a Reserve Job ................................................................. 3-24

Checking the User Name of a Reserve Job..................................3-25

Calling up the List of Already Executed Jobs ................................ 3-26

Opening the Noncomplete Job List...............................................3-27

Interrupting the Setup of a Reserve Job ....................................... 3-28

3.7 Interrupting a Copy Job..............................................................3-30

3.8 Recalling System Settings of the Last Job...............................3-33

3.9 Saving and Recalling System Settings .....................................3-34

Saving System Settings ................................................................ 3-34

Recalling System Settings ............................................................3-37

3.10 Check System Meter Count........................................................3-39

Viewing the Meter Counts.............................................................3-39

Printing the Counter List................................................................3-40

Di850 IVZ-3

Page 5

3.11 Enabling Energy Saving Modes ................................................ 3-41

Enabling Energy Saving Mode ..................................................... 3-42

Enabling Auto Shut Off Mode ....................................................... 3-43

3.12 Using the Bypass Tray............................................................... 3-44

Load the Paper on to the Bypass Tray......................................... 3-44

Processing Tab Papers ................................................................ 3-45

3.13 Using the Help Mode .................................................................. 3-46

Open Help Topic Overview........................................................... 3-47

Call Help for a Specific Cycle ....................................................... 3-48

3.14 Using Bookmark Function......................................................... 3-49

4 Basic Functions

4.1 Setting the Output Mode .............................................................. 4-1

Non Sort – Output to the Main Tray................................................ 4-3

Sort – Output to the Main Tray ....................................................... 4-4

Staple – Output to the Main Tray.................................................... 4-6

Group – Output to the Main Tray.................................................... 4-9

Output to the Sub Tray ................................................................. 4-11

Folding, Stapling & Folding and Trimming.................................... 4-14

Adding Front and Back Cover Sheets .......................................... 4-19

Hole-Punch ................................................................................... 4-22

Z-Fold ........................................................................................... 4-25

Manual Stapling, Punching or Folding.......................................... 4-28

Output without Finisher................................................................. 4-31

Using two Systems in Tandem..................................................... 4-35

4.2 Setting the Copy Mode............................................................... 4-40

Creating 1 and 2-sided Copies (Using the EDH).......................... 4-41

Creating 2-sided Copies (Using the Original Glass)..................... 4-43

4.3 Adjusting the Contrast ............................................................... 4-46

Enabling Auto Exposure Mode ..................................................... 4-47

Manually Adjusting Copy Density................................................. 4-48

Adjusting the Image Density......................................................... 4-49

4.4 Setting the Zoom Ratio .............................................................. 4-51

Enabling Automatic Magnification Selection (AMS) ..................... 4-52

Selecting a Preset Zoom Ratio..................................................... 4-54

Selecting User-set Zoom Ratios ................................................... 4-55

Horizontal/Vertical Stretch ............................................................ 4-56

IVZ-4 Di850

Page 6

4.5 Setting the Copy Paper Size ......................................................4-57

Enabling Auto Paper Select Mode (APS)......................................4-58

Manually Selecting a Paper Tray ..................................................4-60

Specifying the Paper Type/Size for the Bypass Tray....................4-61

Specify Copy Start on Wide Size Paper

for the Bypass Tray ....................................................................... 4-63

4.6 Applying Functions.....................................................................4-65

Storing Originals (from the Original Glass) ................................... 4-66

Storing Originals (from EDH) ........................................................ 4-68

Using Rotation Mode.....................................................................4-70

Set Original Position (Special Originals) ....................................... 4-74

Setting Text/Photo Enhance (Special Originals) ...........................4-76

Copying Mixed Sizes (Special Originals) ...................................... 4-78

Copying Z-Folded Originals (Special Originals)............................4-80

Feeding Originals Individually – SDF

(Special Originals)......................................................................... 4-82

Defining Special Original Types (Special Originals)...................... 4-86

5 Applications

5.1 Adding Inserts and Cover Sheets................................................ 5-2

Information on: Inserts and Cover Sheets.......................................5-3

Procedure: Adding Inserts and Cover Sheets.................................5-4

5.2 Executing Chapter Mode..............................................................5-6

Information on: Chapter Mode ........................................................5-6

Procedure: Executing Chapter Mode..............................................5-7

5.3 Creating Combinations................................................................. 5-9

Information on: Combination .........................................................5-10

Procedure: Creating Combinations...............................................5-11

5.4 Creating Booklets .......................................................................5-13

Information on: Booklets ...............................................................5-14

Procedure: Creating Booklets.......................................................5-15

5.5 Creating OHP Interleave ............................................................. 5-17

Information on: OHP Interleave..................................................... 5-17

Procedure: Creating OHP Interleave ............................................5-18

5.6 Inserting Images..........................................................................5-20

Information on: Inserting Images...................................................5-20

Procedure: Inserting Images.........................................................5-21

5.7 Processing Dual Page Originals................................................5-23

Information on: Dual Page ............................................................5-24

Procedure: Processing Dual Page Originals.................................5-25

Di850 IVZ-5

Page 7

5.8 Program Job ............................................................................... 5-27

Information on: Program Job ........................................................ 5-27

Procedure: Program Job .............................................................. 5-28

5.9 Using Non-Image Area Erase .................................................... 5-30

Information on: Non-Image Area .................................................. 5-31

Procedure: Using Non-Image Area Erase.................................... 5-32

5.10 Creating Reverse Images........................................................... 5-33

Information on: Reverse Image .................................................... 5-33

Procedure: Creating Reverse Images .......................................... 5-34

5.11 Using Image Repeat Mode......................................................... 5-35

Information on: Repeat................................................................. 5-36

Procedure: Using Image Repeat Mode ........................................ 5-38

5.12 Using Frame/Fold Erasure......................................................... 5-40

Information on: Frame/Fold Erasure............................................. 5-40

Procedure: Using Frame/Fold Erasure......................................... 5-41

5.13 Using Auto Layout...................................................................... 5-43

Information on: Auto Layout ......................................................... 5-43

Procedure: Using Auto Layout...................................................... 5-44

5.14 Using Full-Image Area................................................................ 5-45

Information on: Full-Image Area ................................................... 5-45

Procedure: Using Full-Image Area ............................................... 5-46

5.15 Creating a File Margin ................................................................ 5-47

Information on: Image Shift .......................................................... 5-48

Procedure: Creating a File Margin................................................ 5-49

5.16 Using Stamp/Overlay ................................................................. 5-51

Information on: Using Stamp/Overlay........................................... 5-52

Procedure: Using Stamp .............................................................. 5-55

Procedure: Using Watermark ....................................................... 5-57

Procedure: Using Overlay ............................................................ 5-59

Procedure: Overlay Memory (store image) .................................. 5-61

Procedure: Overlay Memory (call up image)................................ 5-64

6 Network Functions

6.1 Server Functions .......................................................................... 6-1

Storing a Job .................................................................................. 6-3

Deleting a Job................................................................................. 6-6

Storing and Printing a Job .............................................................. 6-8

Calling up Jobs from the Hard Drive............................................. 6-11

IVZ-6 Di850

Page 8

6.2 Web Functions ............................................................................6-14

Starting Web Utilities .....................................................................6-15

Calling up System Status ..............................................................6-17

Calling up Job Status .................................................................... 6-18

Call up and Edit Hard Drive Data..................................................6-20

E-Mail Transmission Setting .........................................................6-24

7 Settings in Key Operator Mode

7.1 Overview ........................................................................................7-2

Calling up Key Operator Mode........................................................ 7-2

Leaving Key Operator Mode...........................................................7-2

Overview of the Key Operator Mode Menu.....................................7-3

7.2 (1) System Initial Setting ..............................................................7-5

(1) Date & Time Setting................................................................... 7-5

(2) Language Select Setting............................................................7-7

(3) IP Address Setting ..................................................................... 7-8

(4) E-Mail Transmission Setting .................................................... 7-10

7.3 (2) Copier Initial Setting..............................................................7-13

7.4 (3) User Setting Mode .................................................................7-15

(1) Setting User density Level 1....................................................7-15

(2) Setting User Density Level 2 ................................................... 7-17

(3) Setting the Zoom Ratio (Lens Mode).......................................7-19

7.5 (4) E.K.C. Function Setting.........................................................7-20

Calling up E.K.C. Mode................................................................. 7-20

(1) E.K.C. Data Edit....................................................................... 7-21

(2) E.K.C. All Count Reset ............................................................7-27

(3) E.K.C. Function Setting ...........................................................7-28

7.6 (5) Program Memory Lock/Delete.............................................. 7-30

Locking and Unlocking Program

Memory Positions..........................................................................7-30

Deleting System Settings ..............................................................7-31

7.7 (6) Paper Type/Special Size Setting ..........................................7-32

Specifying the Paper Type ............................................................7-32

Specifying the Paper Size .............................................................7-33

Set Copy Start to Wide Size Paper ............................................... 7-35

7.8 (7) Panel Contrast/Key Sound Adjustment...............................7-37

7.9 (8) Key Operator Data Setting ....................................................7-38

7.10 (9) Weekly Timer.......................................................................... 7-39

Calling up Weekly Timer Mode .....................................................7-39

(1) Weekly Timer ON/OFF Setting ...............................................7-40

(2) Timer Setting ........................................................................... 7-41

Di850 IVZ-7

Page 9

(3) Timer Action ON/OFF Setting ................................................. 7-44

(4) Lunch Hour Off Setting............................................................ 7-46

(5) Timer Interrupt Password Setting............................................ 7-47

7.11 (10) Control Panel Adjustment .................................................. 7-48

7.12 (11) Set auto tray selection........................................................ 7-49

7.13 (12) Energy Saver Setting .......................................................... 7-50

7.14 (13) Memory Switch Setting....................................................... 7-51

Changing Settings ........................................................................ 7-51

Overview of Settings..................................................................... 7-52

7.15 (14) Machine Management List Print ........................................ 7-57

7.16 (15) Call Remote Center ............................................................. 7-58

7.17 (16) Side 2 Lens Adjustment ..................................................... 7-60

7.18 (17) Finisher Adjustment ........................................................... 7-61

7.19 (18) HDD Management Setting .................................................. 7-63

(1) Password List/Delete ............................................................. 7-63

(2) JOB Auto Delete Period Setting.............................................. 7-65

(3) State of HDD Capacity............................................................ 7-66

7.20 (19) Scan Transmission Object Change/Del. ........................... 7-67

7.21 (20) Non-Image Area Erase Setting........................................... 7-67

8 Troubleshooting

8.1 If Your Copy Is Incorrect.............................................................. 8-1

8.2 Your System Is Not Working Correctly ...................................... 8-3

8.3 If the PM Call Message Is Displayed........................................... 8-6

If the System No Longer Operates... .............................................. 8-6

If the System Still Operates Partially... ........................................... 8-7

8.4 If the Memory "Overflows" .......................................................... 8-8

. . . while the current job is under way ............................................ 8-8

. . . during setup of a reserve job .................................................... 8-8

8.5 If the "Please Switch OFF/ON" Screen Appears........................ 8-9

8.6 Clearing a Paper Jam ................................................................. 8-10

8.7 Emptying the Hole Punch Unit Waste Container..................... 8-11

8.8 Emptying the Trimming Unit Waste Container ........................ 8-13

IVZ-8 Di850

Page 10

9Appendix

9.1 System Maintenance.....................................................................9-1

Cleaning System Parts.................................................................... 9-1

Cleaning the Original Cover and Original Glass .............................9-2

9.2 Specifications................................................................................ 9-3

System Di850..................................................................................9-3

Document Feeder EDH-5................................................................9-5

Finisher FN-115 (optional), Finisher FN-7 (optional).......................9-5

Trimming Unit C (optional for Finisher FN-115/FN-7).....................9-6

TMG-2 Trimming Unit (optional for FN-7 Finisher)..........................9-6

PK-3 Hole Punch Unit (optional) ..................................................... 9-7

ZK-2 Punch/Z-fold Unit (optional)....................................................9-7

Large Capacity Cassette C-403N (optional) ...................................9-8

Large Capacity Cassette C-404N (optional) ...................................9-8

9.3 Consumables.................................................................................9-9

9.4 You Can Process This Paper.....................................................9-10

. . . with Paper Trays 1, 2, and 3 ...................................................9-10

. . . with the Large Capacity Cassette LCC (optional)...................9-11

. . . with the Bypass Tray............................................................... 9-13

. . . with the Automatic Duplex Unit ............................................... 9-14

. . . with the Cover Inserter C (optional) ........................................9-14

. . . with the Finishers (optional) ....................................................9-15

. . . with the Hole Punch Unit and Punch/Z-fold Unit

(optional) .......................................................................................9-17

TMG-2 Trimming Unit (optional for FN-7 Finisher)........................ 9-18

9.5 CE Marking (Declaration of Conformity)...................................9-19

9.6 Index.............................................................................................9-20

Di850 IVZ-9

Page 11

IVZ-10 Di850

Page 12

Introduction

1 Introduction

1.1 We Want You to Be a Satisfied Customer

Thank you for choosing a Minolta System.

To ensure the best performance and effective use of your system, this

manual provides information on the following topics:

G Standard operator procedures

G Basic functions

G Special applications

G Settings in key operator mode

G Troubleshooting

Please read this manual carefully before using your system. Always keep

the manual within reach. A holder for the manual is attached to the back

of the system.

For further information and assistance in the event of difficulties, please

contact:

G Your technical representative for Minolta

G The Minolta hotline, tel. 08 00 /6 46 65 82 (toll-free)

G Our Internet website http://www.minolta.com

Please keep the serial number (refer to the identification plate on your

system) and the system's date of purchase handy to ensure fast, accurate

assistance in the event of difficulties.

. . . because we want you to be a satisfied customer.

1

Di850 1-1

Page 13

1

1.2 Protecting the Environment. . .

Minolta supports the challenge maintaining the environment and does all

that it can to actively participate in preventing and resolving ecological

problems. Our production is certified with ISO 9000 (quality management)

and ISO14001 (environment management).

Takeback and Reutilization

Minolta partners take back old machines and systems as well as empty

and used toner and drum units for recycling and reclaiming the materials.

You can obtain further information by calling 08 00 / 6 46 65 82 (toll-free).

Introduction

What is Energy Star

After long periods of idleness, Energy Star

Saver Mode or turn themselves off. This function can reduce the annual

energy costs for the unit by up to 60%.

Systems with a high copying speed automatically switch to 2-sided

copying mode. This reduces the costs for paper and the volume of paper

consumed.

Did you know that manufacturing a sheet of paper requires 10 times as

much energy as making a copy?

The conservation of paper thus also has a direct global effect on the

conservation of energy.

This system complies with the Energy Star

Use of Recycled Paper

This system is designed to use recycled paper that conforms to ENV

12281 or DIN 19309. Your local MINOLTA representative will be pleased

to provide more information.

®

?

®

systems switch to Energy

®

energy efficiency criteria.

1-2 Di850

Page 14

Introduction

1.3 Guide to this Manual

How is this Manual Structured?

If you are not sure where to locate the information you need, please refer

to this section. The following table will help you. For detailed information

on specific issues, refer to the index at the end of the manual.

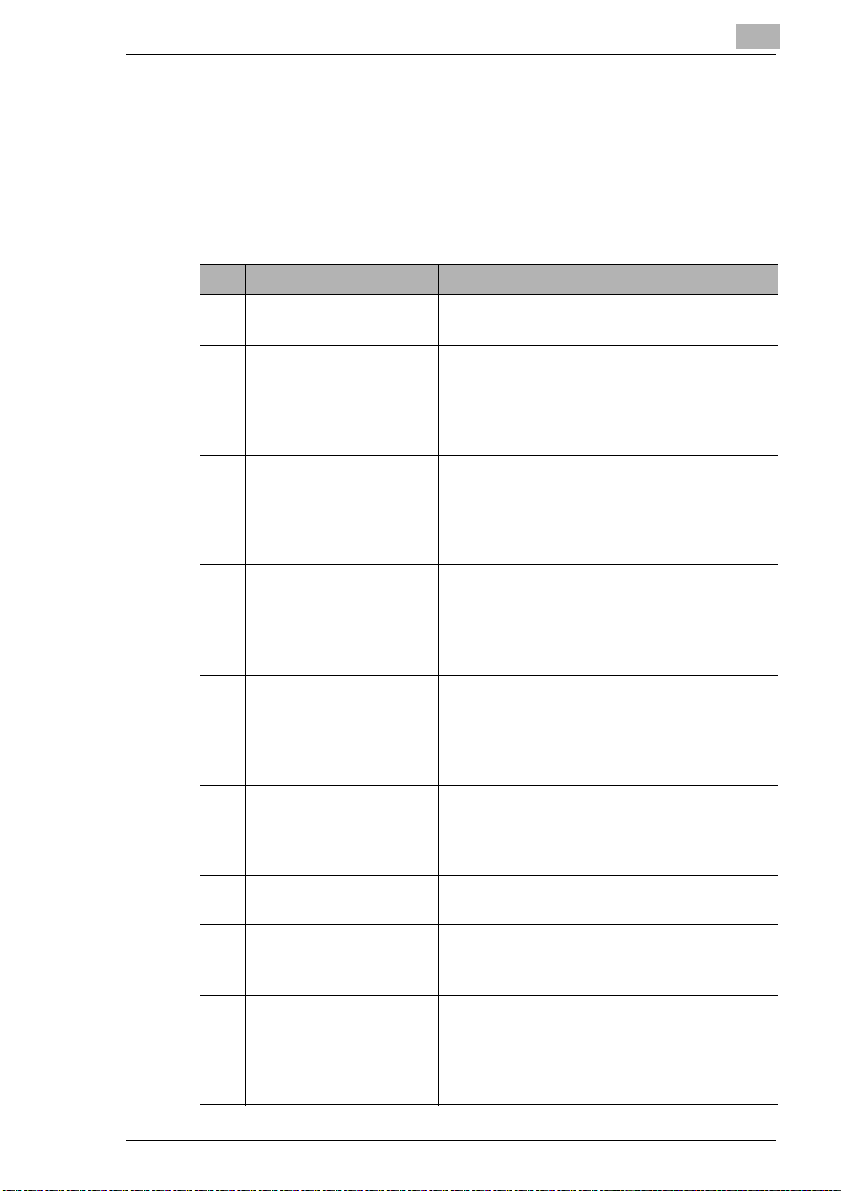

No. Chapter Description

1 Introduction This chapter contains introductory information,

2 Getting to Know Your

System

3 Initial Steps . . . This chapter shows you how to carry out

4 Basic Functions This chapter describes how to choose basic

5 Applications This chapter shows you how to use special

6 Network Functions This chapter describes how to store data on

7 Settings in Key Operator

Mode

8 Troubleshooting This chapter contains tables and instructions

9 Appendix The appendix contains a collection of useful

1

especially for the effective use of this manual.

This chapter will familiarize you with your

system and its features:

• System layout

• Safe working with the system

• Connecting the system

frequent operating tasks, such as:

• Loading originals

• Starting the copy cycle

• Reserving jobs

system functions to suit your needs, such as:

• Adjusting the contrast

• Setting the zoom ratio

• Setting the copy paper size

applications correctly, such as:

• Adding inserts and cover sheets

• Creating reverse images

• Creating a file margin

files on the hard drive (optional) as well as how

to monitor the system by utilizing the Web

Utilities.

In this chapter you will learn how to change the

default settings of the system.

to help you recognize faults and eliminate

malfunctions.

supplementary information such as:

• System maintenance

•Specifications

• Index

Di850 1-3

Page 15

1

Introduction

A Brief Explanation of the Conventions Used in this Manual

A variety of conventions and types of illustrations are used for special

emphasis in this manual. The following examples show the most

important conventions and how to respond to them.

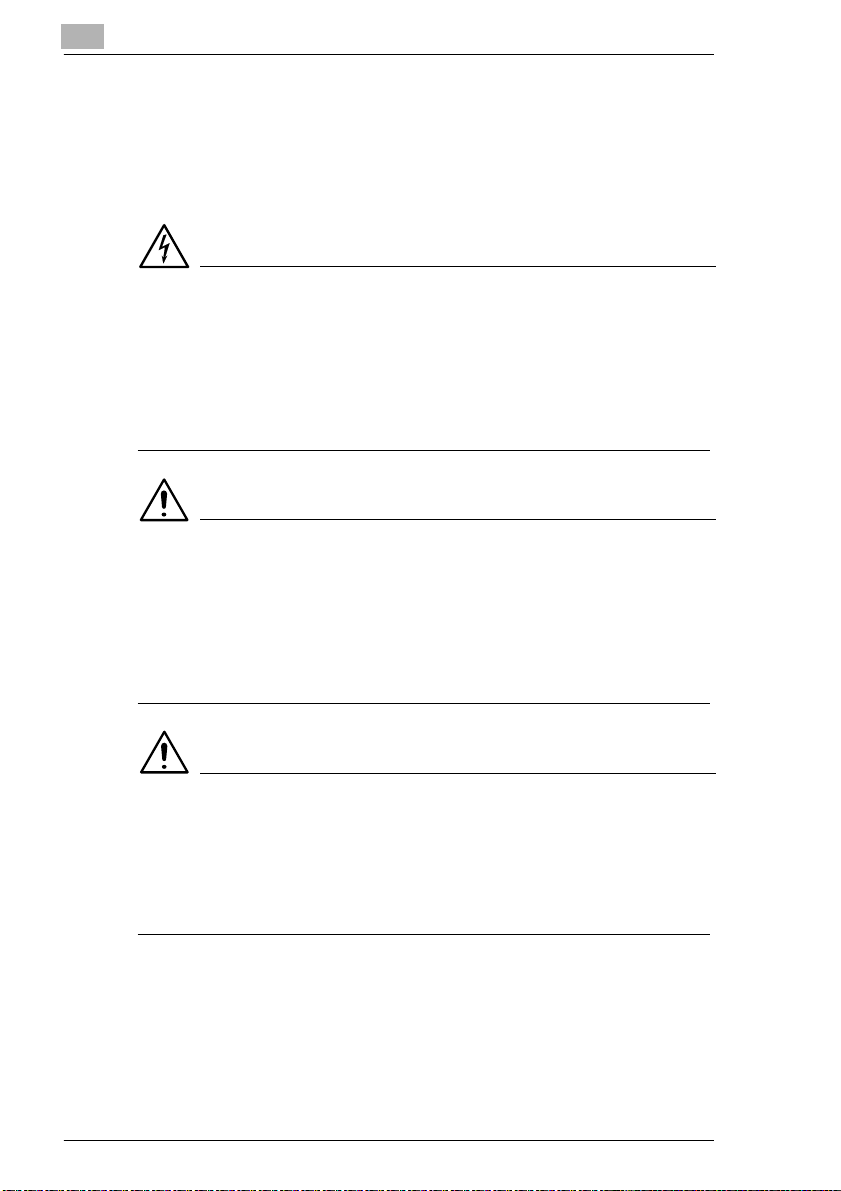

DANGER

This is a danger warning!

The danger warning points out a danger of potentially serious injury or

death. Not observing the danger warning can lead to serious personal

injury.

§ The arrow marks the precautionary measure required to avoid the

danger.

WARNING

This is a warning!

The warning points out a hazardous situation for persons and/or products.

Not observing the warning can lead to personal injury and/or serious

damage to the system.

§ The arrow marks the precautionary measure required to avoid the

danger.

CAUTION

This is a caution!

The caution points out a potential and dangerous situation. Not observing

the caution can lead to personal and/or system damage.

§ The arrow marks the precautionary measure required to avoid the

danger.

1-4 Di850

Page 16

Introduction

[START] e.g. control panel key [START] = key on the control panel

1

e.g. key [START] = key on the touch screen

ERROR

§ Individual action to be performed

A list begins:

G These bullets indicate a list.

G Lists with bullets are not in any specific order.

H Where a list with white bullets follows a list with black bullets, the white

bullets are ranked below the black bullets.

H

G This is the end of the list.

Step 1 of a sequence of actions

1

Step 2 of a sequence of actions

2

?

§ The action described here is

Step 3 of a sequence of actions

3

H This bullet indicates a list within

H

Message on the display panel with the text ERROR

(no further steps)

This will show you what

needs to be done

This is additional assistance.

sure to achieve the results you

desire.

a sequence of actions.

This is a helpful hint

Texts highlighted in this manner contain useful little tips and tricks for

the copying process.

A Brief Explanation of Important Concepts and Symbols

Paper feeding direction, length and width, lengthwise and crosswise are

standard terms. They are defined below.

Di850 1-5

Page 17

1

Introduction

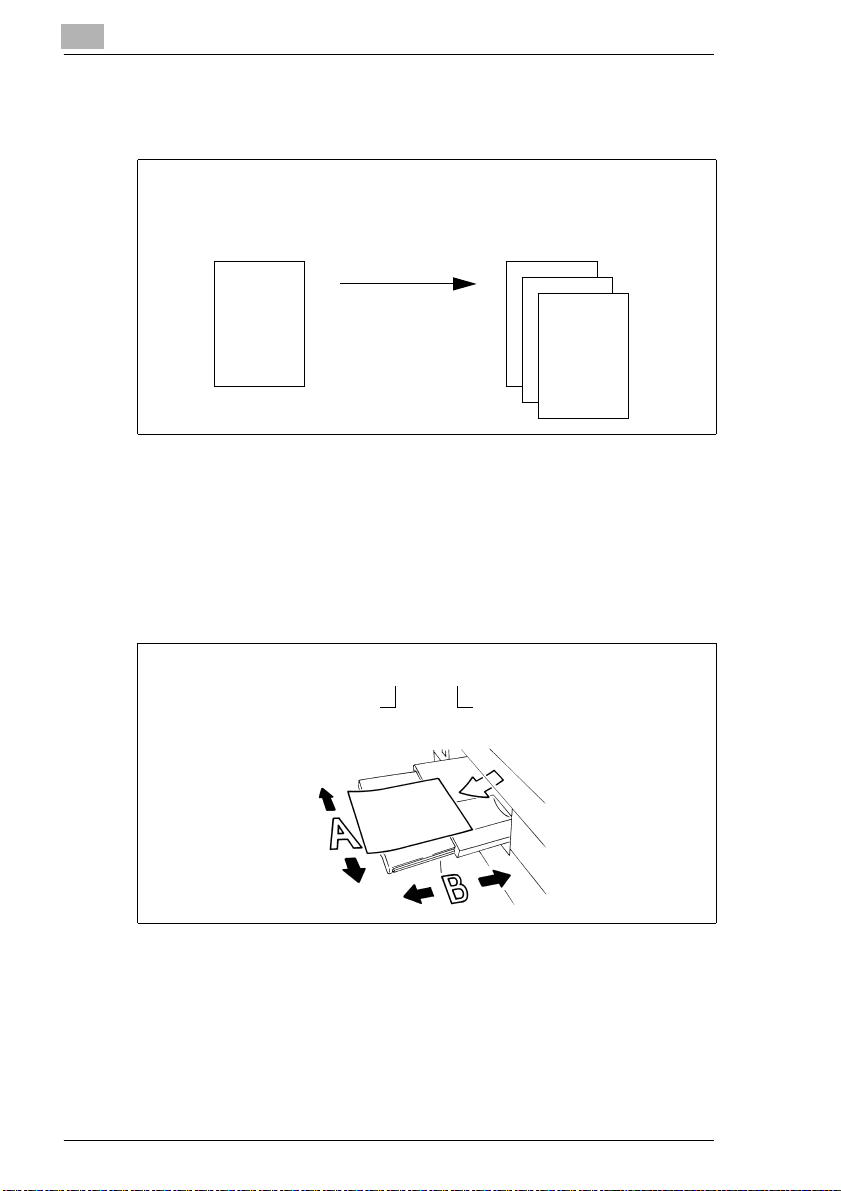

Original and copy

The original is the document being duplicated by the copy cycle.

Original

(document to be copied)

Copy cycle

enlarge,

reduce

sort.

Feeding direction

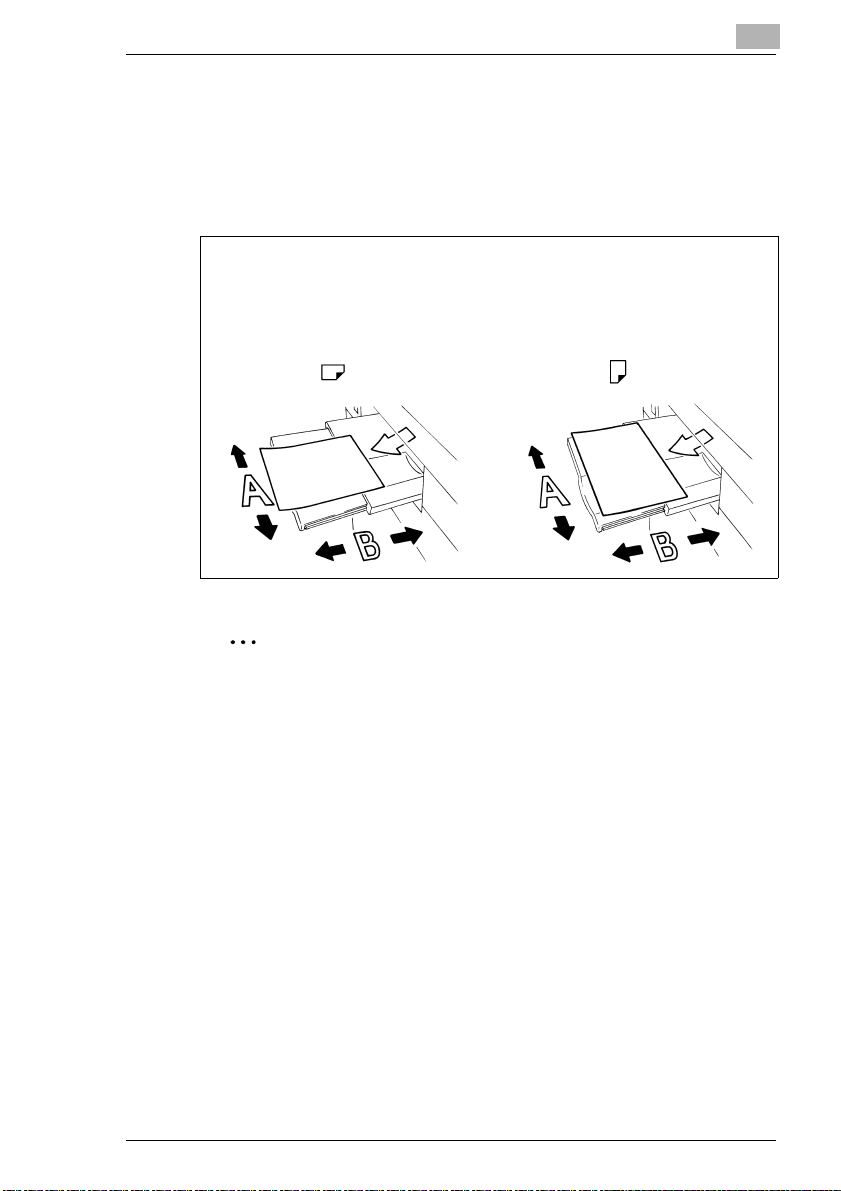

The feeding direction is the paper's path through the system.

Width and length

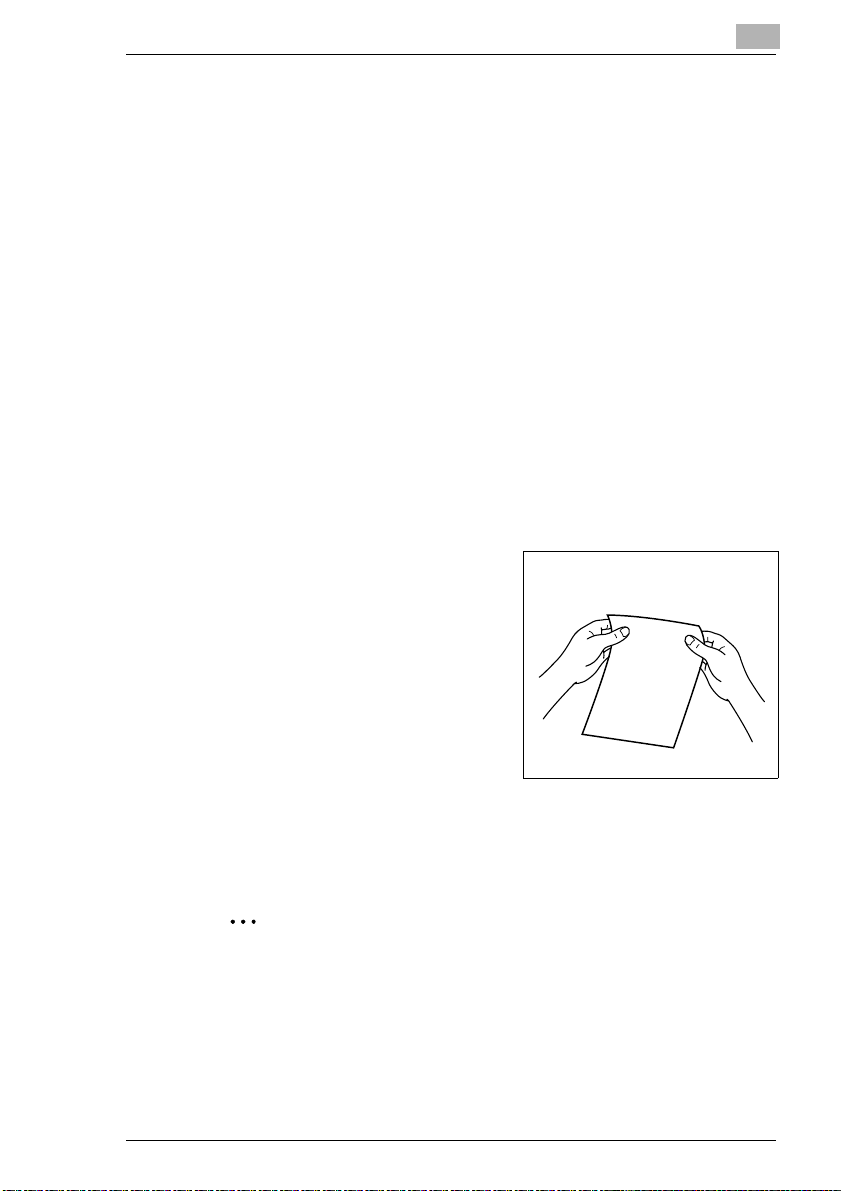

Whenever paper dimensions are specified in the Owner's Manual, the first

value always refers to the width of the paper (side A) and the second to

the length (side B).

(copy of the original document)

,

Copy

21 x 29.7 cm

Width of the paper

(side A)

Length of the paper

(side B)

1-6 Di850

Page 18

Introduction

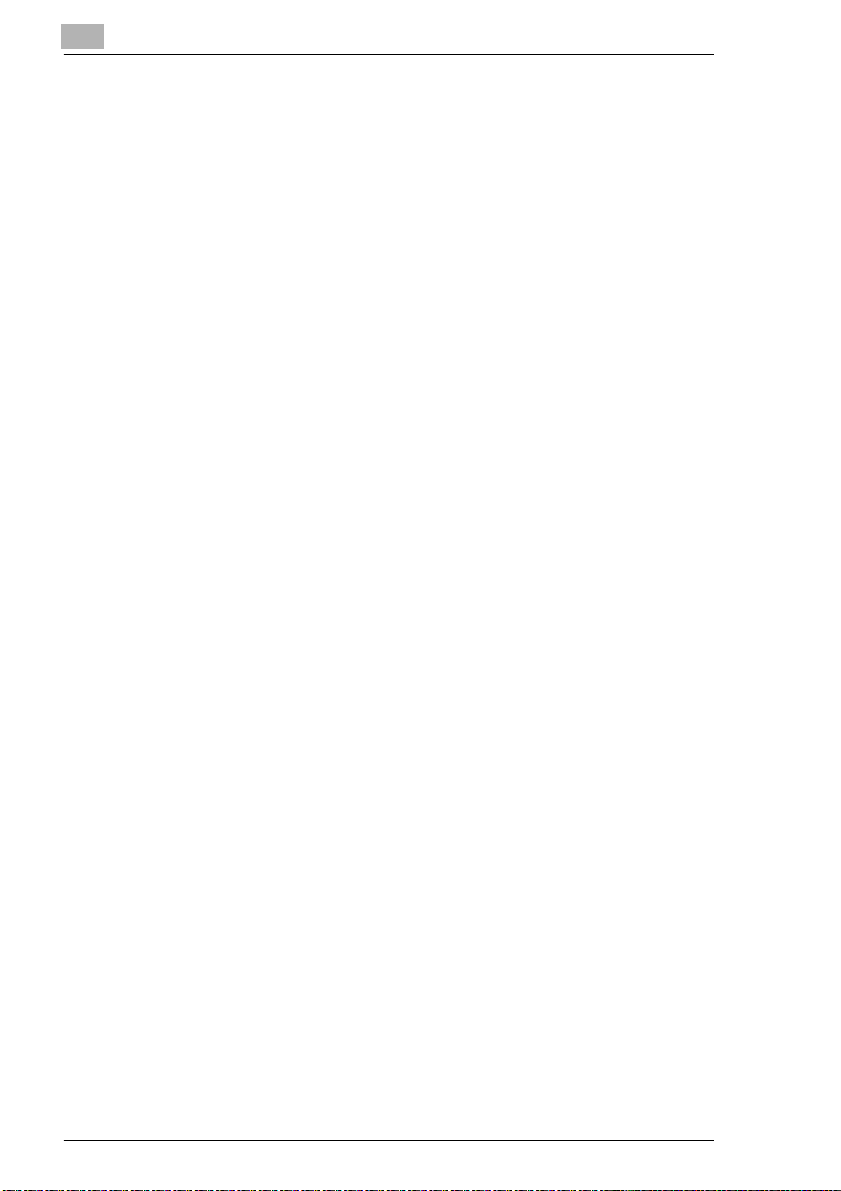

Lengthwise and crosswise

If side A of the paper format is shorter than side B, this is referred to as

lengthwise. The size label is specified with an “R” e.g. A4R.

If side A of the paper format is longer than side B, this is referred to as

crosswise. The size is not identified in any more detail, e.g. A4.

1

A4R A4

21 x 29.7 cm 29.7 x 21 cm

Lengthwise Crosswise

Size data with or without "R"?

Lengthwise sizes are specified with an "R". Sizes for which it is clear

which direction they have to be inserted, such as A3 (can only be fed

lengthwise), the "R" is omitted.

Di850 1-7

Page 19

1

1.4 Overview of System Features

The digital technology and the memory capacities of this system give it a

range of features that goes far beyond common copier functions.

The following pages provide an overview of the range of features offered

by this system.

General Features

All-Image Area

Copy originals without losing any of the edge.

Auto Layout

Automatically centers a copy on the copy paper.

Booklet

Combine A4 originals (1-2 or 2-2) into A5 or A4 booklets.

Chapter

Automatically copy previously specified chapter titles on right side sheets.

This feature is only available in duplex mode (1-2).

Combination

Copy 2, 4 or 8 originals onto a single copy paper sheet.

Contrast Range

Configure up to seven contrast ranges for four copy modes (automatic,

increase contrast, photo and text).

Dual Page

Copy two pages from an open book onto two single A4 pages (1-1) or

onto one A4 page (1-2). You can combine this feature with the Title and

Back features.

Duplex

Make 2-sided copies from 1- or 2-sided originals.

Energy Saver

Save energy using: auto low power and auto shut off modes.

Frame/Fold Erasure

Removes copy edges from 1 to 300 mm and/or fold marks from 1 to 99

mm, for example when copying from books.

Hole Punch for Finisher FN-7 (optional) or FN-115 (optional)

(only available with PK-3 or ZK-2 punch units – optional extras)

Punches a set of four holes into the finished copies.

Image Insert

Store image data from a document placed on the original glass. The

stored image data can be inserted into another original set, which has

been read in through the EDH.

Introduction

1-8 Di850

Page 20

Introduction

Image Shift

Create an image shift from 0 to 250 mm in 1 mm steps by shifting the

image area and if necessary also reducing it.

Interrupt Mode

Interrupt a copy cycle to copy urgent documents without waiting.

Job Status List

View an overview of the current copy job, other reserved copy jobs and

copy jobs that have already been processed. The status list can also be

used to change the order for processing pending copy jobs.

Magnification Ratio (fixed, variable)

Selecting a Magnification Ratio.Eight fixed and three user-defined

magnification ratios can be selected. Or choose a user-set zoom ratio

within the range of 25% to 400% in 0,1% increments.

Manual Shut Off

Manually shut off the copier to conserve energy.

Meter Count

Display a list with various meter counts: Total Count, Copy Count, Printer

Count and Maintenance Count.

Mixed Original (different-sized originals)

Copy a set of mixed size originals using the APS and AMS features.

AMS = Automatic magnification selection to copy mixed sizes onto a

desired paper size.

APS = Automatic paper selection to select copy paper based on the

originals and a magnification ratio.

Non-Image Area Erase

Copy with the original cover open without getting the familiar black edges.

Non STD Size for Bypass Tray

Specify special sizes for the bypass tray (to prevent faulty paper feeding).

Non STD Size Original

Specify nonstandard sizes for originals.This allows automatic selection of

an appropriate copy paper.

OHP Interleave

Insert blank or printed interleaves when copying onto transparencies.

Overlay

Copy two originals to one copy. For example, a letterhead and a text can

be copied together onto a page in one process.

Overlay Memory

Functions as with overlay mode. However, the overlay image is

permanently saved on the hard disk and can be recalled as required.

1

Di850 1-9

Page 21

1

Introduction

Overlay Memory

Store templates to use with the image overlay feature.

Paper Capacity

Total of 2,150 sheets (2 × 500 sheet drawer, 1 × 1,000 sheet drawer and

150 sheet bypass tray). Optionally available large capacity cassette holds

up to 4,000 sheets (80g/m²).

Program Job

Scan originals using various copier configurations and then make the

copies in a single process.

Program Memory

Store and call up to 30 copy job configurations.

Proof Copy

Test the copier settings using a proof copy before starting large copy jobs.

Repeat

Make multiple copies of a document onto one copy.

Reserve Jobs

Prepare further copier jobs while the copier is still busy processing the

output of a job.

Reverse Image

Make copies using inverse color values (black becomes white, white

becomes black).

Rotation Sort/Rotation Group

Output grouped or sorted copy sets, alternating lengthwise and crosswise.

Server Functions (Optional)

Store and call up copy jobs from a hard drive.

Sheet/Cover Insertion

Insert up to 30 separator sheets and/or cover and back sheets from one

of the paper drawers or from the bypass tray. The inserts, cover and back

sheets can be printed or blank as desired.

Simplex

Make 1-sided copies from 2-sided originals (2-1).

Stamp

Overprint copies with a stamp (set or page number) or print a watermark

on copies.

Staple

Specify a stapling position and the number of staples for each copy set.

Status Area

Shows the current system status for better control.

1-10 Di850

Page 22

Introduction

STD Size Original (Special)

Detection of standard sizes that usually are not recognized by an

automatic size detection unit.

Store Mode

Store originals that have been read in using the EDH or the original glass.

Tab Papers

Copying from and to tab papers gives an exact copy of items such as

register tab texts.

Tandem Operation (only with two systems)

Combine two systems into one unit. This lets you complete a copy job in

half the time.

Text/Photo Enhance

Improve exposure for optimizing the output of originals that contain text,

photographs or very light copy areas.

Trimmer Function for FN-7 Finisher

(only with optional TMG-2 trimmer unit)

stapled/folded booklet to make the edge even.

User-set Density

Define two user-defined density settings, which then can be called up on

the touch screen.

User-set Zoom Ratio

Define up to three user-defined zoom ratios, which then can be called up

on the touch screen.

Weekly Timer

Specify times at which the copier is to switch on and switch off. These

times can be specified as individual times or blocks of time. Holidays can

be scheduled for up to a year in advance using the calendar function.

Wide Size Paper

Process copy paper sizes that are larger than the standard sizes.

Z-fold for Finisher FN-7 (optional) or FN-115 (optional)

(only available with ZK-2 punch unit for Z-fold – optional)

Provides A3 copies with a Z-fold or folds B4 copies twice.

Z-Folded Original

Automatically feed in originals with Z folds using the EDH.

1

Trims the front edge of a

Di850 1-11

Page 23

1

Introduction

Automatic Features

Auto Low Power

Automatically reduces the power consumption after a specified idle time.

Auto Panel Reset

Automatically resets the copier settings to their defaults after a specified

time.

Auto Shut Off

Automatically shuts off the copier after a specified idle time.

Automatic Exposure Selection (AE)

The most appropriate exposure level is selected automatically based on

the originals being processed.

Automatic Magnification Selection (AMS)

Automatically selects a zoom ratio to copy mixed sized originals onto a

desired size of paper.

Automatic Paper Selection (APS)

Automatically selects the appropriate copy paper based on the originals

and a magnification ratio.

Automatic Tray Switching (ATS)

Automatically switches the paper trays when paper runs out. This enables

copying to be continued without interruption when a paper tray is emptied.

Rotation

Automatic rotation of the image area when the alignment of the originals

does not correspond to the paper alignment.

1-12 Di850

Page 24

Introduction

Finishing Features

Output with Finisher FN-7 (Optional) or FN-115 (Optional)

The following finishing modes are available:

G Main tray

G Sub tray

G Booklet output (only FN-7)

G Trim output (only FN-7 with installed

Output with Finisher FN-7 (optional) or FN-115 (optional) with Cover

Inserter C (optional)

Insert separating sheets and/or covers and staple manually.

Output without Finisher

The following finishing modes are available:

G Non Sort

G Rotation Sort

G Group

G Rotation Group

1

Non Sort, Sort, Staple and Group

Non Sort (face down), Non Sort (face up), Group (face down), Group

(face up)

Stapling & folding, folding

TMG-2 trim unit – optional)

Trimming

Copies are output in the order in which the originals were scanned.

Copies are output in the order in which the originals were read. The

copy sets are output alternating lengthwise and crosswise.

The copies are output in groups.

The copies are output in groups. The copy sets are output alternating

lengthwise and crosswise.

Di850 1-13

Page 25

1

Introduction

Features that can only be Set Up by a Service Technician

The following features can only be set up by a service technician. If you

want to have the following features set up for your use, contact your

technical representative.

Key Operator Password

The service technician can define a 4-digit key operator mode master

code. Access to key operator mode then can only be acquired after

entering the master code.

E.K.C. Master Key Code

The service technician can define an 8-digit E.K.C. master key code.

Access to the settings for the E.K.C. counter then can only be acquired

after entering the master code.

Weekly Timer Master Key Code

The service technician can define a 4-digit weekly timer master code.

Access to the settings for the weekly timer then can only be acquired after

entering the master code.

View the Weekly Timer Times on the Help Screen

The service technician can set up a key on the help screen to call up the

weekly timer times. This key then allows the user to view the weekly timer

times.

Touch Screen Contrast Settings on the Help Screen

The service technician can set up a key on the help screen to adjust the

contrast of the touch screen.

Messages: ADD TONER and PM CALL

The service technician can set up the system to display the following

messages automatically:

When the toner level in the bottle is very low:

When maintenance is required:

PM CALL

ADD TONER

.

1-14 Di850

Page 26

Introduction

WWW-Server Function

If the system is networked to a PC, you can view the current system status

on the PC using a web browser:

G

G Browser

G

G

1

URL

http:// (system IP address or Host Name)

Internet Explorer 5.0 or Netscape 4.0 or higher

Displayed items

Paper magazine configuration, accessories configuration etc.

Access to the WWW server

Via browser's URL

Di850 1-15

Page 27

1

Introduction

1-16 Di850

Page 28

Getting to Know Your System

2 Getting to Know Your System

2.1 System Overview

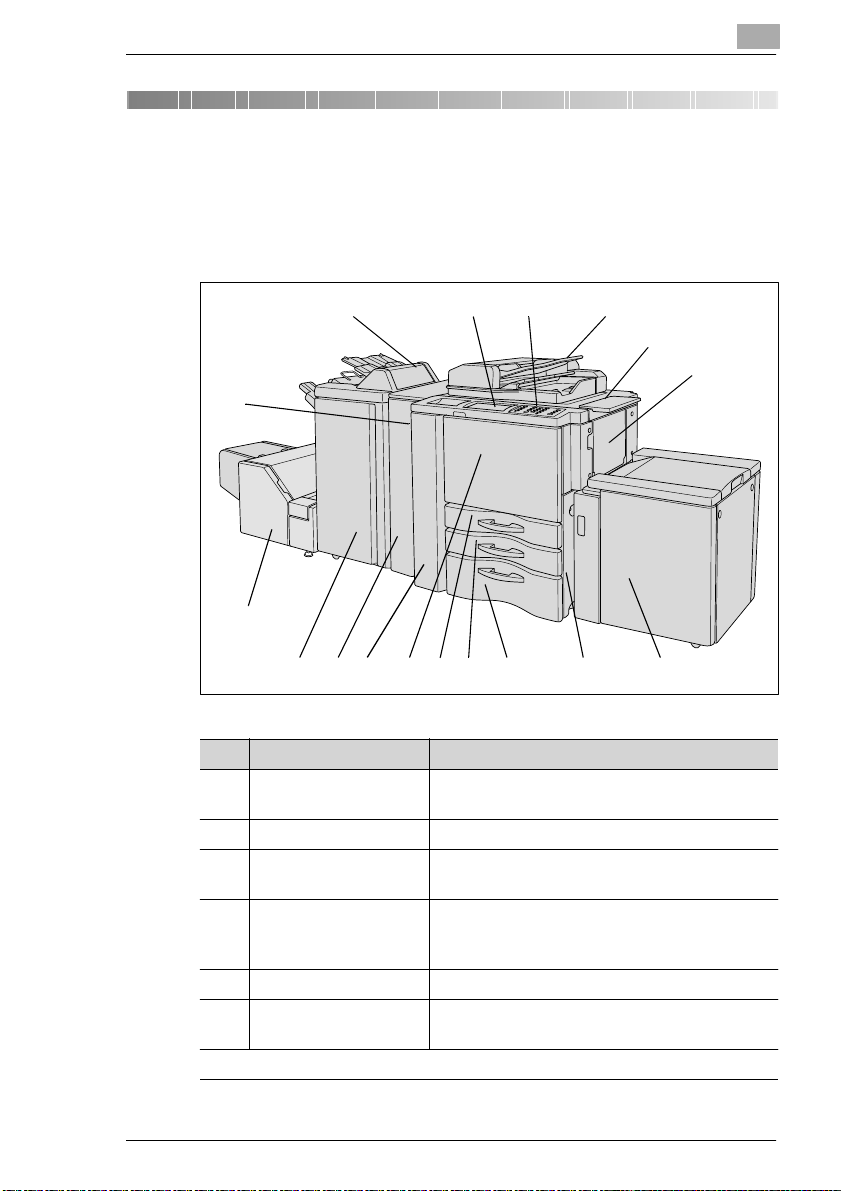

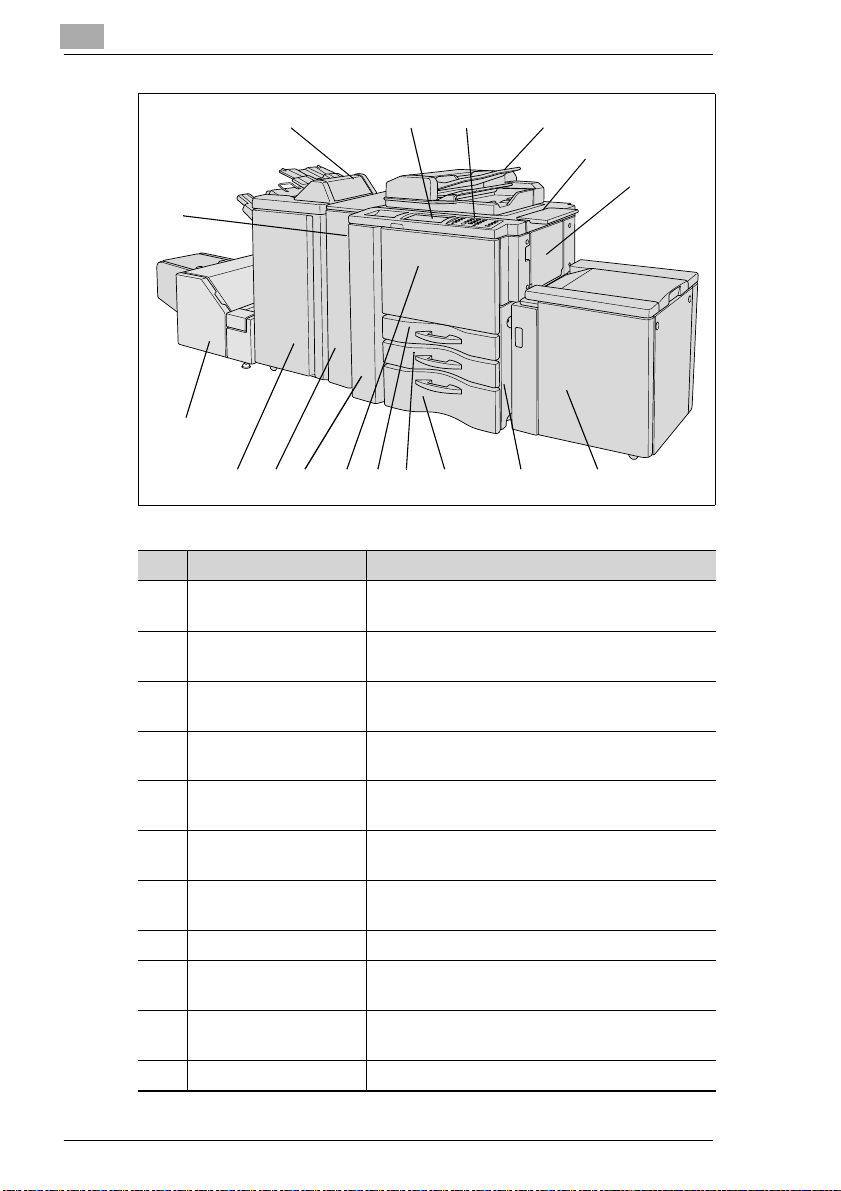

External System Overview

2

15

14

13

1112

Item Name Description

1 EDH Electronic Document Handling Tray

2 Document shelf Surface for placing originals o r copies

3 Bypass Tray Holds up to 150 sheets of standard paper

4 Large Capacity

Cassette LCC

(optional)

5 Right-hand door Open this door to clear paper misfeeds.

6 Tray 3 Universal drawer holds up to 1,000 sheets

...continuedonnextpage

16 17

8

Feeds in originals page by page automatically.

(80g/m²) or 1 sheet of special paper

Holds up to 4,000 sheets of standard paper

(80 g/m²)

(80g/m²) of various sizes

1

2

3

4567910

Di850 2-1

Page 29

2

Getting to Know Your System

15

16 17

1

2

3

14

13

1112

Item Name Description

7 Tray 2 Universal drawer holds up to 500 sheets

8 Tray 1 Universal tray holds up to 500 sheets of paper

9 Front door Open this door to change the toner or clear a

10 Left door Open this door together with the front door to

11 Punch unit or Punch/Z-

fold unit (optional)

12 Finisher (optional) Used for regulated,stacked or sorted output of

13 Trimming Unit

(optional)

14 Power Switch Switches the system off

15 Cover Inserter

(optional)

16 LCD touch screen Touch-sensitive screen for viewing and

17 Control panel Provides the keys for operating the system

8

(80g/m²) of v arious sizes

(80g/m²) of v arious sizes

paper jam.

clear a paper jam.

Used for punching holes and Z-folding copies

copies

Used for trimming the front edge of a stapled/

folded booklet

Inserts cover sheets

modifying system jobs and settings

4567910

2-2 Di850

Page 30

Getting to Know Your System

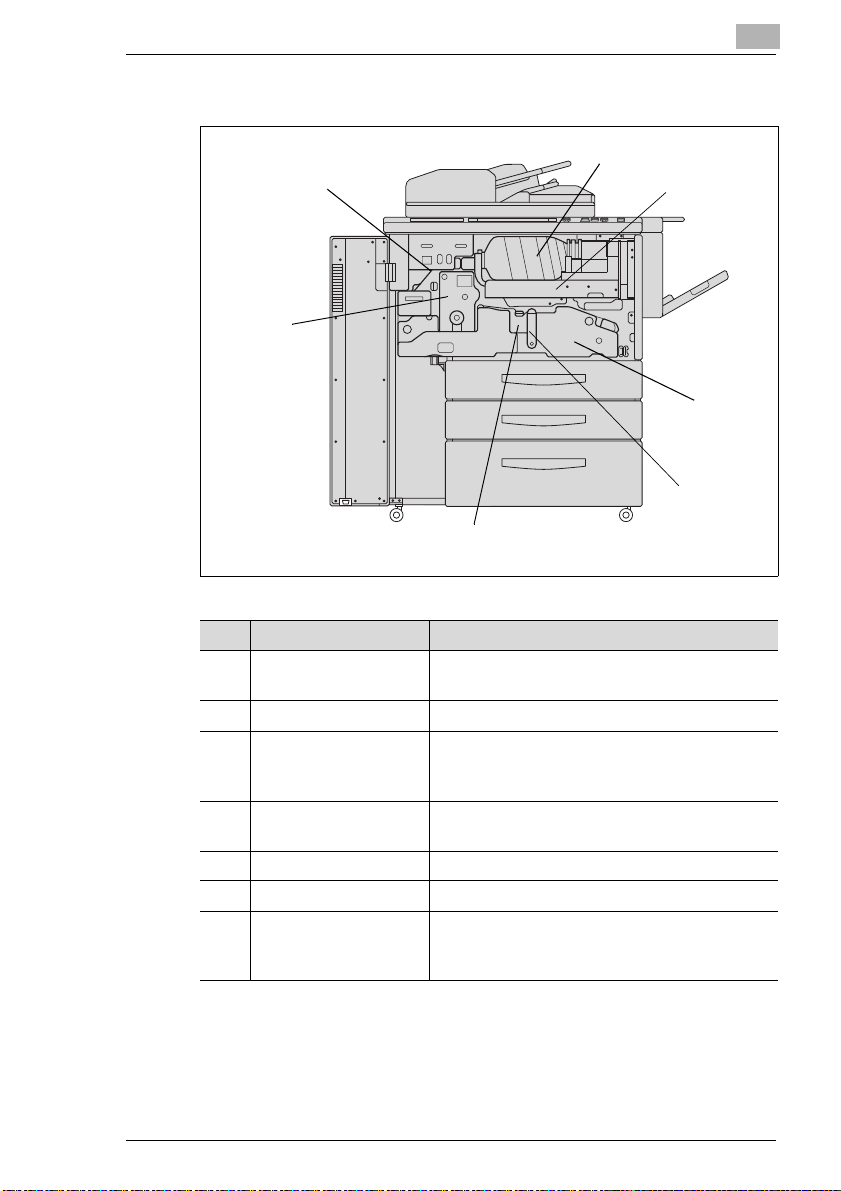

Internal System Overview

7

6

2

1

2

3

4

5

Item Name Description

1 Toner bottle • Contains the toner.

• Has to be replaced when toner runs out.

2 Toner Holder Holds the toner bottle

3 Transport Fuser Unit Transports the paper through the drum unit and

fixer unit. The transport carriage can be pulled

out to clear a paper jam.

4 Lever A Release this lever to clear a paper jam in this

5 Drum unit The copy image is generated on the drum unit.

6 Fixer unit Fuses the toner onto the copy paper.

7 RESET switch (for service personnel use only)

area.

Interrupts the power supply when the button is

pressed.

Di850 2-3

Page 31

2

2.2 Options (Accessories)

Finisher FN-115/FN-7

The finishers provide regulated output and sorting of copies.

The FN-115 provides the following functions:

G Sort

G Staple

G Group

The FN-7 provides these additional following functions:

G Folding

G Folding & Stapling (for creating booklets)

G Trimming (with installed TMG-2 trimming unit – optional)

CAUTION

Device damage by incorrect assessment of spacial requirements

The offset trays of a finisher move downward during the output cycle.

Objects below the offset trays may seriously damage them.

§ Do not place any objects below the offset trays of the finisher.

Getting to Know Your System

CAUTION

Danger of injury!

The Finisher FN-7 booklet output is fitted with a folding unit.

§ Do not reach into the booklet output of the Finisher when you are

removing folded or stapled booklets.

Do not exceed the capacity of the offset trays!

Do not exceed the capacity of the finisher offset trays, otherwise a

paper misfeed may occur. You should empty the offset trays during a

large copy job to avoid exceeding the capacity. For more information,

see page 9-15.

2-4 Di850

Page 32

Getting to Know Your System

Finisher FN-115/FN-7 (external overview)

2

2

3

1

2

1

6

FN-115 FN-7

Item Name Description

1 Main Tray Copies are output here

2 Top offset tray Copies are output here

3 Top offset tray paper

misfeed door

4 Finisher door Open this door to

5 Booklet output

(only FN-7)

6 Booklet Basket

(only FN-7)

4

•Non Sort

• Sort (with offset)

•Staple

• Group (with offset)

•Non Sort

• Group (printed side down/up)

Open this door to clear paper misfeeds

• clear a paper misfeed

• fill the staple cartridges

Copies processed using the “Folding” or

“Stapling & Folding” features are output here.

Catches copies discharged by the booklet

output.

3

45

Di850 2-5

Page 33

2

Getting to Know Your System

Finisher FN-115/FN-7 (internal overview)

1

2

3

4

5

6

1

2

3

4

5

6

7

8

6

6

9

9

Item Name Description

1 Lever for opening the

paper-jam door

2 Transport rollers Rotate the transport rollers to feed jammed

3 Lever for opening the

paper-jam door

4

5 Staple unit Staples copies and, with the FN-7, also turns

6 Handle on the stapler

unit

7 Lever for opening the

paper-jam door

8 Transport rollers Rotate the tr ansport rollers to transport jammed

9 Staple cartridges Replace the staple cartridges when the staples

Open the paper-jam door to remove jammed

paper

paper further

Open the paper-jam door to remove jammed

paper

them into booklets

Pull the stapler unit out by this handle, to

remove jammed paper or fill the staple

cartridges

Open the paper-jam door to remove jammed

paper

paper out of the staple unit

run out

FN-7FN-115

2-6 Di850

Page 34

Getting to Know Your System

Cover Inserter C for Finisher

The Cover Inserter is a paper feeding unit for the finishers. It can be used,

for example, to feed in cover stock for creating booklets.

Paper fed by the cover inserter is sent directly to the finisher; it does not

run through the copier. The paper fed from the cover inserter thus cannot

be printed during cover insertion.

2

3

2

1

Item Name Description

1 Control panel Keys for operating manually cover inserter B

2 Tray Place cover pages for automatic feed

3 Guide plates Ensure correct alignment of the paper stack

Di850 2-7

Page 35

2

Getting to Know Your System

Large Capacity Cassette (LCC) C-403N/C-404N

Additional paper tray with a capacity of up to 4,000 sheets (80 g/m²) of

paper.

1

2

3

2

3

1

4

4

5

6

6

7

5

7

C-403N C-404N

Item Name Description

1 Upper cover Open the top cover to add more paper

2 Left door Open this door to clear paper misfeeds

3 Lever for opening the

paper-jam door

4 Guide plates Ensure correct alignment of the paper stack

5 Button for lowering the

paper plate

6 Paper plate Automatically lifts the paper stack

7 Rear tray Ensures correct alignment of the paper stack

Open the paper-jam door to remove jammed

paper

Press this button to lower the paper plate and

refill with new paper

2-8 Di850

Page 36

Getting to Know Your System

TMG-2 Trimming Unit (optional for FN-7 Finisher)

The trimming unit lets you trim the front edge of stapled or folded booklets.

This ensures a smooth booklet edge.

CAUTION

Incorrect handling can cause damage to the system!

Incorrect handling can cause damage to the system. Observe the

following safety precautions to prevent system damage.

§ Never place any objects on or in the trimming unit.

§ Do not use the trimming unit for storing copy materials or other objects.

Always keep the tray cover closed!

It is not possible to start a copy cycle if the tray cover is not closed.

If the tray cover of the trimming unit is opened during a copy cycle, the

system stops the cycle automatically. This leads to a paper misfeed.

2

6

5

7

8

Item Name Description

1 Front right panel Open this panel to clear paper misfeeds

Di850 2-9

4

1

3

2

Page 37

2

Getting to Know Your System

Item Name Description

2 Front door Open the front door to clear a paper jam or to

empty the waste container

3 Drawer Receives the trimmed booklets

4 Tray Moves in steps to the left when booklets that

have been trimmed are output

5 Tray cover Open this cover to remove the completed,

trimmed booklets

6 Transport rollers Rotate the tr ansport rollers to transport jammed

paper out of the unit

7 Waste container Collects waste paper

8 Lever for opening the

paper-jam door

Open the paper-jam door to remove jammed

paper

2-10 Di850

Page 38

Getting to Know Your System

PK-3 Hole Punch Unit

Punches four holes in copies.

2

3

4

5

2

1

6

Item Name Description

1 Front door Open the front door

• to clear paper misfeeds

• to empty the waste container

2 Lever for opening the

paper-jam door

3

4 Transport rollers Rotate the transport rollers to feed jammed

5 Lever for opening the

paper-jam door

6 Waste container This is where the punch wastes are collected

Open the paper-jam door to remove jammed

paper

paper further

Open the paper-jam door to remove jammed

paper

Di850 2-11

Page 39

2

Getting to Know Your System

ZK-2 Punch/Z-fold Unit

Punches 4 holes into copies and/or Z-folds them.

3

4

5

2

1

6

Item Name Description

1 Front door Open the front door

• to clear paper misfeeds

• to empty the waste container

2 Lever for opening the

paper-jam door

3 Transport rollers Rotate the transport rollers to feed jammed

4 Handle Pull the unit out by the handle to clear a paper

5 Lever for opening the

paper-jam door

6 Waste container This is where the punch wastes are collected

Open the paper-jam door to remove jammed

paper

paper further

jam

Open the paper-jam door to remove jammed

paper

2-12 Di850

Page 40

Getting to Know Your System

Memory Expansions

Expand the memory capacity of the system. This allows more originals to

be read into the document memory, for example.

The following extended memory units can be purchased:

G 64 MB extended memory

G 128 MB extended memory

Pi8500 Printcontroller

Allows the system to be used as a printer.

2

Di850 2-13

Page 41

2

Getting to Know Your System

2.3 Safe Working with Your System

The improper use of your system may result in health hazards, electrical

shock or even fires. Please observe the following precautions for the safe

use of your system.

DANGER

Incorrect use of the system can result in fire and/or electrical shock!

The system is equipped with high-voltage components. Incorrect use of

the system may result in fire or electrical shock. Observe the following

safety precautions to prevent injury and system damage.

§ Never use flammable sprays, liquids or gasses near the system.

§ Never remove any safety equipment.

§ Do not touch areas designated with safety labels.

§ When you clear a paper jam etc. only touch the specially marked

areas.

§ Do not make design changes to the system.

§ Never unplug the system with wet hands.

§ Ensure that the power supply provides the correct supply voltage for

the system.

§ Never connect the system to a multiple-socket extension cord.

§ Do not place coffee cups, bottles or other containers with liquids on the

system. If liquids should ever accidentally be spilled or splashed into

the system, switch the system off immediately. Unplug the power

cable. Consult your technical representative.

§ Never insert paper clips, staples or other small pieces of metal into the

openings of the system. If metal items should ever accidentally fall into

the system, switch the system off immediately. Unplug the power

cable. Consult your technical representative.

§ Do not dismantle the system.

§ Allow only specially trained and authorized service personnel carry out

maintenance and repairs.

§ Never touch the drum unit.

2-14 Di850

Page 42

Getting to Know Your System

DANGER

Incorrect use of the system can result in fire and/or electrical shock!

The system is equipped with high-voltage components. Incorrect use of

the system may result in fire or electrical shock. Observe the following

safety precautions to prevent injury and system damage.

§ Note that the system is still switched on even when it is in low power

mode or in weekly timer mode.

§ Always switch off the system using the power switch if the system is

not going to be used for a long time.

§ Always unplug the power cable when the system is not going to be

used for a long time.

DANGER

Incorrect use of the power cable can result in fire and/or electrical

shock!

The system is equipped with high-voltage components. Incorrect handling

of the system's power cable may cause damage to the cable. This could

result in fire and/or cause electrical shock. Observe the following safety

precautions to prevent injury and system damage.

§ Be sure that the power cable is not damaged. If this is not the case,

switch off the system immediately. Unplug the power cable. Consult

your technical representative. Do not repair the network cable.

§ Do not pull directly on the power cable itself when unplugging the

power cable from the power outlet.

§ Do not move the system unless it is unplugged.

§ Never place heavy objects on the power cable.

§ Do not pull or bend the power cable.

§ Do not place the system on cables belonging to other devices.

§ Ensure that no cables of other devices get pinched in the system.

§ Be sure that the power cable sits correctly in the power outlet.

§ Always make sure that the power outlet is visible and accessible at all

times.

2

Di850 2-15

Page 43

2

Getting to Know Your System

§ Keep the network connector and the socket free from dust.

§ Never use any extension cords to connect the system to a power

outlet.

§ Never connect the system to a multiple-socket extension cord.

DANGER

System overheating can result in fire and/or electrical shock!

The system is equipped with high-voltage components. Incorrect use or

faulty operation of the system may cause the system to overheat. Observe

the following safety precautions to prevent injury and system damage.

§ Switch off the system immediately if it becomes unusually hot, smoke

rises from the system or you detect an unusual smell. Unplug the

power cable. Consult your technical representative.

§ If a fuse is tripped during a procedure, repeat the procedure. If a fuse

is tripped again, switch the system off immediately. Consult your

technical representative.

§ Be sure the fuses are sufficient for the nominal current ratings.

§ Always unplug the power cable when the system is not going to be

used for a long time.

CAUTION

Improper operation of the system can cause injury!

Incorrect operation of the system can lead to personal injury. Observe the

following safety precautions to prevent injuries.

§ Never touch the fusing unit. The fusing unit is hot.

§ When carrying out a procedure, touch only those parts of the system

that must be touched for this procedure as described in this manual.

§ Never put your hands into the booklet output of the finisher.

§ Never put your hands into the output tray of the finisher.

2-16 Di850

Page 44

Getting to Know Your System

CAUTION

Damage to the system by external influences!

External influences can cause damage to the system. Observe the

following safety precautions to prevent system damage.

§ Do not subject the system to vibrations.

§ Never bring any magnetized object near the system.

§ Never place any objects heavier than 6.8 kg and/or thicker than 30 mm

onto the system.

§ Do not put any objects under the main tray of the finisher. During the

output cycle, the finisher moves downward and can be damaged by

objects in its way.

CAUTION

Incorrect handling can cause damage to the system!

Incorrect handling can cause damage to the system. Observe the

following safety precautions to prevent system damage.

§ Do not open any doors on the system during printing.

§ Do not switch the system off during printing.

§ Ensure that the trays are not overloaded during copying. Observe the

specifications provided in the appendix! If necessary, remove finished

copies during the process to avoid overloading the trays.

§ Only use the copier and special paper that are expressly specified in

this manual.

§ Never use stapled or conductive paper.

2

CAUTION

A negligible amount of ozone is released during printing!

While this is not a health hazard, it may result in an unpleasant odor. It is

recommended that the room be well ventilated.

§ Locate the system in a well-ventilated room.

Di850 2-17

Page 45

2

Getting to Know Your System

Laser Safety

This system is equipped with a laser. If the system is operated in

accordance with the instructions in this manual, the laser poses no

possibility of danger.

The laser radiation is completely confined within the machine housing.

The laser beam cannot escape the housing at any time of operation.

This system is certified as a Class 1 laser product. This means that the

system does not generate any hazardous laser radiation.

Internal Laser Radiation

Mean radiation output:

1220 µW at the laser opening of the printer head.

Wave length: 665-695 nm

This system operates using a Class IIIb laser diode that emits an invisible

laser beam. The laser diode and scanning polygon mirror are incorporated

in the print head unit.

The print head unit is NOT A FIELD SERVICE ITEM. It may not be opened

under any circumstances.

Print head

The above illustration indicates the location of the print head of the

system.

2-18 Di850

Page 46

Getting to Know Your System

This is a semiconductor laser system. The maximum radiation capacity of

the laser diode is 20 mW. The wavelength is 665-695 nm.

Laser safety label on the back of the system

CLASS 1 LASER PRODUCT

APPAREIL A RAYONNEMENT

LASER DE CLASSE 1

LASER KLASSE 1

2

DANGER

Hazardous laser radiation!

Operating the system in a manner that does not conform to the

descriptions provided in this manual can lead to the release of hazardous

radiation.

§ Operate the system only in accordance with the instructions provided

in this manual.

Di850 2-19

Page 47

2

Getting to Know Your System

Safety Label

DANGER

Safety labels indicate hazard areas. Incorrect handling in hazard

areas can lead to serious personal injury and/or damage to articles.

§ Use this operating manual to familiarize yourself with the hazards

before carrying out any activity in a hazard area.

§ Clean soiled safety labels to keep them visible and legible. Replace

safety labels if they become illegible. For further information, consult

your technical representative.

This internal area is very

Cette zone interne est

Große Hitze im Innenbereich!

très chaude. Pour éviter

hot. To avoid getting

burned, DO NOT TOUCH.

CAUTION

ATTENTION

VORSICHT

PRECAUCION

ATTENZIONE

2

2

1

(on both sides of

the fusing unit)

(on the front

and inside the

fusing unit)

NICHT BERÜHREN, um

de se brûler, NE PAS LA

Verbrennungen zu

TOUCHER.

vermeiden!

(on both sides of the fusing unit)

CAUTION

Burn hazard!

The fusing unit is very hot.

Do not touch the fusing unit.

CAUTION

Danger of injury!

The fixing/transport unit is heavy.

Pull the unit out carefully and slowly.

Esta zona interior está

Questa area interna è

estremamente calda. Per

muy caliente. Para no

evitare di rimanere ustionati,

quemarse NO TOCAR.

NON IMMETTERVI LE MANI.

CAUTION

Danger of injury!

Do not place your hands between the

fixing/transport unit and the main

unit.

WARNING

DANGER

WARNUNG

ADVERTENCIA

AVVERTIMENTO

WARNING

This area generates

high voltage.

If touched, electrical

shock may occur!

DO NOT TOUCH!

2-20 Di850

Page 48

Getting to Know Your System

DANGER

Safety labels indicate hazard areas. Incorrect handling in hazard

areas can lead to serious personal injury and/or damage to articles.

§ Use this operating manual to familiarize yourself with the hazards

before carrying out any activity in a hazard area.

§ Clean soiled safety labels to keep them visible and legible. Replace

safety labels if they become illegible. For further information, consult

your technical representative.

2

Tra y 1

Tra y 3

FN-7 Finisher

(FN-7 only)

CAUTION

Danger of injury!

A roller unit is located in the

booklet output. Do not put your

hands in the output tray of the

booklet output.

Tra y 2

CAUTION

Danger of injury!

Do not place your hands

between the paper tray

and the main unit.

(FN-115/FN-7)

CAUTION

Danger of injury!

Do not put your hands into

the feed or output

chambers of the finisher.

(FN-115/FN-7)

CAUTION

Danger of injury!

Never place your hands on the output copier

paper stack when the Finisher copy tray is

moving upwards.

Di850 2-21

Page 49

2

Getting to Know Your System

System serial number

The serial number is located on a label at the following position:

Make a note of the serial number of your system in the table below. Please

keep this information at hand in the event of any questions for fast help in

the event of problems.

Model:

Serial No.:

2-22 Di850

Page 50

Getting to Know Your System

2.4 Transporting the System

If you need to transport the system, please consult your technical

representative.

2.5 Installing the System

Environmental Requirements

The optimal environmental requirements of the system are as follows.

G Temperature from 10°C to 30°C / 50 to 86°F

(maximum fluctuation of 10°C / 50°F per hour)

G Humidity of 10% to 80%

(maximum fluctuation of 20% per hour)

Installation Site

The installation site must meet the following requirements:

G an area that is dry and free of dust

G a level surface free of undue vibrations

G provision for good ventilation

G a location away from curtains or other easily-inflammable materials

G away from personnel so that no one is subjected to the direct exhaust

air of the system

The system must be protected from the following influences:

G splashing liquids

G direct sunlight

G strong temperature fluctuations

G direct air flow from heating or air conditioning units

2

CAUTION

Damage to the system by external influences!

The main tray of the finisher lowers during the output cycle. Objects

located under the main tray can damage the main tray.

§ Do not put any objects under the main tray of the finisher.

Di850 2-23

Page 51

2

Getting to Know Your System

Space required for System

CAUTION

Device damage by incorrect assessment of spacial requirements

Always ensure sufficient free space around the system. Too little space

can cause damage to the system, for example from overheating.

Furthermore operation is hindered by too little free space.

§ Leave sufficient space between the back of the device and the wall to

ensure adequate ventilation.

§ Do not put any objects under the main tray of the finisher. The main

tray lowers during the output cycle. Objects located under the main

tray can cause serious damage to the main tray.

Units in mm

400

1160

475

887

1762

400

1560

Di850

100 100

546321

1807

2337

887

386

530

Di850 + FN-115/FN-7 + C-403N

400

1160

1560

1845

120

775

120

950

775

1845

950

2-24 Di850

Page 52

Getting to Know Your System

2

Units in mm

950

400

150

1118

174

546

2831

887

3601

100

626

1560

1160

770

775

1845

120

Di850 + FN-7 + TMG-2 + PK-3/ZK-2 + C-404N

Storing Supplies

WARNING

Toner can be hazardous to your health!

Toner is harmful to your health.

§ If you get any toner on your hands, immediately wash them thoroughly

with soap and cold water.

§ Never dispose of an empty toner bottle in a fire. The remaining toner

left in the bottle can ignite and cause a hazardous situation.

Ensure that supplies are stored:

G in their original, sealed packaging

G protected from direct sunlight and heat sources

G in a cool, dry, dust-free location

G out of the reach of children

2.6 Connecting the System

Voltage and Frequency Tolerances

The system needs a reliable, consistent power supply. Please call your inhouse technical support if required.

G Voltage ± 10%

G Frequency ± 0.3%

Di850 2-25

Page 53

2

Getting to Know Your System

2.7 Switching the System on and off

Switching the System on

The power switch is located on the left side of the main unit.

§ Switch the power switch (POWER)

to the I position.

The warm-up phase (about 6

minutes) begins, during which

various warm-up indications are

displayed on the touch screen.

If the system will not let you

?

switch it on using the power

switch...

The system is equipped with an extra internal power switch

(RESET switch). This switch is only used by service and

maintenance personnel. For more information, see page 2-3.

§ Be sure that the RESET switch is set to the I position.

§ Do not use the RESET switch to switch the system on or off under

normal operating conditions.

Initial System Settings:

G Number of copies: 1

G Zoom ratio: 1:1

G EDH ON

G Copy mode: 1>1