Konica Minolta DI750PE User Manual

7664-4133-01

Di750PE

Operator’s Manual

Recycled paper is used for the inside pages of this book.

Di750PE

Network Printing System

Operator’s Manual

Thank you for choosing Minolta quality. For over 30 years Minolta has been a leader on

the forefront of office equipment technology and service. Our desire has always been to

bring you highly reliable products. We pledge to continue to provide you, our customer,

with our state of the art equipment, as well as full customer service for all our products.

We look forward to a long healthy relationship with you and our company. If you have any

questions or comments about Minolta, our product or service, please let us know. Our fax

number is 800-237-8087 (for the U.S.A. and Canada). Thank you again.

This operator’s manual explains how to operate the copier and replenish its supplies. It

also gives some troubleshooting tips as well as general precautions to be observed when

operating the copier.

To ensure the best performance and effective use of your copier, read this manual

carefully until you familiarize yourself thoroughly with the copier’s operation and features.

After you have read through the manual, keep it ready for reference.

Please use this manual as a quick and handy reference tool for immediately clarifying any

questions which may arise.

Contents

Section 1: Introduction

To the User ...................................................................................................................1-2

Features Overview........................................................................................................ 1-3

Section 2: Safety Information

User Instructions ...........................................................................................................2-2

Machine Safety Labels ................................................................................................. 2-2

Label Locations......................................................................................................2-3

Installation and Power Requirements ........................................................................... 2-5

Machine Handling and Care .........................................................................................2-7

Routine Safety .............................................................................................................. 2-8

Finisher Capacity Requirements .................................................................................. 2-9

Regulations .................................................................................................................2-11

FCC Regulations ................................................................................................. 2-11

ICES Regulations ................................................................................................ 2-11

Laser Safety.........................................................................................................2-11

Internal Laser Radiation ......................................................................................2-12

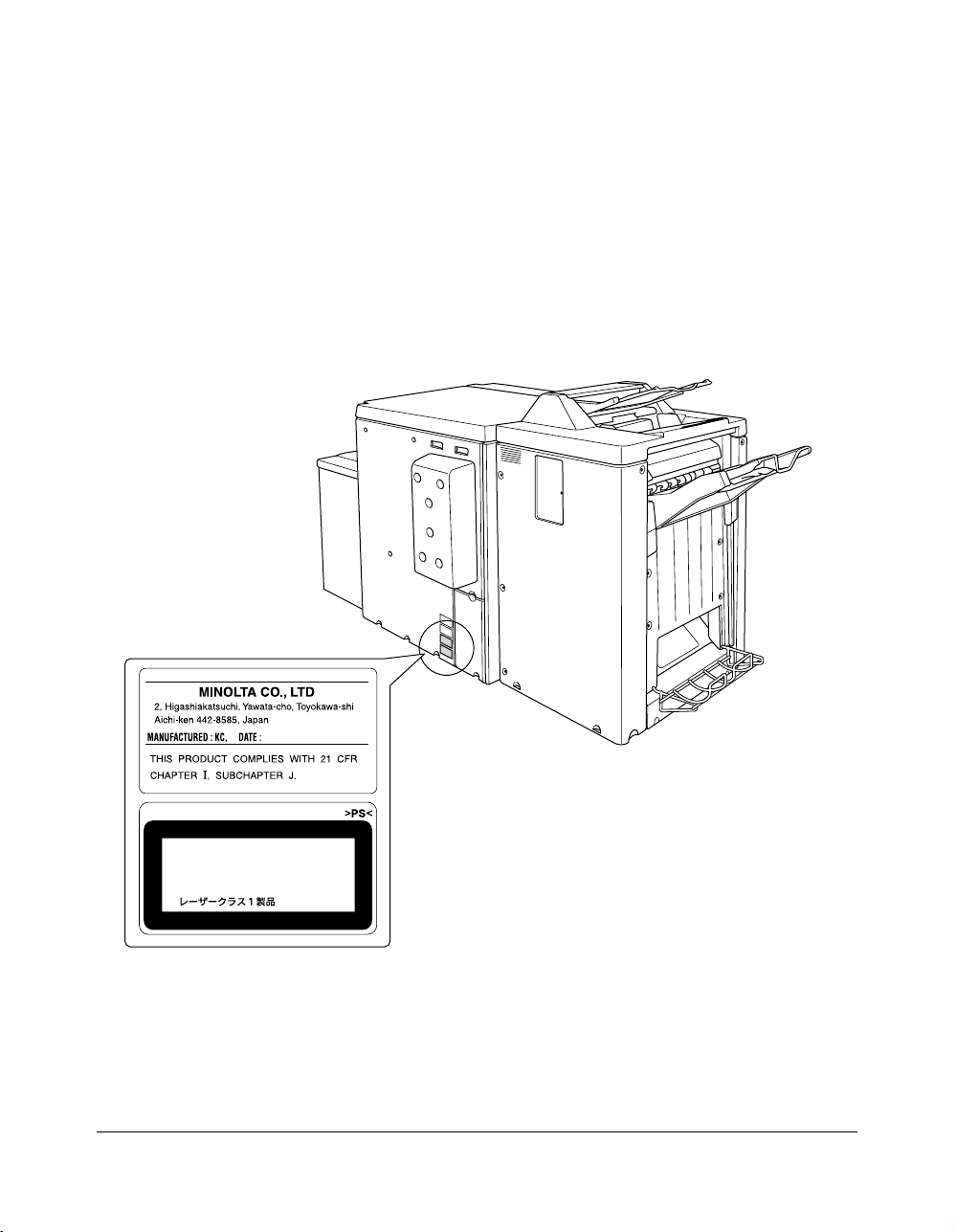

Laser Safety Label ............................................................................................... 2-15

Ozone Release ....................................................................................................2-16

Section 3: Machine Information

Di750PE Overview ........................................................................................................ 3-2

Key Operator Functions.........................................................................................3-3

Service, Repairs and Supplies .............................................................................. 3-3

Machine Labels......................................................................................................3-3

Service Settings ..................................................................................................... 3-4

External Machine ..........................................................................................................3-5

Internal Machine ........................................................................................................... 3-7

Standard Equipment .....................................................................................................3-8

Optional Equipment ...................................................................................................... 3-8

Finisher/Large Capacity Cassette ....................................................................... 3-10

Trimming Unit ......................................................................................................3-11

Punch Kit ............................................................................................................. 3-12

Site Requirements ...................................................................................................... 3-13

Specifications .............................................................................................................. 3-14

Contents

Section 4: Media Information

Main Body Trays ...........................................................................................................4-2

Large Capacity Cassette (C-305) (Option) ................................................................... 4-3

Large Capacity Cassette (C-305L) (Option) ................................................................. 4-3

Automatic Duplex Unit .................................................................................................. 4-4

Multi-Sheet Bypass Tray and Tab Sheets ....................................................................4-4

FN-104/FN-4 Finisher (Option) ..................................................................................... 4-5

Primary (Main) Tray ...............................................................................................4-5

Secondary (Sub) Tray ........................................................................................... 4-5

FN-4 Finisher Booklet Tray.................................................................................... 4-6

Cover Inserter A (Option).............................................................................................. 4-7

Paper in Punch Kit (PK-1) (Option) .............................................................................. 4-7

Paper in Trimming Unit (TMG-1) (Option) ....................................................................4-7

Paper Supply Message................................................................................................. 4-8

Paper Weight Compatibility Chart ................................................................................ 4-9

Section 5: Printing Operations

Introduction ...................................................................................................................5-2

Wake Up Screen.................................................................................................... 5-2

Warm Up Screem .................................................................................................. 5-2

Control Panel ................................................................................................................5-3

The Basic Screen ......................................................................................................... 5-3

Check Mode Message ..................................................................................................5-4

Check Mode Screen ..............................................................................................5-4

Reservation List ............................................................................................................5-5

Screen Display....................................................................................................... 5-5

Help Mode..................................................................................................................... 5-5

Change of Job Order .................................................................................................... 5-6

Job Deletion ..................................................................................................................5-7

Previous Job List .......................................................................................................... 5-8

Change Setting .............................................................................................................5-9

Print Size..................................................................................................................... 5-10

Selecting Paper Type/Size for Multi-Sheet Bypass Tray .................................... 5-10

Auto Low Power Mode................................................................................................ 5-11

The Counter List ......................................................................................................... 5-12

View the Counter List .......................................................................................... 5-12

Print the Counter List ........................................................................................... 5-12

Weekly Timer Function ...............................................................................................5-13

Timer Interrupt .....................................................................................................5-13

Contents

Section 6: Output Modes

FN-104/FN-4 Finisher Specifications............................................................................ 6-2

Finisher Type .........................................................................................................6-2

Primary (Main) Tray ...............................................................................................6-2

Secondary (Sub) Tray ........................................................................................... 6-3

Booklet Tray (FN-4 Finisher only) ......................................................................... 6-3

Cover Inserter A..................................................................................................... 6-3

Punch Kit ............................................................................................................... 6-4

Trimming Unit Tray (FN-4 Finisher only) ...............................................................6-4

Non-Sort Mode Using Primary (Main) Tray ..................................................................6-5

Sort Mode Using Primary (Main) Tray ..........................................................................6-6

Staple-Sort Mode Using Primary (Main) Tray .............................................................. 6-7

Folding, Stapling & Folding and Trimming Modes........................................................ 6-8

Punching Mode ...........................................................................................................6-10

Cover Inserter A..........................................................................................................6-11

Manual Stapling ..........................................................................................................6-12

Output Mode for Machine without Finisher.................................................................6-14

Section 7: Maintenance & Supplies

Loading Paper............................................................................................................... 7-2

Paper Indicator ...................................................................................................... 7-2

Paper Empty Indicator ...........................................................................................7-2

Using the HELP Key .............................................................................................. 7-2

Loading Paper in Tray 1, 2, and 3 .........................................................................7-3

Loading Paper in Multi-Sheet Bypass Tray ........................................................... 7-4

Loading Paper in Tray 4 (C-305/C-305L) ..............................................................7-5

Loading Tabbed Sheets in Tray 1, 2, or 3 .............................................................7-6

Loading Tabbed Sheets in Multi-Sheet Bypass Tray ............................................7-7

Loading Tabbed Sheets in Tray 4 (C-305/C-305L) ...............................................7-8

Adding Toner ................................................................................................................ 7-9

Inserting a New Staple Cartridge into FN-104/FN-4 Finisher..................................... 7-10

Empty Trash Basket of TMG-1 Trimming Unit ........................................................... 7-11

Empty Trash Basket of PK-1 Punch Kit ...................................................................... 7-12

Preventive Maintenance .............................................................................................7-13

Reading the PM Count ........................................................................................ 7-13

Printing the PM Count ......................................................................................... 7-13

Clearing Mishandled Paper ........................................................................................ 7-14

Jam Location Screen ...........................................................................................7-14

Troubleshooting Tips ...........................................................................................7-15

Contents

Section 8: Key Operator Mode

To the Key Operator ..................................................................................................... 8-2

How to Access the Key Operator Mode ................................................................ 8-3

Function Menu Map ......................................................................................................8-4

System Initial Setting [1] ...............................................................................................8-6

Date & Time Setting [1] ......................................................................................... 8-6

Language Select Setting [2] .................................................................................. 8-7

ECM (Electronic Copy Monitor) Function Setting [4].................................................... 8-8

How to Access the ECM Setting Mode ................................................................. 8-9

E.C.M. Data Edit [1] .............................................................................................8-10

E.C.M. All Count Reset [2]................................................................................... 8-14

E.C.M. Function Setting [3].................................................................................. 8-15

Paper Type / Special Size Set [6] ............................................................................... 8-16

Panel Contrast / Key Sound Adjustment [7] ...............................................................8-18

Key Operator Data Setting [8] ....................................................................................8-19

Weekly Timer [9] .........................................................................................................8-20

How to Access the Weekly Timer Setting Mode ................................................. 8-21

Weekly Timer On/Off Setting [1] .......................................................................... 8-22

Timer Setting [2] .................................................................................................. 8-23

Timer Action On/Off Setting [3] ........................................................................... 8-25

Lunch Hour Off Setting [4] ...................................................................................8-27

Timer Interrupt Password Setting [5] ................................................................... 8-28

Control Panel Adjustment [10] .................................................................................... 8-29

Tray Size Setting [11] ................................................................................................. 8-30

Energy Saver Setting [12] ........................................................................................... 8-31

Memory Switch Setting [13] ........................................................................................ 8-32

Machine Management List Print [14] ..........................................................................8-34

Side 2 Lens Adjustment [16].......................................................................................8-35

Finisher Adjustment [17] .............................................................................................8-36

Key Operator ECM Form ............................................................................................8-38

Index

Section 1: Introduction

To the User ....... 1-2

Features Overview ....... 1-3

Introduction 1-1

Introduction

To the User

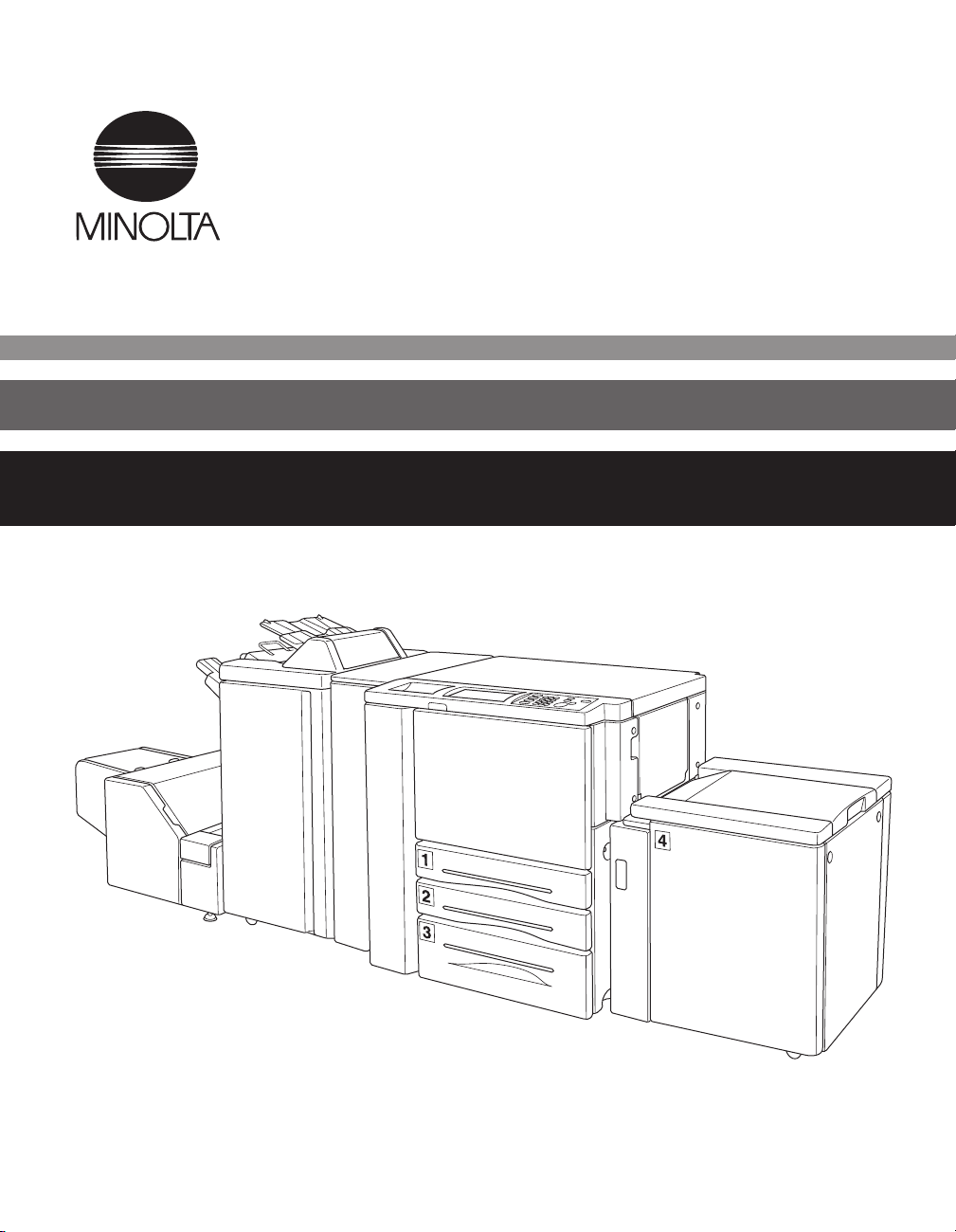

Welcome to the Di750PE Network Printing System, which includes the main body

engine, the print controller, and the optional network interface card.

This Operator’s Manual describes the layout of the main body machine configured with

both standard and optional equipment and explains control panel functions and

procedures for all operations. This manual also includes basic engine specifications,

information on media requirements, maintenance, supplies, safety measures and

troubleshooting tips.

Be sure to read this manual thoroughly before operating the equipment and keep it in a

handy location for the convenience of all users.

1-2 Introduction

Introduction

Features Overview

Di750PE Network Printing System connects the Di750 main body engine to the

MicroPress Server via PrintLink 075m.

Di750PE is electronically digitized into data bits and stored into memory where the data

may be retrieved and output in various ways controlled by software. The digitized image

is represented as pixels on a screen or as dots per inch (dpi) on hard print.

• 600dpi Mode

Scans with a high resolution (600dpi).

• All-Image Area

Prints completely to the edges of the paper to avoid image loss.

• ATS - Automatic Tray Switching

Automatically switches to another tray when a tray becomes empty during a print job.

• Auto Low Power

Automatically lowers the power after a specified period of printer inactivity.

• Auto Reset

Automatically resets to auto mode defaults after a specified period of printer inactivity.

• Auto Shut-Off

Automatically shuts off the main body power after a specified period of printer inactivity.

• Duplex Mode

Selects the duplex printing mode.

• Energy Saver

Automatically reverts to nominal optimal efficiency power after a specified period of

printer inactivity. Normal power resumes after a brief warm up period by pressing the

[Energy Saver On/Off] key on the Control panel.

• Manual Shut-off

Shuts off the main power with the [POWER SAVER ON/OFF] key.

• Non STD Size for Multi-Sheet Bypass Tray

Allows you to indicate a special paper size to be loaded in the Multi-sheet bypass tray.

Introduction 1-3

Introduction

Features Overview (continued)

• Output modes with FN-104/FN-4 Finisher Installed:

Non-Sort, Sort, Staple-Sort, and Group modes using the primary (main) tray

Non-Sort Face Down exit, Non-Sort Face Up exit, Group Face Down exit, and

Group Face Up exit modes using the secondary (sub) tray

Stapling & Folding, and Folding modes using the booklet tray (FN-4 only)

• Output modes with FN-104/FN-4 Finisher and Cover Inserter A Installed:

Cover Sheet mode

Manual Staple mode

For details of each output mode, see Section 6: Output Modes.

• Punching Mode for FN-104/FN-4 Finisher with PK-1 Punch Kit Installed:

Punch three holes in output prints

• Repeat Image

Repeats the selected horizontal image area down the page as many times as permitted

by the repeat width setting (10 ~ 150mm) permits in manual or auto mode.

• Reserve

Scans subsequent print jobs while the Di750PE is busy printing or printing.

• Resolution (600dpi)

600dpi resolution mode provides optimal image quality for photos, complicated graphics

and text requiring very high compression.

• Reverse Image

Reverses the image from black-on-white to white-on-black or vice versa.

• Staple

Selects the stapling position and number of staples (3 positions).

• STD Size (Special)

Detects standard paper sizes (A4R and A5) not normally detected when loaded in a

main body tray. A5R and F4 sizes are also available from the Multi-sheet bypass tray.

• Total Paper Capacity

2,150 sheets (two 500-sheet trays/1,000-sheet tray/150-sheet MSB tray)

1-4 Introduction

Introduction

Features Overview (continued)

• Total Paper Capacity with C-305/C-305L

6,150 sheets (two 500-sheet trays/150-sheet MSB tray/1,000-sheet tray/4,000-sheet opt.

LCC)

• Trimming mode for FN-4 Finisher with TMG-1 Trimming Unit installed:

Trim the end of folded or stapled & folded booklets.

• Weekly Timer

Functions according to the needs of each work environment by turning off the main body

power daily/weekly/during lunch time/on holidays, and provides the Timer Interrupt mode

for temporary use of the machine when it is set in the daily/weekly/holiday Power Off

Mode.

Introduction 1-5

Section 2: Safety Information

User Instructions ....... 2-2

Machine Safety Labels ....... 2-2

Label Locations ......... 2-3

Installation and Power Requirements ....... 2-5

Machine Handling and Care ....... 2-7

Routine Safety ....... 2-8

Finisher Capacity Requirements ....... 2-9

Regulations ..... 2-11

FCC Regulations ....... 2-11

ICES Regulations....... 2-11

Laser Safety ....... 2-11

Internal Laser Radiation ....... 2-12

Laser Safety Label....... 2-15

Ozone Release ....... 2-16

Safety Information 2-1

Safety Information

User Instructions

The following pages include important safety information, which you must read and

understand before you attempt to operate the printer. If you have any concerns about

safety matters, please contact your service representative. Keep this manual

permanently located with the printer, so that this safety information is readily available.

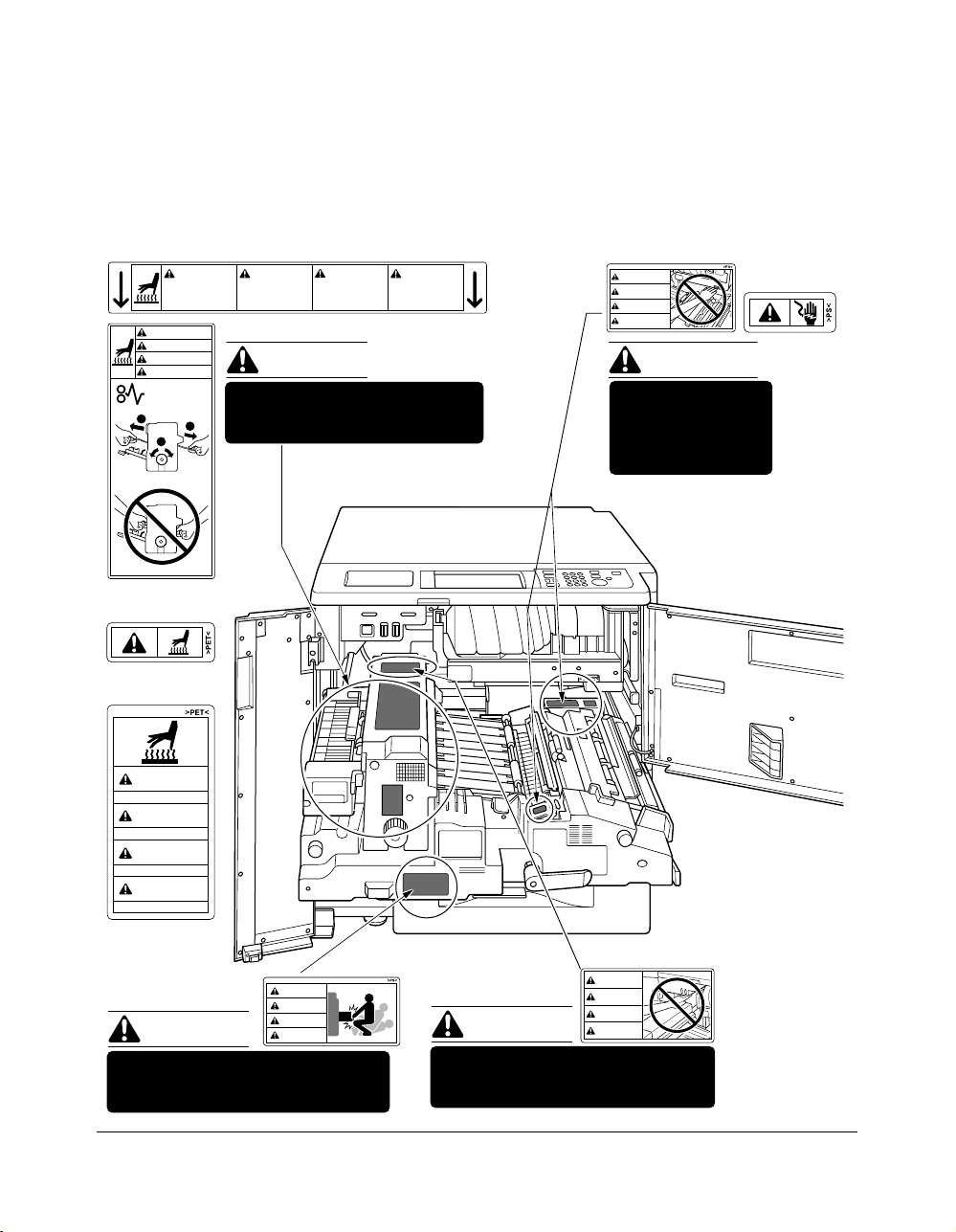

Machine Safety Labels

Machine safety labels are attached to the internal area of the printer. The purpose of

safety labels is to alert you of imminent or potentially hazardous situations or conditions.

Be sure to heed all safety label information. If any safety label becomes illegible due to

soilage, etc., please contact your service representative for information about label

replacements. Sample safety labels are shown on the following page.

TO AVOID GETTING BURNED Do not touch any machine area that you are advised not

to touch by a warning or caution label.

DO NOT REMOVE WARNING OR CAUTION LABELS

Clean labels as needed to maintain legibility. If any warning or caution label is removed

or becomes illegible from soilage, please contact your service representative for

information about label replacements.

The following standard safety categories are commonly used on product labeling.

DANGER:

Danger indicates an imminent hazardous situation, which, if not avoided, will

result in death or serious injury.

Note: The DANGER category is not required for this product, and is included here for general user

information.

WARNING:

Warning indicates a potentially hazardous situation, which, if not avoided, could

result in death or serious injury.

CAUTION:

Caution indicates a potentially hazardous situation, which, if not avoided, may

result in minor or moderate bodily injury.

NOTICE: Notice provides information on the correct handling or use of the machine to prevent

breakage of the printer or some machine part, etc. It does not indicate concern for personal safety.

2-2 Safety Information

Safety Information

Machine Safety Labels (continued)

Label Locations

CAUTION

This internal area is very

hot. To avoid getting

burned, DO NOT TOUCH.

CAUTION

ATTENTION

PRECAUCION

CUIDADO

ATTENTION

Cette zone interne est

très chaude. Pour éviter

de se brûler, NE PAS LA

TOUCHER.

(Both sides of the fixing unit)

CAUTION

PRECAUCION

Esta zona interior está

muy caliente. Para no

quemarse NO TOCAR.

The fixing unit is very hot.

2

1

To avoid getting burned DO NOT

2

TOUCH.

(Top surface of

the fixing unit)

(Inside of

the fixing unit)

CAUTION

High temperature!

ATTENTION

Température élevée!

PRECAUCION

¡Temperatura alta!

CUIDADO

Alta temperatura!

(Front side of

the fixing unit)

CAUTION

ATTENTION

CAUTION

PRECAUCION

CUIDADO

The conveyance fixing unit is heavy.

Use care and draw it out gently;

otherwise you may be injured.

CUIDADO

Alta temperatura. NÃO

TOQUE nesta área

interior, pois há risco de

queimadura.

CAUTION

DO NOT put your hand between the

main body and developing fixing

unit; otherwise you may be injured.

WARNING

DANGER

ADVERTENCIA

ADVERTÊNCIA

WARNING

This area generates

high voltage. If

touched, electrical

shock may occur. DO

NOT TOUCH!

CAUTION

ATTENTION

PRECAUCION

CUIDADO

Safety Information 2-3

Safety Information

Machine Safety Labels (continued)

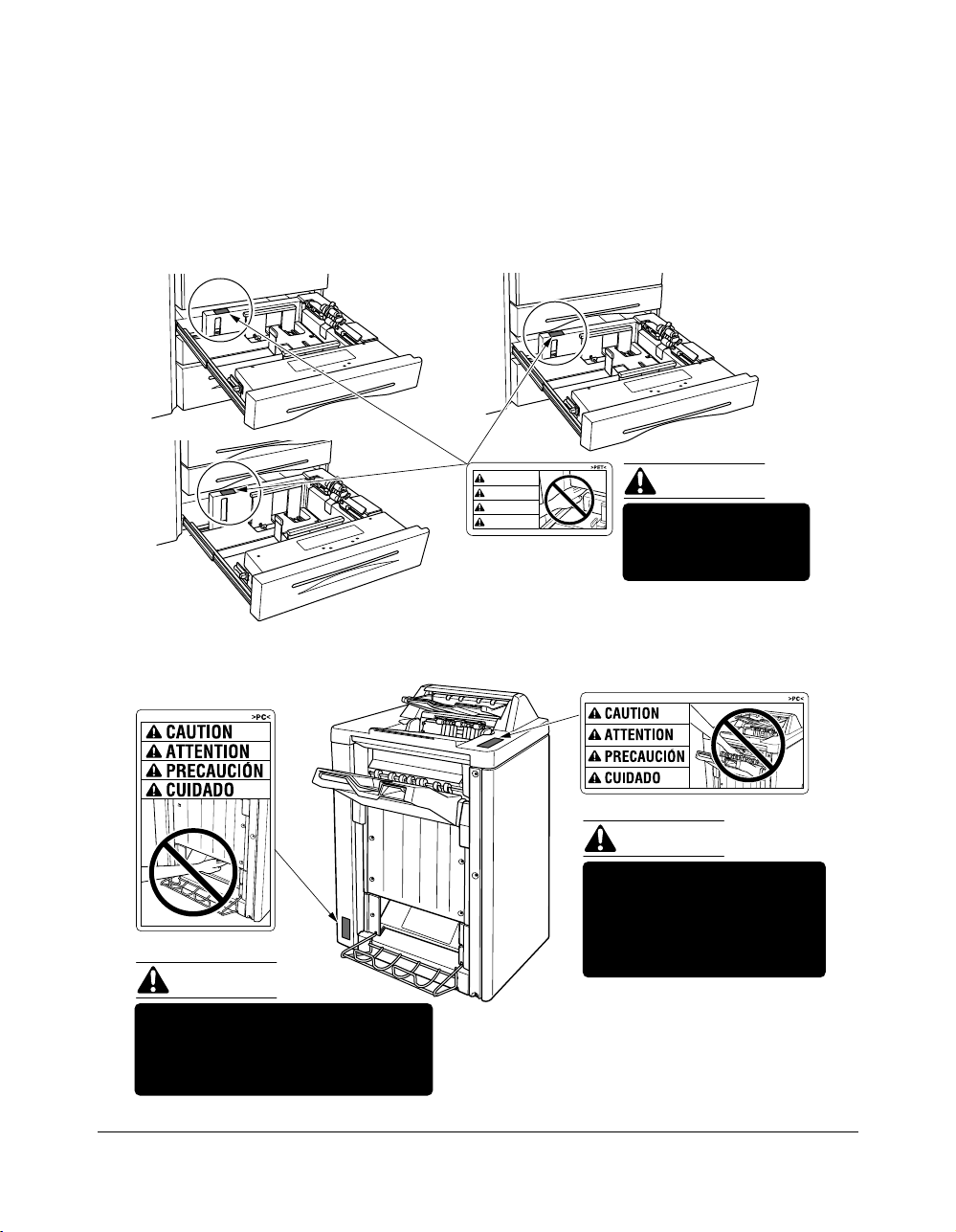

Label Locations (continued)

Tray 3

Tray 1

CAUTION

ATTENTION

PRECAUCION

CUIDADO

Tray 2

CAUTION

DO NOT put your hand

between the main body

and tray; otherwise you

may be injured.

(FN-104/FN-4)

CAUTION

(FN-4 only)

CAUTION

Inside the lower paper exit outlet

is the roller drive unit.

DO NOT put your hand into it;

otherwise you may be injured.

2-4 Safety Information

Use care after opening the

paper exit outlet. DO NOT

put your hand into it;

otherwise you may be

injured.

FN-4 Finisher

Safety Information

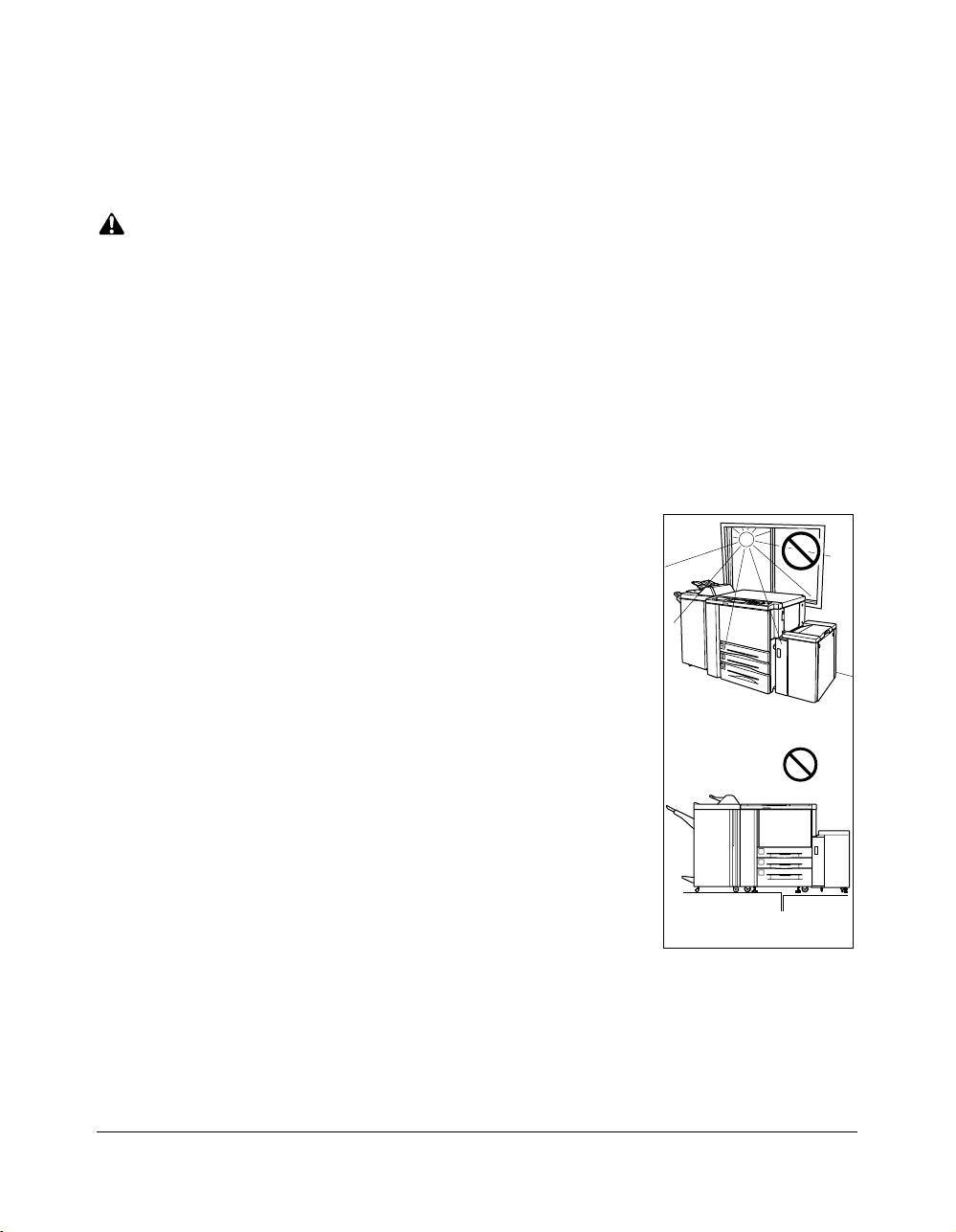

Installation and Power Requirements

CAUTION:

FAILURE TO HEED THE FOLLOWING CAUTIONS MAY RESULT IN BODILY INJURY AND/OR

MACHINE DAMAGE

❒ FIRE PREVENTION

Install machine away from flammable or volatile materials. Routinely check for abnormal

heat from power cord and/or plug.

❒ SHORT CIRCUIT FROM WATER DAMAGE

Do not install or operate this equipment outdoors near a lake, pond, or river, etc.; and do

not allow the machine to come in contact with splashes of rain, water, or any liquid.

❒ TEMPERATURE AND HUMIDITY

Install the machine away from direct sunlight, heat sources

(stoves, heaters) and cold temperatures (air conditioners).

Avoid any environment that is outside 50°~86°F (10°~30°C),

with 10~80% humidity.

❒ VENTILATION

Do not allow the machine to come in contact with dust or

ammonia gas, or fumes from printing or cleaning solutions,

etc.; otherwise, image quality will be poor. Install the machine

in a well-ventilated area, for comfort; otherwise, an ozone odor

will be detected during large print runs. When in use, the

printer generates ozone in amounts too small to be hazardous

to the human body.

Temperature

❒ VIBRATIONS

If the machine is constantly vibrated or jolted, trouble may

occur. Install the machine on a level, horizontal floor, free from

vibrations.

❒ SPACE ALLOTMENT

Vibration

Install machine in an area with adequate space for performing printer operations,

replacing supply items, and conducting preventive maintenance. See Site Requirements,

Section 3.

❒ MACHINE RELOCATION

Before moving the machine to another location, contact your service representative.

Safety Information 2-5

Safety Information

Installation and Power Requirements (continued)

CAUTION:

FAILURE TO HEED THE FOLLOWING CAUTIONS MAY RESULT IN MACHINE DAMAGE,

OVERHEATING, RISK OF ELECTRICAL SHOCK, AND/OR PERSONAL INJURY

PLUG SOCKET

A plug socket is limited in capacity. Use an exclusive power source for this machine;

otherwise, overheating and/or smoking may occur. The total power consumption of the

main body, plus all peripherals, must not exceed the capacity of the main power supply.

Be sure the socket outlet is near the equipment and is easily accessible.

PLUG AND CORD (LEAD)

Unless the power plug is firmly inserted into the socket, an accident from overheating

and/or smoking may occur. Firmly insert the power cord plug into the electrical outlet

before turning on the printer power switch. If the inserted plug is loose in the socket,

disconnect it, and consult an electrician for repair; but, do not attempt to operate the

machine. Be sure the socket outlet is near the equipment and is easily accessible.

A damaged power cord may result in overheating, short circuit or fire. Do not bend,

crush, wind, kick or strike the cord with any item. Do not roll up the cord. If the main body

power cord is bent or damaged, immediately contact your service representative; do not

attempt to repair it yourself, or continue to operate the machine.

ADAPTERS AND PLURAL LOADS

Never use adapters and never connect plural loads or a branched socket to one socket

outlet; otherwise, overheating or fire may occur.

EXTENSION CORDS (LEADS)

An extension cord or lead is limited in capacity. Unless the cord or lead has adequate

capacity, smoking and overheating may occur. Should smoking and/or overheating

occur, contact an electrician immediately. If you require further information about power

requirements, power consumption, extension cords, adapters and connectors, please

contact your service representative, and consult your electrician.

2-6 Safety Information

Safety Information

Machine Handling and Care

WARNING:

FAILURE TO HEED THE FOLLOWING WARNING MAY RESULT IN DEATH OR SERIOUS INJURY AND/

OR MACHINE DAMAGE

MACHINE CONTACT

Never touch internal high voltage area indicated with a WARNING label.

Never touch the drum surface.

Never put your hand into the developing unit when removing mishandled paper.

CAUTION:

FAILURE TO HEED THE FOLLOWING CAUTIONS MAY RESULT IN MACHINE DAMAGE,

OVERHEATING, AND/OR PERSONAL INJURY

MACHINE CONTACT

Never touch internal high temperature or magnetism areas indicated with a CAUTION

label. Never insert your hand into the fixing unit when removing paper. Never touch the

inside of the main body for any purpose except moving mishandled paper or adding

toner. Use care when withdrawing the conveyance fixing unit.

MACHINE CARE

Do not drop paper clips, staples or other small metallic objects into the printer, or spill

water or any other liquid into the machine.

Do not use the machine surface to support vases, books, etc. These items will interfere

with the work space and may cause damage to the machine or to original documents.

ABNORMAL CONDITIONS

If any abnormal sound, odor, or smoke generates from the machine, immediately stop

using the printer, turn off the main power switch, disconnect the plug and contact your

service representative.

If a circuit breaker is tripped, or if a fuse blows, stop using the machine and contact an

electrician. If more detailed information is needed regarding the power source or power

consumption of this machine, contact your service representative.

MACHINE MODIFICATION

Do not modify the machine in any way or remove any part or screw. Never attempt to

perform any maintenance function that is not specifically described in this manual. Do

not connect the machine with any options other than those specified.

Safety Information 2-7

Safety Information

Routine Safety

CAUTION:

FAILURE TO HEED THE FOLLOWING CAUTIONS MAY RESULT IN MACHINE DAMAGE,

OVERHEATING, AND/OR PERSONAL INJURY

PERIODIC CHECK

Check for loose connection or excessive heat on power plug, damage to power cord

and/or plug (creased, frayed, scratched or cut, etc.). Be sure the plug is inserted fully,

and ground wire is connected correctly. If any abnormality occurs, do not continue to

operate the machine.

SERVICE MESSAGES

If a service message displays, turn the machine off, disconnect the power cord from the

outlet, and report the condition to your service representative.

TONER

Check to be sure toner in storage is out of the reach of children, or anyone who may be

incapable of handling it in a safe manner. Although toner is nontoxic, do not inhale or

swallow toner or allow it to come in contact with eyes. If toner is inhaled, consult a

physician immediately. If swallowed, drink plenty of water and consult a physician

immediately. If eye contact occurs, flush eyes with plenty of water and consult a

physician immediately.

PAPER

Check paper to be sure it is according to the specifications outlined in Section 4.

CLEANING MATERIALS

Check the type of cleaning material used on your machine to be sure it is recommended

by us. If necessary, check with your service representative. Never use cleaning

materials for purposes other than cleaning, and be sure to keep all cleaning materials

out of the reach of children or anyone who is incapable of using them safely.

ENERGY SAVER

Use Energy Saver mode for short periods of machine inactivity. When not using the

machine for long periods of time, turn power off, unless the weekly timer function is

operating.

DISPOSAL OF THE PRINTER

Dispose of this printer according to your local regulations.

2-8 Safety Information

Safety Information

Finisher Capacity Requirements

CAUTION:

FAILURE TO HEED THE FOLLOWING CAUTIONS MAY RESULT IN BODILY INJURY AND/OR

MACHINE DAMAGE

FINISHER PAPER CAPACITY

To prevent paper misfeed, do not exceed the paper capacity of the Finisher.

FN-104/FN-4 Finisher paper weight: 16 lb ~ 24 lb

When the selected print quantity exceeds the maximum paper capacity, remove sheets

as they are output from the finisher.

Paper capacities below are stated for 20 lb Bond. This Finisher also accepts the wide

orientation of regular sizes stated below.

Finisher FN-104/FN-4

Primary (Main) tray: Non-sort/Sort/Group mode

500 sheets (5.5"x8.5"R)

3,000 sheets (8.5"x11", 8.5"x11"R)

1,500 sheets (11"x17", 8.5"x14")

The Secondary (sub) tray can be unloaded while the Di750PE is running.

Set production is not limited by the capacity of the Secondary (sub) tray.

Primary (Main) tray: Staple-Sort mode

1,000 sheets* (11"x17" ~ 8.5"x11"/R)

* The maximum capacity varies according to the number of sheets to be

stapled.

Secondary (Sub) tray: Non-sort mode

200 sheets max.

Booklet tray (FN-4 only)

100 sheets max. (11"x17", 8.5"x14", 8.5"x11", A4R)

(The maximum number of sheets varies, depending on the number of pages in

the booklet and whether Folding or Stapling & Folding is selected.)

Trimming unit tray (FN-4 with TMG-1 only)

512 sheets max. (11"x17", 8.5"x14", 8.5"x11", A4R)

(The maximum number of sheets varies, depending on the number of pages in

the booklet and whether Folding or Stapling & Folding is selected. See p. 4-7.)

Safety Information 2-9

Safety Information

Finisher Capacity Requirements (continued)

CAUTION:

FAILURE TO HEED THE FOLLOWING CAUTIONS MAY RESULT IN BODILY INJURY AND/OR

MACHINE DAMAGE

FN-4 FINISHER BOOKLET MODE OUTLET

Inside the Booklet mode outlet is the roller drive unit. DO NOT put your hand into it when

removing the folded or stapled & folded sheet; otherwise you may be injured.

FN-104/FN-4 FINISHER PAPER EXIT OUTLET

To avoid injury when stapling large size prints, DO NOT put your hand into the open

Paper exit outlet.

2-10 Safety Information

Safety Information

Regulations

FCC Regulations

WARNING

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate ratio

frequency energy and if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the

user will be required to correct the interference at his own expense.

The design and production of this unit conform to FCC Regulations, and any changes or

modifications must be registered with the FCC and are subject to FCC control. Any

changes made by the purchaser or user without first contacting the manufacturer will be

subject to penalty under FCC regulations.

This device must be used with shielded interface cables. The use of non-shielded cable

is likely to result in interference with radio communications and is prohibited under FCC

rules.

FCC-F01

ICES Regulations

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

IC-F03

Laser Safety

This is a digital machine which operates by means of a laser. There is no possibility of

danger from the laser, provided the machine is operated according to the instructions in

this manual.

Since radiation emitted by the laser is completely confined within protective housing, the

laser beam cannot escape from the machine during any phase of user operation.

This machine is certified as a Class 1 laser product. This means the machine does not

produce hazardous laser radiation.

Safety Information 2-11

Safety Information

Regulations (continued)

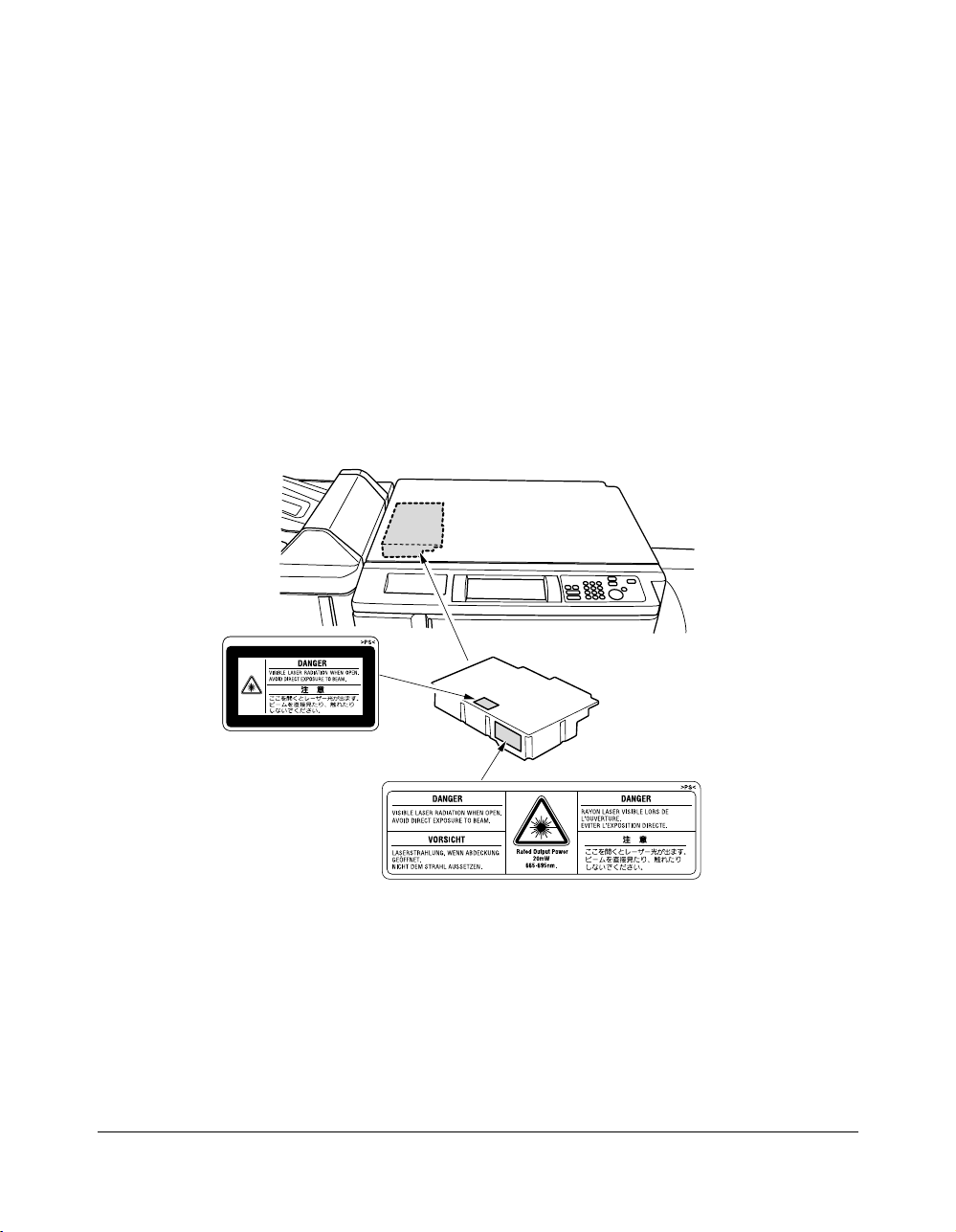

Internal Laser Radiation

Maximum Average Radiant Power: 1220 µW at the laser aperture of the print head unit.

Wavelength: 665-695 nm

This product employs a Class IIIb Laser Diode that emits an invisible laser beam.

The Laser Diode and Scanning Polygon Mirror are incorporated in the print head unit.

The print head unit is NOT A FIELD SERVICE ITEM.

Therefore, the print head unit should not be opened under any circumstances.

Printer head unit

2-12 Safety Information

Safety Information

Regulations (continued)

For the United States

CDRH regulation

This machine is certified as a Class 1 Laser product under the Radiation Performance

Standard according to the Food, Drug and Cosmetic Act of 1990. Compliance is

mandatory for Laser products marketed in the United States and is reported to the

Center for Devices and Radiological Health (CDRH) of the U.S. Food and Drug

Administration of the U.S. Department of Health and Human Services (DHHS). This

means that the device does not produces hazardous laser radiation.

The label shown on page 2-15 indicates compliance with the CDRH regulations and

must be attached to laser products marketed in the United States.

CAUTION:

Use of controls, adjustments or performance of procedures other than those specified in

this manual may result in hazardous radiation exposure.

This is a semiconductor laser. The maximum power of the laser diode is 20 mW and the

wavelength is 665-695 nm.

For European Users

CAUTION:

Use of controls, adjustments or performance of procedures other than those specified in

this manual may result in hazardous radiation exposure.

This is a semiconductor laser. The maximum power of the laser diode is 20 mW and the

wavelength is 665-695 nm.

For Denmark Users

ADVARSEL

Usynlig laserstråling ved åbning, når sikkerhedsafbrydere er ude af funktion. Undgå

udsættelse for stråling. Klasse 1 laser produkt der opfylder IEC60825 sikkerheds kravene.

Dansk: Dette er en halvlederlaser. Laserdiodens højeste styrke er 20 mW og

bølgelængden er 665-695 nm.

Safety Information 2-13

Safety Information

Regulations (continued)

For Finland, Sweden Users

LOUKAN 1 LASERLAITE

KLASS 1 LASER APPARAT

VAROITUS!

Laitteen Käyttäminen muulla kuin tässä käyttöohjeessa mainitulla tavalla saattaa

altistaa käyttäjän turvallisuusluokan 1 ylittävälle näkymättömälle lasersäteilylle.

Tämä on puolijohdelaser. Laserdiodin suurin teho on 20 mW ja aallonpituus on 665-695 nm.

VARNING!

Om apparaten används på annat sätt än i denna bruksanvisning specificerats, kan

användaren utsättas för osynlig laserstrålning, som överskrider gränsen för laserklass 1.

Det här är en halvledarlaser. Den maximala effekten för laserdioden är 20 mW och

våglängden är 665-695 nm.

VARO!

Avattaessa ja suojalukitus ohitettaessa olet alttiina näkymättömälle lasersäteilylle. Älä

katso säteeseen.

VARNING!

Osynlig laserstrålning när denna del är öppnad och spärren är urkopplad. Betrakta ej

strålen.

For Norway Users

ADVERSEL

Dersom apparatet brukes på annen måte enn spesifisert i denne bruksanvisning, kan

brukeren utsettes for unsynlig laserstråling som overskrider grensen for laser klass 1.

Dette en halvleder laser. Maksimal effekt till laserdiode er 20 mW og bølgelengde er

665-695 nm.

2-14 Safety Information

Safety Information

Regulations (continued)

Laser Safety Label

A laser safety label is attached to the outside of the machine as shown below.

CLASS 1 LASER PRODUCT

APPAREIL A RAYONNEMENT

LASER DE CLASSE 1

LASER KLASSE 1

Safety Information 2-15

Safety Information

Regulations (continued)

Ozone Release

NOTE

= Locate the Machine in a Well Ventilated Room =

A negligible amount of ozone is generated during normal operation of this machine. An

unpleasant odor may, however, be created in poorly ventilated rooms during extensive

machine operations. For a comfortable, healthy, and safe operating environment, it is

recommended that the room well ventilated.

REMARQUE

= Placer l’appareil dans une pièce largement ventilée =

Une quantité d’ozone négligable est dégagée pendant le fonctionnement de l’appareil

quand celui-ci est utilisé normalement. Cependant, une odeur désagréable peut être

ressentie dans les pièces dont l’aération est insuffisante et lorsque une utilisation

prolongée de l’appareil est effectuée. Pour avoir la certitude de travailler dans un

environnement réunissant des conditions de confort, santé et de sécurité, il est

préférable de bien aérer la pièce ou se trouve l’appareil.

2-16 Safety Information

Section 3: Machine Information

Di750PE Overview ....... 3-2

Key Operator Functions......... 3-3

Service, Repairs and Supplies......... 3-3

Machine Labels......... 3-3

Service Settings......... 3-4

External Machine ....... 3-5

Internal Machine ....... 3-7

Standard Equipment ....... 3-8

Optional Equipment ....... 3-8

Finisher/Large Capacity Cassette....... 3-10

Trimming Unit....... 3-11

Punch Kit....... 3-12

Site Requirements ..... 3-13

Specifications ..... 3-14

Machine Information 3-1

Loading...

Loading...