Konica Minolta DF-612, MS-501, SP-503 Service Manual

DF-612 SP-503 MS-501

Option Printer

SERVICE MANUAL

Code Y109850-7

PUBLICATION ISSUED BY:

Olivetti S.p.A.

77, Via Jervis - 10015 Ivrea (TO)

Italy

Copyright © 2008, Olivetti

All rights reserved

Revision history

After publication of this service manual, the parts and mechanism may be subject to change for

improvement of their performance.

Therefore, the descriptions given in this service manual may not coincide with the actual machine.

When any change has been made to the descriptions in the service manual, a revised version will be

issued with a revision mark added as required.

Revision mark:

• To indicate clearly a section revised, is shown at the left margin of the revised section.

The number inside represents the number of times the revision has been made.

• To indicate clearly a page that contains the revision, is shown near the page number of the

corresponding page.

The number inside represents the number of times the revision has been made.

NOTE

Revision marks shown in a page are restricted only to the latest ones with the old ones deleted.

• When a page revised in Ver. 2.0 has been changed in Ver. 3.0:

The revision marks for Ver. 3.0 only are shown with those for Ver. 2.0 deleted.

• When a page revised in Ver. 2.0 has not been changed in Ver. 3.0:

The revision marks for Ver. 2.0 are left as they are.

1

1

1

1

DF-612/SP-503/MS-501Outline

MaintenanceAdjustment / Setting

Troubleshooting

Field Service Ver. 1.0 Jun. 2008

CONTENTS

DF-612/SP-503/MS-501

Outline

1. Product specification ............................................................................................... 1

Maintenance

2. Periodical check ...................................................................................................... 5

2.1 Maintenance procedure (Periodical check parts) ................................................. 5

2.1.1 Separation roller............................................................................................ 5

2.1.2 Feed roller/pick-up roller ............................................................................... 8

2.1.3 Regist rollers/exit rollers................................................................................ 9

3. Other ..................................................................................................................... 10

3.1 Disassembly/adjustment prohibited items .......................................................... 10

3.2 Disassembly/Assembly/Cleaning list (other parts).............................................. 11

3.2.1 Disassembly/Assembly parts list................................................................. 11

3.2.2 Cleaning parts list ....................................................................................... 11

3.3 Disassembly/Assembly procedure...................................................................... 12

3.3.1 Front cover .................................................................................................. 12

3.3.2 Rear cover/Rear left cover/Rear lower cover .............................................. 13

3.3.3 Document feed tray rear cover.................................................................... 14

3.3.4 Auto document feeder tray.......................................................................... 15

3.3.5 Document feed tray..................................................................................... 16

3.3.6 ADF scanner assy....................................................................................... 17

3.3.7 Feed roller/pick-up roller ............................................................................. 19

3.3.8 Transport roller 1, 2 ..................................................................................... 23

3.3.9 DF control board (DFCB) ............................................................................ 24

3.3.10 Print lamp board (PLB) ............................................................................... 24

3.3.11 Take-up motor (M1)..................................................................................... 25

3.3.12 Transport motor (M2) .................................................................................. 25

3.3.13 Cooling fan (FM1) ....................................................................................... 27

3.3.14 Stamp unit ................................................................................................... 28

3.3.15 Spare TX Marker Stamp 2 .......................................................................... 29

3.4 Cleaning procedure ............................................................................................ 30

3.4.1 White sheet ................................................................................................. 30

3.4.2 Registration sensor ..................................................................................... 30

3.4.3 Black sheet (ADF glass assy) ..................................................................... 31

Y109850-7 Service Manual i

DF-612/SP-503/MS-501

Outline

MaintenanceAdjustment / Setting

Troubleshooting

Field Service Ver. 1.0 Jun. 2008

Adjustment/Setting

4. How to use the adjustment section ....................................................................... 33

5. Service Mode ........................................................................................................ 34

5.1 Service Mode setting procedure......................................................................... 34

5.2 ADF Adjustment ................................................................................................. 34

5.2.1 Zoom........................................................................................................... 34

5.2.2 Feed............................................................................................................ 35

5.2.3 Regist Loop................................................................................................. 37

5.2.4 Erasure Width ............................................................................................. 37

5.2.5 Paper Passage ........................................................................................... 38

5.3 Sensor Check (Scan) ......................................................................................... 39

5.3.1 ADF............................................................................................................. 39

6. Mechanical adjustment ......................................................................................... 40

6.1 Adjusting skew feed............................................................................................ 40

Troubleshooting

7. Jam display ........................................................................................................... 43

7.1 Initial check items ............................................................................................... 43

7.2 Misfeed display................................................................................................... 43

7.2.1 Misfeed display resetting procedure ........................................................... 43

7.3 Sensor layout...................................................................................................... 44

7.4 Solution .............................................................................................................. 44

7.4.1 Turnover section misfeed............................................................................ 44

7.4.2 Paper feed section misfeed......................................................................... 45

7.4.3 Transport section misfeed........................................................................... 45

7.4.4 Paper exit section misfeed .......................................................................... 46

7.4.5 Image reading section misfeed ................................................................... 46

ii Service Manual Y109850-7

Field Service Ver. 1.0 Jun. 2008 1. Product specification

DF-612/SP-503/MS-501Outline

Outline

1. Product specification

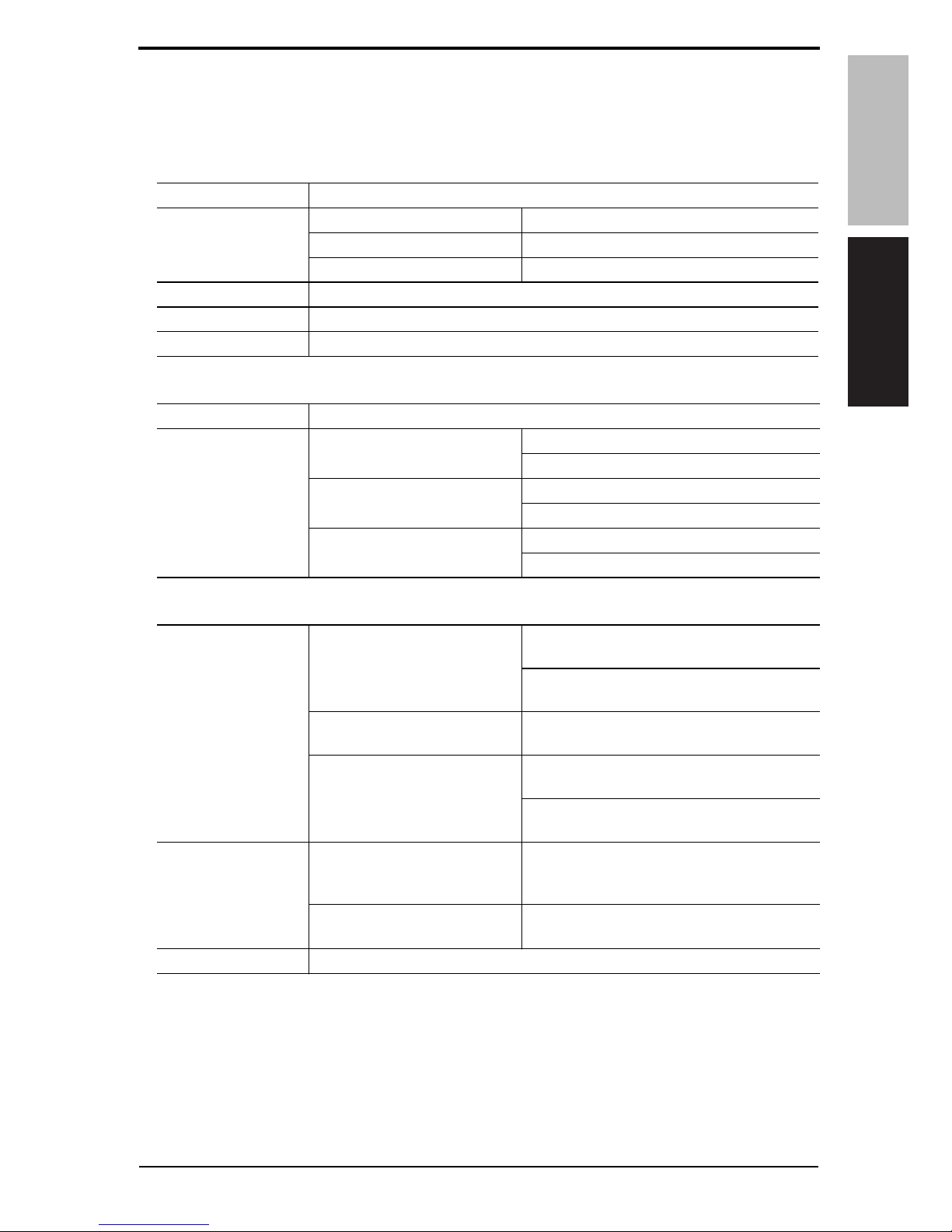

A. Type

B. Functions

C. Paper type

*1: For the combined original detection mode, refer to the mixed original detection enabled

size combination table.

Name Reverse automatic document feeder

Type Image reading section Sheet-through system

Turnover section Switchback system

Exit section Straight exit system

Installation Screw cramp to the main unit

Document alignment Center

Document loading Face up

Mode Standard mode, Mixed original detection mode, FAX mode

Document feed speed Copy 1-sided mode: 20 pages/min

2-sided mode: 10 pages/min

Color scan

(300 dpi)

1-sided mode: 20 pages/min

2-sided mode: 10 pages/min

Monochrome scan

(300 dpi)

1-sided mode: 40 pages/min

2-sided mode: 20 pages/min

Type of document Standard mode

Plain paper

1-sided mode

38 to 128 g/m

2

(10 to 34 lb)

2-sided mode

50 to 128 g/m

2

(13.25 to 34 lb)

Mixed original detection mode

Plain paper

1-sided / 2-sided mode

50 to 128 g/m

2

(13.25 to 34 lb)

FAX mode

Plain paper

1-sided mode

38 to 128 g/m

2

(10 to 34 lb)

2-sided mode

50 to 128 g/m

2

(13.25 to 34 lb)

Detectable document

size*1

(Standard mode,

FAX mode)

Metric area A5, A5S, B5, B5S, A4, A4S, B4, A3,

5

1

/2 x 8 1/2, 5 1/2 x 8 1/2S, FLS

(China only: 8K, 16K, 16KS)

Inch area 5

1

/2 x 8 1/2S, 8 1/2 x 11, 8 1/2 x 11S,

8

1

/2 x 14, 11 x 17, A4

Capacity 70 sheets (80 g/m

2

)

Y109850-7 Service Manual 1

1. Product specification Field Service Ver. 1.0 Jun. 2008

DF-612/SP-503/MS-501

Outline

D. Paper feed prohibited originals

• If fed, trouble occurrence will be highly possible.

E. Paper feed not guaranteed originals

• If fed, paper feed will be possible to some extent but trouble occurrence will be possible.

Type of original Possible trouble

Sheets stapled or clipped together Paper feed failure, damaged sheet, defective drive

mechanism due to jammed staples or clips

Book original Paper feed failure, damaged sheet

Sheets glued together Paper feed failure, damaged sheet

Sheets clipped or notched Damaged sheet, transport failure

Sheets patched Patched part folded or torn sheet

Sheets folded, torn or wrinkled Paper feed failure, damaged sheet,

transport failure

Original weighing less than 38 g/m

2

(10 lb) or

128 g/m

2

(34 lb) or more

Paper feed failure, transport failure

Sheets severely curled (15 mm or more) Sheets misfed due to being dog-eared or fed in

askew

OHP film (Transparency film) Paper feed failure, transport failure

Label paper Paper feed failure, transport failure

Glossy photographic paper or glossy enamel

paper

Transport failure, damaged sheet

Type of Original Possible Trouble

Sheets lightly curled (Curled amount: 10 to 15 mm) Dog-eared, exit failure, transport failure

Heat sensitive paper Edge folded, exit failure, transport failure

Intermediate paper Paper feed failure, transport failure

Paper immediately after paper exit from the main unit Paper feed failure, transport failure

Paper with many punched holes (e.g., loose leaf) limited

to vertical feeding

Multi-page feed due to flashes from holes

Sheets two-folded or Z-folded Transport failure, image deformation

Sheets with 2 to 4 holes Transport failure

Ink jet paper Paper feed failure, transport failure

Sheets with smooth surface (Coated paper) Paper feed failure, transport failure

Sheets with rough surface (e.g., letterhead) Paper feed failure

2 Service Manual Y109850-7

Field Service Ver. 1.0 Jun. 2008 1. Product specification

DF-612/SP-503/MS-501Outline

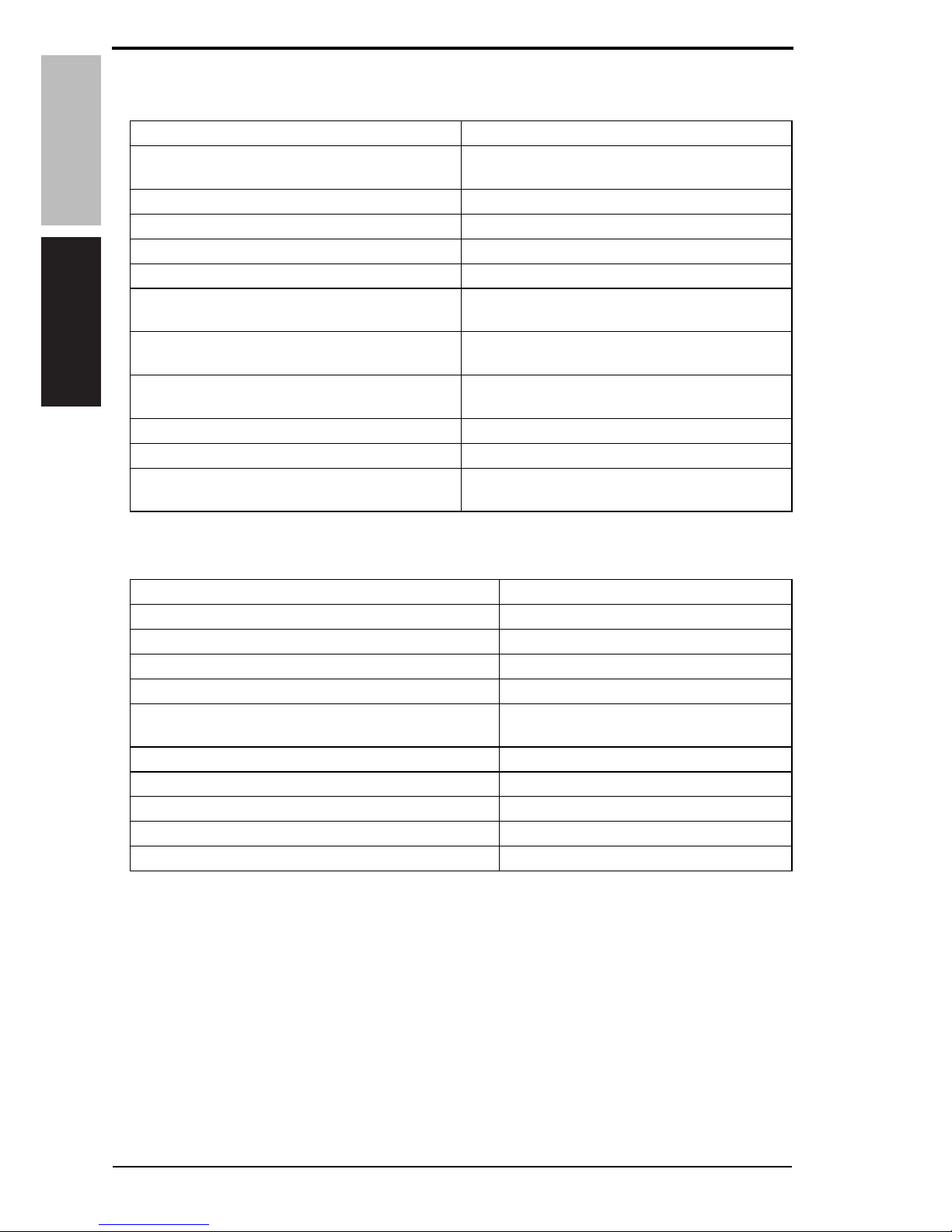

F. Mixed original feed chart

For metric

For inch

G. Machine specifications

H. Operating environment

Conforms to the operating environment of the main unit.

NOTE

• These specifications are subject to change without notice.

Max. original

size

297 mm 257 mm 210 mm 182 mm 148 mm

Mixed original size A3 A4 B4 B5 A4S A5 B5S A5S

297 mm

A3 OKOK------

A4 OKOK------

257 mm

B4 xxOKOK----

B5 xxOKOK----

210 mm

A4S xxxxOKOK- -

A5 xxxxOKOK- -

182 mm B5S xxxxxxOK-

148 mm A5S xxxxxxxOK

Max. original

size

11

8

1

/

2

51/

2

Mixed original size 11 x 17

8

1

/2 x 11 8 1/2 x 14 8 1/2 x 11S 5 1/2 x 8 1/251/2 x 8 1/2S

11

11 x 17 OK OK - - - -

8

1

/2 x 11

OK OK - - - -

8

1

/

2

81/2 x 14

x x OK OK OK -

8

1

/2 x 11S

x x OK OK OK -

5

1

/2 x 8 1/

2

x x OK OK OK -

5

1

/

2

51/2 x 8 1/2S

xx x x x OK

OK Mixed original feed available

x No. mixed original feed

- Can not set original

Power requirements DC 24 V (supplied from the main unit)

Max. power consumption 55 W or less

Dimensions 551 mm (W) x 511 mm (D) x 118 mm (H)

21.7 inch (W) x 20.1 inch (D) x 4.7 inch (H)

Weight 8.1 kg (17.85 lb)

Y109850-7 Service Manual 3

1. Product specification Field Service Ver. 1.0 Jun. 2008

DF-612/SP-503/MS-501

Outline

Blank Page

4 Service Manual Y109850-7

Field Service Ver. 1.0 Jun. 2008 2. Periodical check

DF-612/SP-503/MS-501

Maintenance

Maintenance

2. Periodical check

2.1 Maintenance procedure (Periodical check parts)

NOTE

• The alcohol described in the cleaning procedure of maintenance represents the

isopropyl alcohol.

2.1.1 Separation roller

A. Periodically cleaning parts/cycle

• Separation roller: Every 30,000 originals feed

B. Periodically replaced parts/cycle

• Separation roller: Every 100,000 originals feed

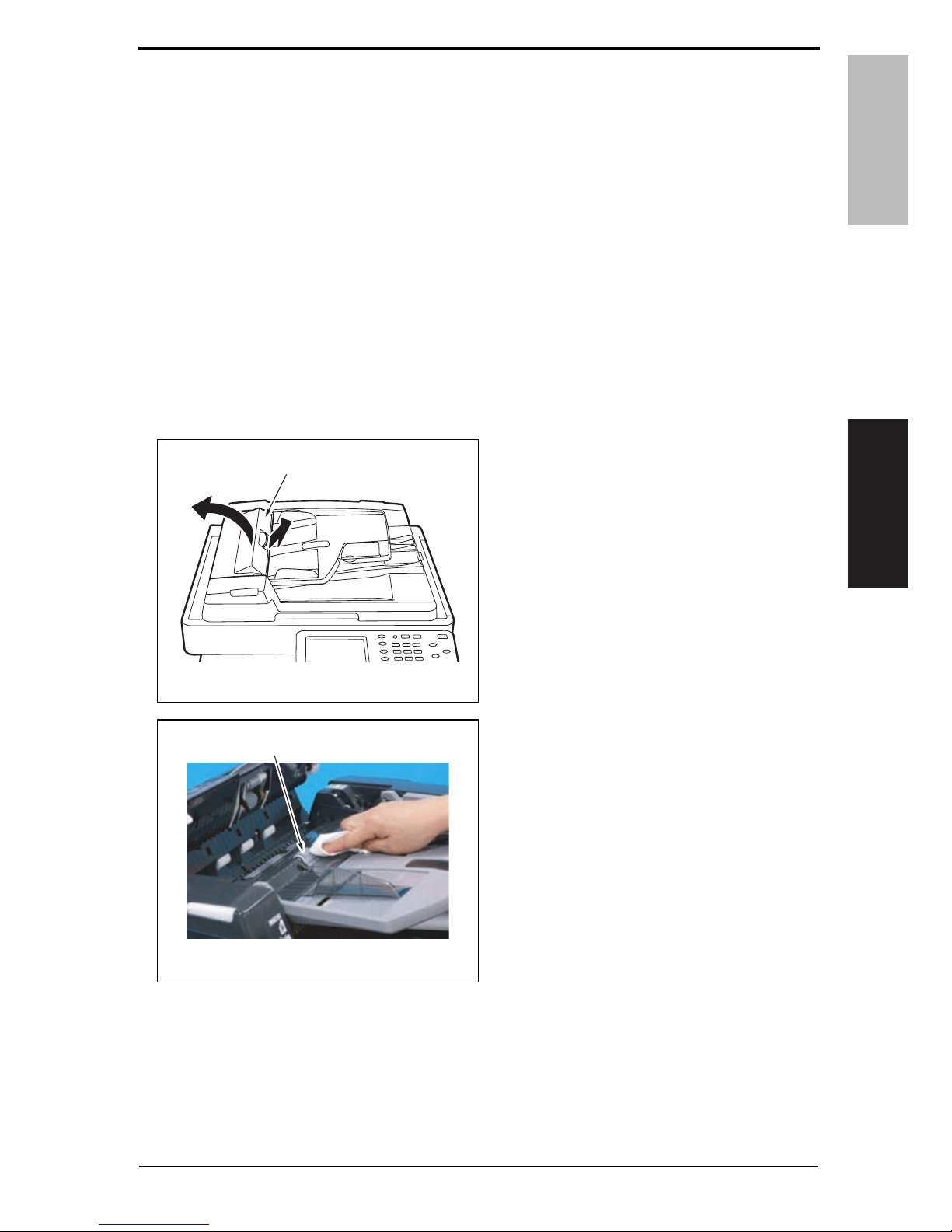

C. Cleaning procedure

1. Open the feed cover [1].

2. Using a cleaning pad dampened with

alcohol, wipe the separation roller [1]

clean of dirt.

A0EYF2C500DA

[1]

A0EYF2C001DA

[1]

Y109850-7 Service Manual 5

2. Periodical check Field Service Ver. 1.0 Jun. 2008

DF-612/SP-503/MS-501

Maintenance

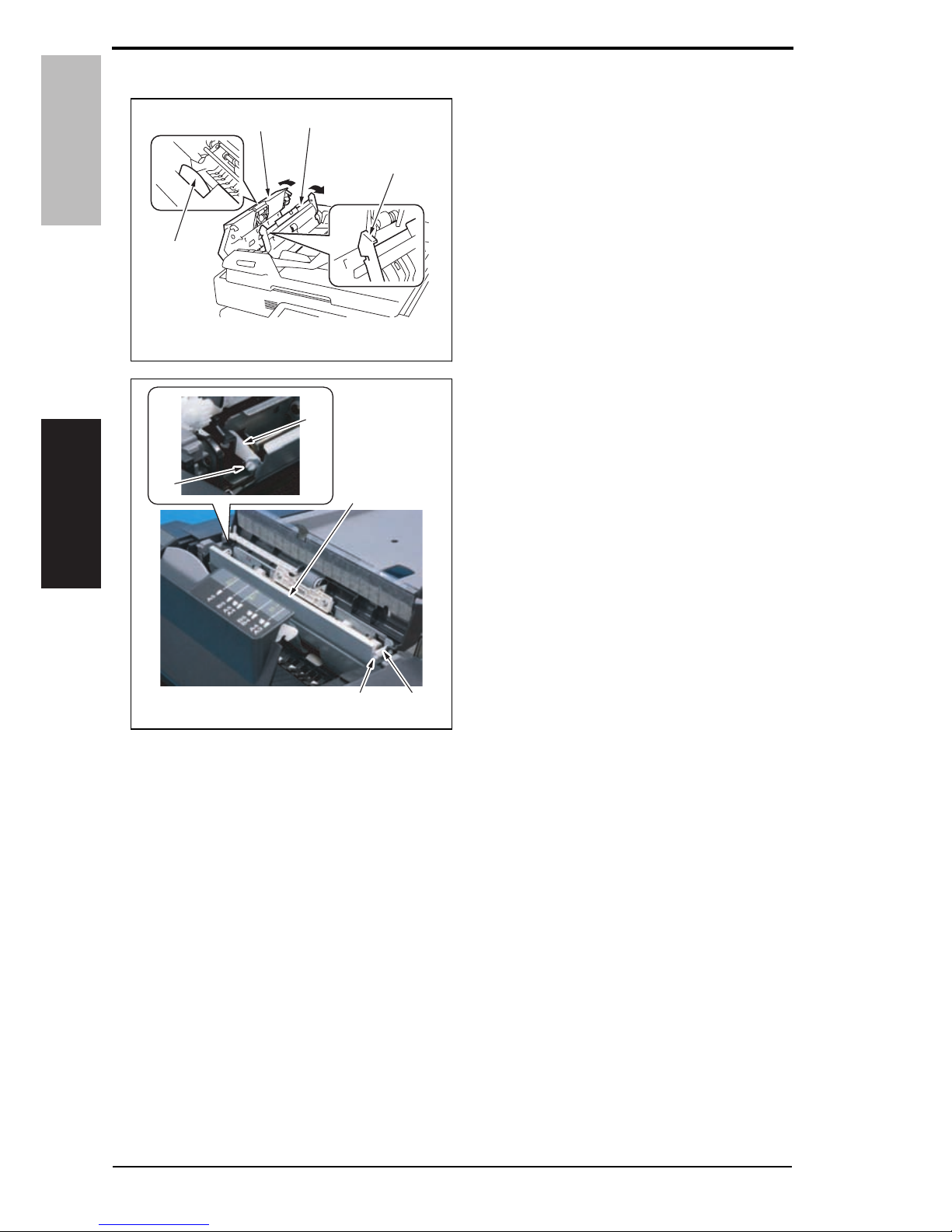

D. Replacing procedure

1. Pull the lever [1] to open the feed

cover [2].

2. Raise the knob [3] and open the document guide [4].

3. Unhook the tab [1] and remove the

two arms [2].

4. Open the frame [3].

A0EYF2C511DA

[1]

[2]

[4]

[3]

A0EYF2C002DA

[1]

[1]

[2]

[2]

[3]

6 Service Manual Y109850-7

Field Service Ver. 1.0 Jun. 2008 2. Periodical check

DF-612/SP-503/MS-501

Maintenance

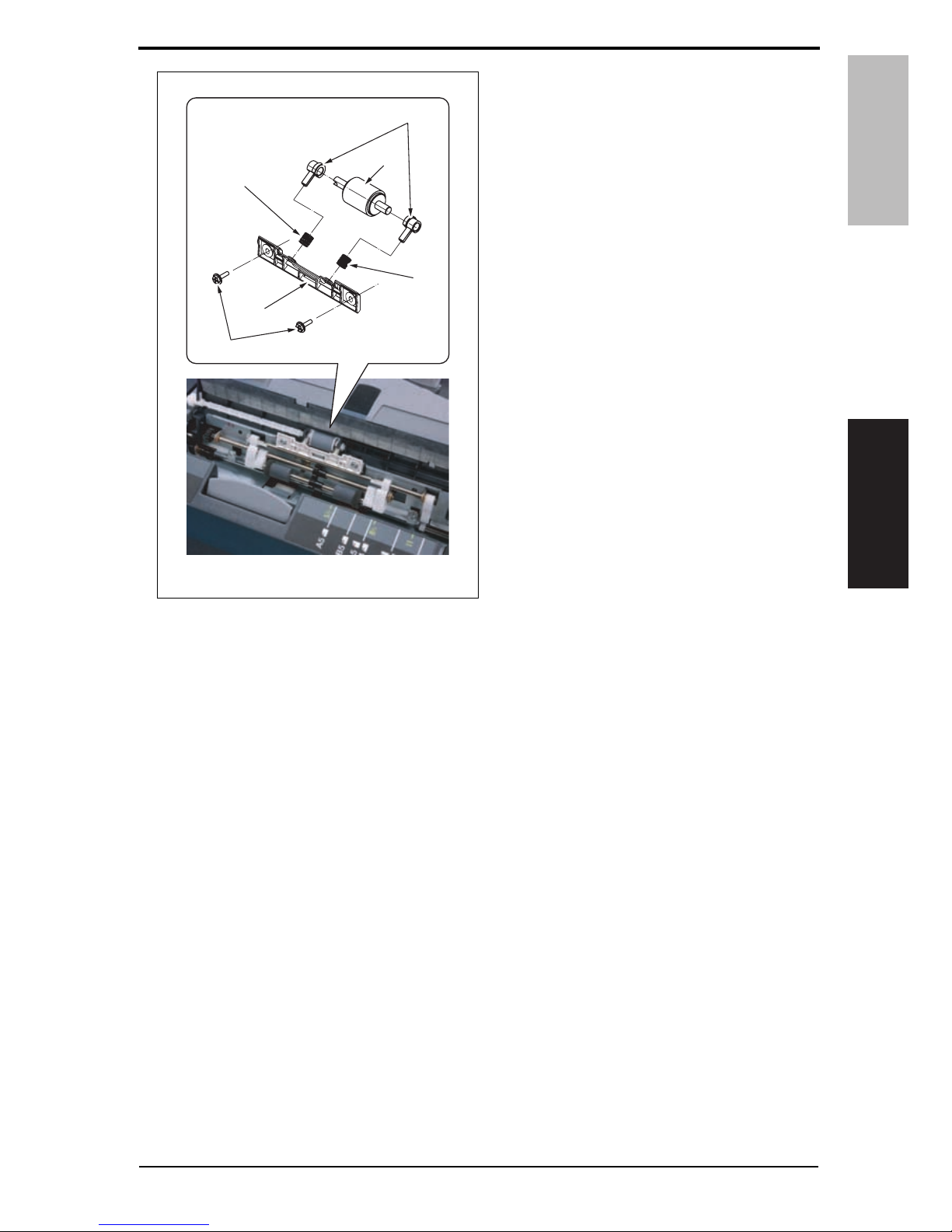

5. Remove two screws [1] and the plate

[2].

6. Remove two springs [3], two bearing

splits [4], and the separator roller [5].

A0EYF2C003DA

[1]

[2]

[3]

[3]

[5]

[4]

Y109850-7 Service Manual 7

2. Periodical check Field Service Ver. 1.0 Jun. 2008

DF-612/SP-503/MS-501

Maintenance

2.1.2 Feed roller/pick-up roller

A. Periodically cleaning parts/cycle

• Feed roller: Every 30,000 originals feed

• Pick-up roller: Every 30,000 originals feed

B. Cleaning procedure

1. Open the feed cover [1].

2. Using a cleaning pad dampened with

alcohol, wipe the feed roller [1]/pickup roller [2] clean of dirt.

A0EYF2C500DA

[1]

A0EYF2C004DA

[2]

[1]

8 Service Manual Y109850-7

Field Service Ver. 1.0 Jun. 2008 2. Periodical check

DF-612/SP-503/MS-501

Maintenance

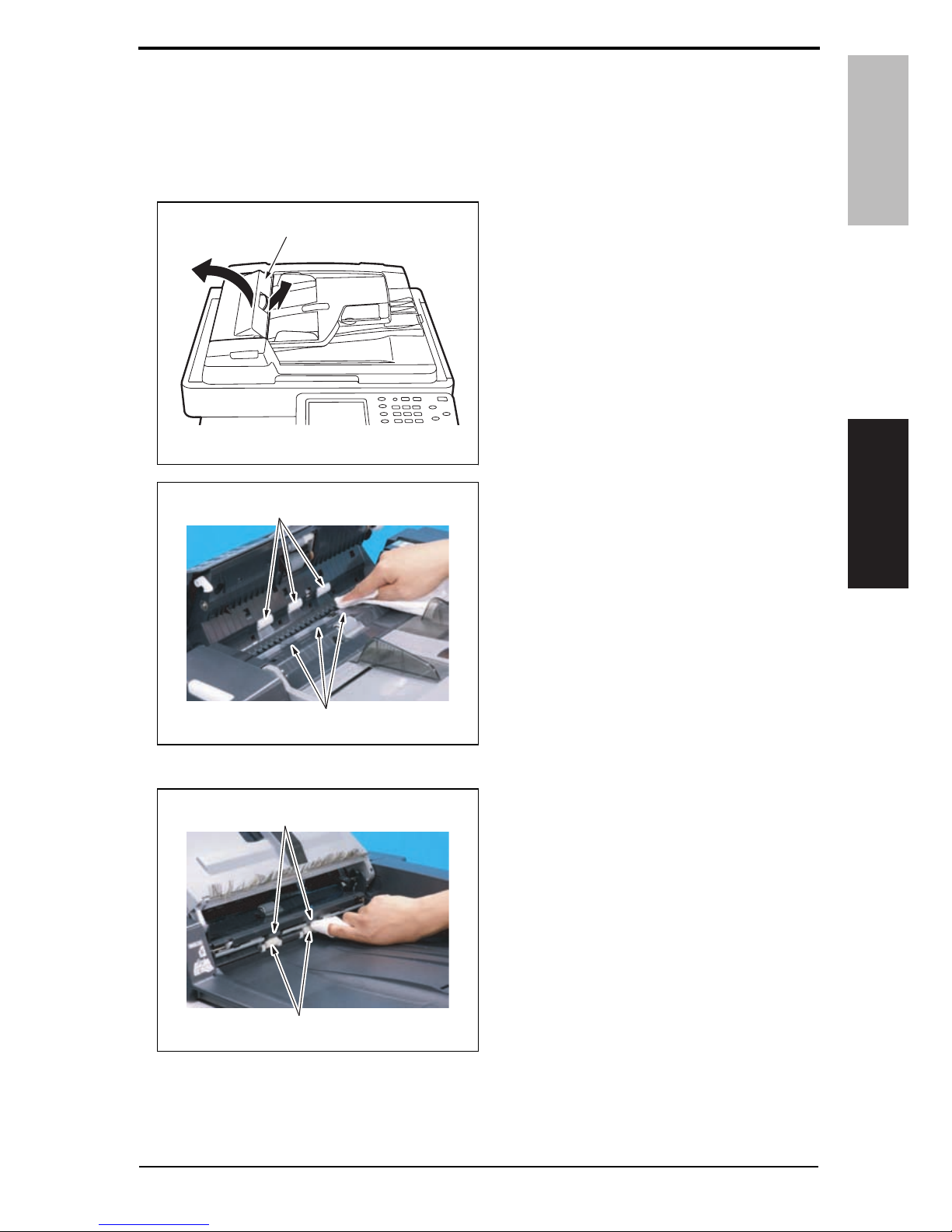

2.1.3 Regist rollers/exit rollers

A. Periodically cleaning parts/cycle

• Regist rollers: Every 30,000 originals feed

• Exit rollers: Every 30,000 originals feed

B. Cleaning procedure

1. Open the feed cover [1].

2. Using a cleaning pad dampened with

alcohol, wipe three regist rollers [1]

and three rolls [2] clean of dirt.

3. Lift up the document feed tray.

4. Using a cleaning pad dampened with

alcohol, wipe two exit rollers [1] and

two rolls [2] clean of dirt.

A0EYF2C500DA

[1]

A0EYF2C042DA

[1]

[2]

A0EYF2C043DA

[1]

[2]

Y109850-7 Service Manual 9

3. Other Field Service Ver. 1.0 Jun. 2008

DF-612/SP-503/MS-501

Maintenance

3. Other

3.1 Disassembly/adjustment prohibited items

A. Paint-locked screws

NOTE

• To prevent loose screws, a screw lock in blue or green series color is applied to

the screws.

• The screw lock is applied to the screws that may get loose due to the vibrations

and loads created by the use of machine or due to the vibrations created during

transportation.

• If the screw lock coated screws are loosened or removed, be sure to apply a screw

lock after the screws are tightened.

B. Red-painted screws

NOTE

• The screws which are difficult to be adjusted in the field are painted in red in order

to prevent them from being removed by mistake.

• Do not remove or loosen any of the red-painted screws in the field. It should also

be noted that, when two or more screws are used for a single part, only one representative screw may be marked with the red paint.

C. Variable resistors on board

NOTE

• Do not turn the variable resistors on boards for which no adjusting instructions

are given in Adjustment/Setting.

D. Removal of PWBs

CAUTION

• When removing a circuit board or other electrical component, refer to “Handling of

PWBs” and follow the corresponding removal procedures.

• The removal procedures given in the following omit the removal of connectors and

screws securing the circuit board support or circuit board.

• Where it is absolutely necessary to touch the ICs and other electrical components

on the board, be sure to ground your body.

10 Service Manual Y109850-7

Field Service Ver. 1.0 Jun. 2008 3. Other

DF-612/SP-503/MS-501

Maintenance

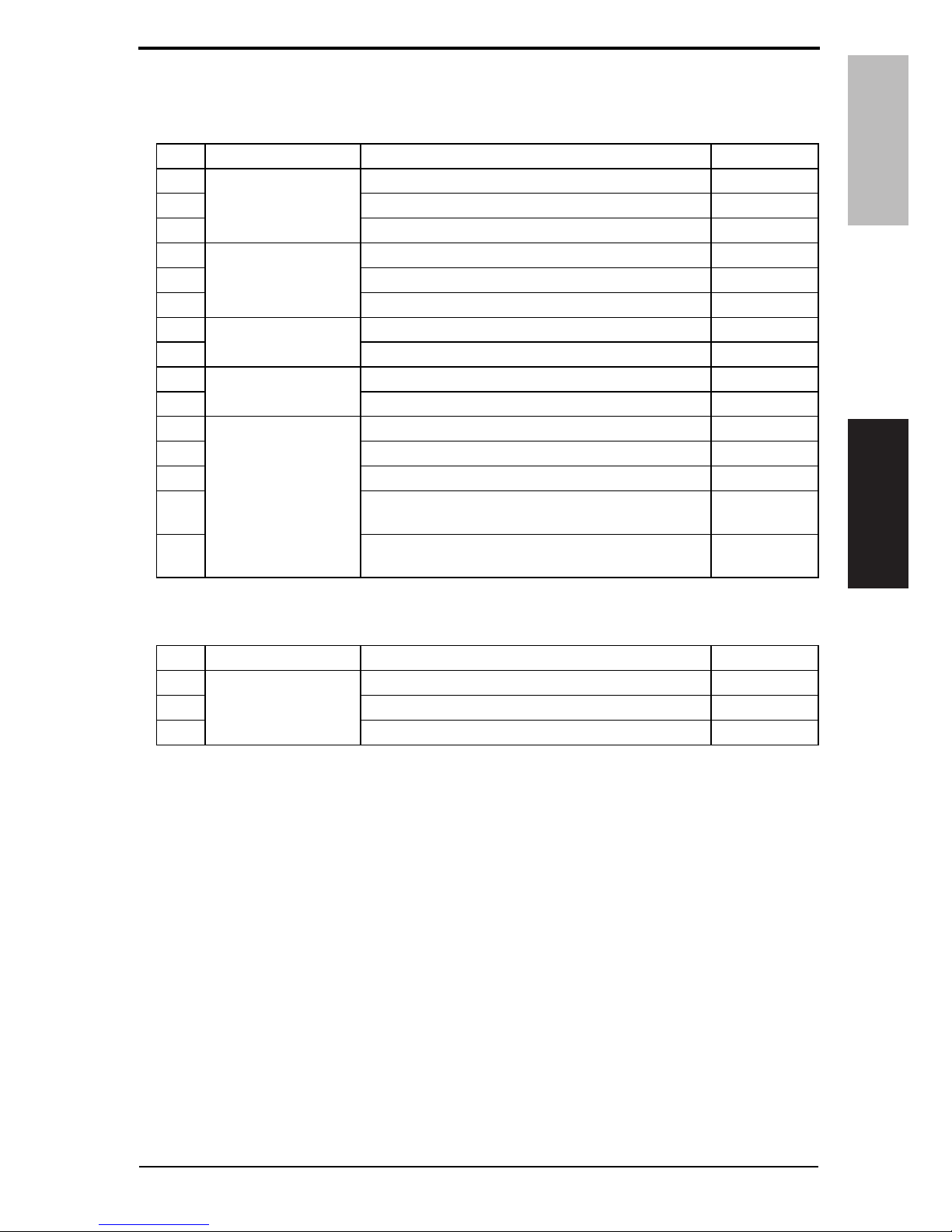

3.2 Disassembly/Assembly/Cleaning list (other parts)

3.2.1 Disassembly/Assembly parts list

3.2.2 Cleaning parts list

No. Section Part name Ref. page

1

Exterior parts

Front cover P. 1 2

2 Rear cover/Rear left cover/Rear lower cover P. 1 3

3 Document feed tray rear cover P. 1 4

4

Units

Auto document feeder unit P. 1 5

5 Document feed tray P. 1 6

6 ADF scanner assy P. 1 7

7

Rollers

Feed roller/Pick-up roller P. 1 9

8 Transport roller 1, 2 P. 2 3

9

PWBs

DF control board (DFCB) P. 2 4

10 Print lamp board (PLB) P. 2 4

11

Others

Take-up motor (M1) P. 2 5

12 Transport motor (M2) P. 2 5

13 Cooling fan (FM1) P. 2 7

14

SP-503

Stamp unit

P. 2 8

15

MS-501

Spare TX Marker Stamp 2

P. 2 9

No. Section Part name Ref. page

1

Transport section

White sheet P. 3 0

2 Registration sensor P. 3 0

3 Black sheet (ADF glass assy) P. 3 1

Y109850-7 Service Manual 11

Loading...

Loading...