Konica Minolta DF-502 Service Manual

SERVICE MANUAL

DF-502

THEORY OF OPERATION

2005.04

Ver. 1.0

After publication of this service manual, the parts and mechanism may be subject to change for

improvement of their performance.

Therefore, the descriptions given in this service manual may not coincide with the actual machine.

When any change has been made to the descriptions in the service manual, a revised version will be

issued with a revision mark added as required.

Revision mark:

• To indicate clearly a section revised, show to the left of the revised section.

A number within represents the number of times the revision has been made.

1

1

• To indicate clearly a section revised, show in the lower outside section of the correspond-

1

ing page.

A number within represents the number of times the revision has been made.

1

NOTE

Revision marks shown in a page are restricted only to the latest ones with the old ones deleted.

• When a page revised in Ver. 2.0 has been changed in Ver. 3.0:

The revision marks for Ver. 3.0 only are shown with those for Ver. 2.0 deleted.

• When a page revised in Ver. 2.0 has not been changed in Ver. 3.0:

The revision marks for Ver. 2.0 are left as they are.

2005/04 1.0 — Issue of the first edition

Date Service manual Ver. Revision mark Descriptions of revision

Theory of Operation Ver. 1.0 Apr. 2005

CONTENTS

Outline

1. Product specification ............................................................................................... 1

Composition/Operation

2. Automatic Document Feeder (DF-502) ................................................................... 3

2.1 Construction ......................................................................................................... 3

2.2 Operation .............................................................................................................. 4

2.2.1 Document Take-Up and Feed ....................................................................... 4

2.2.2 Document Transport...................................................................................... 5

2.3 Electrical Parts Layout .......................................................................................... 6

2.4 Document Separating Mechanism........................................................................ 7

2.5 Document Exit Mechanism ................................................................................... 8

2.6 Document Size Detection Mechanism.................................................................. 9

DF-502OutlineComposition/Operation

2.7 Raised/Lowered Position Detection Mechanism................................................... 9

i

DF-502

OutlineComposition/Operation

Theory of Operation Ver. 1.0 Apr. 2005

Blank page

ii

Theory of Operation Ver. 1.0 Apr. 2005 1. Product specification

Outline

1. Product specification

Name Automatic Document Feeder

Installation Inserted in top portion of the copier

Modes Standard = 1-sided original

Mixed Original = 1-sided original

Document Loading Left-hand side, face up

Types and Sizes of Document

Standard Mixed Original

Ty pe

Sizes

Document Alignment Center

Capacity

Power Requirements DC24 V, DC5 V (supplied from the copier)

Power Consumption 36 W or less

Dimensions Width = 598 mm, Depth = 483 mm, Height = 102 mm

Mass 6.3 kg

Operating Environment Conforms to that of the copier

Plain paper (50 to 110 g/m2) Plain paper (60 to 90 g/m2)

A3, A4 R, A4, A5 R, B4, B5 R, B5,

11 x 17, 11 x 14, Legal, Letter R, Letter,

Invoice R, and Invoice

50 sheets max. (80 g/m

A3 and A4, B4 and B5, 11 x 17 and

Letter, Legal and Letter R, Legal and

Invoice, Letter R and Invoice

2

)

DF-502Outline

Types of Originals Not Guaranteed for Reliable Feeding

Type of Original Possible Problems

Sheets stapled or clipped together

Sheets glued together Take-up failure, damaged sheet

Sheets folded, torn, or wrinkled Take-up failure, damaged sheet

Sheets severely curled

Take-up failure, damaged sheet, defective drive

mechanism due to jammed staples or clips

Sheet misfed due to its being dog-eared or fed in

askew

1

1. Product specification Theory of Operation Ver. 1.0 Apr. 2005

DF-502

Outline

Blank page

2

Theory of Operation Ver. 1.0 Apr. 2005 2. Automatic Document Feeder (DF-502)

Composition/Operation

2. Automatic Document Feeder (DF-502)

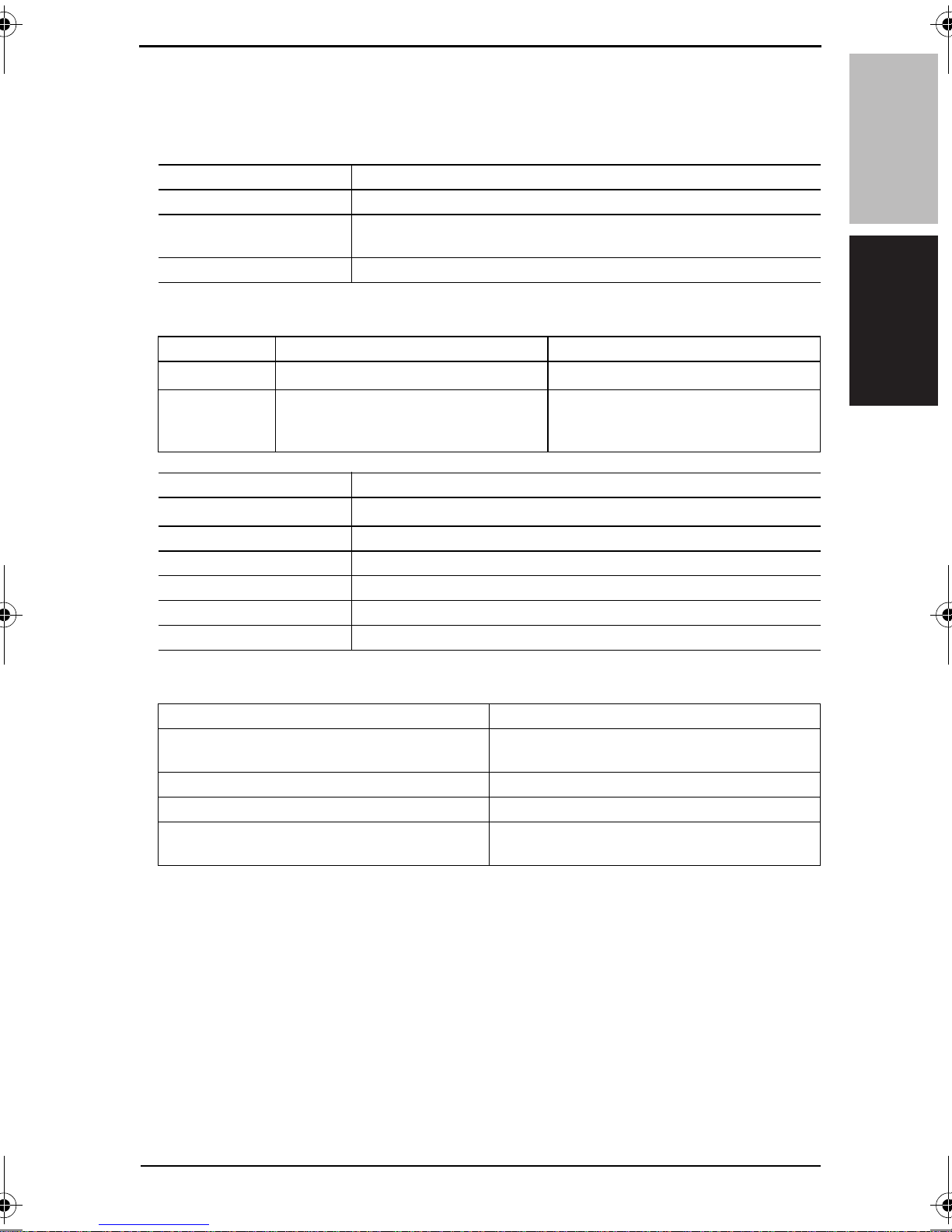

2.1 Construction

1

6

5

DF-502Composition/Operation

2

3

4

[1] Main Motor [4] Registration Rollers

[2] Pick-Up Roller [5] Take-Up Roller

[3] Exit Rollers [6] Take-Up Clutch

4688M502AA

3

2. Automatic Document Feeder (DF-502) Theory of Operation Ver. 1.0 Apr. 2005

2.2 Operation

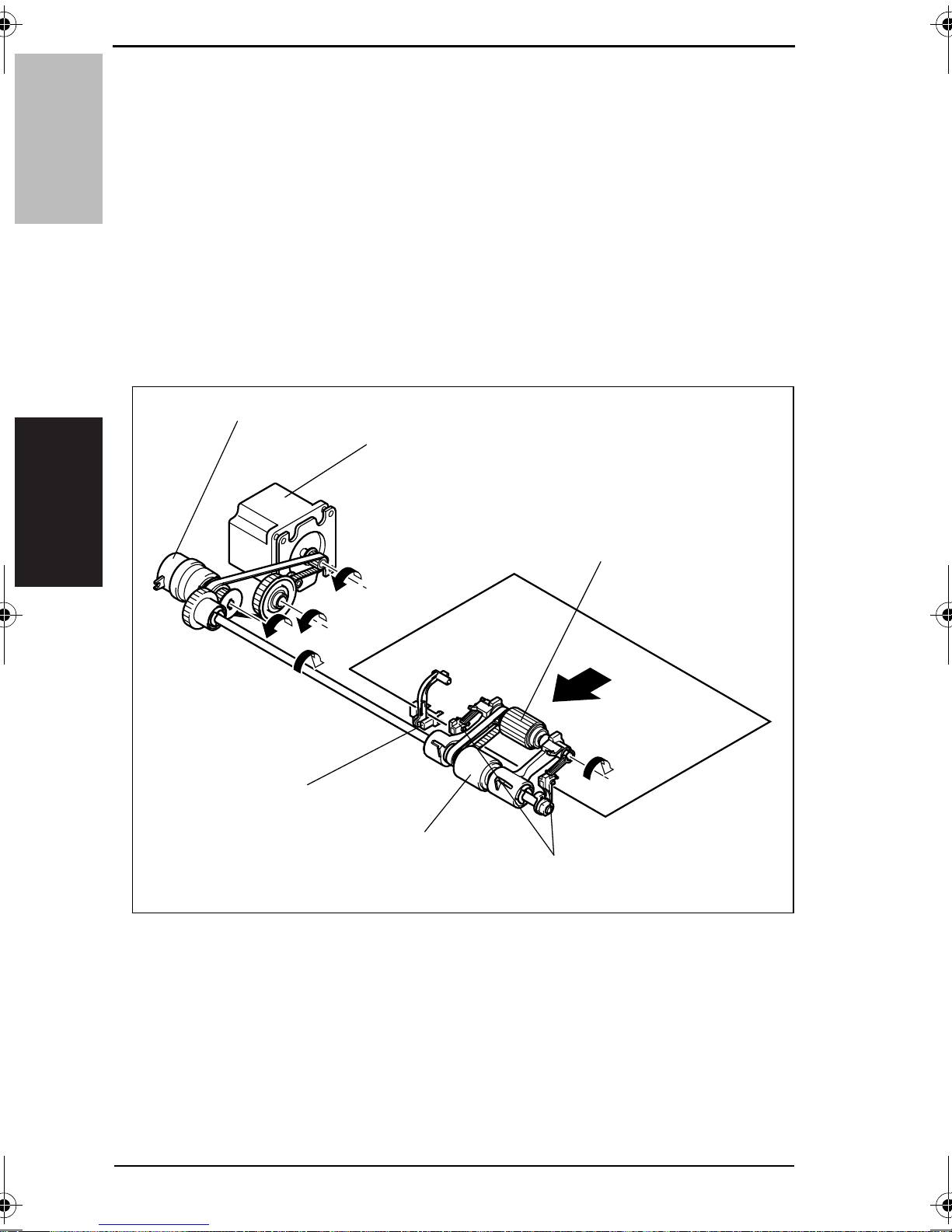

2.2.1 Document Take-Up and Feed

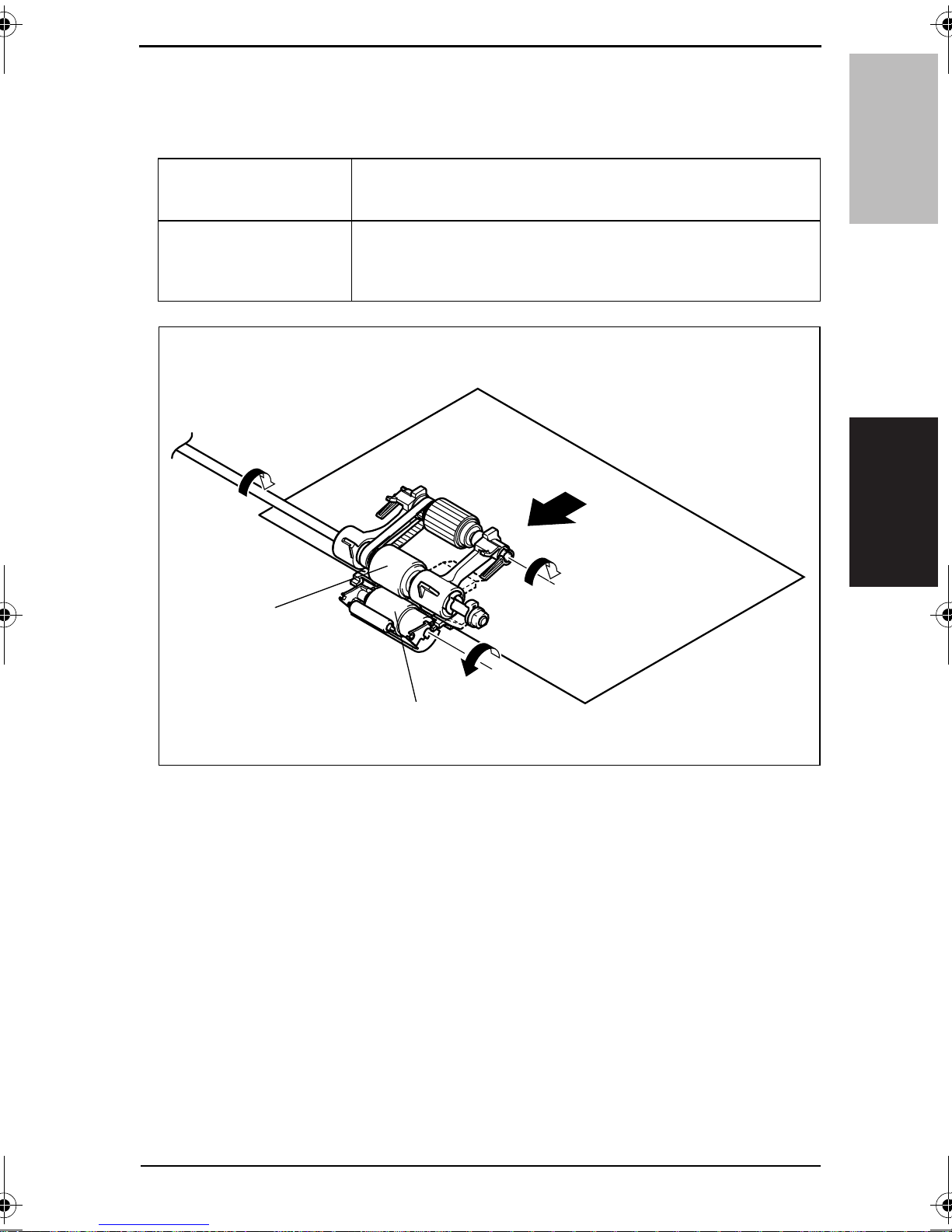

• The document is taken up as the Pick-Up Roller and Take-Up Roller turn.

DF-502

• The Pick-Up Roller transports the document up to the Take-Up Roller.

• After a scan is completed, the Main Motor is turned backward to raise the Pick-Up Roller.

• The Pick-Up Roller and the Take-Up Roller are turned through the Paper Take-Up Clutch

and by a gear train and a belt driven by the Main Motor.

• The Paper Empty Sensor is used to detect a document loaded on the Document Loading

Tr ay.

• The Document Stoppers determine the leading edge position of the document loaded on

the Document Loading Tray. They are in the lowered, swung-down position in the

standby state and swing upward when the document is to be taken up.

• The swing-up and swing-down motion of the Document Stoppers is operatively connected to the raising and lowering of the Pick-Up Roller.

Paper Take-Up Clutch (CL1)

Main Motor (M1)

Composition/Operation

Pick-Up Roller

Paper Empty Sensor (PC2)

4688M005AA

Take-Up Roller

Document Stoppers

4

Theory of Operation Ver. 1.0 Apr. 2005 2. Automatic Document Feeder (DF-502)

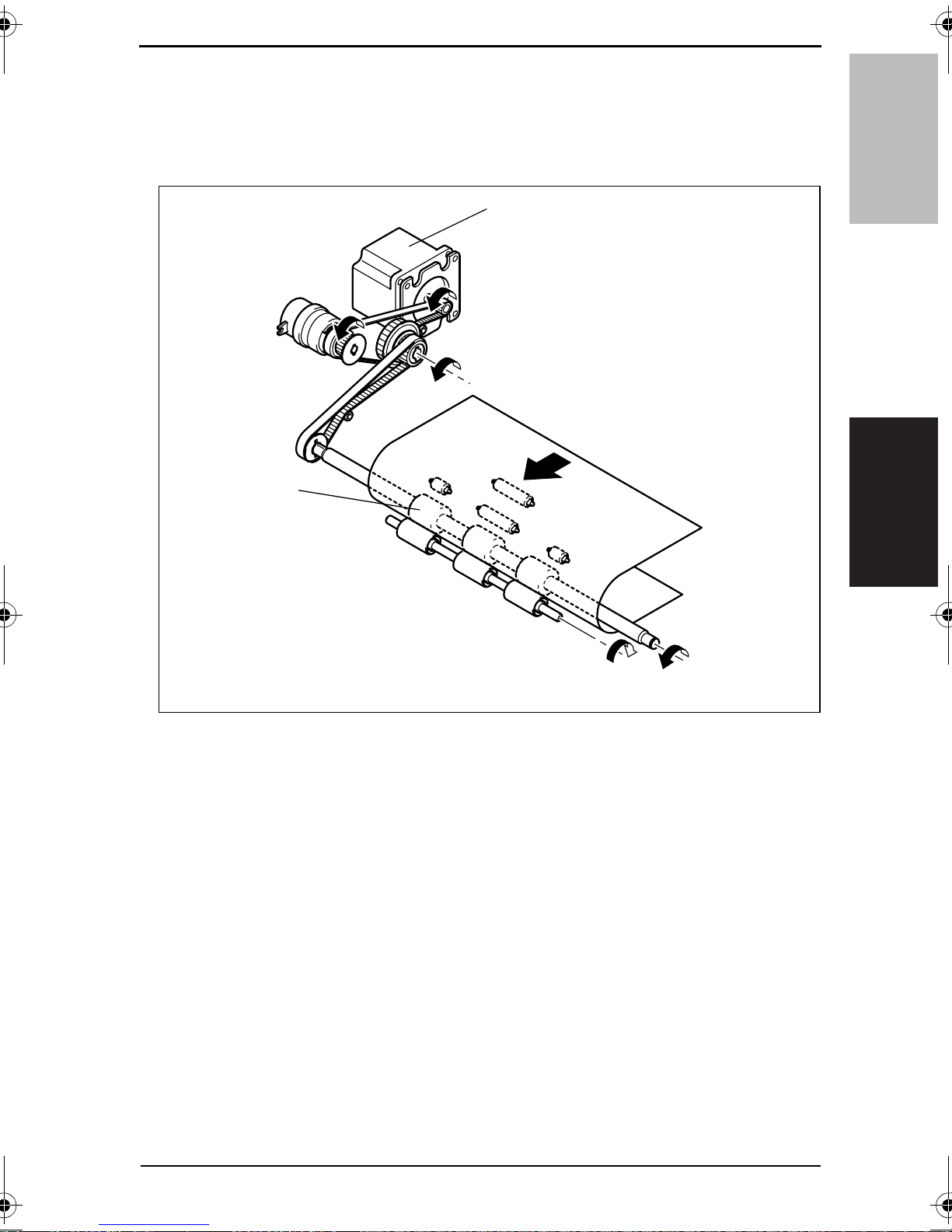

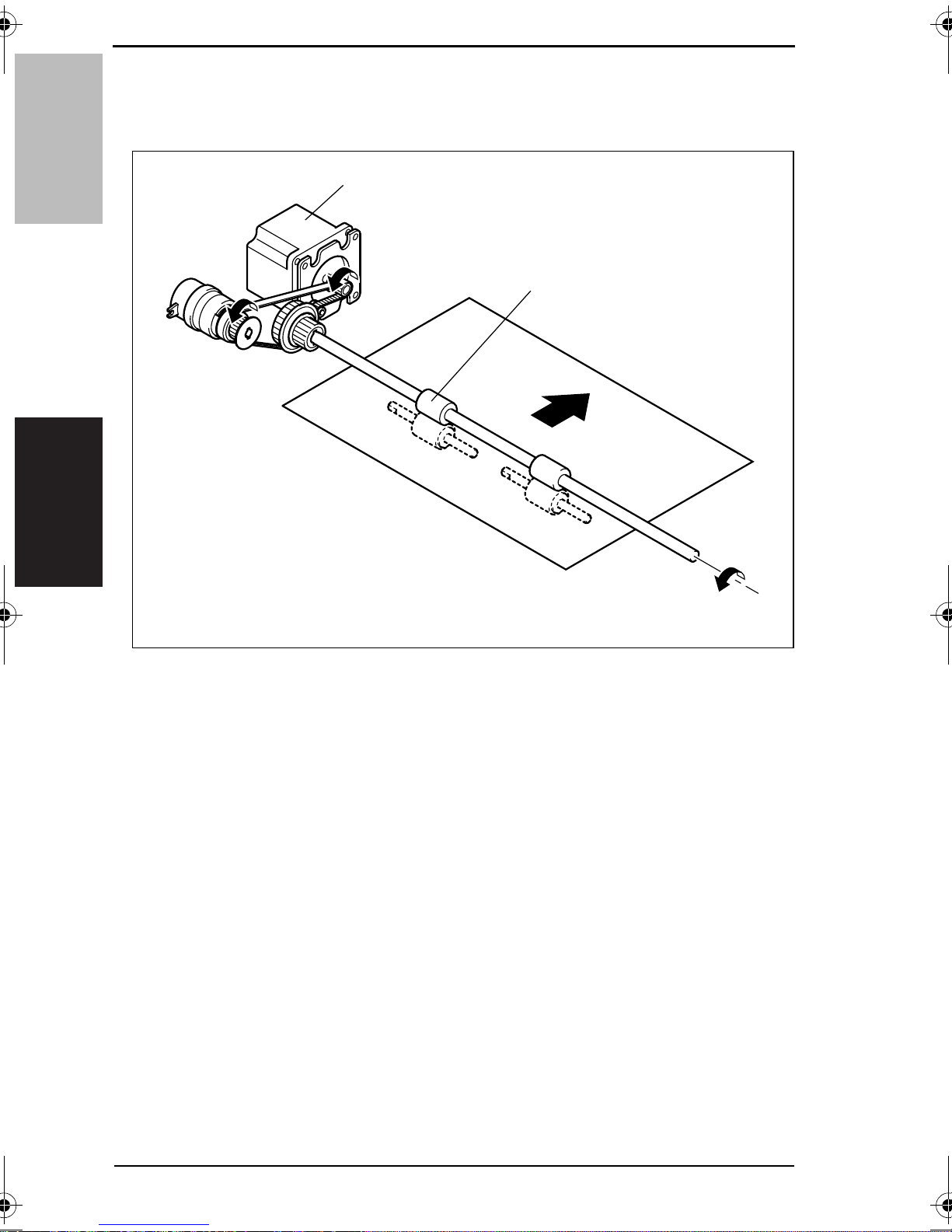

2.2.2 Document Transport

• The document taken up is transported to the document scanning position of the copier

by the Registration Rollers.

• The Registration Rollers are turned by a gear train and belts which are driven by the

Main Motor.

Main Motor (M1)

DF-502Composition/Operation

Registration Rollers

4688M007AA

5

2. Automatic Document Feeder (DF-502) Theory of Operation Ver. 1.0 Apr. 2005

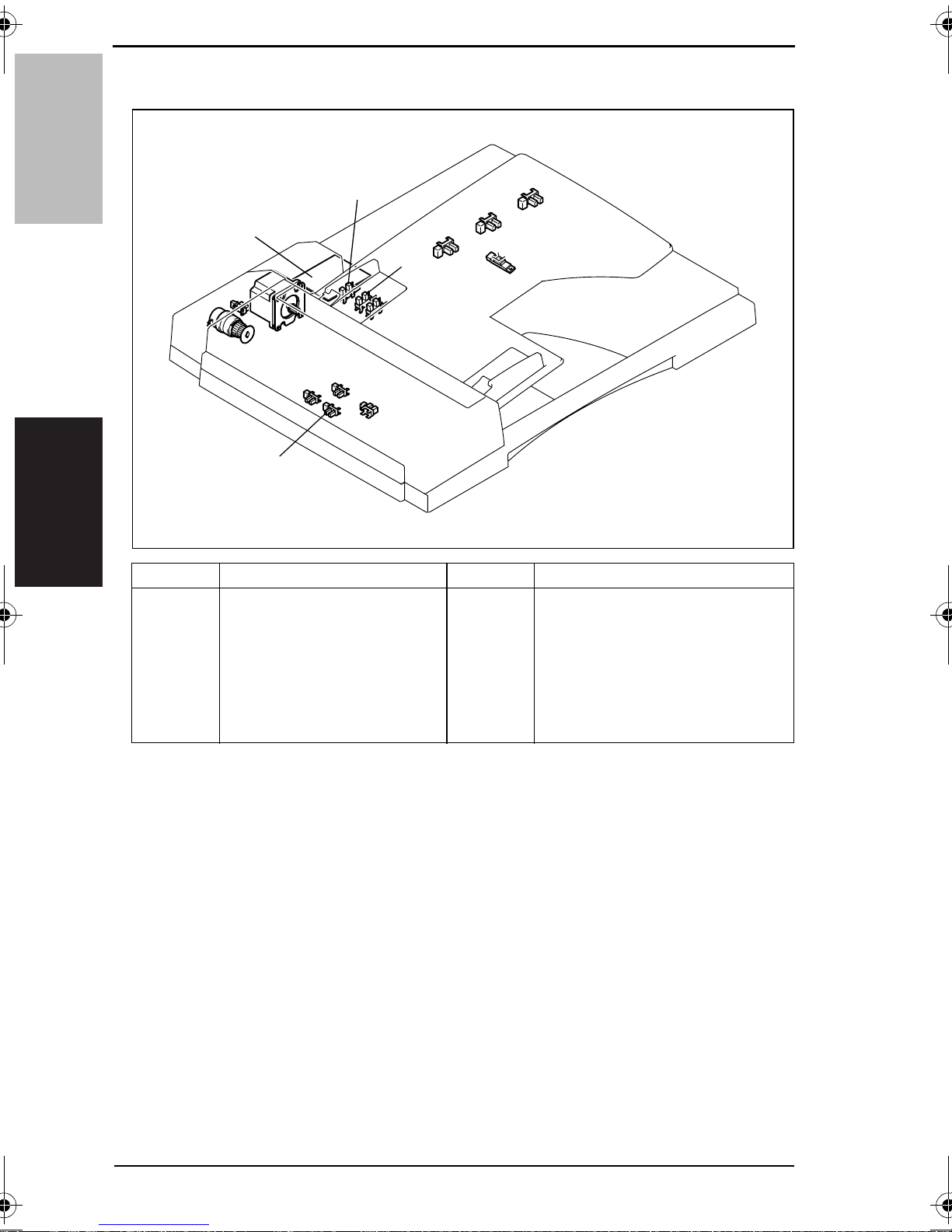

2.3 Electrical Parts Layout

DF-502

CL1

Composition/Operation

Symbol Name Symbol Name

PWB

M1

CL1

PC1

PC2

PC3

PC4

PC12

PWB

PC1

PC2

PC4

PC3

Interface Board

Main Motor

Paper Take-Up Clutch

Take-Up Cover Open/Close

Detecting Sensor

Paper Empty Sensor

Registration Sensor

Separator Sensor

PC11

PC10

PC5

PC6

PC8

PC5

PC6

PC7

PC8

PC9

PC10

PC11

PC12

PC9

PC7

4688M505CA

Paper Exit Sensor

Length Size Detection Sensor 1

Length Size Detection Sensor 2

Length Size Detection Sensor 3

Length Size Detection Sensor 4

Width Size Detection Sensor 1

Width Size Detection Sensor 2

Width Size Detection Sensor 3

6

Theory of Operation Ver. 1.0 Apr. 2005 2. Automatic Document Feeder (DF-502)

2.4 Document Separating Mechanism

• The coefficient of friction between the Take-Up Roller and Separation Roller is effectively

used to prevent double feed of paper.

When one sheet of paper is

taken up

When two or more sheets of

paper are taken up

Since the friction coefficient on the top side of the paper is equal to that

on the underside of the paper, the Separation Roller is turned by the

Take-up Roller. This feeds the paper forward.

The friction coefficient between the sheets of paper is smaller than that

between the paper and Separation Roller. This stops the Separation

Roller, allowing only the first sheet of paper to be transported by the

Take-up Roller.

DF-502Composition/Operation

Take-Up Roller

Separation Roller

4688M006AA

7

2. Automatic Document Feeder (DF-502) Theory of Operation Ver. 1.0 Apr. 2005

2.5 Document Exit Mechanism

• The document is fed out of the ADF by the Exit Roller.

• The Exit Roller is driven by gears and a belt which are driven by the Main Motor.

DF-502

Composition/Operation

Main Motor (M1)

Exit Rollers

4688M008AA

8

Theory of Operation Ver. 1.0 Apr. 2005 2. Automatic Document Feeder (DF-502)

2.6 Document Size Detection Mechanism

• The document size is determined by means of two different systems of document width

detection and document length detection.

✽ Document Width Detection

• The width of an original is detected by the combination of Paper Width Sensors as

detected while the original is being taken up.

• Each sensor is located as follows with reference to the Document Edge Guide in the rear.

✽ Document Length Detection

• The length of the original is detected by the Paper Length Sensor when the document is

loaded in the unit.

• The Paper Length Sensor is located at the Document Loading Tray.

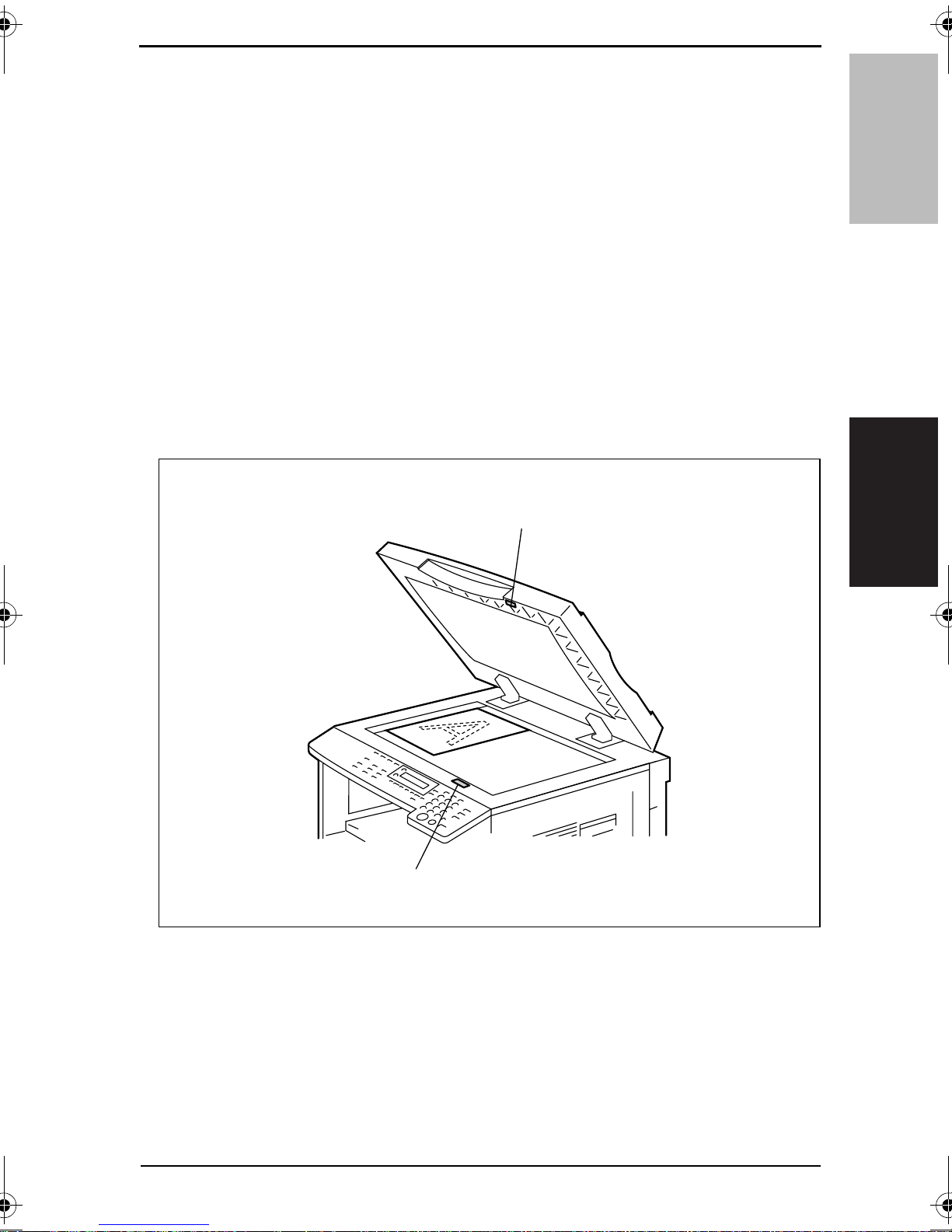

2.7 Raised/Lowered Position Detection Mechanism

• There is a magnet installed in the ADF body to allow the copier to know that the ADF is

raised or lowered.

• This magnet actuates the Size Reset Switch on the copier.

Magnet

DF-502Composition/Operation

Size Reset Switch (S5)

4034M521AA

9

2. Automatic Document Feeder (DF-502) Theory of Operation Ver. 1.0 Apr. 2005

DF-502

Composition/Operation

Blank page

10

Loading...

Loading...