Page 1

SERVICE MANUAL

Models

DF318/DF-320

APRIL 2004

CSM-DF318/DF320

KONICA MINOLTA BUSINESS SOLUTIONS U.S.A., INC.

Page 2

Page 3

DF318/DF320

SERVICE MANUAL

APRIL 2004

Page 4

IMPORTANT NOTICE

Because of the possible hazards to an inexperienced

person servicing this equipment, as well as the risk of

damage to the equipment, Konica Minolta Business

Solutions U.S.A., Inc. strongly recommends that all

servicing be performed by Konica Minolta-trained service technicians only.

Changes may have been made to this equipment to

improve its performance after this service manual was

printed. Accordingly, Konica Minolta Business Solutions

U.S.A., Inc., makes no representations or warranties,

either expressed or implied, that the information contained in this service manual is complete or accurate. It

is understood that the user of this manual must assume

all risks or personal injury and/or damage to the equipment while servicing the equipment for which this service manual is intended.

Corporate Publications Department

© 2004, KONICA MINOLTA BUSINESS SOLUTIONS U.S.A. , INC.

All rights reserved.

Printed in U.S.A.

Page 5

CONTENTS

CONTENTS

SAFETY AND IMPORTANT WARNING ITEMS

Refer to the 7145/7235/7228/7222 service manual on page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-1

I OUTLINE

1. DF-318/DF-320 PRODUCT SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

2. CENTER CROSS-SECTIONAL DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

3. DRIVE SYSTEM DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

3.1 Paper feed drive section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

3.2 Conveyance/Paper exit drive section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

3.3 Reverse drive section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

II UNIT EXPLANATION

1. PAPER FEED/REVERSAL/EXIT SECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

1.1 Composition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

1.2 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

1.2.1 Single sided original mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

1.2.2 Double sided original mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

1.2.3 Mixed original mode and Z-folded original mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

1.2.4 Original size detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

1.2.5 Allowed size combination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

1.2.6 Control of the verification stamp for FAX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

I OUTLINEII UNIT EXPLANATIONIII DIS./ASSEMBLY

III DISASSEMBLY/ASSEMBLY

1. PAPER FEED/REVERSAL/EXIT SECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

1.1 Replacing the paper feed roller and the feed rubber. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

1.2 Replacing the double feed prevention roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

1.3 Replacing the read roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

1.4 Removing and reinstalling the paper dust removing brush . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

1.5 Replacing the verification stamp for FAX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

2. EXTERNAL SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

2.1 Removing and reinstalling the RADF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

i

Page 6

CONTENTS

I OUTLINE

II UNIT EXPLANATION

III DIS./ASSEMBLY

Blank page

ii

Page 7

DF-318/DF-320 PRODUCT SPECIFICATIONS

IOUTLINE

1. DF-318/DF-320 PRODUCT SPECIFICATIONS

A. Type

Type: Sheet-through Type reversible DF

B. Functions

Original size (for metric area): A3, B4, A4, A4R, B5, B5R, A5, A5R, 11 x 17, 8.5 x 14, 8.5 x 11

Original size (for inch area): 11 x 17, 8.5 x 14, 8.5 x 11, 8.5 x 11R, 5.5 x 8.5, 5.5 x 8.5R

A3, B4, A4, B5, B5R, B6R

• Mixing of original size possible.

Original type

Plain paper: 50g/m

Special paper: Original feed and conveyance ability may be inferior those of high-

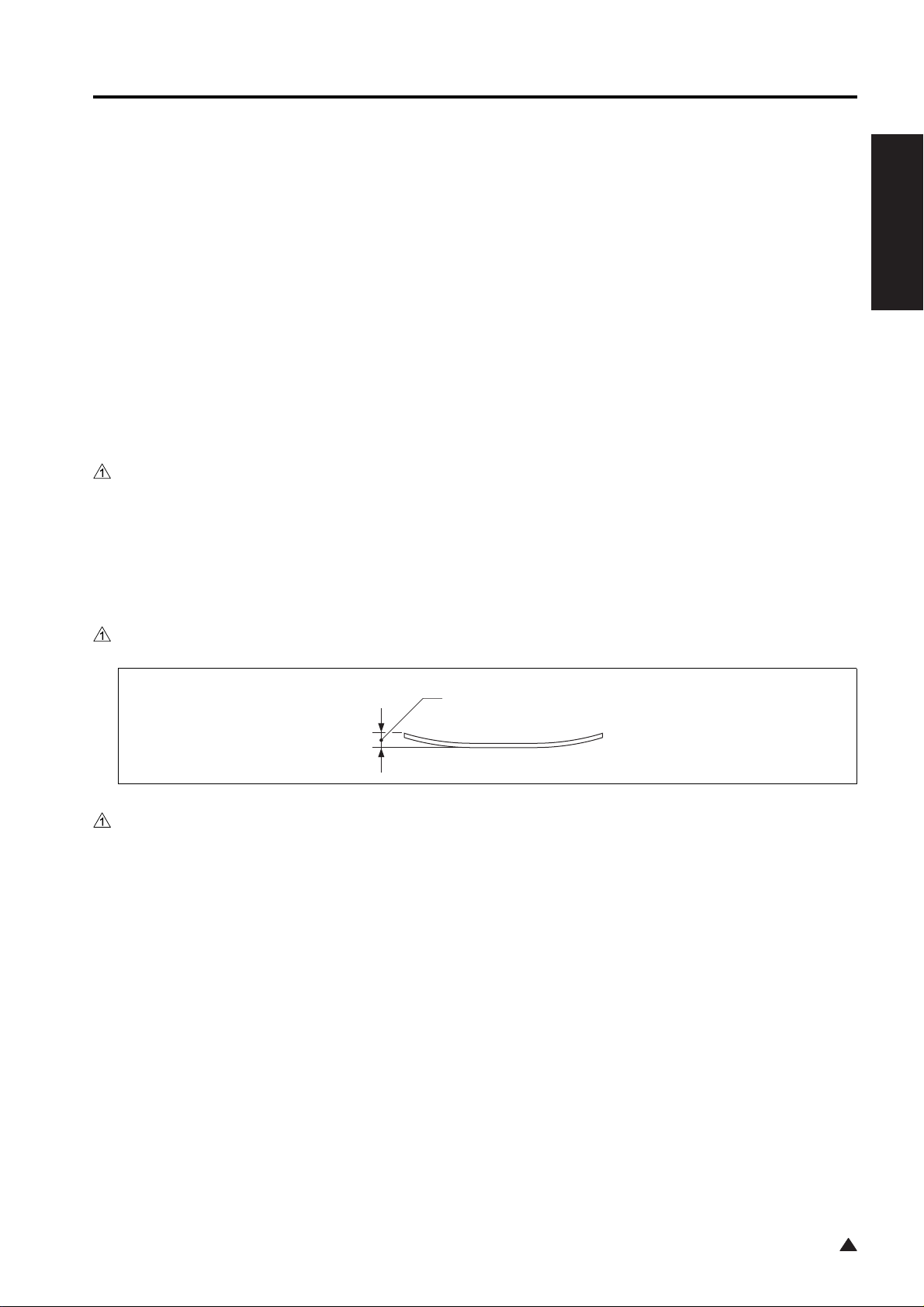

Original Curling (5 sheet): h = 10mm or less (80g/m

2

to 130g/m2 (13lbs to 34lbs), high-quality paper (DF-318)

2

35g/m

quality original mentioned above.

The following types of original cannot be used:

• OHP film, Blueprint masters, Offset masters, Bonded original

to 130g/m2 (13lbs to 34lbs), high-quality paper (DF-320)

2

or 20lbs high-quality paper)

h

I OUTLINE

2

Amount of originals to be stacked: 50 sheets max. (80g/m

(Original curling: 10mm or less)

80 sheets max. (80g/m

(Original curling: 1mm or less)

Original scan speed (A4 size): Single side mode: 45 sheets/minute

Double side mode: 34 sheets/minute

Original feed layout: Face-up placement, centre standard

Original image read position: At the slit glass section

or 20lbs high-quality paper)

2

or 20lbs high-quality paper)

C. Machine Data

Power source: 24VDC/5V (supplied from the main body)

Power consumption: Maximum 100VA

Weight: Approx. 11kg (including about 1.1kg for platen)

Dimensions: 576mm (W) x 502mm (D) x 100mm (H)

(Excluding the original feed tray)

1-1

1

Page 8

DF-318/DF-320 PRODUCT SPECIFICATIONS

D. Maintenance

Maintenance: Same as the main body

E. Operating Environment

I OUTLINE

Temperature: 10°C to 30°C (50°F to 86°F)

Humidity: 10% RH to 80% RH

Note:

• The information herein may be subject to change for improvement without notice.

1-2

Page 9

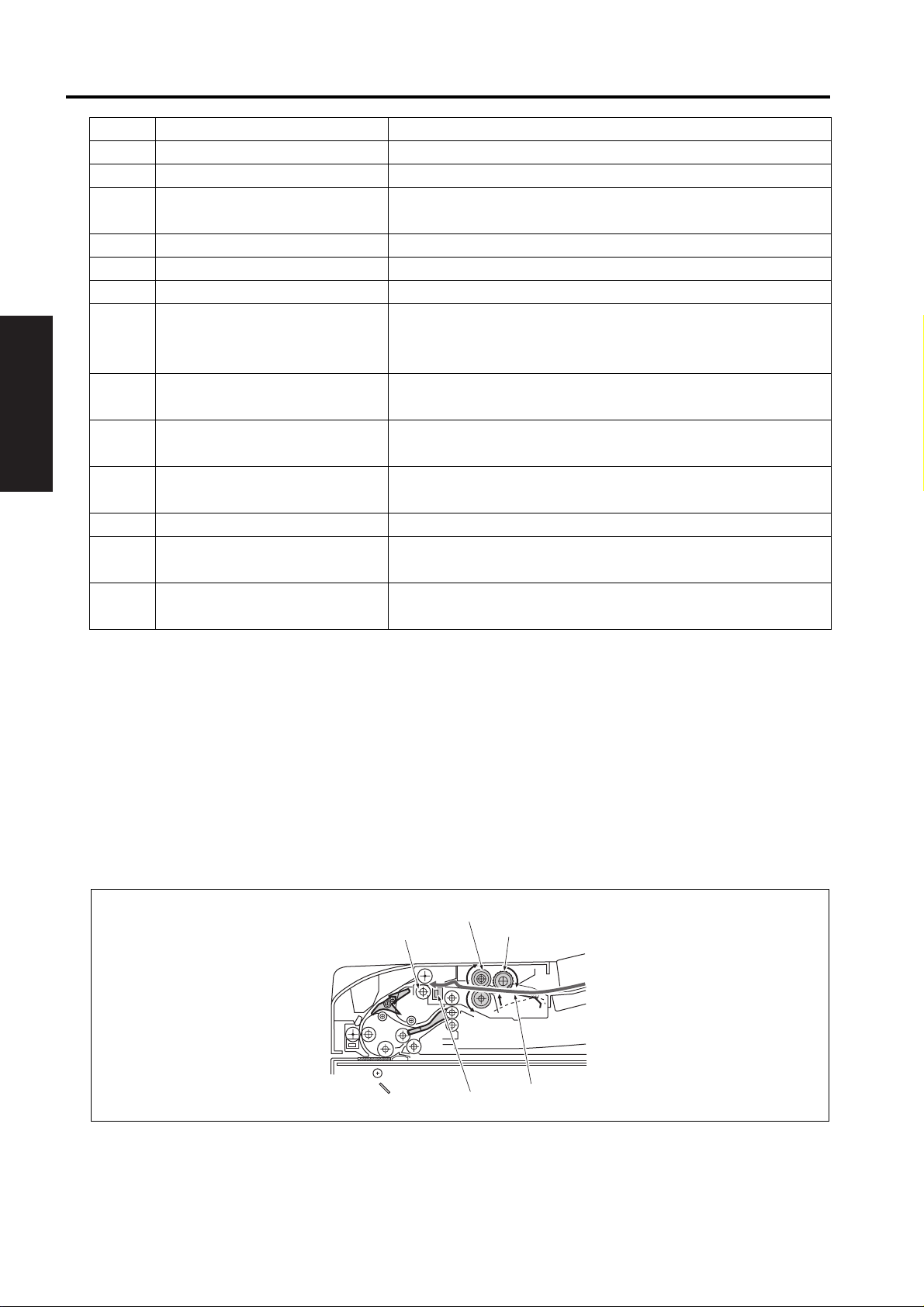

CENTER CROSS-SECTIONAL DIAGRAM

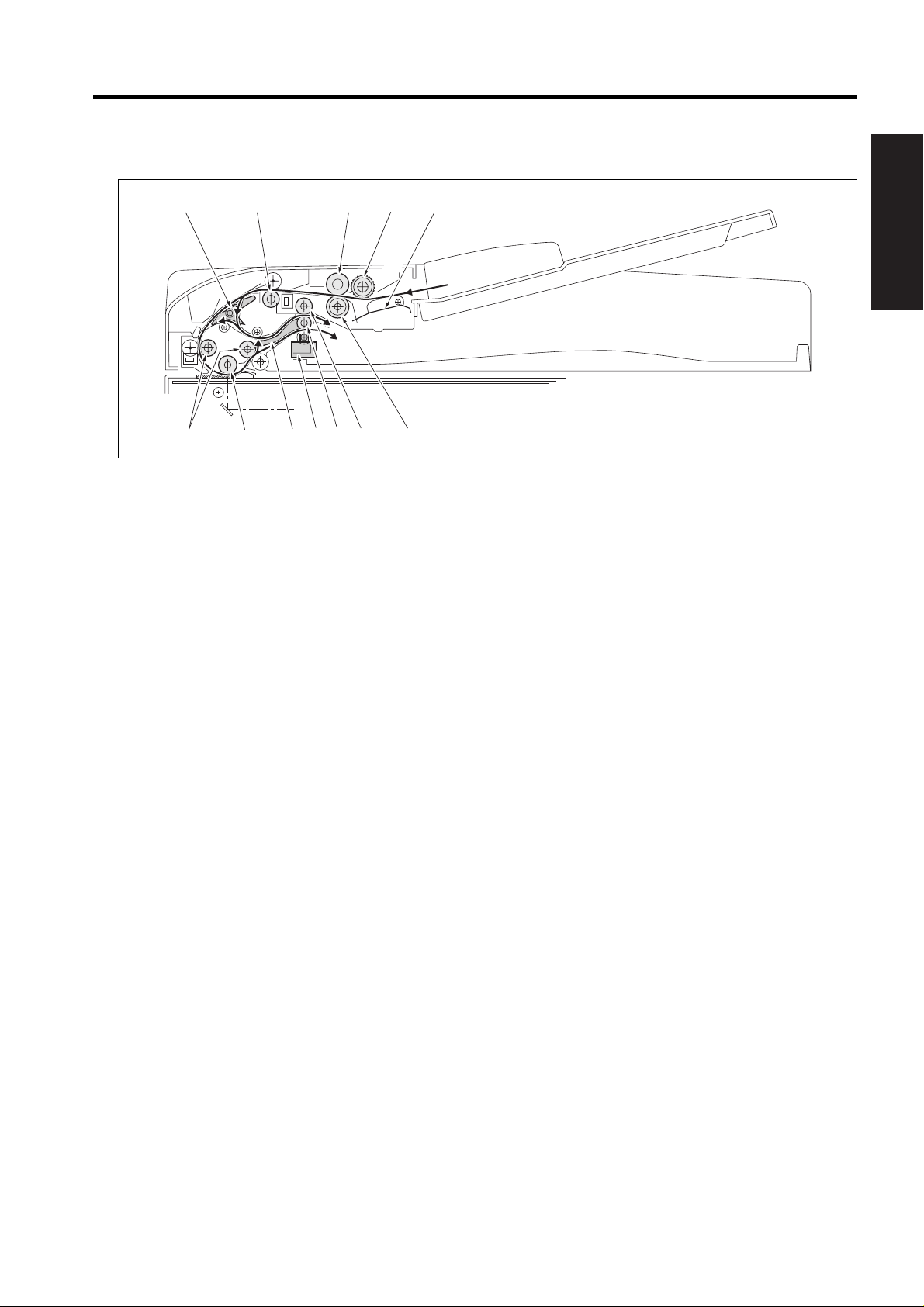

2. CENTER CROSS-SECTIONAL DIAGRAM

[10]

[8]

[9]

[11]

[12]

I OUTLINE

[3]

[7]

[1] Double feed prevention roller [7] Conveyance roller

[2] Reverse roller [8] Reverse guide

[3] Paper exit roller [9] Registration roller

[4] SD303 (Stamp solenoid) [10] Feed roller

[5] Paper exit guide [11] Paper feed roller

[6] Read roller [12] Paper up/down plate

[6]

[5] [4]

[1][2]

1-3

Page 10

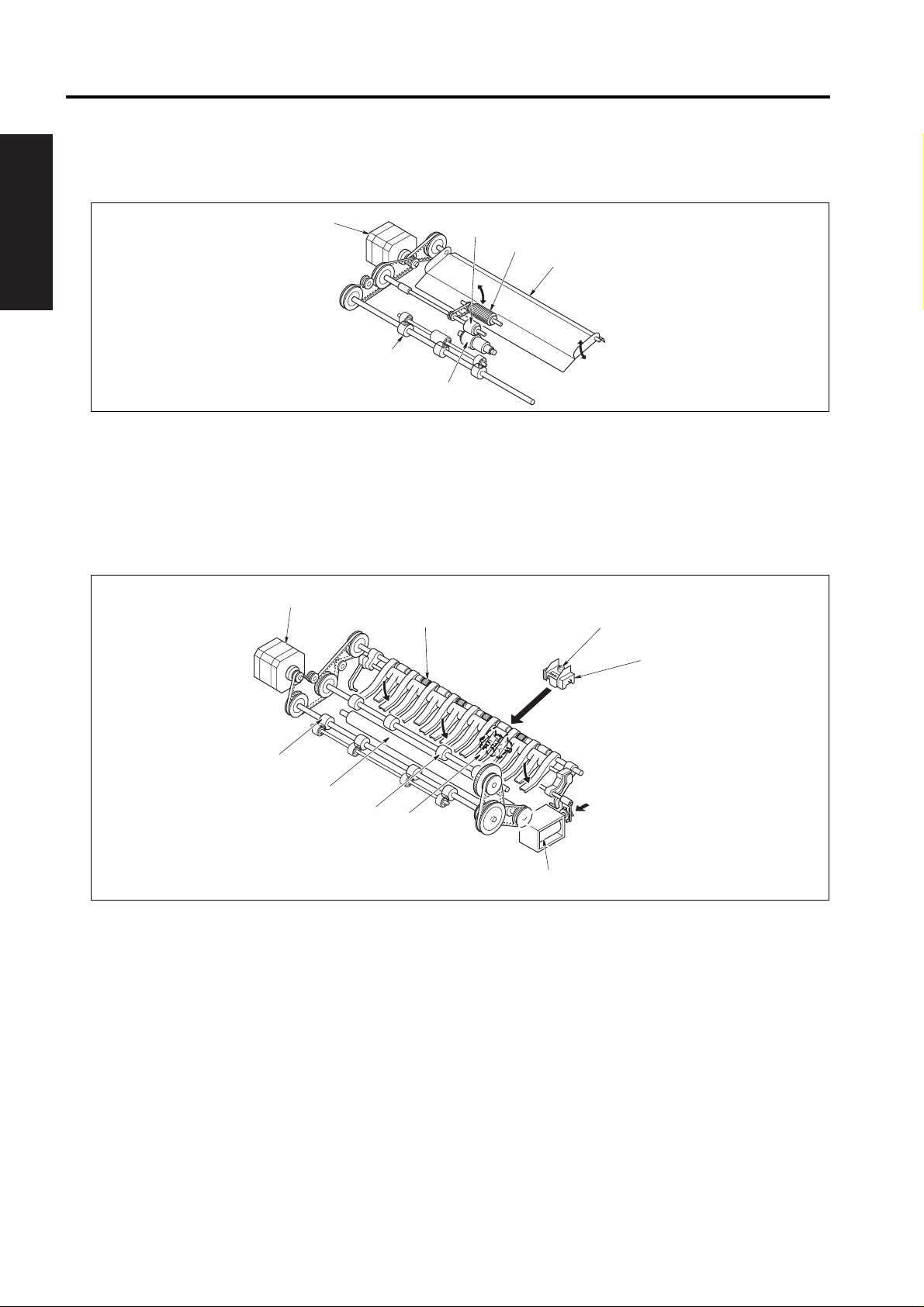

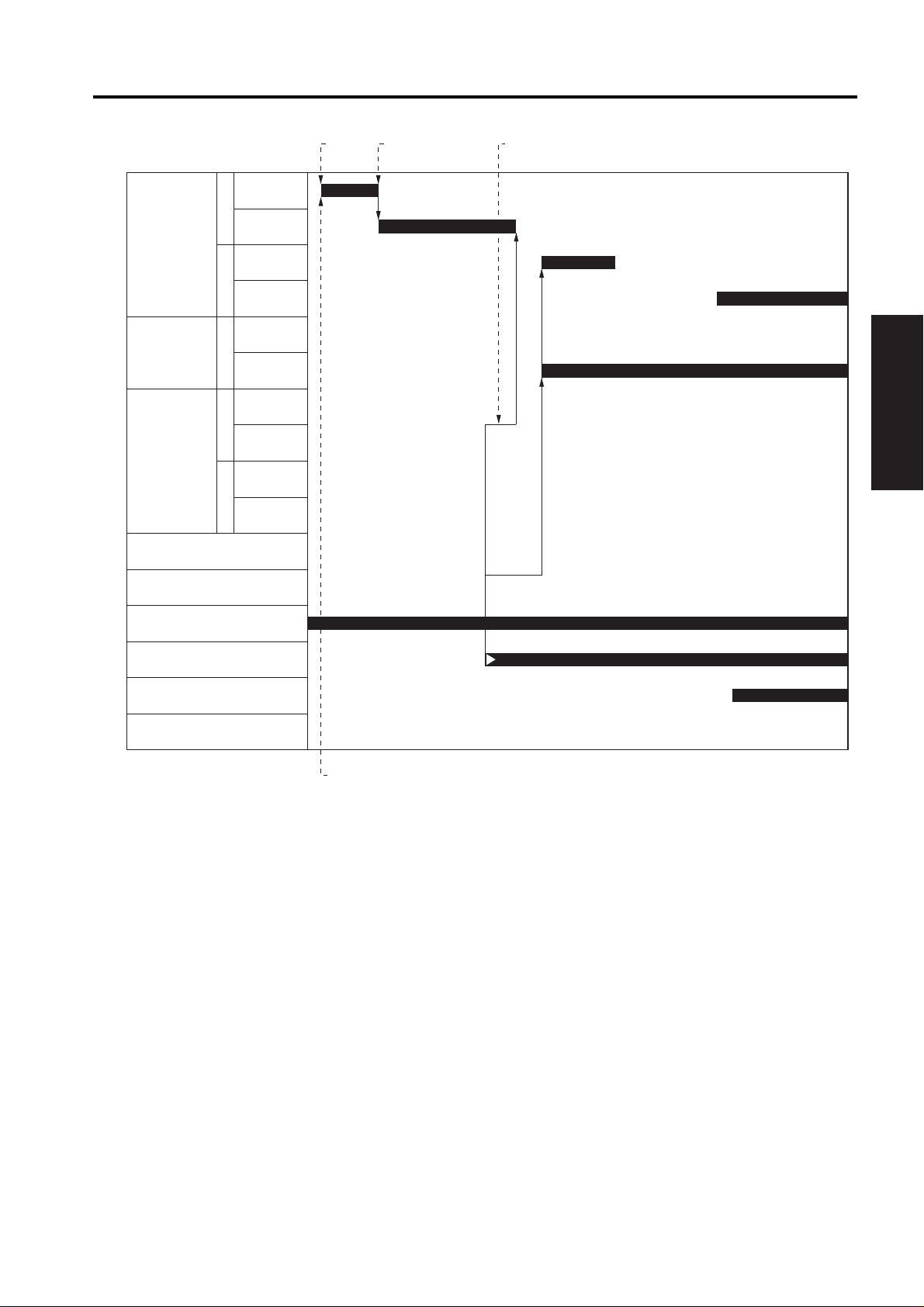

DRIVE SYSTEM DIAGRAM

3. DRIVE SYSTEM DIAGRAM

3.1 Paper Feed Drive Section

I OUTLINE

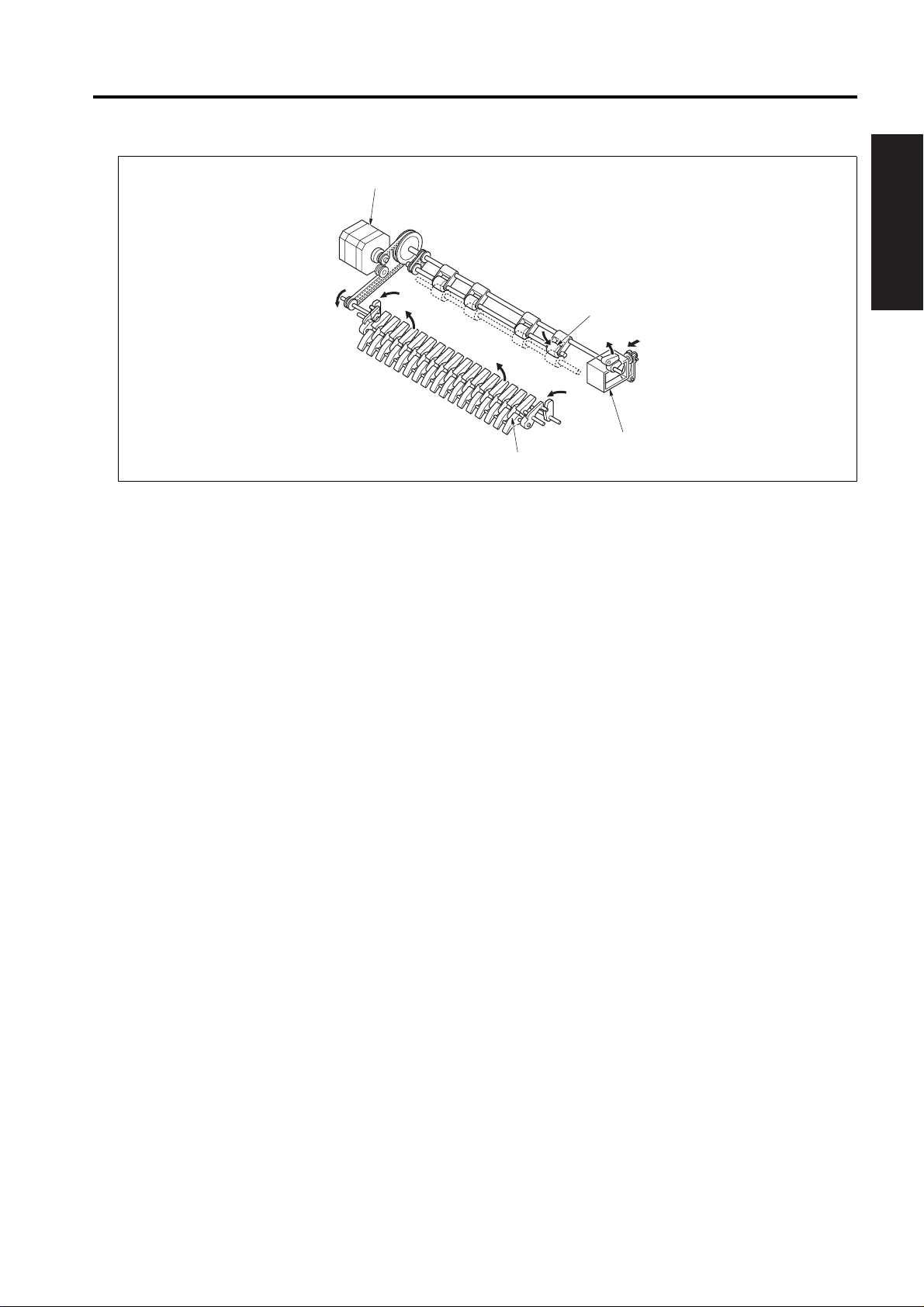

3.2 Conveyance/Paper Exit Drive Section

[3]

[2]

[1] Double feed prevention roller [4] Feed roller

[2] Registration roller [5] Paper feed roller

[3] M301 (Original feed motor) [6] Paper up/down plate

[7]

[8]

[4]

[5]

[6]

[1]

[9]

[1]

[6]

[5]

[4]

[3]

[2]

[1] SD303 (Stamp solenoid) [6] Before-read roller

[2] SD301 (Paper exit solenoid) [7] M302 (Original conveyance motor)

[3] Paper exit guide [8] Paper exit roller

[4] After-read roller [9] Verification stamp for FAX

[5] Read roller

1-4

Page 11

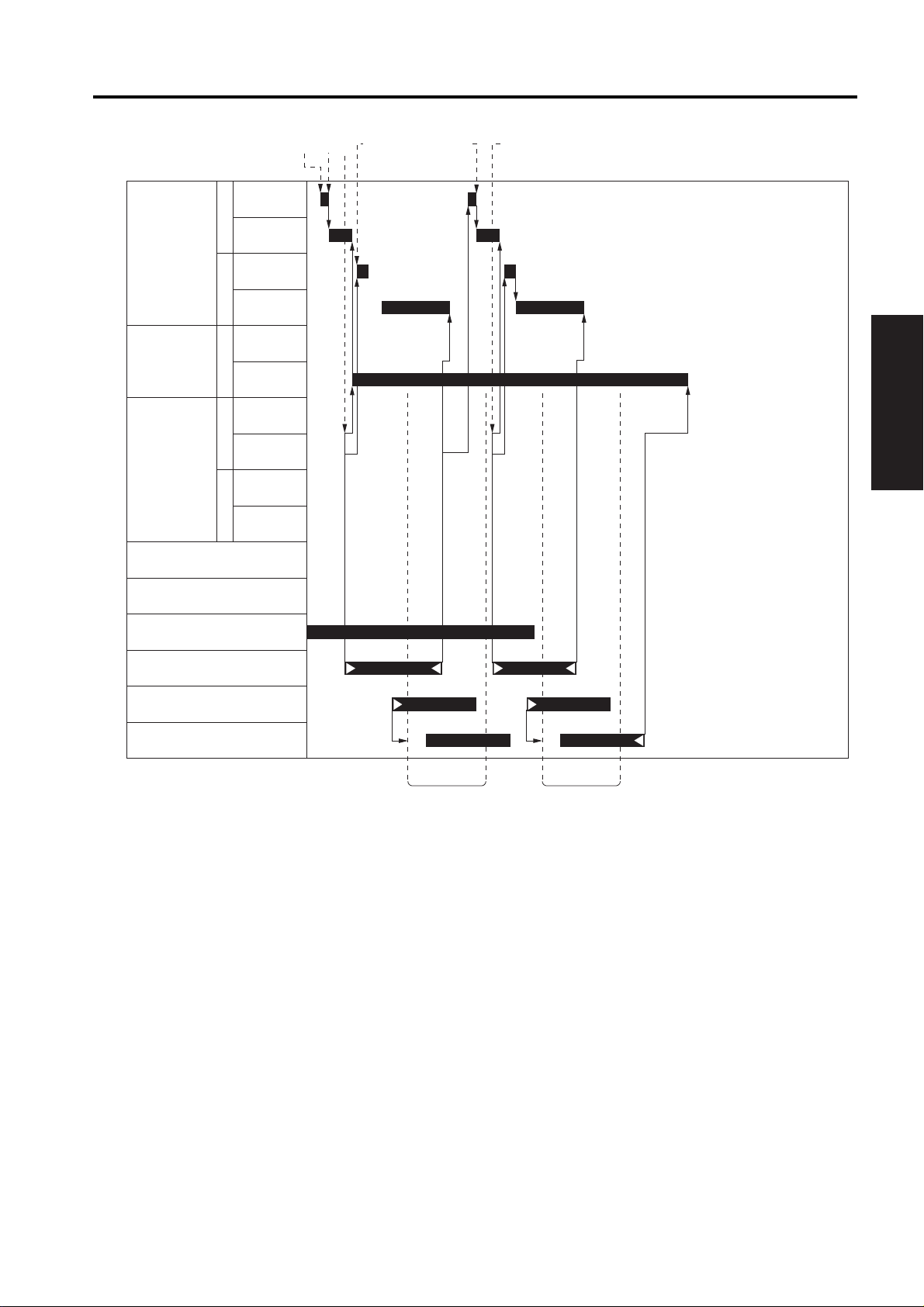

DRIVE SYSTEM DIAGRAM

3.3 Reverse Drive Section

[3]

[4]

[1]

[2]

[1] SD302 (Pressure roller solenoid) [3] M303 (Original reverse motor)

[2] Reverse guide [4] Reverse roller

I OUTLINE

1-5

Page 12

DRIVE SYSTEM DIAGRAM

I OUTLINE

Blank page

1-6

Page 13

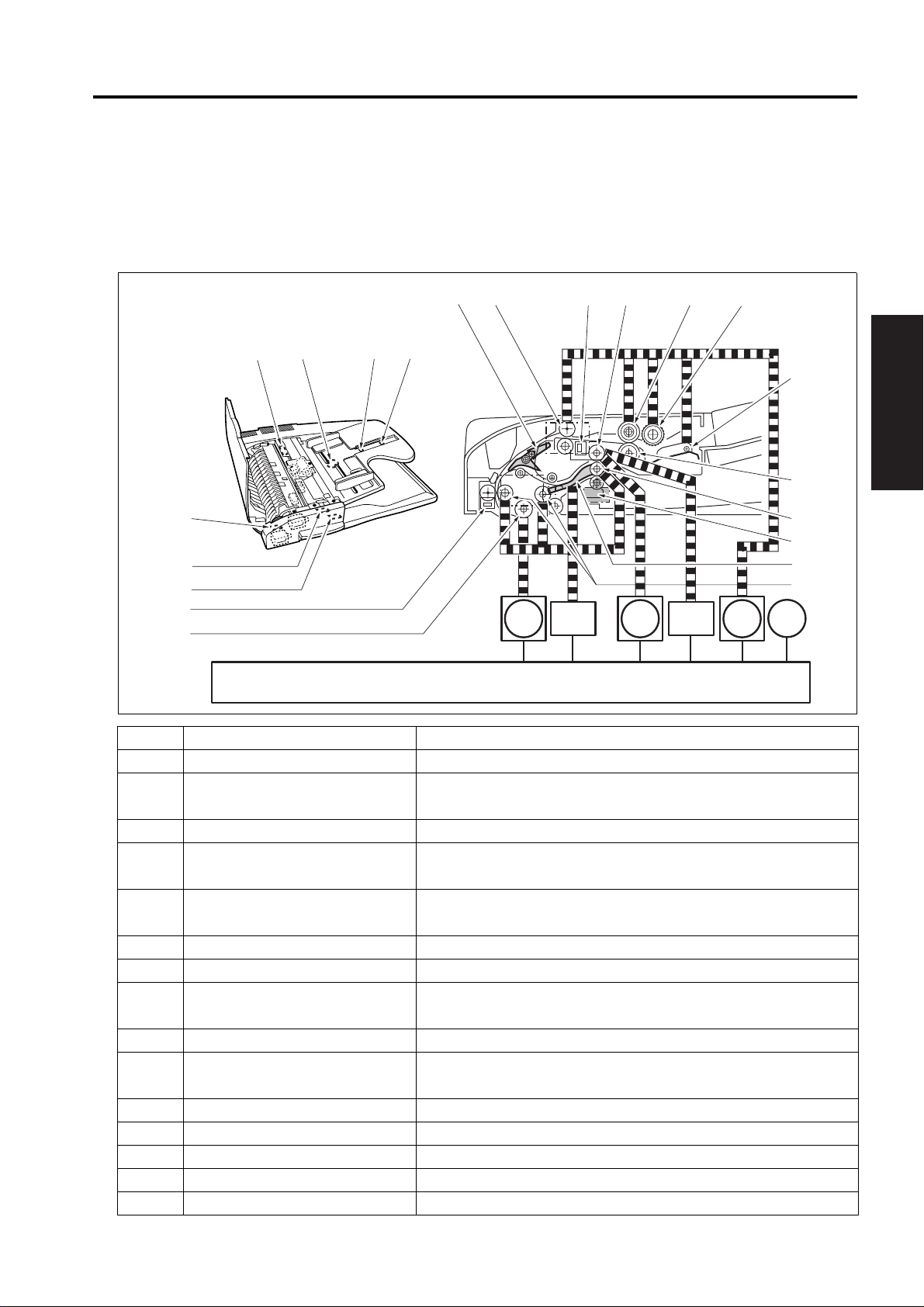

PAPER FEED/REVERSAL/EXIT SECTION

II UNIT EXPLANATION

1. PAPER FEED/REVERSAL/EXIT SECTION

1.1 Composition

[16]

[17] [18] [19] [20] [21]

[13]

[12]

[11]

[10]

[9]

[8]

[7]

Symbol Name Function or method

[1] Paper up/down plate Lift the original to the paper feed roller while feeding original

[2] Double feed prevention roller Double feed prevention of original

[3] Paper exit roller Original exit

[4] SD303 (Stamp solenoid) Affix the verification stamp

[5] Paper exit guide Switching-over of the conveyance path original exited

[6] Conveyance roller Original conveyance

[7] Read roller Original conveyance

[8] PS309

(Original conveyance sensor)

[9] PS301 (No original sensor) No paper detection in the paper feed tray

[10] PS304

(Cover open/close sensor)

[11] PS303 (DF open/close sensor) RADF open/close detection

[12] PS302 (Original exit sensor) Detection of original exited

[13] VR301 (Original size VR) Detection of original size in the main scanning direction

[14] PS305 (Original size sensor /1) Detection of original size in the sub-scanning direction

[15] PS306 (Original size sensor /2) Detection of original size in the sub-scanning direction

[14]

[15]

M303M302 SD301 SD302

DFDB

Torque limiter method

24VDC drive

SD301 (Paper exit solenoid) open/close method

Original detection just before the read section

Detection of the open/close of the open/close cover

M301

FM301

[1]

[2]

[3]

[4]

[5]

[6]

II UNIT EXPLANATION

2-1

Page 14

PAPER FEED/REVERSAL/EXIT SECTION

Symbol Name Function or method

[16] Reverse guide Switching-over of the conveyance path for original

[17] Registration roller Original skew correction, original conveyance

[18] PS308

(Original registration sensor)

[19] Reverse roller Reversal of original

[20] Feed roller Feeding of original

[21] Paper feed roller Picking-up of original

DFDB DF drive board RADF drive board

M301 Original feed motor Driving of original feed section

M302 Original conveyance motor Driving of original conveyance section

II UNIT EXPLANATION

M303 Original reverse motor Driving of original reversal section

FM301 Cooling fan Cooling of M302 (Original conveyance motor)

SD301 Paper exit solenoid Opening/closing of the paper exit guide

SD302 Pressure roller solenoid Pressing/releasing of the reverse roller

Original detection just before the registration roller

The control is made by the main body's CB (Main body control

board).

24VDC stepping motor

24VDC stepping motor

24VDC stepping motor

24VDC drive

24VDC drive

1.2 Operation

1.2.1 Single sided original mode

A. The original set in the paper feed tray is pressed against the paper feed roller by the paper up/

down plate, and then struck against the registration roller by the paper feed roller and the feed

roller to form a loop. The amount of the loop is controlled according to a value registered by

the timer after the leading edge of the original turns on the PS308 (Original registration sen-

sor).

[4]

[2]

[5]

[1]

[3]

[1] Paper up/down plate [4] Feed roller

[2] PS308 (Original registration sensor) [5] Paper feed roller

[3] Registration roller

2-2

Page 15

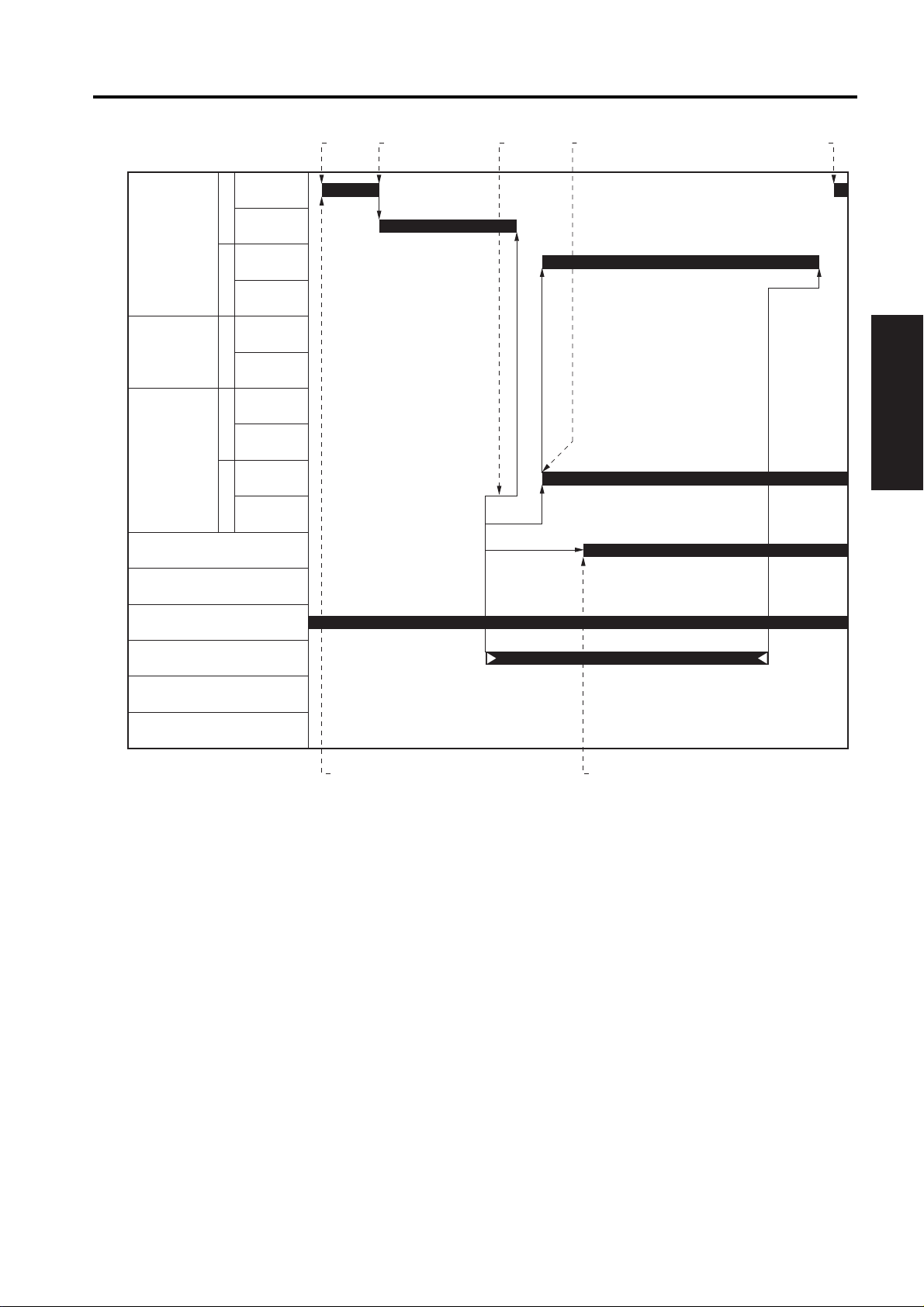

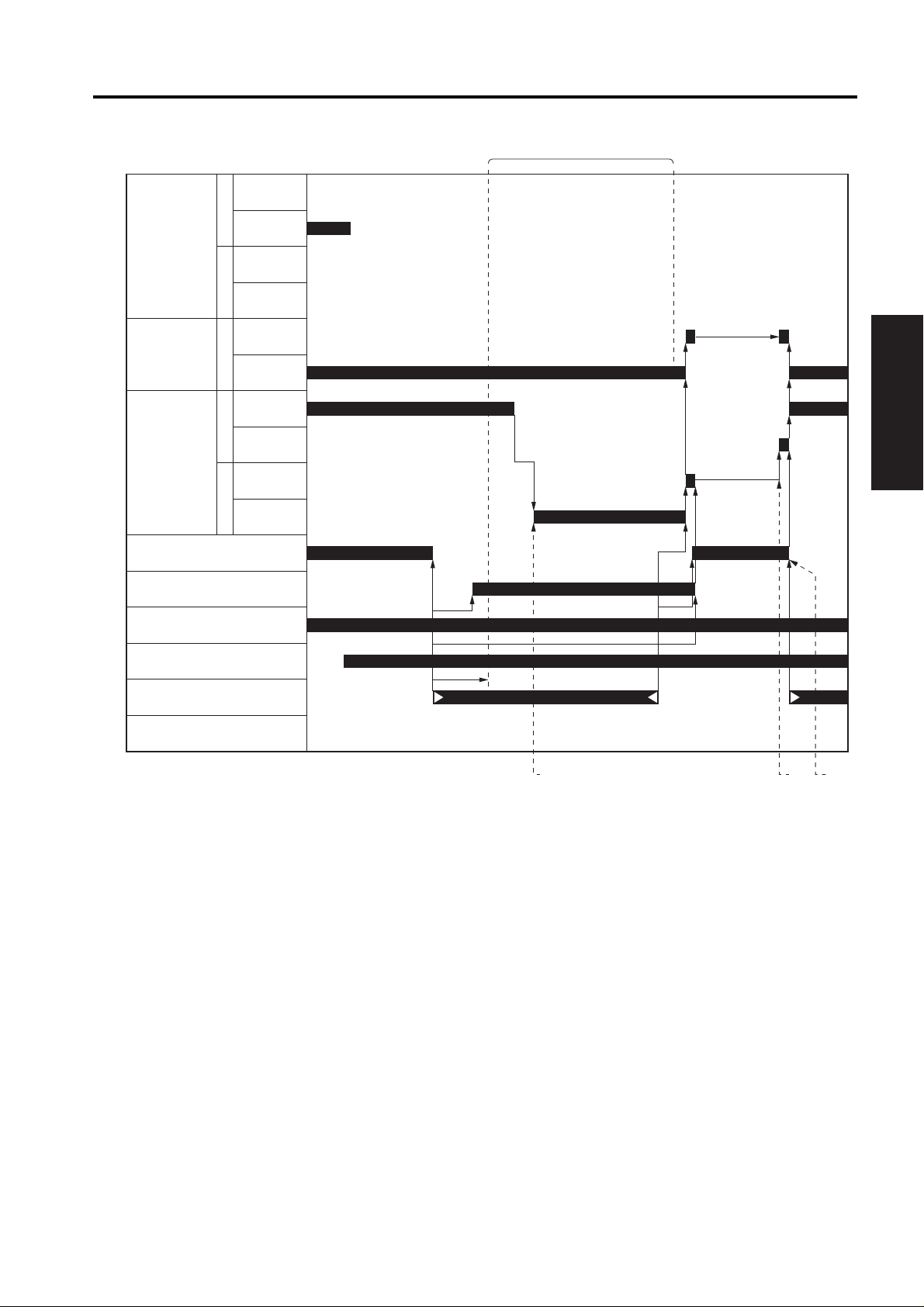

PAPER FEED/REVERSAL/EXIT SECTION

[4][3][2]

M301

(Original

feed motor)

M302 (Original

conveyance

motor)

M303 (Original

reverse motor)

SD302 (Pressure roller solenoid)

SD301 (Paper exit solenoid)

PS301 (No original sensor)

100mm/s

F

250mm/s

460mm/s

R

230mm/s

230mm/s

F

460mm/s

230mm/s

F

460mm/s

460mm/s

R

230mm/s

II UNIT EXPLANATION

PS308 (Original registration sensor)

PS309 (Original conveyance sensor)

PS302 (Original exit sensor)

[1]

[1] START button ON [3] Pre-feed

[2] Paper up/down plate, pressed down [4] Loop formation

2-3

Page 16

PAPER FEED/REVERSAL/EXIT SECTION

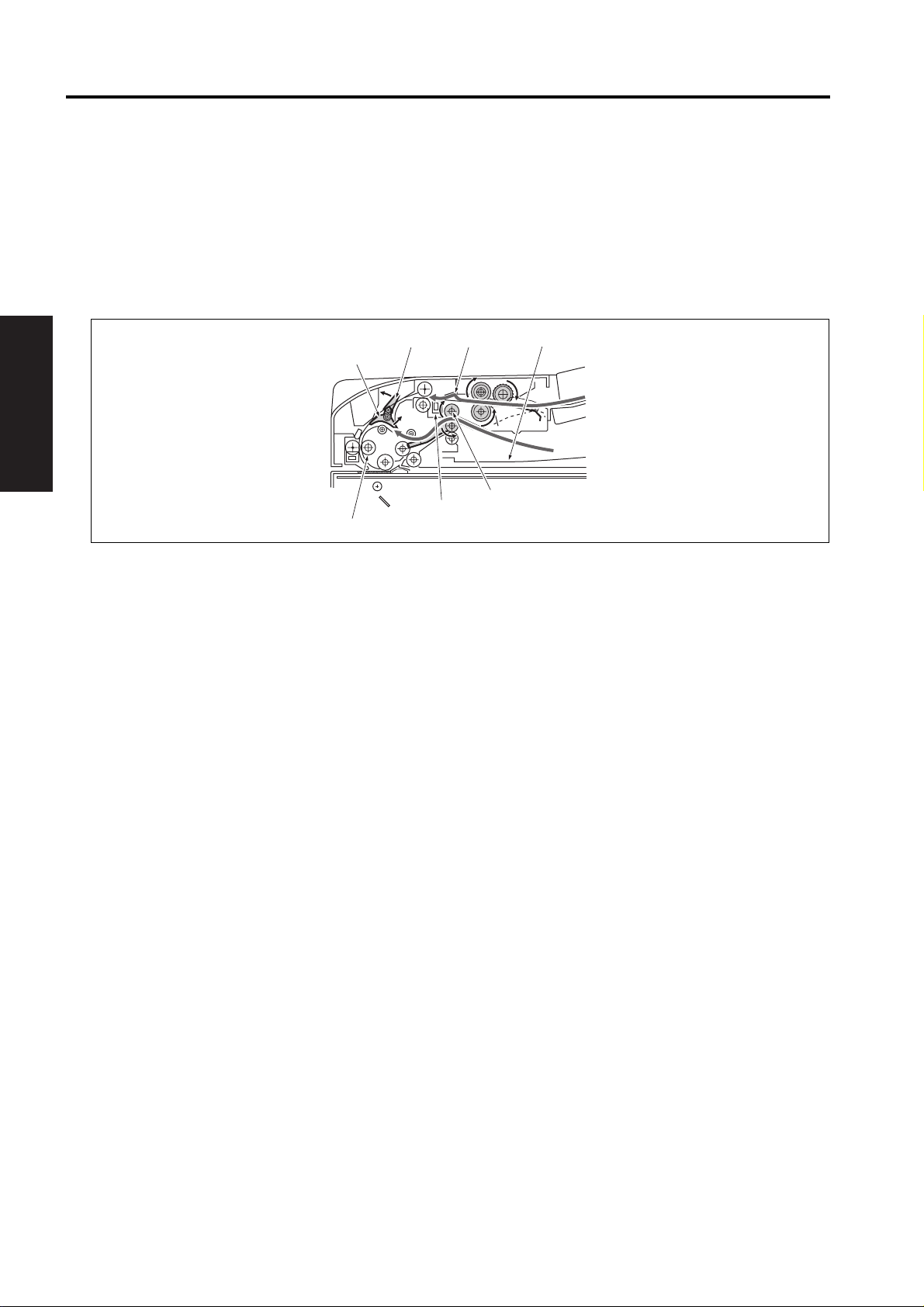

B. After the loop is formed at the registration roller section, the M301 (Original feed motor) rotates

backward and the M302 (Original conveyance motor) re-feeds paper. The original is scanned at

the slit glass section according to a value registered by the timer after the leading edge of the

original turns on the PS 309 (Original conveyance sensor). At this time, if there are originals in

the tray, the next original is pre-fed according to a value registered by the timer after the trail-

ing edge of the preceding original turns off the PS308 (Original registration sensor). When the

trailing edge of the last original turns off the PS309 (Original conveyance sensor), the M301

goes off. When the PS302 (Original exit sensor) detects the trailing edge of the last original, the

M302 goes off to finish the scanning of the original.

II UNIT EXPLANATION

[4]

[5]

[1]

[3]

[1] Paper exit roller [4] Next original

[2] Paper exit guide [5] Paper exit tray

[3] Slit glass (Original reader)

[2]

2-4

Page 17

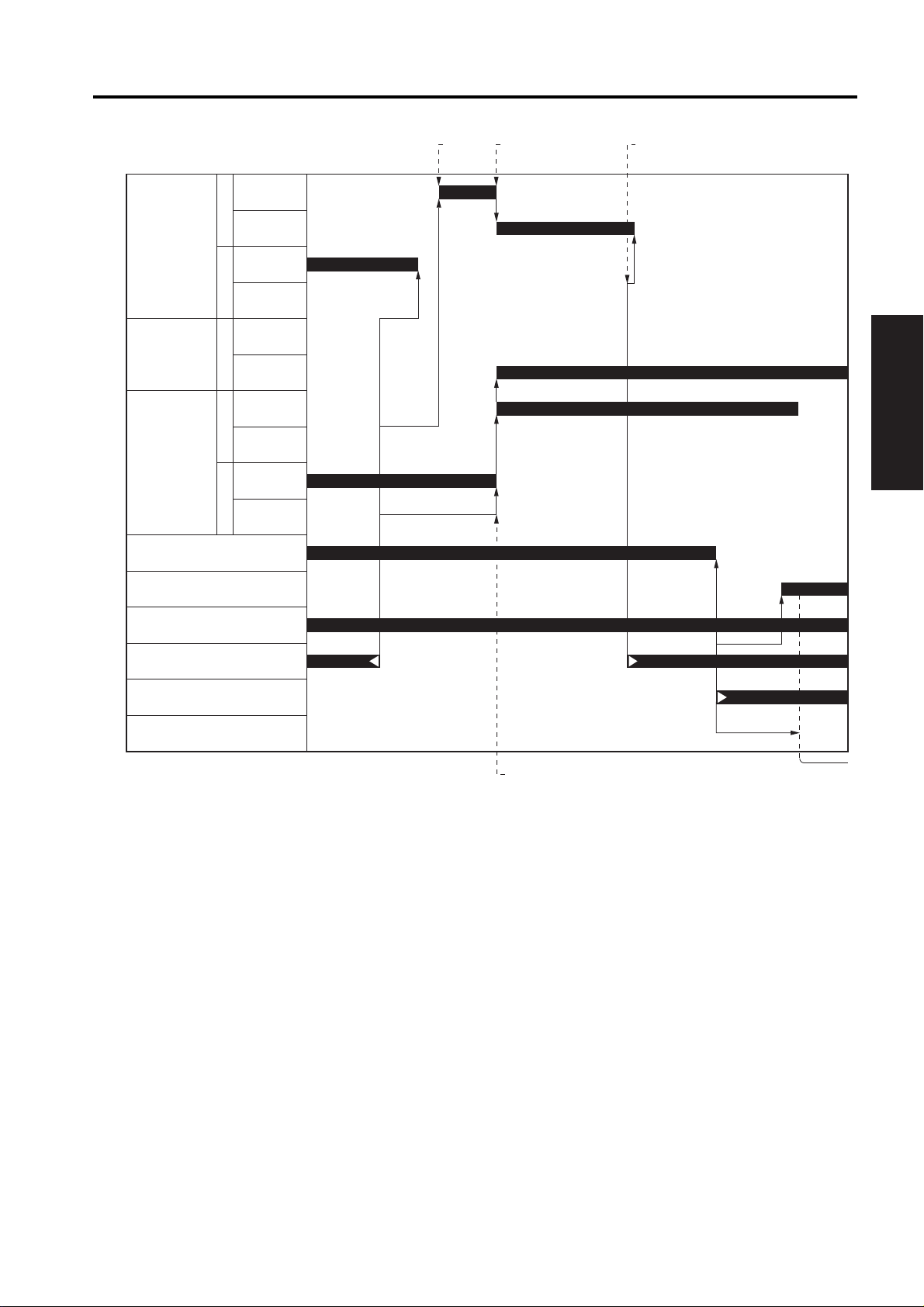

PAPER FEED/REVERSAL/EXIT SECTION

[6][4][3][2][1] [7]

M301

(Original

feed motor)

M302 (Original

conveyance

motor)

M303 (Original

reverse motor)

SD302 (Pressure roller solenoid)

SD301 (Paper exit solenoid)

PS301 (No original sensor)

100mm/s

F

250mm/s

460mm/s

R

230mm/s

460mm/s

F

230mm/s

230mm/s

F

460mm/s

R

460mm/s

230mm/s

II UNIT EXPLANATION

PS308 (Original registration sensor)

PS309 (Original conveyance sensor)

PS302 (Original exit sensor)

[5] [8]

[1] Turning on the START button to press

down the paper up/down plate

[2] Pre-feeding [7] Loop formation of the 2nd paper

[3] Loop formation of the 1st paper [8] Scanning of the 2nd original

[4] Re-feeding of the 1st paper

[5]

Scanning of the 1st paper

[6]

Pre-feeding of the 2nd paper

2-5

Page 18

PAPER FEED/REVERSAL/EXIT SECTION

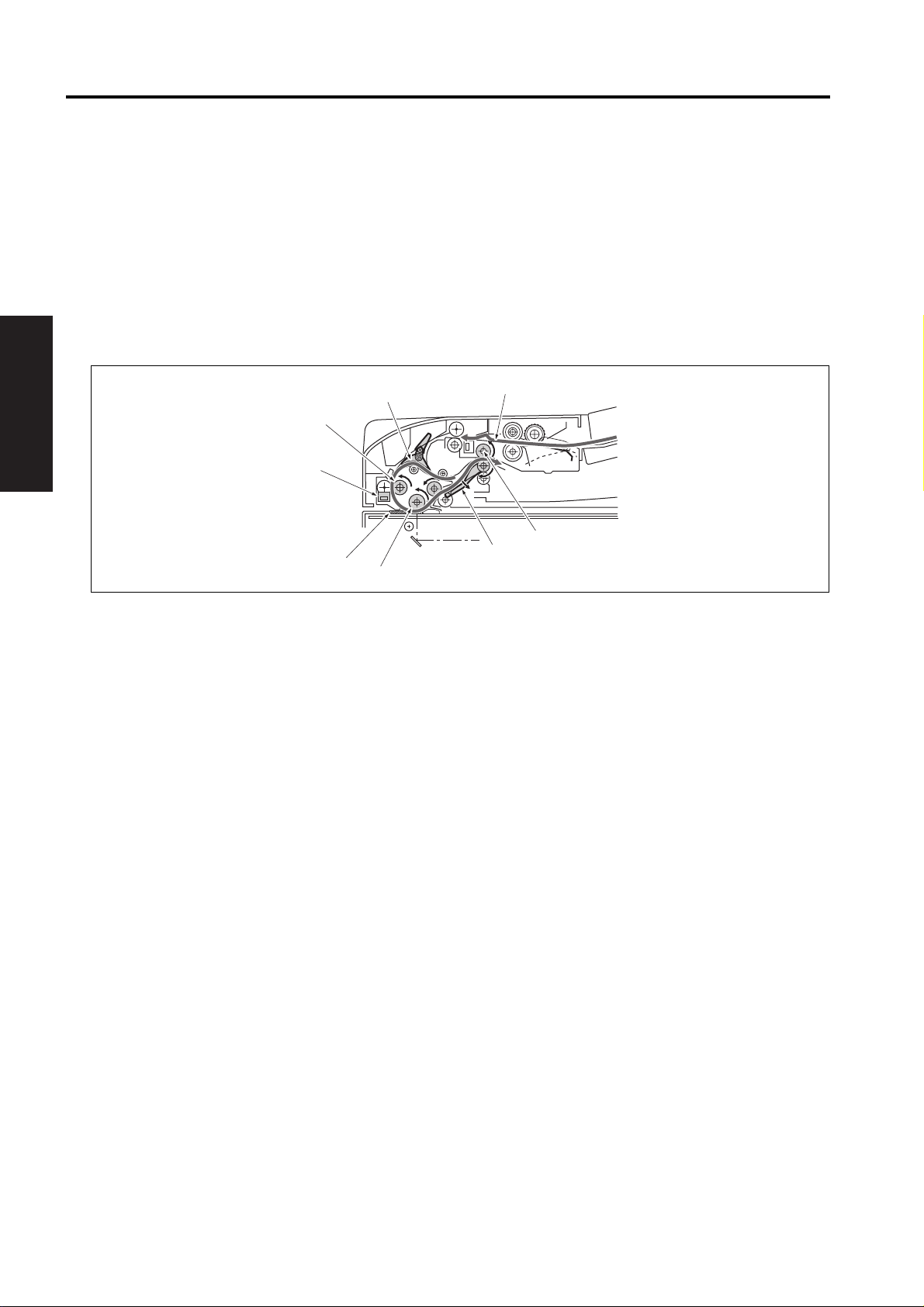

1.2.2 Double sided original mode

A. In the double sided original mode, the original is reversed and its back side is scanned first,

and then the front side is scanned before being straight ejected. Copying originals in their

scanned order may cause the copied sheets to get out of their specified pagination. To avoid

this, image processing is used for page alignment. The original set in the paper feed tray is

pressed against the paper feed roller by the paper up/down plate, and then struck against the

registration roller by the paper feed roller and the feed roller to form a loop. The amount of the

loop is controlled according to a value registered by the timer after the leading edge of the

original turns on the PS308 (Original registration sensor). After the loop is formed at the regis-

tration roller section, the M301 (Original feed motor) rotates backward to re-feed paper. Upon

backward rotation of the M301, the M303 (Original reverse motor) also rotates backward to

open the reverse guide and convey the original to the reverse roller. The reverse roller can

release pressure through the SD302 (Roller pressure solenoid). It turns on the SD302 (Press-

ing by reverse roller) according to the value registered by the timer after the PS308 is turned

II UNIT EXPLANATION

on to convey the original to the paper exit tray side.

[3]

[4]

[5]

[3]

[1]

[2]

[1] Reverse roller [3] Registration roller

[2] PS308 (Original registration sensor) [4] M303 (Original reverse motor)

[3] Reverse guide

2-6

Page 19

PAPER FEED/REVERSAL/EXIT SECTION

[4] [5][3] [7][2]

M301

(Original

feed motor)

M302 (Original

conveyance

motor)

M303 (Original

reverse motor)

SD302 (Pressure roller solenoid)

SD301 (Paper exit solenoid)

PS301 (No original sensor)

100mm/s

F

250mm/s

460mm/s

R

230mm/s

460mm/s

F

230mm/s

230mm/s

F

460mm/s

460mm/s

R

230mm/s

II UNIT EXPLANATION

PS308 (Original registration sensor)

PS309 (Original conveyance sensor)

PS302 (Original exit sensor)

[1]

[1]

START button ON

[2]

Paper up/down plate, pressed down

[3] Pre-feed [6] Pressing by the reverse roller

[4] Loop formation [7] Pressing of the 2nd original up/down plate

[5] Switching of the reverse guide to the

[6]

reverse section side

2-7

Page 20

PAPER FEED/REVERSAL/EXIT SECTION

B. According to the value registered by the timer after the PS308 (Original registration sensor)

detects the trailing edge of the original, the M302 (Original conveyance motor) and the M303

(Original reverse motor) rotate forward to reverse the original and convey the back side to the

slit glass section. The reverse guide is closed by the forward rotation of the M303 and the flap-

per[4] is opened by the rigidity of the original. As a result, the original is guided to the convey-

ance roller. At this time, if there is a succeeding original in the tray, it is pre-fed according to

the value registered by the timer after the trailing edge of the preceding original turns off the

PS308 (Original registration sensor).

[4]

II UNIT EXPLANATION

[3]

[5] [6] [7]

[2]

[1]

[1] Reverse roller [5] Reverse guide

[2] PS308 (Original registration sensor) [6] Next original

[3] Conveyance roller [7] Paper exit tray

[4] Flapper

2-8

Page 21

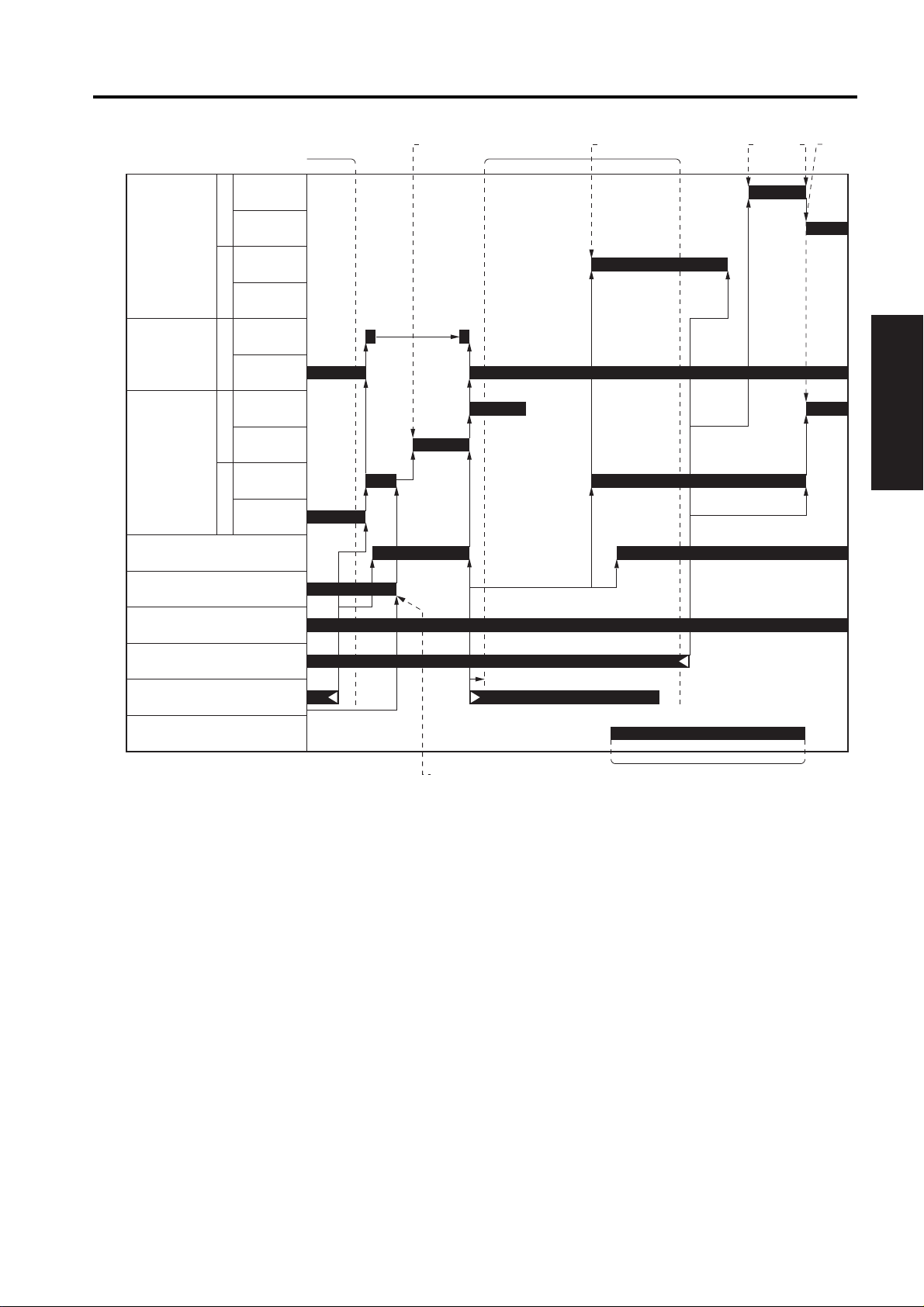

PAPER FEED/REVERSAL/EXIT SECTION

M301

(Original

feed motor)

M302 (Original

conveyance

motor)

M303 (Original

reverse motor)

SD302 (Pressure roller solenoid)

SD301 (Paper exit solenoid)

100mm/s

F

250mm/s

460mm/s

R

230mm/s

460mm/s

F

230mm/s

230mm/s

F

460mm/s

460mm/s

R

230mm/s

[2][1]

[4]

II UNIT EXPLANATION

PS301 (No original sensor)

PS308 (Original registration sensor)

PS309 (Original conveyance sensor)

PS302 (Original exit sensor)

[1]

Pressing of the 2nd original up/down plate

[2]

Pre-feeding of the 2nd original

[3] Reversing of the 1st original

(from front to back)

[3]

[4]

Loop formation of the 2nd original

[5]

Scanning of the back of the 1st original

[5]

2-9

Page 22

PAPER FEED/REVERSAL/EXIT SECTION

C. According to a value registered by the timer after the leading edge of the original turns on the

PS 309 (Original conveyance sensor), the back side of the original is scanned at the slit glass

section. At this time, the SD301 (Paper exit solenoid) is turned on to close the paper exit guide,

and a original the back side of which has been scanned is conveyed to the reverse roller. The

SD301 is turned on according to a value registered by the timer after the leading edge of the

original turns on the PS309. Paper conveyed to the reverse roller switches back and conveys

again an original to the conveyance roller, thus replacing the back side of the original with its

front side. Since the leading and trailing edges of an original larger than B5R is overlapped

each other while in switching back at this reversal section, the SD302 (Roller pressure sole-

noid) is turned off to release the pressure of the reverse roller.

II UNIT EXPLANATION

[7]

[8]

[6]

[5]

[1]

[4]

[3]

[1] Reverse roller [5] PS309 (Original conveyance sensor)

[2] Paper exit guide [6] Conveyance roller

[3] Read roller [7] Flapper

[4] Slit glass [8] Next original

[2]

2-10

Page 23

PAPER FEED/REVERSAL/EXIT SECTION

[1]

M301

(Original

feed motor)

M302 (Original

conveyance

motor)

M303 (Original

reverse motor)

SD302 (Pressure roller solenoid)

SD301 (Paper exit solenoid)

PS301 (No original sensor)

100mm/s

F

250mm/s

460mm/s

R

230mm/s

460mm/s

F

230mm/s

230mm/s

F

460mm/s

460mm/s

R

230mm/s

II UNIT EXPLANATION

PS308 (Original registration sensor)

PS309 (Original conveyance sensor)

PS302 (Original exit sensor)

[1]

Scanning of the back of the 1st original

[2]

Switching-back of the 1st original

[2] [3] [4]

[3] Reversing of the 1st original

(from back to front)

[4] SD302 (Roller pressure solenoid) release

2-11

Page 24

PAPER FEED/REVERSAL/EXIT SECTION

D. According to a value registered by the timer after the leading edge of the original turns on the

PS309 (Original conveyance sensor), the scanning of the back of the original is made at the slit

glass section. Since the SD301 (Paper exit solenoid) is off at this time, the paper exit guide is

left open and the original the front of which has been scanned is conveyed to the paper exit

roller to be exited. While the back of the original is being scanned, the SD301 goes off accord-

ing to a value registered by the timer after the leading edge of the original turns on the PS309.

[6]

[5]

[7]

[4]

II UNIT EXPLANATION

[3]

[1] Paper exit roller [5] Next original

[2] Paper exit guide [6] Reverse roller

[3] Slit glass [7] Paper exit tray

[4] PS309 (Original conveyance sensor)

[2]

[1]

2-12

Page 25

PAPER FEED/REVERSAL/EXIT SECTION

M301

(Original

feed motor)

M302 (Original

conveyance

motor)

M303 (Original

reverse motor)

SD302 (Pressure roller solenoid)

SD301 (Paper exit solenoid)

100mm/s

F

250mm/s

460mm/s

R

230mm/s

460mm/s

F

230mm/s

230mm/s

F

460mm/s

460mm/s

R

230mm/s

[3][1]

[4] [5] [7] [8] [9]

II UNIT EXPLANATION

PS301 (No original sensor)

PS308 (Original registration sensor)

PS309 (Original conveyance sensor)

PS302 (Original exit sensor)

[6][2]

[1] Scanning of the back of the 1st original [5] Re-feeding of the 2nd original

[2] Switching of the paper exit guide in the

direction of the paper exit

[3] Reversing of the 1st original

(from back to front)

[6]

Exiting of the 1st original

[7]

Pressing of the 3rd original up/down plate

[8]

Pre-feeding of the 3rd original

[9]

Reversing of the 2nd original

(from front to back)[4] Scanning of the front of the 1st original

2-13

Page 26

PAPER FEED/REVERSAL/EXIT SECTION

1.2.3 Mixed original mode and Z-folded original mode

The mixed original mode supports both the same series original and the different series original. The oper-

ation of the original conveyance in the mixed original mode is the same as that of the normal double sided

original mode, regardless of a single sided mode or double sided mode.

Although the detection of original size in the normal mode is made at the time when the original is set in

the paper feed tray, the size detection in the mixed original mode, however, is made based on the length of

time when the original passes through the PS308 (Original registration sensor) while the original is being

sent from the paper feed tray to the reverse roller. The original detection like this is applicable to all origi-

nals.

In the Z-folded original mode, the same detection operation as that for the mixed original sizes mode is

made only on the first original to determine the original size. However, the normal operation of original con-

veyance is made for originals on and after the 2nd original.

II UNIT EXPLANATION

[1]

[2]

[1] Reverse roller [2] PS308 (Original registration sensor)

2-14

Page 27

PAPER FEED/REVERSAL/EXIT SECTION

1.2.4 Original size detection

A. Normal copy mode

(1) Main scanning direction

Detected by the value of resistance of the VR301 (Original size VR) that is interlocked with the posi-

tion of the guide plate above the paper feed tray.

(2) Sub-scanning direction

Detected by the combination of the PS305 (Original size sensor /1) and the PS306 (Original size sen-

sor 2/) when they are turned on and off.

B. Mixed original mode and Z-folded original mode

(1) Main scanning direction

The width of the largest original of the mixed original sizes is detected by the value of resistance of the

VR301 (Original size VR) that is interlocked with the position of the guide plate above the paper feed

tray.

(2) Sub-scanning direction

Detection is made based on the length of time when the original passes through the PS308 (Original

registration sensor).

II UNIT EXPLANATION

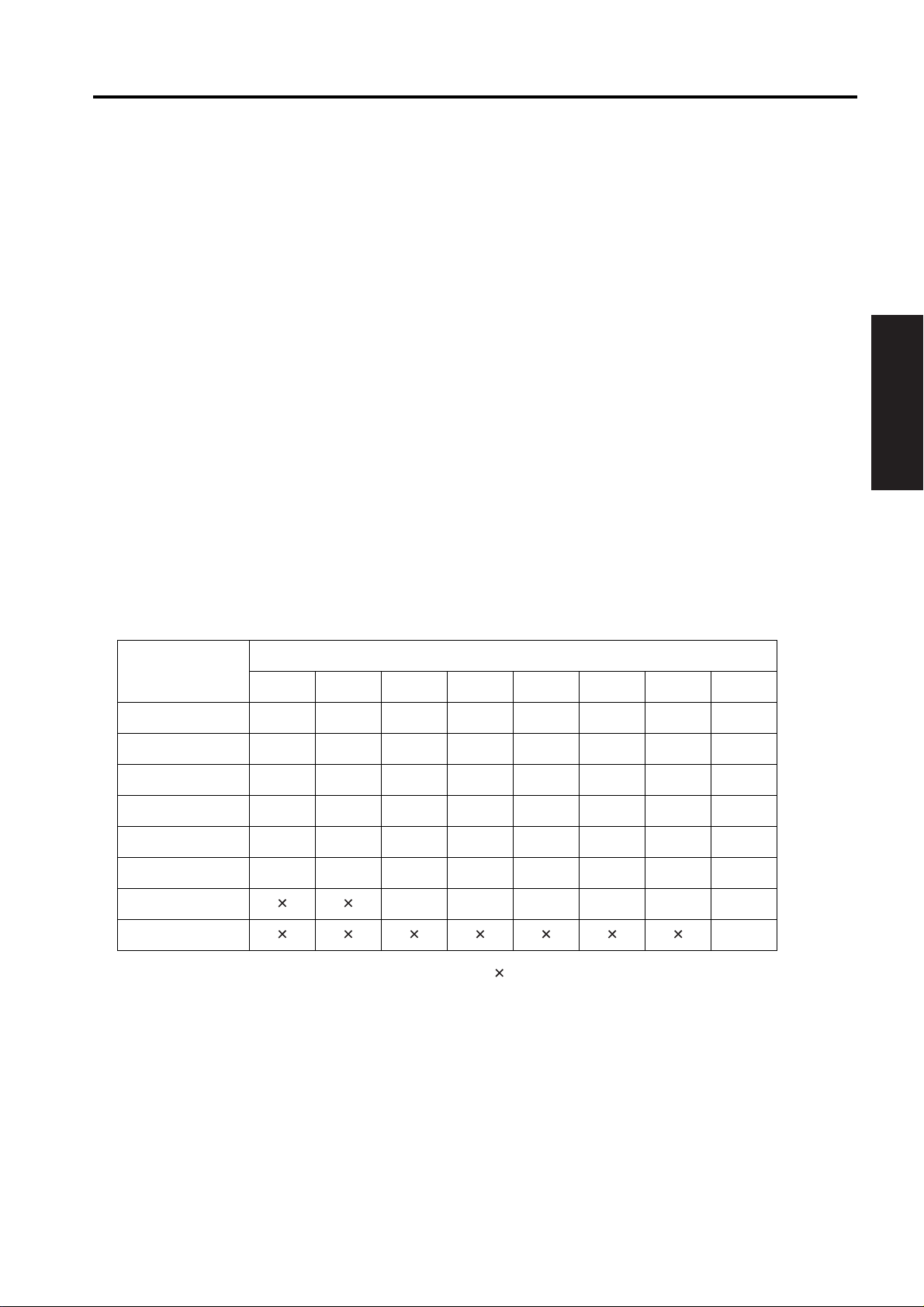

1.2.5 Allowed size combination

A. For metric area

Other originals Standard originals (the maximum original size detected by the guide plate)

A3 A4 B4 B5 A4R A5 B5R A5R

A3 {——————

A4 {——————

B4 ~~{————

B5 ~~{————

A4R ~~~~{——

A5 ~~~~{——

B5R ~~~~—

A5R

(: same size, {: same series, ~: different series, : no mixed loading, —: not supported)

2-15

Page 28

PAPER FEED/REVERSAL/EXIT SECTION

B. For inch area

Other originals Standard originals (the maximum original size detected by the guide plate)

11 x 17 8.5 x 11 8.5 x 14 8.5 x 11R 5.5 x 8.5 5.5 x 8.5R

11 x 17 {————

8.5 x 11 {————

8.5 x 14 ~~{{—

8.5 x 11R ~~{{—

5.5 x 8.5 ~~{{—

5.5 x 8.5R — — — — —

(: same size, {: same series, ~: different series, : no mixed loading, —: not supported)

II UNIT EXPLANATION

1.2.6 Control of the verification stamp for FAX

A. Operation of the verification stamp for FAX

In the FAX mode, a stamp showing that the original has been scanned is affixed on the original face

that has been scanned (for the double sided original mode, a stamp is affixed on front side only). The

stamp is driven by the SD303 (Stamp solenoid) and stamping is made when the original passes

through the paper exit roller. At this time, the M302 (Original conveyance motor) is turned off tempo-

rarily to stop the original.

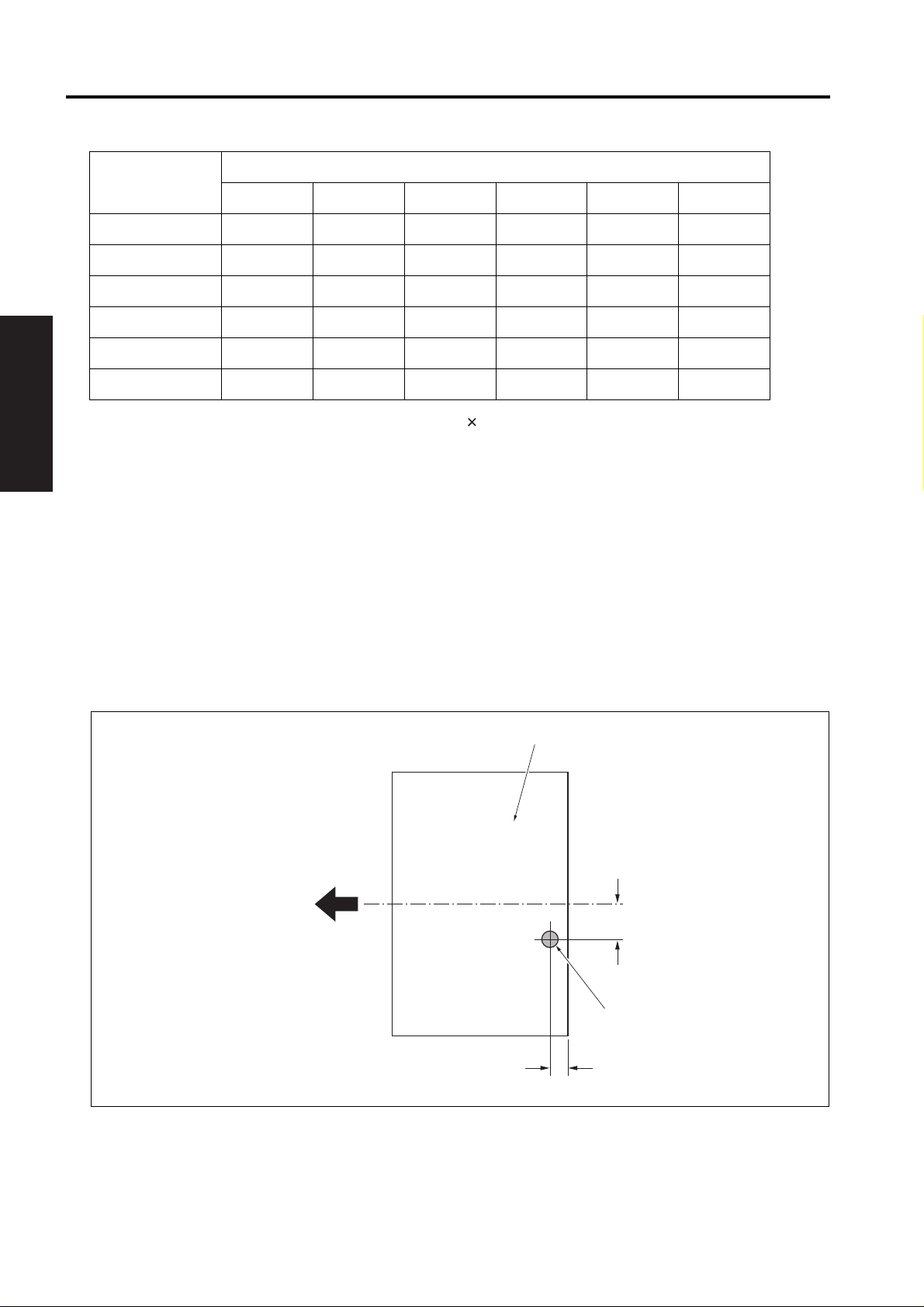

B. Stamping position

[5]

[4]

[1]

[2]

[3]

[1] 51mm ± 5mm [4] Direction of original conveyance

[2] Stamping position [5] Front of the original

[3] 10mm ± 2mm

2-16

Page 29

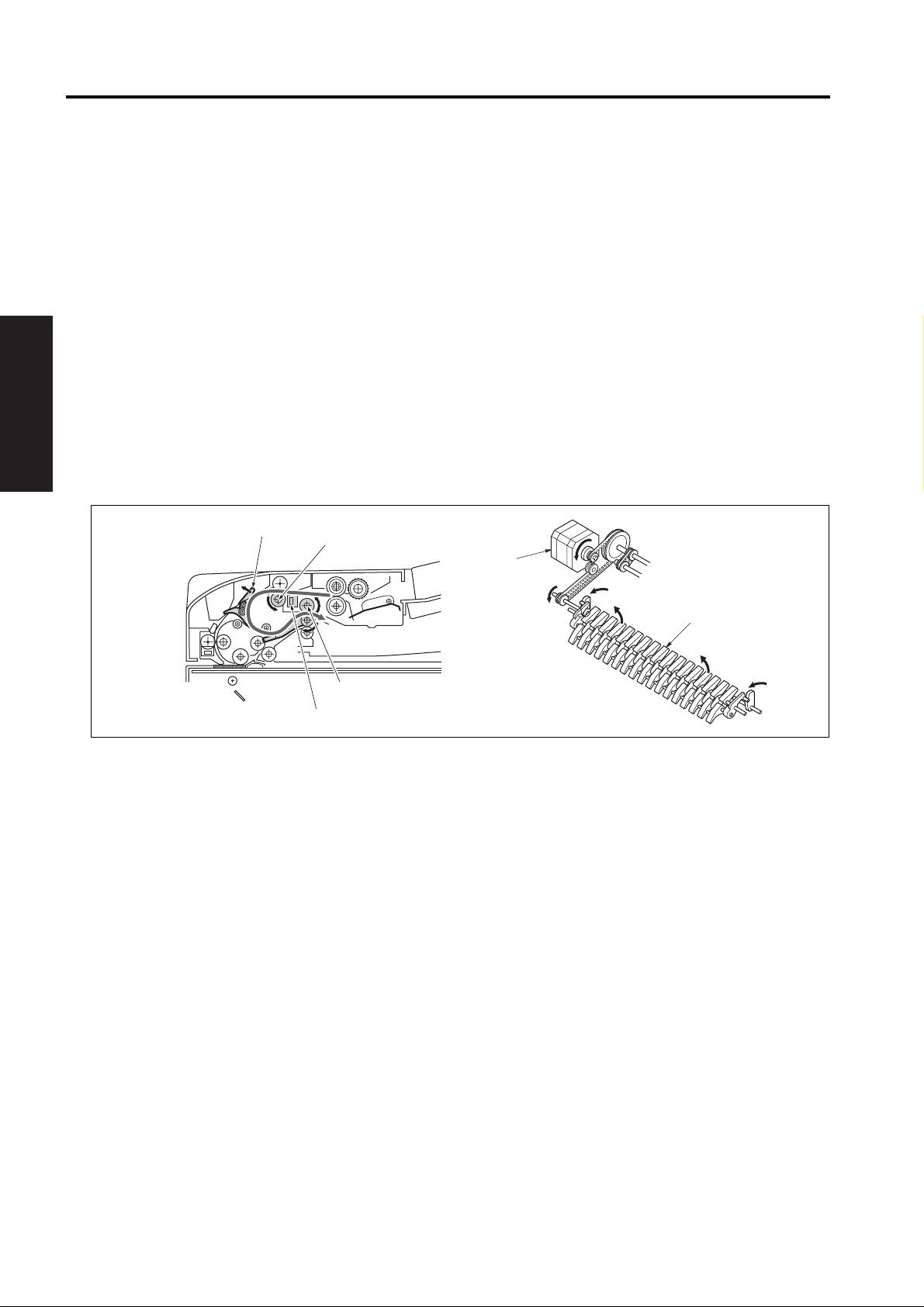

PAPER FEED/REVERSAL/EXIT SECTION

III DISASSEMBLY/ASSEMBLY

Caution:

• Make sure the power cord of the copier is

unplugged from the power outlet before dis-

assembly or assembly.

1. PAPER FEED/REVERSAL/ EXIT SECTION

1.1 Replacing the Paper Feed

Roller and the Feed Rubber

A. Periodically replaced parts/cycle

• Paper feed roller: Every 1,200,000 copies (once

for every 300,000 copies for actual durable

count) (7145)

• Paper feed roller: Every 1,000,000 copies (once

for every 300,000 copies for actual durable

count) (7235/7228/7222)

• Feed rubber: Every 960,000 copies (once for

every 250,000 copies for actual durable count)

(7145)

• Feed rubber: Every 1,000,000 copies (once for

every 250,000 copies for actual durable count)

(7235/7228/7222)

III DIS./ASSEMBLY

B. Procedure

1. Open the open/close cover.

2. Remove the 2 screws [1] and remove the paper

feed unit [2].

[2]

[1]

[2]

3-1

1

Page 30

PAPER FEED/REVERSAL/EXIT SECTION

3. Remove the 2 stop rings [1] and the 2 bearings

[2], and remove the paper feed roller assembly

[4] from the paper feed unit [3].

4. Remove the stop ring [5] and remove the bear-

ing [6].

5. Pull out the shaft [7] and remove the paper feed

roller [8].

6. Remove the 3 stop rings [9] and the bearing

[10]. Pull out the shaft [11] and remove the feed

roller [12].

7. Remove the feed rubber from the feed roller

[12].

Note:

• Be sure to install the paper feed roller so that the

one-way clutch comes to the rear side.

• Be sure to install the feed roller so that the one-

way clutch comes to the front side.

• When installing the feed rubber, take note of the

direction of the paint mark [13].

[5]

[1]

[6]

[2]

[8]

[9]

[4]

[1]

[2]

[7]

[3]

[13]

[11]

[12][10]

8. Reinstall the above parts following the removal

steps in reverse.

III DIS./ASSEMBLY

3-2

Page 31

PAPER FEED/REVERSAL/EXIT SECTION

1.2 Replacing the Double Feed

Prevention Roller

A. Periodically replaced parts/cycle

• Double feed prevention roller: Every 960,000

copies (once for every 250,000 copies for actual

durable count) (7145)

• Double feed prevention roller: Every 1,000,000

copies (once for every 250,000 copies for actual

durable count) (7235/7228/7222)

B. Procedure

1. Open the open/close cover.

2. Remove the paper feed unit.

3. Remove the double feed prevention roller unit

[1].

4. Remove the E-ring [1], and pull out the double

feed prevention roller [3] to remove it from the

shaft [2].

Note:

• Be sure to install the double feed prevention roller

[3] so that the paint mark [4] turns in the direction

shown in the drawing.

5. Reinstall the above parts following the removal

steps in reverse.

[1]

[2]

[3]

[1]

III DIS./ASSEMBLY

[1]

[4]

3-3

1

Page 32

PAPER FEED/REVERSAL/EXIT SECTION

1.3 Replacing the Read Roller

A. Procedure

1. Open the RADF.

2. Remove the 3 screws [1], and remove the cover

[2].

[1]

[2]

[1]

3. Remove the screw [1], and remove the guide

[2].

4. Remove the 2 E-rings [3].

III DIS./ASSEMBLY

5. Slide up the read roller [1], and pull out the pin

[2] to remove the pulley [3].

6. Move the bearing [4] downward, then remove

the read roller [1].

7. Reinstall the above parts following the removal

steps in reverse.

[1]

[2]

[3]

[3]

[3]

[2]

[1]

Note:

• When the read roller gets soiled, clean it with

water or glass cleaner. Avoid use of alcohol for

cleaning. (Using alcohol may deteriorate the con-

veyance ability of the read roller.)

[1]

[4]

3-4

Page 33

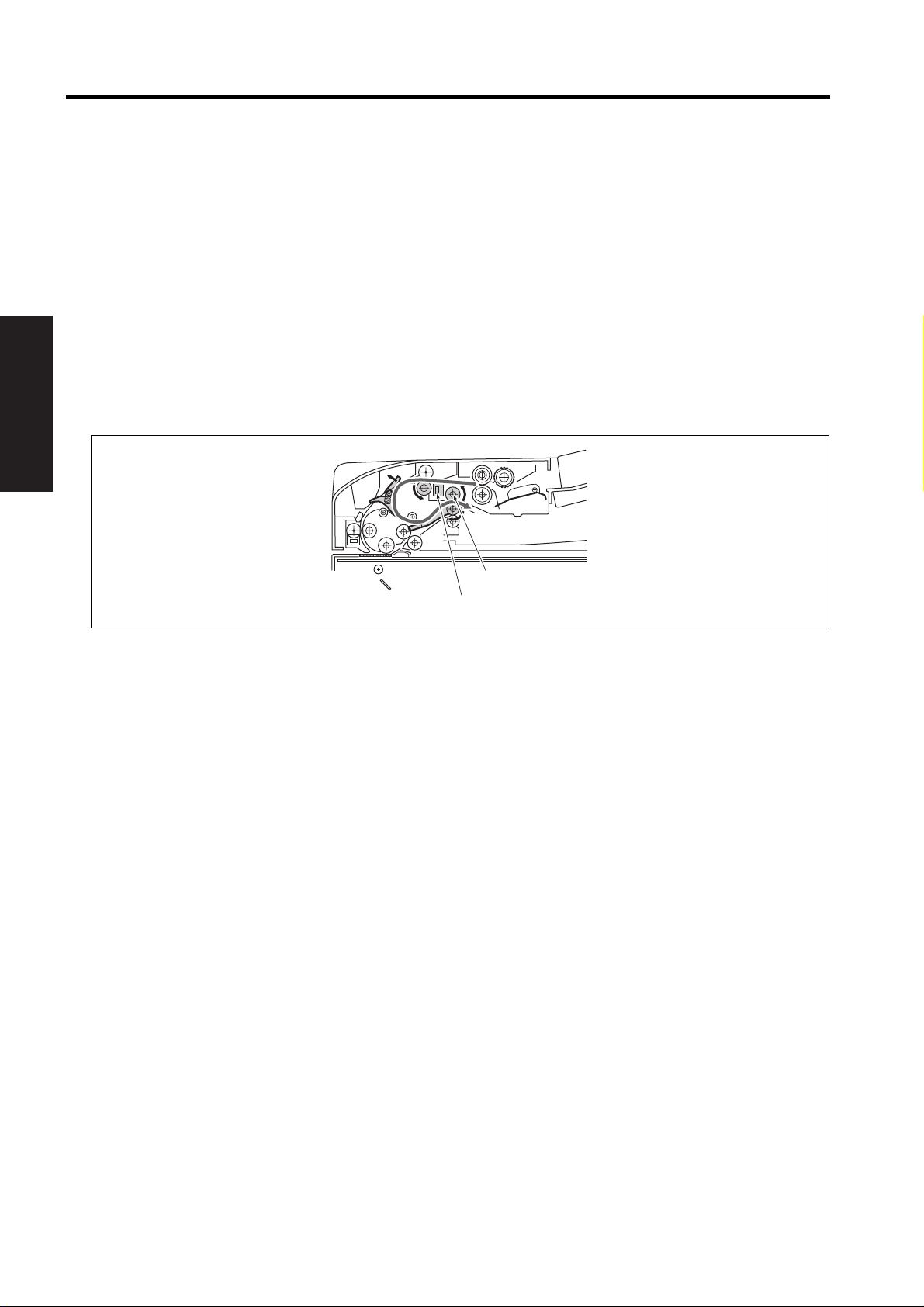

PAPER FEED/REVERSAL/EXIT SECTION

1.4 Removing and Reinstalling

the Paper Dust Removing

Brush

A. Procedure

1. Open the open/close cover.

2. Remove the screw [1], and then remove the

paper dust removing brush [2].

3. Reinstall the above parts following the removal

steps in reverse.

[2]

[1]

III DIS./ASSEMBLY

3-5

Page 34

PAPER FEED/REVERSAL/EXIT SECTION

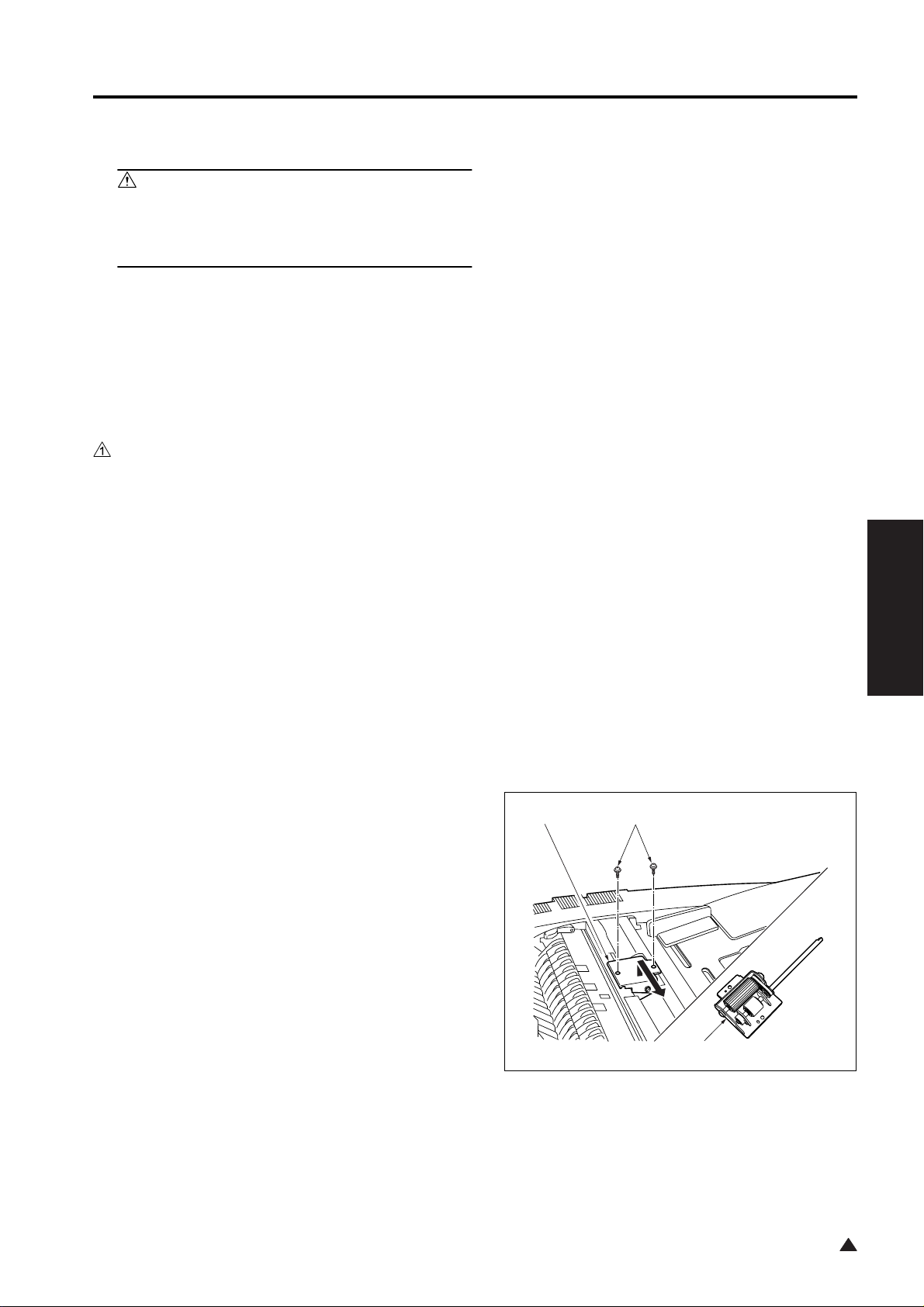

1.5 Replacing the Verification Stamp for FAX

A. Procedure

1. Open the RADF.

2. Open the paper exit tray [1].

3. Open the verification stamp for FAX unit [2] and

pull out the verification stamp [3].

4. Reinstall the above parts following the removal

steps in reverse.

Note:

• Be careful not to soil the paper exit roller with the

verification stamp.

• Be careful not to damage the plunger of the verifi-

cation stamp.

[3]

[2]

[1]

III DIS./ASSEMBLY

3-6

Page 35

EXTERNAL SECTION

2. EXTERNAL SECTION

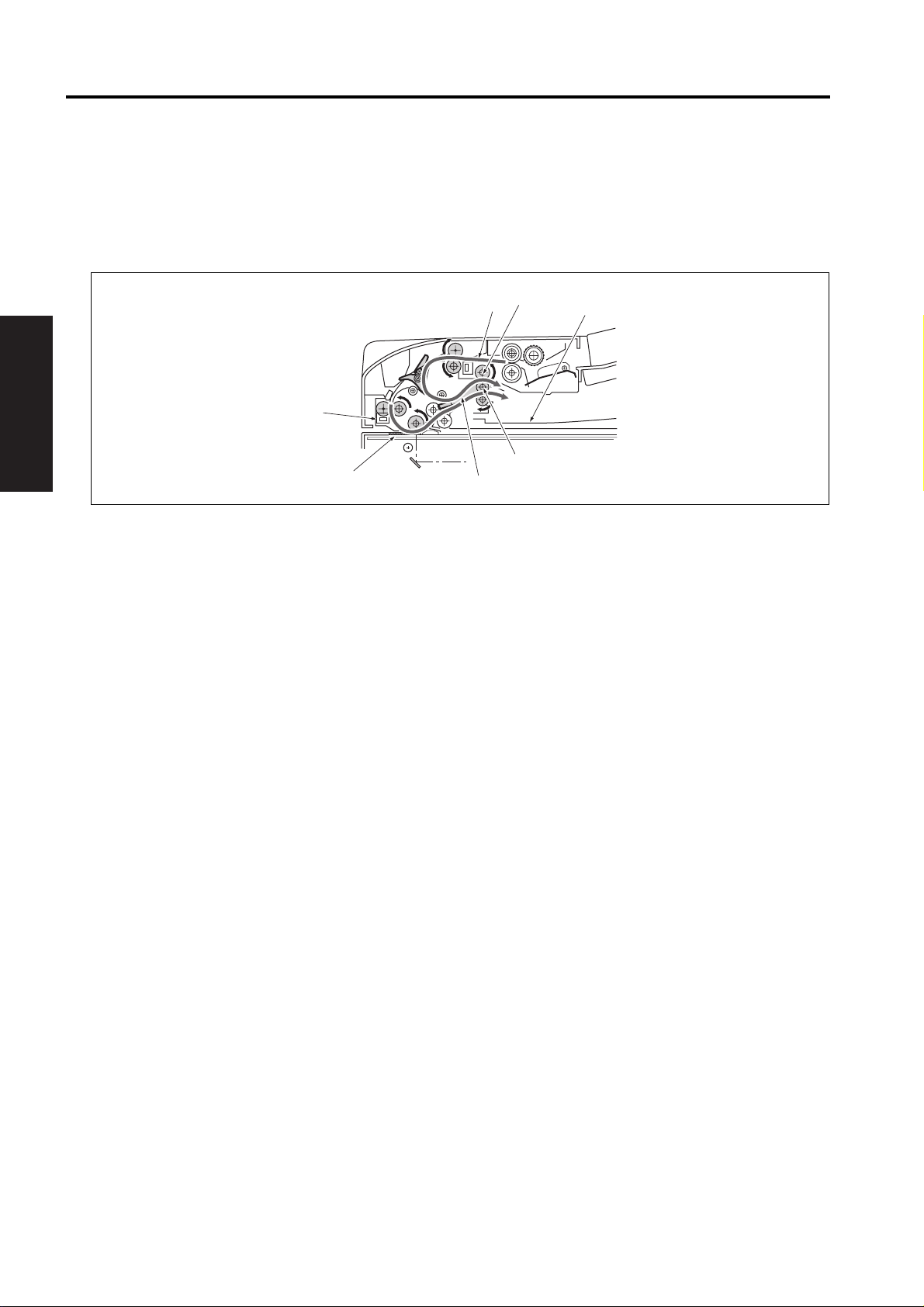

2.1 Removing and Reinstalling the RADF

A. Procedure

1. Remove the 2 screws [1] and remove the cable

cover [2].

[2]

2. Remove the 2 screws [1] and the cable stay [2],

and then remove the 2 relay connectors.

[1]

III DIS./ASSEMBLY

[1]

[2]

3-7

Page 36

EXTERNAL SECTION

3. In the case of the DF-318

Loosen the 2 screws [1] and slide down the

stopper [2].

In the case of the DF-320

Remove the 2 screws [1] and remove the stop-

per [2].

4. Remove the screw [3].

[1][2]

[3]

III DIS./ASSEMBLY

5. Open the RADF [1] vertically.

6. Press the jam release lever [2] and open the

[3][1]

paper exit tray [3].

[2]

1

3-8

Page 37

7. Remove the screw [1] and remove the RADF [2]

while lifting it up.

8. Remove the paper exit tray [3] while lifting it up.

9. Reinstall the above parts following the removal

steps in reverse.

EXTERNAL SECTION

Note:

• After installing the RADF, be sure to conduct

“RADF height adjustment” and “RADF distortion

adjustment”.

[2]

[1][3]

III DIS./ASSEMBLY

3-9

Page 38

EXTERNAL SECTION

III DIS./ASSEMBLY

Blank page

3-10

Page 39

PARTS CATALOG

Model

DF-318

NOVEMBER 2002

KONICA BUSINESS TECHNOLOGIES, INC.

Page 40

Page 41

How to use this catalog

This parts catalog includes illustrations and part numbers for all replacement parts and assemblies used in this model.

Model-specific parts are identified in the illustrations with reference

numbers. Use the reference number to locate the corresponding part

number on the facing page.

Common hardware items, such as screws, nuts, washers, and pins, are

identified in the illustrations with reference letters. Use the reference letter to locate the corresponding part number on the hardware listing in the

lower right hand corner of the facing page.

If you know a part number, but don’t know where the part is used, use

the numerical index to determine the page number and reference number for that part. Because some common parts are used in several

places, there may be more than one entry. Refer to the illustrations to see

where the part may be used.

If you know a part’s description, but don’t know where to look to find

the part number, use the alphabetical index to determine likely page and

reference numbers. Then look at the illustrations to determine that you

have identified the correct part. Locate the part number using the listing

on the opposite page.

Retail pricing that appears with the numerical index, while valid when

this catalog was printed, is subject to change without notice. The prices

are only suggested prices and are provided only for reference. Dealers

may determine their own selling prices. For up-to-date pricing, refer to

current Konica price lists or contact the Konica Parts Distribution Center.

How to order parts

Use standard Konica parts ordering procedures to obtain these parts.

For ordering options, contact Konica’s Parts Distribution Center.

When ordering parts, be sure to specify part numbers exactly as listed in

this catalog.

NOTE: Electrical parts may include previously used components.

Model DF-318 Konica Business Technologies, Inc. Page iii

1st Edition November, 2002

Page 42

This page left blank intentionally.

Page iv Konica Business Technologies, Inc. Model DF-318

November, 2002 1st Edition

Page 43

How to use this catalog . . . . . . . . . . . . . . . . . . . . . . . . . iii

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Rollers/Guides . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Paper Feed Section . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Paper Transfer Section . . . . . . . . . . . . . . . . . . . . . . . . . 8

Paper Exit Section . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Open/Close . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Paper Feed Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Contents

Alphabetical Index . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Numerical Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Model DF-318 Konica Business Technologies, Inc. Page 1

1st Edition November, 2002

Page 44

HOUSING

Page 2 Konica Business Technologies., Inc. Model DF-318

November, 2002 1st Edition

Page 45

REF. PART NUMBER DESCRIPTION

NO.

1 14GA12030 Front cover

2 13GL76080 Shaft holder/E

3 13GL45600 Positioning stopper/Front

4 13GL46160 Lock catch

5 14GA10110 Hinge/L

6 13GL46030 Original cover hinge

7 13GL46710 Hinge plate

8 13GL10191 Hinge mount plate/R

9 14GA12020 Rear cover

10 14GA46970 Solenoid set part/A

11 14GA-4801 Original exit tray assembly

12 13GL46100 Lock spring

13 14GA46080 Lock lever/A

14 13GL10320 Hinge stopper

15 14GA-1660 Hinge/R assembly

16 14GA-9010 RADF control unit

17 13GL10250 Hold spring/B

18 14GA90040 RADF wiring/4

19 13GL97081 Cleaning label/1

20 13GL10200 Hinge upper plate/R

HARDWARE

REF.

LTR.

a 00Z184061

b 00Z183041

c 00Z254101

d 00Z670306

e 00Z925103

f 00Z670406

g 00Z193041

h 00Z920034

i 00Z926251

j 00Z183042

k 00Z193062

m 00Z253081

PART

NUMBER

Model DF-318 Konica Business Technologies., Inc. Page 3

1st Edition November, 2002

Page 46

ROLLERS/GUIDES

Page 4 Konica Business Technologies., Inc. Model DF-318

November, 2002 1st Edition

Page 47

REF. PART NUMBER DESCRIPTION

NO.

1 13GL45151 Driving release roller/A

2 13GL15240 Reversal shaft holder

3 113620600 Pin (A)

4 13GL76590 Conveyance driving pulley/D (Z=42)

5 13GL40500 Slide sheet/A

6 466076020 Paper feeding shaft holder

7 13GL45840 Toque rotary spring

8 13GL77550 Driving reverse belt (L=60/96)

9 13GL76600 Conveyance driving pulley/E (Z=17)

10 13GL76610 Conveyance driving pulley/F (Z=17)

11 13GL40350 Connecting collar

12 13GL40341 Toque limiter/B

13 13GL-4050 Double feed preventive roller/A assembly

14 13GL10300 Rotary spring

15 13GL40050 Double feed preventive plate

16 13QA85510 Sensor/1

17 13GL45591 Electrify preventive sheet

18 13GL46661 Paper exit detecting plate

19 13GL40380 Stopper part/A

20 13GL-4041 Double feed preventive roller

21 14GA-1531 Solenoid/A assembly

22 13GL-4012 Paper feed guide plate/Lower assembly

23 13GL45210 Driving release lever/1

24 13GL40550 Conveyance auxiliary sheet

25 08AA85510 Photosensor

26 13GL46690 Neutralizing brush

27 13GL45200 Pressure spring

28 13GL45190 Pressure part

29 13GL40240 Double feed preventive spring

HARDWARE

REF.

LTR.

a 00Z194081

b 00Z926251

c 00Z193041

d 00Z921930

e 00Z193061

f 00Z670406

PART

NUMBER

Model DF-318 Konica Business Technologies., Inc. Page 5

1st Edition November, 2002

Page 48

PAPER FEED SECTION

Page 6 Konica Business Technologies., Inc. Model DF-318

November, 2002 1st Edition

Page 49

REF. PART NUMBER DESCRIPTION

NO.

1 13GL40250 Original pressure sheet

2 12QV40190 Paper feed roller/B

3 12QV40340 Paper supply rubber

4 13GL76021 Shaft holder/B

5 13GQ76020 Shaft holder/A

6 13GL40060 Paper feed mount part

7 12QV76590 Feeding pulley/A

8 13GL77540 Feeding belt (L=92)

9 13GL40260 Sticking part

10 454078050 Pin

11 13GL76030 Shaft holder/C

12 13GL40110 Paper feed roller/A

13 08AA85510 Photosensor

14 12QV76600 Feeding pulley/B

15 12QV40740 Belt regulating part

16 14GA90010 RADF wiring/1

17 13GL40320 Paper feed coupling/A

18 13GL40330 Paper feed coupling spring

19 13GL76520 Paper feed driving pulley (Z=36)

20 466076020 Paper feeding shaft holder

21 13GL40290 Remained detecting actuator/B

22 13GL76010 Shaft holder/A

23 13GL40070 Paper feed guide plate/B

24 13GL40270 Remained detecting actuator/A

25 14GA-1740 Driving motor/2assembly

26 13GL40400 Toque limiter/C

27 13GL76660 Original pressure pulley (Z=40)

28 13GL40460 Original pressure spring/A

29 14GA77510 Paper feed belt/A (L=262)

30 14GA77580 Original pressure belt (L=116)

31 14GA-4060 Feeding unit

HARDWARE

REF.

LTR.

PART

NUMBER

a 00Z921930

b 00Z193041

c 00Z670406

d 00Z712106

e 00Z183041

f 00Z670206

Model DF-318 Konica Business Technologies., Inc. Page 7

1st Edition November, 2002

Page 50

PAPER TRANSFER SECTION

Page 8 Konica Business Technologies., Inc. Model DF-318

November, 2002 1st Edition

Page 51

REF. PART NUMBER DESCRIPTION

NO.

1 13GL12040 Side cover

2 14GA45620 Adjusting lever/Front

3 14GA45570 Adjusting spring/A

4 56AA85520 Conveyance photosensor

5 14GA90030 RADF wiring/3

6 13GL77521 Reading drive belt (L=332)

7 13GL45040 Conveyance driven roller/A

8 13GL15060 Pulley shaft/A

9 13GL45060 Conveyance driven spring/A

10 13GL45031 Conveyance driving roller/A

11 13GL45530 Reading shaft holder/Front

12 14GA45550 Adjusting lever/Rear

13 13GL45540 Reading shaft holder/Rear

14 466078010 Pin A

15 13GL76640 Reading connect pulley/1 (Z=23)

16 13GL77571 Reading connect belt (L=94)

17 13GL76650 Reading connecting pulley/2 (Z=23)

18 454078050 Pin

19 13GL45521 Reading roller

20 13GL45110 Conveyance driving roller/B

21 13GL45140 Conveyance driven spring/B

22 13GL76040 Shaft holder/F

23 13GL45070 Conveyance guide part/Upper

24 13GL45120 Conveyance driven roller/Rear

25 13GL45250 Conveyance driven roller/Middle

26 13GL45100 Conveyance guide part/3

27 13GL45090 Conveyance guide part/2

28 13GL45080 Conveyance guide part/1

29 13GL45130 Conveyance driven shaft/B

30 113620600 Pin (A)

31 13GL76671 Conveyance driving pulley/G (Z=48)

32 13GL76630 Jam handling pulley (Z=34)

33 12ER40350 Sticking part

34 13GL15040 Idler pulley/A

35 25AA48670 Belt hold plate/B

36 14GA-1730 Driving motor/1 assembly

37 13GL76570 Conveyance driving pulley/B (Z=48)

HARDWARE

REF.

LTR.

a 00Z193041

b 00Z670406

c 00Z670306

d 00Z670606

e 00Z193061

f 00Z183041

g 00Z193062

h 00Z163061

PART

NUMBER

Model DF-318 Konica Business Technologies., Inc. Page 9

1st Edition November, 2002

Page 52

PAPER EXIT SECTION

Page 10 Konica Business Technologies., Inc. Model DF-318

November, 2002 1st Edition

Page 53

REF. PART NUMBER DESCRIPTION

NO.

1 13GL76060 Shaft holder/D

2 13GL73020 Open-close actuator

3 13GL73010 Open-close part

4 13GL73030 Detecting spring

5 13GL46780 Paper exit guide spring/Front

6 13GL-4850 Paper exit guide stopper/A assembly

7 14GA-1750 Driving motor/3 assembly

8 13GL76580 Conveyance driving pulley/C (Z=36)

9 113620600 Pin (A)

10 14GA97050 Jam release label

11 13GL45161 Driving release roller/B

12 466078010 Pin A

13 13GL46600 Paper exit driving roller/A

14 13GL15120 Tension spring/B

15 13GL-4860 Paper exit guide stopper/B assembly

16 13GL46750 Paper exit guide spring/Rear

17 13GL15030 Tension spring/A

18 13GL46060 Collar/A

19 14GA77530 Conveyance driving belt (L=200)

20 13GL46610 Paper exit driven roller

21 13GL46260 Paper exit pressure spring/Rear

22 13GL46640 Paper exit actuator/1

23 13GL46680 Paper exit detecting spring

24 13GL46650 Paper exit actuator/2

25 13GL15190 Tension spring/B

26 13GL46250 Paper exit pressure spring/Front

27 14GA46940 Positioning spring/A

28 14GA46630 Paper exit driven spring

29 14GA-4870 Paper exit guide plate/A assembly

30 14GA46980 Paper exit driven spring/B

31 13GL-1570 Tension plate/A assembly

32 13GL15260 Idler pulley/C

HARDWARE

REF.

LTR.

a 00Z670406

b 00Z670306

c 00Z253081

d 00Z670206

e 00Z193041

f 00Z183041

g 00Z610301

h 00Z193081

i 00Z252081

PART

NUMBER

Model DF-318 Konica Business Technologies., Inc. Page 11

1st Edition November, 2002

Page 54

PAPER EXIT SECTION

Page 12 Konica Business Technologies., Inc. Model DF-318

November, 2002 1st Edition

Page 55

REF. PART NUMBER DESCRIPTION

NO.

1 14GA-4640 Jam release arm/F assembly

2 26NA80510 Main body fan motor

3 13GL40480 Double feed release plate/A

4 14GA-4530 Conveyance guide part assembly

5 14GA-4650 Jam release arm/R assembly

6 454078050 Pin

7 14GA-1540 Paper exit solenoid assembly

8 13GL76560 Conveyance driving pulley/A (Z=18)

9 13GL46550 Paper exit guide lever/A

10 13GL-4581 Conveyance guide cam assembly

11 13GL45630 Conveyance neutralizing sheet/A

12 13GL15231 Toque limiter/A

13 466076020 Paper feeding shaft holder

14 13GL45430 Conveyance driven roller

15 13GL40510 Release wire/A

16 13GL45421 Conveyance guide part/B

17 13GL40490 Support part/A

18 13GL46560 Paper exit guide lever/B

19 13GL76080 Shaft holder/E

20 08AA85510 Photosensor

21 13GL45411 Conveyance guide part/A

HARDWARE

REF.

LTR.

a 00Z193061

b 00Z253081

c 00Z163061

d 00Z670406

e 00Z193041

f 00Z193301

h 00Z193041

i 00Z163041

PART

NUMBER

Model DF-318 Konica Business Technologies., Inc. Page 13

1st Edition November, 2002

Page 56

OPEN/CLOSE COVER

Page 14 Konica Business Technologies., Inc. Model DF-318

November, 2002 1st Edition

Page 57

REF. PART NUMBER DESCRIPTION

NO.

1 13GL40390 Hold spring/A

2 13GL76510 Registration unit driving pulley

3 13GL40160 Registration unit pressure spring

4 13QA41430 Sensor auxiliary sheet/2

5 13GL40140 Registration unit driven roller

6 13GL40410 Registration unit driven roller

7 13GL77561 Jam handling belt (L=66)

8 13GL40100 Shaft support part

9 13GL40430 Cleaning part/A

10 13GL40420 Paper feed cleaning part

11 14GA77510 Paper feed belt/A (L=262)

12 13GL40130 Registration unit driving roller

13 13GL-1202 Open-close cover assembly

14 090075530 Bearing

HARDWARE

REF.

LTR.

a 00Z193041

b 00Z670606

c 00Z253081

PART

NUMBER

Model DF-318 Konica Business Technologies., Inc. Page 15

1st Edition November, 2002

Page 58

PAPER FEED TRAY

Page 16 Konica Business Technologies., Inc. Model DF-318

November, 2002 1st Edition

Page 59

REF. PART NUMBER DESCRIPTION

NO.

1 13GL42040 Regulating side plate/Rear

2 13GL42030 Regulating side plate/Front

3 13GL97030 Paper feed label/A

4 13GL42050 Wiring cover

5 396040611 Rack

6 55GA42210 Lock

7 13GL-1580 Support plate/A assembly

8 14GA97070 Original regulating label/A

9 466077130 Pinion

10 13GL42022 Paper feed cover/Lower

11 13FG-9330 Size detecting board assembly

12 13GL77030 Detecting pinion (Z=124)

13 13QA85520 Sensor/2

14 14GA90020 RADF wiring/2

15 14GA97040 Paper feed label/B

16 13GL42014 Paper feed tray

HARDWARE

REF.

LTR.

a 00Z193041

b 00Z253081

PART

NUMBER

Model DF-318 Konica Business Technologies., Inc. Page 17

1st Edition November, 2002

Page 60

WIRING

Page 18 Konica Business Technologies., Inc. Model DF-318

November, 2002 1st Edition

Page 61

REF. PART NUMBER DESCRIPTION

NO.

1 14GA90010 RADF wiring/1

2 14GA90020 RADF wiring/2

3 14GA90030 RADF wiring/3

4 14GA90040 RADF wiring/4

Model DF-318 Konica Business Technologies., Inc. Page 19

1st Edition November, 2002

Page 62

This page left blank intentionally.

Page 20 Konica Business Technologies, Inc. Model DF-318

November, 2002 1st Edition

Page 63

Alphabetical Index

PART PAGE REF.

DESCRIPTION NO. NO.

A

Adjusting lever/Front . . . . 9 2

Adjusting lever/Rear . . . . 9 12

Adjusting spring/A . . . . . 9 3

B

Bearing . . . . . . . . . . . 15 14

Belt hold plate/B . . . . . . 9 35

Belt regulating part . . . . . 7 15

C

Cleaning label/1 . . . . . . 3 19

Cleaning part/A . . . . . . 15 9

Collar/A . . . . . . . . . . 11 18

Connecting collar . . . . . 5 11

Conveyance auxiliary sheet 5 24

Conveyance driven roller . . 13 14

Conveyance driven roller/A 9 7

Conveyance driven

roller/Middle . . . . . . 9 25

Conveyance driven

roller/Rear . . . . . . . 9 24

Conveyance driven shaft/B . 9 29

Conveyance driven spring/A 9 9

Conveyance driven spring/B 9 21

Conveyance driving belt

(L=200) . . . . . . . . 11 19

Conveyance driving pulley/A

(Z=18) . . . . . . . . . 13 8

Conveyance driving pulley/B

(Z=48) . . . . . . . . . 9 37

Conveyance driving pulley/C

(Z=36) . . . . . . . . . 11 8

Conveyance driving pulley/D

(Z=42) . . . . . . . . . 5 4

Conveyance driving pulley/E

(Z=17) . . . . . . . . . 5 9

Conveyance driving pulley/F

(Z=17) . . . . . . . . . 5 10

Conveyance driving pulley/G

(Z=48) . . . . . . . . . 9 31

Conveyance driving roller/A 9 10

Conveyance driving roller/B 9 20

Conveyance guide cam

assembly . . . . . . . . 13 10

Conveyance guide part

assembly . . . . . . . . 13 4

Conveyance guide part/1 . 9 28

Conveyance guide part/2 . 9 27

Conveyance guide part/3 . 9 26

Conveyance guide part/A . 13 21

Conveyance guide part/B . 13 16

Conveyance guide

part/Upper . . . . . . . 9 23

Conveyance neutralizing

sheet/A . . . . . . . . 13 11

Conveyance photosensor . 9 4

PART PAGE REF.

DESCRIPTION NO. NO.

D

Detecting pinion (Z=124) . . 17 12

Detecting spring . . . . . . 11 4

Double feed preventive plate 5 15

Double feed preventive roller 5 20

Double feed preventive

roller/A . . . . . . . . . 5 13

Double feed preventive spring 5 29

Double feed release plate/A 13 3

Driving motor/1 assembly . 9 36

Driving motor/2assembly . . 7 25

Driving motor/3 assembly . 11 7

Driving release lever/1 . . . 5 23

Driving release roller/A . . . 5 1

Driving release roller/B . . . 11 11

Driving reverse belt (L=60/96) 5 8

E

Electrify preventive sheet . . 5 17

F

Feeding belt (L=92) . . . . 7 8

Feeding pulley/A . . . . . . 7 7

Feeding pulley/B . . . . . . 7 14

Feeding unit . . . . . . . . 7 31

Front cover . . . . . . . . . 3 1

H

Hinge mount plate/R . . . . 3 8

Hinge plate . . . . . . . . . 3 7

Hinge stopper . . . . . . . 3 14

Hinge upper plate/R . . . . 3 20

Hinge/L . . . . . . . . . . . 3 5

Hinge/R assembly . . . . . 3 15

Hold spring/A . . . . . . . . 15 1

Hold spring/B . . . . . . . . 3 17

I

Idler pulley/A . . . . . . . . 9 34

Idler pulley/C . . . . . . . . 11 32

J

Jam handling belt (L=66) . . 15 7

Jam handling pulley (Z=34) 9 32

Jam release arm/F assembly 13 1

Jam release arm/R assembly 13 5

Jam release label . . . . . . 11 10

L

Lock . . . . . . . . . . . . 17 6

Lock catch . . . . . . . . . 3 4

PART PAGE REF.

DESCRIPTION NO. NO.

Lock lever/A . . . . . . . . . 3 13

Lock spring . . . . . . . . . 3 12

M

Main body fan motor . . . . 13 2

N

Neutralizing brush . . . . . 5 26

O

Open-close actuator . . . . 11 2

Open-close cover assembly 15 13

Open-close part . . . . . . 11 3

Original cover hinge . . . . 3 6

Original exit tray assembly . 3 11

Original pressure belt

(L=116) . . . . . . . . . 7 30

Original pressure pulley

(Z=40) . . . . . . . . . 7 27

Original pressure sheet . . . 7 1

Original pressure spring/A . 7 28

Original regulating label/A . 17 8

P

Paper exit actuator/1 . . . . 11 22

Paper exit actuator/2 . . . . 11 24

Paper exit detecting plate . . 5 18

Paper exit detecting spring . 11 23

Paper exit driven roller . . . 11 20

Paper exit driven spring . . . 11 28

Paper exit driven spring/B . 11 30

Paper exit driving roller/A . . 11 13

Paper exit guide lever/A . . 13 9

Paper exit guide lever/B . . 13 18

Paper exit guide plate/A

assembly . . . . . . . . 11 29

Paper exit guide spring/Front 11 5

Paper exit guide spring/Rear 11 16

Paper exit guide stopper/A

assembly . . . . . . . . 11 6

Paper exit guide stopper/B

assembly . . . . . . . . 11 15

Paper exit pressure

spring/Front . . . . . . . 11 26

Paper exit pressure

spring/Rear . . . . . . . 11 21

Paper exit solenoid assembly 13 7

Paper feed belt/A (L=262) . 7 29

Paper feed belt/A (L=262) . 15 11

Paper feed cleaning part . . 15 10

Paper feed coupling spring . 7 18

Paper feed coupling/A . . . 7 17

Paper feed cover/Lower . . 17 10

Paper feed driving pulley

(Z=36) . . . . . . . . . 7 19

Paper feed guide plate/B . . 7 23

Model DF-318 Konica Business Technologies, Inc. Page 21

1st Edition November, 2002

Page 64

PART PAGE REF.

DESCRIPTION NO. NO.

Paper feed guide

plate/Lower assembly . 5 22

Paper feed label/A . . . . . 17 3

Paper feed label/B . . . . . 17 15

Paper feed mount part . . . 7 6

Paper feed roller/A . . . . . 7 12

Paper feed roller/B . . . . . 7 2

Paper feed tray . . . . . . . 17 16

Paper feeding shaft holder . 5 6

Paper feeding shaft holder . 7 20

Paper feeding shaft holder . 13 13

Paper supply rubber . . . . 7 3

Photosensor . . . . . . . . 5 25

Photosensor . . . . . . . . 7 13

Photosensor . . . . . . . . 13 20

Pin . . . . . . . . . . . . . 7 10

Pin . . . . . . . . . . . . . 9 18

Pin . . . . . . . . . . . . . 13 6

Pin (A) . . . . . . . . . . . 5 3

Pin (A) . . . . . . . . . . . 9 30

Pin (A) . . . . . . . . . . . 11 9

Pin A . . . . . . . . . . . . 9 14

Pin A . . . . . . . . . . . . 11 12

Pinion . . . . . . . . . . . . 17 9

Positioning spring/A . . . . 11 27

Positioning stopper/Front . . 3 3

Pressure part . . . . . . . . 5 28

Pressure spring . . . . . . . 5 27

Pulley shaft/A . . . . . . . . 9 8

R

RADF control unit . . . . . . 3 16

RADF wiring/1 . . . . . . . 7 16

RADF wiring/1 . . . . . . . 19 1

RADF wiring/2 . . . . . . . 17 14

RADF wiring/2 . . . . . . . 19 2

PART PAGE REF.

DESCRIPTION NO. NO.

RADF wiring/3 . . . . . . . 9 5

RADF wiring/3 . . . . . . . 19 3

RADF wiring/4 . . . . . . . 3 18

RADF wiring/4 . . . . . . . 19 4

Rack . . . . . . . . . . . . 17 5

Reading connect belt (L=94) 9 16

Reading connect pulley/1

(Z=23) . . . . . . . . . 9 15

Reading connecting pulley/2

(Z=23) . . . . . . . . . 9 17

Reading drive belt (L=332) . 9 6

Reading roller . . . . . . . . 9 19

Reading shaft holder/Front . 9 11

Reading shaft holder/Rear . 9 13

Rear cover . . . . . . . . . 3 9

Registration unit driven roller 15 5

Registration unit driven roller 15 6

Registration unit driving

pulley . . . . . . . . . . 15 2

Registration unit driving roller 15 12

Registration unit pressure

spring . . . . . . . . . . 15 3

Regulating side plate/Front . 17 2

Regulating side plate/Rear . 17 1

Release wire/A . . . . . . . 13 15

Remained detecting

actuator/A . . . . . . . . 7 24

Remained detecting

actuator/B . . . . . . . . 7 21

Reversal shaft holder . . . . 5 2

Rotary spring . . . . . . . . 5 14

S

Sensor auxiliary sheet/2 . . 15 4

Sensor/1 . . . . . . . . . . 5 16

Sensor/2 . . . . . . . . . . 17 13

PART PAGE REF.

DESCRIPTION NO. NO.

Shaft holder/A . . . . . . . 7 5

Shaft holder/A . . . . . . . 7 22

Shaft holder/B . . . . . . . 7 4

Shaft holder/C . . . . . . . 7 11

Shaft holder/D . . . . . . . 11 1

Shaft holder/E . . . . . . . 3 2

Shaft holder/E . . . . . . . 13 19

Shaft holder/F . . . . . . . 9 22

Shaft support part . . . . . 15 8

Side cover . . . . . . . . . 9 1

Size detecting board

assembly . . . . . . . 17 11

Slide sheet/A . . . . . . . 5 5

Solenoid set part/A . . . . 3 10

Solenoid/A assembly . . . 5 21

Sticking part . . . . . . . . 7 9

Sticking part . . . . . . . . 9 33

Stopper part/A . . . . . . . 5 19

Support part/A . . . . . . 13 17

Support plate/A assembly . 17 7

T

Tension plate/A assembly . 11 31

Tension spring/A . . . . . 11 17

Tension spring/B . . . . . 11 14

Tension spring/B . . . . . 11 25

Toque limiter/A . . . . . . 13 12

Toque limiter/B . . . . . . 5 12

Toque limiter/C . . . . . . 7 26

Toque rotary spring . . . . 5 7

W

Wiring cover . . . . . . . . 17 4

Page 22 Konica Business Technologies, Inc. Model DF-318

November, 2002 1st Edition

Page 65

Numerical Index

PART PAGE REF.

NUMBER NO. NO.

08AA85510 5 25

08AA85510 7 13

08AA85510 13 20

090075530 15 14

113620600 5 3

113620600 9 30

113620600 11 9

12ER40350 9 33

12QV40190 7 2

12QV40340 7 3

12QV40740 7 15

12QV76590 7 7

12QV76600 7 14

13FG-9330 17 11

13GL-1202 15 13

13GL-1570 11 31

13GL-1580 17 7

13GL-4012 5 22

13GL-4041 5 20

13GL-4050 5 13

13GL-4581 13 10

13GL-4850 11 6

13GL-4860 11 15

13GL10191 3 8

13GL10200 3 20

13GL10250 3 17

13GL10300 5 14

13GL10320 3 14

13GL12040 9 1

13GL15030 11 17

13GL15040 9 34

13GL15060 9 8

13GL15120 11 14

13GL15190 11 25

13GL15231 13 12

13GL15240 5 2

13GL15260 11 32

13GL40050 5 15

13GL40060 7 6

13GL40070 7 23

13GL40100 15 8

13GL40110 7 12

13GL40130 15 12

13GL40140 15 5

13GL40160 15 3

13GL40240 5 29

13GL40250 7 1

13GL40260 7 9

13GL40270 7 24

13GL40290 7 21

13GL40320 7 17

13GL40330 7 18

13GL40341 5 12

13GL40350 5 11

13GL40380 5 19

13GL40390 15 1

13GL40400 7 26

13GL40410 15 6

13GL40420 15 10

13GL40430 15 9

13GL40460 7 28

13GL40480 13 3

13GL40490 13 17

13GL40500 5 5

PART PAGE REF.

NUMBER NO. NO.

13GL40510 13 15

13GL40550 5 24

13GL42014 17 16

13GL42022 17 10

13GL42030 17 2

13GL42040 17 1

13GL42050 17 4

13GL45031 9 10

13GL45040 9 7

13GL45060 9 9

13GL45070 9 23

13GL45080 9 28

13GL45090 9 27

13GL45100 9 26

13GL45110 9 20

13GL45120 9 24

13GL45130 9 29

13GL45140 9 21

13GL45151 5 1

13GL45161 11 11

13GL45190 5 28

13GL45200 5 27

13GL45210 5 23

13GL45250 9 25

13GL45411 13 21

13GL45421 13 16

13GL45430 13 14

13GL45521 9 19

13GL45530 9 11

13GL45540 9 13

13GL45591 5 17

13GL45600 3 3

13GL45630 13 11

13GL45840 5 7

13GL46030 3 6

13GL46060 11 18

13GL46100 3 12

13GL46160 3 4

13GL46250 11 26

13GL46260 11 21

13GL46550 13 9

13GL46560 13 18

13GL46600 11 13

13GL46610 11 20

13GL46640 11 22

13GL46650 11 24

13GL46661 5 18

13GL46680 11 23

13GL46690 5 26

13GL46710 3 7

13GL46750 11 16

13GL46780 11 5

13GL73010 11 3

13GL73020 11 2

13GL73030 11 4

13GL76010 7 22

13GL76021 7 4

13GL76030 7 11

13GL76040 9 22

13GL76060 11 1

13GL76080 3 2

13GL76080 13 19

13GL76510 15 2

13GL76520 7 19

PART PAGE REF.

NUMBER NO. NO.

13GL76560 13 8

13GL76570 9 37

13GL76580 11 8

13GL76590 5 4

13GL76600 5 9

13GL76610 5 10

13GL76630 9 32

13GL76640 9 15

13GL76650 9 17

13GL76660 7 27

13GL76671 9 31

13GL77030 17 12

13GL77521 9 6

13GL77540 7 8

13GL77550 5 8

13GL77561 15 7

13GL77571 9 16

13GL97030 17 3

13GL97081 3 19

13GQ76020 7 5

13QA41430 15 4

13QA85510 5 16

13QA85520 17 13

14GA-1531 5 21

14GA-1540 13 7

14GA-1660 3 15

14GA-1730 9 36

14GA-1740 7 25

14GA-1750 11 7

14GA-4060 7 31

14GA-4530 13 4

14GA-4640 13 1

14GA-4650 13 5

14GA-4801 3 11

14GA-4870 11 29

14GA-9010 3 16

14GA10110 3 5

14GA12020 3 9

14GA12030 3 1

14GA45550 9 12

14GA45570 9 3

14GA45620 9 2

14GA46080 3 13

14GA46630 11 28

14GA46940 11 27

14GA46970 3 10

14GA46980 11 30

14GA77510 7 29

14GA77510 15 11

14GA77530 11 19

14GA77580 7 30

14GA90010 7 16

14GA90010 19 1

14GA90020 17 14

14GA90020 19 2

14GA90030 9 5

14GA90030 19 3

14GA90040 3 18

14GA90040 19 4

14GA97040 17 15

14GA97050 11 10

14GA97070 17 8

25AA48670 9 35

26NA80510 13 2

Model DF-318 Konica Business Technologies, Inc. Page 23

1st Edition November, 2002

Page 66

PART PAGE REF.

NUMBER NO. NO.

396040611 17 5

454078050 7 10

454078050 9 18

454078050 13 6

466076020 5 6

PART PAGE REF.

NUMBER NO. NO.

466076020 7 20

466076020 13 13

466077130 17 9

466078010 9 14

466078010 11 12

PART PAGE REF.

NUMBER NO. NO.

55GA42210 17 6

56AA85520 9 4

Page 24 Konica Business Technologies, Inc. Model DF-318

November, 2002 1st Edition

Page 67

PARTS CATALOG

Model

DF-320

MARCH 2004

KONICA MINOLTA BUSINESS SOLUTIONS U.S.A., INC.

Page 68

Page 69

HOW TO USE THIS CATALOG

This parts catalog includes illustrations and part numbers for all replacement parts and assemblies used in this model.

Model-specific parts are identified in the illustrations with reference

numbers. Use the reference number to locate the corresponding part

number on the facing page.

Common hardware items, such as screws, nuts, washers, and pins, are

identified in the illustrations with reference letters. Use the reference letter to locate the corresponding part number on the hardware listing in the

lower right hand corner of the facing page.

If you know a part number, but don’t know where the part is used, use

the numerical index to determine the page number and reference number for that part. Because some common parts are used in several

places, there may be more than one entry. Refer to the illustrations to see

where the part may be used.

If you know a part’s description, but don’t know where to look to find

the part number, use the alphabetical index to determine likely page and

reference numbers. Then look at the illustrations to determine that you

have identified the correct part. Locate the part number using the listing

on the opposite page.

Retail pricing that appears with the numerical index, while valid when

this catalog was printed, is subject to change without notice. The prices

are only suggested prices and are provided only for reference. Dealers

may determine their own selling prices. For up-to-date pricing, refer to

current Konica price lists or contact the Konica Parts Distribution Center.

How to order parts

Use standard Konica parts ordering procedures to obtain these parts. For

ordering options, contact Konica’s Parts Distribution Center.

When ordering parts, be sure to specify part numbers exactly as listed in

this catalog.

NOTE: Electrical parts may include previously used components.

Model DF-320 Konica Minolta Business Solutions U.S.A., Inc. Page iii

1st Edition March, 2004

Page 70

This page left blank intentionally.

Page iv Konica Minolta Business Solutions U.S.A., Inc. Model DF-320

March, 2004 1st Edition

Page 71

How to Use This Catalog . . . . . . . . . . . . . . . . . . . . . . . . iii

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Rollers/Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Paper Feed Section . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Paper Transfer Section . . . . . . . . . . . . . . . . . . . . . . . . . 8

Paper Exit Section . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Open/Close Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Paper Feed Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

CONTENTS

Alphabetical Index . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Numerical Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Model DF-320 Konica Minolta Business Solutions U.S.A., Inc. Page 1

1st Edition March, 2004

Page 72

HOUSING

Page 2 Konica Minolta Business Solutions U.S.A., Inc. Model DF-320

March, 2004 1st Edition

Page 73

REF. PART NUMBER DESCRIPTION

NO.

1 14GA12031 Front cover

2 13GL15050 Pulley holder/A

3 13GL45600 Positioning stopper/front

4 13GL46160 Lock catch

5 14QH10110 Hinge/L

6 13GL46030 Original cover hinge

7 13GL46710 Hinge plate

8 13GL10191 Hinge mount plate/R

9 14GA12020 Rear cover

10 14GA46970 Solenoid set part/A

11 14QH-4800 Original exit tray assembly

12 14QH46100 Lock spring

13 14GA46080 Lock lever/A

14 13GL10320 Hinge stopper

15 14QH-1660 Hinge/R assembly

16 14QH-9010 RADF control unit

17 14QH10250 Hold spring/B

18 14GA90040 RADF wiring/4

19 14QH10200 Hinge upper plate/R

HARDWARE

REF.

LTR.

a 00Z184061

c 00Z254101

d 00Z670306

e 00Z925103

f 00Z670406

g 00Z193041

h 00Z920034

i 00Z926251

j 00Z183042

k 00Z193062

m 00Z253081

PART

NUMBER

Model DF-320 Konica Minolta Business Solutions U.S.A., Inc. Page 3

1st Edition March, 2004

Page 74

ROLLERS/GUIDES

Page 4 Konica Minolta Business Solutions U.S.A., Inc. Model DF-320

March, 2004 1st Edition

Page 75

REF. PART NUMBER DESCRIPTION

NO.

1 13GL45151 Driving release roller/A

2 13GL15240 Reversal shaft holder

3 56AA17320 Pin/A

4 13GL76590 Conveyance driving pulley/D (Z=42)

5 13GL40500 Slide sheet/A

6 466076020 Paper feeding shaft holder

7 14QH45840 Toque rotary spring

8 14QH77550 Driving reverse belt (L=60/96)

9 13GL76600 Conveyance driving pulley/E (Z=17)

10 13GL76610 Conveyance driving pulley/F (Z=17)

11 13GL40350 Connecting collar

12 14QH40340 Toque limiter/B

13 14QH-4050 Double feed preventive roller/A assembly

14 14QH10300 Rotary spring

15 13GL40050 Double feed preventive plate

16 13QA85510 Sensor/1

17 14QH45590 Electrify preventive sheet

18 14QH46660 Paper exit detecting plate

19 13GL40380 Stopper part/A

20 14QH-4040 Double feed preventive roller assembly

21 14GA-1531 Solenoid/A assembly

22 14QH-4010 Paper feed guide plate/lower assembly

23 13GL45210 Driving release lever/1

24 13GL40550 Conveyance auxiliary sheet

25 08AA85510 Photosensor

26 14QH46690 Neutralizing brush

27 14QH45200 Pressure spring

28 13GL45190 Pressure part

29 14QH40240 Double feed preventive spring

HARDWARE

REF.

LTR.

a 00Z194081

b 00Z926251

c 00Z193041

d 00Z921930

e 00Z193061

f 00Z670406

g 00Z921943

h 00Z670306

i 00Z113061

PART

NUMBER

Model DF-320 Konica Minolta Business Solutions U.S.A., Inc. Page 5

1st Edition March, 2004

Page 76

PAPER FEED SECTION

Page 6 Konica Minolta Business Solutions U.S.A., Inc. Model DF-320

March, 2004 1st Edition

Page 77

REF. PART NUMBER DESCRIPTION

NO.

1 14QH40250 Original pressure sheet

2 14QH40190 Paper feed roller/B

3 14QH40350 Paper supply rubber

4 14QH76020 Shaft holder/B

5 14QH76030 Shaft holder/A

6 13GL40061 Paper feed mount part

7 14QH76590 Feeding pulley/A (Z=22)

8 14QH77540 Feeding belt (L=92)

9 13GL40260 Sticking part

10 454078050 Pin

11 13GL76030 Shaft holder/C

12 14QH40110 Paper feed roller/A

13 08AA85510 Photosensor

14 14QH76600 Feeding pulley/B

15 14QH40740 Belt regulating part

16 14GA90010 RADF wiring/1

17 13GL40320 Paper feed coupling/A

18 14QH40330 Paper feed coupling spring

19 14QH76520 Paper feed driving pulley (Z=36)

20 466076020 Paper feeding shaft holder

21 14QH-4060 Feeding unit

22 13GL76010 Shaft holder/A

23 14QH40070 Paper feed guide plate/B

24 14QH40660 Shaft positioning part

25 14GA-1740 Driving motor/2 assembly

26 14QH40400 Toque limiter/C

27 13GL76660 Original pressure pulley (Z=40)

28 14QH40460 Original pressure spring/A

29 14GA77510 Paper feed belt/A (L=262)

30 14GA77580 Original pressure belt (L=116)

HARDWARE

REF.

LTR.

PART

NUMBER

a 00Z921930

b 00Z193041

c 00Z670406

d 00Z712106

e 00Z183041

f 00Z670206

Model DF-320 Konica Minolta Business Solutions U.S.A., Inc. Page 7

1st Edition March, 2004

Page 78

PAPER TRANSFER SECTION

Page 8 Konica Minolta Business Solutions U.S.A., Inc. Model DF-320

March, 2004 1st Edition

Page 79

REF. PART NUMBER DESCRIPTION

NO.

1 13GL12041 Side cover

2 14GA45620 Adjusting lever/front

3 14GA45570 Adjusting spring/A

4 56AA85520 Conveyance photosensor

5 14GA90030 RADF wiring/3

6 13GL77521 Reading drive belt (L=332)

7 13GL45040 Conveyance driven roller/A

8 13GL15060 Pulley shaft/A

9 14QH45060 Conveyance driven spring/A

10 13GL45031 Conveyance driving roller/A

11 13GL45530 Reading shaft holder/front

12 14GA45550 Adjusting lever/rear

13 13GL45540 Reading shaft holder/rear

14 466078010 Pin A

15 13GL76640 Reading connect pulley/1 (Z=23)

16 13GL77571 Reading connect belt (L=94)

17 13GL76650 Reading connecting pulley/2 (Z=23)

18 454078050 Pin

19 14QH45520 Reading roller

20 14GA45110 Conveyance driving roller/B

21 14QH45140 Conveyance driven spring/B

22 14QH76040 Shaft holder/F

23 13GL45070 Conveyance guide part/upper

24 12ER40350 Sticking part

25 13GL15040 Idler pulley/A

26 14QH48670 Belt hold plate/B

27 14GA-1730 Driving motor/1 assembly

28 13GL76570 Conveyance driving pulley/B (Z=48)

29 14GA-4570 Conveyance driven shaft/B assembly

30 56AA17320 Pin/A

31 13GL76671 Conveyance driving pulley/G (Z=48)

32 13GL76630 Jam handling pulley (Z=34)

HARDWARE

REF.

LTR.

PART

NUMBER

a 00Z193041

b 00Z670406

c 00Z670306

d 00Z670606

e 00Z193061

f 00Z183041

g 00Z193062

h 00Z163061

Model DF-320 Konica Minolta Business Solutions U.S.A., Inc. Page 9

1st Edition March, 2004

Page 80

PAPER EXIT SECTION

Page 10 Konica Minolta Business Solutions U.S.A., Inc. Model DF-320

March, 2004 1st Edition

Page 81

REF. PART NUMBER DESCRIPTION

NO.

1 14QH76060 Shaft holder/D

2 13GL73021 Open/close actuator

3 13GL73011 Open/close part

4 14QH73030 Detecting spring

5 14QH46780 Paper exit guide spring/front

6 13GL-4850 Paper exit guide stopper/A assembly

7 14GA-1750 Driving motor/3 assembly

8 13GL76580 Conveyance driving pulley/C (Z=36)

9 56AA17320 Pin/A

10 14GA97050 Jam release label

11 13GL45161 Driving release roller/B

12 466078010 Pin A

13 14QH46600 Paper exit driving roller/A

14 14QH15120 Tension spring/B

15 13GL-4860 Paper exit guide stopper/B assembly

16 14QH46750 Paper exit guide spring/rear

17 14QH15030 Tension spring/A

18 13GL46060 Collar/A

19 14GA77530 Conveyance driving belt (L=200)

20 13GL46610 Paper exit driven roller

21 14QH46260 Paper exit pressure spring/rear

22 13GL46640 Paper exit actuator/1

23 14QH46680 Paper exit detecting spring

24 13GL46650 Paper exit actuator/2

25 14QH15190 Tension spring/B

26 14QH46250 Paper exit pressure spring/front

27 14GA46940 Positioning spring/A

28 14GA46630 Paper exit driven spring

29 14GA-4870 Paper exit guide plate/A assembly

30 14GA46980 Paper exit driven spring/B

31 13GL-1570 Tension plate/A assembly

32 13GL15260 Idler pulley/C

HARDWARE

REF.

LTR.

a 00Z670406

b 00Z670306

c 00Z253081

d 00Z670206

e 00Z193041

f 00Z183041

g 00Z610301

h 00Z193081

i 00Z252081

PART

NUMBER

Model DF-320 Konica Minolta Business Solutions U.S.A., Inc. Page 11

1st Edition March, 2004

Page 82

PAPER EXIT SECTION

Page 12 Konica Minolta Business Solutions U.S.A., Inc. Model DF-320

March, 2004 1st Edition

Page 83

REF. PART NUMBER DESCRIPTION

NO.

1 14GA-4640 Jam release arm/F assembly

2 27LA80510 Main body fan motor

3 13GL40481 Double feed release plate/A

4 14GA-4530 Conveyance guide part assembly

5 14GA-4650 Jam release arm/R assembly

6 454078050 Pin

7 14GA-1540 Paper exit solenoid assembly

8 13GL76560 Conveyance driving pulley/A (Z=18)

9 13GL46550 Paper exit guide lever/A

10 13GL-4581 Conveyance guide cam assembly

11 14QH45630 Conveyance neutralizing sheet/A

12 14QH15230 Toque limiter/A

13 466076020 Paper feeding shaft holder

14 13GL45430 Conveyance driven roller

15 14QH40510 Release wire/A

16 13GL45422 Conveyance guide part/B

17 13GL40490 Support part/A

18 14QH46560 Paper exit guide lever/B

19 13GL76080 Shaft holder/E

20 08AA85510 Photosensor

21 13GL45412 Conveyance guide part/A

22 14QH40530 Double feed release spring/A

HARDWARE

REF.

LTR.

a 00Z193061

b 00Z253081

c 00Z163061

d 00Z670406

e 00Z193041

f 00Z193301

g 00Z163041

h 00Z193041

PART

NUMBER

Model DF-320 Konica Minolta Business Solutions U.S.A., Inc. Page 13

1st Edition March, 2004

Page 84

OPEN/CLOSE COVER