Page 1

SERVICE MANUAL

MODEL

DF-311

JUNE 1998

CSM-DF311

Page 2

Page 3

TABLE OF CONTENTS

SAFETY PRECAUTIONS ...................................................... v

DF-311

SPECIFICATIONS..................................................................1

Type ................................................................................1

Functions........................................................................1

Machine Data ................................................................. 1

Maintenance...................................................................1

Operating Environment .................................................. 1

CENTER CROSS SECTION..................................................2

DRIVE SYSTEM DIAGRAM.....................................................2

ORIGINAL CONVEYANCE PROCESS ..................................3

Single -side Original Copy Mode ................................... 3

Double-side Original Copy Mode ................................... 4

Mixed Original Copy Mode..............................................4

EXTERNAL SECTION............................................................5

Construction...................................................................5

Mechanisms...................................................................5

Disassembly and Reassembly .....................................6

PAPER FEED/PAPER EXIT SECTION...................................8

Construction...................................................................8

Mechanism.....................................................................8

Disassembly and Reassembly .....................................9

Paper Feed/Conveyance/Scan Control ........................ 1 1

Paper Exit/Reverse Conveyance Control .....................1 3

Original Size Detection Control....................................1 5

DIAGRAMS

ELECTRICAL PARTS LAYOUT DIAGRAM.........................17

CONNECTOR LAYOUT DIAGRAM ......................................18

DF-311

iii

Page 4

DF-311

This page left blank intentionally.

iv

Page 5

PRODUCT SPECIFICATIONS

DF-311

Type

Type: Sheet-through type reversible DF

Functions

Originals size: 11X17,8.5X14,8.5X11, 8.5X11R,

8.5X5.5, 8.5X5.5R, 5.5X8.5R

· Double sided copy of 5.5X8.5

originals is not possible.

· All sizes are detected

automatically.

· Mixing of original sizes

possible.

Kinds of originals

Ordinary paper: 14 to 36 lb. fine quality paper

Special paper: Paper feed and conveyance

ability may sometimes be inferior

to those of 14 to 36 lb. fine quality

paper.

The following kinds of paper

cannot be used:

· OHP film

· Blueprint masters

· Label paper

· Offset masters

· Pasted originals

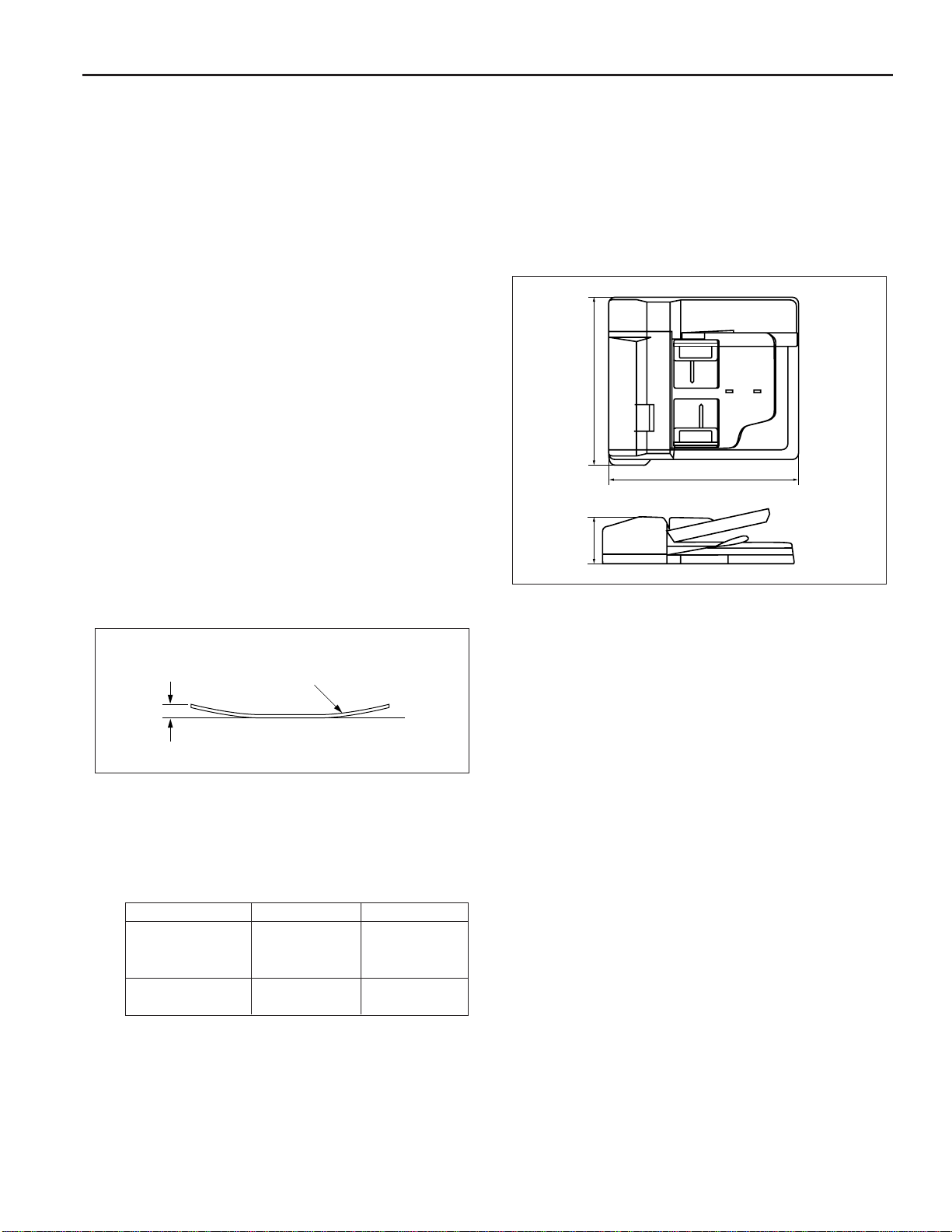

Machine Data

Power source: 24 V DC / 5 V (supplied from main

body)

Max. power consumption:

40 W

Weight: Approximately 30 lb.

Machine dimensions :

Unit: inches

22.0

23.2

5.9

Maintenance

Maintenance: Same as main body

Original

Curling

Original curling: 10 mm maximum.

Maximum number of stacked originals:

50 sheets (22 lb.)

Original read speed (copies per minute)

Mode

Single-sided

original to Single-

sided copy

Dual-sided original

to duplex copy

Original feed layout: Face-up setting, centered, U-turn

Original size

8.5x11

8.5x11

feed/straight paper exit, reversal

section mounted at paper exit

side.

Feed speed

40

28

Operating Environment

Temperature: 50°F ~ 91°F

Humidity: 20% to 80%RH

Note: The contents of this manual may be changed without

prior notice.

Original image read position:

At the slit glass section

1

Page 6

DF-311

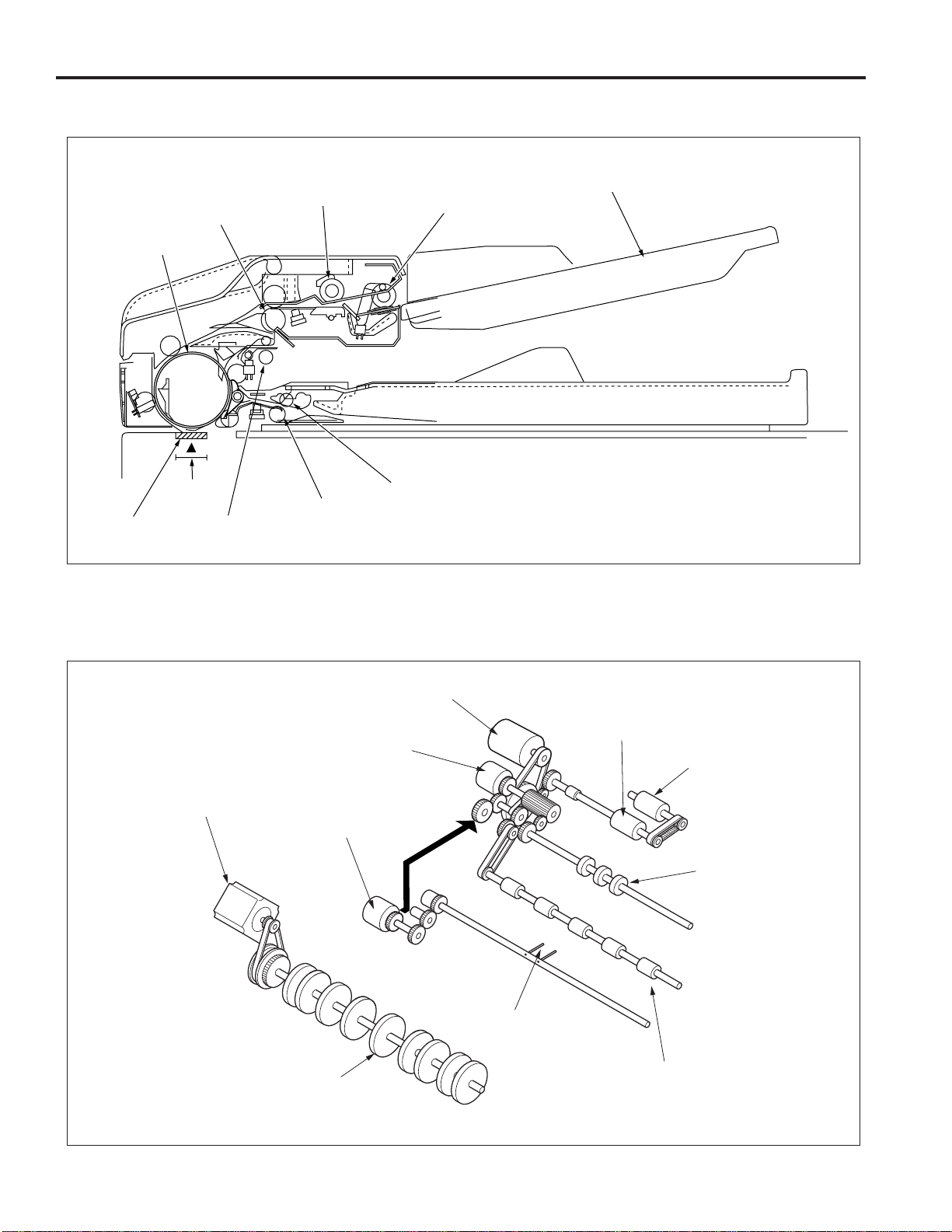

CENTER CROSS-SECTIONAL DRAWING

Registration roller

Conveyance roller

Original

image read

Slit glass

position

Separation roller

Pressure pulley

Reversal roller

Paper exit roller

Paper feed roller

DRIVE SYSTEM DRAWING

Paper feed tray

Original conveyance

motor (M301)

Original feed clutch

(CL302)

Original pick-up clutch

(CL301)

Conveyance roller

Original feed motor

(M302)

Separation roller

Paper feed roller

Registration roller

Pressure pin

Paper exit roller

2

Page 7

ORIGINAL CONVEYANCE PROCESS

DF-311

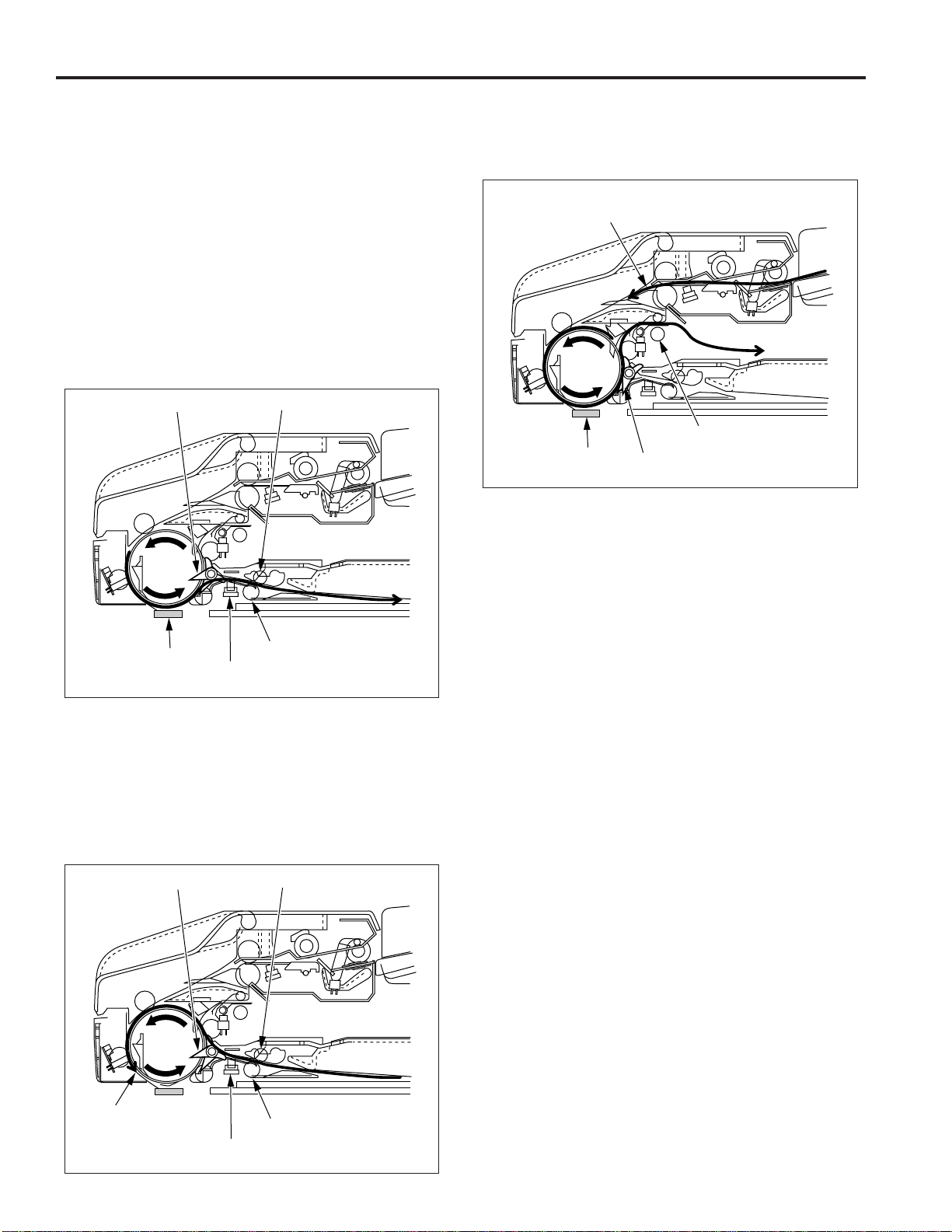

As the figure below shows, the DF-311 is composed of the

paper feed section, conveyance section, reversal section and

paper exit section.

Conveyance

section

Reversal section

Slit glass

(Read section)

Paper feed section

Paper exit section

The originals, which have been placed in the paper feed tray

with the front side facing up, are fed starting with the topmost

original. Originals that are fed are not conveyed to the original

glass. Reading is carried out as the original passes by the slit

glass section set midway through the conveyance path.

The operational modes of the DF-311 include three modes: (a)

single side original copy mode, (b) double side original copy

mode, (c) mixed original copy mode. The conveyance path is

different for each mode.

When PS306 goes on, pre-feed is carried out by the registration roller and the original is conveyed to the conveyance roller.

The conveyance roller conveys the original to the position

where PS308 (original feed detect) goes on. The original stops

at the scanning standby position.

Registration roller

Scanning standby

PS308

(Original feed detect)

position

Conveyance roller

PS306

(Original registration)

When scan is started, the conveyance roller rotates again in

the forward direction to convey the original. If there is another

original at this time, pre-feed is carried out.

Reading of the original is carried out when the original passes

over the slit glass. Originals which have been read are conveyed around the circumference of the conveyance roller by

closing of the guide plate and are ejected to the paper exit

section via the paper exit roller.

Single side original copy mode (single

side to single side copy, single side to

double side copy)

The originals set in the paper feed tray are fed by means of the

paper feed roller and separation roller to the position where

PS306 (original registration) goes on.

Separation roller

Registration roller

PS306 (Original registration)

Paper feed roller

Next original

Paper exit roller

Slit glass

Guide plate

3

Page 8

DF-311

Double side original copy mode

(double side to single side copy, double side to

double side copy)

The conveyance operation from feeding of the double sided

original to the front side scanning standby position is the same

as that for the single side original copy mode.

When scanning starts and reading of the front side is completed,

the original is conveyed to the reversal section when the guide

plate opens and the paper exit path is blocked.

When PS309 (original reversal detect) detects the leading

edge of the original that has been conveyed to the reversal

section and goes ON, pressure is applied to the pressure

pulley. As a result, the reversal roller and pressure pulley clasp

the original on both sides and convey it to the inside of the

reversal section.

Guide plate

Slit glass

Pressure pulley

Reversal roller

PS309

(Original reversal)

When scanning of the back side starts, the guide plate is

closed. As a result, the original which has been read is

conveyed around the circumference of the conveyance roller

and is ejected to the paper exit section via the paper exit roller.

Next original

Paper exit roller

Slit glass

Guide plate

Mixed original copy mode

The mixed original copy mode can handle both the same

series and different series of originals.

The size of the original in the conveyance direction is determined by the ON time of PS306, size detection operation take

place prior to the scanning operation.

The original then stops at the scanning standby position. The

subsequent operations are the same for all copy modes. For

details on the size detection operation, refer to Paper Feed/

Paper Eject section “Original Size Detection Control”.

When PS309 detects the trailing edge of the original and goes

OFF, the reversal roller rotates in the reverse direction to feed

the original from the reversal section to the conveyance roller.

Since the original passes over the top of the guide plate at this

time, the front and back sides are reversed and the original is

sent to the conveyance roller.

The conveyance roller conveys the original to the scanning

standby position.

Guide plate

Scanning

standby position

Pressure pulley

Reversal roller

PS309

(Original reversal)

4

Page 9

EXTERNAL SECTION

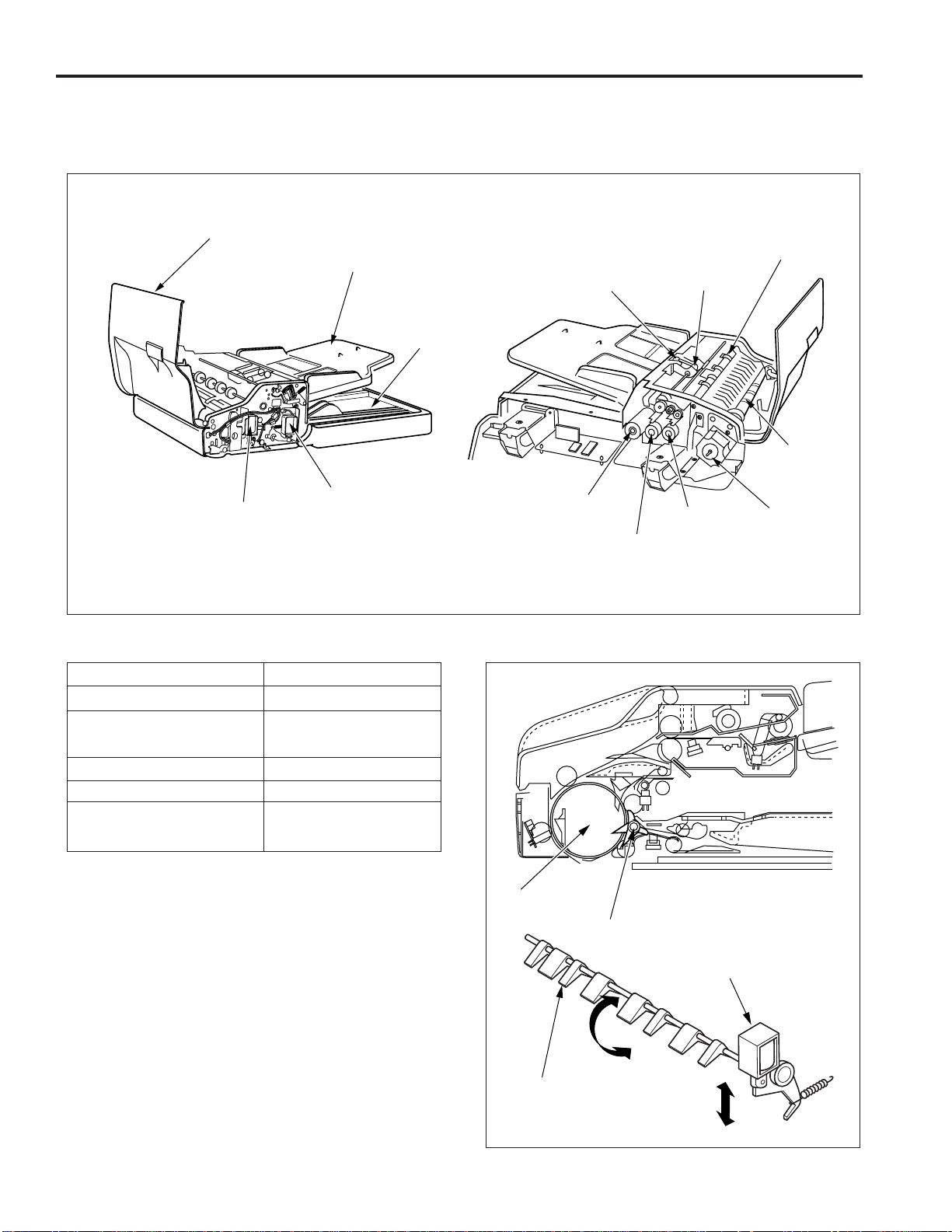

Construction

Open/close

cover

DF-311

Paper feed tray

Paper exit section

(Paper exit tray)

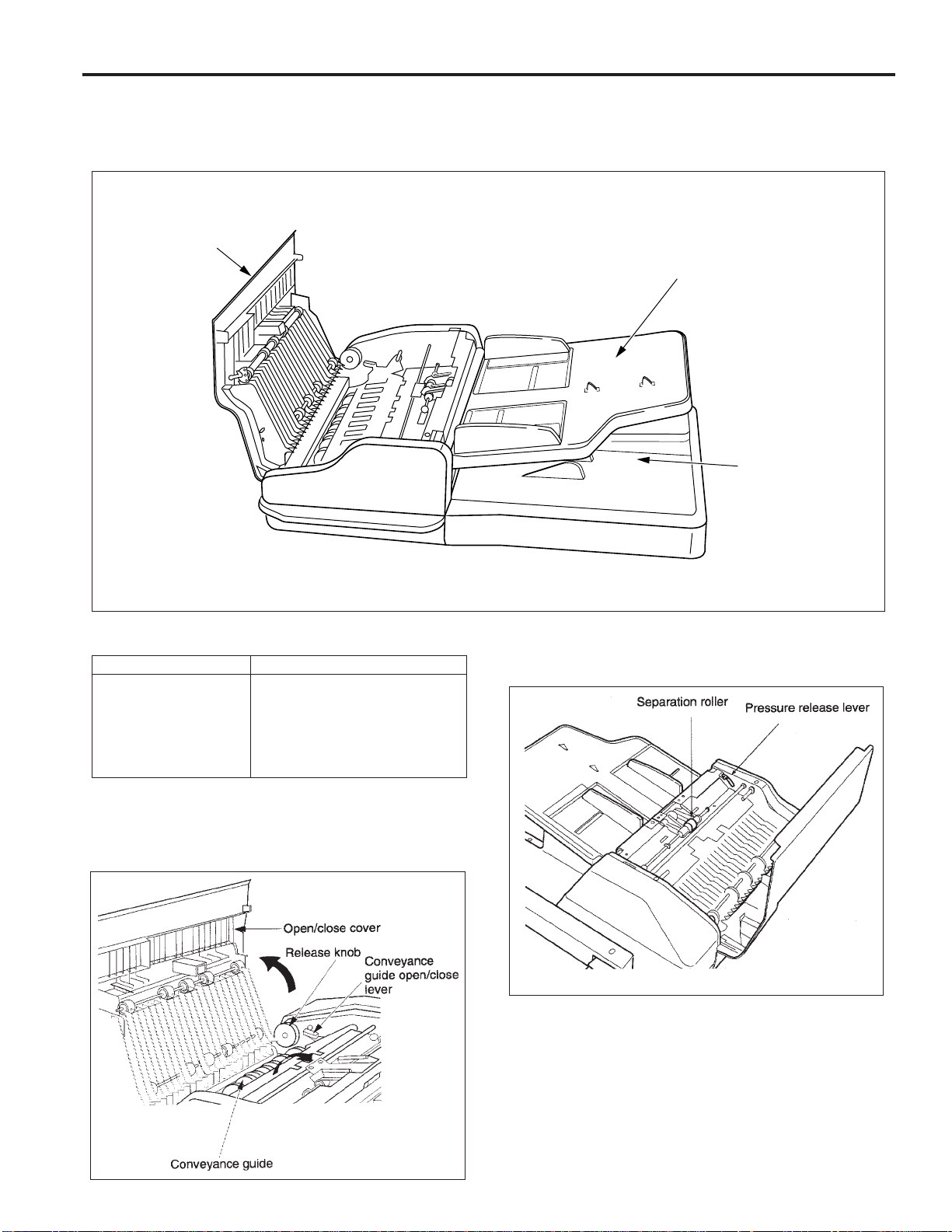

Mechanism

Mechanisms

Jam clearance

∗ 1

∗∗

∗1: Jam clearance

∗∗

If a paper jam occurs during the feed process, open the open/

close cover, raise the conveyance guide open/close lever, and

rotate the release knob to remove the jammed original.

Open/close cover

Release knob

Conveyance guide open/close lever

Pressure release lever

Platen guide

Methods

If the jammed original is hard to remove, operate the pressure

release lever to remove the pressure of the separation roller,

and then remove the original.

5

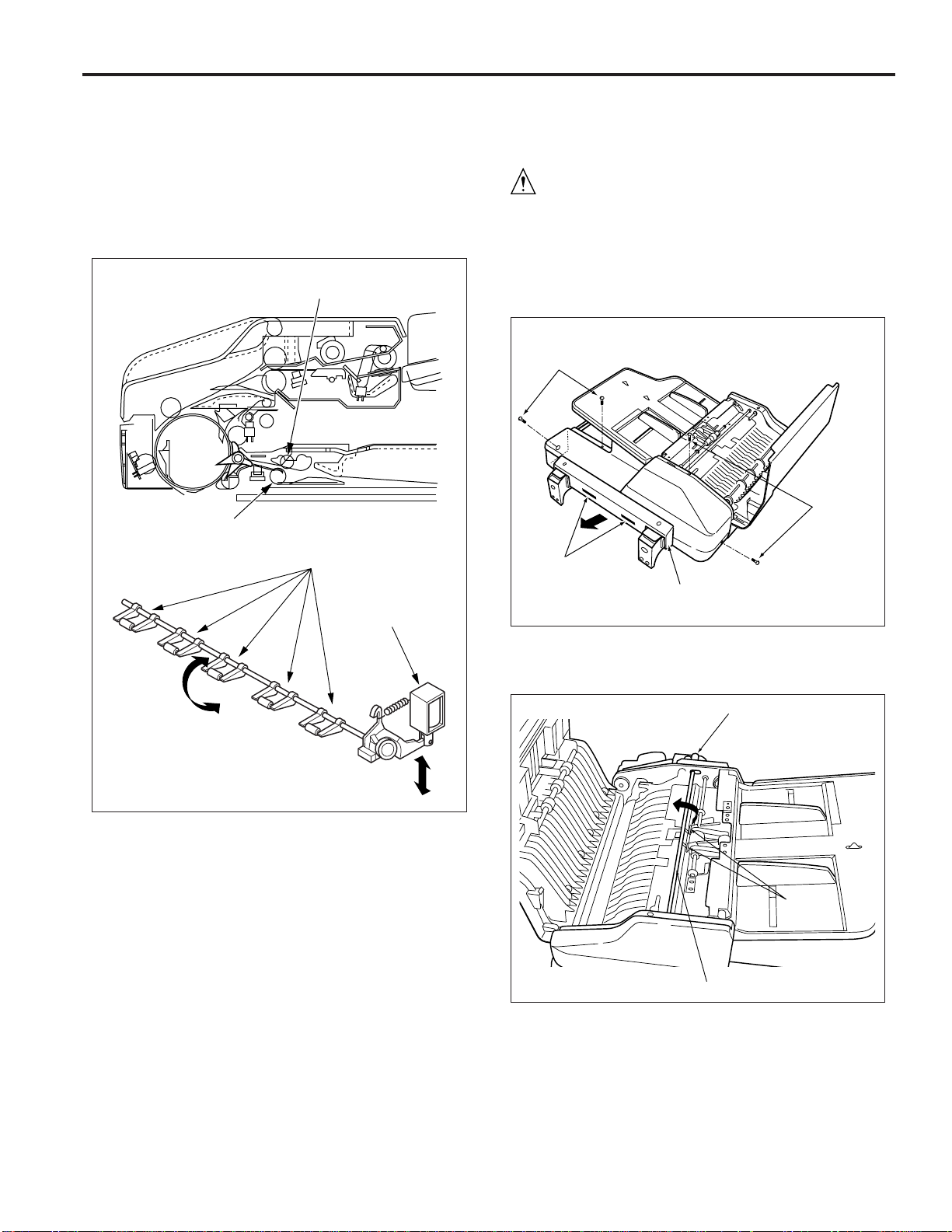

Page 10

DF-311

If a paper jam occurs during the reversal process, the jammed

sheet can be removed by opening the platen guide.

Lock

Platen

guide

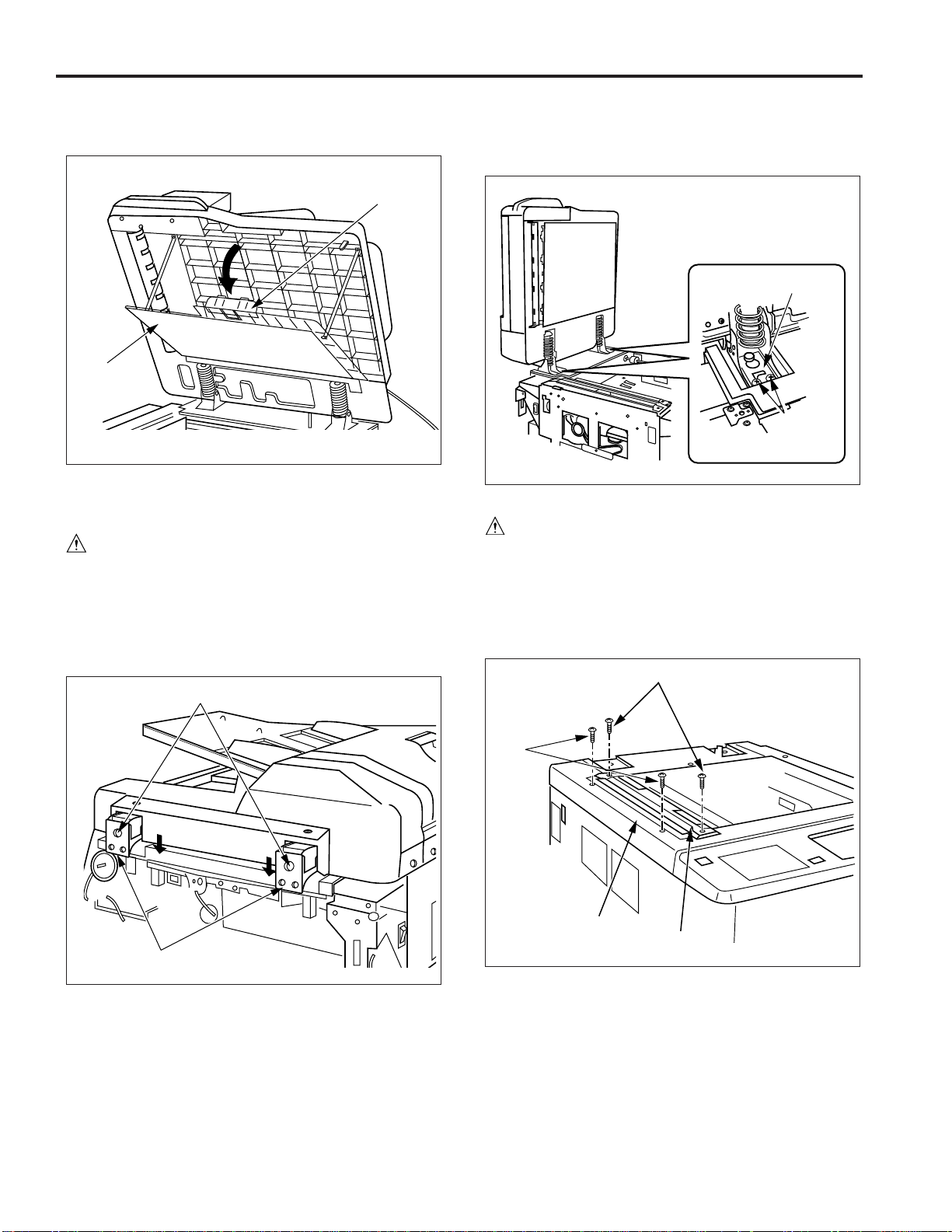

Disassembly and Reassembly

Removing the RADF

Caution: Be sure that the power cord has been un-

plugged from the power outlet.

Procedure

(1) Disconnect the RADF connector (CN100) from the right

side of the main body.

(2) Loosen the set screws of the stoppers (one each), lower

the stoppers, then tighten the screws again.

Stoppers

Caution: When the stopper brackets are removed, the RADF

will tend to fall towards the rear. To prevent this, be

sure to support it.

Stopper bracket

Set screws

Reinstalling the RADF

Caution: Be sure that the power cord has been un-

plugged from the power outlet.

Procedure

(1) Remove the two set screws, then remove the original

stopper plate.

(2) Remove the two set screws, then remove the read cover

(left).

Set screws

Set screws

(3) Raise the RADF.

(4) Remove the two set screws holding the stopper bracket.

(5) While supporting the RADF, remove the two stopper

brackets and remove the RADF.

Set

screws

Read cover (left)

Original stopper

plate

(3) Attach the two RADF position adjusting jigs to the original

stopper plate mounting holes.

(4) Install the RADF and provisionally fasten the two stopper

brackets with the set screws.

Caution: Fit the oblong cutouts in the stopper brackets onto

the guide screws.

6

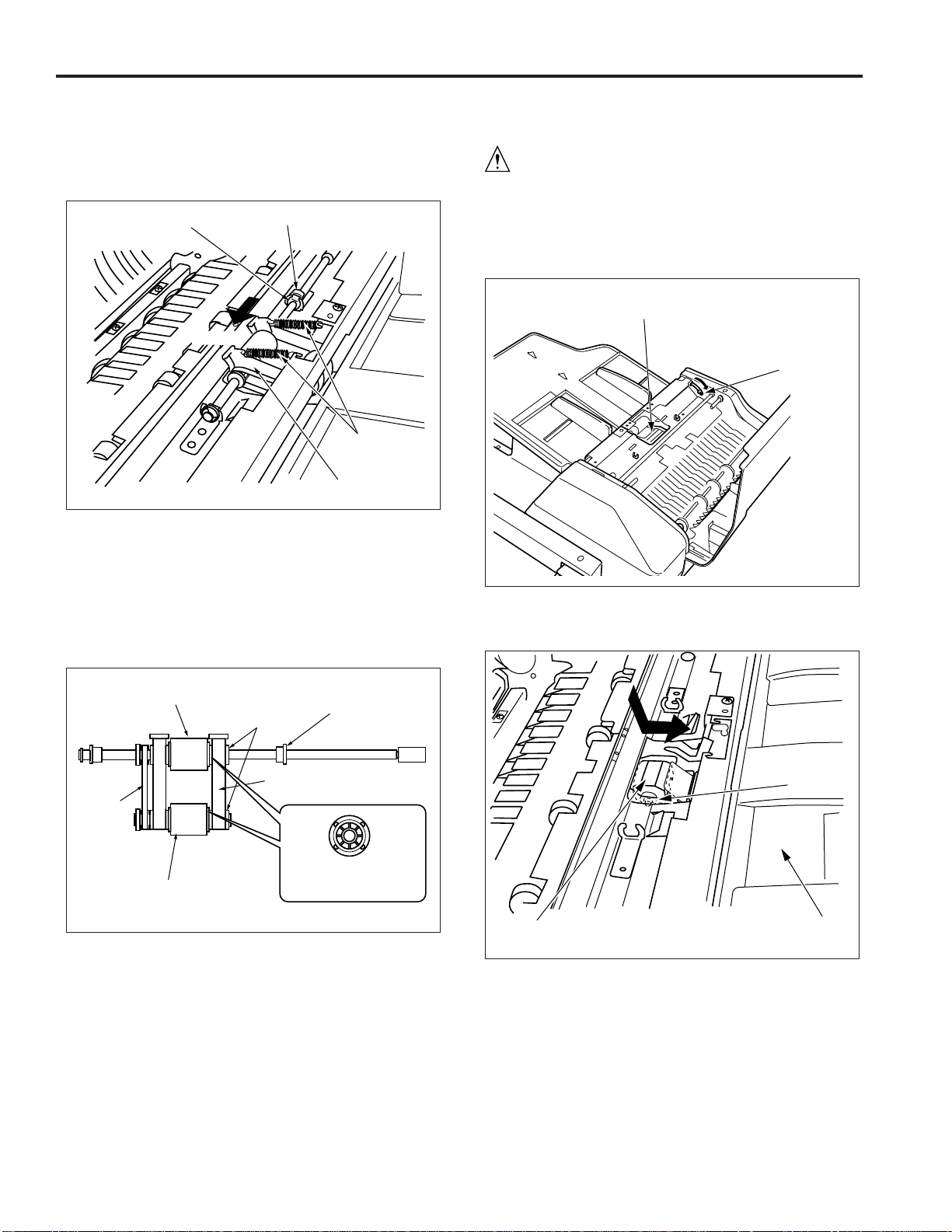

Page 11

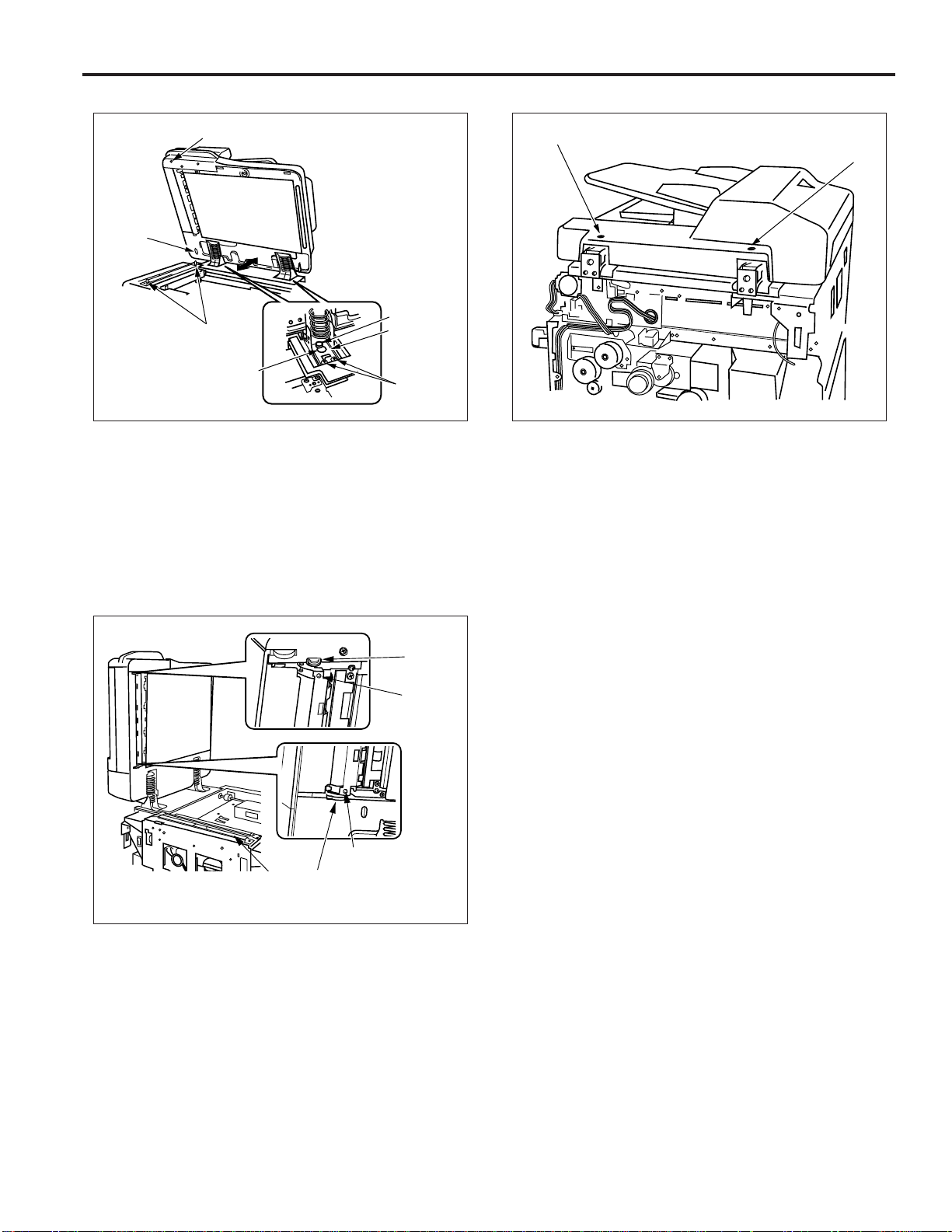

DF-311

Guide hole (round)

Guide hole

(oblong)

Guide screw

RADF position adjusting jigs

Pear-shaped

hole

Stopper

bracket

Set screws

(5) Close the RADF and slide the entire assembly back or

forward so that the guide holes match the RADF position

adjusting jigs.

(6) When the correct position has been established, carefully

open the RADF without disturbing its position and

permanently tighten the stopper brackets that were

provisionally fastened previously.

(7) Close the RADF and verify that the two read position

stoppers both contact the original glass (1).

Set screw B

Set screw A

(9) Remove the two RADF position adjusting jigs and install

the original stopper plate .

(10) Install the read cover (left).

Stopper

Projection

Projection

Original

glass (1)

Stopper

(8) Adjust set screws A and B alternately, until both stoppers

contact the slit glass.

Caution: Repeat step (8) until both stoppers contact the

original glass (1).

7

Page 12

DF-311

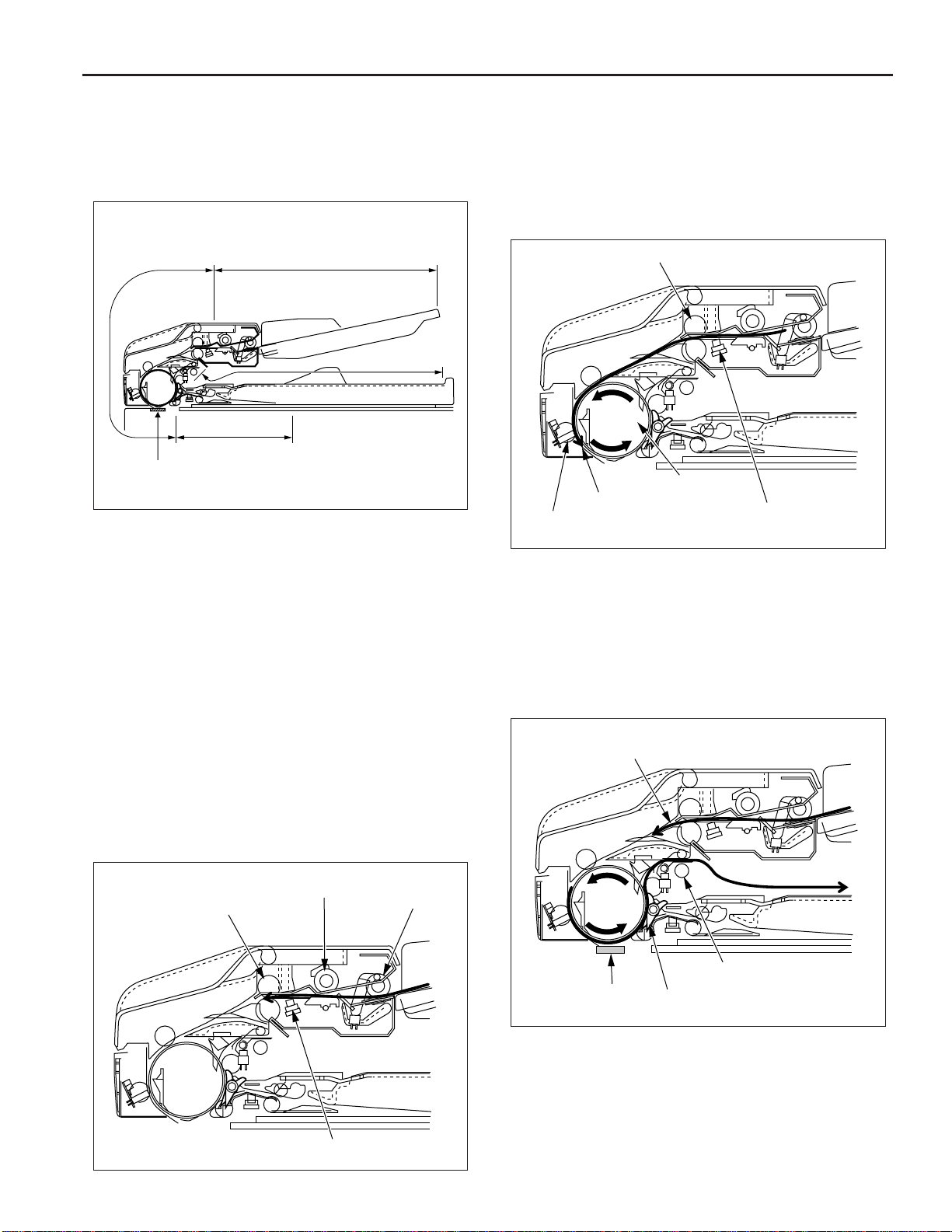

PAPER FEED/PAPER EXIT SECTION

Construction

Open/close cover

Guide plate solenoid (SD301)

Mechanism

Mechanisms

Paper feed

Double feed prevention

Conveyance

Conveyance path switching

∗1

Reversal feed

∗2

Paper feed tray

Paper exit tray

Original pressure

solenoid (SD302)

Methods

Paper feed roller

Double feed prevention pad

Separation roller

Conveyance roller

Guide plate

Reversal roller pressure

Reversal roller turn-back

Paper feed roller

Original feed motor

(M302)

Original feed clutch

(CL302)

Separation roller

Original

pick-up

clutch

(CL301)

Registration

roller

Conveyance

roller

Original

conveyance motor

(M301)

∗∗

∗1: Conveyance path switching

∗∗

In the double side original copying, the conveyance path after

the end of reading operations differs for front side copies and

back side copies. Change of the conveyance path is carried

out by the flapper. Turning the guide plate solenoid (SD301)

ON and OFF switches between the reversal section and the

paper exit section.

Conveyance roller

Guide plate

Guide plate solenoid

(SD301)

Flapper

8

Page 13

∗∗

∗2: Reversal feed

∗∗

During double side original copy operation, the original conveyed to the reversal section is held in the standby mode on the

reversal roller. Reversal feed is activated by bringing the

pressure pulleys into contact with the reversal roller. Pressure

of the pressure pulleys is conducted by the original pressure

solenoid (SD302).

Pressure pulley

Reversal roller

DF-311

Disassembly and Reassembly

Removing and Reinstalling the paper feed roller/

separation roller

Caution: Be sure that the power cord has been un-

plugged from the power outlet.

Procedure

(1) Open the open/close cover. Remove the four set screws

to remove the rear cover.

(2) While gently pulling out at the rear to free the locating

parts.

Set screws

Set screws

Pressure pulleys

Original pressure

solenoid (SD302)

Locating parts

Rear cover

(3) Rotate the gear until the two pressure pins on the pickup

shaft point up.

Gear

Pressure

pin

Pick-up shaft

Caution: The pick-up shaft cannot be turned directly. Be sure

to rotate it via the gear.

9

Page 14

DF-311

(4) Remove the two springs.

(5) Remove the stop ring and slide the bearing to the side.

(6) Slide the paper feed roller assembly towards the front

side, then remove it.

Bearing

Front

Stop ring

Springs

Paper feed

roller assembly

(7) Remove the bearing.

(8) Remove the two stop rings, then remove the guide lever.

(9) Remove the separation roller and paper feed roller.

Caution: When re-installing the separation roller, pay atten-

tion to correct roller orientation. (The correct orientation can be determined by looking at the side

shape of the roller.)

Removing and Reinstalling the double feed

prevention pad

Caution: Be sure that the power cord has been un-

plugged from the power outlet.

Procedure

(1) Remove the paper feed roller assembly.

(2) Push the pressure release lever so that pressure on the

double feed prevention pad is released.

Double feed

prevention pad

Pressure

release lever

(3) Push the double feed prevention pad down, slide it

towards the paper feed tray, and then remove it.

Separation roller

Stop rings

Guide lever

Paper

feed

drive

belt

Paper feed roller

Bearing

Side shape of roller

(10) Reinstall the paper feed roller and separation roller in the

opposite sequence to removal.

Caution: When reinstalling the paper feed roller assembly,

ensure that the two pressure pins on the pickup

shaft point upwards.

Pressure

spring

Double feed prevention pad

Paper feed tray

(4) Reinstall the double feed prevention pad in the opposite

sequence to removal.

Caution: When re-installing the double feed prevention pad,

be sure that the double feed prevention pad pressure spring is in the correct position.

10

Page 15

DF-311

Paper feed/conveyance/scan control

Paper feed takes place by transmitting the drive force of motor

M302 (original feed) to the paper feed roller and separation

roller. Conveyance takes place by transmitting the drive force

of motor M301 (original conveyance) to the conveyance roller.

M301 and M302 are controlled by the DF CB (DF control

board).

Operation

Sensor adjustment when the power is ON.

When SW2 (sub-power) is ON, a sensitivity PS306 (original

registration) and PS308 (original feed detect) is adjusted

automatically. However, if the RADF open/close cover is open

or an original is inside of the RADF, there will be no automatic

adjustment.

Original pressure operation

When a control signal from the main body is received, CL301

(original pickup) goes ON, and after the specified time M302

starts to rotate in the forward direction. This causes the paper

feed roller to be lowered, applying pressure to the original.

After the specified time, M302 and CL301 go OFF, but the

pressure on the original is maintained.

Paper feed operation

When CL302 (original feed) goes ON, the driving force of

M302 is transmitted to the paper feed roller and the

separation roller.

CL302 goes ON at the same time as M302 performs forward

rotation. When M302 switches from forward to reverse rotation, paper feed starts.

When PS306 (original registration) goes ON, the reverse

rotation of M302 is switched OFF after the specified time.

Pre-feed of first sheet

When the reverse rotation of M302 stops, the motor starts

again to rotate in forward direction after the specified time.

This causes the original to be moved to the conveyance

roller.

At the specified time after forward rotation of M302 has

started, M301 (original conveyance) goes ON and moves

the original from the conveyance roller to the scanning

standby position.

When PS308 (original feed detect) detects the leading

edge of the original and turns ON, CL302 and M302 go OFF.

After the specified time, M301 slows down and then goes

OFF. At this point, the original still moves a small distance

further due to the inertia of the conveyance roller and then

stops. This is the scanning standby position.

Pre-feed of second and further sheets

The forward rotation of M302 starts the pre-feed process of

the following original, but because the motor immediately

goes OFF, the original temporarily stops before reaching the

conveyance roller. When M301 begins the scanning operation, the forward rotation of M302 starts again. Pre-feed of the

original then is carried out while the preceding original is being

scanned.

Scanning operation (except last original)

At the specified time after M301 goes OFF, it goes ON

again and conveys the original over the slit glass area

of the main body, where scanning is performed.

When PS306 detects the trailing edge of the original that

is being scanned and goes OFF, CL302 again goes ON

and the feed operation of the next original starts.

11

Revised 10/00

Page 16

DF-311

Scanning operation (last original)

During scanning, when M301 is ON and one of the

sensors PS302 (original size detect 1), PS303 (original

size detect 2), or PS305 (no original detect) goes OFF, the

original currently being scanned is the last one.

A sensor that is used to judge the last original differs depending

on the original size.

When PS307 (original exit detect) goes OFF, M301 also

is switched OFF after the specified time.

Original pressure release

When M301 completes the scanning operation for the last

original and goes OFF, CL301 and M302 go ON which causes

the original pressure to be released. After the specified time,

CL301 and M302 go OFF.

Signals

Input signals

PS302 (PS302 → PTDB → DF CB)

Original length detection signal

[L]: Original is detected

[H]: Original is not detected

PS303 (PS303 → PTDB → DF CB)

Original length detection signal

[L]: Original is detected

[H]: Original is not detected

PS304 (PS304 → DF CB)

M301 encoder surface slit detection signal

[L]: Slit is not detected

[H]: Slit is detected

PS305 (PS305 → DF CB)

No original detection signal at the paper feed tray

[L]: Original is detected

[H]: Original is not detected

PS306 (PS306 → DF CB)

Original detection signal at the conveyance roller

entrance section

[L]: Original is detected

[H]: Original is not detected

PS307 (PS307 → DF CB)

Original detection signal at the paper exit section

[L]: Original is detected

[H]: Original is not detected

PS308 A, B (PS308 → DF CB)

Original detection signal at the pre-scanning standby

position

[L]: Original is detected

[H]: Original is not detected

DF RXD (MAIN BODY → DF CB)

Serial data line for transmitting operation status information from control board in main body to RADF.

DSR (MAIN BODY → DF CB)

Send request from main body to RADF.

RTS (MAIN BODY → DF CB)

Send enable from main body to RADF.

Output signals

M301 DRIVE A, A, B, B (DF CB → M301)

M301 (original conveyance) ON/OFF drive signal

M302 DRIVE 1, 2 (DF CB → M302)

M302 drive signal

M302 rotation direction is controlled by switching the

current direction of these two signals.

State

Forward rotation

Reverse rotation

Stop

CL301 DRIVE (DF CB → CL301)

CL301 (original pick-up) ON/OFF drive signal

[L]: CL301 ON

[H]: CL301 OFF

CL302 DRIVE (DF CB → CL302)

CL302 (original feed) ON/OFF drive signal

[L]: CL302 ON

[H]: CL302 OFF

DF TXD (DF CB → MAIN BODY)

Serial data line for transmitting operation status information from RADF to main body control board.

DTR (DF CB → MAIN BODY)

Send request from RADF to main body.

CTS (DF CB → MAIN BODY)

Send enable from RADF to main body.

VAL ID (DF CB → MAIN BODY)

Image forming start signal

M302 DRIVE 1

H

L

L

M302 DRIVE 2

L

H

L

12

Page 17

Paper exit/reverse conveyance control

DF-311

Paper path switching in the exit area is carried out by

solenoid SD301 (guide plate) which operates a guide plate.

In duplex copy mode, the pressure pulley in the reversal

section is operated by the SD302 (original pressure).

SD301 and SD302 are controlled by the DF CB (DF control

board).

PS307

Operation

Sensor adjustment when the power is ON.

When SW2 (sub power) is ON, a sensitivity of PS309 (original

reversal detect) is adjusted automatically. However, if the

RADF open/close cover is open or an original is in the inside of

the RADF, there will be no automatic adjustment.

13

Revised 10/00

Page 18

DF-311

Paper exit operation

In single-sided copy mode and when copying the reverse side

of a sheet in duplex copy mode, SD301 is OFF and the flapper

is closed. The original is therefore conveyed to the paper exit

section after scanning.

Reversal paper exit operation

When copying the first side of a sheet in duplex copy mode, at

the specified time after M301 (original conveyance) goes ON

and scanning starts, SD301 goes ON and the flapper opens.

This causes the original to be sent to the reversal section after

scanning.

At the same time as SD301 goes ON, M302 (original feed)

starts reverse rotation and the drive force is transmitted to the

reversal roller.

When PS309 (original reversal detect) detects the leading

edge of the original and goes ON, the SD302 goes ON after the

specified time and applies pressure to the pressure pulley. As

a result, the original which has been conveyed to the reversal

section is caught between the reversal roller and pressure

pulley, and conveyed to the inside of the reversal section.

Reversal feed operation

When PS309 detects the trailing edge of the original and goes

OFF, both the M301 and M302 go OFF after the specified time,

and conveyance operation of the original is stopped.

After a predetermined OFF interval, M302 starts reverse

rotation and feeds the original to the conveyance roller side of

the reversal section. At this time, PS309 again goes ON and

SD302 goes OFF after the specified time. M302 goes OFF

after the specified time from PS309 goes OFF.

Pre-feed operation of next original when reading back

side of original

When PS309 goes OFF, M301 and M302 start forward rotation

after the specified time, and next original pre-feed is carried

out.

Signals

Input signals

PS304 (PS304 → DF CB)

M301 encoder surface slit detection signal

[L]: Slit is not detected

[H]: Slit is detected

PS307 (PS307 → DF CB)

Original detection signal at the paper exit section

[L]: Original is detected

[H]: Original is not detected

PS309 (PS309 → DF CB)

Original detection signal at the reversal section

[L]: Original is detected

[H]: Original is not detected

DF RXD (MAIN BODY → DF CB)

Serial data line for transmitting operation status informa

tion from control board in main unit to RADF.

DSR (MAIN BODY → DF CB)

Send request from main body to RADF.

RTS (MAIN BODY → DF CB)

Send enable from main body to RADF.

Output signals

M301 DRIVE A, A, B, B (DF CB → M301)

M301 (original conveyance) ON/OFF drive signal

M302 DRIVE 1, 2 (DF CB → M302)

M302 drive signal

M302 rotation direction is controlled by switching the

current direction of these two signals.

State

Forward rotation

Reverse rotation

Stop

SD301 DRIVE (DF CB → CL301)

SD301 (flapper ) ON/OFF drive signal

[L]: SD301 ON

[H]: SD301 OFF

SD302 DRIVE (DF CB → SD302)

SD302 (original pressure) drive signal

[L]: SD302 ON

[H]: SD302 OFF

DF TXD (DF CB → MAIN BODY)

Serial data line for transmitting operation status informa

tion from RADF to main body control board.

DTR (DF CB → MAIN BODY)

Send request from RADF to main body.

CTS (DF CB → MAIN BODY)

Send acknowledgment from RADF to main body.

VAL ID (DF CB → MAIN BODY)

Image forming start signal

M302 DRIVE 1

H

L

L

M302 DRIVE 2

L

H

L

14

Page 19

DF-311

Original size detection control

Operation

Normal copy mode

The DF CB detects the original size from a combination of the

following signals.

(1) Detection of size in the direction of the drum shaft (width)

The guide plate is connected to the VR301 and the

resistance value differs according to the position of the

guide plate. Thus, it is possible to detect the width

measurements of the original.

(2) Detection of size in the direction of original feed

There is detection of the length measurements

of the original according to a combination of ON/OFF of

PS302 and PS303.

Original size detection in the mixed original copy mode.

Judgment of size in the mixed original copy mode is carried out

under the following conditions.

(1) Size detection in the direction of drum shaft (width).

There is judgment of the width measurements of the

largest original of the mixed originals by means of the

guide plate position.

(2) Detection of size in the conveyance direction of the

original.

There is judgment of the length measurements of the

originals according to the time when PS306 (original

registration) goes ON after feeding of the original from the

registration roller.

(3) Size detection operation according to the direction of

original feed.

When original pre-feed is started with the registration

roller, M301 (original feed detect) rotates forward after

the specified time from PS306 goes ON and the original

is conveyed to the paper exit section. The forward

rotation of the M301 is continued until PS306 detects the

trailing edge of the original and goes OFF. At this time,

depending on the ON time of PS306, there is detection of

the size of the original feed direction.

The size of the original placed in the paper feed tray is detected

by PS302 (original size detect 1), PS303 (original size detect

2), and VR301 (original size detect).

PS302, PS303, and VR301 are controlled by the DF CB (DF

control board) via the PTBD (Paper tray board).

Inside the DF CB is a non-volatile memory for recording the

timing data and original size detection threshold values.

15

Registration roller

PS308

(Original feed detect)

PS306

(Original registration)

Conveyance roller

Page 20

DF-311

M301 rotates in the reversal direction after the specified time

from PS306 goes OFF and returns the leading edge of the

original that has been conveyed to the paper exit section to the

scanning standby position. The trailing edge of the original

which has been returned is conveyed to the exit section due to

the configuration of the conveyance section. The reversal

rotation of the M301 stops after the specified time from PS308

(original feed detect) detects the leading edge of the original

and goes ON.

Scanning standby

position

PS308

(Original feed detect)

Conveyance roller

List of the possible mixing of sizes.

(

: Same size : Same series : Different series ✕ : Mixing

not possible – : Setting not possible.)

(1) AB series

Standard original (maximum original size that is detected with the guide plate).

A4 B4 B5 A5R B6RA3 B5RA5A4R

A3

A4

B4

B5

A4R

A5

Other originalsOther originals

B5R

A5R

B6R

✕

✕

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

✕

✕

✕

✕

✕

✕

✕

✕

✕

✕

✕

–✕

✕

(2) Inch series

Standard original (maximum original size that is detected with the guide plate).

11x17 8.5x5.5

11x17

8.5x11

8.5x14

8.5x11R

8.5x5.5

8.5x5.5R

8.5x11 8.5x14

✕

–

–

✕✕

8.5x11R

–

–

✕

8.5x5.5R

–

–

✕

–

–

–

–

–

–

–

–

–

–

–

–

–

Following this, there is the same reading as in the normal mode

(scanning operation).

2nd original

1st original

The original size detection operation with the second original

and subsequent originals has a different start timing for the

single side mode and double side mode.

Single side mode: At time of starting scanning operation of

former original.

Double side mode: At time of starting scanning operation of

former original back side.

Signals

Input signals

PS302 (PS302 → PTBD → DF CB)

Original length detection signal

[L]: Original is detected

[H]: Original is not detected

PS303 (PS303 → PTBD → DF CB)

Original length detection signal

[L]: Original is detected

[H]: Original is not detected

VR301 (VR301 → PTBD → DF CB)

Original width detection signal

DF RXD (MAIN BODY → DF CB)

Serial data line for transmitting operation status informa

tion from control board in main body to RADF.

DSR (MAIN BODY → DF CB)

Send request from main body to RADF.

RTS (MAIN BODY → DF CB)

Send acknowledgment from main body to RADF.

Output signals

DF TXD (DF CB → MAIN BODY)

Serial data line for transmitting operation status informa

tion from RADF to main body control board.

DTR (DF CB → MAIN BODY)

Send request from RADF to main body.

CTS (DF CB → MAIN BODY)

Send enable from RADF to main body.

16

Page 21

ELECTRICAL PARTS LAYOUT DRAWING

8

7

6

9

19

DF-311

2

14

15

10

1. Switches and Sensors

1 MS301 Cover open/close detect MS

2 PS301 RADF open/close detect PS

3 PS302 Original size detect sensor 1

4 PS303 Original size detect sensor 2

5 PS304 Motor clock detect sensor

6 PS305 No original detect sensor

7 PS306 Original registration sensor

8 PS307 Original exit detect sensor

9 PS308 Original feed detect sensor

10 PS309 Original reversal detect sensor

11 VR301 Original size detect VR

3

411

13

18

5

1

17

16

12

2. Loads

12 M301 Original conveyance motor

13 M302 Original feed motor

14 SD301 Guide plate solenoid

15 SD302 Original pressure solenoid

16 CL301 Original pick-up clutch

17 CL302 Original feed clutch

3. PCBs and Others

18 DFCB DF control board

19 PTBD Paper tray board

17

Page 22

DF-311

CONNECTOR LAYOUT DRAWING

33(W:3 PIN)

10(W:5 PIN)

16(GY:16 PIN)

35(W:4 PIN)

40/41(W:4 PIN)

28(W:3 PIN)

15(W:3 PIN)

37(W:2 PIN)

31/32(W:3 PIN)

42/43(W:3 PIN)

30(W:3 PIN)

29(W:3 PIN)

34(W:4 PIN)

18(W:11 PIN)

12(W:3 PIN)

11(W:6 PIN)

39(W:2 PIN)

25(W:3 PIN)

26(W:3 PIN)

20(W:3 PIN)

21(W:4 PIN)

23(W:4 PIN)

1(GY:16 PIN)

2(W:3 PIN)

18

3(W:10 PIN)

4(W:4 PIN)

5(W:5 PIN)

6(W:10 PIN)

7(W:9 PIN)

8(W:5 PIN)

Page 23

PARTS CATALOG

MODEL

DF-311

Used on Models 7033 & 7040

JUNE 1998

CSM --DF311

Page 24

Page 25

How to use this catalog

This parts catalog includes illustrations and part numbers for all replacement parts and assemblies used in this model.

Model-specific parts are identified in the illustrations with reference

numbers. Use the reference number to locate the corresponding part

number on the facing page.

Common hardware items, such as screws, nuts, washers, and pins, are

identified in the illustrations with reference letters. Use the reference letter to locate the corresponding part number on the hardware listing in the

lower right corner of the facing page.

If you know a part number, but don’t know where the part is used, use

the numerical index to determine the page number and reference number for that part. Because some common parts are used in several

places, there may be more than one entry. Refer to the illustrations to see

where the part may be used.

If you know a part’s description, but don’t know where to look to find

the part number, use the alphabetical index to determine likely page and

reference numbers. Then look at the illustrations to determine that you

have identified the correct part. Locate the part number using the listing

on the opposite page.

Retail pricing that appears with the numerical index, while valid when

this catalog was printed, is subject to change without notice. The prices

are only suggested prices and are provided only for reference. Dealers

may determine their own selling prices. For up-to-date pricing, refer to

current Konica price lists or contact the Konica Parts Distribution Center.

How to order parts

Use standard Konica parts ordering procedures to obtain these parts. For

ordering options, contact Konica’s Parts Distribution Center.

When ordering parts, be sure to specify part numbers exactly as listed in

this catalog.

NOTE: Electrical parts may include previously used components.

Model DF-311 Konica Business Technologies, Inc. Page iii

1st Edition June, 1998

Page 26

This page left blank intentionally.

Page iv Konica Business Technologies, Inc. Model DF-311

June, 1998 1st Edition

Page 27

How to use this catalog . . . . . . . . . . . . . . . . . . . . . . . . . iii

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Machine parts

DF-311 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Alphabetical index . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Numerical index, Retail price list . . . . . . . . . . . . . . . . . . . . 23

Contents

Model DF-311 Konica Business Technologies, Inc. Page 1

1st Edition June, 1998

Page 28

DF-311

Page 2 Konica Business Technologies., Inc. Model DF-311

June, 1998 1st Edition

Page 29

REF. PART NUMBER DESCRIPTION

NO.

1 120A10450 Ground spring

2 120A10350 Stopper

3 120A12050 Rear cover

4 120A12040 Cover

5 120A-1140 Hinge (left) ass’y

6 * Not used

7 120A10140 Bracket

8 120A10150 Base plate

9 120A-9010 DF-311 control board

10 120A-9510 EPROM

11 120A12060 Front cover

12 120A12010 Base cover

13 120A14040 Stopper arm

14 120A-1410 Pressure plate ass’y

15 120A10130 Reinforcing plate

16 120A-1180 Hinge right ass’y

17 * Not used

18 120A10220 Hinge fixed screw

19 120A10200 ADJ plate

20 120A10210 Hinge screw

Model DF-311 Konica Business Technologies., Inc. Page 3

1st Edition June, 1998

Page 30

DF-311

Page 4 Konica Business Technologies., Inc. Model DF-311

June, 1998 1st Edition

Page 31

REF. PART NUMBER DESCRIPTION

NO.

1 120A12030 Open-close cover handle

2 120A12020 Open-close cover

3 120A10190 Guide plate spring

4 120A45060 Roller

5 120A45610 Roller shaft

6 120A45600 Open-close roller plate spring

7 120A10170 Open-close cover lever

8 120A10180 Open-close cover spring

9 120A45570 Spring

10 120A45170 Reflect plate

11 120A10160 Open-close cover shaft

12 120A45590 Roller

13 120A45580 Roller shaft

14 120A45240 Roller

15 120A97010 Seal

16 120A45510 Guide plate (A)

17 120A45530 Exit roller plate spring

18 120A45520 Paper exit roller

19 120A45540 Guide plate (B)

20 120A45560 Spring

21 120A73030 Spring

22 120A73020 Actuator

23 120A85520 Photosensor

24 120A73010 Sensor holder

25 120A45100 Roller plate spring

26 120A73040 Harness plate

27 120A10070 Upper guide

28 120A45080 Roller shaft

29 120A45090 Roller

30 120A45070 Roller

31 120A-1210 Fulcrum plate ass’y

32 120A77050 Gear

33 120A77030 Gear

34 120A45680 Bushing

35 * Not used

36 120A10080 Side plate front ass’y

37 120A-1030 Side plate rear ass’y

38 120A45550 Guide

39 120A10230 Bracket

40 120A10330 Cushion

41 * Not used

42 120A45700 Shaft holder

43 120A45690 Bushing

Model DF-311 Konica Business Technologies., Inc. Page 5

1st Edition June, 1998

Page 32

DF-311

Page 6 Konica Business Technologies., Inc. Model DF-311

June, 1998 1st Edition

Page 33

REF. PART NUMBER DESCRIPTION

NO.

1 120A80010 Motor

2 120A45200 Gear

3 120A15080 Paper reverse tension spring

4 120A45190 Shaft gear

5 120A77030 Gear

6 120A77020 Gear

7 120A15060 Motor tension plate

8 120A15070 Motor mounting plate

9 120A15020 Belt (L=200)

10 120A76520 Pulley (Z=50,88)

11 120A75010 Bearing

12 120A77010 Gear (Z=20)

13 120A77040 Gear (Z=20,50)

14 120A10020 Adjusting plate (rear)

15 120A10010 Spacer rear

16 120A10060 Bracket

17 120A73050 Bracket sensor

18 120A85540 Read sensor

19 120A-4520 Roller plate spring ass’y

20 120A45020 Sensor mylar

21 * Not used

22 * Not used

23 * Not used

24 * Not used

25 120A45180 Shaft roller ass’y

26 120A10090 Spacer front

27 120A10050 Guide (rear)

28 120A-1060 Guide ass’y (rear)

29 * Not used

30 * Not used

31 * Not used

32 * Not used

33 * Not used

34 * Not used

35 120A45680 Bushing

36 120A76510 Pulley

37 120A77060 Gear

38 120A90060 Wiring ass’y read sensor

Model DF-311 Konica Business Technologies., Inc. Page 7

1st Edition June, 1998

Page 34

DF-311

Page 8 Konica Business Technologies., Inc. Model DF-311

June, 1998 1st Edition

Page 35

REF. PART NUMBER DESCRIPTION

NO.

1 120A45130 Front guide

2 120A45120 Rear guide

3 120A45140 Upper shaft spacer

4 120A45110 Shaft (upper)

5 120A45150 Pressure roller fulcrum shaft

6 120A45160 Lower guide

7 120A44020 Roller

8 120A44030 Pressure roller spring

9 120A44010 Roller arm

10 120A44040 Pressure holder pin

11 120A45040 Guide plate

12 120A45060 Roller

13 120A45050 Roller shaft

14 120A-4750 Solenoid ass’y

15 120A73160 Solenoid mounting plate

16 120A44050 Lever

17 120A44080 Lever spring

18 120A44060 Separate arm

19 120A44070 Separator spring

20 120A-4430 Solenoid ass’y

21 120A73150 Solenoid mounting plate

22 120A45030 Roller

23 120A45640 Plate guide spring

24 120A-4740 Lead sensor holder ass’y

25 * Not used

26 120A45830 Platen guide mylar

27 120A45620 Platen guide

28 120A45650 Spacer

29 120A45010 Roller plate spring

30 120A45630 Platen guide plate (R)

31 120A-4730 Platen guide plate ass’y

32 120A45020 Sensor mylar

33 120A85510 Photosensor

34 120A10030 Base plate

35 120A10040 Plate

36 120A45670 Shaft holder

37 120A45660 Screw

38 * Not used

39 * Not used

40 * Not used

41 * Not used

42 * Not used

43 120A15010 Belt

44 * Not used

45 120A45690 Bushing

46 120A45700 Shaft

47 * Not used

48 120A76580 Pulley

Model DF-311 Konica Business Technologies., Inc. Page 9

1st Edition June, 1998

Page 36

DF-311

Page 10 Konica Business Technologies., Inc. Model DF-311

June, 1998 1st Edition

Page 37

REF. PART NUMBER DESCRIPTION

NO.

1 120A76560 Pulley

2 120A15050 Timing belt 4 (L=124)

3 120A45440 Pick-up holder

4 120A45470 Pick-up spring

5 120A45820 Conveyance roller

6 * Not used

7 120A45420 Separation shaft

8 * Not used

9 12TK15290 Clip

10 120A15110 Joint shaft

11 120A45380 Lever

12 120A45370 Lever spring

13 120A45430 Pick-up roller shaft

14 120A-4610 Lever bracket ass’y

15 120A15100 Motor tension shaft

16 120A77050 Gear

17 120A45680 Bushing

18 120A10120 Upper guide

19 120A10110 Lower guide

20 120A45330 Lower guide mylar (A)

21 120A45360 Foam pad (front)1

22 120A45350 Sponge sheet (F)

23 120A45340 Sponge sheet (low)

24 120A-4580 Separation pad ass’y

26 120A45210 Fanning spring hold. mtg. plt.

25 * Not used

27 120A45220 Fanning spring

28 120A45290 Stopper shaft

29 120A-4740 Read sensor holder ass’y

30 120A45020 Sensor mylar

31 120A85510 Photosensor

32 120A45230 Neutralizing brush

33 120A45250 Shaft

34 120A85520 Photosensor

35 120A10100 Separation base

36 120A45260 Fanning plate spring

37 * Not used

38 * Not used

39 * Not used

40 * Not used

41 * Not used

42 * Not used

43 120A-7380 Sensor mounting plate

44 120A73190 Spring

45 120A73200 Sensor actuator

46 120A45500 Pick cam

47 120A45310 Lever shutter

48 120A45300 Stopper auxiliary

49 120A45270 Fanning lever holder

50 120A45320 Spring shutter

Model DF-311 Konica Business Technologies., Inc. Page 11

1st Edition June, 1998

Page 38

DF-311

Page 12 Konica Business Technologies., Inc. Model DF-311

June, 1998 1st Edition

Page 39

REF. PART NUMBER DESCRIPTION

NO.

51 120A45280 Fanning lock plate spring

52 120A-4670 Shaft ass’y

53 120A45720 Clip

54 120A45790 Mylar

Model DF-311 Konica Business Technologies., Inc. Page 13

1st Edition June, 1998

Page 40

DF-311

Page 14 Konica Business Technologies., Inc. Model DF-311

June, 1998 1st Edition

Page 41

REF. PART NUMBER DESCRIPTION

NO.

1 120A10240 Switch plate spring

2 120A73120 Microswitch mounting plate

3 120A86010 Microswitch

4 120A77060 Gear

5 120A45390 Lever latch

6 120A45910 Spring

7 120A77070 Gear (Z=25)

8 120A73060 Mounting plate

9 120A45400 Connecting shaft

10 120A82010 Clutch

11 120A45720 Clip

12 120A45410 Separator connect shaft

13 120A77030 Gear (Z=20)

14 120A15090 Drive connecting shaft

15 120A82020 Clutch

16 120A80020 Motor

17 120A-1540 Motor mounting plate

18 120A77010 Gear (Z=20)

19 120A77080 Gear (Z=18)

20 120A76510 Pulley (Z=25,30)

21 120A15040 Belt (L=124)

22 120A76530 Pulley (Z=16)

23 120A76540 Pulley

24 120A15030 Belt (L=166)

25 120A85550 Photosensor

26 120A73070 Sensor mounting plate

27 * Not used

28 * Not used

29 * Not used

30 120A45680 Bushing

31 * Not used

32 * Not used

33 120A90070 Clutch wiring

Model DF-311 Konica Business Technologies., Inc. Page 15

1st Edition June, 1998

Page 42

DF-311

Page 16 Konica Business Technologies., Inc. Model DF-311

June, 1998 1st Edition

Page 43

REF. PART NUMBER DESCRIPTION

NO.

1 120A40010 Tray guide front

2 120A40020 Tray guide rear

3 120A40030 Tray

4 120A40040 Tray lock

5 120A77090 Pinion gear (Z=52)

6 120A73110 Gear plate

7 120A40050 Tray sensor lever

8 120A90110 Wiring

9 120A85520 Photosensor

10 * Not used

11 120A88010 Board, tray

12 120A-1190 Tray fulcrum ass’y

13 120A40060 Tray lower cover

14 * Not used

15 * Not used

16 120A90100 Tray, wiring

17 120A90120 Wiring, TR

Model DF-311 Konica Business Technologies., Inc. Page 17

1st Edition June, 1998

Page 44

DF-311

Page 18 Konica Business Technologies., Inc. Model DF-311

June, 1998 1st Edition

Page 45

REF. PART NUMBER DESCRIPTION

NO.

1 120A90010 Wiring, SBS

2 120A90020 Wiring, EXITS

3 120A90030 Wiring, sensor

4 120A90040 Wiring, SOL

5 120A90050 Wiring, relay

6 120A90060 Wiring, RDS

7 120A90070 Wiring, clutch

8 120A90080 Wiring, IF

9 120A90090 Wiring, DF open

10 120A90100 Wiring, tray

11 120A90110 Wiring, VR

12 120A90120 Wiring, TR

13 120A90130 Wiring, drive

Model DF-311 Konica Business Technologies., Inc. Page 19

1st Edition June, 1998

Page 46

This page left blank intentionally.

Page 20 Konica Business Technologies, Inc. Model DF-311

June, 1998 1st Edition

Page 47

Alphabetical index

PART PAGE REF.

DESCRIPTION NO. NO.

A

ADJ plate . . . . . . . . . . 3 19

Actuator . . . . . . . . . . 5 22

Adjusting plate (rear) . . . . 7 14

B

Base cover . . . . . . . . . 3 12

Base plate . . . . . . . . . 3 8

Base plate . . . . . . . . . 9 34

Bearing . . . . . . . . . . . 7 11

Belt . . . . . . . . . . . . . 9 43

Belt (L=124) . . . . . . . . 15 21

Belt (L=166) . . . . . . . . 15 24

Belt (L=200) . . . . . . . . 7 9

Board, tray . . . . . . . . . 17 11

Bracket . . . . . . . . . . . 3 7

Bracket . . . . . . . . . . . 5 39

Bracket . . . . . . . . . . . 7 16

Bracket sensor . . . . . . . 7 17

Bushing . . . . . . . . . . 5 34

Bushing . . . . . . . . . . 5 43

Bushing . . . . . . . . . . 7 35

Bushing . . . . . . . . . . 9 45

Bushing . . . . . . . . . . 11 17

Bushing . . . . . . . . . . 15 30

C

Clip . . . . . . . . . . . . . 11 9

Clip . . . . . . . . . . . . . 13 53

Clip . . . . . . . . . . . . . 15 11

Clutch . . . . . . . . . . . 15 10

Clutch . . . . . . . . . . . 15 15

Clutch wiring . . . . . . . . 15 33

Connecting shaft . . . . . . 15 9

Conveyance roller . . . . . 11 5

Cover . . . . . . . . . . . . 3 4

Cushion . . . . . . . . . . 5 40

D

DF-311 control board . . . 3 9

Drive connecting shaft . . . 15 14

E

EPROM . . . . . . . . . . 3 10

Exit roller plate spring . . . 5 17

F

Fanning lever holder . . . . 11 49

Fanning lock plate spring . 13 51

Fanning plate spring . . . . 11 36

Fanning spring . . . . . . . 11 27

Fanning spring hold. mtg. plt. 11 26

Foam pad (front) 1 . . . . . 11 21

PART PAGE REF.

DESCRIPTION NO. NO.

Front cover . . . . . . . . . 3 11

Front guide . . . . . . . . . 9 1

Fulcrum plate ass’y . . . . . 5 31

G

Gear . . . . . . . . . . . . 5 32

Gear . . . . . . . . . . . . 5 33

Gear . . . . . . . . . . . . 7 2

Gear . . . . . . . . . . . . 7 5

Gear . . . . . . . . . . . . 7 6

Gear . . . . . . . . . . . . 7 37

Gear . . . . . . . . . . . . 11 16

Gear . . . . . . . . . . . . 15 4

Gear (Z=18) . . . . . . . . 15 19

Gear (Z=20) . . . . . . . . 7 12

Gear (Z=20) . . . . . . . . 15 13

Gear (Z=20) . . . . . . . . 15 18

Gear (Z=20,50) . . . . . . . 7 13

Gear (Z=25) . . . . . . . . 15 7

Gear plate . . . . . . . . . 17 6

Ground spring . . . . . . . 3 1

Guide . . . . . . . . . . . . 5 38

Guide (rear) . . . . . . . . 7 27

Guide ass’y (rear) . . . . . 7 28

Guide plate . . . . . . . . . 9 11

Guide plate (A) . . . . . . . 5 16

Guide plate (B) . . . . . . . 5 19

Guide plate spring . . . . . 5 3

H

Harness plate . . . . . . . 5 26

Hinge (left) ass’y . . . . . . 3 5

Hinge fixed screw . . . . . 3 18

Hinge right ass’y . . . . . . 3 16

Hinge screw . . . . . . . . 3 20

J

Joint shaft . . . . . . . . . 11 10

L

Lead sensor holder ass’y . . 9 24

Lever . . . . . . . . . . . . 9 16

Lever . . . . . . . . . . . . 11 11

Lever bracket ass’y . . . . . 11 14

Lever latch . . . . . . . . . 15 5

Lever shutter . . . . . . . . 11 47

Lever spring . . . . . . . . 9 17

Lever spring . . . . . . . . 11 12

Lower guide . . . . . . . . 9 6

Lower guide . . . . . . . . 11 19

Lower guide mylar (A) . . . 11 20

M

Microswitch . . . . . . . . . 15 3

PART PAGE REF.

DESCRIPTION NO. NO.

Microswitch mounting plate . 15 2

Motor . . . . . . . . . . . . 7 1

Motor . . . . . . . . . . . . 15 16

Motor mounting plate . . . . 7 8

Motor mounting plate . . . . 15 17

Motor tension plate . . . . . 7 7

Motor tension shaft . . . . . 11 15

Mounting plate . . . . . . . 15 8

Mylar . . . . . . . . . . . . 13 54

N

Neutralizing brush . . . . . 11 32

O

Open-close cover . . . . . . 5 2

Open-close cover handle . . 5 1

Open-close cover lever . . . 5 7

Open-close cover shaft . . . 5 11

Open-close cover spring . . 5 8

Open-close roller plate spring 5 6

P

Paper exit roller . . . . . . . 5 18

Paper reverse tension spring 7 3

Photosensor . . . . . . . . 5 23

Photosensor . . . . . . . . 9 33

Photosensor . . . . . . . . 11 31

Photosensor . . . . . . . . 11 34

Photosensor . . . . . . . . 15 25

Photosensor . . . . . . . . 17 9

Pick cam . . . . . . . . . . 11 46

Pick-up holder . . . . . . . 11 3

Pick-up roller shaft . . . . . 11 13

Pick-up spring . . . . . . . 11 4

Pinion gear (Z=52) . . . . . 17 5

Plate . . . . . . . . . . . . 9 35

Plate guide spring . . . . . 9 23

Platen guide . . . . . . . . 9 27

Platen guide mylar . . . . . 9 26

Platen guide plate (R) . . . 9 30

Platen guide plate ass’y . . 9 31

Pressure holder pin . . . . . 9 10

Pressure plate ass’y . . . . 3 14

Pressure roller fulcrum shaft 9 5

Pressure roller spring . . . . 9 8

Pulley . . . . . . . . . . . . 7 36

Pulley . . . . . . . . . . . . 9 48

Pulley . . . . . . . . . . . . 11 1

Pulley . . . . . . . . . . . . 15 23

Pulley (Z=16) . . . . . . . . 15 22

Pulley (Z=25,30) . . . . . . 15 20

Pulley (Z=50,88) . . . . . . 7 10

R

Read sensor . . . . . . . . 7 18

Read sensor holder ass’y . . 11 29

Model DF-311 Konica Business Technologies, Inc. Page 21

1st Edition June, 1998

Page 48

PART PAGE REF.

DESCRIPTION NO. NO.

Rear cover . . . . . . . . . 3 3

Rear guide . . . . . . . . . 9 2

Reflect plate . . . . . . . . 5 10

Reinforcing plate . . . . . . 3 15

Roller . . . . . . . . . . . . 5 4

Roller . . . . . . . . . . . . 5 12

Roller . . . . . . . . . . . . 5 14

Roller . . . . . . . . . . . . 5 29

Roller . . . . . . . . . . . . 5 30

Roller . . . . . . . . . . . . 9 7

Roller . . . . . . . . . . . . 9 12

Roller . . . . . . . . . . . . 9 22

Roller arm . . . . . . . . . . 9 9

Roller plate spring . . . . . 5 25

Roller plate spring . . . . . 9 29

Roller plate spring ass’y . . 7 19

Roller shaft . . . . . . . . . 5 5

Roller shaft . . . . . . . . . 5 13

Roller shaft . . . . . . . . . 5 28

Roller shaft . . . . . . . . . 9 13

S

Screw . . . . . . . . . . . . 9 37

Seal . . . . . . . . . . . . . 5 15

Sensor actuator . . . . . . . 11 45

Sensor holder . . . . . . . . 5 24

Sensor mounting plate . . . 11 43

Sensor mounting plate . . . 15 26

Sensor mylar . . . . . . . . 7 20

Sensor mylar . . . . . . . . 9 32

Sensor mylar . . . . . . . . 11 30

Separate arm . . . . . . . . 9 18

Separation base . . . . . . 11 35

Separation pad ass’y . . . . 11 24

Separation shaft . . . . . . 11 7

PART PAGE REF.

DESCRIPTION NO. NO.

Separator connect shaft . . 15 12

Separator spring . . . . . 9 19

Shaft . . . . . . . . . . . 9 46

Shaft . . . . . . . . . . . 11 33

Shaft (upper) . . . . . . . 9 4

Shaft ass’y . . . . . . . . 13 52

Shaft gear . . . . . . . . . 7 4

Shaft holder . . . . . . . . 5 42

Shaft holder . . . . . . . . 9 36

Shaft roller ass’y . . . . . 7 25

Side plate front ass’y . . . 5 36

Side plate rear ass’y . . . 5 37

Solenoid ass’y . . . . . . . 9 14

Solenoid ass’y . . . . . . . 9 20

Solenoid mounting plate . 9 15

Solenoid mounting plate . 9 21

Spacer . . . . . . . . . . 9 28

Spacer front . . . . . . . . 7 26

Spacer rear . . . . . . . . 7 15

Sponge sheet (F) . . . . . 11 22

Sponge sheet (low) . . . . 11 23

Spring . . . . . . . . . . . 5 9

Spring . . . . . . . . . . . 5 20

Spring . . . . . . . . . . . 5 21

Spring . . . . . . . . . . . 11 44

Spring . . . . . . . . . . . 15 6

Spring shutter . . . . . . . 11 50

Stopper . . . . . . . . . . 3 2

Stopper arm . . . . . . . . 3 13

Stopper auxiliary . . . . . 11 48

Stopper shaft . . . . . . . 11 28

Switch plate spring . . . . 15 1

T

Timing belt 4 (L=124) . . . 11 2

PART PAGE REF.

DESCRIPTION NO. NO.

Tray . . . . . . . . . . . . 17 3

Tray fulcrum ass’y . . . . . 17 12

Tray guide front . . . . . . 17 1

Tray guide rear . . . . . . . 17 2

Tray lock . . . . . . . . . . 17 4

Tray lower cover . . . . . . 17 13

Tray sensor lever . . . . . 17 7

Tray, wiring . . . . . . . . . 17 16

U

Upper guide . . . . . . . . 5 27

Upper guide . . . . . . . . 11 18

Upper shaft spacer . . . . 9 3

W

Wiring . . . . . . . . . . . 17 8

Wiring ass’y, read sensor . 7 38

Wiring, DF open . . . . . . 19 9

Wiring, EXITS . . . . . . . 19 2

Wiring, IF . . . . . . . . . 19 8

Wiring, RDS . . . . . . . . 19 6

Wiring, SBS . . . . . . . . 19 1

Wiring, SOL . . . . . . . . 19 4

Wiring, TR . . . . . . . . . 17 17

Wiring, TR . . . . . . . . . 19 12

Wiring, VR . . . . . . . . . 19 11

Wiring, clutch . . . . . . . 19 7

Wiring, drive . . . . . . . . 19 13

Wiring, relay . . . . . . . . 19 5

Wiring, sensor . . . . . . . 19 3

Wiring, tray . . . . . . . . 19 10

Page 22 Konica Business Technologies, Inc. Model DF-311

June, 1998 1st Edition

Page 49

Numerical index

PART PAGE REF. SUGGESTED

NUMBER NO. NO. RETAIL

120A-1030 . . . . 5 37

120A-1060 . . . . 7 28

120A-1140 . . . . 3 5

120A-1180 . . . . 3 16

120A-1190 . . . . 17 12

120A-1210 . . . . 5 31

120A-1410 . . . . 3 14

120A-1540 . . . . 15 17

120A-4430 . . . . 9 20

120A-4520 . . . . 7 19

120A-4580 . . . . 11 24

120A-4610 . . . . 11 14

120A-4670 . . . . 13 52

120A-4730 . . . . 9 31

120A-4740 . . . . 9 24

120A-4740 . . . . 11 29

120A-4750 . . . . 9 14

120A-7380 . . . . 11 43

120A-9010 . . . . 3 9

120A-9510 . . . . 3 10

120A10010 . . . . 7 15

120A10020 . . . . 7 14

120A10030 . . . . 9 34

120A10040 . . . . 9 35

120A10050 . . . . 7 27

120A10060 . . . . 7 16

120A10070 . . . . 5 27

120A10080 . . . . 5 36

120A10090 . . . . 7 26

120A10100 . . . . 11 35

120A10110 . . . . 11 19

120A10120 . . . . 11 18

120A10130 . . . . 3 15

120A10140 . . . . 3 7

120A10150 . . . . 3 8

120A10160 . . . . 5 11

120A10170 . . . . 5 7

120A10180 . . . . 5 8

120A10190 . . . . 5 3

120A10200 . . . . 3 19

120A10210 . . . . 3 20

120A10220 . . . . 3 18

120A10230 . . . . 5 39

120A10240 . . . . 15 1

120A10330 . . . . 5 40

120A10350 . . . . 3 2

120A10450 . . . . 3 1

120A12010 . . . . 3 12

120A12020 . . . . 5 2

120A12030 . . . . 5 1

120A12040 . . . . 3 4

120A12050 . . . . 3 3

120A12060 . . . . 3 11

120A14040 . . . . 3 13

120A15010 . . . . 9 43

120A15020 . . . . 7 9

120A15030 . . . . 15 24

120A15040 . . . . 15 21

120A15050 . . . . 11 2

120A15060 . . . . 7 7

120A15070 . . . . 7 8

120A15080 . . . . 7 3

120A15090 . . . . 15 14

120A15100 . . . . 11 15

PART PAGE REF. SUGGESTED

NUMBER NO. NO. RETAIL

120A15110 . . . . 11 10

120A40010 . . . . 17 1

120A40020 . . . . 17 2

120A40030 . . . . 17 3

120A40040 . . . . 17 4

120A40050 . . . . 17 7

120A40060 . . . . 17 13

120A44010 . . . . 9 9

120A44020 . . . . 9 7

120A44030 . . . . 9 8

120A44040 . . . . 9 10

120A44050 . . . . 9 16

120A44060 . . . . 9 18

120A44070 . . . . 9 19

120A44080 . . . . 9 17

120A45010 . . . . 9 29

120A45020 . . . . 7 20

120A45020 . . . . 9 32

120A45020 . . . . 11 30

120A45030 . . . . 9 22

120A45040 . . . . 9 11

120A45050 . . . . 9 13

120A45060 . . . . 5 4

120A45060 . . . . 9 12

120A45070 . . . . 5 30

120A45080 . . . . 5 28

120A45090 . . . . 5 29

120A45100 . . . . 5 25

120A45110 . . . . 9 4

120A45120 . . . . 9 2

120A45130 . . . . 9 1

120A45140 . . . . 9 3

120A45150 . . . . 9 5

120A45160 . . . . 9 6

120A45170 . . . . 5 10

120A45180 . . . . 7 25

120A45190 . . . . 7 4

120A45200 . . . . 7 2

120A45210 . . . . 11 26

120A45220 . . . . 11 27

120A45230 . . . . 11 32

120A45240 . . . . 5 14

120A45250 . . . . 11 33

120A45260 . . . . 11 36

120A45270 . . . . 11 49

120A45280 . . . . 13 51

120A45290 . . . . 11 28

120A45300 . . . . 11 48

120A45310 . . . . 11 47

120A45320 . . . . 11 50

120A45330 . . . . 11 20

120A45340 . . . . 11 23

120A45350 . . . . 11 22

120A45360 . . . . 11 21

120A45370 . . . . 11 12

120A45380 . . . . 11 11

120A45390 . . . . 15 5

120A45400 . . . . 15 9

120A45410 . . . . 15 12

120A45420 . . . . 11 7

120A45430 . . . . 11 13

120A45440 . . . . 11 3

120A45470 . . . . 11 4

120A45500 . . . . 11 46

PART PAGE REF. SUGGESTED

NUMBER NO. NO. RETAIL

120A45510 . . . . 5 16

120A45520 . . . . 5 18

120A45530 . . . . 5 17

120A45540 . . . . 5 19

120A45550 . . . . 5 38

120A45560 . . . . 5 20

120A45570 . . . . 5 9

120A45580 . . . . 5 13

120A45590 . . . . 5 12

120A45600 . . . . 5 6

120A45610 . . . . 5 5

120A45620 . . . . 9 27

120A45630 . . . . 9 30

120A45640 . . . . 9 23

120A45650 . . . . 9 28

120A45660 . . . . 9 37

120A45670 . . . . 9 36

120A45680 . . . . 5 34

120A45680 . . . . 7 35

120A45680 . . . . 11 17

120A45680 . . . . 15 30

120A45690 . . . . 5 43

120A45690 . . . . 9 45

120A45700 . . . . 5 42

120A45700 . . . . 9 46

120A45720 . . . . 13 53

120A45720 . . . . 15 11

120A45790 . . . . 13 54

120A45820 . . . . 11 5

120A45830 . . . . 9 26

120A45910 . . . . 15 6

120A73010 . . . . 5 24

120A73020 . . . . 5 22

120A73030 . . . . 5 21

120A73040 . . . . 5 26

120A73050 . . . . 7 17

120A73060 . . . . 15 8

120A73070 . . . . 15 26

120A73110 . . . . 17 6

120A73120 . . . . 15 2

120A73150 . . . . 9 21

120A73160 . . . . 9 15

120A73190 . . . . 11 44

120A73200 . . . . 11 45

120A75010 . . . . 7 11

120A76510 . . . . 7 36

120A76510 . . . . 15 20

120A76520 . . . . 7 10

120A76530 . . . . 15 22

120A76540 . . . . 15 23

120A76560 . . . . 11 1

120A76580 . . . . 9 48

120A77010 . . . . 7 12

120A77010 . . . . 15 18

120A77020 . . . . 7 6

120A77030 . . . . 5 33

120A77030 . . . . 7 5

120A77030 . . . . 15 13

120A77040 . . . . 7 13

120A77050 . . . . 5 32

120A77050 . . . . 11 16

120A77060 . . . . 7 37

120A77060 . . . . 15 4

120A77070 . . . . 15 7

Model DF-311 Konica Business Technologies, Inc. Page 23

1st Edition June, 1998

Page 50

PART PAGE REF. SUGGESTED

NUMBER NO. NO. RETAIL

120A77080 . . . . 15 19

120A77090 . . . . 17 5

120A80010 . . . . 7 1

120A80020 . . . . 15 16

120A82010 . . . . 15 10

120A82020 . . . . 15 15

120A85510 . . . . 9 33

120A85510 . . . . 11 31

120A85520 . . . . 5 23

120A85520 . . . . 11 34

120A85520 . . . . 17 9

120A85540 . . . . 7 18

PART PAGE REF. SUGGESTED

NUMBER NO. NO. RETAIL

120A85550 . . . . 15 25

120A86010 . . . . 15 3

120A88010 . . . . 17 11

120A90010 . . . . 19 1

120A90020 . . . . 19 2

120A90030 . . . . 19 3

120A90040 . . . . 19 4

120A90050 . . . . 19 5

120A90060 . . . . 7 38

120A90060 . . . . 19 6

120A90070 . . . . 15 33

120A90070 . . . . 19 7

PART PAGE REF. SUGGESTED

NUMBER NO. NO. RETAIL

120A90080 . . . 19 8

120A90090 . . . 19 9

120A90100 . . . 17 16

120A90100 . . . 19 10

120A90110 . . . 17 8

120A90110 . . . 19 11

120A90120 . . . 17 17

120A90120 . . . 19 12

120A90130 . . . 19 13

120A97010 . . . 5 15

12TK15290 . . . 11 9

Page 24 Konica Business Technologies, Inc. Model DF-311

June, 1998 1st Edition

Loading...

Loading...